Patents

Literature

1190 results about "Methanesulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methanesulfonic acid (MsOH) is a colorless liquid with the chemical formula CH₃SO₃H. It is the simplest of the alkylsulfonic acids. Salts and esters of methanesulfonic acid are known as mesylates (or methanesulfonates, as in ethyl methanesulfonate). It is hygroscopic in its concentrated form. Methanesulfonic acid may be considered an intermediate compound between sulfuric acid (H₂SO₄), and methylsulfonylmethane ((CH₃)₂SO₂), effectively replacing an –OH group with a –CH₃ group at each step. This pattern can extend no further in either direction without breaking down the –SO₂– group. Methanesulfonic acid can dissolve a wide range of metal salts, many of them in significantly higher concentrations than in hydrochloric or sulfuric acid.

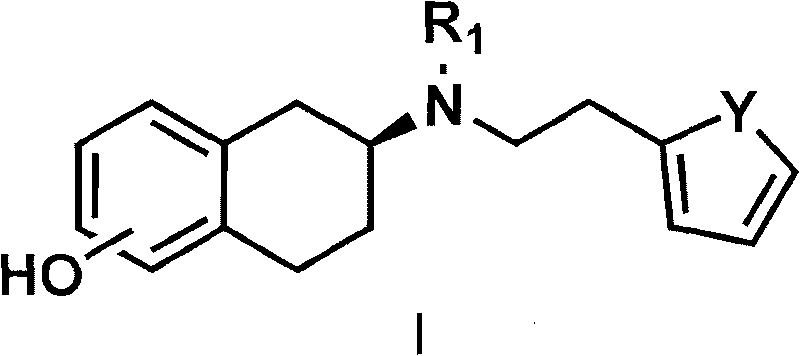

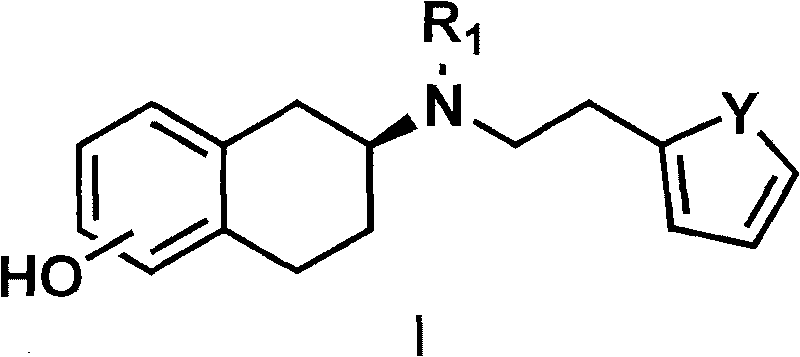

Method for preparing rotigotine and derivative thereof

InactiveCN101717392AHigh optical puritySimple and fast operationOptically-active compound separationOrganic racemisationP-Toluenesulfonic acidSolvent

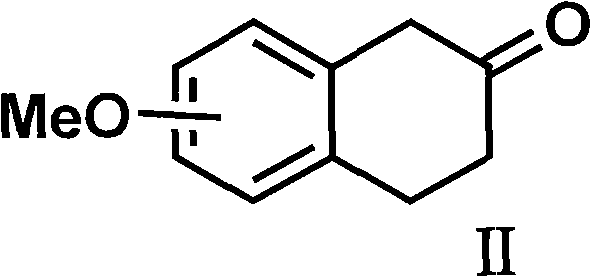

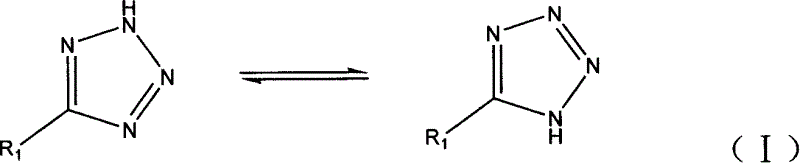

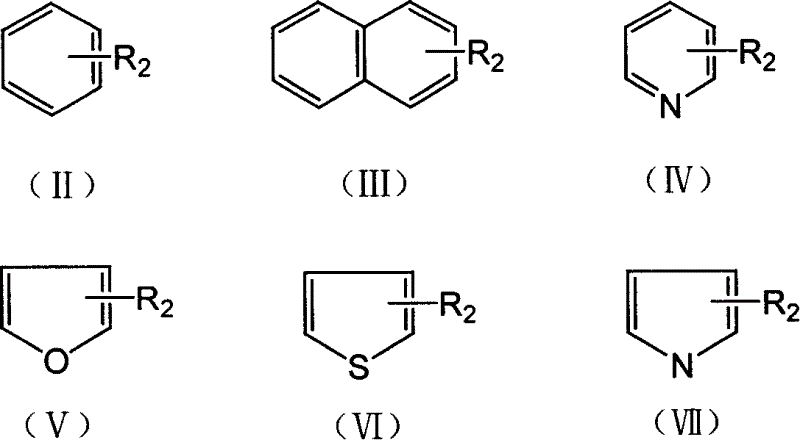

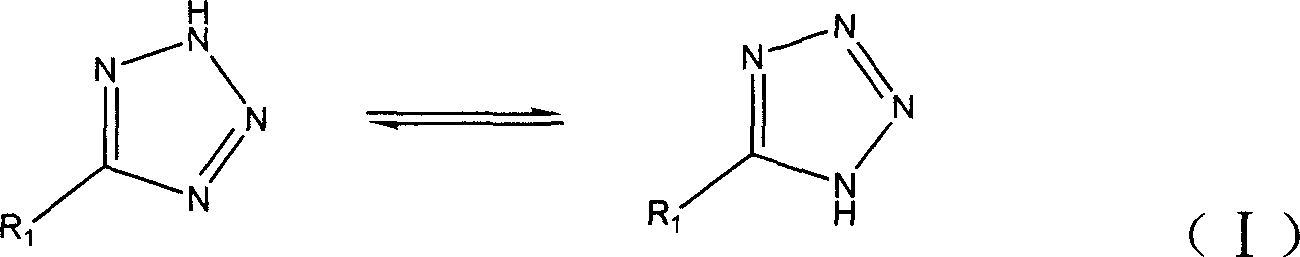

The invention discloses a method for preparing a compound of a formula (I) or pharmaceutically acceptable salts thereof. The method is characterized by comprising the following steps of: (1) using a compound of a formula (II) as a raw material and carrying out a reduction and amination reaction with an appropriate reducing agent to obtain a compound of a formula (III); (2) using 2-quinary heterocyclic substituted ethanol as a raw material and reacting to obtain a compound of a formula (IV) under the conditions of appropriate reagent, temperature and solvent; (3) after carrying out chiral separation on the compound of the formula (III), carrying out a condensation reaction with the compound of the formula (I) under an alkaline condition to obtain a compound of a formula (V); and (4) carrying out demethylation protection on the compound of the formula (V) under the condition of appropriate temperature and solvent to obtain the compound of the formula (I), wherein R1 in each formula is selected from C1-8 alkyl groups or aromatic bases which can be arbitrarily substituted, X is selected from halogen atoms or p-toluenesulfonic acid groups and methanesulfonic acid groups for protecting alcoholic extract hydroxyl groups, and Y is selected from O, S and N. A target product obtained by the method has high optical purity, convenient operation, lower cost, higher yield and less pollution and is suitable for industrialized production.

Owner:苏州凯达生物医药技术有限公司

Deodorizing method, deodorizer, method of manufacturing deodorizer, and deodorizing apparatus

InactiveUS6010666AImprove responseImprove adsorption capacityGas treatmentOther chemical processesMethyl disulfideFoul odors

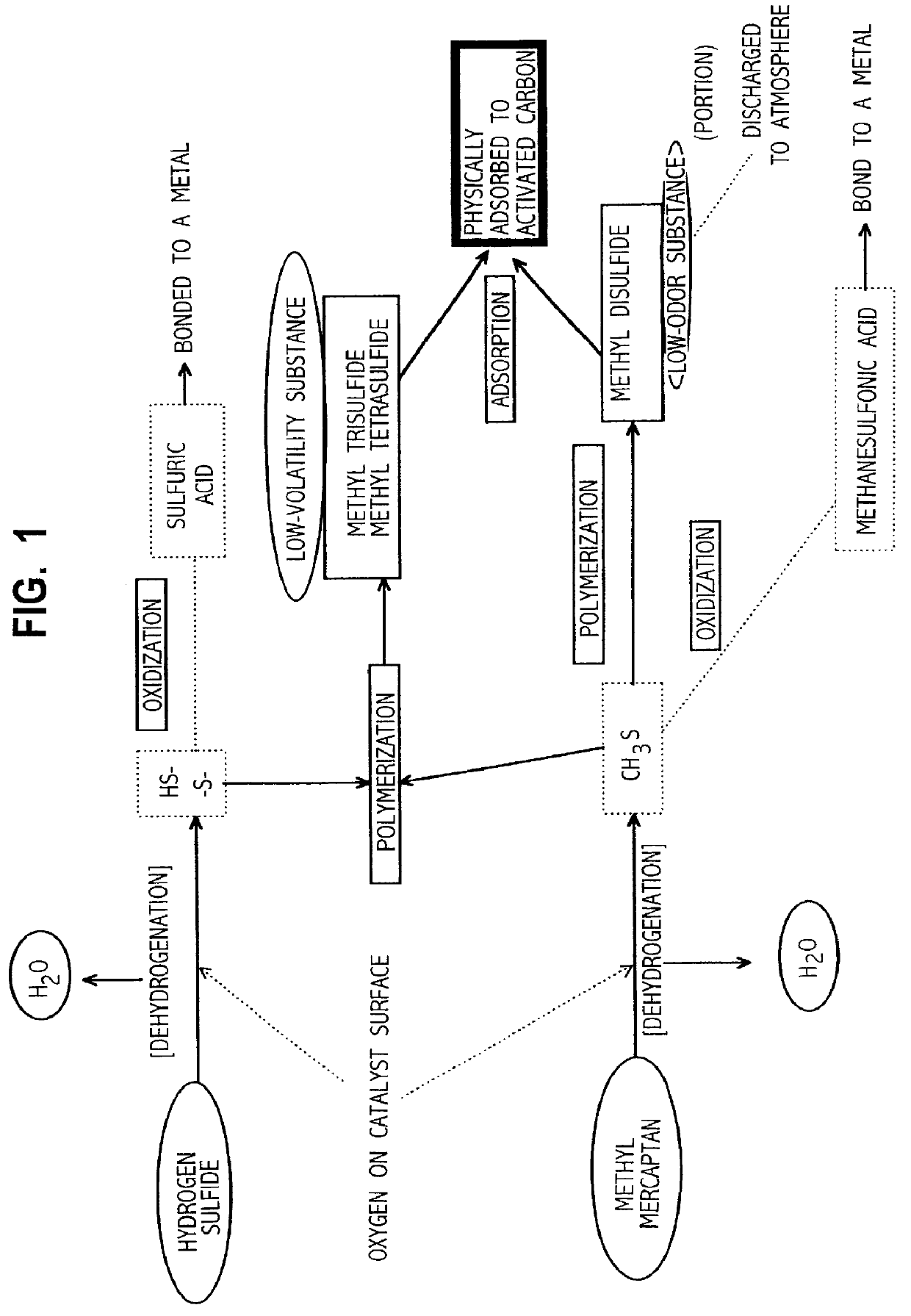

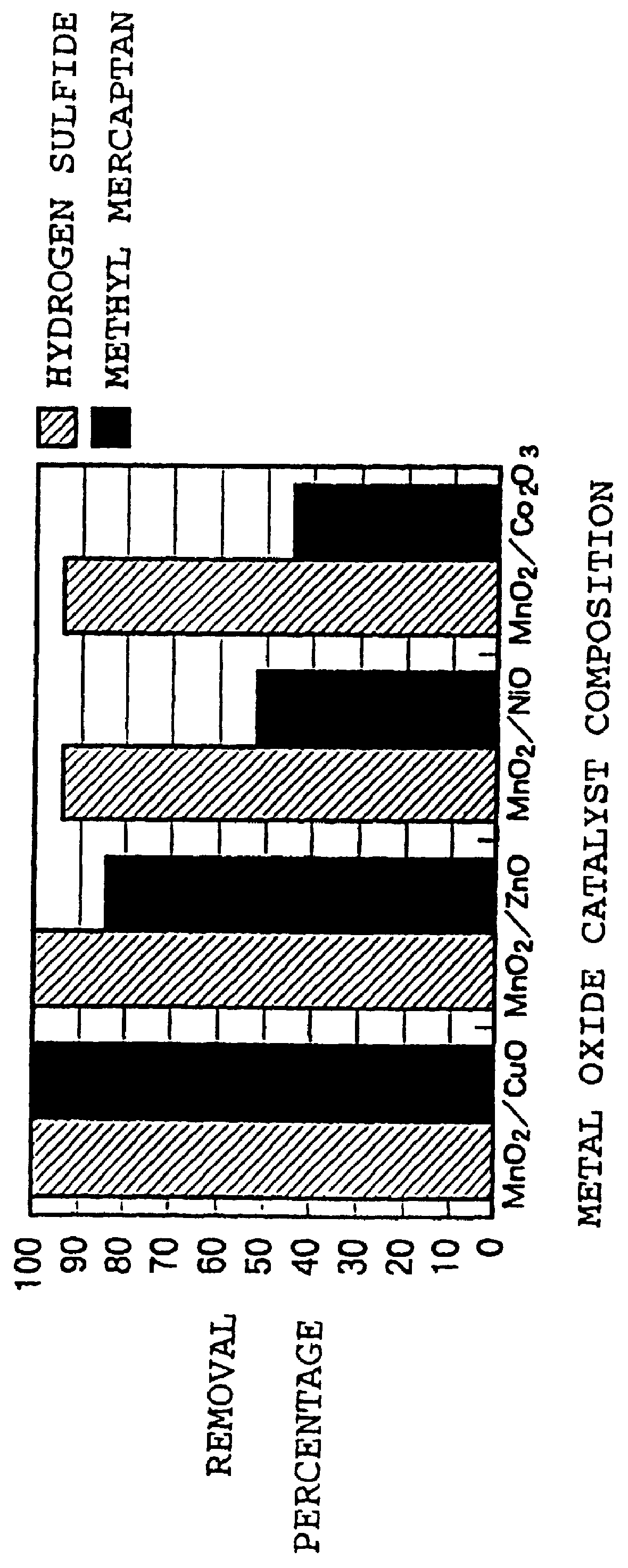

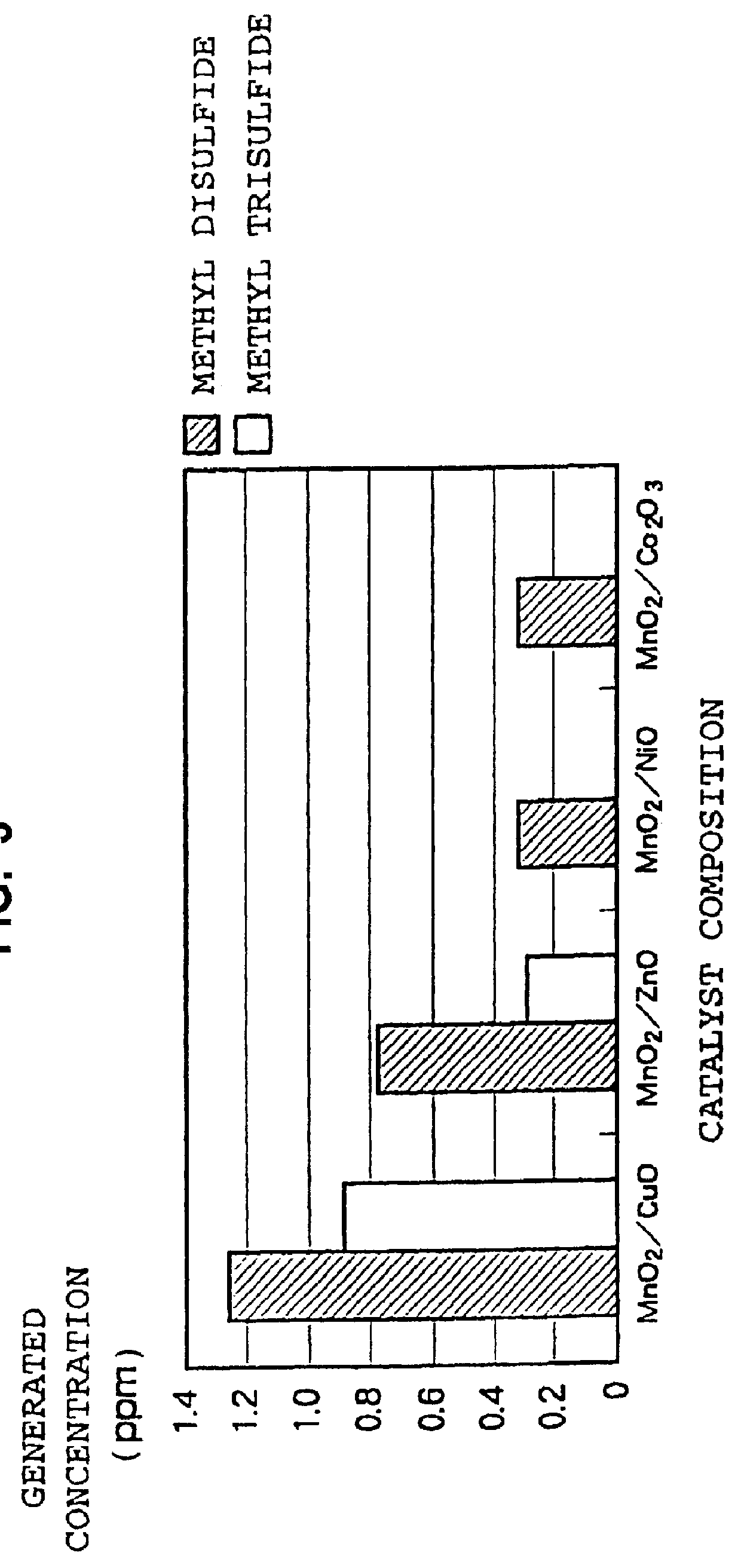

PCT No. PCT / JP96 / 00748 Sec. 371 Date Nov. 15, 1996 Sec. 102(e) Date Nov. 15, 1996 PCT Filed Mar. 22, 1996 PCT Pub. No. WO96 / 29099 PCT Pub. Date Sep. 26, 1996Hydrogen sulfide is dehydrogenated to generate a HS group and an S group. The HS group is oxidized to generate sulfuric acid, which is bonded to a metal. The S group is polymerized with a CH3S group to generate methyl trisulfide or methyl tetrasulfide, which is adsorbed to an adsorbent. Methyl mercaptan is dehydrogenated, for example, to generate a CH3S group. A portion of the CH3S group is oxidized to generate methanesulfonic acid, which is bonded to a metal. Another portion of the CH3S group is polymerized with the CH3S group itself to generate methyl disulfide, at least a portion of which is adsorbed to an adsorbent. Still another portion of the CH3S group is polymerized with the S group to generate methyl trisulfide or methyl tetrasulfide, which is physically adsorbed to an adsorbent. In this manner, malodor components including hydrogen sulfide and methyl mercaptan can efficiently be removed without producing or release of harmful secondary products. A simple-structure, compact deodorizing apparatus including appropriate metal oxide catalyst and an adsorbent material suitable for achieving the above deodorizing functions is incorporated in a toilet bowl.

