Patents

Literature

185 results about "Excess oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Excess Oxygen can cause pulmonary oxygen toxicity which results in a lot of damage to the body tissues. To summarize briefly, the excess oxygen can cause, pulmonary toxicity, Acute respiratory distress syndrome, rertolental fibroplasia, convulsions and Paul burt effect.

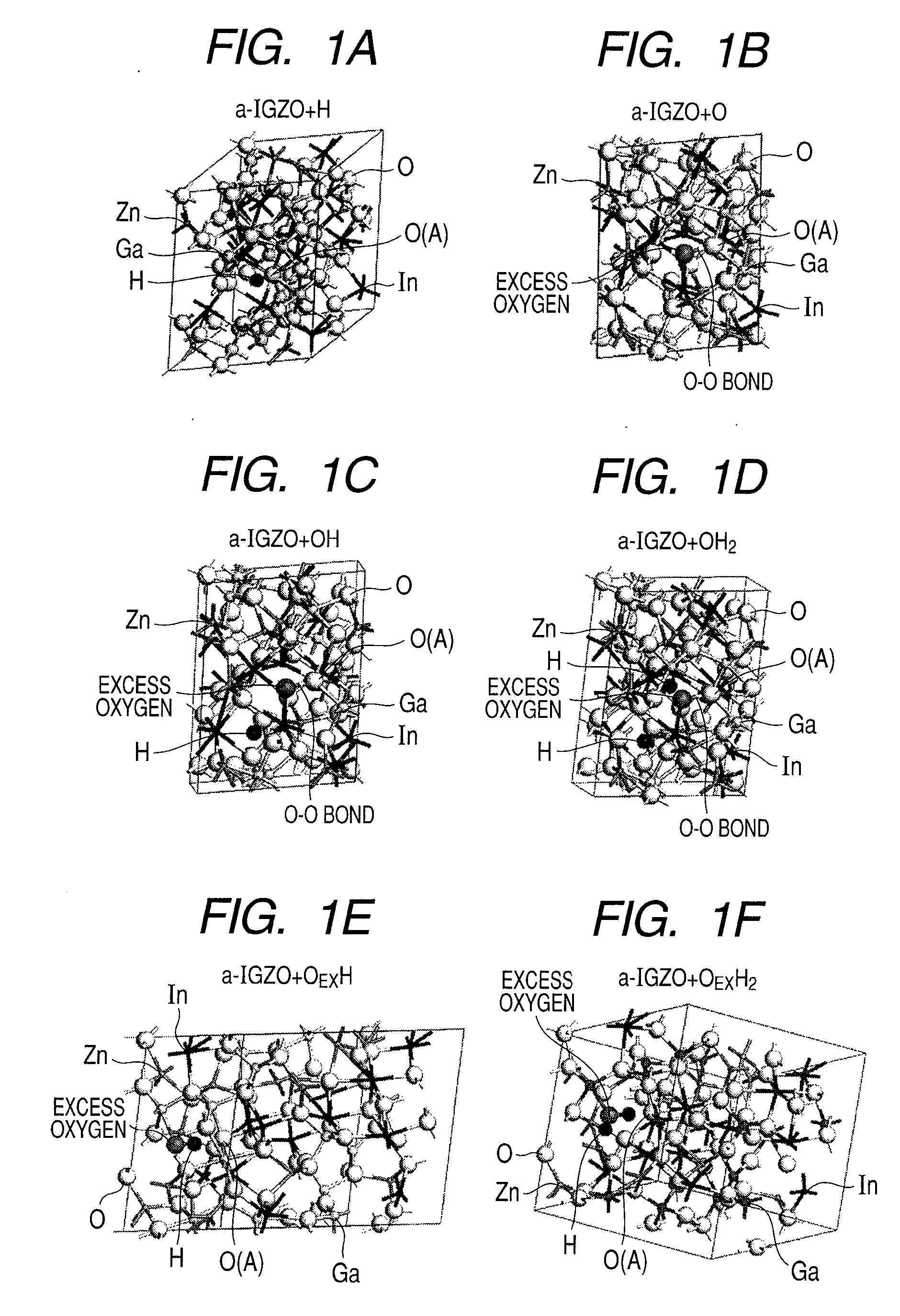

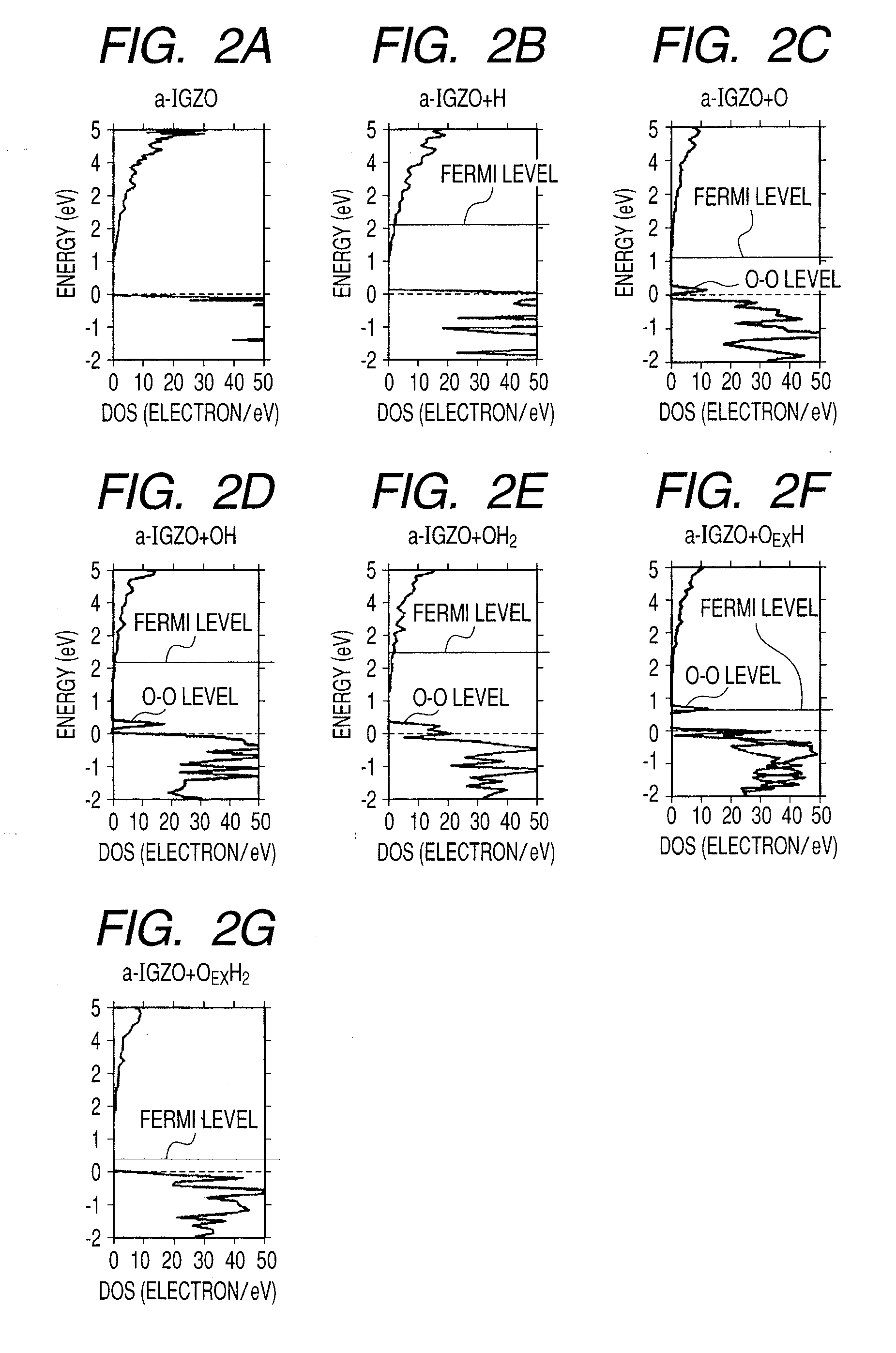

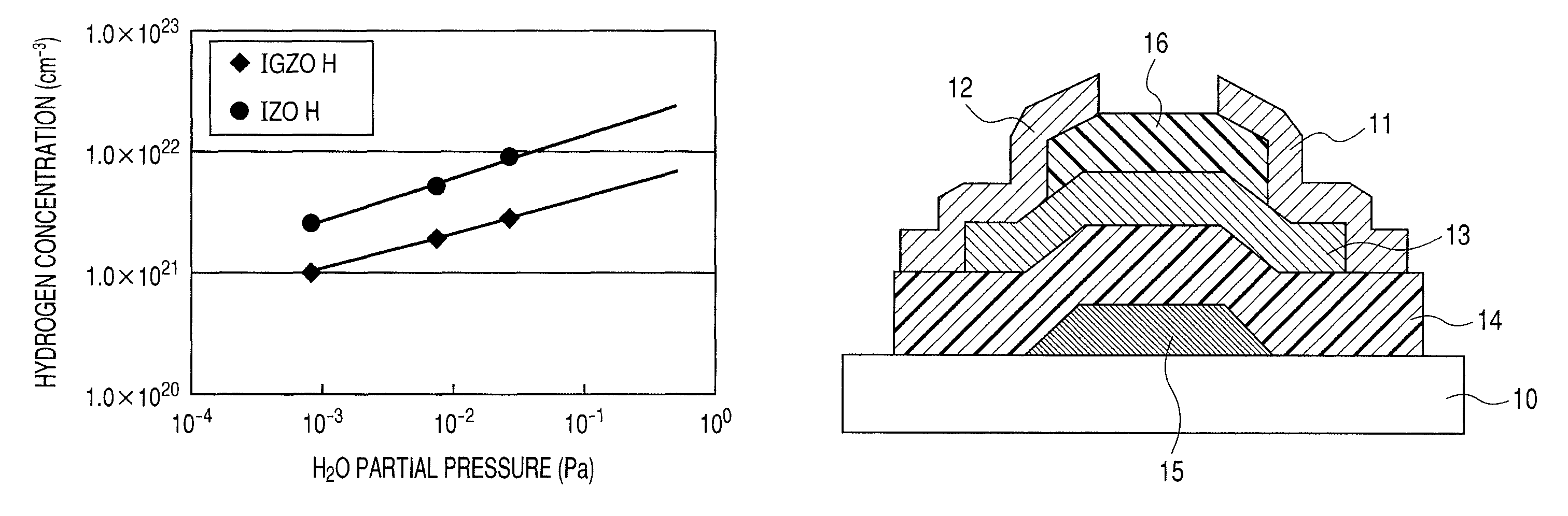

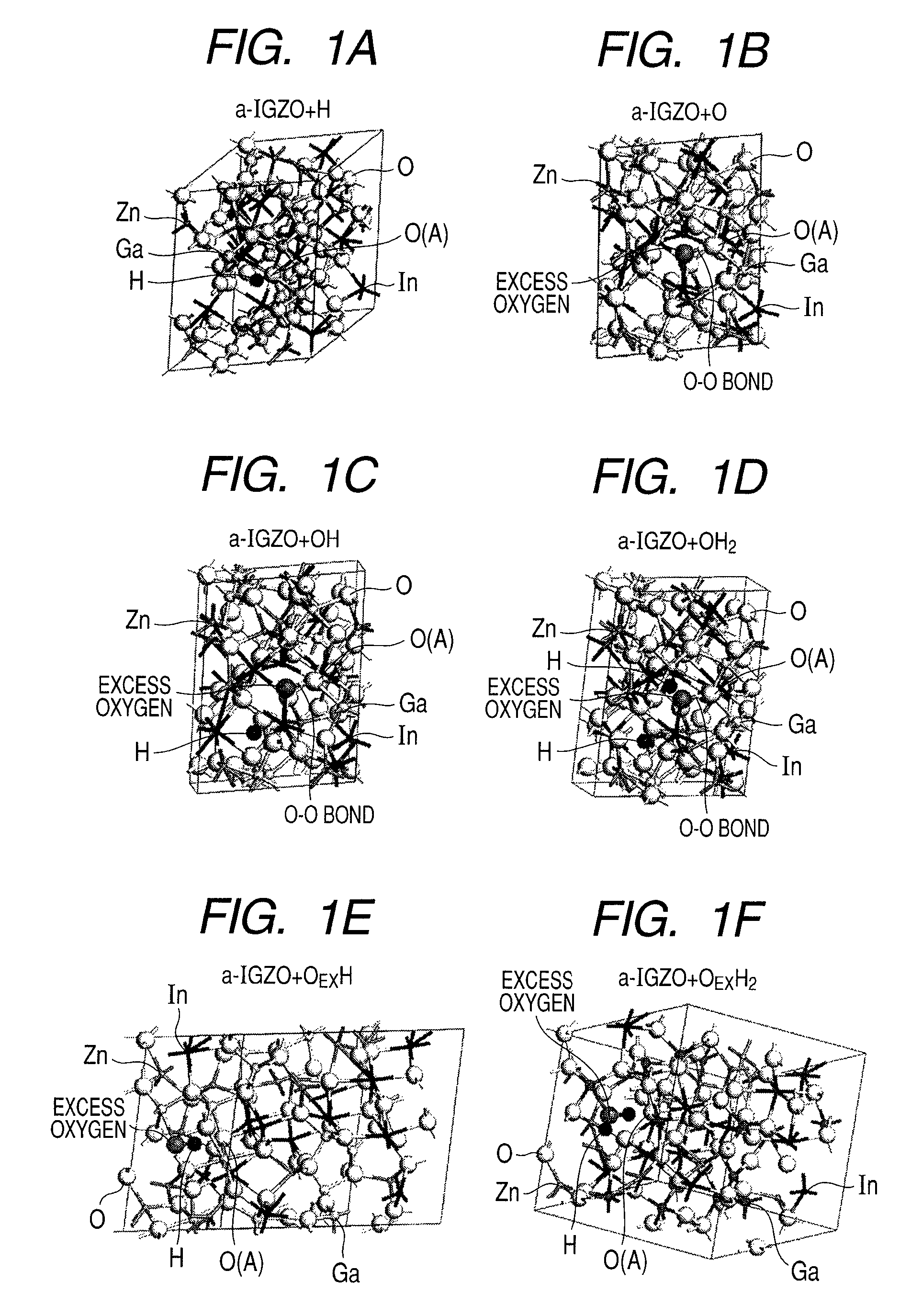

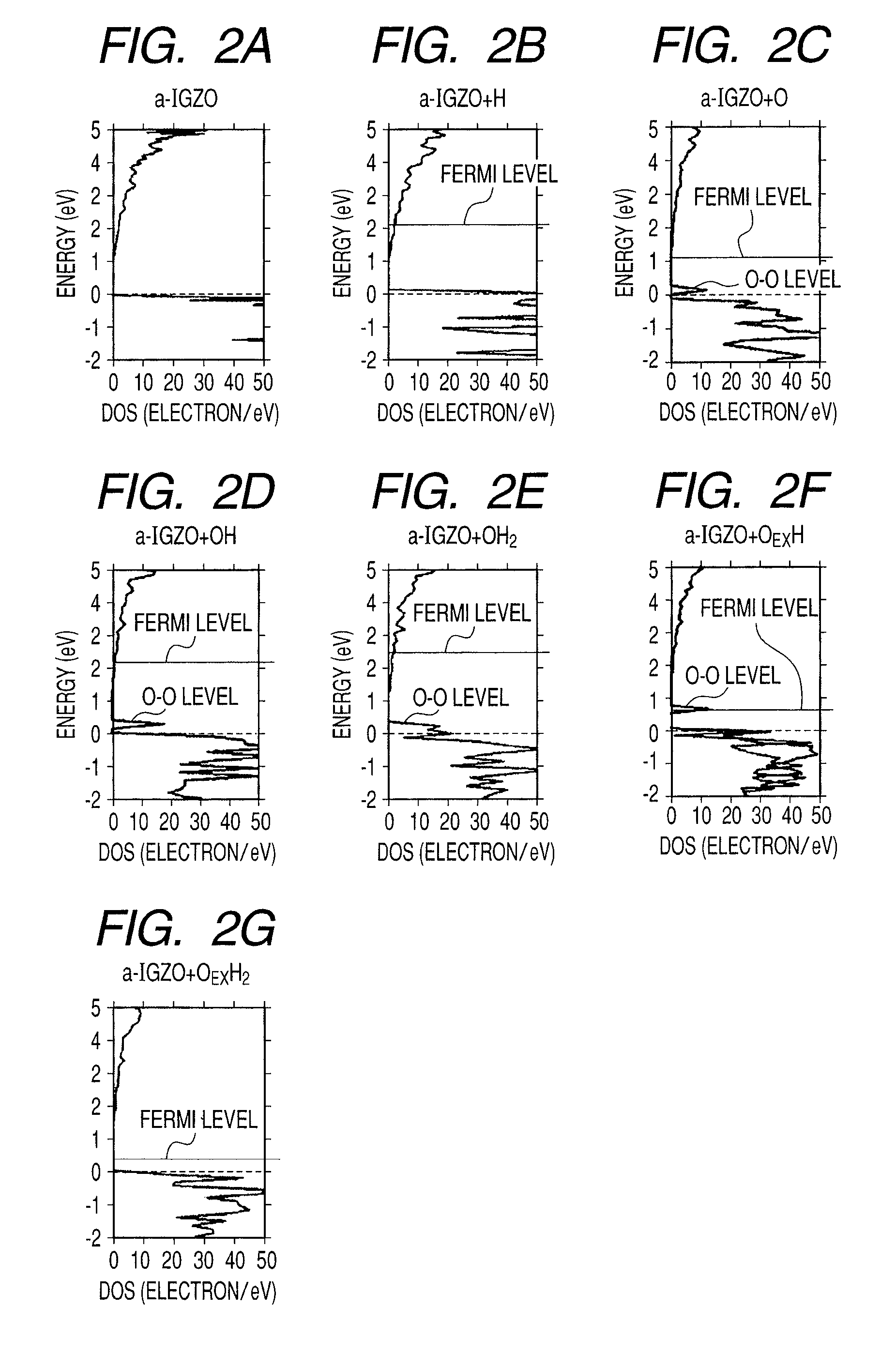

Amorphous oxide semiconductor and thin film transistor using the same

InactiveUS20100051938A1Improve transistor characteristicsLow costTransistorSemiconductor/solid-state device manufacturingIndiumHydrogen

There is provided an amorphous oxide semiconductor including hydrogen and at least one element of indium (In) and zinc (Zn), the amorphous oxide semiconductor containing one of hydrogen atoms and deuterium atoms of 1×1020 cm−3 or more to 1×1022 cm−3 or less, and a density of bonds between oxygen and hydrogen except bonds between excess oxygen (OEX) and hydrogen in the amorphous oxide semiconductor being 1×1018 cm−3 or less.

