Patents

Literature

78results about How to "Minimizes and remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

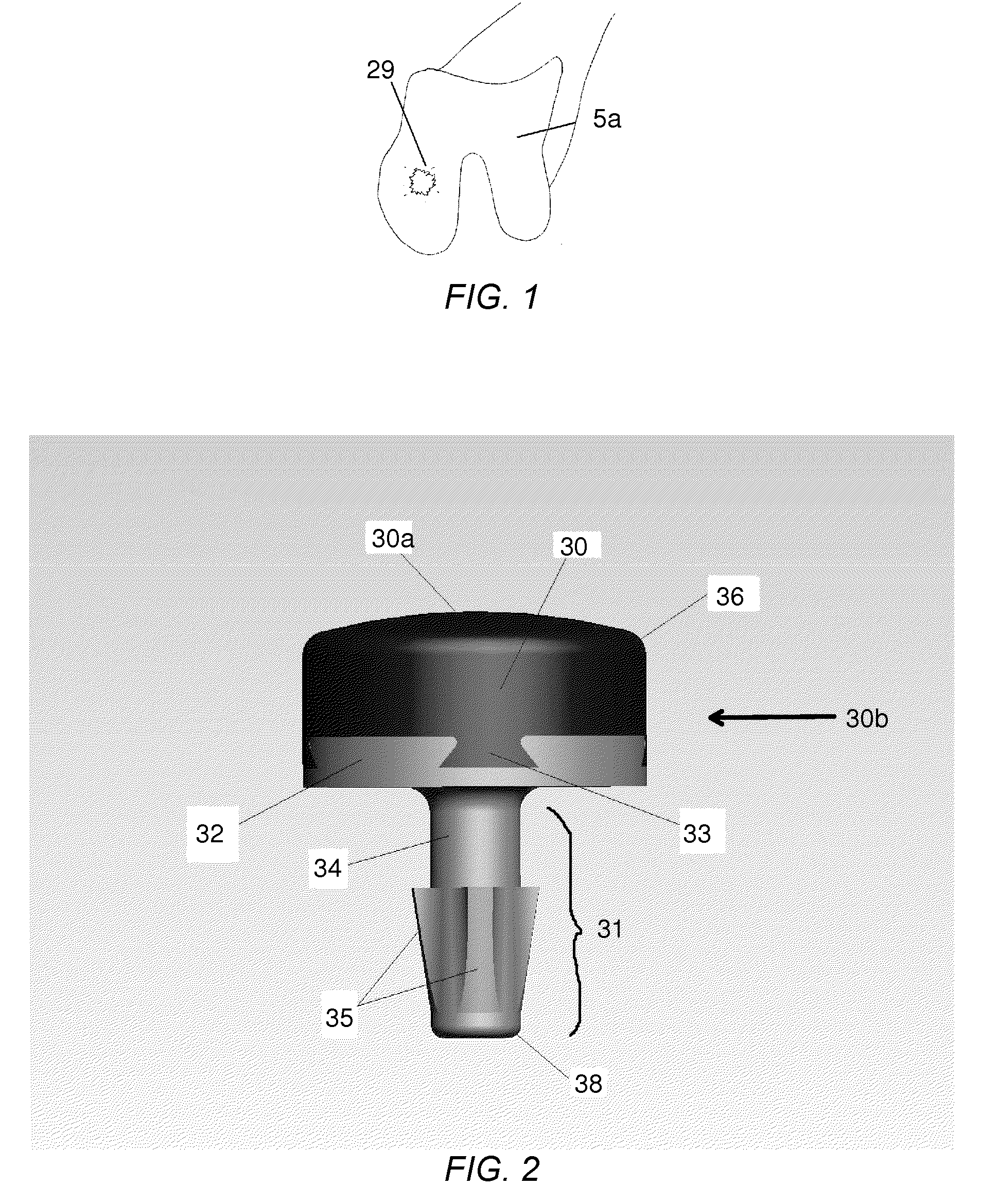

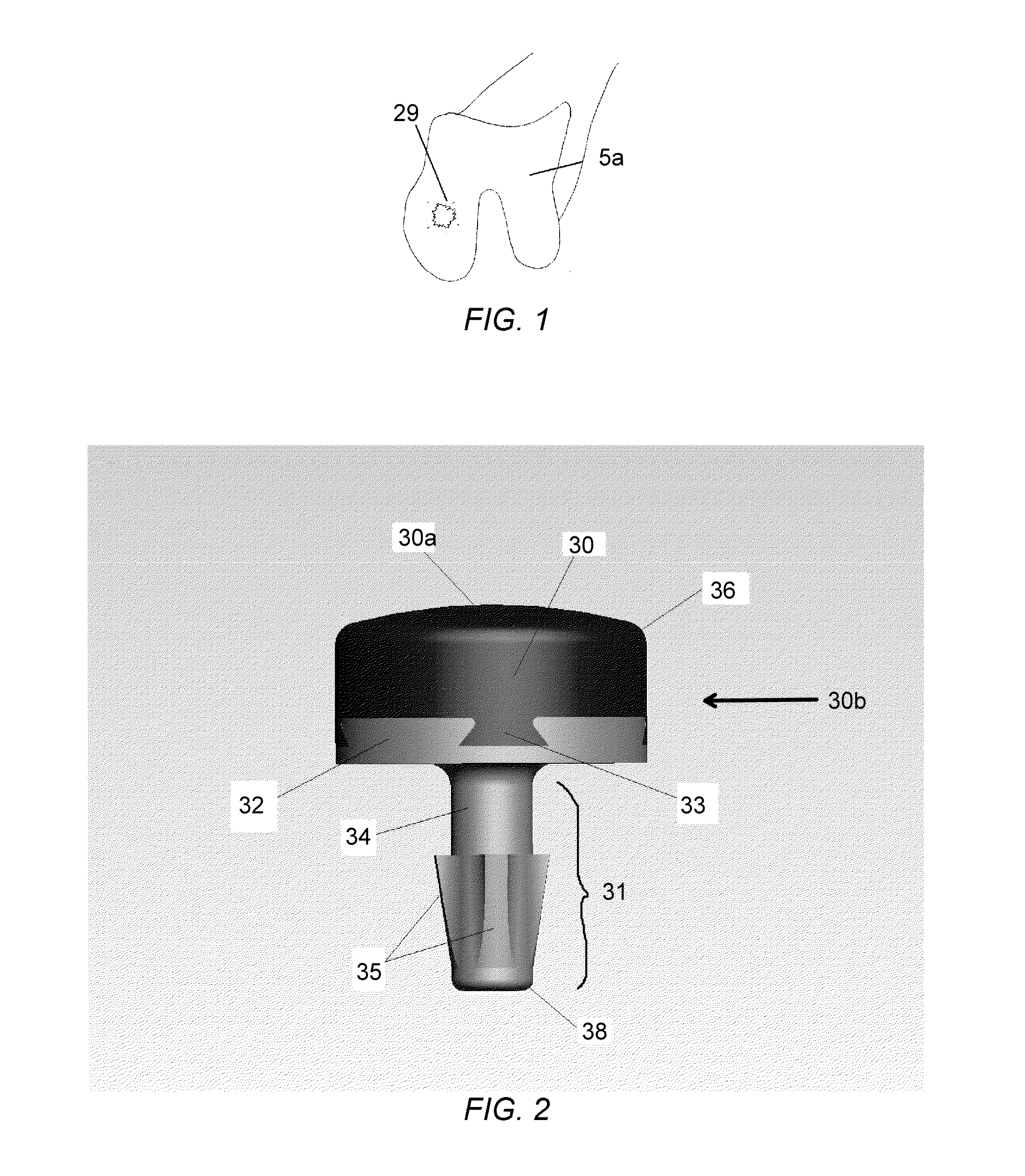

Method for repairing intervertebral discs

ActiveUS20080103564A1Increase pressureHalt leakageDiagnosticsPharmaceutical delivery mechanismIntervertebral discBiomedical engineering

A method of repairing a defect in an annulus fibrosus of an intervertebral disc, without excising the entire nucleus pulposus of the disc. The method includes inserting an introducer needle through the annulus fibrosus by puncturing the annulus fibrosus with the introducer needle, injecting an in situ curable, bio-compatible polymerizable or polymeric material composition into the disc through the introducer needle directly or indirectly so that the in situ curable composition contacts a defect in the annulus fibrosus; and curing said material in situ.

Owner:PAUZA KEVIN

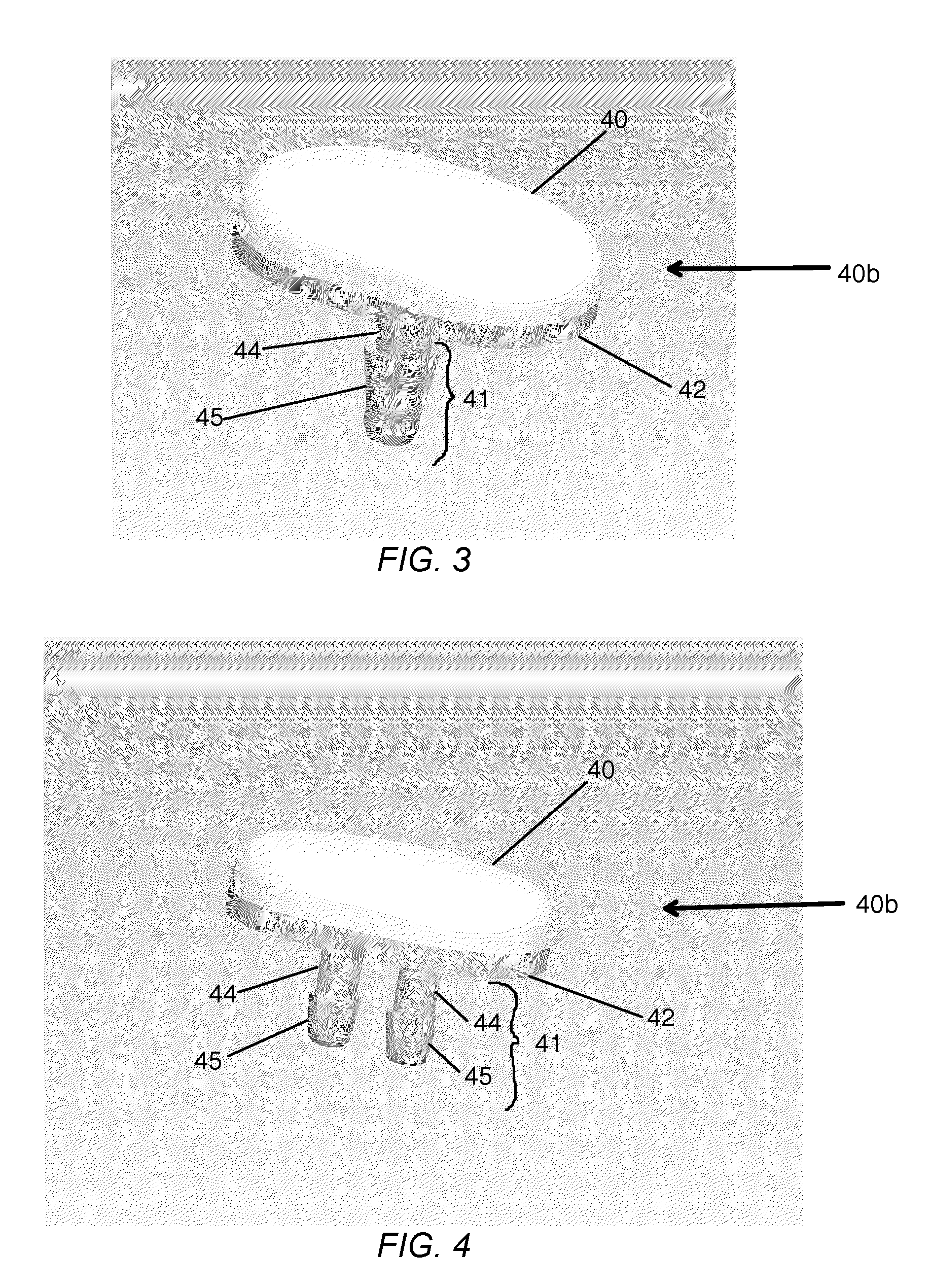

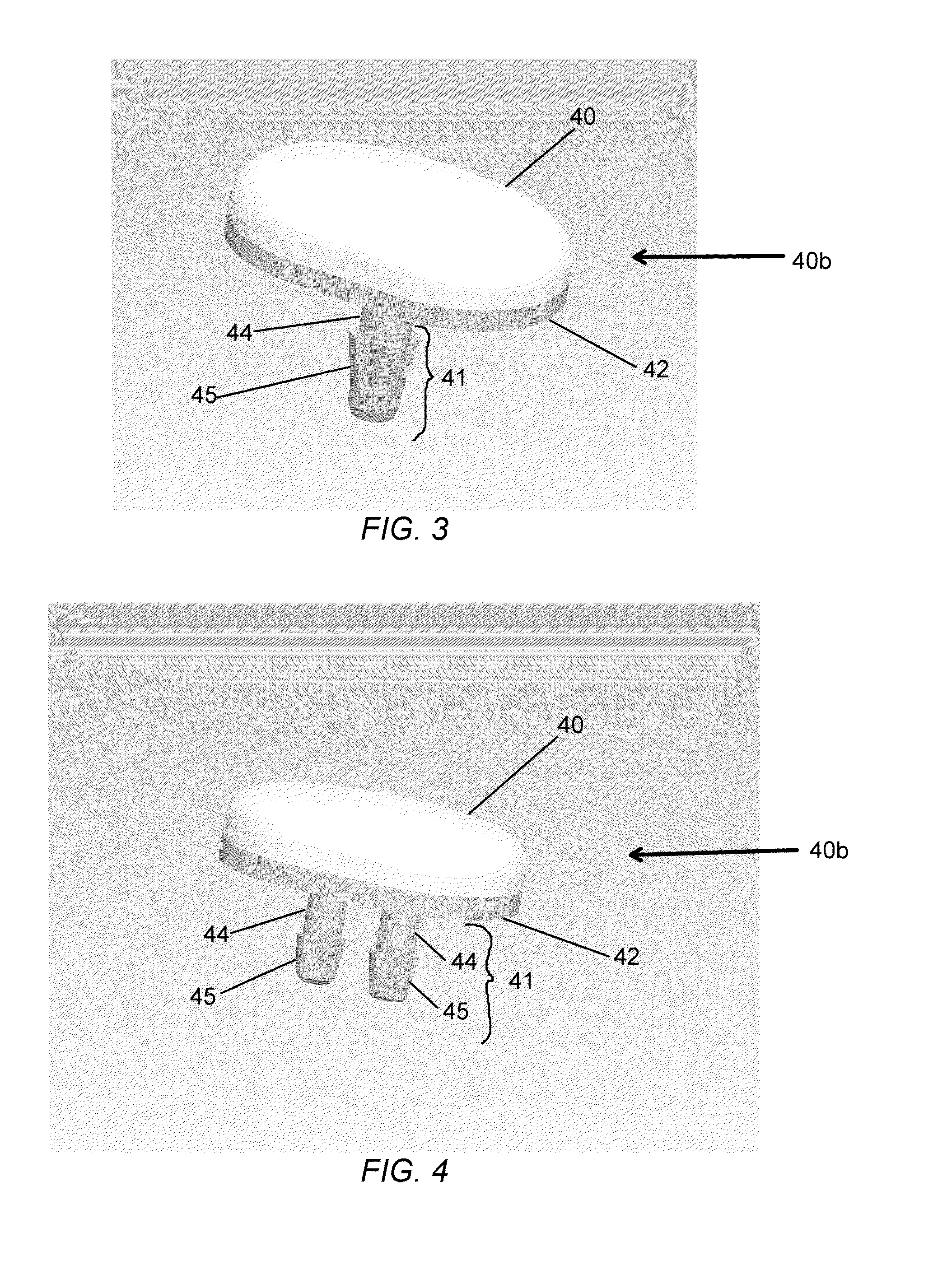

Partial joint resurfacing implant, instrumentation and method

InactiveUS20110009964A1Maximizes defect coverageMinimizing host boneSurgeryLigamentsLocking mechanismTarsal Joint

A partial resurfacing implant for use in repairing an articular cartilage defect site that includes a top articulating portion having a top surface that is configured with at least one radius of curvature to approximate the surface contour of the articular cartilage surrounding the defect site. The implant also includes a supporting plate that has a top surface and a bottom surface. The top surface is attached to the top articulating portion by a locking mechanism. The bottom surface of the supporting plate is constructed to facilitate the insertion of the implant into the defect site. Extending from the bottom surface of the supporting plate is at least one implant fixation portion. The at least one implant fixation portion is integrally connected to and is oriented about normal relative to the bottom surface. A method of repairing an articular cartilage defect with the partial joint resurfacing implant is also disclosed.

Owner:BIOPOLY

Multi-step polishing solution for chemical mechanical planarization

InactiveUS20050194357A1Increase ratingsHigh removal rateEdge grinding machinesPigmenting treatmentInorganic saltsCopper

The present invention provides a multi-step aqueous composition useful for polishing a tantalum barrier material and copper from a semiconductor wafer, comprising by weight percent 0.1 to 30 oxidizer, 0.01 to 3 inorganic salt or acid, 0.01 to 4 inhibitor, 0.1 to 30 abrasive, 0 to 15 complexing agent and balance water, wherein the aqueous composition has a pH between 1.5 to 6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

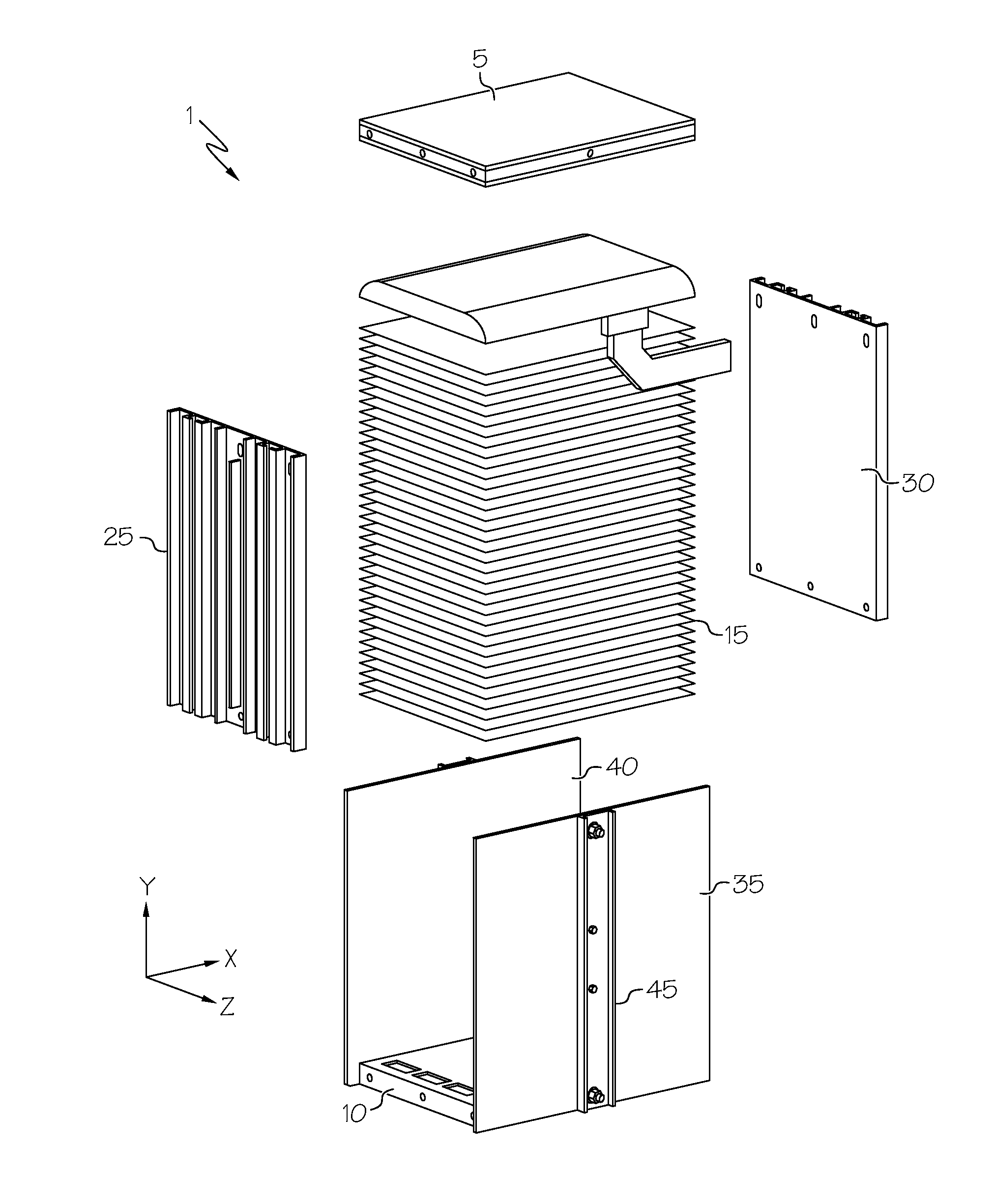

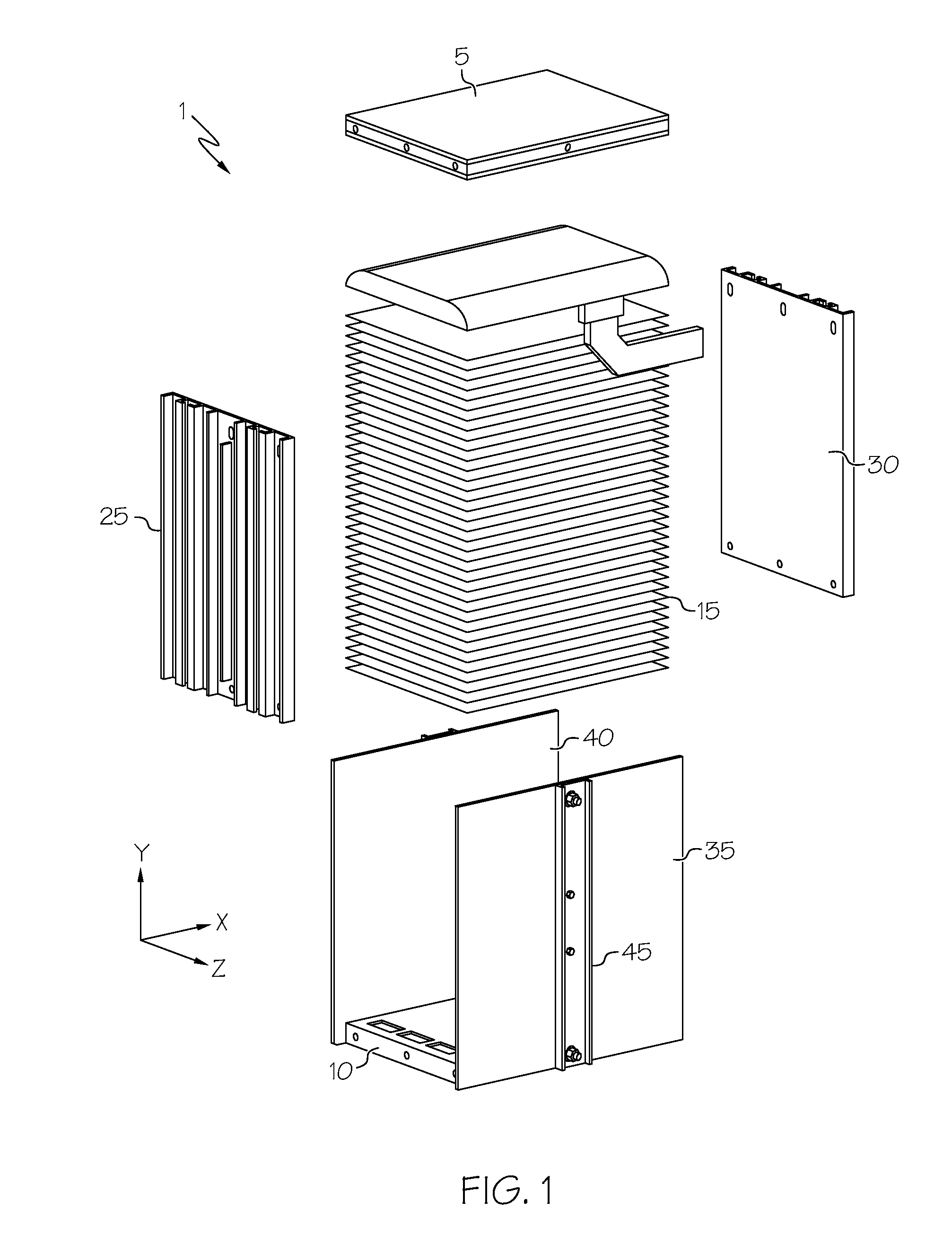

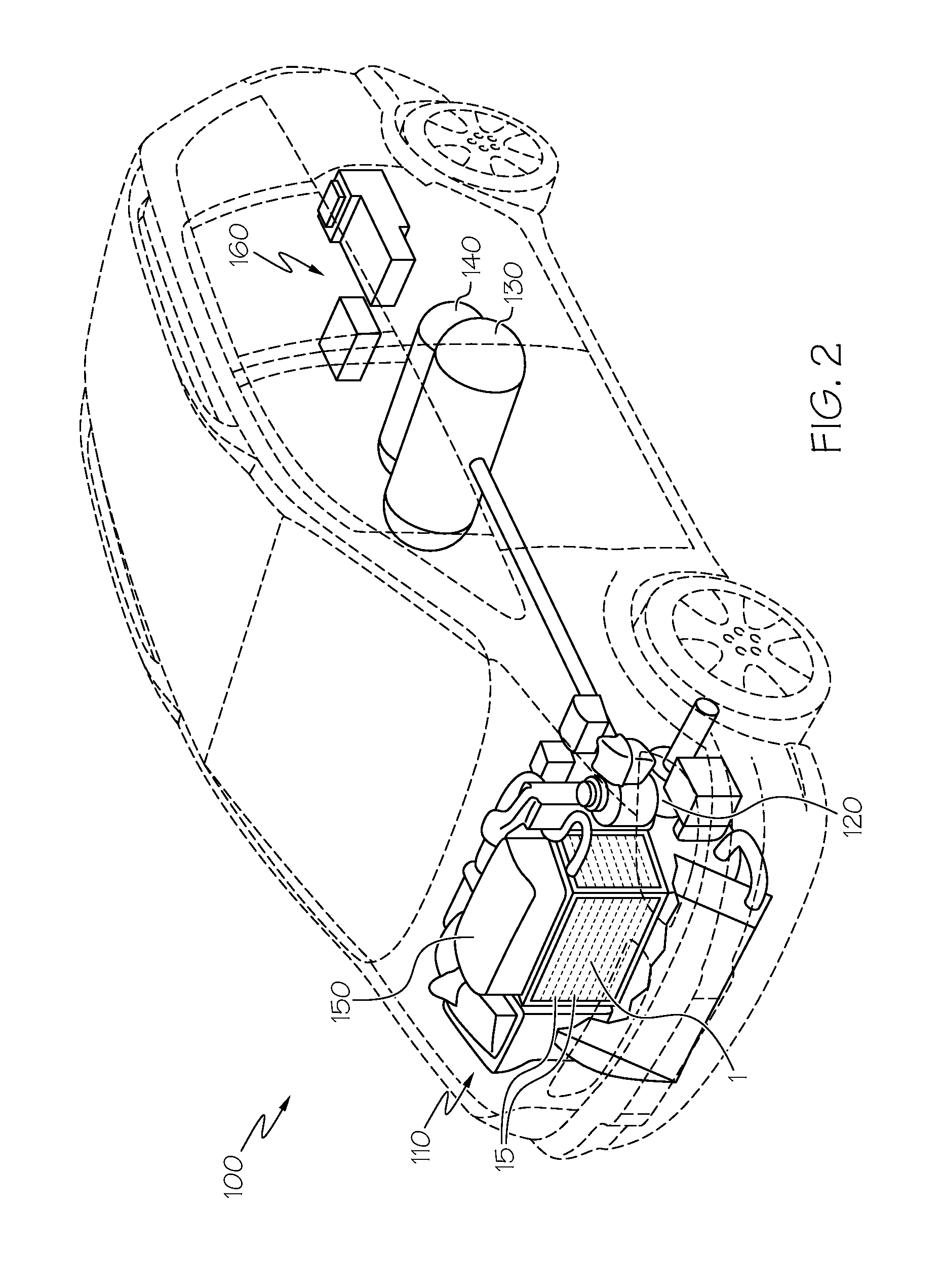

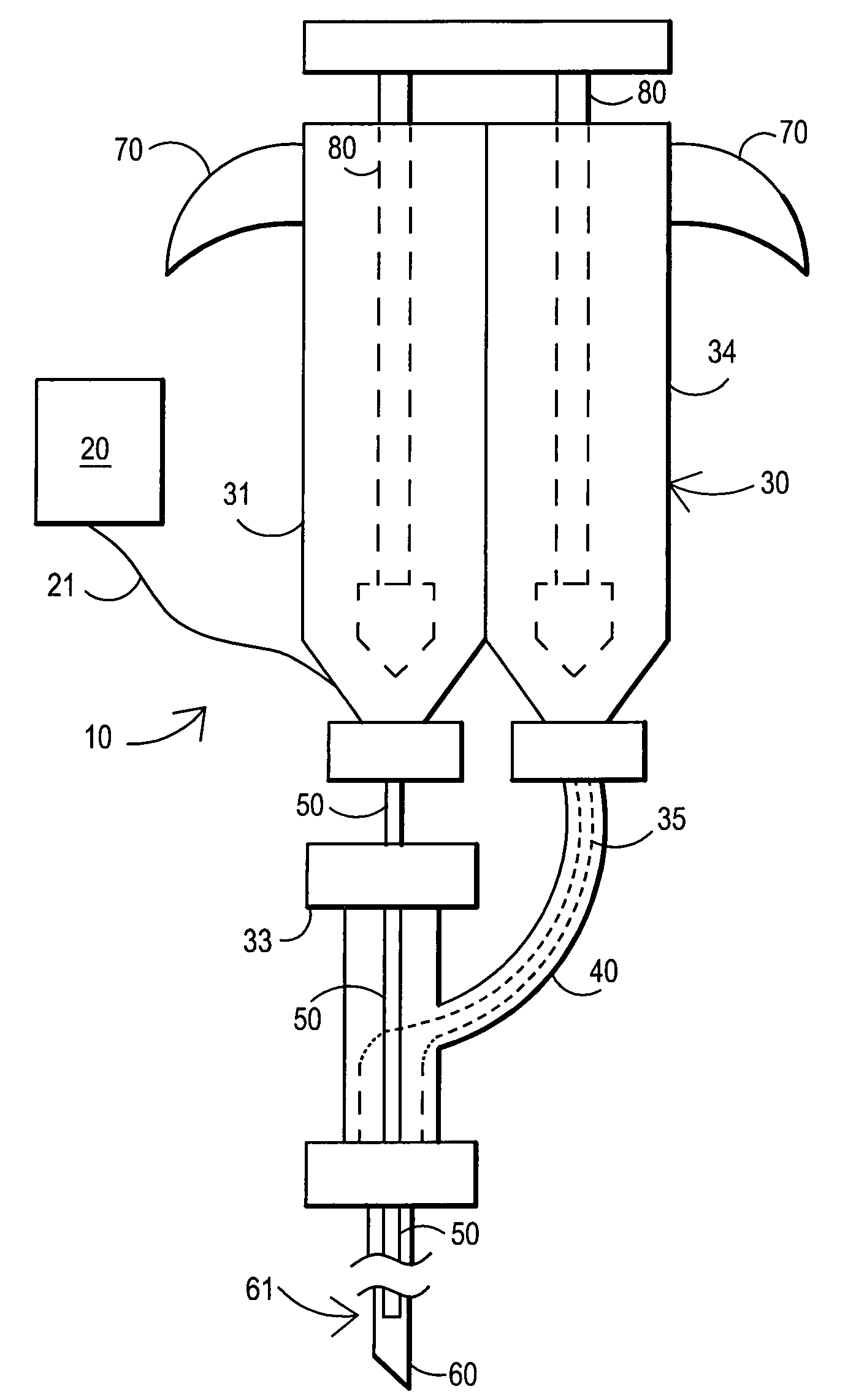

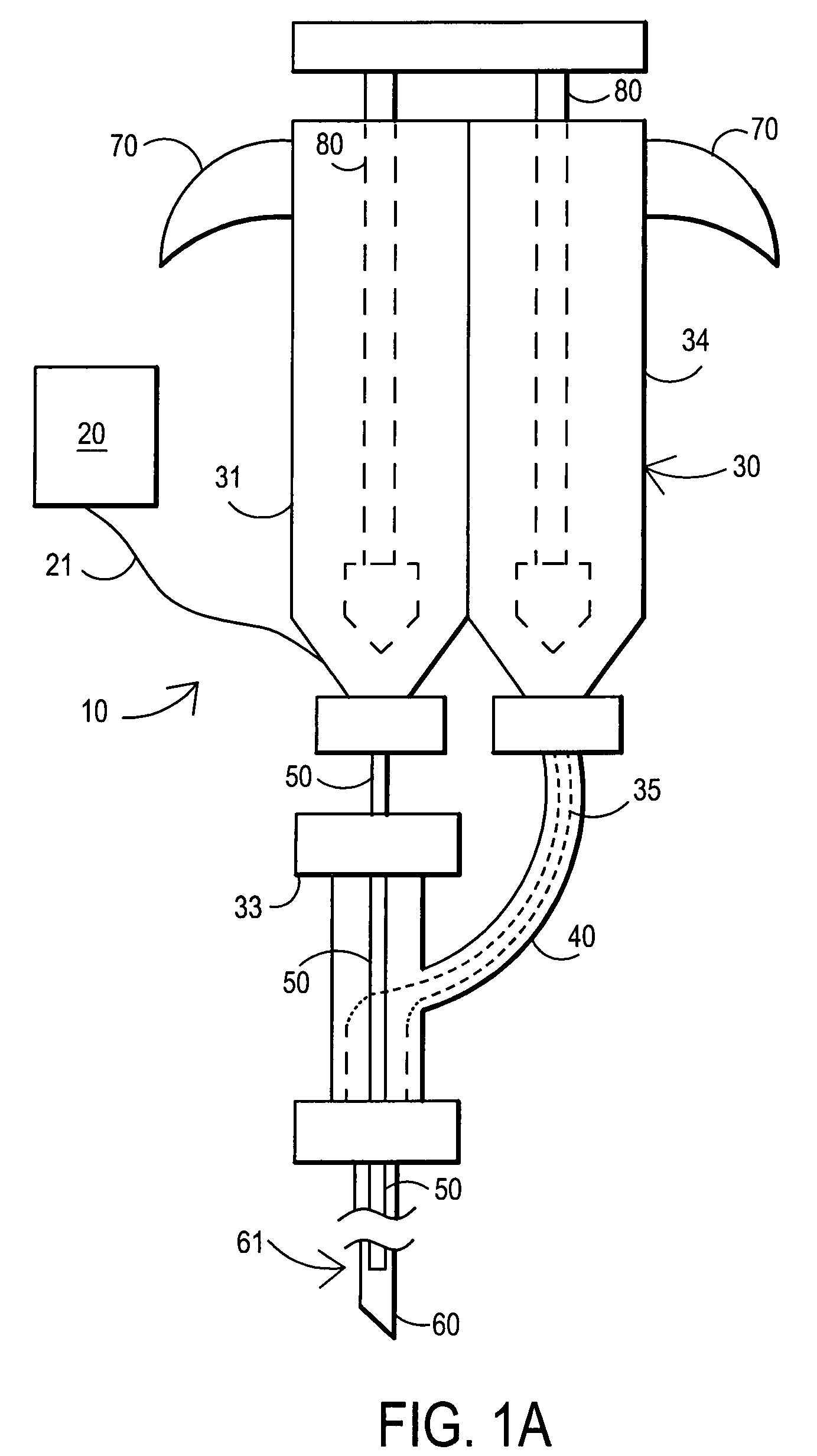

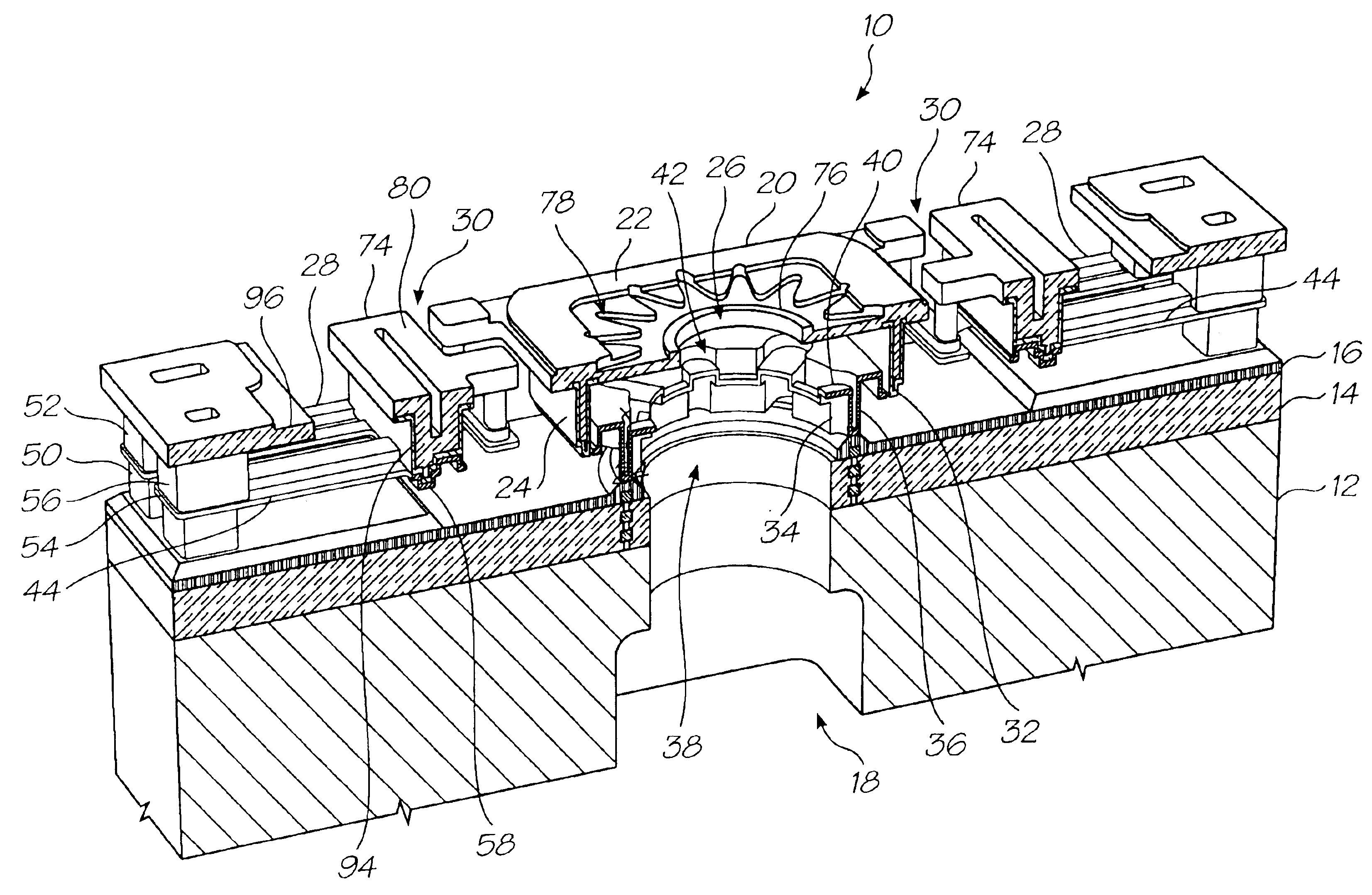

Fuel cell stack assembly - datum design for fuel cell stacking and collision protection

ActiveUS20160072145A1Improve the immunityIncrease thickness dimensionFuel cells groupingCell component detailsInterference fitFuel cells

A system and method for aligning and reducing the relative movement between adjacent fuel cells within a fuel cell stack. The inter-cell cooperation between fuel cells along a stacking dimension is enhanced by one or more datum placed along the edge of a bipolar plate that makes up a part of a cell-containing assembly. The datum is shaped along a thickness dimension that substantially coincides with the cell stacking dimension to promote a nested fit with a comparable datum on an adjacently-stacked bipolar plate. This nesting facilitates an interference fit that enhances the resistance to sliding movement between respective cells that may otherwise arise out of the occurrence of a significant acceleration along the dimension that defines the major surfaces of the plates, cells and their respective assemblies. In one form, the use of welding, bonding or related attachment of the datum to the plate promotes enhanced metallic support without the need for increasing the plate footprint and without having to overmold the datum directly onto the plate.

