Patents

Literature

619results about How to "Guaranteed bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold-plating method of high silicon-aluminum composite material

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

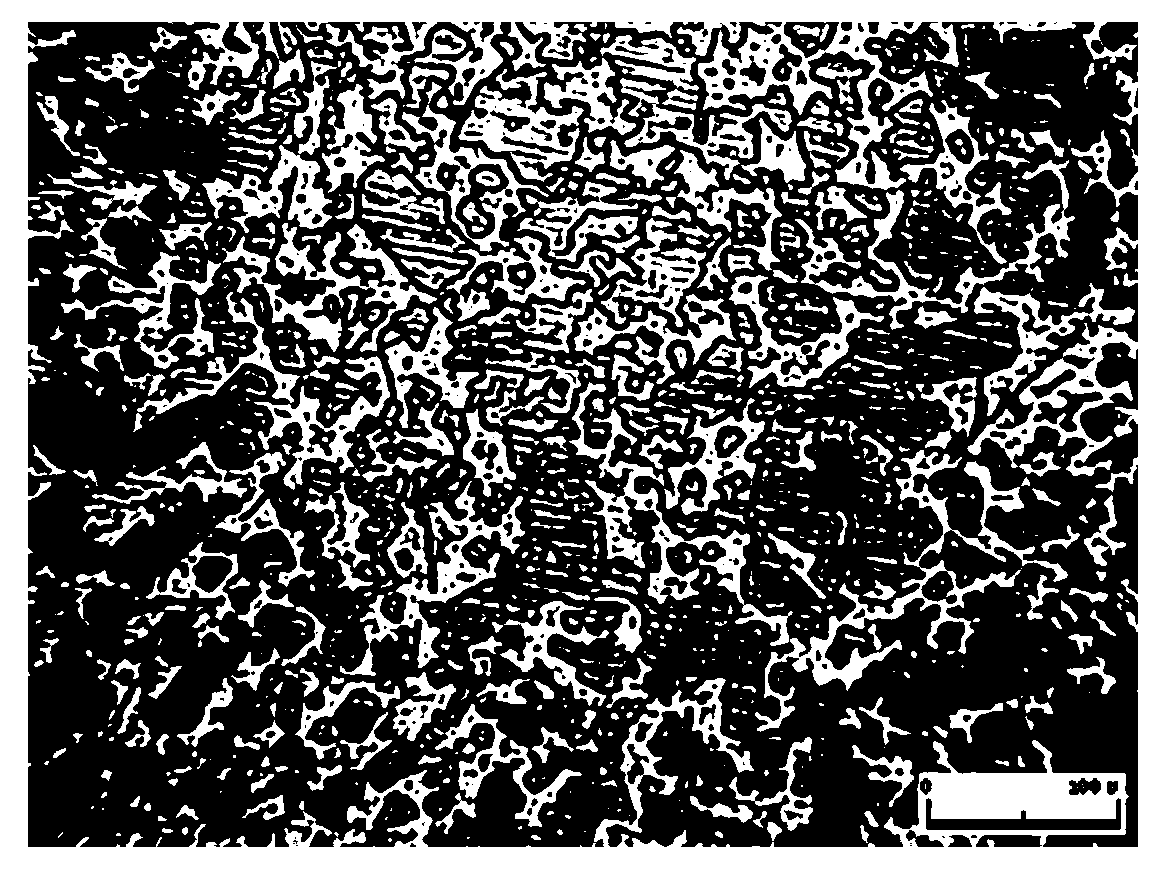

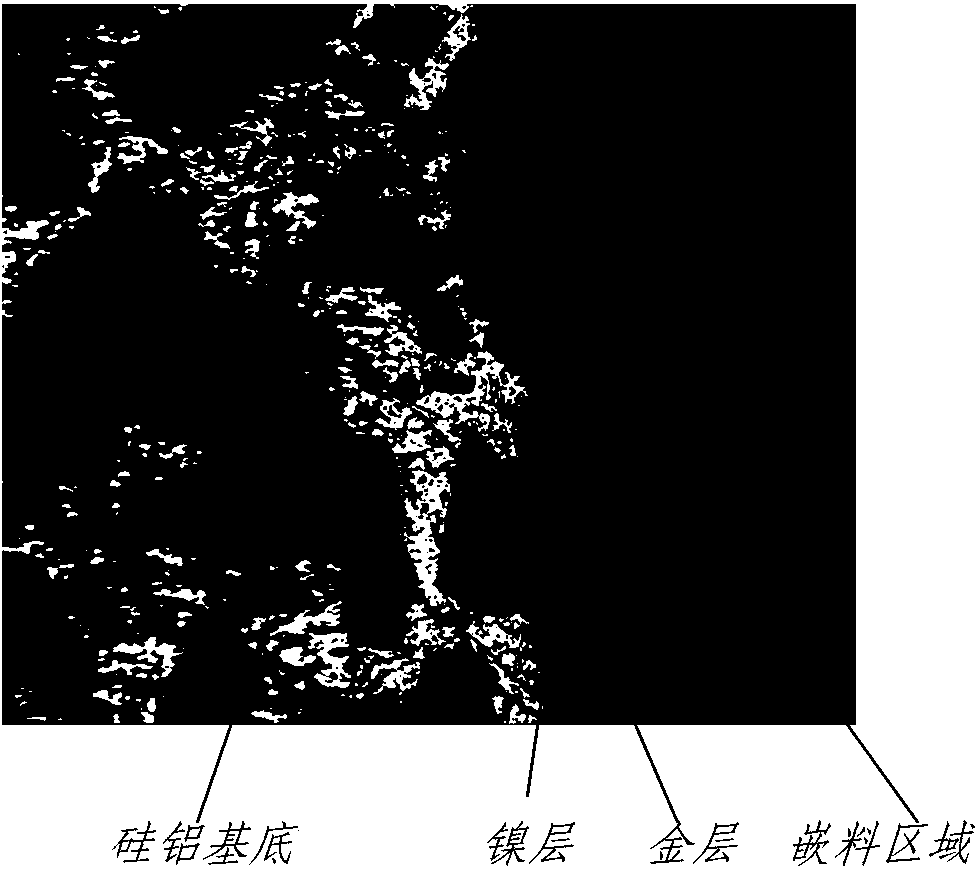

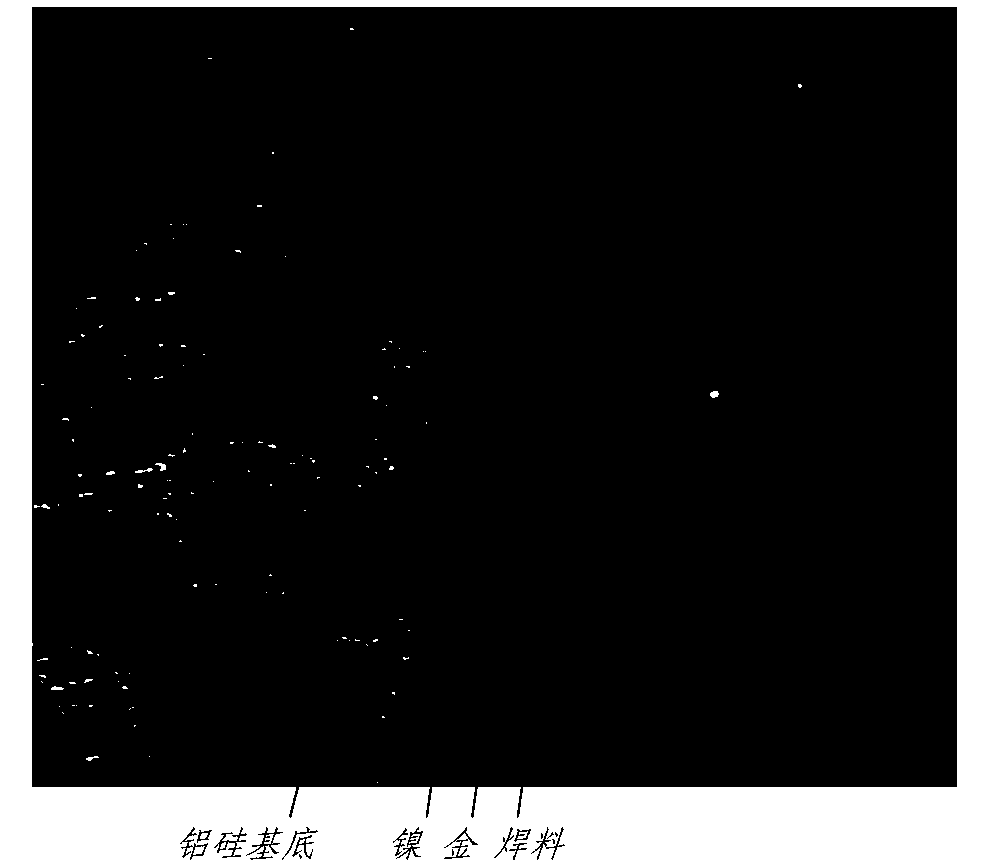

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

LED high heat conduction ceramic copper coating heat radiation circuit board

InactiveCN101483217AFast heat conductionStrong conductivityPrinted circuit manufactureCooling/ventilation/heating modificationsCopper foilMagnesium

The invention discloses a Light-Emitting Diode (LED) high heat conduction ceramic bonding copper heat dissipation circuit board characterized in that a copper foil is compounded on both sides of a ceramic chip, a copper-aluminum spinelle eutectic interface is between the copper foil and the ceramic substrate; a circuit formed by two faces of copper foils of the ceramic substrate are interconnected and guided through a sintered via hole. The invention employs the process principle that the low temperature thermal oxidized copper foil and the ceramic can form the eutectic interface. At 1060 DEG C-1080 DEG C, the copper and an oxide film form a trace amount of copper-cuprous oxide eutectic liquid phase. The eutectic liquid phase and aluminum, magnesium, zirconium and oxygen elements in the ceramic form the copper-aluminum spinelle eutectic interface and the copper foil and the ceramic substrate form a firm compound structure. The invention has excellent performance of high heat conduction, strong conduction ability, high adhesive force and low interconnection via hole resistance, and obviously improves the operation life and reliability by applying to the LED chip package.

Owner:宋立峰

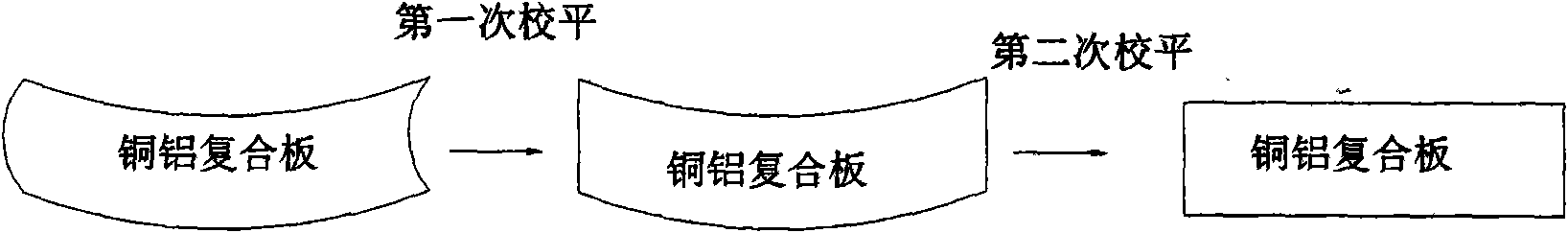

Manufacturing method of copper-aluminum composite board

InactiveCN101559557APrevent oxidationImprove bindingTemperature control deviceTension/compression control deviceCopperAluminum composites

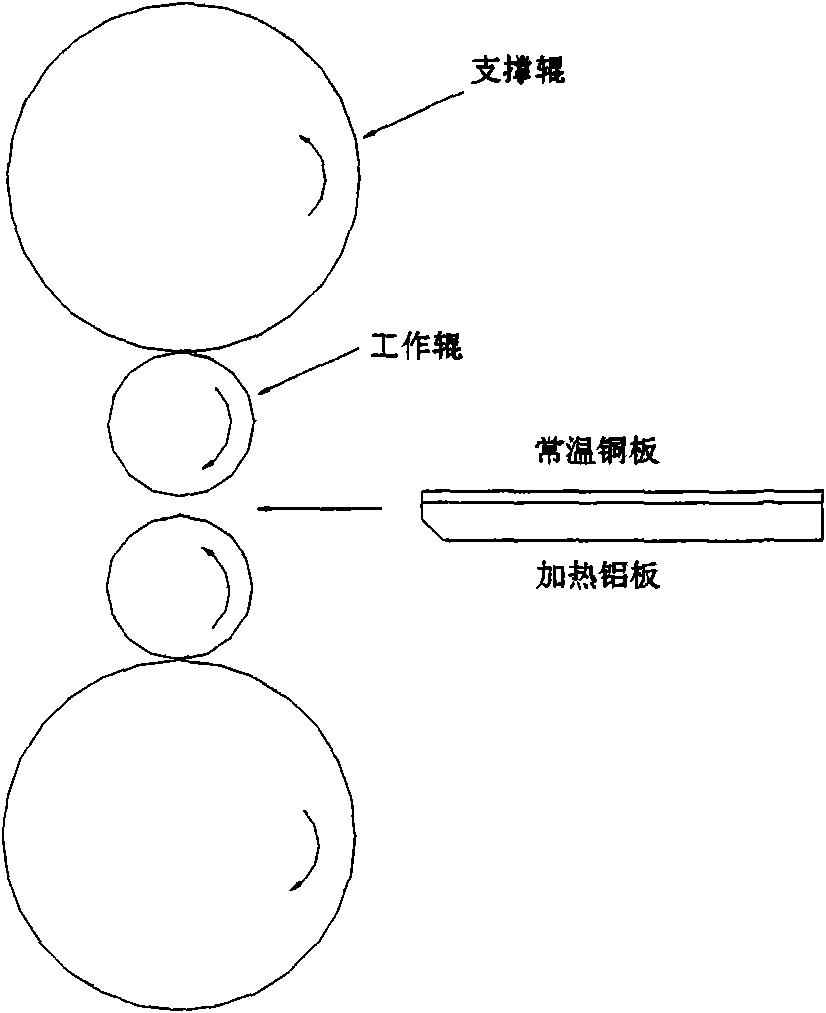

The invention discloses a manufacturing method of a copper-aluminum composite board, comprising the following steps: 1. removing oil for preliminary treatment; 2. grinding a junction surface; 3. heating an aluminum board, not heating a copper board and performing inreversible and isodromic rolling in one pass; 4. adopting a common leveler with fifteen rollers to carry out twice leveling; and 5. cutting to form into finished products. The invention solves the problem that the bonding strength of copper and aluminum is lower and achieves the beneficial effects of producing the high-quality copper-aluminum composite boards in batch with low cost.

