Patents

Literature

189 results about "Diesel combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low emission diesel combustion system with low charge-air oxygen concentration levels and high fuel injection pressures

InactiveUS6857263B2Cost effectiveLower Level RequirementsLiquid coolingEngine sealsLow loadMass ratio

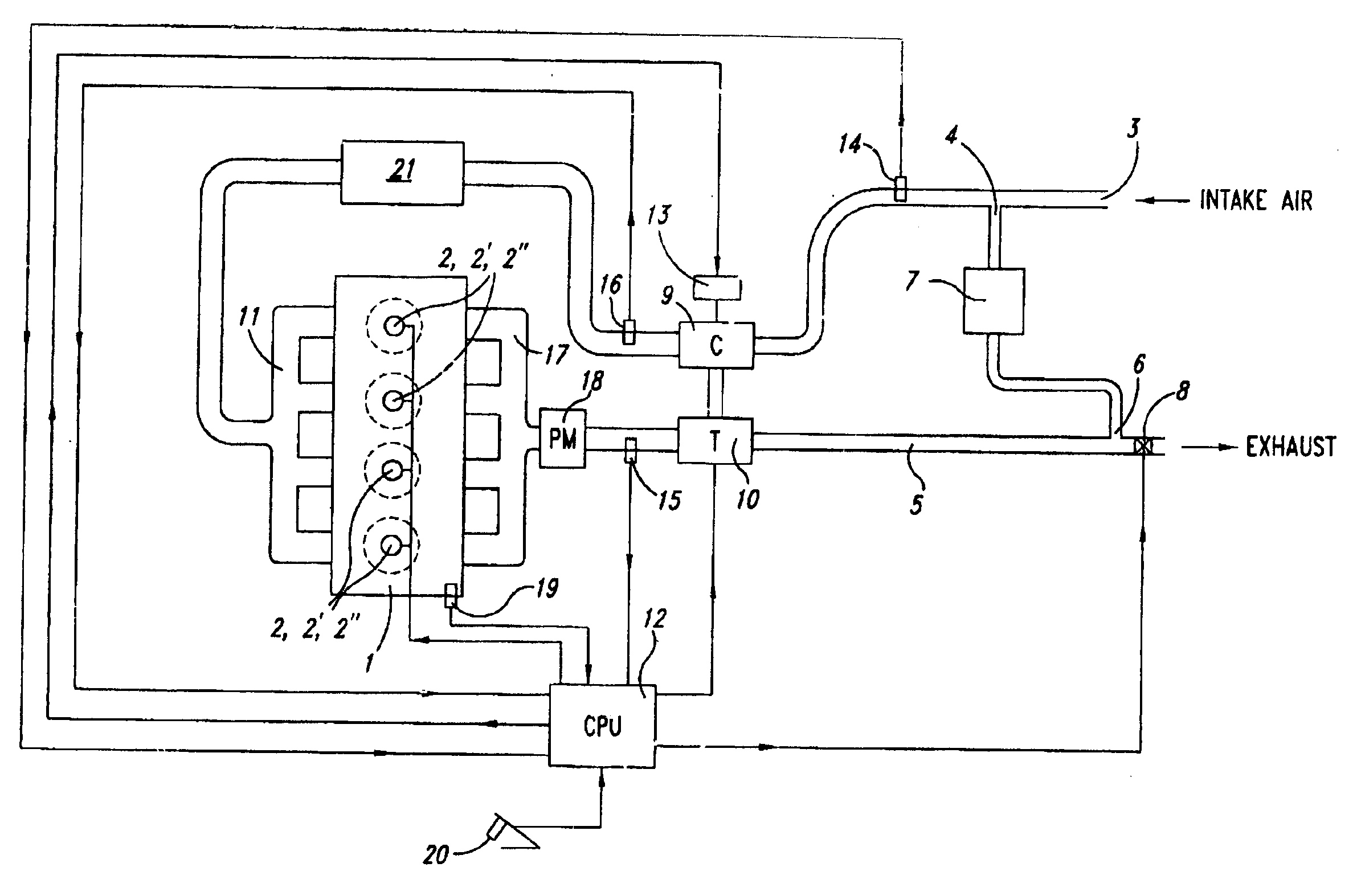

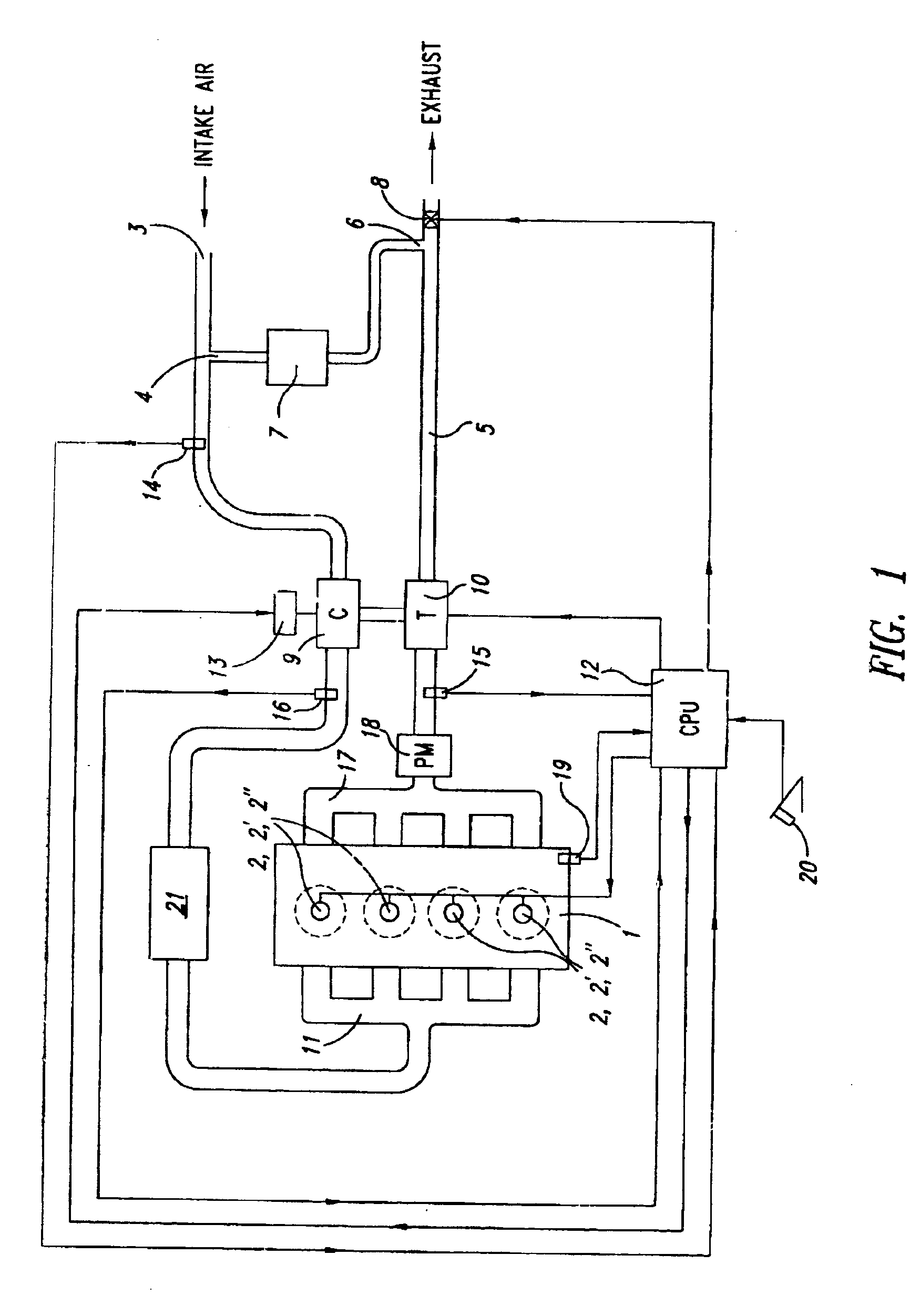

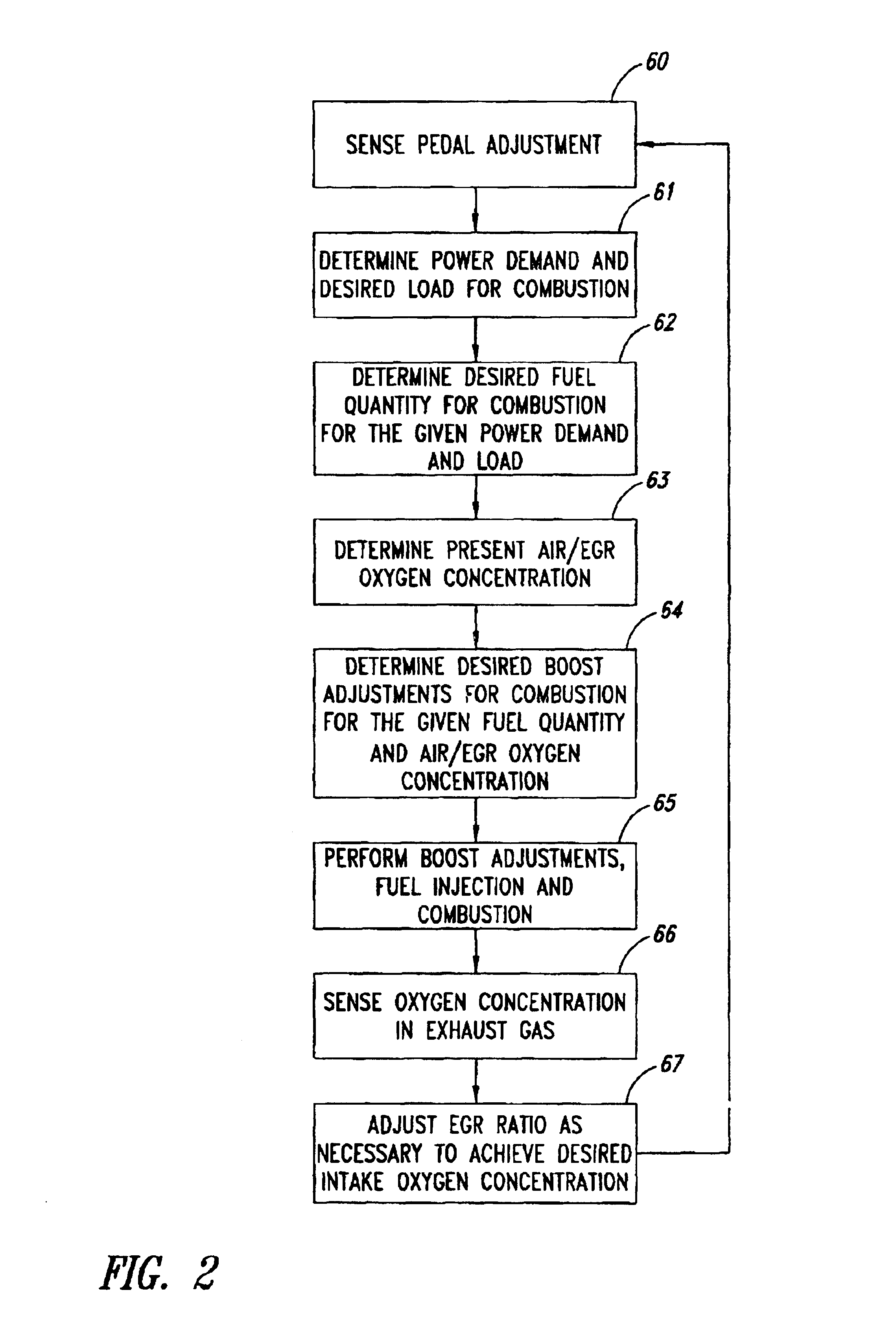

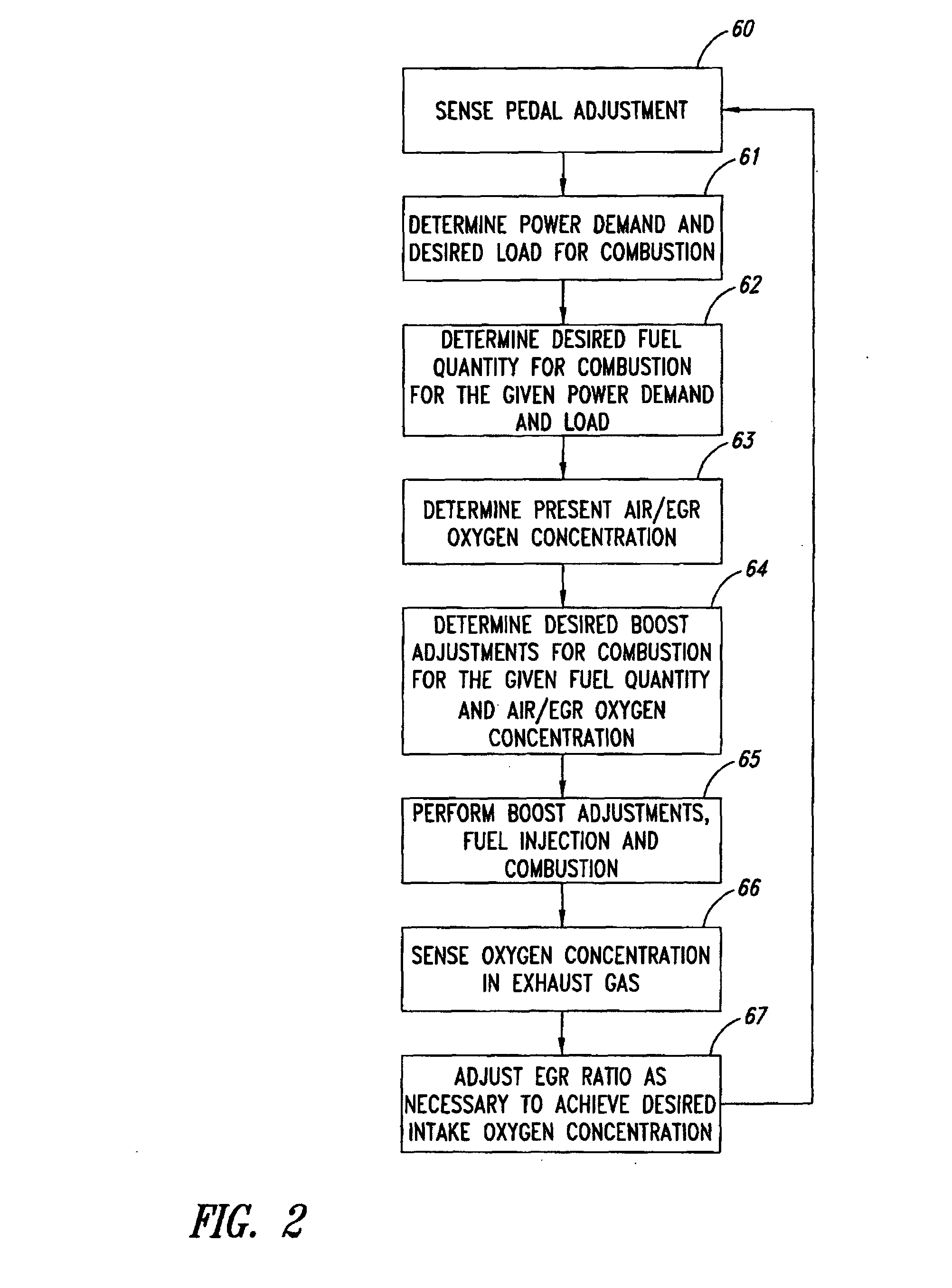

This invention sets forth a commercially viable diesel combustion system that meets environmentally acceptable levels of NOx emissions (i.e. 0.2 g / bhp-hr or lower across a full map of engine speeds and loads) without the need for use of NOx aftertreatments, and simultaneously maintains engine-out PM emissions relatively close (e.g. with smoke levels at or below 3 BSN) to environmentally acceptable PM post-aftertreatment levels. The invention achieves these results by operating within a unique combination of parameters. These parameters comprise: (1) charge-air oxygen concentration below 16%, preferably between 10% and 15%, more preferably between 11% and 14%, and most preferably between 12% and 13.5% for virtually all engine operating conditions (but not necessarily at no-load or low load conditions), (2) fuel injection pressures at or exceeding 1800 bar, preferably exceeding 2100 bar, more preferably exceeding 2300 bar, and most preferably exceeding 2500 bar, at most engine speeds and loads, and (3) charge-air mass / fuel mass ratio between 25:1 and 45:1 for medium and high loads. Furthermore, the system is preferably run continuously slightly lean of stoichiometry, providing just enough excess oxygen to facilitate completeness of combustion and to maintain an exhaust oxygen level sufficient for continuous trap regeneration at a balance point in operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

