Patents

Literature

58results about How to "Small speed change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

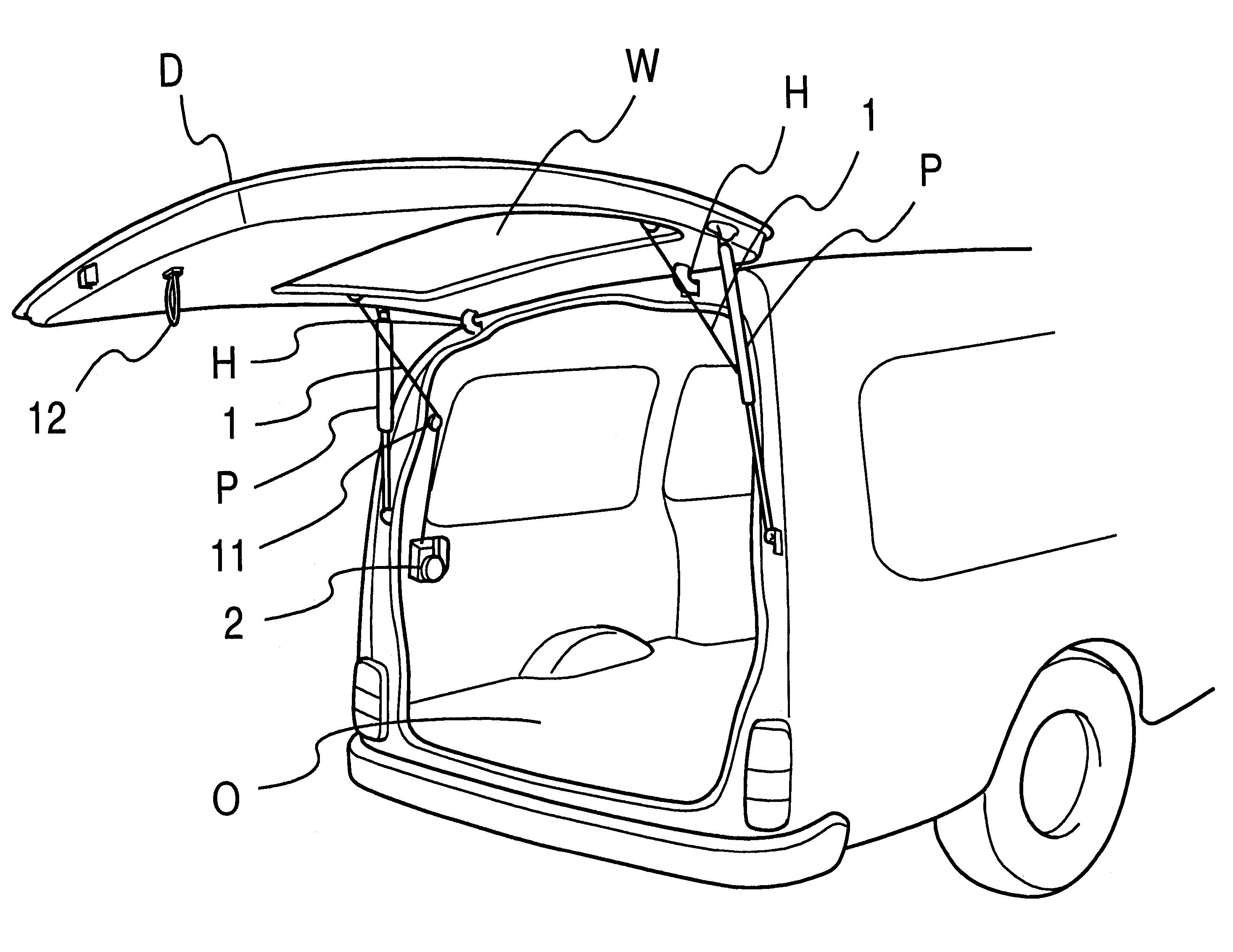

