Patents

Literature

45results about How to "Easy to heat and melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

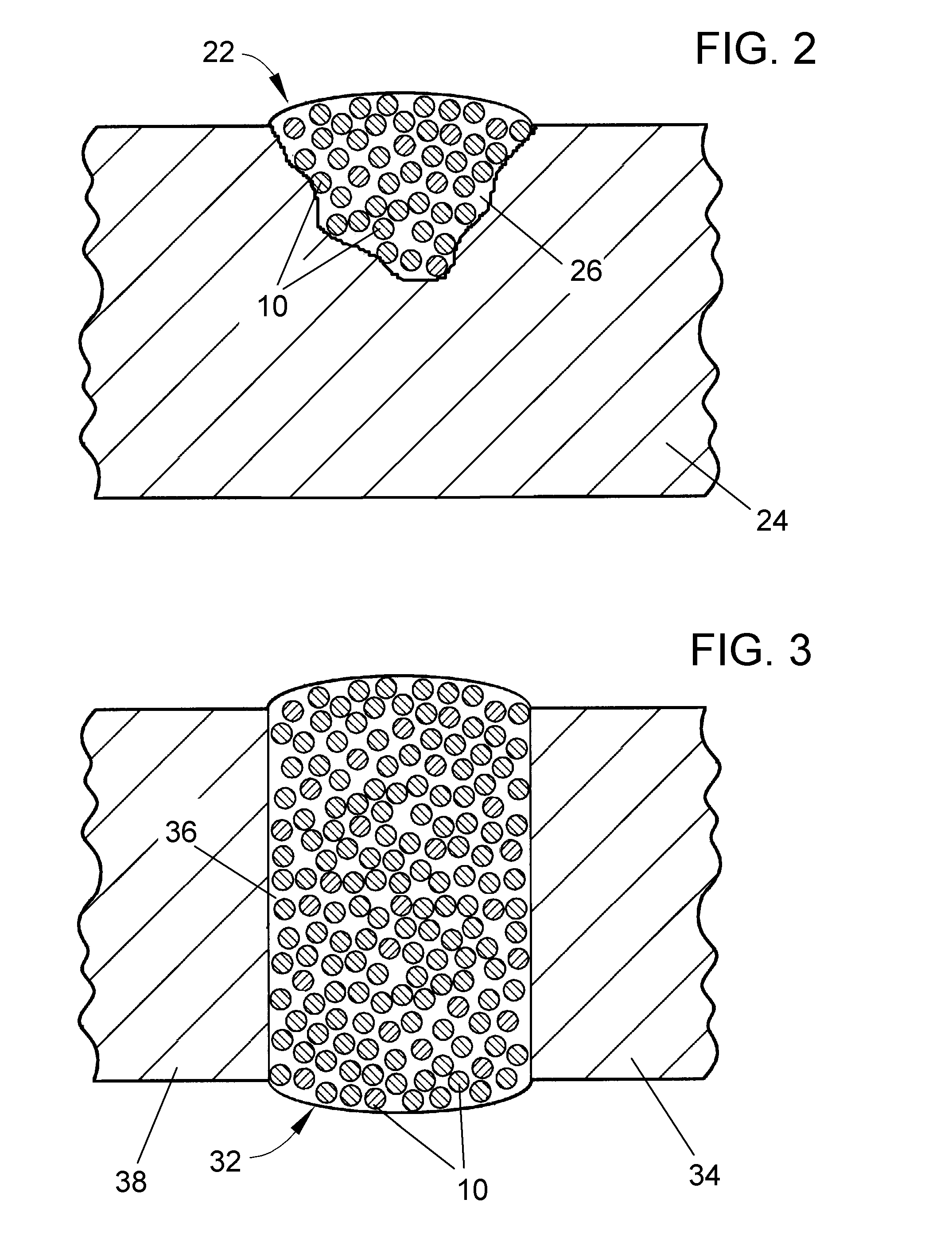

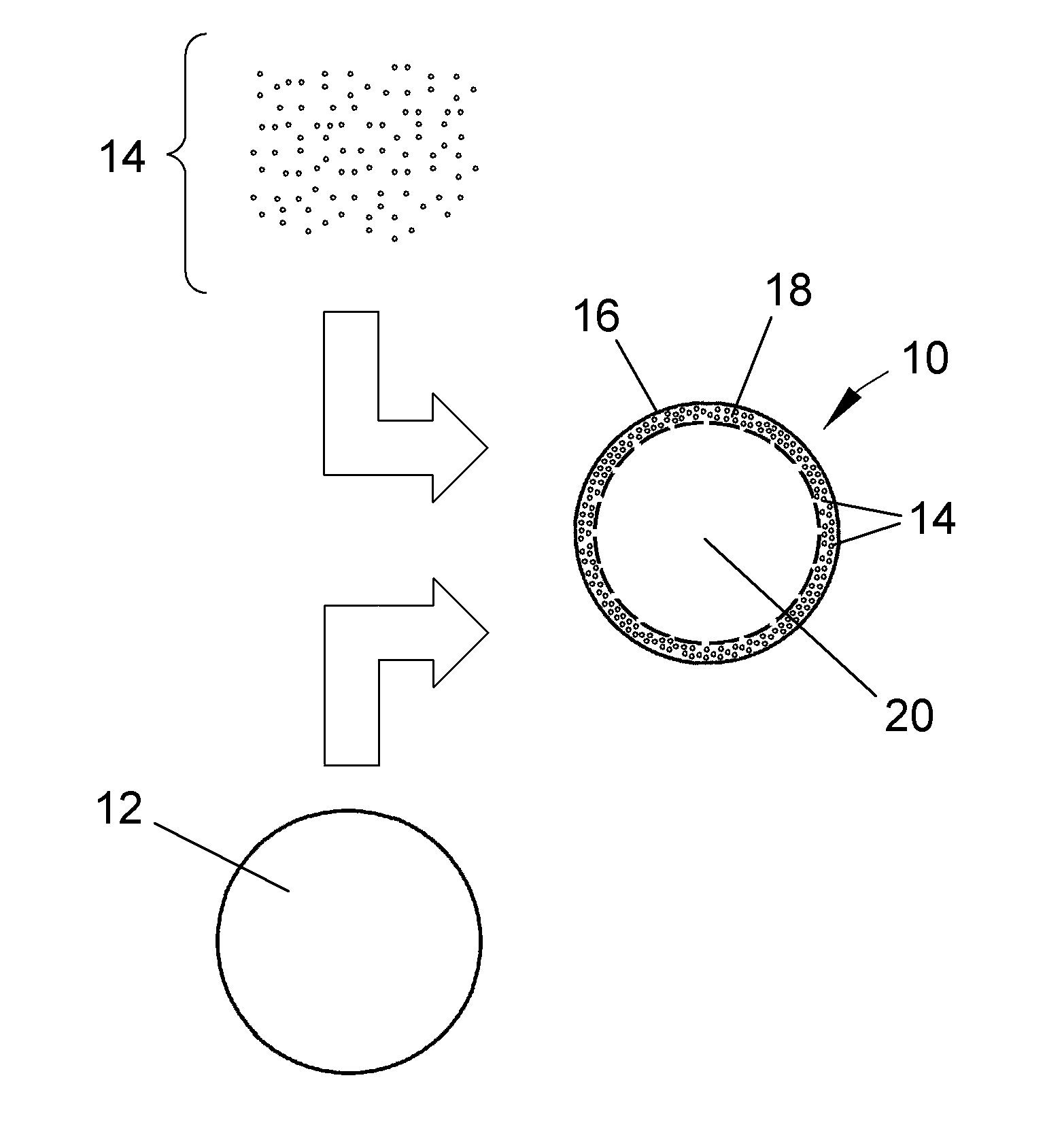

Braze materials and processes therefor

ActiveUS20090014505A1Improve the heating effectPromote meltingWelding/cutting media/materialsThin material handlingMetallic materialsCarbide

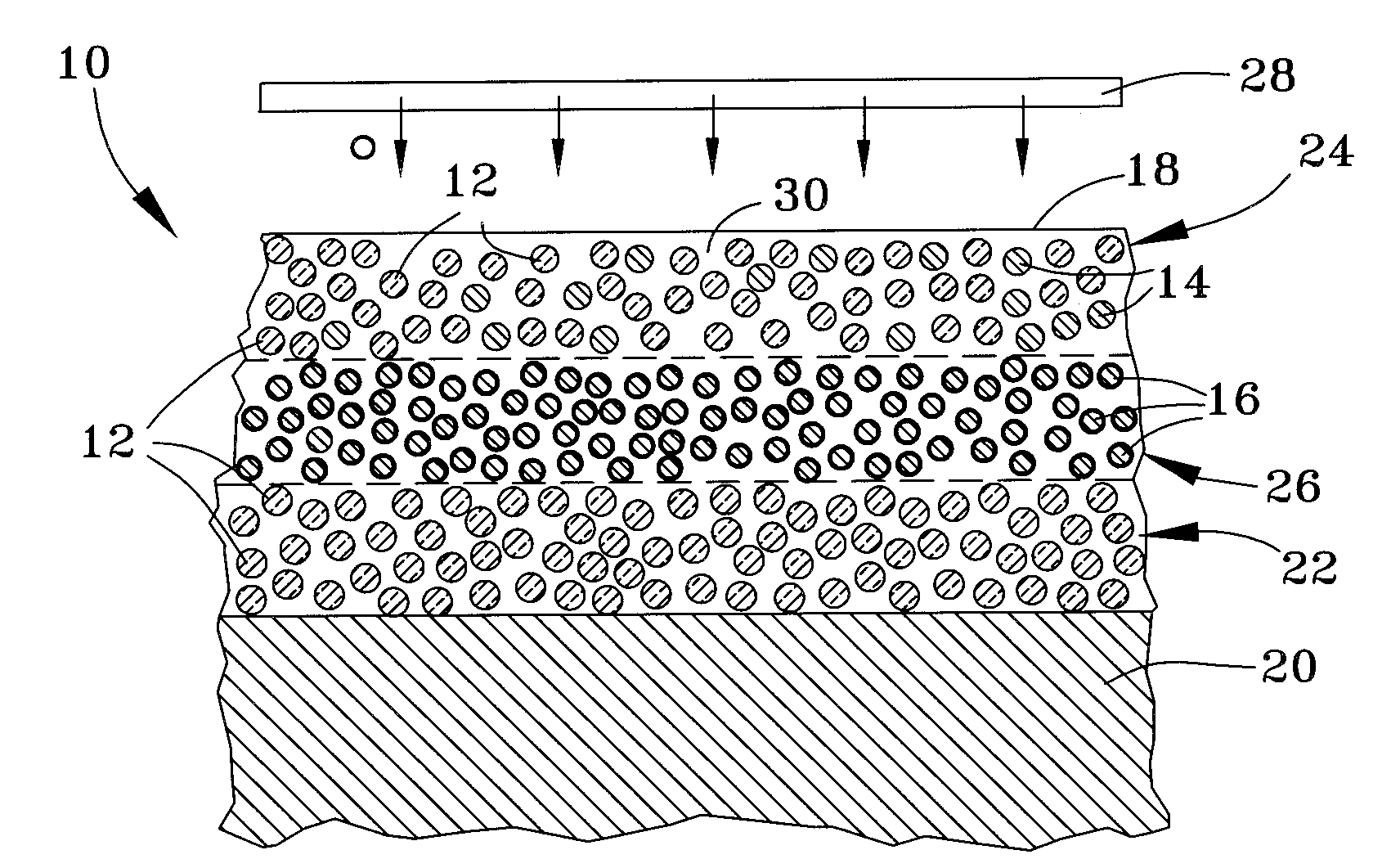

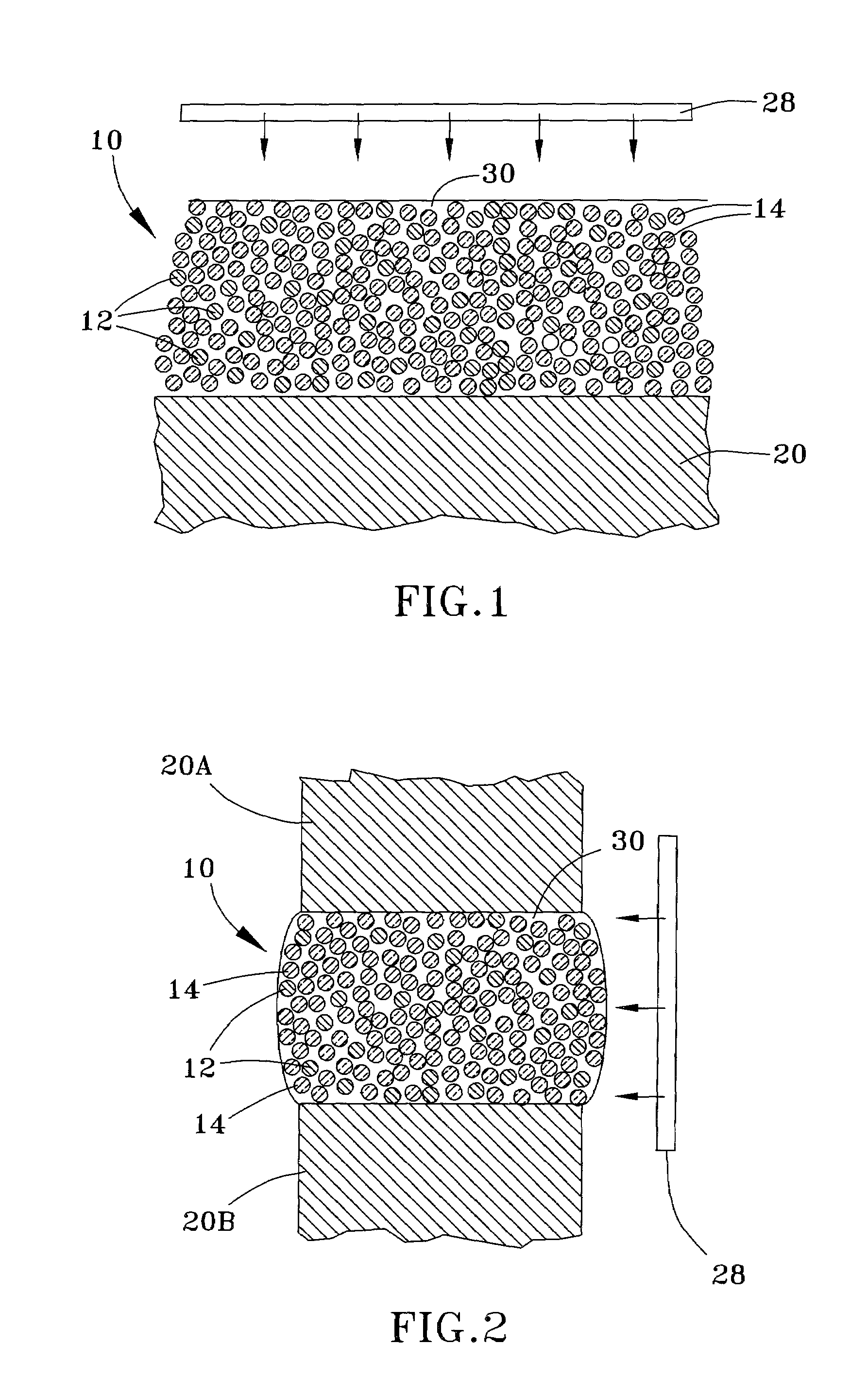

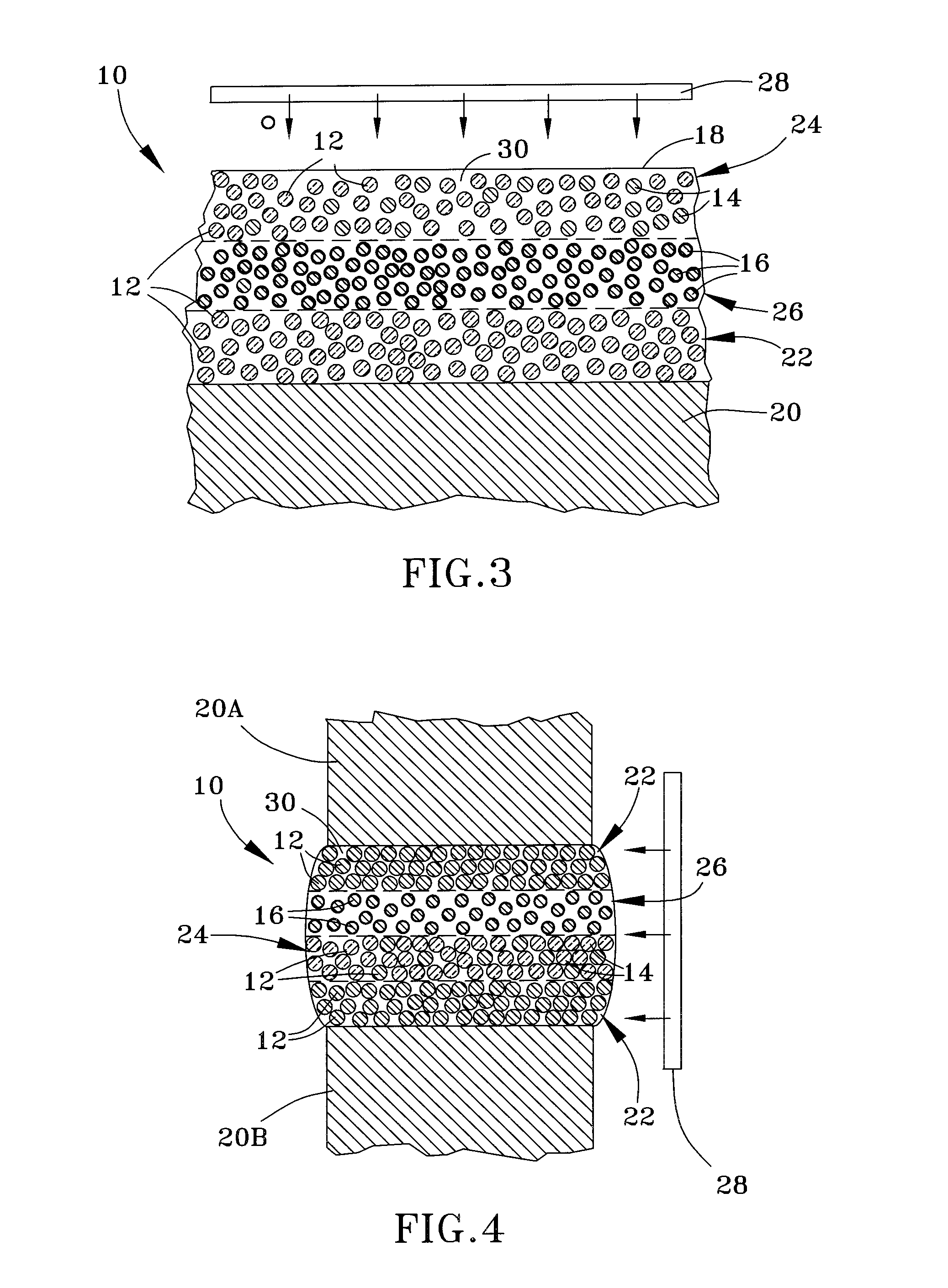

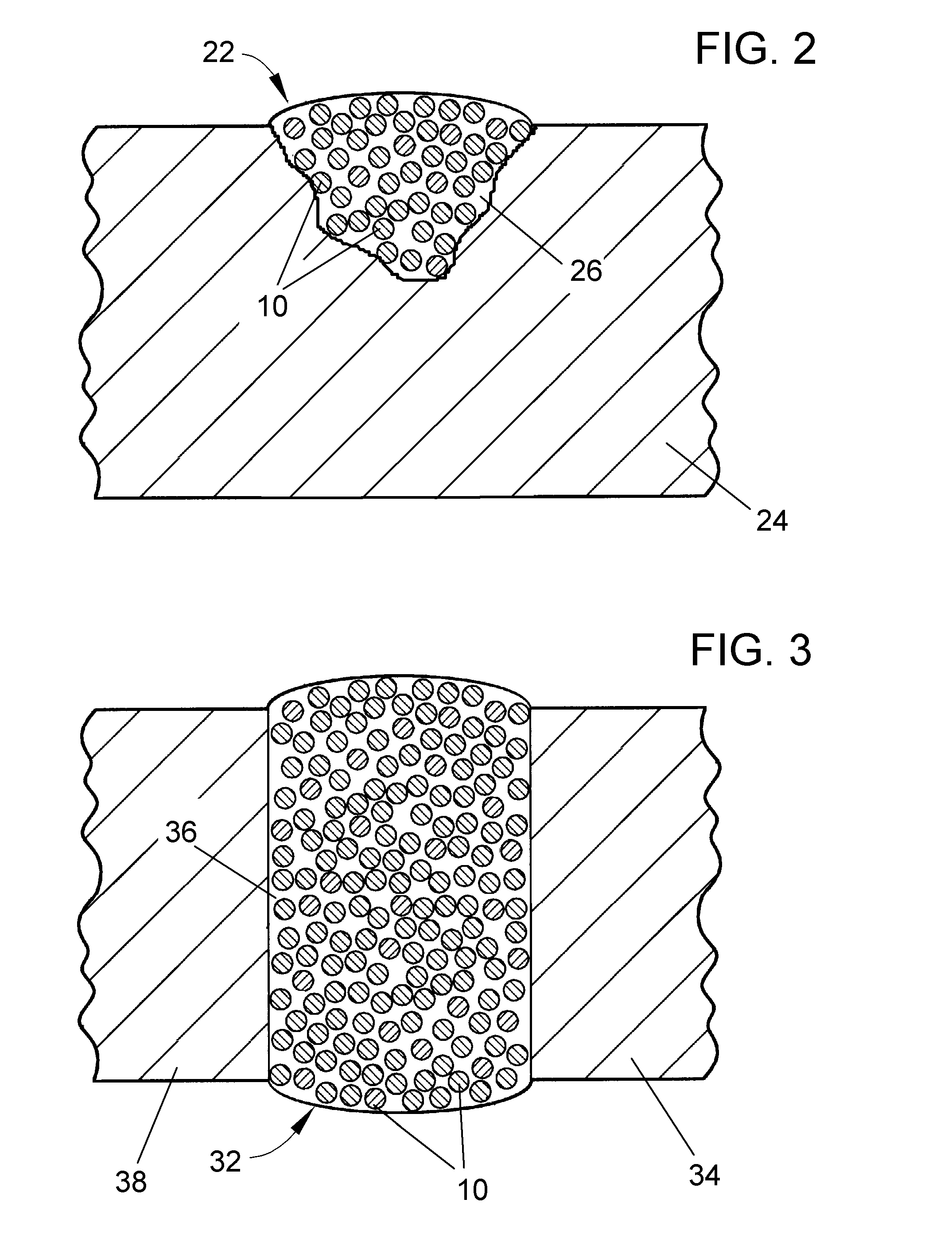

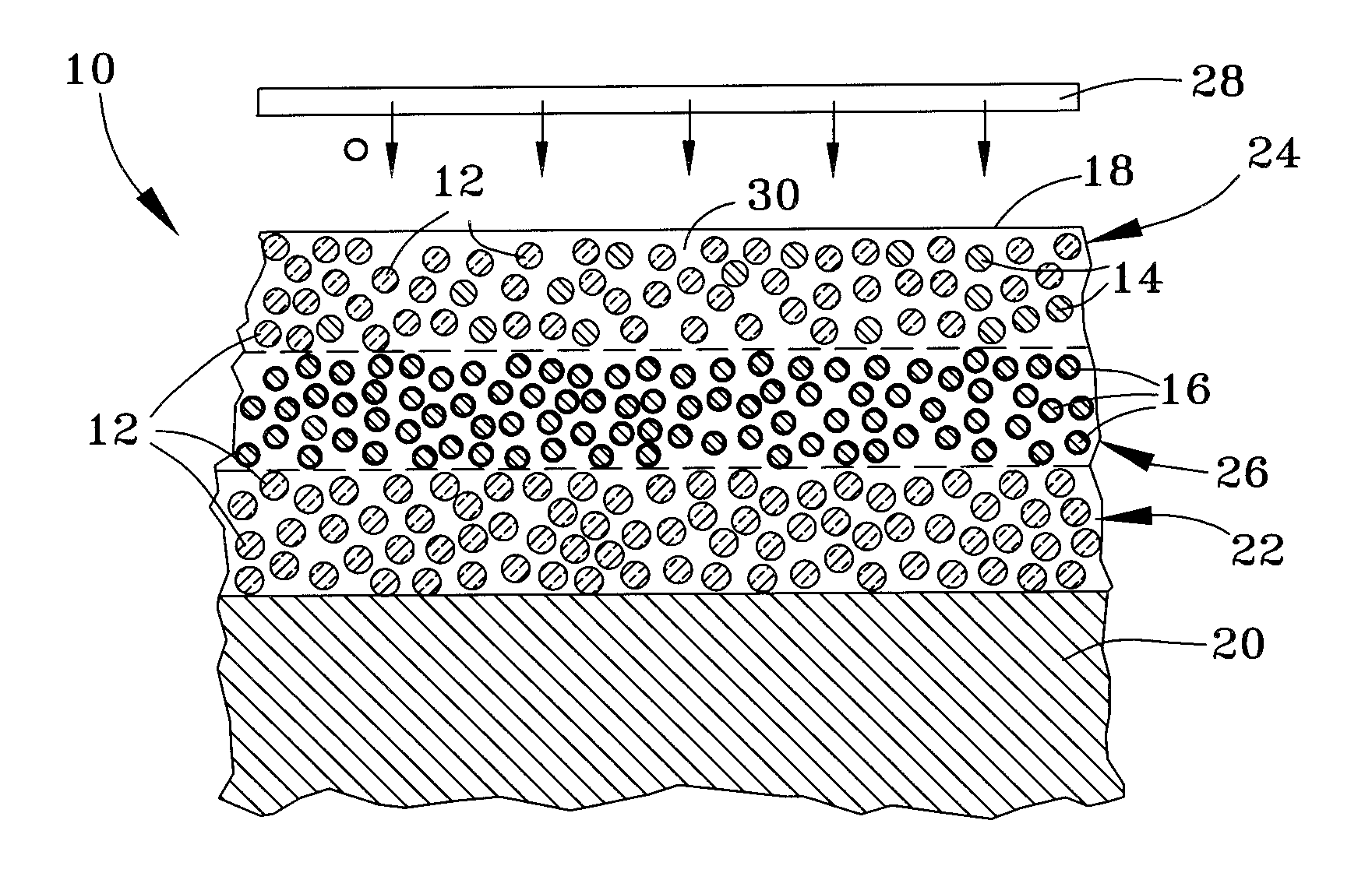

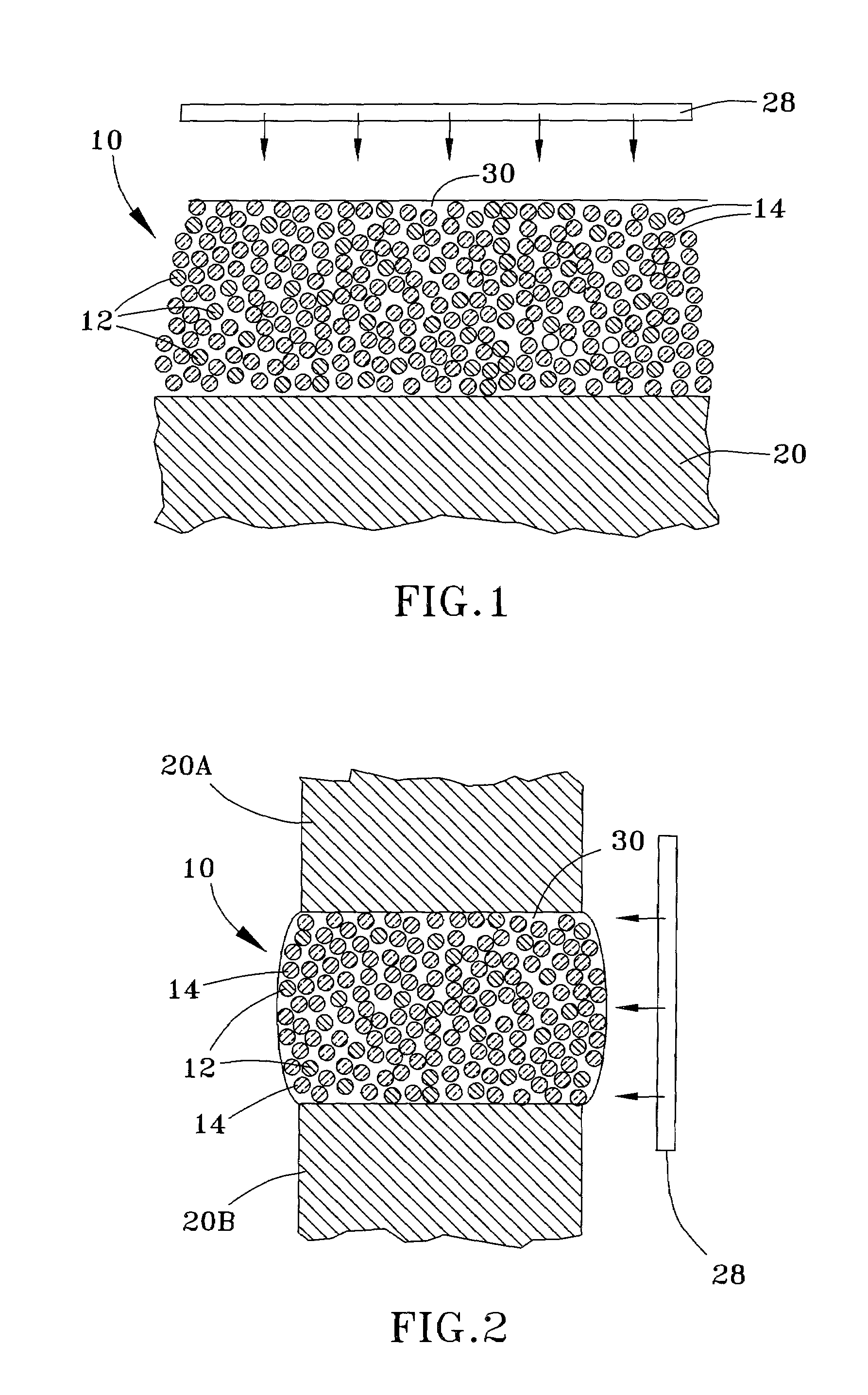

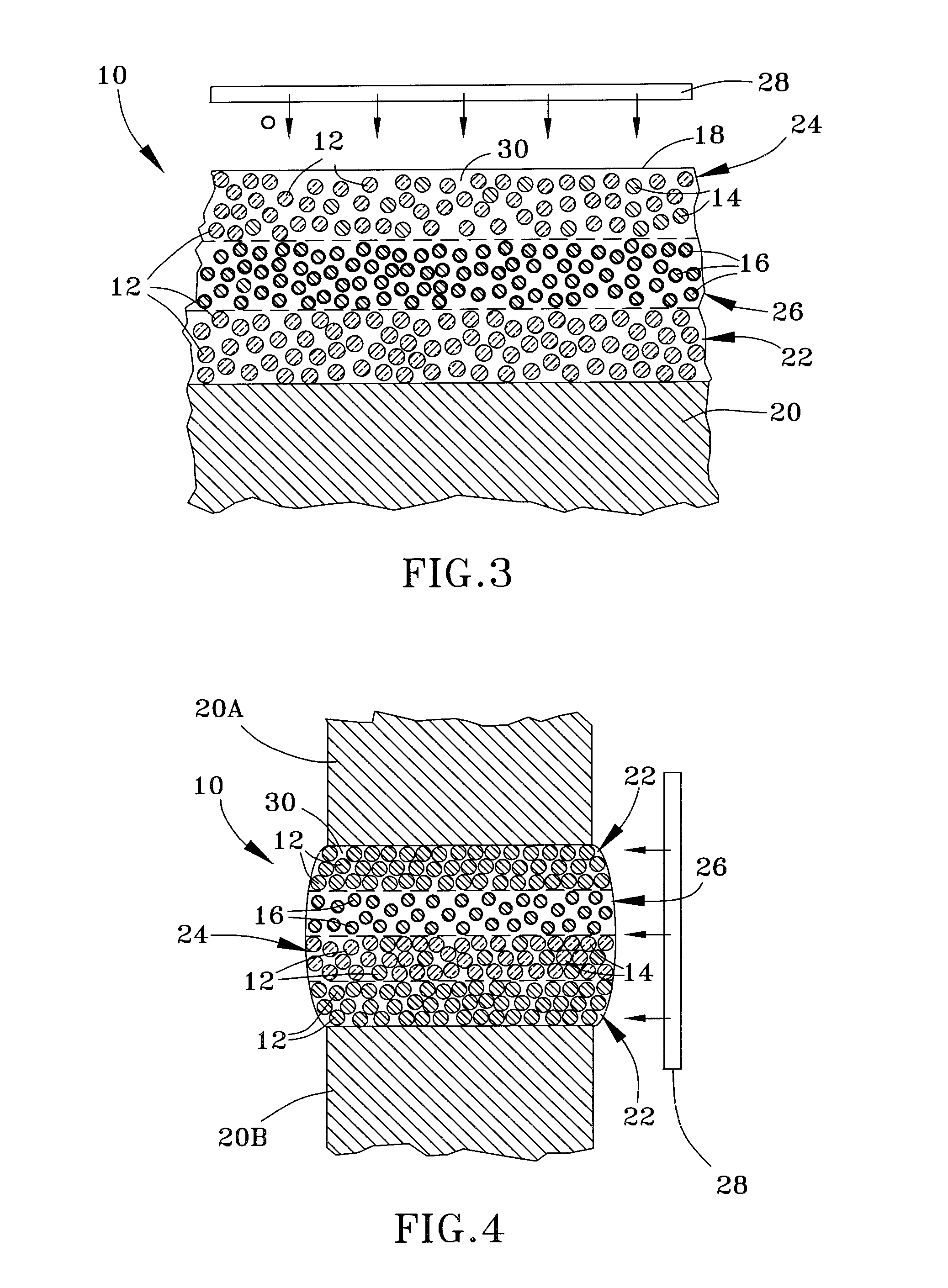

Braze materials and processes for using braze materials, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze material contains a plurality of first particles of a metallic material having a melting point, and a plurality of second particles comprising at least one nonmetallic material chosen from the group consisting of oxides, carbides, and nitrides of at least one metal. The nonmetallic material is more susceptible to heating by microwave radiation than the metallic material of the first particles, and the nonmetallic material is present in the braze material in an amount sufficient to enable the first particles to completely melt when the first and second particles are subjected to heating by microwave radiation.

