Patents

Literature

672results about How to "Promote fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

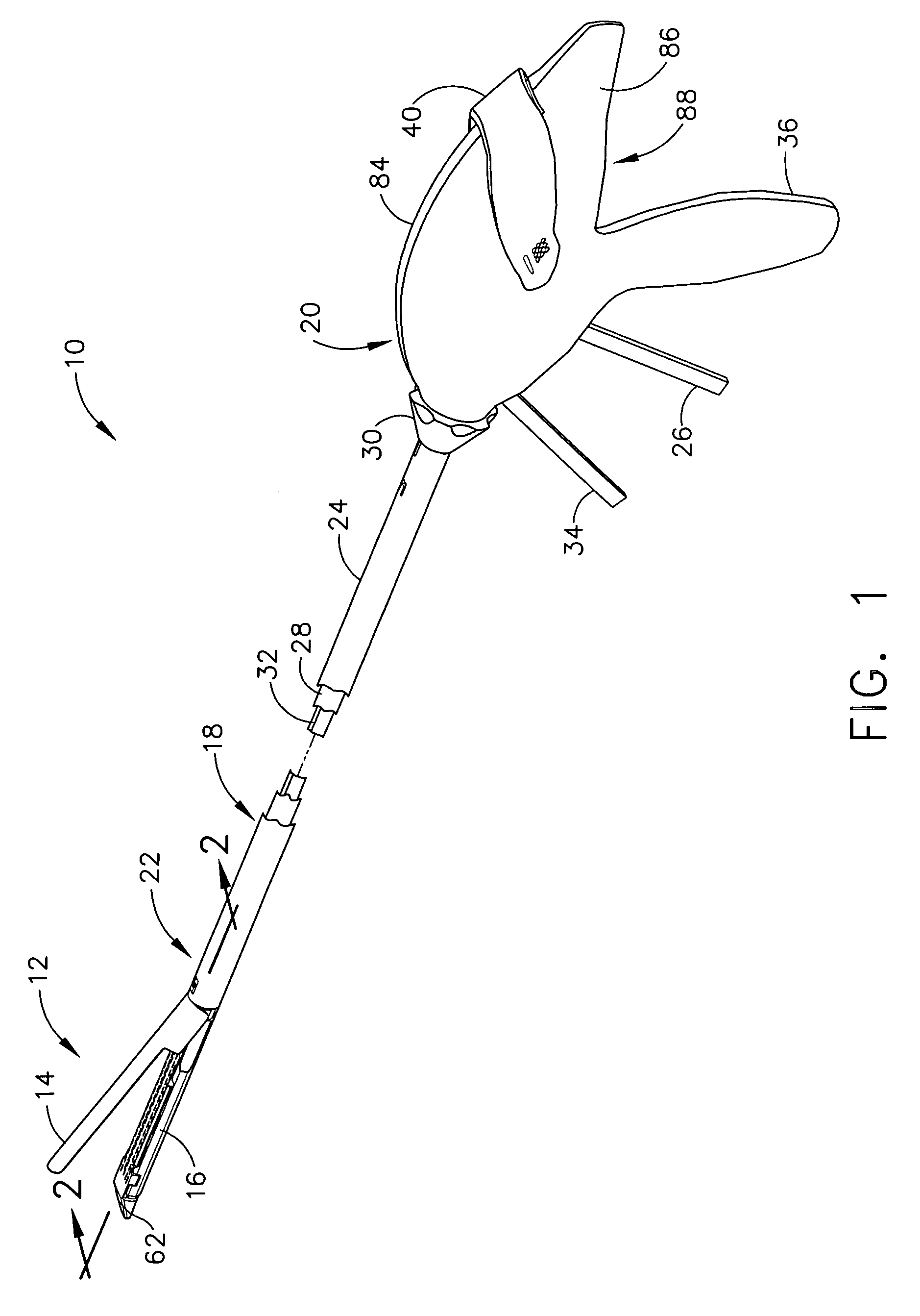

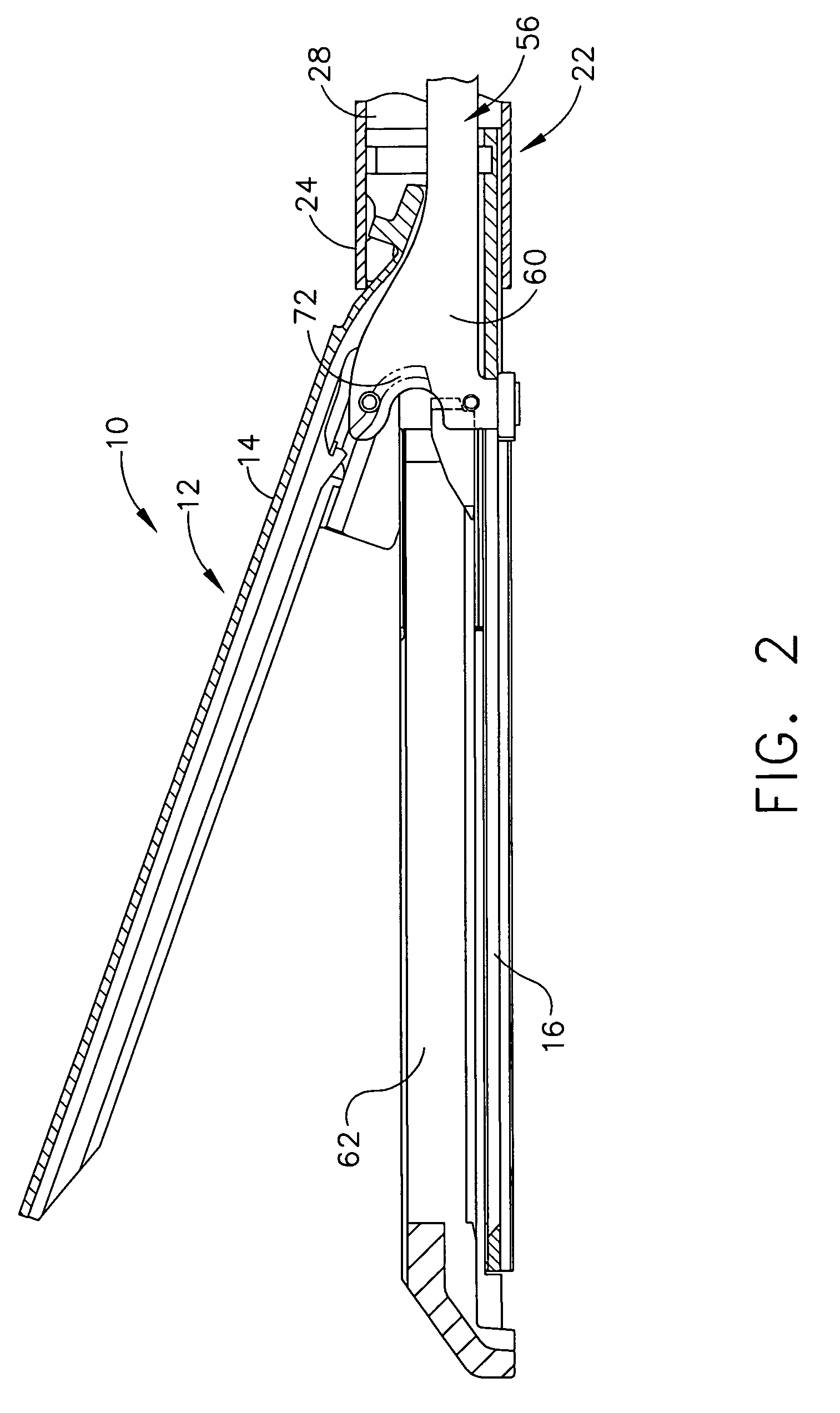

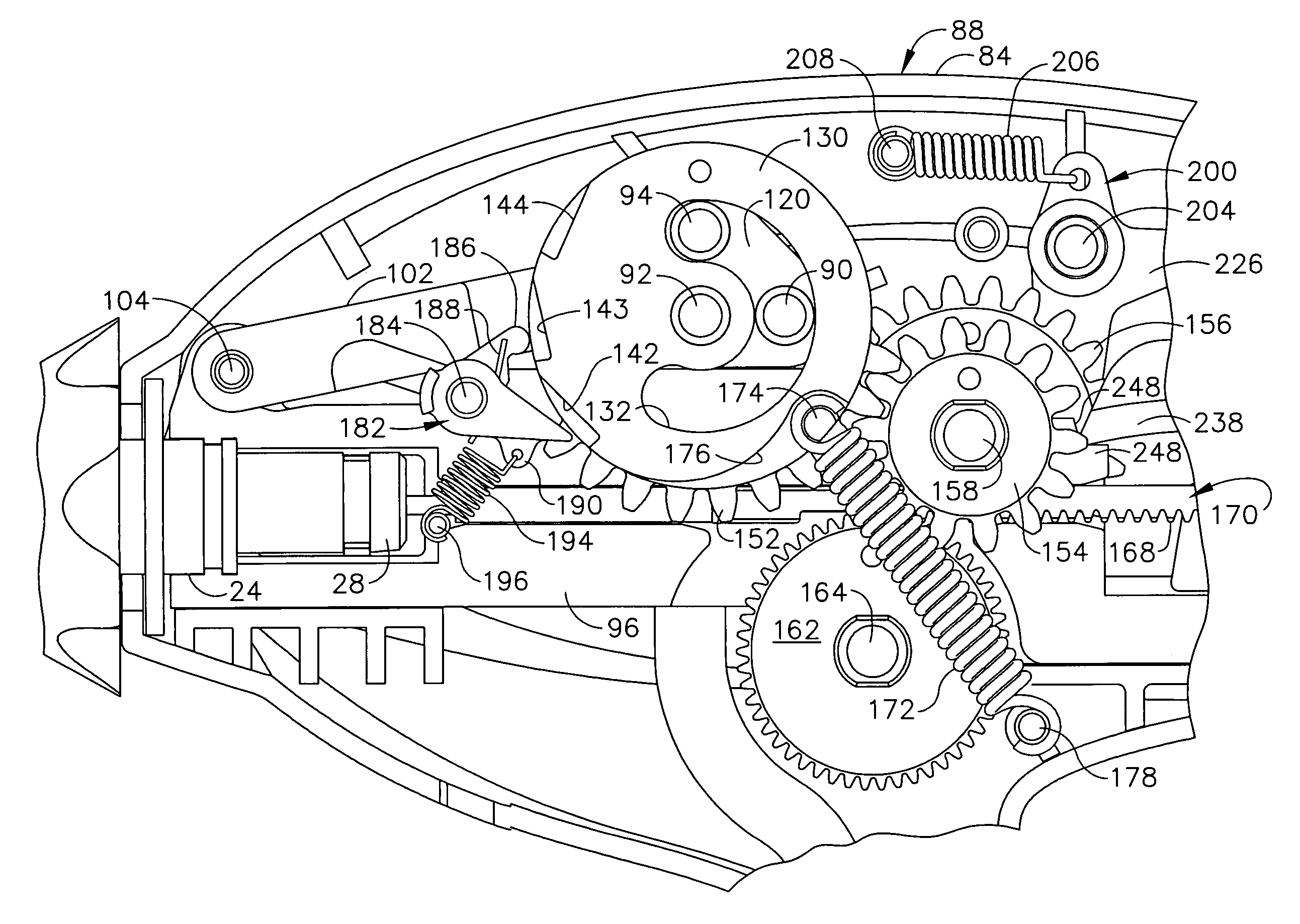

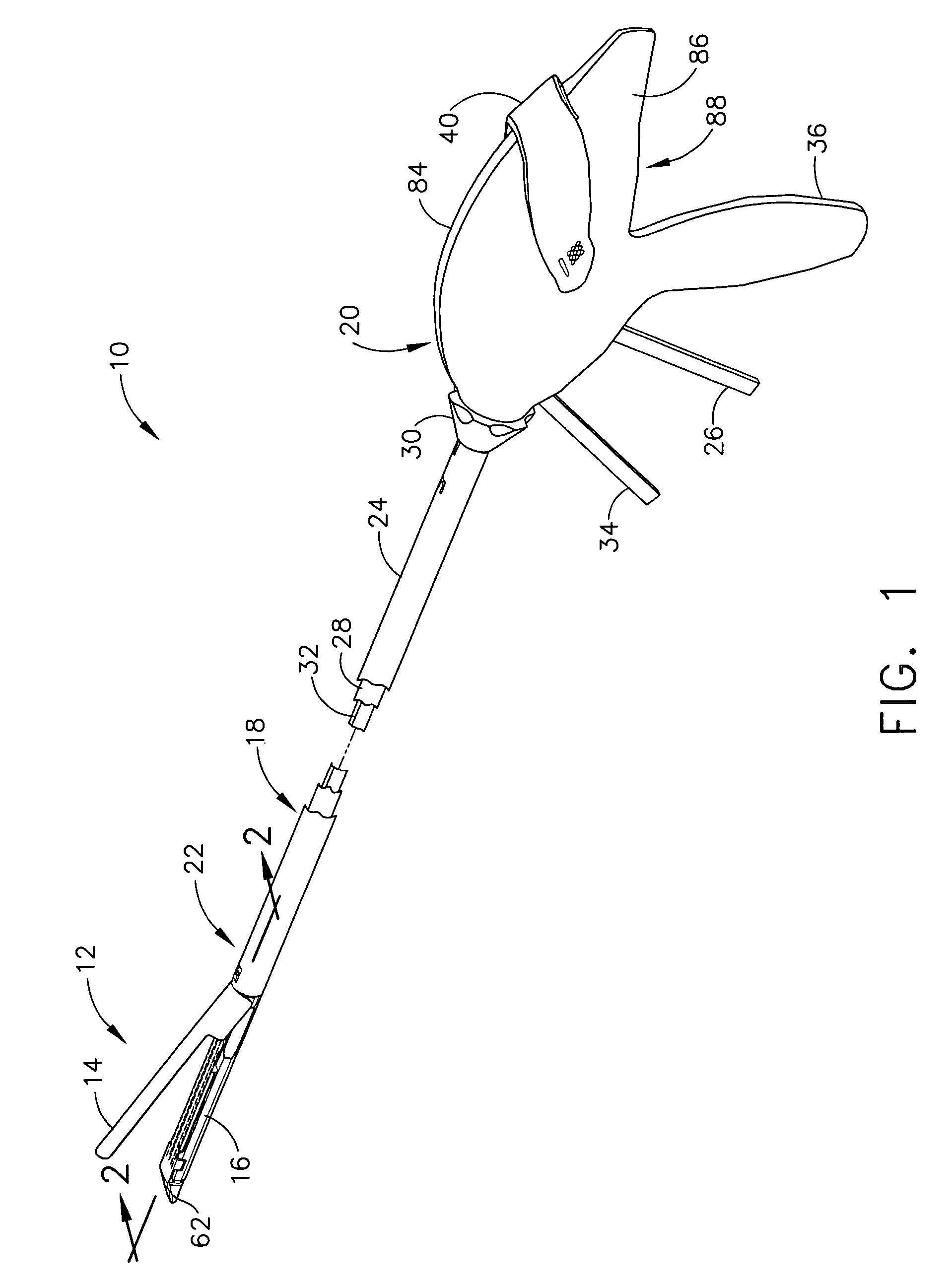

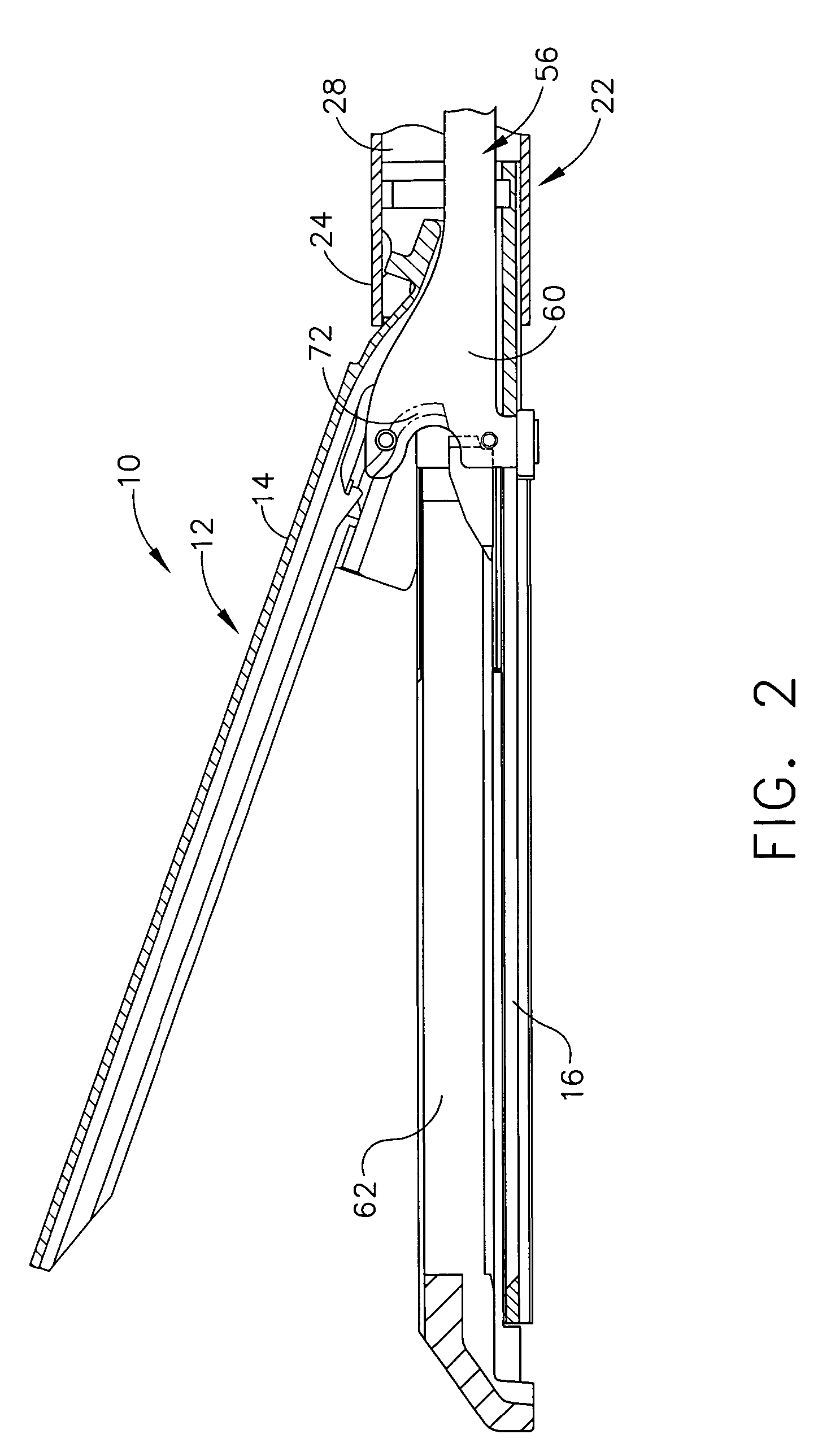

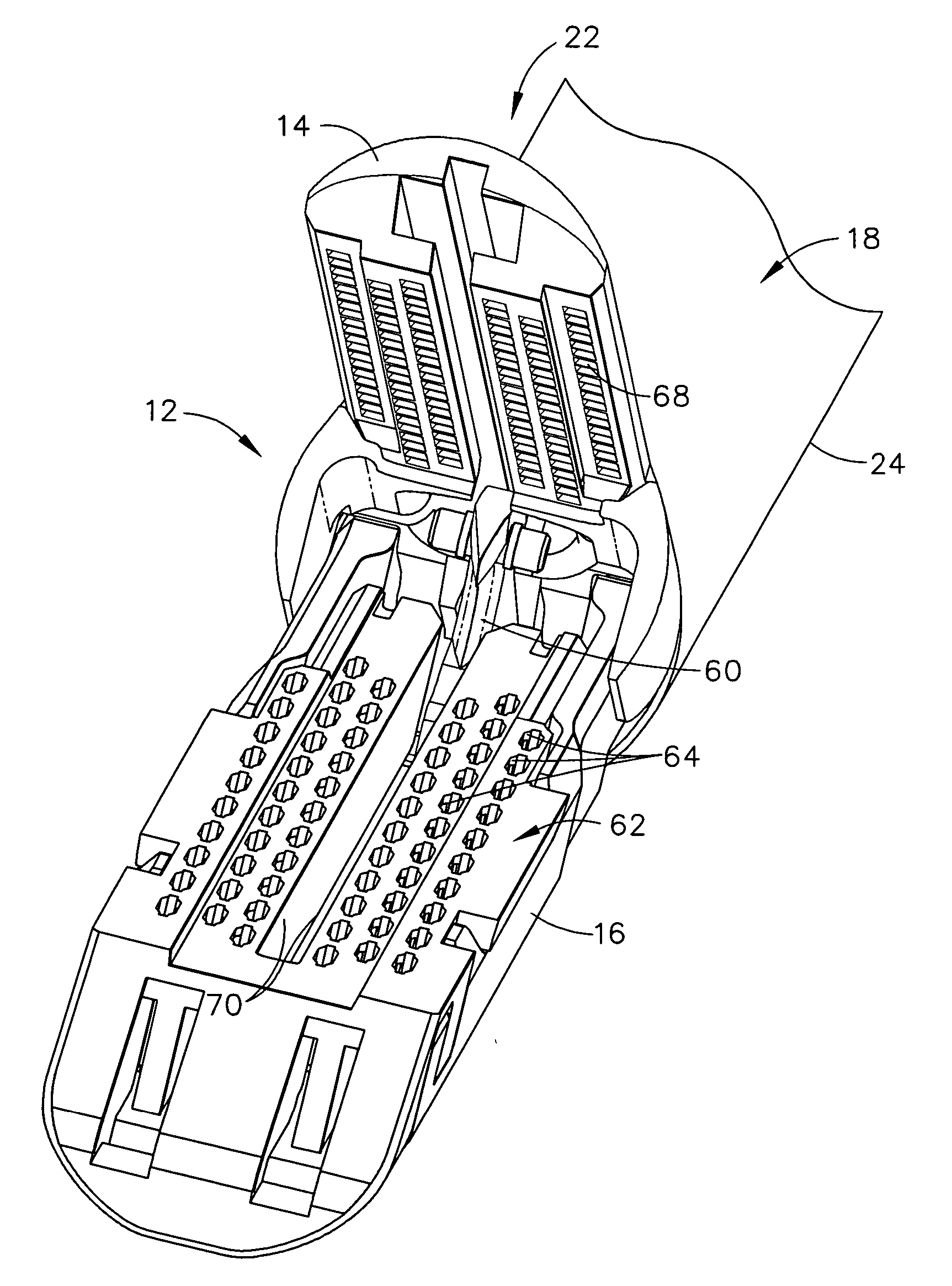

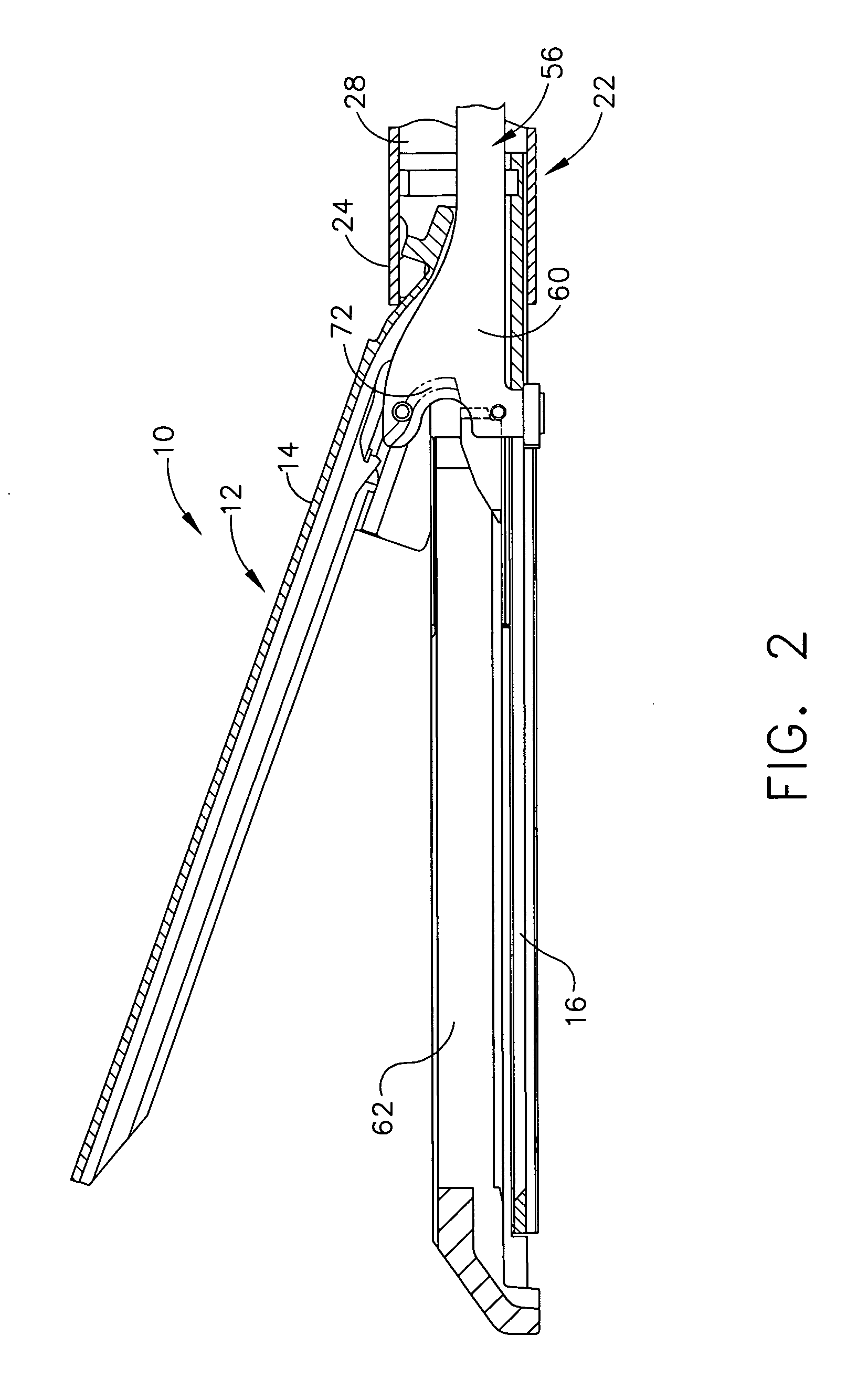

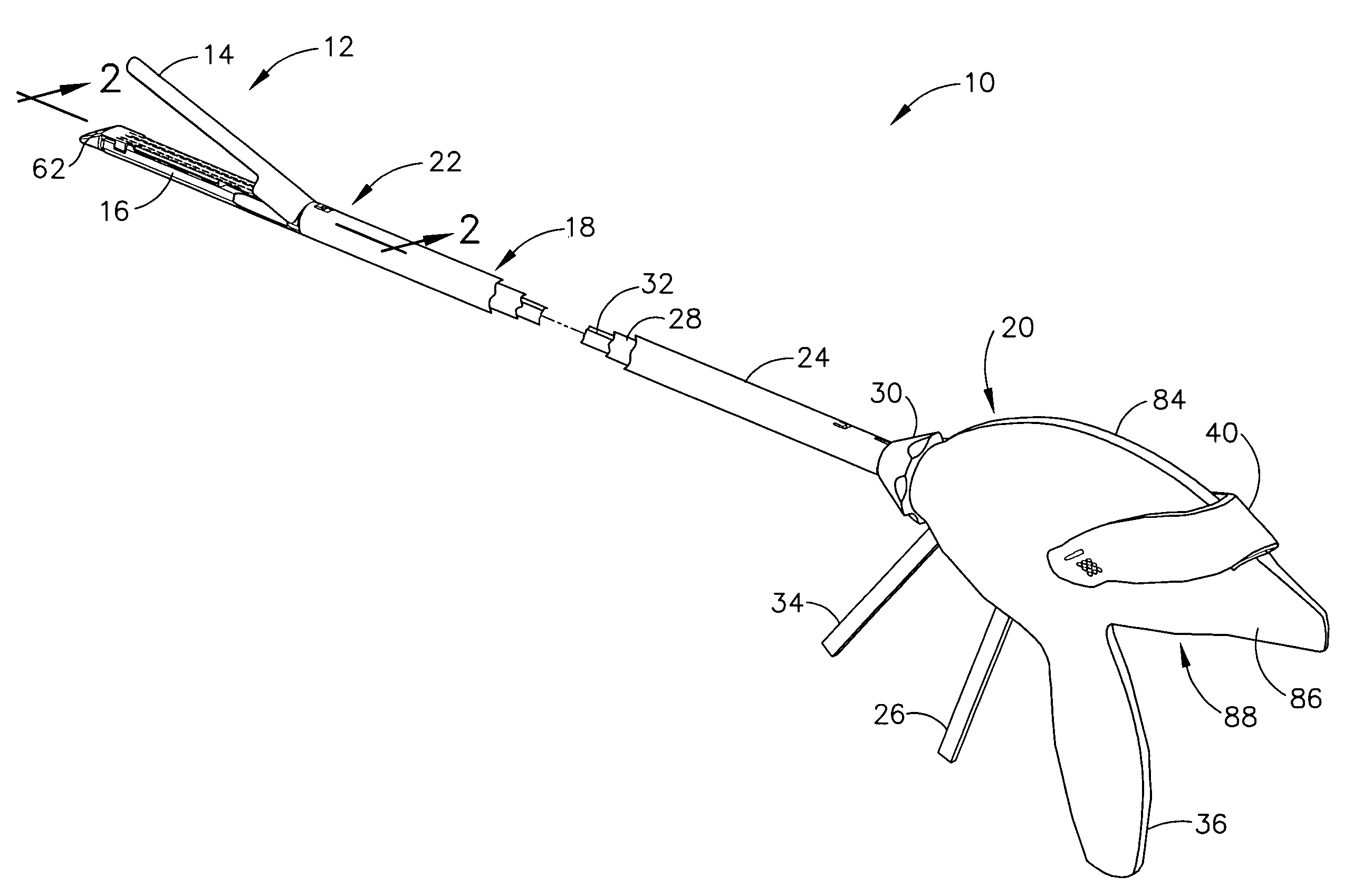

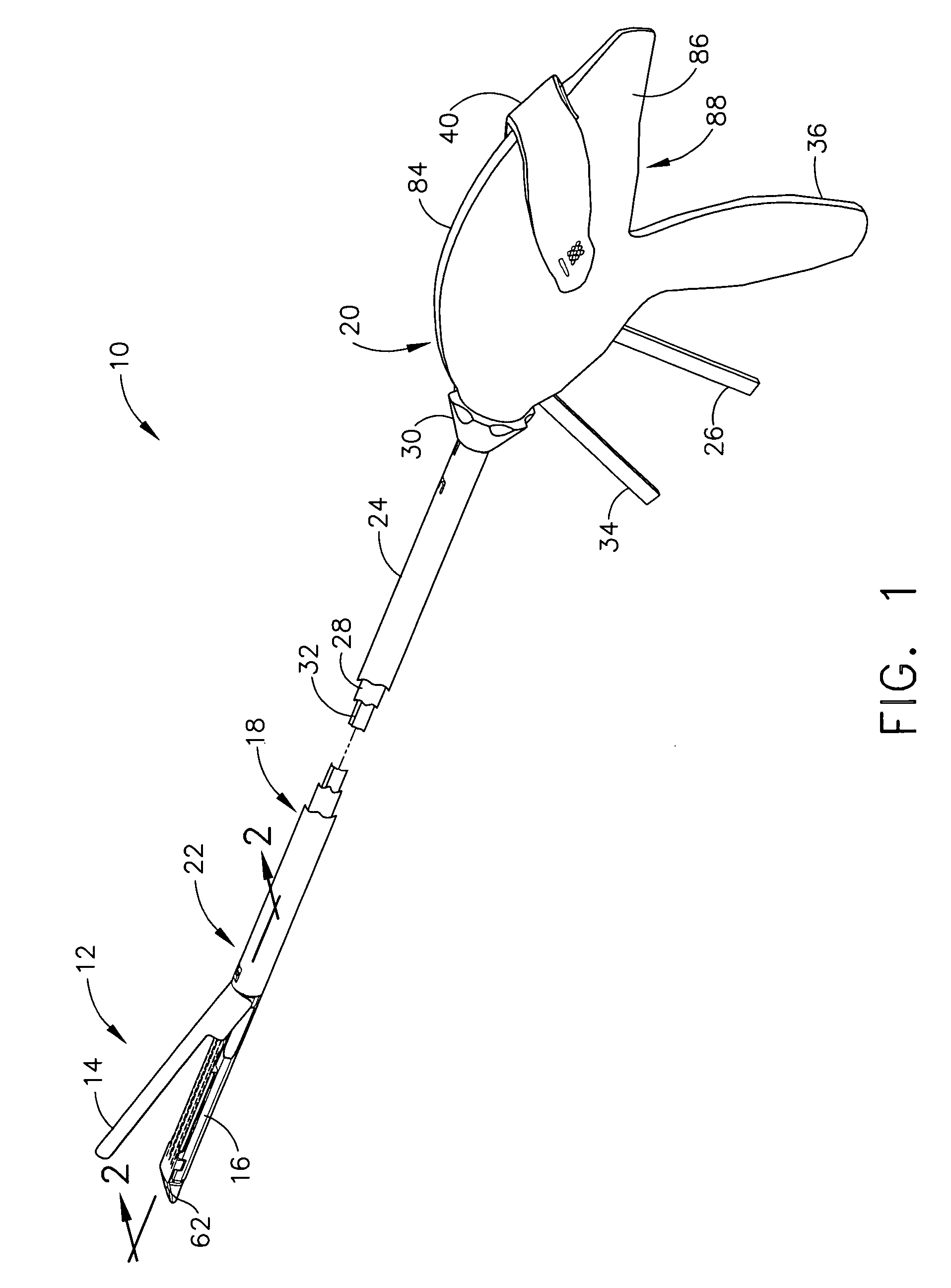

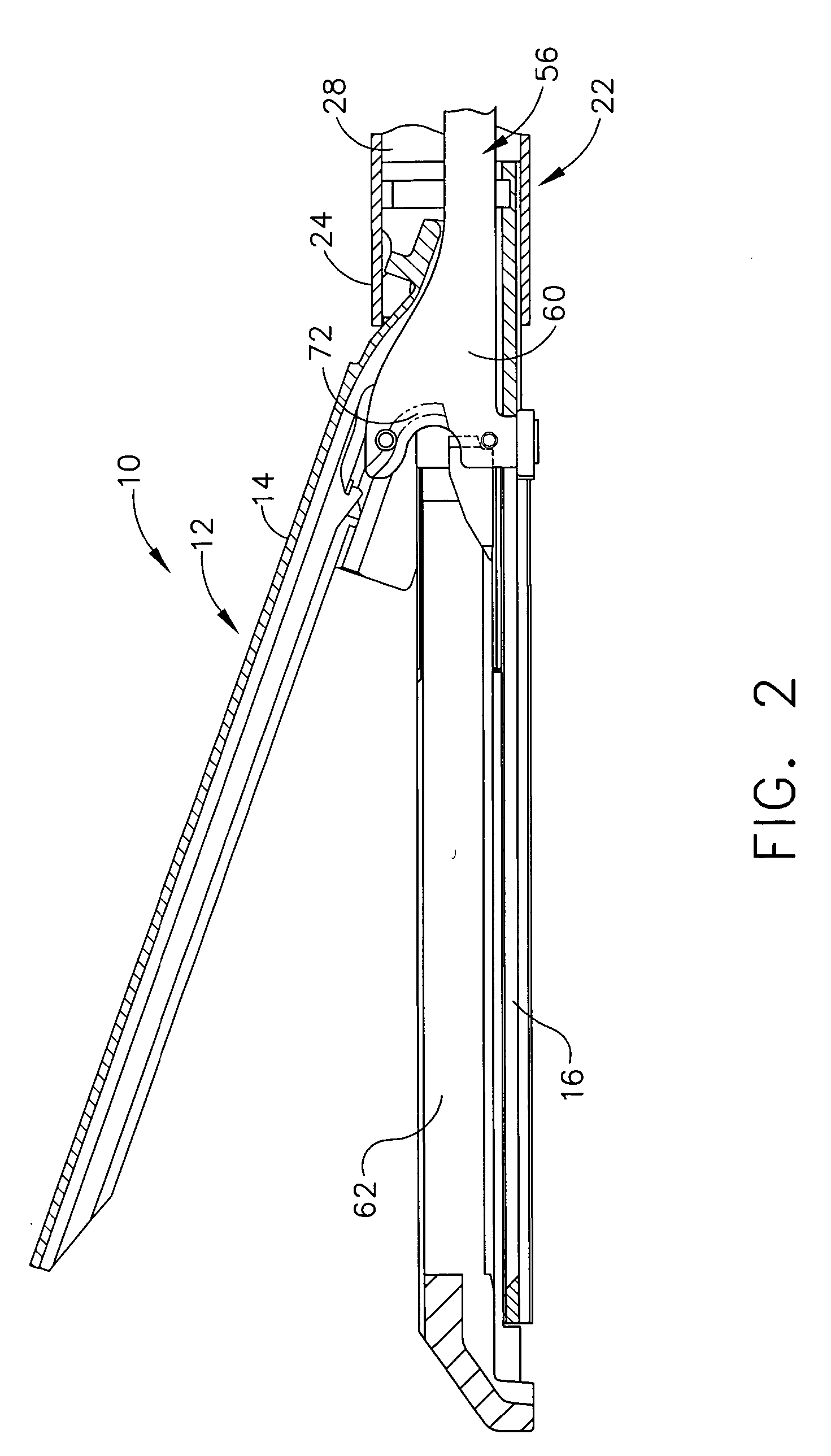

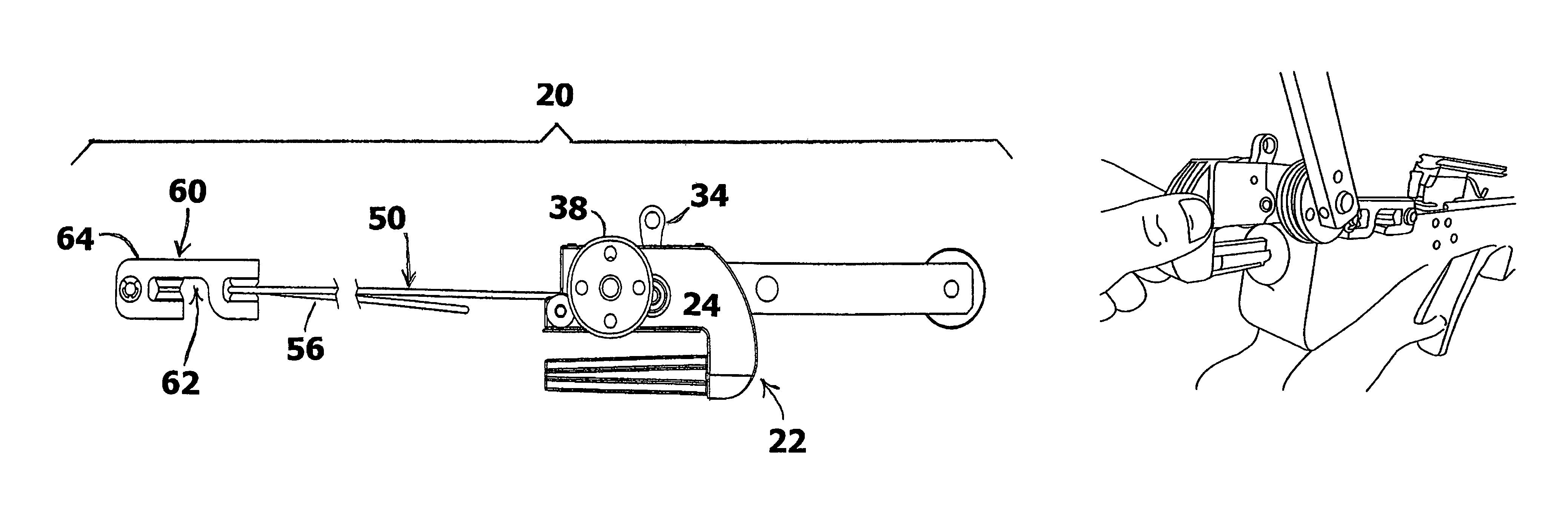

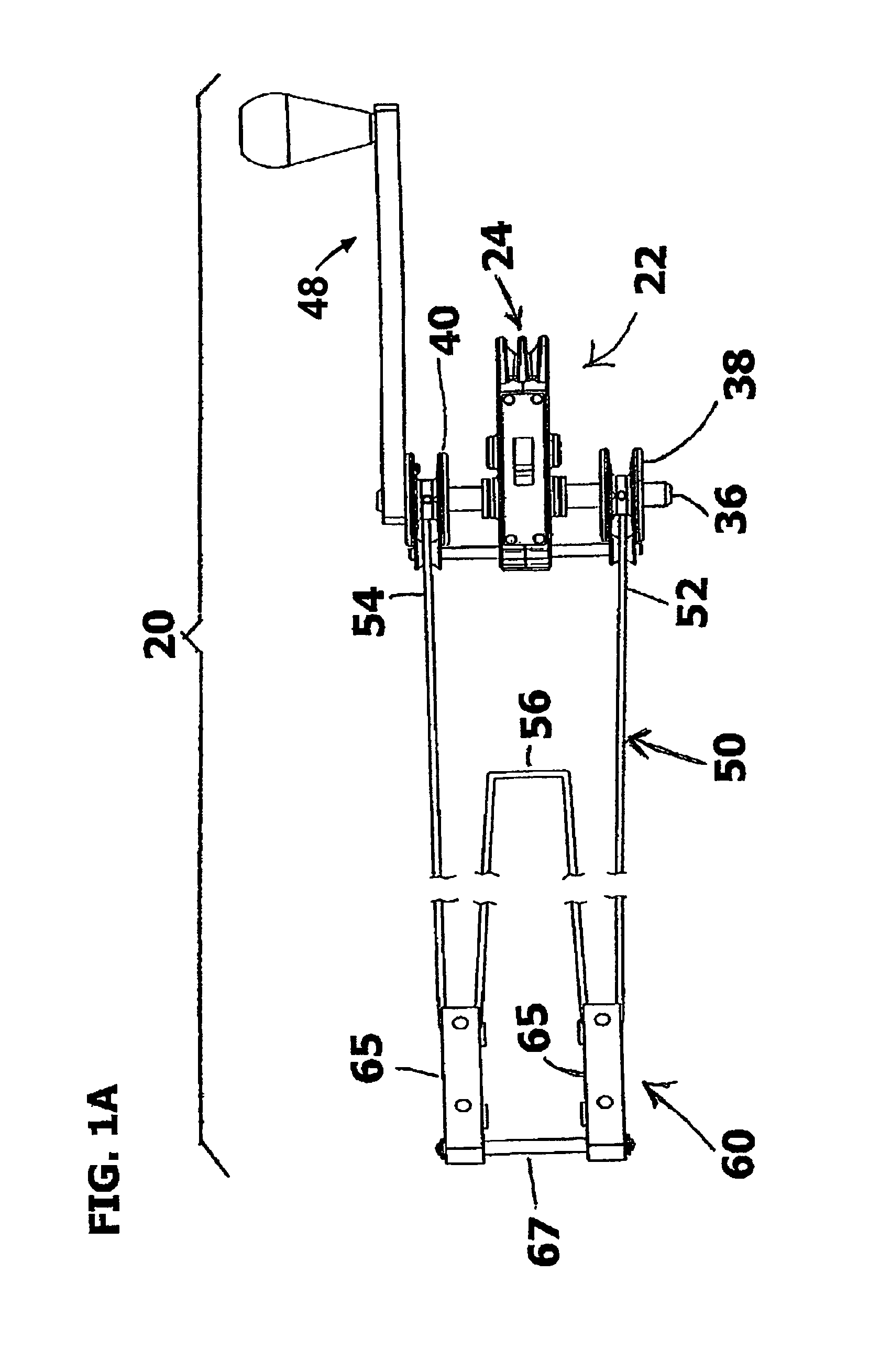

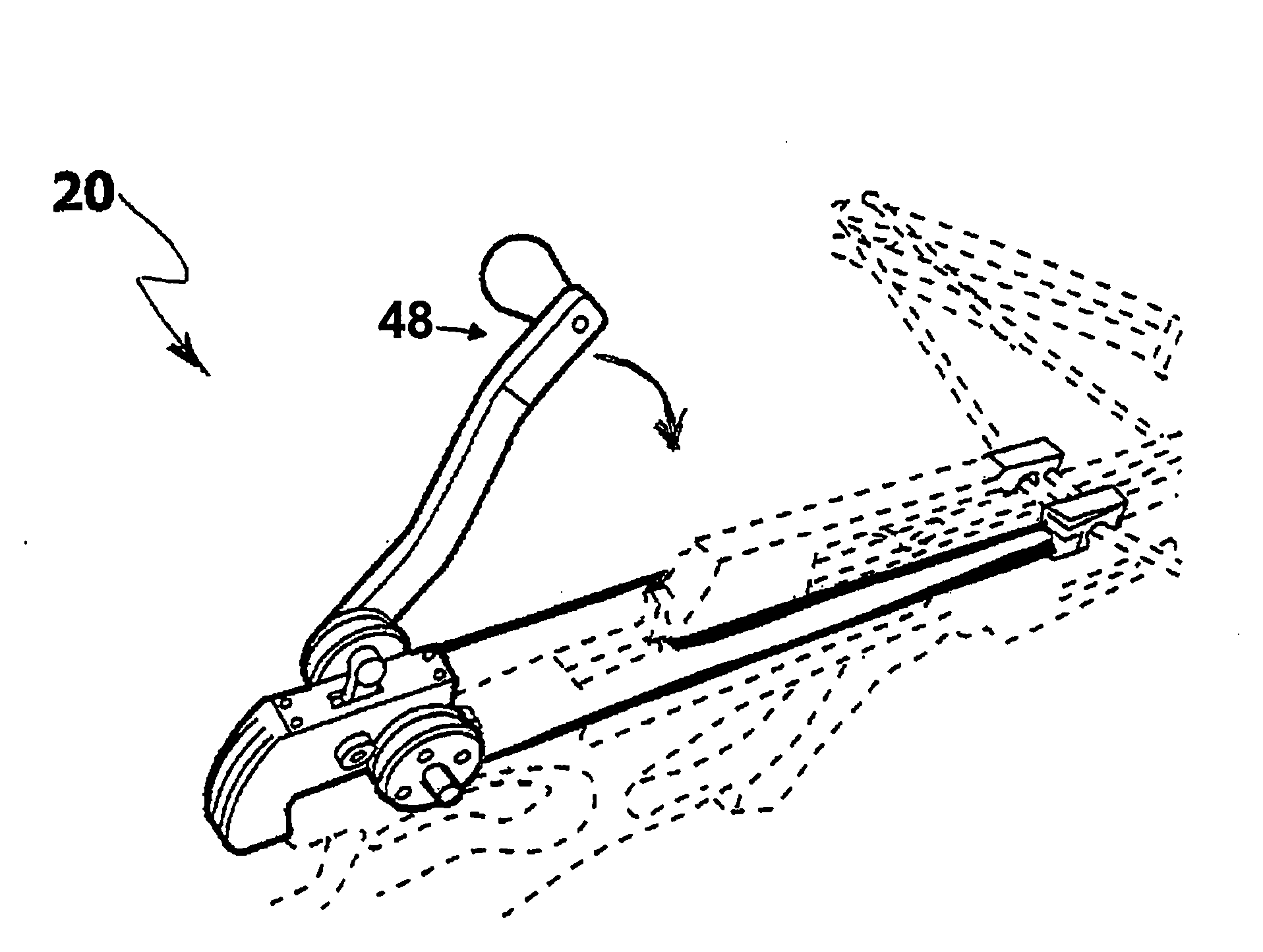

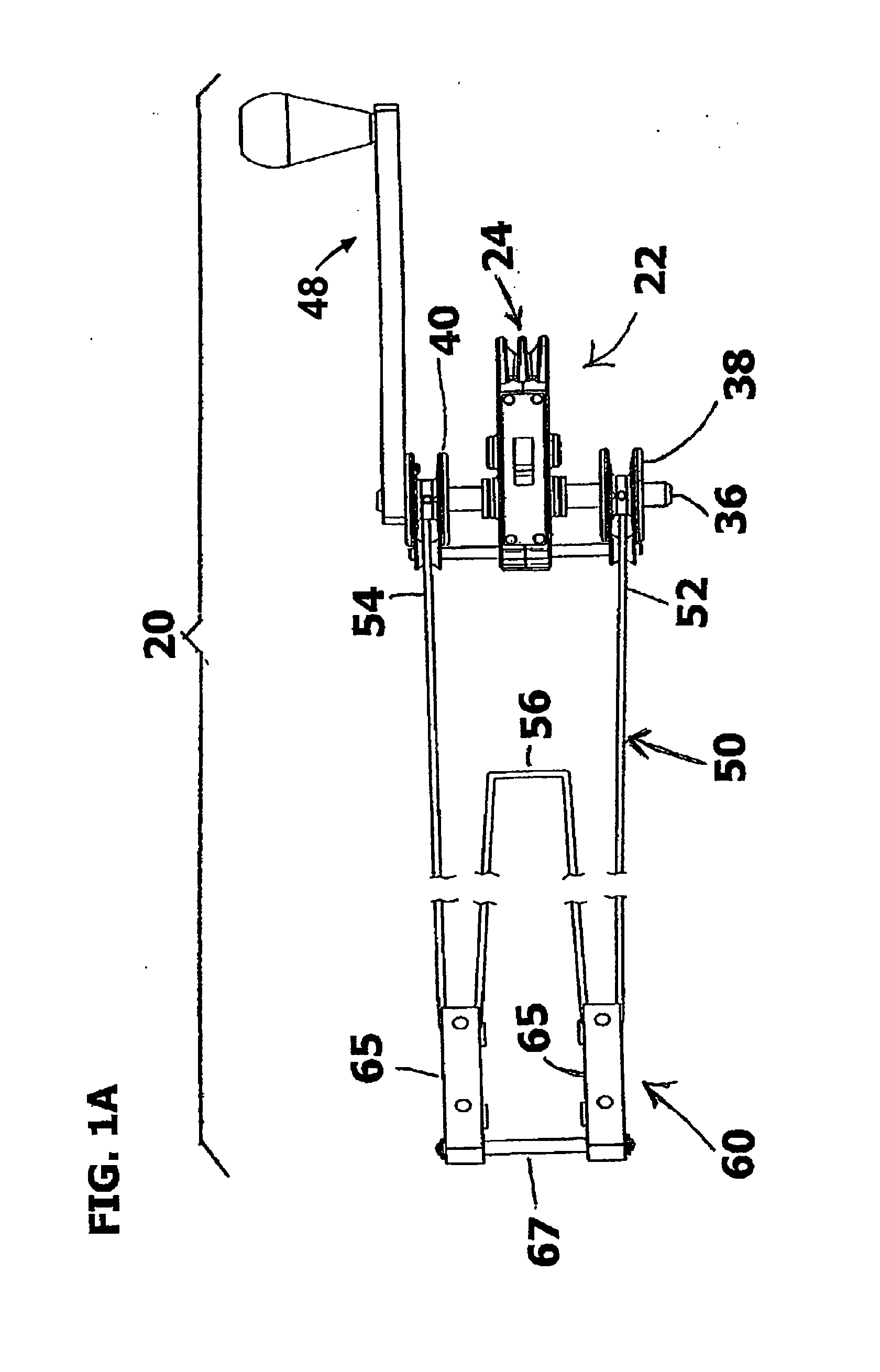

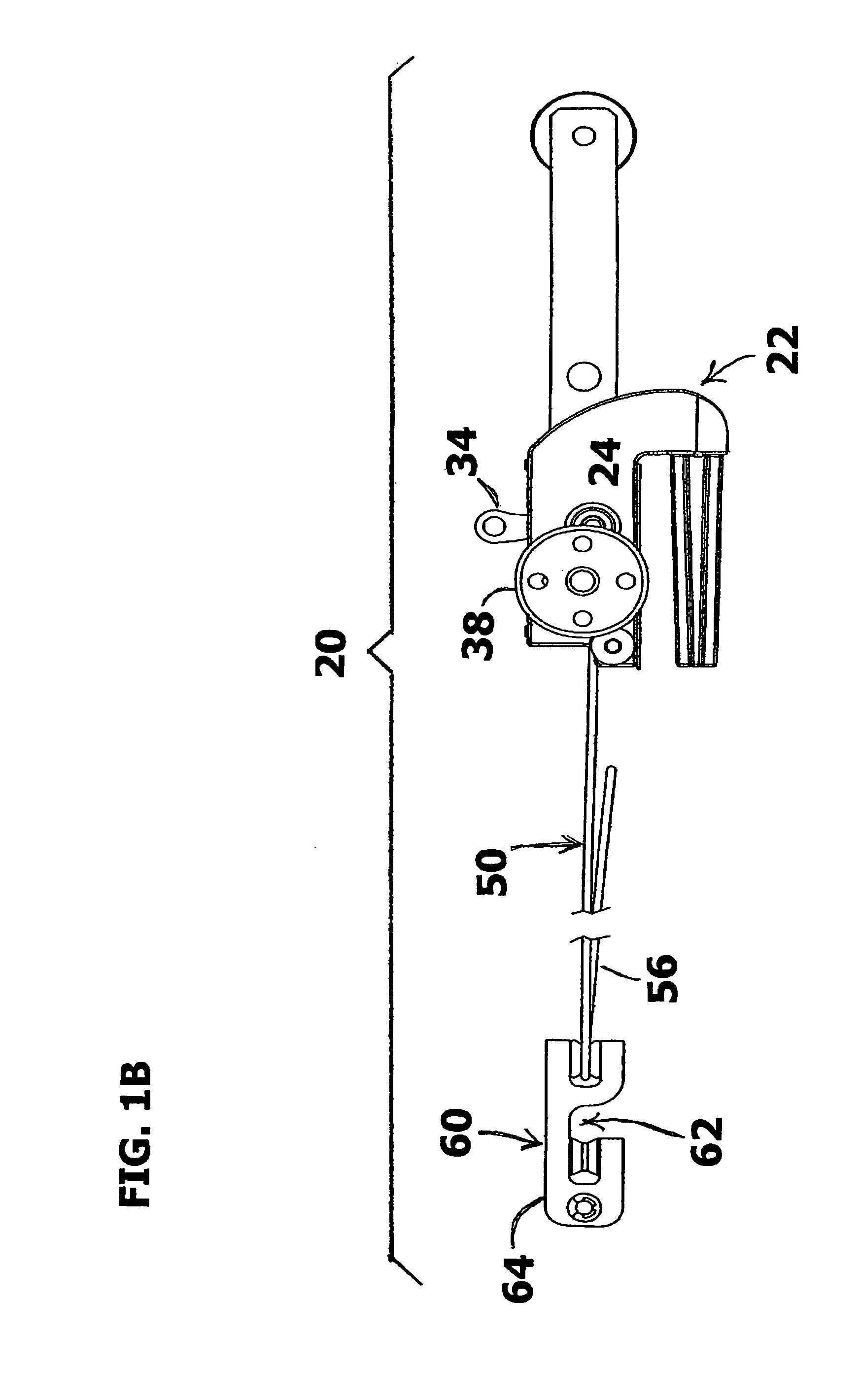

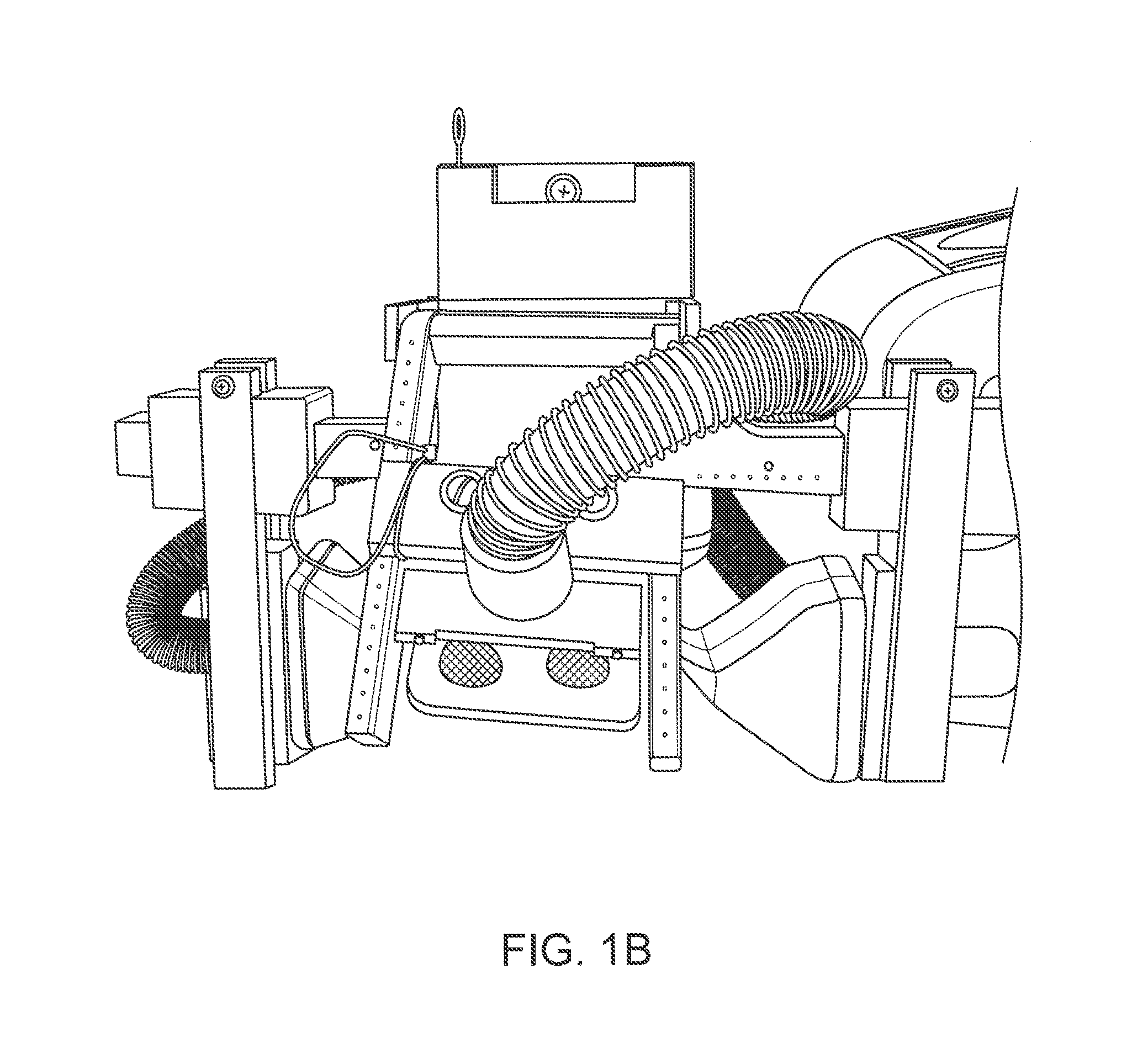

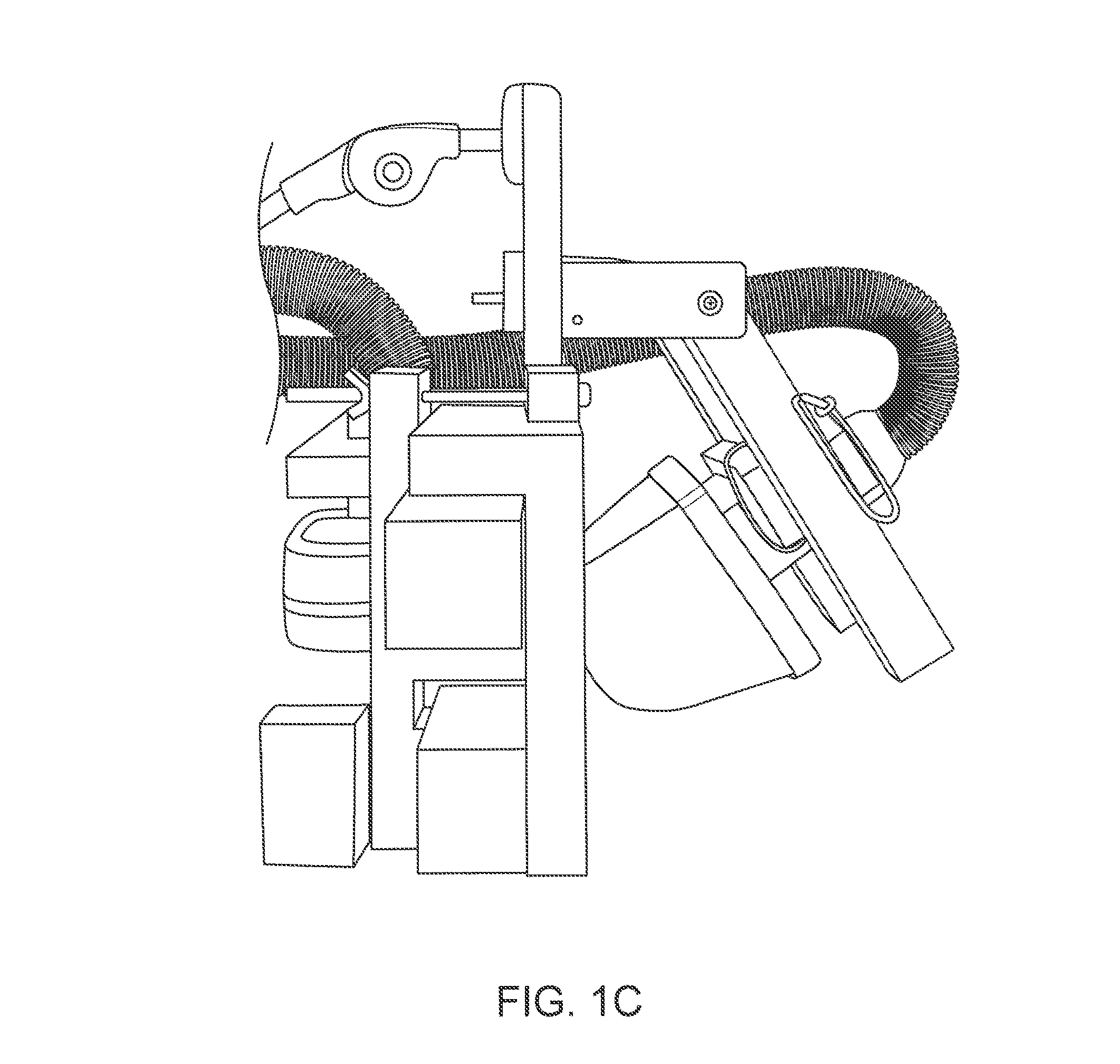

Surgical stapling instrument incorporating a multistroke firing mechanism having a rotary slip-clutch transmission

ActiveUS7128254B2Promote fireIncrease forceSuture equipmentsStapling toolsSurgical stapleEngineering

A surgical stapling and severing instrument particularly suited to endoscopic procedures incorporates a handle that produces separate closing and firing motions to actuate an end effector. In particular, the handle produces multiple firing strokes in order to reduce the required amount of force required to fire (i.e., staple and sever) the end effector.