Owner:GM GLOBAL TECH OPERATIONS LLC

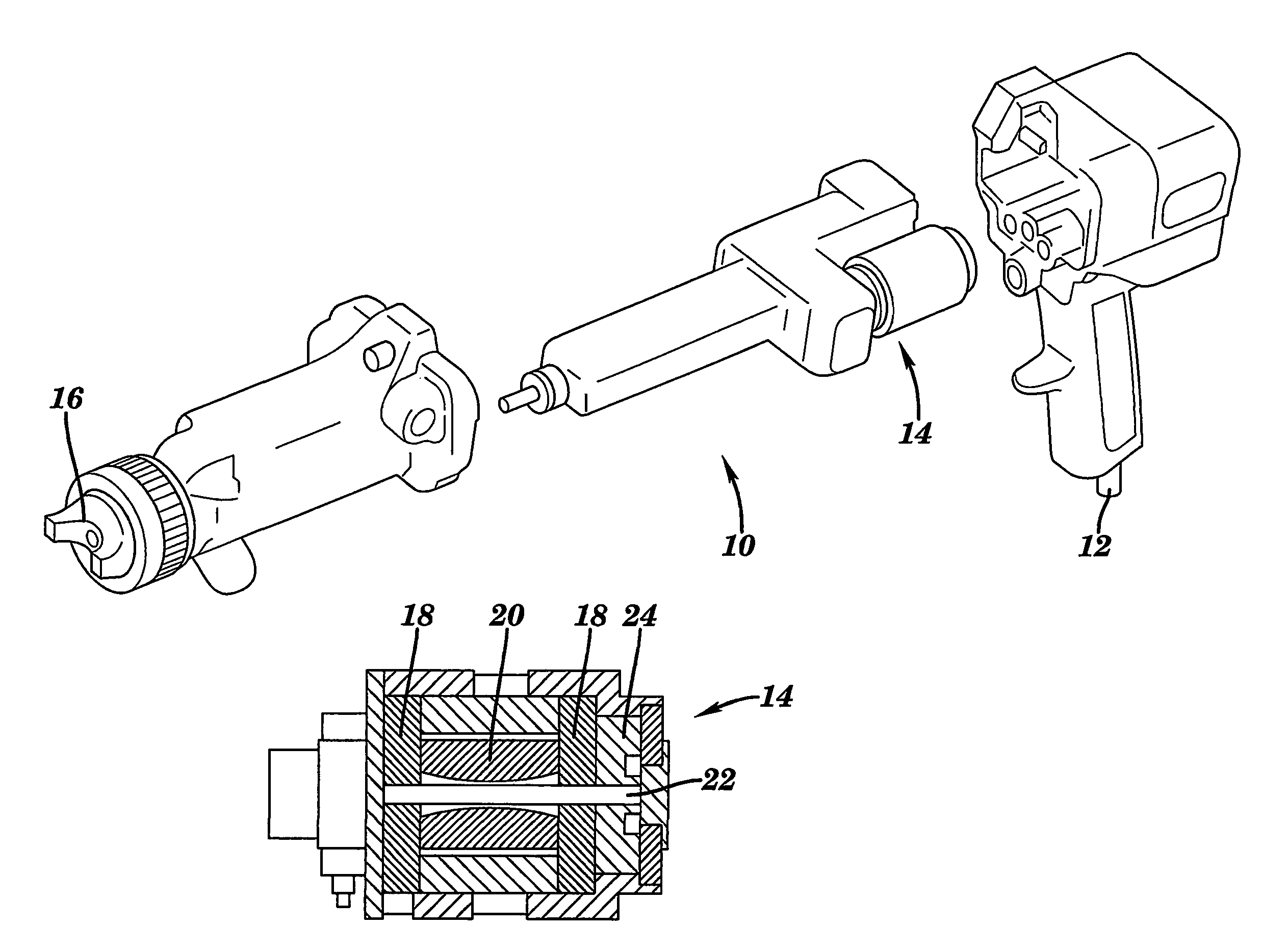

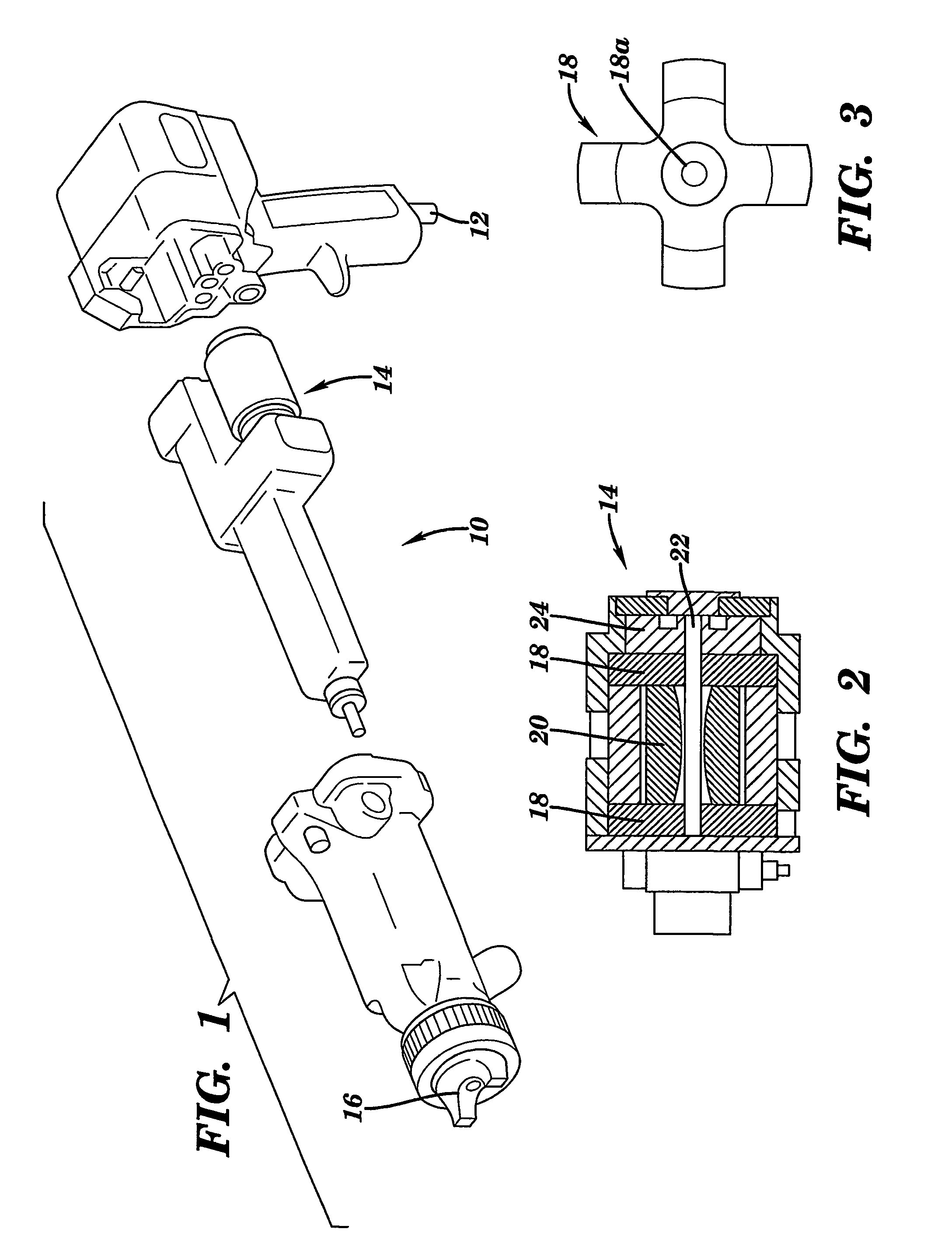

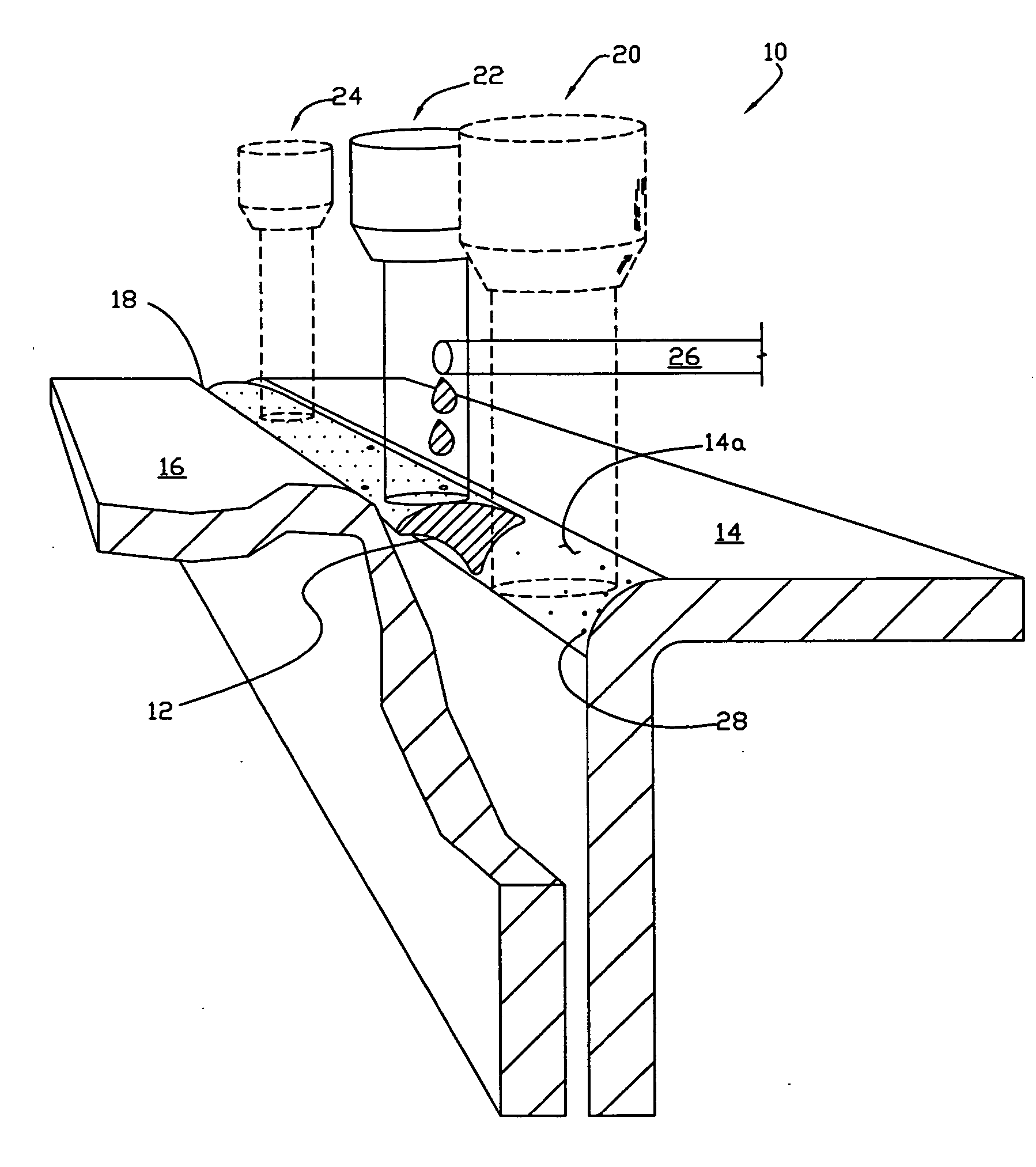

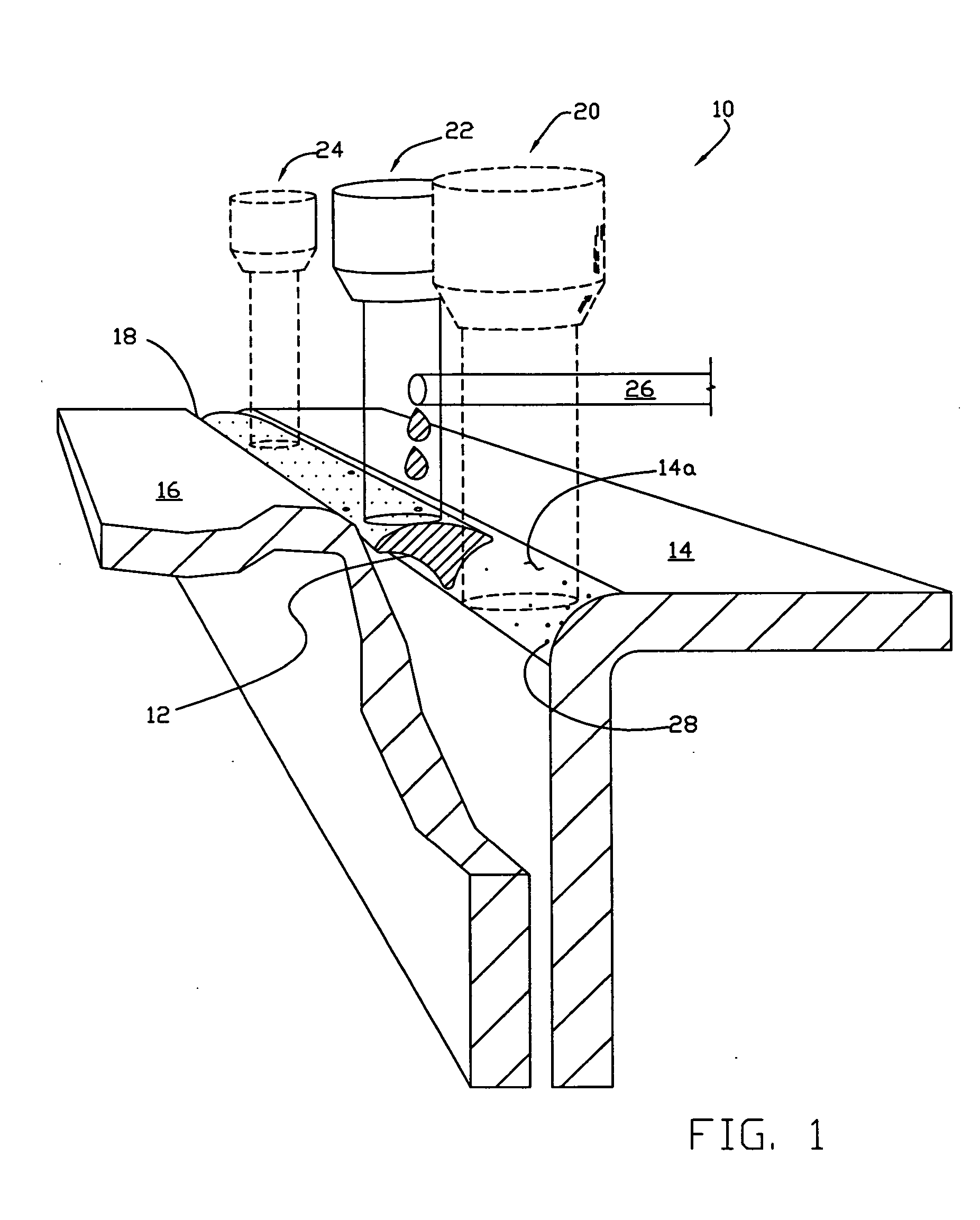

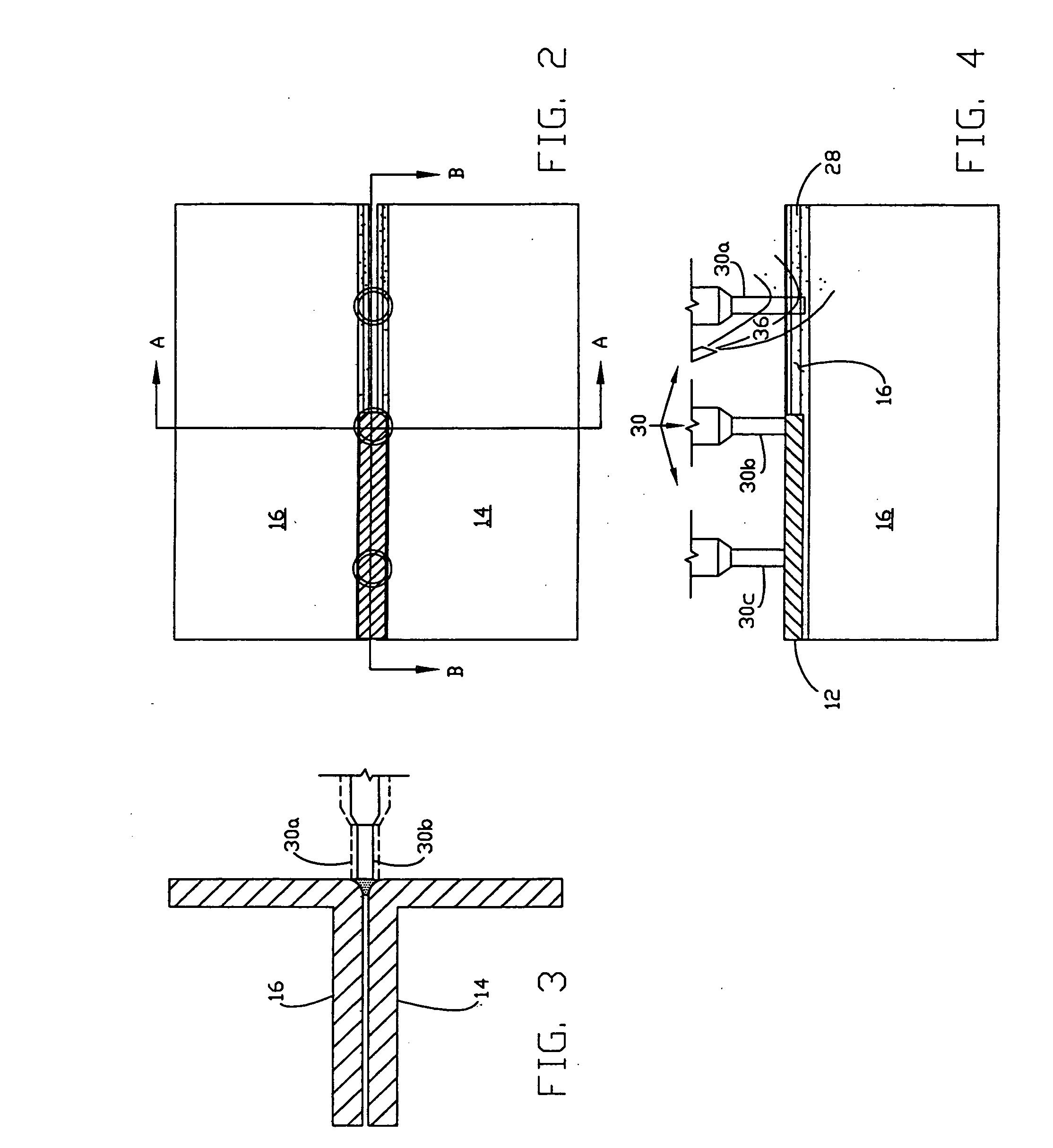

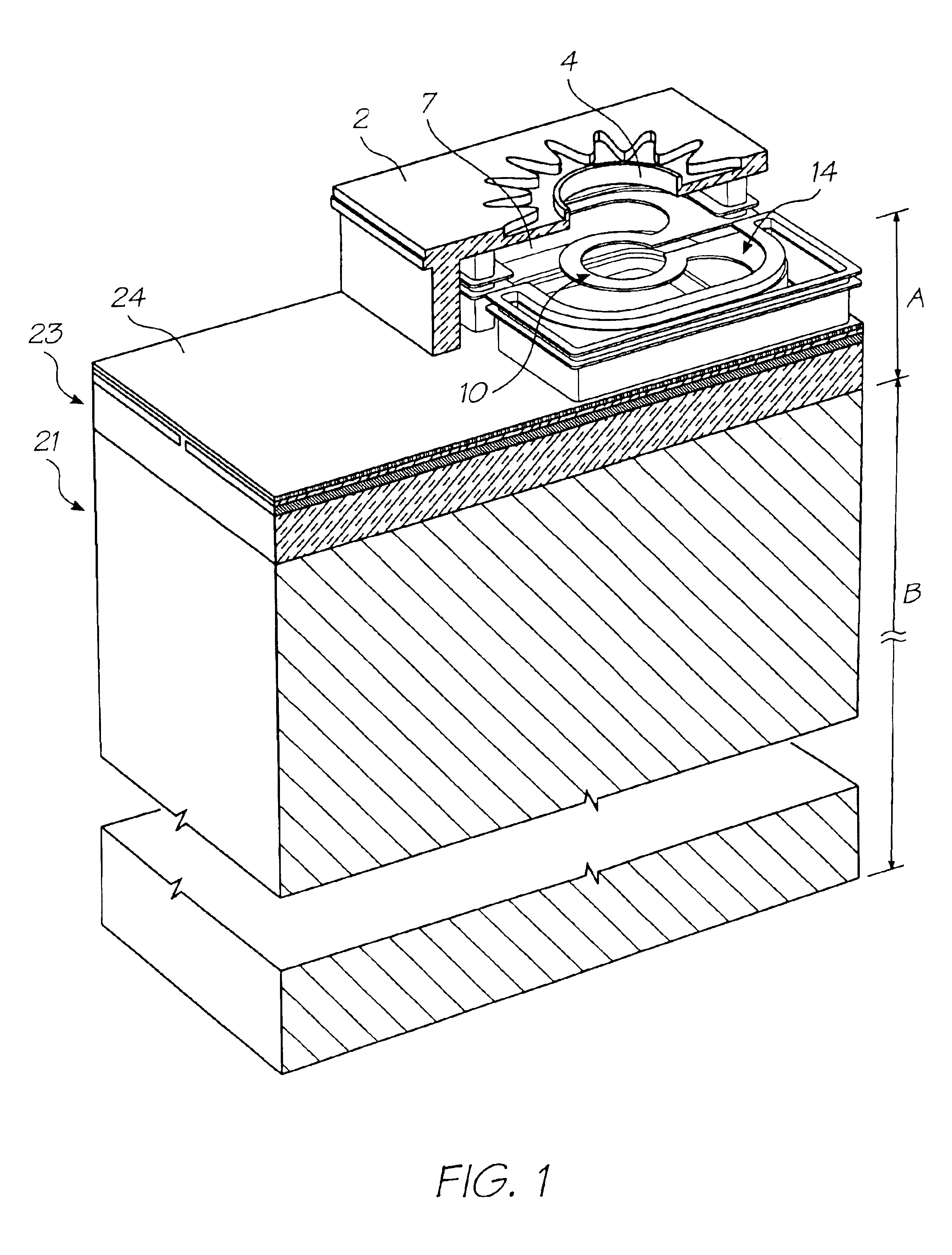

Solvent resistant bearings for self-generating electrostatic spray gun

InactiveUS7226004B2Improve bearing lifeFailure can be causedBurnersLiquid spraying plantsImpellerAlternator

An electrostatic spray gun (10) having an air powered alternator-turbine (14) with a rotating impeller (24) therein mounted in bearings (18) is provided with bearings (18) which are coated with a solvent resistant material. This coating is provided on all surfaces of the bearing (18) except for the inner diameter (18A) which contains the impeller (24). This construction prevents leaching of the oil out of the bearing (18) and into the airstream and also is resistant to paint should the spray gun (10) become immersed in such.

Owner:GRACO INC

Semiconductor system with surface modification

ActiveUS20070287277A1Thorough understandingImprove corrosion resistanceSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsElectrical conductorDielectric layer

A semiconductor system includes: providing a dielectric layer; providing a conductor in the dielectric layer, the conductor exposed at the top of the dielectric layer; capping the exposed conductor; and modifying the surface of the dielectric layer, modifying the surface of the dielectric layer, wherein modifying the surface includes cleaning conductor ions from the dielectric layer by dissolving the conductor in a low pH solution, dissolving the dielectric layer under the conductor ions, mechanically enhanced cleaning, or chemisorbing a hydrophobic layer on the dielectric layer.