Owner:GENERAL ELECTRIC CO

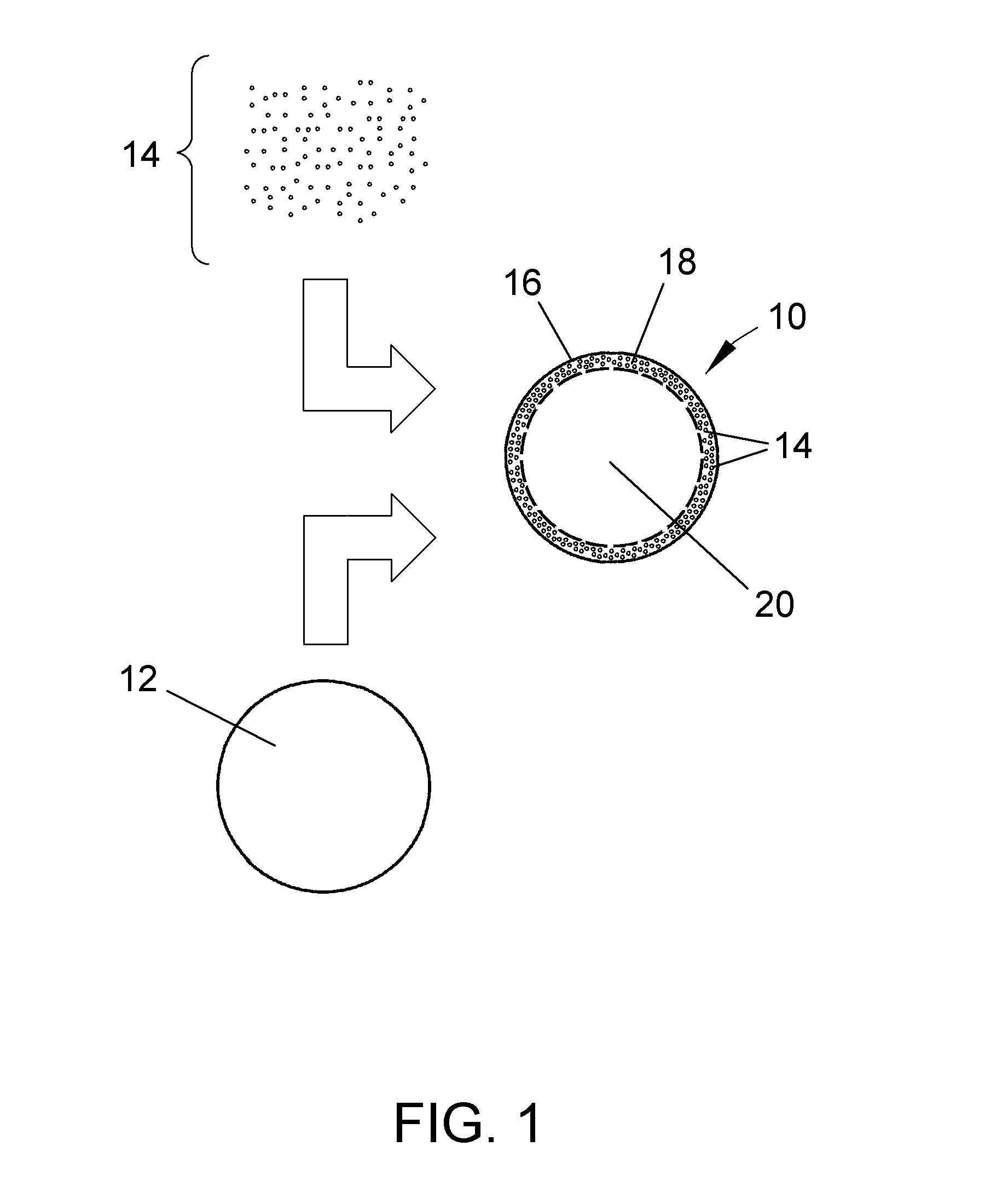

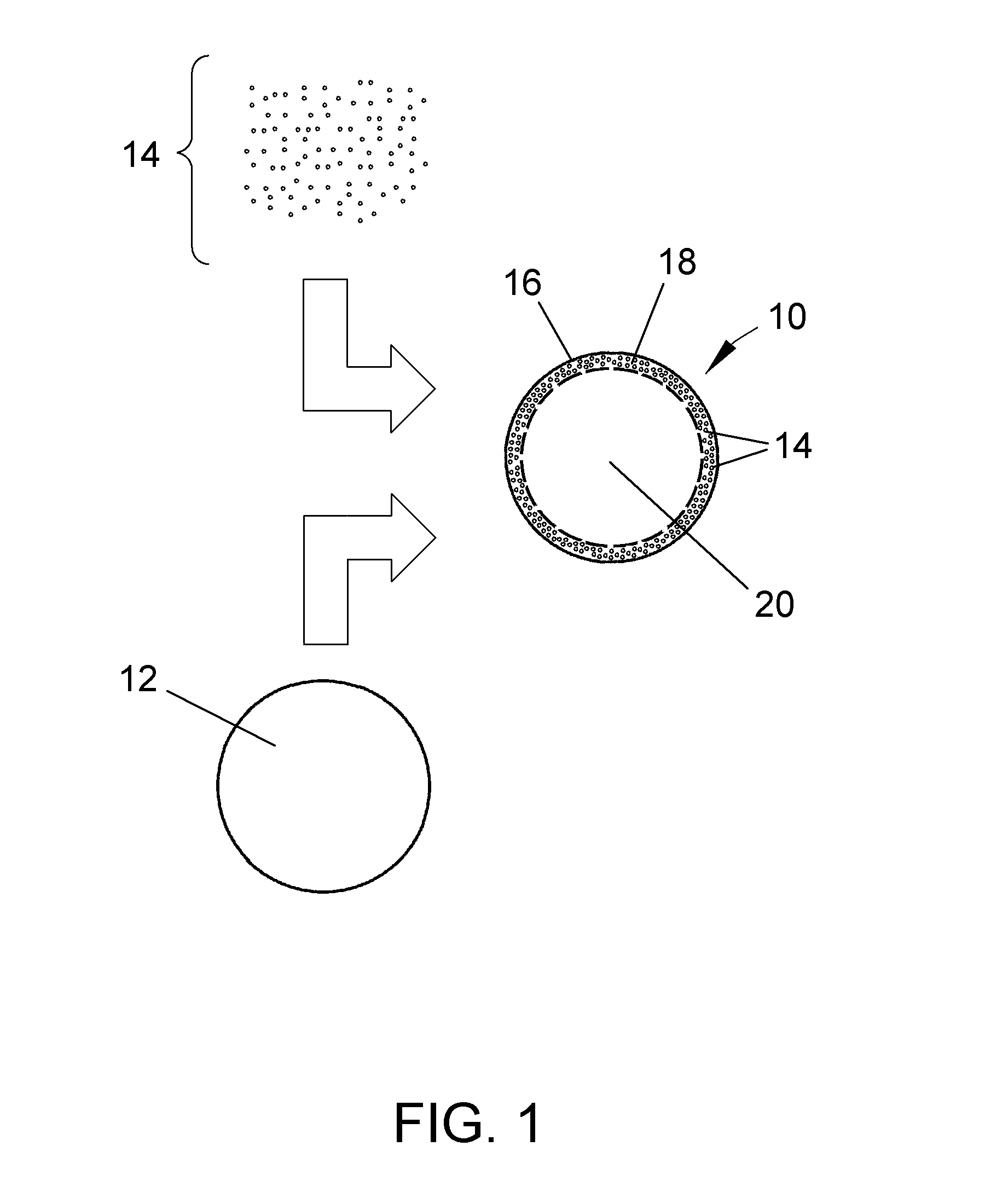

Braze material and processes for making and using

ActiveUS20080142575A1Improve mechanical propertiesImprove the heating effectWelding/cutting media/materialsThin material handlingParticulatesSuperalloy

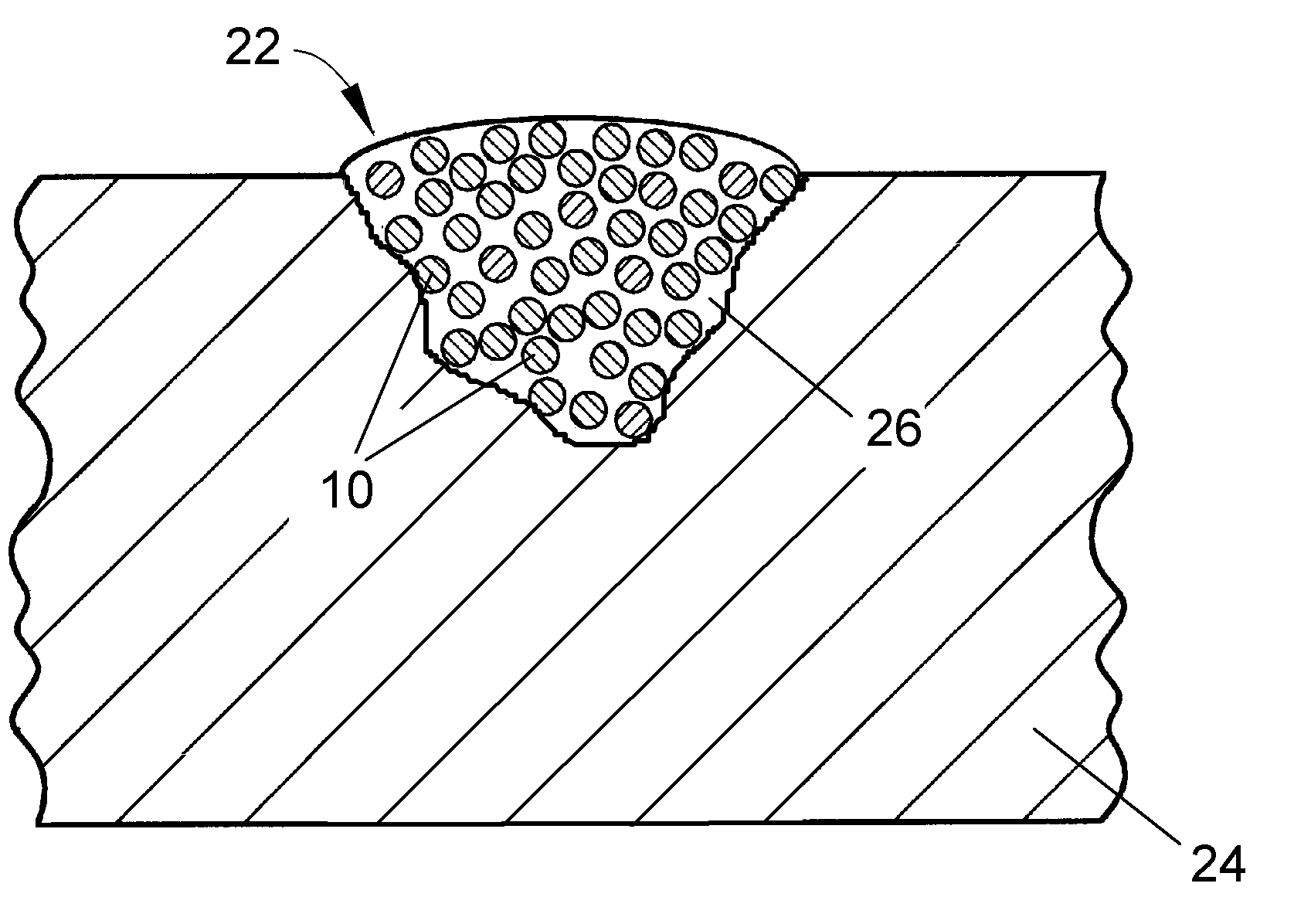

A braze material and processes for making and using the material, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze material is composed of particles with melt-modifying constituents that are limited to the surfaces of the particles, yet are capable of sufficiently promoting the heating of the particles by conventional means and microwave radiation to achieve at least partial melting of the particles. The melt-modifying constituents are in the form of particulates embedded in the outer surface region of each particle. The particulates are formed of melting point depressant(s) and / or microwave coupling enhancer(s), are much smaller than the particle in which they are embedded.

Owner:GENERAL ELECTRIC CO

Braze material and processes for making and using

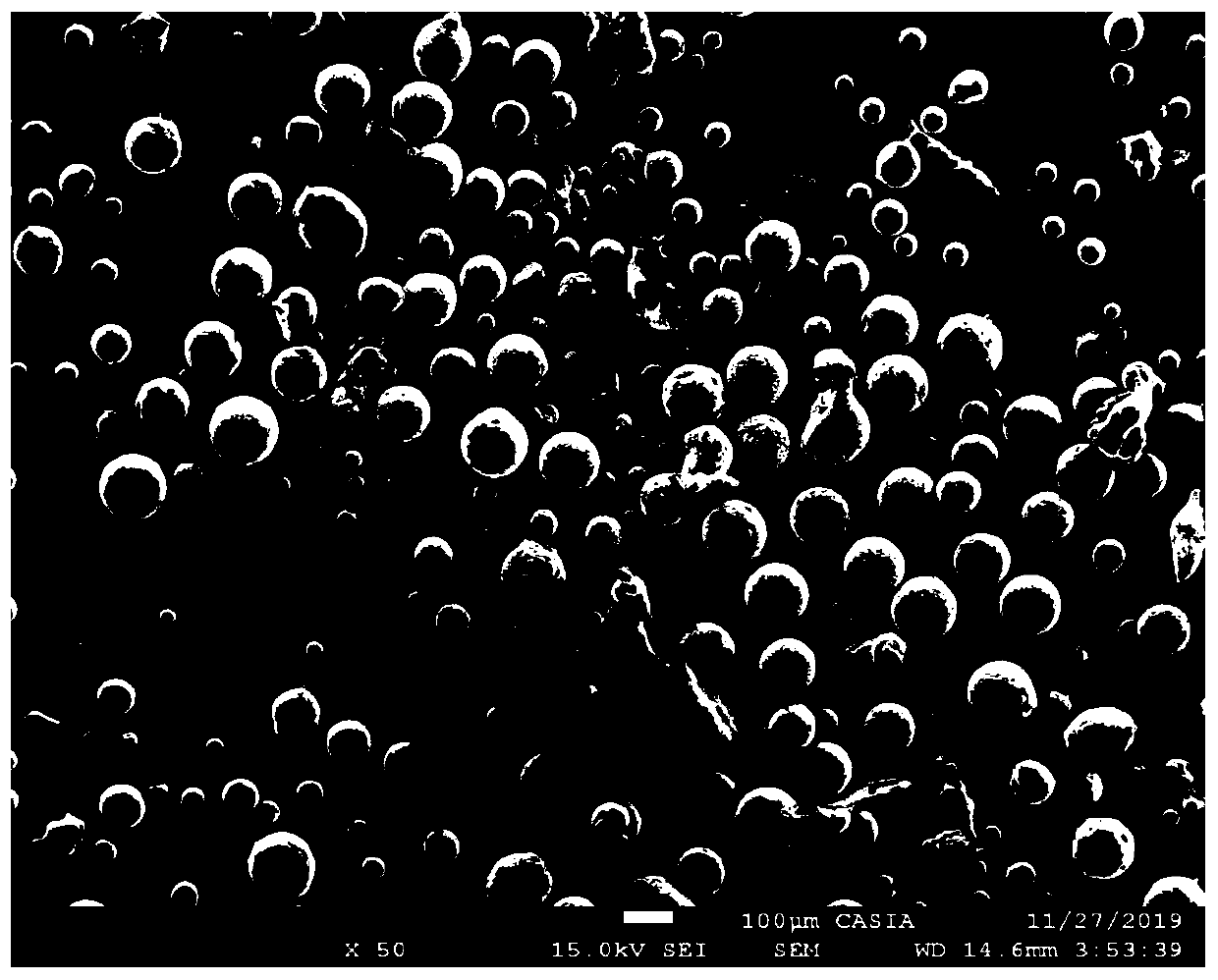

ActiveUS7946467B2Improve mechanical propertiesEasy to heat and meltWelding/cutting media/materialsThin material handlingParticulatesMicrowave

A braze material and processes for making and using the material, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze material is composed of particles with melt-modifying constituents that are limited to the surfaces of the particles, yet are capable of sufficiently promoting the heating of the particles by conventional means and microwave radiation to achieve at least partial melting of the particles. The melt-modifying constituents are in the form of particulates embedded in the outer surface region of each particle. The particulates are formed of melting point depressant(s) and / or microwave coupling enhancer(s), are much smaller than the particle in which they are embedded.

Owner:GENERAL ELECTRIC CO

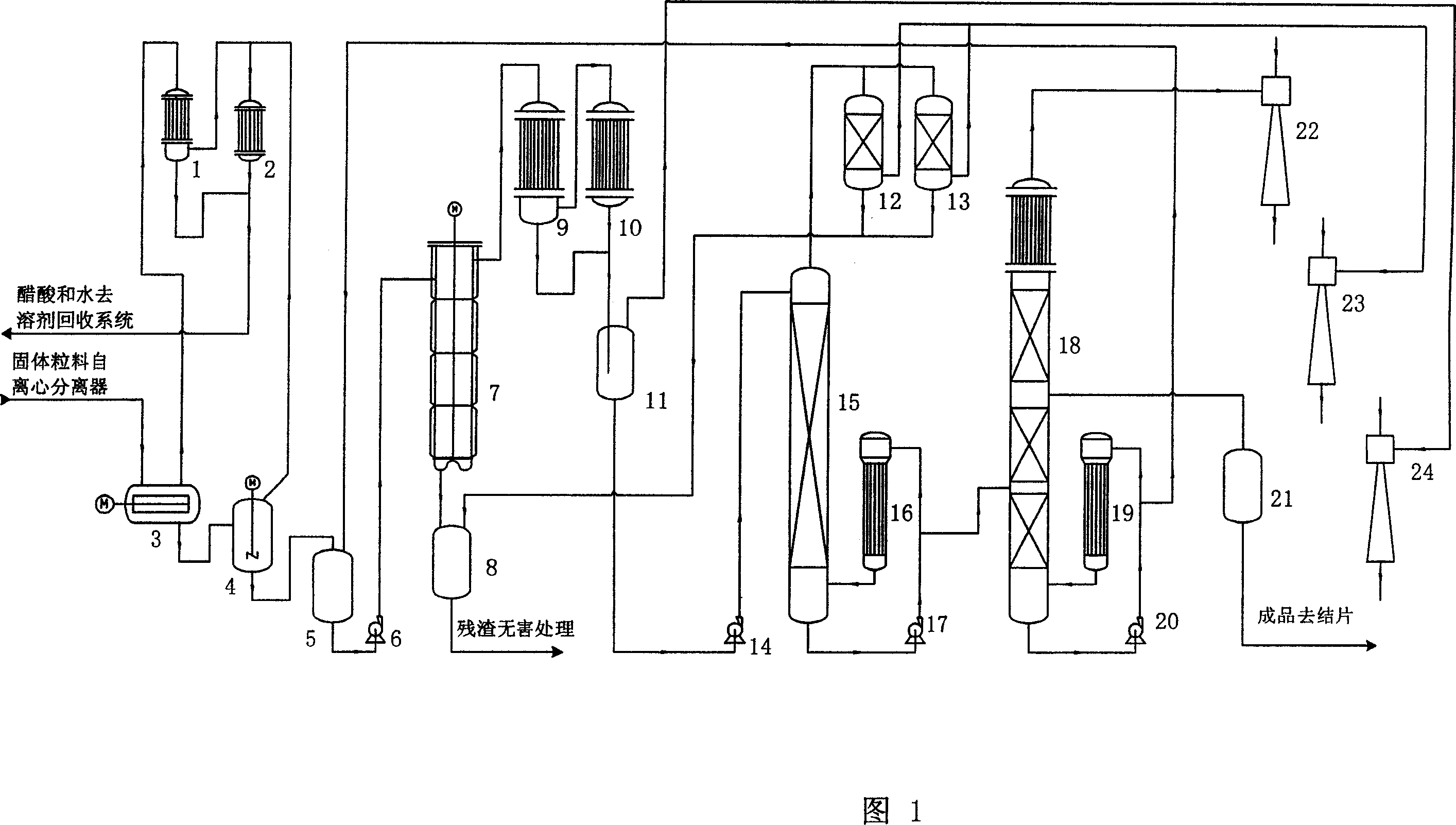

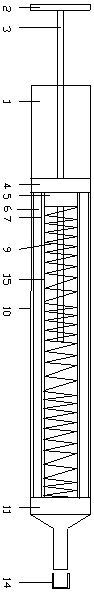

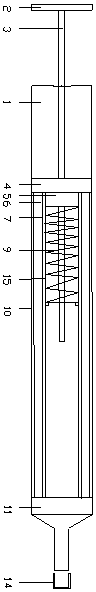

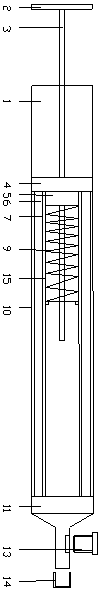

Continuous production process of high purity trimellitic anhydride with trimellitic acid

The continuous production process of high purity trimellitic anhydride with trimellitic acid includes the following steps: smelting trimellitic acid and eliminating acetic acid and water in the first kettle, and eliminating water inside trimellitic acid molecule in the second kettle to form trimellitic anhydride; eliminating heavy components in crude trimellitic anhydride product in one heavy component eliminating evaporator; eliminating light components in the evaporator of one light component eliminating tower; and rectifying through condensing trimellitic anhydride in the condenser on the top of the light component eliminating tower to obtain trimellitic anhydride product fed to the product tank. The present invention has stable product quality, high product purity, high product yield, low power consumption and other advantages.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Braze materials and processes therefor

ActiveUS8342386B2Easy to heat and meltImprove mechanical propertiesWelding/cutting media/materialsThin material handlingMicrowaveMetallic materials

Braze materials and processes for using braze materials, such as for use in the manufacturing, coating, repair, and build-up of superalloy components. The braze material contains a plurality of first particles of a metallic material having a melting point, and a plurality of second particles comprising at least one nonmetallic material chosen from the group consisting of oxides, carbides, and nitrides of at least one metal. The nonmetallic material is more susceptible to heating by microwave radiation than the metallic material of the first particles, and the nonmetallic material is present in the braze material in an amount sufficient to enable the first particles to completely melt when the first and second particles are subjected to heating by microwave radiation.