Owner:上海新东蒸发器有限公司

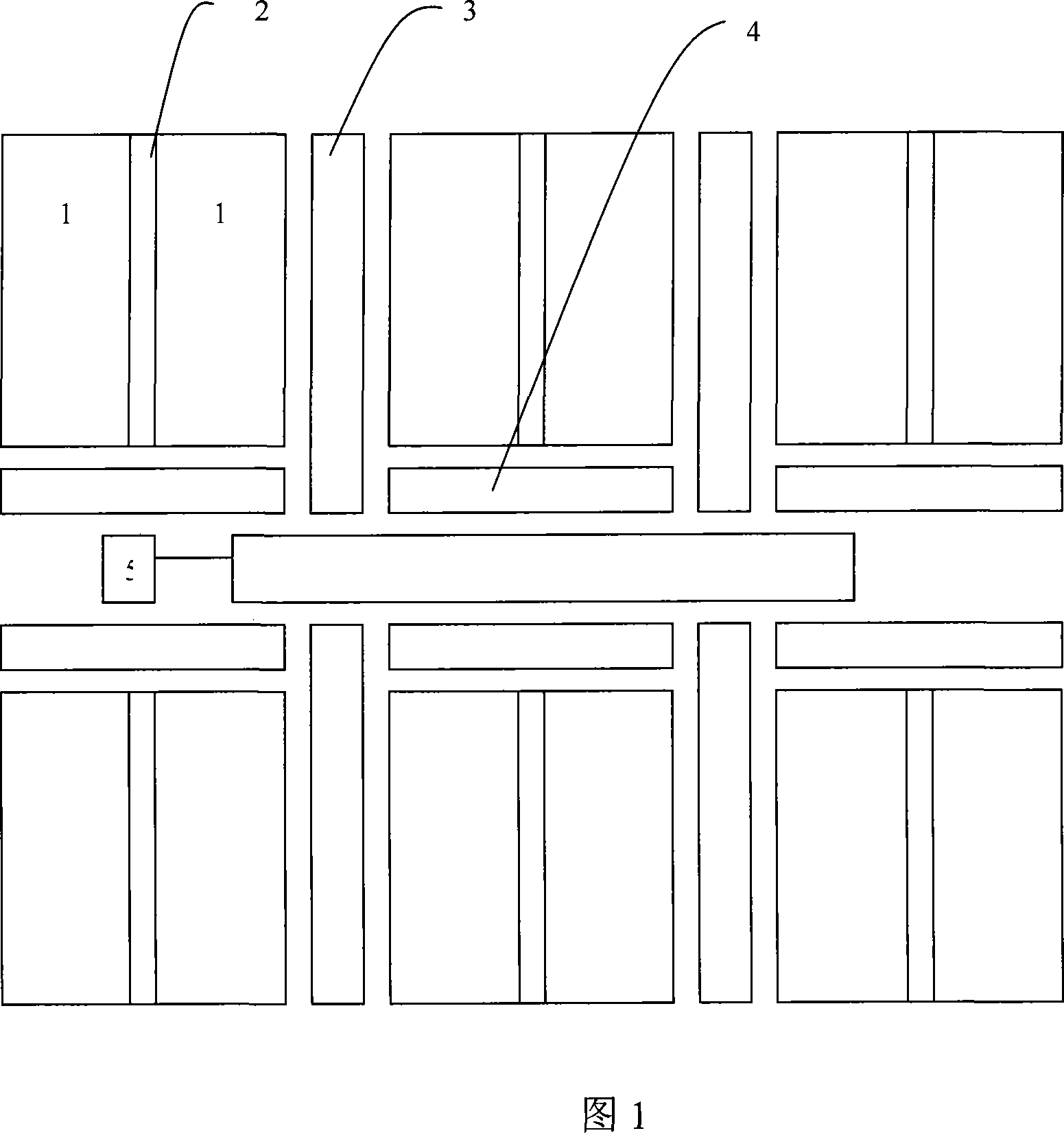

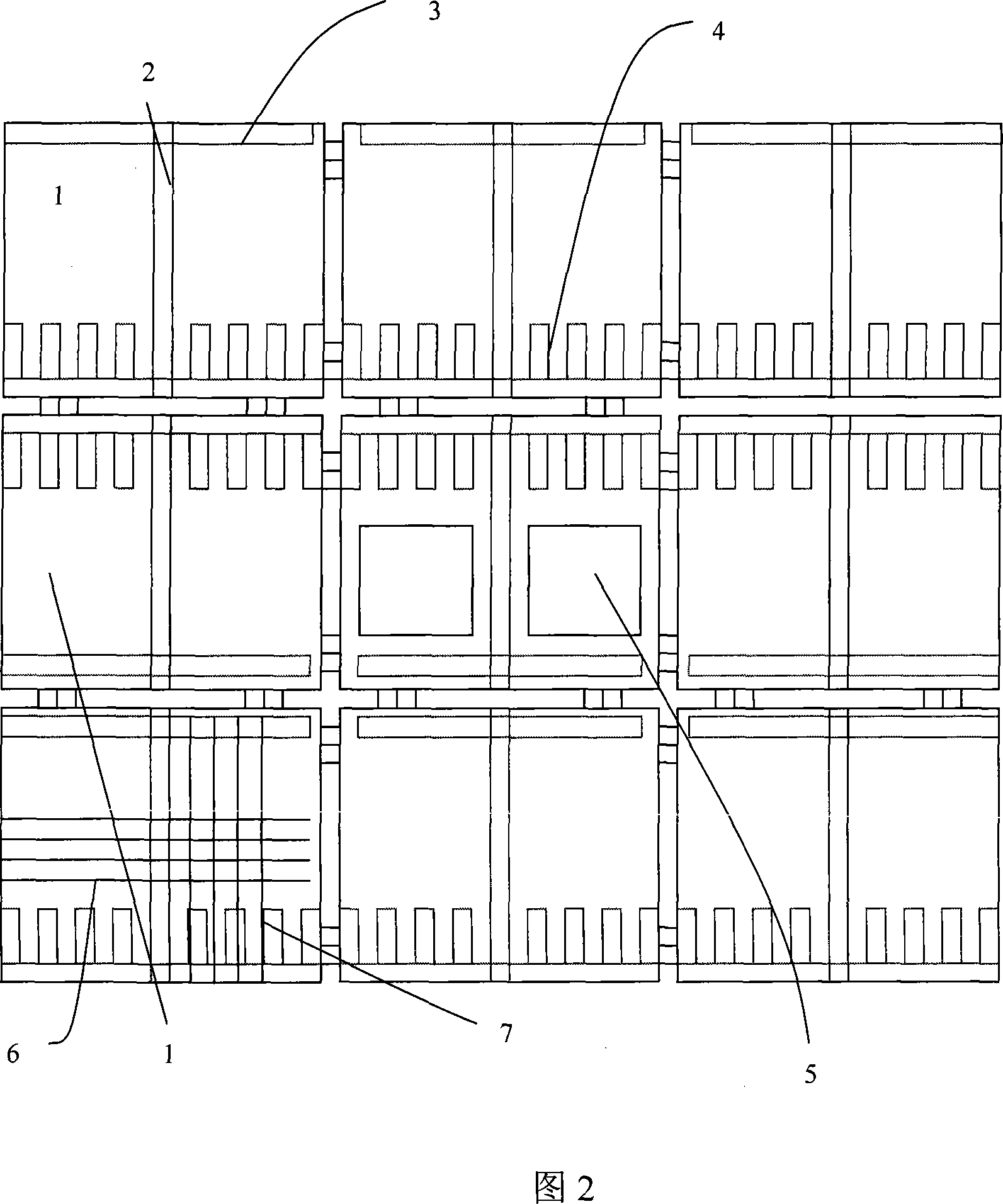

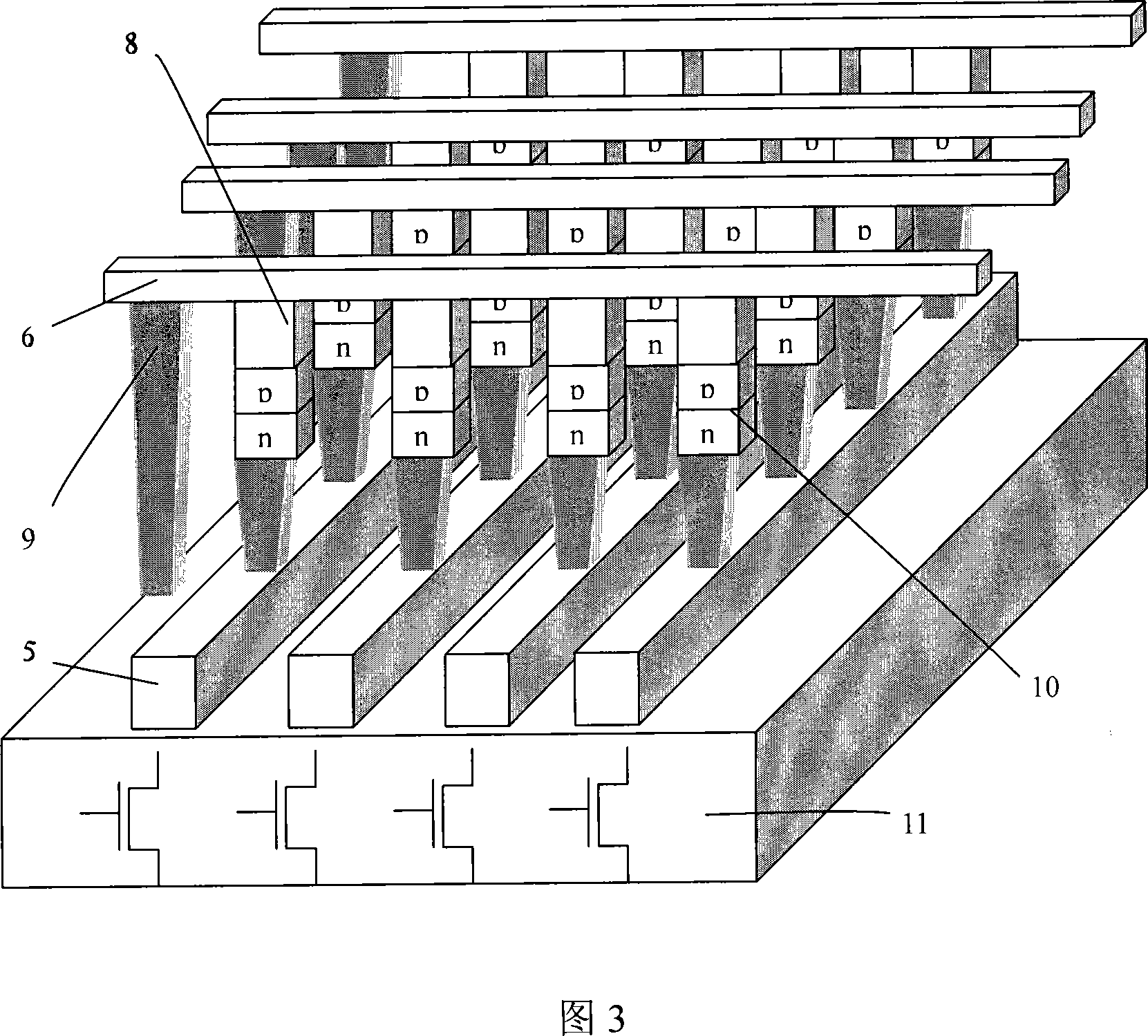

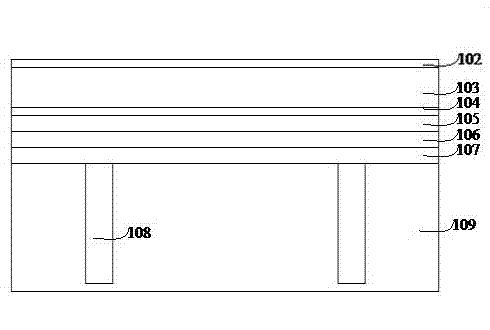

Structure of high-density phase transition memory and process of preparation thereof

ActiveCN101232038AReasonable power distributionPerformance is not affectedSemiconductor/solid-state device detailsSolid-state devicesPhase-change memoryEngineering

The invention relates to a high-density phase change memory cell structure, a 3D circuit design layout and the manufacture process of phase change random access memory (PCRAM) chip. The invention can achieve a high-density memory array of the PCRAM chip by arranging a peripheral circuit based on CMOS (complementary metal oxide semiconductor) process below the memory array by the 3D layout design, wherein the peripheral circuit chip is planarized by CMP (chemical mechanical polishing) process. A P- or N-type silicon wafer is subjected to epitaxial technology to form an N / P (or P / N) junction, and the silicon wafer is bonded with a CMOS silicon wafer at low temperature by an alignment device. An integrated N / P (or P / N) junction on the CMOS wafer can be achieved by employing wafer stripping or back-thinning technology, a reversible phase change resistor is then prepared by the integral N / P (or P / N) junction and interconnected with the junction through copper, and the common package technology is adopted to achieve the entire chip, thus integrally achieving the three-dimensional 1R1D chip structure.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Stimulus-responsive self-repair anticorrosive coating material and preparation method

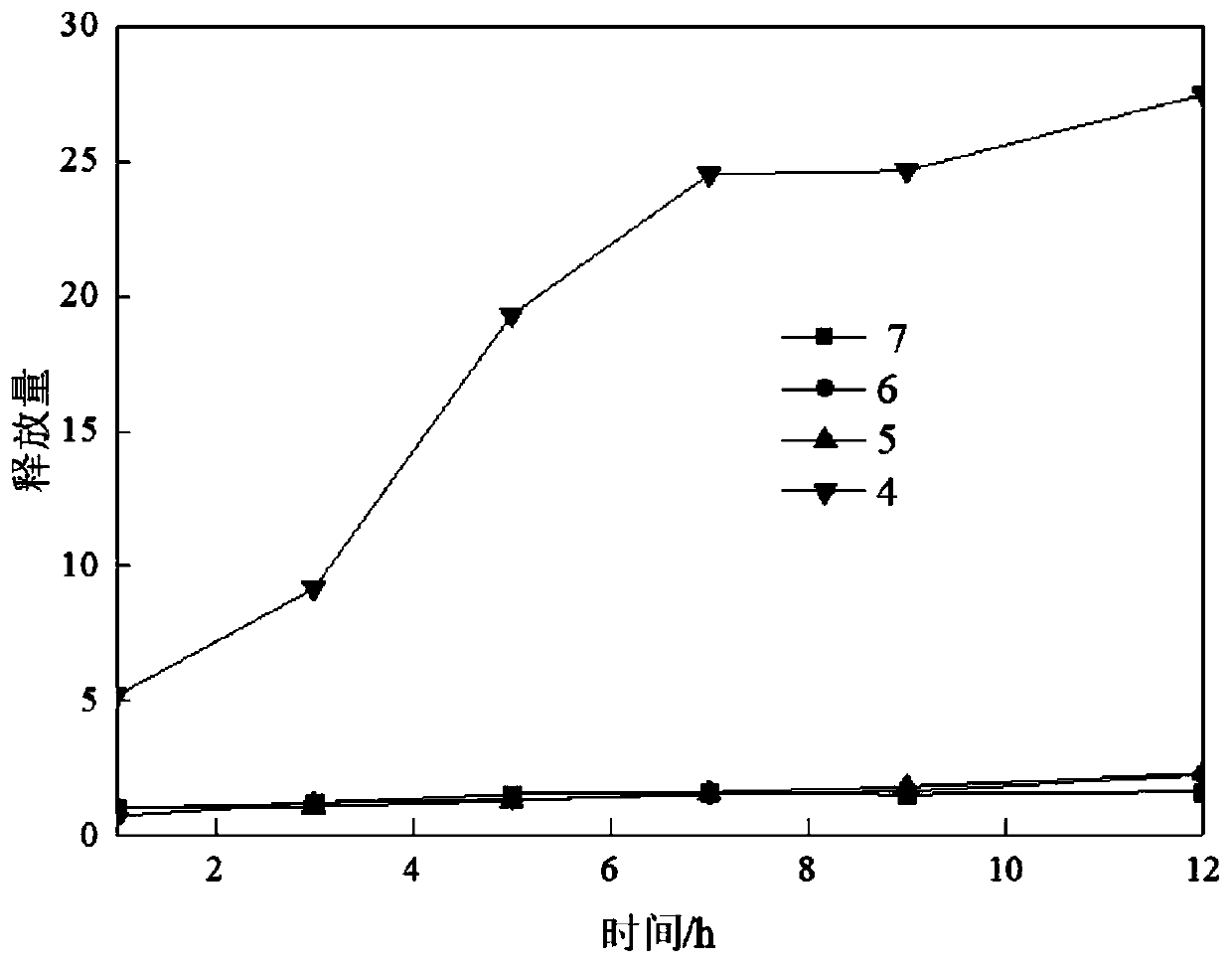

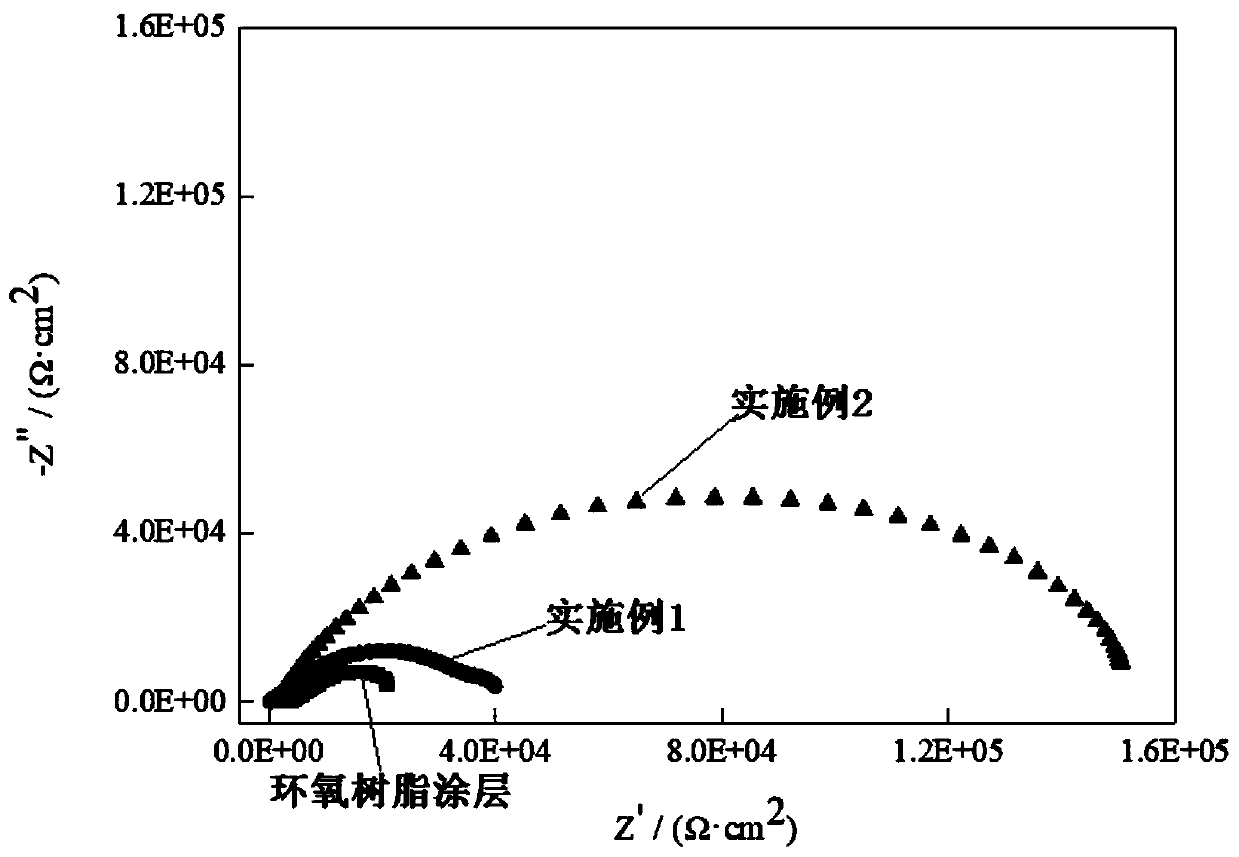

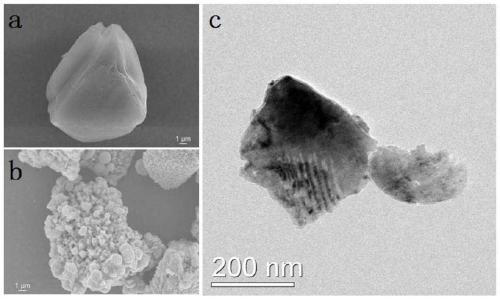

ActiveCN110105843AImprove anti-corrosion performanceIncrease load rateAnti-corrosive paintsEpoxy resin coatingsCationic polyelectrolytesLayer by layer self assembly

The invention discloses a stimulus-responsive self-repair anticorrosive coating material and a preparation method. The coating material comprises a CuO microcapsule and a coating matrix. The CuO microcapsule comprises a capsule core and a capsule core carrier, the capsule core is a corrosion inhibitor, and the capsule core carrier is porous CuO; and the surface of the CuO microcapsule is coated byan anionic polyelectrolyte layer and a cationic polyelectrolyte layer alternately. The invention successfully constructs the anticorrosive coating material with ph responsiveness and self-repair dualefficacy. The porous CuO can improve the loading rate and encapsulation rate of the capsule core substance; at the same time, the anionic polyelectrolyte can be adsorbed on the surface by means of layer-by-layer self-assembly, under the action of Coulomb force, then cationic polyelectrolyte can be adsorbed on the surface, thus improving the dispersibility of the microcapsule in the coating, solving the agglomeration problem of the porous substance CuO, and at the same time improving the bonding performance of the capsule core carrier and the coating matrix, and the anticorrosion performance of the coating material can be further improved.