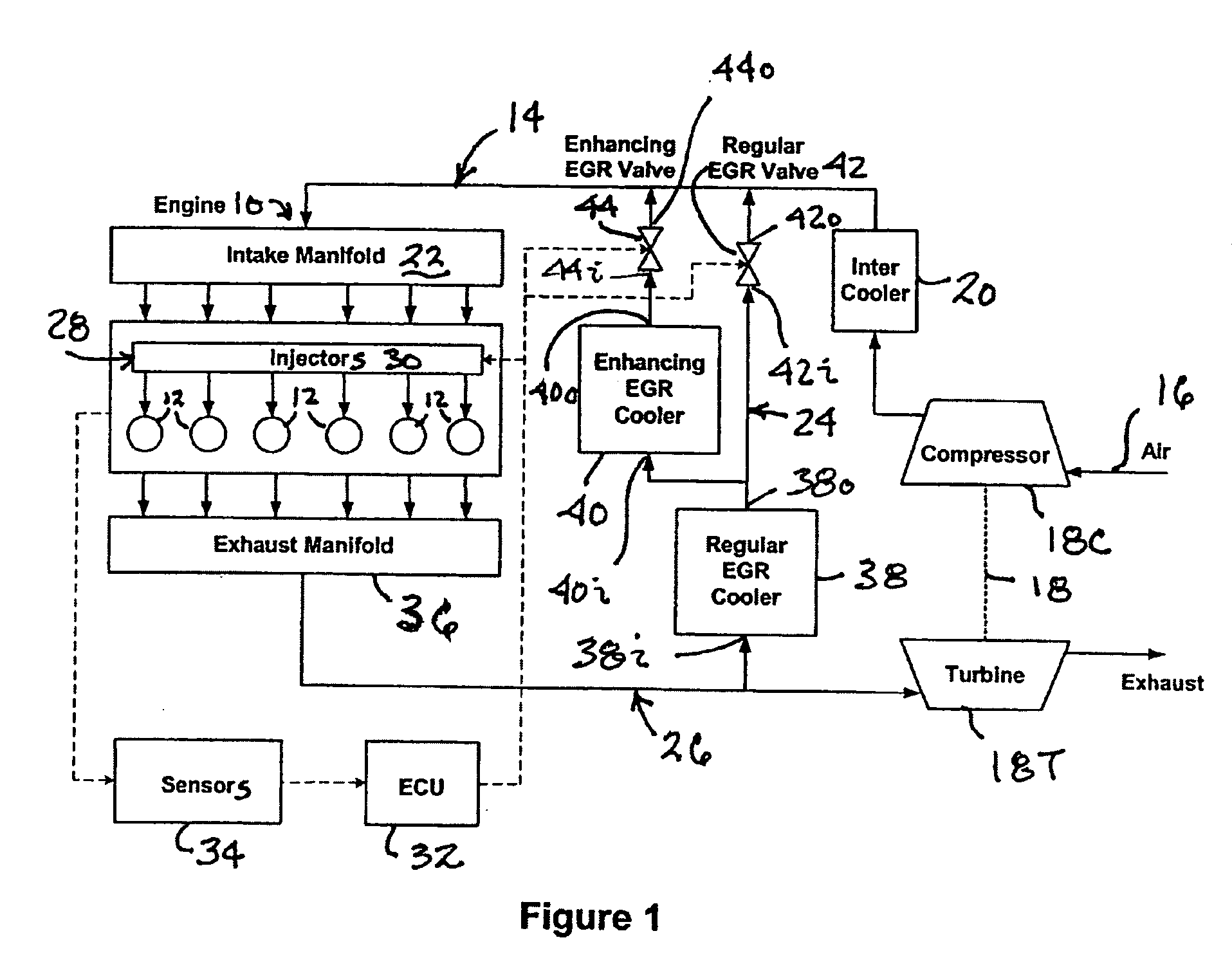

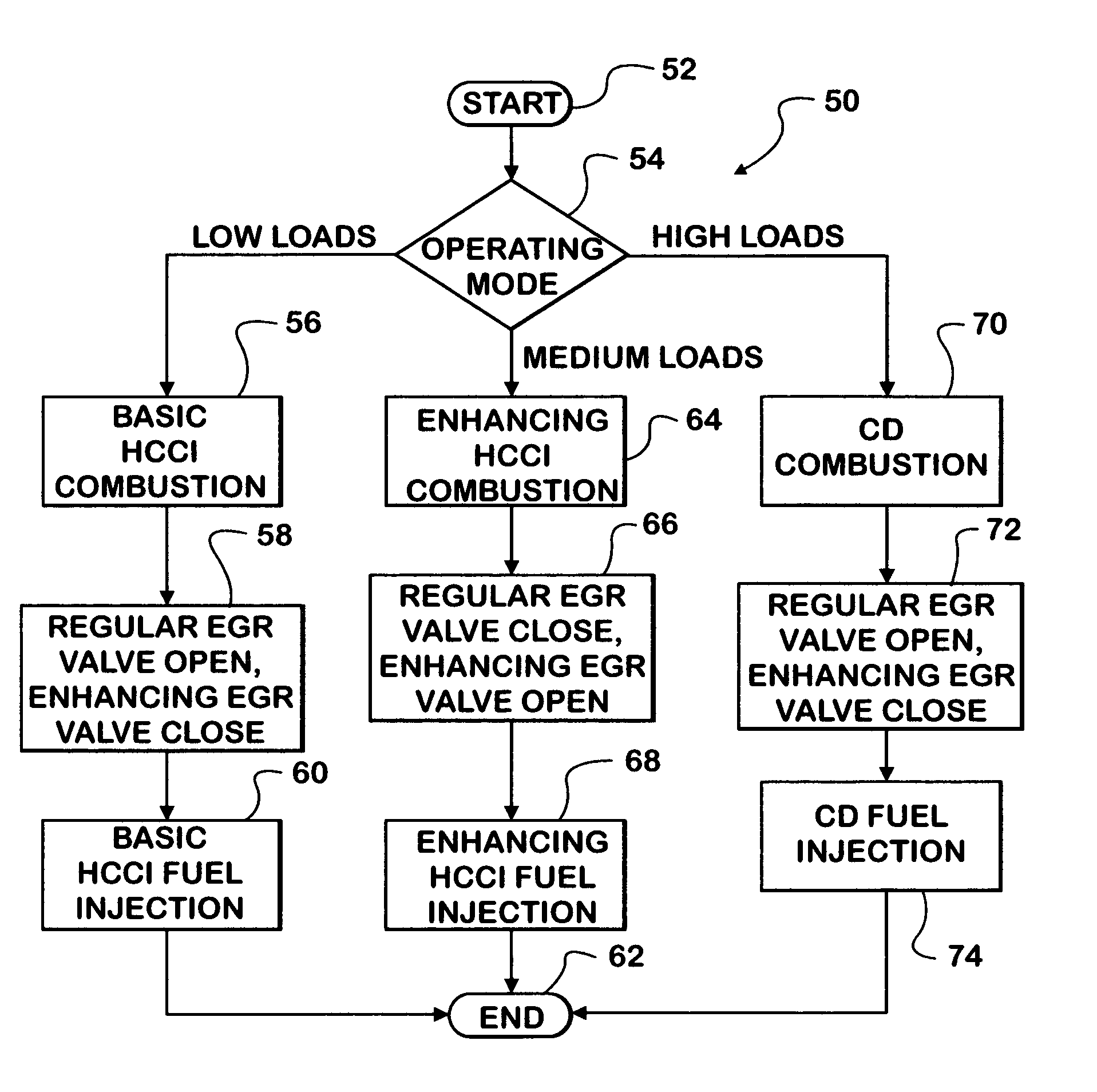

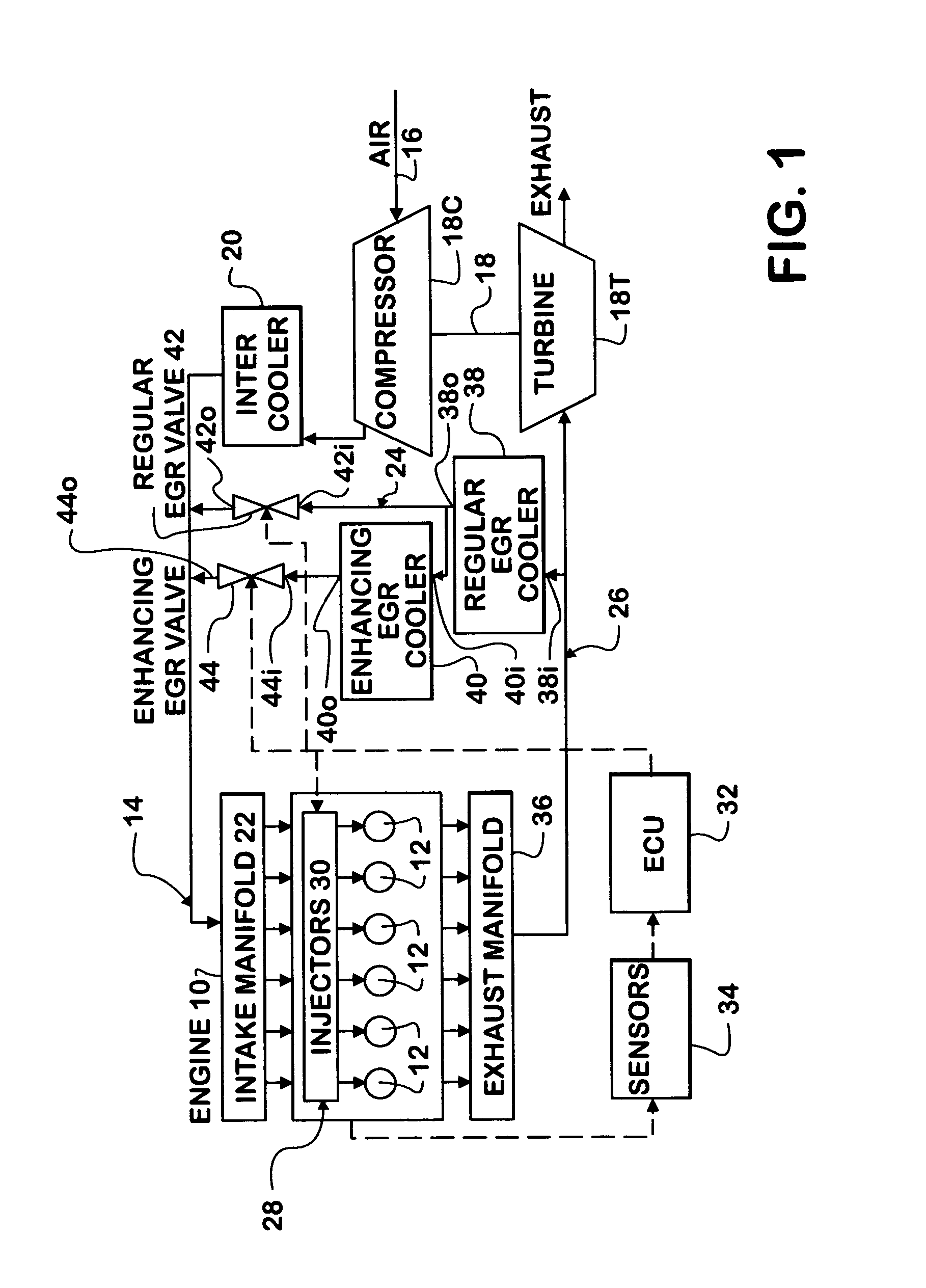

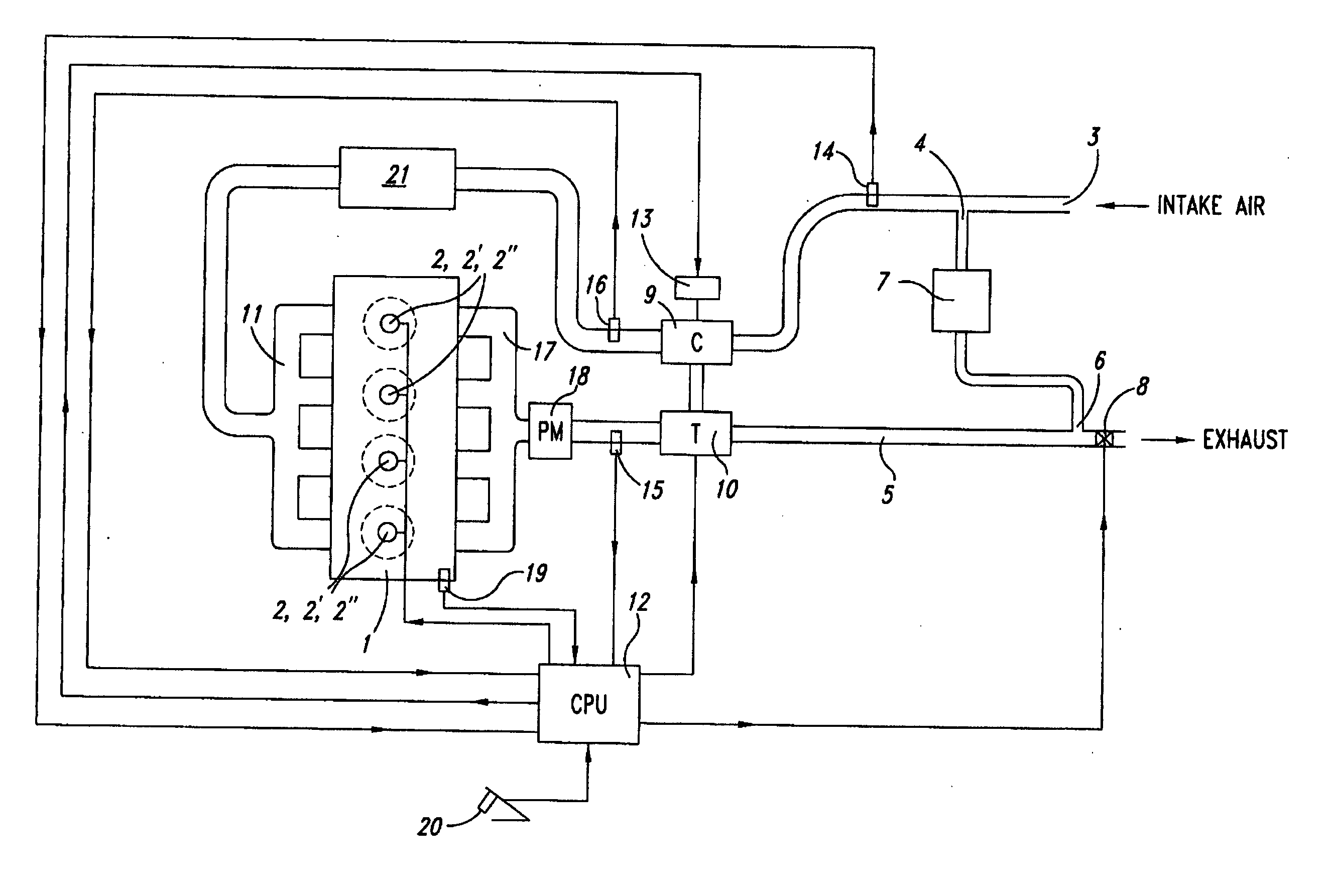

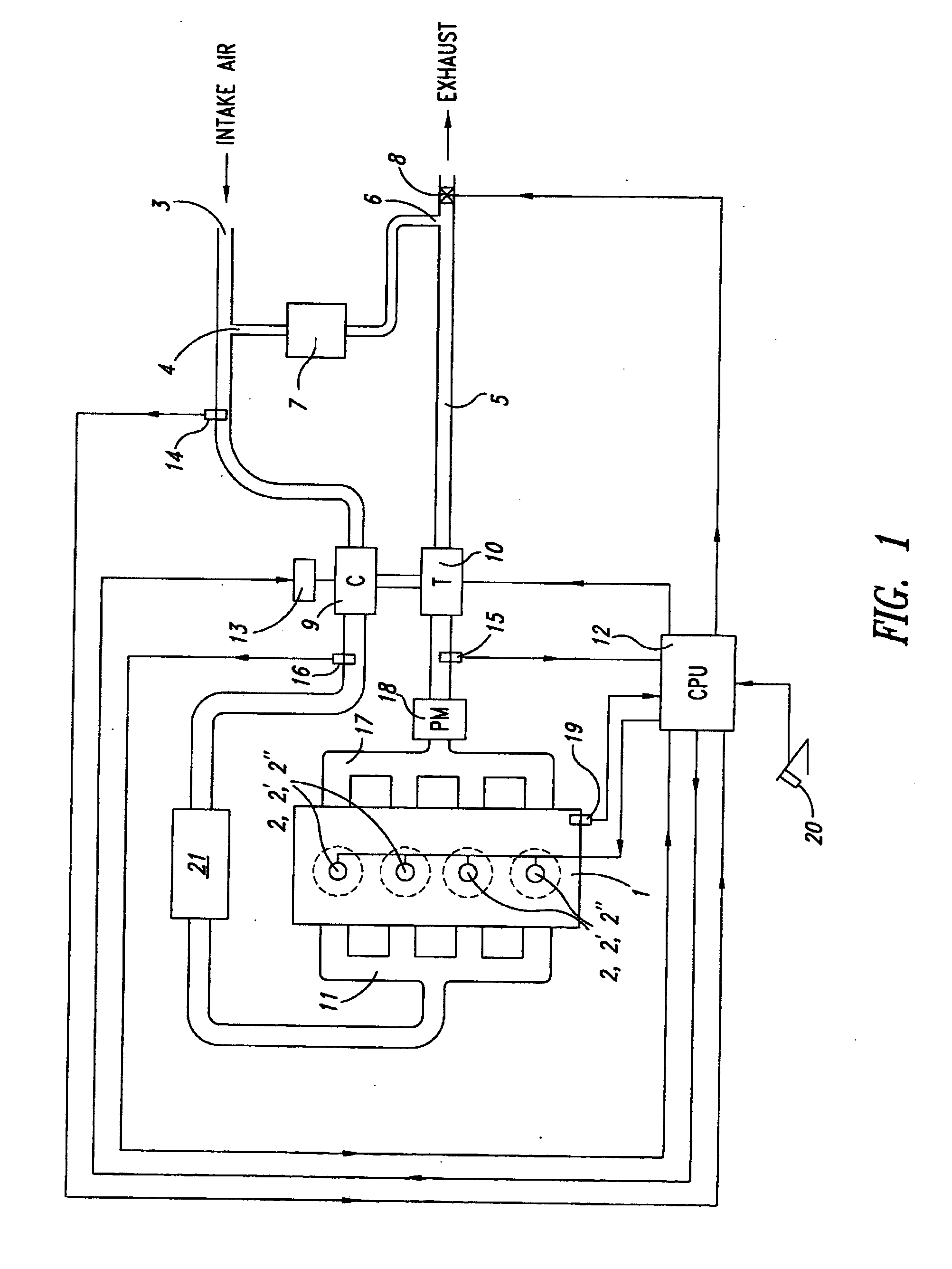

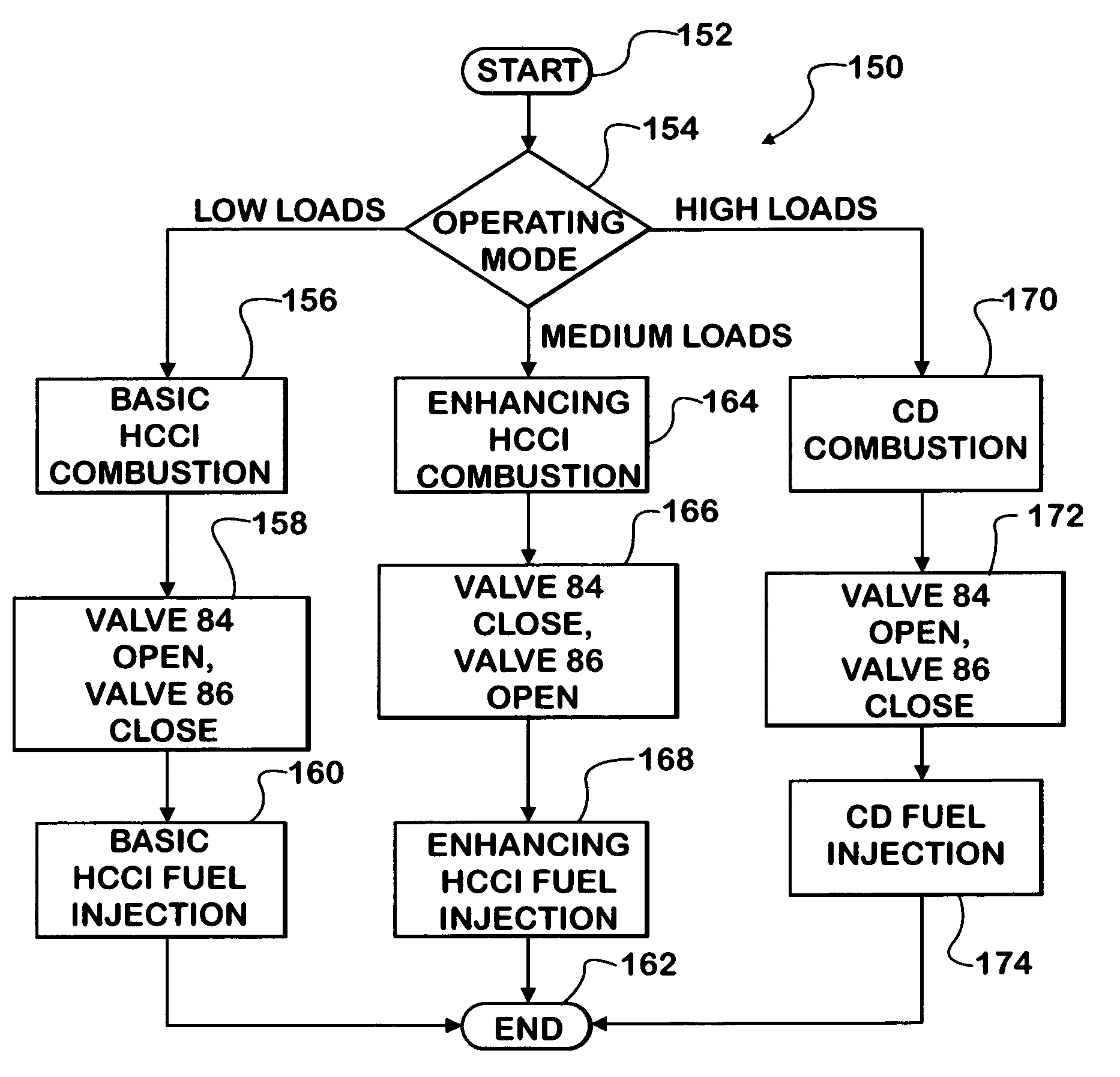

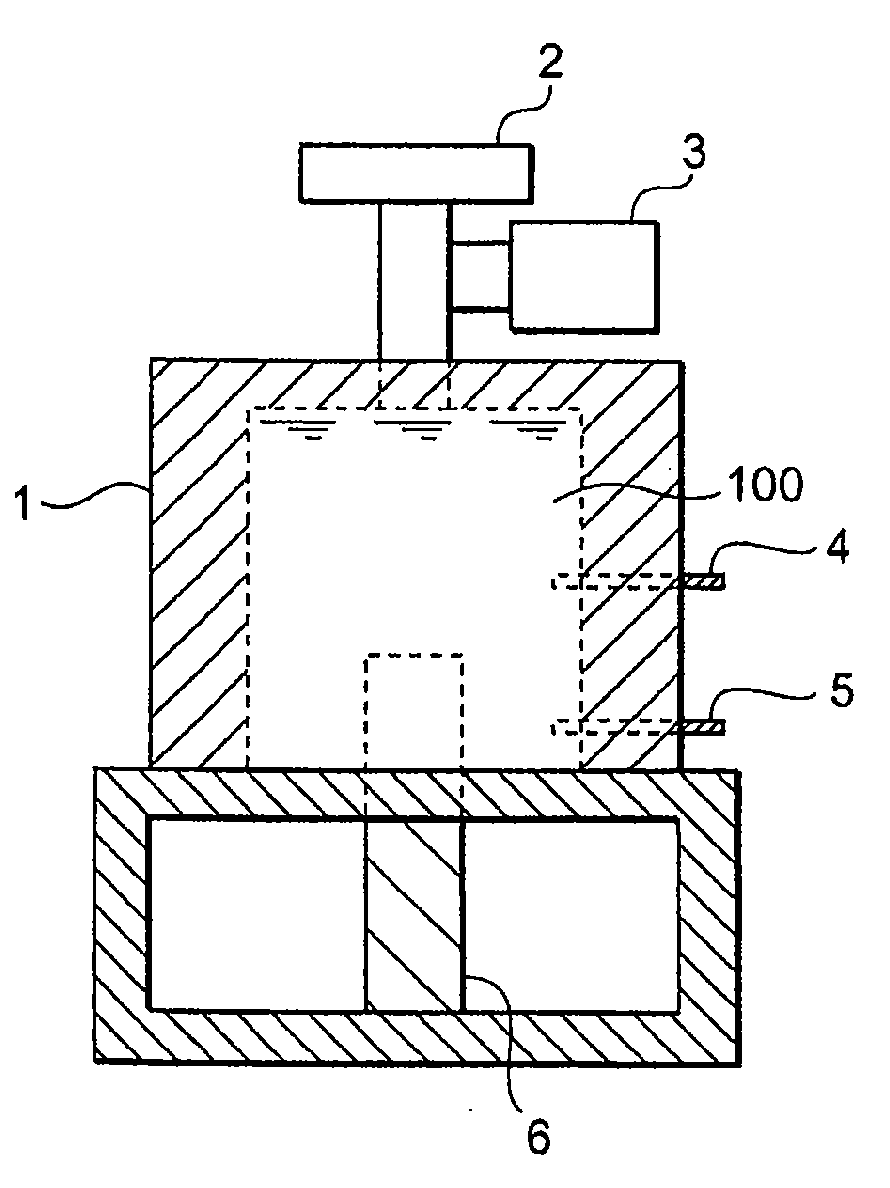

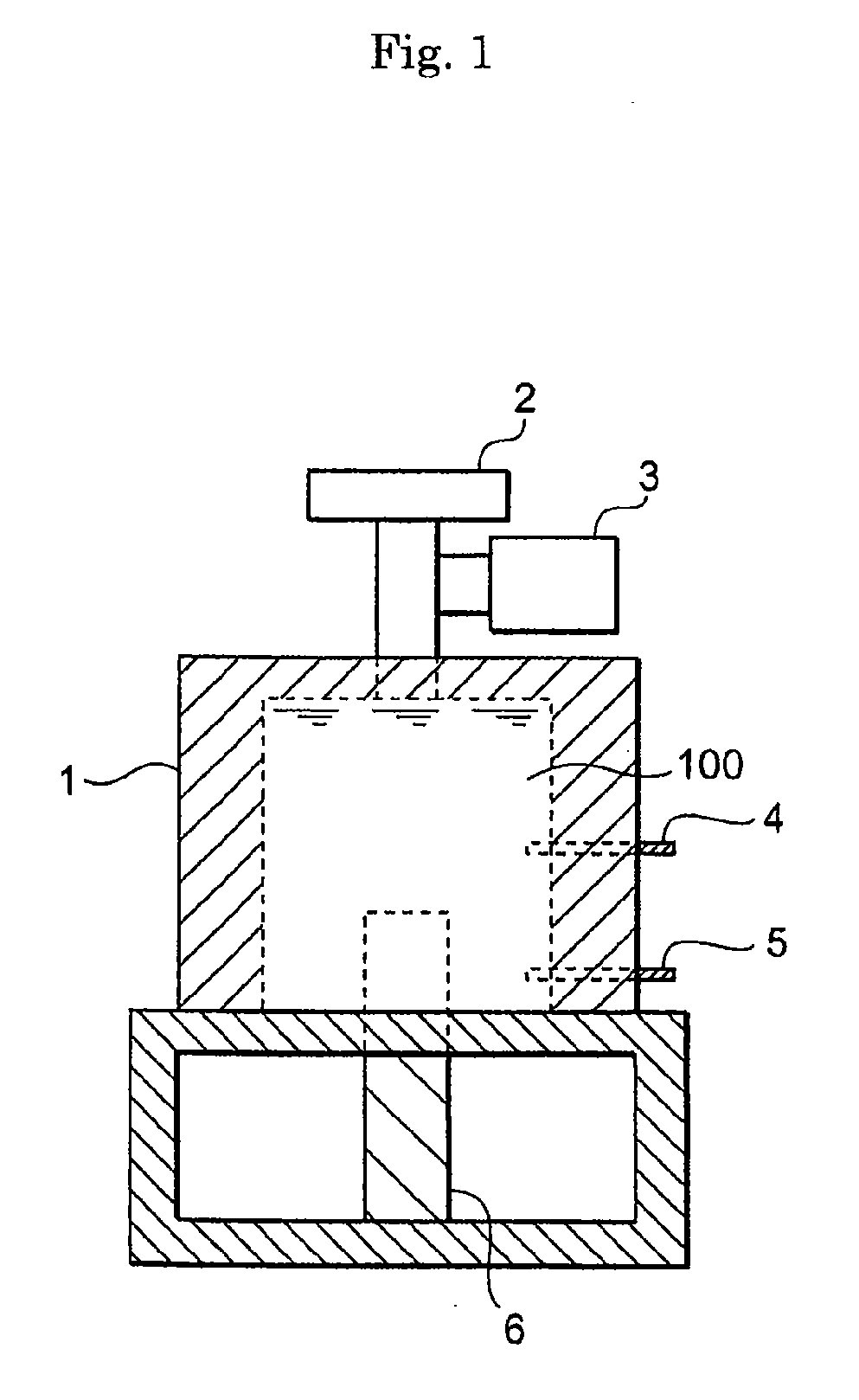

Control strategy for expanding diesel HCCI combustion range by lowering intake manifold temperature

ActiveUS20060200297A1Large loading rangeWide speed rangeElectrical controlInternal combustion piston enginesHcci combustionLow load

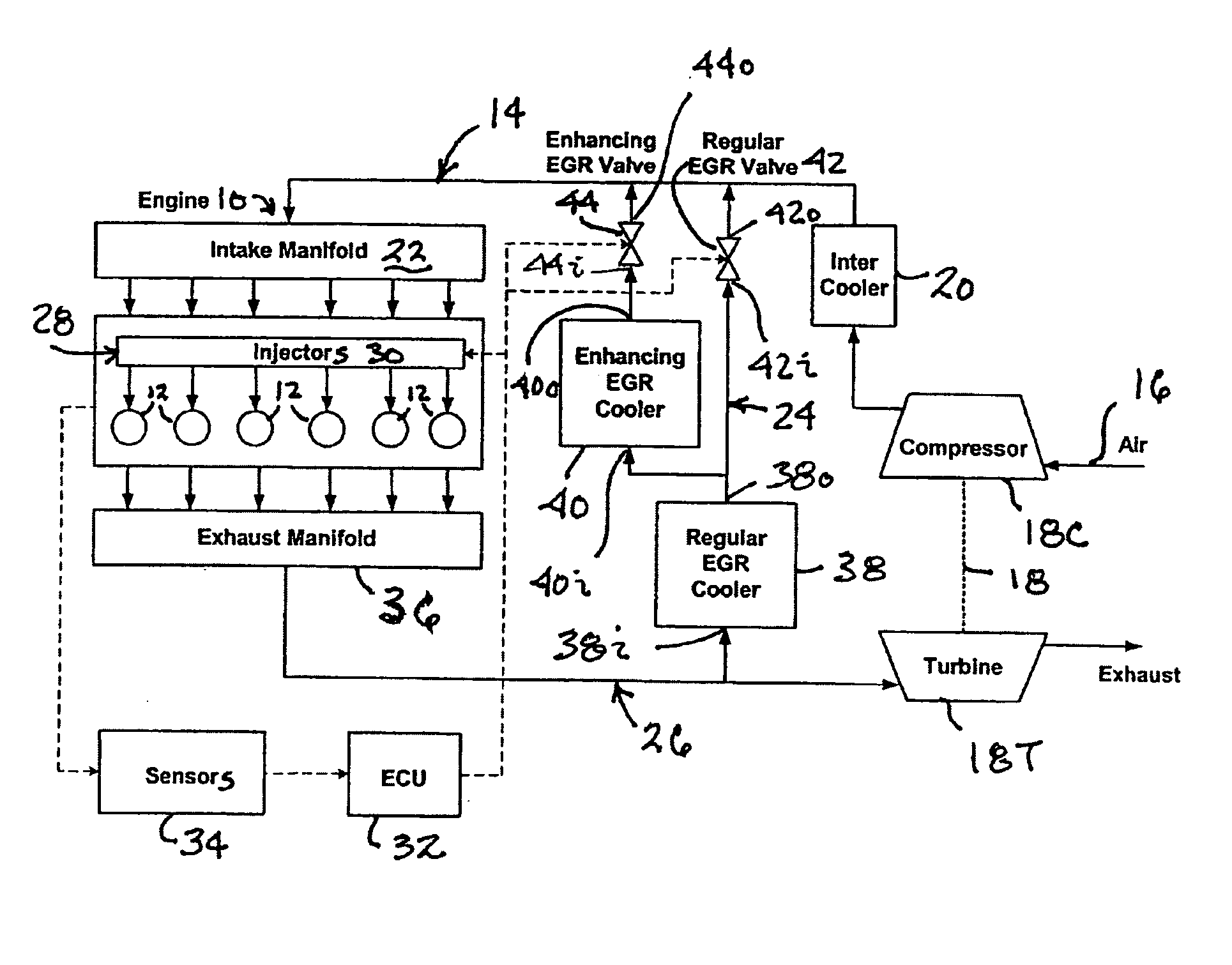

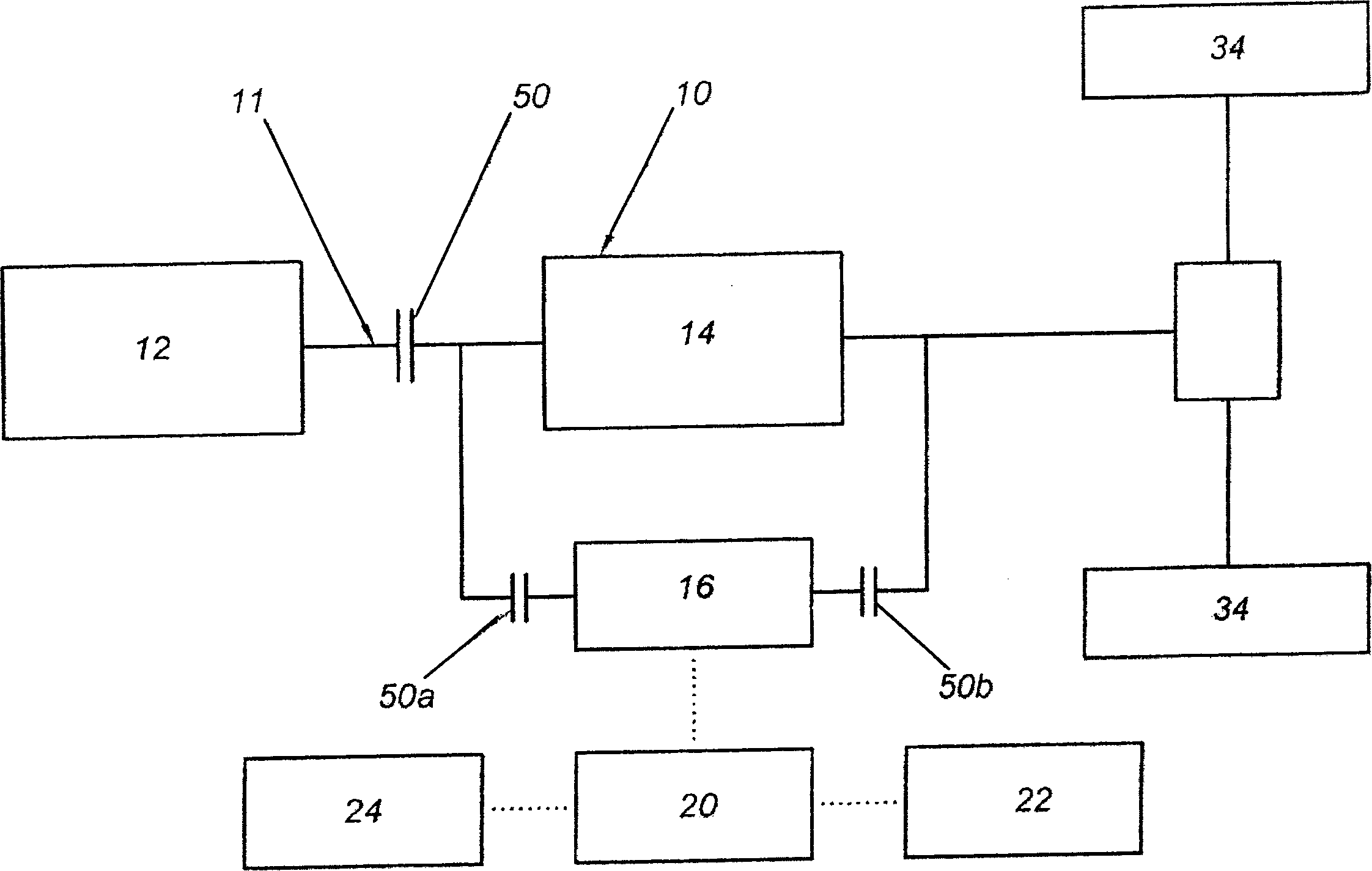

An engine (10, 100) utilizes “regular EGR cooling” when operating in HCCI mode within a low load range and “enhanced EGR cooling” that allows the engine to continue to operate in HCCI mode when engine load increases beyond the low load range. When engine load increases to a high load range, the combustion mode changes over to conventional diesel combustion, and exhaust gas recirculation reverts to “regular EGR cooling”. In a first embodiment, cooling is provided by two heat exchangers, one being a regular EGR cooler always used when cooling is needed and the other, an enhancing EGR cooler that is selectively used. In a second embodiment, cooling is also provided by two heat exchangers, one being an EGR cooler through which liquid coolant always flows when cooling is needed, and the other being a radiator used selectively to cool the liquid coolant before it enters the EGR cooler.

Owner:INT ENGINE INTPROP CO LLC +1

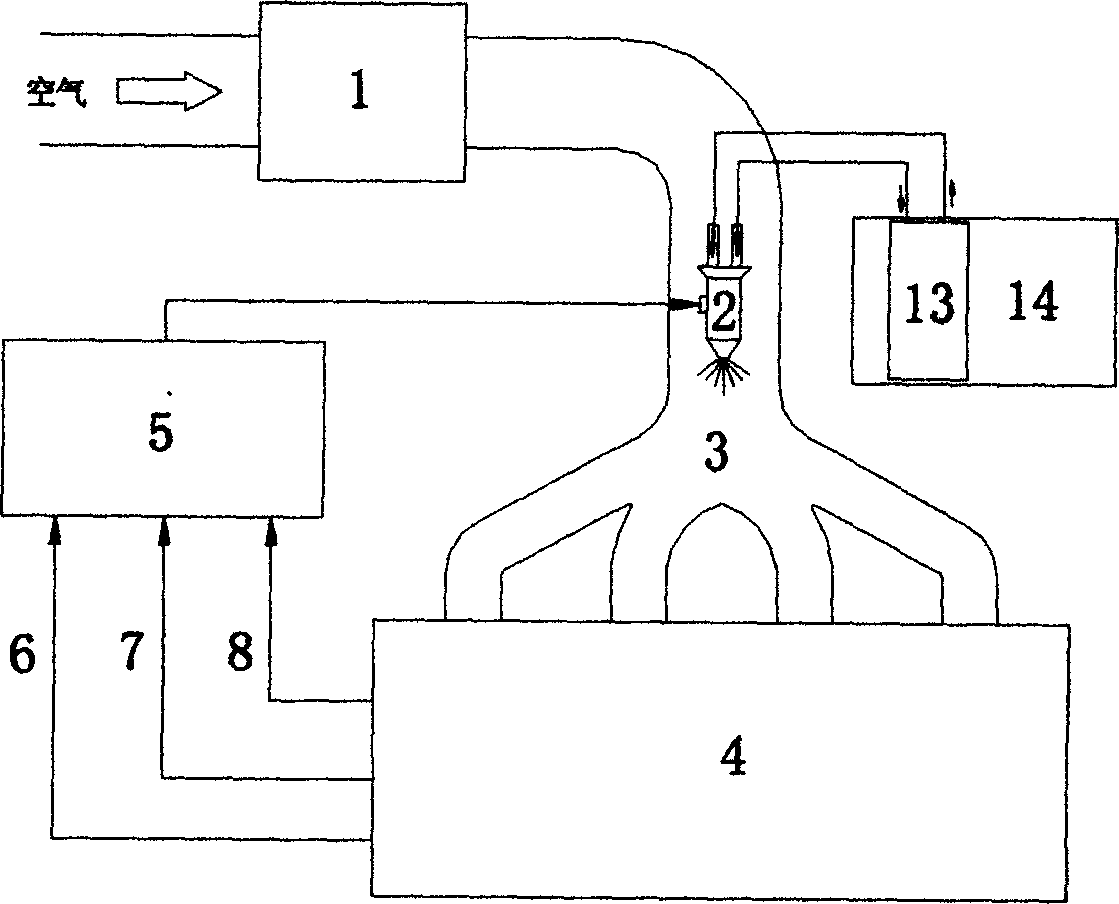

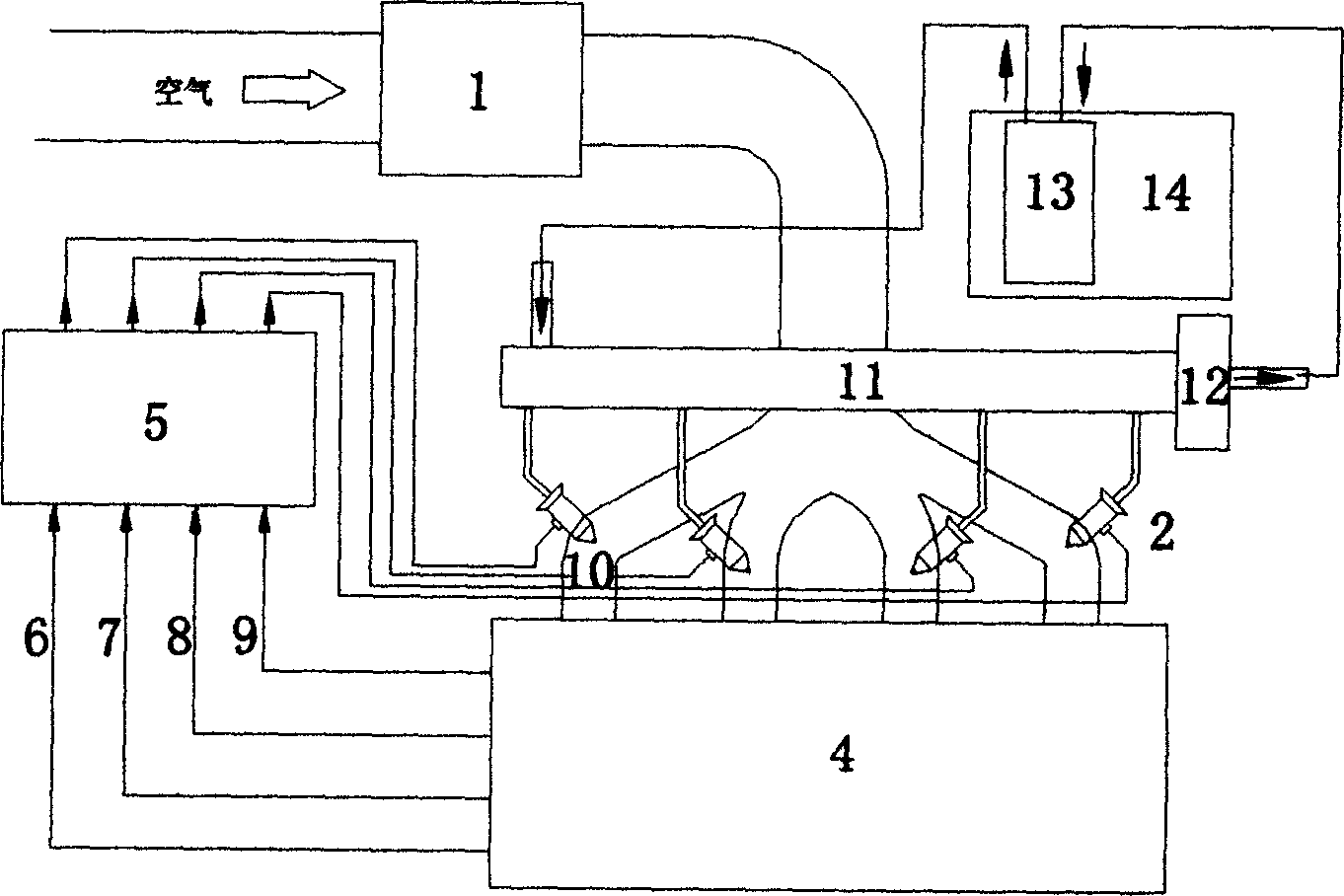

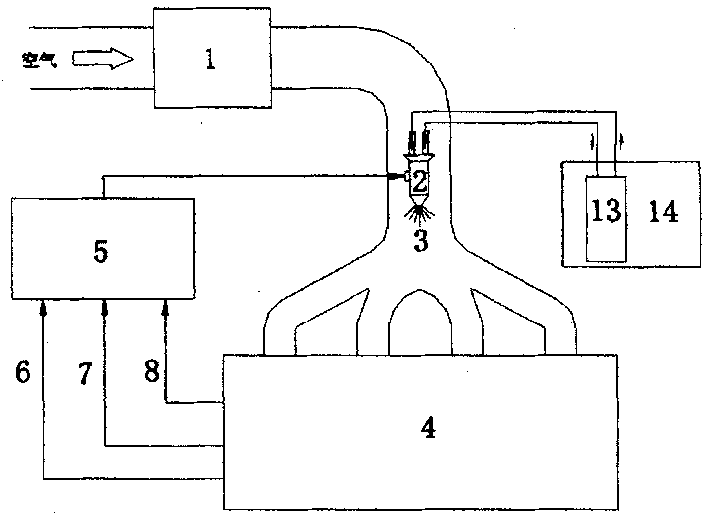

Diesel engine intake alcohol injection apparatus and injection control method

InactiveCN1470752AEmission reductionEasy to modifyElectrical controlMachines/enginesAlcoholInlet channel

The present invention discloses an air-intake alcohol-spraying device of desel engine and its spray control method. Said device is mainly formed from nozzle mounted in the air inlet tube of engine ornozzle mounted in the inlet channel of every cylinder, electric control unit for driving nozzle to open or close it and various sensors of engine load, rotating speed, cam shaft position and cooling water temp. for transferring information to electric control unit. Said invention can substituted diesel oil by partial alcohol fuel, so that the carbon smoke discharge can be reduced by 40%, at the same time the discharge of NOx also can be reduced by above 30%.

Owner:TIANJIN UNIV

Control strategy for expanding diesel HCCI combustion range by lowering intake manifold temperature

ActiveUS7017561B1Large loading rangeWide speed rangeNon-fuel substance addition to fuelInternal combustion piston enginesHcci combustionLow load

Owner:INT ENGINE INTPROP CO LLC

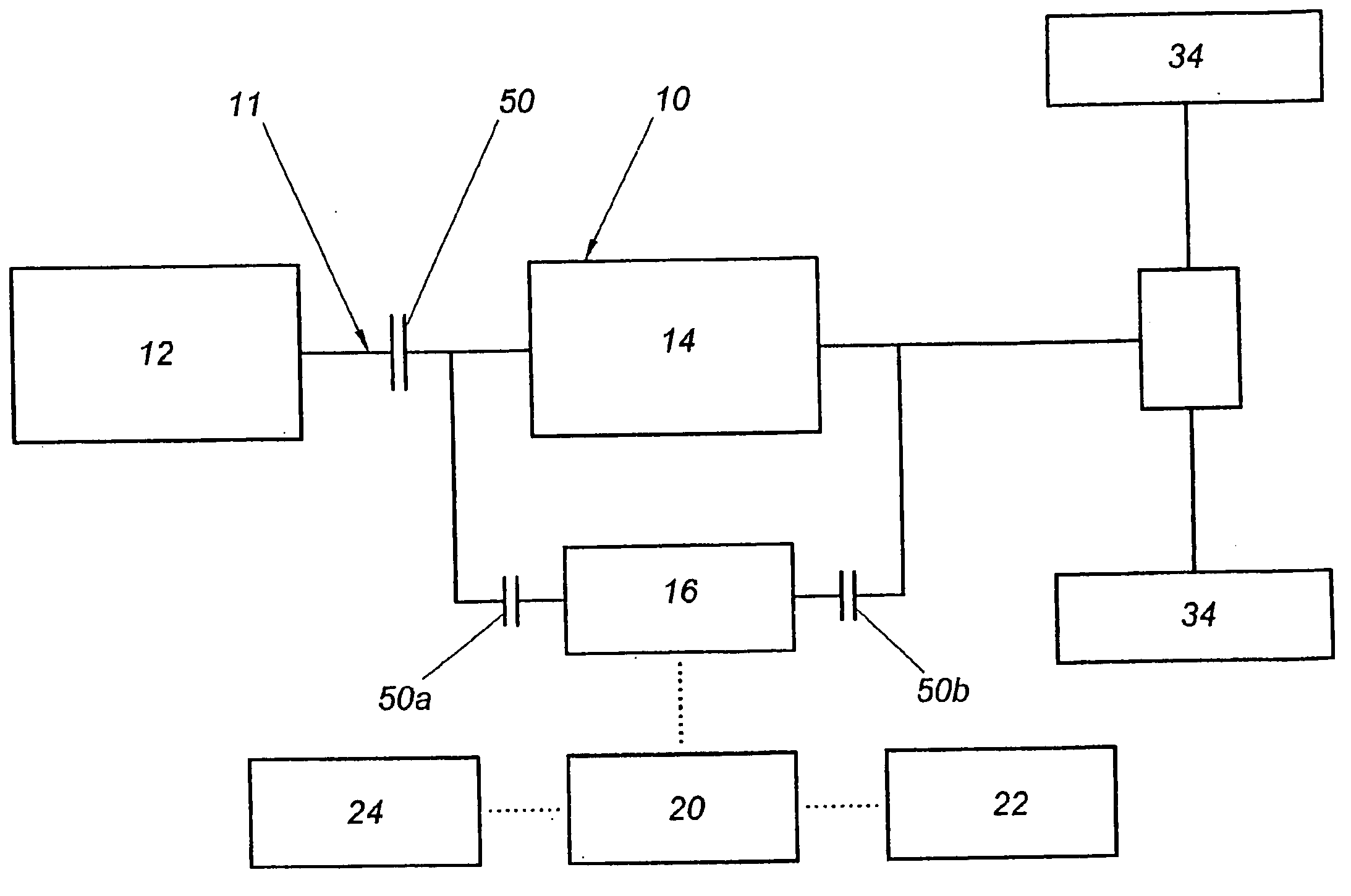

Method for operating a hybrid vehicle

ActiveUS20060042587A1Emission reductionReduce fuel consumptionElectrical controlInternal combustion piston enginesParticulatesNitrogen oxides

The invention relates to a method for operating a hybrid vehicle with a drive train which comprises an internal combustion engine driven by diesel fuel and at least one electric driving machine. In order to reduce the nitrogen oxide and exhaust particulate emissions it is provided that the internal combustion engine is operated with an alternative diesel combustion method in at least one operating range of the vehicle and the electric driving machine is switched in.