Owner:TOTO LTD

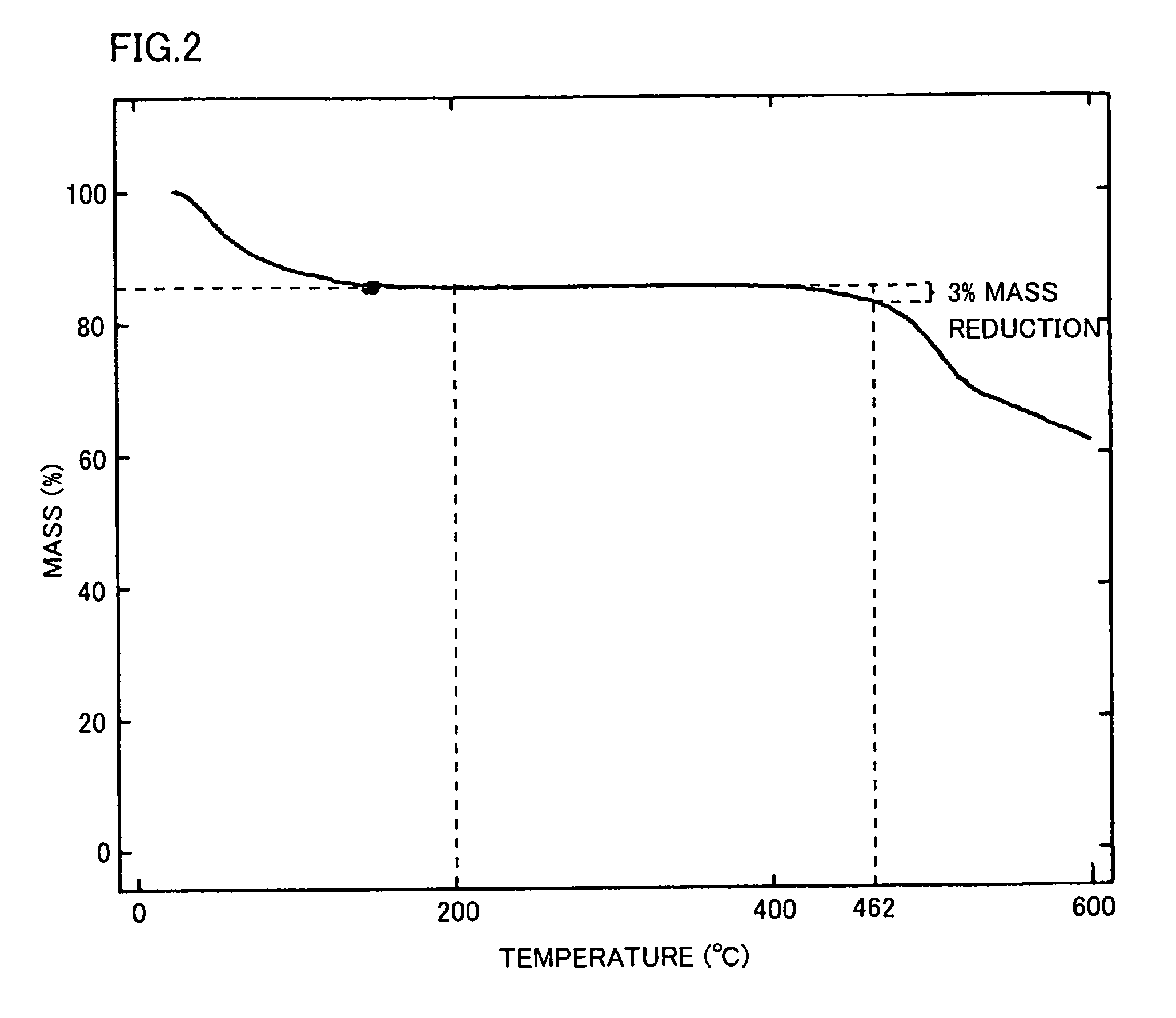

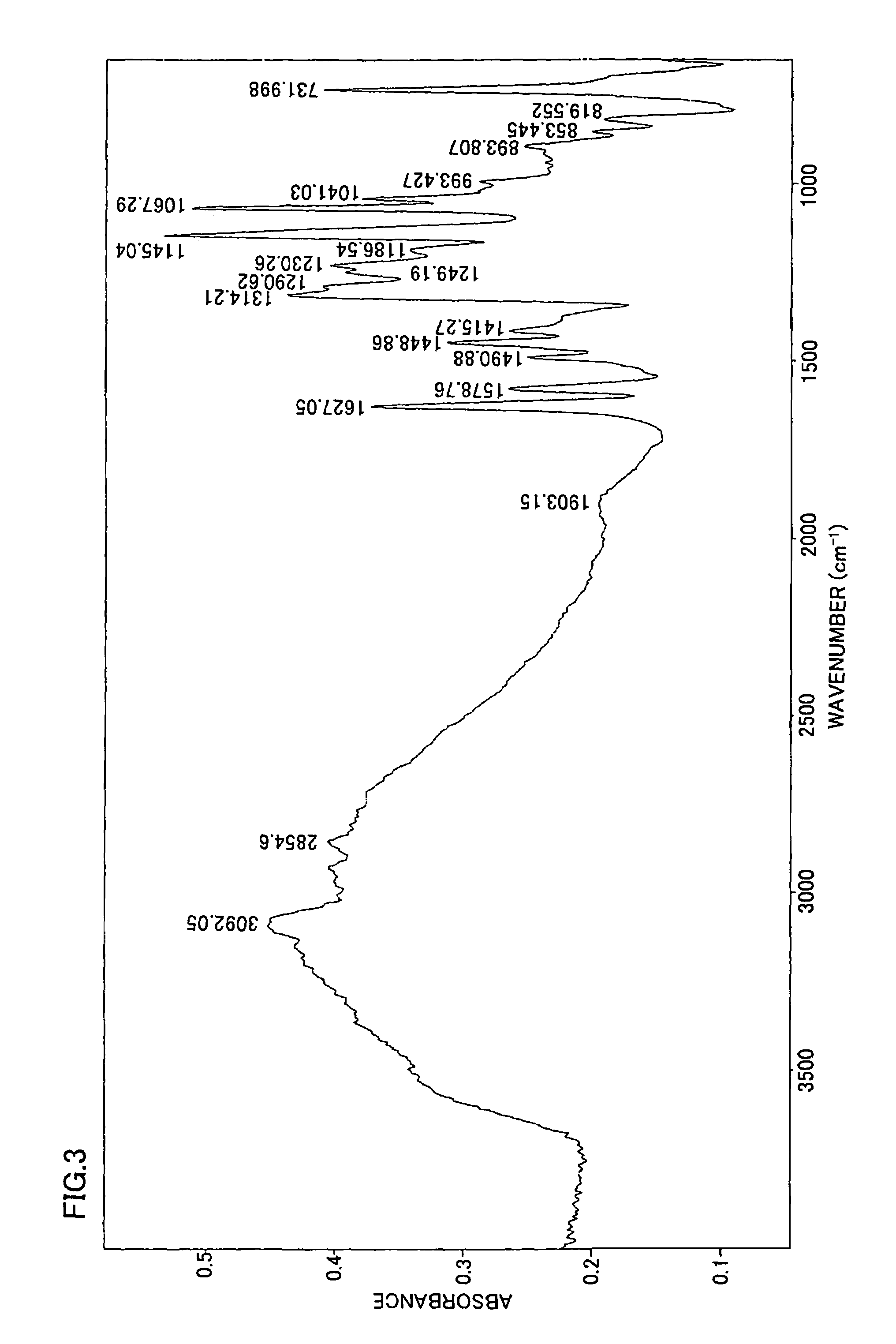

Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

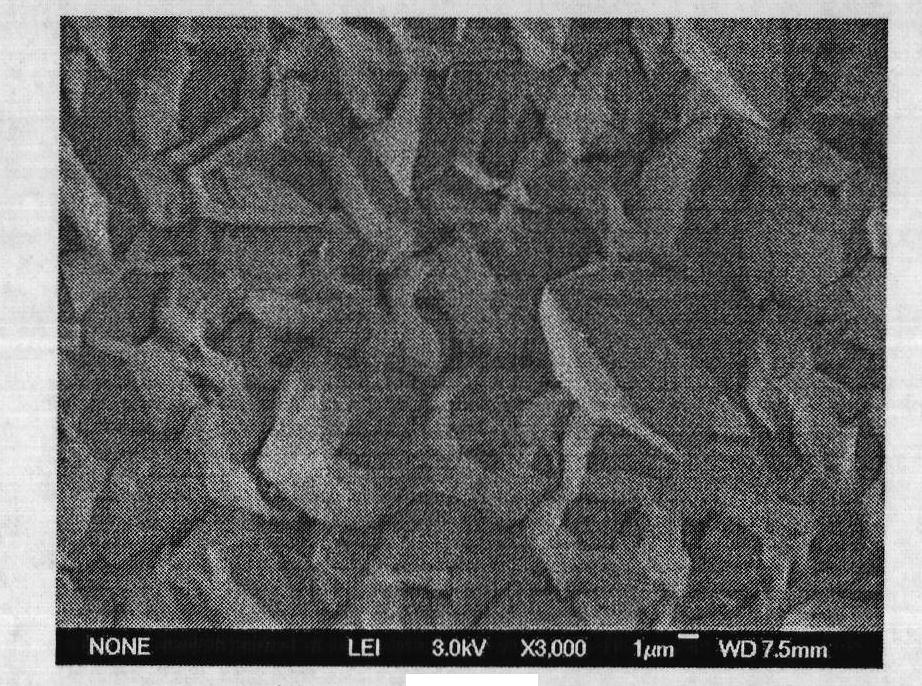

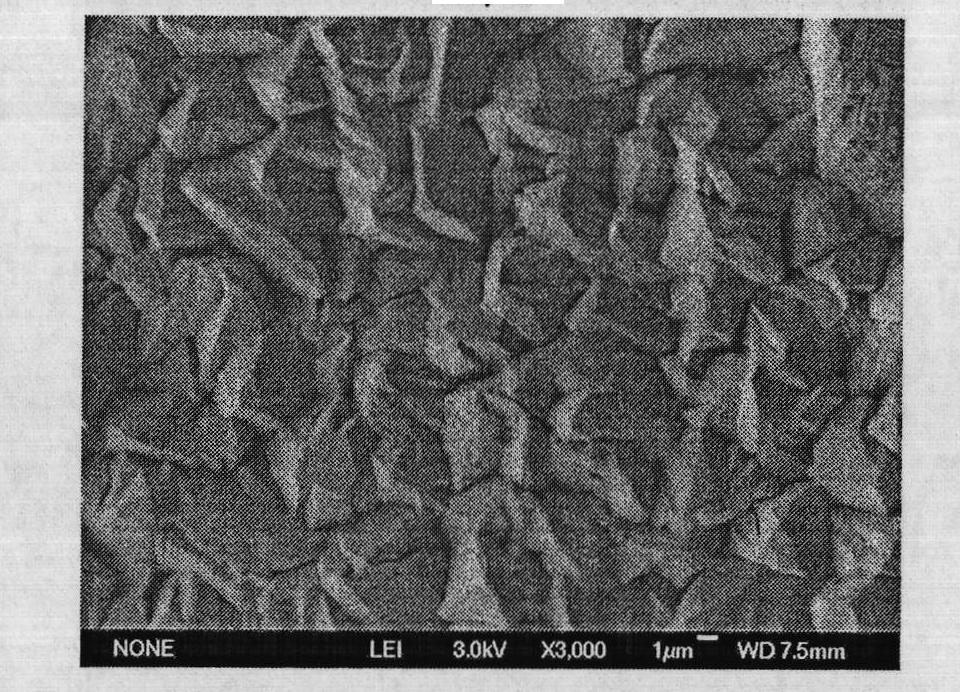

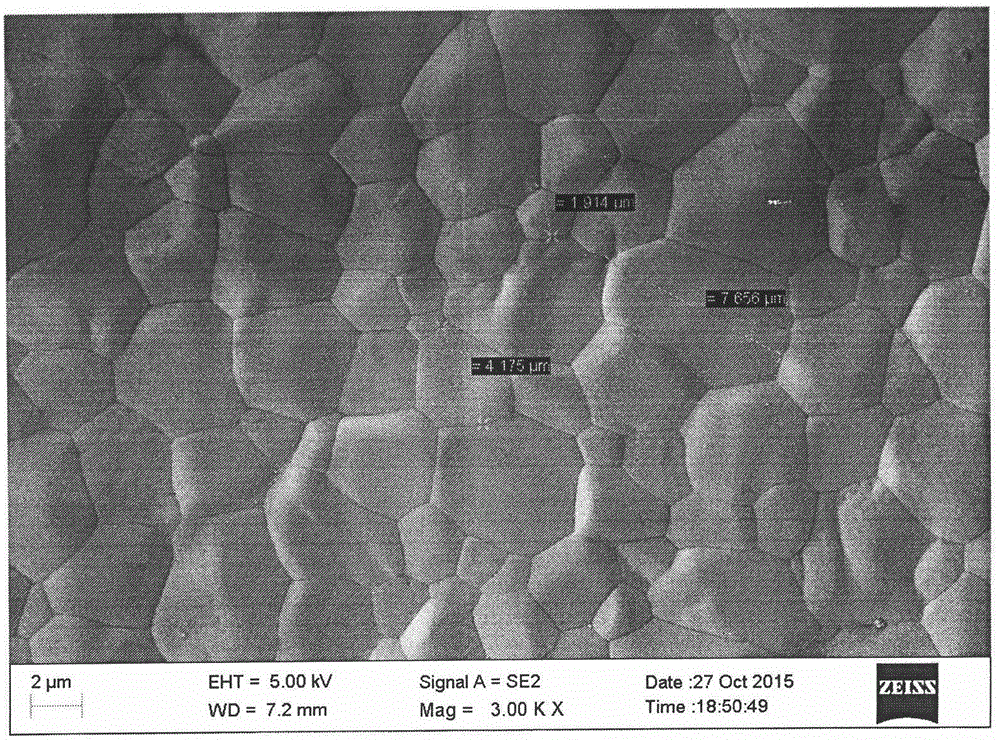

The invention relates to a methanesulfonic acid-based matte pure tin electroplating solution and an additive thereof. Each liter of an aqueous solution agent of the additive comprises the following components based on concentration: 1.5g / L-3g / L of grain refiner, 100g / L-200g / L of non-ionic surfactant, 10g / L-30g / L of antioxidant and 100g / L-150g / L of organic solvent, wherein the grain refiner is particularly heterocyclic compounds, amine compounds or a mixture of the two. The electroplating solution prepared by the additive in the invention has the advantages of good scatter performance, high flexibility and extensibility of the pure tin-based electroplating layer, and good weldability, and prevents the tin whisker from growing for a long time; and meanwhile, the electroplating solution contains no non-biodegradable substances or surfactant harmful to the environment and the like, thus facilitating the treatment of sewage and meeting the requirements for environmental protection. The invention is worthy of popularizing and applying.

