Method and device for preparing spherical metal powder through hot wire assisted plasma arc

A metal powder, plasma spray gun technology, applied to the preparation of spherical metal powder by ion hot wire spraying, powder metallurgy technology and surface engineering fields, can solve problems such as poor sphericity, high airflow velocity, arc extinguishing, etc. Efficiency, large operating process window, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

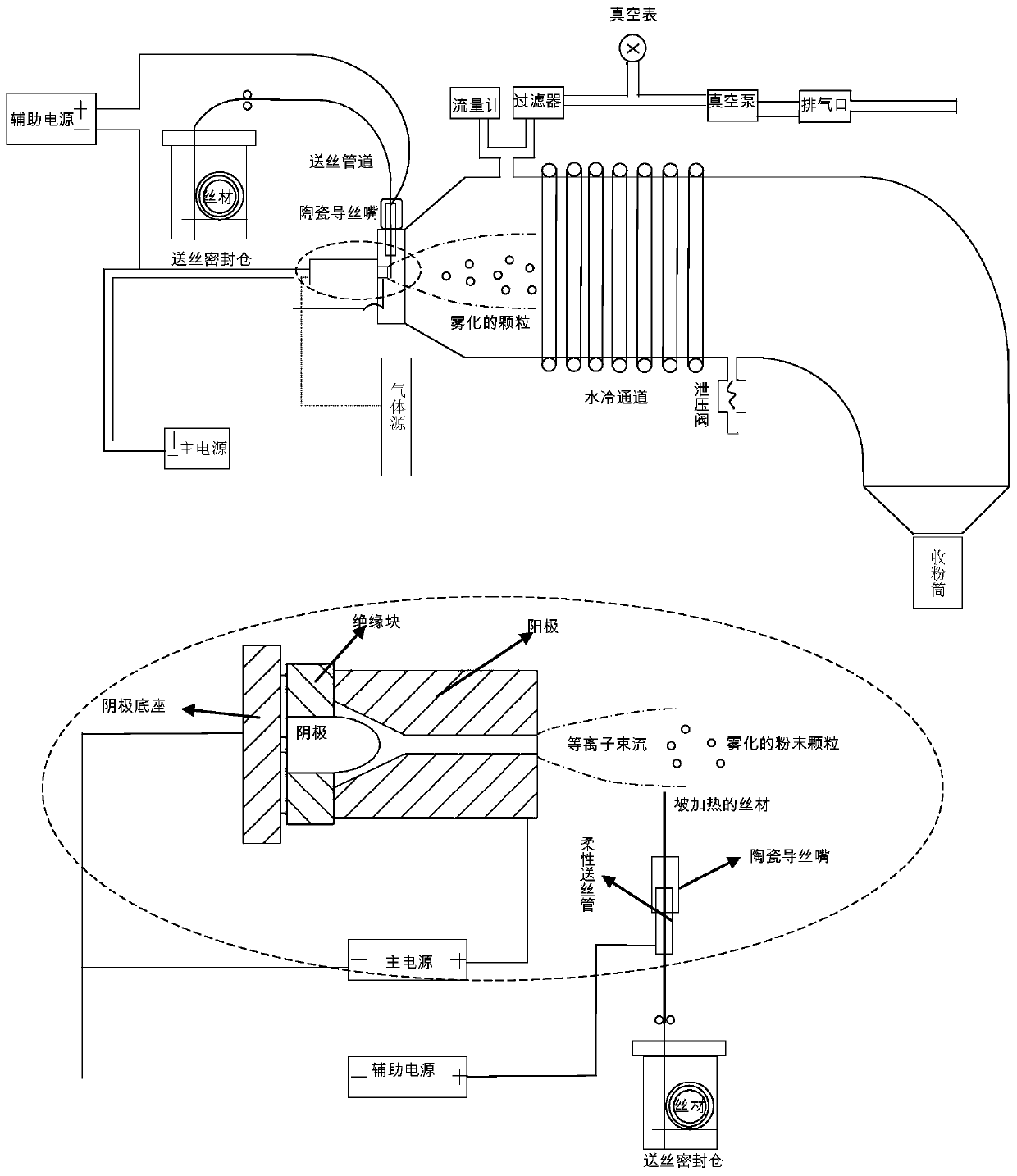

Method used

Image

Examples

example 1

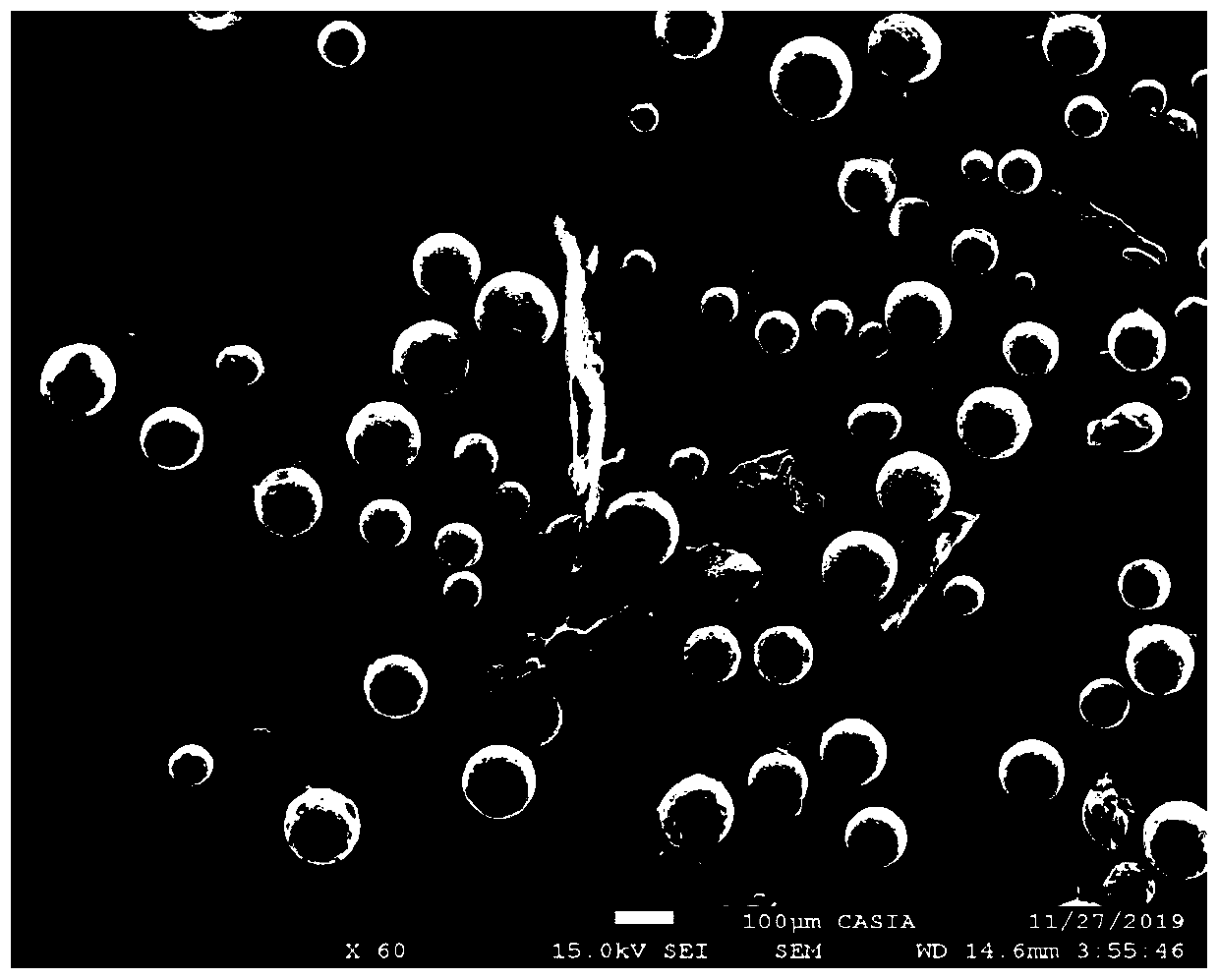

[0034] A plate of iron-based wire (17Cr-13Ni) with a diameter of 1.2 mm is selected as the raw material wire, and an anode nozzle with a diameter of 6.5 mm. Place the wire material on the wire feeder in the wire feeding sealed chamber, so that the wire material passes through the flexible wire feeding pipe and the ceramic wire guide nozzle to reach the center of the front end of the nozzle. The vertical distance from the wire material to the nozzle is 2 mm, and the feeding speed is set to Set at 50mm / s. Turn on the vacuum pump to vacuumize the whole set of equipment. When the pressure reaches -0.1Mpa, turn off the vacuum pump; put argon into the device to make the internal pressure reach 0.1Mpa, then turn on the vacuum pump again to draw vacuum, repeat the above operation three times until the entire pipeline It is an argon atmosphere; use the plasma arc as the heat source, adjust the parameters as current 400A, hydrogen 5L / min, argon 100L / min, after the arc is stable, adjust ...