Owner:LAM RES CORP

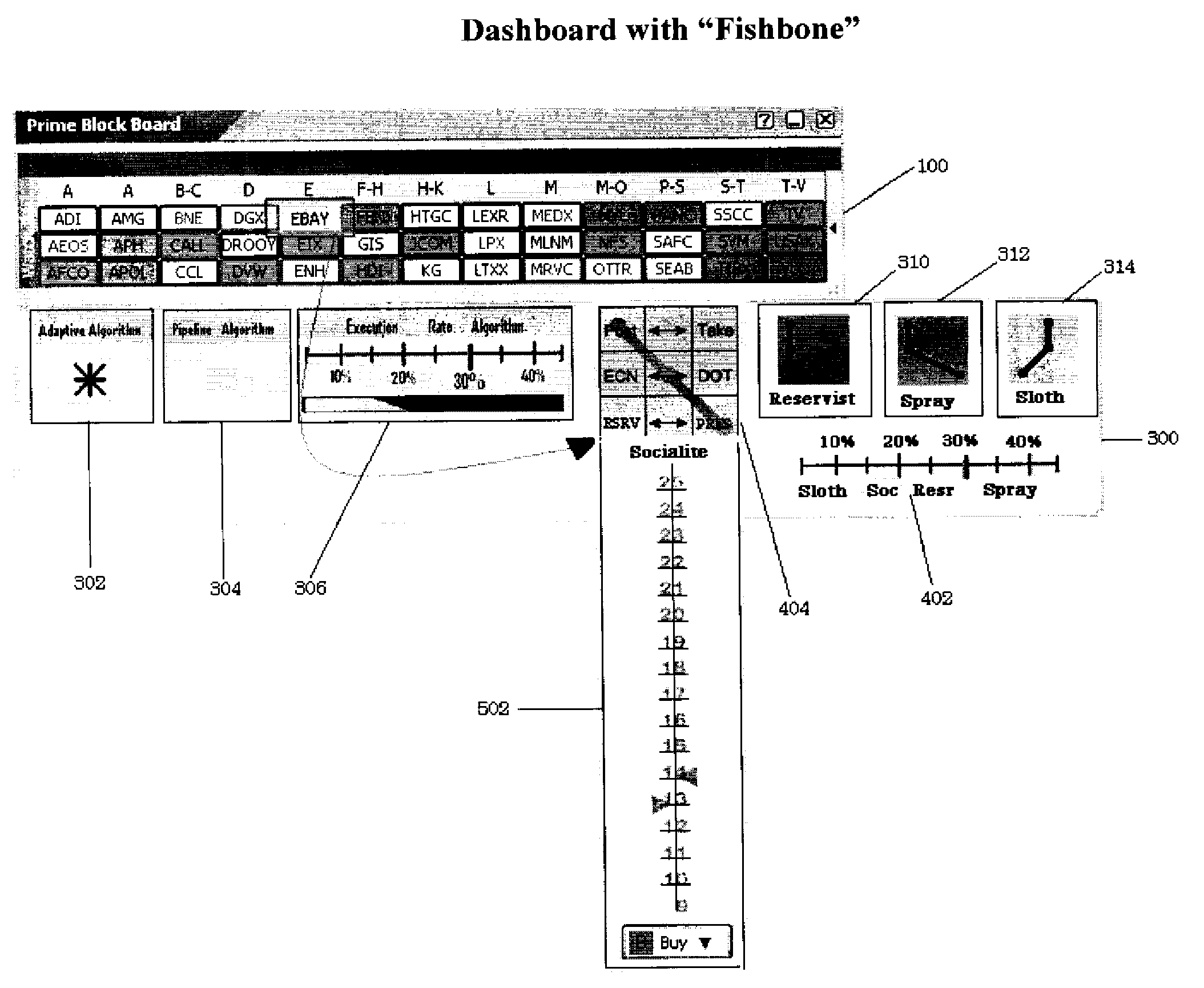

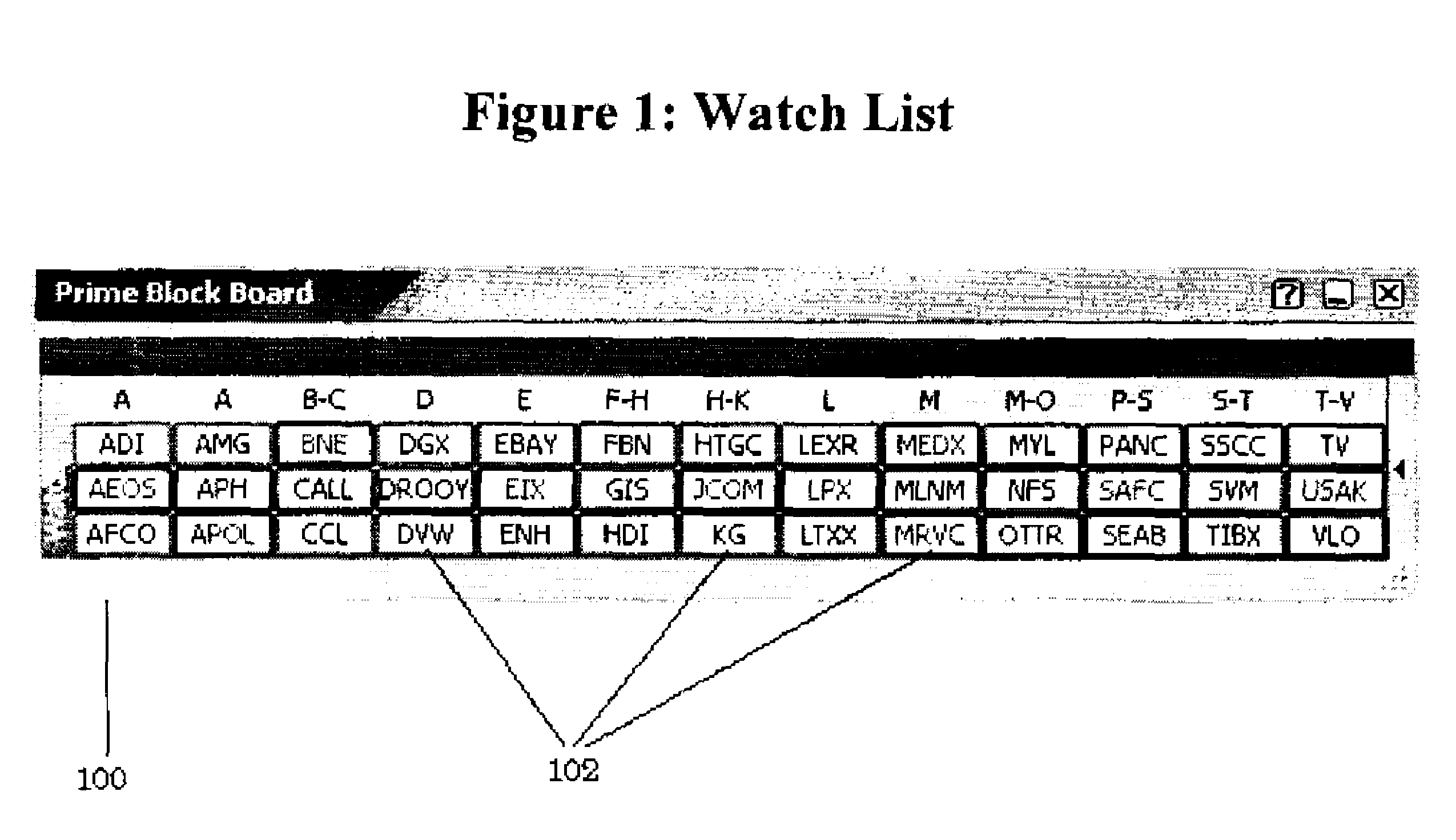

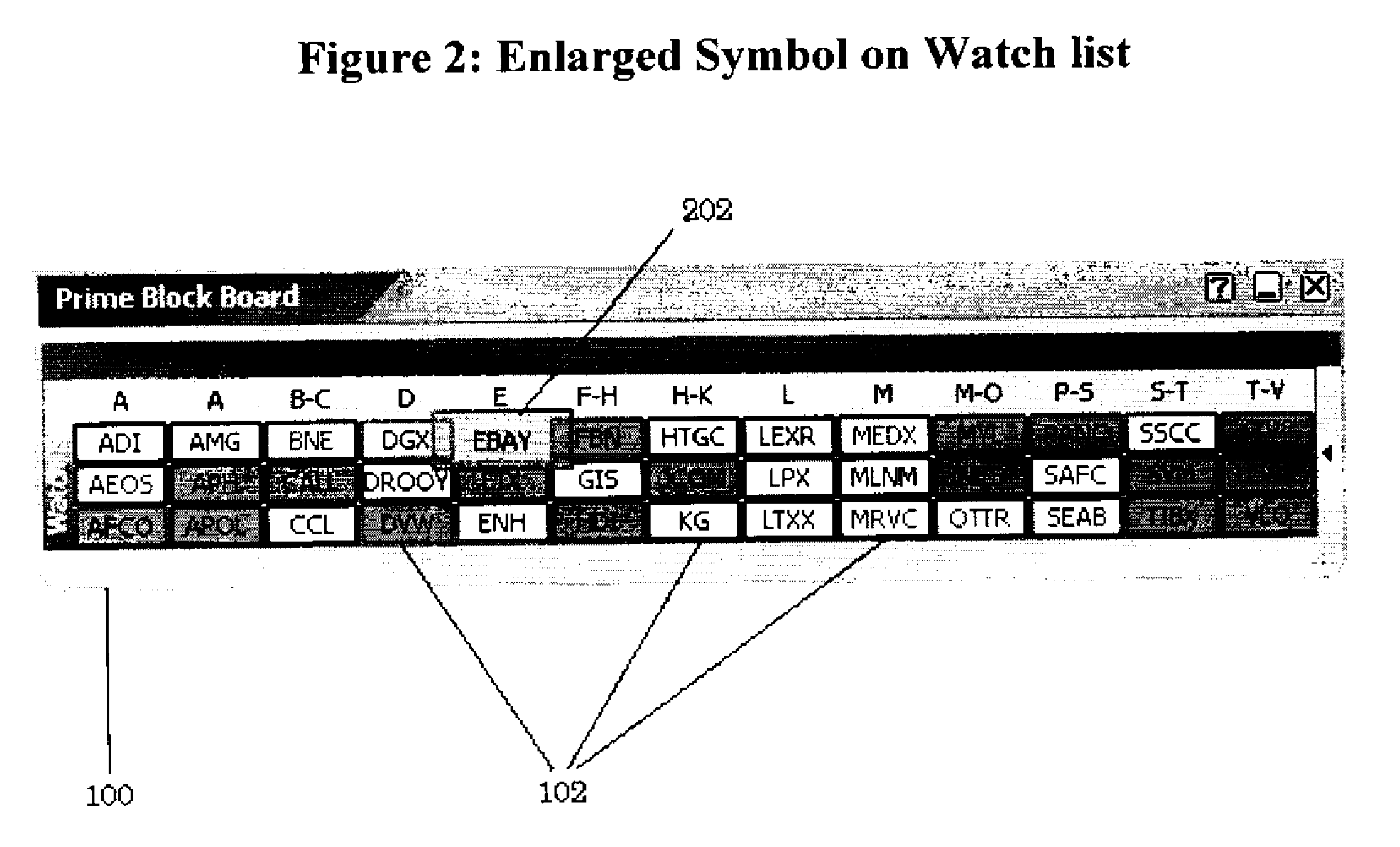

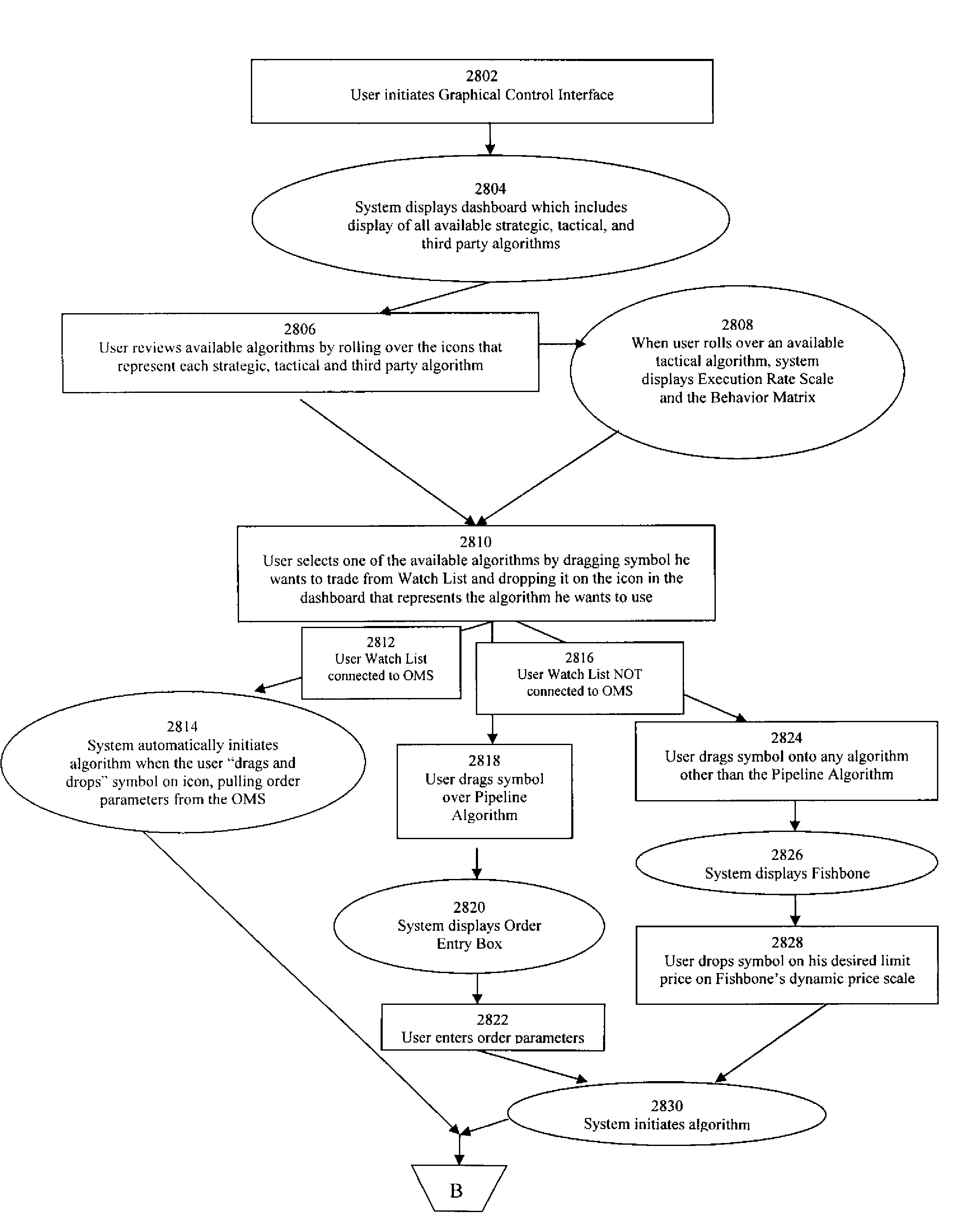

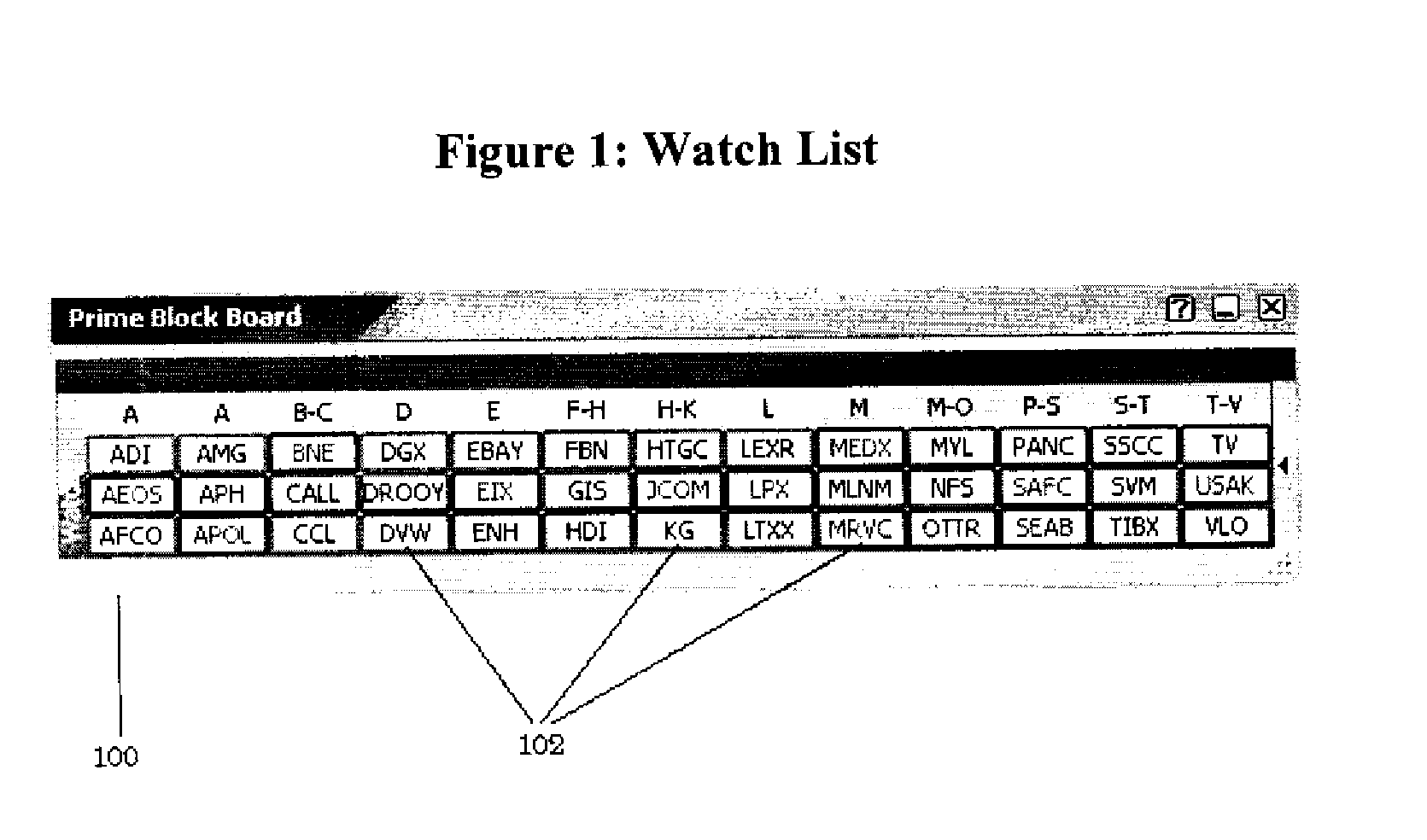

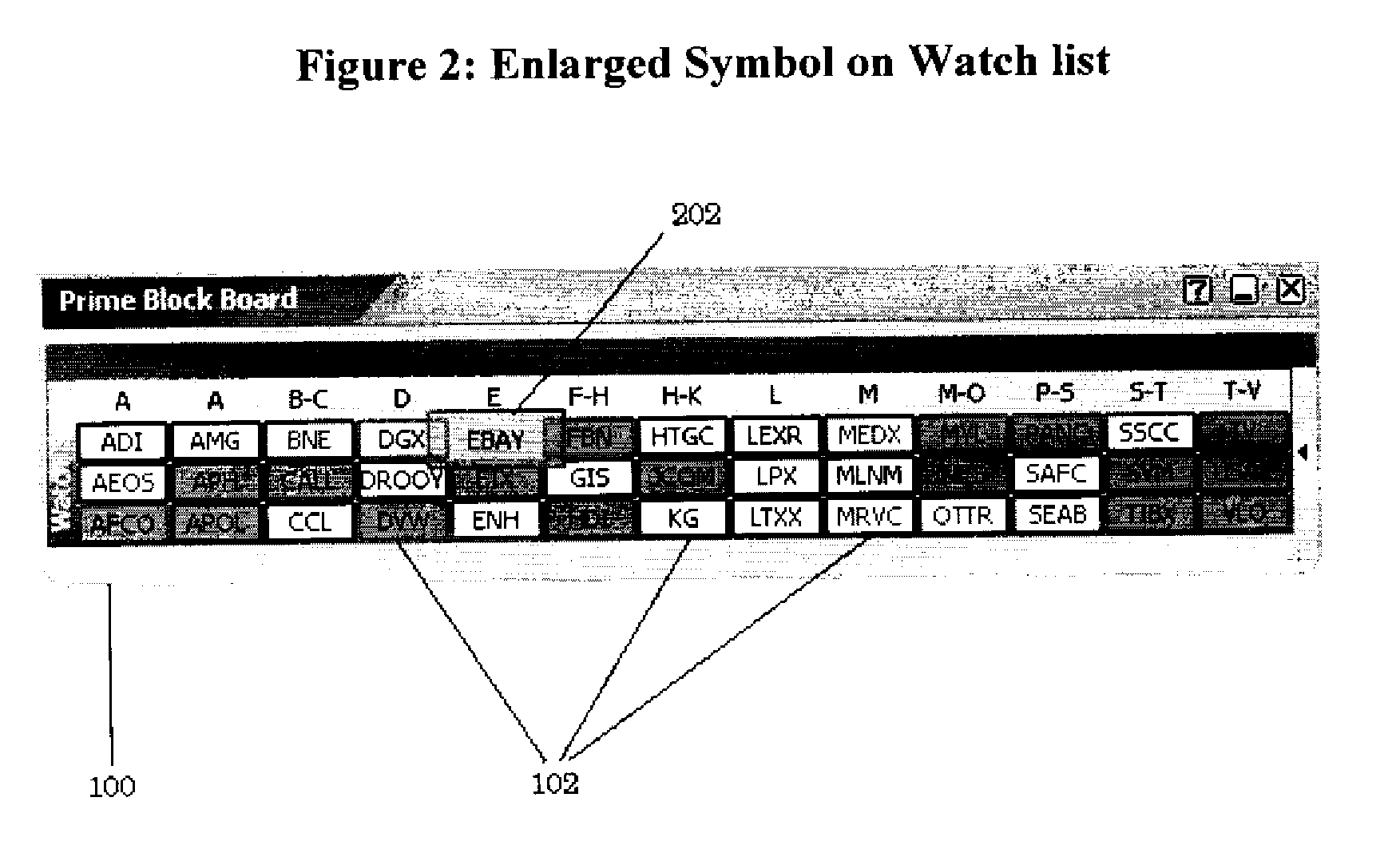

Coordination of algorithms in algorithmic trading engine with fast switching and safe mode

A graphical user interface is used along with an automated algorithm selection function to enable market participants to initiate automated, multi-algorithm trading strategies through a single drag and drop motion. A symbol representing a security can be dragged and dropped onto an icon representing a tactical or strategic algorithm. Other features of the graphical user interface show information such as the progress of the algorithms. Fast switching and safe mode are used to minimize a cost associated with algorithm switching.