Owner:CANON KK

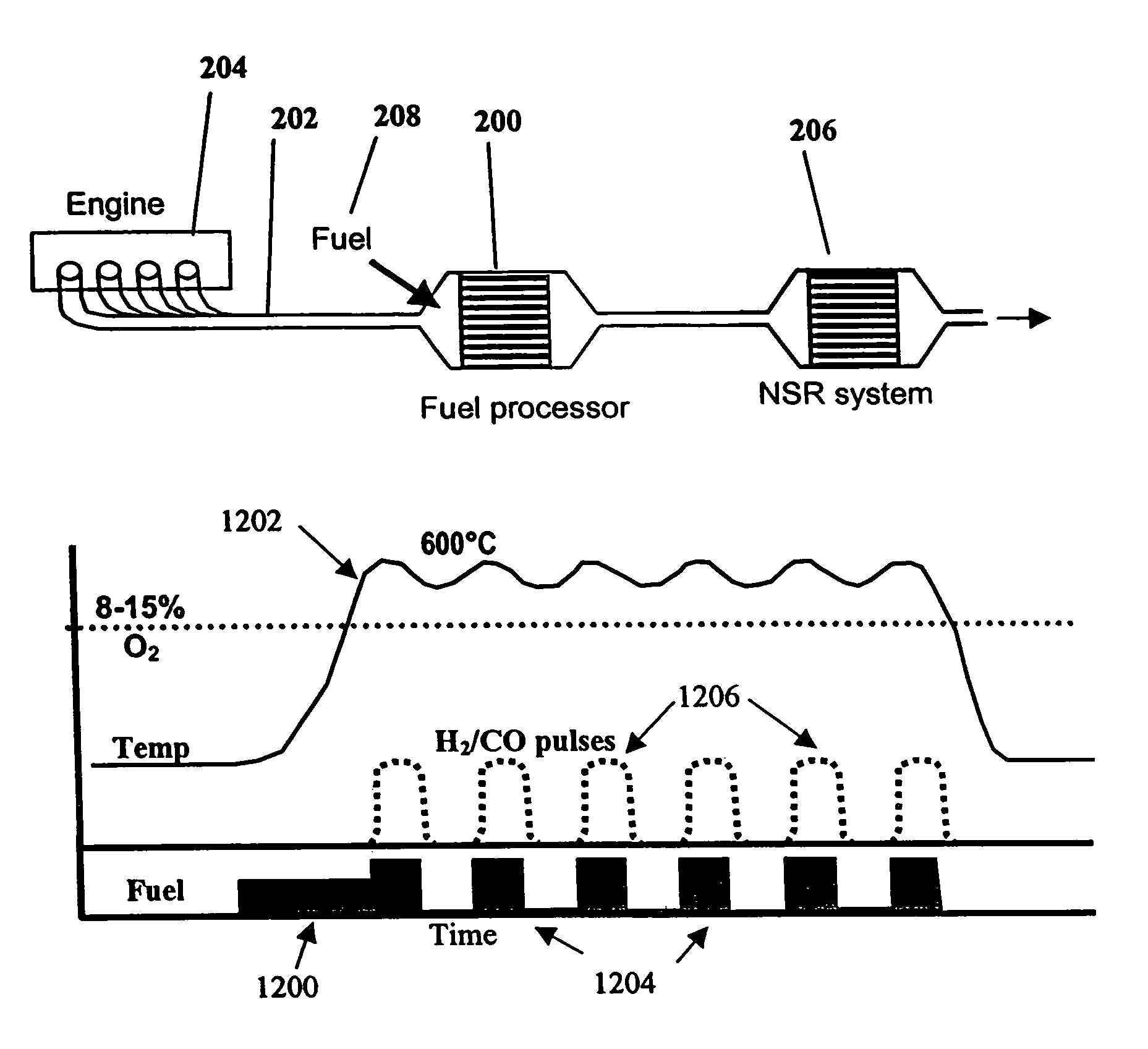

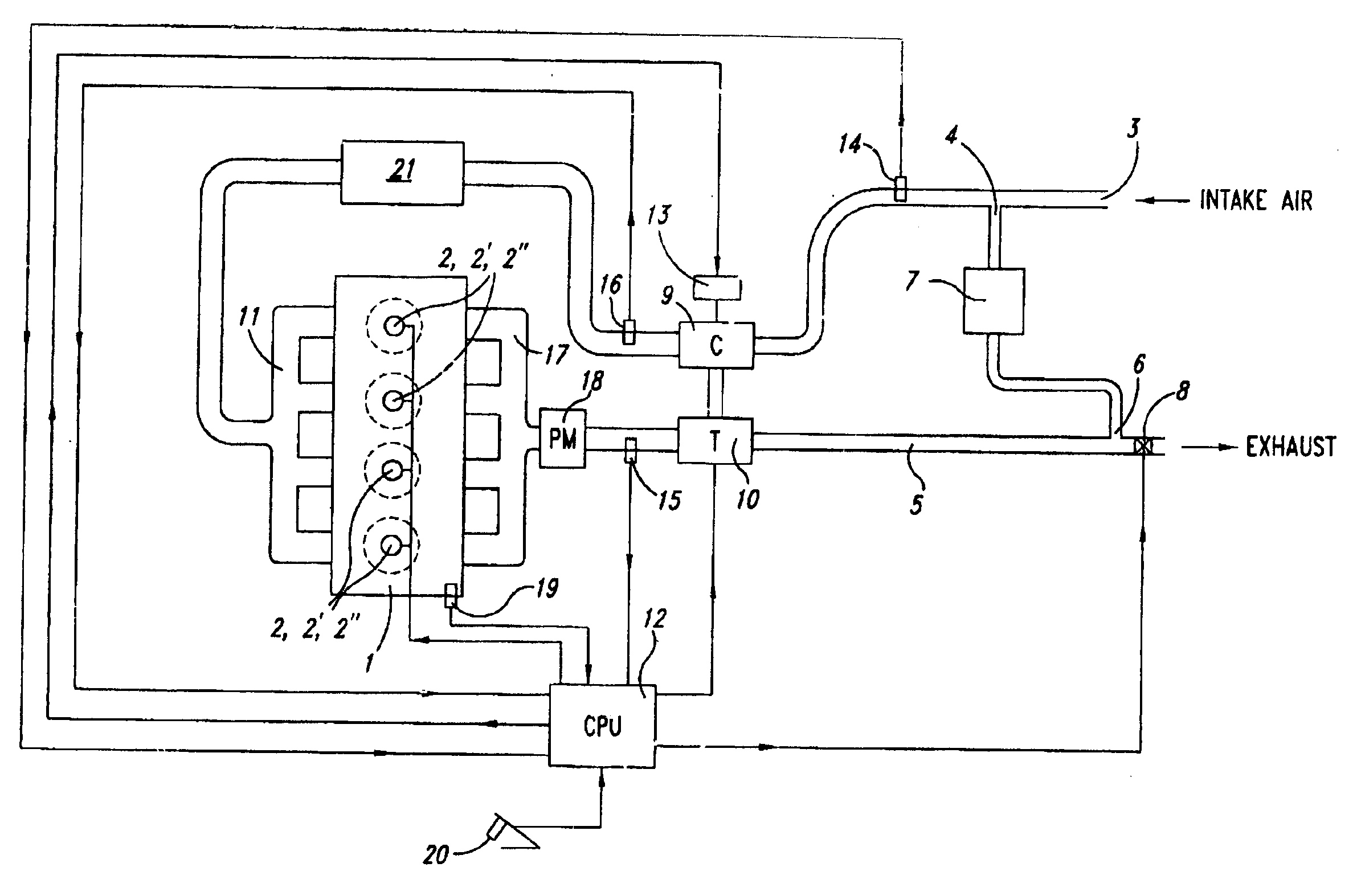

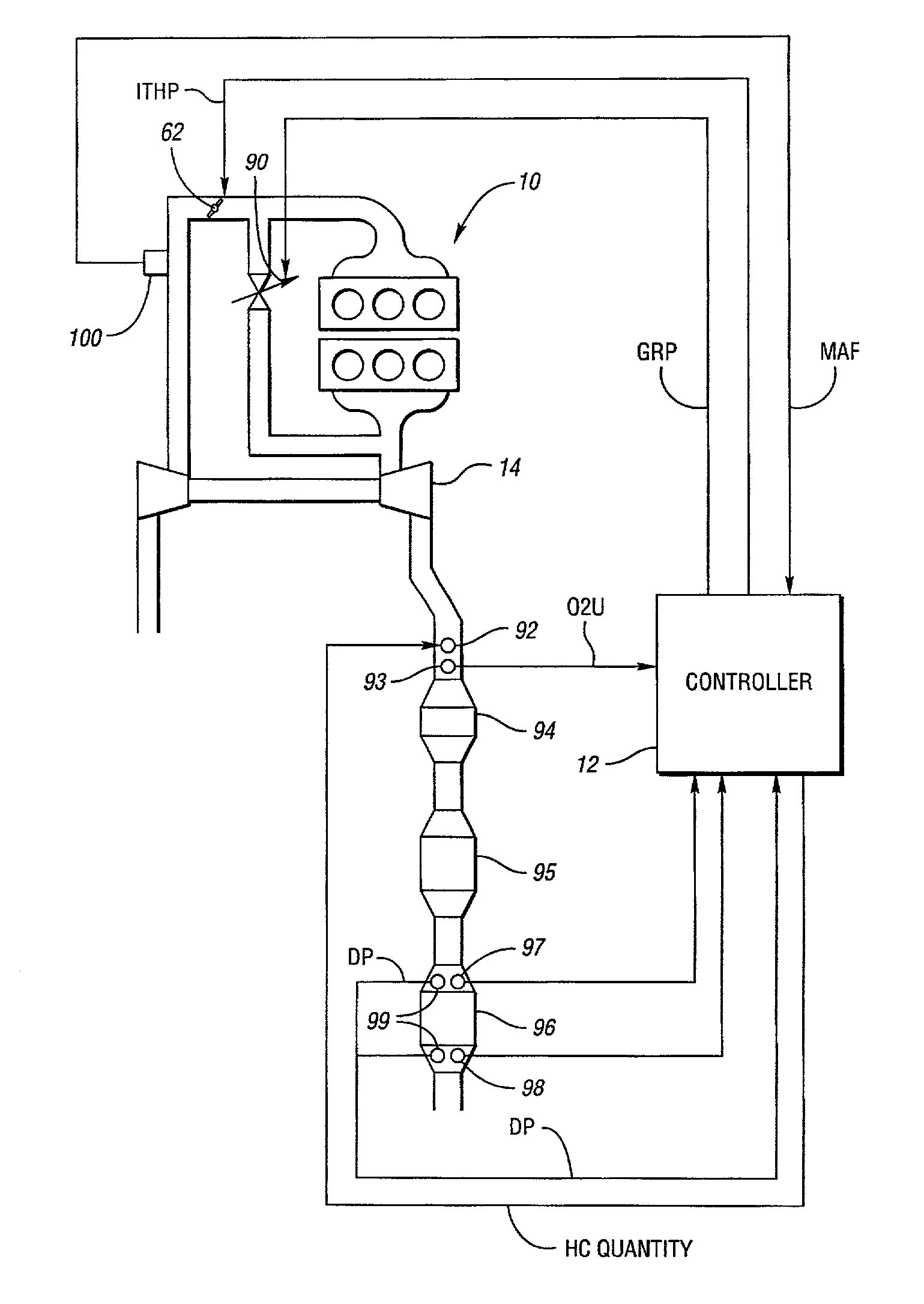

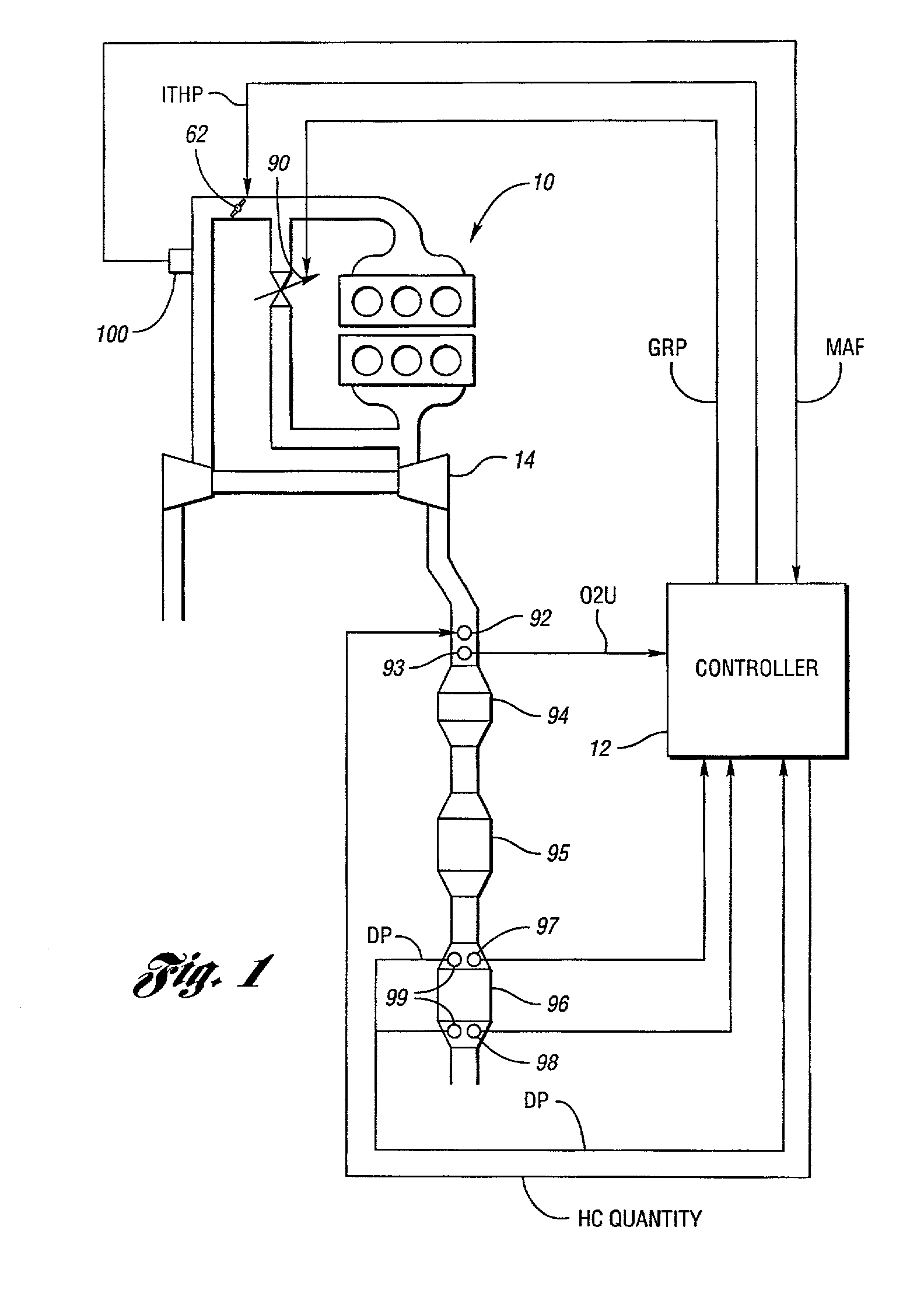

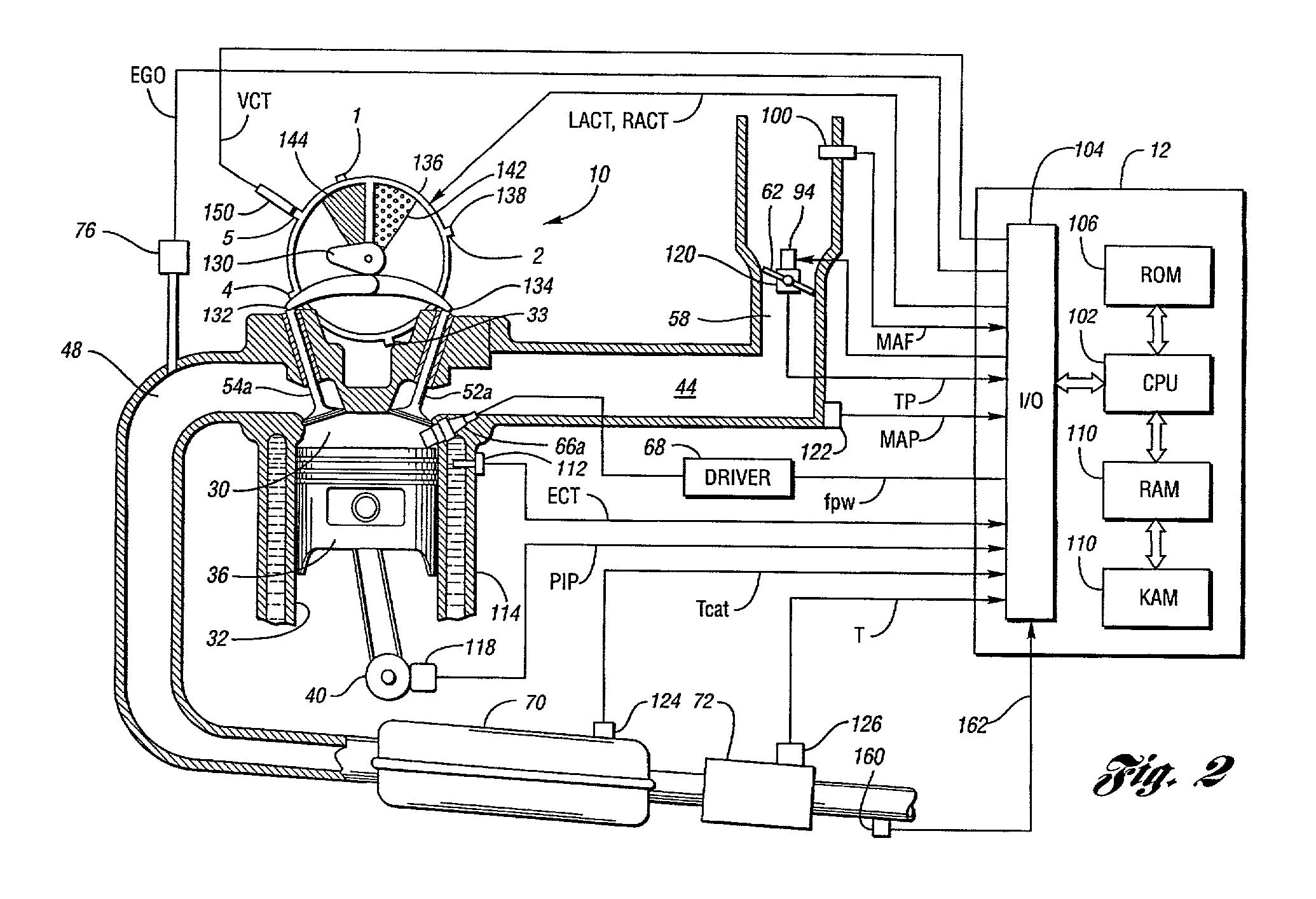

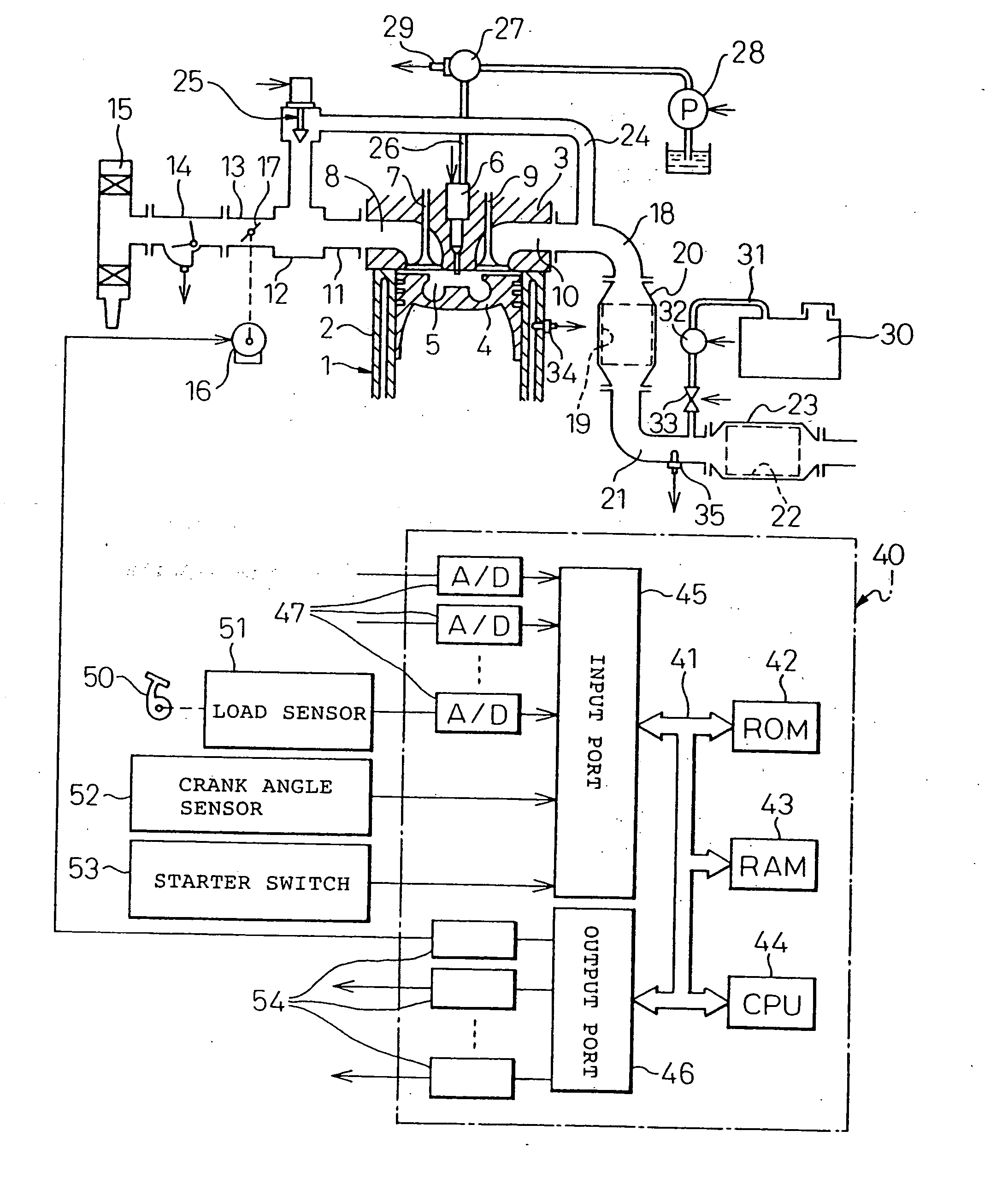

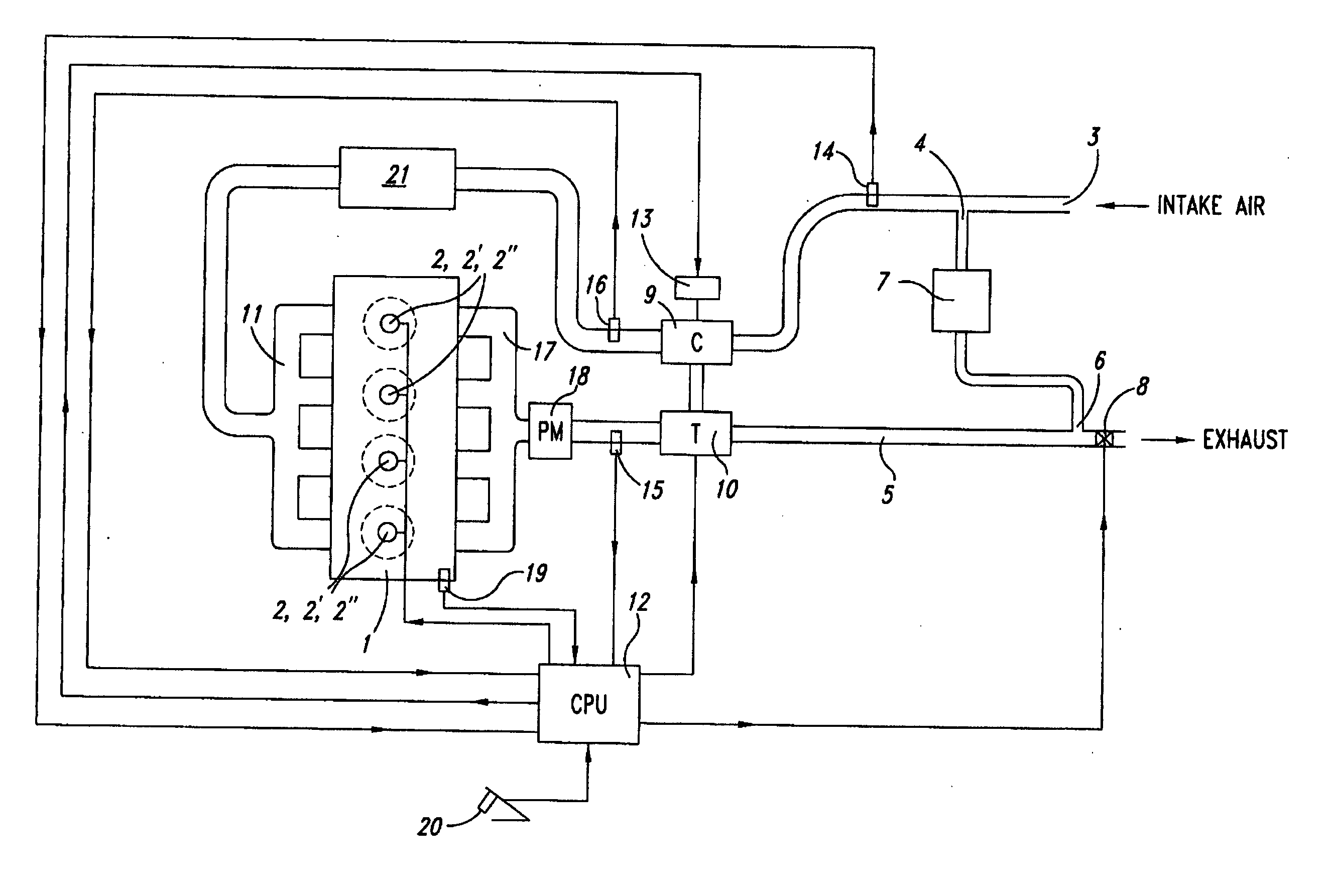

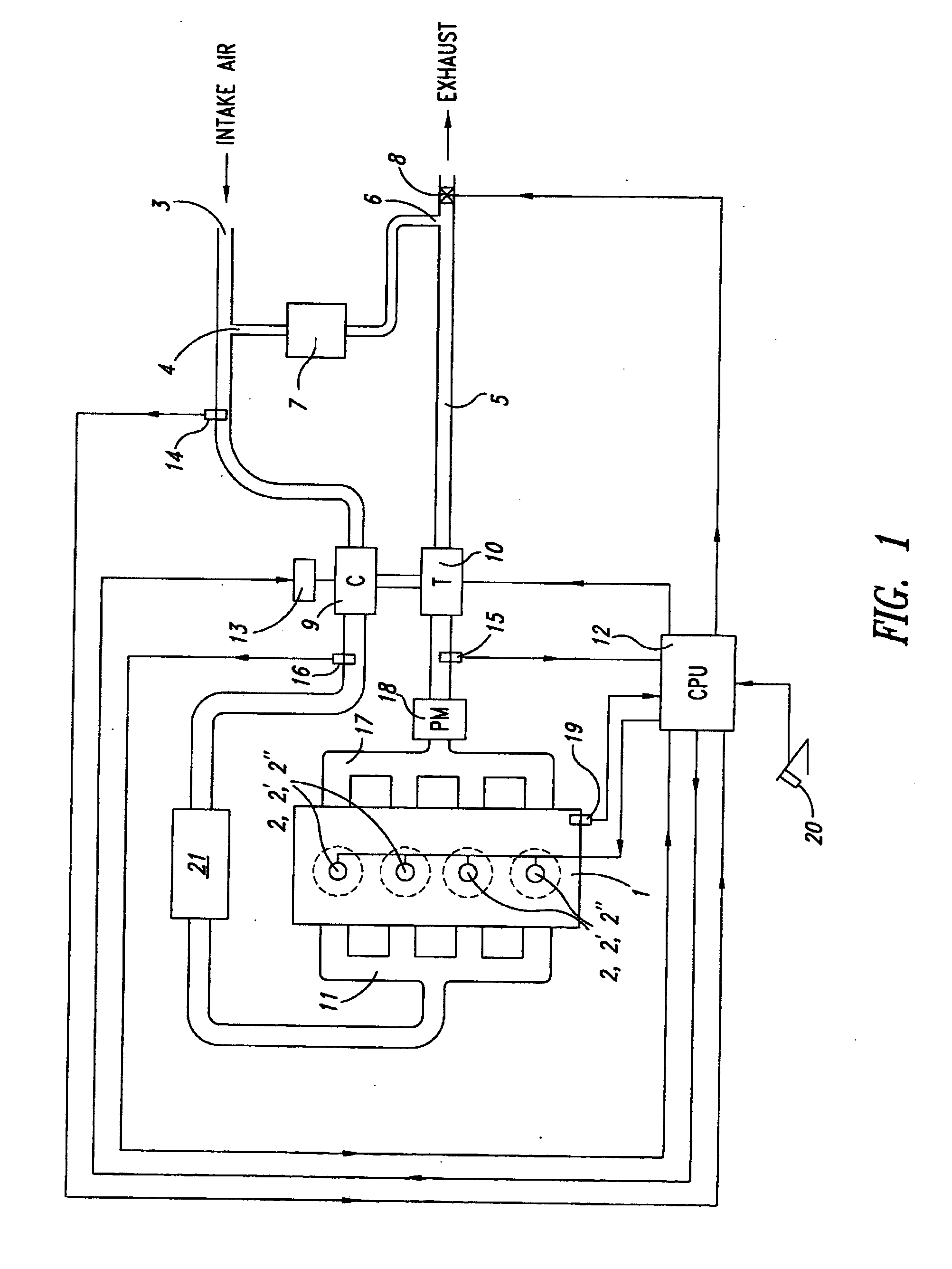

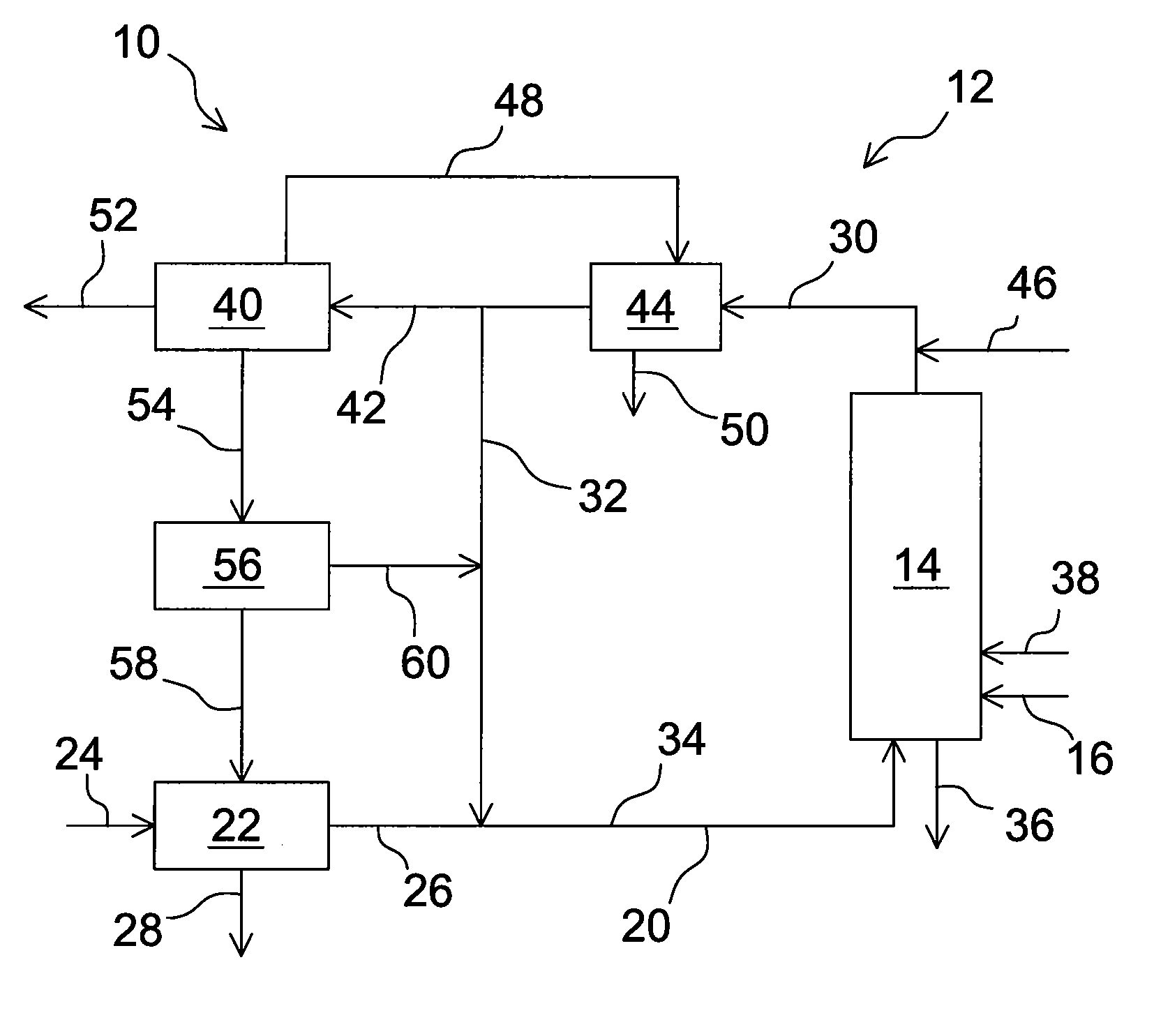

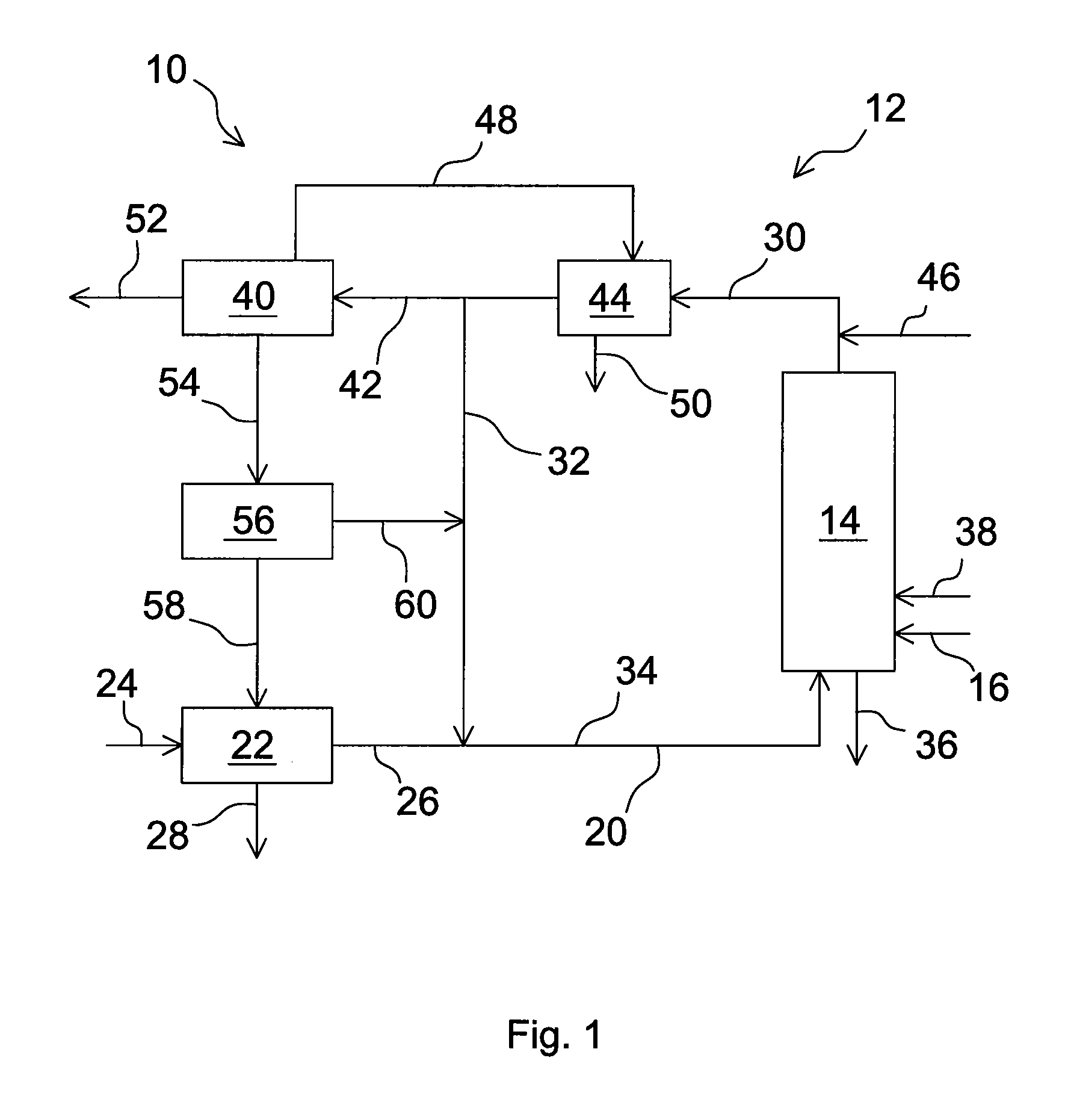

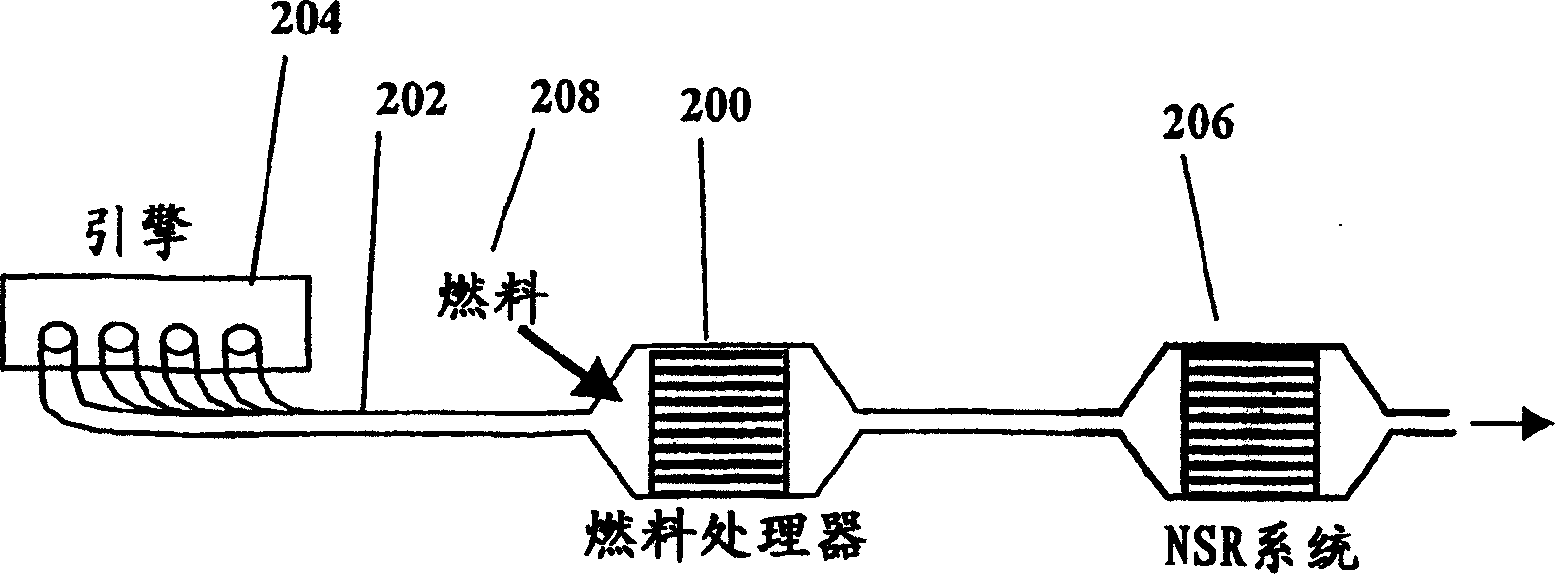

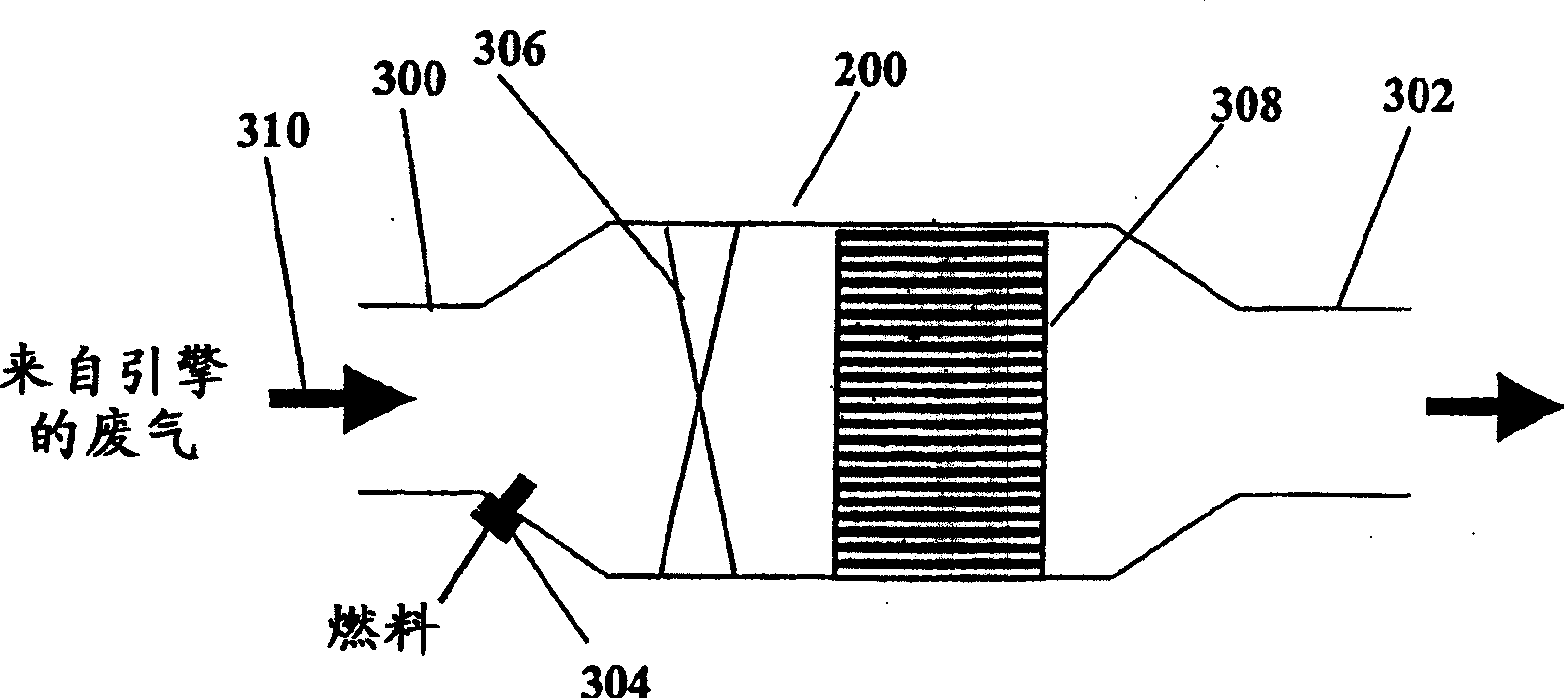

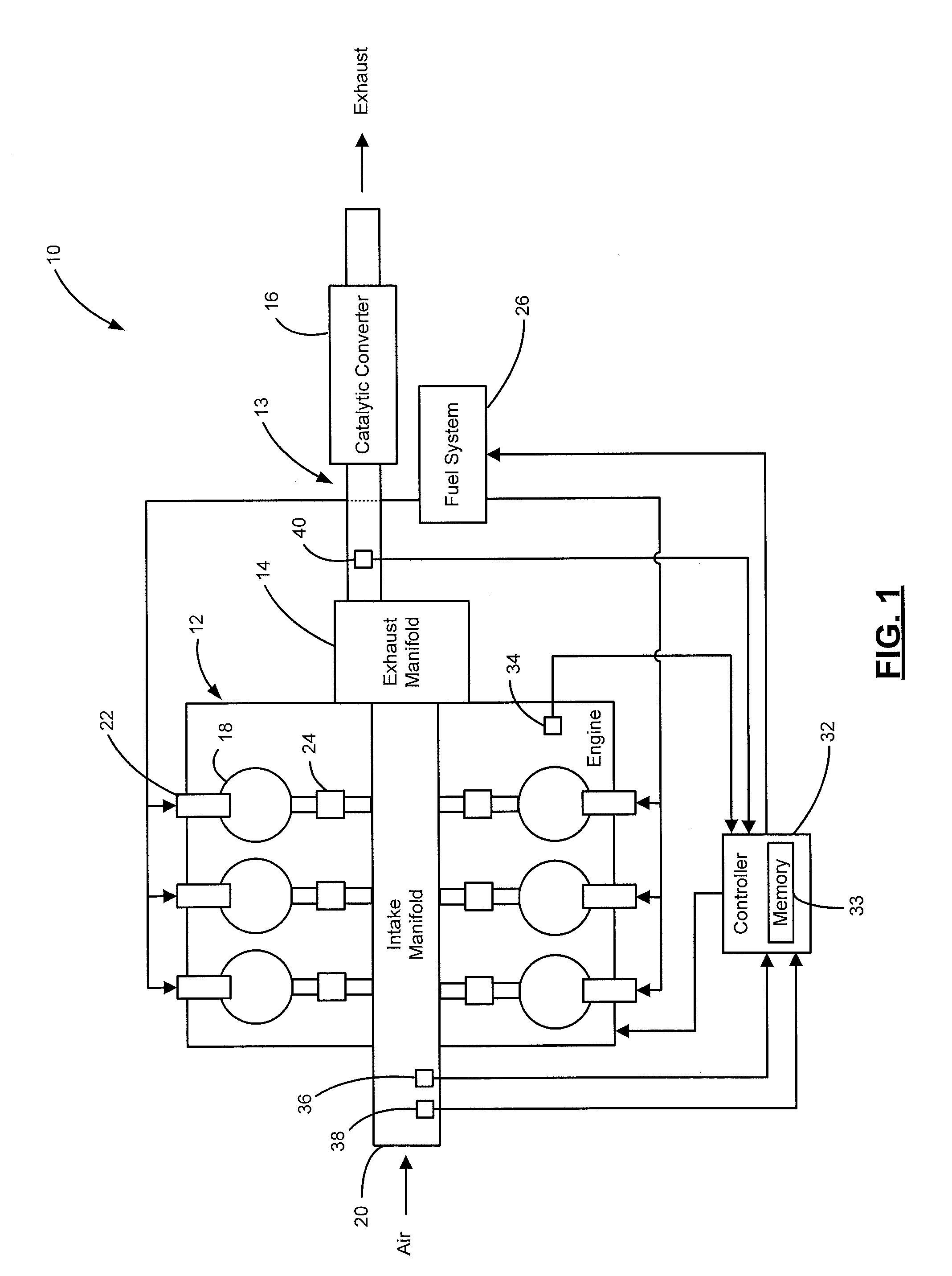

System and methods for improved emission control of internal combustion engines using pulsed fuel flow

InactiveUS7082753B2Save oilReducing greenhouse gas emissionExhaust apparatusCombustion enginesPartial oxidationExternal combustion engine

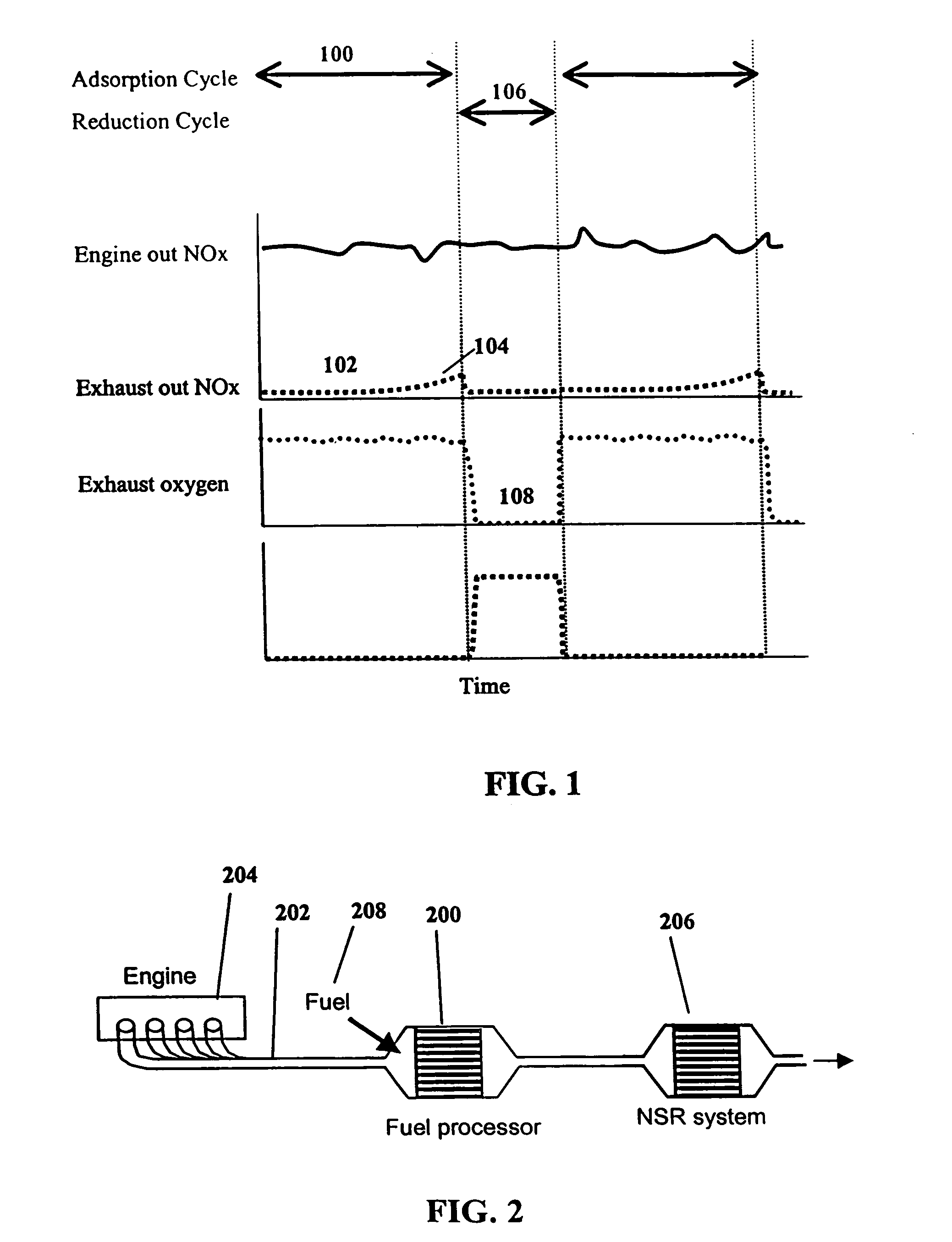

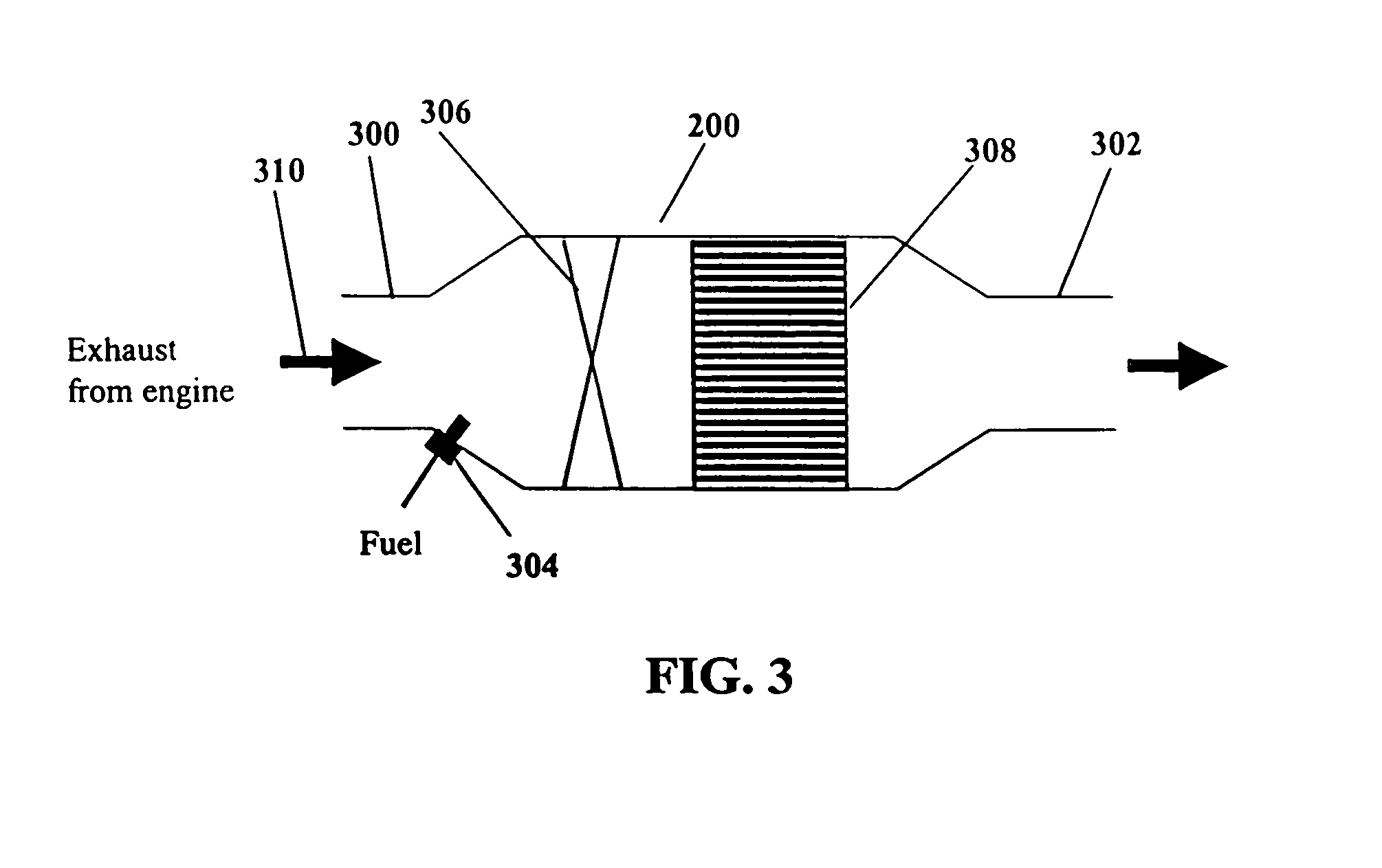

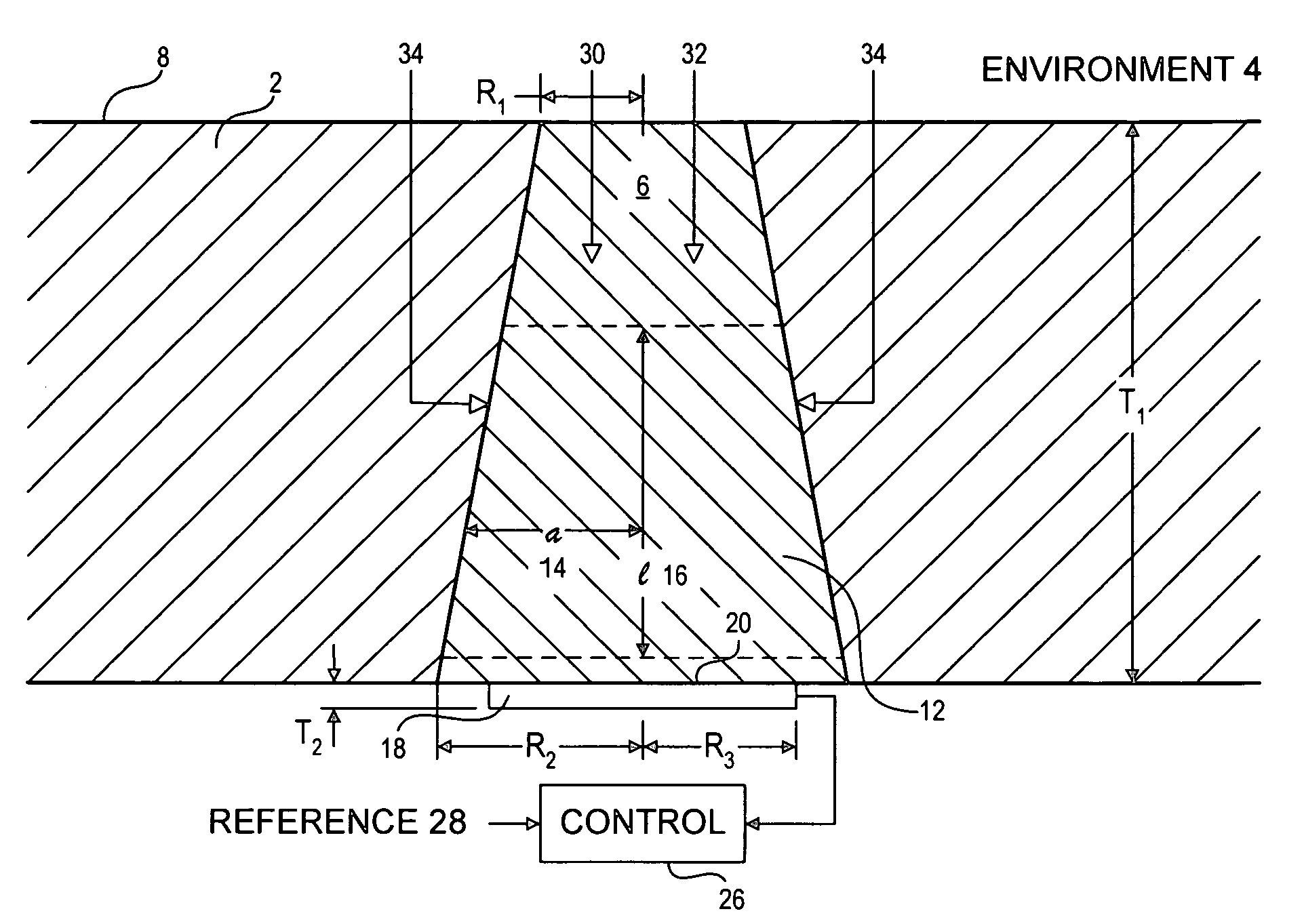

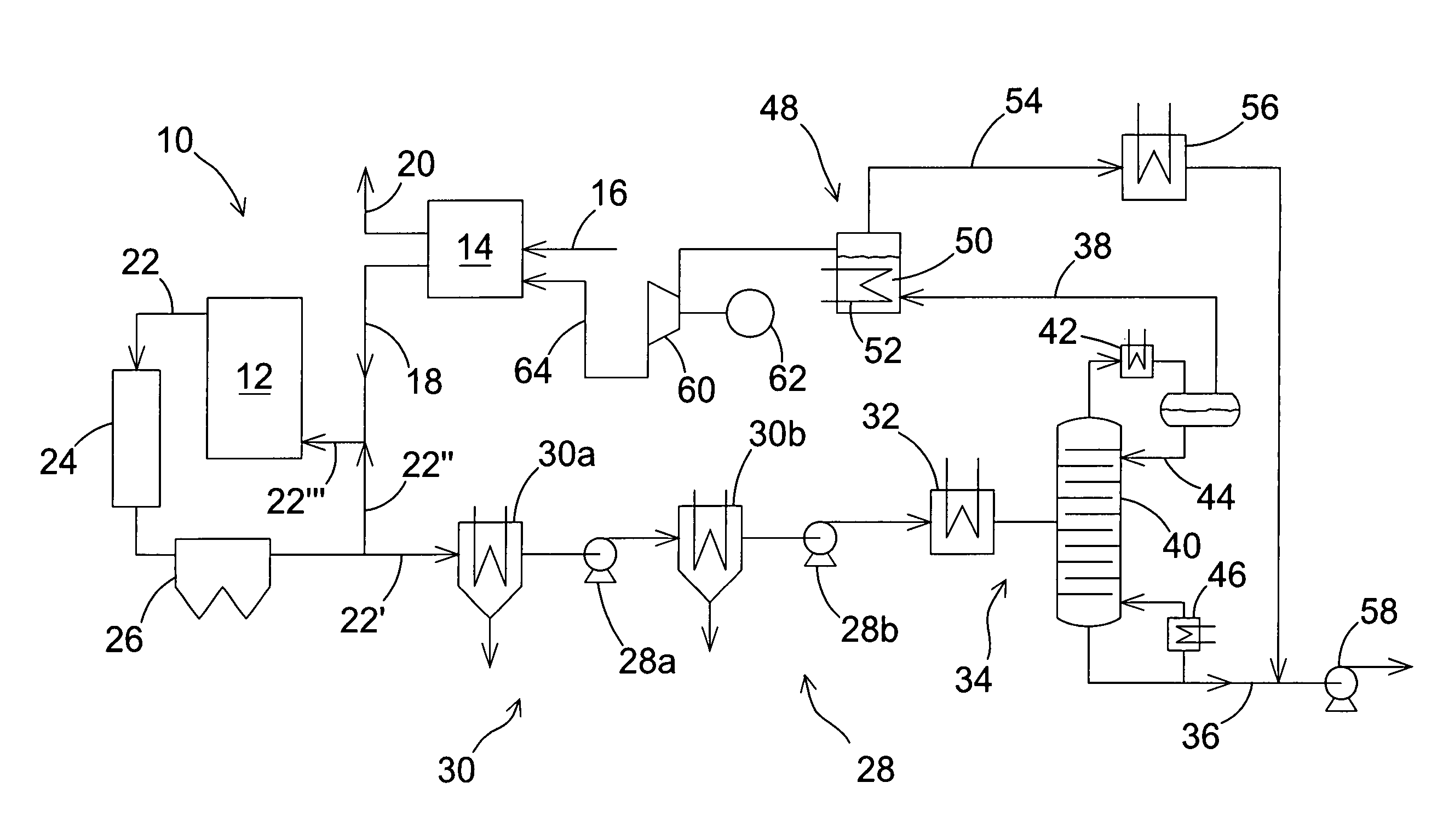

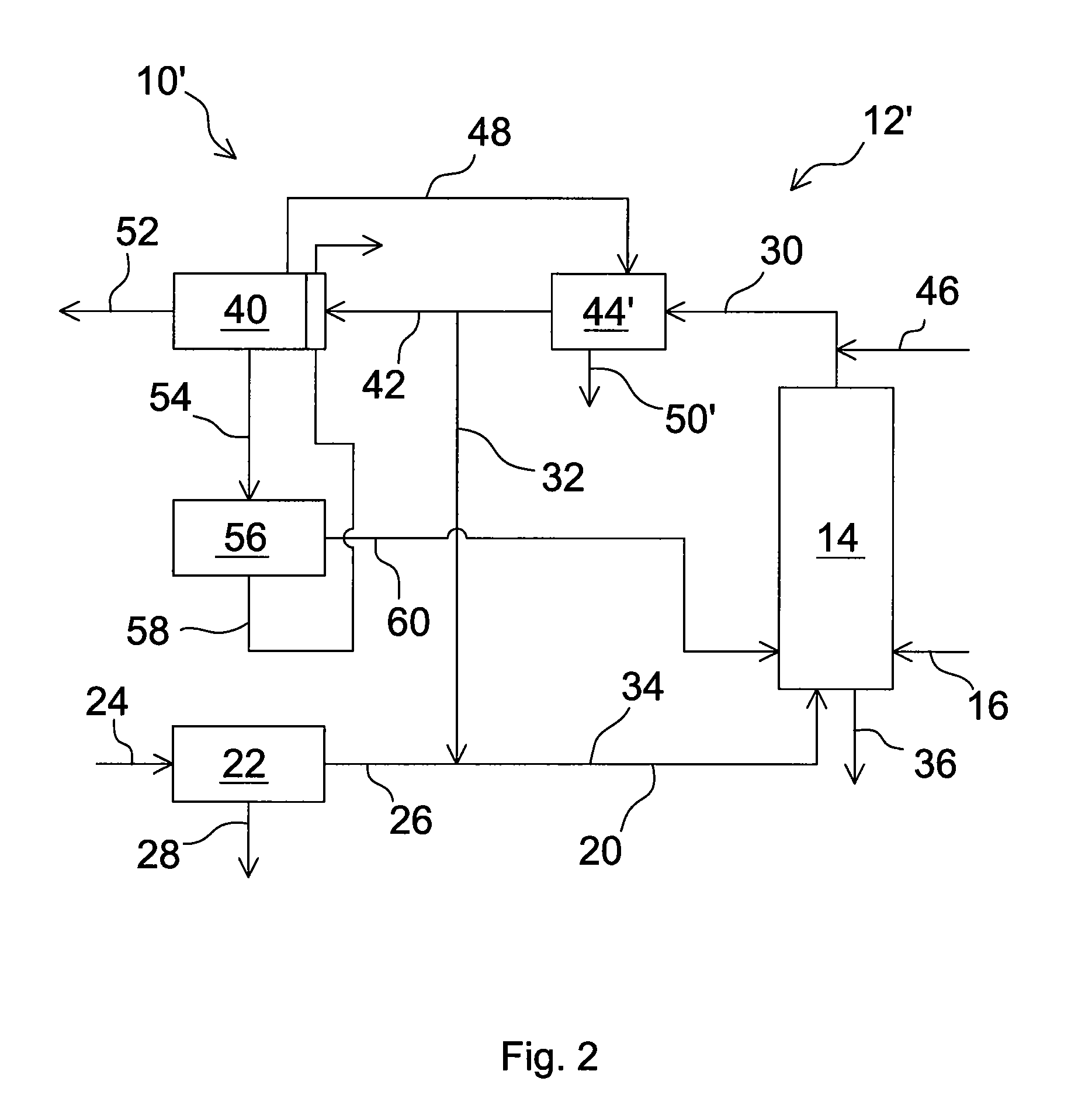

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction (“NSR”) emission control systems. The system generally includes a NSR catalyst, a fuel processor located upstream of the NSR catalyst, and at least one fuel injection port. The fuel processor converts a fuel into a reducing gas mixture comprising CO and H2. The reducing gas mixture is then fed into the NSR catalyst, where it regenerates the NSR adsorbent, reduces the NOx to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor generally includes one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration using pulsed fuel flow. Control strategies are also provided.