Owner:SUN YAT SEN UNIV

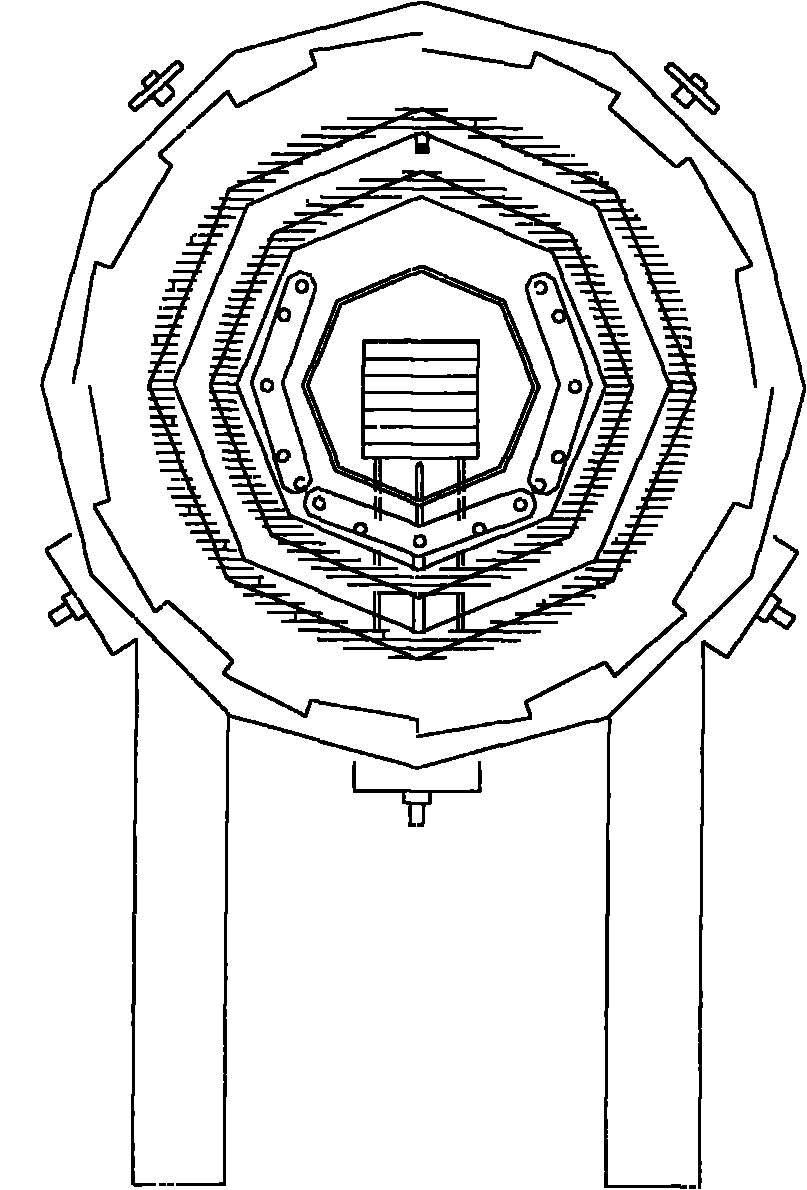

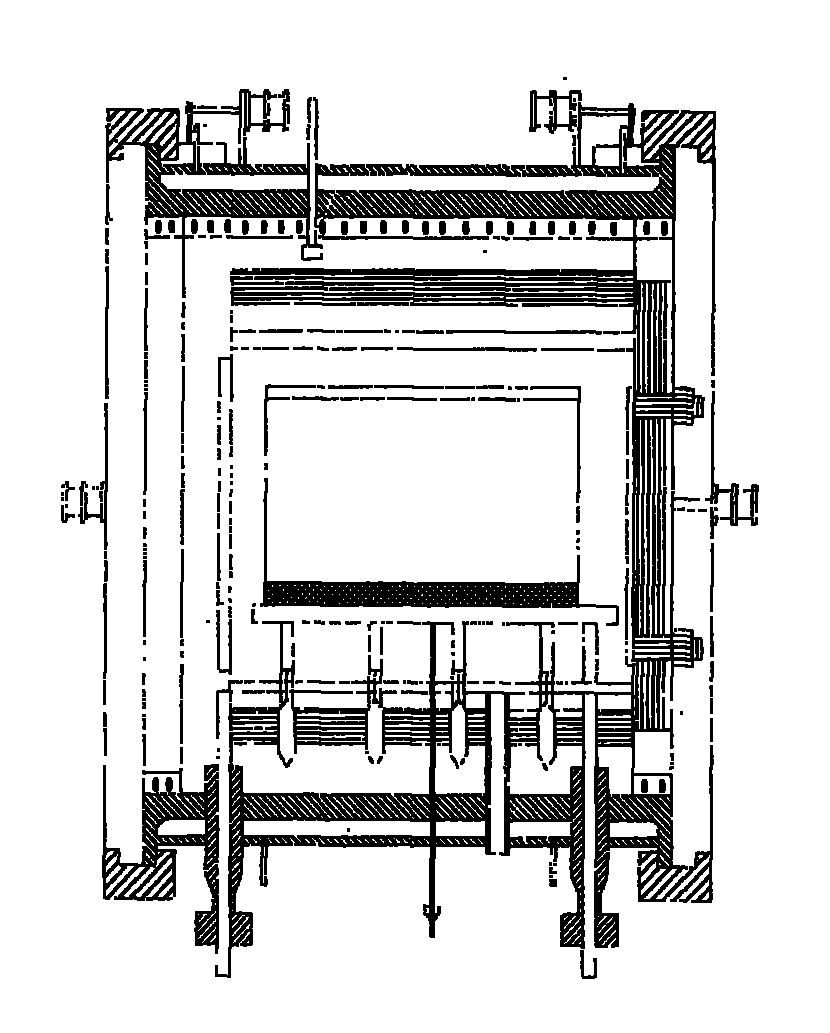

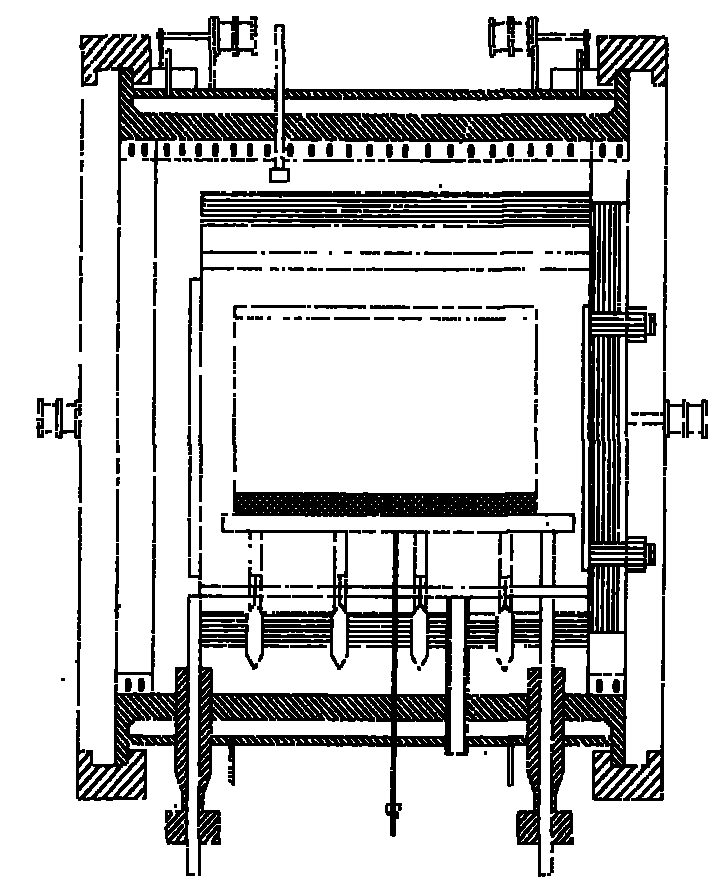

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

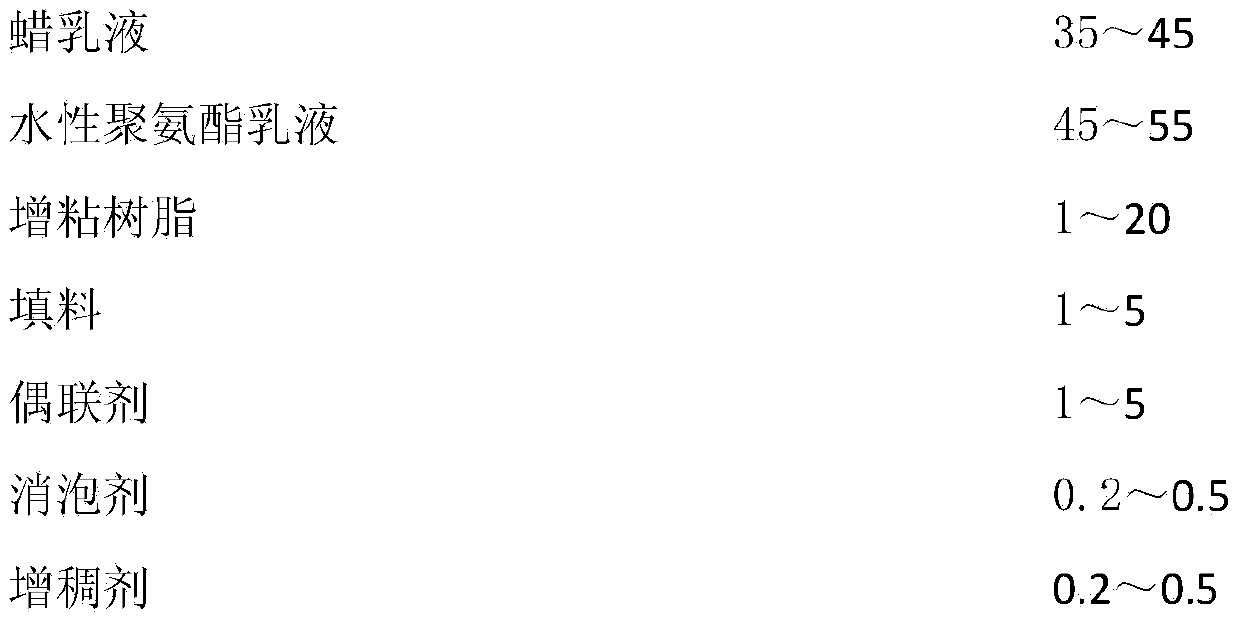

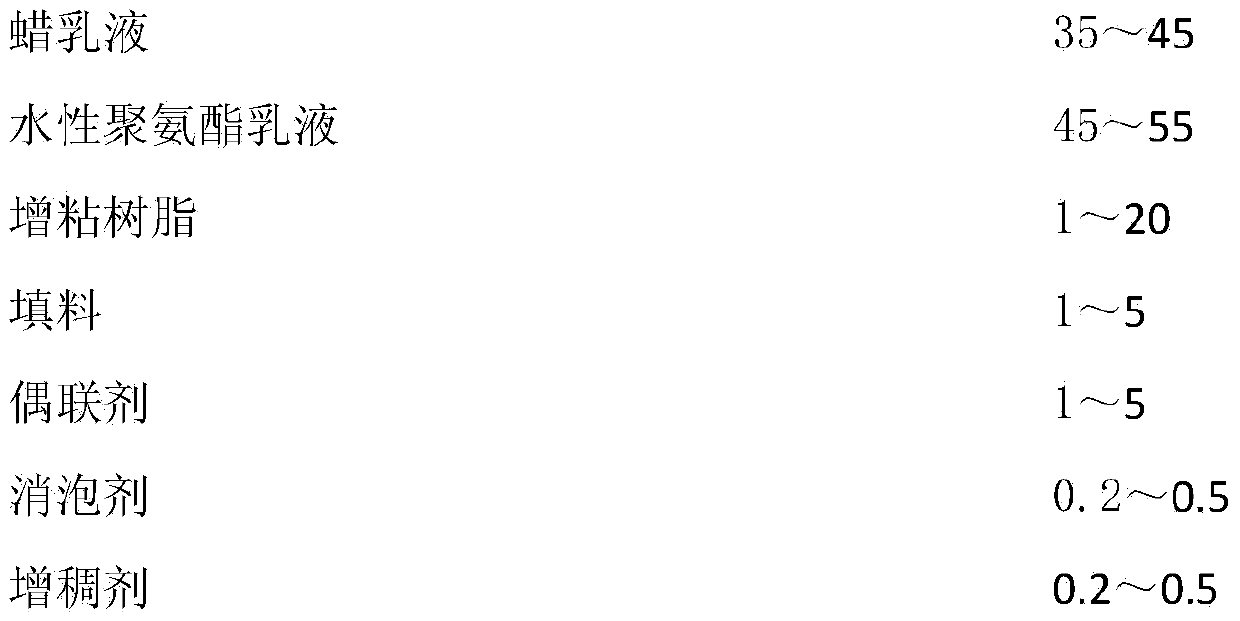

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461AGood adhesionAdhesivelyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWaxWater based

The invention discloses water-based paper and plastic laminating / peelable adhesive and a method for manufacturing the same. The water-based paper and plastic laminating / peelable adhesive comprises, by mass, 35-45 parts of wax emulsion, 45-55 parts of water-based polyurethane emulsion, 1-20 parts of tackifying resin, 1-5 parts of additives, 1-5 parts of coupling agents, 0.2-0.5 part of defoamers and 0.2-0.5 part of thickeners. The water-based paper and plastic laminating / peelable adhesive and the method have the advantages that the wax emulsion, the water-based polyurethane emulsion, the additives, the tackifying resin, the coupling agents, the thickeners and the defoamers are compounded with one another to finally manufacture the water-based paper and plastic laminating / peelable adhesive, the water-based paper and plastic laminating / peelable adhesive is high-temperature-resistant and is high in initial adhesion, permanent adhesion and peel strength when used for laminating paper and plastics, the paper cannot be torn by an adhesion surface of a film when separated from the plastics, and is prevented from being damaged, and the adhesion surface is not sticky after the paper is separated from the plastics.

Owner:SOUTH CHINA UNIV OF TECH

Low-concentration weakly alkaline cyanide-free copper plating and bath solution preparing method

The invention relates to a bath solution preparing method and a low-concentration weakly alkaline cyanide-free copper plating which can ensure that the bonding force exists between a plating layer and a matrix, the plating solution has best stability, better dispersing capacity and deep plating capacity and simple process maintenance. The low-concentration weakly alkaline cyanide-free copper plating comprises a main salt, a conductive salt, a main complexing agent and a secondary complexing agent, wherein the main salt is copper chloride, the conductive salt comprises a mixture of sodium chloride, potassium chloride and ammonium chloride, the main complexing agent is a mixture of tartrate, citrate, nitrilotris(methylene)]tris-phosphonic acid salt, (1-Hydroxyethylidene)bis-phosphonic acid tetrasodium salt and ethylenediamine tetra(methylenephosphonic acid) salt; and the secondary complexing agent is a mixture of ortho-hydroxybenzoic acid, succinimide and derivatives thereof and dimethyl hydantoin. The invention has the advantages of capability of ensuring the bonding force of the plating and the matrix, best stability and better dispersing capacity and deep plating capacity and simple process maintenance.

