Emissionless Oxyfuel Combustion Process and a Combustion System Using Such a Process

a technology of oxyfuel combustion process and combustion system, which is applied in the direction of emission prevention, combustion types, lighting and heating apparatus, etc., can solve the problems of reducing the total efficiency of the combustion system, uncondensed gas stream, and uncondensed gas stream may comprise a considerable amount, and achieves low nh3/nox ratio, high nox removal efficiency, and very effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

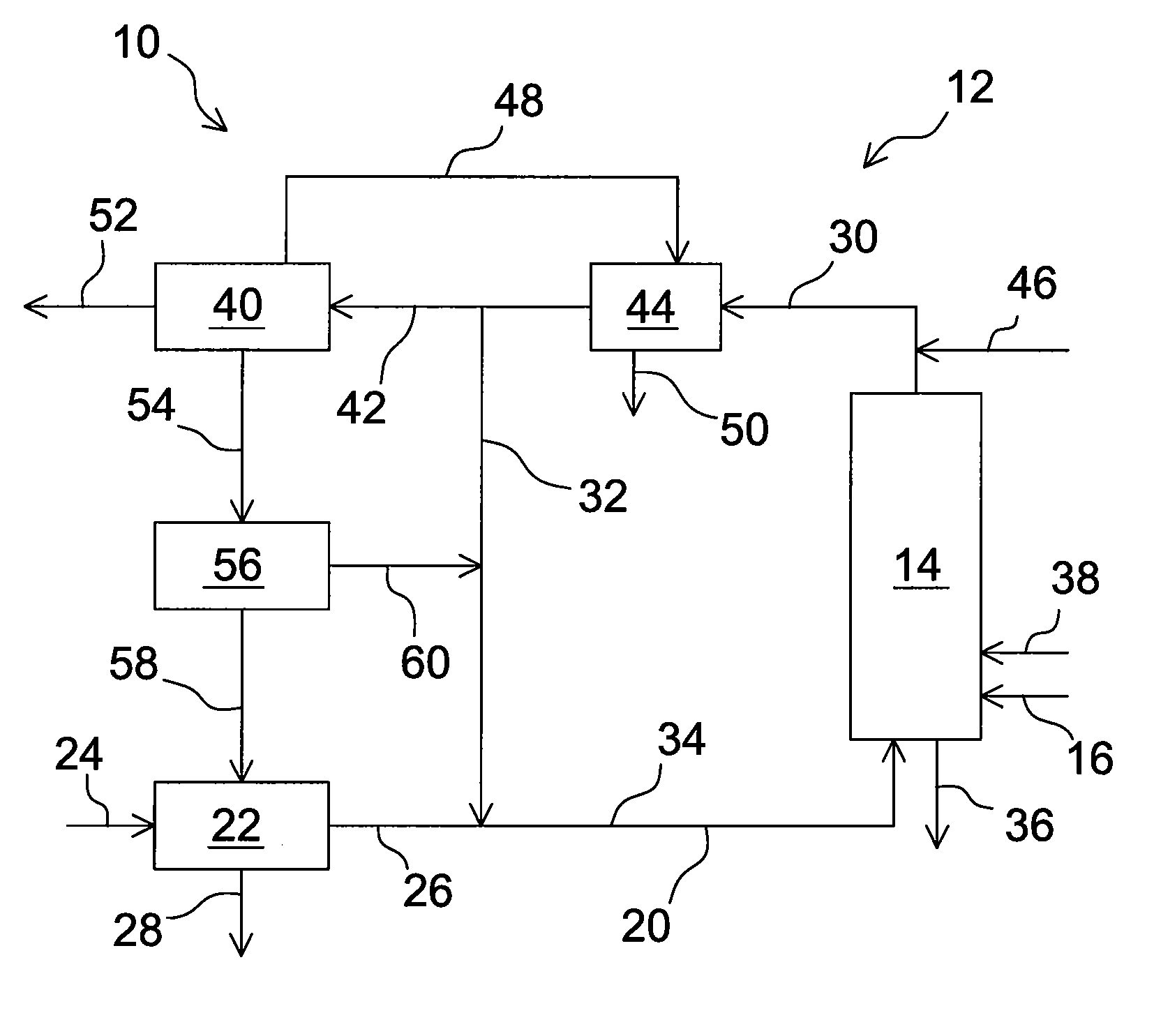

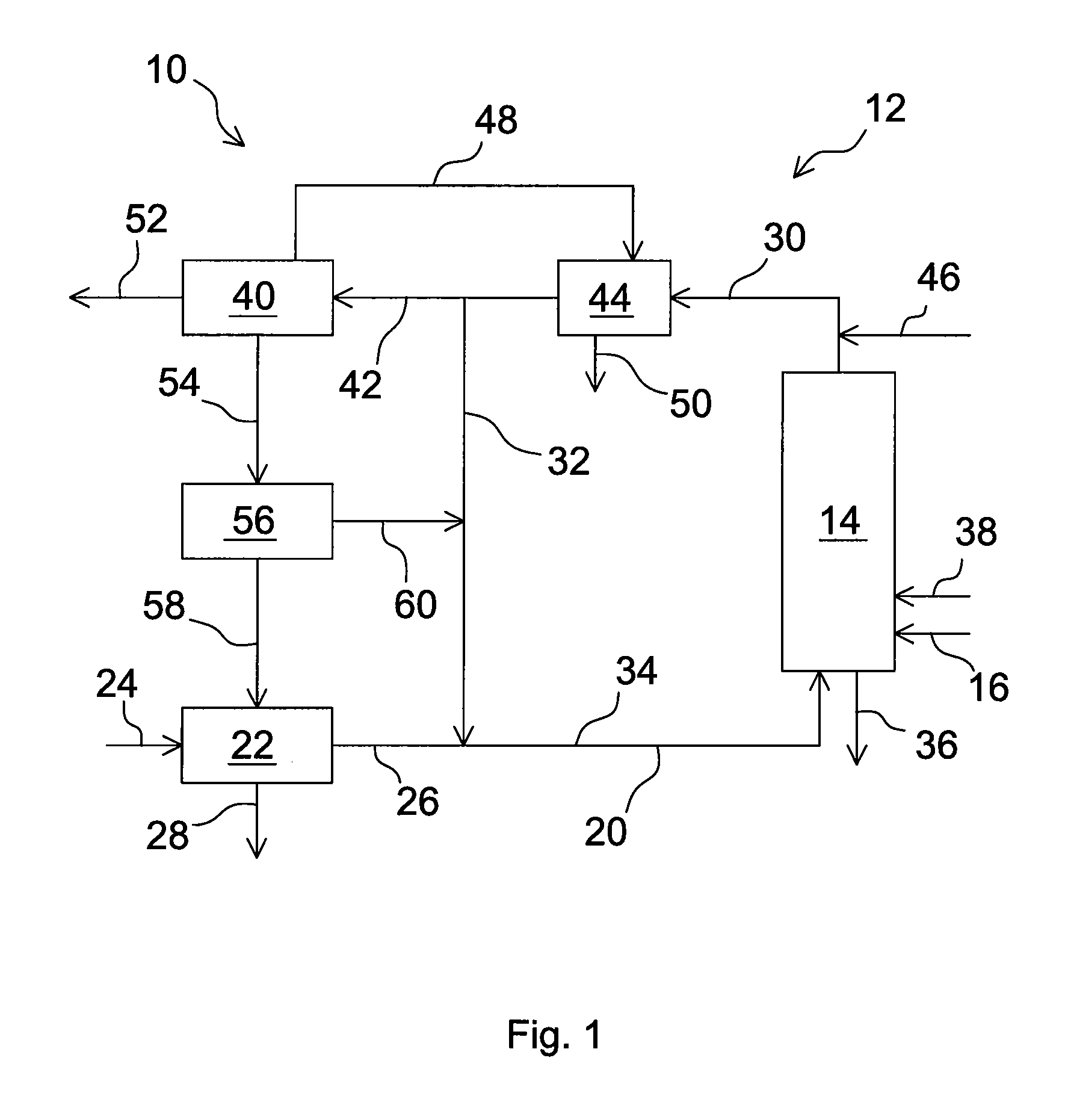

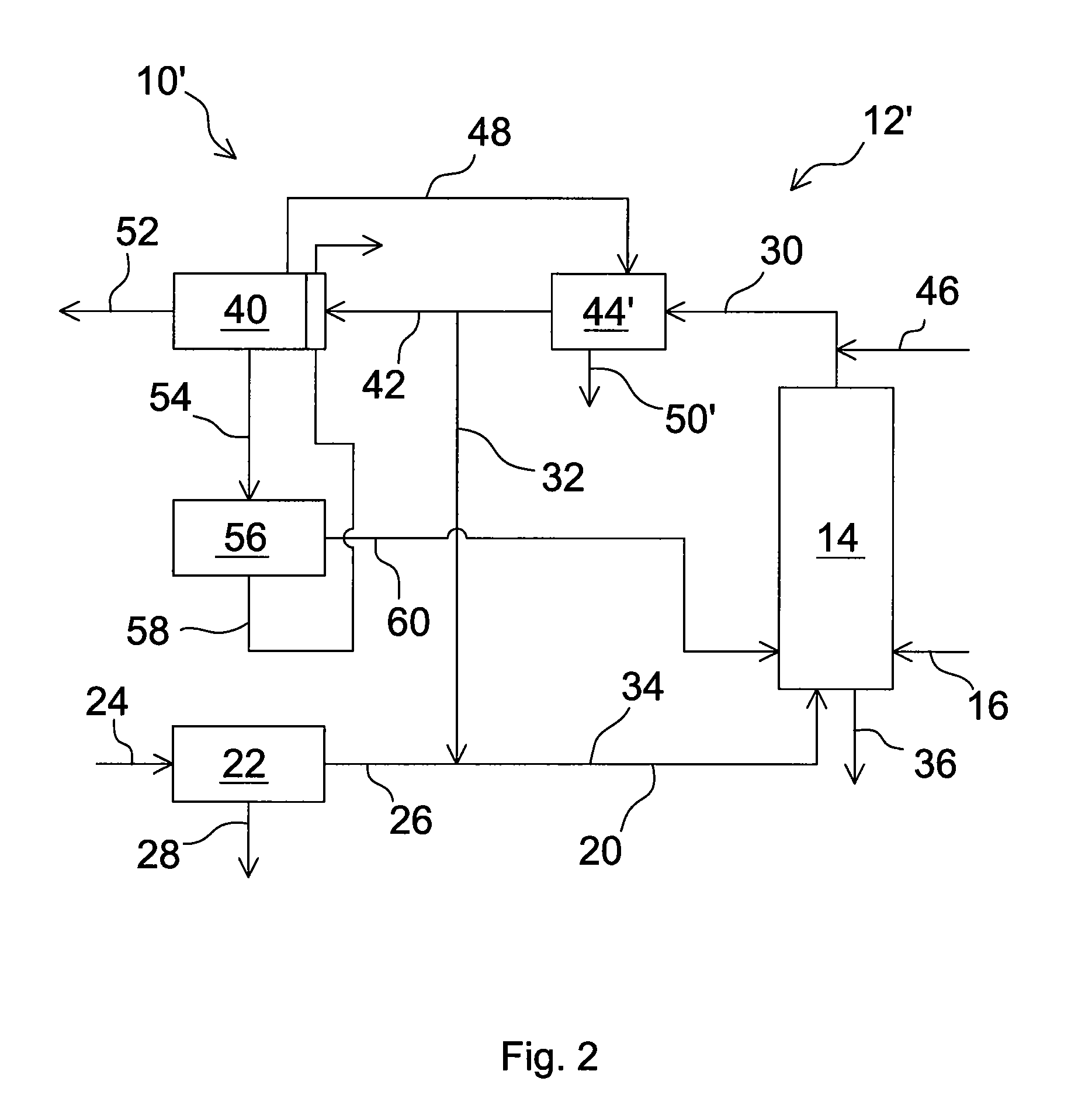

[0033]FIG. 1 schematically discloses an oxyfuel combusting combustion system 10, comprising a circulating fluidized bed (CFB) boiler 12 with a furnace 14 for combusting carbonaceous fuel introduced to the furnace by fuel feeding means 16. The term furnace 14 is here used to refer to the actual furnace as well as to the conventional hot recycling loop and possible heat exchange chambers connected to the furnace. The combustion system 10 comprises an oxygen channel 20, for feeding oxygen from a source of oxygen 22, such as a cryogenic air separation unity (ASU), to the furnace. The ASU converts an incoming air stream 24 to a first stream 26 comprising mainly oxygen (O2), and another stream, nitrogen (N2) rich stream 28, which is released to the atmosphere or conducted to another application.

[0034]The combustion process produces exhaust gas, comprising a high amount, for example, about 75%, of carbon dioxide (CO2) and having water and excess O2 as its other main components. The exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com