Patents

Literature

113results about How to "Play a pinning role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

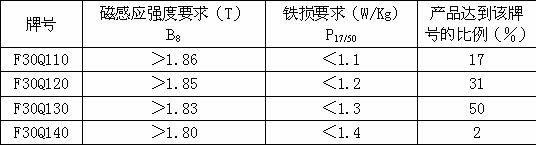

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

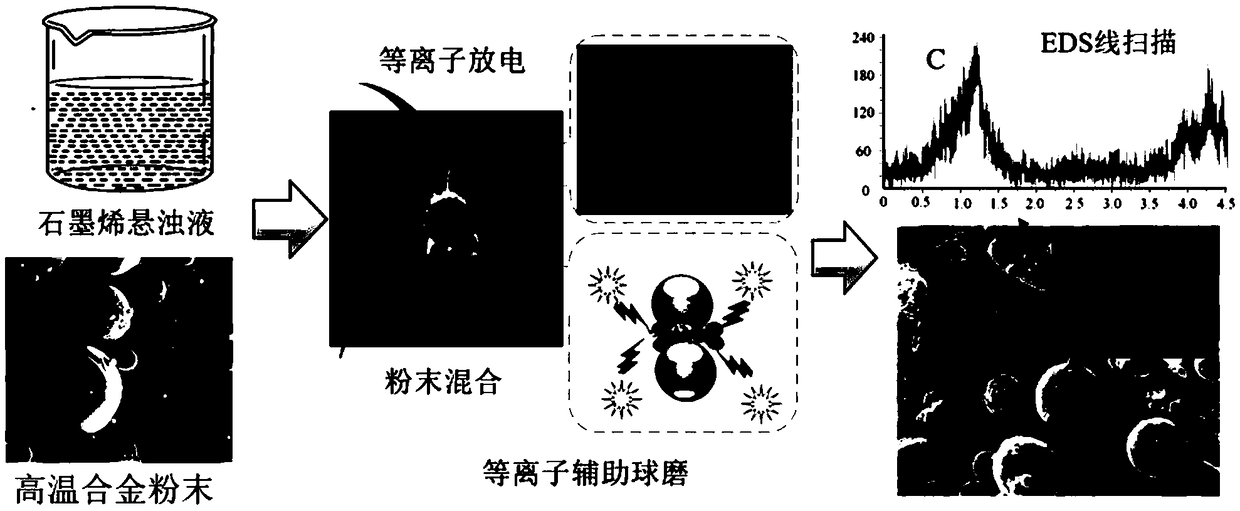

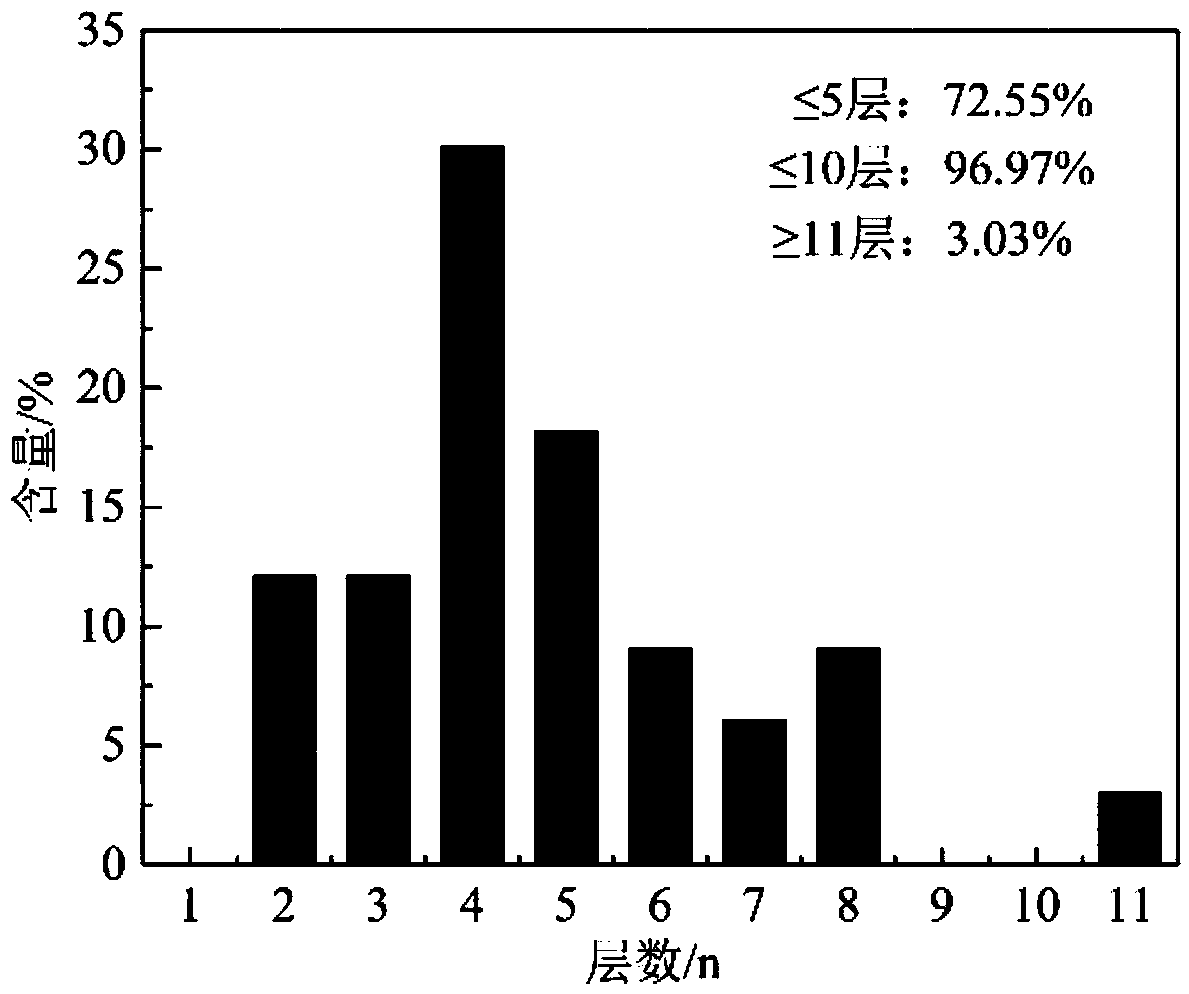

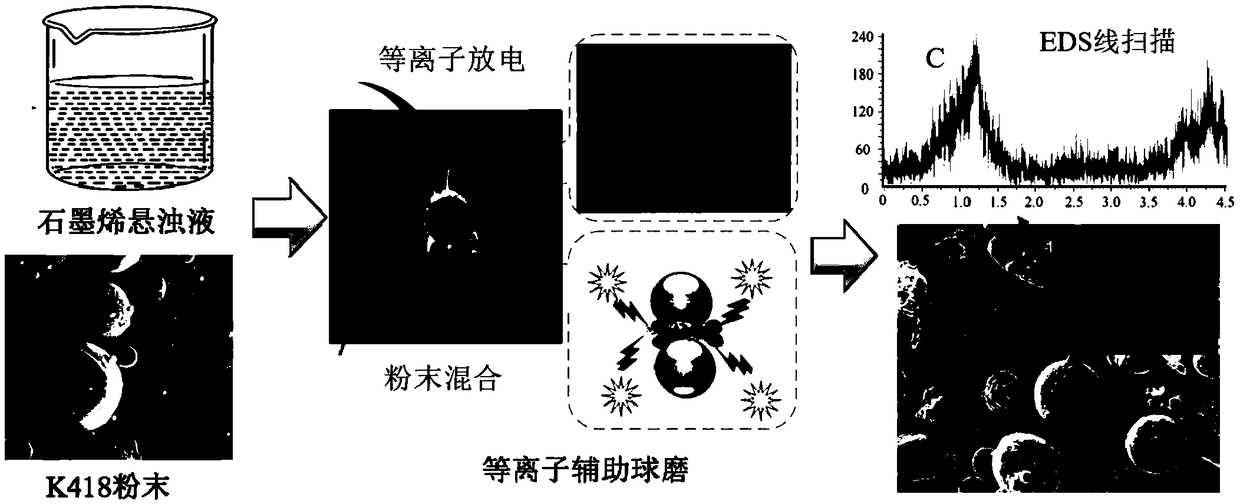

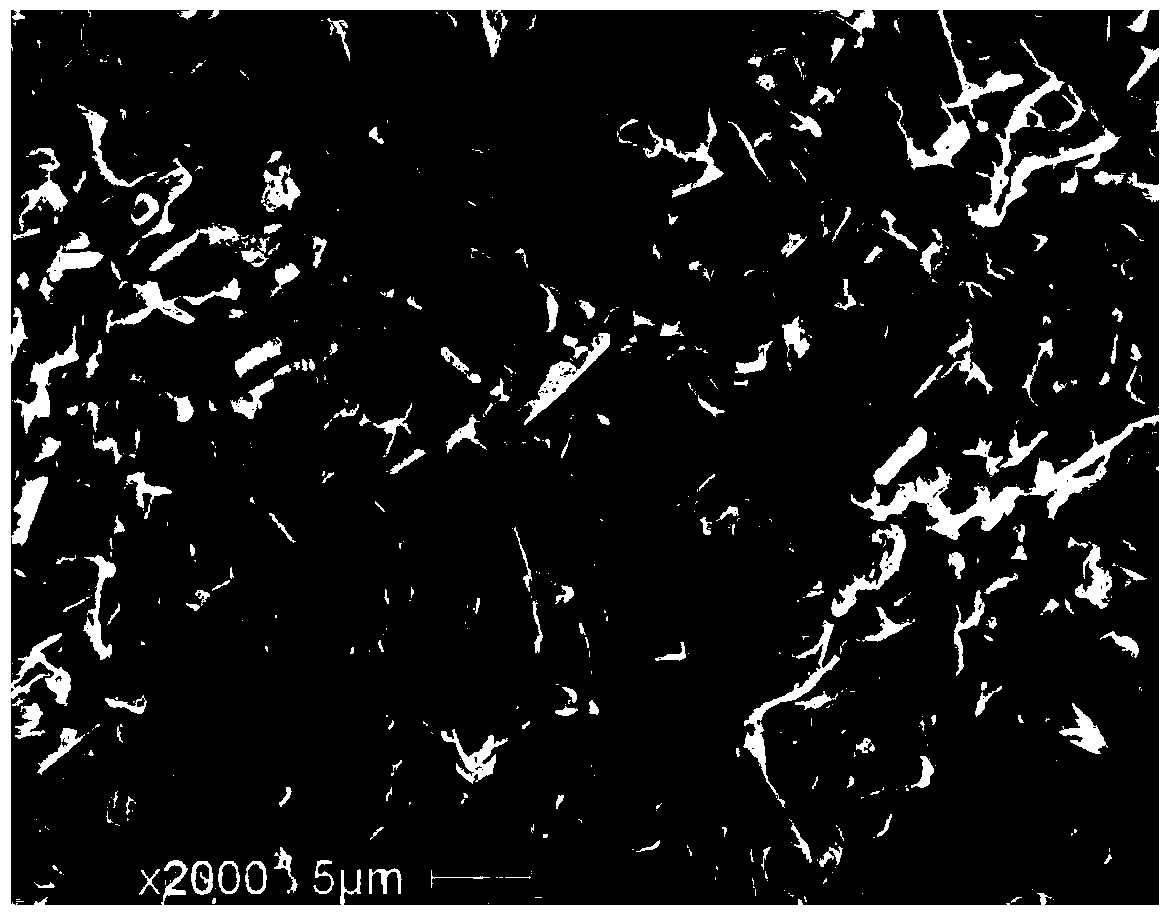

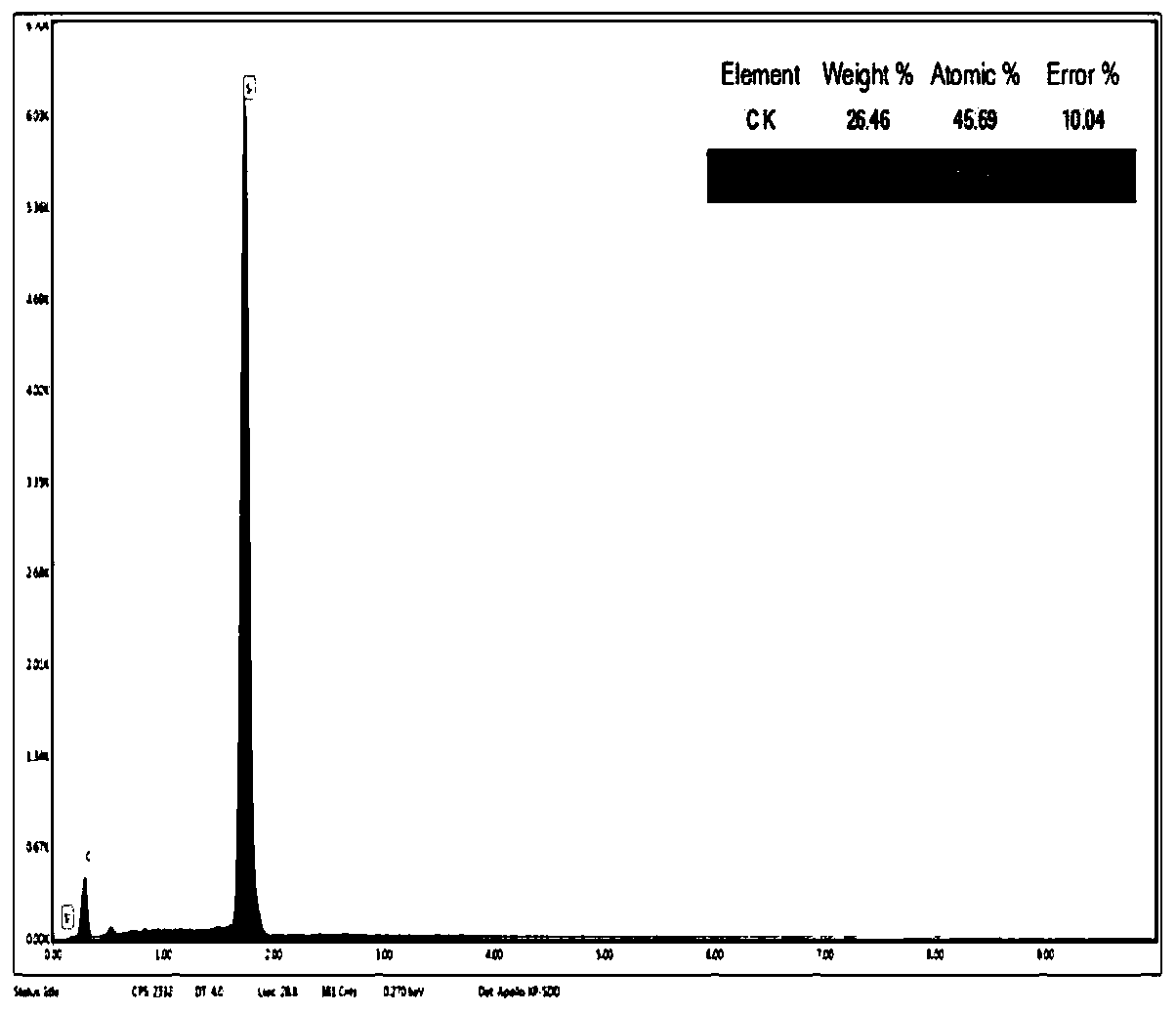

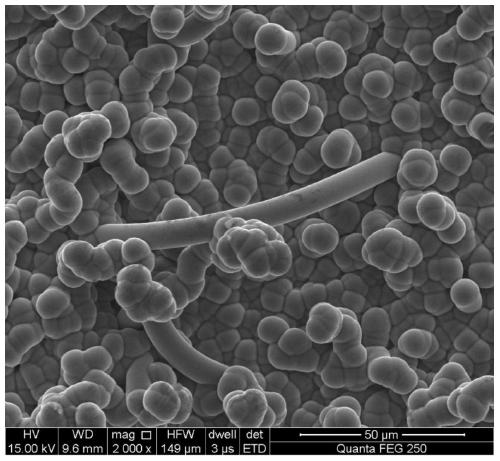

Preparation method of graphene alloy nanocomposite and SLM (Selective Laser Melting) forming process

