Patents

Literature

186results about How to "Not easy to melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

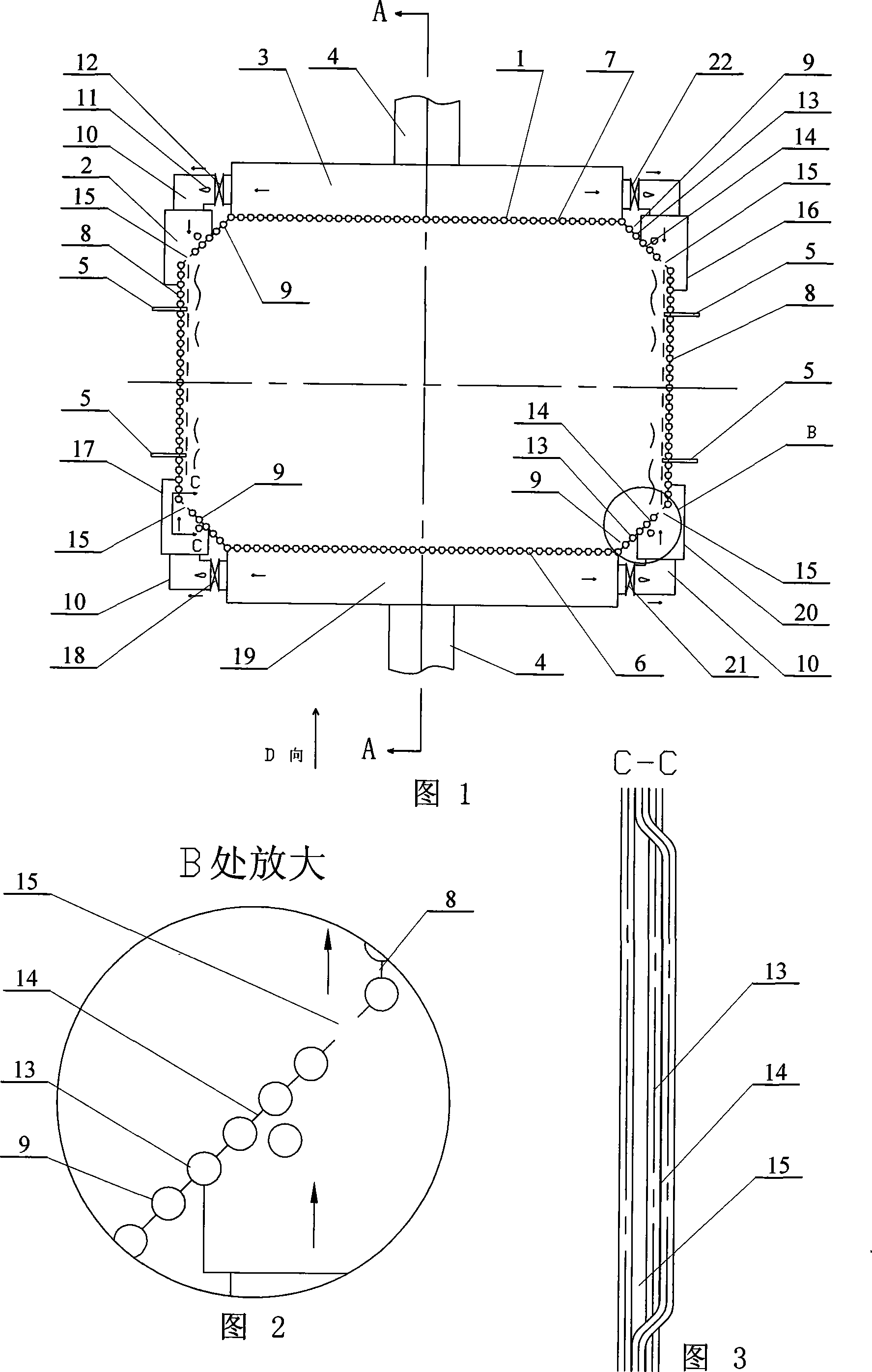

W-shape flame boiler for preventing side wall water cooling wall slagging scorification

ActiveCN101050854AAccelerated slagging problemReduce the temperatureSteam boilersCombustion chambersScarificationWing wall

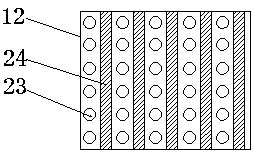

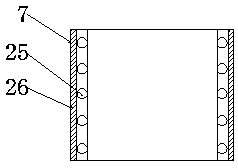

A W type of flame boiler enabling to prevent water-cooled wall of wing walls from slagging scarification is prepared for setting four wall-wind fans separately on external sides of four wing walls and arranging ventilation gap on each of four wing walls.

Owner:HARBIN INST OF TECH

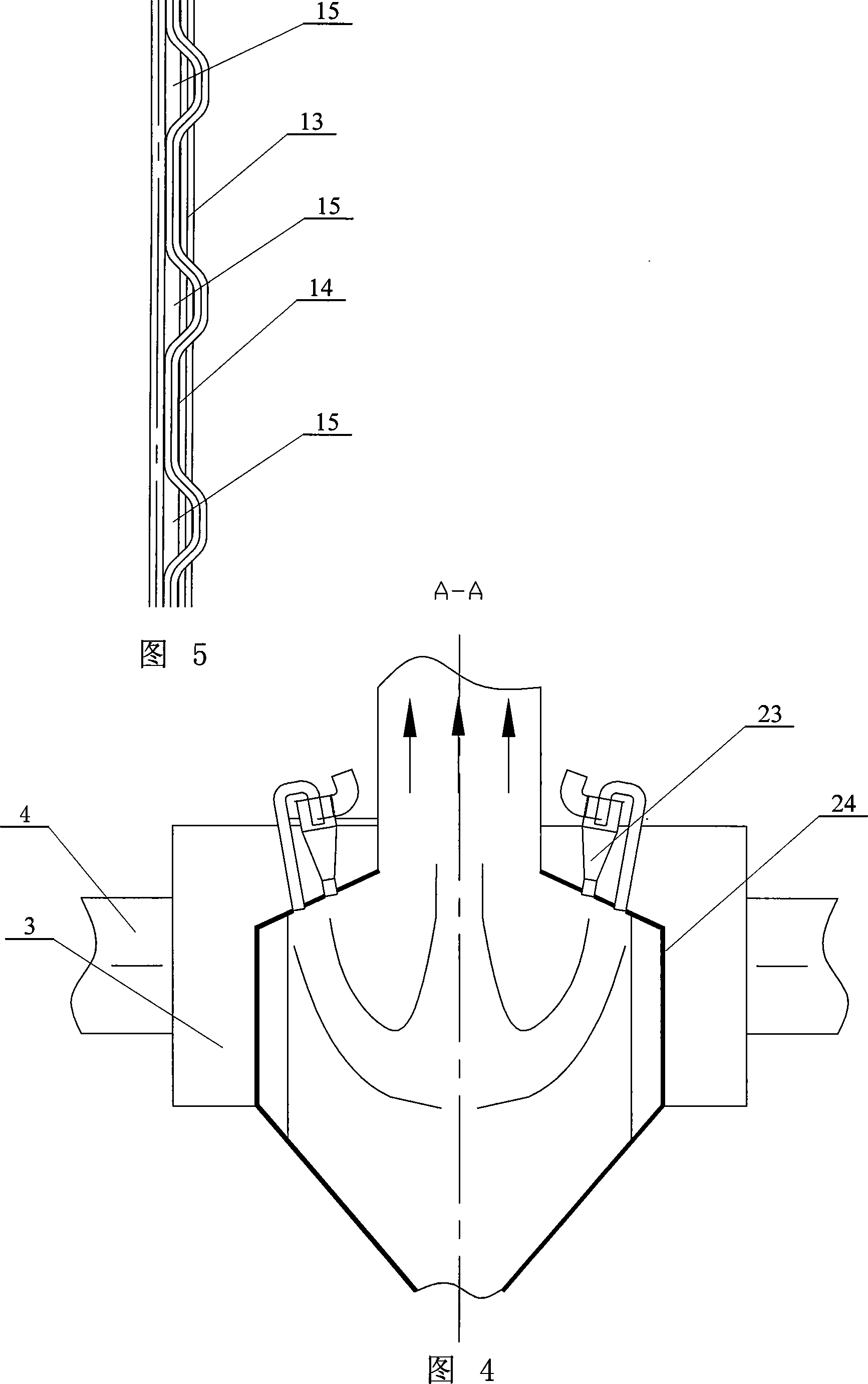

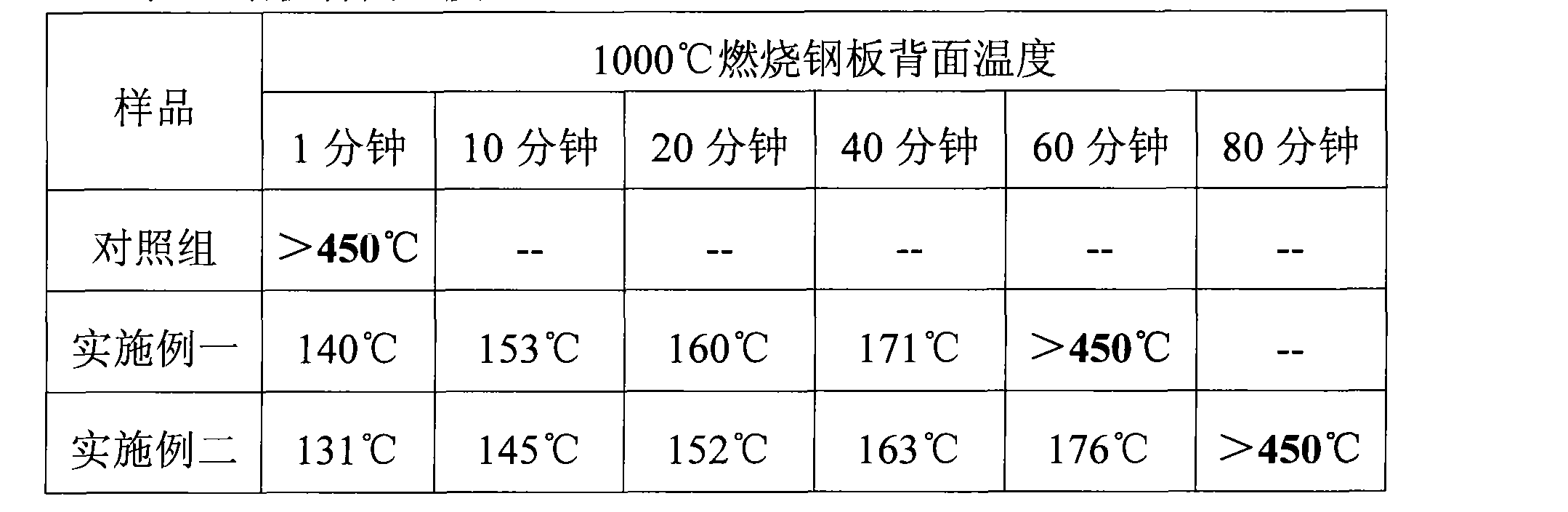

Transparent halogen-free fire-resisting paint constituent

InactiveCN101434760AImprove toughnessNot easy to crackFireproof paintsPolyurea/polyurethane coatingsSolventChemistry

The invention provides a transparent halogen-free fire-retardant paint composition, which consists of 100phr (Parts per Hundred of Resin) of adhesive, 50-400phr of solvent, 50-300phr of foaming agent, 10-200phr of carburetant, 1-100phr of carbonizing promoter and 0-100phr of auxiliary additive; wherein, the carbonizing promoter is a phosphorus-containing compound with reaction functional groups. A coat formed by the transparent halogen-free fire-retardant paint composition nearly generates no smoke when being heated but instantly generates an expanding layer of high toughness. The expanding layer is not likely to crack, does not melt, drop and droop and moreover, is capable of effectively obstructing oxygen and heat to fulfill fire-retardant effect. The paint composition has excellent compatibility and dispersibility among the ingredients, therefore has eminent transparency and can be used for the fire prevention of various buildings, furniture or in decoration without damaging the original appearance view thereof.

