Patents

Literature

256 results about "Cordierites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cordierites is a genus of fungi in the family Helotiaceae. The genus contains 3 species.

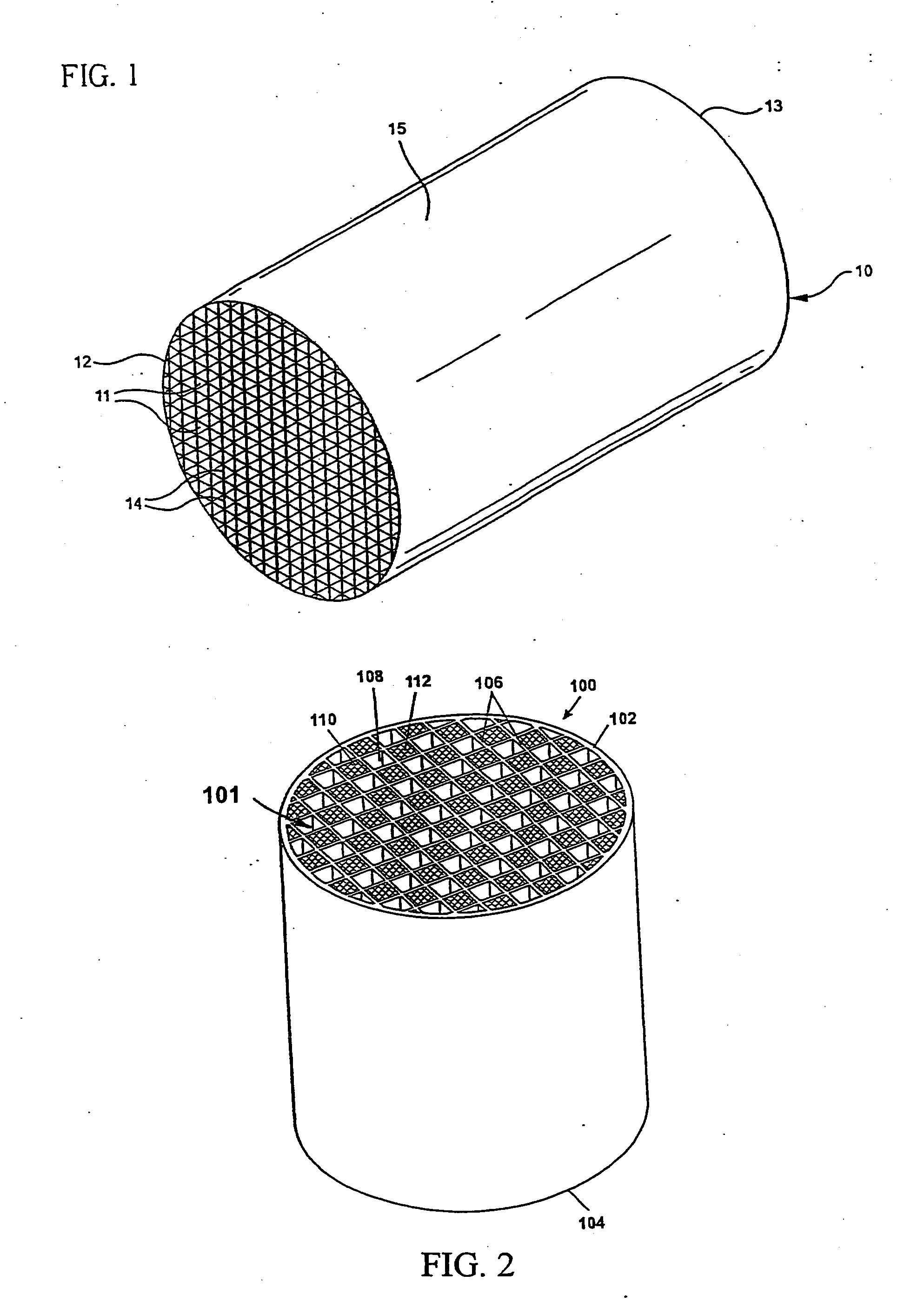

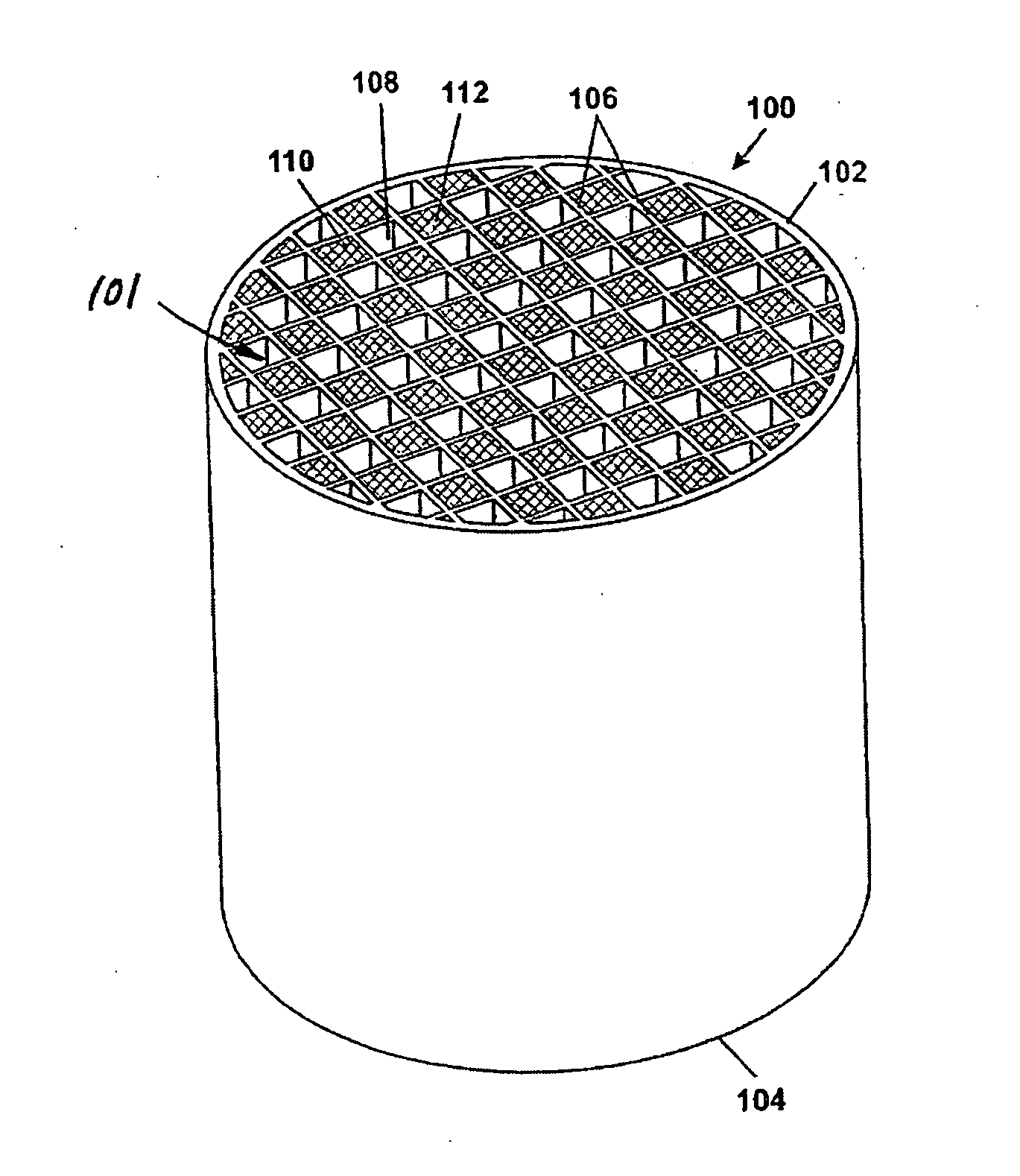

Cordierite ceramic body and method

InactiveUS6864198B2Lower overall pressure dropHigh filtration efficiencyDispersed particle filtrationTransportation and packagingPorosityFiltration