Owner:GENERAL ELECTRIC CO

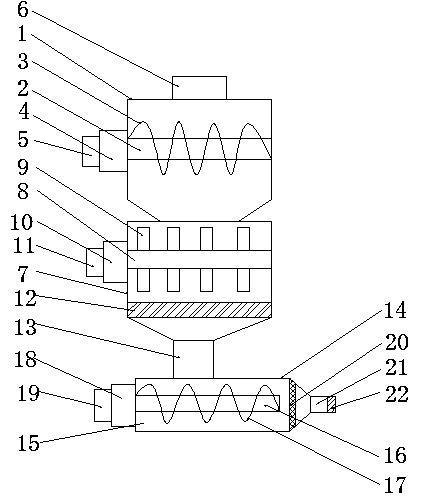

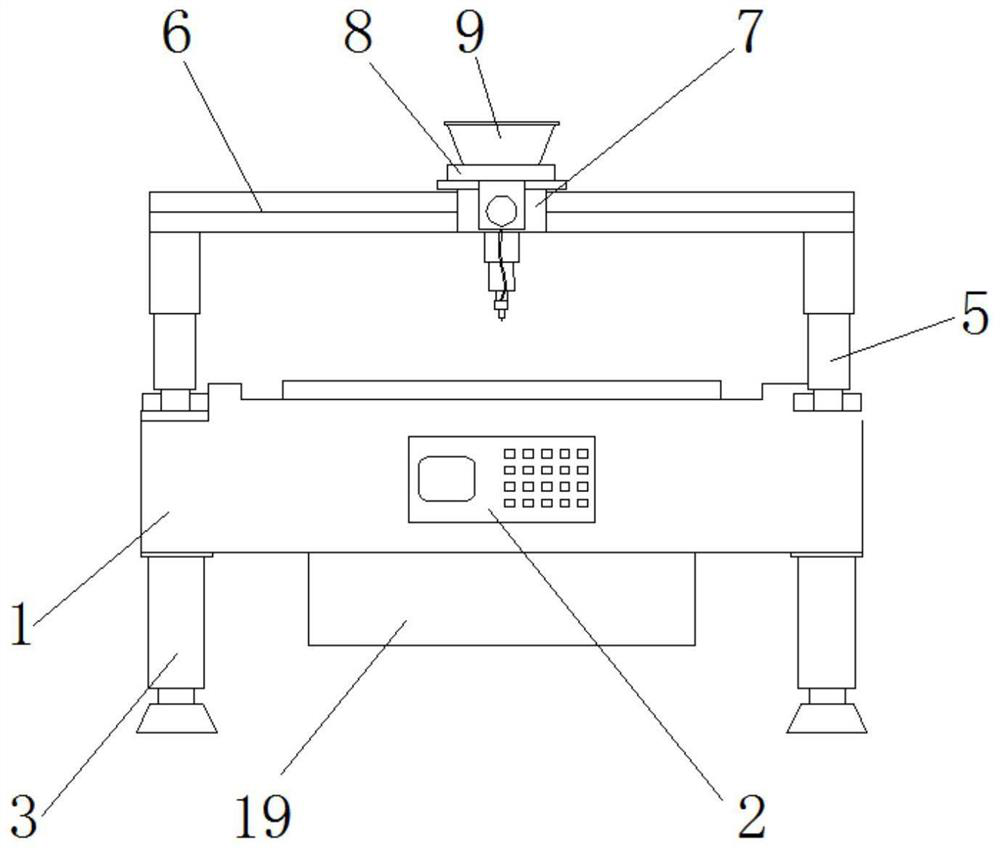

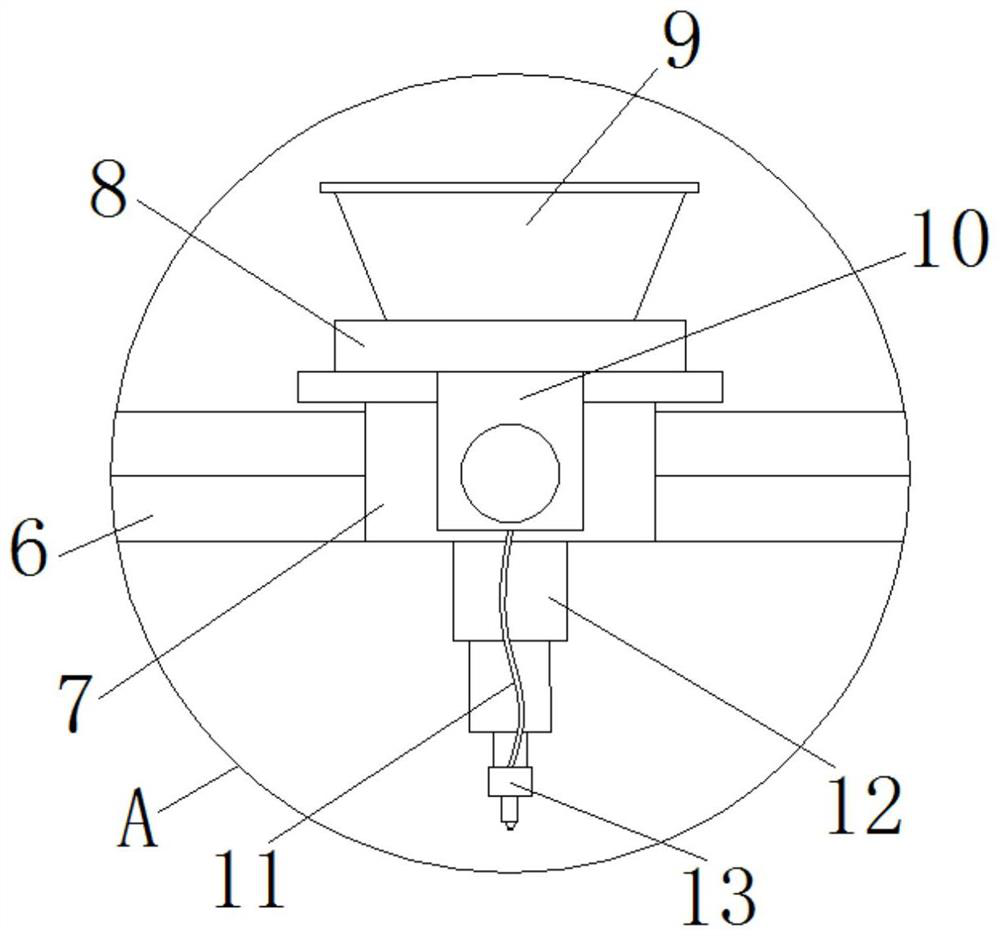

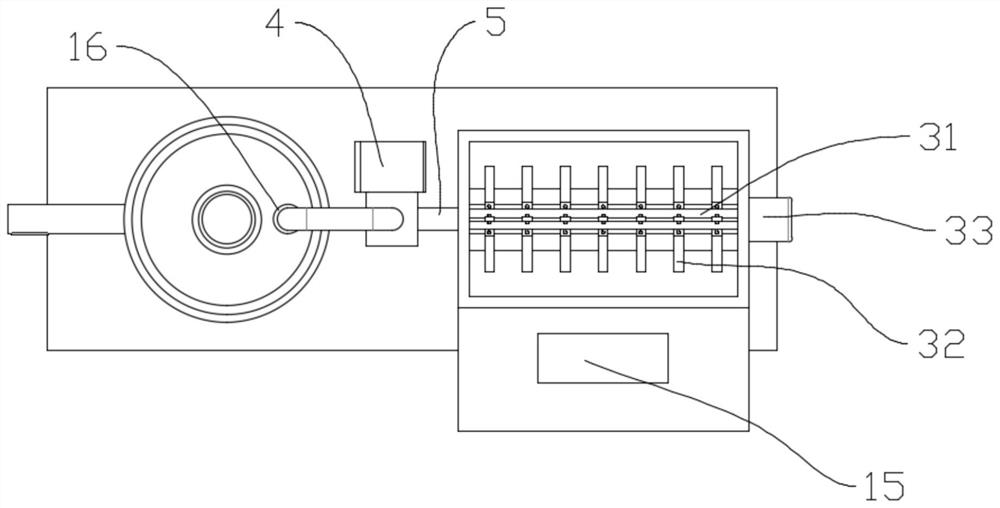

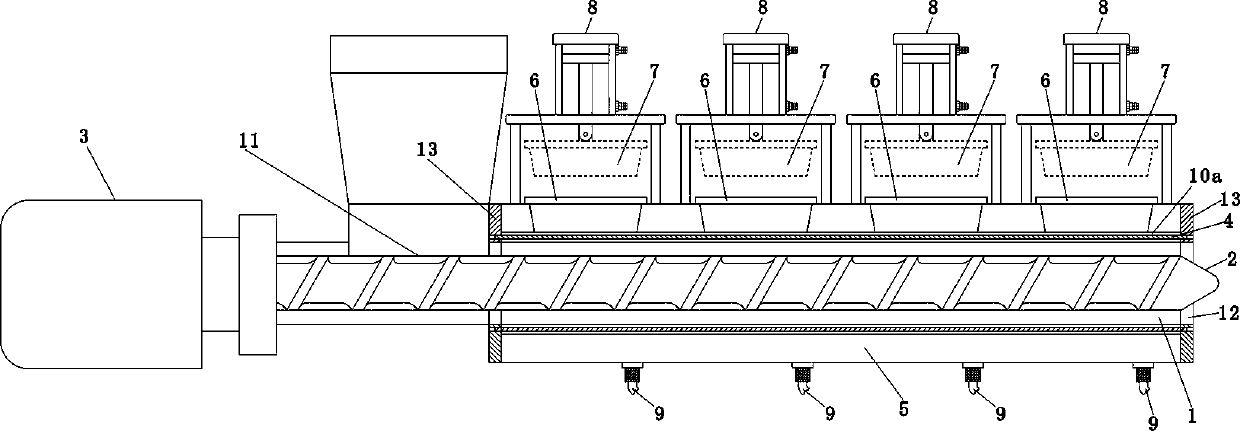

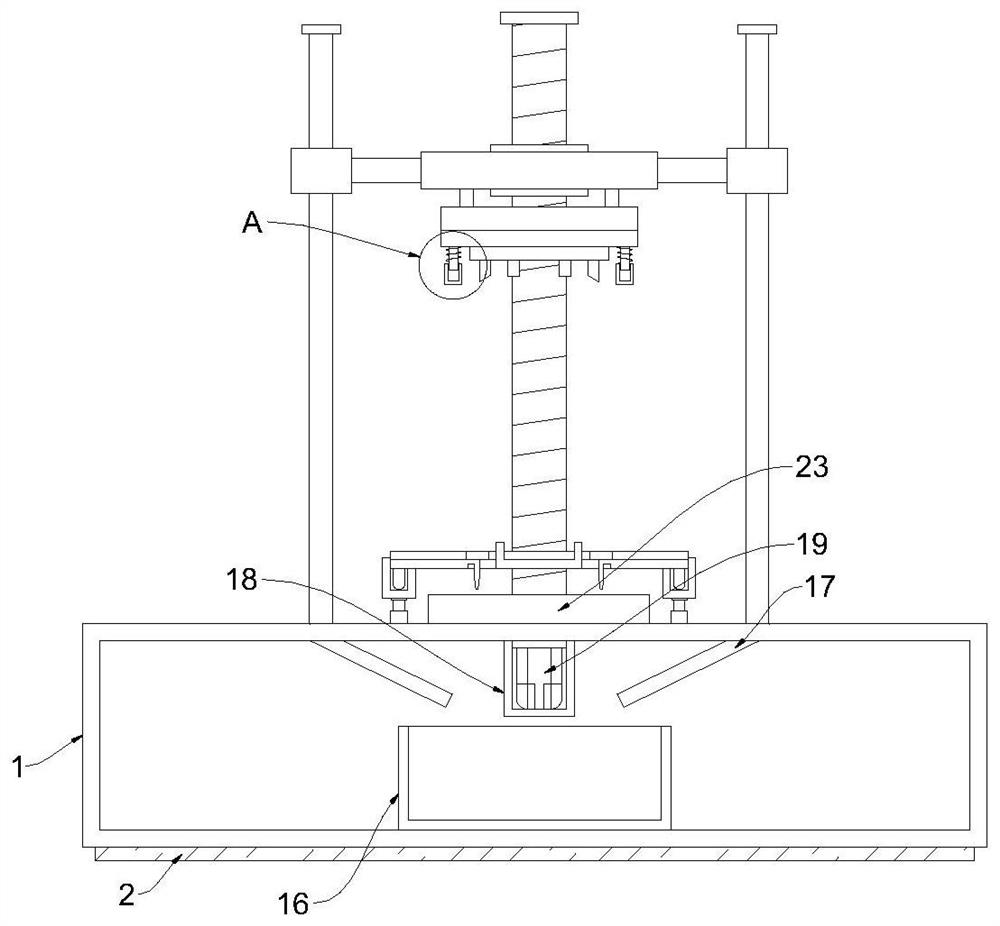

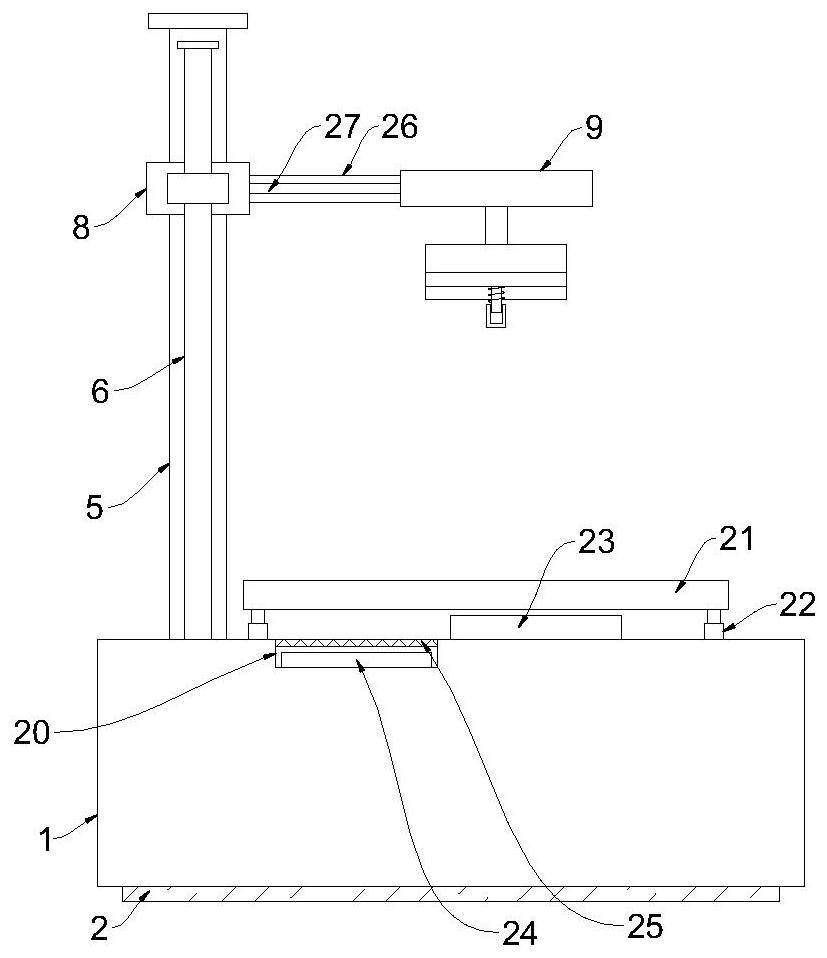

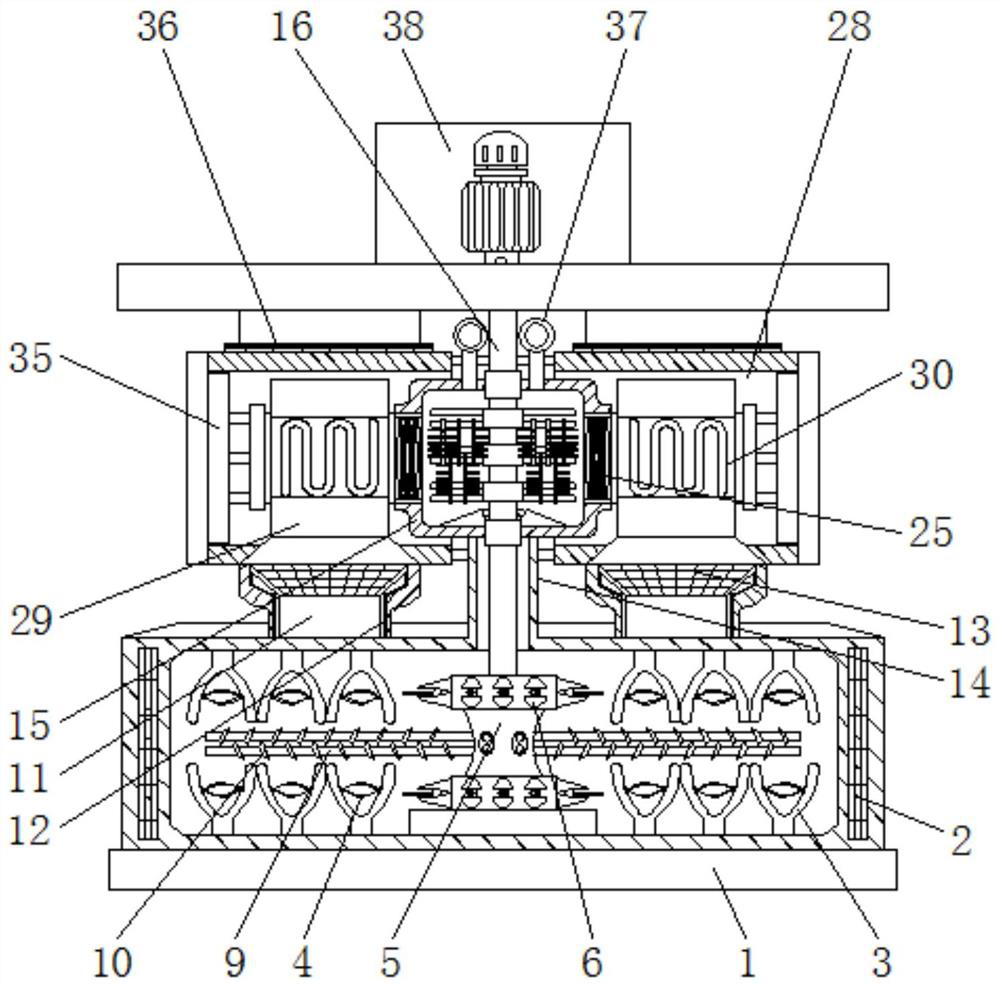

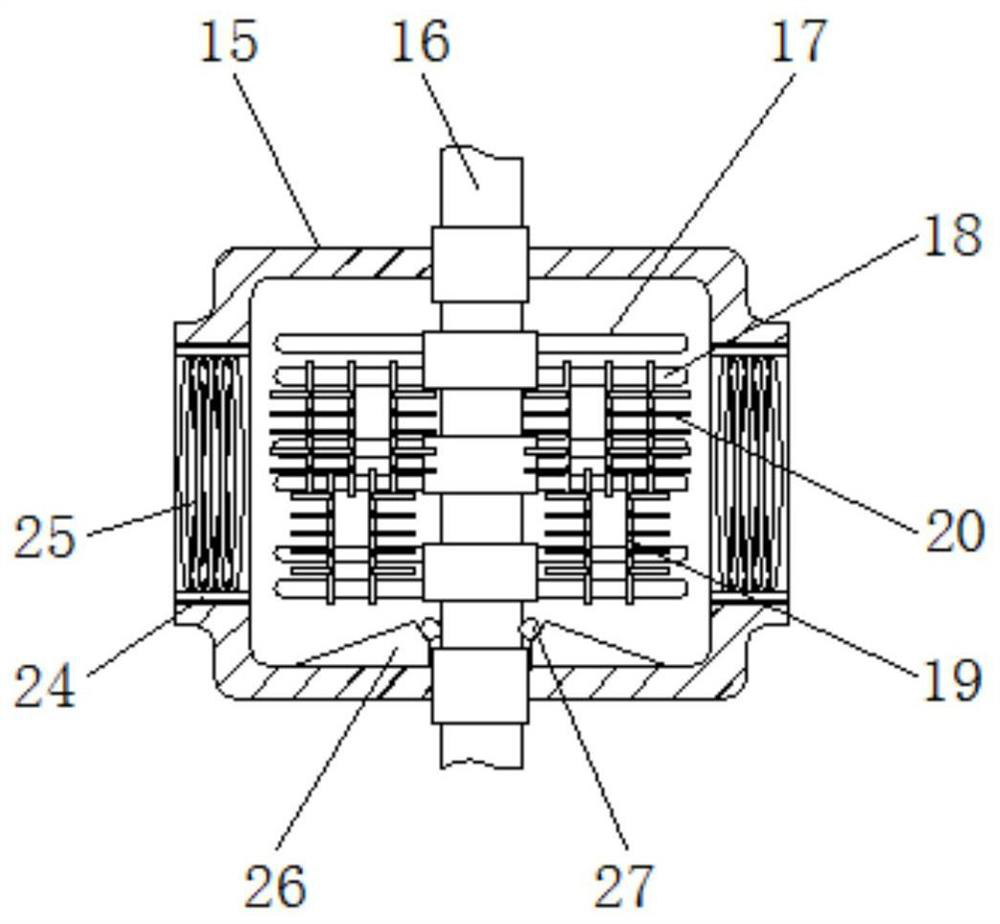

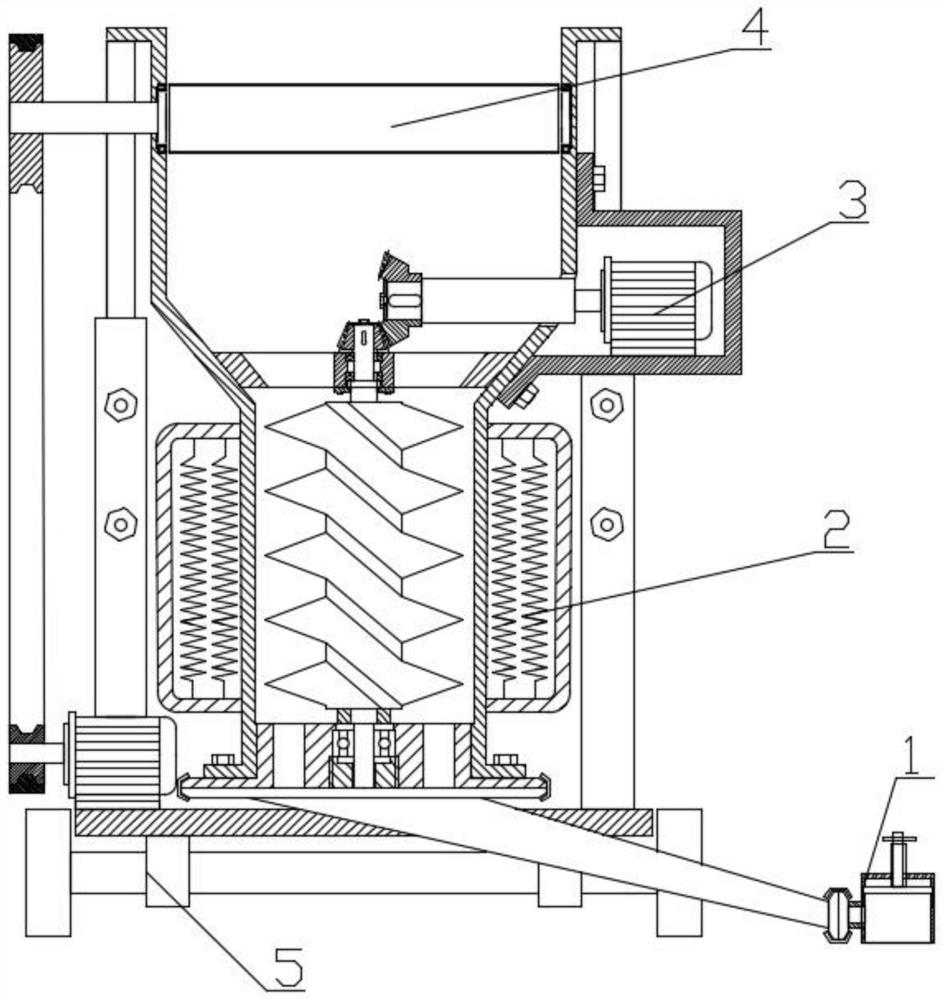

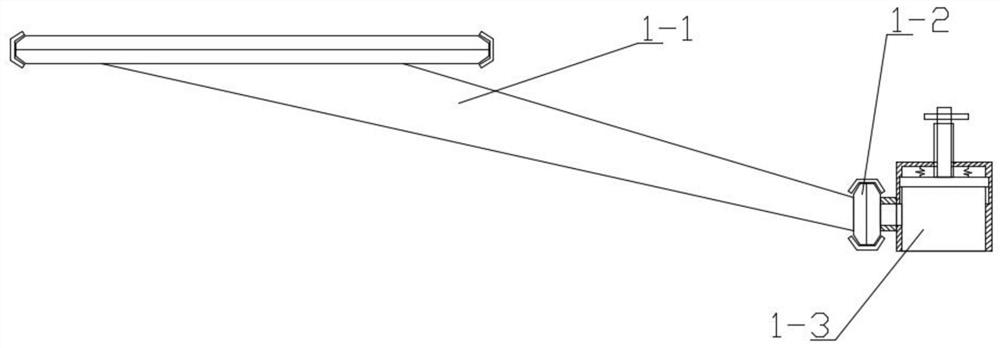

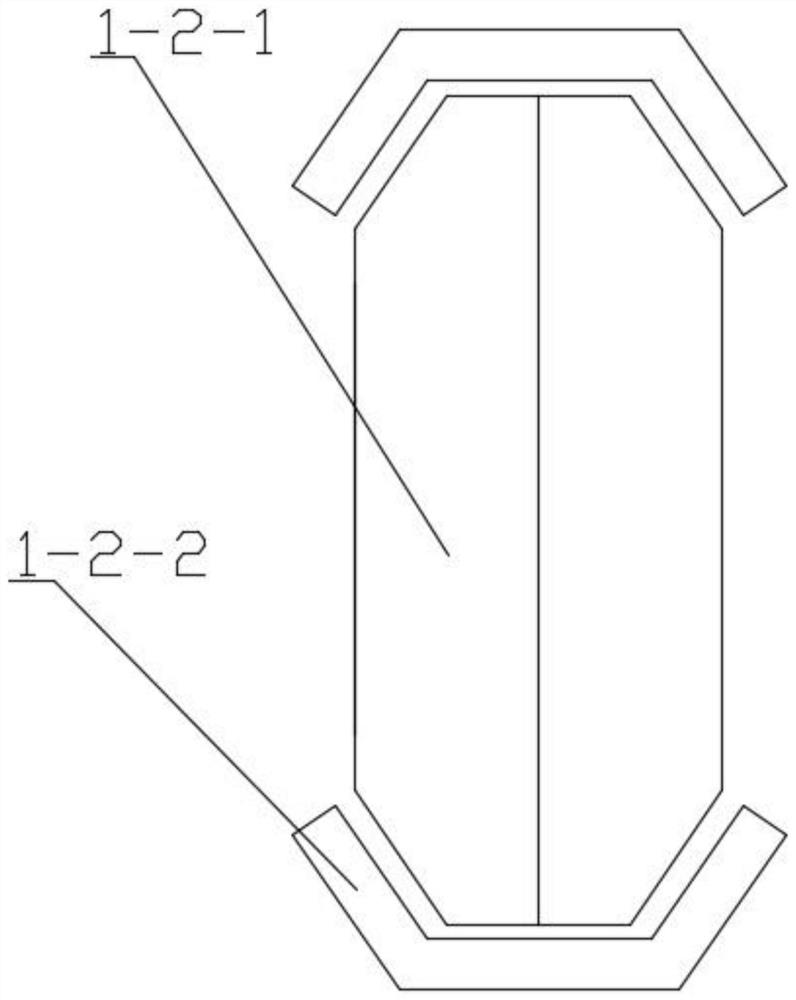

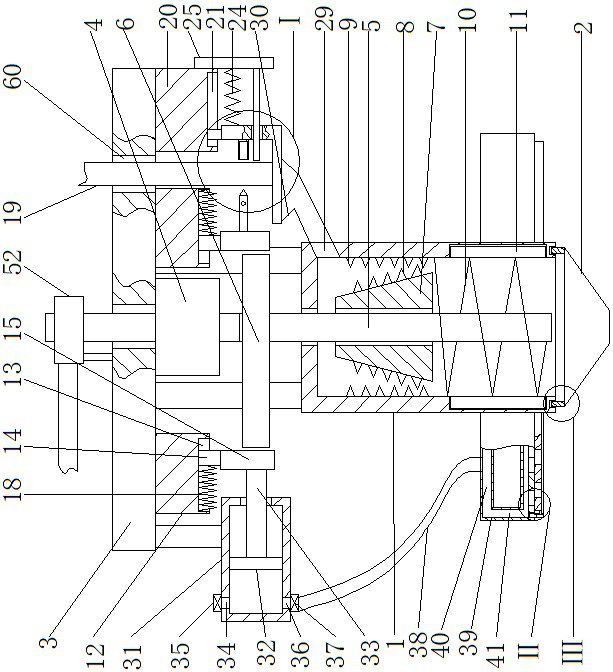

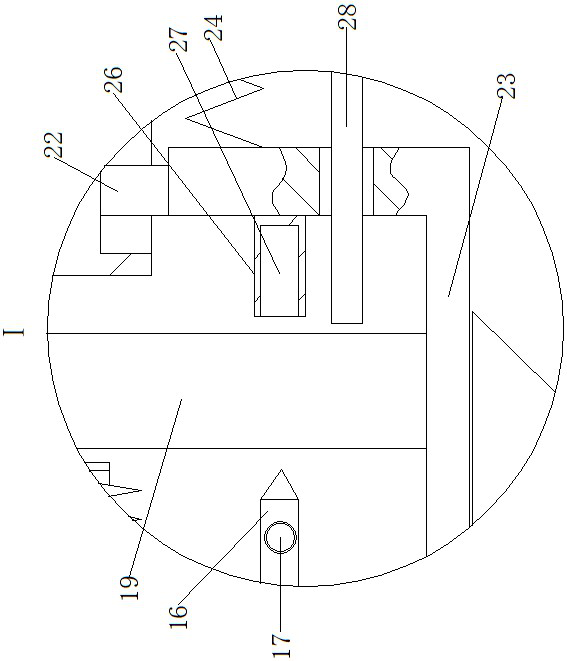

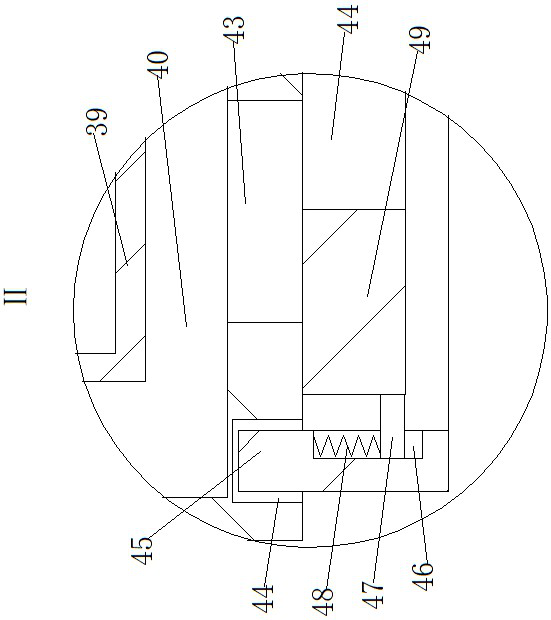

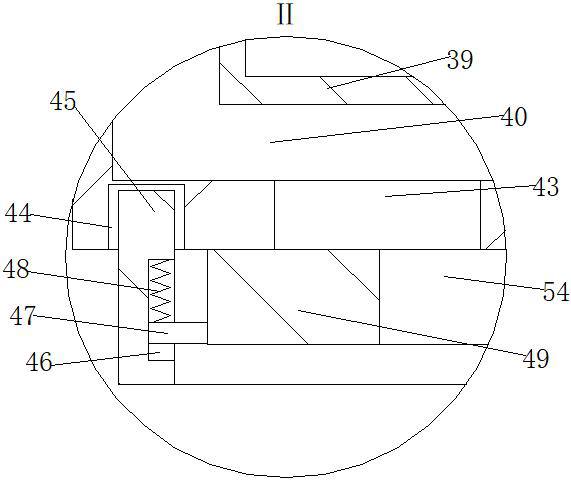

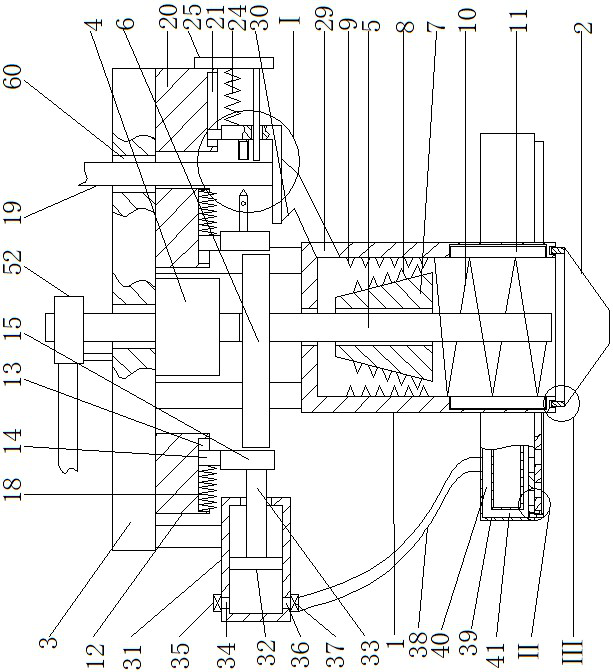

Intelligent injection molding equipment for vehicle part production

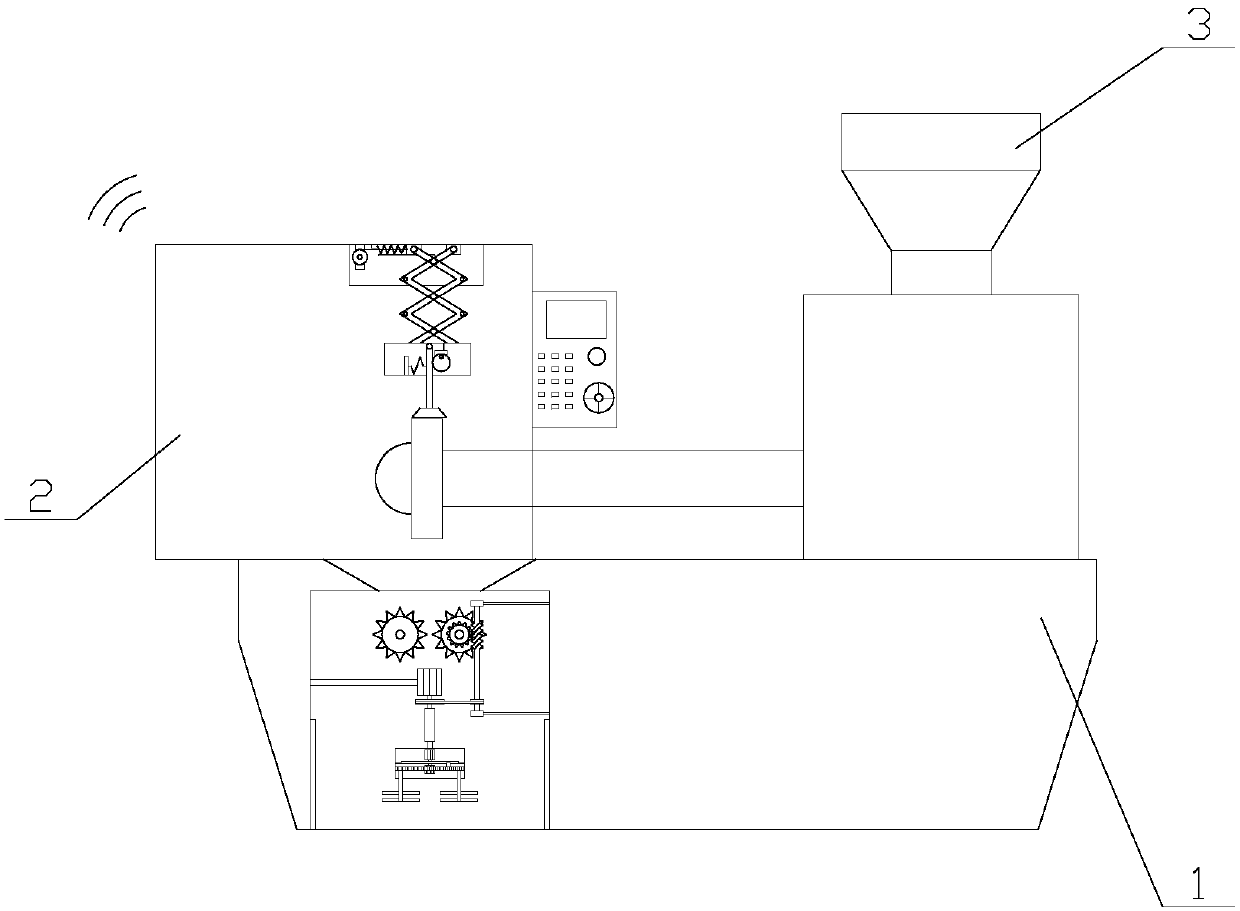

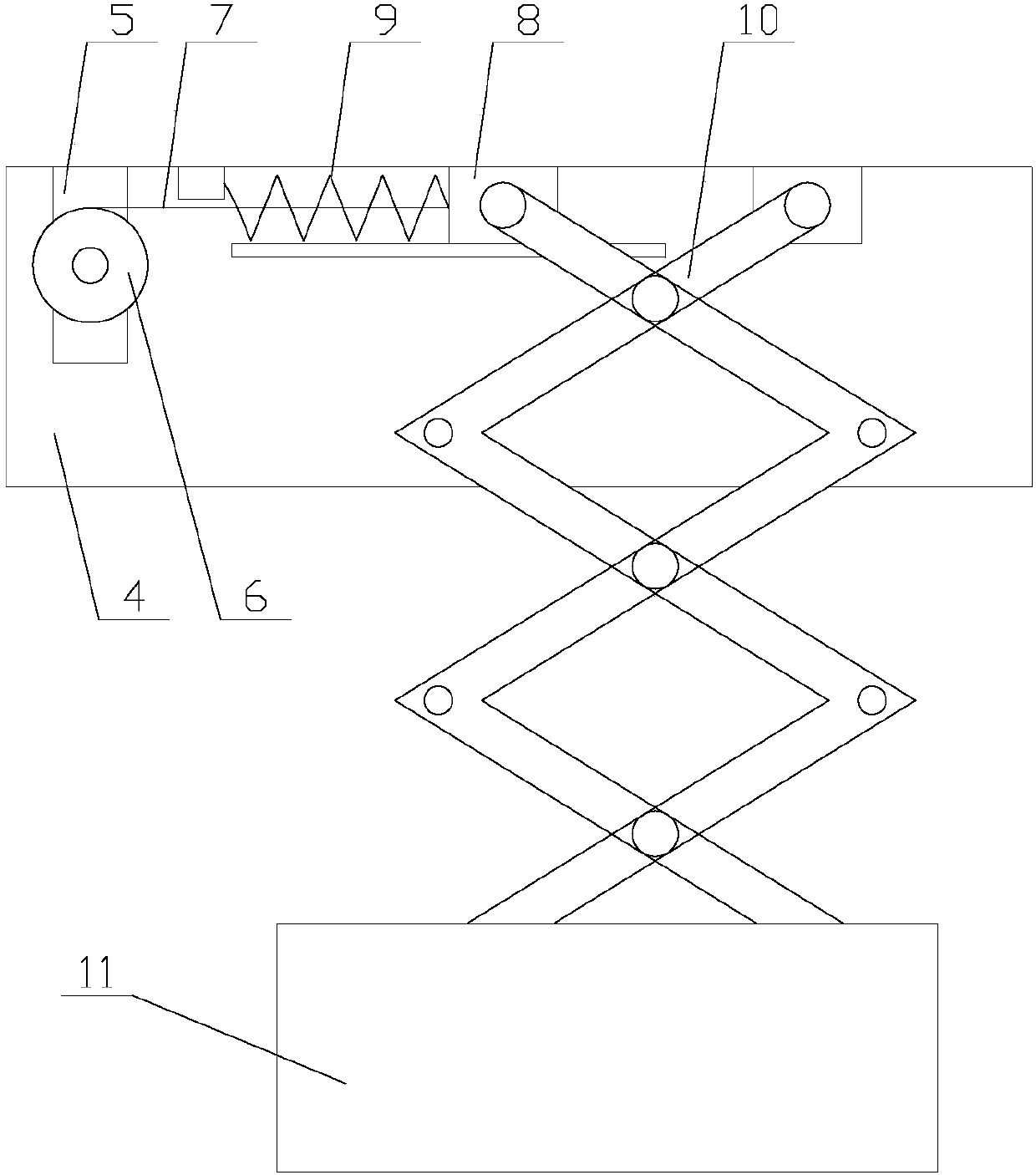

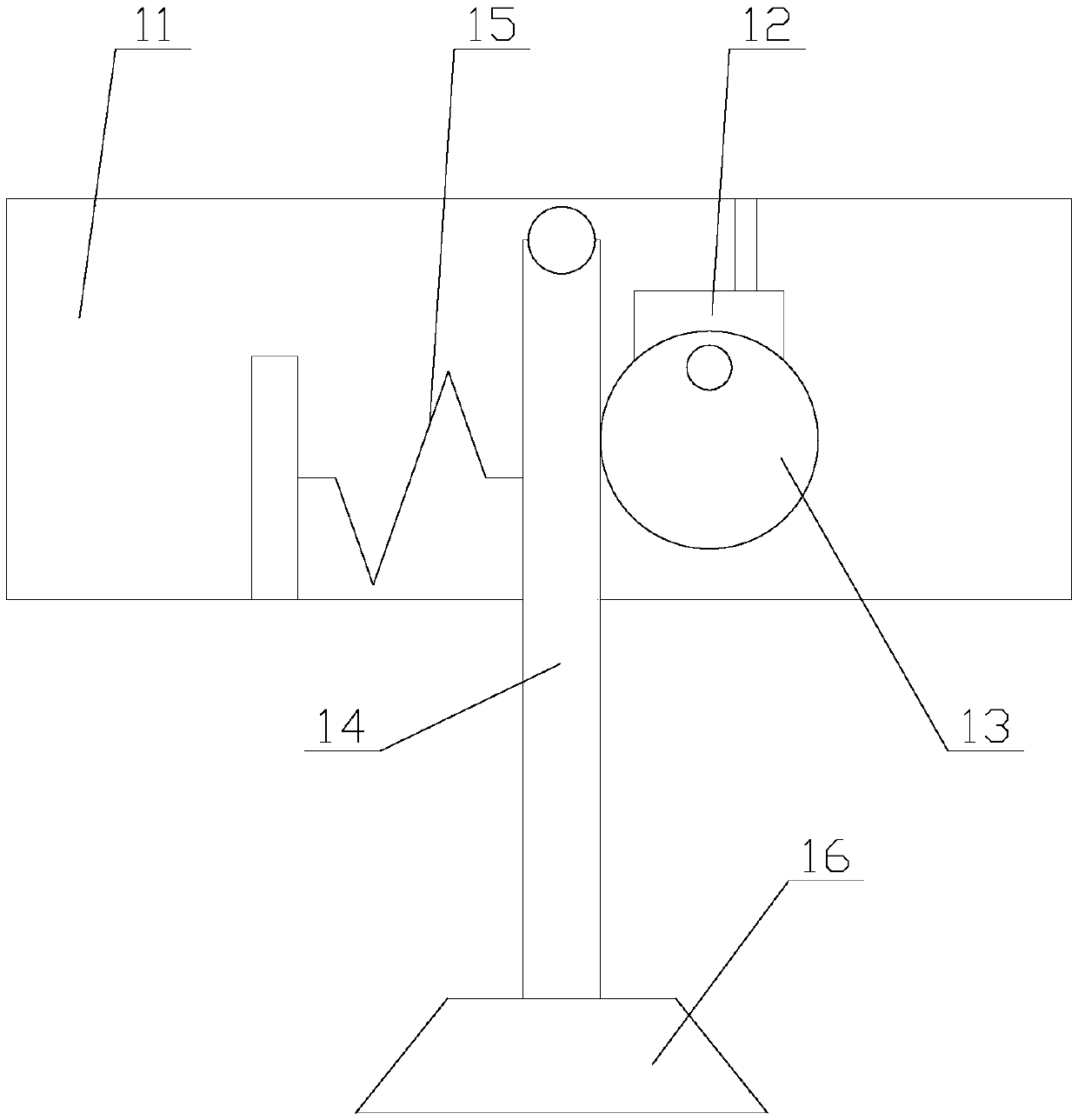

ActiveCN107825655AImprove practicalityAvoid affecting the injection molding effectPlastic recyclingEngineeringRecovery mechanism

The invention relates to intelligent injection molding equipment for vehicle part production. The equipment comprises a main body, a production chamber and a charging box, and further comprises a cleaning mechanism and a recovery mechanism; the cleaning mechanism comprises a lifting module and a cleaning module; the cleaning module comprises a driving chamber, a second motor, a rotating wheel, a swing rod and a cleaning brush; and the recovery mechanism comprises a recovery chamber, a crushing module and a stirring module. In the intelligent injection molding equipment for vehicle part production, the cleaning brush of the cleaning mechanism swings back and forth to sweep off accumulated materials on a nozzle to prevent influence on the injection molding effect, so that the product qualityis improved; compared with manual cleaning, the cleaning mode is safer and more efficient; wastes and the swept accumulated materials can be recovered and crushed through the recovery mechanism to achieve heating and melting; and through uniform stirring, the materials are thoroughly molten to achieve future reutilization, so that the cost investment is saved, and the practicability of the injection molding equipment is greatly improved.

Owner:南通柏源汽车零部件有限公司

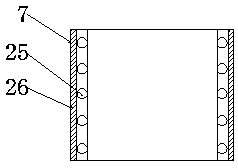

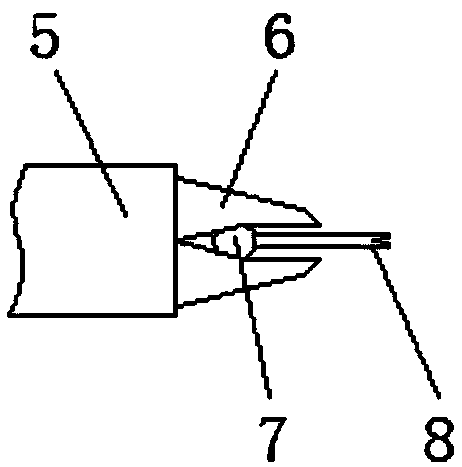

Extrusion injection device for plastic production