Owner:AVL LIST GMBH

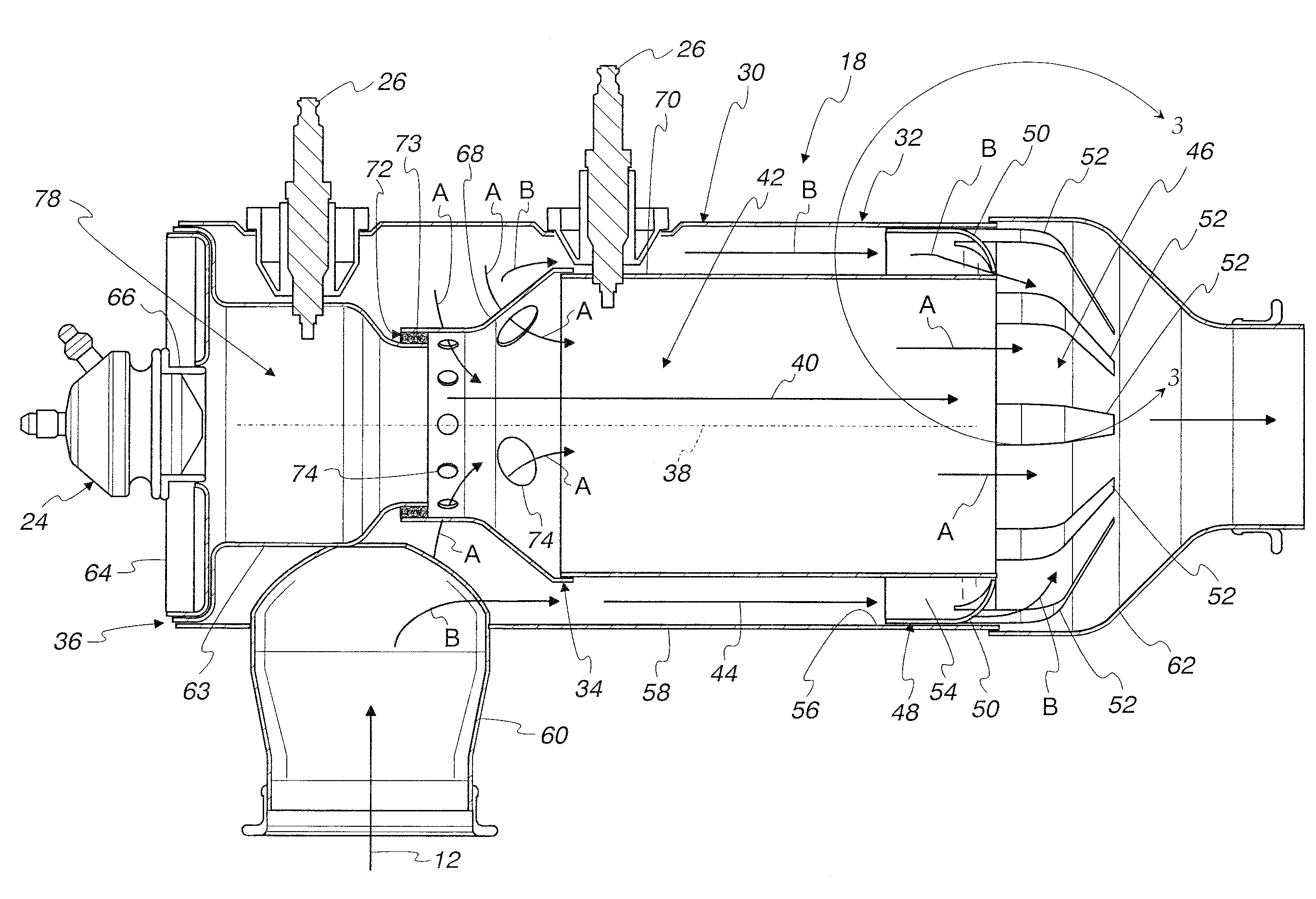

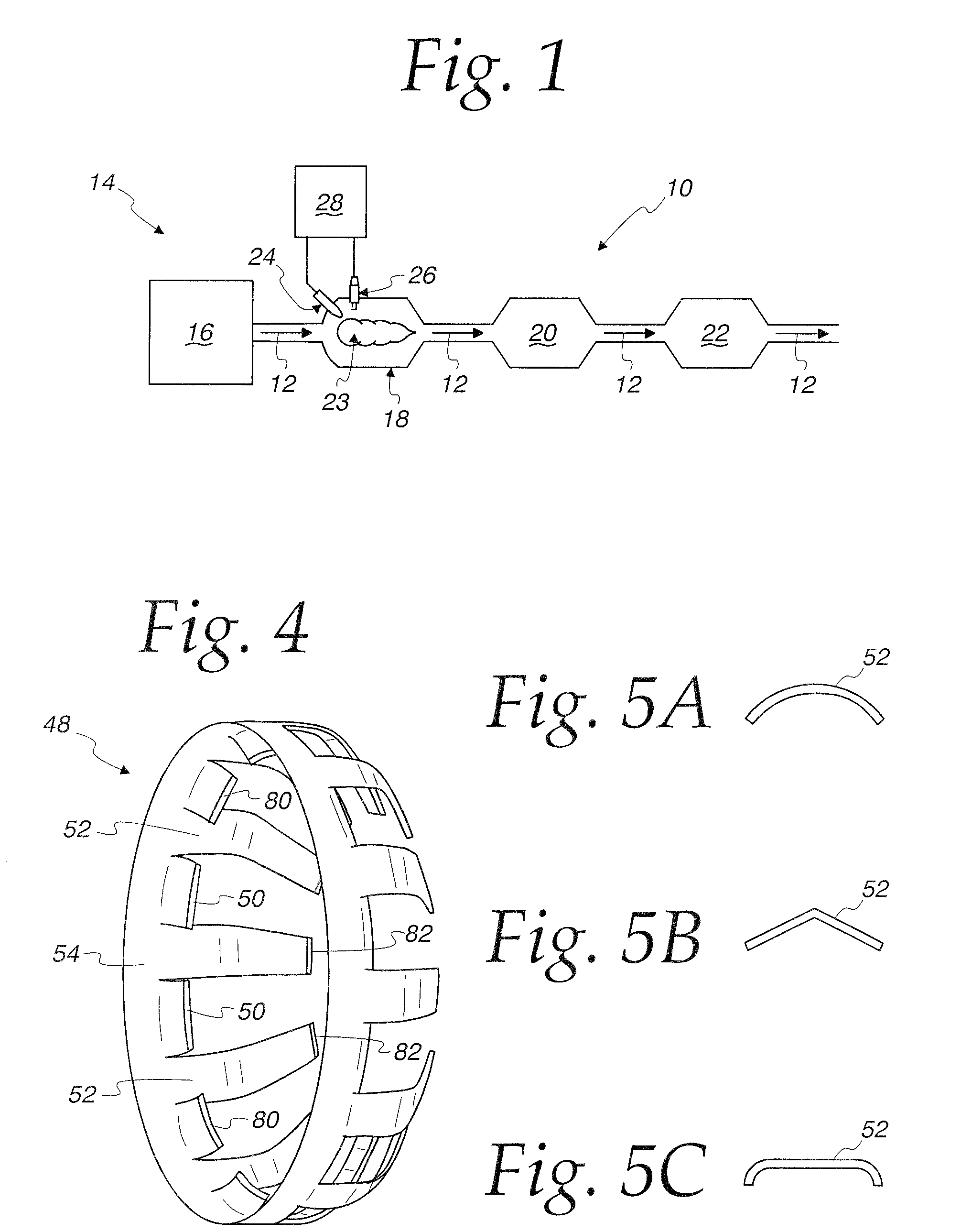

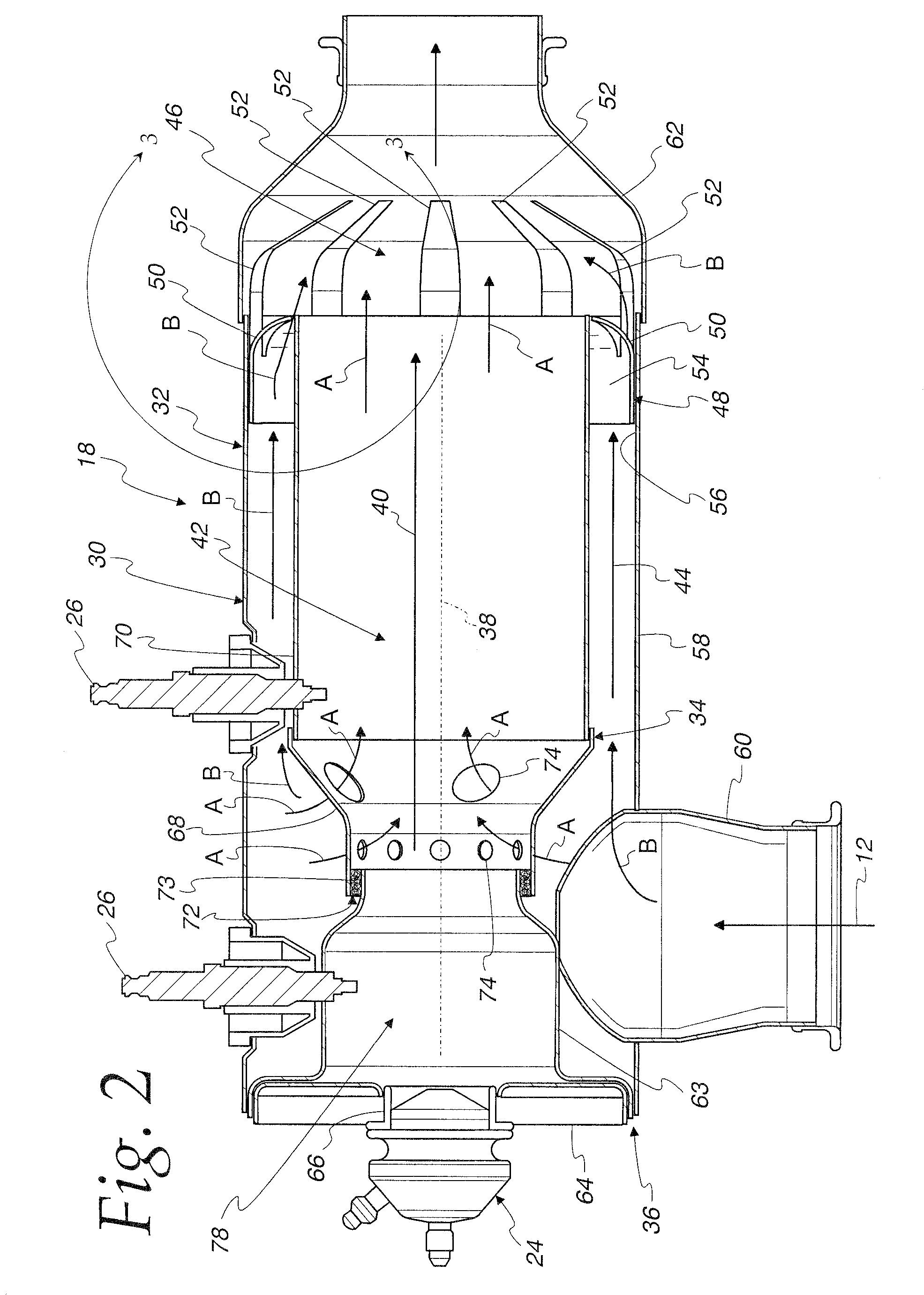

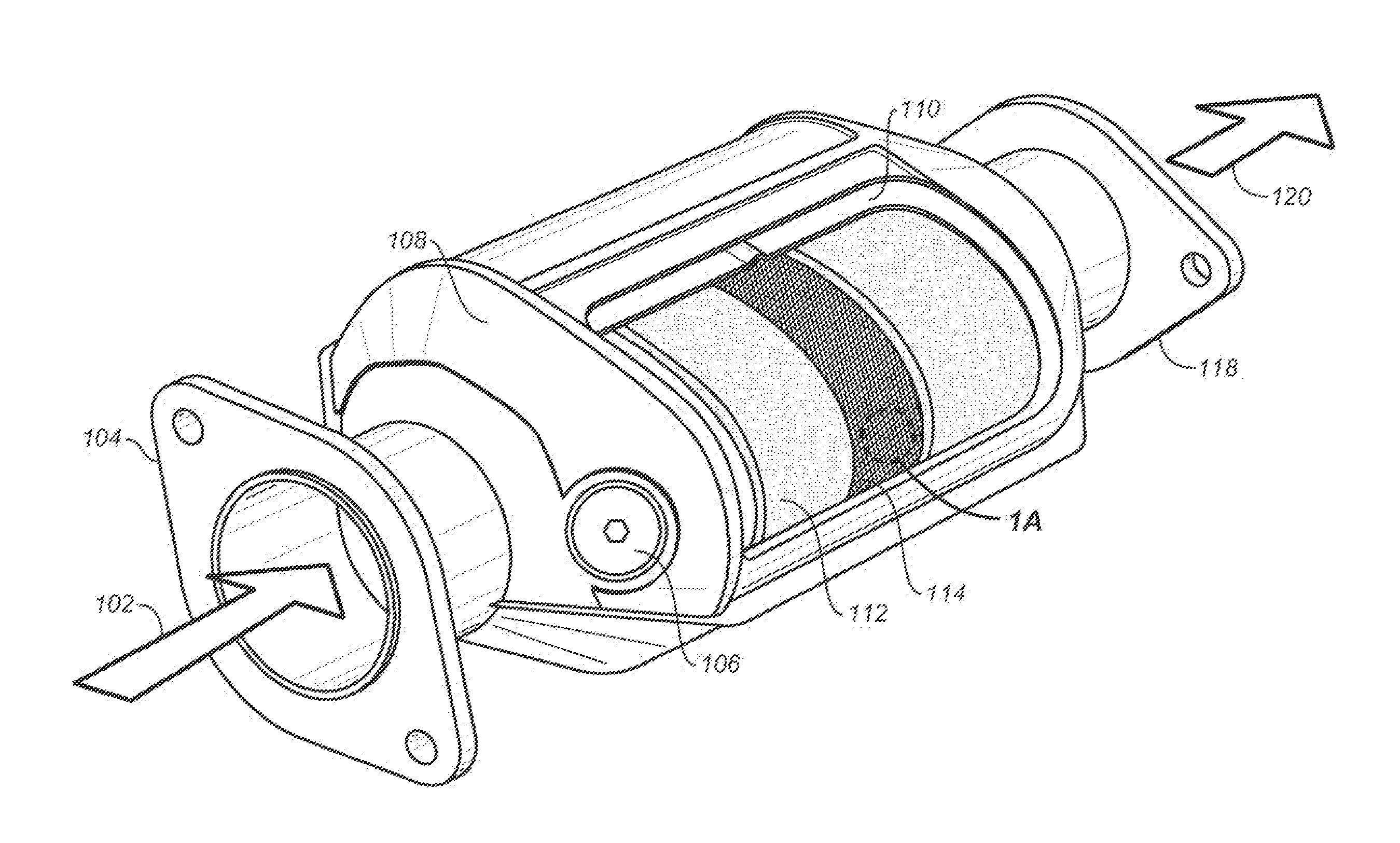

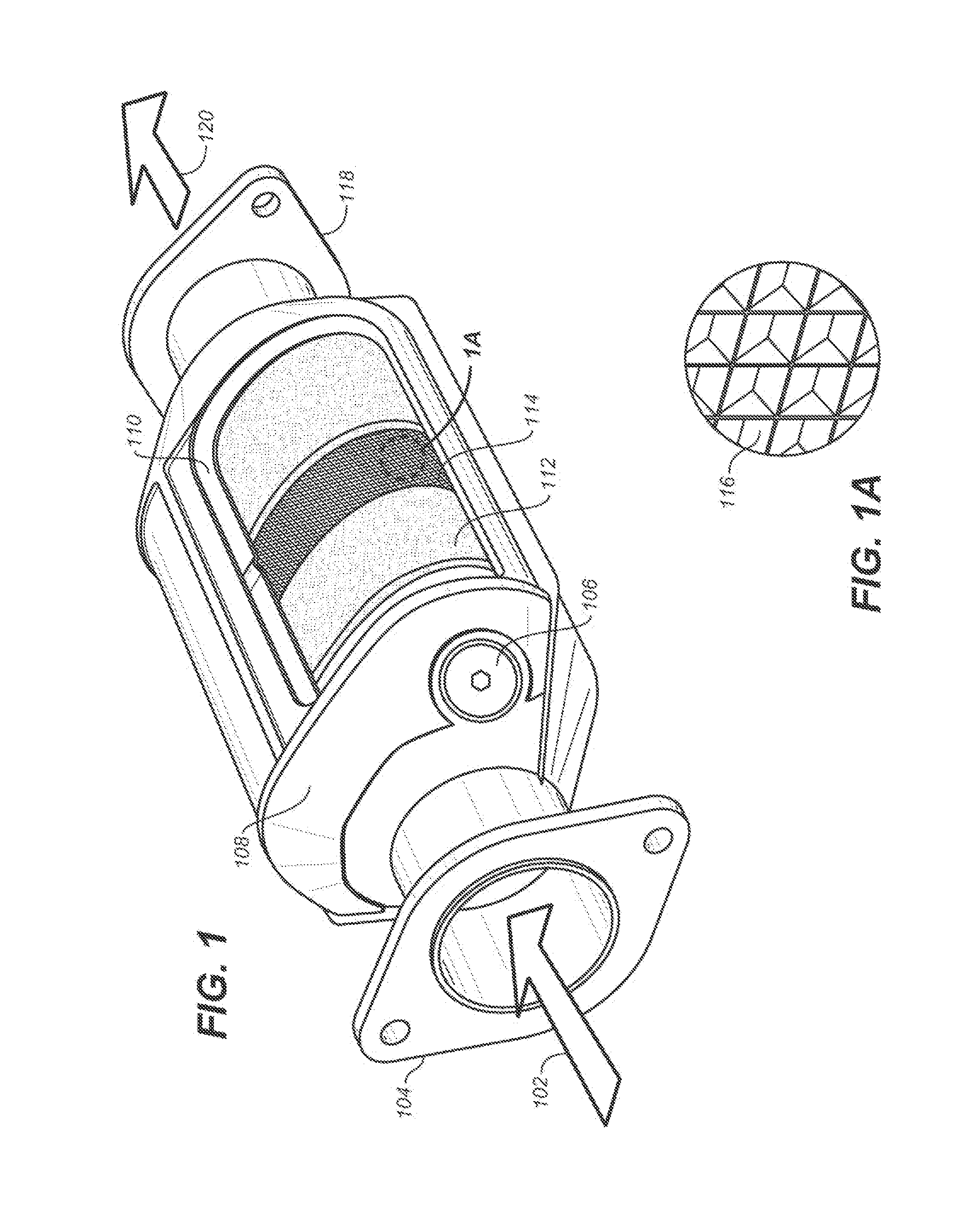

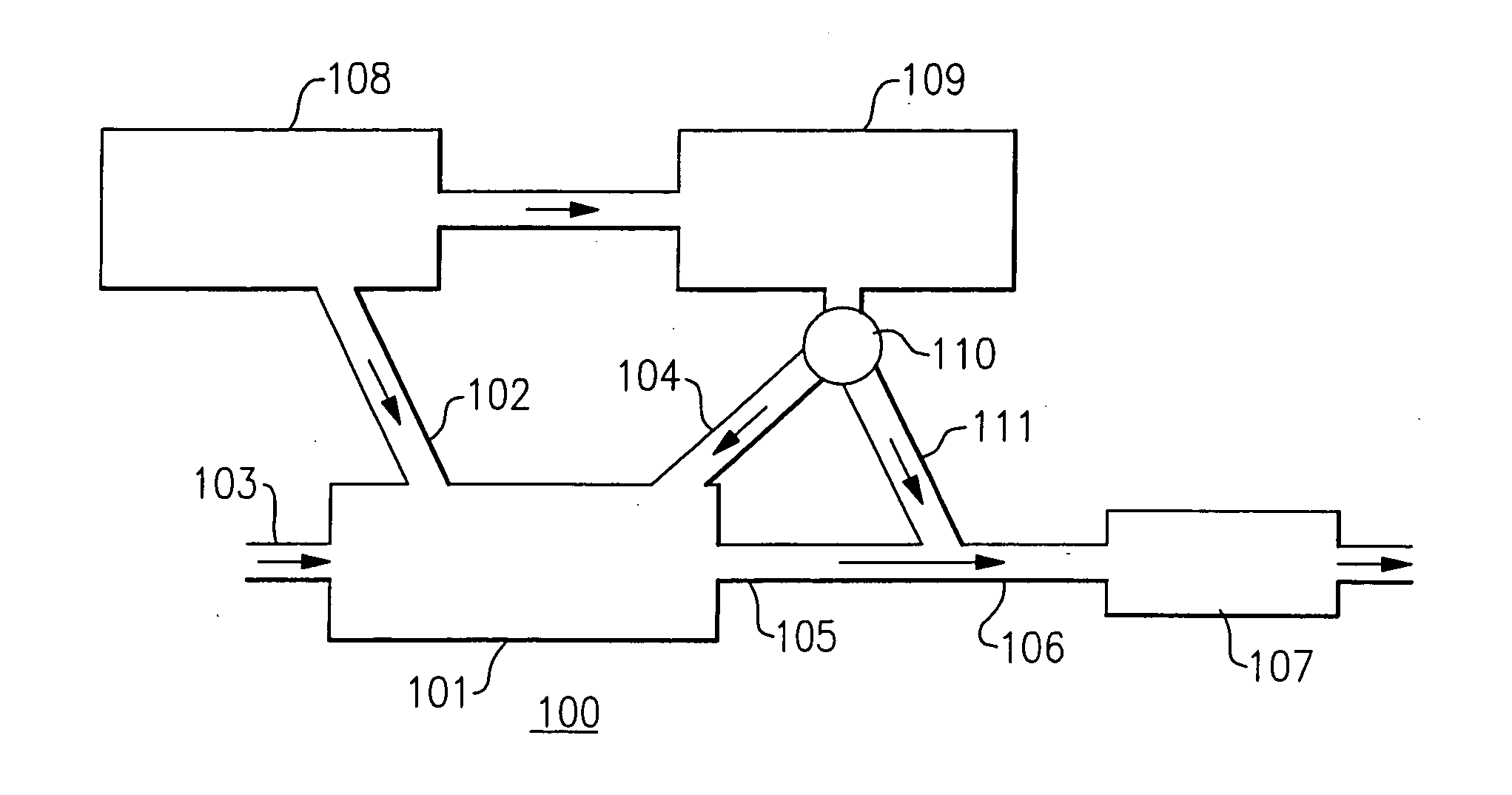

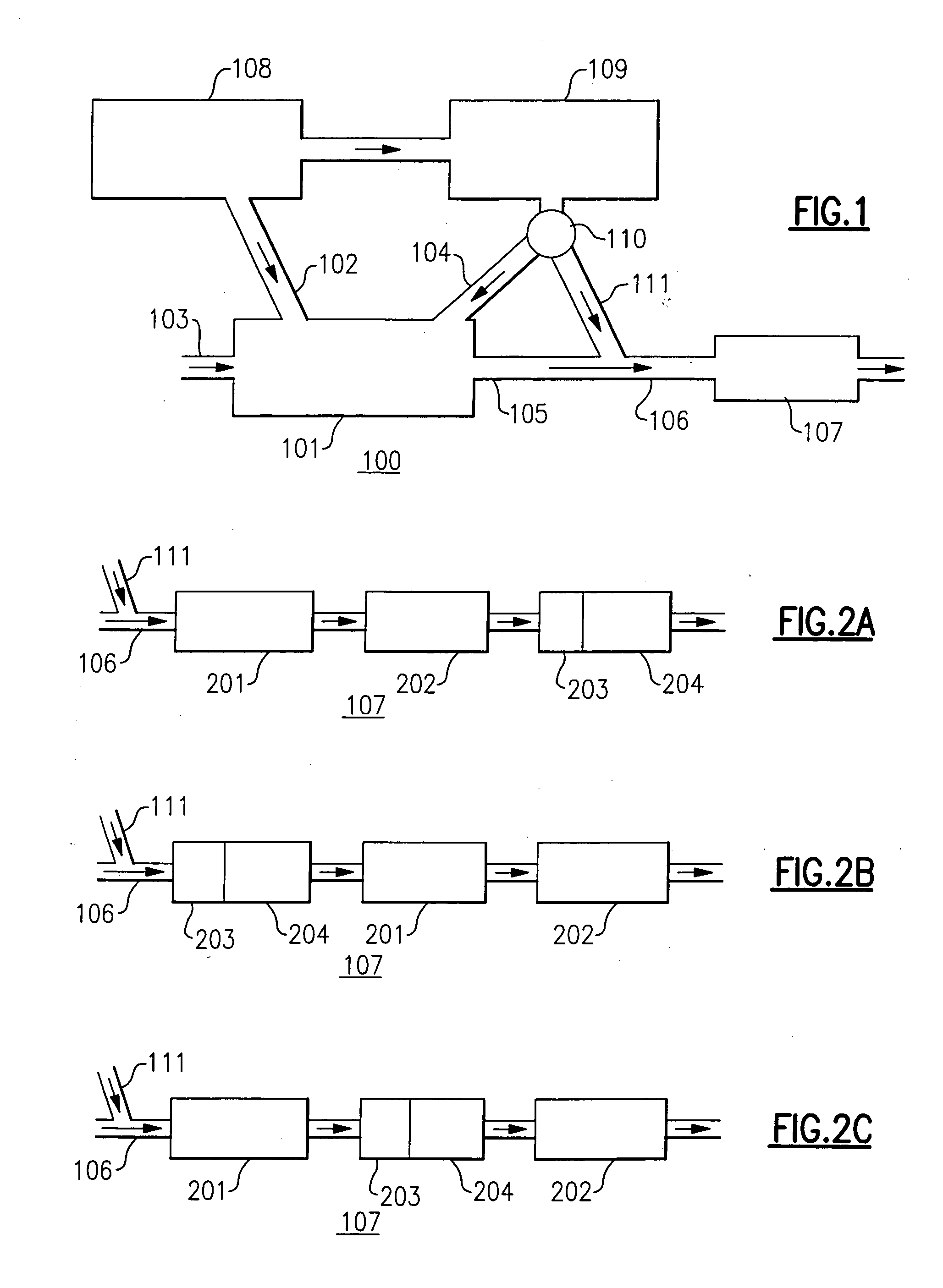

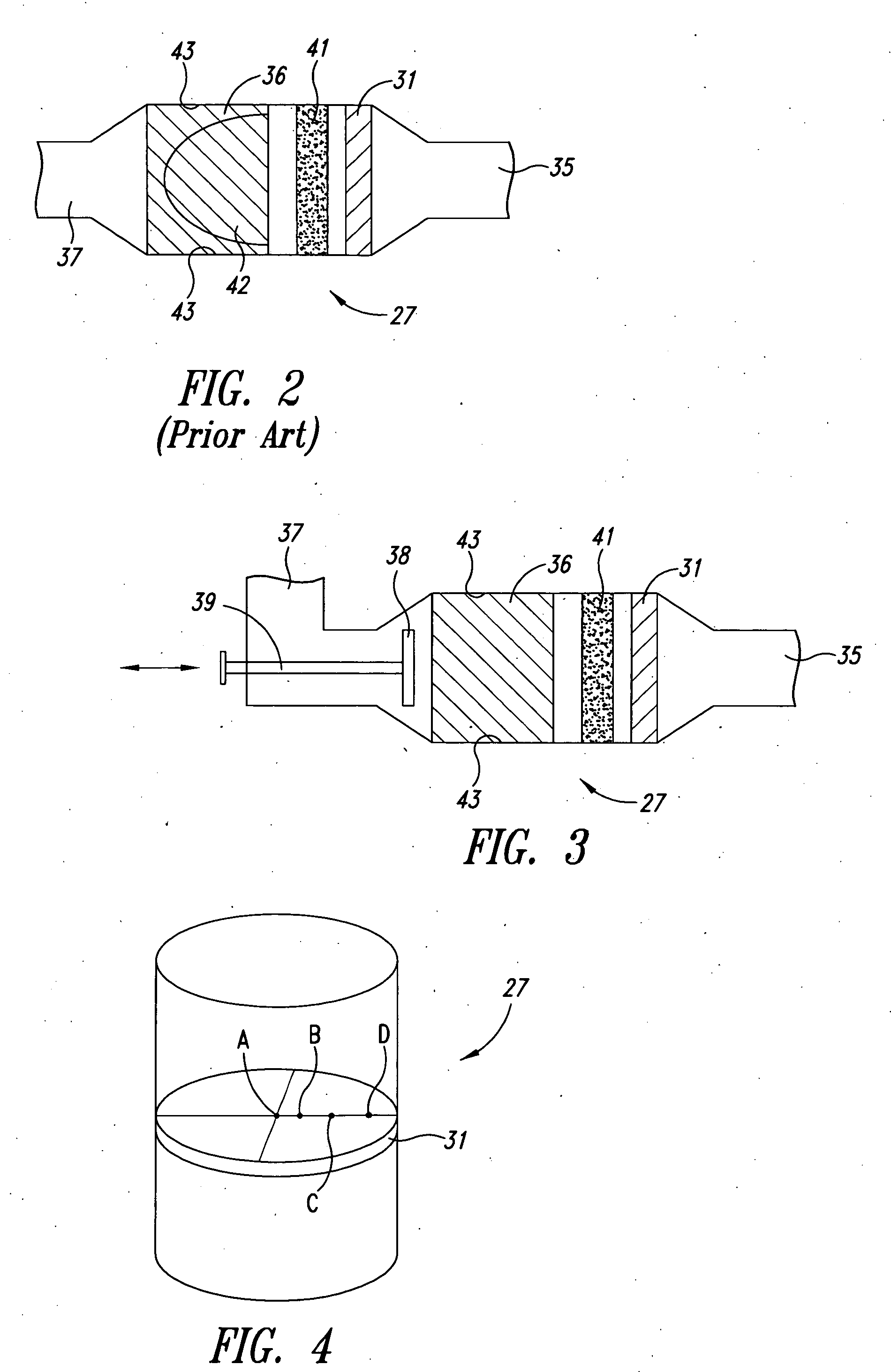

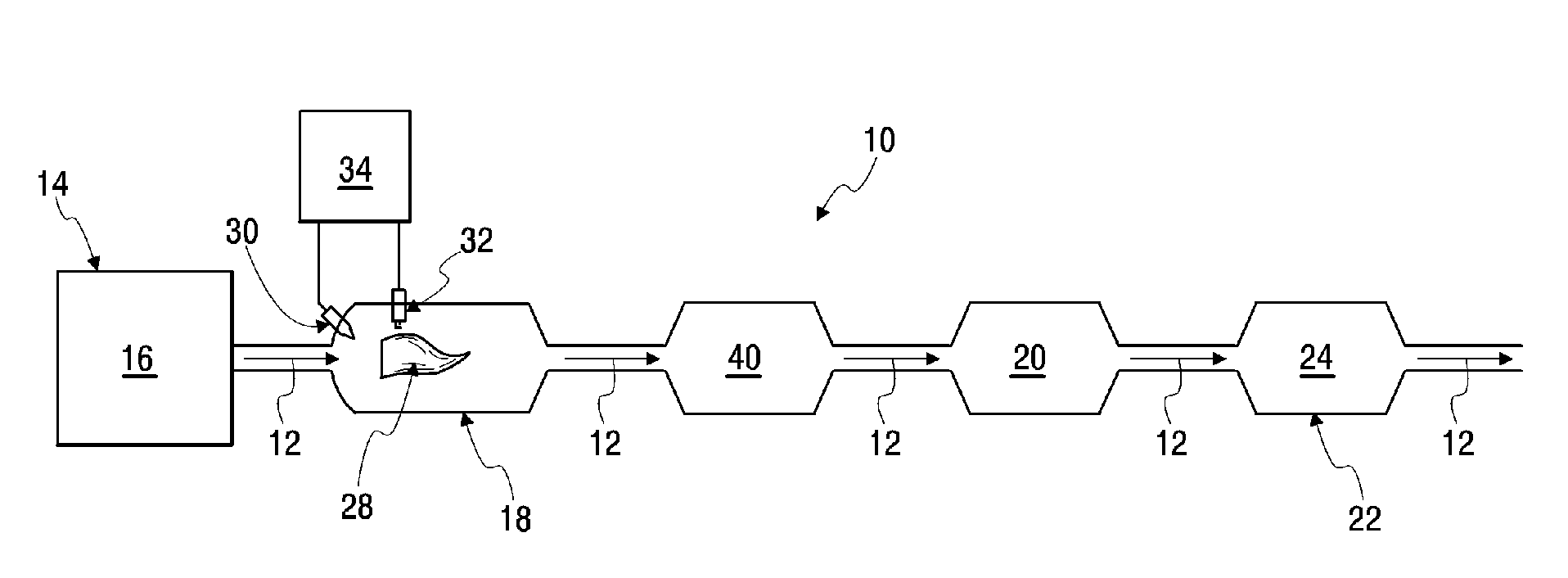

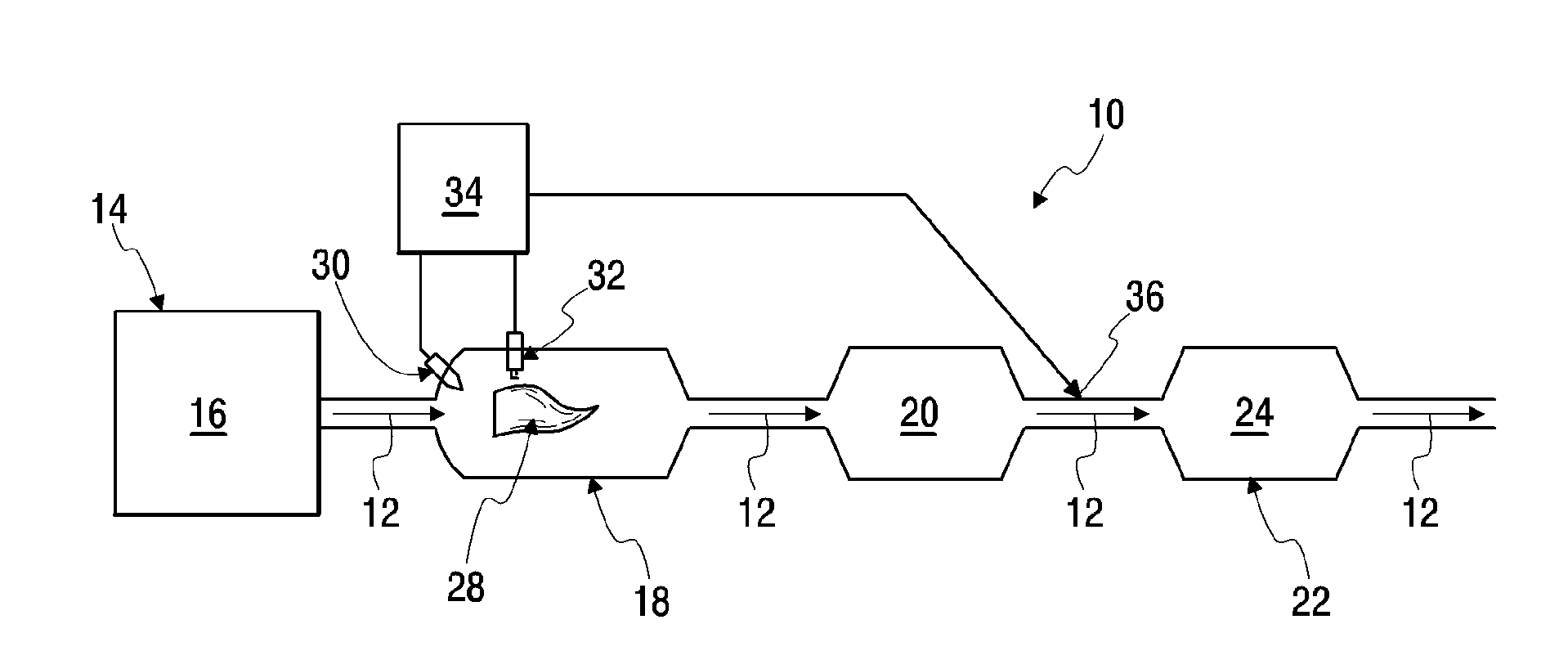

Burner for a Diesel Aftertreatment System

InactiveUS20110061369A1Increase temperatureExhaust apparatusSilencing apparatusCombustorDiesel combustion

A burner (18) is provided for use in a diesel exhaust gas treatment system (10) to treat an exhaust flow (12) from a diesel combustion process (14). The burner (18) includes an inner housing (34) defining a combustion flow path (40) to direct a first portion of the exhaust flow (12) through an ignition zone (42) wherein fuel is ignited, an outer housing (32) surrounding the inner housing (34) to define an annular bypass flow path (44) between the inner and outer housings (34, 32) to bypass a second portion of the exhaust flow (12) around the ignition zone (42), and a mixer (48) including a plurality of flow restrictor fingers (50) that extend across the bypass flow path (44) to restrict an available flow area of the bypass flow path (44), and a plurality of mixer fingers (52) having portions that extend inwardly from a location downstream from the inner housing (34).

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Low emission diesel combustion system with low charge-air oxygen concentration levels and high fuel injection pressures

InactiveUS20040055282A1Lower levelReduce the temperatureLiquid coolingEngine sealsLow loadMass ratio

This invention sets forth a commercially viable diesel combustion system that meets environmentally acceptable levels of NOx emissions (i.e. 0.2 g / bhp-hr or lower across a full map of engine speeds and loads) without the need for use of NOx aftertreatments, and simultaneously maintains engine-out PM emissions relatively close (e.g. with smoke levels at or below 3 BSN) to environmentally acceptable PM post-aftertreatment levels. The invention achieves these results by operating within a unique combination of parameters. These parameters comprise: (1) charge-air oxygen concentration below 16%, preferably between 10% and 15%, more preferably between 11% and 14%, and most preferably between 12% and 13.5% for virtually all engine operating conditions (but not necessarily at no-load or low load conditions), (2) fuel injection pressures at or exceeding 1800 bar, preferably exceeding 2100 bar, more preferably exceeding 2300 bar, and most preferably exceeding 2500 bar, at most engine speeds and loads, and (3) charge-air mass / fuel mass ratio between 25:1 and 45:1 for medium and high loads. Furthermore, the system is preferably run continuously slightly lean of stoichiometry, providing just enough excess oxygen to facilitate completeness of combustion and to maintain an exhaust oxygen level sufficient for continuous trap regeneration at a balance point in operation.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

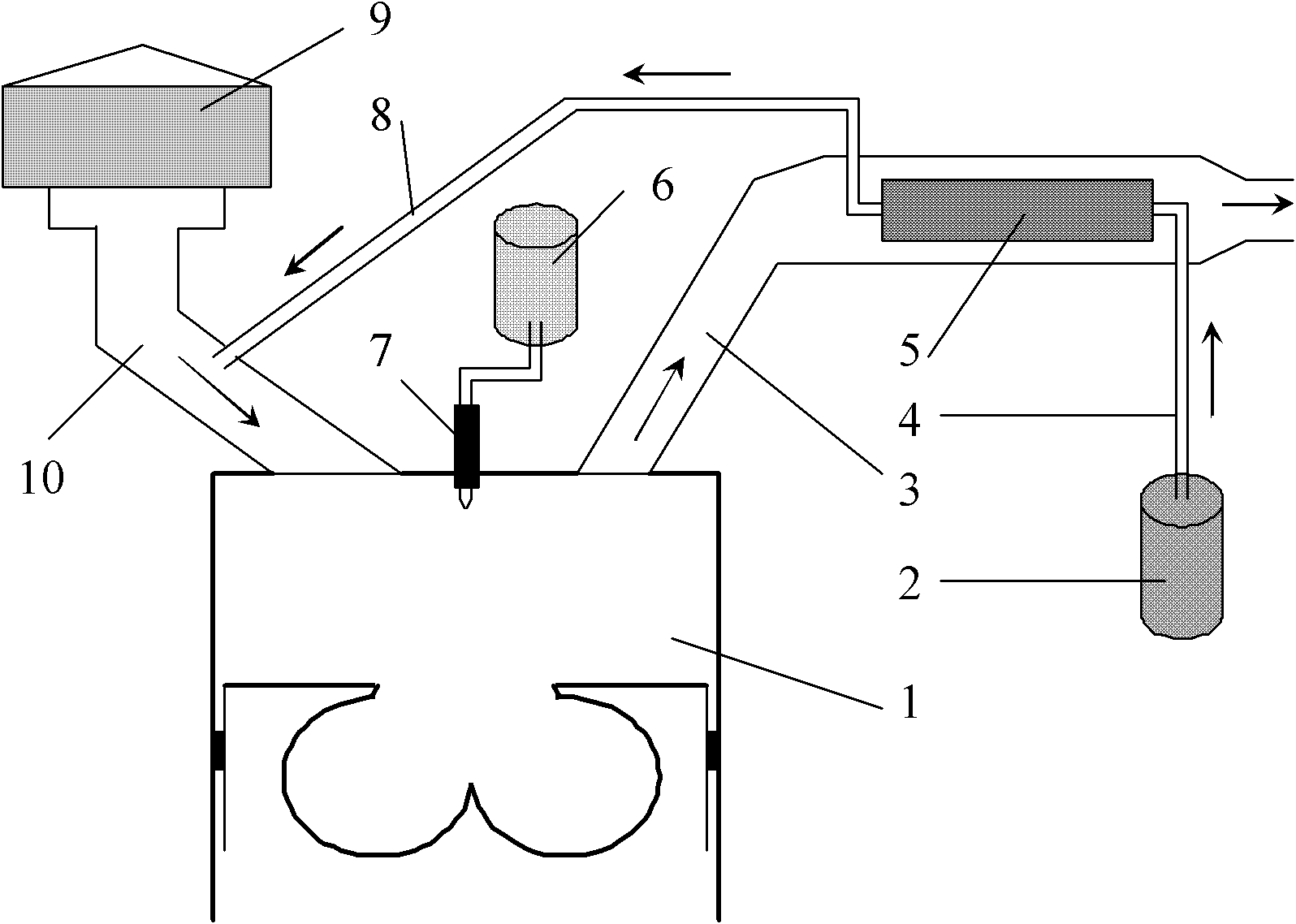

Apparatus capable of simultaneously measuring diesel spray structure and combustion characteristic and method thereof

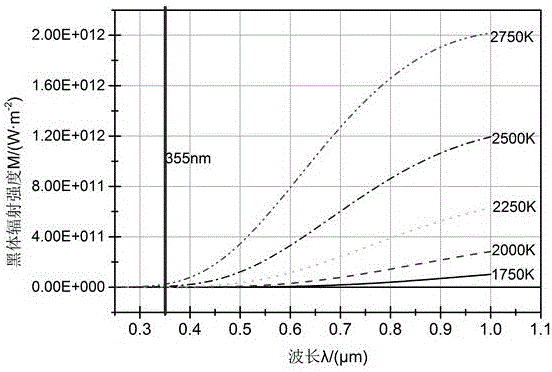

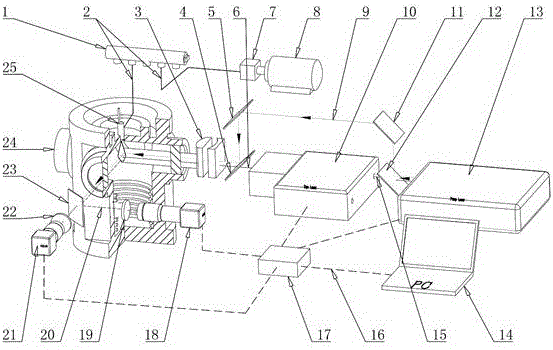

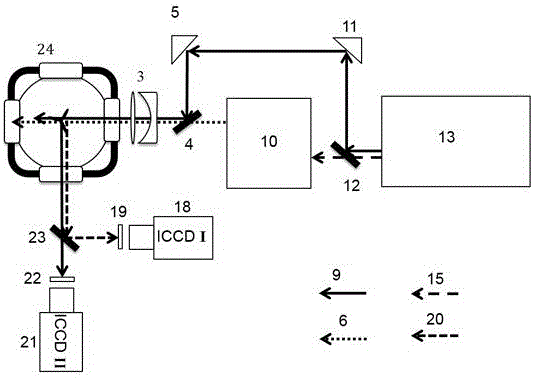

ActiveCN106404410AReduce radiation interferenceAchieve resolutionInternal-combustion engine testingDiesel sprayDiesel combustion

The invention belongs to the diesel spray and combustion visualization research field and discloses a measurement apparatus capable of simultaneously measuring a diesel spray structure and a combustion characteristic based on a laser diagnosis technology and a method thereof. In the past, test researches of a diesel spray characteristic and the combustion characteristic can not be performed simultaneously. In the invention, through using a Mie scattering technology of a laser and a laser induced fluorescence technology (OH-PLIF), the spray structure and the combustion characteristic during diesel combustion can be simultaneously measured and researched. The corresponding apparatus comprises a laser system, a constant volume combustion bomb system, a fuel oil supply system, a signal synchronization system and a signal acquisition system. The test apparatus can simultaneously carry out test researches of a liquid phase length of diesel spray and OH-PLIF distribution under a combustion condition, simultaneously can indicate a liquid phase area in a diesel combustion OH-PLIF distribution map and solves an interference problem of a liquid phase signal to a laser-induced fluorescence signal.

Owner:JIANGSU UNIV

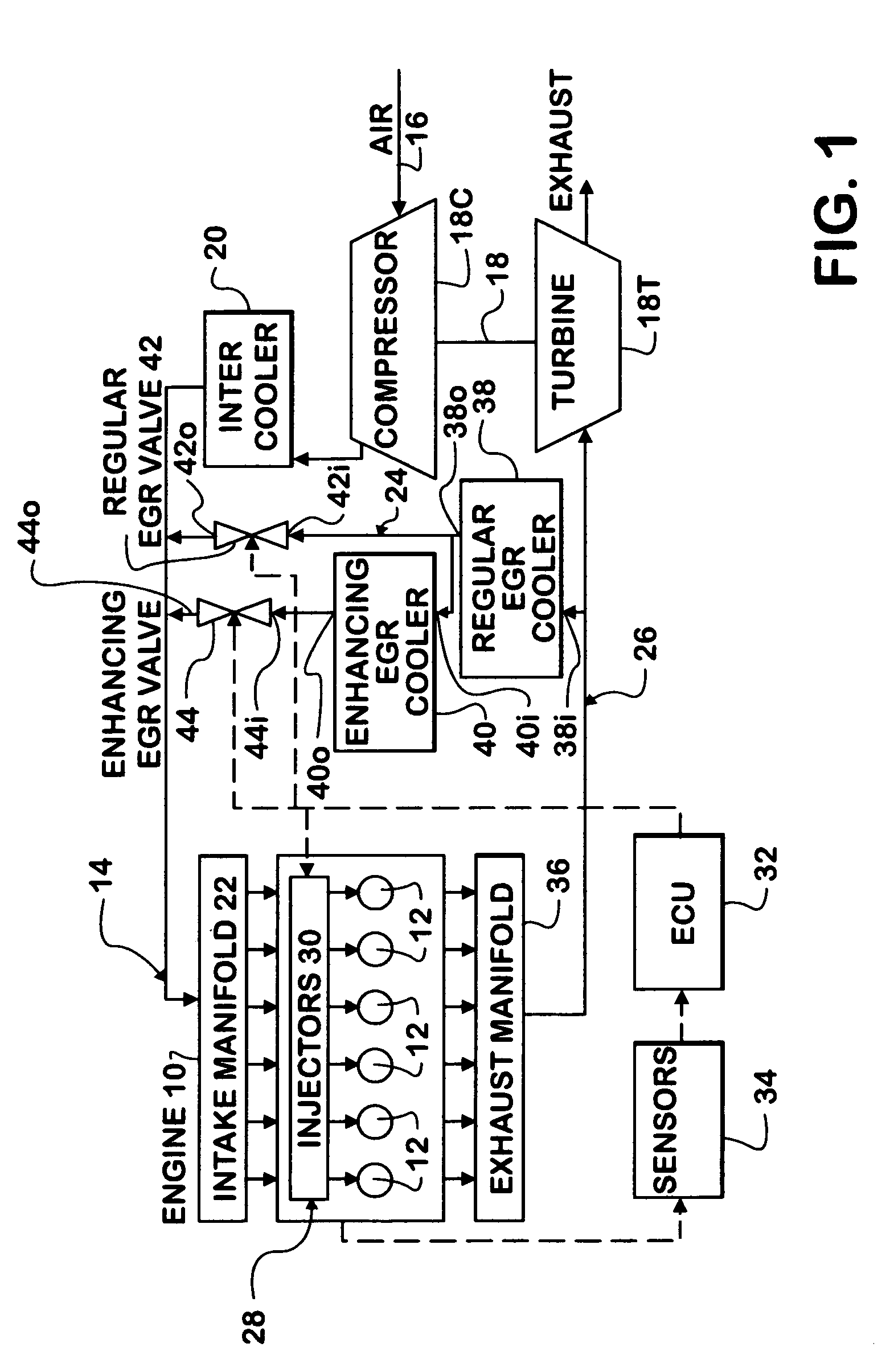

Method and device for reducing fuel consumption of diesel engine by catalytic decomposition of oxygen-containing fuel

InactiveCN102278240AEmission reductionReduce consumptionInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberExternal energy

A method and device for reducing fuel consumption of a diesel engine by catalytic decomposition of oxygen-containing fuel belong to the technical field of diesel engine combustion energy saving and emission reduction. In the present invention, the oxygen-containing fuel is fed into the catalytic reactor installed in the exhaust channel of the diesel engine, and the catalytic reactor is heated by the waste heat of the tail gas discharged from the combustion chamber, so that the oxygen-containing fuel is catalytically decomposed, and the generated hydrogen-rich and carbon monoxide-rich The decomposed gas enters the intake port, mixes with air, and enters the combustion chamber. At the same time, the emulsified oil is sprayed from the nozzle. The atomized emulsified oil evaporates, mixes, ignites and burns in the combustion chamber, and pushes the piston to do work. The system of the present invention makes full use of the waste heat of the exhaust gas of the diesel engine, and can realize the catalytic decomposition of the oxygen-containing fuel without providing energy from the outside. At the same time, combined with the use of emulsified oil, the comprehensive fuel saving rate of the diesel engine can reach 10-15%, and can be greatly improved. Reduce the emission of pollutants such as nitrogen compounds and soot, so as to achieve the purpose of energy saving and emission reduction.