Owner:HANGZHOU HAISHANG TECH

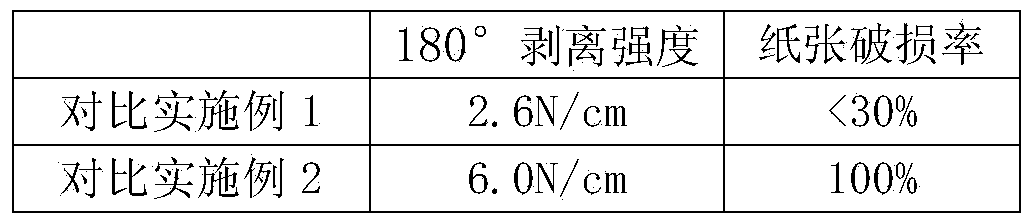

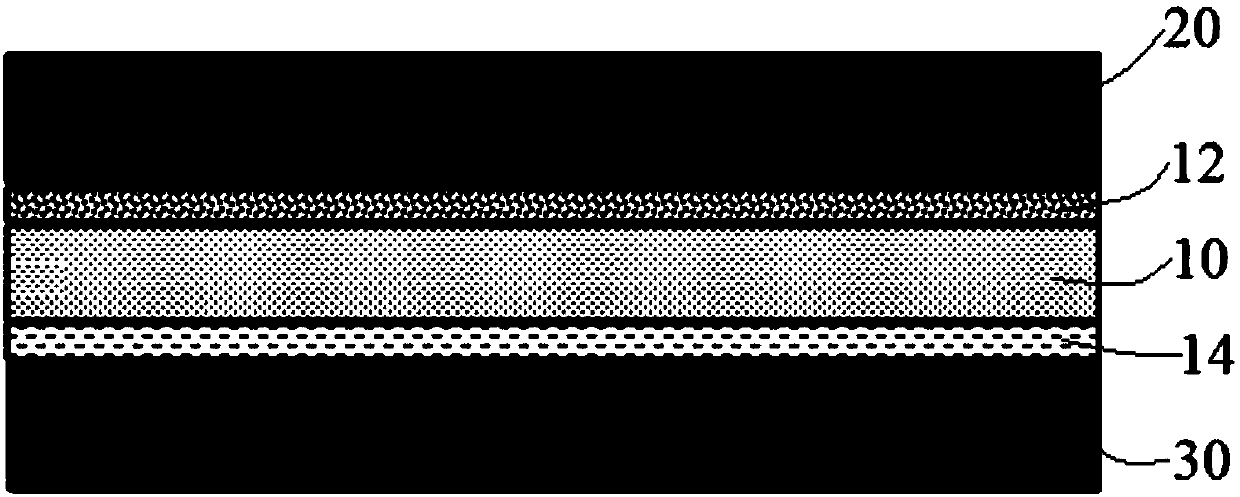

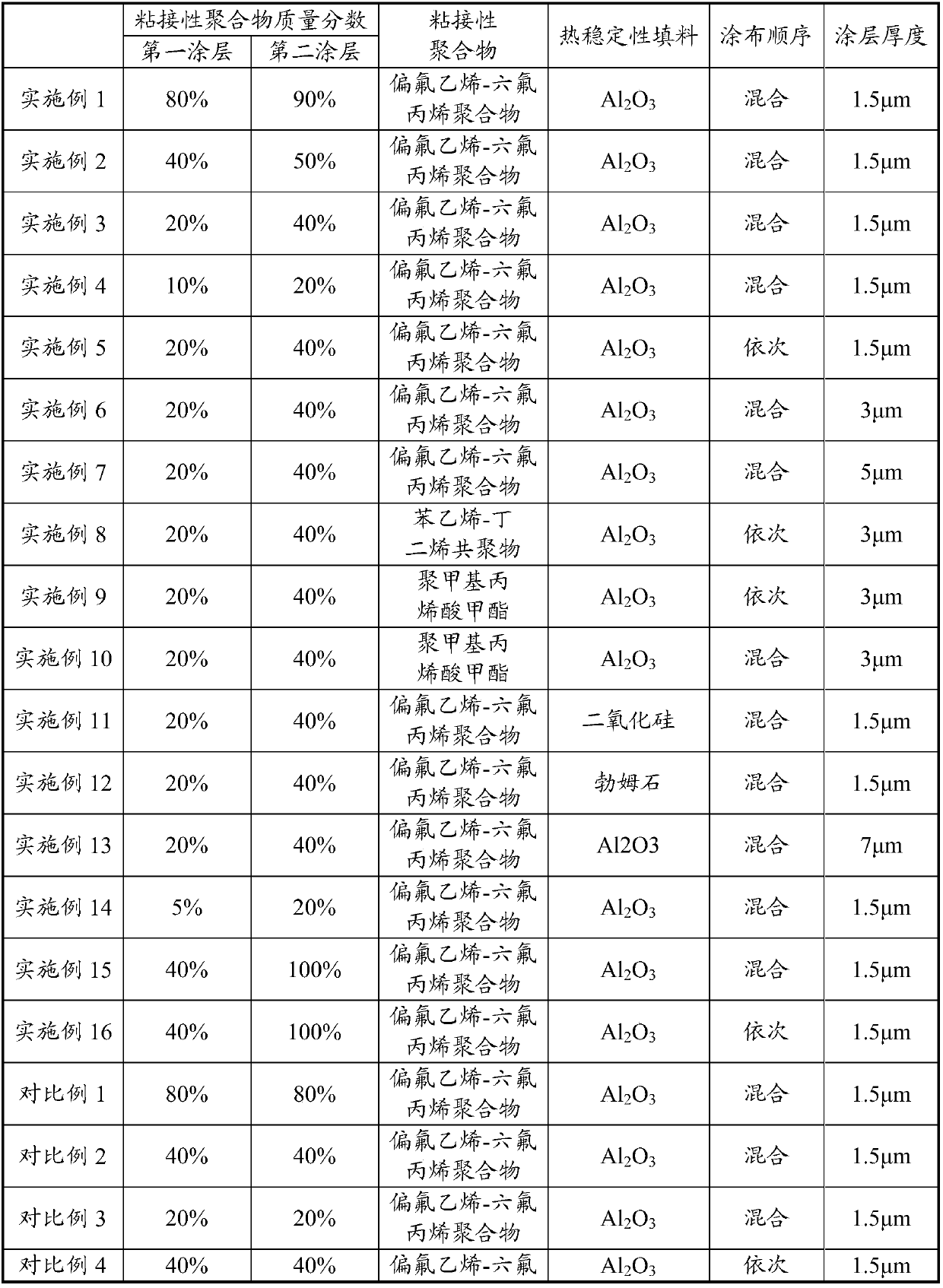

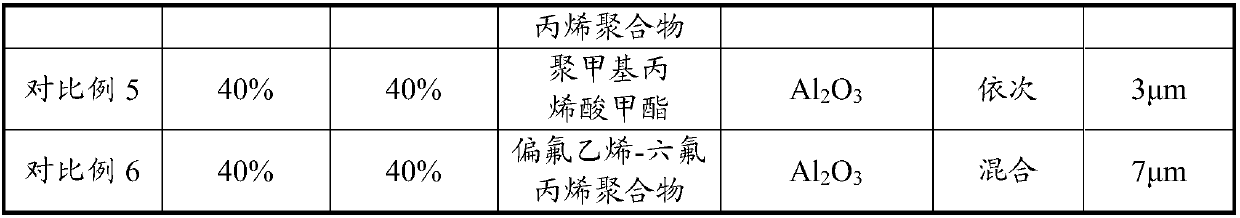

Lithium ion battery and coating separator thereof

ActiveCN107611314AImprove cycle lifeSatisfy expansionSecondary cellsCell component detailsPorous substrateLithium-ion battery

The invention discloses a lithium ion battery and a coating separator used by the same. The coating separator comprises a porous substrate and a coating layer, wherein the coating layer is coated on asurface of the porous substrate, the porous substrate comprises a first surface and a second surface, the facing directions of the first surface and the second surface are opposite, the coating layercomprises a first coating layer and a second coating layer, the first coating layer is arranged on the first surface of the porous substrate, the second coating layer is arranged on the second surface of the porous substrate, the first coating layer and the second coating layer both comprise adhesive polymers, and the mass percent of the adhesive polymer in the first coating layer is smaller thanthat of the adhesive polymer in the second coating layer. Compared with the prior art, the coating separator has the advantages that different separator coating layers are designed according to a positive electrode and a negative electrode, so that the lithium ion battery can simultaneously conform to requirements of the battery on hardness and dynamic characteristic.

Owner:NINGDE AMPEREX TECH

Electroplating technology for bearing quaternary alloy

The invention relates to a technology for electroplating quaternary alloy at the inner surface of a bearing, comprising the steps of ultrasonic oil removal, chemical oil removal, electrochemical oil removal, electrolysis pickling, pickling, electronickelling of grid, recovery, electroplating of Pb-Sn-Cu alloy, electroplating of indium layer; washing with hot water, drying, heat diffusion treatment, etc., the bearing quaternary alloy formed by four metallic chemical elements including lead, tin, copper and indium has firm bonding with substrate, good fatigue strength, carrying capacity and abrasive resistance, long service life, strong corrosive resistance and surface performance and high added value, and is widely used as a surface treatment technology for the bearing on aircraft engine, high-performance car, ship and heavy-duty vehicle engine.

Owner:四川双飞虹精密部件有限公司

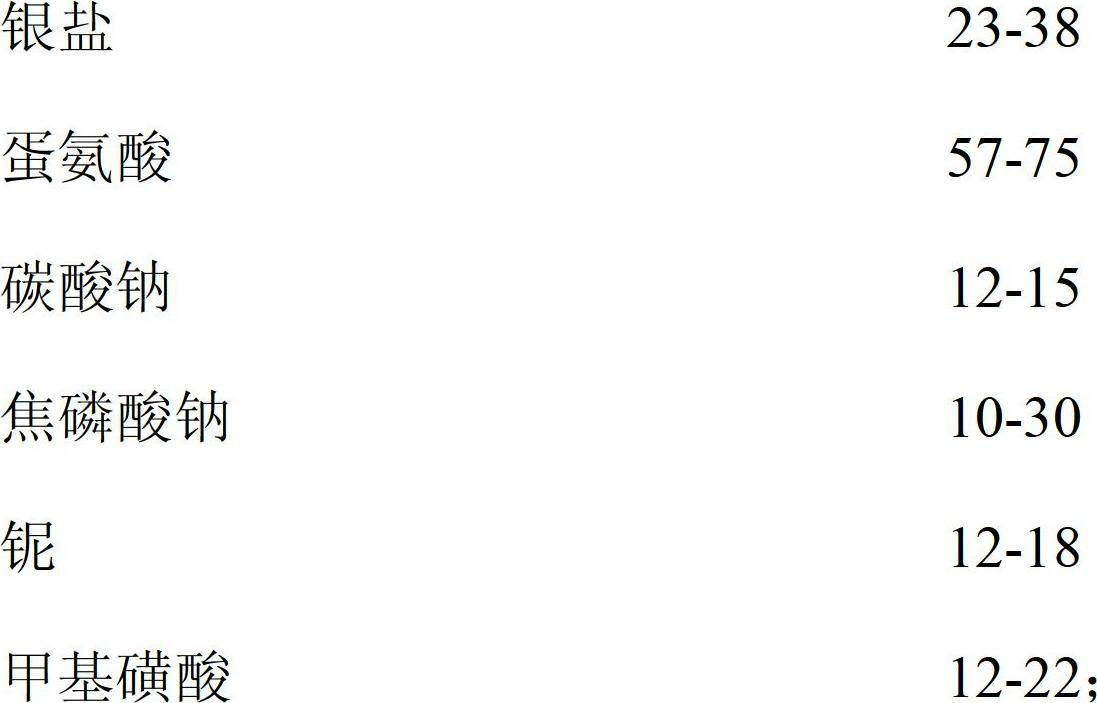

Electrosilvering solution and electrosilvering method

The invention relates to an electrosilvering solution and an electrosilvering method. The electrosilvering solution comprises silver salt, methionine, sodium carbonate, sodium pyrophosphate, niobium chloride and methanesulfonic acid, wherein the silver salt is silver nitrate. The electrosilvering method comprises the following steps of (1) polishing, (2) deoiling, (3) primary washing, (4) pre-electrosilvering, (5) secondary washing, (6) electrosilvering and (7) antitarnishing. The electrosilvering solution used in the electrosilvering is the electrosilvering solution disclosed by the invention. With the electrosilvering solution and the electrosilvering method provided by the invention, a dense silver coating with good bonding force can be obtained.