Owner:CORNING INC

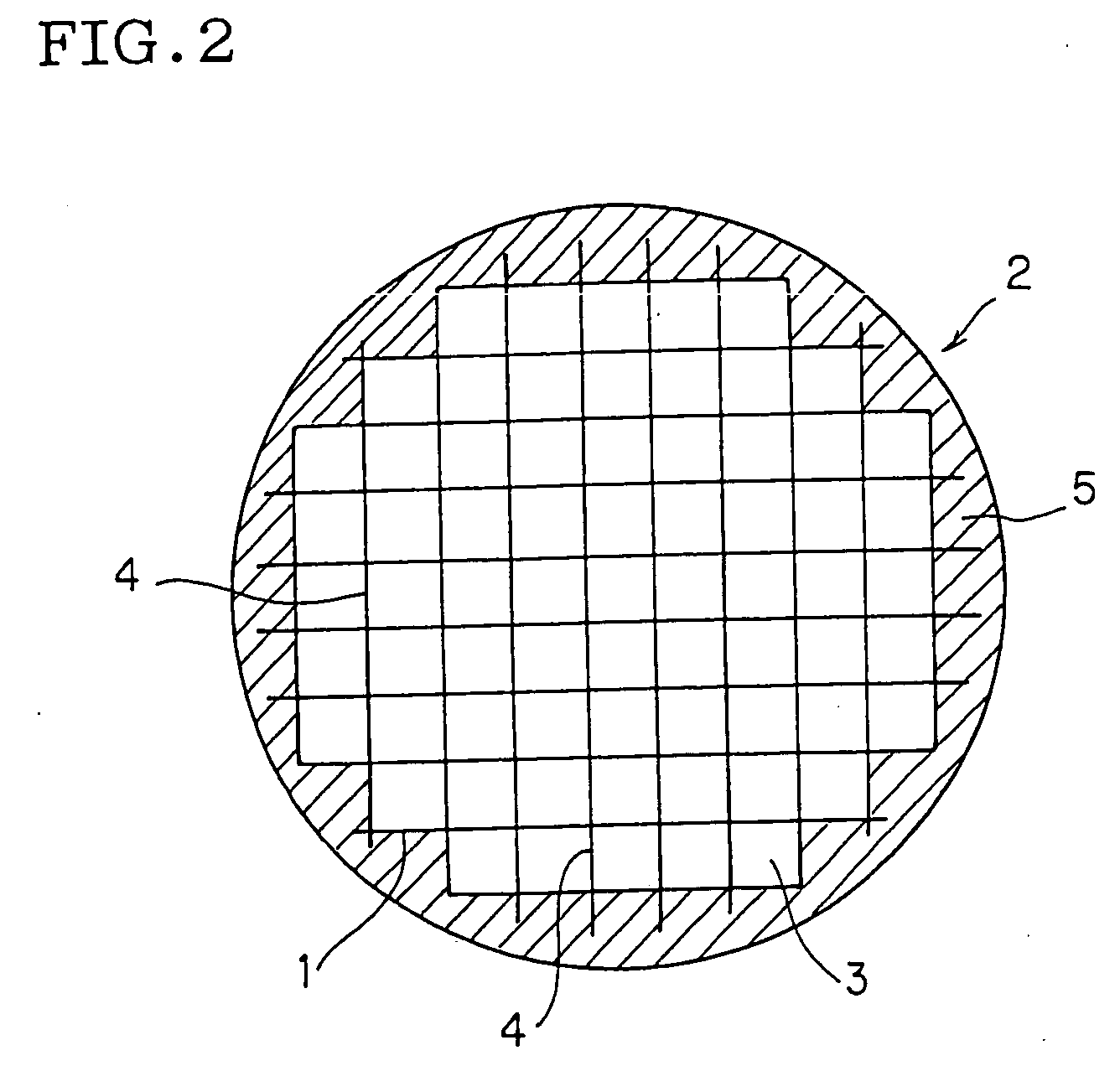

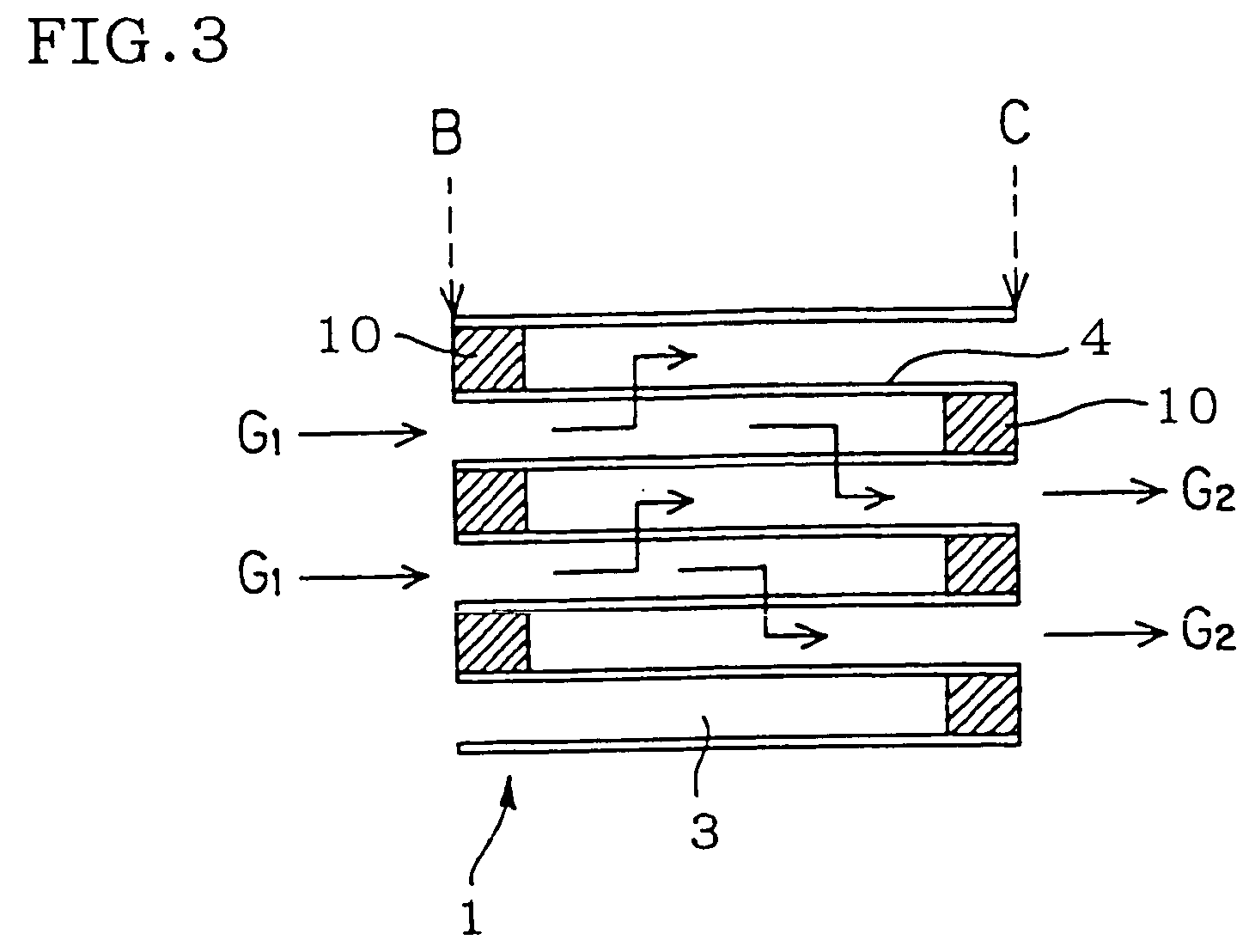

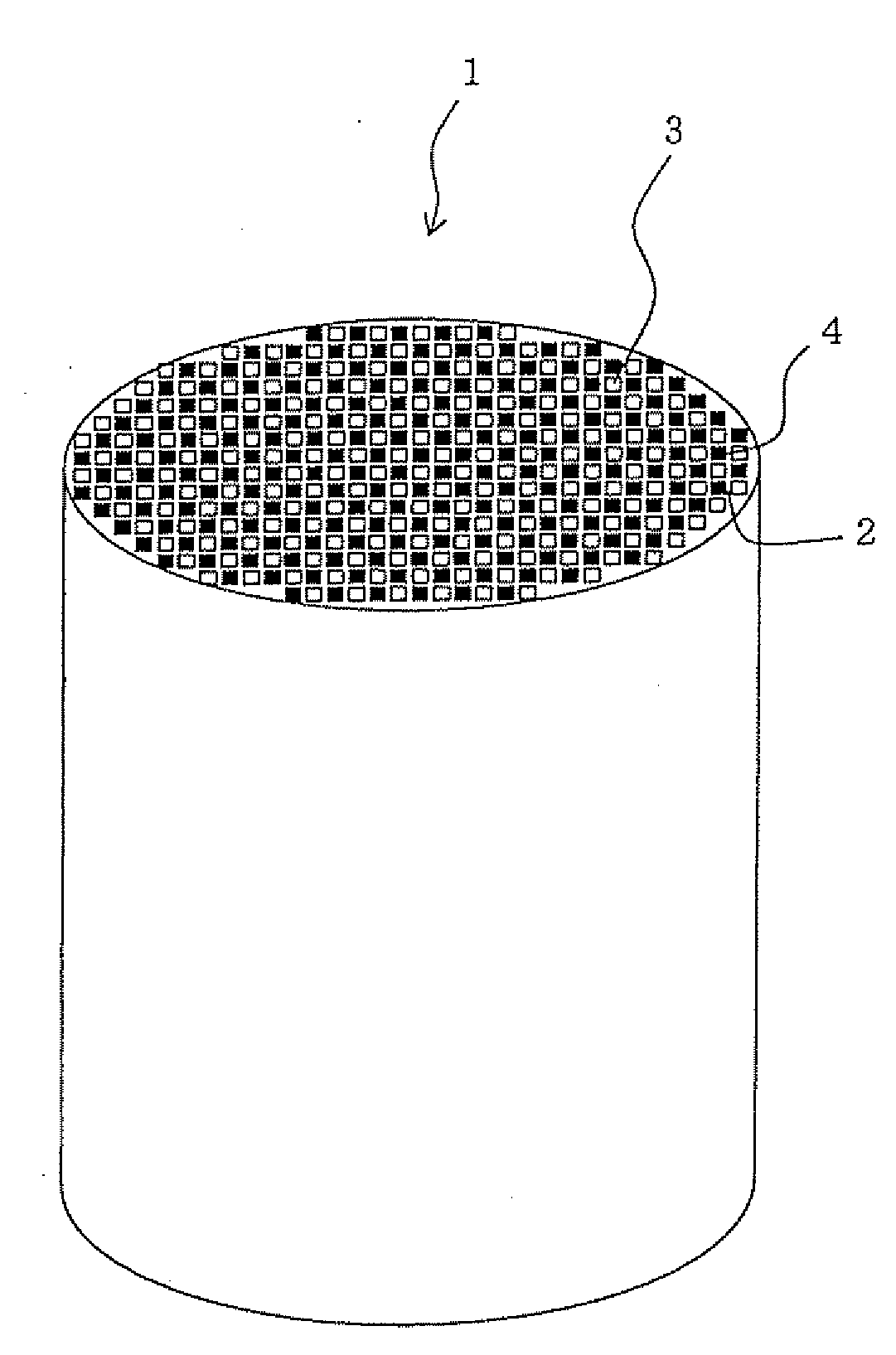

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

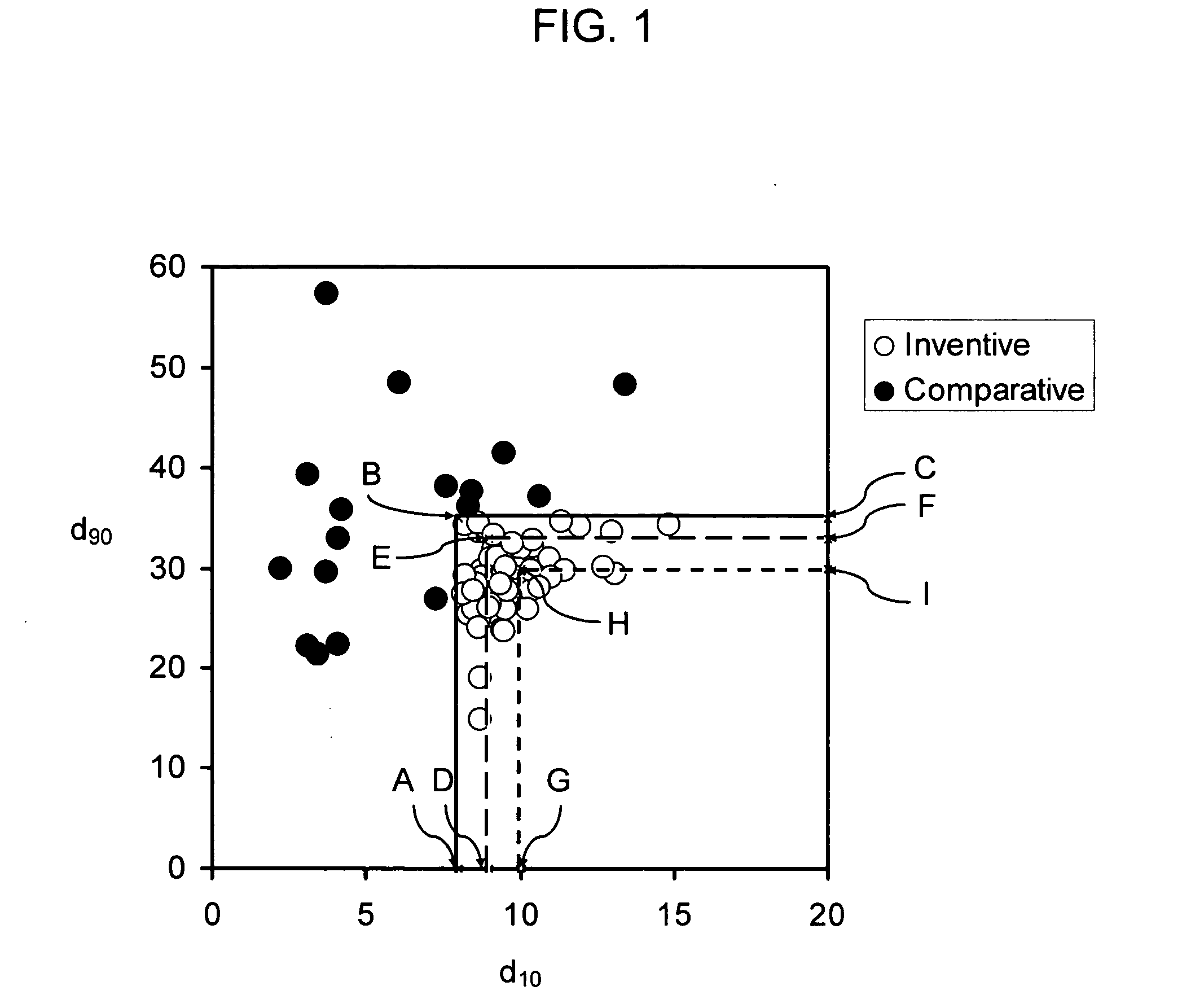

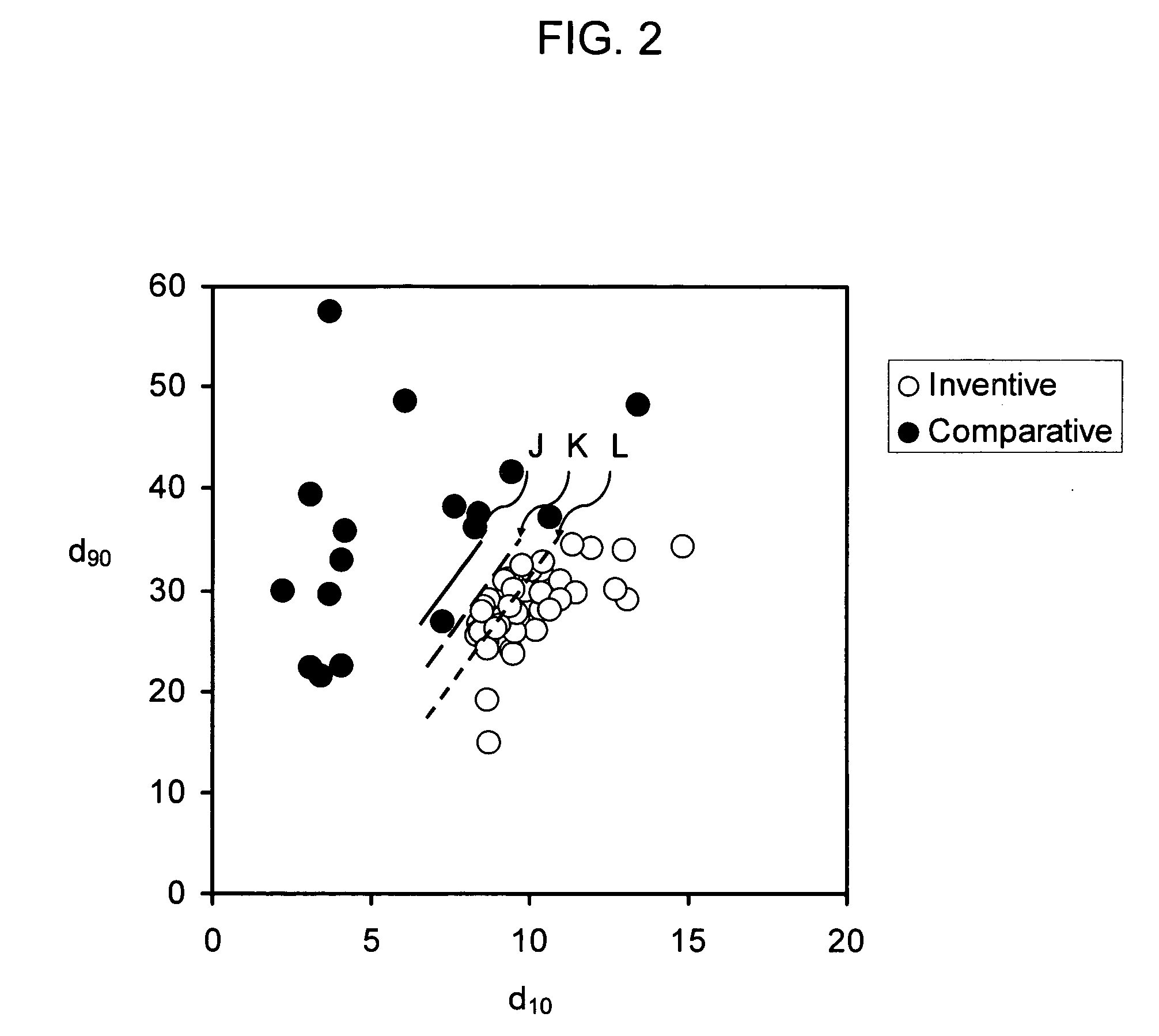

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

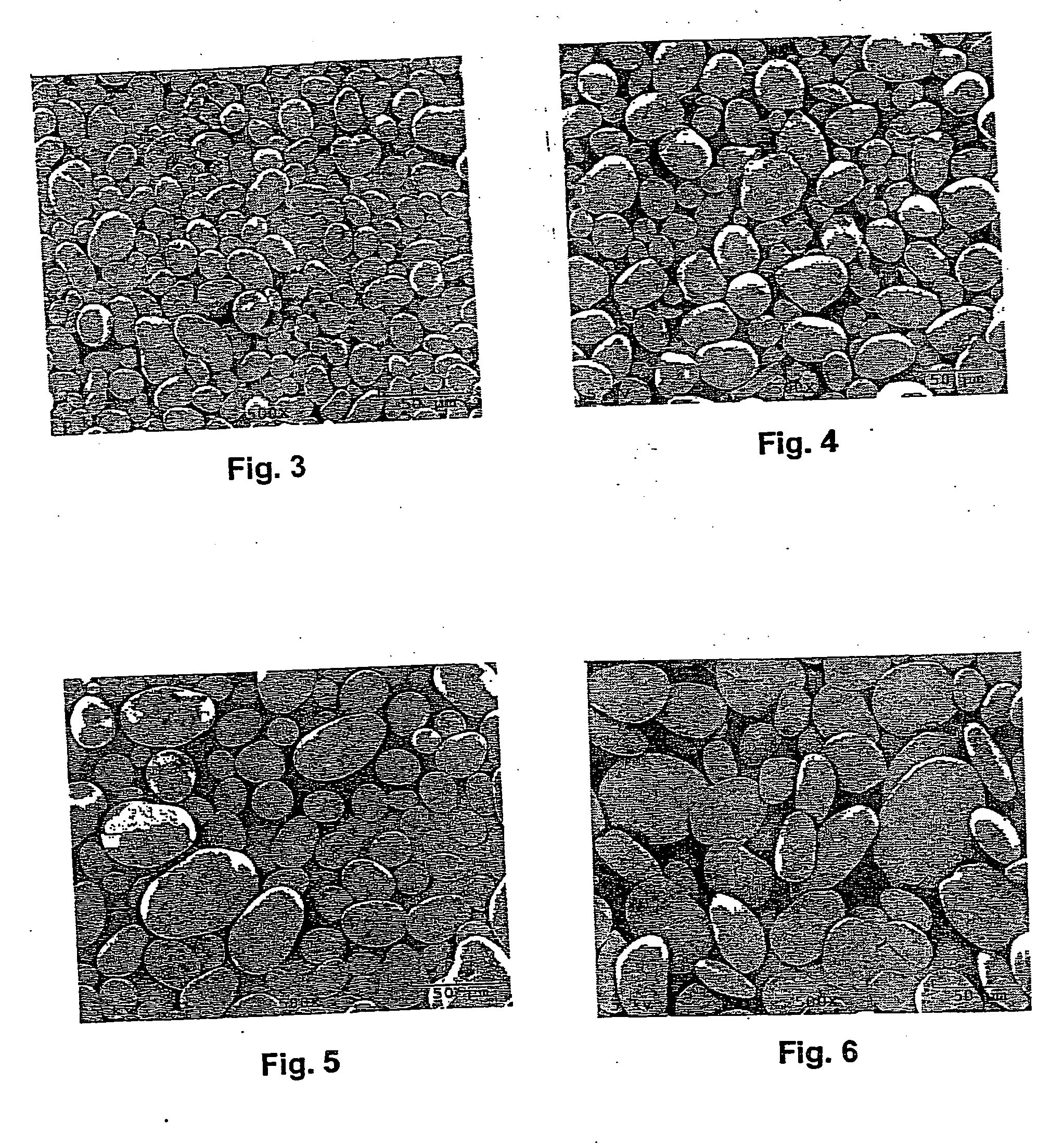

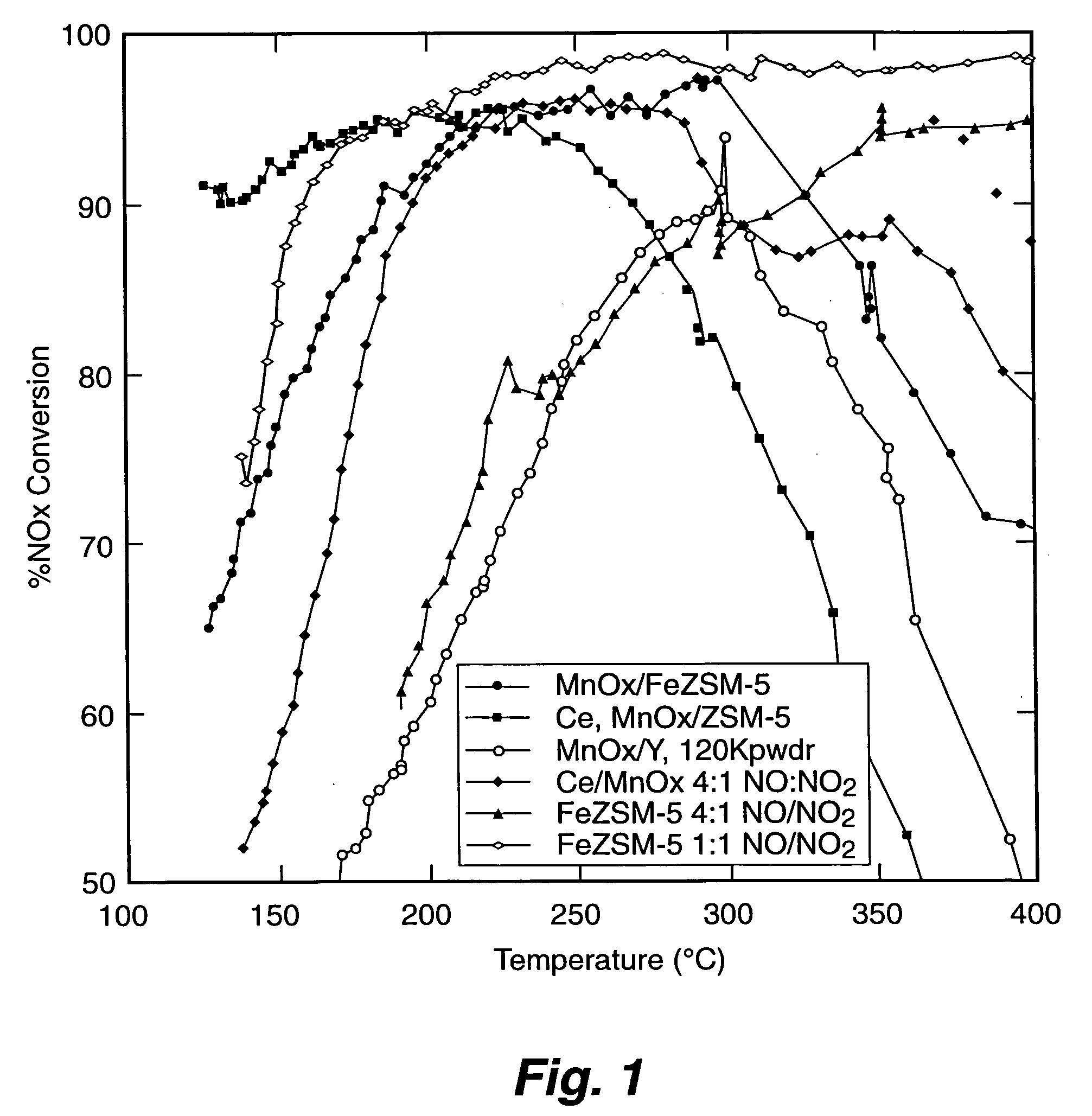

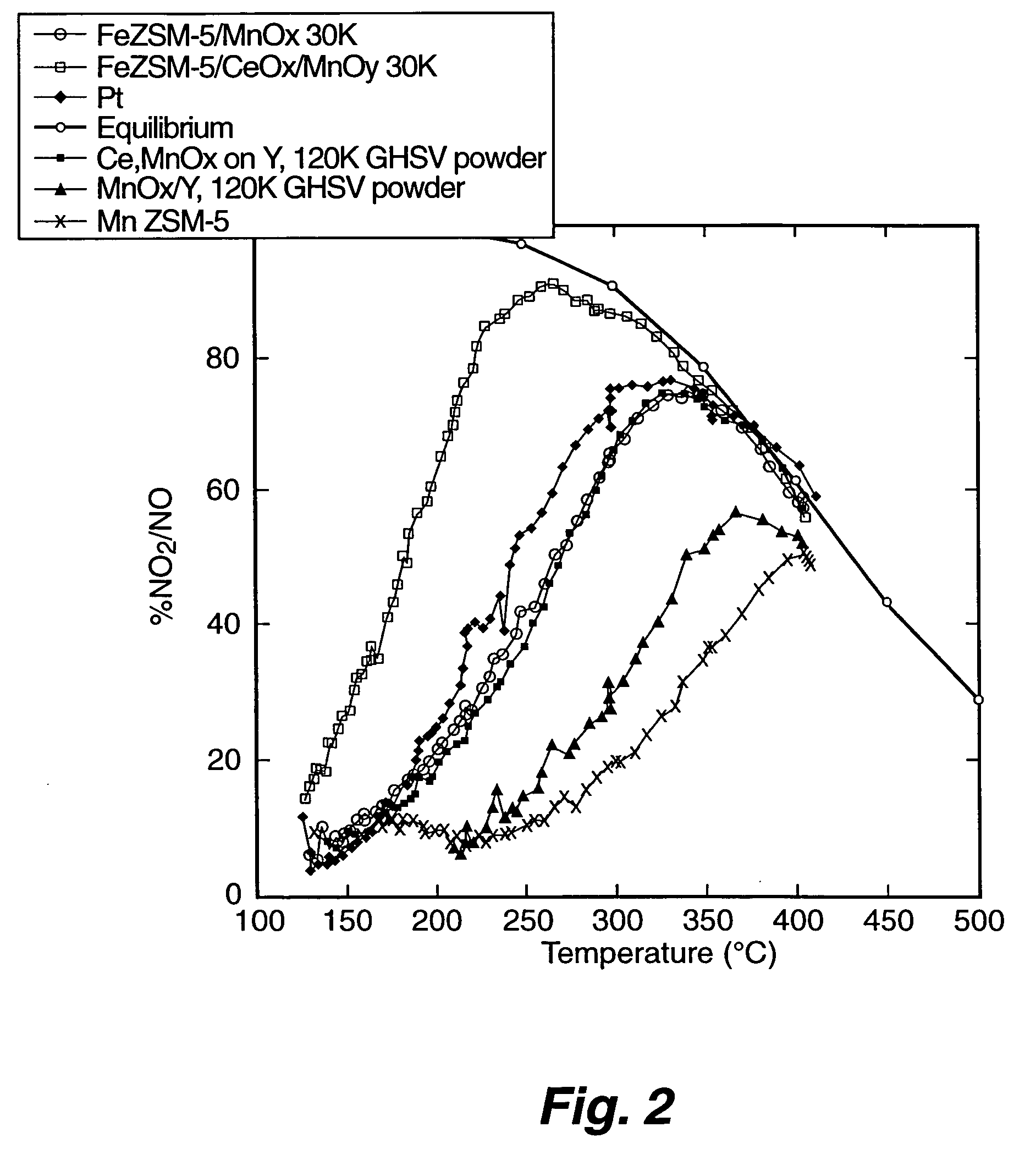

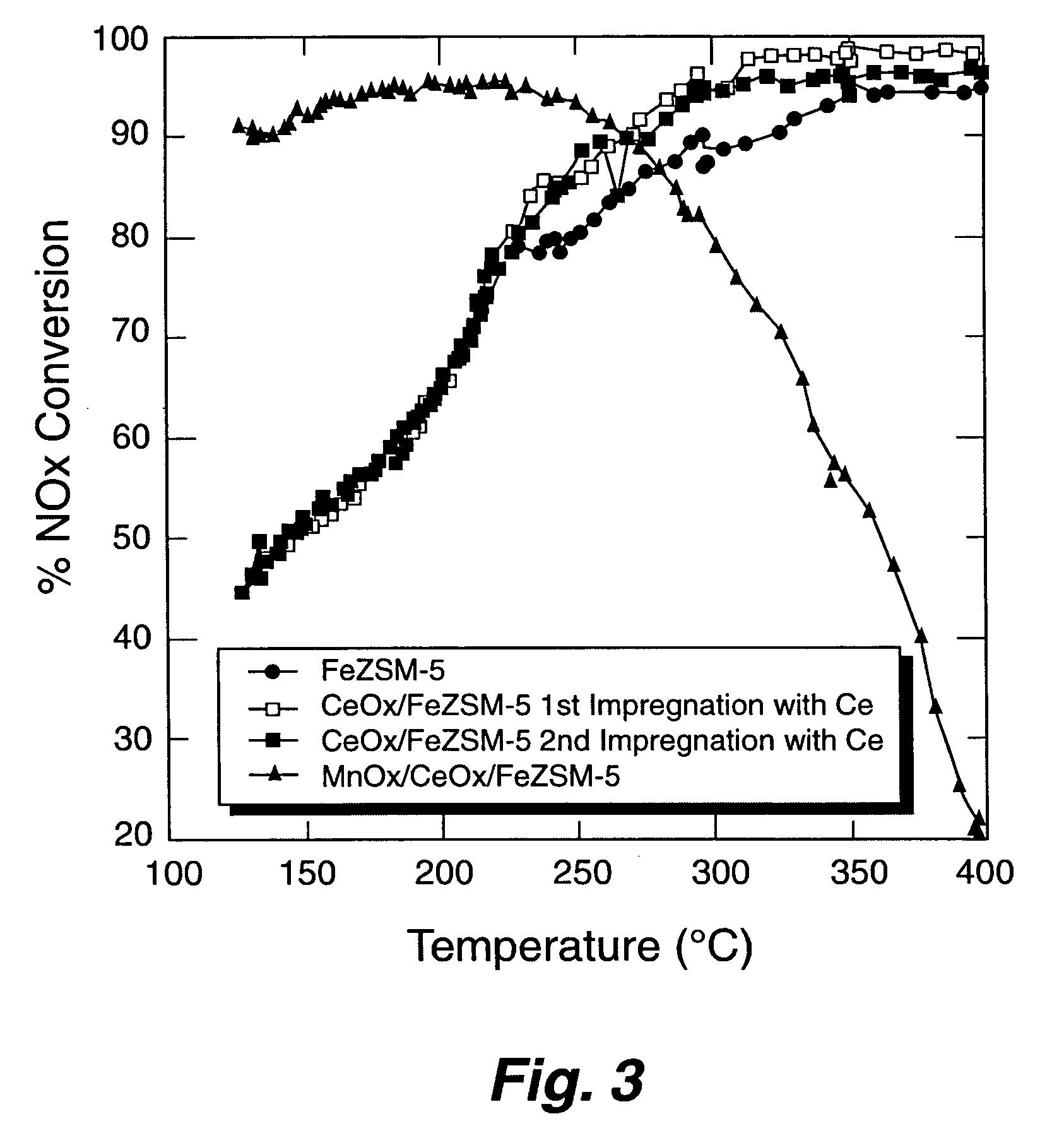

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

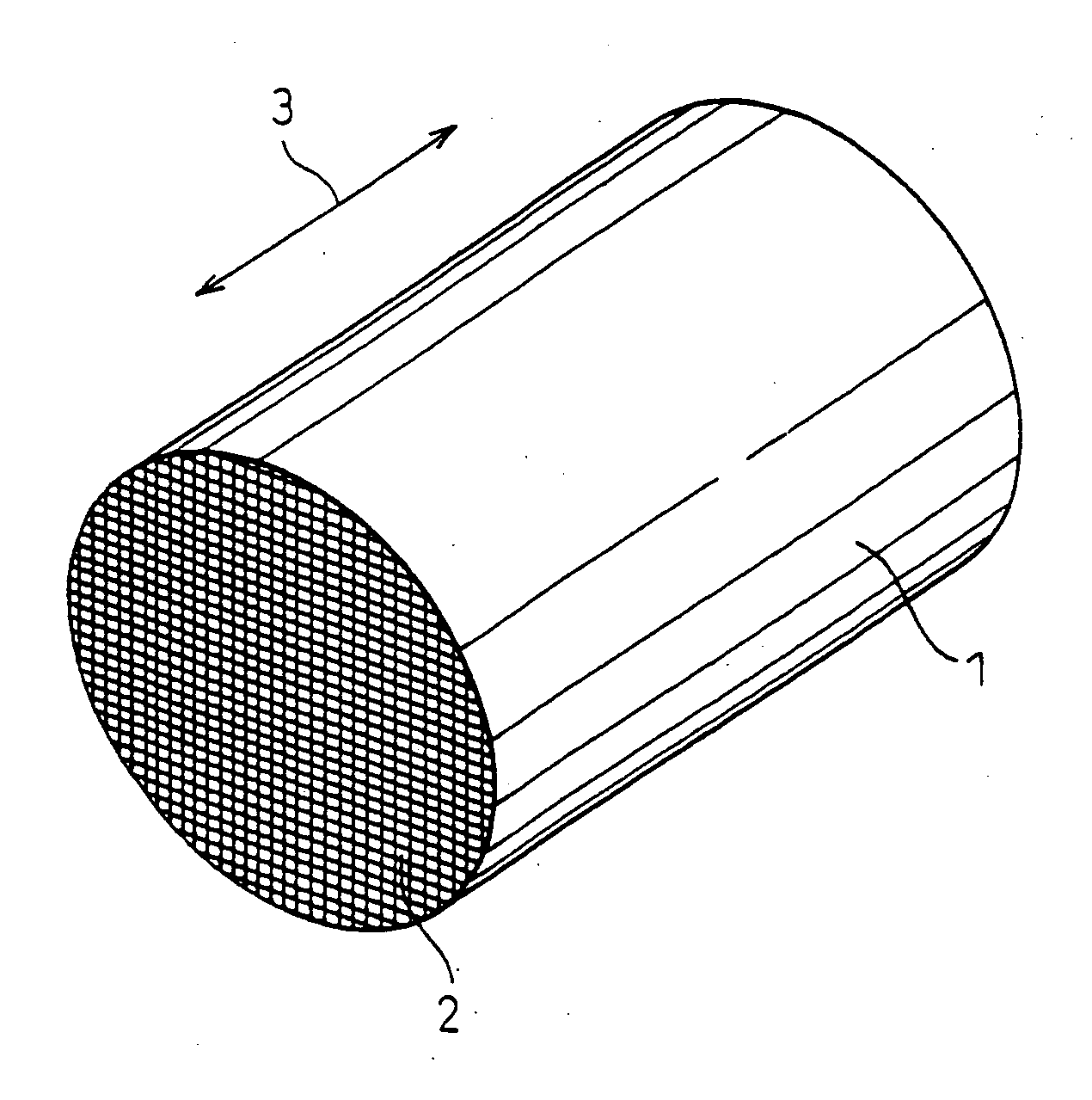

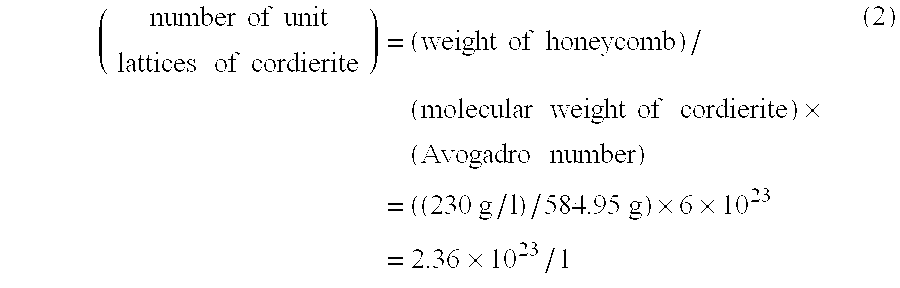

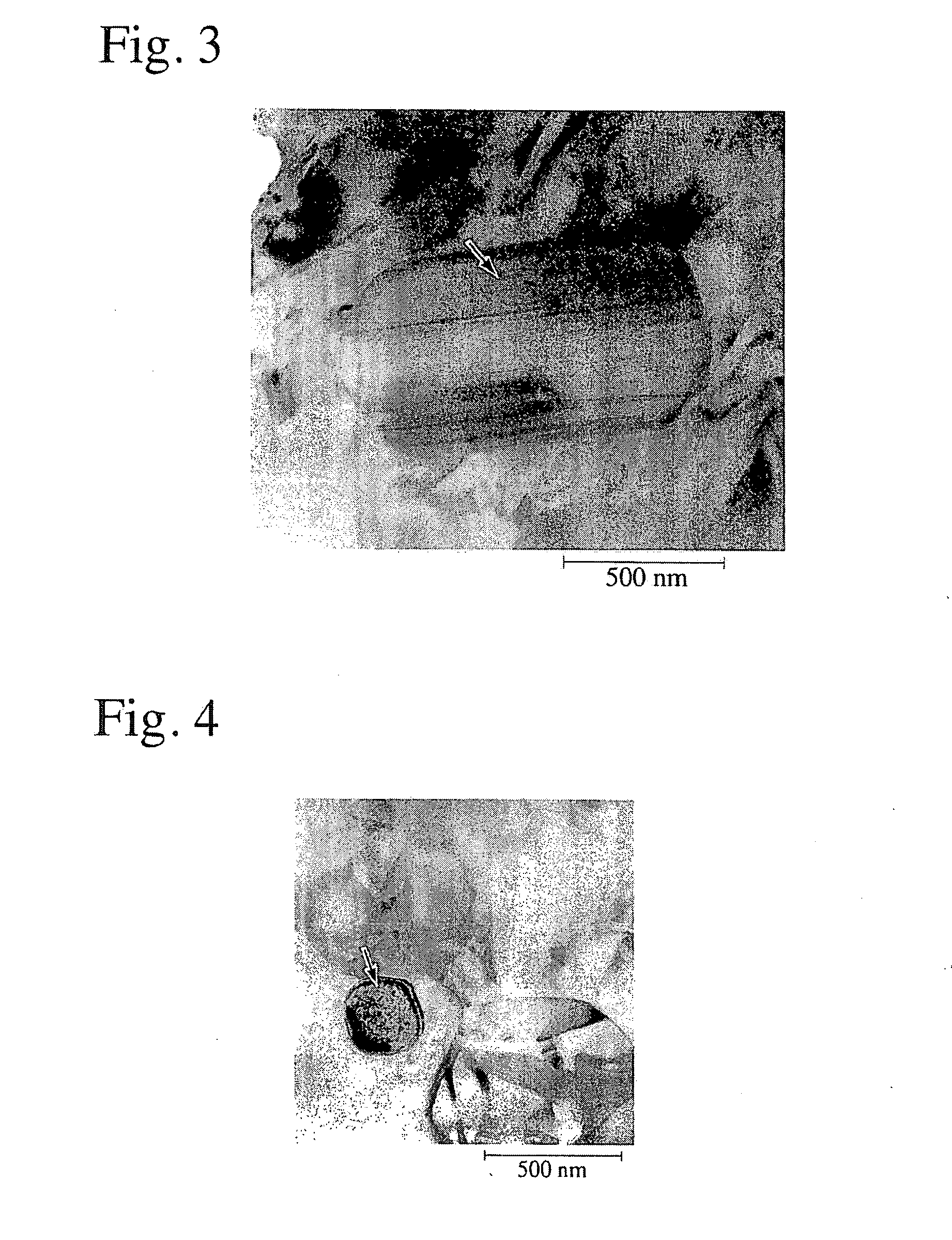

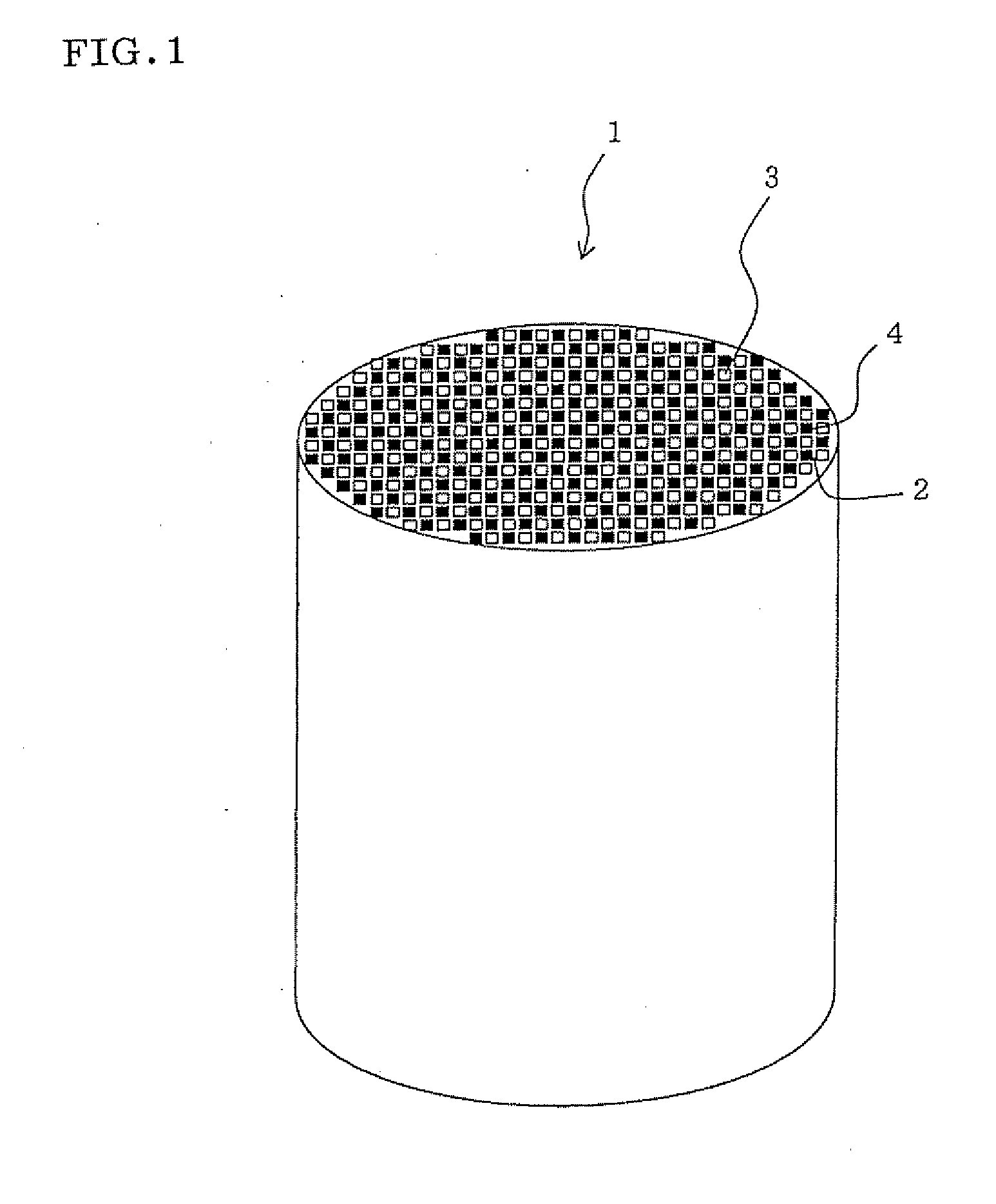

Ceramic support capable of supporting a catalyst, a catalyst-ceramic body and processes for producing same

InactiveUS20070173403A1Easy to cleanExhibits its performance more effectivelyMembranesSemi-permeable membranesLattice defectsOxygen vacancy

A ceramic support capable of supporting a catalyst comprising a ceramic body having fine pores with a diameter or width up to 1000 times the ion diameter of a catalyst component to be supported on the surface of the ceramic body, the number of the fine pores being not less than 1×1011 pores per liter, is produced by introducing oxygen vacancies or lattice defects in the cordierite crystal lattice or by applying a thermal shock to form fine cracks.