Owner:CHINA GENERAL PLASTICS

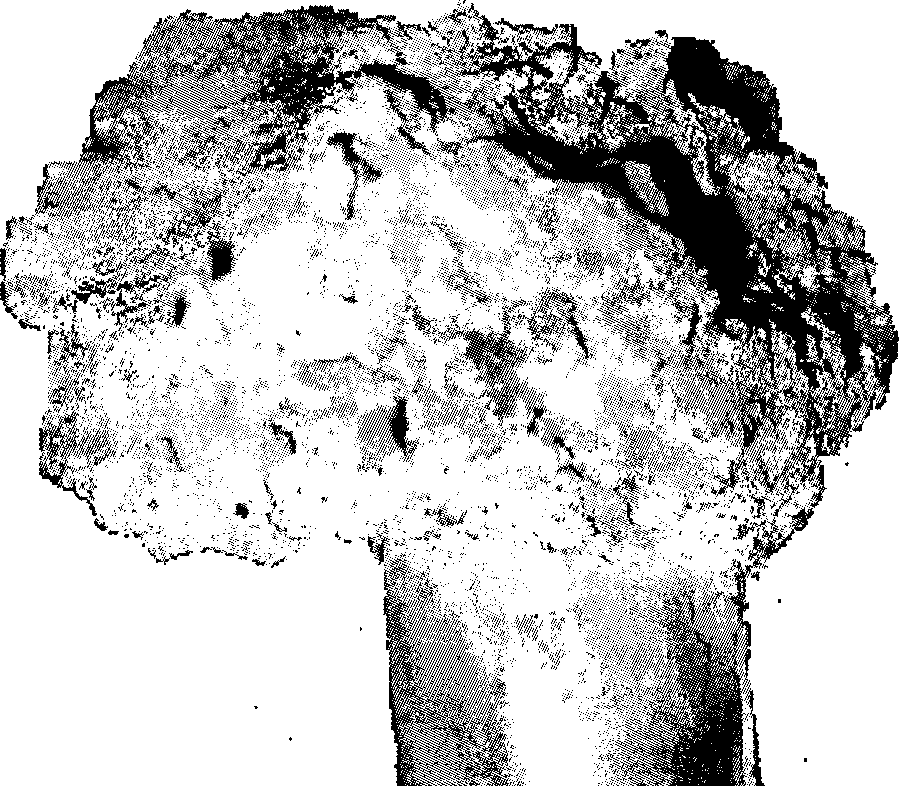

Method for improving combined blown converter campaign length by metal furnace cinder composite mushroom

Owner:CENT IRON & STEEL RES INST

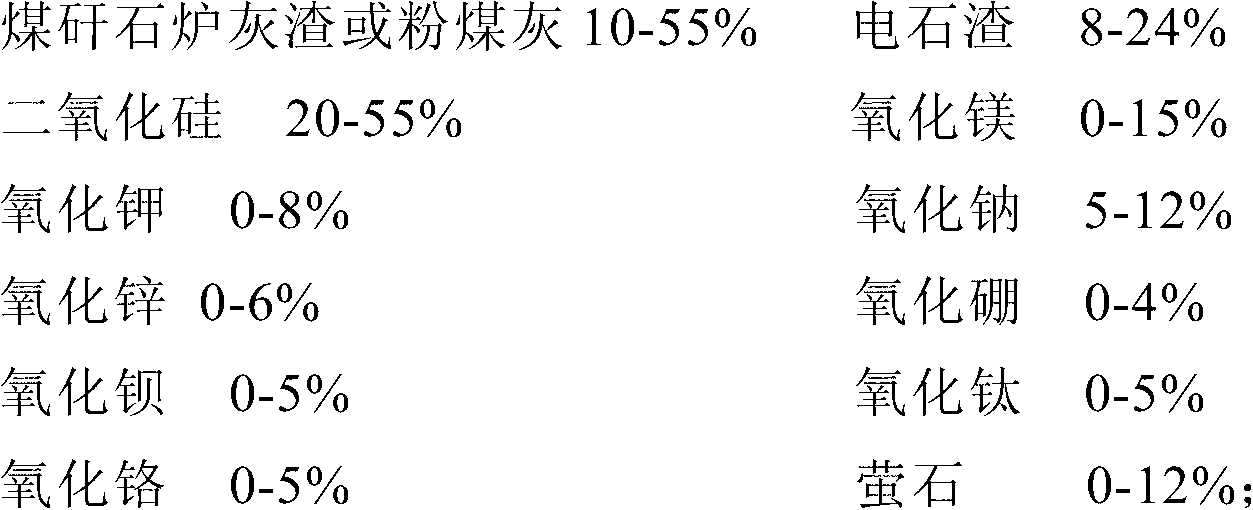

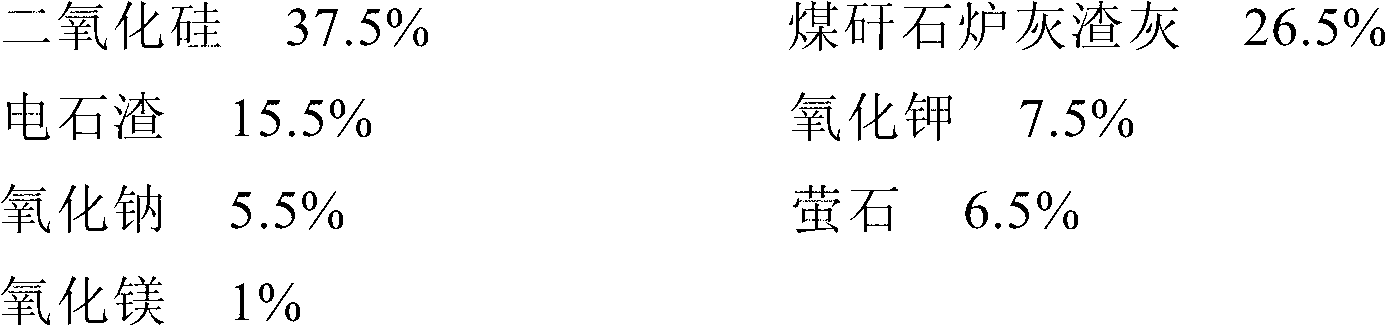

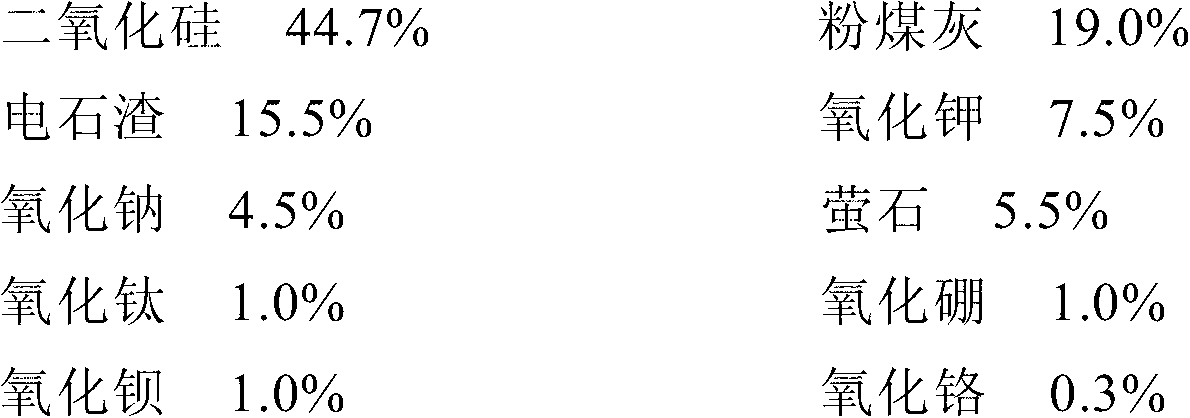

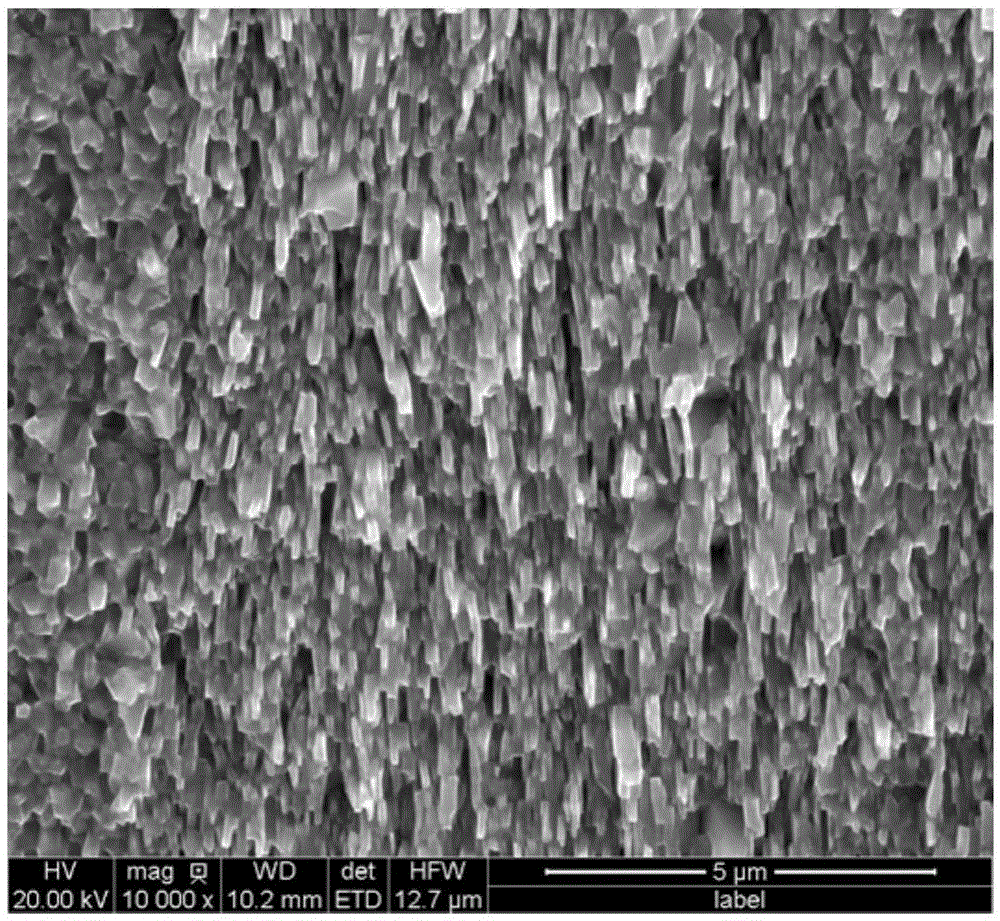

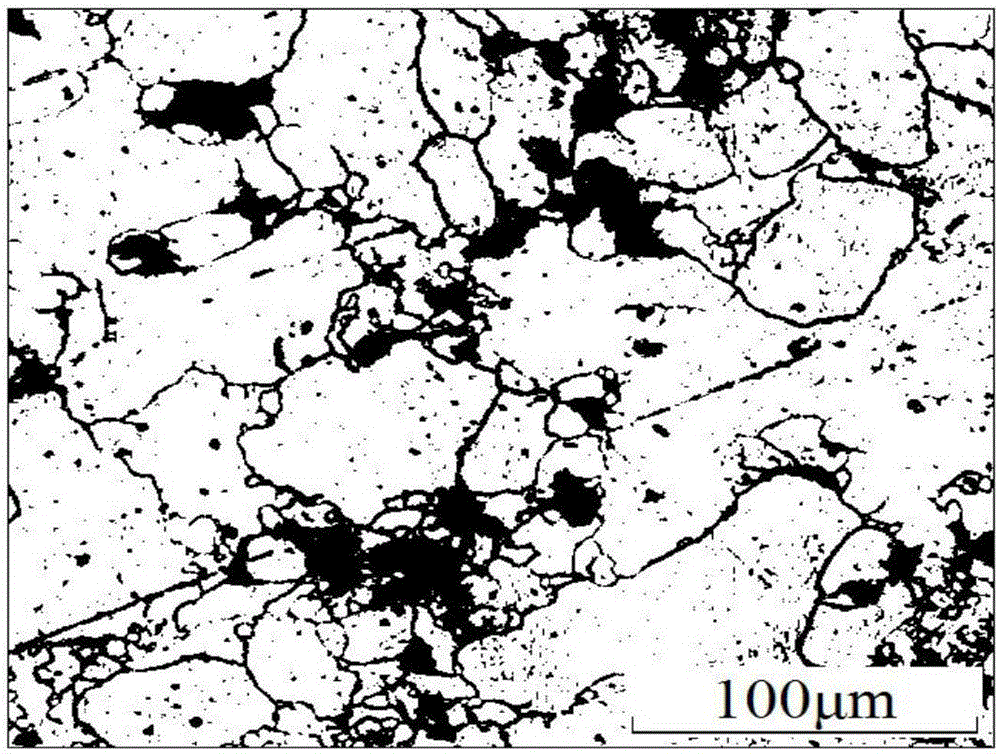

Method for preparing microcrystalline glass from kaolin-type coal gangue or fly ash and carbide slag

The invention discloses a method for preparing microcrystalline glass from kaolin-type coal gangue or fly ash and carbide slag. The method comprises the following steps of: (1) pre-treatment of raw materials: the coal gangue needs to be sequentially subjected to carbon removal and iron removal, the fly ash can be directly subjected to iron removal, and the carbide slag needs to be subjected to graphite electrode chip removal; (2) material proportioning: the refractory coarse slag obtained after burning the coal gangue needs to be added in the proportioned materials; (3) melting: melting is performed in a low-temperature range, a part of unmelted mass points is reserved, and air bubbles in melted solution are eliminated; (4) forming: forming is performed by adopting a calendaring method, a pouring method or a sintering method; and (5) heat treatment: a microcrystalline glass blank is obtained via heat treatment, and the finished product is obtained after finish machining. According to the invention, wastes such as the kaolin-type coal gangue or the fly ash and the carbide slag can be abundantly used for producing high-performance microcrystalline glass containing granular patterns, which is similar to natural stone, and even similar to natural jade.

