Combined cold-heat-power supplying circulation system driven by solid oxide fuel cell

A solid oxide, combined cooling, heating and power technology, used in solid electrolyte fuel cells, fuel cell heat exchange, fuel cell additives, etc. Control and other issues to achieve the effect of improving utilization, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

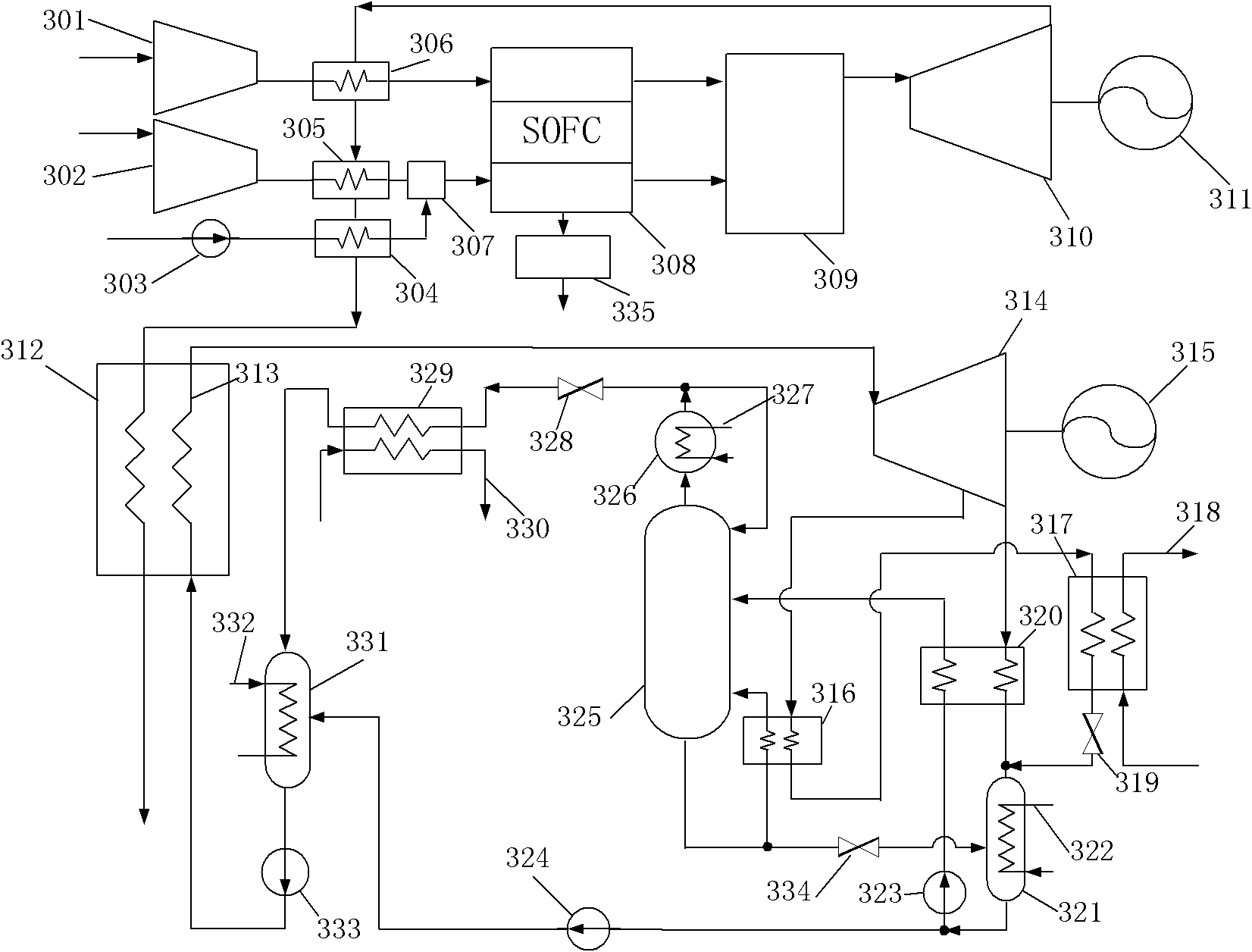

[0018] see figure 1 As shown, the combined cooling, heating and power circulation system driven by the solid oxide fuel cell of the present invention includes a first compressor 301, a second compressor 302, and a water pump 303, which are connected to the first compressor 301, the second compressor 302, and the water pump respectively. The first heater 306 connected to the output end of 303, the second heater 305, the third heater 304, the output end of the second heater 305 and the third heater 306 is connected with a mixer 307; the mixer 307 and the output end of the first heater 306 are connected to a solid oxide fuel cell 308, one of the output ends of the solid oxide fuel cell 308 outputs alternating current through an inverter 335, and the other is connected to an afterburner 309, the afterburner The output end of the combustion chamber 309 is connected with a gas turbine 310, which is used to drive the first generator 311 to generate electricity; in addition, one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com