Owner:济南德锡科技有限公司

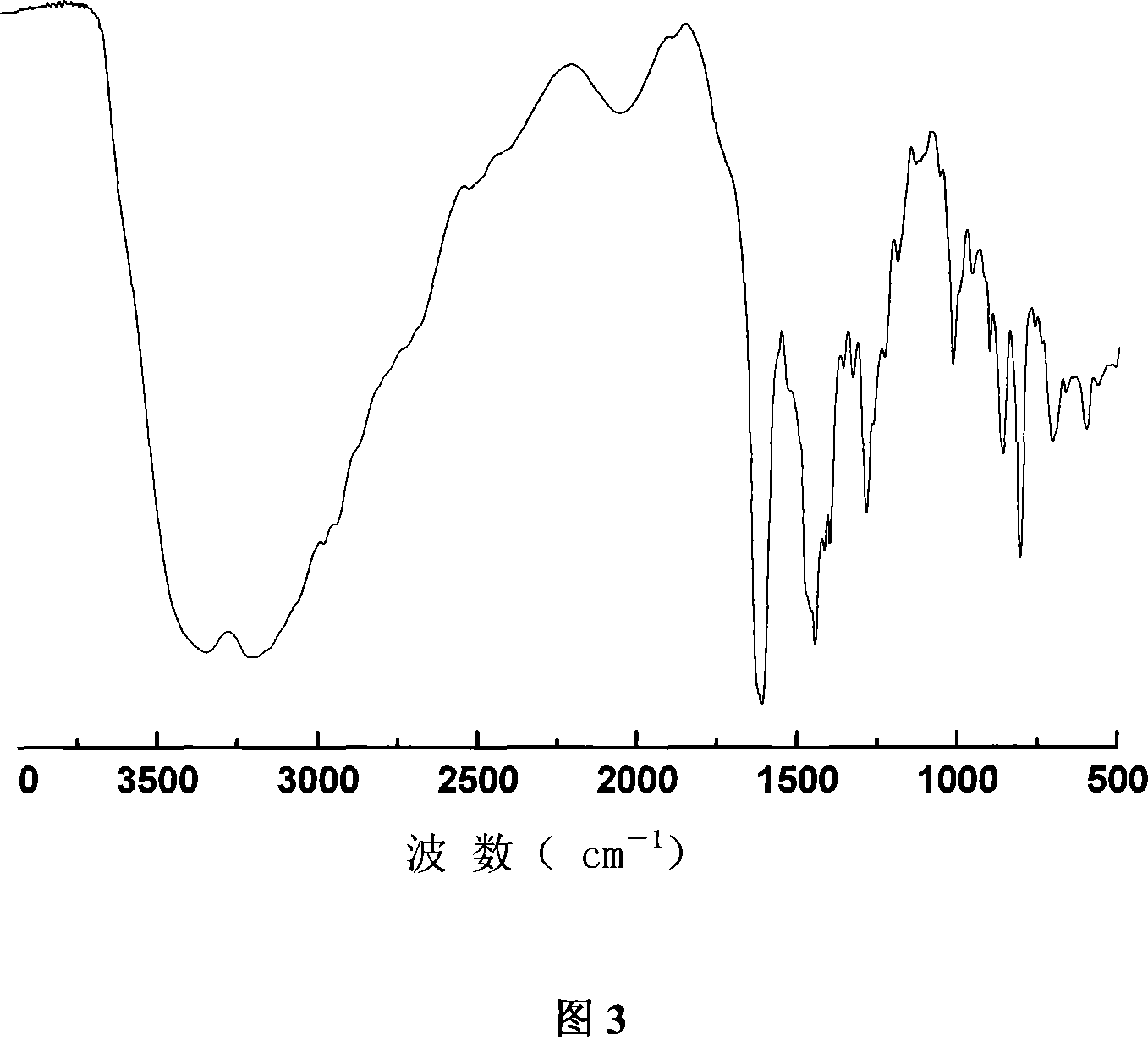

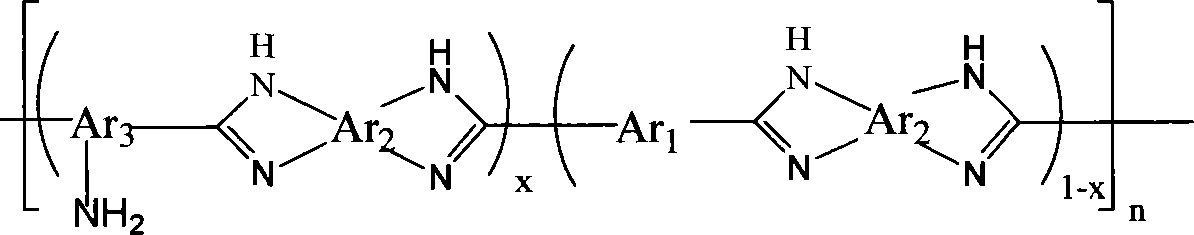

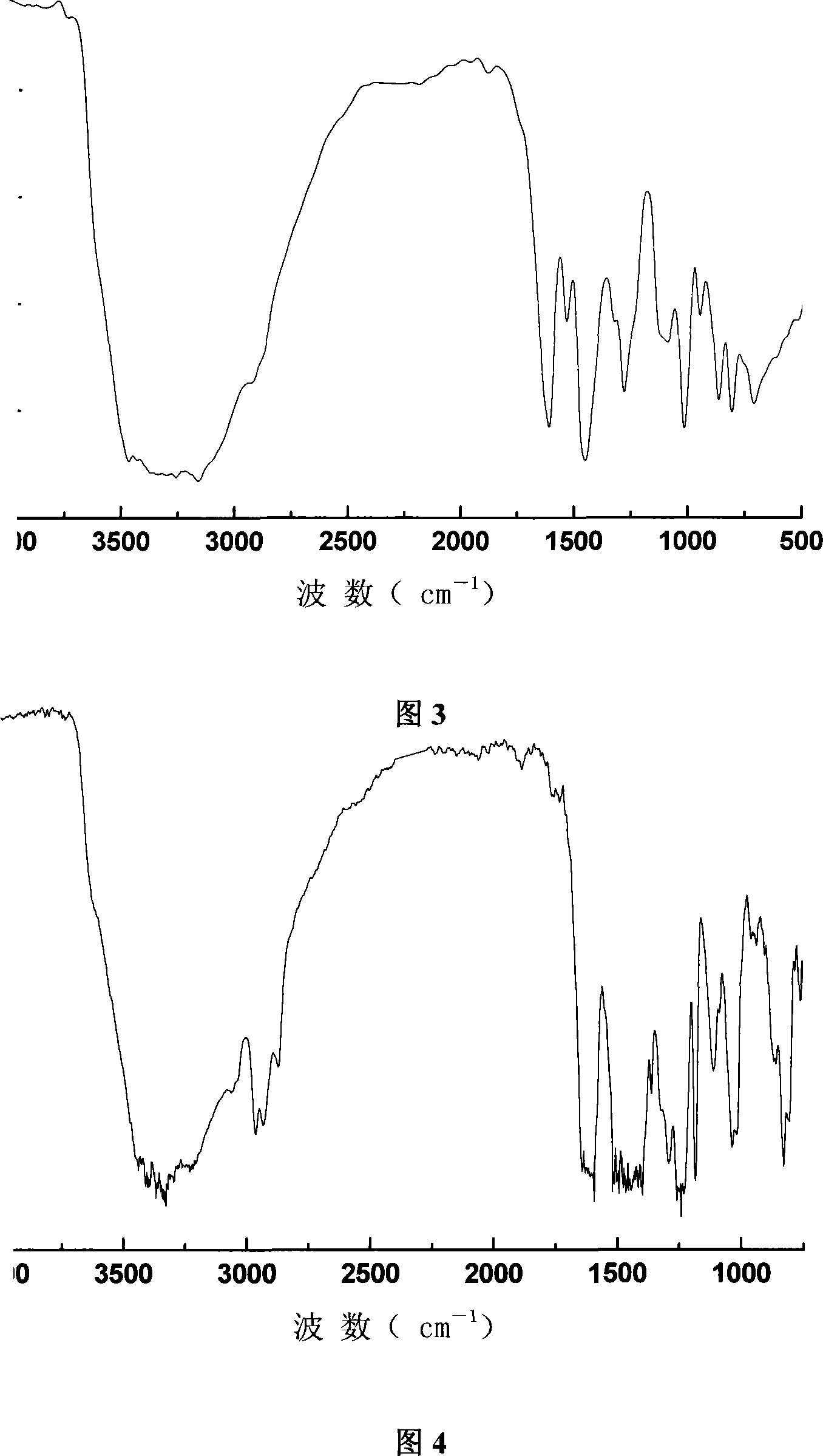

Production method for 2 or multi-halohydrocarbon crosslinked polybenzimidazole crosslinked membrane

The invention relates to a preparation method of a polybenzimidazole crosslinking membrane that is crosslinked with bihalohydrocarbon or polyhalohydrocarbon, which takes amino dibasic acid and aromatic tetraamine as monomer raw material and polyphosphoric acid as reaction medium and reaction is carried out for 5-30 hours at 150-220 DEG C under the nitrogen protection condition so as to obtain homopolymer containing amino polybenzimidazole, and takes the amino dibasic acid, nonaminonic dibasic acid and the aromatic tetraamine as the monomer raw materials to prepare copolymer containing amino polyphosphoric under the same conditions. The prepared homopolymer and the copolymer of the polybenzimidazole have good dissolvability in solvents of dimethyl sulphoxide, N, N-dimethylacetamide, phosphate, vitriol and methane-sulforic acid, etc. Both the structures of the homopolymer and the copolymer of the polybenzimidazole contain amino that can be used for crosslinking. The bihalohydrocarbon or the polyhalohydrocarbon is used as cross linking agent. The polybenzimidazole crosslinking membrane with good property can be prepared through crosslinking reaction of the amino contained in the polybenzimidazole and the bihalohydrocarbon or the polyhalohydrocarbon.

Owner:SHANGHAI JIAO TONG UNIV

Process for producing high-strength polypyrrole film

InactiveUS20060275660A1Easily formHigh mechanical strengthElectrolysis componentsElectrode manufacturing processesIonPyrrole

In polypyrrole films obtained by a process for producing polypyrrole films comprising the steps of forming polypyrrole layers on working electrodes by electrochemical polymerization methods using pyrroles and / or pyrrole derivatives, followed by stripping off said polypyrrole layers, wherein said electrochemical polymerization methods use electrolytes including organic compounds comprising at least one bond or one functional group of ether bond, ester bond, carbonate bond, hydroxyl group, nitro group, sulfone group, and nitryl group and / or halogenated hydrocarbon as lo solvents and wherein said electrolytes include anions including trifluoromethanesulfonate ion and / or plural of fluorine atoms which bond to central atom and said working electrodes are metal electrodes, conductivity can be stably sustainable in the presence of oxygen and are excellent in mechanical strength.

Owner:EAMEX

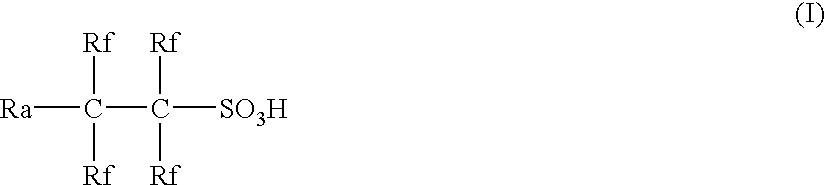

Radiation-sensitive resin composition

A radiation-sensitive resin composition comprising (A) an acid-dissociable group-containing polysiloxane and (B) a photoacid generator containing trifluoromethane sulfonic acid or a compound which generates an acid of the following formula (I),wherein Rf individually represents a fluorine atom or a trifluoromethyl group, and Ra represents a hydrogen atom, a fluorine atom, a linear or branched alkyl group having 1-20 carbon atoms, or a linear or branched fluoroalkyl group having 1-20 carbon atoms, a substituted or unsubstituted monovalent cyclic hydrocarbon group having 3-20 carbon atoms, or a substituted or unsubstituted monovalent cyclic fluoro-hydrocarbon group having 3-20 carbon atoms. The radiation-sensitive resin composition of the present invention exhibits superior resolution, while maintaining high transparency to radiations and high dry etching resistance. The resin composition thus can greatly contribute to the lithography process that will become more and more minute in the future.