Owner:北京盛康宁科技开发有限公司

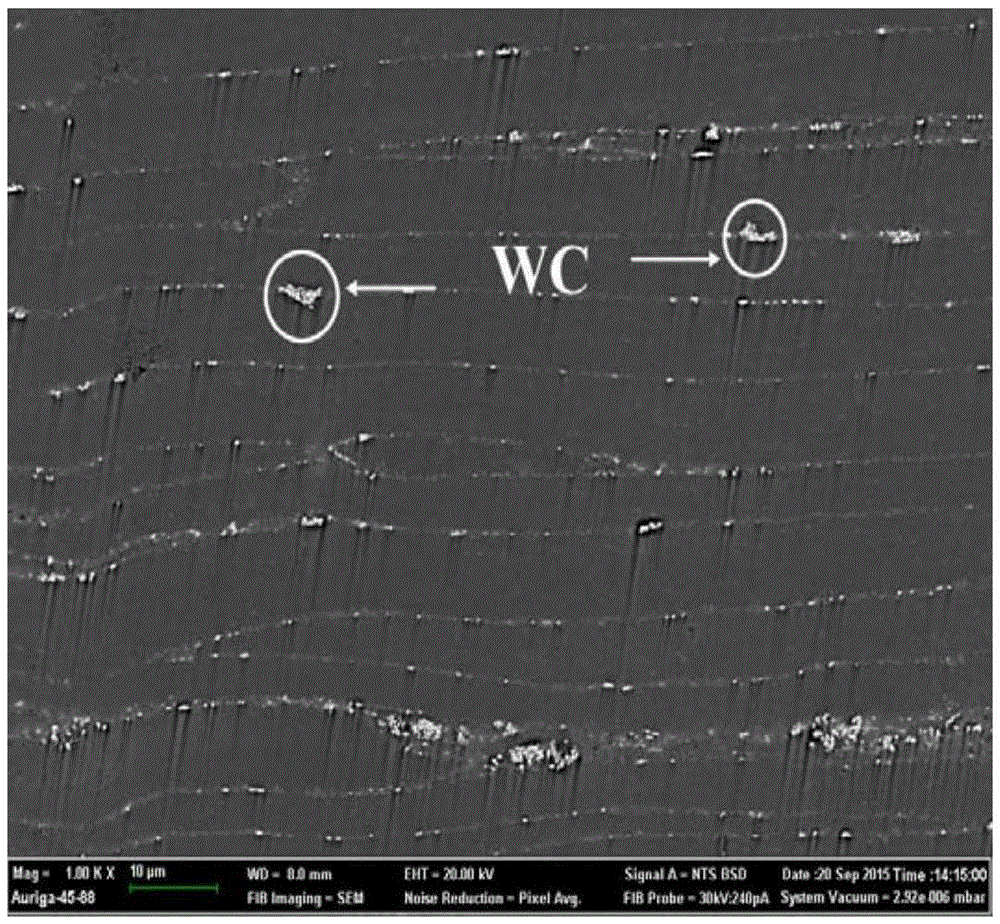

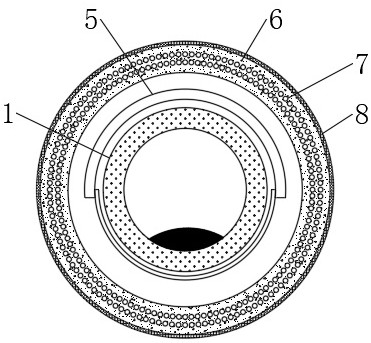

Nanocrystalline thermal deformation rare-earth permanent magnet material with high coercivity and preparation method of nanocrystalline thermal deformation rare-earth permanent magnet material

ActiveCN105321645AImprove magnetic propertiesNot easy to meltInorganic material magnetismRare earthCarbide

The invention relates to a preparation method of a nanocrystalline thermal deformation rare-earth permanent magnet material with high coercivity. The method comprises the steps as follows: (1) alloy powder and a high melting point additive are respectively provided, wherein the high melting point additive is at least one of refractory carbide, nitride and oxide; (2) the alloy powder and the high melting point additive are mixed evenly to obtain mixed magnetic powder, wherein the mass ratio of the high melting point additive in the mixed magnetic powder is greater than or equal to 0.01% and is smaller than or equal to 10%; and (3) hot press molding and thermal deformation molding are sequentially carried out on the mixed magnetic powder, so as to obtain the nanocrystalline thermal deformation rare-earth permanent magnet material with high coercivity. The invention further provides the nanocrystalline thermal deformation rare-earth permanent magnet material with high coercivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method, product and use of modified vinylene chloride plastics

InactiveCN102140211AImprove thermal stabilityImprove toughnessPlastic/resin/waxes insulatorsInsulated cablesPlasticizerPolyvinyl chloride

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

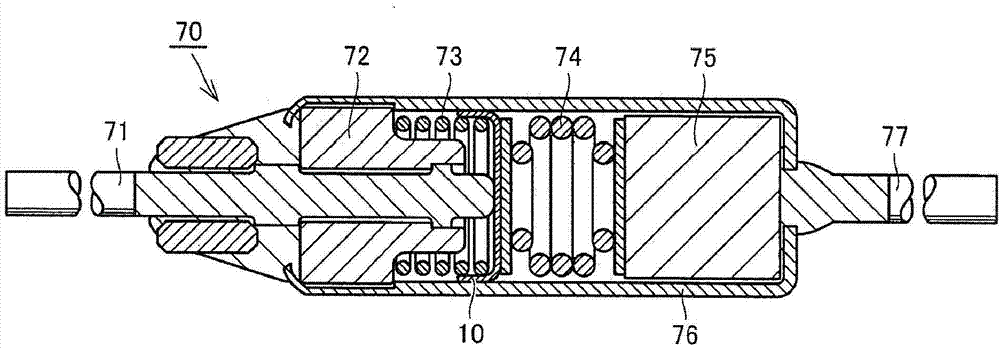

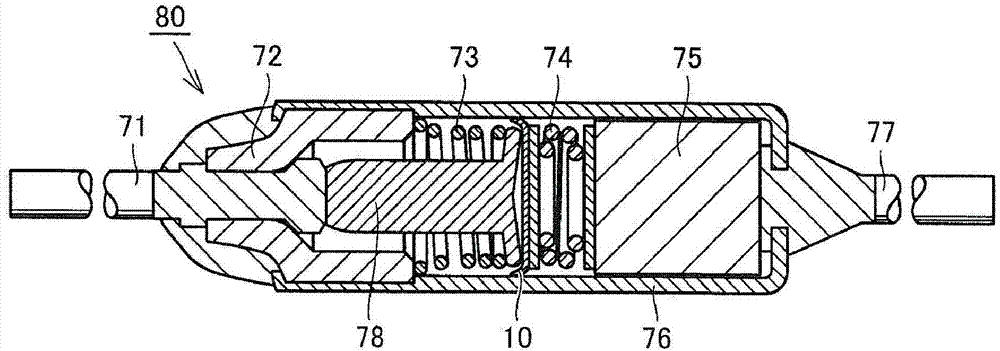

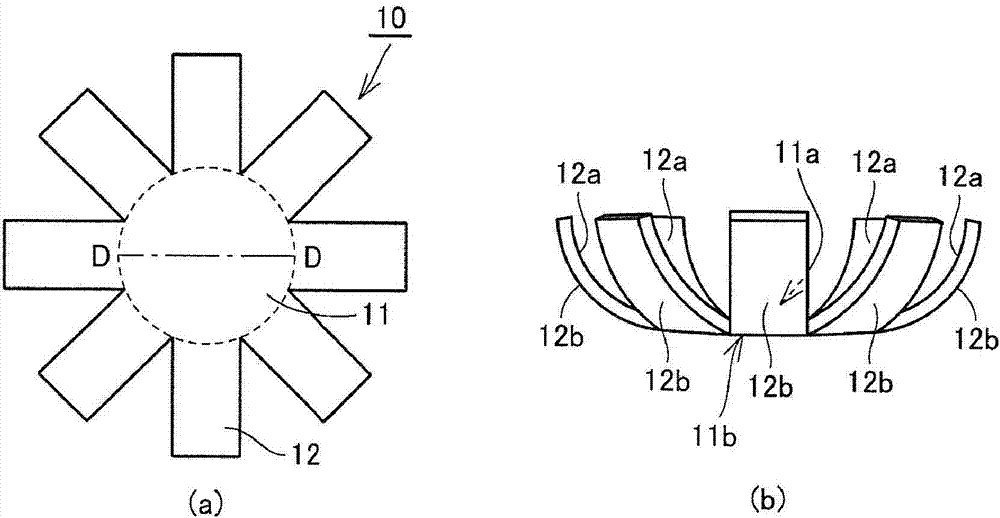

Temperature fuse and sliding electrode used in temperature fuse

InactiveCN103946946ANot easy to meltImprove featuresContact materialsHeating/cooling contact switchesThin metalSurface layer

Owner:NEC SCHOTT COMPONENTS CORP

Carp bait

The invention relates to the technical field of bait, in particular to carp bait. The carp bait is prepared from raw materials, by weight, 3-4% of antarctic krill meal, 2-3% of European whitefish meal, 12-15% of rye, 10-12% of rice bran, 25-30% of corn flour, 12-15% of soybean meal, 8-10% of wheat straw powder, 5-6% of corn immature stem leaves, 5-6% of fresh corn steep liquor, 4-5% of strong flour, 1-2% of lamb liver meal, 2-3% of mushroom residue, 2-3% of pumpkin seeds, 0.2-0.5% of ground sesame seed oil, 1-2% of cyperus rotundus, 2-3% of puffed field snail meal, proper salt and 0.2-0.5% of phagostimulant. The carp bait contains various raw materials that carps like to eat, the raw materials are subjected to fermentation treatment to enable the bait to have unique fragrance and flavors of the ground sesame seed oil, the cyperus rotundus, the field snail meal and the like, and accordingly the carps can be well baited; after entering water, the bait is not easy to dissolve, so that probability of hooking of the carps is increased.

Owner:ANHUI SANFENZHONG FISHING TACKLE

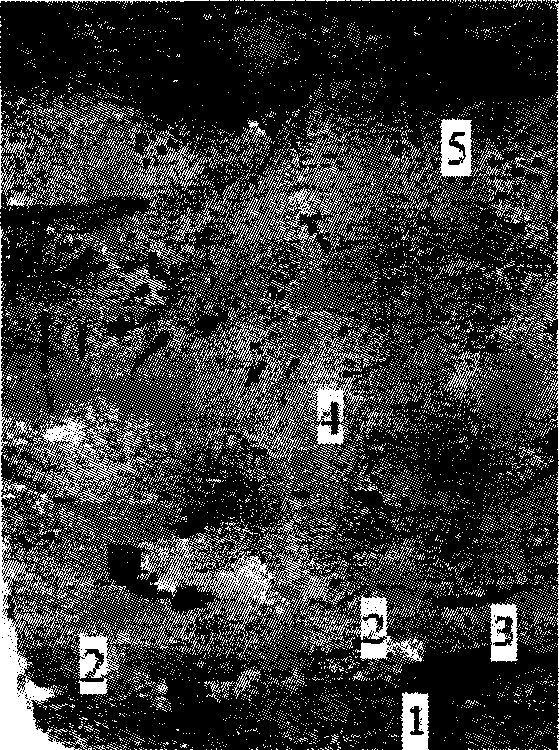

Nitride aluminum hydrolyzing combined fire-resistant material

A fire resisting material combining with aluminium nitride hydrolysis belongs to a fire resisting material with the following components: 87-99 shares of primary fire resisting material with a high melting point, 0.2-8 shares of aluminium nitride, 0.02-5 shares of additive; adding 2-7 shares of water (relative to the total dosage) and blending during construction and solidifying and combining of the fire resisting material in virtue of the hydrolysis reaction of the aluminium nitride. The filling compound is independent with the cement, phosphate and silica micropowder. The fire resisting material is solidified and combined by aluminium nitride hydrolysis to produce AlOOH, Al(OH)3 and consuming water. The filling compound has excellent anti-erosion capacity and elevated temperature strength because it avoids the effects of cement, phosphate and silica micropowder to the elevated temperature.

Owner:江苏苏嘉集团新材料有限公司

Pullulan-containing chocolate and process for producing products thereof

The invention relates to pullulan-containing chocolate and a process for producing products thereof. The process comprises the following steps of: when the pullulan is used as a film coating agent: fully dissolving pullulan in pure water to prepare aqueous solution at a weight concentration of 0.5 to 5 percent for later use, weighing up all raw materials according to the formula of the chocolate, and evenly coating the prepared aqueous solution of pullulan on the surface of a mould during injection moulding; and when the pullulan is used as an emulsifier: fully dissolving pullulan in pure water to prepare aqueous solution at a weight concentration of 0.5 to 1 percent for later use, melting cocoa butter in the formula at a temperature of less than or equal to 60 DEG C, mixing the melted cocoa butter with other raw materials except lecithin and pullulan, fine-grinding the mixture at a temperature of between 40 and 50 DEG C for 16 to 22 hours until the degree of fineness is less than or equal to 20mum and the water content is less than 1 percent, adding lecithin and aqueous solution of pullulan respectively, refining the mixed solution at a temperature of between 48 and 65 DEG C for 24 to 48 hours until the chocolate pulp is in a certain fluid state, performing the working procedures of temperature regulation, thermal preservation, injection moulding, jumping vibration, cooling, demoulding, picking, packaging and storing. With the pullulan, the chocolate offers a fine taste, is insusceptible to melting and frosting and can be stored for a long time.