InactiveCN109454240AImproves Strength and ToughnessReduced hot cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencyCvd grapheneInterfacial reaction

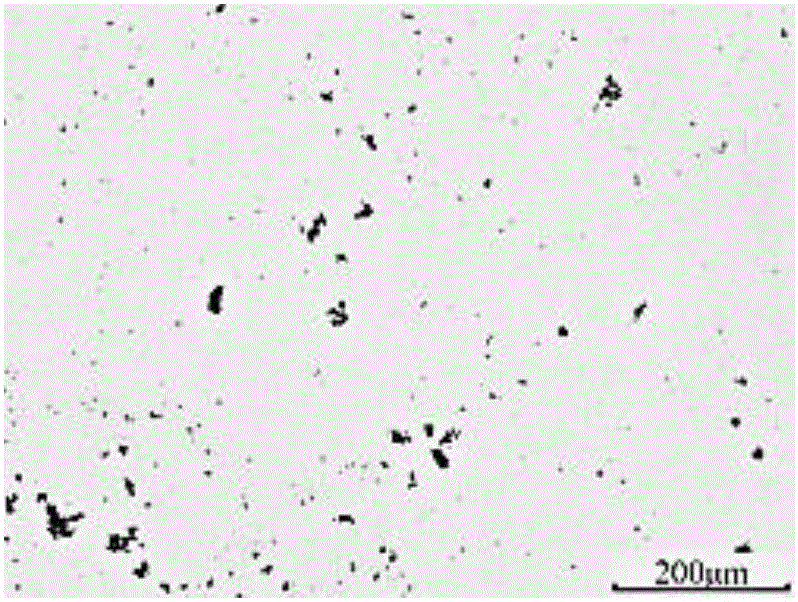

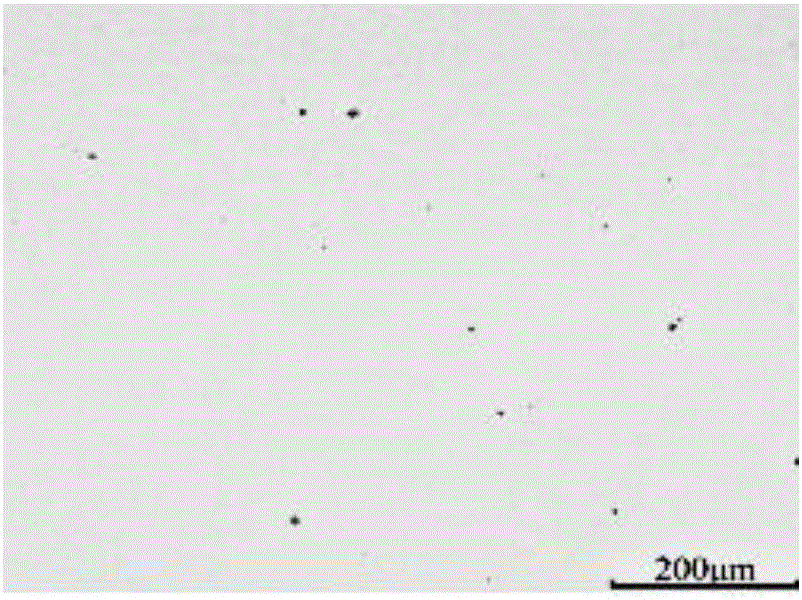

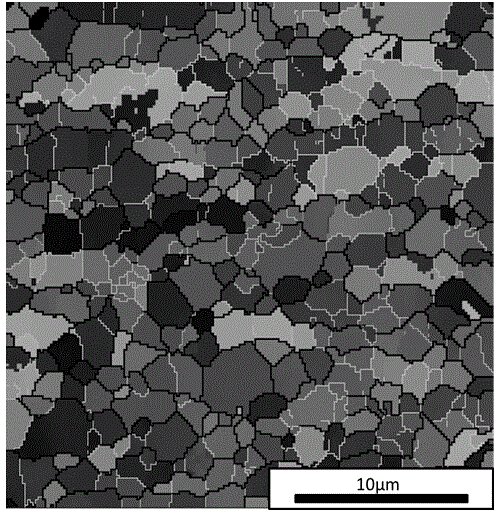

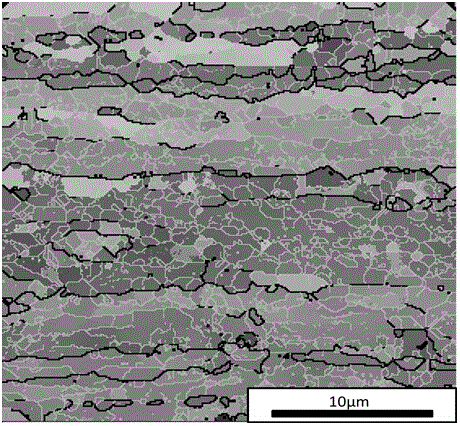

The invention discloses a preparation method of a graphene alloy nanocomposite and an SLM (Selective Laser Melting) forming process. According to the preparation method, turbid liquid is prepared through the ultrasonic vibration of anhydrous ethanol, so that the graphene is uniformly dispersed in the anhydrous ethanol, the graphene is uniformly dispersed, then after the graphene anhydrous ethanolturbid liquid is mixed with high-temperature alloy in proportion, the graphene and partial residue are distributed in the grain boundary and crystals by participating in the interfacial reaction, so that the strength and toughness of a formed part are improved, and the hot cracking tendency is reduced; the addition of graphene changes the organization form of the material; and in the SLM forming process, the graphene in the graphene high temperature alloy nanocomposite is used as a heterogeneous nucleating agent, and increases the nucleation rate in the solidification crystallization process.The graphene high temperature alloy nanocomposite is prepared by the dielectric barrier discharge plasma-assisted ball milling technique. The plasma enhances the activity of powder, so that columnar crystals preferentially growing change to isometric crystals, grains are refined and the performances are improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

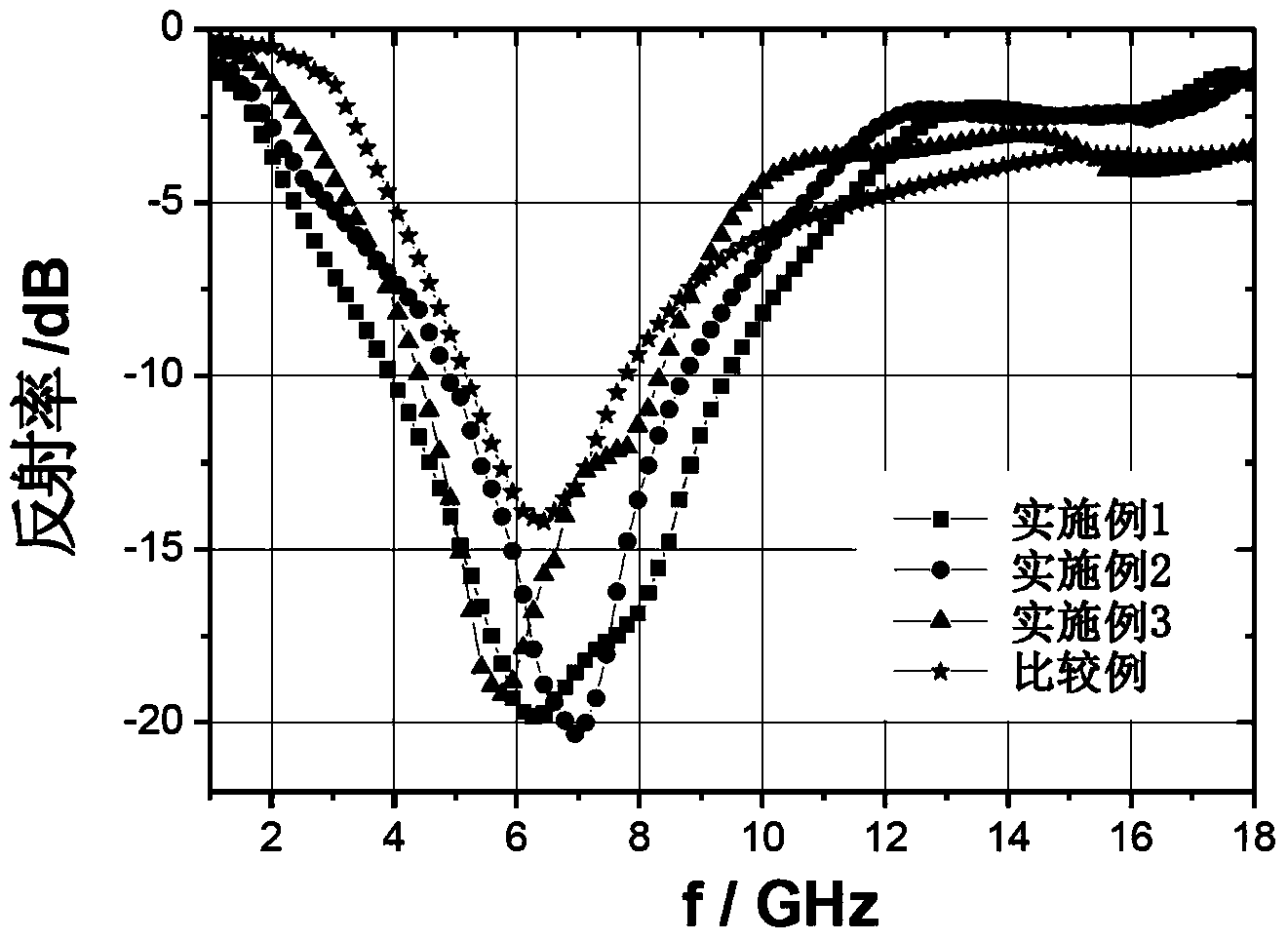

Ferrite wave-absorbing material and preparation method thereof

InactiveCN103482969AHigh strengthHigh curie temperatureOther chemical processesCeramic sinteringRare-earth element

The invention relates to a ferrite wave-absorbing material and a preparation method of the ferrite wave-absorbing material. A ferrite is mingled with a rare earth element of samarium and is of a Co2 Z-type planar hexagonal structure. The chemical formula of the ferrite is 3(Ba0.5Sr0.5)O 2CoO yFe2O3 xSm2O3, wherein x and y are mole numbers, 0.15<=x<=0.5, and 10<=y<=12. According to the preparation method of the ferrite wave-absorbing material, on the basis of the traditional ferrite ceramic sintering technology, the Sm element is mingled in to adjust and control the microstructure of the material. Thus, the purpose of improving the electromagnetic property of the material is achieved, the raw materials are easy to obtain, complex equipment is not needed, the technology is easy to operate and master, the cost is low, and the preparation method of the ferrite wave-absorbing material is suitable for large-scale production. The Co2 Z-type ferrite wave-absorbing powder mingled with the rare earth element of samarium can be used for preparing a wave-absorbing coating and has high practical value and extensive application prospects in the electromagnetic shielding and cloaking field.

Owner:CENT IRON & STEEL RES INST

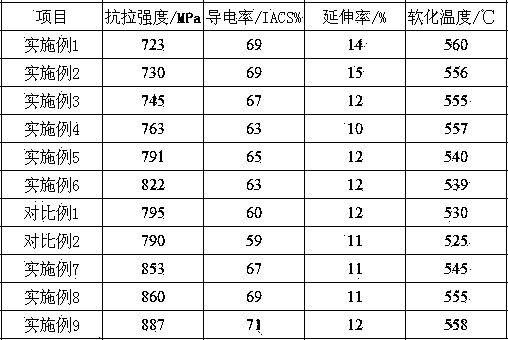

High-strength Cu-Ni-Si alloy and preparation method thereof

The invention relates to a high-strength Cu-Ni-Si alloy and preparation method thereof. The alloy comprises 2.0-6.0% of Ni, 0.5-1.5% Si, 0.5-1.0% of Ti, 0.5-1.0% of Mn, 0.5-1.0% of Ag and the balance of copper and unavoidable impurity elements. The preparation method sequentially comprises the following steps of smelting; casting; homogenization treatment; hot rolling and solution treatment; pre-cold rolling and aging treatment; and cold-rolling deformation. A Ni2Si non-oxide reinforcing phase is generated in the alloy disclosed by the invention; after the rolling is carried out repeatedly, the nucleation positions of precipitated phases can be increased, the more the broken grains, the more grain boundaries, the more nucleation positions of the precipitated phases and the more the precipitated phases; and under the condition that aging treatment is carried out repeatedly, the more precipitated phases are precipitated and thus the comprehensive performance of the alloy is dramatically increased, the strength, the elongation property at a high temperature and the electric conductivity are improved and the bending workability of the alloy is also improved.