Owner:JSR CORPORATIOON

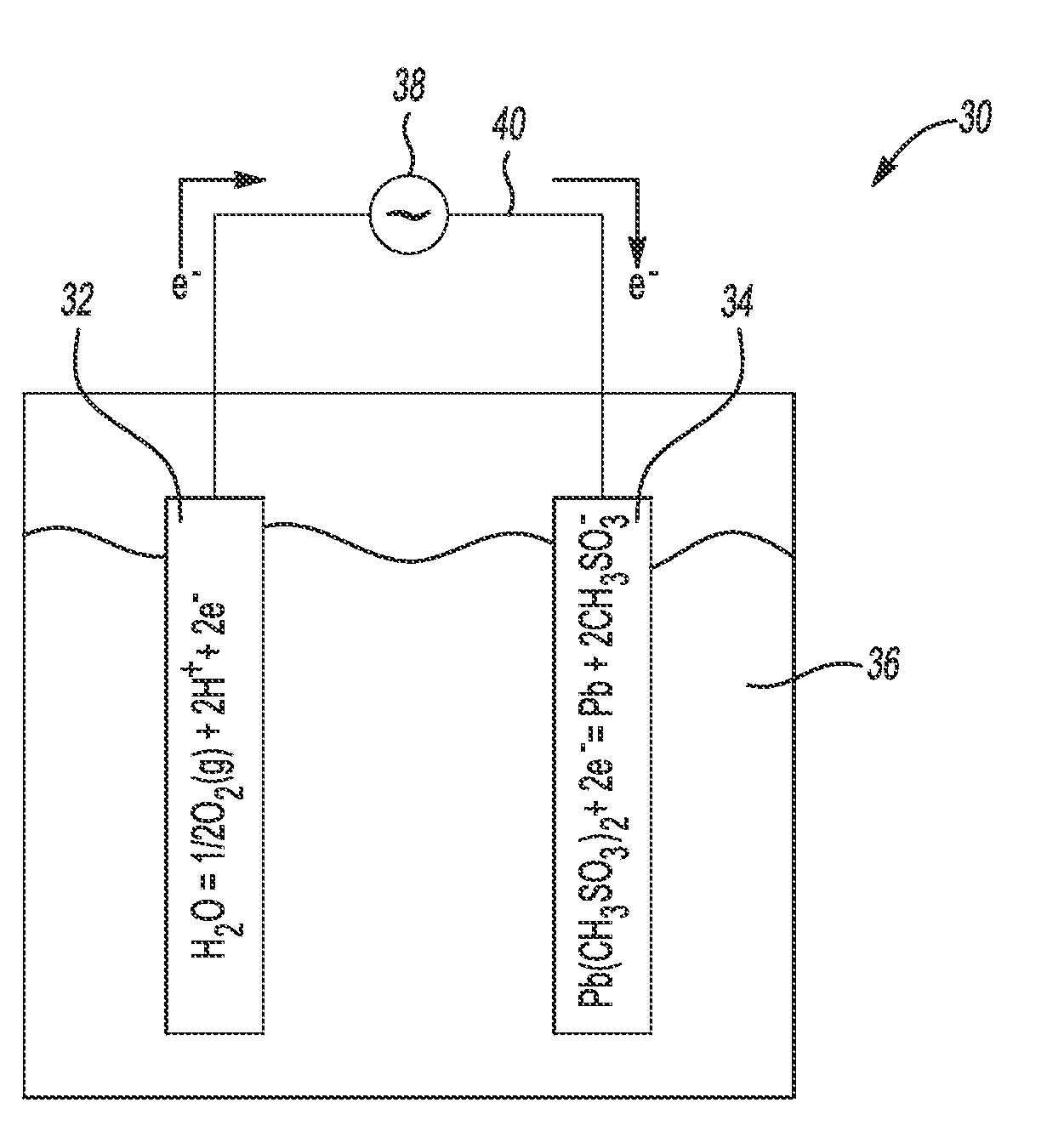

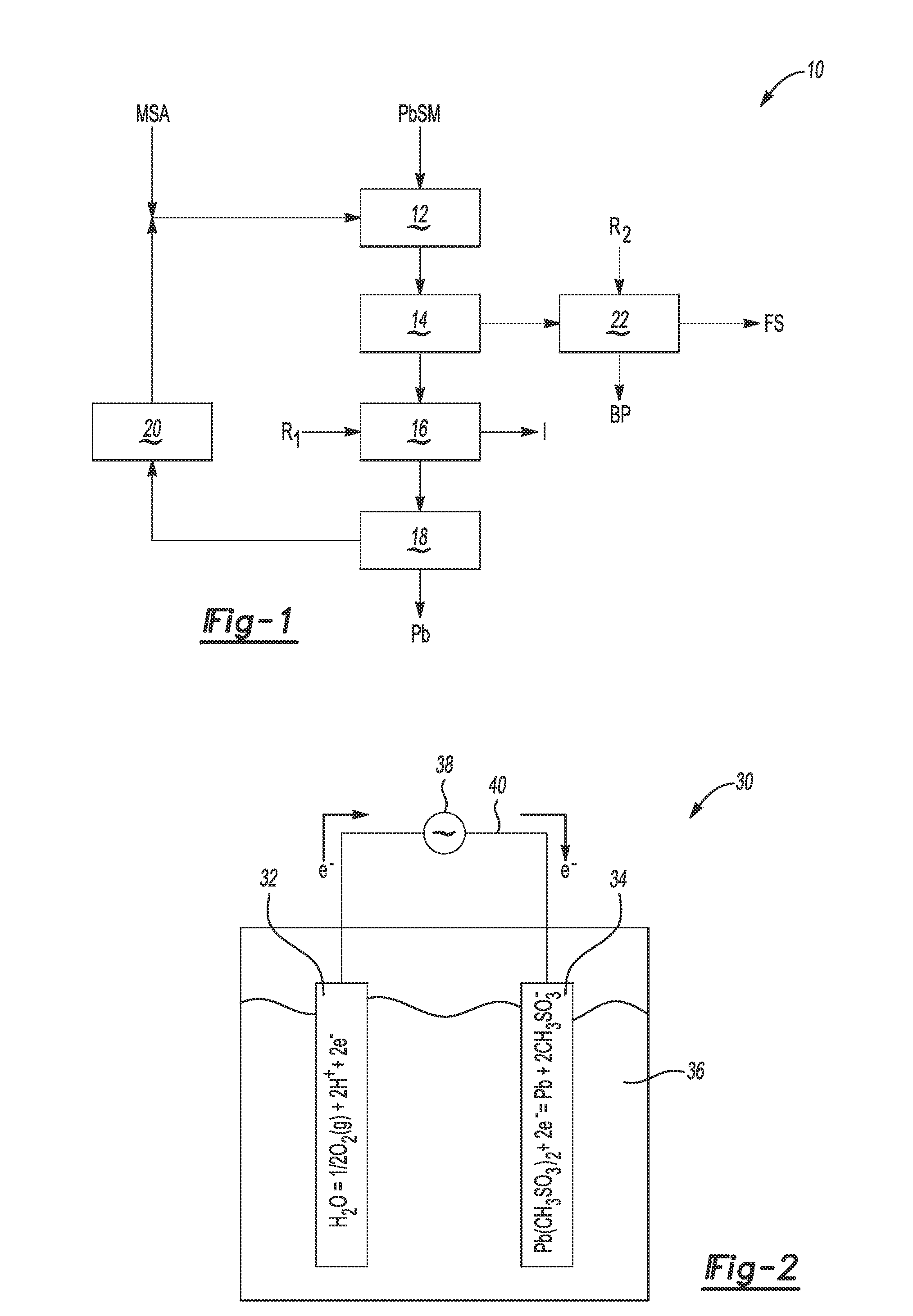

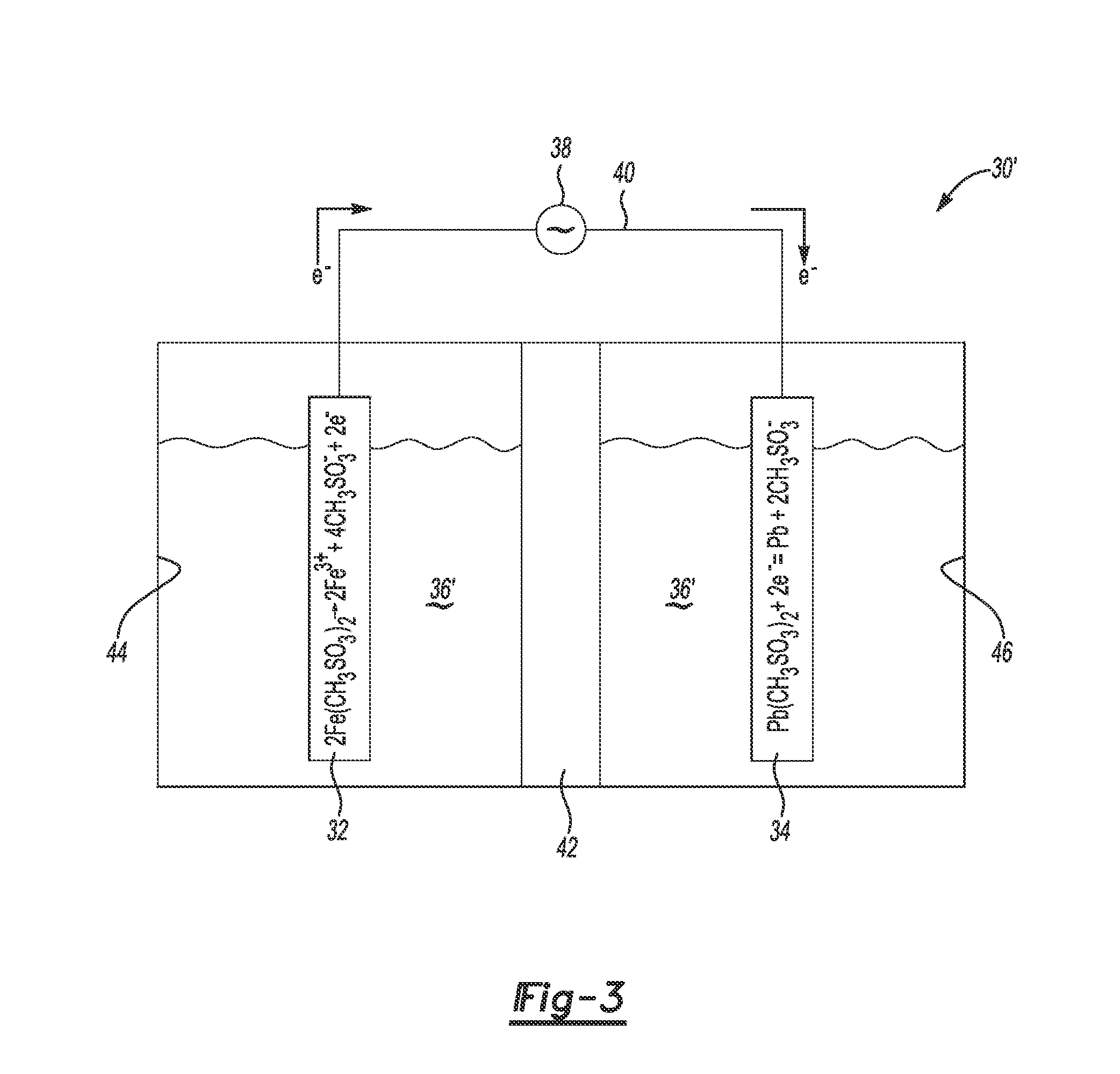

Recovering lead from a lead material including lead sulfide

In an example of a method for recovering lead from a lead material including lead sulfide, methane sulfonic acid is selected as a leaching acid for the lead material. The lead material is exposed to a solution including the methane sulfonic acid and i) ferric methane sulfonate or ii) oxygen, which leaches lead from the lead sulfide in the lead material, and generates a liquid leachate including a lead-methane sulfonate salt. The liquid leachate is purified, and lead is recovered from the purified liquid leachate using electrolysis.

Owner:THE UNIV OF BRITISH COLUMBIA

Method for producing polybenzimidazole crosslinked membrane with epoxy compound

The invention relates to a method for preparing a polybenzimidazole crosslinking membrane by using epoxy compounds, which takes amino dibasic acid and aromatic tetraamine as monomer raw material and polyphosphoric acid as reaction medium and reaction is carried out for 5-30 hours at 150-220 DEG C under the nitrogen protection condition so as to obtain homopolymer containing amino polybenzimidazole, and takes the amino dibasic acid, nonaminonic dibasic acid and the aromatic tetraamine as the monomer raw materials to prepare copolymer containing amino polyphosphoric under the same conditions. The prepared homopolymer and the copolymer of the polybenzimidazole have good dissolvability in solvents of dimethyl sulphoxide, N, N- dimethylacetamide, phosphate, vitriol and methane-sulforic acid, etc. The bifunctionality or polyfunctional epoxy compounds are used as cross linking agent. The polybenzimidazole crosslinking membrane that has good property can be prepared through crosslinking reaction of the amido contained in the polybenzimidazole and epoxy functional groups contained in the bifunctionality or polyfunctional epoxy compounds.

Owner:SHANGHAI JIAO TONG UNIV

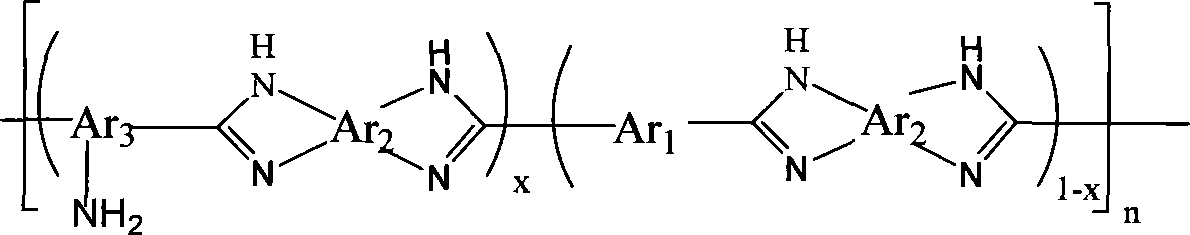

Novel synthesis method for pimavanserin

ActiveCN105820110AEasy to crystallize and purifyHigh yieldOrganic chemistrySynthesis methodsPhosphoric acid

The invention provides a novel synthesis method for pimavanserin. The method comprises the steps that a compound formula (1a) is adopted as a raw material for preparing an active urea compound formula (1) and then subjected to a reaction with a compound formula (2) under an alkaline system to obtain a pimavanserin free alkali formula (3), and then pimavanserin free alkali forms a salt with tartaric acid to obtain a pimavanserin half tartrate formula (4). The method is simple in technological path, low in cost and suitable for industrial production. The formula is shown in the description, wherein HmA is the general formula of m-basic acid, HnA is the general formula of n-basic acid, m and n are 1 or 2 or 3, and the m-basic acid and the n-basic acid are selected from sulfuric acid, hydrochloric acid, phosphoric acid, p-toluenesulfonic acid, benzenesulfonic acid, methanesulfonic acid, methanoic acid, acetic acid, trifluoroacetic acid, oxalic acid, citric acid or tartaric acid.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

Process for producing 4-amino-1-hydroxybutylidene-1,1-bisphosphonic acid and its trihydrated monosodium salt

InactiveUS6573401B1Easy to adaptHigh yieldGroup 5/15 element organic compoundsRecord information storagePhosphorous acidHydrolysis

The invention relates to a process for the preparation of 4-amino-1-hydroxybutylidene-1,1-bisphosphonic acid and of the trihydrated monosodium salt thereof, consisting of reacting 4-aminobutyric acid with a phosphonation mixture formed by phosphorous acid and methanesulfonic anhydride and thereafter hydrolyzing the product of said reaction and isolating the products by adjustment of the pH.

Owner:MEDICHEM

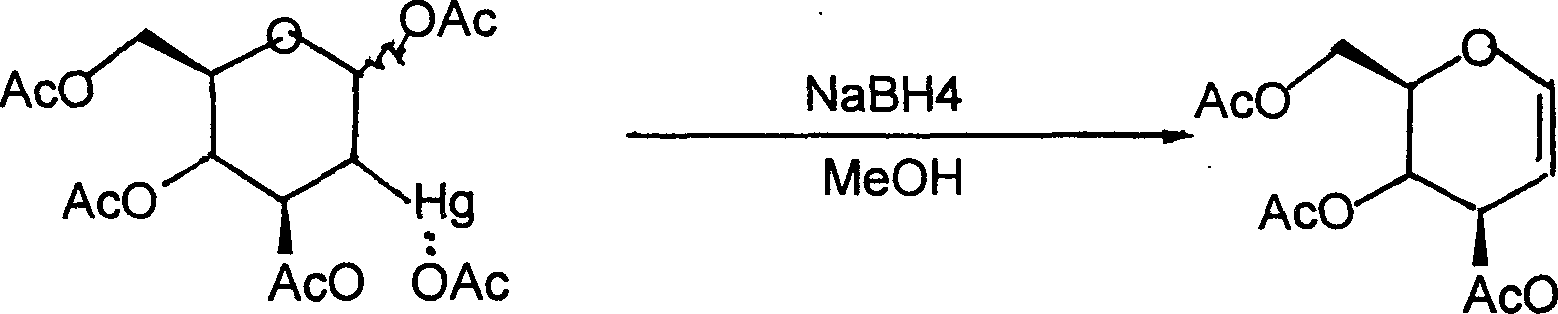

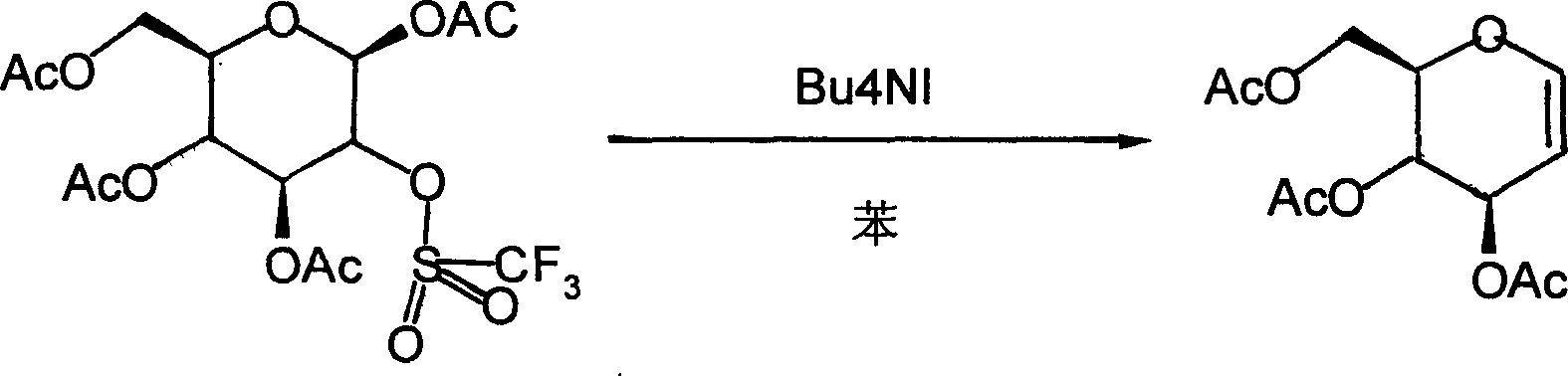

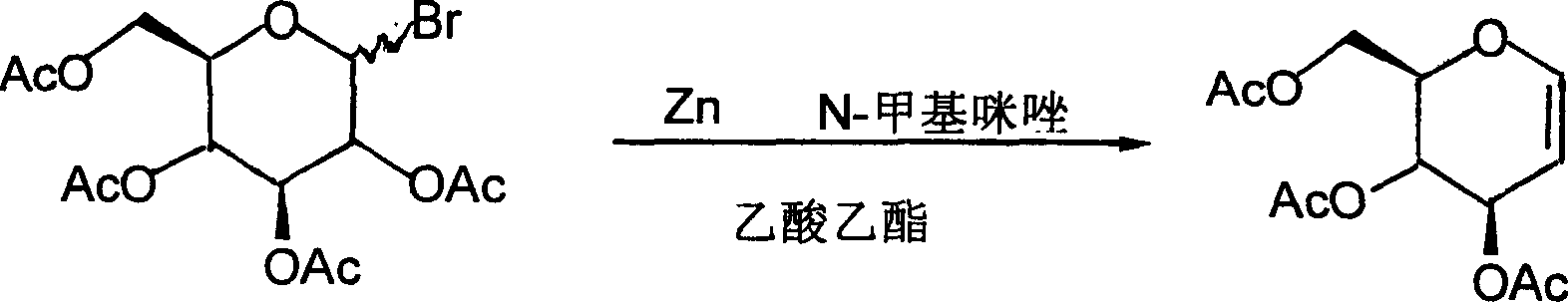

Method for preparing acetylated glucal

InactiveCN1803818ASimple and efficient synthesisWork lessSugar derivativesSugar derivatives preparationP-Toluenesulfonic acidMethanesulfonic acid

The disclosed preparation method for acetylized glucal comprises: preparing the D-acetylized glucose catalyzed by acids (HClO4, H2SO4, ZnCl2, AlCl3, p-toluenesulfonic acid and methanesulfonic acid); without separation or purification, leading directly the product into HBr or equivalent (such as PBr3 and water) to obtain and then recrystallize the coarse 1-bromoacetyl glucose with one of ethyl ether, propyl ether and isopropyl ether; adding Zn, ZnCl2, methanol and Co-ion catalyst to prepare the coarse target; recrystallizing with alcohol for the refined product. This invention saves step and reduces cost.