Owner:PORTWARE LLC

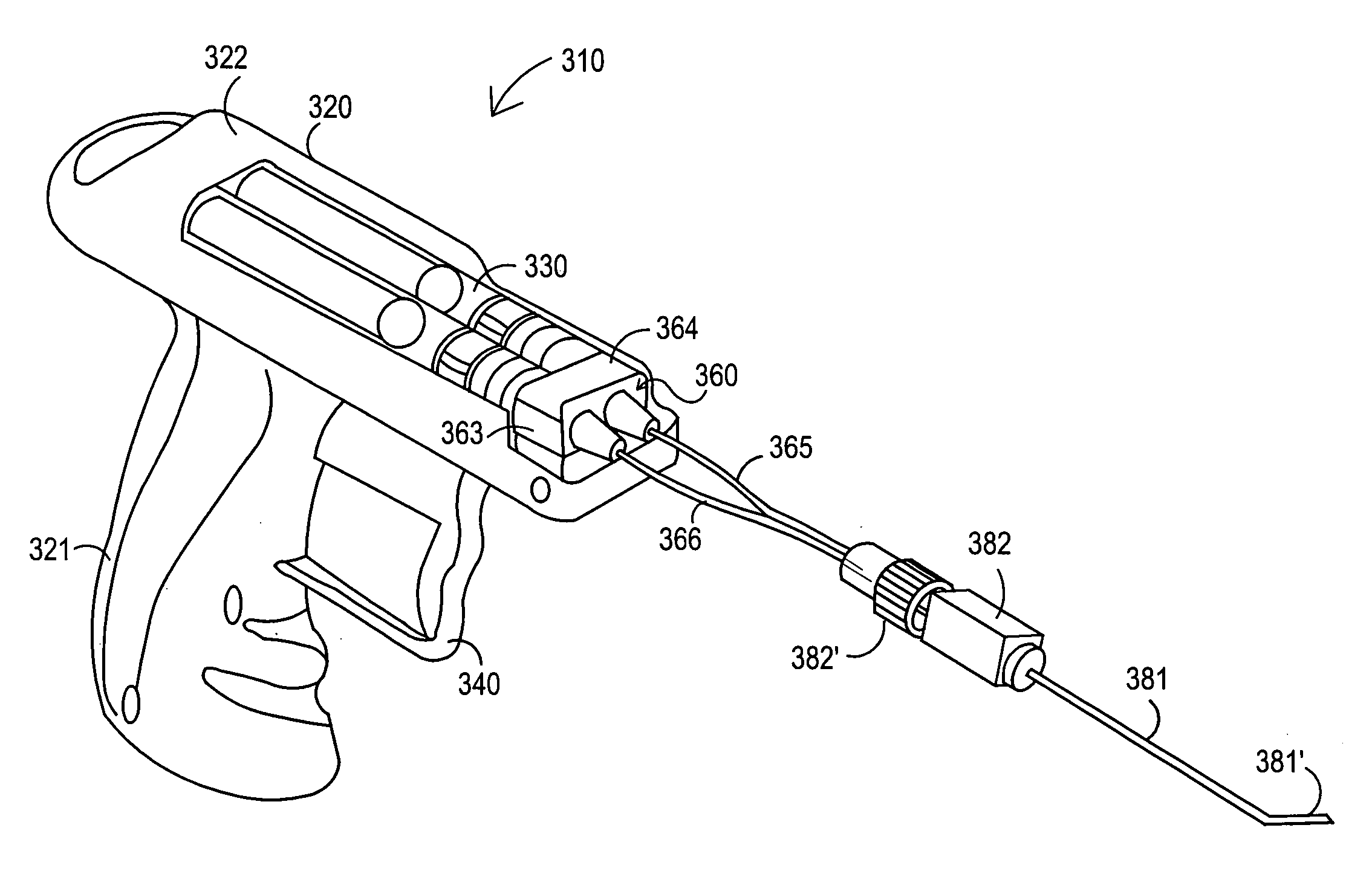

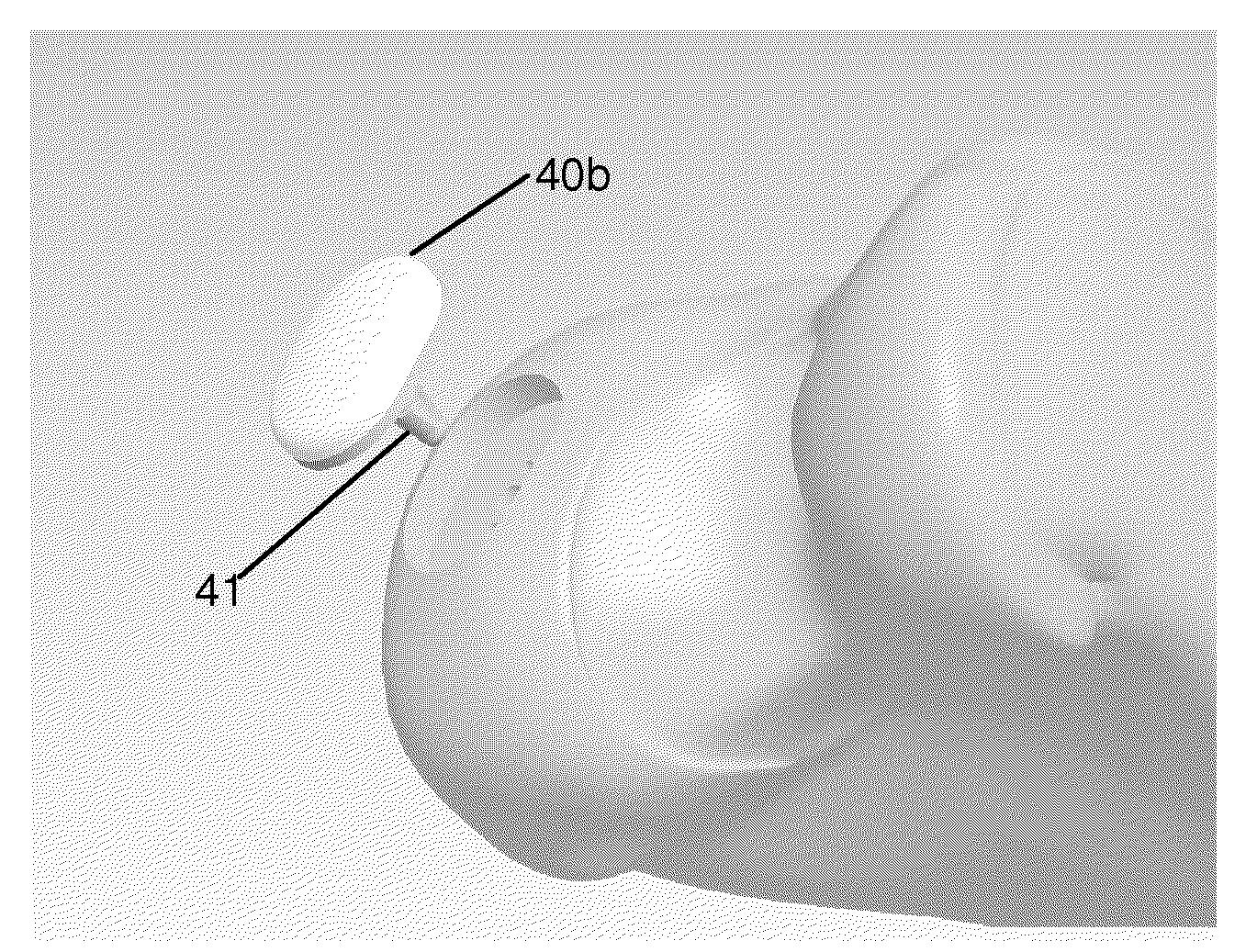

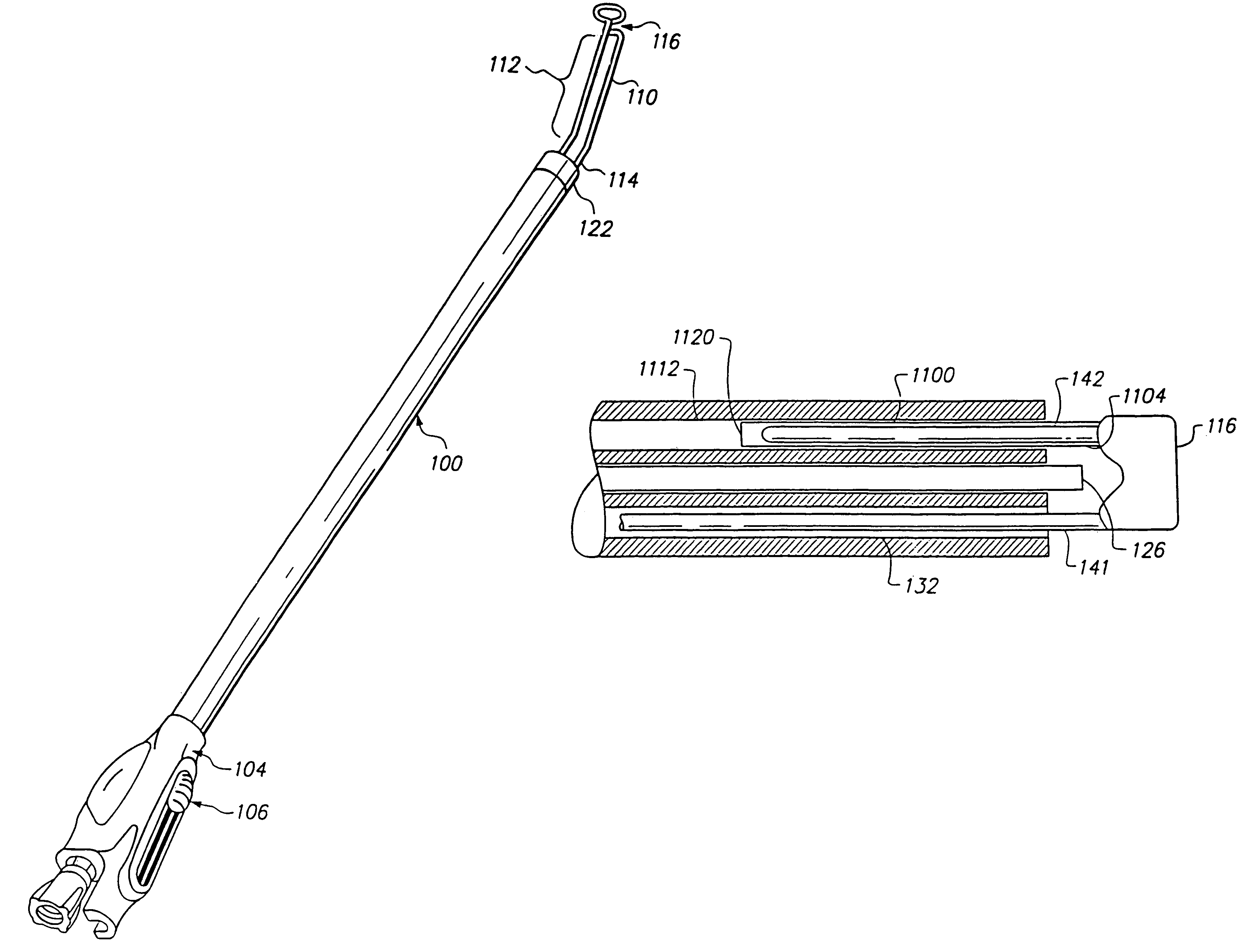

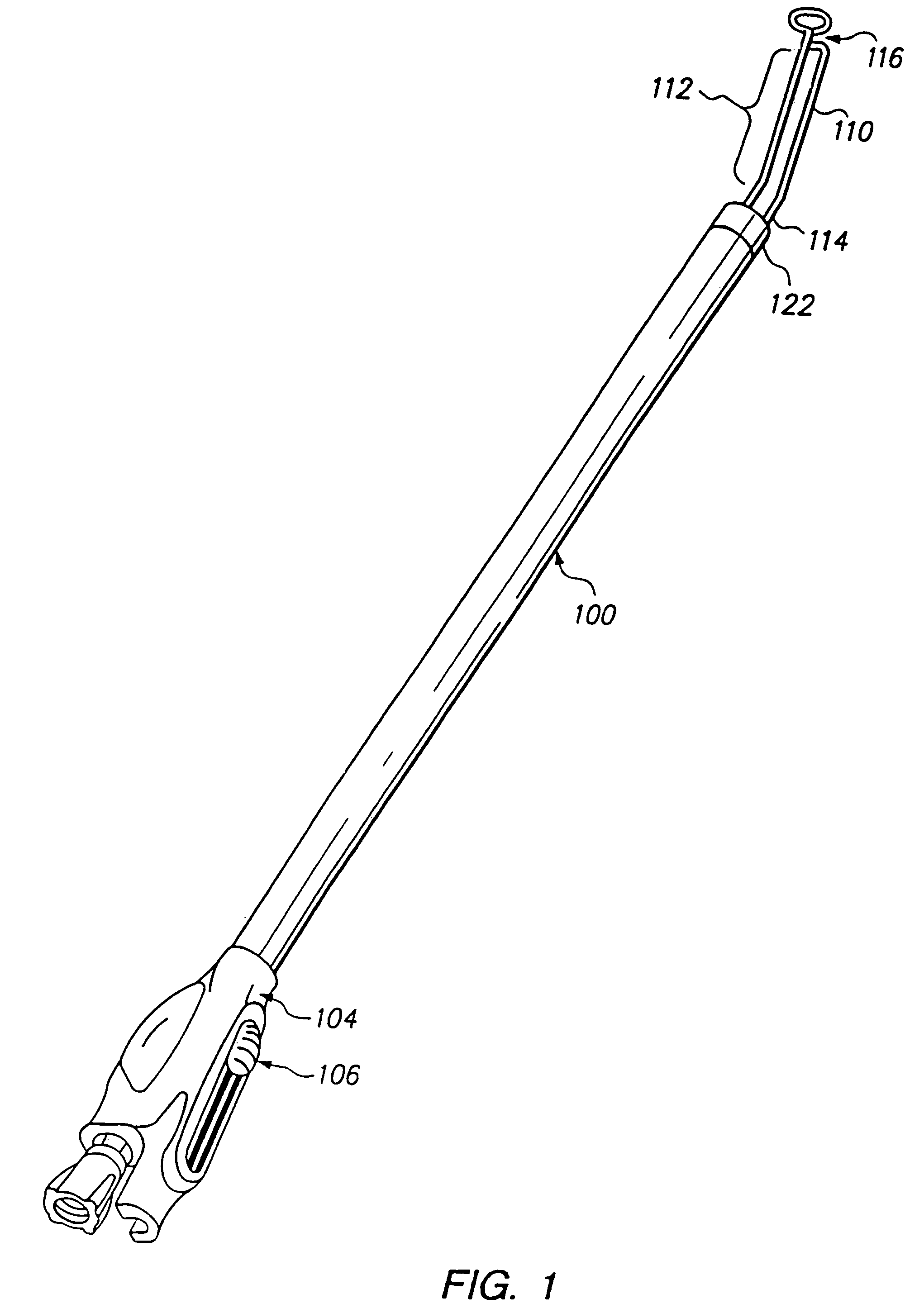

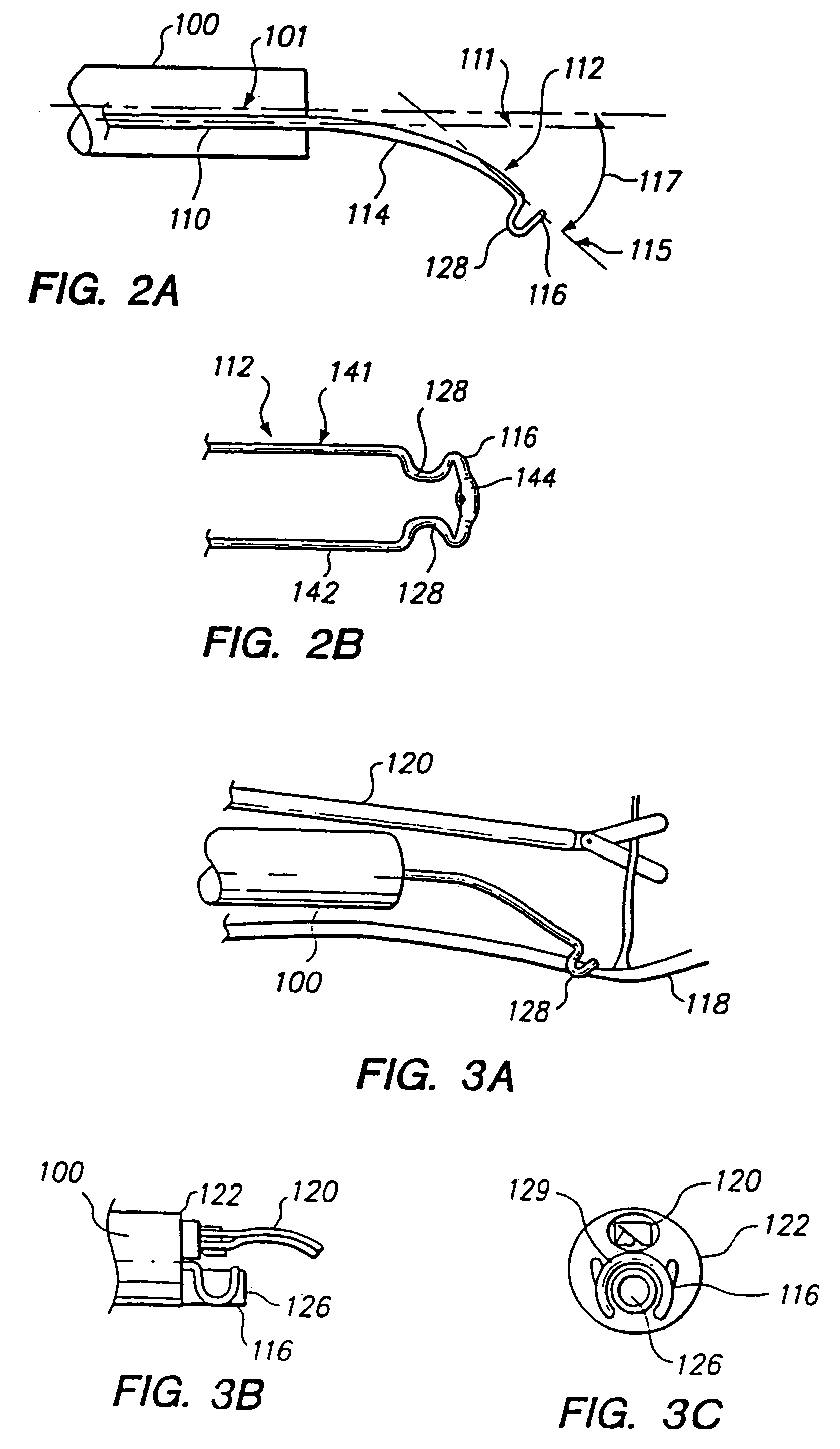

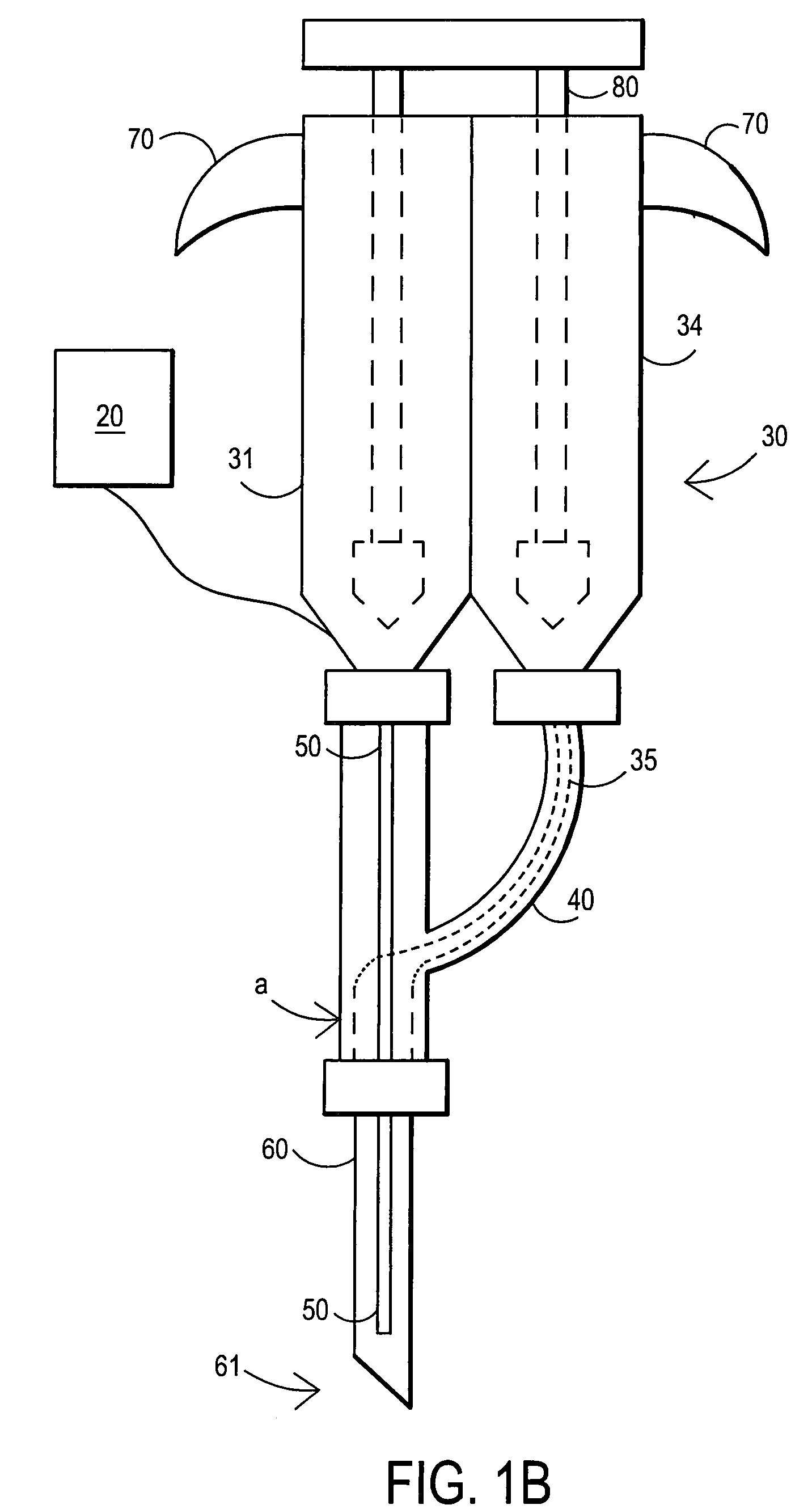

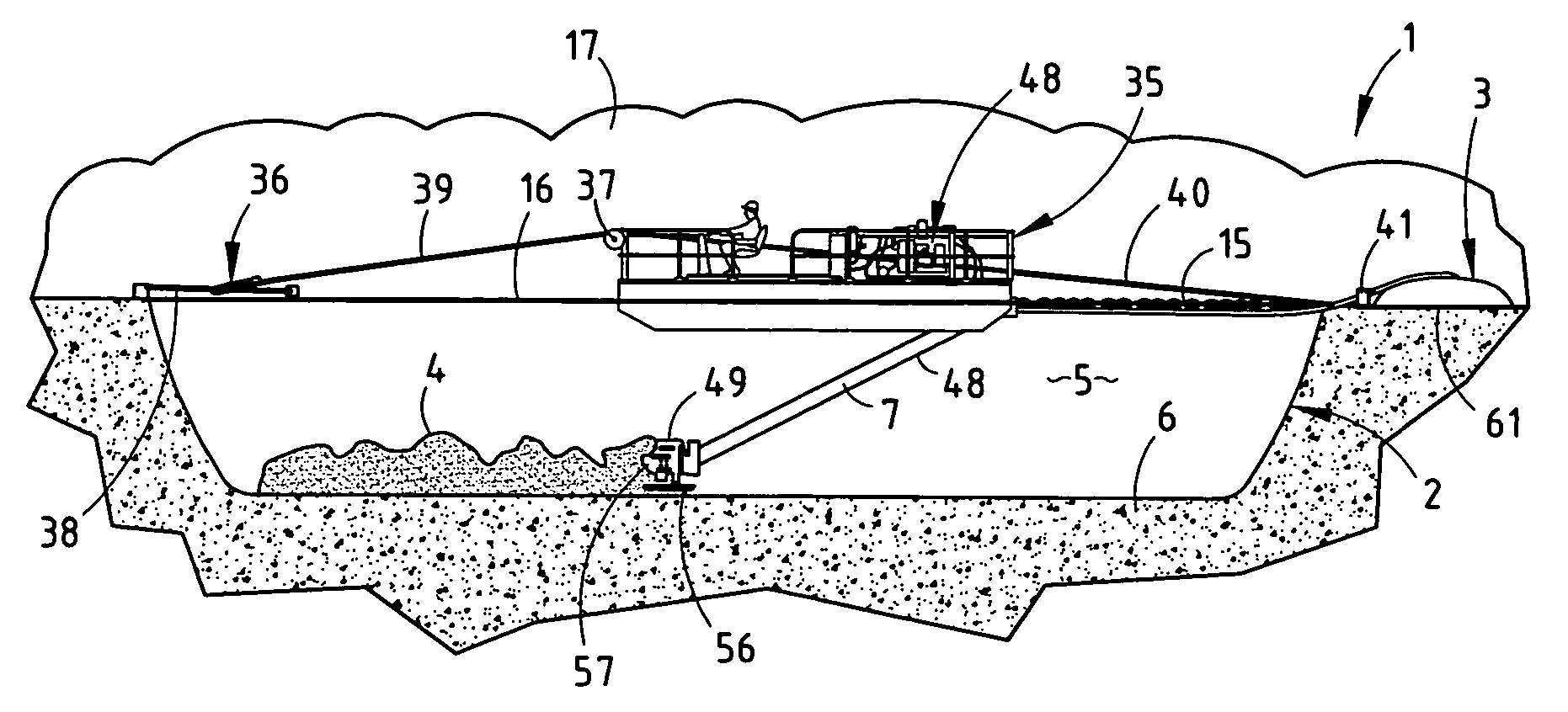

Cannula-based surgical instrument

A retractor and a surgical tool are positioned within a cannula, and a dissection cradle of the retractor is positioned at the distal end of the cannula. The retractor includes a dissection cradle that is resiliently supported along an axis skewed relative to the axis of the cannula. The dissection cradle, in operation, is extended to cradle the target vessel, and the retractor may be fully extended to urge the vessel away from the axis of the cannula to isolate a side branch for exposure to a surgical tool. The retractor includes a hollow support and a spray nozzle disposed in the distal end of the retractor to form an irrigation system and lens washer that can be selectively positioned to direct the spray of irrigation fluid at a remote surgical site or at an endoscopic lens.

Owner:MAQUET CARDIOVASCULAR LLC

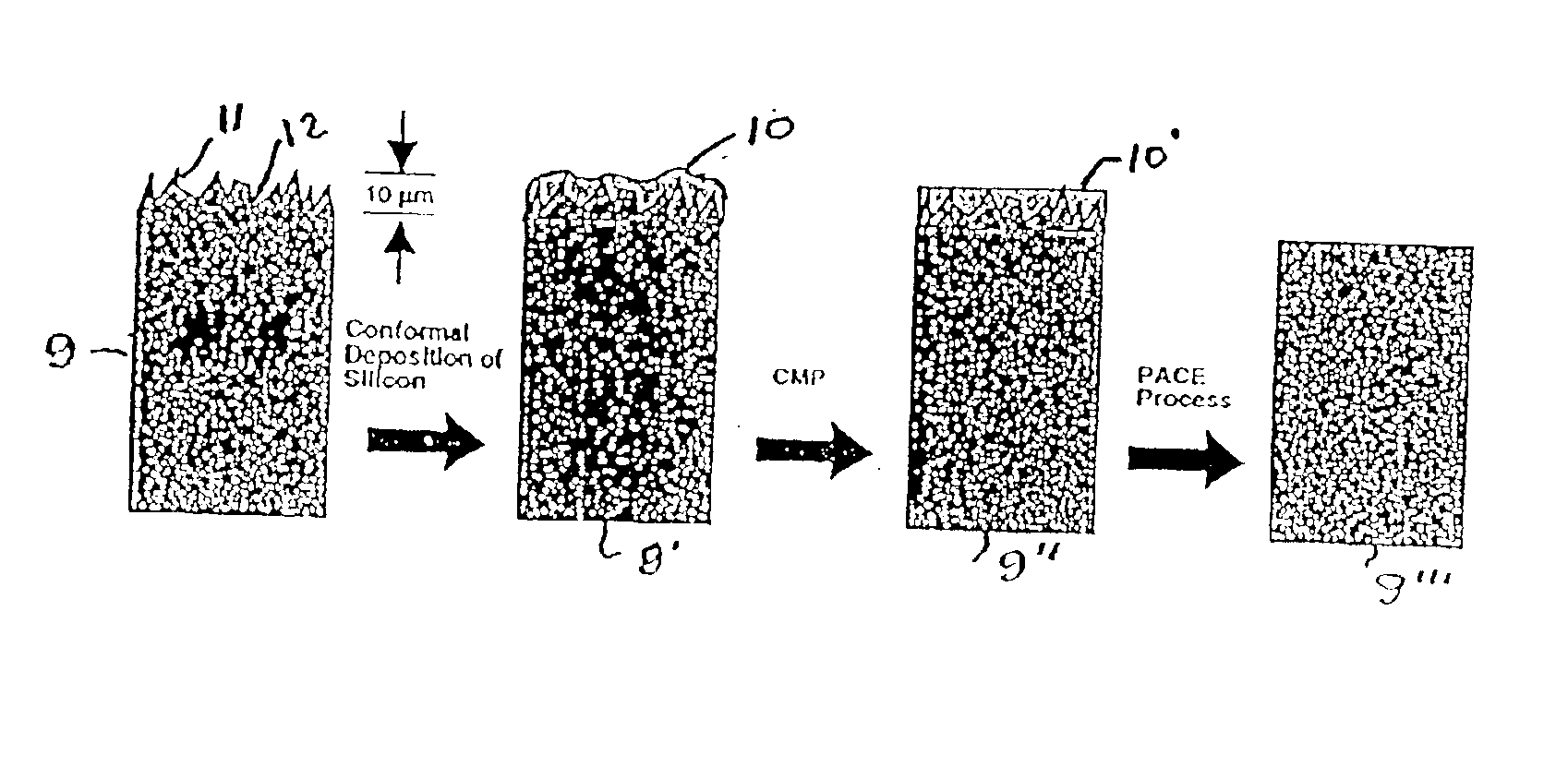

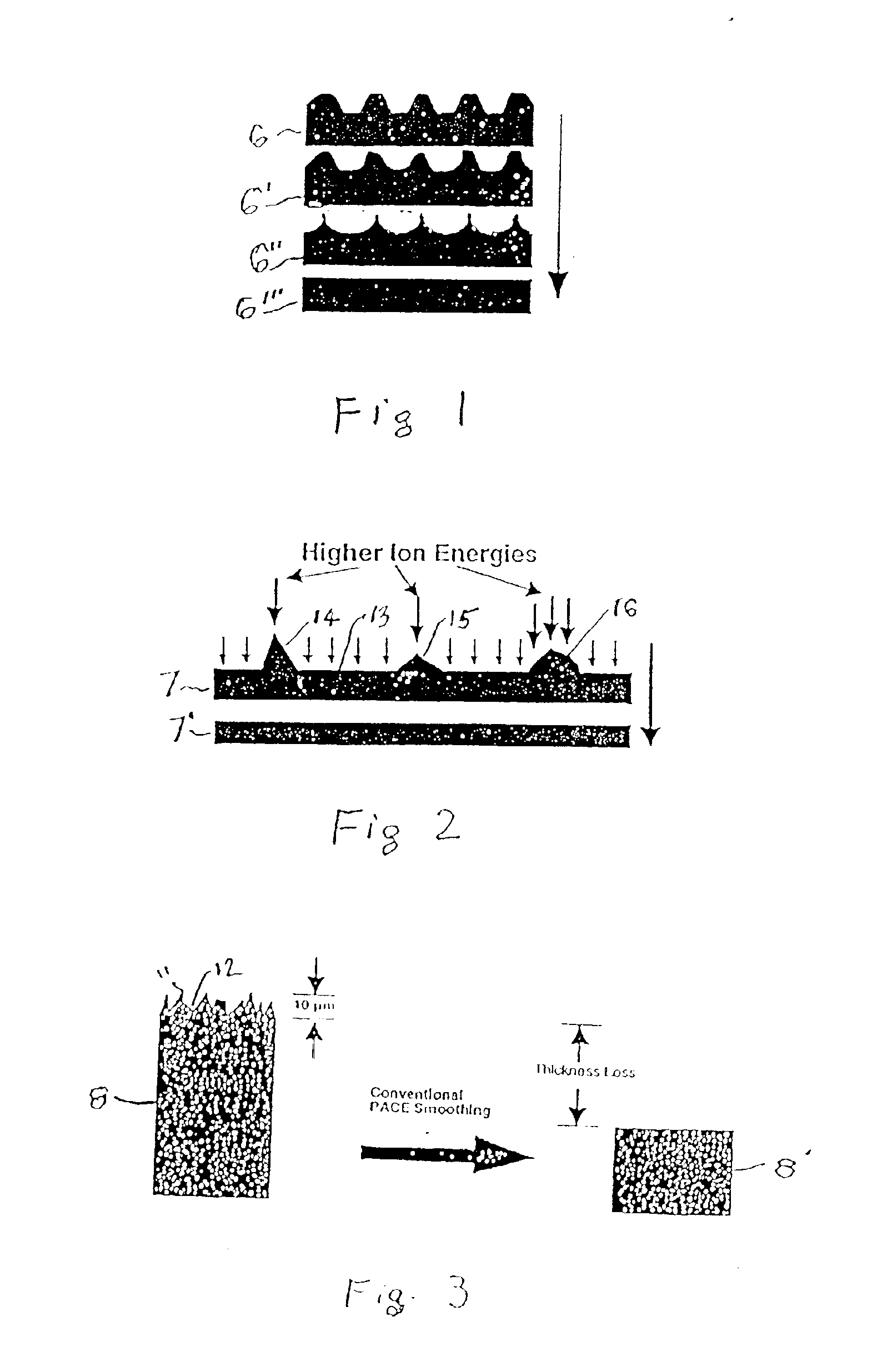

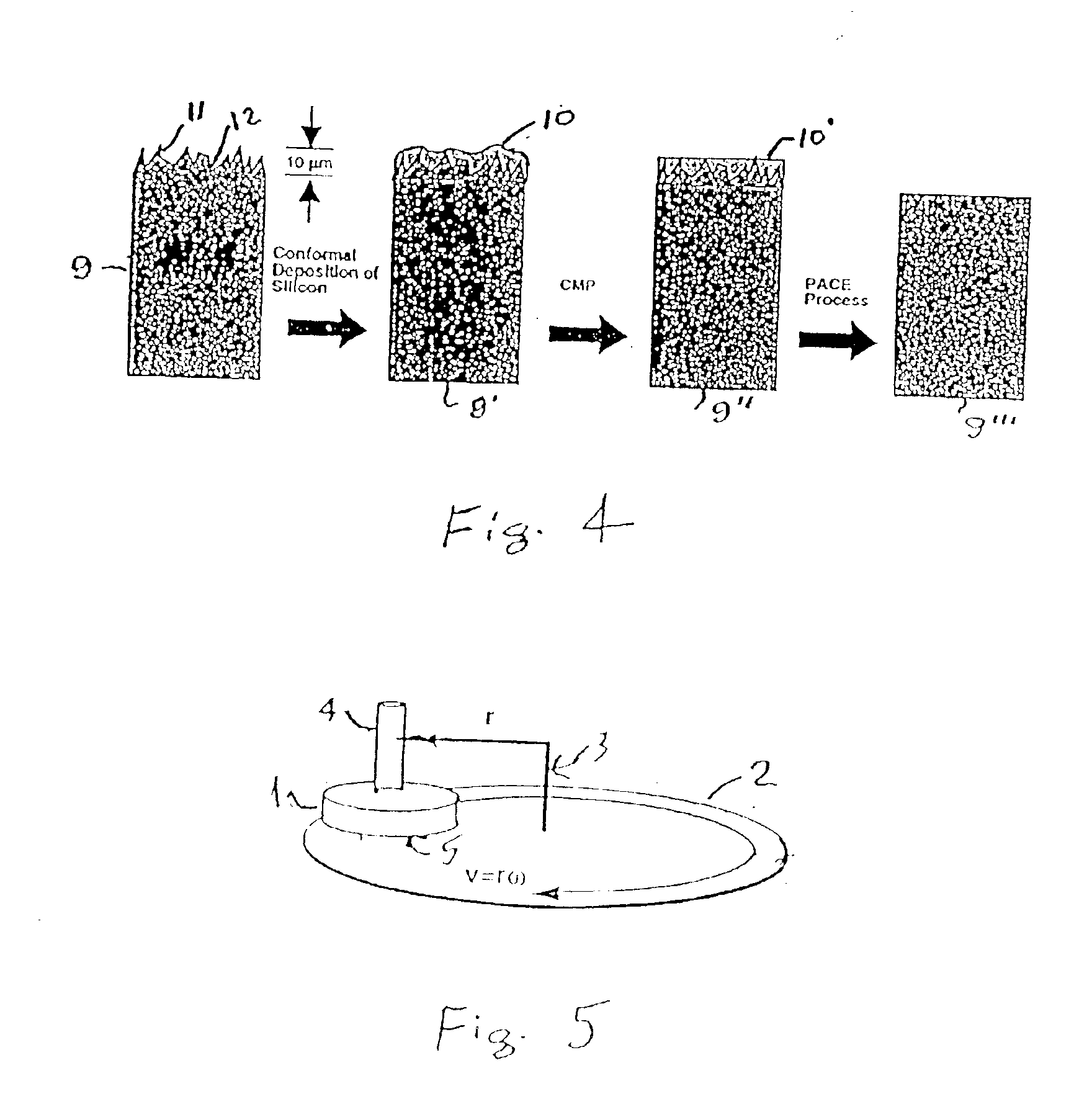

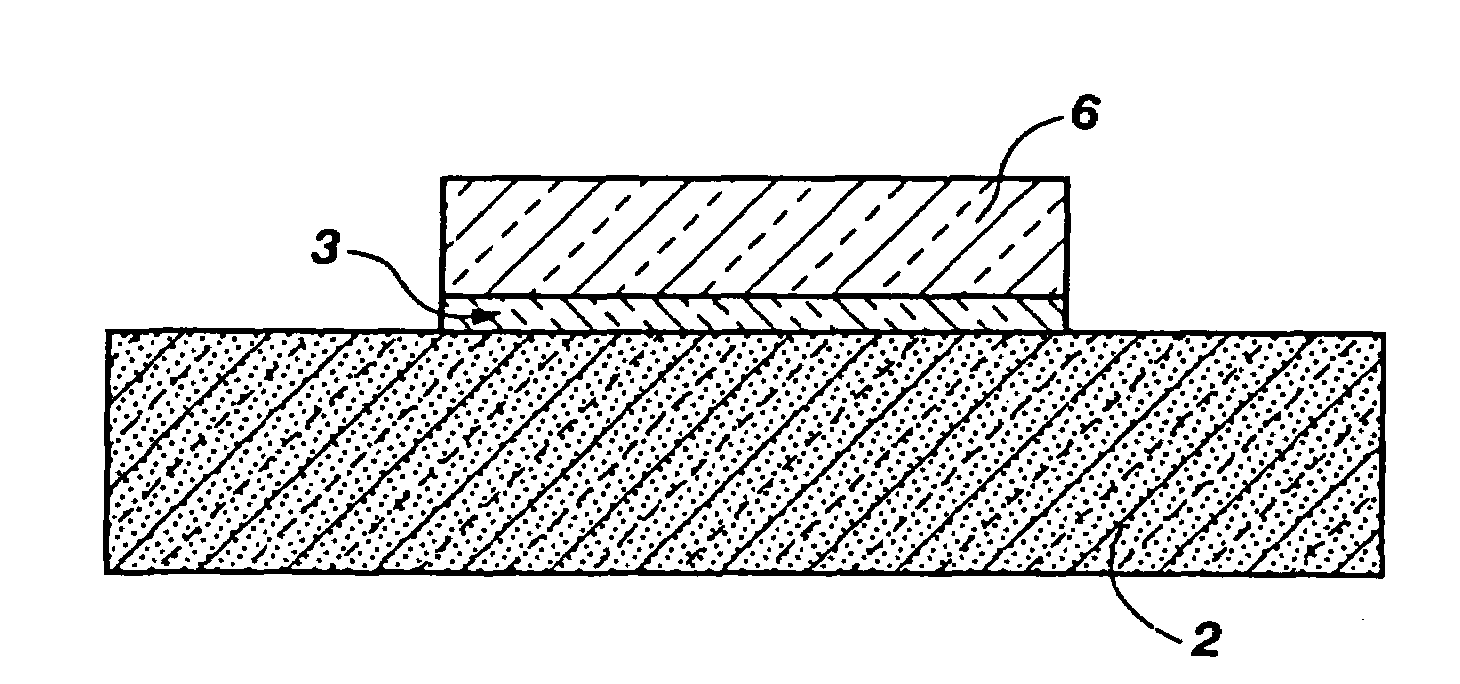

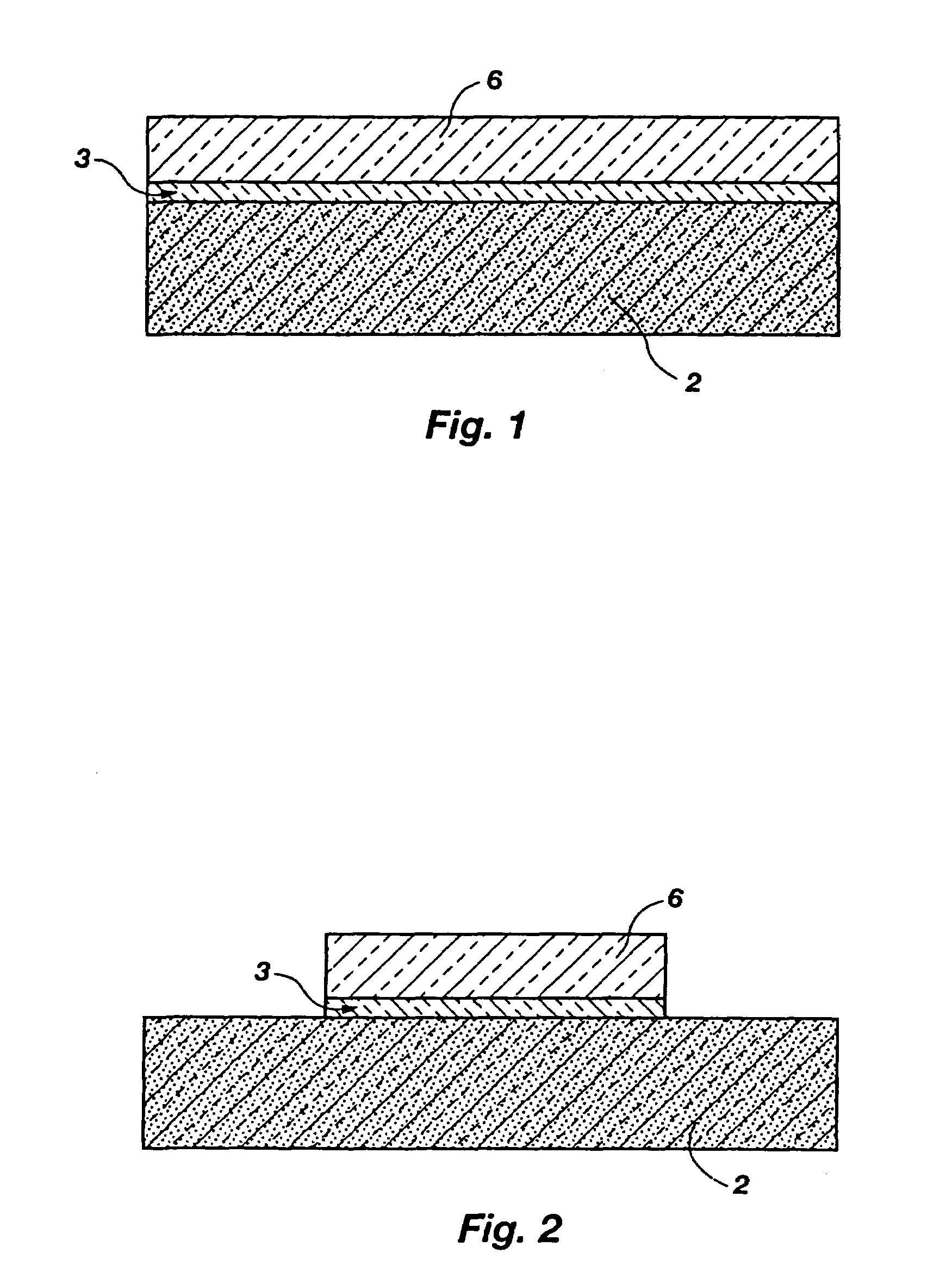

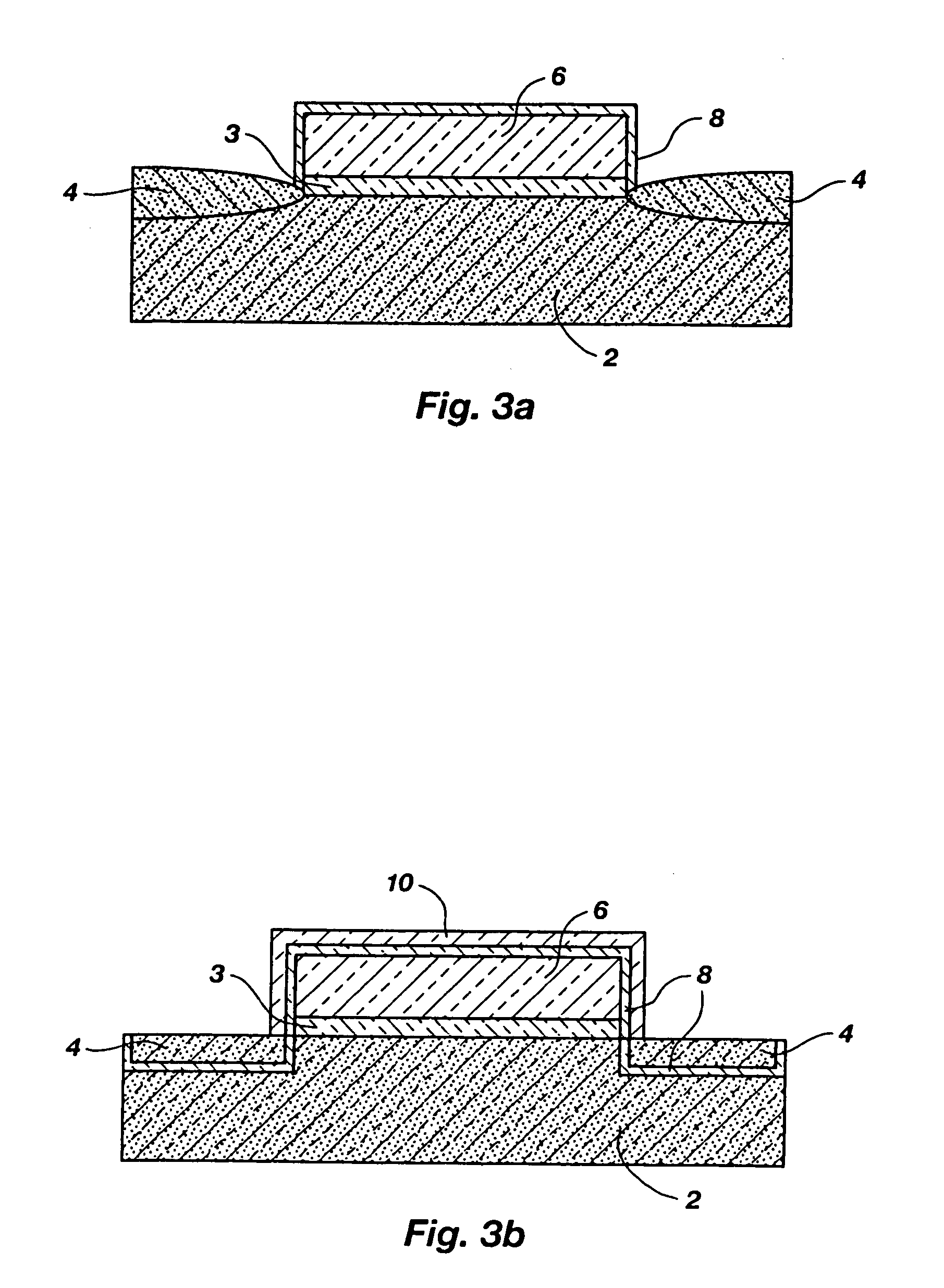

Process for smoothing a rough surface on a substrate by dry etching

InactiveUS6858537B2Quantity minimizationMinimizes and removeDecorative surface effectsSemiconductor/solid-state device manufacturingPreferential etchingCarbide silicon

A process for smoothing a rough surface on a substrate, such as a diamond or silicon carbide substrate, said rough surface including protruding peak portions separated by valleys, said smoothing comprising (a) depositing a coating on said rough surface so as to adhere to and to fill at least the valleys of said rough surface, (b) mechanically polishing the thus coated rough surface so as to achieve a smooth coated surface, and (c) dry etching the smooth coated surface, such as by PACE, so as to remove the remaining coating and at least protruding peak portions of the substrate so as to achieve a smooth surface on the substrate, wherein in the mechanical polishing step (b) the coating is removed at a rate of reduction of thickness greater than the rate at which the substrate is subject to reduction of thickness by the mechanical polishing, and in the dry etching step (c) the coating and substrate are removed at substantially the same or a similar rate of reduction of thickness, and, if necessary, steps (a), (b) and (c) are repeated, or the coating and substrate are removed in separate, alternate preferential etching steps.

Owner:HRL LAB

Multi-step polishing solution for chemical mechanical planarization

InactiveUS6971945B2Increase ratingsHigh removal rateEdge grinding machinesPigmenting treatmentInorganic saltsCopper

The present invention provides a multi-step aqueous composition useful for polishing a tantalum barrier material and copper from a semiconductor wafer, comprising by weight percent 0.1 to 30 oxidizer, 0.01 to 3 inorganic salt or acid, 0.01 to 4 inhibitor, 0.1 to 30 abrasive, 0 to 15 complexing agent and balance water, wherein the aqueous composition has a pH between 1.5 to 6.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

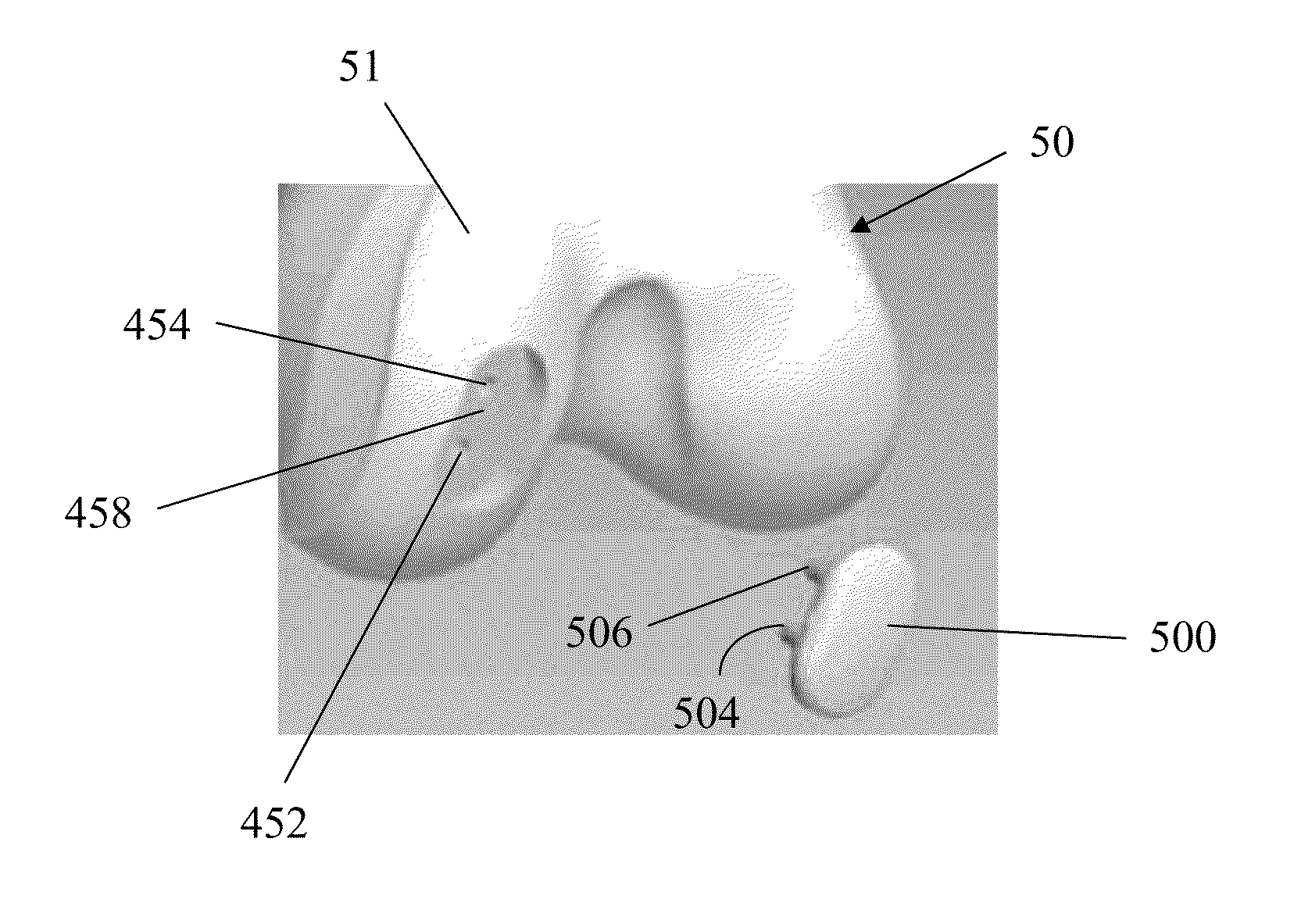

Partial joint resurfacing implant, instrumentation, and method

ActiveUS20130184820A1Maximizes defect coverageMinimizes or removeDiagnosticsLigamentsSacroiliac jointChondral defect

A method of repairing an articular cartilage defect with the partial joint resurfacing implant includes surgically creating an opening in the articular cartilage defect site. The method also includes obtaining a partial resurfacing implant which is implanted into the opening. The partial resurfacing implant includes a top articulating portion, an implant fixation portion, and a locking mechanism. The implant fixation portion including an upper segment coupled to the top articulating portion and a bone interfacing segment configured to facilitate insertion into the articular cartilage defect site. The method further includes the bone interfacing segment being inserted into the opening with the top articulating portion and adjacent articular cartilage being positioned to each other to facilitate motion and load transfer over the defect site. Another method of repairing an articular cartilage defect with a partial joint resurfacing implant and a partial joint resurfacing implant are also disclosed.