The invention discloses an extrusion injection device for plastic production. The extrusion injection device comprises a smashing box, smashing rollers are arranged in the smashing box, smashing blades are arranged on the smashing rollers, the lower end of the smashing box is provided with a fusion box, a rotary shaft is arranged in the fusion box, a rotary rod is fixed on the the rotary shaft, aseparation plate is arranged in the fusion box, the separation plate is provided with a plurality of through holes, a plurality of first heating pipes are arranged in the separation plate, a pluralityof second heating pipes are arranged in the side wall of the fusion box, the lower end of the fusion box is provided with a pipeline, the lower end of the pipeline is provided with an extrusion container, the extrusion container is provided with an extrusion cavity, the extrusion cavity is provided with a screw, the screw is provided with a screw panel, the right end of the extrusion is providedwith a filtration device, the right end of the extrusion container is provided with an injection molding pipe, the right end of the injection molding pipe, the side wall of the extrusion container isinternally provided with a first electromagnetic heating ring, the side wall of the injection molding pipe is internally provided with a second electromagnetic heating ring. The extrusion injection device provided by the invention not only has good fusion effect, but also improves the quality of the product.

Owner:杨炎重

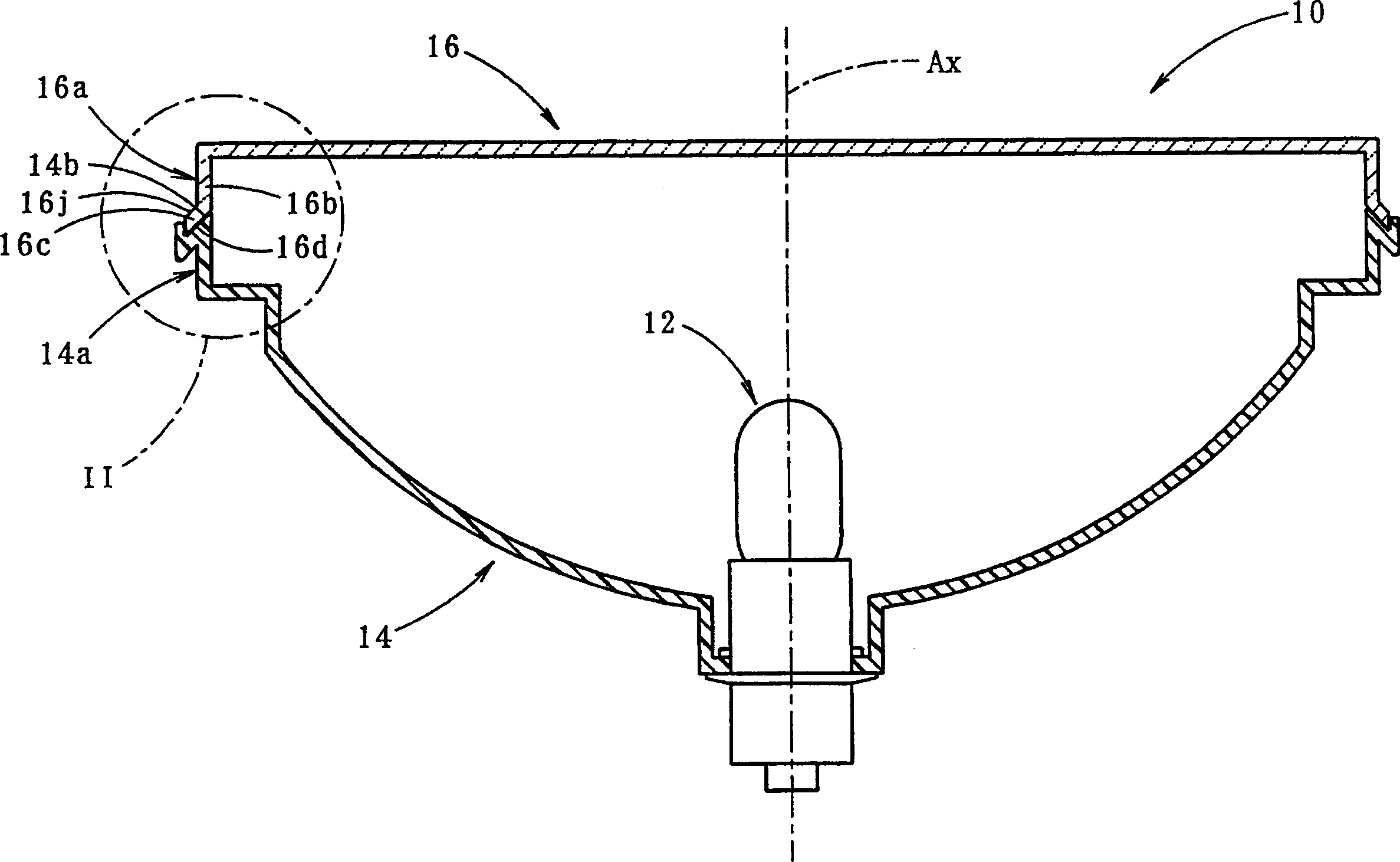

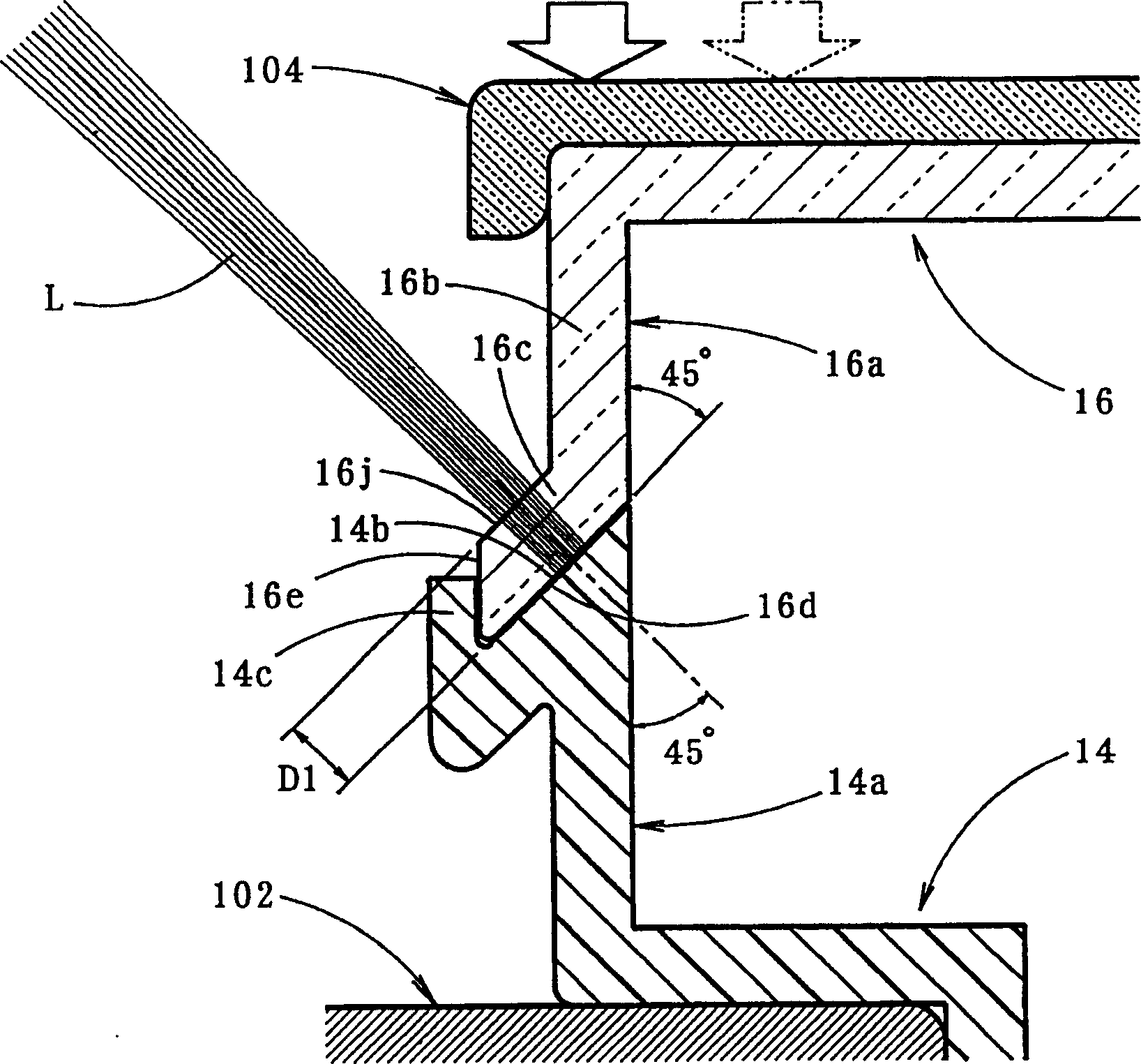

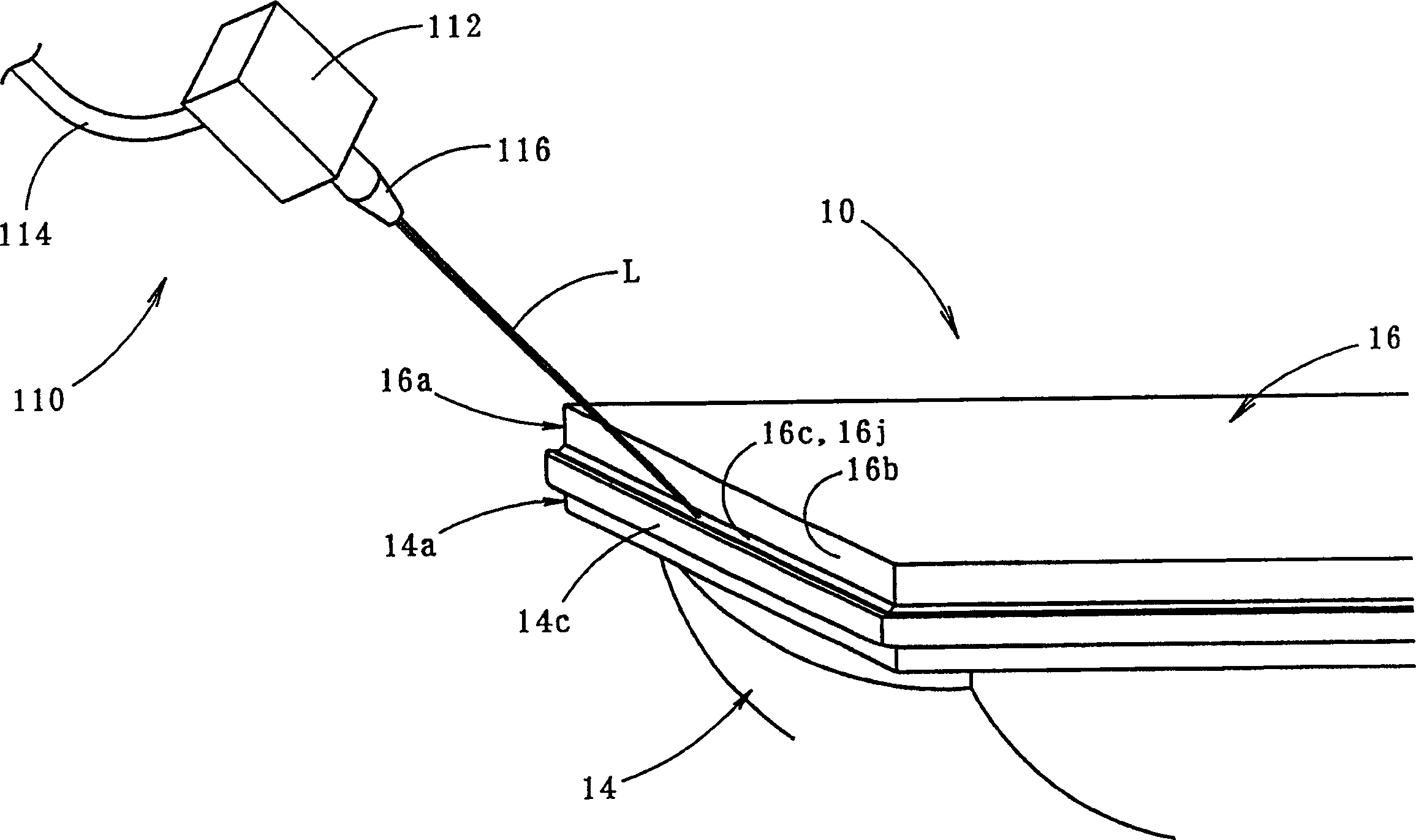

Automotive lamp unit and making method thereof

InactiveCN1157553CImprove appearance qualityHigh bonding strengthOptical signallingVehicle lighting systemsLight beamAbutment

A vehicular lamp in which bonding failure between a front lens and a lamp body is prevented while enhancing the bonding strength and improving the quality of the outer appearance around the bonded surface therebetween. An end surface of a seal leg of a front lens and a receiving surface of a lamp body are bonded through laser beam welding so as to improve the outer appearance quality of the area around the bonded surfaces. The end surface is formed on an end portion of the seal leg that is bent and extended outward at a predetermined angle with respect to the bonding direction. The laser beam is irradiated onto the receiving surface through the end portion from a direction substantially orthogonal to the end surface. The resultant permeation distance of the laser beam is made short, resulting in a sufficient amount of irradiation energy. When pressure is applied to the base end portion of the seal leg by pressing on the front lens, the end surface and the receiving surface are brought into abutment in the width direction with uniform pressure.