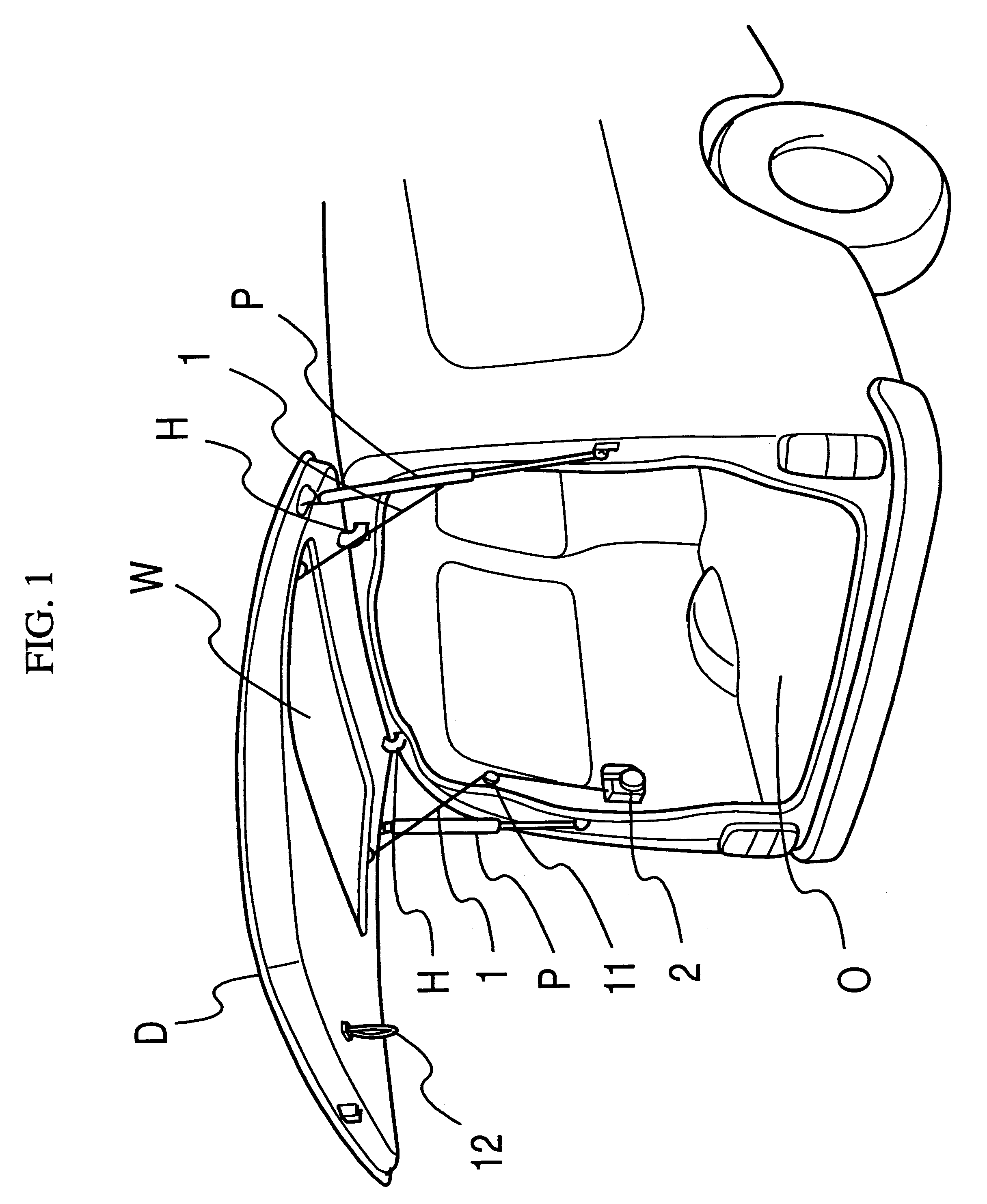

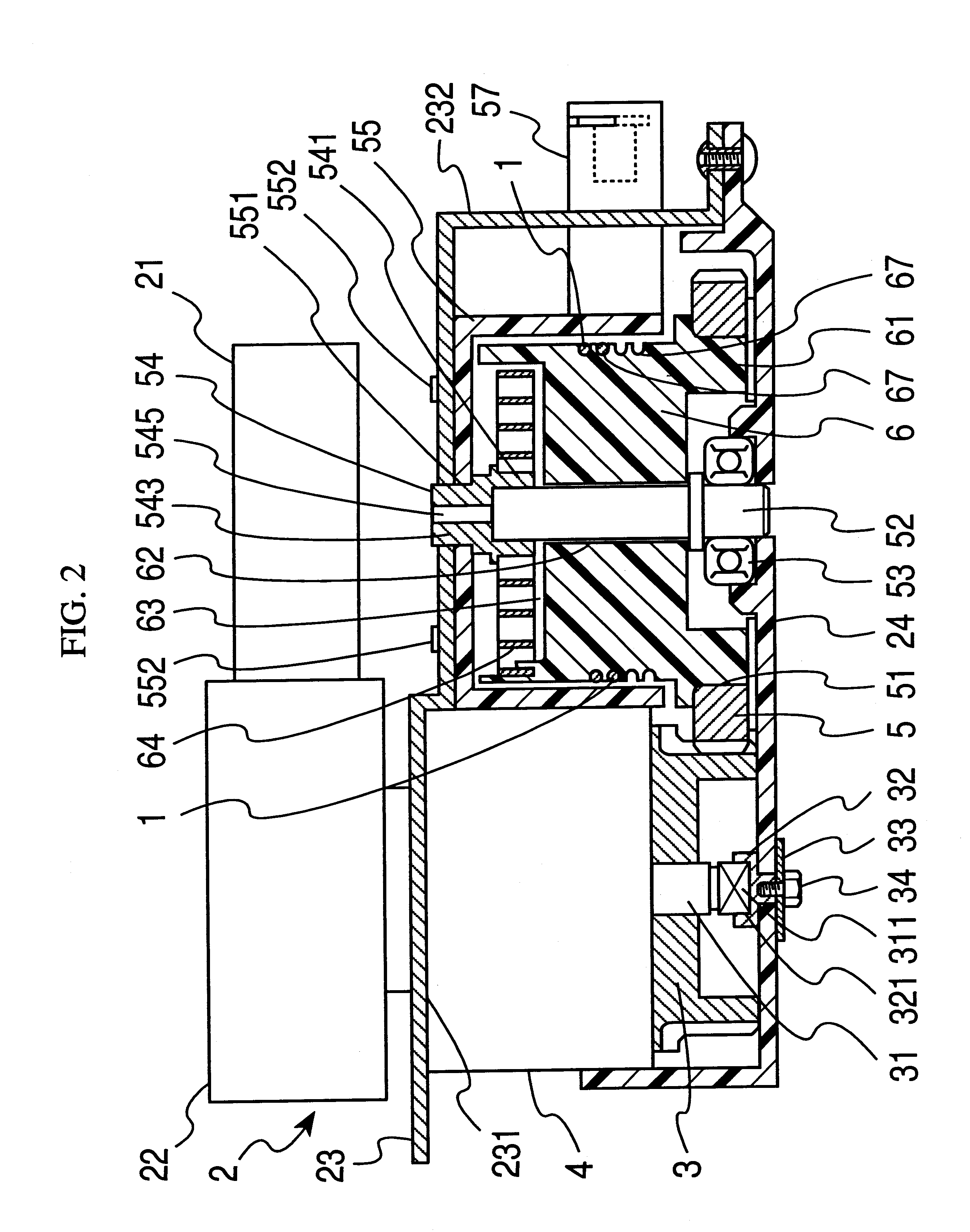

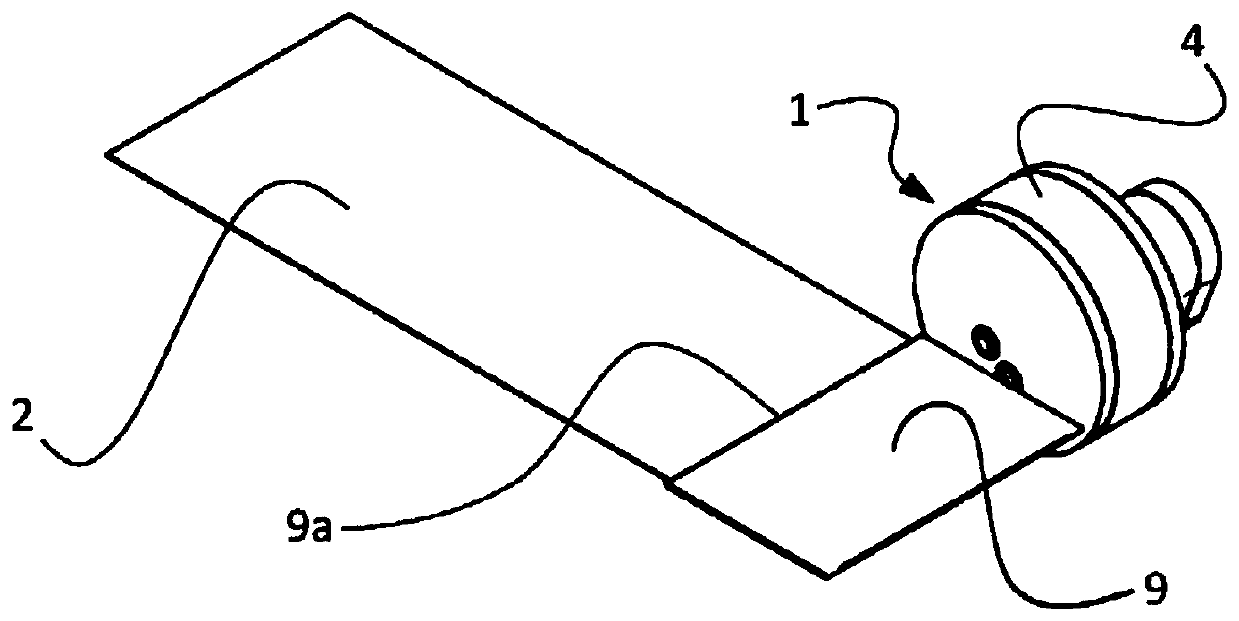

Automatic closer of pop-up door of vehicle

InactiveUS6185868B1Small speed changeEliminate needSuperstructure subunitsMonocoque constructionsDrive motorEngineering