Owner:东莞市闻誉实业有限公司

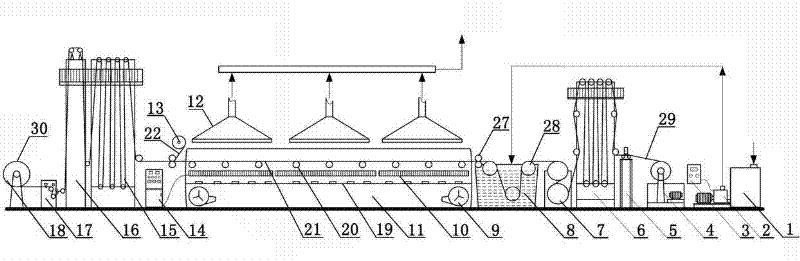

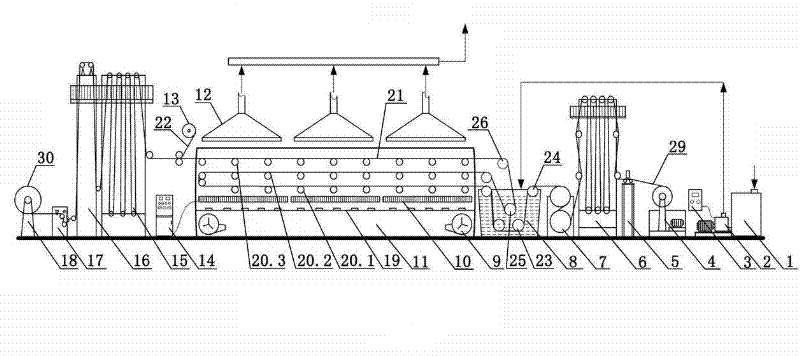

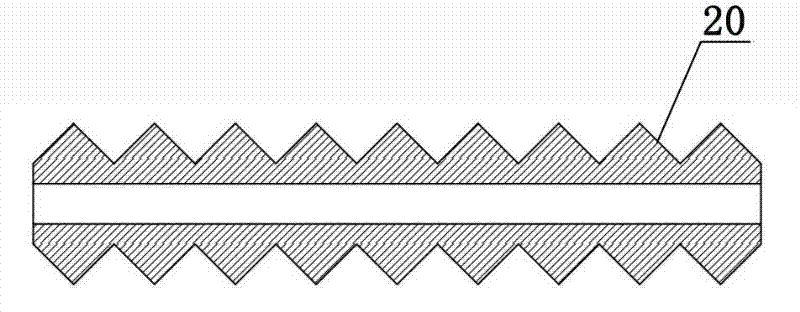

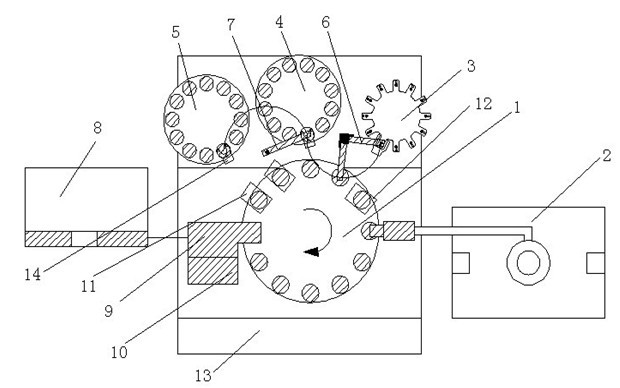

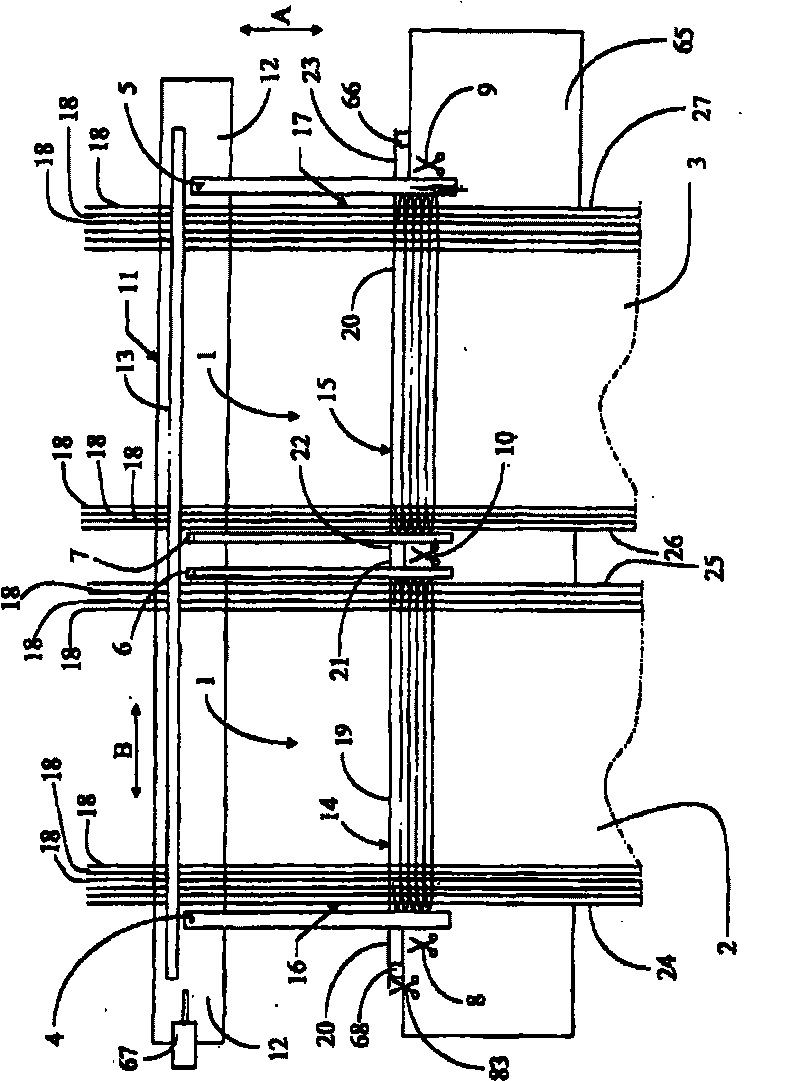

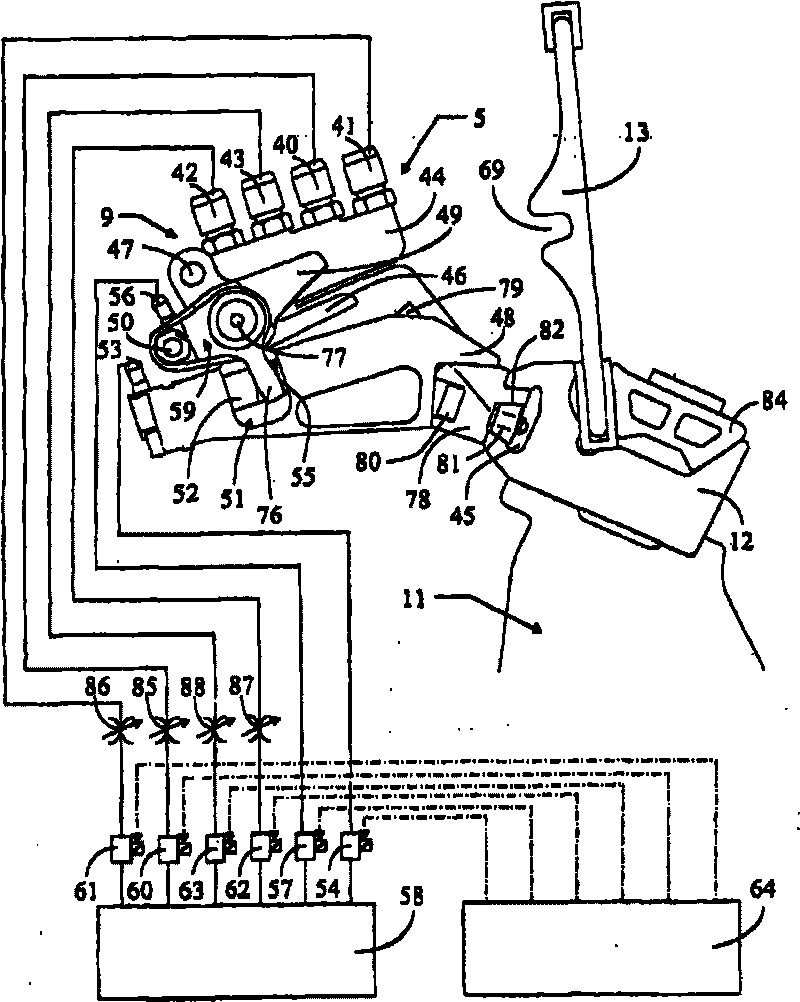

Production equipment and method of self-adhesive layer band

InactiveCN102350852AGuaranteed bondingControl UniformityLamination ancillary operationsFilm/foil adhesivesEngineeringError correcting

Production equipment and a method of a self-adhesive layer band. A base material is treated by a base material unfolding machine, a head-tail-overlapping machine, a base material buffering adjusting bracket and a base material dryer successively, enters into a gluing pool for gluing, then enters a dryer for drying; the dried base material is rolled with an isolated film on a surface thereof by a mulch applicator, cooled by a self-adhesive layer buffering adjusting bracket and adjusted by an automatic error correcting controller; then the base material can be packaged by a product winder and finally cut into dimensions required by production specifications by a cutting machine. After gluing, the base material is dried and returns to the gluing pool for a second gluing; and base material enters into the dryer again for drying after the second gluing, so as to increase peeling intensity of a self-adhesive waterproof coiled material and bonding strength of the material with a base, accelerate drying speed and increase product quality. According to the invention, base material treatment, gluing, drying, coating, cooling, rolling and packaging can be finished in a line, so as to realizeflexible operation, high degree of automation and good product quality.

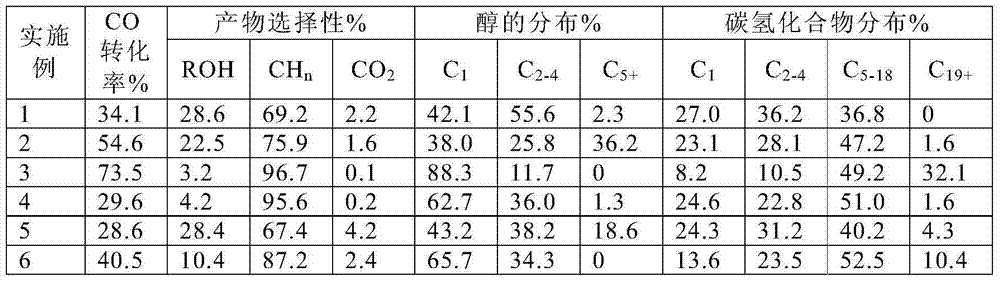

Catalyst for Fischer-Tropsch synthesis by using heteroatom hybridization mesoporous carbon to load cobalt base, preparation method and application

InactiveCN103691468AGood dispersionAvoid dopingLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsHeteroatomHigh activity

The invention discloses a catalyst for Fischer-Tropsch synthesis by using heteroatom hybridization mesoporous carbon to load cobalt base. The catalyst is characterized by comprising the following materials in percentage by weight: 10-20% of metal cobalt and 80-90% of heteroatom hybridization mesoporous carbon carrier. The catalyst disclosed by the invention has the advantages of high activity and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

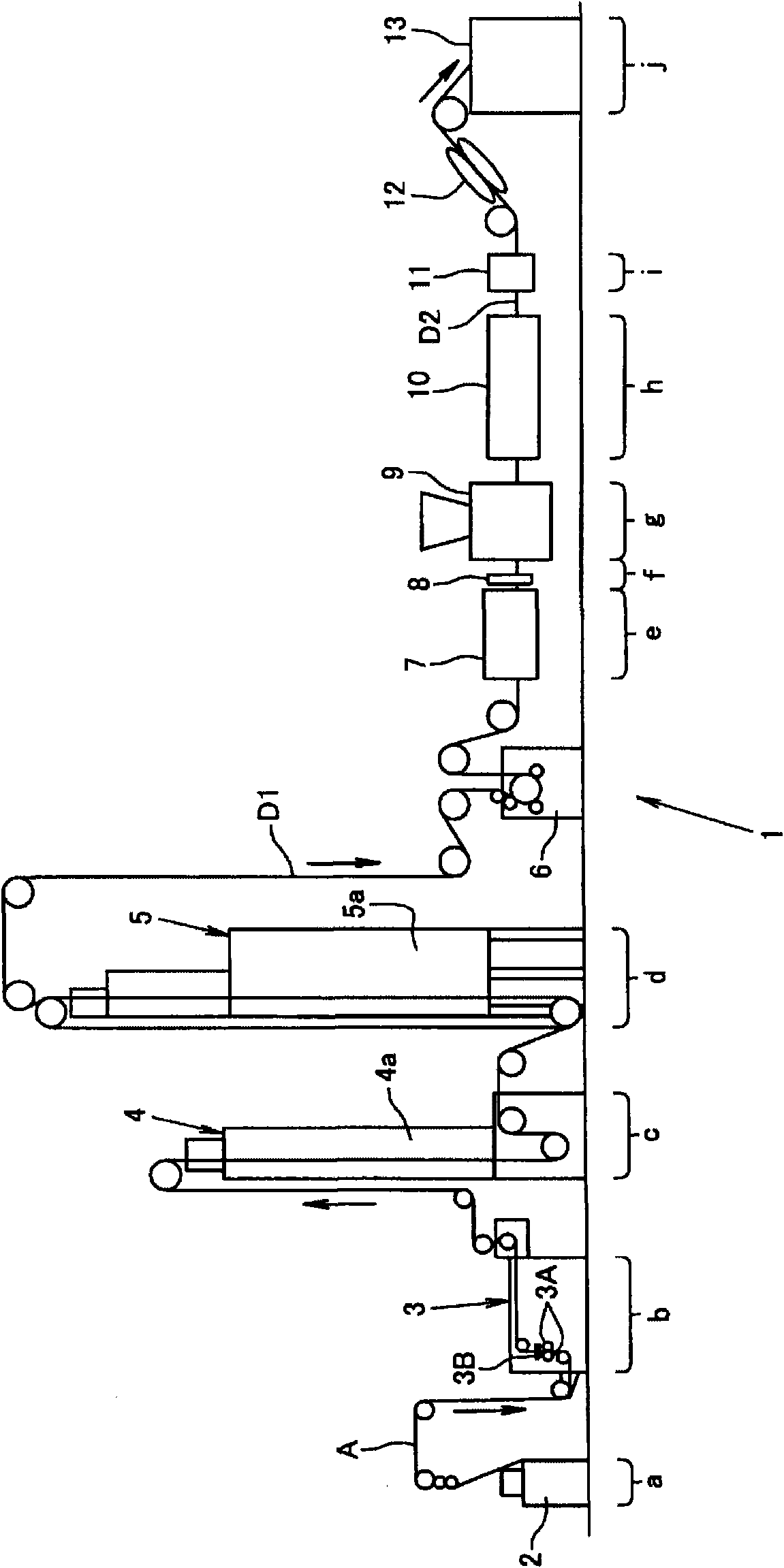

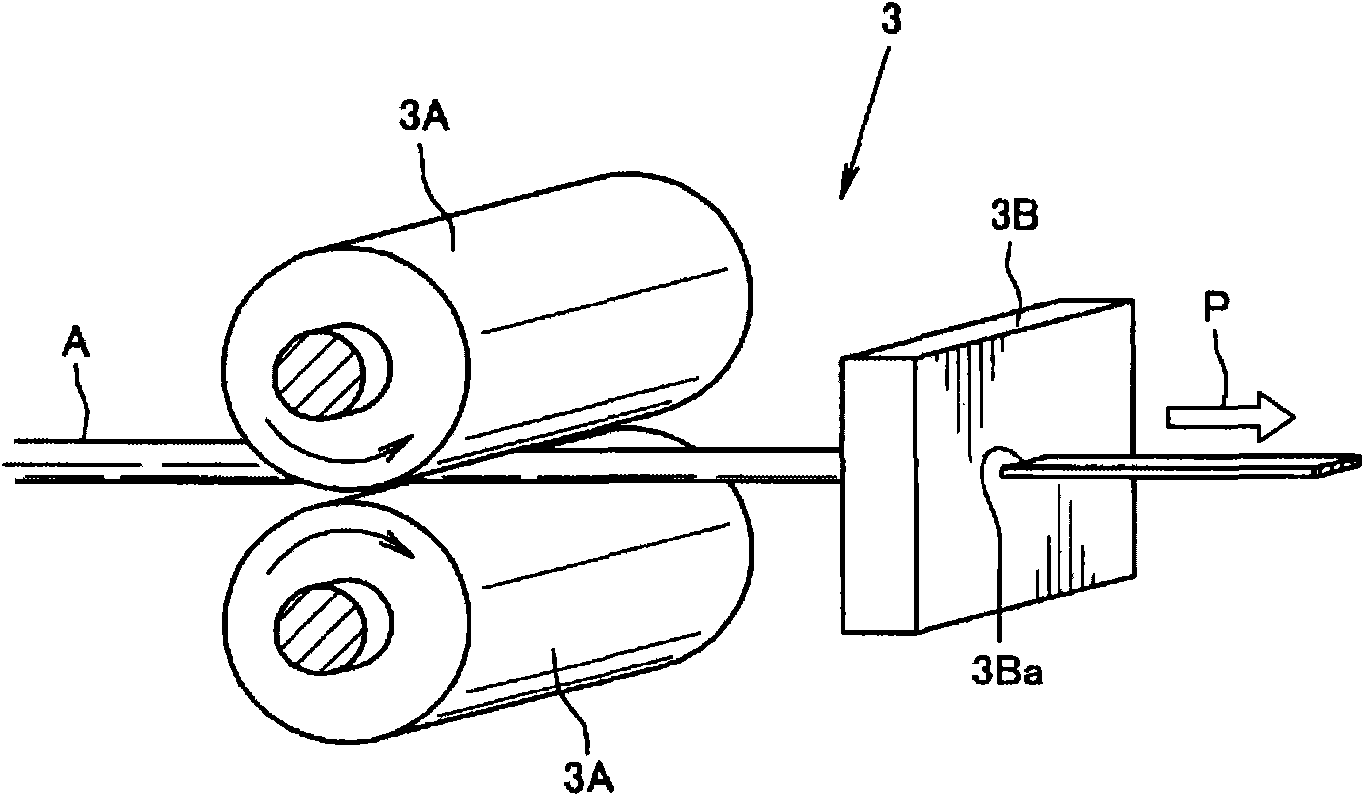

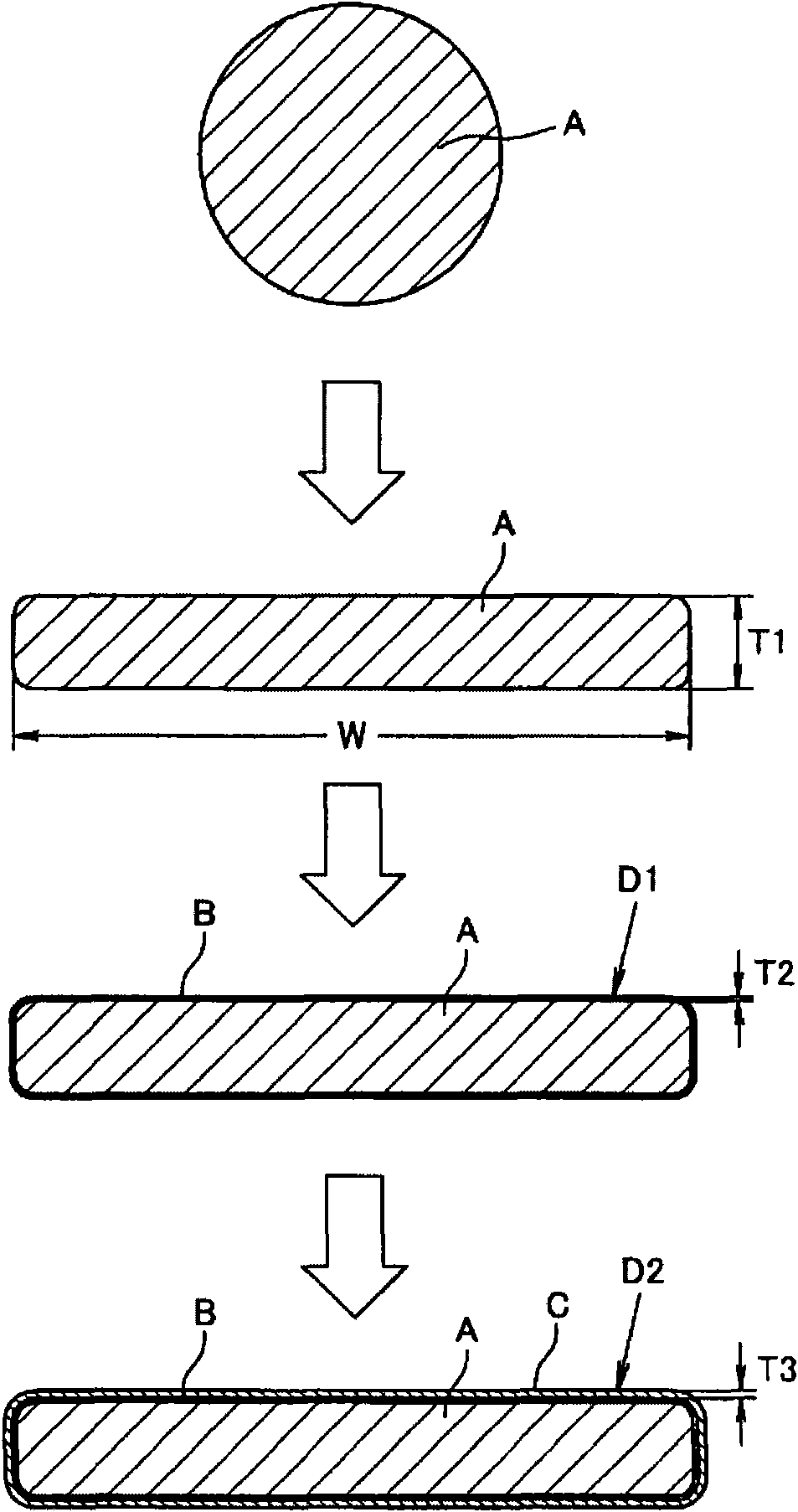

Method and apparatus for producing insulated wire

ActiveCN101558459AIncrease temperatureImprove adhesionInsulatorsInsulating conductors/cablesElectrical conductorEngineering