Owner:CILAG GMBH INT

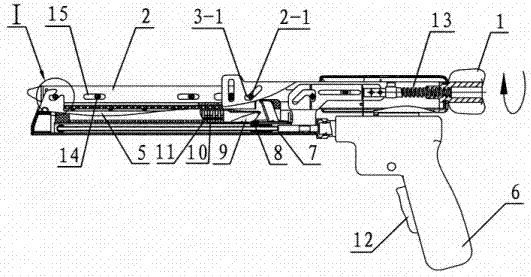

Surgical stapling instrument incorporating a multistroke firing mechanism having a rotary transmission

ActiveUS7367485B2Promote fireIncrease forceSuture equipmentsStapling toolsSurgical stapleEngineering

A surgical stapling and severing instrument particularly suited to endoscopic procedures incorporates a handle that produces separate closing and firing motions to actuate an end effector. In particular, the handle produces multiple firing strokes in order to reduce the required amount of force required to fire (i.e., staple and sever) the end effector.

Owner:CILAG GMBH INT

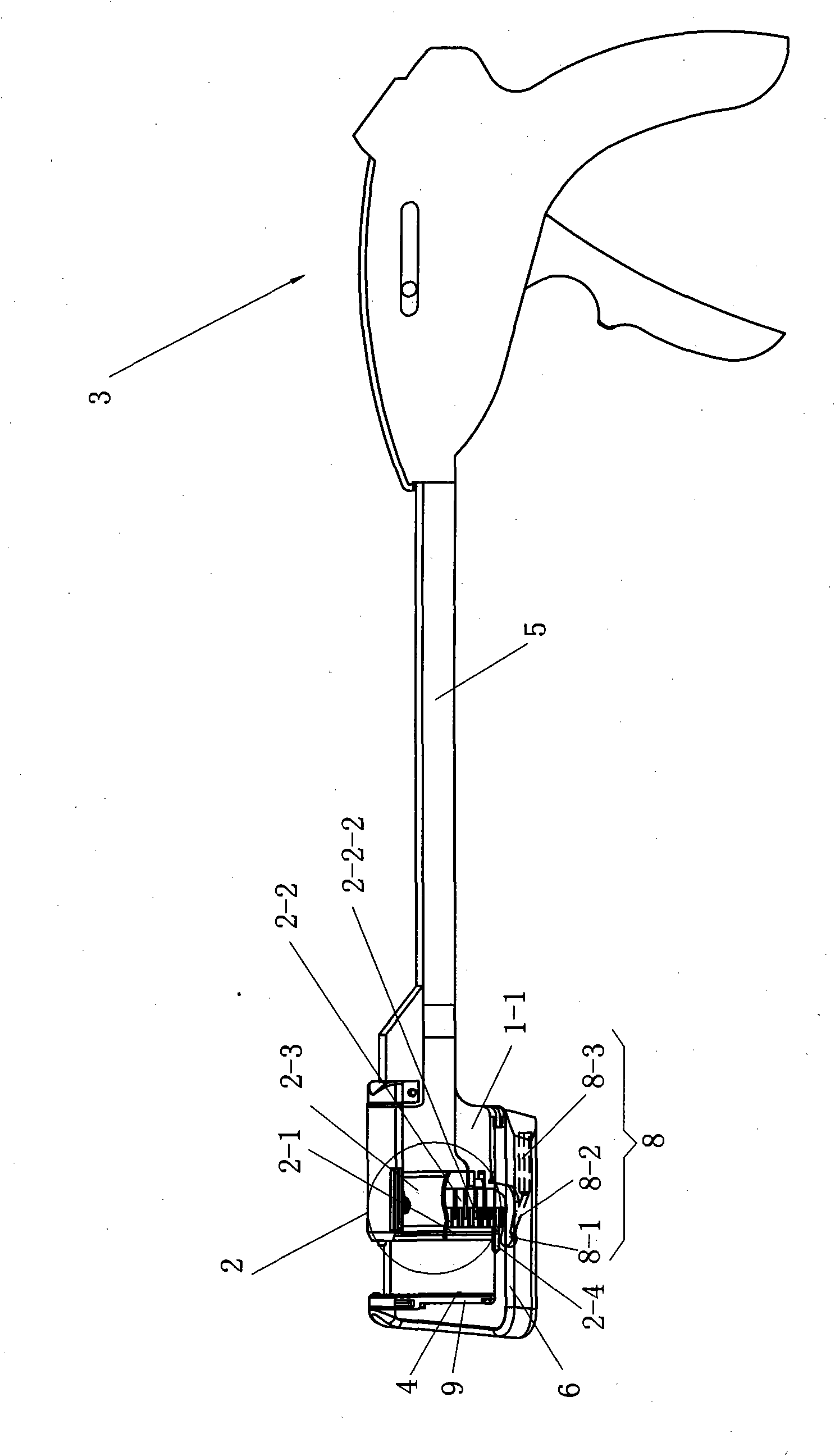

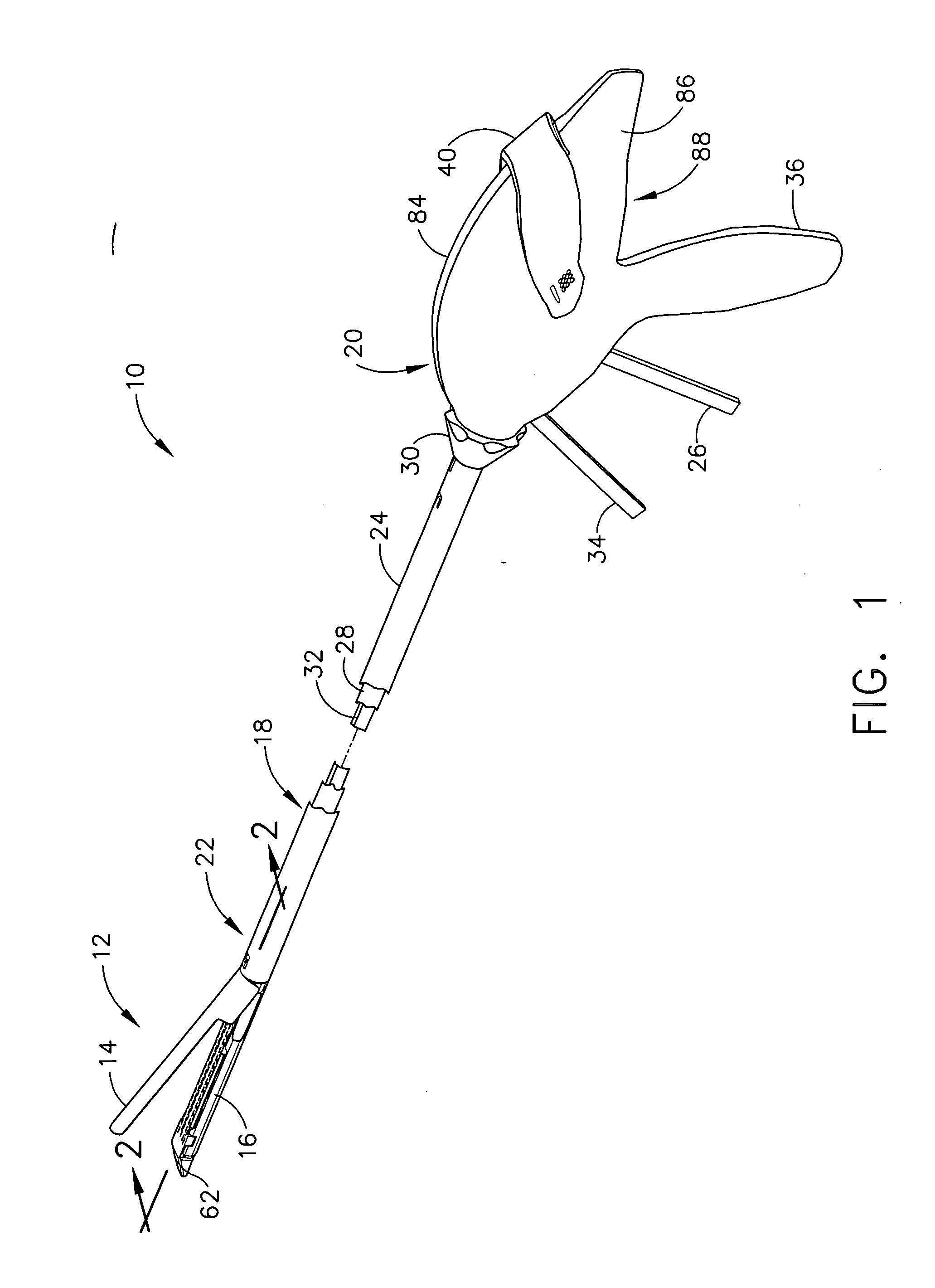

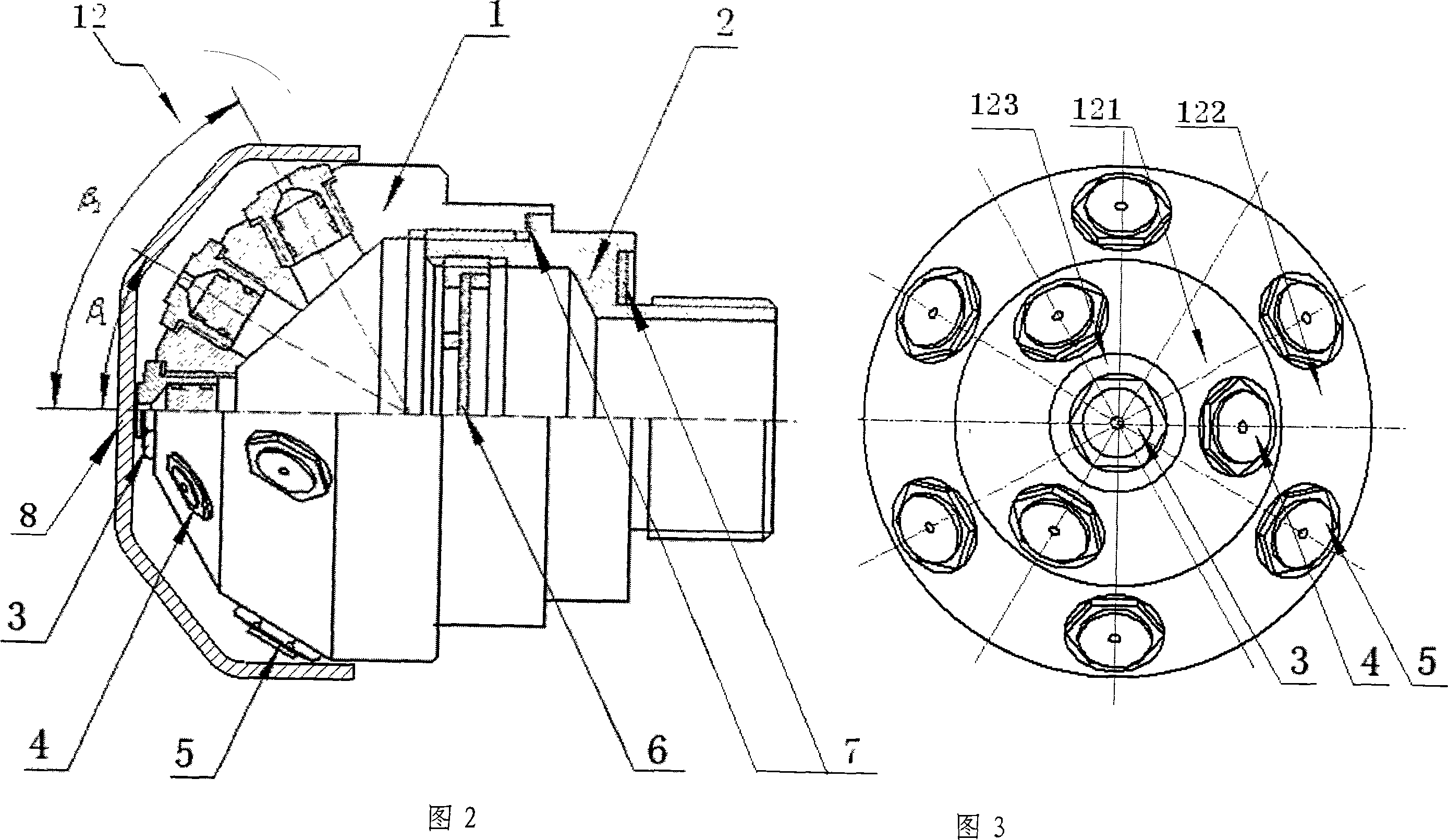

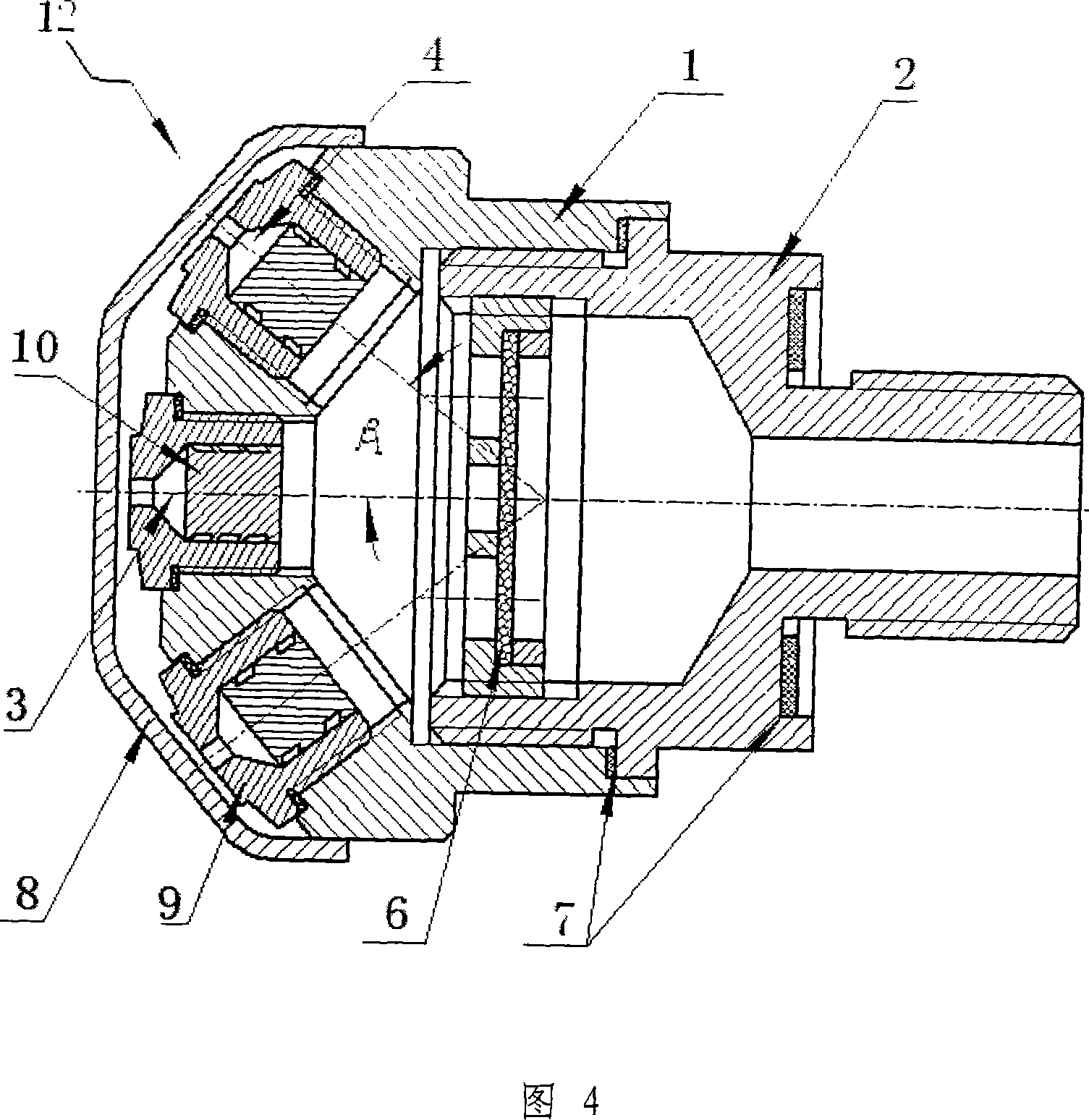

Arc-shaped cutting anastomat

ActiveCN101912284AGood assembly firmnessImprove reliabilitySurgical staplesDistal anastomosisEngineering

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

Arc-shaped cutting anastomat

The invention relates to an arc-shaped cutting anastomat comprising an anastomosis nail shaping mechanism, a nail pushing assembly, a trigger handle, a nail supporting seat, a base of the nail supporting seat, a knife cushioning ring and two splints, wherein the nail pushing assembly comprises a cutting knife, a nail pushing sheet, a nail bin and a guide post; the end of the nail pushing sheet and both sides of the cutting knife are respectively provided with a plurality of inner nail pushing dental sheets which are near the cutting knife and a plurality of outer nail pushing dental sheets which are far away from the cutting knife; the cutting knife and the nail pushing sheet are injected and molded at a time to be fixed together; the outer side of the each outer nail pushing dental sheeton the nail pushing sheet is provided with a reinforcing rib; the inner side of each nail pushing dental sheet on the nail pushing sheet is provided with a reinforcing rib; both ends of the first guide surfaces of the nail pushing dental sheets are respectively connected with the first contact surfaces and the second contact surfaces of the nail pushing dental sheets through concave arc-shaped connecting surfaces, and both ends of the second guide surfaces thereof are respectively connected with the first contact surfaces and the second contact surfaces through the concave arc-shaped connecting surfaces; and the first contact surfaces and the second contact surfaces are respectively in contact with the inner walls of the nail pushing dental sheet holes of the nail bin. The invention has the advantages of good trigger anastomosis shaping effect and high safety.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