Owner:BIOPOLY

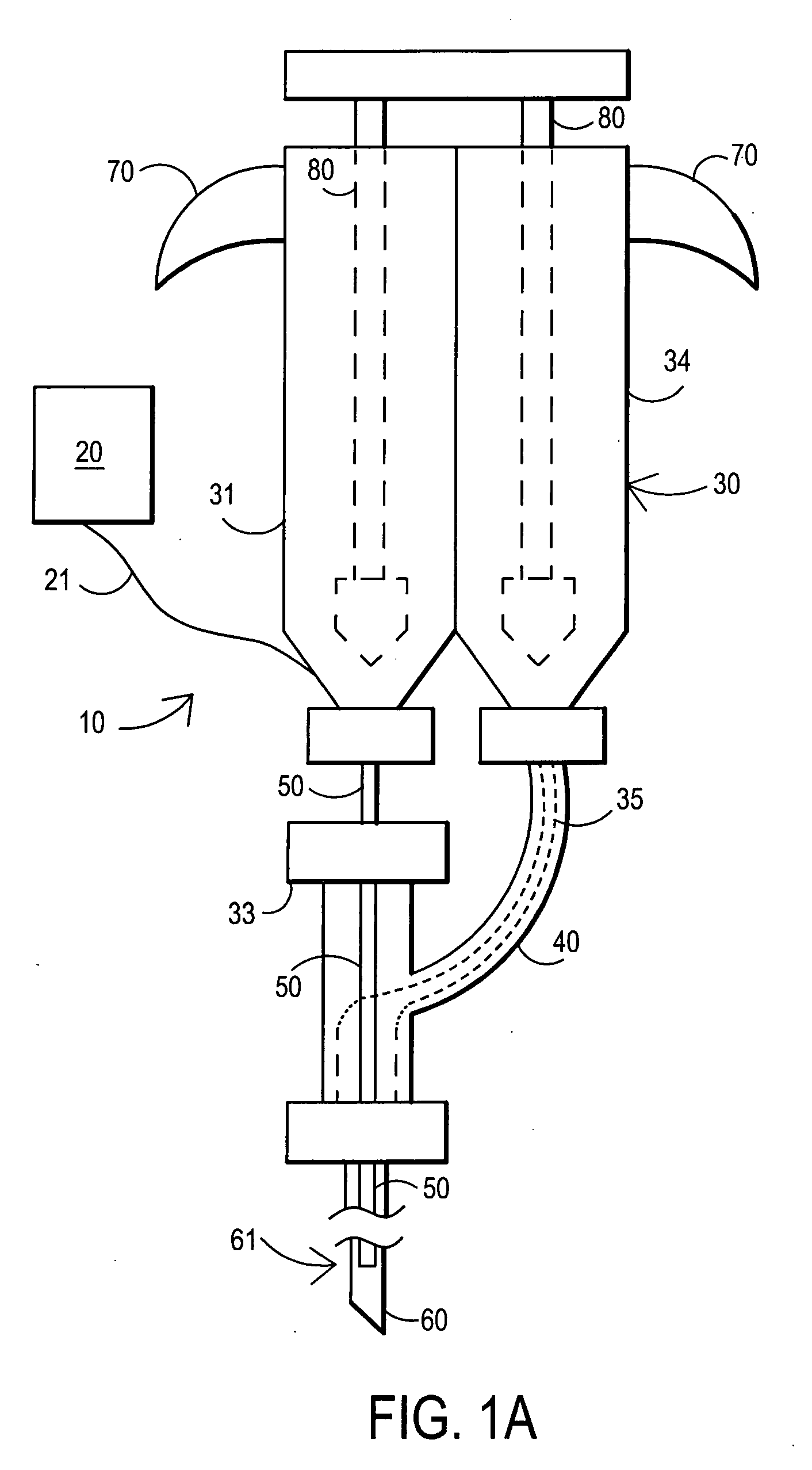

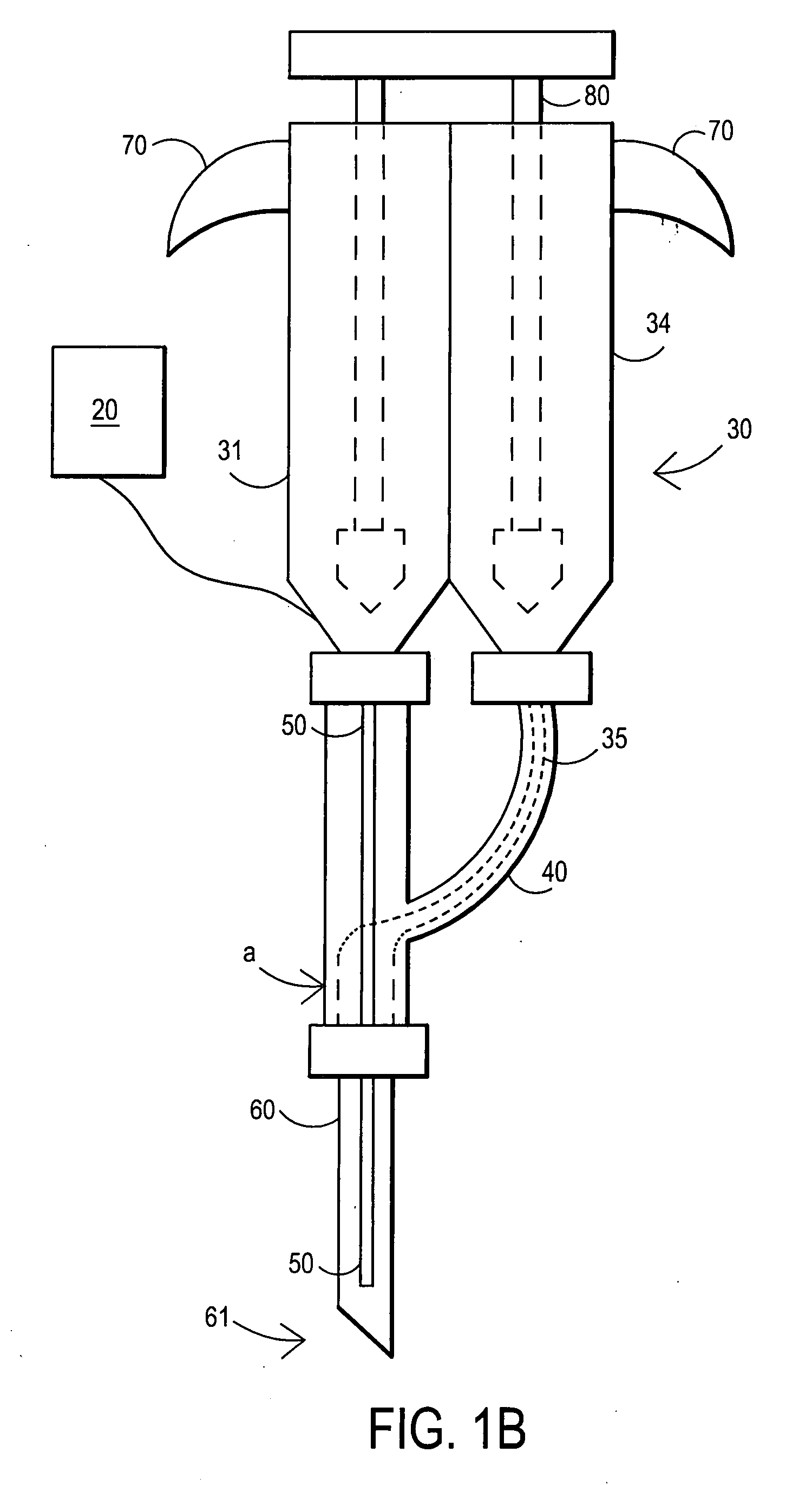

Method for repairing intervertebral discs

ActiveUS8357147B2Reduce and eliminate migrationAvoid contactDiagnosticsMedical devicesIntervertebral diskBiomedical engineering

A method of repairing a defect in an annulus fibrosus of an intervertebral disc, without excising the entire nucleus pulposus of the disc. The method includes inserting an introducer needle through the annulus fibrosus by puncturing the annulus fibrosus with the introducer needle, injecting an in situ curable, bio-compatible polymerizable or polymeric material composition into the disc through the introducer needle directly or indirectly so that the in situ curable composition contacts a defect in the annulus fibrosus; and curing said material in situ.

Owner:PAUZA KEVIN

Multi-heat source laser brazing system and method

InactiveUS20060261045A1Reduce the possibilityLow costSoldering apparatusMetal working apparatusPorosityOptoelectronics

An improved brazing system having a plurality of heat sources is adapted for brazing in tandem a plurality of adjacent workpieces and for reducing porosity in the braze joint. The system preferably includes a first laser beam that engages the workpieces to vaporize surface contaminants thereupon, a second laser beam configured to melt the brazing material, and a third laser beam configured to further heat the material, so as to extend the thermal cycle thereof or re-melt the material.

Owner:GM GLOBAL TECH OPERATIONS LLC

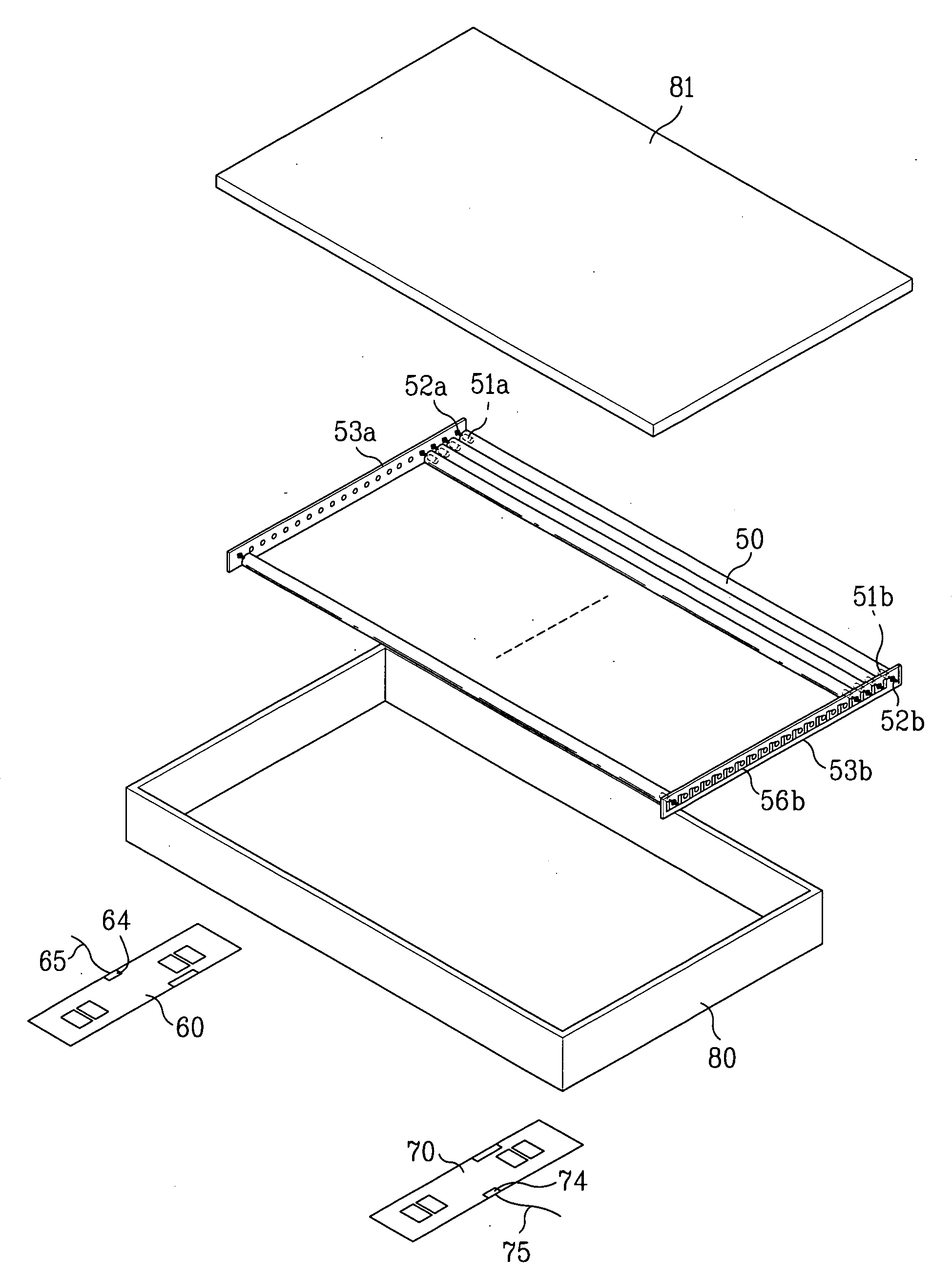

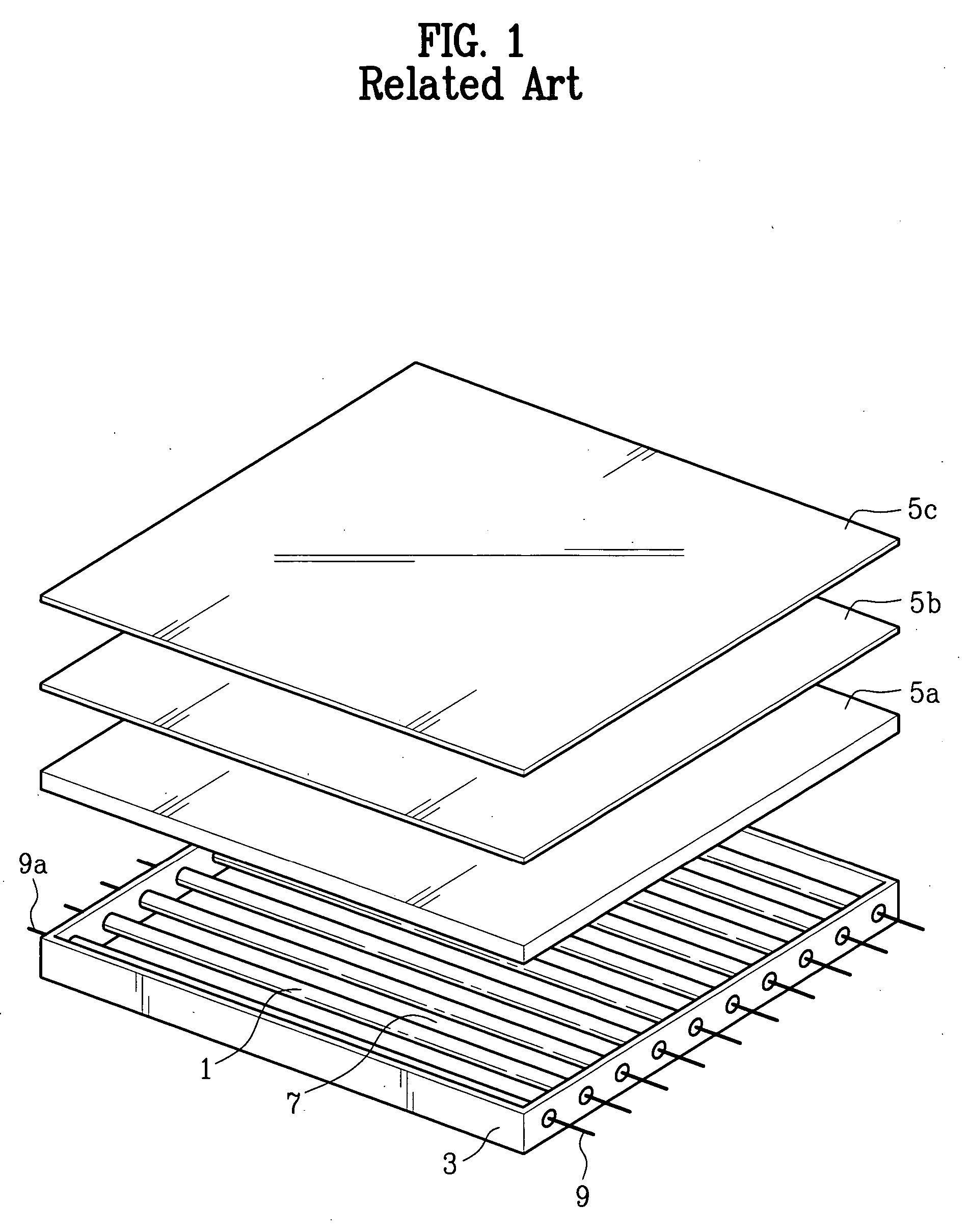

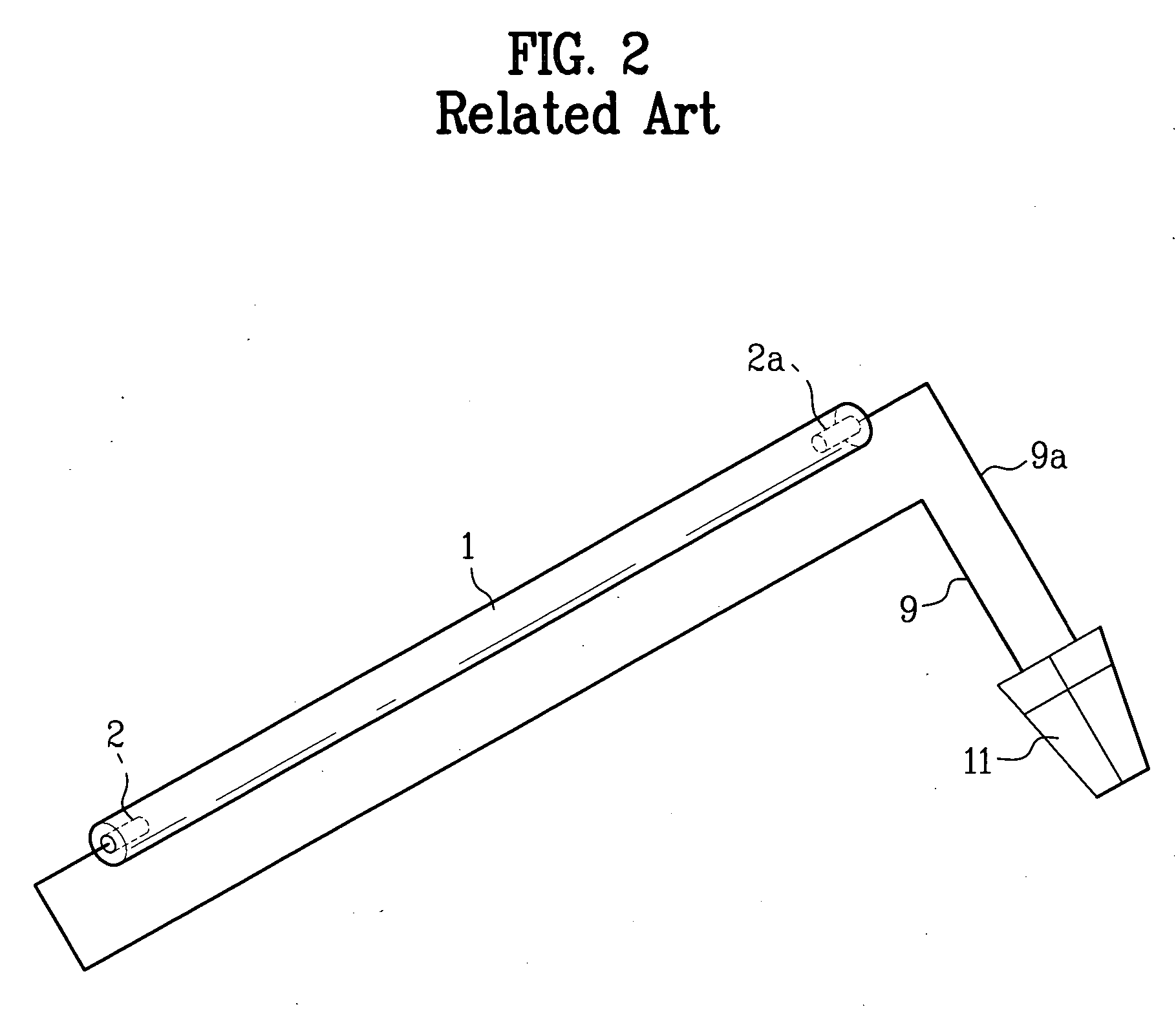

Backlight unit

ActiveUS20060023471A1Minimizes and removeReduce in quantityStatic indicating devicesElectric circuit arrangementsEngineeringElectrical and Electronics engineering

Owner:LG DISPLAY CO LTD

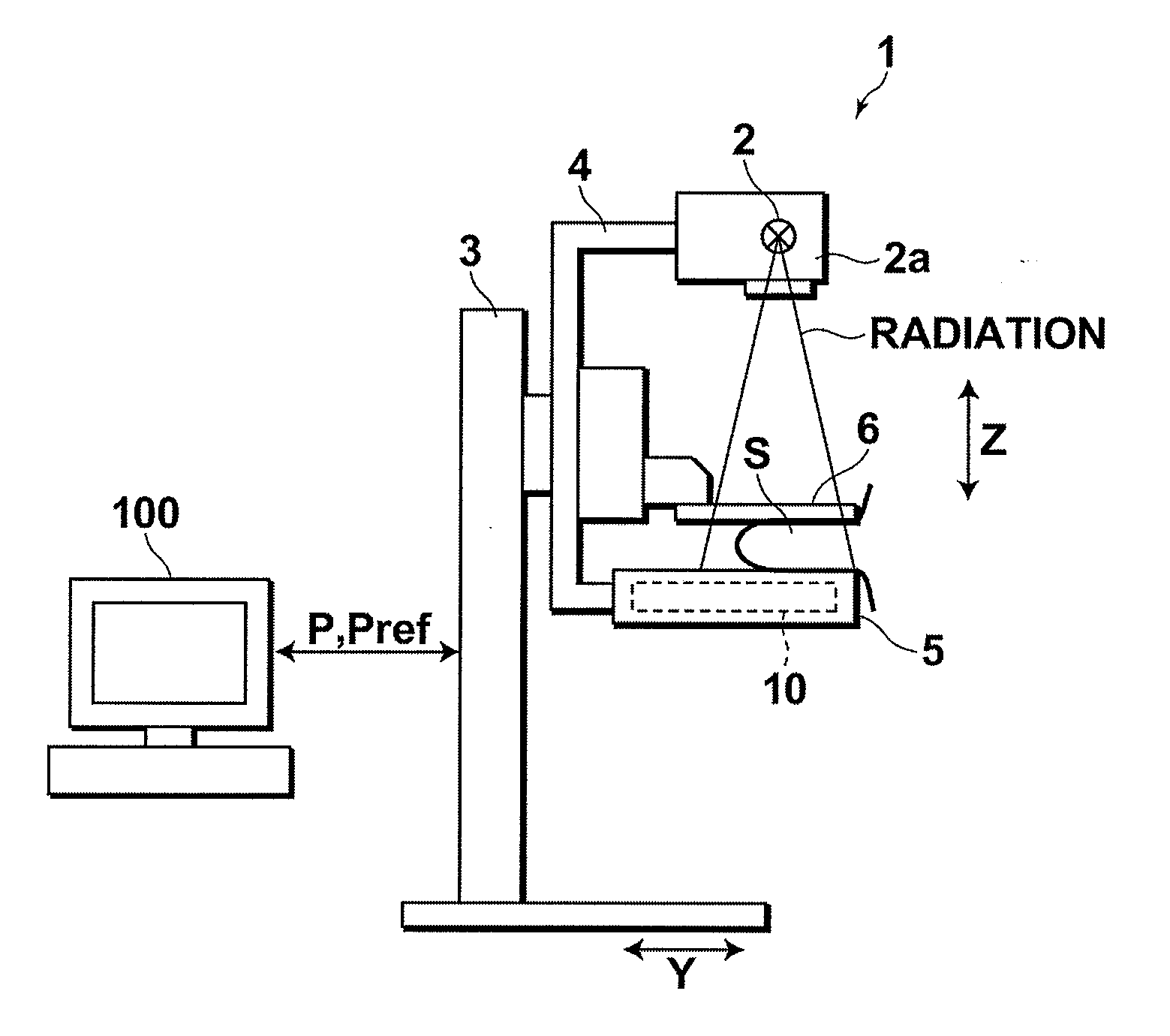

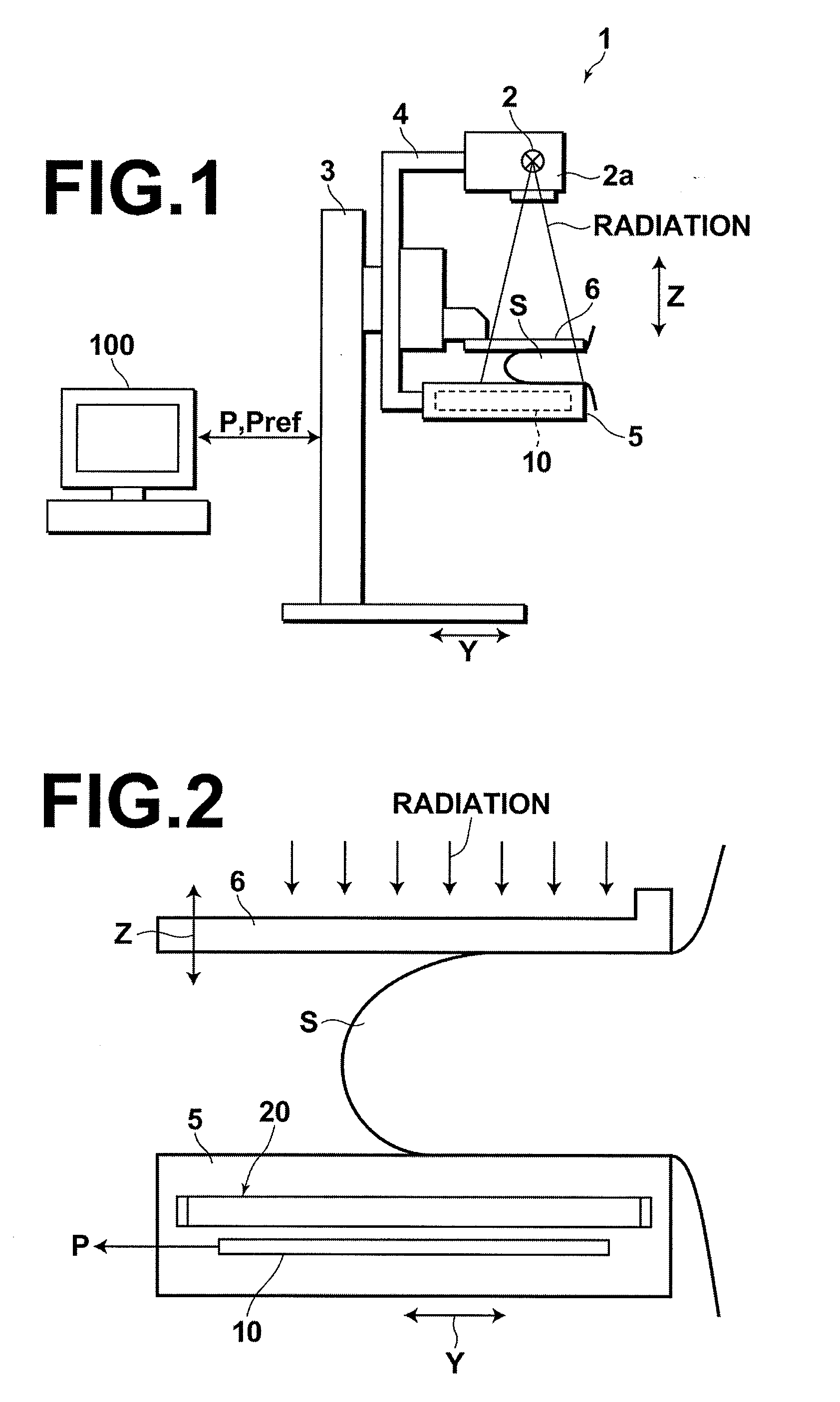

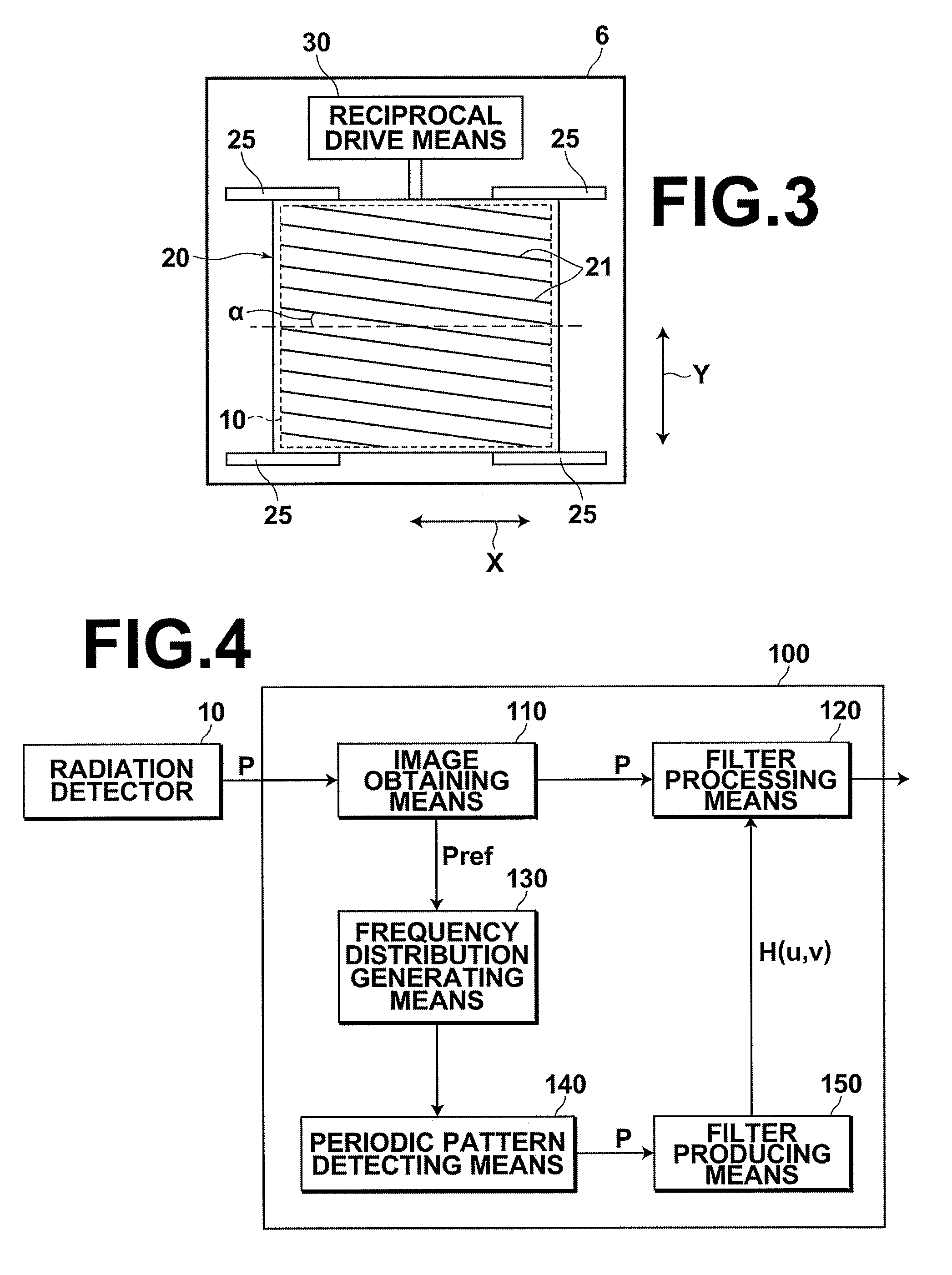

Radiation image processing apparatus

ActiveUS20090214130A1Minimizes and removeAccurate removalImage enhancementImage analysisImaging processingSpatial frequency

A filter processing means removes periodic patterns caused by a scattered radiation removing means from radiation images, which are obtained by detecting radiation that has passed through the scattered radiation removing means with a radiation detector. The filter processing means removes only the spatial frequency components of the periodic pattern from the radiation images.