Owner:HENAN UNIV OF SCI & TECH

Pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion and preparation method thereof

ActiveCN103334055AAccelerated corrosionImproved resistance to hydrogen sulfide stress corrosion cracking (SCC)Carbon corrosionChemical composition

The invention relates to a pipeline steel, especially to a pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion, and also relates to a preparation method thereof, and belongs to the field of pipeline steel manufacturing technology. The pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion comprises following chemical compositions in mass percent, C 0.02 to 0.08%, Si 0.10 to 0.50%, Mn 0.10 to 0.50%, V 0.01 to 0.20%, Al 0.01 to 0.05%, Cu 0.10 to 0.50%, Cr 2.0 to 6.0%, Ni 0.3% or less, Nb 0.3% or less, Ti 0.3% or less, P 0.02% or less, and S 0.005% or less, with the balance being Fe or impurity elements which are unavoidable. The pipeline steel is resistant against both carbon dioxide and hydrogen sulfide corrosion, and can be used in an environment with both of the two corrosive gases, and the resistance against carbon dioxide and hydrogen sulfide corrosion of the pipeline steel is 2 times or more of that of currently used carbon steel.

Owner:NANJING IRON & STEEL CO LTD

Wear-resistant flux-cored wire for stainless steel

InactiveCN106514047AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a wear-resistant flux-cored wire for stainless steel. The wear-resistant flux-cored wire consists of a flux core and a stainless steel sheath coating the outer side of the flux core, wherein the flux core comprises the following raw materials in parts by weight: 15-22 parts of chromium powder, 1-4 parts of titanium powder, 0.5-2 parts of nickel powder, 1-4 parts of silicon calcium alloy, 1-4 parts of magnalium, 4.5-7 parts of ferromanganese, 2-5 parts of ferromolybdenum, 2-4 parts of ferrocolumbium, 4-8 parts of rare earth ferroalloy, 4-8 parts of vanadium-nitrogen alloy, 6-9 parts of carbonate, 3-6 parts of graphite and 100-150 parts of iron powder. The wear-resistant flux-cored wire for stainless steel has favorable wear resistance, corrosion resistance, heat resistance and mechanical property; a deposited metal structure is compact, pore-free and crack-free; and the wear-resistant flux-cored wire for stainless steel can be favorably combined with a base material and is stable in performance.

Owner:天长市通联焊业有限公司

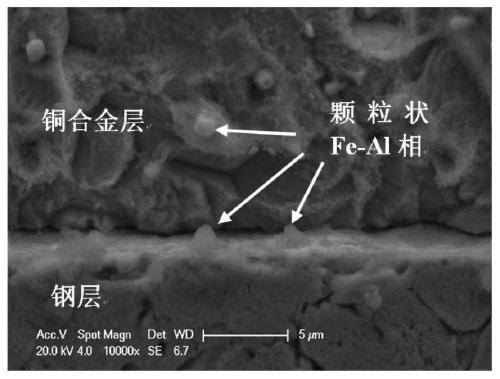

Copper steel composite material, arc additive preparing method and application of copper steel composite material and tin bronze alloy

ActiveCN110039154AHigh bonding strengthImprove wear resistanceAdditive manufacturing apparatusArc welding apparatusSheet steelUltimate tensile strength

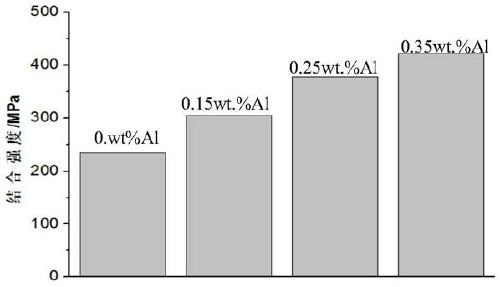

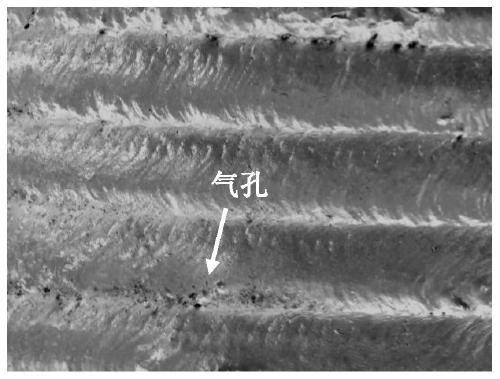

The invention discloses a copper steel composite material, an arc additive preparing method and application of the copper steel composite material and a tin bronze alloy. The composite material is composed of a copper alloy layer and a steel layer. The copper alloy layer is novel tin bronze and comprises the following components including, by weight percent, 5%-10% of Sn, 0.15%-0.35% of Al, 0.05%-0.2% of Si, smaller than 0.01% of Pb, smaller than 0.01% of Ni and the balance Cu. A preparing technology of the composite material includes the steps that firstly, casting of a novel tin bronze alloybar is conducted; secondly, the alloy bar is subjected to extruding and drawing technologies, and a wire with the diameter being 0.8 mm to 1.6 mm is prepared; and thirdly, the wire is arranged on thesurface of a steel plate in an arc additive manner, and the copper / steel composite material is obtained. The copper steel composite material is high in combination strength and has dendrite tissue which is compact, uniform and fine, and the wear reducing and resisting performance and the bearing performance are high.

Owner:SOUTHEAST UNIV

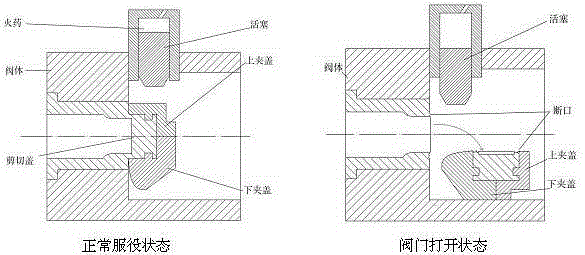

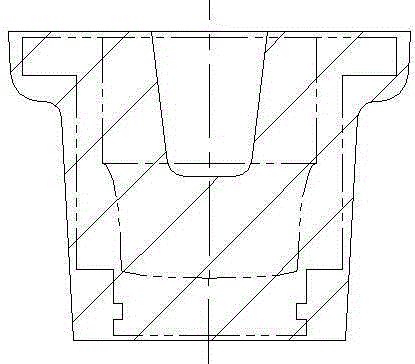

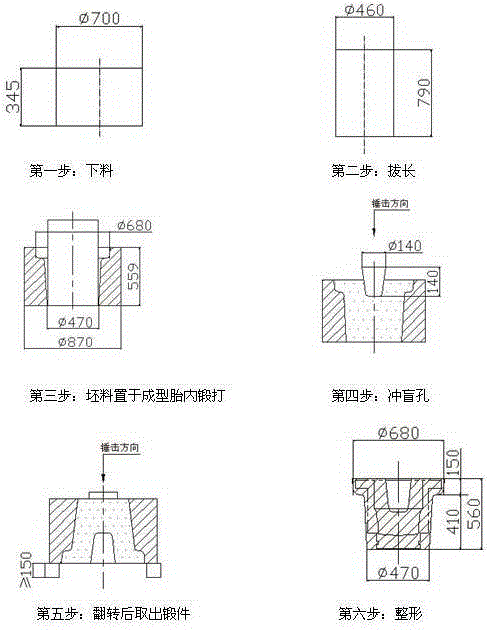

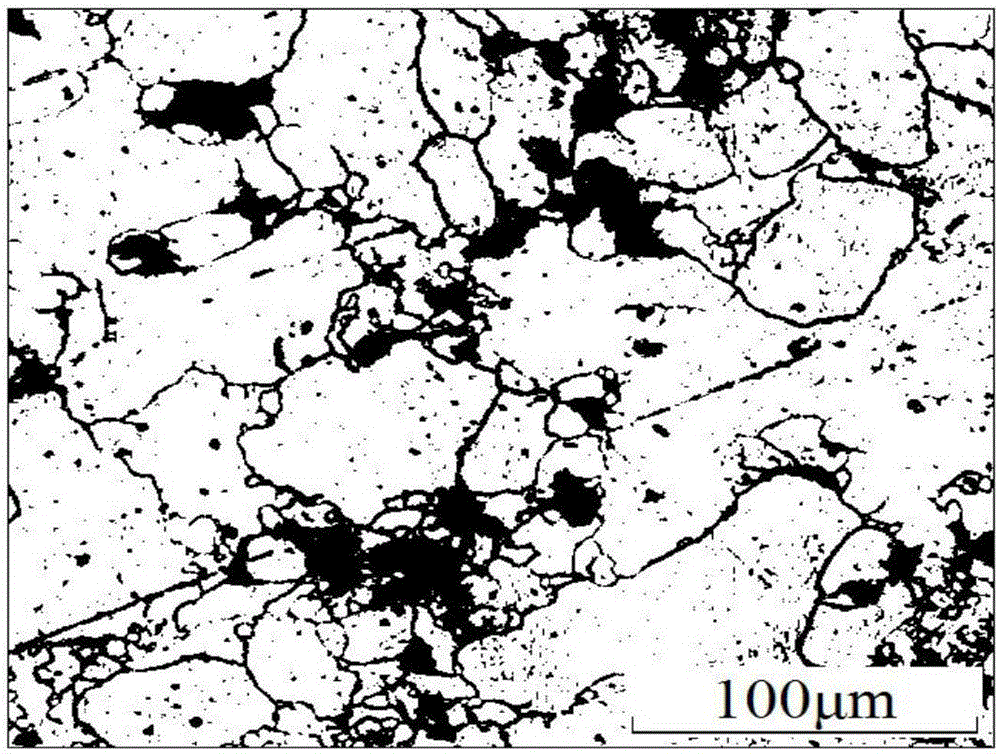

Crystalline grain control method for GH690 alloy shear cover of explosion valve

ActiveCN105170865AAddressing inhomogeneitySolve the problem of abnormal grain growthValve arrangementsMetal-working apparatusAlloyMaterials processing

The invention discloses a crystalline grain control method for a GH690 alloy shear cover of an explosion valve and belongs to the technical field of material machining. The method aims to solve the problems that the structure of a forge piece of the GH690 alloy material shear cover of the explosion valve is not even, and crystalline grains abnormally grow up. A heat treatment machining is organically combined with a forging machining, and the machining method that large deformation free forging is implemented at a high temperature (1020 DEG C to 1150 DEG C), small deformation foetal die forging is implemented at a medium temperature (710 DEG C to 850 DEG C), and the inhibition function of carbide second-phase particles on moving of a grain boundary is used for restraining the abnormal growth of the crystalline grains in forging machining of the shear cover in an auxiliary mode is provided. According to the crystalline grain control method for the GH690 alloy shear cover of the explosion valve, the forging piece forming and crystalline grain refinement are conducted synchronously, and the shear cover forge piece is obtained through heating twice; the machining limitation that a forging piece with the simple structure is subjected to high-temperature multiple-time hierarchical forging machining at present is overcome; the forging heating number is reduced; the follow-up heating treatment of the forging piece of the GH690 nickel-based alloy sheer cover is avoided. The structure with even carbides and refined crystalline grains of the GH690 alloy shear cover of the explosion valve forged through the method can be obtained.

Owner:DALIAN UNIV OF TECH +1

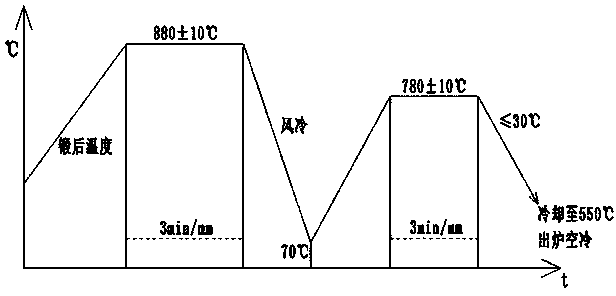

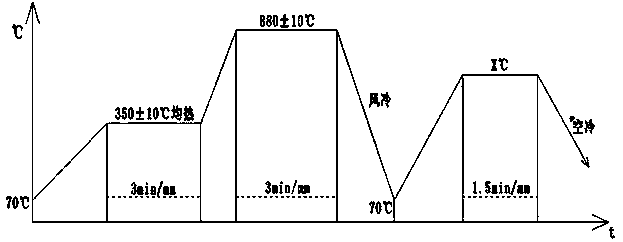

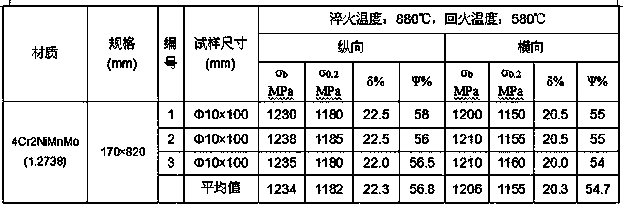

Pre-hardening plastic die steel

ActiveCN103774059AImprove corrosion resistanceImprove anti-corrosion performanceMetallurgyAir cooling

The invention relates to pre-hardening plastic die steel. The preparation method comprises the following steps: adding 0.05-0.15%V of microalloying elements into 4Cr2NiMnMo; after pleiotropic deformation, carrying out fine treatment and pre-hardening treatment, wherein the pleiotropic deformation comprises radial and axial forging deformation of the die steel and transverse and vertical pleiotropic deformation with the forging ratio greater than or equal to 8; the fine treatment comprises the following step: by taking the temperature of the forged die steel with the product thickness as a starting point, heating to 880+ / -10 DEG C; and after insulating at a speed of 3min / mm, discharging and air-cooling to 70 DEG C for spheroidizing annealing, wherein the specific process comprises the following steps: quickly heating to 780+ / -10 DEG C*3min / mm; and then cooling to 550 DEG C for discharging and air cooling at a speed less than or equal to 30 DEG C / h; the pre-hardening treatment comprises the following steps: heating the die steel with the product thickness from 70 DEG C to 350+ / -10 DEG C; insulating at the speed of 3min / mm; then heating to 880+ / -10 DEG C; then, insulating at the speed of 3min / mm; and then air-cooling to 70 DEG C and tempering.