Owner:天津实发中科百奥工业生物技术有限公司

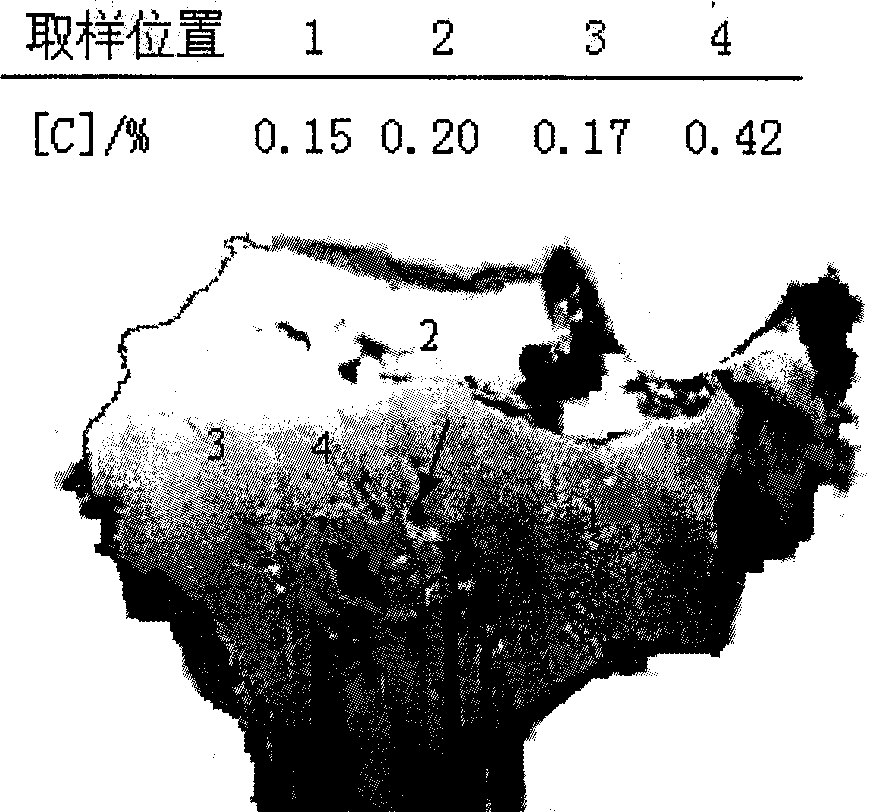

Modifier applied to refining treatment of grains and structures of cast steel

The invention discloses a modifier applied to refining treatment of grains and structures of cast steel and relates to smelting of cast steel. The modifier is a fine grain modifier prepared by mixing ferrotitanium powder, ferrovanadium powder and ferroniobium powder obtained by an atomization method according to a set ratio, and mixing the mixed powder with rare earth ferrosilicon particles according a set ratio. The modifier comprises the following elements in percentage by weight: 8-15% of Ti, 8-15% of V, 10-18% of Nb, 15-22% of Si, 8-14% of RE and the balance of Fe. Through the modifier, the defects that particles of the modifier applied to refining treatment of grains and structures of cast steel are not fine enough, the refining effect is not ideal, the preparation process is complex and the preparation cost is high in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

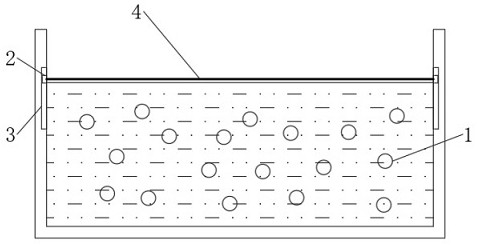

Air floating type petroleum sewage treatment device and treatment method thereof

ActiveCN112093853ADiffusion fastImprove adsorption capacityFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsPlant fibreSewage

The invention discloses an air floating type petroleum sewage treatment device and a treatment method thereof, which belong to the field of sewage treatment. An air floating type adsorption layer at the outer end of a petroleum adsorption ball is settled to the bottom of sewage under the action of load, so that the air floating type adsorption layer is quickly diffused and adsorbed at the water bottom; when the petroleum adsorption balls are thrown into sewage, the sewage is in contact reaction with the effervescent disintegrant in the water-soluble decomposition film and releases a large amount of carbon dioxide and heat, so that the water-soluble decomposition film is decomposed in hot water, the magnetic adsorption balls are dispersed and adsorb petroleum, and on the other hand, the contact area between the magnetic adsorption balls and the petroleum is increased through the convex blocks; the suspension ball floats in water through the plant fibers, the water-absorbing resin adsorbs petroleum, the magnetic attraction type adhesion ball and the hollow rubber floating on the water surface attract each other, and the petroleum is brought out of the water to the water surface through the magnetic attraction type adhesion ball.

Owner:大庆腾辉石油工程技术服务有限公司

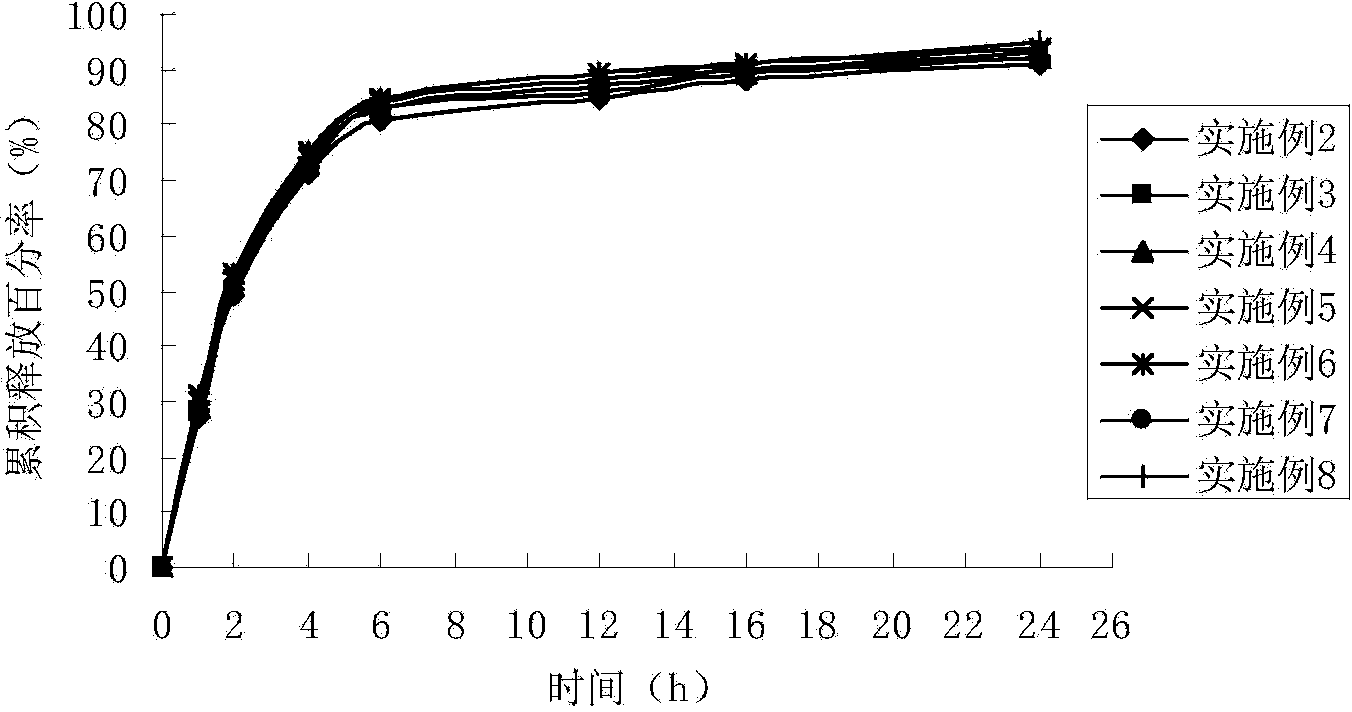

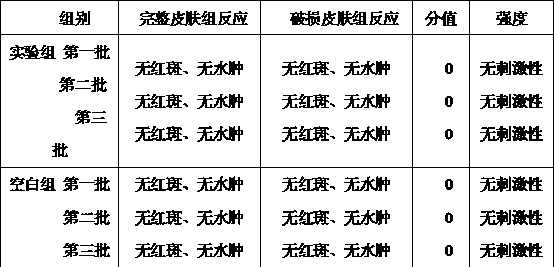

Povidone-iodine vaginal swelling suppository, as well as preparation method and detection method thereof

ActiveCN103720640AGuaranteed effective concentrationPrevent outflowAntibacterial agentsAntimycoticsGynecologyPolyethylene glycol

The invention relates to a povidone-iodine vaginal swelling suppository, as well as a preparation method and a detection method thereof. The swelling suppository comprises a drug-containing matrix formed by povidone-iodine and a matrix, and a swelling carrier, wherein povidone-iodine, a capsule material and pregelatinized starch are used to prepare a micro-capsule, so that the volatilization of povidone-iodine can be reduced, and the effect of slowly releasing a drug can be achieved; nonoxynol-10, polyethylene glycol glyceride octoate caprate, stearyl alcohol and magnesium aluminum silicate are also added into the drug-containing matrix. The prepared swelling suppository is high in stability, and difficult in deformation or rancidity or melting and has good lubricating performance; seven original advanced technologies are adopted, so that the povidone-iodine vaginal swelling suppository has the beneficial effects of preventing liquid medicine from overflowing, avoiding secondary infection and the like.

Owner:哈尔滨田美药业股份有限公司

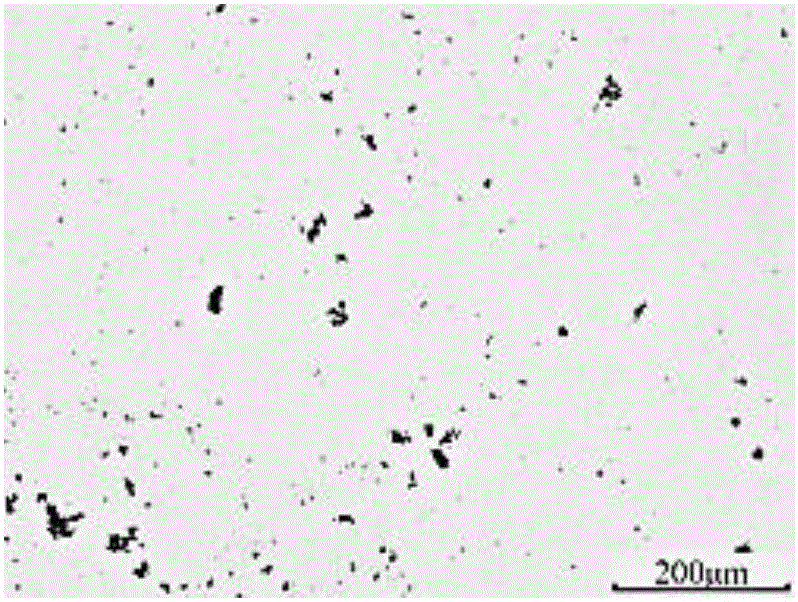

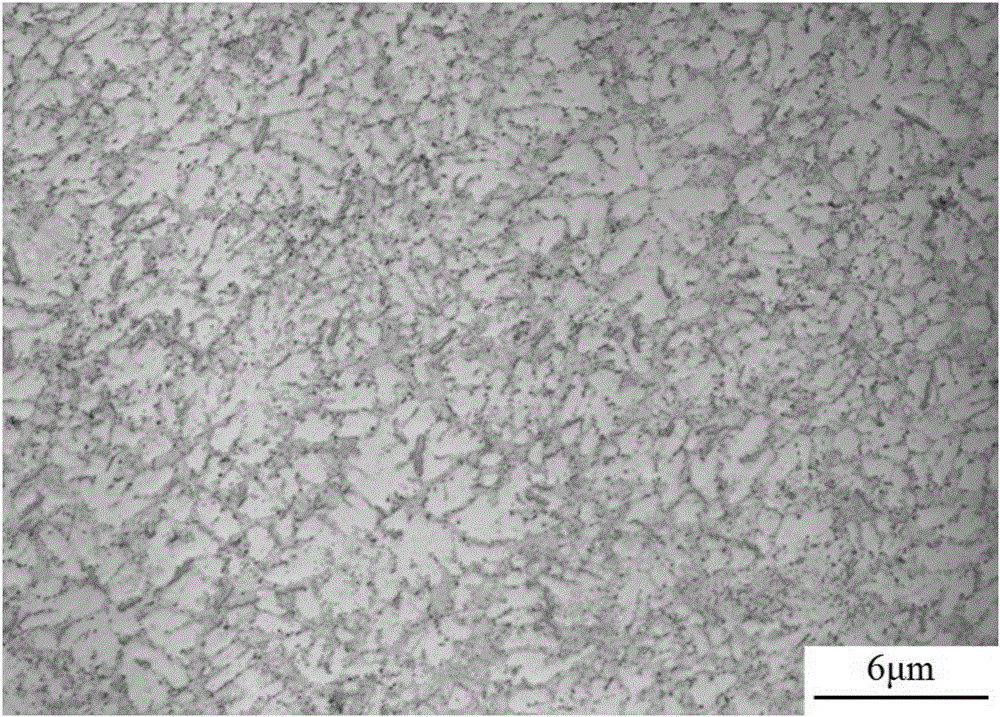

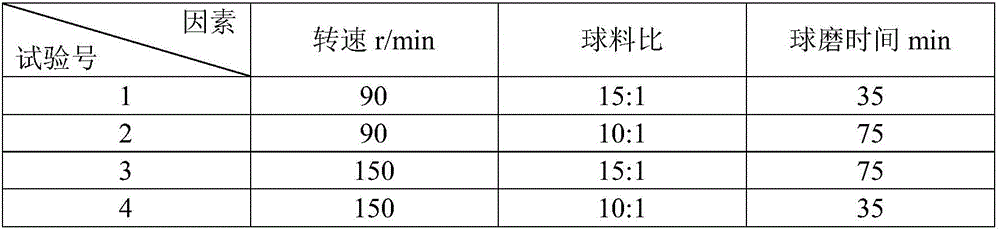

Ultra-fine-grain NdFeB permanent magnetic material and preparation method thereof

The invention discloses an ultrafine-grain NdFeB permanent magnetic material and a preparation method thereof. The permanent magnetic material comprises raw materials including, by weight, 25-35% of Nd, 55-70% of Fe, 0.5-1.8% of B and an auxiliary material, the auxiliary material is nanoscale high-melting-point metal powder, and the nanoscale high-melting-point metal powder accounts for 0.5-2% of total weight of Nd, Fe and B. The preparation method includes: tableting; breaking; fine grinding; adding the auxiliary material; wet ball milling; scattering; pressing for forming; sintering. The magnetic material and the preparation method have the advantages that the advantage that nanoscale high-melting-point metal is difficult to melt in the process of sintering is utilized to realize pinning effect at a grain boundary to prevent NdFeB grain growth so as to prepare the NdFeB permanent magnetic material having ultrafine-grain tissue, and the permanent magnetic material is enabled to have extremely high coercivity without adding rare earth elements like Dy and Tb.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Tubular welding wire for antiwear, heat resistant and antishock bead welding

InactiveCN1739906AUniform amount of powderImprove crack resistanceWelding/cutting media/materialsSoldering mediaChromium carbideNiobium

The tubular bead welding wire is made through rolling H08A steel belt into U shape and adding chromium carbide, molybdenum powder, niobium powder, graphite, WC and ferrovanadium in certain proportion. The present invention has proper amount of graphite and chromium carbide, homogeneous powder in the welding wire, greatly reduced floating, high welding seam wear resistance, high anticracking property of the bead welded layer, long service life of the welded part and other advantages.