example 2

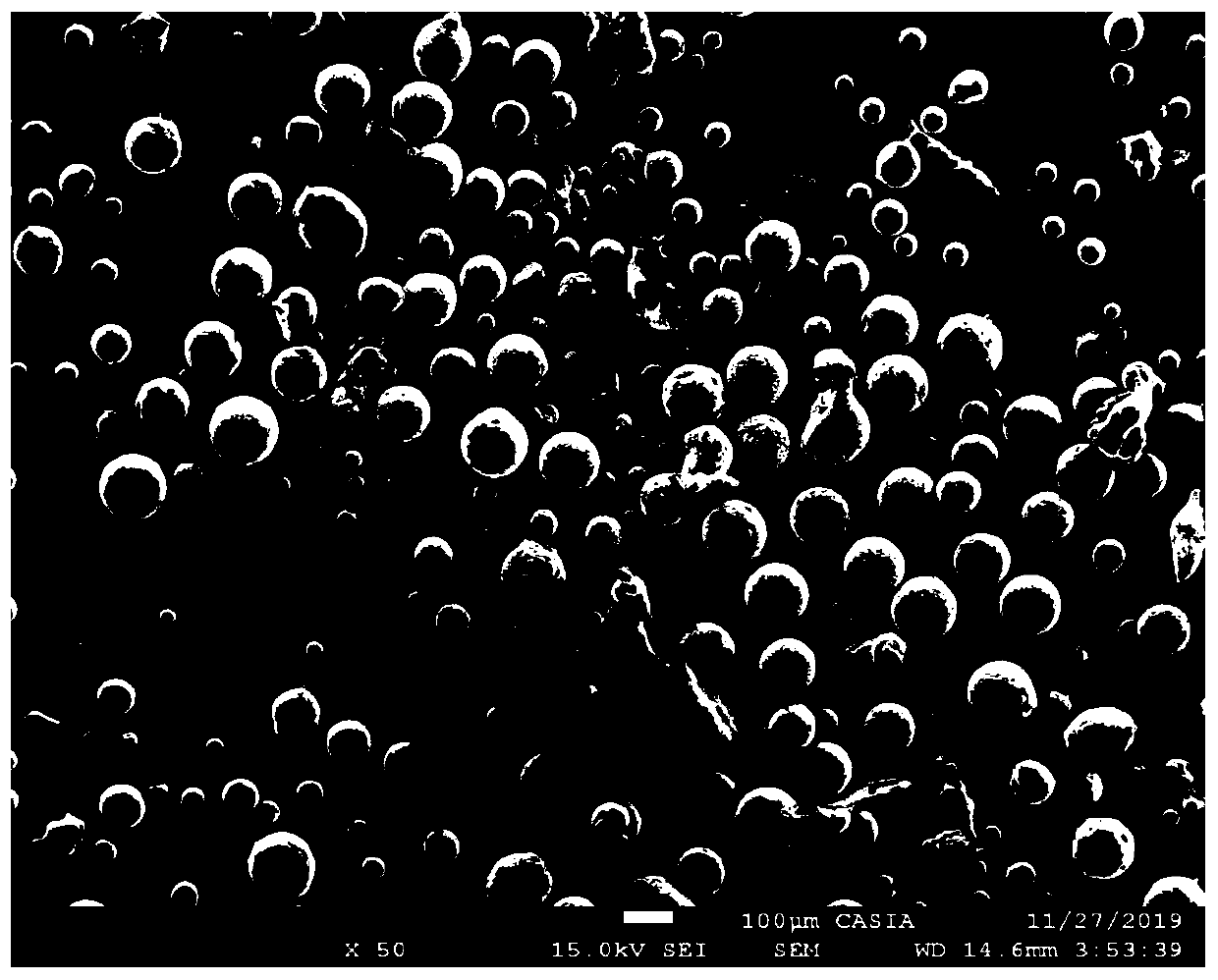

[0036]Select a plate of iron-based wire (17Cr-10Ni) with a diameter of 1.4mm as the raw material, select a plasma anode nozzle with an outlet diameter of 7mm, and place the wire on the wire feeder in the wire feeding sealed chamber, so that the wire is sequentially Go through the wire feeding pipe and wire guide tube to the center of the nozzle, make the vertical distance from the metal wire to the nozzle 4mm, set the feeding speed to 70mm / s, turn on the vacuum pump to vacuumize the whole set of equipment, when the pressure reaches Turn off the vacuum pump at -0.1Mpa; put argon gas into the device to make the internal pressure reach 0.1Mpa, and then turn on the vacuum pump again to draw a vacuum, repeat the above operation three times until the whole pipeline is argon atmosphere; use the plasma arc as the heat source, adjust the parameters The current is 450A, the hydrogen gas is 6L / min, and the argon gas is 80L / min. After the arc is stable, adjust the wire feeding speed to 80m...

example 3

[0038] Select a plate of iron-based wire (15Cr-9Ni) with a diameter of 1.6 mm as the raw material wire, select a plasma anode nozzle with an outlet diameter of 7.5 mm, and place the wire on the wire feeder in the wire feeding sealed chamber to make the wire Go through the wire feeding pipe and wire guide tube to the center of the nozzle in turn, make the vertical distance from the metal wire to the nozzle 5mm, set the feeding speed to 75mm / s, turn on the vacuum pump to vacuumize the whole set of equipment, when the pressure Turn off the vacuum pump when it reaches -0.1Mpa; put argon gas into the device to make the internal pressure reach 0.1Mpa, then turn on the vacuum pump again to draw a vacuum, repeat the above operation three times until the whole pipeline is argon atmosphere; use the plasma arc as the heat source, adjust The parameters are current 500A, hydrogen 6.5L / min, argon 80L / min. After the arc is stable, adjust the wire feeding speed to 95mm / s, then turn on the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com