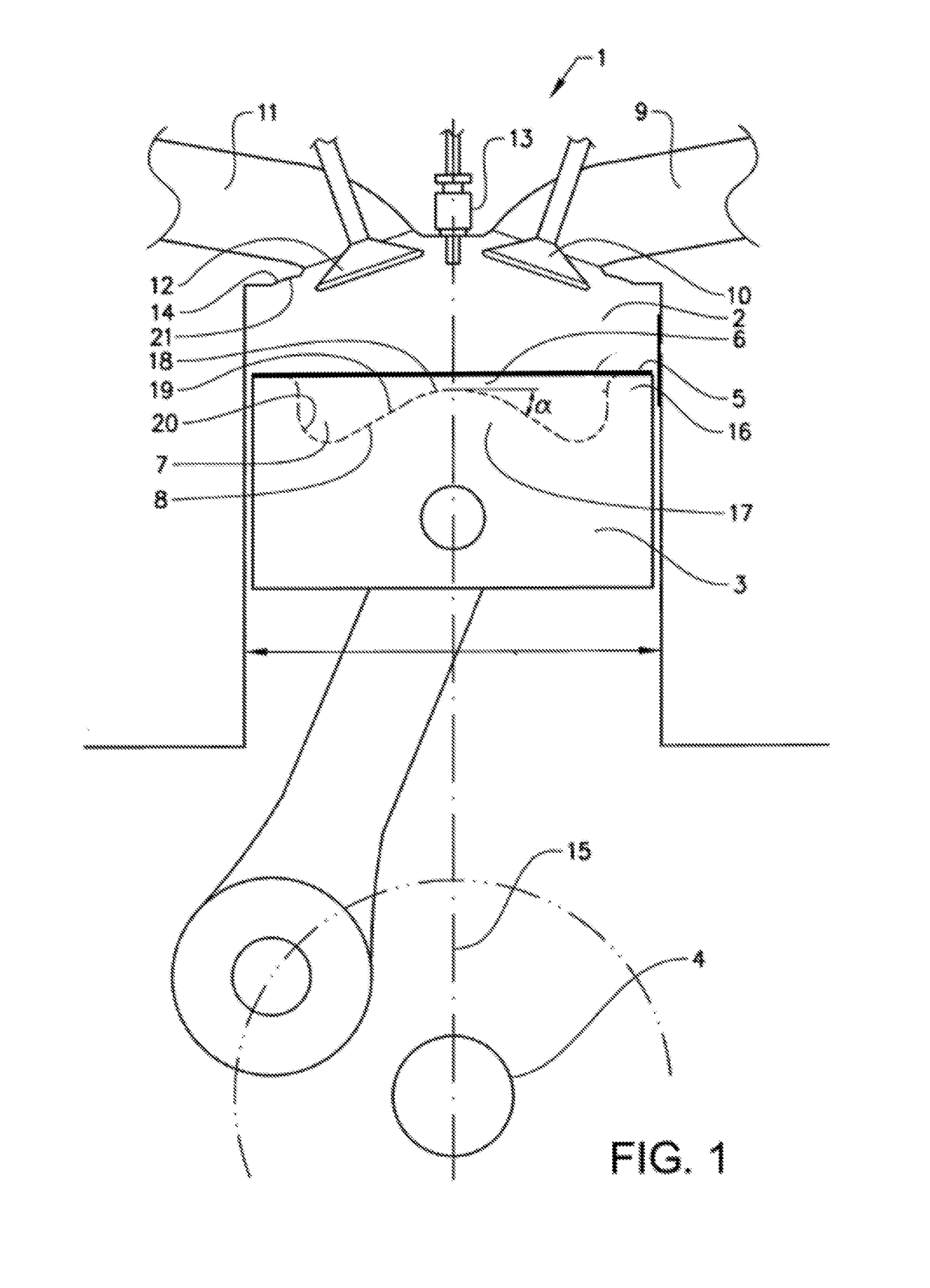

Patents

Literature

39results about How to "Reduce smoke and dust emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

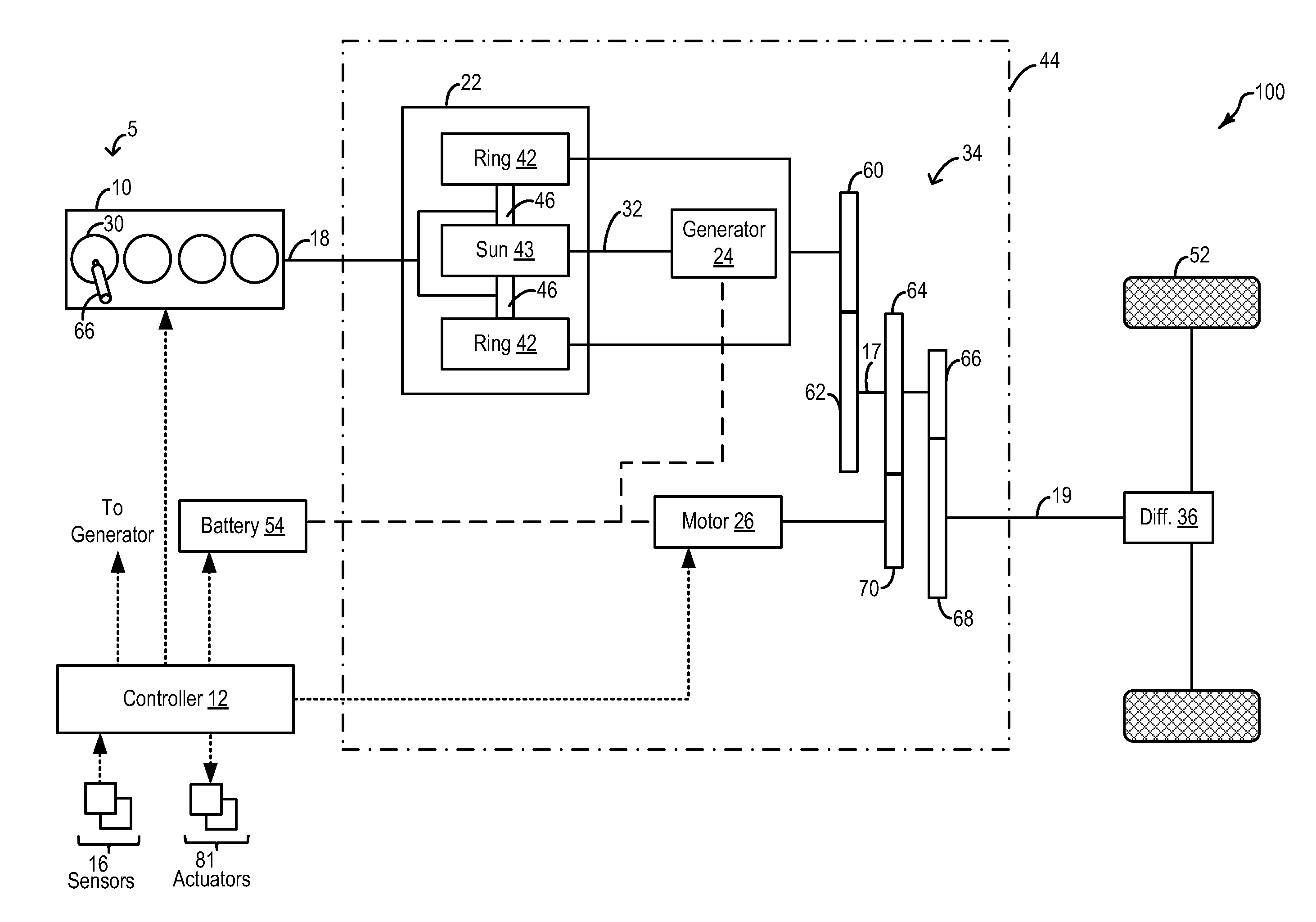

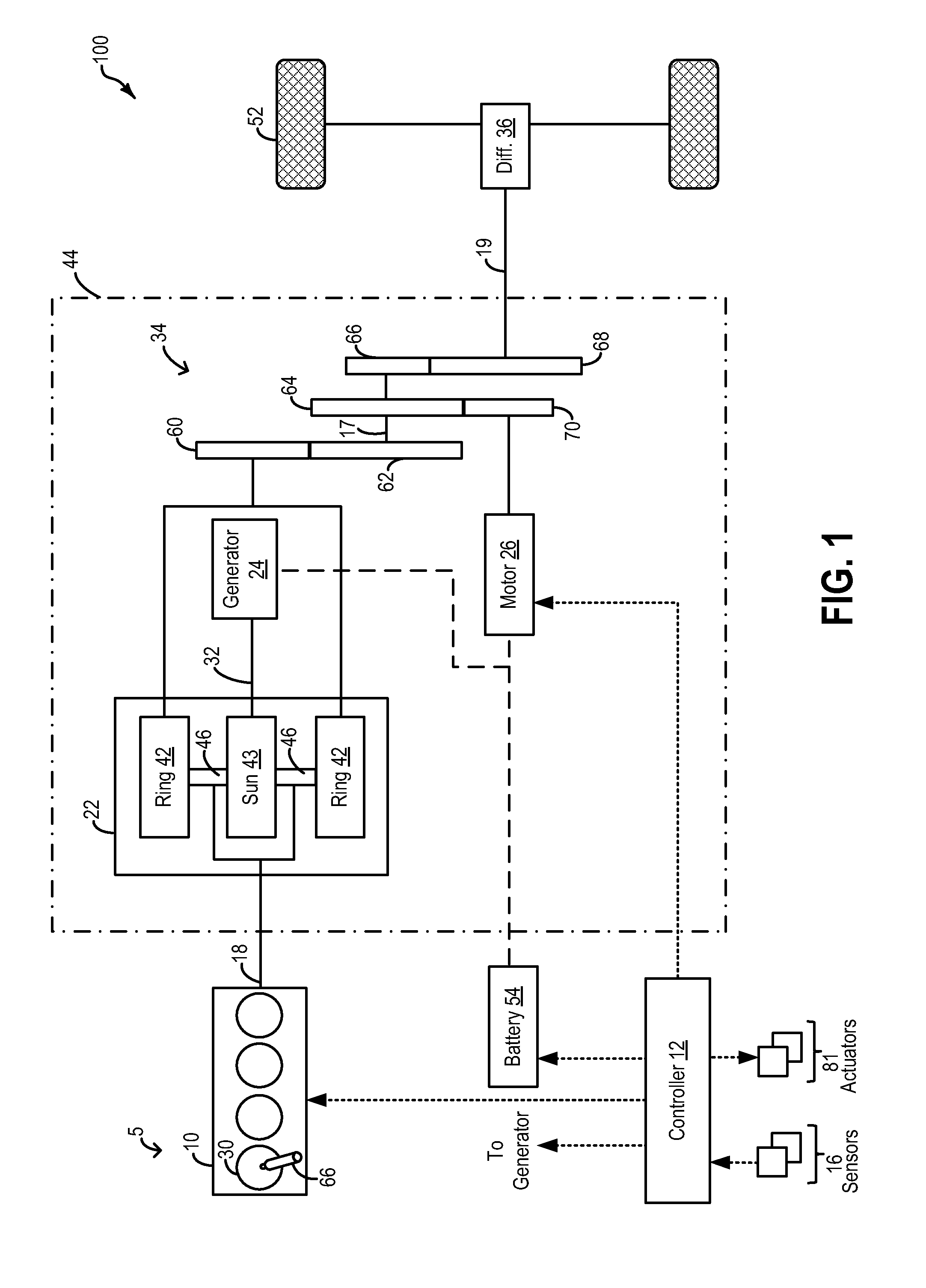

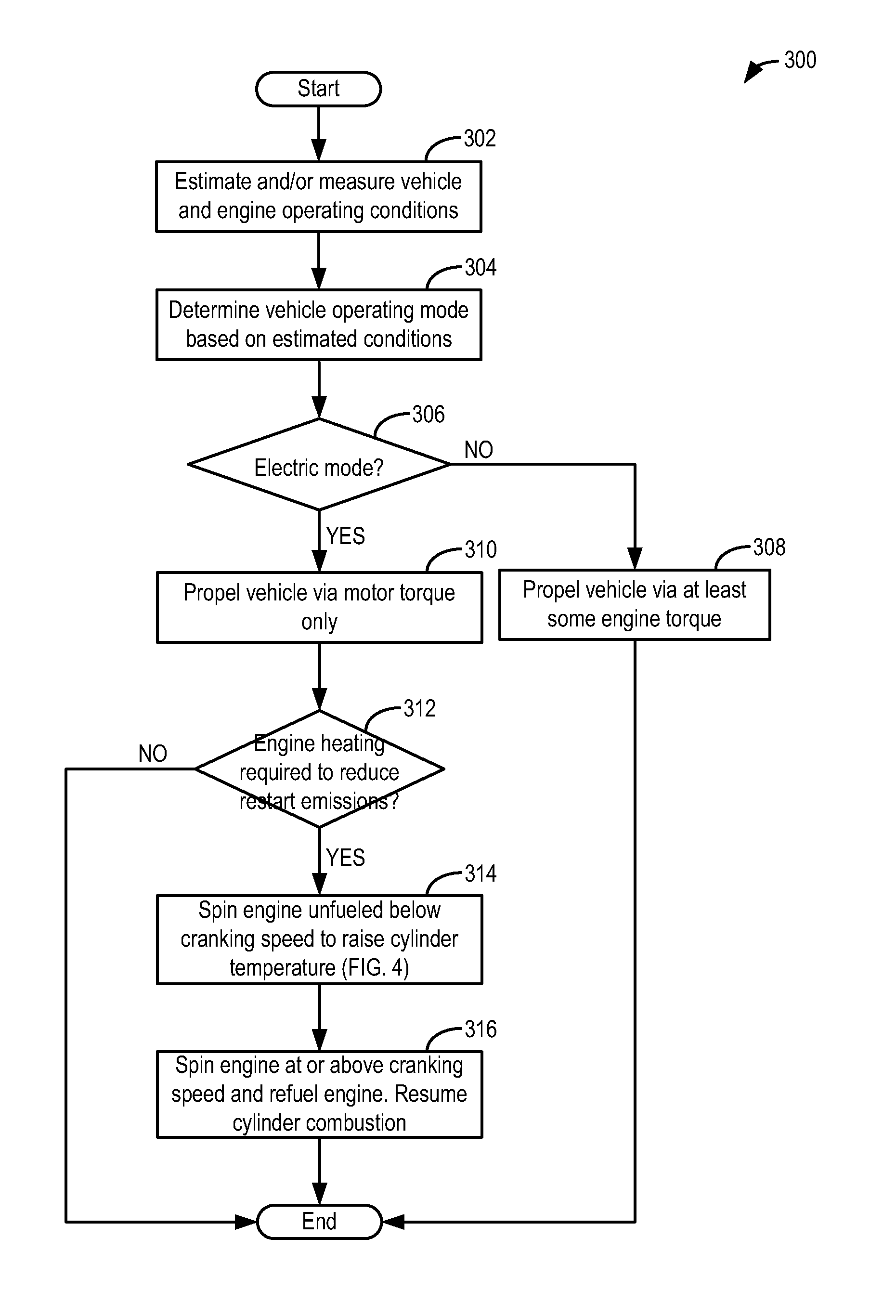

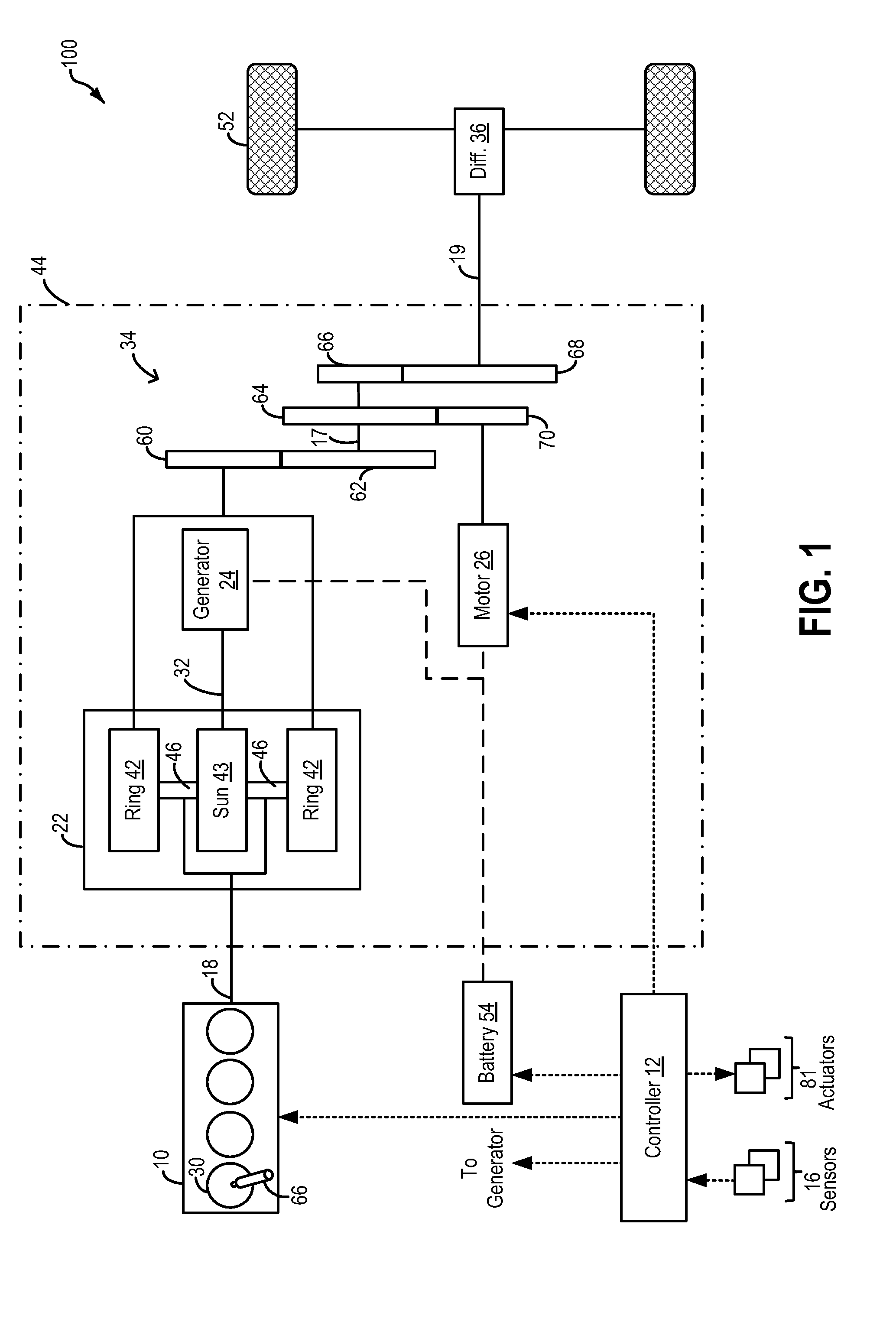

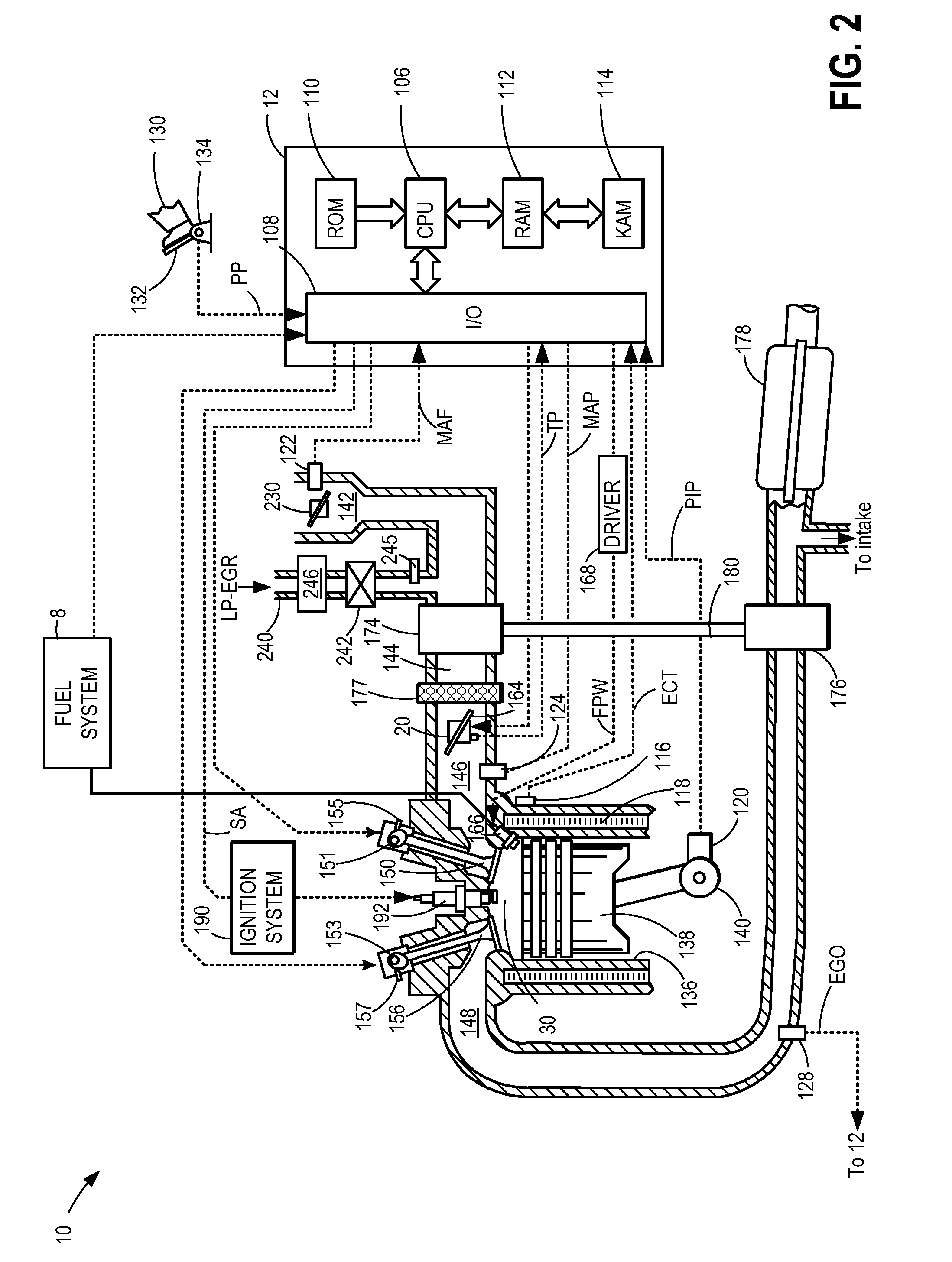

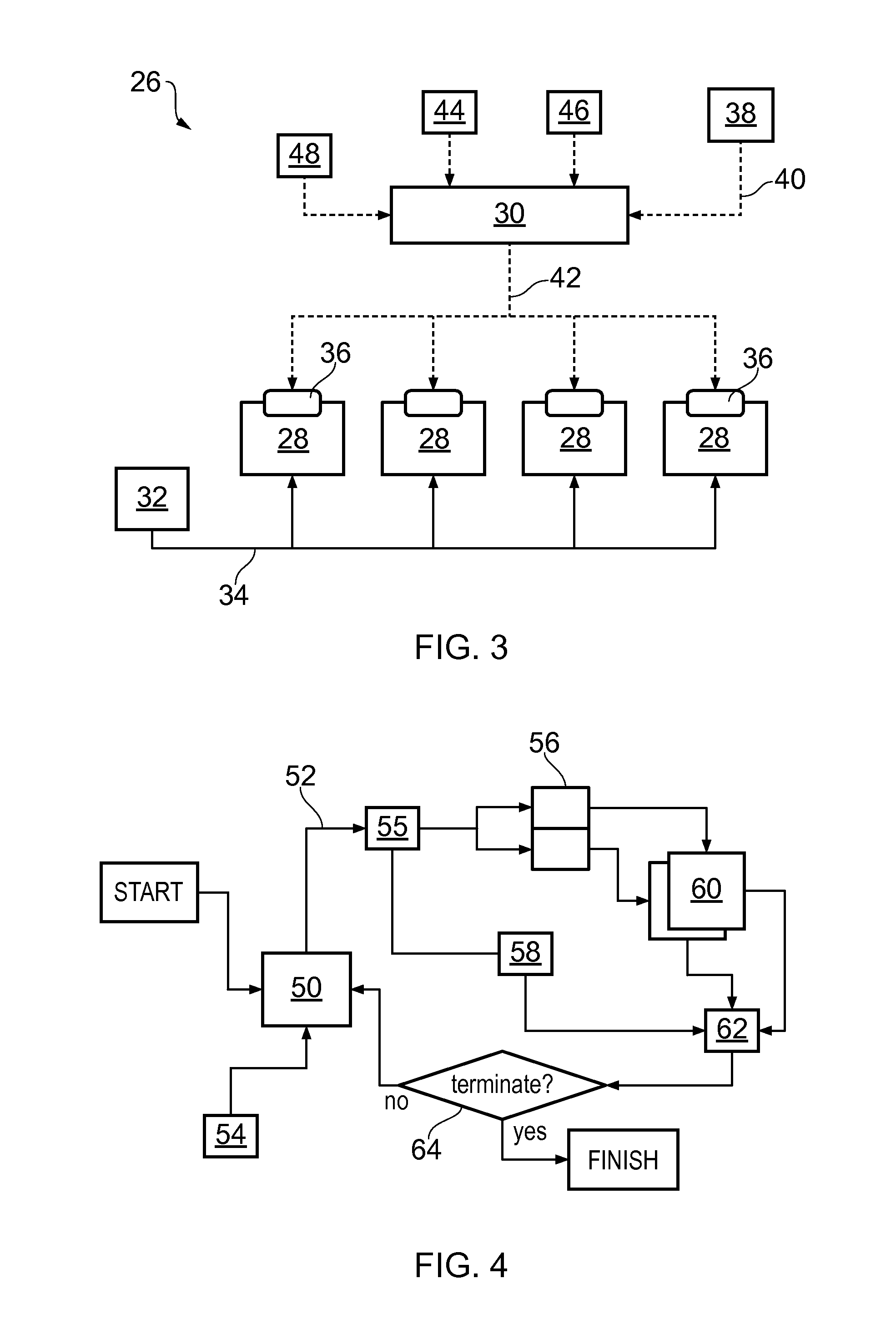

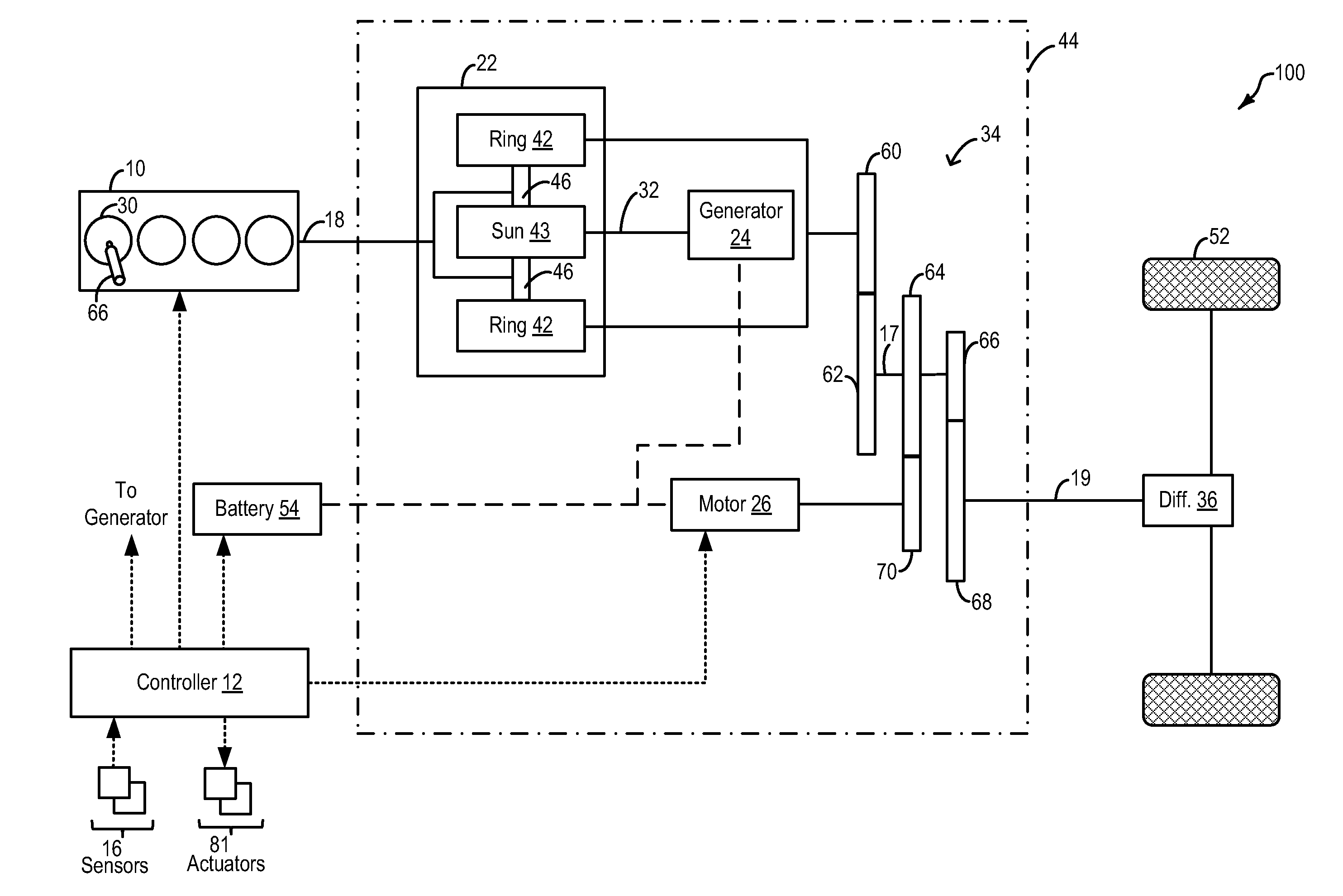

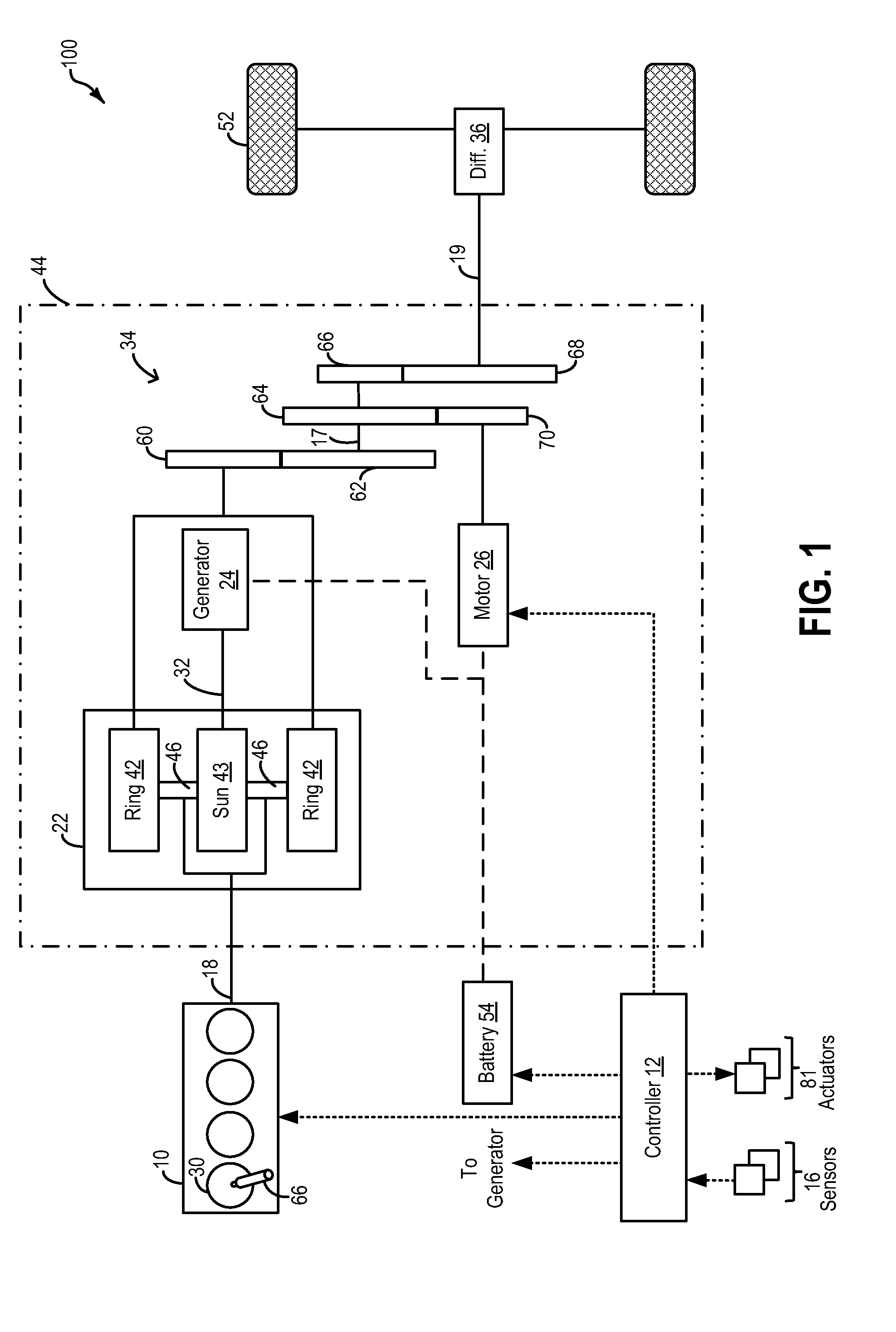

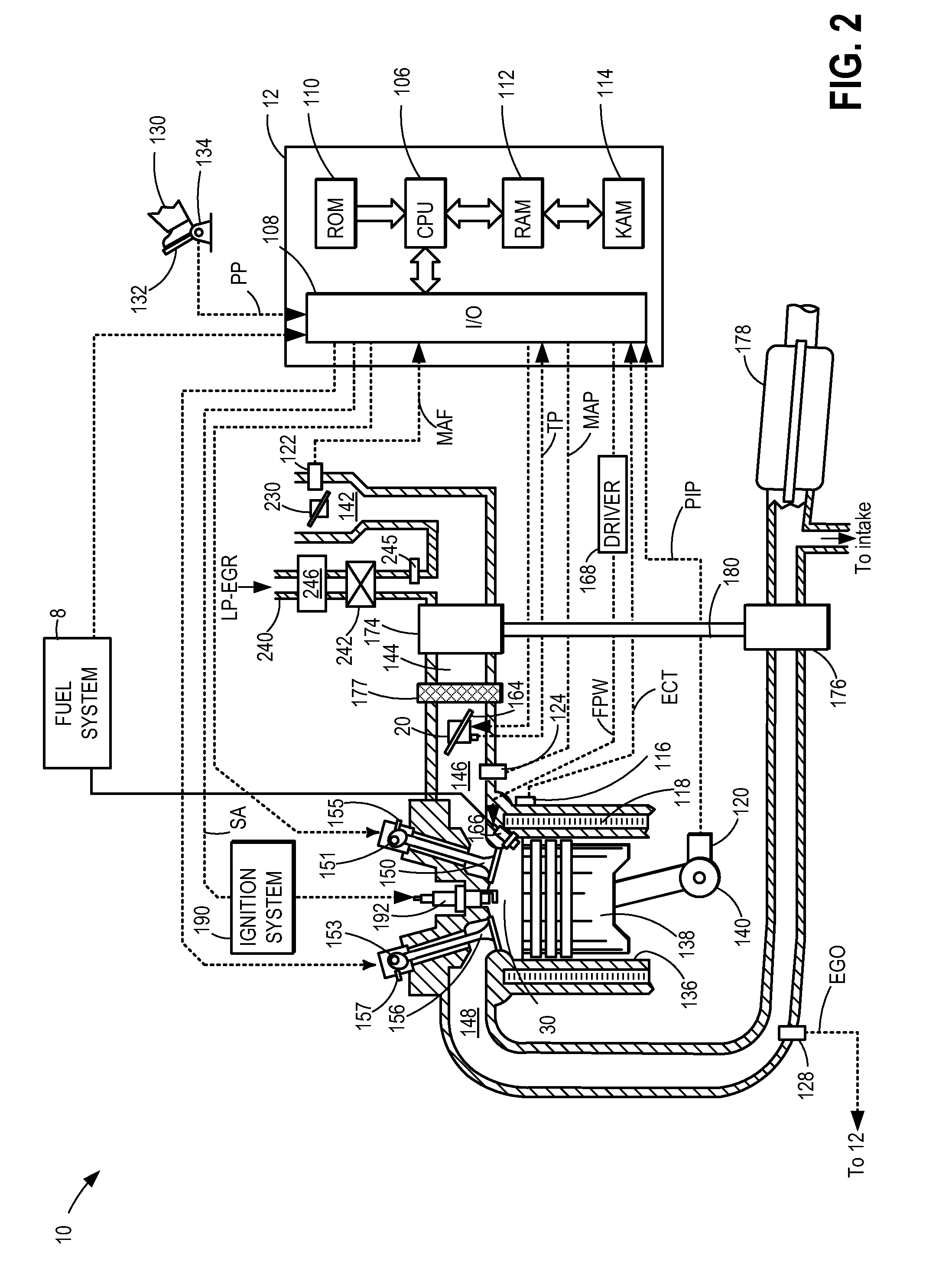

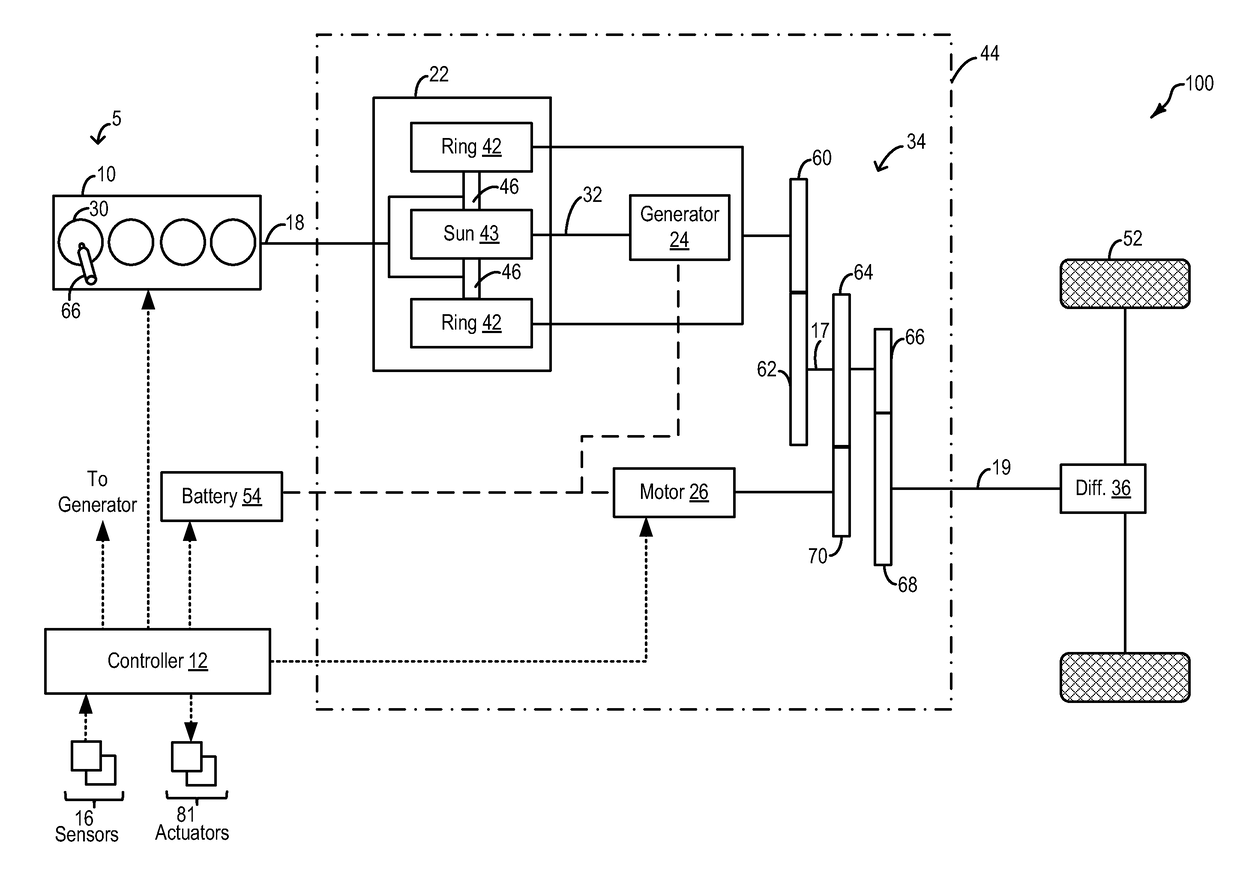

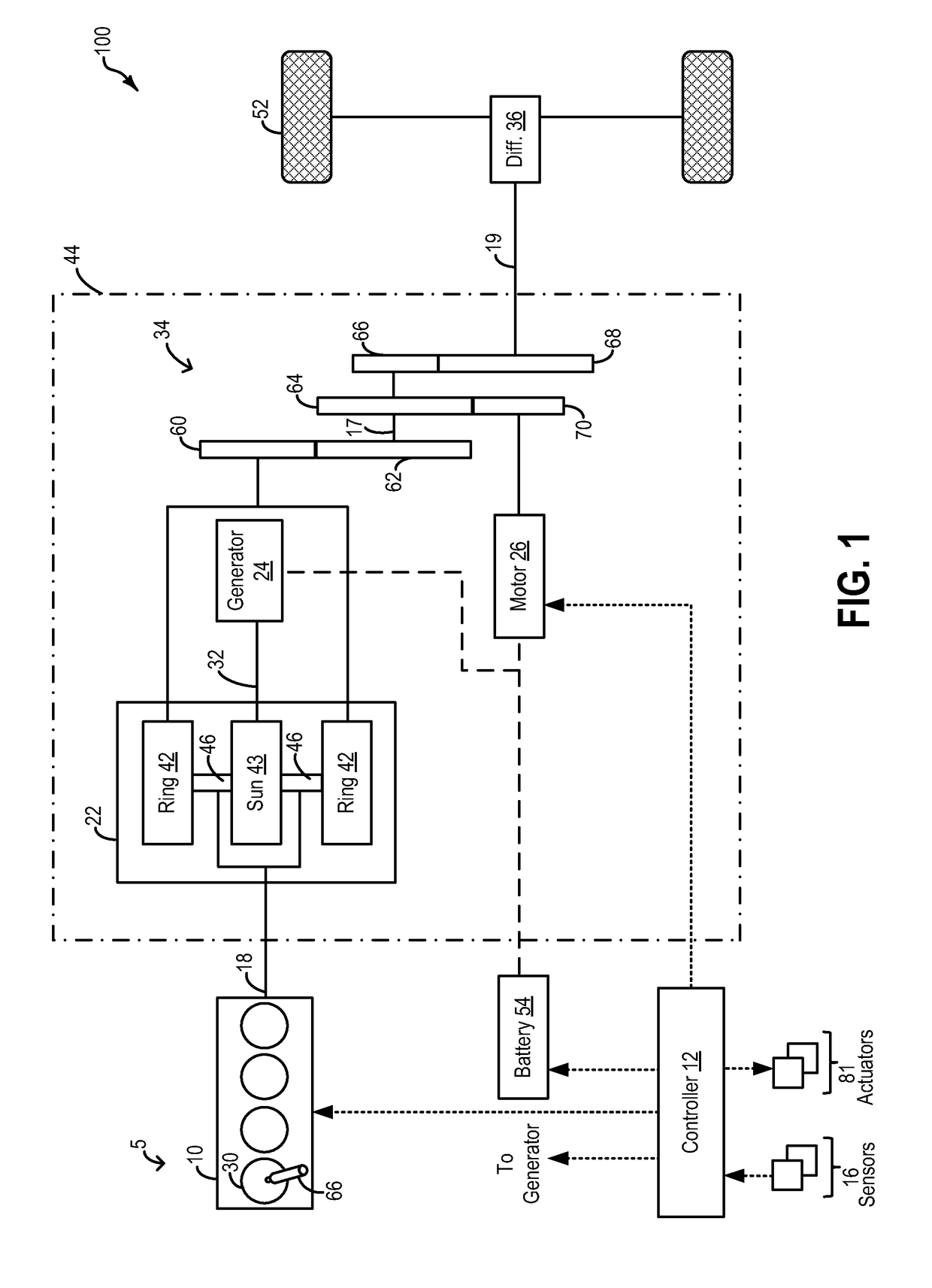

Method and system for engine control

ActiveUS20150285161A1Improve fuel efficiencyImprove cooling effectHybrid vehiclesElectrical controlCombustionEngineering

Methods and systems are provided for using compression heating to heat a cylinder piston before cylinder combustion is resumed. Cylinder heating is achieved using combinations of slow unfueled engine rotation where the engine cylinders are heated via compression stroke heating, and slow compressor rotation where the cylinders are heated via compression heating. One or more intake or exhaust heaters may be concurrently operated to expedite cylinder heating.