Owner:INT ENGINE INTPROP CO LLC

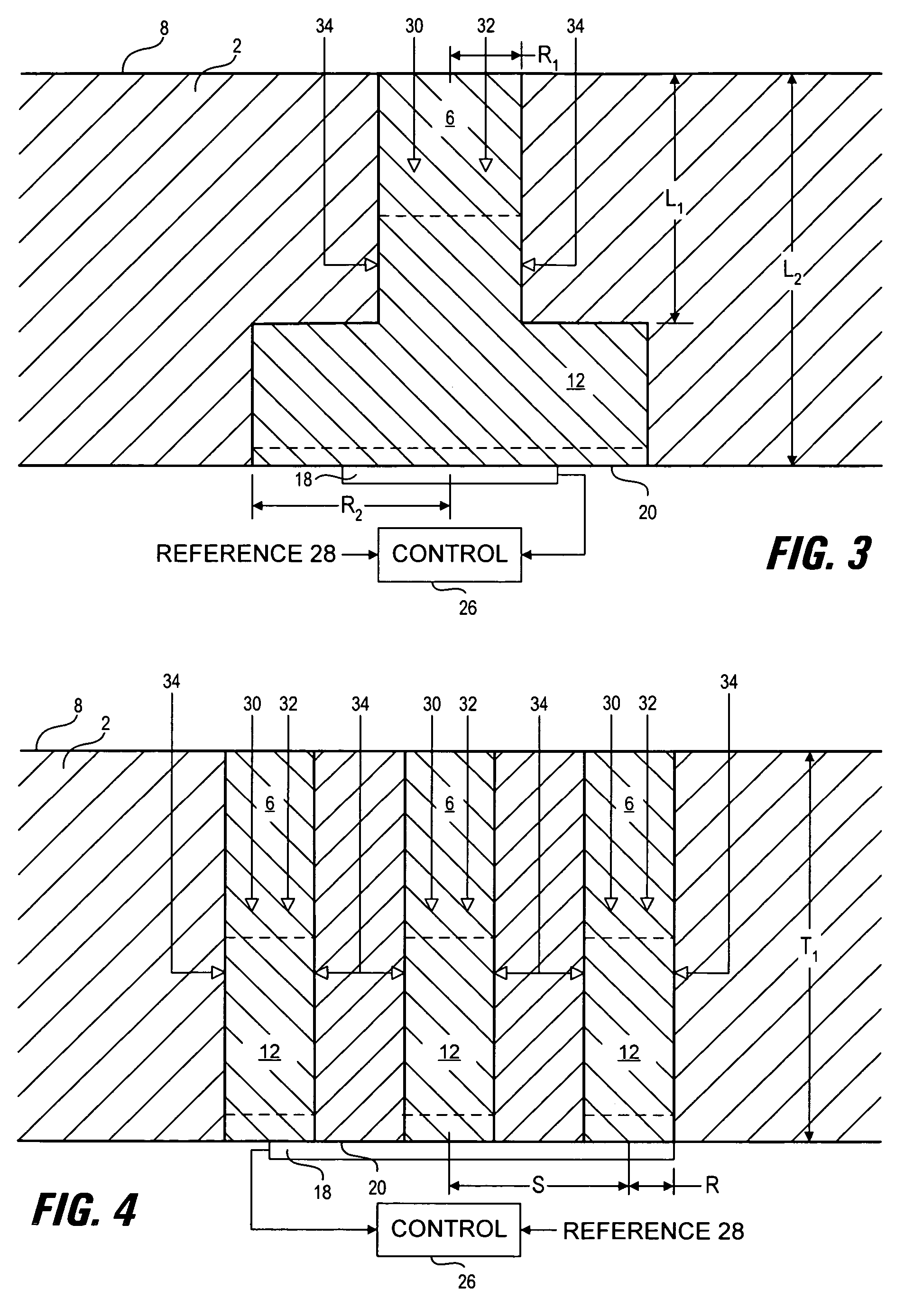

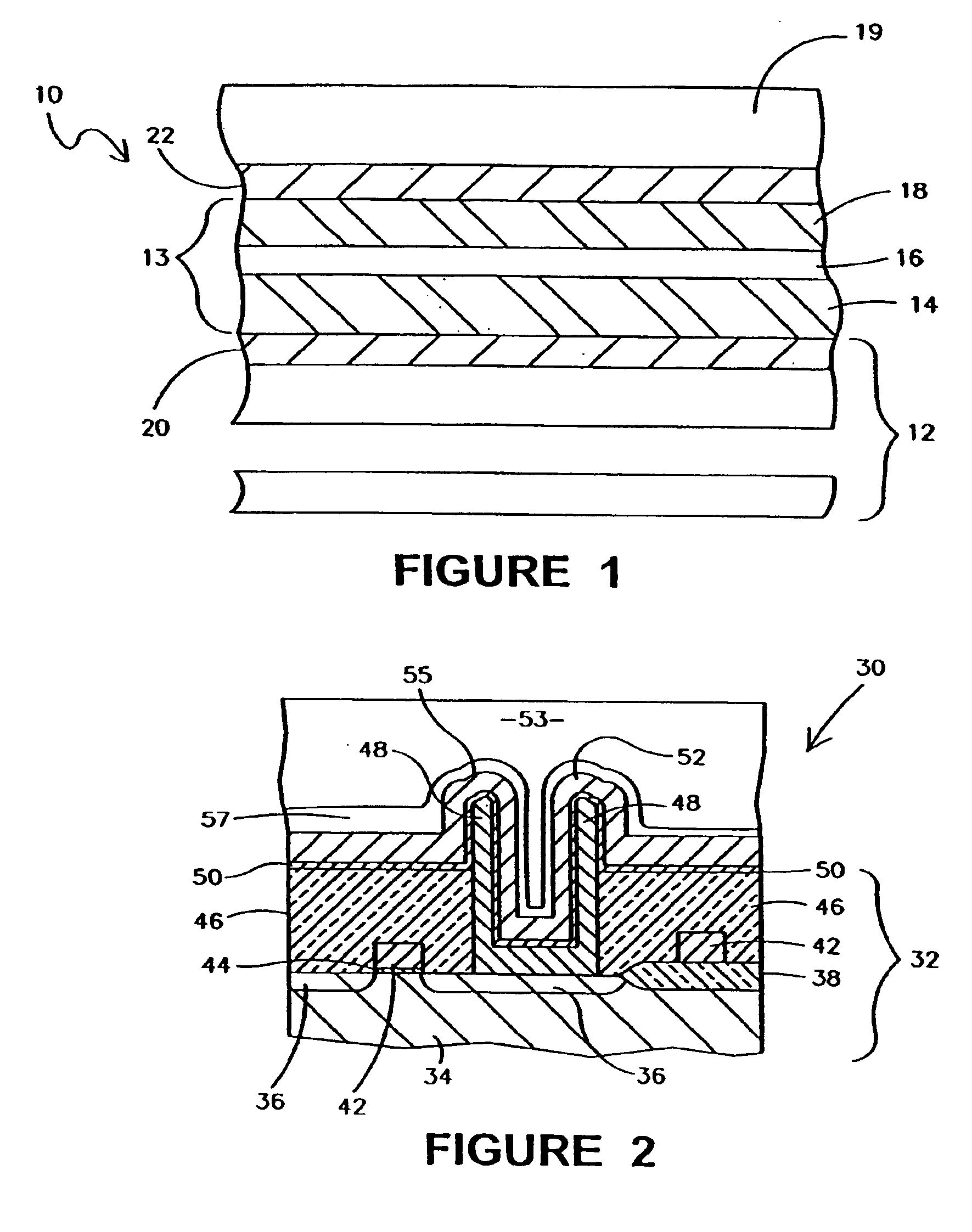

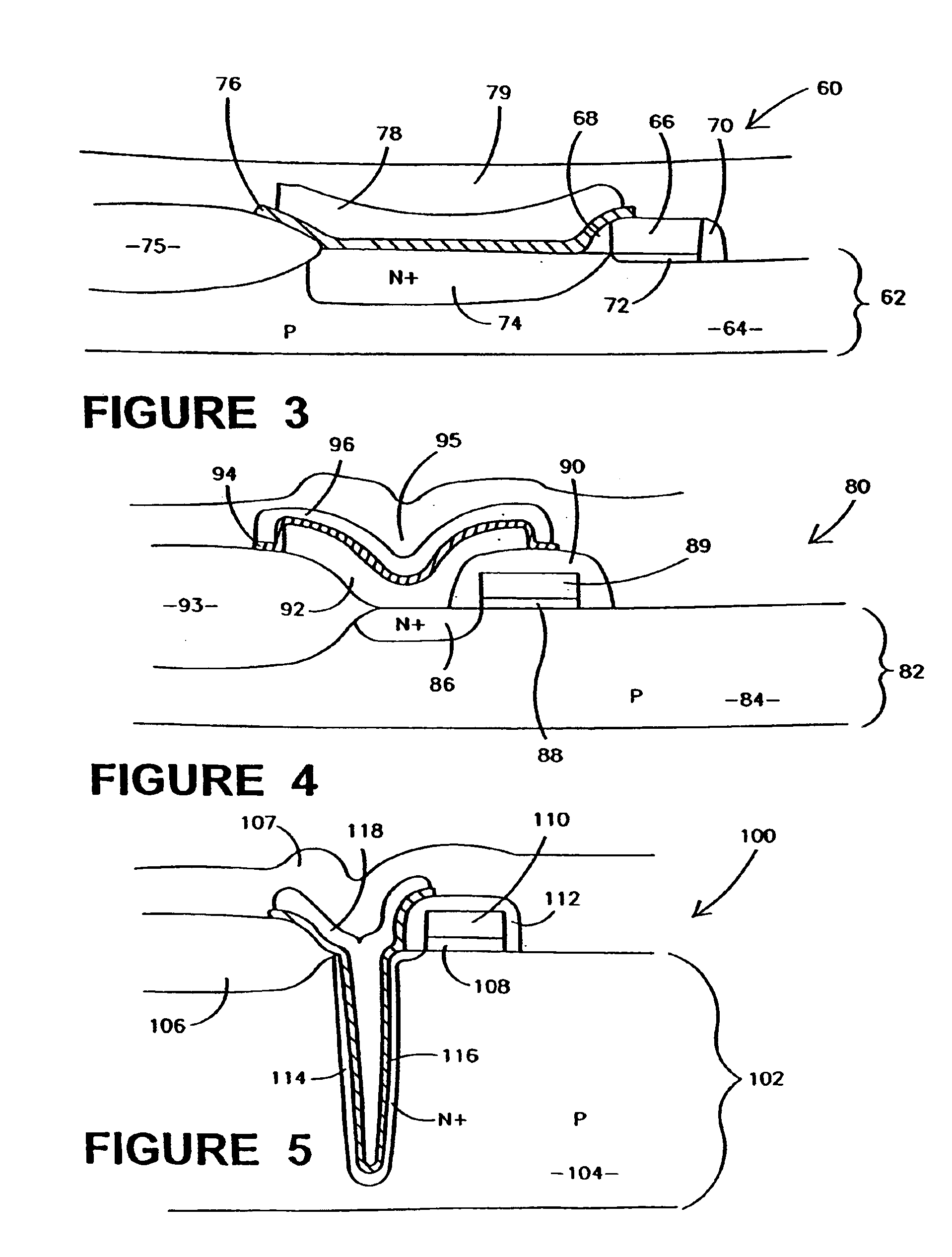

Membrane and electrode structure for implantable sensor

ActiveUS7336984B2Limited accessDiagnostic recording/measuringSensorsEnvironmental designExcess oxygen

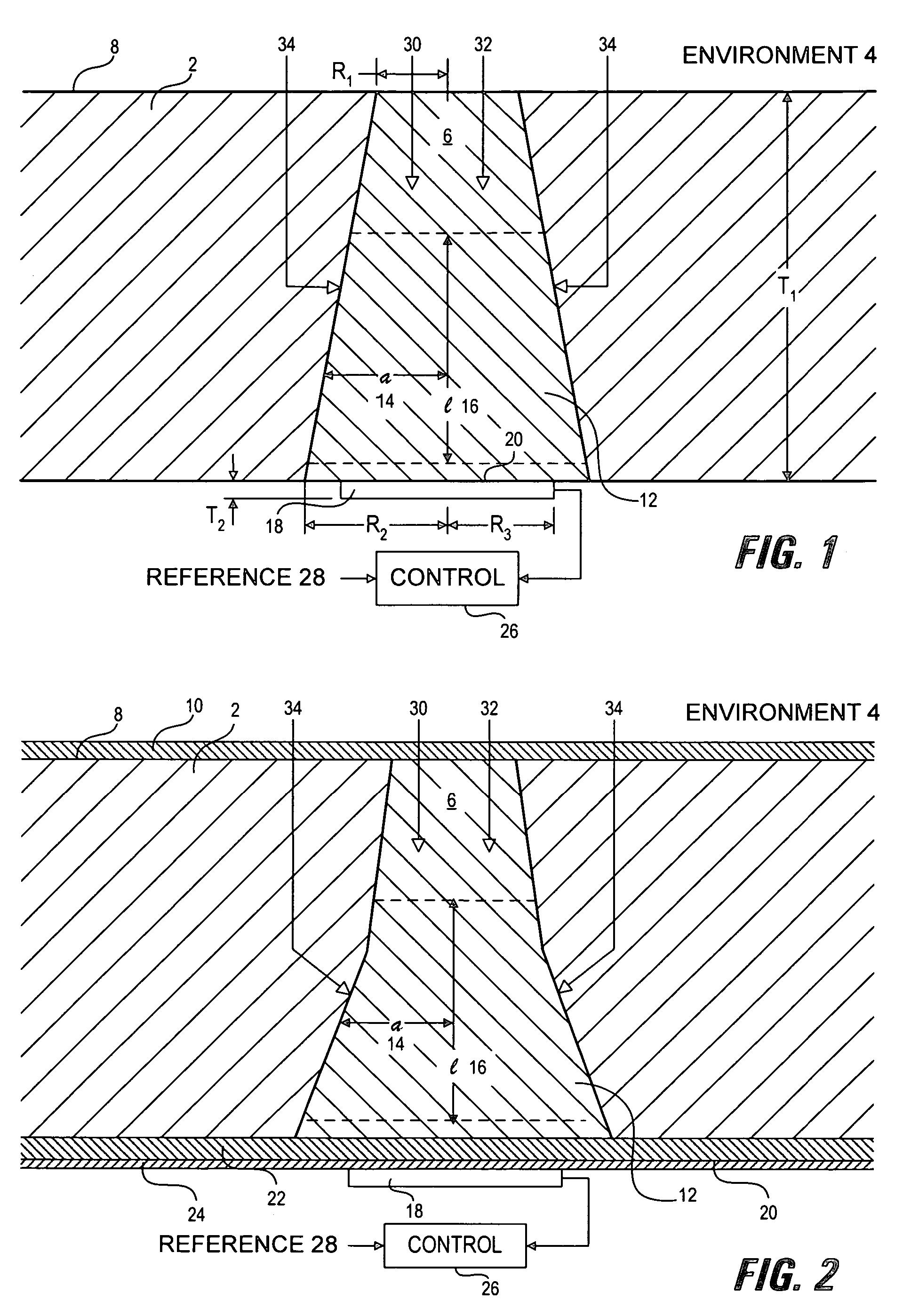

The invention is the design of a biological measuring device for the determination of the concentration of biomolecules (e.g. glucose) in an environment which is designed for implantation into an individual or for use in the context of an external apparatus. The device contains a composite membrane that is essentially entirely permeable to oxygen and permeable to larger biomolecules only in discrete hydrophilic regions. The membrane diffusionally limits the access of biomolecules to an enzyme, present in the hydrophilic region that catalyzes the oxidation of the biomolecule to produce hydrogen peroxide. A sensor in communication with the hydrophilic region is used to determine the amount of product produced or the amount of excess oxygen present allowing for the concentration of the biomolecule to be determined.

Owner:RGT UNIV OF CALIFORNIA

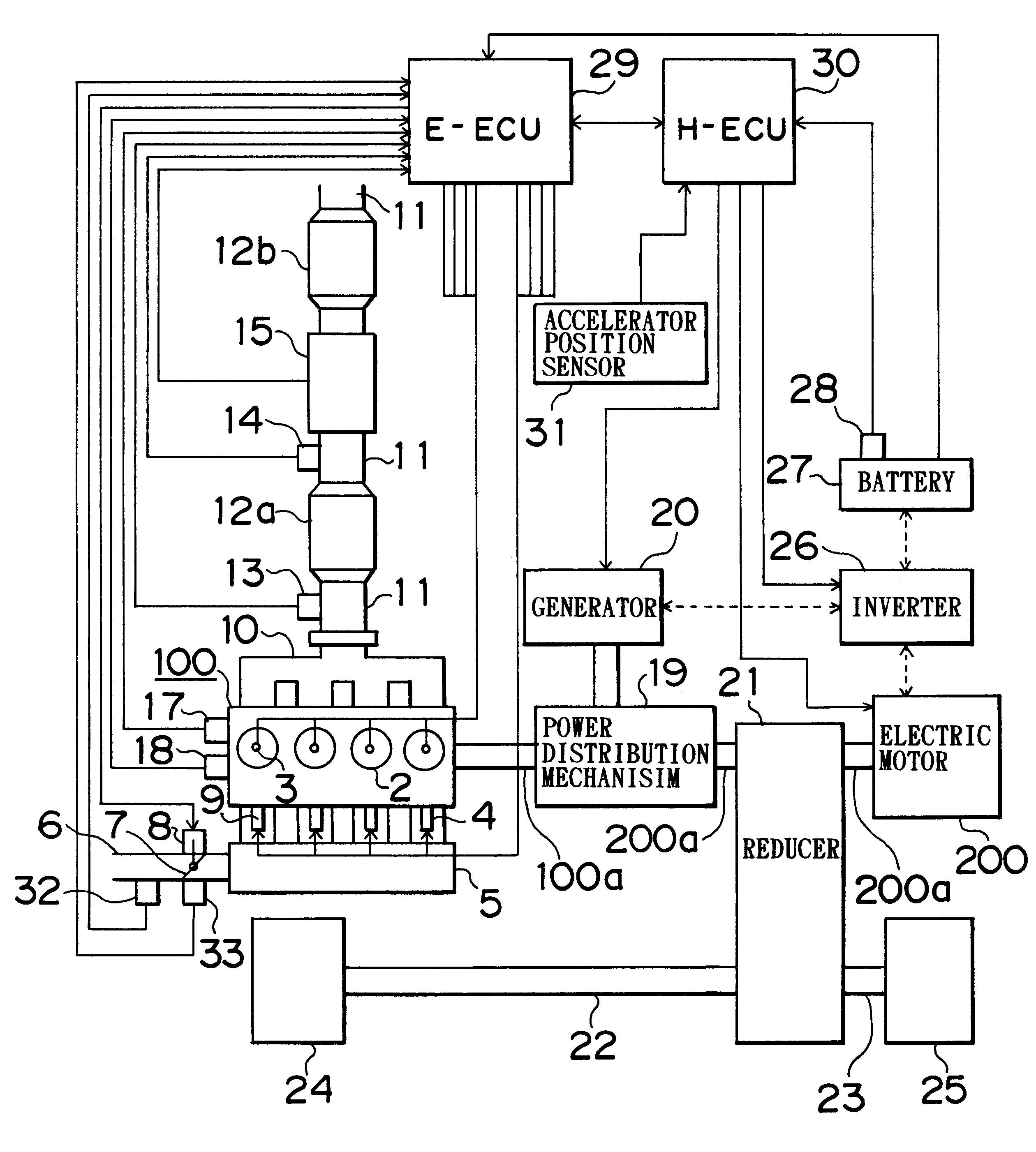

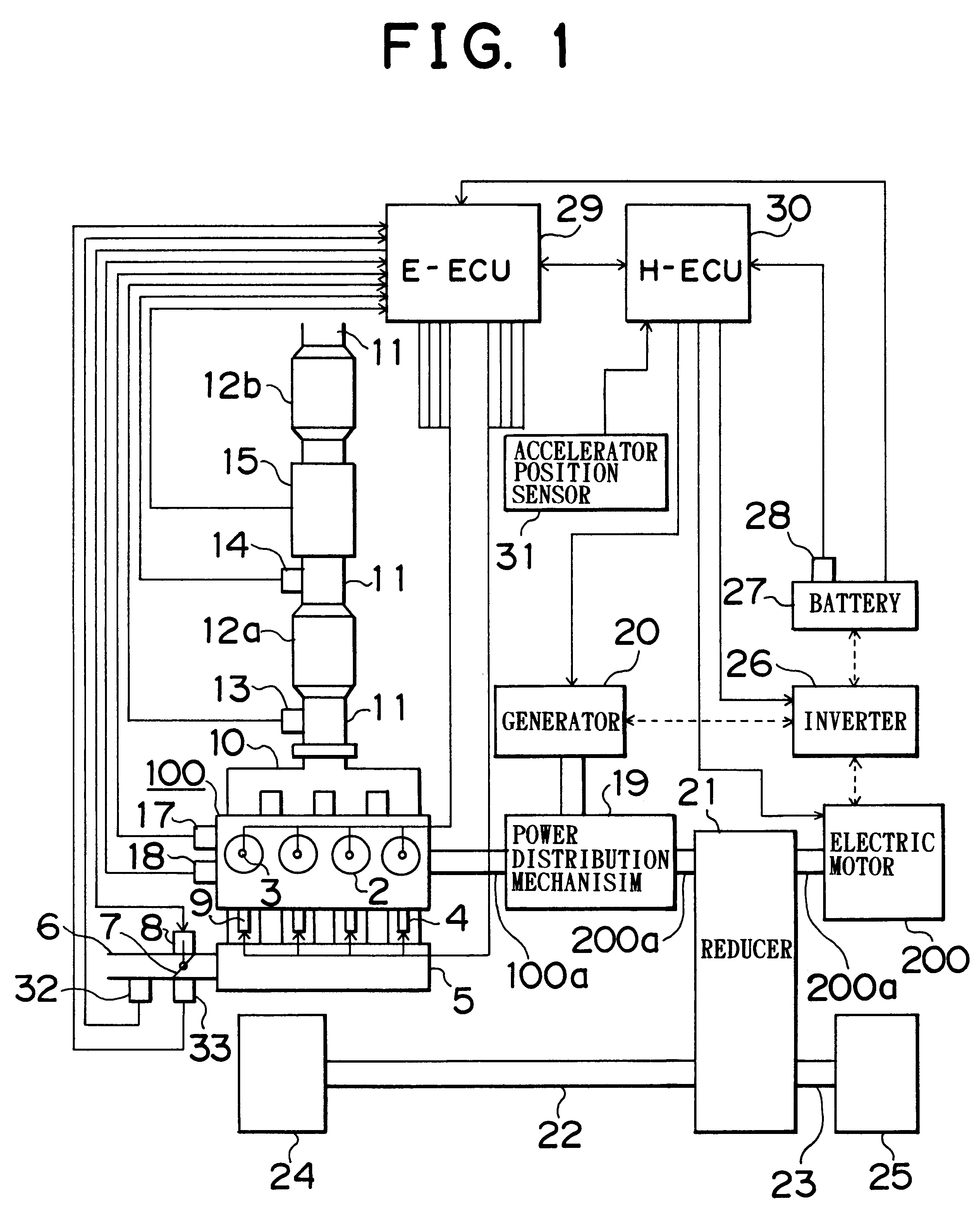

Exhaust gas purifier and method of purifying exhaust gas for a hybrid vehicle

InactiveUS6321530B1Electrical controlInternal combustion piston enginesPower controllerExcess oxygen

A hybrid vehicle driven using power from an internal combustion engine and power from an auxiliary power source, includes an exhaust gas purification catalyst disposed in an exhaust passage of the engine. The catalyst stores oxygen and a power controller causes the engine to discharge exhaust gas including excess oxygen and causes the auxiliary power source to assist the engine in driving the vehicle when oxygen is to be stored in the exhaust gas purification catalyst. It is possible to supply the catalyst with exhaust gas containing excess oxygen while inhibiting the driveability from being adversely affected.