Owner:李波 +1

High-molecular material with health care effect

The invention relates to a high-molecular material with a health care effect. The high-molecular material comprises the following raw materials, by weight, 47-84% of a high-molecular compound, 13-28% of tourmaline powder and 3-25% of nanometer negative ion powder. The high-molecular compound is propionate fiber or cellulose acetate fiber or plastic titanium. According to the invention, color fiber powder for changing color of the high-molecular compound also can be added. The high-molecular material generates 2-18 microns of far infrared emission, and release amount of negative ions reaches 500-50000 per cubic centimetre. Legs of glasses, spectacle frames or nose pads prepared from the high-molecular material have functions of releasing negative ions, emitting far infrared rays and changing colors of macromolecules, have a good health care effect and can be used to effectively relieve fatigue and acerbity of wearers' eyes.

Owner:葛家波

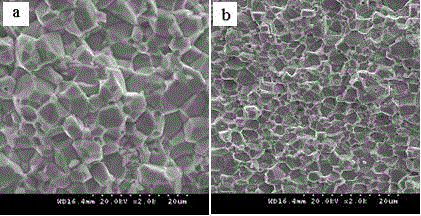

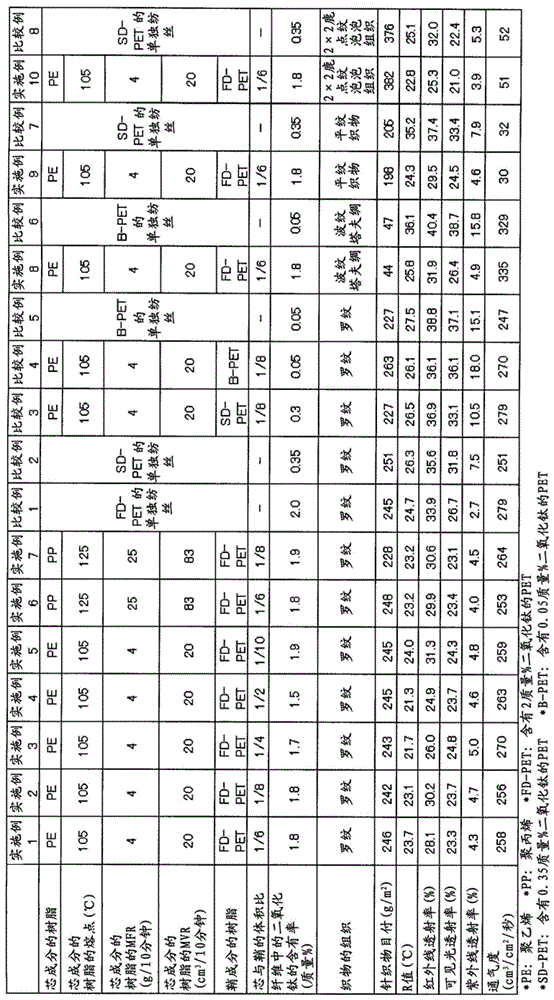

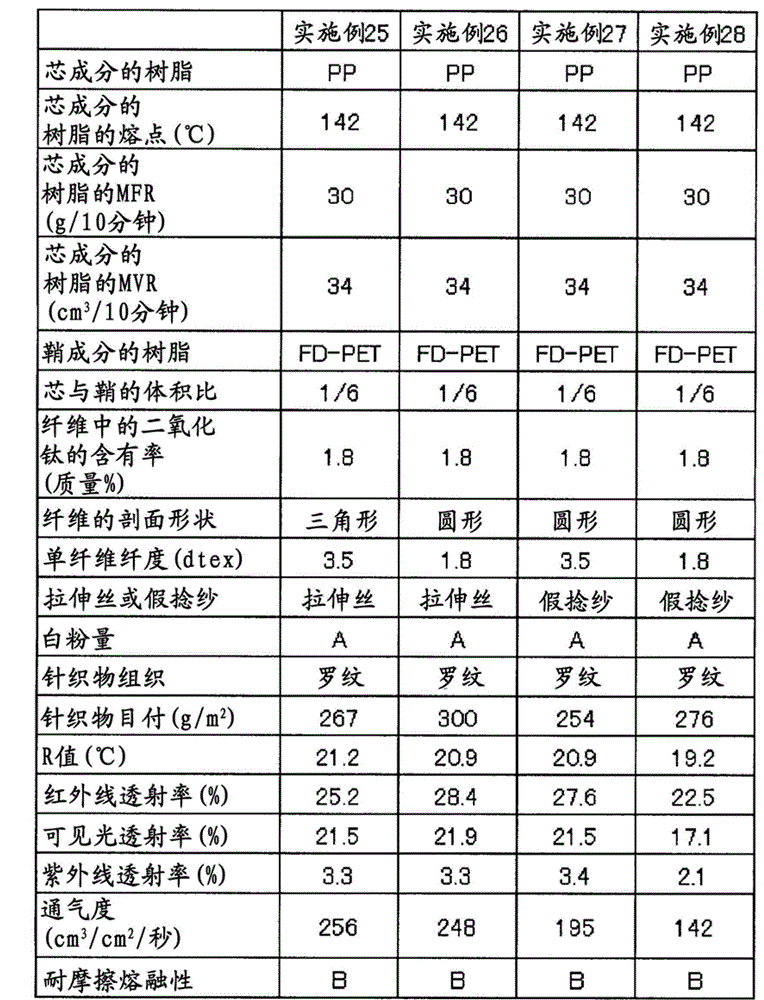

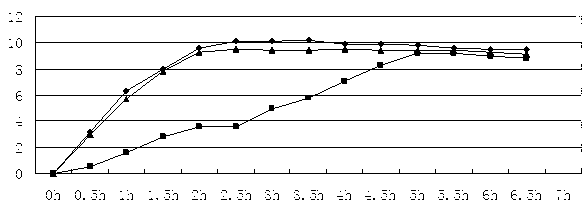

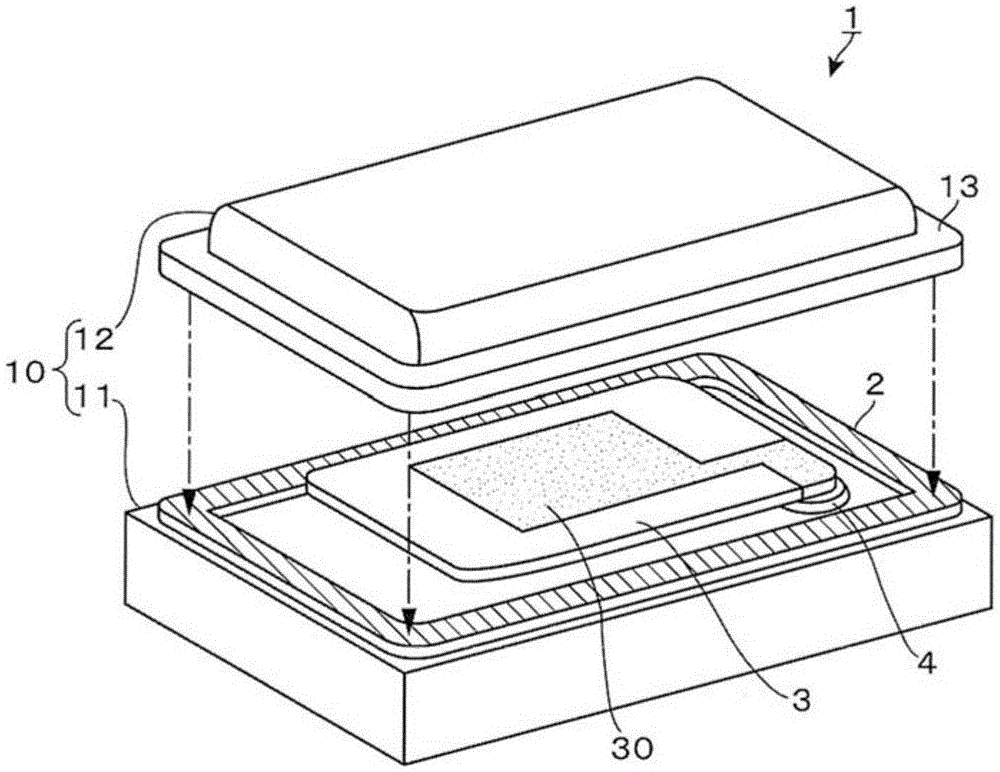

Sheath-core compound fiber, false twist textured yarn composed thereof, method for manufacturing the same, and woven knit fabric including the fiber

The present invention provides a fiber having excellent stability in spinning process and excellent passing of the fiber in false twist yarn process; and a woven knit fabric blocking a radiation heat from the sun with use of the fiber without losing the texture of the fiber. The present invention provides a sheath-core compound fiber having a center core and a sheath, and the sheath-core compound fiber includes 1 to 3% by mass of titanium dioxide. The core of the sheath-core compound fiber mainly contains a resin having a refractive index A, and the sheath of the sheath-core compound fiber mainly contains a refractive index B. The sheath-core compound fiber wherein the refractive index A and the refractive index B satisfy the following formula (1), and a woven knit fabric including the sheath compound fiber having a fiber area weight of 40 to 400 g / m<SP>2< / SP>. |A-B| >= 0.01 (1).

Owner:MITSUBISHI CHEM CORP +1

Ointment preparation for treating haemorrhoids and preparation method for ointment preparation

InactiveCN102920915AAvoid conversionEnhance pharmacological effectsInorganic boron active ingredientsHydroxy compound active ingredientsMixed hemorrhoidExternal haemorrhoids

The invention relates to an ointment preparation which is prepared from natural plants used as main pharmaceutic components and specific pharmaceutic adjuvant and is used for treating haemorrhoids, and a preparation method for the ointment preparation. The ointment preparation for treating haemorrhoids is prepared from the flowing raw materials and adjuvant in part by weight: 80 parts of notoginseng root, 80 parts of parslane herb, 110 parts of lightyellow sophora root, 100 parts of common bletilla tuber, 100 parts of selinum japenious seed, 100 parts of dahurian patrinia herb, 65 parts of Chinese mugwort leaf, 100 parts of pagoda tree pod, 65 parts of honeysuckle flower, 65 parts of divaricate saposhnikovia root, 50 parts of alum, 50 parts of borax, 5 parts of borneol, 30 parts of liquoric root, 750 to 850 parts of mineral butter, 30 to 70 parts of wool grease, 1 to 20 parts of dimethylsulfoxide, 1 to 20 parts of silicone, 1 to 10 parts of butyl hydroxy anisd, and 1 to 5 parts of polysorbate 80. The medicine is mainly used for treating acute attack of haemorrhoids, internal hemorrhoids blooding and prolapsing, incarceration, perianal abscess, external hemorrhellood, and mixed hemorrhoid sore pain, relieving swelling of postoperative anus edge, and diminishing inflammation, relieving pain and stopping bleeding of local part of the anus. The medicine can also be used as a health-care product for cleaning the anus.