Owner:TSINGHUA UNIV

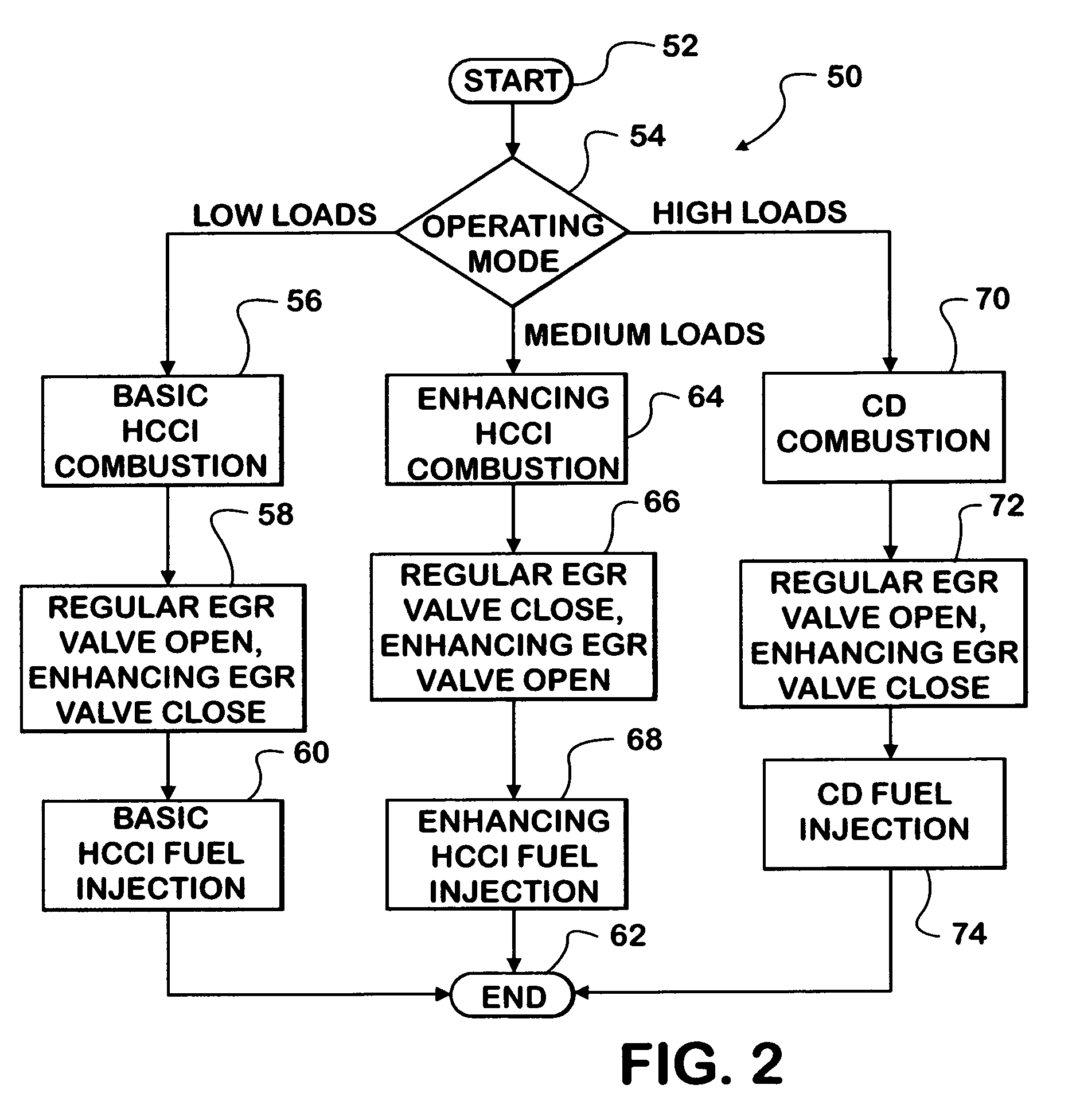

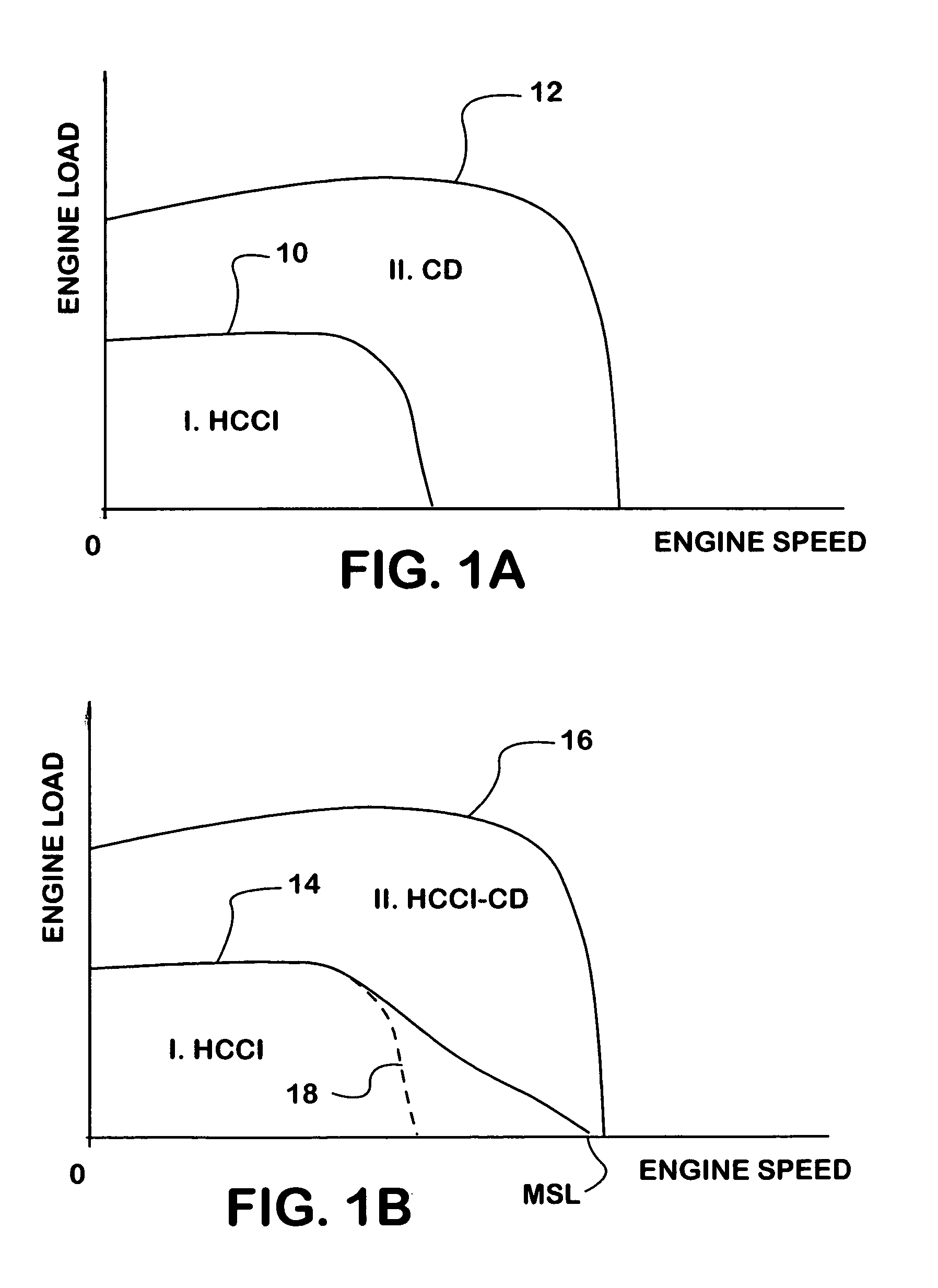

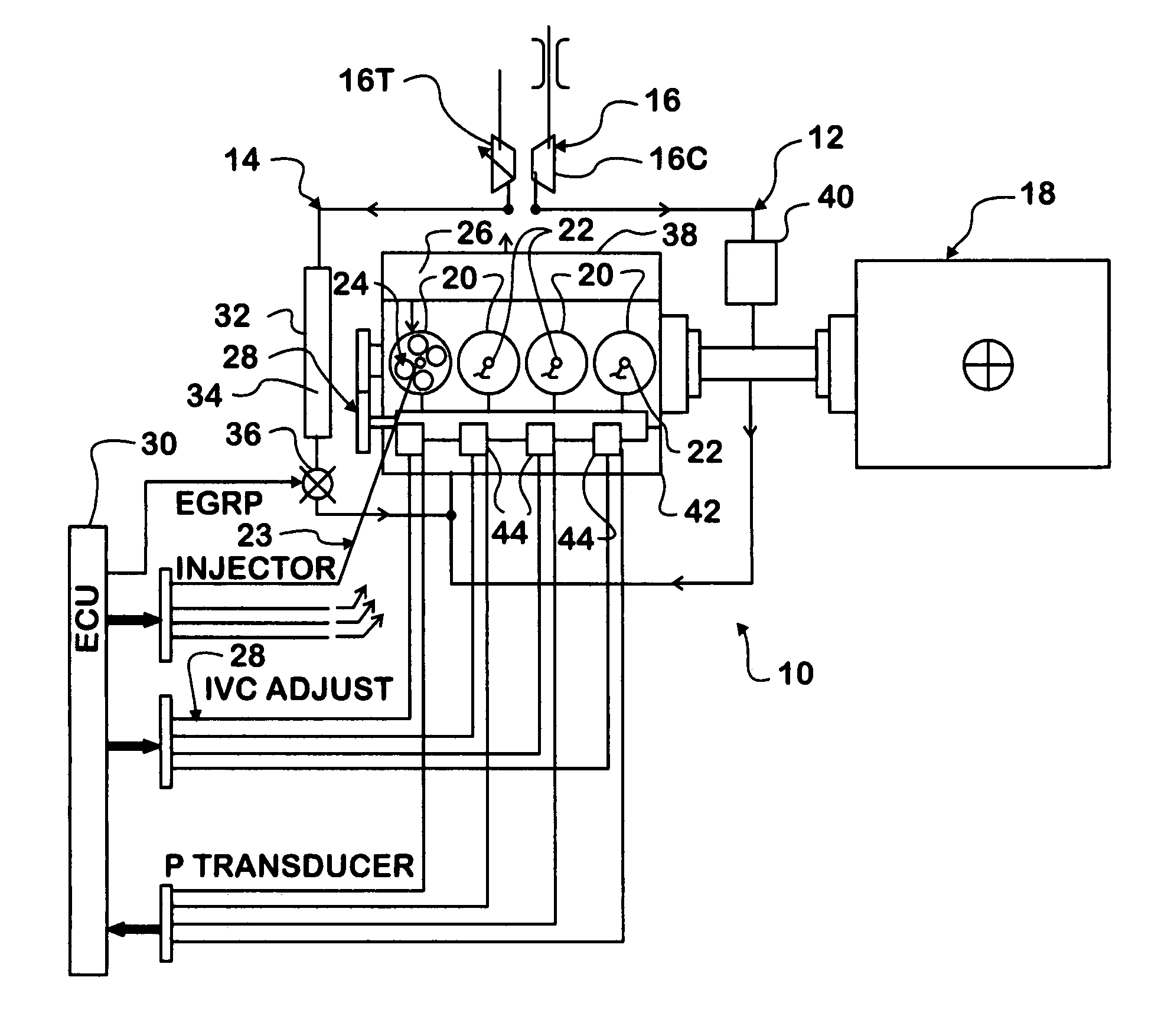

Control strategy for expanding diesel HCCI combustion range by lowering intake manifold temperature

ActiveUS7171957B2Less undesirableCompromise performanceElectrical controlInternal combustion piston enginesHcci combustionLow load

An engine (10, 100) utilizes “regular EGR cooling” when operating in HCCI mode within a low load range and “enhanced EGR cooling” that allows the engine to continue to operate in HCCI mode when engine load increases beyond the low load range. When engine load increases to a high load range, the combustion mode changes over to conventional diesel combustion, and exhaust gas recirculation reverts to “regular EGR cooling”. In a first embodiment, cooling is provided by two heat exchangers, one being a regular EGR cooler always used when cooling is needed and the other, an enhancing EGR cooler that is selectively used. In a second embodiment, cooling is also provided by two heat exchangers, one being an EGR cooler through which liquid coolant always flows when cooling is needed, and the other being a radiator used selectively to cool the liquid coolant before it enters the EGR cooler.

Owner:INT ENGINE INTPROP CO LLC +1

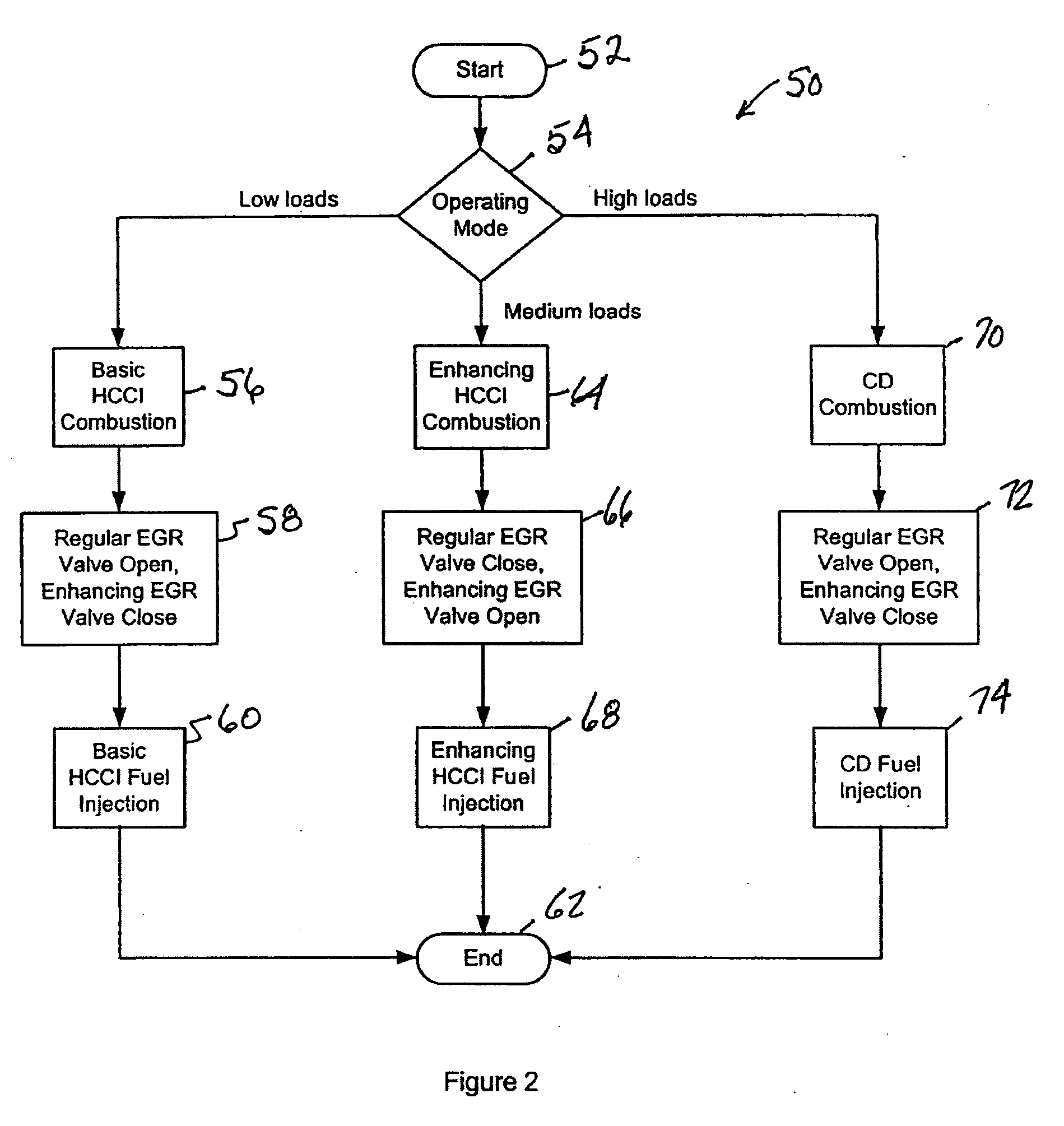

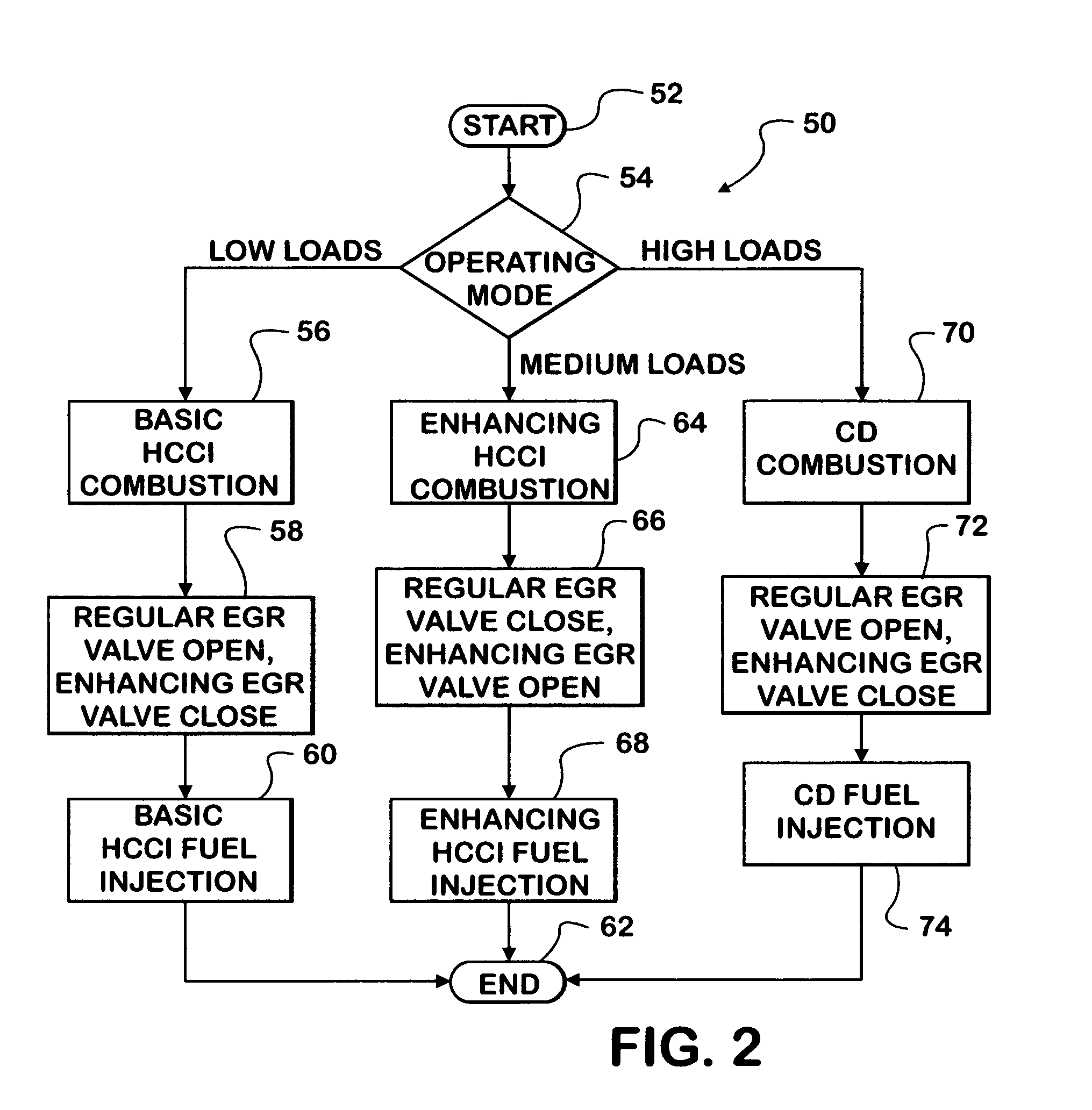

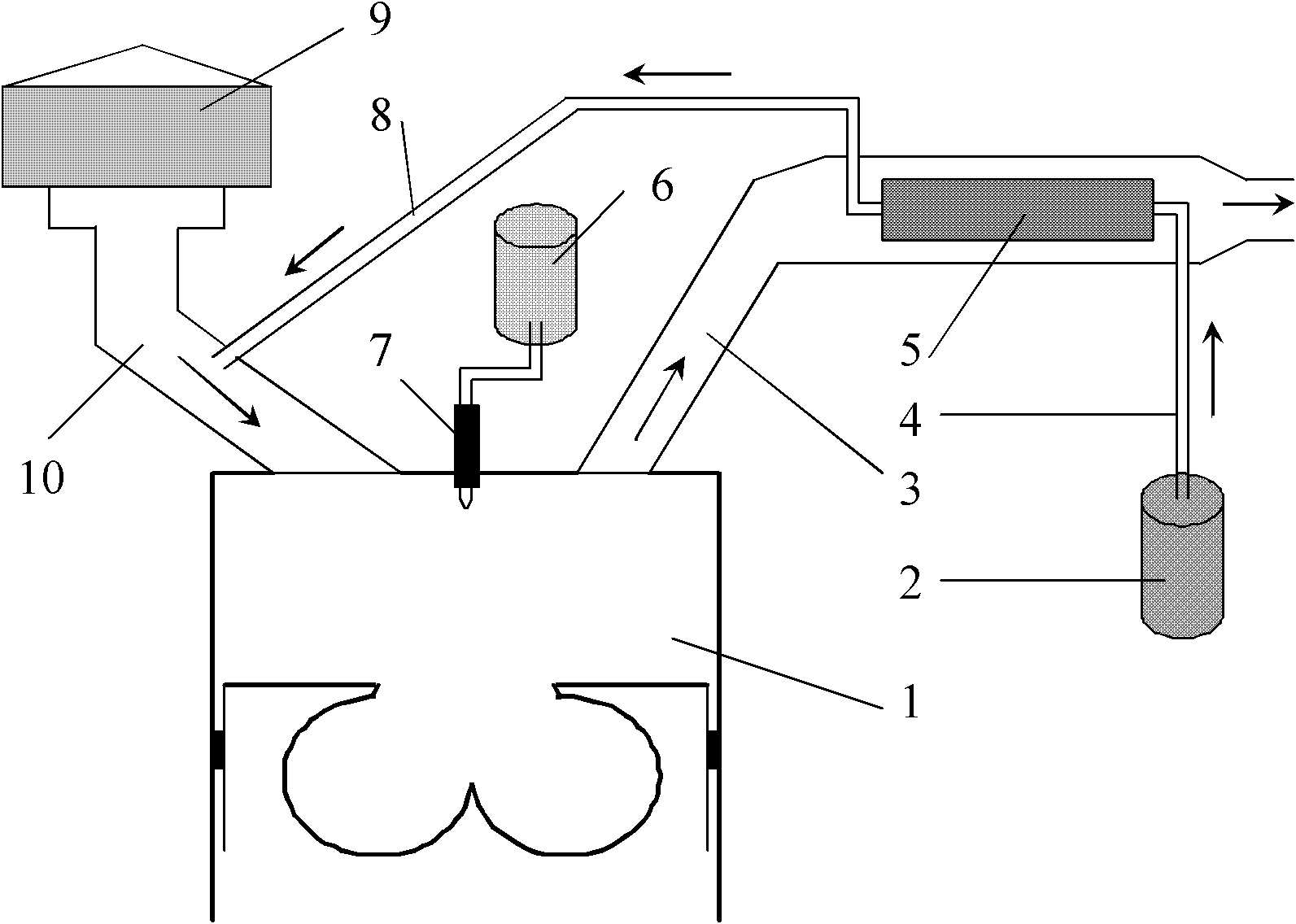

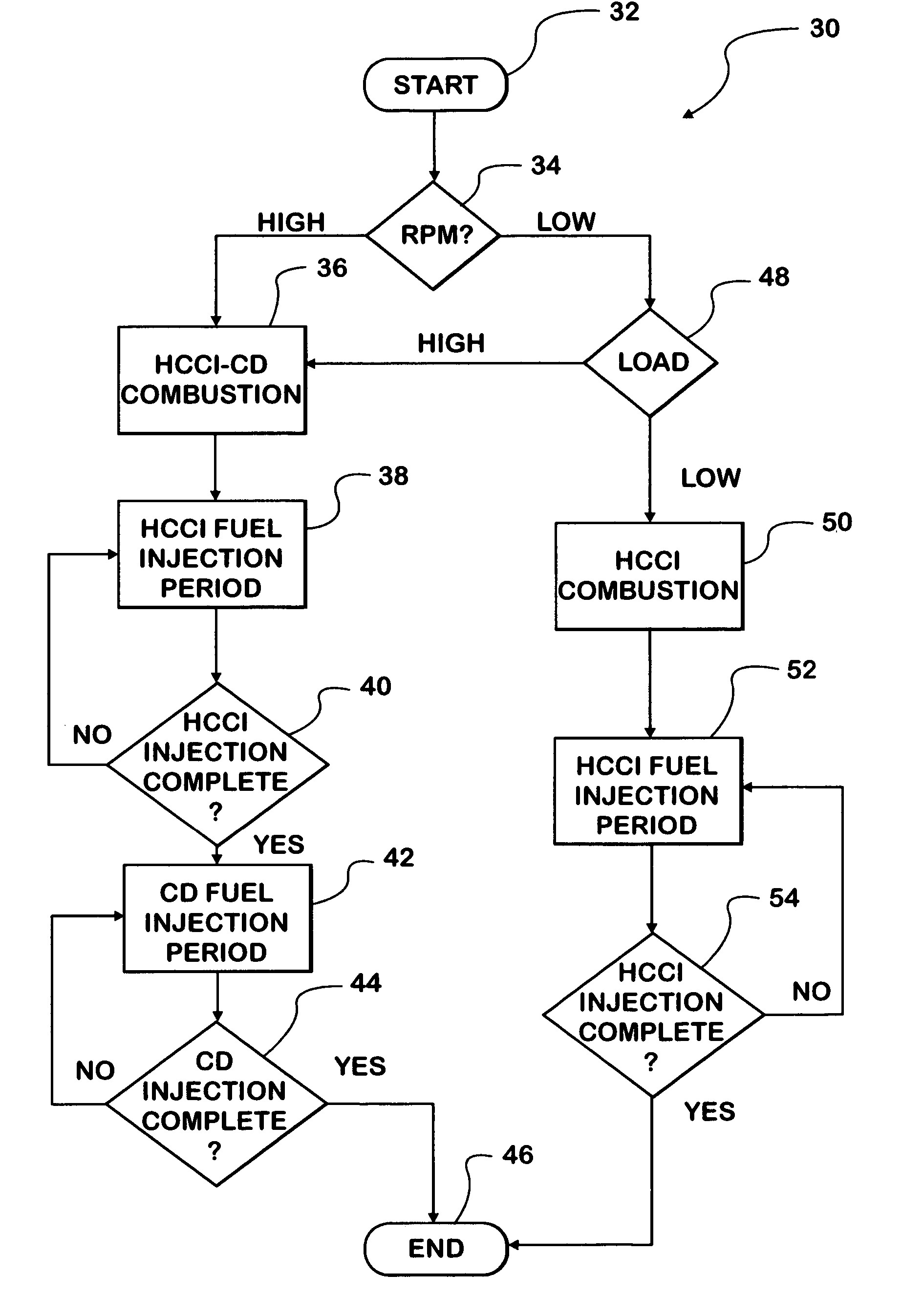

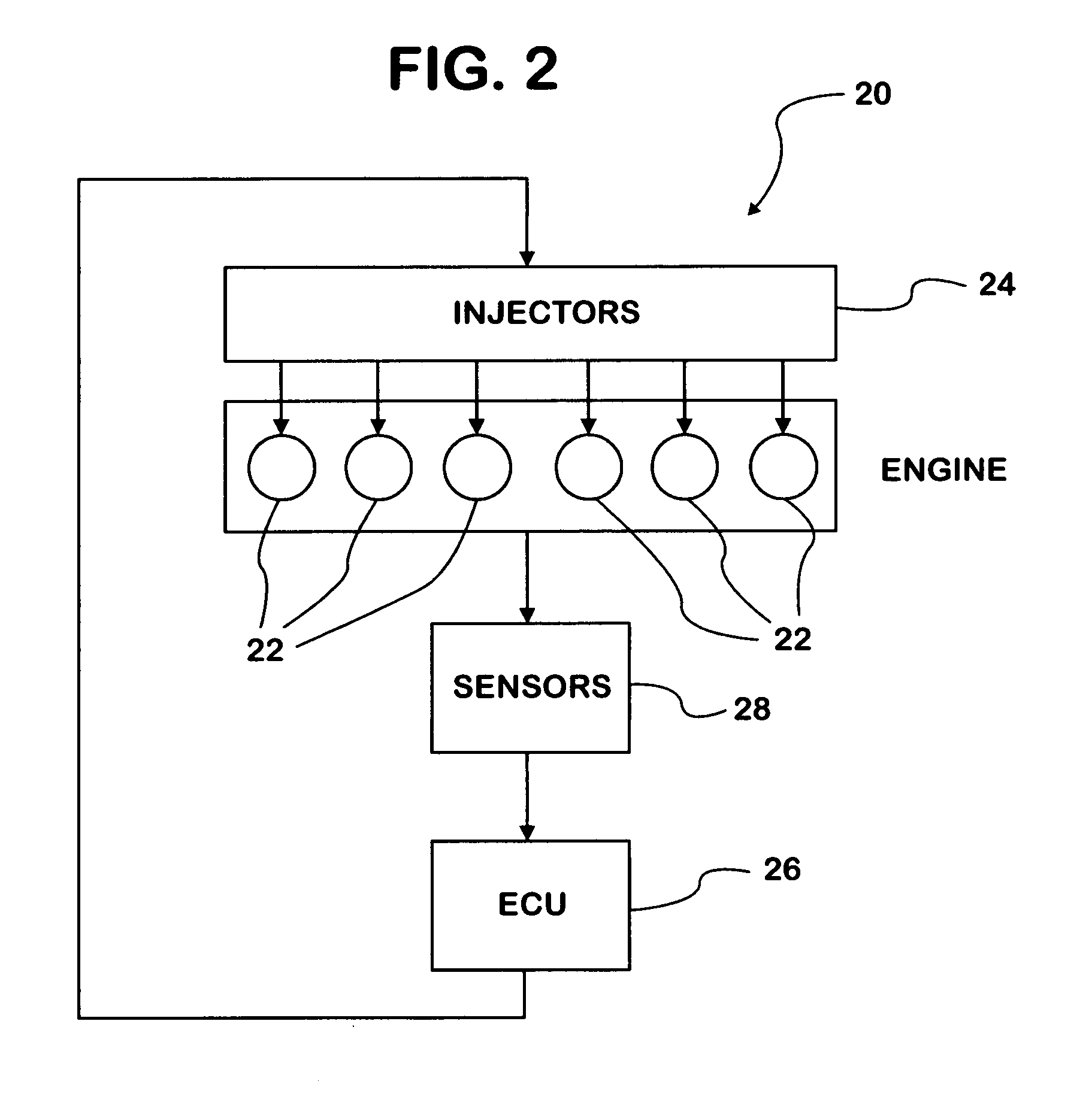

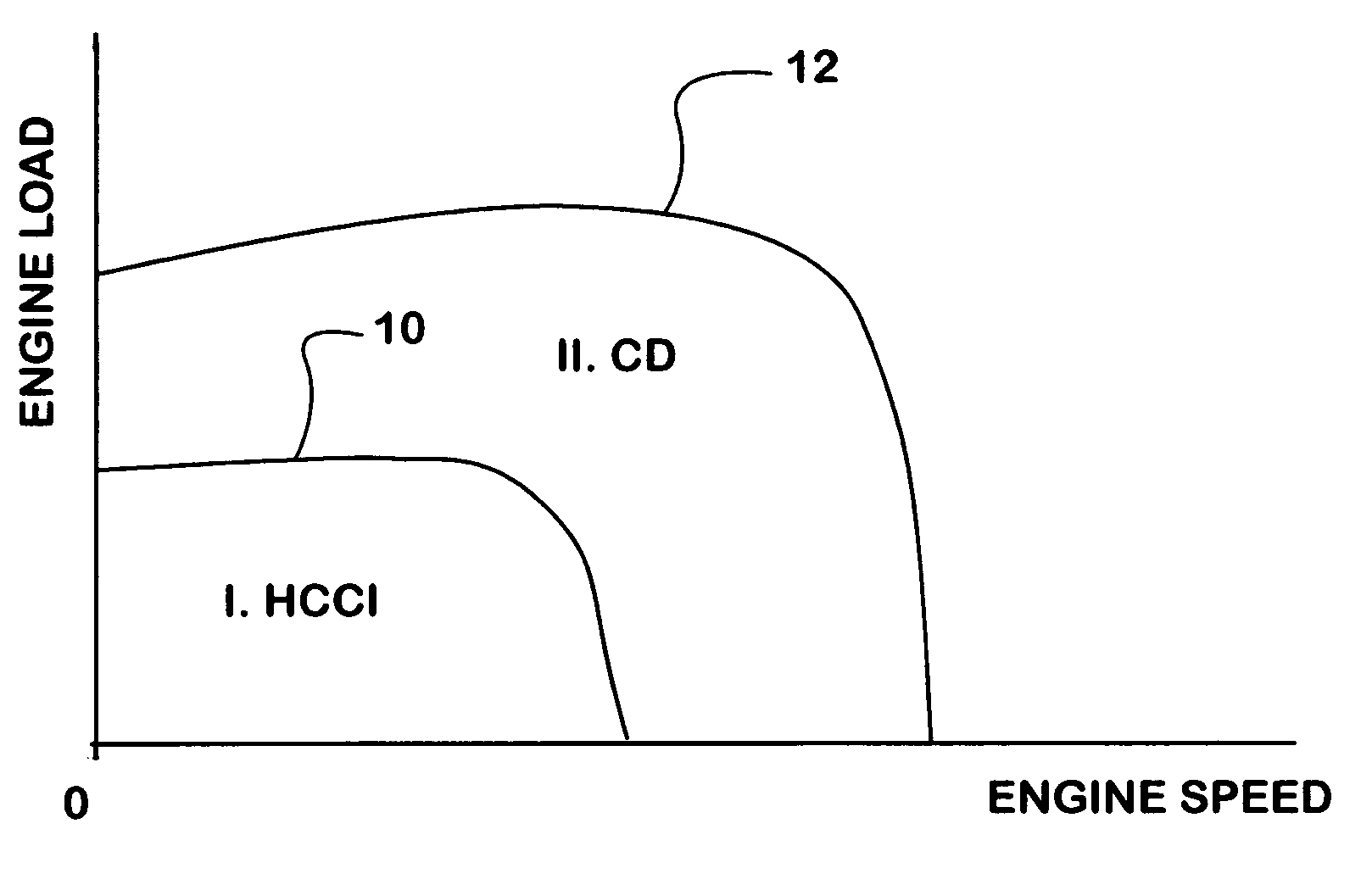

Control strategy for HCCI-CD combustion in a diesel engine using two fuel injection phases

ActiveUS7021276B2Easy to useReduce generationElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionControl system

Owner:INT ENGINE INTPROP CO LLC

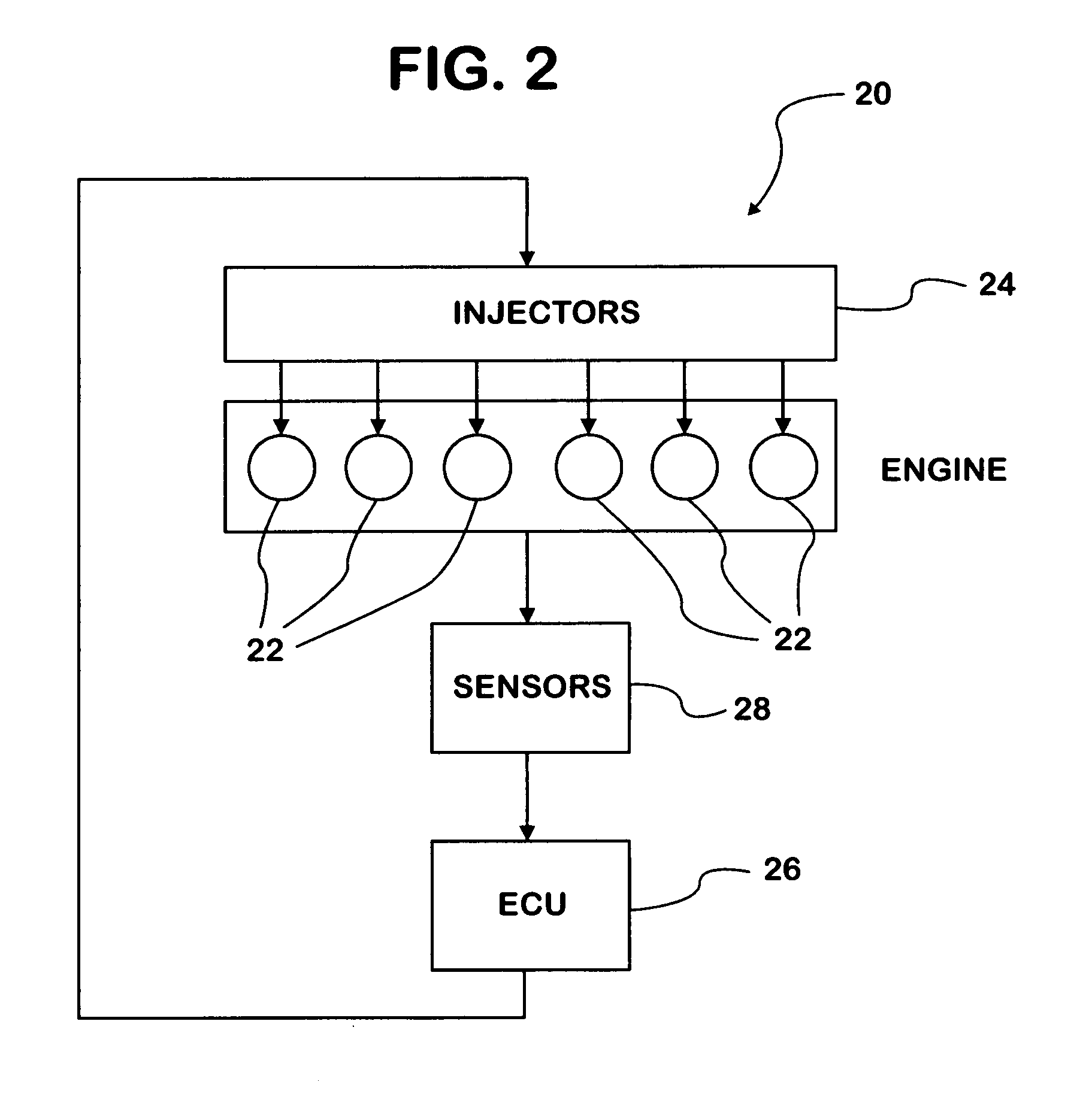

Control strategy for HCCI-CD combustion in a diesel engine using two fuel injection phases

ActiveUS20050211218A1Easy to useReduce generationElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionControl system

A compression ignition engine (20) has a control system (26) for processing data, one or more combustion chambers (22), and fuel injectors (24) for injecting fuel into the combustion chambers. The control system controls fueling using a result of the processing of certain data, such as engine speed and engine load, to select one of two fueling modes (HCCI, HCCI-CD) for operating the engine. When the result of the processing selects the HCCI mode, the engine is fueled to cause homogeneous-charge compression-ignition (HCCI) combustion within the combustion chambers. When the result of the processing selects the HCCI-CD mode, the engine is fueled to create a substantially homogeneous combustible charge within each combustion chamber that is compressed to auto-ignition, and after auto-ignition, more fuel is injected to provide additional combustion in the manner of the conventional diesel combustion.