Owner:KOITO MFG CO LTD

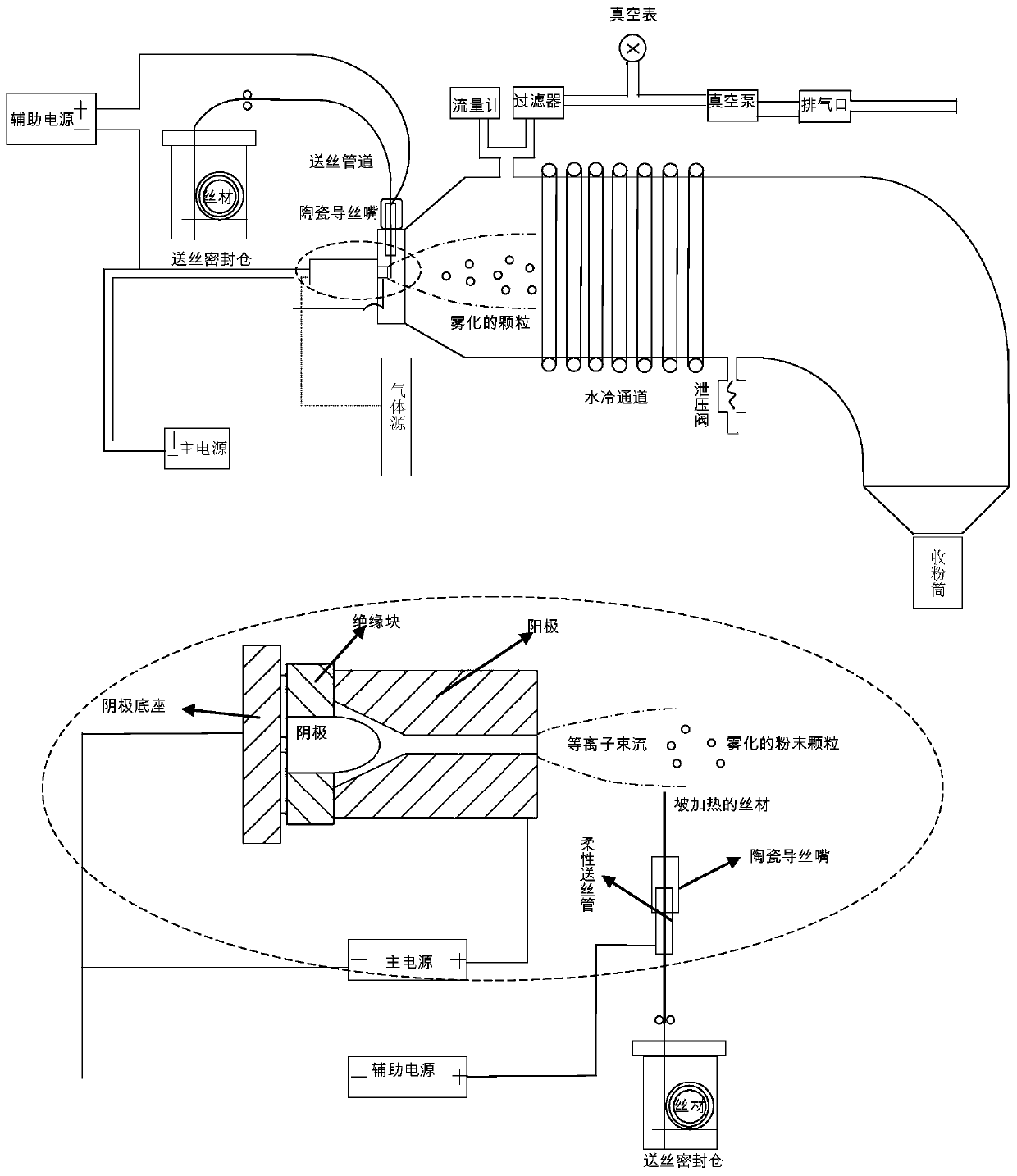

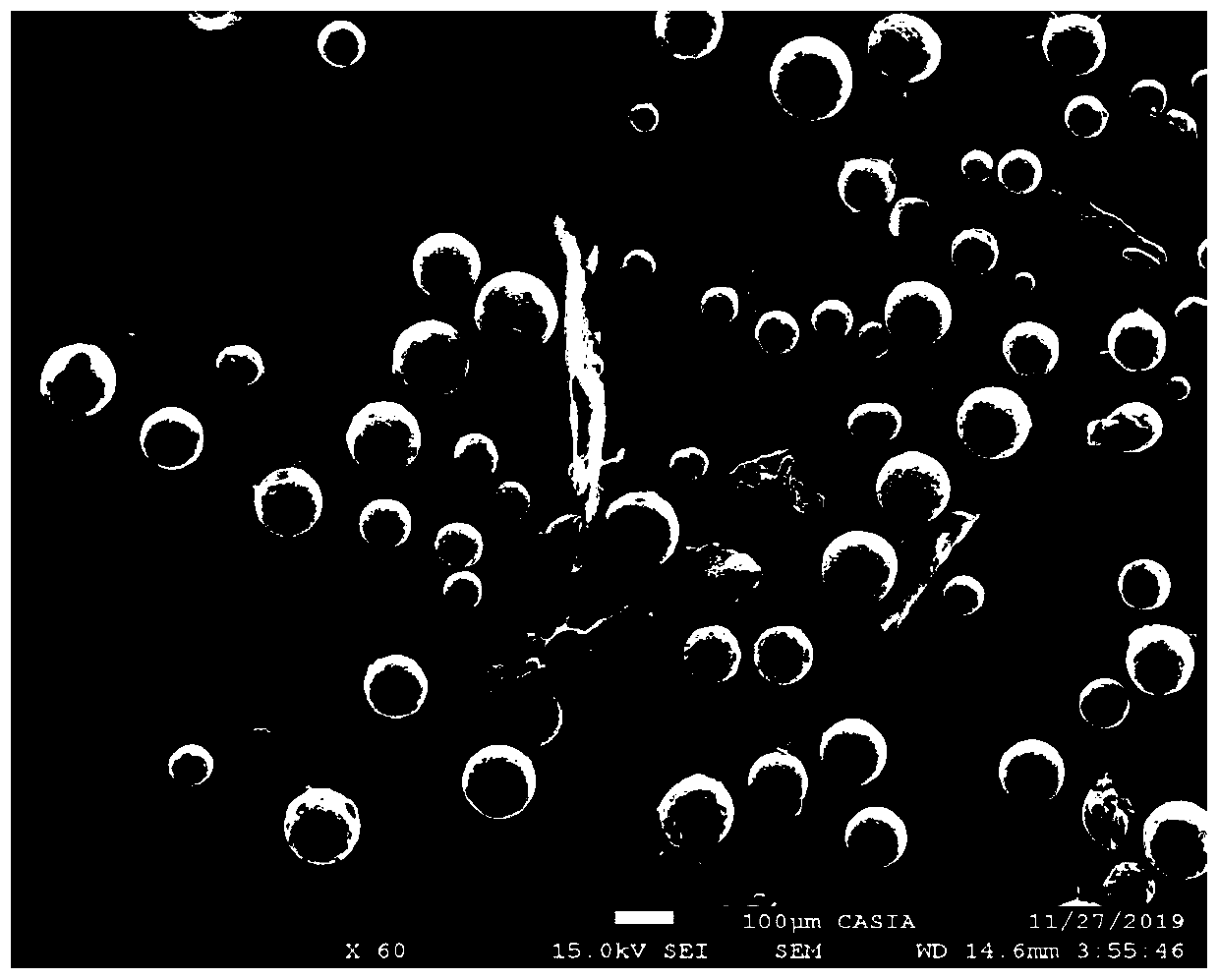

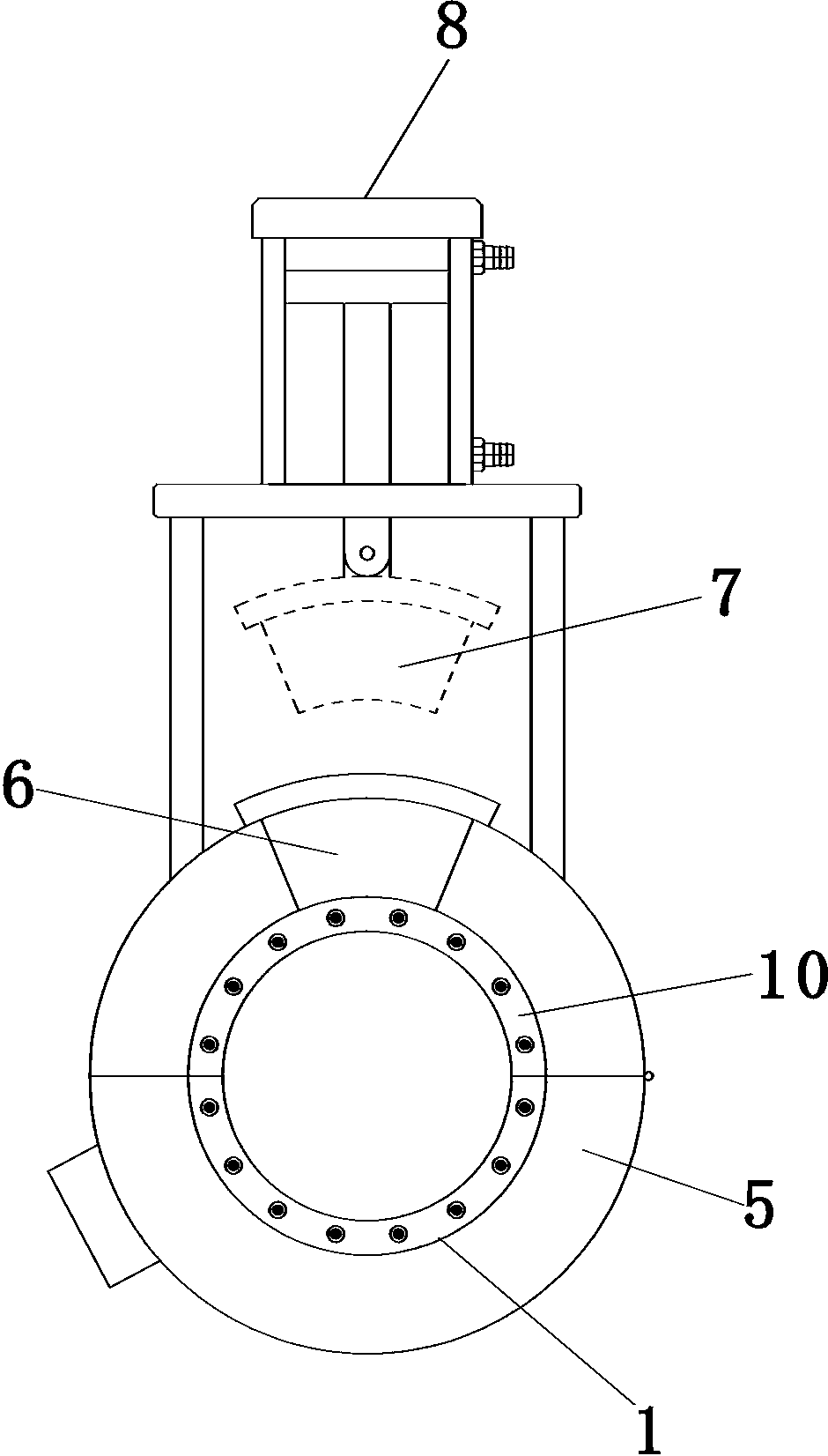

Method and device for preparing spherical metal powder through hot wire assisted plasma arc

PendingCN110919017AImprove milling efficiencySimple device structureIncreasing energy efficiencyHot filamentHeating power

The invention discloses a method and device for preparing spherical metal powder. According to the method, a direct-current plasma arc is used for heating and melting and atomizing a metal wire, an auxiliary power source is directly applied to the metal wire, a main power source and the auxiliary power source are insulated, the auxiliary power source carries out resistance heating on the wire, andheating power needed by wire melting and atomizing can be greatly reduced. The invention further discloses the device using the method for preparing the spherical metal powder. The device comprises apowdering pipeline, a power source including the main power source and the auxiliary power source, a plasma spraying gun, an insulation mechanism, a wire feeding device, a powder flying pipeline, a powder collecting cylinder. A spraying gun cathode is connected with a negative electrode of the main power source, a through hole is formed in the front end of an anode, the insulation mechanism comprises an insulation gasket on the front end of an anode nozzle and an insulation ceramic wire guide nozzle on the front end of a wire feeding pipeline, the wire feeding device is arranged in a seal binand is provided with the wire feeding pipeline connected with a spraying gun, and the powder collecting cylinder is arranged on the tail of the powder flying pipeline.

Owner:BEIJING UNIV OF TECH

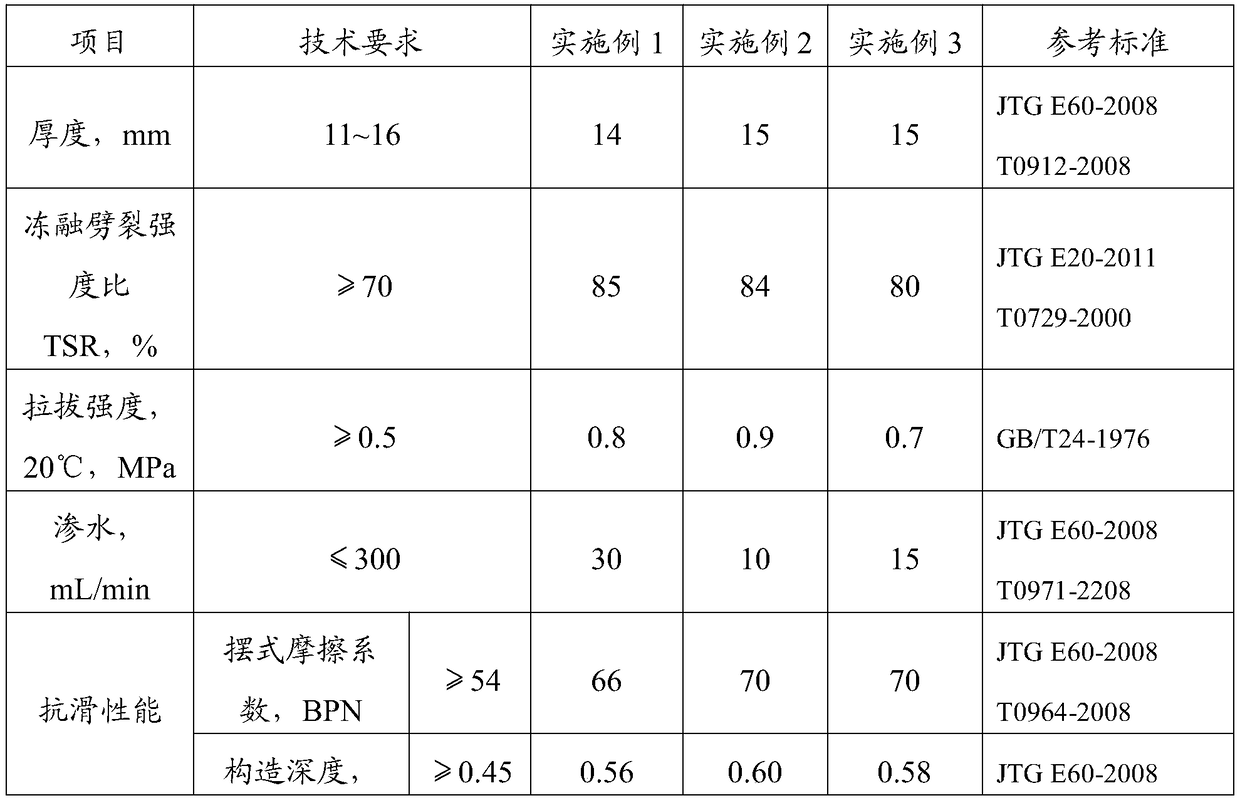

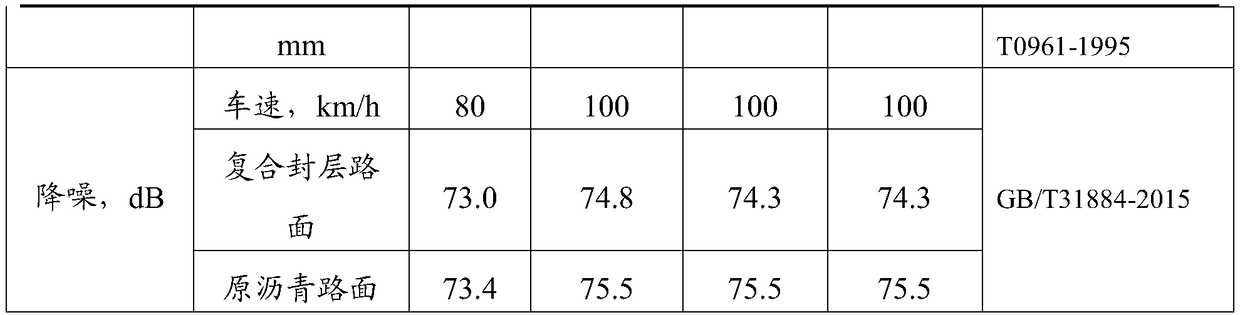

Composite pavement sealing layer and preparation method and application thereof

ActiveCN109133728AImprove wear resistanceImprove high temperature stabilityIn situ pavingsEmulsionSurface layer

The invention provides a composite pavement sealing layer and a preparation method and application thereof and belongs to the technical field of road maintenance. The composite pavement sealing layerprovided by the invention comprises a bottom layer arranged on the surface of a to-be-treated road and a surface layer arranged on the surface of the bottom layer, wherein the bottom layer is formed by a normal temperature modified asphalt mixture which comprises asphalt, an asphalt modifier and aggregate; the surface layer is formed by a sand-containing fog seal layer mixture which comprises a waterborne concentrated cover material, an acrylic resin emulsion, fine sand and water; and the waterborne concentrated cover material comprises asphalt, emulsifier, argil and water. The composite pavement sealing layer provided by the invention has the beneficial effects that the softening point of the asphalt is reduced by utilizing the asphalt modifier, so that the mixing of the normal temperature modified asphalt mixture and the paving of the bottom layer can be realized under normal temperature conditions; and meanwhile, by utilizing the surface layer formed by the sand-containing fog sealing layer mixture, water on the road surface can be effectively prevented from sinking in road and damaging the bottom layer, so that the waterproof performance of the road surface is improved.

Owner:北京路凯泰公路养护工程有限公司

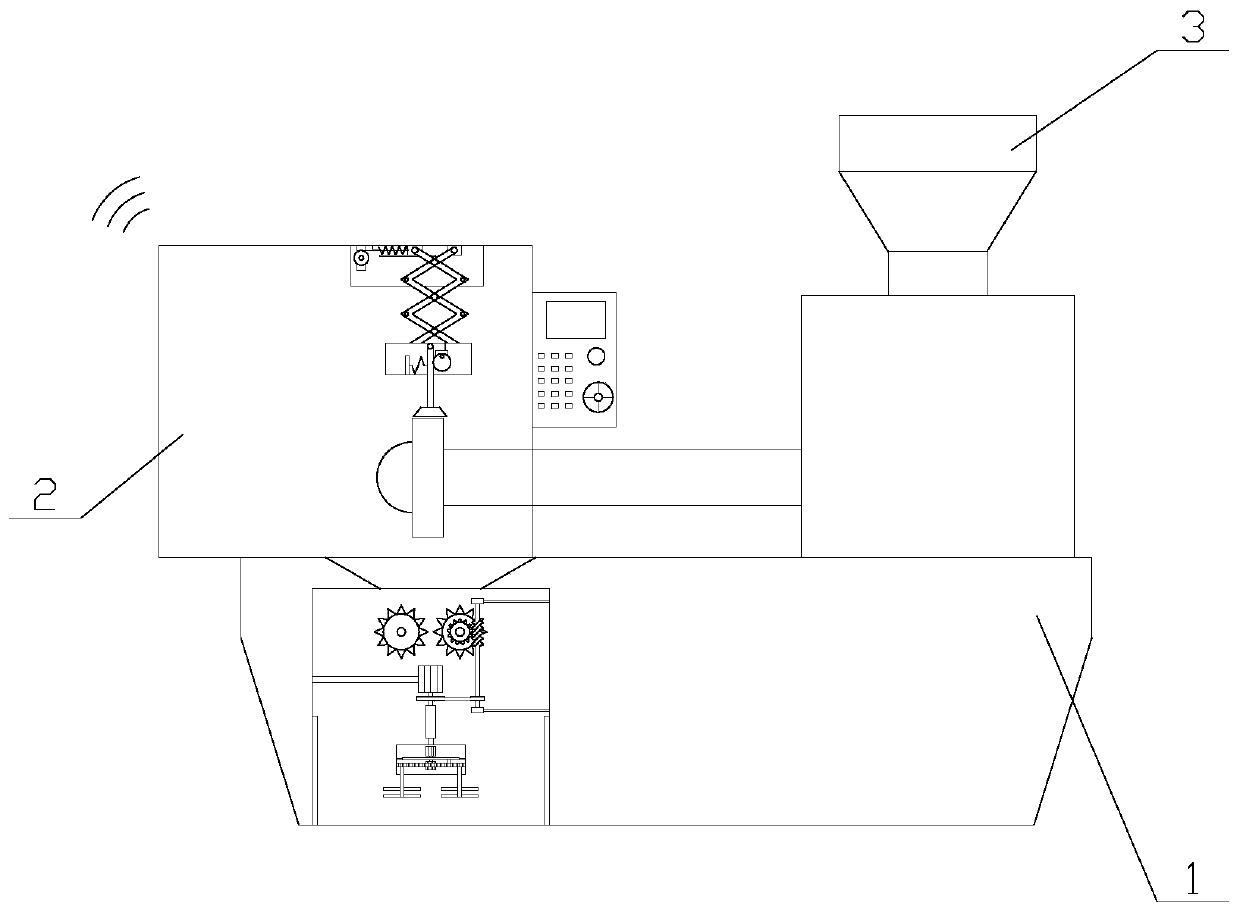

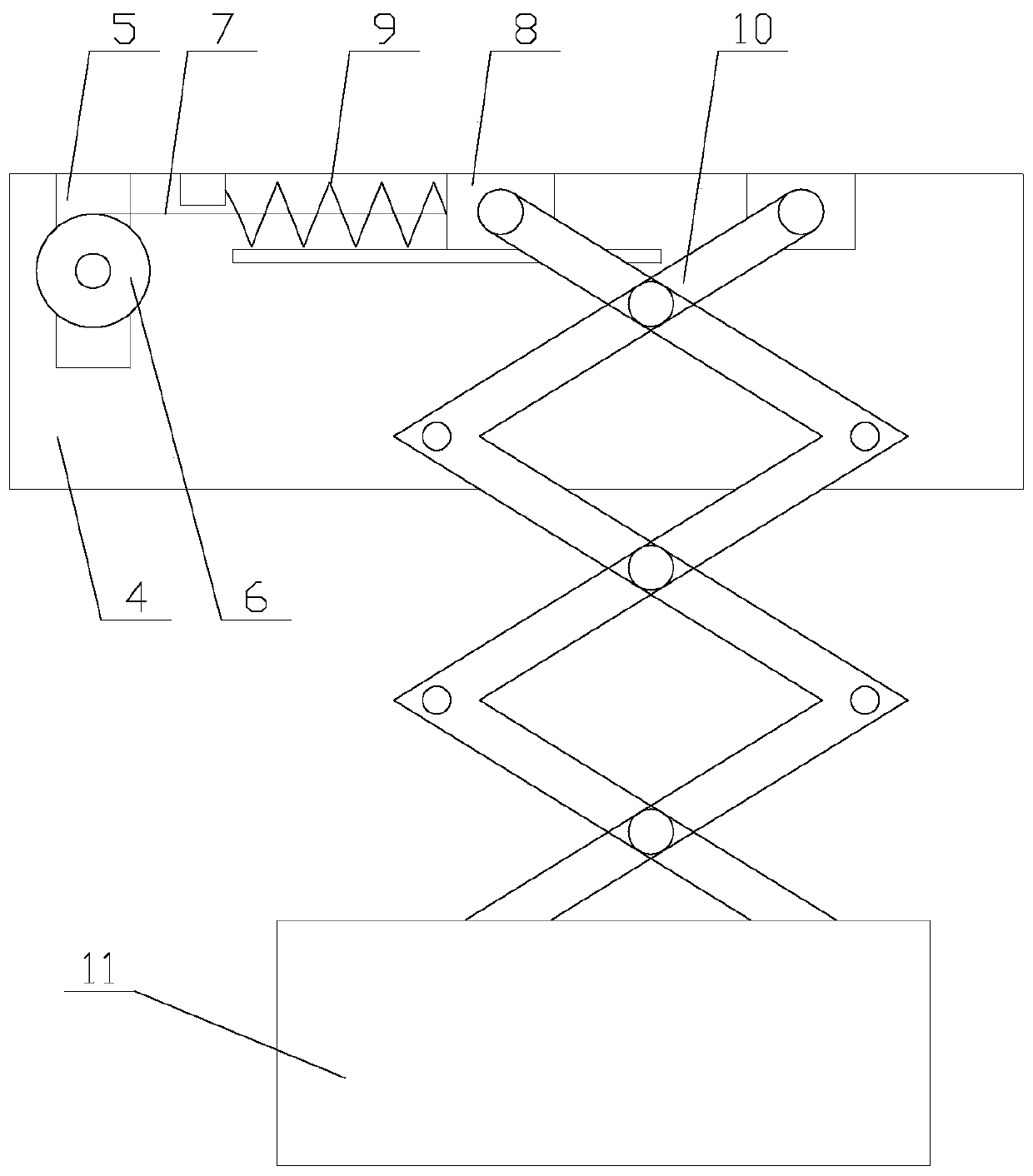

Waste recovery device of 3D printing device

PendingCN112454900AReach the effect of recyclingEasy to transportAdditive manufacturing apparatusManufacturing recyclingElectric machineryWaste material

The invention discloses a waste recovery device of a 3D printing device. The waste recovery device comprises a printing table, wherein a control panel is arranged on the front surface of the printingtable, supporting legs are fixedly connected to the lower surface of the printing table, an electric sliding rail is fixedly connected to the upper surface of the printing table, a telescopic column is arranged on the upper surface of the electric sliding rail, a cross rod is fixedly connected to the top end of the telescopic column, an electric sliding block is arranged on the surface of the cross rod, a fixing base is arranged on the upper surface of the electric sliding block, and a feeding funnel is fixedly connected to the upper surface of the fixing base. According to the waste recoverydevice of the 3D printing device, through the arrangement of the a waste leaking hole, the conveying of waste generated by printing is facilitated, through the arrangement of a crushing box, a crushing motor and a crushing roller, printing waste fed from the first waste leaking hole can be crushed, and through the arrangement of a waste collecting box, the collection of the crushed printing wastein the crushing box is facilitated, and the 3D printing device has the effect of waste recovery.