Owner:TOYOTA JIDOSHA KK

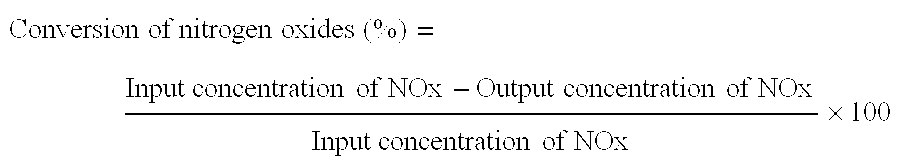

Catalyst and method for reduction of nitrogen oxides

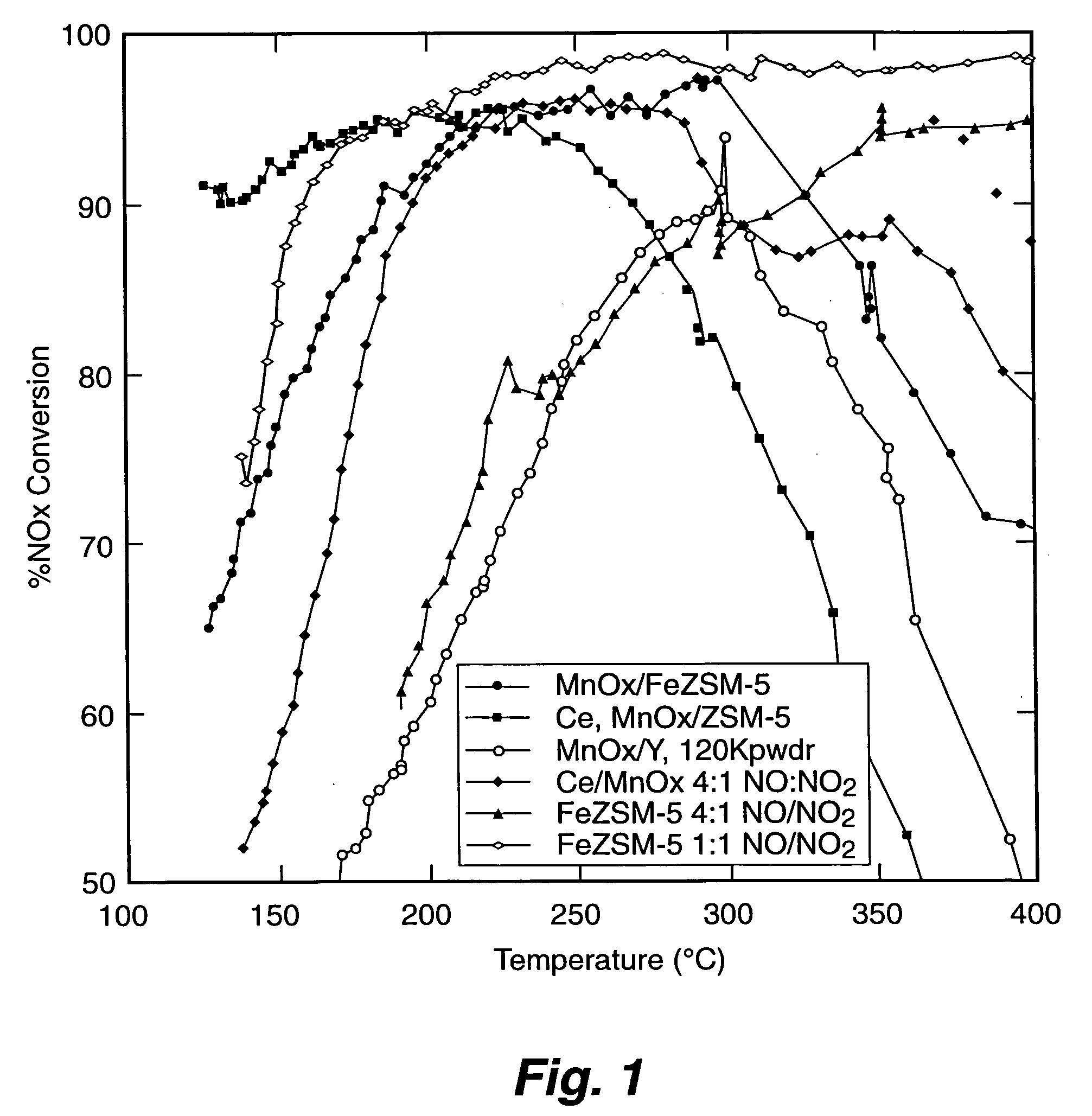

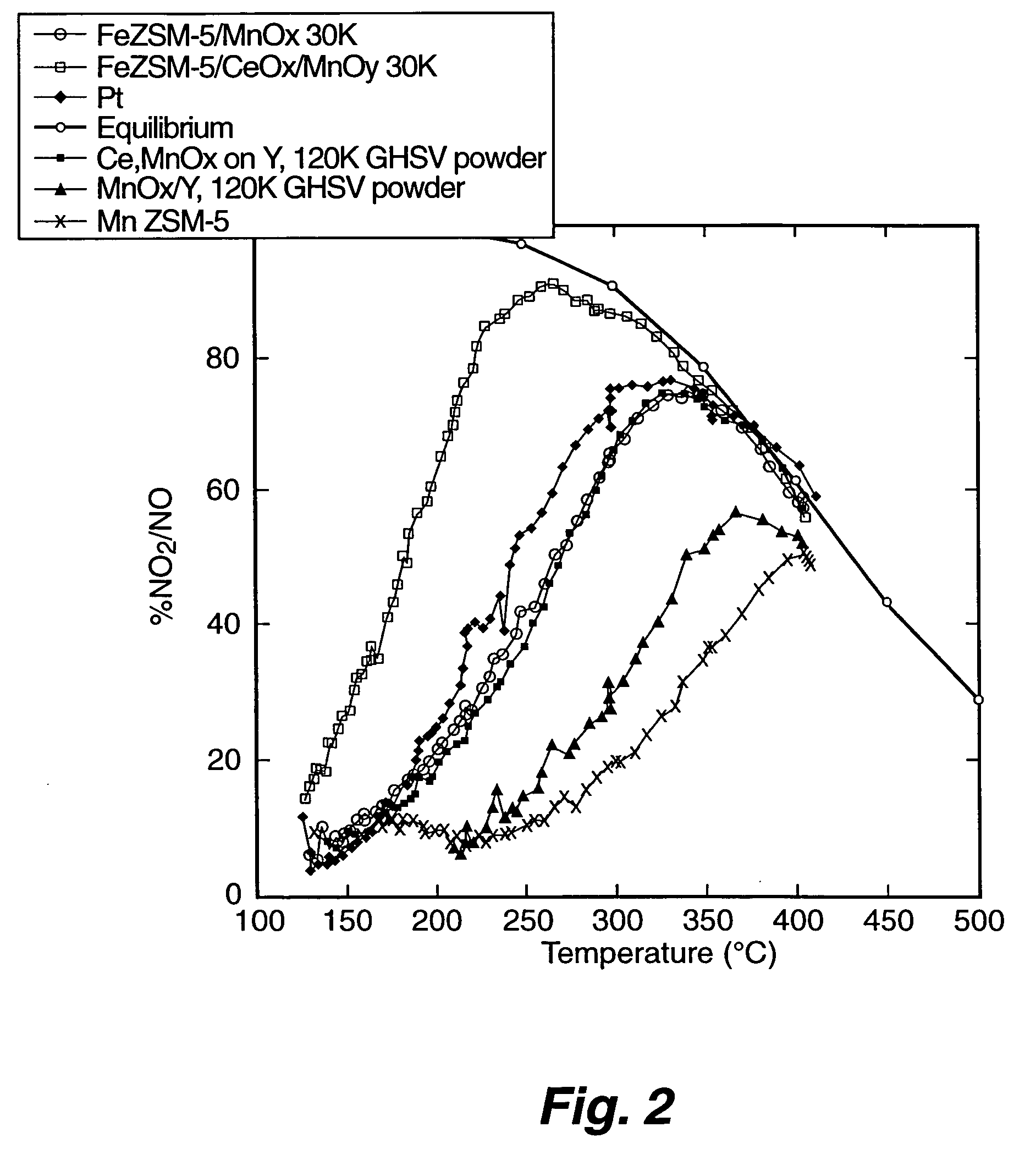

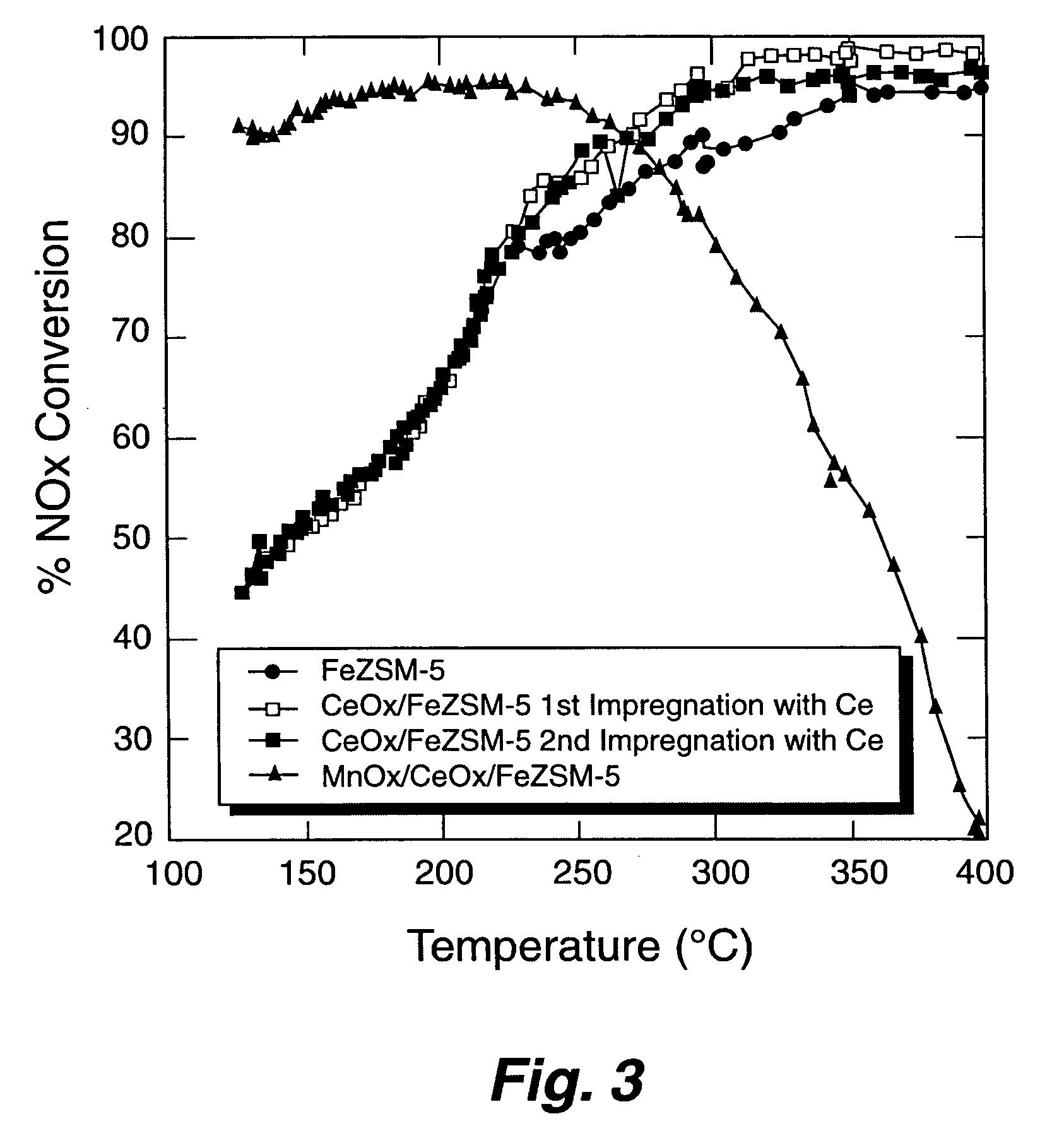

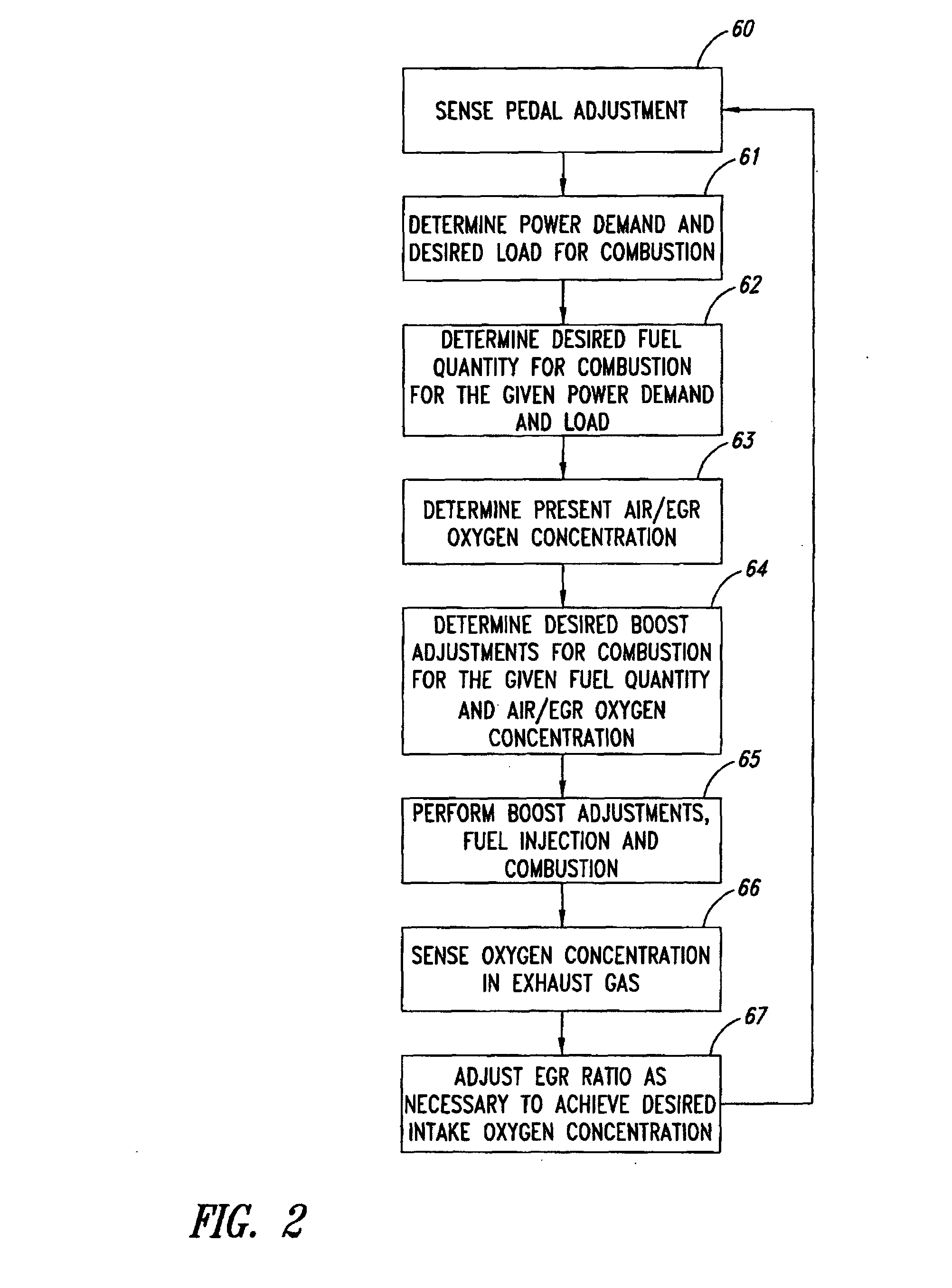

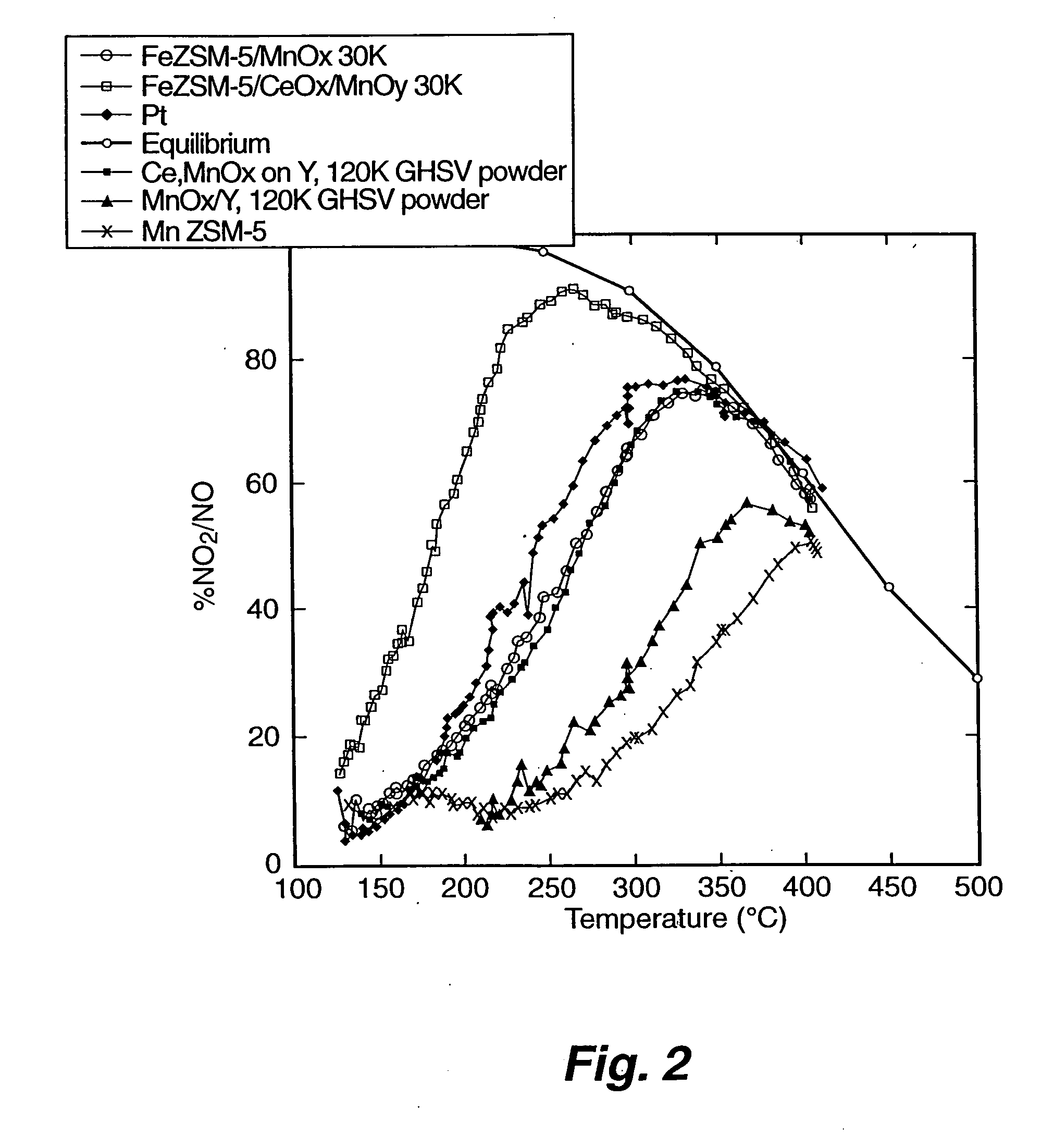

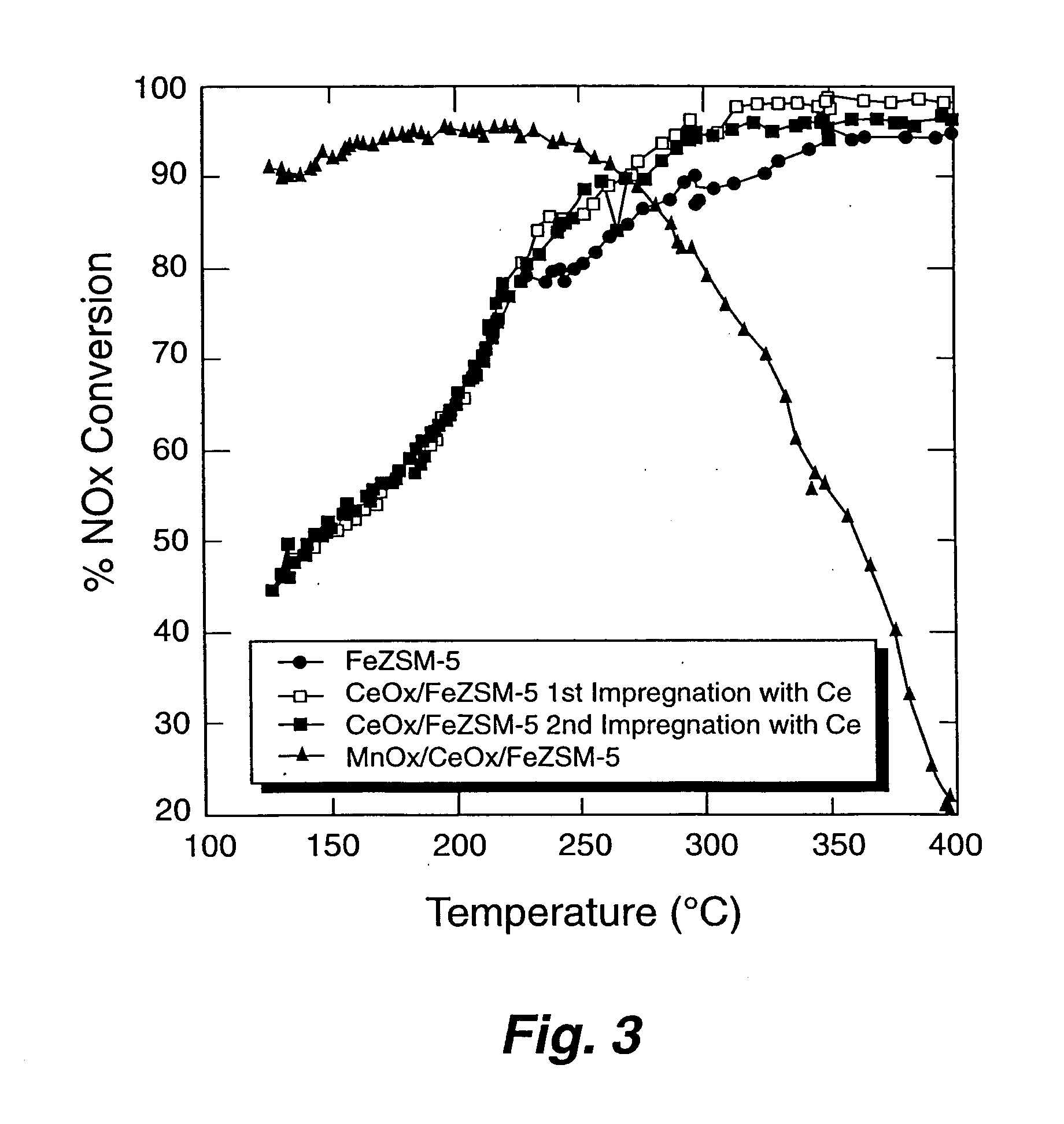

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

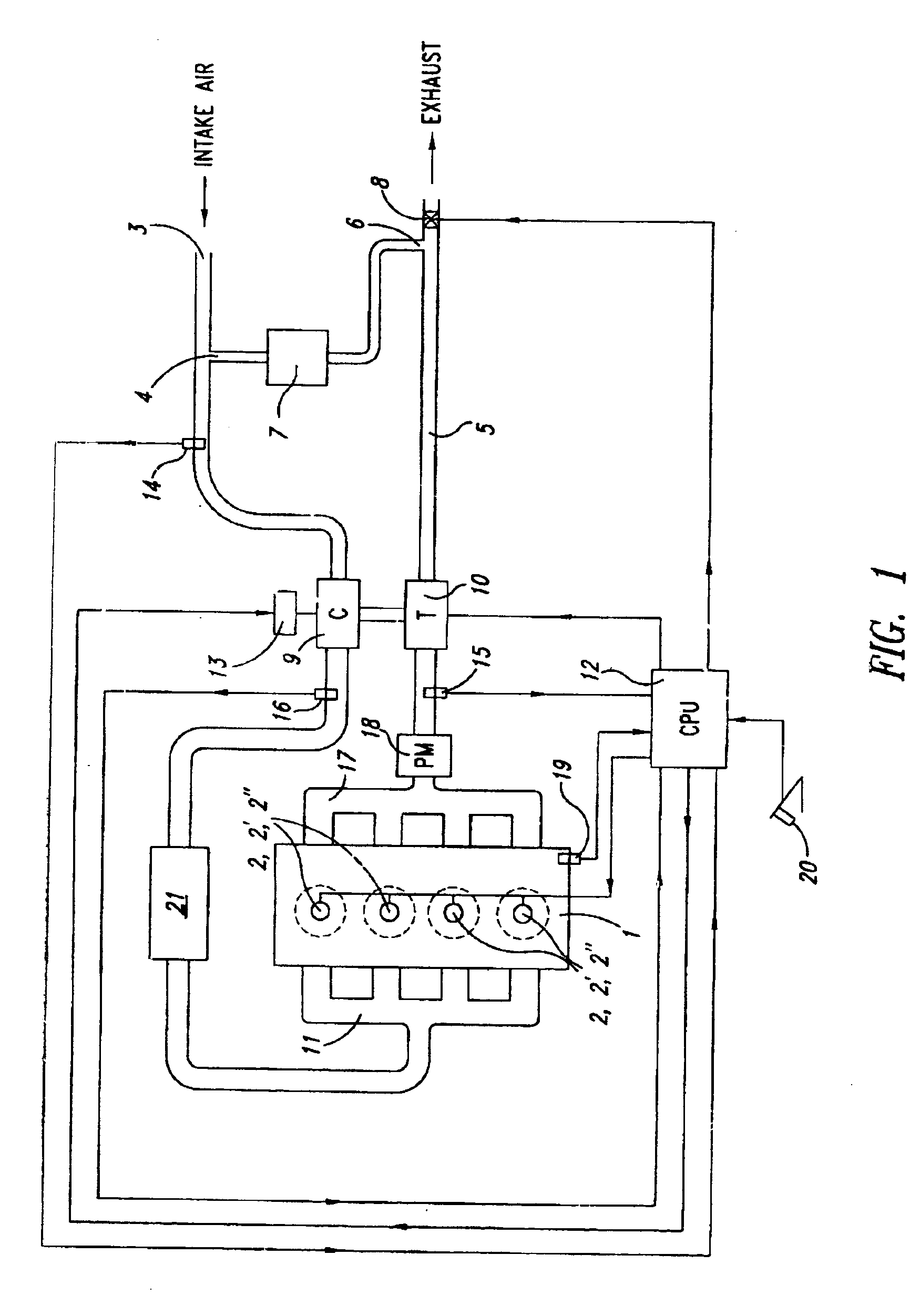

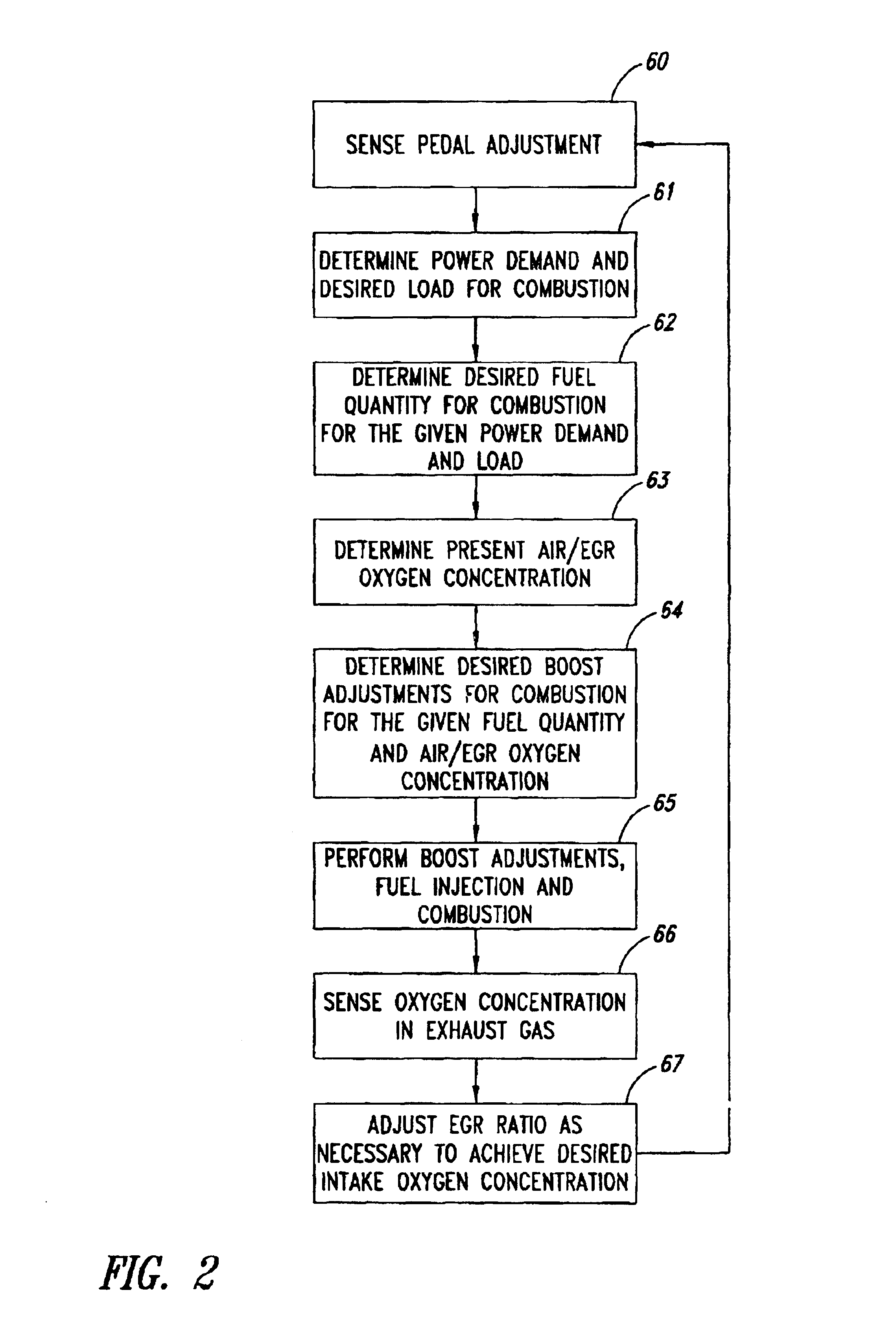

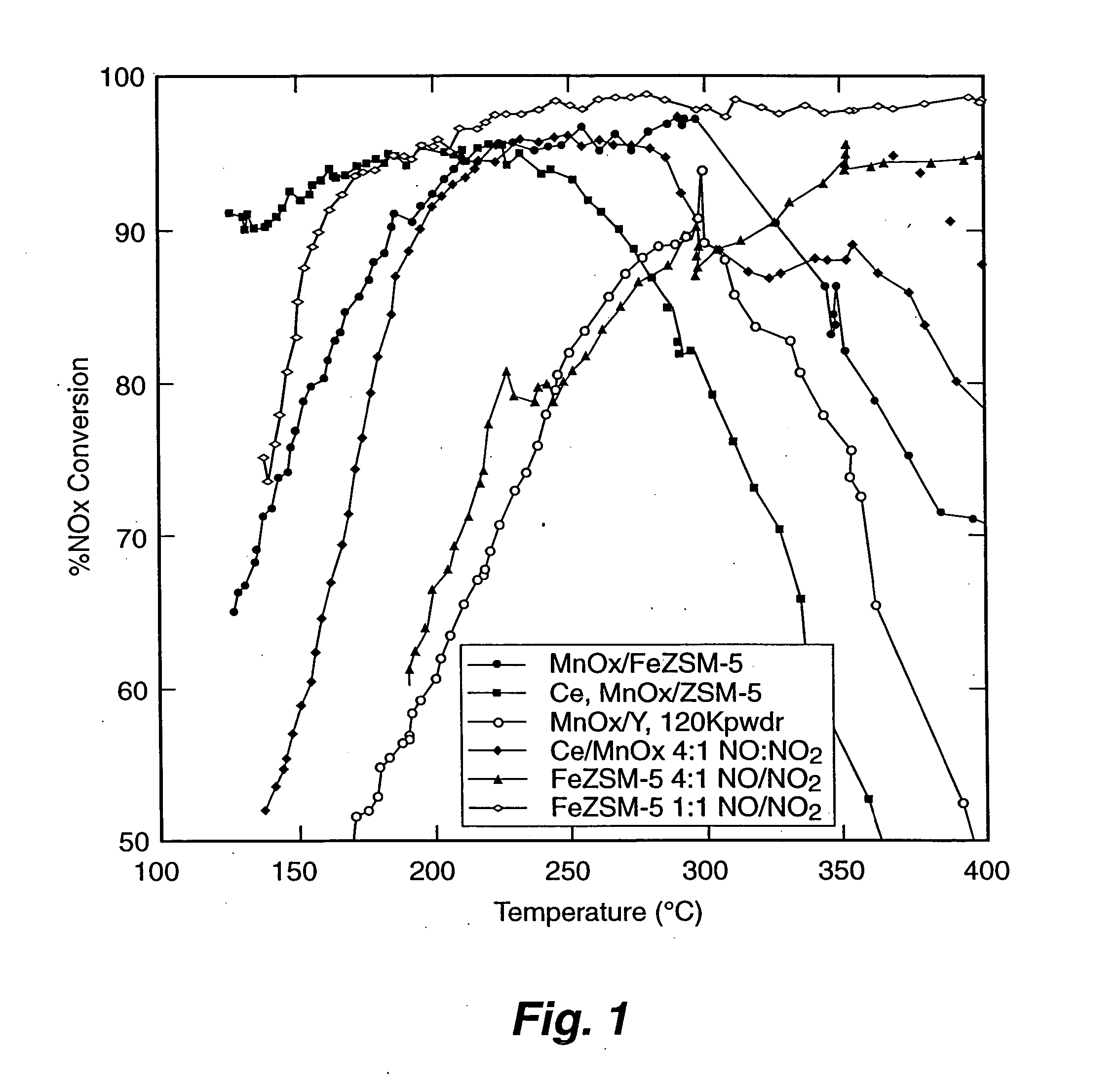

Low emission diesel combustion system with low charge-air oxygen concentration levels and high fuel injection pressures

InactiveUS6857263B2Cost effectiveLower Level RequirementsLiquid coolingEngine sealsLow loadMass ratio

This invention sets forth a commercially viable diesel combustion system that meets environmentally acceptable levels of NOx emissions (i.e. 0.2 g / bhp-hr or lower across a full map of engine speeds and loads) without the need for use of NOx aftertreatments, and simultaneously maintains engine-out PM emissions relatively close (e.g. with smoke levels at or below 3 BSN) to environmentally acceptable PM post-aftertreatment levels. The invention achieves these results by operating within a unique combination of parameters. These parameters comprise: (1) charge-air oxygen concentration below 16%, preferably between 10% and 15%, more preferably between 11% and 14%, and most preferably between 12% and 13.5% for virtually all engine operating conditions (but not necessarily at no-load or low load conditions), (2) fuel injection pressures at or exceeding 1800 bar, preferably exceeding 2100 bar, more preferably exceeding 2300 bar, and most preferably exceeding 2500 bar, at most engine speeds and loads, and (3) charge-air mass / fuel mass ratio between 25:1 and 45:1 for medium and high loads. Furthermore, the system is preferably run continuously slightly lean of stoichiometry, providing just enough excess oxygen to facilitate completeness of combustion and to maintain an exhaust oxygen level sufficient for continuous trap regeneration at a balance point in operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

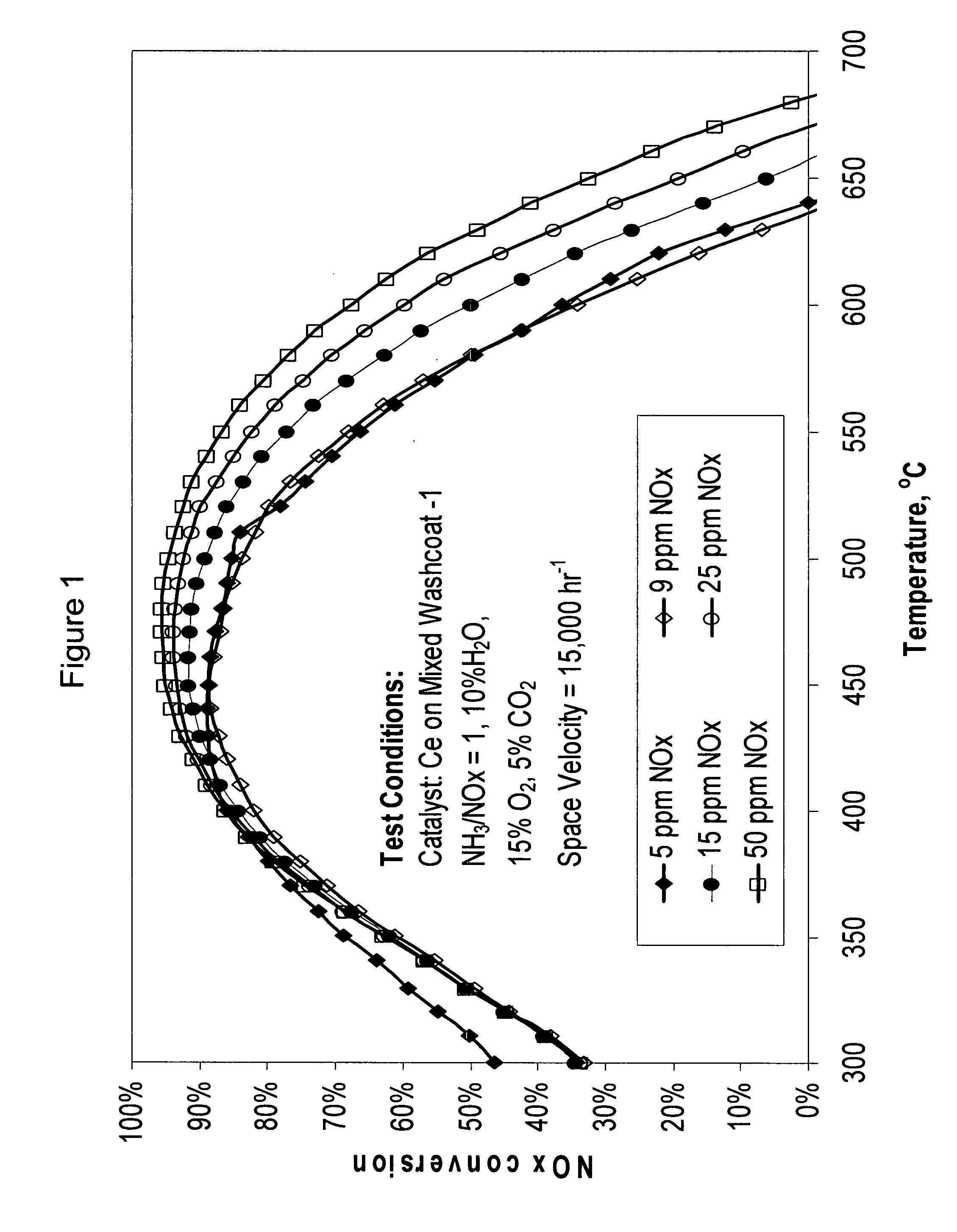

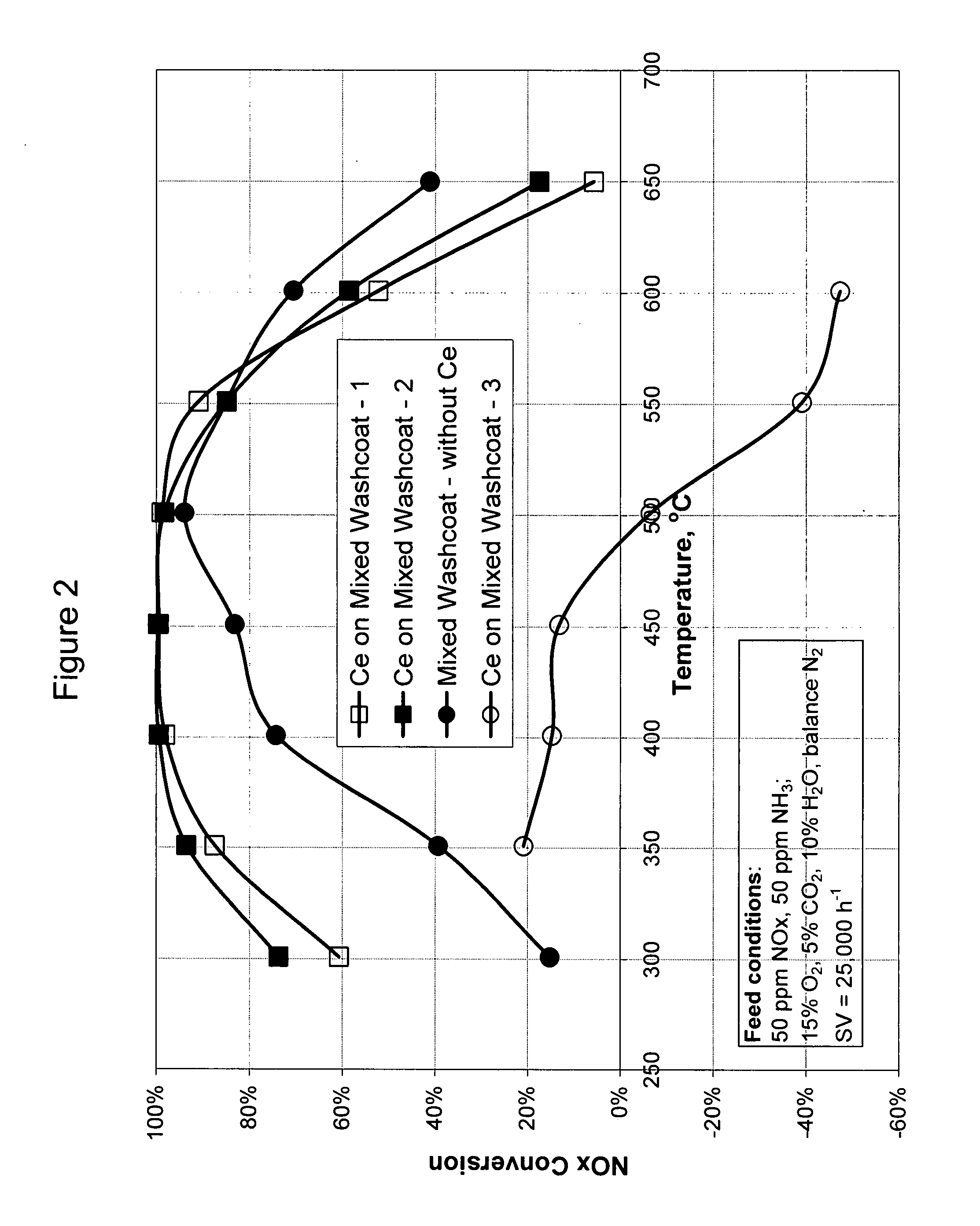

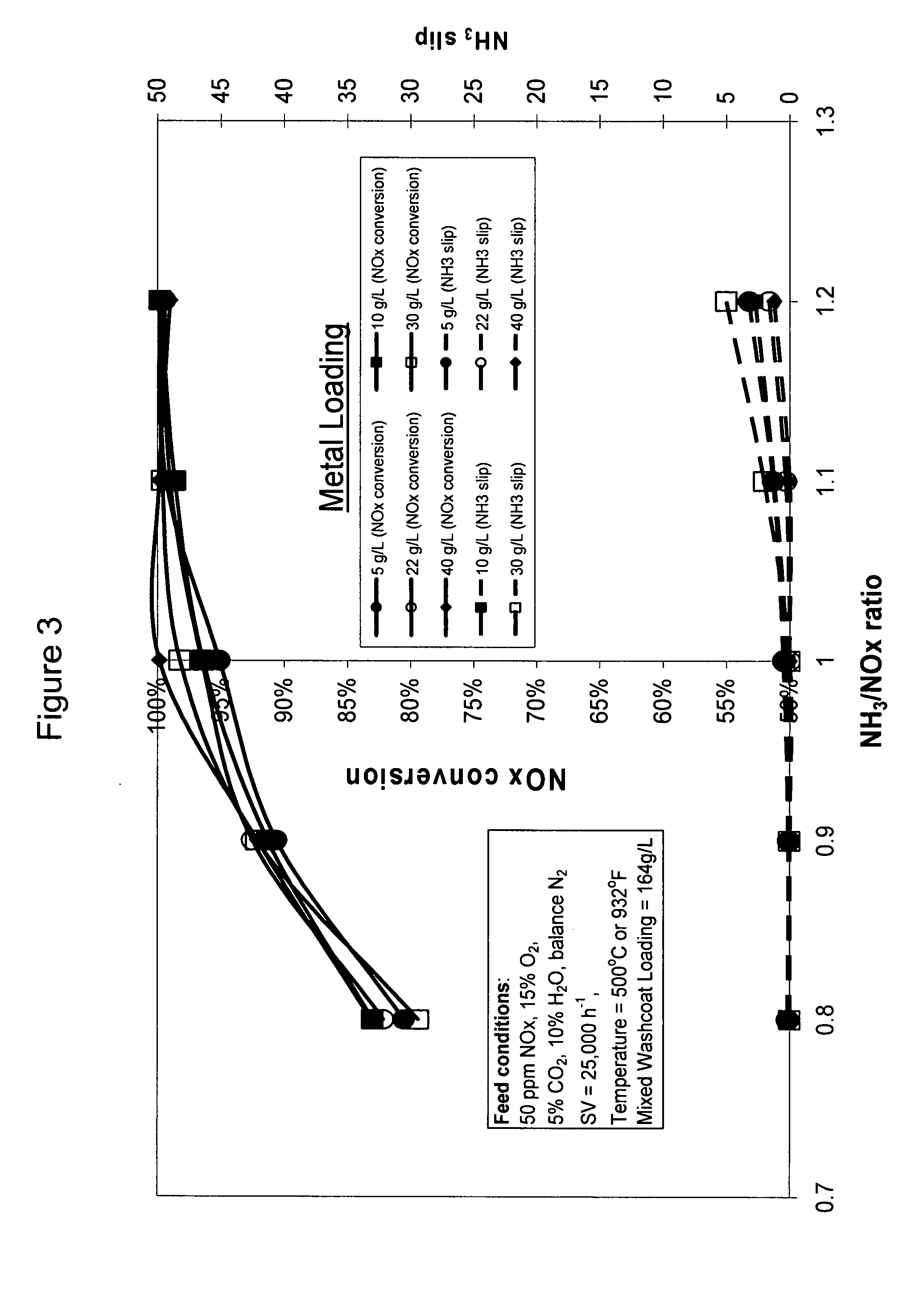

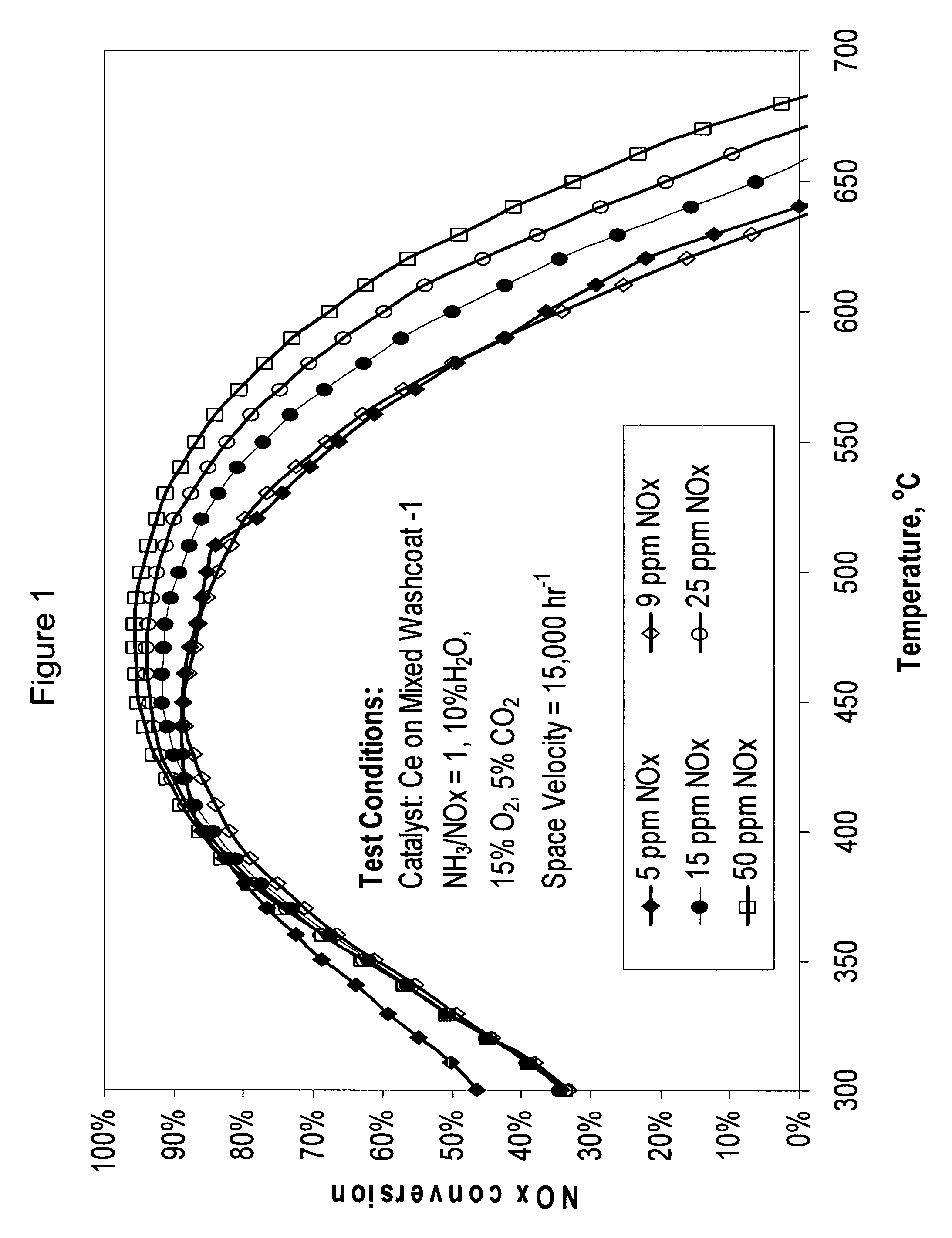

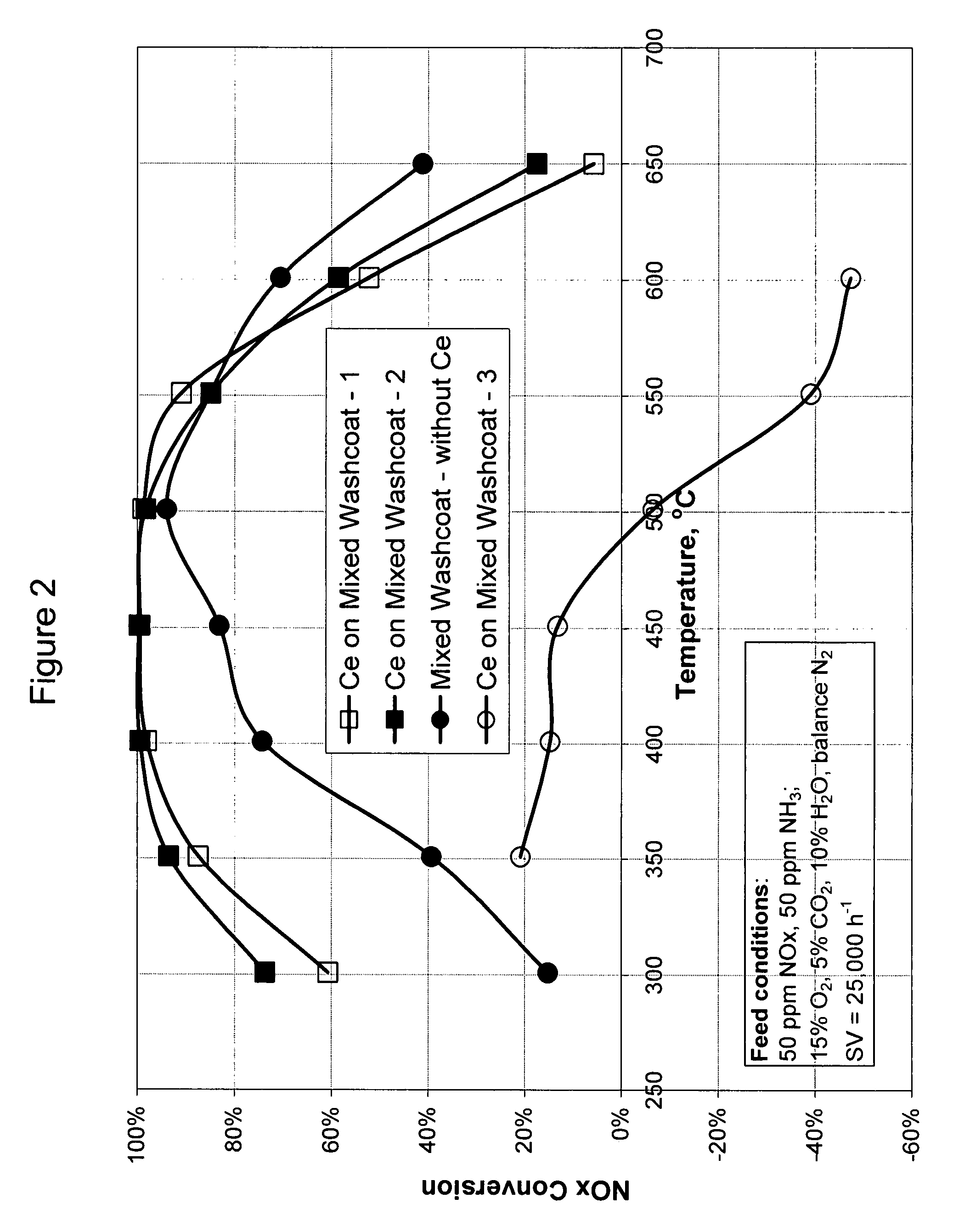

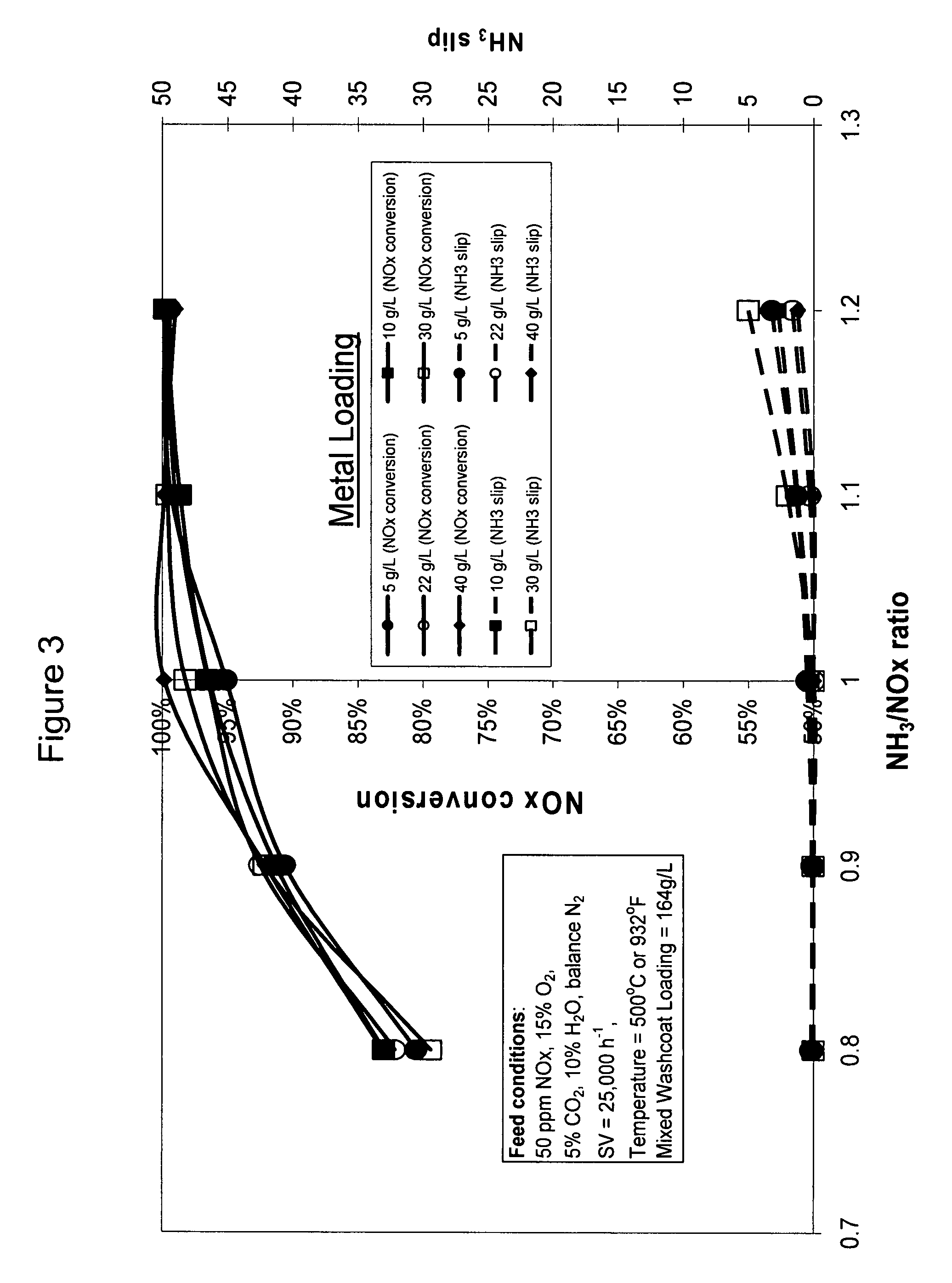

High temperature ammonia SCR catalyst and method of using the catalyst

ActiveUS20080167178A1Reduce selection requirementsMolecular sieve catalystsInternal combustion piston enginesCeriumMordenite

A catalyst and a method for selectively reducing nitrogen oxides (“NOx”) with ammonia are provided. The catalyst includes a first component comprising a zeolite or mixture of zeolites selected from the group consisting of ZSM-5, ZSM-11, ZSM-12, ZSM-18, ZSM-23, MCM-zeolites, mordenite, faujasite, ferrierite, zeolite beta, and mixtures thereof; a second component comprising at least one member selected from the group consisting of cerium, iron, copper, gallium, manganese, chromium, cobalt, molybdenum, tin, rhenium, tantalum, osmium, barium, boron, calcium, strontium, potassium, vanadium, nickel, tungsten, an actinide, mixtures of actinides, a lanthanide, mixtures of lanthanides, and mixtures thereof; optionally an oxygen storage material and optionally an inorganic oxide. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia at high temperatures. The catalyst has high hydrothermal stability. The catalyst has high activity for conversion of low levels of nitrogen oxides in exhaust streams. The catalyst and the method may have special application to selective reduction of nitrogen oxides in exhaust gas from gas turbines and gas engines, although the catalyst and the method have broad application to a wide range of gas streams that have excess oxygen and high temperatures. The temperature of exhaust gas from gas turbines and gas engines is high. Both the high temperature and the low levels of inlet NOx are challenging for selective catalytic reduction (SCR) catalysts.