Owner:INT ENGINE INTPROP CO LLC

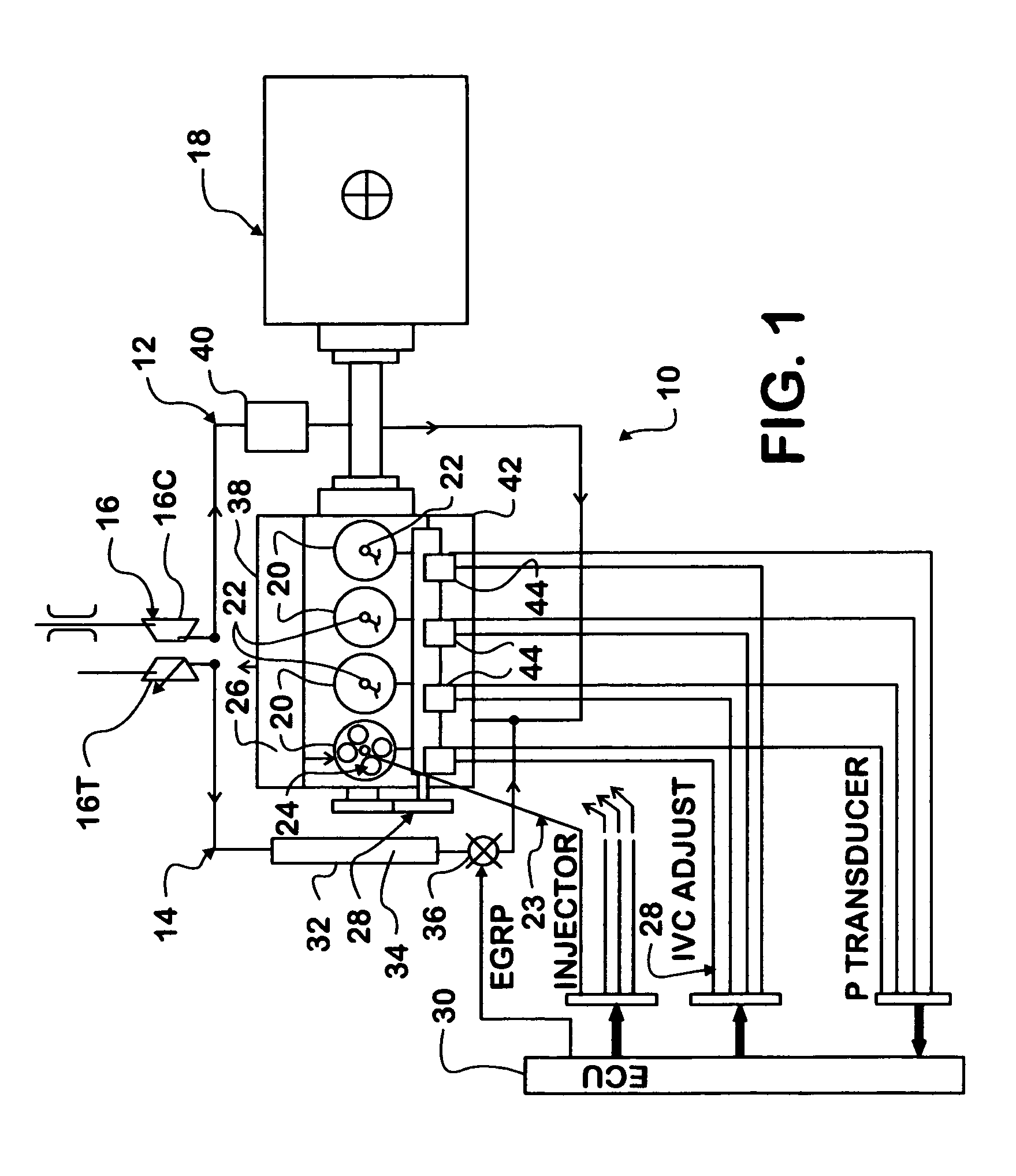

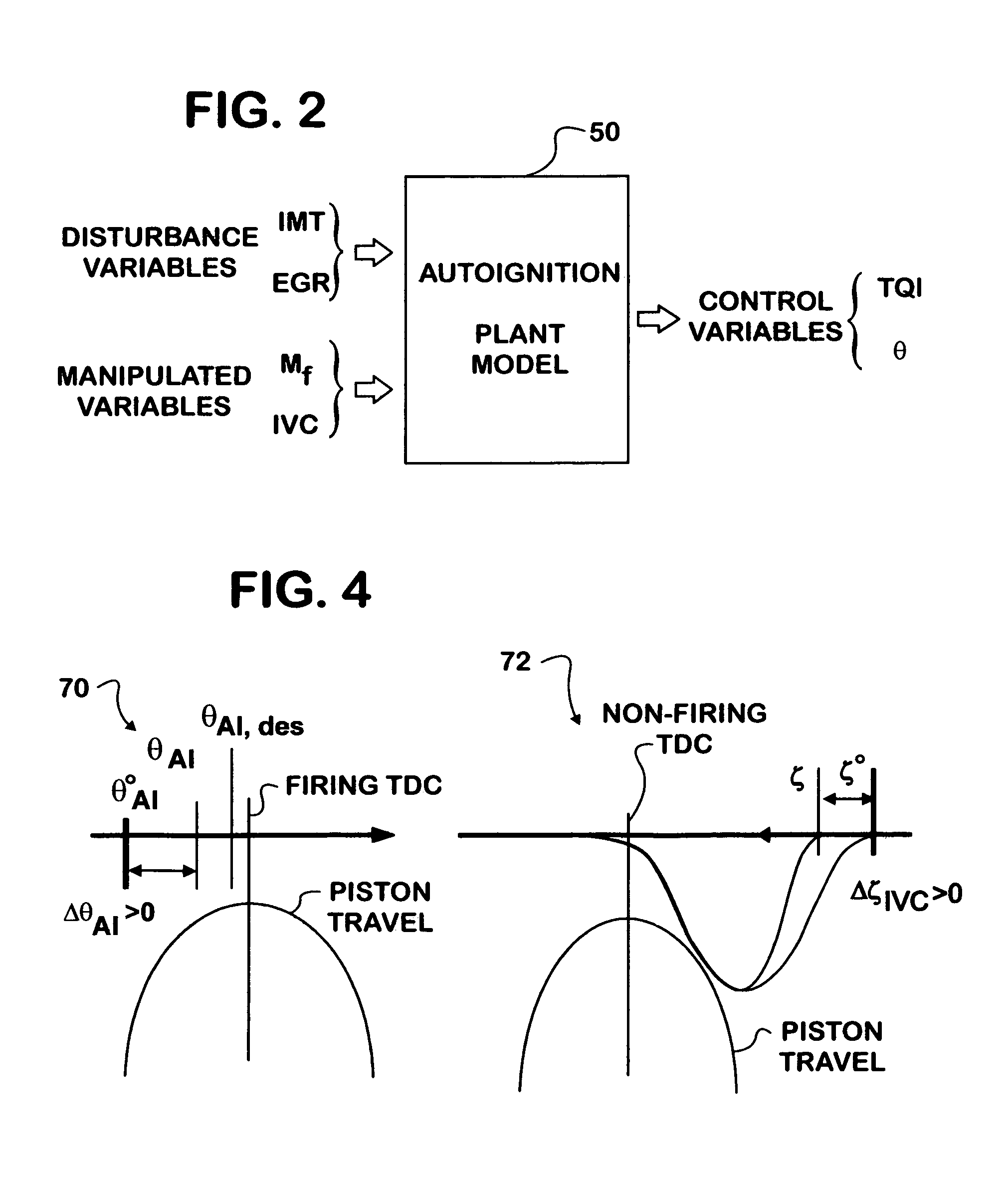

Model-based controller for auto-ignition optimization in a diesel engine

ActiveUS7184877B1Minimize changesWell mixedElectrical controlInternal combustion piston enginesDiesel combustionModel based controller

A diesel engine (10) operates by alternative diesel combustion. Formation of fuel and charge air mixtures is controlled by processing a particular set of values for certain input data according to a predictor algorithm model (50) to develop data values for predicted time of auto-ignition and resulting torque, and also develop data values for control of fuel and air that will produce the predicted time of auto-ignition and resulting torque. The data values developed by the predictor algorithm and data values for at least some of the input data are processed according to a control algorithm (52) that compensates for any disturbance introduced into any of the data values for at least some of the input data being processed by the control algorithm. This causes the systems to be controlled by compensated data values that produce predicted time of auto-ignition and resulting torque in the presence of any such disturbance.

Owner:INT ENGINE INTPROP CO LLC

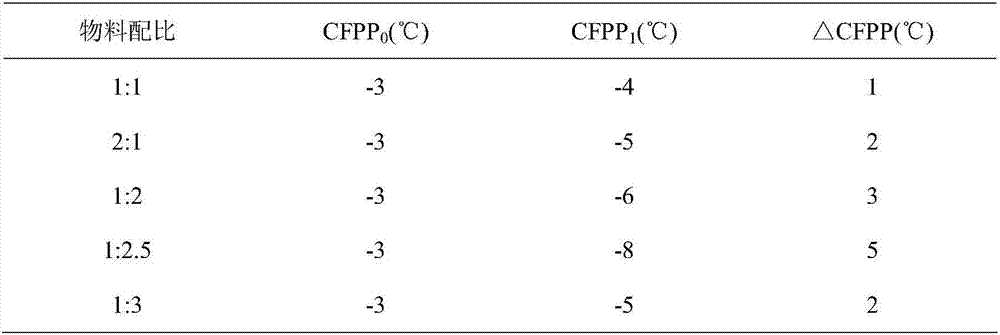

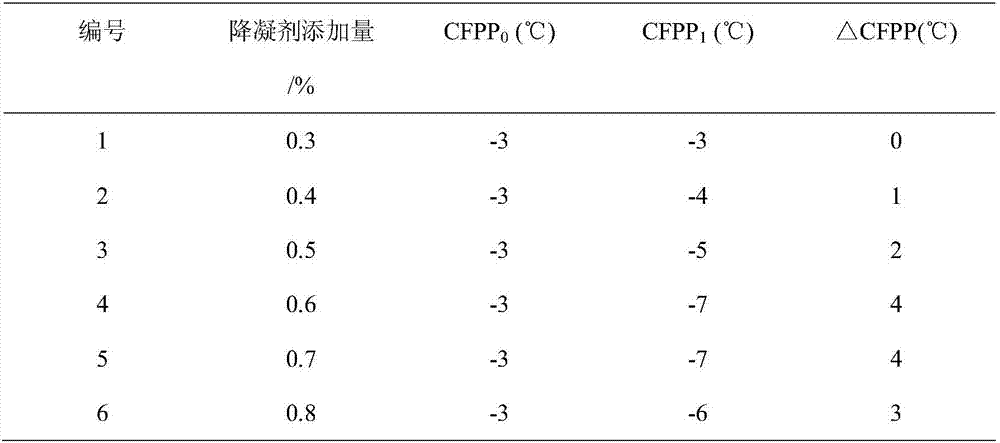

Clean diesel pour point depressant and preparation method thereof

InactiveCN106947556ARaise the ratioLow costOrganic compound preparationCarboxylic acid esters preparationRotary evaporatorDiesel combustion

The invention relates to a clean diesel pour point depressant and a preparation method thereof. The clean diesel pour point depressant is composed of long carbon chain fatty acid, low-carbon alcohol and low-carbon acid. The preparation method comprises the following concrete steps: weighing oleic acid by weight; adding glycerol, and carrying out heating under stirring until the oleic acid and the glycerol are dissolved; measuring the rate of esterification through an acid-base titration method; after a period of time, adding methacrylic acid, carrying out caustic washing and alcohol washing, then removing water through a rotary evaporator, and carrying out drying in an oven so as to obtain a target product namely methacrylic acid-glyceryl monooleate. According to the invention, by adopting an additive-free solvent and a catalyst, materials are economical, and cleanness and environment protection are realized. The pour point depressant provided by the invention has a formula applicable to good improvement of fluidity of diesel at a low temperature, and specifically meets the requirements of a diesel engine for clean and environment-friendly combustion tail gas emission in the process of diesel combustion.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

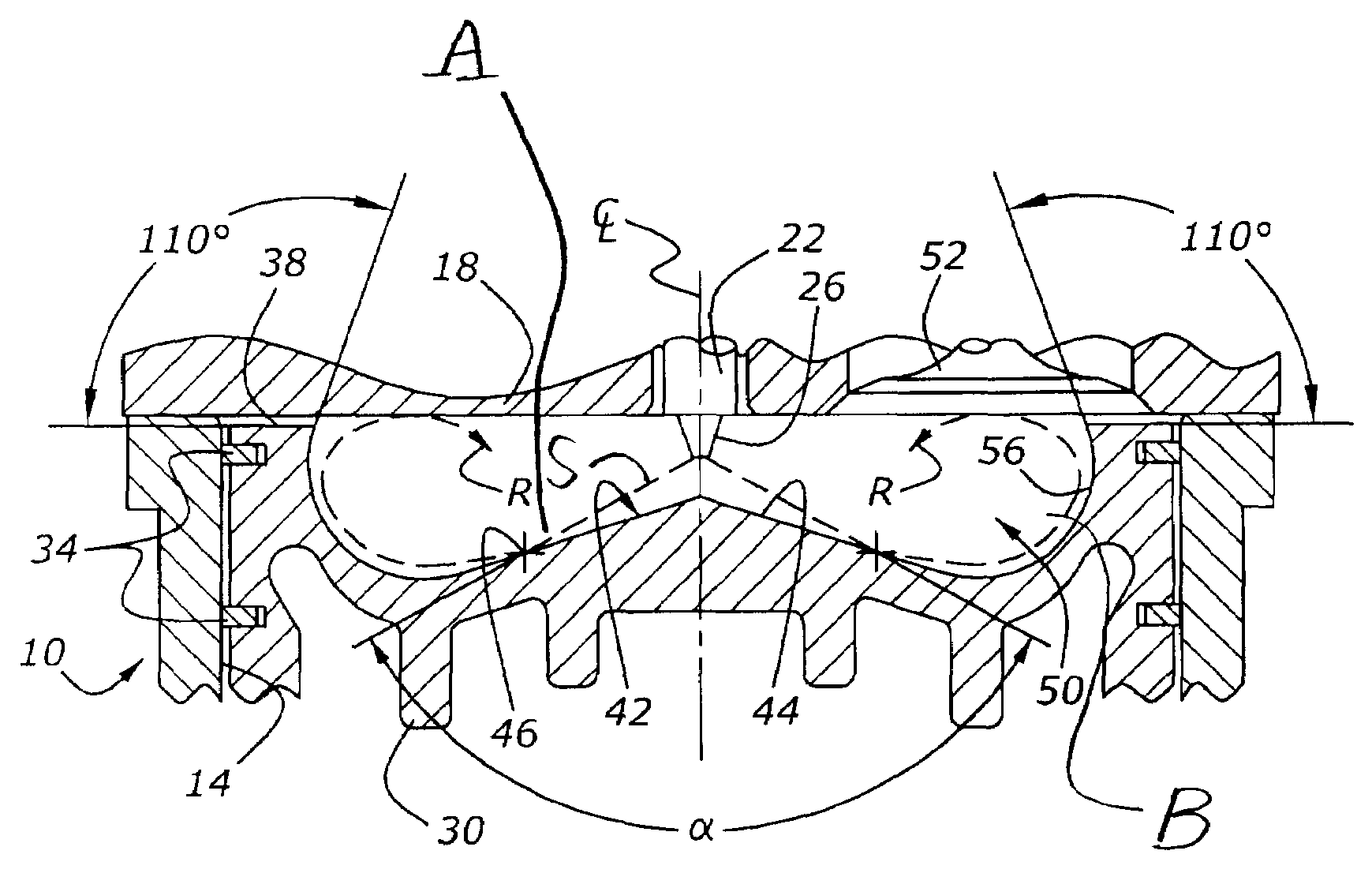

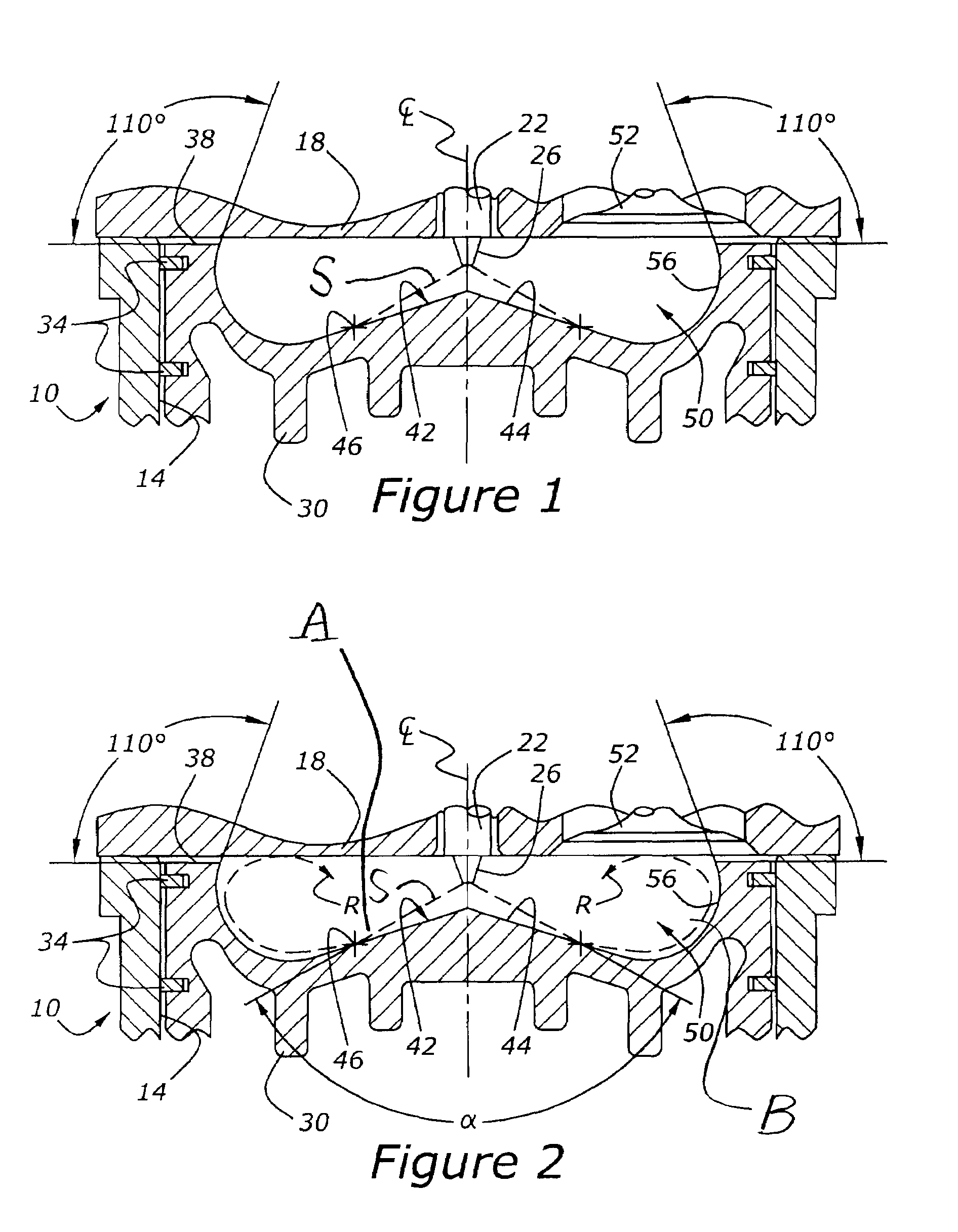

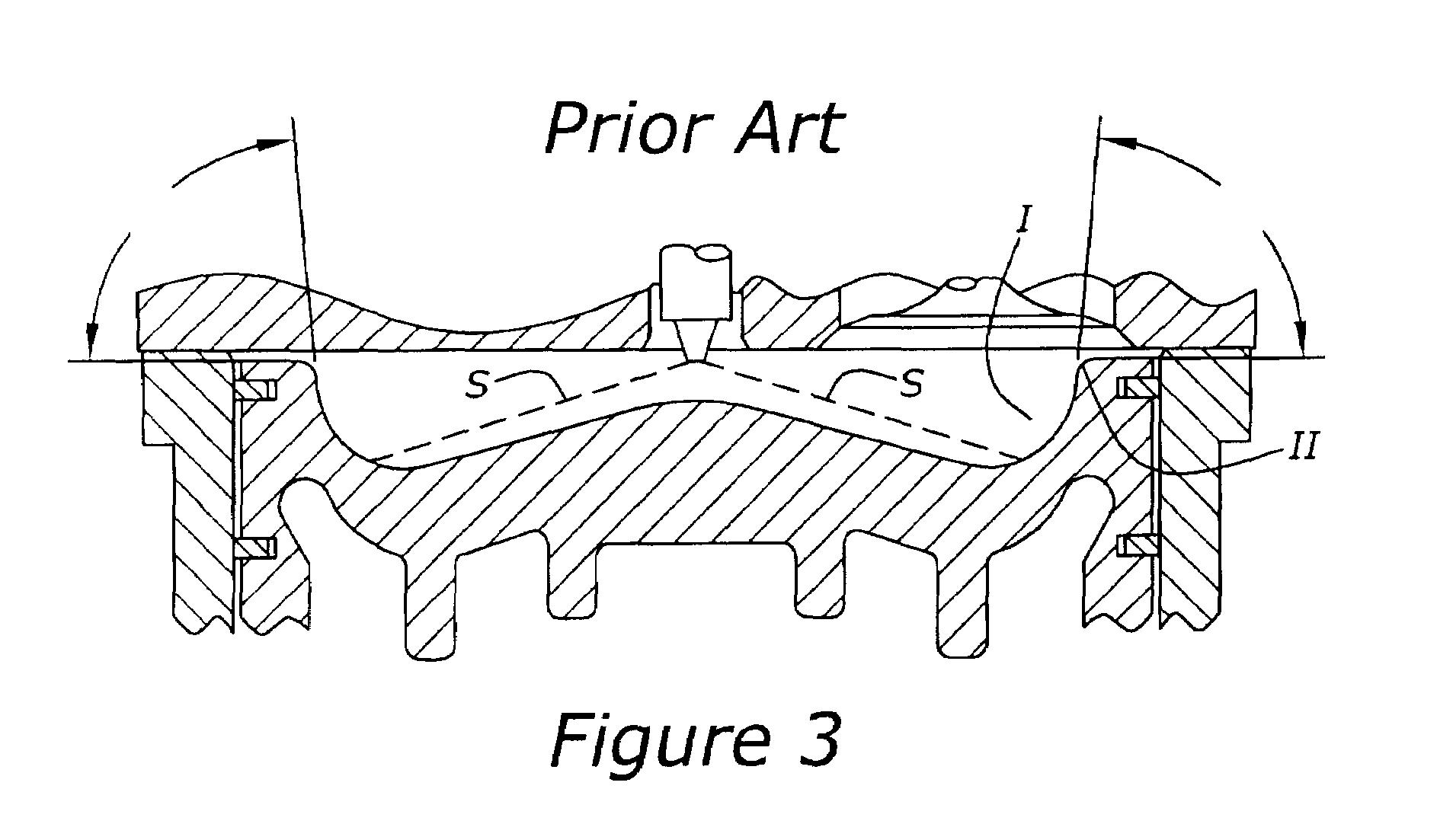

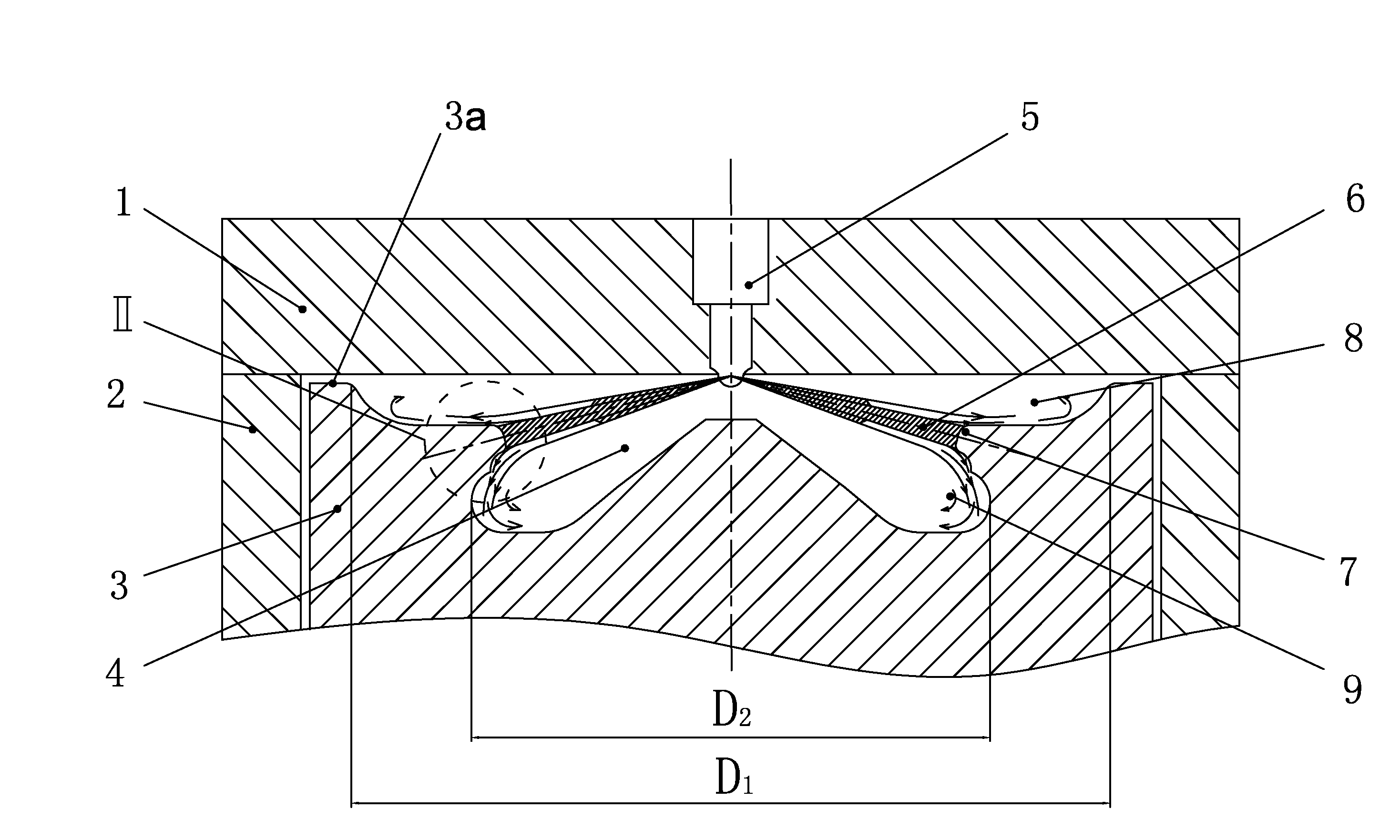

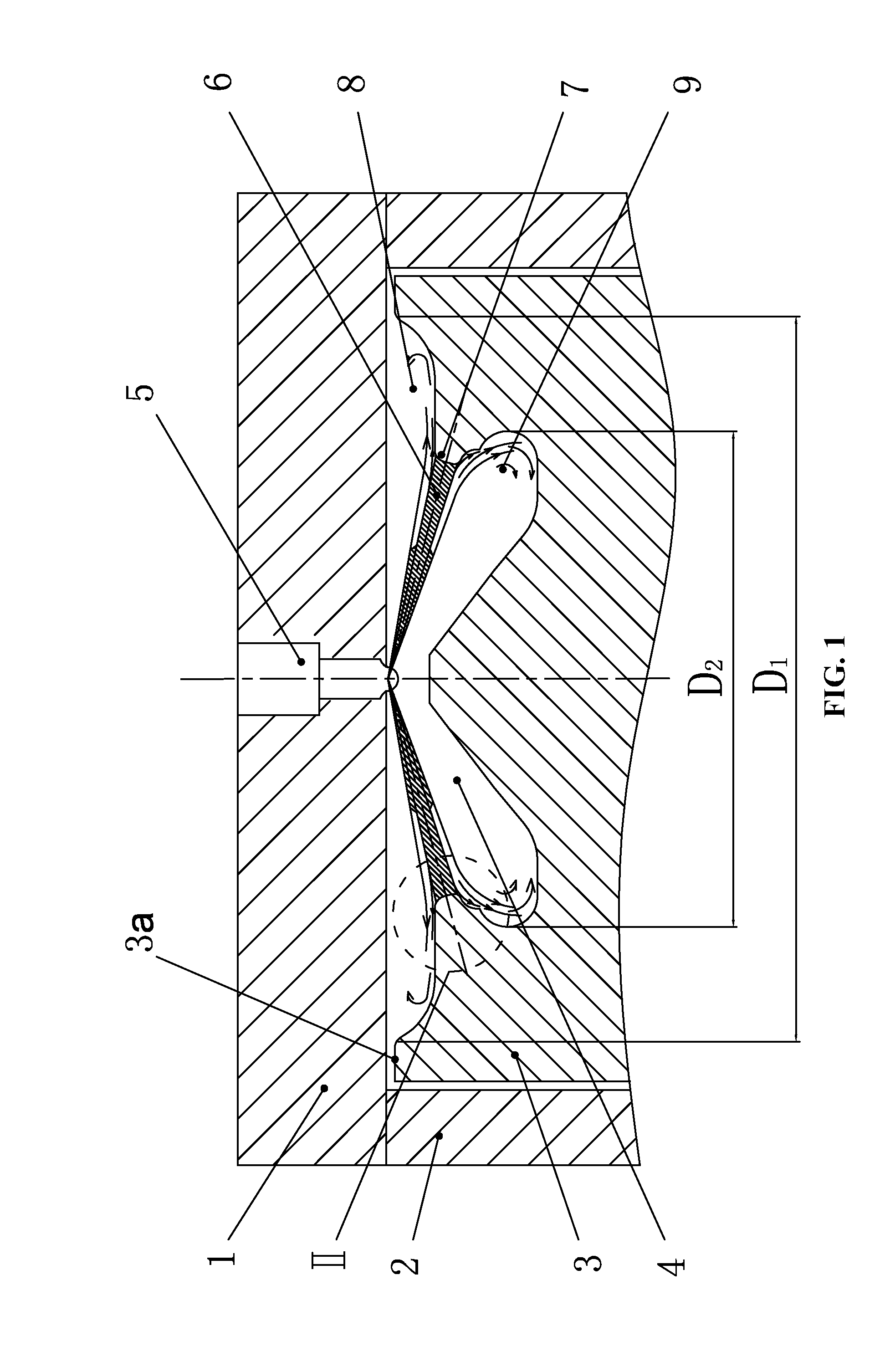

Diesel combustion system with re-entrant piston bowl

ActiveUS7431012B1Reduce fuel consumptionImprove economyInternal combustion piston enginesMomentumFuel efficiency

A diesel combustion system with a re-entrant piston bowl utilizes momentum interaction with the bowl at multiple locations to cause recirculation of the partially burned fuel and combustion products in a toroidal flow so as to consume soot formed during an earlier portion of the combustion process, while reducing the formation of NOx and improving fuel efficiency of the engine.

