High-performance cyanide-free silver pre-plating liquid

A technology of cyanide-free silver plating and pre-plating solution, which is applied in the field of electrochemical silver plating, can solve the problem of "weak bonding force between the substrate and the coating, etc., and achieve strong process operability, good bonding force, dispersion ability and covering ability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

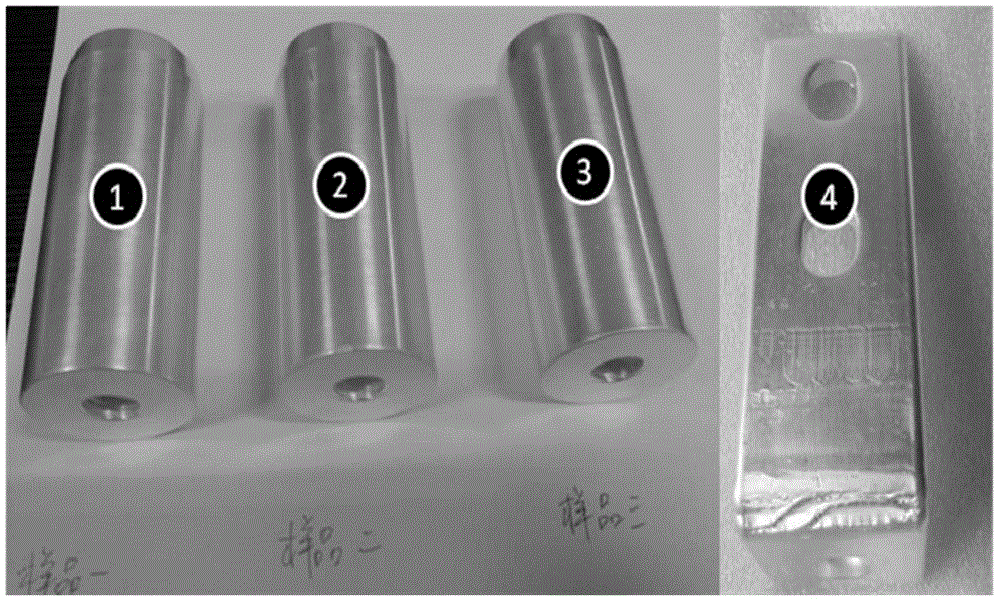

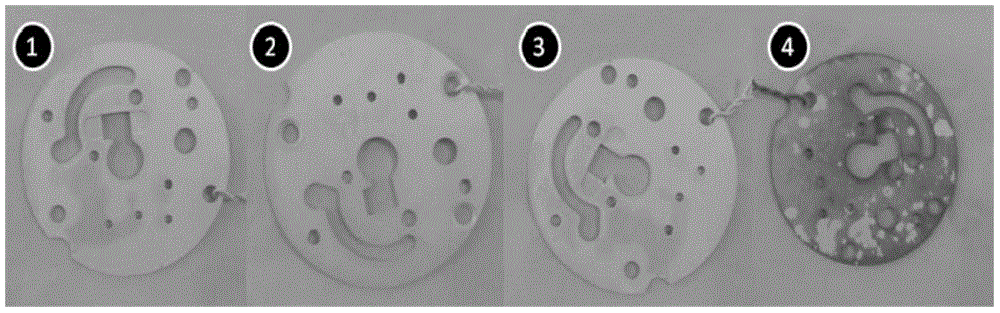

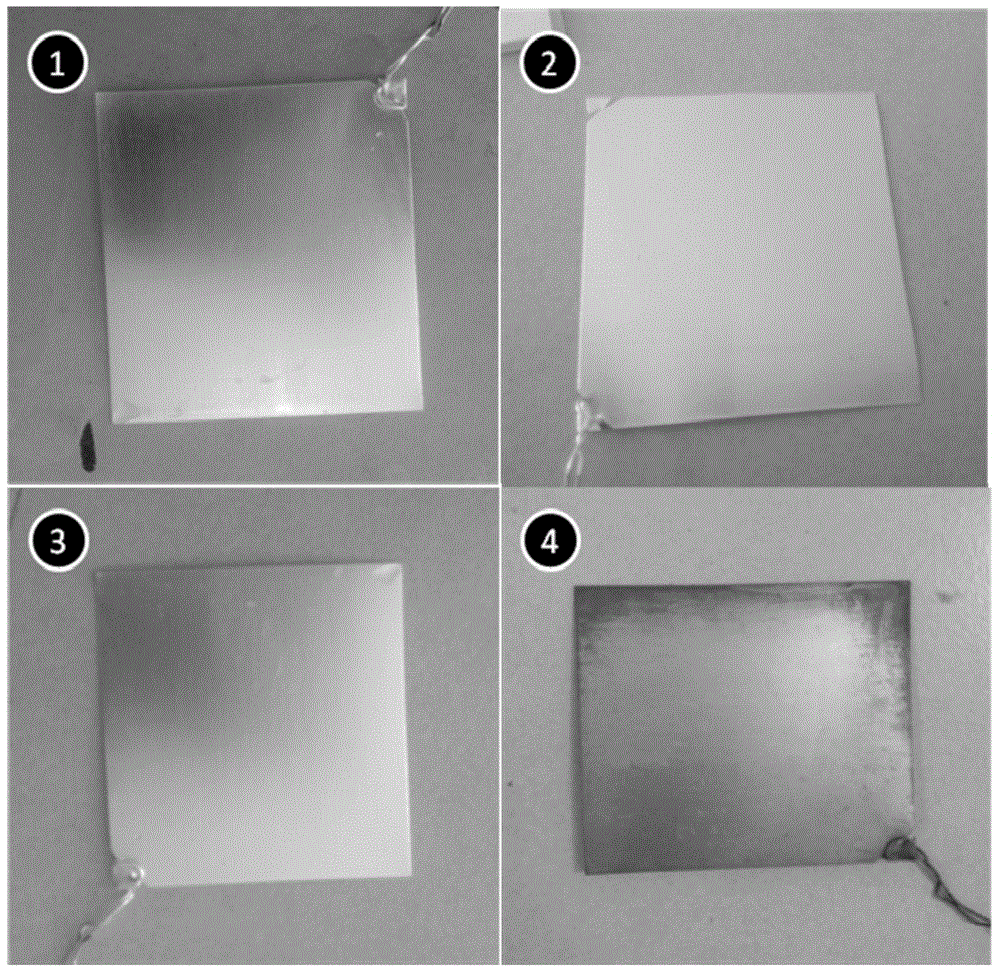

Embodiment 1

[0034] (1), substrate activation treatment

[0035] First put the polished and water-washed plated substrate into a mixed aqueous solution containing 180g / L of concentrated sulfuric acid and 25g / L of OP emulsifier, soak for 3 minutes at 80°C, and then transfer to a solution containing 100g / L of concentrated hydrochloric acid and dodecane In the mixed aqueous solution of 10g / L sodium persulfate, immerse at room temperature for 2 minutes, take it out and rinse it with distilled water; Soak in the mixed aqueous solution at 80°C for 60 seconds, take it out and rinse it with distilled water for later use.

[0036] (2), composition and preparation process of cyanide-free silver plating pre-plating solution

[0037] The composition of the cyanide-free silver plating pre-plating solution is: silver nitrate 1g / L, methanesulfonic acid 20g / L, hydantoin 20g / L, potassium hydroxide 50g / L, potassium carbonate 50g / L; The preparation process of the solution is as follows: first add pure wate...

Embodiment 2

[0049] Step (1) is the same as step (1) in Example 1.

[0050] (2), composition and preparation process of cyanide-free silver plating pre-plating solution

