Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

An in-situ composite material and rare earth element technology, applied in the field of non-ferrous metal materials, can solve the problems of high melting point, limit the preparation and application of new materials, large immiscible gap, etc., achieve high yield, improve aging and annealing temperature, increase Effects of Strength and Conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

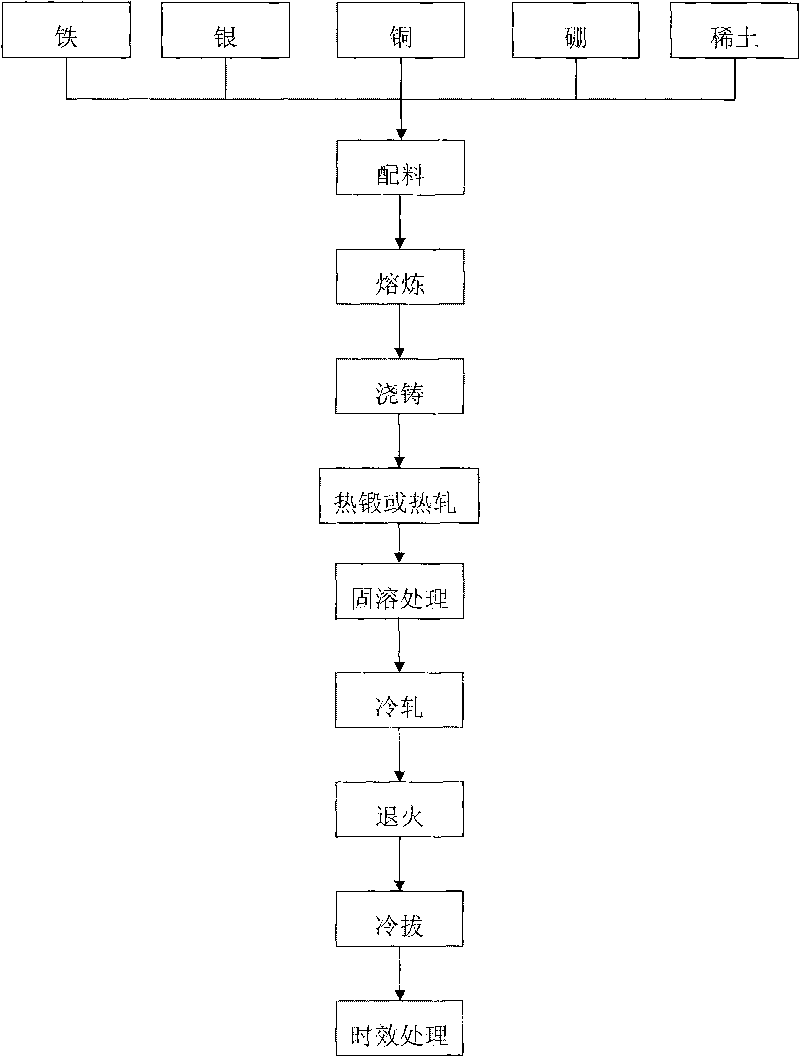

Method used

Image

Examples

Embodiment 1

[0031] (1) Ingredients: According to the requirements of the chemical composition, 8% of pure iron, 0.05% of pure silver, 0.05% of boron-containing alloy, 0.01% of rare earth Ce, and electrolytic copper that meet the mass percentage of the formula are used as the balance to obtain the ingredients;

[0032] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0033] (3) Casting: pouring molten metal into a graphite mold to obtain an ingot;

[0034] (4) Hot rolling: put the above-mentioned casting ingot into a heat treatment furnace, heat it to 880° C., keep it warm for 3 hours, and then hot-roll it on a conventional hot rolling mill to make it reach 40% deformation;

[0035] (5) Solution treatment: put the hot-rolled alloy into a heat treatment furnace, heat it to 950°C, keep it warm for 1 hour, and then quench it into cold water for rap...

Embodiment 2

[0044] (1) Ingredients: According to the chemical composition requirements, 10% iron-containing alloy, 0.05% pure silver, 0.05% boron-containing alloy, 0.01% rare earth lanthanum, and electrolytic copper are used as the balance to obtain the ingredients according to the mass percentage of the formula;

[0045] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0046] (3) Casting: pouring molten metal into a graphite mold to obtain an ingot;

[0047] (4) Hot forging: Put the above-mentioned cast casting into a heat treatment furnace, heat it to 900°C, keep it warm for 3 hours, and then hot-roll it on a conventional hot rolling mill to achieve a deformation of 40%;

[0048] (5) Solution treatment: put the hot-rolled alloy into a heat treatment furnace, heat it to 980°C, keep it warm for 1 hour, and then quench it into cold water for rap...

Embodiment 3

[0057] (1) Ingredients: According to the chemical composition requirements, 15% of pure iron, 0.1% of silver-containing alloy, 0.05% of boron-containing alloy, 0.01% of rare earth yttrium, and electrolytic copper are used as the balance to obtain the ingredients according to the mass percentage of the formula;

[0058] (2) Smelting: Put the prepared ingredients into an intermediate frequency electromagnetic induction furnace, and melt for 25 minutes according to the conventional copper alloy smelting process;

[0059] (3) Casting: pouring molten metal into a water-cooled steel mold to obtain an ingot;

[0060](4) Hot forging: put the above-mentioned cast casting into a heat treatment furnace, heat it to 930°C, keep it warm for 3 hours, and then hot-roll it on a conventional hot rolling mill to achieve a deformation of 40%;

[0061] (5) Solution treatment: put the hot-rolled alloy into a heat treatment furnace, heat it to 1000°C, keep it warm for 1 hour, and then quench it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com