Owner:NIPPON SOKEN +1

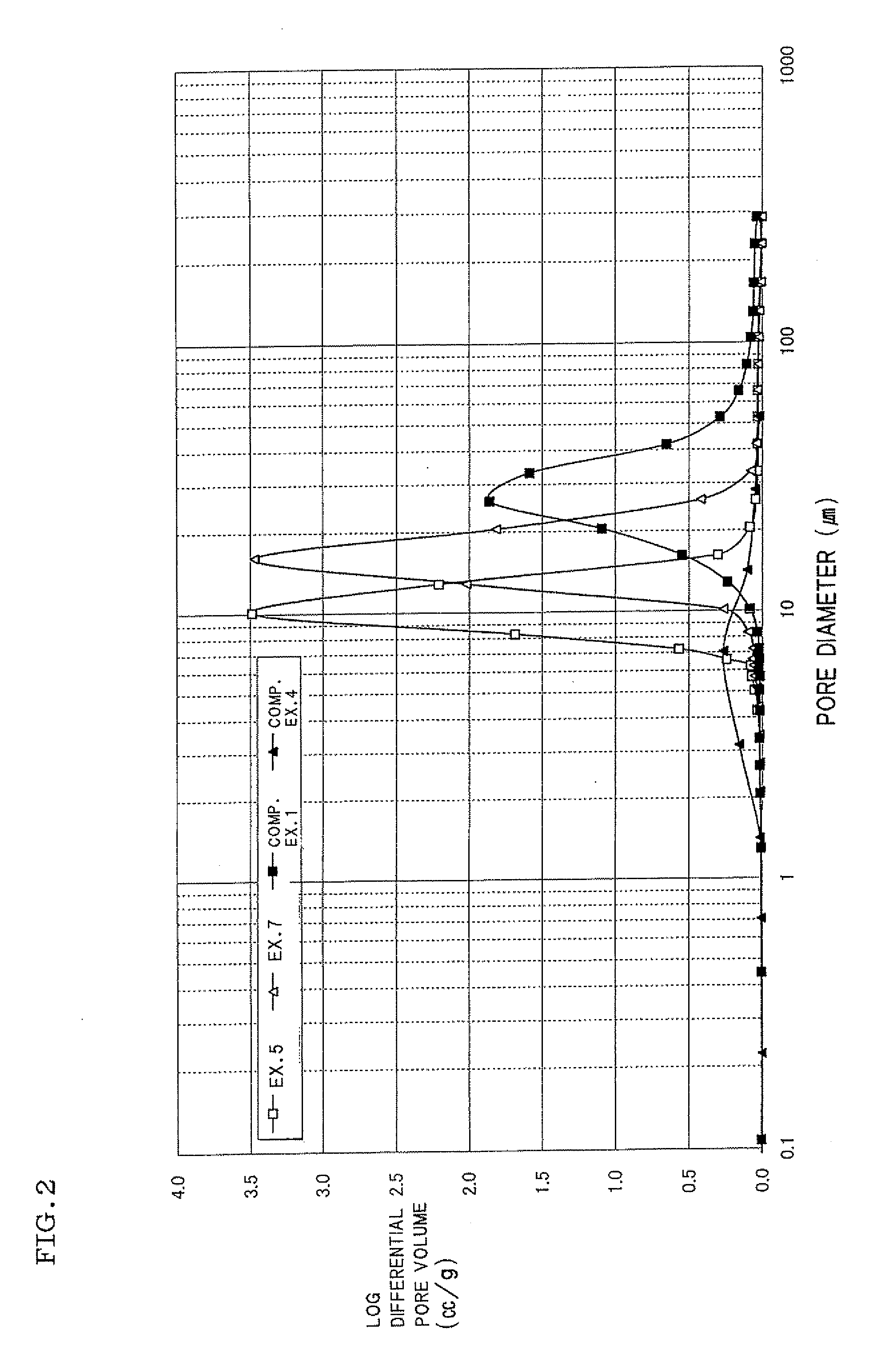

High porosity cordierite composition

ActiveUS20070261378A1Reduce stressImprove filtration efficiencyCombination devicesAuxillary pretreatmentFiltrationCordierites

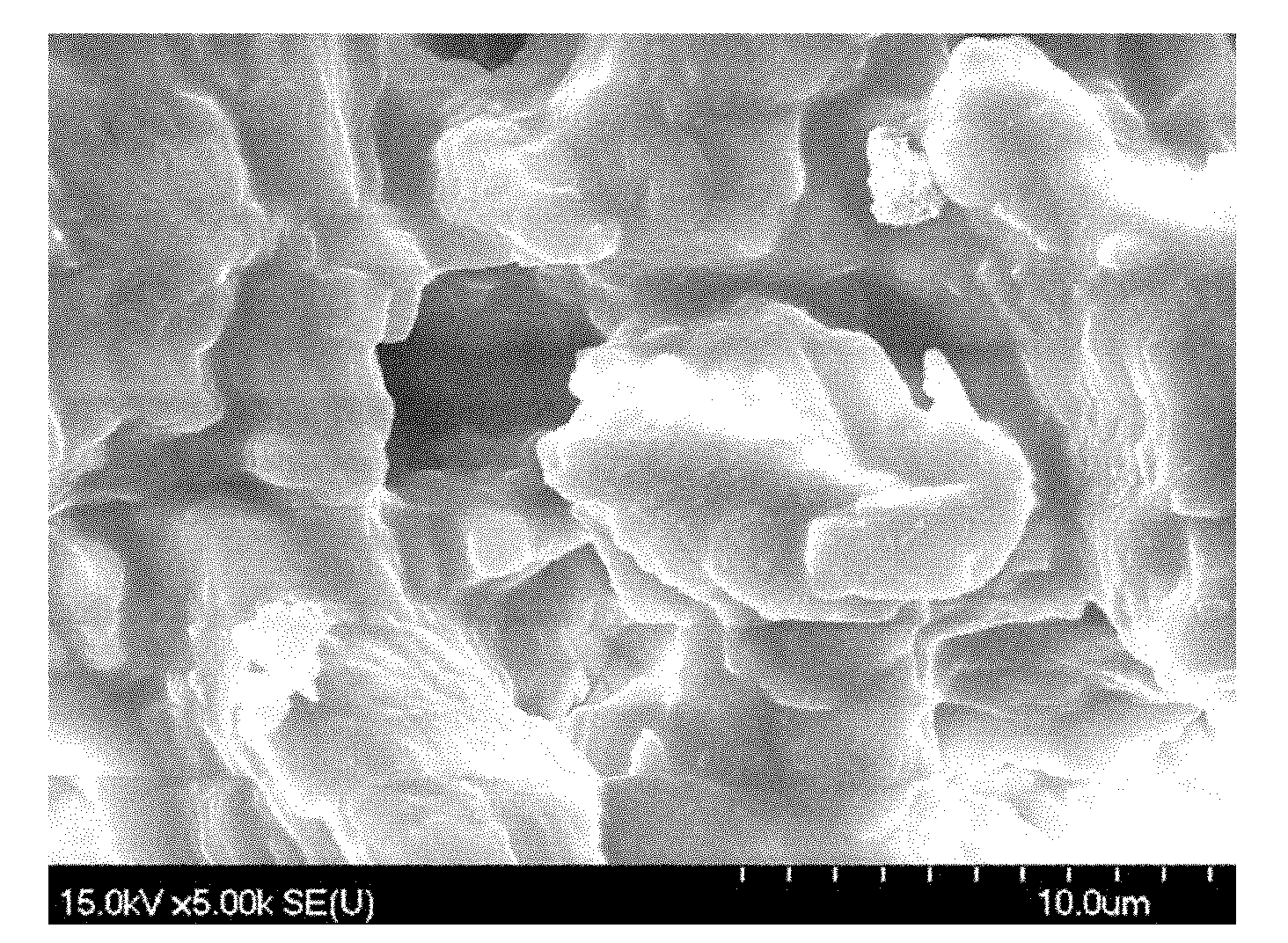

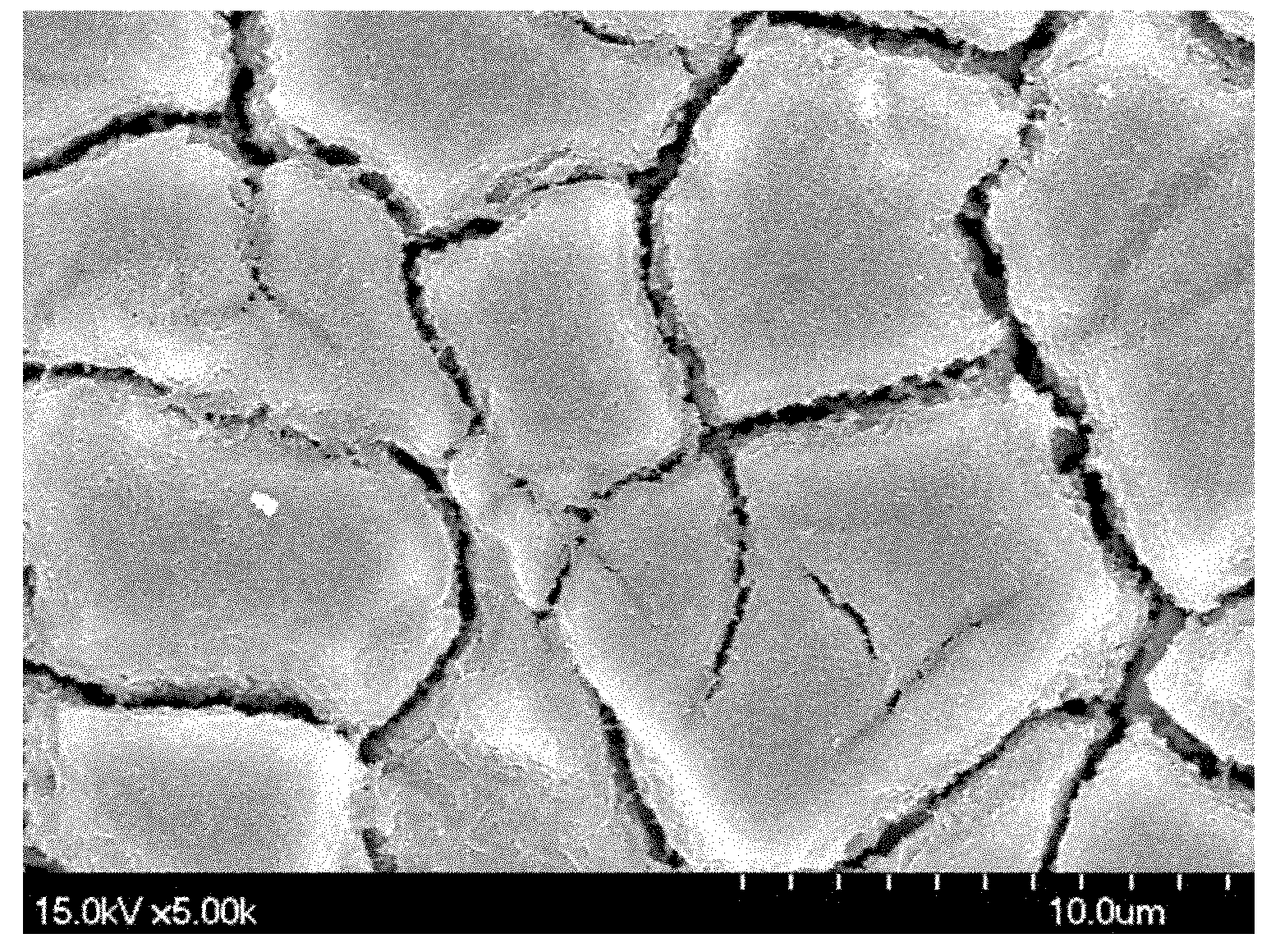

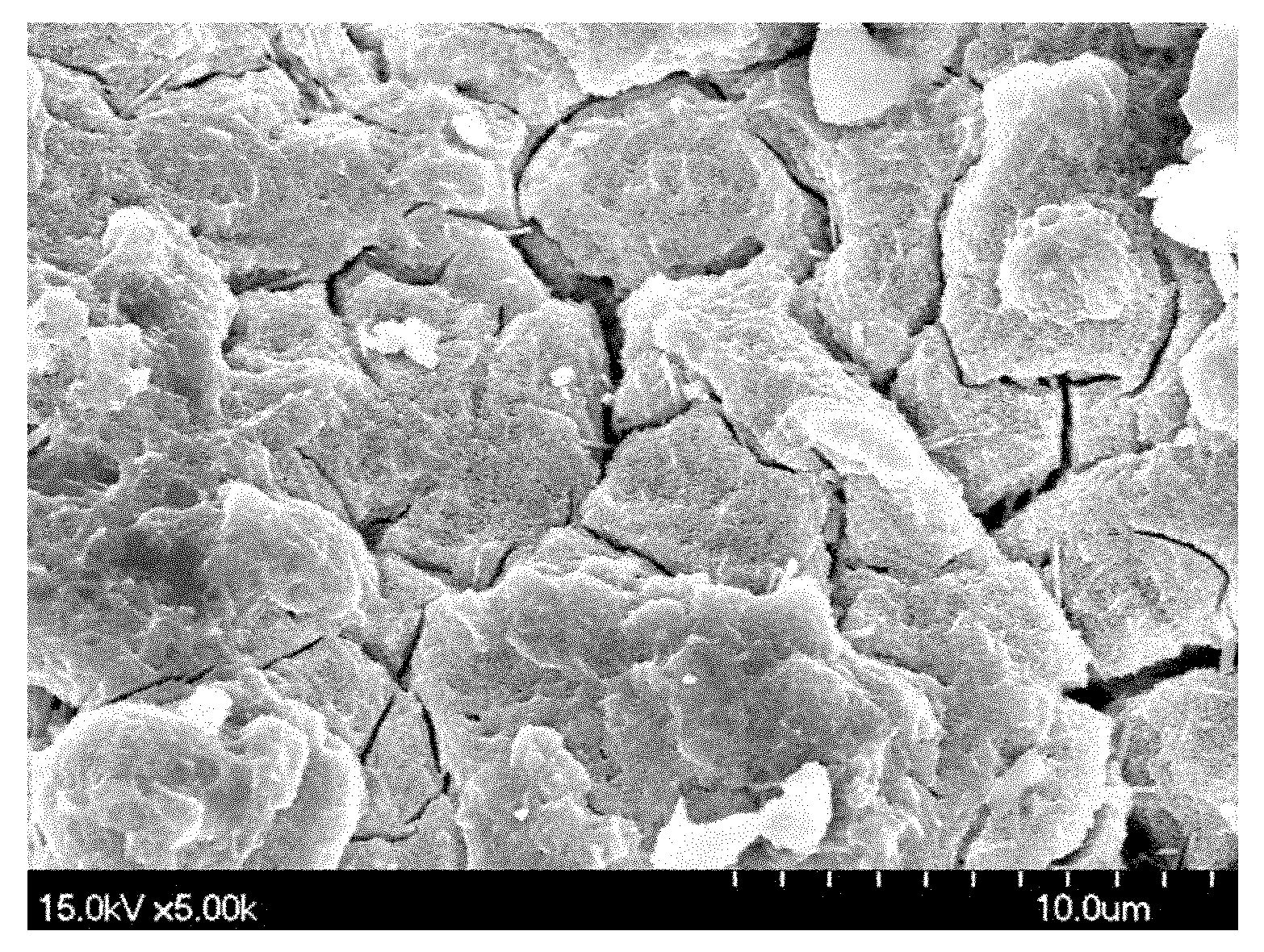

Disclosed are ceramic articles, which in one aspect are composed predominately of a cordierite having a composition close to that of Mg2Al4Si5O18. The ceramic articles possess a microstructure characterized by a unique combination of relatively high porosity and relatively narrow pore size distribution, both as measured by mercury porosimetry, that render the ceramic structure useful for ceramic filter applications requiring high thermal durability and high filtration efficiency coupled with low pressure drop along the length of the filter. Such ceramic bodies are particularly well suited for filtration applications, such as diesel exhaust filters or DPFs. Also disclosed are methods for the manufacture of the ceramic articles described herein.

Owner:CORNING INC

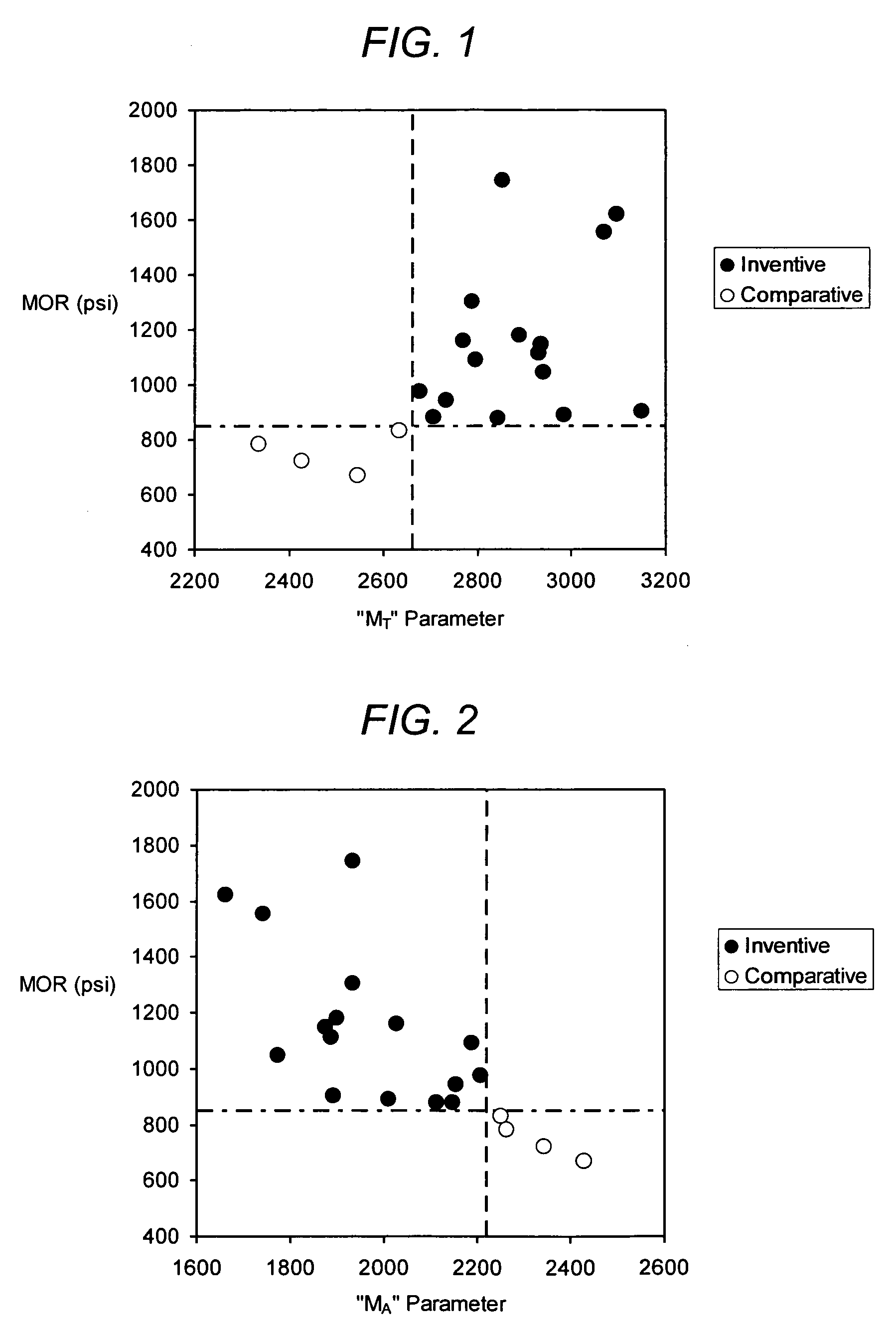

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS20070119133A1Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