Owner:CATALYTIC SOLUTIONS INC

Control for diesel engine with particulate filter

ActiveUS7137246B2Limit exothermic reactionLimit exothermic reaction rateElectrical controlInternal combustion piston enginesExcess oxygenDiesel particulate filter

A system and method are described for operating a diesel engine and particulate filter during self-sustained filter regeneration. In particular, a method is described for preventing over-temperature during filter regeneration by limiting excess oxygen supplied to the particulate filter.

Owner:FORD GLOBAL TECH LLC

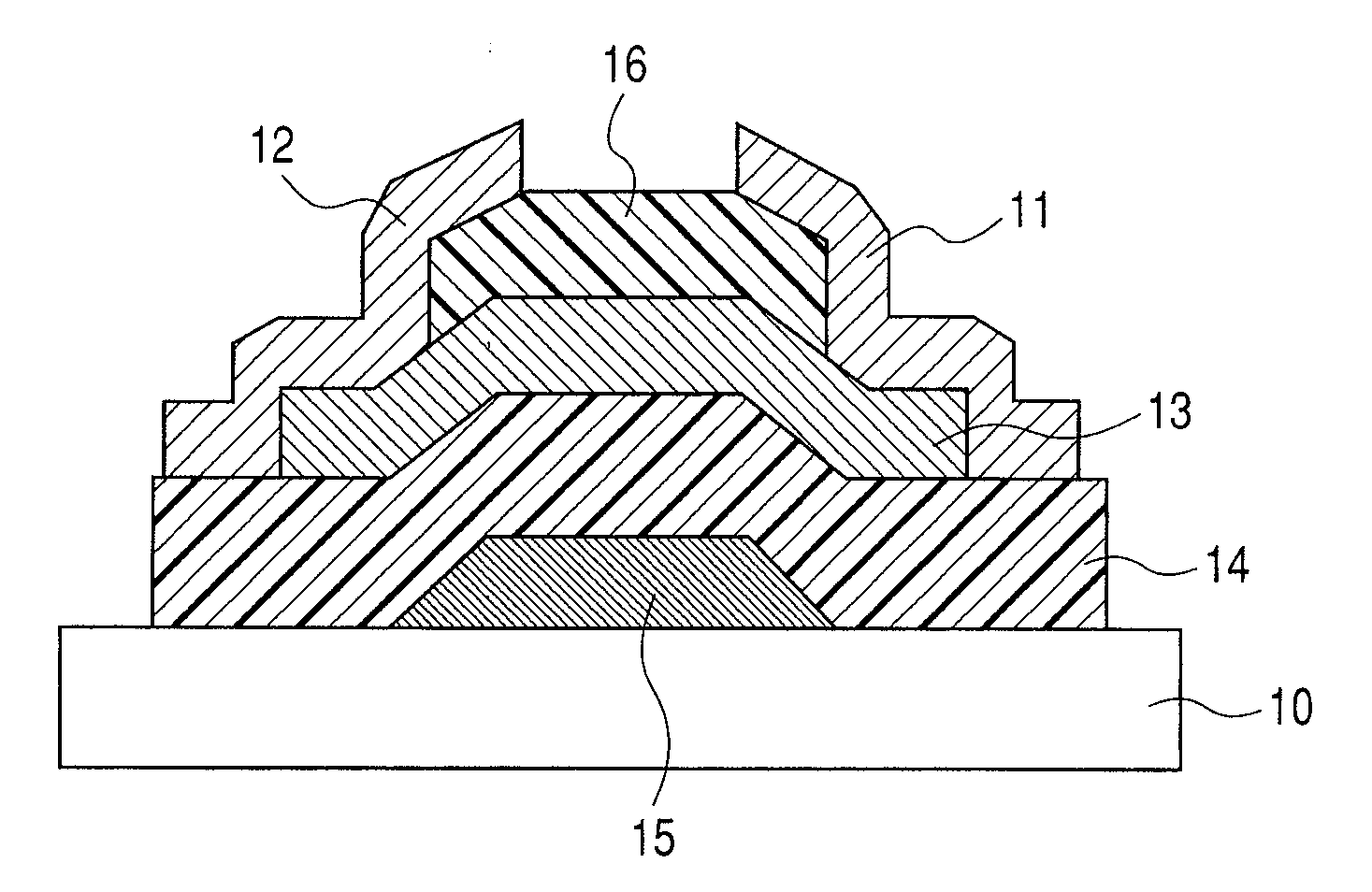

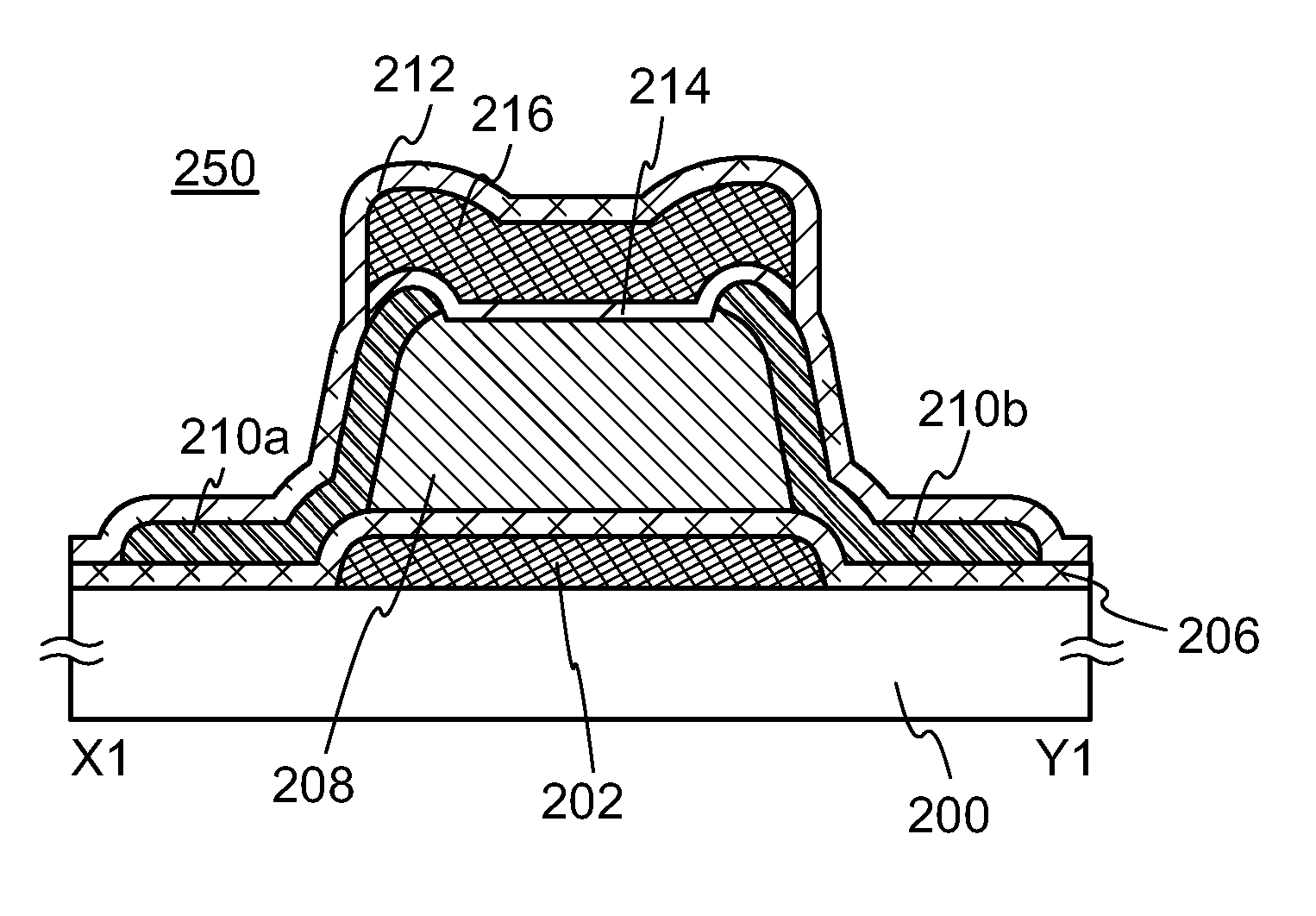

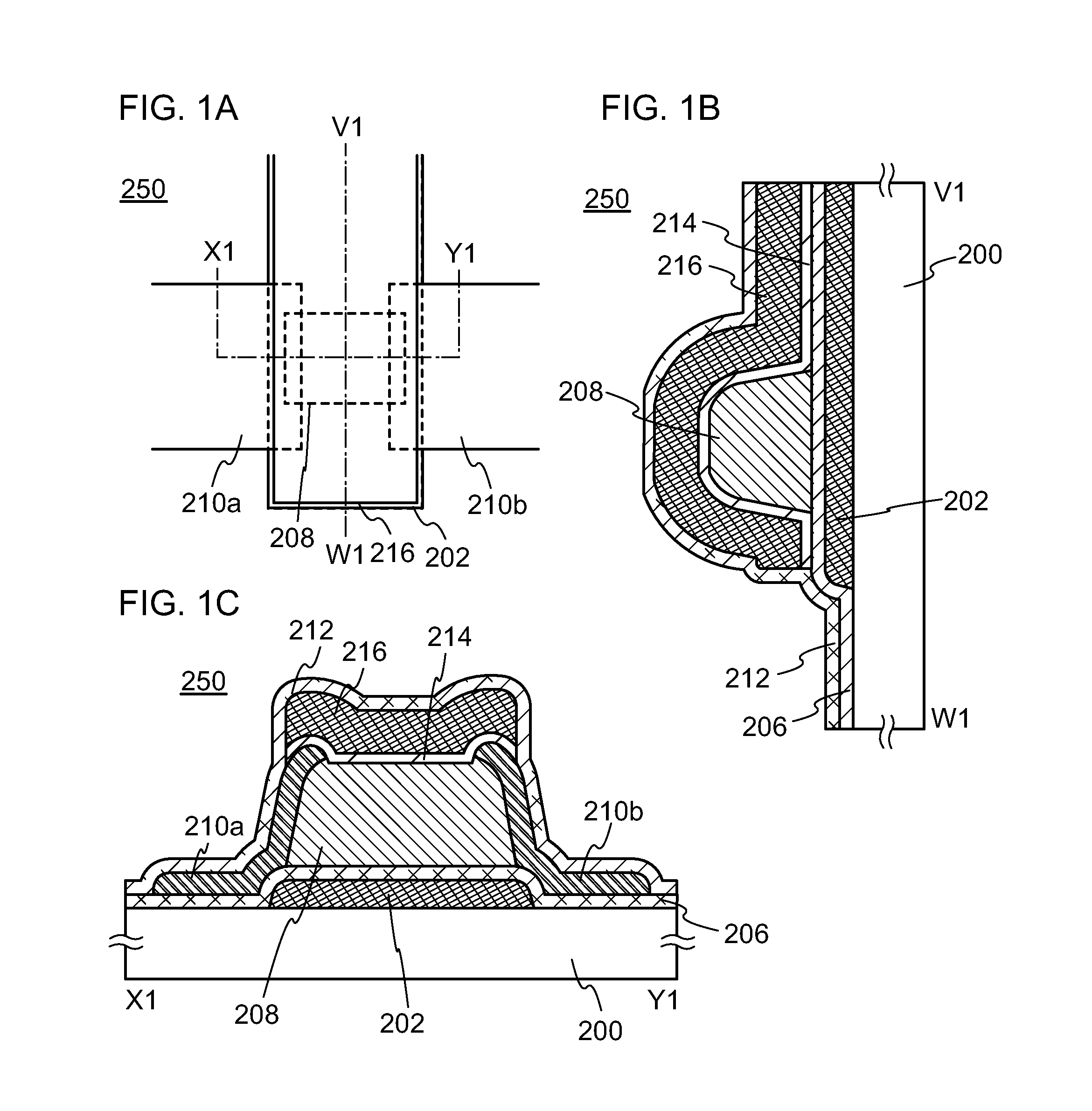

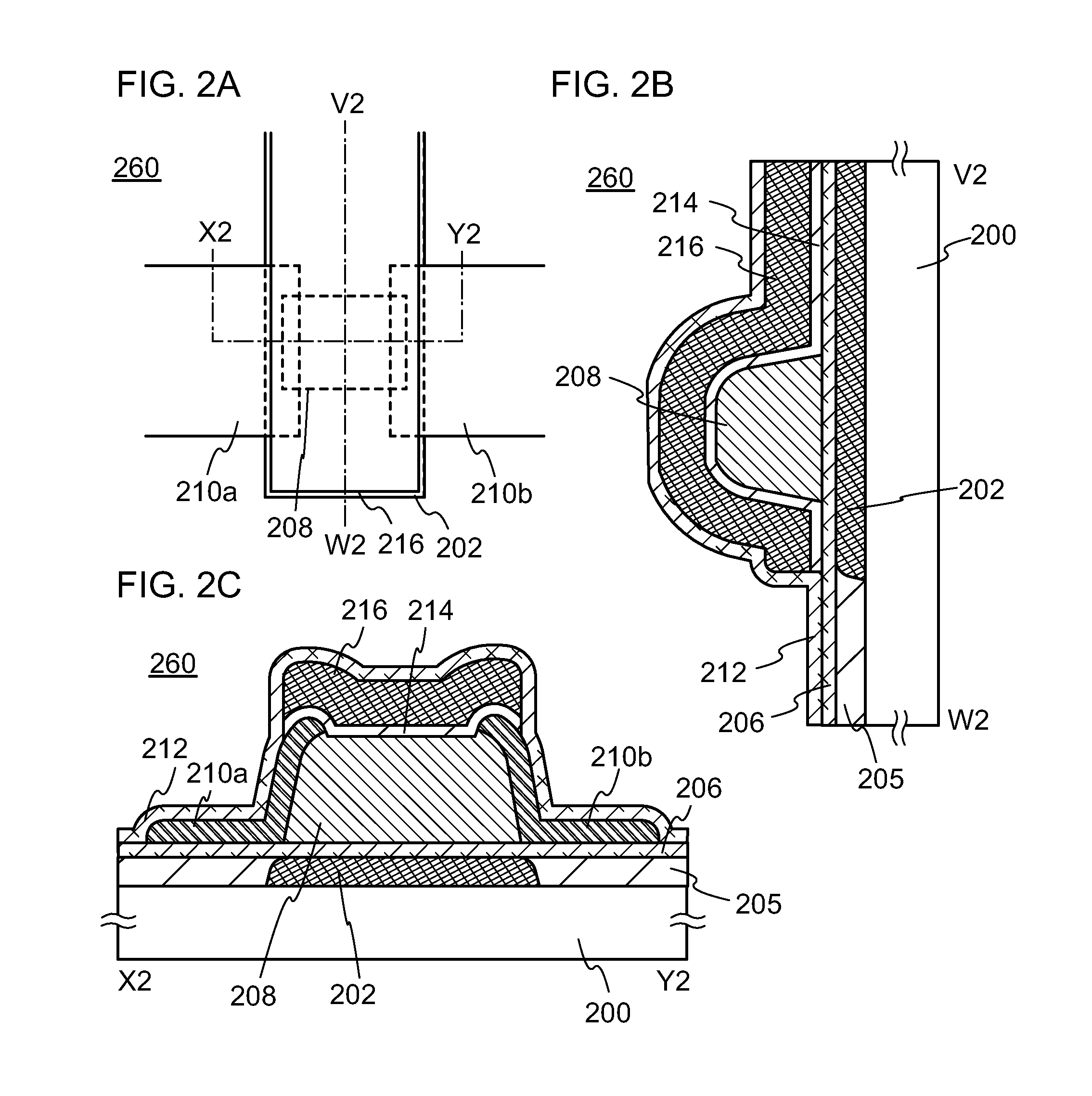

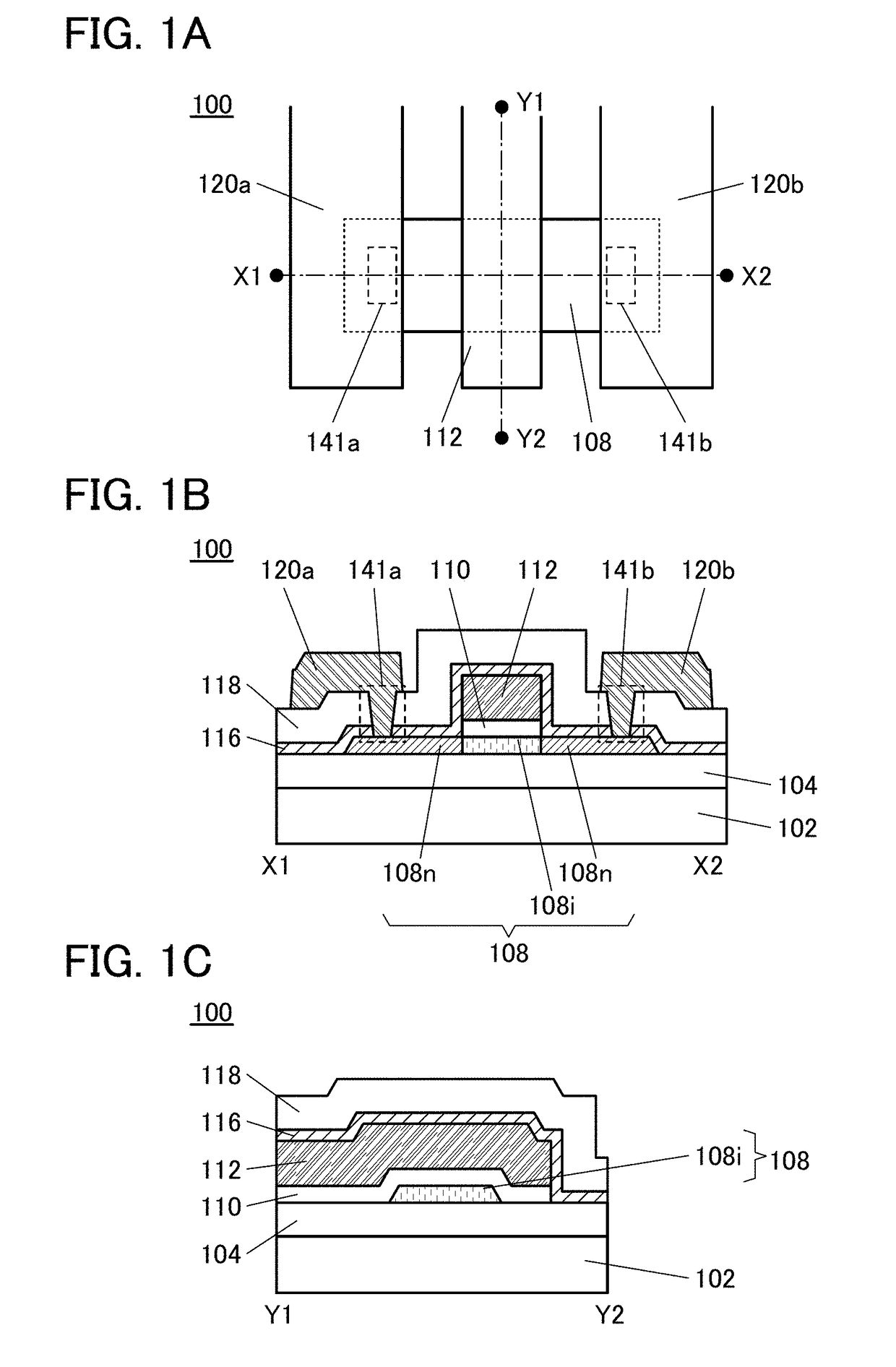

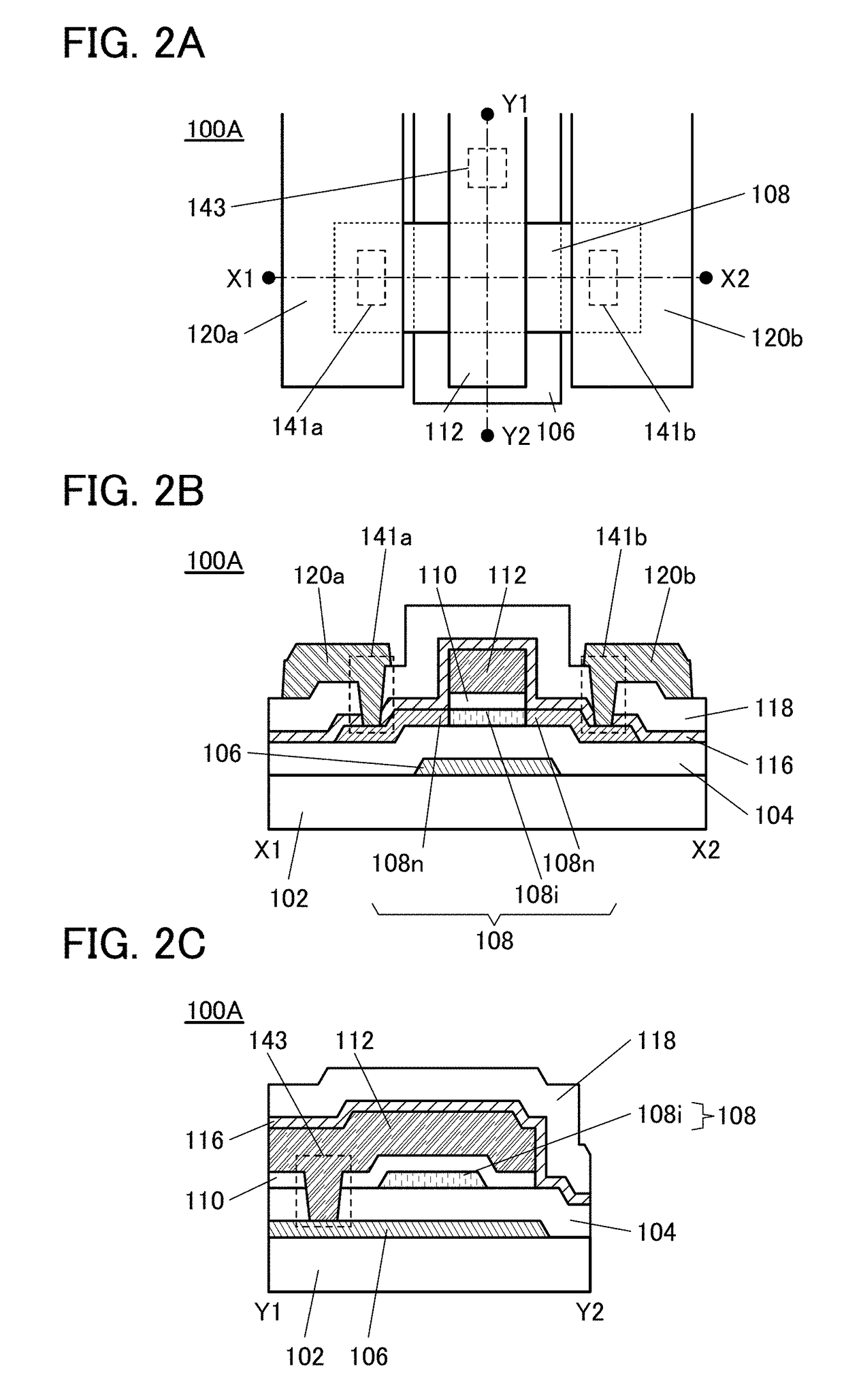

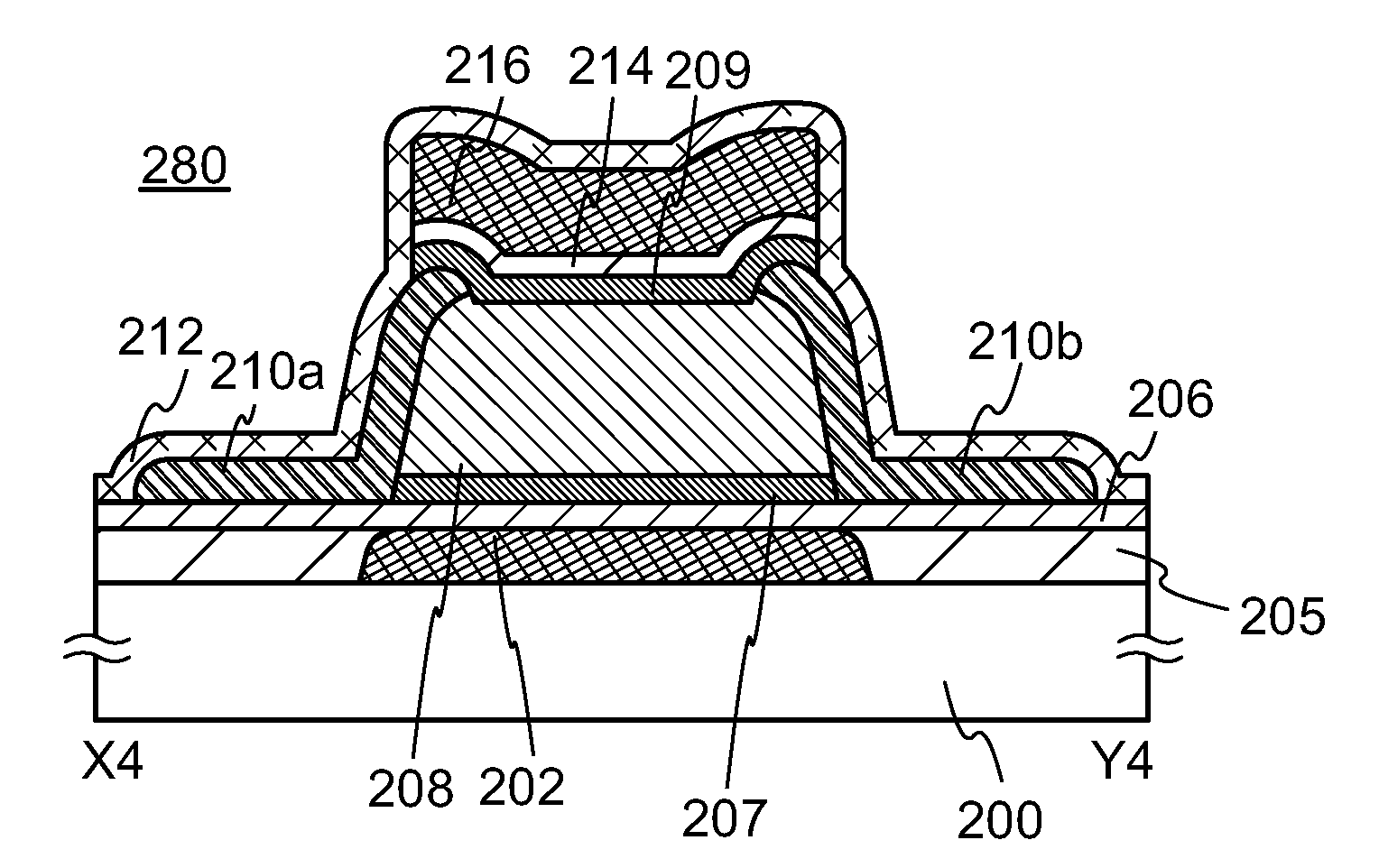

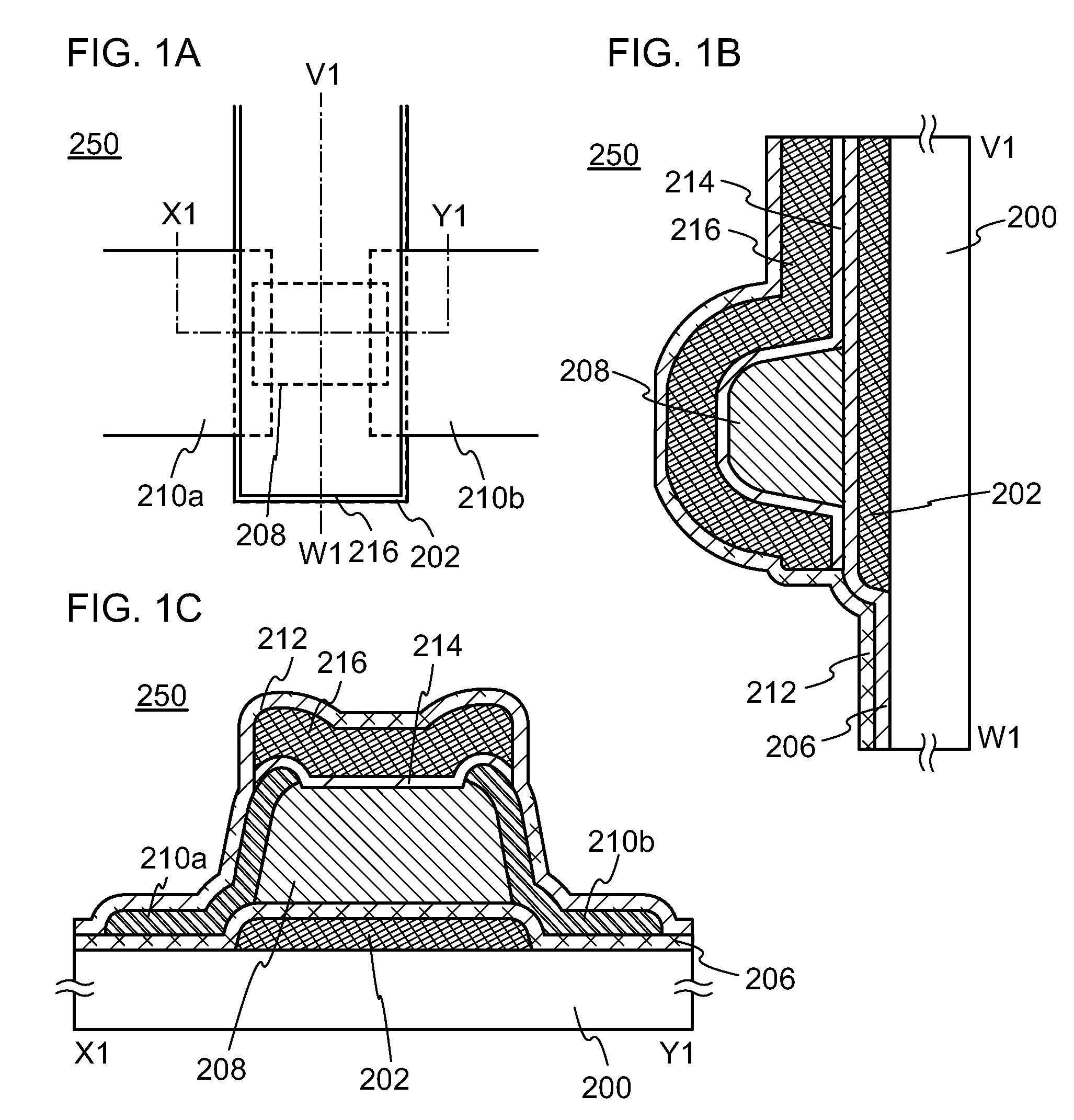

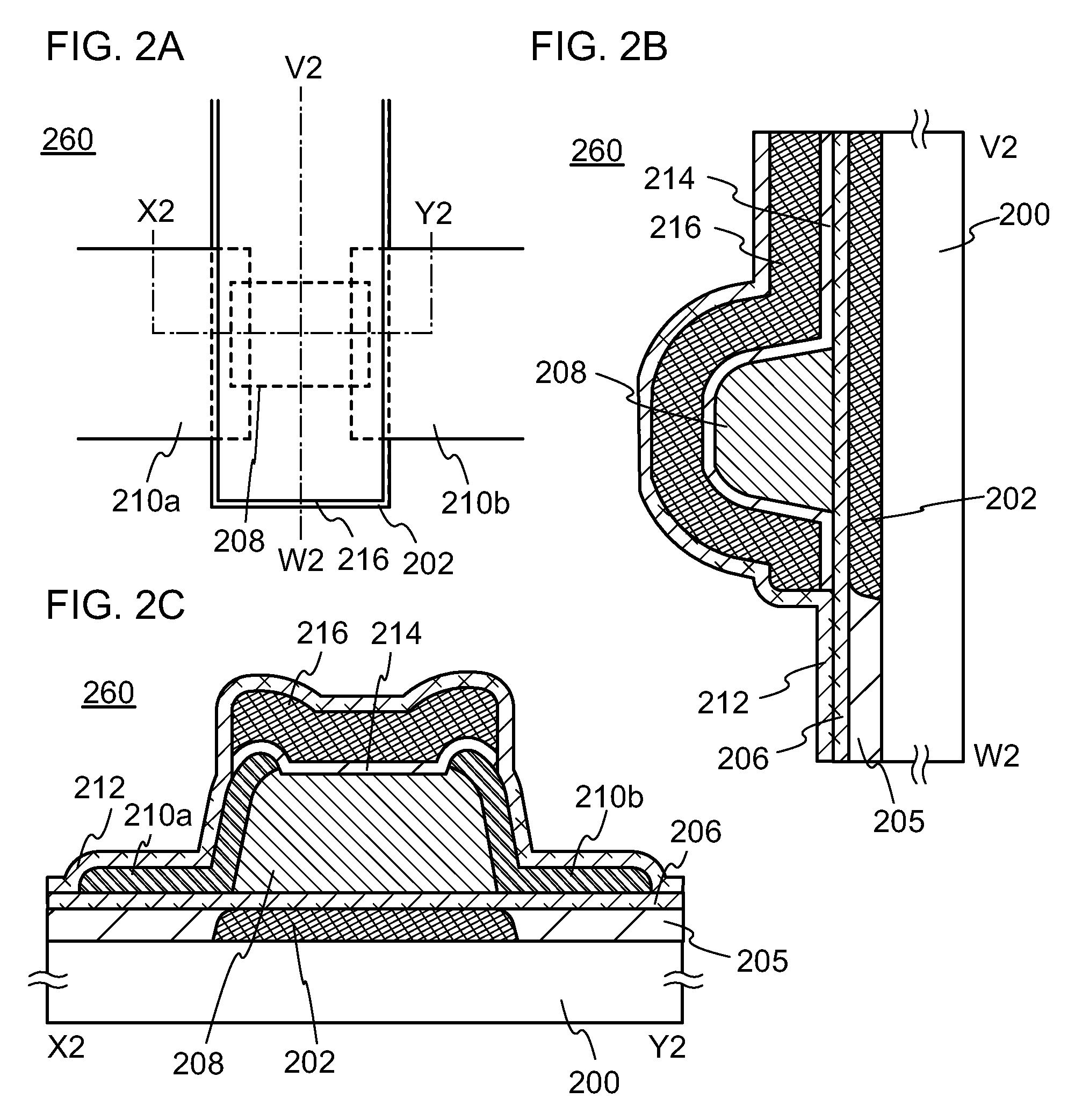

Semiconductor device

ActiveUS20140339538A1Minimizes and removeThreshold voltage can be controlledTransistorSolid-state devicesHydrogenExcess oxygen

To provide a semiconductor device that includes an oxide semiconductor and is miniaturized while keeping good electrical properties. In the semiconductor device, an oxide semiconductor layer is surrounded by an insulating layer including an aluminum oxide film containing excess oxygen. Excess oxygen in the aluminum oxide film is supplied to the oxide semiconductor layer including a channel by heat treatment in a manufacturing process of the semiconductor device. Furthermore, the aluminum oxide film forms a barrier against oxygen and hydrogen. It is thus possible to suppress the removal of oxygen from the oxide semiconductor layer surrounded by the insulating layer including an aluminum oxide film, and the entry of impurities such as hydrogen into the oxide semiconductor layer; as a result, the oxide semiconductor layer can be made highly intrinsic. In addition, gate electrode layers over and under the oxide semiconductor layer control the threshold voltage effectively.

Owner:SEMICON ENERGY LAB CO LTD

Method of and apparatus for CO2 capture in oxy-combustion

InactiveUS20080184880A1Efficient methodLow costCombination devicesSolidificationPower stationCombustion chamber

A method of and an apparatus for capturing CO2 from flue gas emanating from a carbonaceous fuel combusting power plant, which includes a source of oxygen and a combustion chamber for combusting the fuel with oxygen and thereby producing flue gas that includes CO2, water and excess oxygen as its main components. At least a portion of the flue gas is compressed to a pressure higher than about sixty bar, the compressed flue gas is cooled in a primary CO2 separating unit for capturing a first portion of the CO2 by condensing it to produce a liquid CO2 stream and a high pressure vent gas stream that includes oxygen and excess CO2, the liquid CO2 stream is discharged from the power plant, and the high pressure vent gas stream is conducted to a secondary CO2 separating unit for capturing a second portion of the CO2 by adsorbing it to an adsorbing material.

