Copper steel composite material, arc additive preparing method and application of copper steel composite material and tin bronze alloy

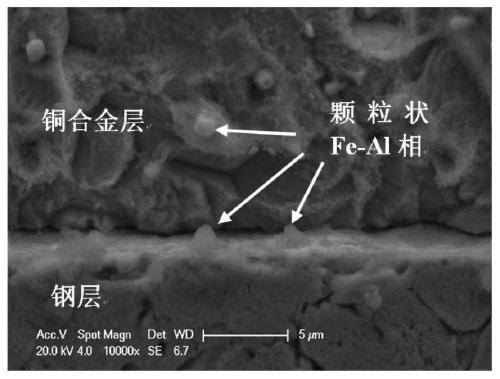

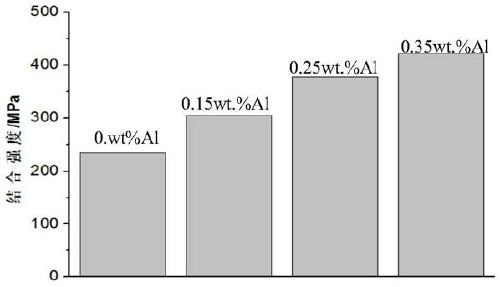

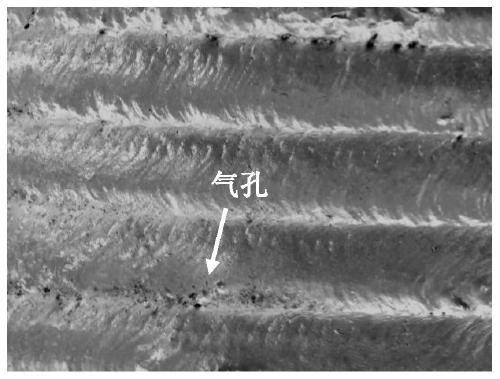

A composite material, tin bronze technology, applied in arc welding equipment, additive processing, manufacturing tools, etc., can solve the problems of coarse microstructure, low bonding strength of additive layer, poor wear resistance, etc., to improve bonding strength, The effect of high aluminum content and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Melting and casting of new tin bronze alloy rods. Sn, Al, Si, and Cu are mixed according to the ratio of 5wt.% Sn by mass percentage, 0.15wt.% Al, 0.05wt.% Si, and the balance is Cu, heated to a molten state and cast into a 5mm diameter Alloy bars.

[0043] (2) The alloy rod is prepared into a wire with a diameter of 0.8 mm through extrusion and drawing processes.

[0044] (3) Adding the wire material to the surface of the steel plate by electric arc.

[0045] The arc additive process includes the following steps:

[0046] (1) Polish the surface of the steel plate, remove the oxide layer of the steel plate, clean the oil stain and metal powder on the surface of the steel plate with an organic solvent, and then preheat the steel plate to 140°C;

[0047] (2) The new tin bronze wire arc is added to the surface of the steel plate through the CMT digital inverter welding power supply. The parameters of the arc additive process are: current 60A, voltage 12V, argon flo...

Embodiment 2

[0049] (1) Melting and casting of new tin bronze alloy rods. Sn, Al, Si, and Cu are mixed according to the mass percentage of 8wt.% Sn, 0.21wt.% Al, 0.1wt.% Si, and the balance is Cu, heated to a molten state and cast into a 6mm diameter Alloy bars.

[0050] (2) The alloy rod is prepared into a wire with a diameter of 1.0 mm through extrusion and drawing processes.

[0051] (3) Adding the wire material to the surface of the steel plate by electric arc.

[0052] The arc additive process includes the following steps:

[0053] (1) Polish the surface of the steel plate, remove the oxide layer of the steel plate, clean the oil stain and metal powder on the surface of the steel plate with an organic solvent, and then preheat the steel plate to 130°C;

[0054] (2) The new tin bronze wire arc is added to the surface of the steel plate through the CMT digital inverter welding power supply. The parameters of the arc additive process are: current 80A, voltage 13V, argon gas flow rate...

Embodiment 3

[0056] (1) Melting and casting of new tin bronze alloy rods. Sn, Al, Si, and Cu are mixed according to the mass percentage: 8wt.% Sn, 0.23wt.% Al, 0.12wt.% Si, and the balance is Cu, heated to a molten state and cast into a 6mm diameter Alloy bars.

[0057] (2) The alloy rod is prepared into a wire with a diameter of 1.2 mm through extrusion and drawing processes.

[0058] (3) Adding the wire material to the surface of the steel plate by electric arc.

[0059] The arc additive process includes the following steps:

[0060] (1) Polish the surface of the steel plate, remove the oxide layer of the steel plate, clean the oil stain and metal powder on the surface of the steel plate with an organic solvent, and then preheat the steel plate to 120°C;

[0061] (2) The new tin bronze wire arc is added to the surface of the steel plate through the CMT digital inverter welding power supply. The parameters of the arc additive process are: electricity 85A, voltage 14.0V, argon gas flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com