Modifier applied to refining treatment of grains and structures of cast steel

A technology of modifiers and grains, which is applied in the field of cast steel smelting, can solve the problems of fine particles of modifiers, complicated preparation process, and high production cost, and achieve the effects of slowing down crystal growth, uniform dispersion, and refined morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

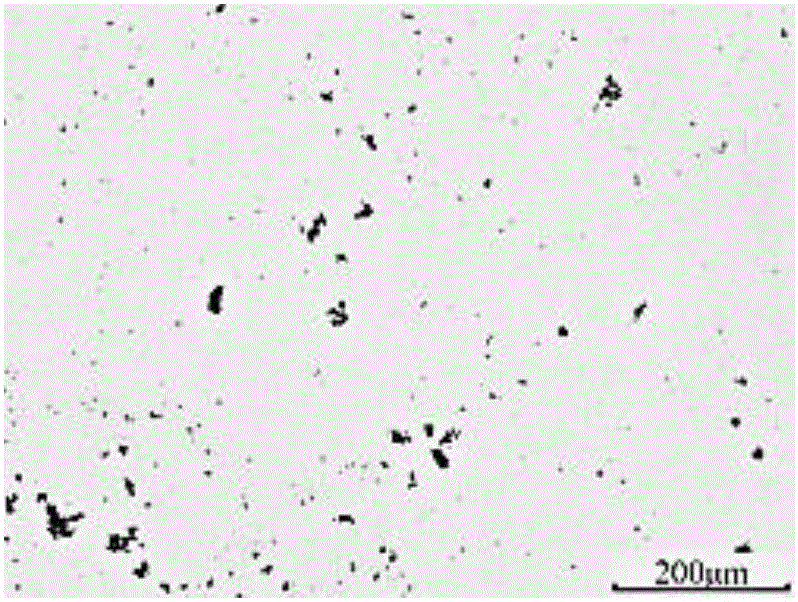

Embodiment 1

[0030] The modifying agent used in the refining treatment of cast steel grains and structures in this embodiment is a powder obtained by atomizing ferro-titanium, ferro-vanadium, and ferro-niobium according to the set ratio and then mixed with the set ratio. The fine-grain modifier prepared by mixing rare earth ferrosilicon particles has the following elements by weight: 8% Ti, 8% V, 10% Nb, 15% Si, 8% RE and the rest are Fe elements. Modifiers are prepared by the following methods:

[0031] In the first step, the raw materials of titanium-iron alloy, vanadium-iron alloy and niobium-iron alloy are weighed according to the weight percentage of the elements set above, and these raw materials are prepared into titanium-iron powder, vanadium-iron powder and niobium-iron powder by atomization method, and the process operation The above-mentioned raw materials are heated in an electric furnace to 150-250°C higher than the melting point to melt all the iron alloys, and the molten met...