Owner:北京联袂义齿技术有限公司

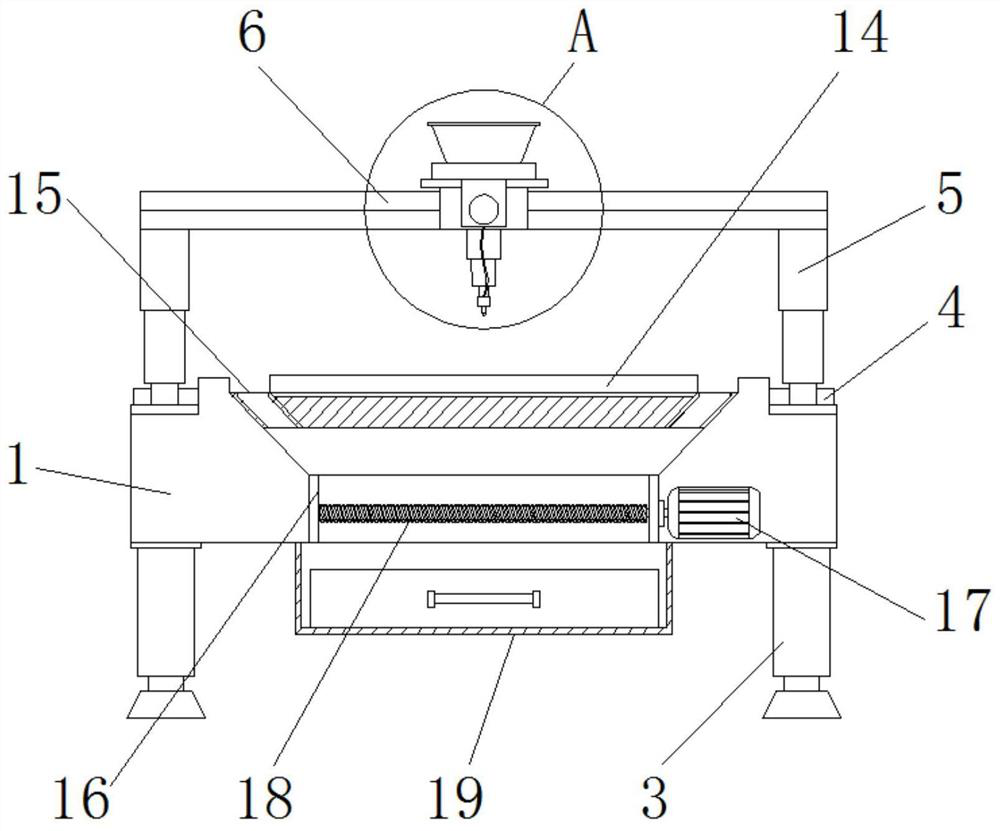

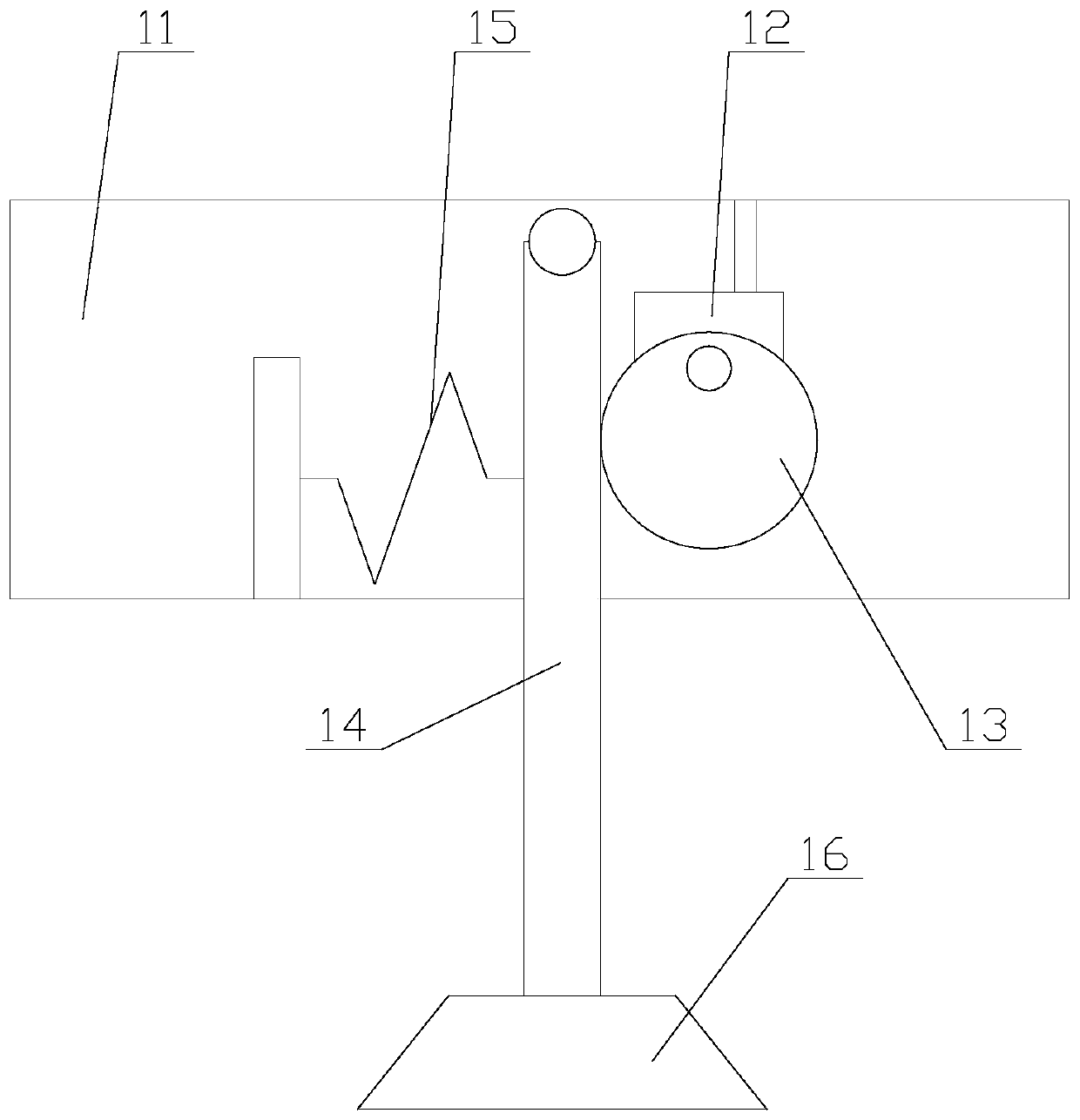

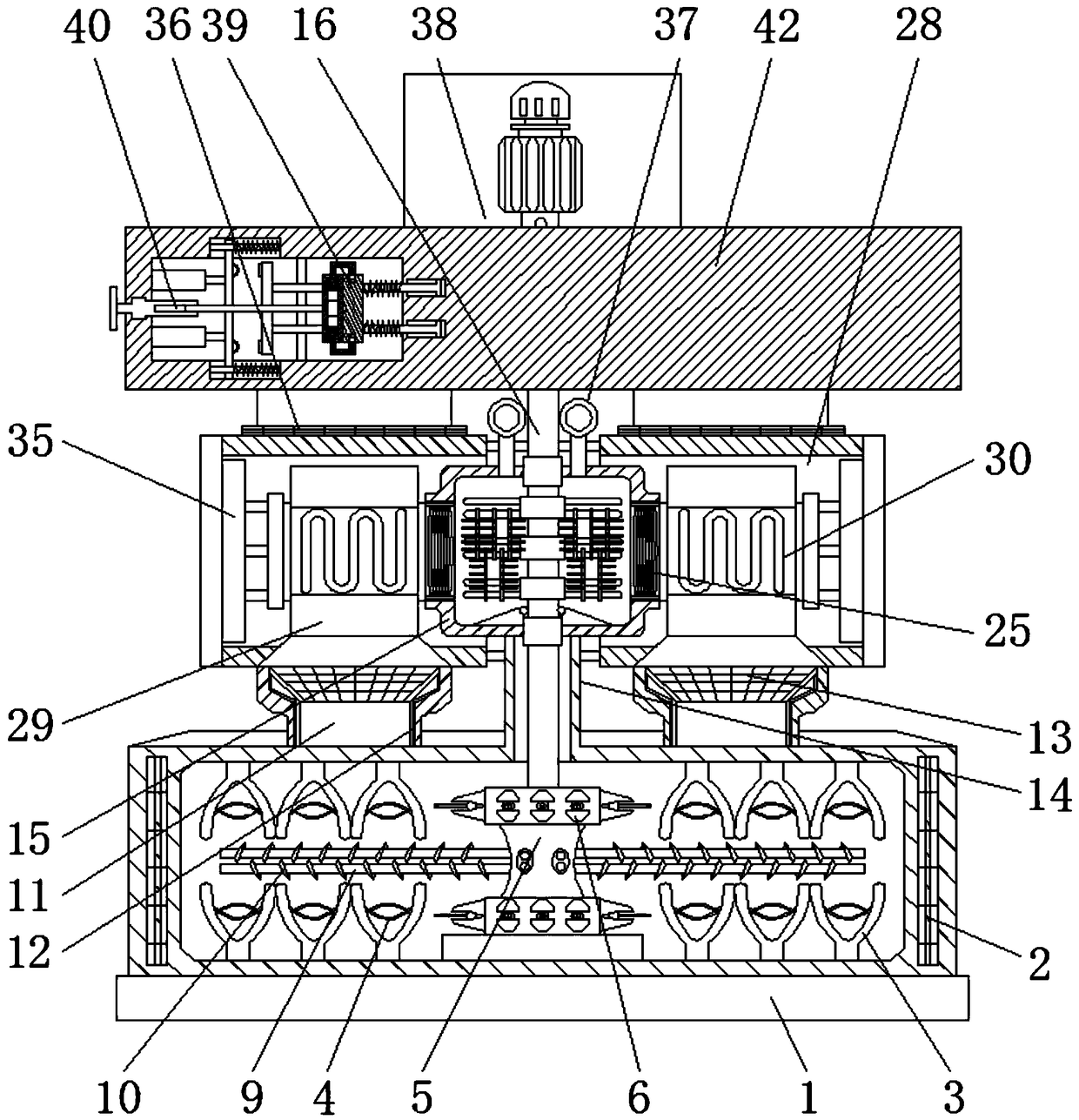

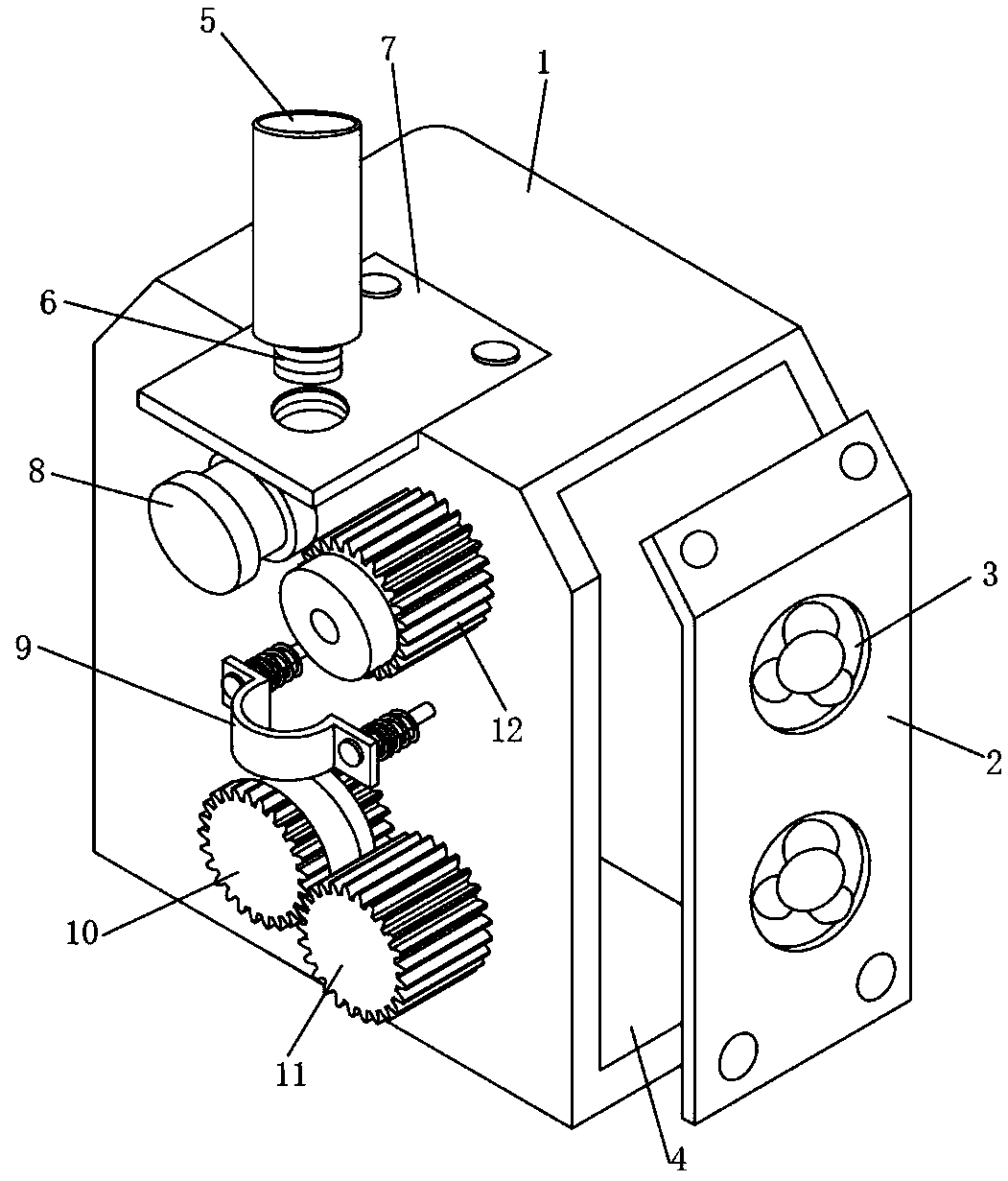

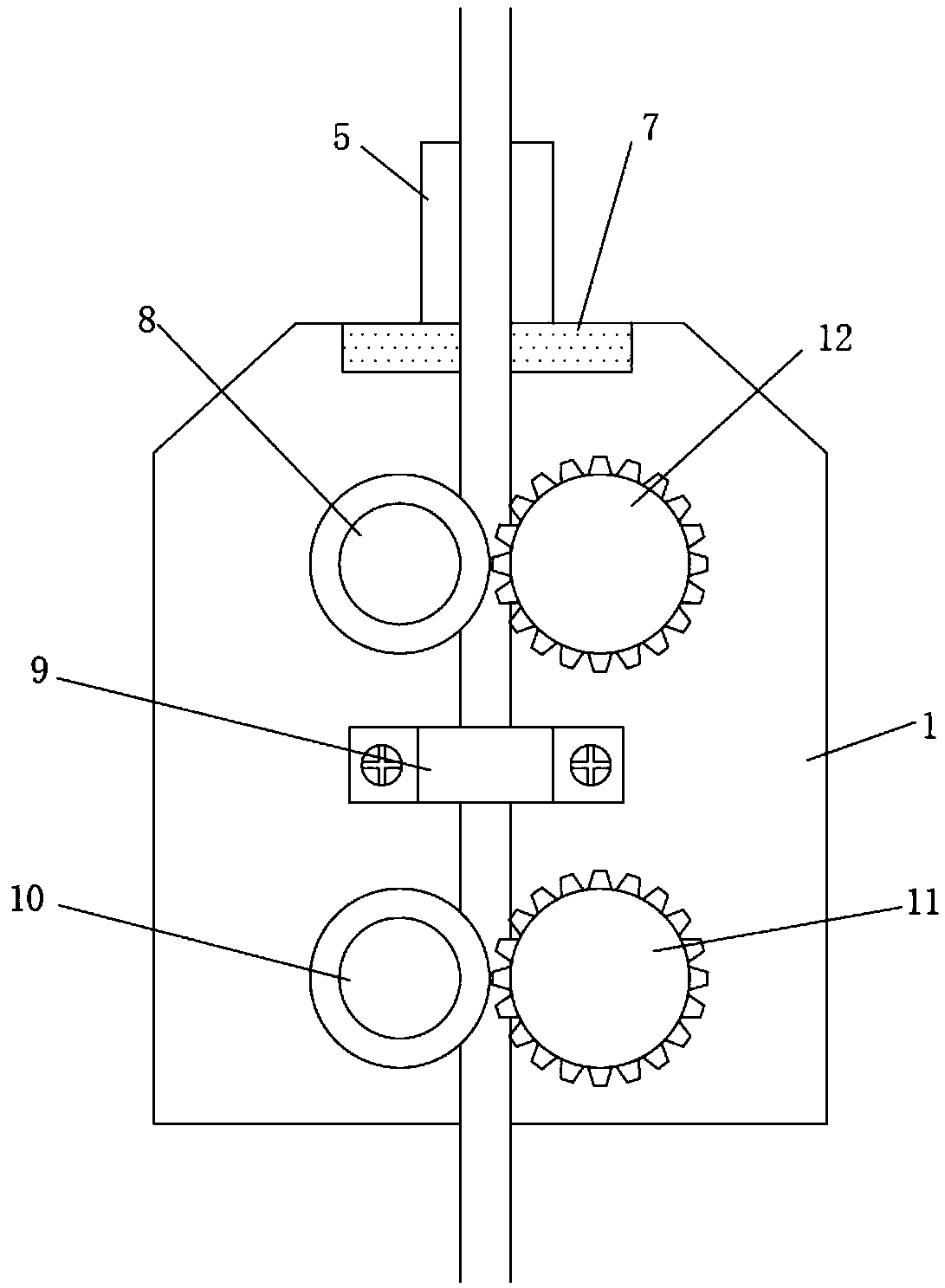

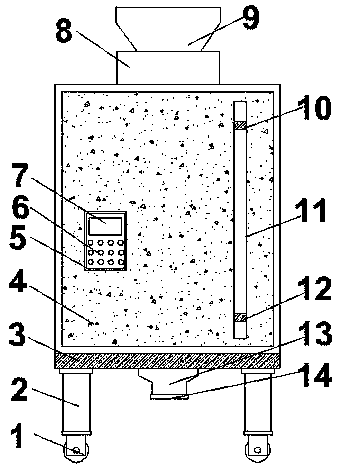

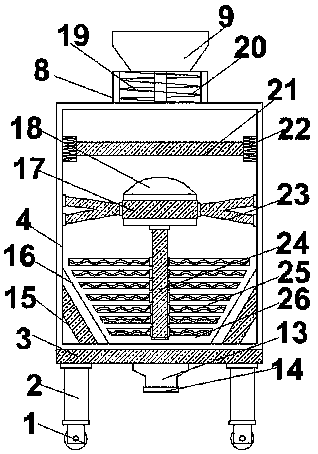

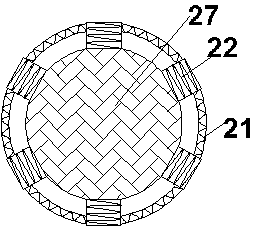

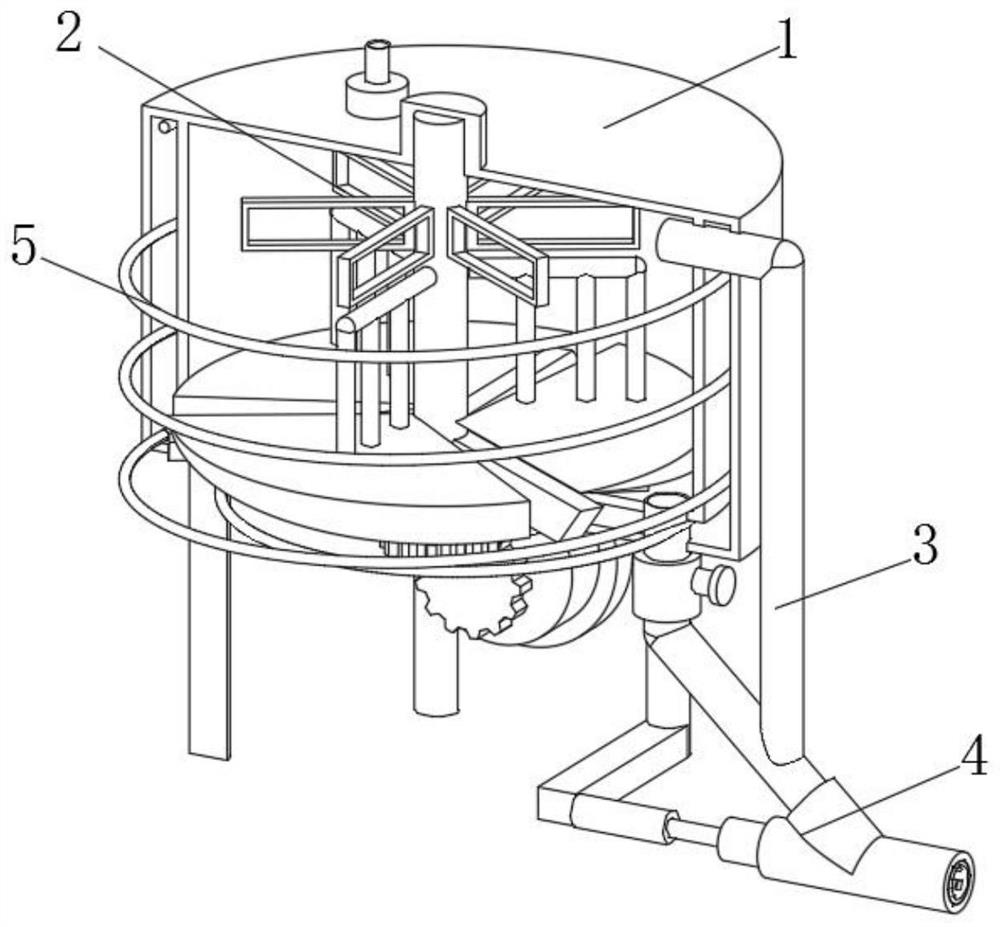

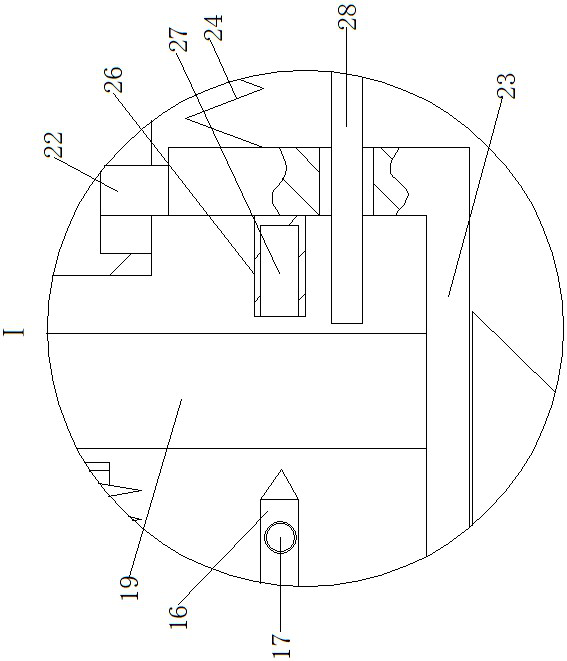

An intelligent injection molding equipment for the production of auto parts

ActiveCN107825655BImprove practicalityAvoid affecting the injection molding effectPlastic recyclingRecovery mechanismScrap

The invention relates to intelligent injection molding equipment for vehicle part production. The equipment comprises a main body, a production chamber and a charging box, and further comprises a cleaning mechanism and a recovery mechanism; the cleaning mechanism comprises a lifting module and a cleaning module; the cleaning module comprises a driving chamber, a second motor, a rotating wheel, a swing rod and a cleaning brush; and the recovery mechanism comprises a recovery chamber, a crushing module and a stirring module. In the intelligent injection molding equipment for vehicle part production, the cleaning brush of the cleaning mechanism swings back and forth to sweep off accumulated materials on a nozzle to prevent influence on the injection molding effect, so that the product qualityis improved; compared with manual cleaning, the cleaning mode is safer and more efficient; wastes and the swept accumulated materials can be recovered and crushed through the recovery mechanism to achieve heating and melting; and through uniform stirring, the materials are thoroughly molten to achieve future reutilization, so that the cost investment is saved, and the practicability of the injection molding equipment is greatly improved.

Owner:南通柏源汽车零部件有限公司

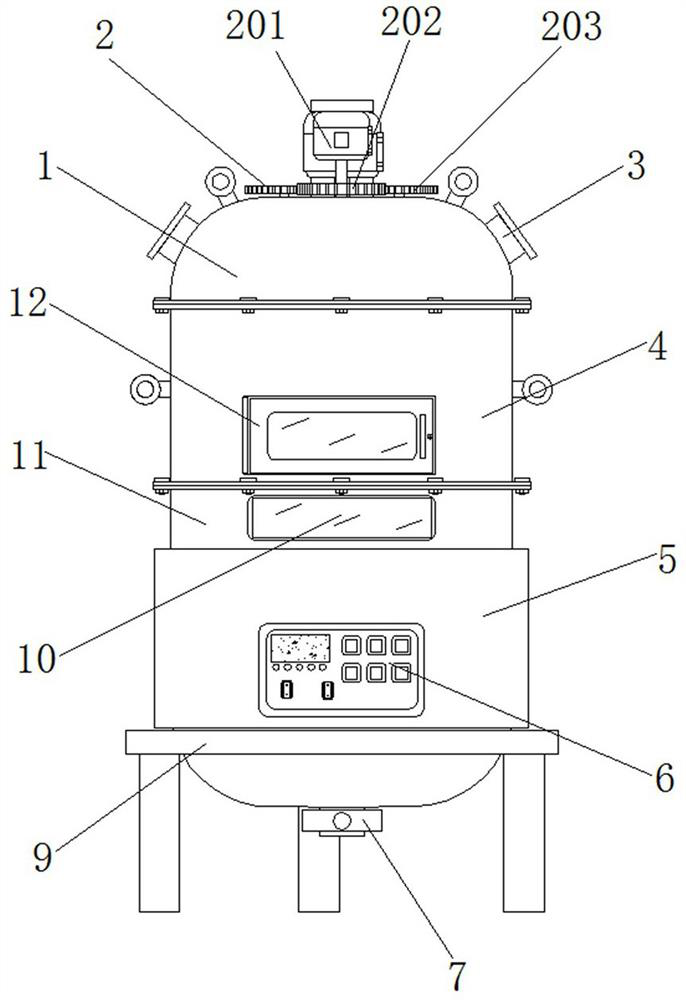

Security-enhanced ventilative pressure discharge and temperature control plastic recycling smelting furnace

InactiveCN108724528AEasy to storeInfluence transfer processCharge composition/statePlastic recyclingTemperature controlIntermittent heating

The invention discloses a security-enhanced ventilative pressure discharge and temperature control plastic recycling smelting furnace and relates to the field of plastic recycling equipment. The smelting furnace comprises a preparation chamber, a partition board and a material melting chamber. The left and right sidewalls of the preparation chamber are both internally provided with electric heating layers. An external heat insulation electric heating guard barrel is arranged on the outer side of the material melting chamber. A cavity is formed in the position, close to the left side, of the interior of the partition board. The left side of the cavity is connected with an electromagnetic control mechanism. The right side of the cavity is connected with a starting mechanism. The electromagnetic control mechanism is in threaded connection with the starting mechanism. The smelting furnace conducts continuous intermittent heating on plastics in the preparation chamber so that the plastics in the preparation chamber can be kept in a fluidic state all the time, and the plastics is stored well. When the plastics gets into the preparation chamber to make contact with the transition thermalization temperature of a transition thermalization tube, the fluidic state of the plastics is ensured. In the starting process, an operator can be protect against direct contact with a high-voltage switch for turning on a machine starting device, and the operation environment is safer.

Owner:安徽圣贝诺建筑装饰工程有限公司

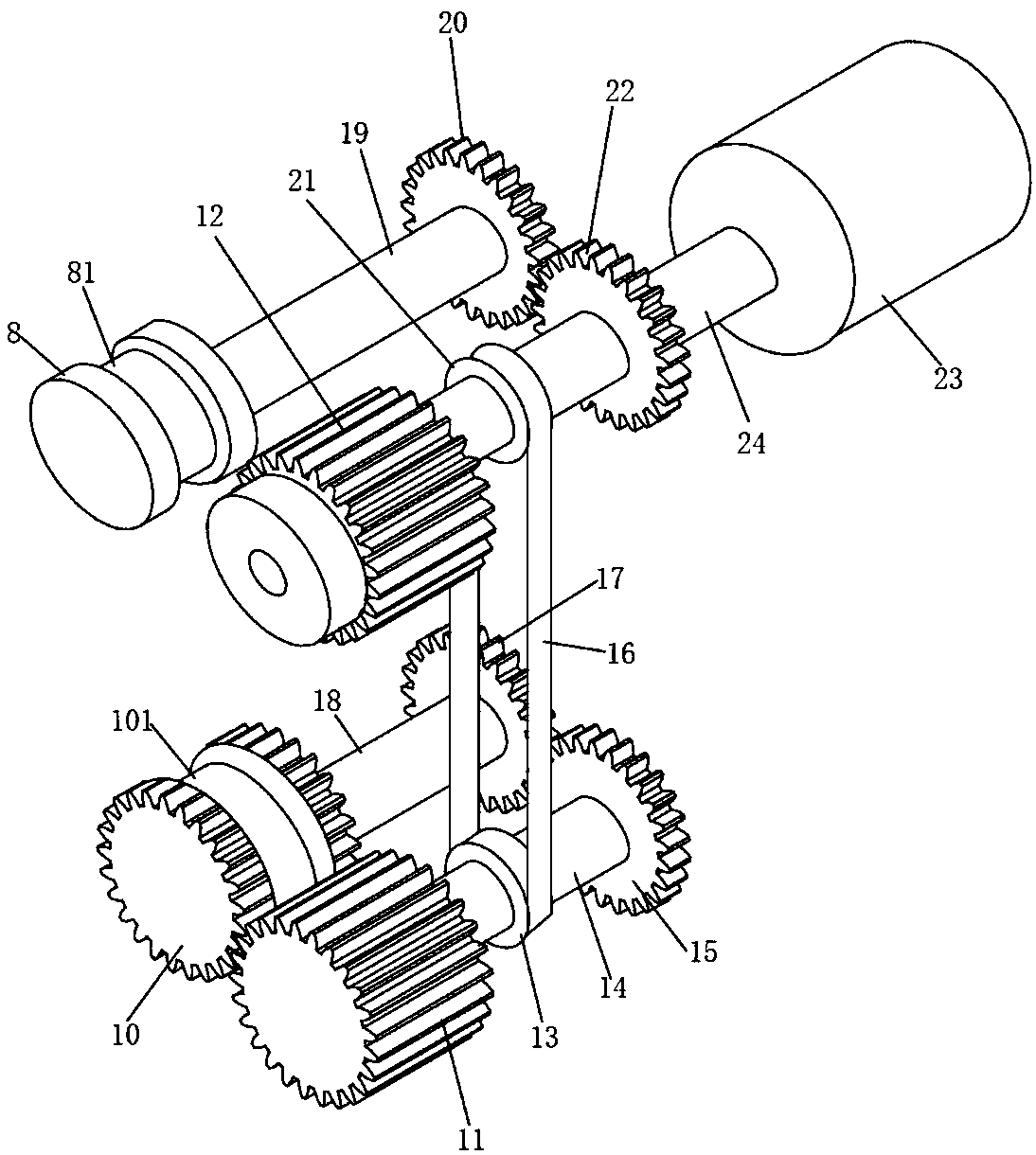

Three-dimensional material adding printer with automatic material guiding function

InactiveCN109094025AReduce settingsLow costManufacturing driving means3D object support structuresSpray nozzleEngineering

The invention discloses a three-dimensional material adding printer with an automatic material guiding function. The printer comprises a protection box body, wherein the inner cavity of an equipment installation cavity is provided with a driving motor; the front part, which extends out of the protection box body, of the first spindle of the output end of the driving motor is connected with a mainmaterial guiding wheel; the front part, which extends out of the protection box body, of a second spindle is connected with an auxiliary material guiding wheel; the front part, which extends out of the protection box body, of the left end of a third spindle is connected with a main material guiding gear; and the front part, which extends out of the protection box body, of the left end of a fourthspindle is connected with an auxiliary material guiding gear. A long and cylindrical printing raw material enters between the arc-shaped spacing plate of an auxiliary spacing device and the front surface of the protection box body so as to reduce the swinging of the long and cylindrical printing raw material; and the auxiliary material guiding gear and the main material guiding gear are both in contact with the surface of the long and cylindrical printing raw material, and the main material guiding gear cuts one side of the surface of the long and cylindrical printing raw material but does notcut off the printing raw material so as to be favorable for the printing material to be heated and melted after the printing raw material enters the venturi of a spray nozzle.

Owner:HEFEI AIRWREN AUTOMATIC EQUIP CO LTD

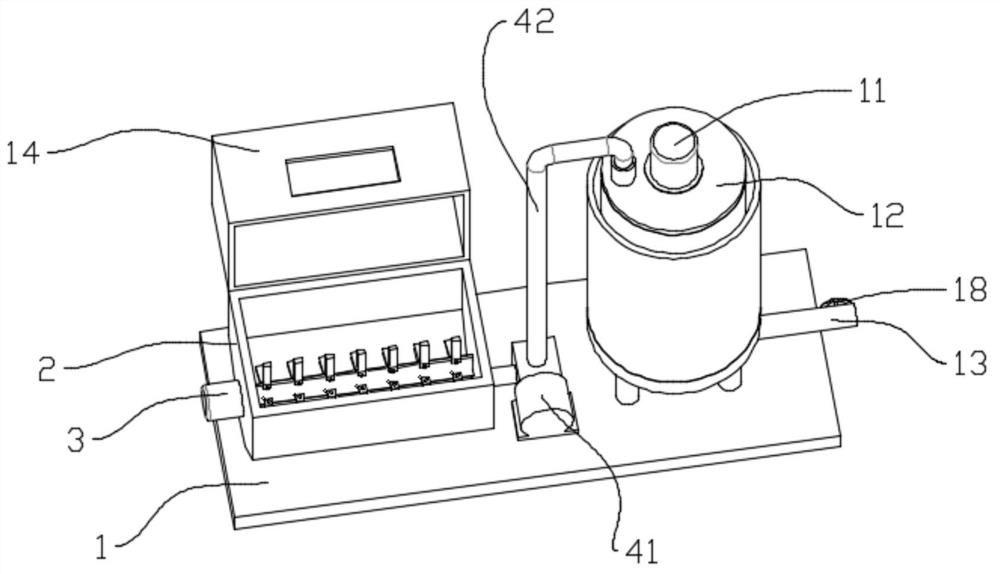

Production device for degradable polypropylene plastics and preparation method of degradable polypropylene plastics

The invention discloses a production device for degradable polypropylene plastics and a preparation method of the degradable polypropylene plastics. The production device is characterized by comprising a bottom plate; a mixing box is fixedly installed on the upper surface of the bottom plate; a mixing mechanism is arranged in the mixing box; the mixing mechanism is installed on the surface of the mixing box through a bearing; a material conveying mechanism is arranged on one side of the mixing box; and the material conveying mechanism is fixedly installed on the upper surface of the bottom plate. A first discharging pipe is fixedly installed on the lower side of the mixing box; the first discharging pipe is connected with the material conveying mechanism; an installation rack is arranged on one side of the material conveying mechanism; and a reactor is fixedly installed on the installation rack. By arranging the mixing box, the degradable polypropylene raw material is easy to place; due to the mixing mechanism, all the raw materials are sufficiently mixed, and the improvement on the quality of the degradable polypropylene plastics is facilitated; and by arranging the material conveying mechanism, the raw materials mixed by the mixing mechanism are easily drawn into the reactor for heating and melting.

