Multi-bed type ventilation air methane regenerative thermal oxidation device

An oxidation device and wind gas technology, applied in gas discharge, safety devices, incinerators, etc., can solve the problems of reducing the average oxidation rate of the device, unqualified purified gas, gas short-circuit, etc., to avoid uneven internal airflow, treatment The effect of reducing the amount of methane and improving the oxidation rate of methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

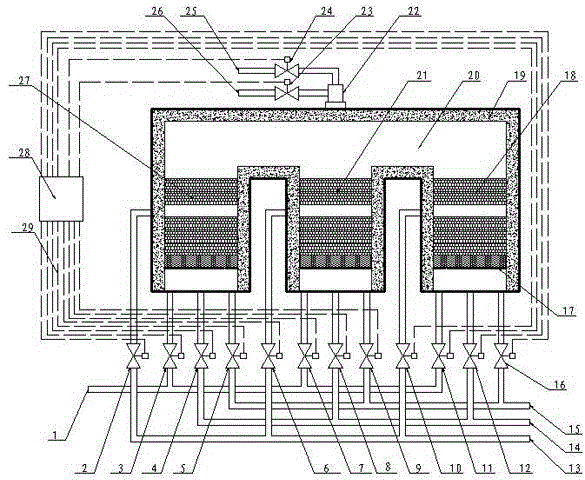

[0021] Such as figure 1 As shown, the embodiment takes a three-bed structure as an example. In the figure: 1. The exhaust air inlet pipe 2, the exhaust valve 3, the intake switching valve 4, the outlet switching valve 5, the purge valve 6, Exhaust valve two 7, inlet switch valve two 8, outlet switch valve two 9, purge valve two 10, exhaust valve three 11, intake switch valve three 12, outlet switch valve three 13, flue gas extraction pipeline 14 , Flue gas outlet pipe 15, purge pipeline 16, purge valve three 17, support grid 18, oxidation bed three 19, thermal insulation refractory material 20, combustion chamber 21, oxidation bed two 22, preheater 23, combustion air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com