Owner:YUNNAN SUNSAIL PHARMA

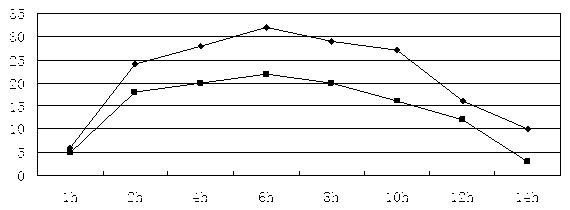

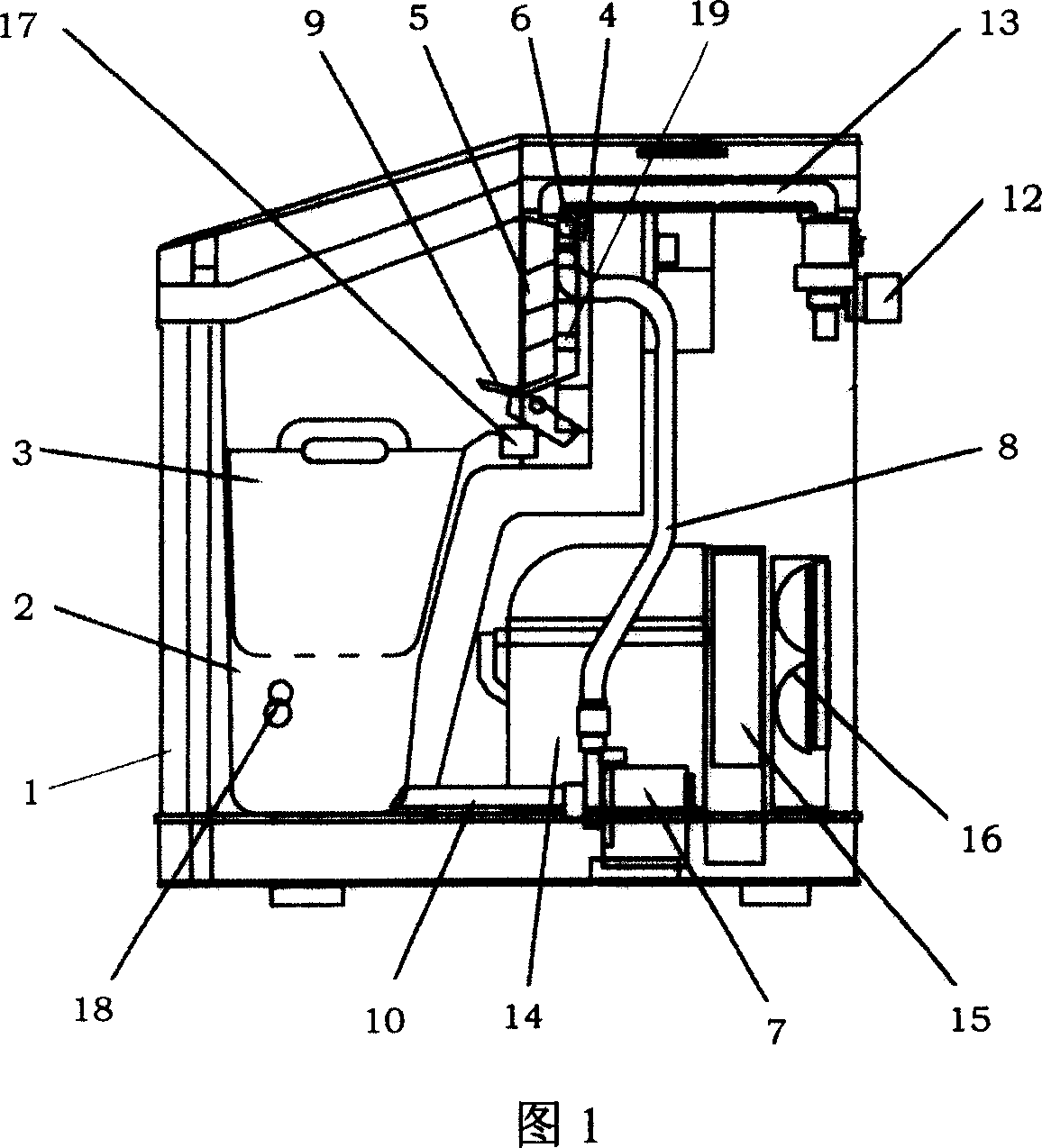

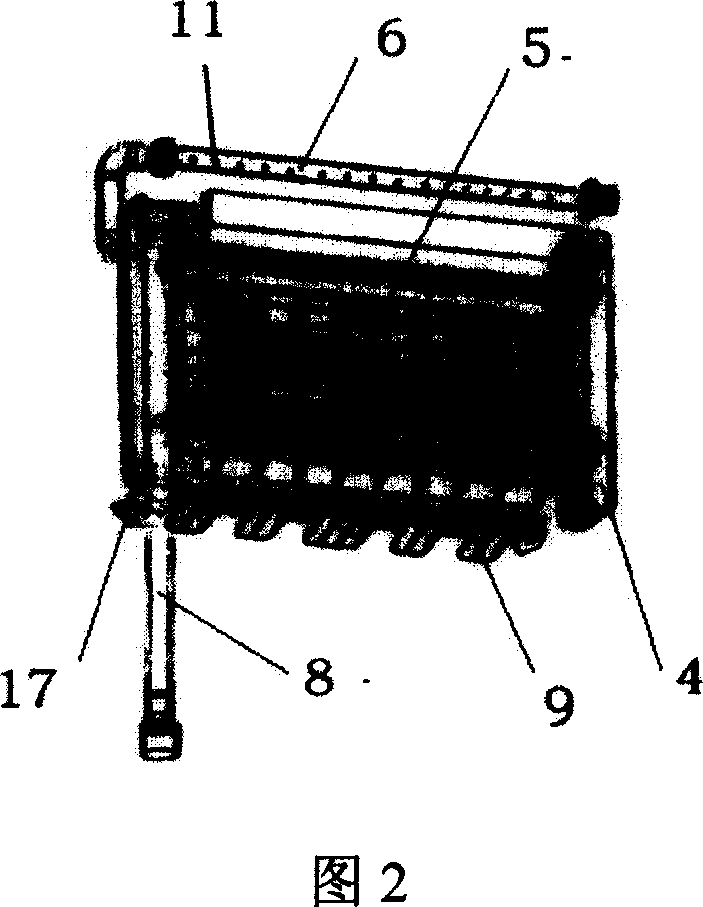

Domestic flowing small ice maker

InactiveCN101074811ANot easy to meltAccurate weightLighting and heating apparatusIce productionIce storageEngineering

This invention is a home mini ice machine, which is used to produce the squarely transparent ice. It includes the ice forming system and freezing system, which are all in the body of the machine. The talked ice system is made up by water box, ice storage box, ice model shelf, ice model, water spraying pipe, water pump, upper and lower water pipes and direction board for the ice. The ice model shelf is fixed on the upper of the water box, there is ice on the ice model shelf, and there is direction board for the ice under the ice model which can be turned over. The ice storage box is under the direction board for the ice and can be freely get and put, and the water pump fixed on the floor of the machine. The outline of the water case connects with the pump, through the inlet pipe the water pump connects with the water spray pipe, and there is many holes on the spray pipe which are toward to the surface of ice model. There is electromagnetic valve of water inlet on the rear of machine, the valve connects with the water inlet pipe which is on the top of water case. This ice from this invention can be squareness, with hole at the middle and solid, and the yield is high.

Owner:周武峰

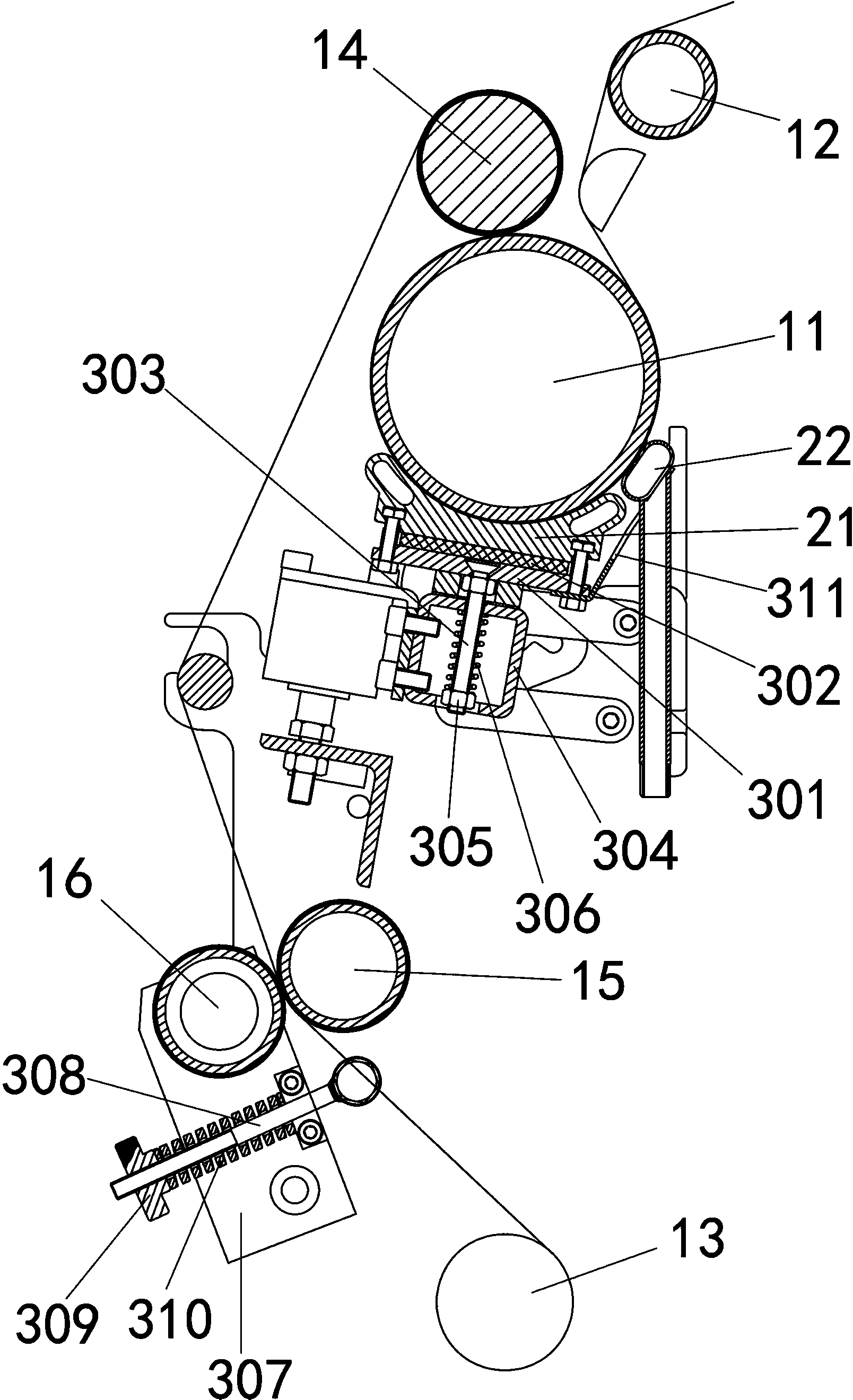

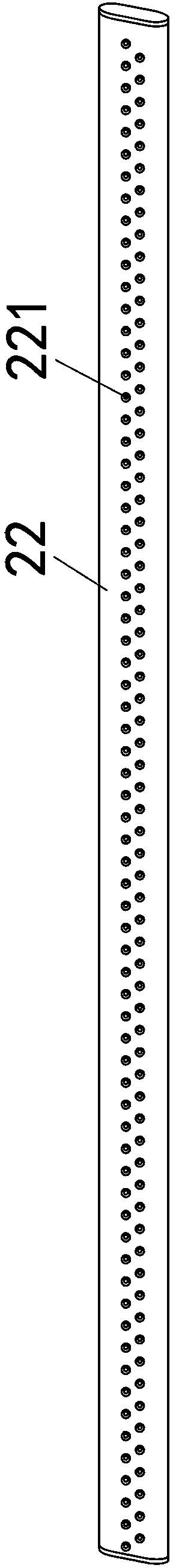

Fabric ironing mechanism

ActiveCN104294515AIncrease profitFlat surfaceTextile treatment by spraying/projectingTextile shapingNozzleEngineering

The invention relates to a fabric treating device, particularly to a fabric ironing mechanism. According to the technical scheme, the fabric ironing mechanism comprises a rubber roller, a collecting roller, a main roller, an arc-shaped ironing board which is positioned below the main roller and used for combining with the main roller for heating fabric, and a steam nozzle which is arranged on the side of the arc-shaped ironing board and is used for spraying steam to the fabric, wherein the steam nozzle and the arc-shaped ironing board are successively arranged in the moving direction of the fabric. The fabric treating device is simple in structure and is not easy to enable the fabric to fade.

Owner:HUZHOU HYUNDAI TEXTILE MACHINERY

Technique for producing sugar-coated haw food in large scale

The invention relates to a technique for producing food, in particular to a technique for producing sugar-coated haw food in large scale, comprising the steps: 1. taking 250 parts by weight of fruit,and cleaning; 2. denucleating or removing the peel; 3. soaking the fruit in sodium benzoate solution for 1-2min; 4. perforating the fruit in strings by bamboo sticks with 6-9 haws on each stick; 5. taking 1-2 parts by weight of rock candy, adding 1-2 parts by weight of water into the rock candy, and heating and decocting the mixture of the rock candy and the water; when syrup is boiling, adding 0.005-0.007 part by weight of sodium pyrosulfite and 0.015-0.03 part by weight of citric acid; after that, decocting for 1-5min; 6. coating the prepared syrup; 7. after being coated, laying the fruit ona bamboo board in a flat way, cooling and air drying; 8. packing by oblatum; 9. vacuum sealing and packing by polyethylene bags, refrigerating and storing. By adopting the technique, the quality guarantee period of the produced sugar-coated haw food is prolonged to 15-20 days, the produced sugar-coated haw food is not easily melted, easy to store and can be produced throughout the year.

Owner:张二军

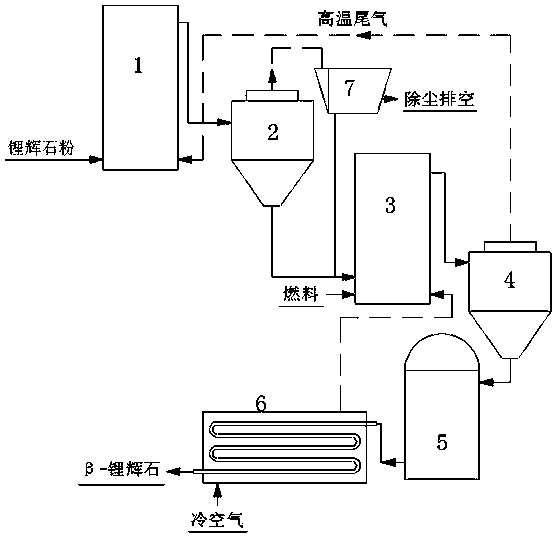

Crystal form transformation method for suspension roasting of natural spodumene

InactiveCN107739847AIncrease profitFast heat transferProcess efficiency improvementMetallurgyCyclonic spray scrubber

The invention provides a crystal form transformation method for suspension roasting of natural spodumene. The crystal form transformation method comprises the following steps: after grinding natural alpha-spodumene to a certain grain size, throwing in a secondary suspension roasting furnace for fluidized drying and preheating, and then after conducting gas-solid separation by a secondary cyclone dust collector and a dust separator in sequence on the preheated spodumene powder, throwing in a primary suspension roasting furnace for suspension roasting at high-temperature gas, so as to enable thespodumene powder to conduct primary crystal form transformation; and after separation by a primary cyclone dust separator, placing high-temperature mineral powder in a heat insulation tank to complete the crystal form transformation, and finally transferring in a cooler for cooling to obtain beta-spodumene. A suspension roasting bed is adopted for roasting, and the crystal form transformation method has the advantages that equipment is simple, equipment investment is small, energy consumption is low, treatment capacity is high, the crystal form transformation temperature is easily controlled,and the crystal form transformation is more complete.