Owner:董丹丹

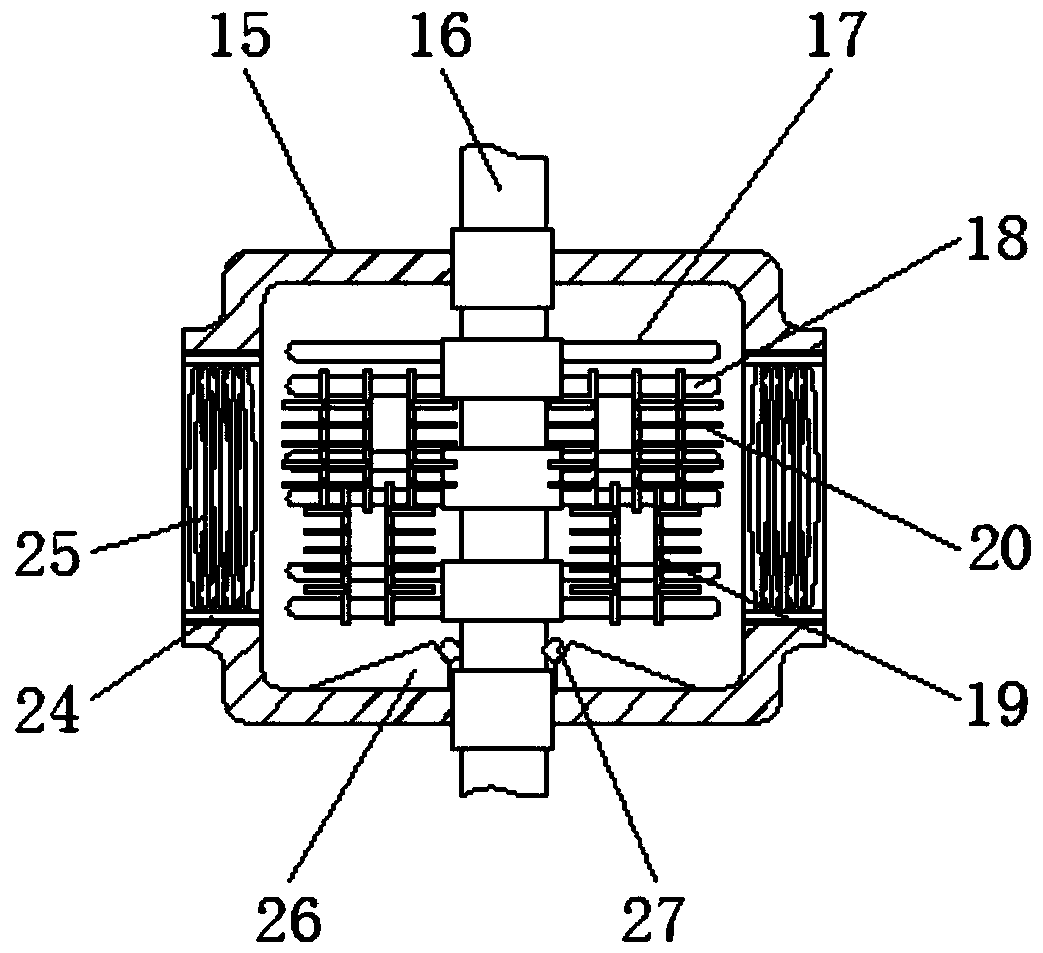

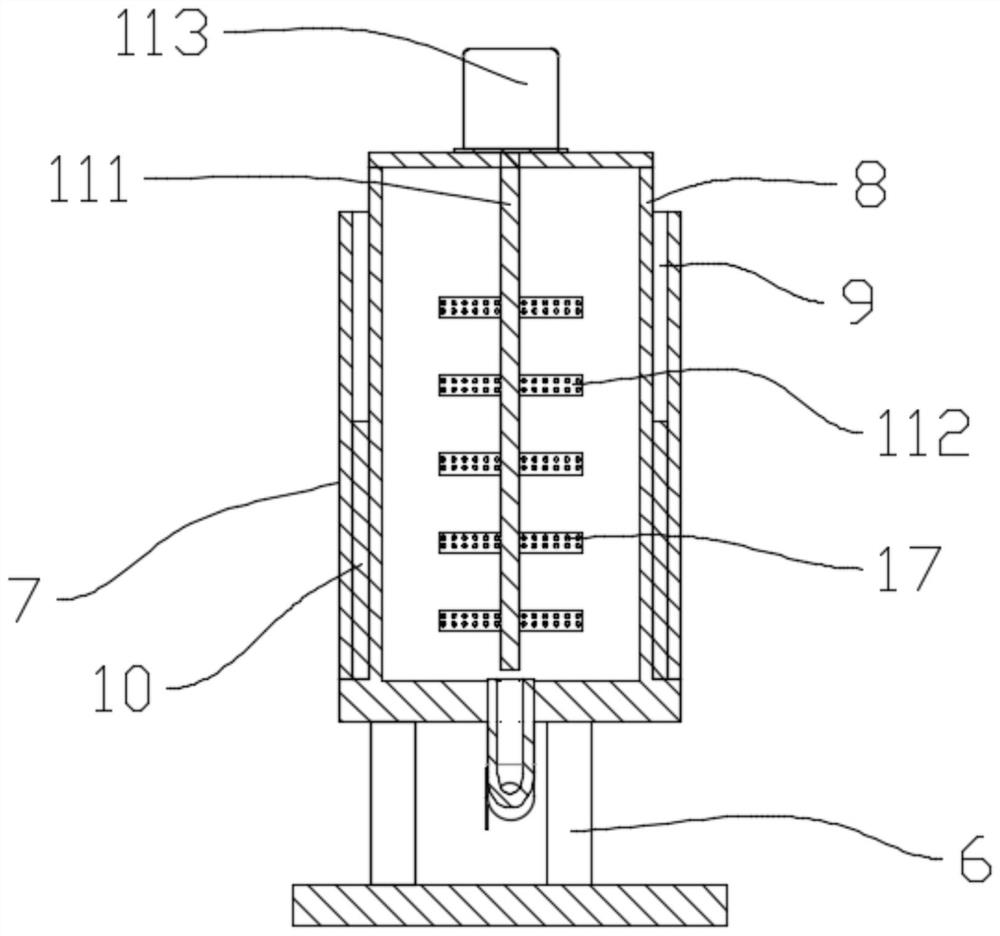

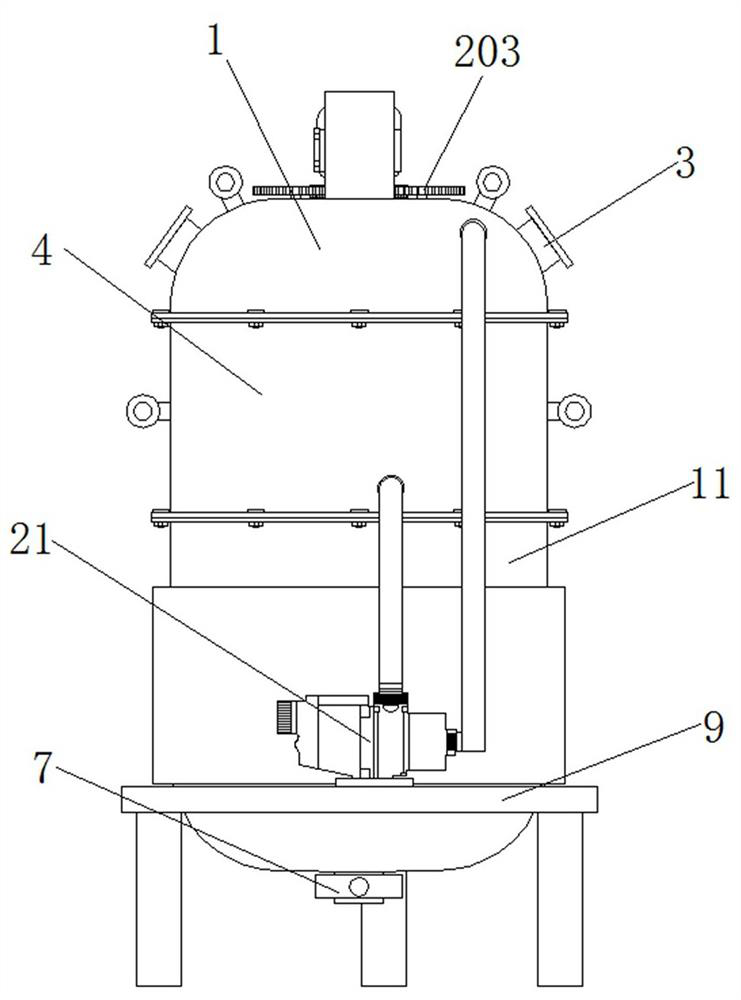

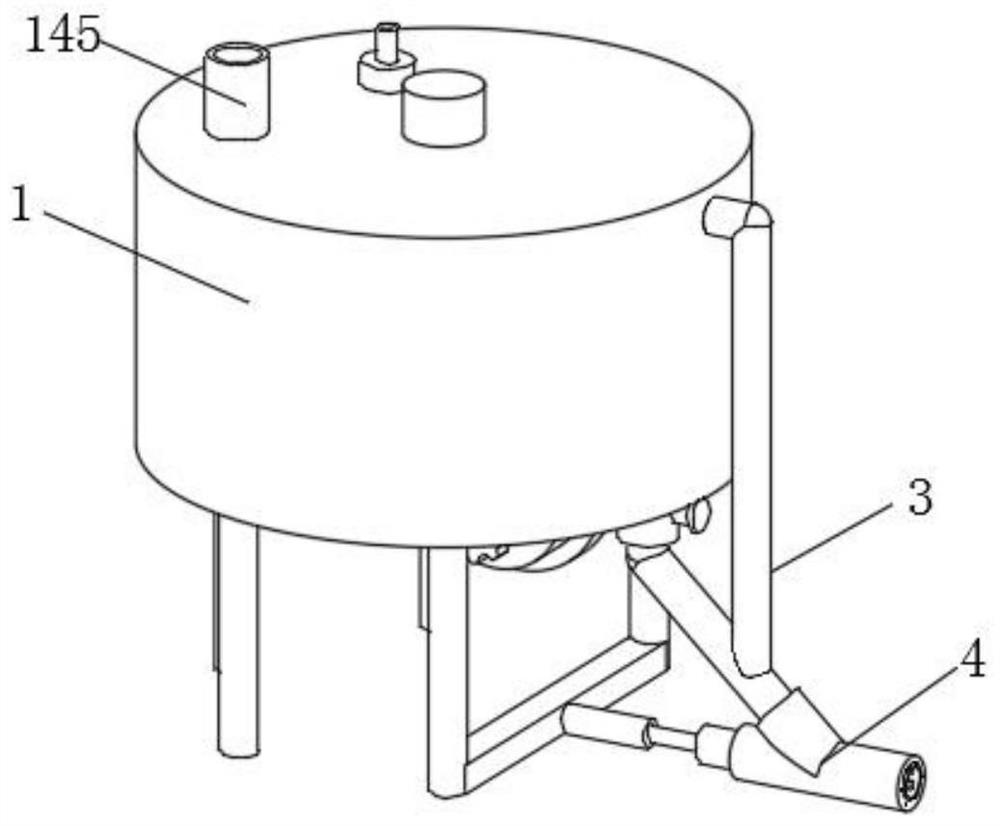

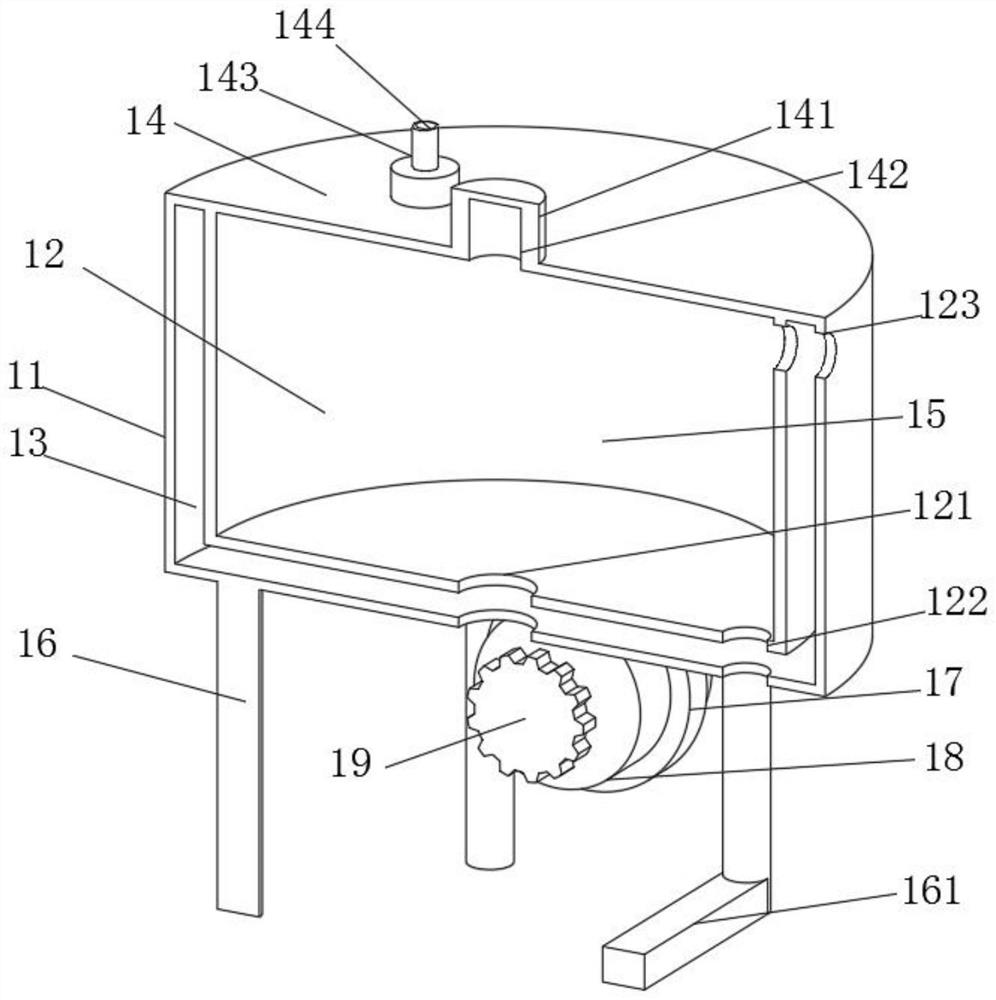

Progress-visualized high-molecular polymerization reaction kettle

InactiveCN113145056AImprove grinding efficiencyEasy to heat and meltChemical/physical/physico-chemical stationary reactorsGrain treatmentsElectric machineEngineering

The invention discloses a progress visualized macromolecule polymerization reaction kettle which comprises a top bin, a middle bin and a bottom bin, a heat preservation bin is arranged on the outer side of the bottom bin, a supporting frame is installed at the bottom of the outer side of the bottom bin, a progress observation window is formed in the top of the outer side of the bottom bin, and a driving motor is installed in the center of the top of the top bin. A first main rotating shaft is installed at the output end of the driving motor, and the bottom of the first main rotating shaft extends into the top bin and is provided with a grinding head. Through cooperative use of the top bin, the middle bin, the auxiliary grinding assembly, the first main rotating shaft and the grinding head, through cooperation of the funnel bin and the grinding head, the first main rotating shaft drives the grinding head to rotate in the forward direction, and the first main rotating shaft drives the funnel bin to rotate in the reverse direction; and the high polymer material grinding efficiency of the device can be greatly improved without increasing the rotating speed of the driving motor, and the crushed high polymer material is easier to heat and melt in the bottom bin, so that the polymerization efficiency of the high polymer material is improved.

Owner:荡麦金属表面技术处理(上海)中心

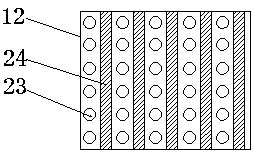

Extrusion mechanism of plastic injection molding machine

InactiveCN110341146AEasy to heat and meltFaster and more even temperatureElectricityPlastic injection molding

The invention discloses an extrusion mechanism of a plastic injection molding machine. The extrusion mechanism of the plastic injection molding machine comprises a material barrel, a screw rod, a motor, a thermocouple and an electric control device, wherein a charge port and a discharge port are formed in the material barrel; the screw rod is arranged in the material barrel, and driven to rotate in the material barrel by the motor; and the thermocouple is used for measuring the temperature of the material barrel. The extrusion mechanism of the plastic injection molding machine is characterizedin that cylindrical chambers parallel to the axial direction are distributed in the annular barrel wall of the material barrel; supports are arranged at the two ends of the material barrel separately; a quartz glass heating pipe is located in each chamber, and the two ends of each quartz glass heating pipe stretch out from the corresponding chamber; the two supports are connected with the two ends of each quartz glass heating pipe separately; a heat-isolation layer is installed at the outer side of the barrel wall of the material barrel; a heat discharge port is formed in the top of the heat-isolation layer; the heat discharge port is provided with a cover and a cylinder; the cylinder is capable of controlling the cover to cover the heat discharge port or being separated from the heat discharge port; and the electric control device controls the power supply of the quartz glass heating pipes and the working of the cylinder according to a signal of the thermocouple. The mechanism has the characteristics of being energy-saving and emission-reducing.

Owner:LONGYUAN IND SHANTOU CITY

Automatic hot punching equipment and using method thereof

The invention discloses automatic hot punching equipment and a using method thereof, relates to the technical field of hot punching equipment, and aims at solving the problems that existing automatichot punching equipment cannot conveniently convey materials, and the materials still need to be manually placed on a to-be-hot-punched platform. A rotating shaft is arranged above a base, sliding rodsare fixedly arranged at the two sides of the rotating shaft, a threaded sleeve is arranged on the outer wall of the rotating shaft in a threaded manner, a hydraulic telescopic rod is fixedly arrangedat the front end of the threaded sleeve, a mounting plate is arranged at the front end of the hydraulic telescopic rod, and a heat insulation plate is arranged below the mounting plate. A movable plate is fixedly arranged below the heat insulation plate, an upper heating plate is fixedly arranged below the movable plate, punching tool bits are fixedly arranged below the upper heating plate, the number of the punching tool bits is two, hot melting pipes are fixedly arranged at the inner sides of the two punching tool bits, and a motor base is fixedly arranged in the base. A servo motor is fixedly mounted in the motor base.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