Owner:FUJIFILM CORP

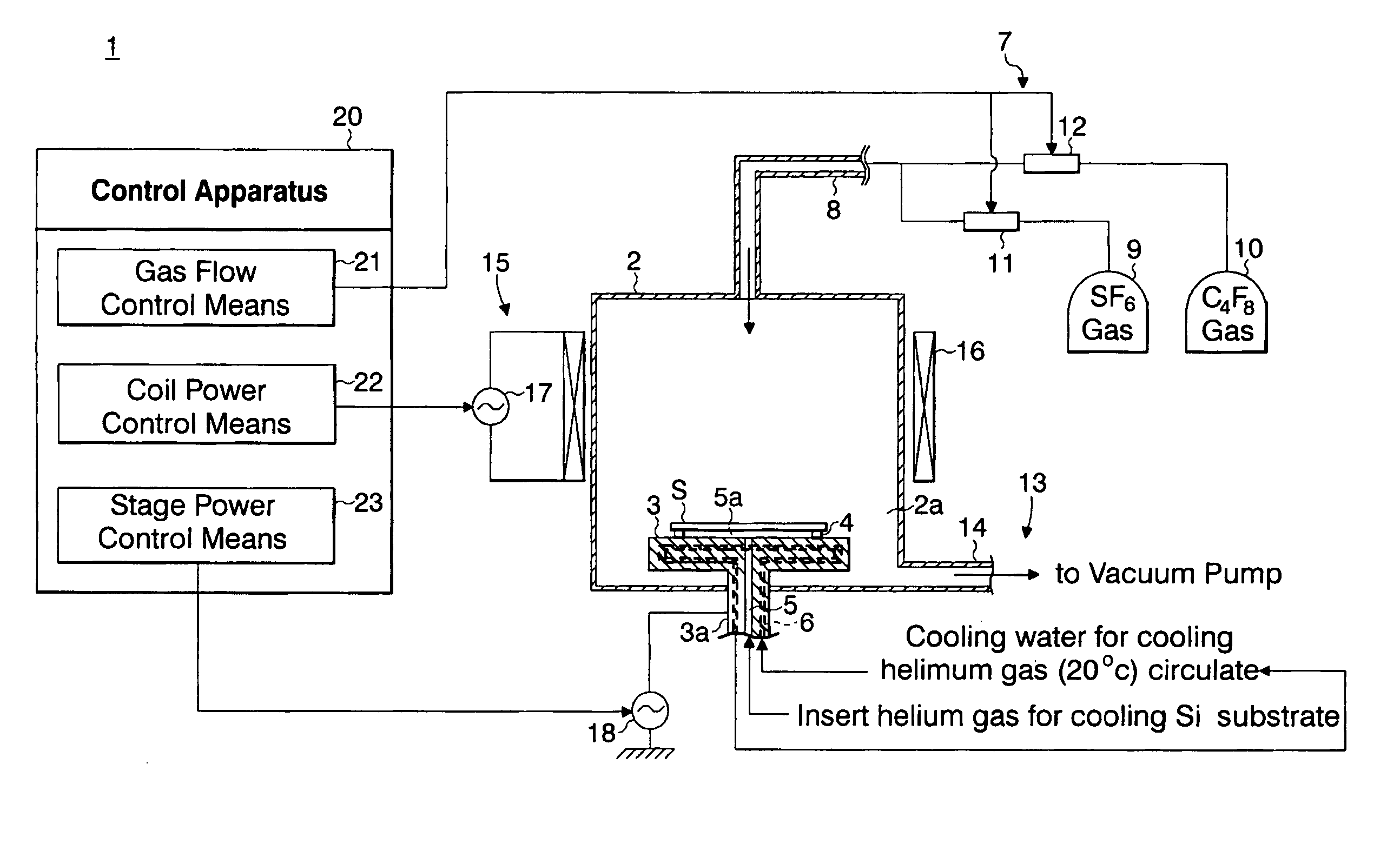

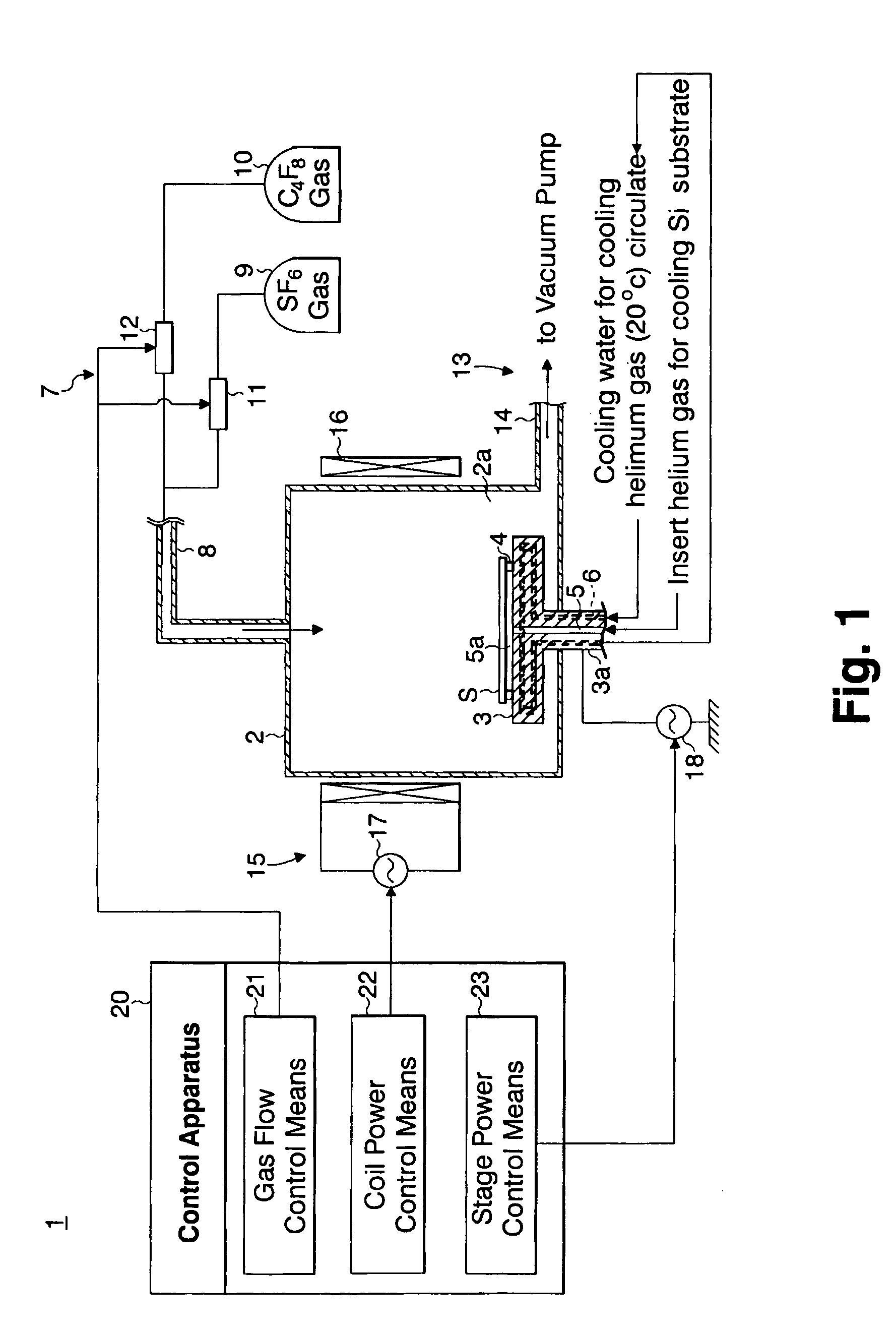

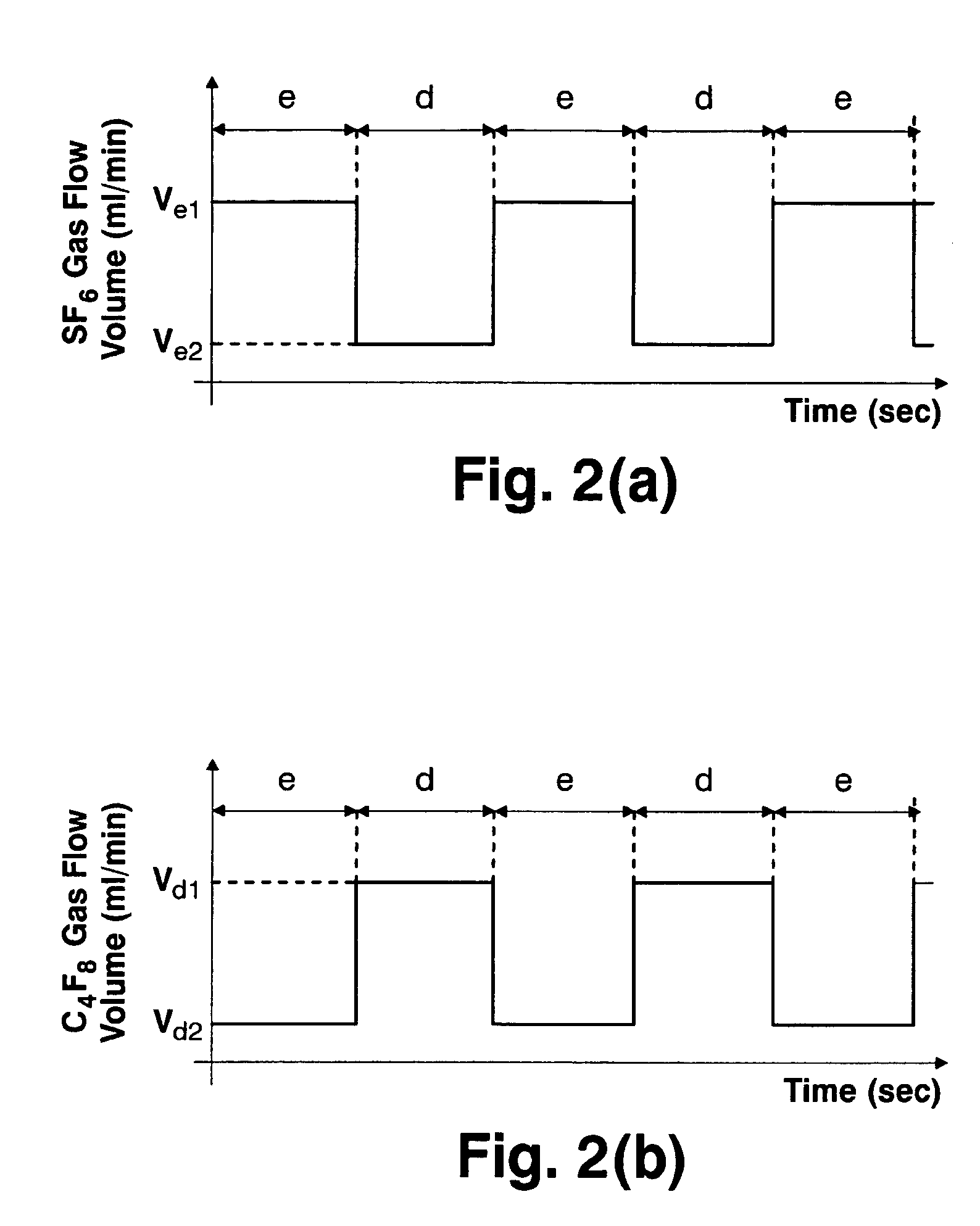

Method for etching of a silicon substrate and etching apparatus

ActiveUS20050130436A1Sufficiently smoothExcellent perpendicularity without reducing the etching speedDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Fluorocarbon

A method for etching a silicon substrate is presented in which fast etching speed and etching structures with smooth and perpendicular wall surfaces are achieved. In the etching step, a constant electric power is applied to the silicon substrate to provide a bias potential. Using a mixture of SF6 gas and fluorocarbon gas, there is a step mainly for the progression of dry etching of the etching ground surface. Similarly, using a mixture gas, there is a step mainly for forming a protective layer on the structure surfaces which are perpendicular with respect to the etching ground surface. These two steps are repeated one after the other. In the step for dry etching, the mixture gas is 5-12 volume of fluorocarbon gas with respect to 100 volume SF6 gas. The mixture gas in the protective film formation step is a mixture of 2-5 volume of SF6 gas with respect to 100 volume fluorocarbon gas.

Owner:SUMITOMO PRECISION PROD CO LTD

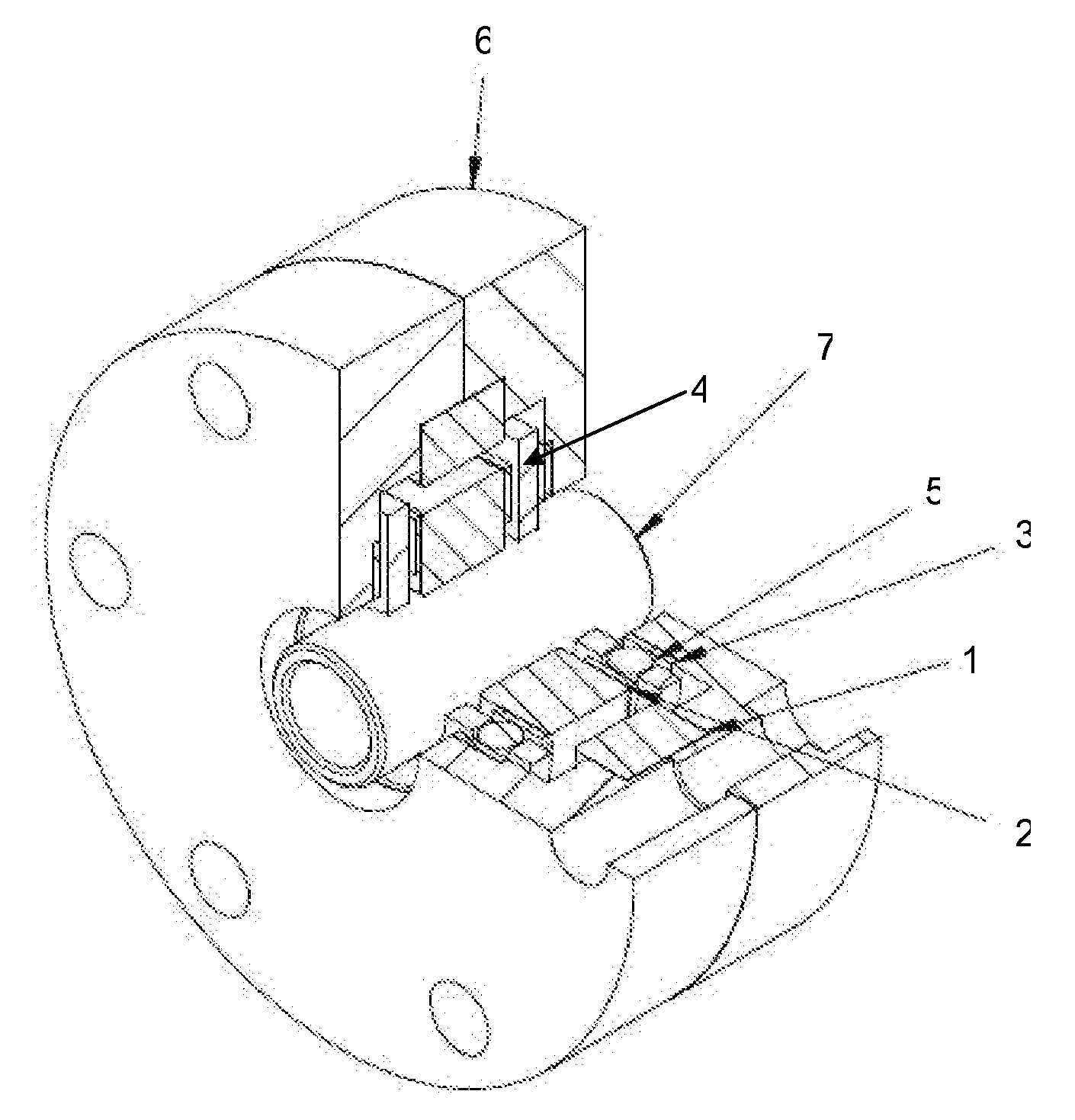

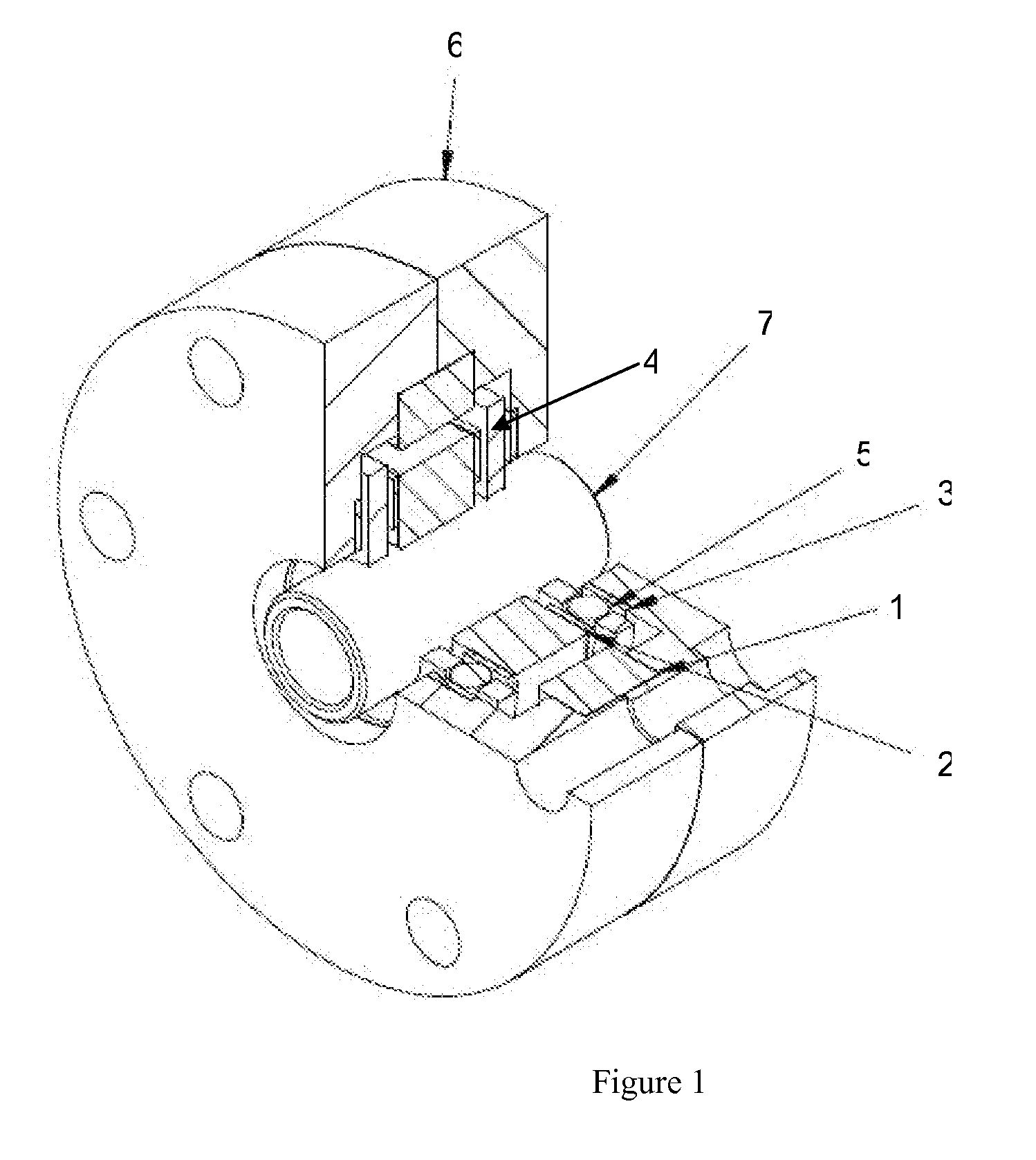

Passive magnetic bearing

InactiveUS20110001379A1MiniaturizationIncrease resistanceBall bearingsMechanical energy handlingMagnetic bearingEngineering

A passive magnetic bearing which has an exceptionally low friction couple. Radial and axial restraint is achieved through magnetic and mechanical means. The embodiment of the passive magnetic bearing has two axially magnetized rings, which each exhibit at least one pair of north and south poles. The magnetized rings are positioned in a manner where the poles are in a repulsive magnetic interaction such that the plane of symmetry which separates the like poles lies perpendicular to the axis of the rotation of a shaft and this radially constrains the movement of the shaft. Axial rigidity is added to the system by the use of ceramic bearings and related axial retaining mechanisms on one of the ring magnets thus maintaining the magnetic bearing in an otherwise unstable axial plane.

Owner:STEORN

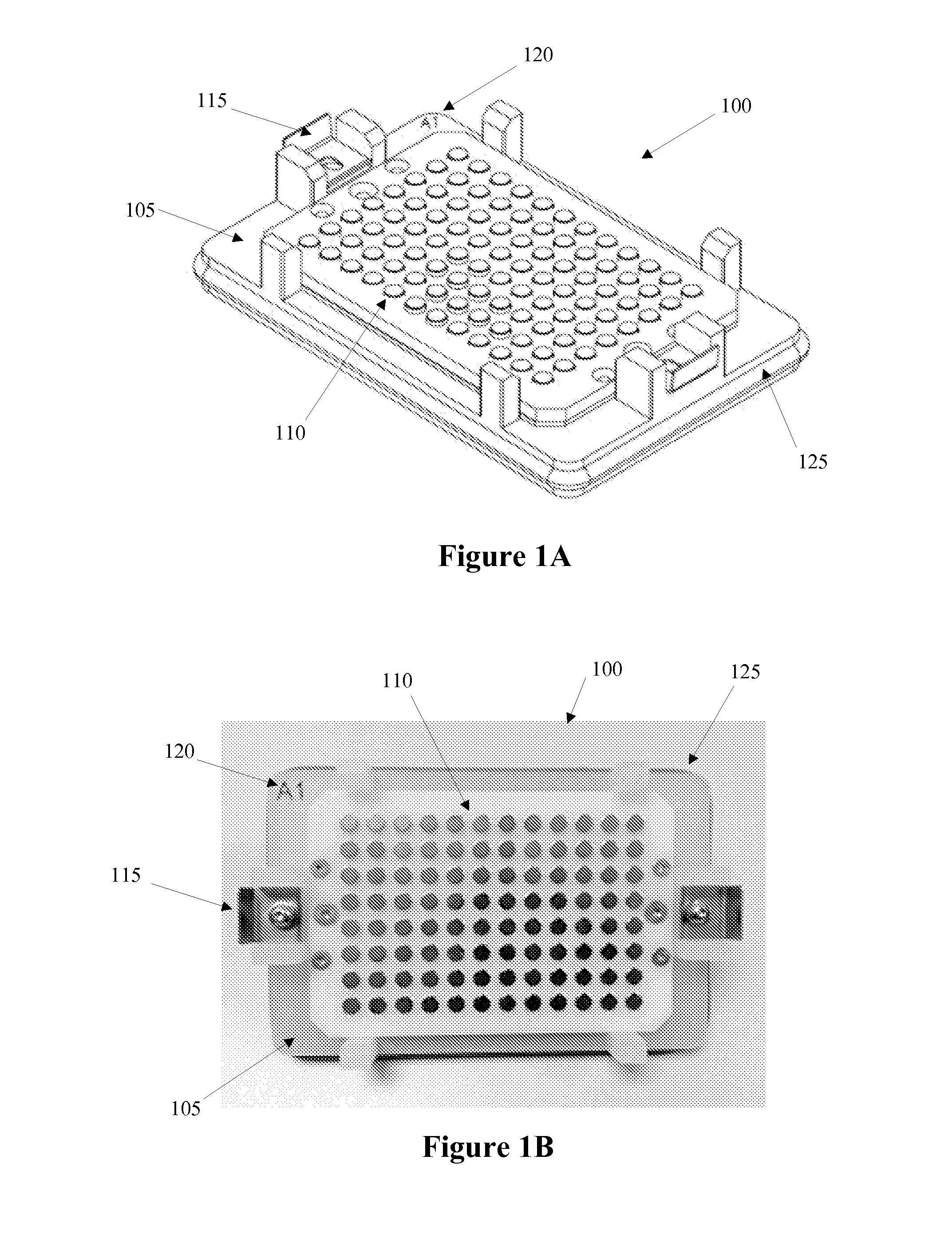

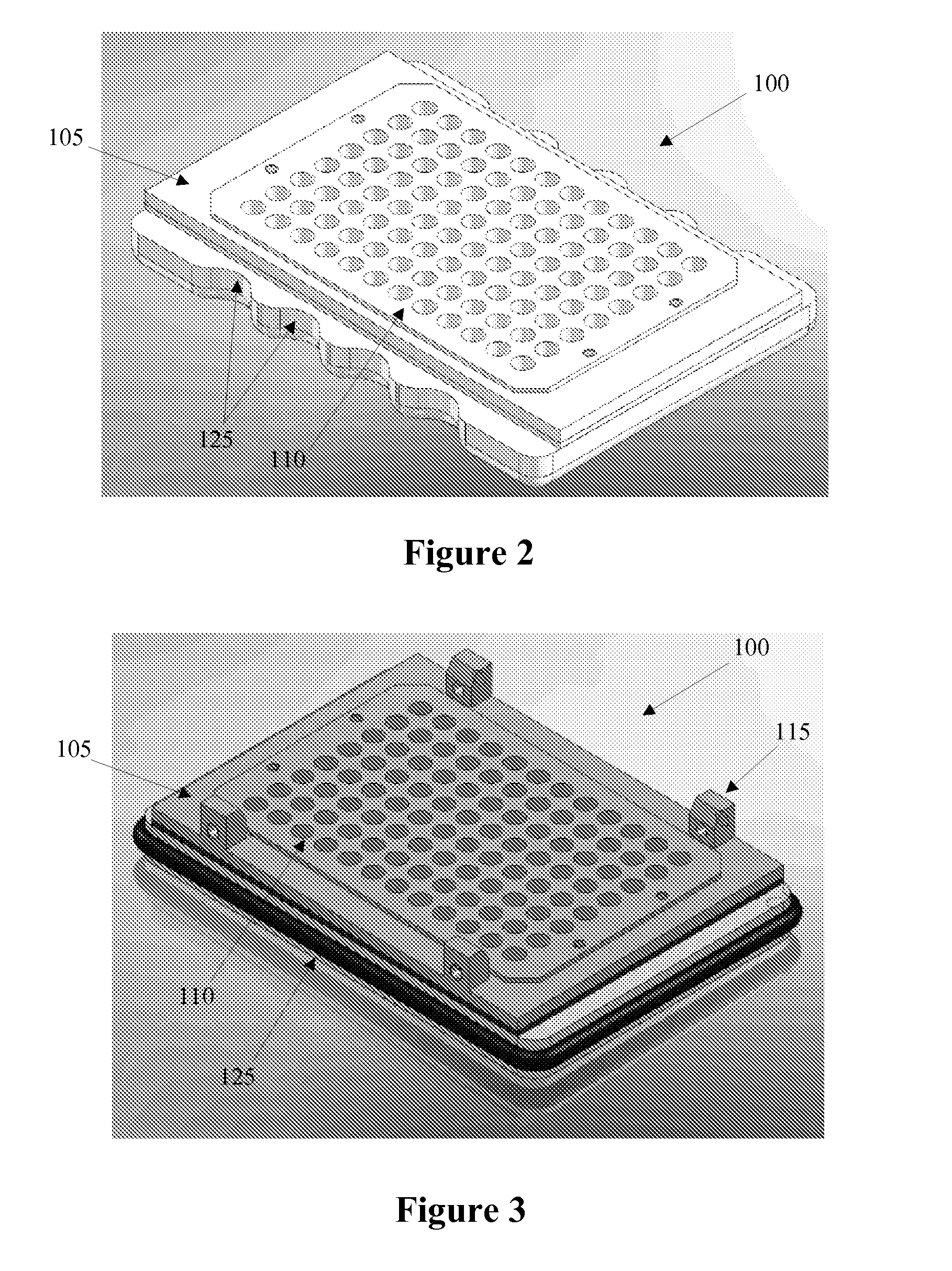

Devices, Systems and Methods for Processing of Magnetic Particles

InactiveUS20120034703A1Effectiveness and efficiencyUniform and consistent magnetic fieldSamplingChemical analysis using titrationHand held devicesMagnetic field

Devices, systems and methods for separation of magnetic particles with either hand held devices or automated instruments. Specifically, the production of magnetic fields for the separation of the particles within containers such as microtiter plates with a magnetic field that is substantially consistent for each well. Certain embodiments produce a magnetic field that is substantially uniform across each well bottom, while other embodiments produce a magnetic field that is stronger toward the outer region of each well.

Owner:AFFYMETRIX INC

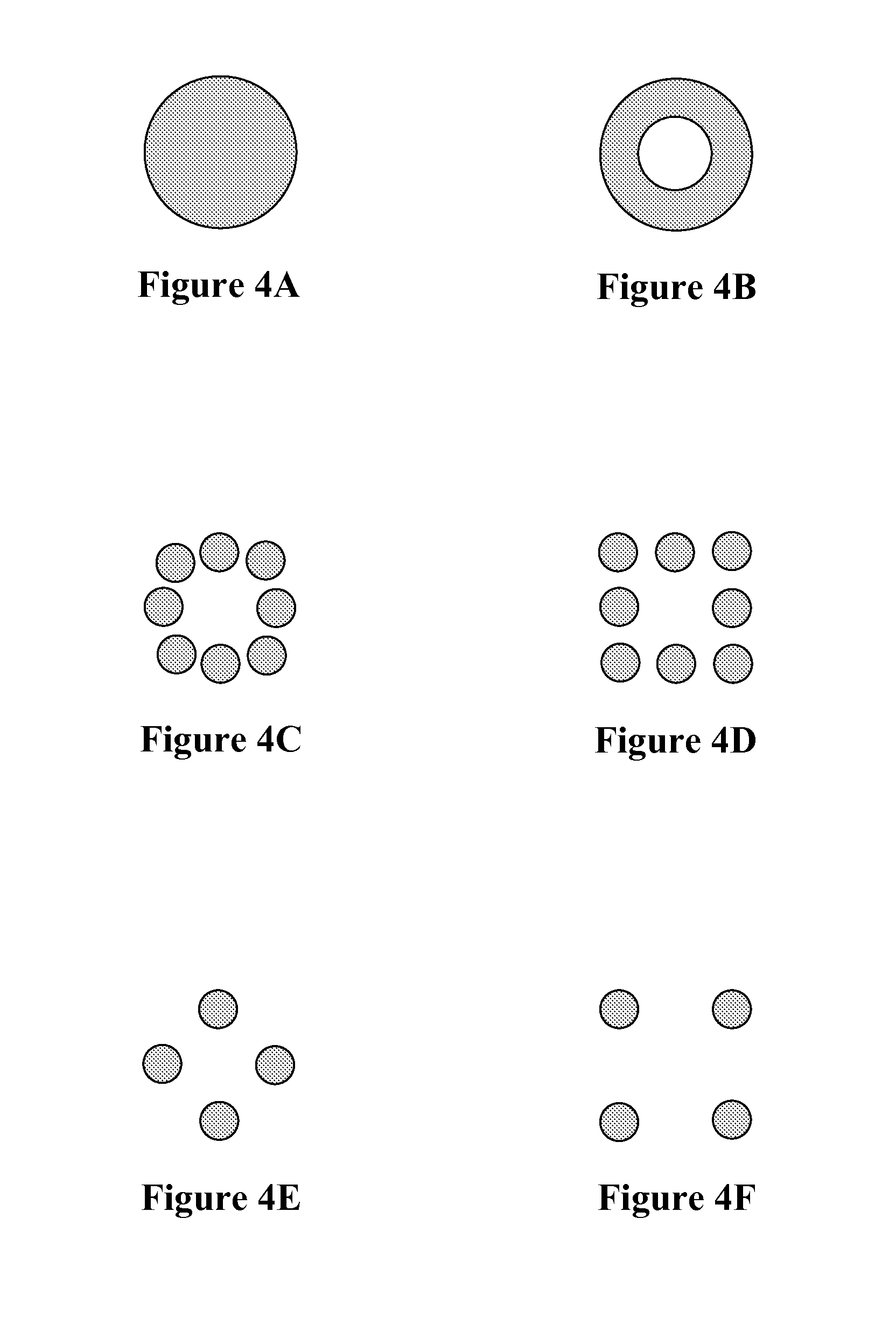

Oxygen-based biomass combustion system and method

InactiveUS20050022553A1Minimize heat lossHeat loss from heating unnecessary oxidant is minimizedSolidificationLiquefactionAutomotive engineeringCarbon dioxide

An oxygen-based biomass solid fuel combustion system and method has an air separator for separating oxygen from air providing a supply of oxygen for feeding oxygen to a solid fuel combustion chamber. An airlock feeds a metered amount of solid fuel to the solid fuel combustion chamber. A burner stage having a firetube for collecting fuel gases from the solid fuel combustion chamber combusts the collected fuel gases with further oxygen from the separator and heats a boiler to generate steam. A heat utilization device (e.g. an electrical generator) may be connected to the steam boiler. Nitrogen-free diluent gases (e.g. argon and carbon dioxide) are used to control combustion process temperatures. The usable heat energy and useful byproducts are extracted from the different stages of the process.

Owner:MUNIZ CESAR A

Etchants and etchant systems with plural etch selectivities

InactiveUS7591959B2Minimizes and removeImprove etch selectivityDecorative surface effectsSemiconductor/solid-state device manufacturingPhosphoric acidSilicon oxide

Owner:MICRON TECH INC

Cleaning solution formulations for substrates

InactiveUS20090072190A1Thorough understandingRemove pollutantsSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsElectrical conductorPhysical chemistry

A semiconductor system includes: providing a dielectric layer; providing a conductor in the dielectric layer, the conductor exposed at the top of the dielectric layer; capping the exposed conductor; and modifying the surface of the dielectric layer, modifying the surface of the dielectric layer, wherein modifying the surface includes cleaning conductor ions from the dielectric layer by dissolving the conductor in a low pH solution, dissolving the dielectric layer under the conductor ions, mechanically enhanced cleaning, or chemisorbing a hydrophobic layer on the dielectric layer.

Owner:LAM RES CORP

Oxidative pretreatment of biomass to enhance enzymatic saccharification

InactiveUS20100159515A1High selectivityMinimize sugar lossWashing/displacing pulp-treating liquorsBiofuelsLignocellulosic biomassSolvent

Lignocellulosic biomass comprising lignin is treated by selective extraction and oxidation of lignin using a solvent solution comprising water in combination with at least one Mn(III) salt to produce readily saccharifiable carbohydrate enriched biomass.

Owner:EI DU PONT DE NEMOURS & CO

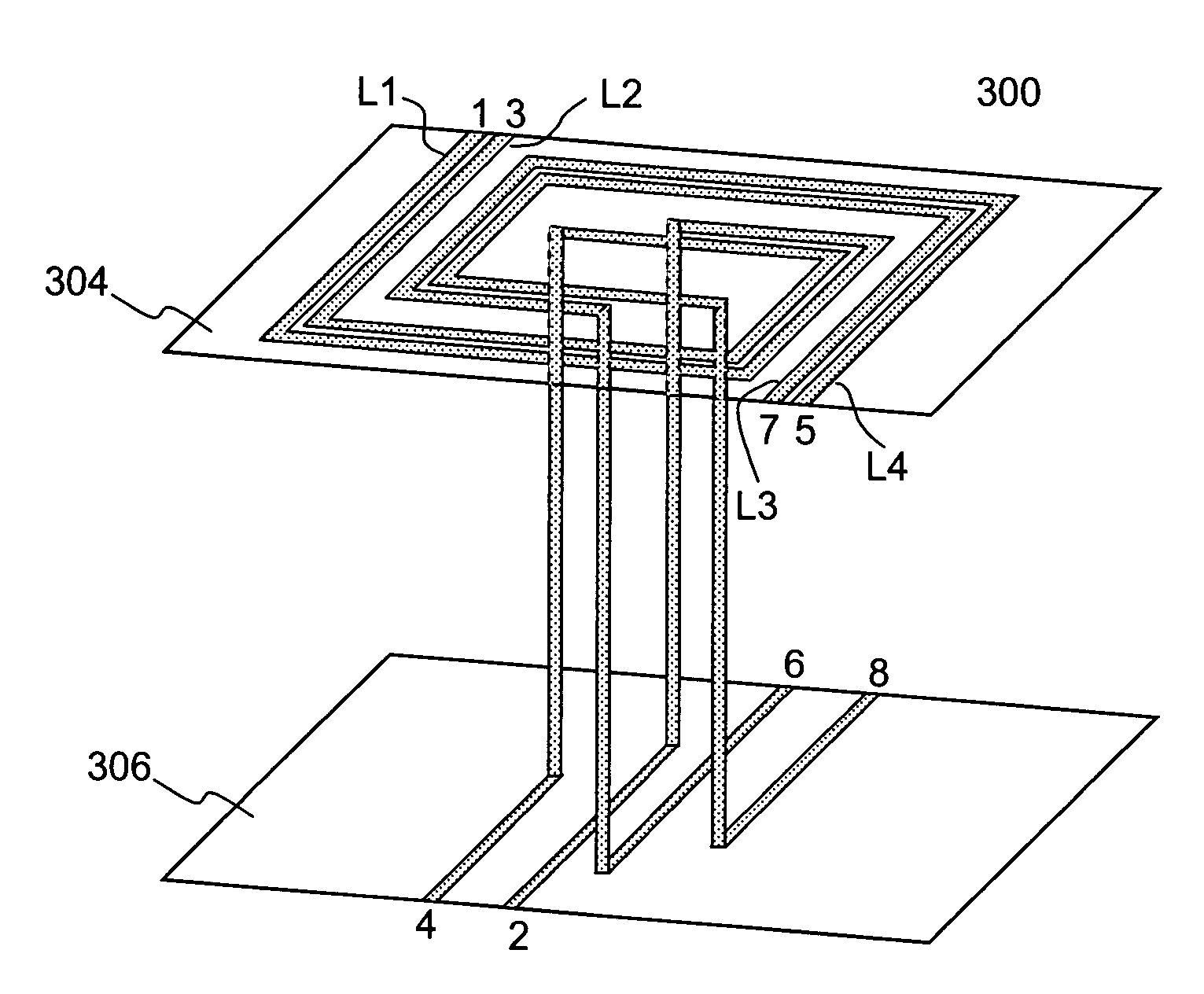

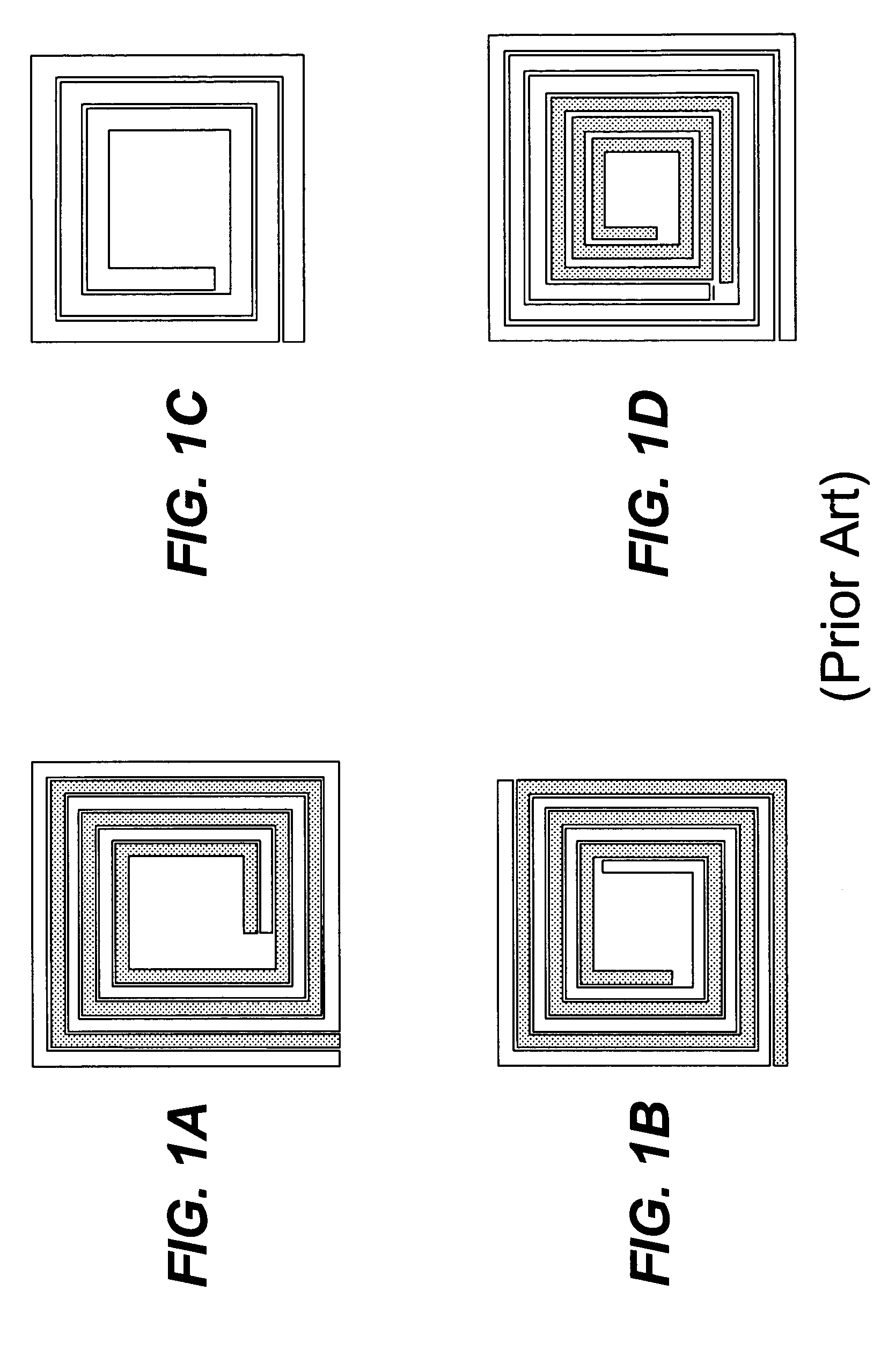

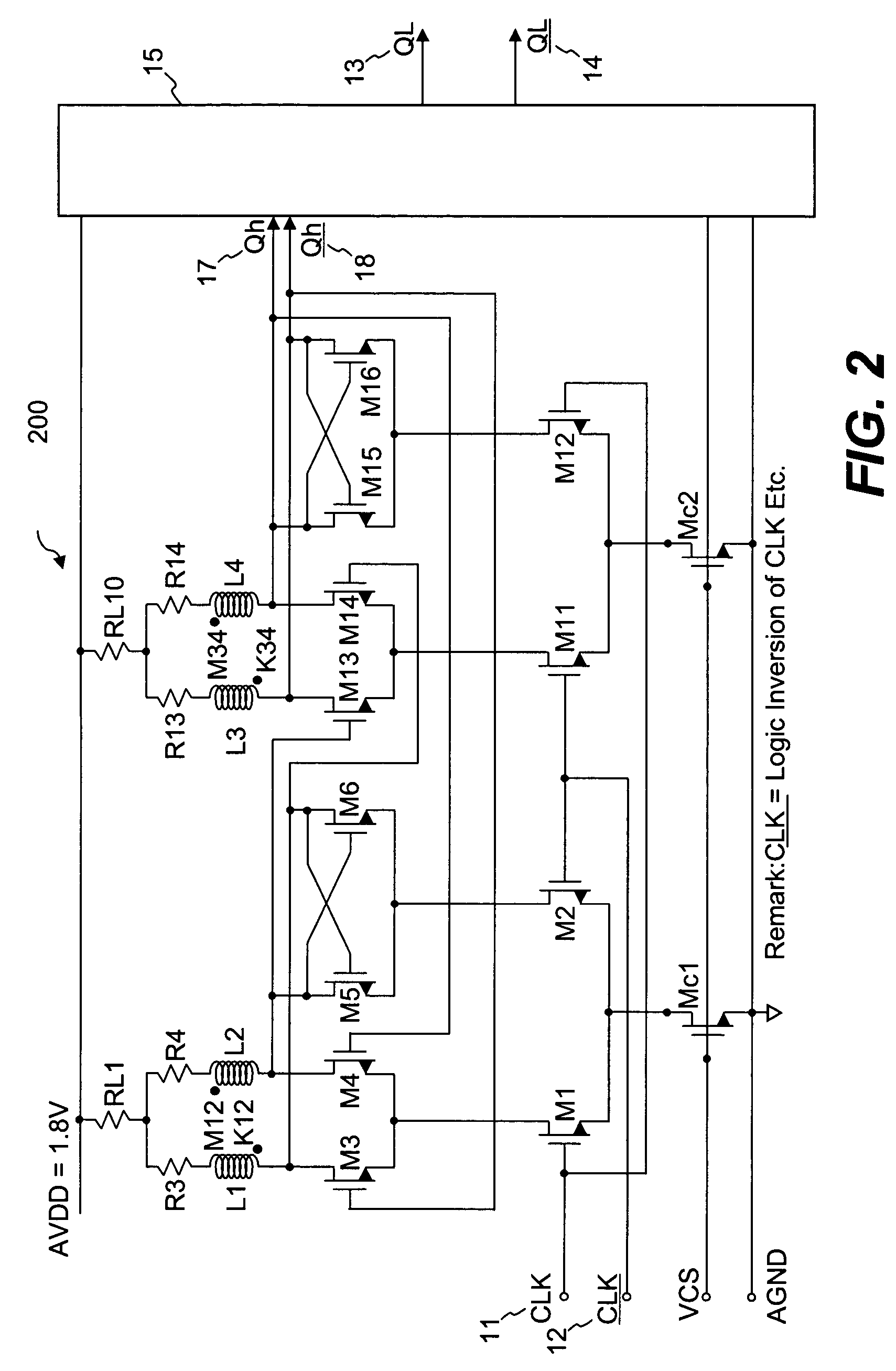

Center-tap transformers in integrated circuits

InactiveUS6970064B2Improve performanceLow costSemiconductor/solid-state device detailsSolid-state devicesElectricityConductor Coil

Techniques for implementing transformers with center-taps are described. Based on an overlay winding structure, according to one embodiment, the primary and the secondary of the transformer are respectively formed on two separate layers that are stacked on top of each other, wherein the secondary includes two segments, the two respective terminals of the two segments are coupled together to a component in a circuit to form a center-tap of the secondary. According to another embodiment, three or more separating windings are formed on separate layers. At least one of the windings is a conducting stripe wound in loops and includes a center-tap that extends across but not electrically connected to the loops of the conducting stripe by detouring the conducting stripe through other layers.