Owner:FUZHOU UNIV

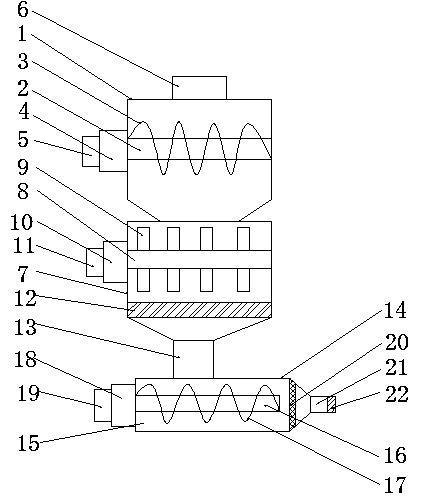

Extrusion injection device for plastic production

The invention discloses an extrusion injection device for plastic production. The extrusion injection device comprises a smashing box, smashing rollers are arranged in the smashing box, smashing blades are arranged on the smashing rollers, the lower end of the smashing box is provided with a fusion box, a rotary shaft is arranged in the fusion box, a rotary rod is fixed on the the rotary shaft, aseparation plate is arranged in the fusion box, the separation plate is provided with a plurality of through holes, a plurality of first heating pipes are arranged in the separation plate, a pluralityof second heating pipes are arranged in the side wall of the fusion box, the lower end of the fusion box is provided with a pipeline, the lower end of the pipeline is provided with an extrusion container, the extrusion container is provided with an extrusion cavity, the extrusion cavity is provided with a screw, the screw is provided with a screw panel, the right end of the extrusion is providedwith a filtration device, the right end of the extrusion container is provided with an injection molding pipe, the right end of the injection molding pipe, the side wall of the extrusion container isinternally provided with a first electromagnetic heating ring, the side wall of the injection molding pipe is internally provided with a second electromagnetic heating ring. The extrusion injection device provided by the invention not only has good fusion effect, but also improves the quality of the product.

Owner:杨炎重

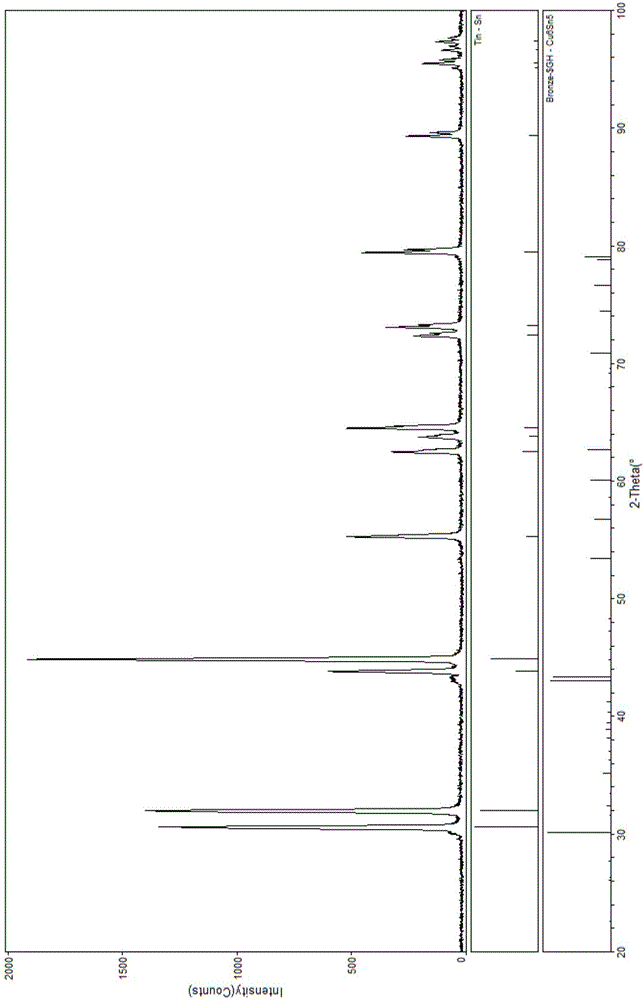

Preparation method of Sn-Cu-Al series lead-free solder

ActiveCN106498197AIncreased microhardnessDoes not play the role of microalloyingWelding/cutting media/materialsSoldering mediaAluminum canIngot

The invention provides a preparation method of Sn-Cu-Al series lead-free solder. The preparation method comprises the following steps of weighing the following components in percentages by weight: tin powder, copper powder and aluminum powder raw materials; evenly mixing the powder by using a planetary ball mill; then pressing the powder into metal blocks; and finally, carrying out smelting by using a nonconsumable vacuum arc furnace, and carrying out cooling to obtain alloy ingots. The lead-free solder can replace traditional solder and are low in price, and meanwhile, the technical problem that aluminum cannot be melted in tin alloy easily is solved. The aluminum serves as a micro-alloyed element, a reinforced phase is formed, the aluminum is uniformly distributed in a tin-copper matrix, and therefore, the microhardness of the matrix is improved effectively.

Owner:GUANGXI UNIV

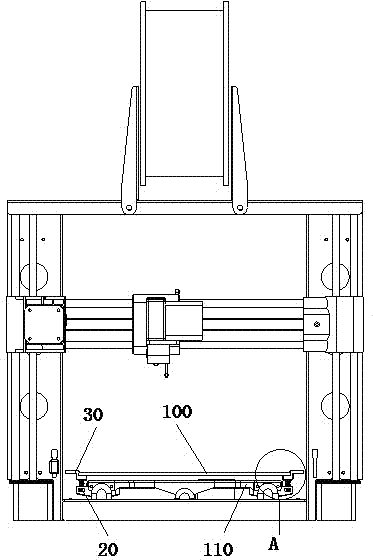

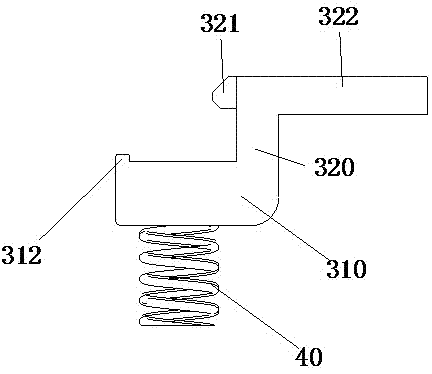

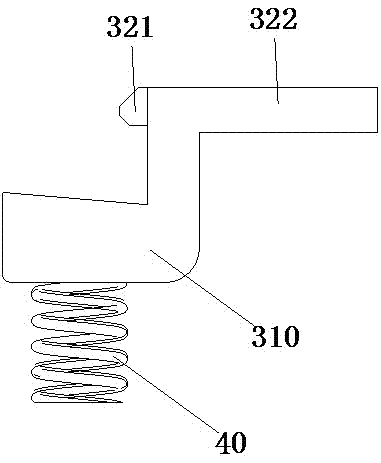

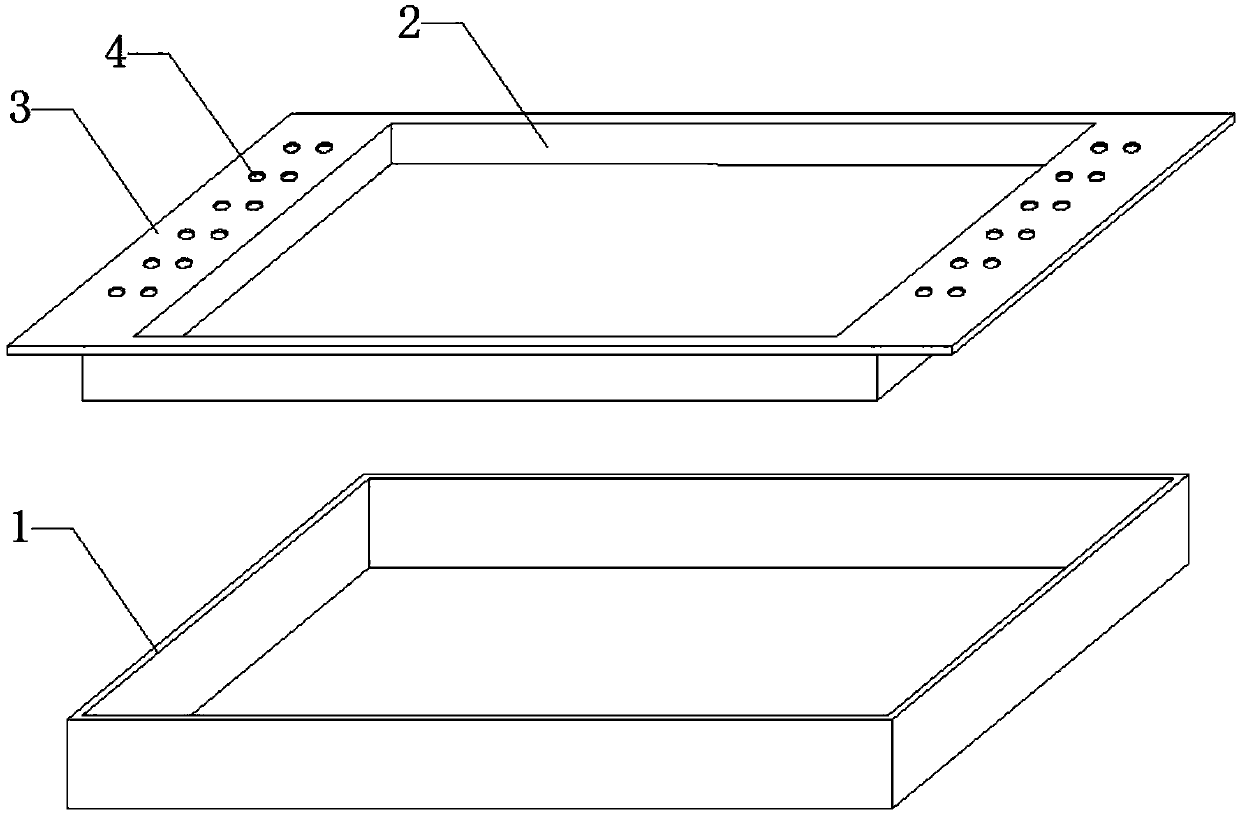

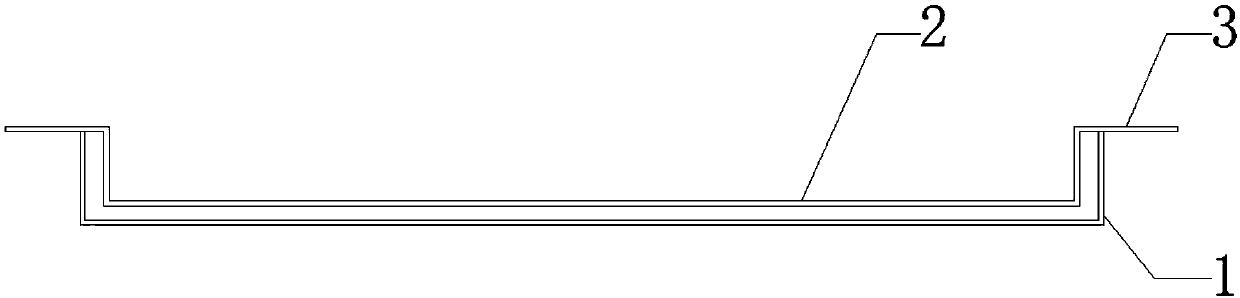

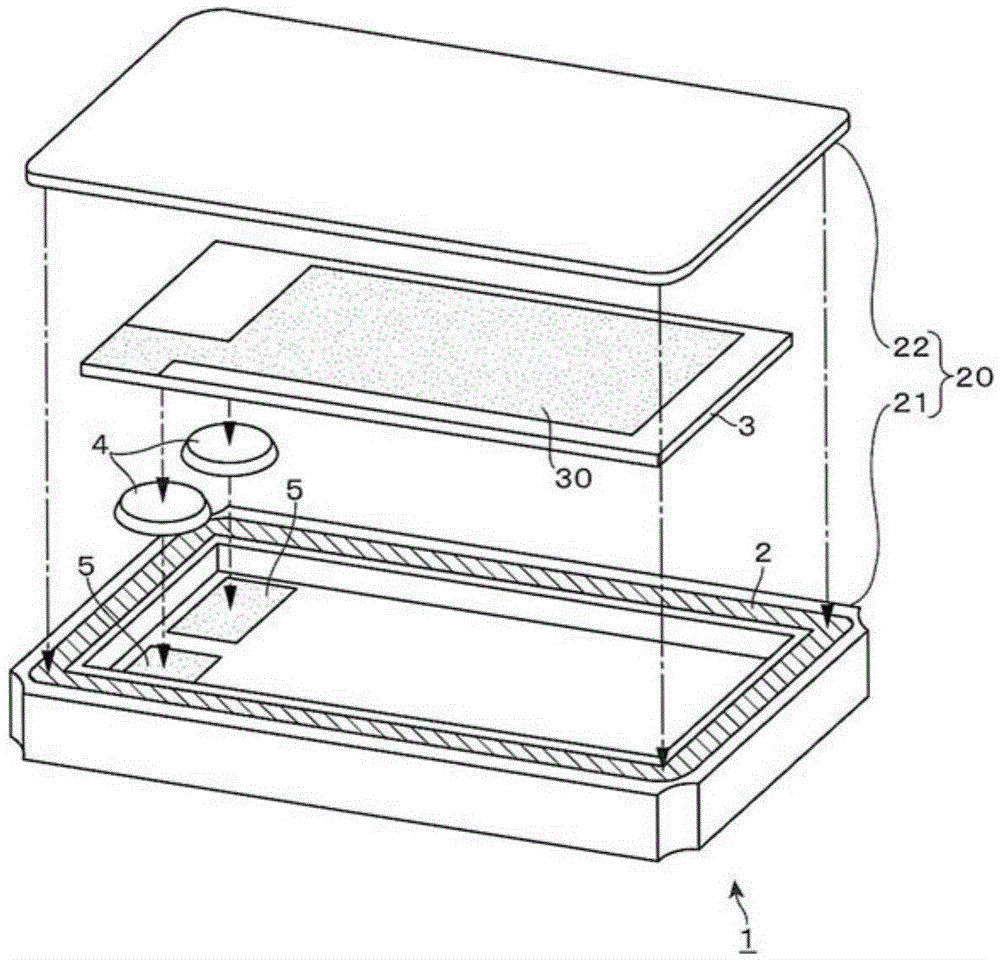

3D printer printing platform

InactiveCN104842558AEasy to disassembleOvercoming the impact on molding qualityAdditive manufacturing apparatusComputer printing3d printer