Owner:朱书汉

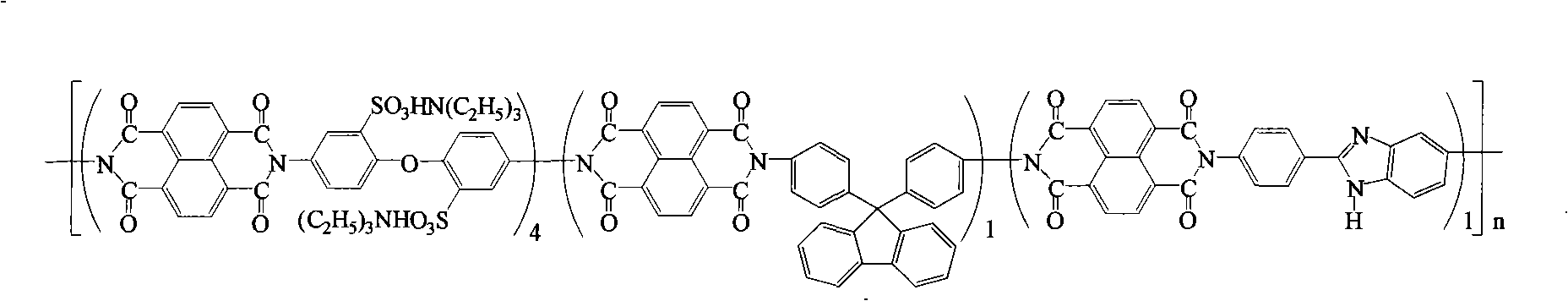

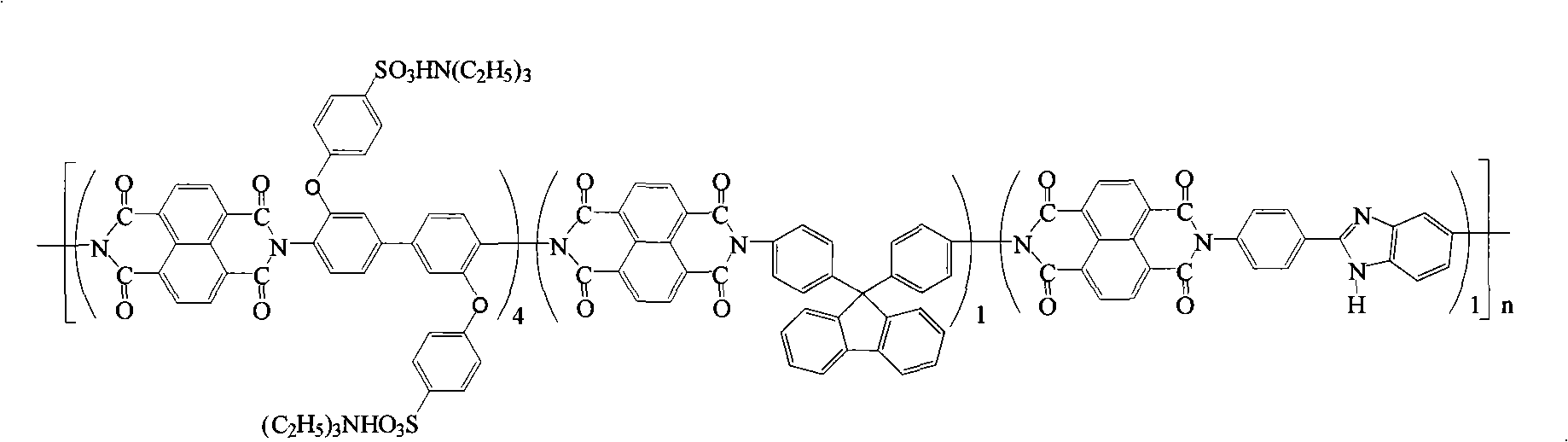

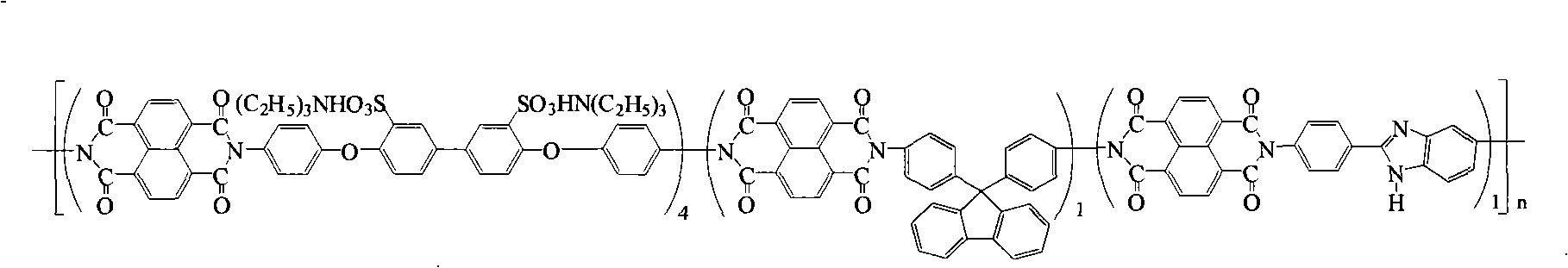

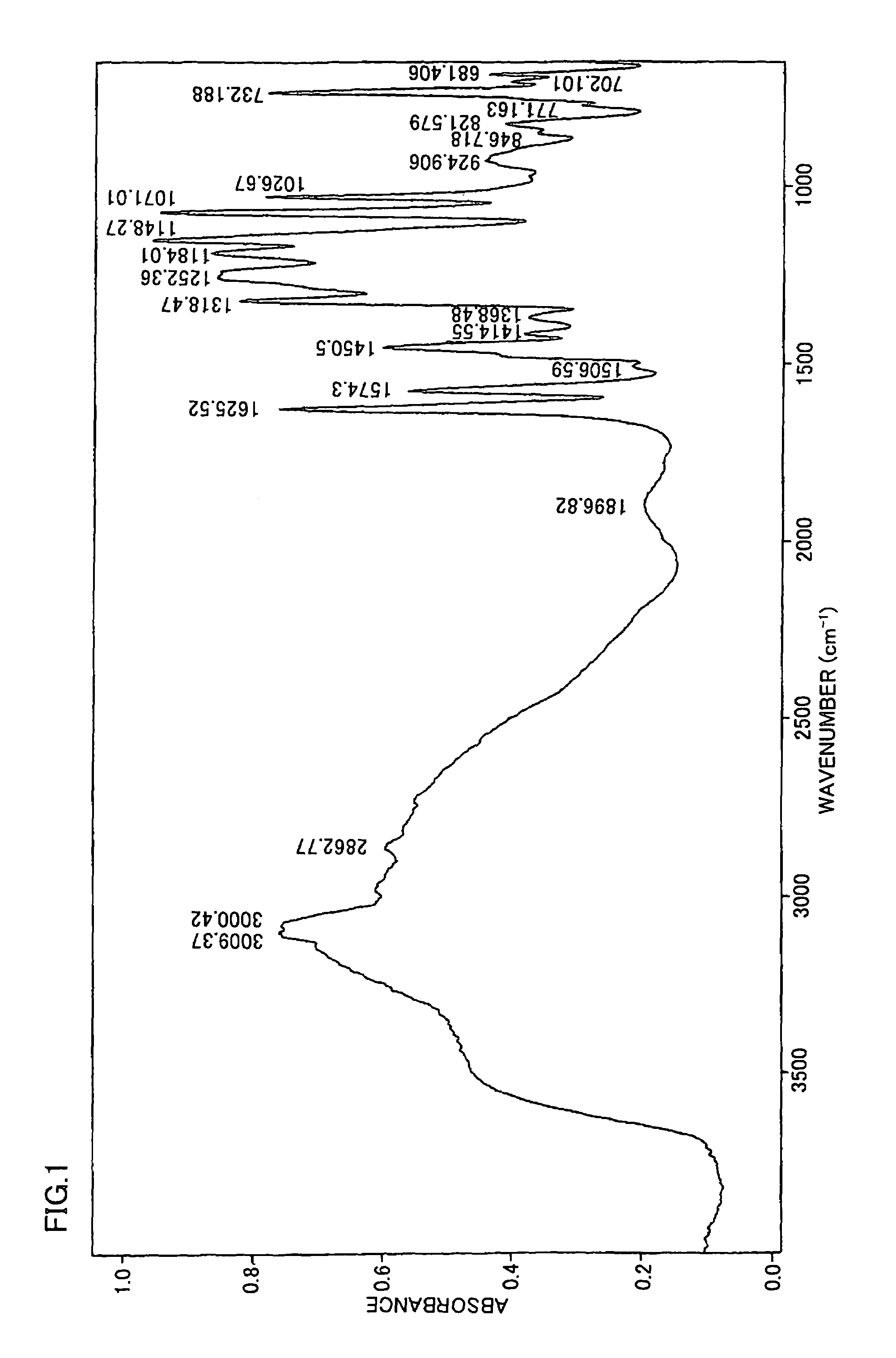

Preparation of glyoxalinyl-containing sulphonation polyimides covalence-ionomer membrane

InactiveCN101407592AExcellent anti-free radical oxidation performanceHigh proton conductivityCell component detailsFuel cell detailsBenzoic acidCross-link

The invention relates to a preparation method of a covalent-ion cross-linked film of sulfonated polyimide containing imidazolyl. The preparation method comprises the following steps: 1, 4, 5, 8-naphthoic tetracarboxylic dianhydride, sulfonated diamine, common non-sulfonated diamine and diamine containing imidazolyl are added into a metacresol medium, the sulfonated polyimide containing imidazolyl is obtained by copolycondensation under the presence of triethylamine and benzoic acid and the protection of nitrogen; a solution casting method and proton exchange are adopted to prepare non-covalent cross-linked sulfonated polyimide film containing imidazolyl which is then processed by methane-sulfonic acid / phosphorus pentoxide solution or phosphoric acid solution or polyphosphoric acid containing phosphorus petoxide so as to prepare the covalent-ion cross-linked film of sulfonated polyimide containing imidazolyl. The covalent-ion cross-linked film obtained by the preparation method has anti-free radical oxidation susceptibility which is far better than the common sulfonated polyimide or non-covalent cross-linked film without containing imidazolyl and has potential application prospect in the fields of fuel cells and the like.

Owner:SHANGHAI JIAO TONG UNIV

Stimuli-responsive textile fabric and method for preparing same

The invention relates to an environment-response intelligent weave fabric and relative preparation. Wherein, adding the fabric which is induced by argon microwave low-temperature plasma to generate free group on surface, into the dual monomer solution of 2-acrylamide-2-methanesulfonic acid and N-isopropyl acrylamide that contains N and N'-methylene dual acrylamide cross linker to process graft polymerization reaction, while the bath ratio is 1:40, to graft the dual intelligent gel on the fiber macromolecule of fabric, to attain said inventive product. When the invention is dry, it has no difference from general fabric, but when it is wet, the gel will adsorb water to expand and block the slits between fibers, to reduce the water and gas permeability of fabric, and avoid outer penetrating into the inner layer of fabric to stop heat emission. The invention can be used to produce army waterproof clothes, heat-accumulation temperature adjustable special clothes, etc.

Owner:TIANJIN POLYTECHNIC UNIV

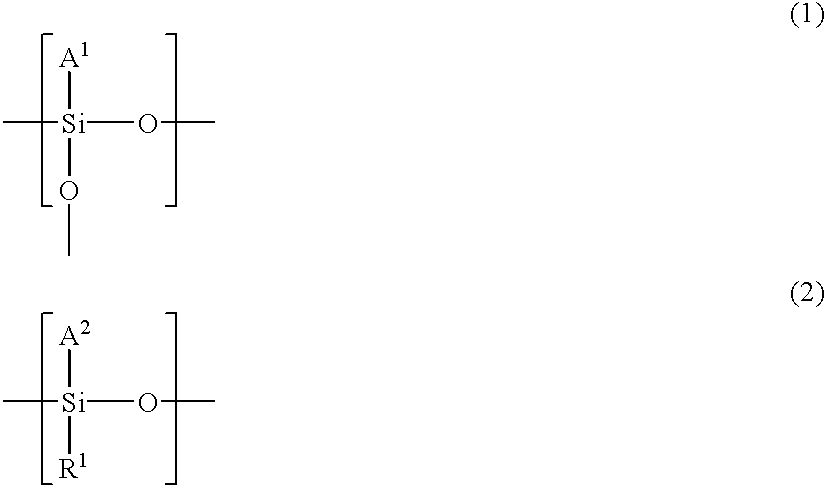

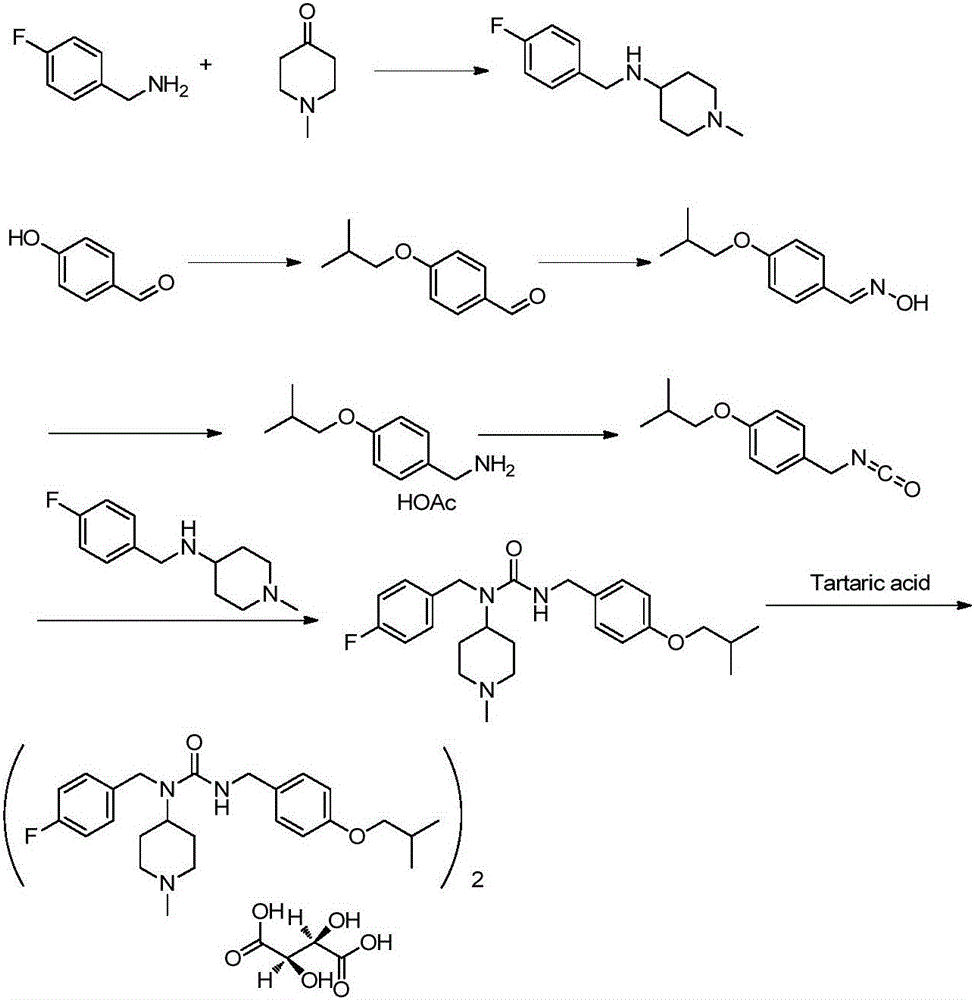

Polybenzazole compound having sulfonic acid group and/or phosphonic acid group, resin composition containing the same, resin molding, solid polymer electrolyte membrane, solid polymer electrolyte membrane/electrode assembly and method of preparing assembly

InactiveUS7288603B2Reduce conductivityExcellent in resistanceIon-exchanger regenerationConductive materialPolymer scienceCarboxylic acid

An object of the present invention is to obtain a novel polymeric material capable of forming a solid polymer electrolyte excellent not only in processability, solvent resistance and durability / stability but also in ion conductivity by introducing sulfonic acid group or phosphonic acid group into a polybenzazole compound having excellent properties in view of heat resistance, solvent resistance, mechanical characteristics and the like.Means attaining the object of the present invention is a polybenzazole compound including an aromatic dicarboxylic acid bond unit having sulfonic acid group and / or phosphonic acid group and satisfying either a condition that inherent viscosity measured in concentrated sulfuric acid is in the range of 0.25 to 10 dl / g or a condition that inherent viscosity measured in a methanesulfonic acid solution is in the range of 0.1 to 50 dl / g.The object of the present invention can be attained also by a resin composition containing the aforementioned polybenzazole compound, a resin molding, a solid polymer electrolyte membrane, a solid polymer electrolyte membrane / electrode assembly and a method of preparing the solid polymer electrolyte membrane / electrode assembly.

Owner:TOYOBO CO LTD

Electrolyte and method for electrolyzing and refining crude lead

InactiveCN104746098AAvoid serious harmAvoid heavy pollutionPhotography auxillary processesHydrometallurgyMethanesulfonic acid

The invention relates to electrolyte and a method for electrolyzing and refining crude lead, and belongs to the technical field of wet-process metallurgy. The electrolyte electrolyzing and refining crude lead is of a methylsulphonic acid solution system comprising methyl lead sulfonate and free methyl sulfonic acid, wherein the concentration of Pb<2+> is 50-200g / L, and the concentration of the free methyl sulfonic acid is 50-160g / L. The method comprises the following steps: placing a solution system electrolyte comprising the methyl lead sulfonate and free methyl sulfonic acid, a to-be-refined crude lead anode plate and a cathode plate into an electrolytic cell, then, applying direct-current power, adding an additive comprising one or a mixture of animal glue, lignosulfonate, aloin and beta-naphthol into the electrolyte to electrolyze for 2-7 days so as to generate cathode lead and anode mud, obtaining national-standard 1# lead ingot after melting and casting cathode lead, performing washing and filter pressing on the anode mud, and then feeding the anode mud to a noble metal extracting process. According to the method, a brand-new methanesulfonic acid solution system is adopted as an electrolyte for electrolysis, so that the method has the characteristic of being remarkable in environment-friendly advantage.

Owner:KUNMING UNIV OF SCI & TECH

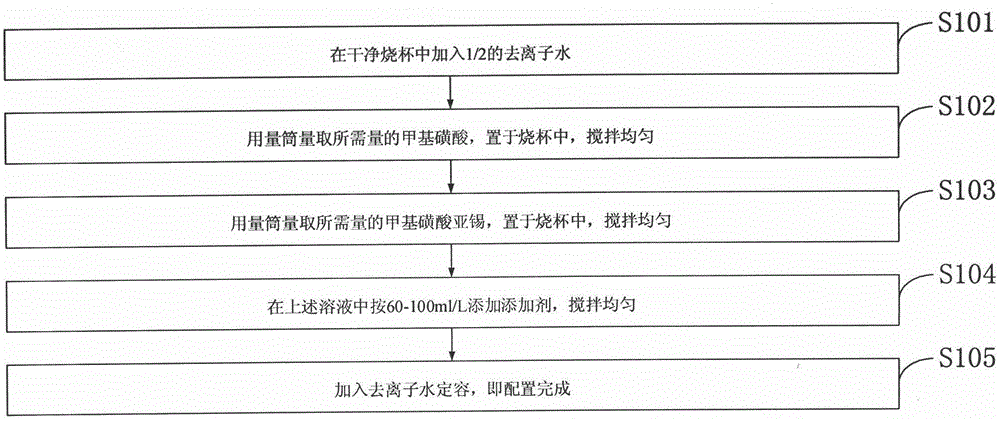

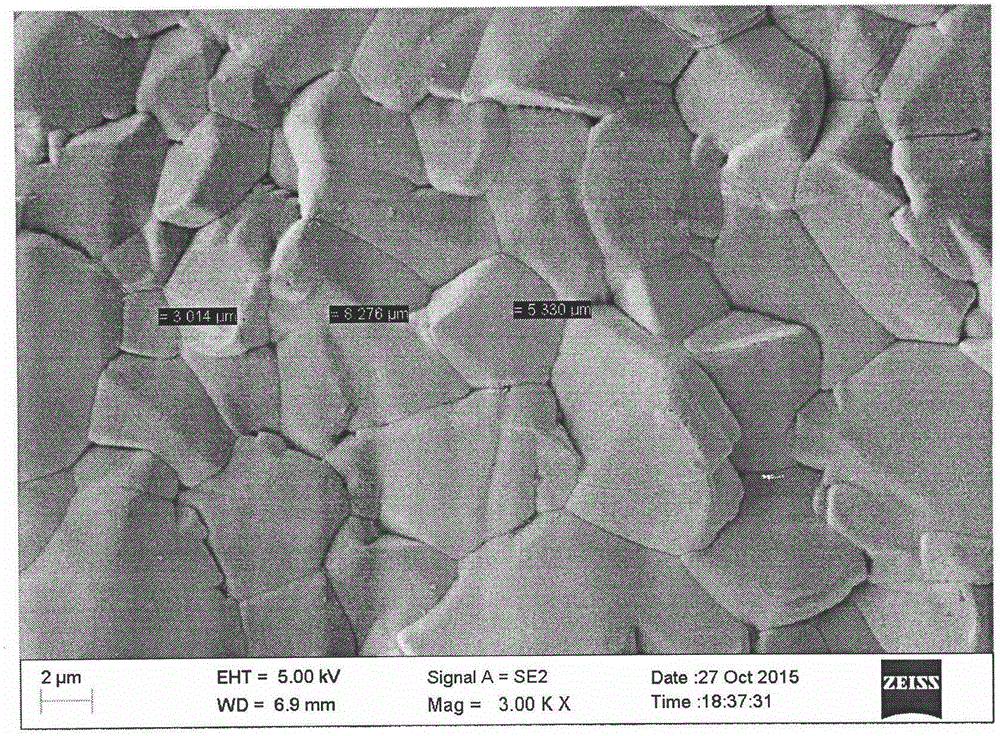

High-speed tinning solution and preparation method thereof

The invention discloses a high-speed tinning solution and a preparation method thereof. Deionized water is added to a clean beaker until the volume of the water accounts for 1 / 2 that of the beaker; a required amount of methanesulfonic acid is measured through a measuring cylinder and put in the beaker, and the mixture is stirred uniformly; a required amount of tin methanesulfonate is measured through the measuring cylinder and put in the beaker, and the mixture is stirred uniformly; additives with the concentration being 60-100 ml / L are added to a tin methanesulfonate solution and stirred uniformly; the deionized water is added until the mixture is in a predetermined volume, and the high-speed tinning solution is prepared. Plating with uniform color and consistent crystal grains is obtained in a wider current density range, formation of tin whisker is effectively controlled, the anti-tarnishing capability and the excellent weldable performance of the plating are guaranteed, the current density can be increased to the greatest extent, the anti-tarnishing capability and the weldable performance are guaranteed, meanwhile, a defoaming agent is not used, and fewer organic impurities are mixed in the plating.