To provide insulated wire producing method and apparatus for producing a high quality corona-resistant insulated wire inexpensively. In the method for producing an insulated wire (D2), a primary coated wire (D1) wherein a primary coating layer (B) is applied to a conductor (A) is preheated at a temperature sufficient for enhancing adhesion of resin to the primary coating layer (B). Subsequently, resin such as polyphenylene sulfide resin is extruded onto the primary coating layer (B) of the preheated primary coated wire (D1), thus producing an insulated wire (D2) coated with a secondary coating layer (C) composed of PPS resin.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD

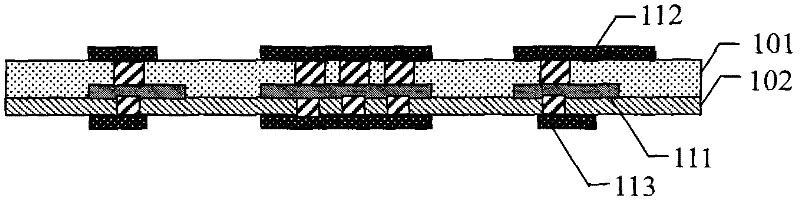

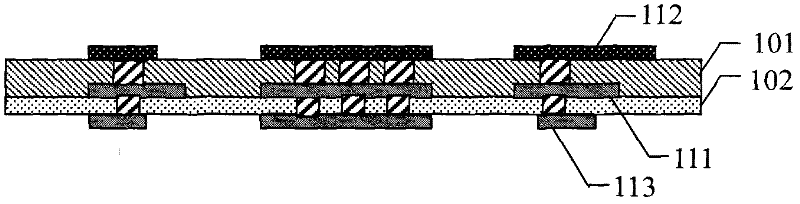

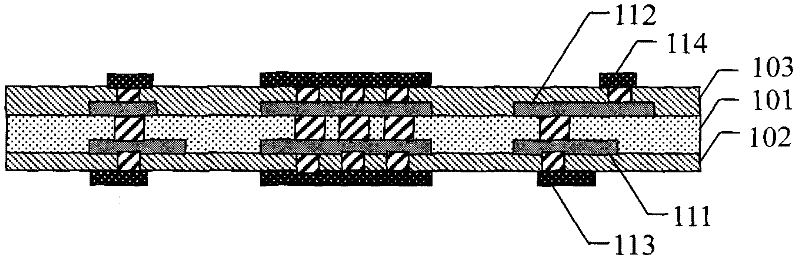

Multilayer circuit board and manufacturing method thereof

InactiveCN102548183AMeet the stiffnessFulfil requirementsInsulating substrate metal adhesion improvementPrinted circuit detailsGlass fiberElectrical and Electronics engineering

The invention discloses a multilayer circuit board and a manufacturing method thereof, relating to the technical field of multilayer circuit board manufacturing and aiming to improve the quality of multilayer circuit boards. The multilayer circuit board comprises multiple circuit layers overlapping with each other, wherein an insulating layer is arranged between two adjacent circuit layers; each circuit layer comprises a power wire layer, a ground wire layer and a signal wire layer; the insulating layers comprise at least a resin slice insulating layer and at least a prepreg insulating layer containing glass fiber cloths; the wiring density of the signal wire layer is greater than that of the power wire layer and / or the ground wire layer; and the resin slice insulating layer is arranged adjacent to the signal wire layer. The manufacturing method can be used for manufacturing the multilayer circuit board.

Owner:PEKING UNIV FOUNDER GRP CO LTD

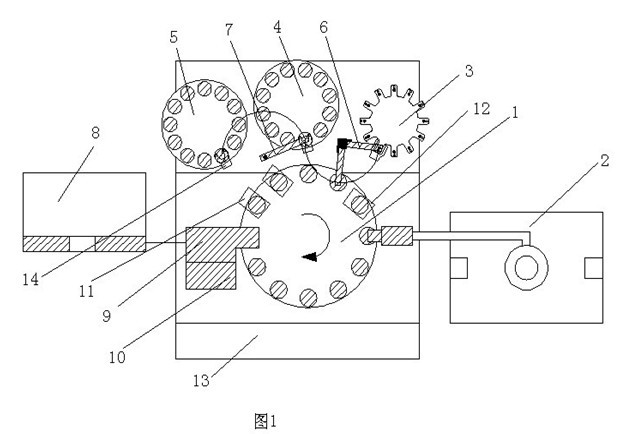

Combined method for producing abrasive cloth flap disc automatically

ActiveCN102152251AIncrease productivityLower requirementGrinding devicesControl systemCombined method

The invention relates to a combined method for producing an abrasive cloth flap disc automatically, aiming at overcoming the defects of low production efficiency and unstable product quality in the prior art. The technical scheme is as follows: an adopted device comprises a main rotating disc, a glue applying system, a pallet loading rotating disc, an abrasive cloth flap disc loading rotating disc, a supporting cover loading rotating disc, a manipulator I, a manipulator II, a material conveying mechanism, a piece planting device, a cutting device, a shaping device, a thickness measuring mechanism and a control system for controlling the operation of all the devices; when workers install a supporting cover and a pallet on the supporting cover loading rotating disc and the pallet loading rotating disc, the pallet is grabbed by the manipulator I and the manipulator II and is placed on the corresponding work station on the main rotating disc; and after thickness measurement, glue applying, piece planting, primary shaping and secondary shaping of the pallet are finished in sequence on the main rotating disc, the pallet is grabbed by the manipulators and is placed on the abrasive cloth flap disc loading rotating disc, so that rod penetration is finished. The combined method is mainly applied in automatic production of the abrasive cloth flap disc.

Owner:谢泽

Electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates

The invention discloses an electroplating method for electrically depositing Ni-Co-B alloy coatings on continuous casting crystallizer copper plates and belongs to the technical field of electroplating. An electroplating solution used by the method comprises the following components according to mass concentration: 170-350g / L of nickel salt, 5-50g / L of cobalt salt, 0.5-4g / L of sodium borohydride,20-60g / L of ethylenediamine and 30-50g / L of buffering agents. The Ni-Co-B alloy coatings prepared from the electroplating solution have high throwing power and excellent corrosion resistance performance; the micro hardness of the Ni-Co-B alloy coatings can reach 1000HV.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

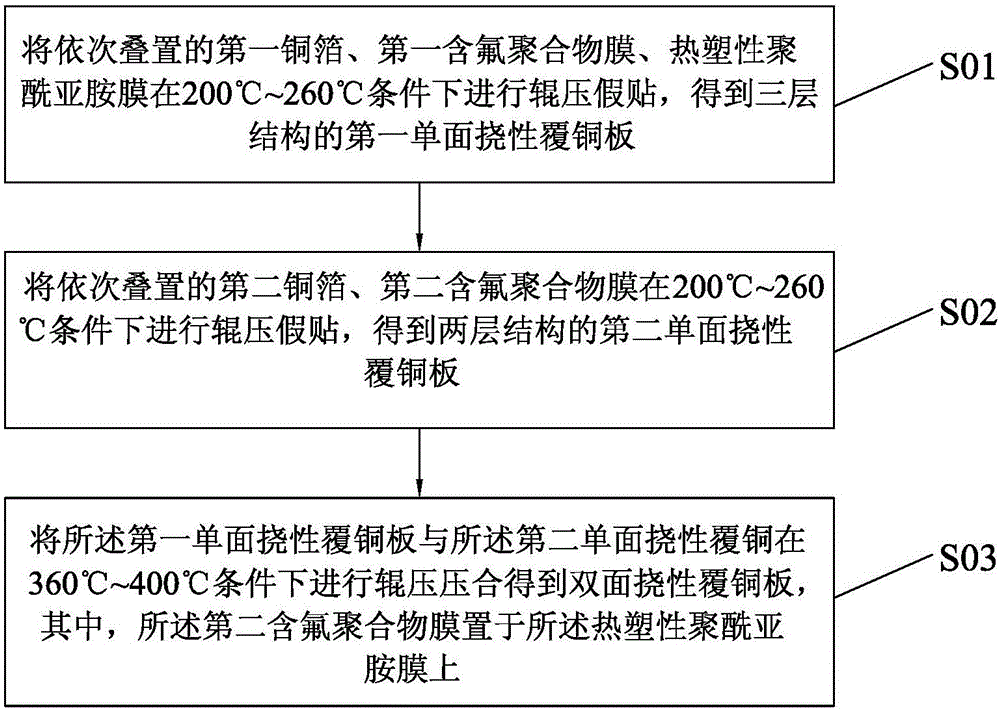

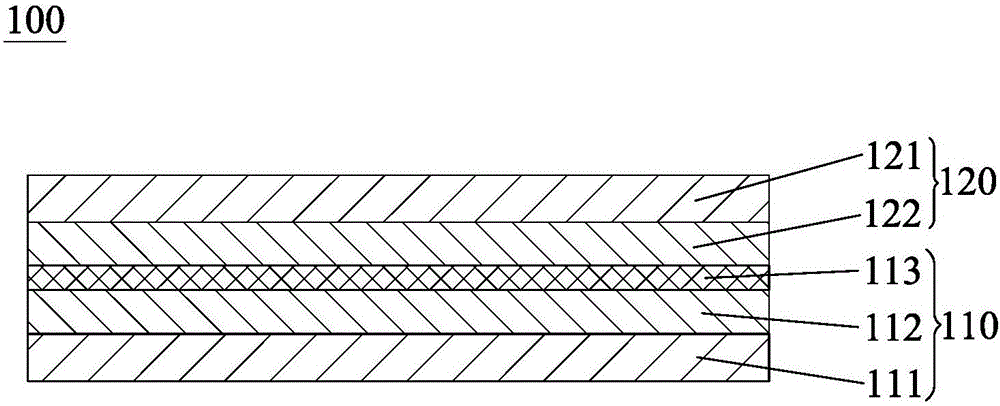

Double-sided flexible CCL (copper-clad plate) and production method thereof

ActiveCN106671511AGuaranteed Dimensional VariationSmall size changeSynthetic resin layered productsLaminationDielectric lossHeat resistance

The invention discloses a production method of a double-sided flexible CCL (copper-clad plate). The production method comprises the following steps: (1) first copper foil, a first fluoropolymer film and a TPI (thermoplastic polyimide) film which are stacked sequentially are subjected to rolling pressing at a low temperature, and a first single-sided flexible CCL with a three-layer structure is obtained; (2) second copper foil and a second fluoropolymer film which are stacked sequentially are subjected to rolling pressing at a low temperature, and a second single-sided flexible CCL with a two-layer structure is obtained; (3) the first single-sided flexible CCL and the second single-sided flexible CCL are subjected to rolling pressing at a high temperature, and the double-sided flexible CCL is obtained, wherein the second fluoropolymer film is arranged on the TPI film. The double-sided flexible CCL obtained with the method has lower dielectric constant and dielectric loss, good heat resistance and excellent mechanical property. The invention further discloses the double-sided flexible CCL produced with the method.

Owner:GUANGDONG SHENGYI SCI TECH

Production method of non heat seal teabag paper

InactiveCN102877378ARetain fiber lengthGuaranteed bondingReinforcing agents additionPaper/cardboardProcess engineeringSizing

The invention discloses a production method of non heat seal teabag paper. Final products can be obtained through a surface sizing process or a coating process in the existing production method of the non heat seal teabag paper, and a plurality of adhesives and additives are needed to add. The production method includes subjecting plant fibers to special processing, and reserving the length of fibers as far as possible during fully fibrillation; and adding appropriate thermosetting type reinforcing agent into the fiber after the special processing to obtain a body paper product through papermaking. The body paper product can be used directly without the surface sizing and the follow-up coating processing and can adapt to processing requirements for modern high-speed packing machines. According to the production method, the defect that final products can be obtained through the surface sizing or coating in the existing production method of the non heat seal teabag paper is overcome, the paper is formed once, the surface sizing or coating process is reduced, usage of chemical additives in the non heat seal teabag paper is reduced, obtained products are environment-friendly and good in processability, simultaneously, the production process is simplified, and the energy consumption and cost are reduced.

Owner:ZHEJIANG WINBON SPECIALTY PAPER

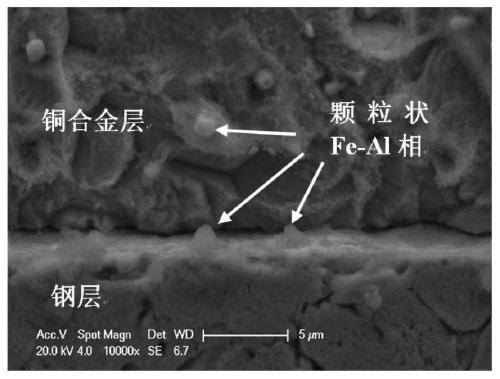

Copper steel composite material, arc additive preparing method and application of copper steel composite material and tin bronze alloy

ActiveCN110039154AHigh bonding strengthImprove wear resistanceAdditive manufacturing apparatusArc welding apparatusSheet steelUltimate tensile strength

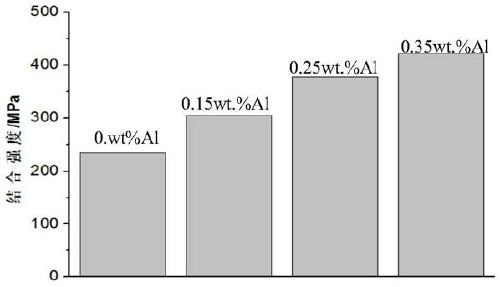

The invention discloses a copper steel composite material, an arc additive preparing method and application of the copper steel composite material and a tin bronze alloy. The composite material is composed of a copper alloy layer and a steel layer. The copper alloy layer is novel tin bronze and comprises the following components including, by weight percent, 5%-10% of Sn, 0.15%-0.35% of Al, 0.05%-0.2% of Si, smaller than 0.01% of Pb, smaller than 0.01% of Ni and the balance Cu. A preparing technology of the composite material includes the steps that firstly, casting of a novel tin bronze alloybar is conducted; secondly, the alloy bar is subjected to extruding and drawing technologies, and a wire with the diameter being 0.8 mm to 1.6 mm is prepared; and thirdly, the wire is arranged on thesurface of a steel plate in an arc additive manner, and the copper / steel composite material is obtained. The copper steel composite material is high in combination strength and has dendrite tissue which is compact, uniform and fine, and the wear reducing and resisting performance and the bearing performance are high.