Owner:ZHANG MINGHAO MARY +1

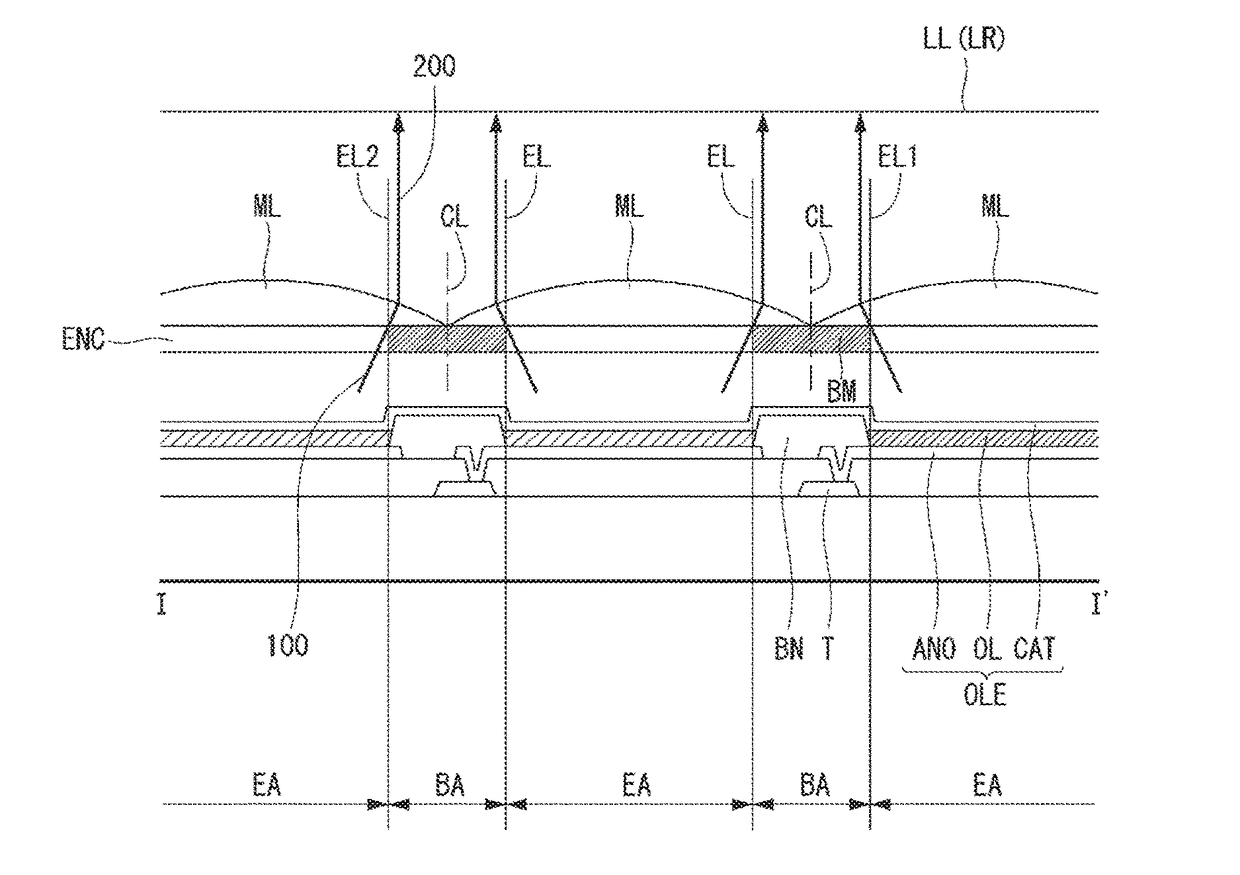

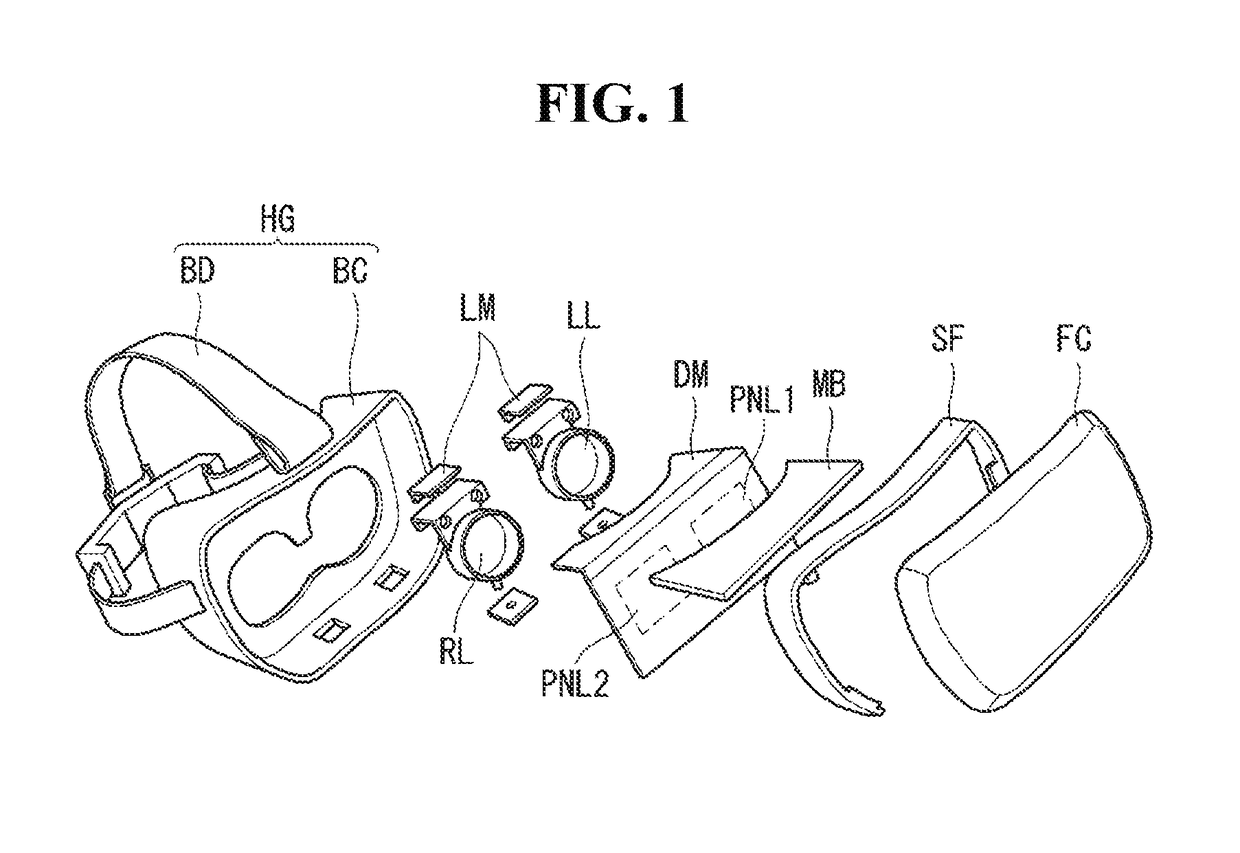

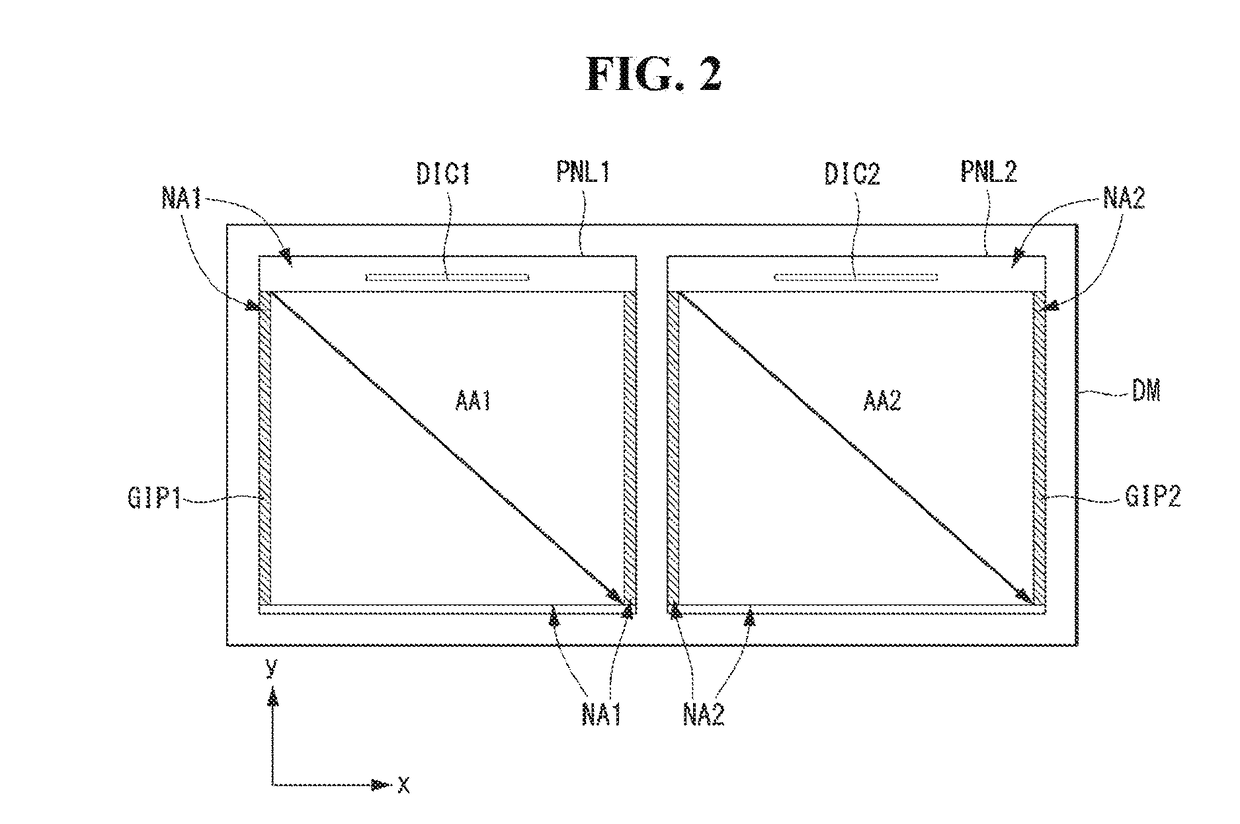

Display for personal immersion apparatus

ActiveUS20170315372A1Reduce fatigueEnhances stereoscope and reality and immersion propertyStatic indicating devicesSolid-state devicesCamera lensDisplay device

The present disclosure relates to a display for a personal immersion apparatus for embodying the virtual reality or the augmented reality. The present disclosure suggests a display for a personal immersion apparatus comprising: a display panel; and an imaging lens; wherein the display panel includes: a plurality of pixel areas disposed on a substrate; an emission area defined in the each pixel area; a non-emission area surrounding the emission area in the each pixel area; and a micro deflector configured to deflect lights scattered over the non-emission area from the emission area to a normal direction with respect to a surface of the substrate, and to provide the deflected lights to the imaging lens, and wherein the imaging lens is disposed apart from the display panel with a focal length of the imaging lens.

Owner:LG DISPLAY CO LTD

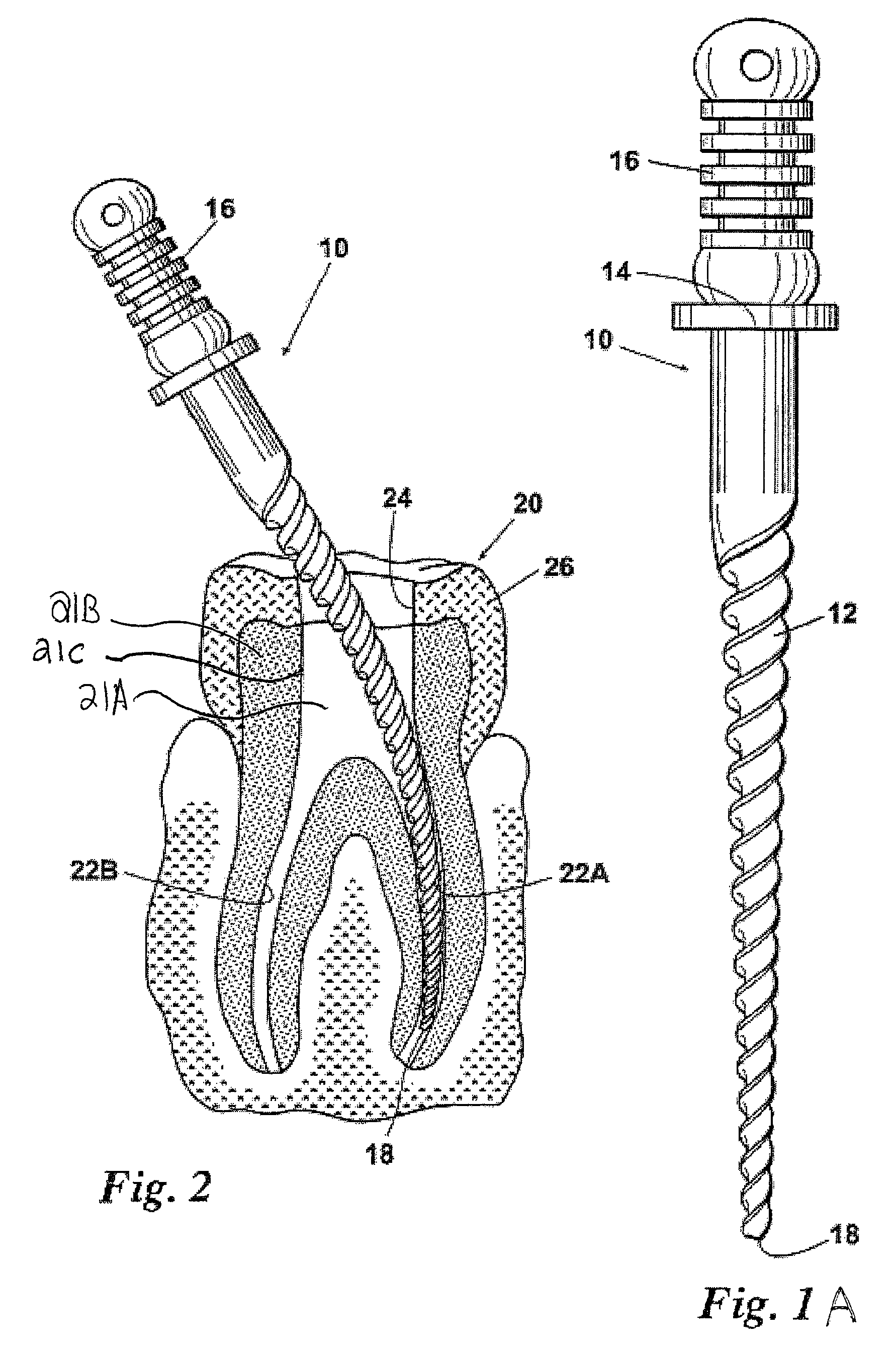

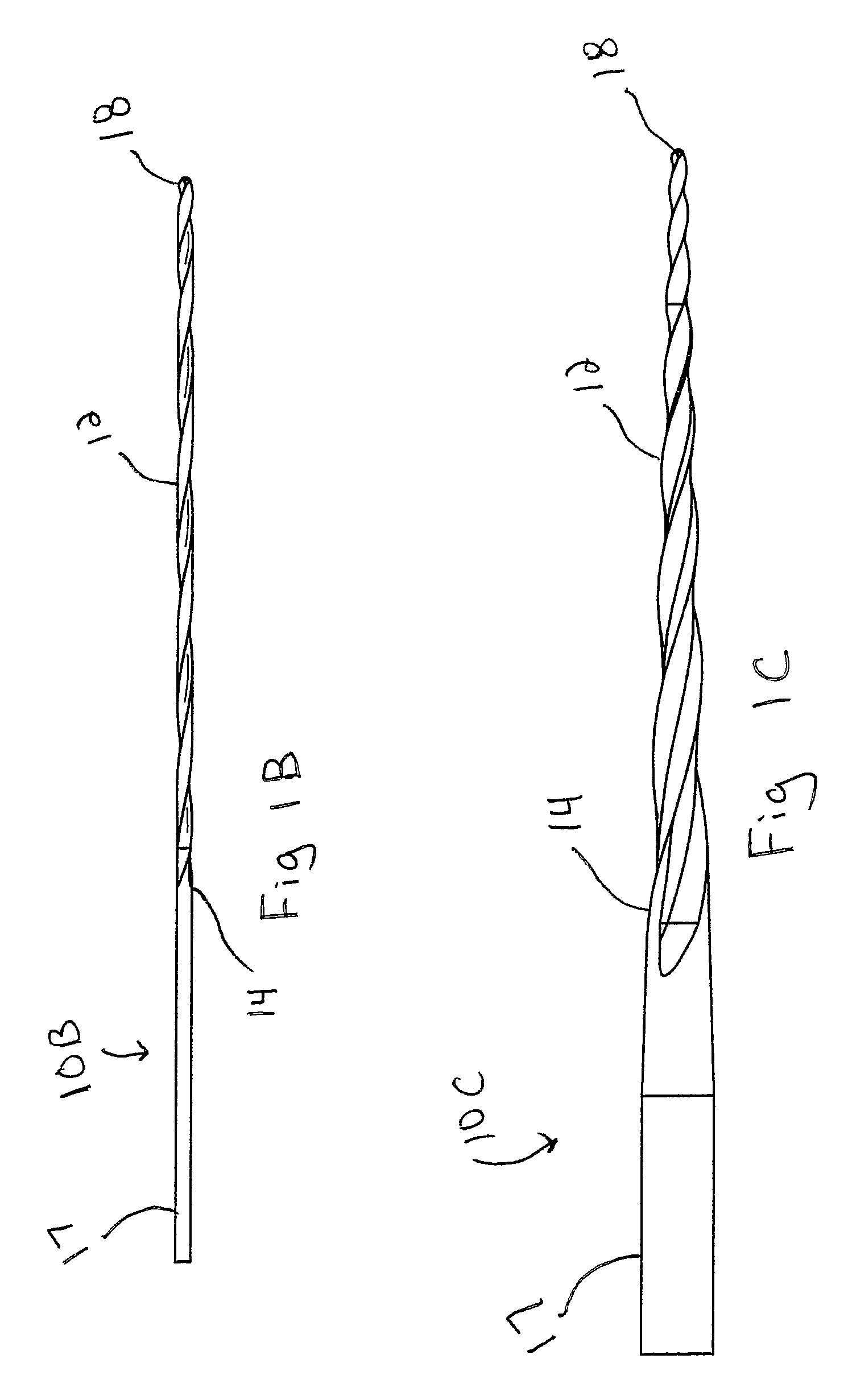

Endodontic instruments and methods of manufacturing thereof

ActiveUS8916009B2Avoid damageMinimizes and removeFurnace typesTeeth cappingEngineeringMechanical engineering

Owner:DENTSPLY SIRONA INC

Process for the preparation of a dealuminated zeolitic material having the bea framework structure

ActiveUS20180022611A1Highly unexpected stabilityReduce inactivation rateMolecular sieve catalystsMolecular sieve catalystOxygenateOxygen compound

The present invention relates to a method for the preparation of a treated zeolitic material having a BEA framework structure comprising the steps of: (i) providing a zeolitic material having a BEA framework structure, wherein the BEA framework structure comprises YO2 and X2O3, wherein Y is a tetravalent element, and X is a trivalent element, and wherein the zeolitic material having a BEA framework structure is obtainable and / or obtained from an organotemplate-free synthetic process; (ii) calcining the zeolitic material provided in step (i) at a temperature of 650° C. or more; and (iii) treating the calcined zeolitic material obtained from step (ii) with an aqueous solution having a pH of 5 or less, as well as to zeolitic materials per se preferably obtainable according to the inventive method and to their use, and to a process for converting oxygenates to olefins employing the inventive zeolitic materials.

Owner:BASF AG

Coordination of algorithms in algorithmic trading engine with fast switching and safe mode

A graphical user interface is used along with an automated algorithm selection function to enable market participants to initiate automated, multi-algorithm trading strategies through a single drag and drop motion. A symbol representing a security can be dragged and dropped onto an icon representing a tactical or strategic algorithm. Other features of the graphical user interface show information such as the progress of the algorithms. Fast switching and safe mode are used to minimize a cost associated with algorithm switching.

Owner:PORTWARE LLC

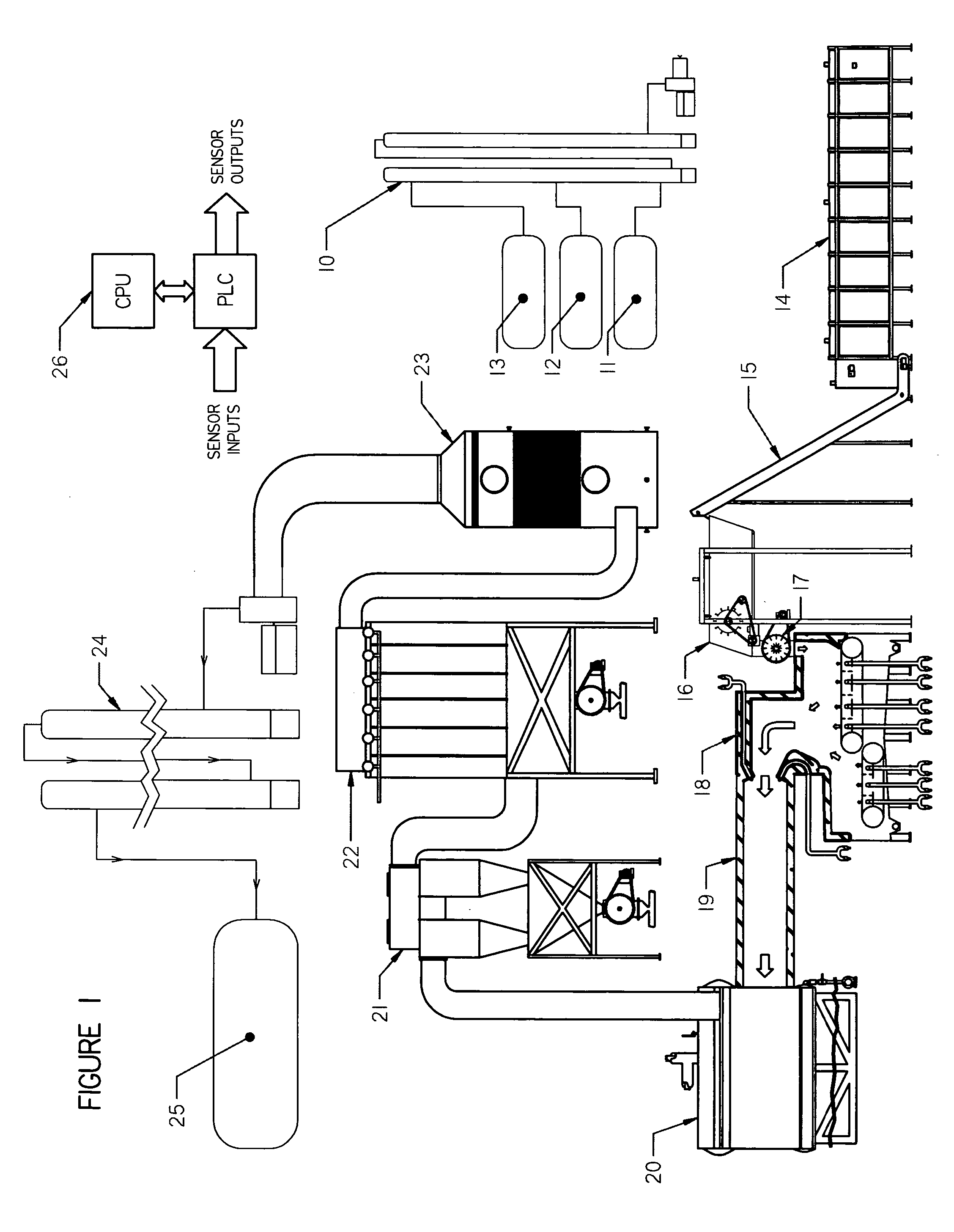

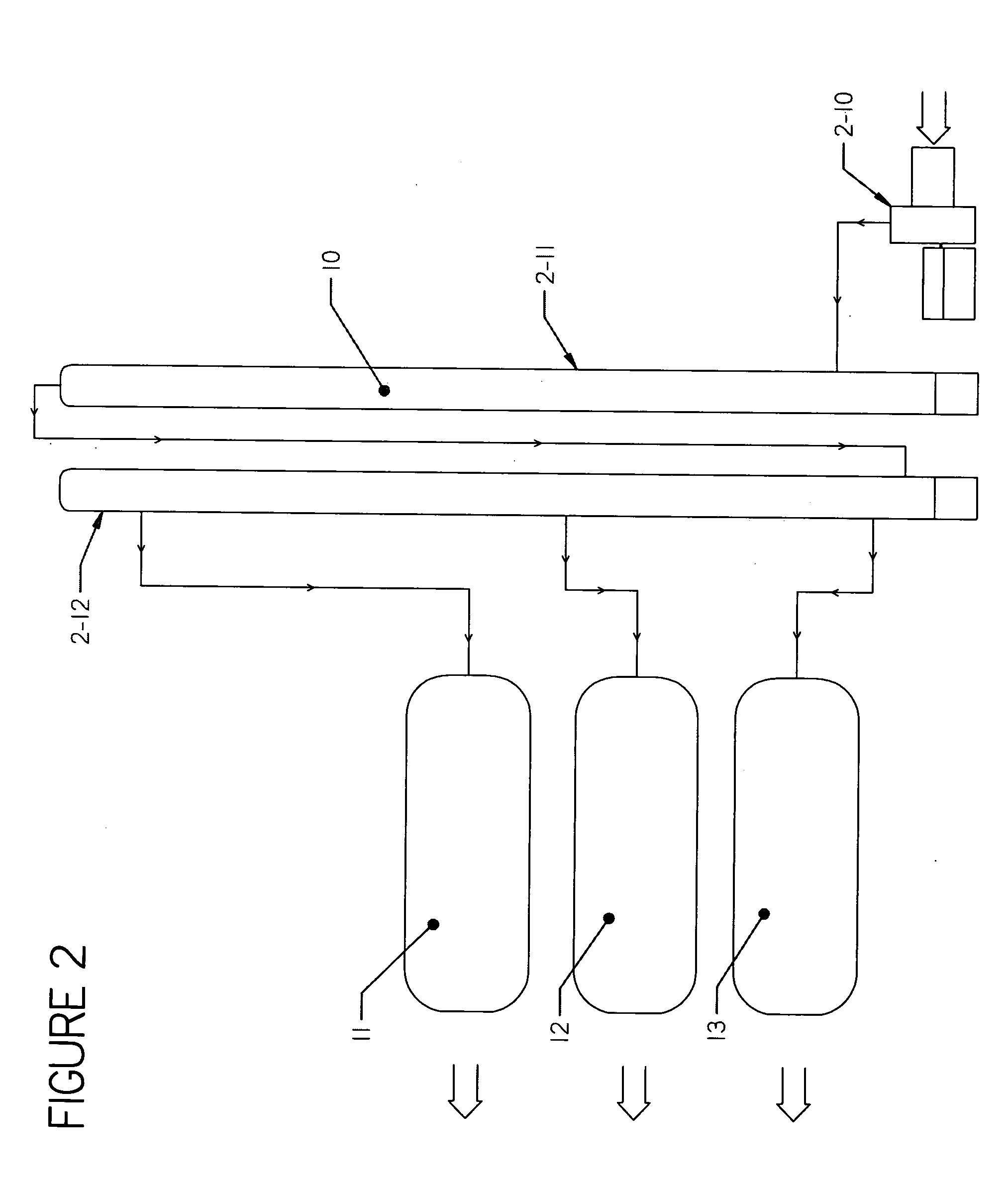

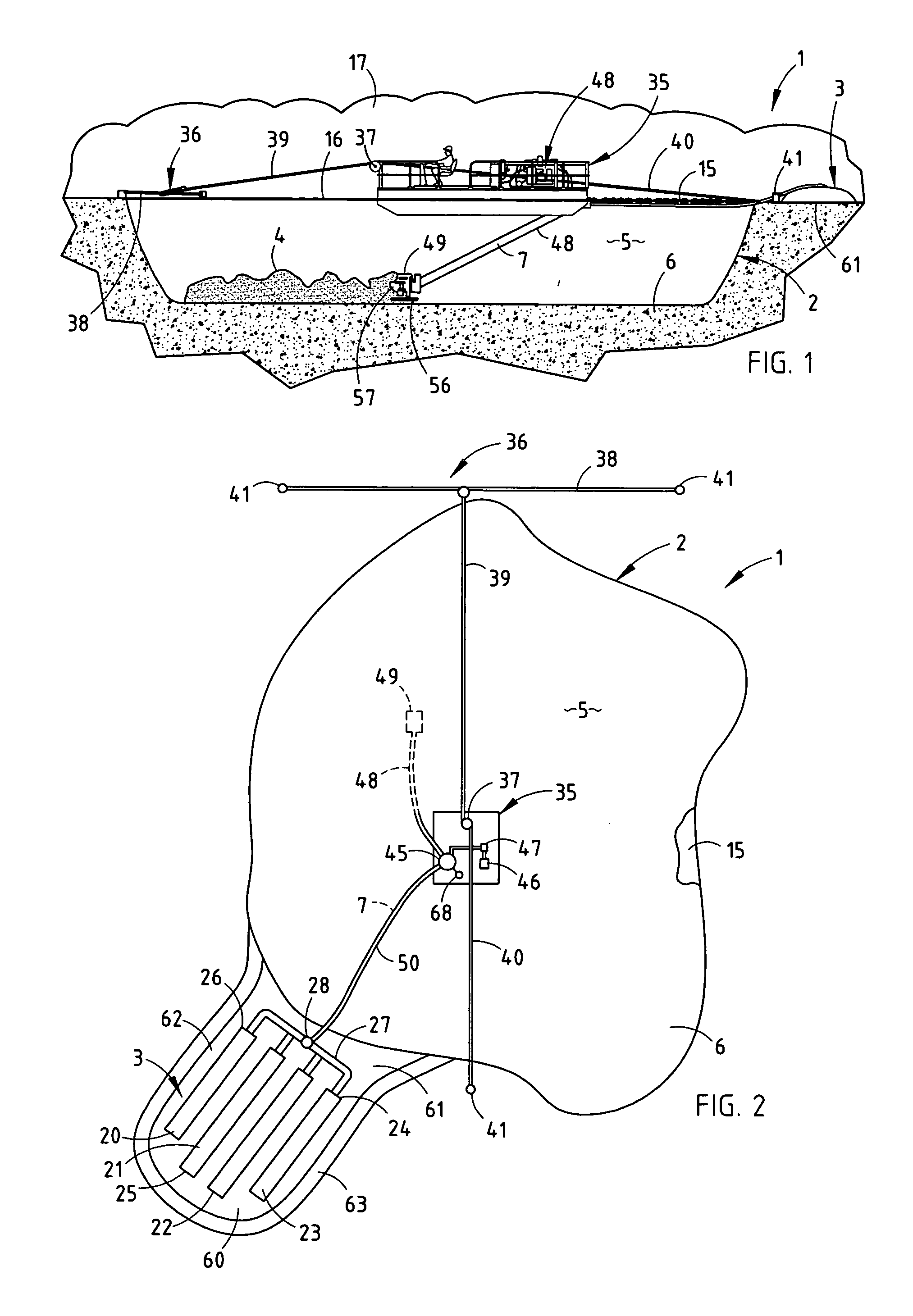

Method and apparatus for remediating wastewater holding areas and the like

InactiveUS20050016931A1Cost effectiveLow costSludge treatment by de-watering/drying/thickeningWater cleaningWastewaterSlurry

A method and apparatus for remediating waster water holding areas and the like includes a closed, foraminous dewatering membrane that is positioned adjacent to the wastewater holding area. Sludge and adjacent water on the bottom of the wastewater holding area are pumped in the form of a sludge slurry into the interior of the dewatering membrane. The water is removed from the sludge slurry by allowing gravitational forces to flow water through the dewatering membrane. The dewatering membrane is then opened, and the dewatered sludge is removed for depositing at an appropriate site.