Owner:胡财基

Sintered magnetic composite material and preparation method thereof

InactiveCN108335819AInhibit growthEliminate direct contactInorganic material magnetismCopper alloyRaw material

The invention discloses a sintered magnetic composite material and a preparation method thereof. The magnetic composite material is prepared by mixing and sintering a material A, a material B, a material C and a copper alloy D, and the weight ratio of the material A, the material B, the material C to the copper alloy D is 0.05:(1-1.3):(0.003-0.008):(0.05-0.09). The sintered magnetic composite material is simple and convenient in preparation technology and simple in process, raw materials for preparation are low in cost, the produced alloy has good performance, industrial production is facilitated, and the prepared permanent magnet material is applicable to electrical equipment industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

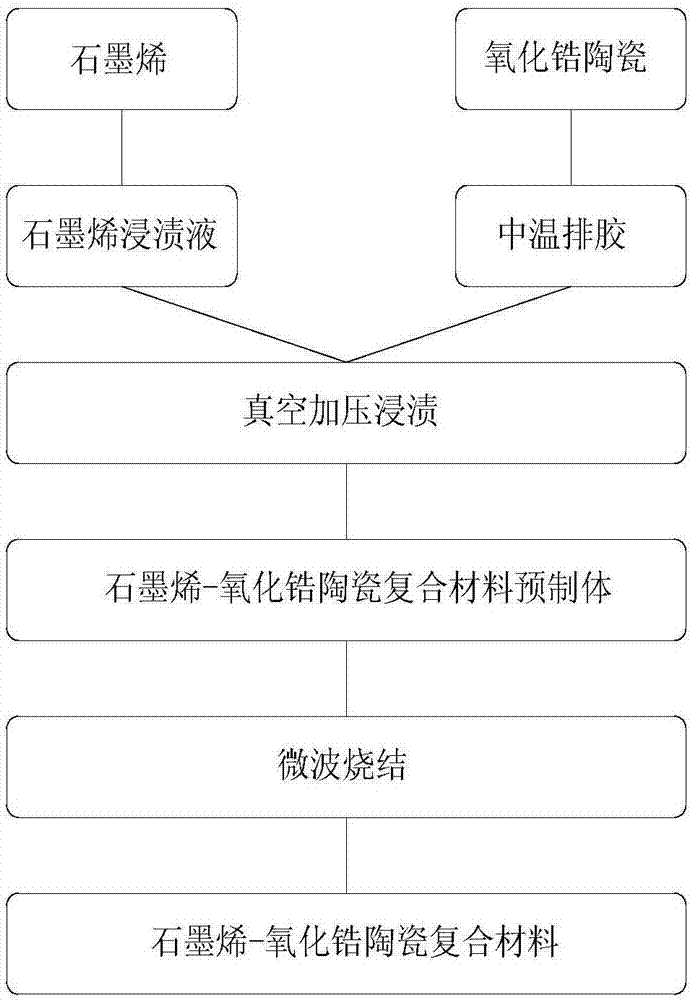

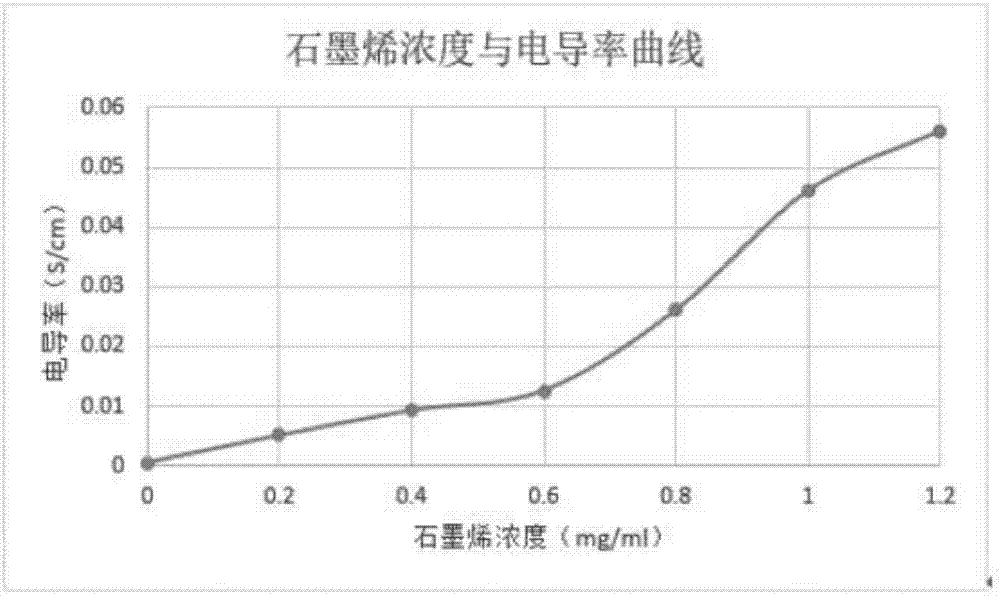

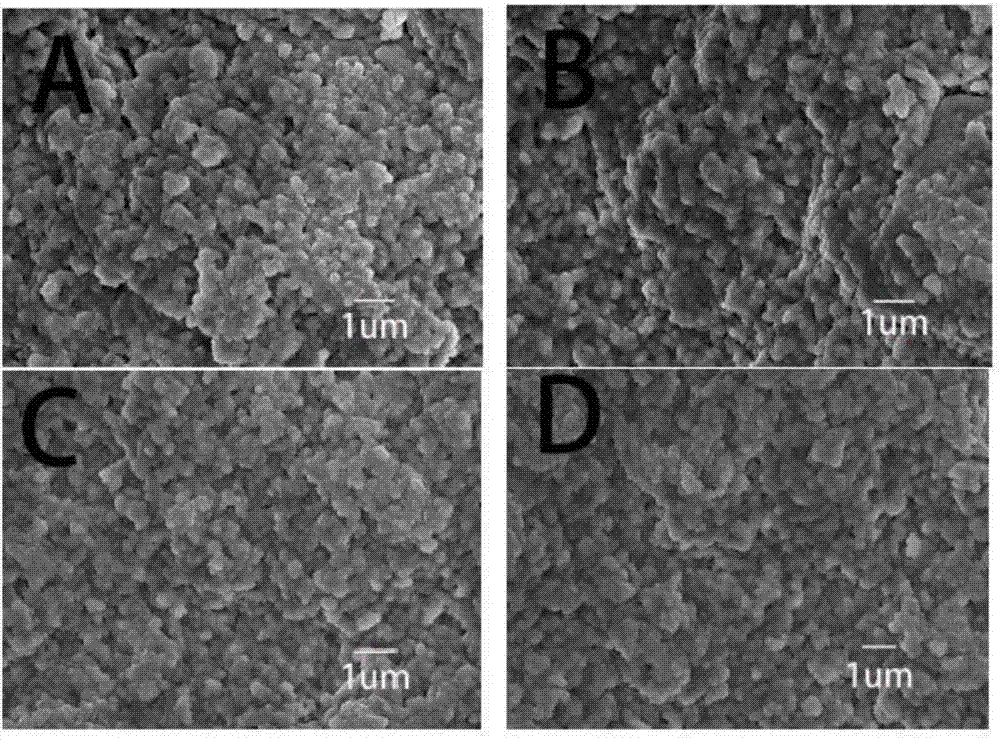

Preparation method of graphene ceramic material

The invention relates to the field of materials, specifically relates to a preparation method of a graphene ceramic material. The preparation method comprises the following steps: (1) taking graphene to prepare a graphene impregnation liquid; (2) carrying out glue discharge treatment on zirconia ceramic; (3) carrying out vacuum pressing impregnation on the graphene impregnation liquid obtained in the first step and the zirconia ceramic after glue discharge obtained in the second step so as to obtain a graphene-zirconia ceramic composite material perform; (4) carrying out microwave sintering on the graphene-zirconia ceramic composite material perform so as to obtain a graphene-zirconia ceramic composite material. Compared with the prior art, the bending strength, breaking tenacity and hardness of the prepared graphene-zirconia ceramic composite material are obviously improved by 37.68%, 35.89% and 18.34% respectively when being compared with those of a relatively common ceramic material, and the macro-mechanical properties are obviously increased; compared with that of a common ceramic material, the electrical conductivity is obviously improved, and the graphene is free of dispersed distribution in a ceramic base body but is of a network-like compact simple-substance structure.

Owner:锐竑(上海)新材料科技有限公司

Modifier applied to refining treatment of grains and structures of cast steel

The invention discloses a modifier applied to refining treatment of grains and structures of cast steel and relates to smelting of cast steel. The modifier is a fine grain modifier prepared by mixing ferrotitanium powder, ferrovanadium powder and ferroniobium powder obtained by an atomization method according to a set ratio, and mixing the mixed powder with rare earth ferrosilicon particles according a set ratio. The modifier comprises the following elements in percentage by weight: 8-15% of Ti, 8-15% of V, 10-18% of Nb, 15-22% of Si, 8-14% of RE and the balance of Fe. Through the modifier, the defects that particles of the modifier applied to refining treatment of grains and structures of cast steel are not fine enough, the refining effect is not ideal, the preparation process is complex and the preparation cost is high in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