Owner:FOSTER WHEELER ENERGY CORP

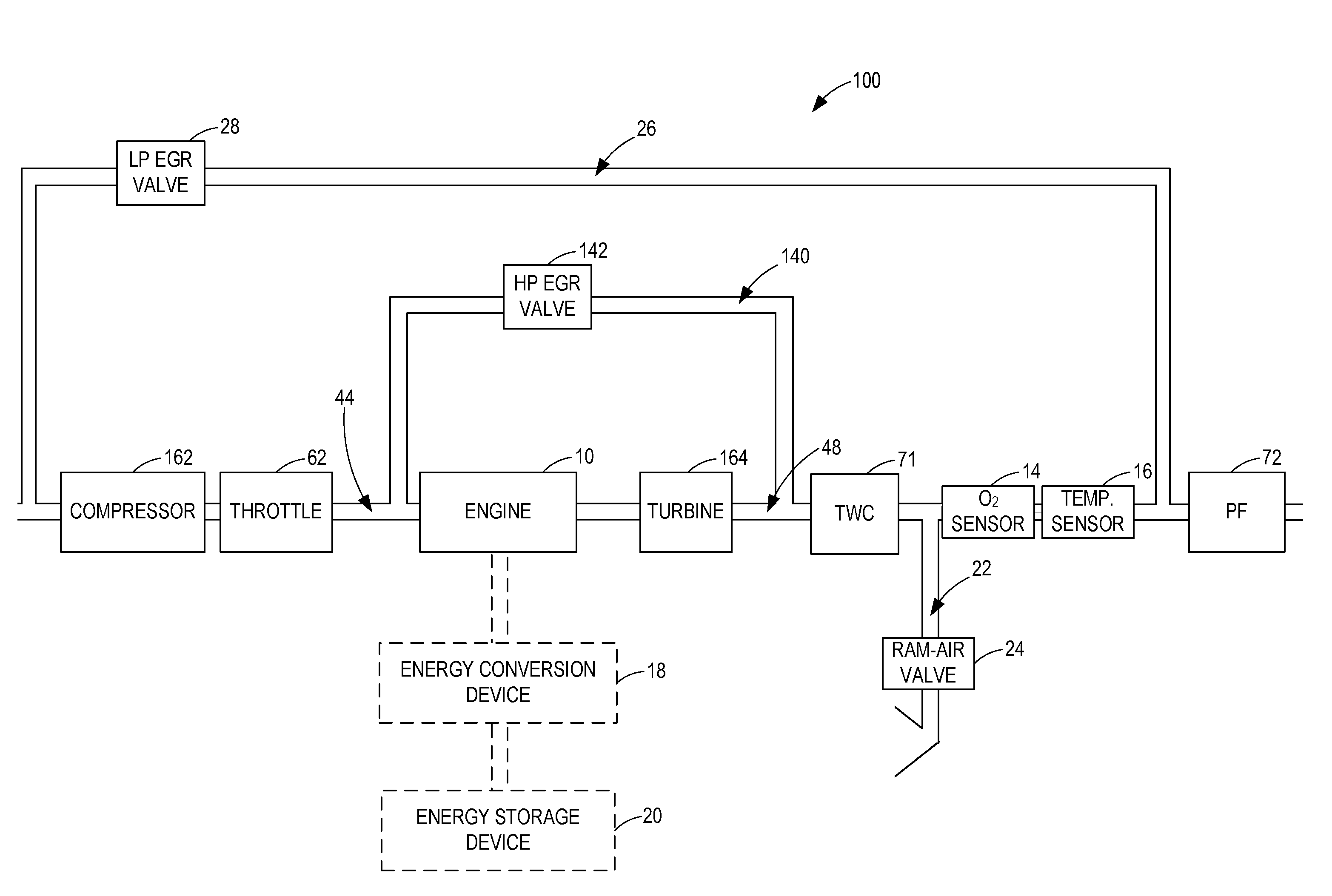

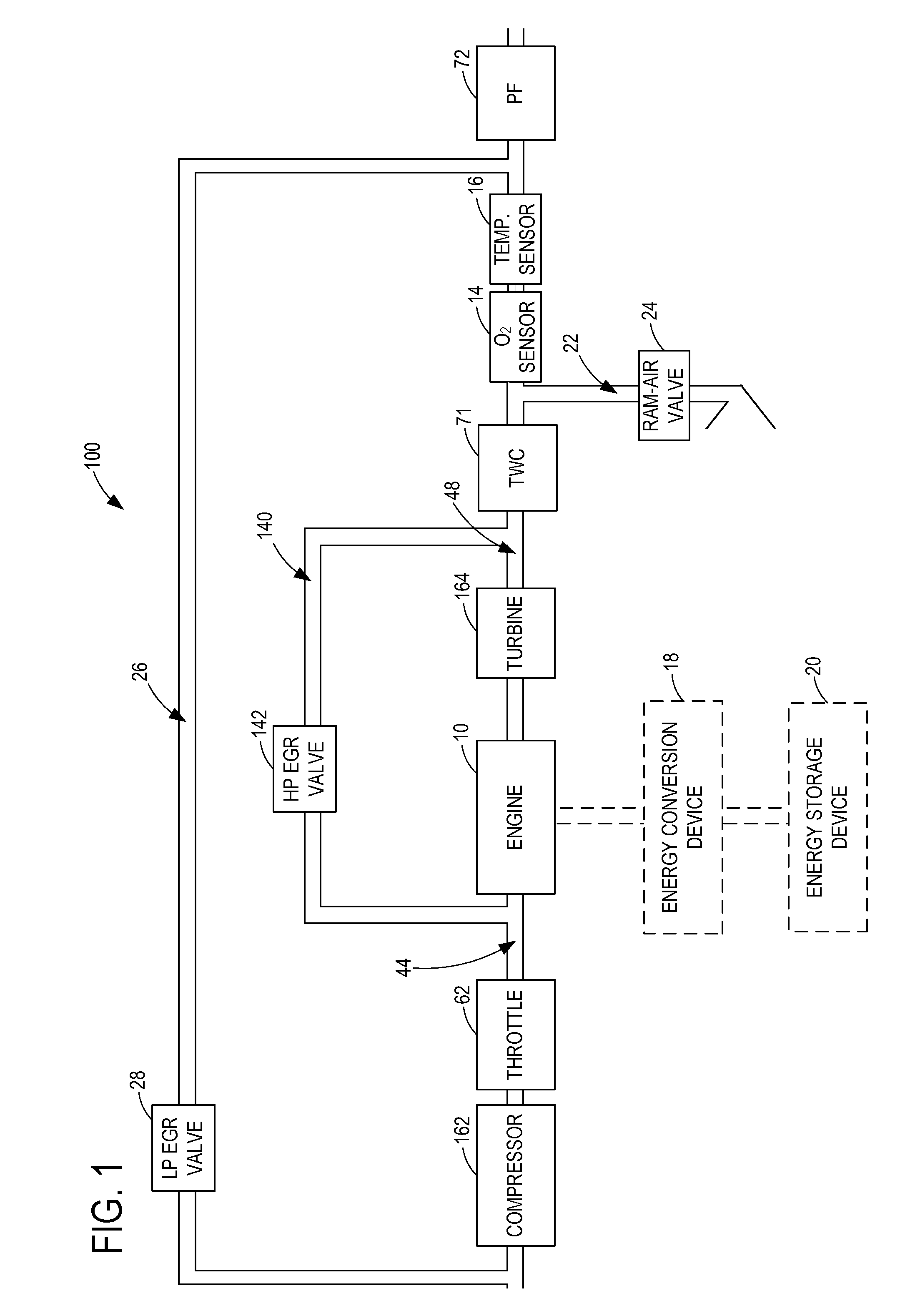

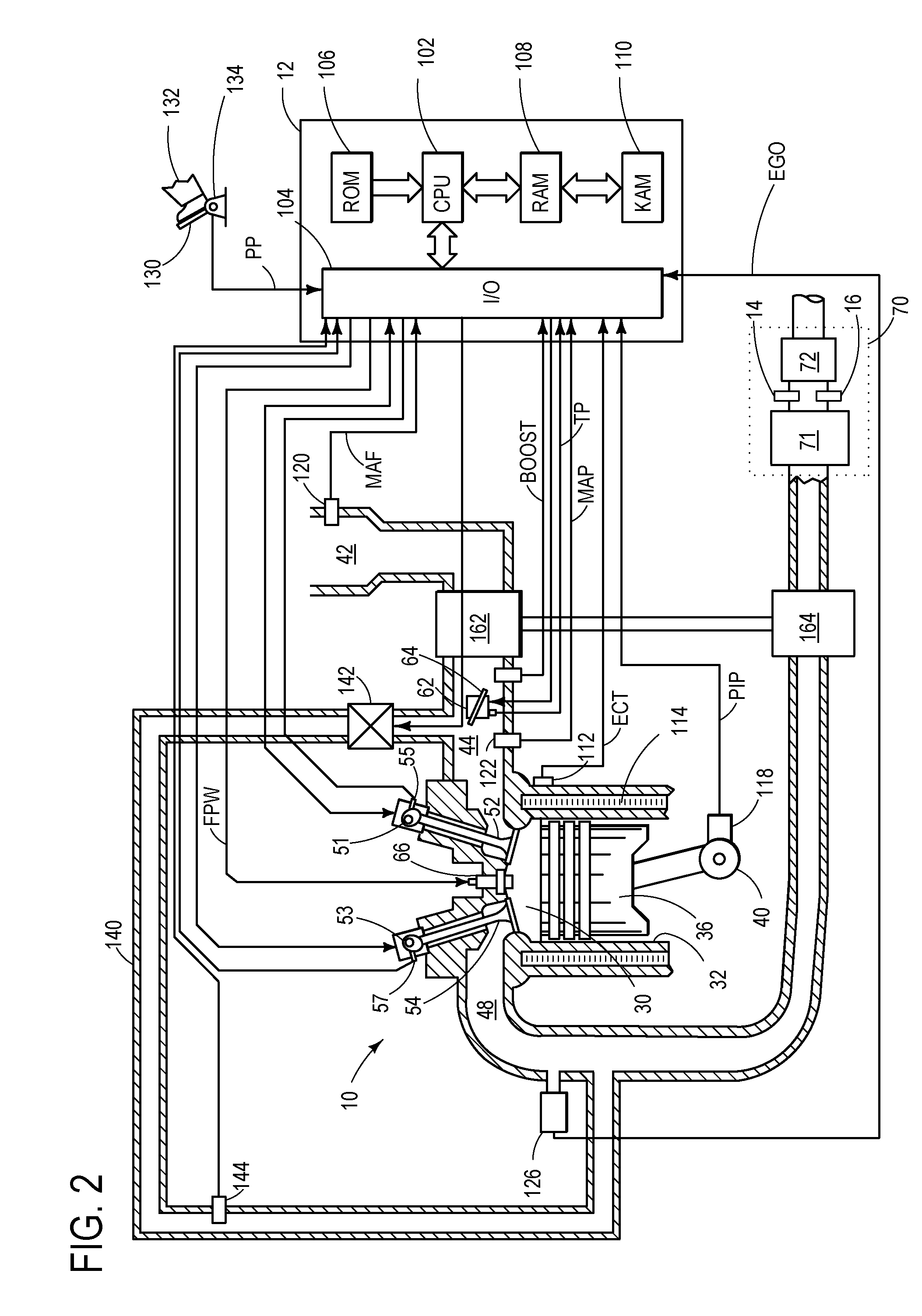

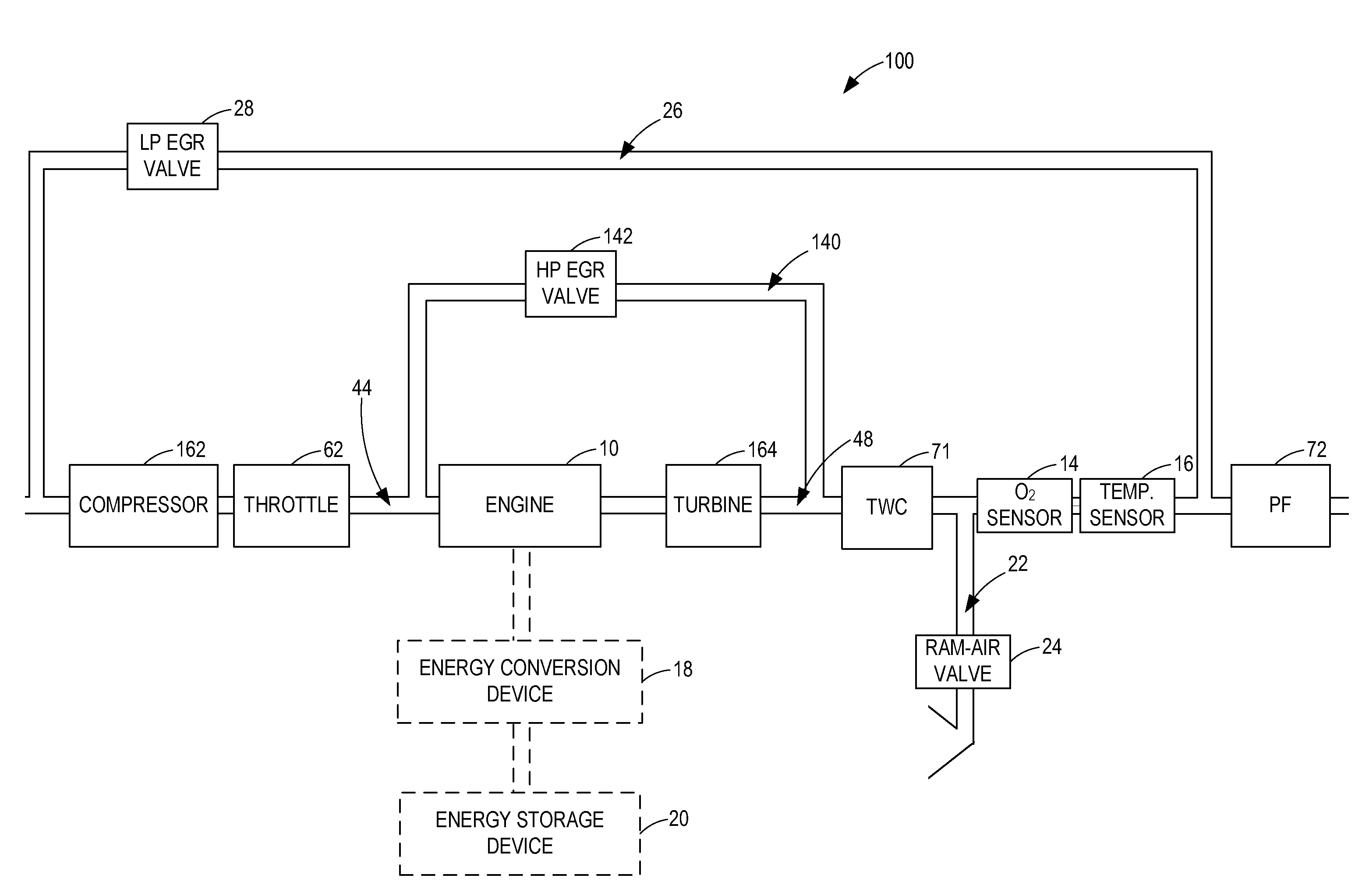

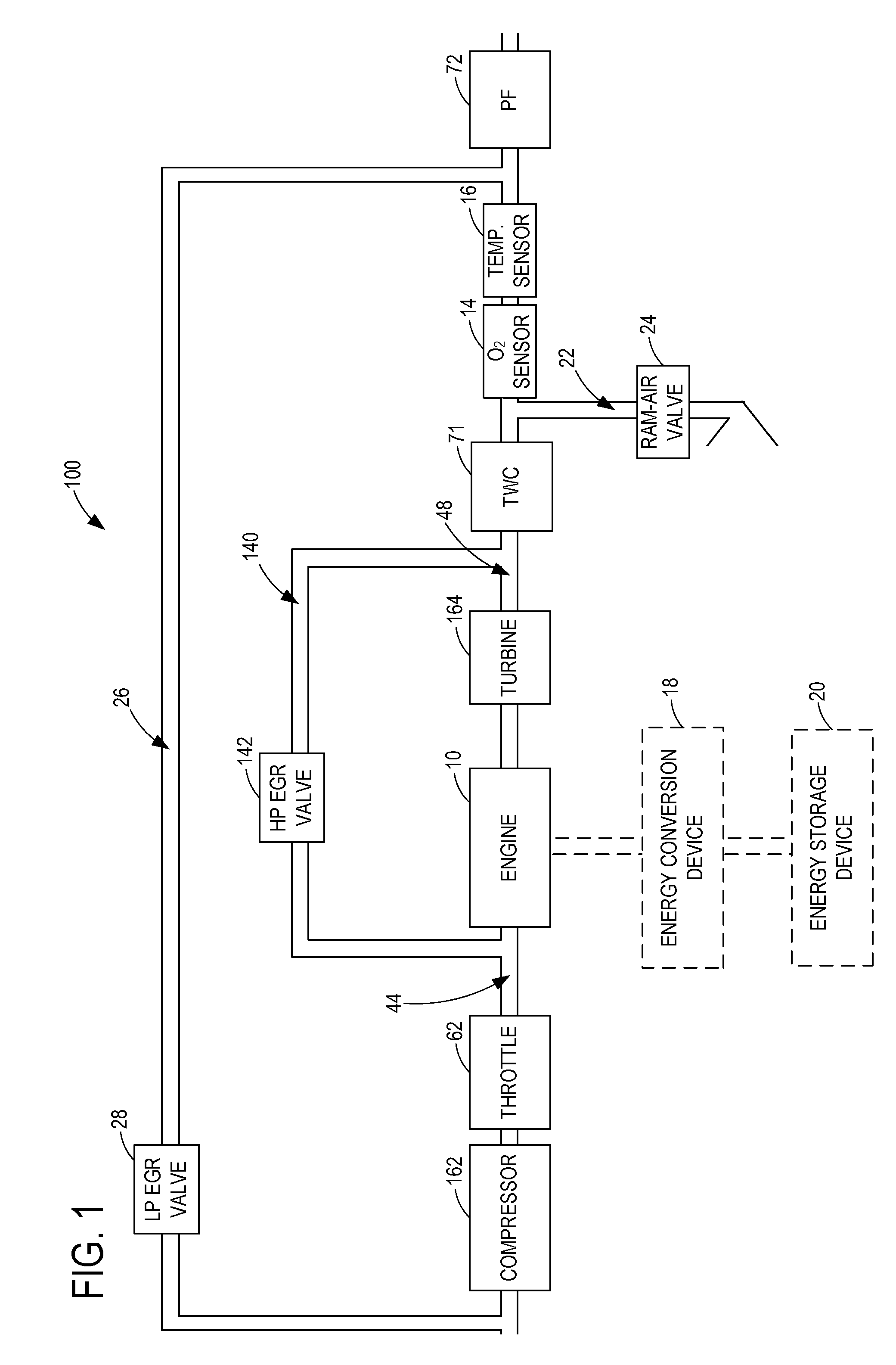

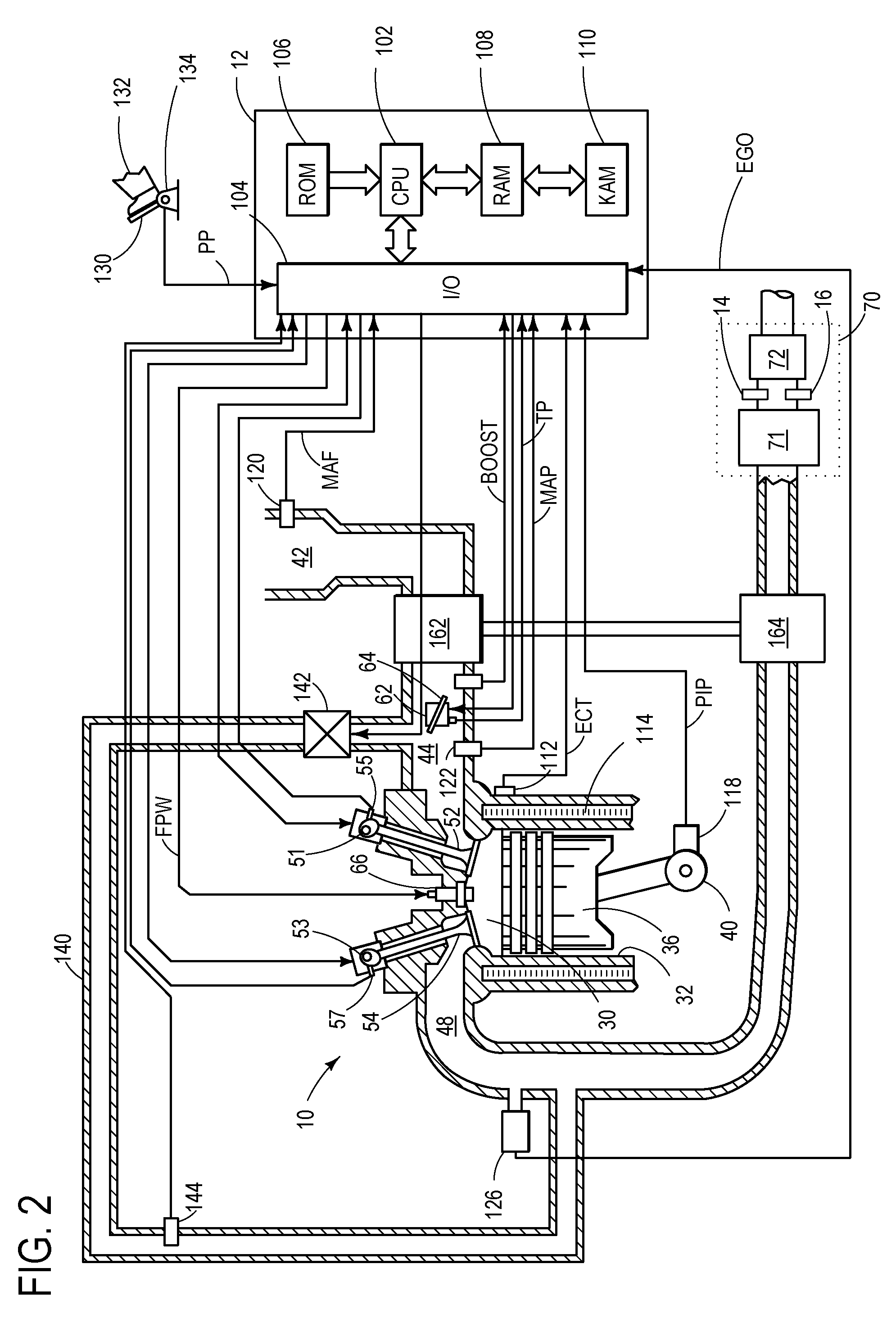

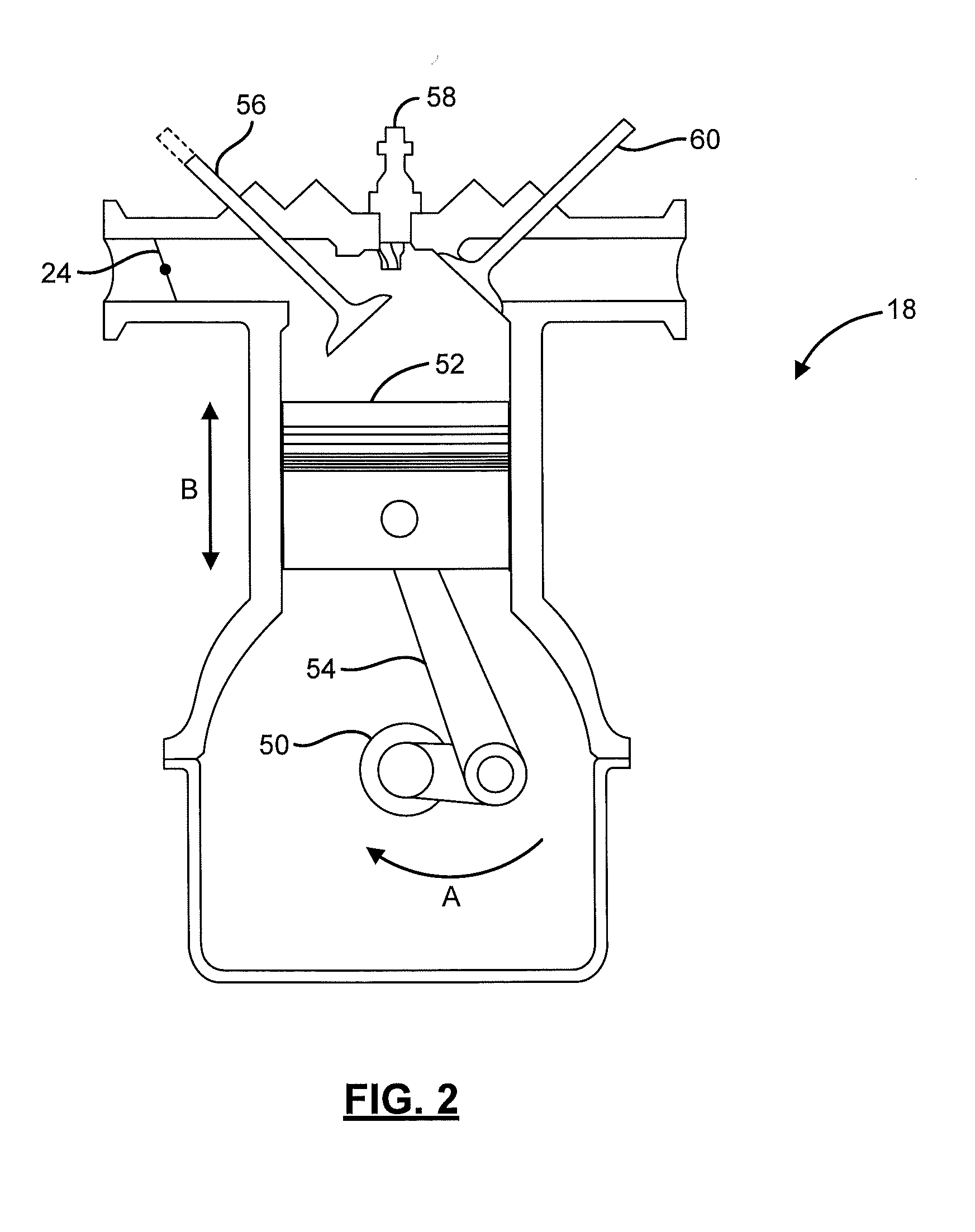

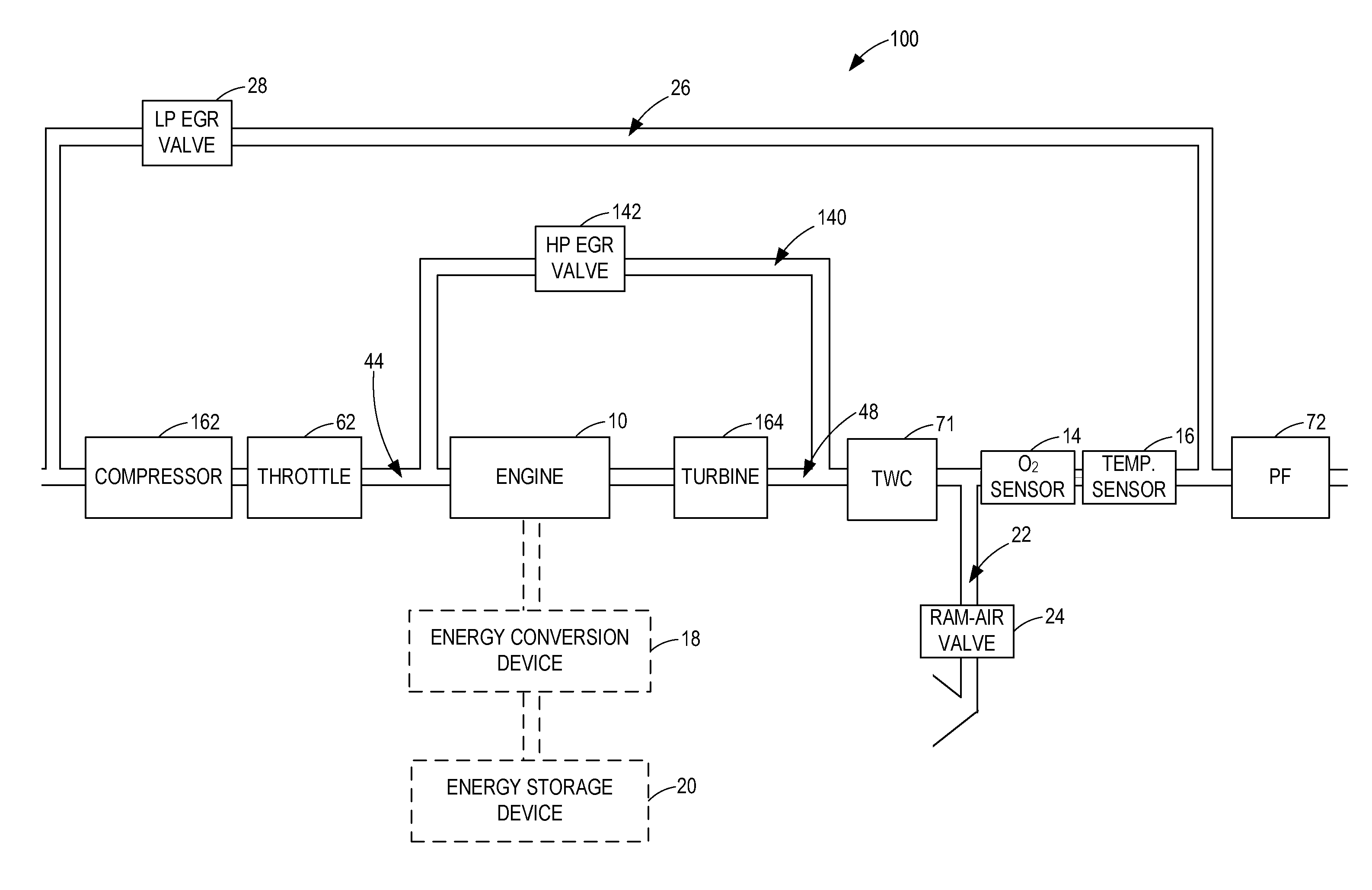

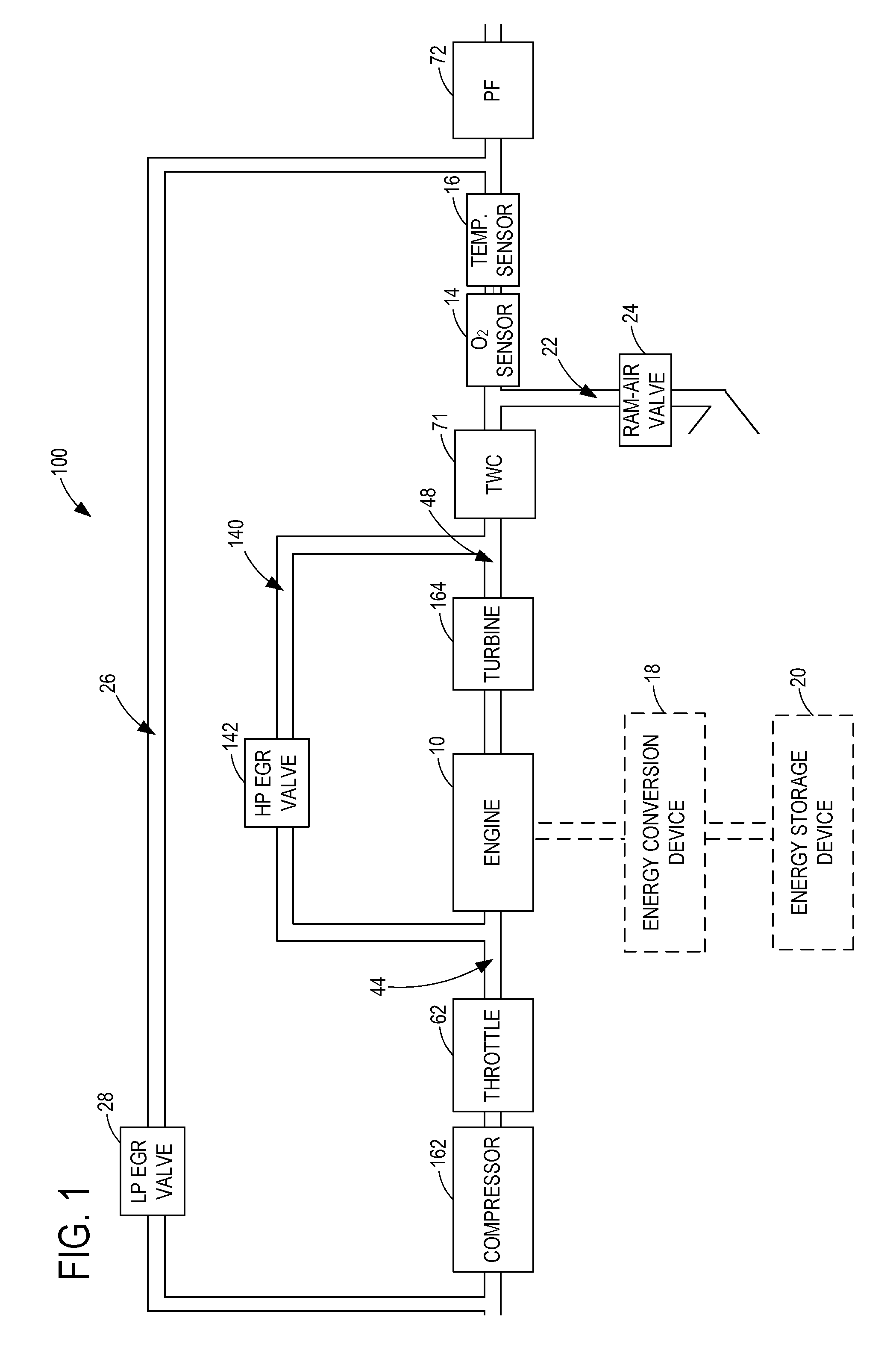

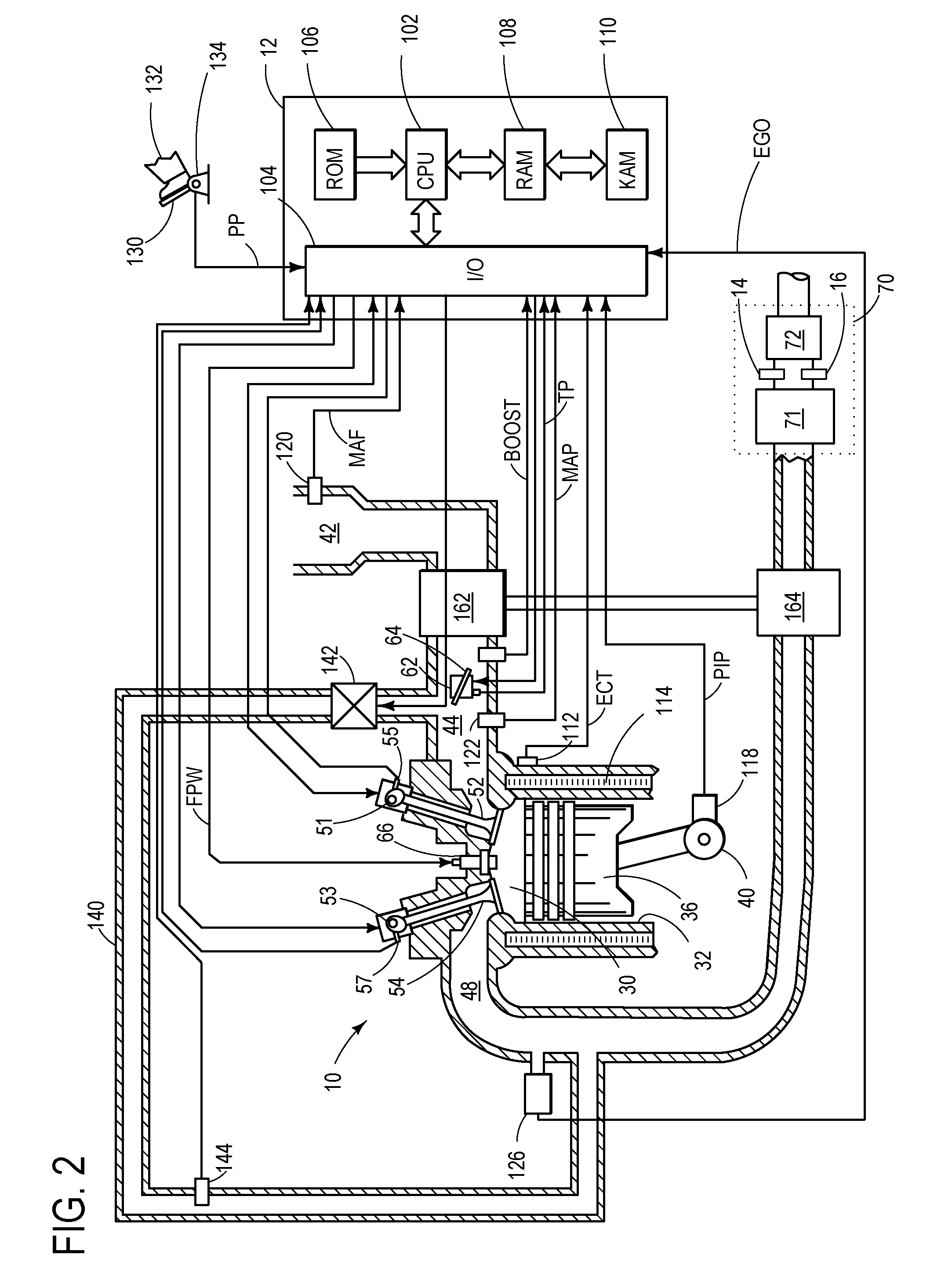

Particulate filter regeneration in an engine coupled to an energy conversion device

ActiveUS20110072791A1Reduce distractionsEmission reductionElectrical controlNon-fuel substance addition to fuelParticulatesExcess oxygen

Systems and methods for controlling regeneration of a particulate filter downstream of an engine coupled to an energy conversion device are provided herein. One exemplary method includes, during first engine shutdown conditions, increasing excess oxygen to the particulate filter by spinning the engine with the energy conversion device, and regenerating the particulate filter. The method also includes, during second engine shutdown conditions, decreasing the excess oxygen to the particulate filter.

Owner:FORD GLOBAL TECH LLC

Particulate filter regeneration during engine shutdown

ActiveUS20110072799A1Reduce nitrogen oxide emissionsAvoid excessive impactInternal combustion piston enginesExhaust apparatusParticulatesExcess oxygen

Systems and methods for controlling regeneration of a particulate filter downstream of an engine in a vehicle are provided herein. One exemplary method includes, during first engine shutdown conditions, increasing excess oxygen to the particulate filter, and regenerating the particulate filter at least during a portion of engine shutdown. The method further includes during second engine shutdown conditions, decreasing the excess oxygen to the particulate filter at least during a portion of engine shutdown.

Owner:FORD GLOBAL TECH LLC

Method for preparing noble metal-supported zeolite catalyst for catalytic reduction of nitrogen oxide

InactiveUS6528031B1High activityMolecular sieve catalystsExhaust apparatusOrganic compoundReducing agent

The present invention provides a method for preparing a catalyst for the reduction of nitrogen oxides by the use of natural gas as a reducing agent in an excess oxygen atmosphere, which comprises of filling zeolite with an organic compound having molecular weight of 100~250 prior to loading catalytically active noble metal components on a zeolite. Since the method according to the present invention supports catalytic active noble metal components on a zeolite under the condition that the pores of zeolite are filled with organic compounds, the noble metal component, which is essential for forming highly active NOx reduction catalyst, can be supported precisely on the desired positions of zeolite pores. Therefore, the NOx reduction catalysts prepared by the present invention are very useful for the purification of exhaust gas in an excessive oxygen atmosphere such as gas turbines, boilers or lean-burn automobiles.

Owner:KOREA RES INST OF CHEM TECH

Amorphous oxide semiconductor and thin film transistor using the same

There is provided an amorphous oxide semiconductor including hydrogen and at least one element of indium (In) and zinc (Zn), the amorphous oxide semiconductor containing one of hydrogen atoms and deuterium atoms of 1×1020 cm−3 or more to 1×1022 cm−3 or less, and a density of bonds between oxygen and hydrogen except bonds between excess oxygen (OEX) and hydrogen in the amorphous oxide semiconductor being 1×1018 cm−3 or less.