Owner:FORD GLOBAL TECH LLC

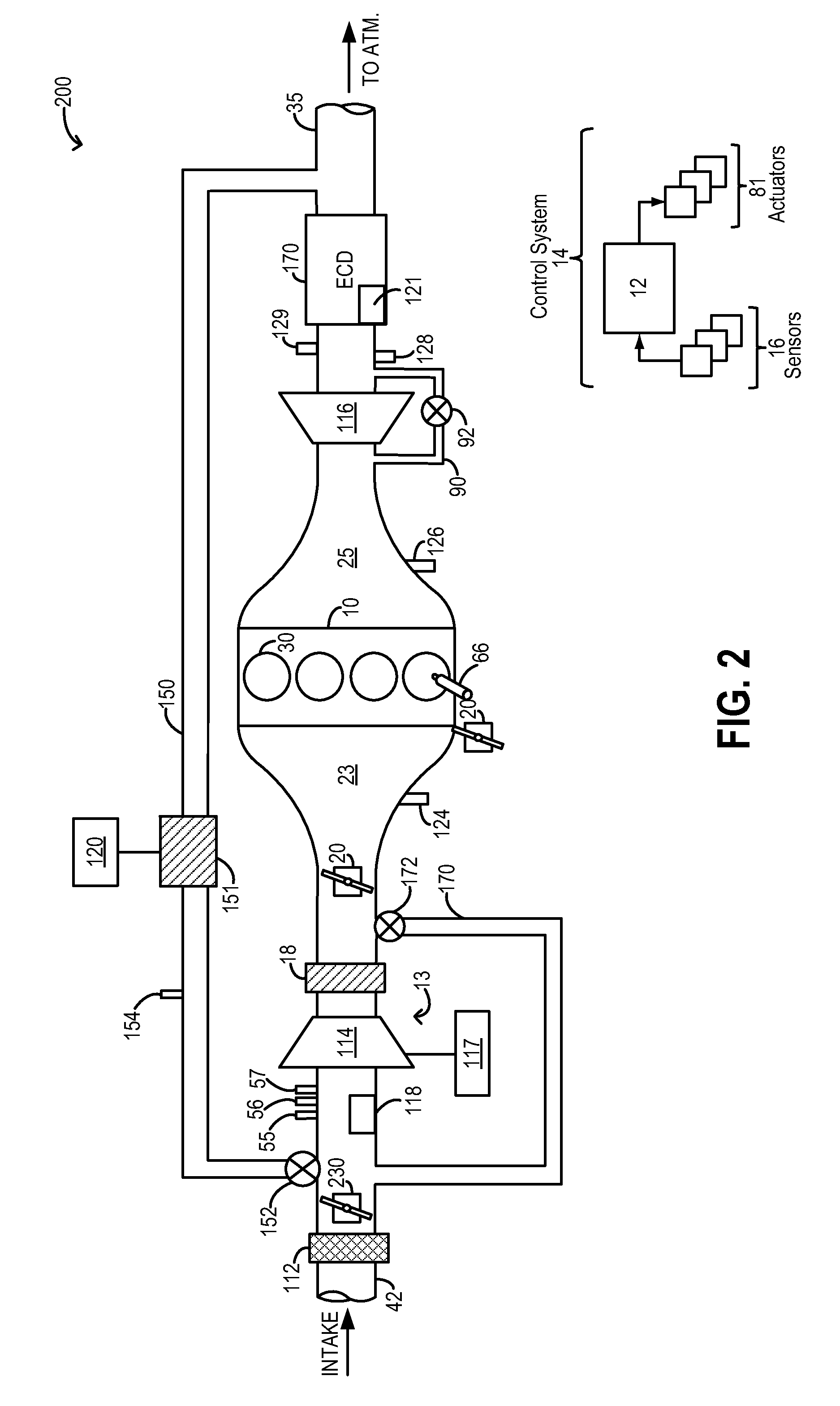

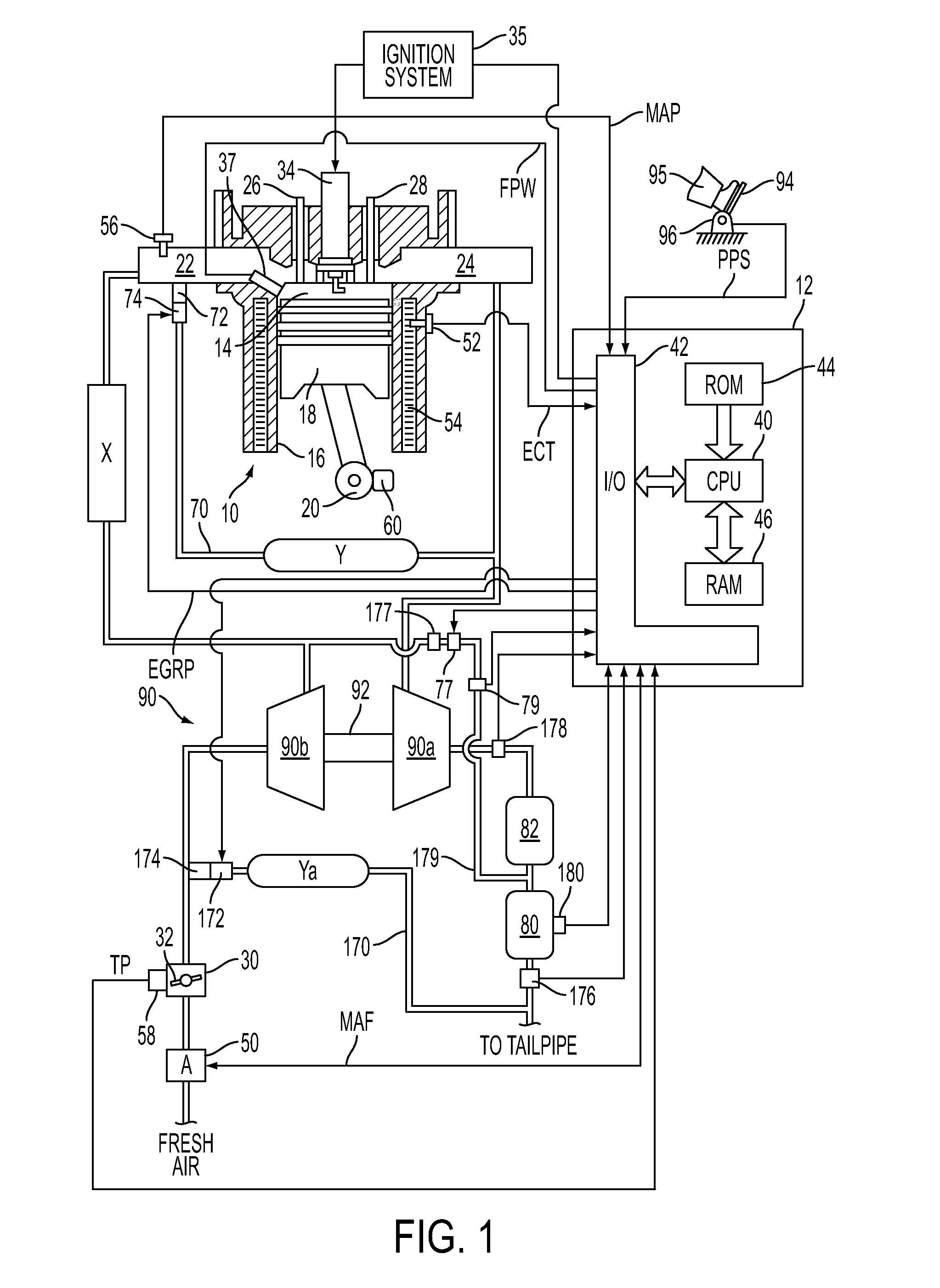

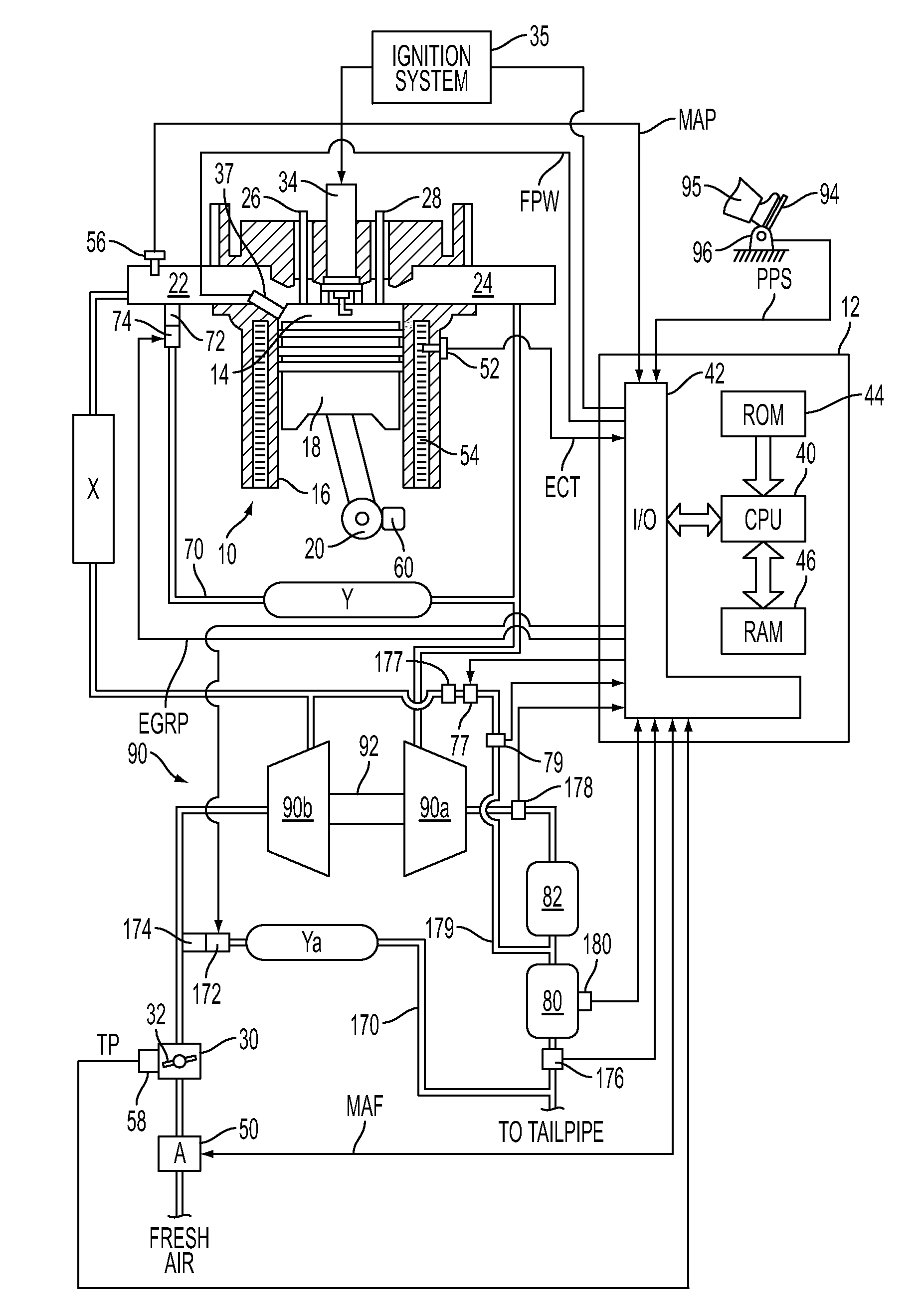

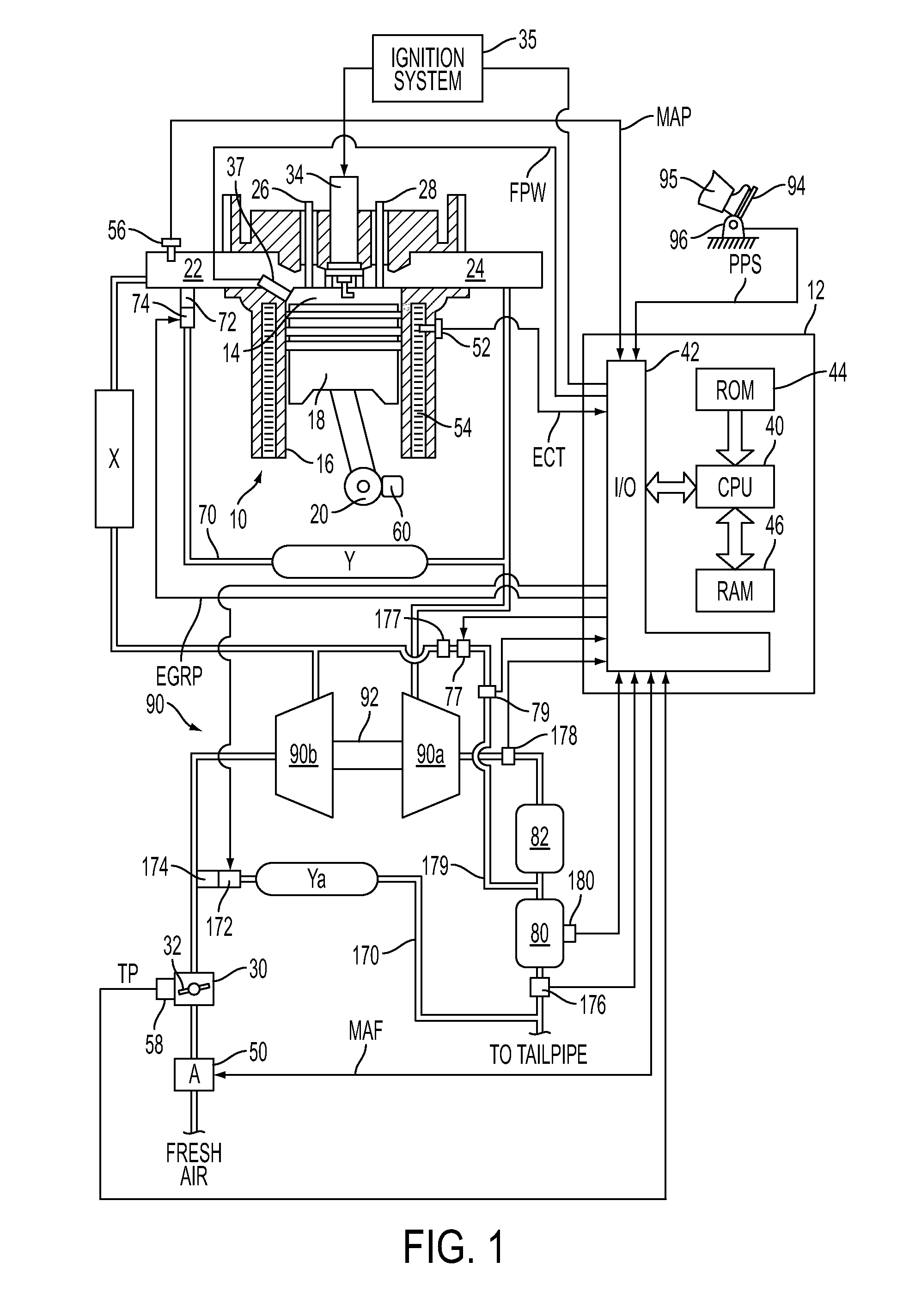

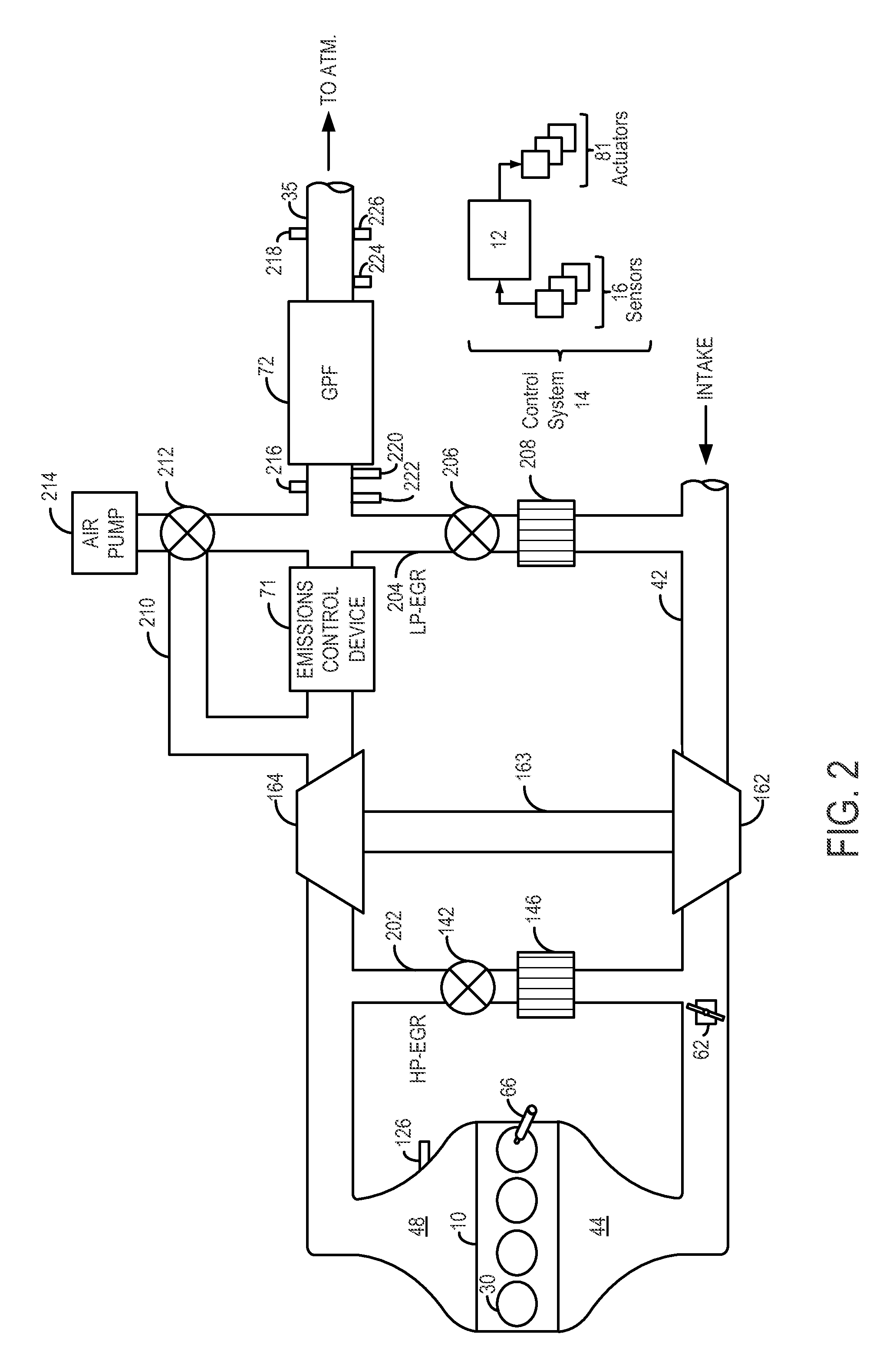

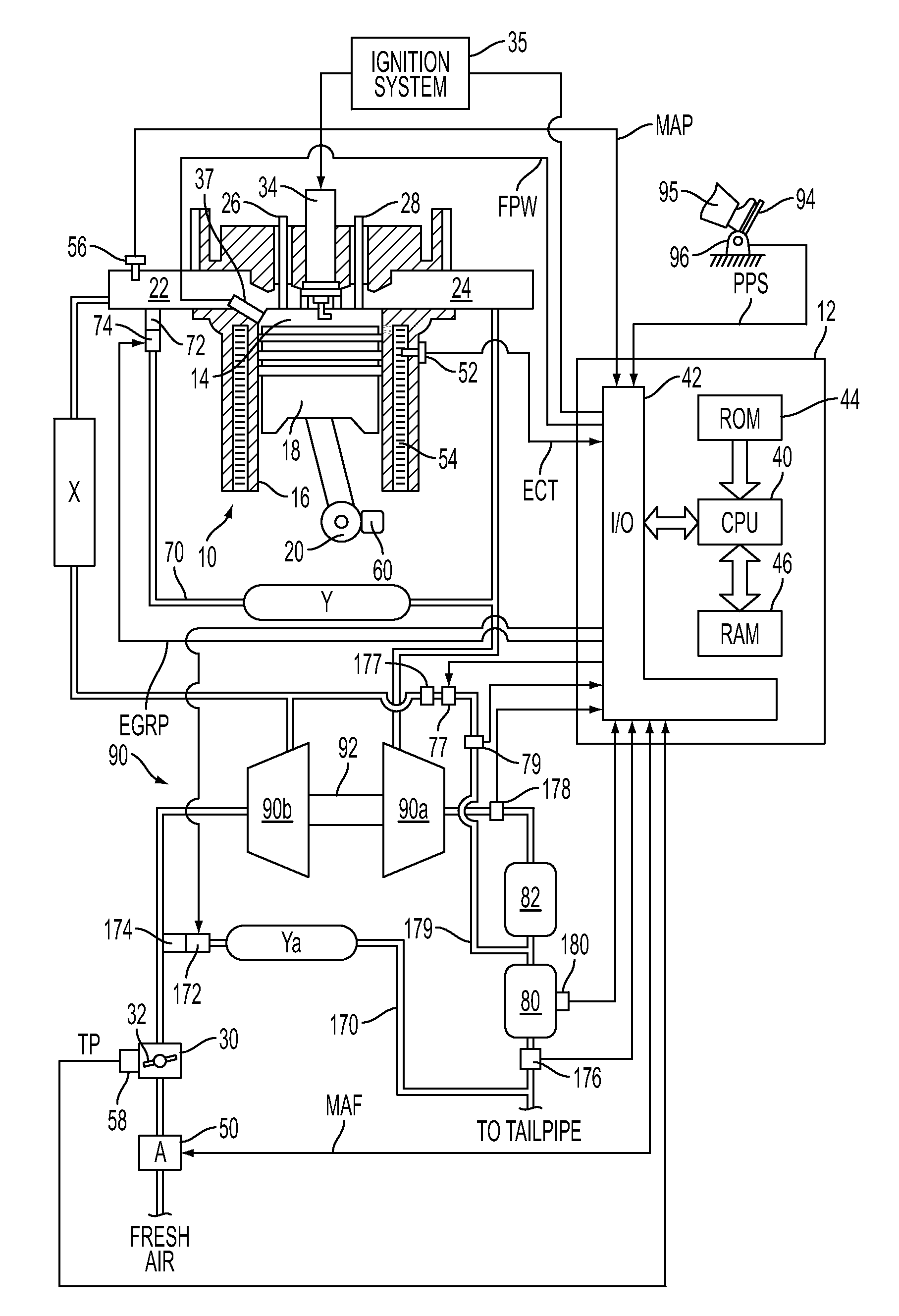

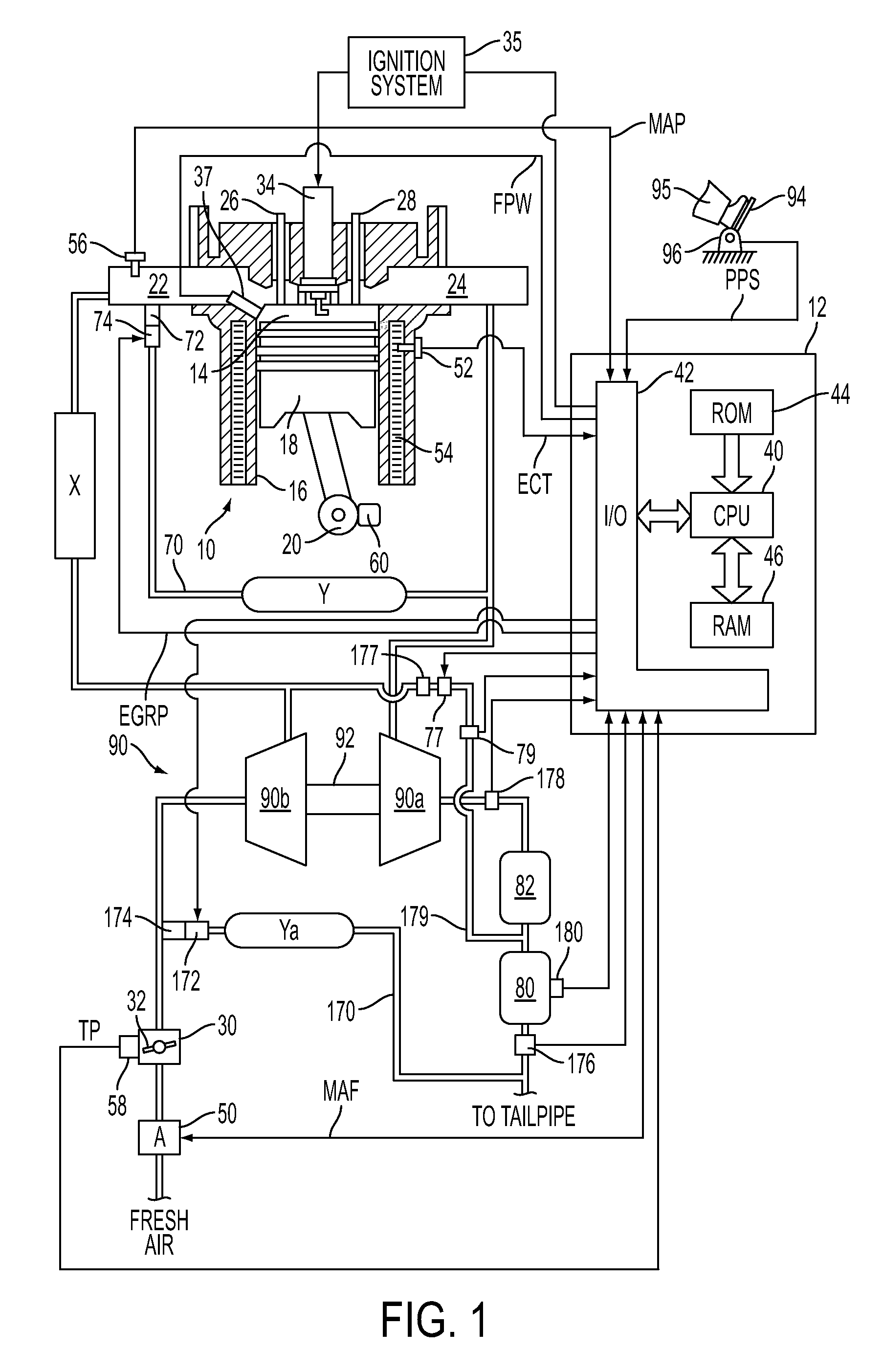

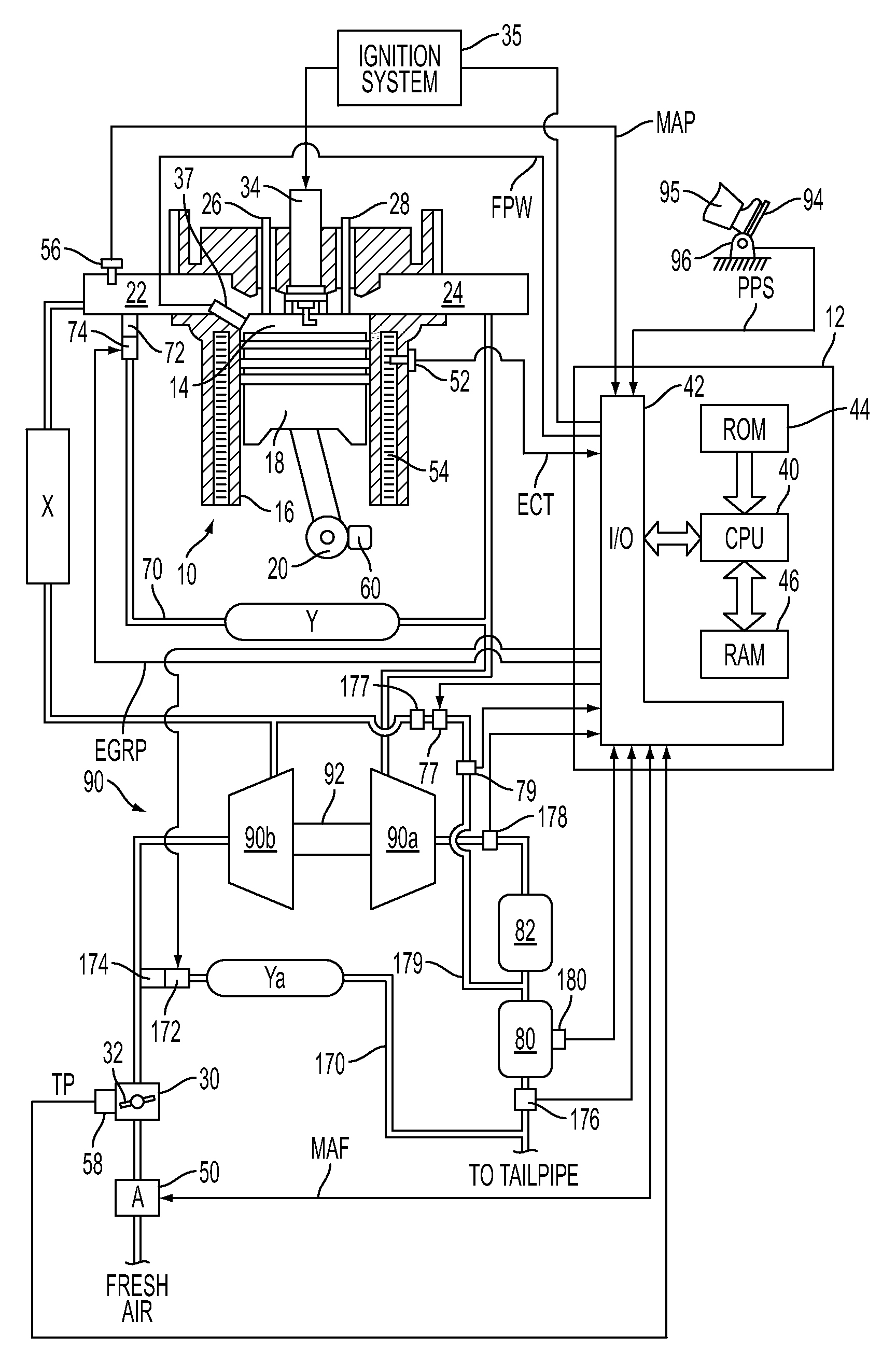

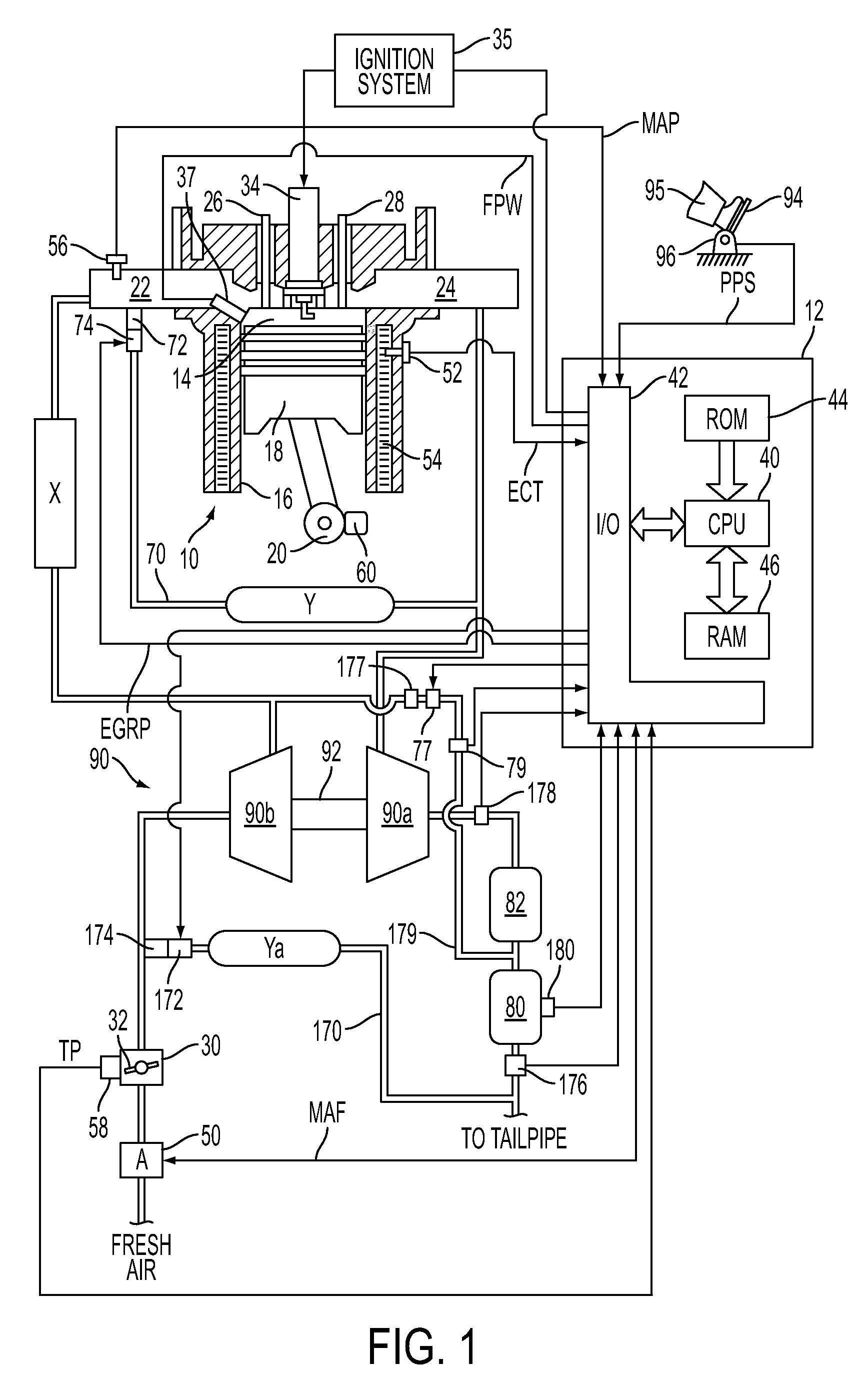

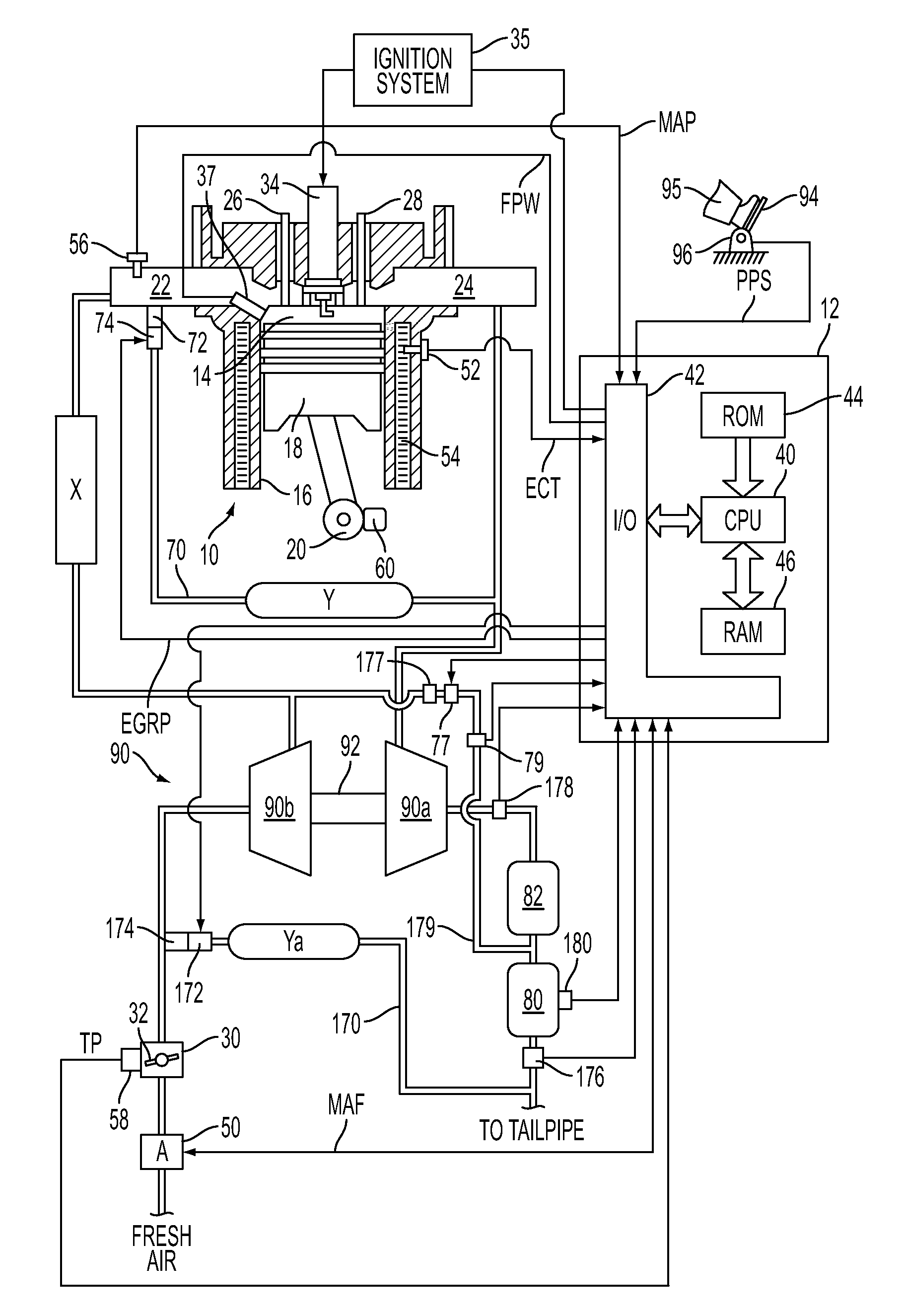

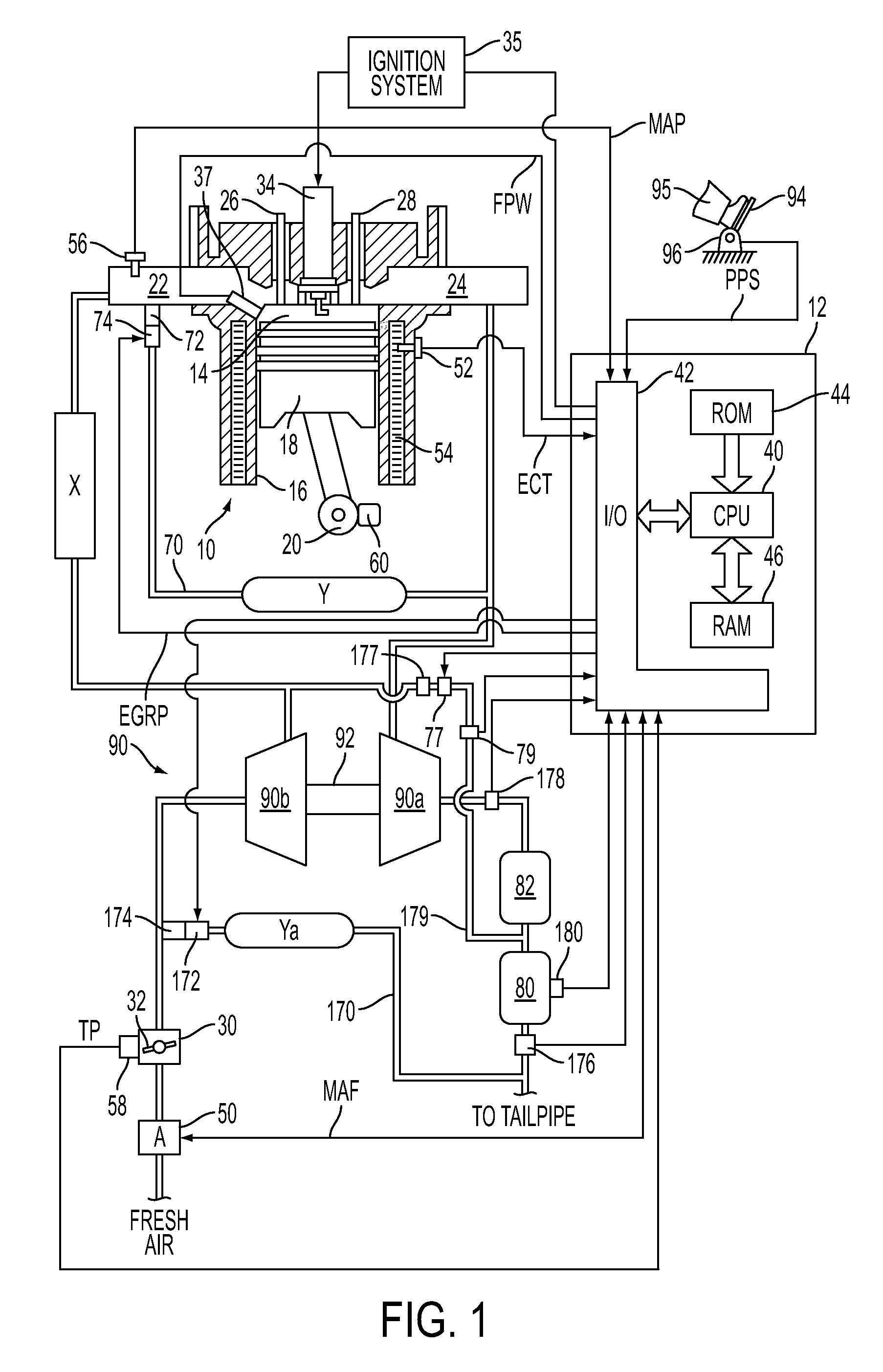

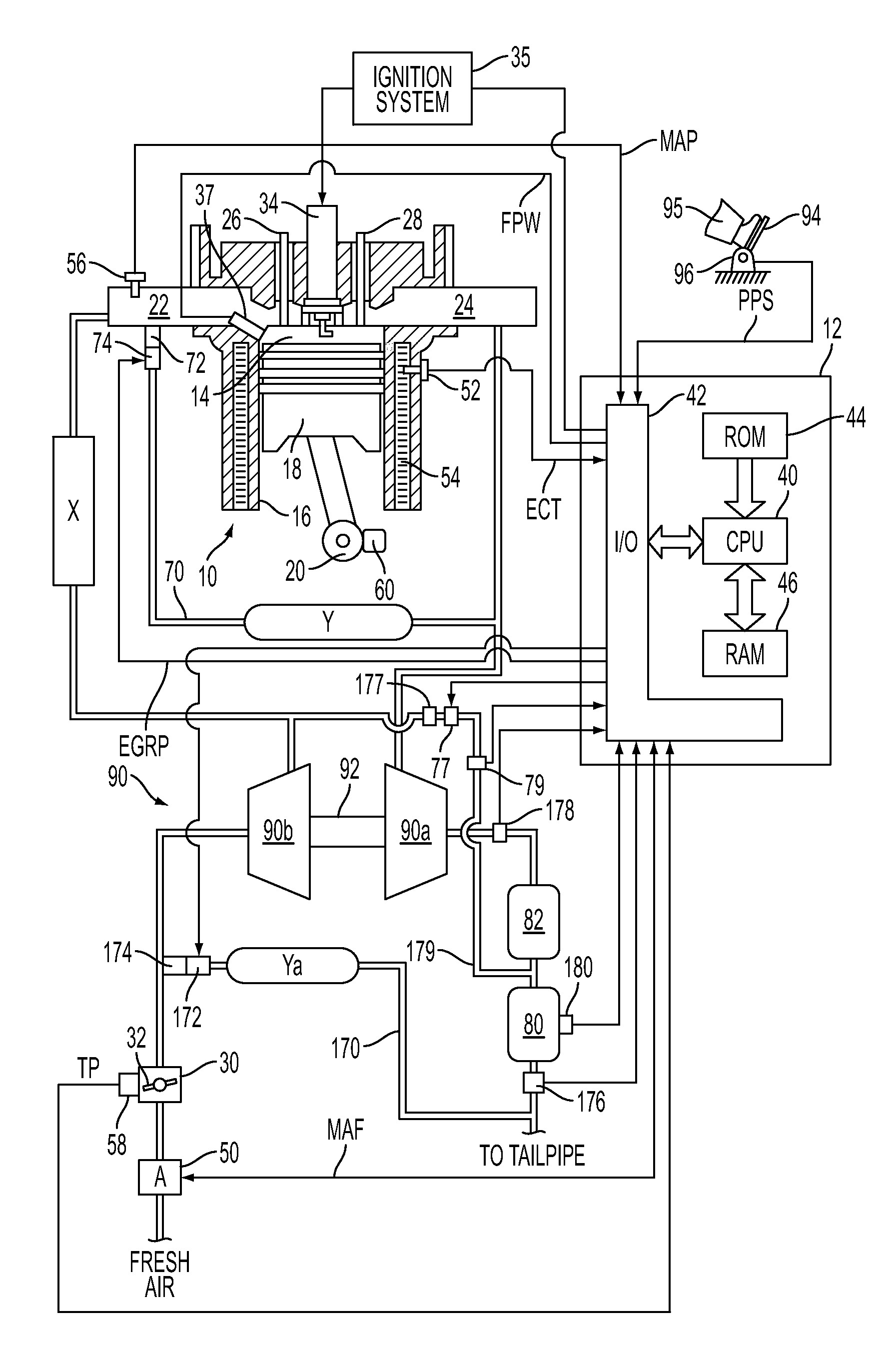

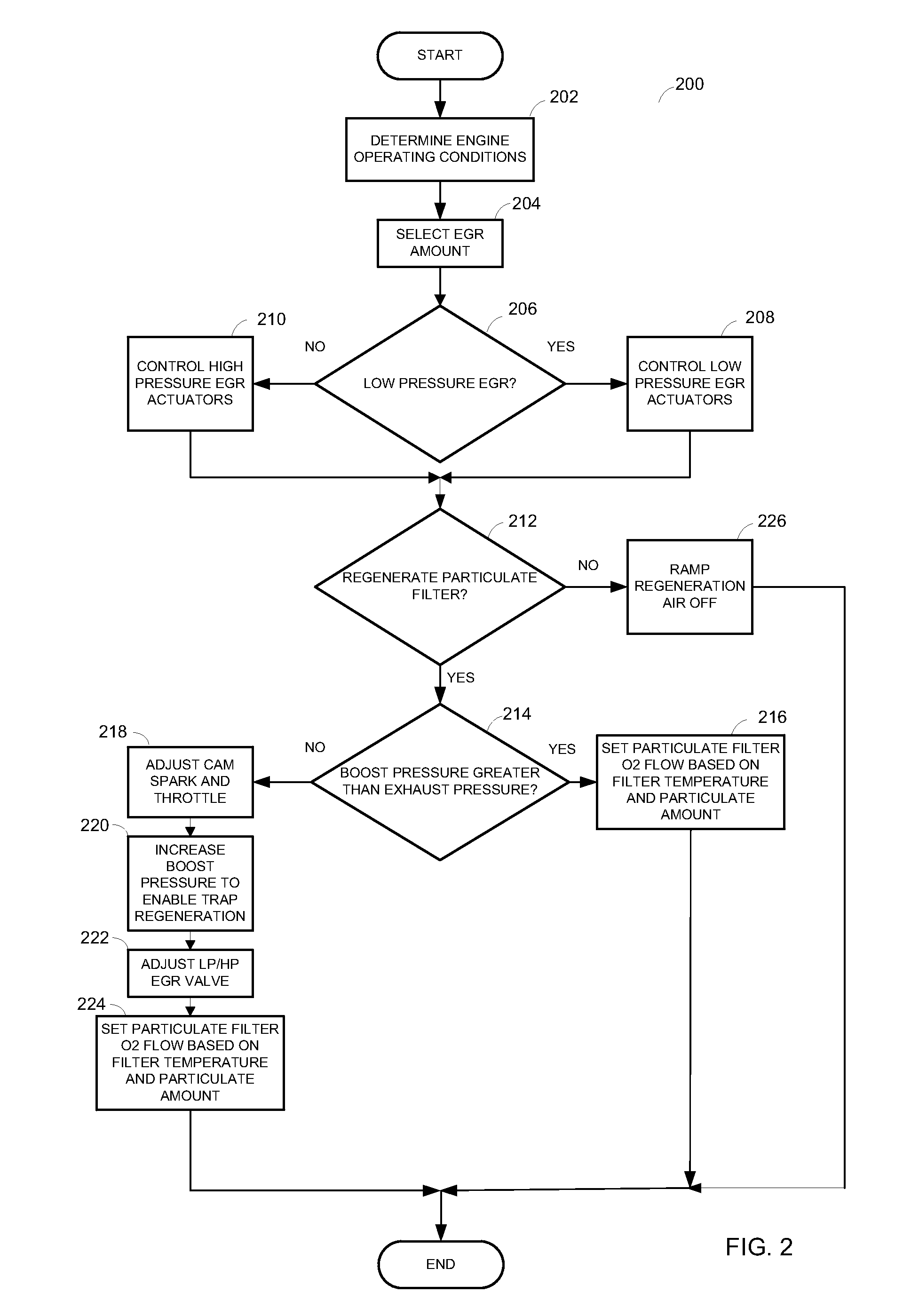

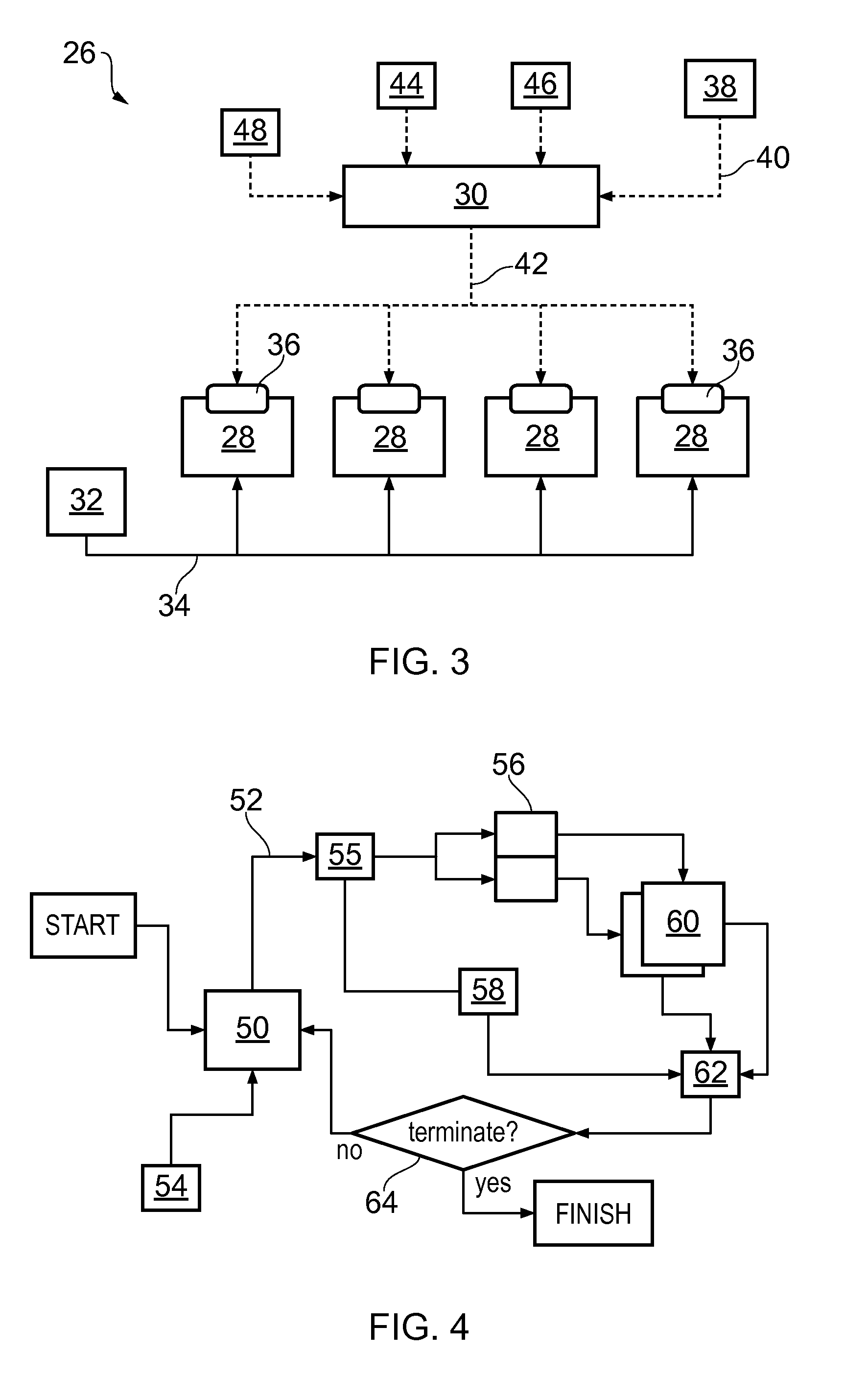

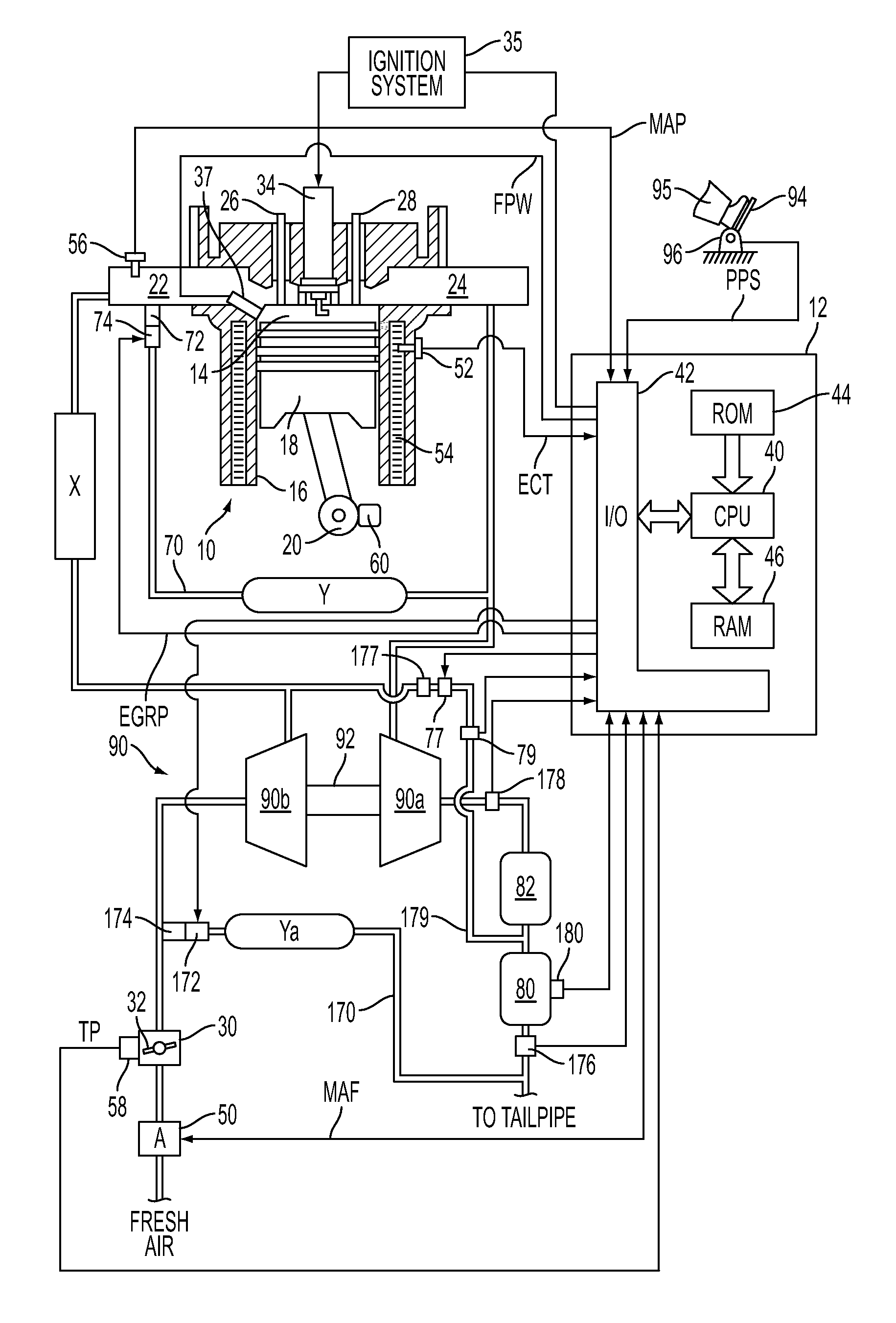

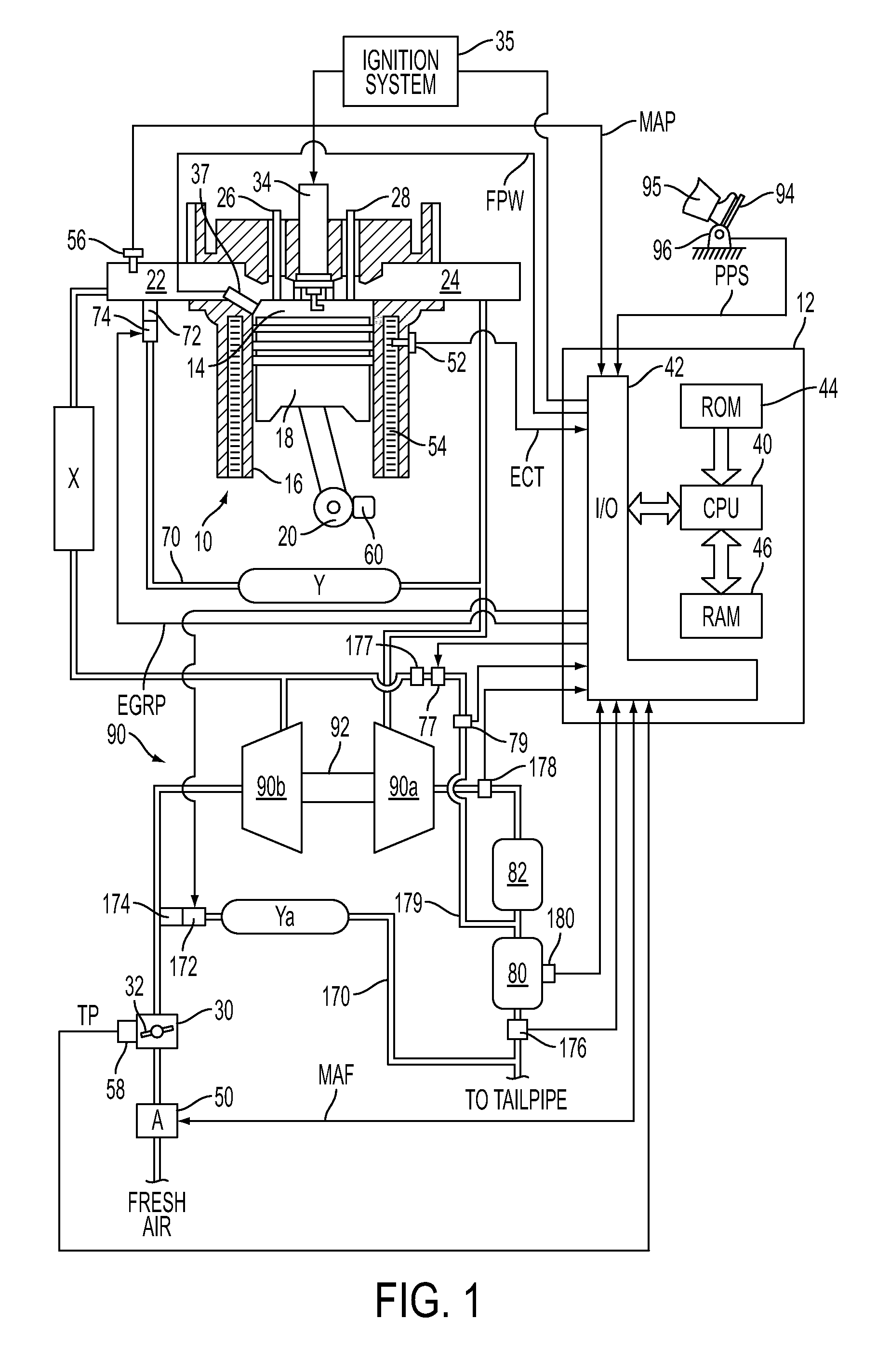

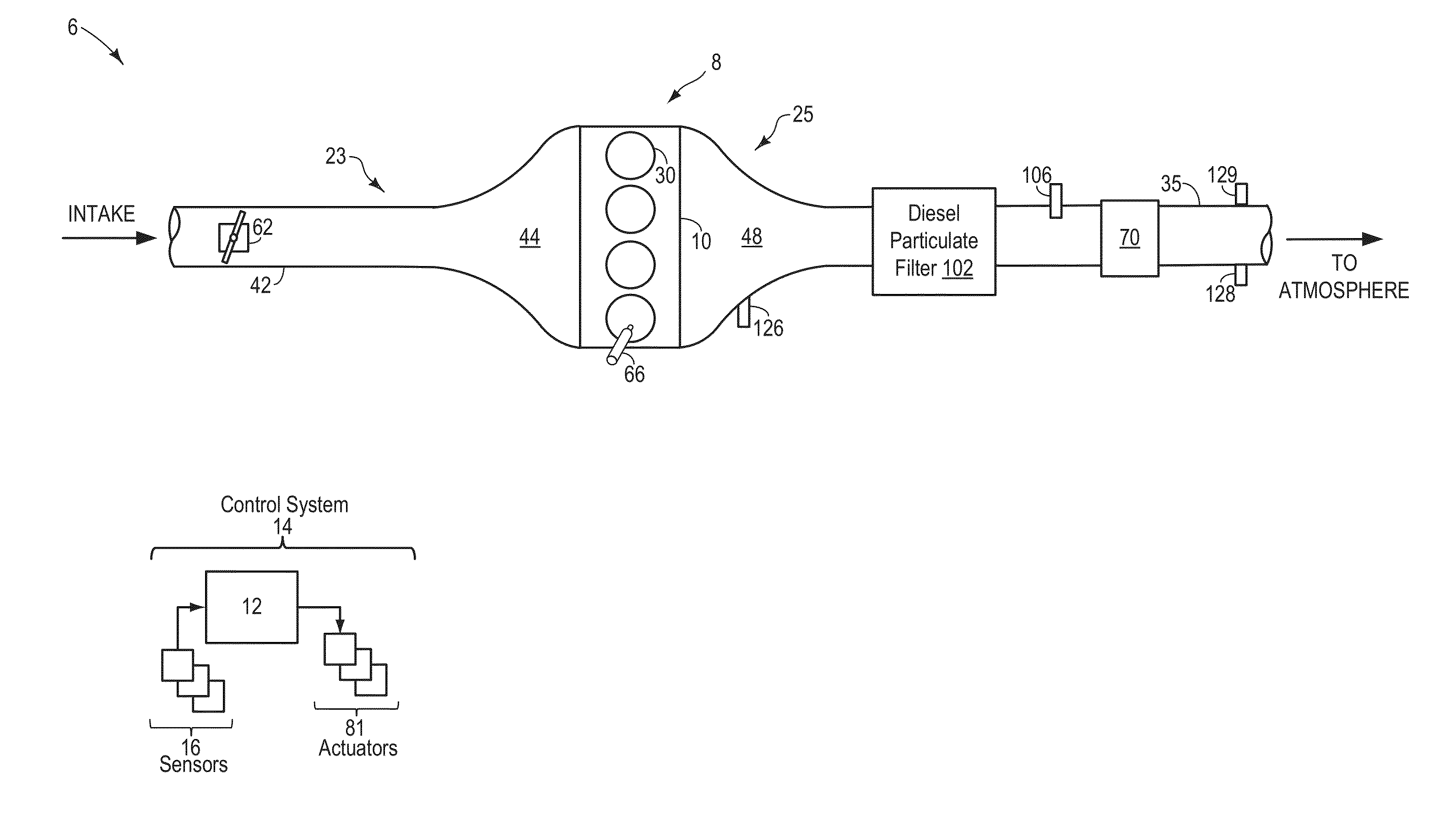