Owner:FUZHOU ZHANXU ELECTRONICS

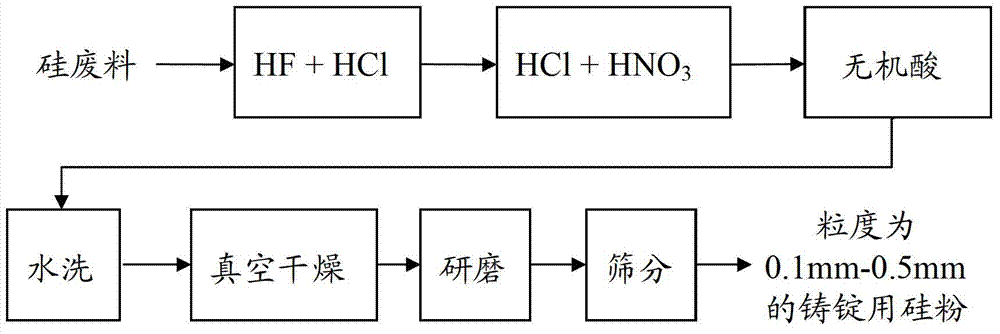

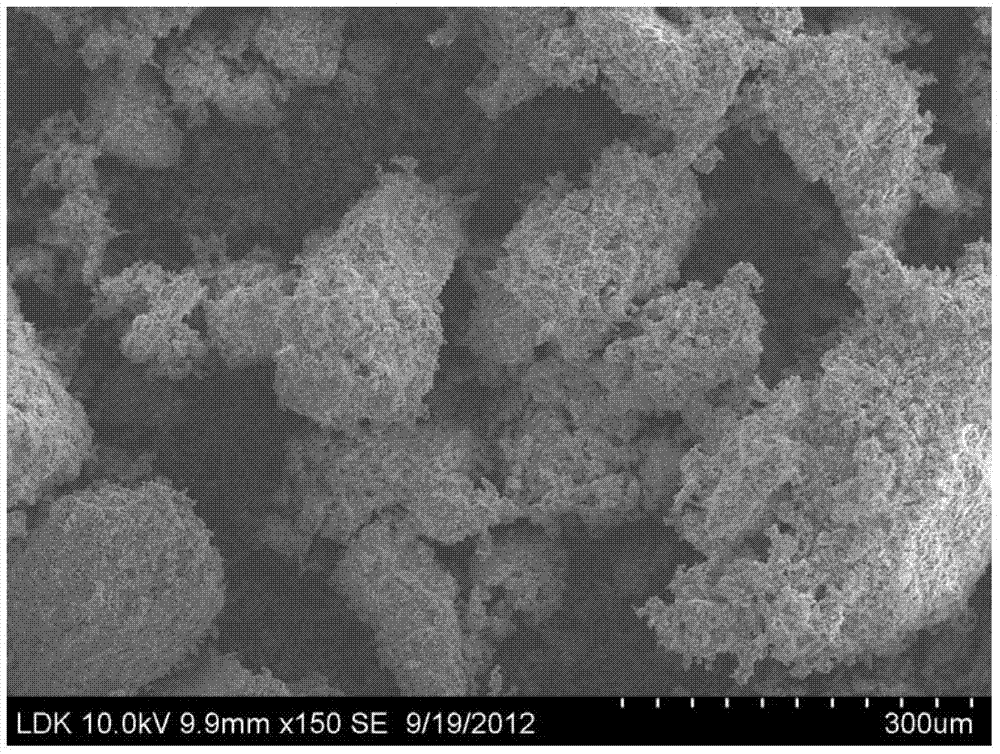

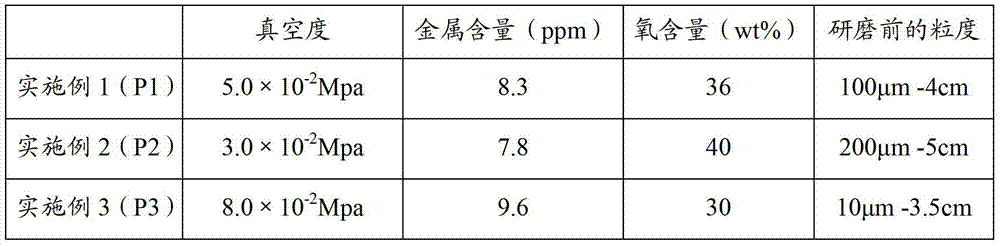

Ingot-casting silicon powder with controllable grain size as well as preparation method and application thereof

ActiveCN103395788AGranularity controllableModerate reunionSilicon compoundsHydrofluoric acidIngot casting

The invention provides a preparation method of ingot-casting silicon powder with controllable grain size. The preparation method comprises the following steps of: pickling silicon waste by using hydrofluoric acid and hydrochloric acid; pickling by using hydrochloric acid and nitric acid; pickling by using inorganic acid; carrying out solid-liquid separation and washing until the pH value is neutral, so as to obtain primary silicon powder; placing the primary silicon powder in a dryer with the temperature of 30-120 DEG C, setting the vacuum degree of the dryer as3.0*10<-2>-8.0*10<-2>MPa, and drying for 2-24 hours, so as to obtain the silicon powder with the grain size of 10 microns to 5 centimeters; grinding the obtained silicon powder, and screening by using a non-metal screen, so as to obtain the ingot-casting silicon powder with the grain size of 0.1-0.5mm. The preparation method can be used for solving a problem that the silicon powder is easy to melt during an ingot-casting process due to the low surface oxidization degree or extremely low grain size of the silicon powder. The invention further provides ingot-casting silicon powder with controllable grain size and application of the ingot-casting silicon powder in the field of solar poly-crystal silicon ingot preparation.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

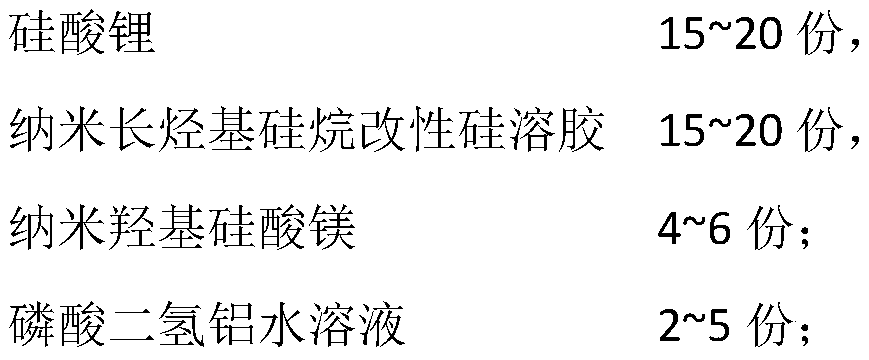

External wall fireproof reflective heat-insulation inorganic coating material and preparation method thereof

InactiveCN111019416AImprove heat resistanceImproved reflective insulation performanceFireproof paintsAntifouling/underwater paintsSilicic acidPhosphate

The invention relates to an external wall fireproof reflective heat-insulation inorganic coating material, which comprises a base material, a filler, an auxiliary agent and water, wherein the base material comprises, by weight, 15-20 parts of lithium silicate, 15-20 parts of nano long hydrocarbonyl silane modified silica sol, 4-6 parts of nano hydroxyl magnesium silicate and 2-5 parts of an aluminum dihydrogen phosphate aqueous solution, and the filler is prepared from the following components in parts by weight: 20 to 25 parts of IR-1000 near-infrared reflective titanium dioxide, 10 to 15 parts of wollastonite powder, 10 to 15 parts of talcum powder and 1 to 5 parts of nano titanium dioxide. The invention also discloses a preparation method of the external wall fireproof reflective heat-insulation inorganic coating material. The coating material has the advantages of being free of VOC, not prone to combustion, good in high temperature resistance, capable of achieving reflective heat-insulation, not prone to corrosion and resistant to mould.

Owner:NIPPONPAINT SICHUAN CO LTD

Coated gelatinized candy and preparation method thereof

The invention discloses coated gelatinized candy and a preparation method thereof. The coated gelatinized candy comprises two part structures including a coating and a confection core, and overcomes the defects that the existing gelatinized candy can generate water, can be melted and adhered and permeate sugar easily. By the catalytic action of transglutaminase, low-melting-point micromolecule proteins in gelatin in the coating material of the gelatinized confection are crosslinked into high-melting-point macromolecule proteins, so that the melting point of the coating layer of the gelatinized candy is improved greatly; meanwhile, the toughness is improved relatively; the product is not affected by the external environment, cannot generate water, be melted, bonded and permeate sugar easily, is soft in mouthfeel, and is high in resilience. The preparation method is efficient and convenient, and has extremely good production effectiveness.

Owner:HANSHAN NORMAL UNIV +1

Formula of pigskin jelly sausage and processing method thereof

The invention provides a formula of pigskin jelly sausage and a processing method thereof, and relates to the processing field of foodstuff. The formula comprises the following components in parts byweight: 30-35 parts of pigskin, 5-7 parts of edible gelatin, 8-12 parts of konjac gum, 4-6 parts of rice starch, 6-8 parts of soybean protein, 2-5 parts of potato starch, 2-3 parts of spice, casing, salt water, and a sodium bicarbonate solution. The invention provides the formula of pigskin jelly sausage and the processing method thereof, the product is not easy to melt, and filling and moulding are stable; after the sausage is cut, the sausage can be preserved at a higher temperature, grease in the pigskin jelly sausage is removed, and the product is rich in collagen and a plurality of nutrient elements; the product has refreshing taste, and more tender mouthfeel.

Owner:CHAOHU MEADVILLE FOOD CO LTD

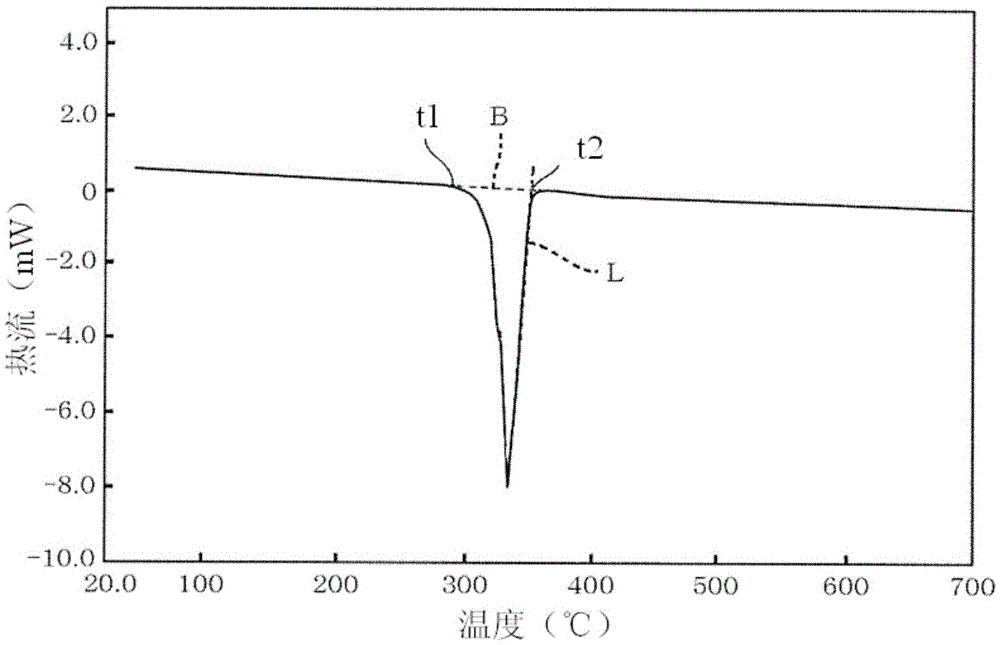

Solder material and electronic component

InactiveCN105834610AReduce the temperatureNot easy to meltImpedence networksWelding/cutting media/materialsTemperature differenceElectronic component

The invention provides a solder material and electronic component. The solder material includes an alloy of at least five elements including Sn, Cu, Sb, and In, and 20 mass % or less of Ag. The solidus temperature of the solder material is higher than 290 DEG C, the liquidus temperature of the solder material is 379 DEG C or less and is higher than the solidus temperature, and the temperature difference between the liquidus temperature and the solidus temperature is 70 DEG C or less. The melting temperature of solder material is reduced therefore. In the temperature range when the solder material is installed on a substrate and refluxed, the solder material is difficult to melt. The phenomenon that the solder material is not melted sufficiently, or the solder material is melted when parts are installed on the substrate is avoided.

Owner:NIHON DEMPA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com