Catalyst for Fischer-Tropsch synthesis by using heteroatom hybridization mesoporous carbon to load cobalt base, preparation method and application

A heterogeneous atom, mesoporous carbon technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problem of active component cluster growth and low doping amount of mesoporous carbon , Unable to disperse active components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

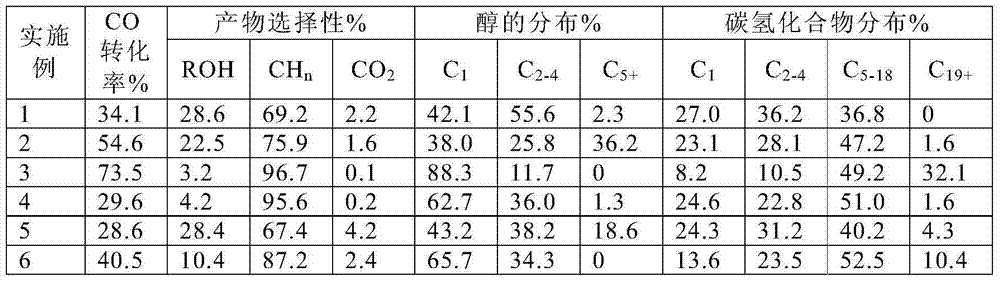

Examples

Embodiment 1

[0029] 3.0g ordered mesoporous silicon SBA-15 (specific surface area is 860m 2 / g, pore size is 6.5nm) placed in a 500ml beaker, 100ml of 20wt.% cyanamide aqueous solution was configured and poured into the beaker, stirred at room temperature for 4h and then centrifuged. Further carbonization treatment in He atmosphere for 5h, the obtained powder was etched with 40wt.% hydrofluoric acid solution to obtain nitrogen hybridized mesoporous carbon. Take 2.0g of mesoporous carbon-nitrogen powder and place it in a reactor, add 340ml of ethanol solution with a concentration of 2mol / L cobalt nitrate for ultrasonic treatment for 2h, and stir the final solution at room temperature until it is dry, then roast it under the protection of helium, 1 ℃ / min was raised to 300℃ for 4 hours to prepare the desired catalyst, the loading of active component cobalt was 17.5wt.%, and the carrier was mesoporous carbon nitrogen.

[0030] The catalytic reaction is carried out in a fixed-bed reactor. Meas...

Embodiment 2

[0032] 3.0g ordered mesoporous silicon SBA-16 (specific surface area is 580m 2 / g, pore diameter of 10.5nm) placed in a 500ml beaker, 32ml of carbon tetrachloride solution of 75wt.% ethylenediamine was poured into the beaker, left at room temperature for 2h, heat treated at 100°C for 8h, and then heated at 600 ℃ in a He atmosphere for 5 h, and the resulting powder was etched with a 10 wt.% hydrofluoric acid solution to obtain nitrogen-doped mesoporous carbon. Take 2.0g of mesoporous carbon nitrogen powder and place it in the reactor, and add 400ml of ethanol solution with a concentration of 0.5mol / L cobalt nitrate for ultrasonic treatment for 2h at the same time, and stir the final solution at room temperature until dry, then roast it under the protection of helium. 0.5°C / min to 300°C for 12 hours to roast the required catalyst, the loading of active components is 10wt.%, and the carrier is mesoporous carbon nitrogen

[0033] The catalytic reaction is carried out in a fixed-b...

Embodiment 3

[0035] 3.0g of ordered mesoporous silicon KIT-6 (with a specific surface area of 960m 2 / g, pore diameter is 4.5nm) placed in a 500ml beaker, 8g of 45wt.% polycarbosilane xylene solution was configured and poured into the beaker, left at room temperature for 12h, heat treated at 80°C for 2h, and then heated in a He atmosphere at 800°C After further carbonization treatment for 5 h, the obtained powder was etched with 40 wt.% hydrofluoric acid solution to obtain silicon-hybridized mesoporous carbon. Take 1.7g of mesoporous silicon carbon powder and place it in a reactor, add 200ml of ethanol solution with a concentration of 1mol / L cobalt acetate and ultrasonically treat it for 2h, and stir the final solution at room temperature until it is dry, then roast it under the protection of helium, 2 ℃ / min was raised to 300℃ for 4h to prepare the desired catalyst, the loading amount of the active component was 20wt.%, and the carrier was mesoporous silicon carbide.

[0036] The cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com