Owner:GE GLOBAL SOURCING LLC

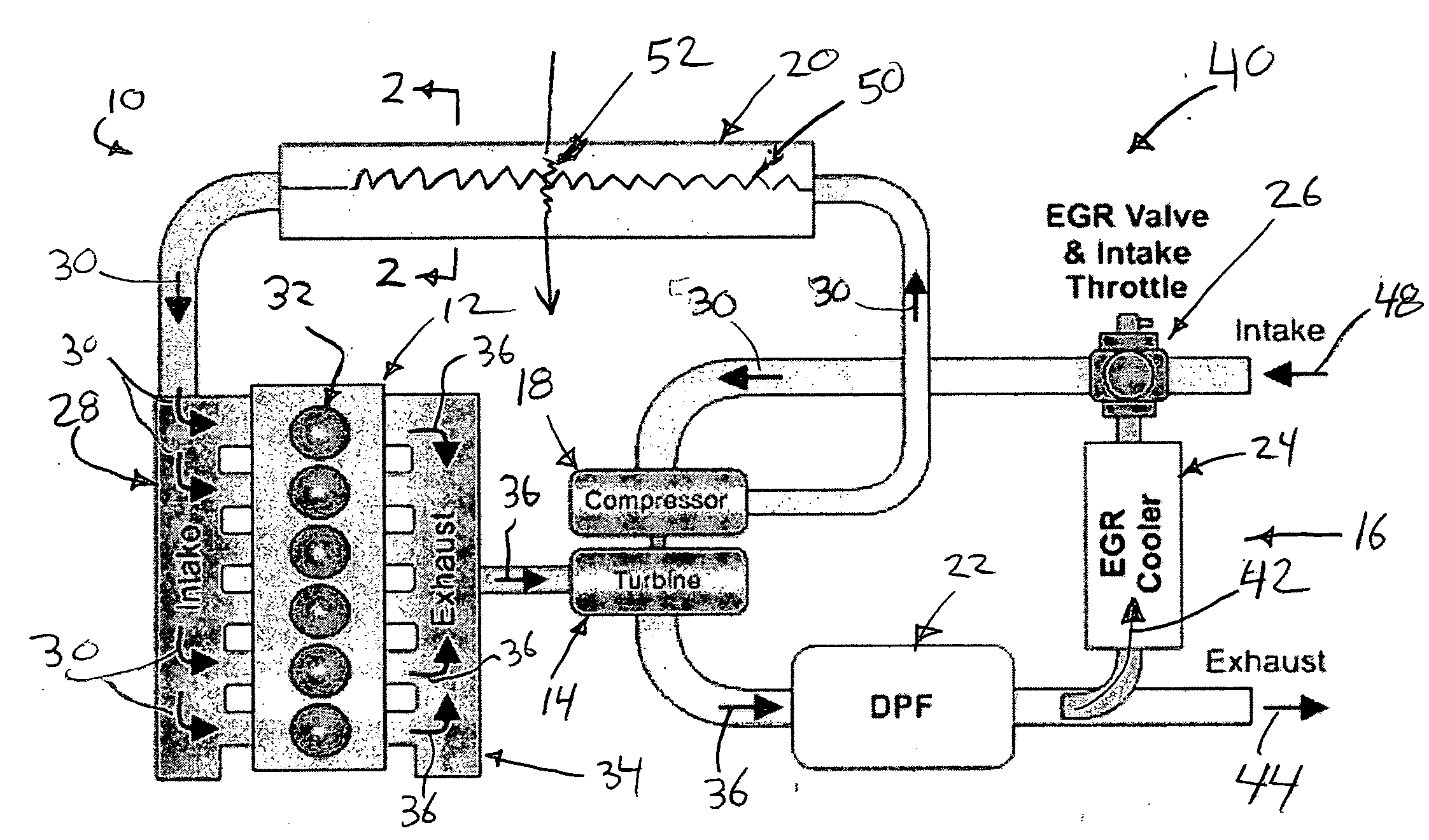

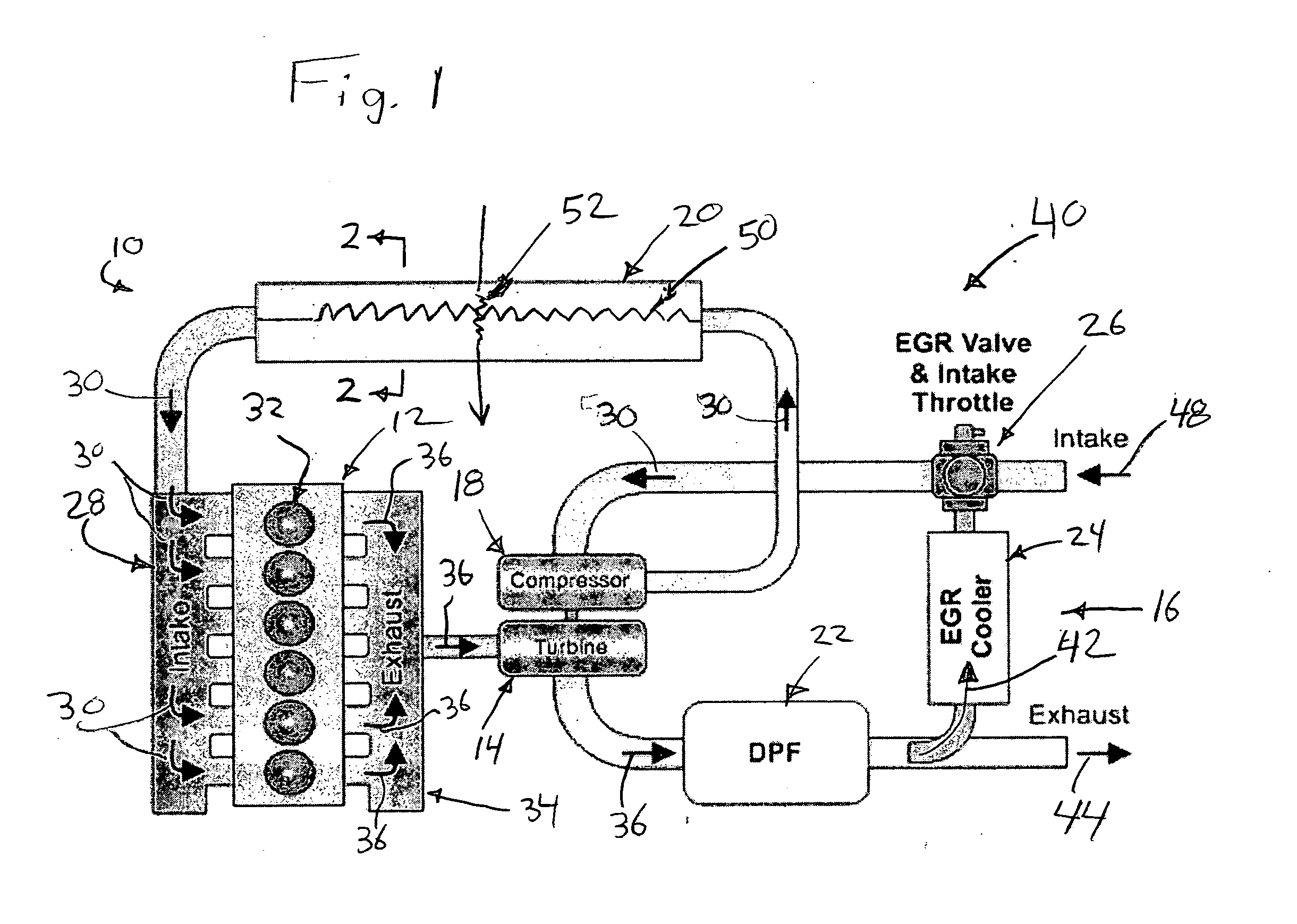

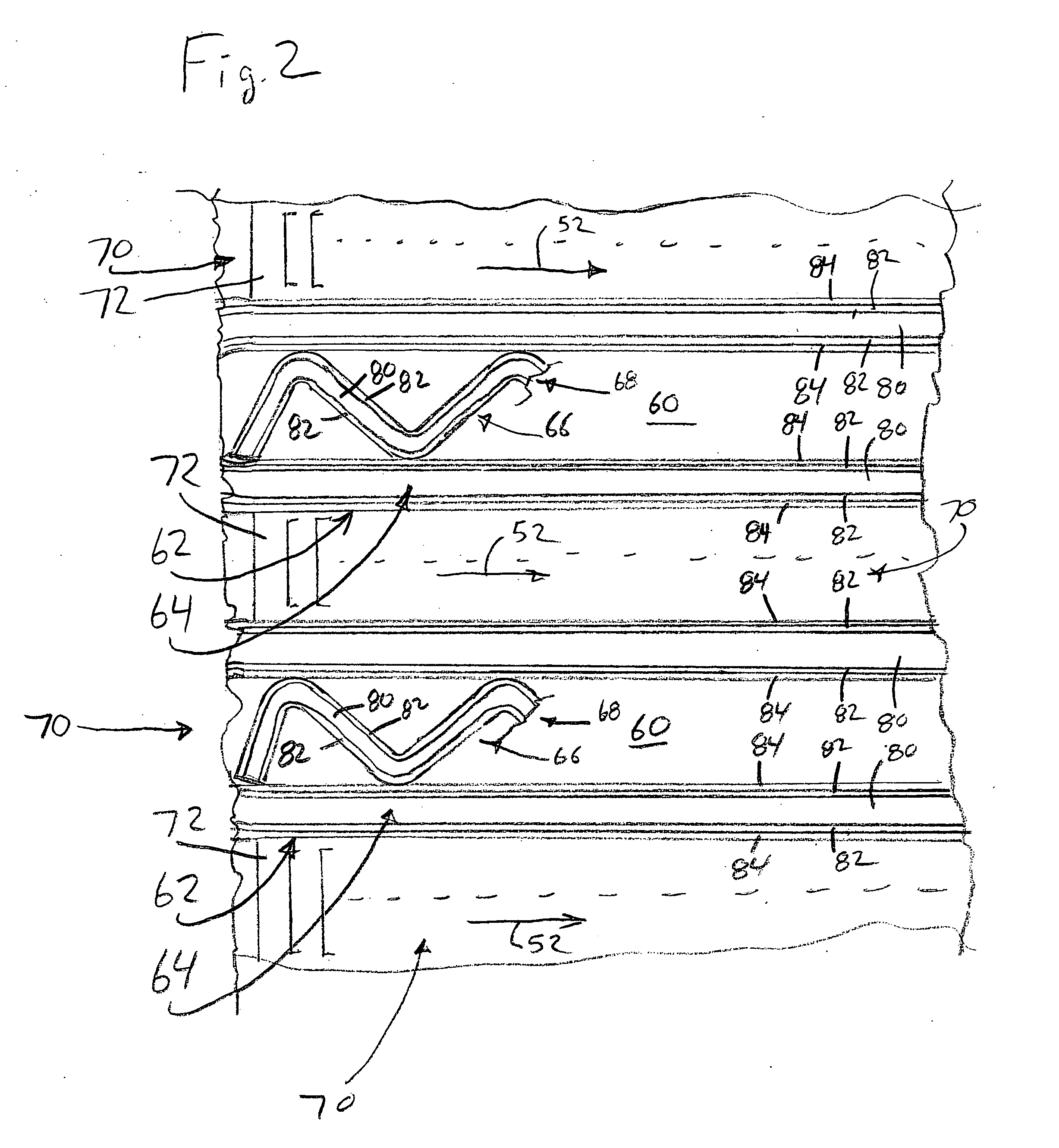

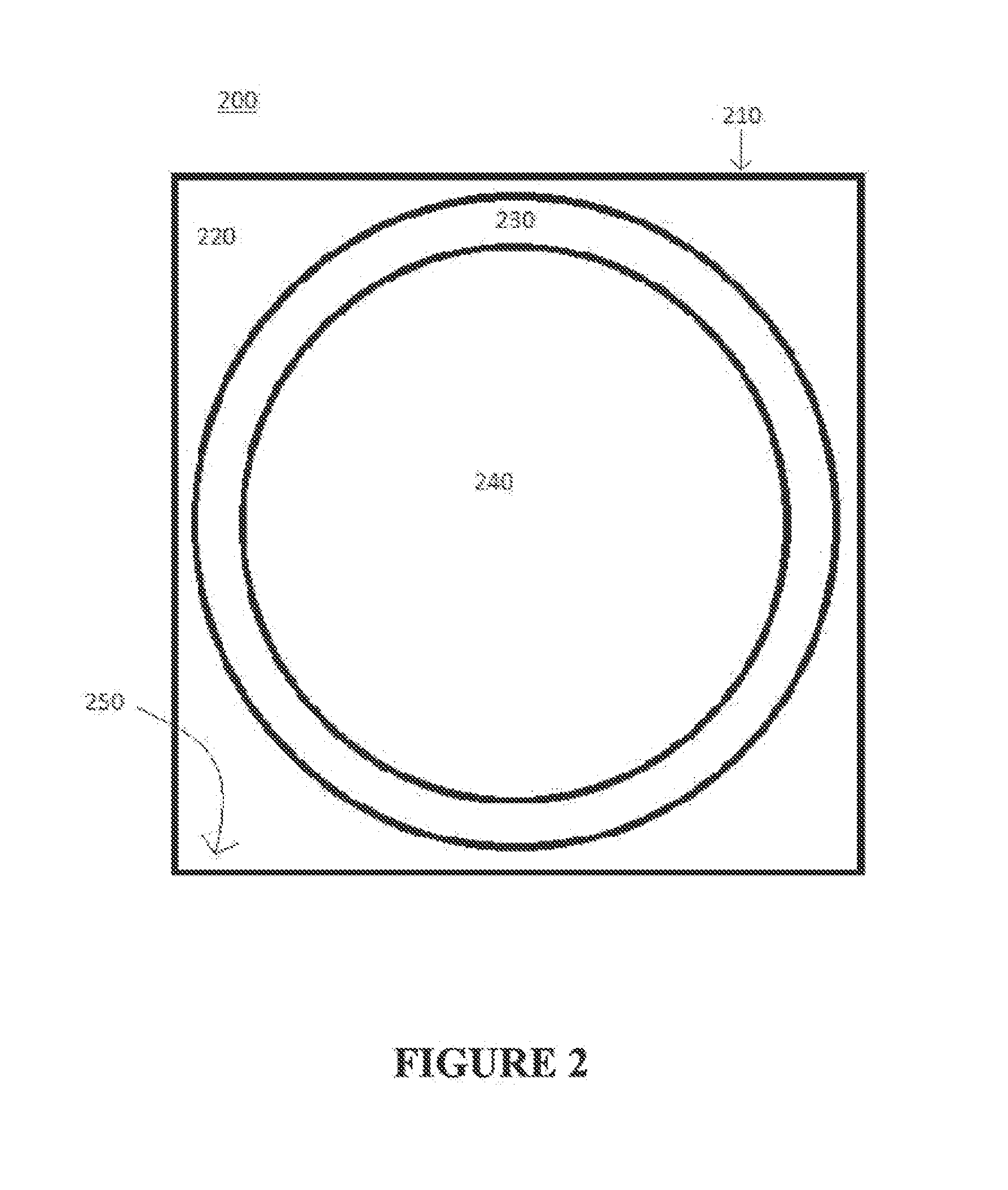

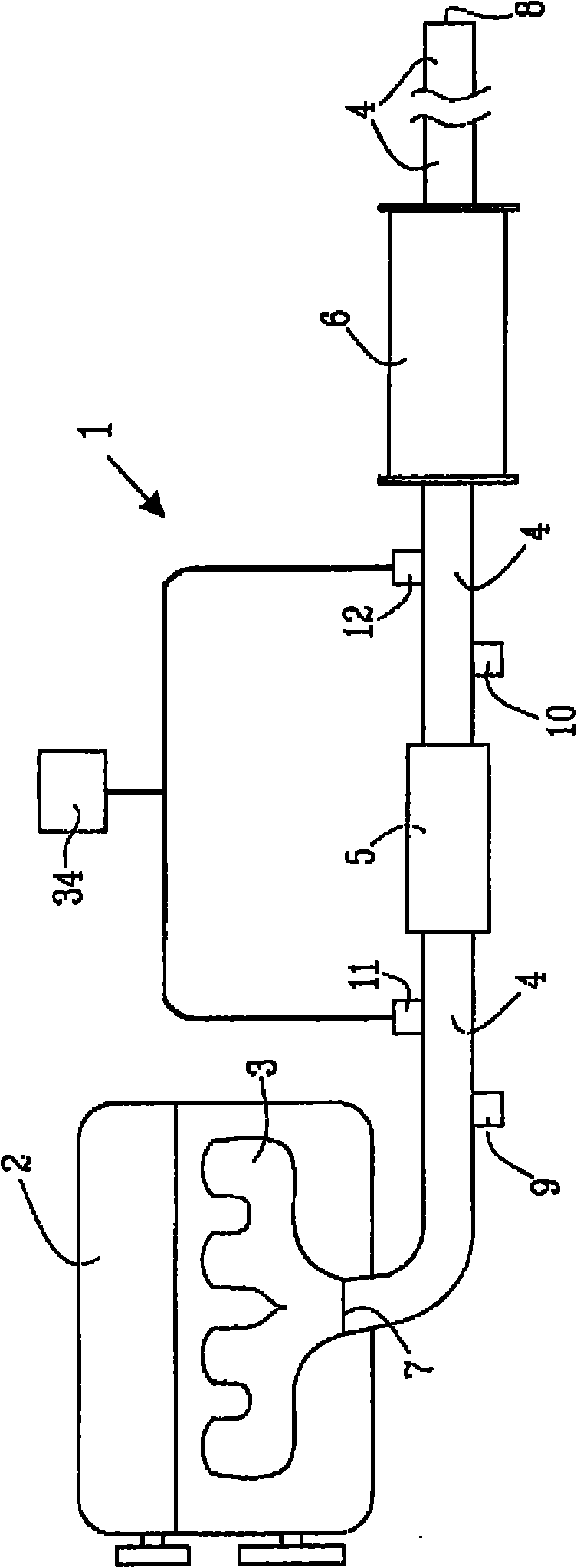

Diesel combustion engine having a low pressure exhaust gas recirculation system employing a corrosion resistant aluminum charge air cooler

A diesel engine system (10) includes a diesel combustion engine (12), an exhaust gas driven turbine (14), an exhaust gas recirculation loop (16), an intake gas compressor (18), a corrosion resistant charge air cooler (CAC) (20), and a diesel particulate filter (DPF) (22). The intake gas flow path (50) in the charge air cooler (20) is defined by a multi-layer material (64, 68) having an inner surface that is wetted by the intake gas flow (30). The multi-layer material (64, 68) has a core layer (80) of corrosion resistant aluminum and at least one layer (82) of high purity aluminum.

Owner:MODINE MFG CO

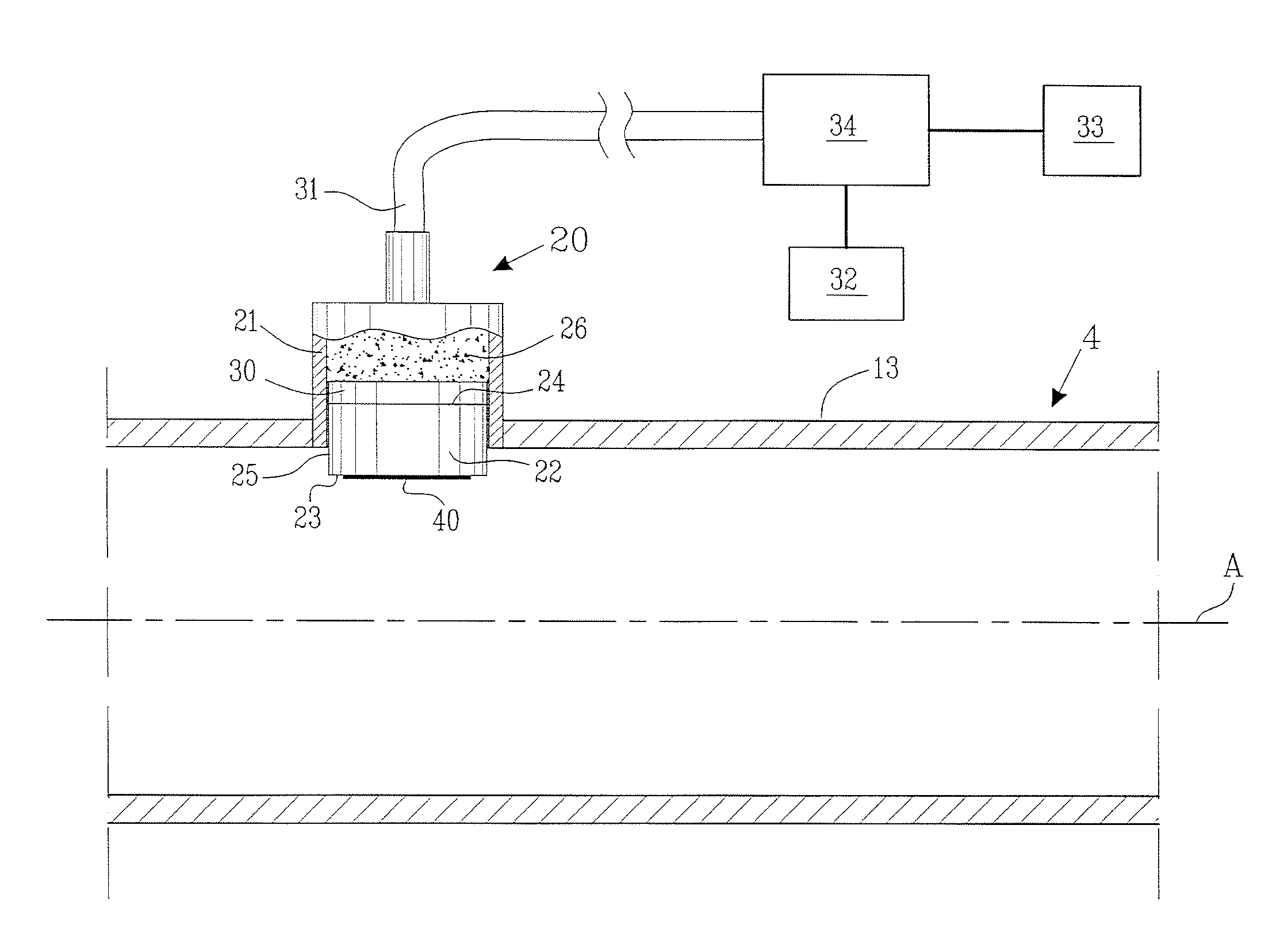

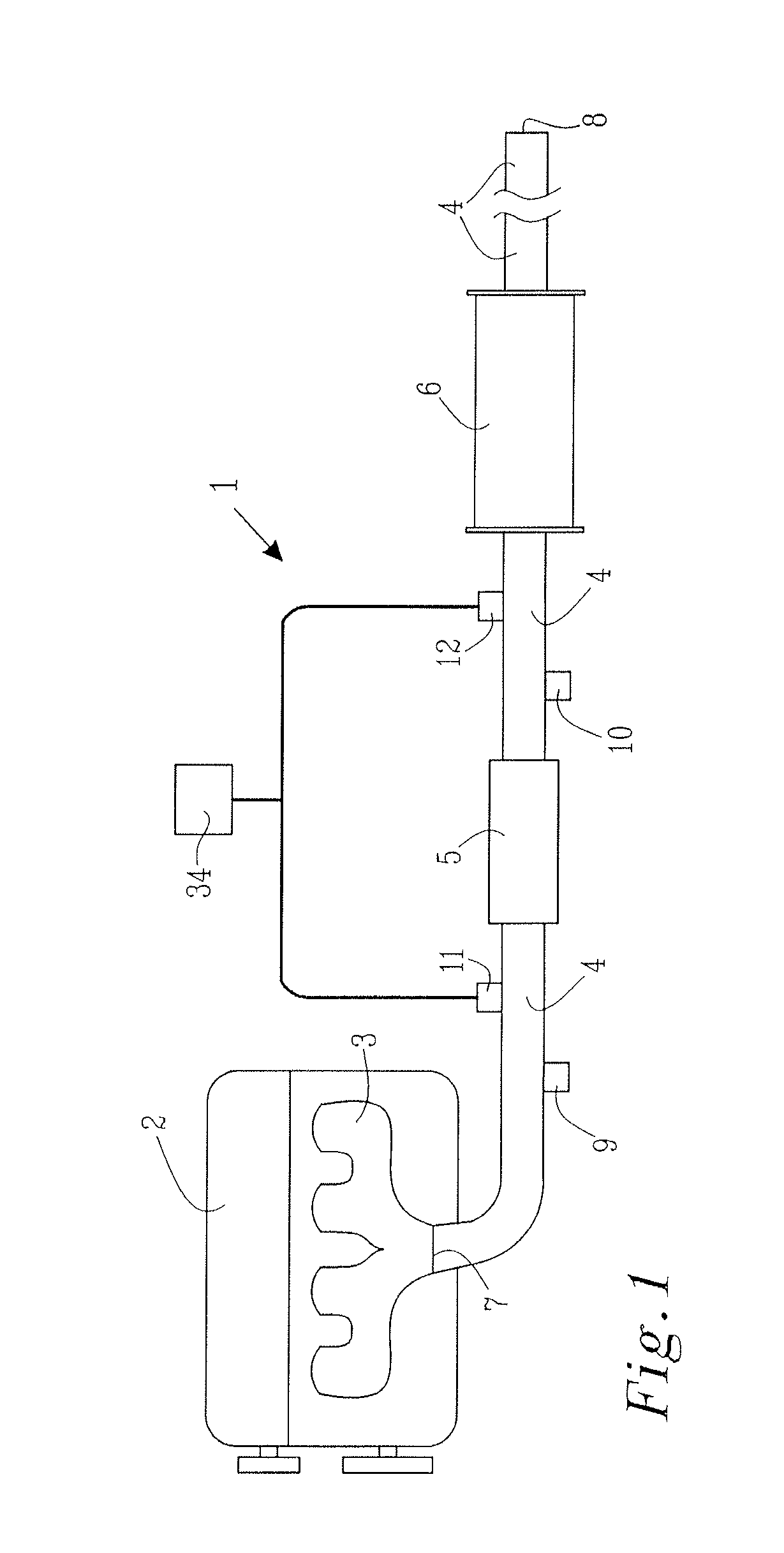

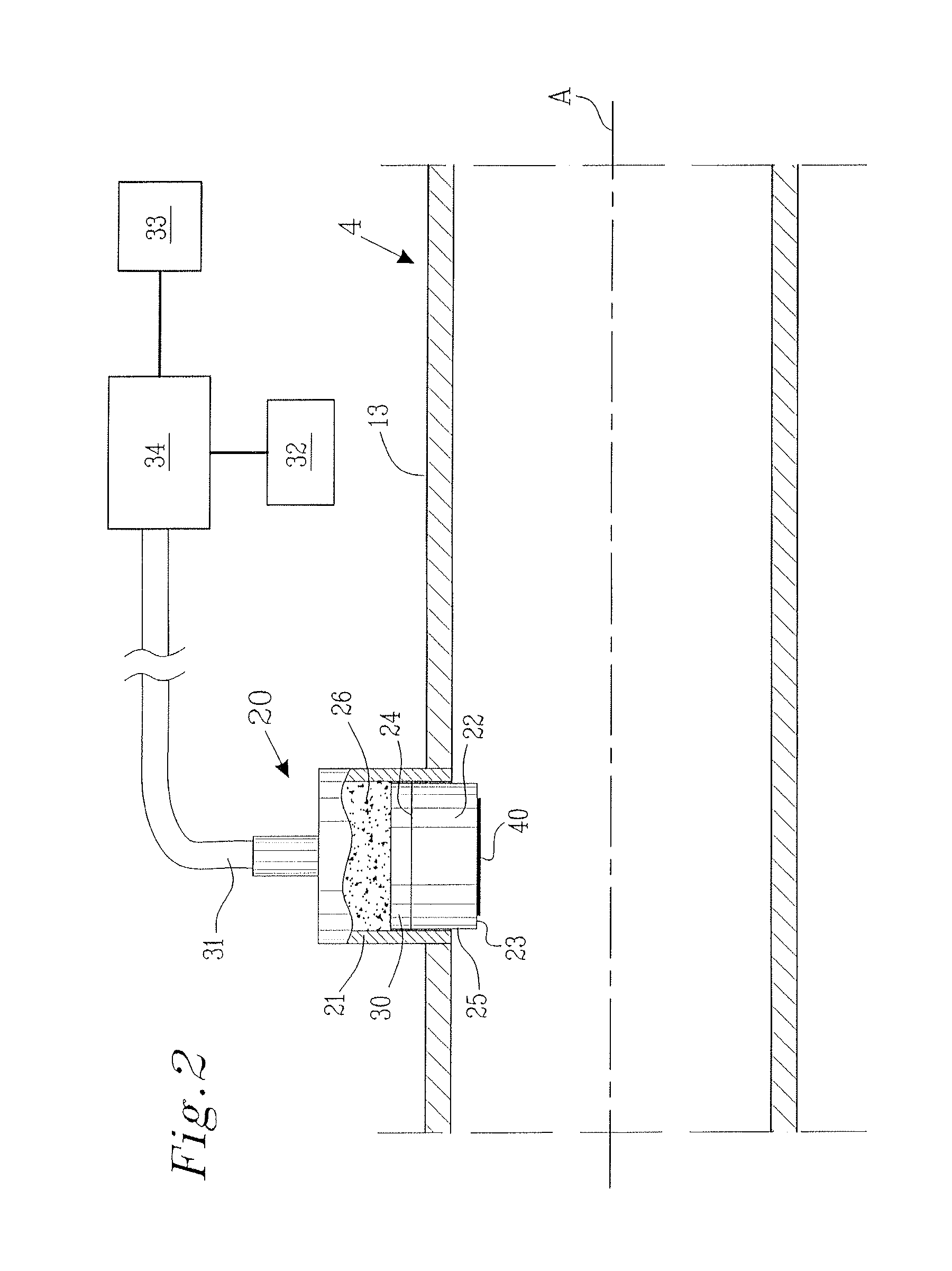

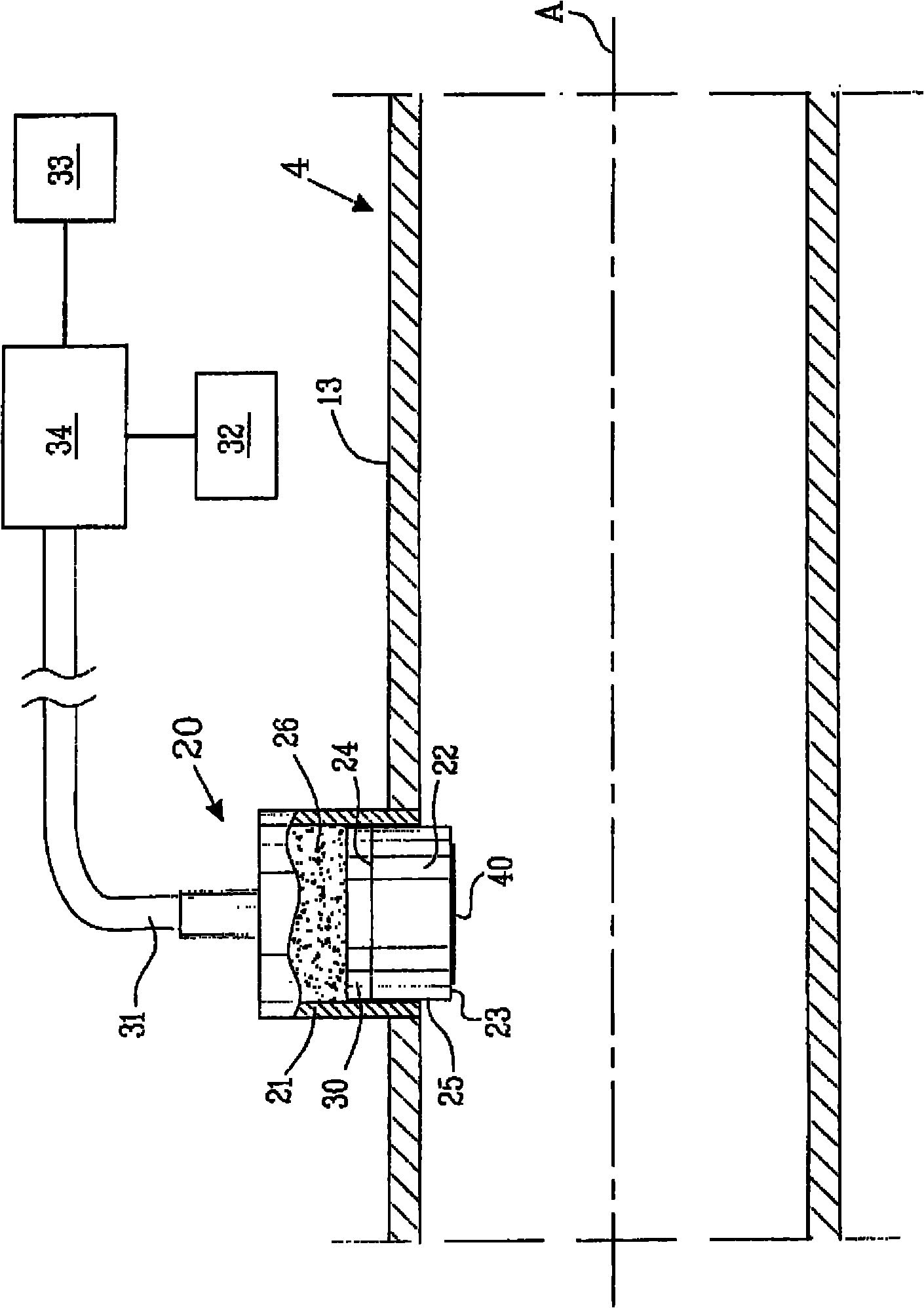

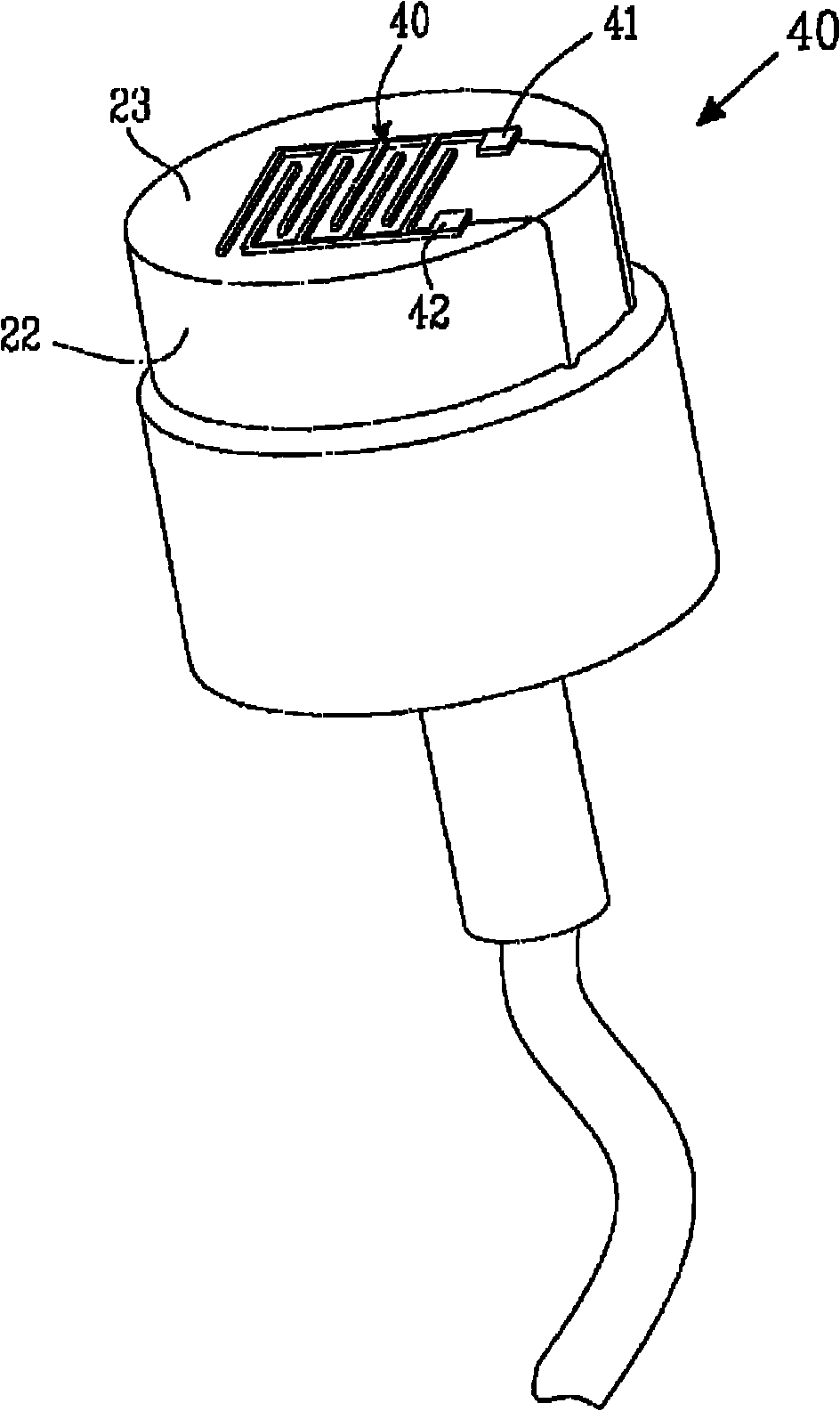

Method and arrangement for detecting particles

InactiveUS20110197571A1Improve Sensing PerformanceImprove conductivityInternal-combustion engine testingExhaust apparatusDiesel combustionEngineering

The present invention relates to a method for detecting particles and a particle sensor arrangement. More specifically, the present invention relates to a method and arrangement for detecting particles in a gas flow, e.g. from a diesel combustion engine. The method comprises the steps of; forcing a particle build up on a sensor element of a particle sensor arrangement by regulating the sensor element to a second temperature; wherein the second temperature is lower than a first temperature, the first temperature being the gas flow temperature. Additionally is the particle build up detected at the sensor element by means of a detector. The present invention provides for an accurate method and arrangement to detect and thereby measure particles present in a gas flow, e.g. from a combustion engine.

Owner:VOLVO TECH +1

Gas Oil Composition

InactiveUS20090044444A1Quality improvementImprove practicalityLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionHomogeneous charge compression ignitionDistillation

The present invention provides a gas oil composition for use in a diesel engine with a geometric compression ratio of 16 or less, equipped with a supercharger and an EGR, containing an FT synthetic base oil and having a sulfur content of 5 ppm by mass or less, an oxygen content of 100 ppm by mass or less, a bulk modulus of 1250 MPa or greater and 1450 MPa or less, a saybolt color of +22 or greater, a lubricity of 400 μm or less, an initial boiling point of 140° C. or higher and an end point of 380° C. or lower in distillation characteristics, and the following characteristics (1) to (3) in each fraction range wherein: (1) the cetane number in a fraction range of lower than 200° C. is 40 or greater and less than 60; (2) the cetane number in a fraction range of 200° C. or higher and lower than 280° C. is 60 or greater and less than 80; and (3) the cetane number in a fraction range of 280° C. or higher is 50 or greater. The gas oil composition is used in a summer or winter season, suitable for both diesel combustion and homogeneous charge compression ignition combustion.

Owner:NIPPON OIL CORP

Method for operating compression ignition internal combustion engine

InactiveUS20060185644A1Improve flammabilityShorten the overall cycleNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionDi-tert-butyl peroxide

An object is to provide a method for operating a compression ignition internal combustion engine which, using a single fuel, can produce diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The operating method includes: employing a fuel containing 95 to 99.5 wt. % of a base fuel made of one or more compounds selected from the group consisting of a hydrocarbon, an alcohol, an ether and a fatty ester, and 0.1 to 5 wt. % of an additive made of one or more compounds selected from the group consisting of an organic peroxide, a nitric ester, a nitrite ester and an azo compound; and producing diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The organic peroxide is di-tert-butyl peroxide. The nitric ester is n-pentyl nitrate. The nitrite ester is n-pentyl nitrite. The azo compound is 2,2-azobis(2,4-dimethylvaleronitrile).

Owner:HONDA MOTOR CO LTD

Catalyst design for heavy-duty diesel combustion engines

ActiveUS9427732B2High catalytic efficiencyOptimizing Control ParametersInternal combustion piston enginesMolecular sieve catalystsConvertersCatalytic transformation

Disclosed are washcoats, coated substrates formed from such washcoats, and catalytic converters for use in diesel applications, such as heavy duty diesel applications. Methods of preparing the coated substrates are also disclosed.