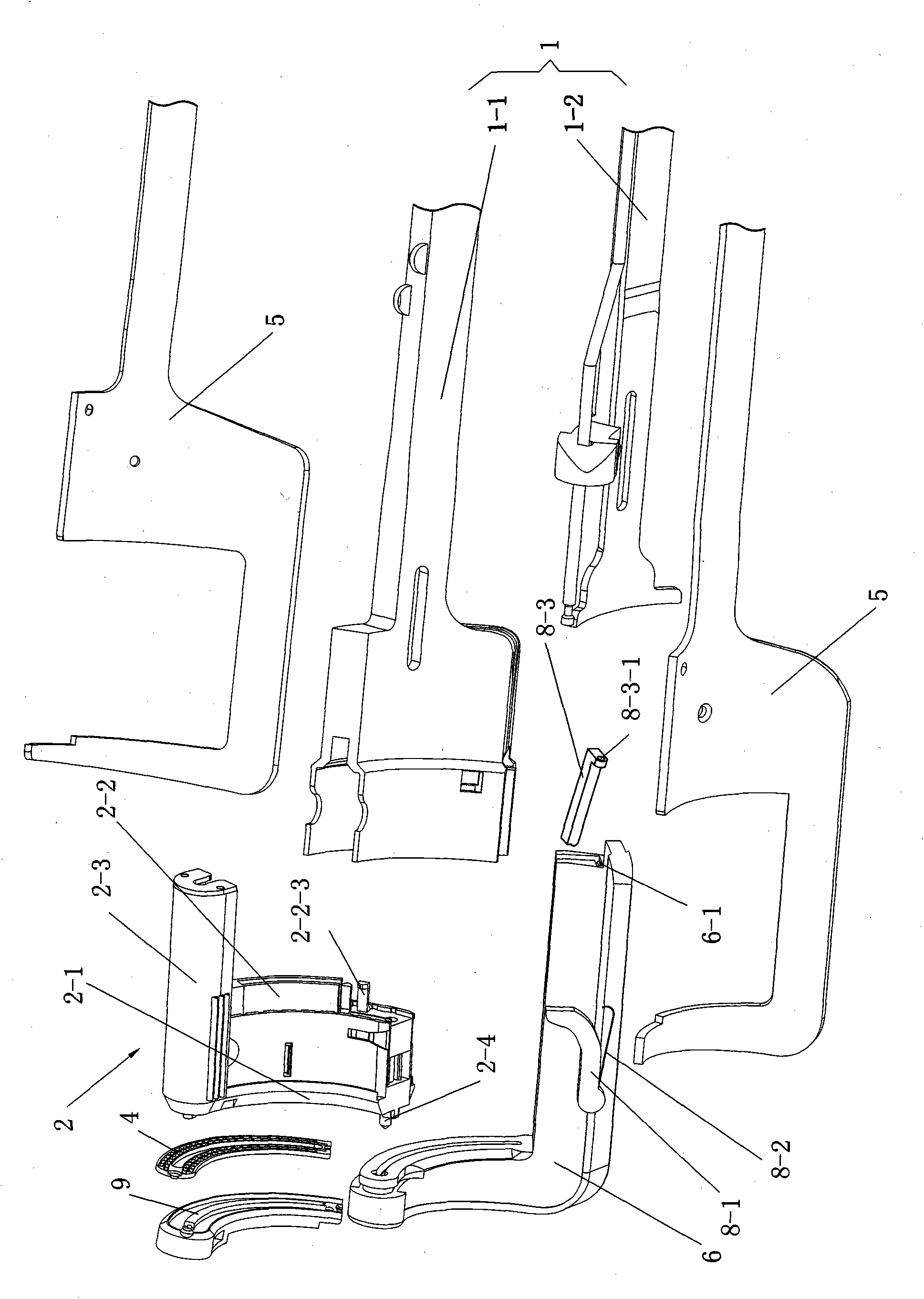

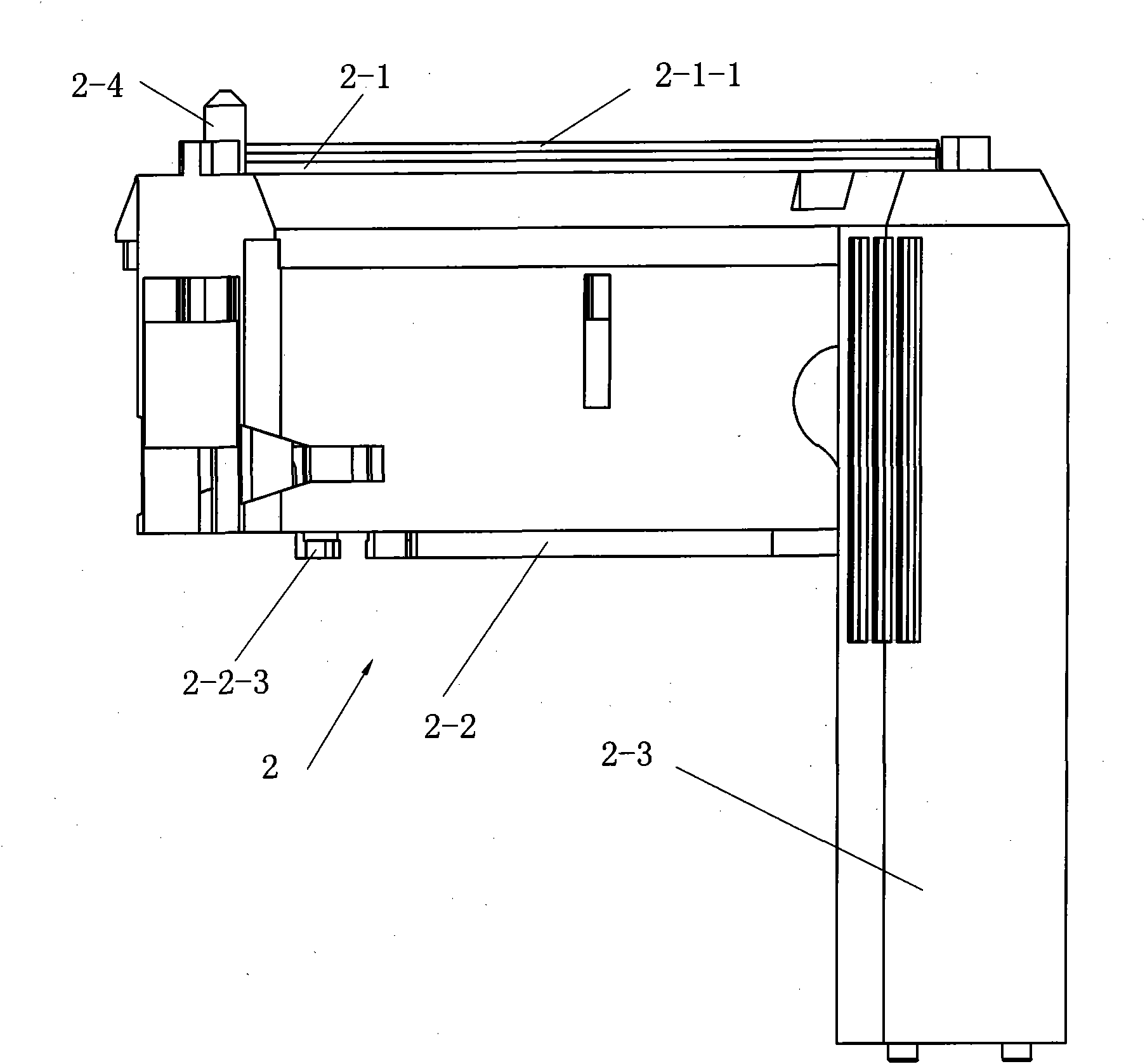

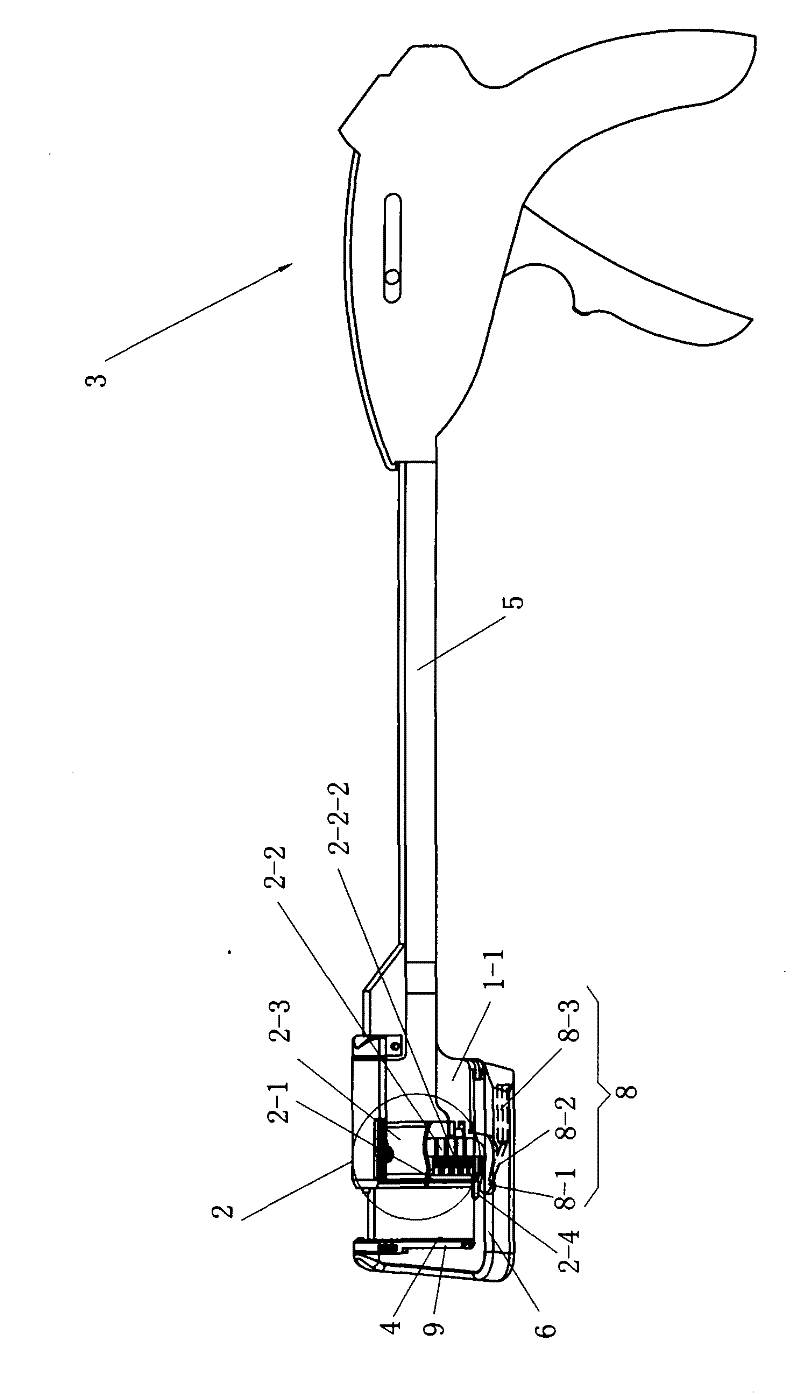

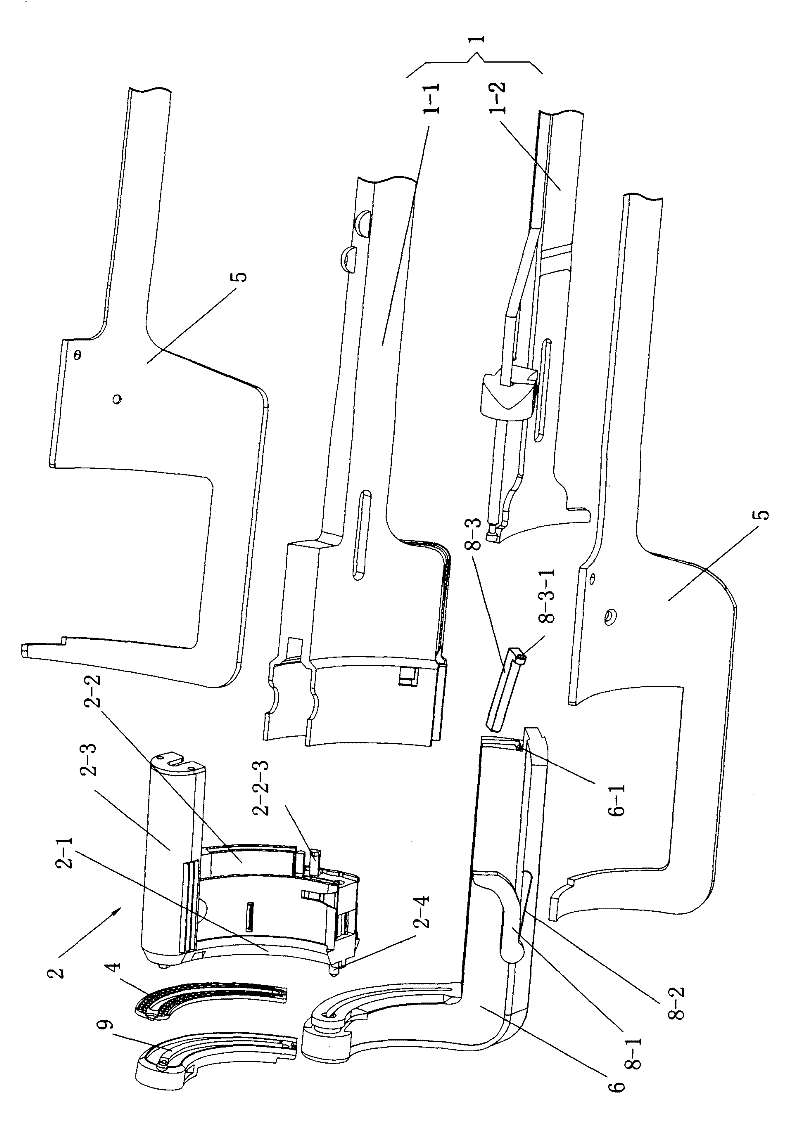

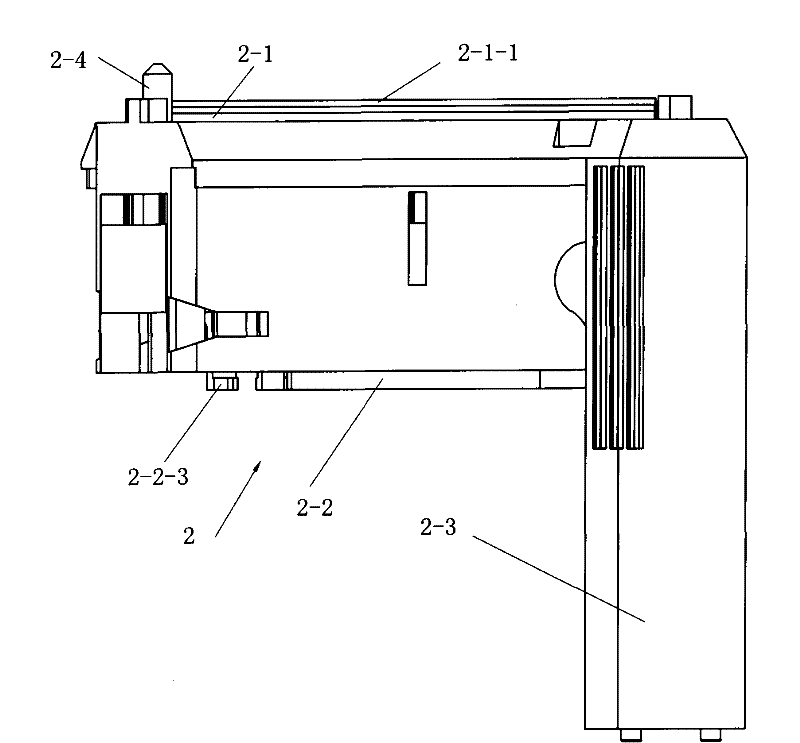

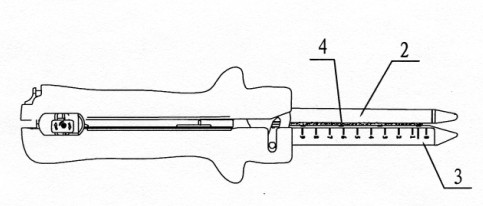

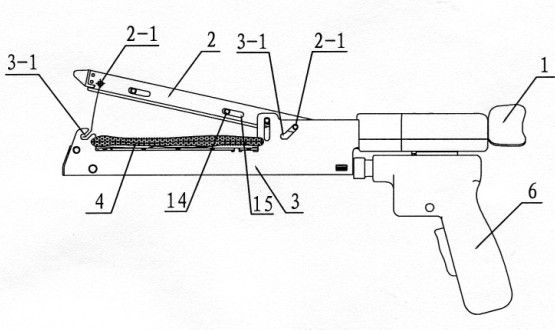

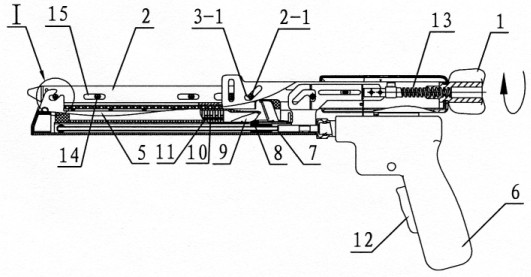

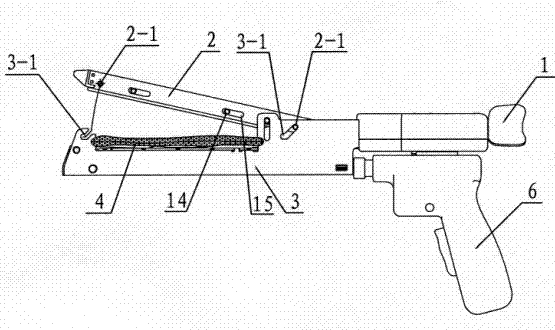

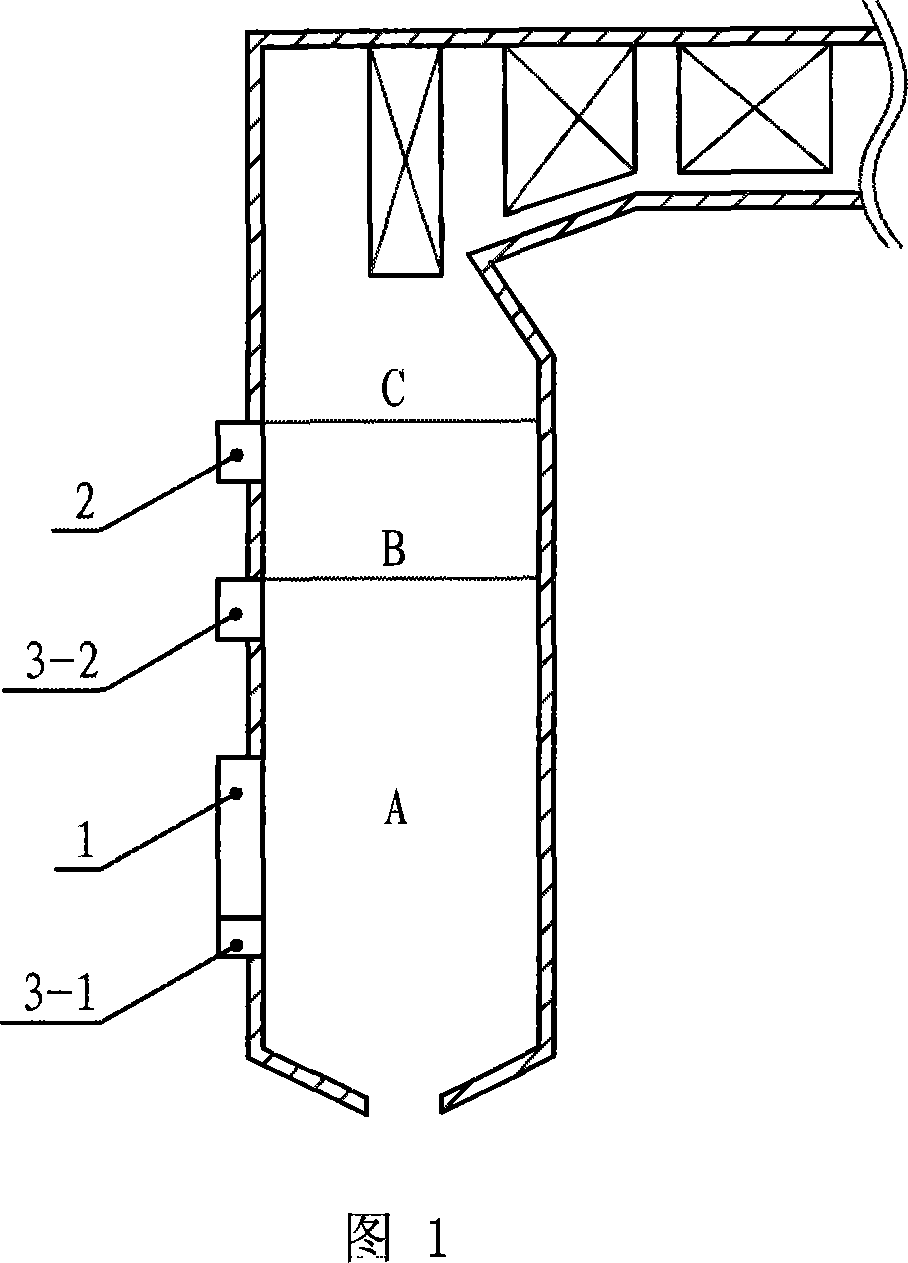

Cutter stapler for surgery

ActiveCN102125450AImprove rigidityImprove forming qualitySurgical staplesSurgery procedureMechanical engineering

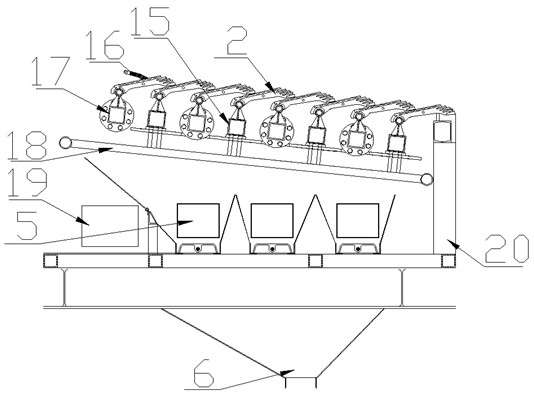

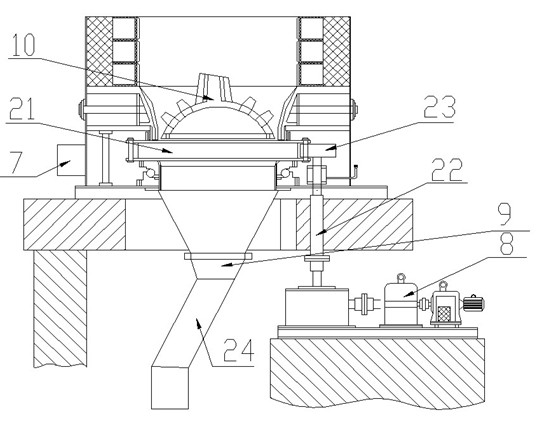

The invention relates to a cutter stapler for surgery. The cutter stapler comprises a pin holder (2), an assembly base (3), an osculating assembly (5), a firing gear (6) and an occlusion device for operating the pin holder (2), wherein the osculating assembly (5) is installed on the assembly base (3), the head part and the middle part of the assembly base (3) are respectively provided with a positioning slot (3-1), and positioning pins (2-1) matched with two positioning slots (3-1) are correspondingly arranged on the pin holder (2). When the cutter stapler is used for osculating thick tissue, a pin pushing part and the osculating assembly can be accurately positioned, the rigidity of the stapler is improved, and the uniformity of front and back inosculation heights and the forming quality of osculating pins can be ensured.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

Cutter stapler for surgery

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

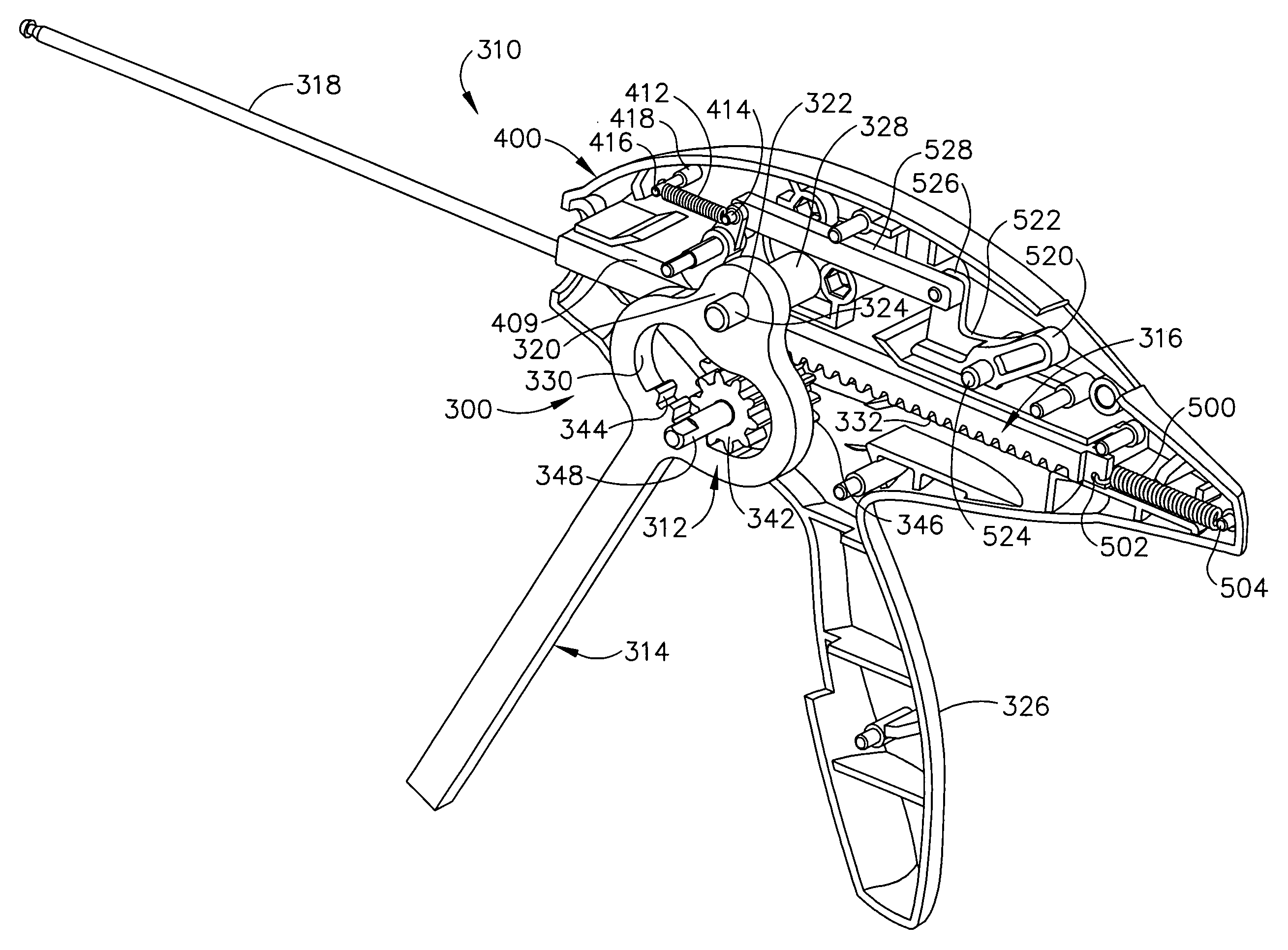

Surgical stapling instrument incorporating a multistroke firing mechanism having a rotary slip-clutch transmission

ActiveUS20060049230A1Promote fireIncrease forceSuture equipmentsStapling toolsSurgical stapleEngineering

A surgical stapling and severing instrument particularly suited to endoscopic procedures incorporates a handle that produces separate closing and firing motions to actuate an end effector. In particular, the handle produces multiple firing strokes in order to reduce the required amount of force required to fire (i.e., staple and sever) the end effector.

Owner:CILAG GMBH INT

Surgical stapling instrument incorporating a multistroke firing mechanism having a rotary transmission

ActiveUS20060000868A1Promote fireIncrease forceSuture equipmentsStapling toolsSurgical stapleEndoscopic Procedure

A surgical stapling and severing instrument particularly suited to endoscopic procedures incorporates a handle that produces separate closing and firing motions to actuate an end effector. In particular, the handle produces multiple firing strokes in order to reduce the required amount of force required to fire (i.e., staple and sever) the end effector.

Owner:CILAG GMBH INT

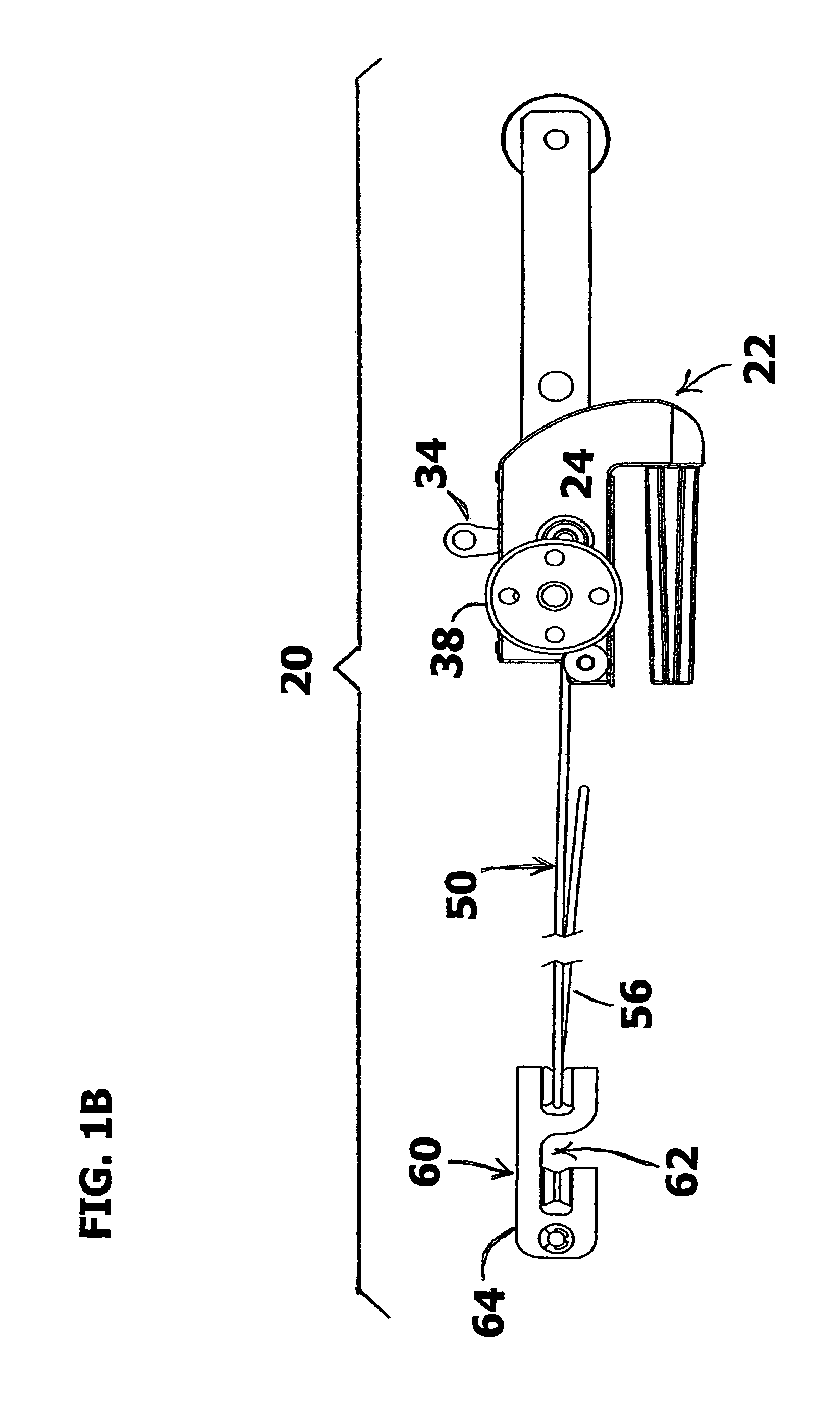

Cocking winch apparatus for a crossbow, crossbow system including the cocking winch apparatus, and method of using same

Owner:FERADYNE OUTDOORS LLC

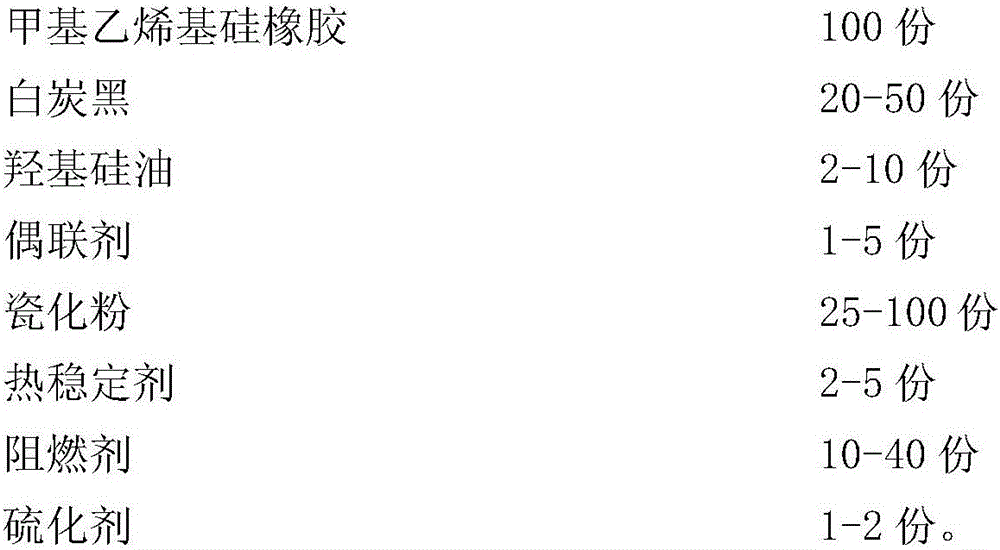

Preparation method of ceramizing fire-resistant silicon rubber

ActiveCN105694471AImprove flame retardant performanceWill not affect other performanceHalogenCombustion

The invention relates to a preparation method of ceramizing fire-resistant silicon rubber. The rubber comprises the following components in parts by weight: 100 parts of methyl vinyl silicon rubber, 20-50 parts of white carbon black, 2-10 parts of hydroxyl silicone oil, 1-5 parts of a coupling agent, 25-100 parts of ceramizing powder, 2-5 parts of a heat stabilizer, 10-40 parts of a fire retardant, and 1-2 parts of a vulcanizer. The preparation method includes the following steps: adding the methyl vinyl silicon rubber in a kneading machine; then adding the white carbon black and the hydroxyl silicone oil; mixing for 30 minutes at the temperature of 80 DEG C; then adding the coupling agent, the ceramizing powder, the heat stabilizer and the fire retardant; mixing for 1-1.5 hours; raising the temperature to be 100 DEG C and keeping high vacuum for 30 minutes; and after cooling to room temperature, adding the vulcanizer on an open mixing machine for mixing to obtain the ceramizing fire-resistant silicon rubber. The rubber has good mechanical property and electrical property at normal temperature, does not contain halogen, is smokeless and non-toxic during combustion, can be extinguished quickly and forms a ceramizing shell to guarantee integrity of the inside.