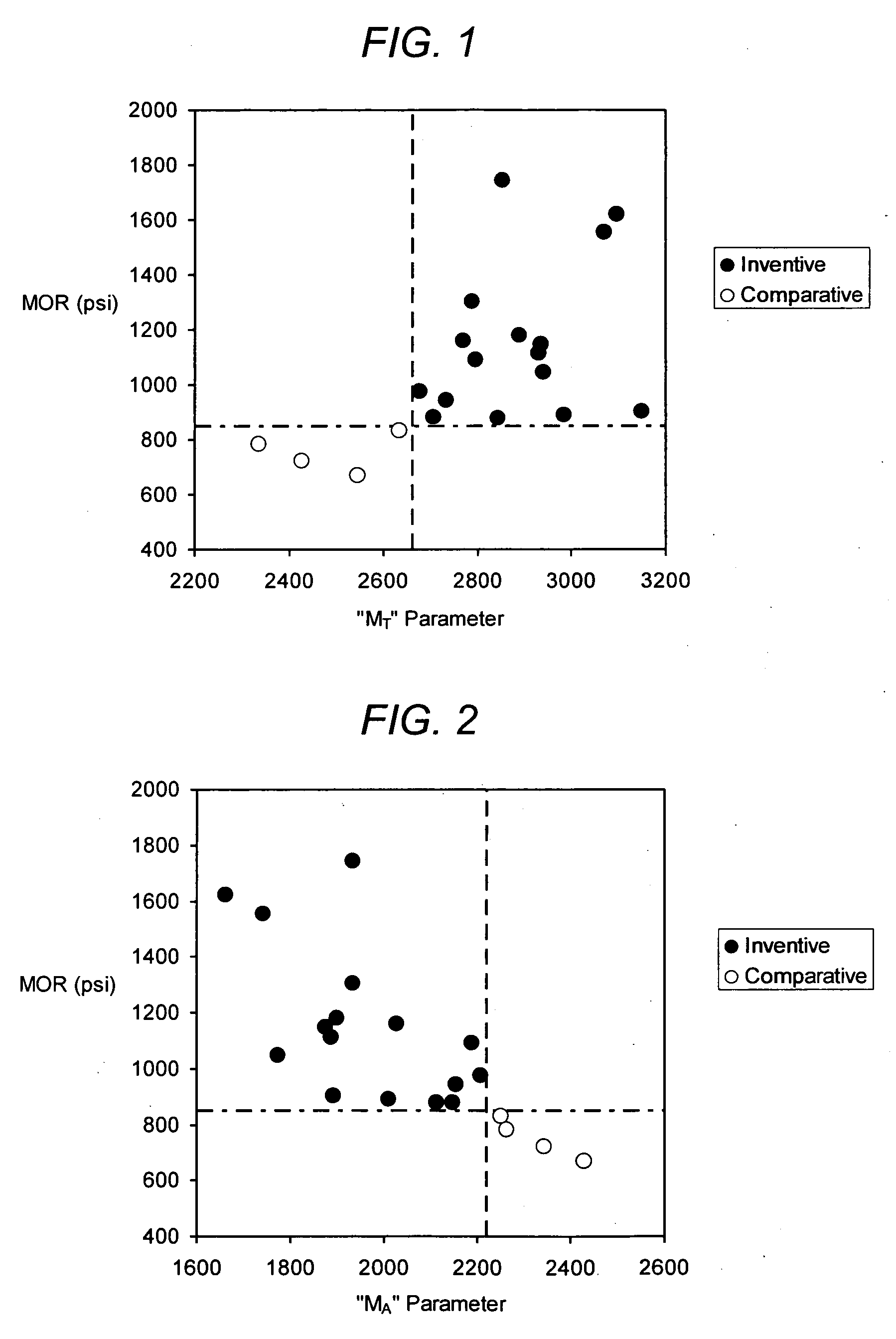

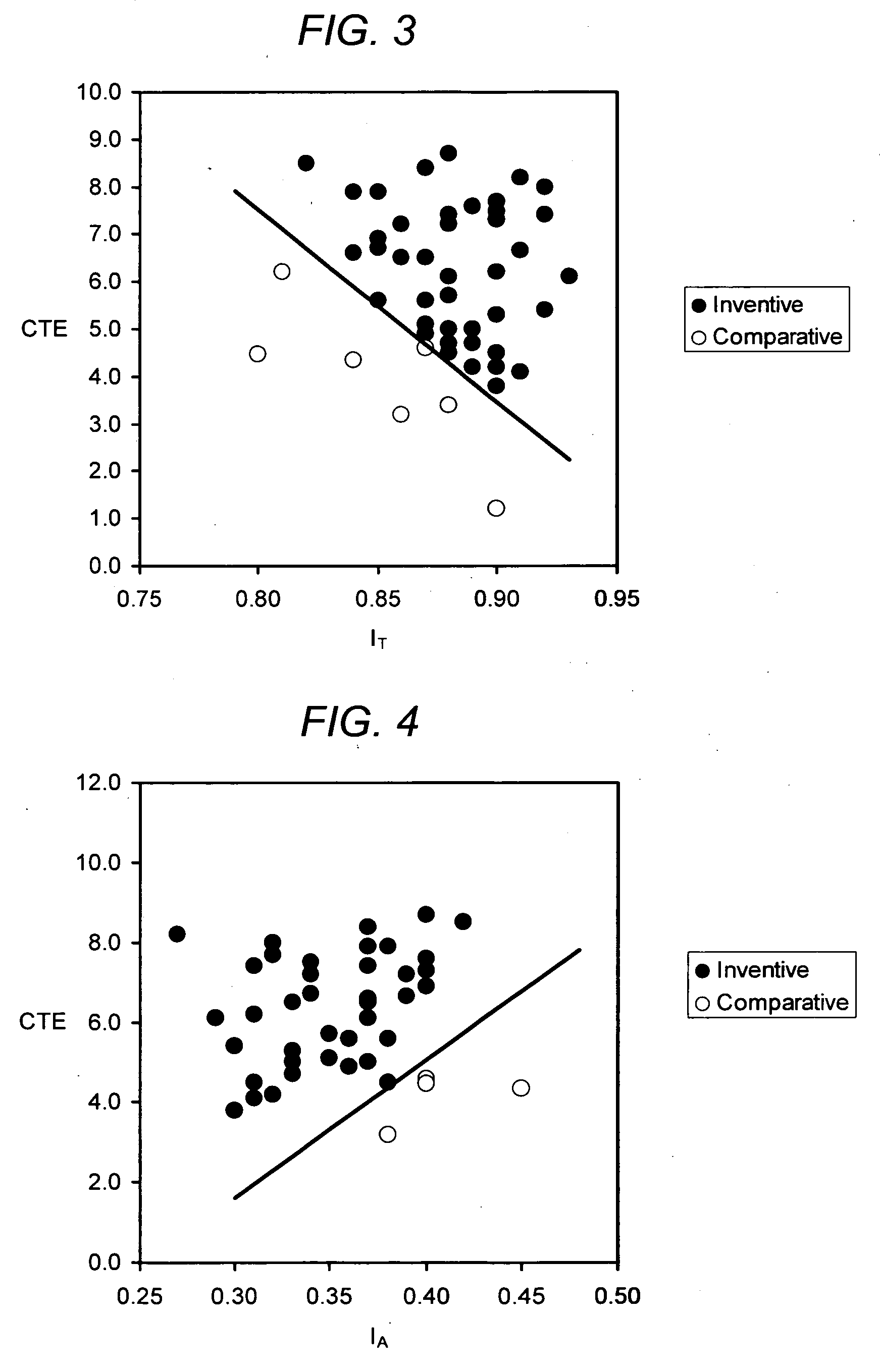

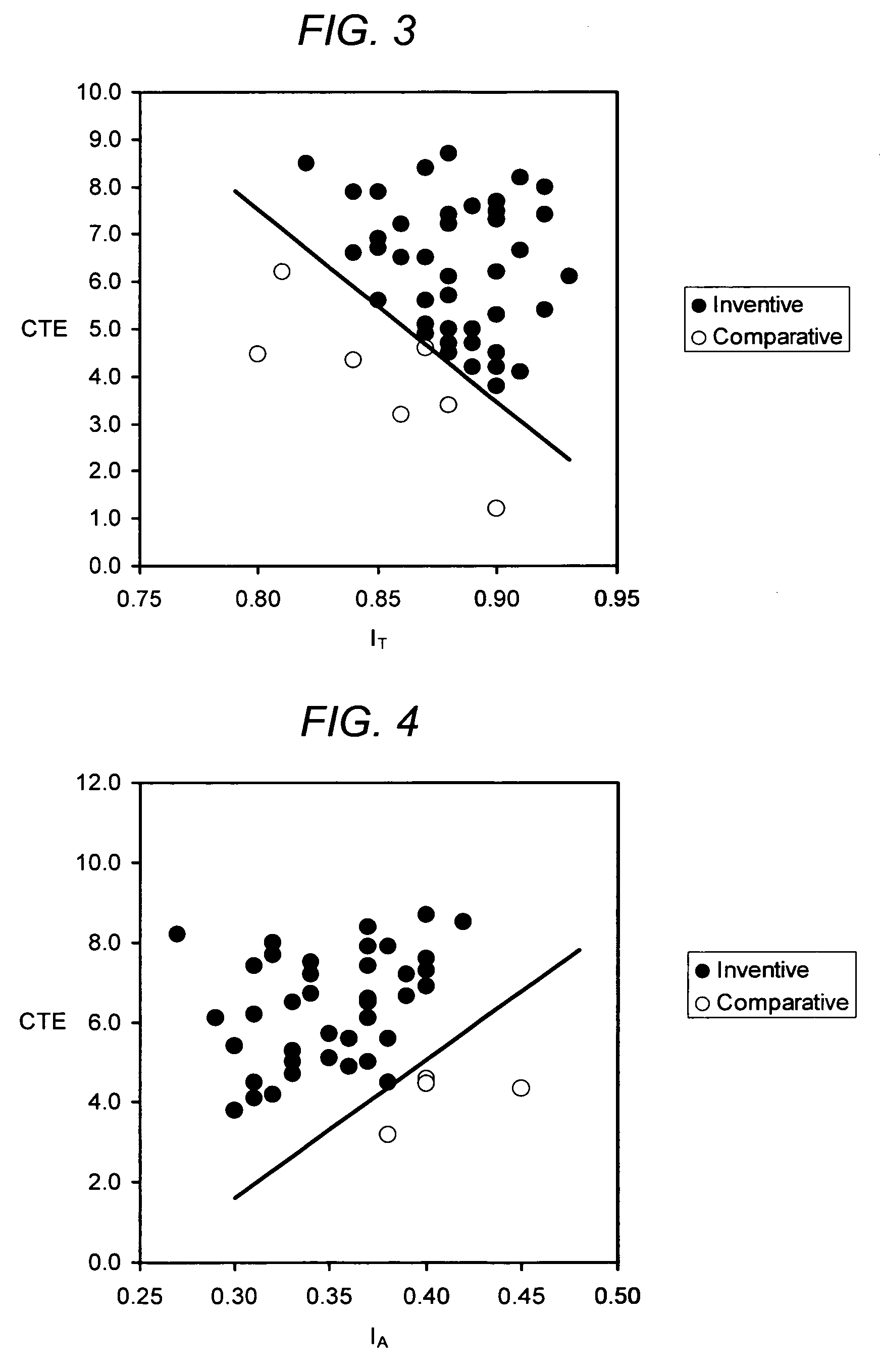

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 wherein MA=3645 (IA)−106 (CTE)+19 (d90)+17 (% porosity), MT=4711 (IT)+116 (CTE)−26 (d90)−28 (% porosity), and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