[0051] The composition of the cyanide-free silver plating pre-plating solution is: silver nitrate 3g / L, methanesulfonic acid 50g / L, hydantoin 50g / L, potassium hydroxide 30g / L, potassium carbonate 30g / L, nicotinic acid 25g / L; The preparation process of the cyanide-free silver plating pre-plating solution is as follows: first add pure water with a total volume of 25% to the plating tank; then add the pre-weighed nicotinic acid, potassium carbonate and potassium hydroxide in sequence, stir and heat up to 27°C ; Dissolve silver nitrate with a small amount of pure water, slowly add it to the above solution under stirring, and adjust the pH value to 10; finally add methanesulfonic acid and hydantoin, and replenish pure water to the required volume.

[0052] (3), pre-plated silver

[0053] With step (1) activated plated base s...

Embodiment 3

[0062] Step (1) is the same as step (1) in Example 1.

[0063] (2), composition and preparation process of cyanide-free silver plating pre-plating solution

[0064] The composition of the cyanide-free silver plating pre-plating solution is: silver nitrate 5g / L, methanesulfonic acid 5g / L, hydantoin 100g / L, potassium hydroxide 10g / L, potassium carbonate 10g / L, nicotinic acid 10g / L. The preparation process of the cyanide-free silver-plating pre-plating solution is as follows: first add 25% pure water to the cleaned plating tank; then add the pre-weighed nicotinic acid, potassium carbonate and potassium hydroxide successively, stir and Raise the temperature to 35°C; then dissolve silver nitrate with a small amount of pure water, slowly add it to the above solution under stirring, and adjust the pH value to 9; finally add methanesulfonic acid and hydantoin, and replenish pure water to the required volume.

[0065] (3), pre-plated silver

[0066] With the plated part substrate aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com