Owner:BEIJING UNIV OF CHEM TECH

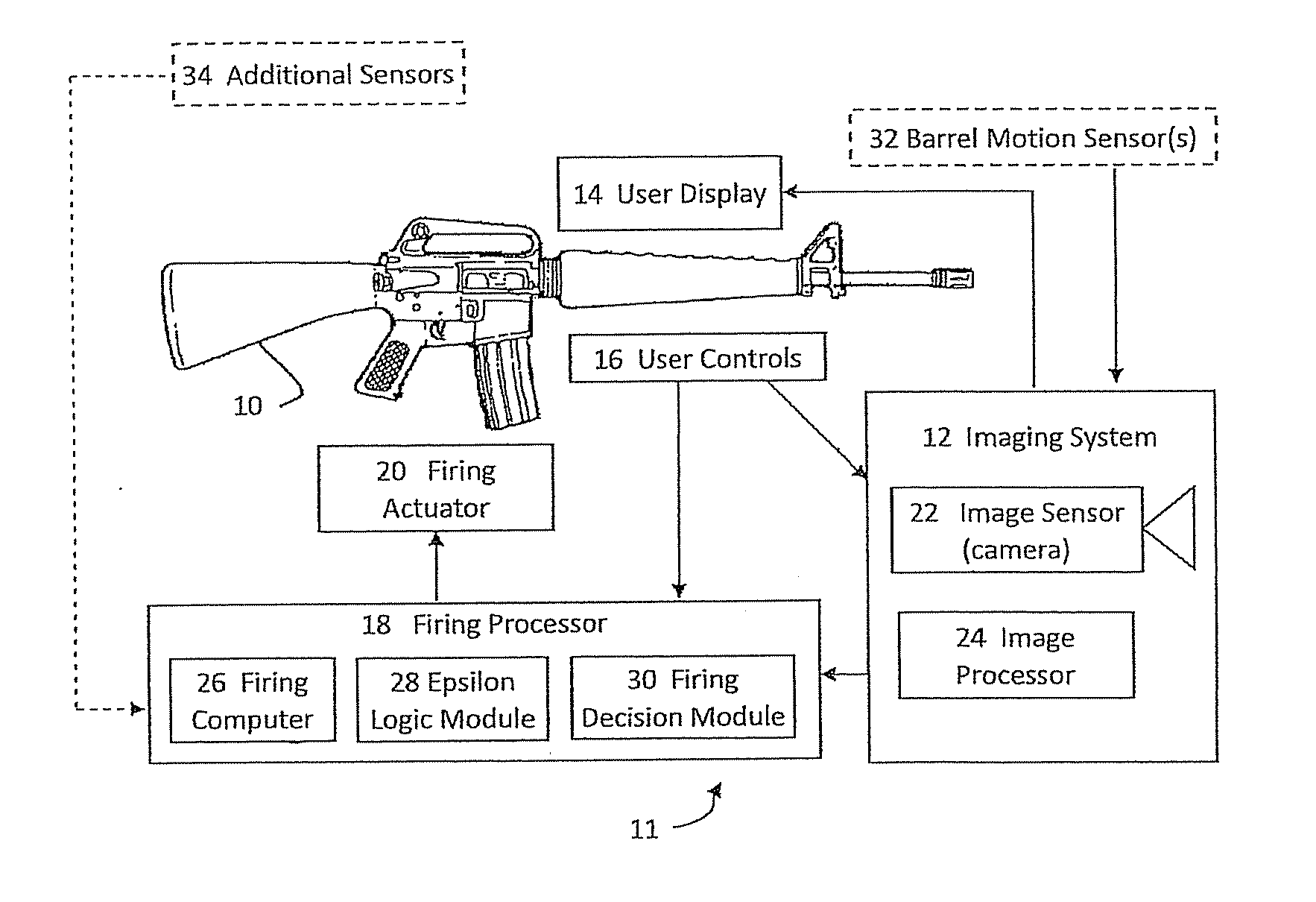

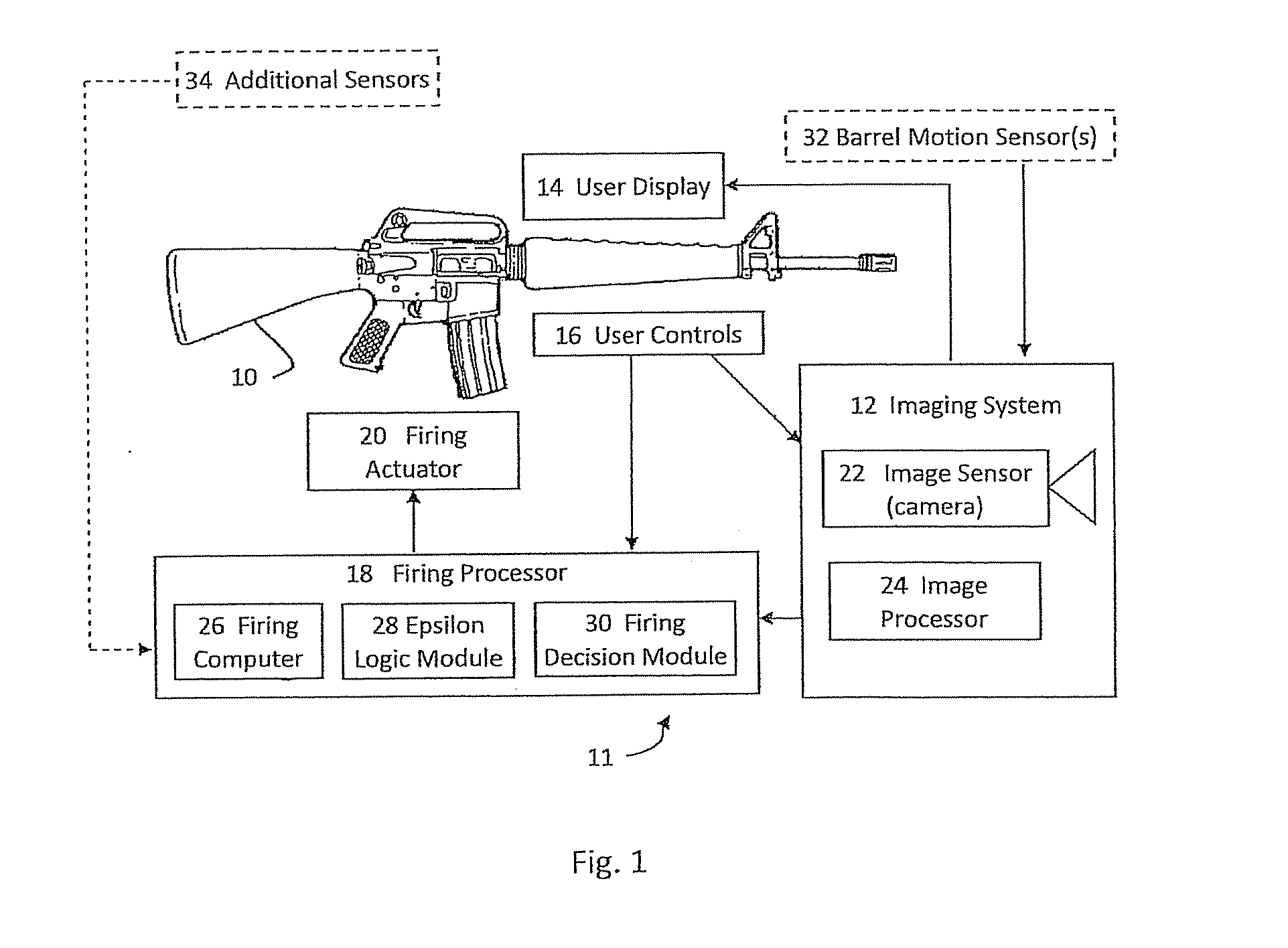

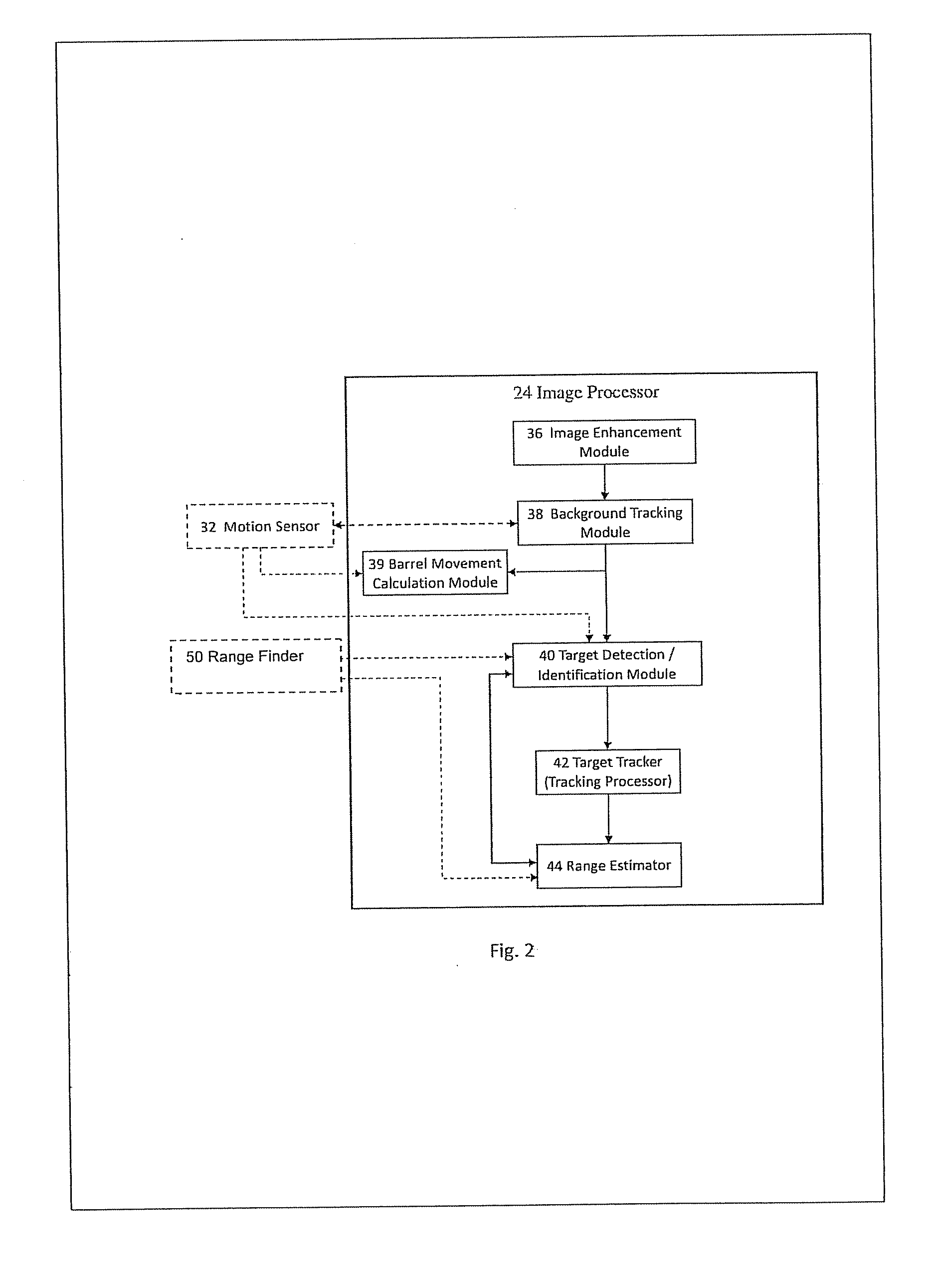

Firearm aiming system with range finder, and method of acquiring a target

ActiveUS20150108215A1Improve firing efficiency and effectivenessImprove effectivenessOptical rangefindersFiring/trigger mechanismsImage systemUser control

An aiming system of an aimable device includes a user display, an imaging system, user controls, a tracker, and a range finder such as a LRF. The imaging system displays, on the user display, an indicator of the direction in which the device points. The user uses the user controls to lock on a target towards which the device points according to the indicator. Then the tracker tracks the target, and the range finder measures the range to the tracked target. The tracker aims the range finder at the target, or alternatively scans the target and its background, one-dimensionally or two-dimensionally.

Owner:SMART SHOOTER

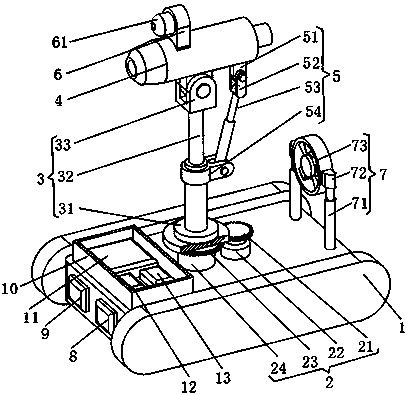

Multifunctional firefighting robot

InactiveCN108379762ASimple structureImprove fire extinguishing effectFire rescueFirefightingFire - disasters

The invention relates to a multifunctional firefighting robot which comprises a tracked robot. A rotary device is arranged in the middle of the upper surface of the tracked robot; an adjusting frame is arranged on the upper surface of a rotary shaft of the rotary device; a high pressure nozzle is arranged at the upper end of a first connecting piece of the adjusting frame; an adjusting device is arranged at the lower end of the right end of the high pressure nozzle; an installation plate is arranged at the upper end of the side surface of the high pressure nozzle; a camera is arranged on the side surface of the installation plate; a smoke dispersing device is arranged at the right end of the upper surface of the tracked robot; a temperature detector and a smoke detector are arranged on theleft side surface of the tracked robot; and a heat insulation box is arranged at the left end of the upper surface of the tracked robot. The multifunctional firefighting robot is simple in structure,capable of detecting and feeding back information of temperature and smoke concentration of a fire disaster zone, entering the fire disaster zone for multi-angle fighting fire, and dispersing dense smoke produced after firefighting, convenient for patients to escape, high in safety, diverse in functions, and convenient to use.

Owner:梁慧薇

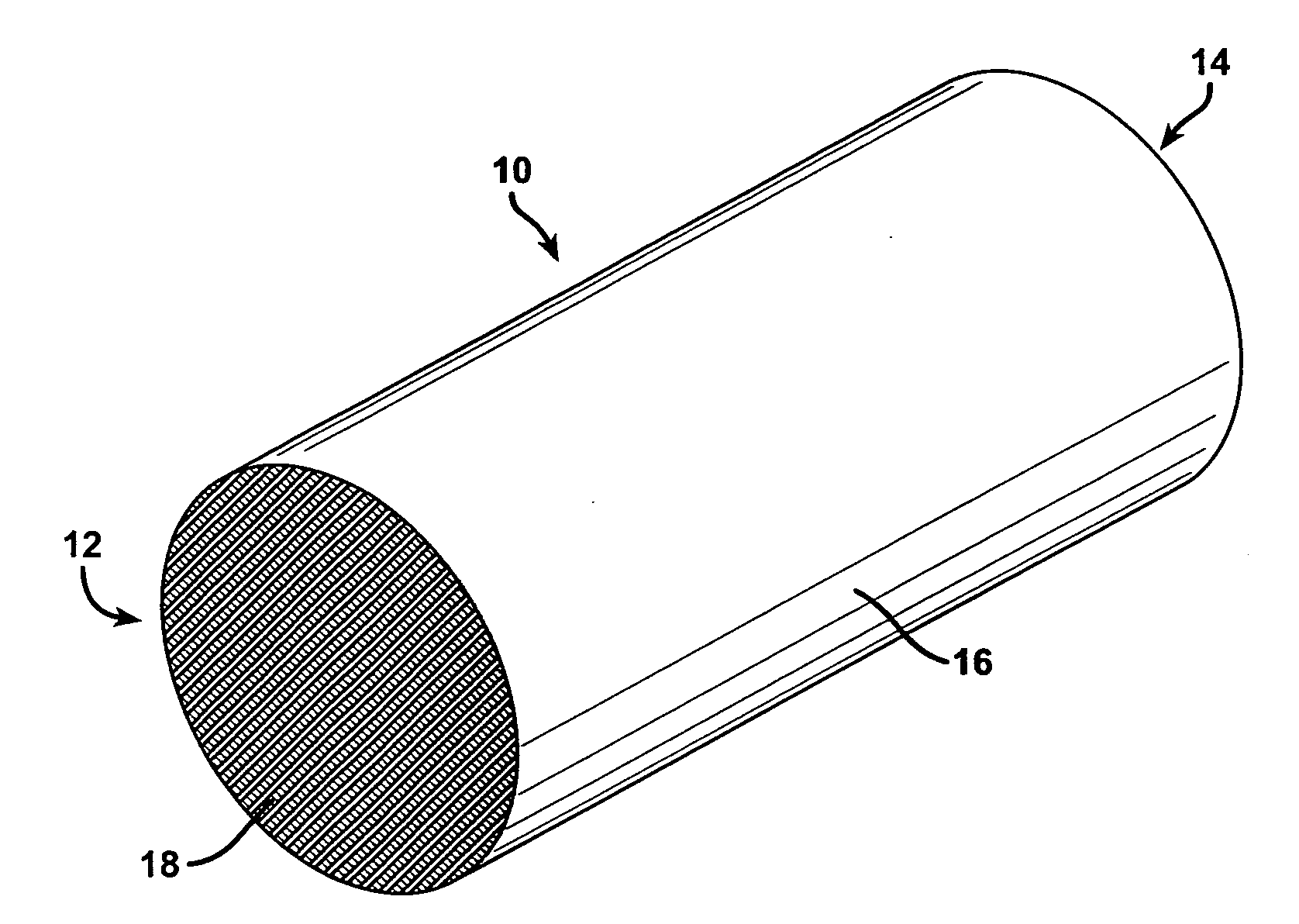

Cocking Winch Apparatus For A Crossbow, Crossbow System Including The Cocking Winch Apparatus, And Method Of Using Same

A crossbow having a bowstring cocking winch apparatus, a cocking winch apparatus usable with a crossbow, and a method of operating the apparatus are described. The cocking winch apparatus includes a projecting alignment member having a non-round cross-sectional shape, where the alignment member is removably securable to a butt portion of a crossbow stock by inserting the alignment member into a correspondingly-shaped hole formed in the stock. The cocking winch apparatus provides a straight and balanced draw to the crossbow bowstring, enabling a user to easily cock the bowstring by rotating a handle to draw the bowstring back, and to place it in cocked position in the crossbow trigger mechanism.

Owner:FERADYNE OUTDOORS LLC

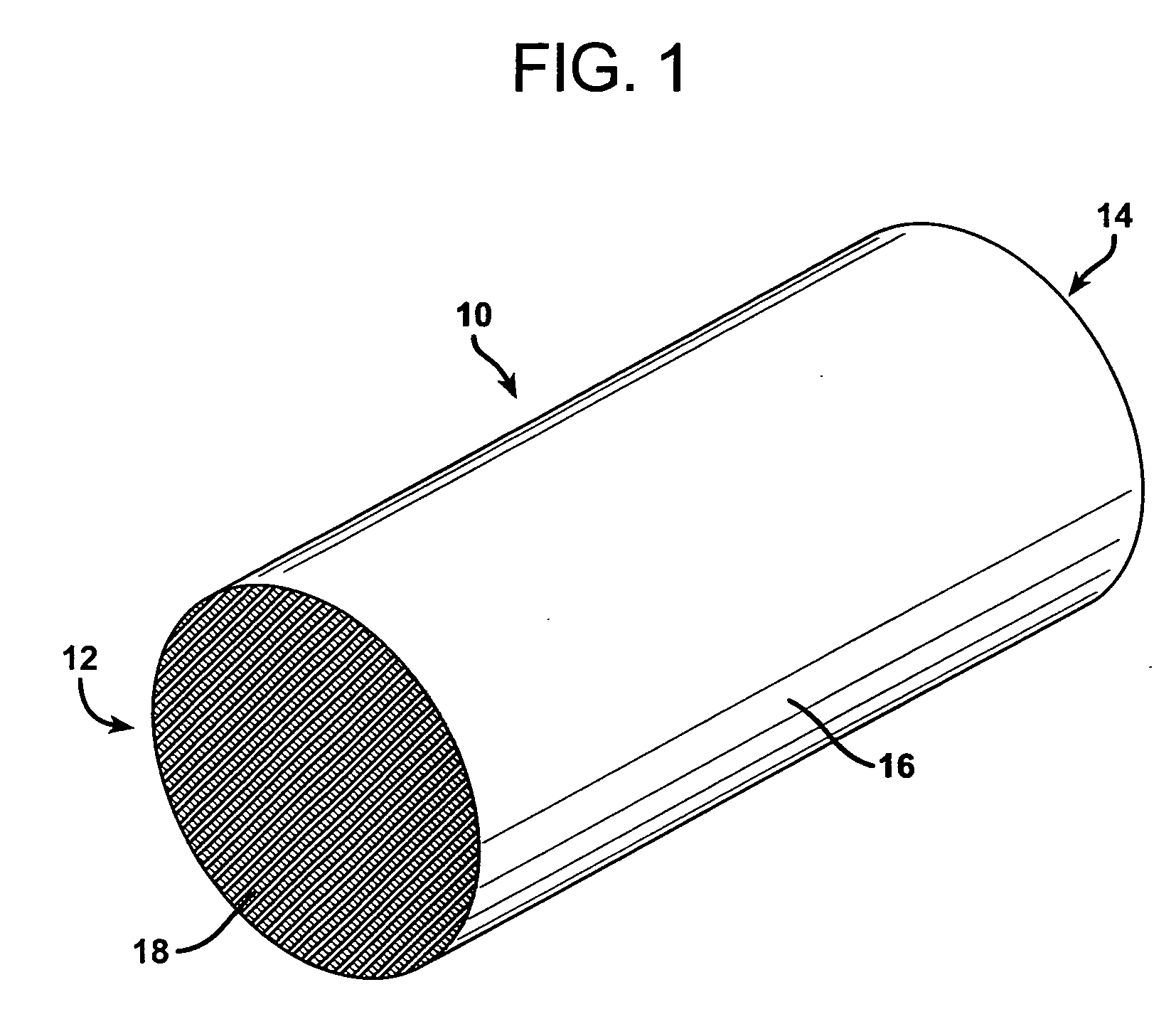

Geopolymer composites and structures formed therefrom

InactiveUS20060251909A1Improve thermal shock resistancePromote fireAlkali metal silicate coatingsCement productionThermal expansionCordierites

Geopolymer composite materials having low coefficient of thermal expansion are disclosed. The materials are useful in high temperature applications due to their low coefficient of thermal expansion and high strength. Also disclosed is a boron modified water glass geopolymer composition that is compatible with ceramic particulate material such as cordierite and fused silica. The geopolymer composite may be extruded to form structures such as honeycomb monoliths, flow filters or used as a plugging or skinning cement and may be fired at temperatures at or below 1100° C. Both the structures and the cement have high green and fired strength, a low coefficient of thermal expansion, and good acid durability. The cost of manufacturing objects using the material of the present invention is substantially reduced, in comparison with typically production methods of cordierite based bodies, due to the substantially shortened firing times.