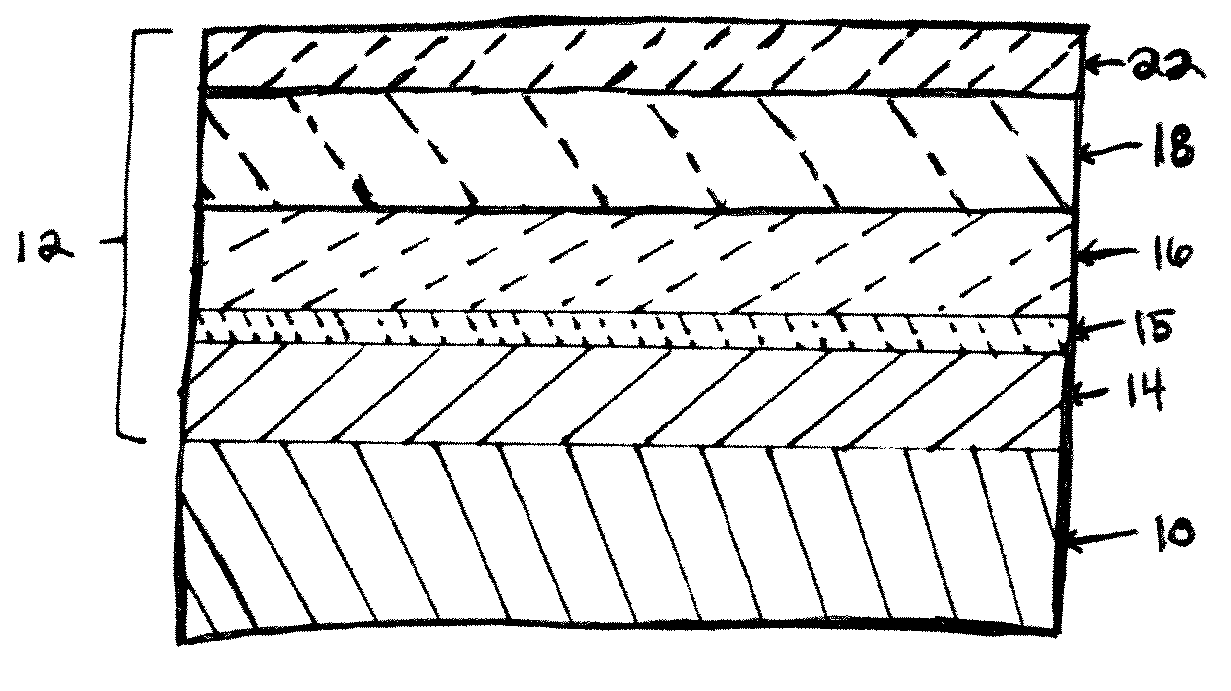

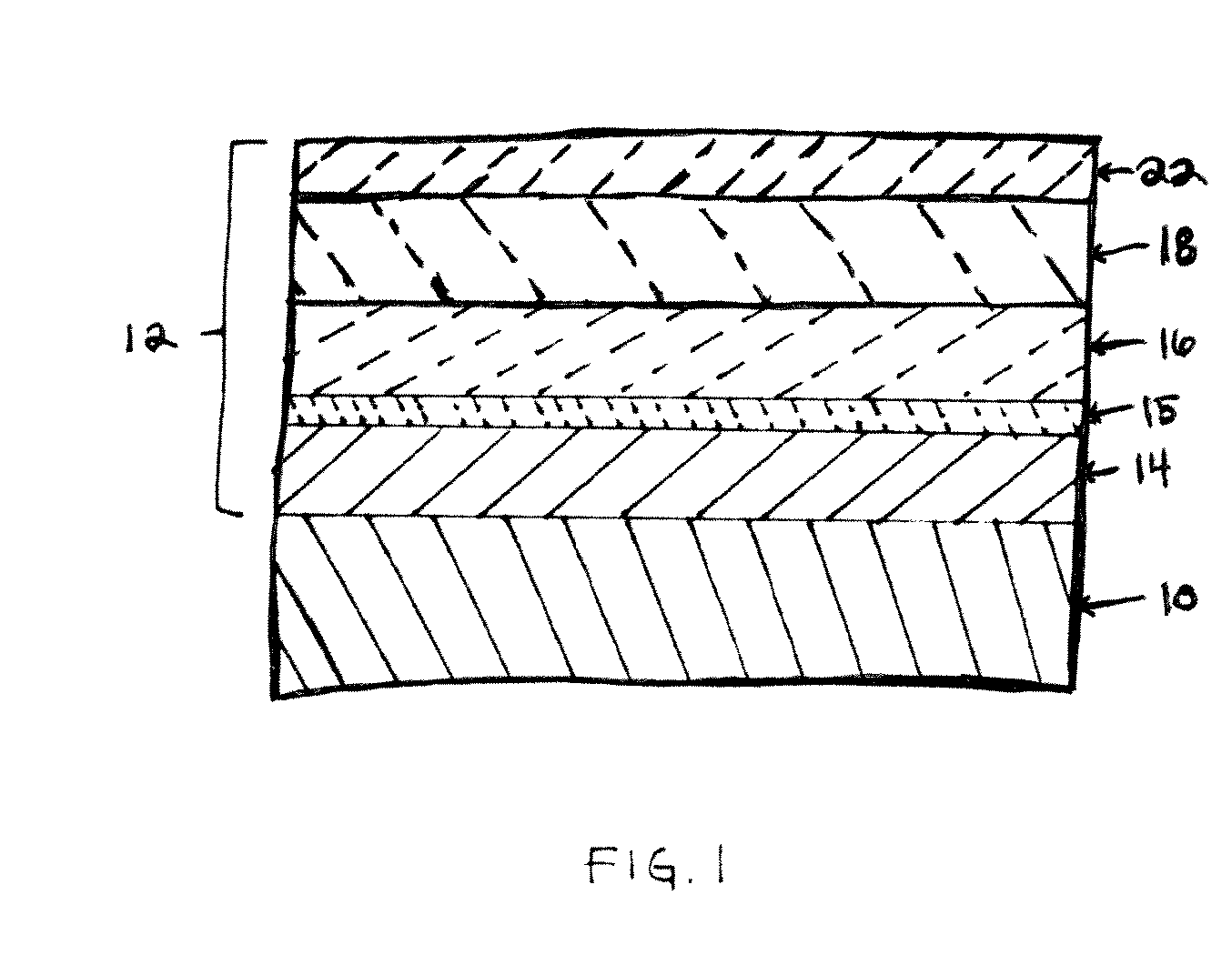

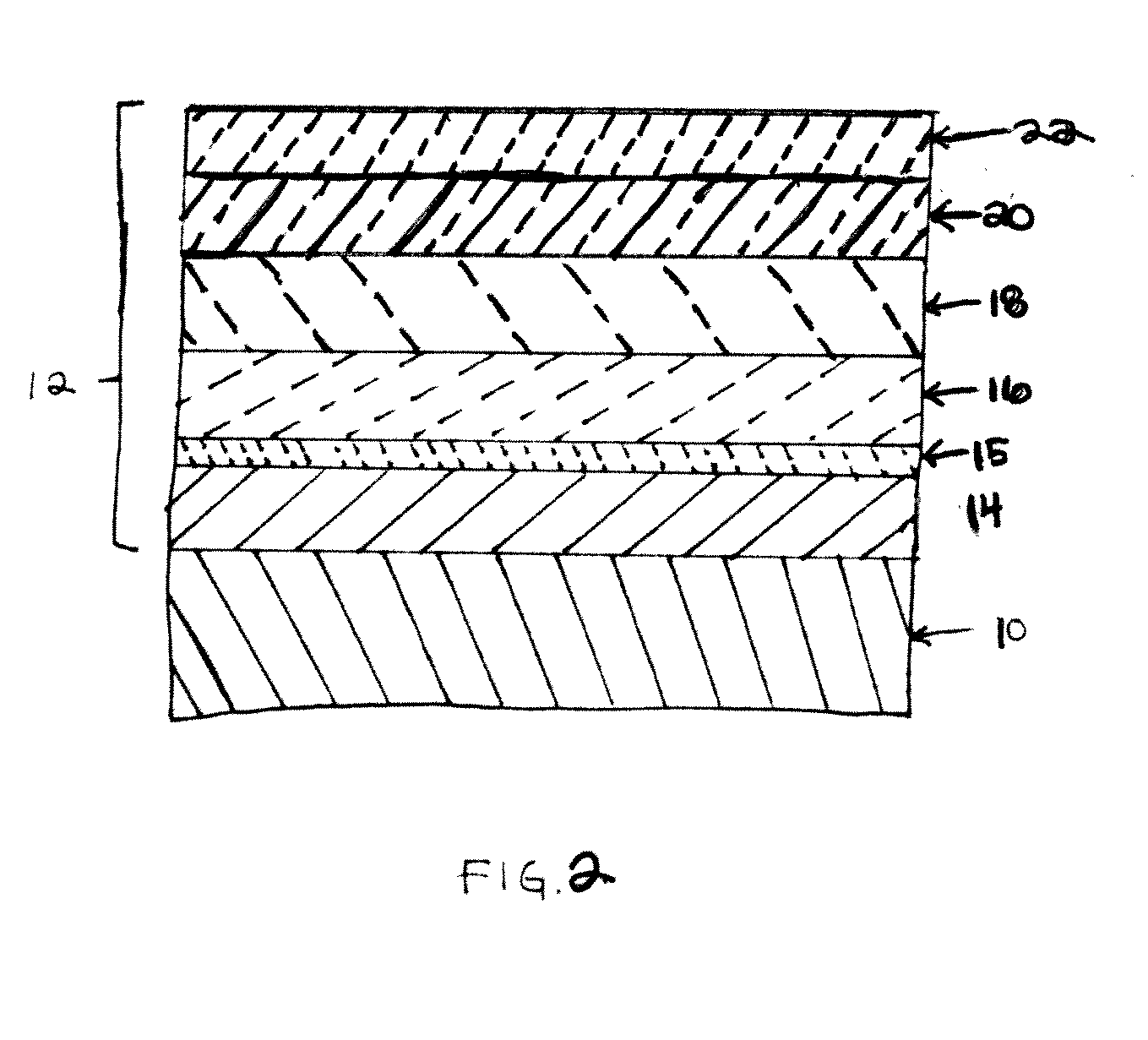

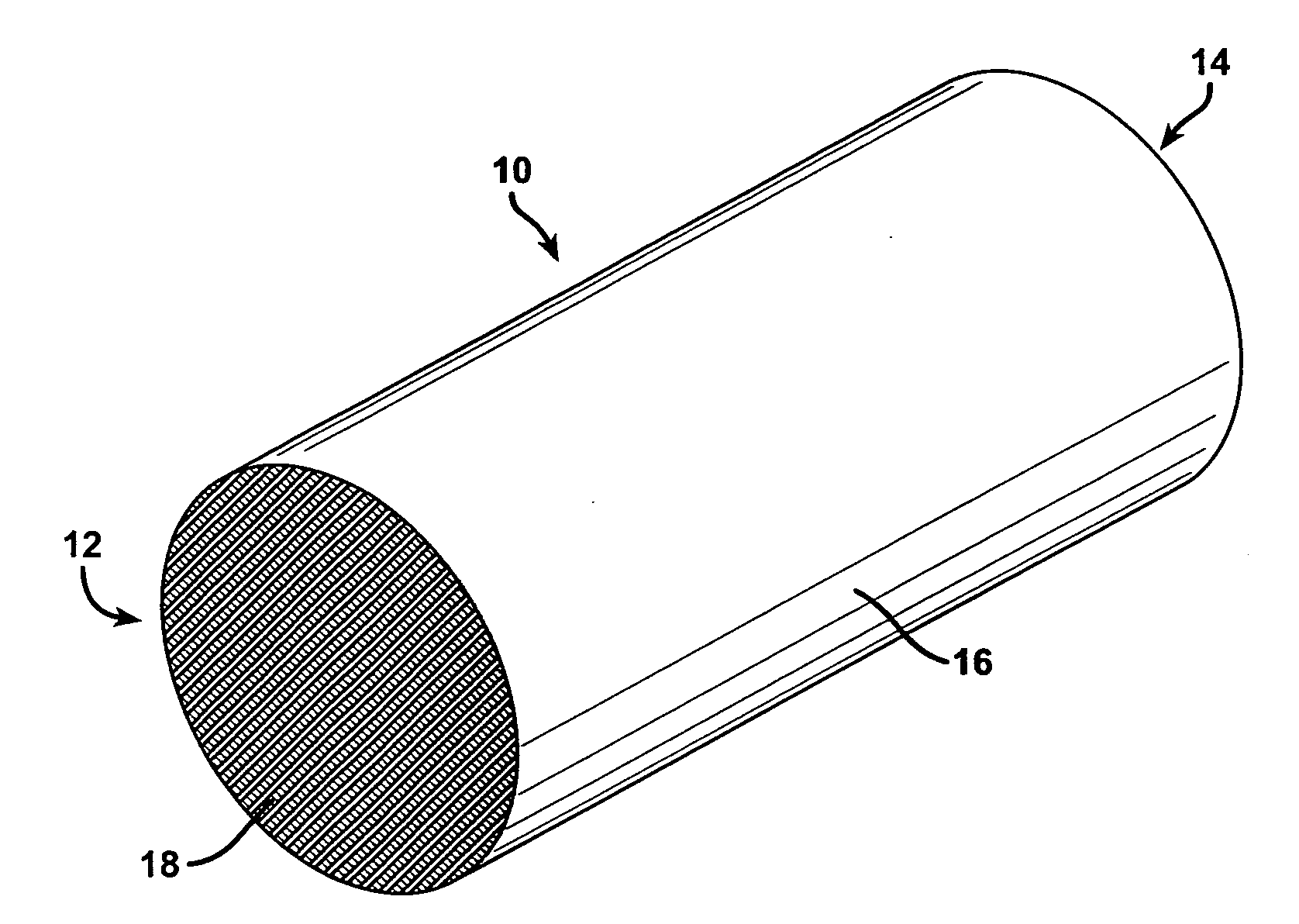

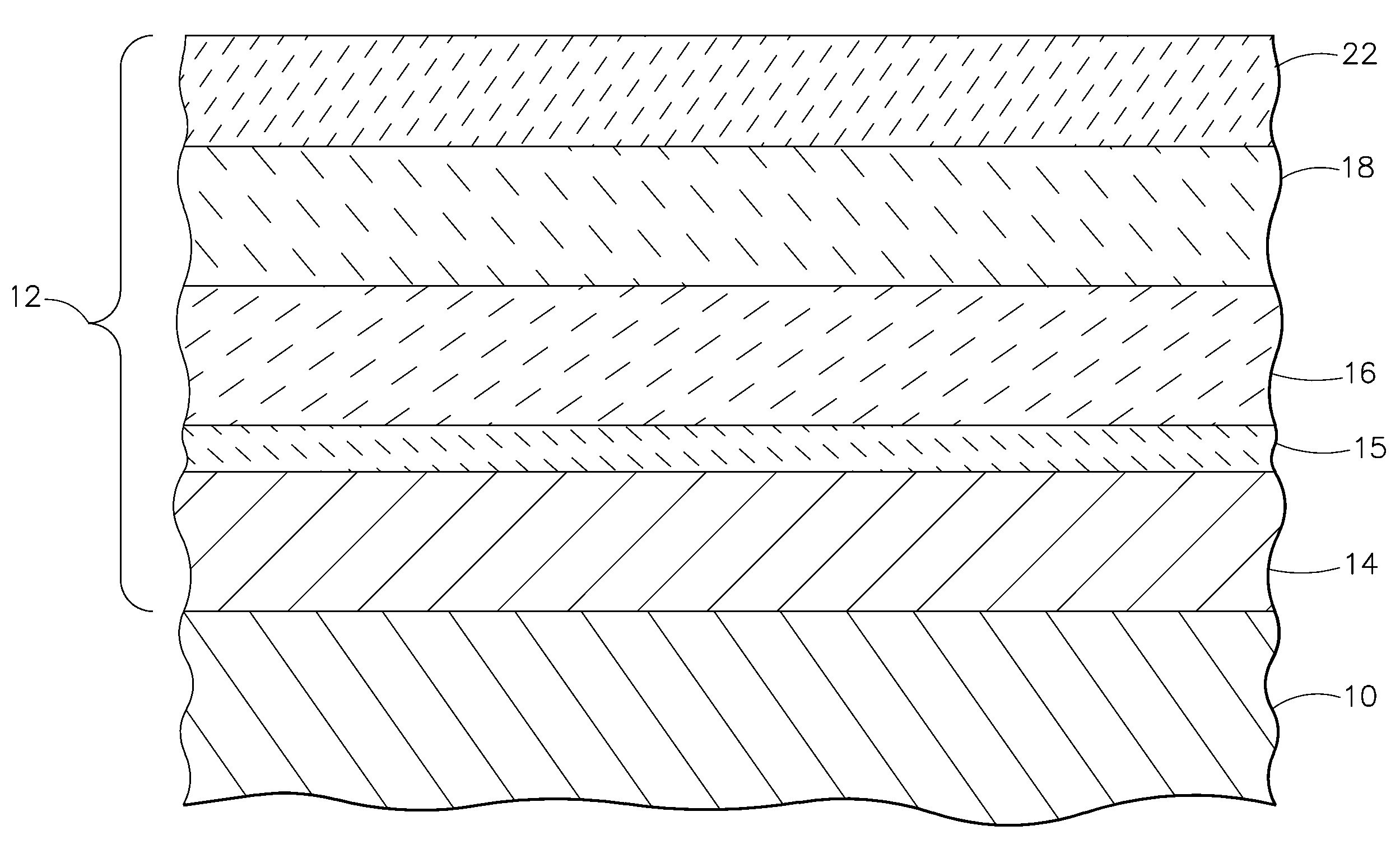

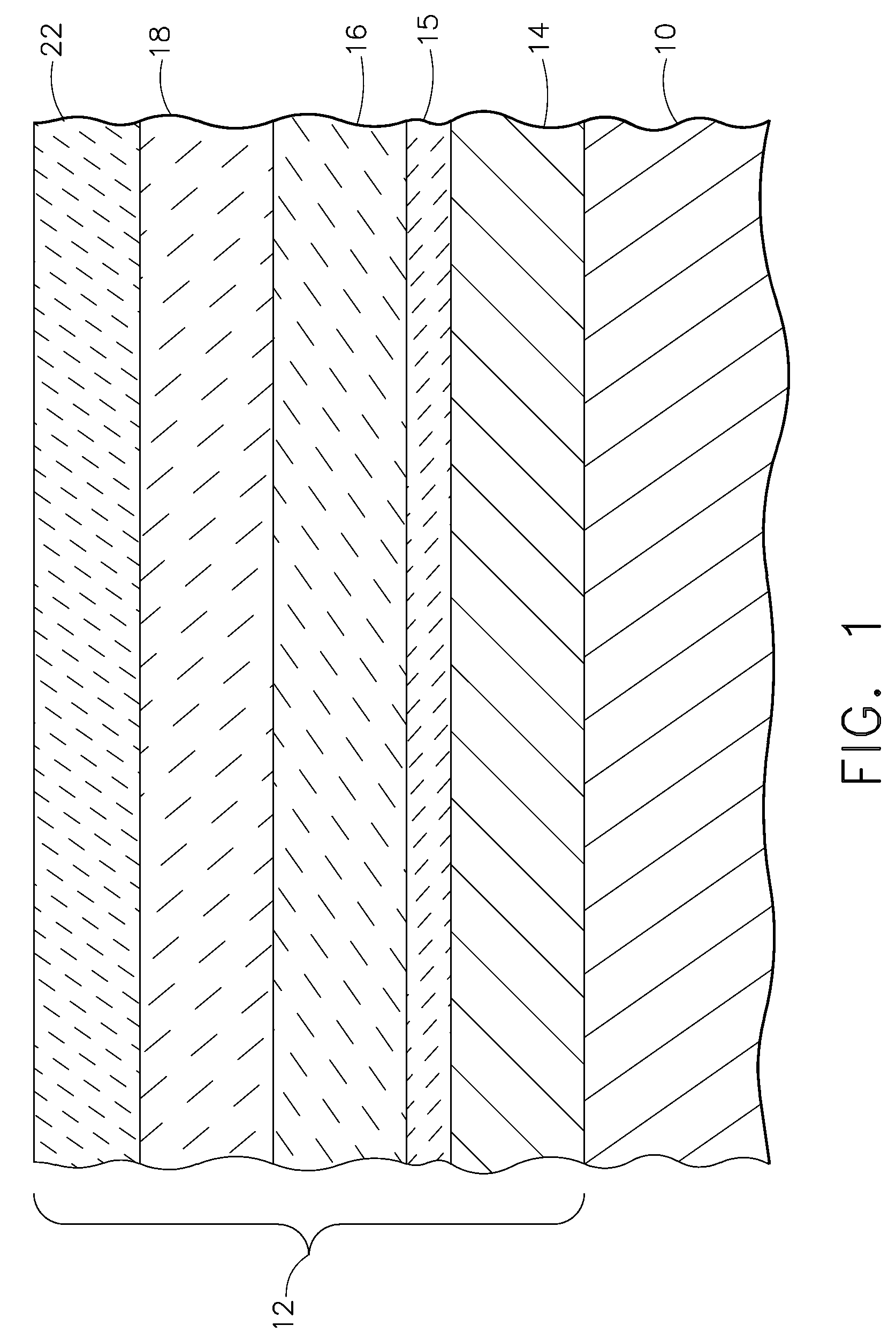

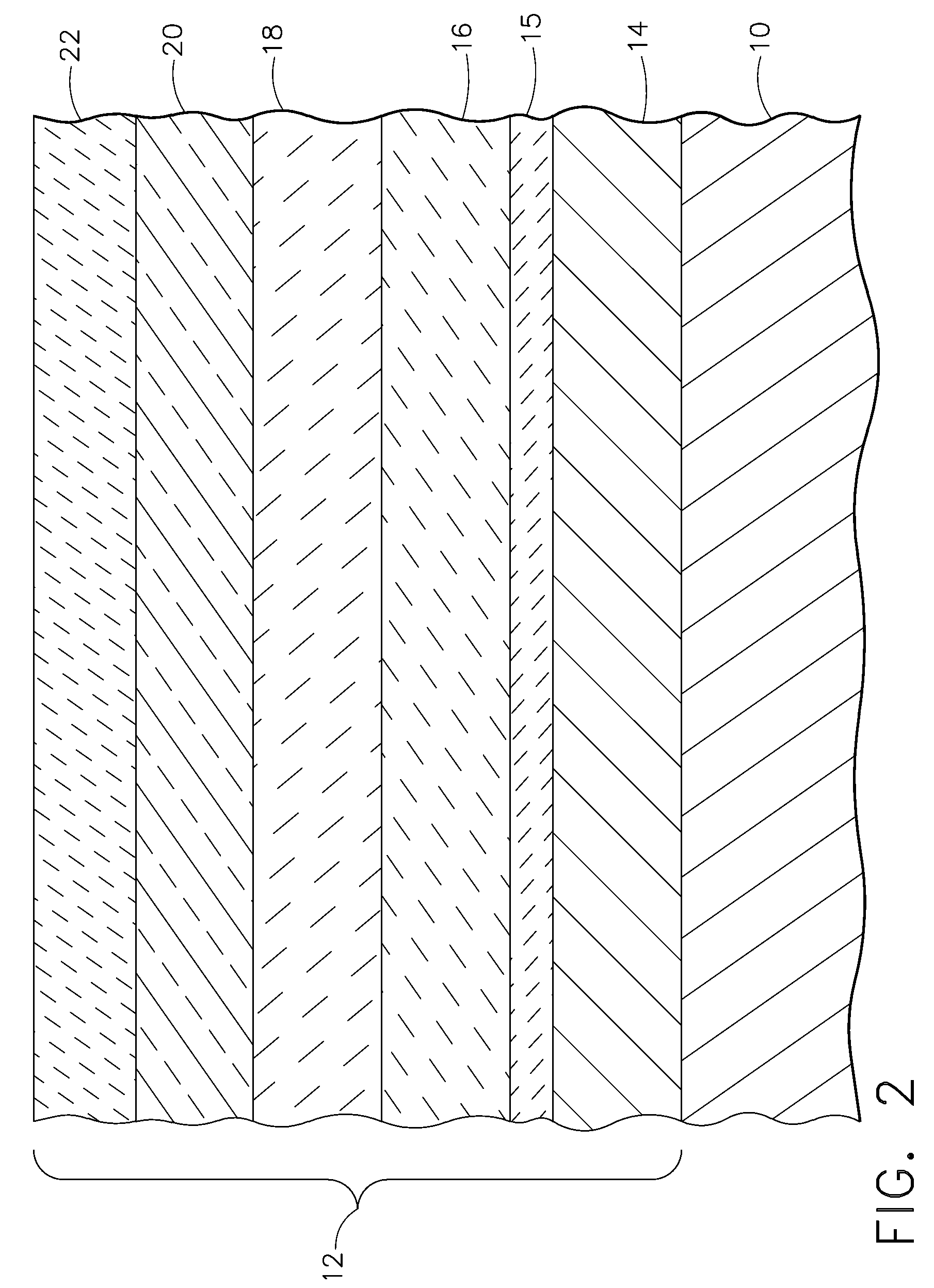

Layered exhaust treatment catalyst

ActiveUS20050282701A1Internal combustion piston enginesOther chemical processesMonitoring systemCordierites

A layered exhaust treatment catalyst comprising: (a) a carrier such as cordierite; (b) a first layer deposited on the carrier comprising a palladium metal component, a platinum metal component and an oxygen storage component such as ceria supported on a refractory metal oxide such as gamma-alumina; and (c) a second layer deposited on the first layer comprising a rhodium metal component, a platinum metal component and an oxygen storage component such as ceria supported on a refractory metal oxide such as gamma-alumina. Preferably, the catalyst also includes a bottom layer interposed between the carrier and the first layer. The bottom layer comprises an oxygen storage component such as ceria supported on a refractory metal oxide such as gamma-alumina. The amount of the oxygen storage component of the catalyst may be “tuned”, i.e., adjusted, to meet the needs of a vehicle's on-board diagnostic (“OBD”) catalyst efficiency monitoring system, without adversely affecting the performance of the catalyst.

