Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

A grate and functional technology, applied in the field of new high-efficiency gasification and combustion composite grate device, can solve the problems of insufficient fuel mixing, weak research foundation, grate system maintenance, etc., and achieve the advantages of ignition and combustion, low emission, To achieve the effect of emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

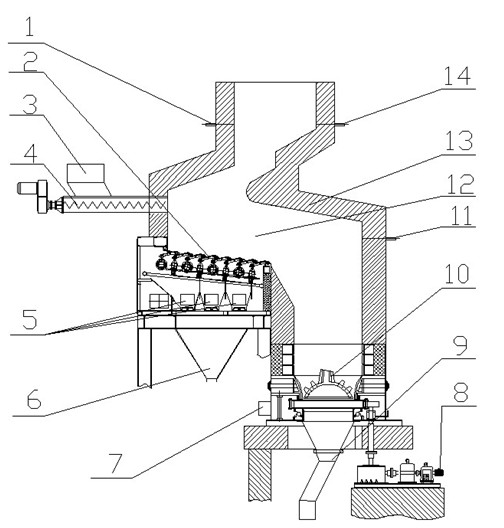

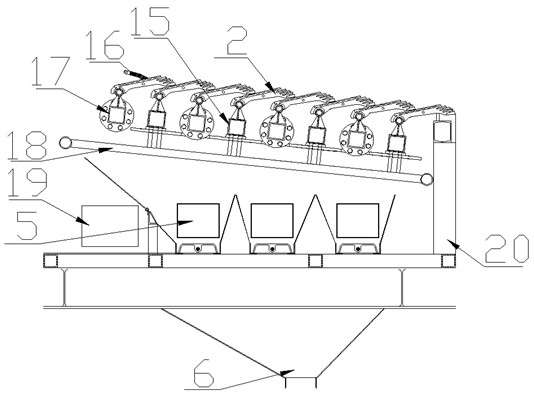

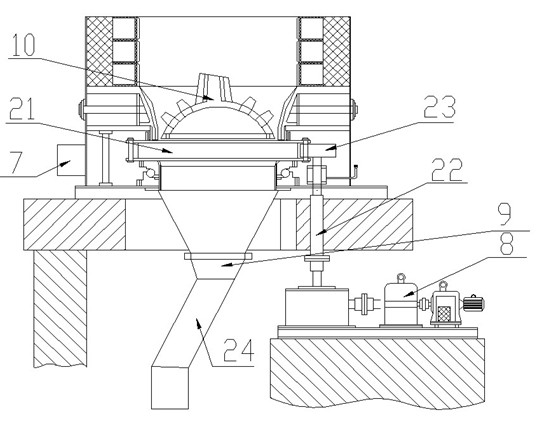

[0008] Such as figure 1 As shown, a new high-efficiency gasification combustion composite fire grate device with a slag function, the main structure includes a furnace 12, a feeding system, an ash collection system, an air distribution system and a two-stage fire grate device. Wherein the ash collection system includes ash cleaning door 19, ash outlet 6, unloading conical funnel 9 and material seal pipe 24, and the air distribution system includes primary air outlet 5, No. 1 secondary air outlet 1, No. 2 secondary air outlet 11, No. 3 secondary tuyere 14 and tertiary tuyere 7, the two-stage fire grate device includes the front section reciprocating fire grate 2 and the rear section rotary fire grate 10, the inside of the furnace 12 is provided with a radiation back arch 13, and the radiation back arch 13 is horizontal The angle between the back arch and the horizontal is 10°. The rear arch is made of high-temperature and corrosion-resistant pouring materials, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com