Owner:济南德锡科技有限公司

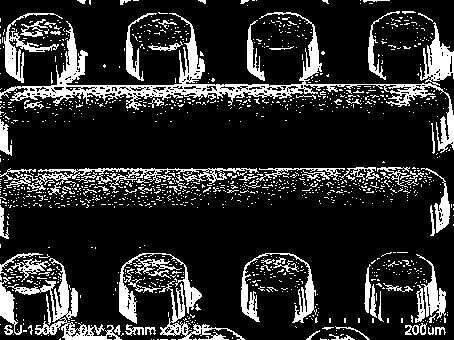

High-speed embossment electroplating method applied to copper interconnection

ActiveCN103103585AFast depositionCrystal fineCellsSemiconductor devicesPolyethylene glycolFatty alcohol

The invention discloses a high-speed embossment electroplating method applied to copper interconnection. A sulfonic acid copper system electroplating liquid is adopted to carry out copper column embossment electroplating; the electroplating conditions are as follows: the current density is 1-25A / dm<2>, and the temperature is 15-35 DEG C; the electroplating liquid comprises 160-350g / L high-purity methanesulfonic acid copper salt, 30-180g / L high-purity methanesulfonic acid and 10-80mg / L chloride ions; the electroplating liquid further comprises 1-10ml / L of an accelerator and 1-10ml / L of a leveling agent; the accelerator is UPB3221A and comprises one or a mixture of several of polydithio dipropane sodium sulfonate, alcohlpropane sulfonate, phenyl dithio propane sodium sulfonate, 3-sulfenyl-1-propanesulfonic acid sodium salt and dimethyl-dithio formamide sulfonic acid; and the leveling agent is UPB3221L and comprises one or a mixture of several of polyethylene glycol, a fatty alcohol alkoxy compound, an ethylene oxide-propylene oxide block copolymer of which the molecular weights are respectively 400, 1,000, 6,000 and 20,000. The high-speed embossment electroplating method applied to copper interconnection, disclosed by the invention, ensures that a copper column has good reliability and uniformity, and at the same time has a relatively high electroplating speed.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Chemical synthesis method of 1,2,3,4-tetra nitroazole kind compound

InactiveCN1718574AHigh reaction yieldReduce manufacturing costOrganic chemistryChemical synthesisCompound a

Owner:ZHEJIANG UNIV OF TECH

Amidoxime group-containing modified silica gel adsorbent and preparation method thereof

InactiveCN103223332AHigh mechanical strengthPromote regenerationOther chemical processesWater/sewage treatment by sorptionN dimethylformamideAcrylonitrile

Belonging to the field of modified silica gel adsorbents, the invention particularly relates to an amidoxime group containing modified silica gel adsorbent specific to heavy metal copper ions in an adsorption solution and a preparation method thereof. The preparation method includes: taking silica gel as a starting raw material, conducting activation by a methanesulfonic acid solution, performing impregnation in a toluene solution of KH580, carrying out drying, then adding the obtained dry particles into an N, N-dimethylformamide solution of acrylonitrile to undergo first modification, and carrying out a treatment, then adding the dried first modified particles into a mixed solution of a hydroxylamine hydrochloride solution and a sodium carbonate solution to perform second modification, and conducting a treatment, thus obtaining dried second modified particles, i.e. an amidoxime group containing modified silica gel adsorbent finished product. Compared with an adsorption capacity of 0.5mg / g of the original silica gel, the adsorption capacity of the amidoxime containing modified silica gel adsorbent involved in the invention is substantially increased to 20mg / g.

Owner:HOHAI UNIV

Electropolishing process for titanium

InactiveUS20080217186A1Electrolysis componentsElectrochemical machining apparatusMedronic acidTitanium

The present invention relates to a method of electrochemical polishing of surfaces of titanium or titanium-containing alloys, such as Nitinol. An electrolyte is used that comprises methanesulfonic acid and one or more alkanediphosphonic acids. These alkanediphosphonic acids can optionally be substituted with hydroxy and / or amino groups. A further aspect of the present invention relates to the use of said electrolyte for the electropolishing of titanium or titanium-containing alloys.

Owner:POLIGRAT GMBH

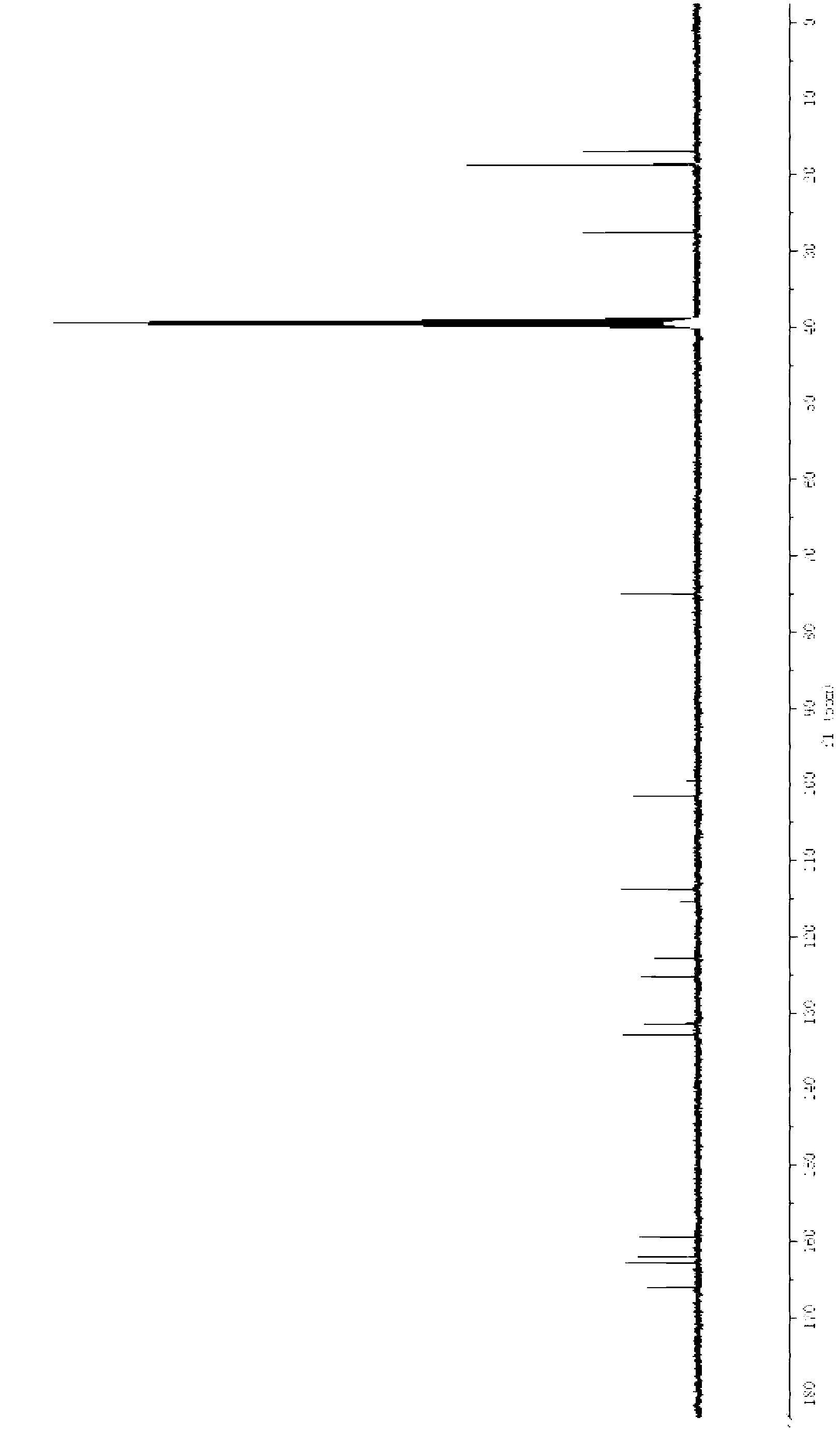

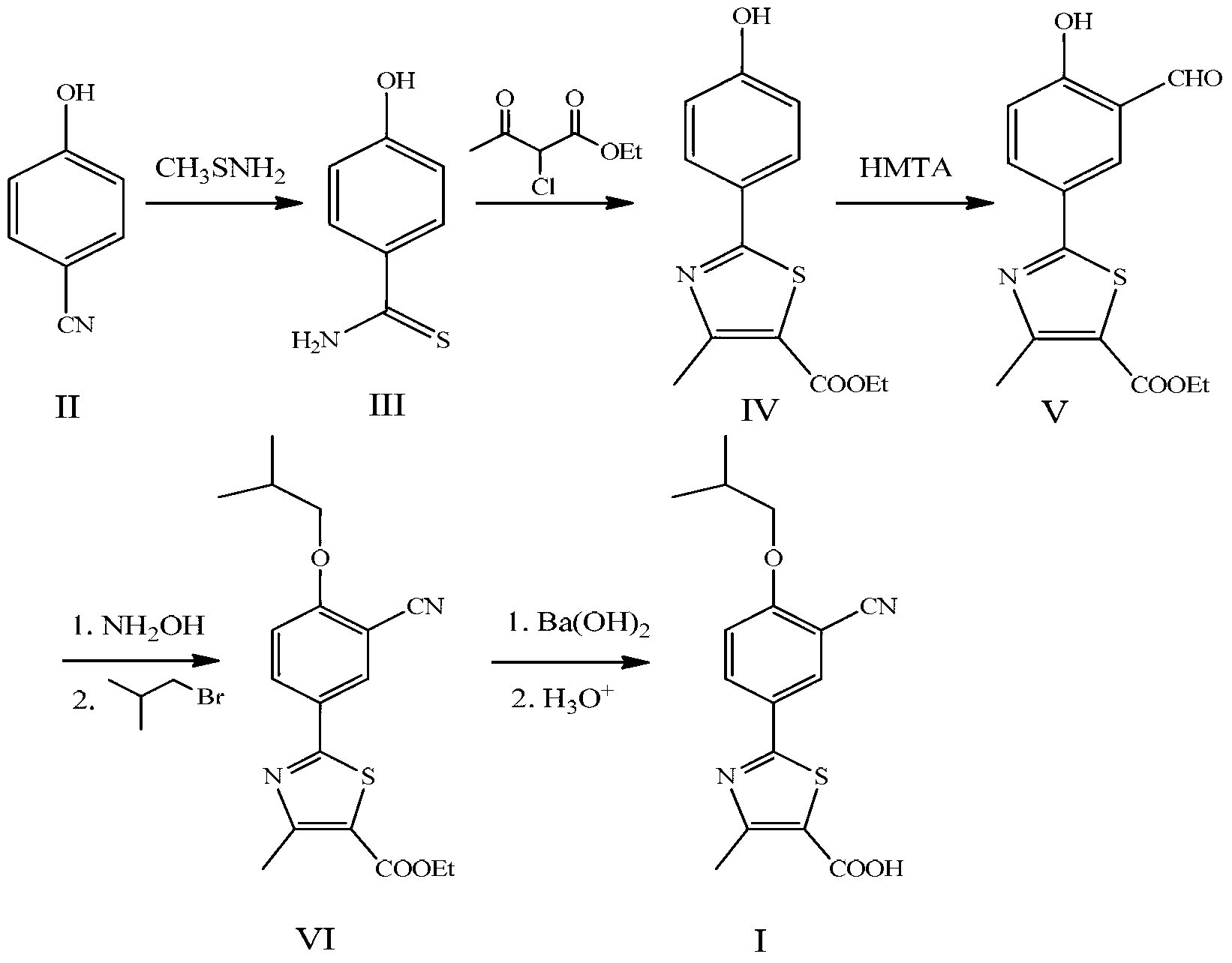

Preparation method for febuxostat

InactiveCN103304512ALow costReduce operation processOrganic chemistryHydroxylamine HydrochlorideToxic material

The invention discloses a preparation method for febuxostat. The preparation method for febuxostat comprises the following steps of: by using 4-hydroxybenzonitrile and thioacetamide as raw materials, and reacting in hydrochloric acid solution to prepare 4-hydroxythiobenzamide; carrying out a reaction on 4-hydroxythiobenzamide and 2-chloroacetoacetic acid ethyl ester to prepare 2-(4-hydroxylphenyl)-4-methylthiazol-5-carboxylic acid ethyl ester; carrying out a reaction on the obtained compound and hexamine in the mixed acid system of methanesulfonic acid and trifluoroacetic acid to prepare 2-(3-formyl-4-hydroxylphenyl)-4-methylthiazole-5-carboxylic acid ethyl ester; synthesising 2-(3-nitrile-4-isobutoxylphenyl) -4-methylthiazole-5-carboxylic acid ethyl ester from the compound, hydroxylamine hydrochloride, potassium carbonate, iso-butyl bromide and the like in a polar protonic solvent via a one-pot method; and finally hydrolyzing in an alkaline condition to obtain the target product, namely, febuxostat. The total yield of the preparation method for febuxostat disclosed by the invention is increased to 66%, the separation steps are reduced, any extremely toxic substance is not involved, and the environmental pollution is less.