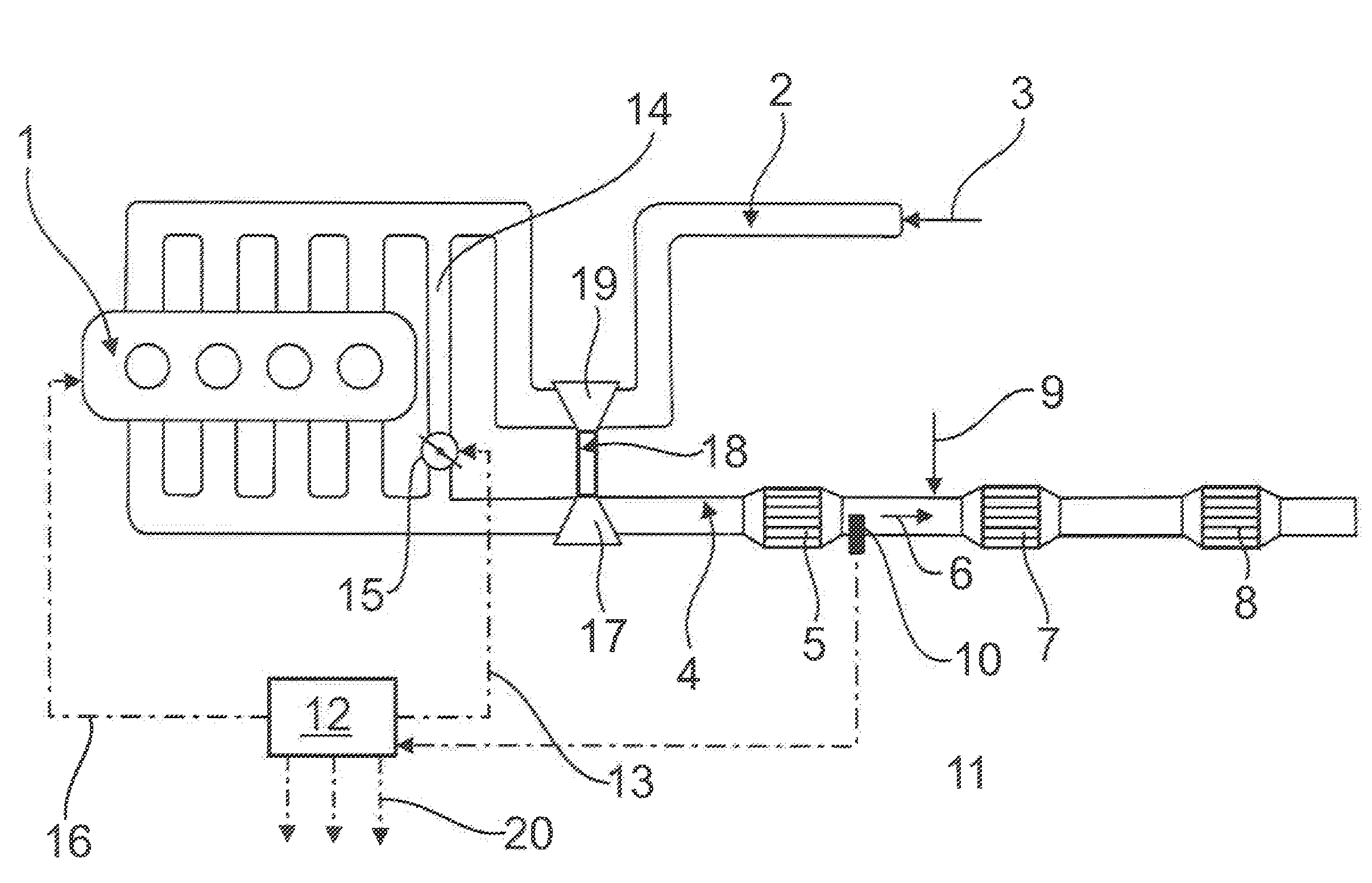

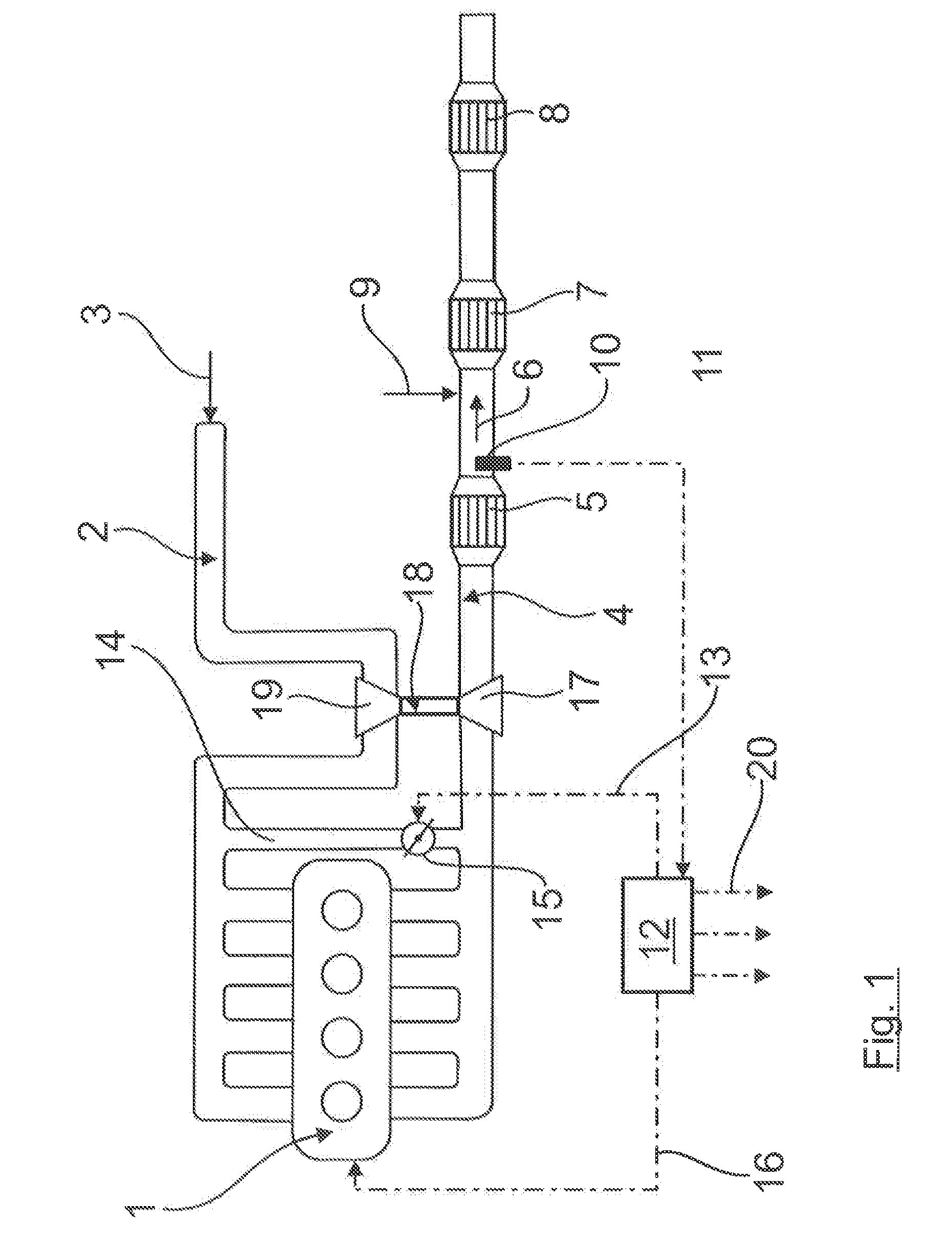

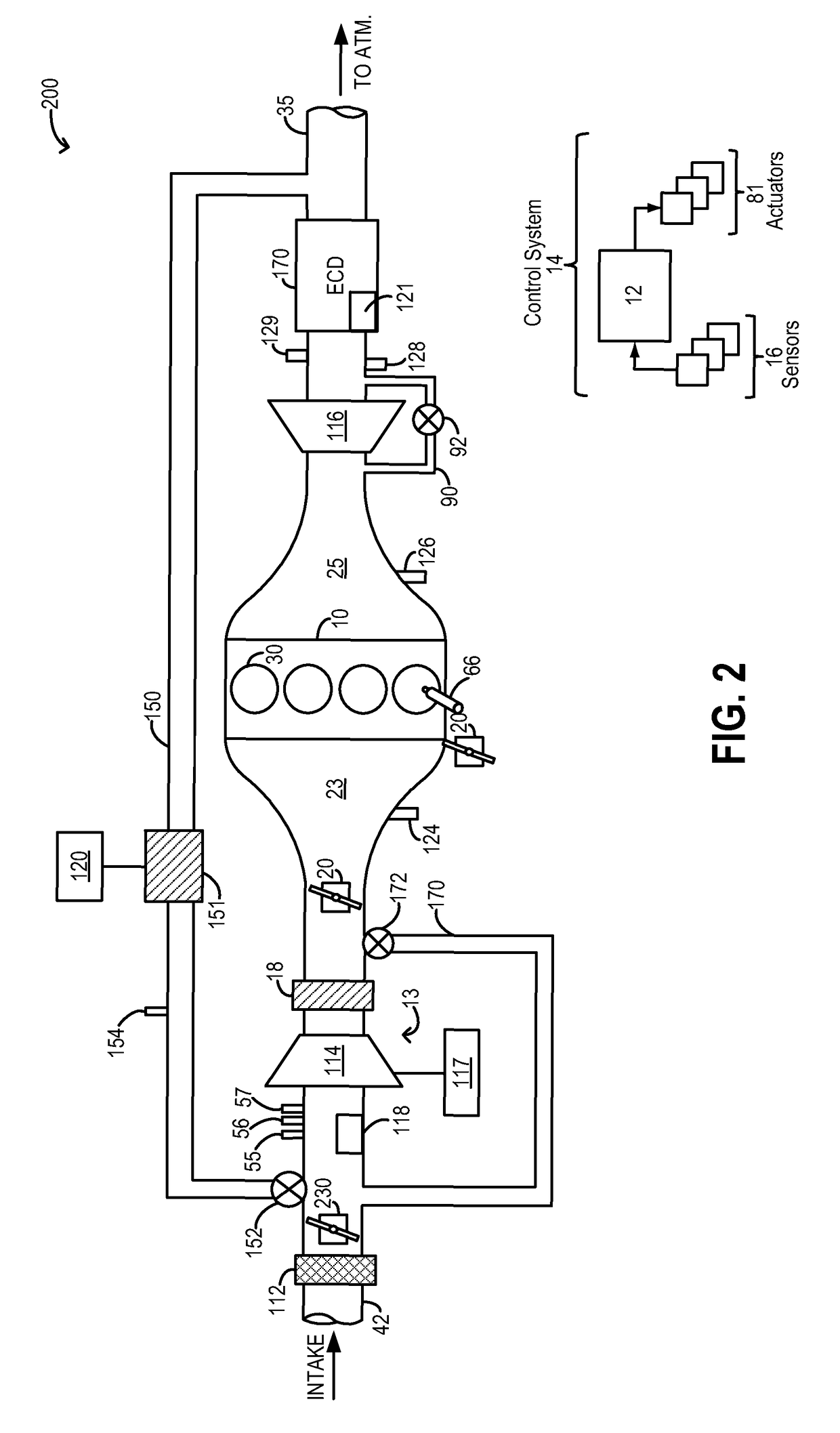

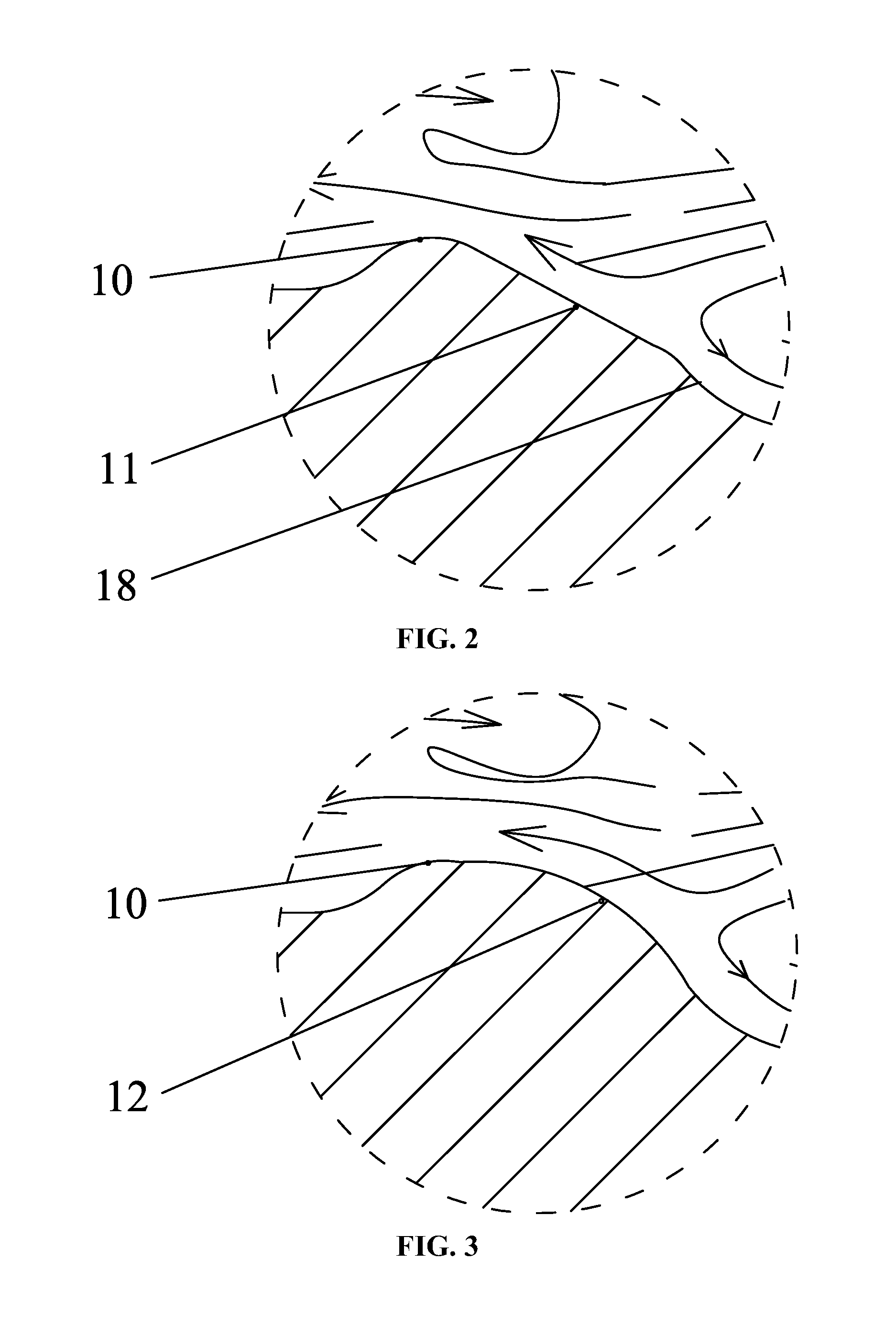

System and method for regenerating a particulate filter for a direct injection engine

ActiveUS20110072794A1Emission reductionReduce engine pumping lossesElectrical controlInternal combustion piston enginesGasolineEnvironmental engineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turobocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter. In this way, regeneration of a particulate filter may be accomplished without disturbing the chemistry of a three-way catalyst located in the exhaust system upstream of the particulate filter.