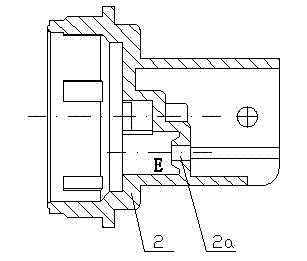

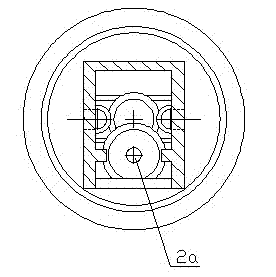

A connection wire is connected to a part of a rear door popped up in a door-opening direction by an urging force. A pulley rotates responsive to a driving motor inside a wire-winding device to wind the connection wire thereon. In this manner, the rear door is automatically closed. The pulley is urged in a connection wire-winding direction by a power spring. A clutch is between the pulley and the driving motor. When the rear door is pressed by an operator's hands in a door-closing direction while the rear door is being closed, the pulley is rotated by the power spring, thus winding the connection wire thereon and preventing the connection wire from becoming loose. At this time, the connection between the pulley and the driving motor is cut off by the clutch. Thus, the pulley is rotated by the power spring freely and rapidly. In this manner, the rear door can be closed manually even while it is being closed automatically. Further, the connection wire can be prevented from becoming loose and from being sandwiched between the body of the vehicle and the periphery of a rear opening thereof.