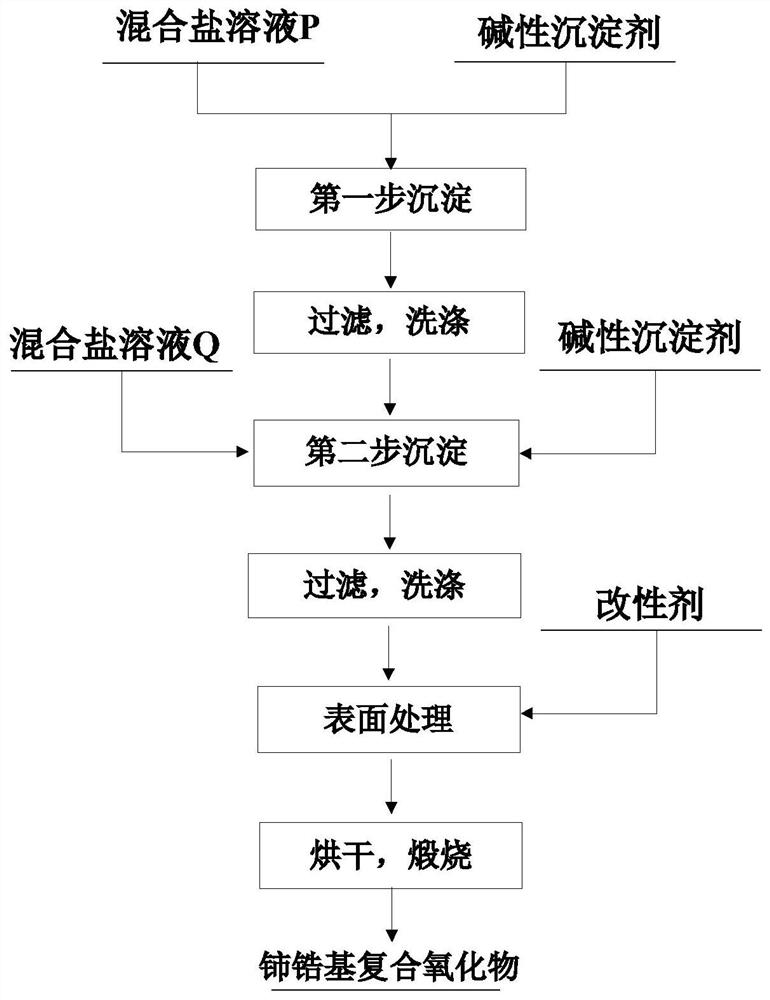

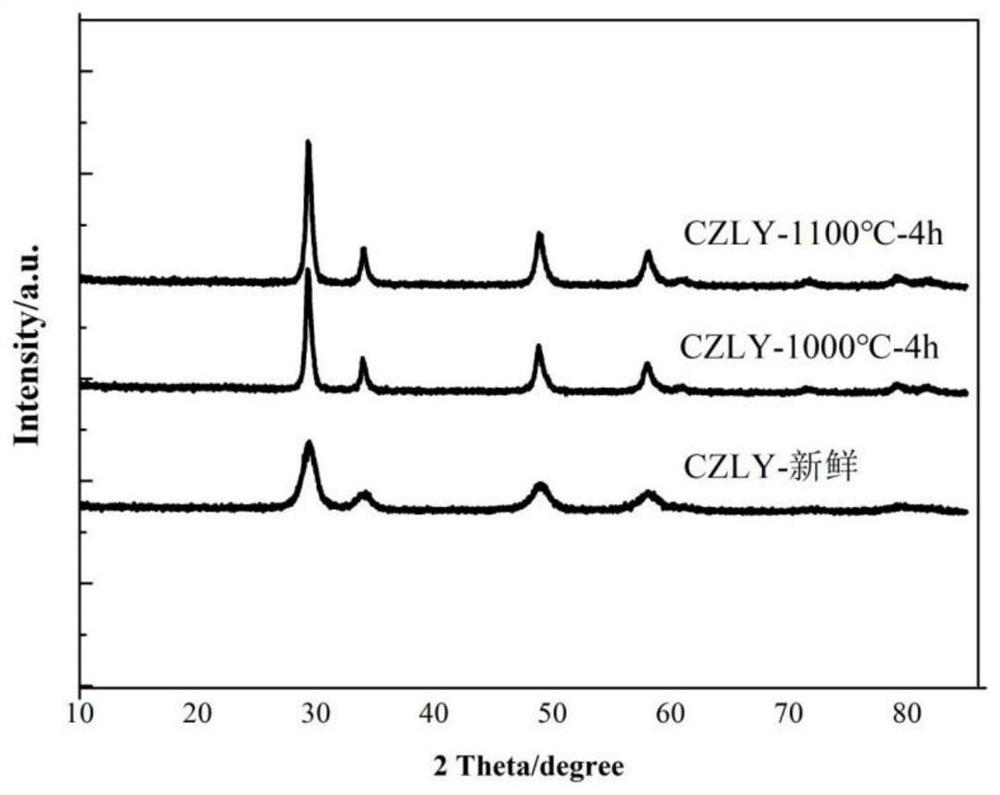

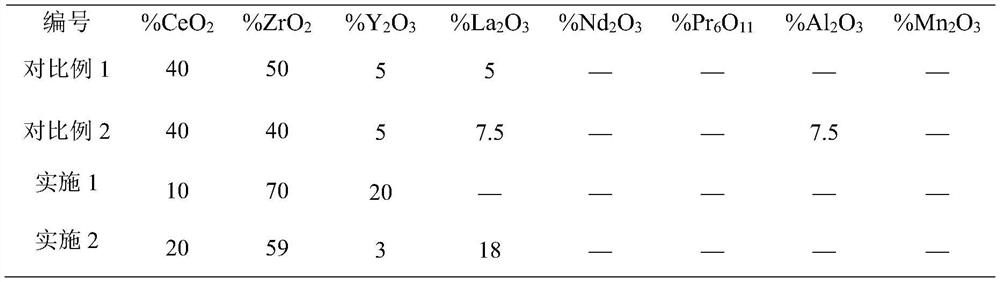

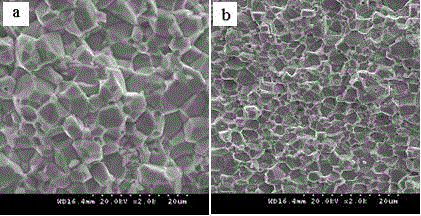

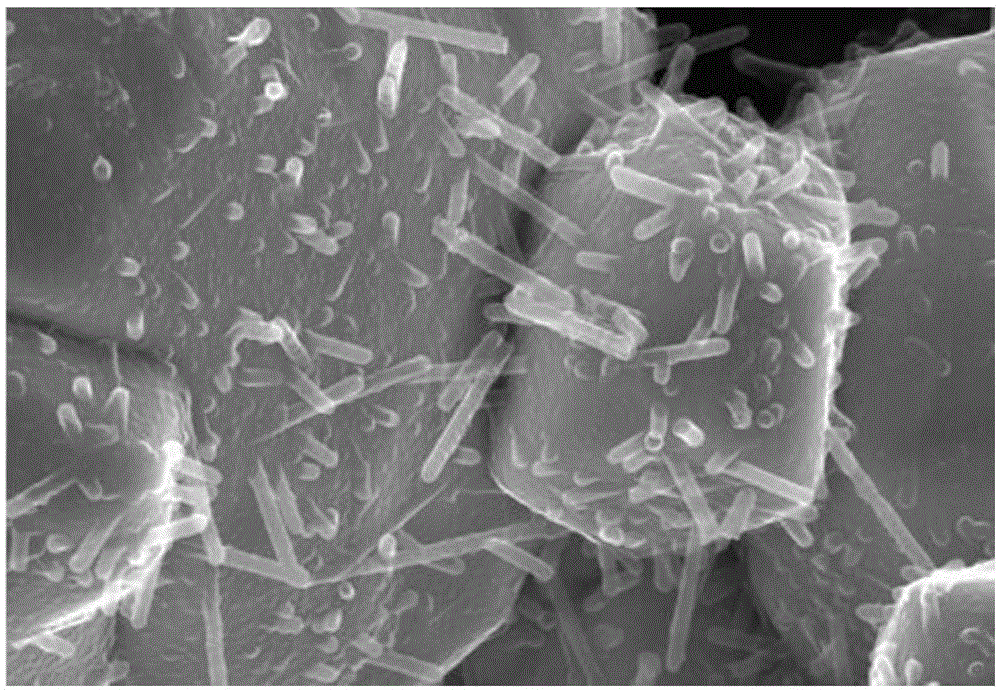

Cerium-zirconium-based composite oxide with core-shell structure, and preparation method thereof

PendingCN111939894AMeet the use requirements of oxygen storageInhibit high temperature sintering phenomenonExhaust apparatusZirconium compoundsPtru catalystOxygen vacancy

The invention relates to a cerium-zirconium-based composite oxide with a core-shell structure, and a preparation method of the cerium-zirconium-based composite oxide. According to the invention, the cerium-zirconium-based composite oxide oxygen storage material with the core-shell structure is prepared through a fractional precipitation method, wherein yttrium post-precipitation is used for segregating yttrium ions (Y<3+>) on the surface of a grain boundary to inhibit the high-temperature sintering phenomenon of the cerium-zirconium-based composite oxide so as to improve the thermal stabilityof the cerium-zirconium-based composite oxide, post-precipitation of a part of zirconium is to enhance the thermal stability, and the yttrium ions have smaller ion radius (0.90 angstrom) and electriccharge quantity, so that the oxygen vacancy formation energy can be reduced, the oxygen storage and release performance can be improved, and the use requirements of catalysts for motor vehicle tail gas purification, industrial waste gas treatment or catalytic combustion and the like can be met.

Owner:RARE EARTH FUNCTIONAL MATERIALS XIONG AN INNOVATION CENT CO LTD +2

Normal-pressure solid-phase sintered silicon carbide ceramic profiled part and manufacture method thereof

InactiveCN106904974AExtended service lifeLarge particle sizeSlip casting mouldsBoron trioxideHigh pressure

The invention discloses a normal-pressure solid-phase sintered silicon carbide ceramic profiled part and a manufacture method thereof. A compact silicon carbide ceramic profiled part product is obtained by material preparation, material mixing through ball milling, high pressure grouting, drying in shade and low temperature drying and high temperature sintering. Through optimized matching of silicon carbide particles at different levels and effective design of channels of a resin die, micrometer powder is introduced to overcome obstruction of die channels, thereby obviously prolonging the service life of the die. The micrometer powder is large in size and small in specific surface area, thereby preventing loss of components, and through matching of particles with different size, sub-micrometer powder is uniformly dispersed in micrometer powder, thereby overcoming low grouting efficiency and nonuniform components. The density of a blank obtained from matching of particles with different size is obviously increased, so that the contraction is reduced and the blank is beneficial for preventing sintering deformation and cracking of a solid-phase sintered silicon carbide ceramic profiled part. Boric acid or / and diboron trioxide is adopted as a sintering aid and is dissolved in a thick liquid, so that the sintering aid is uniformly dispersed, and the density distribution of high-temperature-sintered silicon carbide ceramic profiled part is uniform.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Process for manufacturing corrosion resistant low-chromium tubing and casing in CO2 and H2S coexisted environment

ActiveCN101407019AEnhanced ability for stress corrosion cracking (SSC)Increase low temperature transformation tissue compositionProcess efficiency improvementElectric furnaceElectric arc furnacePetroleum

The invention relates to the technical field of oil pipe material, in particular to a process for preparing a corrosion resistant low-chromium oil sleeve under the coexisting environment of CO2 and H2S. The invention overcomes the problems existing in the prior art. The technical proposal provided by the invention is that the process for preparing the corrosion resistant low-chromium oil sleeve under the coexisting environment of CO2 and H2S orderly comprises the following steps: 1. steel-making, wherein an electrified arc furnace is used to directly reduce iron and pig iron to obtain base metal, the base metal is refined in a ladle furnace and alloyed twice, and finally gas in the base metal is removed; 2. rolling, wherein the correct size of the material required is obtained by the step; and, 3. heat treatment and finishing. Compared with the prior art, the process has the advantages that the material prepared by the process has good CO2 / H2S corrosion resistance and economical efficiency; when used in the underground mining, the material can replace the common carbon steel; and the cost is no more than 150 percent higher than that of the oil sleeve material in the same level, but the material can bring much more benefits.

Owner:XIAN MAURER PETROLEUM ENG LAB

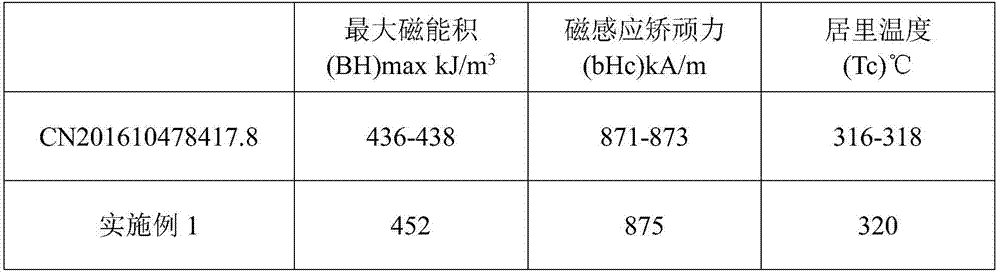

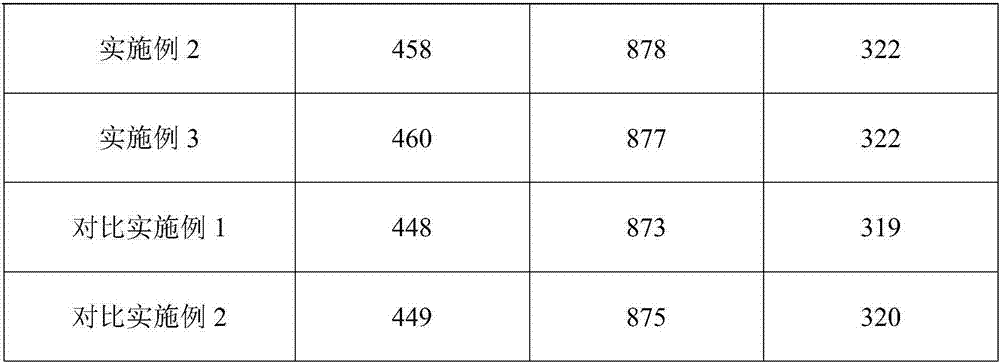

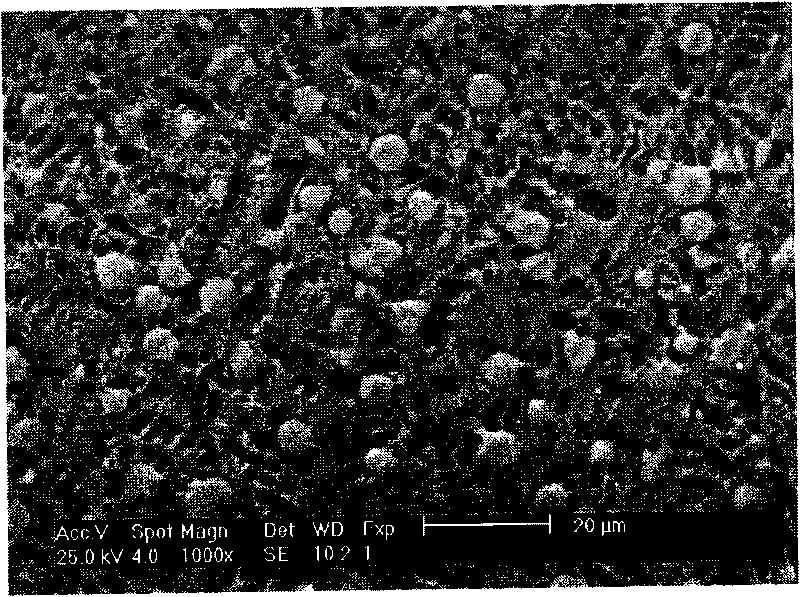

Ultra-fine-grain NdFeB permanent magnetic material and preparation method thereof

The invention discloses an ultrafine-grain NdFeB permanent magnetic material and a preparation method thereof. The permanent magnetic material comprises raw materials including, by weight, 25-35% of Nd, 55-70% of Fe, 0.5-1.8% of B and an auxiliary material, the auxiliary material is nanoscale high-melting-point metal powder, and the nanoscale high-melting-point metal powder accounts for 0.5-2% of total weight of Nd, Fe and B. The preparation method includes: tableting; breaking; fine grinding; adding the auxiliary material; wet ball milling; scattering; pressing for forming; sintering. The magnetic material and the preparation method have the advantages that the advantage that nanoscale high-melting-point metal is difficult to melt in the process of sintering is utilized to realize pinning effect at a grain boundary to prevent NdFeB grain growth so as to prepare the NdFeB permanent magnetic material having ultrafine-grain tissue, and the permanent magnetic material is enabled to have extremely high coercivity without adding rare earth elements like Dy and Tb.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

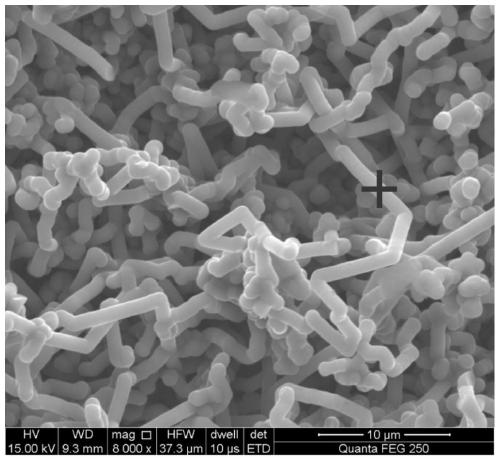

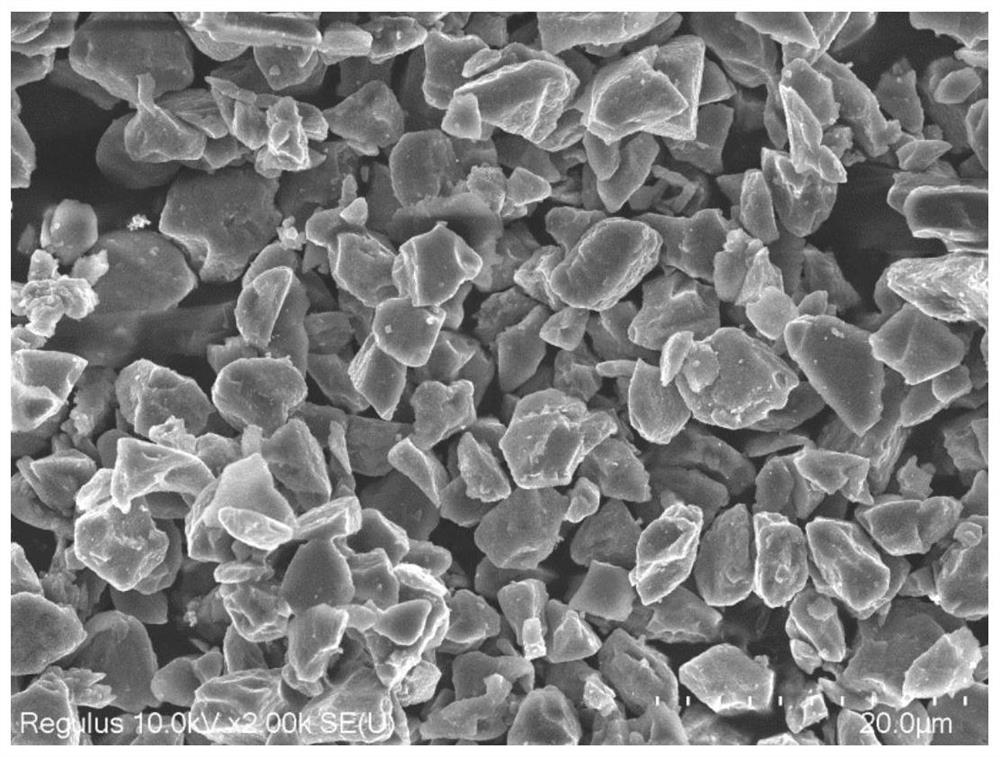

Method for preparing WC/W composite powder through in-situ reaction

ActiveCN105618788AImprove high temperature performancePlay a pinning roleAlloyUltrasonic oscillation

The invention discloses a method for preparing WC / W composite powder through an in-situ reaction. Tungsten powder is poured into a pickling solution, cleaning is conducted after room-temperature ultrasonic oscillation, and then vacuum drying is carried out to obtain W powder with pre-planted defects on the surface; and the W powder with the pre-planted defects on the surface is flatly spread in a corundum crucible, the crucible is horizontally placed in the middle of a tube furnace heating body, then the temperature is increased under the protection of the Ar atmosphere, argon carrying acetone is subjected to the in-situ reaction with the W powder, the temperature is slowly increased for 0.5-4 h, then introduction of the acetone is stopped, and the protective gas is stopped when the temperature of a furnace body is decreased to the room temperature, so that the WC / W composite powder is obtained. According to the WC / W composite powder obtained through the method, WC particles (whiskers) distributed on the surfaces of W particles in a scattered mode can improve the high-temperature property of tungsten-based alloy on the one hand, and on the other hand, a pinning effect is achieved on the strength of the alloy. Accordingly, the high-temperature property of the tungsten-based alloy can be improved when the WC / W composite powder is used for preparing the tungsten-based alloy as original powder.