Owner:FORD GLOBAL TECH LLC

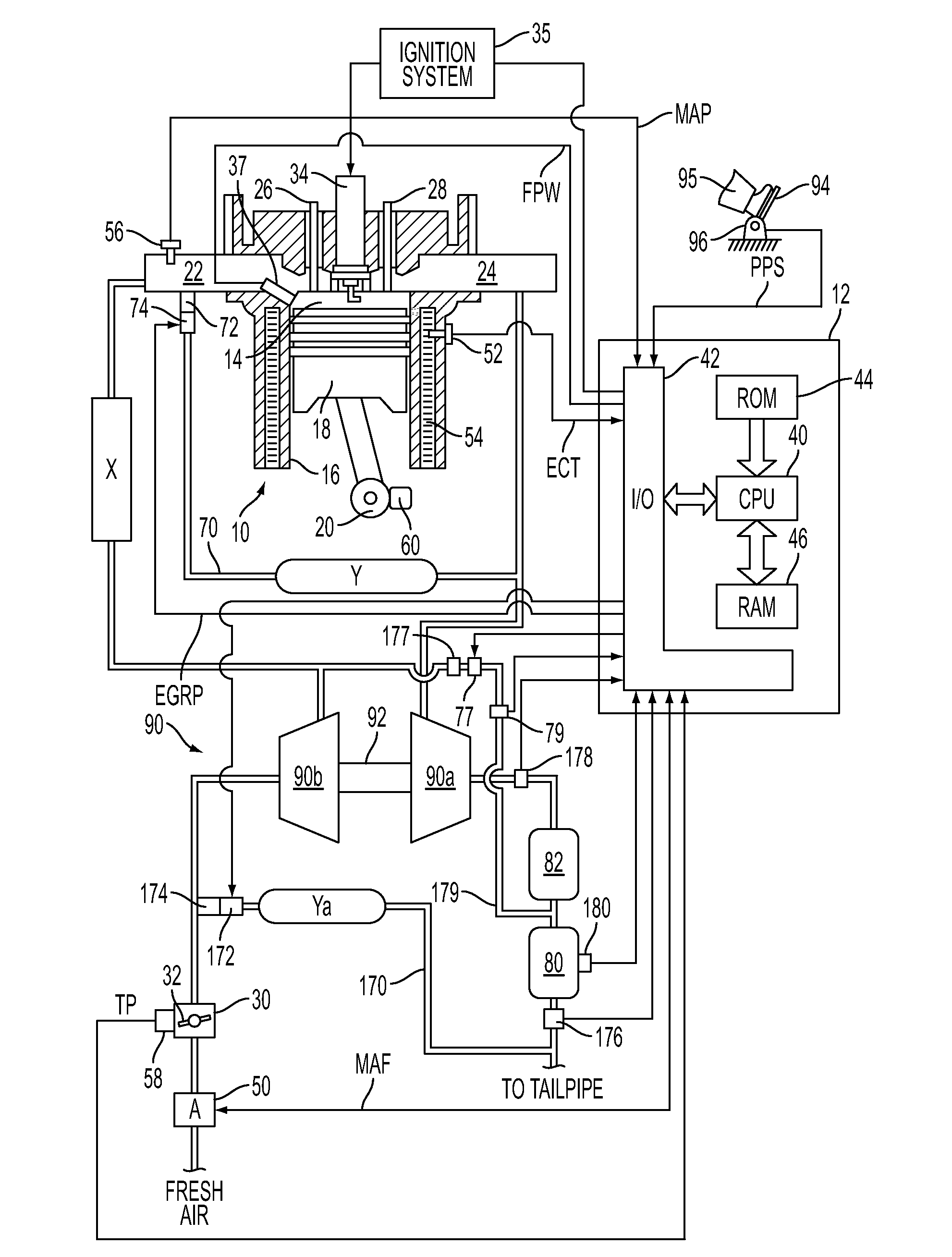

Method and system for engine control

ActiveUS9346451B2Improve cooling effectImprove fuel efficiencyHybrid vehiclesEngine controllersParticulatesRotary engine

Methods and systems are provided for slowly rotating an engine, unfueled, via a motor prior to an imminent engine restart to heat the engine. By rotating the engine so that heat generated in the compression stroke of a cylinder can be transferred to cylinder walls, thereby expediting engine warm-up. By warming the engine before a restart, particulate emissions generated during an engine cold-start due to direct injection of fuel can be reduced.

Owner:FORD GLOBAL TECH LLC

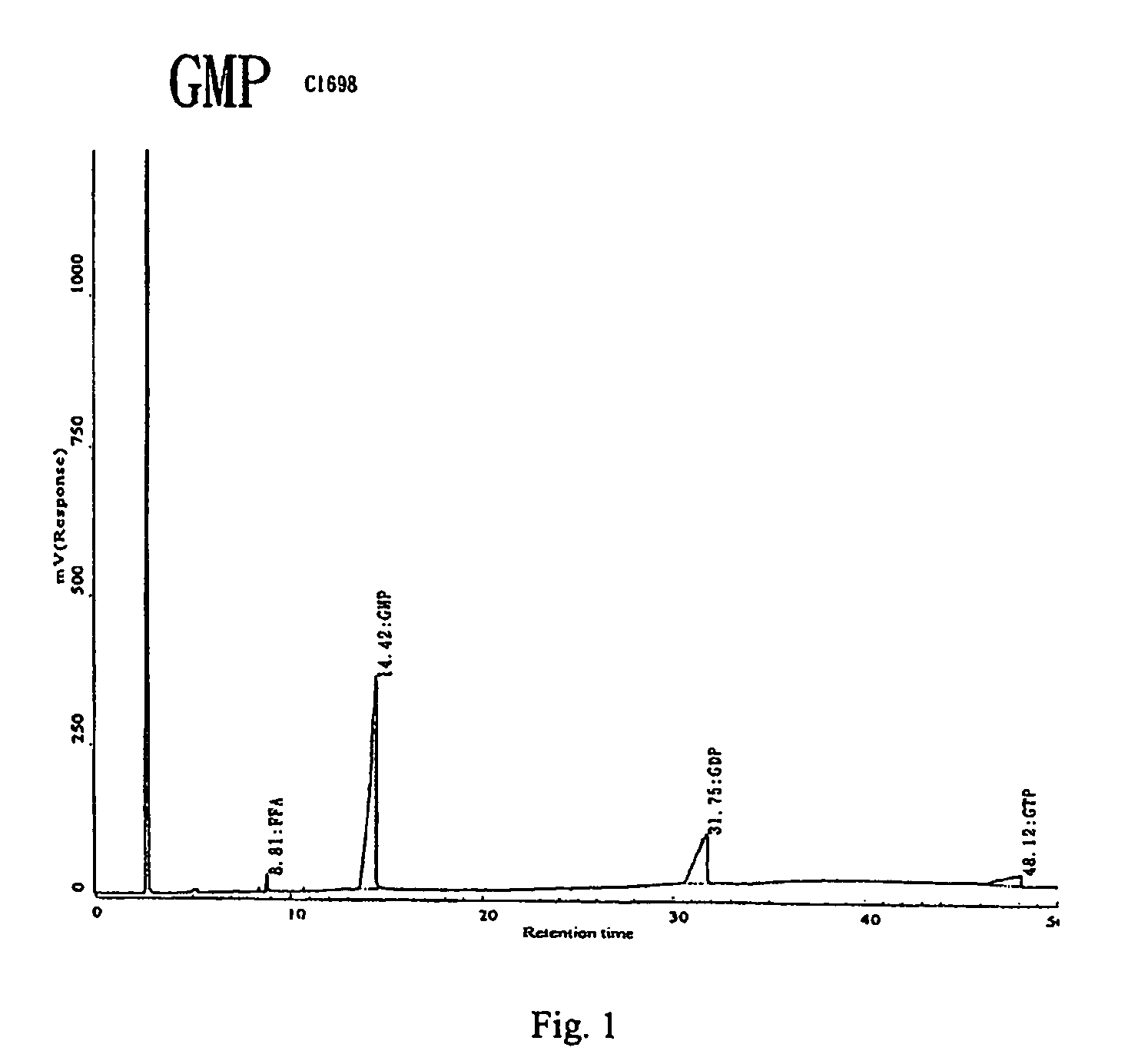

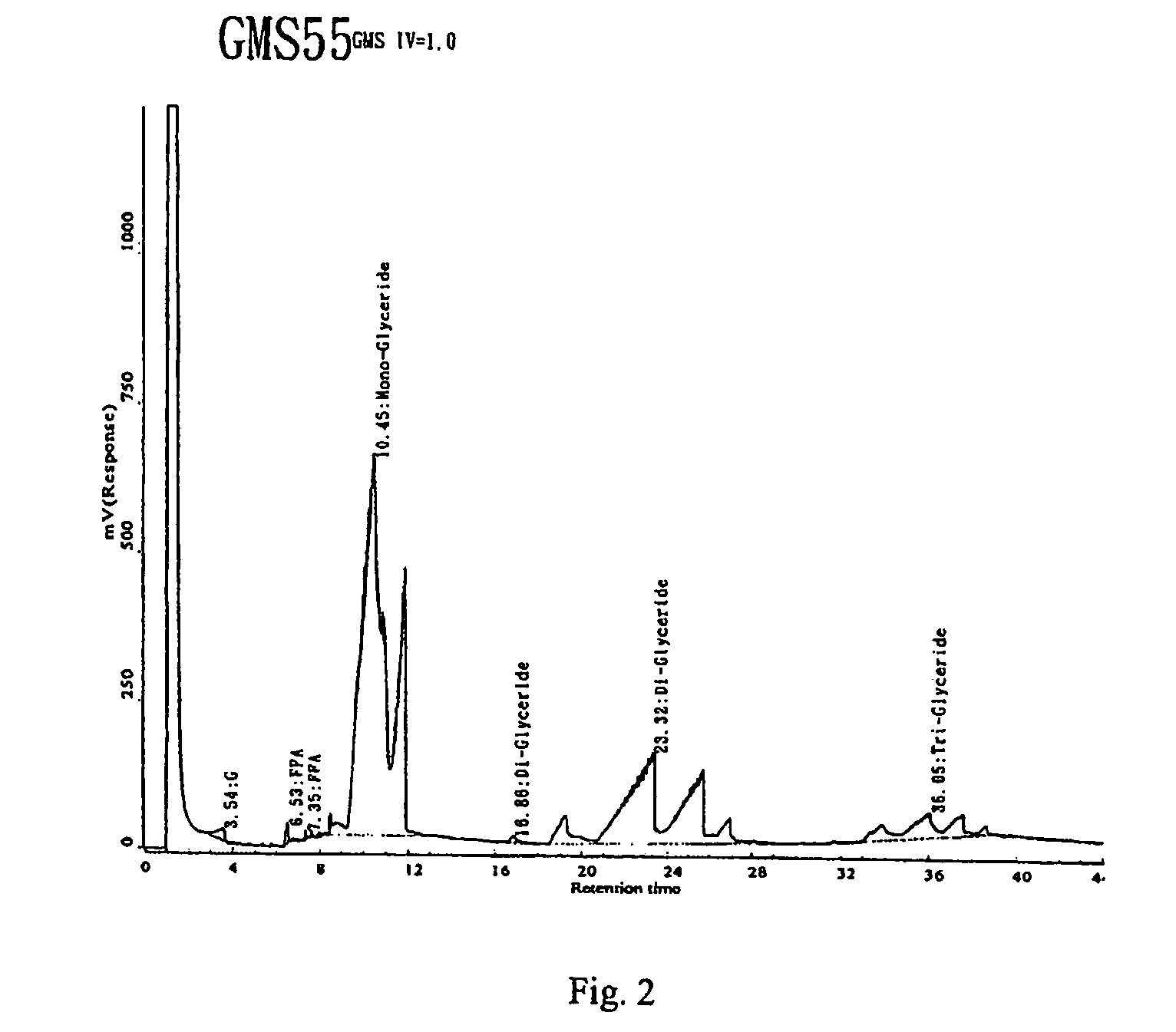

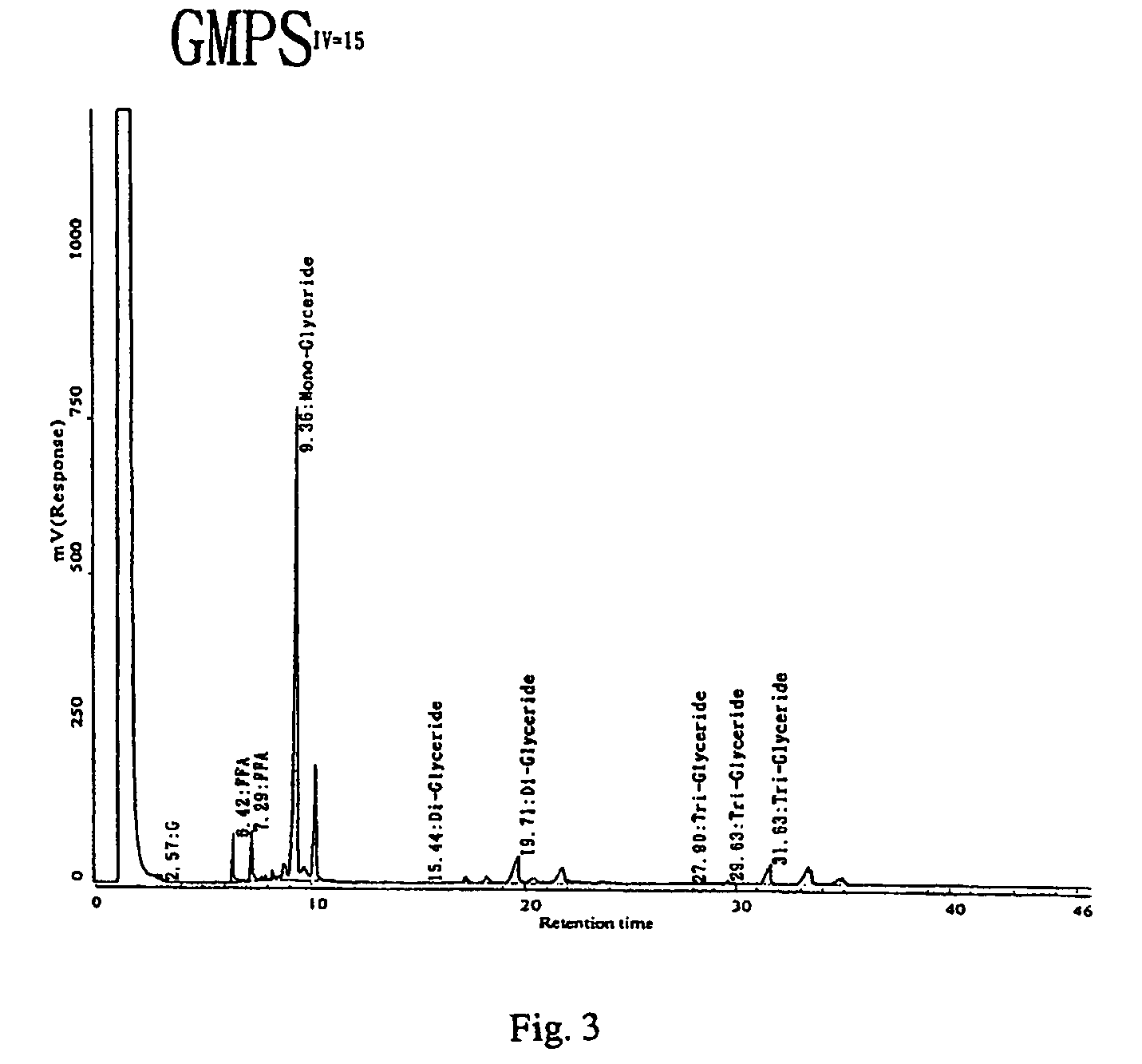

Partial acyl glyceride based biowaxes, biocandles prepared therefrom and their preparation

InactiveUS20080145808A1Promote healthy developmentImprove featuresSolid fuelsCapillary burnersWaxMedicine

The present invention relates to a biowax comprising a partial acyl glyceride selected from the group consisting of a monoacylglyceride, a diacylglyceride and the combination thereof. The present invention also relates to a biocandle comprising a biowax and a wick, and to a method of producing the same.