Owner:BASF CORP

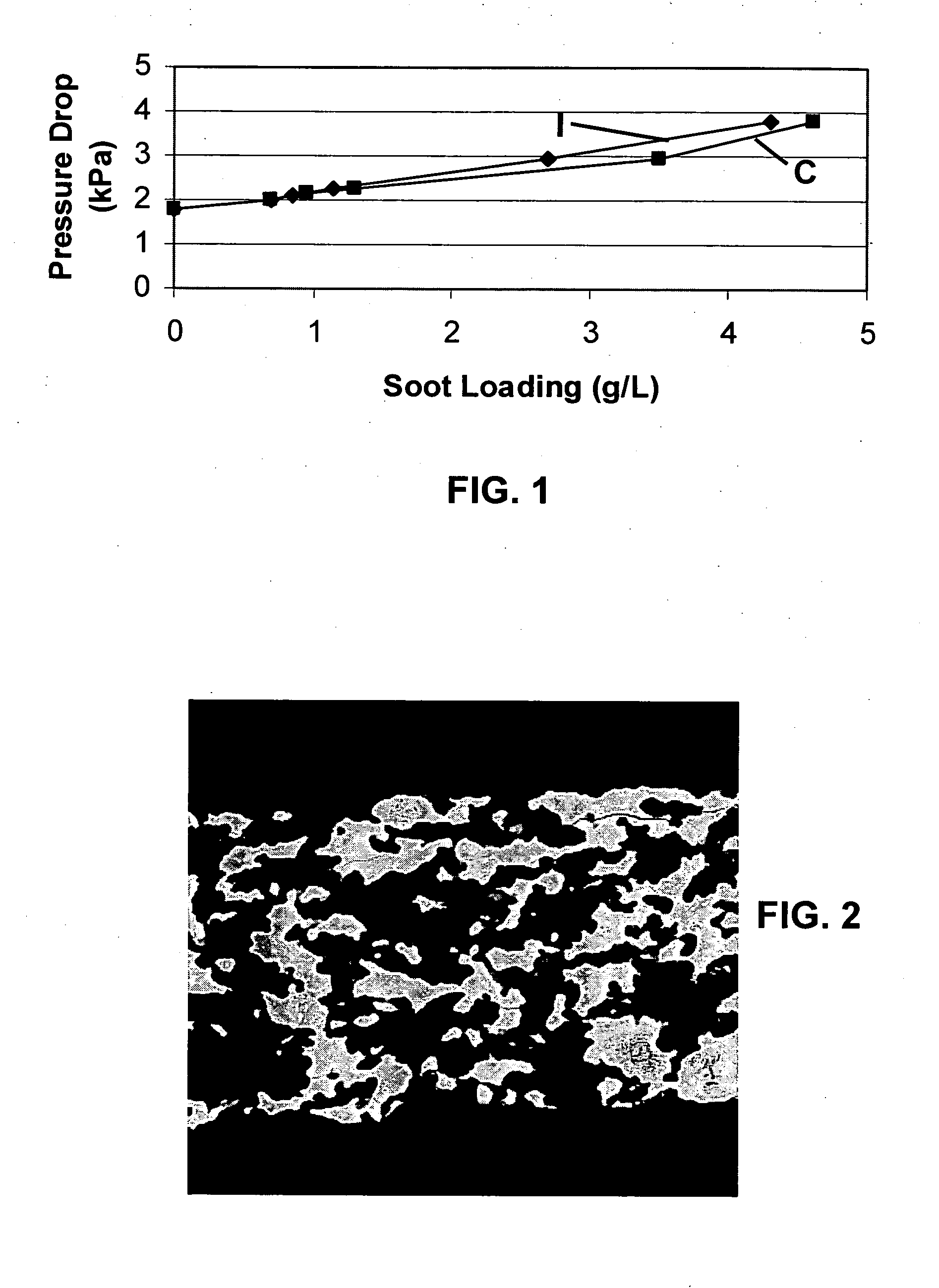

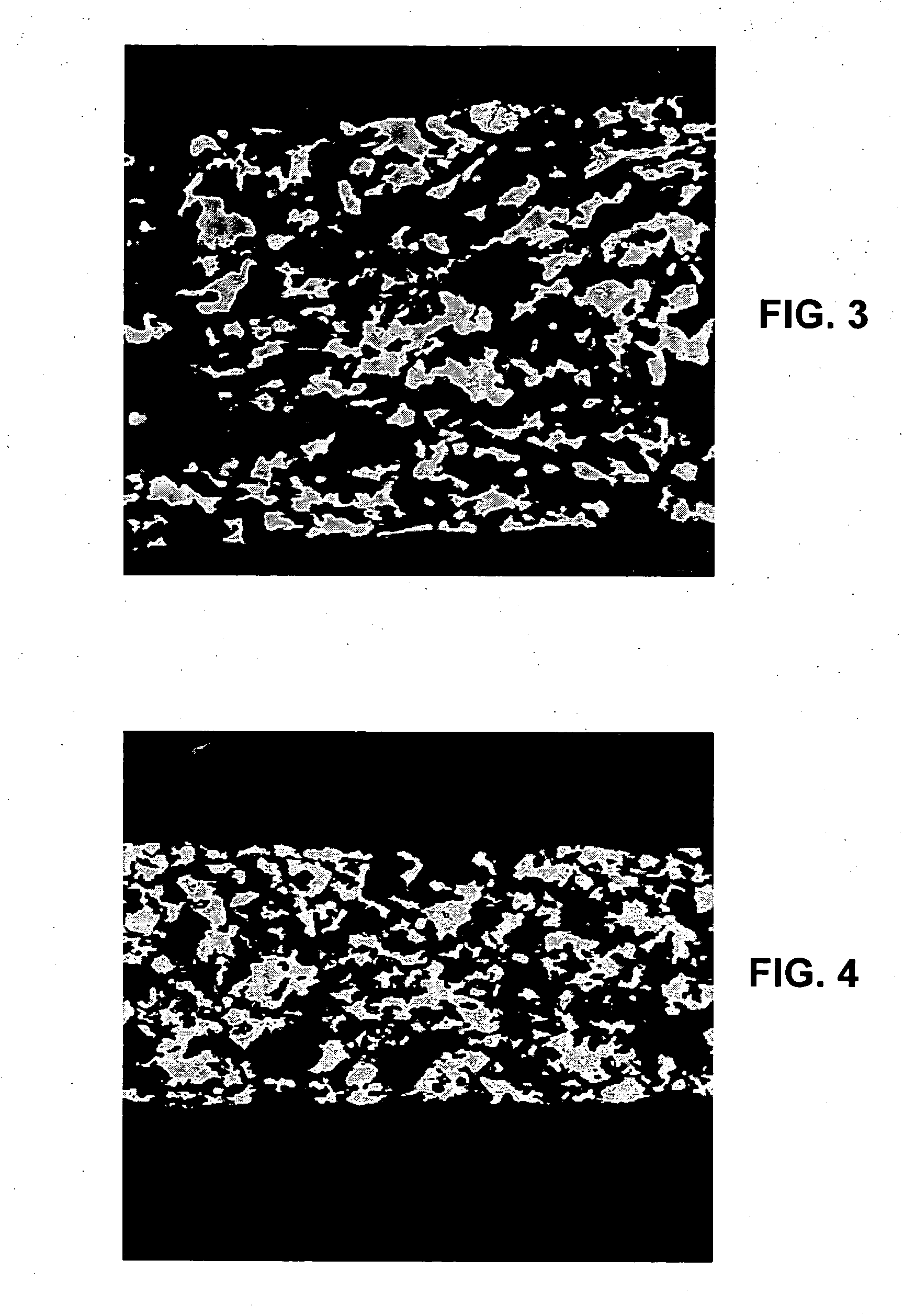

Cordierite filters with reduced pressure drop

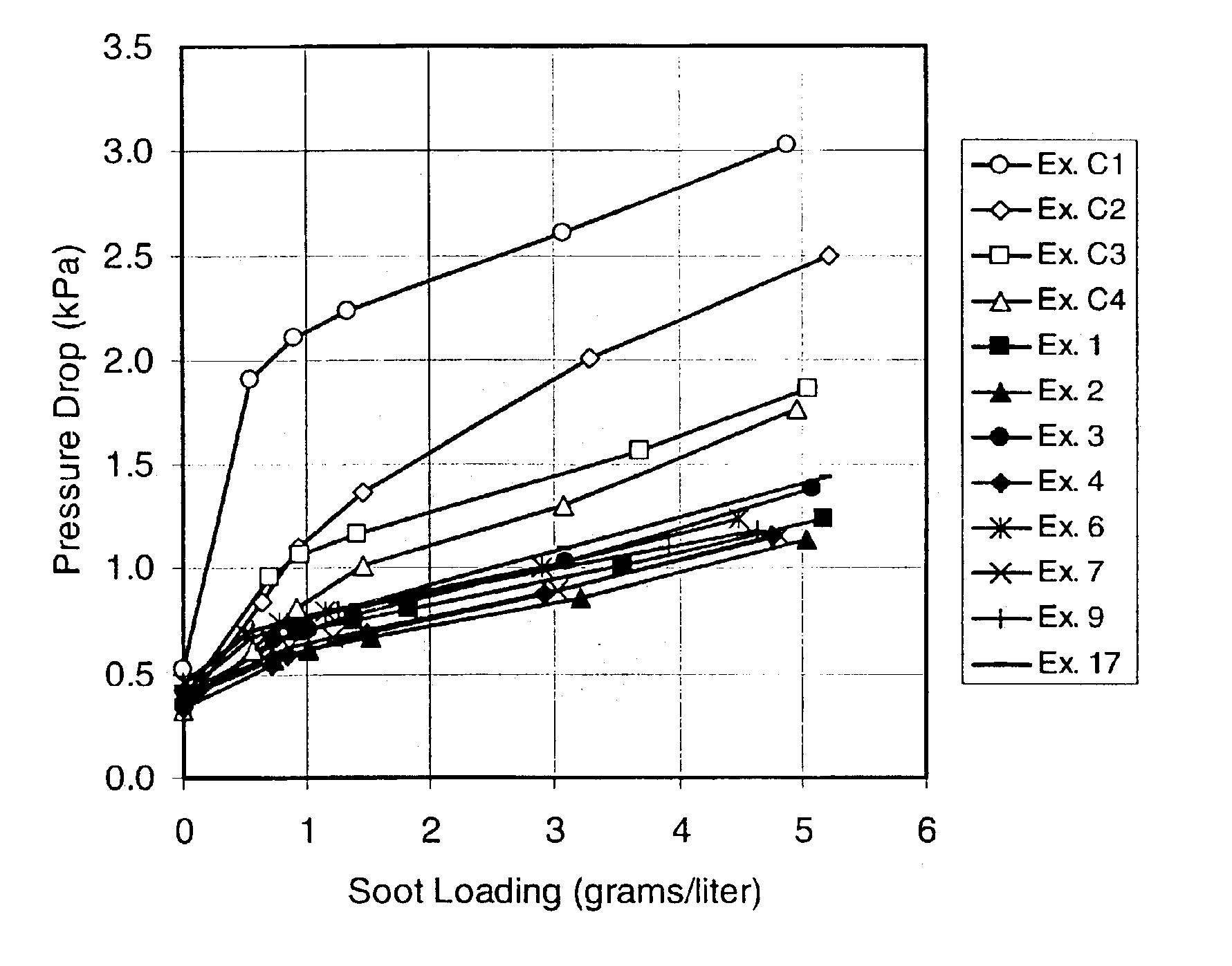

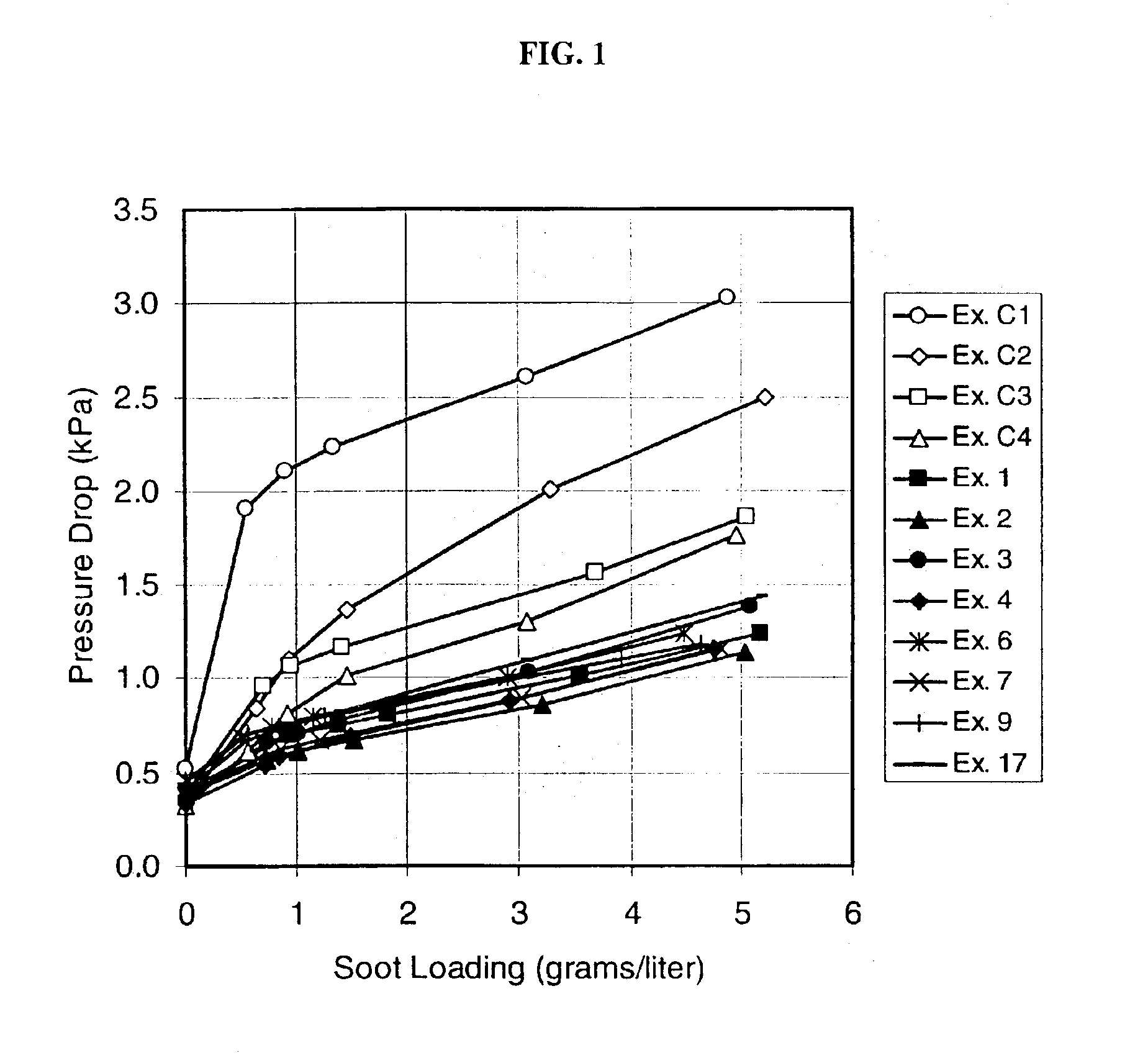

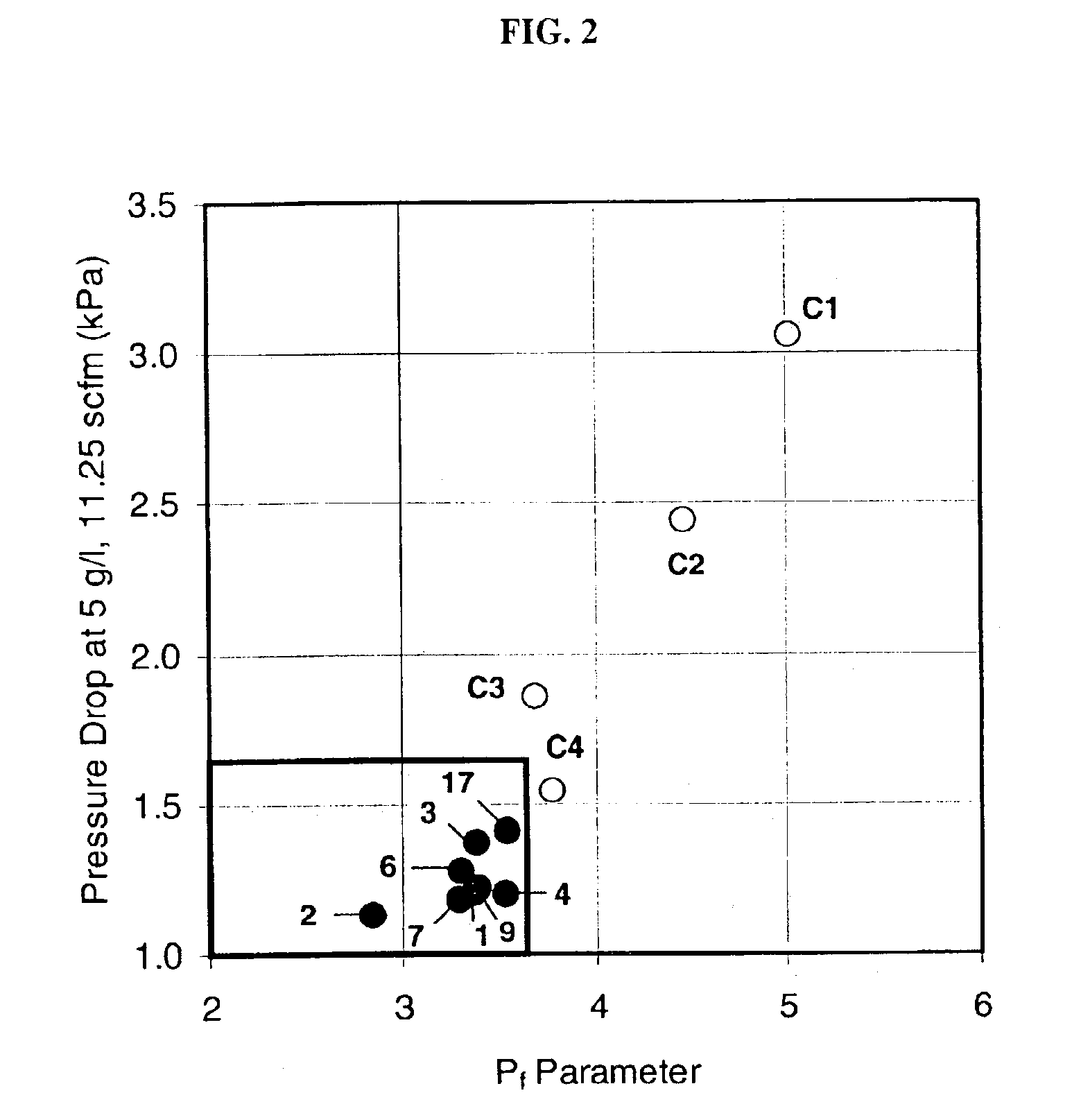

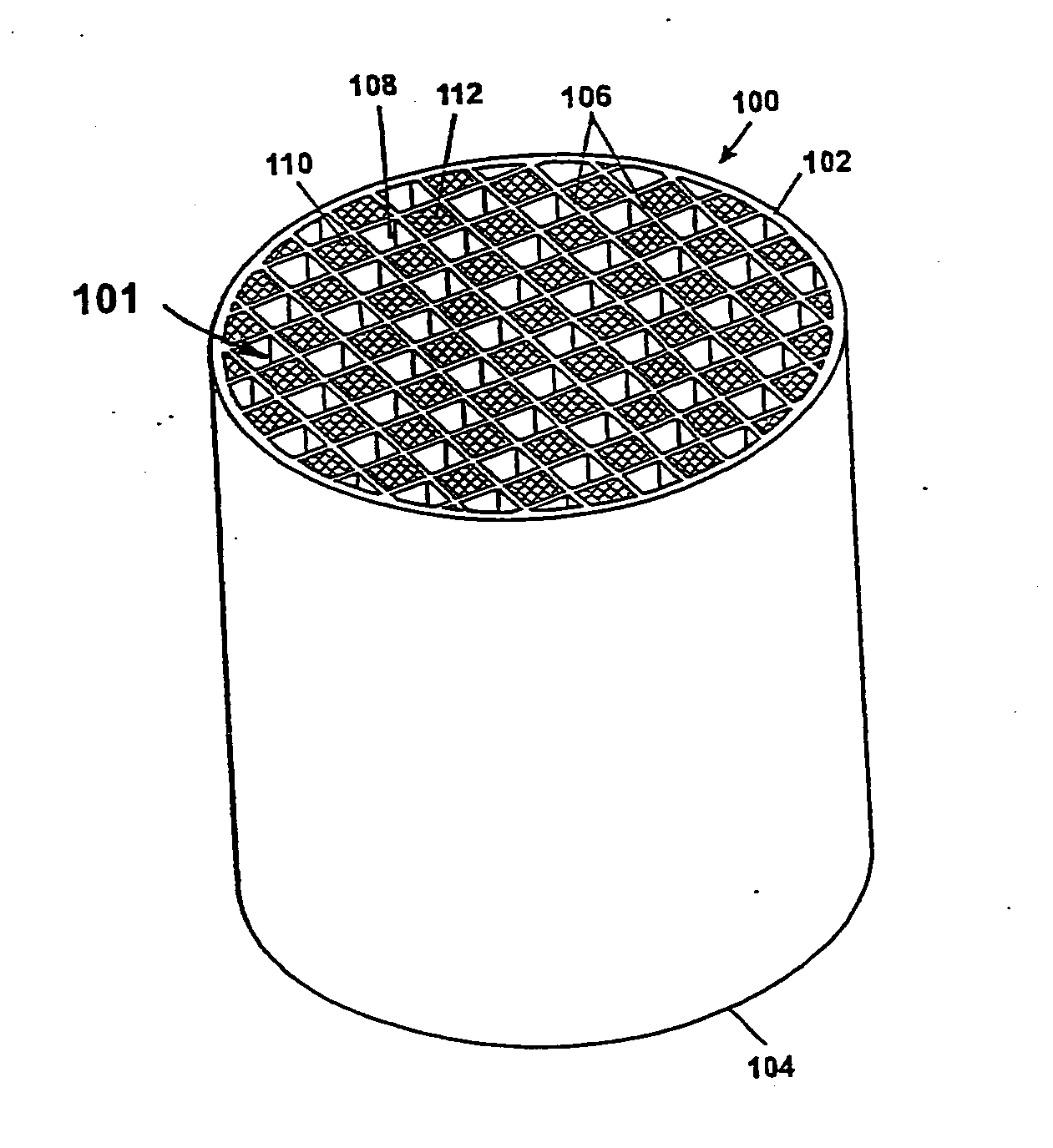

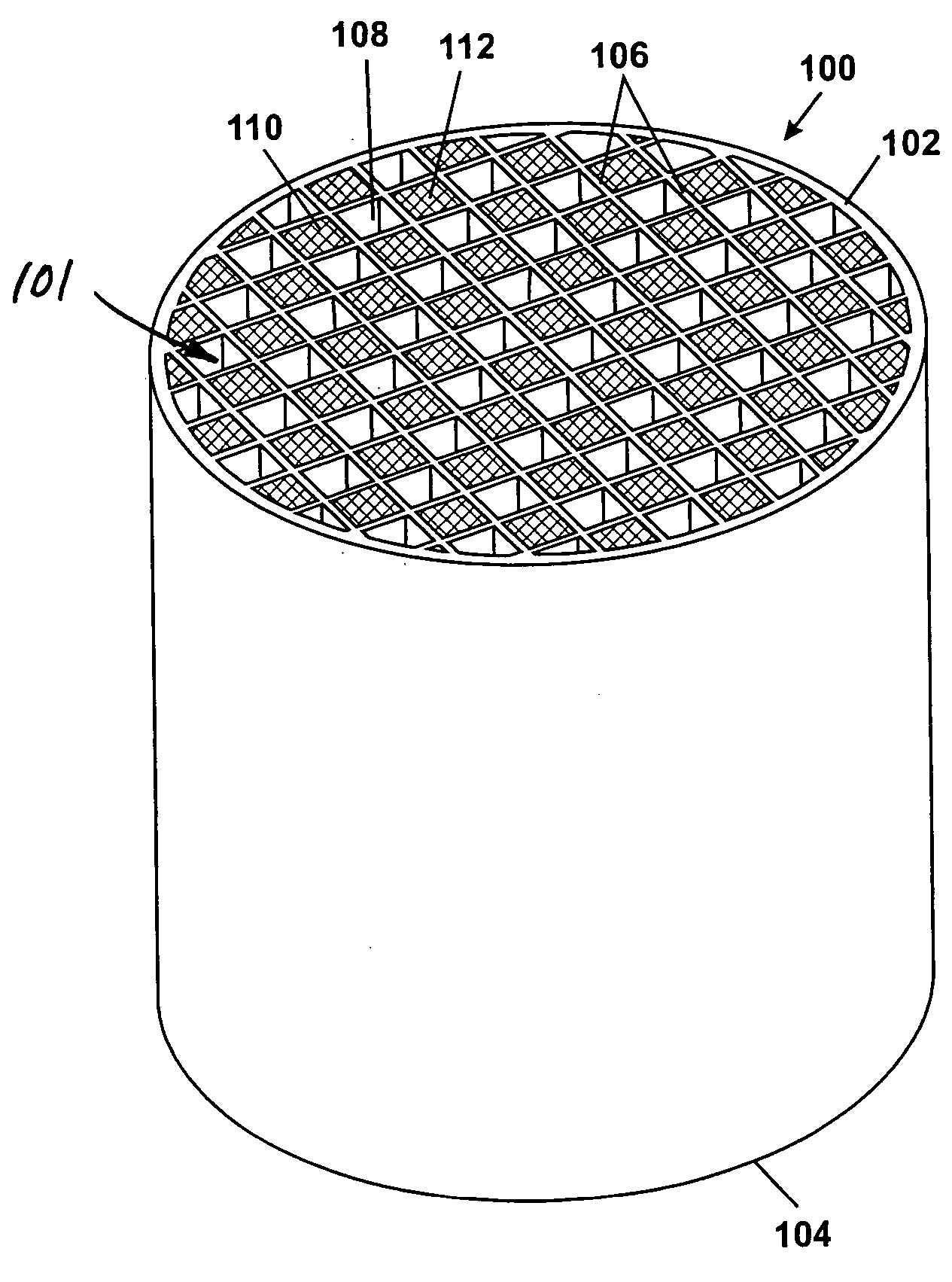

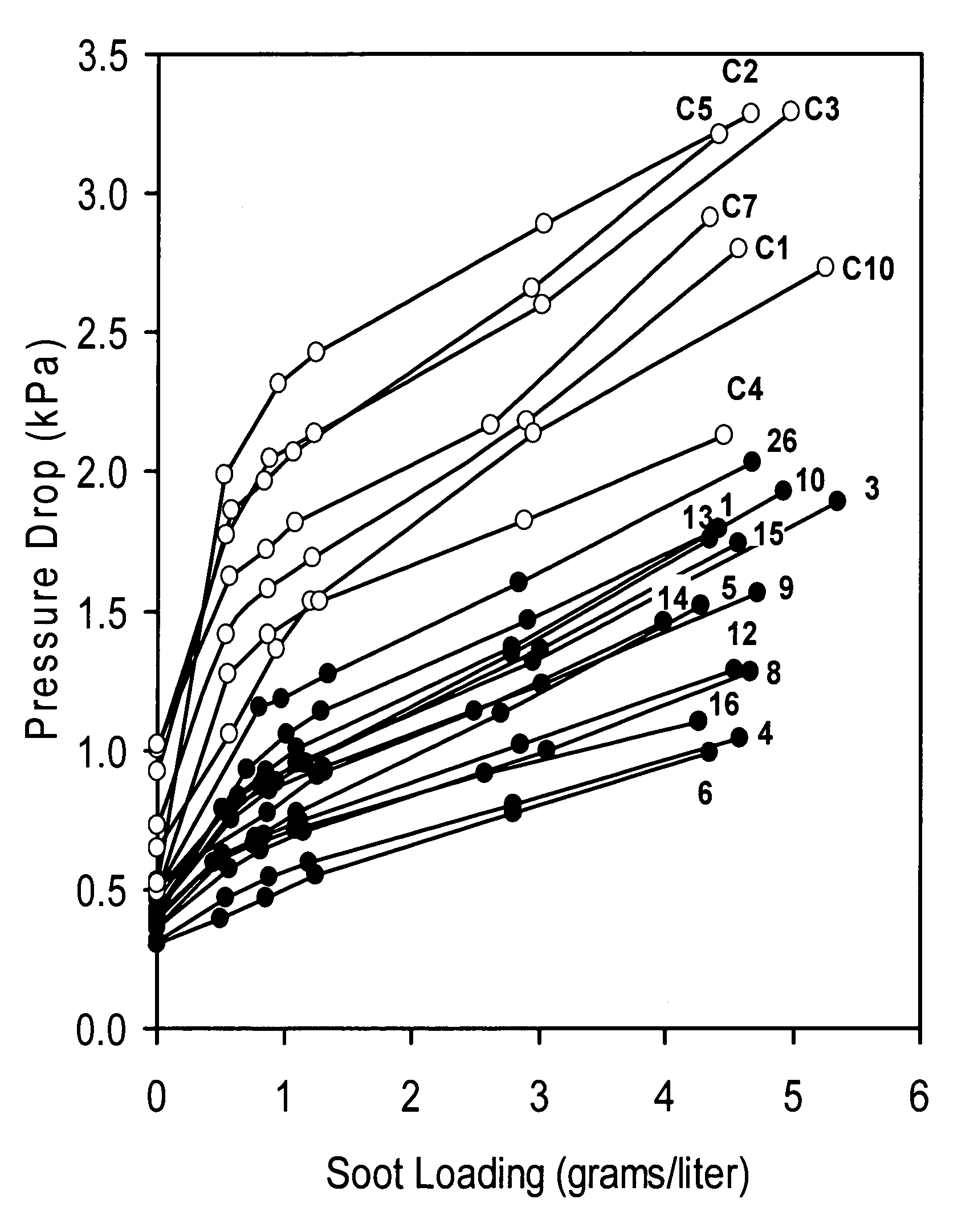

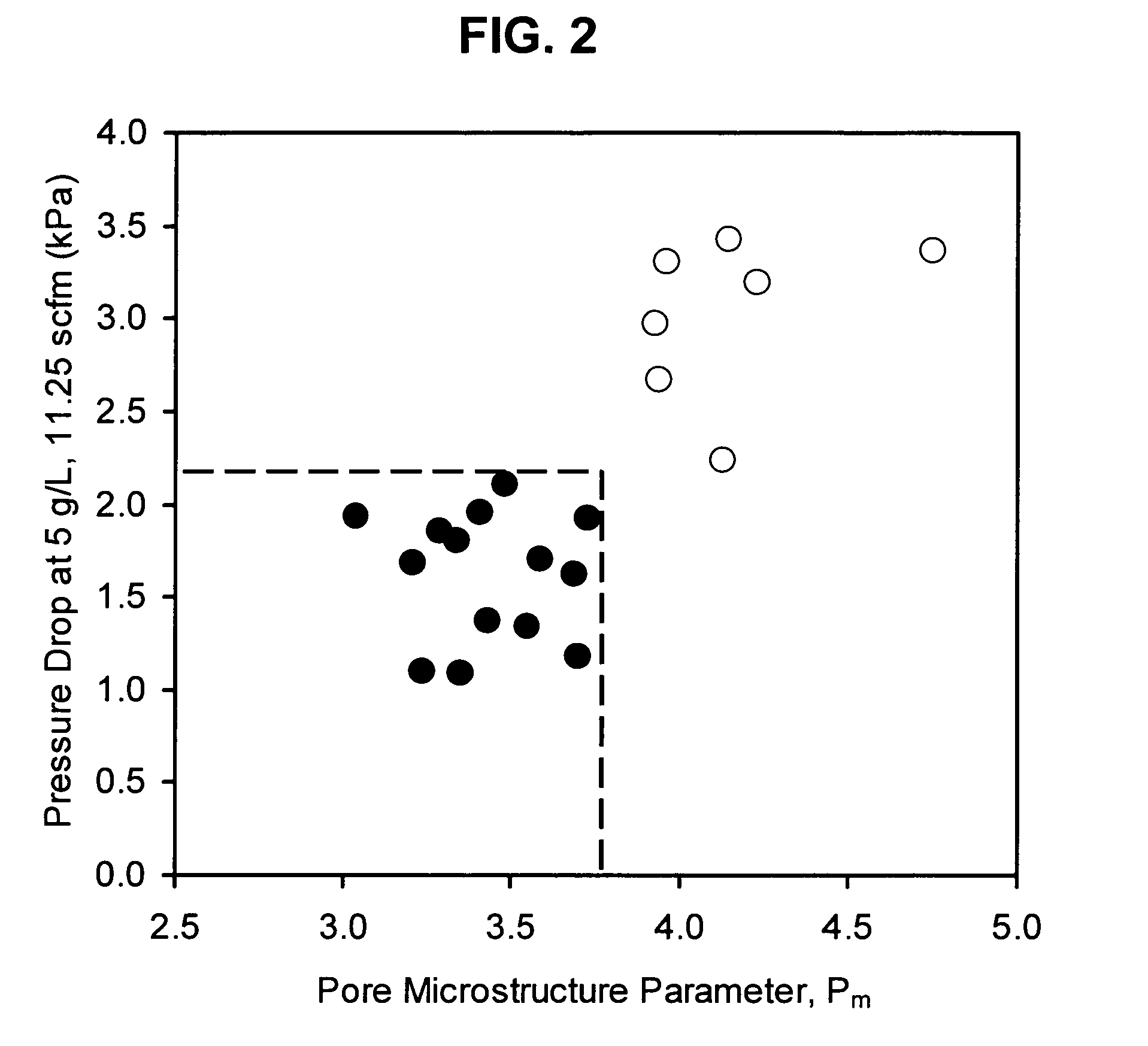

ActiveUS7179316B2Lower overall pressure dropEasy to operateCombination devicesAuxillary pretreatmentMicrometerHoneycomb

A diesel particulate filter comprising a plugged, wall-flow honeycomb filter body composed of cordierite and having a plurality of parallel end-plugged cell channels traversing the body from a frontal inlet end to an outlet end thereof, wherein the filter exhibits a CTE (25–800° C.) of less than 13×10−7 / ° C., a bulk filter density of less than 0.60 g / cm3, a median pore diameter, d50, of less than 25 micrometers, a porosity and pore size distribution that satisfy the relationship Pm≦3.75, wherein Pm is equal to 10.2474{1 / [(d50)2(% porosity / 100)]}+0.0366183(d90)−0.00040119(d90)2+0.468815(100 / % porosity)2+0.0297715(d50)+1.61639(d50−d10) / d50, wherein d10, and d90 are pore diameters at 10% and 90% of the pore size distribution on a volumetric basis, and d10<d50<d90. A method of making the same is also provided.

Owner:CORNING INC

Metal oxide nanorod arrays on monolithic substrates

ActiveUS20140256534A1Improve thermal stabilitySulfur poisoningMolecular sieve catalystsLayered productsCerium(IV) oxideMetal particle

A metal oxide nanorod array structure according to embodiments disclosed herein includes a monolithic substrate having a surface and multiple channels, an interface layer bonded to the surface of the substrate, and a metal oxide nanorod array coupled to the substrate surface via the interface layer. The metal oxide can include ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide. The substrate can include a glass substrate, a plastic substrate, a silicon substrate, a ceramic monolith, and a stainless steel monolith. The ceramic can include cordierite, alumina, tin oxide, and titania. The nanorod array structure can include a perovskite shell, such as a lanthanum-based transition metal oxide, or a metal oxide shell, such as ceria, zinc oxide, tin oxide, alumina, zirconia, cobalt oxide, and gallium oxide, or a coating of metal particles, such as platinum, gold, palladium, rhodium, and ruthenium, over each metal oxide nanorod. Structures can be bonded to the surface of a substrate and resist erosion if exposed to high velocity flow rates.

Owner:UNIV OF CONNECTICUT

Narrow pore size distribution cordierite ceramic honeycomb articles and methods for manufacturing same

ActiveUS20080047243A1Low cleanlinessLow pressureCombination devicesDispersed particle filtrationFiltrationHeat resistance

Disclosed are ceramic honeycomb articles, which are composed predominately of a crystalline phase cordierite composition. The ceramic honeycomb articles possess a microstructure characterized by a unique combination of relatively high total porosity of less than 54%, and relatively narrow pore size distribution having a d10 pore diameter of not less than 8 μm, a d90 pore diameter of not greater than 35 μm, and a value of df=(d50−d10) / d50 of less than 0.50. The articles exhibit high thermal durability and high filtration efficiency coupled with low pressure drop across the filter. Such ceramic articles are particularly well suited for filtration applications, such as diesel exhaust filters or DPFs. Also disclosed are methods for manufacturing the ceramic articles of the present invention.

Owner:CORNING INC

High-temperature smoke selective catalytic reduction (SCR) denitration catalyst, preparation method and application thereof

ActiveCN101961656ALarge specific surface areaAvoid lostPhysical/chemical process catalystsDispersed particle separationAcid strengthCordierites

The invention discloses a high-temperature smoke selective catalytic reduction (SCR) denitration catalyst. The high-temperature smoke SCR denitration catalyst consists of a carrier and an active ingredient loaded on the carrier and is characterized in that: the carrier is a cordierite honey ceramic loaded with a TiO2-SiO2 coating; and the loading capacity of the TiO2-SiO2 coating is 5 to 30 weight percent. The high-temperature smoke SCR denitration catalyst is prepared by loading titanyl sulfate and silica sol serving as raw materials on a cordierite honey ceramic base material by an in-situ precipitation method so as to form the uniform and firm TiO2-SiO2 coating on the surface of the base material, wherein the obtained TiO2-SiO2 coating has high specific surface area and proper acid strength and can effectively promote catalysis.

Owner:ZHEJIANG UNIV OF TECH

Methods for making environmental barrier coatings and ceramic components having cmas mitigation capability

ActiveUS20100159150A1Liquid surface applicatorsMolten spray coatingRare-earth elementALUMINUM PHOSPHATE

Methods of making components having calcium magnesium aluminosilicate (CMAS) mitigation capability involving providing a component; applying an environmental barrier coating to the component, the environmental barrier coating having a separate CMAS mitigation layer including a CMAS mitigation composition selected from rare earth elements, rare earth oxides, zirconia, hafnia partially or fully stabilized with alkaline earth or rare earth elements, zirconia partially or fully stabilized with alkaline earth or rare earth elements, magnesium oxide, cordierite, aluminum phosphate, magnesium silicate, and combinations thereof.

Owner:GENERAL ELECTRIC CO

Geopolymer composites and structures formed therefrom

InactiveUS20060251909A1Improve thermal shock resistancePromote fireAlkali metal silicate coatingsCement productionThermal expansionCordierites

Geopolymer composite materials having low coefficient of thermal expansion are disclosed. The materials are useful in high temperature applications due to their low coefficient of thermal expansion and high strength. Also disclosed is a boron modified water glass geopolymer composition that is compatible with ceramic particulate material such as cordierite and fused silica. The geopolymer composite may be extruded to form structures such as honeycomb monoliths, flow filters or used as a plugging or skinning cement and may be fired at temperatures at or below 1100° C. Both the structures and the cement have high green and fired strength, a low coefficient of thermal expansion, and good acid durability. The cost of manufacturing objects using the material of the present invention is substantially reduced, in comparison with typically production methods of cordierite based bodies, due to the substantially shortened firing times.

Owner:CORNING INC

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

Coating material, ceramic honeycomb structure and method for production thereof

InactiveUS20060121240A1Dispersed particle filtrationLayered productsThird generationVolumetric Mass Density

A coating material of the present invention is a coating material comprising: cordierite powder as a main component having a tap bulk density of 1.3 g / cm3 or more; and water. The coating material is capable of forming a coated wall (outer wall), for example, on the surface of a porous body formed of a ceramic in such a manner that defects such as generation of cracks, and peeling, and a manufacturing yield is satisfactory are not easily generated.

Owner:NGK INSULATORS LTD

Low CTE cordierite honeycomb article and method of manufacturing same

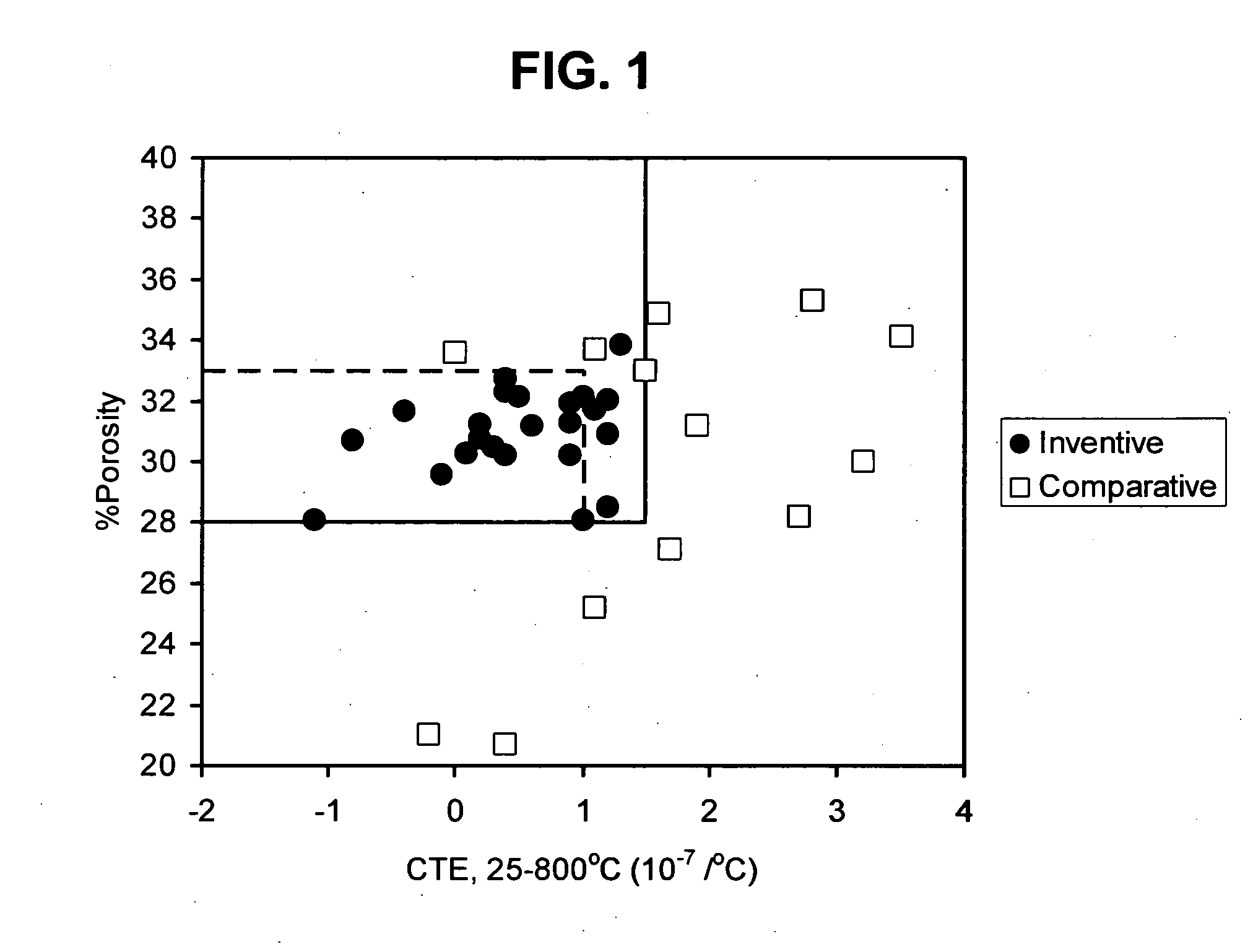

ActiveUS20070141301A1High porosityReduction factorRoof covering using tiles/slatesLayered productsCordieritesPorosity

Disclosed is a honeycomb ceramic article that exhibits a primary crystalline phase of cordierite having a coefficient of thermal expansion (CTE), wherein CTE<1.5×10−7 / ° C. over the temperature range of about 25° C. to about 800° C.; a total porosity, P, of at least 28%, a transverse I-ratio, IT, of less than 0.92; and a pore size distribution wherein at least 60% of the total pore volume is comprised of pores having diameters between 0.5 μm and 5.0 μm. Also provided is a ceramic honeycomb article comprising a phase of cordierite and exhibiting a mean CTE<1.0×10−7 / ° C. (from 25 to 800° C.) in at least one direction, and 28%≦P≦33%. Methods of manufacturing ceramic articles comprising the aforementioned cordierite compositions are also disclosed.