Owner:SOUTH CHINA UNIV OF TECH

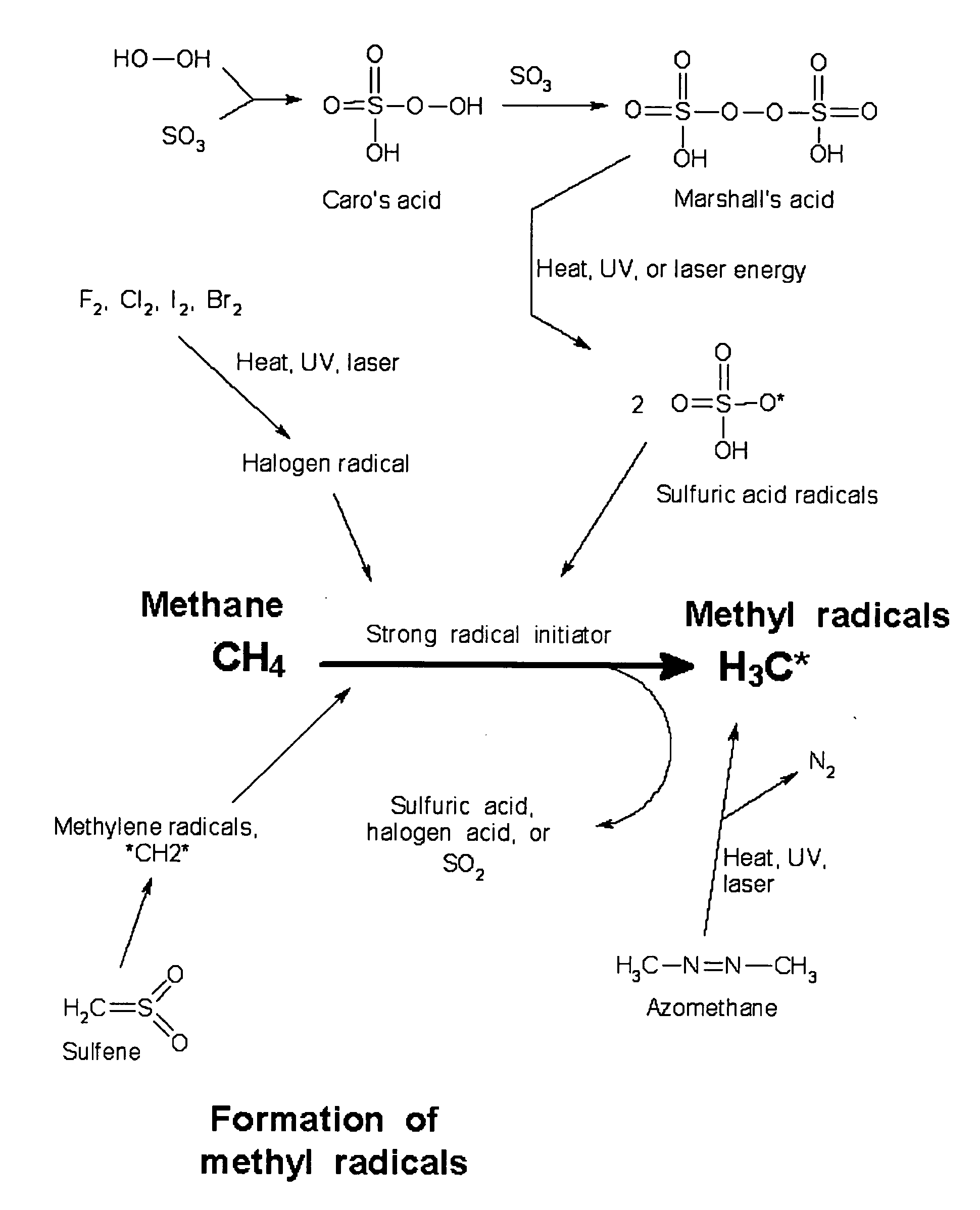

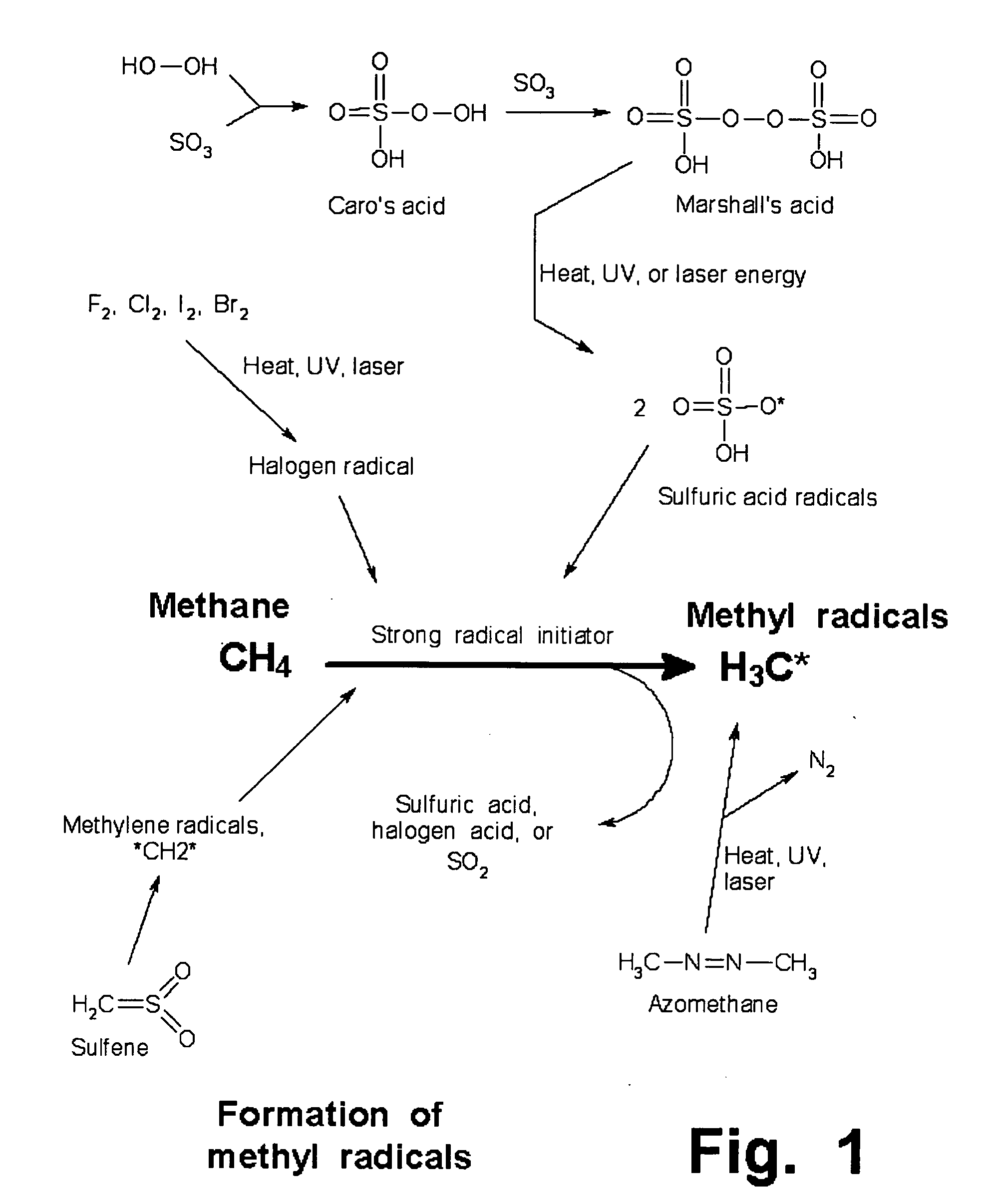

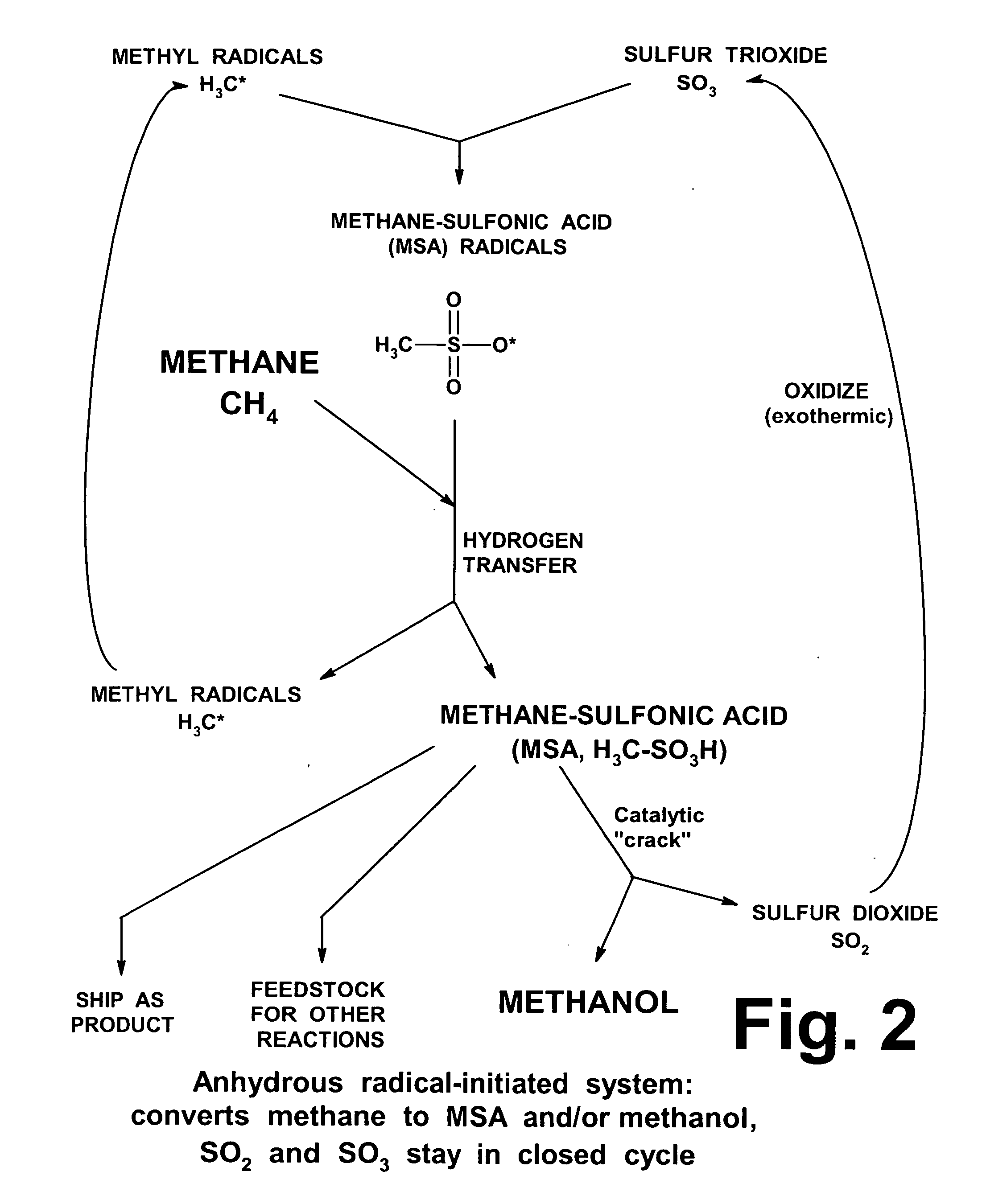

Manufacture of higher hydrocarbons from methane, via methanesulfonic acid, sulfene, and other pathways

InactiveUS20070282151A1Easy to handleChemical industrySulfonic acid esters preparationDimethyl etherPeroxide

Owner:RICHARDS ALAN K

Method for separating and purifying method of polymyxin E methanesulfonic sodium

ActiveCN101525377ASimple processGood reproducibilityPeptidesAntiinfectivesSeparation technologyUltrafiltration

The invention relates to a method for separating and purifying polymyxin E methanesulfonic sodium from a mixture containing small-molecular weight impurities. The method adopts an ultrafiltration membrane with the cutoff molecular weight ranging from 1,000 to 10,000 to carry out separation and purification. The invention also relates to a method used for preparing high-purity E methanesulfonic sodium by controlling reaction conditions and making use of ultrafiltration membrane separation technology. The method comprises the following steps: (a) adding water to dissolve polymyxin E sulfate andthen adding formaldehyde solution in the solution to carry out reaction; (b) adding sodium bisulfite solution in the reaction products of step (a) to carry out reaction continuously; and (c) taking the reaction solution of step (b) and adopting the ultrafiltration membrane to carry out separation and purification. The method of separating and purifying the polymyxin E methanesulfonic sodium has the advantages of low pollution, low energy consumption, simple process, good repeatability and high purity and activity of obtained products.

Owner:SHANGHAI INST OF PHARMA IND +1

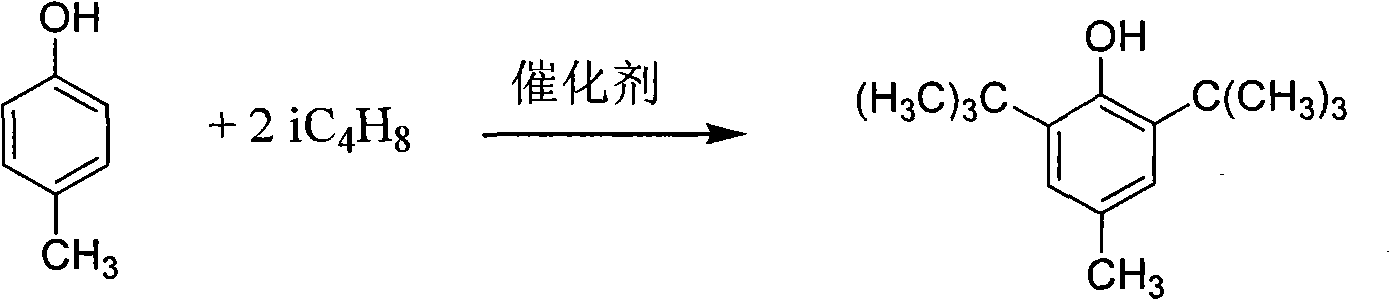

Processing technique of 2,6-ditbutyl-4-methylphenol

The invention mainly discloses a processing technique of 2,6-ditbutyl-4-methylphenol, which mainly comprises the steps of: alkylating methylphenol and isobutene and then neutralizing and washing the alkylated product. The processing technique of the 2,6-ditbutyl-4-methylphenol is characterized in that a catalyst with a usage amount of 0.3-1.5% mole percent of the methylphenol is added in the process of the alkylation of the methylphenol and the isobutene; the alkylated product after being washed is directed refined; methods of reduced pressure distillation and re-crystallization are jointly carried out in the refining process; and then the finished product of the 2,6-ditbutyl-4-methylphenol is obtained through offcentering and drying steps. The processing technique of the 2,6-ditbutyl-4-methylphenol has the advantages as follows: the yield of a course product of BHT (butylated hydroxytoluene) can reach 92% or higher with the adoption of methanesulfonic acid or sulfamic acid as a novel catalyst for the alkylation, and the purity of the pure product can reach 99% or higher through the joint of the reduced pressure distillation and the re-crystallization.

Owner:RUGAO JINLING CHEM

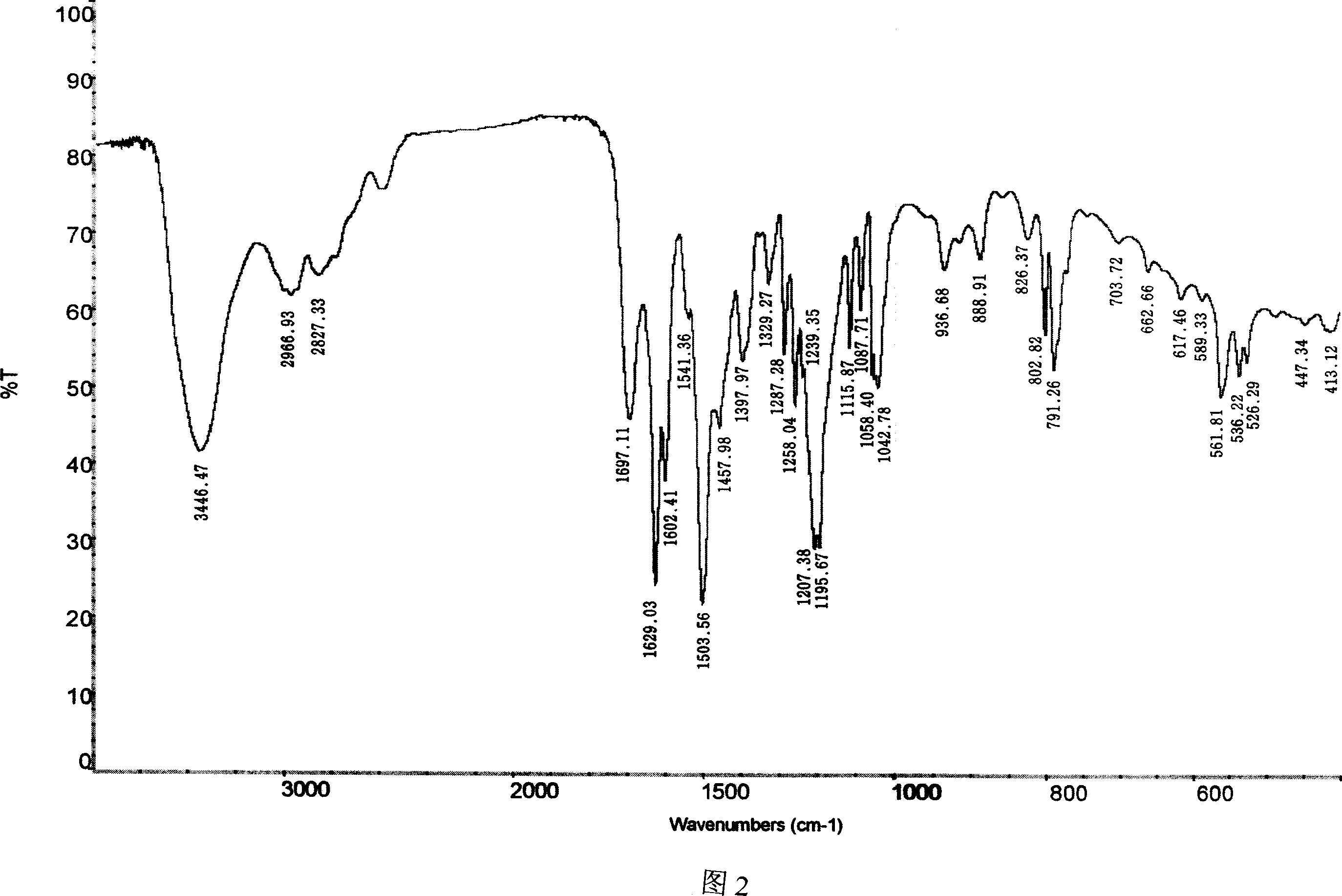

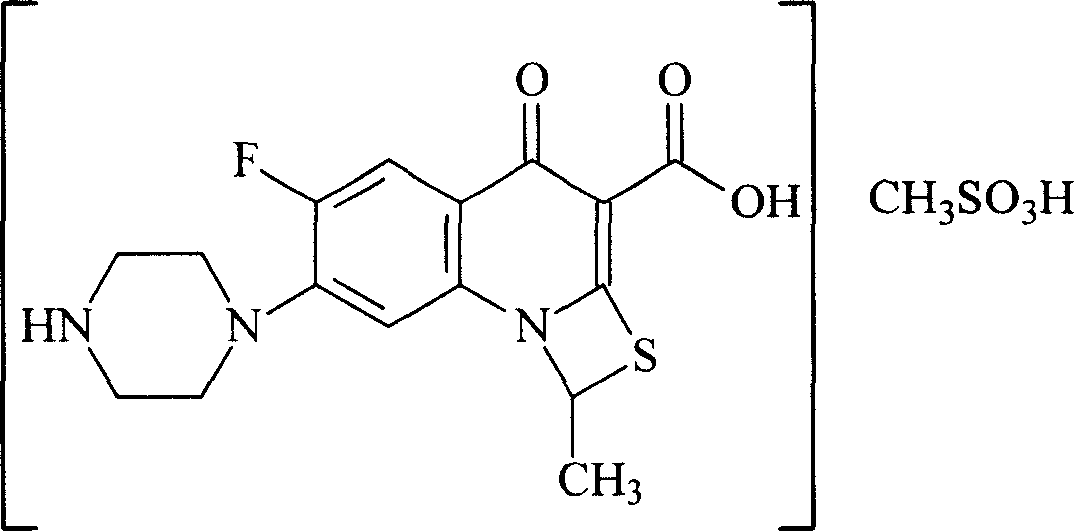

Anti infectious compound and usage

InactiveCN101003540AStrong anti-infection effectStructure determinationPowder deliveryOrganic active ingredientsQuinolineCarboxylic acid

This invention relates to an anti-infective compound, more specifically, 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1, 3] thiazine [3, 2-a] quinoline-3-carboxylic mesylate (compound I), its preparation method and its application. Compound I is prepared by reaction of 6-fluoro-1-methyl-4-oxo-7-(1-piperazine)-4H-[1,3]thiazine[3,2-a]quinoline-3-carboxylic acid and methyl sulfonic acid. Compound I can be used as effective component and mixed with normal pharmaceutical carrier to manufacture anti-infective drug composition, which can be tablets, capsules, granules, injection, eye preparations, ear preparations, gynecological preparations, and external use preparations. Compound I has stable properties, and can be easily dissolved in water, thus can be easily manufactured into various preparations used in clinical treatment. The method has such advantages as simple and reasonable process.

