Electrosilvering solution and electrosilvering method

A technology of electroplating silver and solution, which is applied in the field of electroplating to achieve the effect of reducing pollution, excellent dispersion ability and good leveling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

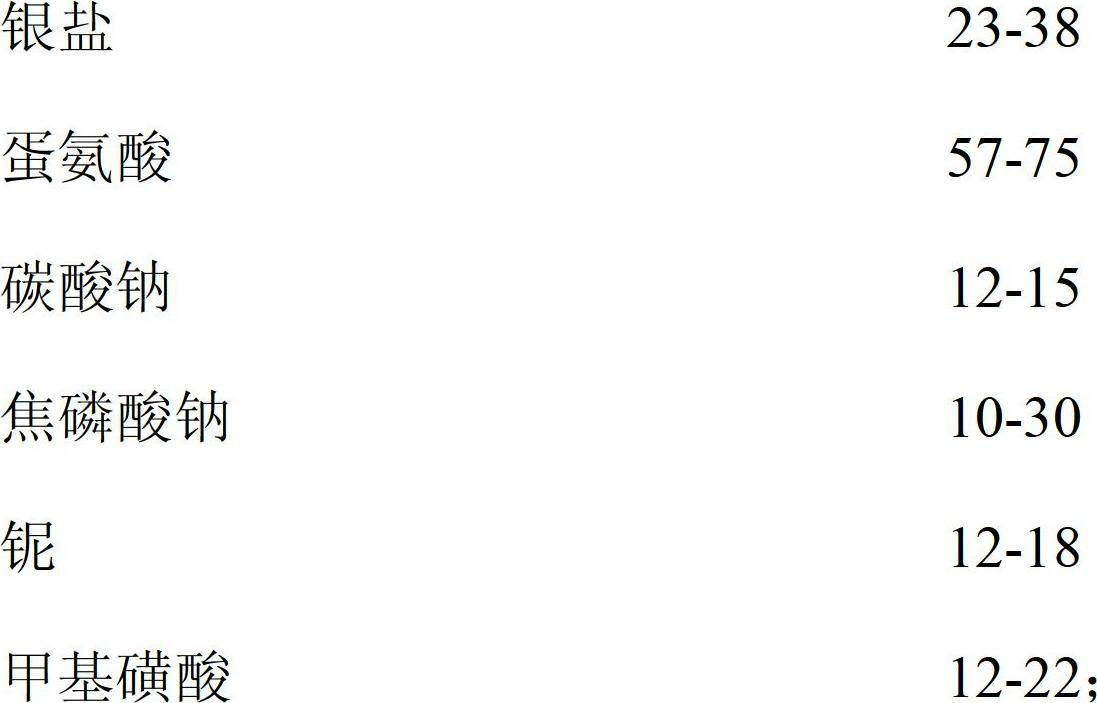

[0045] A kind of electroplating silver solution, comprises by weight parts:

[0046]

[0047]

[0048] Polish the metal substrate successively with coarse sandpaper and fine sandpaper; soak the polished substrate in 11% KOH solution for 10 minutes; remove the oxide film on the surface of the substrate in the washing solution after washing with water; wash with water Finally, pre-dip silver on the surface of the substrate; after washing, connect the substrate to the wire, put it in the electroplating solution, and then plate it with silver; after plating, wash it with water, and put it in a chemical passivation solution for anti-tarnish treatment; finally in the air Let dry naturally. The formula of the pre-silvering solution includes 16g / L silver nitrate and 202g / L thiourea, and the pH value is 3. The washing solution is preferably prepared from concentrated nitric acid, concentrated sulfuric acid and water in a volume ratio of 1:1:1. The silver plating temperature is ...

Embodiment 2

[0050] A kind of electroplating silver solution, comprises by weight parts:

[0051]

[0052] Polish the metal substrate successively with coarse sandpaper and fine sandpaper; soak the polished substrate in a KOH solution with a mass fraction of 15%, take it out after 20 minutes; remove the oxide film on the surface of the substrate in the washing solution after washing with water; wash with water Finally, pre-dip silver on the surface of the substrate; after washing, connect the substrate to the wire, put it in the electroplating solution, and then plate it with silver; after plating, wash it with water, and put it in a chemical passivation solution for anti-tarnish treatment; finally in the air Let dry naturally. The formula of the pre-silvering solution includes 19g / L silver nitrate and 218g / L thiourea, and the pH value is 4. The washing solution is preferably prepared from concentrated nitric acid, concentrated sulfuric acid and water in a volume ratio of 1:1:1. The s...

Embodiment 3

[0054] A kind of electroplating silver solution, comprises by weight parts:

[0055]

[0056] Polish the metal substrate successively with coarse sandpaper and fine sandpaper; soak the polished substrate in a KOH solution with a mass fraction of 25%, take it out after 12 minutes; remove the oxide film on the surface of the substrate in the washing solution after washing with water; wash with water Finally, pre-dip silver on the surface of the substrate; after washing, connect the substrate to the wire, put it in the electroplating solution, and then plate it with silver; after plating, wash it with water, and put it in a chemical passivation solution for anti-tarnish treatment; finally in the air Let dry naturally. The formula of the pre-silvering solution includes 17g / L silver nitrate and 208g / L thiourea, and the pH value is 3.8. The washing solution is preferably prepared from concentrated nitric acid, concentrated sulfuric acid and water in a volume ratio of 1:1:1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com