Owner:CHANT OIL

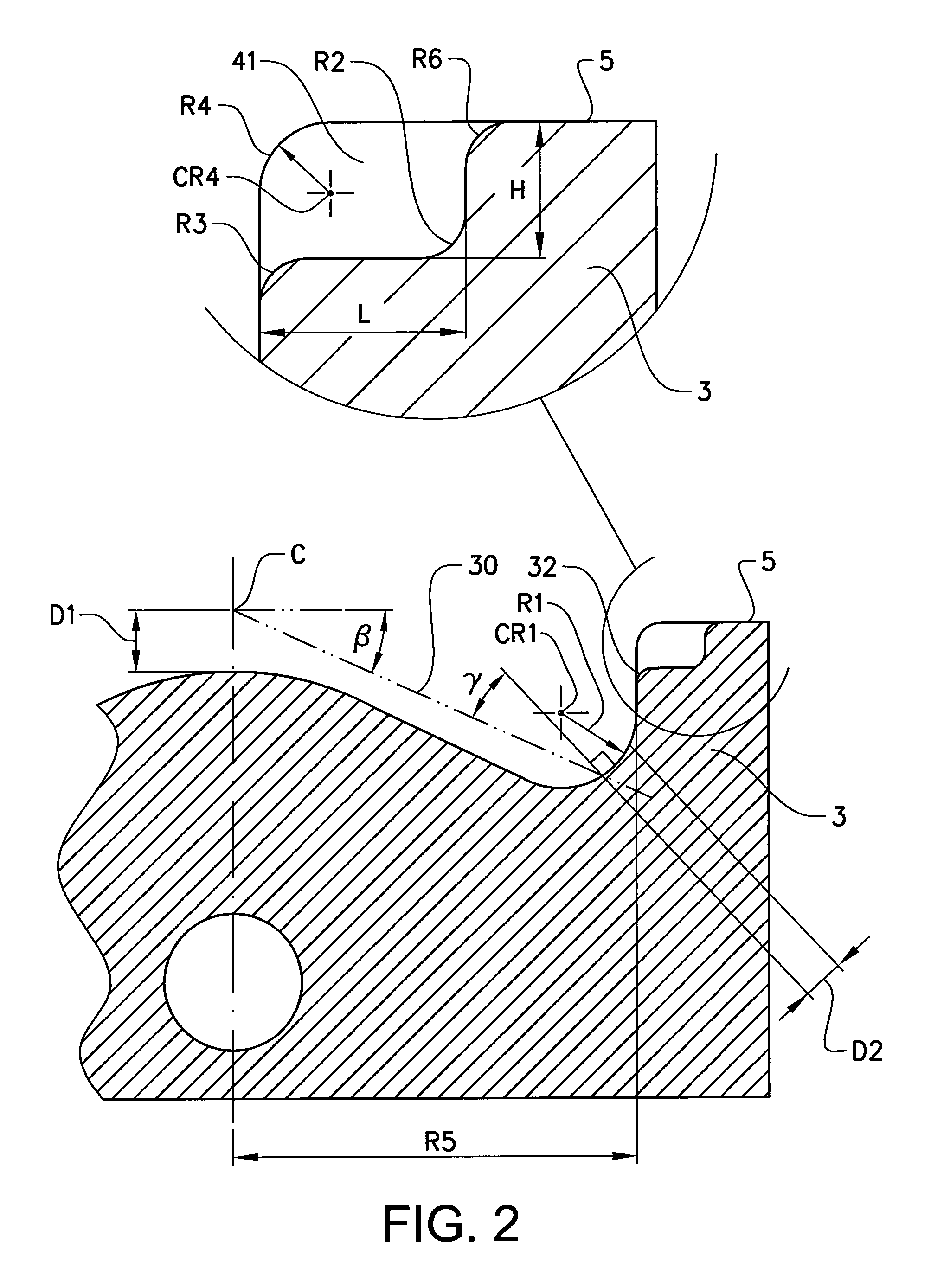

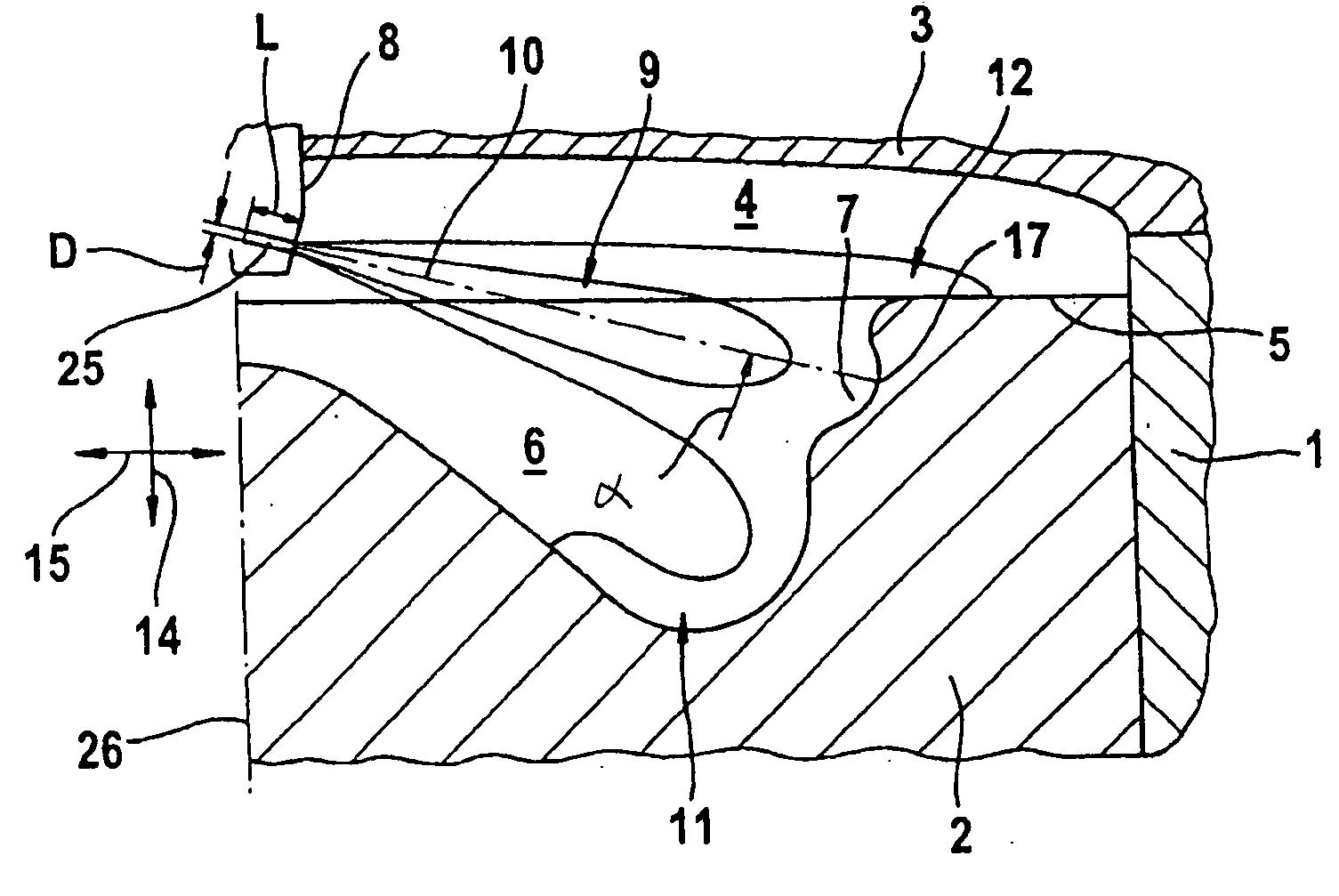

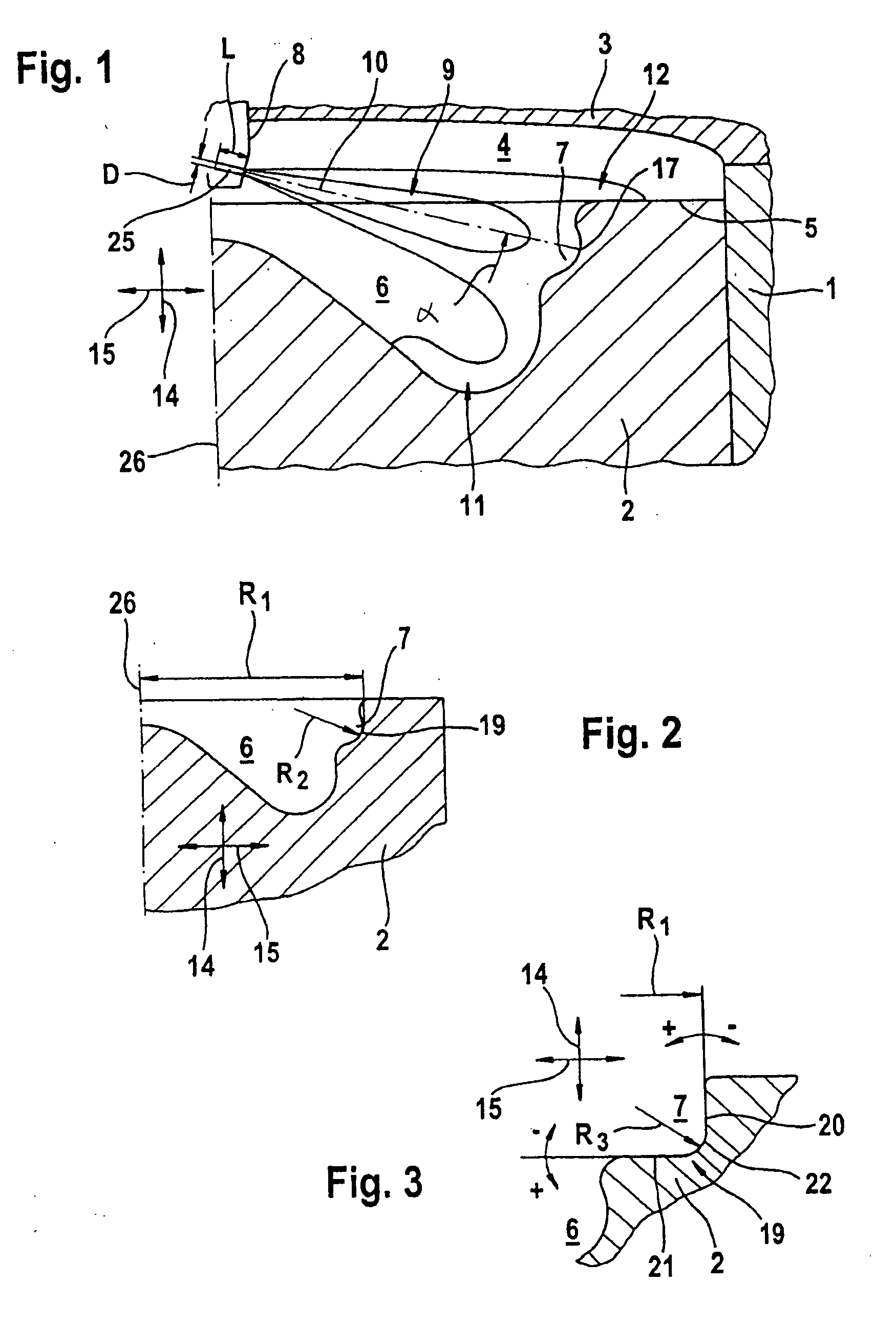

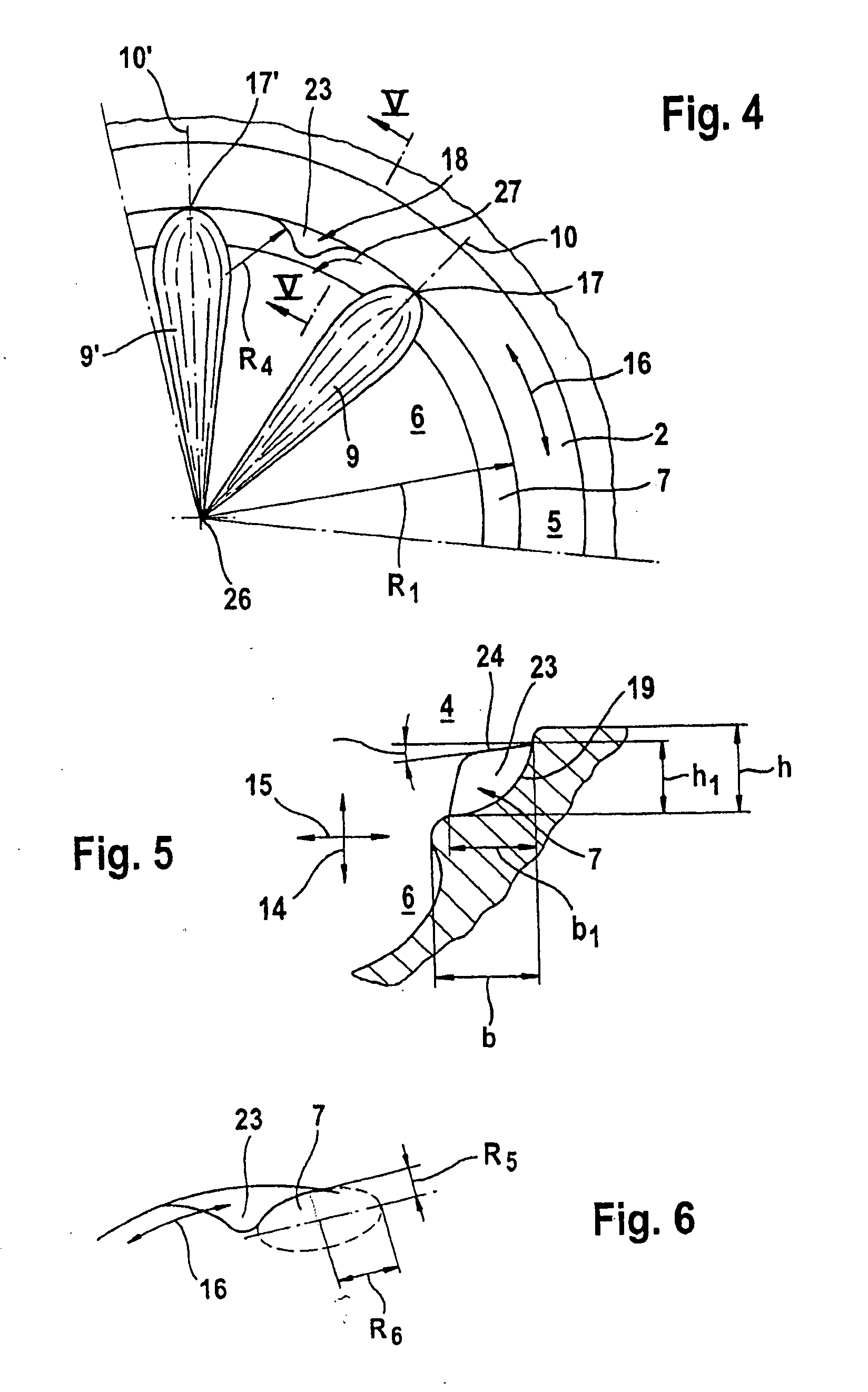

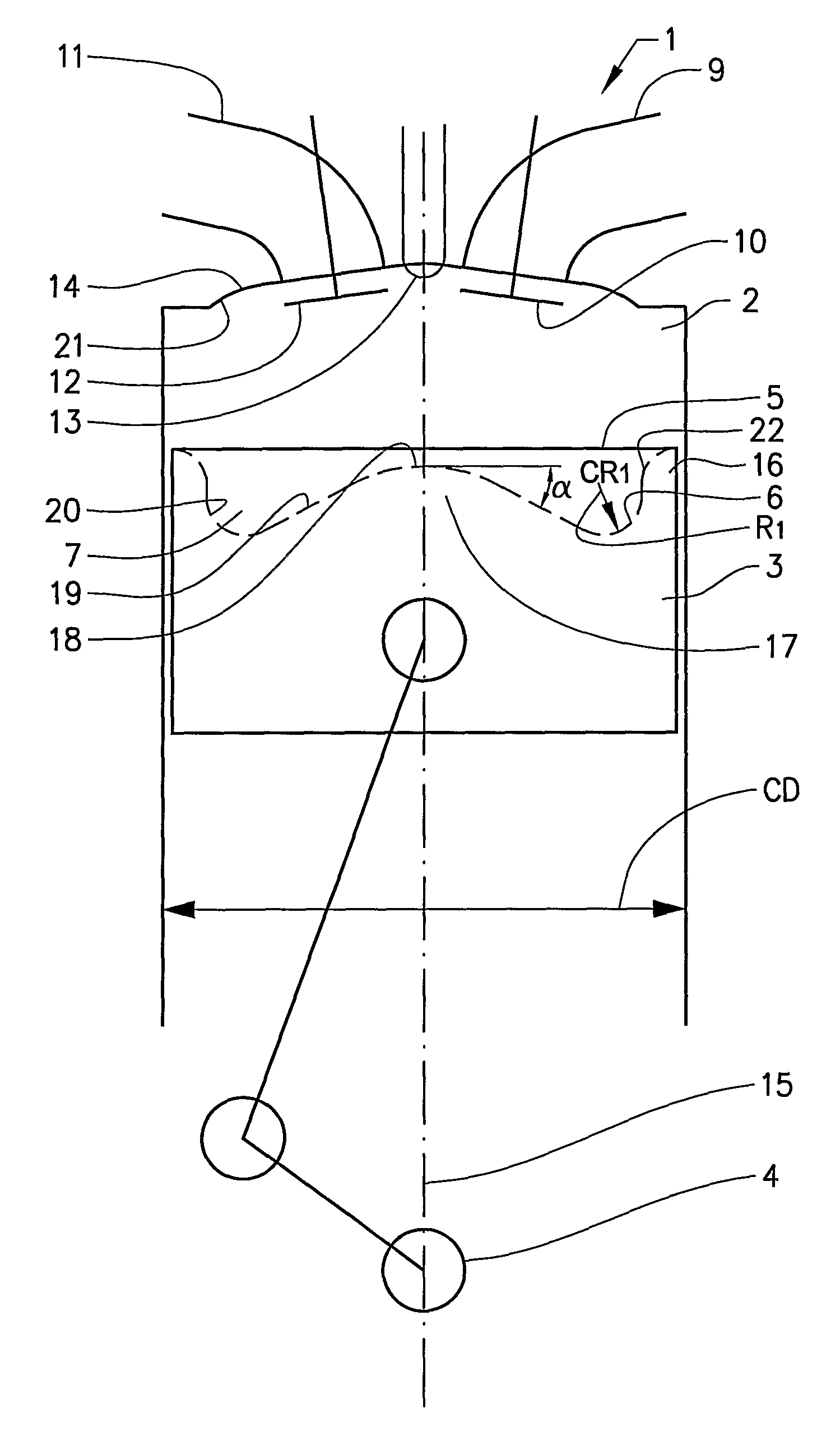

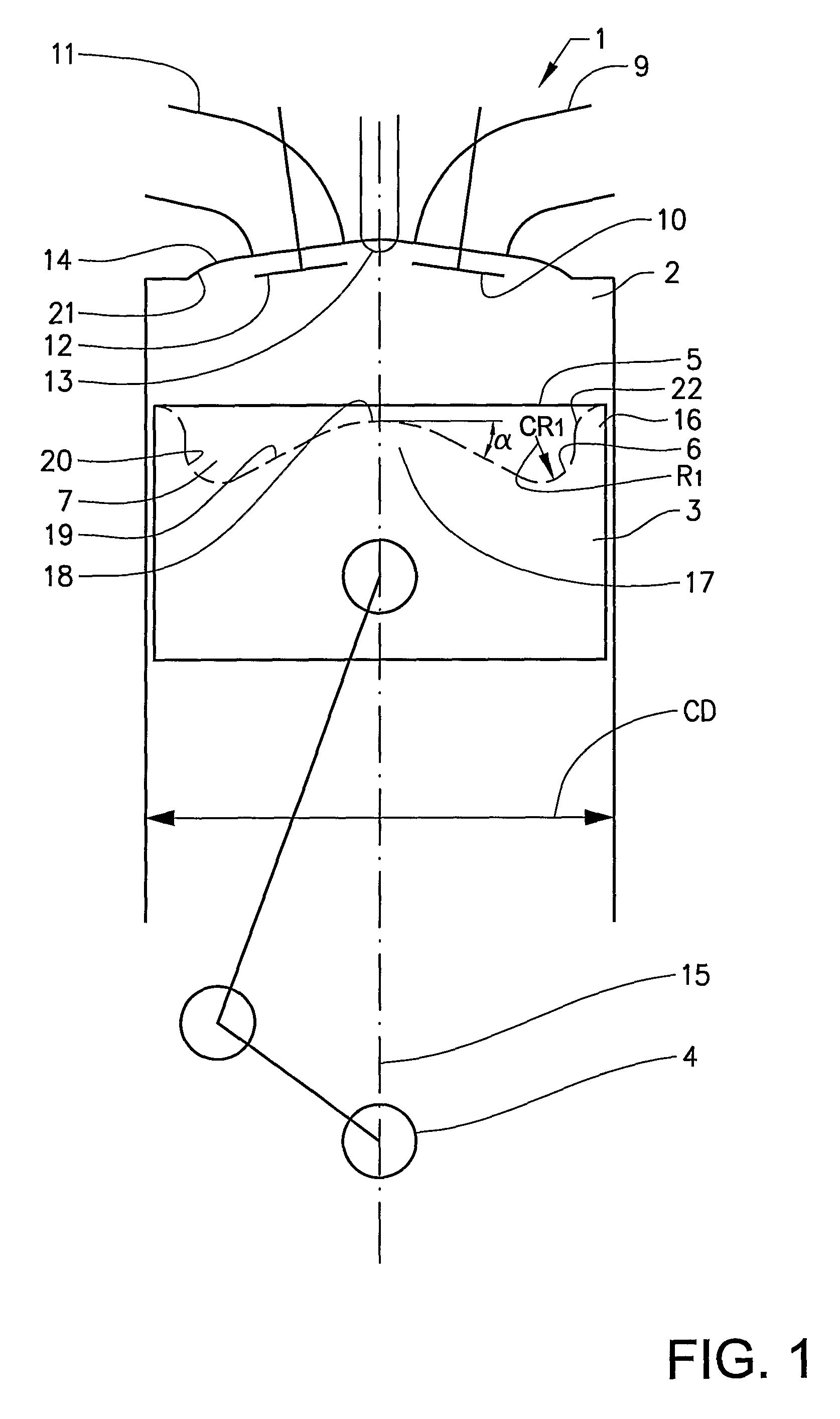

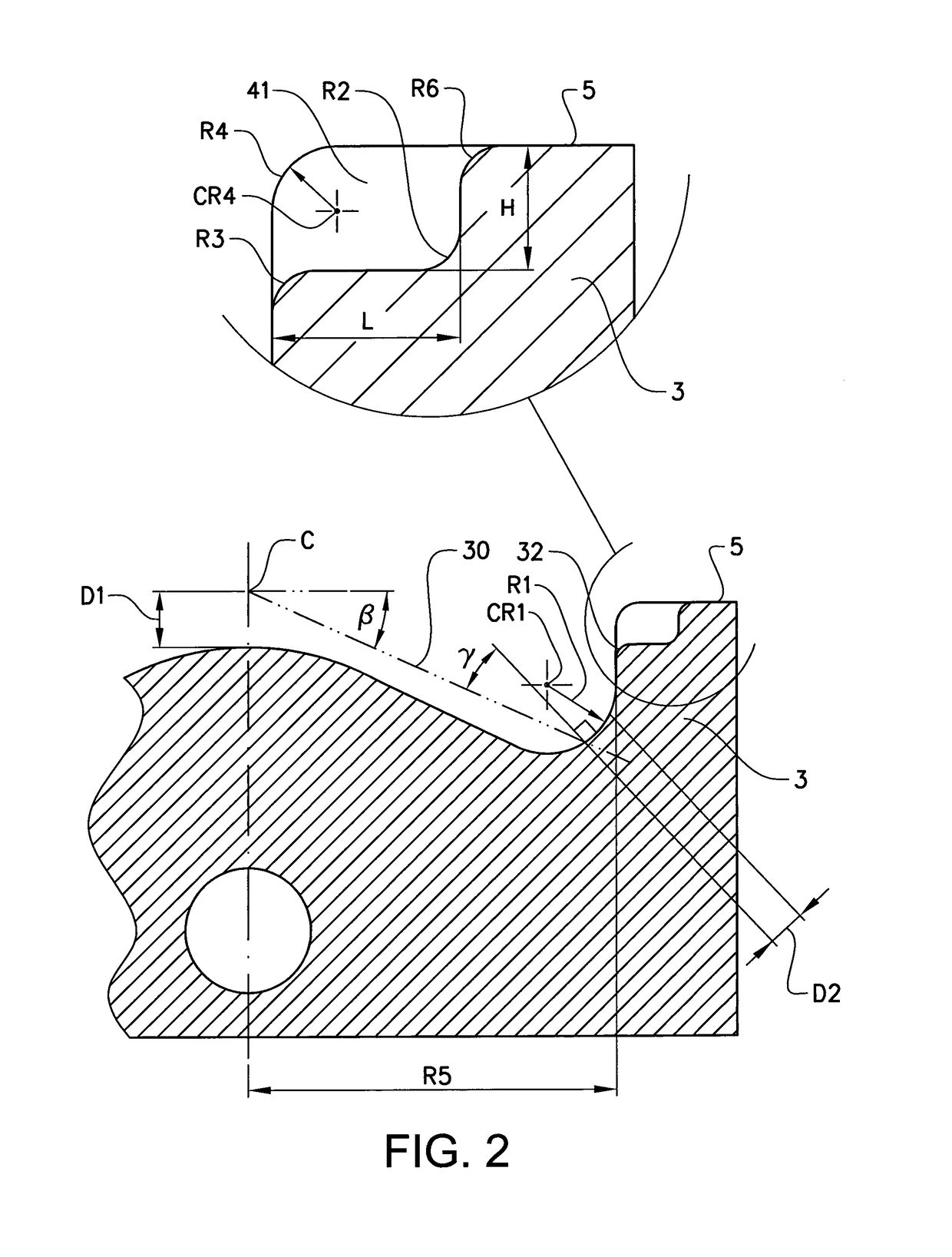

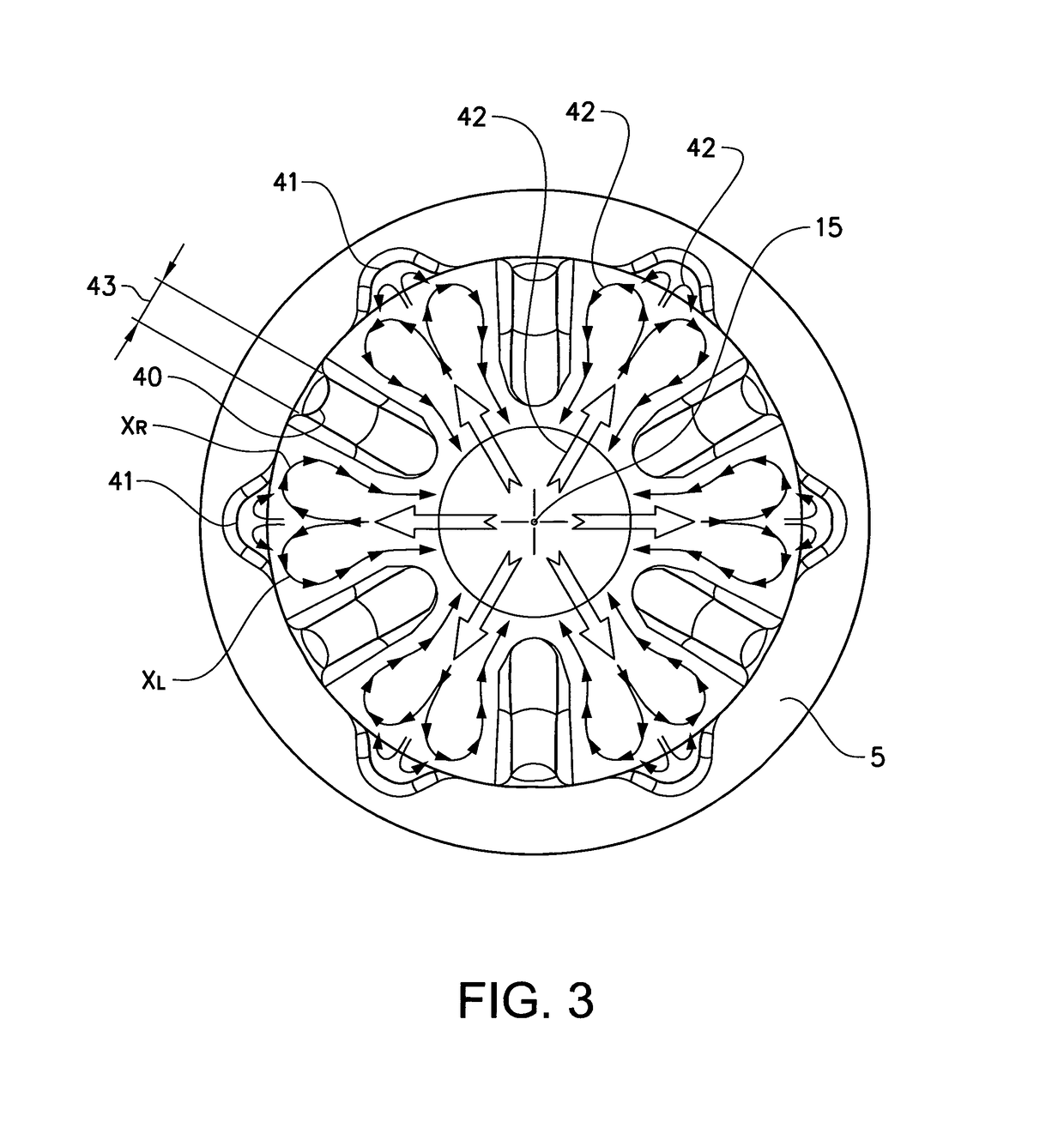

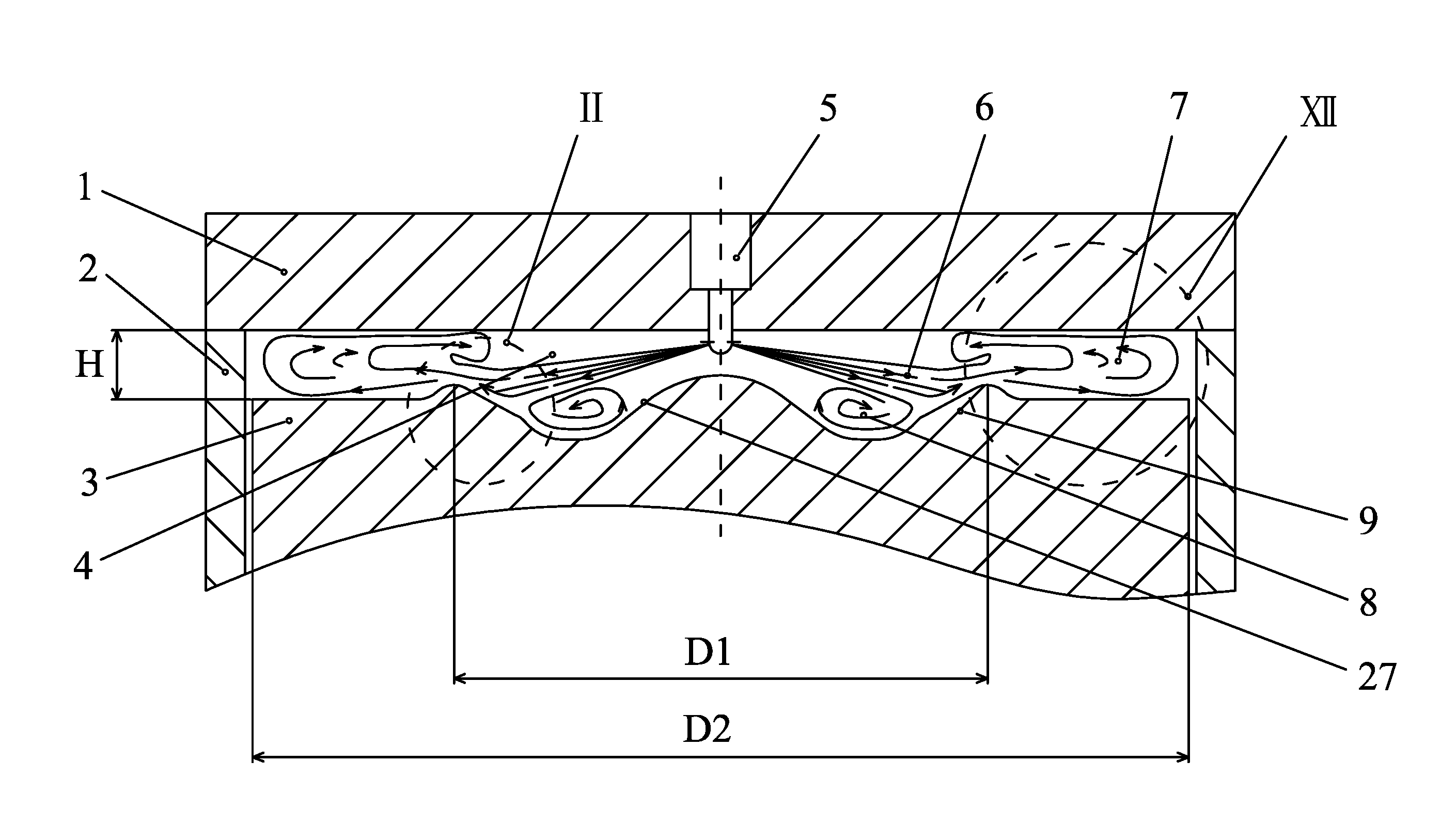

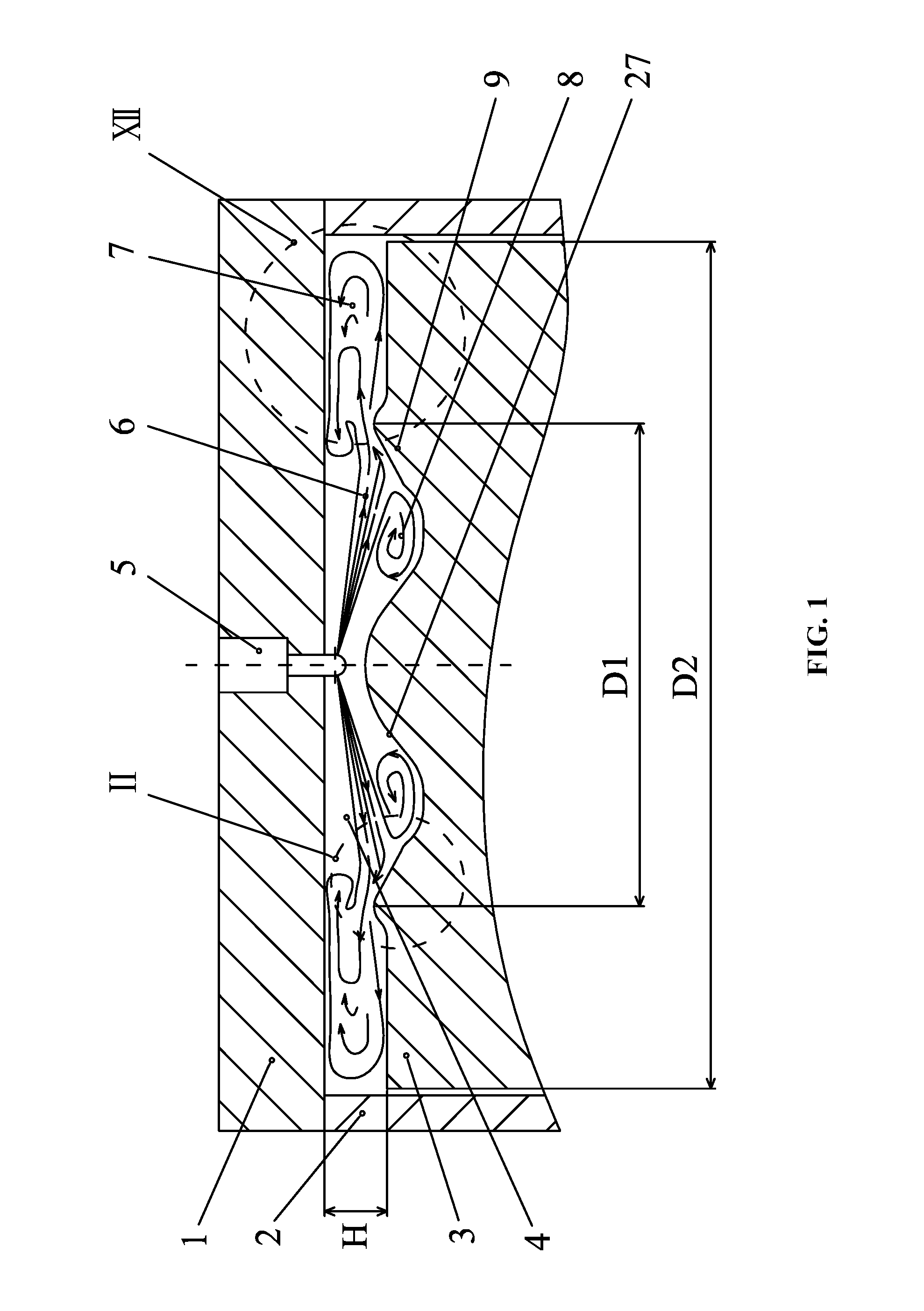

Piston for a cylinder of a combustion engine

ActiveUS20150308371A1Reduce kinetic energy lossReduce smoke and dust emissionsInternal combustion piston enginesPistonsCombustionInternal combustion engine

A piston for a cylinder of a combustion engine includes piston crown including a piston bowl formed by an upwardly facing cavity, the piston bowl including a floor section with a central, and a side section, the side section connecting the inner section with an upper surface of the piston crown, wherein the side section is formed with mutually spaced apart ridges protruding towards the apex, and wherein the side section having at least one recess at an upper end of the side section connecting the side section with the upper surface of the piston crown.

Owner:VOLVO LASTVAGNAR AB

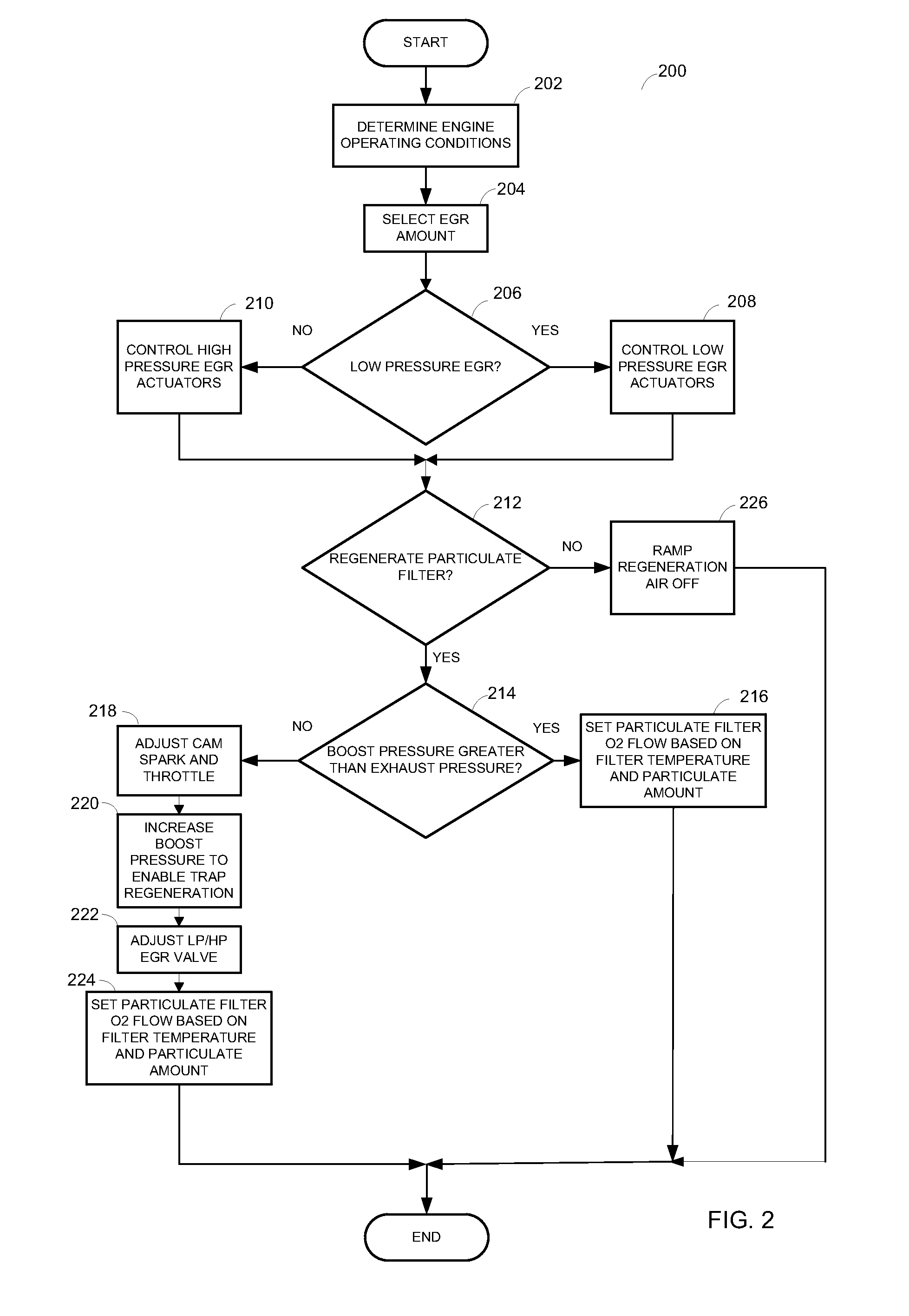

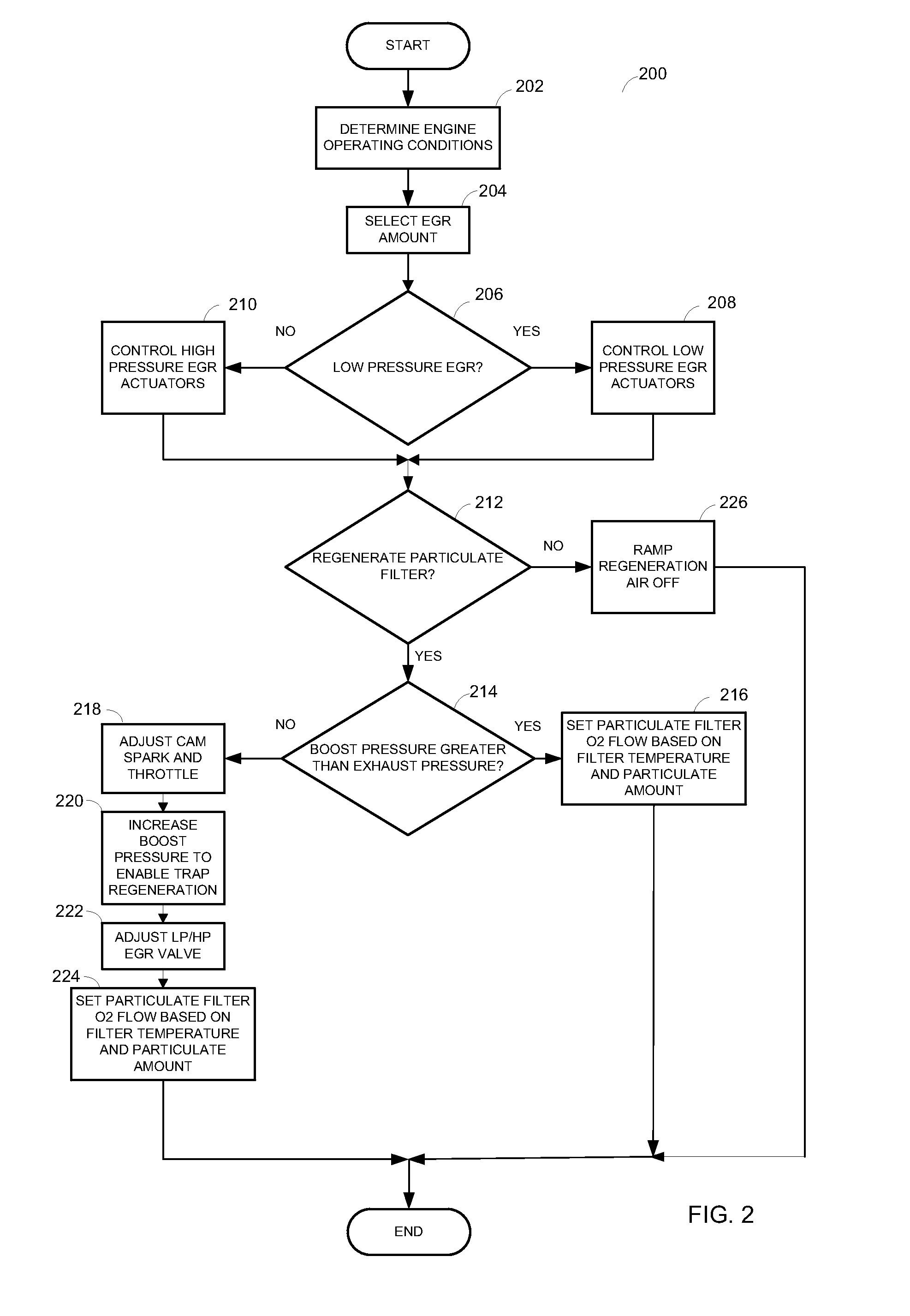

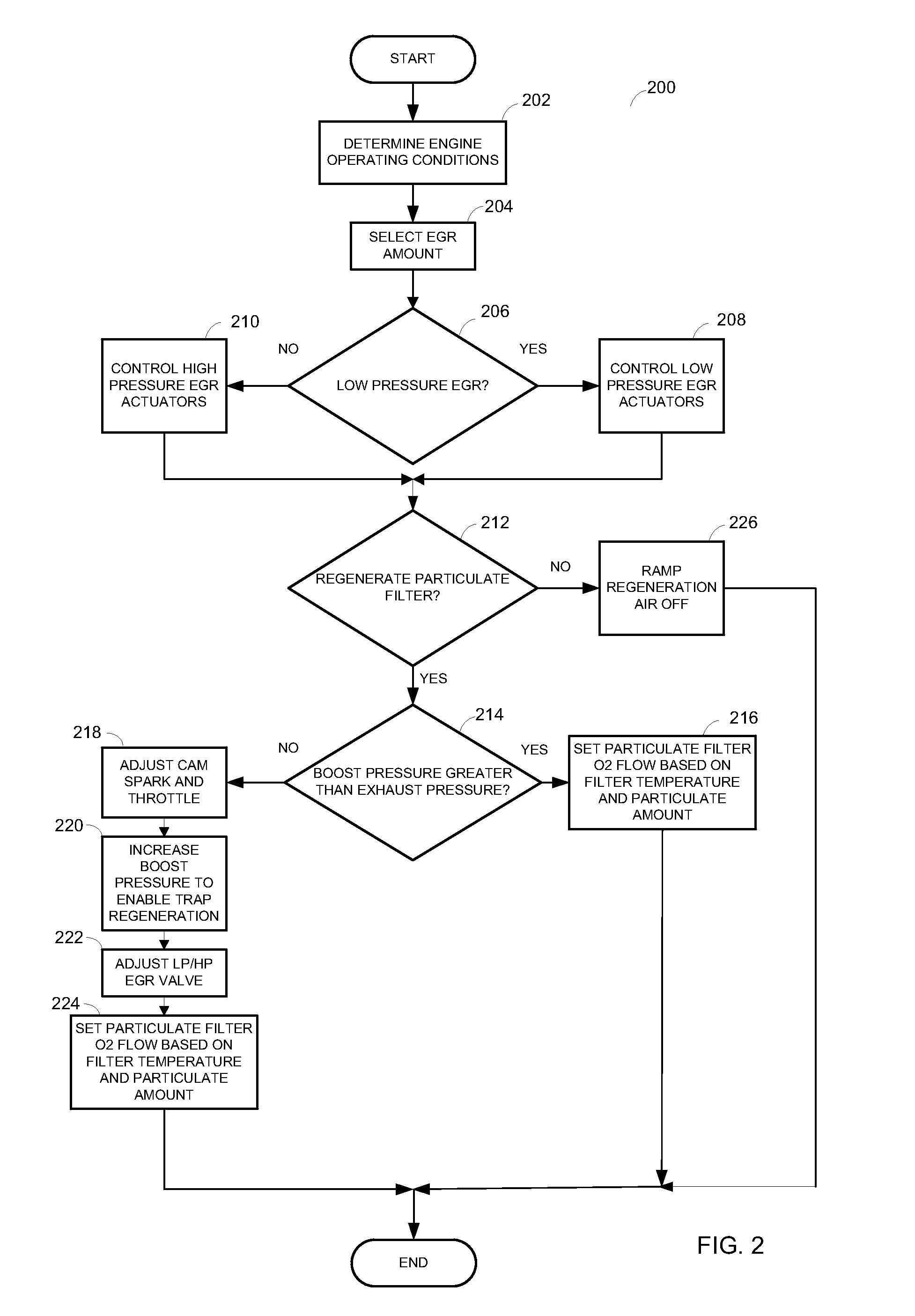

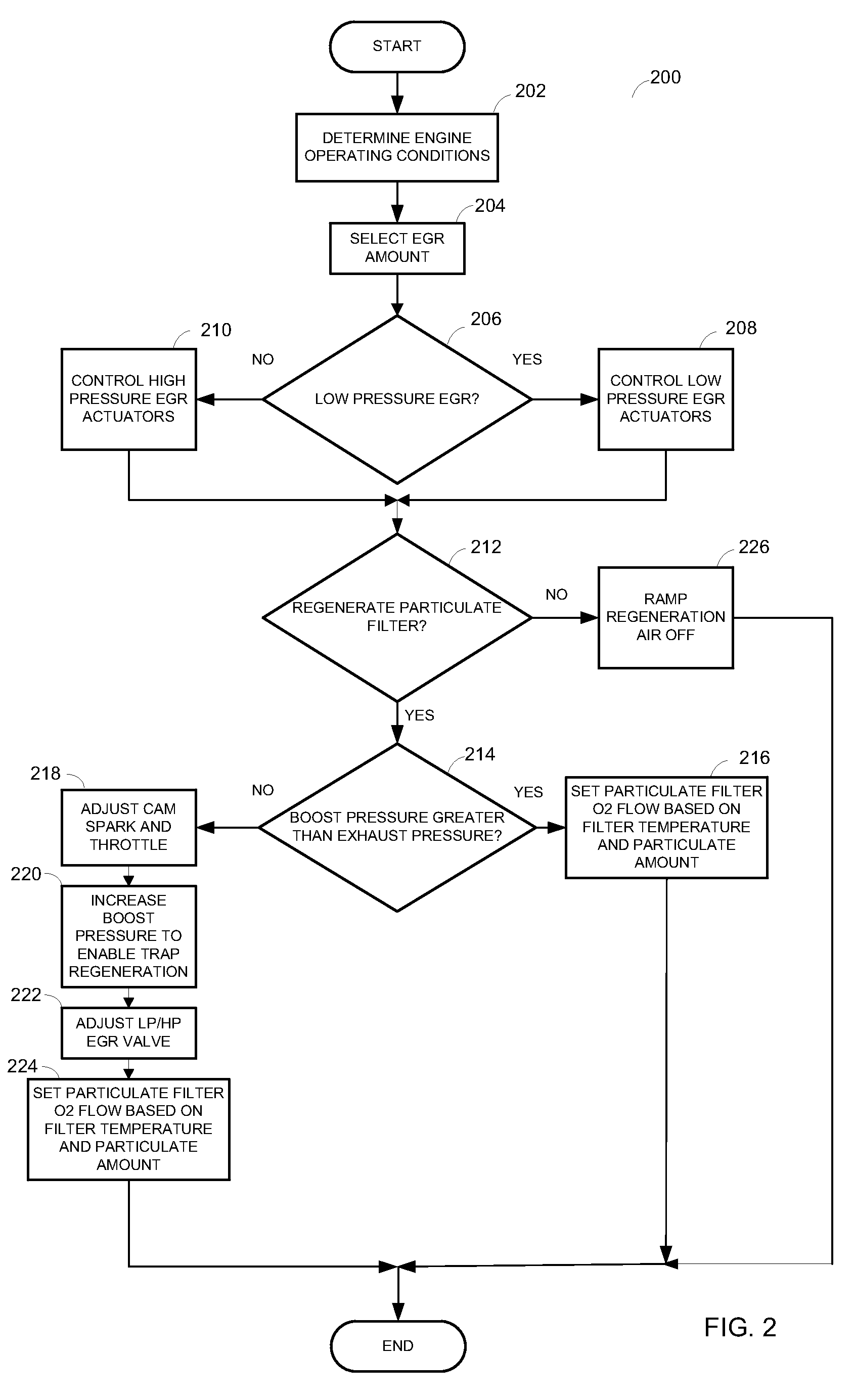

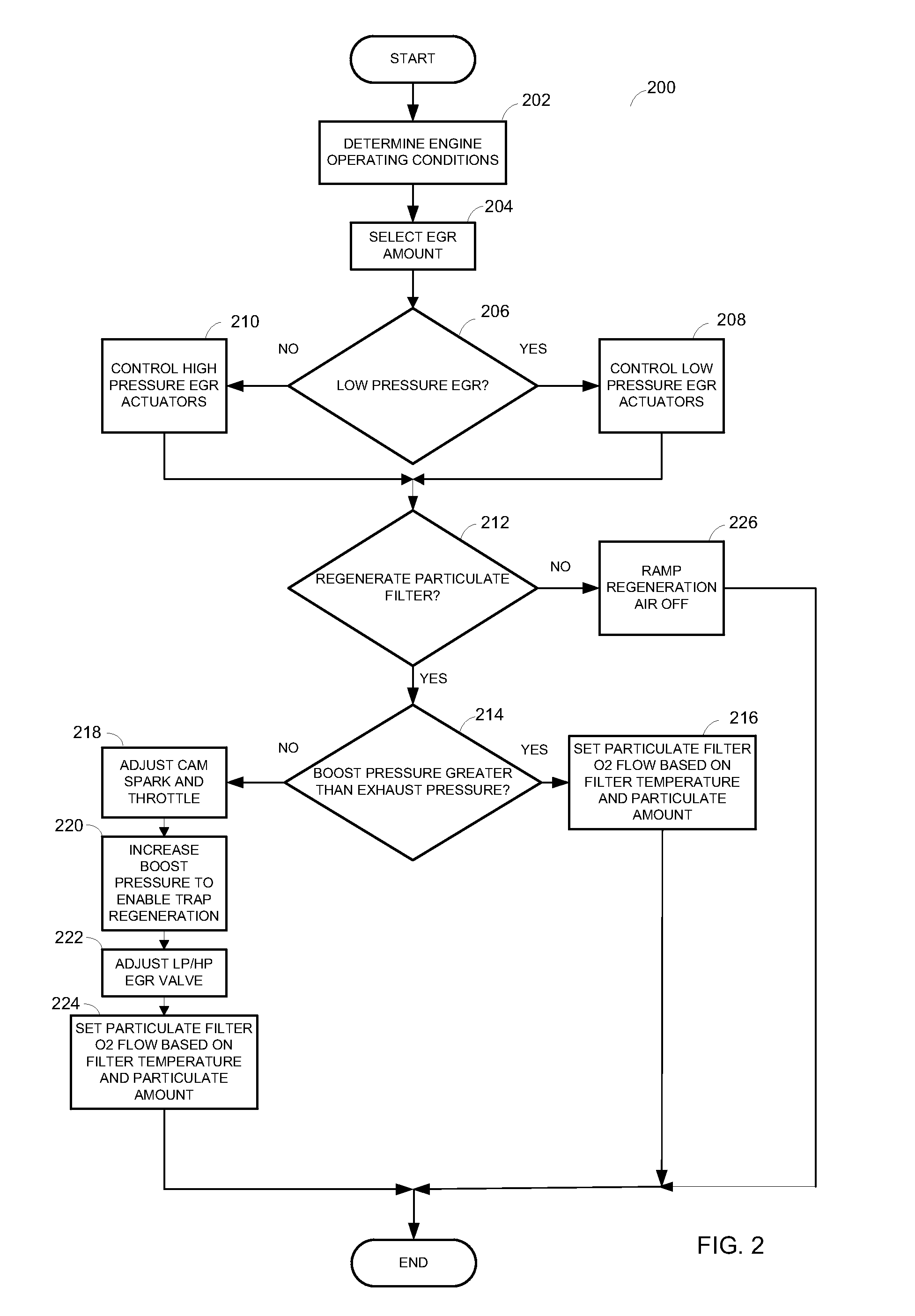

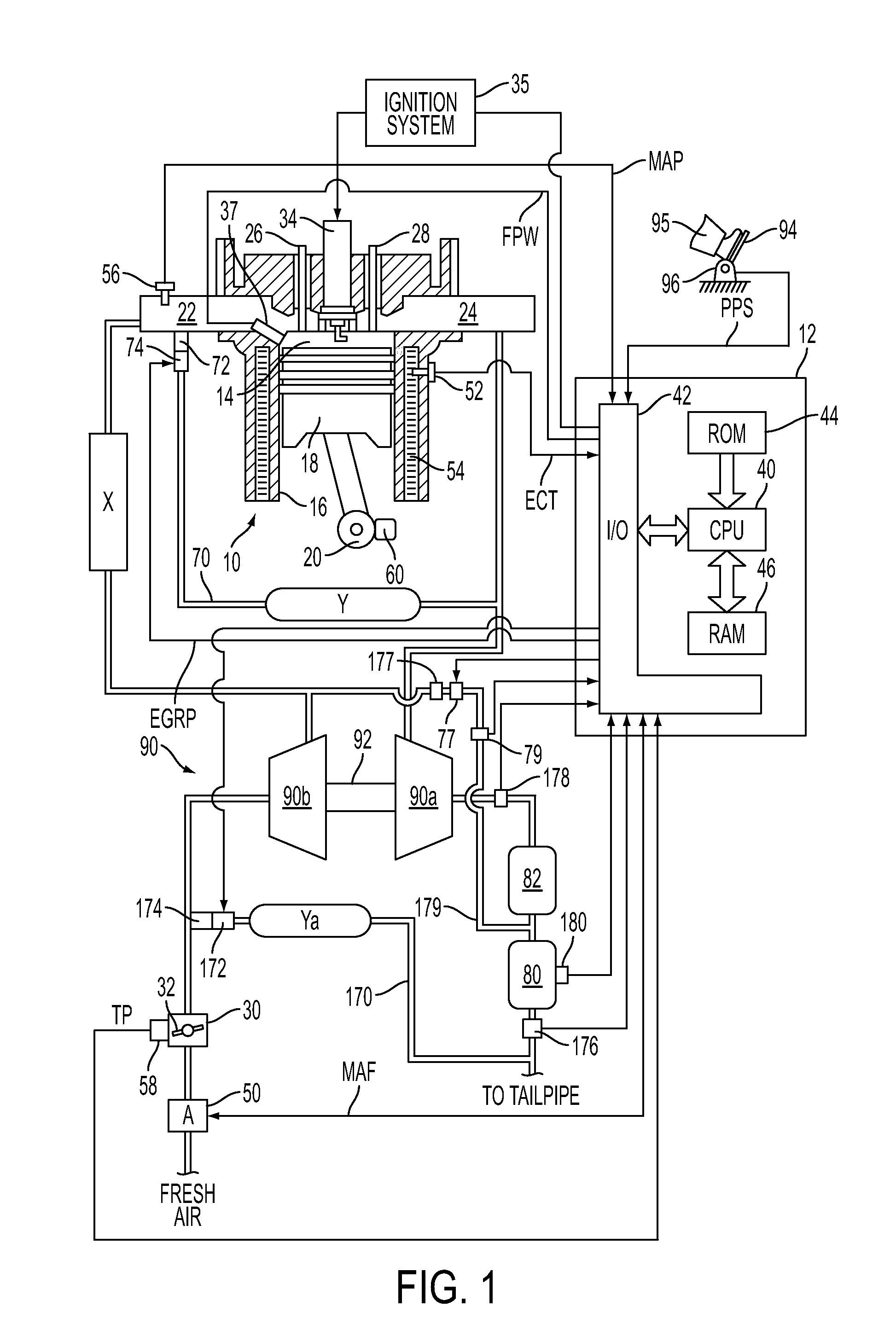

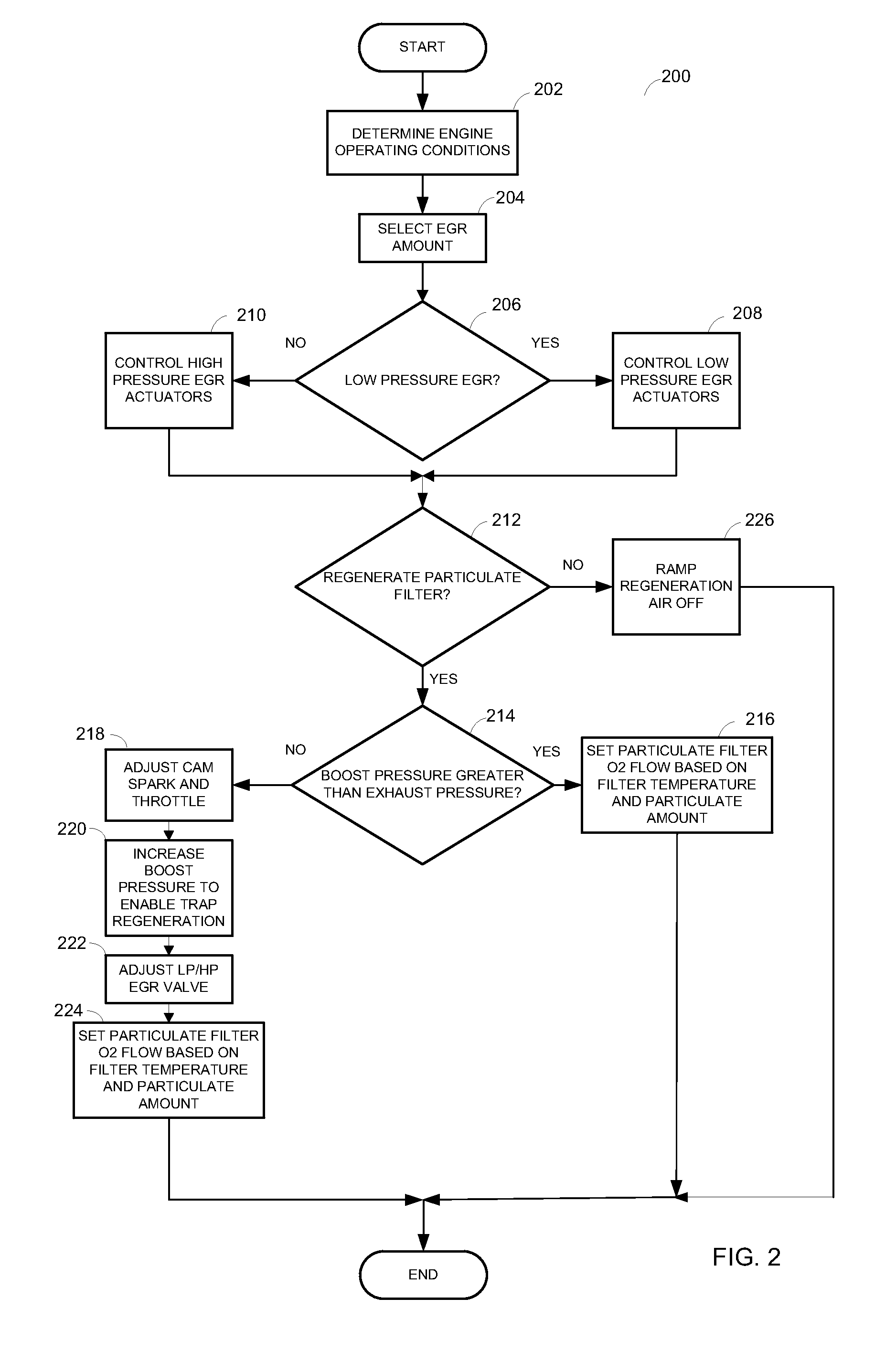

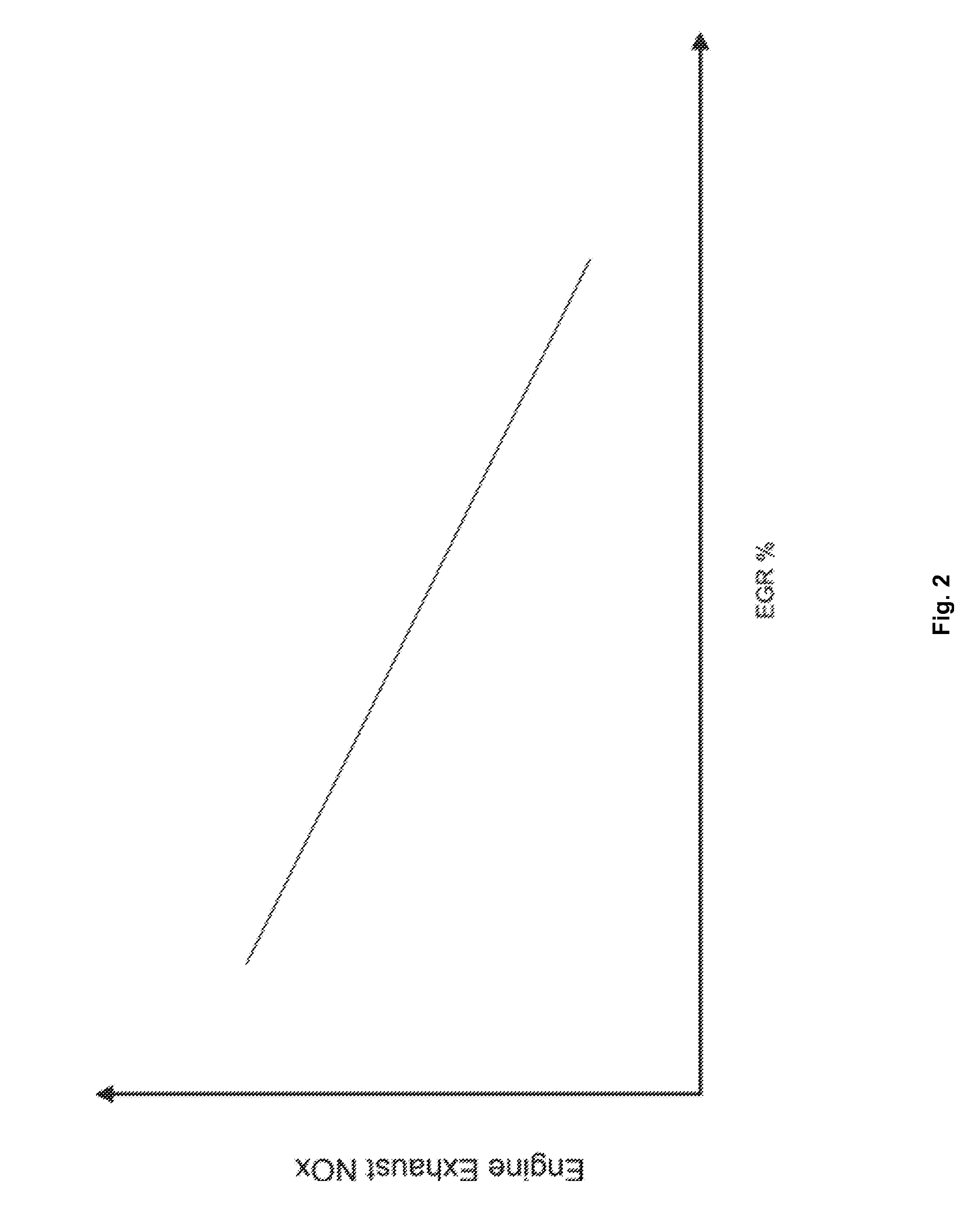

Method for adjusting boost pressure while regenerating a particulate filter for a direct injection engine

ActiveUS20110072803A1Emission reductionReduce engine pumping lossElectrical controlInternal combustion piston enginesGasolineEngineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turbocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter and downstream of a three-way catalyst. The oxygen may be regulated in part by adjusting compressor boost pressure in response to a state of particulate filter regeneration. Further, in one embodiment, engine NOx can be controlled by EGR.