Owner:INFRASTRUCTURE ALTERNATIVES

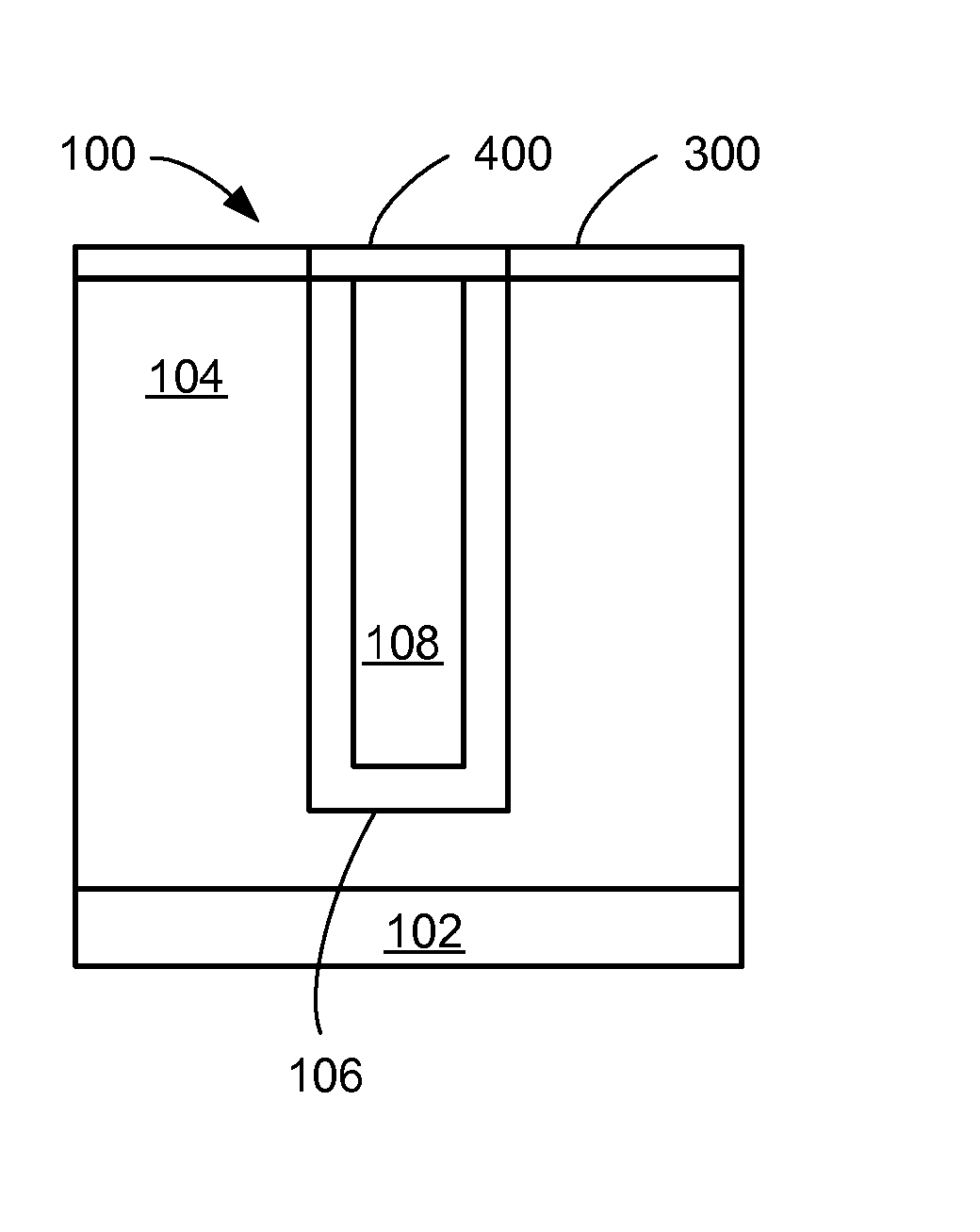

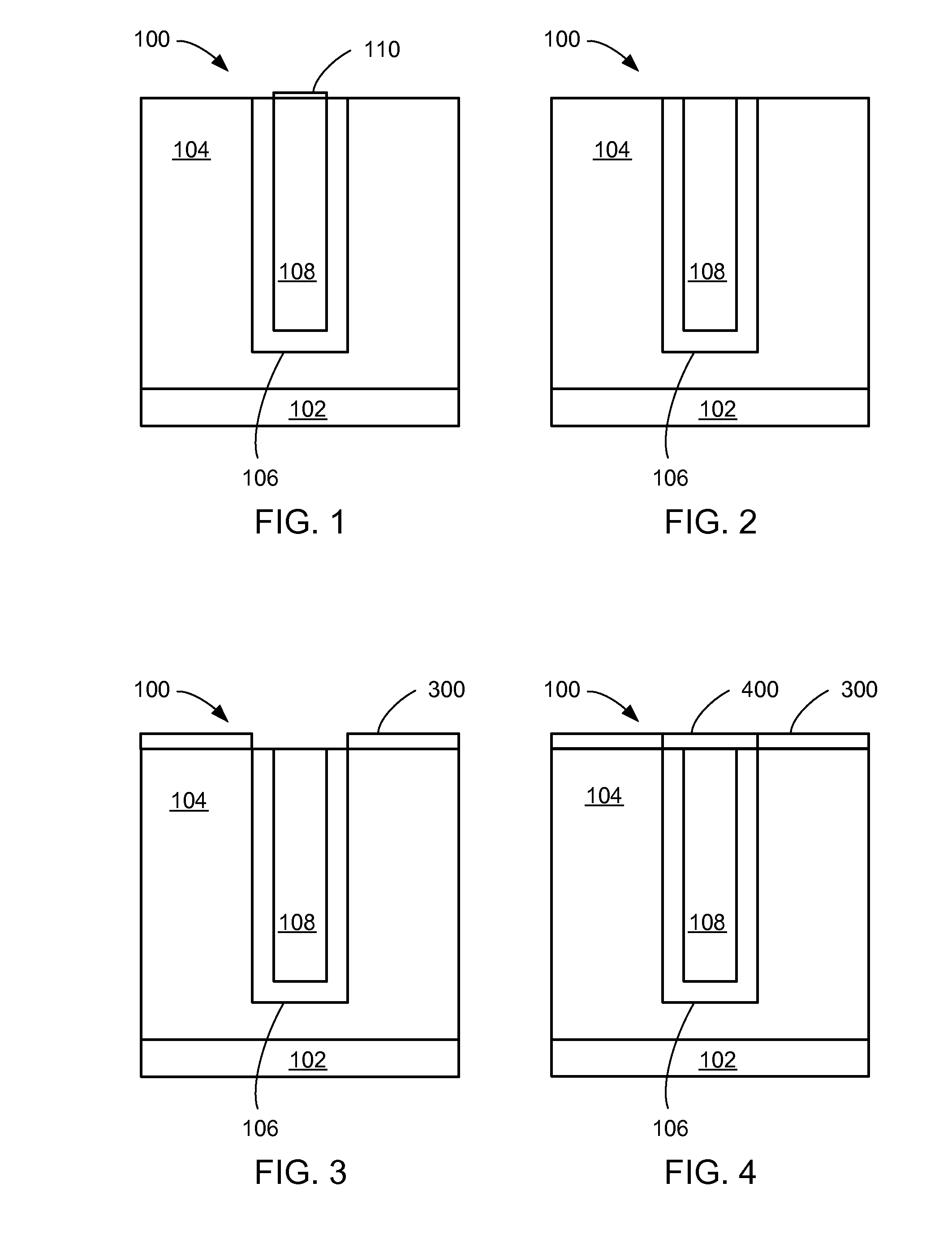

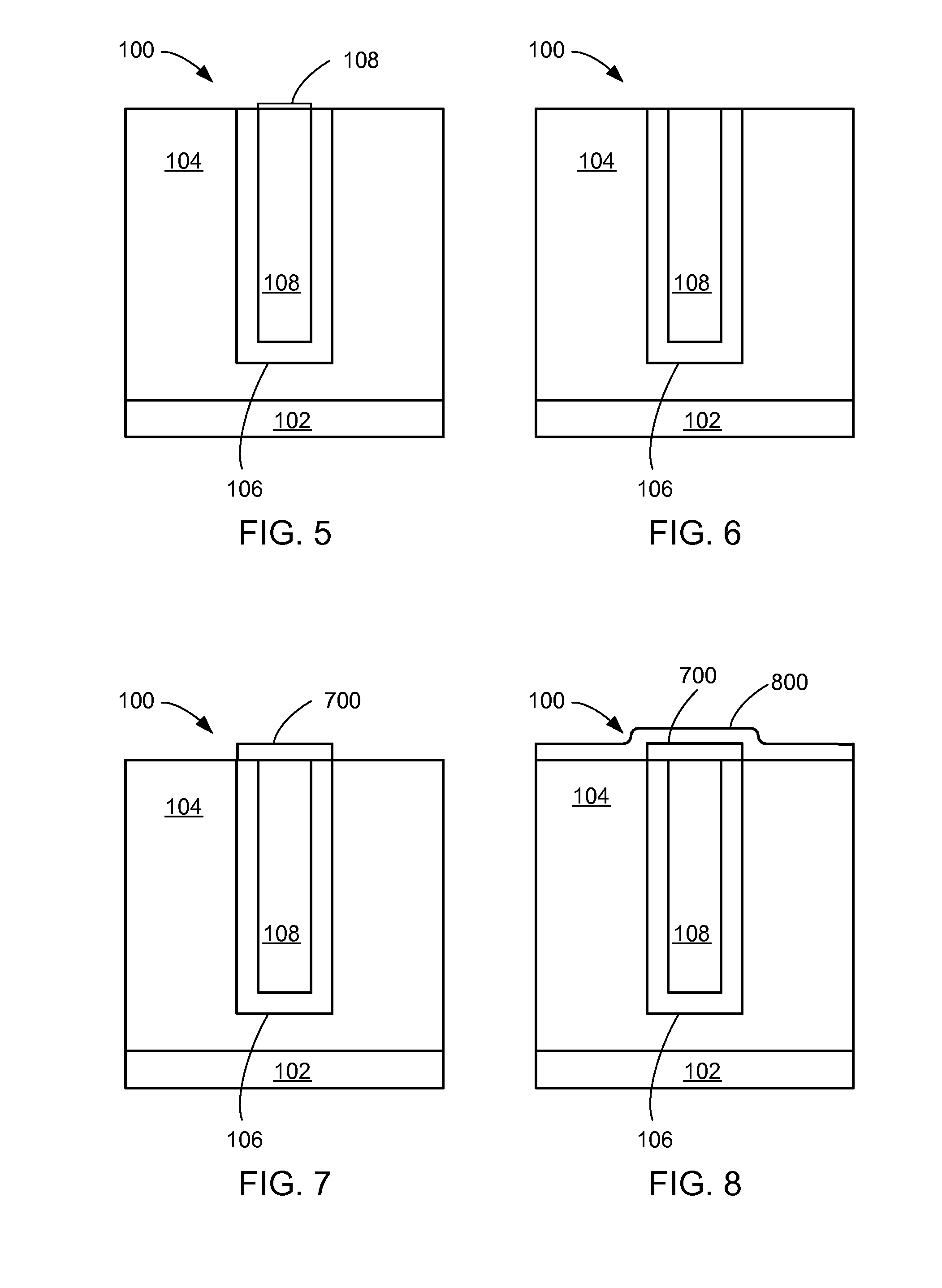

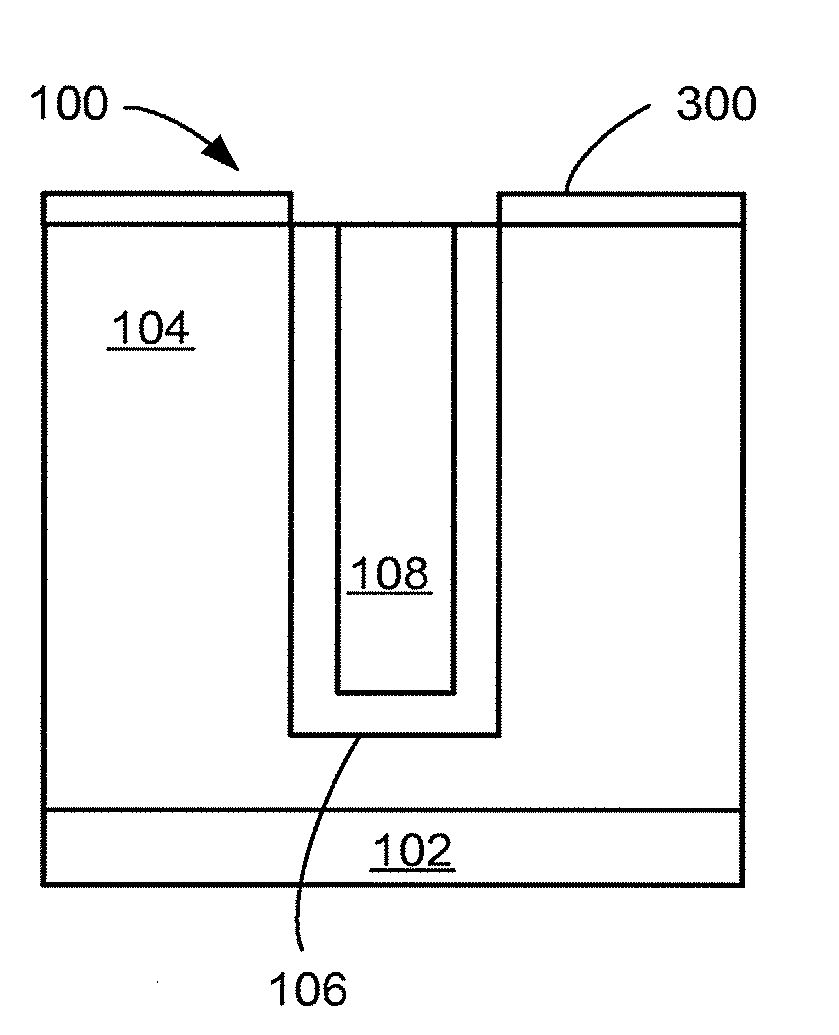

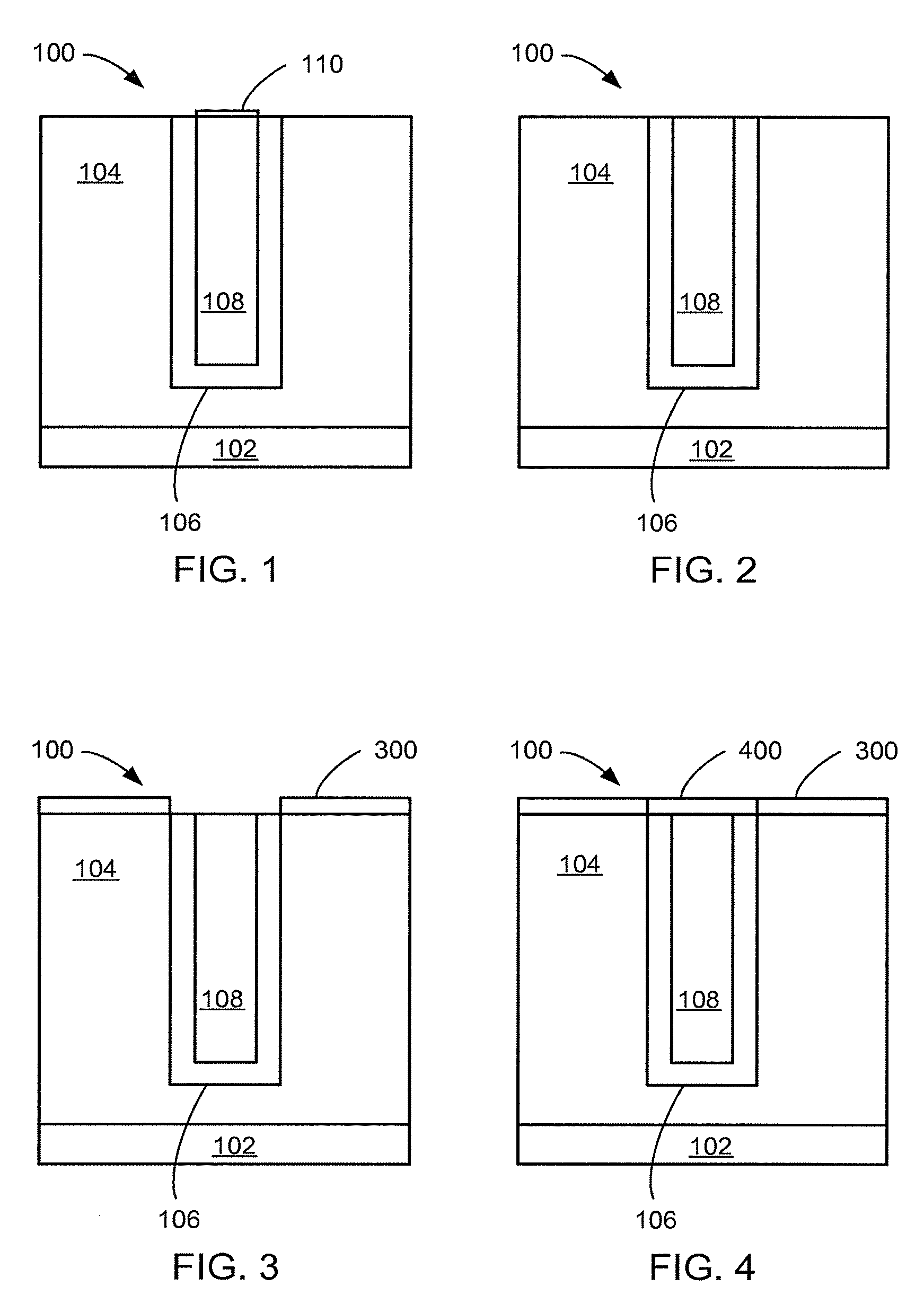

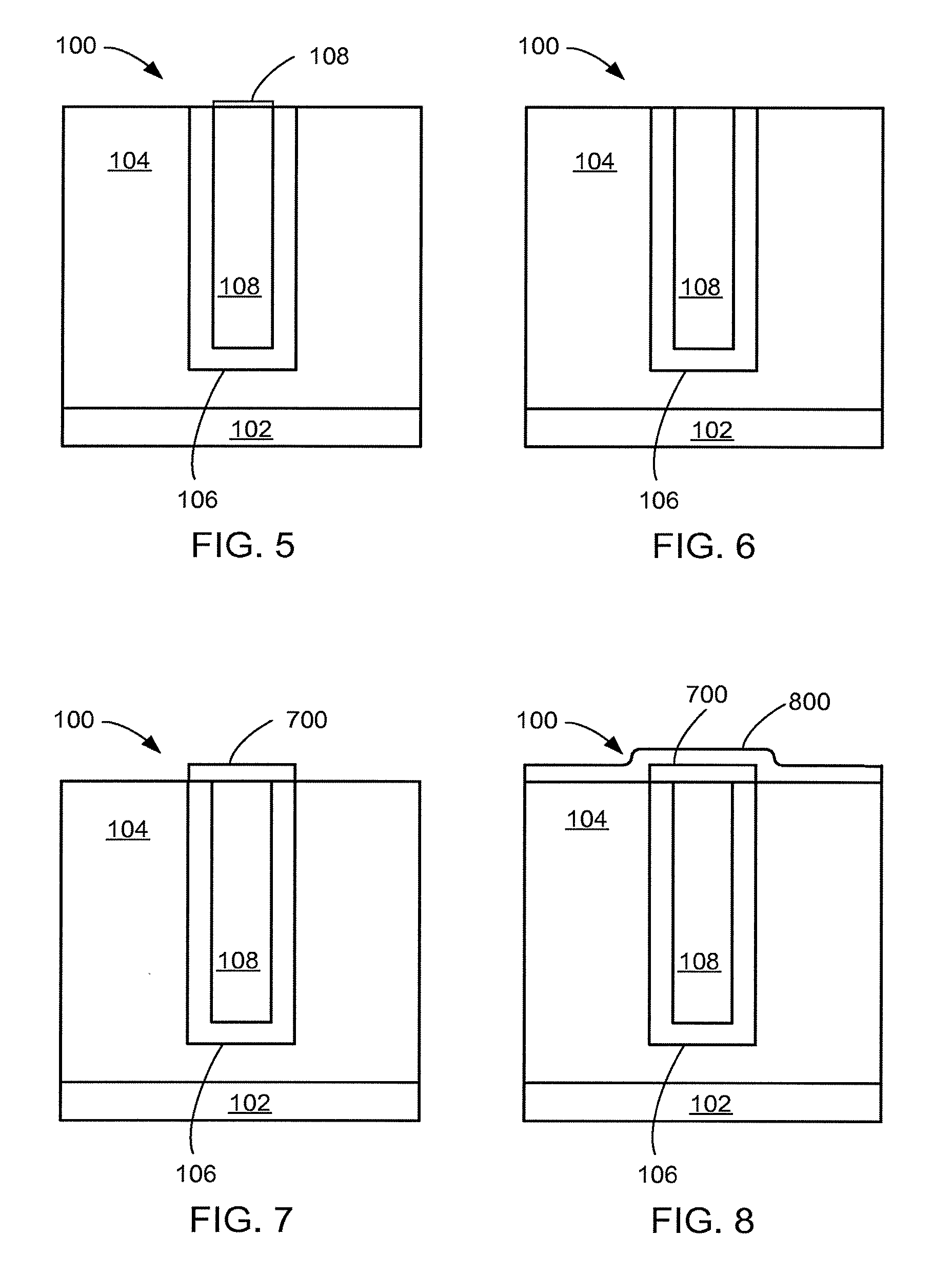

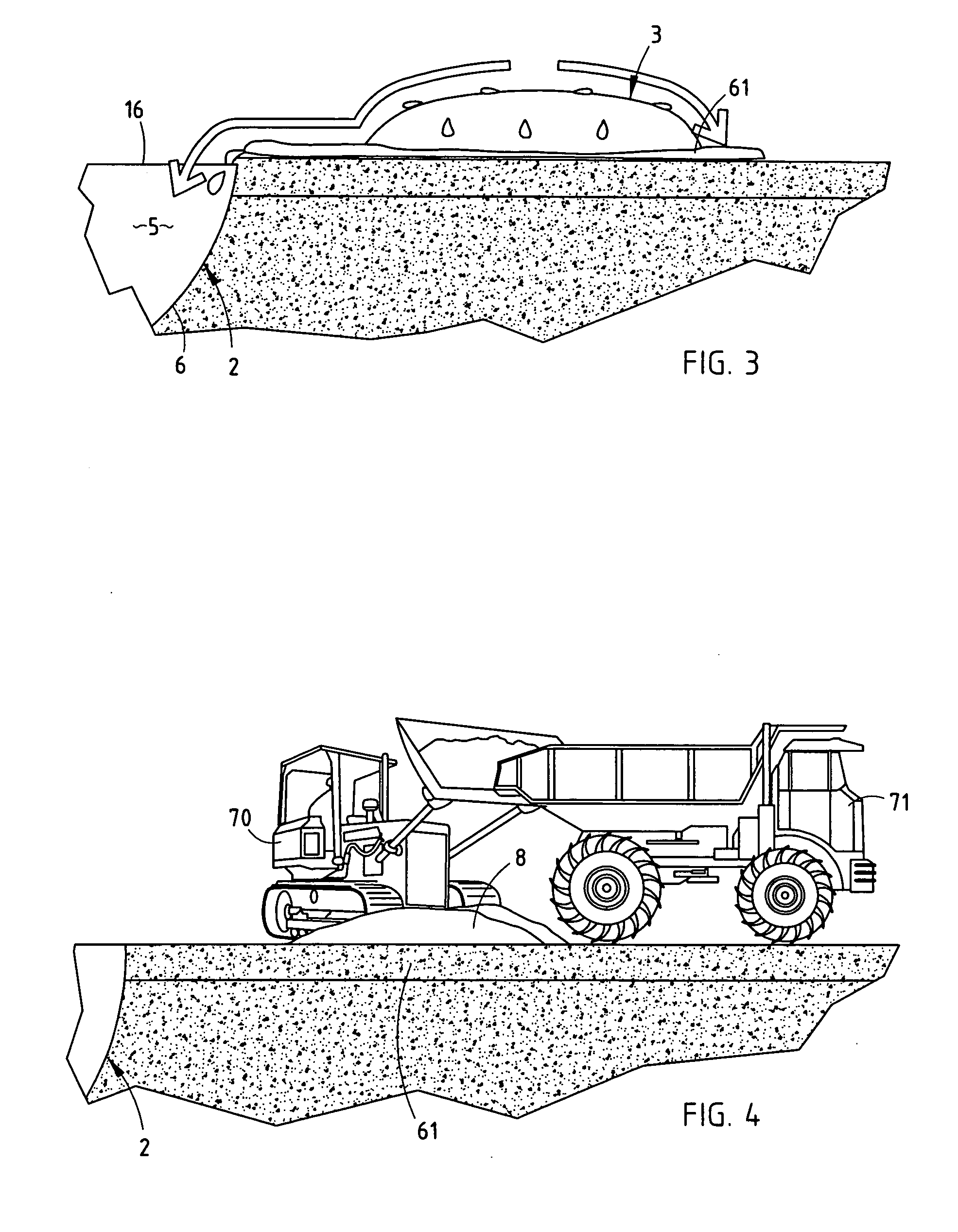

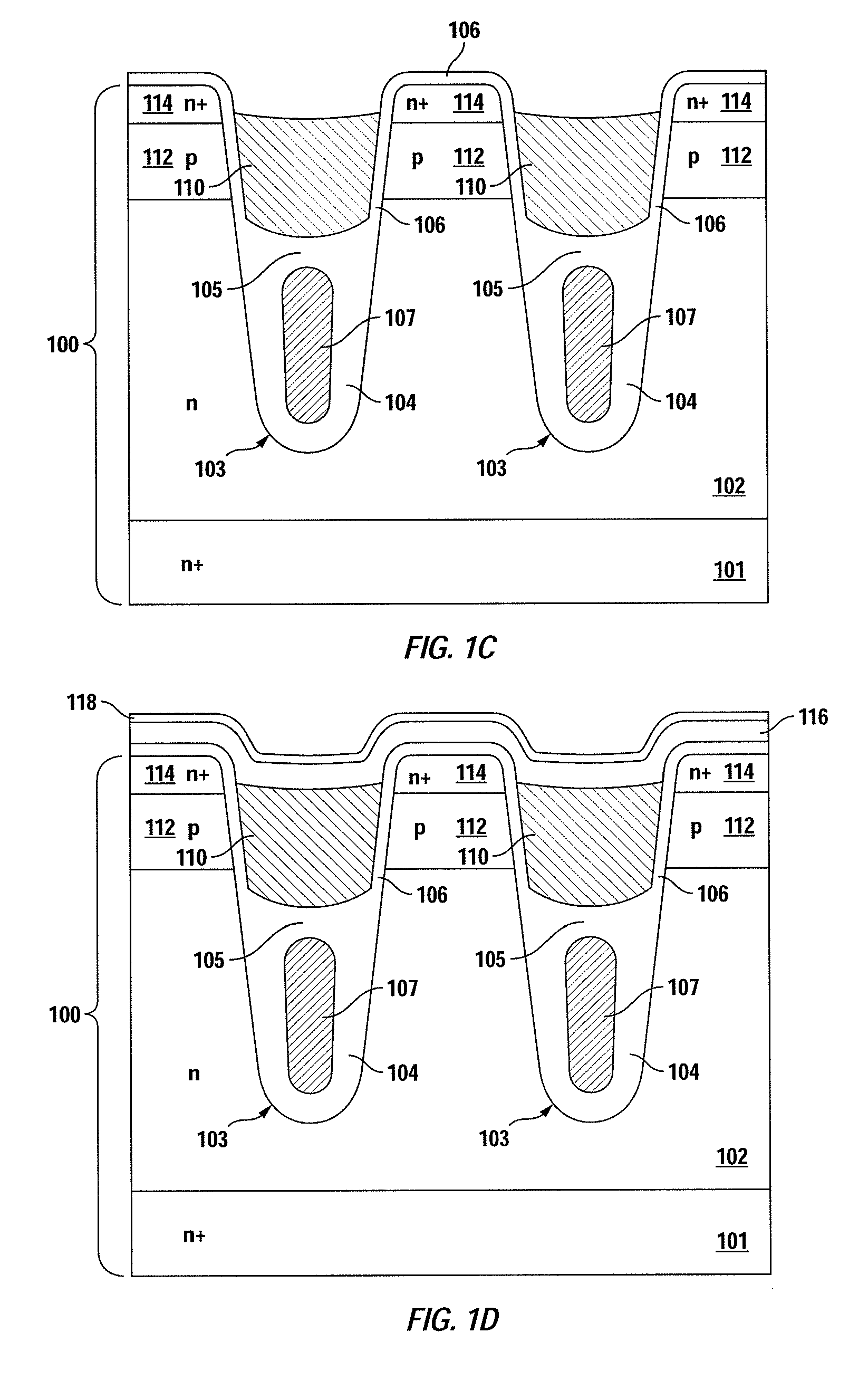

Structure and Method for Forming a Salicide on the Gate Electrode of a Trench-Gate FET

ActiveUS20100244126A1Inhibition formationMinimizes and removeSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideGate dielectric

A method for forming a trench-gate FET includes the following steps. A plurality of trenches is formed extending into a semiconductor region. A gate dielectric is formed extending along opposing sidewalls of each trench and over mesa surfaces of the semiconductor region between adjacent trenches. A gate electrode is formed in each trench isolated from the semiconductor region by the gate dielectric. Well regions of a second conductivity type are formed in the semiconductor region. Source regions of the first conductivity type are formed in upper portions of the well regions. After forming the source regions, a salicide layer is formed over the gate electrode in each trench abutting portions of the gate dielectric. The gate dielectric prevents formation of the salicide layer over the mesa surfaces of the semiconductor region between adjacent trenches.

Owner:SEMICON COMPONENTS IND LLC

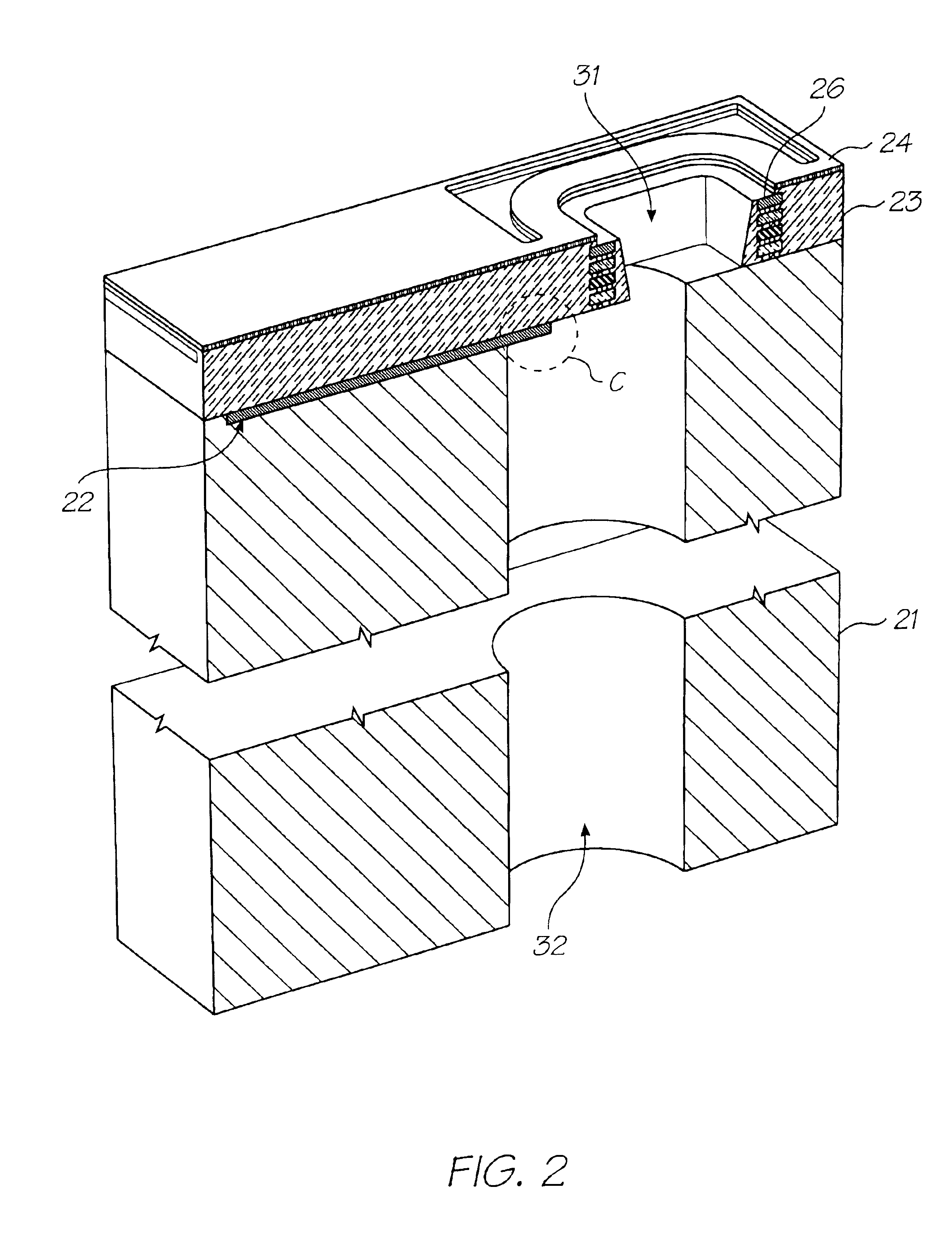

Inkjet printhead with ink supply passage formed from both sides of the wafer by overlapping etches

InactiveUS6962402B2Minimizes and removePrevent leakageRecording apparatusWriting implementsResistDielectric

An inkjet printhead with nozzles 4 and liquid passages 31, 32 leading to each nozzle. The nozzles, ejection actuators 14, associated drive circuitry 22 and liquid passage 31, 32 being formed on and through a wafer 21 using lithographically masked etching technique, such that the wafer has a droplet ejection side and a liquid supply side. Each of the liquid passages is formed by etching a hole 31 partially through the wafer 21 from the droplet ejection side, and etching a passage from the liquid supply side of the wafer 21 to the hole 31. Etching a hole 31 into the wafer 21 from the droplet ejection side means the ink supply passage 32 can stop short of the interface between the dielectric 23 and the wafer 21 to prevent the etchant from tracking sideways and damaging the drive circuitry 22. As the inlet hole 31 is relatively shallow, the removal of the resist is not overly difficult. However, setting the depth of the supply passage etch so that it overlaps the blind end of the hole by more than the combined tolerances of both etching processes ensures an adequate fluid connection to the nozzle. This permits a more compact overall design and higher nozzle packing density.

Owner:MEMJET TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com