Owner:UMICORE AG & CO KG +1

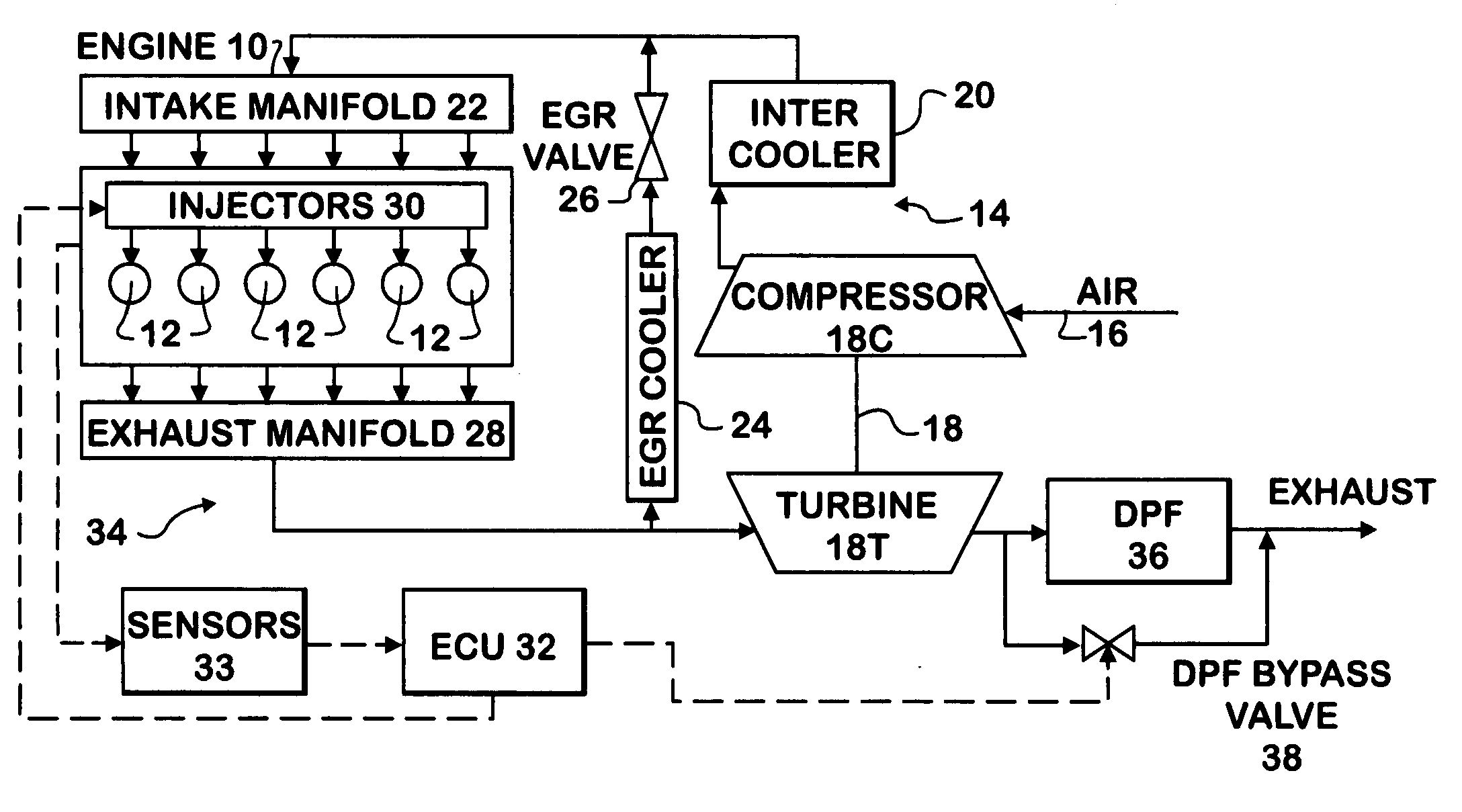

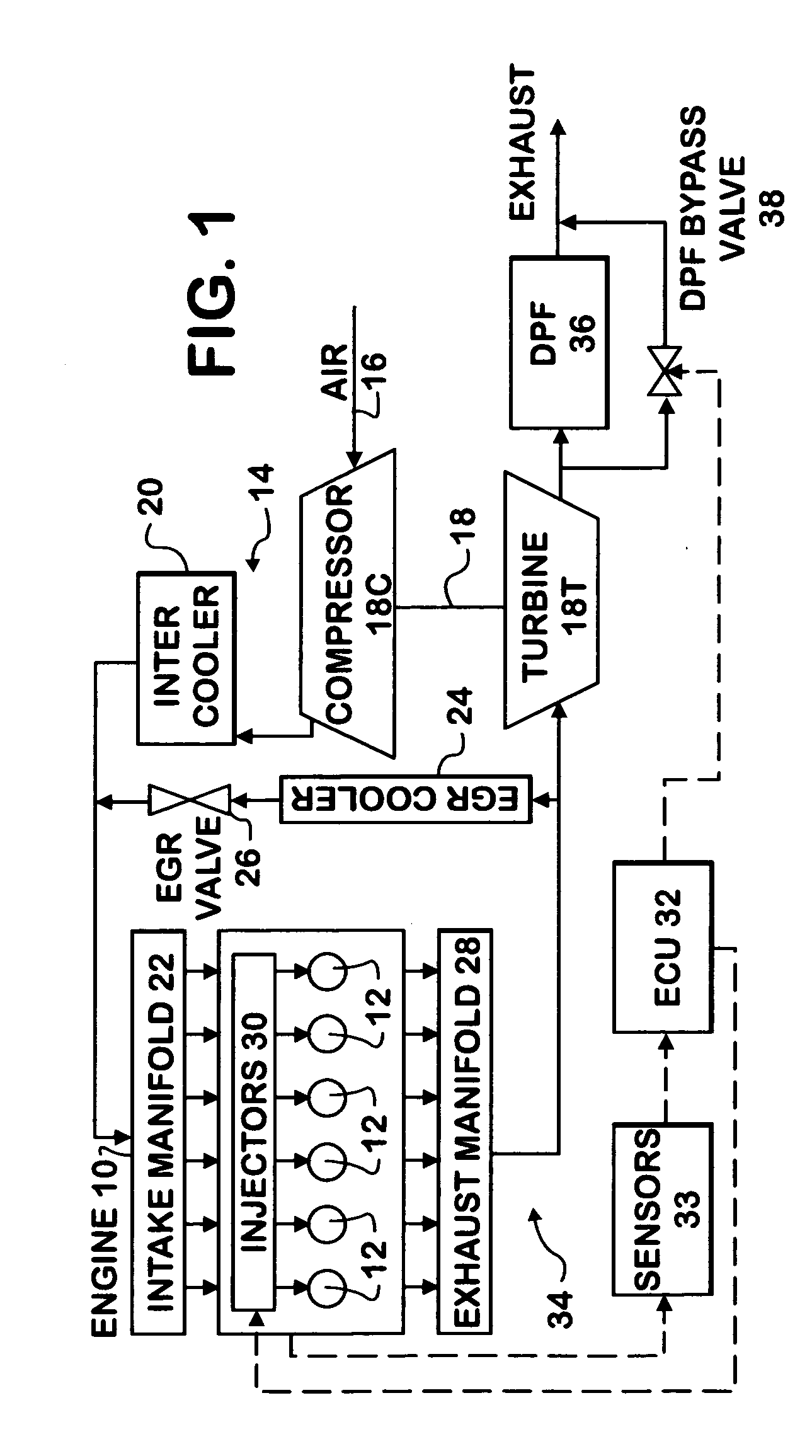

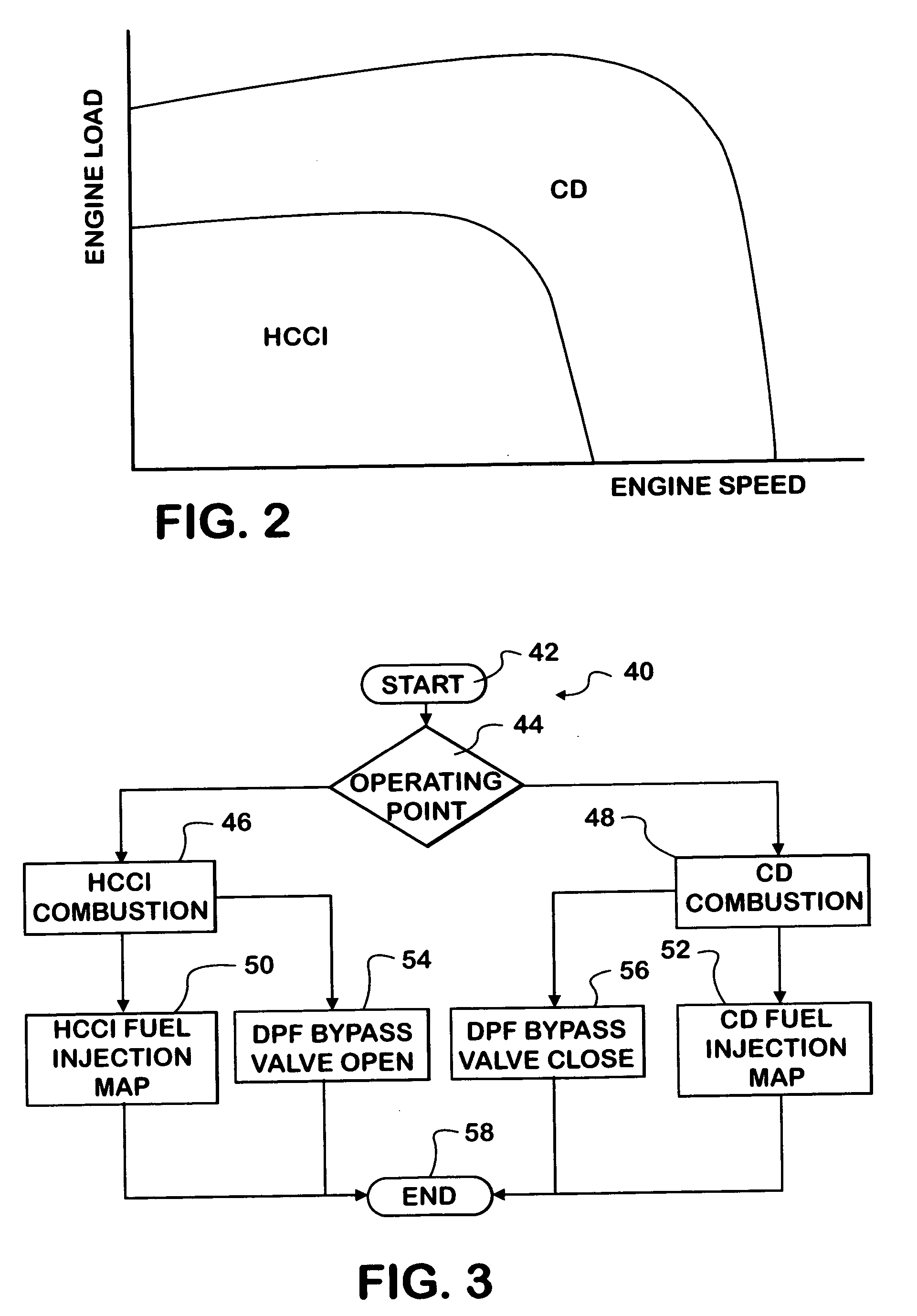

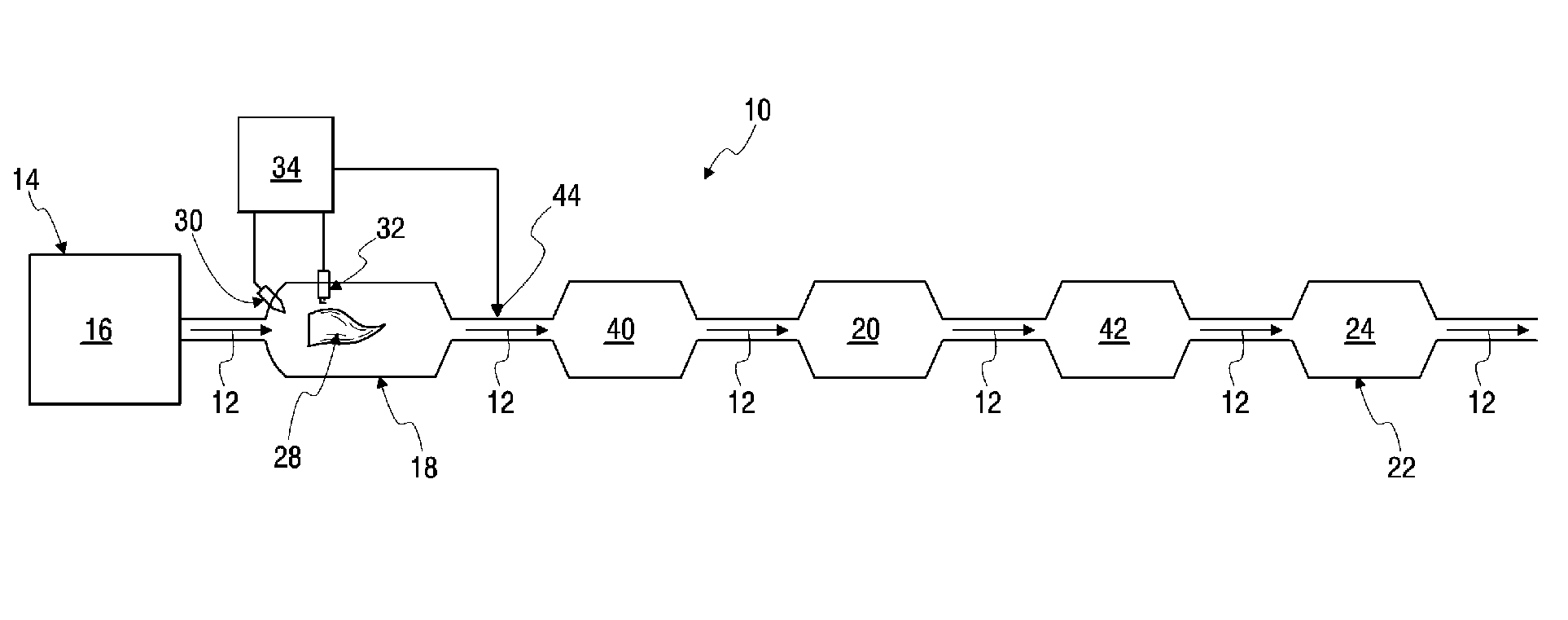

Strategy for selectively bypassing a DPF in a hybrid HCCI combustion engine

ActiveUS20060185353A1Improve operationMinimize disruptionElectrical controlInternal combustion piston enginesHcci combustionDiesel combustion

In a conventional diesel combustion mode, one or more cylinders (12) of an engine (10) is or are fueled to cause conventional diesel combustion in each such cylinder. The resulting exhaust gas is treated by a diesel particulate filter (36) in an exhaust system (34) before exiting the exhaust system. In an alternative diesel combustion mode, such as HCCI, one or more cylinders of the engine are fueled to create in each such cylinder an in-cylinder fuel-air charge that ignites by auto-ignition as the charge is increasingly compressed. Also a bypass valve (38) is opened so that the resulting exhaust gas bypasses the DPF as the exhaust gas passes through the exhaust system.

Owner:INT ENGINE INTPROP CO LLC

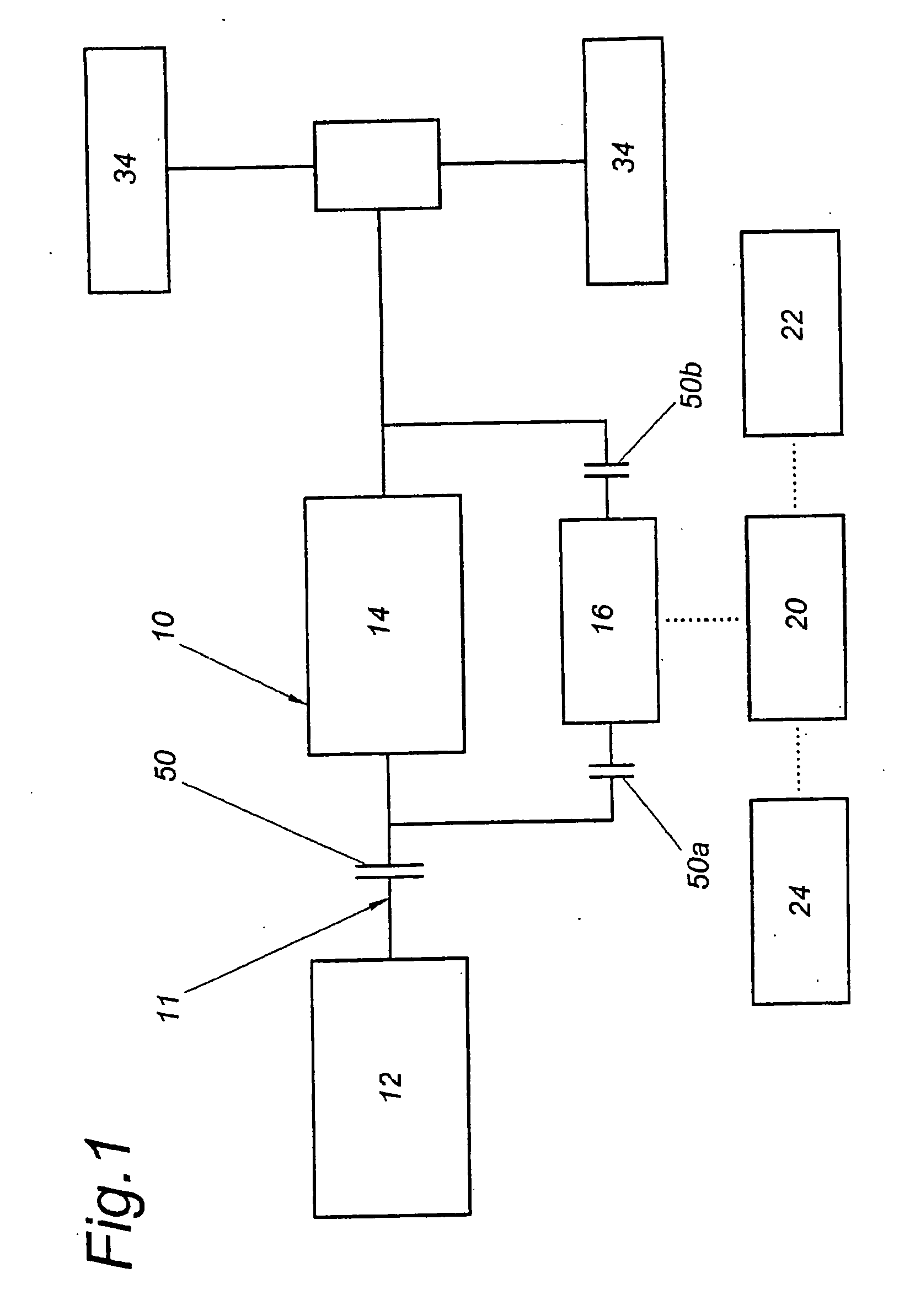

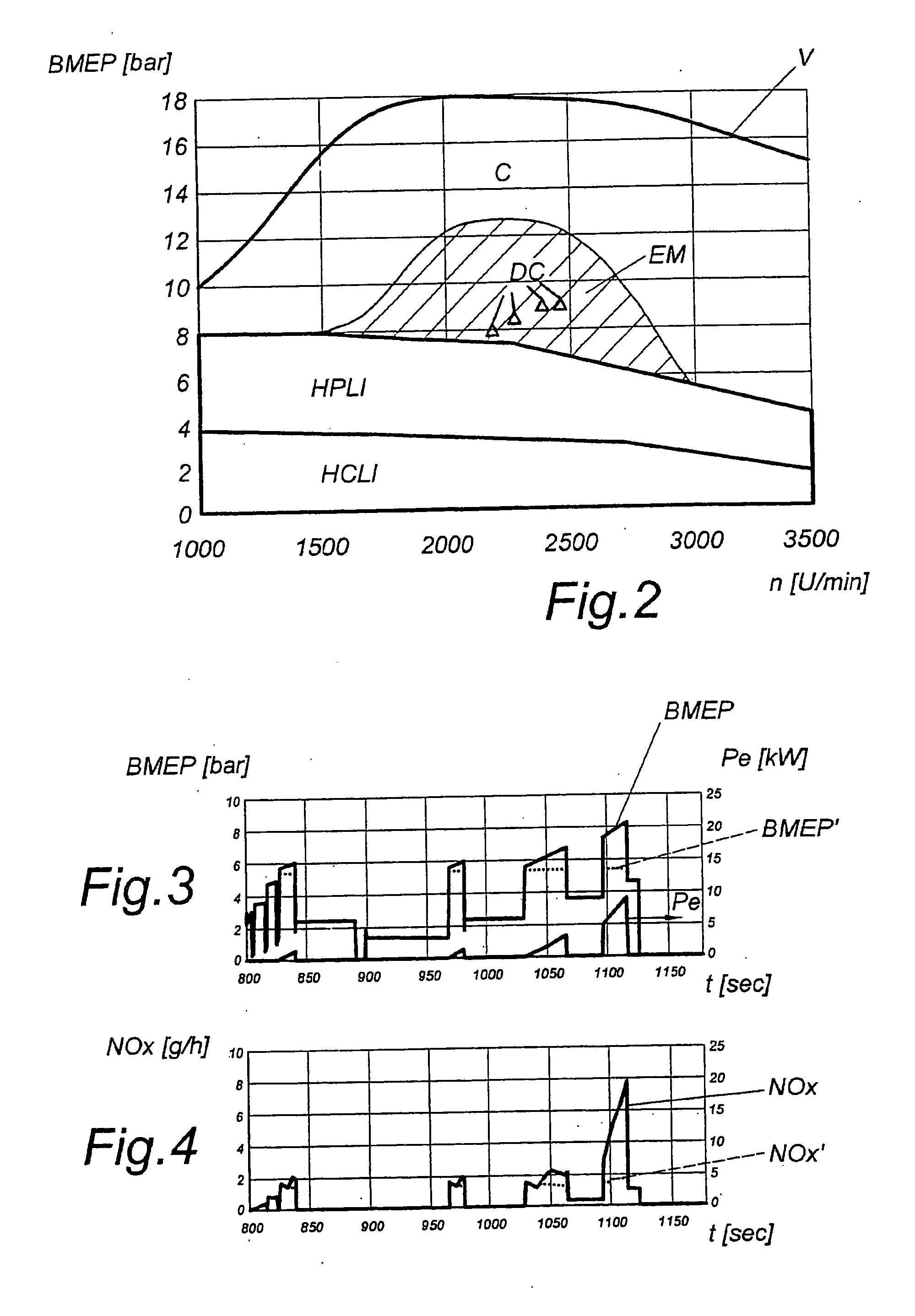

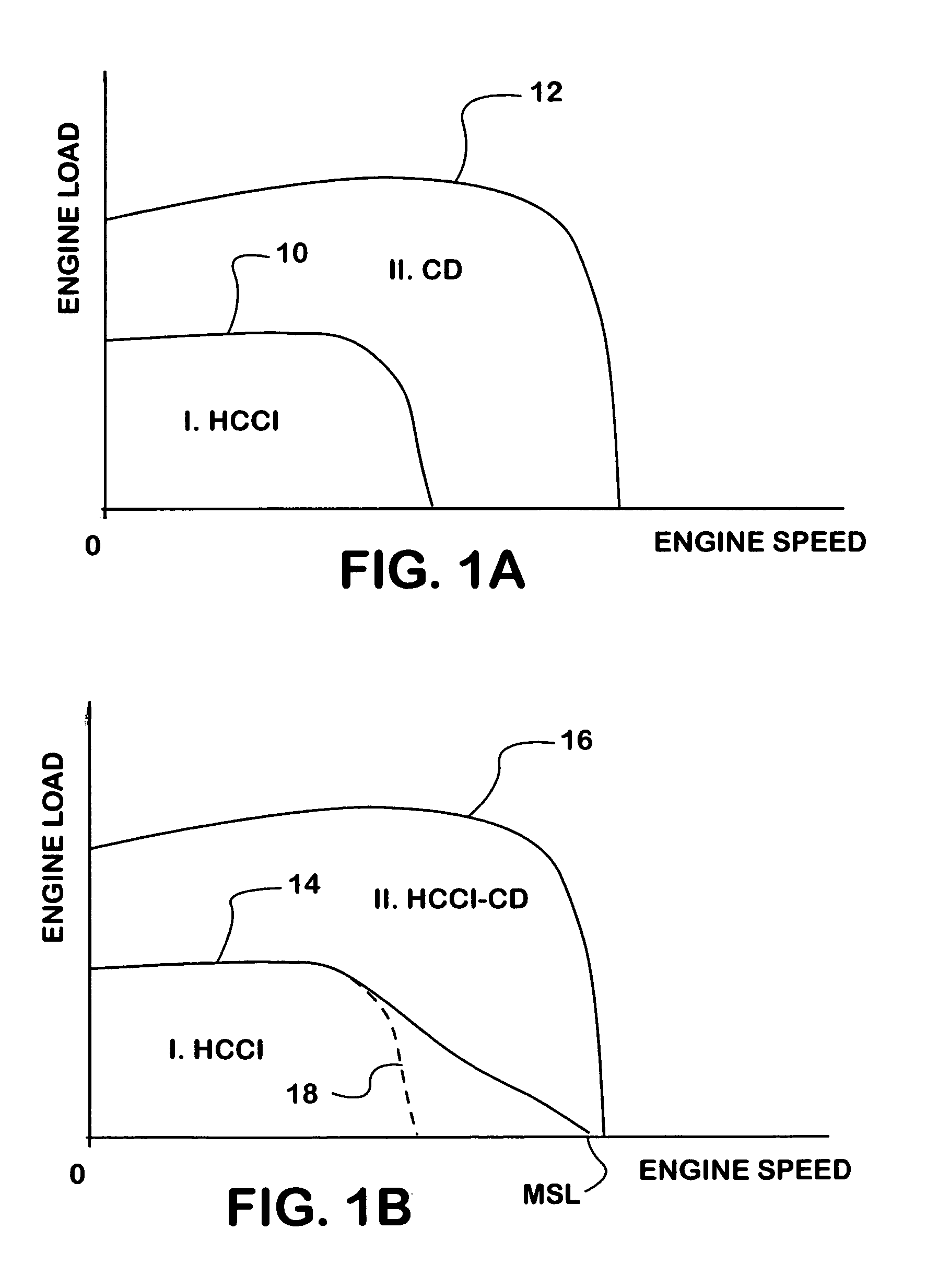

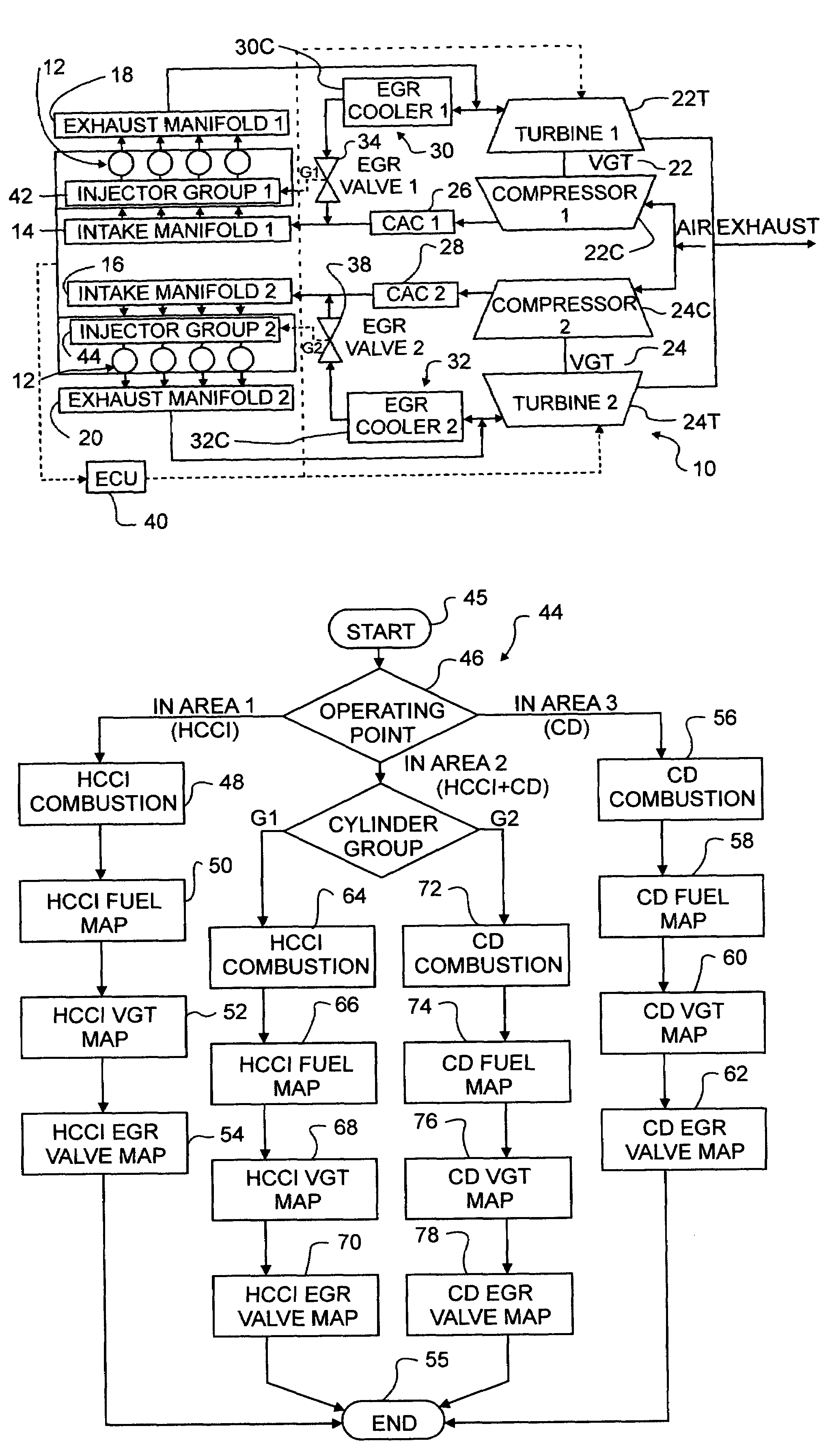

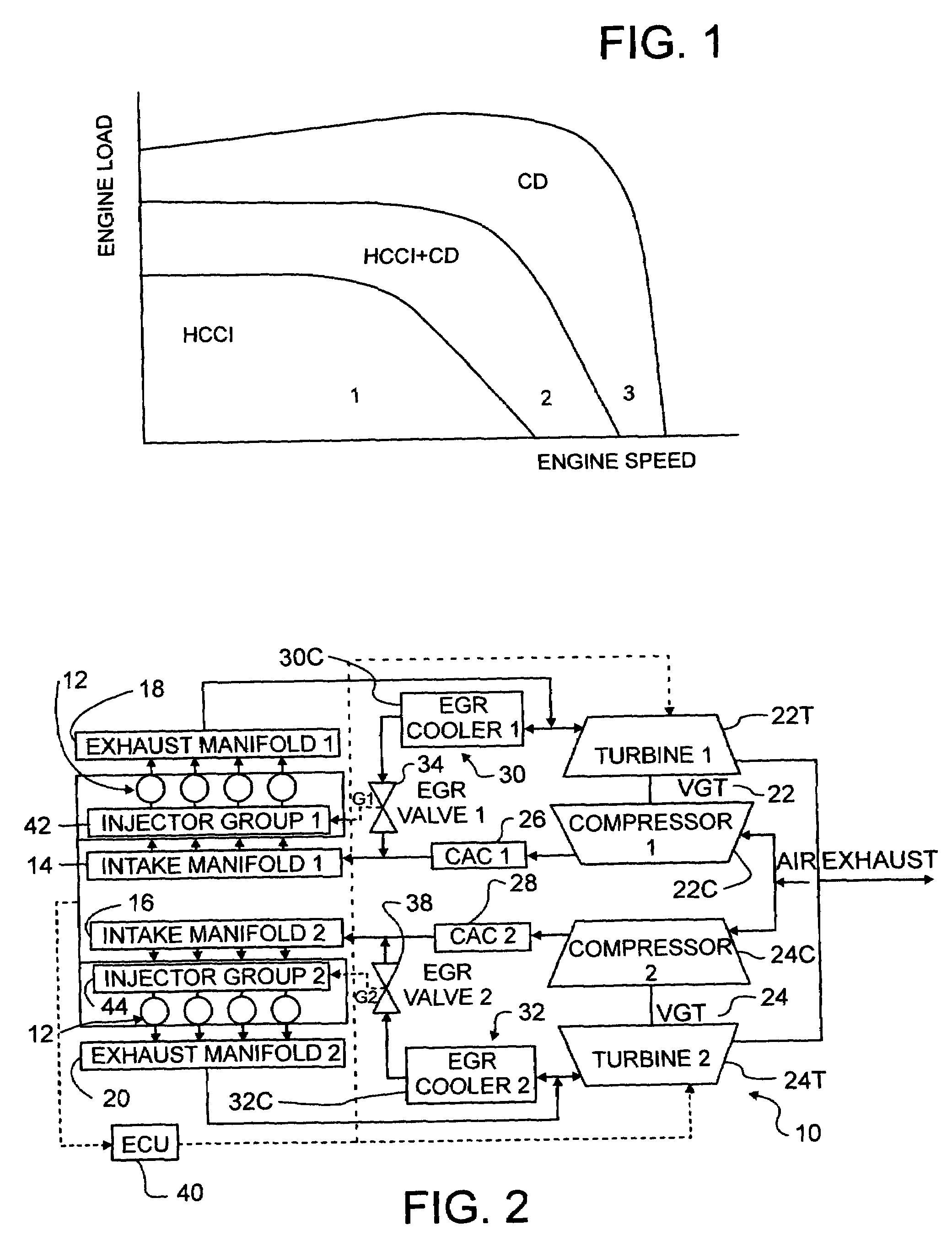

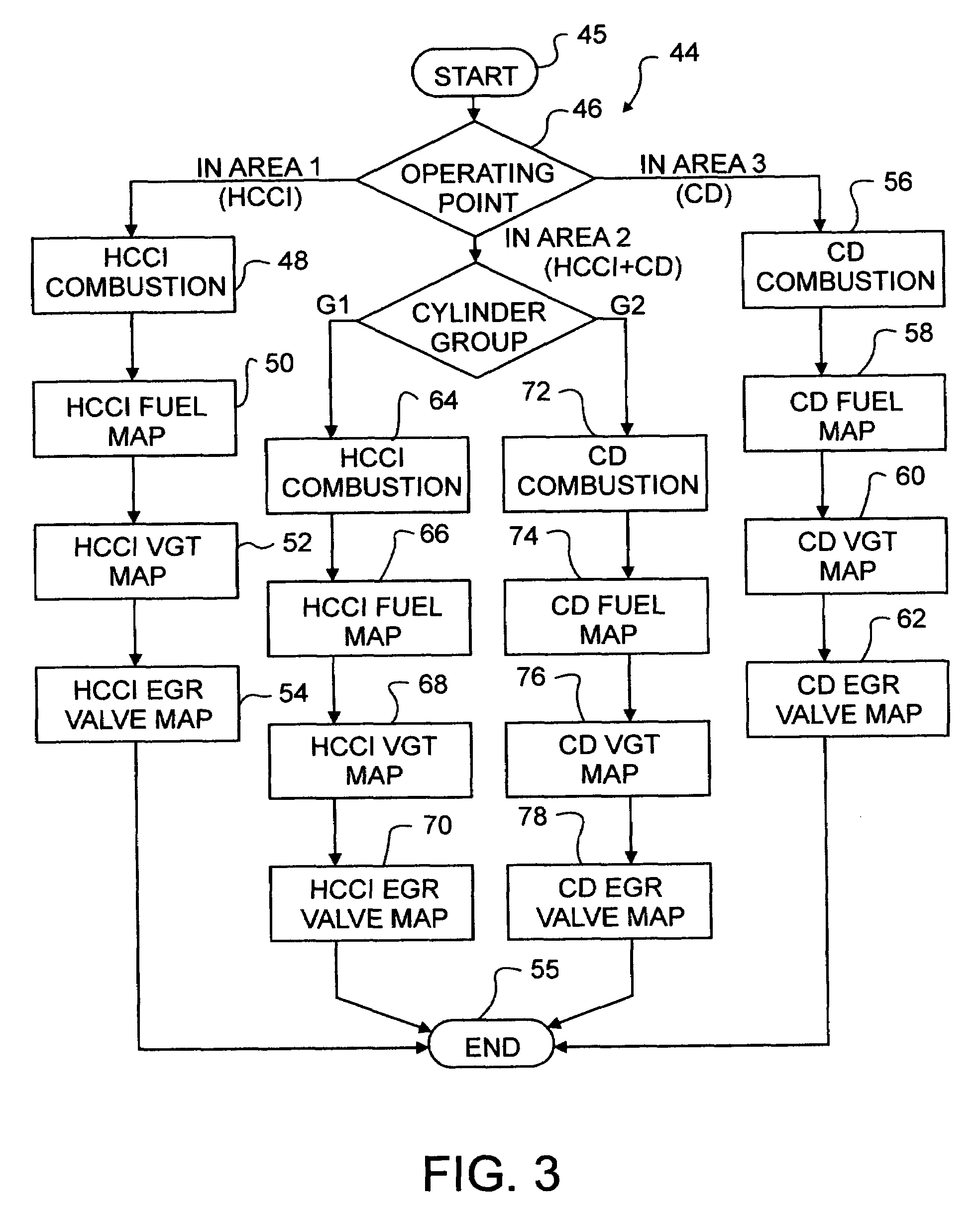

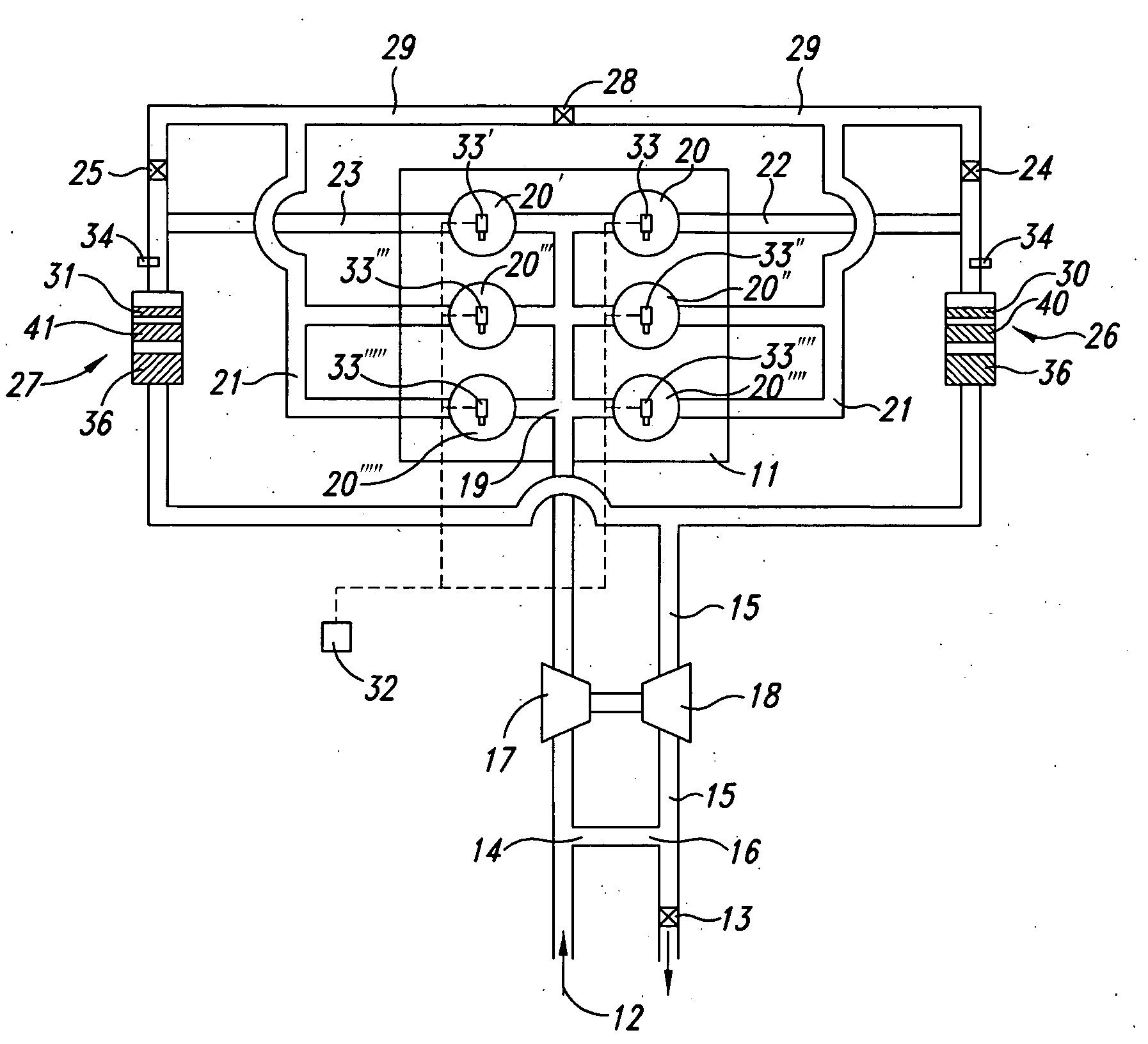

Hybrid combustion in a diesel engine

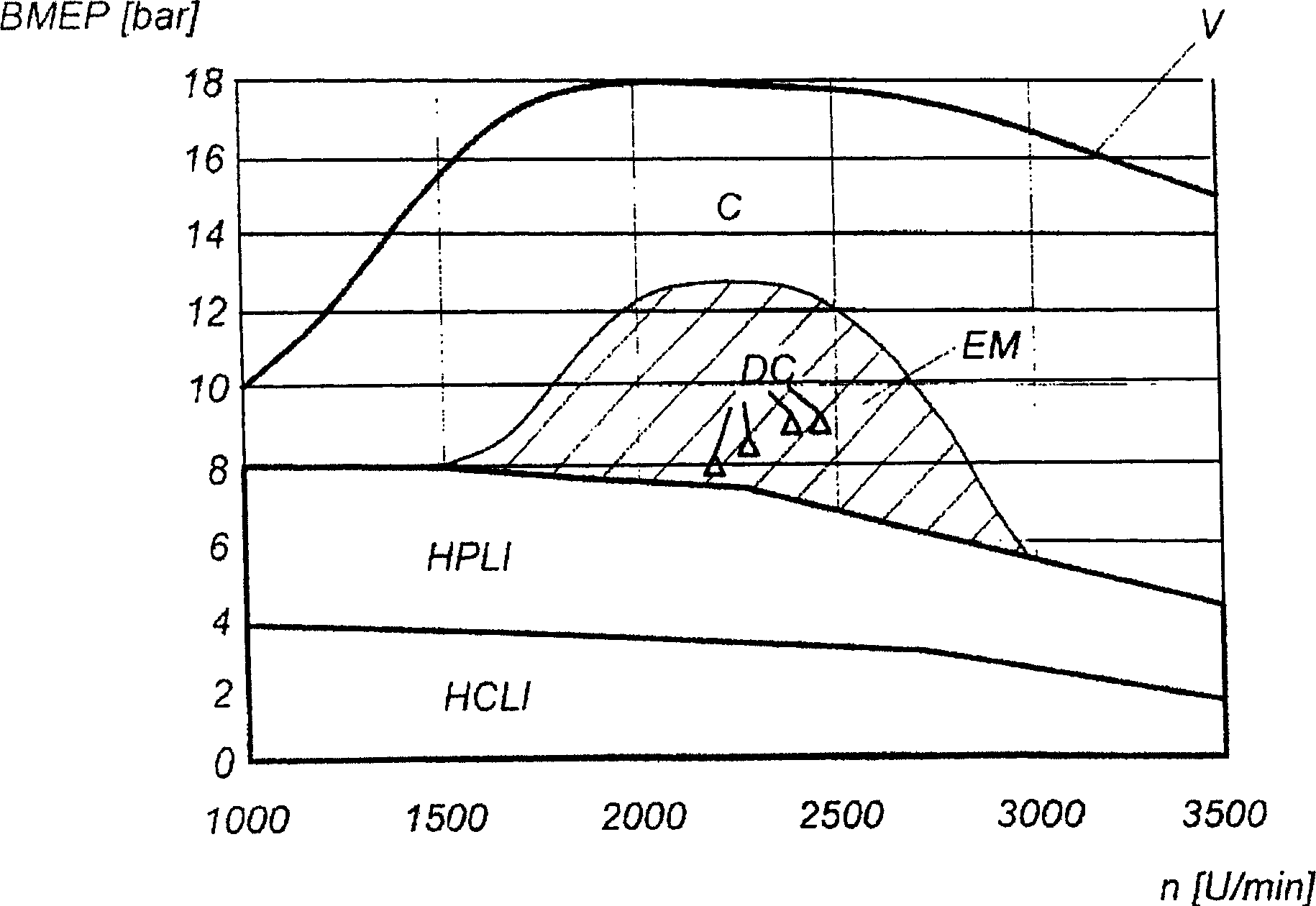

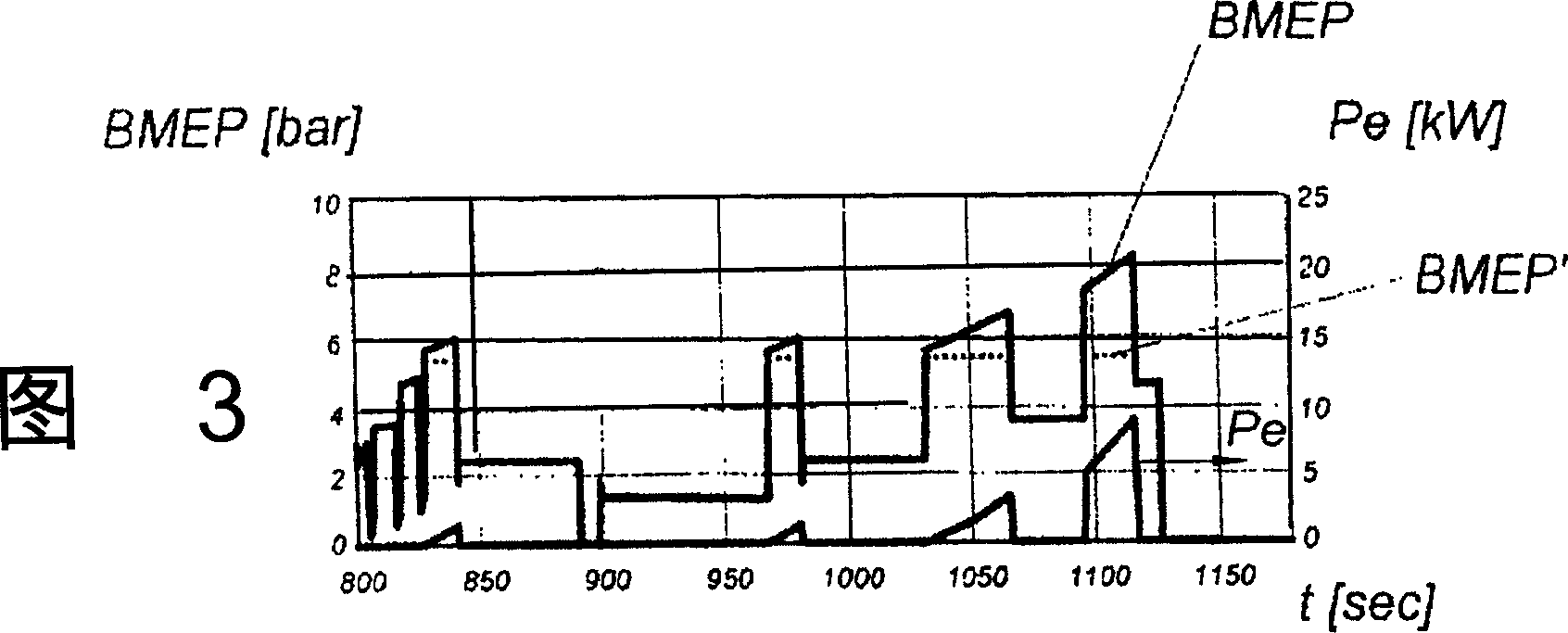

ActiveUS7461627B2Increase rangeElectrical controlInternal combustion piston enginesHcci combustionCombustion chamber

A compression ignition engine (10) has a control system (40), one or more combustion chambers (12), and fuel injectors (42, 44) for injecting fuel into the combustion chambers. The control system controls fueling using a result of the processing of engine speed and engine load to select a particular domain for engine operation (HCCI, HCCI+CD, or CD, —FIG. 1). When the processing selects HCCI, the engine is fueled to cause alternative diesel combustion (such as HCCI) in all combustion chambers. When the processing selects CD, all combustion chambers are fueled for conventional diesel combustion. When the processing selects HCCI+CD, a first group of combustion chambers are fueled for HCCI combustion and a second group for CD combustion. Each group (G1, G2) has its own EGR valve (34, 38) and turbocharger (22, 24).