Owner:FORD GLOBAL TECH LLC

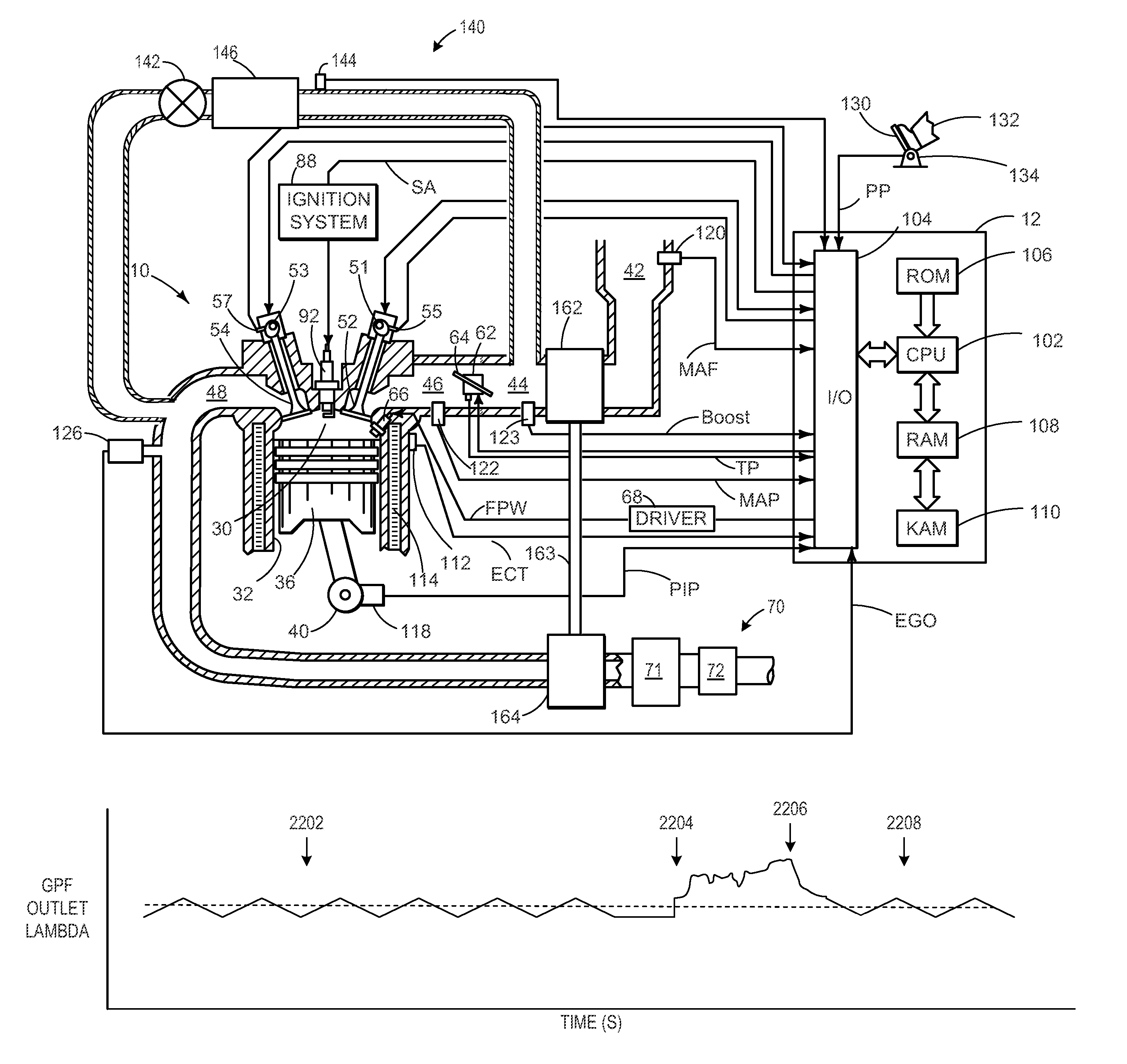

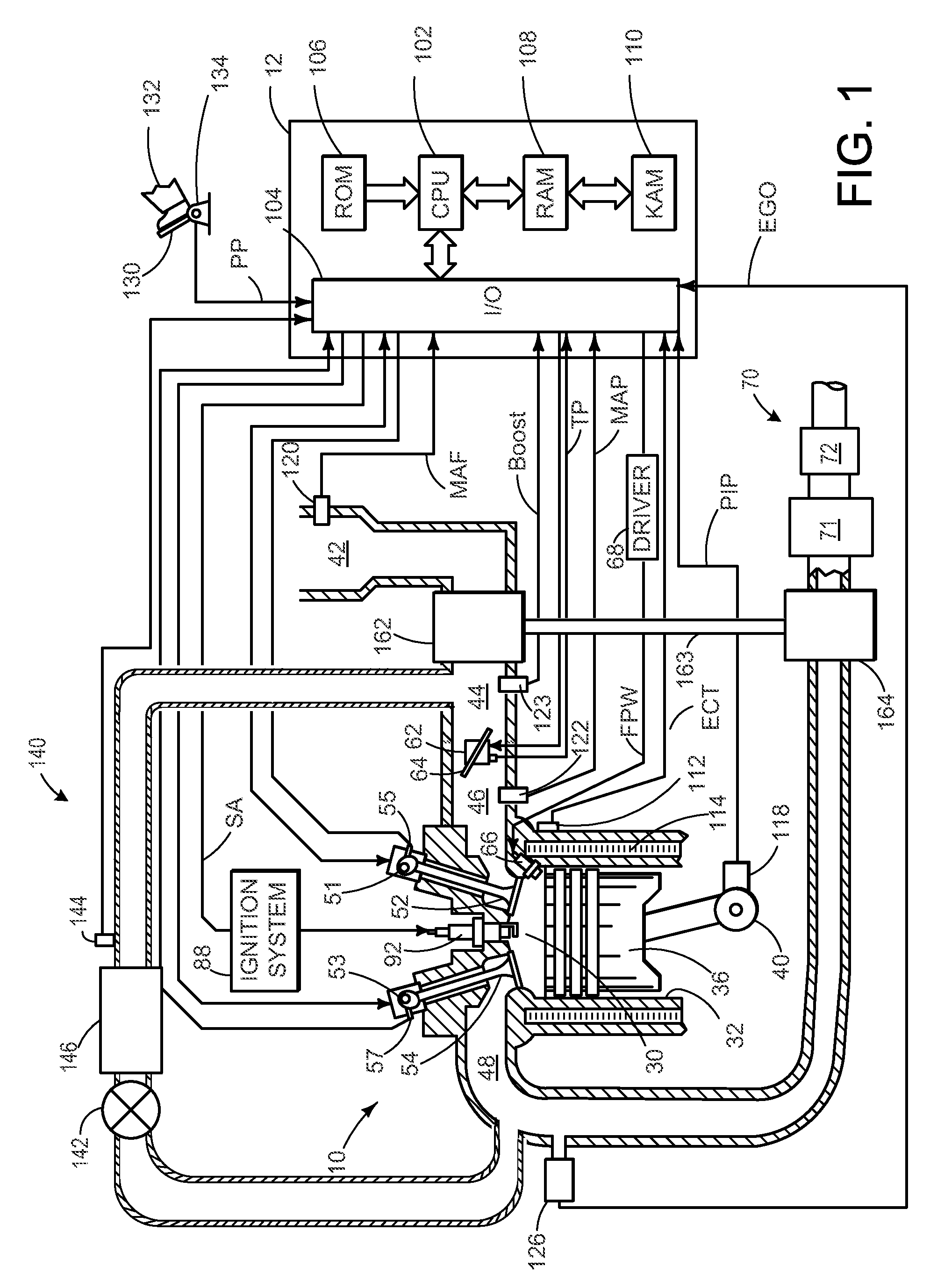

Gasoline particulate filter regeneration and diagnostics

ActiveUS8327628B2Reduce smoke and dust emissionsImprove engine performanceElectrical controlInternal combustion piston enginesParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

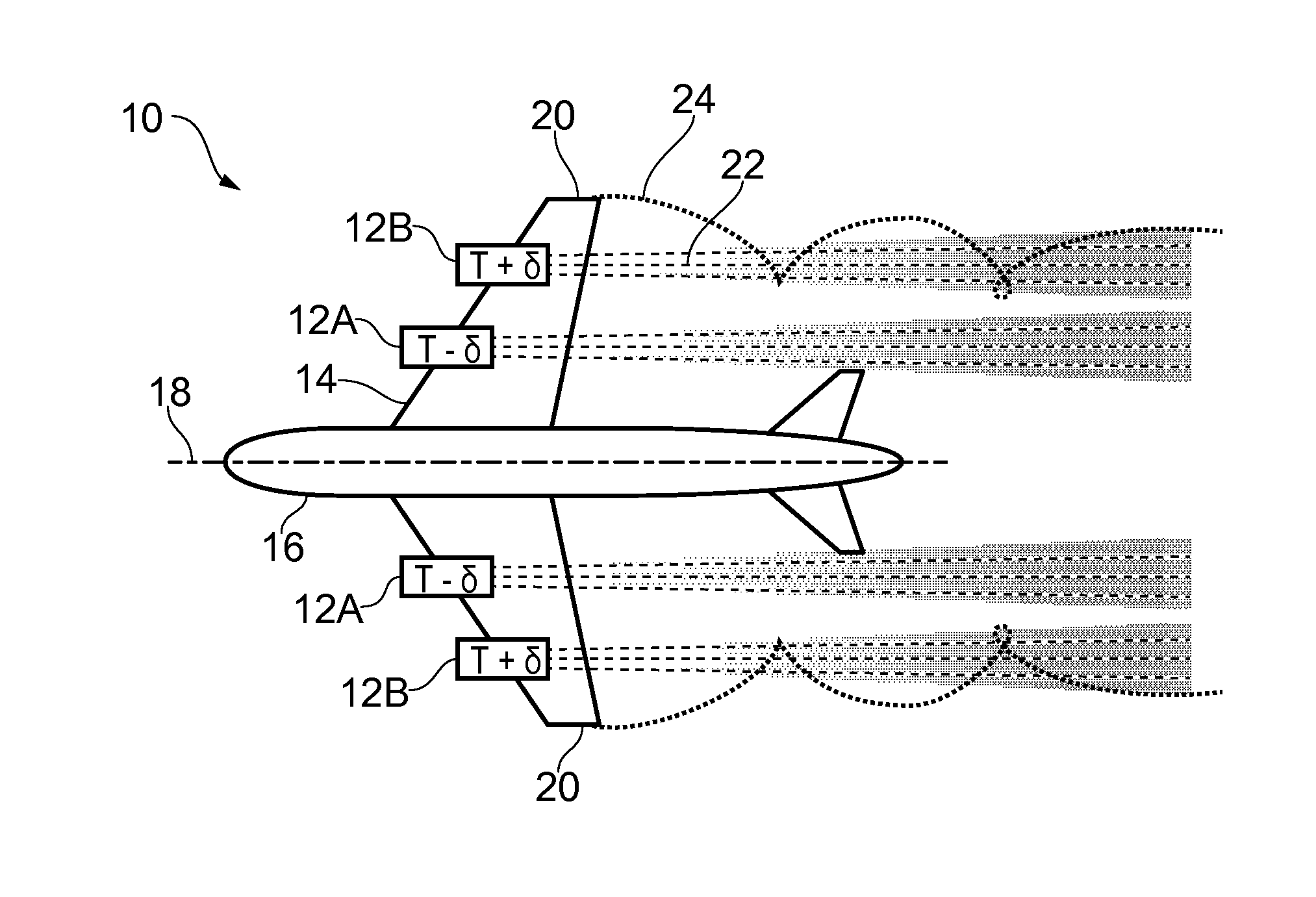

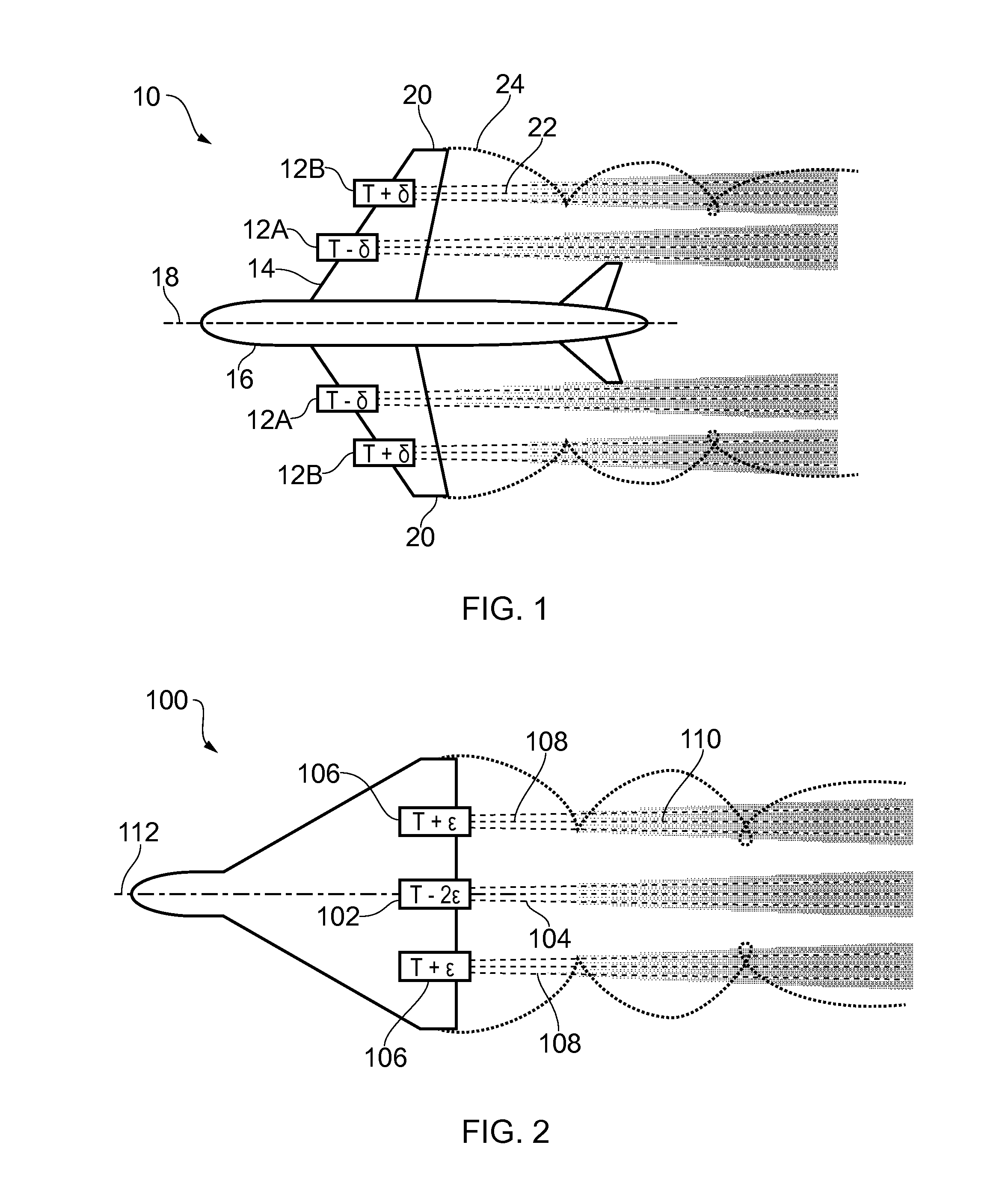

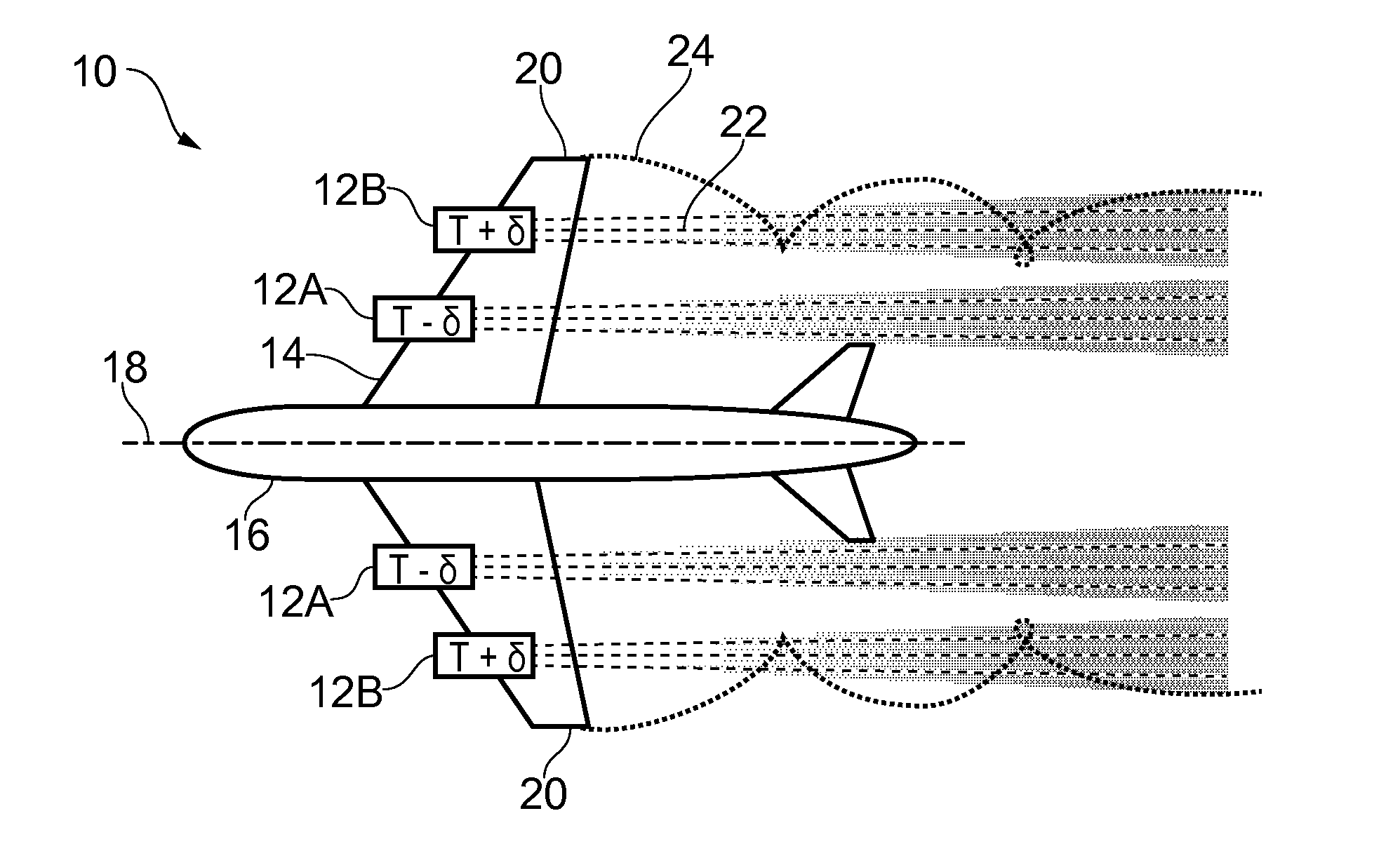

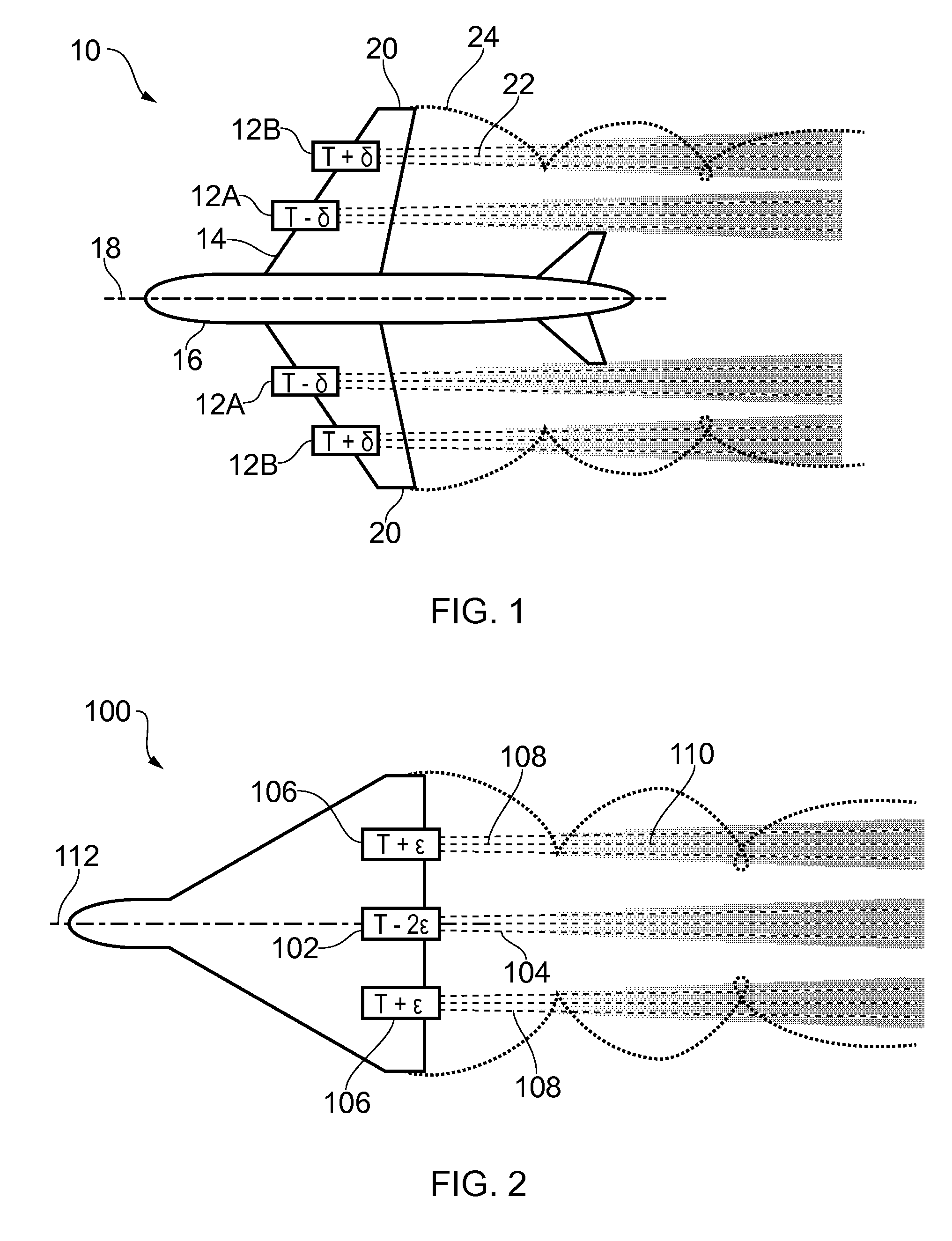

Aircraft vapour trail control system

ActiveUS20150284102A1Reduce depthReduced characteristicsPower plant exhaust arrangementsDigital data processing detailsThrottle controlControl system

The invention concerns an aircraft propulsion control system for an aircraft with a plurality of gas turbine engines mounted at different spaced positions relative to an airframe. One or more sensor is arranged to sense a condition indicative of vapour trail formation by an exhaust flow from one or more of the plurality of engines. A controller is arranged to be responsive to thrust demand for the aircraft and selectively to control each of the engines so as to modify the exhaust flow of at least one engine relative to at least one further engine according to the positions of the engines on the airframe. The proximity of an engine to a vortical wake flow created by the airframe may be used to determine suitable exhaust flow modifications. The controller may output a separate throttle control signal to each engine and / or may adjust the fuel composition supplied to each engine.

Owner:ROLLS ROYCE PLC

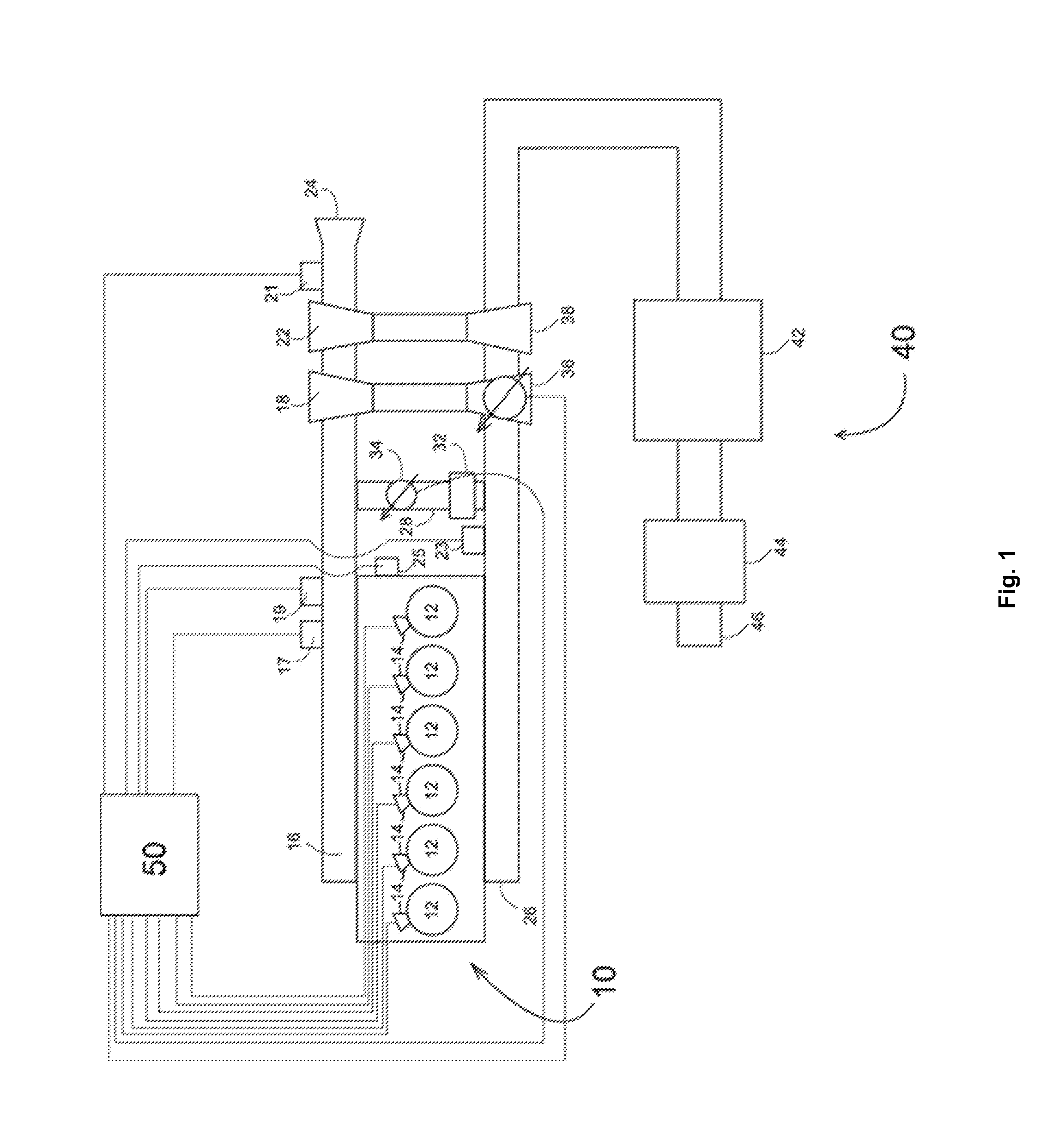

System for regenerating a particulate filter and controlling egr

ActiveUS20110072804A1Emission reductionReduce engine pumping lossElectrical controlInternal combustion piston enginesExhaust fumesGasoline

A system for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turbocharged gasoline engine to the exhaust system by a compressor. Simultaneously, exhaust gases may be pumped from the exhaust system to the intake system for the purpose of reducing NOx while regenerating a particulate filter.

Owner:FORD GLOBAL TECH LLC

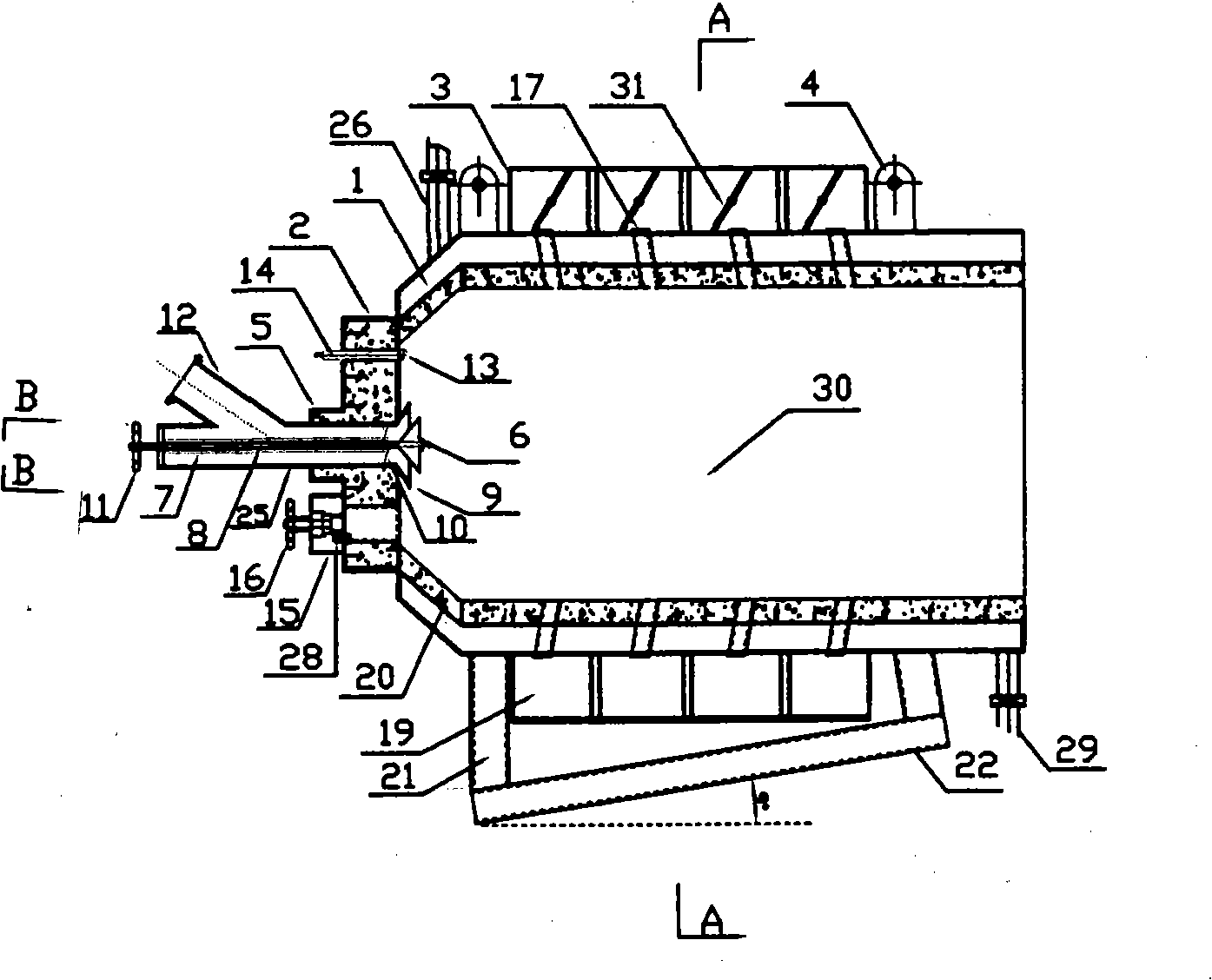

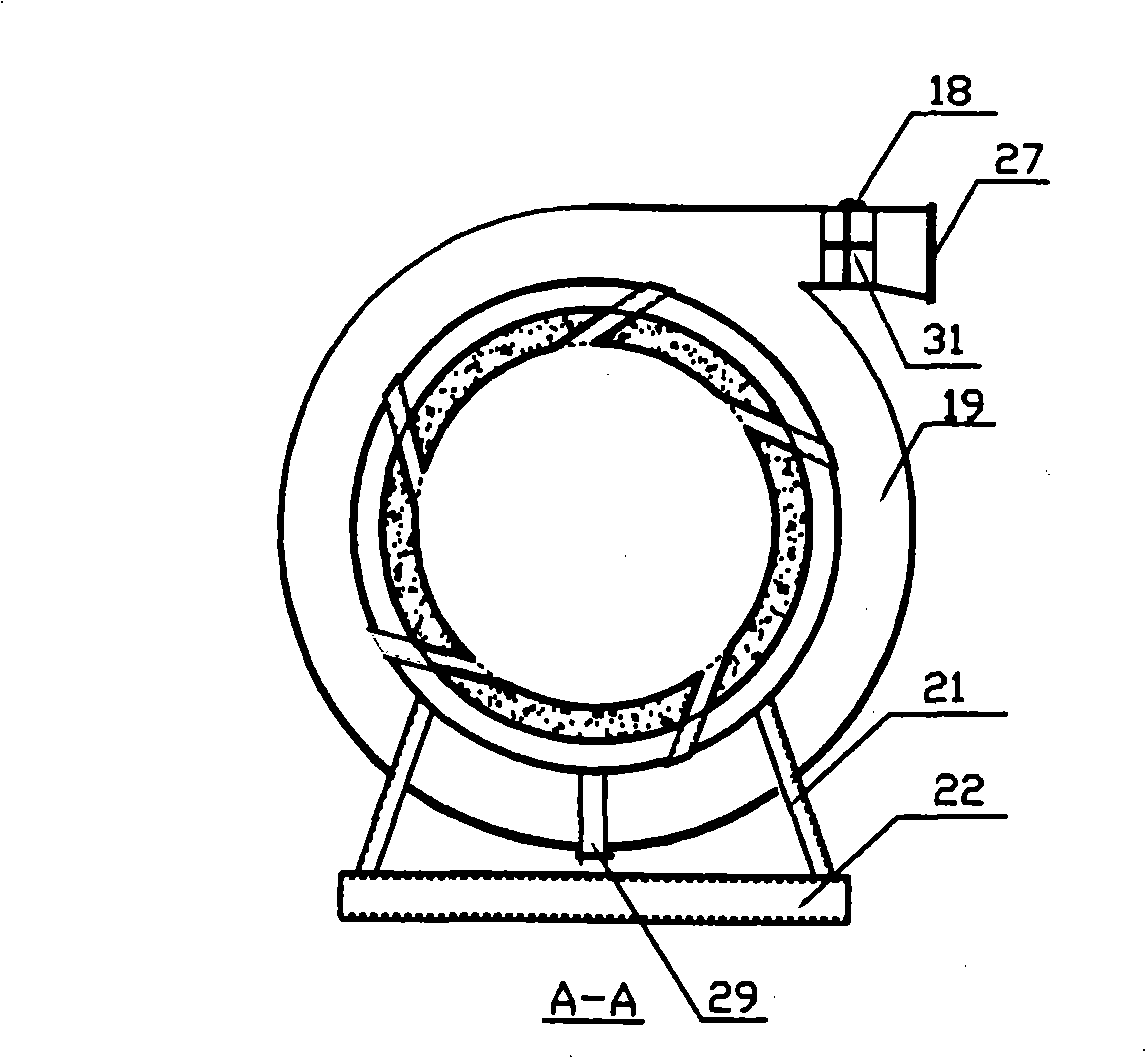

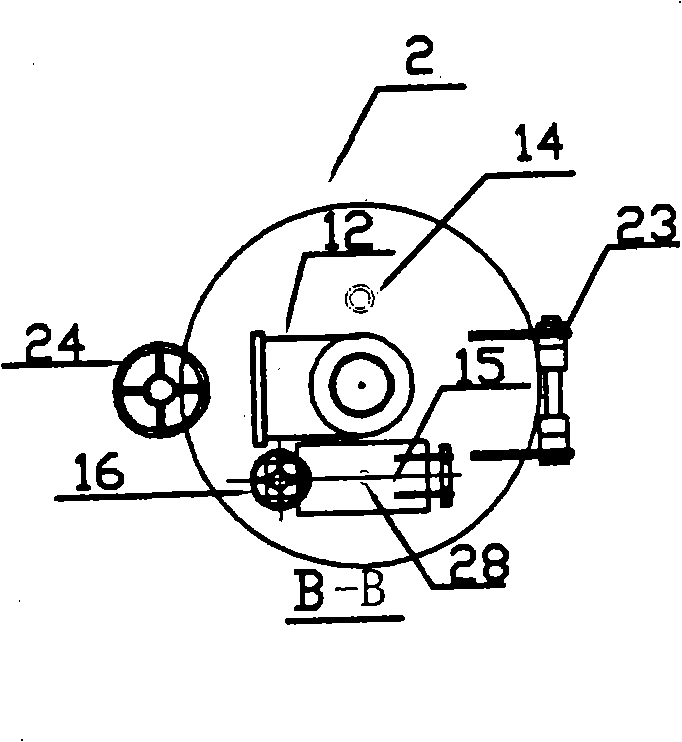

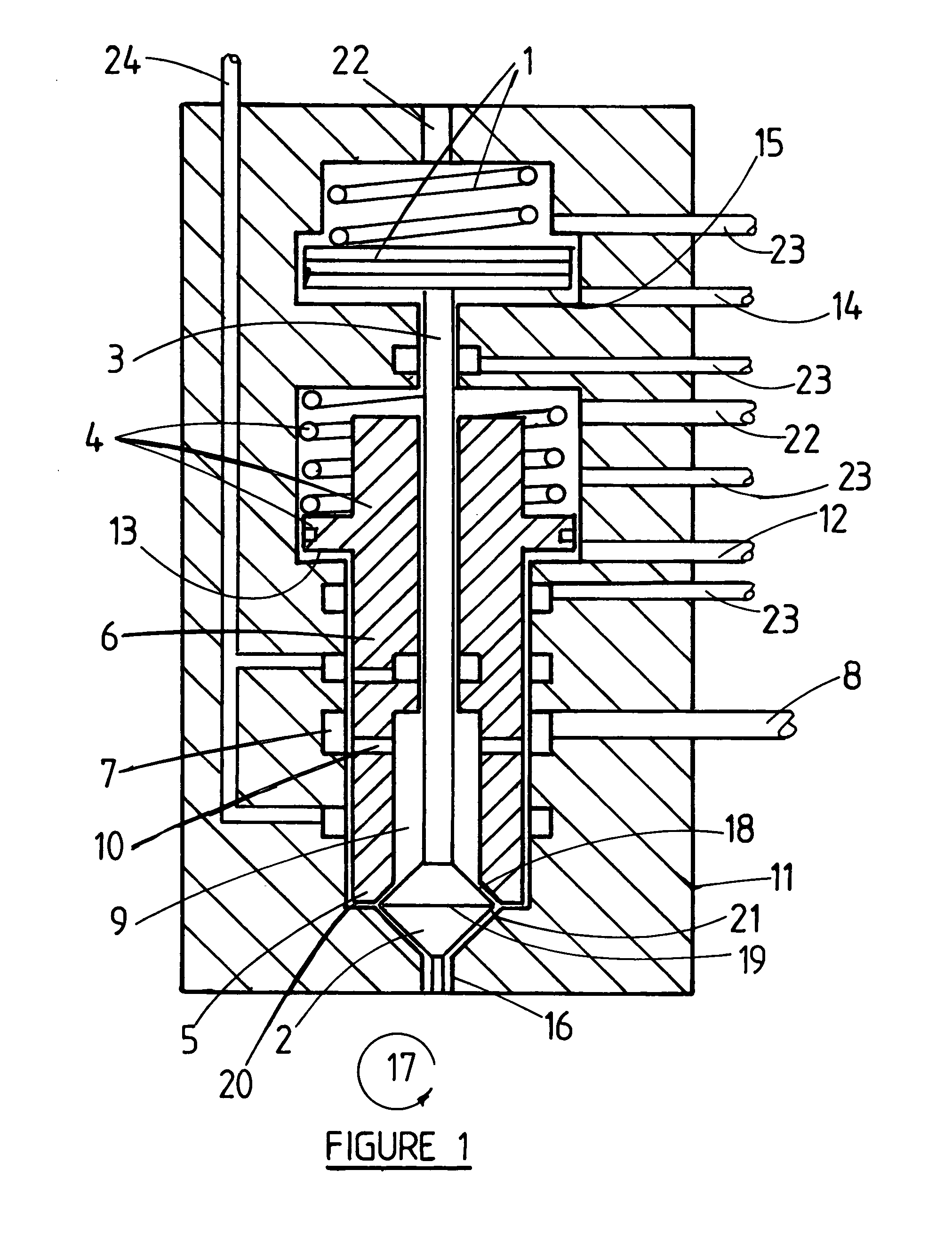

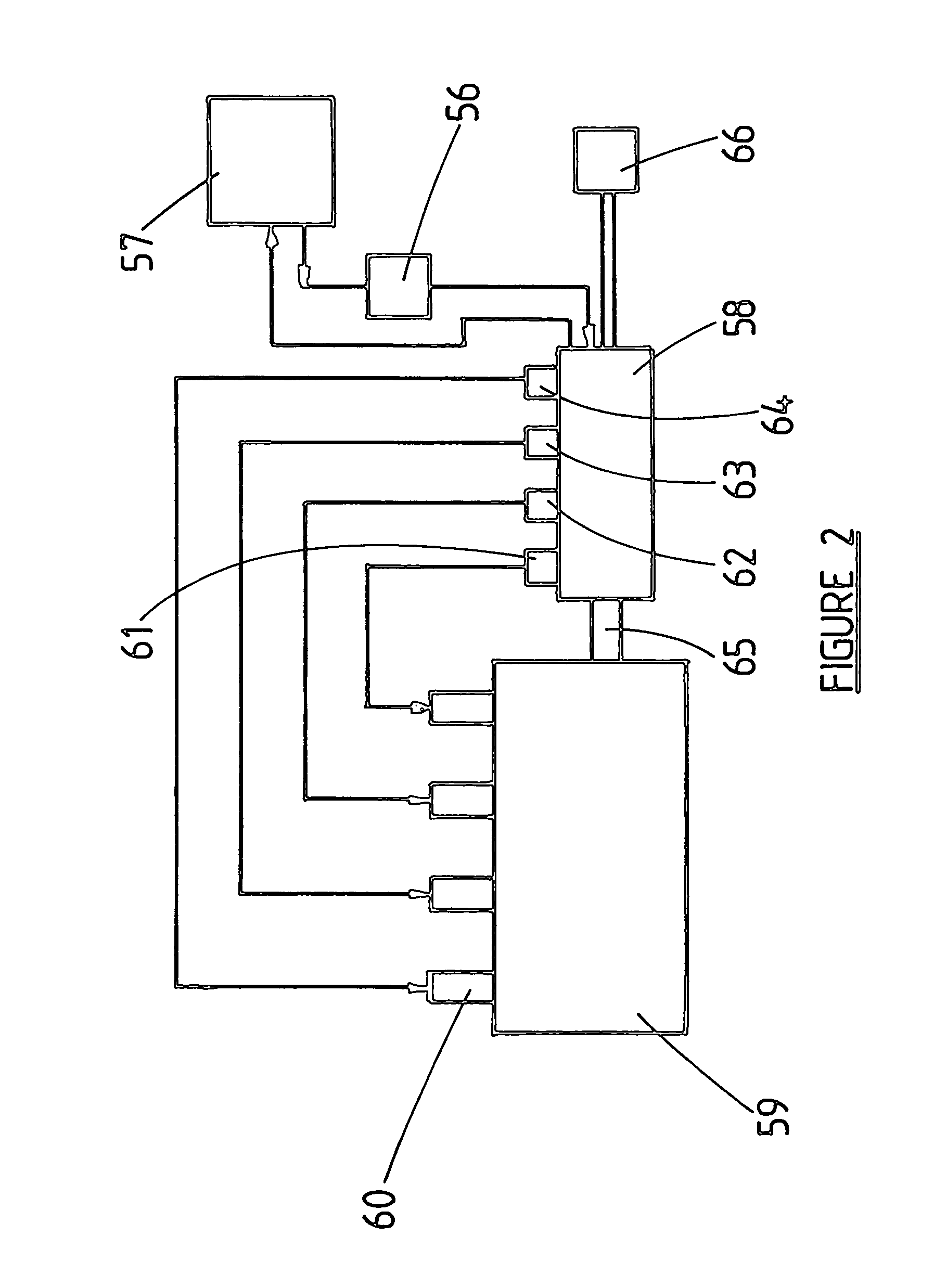

Low NOx liquid state slag-off double-eddy flow coal-powder combustor

ActiveCN101324334ABurn fastReduce smoke and dust emissionsPulverulent fuel combustion burnersSlagCoal

The invention relates to a low-NOx slag tapping double-swirl pulverized coal burner, which is suitable for 2-35 ton steam and hot water boiler and burning devices desired for heat energy for various kinds of industrial productions such as furnace, forging, steel making, road and bridge mixing station, and cold aggregate heating. The low-NOx slag tapping double-swirl pulverized coal burner comprises an adjustable burning device and a cylindrical burning chamber and is characterized in that the housing of the burning chamber is a heat insulating layer; a cooling water channel or a secondary air heat exchange fin is arranged between the housing the burning chamber and a secondary air chamber; a cooling water outlet pipe and a cooling water inlet pipe are respectively arranged on the upper and the lower ends of the cooling water channel; and a primary gas axial flow generator is arranged on the top of the jacket of an adjusting screw. The low-NOx slag tapping double-swirl pulverized coal burner has the advantages of sufficient burning and improved service life.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

Oxygen steaming-free high-strength concrete anticorrosive pipe pile and production method thereof

ActiveCN103641398AEnergy efficient coal and electricityReduce smoke and dust emissionsSolid waste managementHigh strength concreteCoal

The invention discloses an oxygen steaming-free high-strength concrete anticorrosive pipe pile and a production method thereof, the oxygen steaming-free high-strength concrete anticorrosive pipe pile comprises the following components: by weight, 165-220 parts of cement; 85-210 parts of mineral powder; 80-225 parts of ultrafine powder; 700-790 parts of sand; 950-1040 parts of stones; 4.13-5.76 parts of a water reducing agent; 7-10 parts of a rust inhibitor and 120-170 parts of water, and with the water-binder ratio of 0.31 to 0.36. According to the production method, a high pressure oxygen steaming process is omitted, a large number of coal and electric power are saved, emissions of smoke and dust are reduced, the production method is green and environmentally friendly, meets the national low carbon production requirements and reduces the environmental burden of enterprises, and mechanical properties and durability of the produced oxygen steaming-free high-strength concrete anticorrosive pipe pile are superior to that of pipe piles in the prior art.