Owner:GUANGZHOU BAIYUNSHAN PHARMA HLDG CO LTD BAIYUNSHAN PHARMA GENERAL FACTORY +1

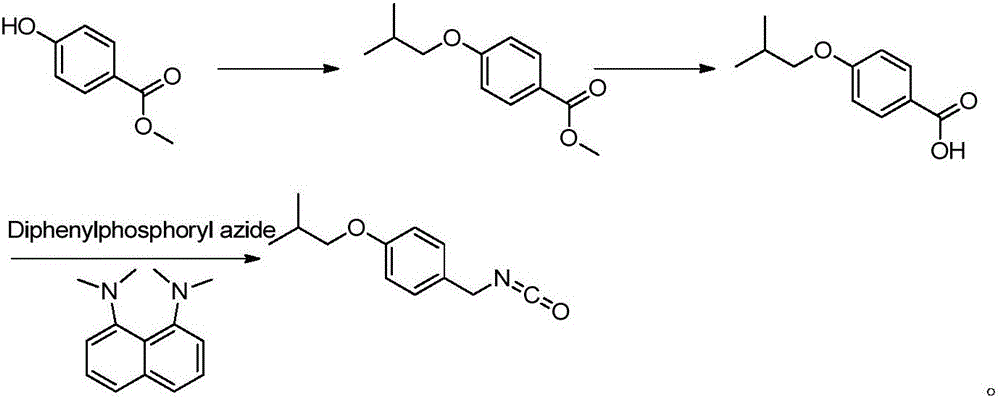

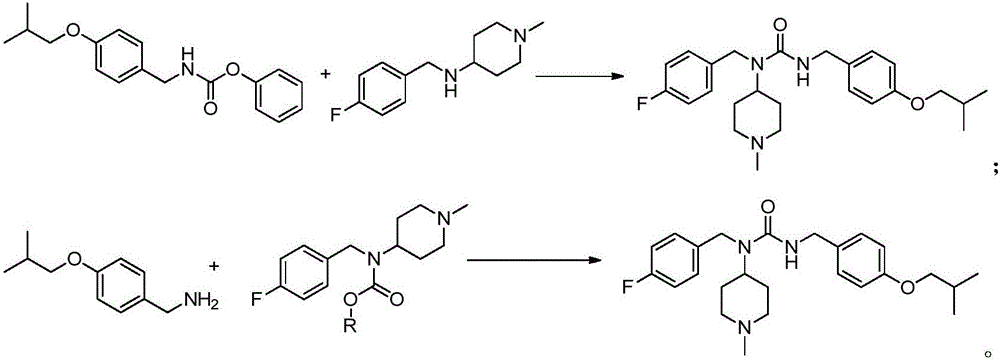

4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions

The present patent application is directed to 4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonic acid salt (formula I), its synthesis and a method for treating and / or preventing a serotonine and / or norepinephrine mediated disease or condition. The present invention is also directed to pharmaceutical compositions comprising the same.

Owner:FAES FARMA SA

Using non-regulated synthetic acid compositions as alternatives to conventional acids in the oil and gas industry

ActiveUS20160347994A1Improve breathabilityLower potentialCleaning apparatusFluid removalAlcoholOil and natural gas

Owner:DORF KETAL CHEM FZE

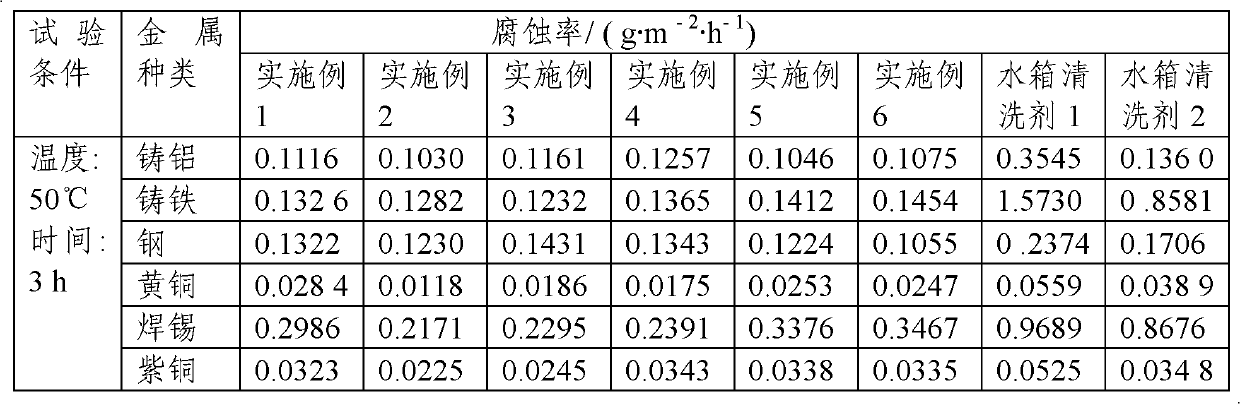

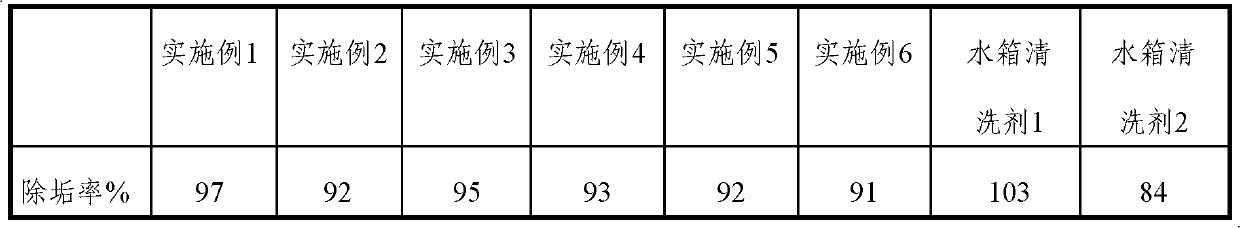

Cleaning agent for automobile cooling system

The invention provides a cleaning agent for an automobile cooling system. The cleaning agent comprises, by weight, 3 to 20% of glycolic acid, 2 to 9% of citric acid, 2 to 10% of methanesulfonic acid, 1 to 10% of ammonium citrate, 0.5 to 7% of a corrosion inhibitor and 0.01 to 2% of a surfactant, with the balance being deionized water. The cleaning agent for the automobile cooling system in the invention can effectively remove calcium scale, magnesium scale and iron rust in the cooling system, is applicable to cleaning of a variety of materials like carbon steel, iron, copper and aluminum in a cooling system of an engine and has the advantages of high efficiency, mildness and a low corrosion rate. The cleaning agent is applicable to general repair and maintenance of an automobile and is used for removing dirt generated due to usage of water as a cooling medium so as to increase the efficiency of heat transfer between the engine and the cooling medium and enable operation of the engine to be smoother.

Owner:CHINA PETROLEUM & CHEM CORP

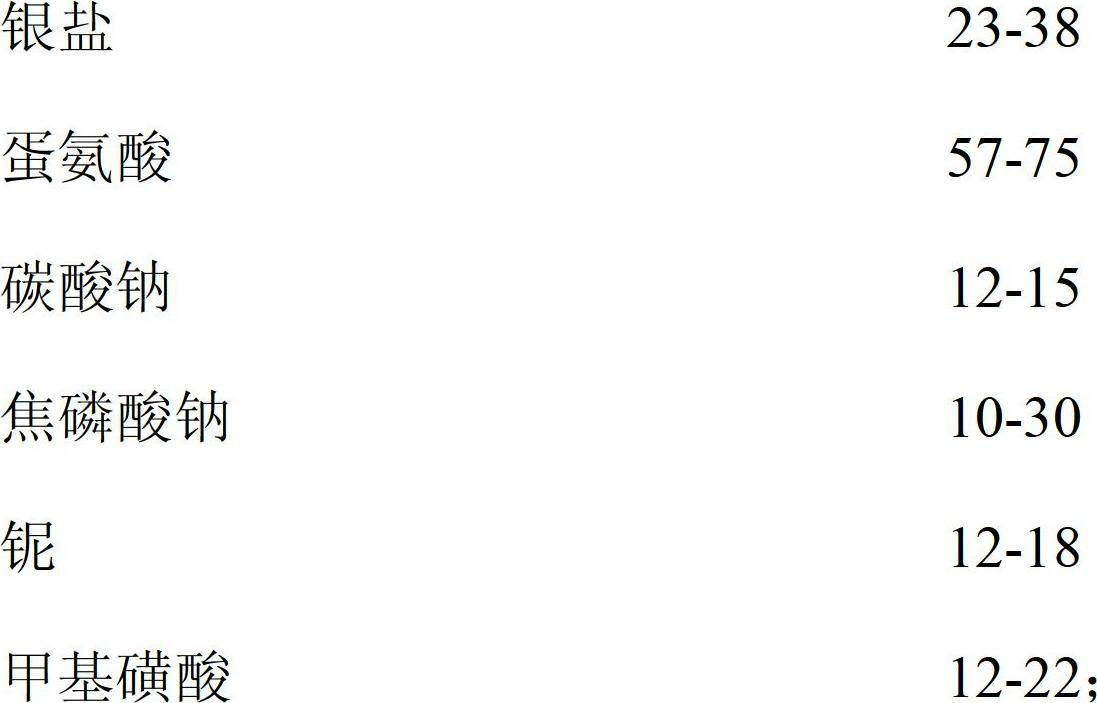

Electrosilvering solution and electrosilvering method

The invention relates to an electrosilvering solution and an electrosilvering method. The electrosilvering solution comprises silver salt, methionine, sodium carbonate, sodium pyrophosphate, niobium chloride and methanesulfonic acid, wherein the silver salt is silver nitrate. The electrosilvering method comprises the following steps of (1) polishing, (2) deoiling, (3) primary washing, (4) pre-electrosilvering, (5) secondary washing, (6) electrosilvering and (7) antitarnishing. The electrosilvering solution used in the electrosilvering is the electrosilvering solution disclosed by the invention. With the electrosilvering solution and the electrosilvering method provided by the invention, a dense silver coating with good bonding force can be obtained.

Owner:东莞市闻誉实业有限公司

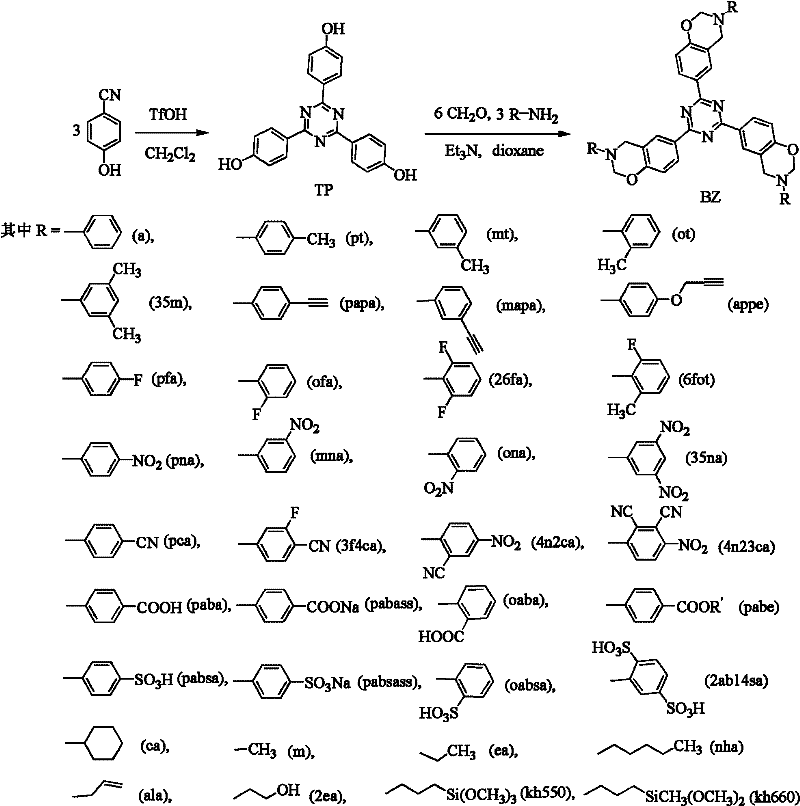

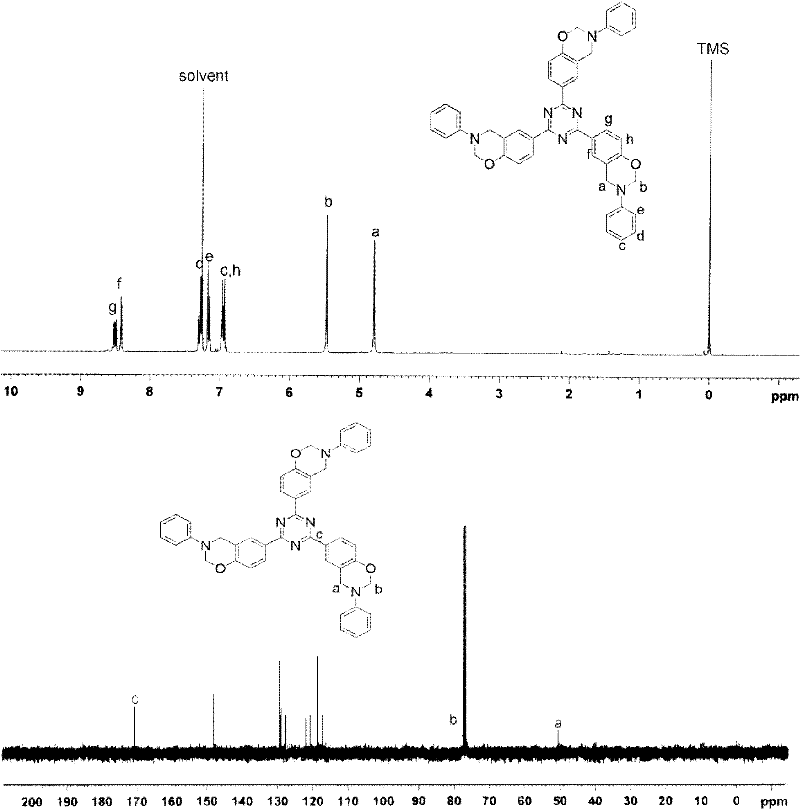

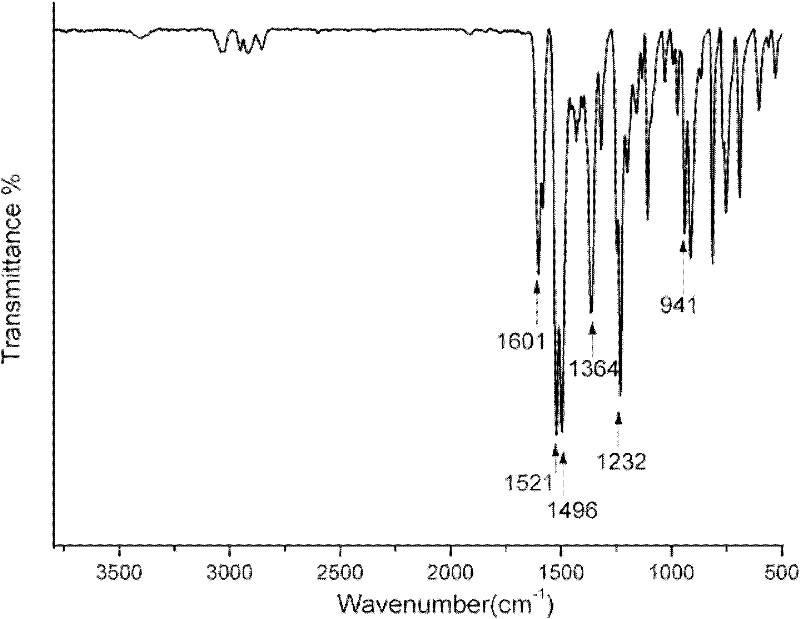

Triazine-containing benzoxazine, triazine-containing benzoxazine polymer, and preparation method thereof

ActiveCN102219785AIncrease contentImprove heat resistanceOrganic chemistryTriflic acidStructural formula

The invention relates to triazine-containing benzoxazine, a triazine-containing benzoxazine polymer, and a preparation method thereof. The preparation method is characterized by: adopting cyanophenol as a raw material; adopting trifluoromethanesulfonic acid or trifluoroacetic acid as a catalyst; synthesizing triazine-containing trihydric phenol (TP for short) in dichloromethane or chloroform or acetone at a common temperature; adopting the synthesized TP, formaldehyde and aminated compounds as reaction raw materials; adopting a alkali as the catalyst, and carrying out a reaction in a alcohol solvent or a ether solvent to synthesize a series of triazine-containing polycyclic benzoxazine monomers (BZ for short) which have not been reported; heating the BZ to carry out a ring-opening polymerization to form polybenzoxazine (PBZ for short). A structural formula of the monomer BZ is shown as follow, substituents R are shown in the specification. The synthesized novel monomer provided by the present invention contains a triazine ring structure, such that the triazine content in the PBZ resin can be substantially raised so as to notably improve heat resistance, residual carbon rate, fire resistance property and wave transmission property of the PBZ.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions 4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions](https://images-eureka.patsnap.com/patent_img/35f3e16c-1b71-446e-bb45-5e49793aaccd/US20070265306A1-20071115-C00001.png)

![4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions 4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions](https://images-eureka.patsnap.com/patent_img/35f3e16c-1b71-446e-bb45-5e49793aaccd/US20070265306A1-20071115-C00002.png)

![4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions 4-[(3-fluorophenoxy)phenylmethyl]piperidine methanesulfonate: uses, process of synthesis and pharmaceutical compositions](https://images-eureka.patsnap.com/patent_img/35f3e16c-1b71-446e-bb45-5e49793aaccd/US20070265306A1-20071115-C00003.png)