Owner:CANON KK

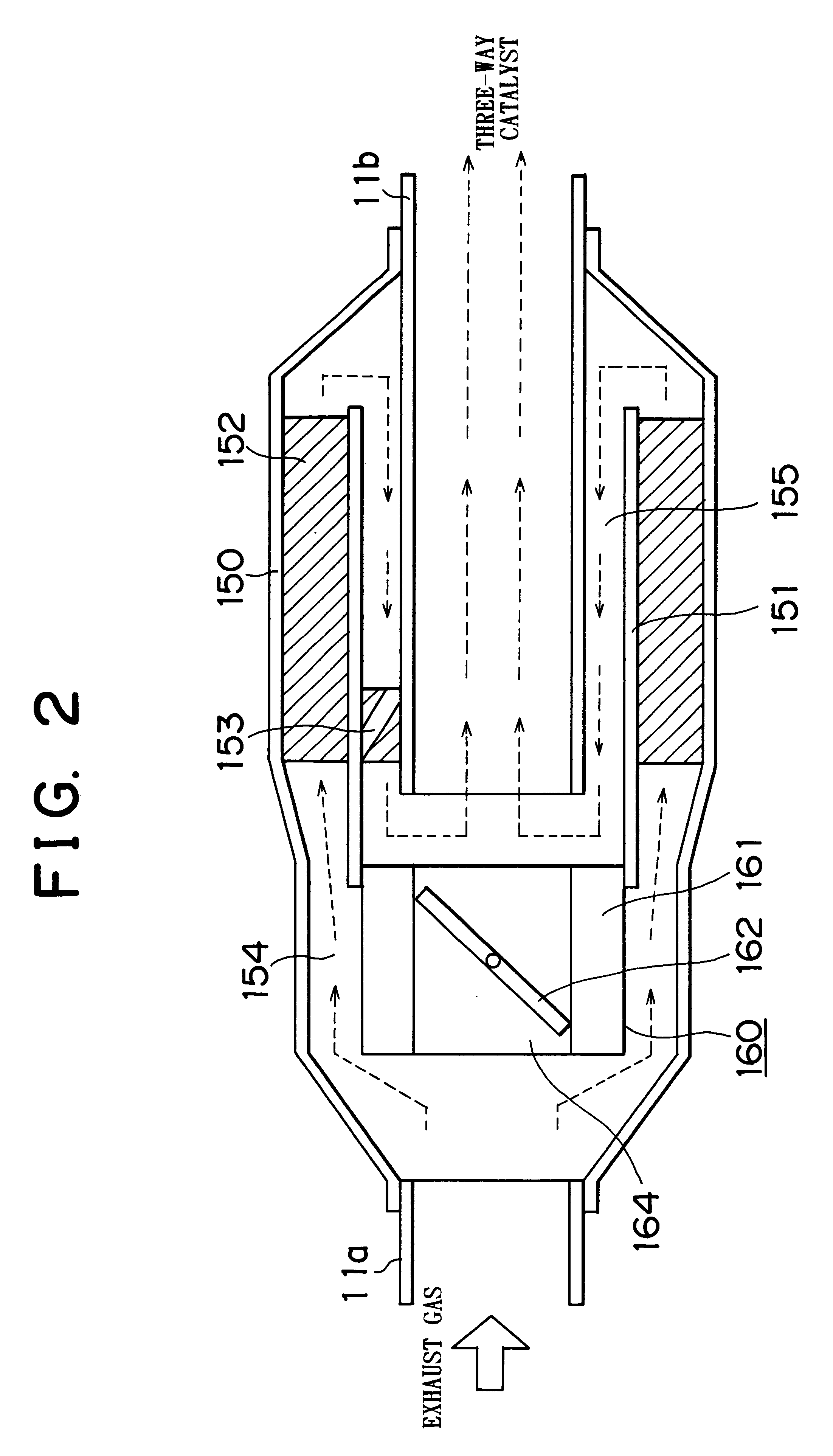

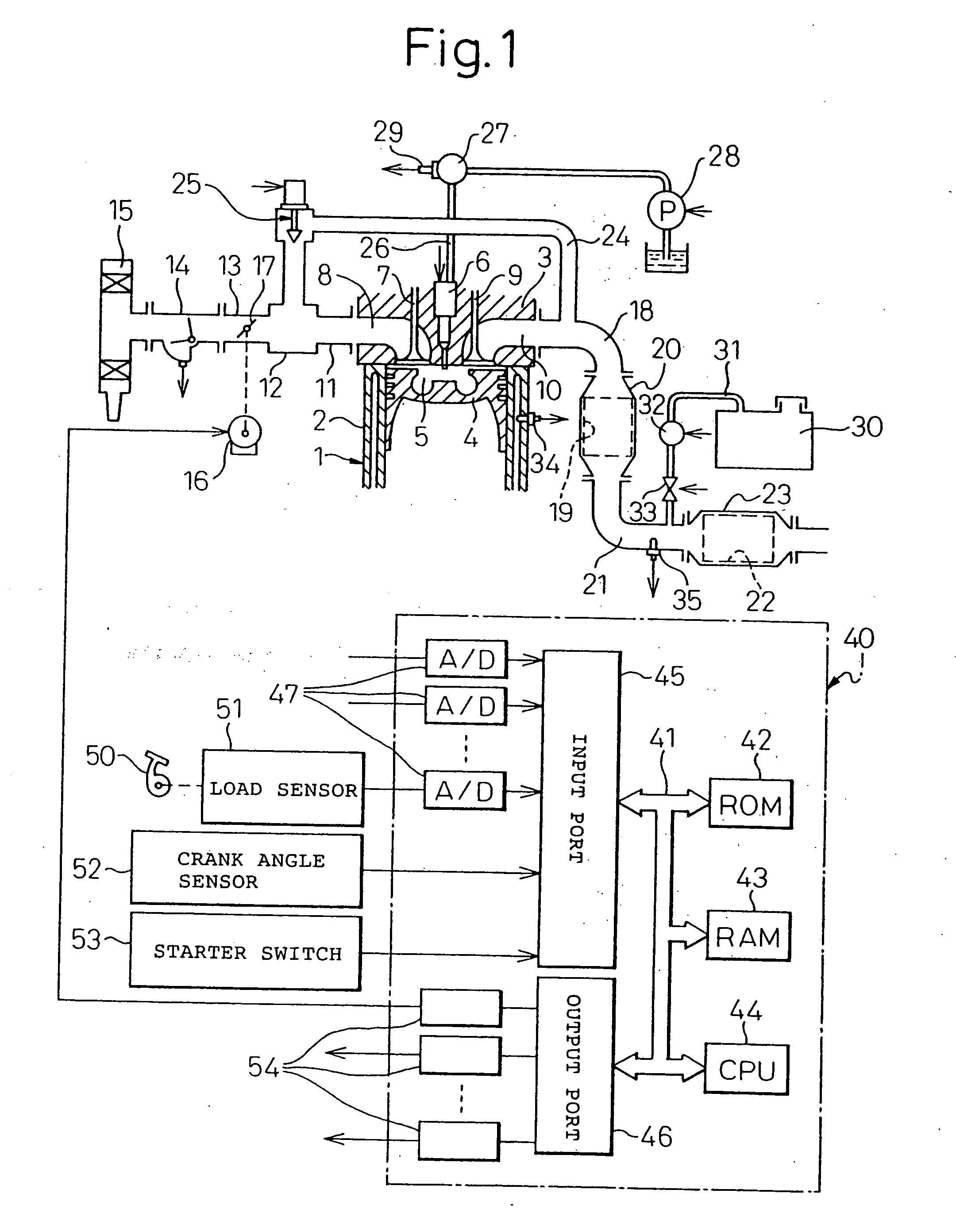

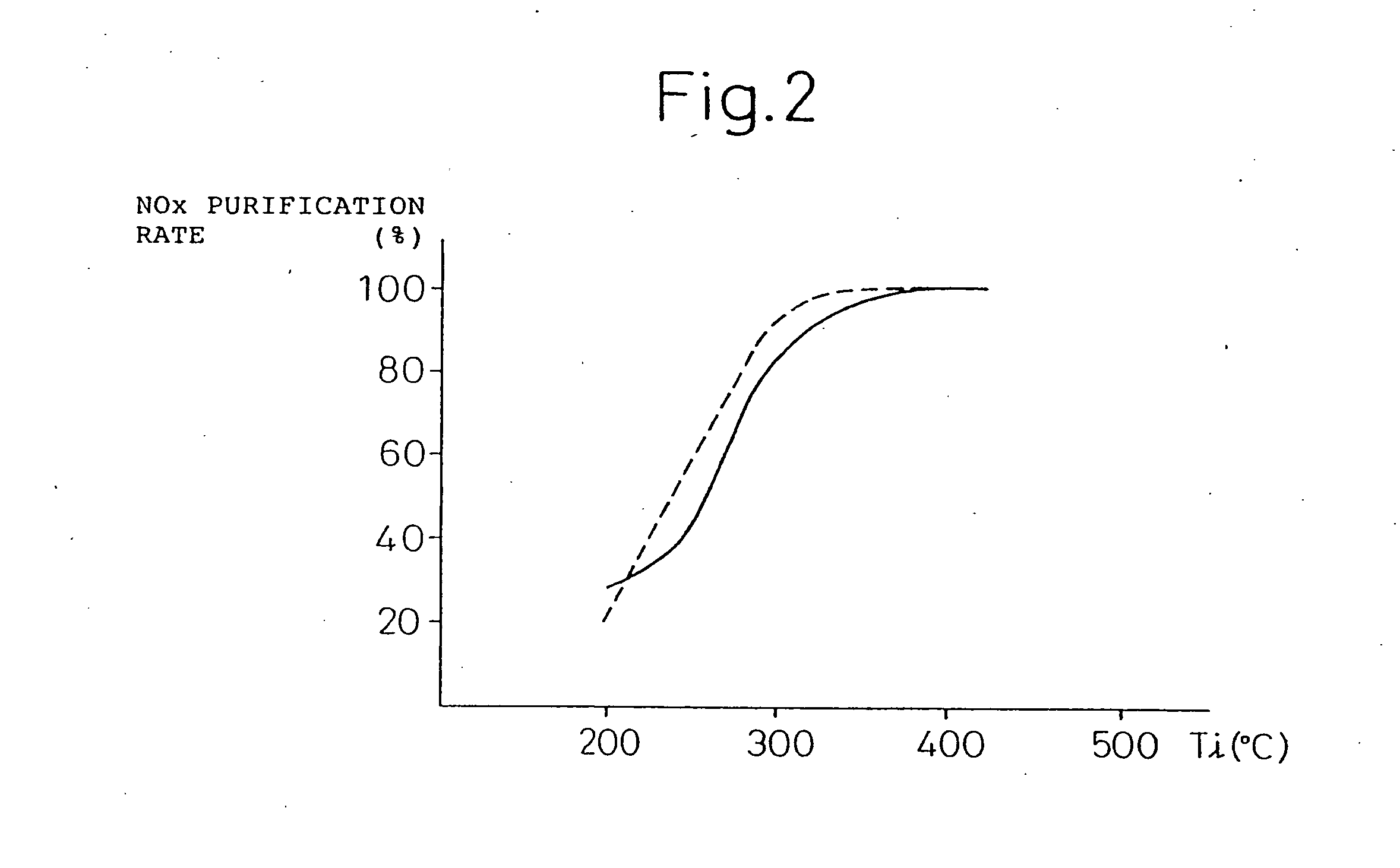

Exhaust gas purification device of internal combustion engine

InactiveUS20050034450A1NOx purification can be made highHigh NOx purification rateElectrical controlNitrogen compoundsExcess oxygenInternal combustion engine

A catalyst (22) suitable for reduction of the NOx in an exhaust gas by ammonia in the presence of excess oxygen is arranged in the exhaust passage (18, 21) of an internal combustion engine. An aqueous urea solution is fed through a flow control valve (33) to the inside of the exhaust passage (21) upstream of the catalyst (22). When the temperature of the catalyst (22) is low, a large amount of the aqueous urea solution is fed to make the urea contained in the aqueous urea solution be stored in the catalyst (22). When the engine is accelerated and the temperature of the catalyst (22) rises, ammonia is released at a little at a time from the inside of the catalyst (22) and the NOx in the exhaust gas is reduced by the released ammonia.

Owner:TOYOTA JIDOSHA KK

Low emission diesel combustion system with low charge-air oxygen concentration levels and high fuel injection pressures

InactiveUS20040055282A1Lower levelReduce the temperatureLiquid coolingEngine sealsLow loadMass ratio

This invention sets forth a commercially viable diesel combustion system that meets environmentally acceptable levels of NOx emissions (i.e. 0.2 g / bhp-hr or lower across a full map of engine speeds and loads) without the need for use of NOx aftertreatments, and simultaneously maintains engine-out PM emissions relatively close (e.g. with smoke levels at or below 3 BSN) to environmentally acceptable PM post-aftertreatment levels. The invention achieves these results by operating within a unique combination of parameters. These parameters comprise: (1) charge-air oxygen concentration below 16%, preferably between 10% and 15%, more preferably between 11% and 14%, and most preferably between 12% and 13.5% for virtually all engine operating conditions (but not necessarily at no-load or low load conditions), (2) fuel injection pressures at or exceeding 1800 bar, preferably exceeding 2100 bar, more preferably exceeding 2300 bar, and most preferably exceeding 2500 bar, at most engine speeds and loads, and (3) charge-air mass / fuel mass ratio between 25:1 and 45:1 for medium and high loads. Furthermore, the system is preferably run continuously slightly lean of stoichiometry, providing just enough excess oxygen to facilitate completeness of combustion and to maintain an exhaust oxygen level sufficient for continuous trap regeneration at a balance point in operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Anti-oxidation health-care wine and its production method

The invention relates to an anti-oxidation health-care wine and its production method, wherein the wine is prepared from the oxidation resistant reactive constituents in grape seed and peel extracted with high grade white spirit or brandy with high ethanol content, the the oxidation resistant reactive constituents in grape seed and peel is proanthocyanidin, resveratrol, polydatin, which can effectively remove excess oxygen-derived free radicals in human bodies.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060159607A1Reduce the temperatureNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

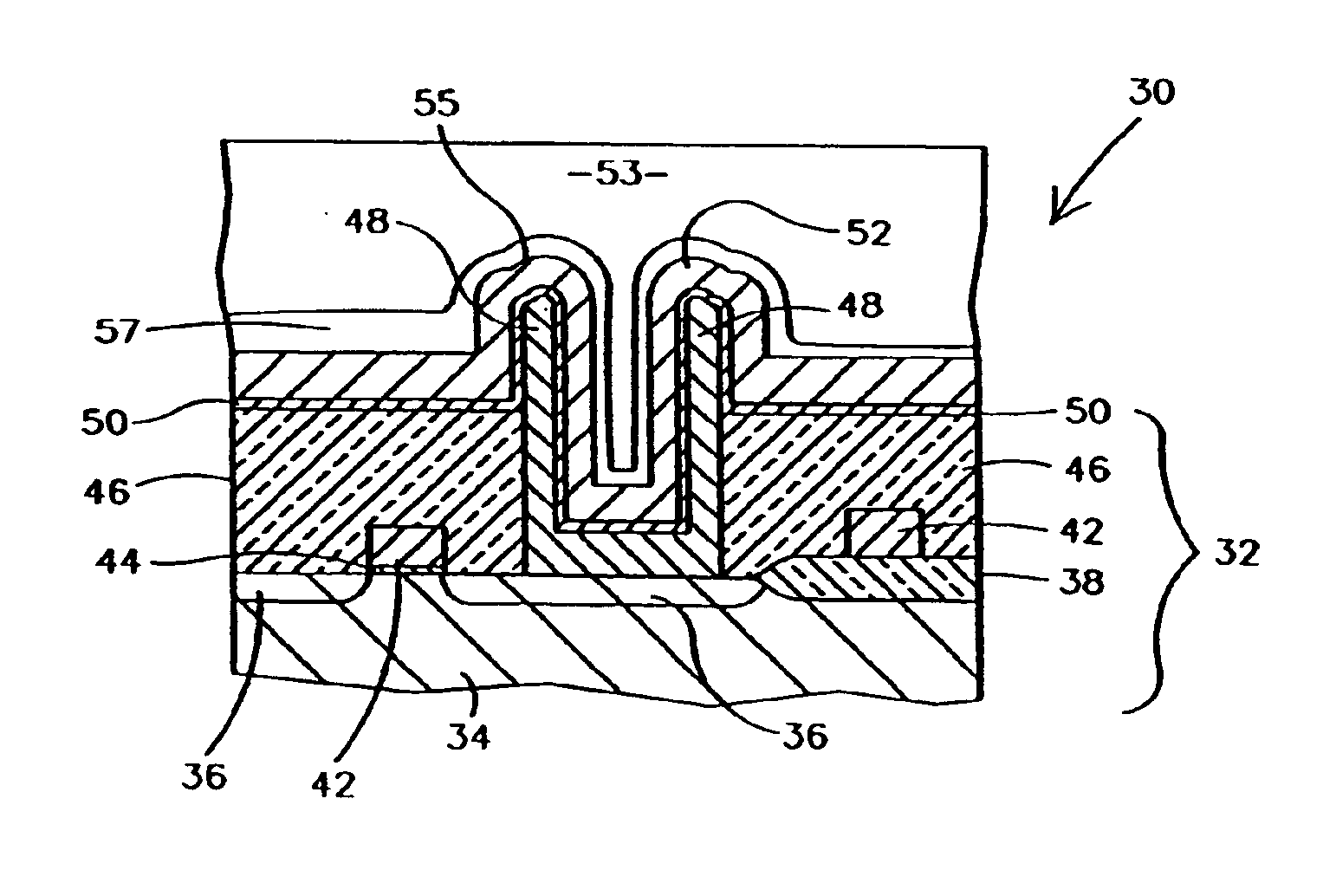

Methods for use in forming a capacitor and structures resulting from same

InactiveUS6890814B2Reduce such oxygen reduction effectImprove leakage currentSemiconductor/solid-state device detailsSolid-state devicesExcess oxygenEngineering

A method for use with the formation of a capacitor includes providing a capacitor structure by forming a first electrode on a portion of a substrate assembly, forming a high dielectric material over at least a portion of the first electrode, and forming a second electrode over the high dielectric material. An additional layer may be formed over at least a portion of the second electrode. The portion of the substrate assembly on which the first electrode is formed and / or the layer formed over the second electrode are formed of an excess oxygen containing material.

Owner:MICRON TECH INC

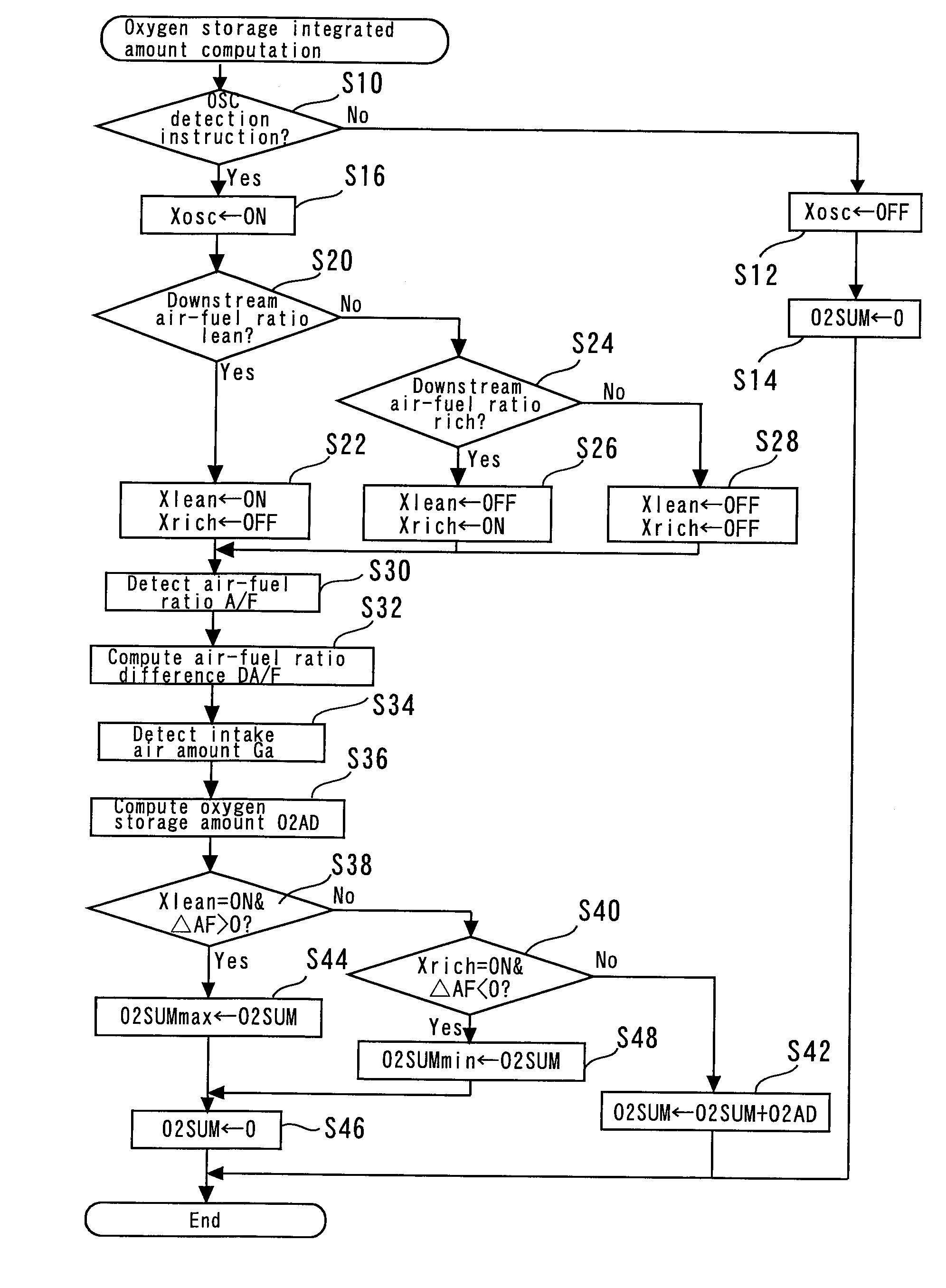

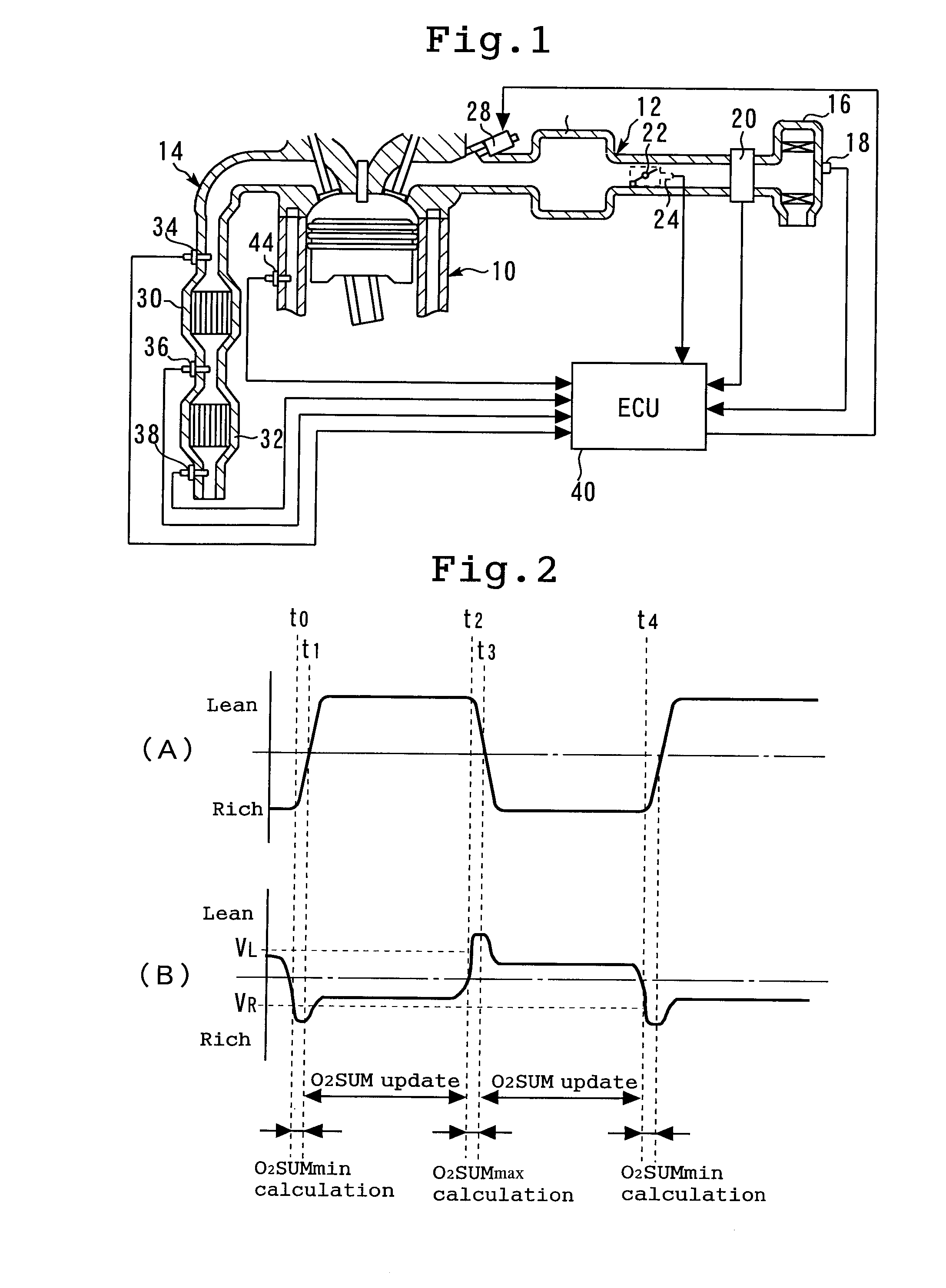

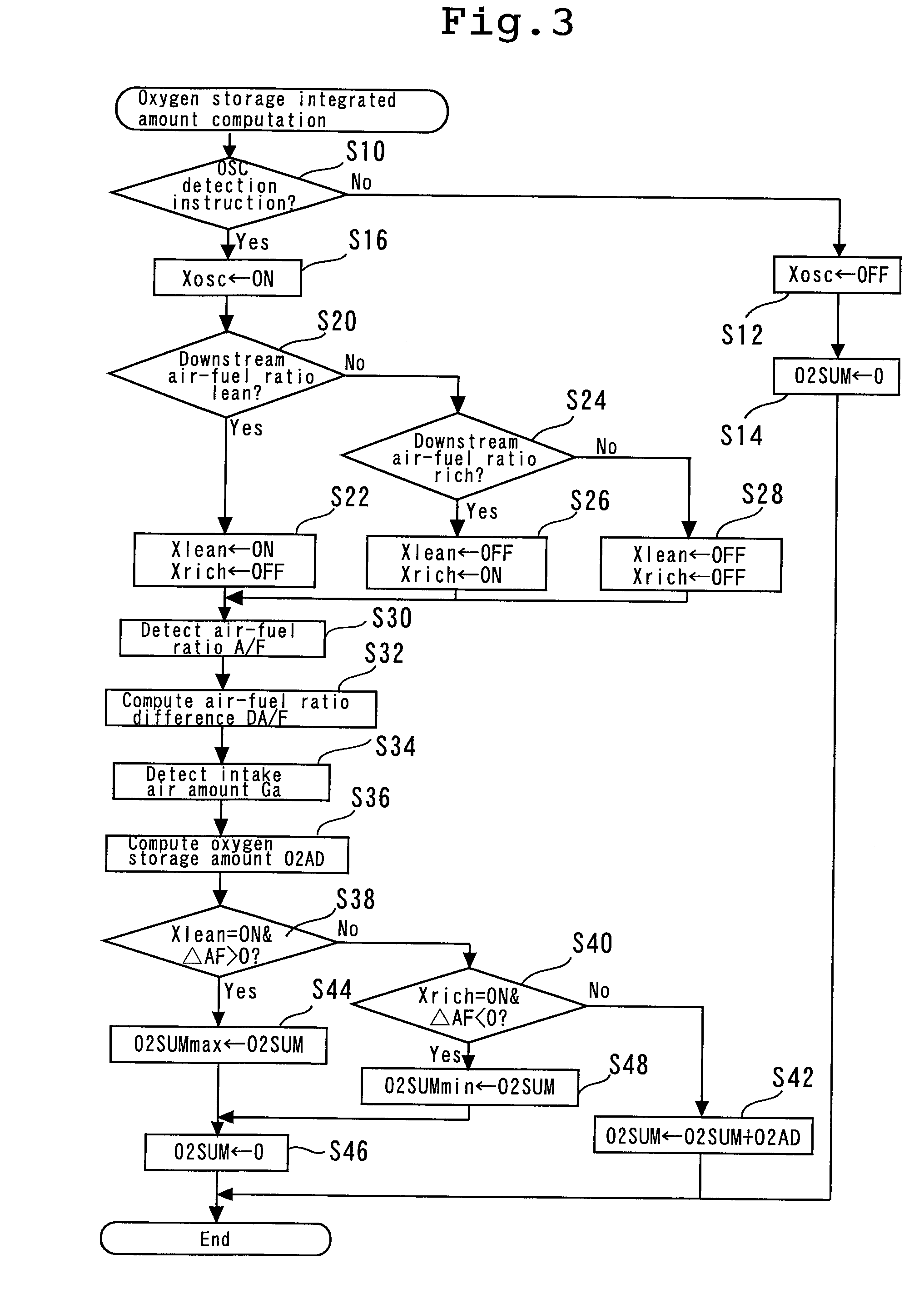

Catalyst deterioration detection device

InactiveUS20090288391A1Eliminate variationAccurately determineElectrical controlInternal combustion piston enginesOxygen sensorExcess oxygen

The present invention detects the deterioration of a catalyst. In accordance with an output from an oxygen sensor, a catalyst deterioration detection device for the catalyst positioned in an exhaust path of an internal combustion engine detects a maximum oxygen storage state where an exhaust gas outflowing downstream of the catalyst contains excess oxygen and a minimum oxygen storage state where the exhaust gas outflowing downstream of the catalyst lacks oxygen. Control is exercised to provide a rich target air-fuel ratio for the internal combustion engine during an oxygen release period between the instant at which the maximum oxygen storage state is detected and the instant at which the minimum oxygen storage state is detected later, and to provide a lean target air-fuel ratio for the internal combustion engine during an oxygen storage period between the instant at which the minimum oxygen storage state is detected and the instant at which the maximum oxygen storage state is detected later. Further, the amount of oxygen released from the catalyst during the oxygen release period or the amount of oxygen stored by the catalyst during the oxygen storage period is detected as an oxygen storage amount. The deterioration of the catalyst is then judged in accordance with the oxygen storage amount. Moreover, when exercising control for catalyst deterioration detection, the catalyst deterioration detection device sets up oxygen storage amount detection conditions for correcting a variation that may occur in the oxygen release period or the oxygen storage period depending on a difference in output detection conditions for the oxygen sensor.

Owner:TOYOTA JIDOSHA KK

Emissionless Oxyfuel Combustion Process and a Combustion System Using Such a Process

InactiveUS20110139046A1Low NH3/NOx ratioEfficient workEmission preventionFluegas recirculationCombustion systemSorbent

A method of combusting carbonaceous fuel in a combustion system. The combustion system includes a source of oxygen and a furnace. The method includes the steps of (a) feeding fuel and combustion gas including oxygen and recycling gas into the furnace for combusting the fuel with the oxygen and producing exhaust gas that includes CO2, water and excess oxygen as its main components, (b) conducting the exhaust gas discharged from the furnace into a scrubber so as to remove pollutants from the exhaust gas, (c) dividing the exhaust gas into a first exhaust gas stream and a second exhaust gas stream, and conducting the second exhaust gas stream as a recycling gas stream into the furnace, (d) conducting the first exhaust gas stream into a CO2 purification and capturing unit (CPU) to produce one or more condensate streams, a purified liquid CO2 stream and a vent gas stream that includes remaining CO2, (e) discharging the purified liquid CO2 stream from the combustion system, (f) conducting the vent gas stream into an adsorption unit so as to adsorb compounds, including remaining CO2, from the vent gas stream to an adsorbing material and to produce a pass-through gas stream, and (g) regenerating the adsorbing material to produce a desorbed gas stream that includes at least a portion of the adsorbed compounds, and conducting at least a portion of the desorbed gas stream into the furnace.

Owner:FOSTER WHEELER ENERGY CORP

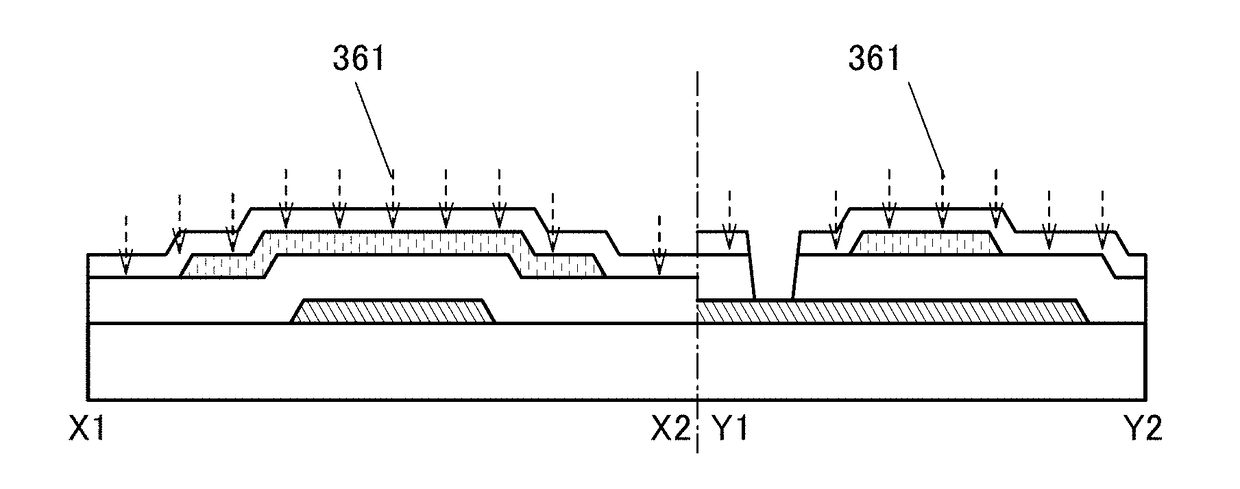

Semiconductor device, manufacturing method thereof, display device, and electronic device

ActiveUS20170243759A1Improve reliabilityReduce conductivityTransistorSolid-state devicesOxygen plasmaDisplay device

The field-effect mobility and reliability of a transistor including an oxide semiconductor film are improved. Provided is a semiconductor device including an oxide semiconductor film. The semiconductor device includes a first insulating film, an oxide semiconductor film over the first insulating film, a second insulating film and a third insulating film over the oxide semiconductor film, and a gate electrode over the second insulating film. The second insulating film comprises a silicon oxynitride film. When excess oxygen is added to the second insulating film by oxygen plasma treatment, oxygen can be efficiently supplied to the oxide semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

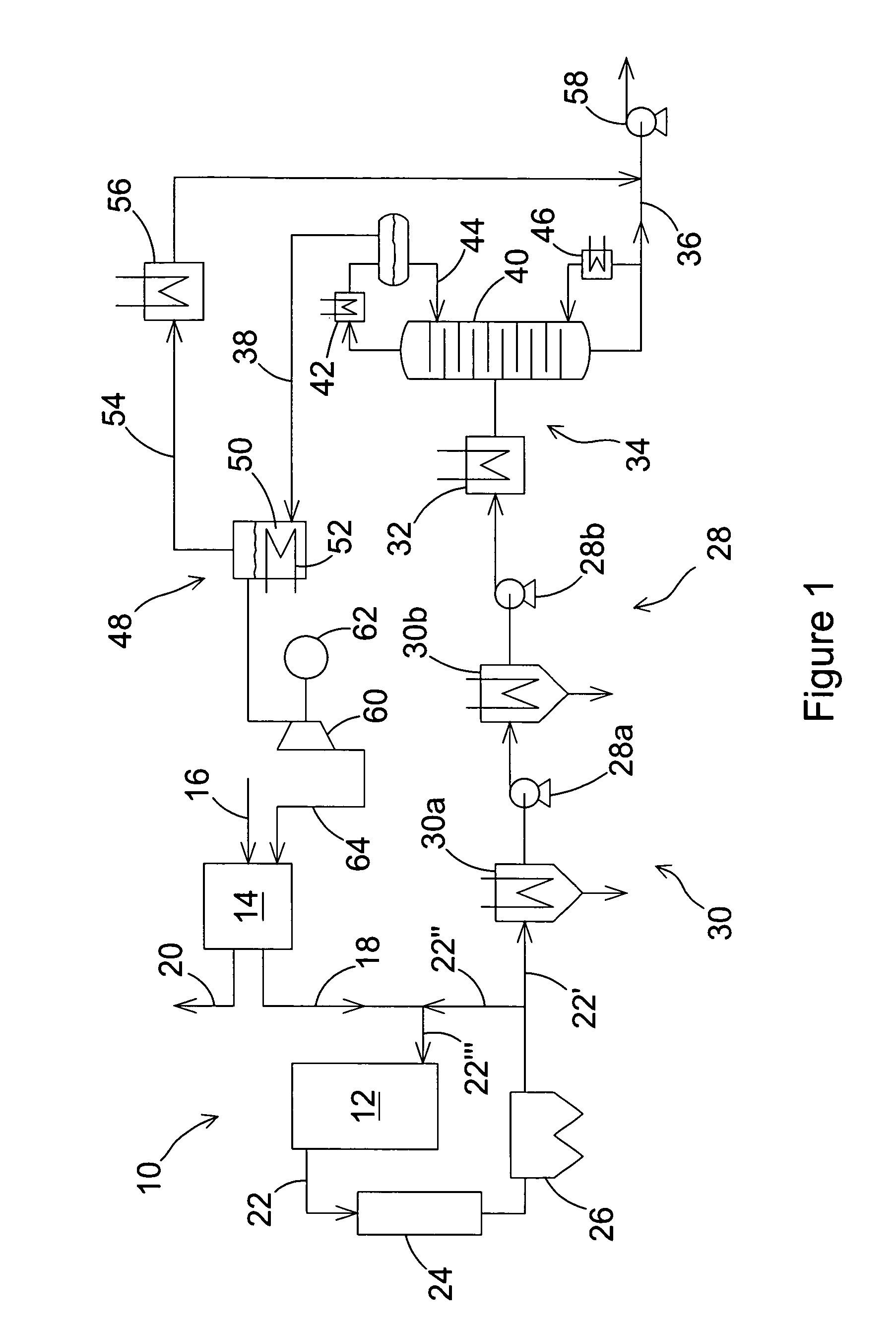

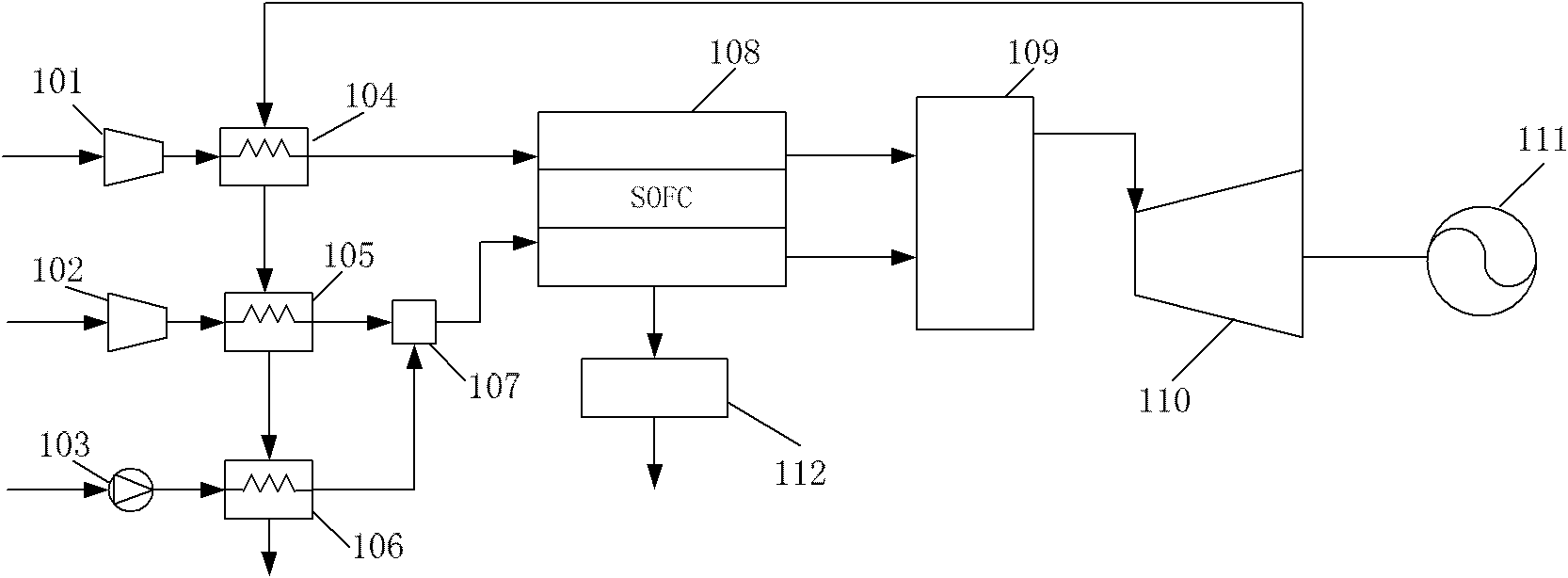

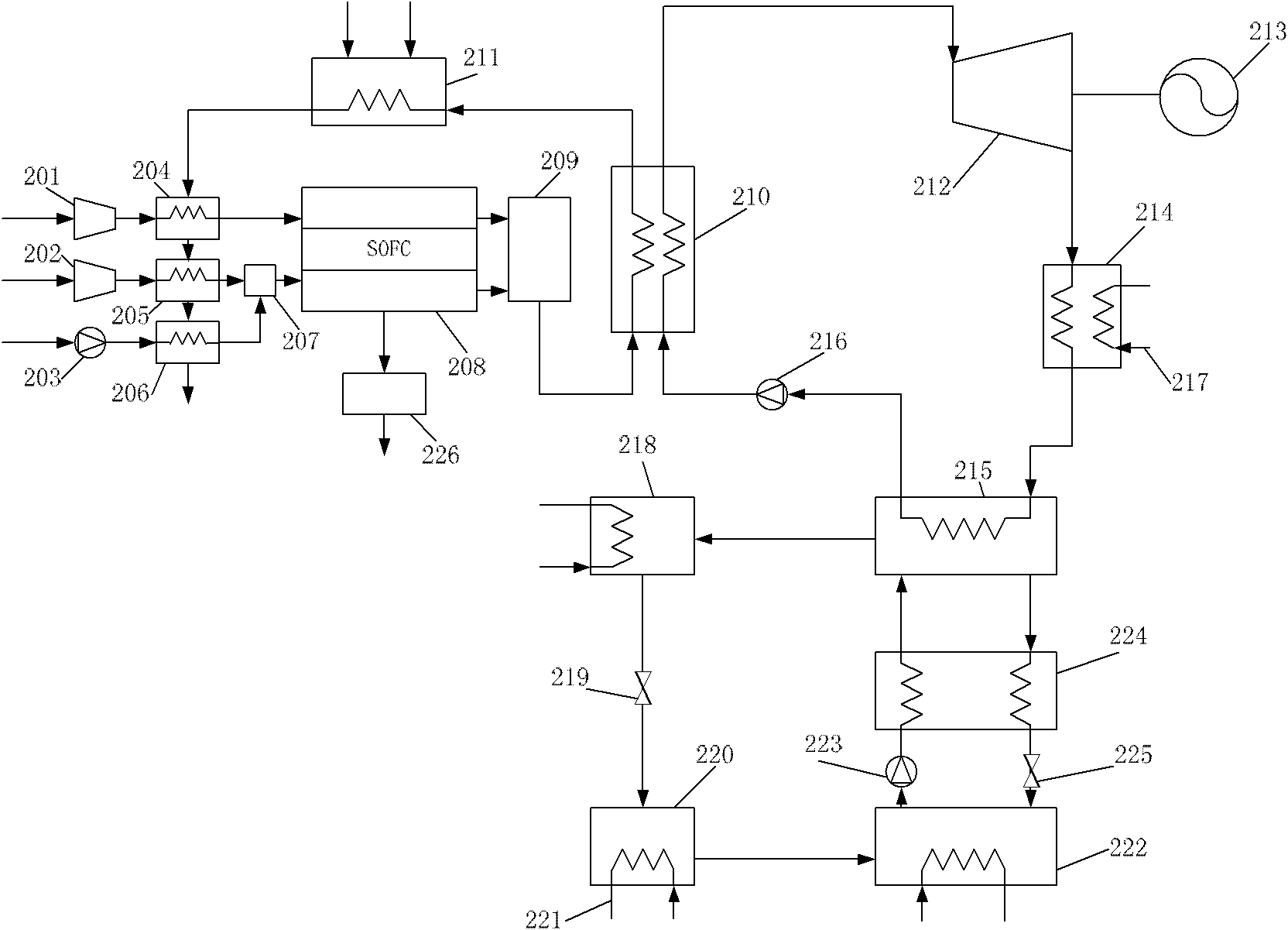

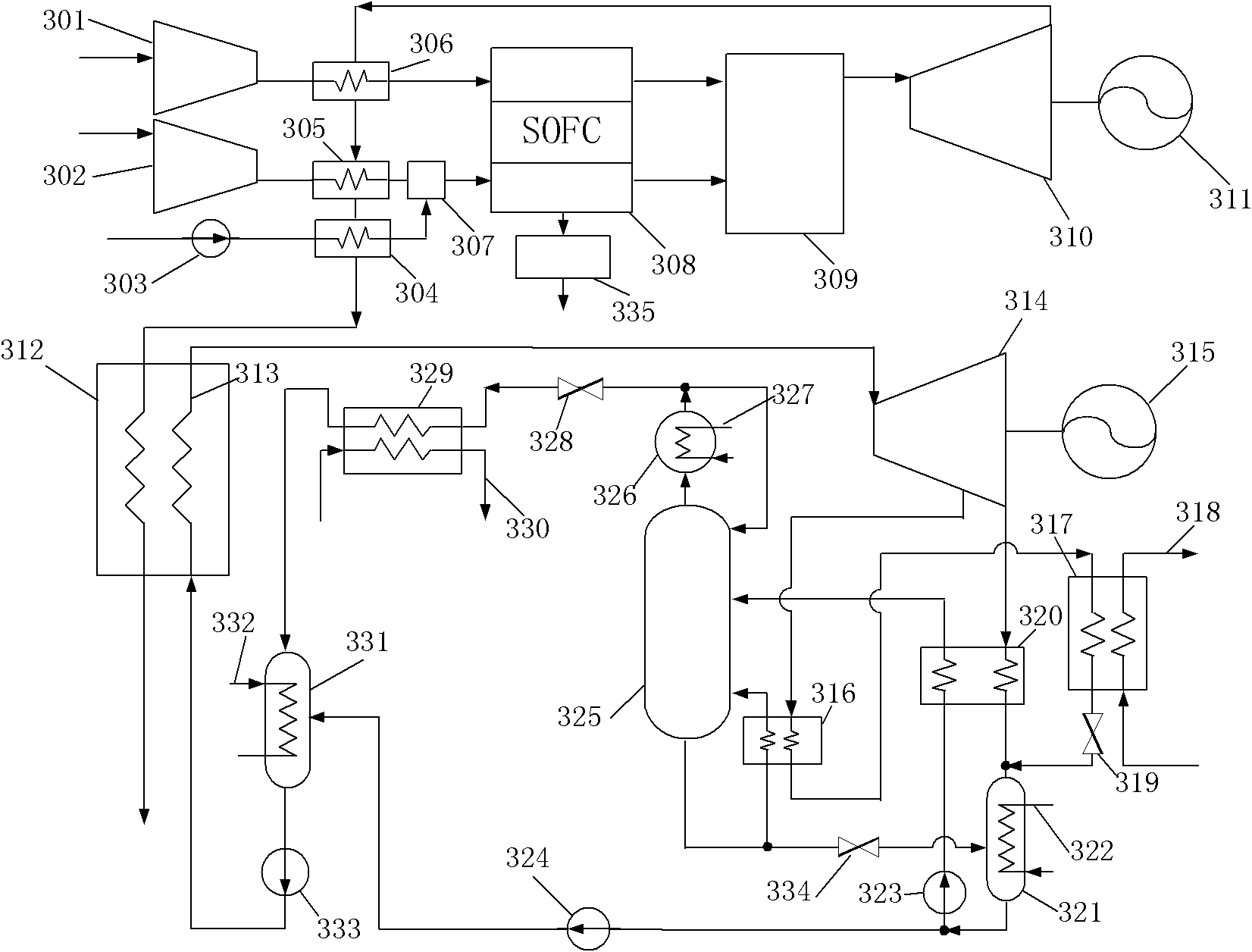

Combined cold-heat-power supplying circulation system driven by solid oxide fuel cell