Owner:XIAN UNIV OF TECH

TiCp/EPS lost foam manufacturing technology and steel matrix composite casting technology by means of TiCp/EPS lost foam

ActiveCN109465386AStrong combinationImprove the comprehensive mechanical properties of the productFoundry mouldsFoundry coresPressure castingThermal treatment

The invention discloses a TiCp / EPS lost foam manufacturing technology and a steel matrix composite casting technology by means of a TiCp / EPS lost foam and relates to the technical field of composite lost foam casting in the metal forming field. The casting technology comprises manufacturing of a TiCp / EPS composite lost foam pattern, pattern coating material smearing, drying, a steel matrix composite lost foam negative pressure casting technology process, a pouring technology, a heat treatment technology and the like. TiC particles and a matrix are firmly combined, the TiC particles are evenlydispersed, the comprehensive mechanical property of a product is improved, and large-sized TiC reinforced steel matrix composite part in complicated shapes can be manufactured by means of lost foam casting.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heat processing technology for improving impact energy of 20CrNiMo alloy steel

The invention provides a heat processing technology for improving the impact energy of 20CrNiMo alloy steel. The technology includes the following steps: I, performing carburizing treatment to the 20CrNiMo alloy steel until the depth of a carburizing layer reaches 1.4 mm to 1.7 mm; II, performing primary quenching; III, performing primary tempering, V, performing secondary quenching; IV, performing secondary tempering. According to the invention, through improving the heat processing technology of the 20CrNiMo alloy steel, the problem that other excellent performances of the 20CrNiMo alloy steel cannot be fully exerted due to lower impact energy is solved, the material usability is better, and the application range is wider.

Owner:XIAN COAL MINING MACHINERY

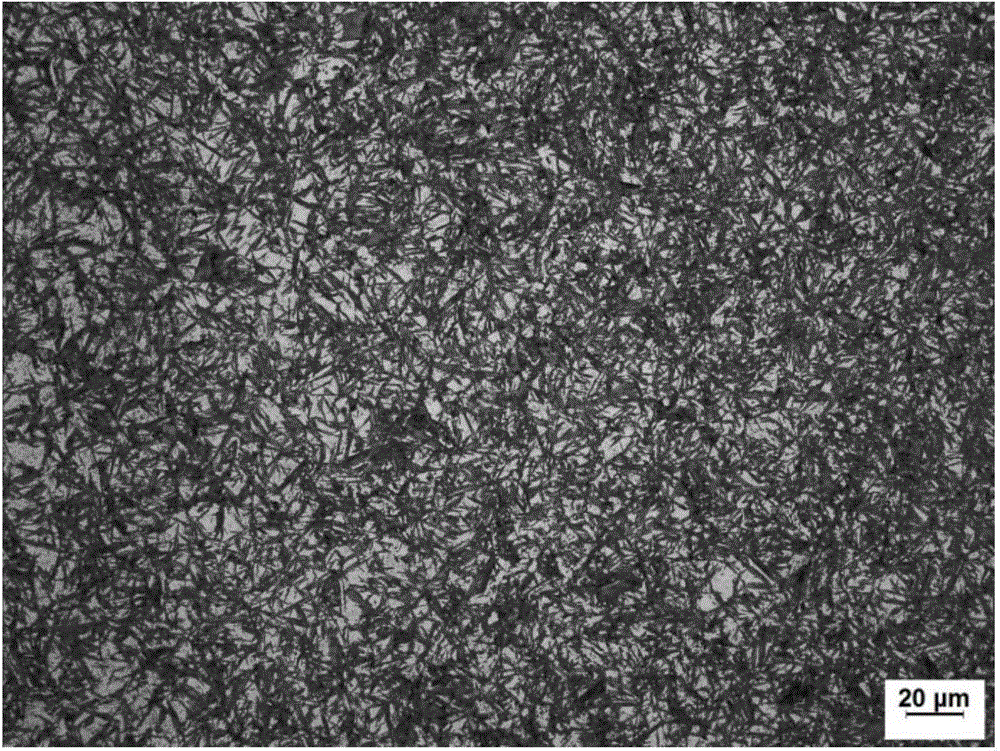

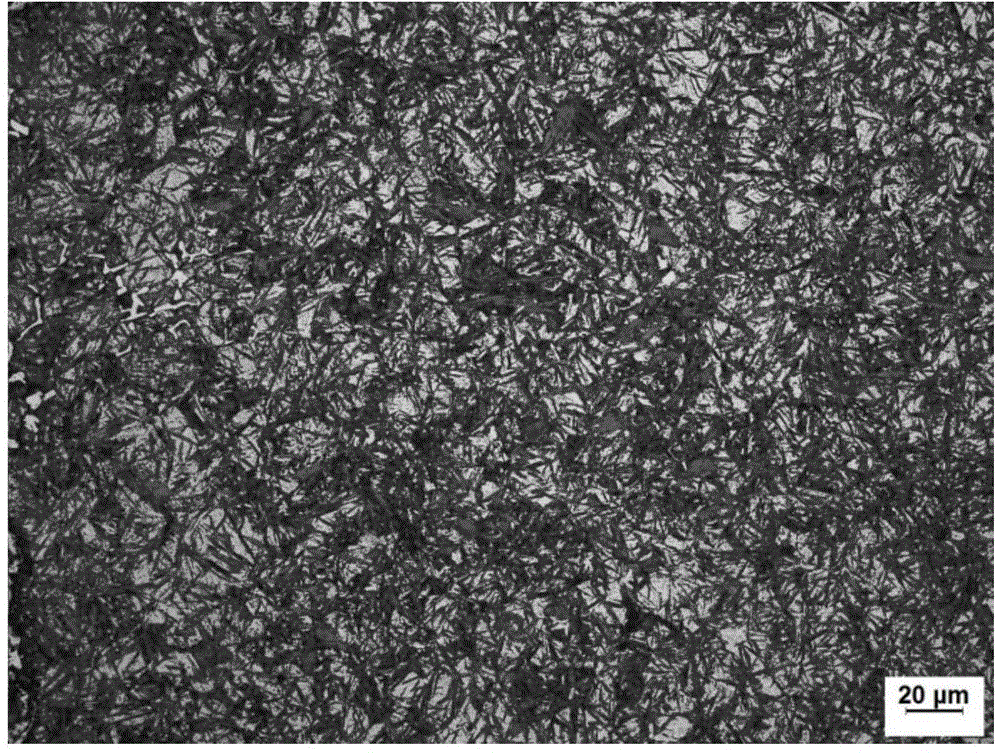

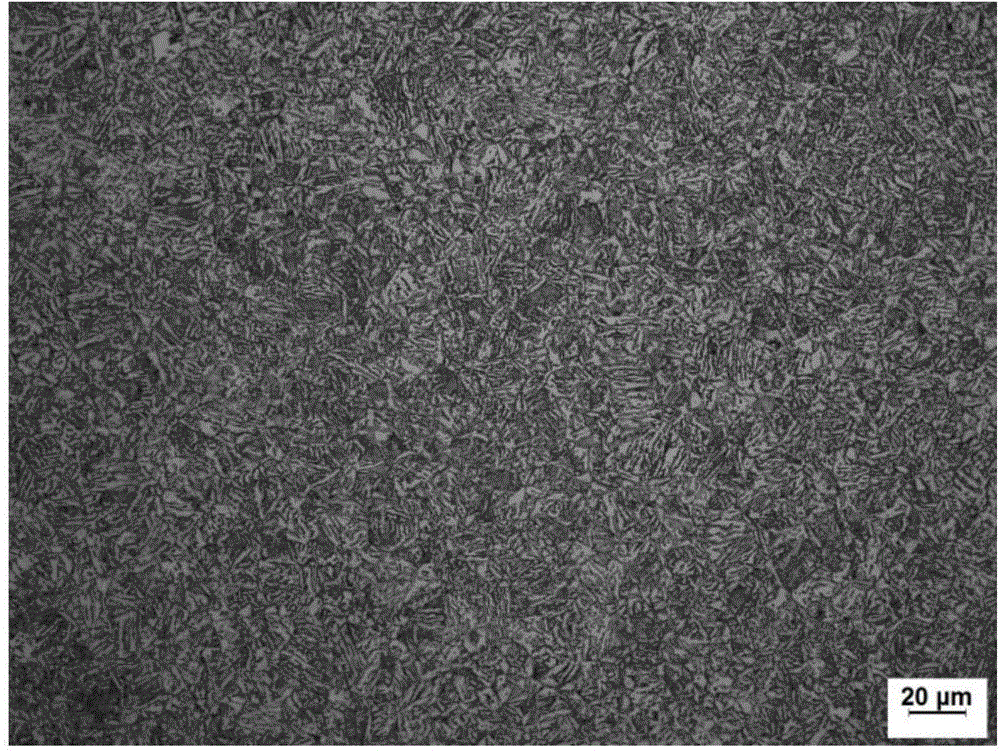

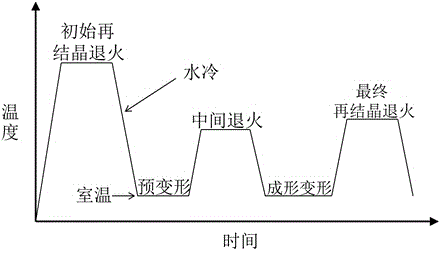

Thermomechanical treatment method for aluminium alloy grain refinement

The invention discloses a thermomechanical treatment method for aluminium alloy grain refinement. The method comprises the following steps: insulating an aluminium alloy for 30-60min for 360-460 DEG C, then cooling the aluminium alloy material to room temperature and then carrying out rolling deformation with a rolling deformation amount of 18-30%, then carrying out low-temperature annealing treatment on the pre-deformed aluminium alloy material for 24-168h at 260-290 DEG C, cooling the aluminium alloy material subjected to the low-temperature annealing to room temperature and then carrying out rolling deformation with a total rolling deformation amount of 80-96%, and finally carrying out recrystallization annealing on the rolled-formed aluminium alloy for 0.5-24h at 260-310 DEG C. The structural state of an aluminium alloy plate treated by the method disclosed by the invention is uniform and fine isometric crystals, thus 1-2[mu]m fine-grain structural state is realized; and moreover, the method disclosed by the invention has the characteristic of no limits on machining equipment, and dimensions of machined workpieces.

Owner:CHONGQING UNIV

Preparation method of high-strength and high-toughness high-entropy alloy

The invention discloses a preparation method of a high-strength and high-toughness high-entropy alloy, and relates to the technical field of alloy material production. The preparation method comprises the following specific steps that high-entropy alloy powder prepared from the components in atomic percent: 27%-30% of Mn, 8%-12% of Co, 8%-12% of Cr, 0.4%-1.3% of C and the balance of Fe is prepared; the high-entropy alloy powder is subjected to ball milling treatment and then pre-pressed, the pressure ranges from 300 MPa to 500 MPa, the pressure is maintained for 200 seconds to 300 seconds, and a pre-pressed block of the high-entropy alloy is obtained; the pre-pressing block is subjected to vacuum annealing, vacuum hot pressing sintering and cold rolling deformation; and the high-entropy alloy sheet subjected to cold rolling deformation is subjected to constraint carbon distribution treatment at the temperature of 400-550 DEG C, and free carbon elements are diffused. The C-containing unequal-atom FeMnCoCrC high-entropy alloy prepared through the method has excellent strength and plasticity combination, and meanwhile, the problems that a high-entropy alloy prepared through a traditional technology is uneven in component and unstable in structure are solved.

Owner:ZHONGBEI UNIV

Ceramic fiber toughened CVD silicon carbide (SiC) composite and preparation method and application thereof

ActiveCN110372408AReduce the chance of sheddingReduce the probability of crackingMirrorsCarbon fibersGas phase

The invention relates to a ceramic fiber toughened CVD silicon carbide (SiC) composite and a preparation method and application thereof. The ceramic fiber toughened CVD SiC composite adopts a C / SiC composite as a substrate, SiC fibers are generated on the substrate in situ, SiC is deposited on the peripheries of the SiC fibers generated in situ, and a SiC layer toughened by the SiC fibers is formed; the SiC layer toughened by the SiC fibers is further internally provided with metal M and / or a carbide of the metal M and / or a silicide of the metal M; and M is selected from one or more of iron, cobalt and nickel. The preparation method of the ceramic fiber toughened CVD SiC composite comprises the steps: pyrolytic carbon is deposited on a carbon fiber perform firstly; then silicon melting andsiliconizing are conducted; then a catalyst, namely the metal M is introduced in a plated mode; SiC whiskers are prepared through vapor deposition; and finally, the SiC layer is prepared. The designed and prepared composite is particularly suitable for a reflector of a space camera.

