Titanium micro-alloyed 400MPa grade high-strength steel bar and production method thereof

A high-strength steel bar and micro-alloying technology, which is applied in the field of iron and steel metallurgy micro-alloying, can solve the problems of high production cost, resource shortage, and occupation of profit margins, so as to improve yield strength and tensile strength, reduce phase transition temperature, Effect of grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

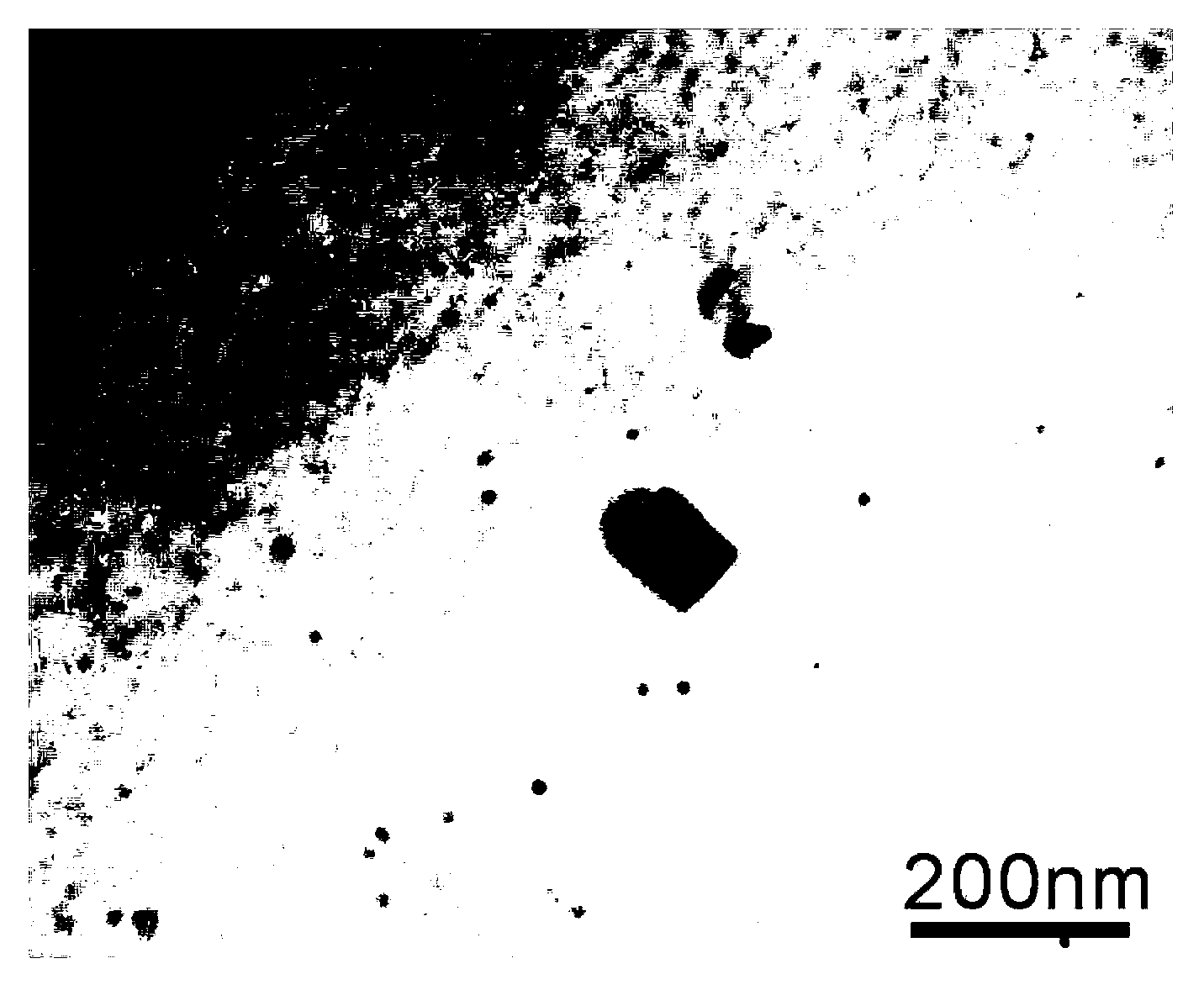

Image

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned titanium microalloyed 400MPa grade high-strength steel bar comprises the following steps:

[0034] a. Smelt steelmaking raw materials into crude steel liquid, tap steel, and carry out deoxidation and alloying during the tapping process;

[0035] b. The molten steel after tapping is sent to the refining furnace for refining and composition fine-tuning, so that it meets the requirements of the steel bar composition and then casts to obtain a billet for rolling steel bars;

[0036]c. Heat the rolled steel billet to 1100-1300°C and keep it warm for 30-150 minutes, then roll it, and finish rolling when it reaches 750-950°C, and air-cool the rolled steel bar to room temperature to obtain titanium micro Alloyed 400MPa high-strength steel bars;

[0037] Among them, alloying of titanium is performed during tapping and after deoxidation, or during refining.