Owner:CORNING INC

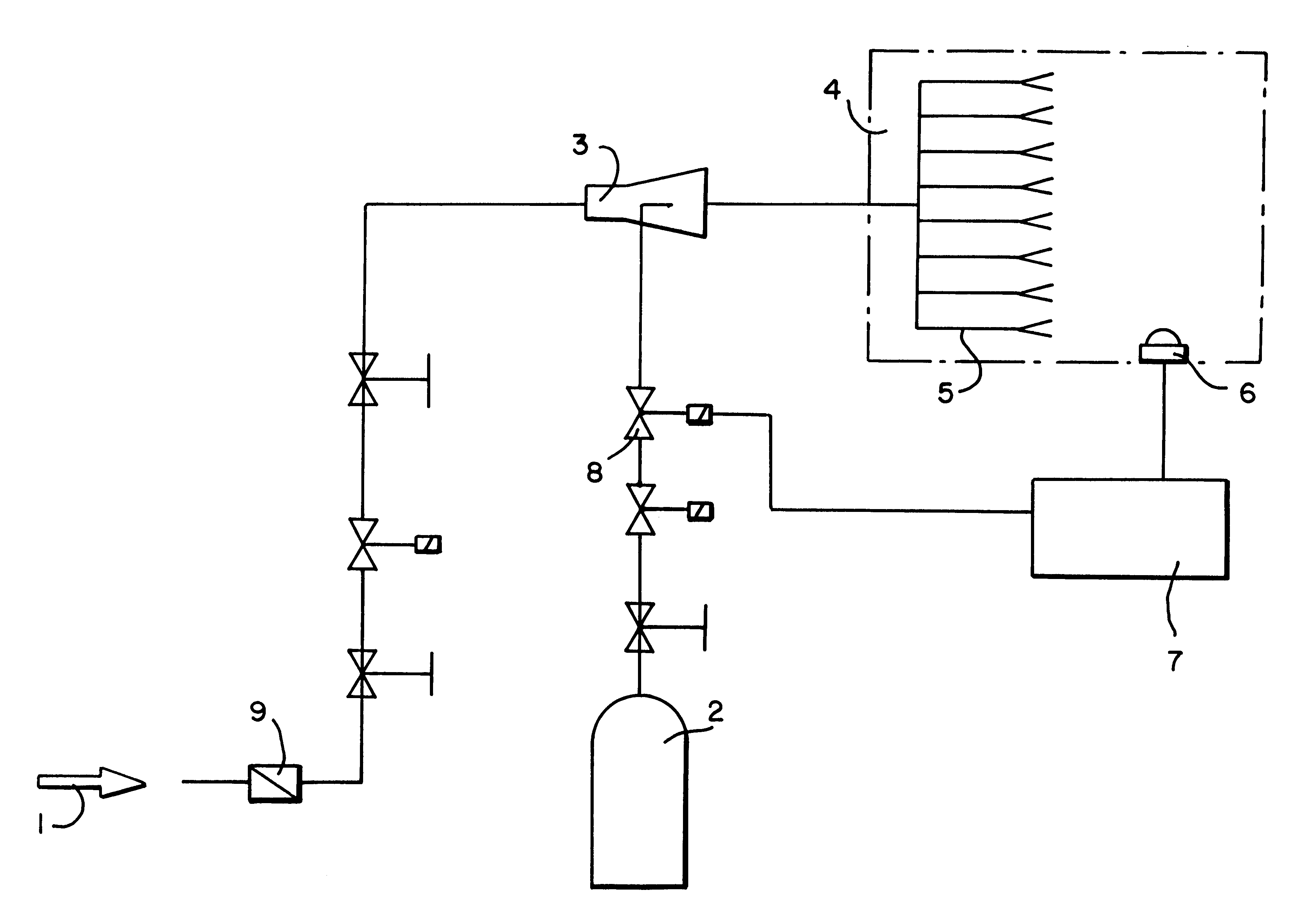

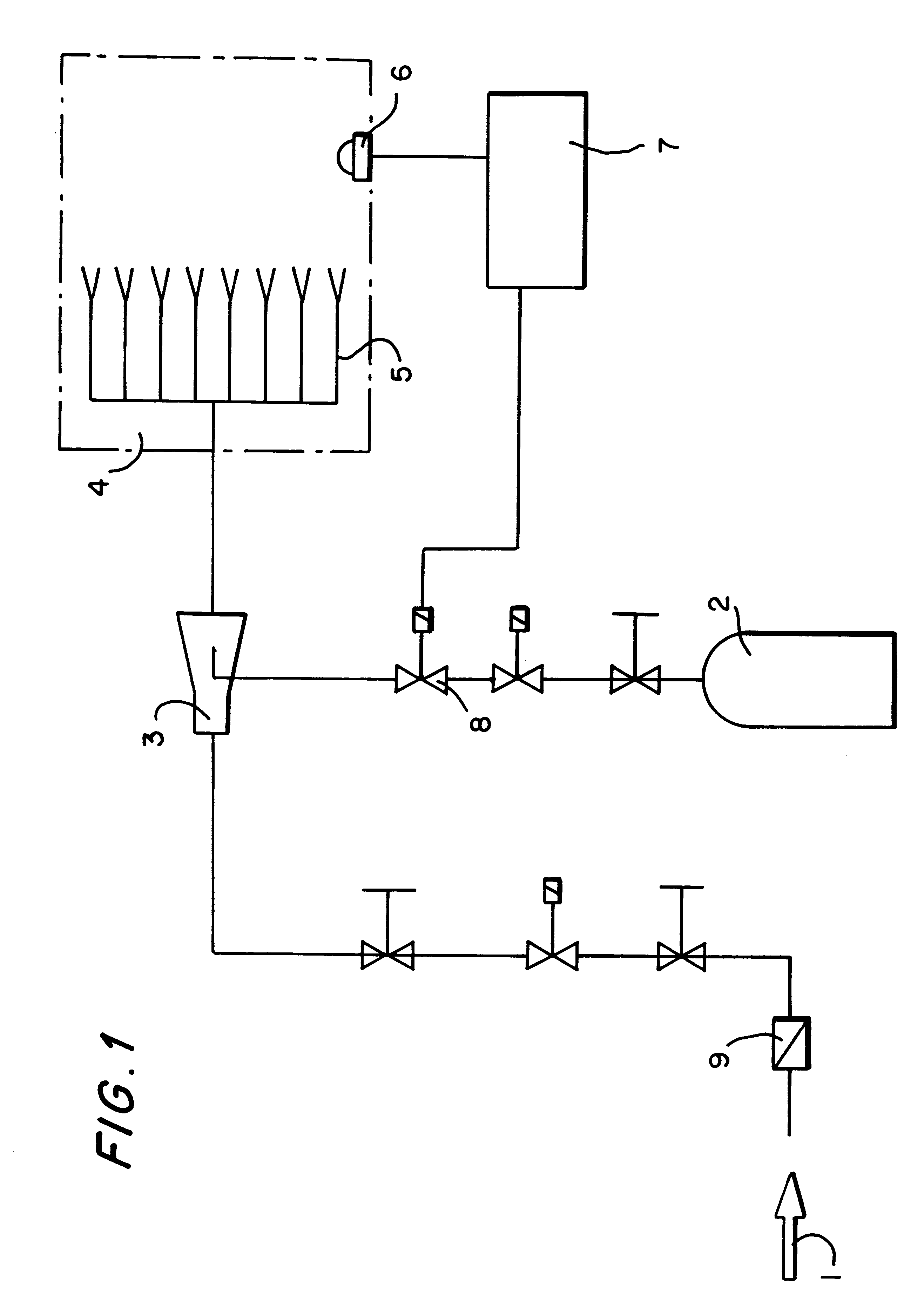

Process and device for atomizing liquid extinguishing agents in stationary extinguishing installations

InactiveUS6173790B1Reduce the amount requiredSmall sizeFire rescueLiquid spraying apparatusAerosol spraySpray nozzle

A process and a device for atomization of a liquid extinguishing medium, in which the liquid extinguishing medium and a liquid inert gas are mixed in a mixing unit to form a liquid extinguishing medium mixture. The mixture is conveyed through a conduit to a distributing device such as extinguishing nozzles. As the mixture exits the distributing device the mixture is atomized, forming an aerosol spray for extinguishing a fire within an extinguishing area defined by the aerosol spray. A detector arranged in the extinguishing area for detection of parameters relating to extinguishing of the fire is connected to an evaluation device which in turn is connected to a control valve. The control valve regulates the quantity of liquid inert gas supplied to the mixing unit.

Owner:ALSTOM (SWITZERLAND) LTD +1

Sub-motor-threshold stimulation of deep brain targets using transcranial magnetic stimulation

ActiveUS8795148B2Great probabilityPromote fireElectrotherapyMagnetotherapy using coils/electromagnetsDiseaseNervous system

Systems and methods for modulating deep brain target regions using an array of TMS electromagnets, wherein each TMS electromagnet stimulates the target at a level that is below motor threshold (MT). Neurological disorders (or disorders having neurological effects) may be treated by sub-MT stimulation of deep-brain targets from an array of TMS electromagnets.

Owner:BRAINSWAY

General multifunctional foam fire-extinguishing agent and its preparing method

InactiveCN1820806AEnhanced burn resistanceImprove film formationFire extinguisherChemistryHydrocarbon

The general multifunctional foam fire-extinguishing agent consists of plant protein 0.8-30 wt%, sugar 0.8-30 wt%, hydrocarbon surfactant 1-12 wt%, fluoric surfactant 0.1-5 wt% and additive 5-20 wt%, except water. The general multifunctional foam fire-extinguishing agent may be used to extinguish fire of alcohol and other polar chemical matter and / or light oil, heavy oil and other non-polar chemical matter. The general multifunctional foam fire-extinguishing agent contains no corrosive chemical matter, and has self-cleaning property, capacity of prolonging the service life of the fire-extinguishing equipment, no toxicity and no harm to human body and no environmental pollution.

Owner:北京特威特科技有限公司

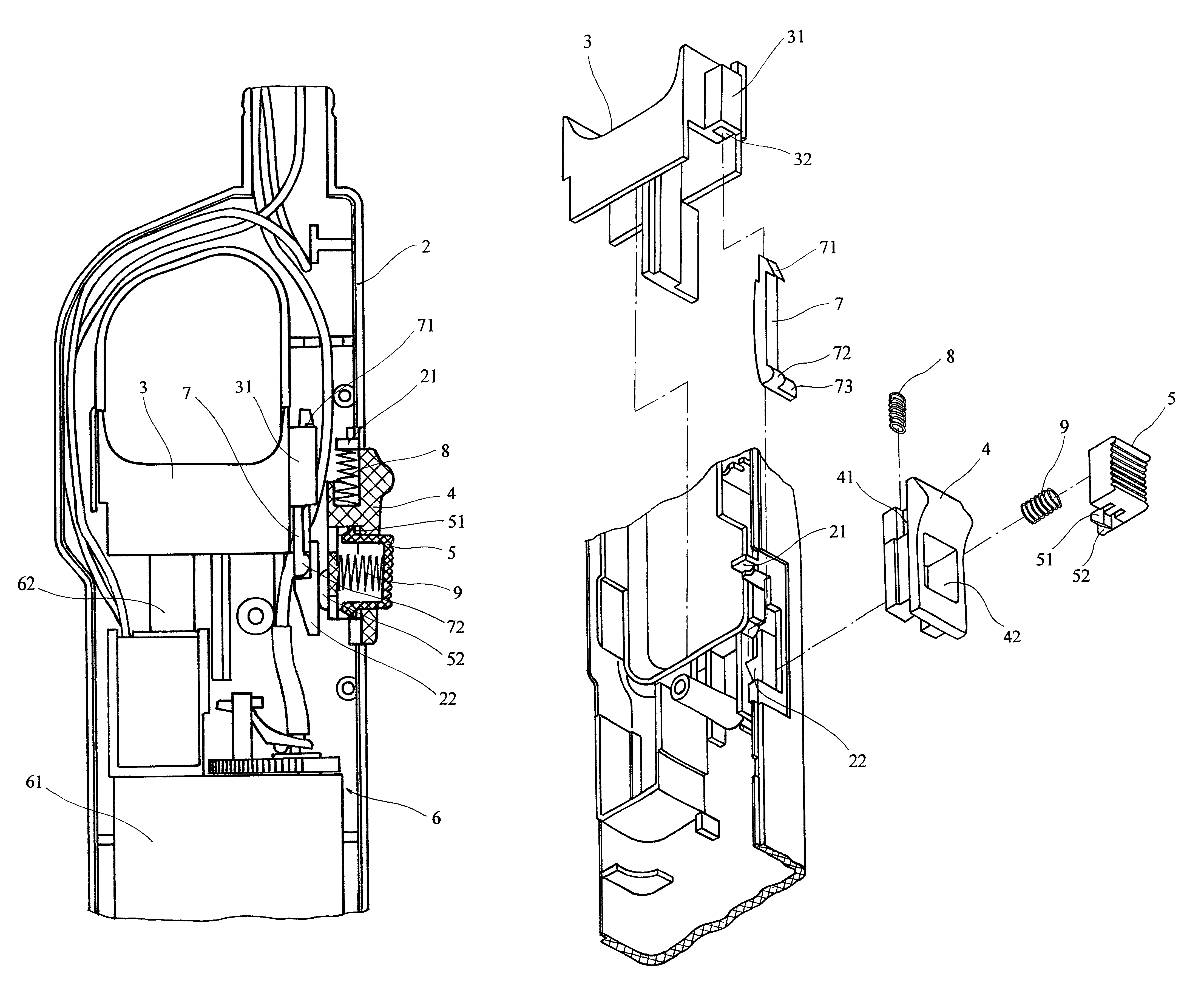

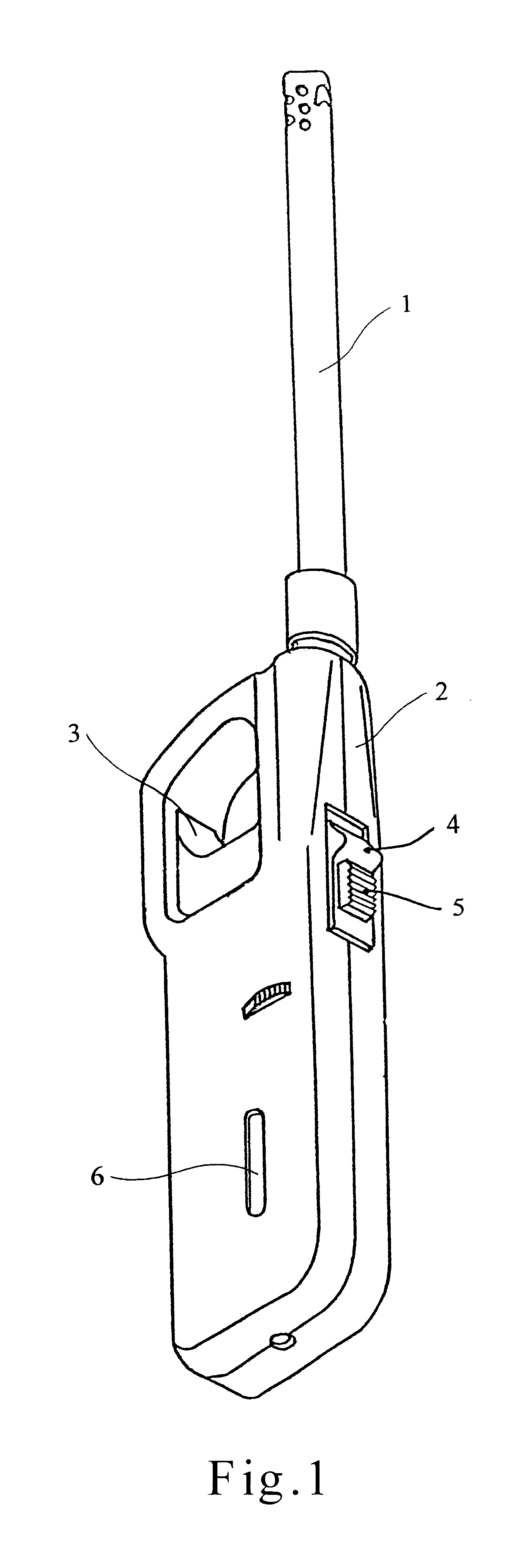

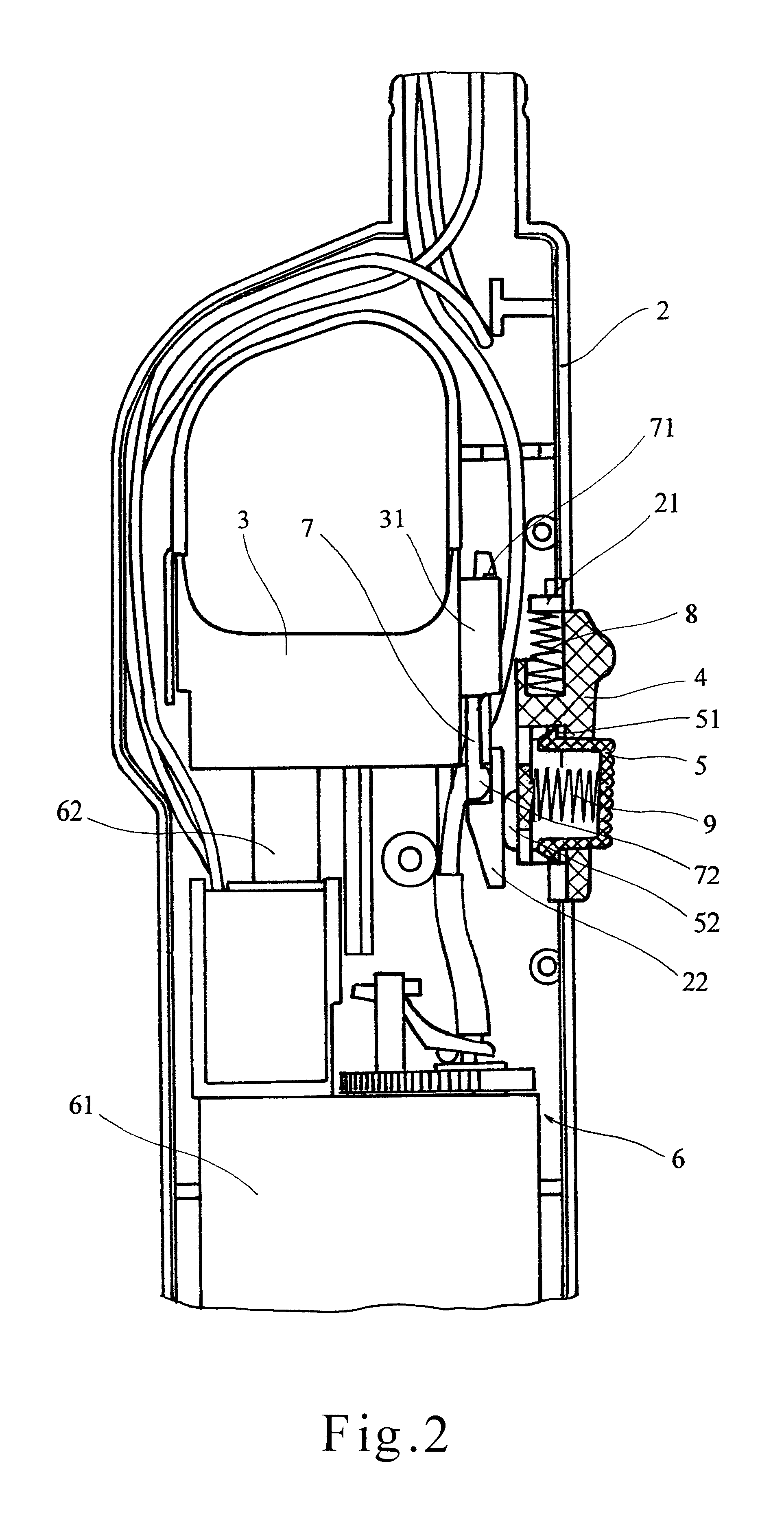

Igniter with a push-button and an elastic bar

InactiveUS6887072B2Promote fireSolve the real problemBranding equipmentIncandescent ignitionNatural statePush ups

Igniter with safety unit, the safety unit comprises a push-button that is arranged at the backside of the gun body and partially protrudes out of the gun body, it can be pushed forward and return relative to the gun body; a elastic limit bar that is arranged at the side of the part of the ignition trigger that is towards the backside of the gun body, in natural condition, its end keeps against a barrier block which is integrated with the inner wall of the gun body; a button that is arranged in the push-button and protrudes out of the push-button, it can be pressed into the gun body and return. A protruding part arranged on the button's inner side protrudes towards a mid-portion of the gun body. In natural condition, the protruding part is towards the blank part, but when the push-button is in pushed up condition, the protruding part is near the end of the elastic limit bar and opposite to it. Thereby, if the button is pressed down, the protruding part of the button pushes the end of the elastic limit bar to make it distort and deflect from the barrier block on the inner wall of the gun body. The locking situation of the ignition trigger can be released. The apparatus can fire the flammable gas only by doing the two compound actions i.e. pressing down the button and pushing up the push-button simultaneously, thus further improving the safety of the ignitor.

Owner:JUDENG ZHANG

Minor cereal rice

InactiveCN101647529APromote fireKeep the flavorFood shapingFood preparationPolygonum fagopyrumFood flavor

The invention relates to minor cereal rice belonging to the technique field of grains. The minor cereal rice is characterized by taking corns or buckwheat or oats or purple sweet potato powder or pumpkin powder as raw materials. The minor cereal rice in rice grain shape is prepared by a technological method comprising the following steps: supermicro-pulverization, mixing with water, extruding foraging, extruding for granulation, cooling, drying and obtaining finished product. The invention overcomes the defect of the single nutrition of rice, prepares five grains with rich nutrition into thevarious-grain rice which is the same as the rice and can be ate by being steamed and mixed with the rice or ate by being mutually mixed, and a steaming method of the various-grain rice is the same asthat of the rice so as to be convenient; and the minor cereal rice also retains the original flavor of the five grains, has smooth mouthfeel because the various-grain rice is in an ellipse shape the same as the rice and is subtle and delicious because the raw materials are pulverized in a supermicro way.

Owner:ZHEJIANG CHENYUN IND

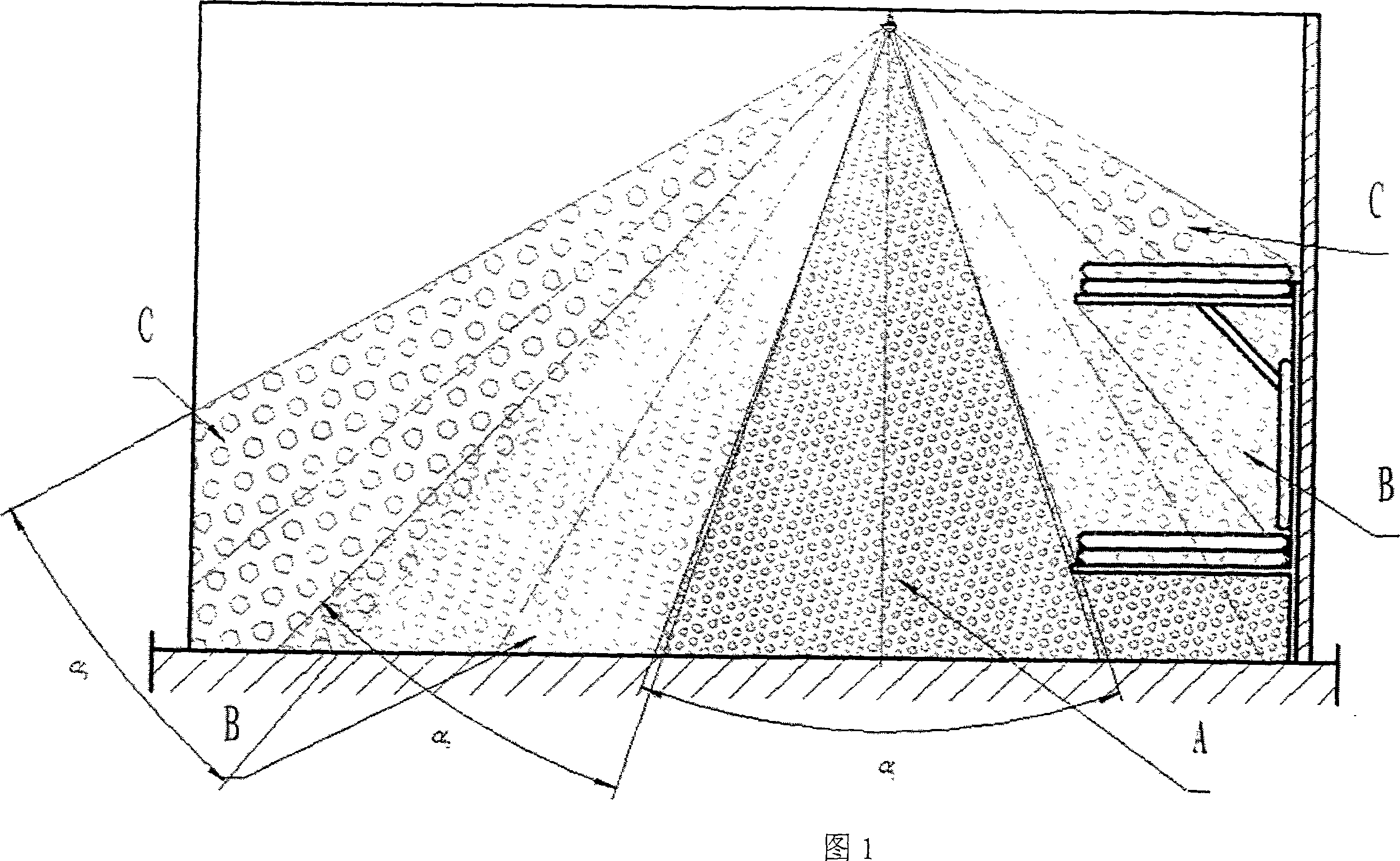

High-pressure extinguishing nozzle with fine spraying for submarine and ship habitation cabin

The invention discloses a high-pressure thin water spray fire-fighting injector used in submarine and ship, comprising injector shell, injector patchplug, central air spout, spherical air spout, outer air spout, internal filtering net, metallic sealing bale and dust shield. The shape of injector shell is two conical surfaces, the top of conical surface neat top part is plain, the central part is equipped with air spout; conical surface near to top is distributed with several spherical sir spouts; outer circle of conical surface near to top is next to another conical surface, a plurality of outer air spouts are installed on said conical surface. The air spouts on different installation surface are intercrossed, the injector shell and central air spout, spherical air spout and outer air spout, and injector shell and injector patch plug are all connected with each other through screw. The sealing employs metallic pad. The air spout is connected with the cavity of injector shell; the cavity of injector patch plug is equipped with stainless steel filtering net; another end of injector patch plug is connected with fire-fighting system through screw, and the injector shell is provided with dust cover.