Owner:TOYOTA SHATAI KK

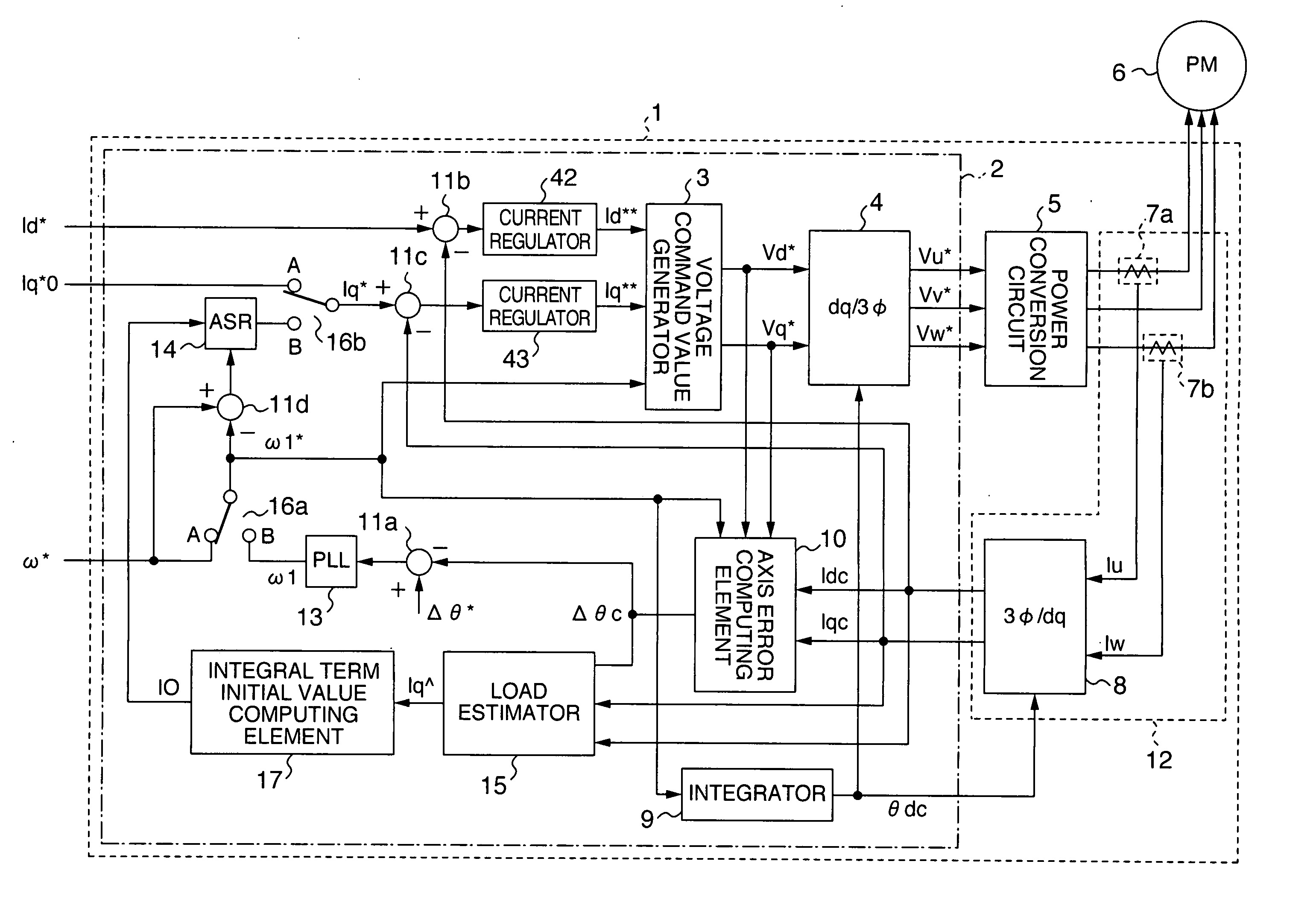

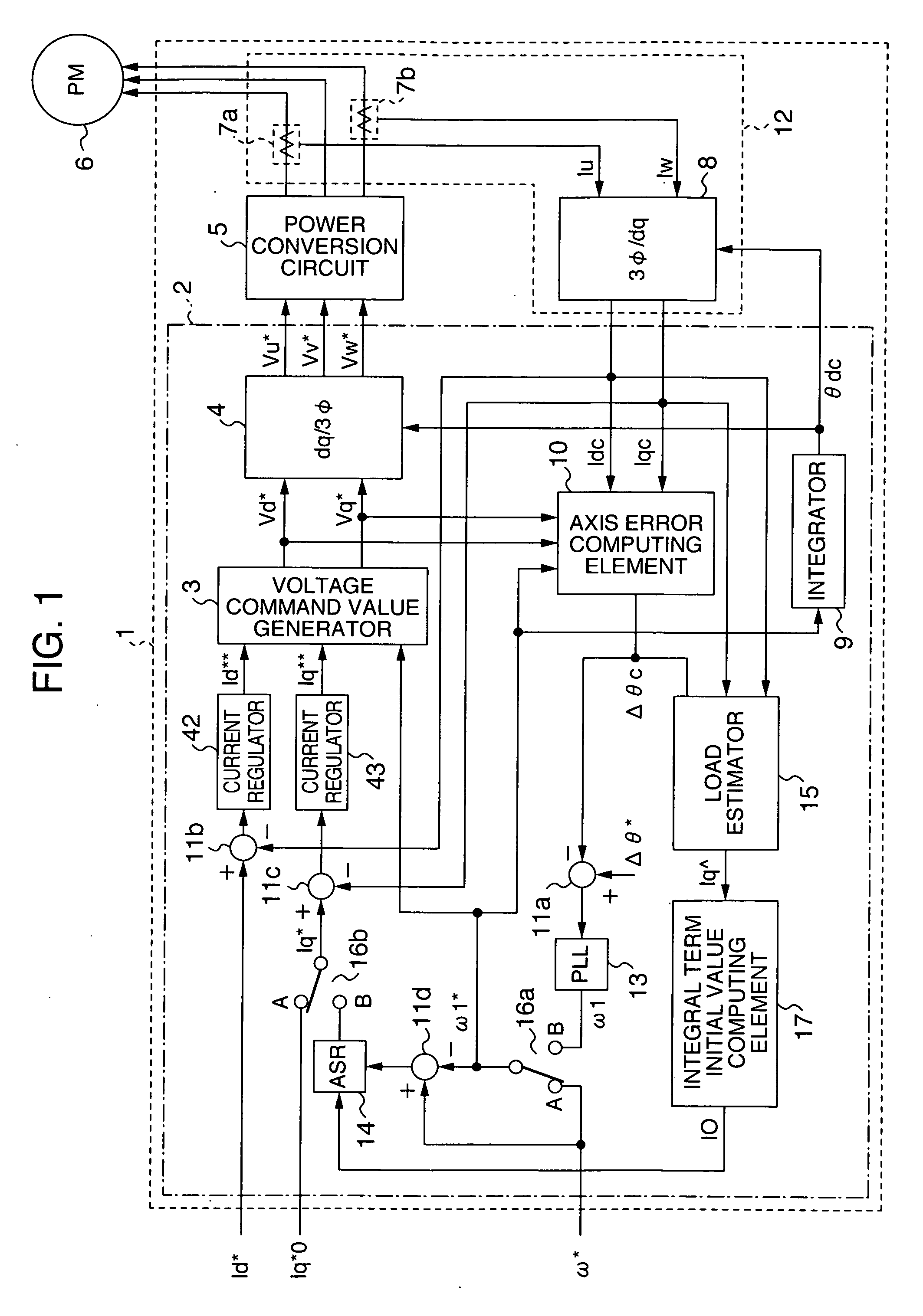

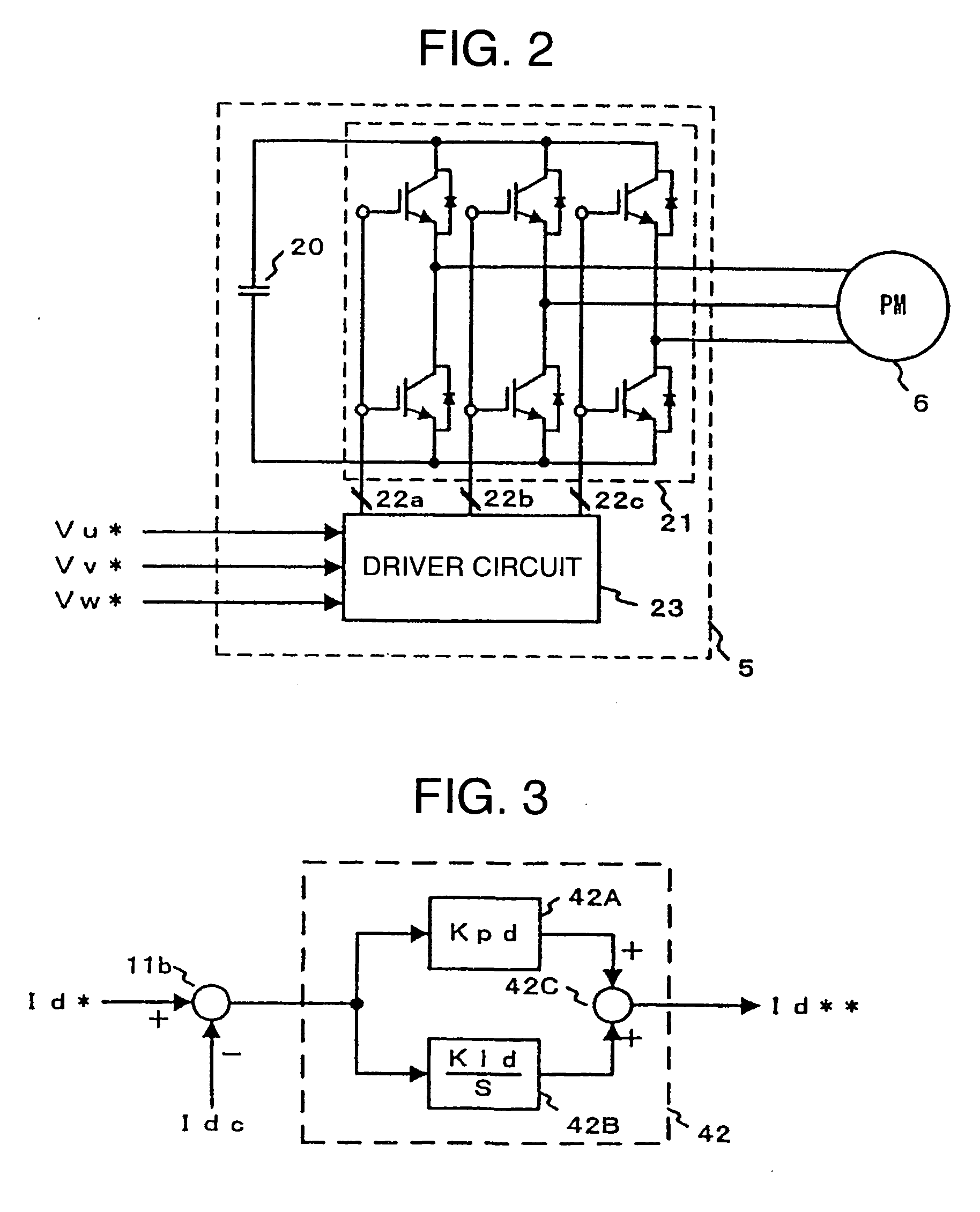

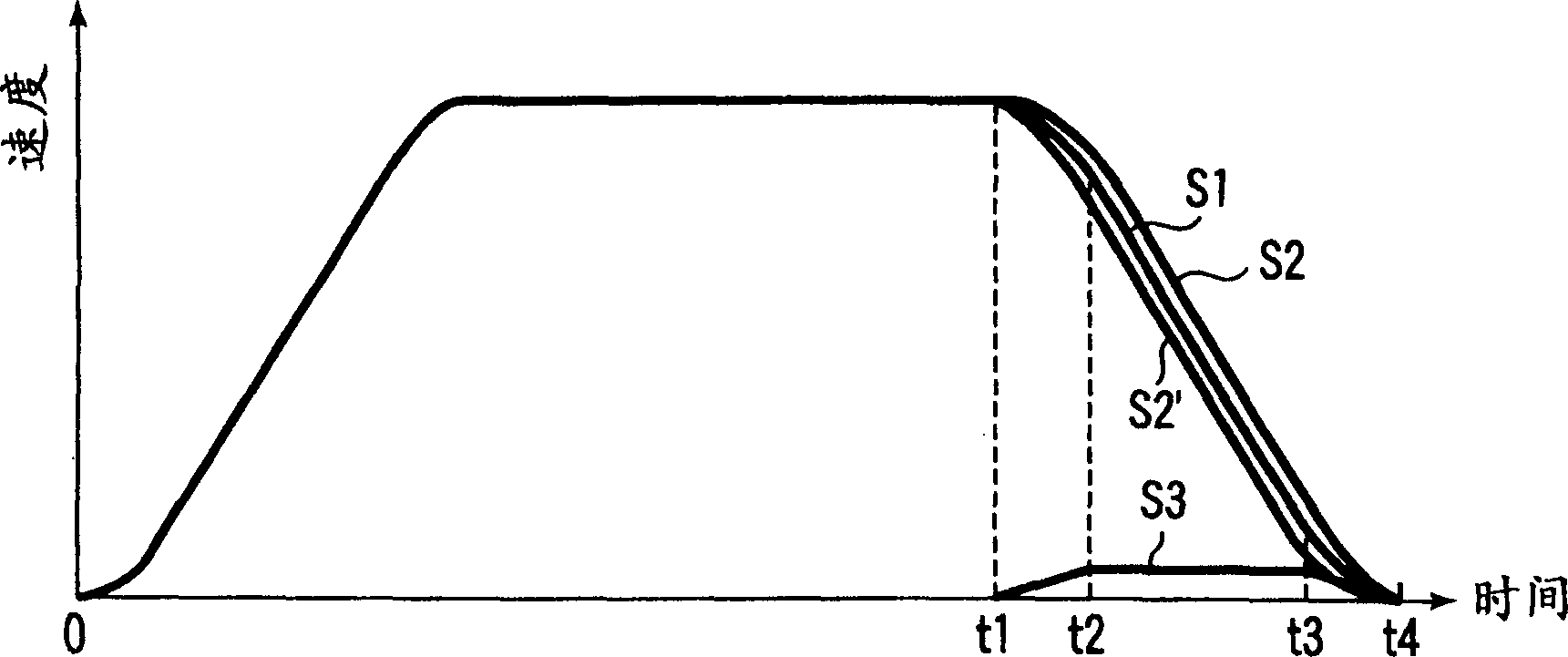

Motor controller, washing machine, air conditioner and electric oil pump

ActiveUS20070024232A1Small speed changeSignificant changeAC motor controlSynchronous motors startersMode switchingChangeover

A motor controller capable of suppressing a large speed change generated at the time of changeover from a synchronous operation mode to a position feedback operation mode and implementing even acceleration characteristics regardless of the load torque by estimating a torque of a permanent magnet motor in the synchronous operation mode for driving the permanent magnet motor and setting an initial value of a current command value in a position sensor-less operation mode on the basis of information of the torque estimated value.