Owner:CENT SOUTH UNIV

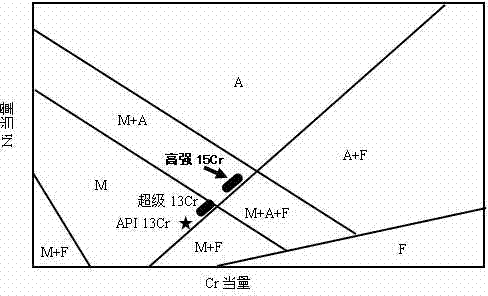

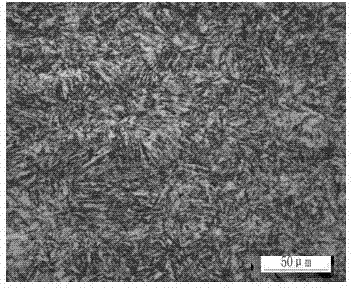

CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells

InactiveCN103938124AWith anti-H

<sub>2</sub>

S stress corrosion cracking performanceIncrease costRigid pipesMartensiteAntimony

A CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells comprises the following compositions in percent by weight: carbon, <=0.03 wt%; silicon, 0.2-0.5 wt%; manganese, 0.2-0.6 wt%; phosphorus, <= 0.02 wt%; sulfur, <= 0.005 wt%; chromium, 14.5-15.3 wt%; molybdenum, 1.7-2.4 wt%; copper, 0.6-1.0 wt%; nickel, 6.5-7.5 wt%; tungsten, 0.4-0.7 wt%; titanium, 0.002-0.007 wt%; boron, 0.001-0.005 wt%; niobium, 0.04-0.09 wt%; vanadium, 0.03-0.07 wt%; nitrogen, 0.01-0.1%; oxygen, <= 0.001 wt%; hydrogen, <= 0.000005 wt%; controlled compositions: arsenic, <=0.03 wt%; antimony, <=0.03 wt%; and antimony, <=0.03 wt%; and the balance iron. According to the 15Cr oil pipe, the minimum yield strength is 925 MPa (125ksi steel grade), the critical usage temperature is 210 DEG C, the CO2 partial pressure can be 10 MPa or more, the Cl<-> concentration can be 120000 mg / L, the 15Cr oil pipe has certain H2S stress corrosion cracking resistant performance, and compared with a super II type 13Cr martensite stainless steel oil pipe material, the increased cost is not large.

Owner:XI'AN PETROLEUM UNIVERSITY

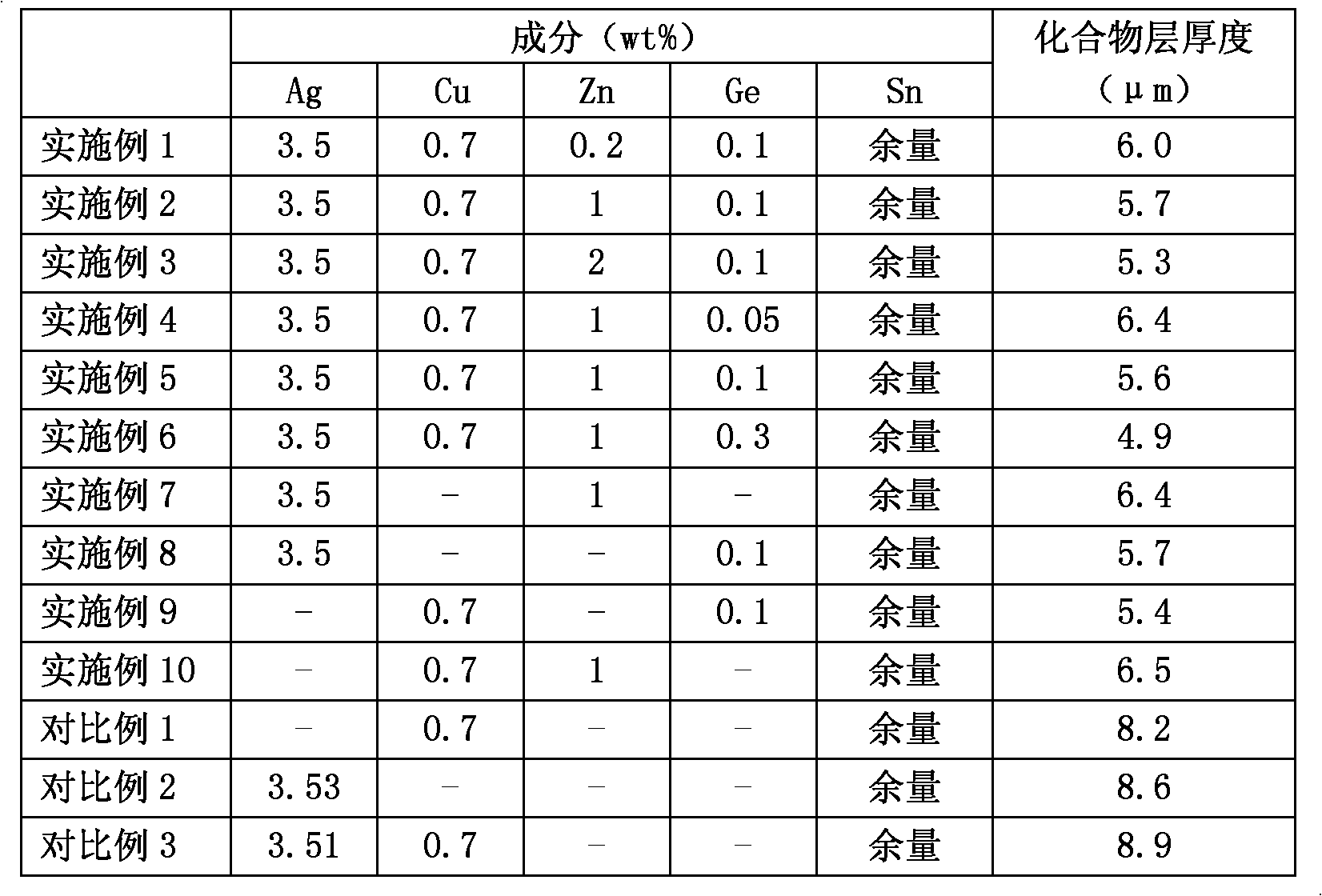

Sn-Ag-Cu-Zn-Ge lead-free solder for inhibiting solid-state interface reaction and preparation method thereof

InactiveCN101791748AImprove wettabilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaAlloyElectronic packaging

The invention relates to an Sn-Ag-Cu-Zn-Ge lead-free solder for inhibiting solid-state interface reaction and a preparation method thereof for the technical field of electronic packaging. The solder comprises the following components in mass percent: 0%-3.5% of Ag, 0%-0.7% of Cu, 0%-2% of Zn, 0%-0.3% of Ge and balance of Sn. The preparation method comprises the following steps: firstly, putting Sn particles into a KCl and LiCl eutectic protection salt solution, heating, adding high-purity Ag wires and / or Cu wires, insulating for the first time, and fully stirring to obtain a uniform Sn-TM solution; then, adding trace Zn foil and / or Ge particles into the alloy solution, insulating for the second time, and fully stirring; and cooling and pouring the solution into a solder mold. The invention solves the problems that in the prior art, because the lead-free solder has high Sn content, the lead-free solder can react with substrate metals easily, thereby causing a large amount of substrates to be dissolved, and simultaneously, a large amount of intermetallic compounds are formed on the interface, thereby seriously influencing the reliability of the interface. The lead-free solder of the invention has simple preparation processes and can be prepared in batch easily.

Owner:SHANGHAI JIAO TONG UNIV

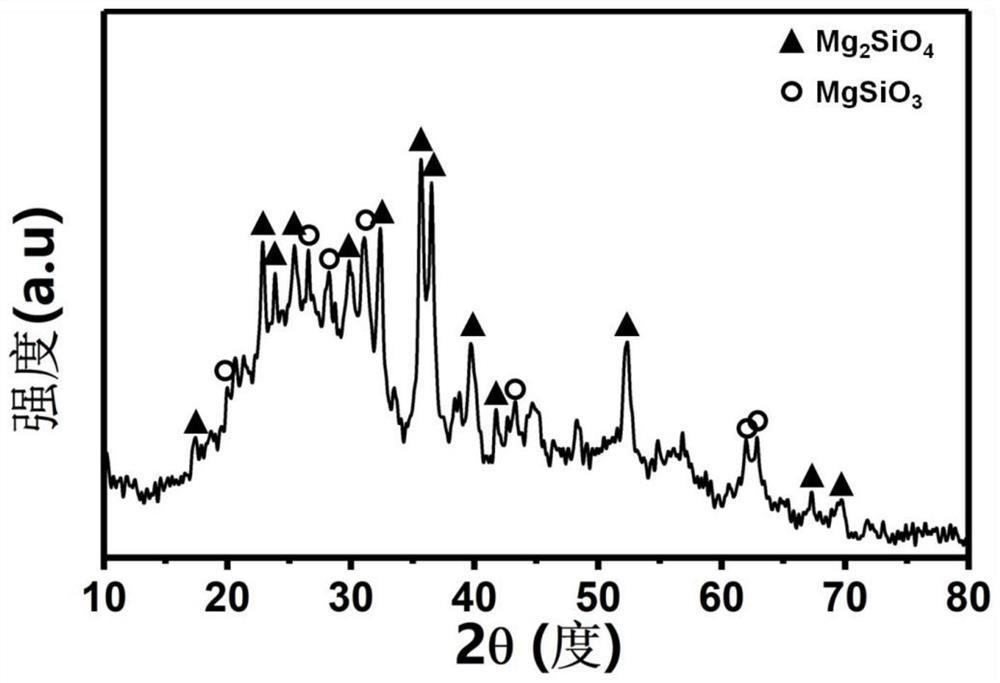

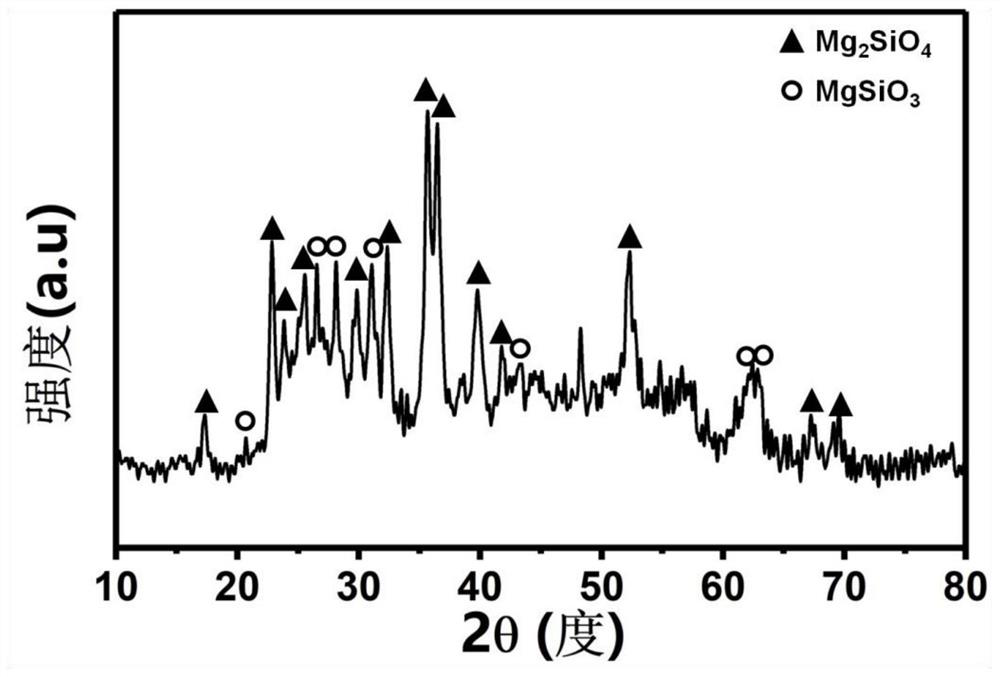

Silicate framework-containing silicon-based negative electrode material, negative plate and lithium battery

ActiveCN112151771ARelieve deformation stressImprove cycle performanceNegative electrodesLi-accumulatorsSilicon basedLithium intercalation

The invention relates to a silicon-based negative electrode material containing a silicate framework, a negative plate and a lithium battery. The silicon-based negative electrode material comprises amodified silicon monoxide material in which a silicate material is dispersedly distributed, the general formula of the modified silicon monoxide material with the silicate material dispersed inside isMxSiOy, X is larger than or equal to 1 and smaller than 6, y is larger than or equal to 3 and smaller than 6, and the element M comprises one or more of Mg, Ni, Cu, Zn, Al, Na, Ca, K, Li, Fe and Co.wherein the grain size is 0.5 nm to 100 nm; in the modified silicon monoxide material, the content of the silicate material accounts for 5%-60% of the total mass of the modified silicon monoxide material; the dispersedly distributed silicate material forms a framework structure of the silicon-based negative electrode material, does not generate a physicochemical reaction along with lithium removaland lithium intercalation of the silicon-based negative electrode material in the circulation process, and keeps the original structure unchanged after multiple times of circulation.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

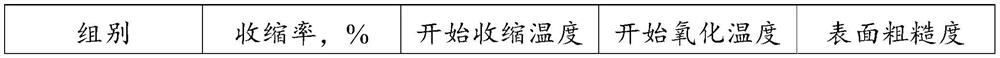

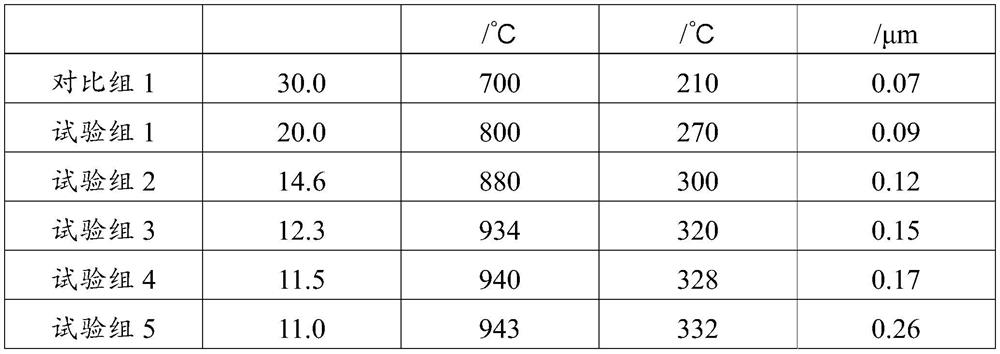

Nickel electrode slurry, preparation method and application thereof

ActiveCN112768234AImprove performanceSuppresses sintering shrinkageFixed capacitor electrodesFixed capacitor dielectricBarium titanateOxidation resistant

The invention discloses a nickel electrode slurry which comprises the following components in parts by weight: 40.05-70 parts of a coated nickel powder, 0.01-5 parts of barium titanate particles, 0-8 parts of an adhesive, 0.5-3 parts of a dispersing agent, 10-40 parts of a solvent and 0-15 parts of a diluent. The coated nickel powder comprises a nickel powder and a barium titanate coating layer coated on the surface of the nickel powder. According to the formula, the coated nickel powder with the barium titanate coating layer and the barium titanate particles doped in the coated nickel powder are selected at the same time, sintering shrinkage of the nickel powder is inhibited through the combined action of the barium titanate with the two structural relations, and the effect is greatly improved; and according to the process, the slurry is dispersed in a manner of combining squeezing and cavitation blasting so that the dispersion effect is enhanced, the mechanical grinding time is shortened, excessive grinding is prevented, the surface characteristics of the nickel powder are kept, and the oxidation resistance of the nickel powder is excellent.