[0038] The invention strictly controls the heating temperature and holding...

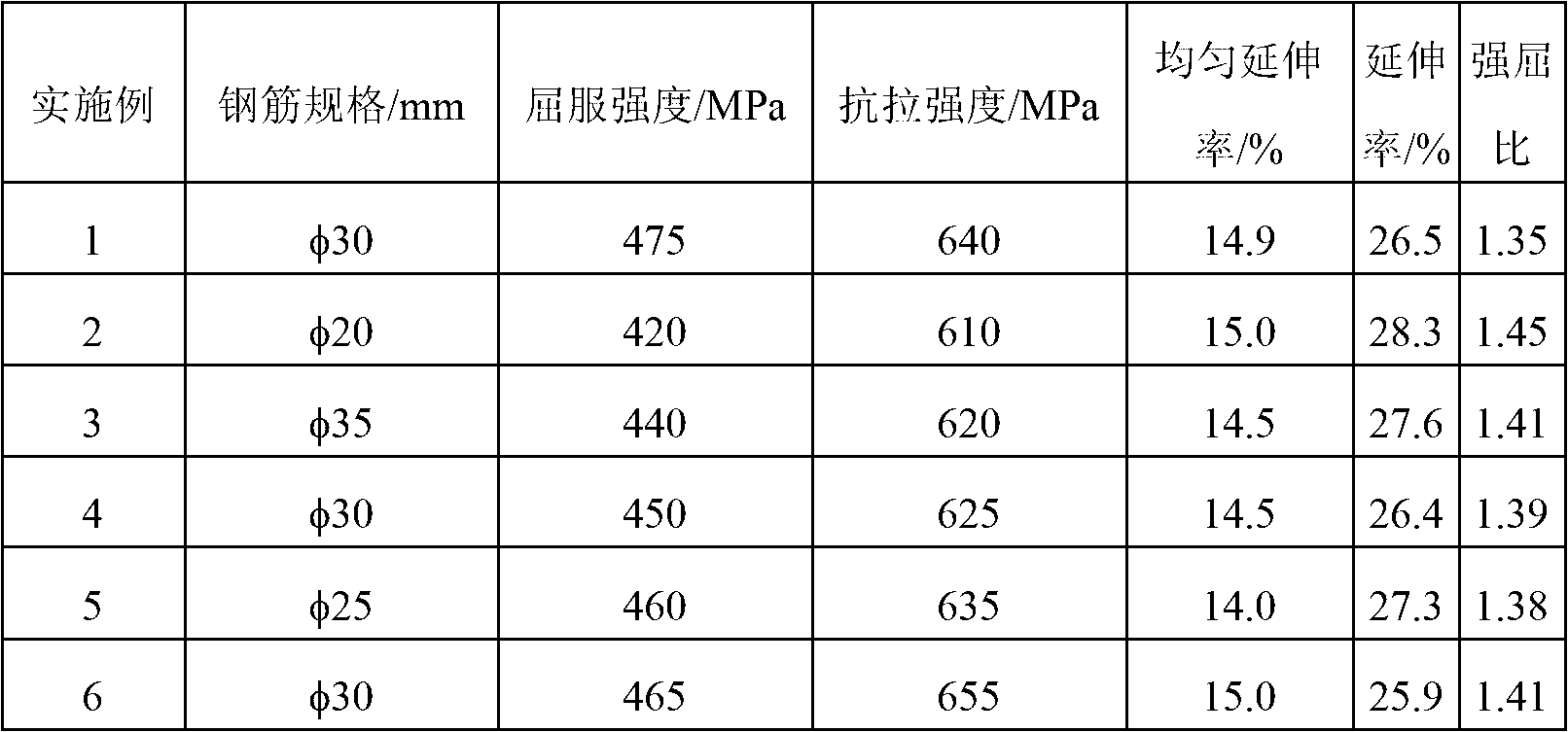

Embodiment 1

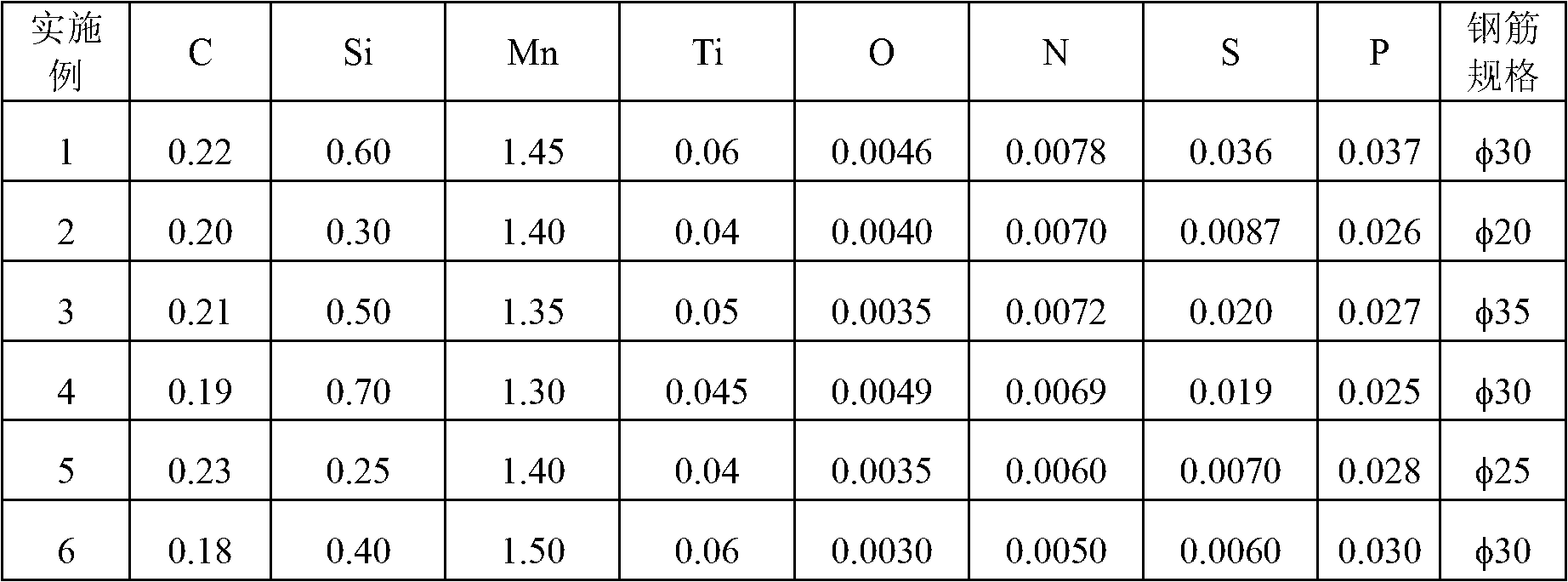

[0047] (1) Using slag iron as raw material to produce HRB400 steel bars, smelting into crude steel through electric furnace through slag making, oxygen blowing and other measures, the crude steel contains [C]0.16%, [P]0.017%, [S]0.073% , [N]72ppm, a[o]73ppm, the temperature is 1683 ℃, and then the steel is tapped, and deoxidation alloying is carried out during the tapping process, and the titanium passes through the bulk Ti-25wt%Si-10wt%Fe master alloy with a particle size of 15mm After adding, the molten steel after deoxidation and alloying is sent to LF furnace for refining and composition fine-tuning, and the obtained molten steel is sent to billet continuous casting, and the composition is shown in Table 1.

[0048] (2) Heat the billet to 1200°C for 1 hour.

[0049] (3) Air-cool or water-cool the above-mentioned heated slab to 1050°C, and then carry out rolling, and the final rolling temperature is 850°C.

[0050] (4) Air-cool the hot-rolled steel bars to room temperature...

Embodiment 2

[0052] (1) Using slag steel as raw material to produce HRB400, through slag making, oxygen blowing and other measures, it is smelted into crude molten steel in electric furnace. Crude molten steel contains [C]0.11%, [P]0.023%, [S]0.078%, [N]69ppm, a[o]62ppm, temperature 1681°C, the crude molten steel meets the requirements and then tapped. Deoxidation alloying is carried out during the tapping process, and titanium is added in the form of Ti-30wt%Si-10wt%Fe cored wire. The molten steel after deoxidation and alloying is sent to LF furnace for refining and composition fine-tuning, and the obtained molten steel is sent to billet continuous casting. The composition is shown in Table 1.

[0053] (2) Heat the billet to 1200°C for 1 hour.

[0054] (3) Air-cool or water-cool the above-mentioned heated slab to 1030°C, and then carry out rolling, and the final rolling temperature is 830°C.

[0055] (4) Air-cool the hot-rolled steel bars to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com