Owner:CORNING INC

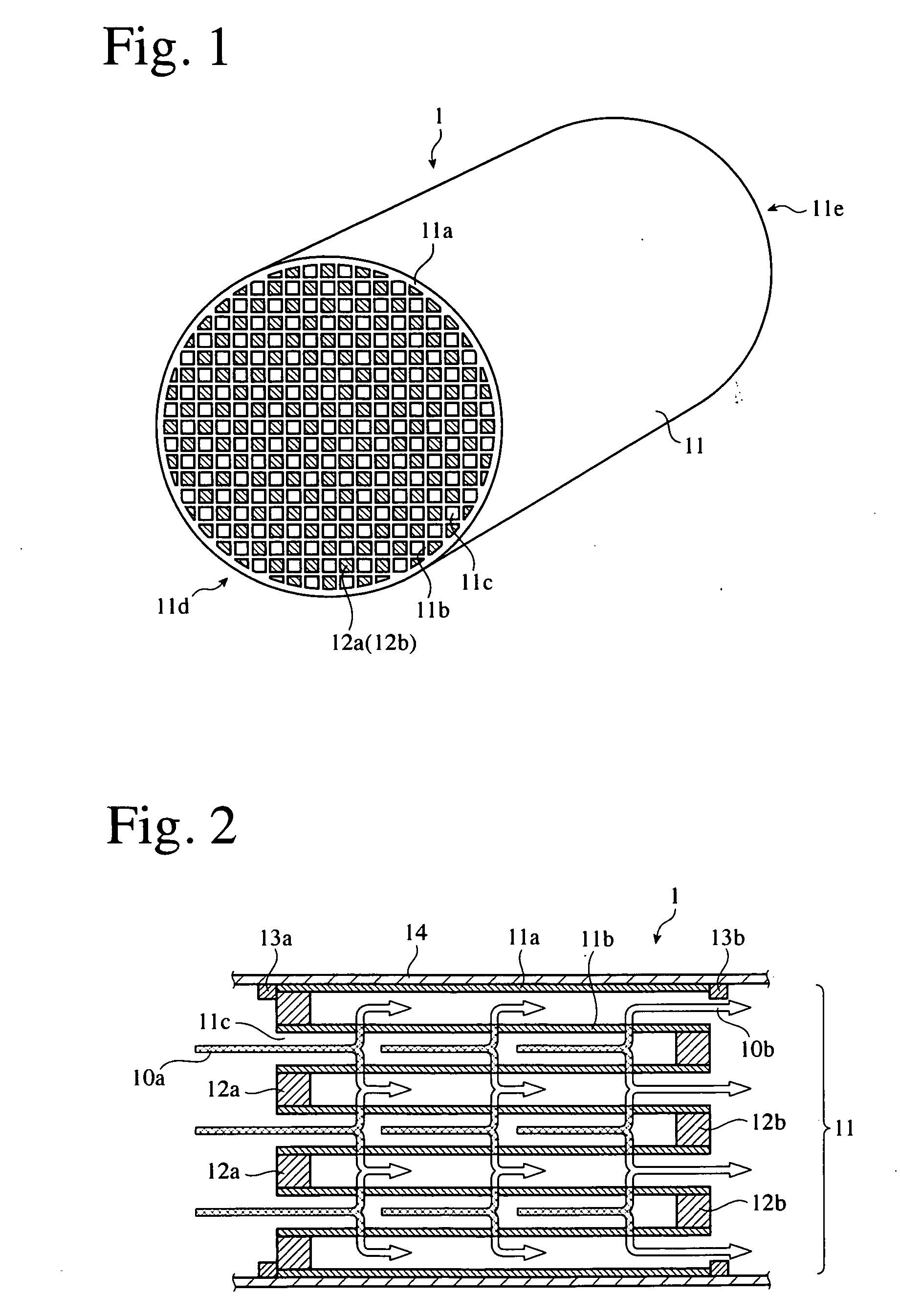

Ceramic honeycomb filter, its production method, and plugging material for ceramic honeycomb filter

ActiveUS20070039298A1Small differenceImprove thermal shock resistanceCombination devicesAuxillary pretreatmentParticulatesOxide matrix

A ceramic honeycomb filter comprising a sintered ceramic honeycomb body having porous partition walls defining flow paths, and plugs formed in predetermined flow paths for removing particulate matter from an exhaust gas passing through the porous partition walls, the sintered ceramic honeycomb body being formed by a cordierite-based ceramic material, at least part of the plugs comprising ceramic particles and an amorphous oxide matrix formed from colloidal oxide.

Owner:HITACHI METALS LTD

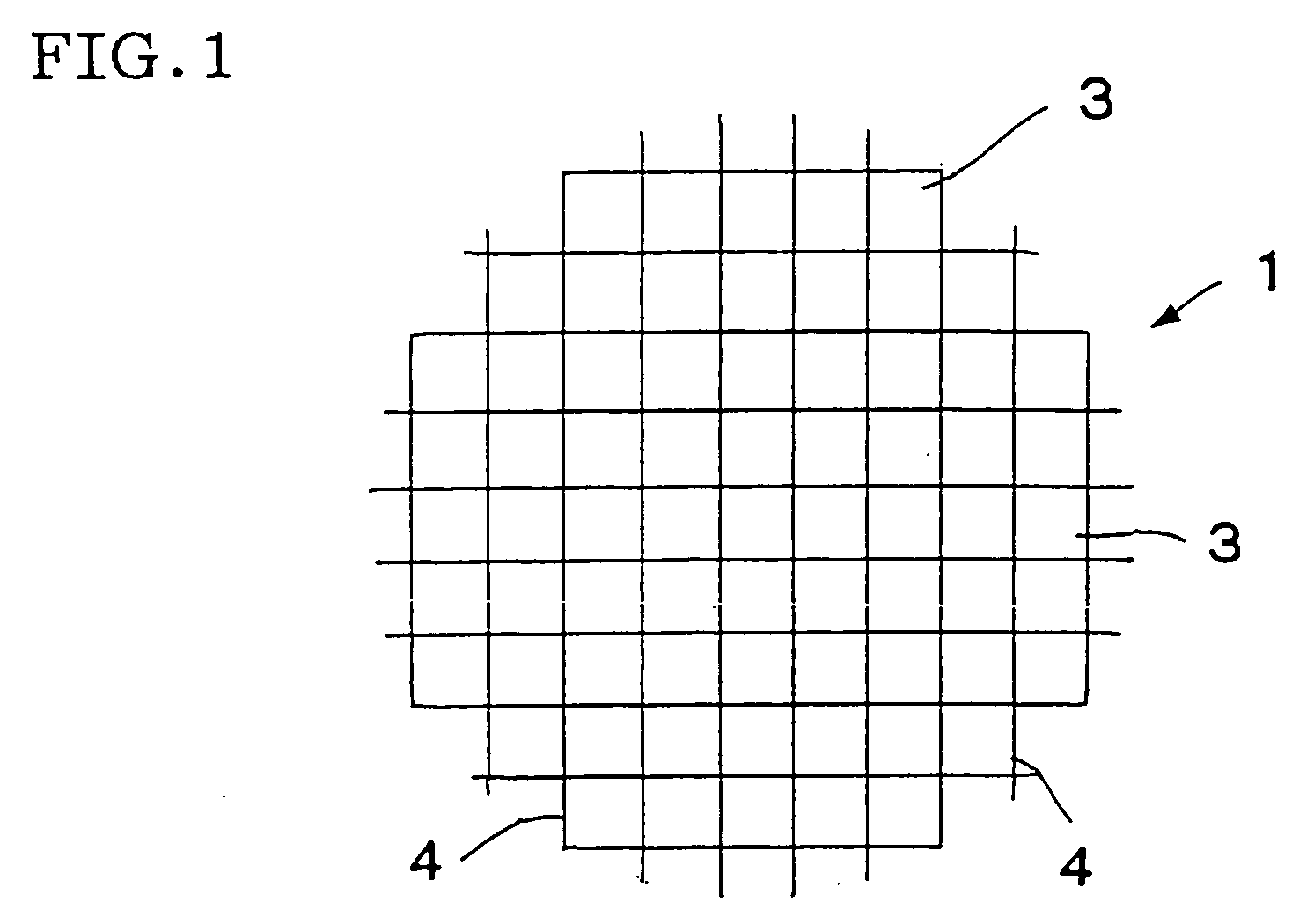

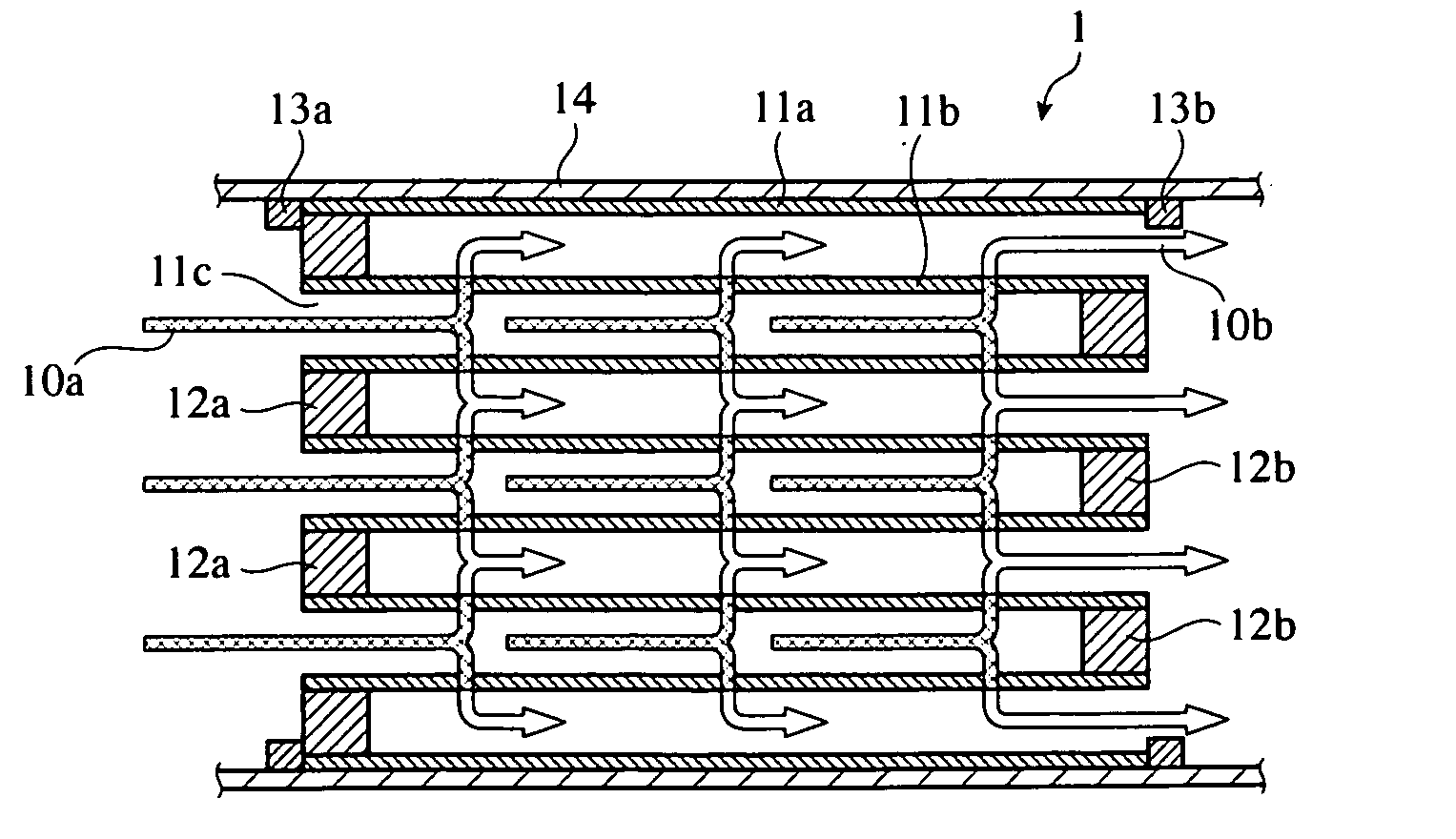

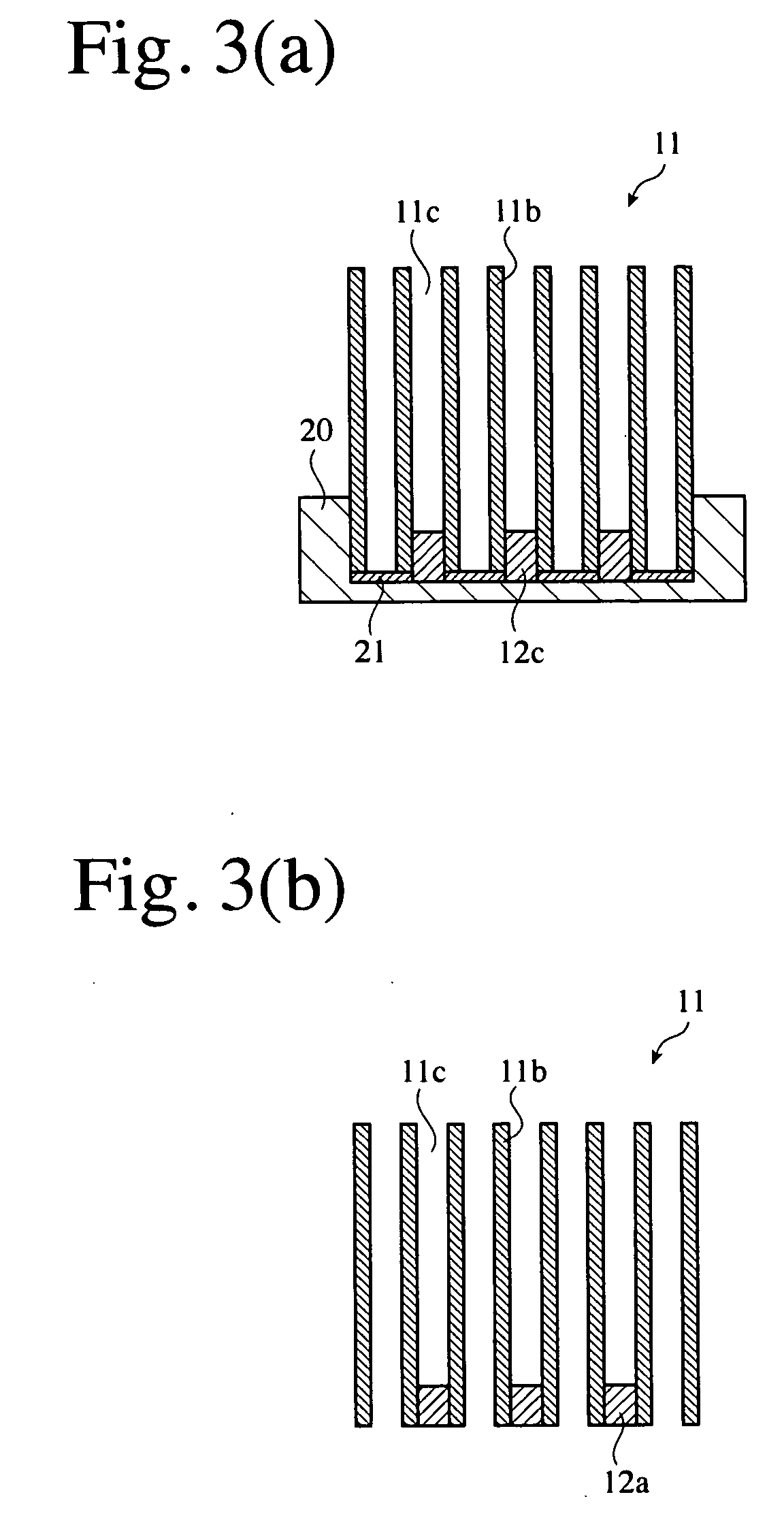

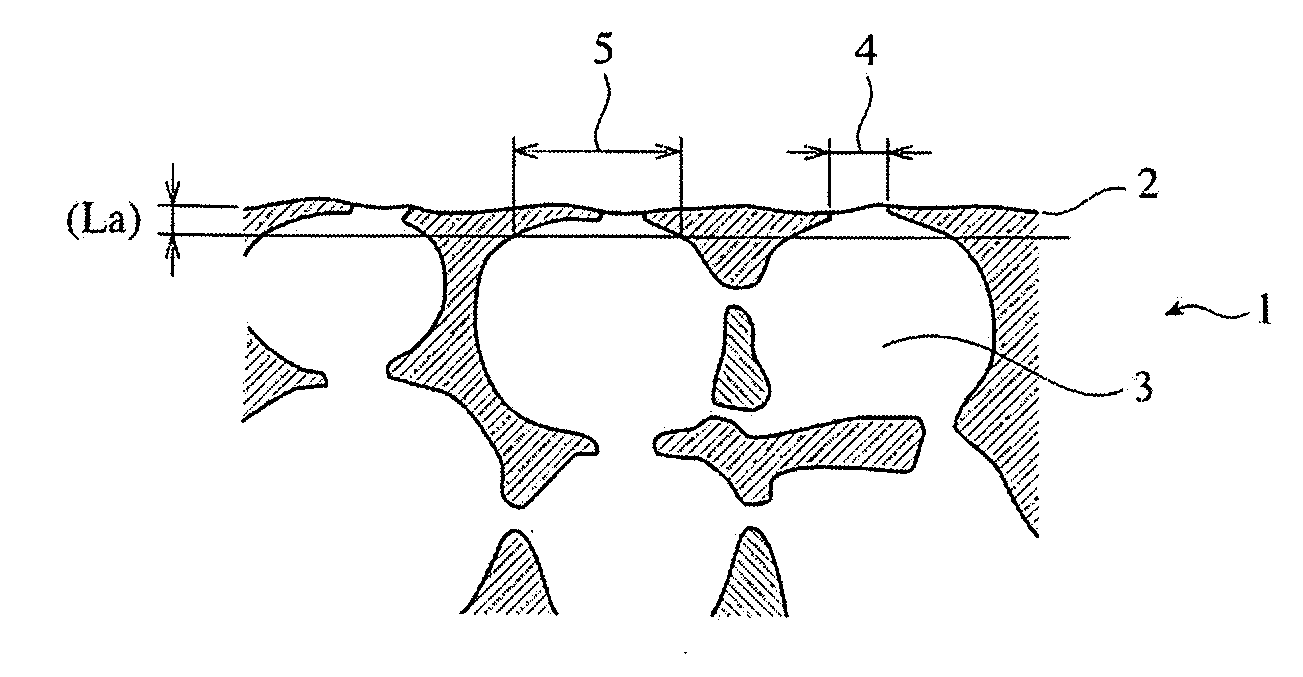

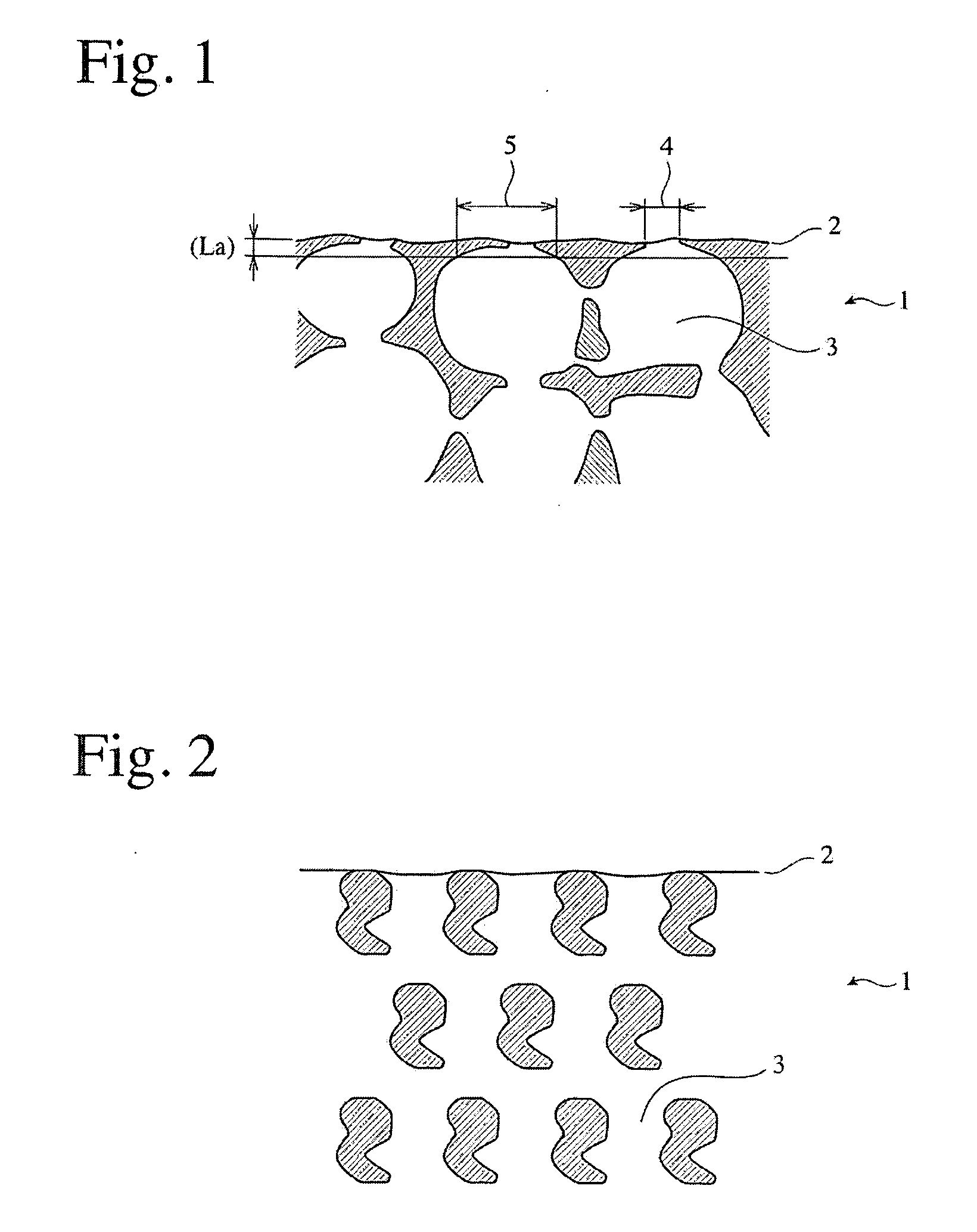

Ceramic honeycomb structure and moldable material usable for its extrusion molding

ActiveUS20070039297A1High particulate-matter-capturing ratioLow pressure lossInternal combustion piston enginesDispersed particle separationX-raySpinel

In a ceramic honeycomb structure having large numbers of flow paths partitioned by porous cell walls, the cell walls have a porosity of 55-75%, with an average pore diameter Da of 10-30 μm and a pore area ratio Sa of 10-30% on their surfaces, and the average length La of the pores at their openings and the average width Lb of the pores at depth La from the surfaces of the cell walls meet the condition of 1.1<Lb / La<5 in an arbitrary vertical cut surface of the cell walls. In the cordierite-based ceramic honeycomb structure, the ceramic contains Fe and a spinel, the amount of the spinel being 4% or less by an X-ray diffraction intensity ratio, and most of the spinel having particle sizes in a range of 0.01-5 μm.

Owner:HITACHI METALS LTD

Porous material and method for production thereof

According to the present invention, a porous material is characterized by comprising: a connected structure formed by combining silicon carbide which is an aggregate with cordierite which is a combining material in a state to hold a large number of pores, and having a porosity of 52 to 70% and a median pore diameter of 15 to 30 μm, and is a porous material having a high porosity and a high strength and having a remarkably low possibility of including defective portions such as cuts and the like causing liquid leakage in a case where the material is used as a filter.

Owner:NGK INSULATORS LTD

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS7520911B2Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 whereinMA=3645(IA)−106(CTE)+19(d90)+17(% porosity),MT=4711(IT)+116(CTE)−26(d90)−28(% porosity),and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

Methods for making environmental barrier coatings and ceramic components having CMAS mitigation capability

Methods of making components having calcium magnesium aluminosilicate (CMAS) mitigation capability involving providing a component; applying an environmental barrier coating to the component, the environmental barrier coating having a separate CMAS mitigation layer including a CMAS mitigation composition selected from rare earth elements, rare earth oxides, zirconia, hafnia partially or fully stabilized with alkaline earth or rare earth elements, zirconia partially or fully stabilized with alkaline earth or rare earth elements, magnesium oxide, cordierite, aluminum phosphate, magnesium silicate, and combinations thereof.