Owner:SOUTHEAST UNIV

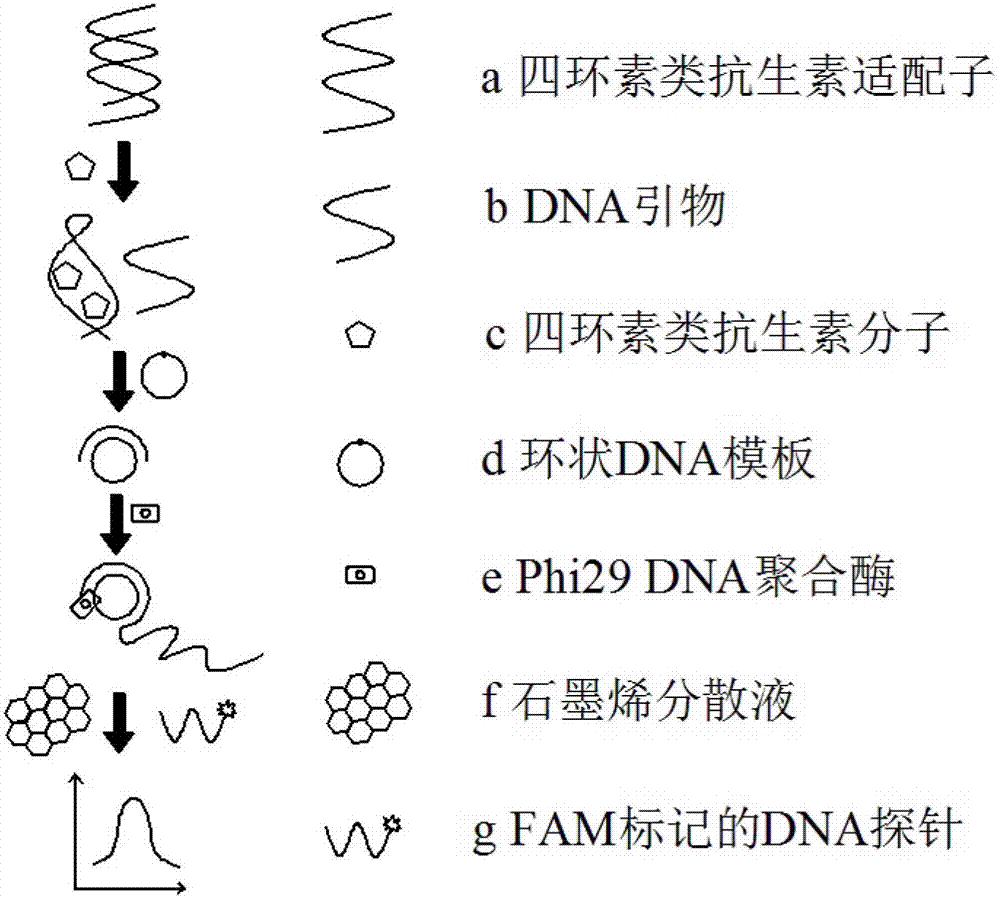

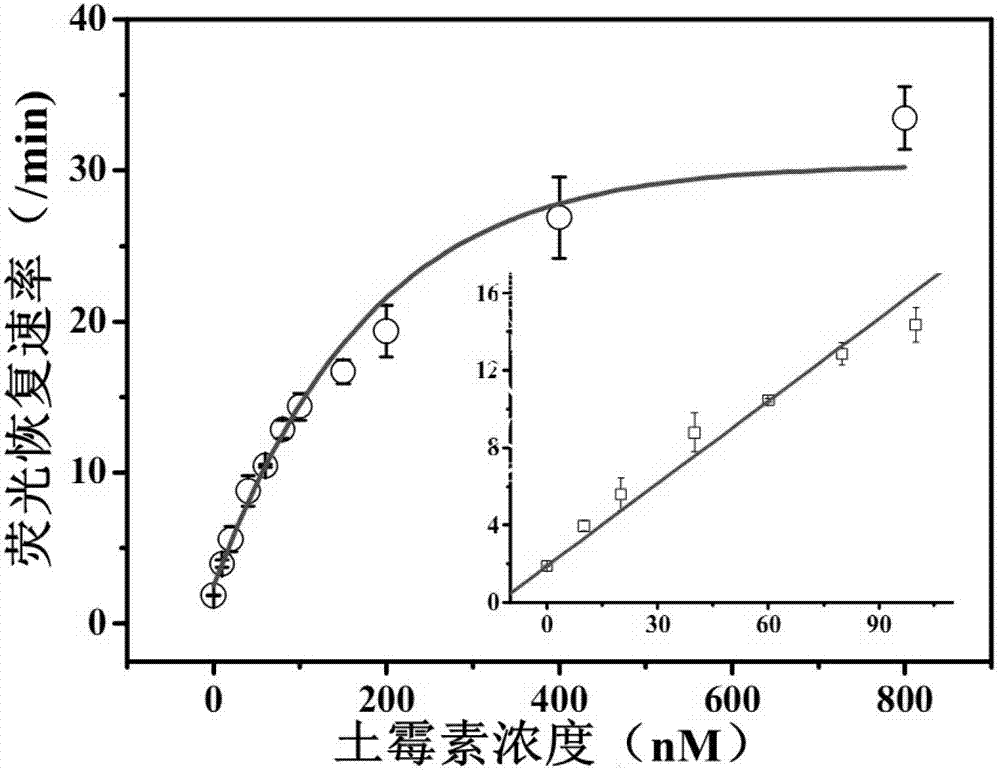

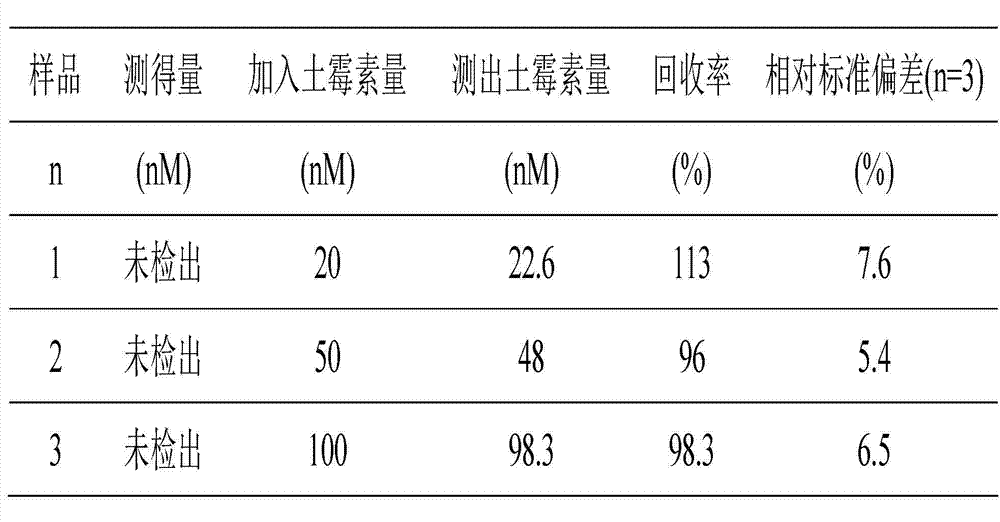

Fluorescence detection method for trace tetracycline antibiotics

The invention relates to a fluorescence detection method for trace tetracycline antibiotics. According to the method, by utilizing the combined action of tetracycline antibiotics molecules and the specificity of an aptamer thereof, an amplification action of a rolling ring amplification signal and high selection action of a graphene molecular beacon as well as combining a fluorescence spectrophotometer, the fluorescence signal of the graphene molecular beacon is obtained, so that quantitative detection of trace tetracycline antibiotics can be realized. According to the method, a plurality of defects of the prior art such as complexity in detection are overcome, the sensitivity and selectivity are improved, and a new method is provided for detection of other small molecule substances or pollutants.

Owner:DALIAN UNIV OF TECH

Improved type conductive marmite and manufacturing method thereof

InactiveCN103193463AFast heating rateGuaranteed bondingCooking-vessel materialsWarming devicesZincTalc

The invention relates to an improved type conductive marmite and a manufacturing method thereof. The improved type conductive marmite is characterized by sequentially comprising a marmite body ceramic, a glaze and a conductive metal aluminum layer, wherein the conductive metal aluminum layer is positioned at an outer bottom; the marmite body ceramic (1) comprises the following components in percentage by weight: 20%-27% of Suzhou No.1 clay, 12%-17% of camwood knots, 3%-8% of Zhangzhou clay, 35%-43% of spodumene and the balance of Gangxi talcum; the glaze (2) comprises the following components in percentage by weight: 25%-35% of the spodumene, 30%-45% of magnesium oxide, 6%-12% of zinc oxide, 3%-7% of Suzhou No.1 clay, 5%-8% of tin oxide,, 8%-15% of silicon micropowder and the balance of self-made fusion cakes; and the conductive metal aluminum layer (4) is completely covered at the bottom of a marmite body. The manufacturing method comprises the following steps of: weighing materials according to the formula of the marmite body ceramic; and stirring, mixing, adding water, vacuumizing, forming, drying, glazing, and finally burning. The improved type conductive marmite disclosed by the invention is possible to be hopeful in large-scale application on an electromagnetic cooker and has a good market prospect.

Owner:刘俊杰

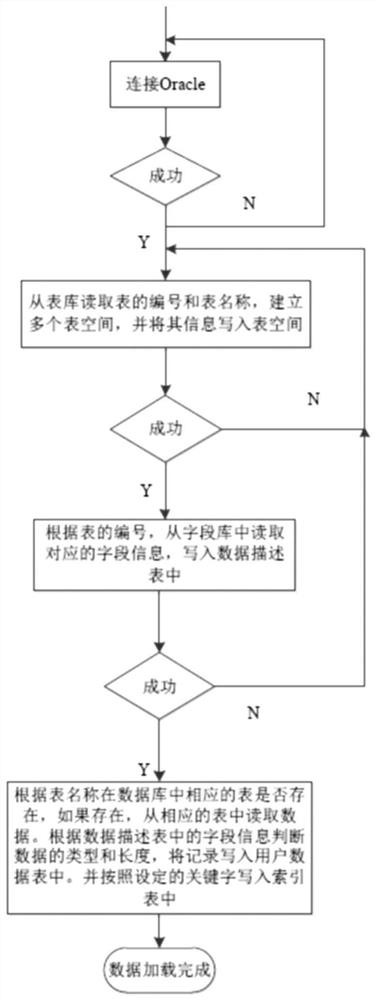

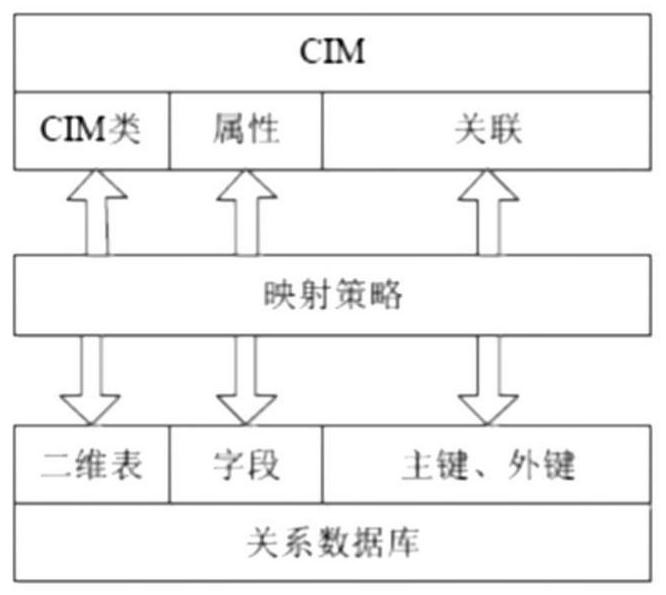

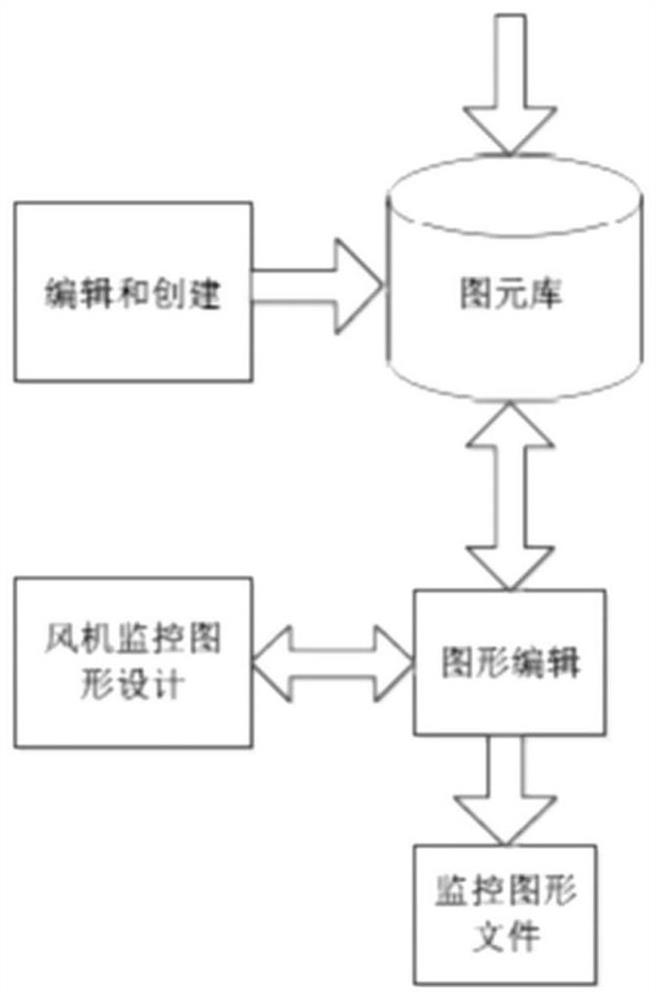

Wind power plant centralized control center SCADA system based on CIM model

InactiveCN111913935AIntegrity guaranteedEnsure safetyDatabase management systemsForecastingNew energyWeather prediction

The invention belongs to the technical field of power system new energy information management, and discloses a wind power plant centralized control center SCADA system based on a CIM model, and the system collects real-time data in a wind power plant, and stores the related data in a real-time database; stores description information and static information of a real-time database, and performs information management; storeshistorical data. The loading method of the real-time database comprises the step of loading the information of the real-time database by reading the related information ofthe database and the relationship among the databases. The wind power plant CIM modeling method is adopted, the wind power plant CIM model is established into the corresponding database model, fusionof the wind power plant and system power system resources is achieved, and analysis and calculation of a wind turbine generator are achieved. According to the invention, weight calculation is carriedout on parameters of the variable pitch system, and convenience is provided for fault diagnosis. Meanwhile, the wind power is predicted according to historical data and weather forecast, and the prediction result is relatively accurate.

Owner:HEBEI UNIV OF TECH

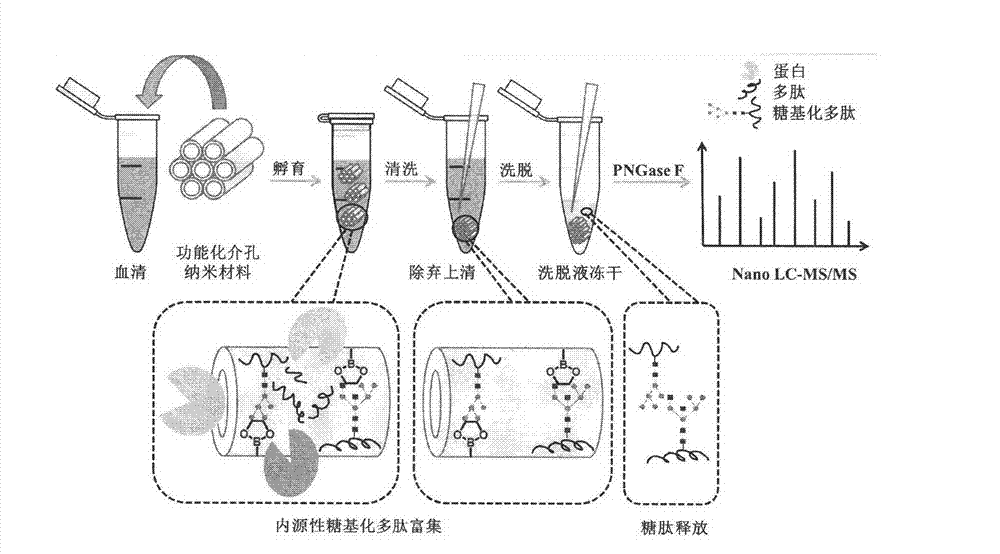

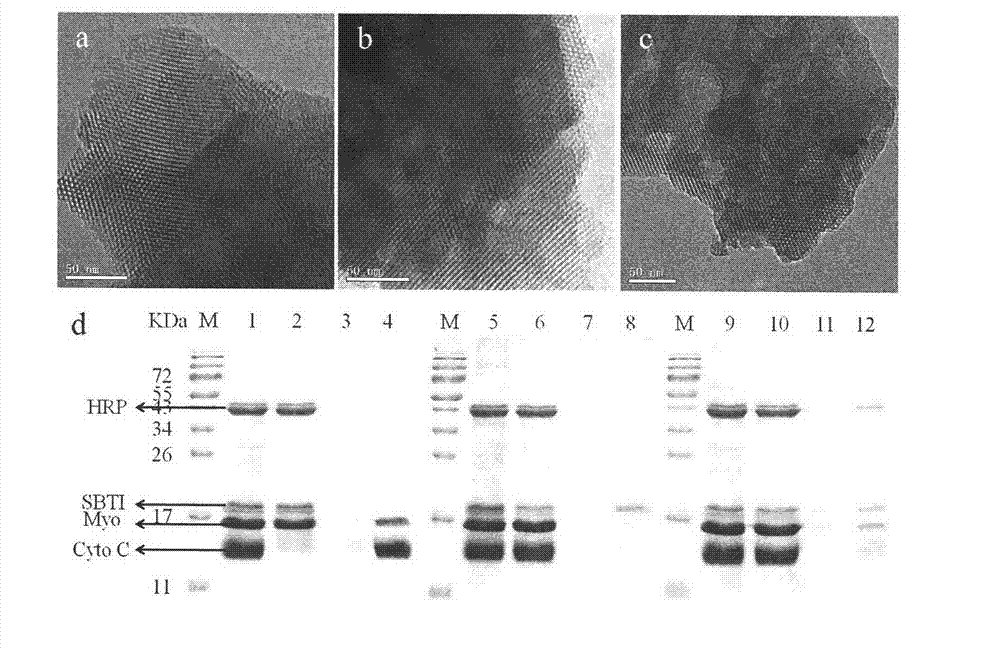

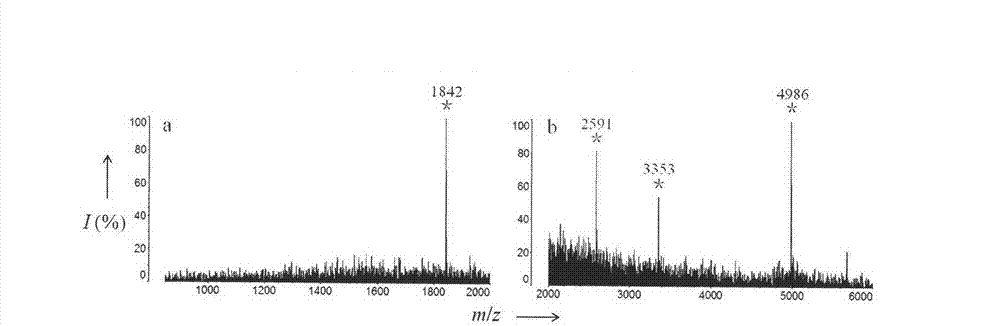

Method for high-selectivity enrichment of serum glycopeptides group

InactiveCN103364494ALarge specific surface areaAvoid degradationComponent separationSorbentGlycopeptide

The invention relates to a new method for high-selectivity enrichment of serum glycopeptides group, and particularly relates to a method for high-selectivity enrichment of serum glycopeptides group by using a functionalization ordered mesoporous nanometer material, belonging to the field of biochemical analysis. The method comprises the following steps of: selecting the functionalization mesoporous nanometer material with an appropriate pore size so as to serve as a sample adsorbent, enriching endogenous glycosylation polypeptides in serum by using the double capacity of capture of glycopeptides combined with functional groups and size exclusion of mesoporous, and after sugar chains in PNGase F glycosidase are excised, carrying out nano-upgrading liquid chromatography-tandem mass spectrometry analysis, and searching and identifying amino acid sequences and corresponding glycosylation sites in a database, thus successfully realizing the revelation of serum glycopeptide epigenomics. The new method provided by the invention is simple in steps, convenient to operate, fast and efficient, can meet glycopeptide epigenomics research requirements and can be used for high-sensitivity detection and identification of the endogenous glycosylation polypeptides and further revelation of the serum glycopeptide epigenomics.

