Preparation method for oxidation catalyst used for purifying diesel exhaust

An oxidation catalyst and diesel engine technology, applied in the field of catalysis, can solve problems such as catalyst deactivation, and achieve the effect of improving oxidation rate and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

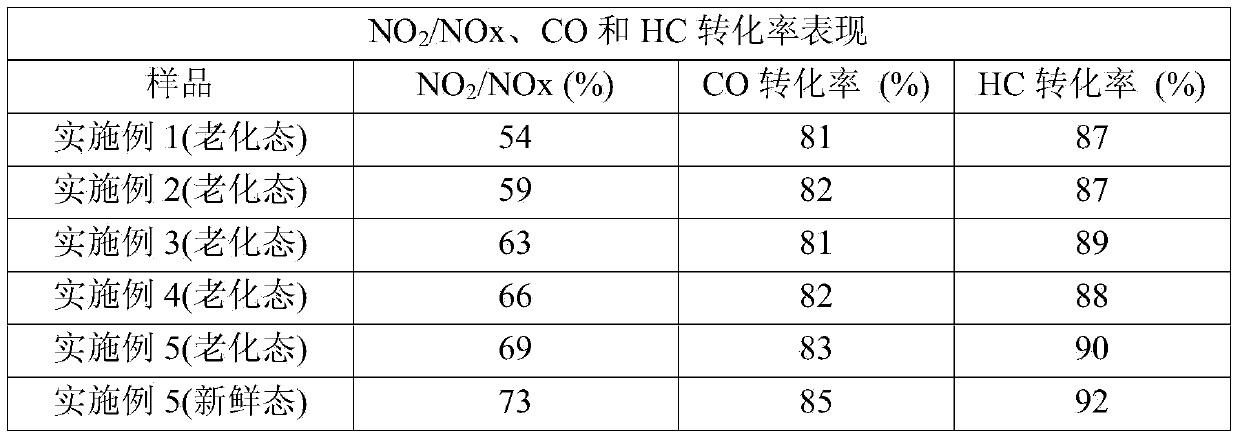

Examples

Embodiment 1

[0026] The catalyst consists of three parts: carrier, coating and noble metal. The catalyst carrier is cordierite honeycomb ceramics with a volume of 1.101L and a pore density of 400 mesh / square foot; the coating contains titanium-silicon-aluminum composite oxide and molecular sieve, and the coating amount is 150 g / L; the used The precious metal is platinum or / and palladium, the total coating amount of precious metal is 3.9 g / L, and the mass ratio of Pt to Pd is 1:2.

[0027] (1) Preparation of the first coating slurry: Take the material according to the titanium-silicon-aluminum composite oxide: water mass ratio of 4:3, stir evenly to form a slurry; use the ball milling process to process the slurry to control the particle size D 90 At 5 μm, a first coating slurry was prepared;

[0028] (2) Preparation of the first precious metal solution: adding precious metals to the first coating slurry obtained in step (1); wherein the mass ratio of noble metal platinum: noble metal pall...

Embodiment 2

[0035] The specific preparation method and activity test are basically the same as in Example 1, except that the mass ratio of Pt:Pd in the total precious metal coating amount is 1:1.

Embodiment 3

[0037] The specific preparation method and activity test are basically the same as in Example 1, except that the mass ratio of Pt:Pd in the total precious metal coating amount is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Coating amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com