Owner:JIANGSU DONGPU PILE

System and method for regenerating a particulate filter for a direct injection engine

ActiveUS8359839B2Emission reductionReduce engine pumping lossesElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turobocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter. In this way, regeneration of a particulate filter may be accomplished without disturbing the chemistry of a three-way catalyst located in the exhaust system upstream of the particulate filter.

Owner:FORD GLOBAL TECH LLC

System for regenerating a particulate filter and controlling EGR

ActiveUS8387370B2Emission reductionReduce engine pumping lossesElectrical controlNon-fuel substance addition to fuelGasolineEnvironmental engineering

A system for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turbocharged gasoline engine to the exhaust system by a compressor. Simultaneously, exhaust gases may be pumped from the exhaust system to the intake system for the purpose of reducing NOx while regenerating a particulate filter.

Owner:FORD GLOBAL TECH LLC

Method for regenerating a particulate filter for a boosted direct injection engine

ActiveUS8464514B2Reduce smoke and dust emissionsImprove engine performanceValve arrangementsElectrical controlGasolineEngineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turobocharged gasoline engine through a cylinder and into the exhaust system by a compressor. In this way, regeneration of a particulate filter may be accomplished without an auxiliary air supply.

Owner:FORD GLOBAL TECH LLC

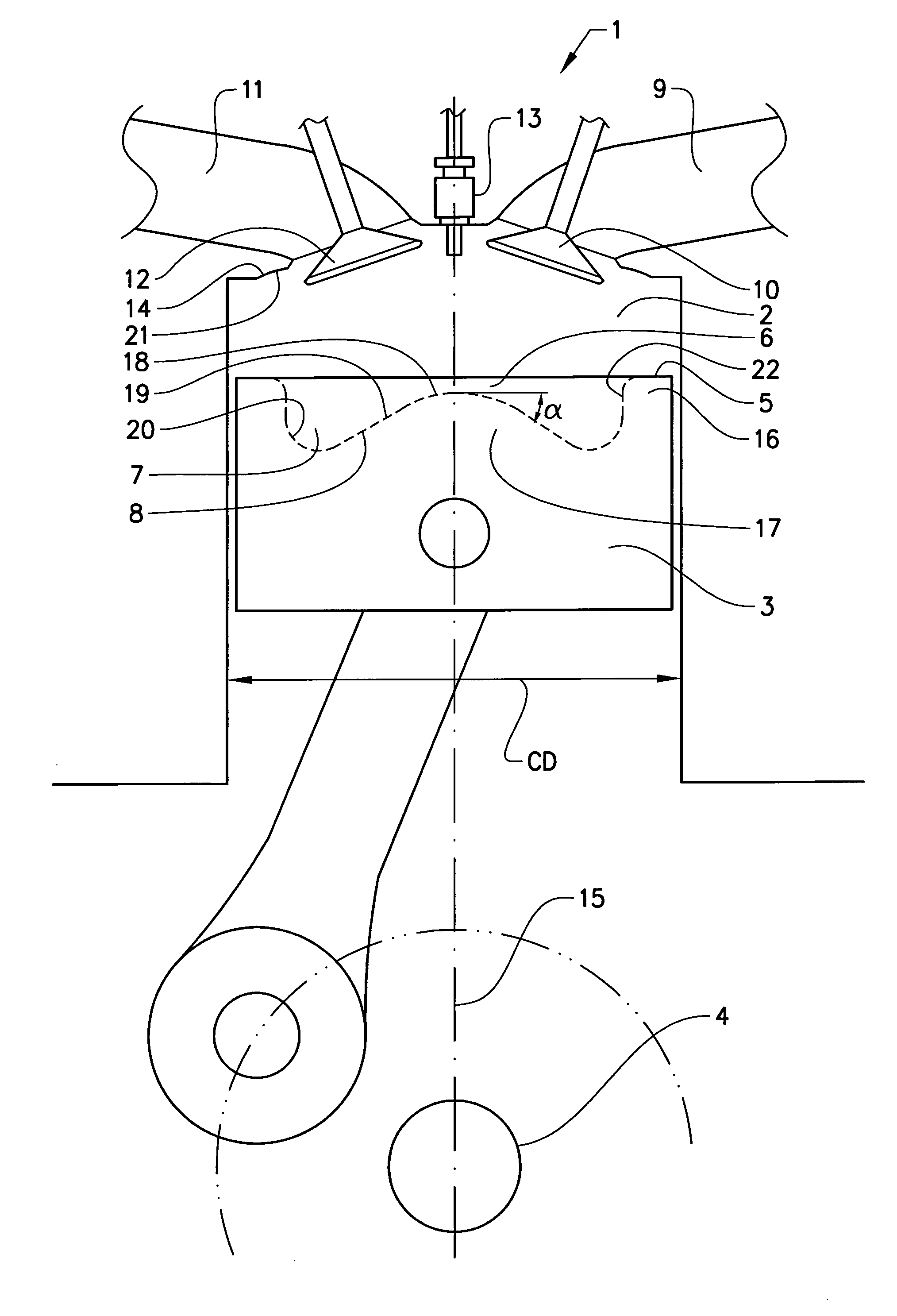

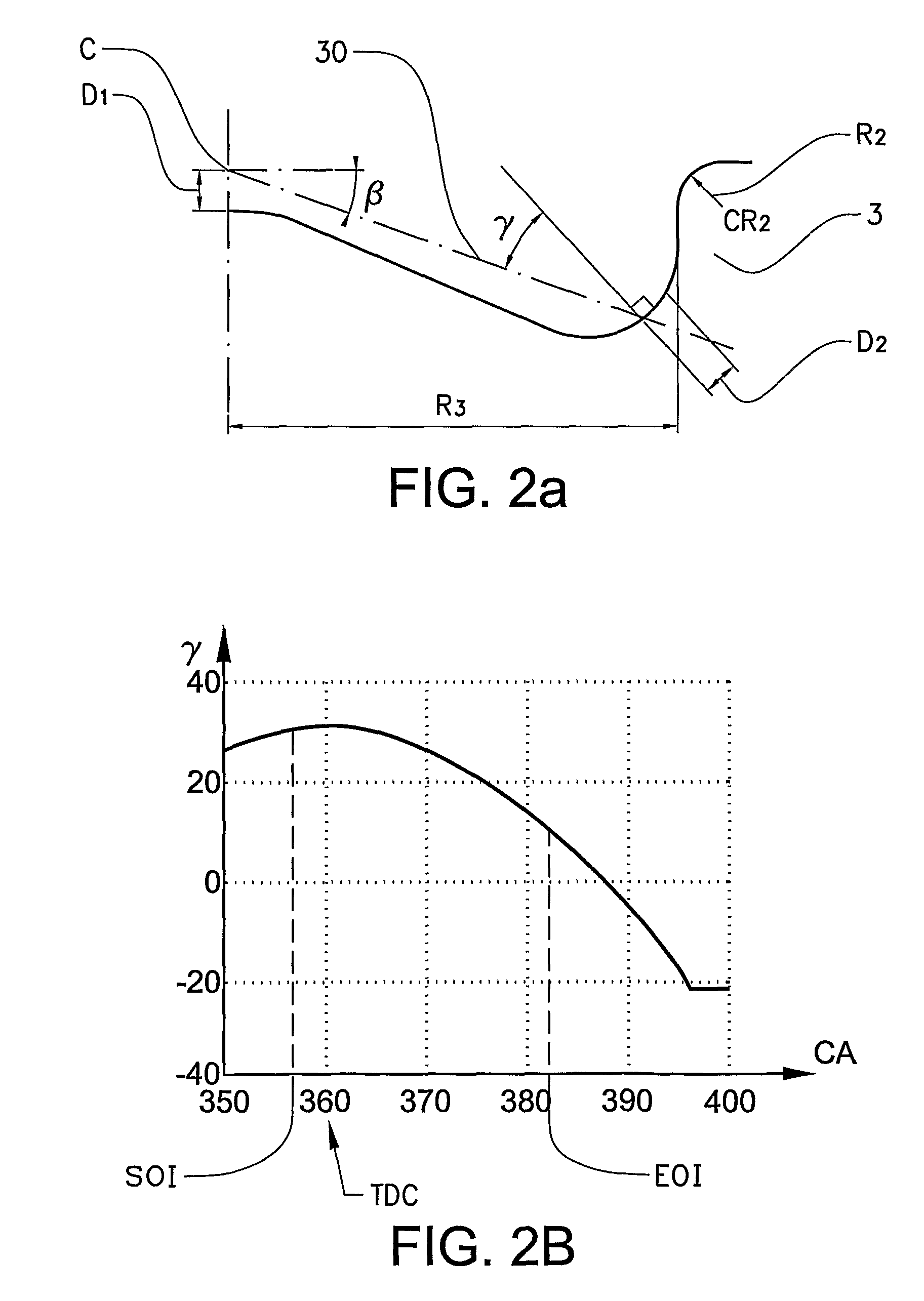

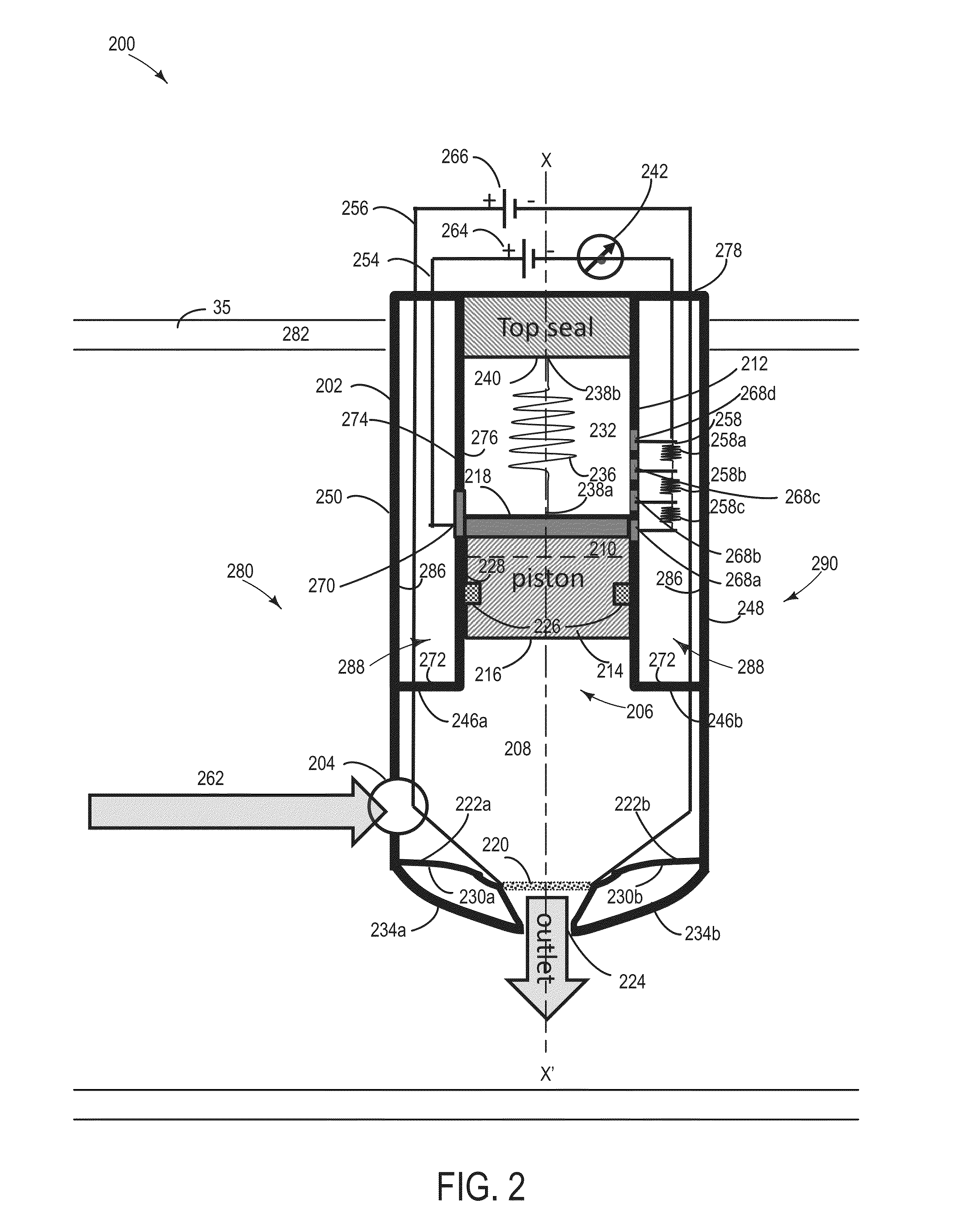

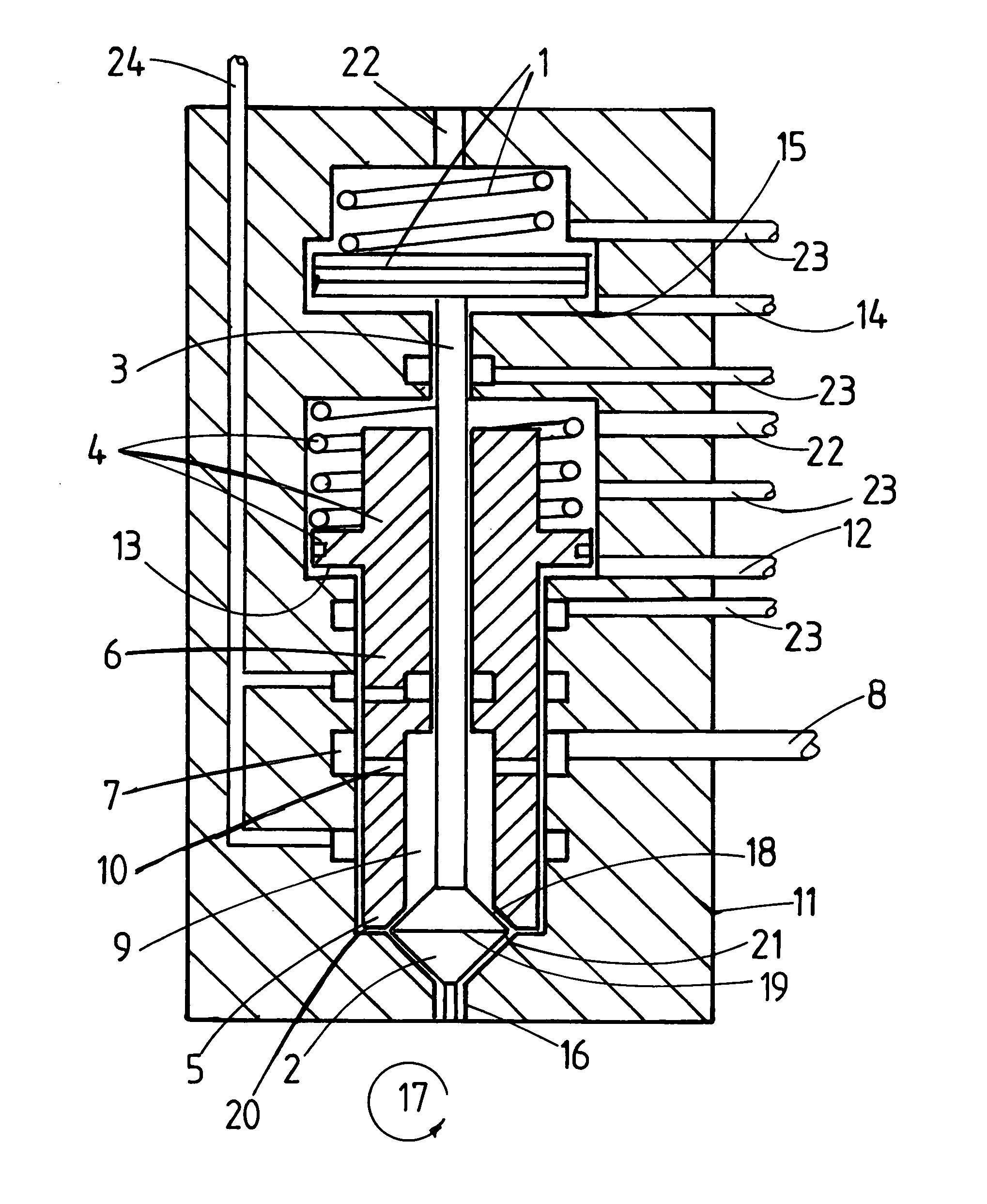

Method for operating an internal combustion engine and internal combustion engine for such a method

ActiveUS20090095251A1Reduce smoke and dust emissionsReduce generationInternal combustion piston enginesFuel injection apparatusCrankInternal combustion engine

In a method for operating a direct-injection auto-ignition internal combustion engine and a correspondingly configured internal combustion engine including a piston top having integrally formed therein a piston recess which merges into an essentially annular stepped space and an injector forming injection jets directed toward the stepped space, the jets are deflected there in such a way that a first part quantity of fuel is directed in an axial direction and a radial direction into the piston recess, a second part quantity of fuel is deflected in the axial direction and the radial direction over the piston top and third part quantities of fuel are deflected into a circumferential direction so as to impinge one onto the other in the circumferential direction and to be deflected radially inwardly, the start of injection and the injection duration being coordinated with one another and with the crank angle of the internal combustion engine in such a way that the third part quantities of adjacent injection jets meet each other in the circumferential direction with a velocity of at least 15 m / s.

Owner:DAIMLER AG

Method and system for engine control

ActiveUS20150283990A1Improve fuel efficiencyImprove cooling effectHybrid vehiclesElectric propulsion mountingAutomotive engineeringWarming up

Methods and systems are provided for slowly rotating an engine, unfueled, via a motor prior to an imminent engine restart to heat the engine. By rotating the engine so that heat generated in the compression stroke of a cylinder can be transferred to cylinder walls, thereby expediting engine warm-up. By warming the engine before a restart, particulate emissions generated during an engine cold-start due to direct injection of fuel can be reduced.

Owner:FORD GLOBAL TECH LLC

Aircraft vapour trail control system

ActiveUS9399521B2Reduce depthReduced characteristicsPower plant exhaust arrangementsDigital data processing detailsThrottle controlControl system

The invention concerns an aircraft propulsion control system for an aircraft with a plurality of gas turbine engines mounted at different spaced positions relative to an airframe. One or more sensor is arranged to sense a condition indicative of vapor trail formation by an exhaust flow from one or more of the plurality of engines. A controller is arranged to be responsive to thrust demand for the aircraft and selectively to control each of the engines so as to modify the exhaust flow of at least one engine relative to at least one further engine according to the positions of the engines on the airframe. The proximity of an engine to a vortical wake flow created by the airframe may be used to determine suitable exhaust flow modifications. The controller may output a separate throttle control signal to each engine and / or may adjust the fuel composition supplied to each engine.

Owner:ROLLS ROYCE PLC

Method for adjusting boost pressure while regenerating a particulate filter for a direct injection engine

ActiveUS8359840B2Emission reductionReduce engine pumping lossesElectrical controlNon-fuel substance addition to fuelGasolineEngineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turbocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter and downstream of a three-way catalyst. The oxygen may be regulated in part by adjusting compressor boost pressure in response to a state of particulate filter regeneration. Further, in one embodiment, engine NOx can be controlled by EGR.

Owner:FORD GLOBAL TECH LLC

Device for reducing soot emissions in a vehicle combustion engine

ActiveUS7918206B2Reduce smoke and dust emissionsInternal combustion piston enginesPistonsInjection pressureCombustion chamber

Owner:VOLVO LASTVAGNAR AB

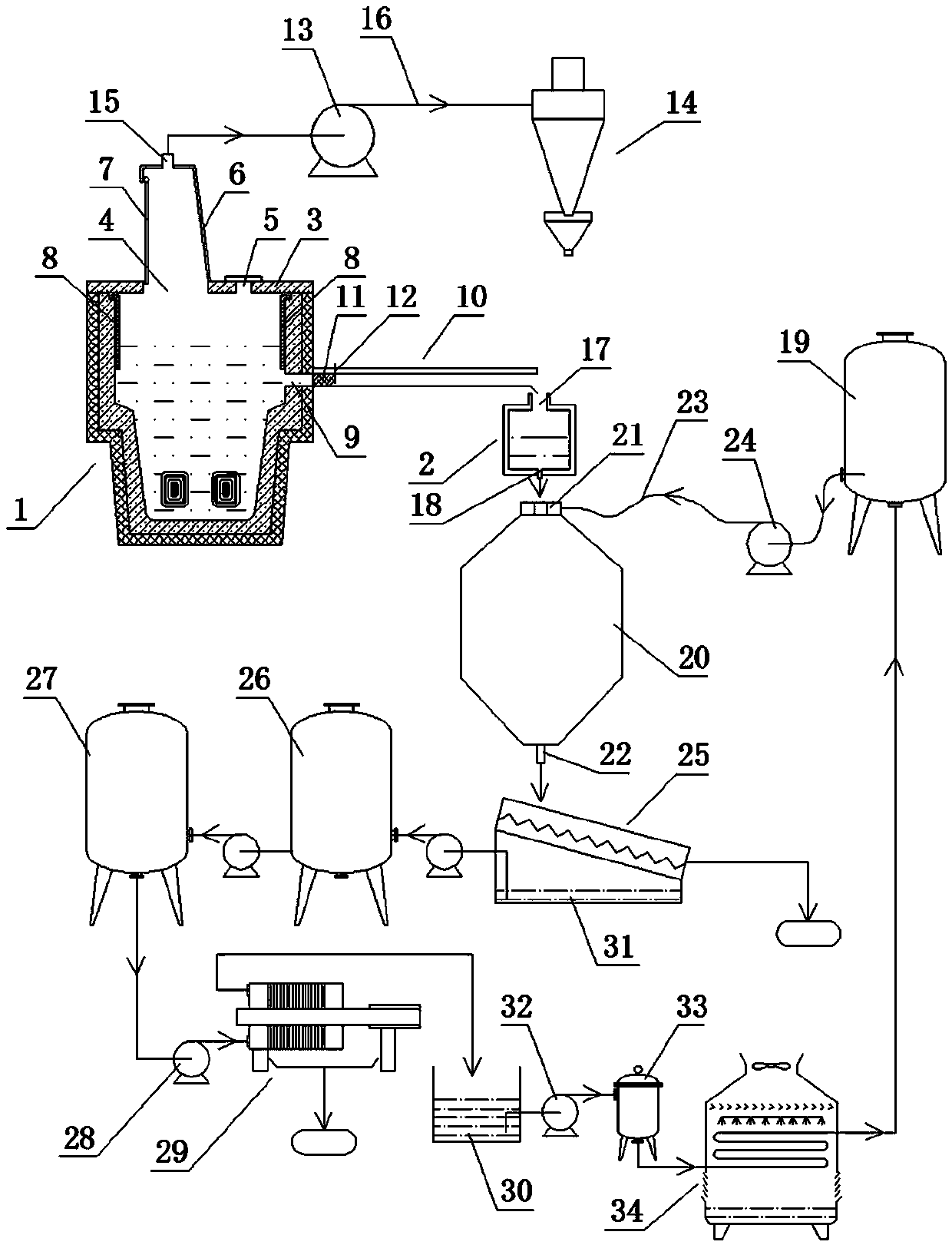

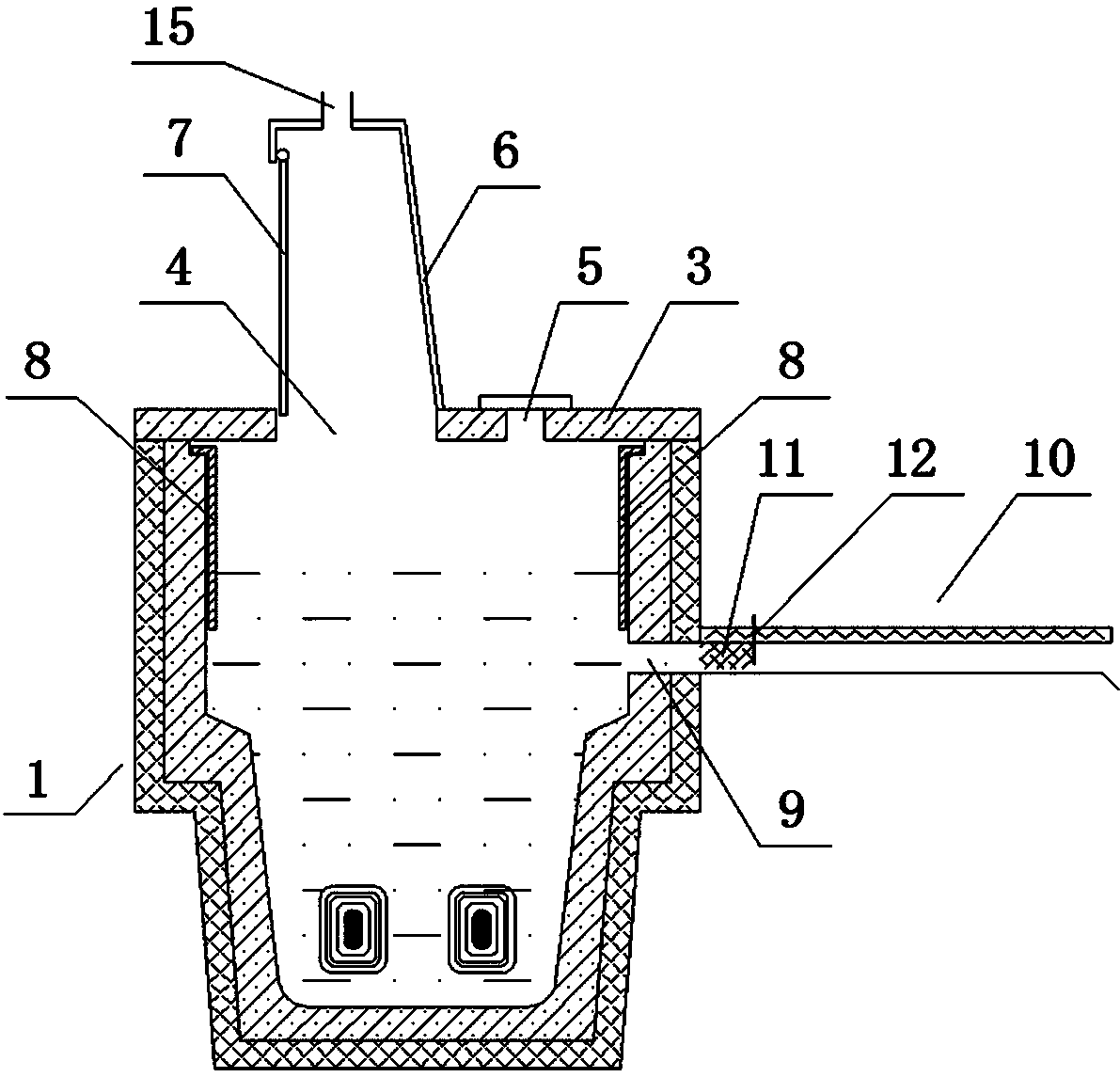

System for producing zinc powder by hydraulic atomization

The invention discloses a system for producing zinc powder by hydraulic atomization. The system comprises a cored induction electric furnace, a dust removal device, a heat insulation leakage package,an atomization device, a screening filter device and a waste water recovery device. A zinc plate feeding opening and a zinc grain feeding opening are formed in a cover of the core induction electric furnace, a smoke and dust box is arranged on the zinc plate feeding opening, an inverted baffle plate is arranged on one side of the smoke and dust box, and zinc plates are laid on the furnace wall ofthe inner side of the cored induction electric furnace; a zinc melt liquid outlet is connected to an electrothermal diversion groove, and flow restricting rock wool and a flow baffle plate are arranged at the front end of the electrothermal diversion groove; the atomization device includes a water storage tank and an atomization tank, and the water storage tank is communicated with an atomizationnozzle through a high pressure hose and a high pressure pump; the waste water recovery device includes a filter and a cooling tower. According to the system, the process controllability is excellent,the efficiency is high, the performance of zinc powder produced is great, waste water produced in the preparation process by hydraulic atomization is effectively treated and recycled, water resourcesare save, the cost is reduced, and the system is safe and reliable without environmental pollution.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

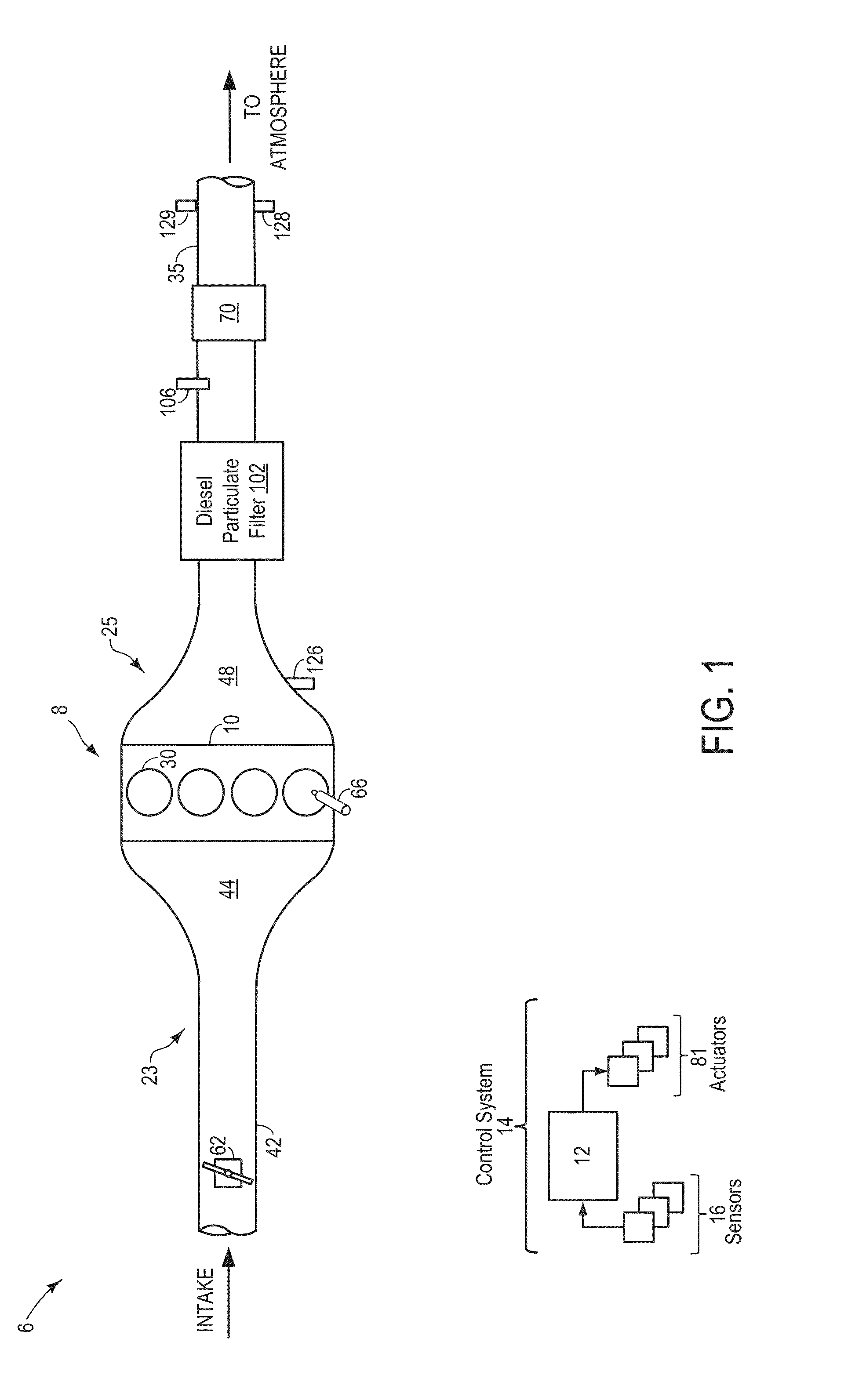

Exhaust soot control system

ActiveUS20160160721A1Reduce smoke and dust emissionsIncrease internal pressureInternal combustion piston enginesExhaust apparatusParticulatesControl system

Systems and methods are described for sensing soot (particulate matter) in an exhaust system of a vehicle. An example system comprises a sensor housing an exhaust inlet, an exhaust outlet, and a soot filter affixed across the exhaust outlet, and a piston with the housing, affixed to a spring via a conductive surface, the spring fluidly separated from the exhaust chamber by a piston seal. The system may further comprise a detection circuit including the conductive surface of a piston and a plurality of resistive elements and a separate regeneration circuit configured to supply electric heat across the soot filter to regenerate the sensor.

Owner:FORD GLOBAL TECH LLC

Piston for a cylinder of a combustion engine

ActiveUS10060386B2Reduce kinetic energy lossReduce smoke and dust emissionsInternal combustion piston enginesPistonsCombustionEngineering

A piston for a cylinder of a combustion engine includes piston crown including a piston bowl formed by an upwardly facing cavity, the piston bowl including a floor section with a central, and a side section, the side section connecting the inner section with an upper surface of the piston crown, wherein the side section is formed with mutually spaced apart ridges protruding towards the apex, and wherein the side section having at least one recess at an upper end of the side section connecting the side section with the upper surface of the piston crown.

Owner:VOLVO LASTVAGNAR AB

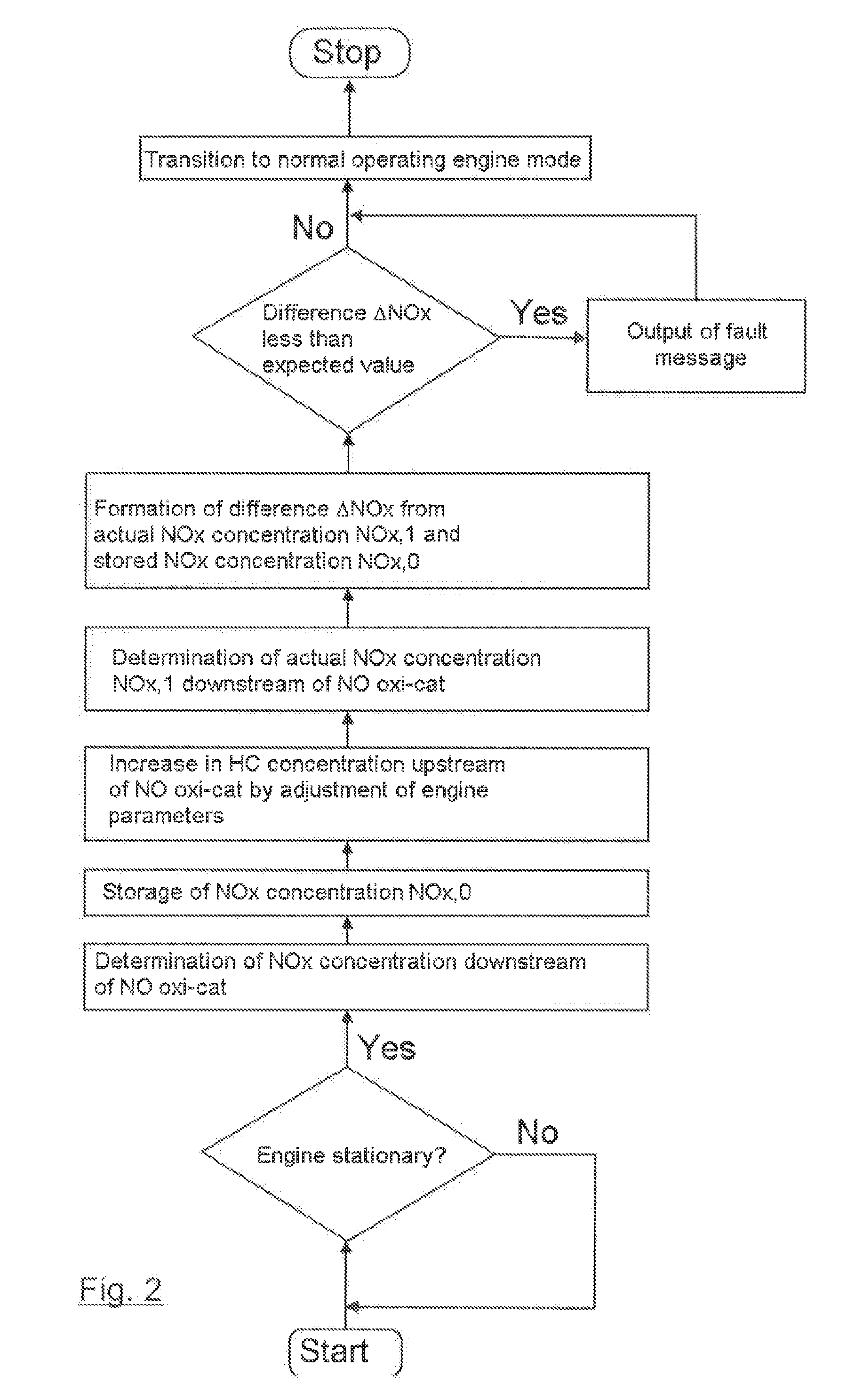

Method and device for testing the function capacity of an no oxidation catalyst

ActiveUS20130276427A1Increased functional reliabilityAccelerate emissionsChemical analysis using catalysisInternal combustion piston enginesProcess engineeringNitrogen oxide

The invention concerns a method and a device for testing the function capacity of an NO oxidation catalyst (5) which is used to reduce nitrous oxides (NOx) contained in the exhaust gas flow of an internal combustion engine (1) operated with air surplus. In the exhaust gas flow which is supplied to the NO oxidation catalyst (5), a change is made in the concentration of a reducing agent and the resulting change in NOx concentration in the exhaust gas flow within the NO oxidation catalyst (5) and / or downstream after the NO oxidation catalyst (5) is determined and used to test its function capacity.

Owner:MAN NUTZFAHRZEUGE AG

Method and system for engine control

ActiveUS9759135B2Improve cooling effectImprove fuel efficiencyHybrid vehiclesElectrical controlCombustionEngineering

Methods and systems are provided for using compression heating to heat a cylinder piston before cylinder combustion is resumed. Cylinder heating is achieved using combinations of slow unfueled engine rotation where the engine cylinders are heated via compression stroke heating, and slow compressor rotation where the cylinders are heated via compression heating. One or more intake or exhaust heaters may be concurrently operated to expedite cylinder heating.