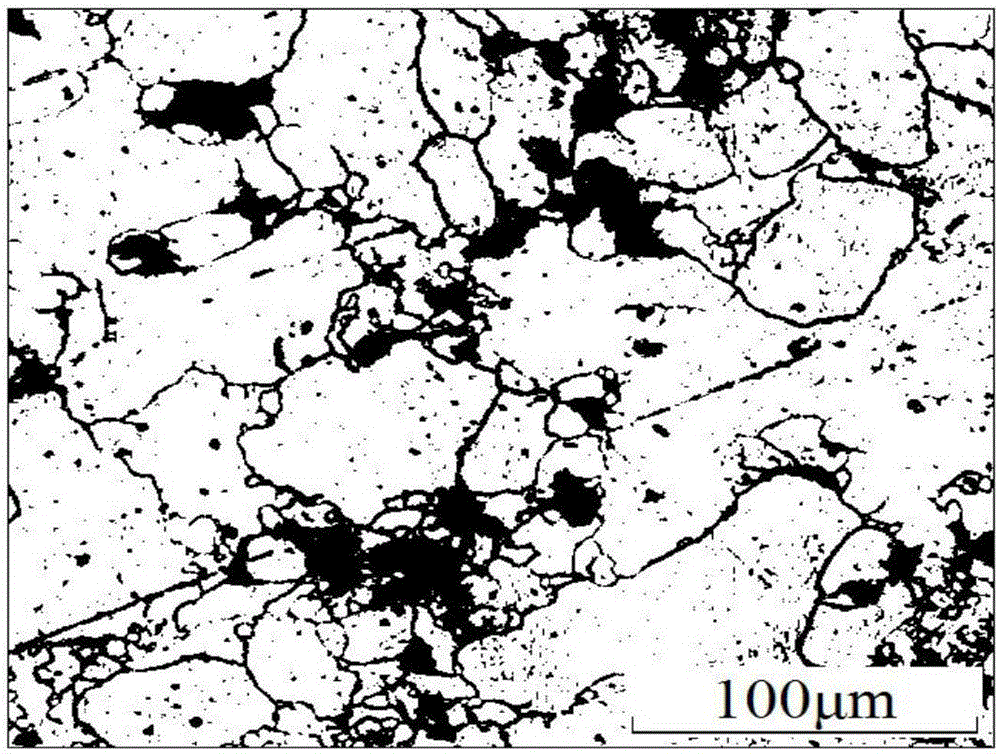

Embodiment 2

[0037]The modifier used for refining grain and structure of cast steel is a kind of powder obtained by atomizing ferro-titanium, ferro-vanadium and ferro-niobium according to the set ratio and then mixed with the set ratio of rare earth ferrosilicon The fine-grain modifier obtained by mixing the particles has a weight percent composition of elements: 15% Ti, 15% V, 18% Nb, 22% Si, 14% RE and the rest are Fe elements. The modifier is used as follows Method made:

[0038] In the first step, the raw materials of titanium-iron alloy, vanadium-iron alloy and niobium-iron alloy are weighed according to the weight percentage of the elements set above, and these raw materials are prepared into titanium-iron powder, vanadium-iron powder and niobium-iron powder by atomization method, and the process operation The above-mentioned raw materials are heated in an electric furnace to 150-250°C higher than the melting point to melt all the iron alloys, and the molten metal flows out from the ...

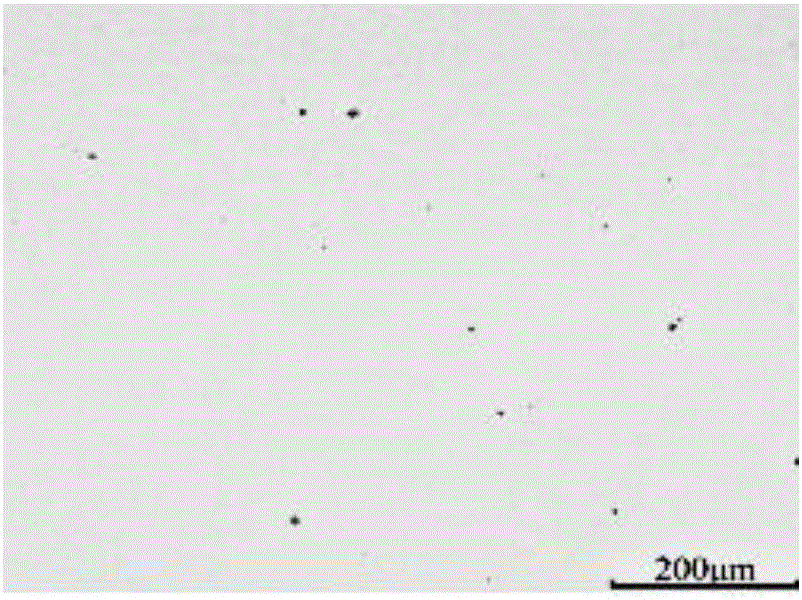

Embodiment 3

[0045] The modifier used for refining grain and structure of cast steel is a kind of powder obtained by atomizing ferro-titanium, ferro-vanadium and ferro-niobium according to the set ratio and then mixed with the set ratio of rare earth ferrosilicon The fine-grain modifier obtained by mixing the particles has a composition in percentage by weight of elements: 10% Ti, 10% V, 12.8% Nb, 17% Si, 10% RE and the rest are Fe elements. The modifier is used as follows Method made:

[0046] In the first step, the raw materials of titanium-iron alloy, vanadium-iron alloy and niobium-iron alloy are weighed according to the weight percentage of the elements set above, and these raw materials are prepared into titanium-iron powder, vanadium-iron powder and niobium-iron powder by atomization method, and the process operation The above-mentioned raw materials are heated in an electric furnace to 150-250°C higher than the melting point to melt all the iron alloys, and the molten metal flows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com