Owner:CHAOZHOU THREE CIRCLE GRP +1

Sintered neodymium-iron-boron material and preparation method therefor

ActiveCN106920615AImprove magnetismHigh melting pointInductances/transformers/magnets manufactureMagnetic materialsFerrite powderMaterials science

The invention discloses a sintered neodymium-iron-boron material and a preparation method therefor. The sintered neodymium-iron-boron material is prepared from iron-based neodymium-iron-boron powder, composite ferrite powder, and nanometer SnO<2>-Ni composite powder in a sintering manner; the iron-based neodymium-iron-boron powder comprises the following components based on mass percentage: 21-25% of Nd, 0.3-0.9% of B, 0.1-0.4% of Sn,0.2-0.9% of Co, 0.3-0.8% of Y, 0.3-0.7% of Ni, 0.1-0.4% of Pb and the balance of Fe; and the iron-based neodymium-iron-boron powder also comprises 0.05-0.3% of AlN micro particles based on weight percentage. The sintered neodymium-iron-boron material disclosed by the invention has extremely high magnetic property; the preparation method for the high-magnetic-energy-product sintered neodymium-iron-boron material does not use many rare and noble materials; and instead, the preparation method is simple in preparation cost, simple in process, convenient to operate, and suitable for popularization.

Owner:XUZHOU NANFANG YONGCI MATERIAL

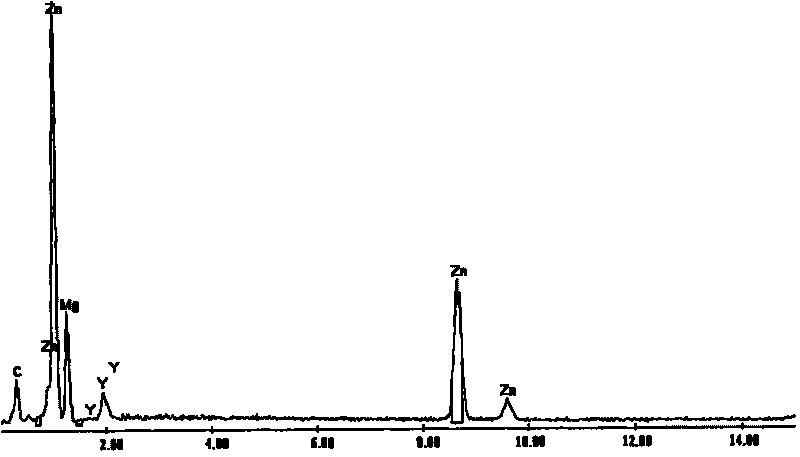

Magnesium-based spherical quasicrystal master alloy and preparation method thereof

The invention provides a magnesium-based spherical quasicrystal master alloy and a preparation method thereof, which relates to a magnesium-based alloy taking zinc as a secondary main component. The alloy is a Mg-Zn-Y-C quaternary magnesium-based icosahedral spherical quasicrystal master alloy comprising the following chemical components: 55.0 to 65.0 percent of Mg, 30.0 to 40.0 percent of Zn, 2.5 to 5.5 percent of Y, and 0.1 to 0.5 percent of C, wherein the diameter of spherical quasicrystals is 3 to 7 mu m; the average diameter of the spherical quasicrystals is 6 mu m; and the volume of the spherical quasicrystals accounts for 40 to 48 percent of the total volume of the alloy. The preparation method is characterized by adopting control over solidification rate, namely pouring molten alloy into a casting mold with cooling rate controllable and controlling the solidification rate in a range between 68.4 and 84.8 K / s. The alloy can improve the mechanical properties of alloy material better when a magnesium alloy matrix is reinforced, and has the advantages of simple process, not high demand for equipment, extensive sources of raw materials, convenience for realizing industrialized production and resource conservation.

Owner:HEBEI UNIV OF TECH

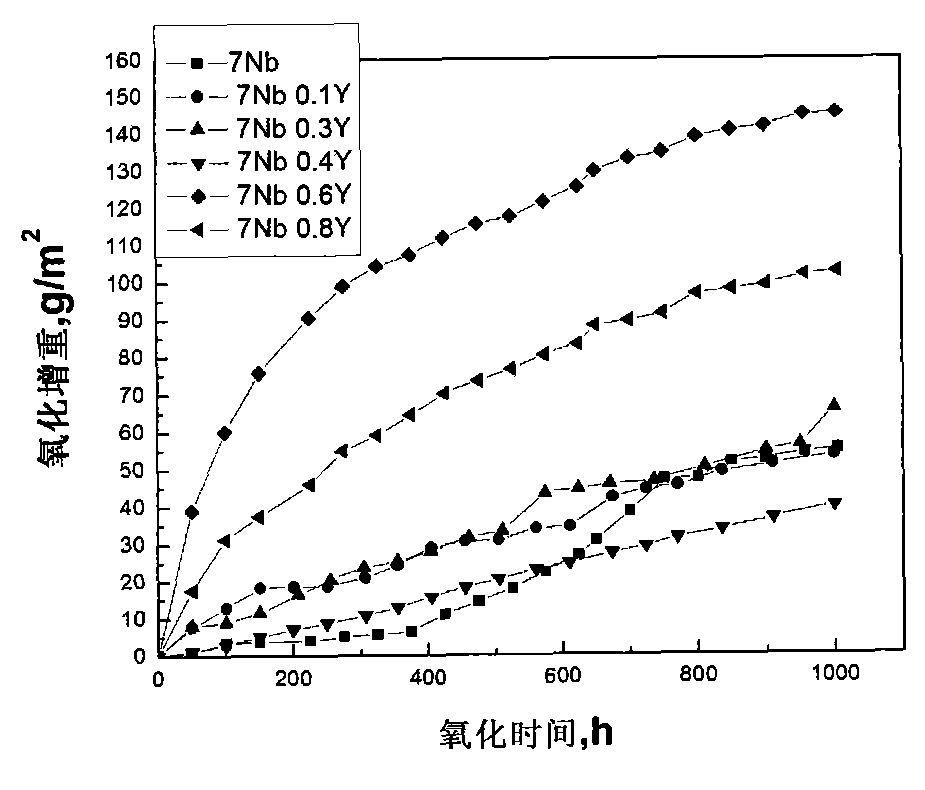

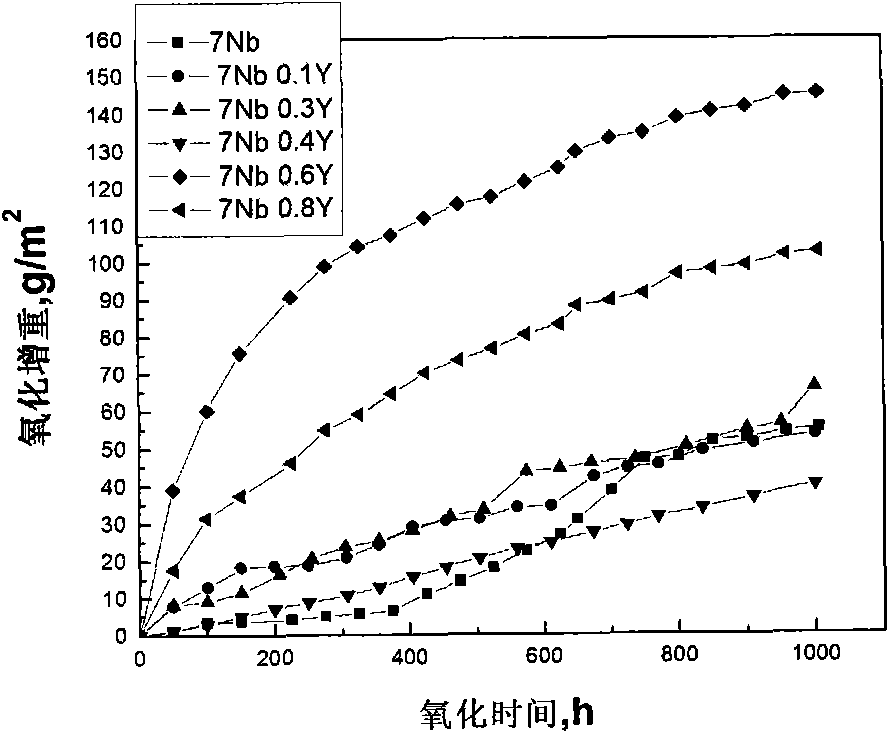

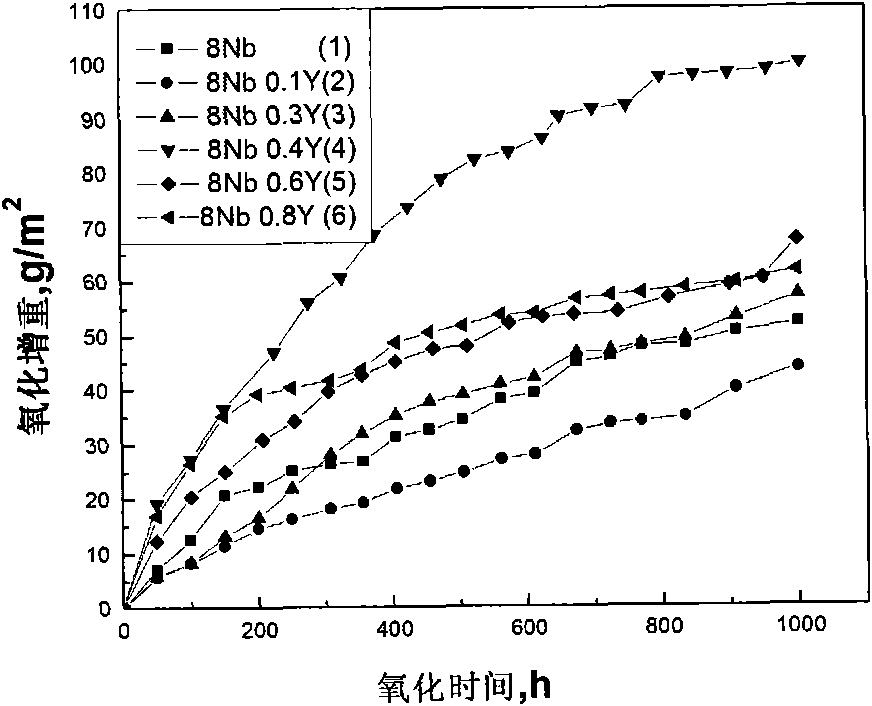

Method for improving long-term oxidation resistance of high-niobium titanium-aluminum alloy through adding yttrium at high temperature

InactiveCN101812604AEnhanced resistance to peelingImprove high temperature long-term oxidation resistanceMetallic materialsYttrium

The invention discloses a method for improving long-term oxidation resistance of a high-niobium titanium-aluminum alloy through adding yttrium at high temperature, belonging to the high temperature oxidization field of the metal material. The invention is characterized in that Y is added in a Ti 45Aa17Nb alloy or a Ti 45Al 8Nb alloy, a tiny yttrium doping high-niobium titanium-aluminum alloy complete lamellar structure is obtained after using vacuum melting and homogenization treatments; the alloy comprises the following components by atomic percent: 46.4-47.9% of Ti, 45% of Al, 7-8% of Nb and 0.1-0.8% of Y; and the homogenization treatment process comprises the following steps: heat insulation is carried out at a temperature of 1320 DEG C for 12h, a converter is insulated for 30 minutes at a temperature of 900 DEG C and then taken out for air cooling. The invention has the advantages that adding proper amount of Y increases the proportion of Al2O3 in an oxide film, reduces the thickness of the oxide film, refines particles producing the oxide, facilitates plastic deformation of the oxide film and reduces cracking of the film; and by epoxidation experiments, after all alloys containing Y go through 1000 cycle periods, no obvious shedding phenomenon occurs in the oxide film, and addition of Y improves the adhesion of the alloy oxide film and raises the use temperature of the high-niobium titanium-aluminum alloy to the temperature of more than 900 DEG C.

Owner:UNIV OF SCI & TECH BEIJING

Nickel-based alloy with high grain-boundary strength and preparation method thereof

The invention relates to a nickel-based alloy with high grain-boundary strength and a preparation method thereof. The nickel-based alloy consists of the chemical components in percentage by weight; 20-25 percent of chromium, 0.2-0.7 percent of copper, 0.01-0.2 percent of carbon, 8.0-10.0 percent of molybdenum, 10-15 percent of cobalt, 0.5-1.5 percent of aluminum, 0.2-0.6 percent of titanium, 0.01-0.02 percent of boron, 0.01-0.03 percent of tungsten, 0.01-0.3 percent of tantalum, 0.02-0.06 percent of rare earth and the balance of nickel and other unavoidable trace impurity elements. The preparation method for the nickel-based alloy with high grain-boundary strength comprises the following steps of (1) preparing raw materials: preparing a proper amount of Incone1617 main material and a small amount of Re, B, Ta and W for component adjustment; and (2) feeding the materials for smelting: putting the materials Cr, Mo, Ta and W which have high smelting points to the bottom of a crucible, then adding the Incone1617 furnace material, sequentially adding the rest of the raw materials, covering the materials with a slag removal agent, and smelting the materials in a vacuum smelting furnace. By the adding of B, Ta and the rare earth elements, the nickel-based alloy is low in environment sensitivity and can achieve effects of purifying the grain boundary and effectively improving the grain-boundary bonding strength.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com