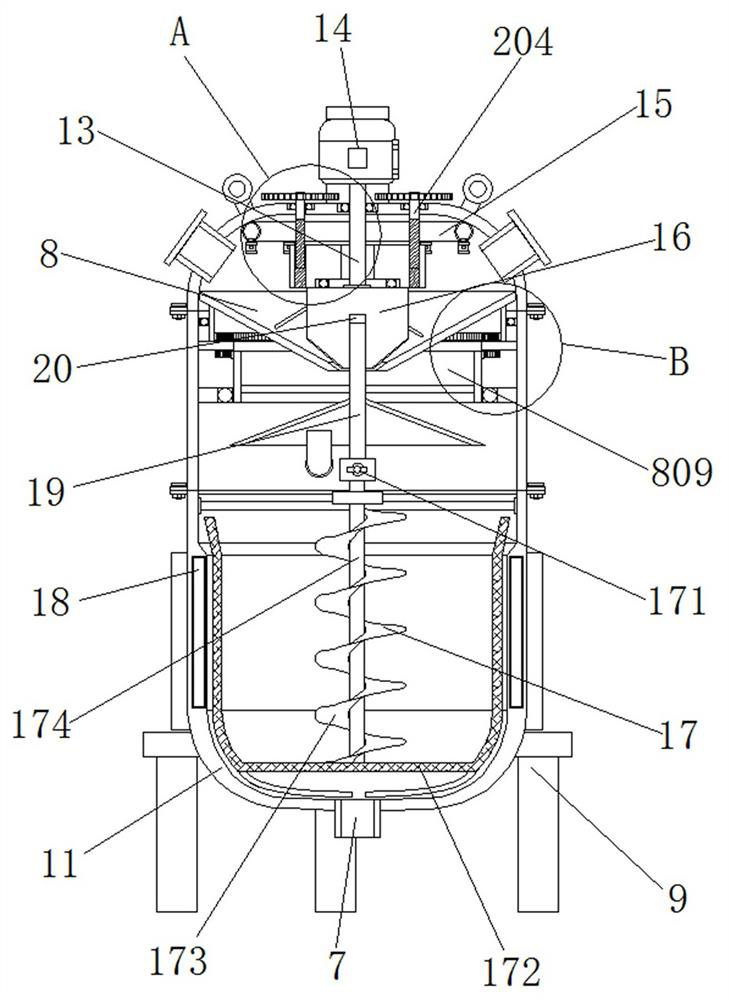

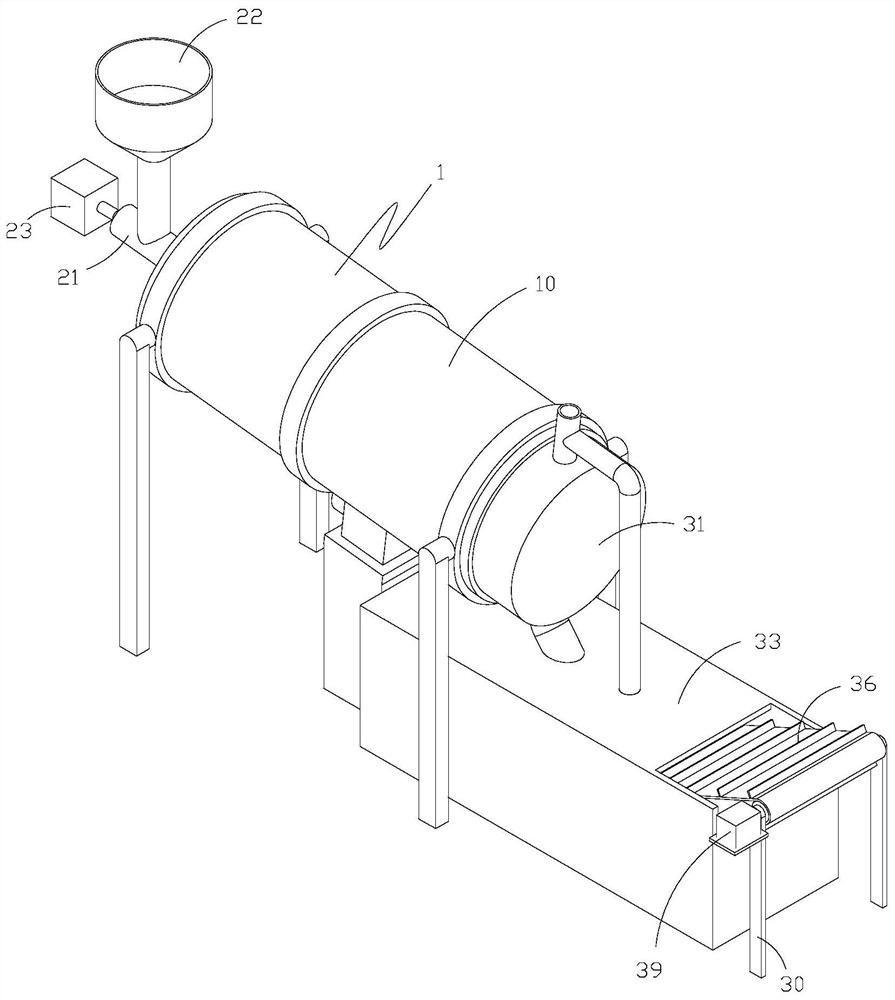

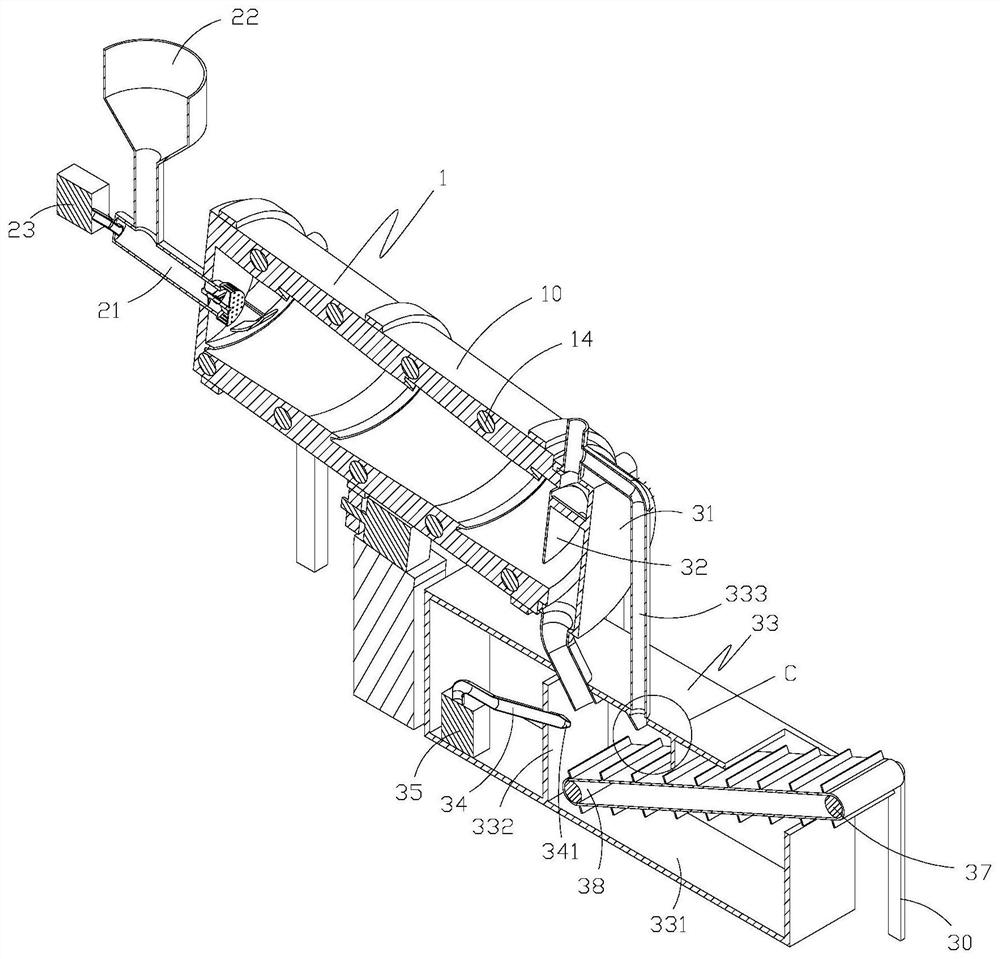

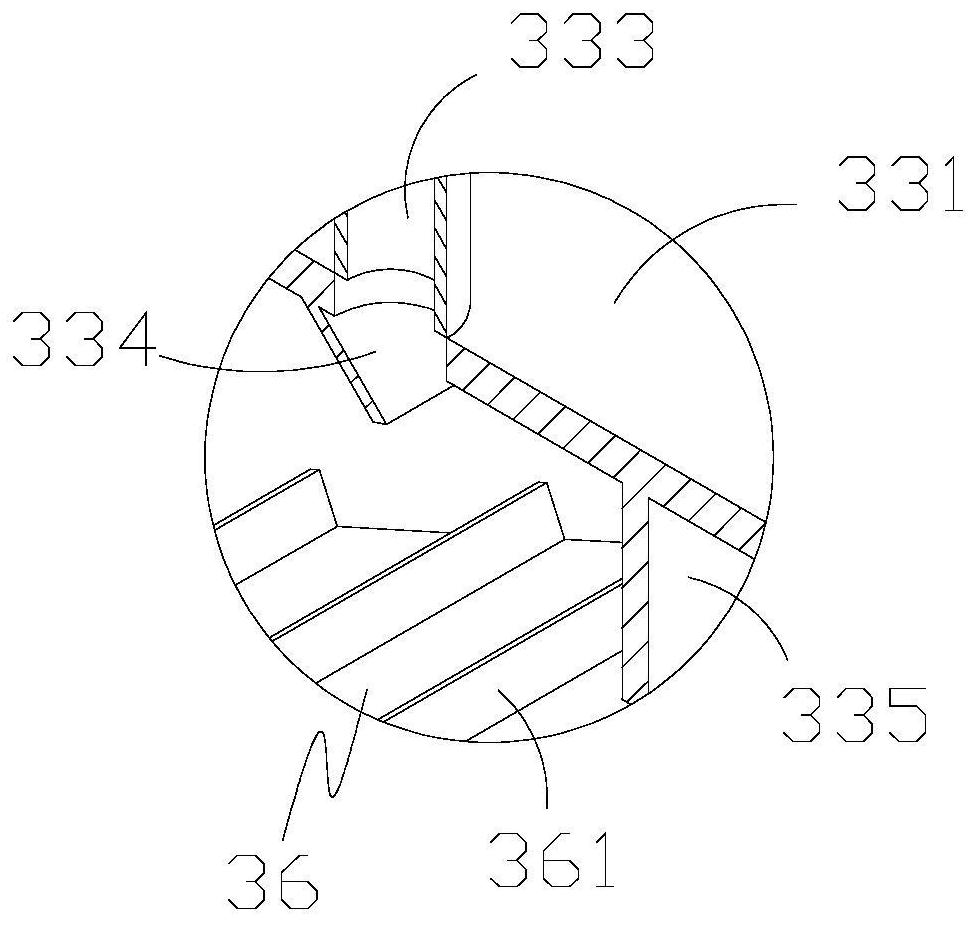

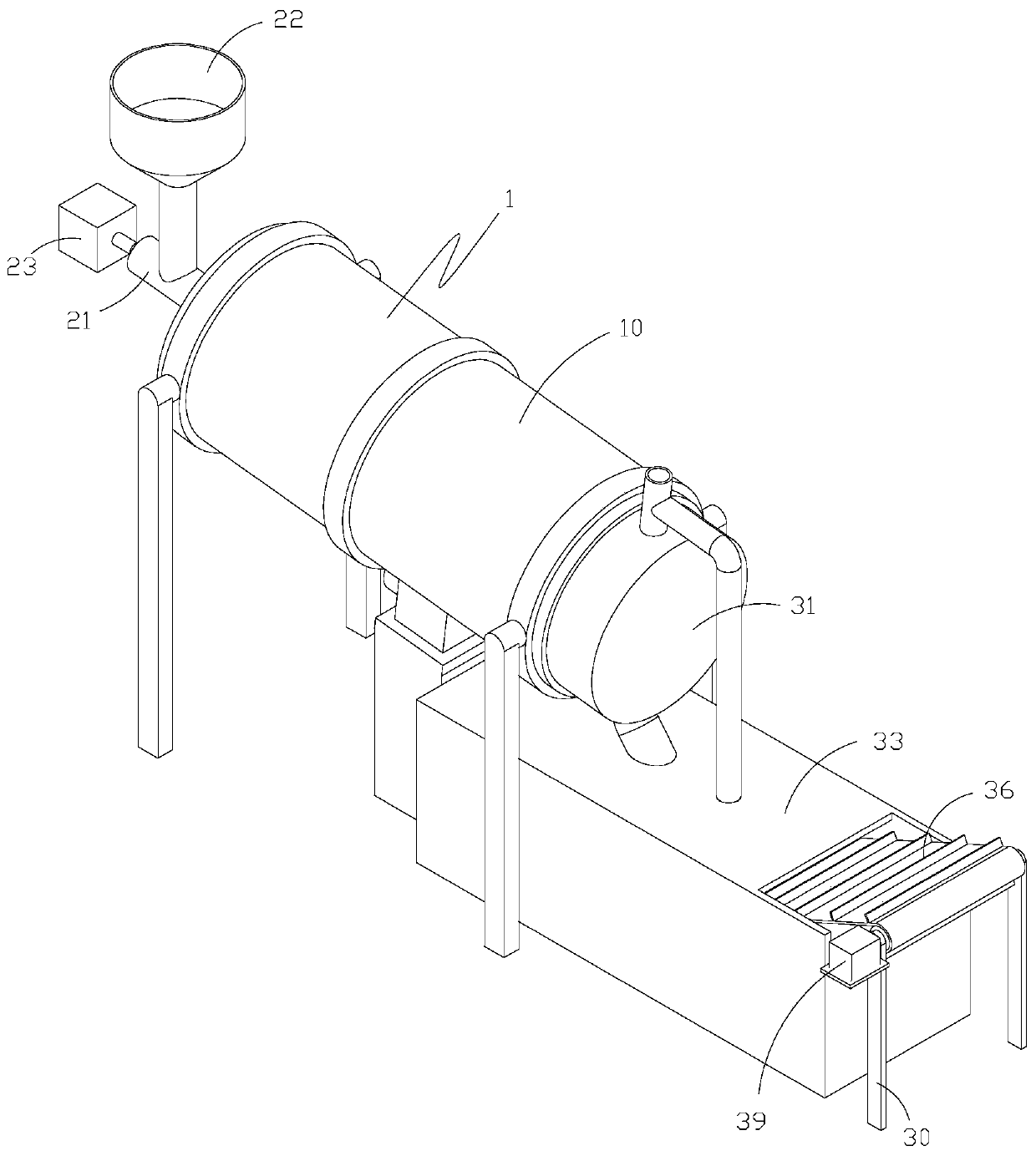

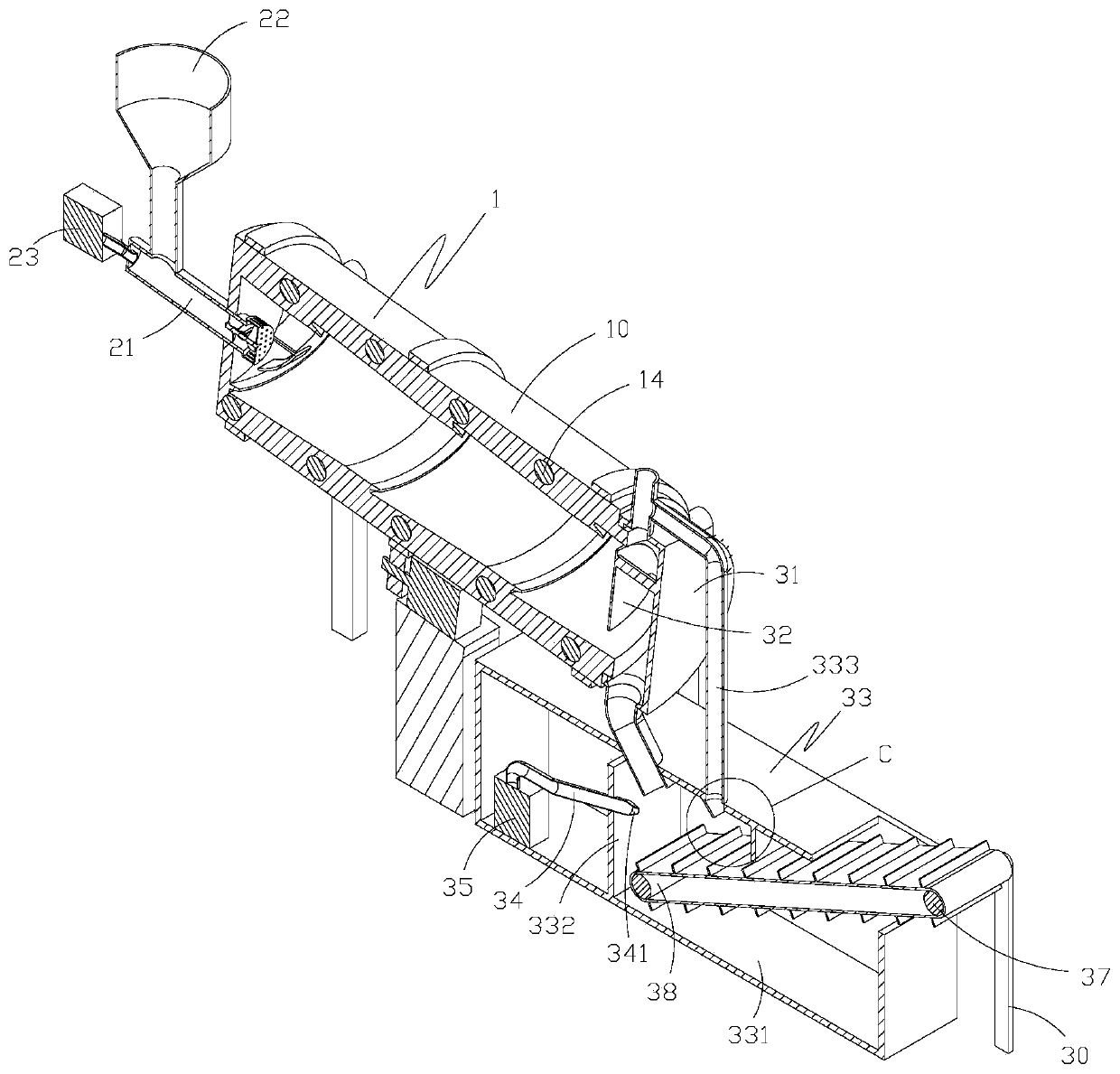

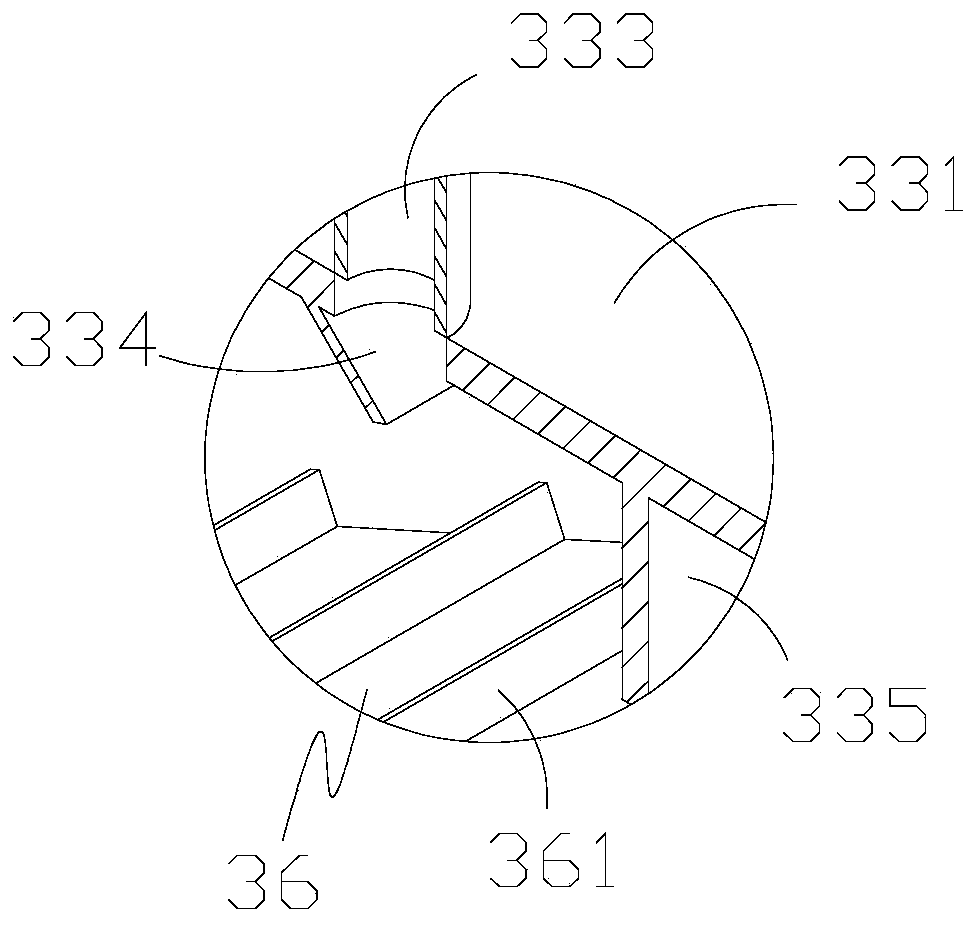

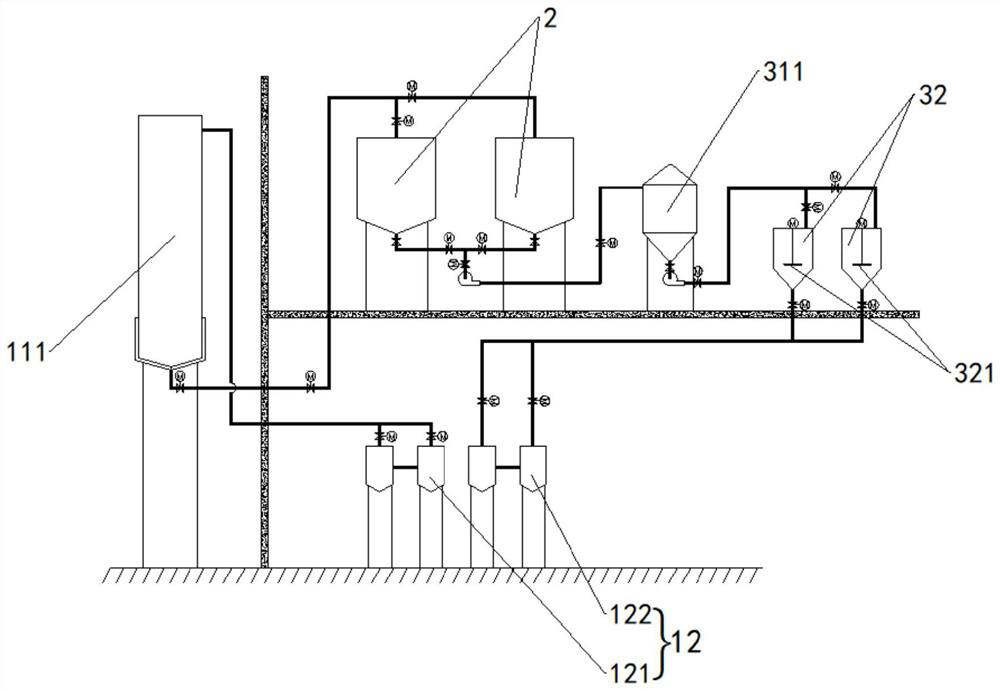

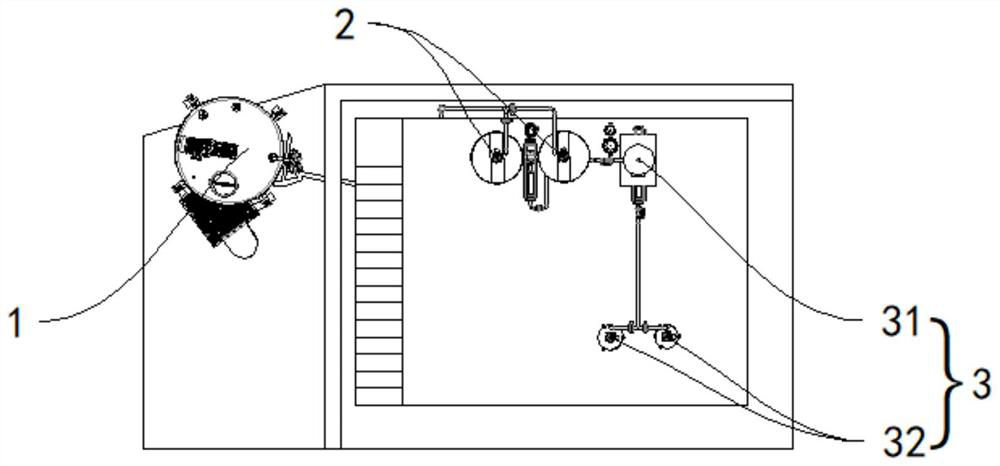

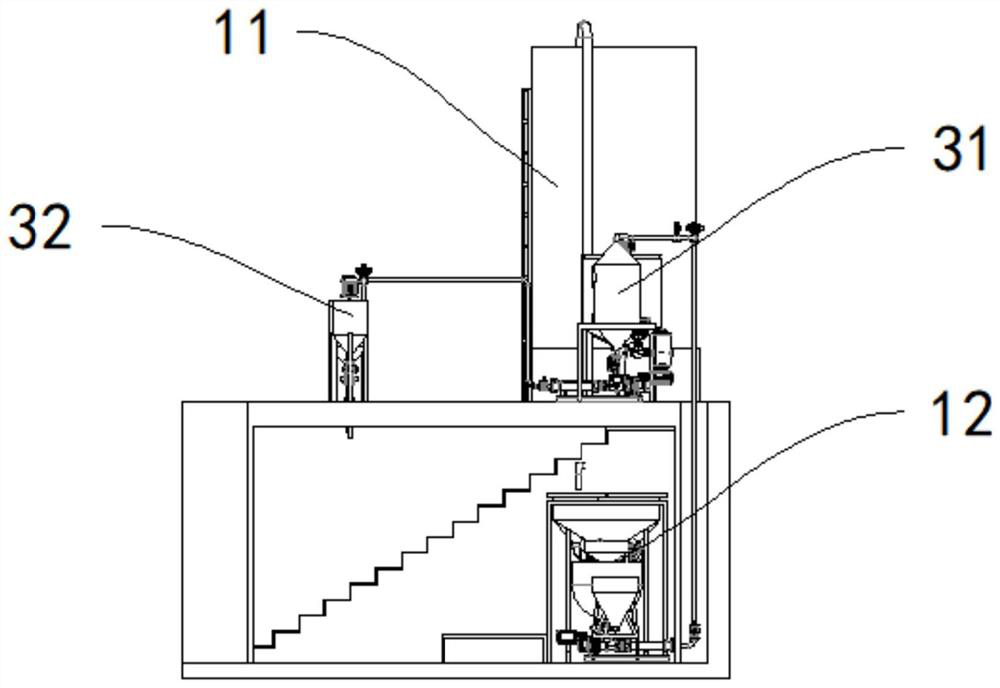

A new processing equipment for molten fly ash

ActiveCN110756569BSpeed up the flowAvoid residueSolid waste disposalTransportation and packagingMechanical engineeringFly ash

The invention discloses a new treatment equipment for molten fly ash, which includes an incineration device, a feeding device matched with the incineration device and a water quenching device matched with the incineration device; the incineration device includes a A rotary kiln that moves back and forth; the water quenching device includes a material receiving part that is rotatably matched with the rotary kiln, an exhaust pipe arranged on the material receiving part, a discharge pipe arranged on the material receiving part and A water quenching pool connected with the discharge pipe; the water quenching pool includes a pool body, an injection device for forming slag into fine particles and a conveying device for taking out fine particles from the pool body; The invention enables rapid cooling of molten slag and formation of fine molten slag particles through the arrangement of water quenching device, injection device and conveying device, which facilitates collection and subsequent treatment, and improves processing efficiency.

Owner:GUANGDONG TAIQUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Novel treatment device used for melting flying ash

ActiveCN110756569AHeating fastEvenly heatedTransportation and packagingSolid waste disposalThermodynamicsProcess engineering

The invention discloses a novel treatment device used for melting flying ash. The novel treatment device used for melting the flying ash comprises an incineration device, an adding device matched withthe incineration device, and a water quenching device matched with the incineration device. The incineration device comprises a rotary kiln which can move back and forth. The water quenching device comprises a receiving component in running fit with the rotary kiln, an exhaust pipe arranged on the receiving component, a discharging pipe arranged on the receiving component, and a water quenching pool communicating with the discharging pipe. The water quenching pool comprises a pool body, a jet device used for forming fine particles by means of molten slag, and a conveying device used for taking the fine particles out of the pool body. According to the novel treatment device, through the arrangement of the water quenching device, the jet device and the conveying device, the molten slag canbe rapidly cooled to form the fine slag particles, collection and subsequent treatment are facilitated, and the processing efficiency is improved.

Owner:GUANGDONG TAIQUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Biodegradable PVA instant film and preparation method thereof

The invention relates to a biodegradable PVA instant film and a preparation method thereof. The processing materials are composed of the following ingredients: 65-75 parts of PVA with alcoholysis degree being 88% and degree of polymerization being 500-3000; 4-6 parts of a pre-modifier, which is formed by compounding of at least a water-soluble zinc salt A, a mineral nucleating agent B with at least a part dissolved in water, at least one organic acid C and at least one water-soluble inorganic acid D; 15-30 parts of a plasticizer; 5-15 parts of deionized water; 0.5-5 parts of a processing aid;and 0.1-10 parts of a solubilizer. In the raw materials of the pre-modifier, zinc salt A and the mineral nucleating agent B are the main ingredients, and the mixed acid added for modification simultaneously produces a synergistic effect, and a coordination reaction occurs to form a three-dimensional porous net structure formed by bonding of multiple active centers and multiple bridging fibers. then, the specific surface area is increased (to facilitate heat melting), presence of polyvinyl alcohol regular molecular chains is destroyed and reduced, the proportion of amorphous structures is increased, fusing and dissolving temperature of polyvinyl alcohol are also greatly reduced, and the problem of water dissolution rate and condensation polymerization is solved.

Owner:安徽鼎正高分子材料科技有限责任公司

Raw material melting device for dust-free PE bag production

The invention discloses a raw material melting device for dust-free PE bag production. The raw material melting device comprises rolling wheels, a melting box and an inclined plate; when the raw material melting device is in use, the raw materials are pushed into a heating box through a feeding hole, and the heating box carries out first heating on the raw materials; then the raw materials are pushed into the melting box through a spiral pushing rod, and an extruding condition exists in the pushing process; the raw materials can be extruded and crushed, so that better subsequent heating and melting can be facilitated; furthermore, the raw materials enter a vibration net, and second heating is carried out through a heating net on the vibration net; the small particle raw materials are leaked to the bottom of the melting box through vibration during the heating process; the raw materials at the bottom of the melting box are finally heated and melted through a heating pipe inside a stirring rod and a heating block in the inclined plate; and after being completely heated and melted, the raw materials are discharged through a discharging port. By virtue of the overall design of the device, the raw materials can be fully melted, so that the quality of the product is guaranteed; and the device is convenient and rapid to use and operate, very high in practicability and convenient to popularize.

Owner:孙立强

Linear low-density polyethylene production device facilitating heating and using method of linear low-density polyethylene production device

ActiveCN112405916AEasy to useIncrease contact timeLinear low-density polyethyleneLow-density polyethylene

The invention relates to the technical field of linear low-density polyethylene heating, in particular to a linear low-density polyethylene production device facilitating heating and a using method ofthe linear low-density polyethylene production device. The linear low-density polyethylene production device comprises a production device body, a stirring device is arranged inside the production device body, a feeding pipe is arranged on one side of the production device body, an extrusion device is arranged at one end of the feeding pipe, the stirring device comprises a rotating shaft, a plurality of rotating frames are annularly, uniformly and fixedly arranged on the side wall of the end, close to the top, of the rotating shaft, iron wire net frames are fixedly connected to the rotating frames, a bottom pressing plate and a rhombic batten are fixedly connected to the side wall, close to the bottom, of the rotating shaft, the extrusion device comprises an extrusion pipe, one end of a straight pipe is fixedly connected with an extrusion outlet pipe, and an air passing device is installed inside the extrusion outlet pipe. According to the linear low-density polyethylene production device, the problem that heat is generated due to the fact that linear low-density polyethylene particles are adhered to objects during heating and melting is mainly solved, meanwhile, when the substances are melted, bubbles can be generated, and the use condition of subsequent linear low-density polyethylene molten liquid is influenced.

Owner:新疆金大禹环境科技有限公司

A multi-channel inlet, ventilating, exhausting, pressure-controlled and temperature-controlled smelting furnace for recycling plastics

InactiveCN108908789BEasy to storeInfluence transfer processPlastic recyclingCharge composition/stateTemperature controlThermal insulation

The invention discloses a multi-channel smelting furnace capable of ventilating, exhausting, pressure-relieving and temperature-controlled recycling of plastics, which includes a preparation chamber and a melting chamber. There is a fixed connection frame, and an external thermal insulation electric heating sleeve is arranged on the outside of the melting chamber, and the melting chamber is located above the fixed connection frame. The multi-channel inlet, ventilated, pressure-exhausted and temperature-controlled smelting furnace for recycled plastic achieves the purpose of continuous and intermittent heating of the plastic in the preparation room through uniformly arranged electric heating racks and electric heating nets installed on each electric heating rack, making the preparation room The plastic in the chamber can be kept in a fluid state at all times, so that the plastic can be better stored in the preparation chamber. When the plastic enters the preparation chamber, it first enters through the feed pipe and contacts the transition heat of the transition heating tube. After heating, ensure its own flow state, and avoid the plastic from condensing on the inner wall of the feed pipe, which will cause the blockage of the feed pipe.

Owner:安徽圣贝诺建筑装饰工程有限公司

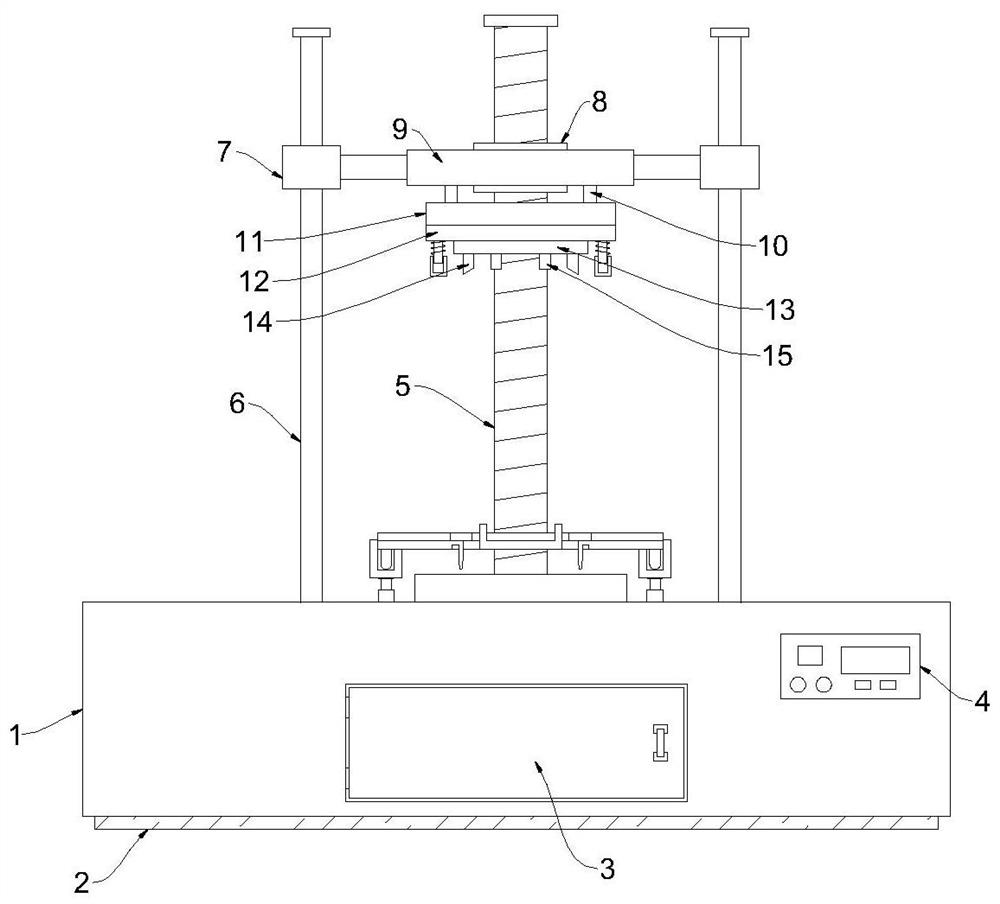

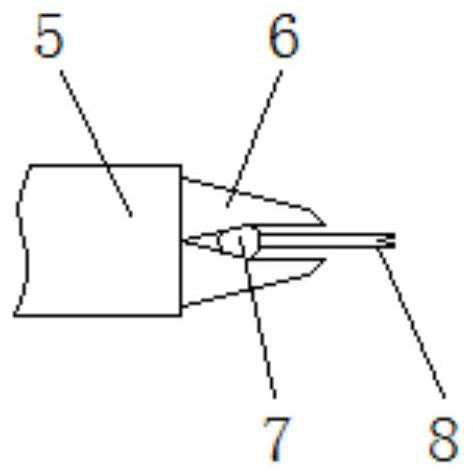

A pcb soldering device

ActiveCN105478947BEasy to heat and meltStandardized operation and easy controlHeating appliancesPrinted circuitsInsulation layerPiston

The invention discloses a pcb welding device which comprises a hollow pipe. One end of the hollow pipe is in sealing connection with a discharging device, and the other end of the hollow pipe is in sealing connection with a connecting part. The discharging pipe is in a funnel shape, and an end cover is detachably arranged on a conical part of the discharging device. A piston is arranged in the hollow pipe, and a copper pipe is arranged on the piston in a penetrating manner in the axis direction of the piston. The outer wall of the copper pipe is in sealing connection with the piston. The copper pipe penetrates the connecting part and can slide along a movable part, and a handle is arranged at the position, different from the end connected with the piston, of the copper pipe. A spring is arranged in the hollow pipe and located between the piston and the discharging device. The hollow pipe is sleeved with a shell, and the two ends of the shell are connected with the discharging device and the connecting part respectively. A heat insulation pad is arranged between the shell and the hollow pipe. A resistance wire is arranged between the heat insulation pad and the hollow pipe. A heat conduction insulation layer is arranged between the hollow pipe and the resistance wire. In the process of utilizing the device for pcb welding, operation standardability is easy to control, and welding quality is guaranteed.

Owner:深圳市全球威科技有限公司

A kind of asphalt smear forming machine for water blocking belt on both sides of the road

ActiveCN109610276BHeight adjustableEasy to heat and meltRoads maintainenceMolding machineMechanical engineering

The invention relates to a water retaining belt former, in particular to an asphalt applying former for water retaining belts on the both sides of a road. A crushing combination crushes raw materialsinto pieces to facilitate heating and smelting; a stirring and feeding combination stirs the raw materials and intensively mixes substances of different kinds, so that the raw materials are heated uniformly; the molten materials are guided, delivered and pushed downwards; and a forming combination is adjustable in height to meet multiple forming requirements. A forming die combination is mounted on the lower side of a heating combination, the lower side of the stirring and feeding combination and the lower side of the crushing combination; the heating combination is mounted on the lower side of the crushing combination and outer side of a frame body combination and connected with the frame body combination; the stirring and feeding combination is mounted on the lower side of the crushing combination and the inner side of the frame body combination and connected with the frame body combination; the crushing combination is mounted on the upper side of the frame body combination and connected with the frame body combination.

Owner:宗广鹏

3D printing spray head for printing clothes

ActiveCN112026167AEmission reductionFast curingManufacturing heating elements3D object support structures3d printWire rod

The invention discloses a 3D printing spray head for printing clothes. The 3D printing spray head comprises a spray head body, wherein the spray head body comprises a spray tube with an opening in thelower end and a spray nozzle connected to the lower end of the spray tube; the top of the spray tube is fixedly connected with a transverse plate through a bracket; a motor with a downward output shaft is fixedly mounted on the bottom center of the transverse plate; the lower end of the output shaft of the motor is fixedly connected with a rotary shaft; a through hole is formed in the top centerof the spray tube; a cam is fixedly arranged on the outer side of the upper part of the rotary shaft in a sleeving manner; and a plurality of first cutting blades are vertically, uniformly and fixedlymounted on the outer side wall of a circular truncated cone-shaped barrel body. According to the 3D printing spray head disclosed by the invention, automatic unloading of a solid-state wire is realized through an L-shaped plate; the rotary shaft drives the first cutting blades to rotate to be matched with second cutting blades to gradually cut up the cut solid-state wire, so that the solid-statewire is quickly molten while passing through a heating device; and the rotary shaft drives auger blades to rotate to achieve the effect of outwards extruding the molten wire. The 3D printing spray head increases the melting speed and the curing speed of the solid-state wire, so that the working efficiency is improved.

Owner:东北师范大学人文学院

A 3D printing nozzle for printing clothing

ActiveCN112026167BEmission reductionFast curingManufacturing heating elements3D object support structuresWire rodElectric machinery

Owner:东北师范大学人文学院

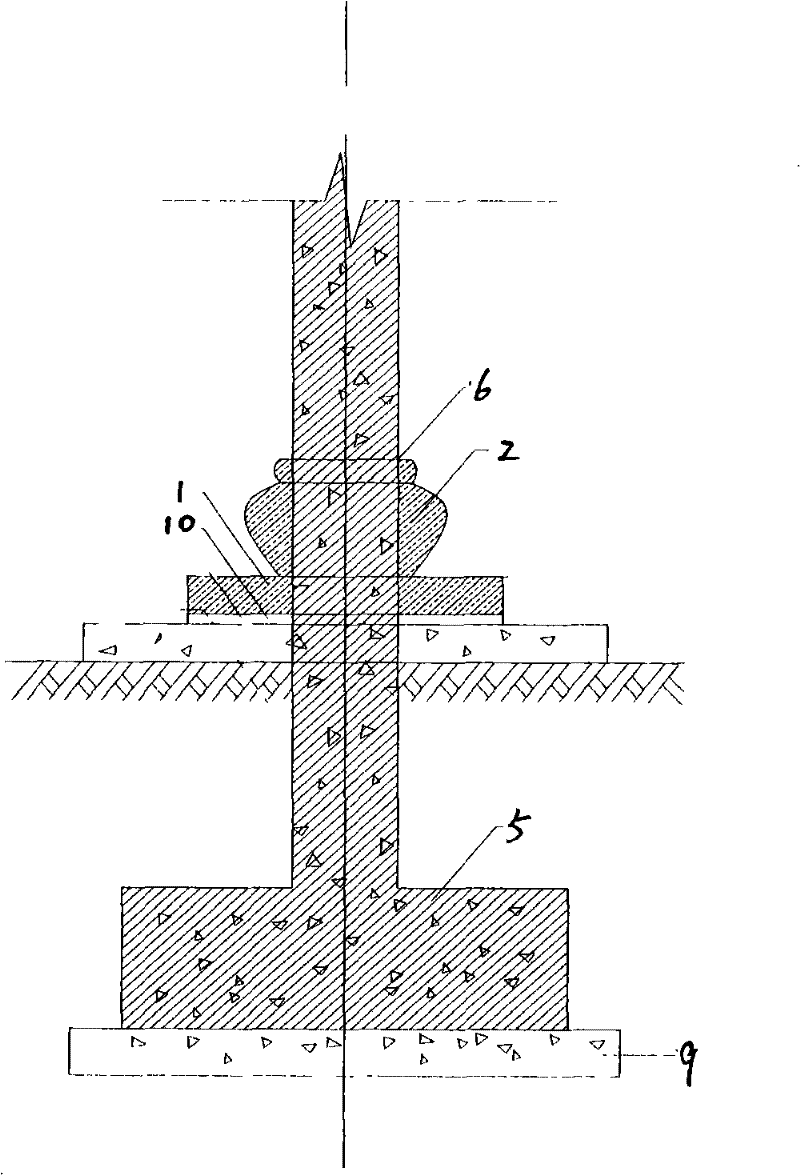

Core-through type pillar base slate, drum step stone, reinforced concrete upright column structure and construction method thereof

InactiveCN101550726BSolve crackingImprove adhesionCovering/liningsForms/shuttering/falseworksReinforced concrete columnStepping stone

The invention discloses a core-through type pillar base slate, drum step stone, reinforced concrete upright column structure, which comprises a pillar base slate, a drum step stone and a reinforced concrete column body. The utility model is characterized in: the pillar base slate and the drum step stone are formed with a core through hole; the reinforced concrete column is passed through the corethrough hole, and is combined with the plinth to form an integrated structure. The construction method comprise includes forming core though holes on the pillar base slate and the drum step stone, hasthe following construction processes: measuring and setting line, forming the core through hole on the pillar base slate, positioning the drum step stone and fixing, binding column steel bars, supporting moulds, pouring column concrete, removing moulds, maintaining, and machining and modifying the reinforced concrete column surface, the pillar base slate and the drum step stone. By integrating the column body, the drum step stone and the pillar base slate, the invention improves the integrity and spatial aesthetic feeling of the great wooden framework in archaize building, achieves great environment benefit, increases machining efficiency greatly, saves material, and protects environment.

Owner:ZHEJIANG BADA CONSTR GRP

Metal casting equipment

PendingCN113732256AEasy to heat and meltEasy to melt and smeltIngot casting plantsIngot castingMolten metal

The invention provides metal casting equipment, which comprises a smelting device, a storage device and a casting device; a first heating piece and a smelting cavity used for smelting metal are arranged in the smelting device; the first heating piece is located in the smelting cavity and used for heating and melting the metal; a storage cavity used for storing molten metal is formed in the storage device and is communicated with the smelting cavity; the casting device comprises an ingot casting furnace and a wire feeding component located on one side of the ingot casting furnace and used for outputting metal wires; the ingot casting furnace is provided with an inner ingot casting cavity and an ingot casting component located in the ingot casting cavity; the ingot casting cavity is communicated with the storage cavity; the ingot casting component is used for solidification and shaping of the molten metal; a molten metal cavity used for collecting the molten metal is formed in the ingot casting component; and a wire outlet of the wire feeding component faces the molten metal cavity. The problem that traditional metal casting equipment is large in cracking tendency is solved; and the meth metal casting equipment in the invention has the advantages of being low in production cost and high in casting speed and temperature.

Owner:佛山市三水凤铝铝业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com