InactiveCN102088099ARealize cascade utilizationIncrease profitFuel cell heat exchangeGas turbine plantsNuclear engineeringHeating power

The invention provides a combined cold-heat-power supplying circulation system driven by a solid oxide fuel cell. Pressurized and heated fuel and pressurized and heated water are mixed, and then the mixture reacts with pressurized and heated air in the solid oxide fuel cell so as to generate power; the excess oxygen and unreacted fuel further react; a turbine is used for applying work to drive a power generator to generate power; and then the exhaust preheats air, water and the fuel for refrigeration and heat supply. The combined cold-heat-power supplying circulation system can effectively utilize the high-temperature residual heat of the fuel cell stack and the pressure energy of the fuel, realizes cascaded utilization of energy, and improves the utilization rate of fossil fuel; compared with the traditional power generation efficiency, the total power generating effect of the combined cold-heat-power supplying circulation system can reach more than 70 percent; and in a condition that the refrigerating capacity and the heating capacity are taken into consideration, the overall heat efficiency of the combined cold-heat-power supplying circulation system can reach more than 80 percent which is far higher than that of the general combined cold-heat-power supplying system.

Owner:XI AN JIAOTONG UNIV

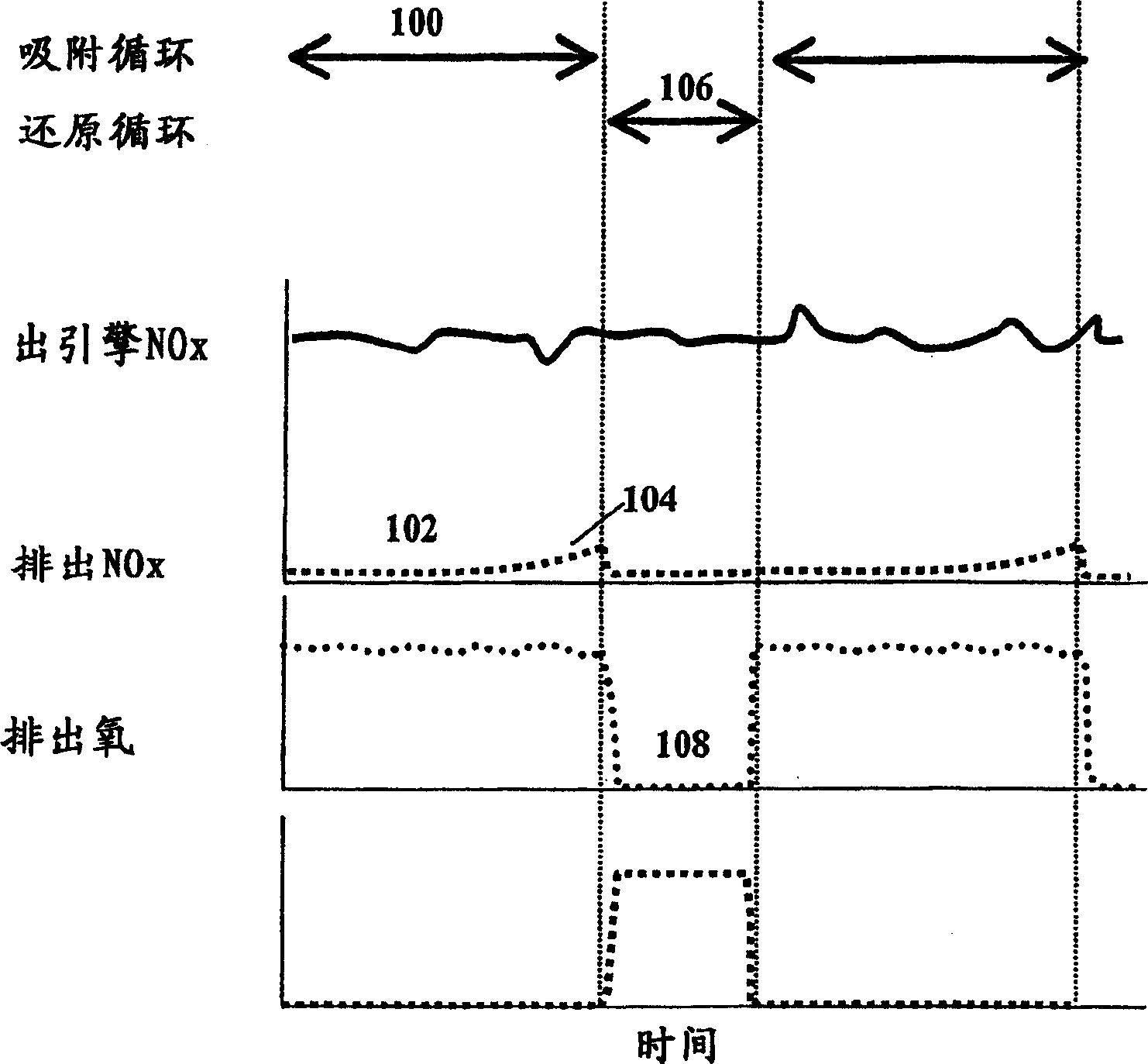

System and methods for improved emission control of internal combustion engines

The present invention provides systems and methods to improve the performance and emission control of internal combustion engines equipped with nitrogen oxides storage-reduction ('NSR') emission control systems (206). The system comprises a NSR catalyst (206), a fuel processor (200) located upstream of the NSR catalyst, and at least one fuel injection port (208). The fuel processor (200) converts a fuel into a reducing gas mixture comprising CO and H>2<. The reducing gas mixture is then fed into the NSR catalyst (206), where it regenerates the NSR adsorbent, reduces the NO>x< to nitrogen, and optionally periodically desulfates the NSR catalyst. The fuel processor (200) comprises one or more catalysts, which facilitate reactions such as combustion, partial oxidation, and / or reforming and help consume excess oxygen present in an engine exhaust stream. The methods of the present invention provide for NSR catalyst adsorbent regeneration. Control strategies are provided to control the system and methods of the invention.

Owner:能量催化系统公司

Semiconductor device

To provide a semiconductor device that includes an oxide semiconductor and is miniaturized while keeping good electrical properties. In the semiconductor device, an oxide semiconductor layer is surrounded by an insulating layer including an aluminum oxide film containing excess oxygen. Excess oxygen in the aluminum oxide film is supplied to the oxide semiconductor layer including a channel by heat treatment in a manufacturing process of the semiconductor device. Furthermore, the aluminum oxide film forms a barrier against oxygen and hydrogen. It is thus possible to suppress the removal of oxygen from the oxide semiconductor layer surrounded by the insulating layer including an aluminum oxide film, and the entry of impurities such as hydrogen into the oxide semiconductor layer; as a result, the oxide semiconductor layer can be made highly intrinsic. In addition, gate electrode layers over and under the oxide semiconductor layer control the threshold voltage effectively.

Owner:SEMICON ENERGY LAB CO LTD

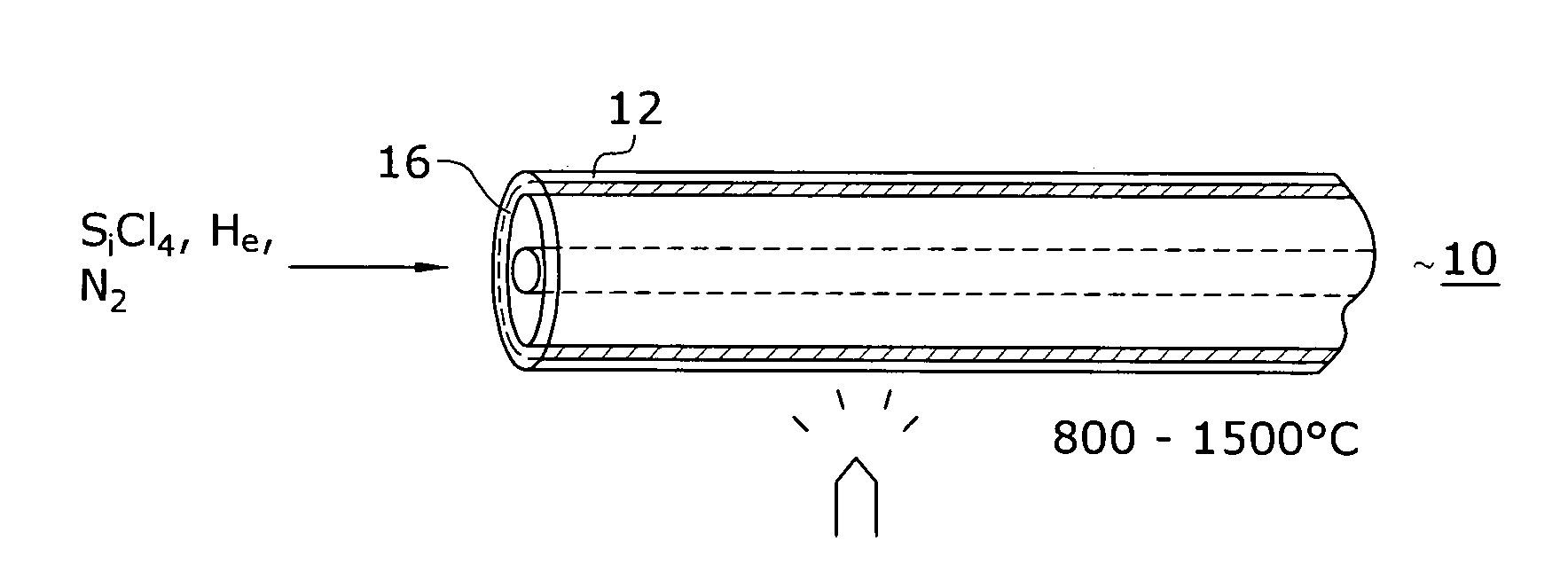

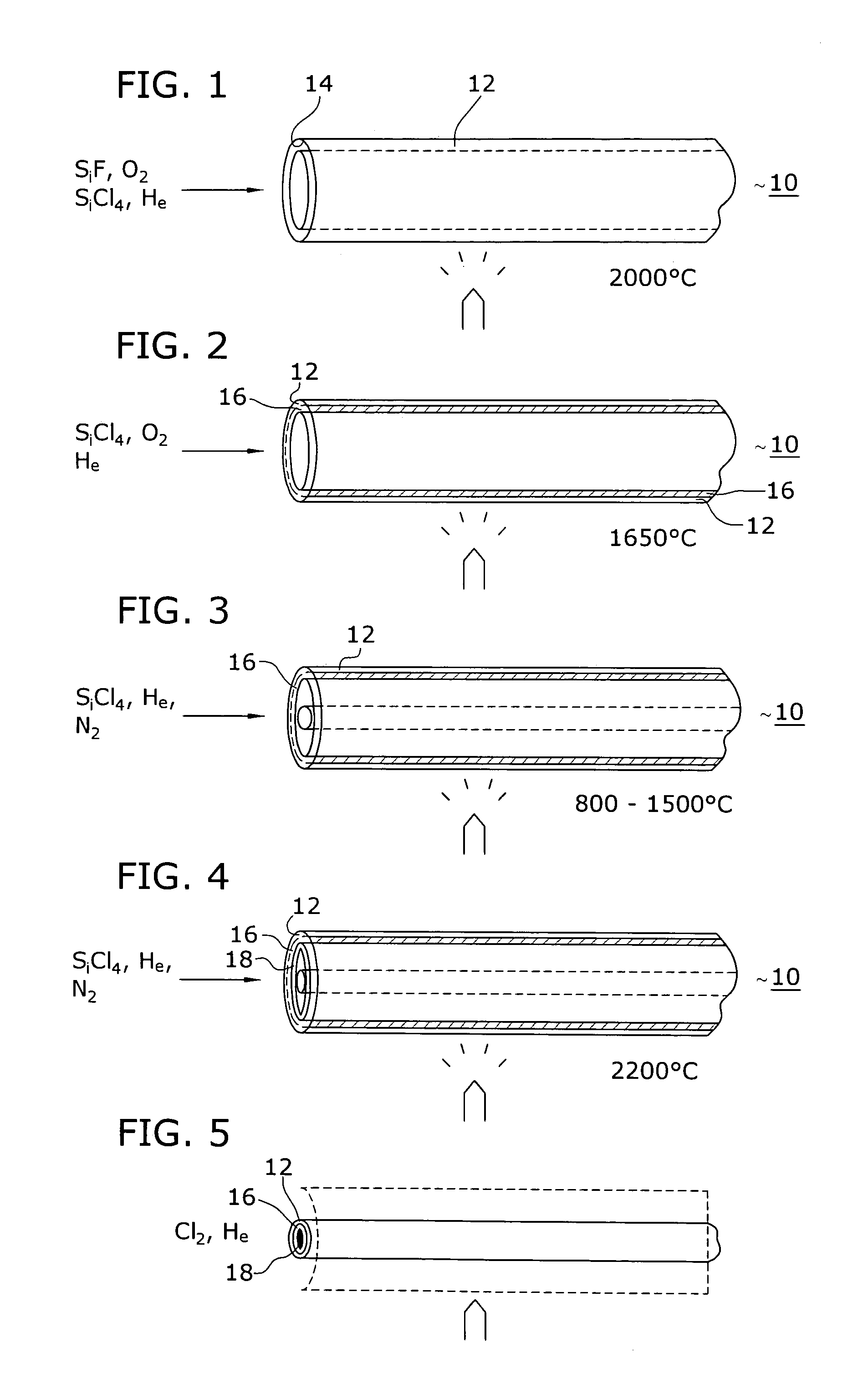

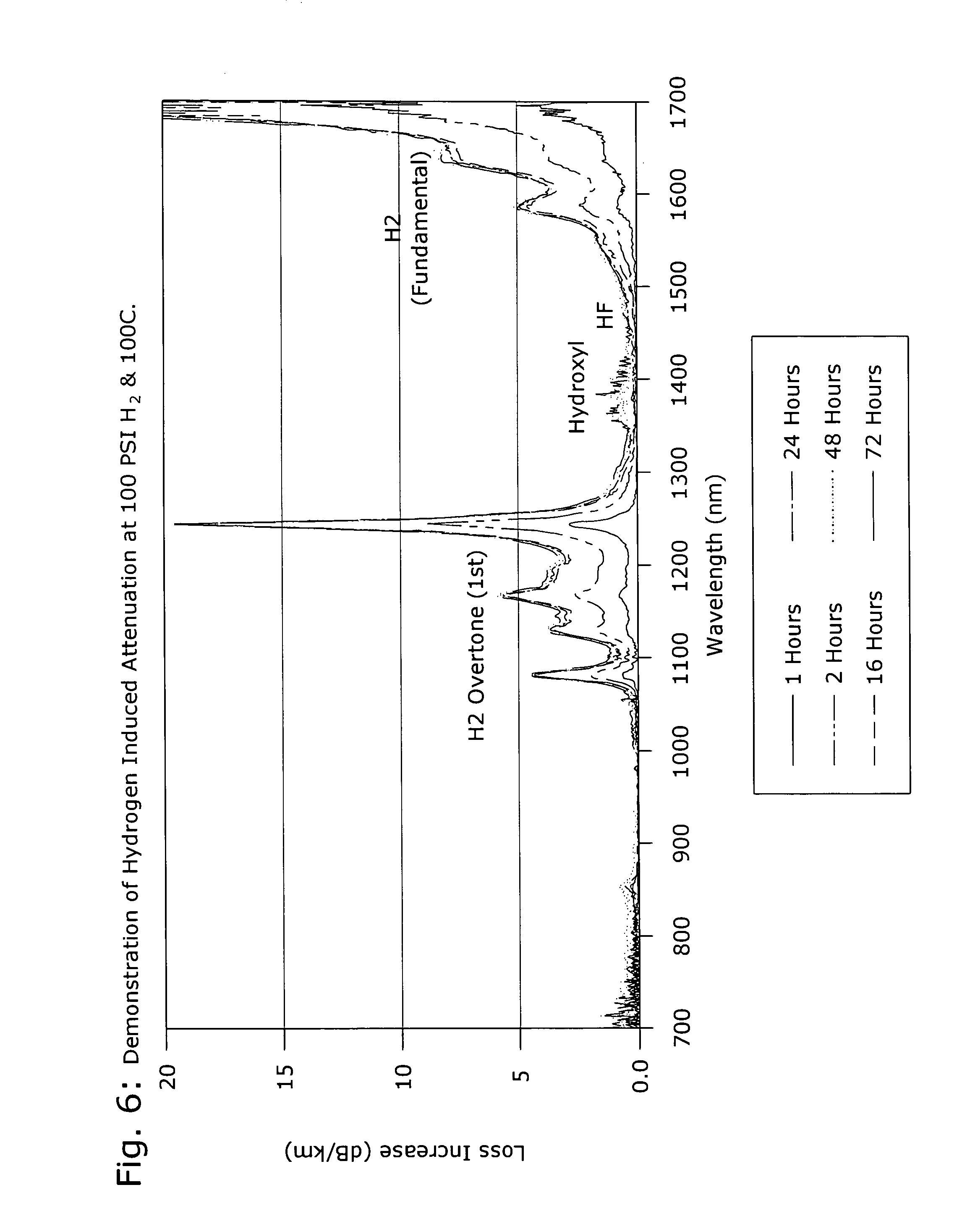

Hydrogen resistant optical fiber formation technique

ActiveUS7752870B1Eliminate formationReducing hydrogen-induced attenuationGlass making apparatusGlass productionFiberState of art

A method of forming an optical fiber preform using, for example, an MCVD process, is modified to reduce the presence of hydrogen-induced transmission losses in an optical fiber drawn from the preform. A relatively porous, unsintered soot layer is first formed (similar to the initial soot layer commonly associated with the solution-doped process of the prior art) and then subjected to a flow of a metal halide (such as SiCl4) to reduce the presence of excess oxygen. It is imperative that the metal halide treatment occur in the absence of oxygen. Sintering of the treated layer, followed by a conventional collapsing process is then used to form the inventive preform. In accordance with the present invention, both the sintering and collapsing steps are performed in a non-oxygen based ambient. When the drawn fiber is then later exposed to hydrogen, the lack of oxygen thus eliminates the formation of Si—OH and the associated attenuation problems.

Owner:BAKER HUGHES INC

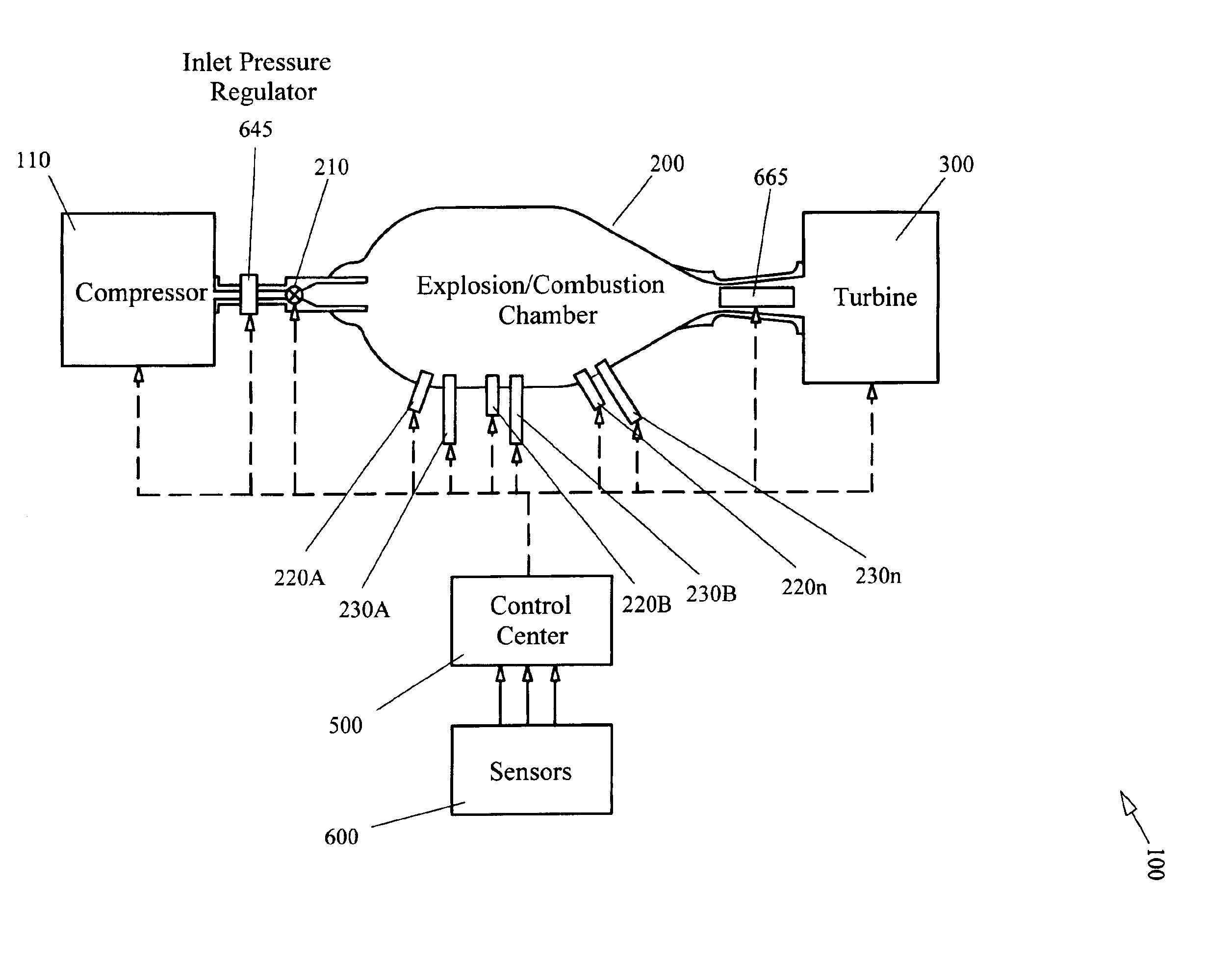

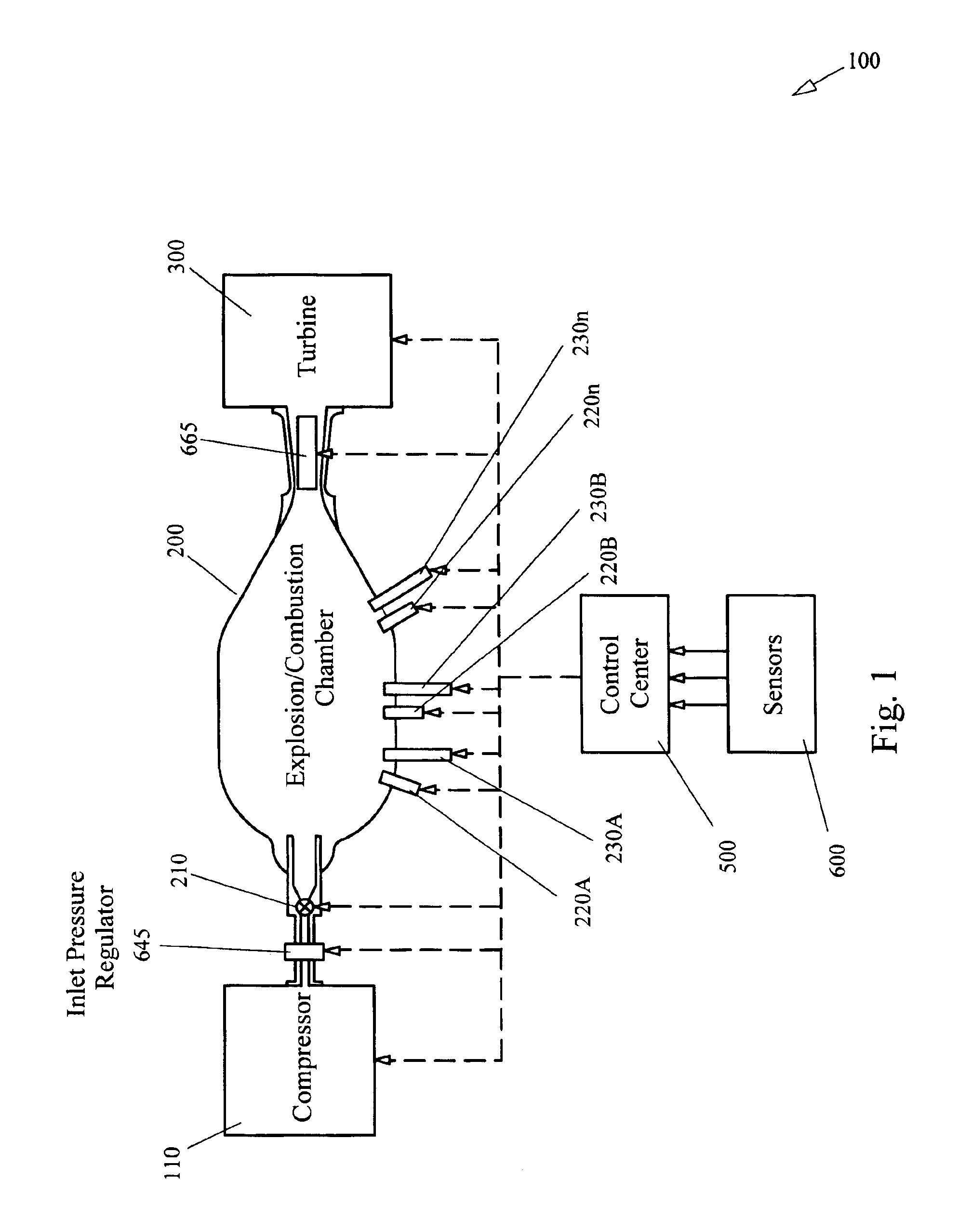

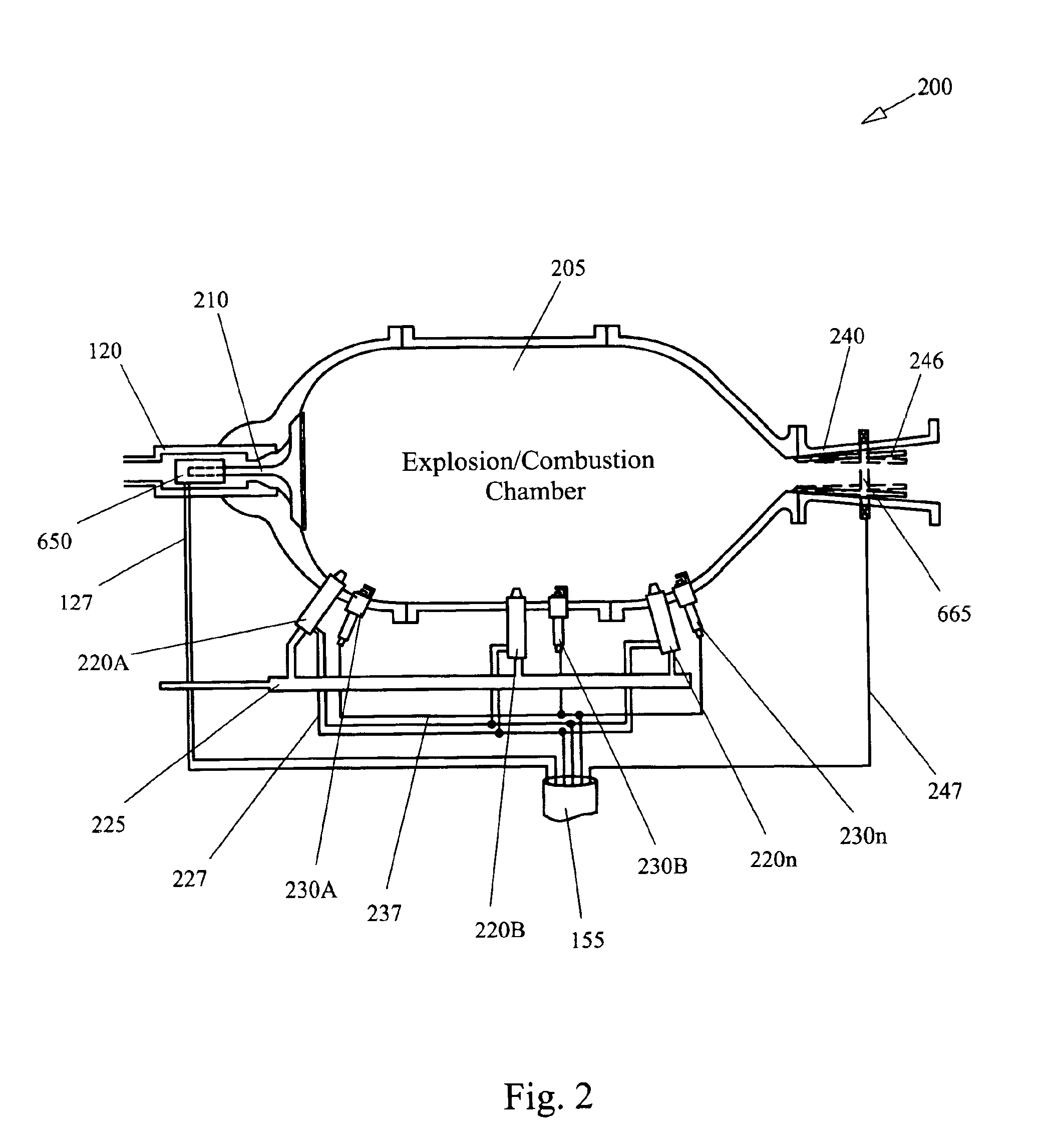

High efficiency low hydrocarbon emmisson hybrid power plant using operational aspects of both internal combustion and jet engines

InactiveUS6920761B2Low level of hydrocarbon emissionImprove fuel efficiencyGas turbine plantsJet propulsion plantsCombustion chamberOperating point

The method and apparatus of the present invention discloses a power plant operating at low inlet pressure and temperature using a combination of conventional internal combustion engine techniques and jet engine techniques. The combination of a unique combustion chamber design, a novel variable impedance blade set turbine and a closed loop control system allows a variable resonant frequency for combusted gases. As the resonant frequency is approached a control mechanism uses sensor data to maintain the operating point such that maximum power output is achieved for a given throttle setting. The combination of the unique combustion chamber design, multiple fuel injector / sparking device pairs, finely atomized fuel, excess oxygen and the closed loop control system further provides a very linear power curve with low exit hydrocarbon pollution levels and high fuel efficiency.

Owner:LAPER DENNIS A

High temperature ammonia SCR catalyst and method of using the catalyst

A catalyst and a method for selectively reducing nitrogen oxides (“NOx”) with ammonia are provided. The catalyst includes a first component comprising a zeolite or mixture of zeolites selected from the group consisting of ZSM-5, ZSM-11, ZSM-12, ZSM-18, ZSM-23, MCM-zeolites, mordenite, faujasite, ferrierite, zeolite beta, and mixtures thereof; a second component comprising at least one member selected from the group consisting of cerium, iron, copper, gallium, manganese, chromium, cobalt, molybdenum, tin, rhenium, tantalum, osmium, barium, boron, calcium, strontium, potassium, vanadium, nickel, tungsten, an actinide, mixtures of actinides, a lanthanide, mixtures of lanthanides, and mixtures thereof; optionally an oxygen storage material and optionally an inorganic oxide. The catalyst selectively reduces nitrogen oxides to nitrogen with ammonia at high temperatures. The catalyst has high hydrothermal stability. The catalyst has high activity for conversion of low levels of nitrogen oxides in exhaust streams. The catalyst and the method may have special application to selective reduction of nitrogen oxides in exhaust gas from gas turbines and gas engines, although the catalyst and the method have broad application to a wide range of gas streams that have excess oxygen and high temperatures. The temperature of exhaust gas from gas turbines and gas engines is high. Both the high temperature and the low levels of inlet NOx are challenging for selective catalytic reduction (SCR) catalysts.

Owner:CATALYTIC SOLUTIONS INC

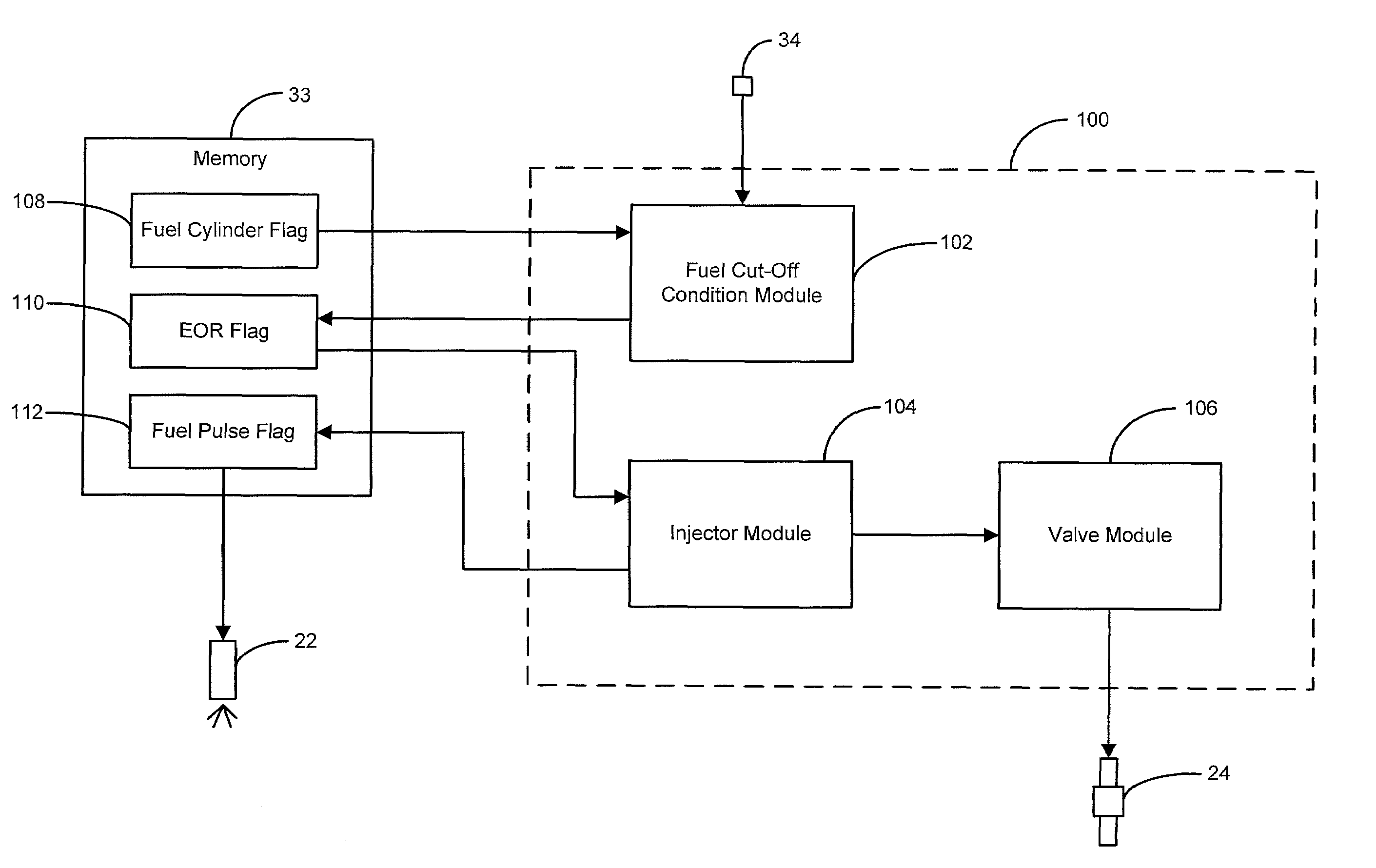

Automotive catalyst excess oxygen reduction system

InactiveUS7258101B1Electrical controlInternal combustion piston enginesExcess oxygenAutomotive catalyst

An excess oxygen reduction system includes a fuel cut-off condition module, an injector module, and a valve module. The fuel cut-off condition module determines whether a fuel cut-off condition exists. The injector module prevents a fuel injector from fueling a cylinder when said fuel cut-off condition exists. The valve module closes an impulse charging valve when said fuel cut-off condition exists.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com