Owner:FORD GLOBAL TECH LLC

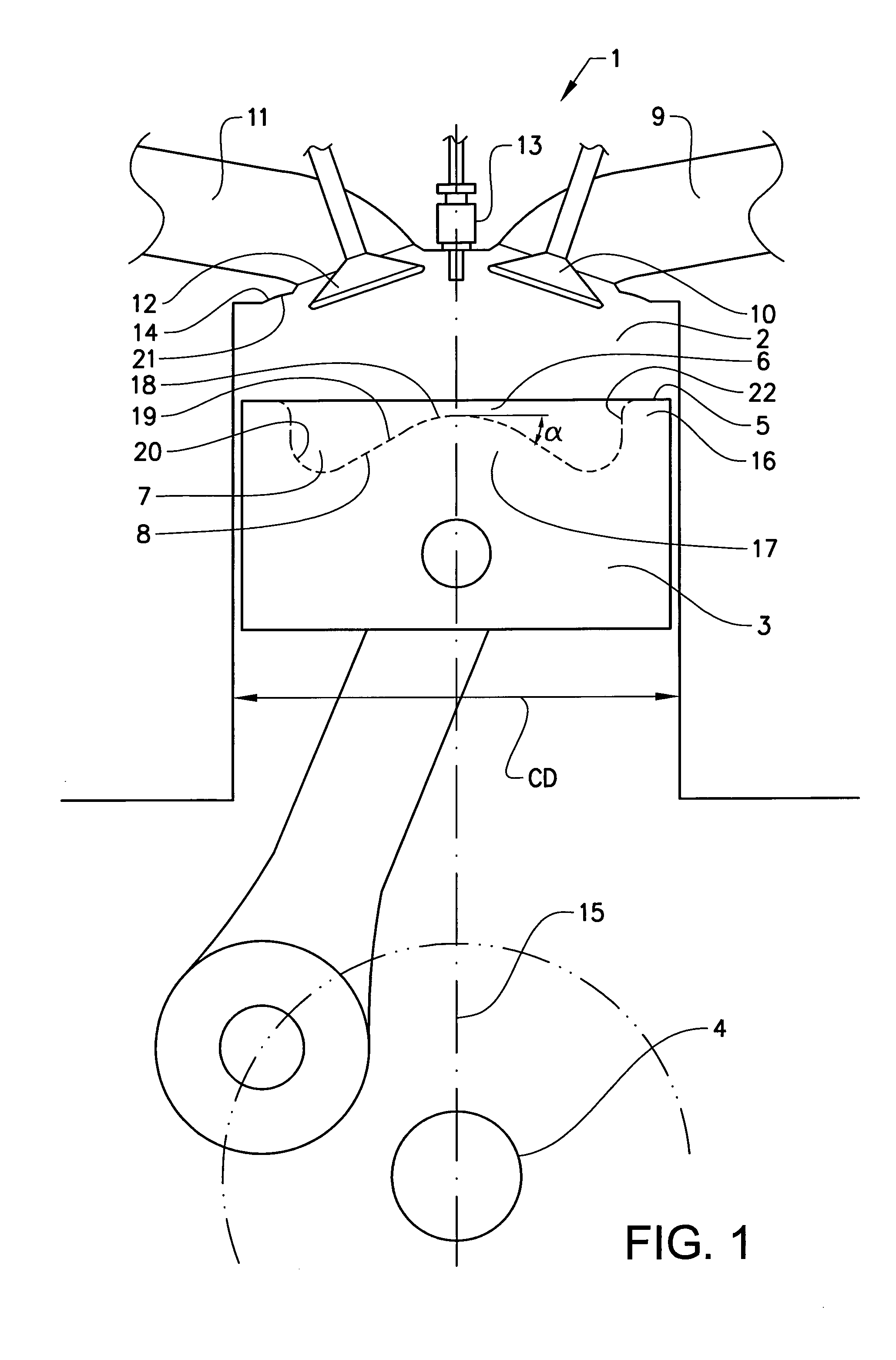

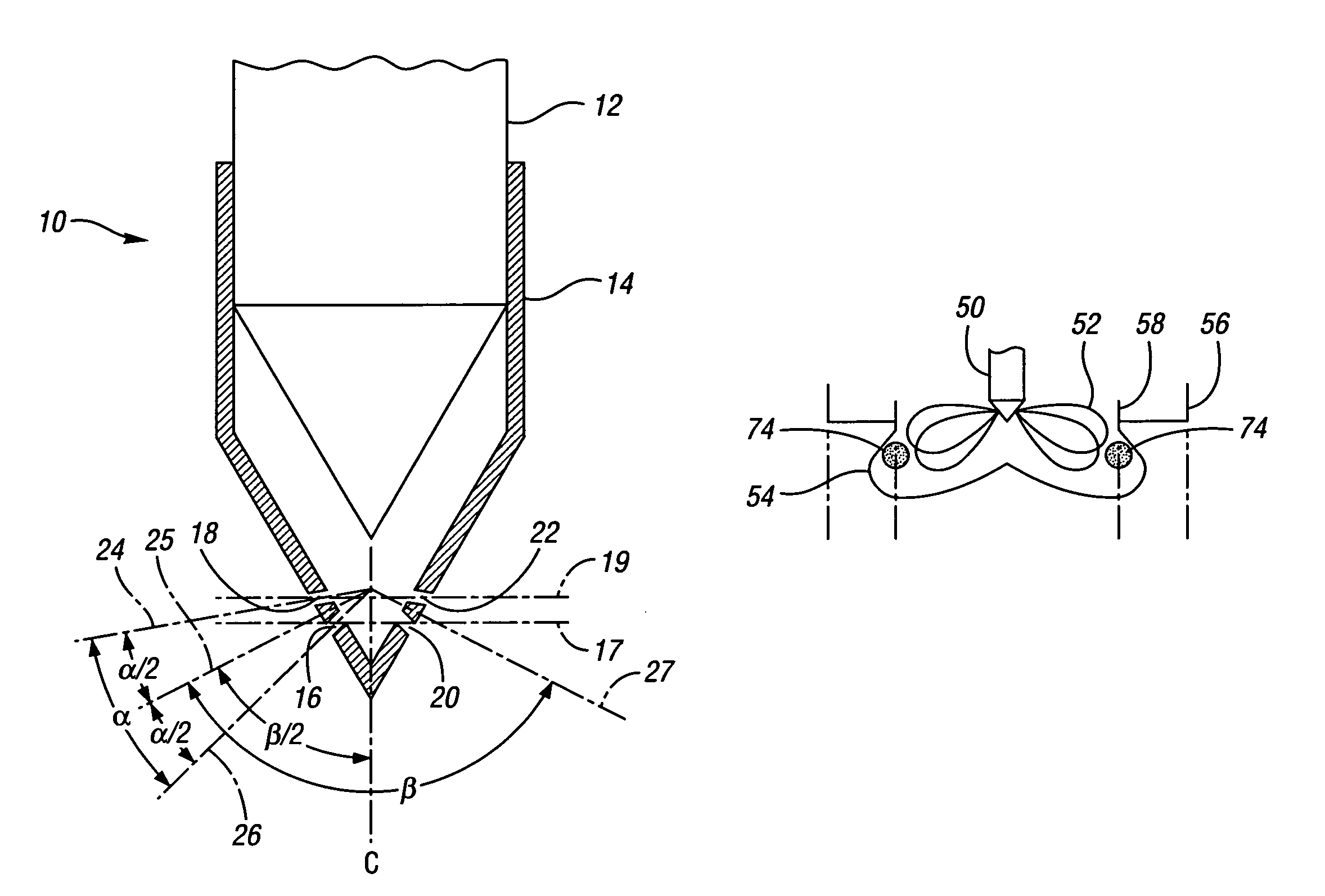

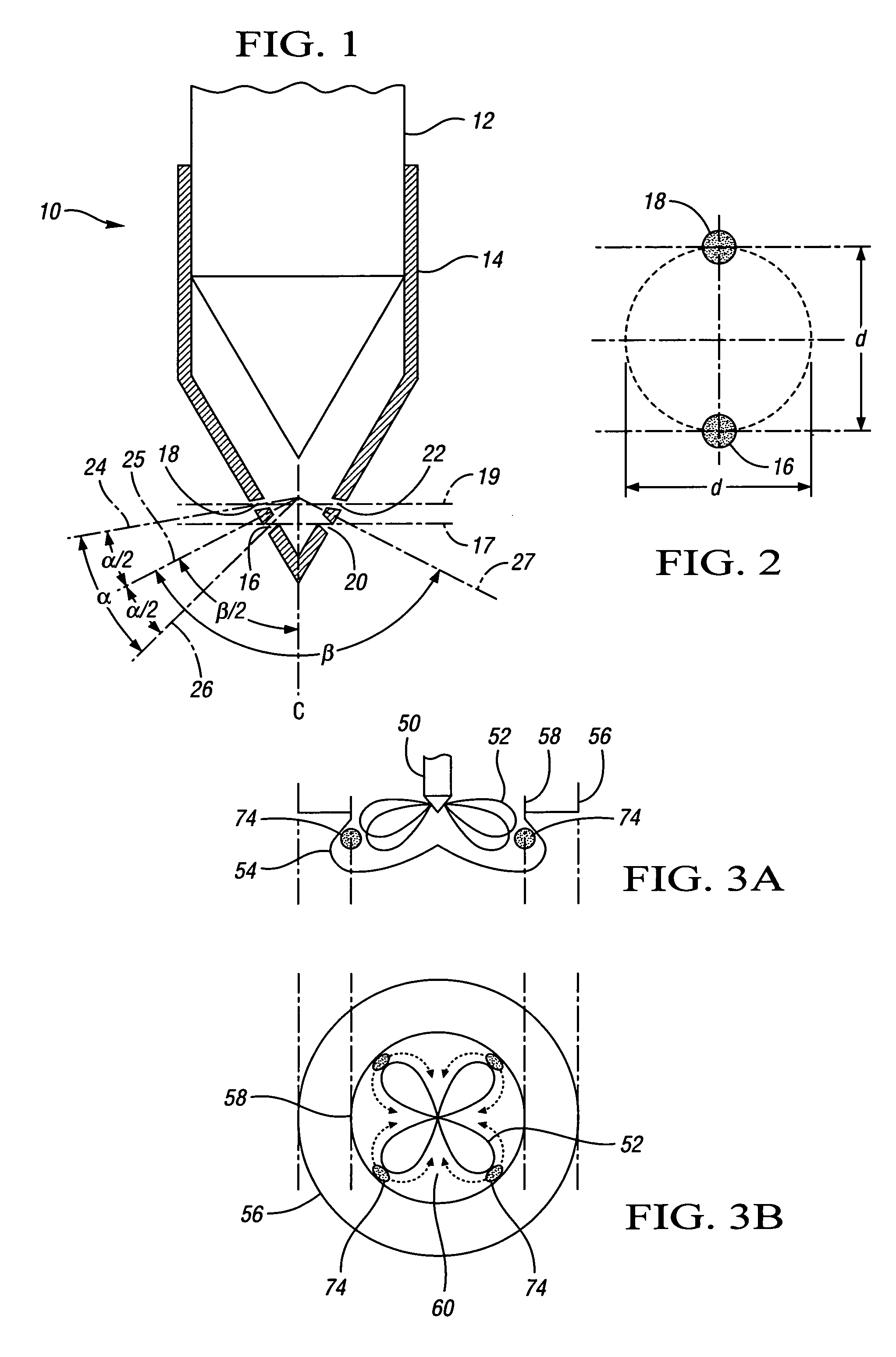

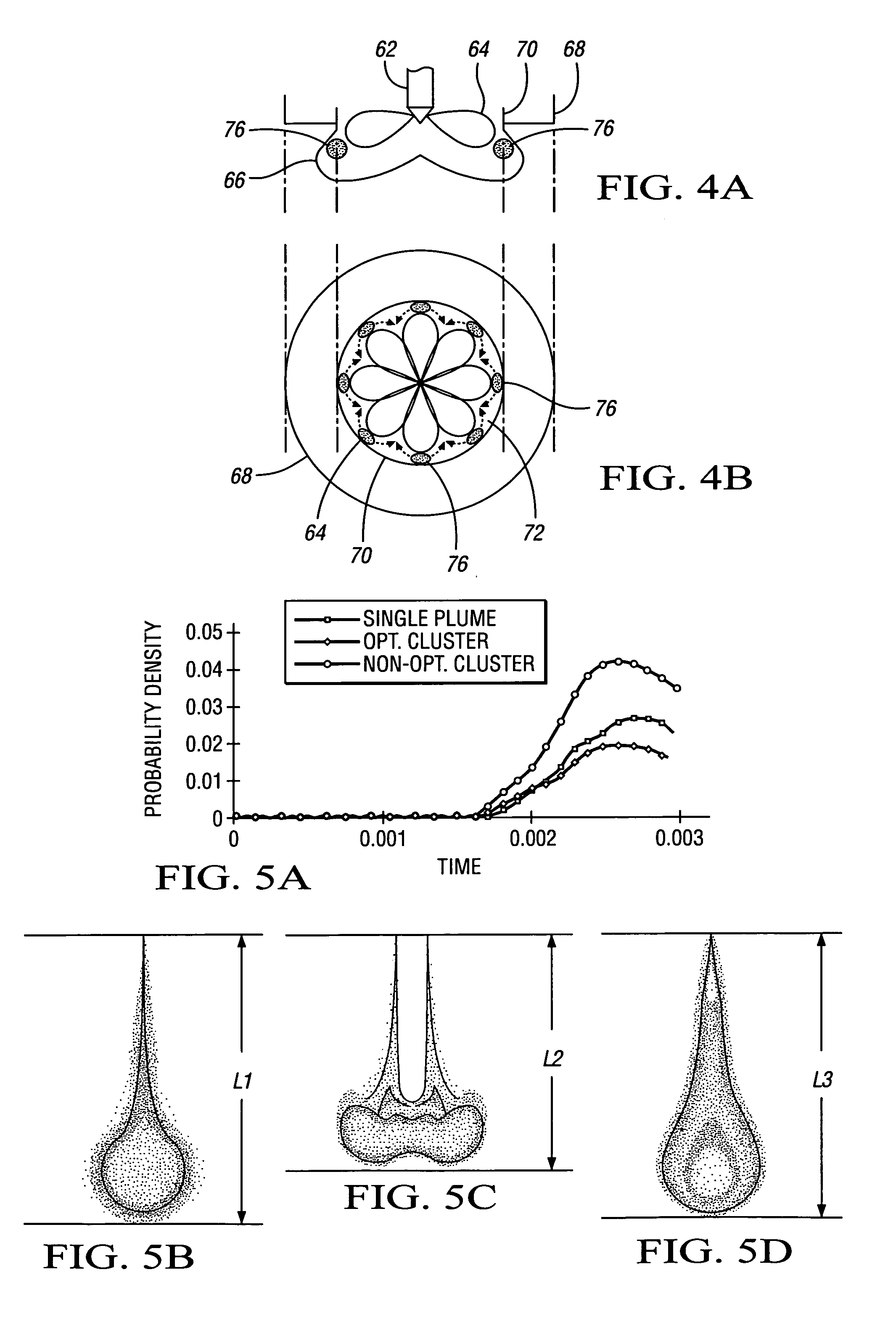

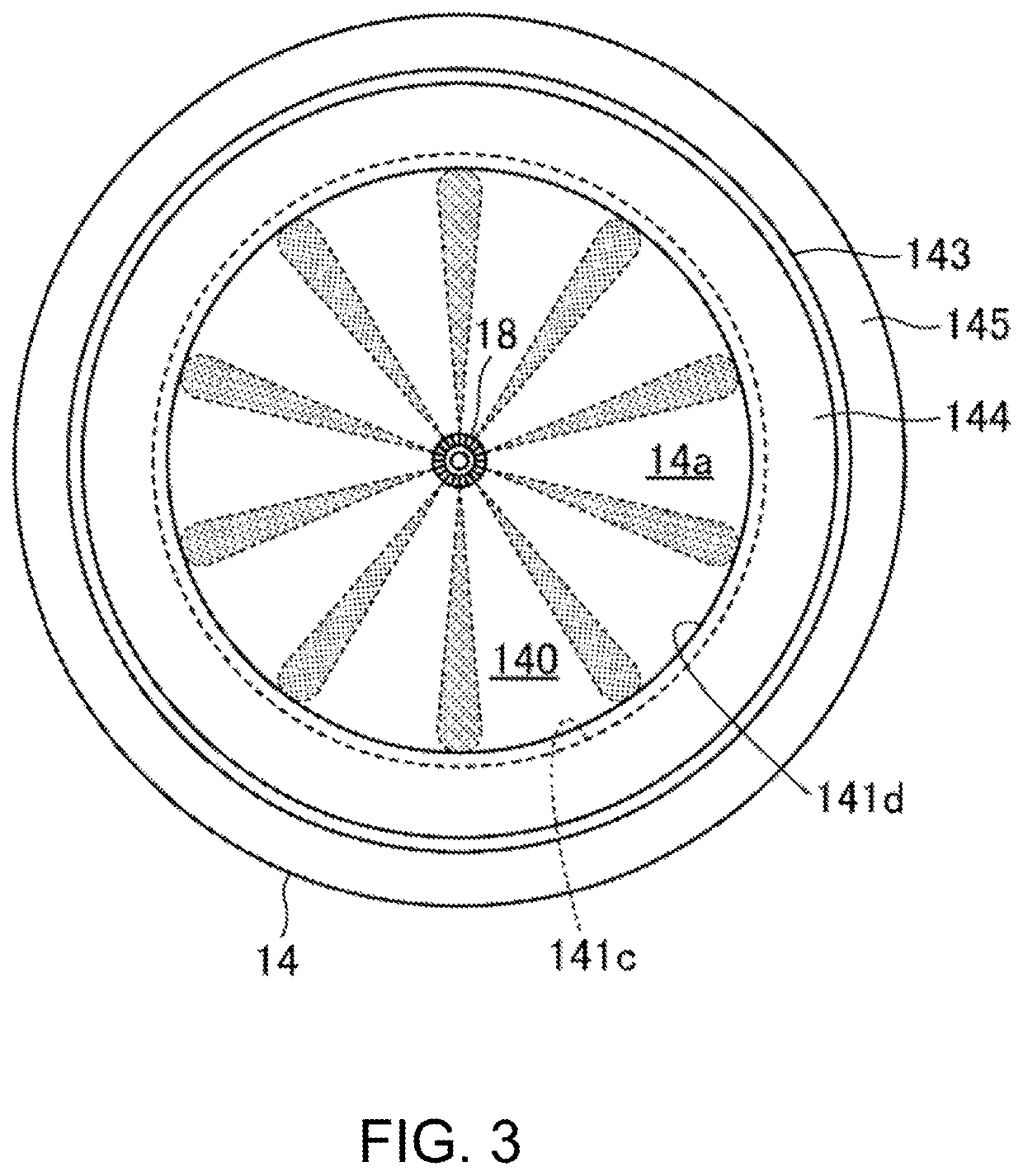

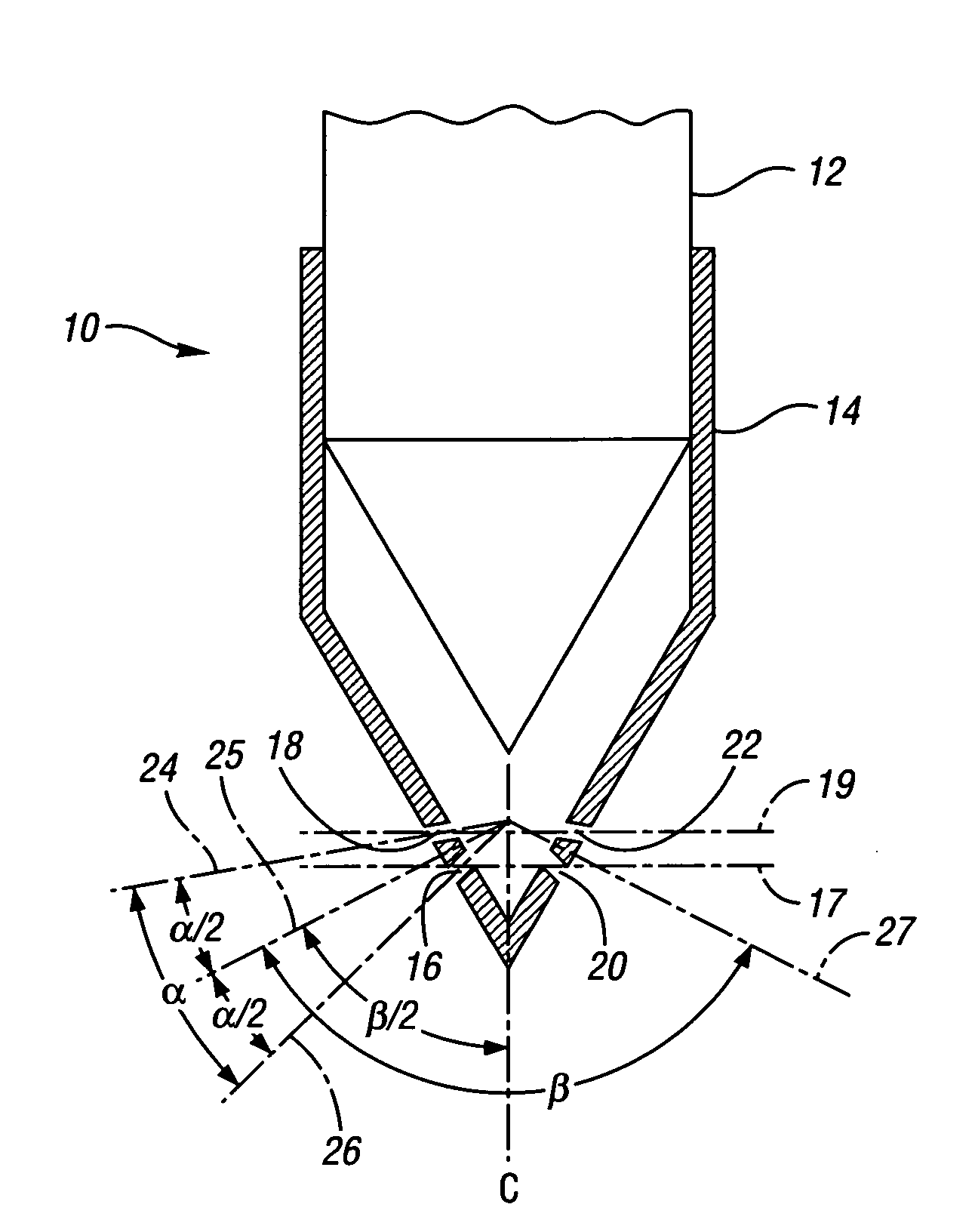

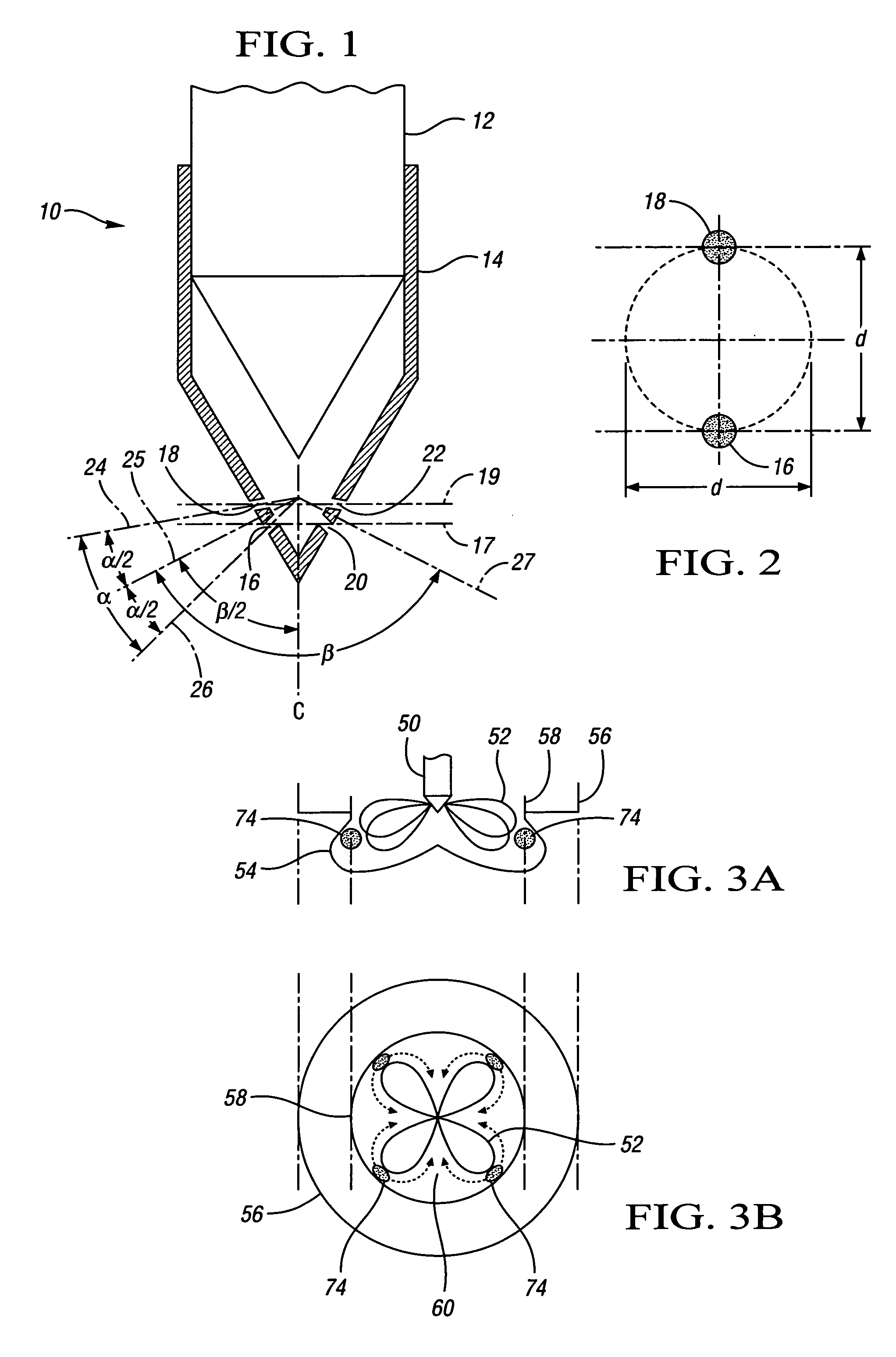

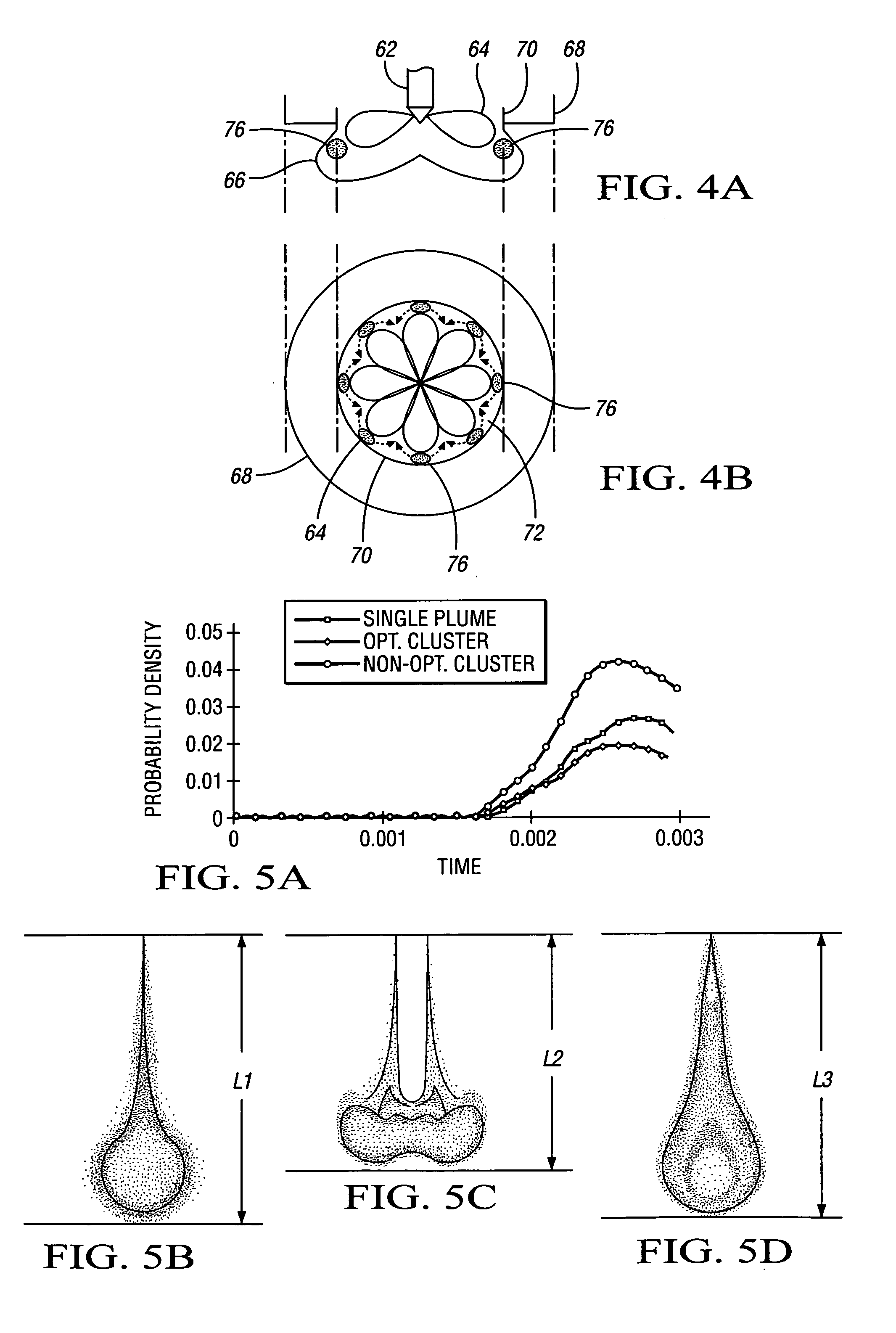

Injector double row cluster configuration for reduced soot emissions

InactiveUS7347182B2Maximize oxidationOptimized cluster distributionInternal combustion piston enginesSpray nozzlesCombustionAir entrainment

A direct injection fuel injector system includes a fuel injector defining nozzle holes in an optimized cluster configuration. Each hole of a conventional multi-hole nozzle is replaced by two smaller, closely spaced holes in a two-hole-per-cluster configuration. The holes within a cluster are configured one above the other, in two horizontal planes or rows, spaced a distance apart from one another. The distance “d” between the nozzle holes in the cluster configuration, the clustered plume angle “α”, which is the angular separation between the centerlines of the nozzle holes, as well as the included spray angle “β”, are optimized through computational fluid dynamics and combustion modeling so that an optimal compromise can be found between liquid penetration, spray penetration and air entrainment, whereby to minimize soot emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Separate igniter fuel injection system

InactiveUS20120097127A1Improve engine efficiencyReduce smoke and dust emissionsFuel injection apparatusMachines/enginesTarEngineering

A separate igniter fuel injection system is described for use with diesel engines operating on tar based slurry fuel with a common rail slurry fuel injection system. The igniter fuel is injected prior to injection of the slurry fuel, during each engine compression stroke, so that the ignition and burning of the igniter fuel will supply hot gases for the evaporation and thermal cracking needed to ignite the tar fuel portions of the slurry. This separate igniter fuel injection system can also be used for cold startup of a diesel engine operated on tar based slurry fuels.

Owner:FIREY JOSEPH CARL

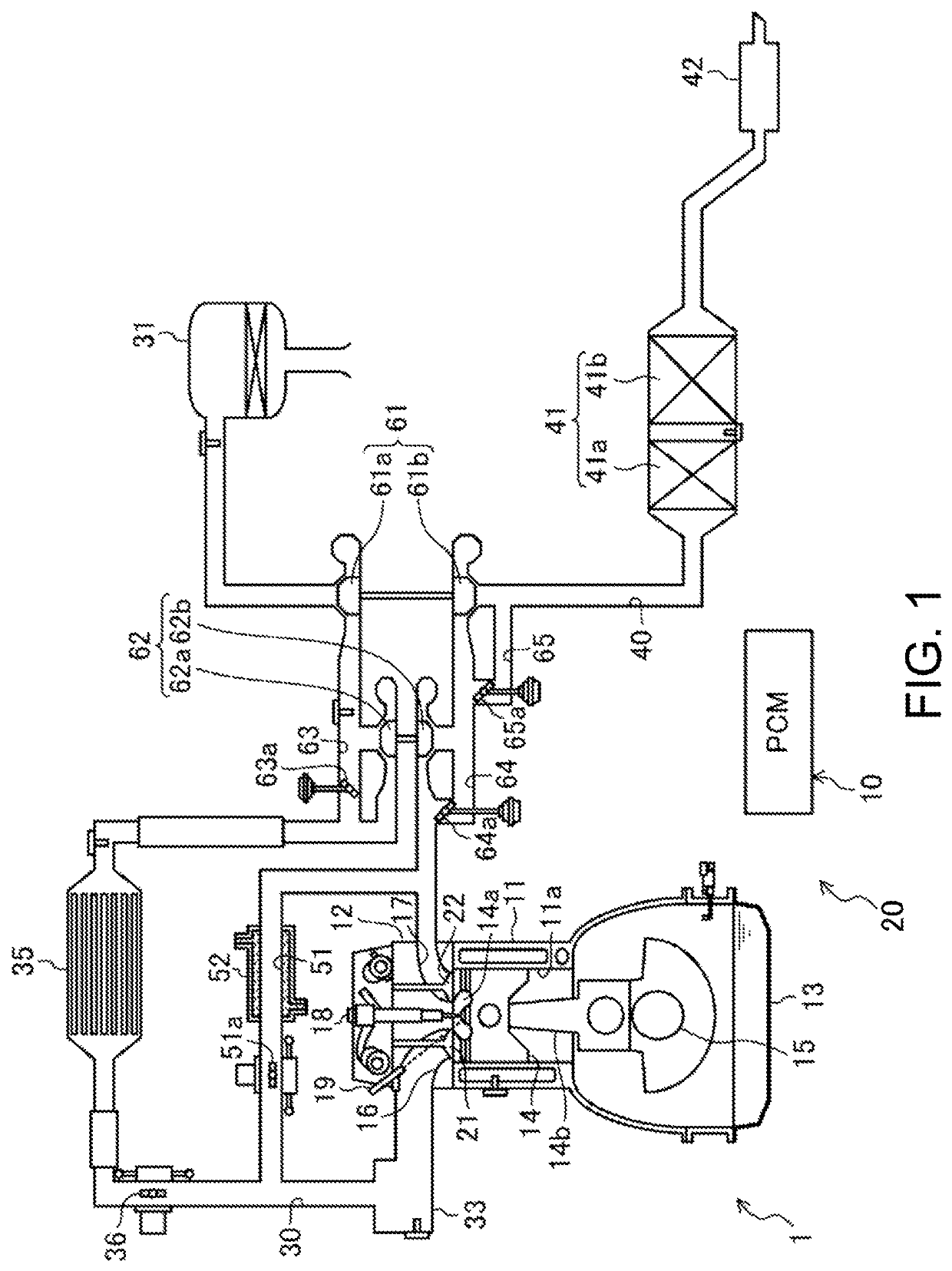

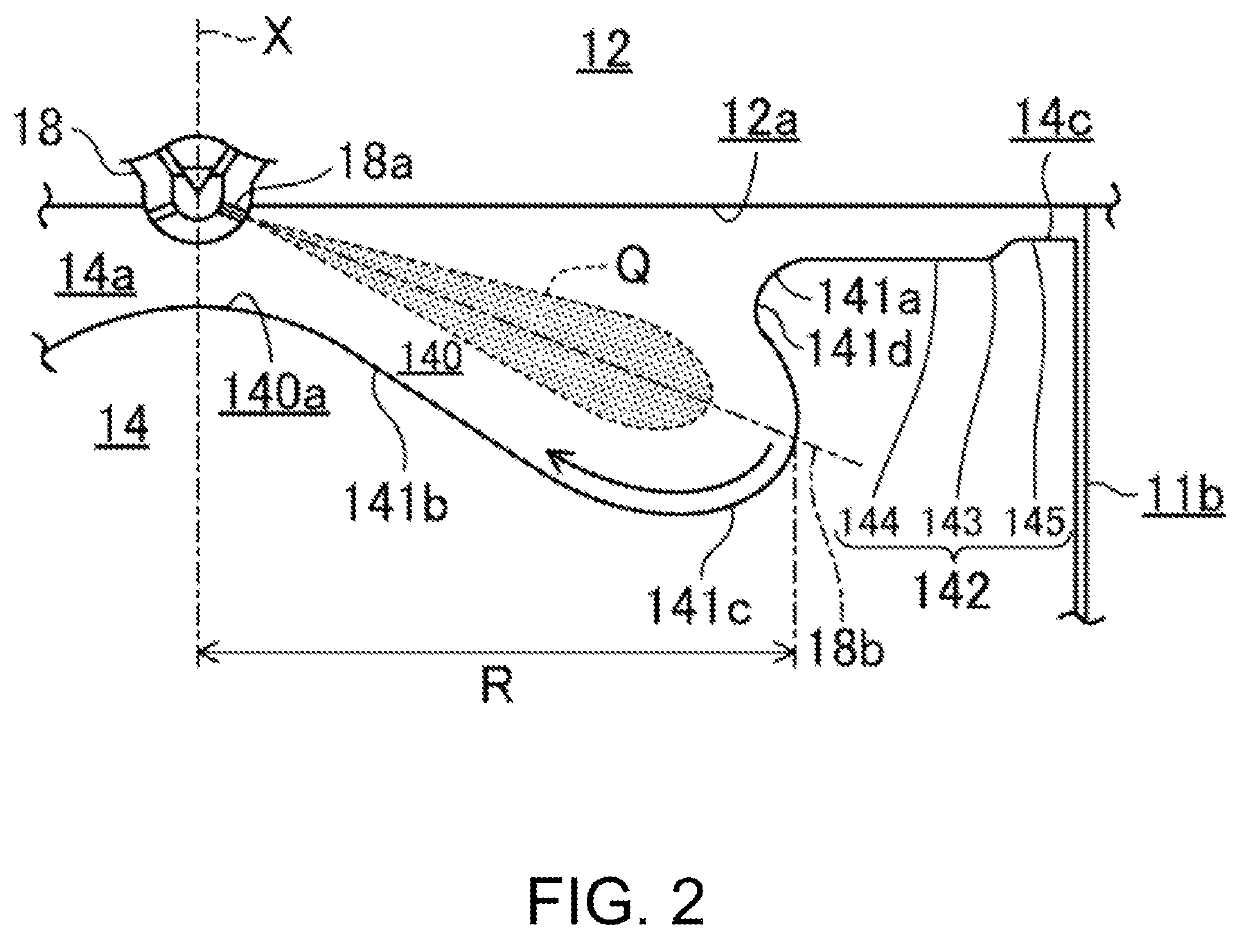

Method and system for controlling engine

ActiveUS10570808B2Reduce smoke and dust emissionsImprove fuel efficiencyElectrical controlInternal combustion piston enginesTop dead centerReciprocating motion

A control system of an engine is provided, which includes a piston formed with a cavity and configured to reciprocate in a cylinder along a center axis of the cylinder, and a fuel injector disposed facing a top surface of the piston and configured to inject fuel along an injection axis. When the piston is located near a top dead center of compression stroke, the fuel injector performs a first injection so that the fuel flows from the fuel injector toward the cavity along the injection axis, collides with an inner surface of the cavity, then flows back toward the fuel injector along the inner surface of the cavity from a position offset from the injection axis. The fuel injector performs a second injection toward the cavity at a timing after the first injection and at which the fuel of the first injection flows back.

Owner:MAZDA MOTOR CORP

Injector double row cluster configuration for reduced soot emissions

InactiveUS20060261193A1Optimized cluster distributionMinimizing soot emissionInternal combustion piston enginesSpray nozzlesAir entrainmentSoot

A direct injection fuel injector system includes a fuel injector defining nozzle holes in an optimized cluster configuration. Each hole of a conventional multi-hole nozzle is replaced by two smaller, closely spaced holes in a two-hole-per-cluster configuration. The holes within a cluster are configured one above the other, in two horizontal planes or rows, spaced a distance apart from one another. The distance “d” between the nozzle holes in the cluster configuration, the clustered plume angle “α”, which is the angular separation between the centerlines of the nozzle holes, as well as the included spray angle “β”, are optimized through computational fluid dynamics and combustion modeling so that an optimal compromise can be found between liquid penetration, spray penetration and air entrainment, whereby to minimize soot emissions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Combustion chamber of diesel engine

InactiveUS20160363042A1Emission reductionImprove combustionInternal combustion piston enginesPistonCombustion chamber

A combustion chamber of diesel engine. The diesel engine includes a cylinder head, a cylinder sleeve, and a piston. The cylinder head, the cylinder sleeve, and the piston form the combustion chamber. The combustion chamber includes a headspace; a central part; and a collision belt. The collision belt includes a collision surface, an upper guide surface, and a lower guide surface. The collision belt is configured to connect the headspace and the central part. The collision surface is an inclined surface, a convex surface, or a concave surface. The first tapered surface includes a second inclined surface, a second curved surface, and a third inclined surface; the second tapered surface includes a fourth inclined surface, a third curved surface, and a second concave surface; the first curved surface includes a second convex surface and a third concave surface.

Owner:DALIAN UNIV OF TECH

Fuel injection pattern and timing

ActiveUS20130166178A1Limit soot emissionMinimizing soot emissionElectrical controlInternal combustion piston enginesCombustion chamberEngineering

A method is provided for operating an engine to limit soot emissions during fuel-enriched operation. The method includes operating the engine using a first fuel injection pattern and timing to inject fuel into a combustion chamber of the engine. The method further includes receiving a request for an increased engine power output and operating the engine using a second fuel injection pattern and timing to inject more fuel into the combustion in response to the request for the increased power output, where the second fuel injection pattern and timing is configured to minimize soot emissions during enriched fuel operations, such as during transient operations.

Owner:INT ENGINE INTPROP CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com