Owner:FUDAN UNIV

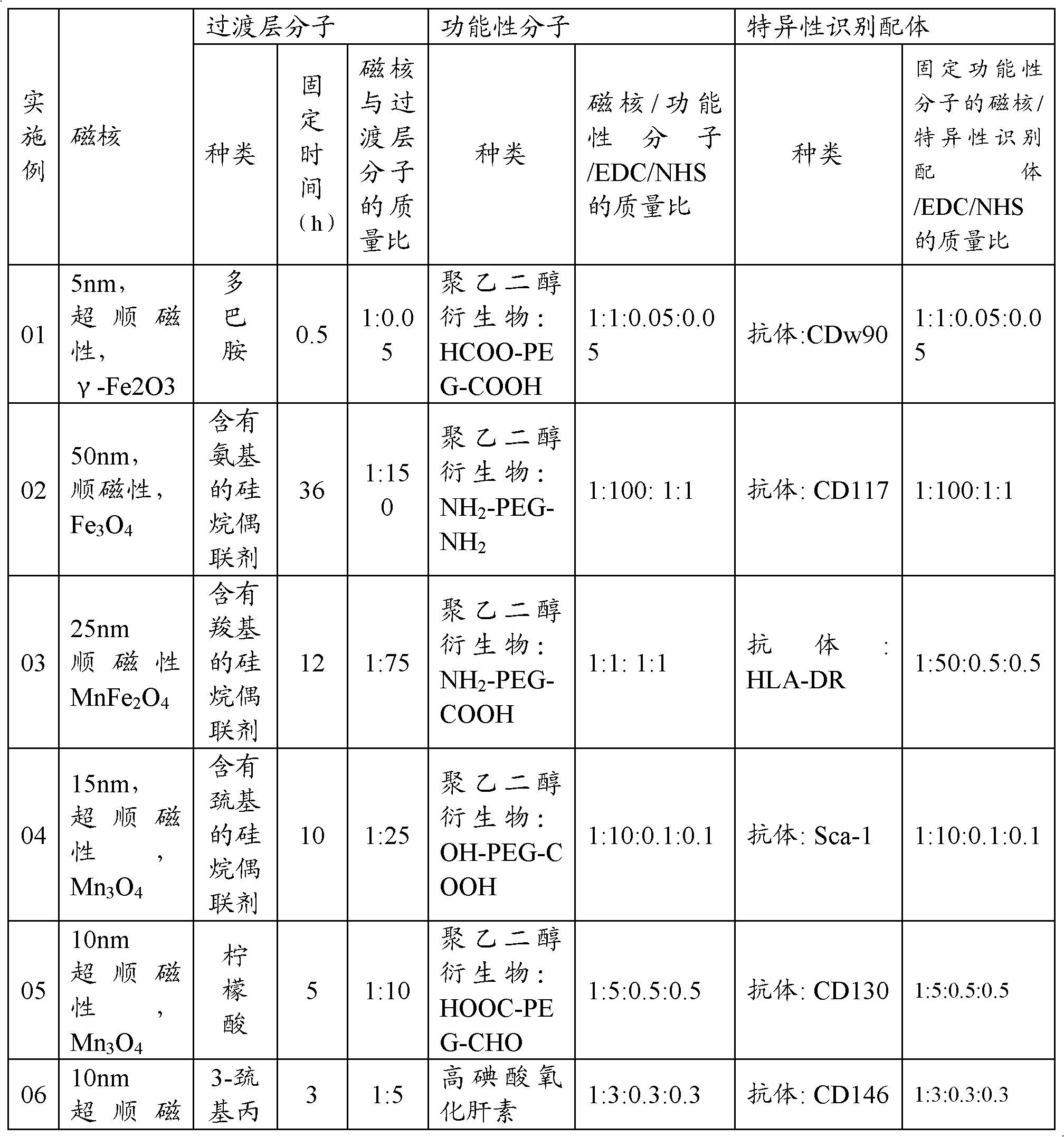

Preparation method of nano magnetic particles for detection and treatment of coronary heart diseases

InactiveCN102085380AIncreased Magnetic Response Imaging StrengthRealize detection and localizationNMR/MRI constrast preparationsPharmaceutical non-active ingredientsChemistryCoronary heart disease

The invention relates to a preparation method of nano magnetic particles for detection and treatment of coronary heart diseases, which comprises the following steps: A, mixing transition layer molecules on the surfaces of magnetic nuclei, wherein the transition layer molecule are compounds which simultaneously contain amino groups, carboxyl groups or hydrosulfide groups and groups capable of reacting with hydroxyl groups; B, on the magnetic nuclei fixed with the transition layer molecules, fixing functional molecules capable of prolonging the residence time of nano particles in blood; and C, on the magnetic nuclei fixed with functional molecules, fixing specific recognition ligands of endothelial progenitor cells or diseased endothelial cells, thus obtaining the nano magnetic particles. The method can be used for preparing magnetic nano particles for early-stage detection and location of diseased endothelial cells of coronary heart diseases, and the detection is sensitive and reliable; the method can be also used for preparing magnetic nano particles for mid-late-stage treatment of coronary heart diseases; and good repairing and treatment effects on coronary heart diseases can be achieved.

Owner:CHENGDU SOUTHWEST JIAOTONG UNIV SCI & TECH GARDEN MANAGEMENT +1

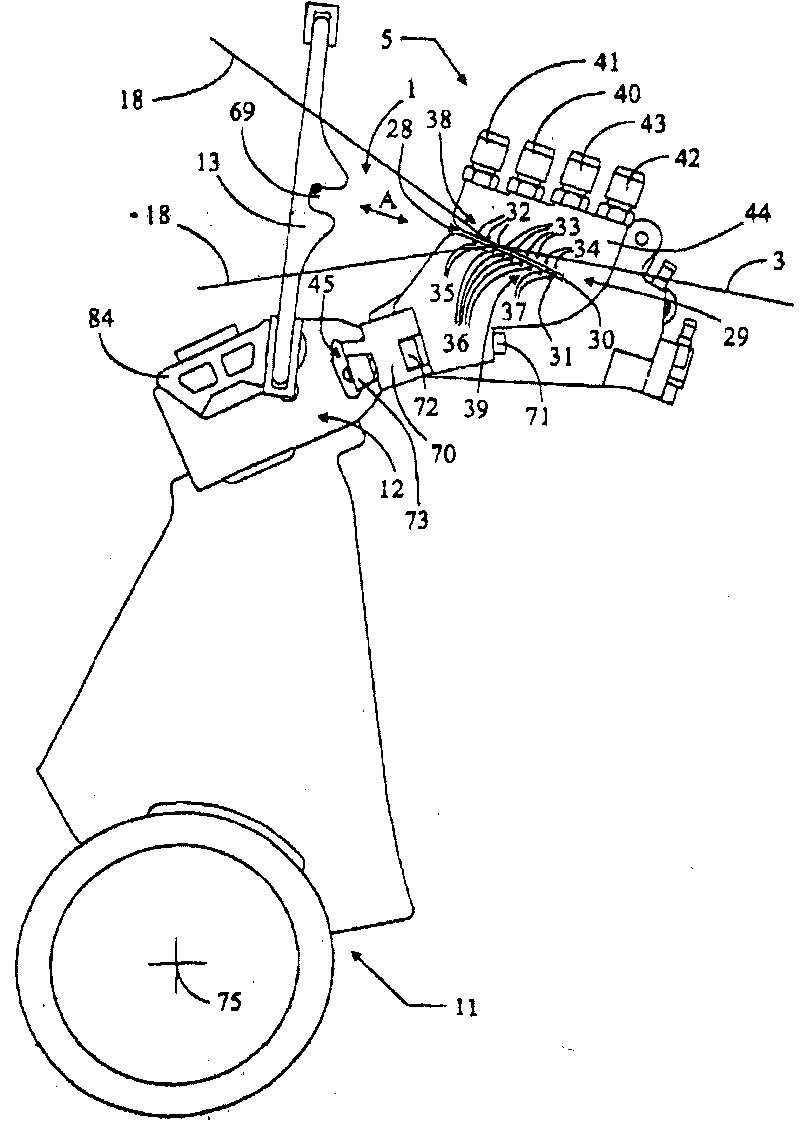

Method for tucking an end of a weft thread into a selvedge of a fabric, and pneumatic tuck-in device

ActiveCN101743348AUse uninterruptedGuaranteed bondingLoomsStructural engineeringMechanical engineering

Owner:PICANOL NV

Airbag type inner framework form traveler and primary tunnel supporting shotcrete construction method

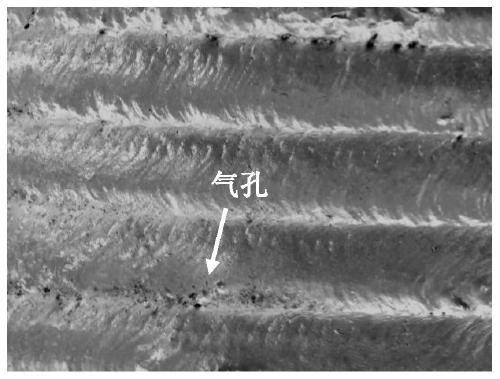

ActiveCN105507927ASimple structureEasy to processMining devicesUnderground chambersShotcreteArchitectural engineering

The invention discloses an airbag type inner framework from traveler and a primary tunnel supporting shotcrete construction method. The form traveler comprises a movable supporting framed bent, an inflatable formwork located on the outer side of the movable supporting framed bent, and a retractable supporting device for supporting the inflatable formwork, and the retractable supporting device is installed on the movable supporting framed bent and located on the inner side of the inflatable formwork. The construction method includes the steps: firstly, forwarding the airbag type inner framework from traveler in place; secondly, performing primary tunnel supporting shotcrete construction; thirdly, performing primary tunnel supporting shotcrete construction on a next tunnel section; fourthly, repeating the third step for multiple times till the primary tunnel supporting shotcrete construction process of all the tunnel sections is finished. The airbag type inner framework from traveler is reasonable in design, simple to construct and good in using effect, resilience rate of primary tunnel supporting shotcrete is effectively controlled through an airbag type inner framework, construction efficiency is high, construction period is short, construction quality is high, and zero resilience rate of primary tunnel supporting shotcrete can be realized.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

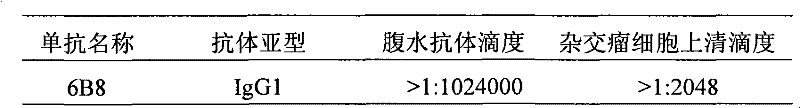

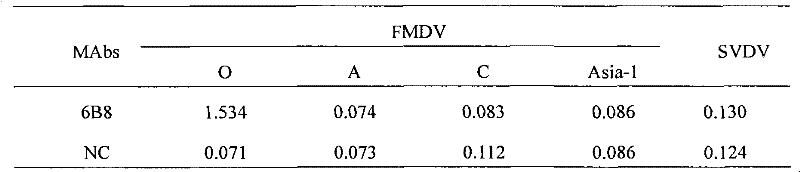

A kind of anti-foot-and-mouth disease virus monoclonal antibody and use

InactiveCN102277332AIncrease acquisition rateHigh potencyMicroorganism based processesImmunoglobulins against virusesMicroorganismImmunologic Technique

The invention relates to the technical field of virus immunology, in particular to a method for preparing an anti-O-type foot-and-mouth disease virus monoclonal antibody and the application of the prepared antibody, and belongs to the field of foot-and-mouth disease prevention and control. The microorganism preservation number of the hybridoma cell line 6B8 capable of specifically secreting monoclonal antibody against type O foot-and-mouth disease virus of the present invention is: CCTCC No: C201049. The subtype of monoclonal antibody produced by the hybridoma cell line hybridoma cell line 6B8 is IgG1. The hybridoma cell line of the invention can be used in preparing reagents for diagnosing type O foot-and-mouth disease. The monoclonal antibody of the invention can be used in the preparation of reagents for diagnosing type O foot-and-mouth disease.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

Method for manufacturing steel and copper bimetallic bearing for excavating machine

The invention discloses a method for manufacturing a steel and copper bimetallic bearing for an excavating machine. The method comprises the following steps of: 1) manufacturing a steel sleeve; 2) manufacturing an annular blank of which the thickness is 0.5 to 1 millimeter by using pure copper powder, sintering the annular blank and the steel sleeve to manufacture a composite steel sleeve, and turning a lining pure copper layer, so that the lining pure copper layer is reduced to 0.2 to 0.3 millimeter; 3) manufacturing a copper-base powder metallurgical material, mixing, compressing to manufacture an annular compressed blank, pressing the compressed blank in the composite steel sleeve to form a combination piece, wherein the copper-base powder metallurgical material consists of the following components in percentage by weight: 12 to 14 percent of -200-mesh aluminum powder, 1 to 3 percent of -300-mesh manganese powder, 0.5 to 1.5 percent of -300-mesh tin powder, 7.5 to 8.5 percent of -200-mesh iron powder, 0.2 to 0.4 percent of -200-mesh cerium powder, 2 to 3 percent of colloid molybdenum disulfide, 4 to 5 percent of -120-mesh crystalline flake graphite and the balance of -200-mesh electrolytic copper powder; 4) sintering the combination piece for forming; and 5) performing aftertreatment.

Owner:平和龙粉末冶金(珠海)有限公司

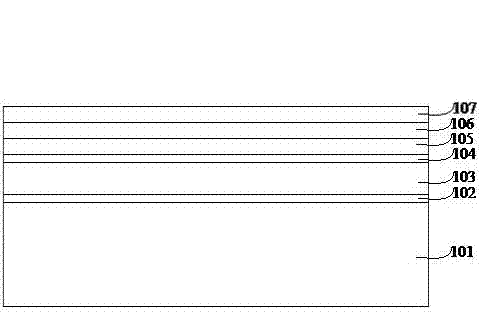

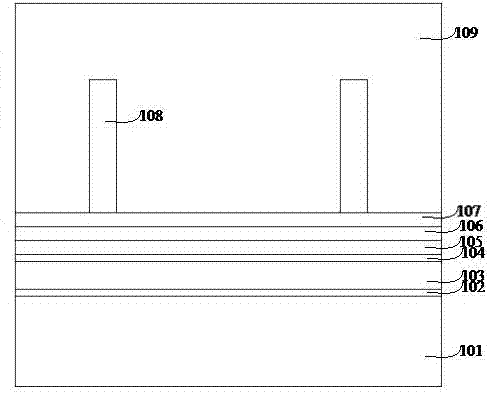

White-light emitting diode with vertical structure and manufacturing method thereof

InactiveCN102637783AGuaranteed stabilityGuaranteed yieldSemiconductor devicesQuantum wellLight-emitting diode

The invention discloses a white-light emitting diode with a vertical structure and a manufacturing method thereof and relates to the fields of illumination and manufacturing of semiconductor photoelectric devices and semiconductors. The white-light emitting diode disclosed by the invention comprises a metal supporting substrate, a metal seed layer, a reflecting metal layer, a P-type GaN-based semiconductor layer, a quantum well source region, an N-type GaN-based semiconductor layer and a passivation layer which are sequentially superposed form bottom to top, wherein an electrode trough on the top of a device is provided with an N-face electrode. The white-light emitting diode is structurally characterized in that a fluorescent powder layer is arranged on the passivation layer. Compared with the prior art, the white-light emitting diode disclosed by the invention is capable of effectively improving the luminescence power of the device and has the characteristics of simple process and low cost.

Owner:TONGFANG OPTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com