Owner:INT ENGINE INTPROP CO LLC

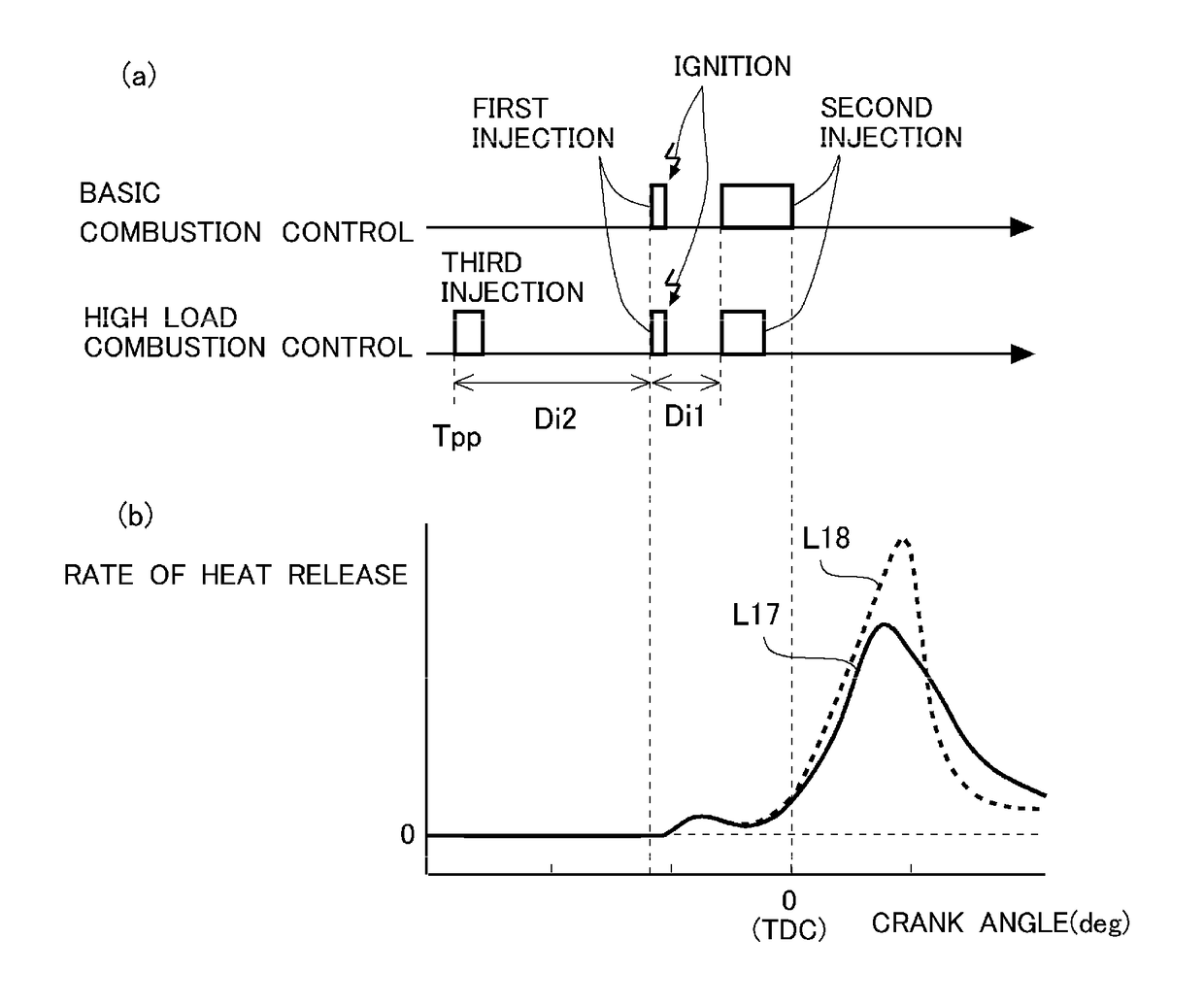

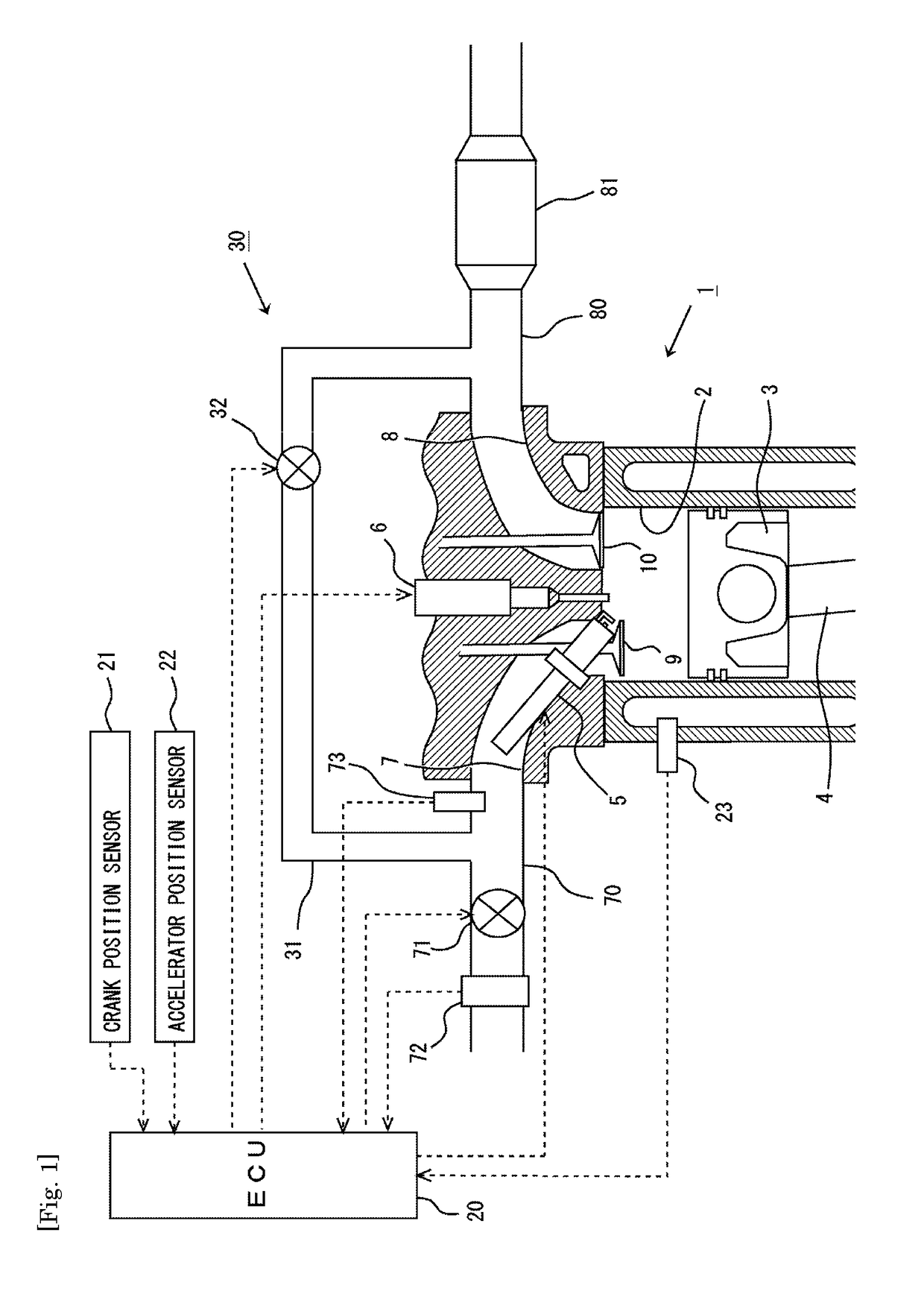

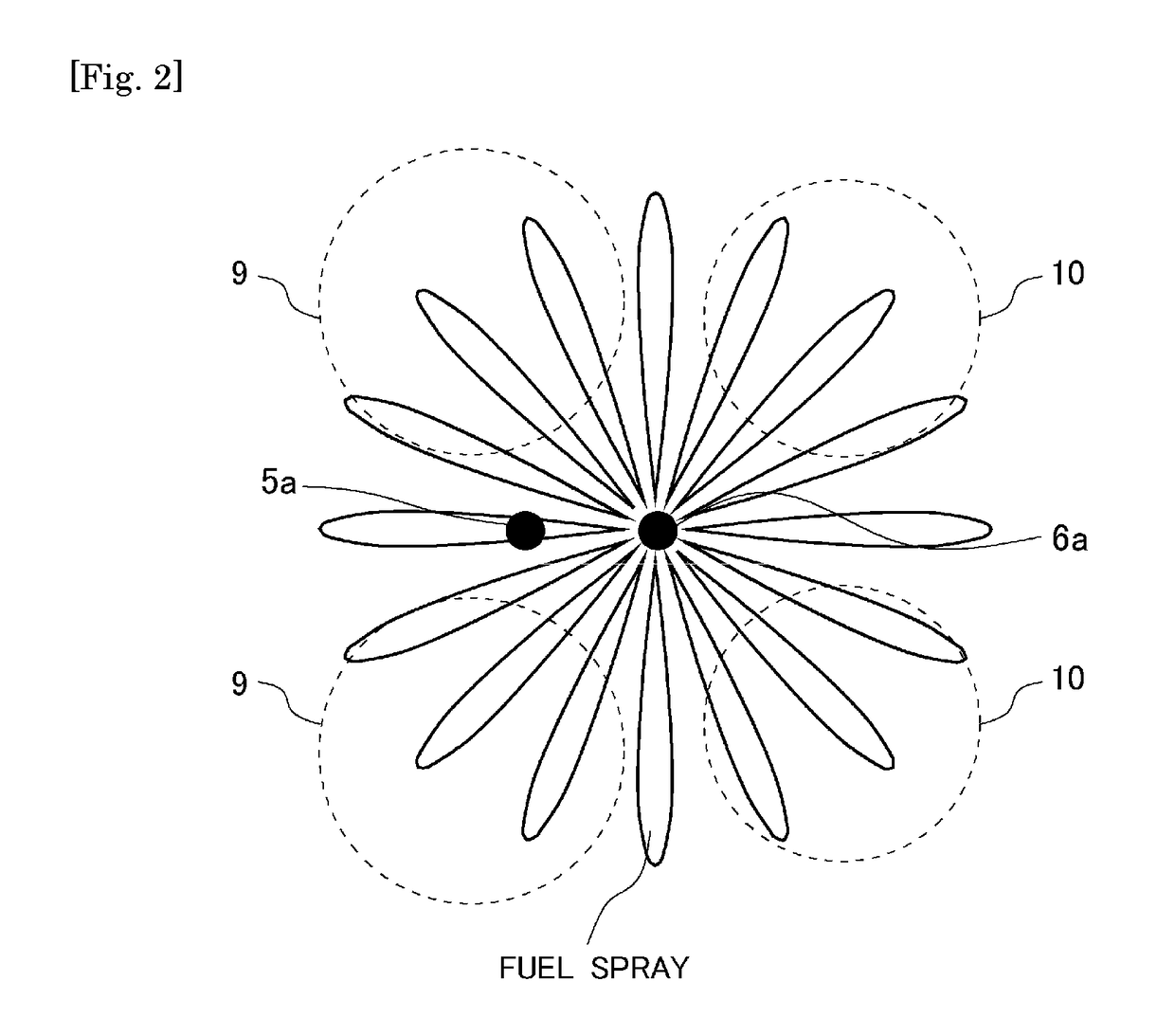

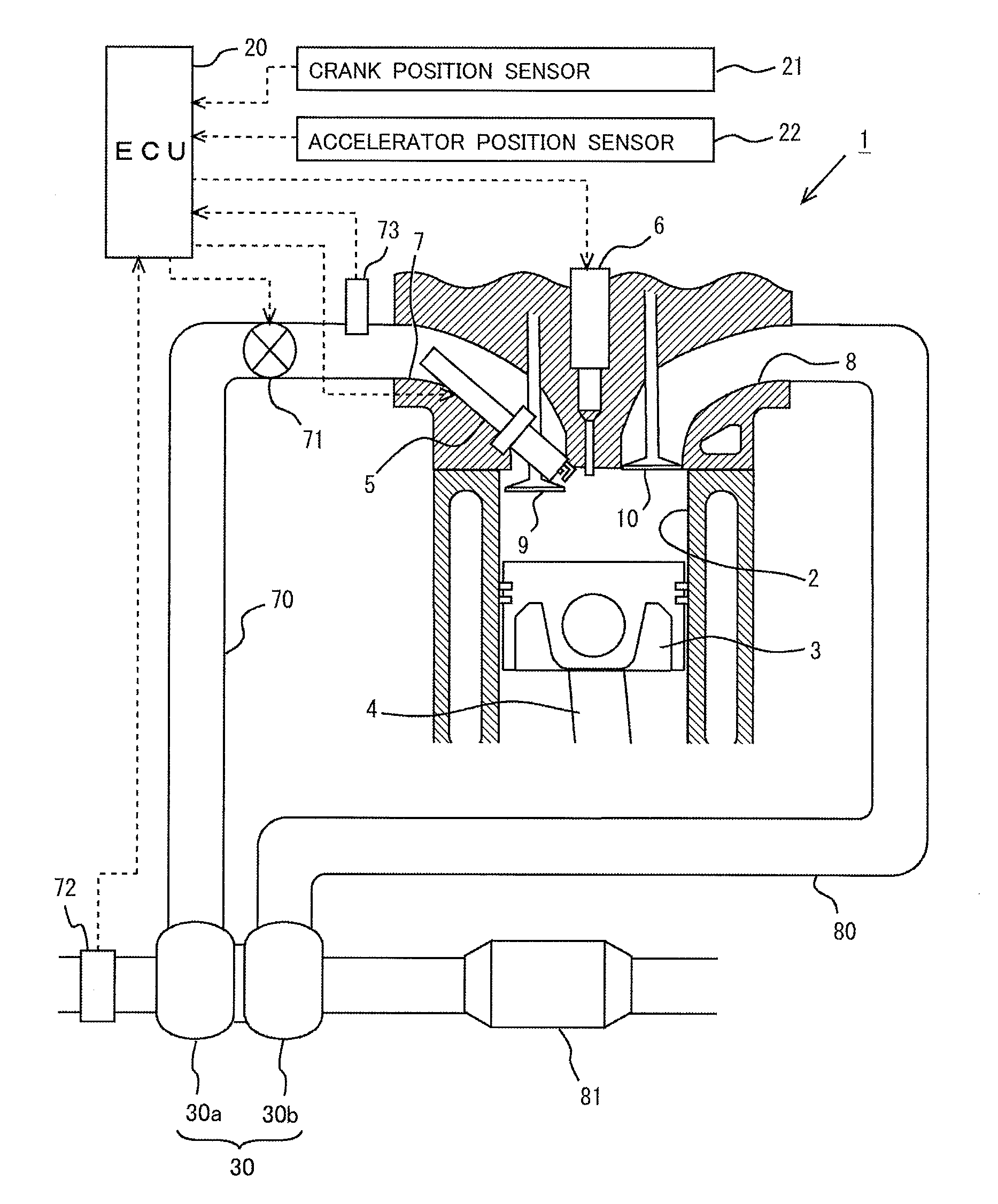

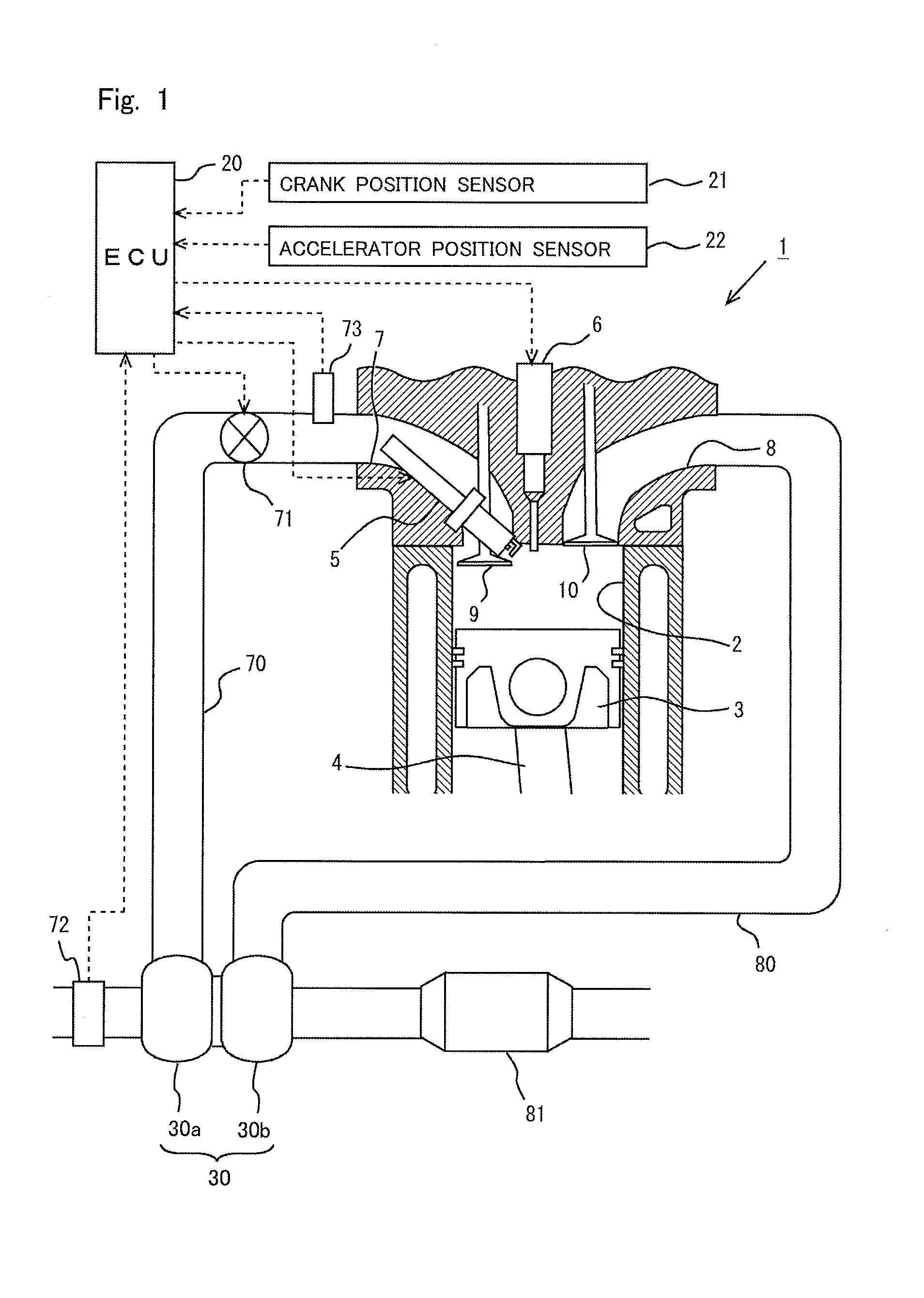

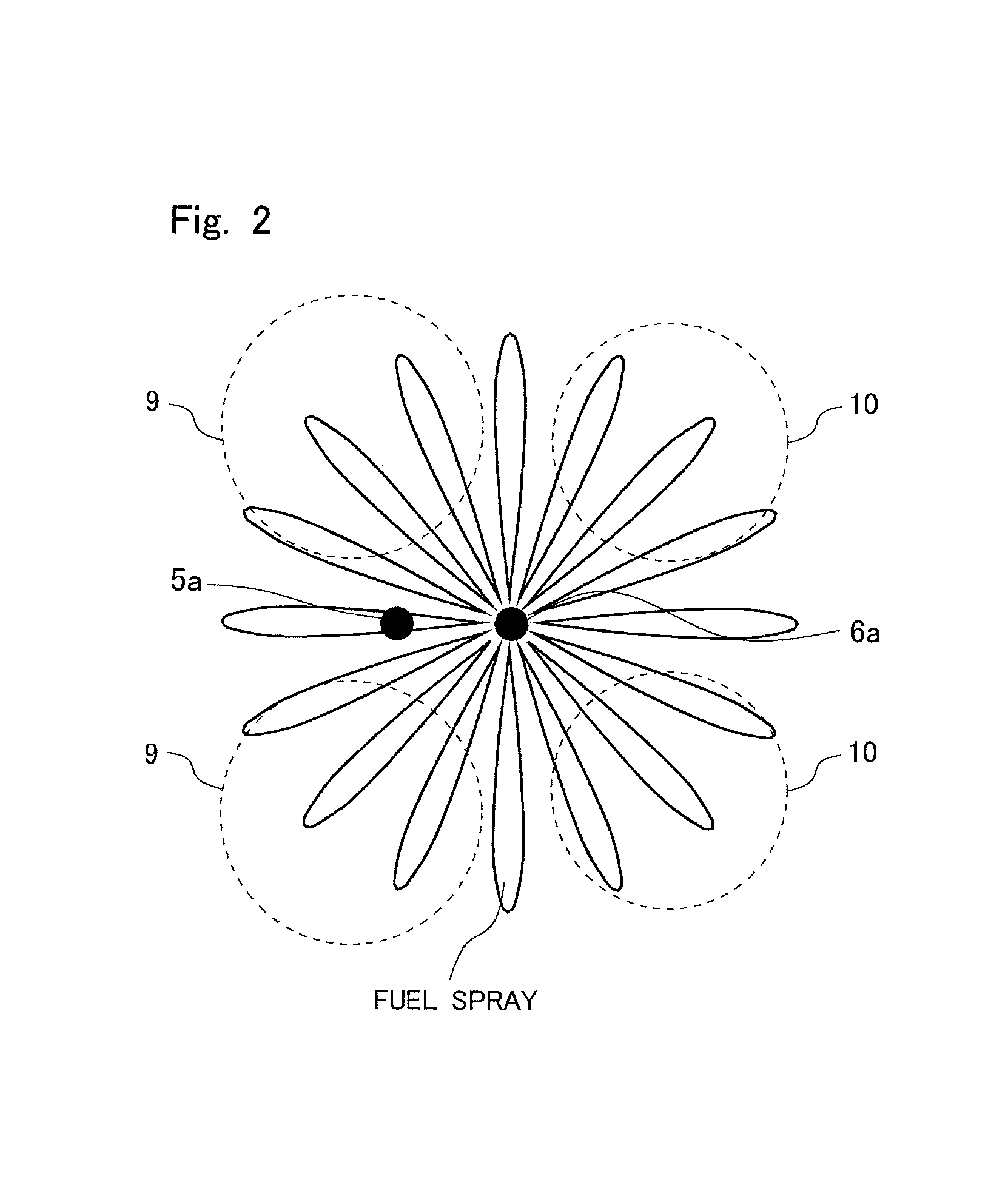

Control apparatus for internal combustion engine

InactiveUS20170284282A1Reduce smokeImprove stabilityElectrical controlInternal combustion piston enginesExternal combustion engineDiesel combustion

An object of the invention is to reduce the amount of smoke generated and to improve the stability of diesel combustion in cases where an EGR apparatus is used in an internal combustion engine that performs diesel combustion using fuel having a relatively high self-ignition temperature. A control apparatus performs first injection at a first injection time during the compression stroke, causes spray guide combustion to occur, and starts to perform second injection at such a second injection time that causes combustion of injected fuel to be started by flame generated by the spray guide combustion, thereby causing self-ignition and diffusion combustion of fuel to occur. The apparatus changes the ratio of the first injected fuel quantity to the total fuel injection quantity and the ratio of the second injected fuel quantity to the total fuel injection quantity for the same total fuel injection quantity in one combustion cycle, based on the EGR rate in the intake air.

Owner:TOYOTA JIDOSHA KK

Method for operating a hybrid vehicle

InactiveCN1757555ASmall speed changeElectrical controlInternal combustion piston enginesNitrogen oxidesDiesel combustion

The invention relates to a method for operating a hybrid vehicle with a drive train which comprises an internal combustion engine driven by diesel fuel and at least one electric driving machine. In order to reduce the nitrogen oxide and exhaust particulate emissions it is provided that the internal combustion engine is operated with an alternative diesel combustion method in at least one operating range of the vehicle and the electric driving machine is switched in.

Owner:AVL LIST GMBH

Process and system for improving combustion and exhaust aftertreatment of motor vehicle engines

InactiveUS20070180819A1Improving fuel combustion and exhaust aftertreatmentHydrogenElectrical controlPartial oxidationHydrogen

A diesel combustion engine system providing improved fuel combustion and exhaust aftertreatment includes: a diesel combustion engine having a liquid fuel intake, an air intake, a reformate intake, and an exhaust outlet; a liquid diesel fuel source in fluid communication with the liquid fuel intake and an on-board catalytic partial oxidation fuel reformer that receives a supply of hydrogen-containing liquid diesel fuel and a supply of air and produces therefrom a hydrogen-rich reformate. An exhaust conduit in fluid communication with the exhaust outlet and the reformer includes a reformate conduit upstream from exhaust aftertreatment components. The system provides for supplying: under conditions of low engine load, reformate or a combination of liquid diesel fuel and reformate to the engine; under conditions of medium engine load, a combination of liquid diesel fuel and reformate to the engine; and, under conditions of high engine load, liquid diesel fuel only to the engine and reformate only to the exhaust conduit.

Owner:DELPHI TECH INC

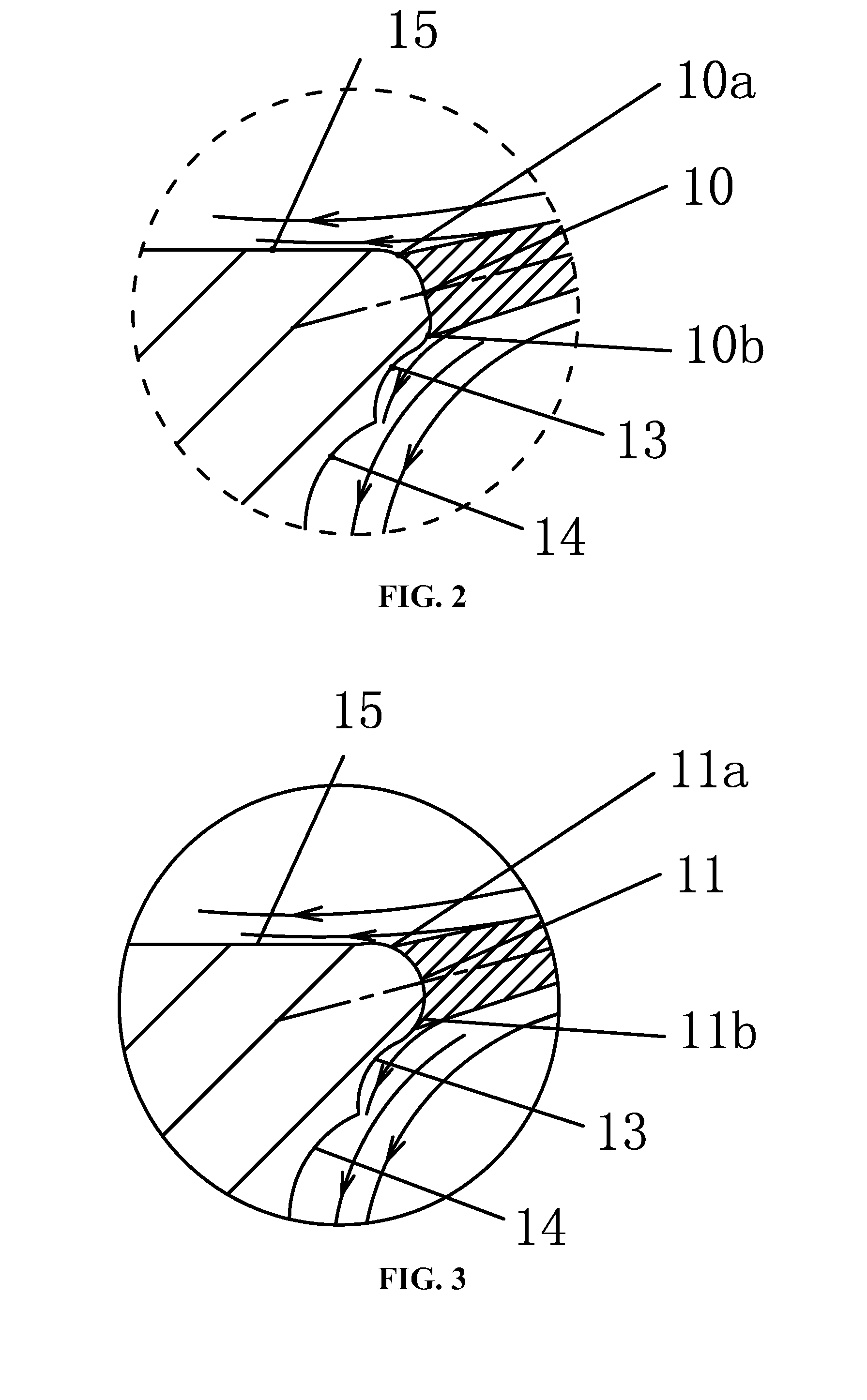

Diesel combustion system

InactiveUS20150053172A1Promote formationImprove combustion performanceInternal combustion piston enginesFuel re-atomisation/homogenisationCombustion chamberCylinder head

A diesel combustion system including an injector and a combustion chamber. The combustion chamber is formed by a cylinder head, a cylinder liner, and a piston. The combustion chamber includes an upper layer and a lower layer. The diameter D1 of the upper layer is larger than the diameter D2 of the lower layer. A junction of the upper layer and the lower layer is provided with an impinging block for rebounding the diesel fuel spray. The impinging block includes an impinging surface, an upper guide surface, and a lower guide surface. When in use, part of the diesel fuel spray is rebounded by the impinging surface, and part of the diesel fuel spray is diffused along the upper guide surface and the lower guide surface of the impinging block to achieve double-layered split flow of the diesel fuel.

Owner:DALIAN UNIV OF TECH

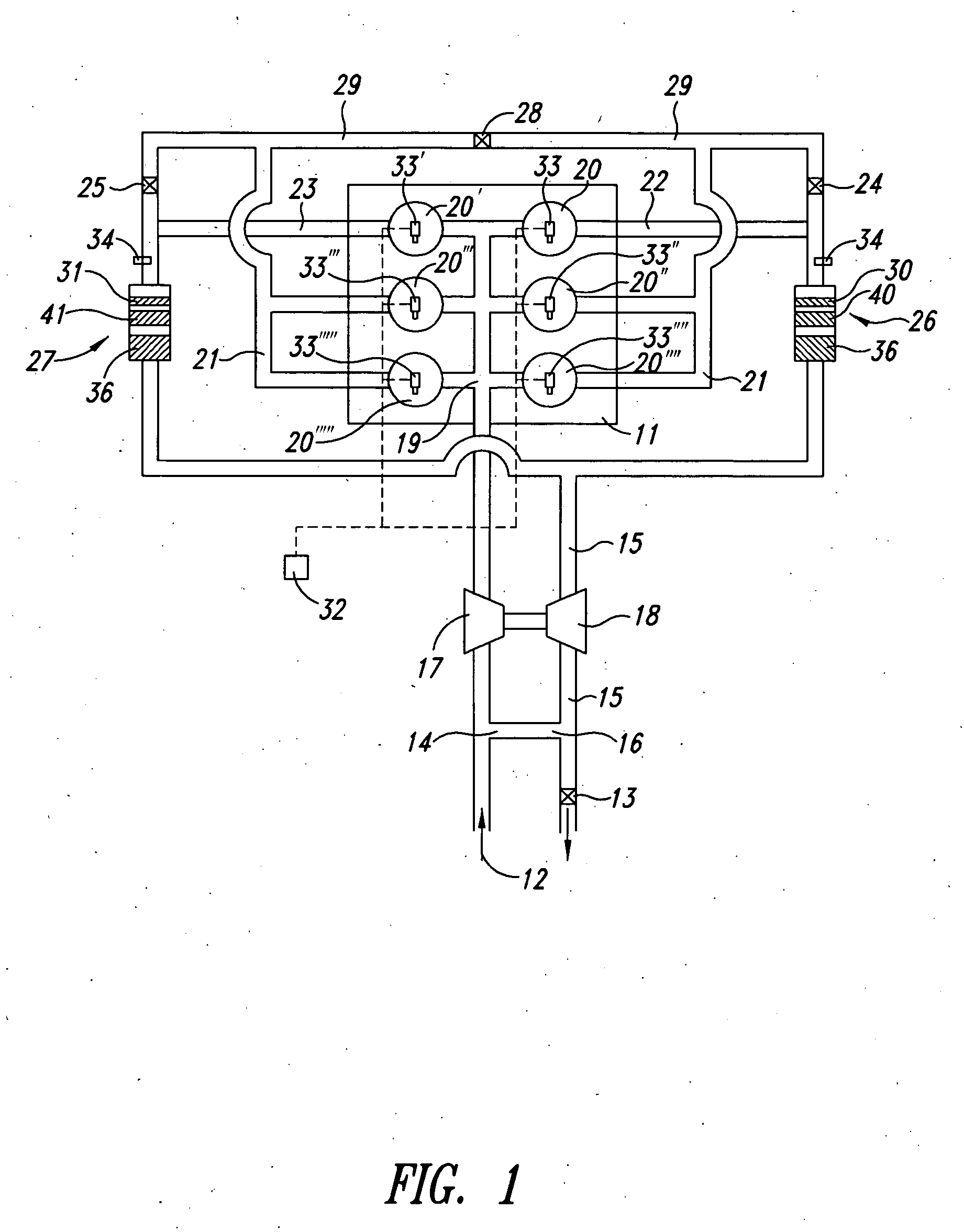

Diesel particulate filter regeneration system

InactiveUS20090019839A1Improve efficiencyMinimal disruptionElectrical controlInternal combustion piston enginesExhaust valveDiesel combustion

A diesel combustion engine comprises multiple particulate filters and corresponding exhaust piping and valving in the exhaust manifold and / or exhaust line, configured to enable regeneration to occur in one of the DPF filters through heating the exhaust from a single cylinder of the engine, while the exhaust from the remaining cylinders is temporarily routed through the other DPF filter during the regeneration event. Flow redirection devices are placed within the DPF filters to direct flow of exhaust gas through the DPF filters during regeneration in a manner to facilitate complete regeneration, including in outer volumes along the interior walls of the DPF filters.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY U S ENVIRONMENTAL PROTECTION AGENCY THE

Diesel aftertreatment system

A diesel exhaust gas aftertreatment system (10) is provided to treat the exhaust (12) from a diesel combustion process (14), such as a diesel compression engine (16). The system (10) includes a burner (18) that selectively supplies the exhaust (12) at an elevated temperature to the rest of the system (10), a diesel particulate filter (20) connected downstream from the burner (18) to receive the exhaust (12) therefrom, and a NOx reducing device (22) connected downstream from the filter (20) to receive the exhaust therefrom.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Method and arrangement for detecting particles

The present invention relates to a method for detecting particles and a particle sensor arrangement. More specifically, the present invention relates to a method and arrangement for detecting particles in a gas flow, e.g. from a diesel combustion engine. The method comprises the steps of,forcing a particle build up on a sensor element of a particle sensor arrangement by regulating the sensor element to a second temperature,wherein the second temperature is lower than a first temperature, the first temperature being the gas flow temperature. Additionally is the particle build up detected at the sensor element by means of a detector. The present invention provides for an accurate method and arrangement to detect and thereby measure particles present in a gas flow, e.g. from a combustion engine.

Owner:VOLVO TECH +1

Control apparatus for internal combustion engine

ActiveUS20160115895A1Improve combustion conditionsIncrease temperatureElectrical controlInternal combustion piston enginesDiesel combustionResponse delay

An object is to improve the combustion condition in an internal combustion engine equipped with a supercharger and performing diesel combustion using fuel having a relatively high self-ignition temperature in an operation state in which the engine load is increased or decreased. A control apparatus performs first injection during the compression stroke, causes spray guide combustion to occur, and starts to perform second injection at such a second injection time that combustion of injected fuel is started by flame generated by the spray guide combustion, thereby causing self-ignition and diffusion combustion of fuel to occur. During a response delay period in changing the boost pressure when changing the engine load of the internal combustion engine to a target engine load, the ratio of the quantity of fuel injected by the first injection to the total fuel injection quantity in one combustion cycle is made higher than the ratio of the quantity of fuel injected in the first injection to the total fuel injection quantity in one combustion cycle during the time when the engine load is equal to the target engine load and the actual boost pressure is equal to a target boost pressure corresponding to the target engine load.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com