Owner:GENERAL ELECTRIC CO

High porosity cordierite ceramic honeycomb article and method

ActiveUS20070142208A1High porosityHigh filtration efficiencyCeramic shaping apparatusCeramicwarePorosityParticulates

The present invention provides materials and methods for the manufacture of high porosity ceramic exhaust filters employing relatively low amounts of pore formers, the filters combining efficient diesel particulate filtration with effective support for exhaust emissions control catalysts. Cordierite-forming ceramic batches comprising non-hydrated transition alumina powders of relatively large particle size provide high porosities with well-controlled pore sizes and with low filter thermal expansion coefficients and good mechanical strengths.

Owner:CORNING INC

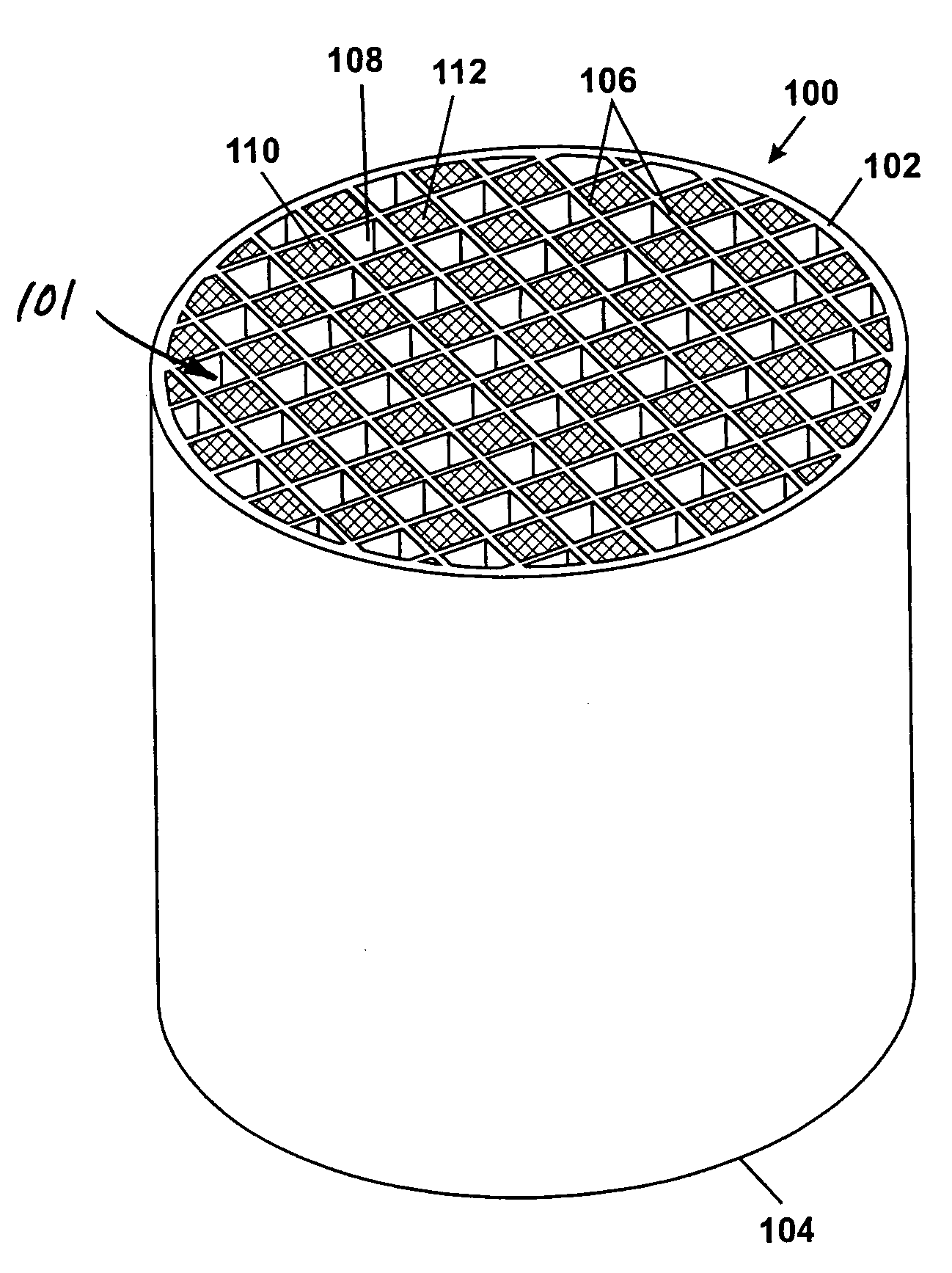

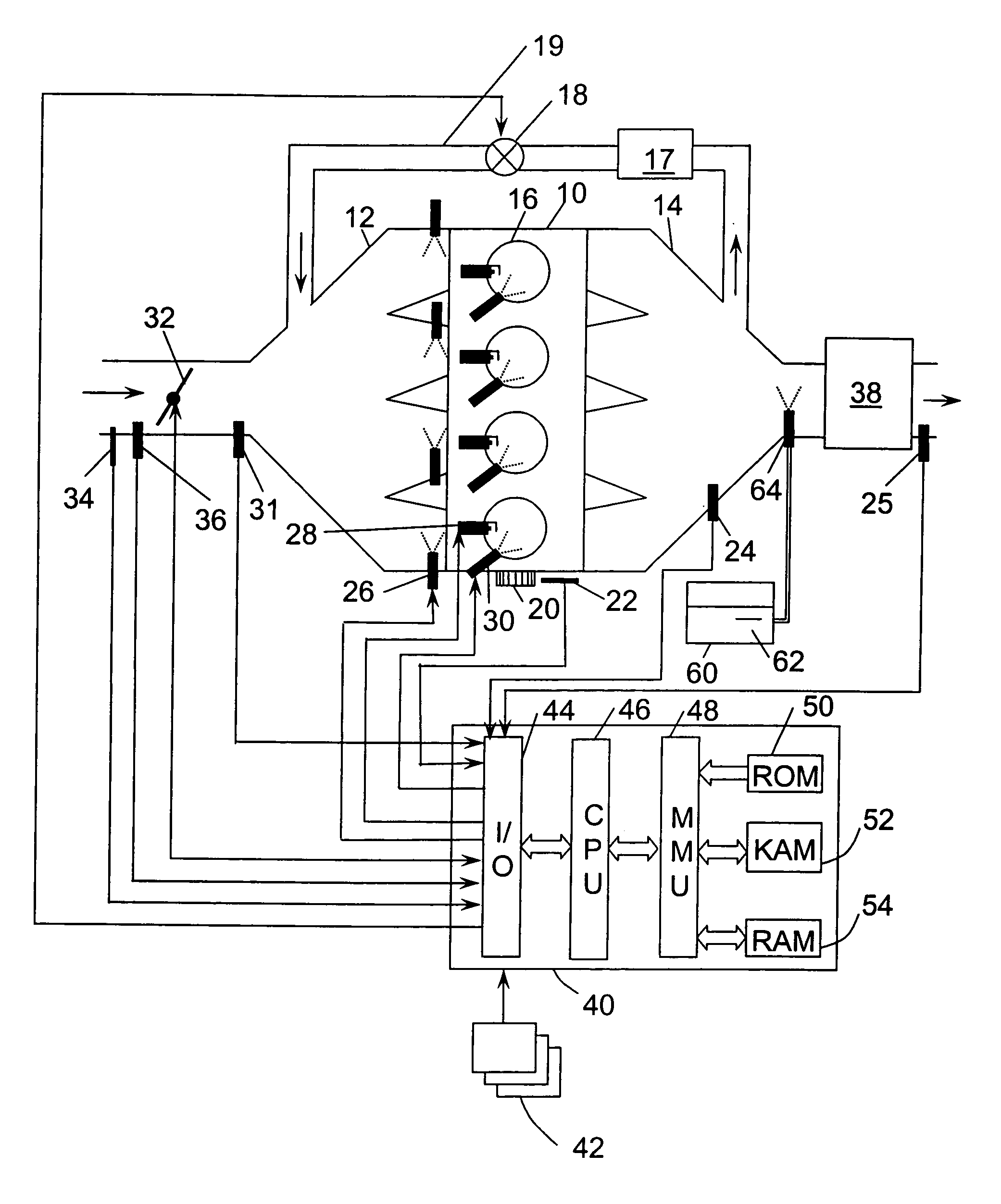

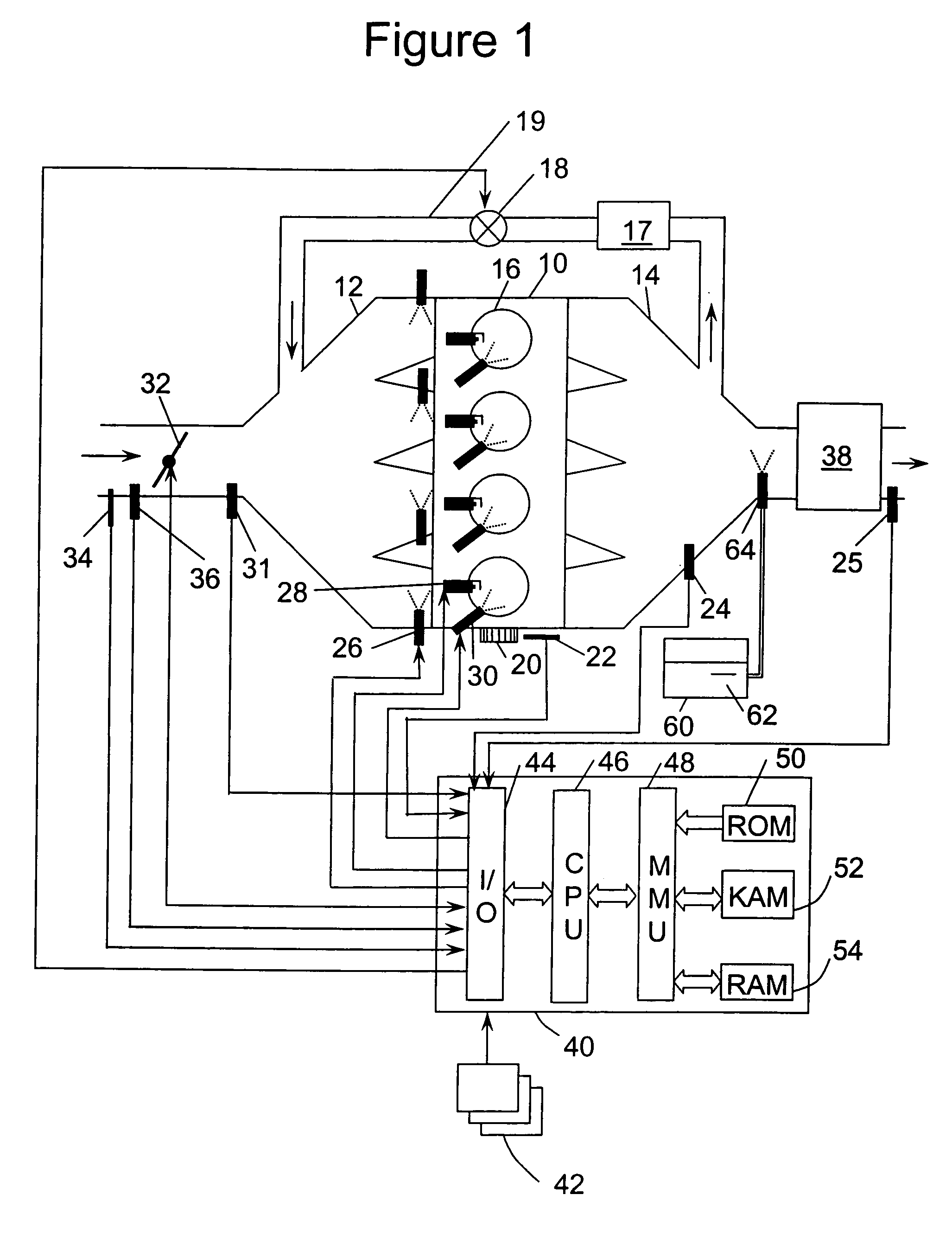

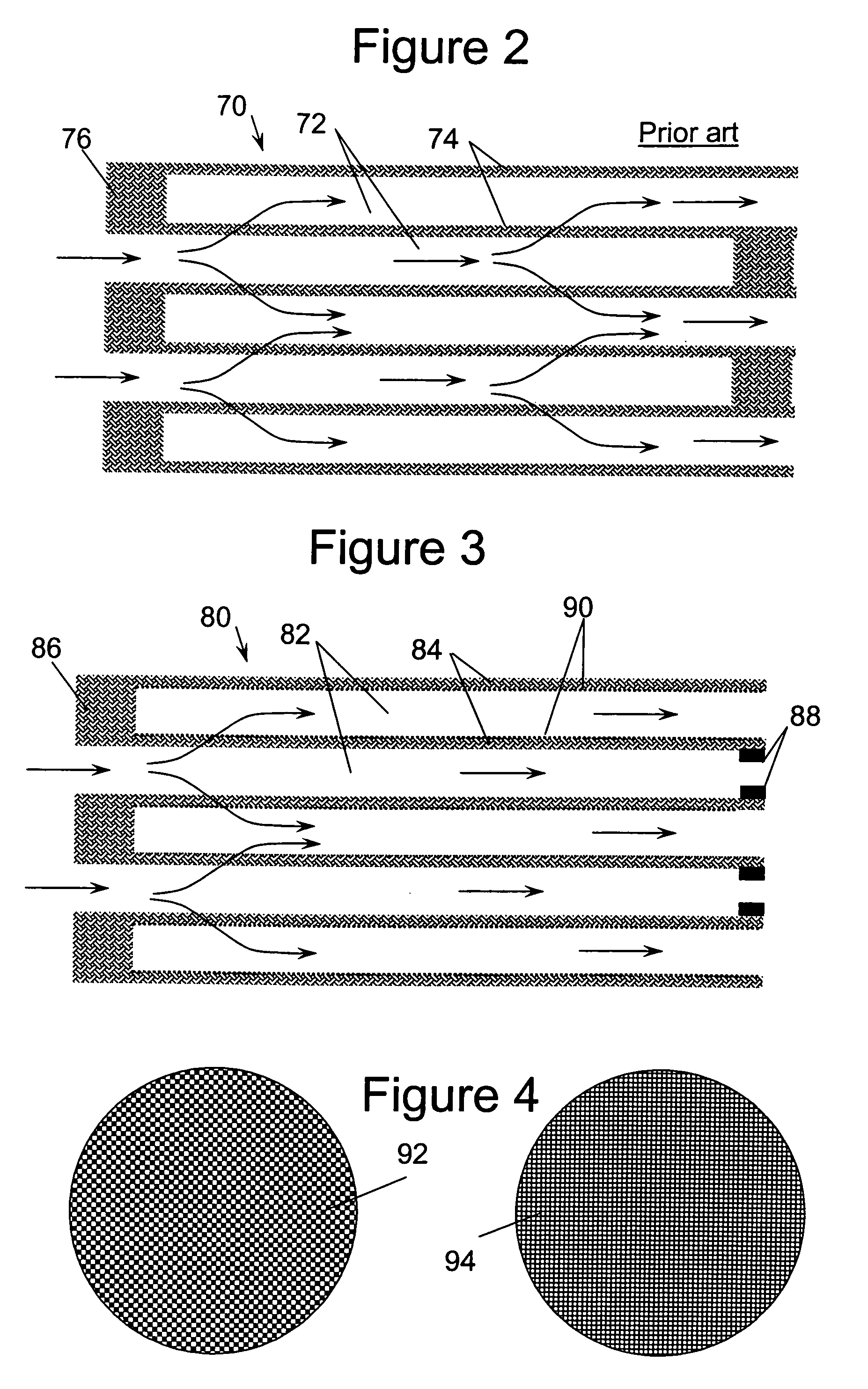

Exhaust aftertreatment device

InactiveUS20060251548A1Easy to controlEasy to manufactureCombination devicesInternal combustion piston enginesInternal combustion engineCordierites

An exhaust aftertreatment device for an internal combustion engine is disclosed which contains multiple, parallel channels of a porous material, such as cordierite or silicon carbide, in which about some of the channels are plugged at an upstream end and other channels remain unplugged. In one embodiment, the substrate has an SCR coating and the engine has a urea supply system. Other embodiments include using TWC and LNT formulations. Several washcoat configurations and other specific geometries and dimensions to encourage crossflow, diffusion, and adsorption are disclosed herein.

Owner:FORD GLOBAL TECH LLC

Method of manufacturing honeycomb structure and honeycomb structure

ActiveUS20050221053A1Reduce and prevent generationPrevent and inhibit pollutionPhysical/chemical process catalystsLayered productsClay mineralsPotassium

There are provided a honeycomb structure and a method of manufacturing the structure, capable of preventing or reducing generation of CO2 or harmful gas during firing to thereby prevent or inhibit pollution and global warming, and capable of obtaining a honeycomb structure having few defects such as cracks and maintaining high strength and low thermal expansion. In a method of manufacturing a honeycomb structure, in which a forming material containing a cordierite forming material and an organic binder is kneaded and formed to prepare a honeycomb-shaped formed article (honeycomb formed article), and the prepared honeycomb formed article is fired to obtain a honeycomb-shaped structure (honeycomb structure) mainly composed of cordierite: the forming material containing a layered clay mineral whose layer charge (X) is 0.2<X≦2 in addition to the cordierite forming material and the organic binder is used; a total amount of at least one element selected from a group consisting of sodium, potassium, and calcium contained in the layered clay mineral is set to 0.5% by mass or less in terms of oxide with respect to a total with the cordierite forming material; and a content ratio of the organic binder is set to 5 parts by mass or less with respect to 100 parts by mass in total of the cordierite forming material and the layered clay mineral.

Owner:NGK INSULATORS LTD

Process for producing honeycomb structure

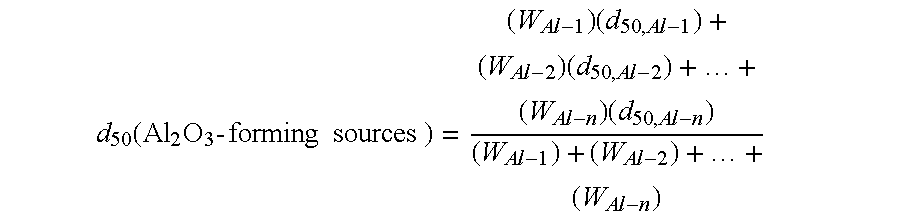

ActiveUS20090011919A1High porosityPhysical/chemical process catalystsExhaust apparatusGranularityCordierites

A process for producing a honeycomb structure by obtaining clay from a cordierite-forming raw material containing an alumina source, a silica source, and a magnesia source; and forming the clay into a honeycomb shape, wherein a material having, in its volume particle size distribution, a 50 volume % particle size (V50) [μm] of 1 to 25 μm is used, as each of alumina source, silica source, and magnesia source; and a material having, in the volume particle size distribution of the whole cordierite-forming raw material, a ratio of 90 volume % particle size (Vall90) [μm] to 10 volume % particle size (Vall10) [μm] [a volume particle size distribution ratio (Vall90 / Vall10)] of 10 or less and a difference (Vall90−Vall10) between 90 volume % particle size (Vall90) [μm] and 10 volume % particle size (Vall10) [μm] of 25 μm or less is used, as the cordierite-forming raw material.

Owner:NGK INSULATORS LTD

Porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and preparation method thereof

ActiveCN104844264ASolve the strength problemSolve the problem of easy wear and tearCeramicwareHeat carrierCarnallite

The invention discloses a porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and belongs to the technical field of porous functional ceramic. A natural inorganic catalyst is taken as an active ingredient of the porous ceramic-loaded catalyst, is subjected to smashing, grinding, and screening, and is mixed with a ceramic aggregate, a pore forming agent, and a binder at a mass ratio of 30-40:40-50:5-10:10-15; an obtained mixture is processed so as to obtain a porous ceramic body material; the porous ceramic body material is subjected to drying, sintering, and activation so as to obtain the porous ceramic-loaded catalyst; wherein the active ingredient is one or a combination of a plurality of ingredients selected from dolomite, limestone, diatomite, kaoline, olivine, cordierite, montmorillonite, hydrotalcite, carnallite, beryl, celestite, and gypsum at random, and dolomite and montmorillonite preferably. The porous ceramic prepared via above steps can be taken as a catalyst of biomass pyrolysis liquidation processes and a reactor internal heat carrier at the same time, possesses activity on biomass pyrolysis processes, is capable of increasing bio oil yield, improving bio oil quality, and reducing biomass pyrolysis reaction conditions.

Owner:SHANDONG UNIV OF TECH

Production method of anti-bacterial external wall tiles

The invention provides a production method of anti-bacterial external wall tiles, wherein a glazing layer is applied on the tiles through the following steps: (A) spraying a ground glaze layer on a bottom green body, naturally air-drying the ground glaze layer to immobilize it; (B) spraying a layer of active water repellent to form a layer of hydrocarbon chains being hydrophobic; (C) spraying a cover glaze slurry, naturally air-drying the cover glaze slurry to form an antibacterial glaze slurry layer; and (D) spraying a protective glaze insulating layer. The cover glaze includes, by weight, 29% of quartz powder; 20% of potassium feldspar, 10% of wollastonite, 5.5% of calcite, 4% of dolomite, 2.5% of cordierite, 5% of zirconium phosphate, 6.5% of aluminum oxide, 2% of zinc oxide, 4.5% of a frit, 5% of zirconium silicate and 8% of titanium oxide. The anti-bacterial external wall tile is a novel functional ceramic product, has the anti-bacterial, mildew-proofing, decomposition and deodorization effects, can avoid invasion to human from various infections, can keep the external wall of buildings to be clean and can avoid mildew pollution.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Method for preparing integral biomass gasified tarcracking catalyst

ActiveCN1935380AHigh activityHigh reaction space velocityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCordieritesVacuum pump

The present invention provides a preparation method of integral type biomass tar cracking catalyst with high reaction intensity, high tar cracking rate and good selectivity. Said method includes the following steps: (1), using oxalic acid to treat carrier: placing the cordierite in the constant-boiling oxalic acid solution whose concentration is 30-40%, treating for 20-30 min, drying and calcining; (2),coating liquor coating: making nano-grade gamma-Al2O3 be mixed with ethyl alcohol and water, grinding them, placing the above-mentioned cordierite into the above-mentioned solution, soaking said cordierite, at the same time vacuum pumping for 40-60 min, taking out residue, ageing, drying, calcining and repeatedly coating to make the coating rate be reached to 8-15%; (3), soaking by using active component solution: preparing Ni(NO3)2 solution, soaking the above-mentioned cordierite in the above-mentioned solution, ageing, drying, calcining and repeatedly coating to make its coating rate be up to above 5%.

Owner:茂名市泓宇能源科技有限公司

Low-melting lead-free solder glass and uses thereof

The low melting solder glass contains, in wt. % on an oxide basis, >1-2, SiO2; 5-10, B2O3; 4.5-12, ZnO; 79-88, Bi2O3; and 0.6-2, Al2O3, and a weight ratio of SiO2 to Al2O3 of <2. The solder glass preferably contains from 80.5 to 85 wt. % of Bi2O3 and is free of lead. This solder glass has a linear thermal expansion coefficient α(20-300) of <11.5×10−6 / K and a transformation temperature Tg of <380° C. A solder glass preparation for connecting or sealing a glass part with a metal part contains the low melting solder glass and up to 20 wt. % of β-eukryptite, cordierite, mullite, willemite or zircon.

Owner:SCHOTT AG

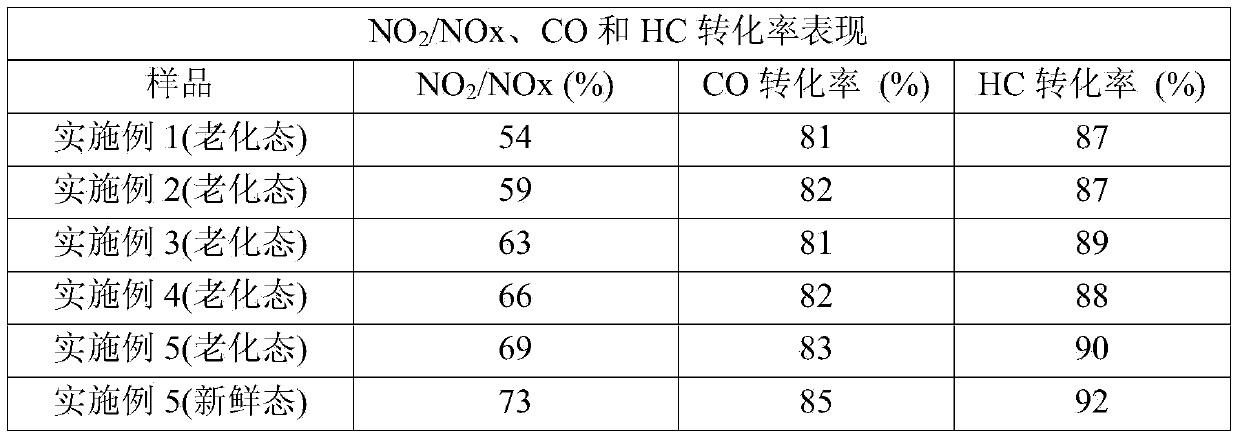

Preparation method for oxidation catalyst used for purifying diesel exhaust

ActiveCN103752338AIncrease oxidation rateImprove thermal stabilityMolecular sieve catalystsDispersed particle separationGas phaseHeat stability

The invention relates to a preparation method for an oxidation catalyst used for purifying diesel exhaust and belongs to the technical field of catalysis. The catalyst has a higher conversion ratio to hydrocarbon and carbon monoxide inside the diesel exhaust, and can be used for oxidizing nitric oxide into nitrogen dioxide. The catalyst takes cordierite honeycomb ceramics or Fe-Cr-Al metallic honeycombs as a base body, takes a titanium, silicon and aluminum composite oxide and a molecular sieve as coating layers, and takes Pt or / and Pd as an active component. The catalyst is divided into two layers adopting use levels of Pt and Pd in varying proportions, so as to adjust the proportion of the nitrogen dioxide in the exhaust. The oxidation catalyst can effectively lower HC and CO of gaseous phases in diesel engine exhaust, can effectively improve the oxygenation efficiency of NO, and has better heat stability.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com