Power station boiler low-NOx cofiring system coupling semicoke and sludge blending combustion

A power plant boiler and semi-coke technology, which is used in combustion air/fuel supply, water/sludge/sewage treatment, sludge treatment, etc. Stability and other issues, to achieve the effect of large-scale harmless treatment, harmless treatment, and reduction of carbon content in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

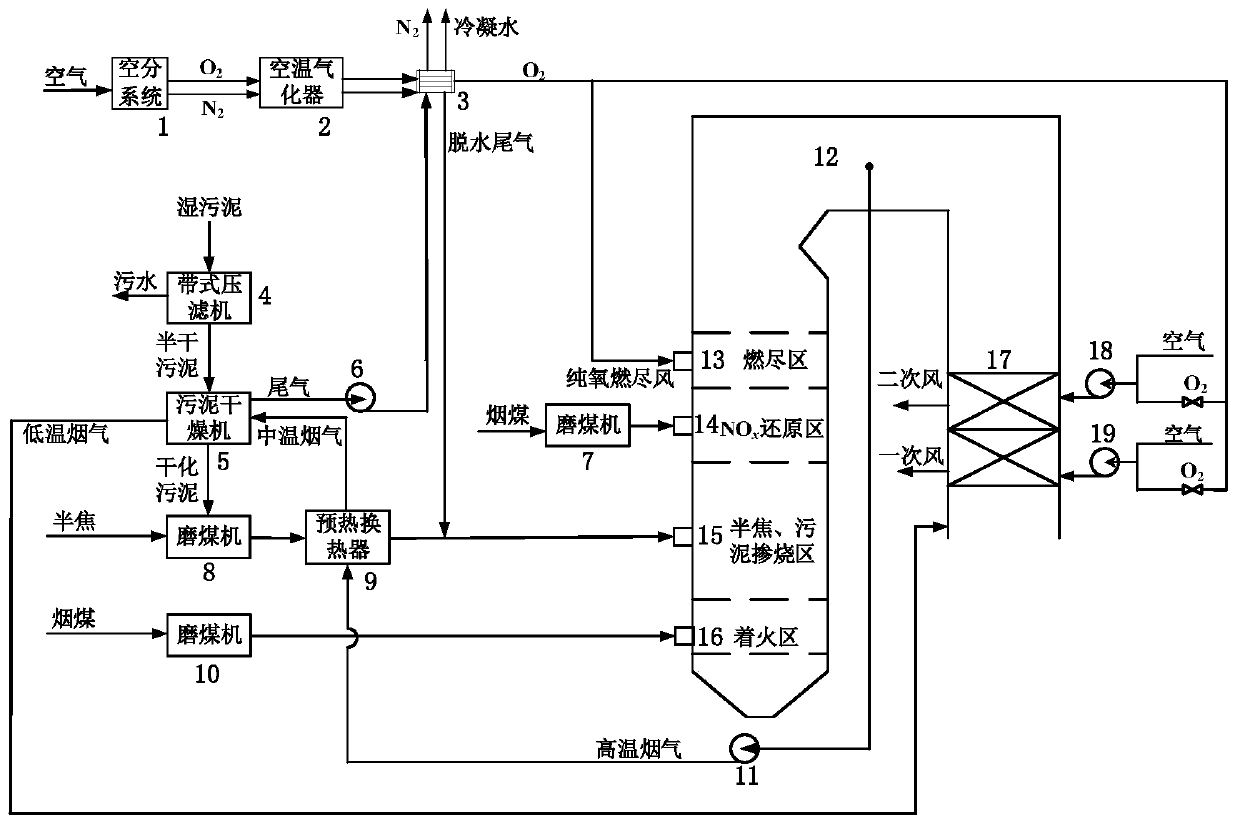

[0028] see figure 1 , a power plant boiler that couples semi-coke and sludge mixed combustion proposed by the present invention with low NO x The co-combustion system, including the air separation system 1, is connected with the air temperature vaporizer 2, and the obtained low-temperature O 2 and N 2 into the condenser 3, the heated O 2 Enter the furnace through the burn-off air nozzle 13, the belt filter press 4 is connected with the sludge dryer 5, the first induced draft fan 6, the first bituminous coal pulverizer 7 is connected with the first bituminous coal burner 14, semi-coke and dry Coal pulverizer 8 used for sludge pulverization, heat exchanger 9 for preheating semi-coke and sludge mixed fuel is connected with burner 15, second bituminous coal pulverizer 10 is connected with second bituminous coal burner 16, second pilot Fan 11, boiler body 12, air prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com