Owner:BEIHANG UNIV

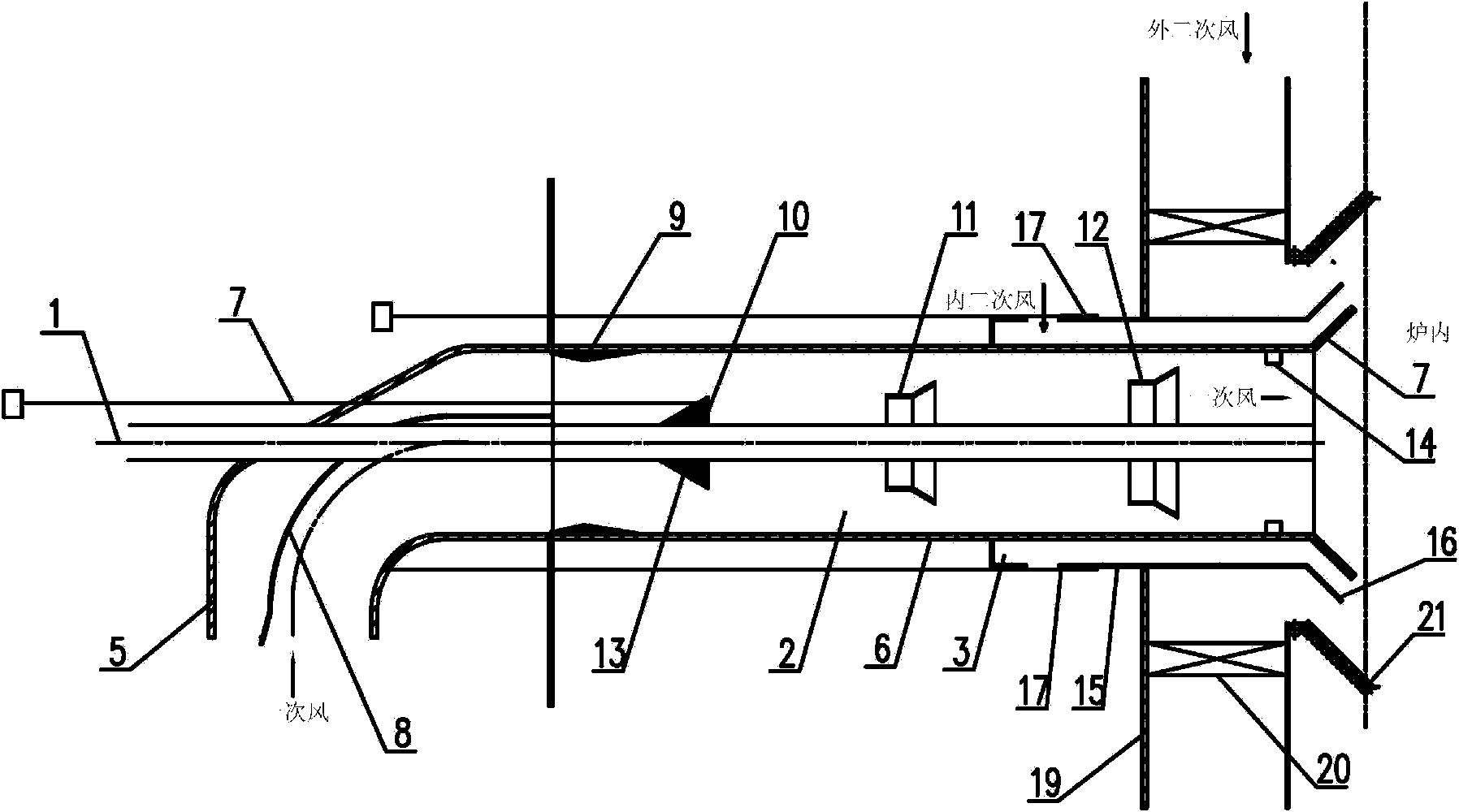

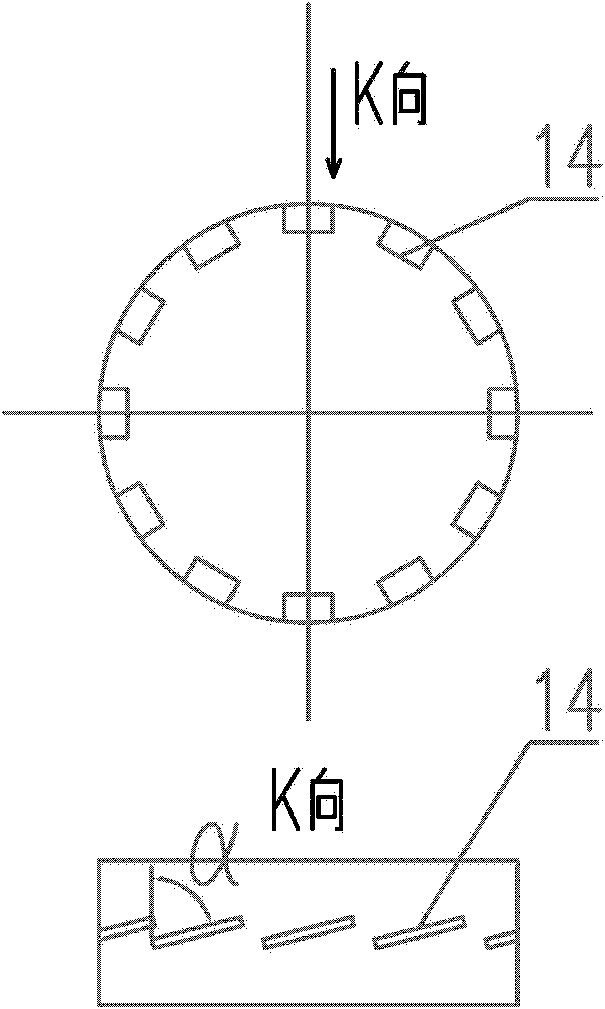

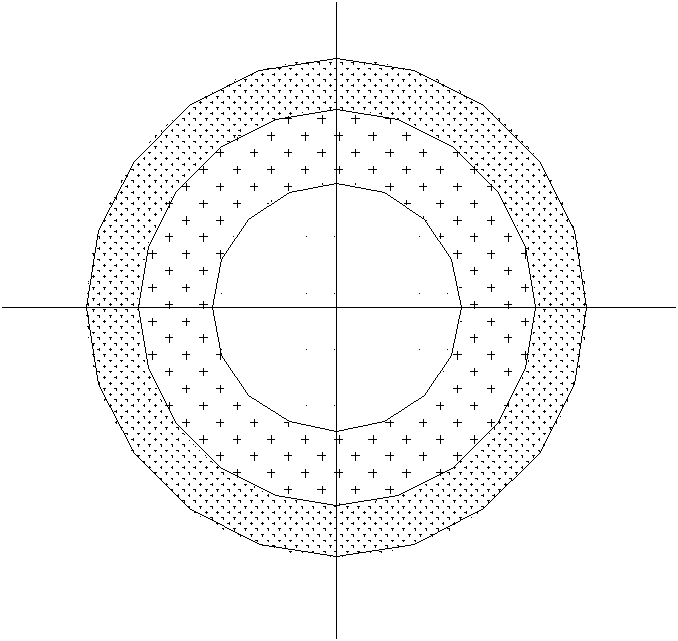

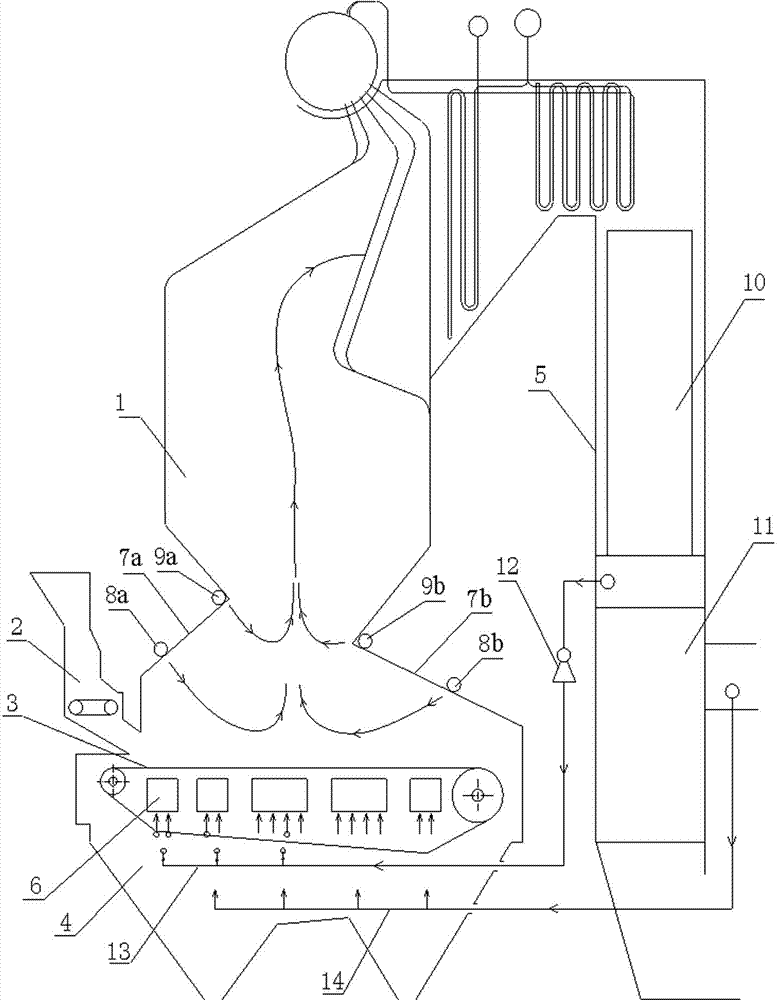

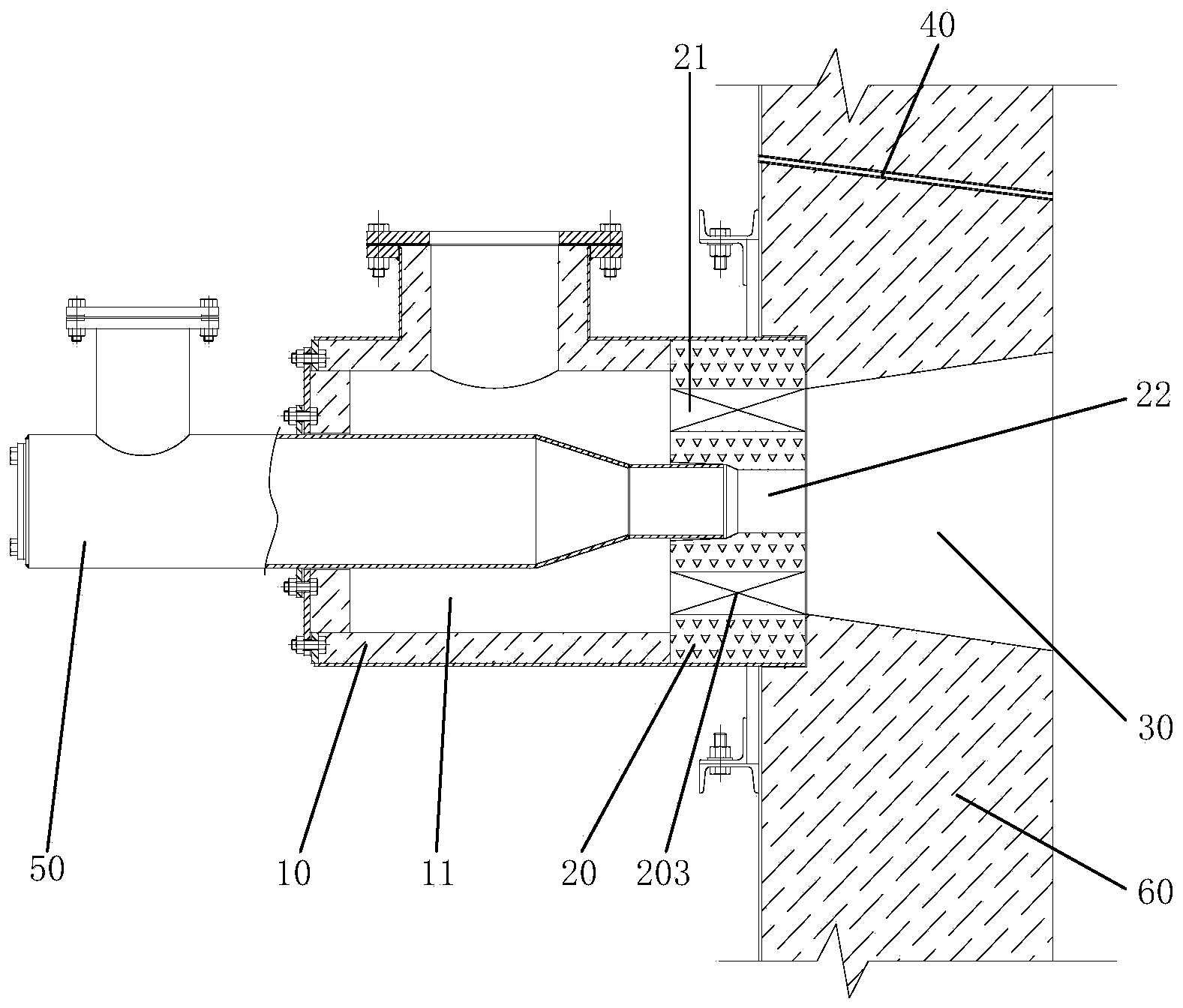

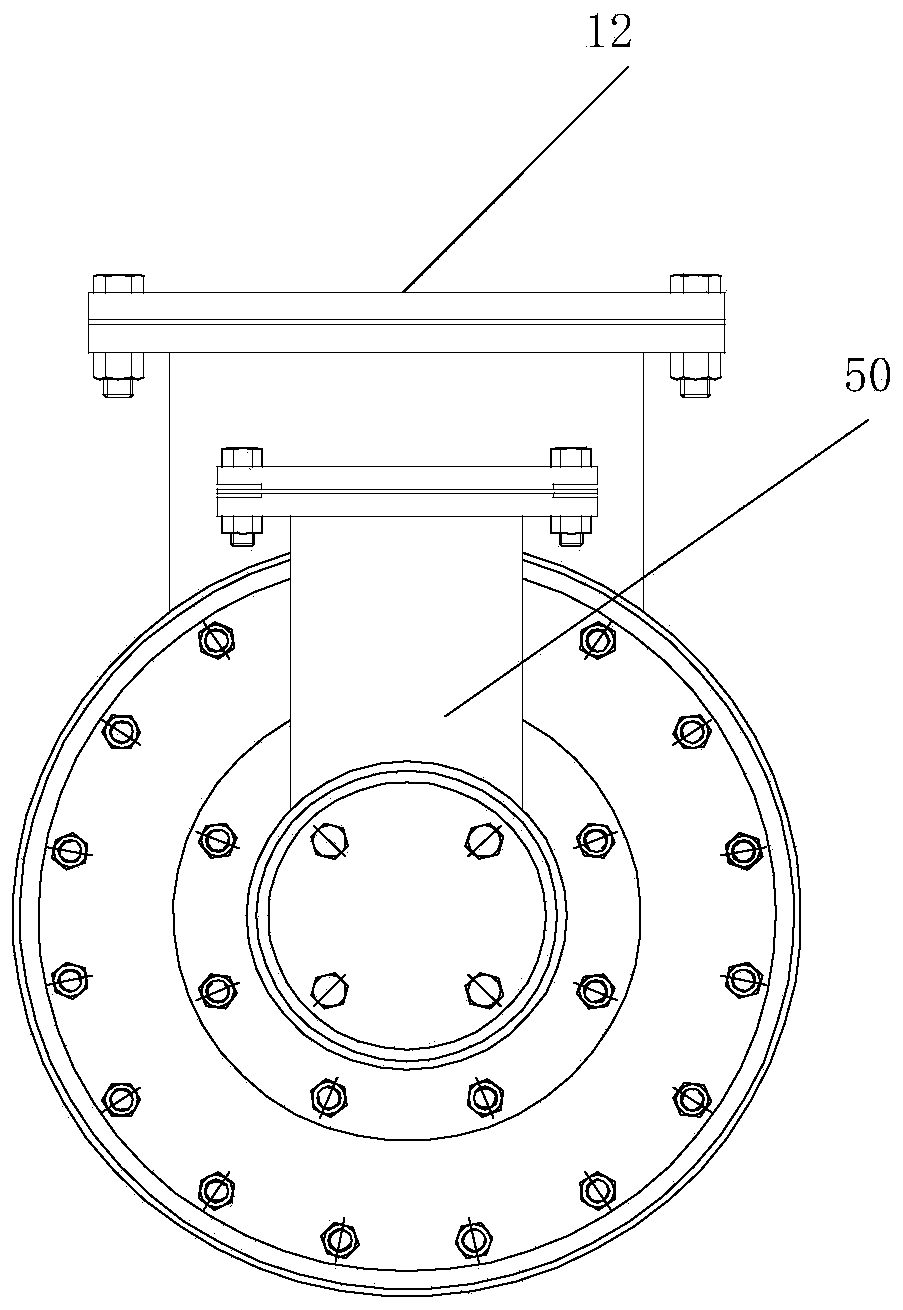

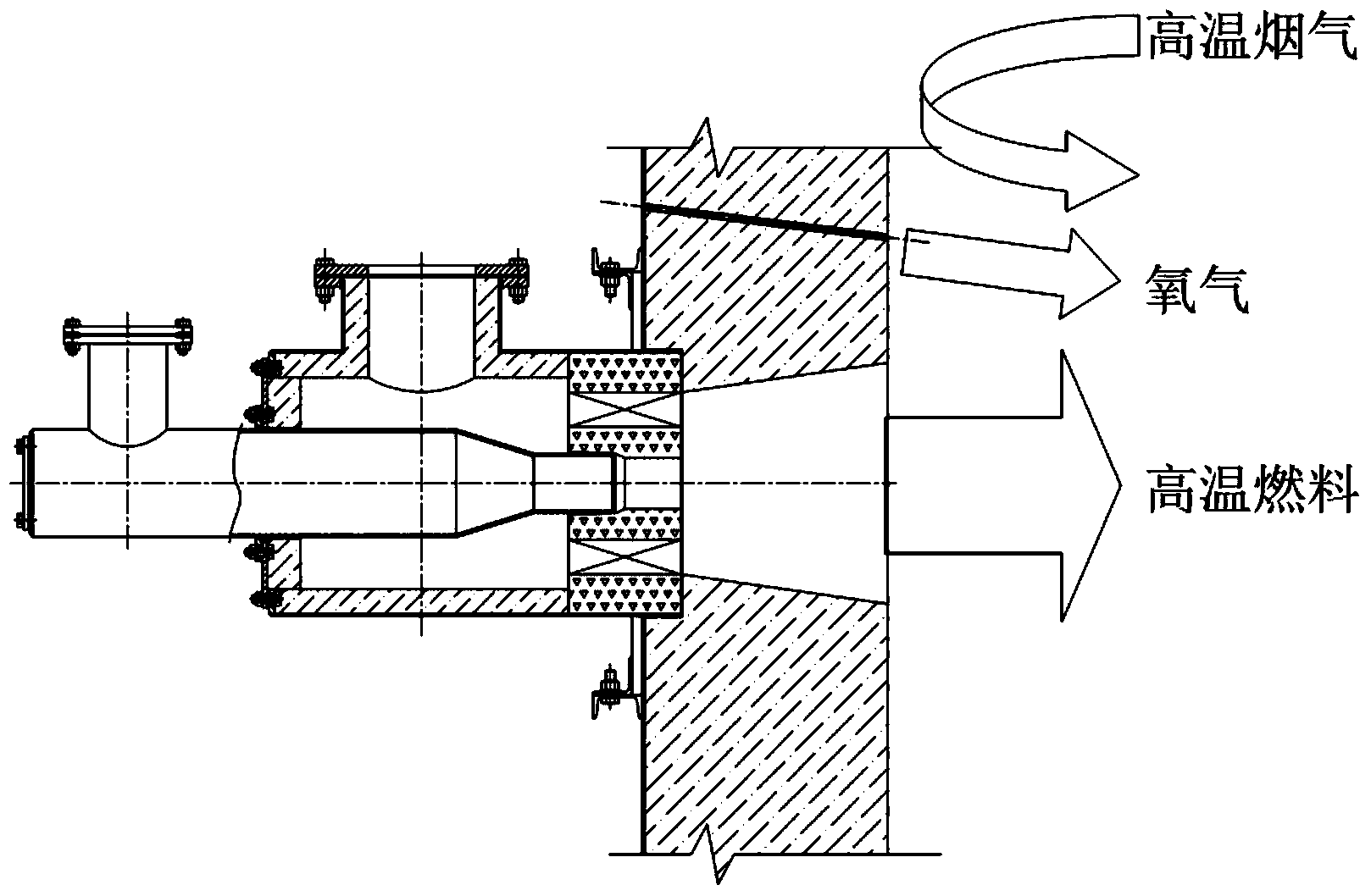

Swirl pulverized-coal burner based on multi-level pulverized-coal concentration

InactiveCN101832550AEmission reductionImprove rigidityPulverulent fuel combustion burnersCombustorEngineering

The invention provides a swirl pulverized-coal burner based on multi-level pulverized-coal concentration, comprising a central oil gun, a primary air pipe, a secondary inner air pipe and a secondary outer air pipe, wherein, the central oil gun is arranged in the center of the primary air pipe; the secondary inner air pipe is fixedly arranged outside the primary air pipe, and the secondary outer air pipe is vertically arranged outside the secondary inner air pipe. The swirl pulverized-coal burner realizes deep dense-weak combustion, achieves low NOx combustion and stable combustion by coordinating with a reasonable aerodynamic field; and the swirl pulverized-coal burner has the advantages of simple structure, low resistance and convenient operation, and can effectively prevent abrasion and is easily applied to the process of burner reformation.

Owner:SHANGHAI JIAO TONG UNIV

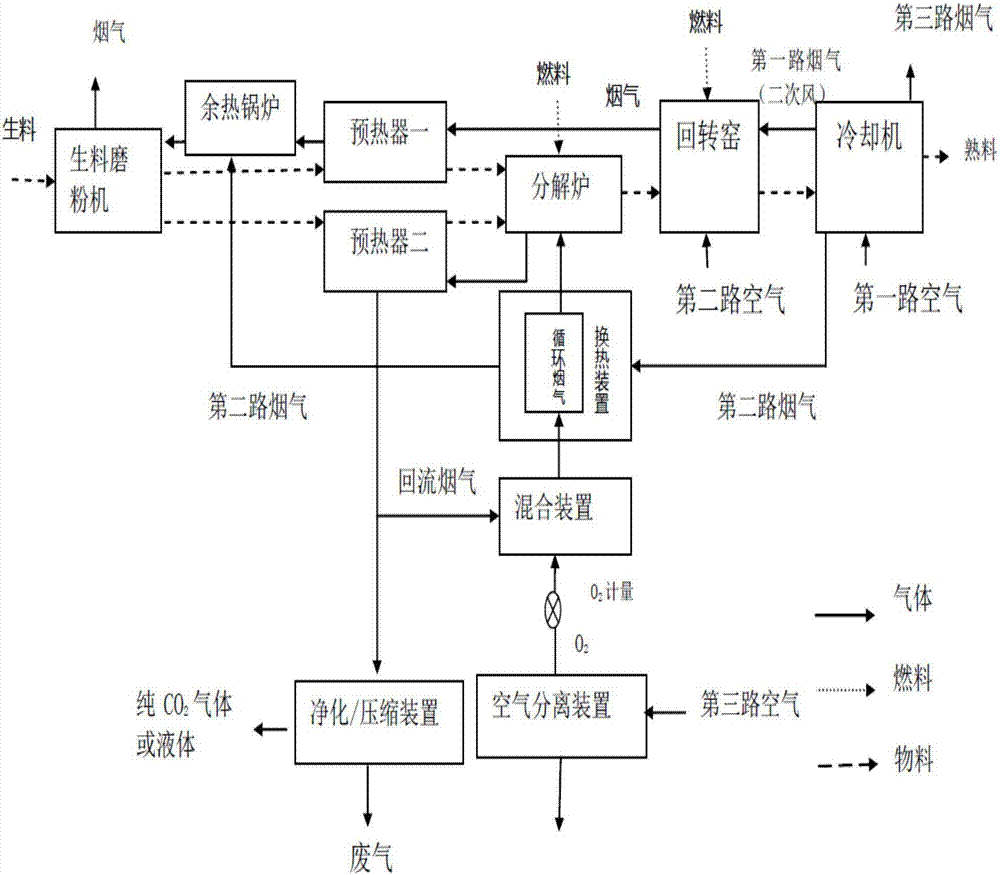

Oxygen/carbon dioxide combustion technique applied to cement clinker production process

InactiveCN107235647ASignificant emission reductionEmission reductionRotary drum furnacesCarbon captureDecompositionMixed gas

The invention discloses an oxygen / carbon dioxide combustion technique applied to a cement clinker production process. The oxygen / carbon dioxide combustion technique comprises the following steps: cooling a clinker by a first path of air, feeding a first path of high-temperature fume as secondary air into a rotary kiln after clinker cooling, preheating a second path of high-temperature fume by a heat exchange device, introducing an O2 / CO2 gas of a decomposition furnace, and feeding into a waste heat boiler for waste heat power generation; feeding a second path of air into the rotary kiln through a combustor; feeding fume discharged from the tail end of the rotary kiln into a preheater I for preheating a raw material, and feeding fume discharged from the preheater I into the waste heat boiler; feeding fume discharged from the decomposition furnace into a preheater II for preheating the raw material; generating backflow fume of which the CO2 concentration is greater than 95% from the preheater II, mixing a part of the backflow fume with oxygen separated from a third path of air, preheating, feeding the mixed gas as an O2 / CO2 atmosphere for raw material decomposition into the decomposition furnace, and performing purification, dust collection and concentration on the other part of the mixed gas, thereby obtaining CO2 of which the concentration is greater than 99%. Compared with a conventional cement clinker production process, the cement clinker production process disclosed by the invention has the advantage that the emission amount of CO2 is reduced by 60-75%.

Owner:CHINA BUILDING MATERIALS ACAD

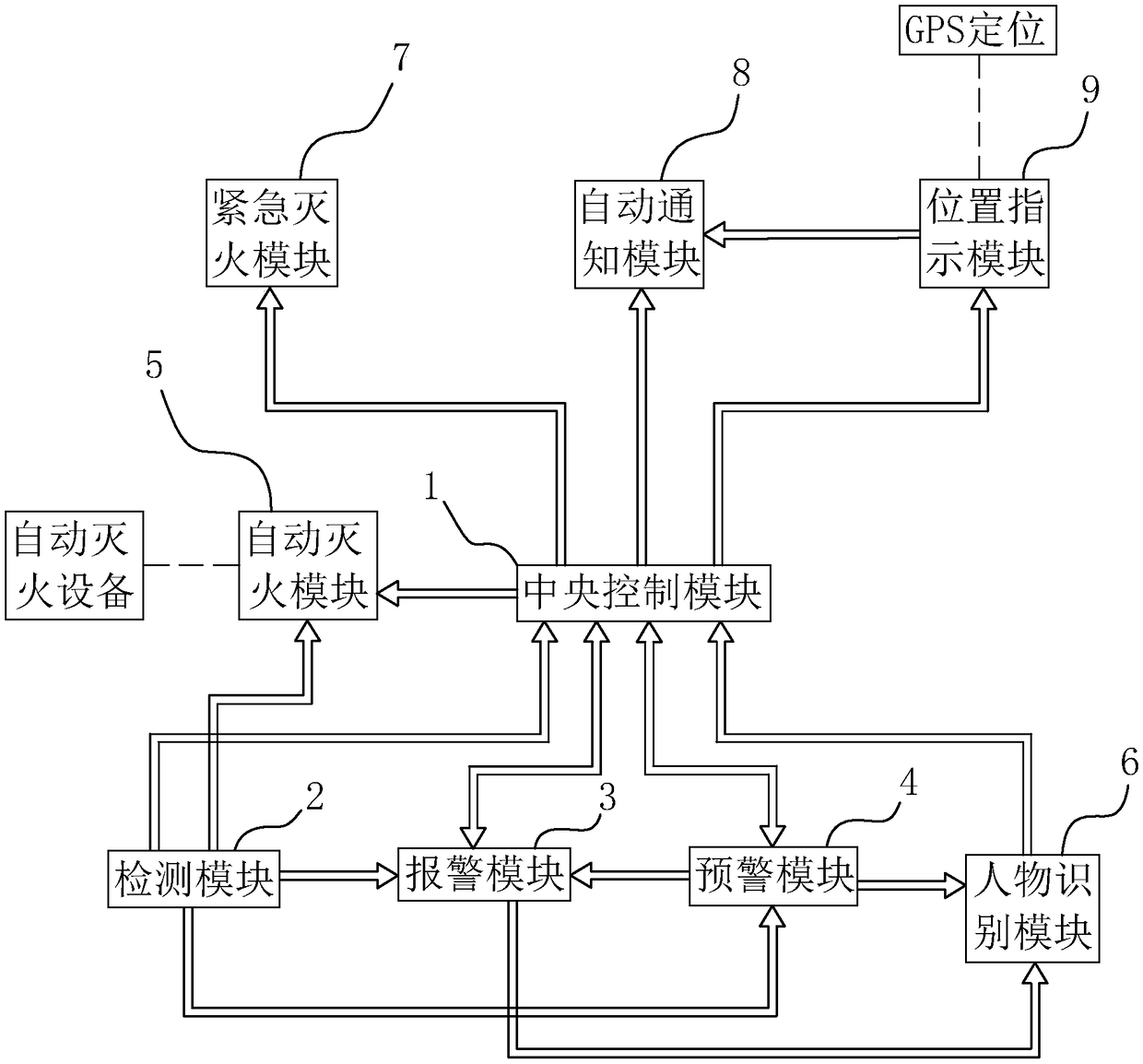

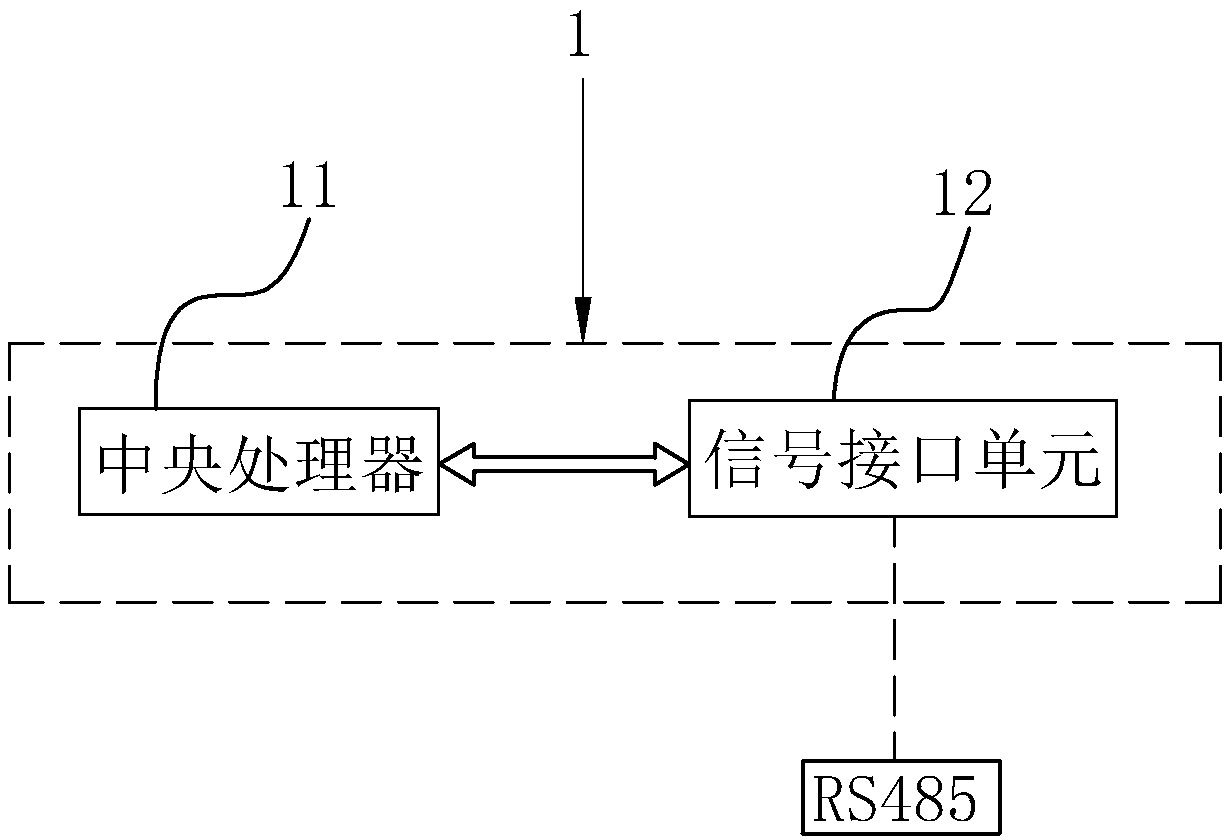

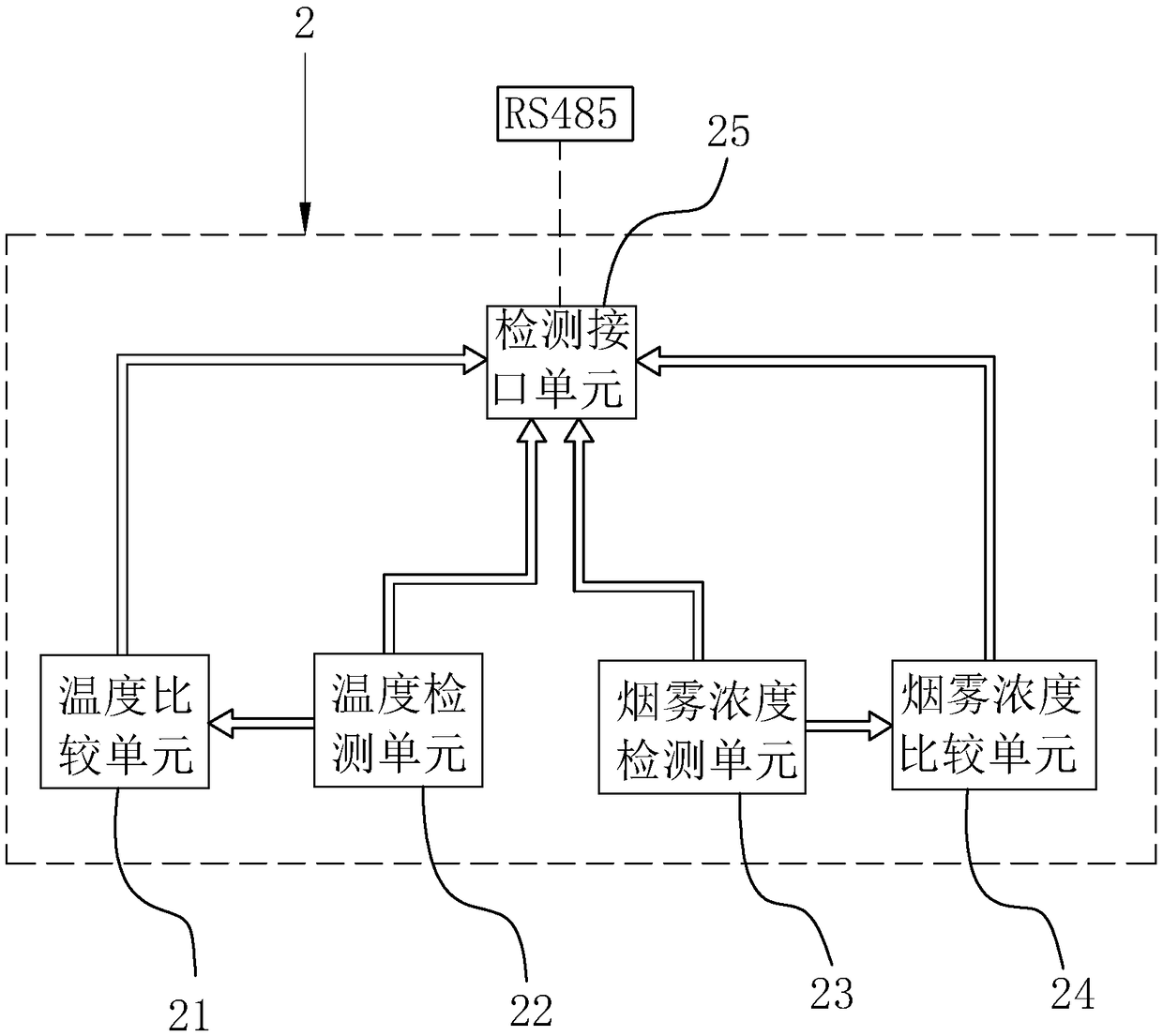

Fireproof alarm system for intelligent buildings

InactiveCN108765843AConvenient commandEasy to viewNon-mechanical controlsFire rescueIntelligent lightingComputer module

The invention discloses a fireproof alarm system for intelligent buildings, and belongs to the field of fire safety. The technical scheme point thereof comprises a detection module, an early warning module, an alarm module, a person recognition module and a central control module. The detection module detects the temperature and the smoke concentration situation in a security area, the detection module controls the early warning module to perform small-range alarm on a detected area and collects image information of the detected area when a suspected fire occurs, and the detection module controls the alarm module to alarm all areas and collects images of all areas when the fire is detected. The person recognition module transmits an image where someone may exist in the image information toa central processing module. The central processing module displays the image information, and the staff controls the other modules according to the image information through the central processing module, thereby solving the problem that the suspected fire in the security area is difficult to deal with, and achieving the effect that the staff correspondingly responds through the image information.

Owner:浙江鑫飞智能工程有限公司

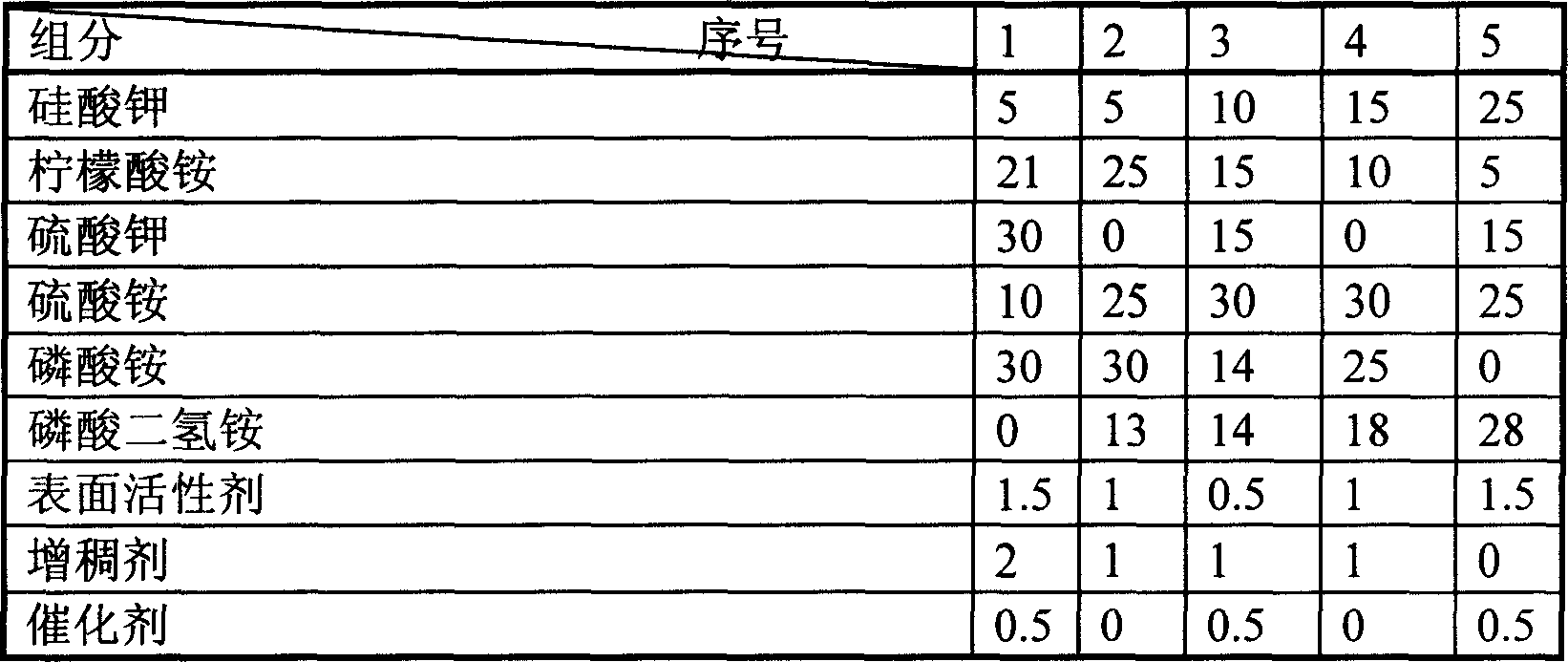

New type fire agent recipe for forest fire and technique

InactiveCN1695752AInhibition of re-ignitionFire extinguishing speedFire extinguisherPhosphoric acidChemistry

A fire-extinguishing chemical for forest is proportionally prepared from potassium siliate, ammonium, citrate, the potassium salt and / or ammonium salt of sulfuric acid and phosphoric acid, poly-5-vinyl-1,2-dimethylpyridine-methylsulfate, carboxymethyl cellulose, and the mixture of cupper sulfate and ferrocene through ball grinding and granulating.

Owner:景中兴

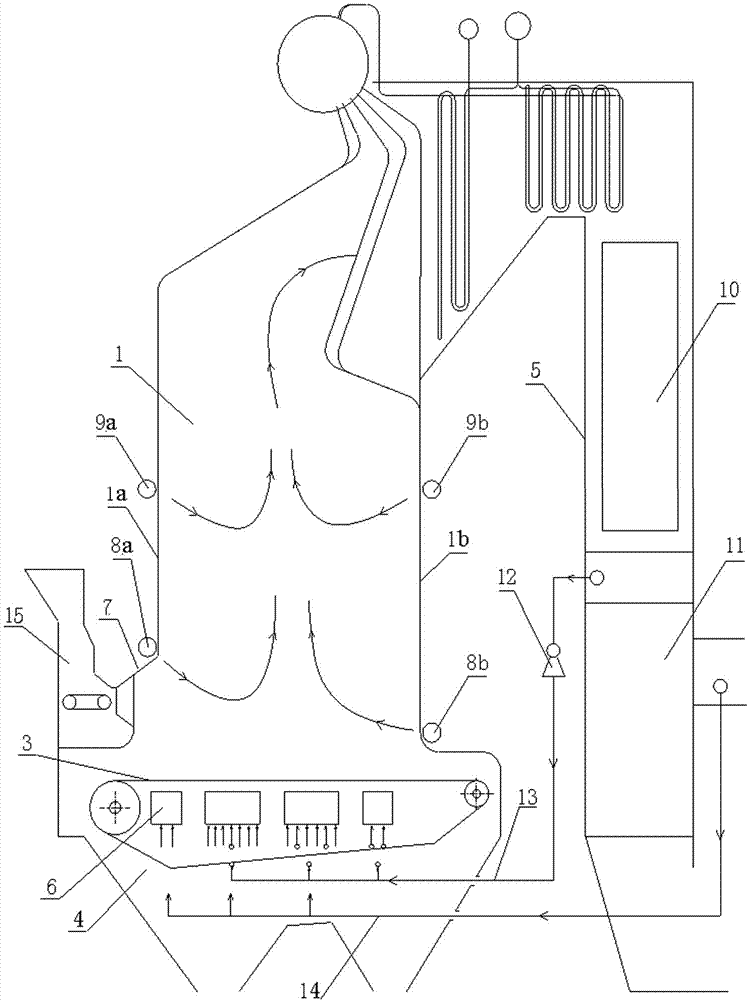

Coupling staged combustion and smoke recirculation low NOx chain grate furnace

ActiveCN104748104APromote fireStable combustion is goodSolid fuel combustionIndirect carbon-dioxide mitigationThermodynamicsSlag

The invention discloses a coupling staged combustion and smoke recirculation low NOx chain grate furnace. The chain grate furnace is composed of a hearth, a coal feeder, a chain grate stoker, a slag hopper and a tail flue. The hearth is divided into an upper hearth part and a lower hearth part through a front furnace arch and a rear furnace arch. Secondary air and over fire air are arranged in a suspension combustion area of the lower hearth body to organize staged combustion in the suspension combustion area, the secondary air of the lower hearth body is fed through secondary air spraying ports in the lower areas of the front furnace arch and the rear furnace arch, the over fire air is fed through over fire air spraying ports in the intersection of the upper hearth body and the lower hearth body, primary air is fed in a segmented mode below the stoker so as to organize the staged combustion of a stocker combustion area, low-temperature furnace smoke is extracted from the tail flue to be fed to the bottom of the stoker through a recirculation draught fan to perform recirculation, coal particles in the furnace are in the state far away from the stoichiometric ratio combustion state for a long time through two-layer staged combustion of the stocker combustion area and the suspension combustion area and smoke recirculation of the stoker combustion area, and efficient and low NOx combustion of the chain grate furnace is achieved.

Owner:江苏朗润环保科技有限公司

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

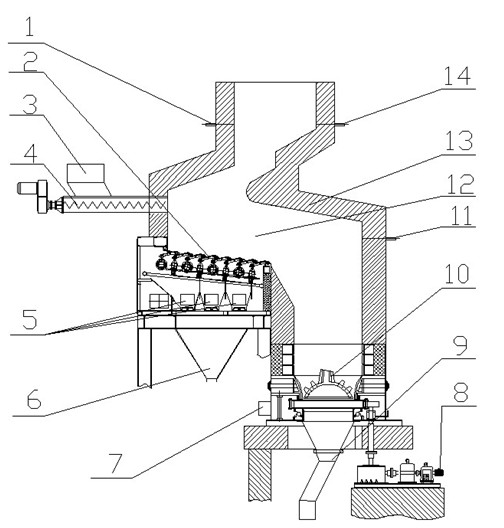

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

Oxygen-enriched and flameless gas burner and control method thereof

ActiveCN104266190ASimple structureEasy to implementIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHearth

The invention discloses an oxygen-enriched and flameless gas burner which comprises a burner casing, an air distribution plate, a prechamber, an oxygen nozzle and a fuel nozzle. A channel penetrating a wall body of a furnace wall of a heating furnace is arranged on the furnace wall. The burner casing is installed on one side of the channel, and the prechamber is formed in the space in the channel. A combustion-supporting air channel is arranged on the burner casing, and the fuel nozzle penetrates through the burner casing in an inserting mode. A fuel channel is arranged on the fuel nozzle. An air inlet and a fuel inlet are arranged on the air distribution plate. The oxygen nozzle is provided with an oxygen pipe and installed on the furnace wall of the heating furnace, the oxygen channel is communicated with a hearth of the heating furnace, the oxygen nozzle is slantingly arranged on the furnace wall of the heating furnace, and a spray head end of the oxygen nozzle is close to the prechamber. The oxygen-enriched and flameless gas burner organically combines the dilution combustion technology and the oxygen-enriched combustion technolog, achieves flameless combustion in the furnace, meanwhile optimizing temperature distribution in the furnace, and reduces NOx emission.

Owner:WISDRI WUHAN WIS IND FURNACE

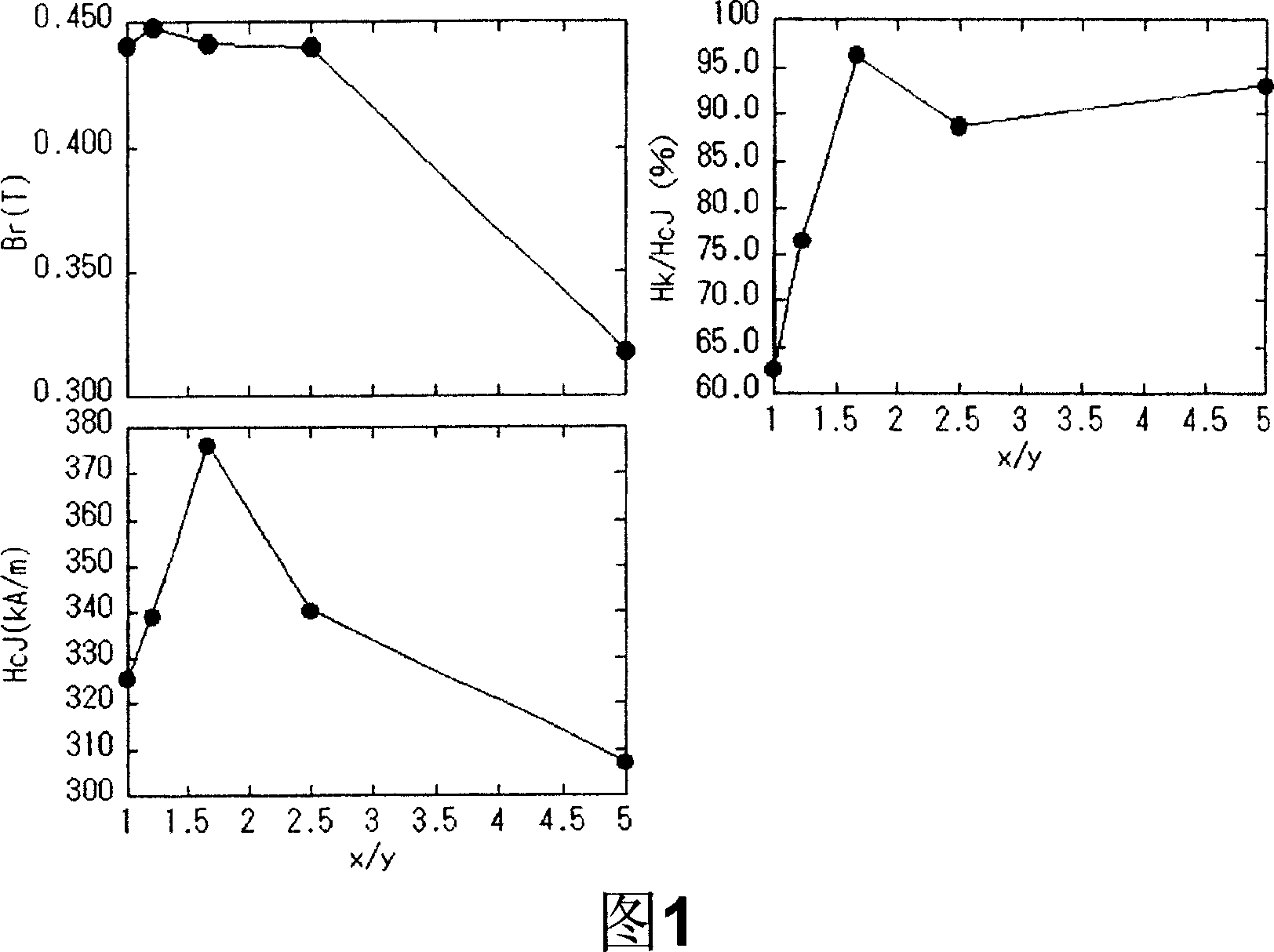

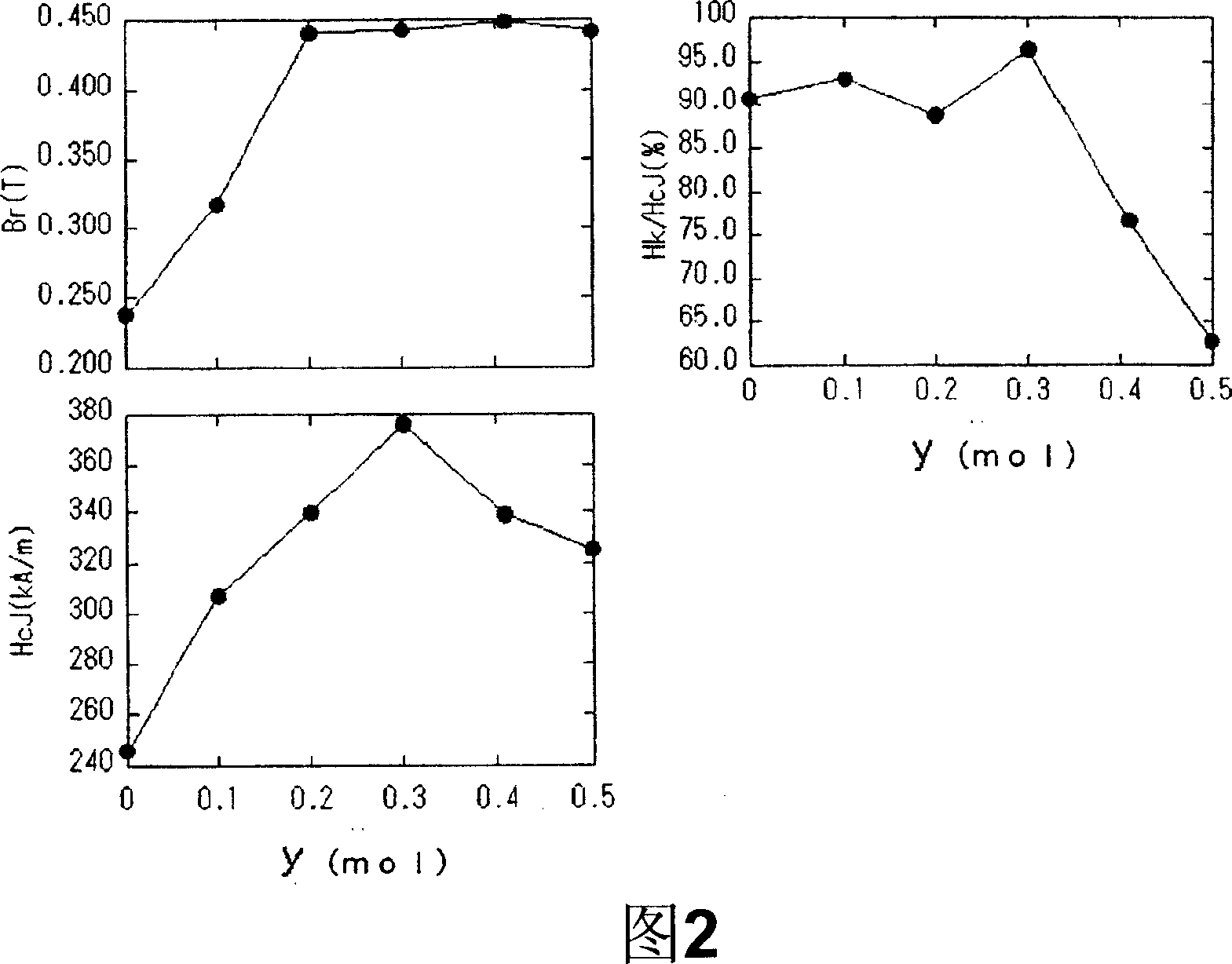

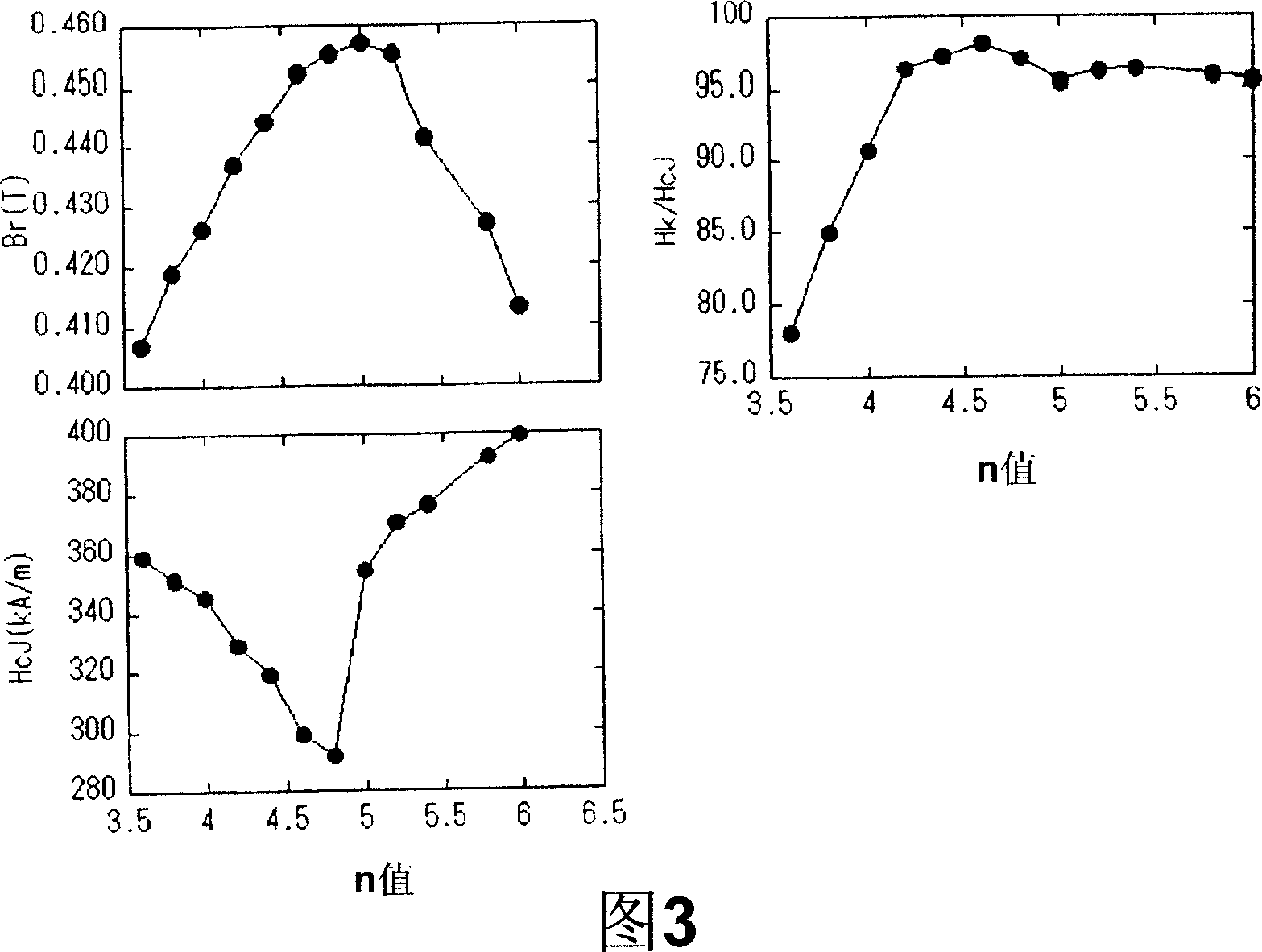

Oxide magnetic material and sintered magnet

ActiveCN1956935AImprove HcjHigh aspect ratioInorganic material magnetismInductances/transformers/magnets manufactureSintered magnetsMaterials science

An oxide magnetic material according to the present invention is represented by the formula: (1-x)CaO (x / 2)R 2 O 3 (n-y / 2)Fe 2 O 3 yMO, where R is at least one element selected from the group consisting of La, Nd and Pr and always includes La, M is at least one element selected from the group consisting of Co, Zn, Ni and Mn and always includes Co, and the mole fractions x, y and n satisfy 0.4 |x |0.6, 0.2 |y |0.35, 4 | n | 6, and 1.4 |x / y | 2.5. The oxide magnetic material includes a ferrite having a hexagonal M-type magnetoplumbite structure as a main phase.

Owner:HITACHI METALS LTD

Ferro-nickel slag ceramic and preparation method thereof

ActiveCN107935555APromote fireImprove mechanical propertiesCeramic materials productionClaywaresCeramic sinteringCalcium in biology

The invention provides a ferro-nickel slag ceramic and a preparation method thereof. The preparation method comprises the following steps of selecting one or multiple of quartz, silicon and aluminum-rich raw material and calcium raw material; mixing 20 to 65wt% of ferro-nickel slag, 0 to 10wt% of quartz, 20 to 70wt% of silicon and aluminum-rich raw material and 0 to 30wt% of calcium raw material;grinding, granulating, forming, and firing, so as to obtain the ferro-nickel slag ceramic. The preparation method has the advantages that the ferro-nickel slag can be used in a batch way, the preparation method is simple, the implementing is easy, and the industrialized production is favorably realized; the crystal phases in the prepared building ceramic materials (ceramic tiles and ceramic sintering bricks), industrial ceramics and other ceramic materials contain one or multiple of anorthite, spinel, olivine and cordierite, the sintering is easy, and the mechanical property is excellent.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com