Owner:HITACHI POWER SEMICON DEVICE +2

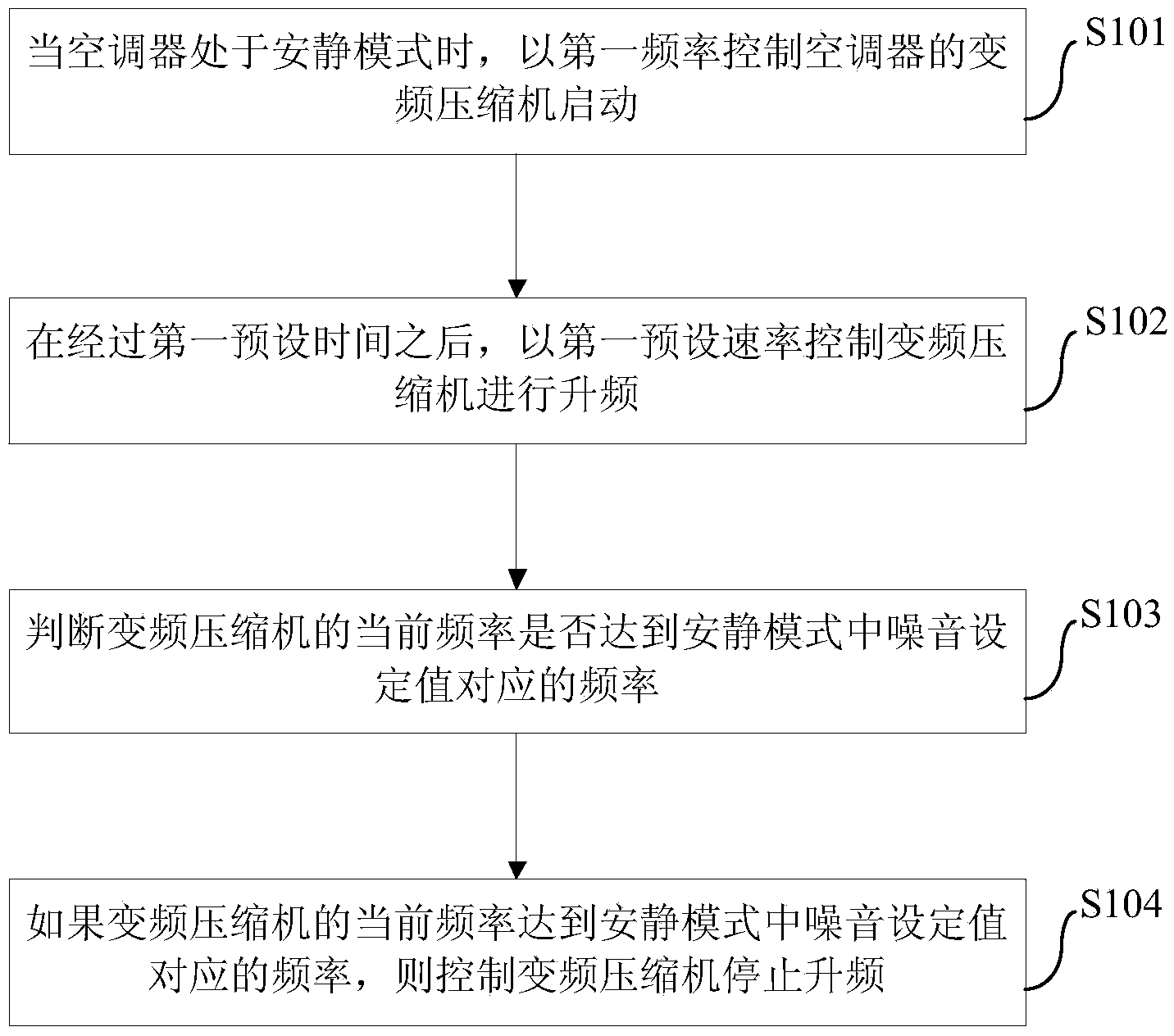

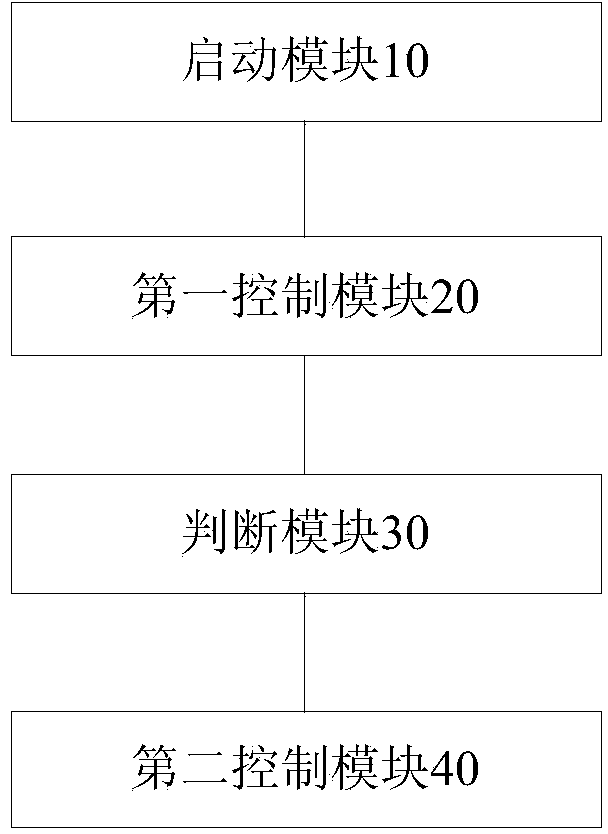

Control method of air conditioner, control device of air conditioner and air conditioner

ActiveCN104266310AReduce flow and impactReduce mechanical noiseMechanical apparatusSpace heating and ventilation safety systemsIndoor outdoorThrottle

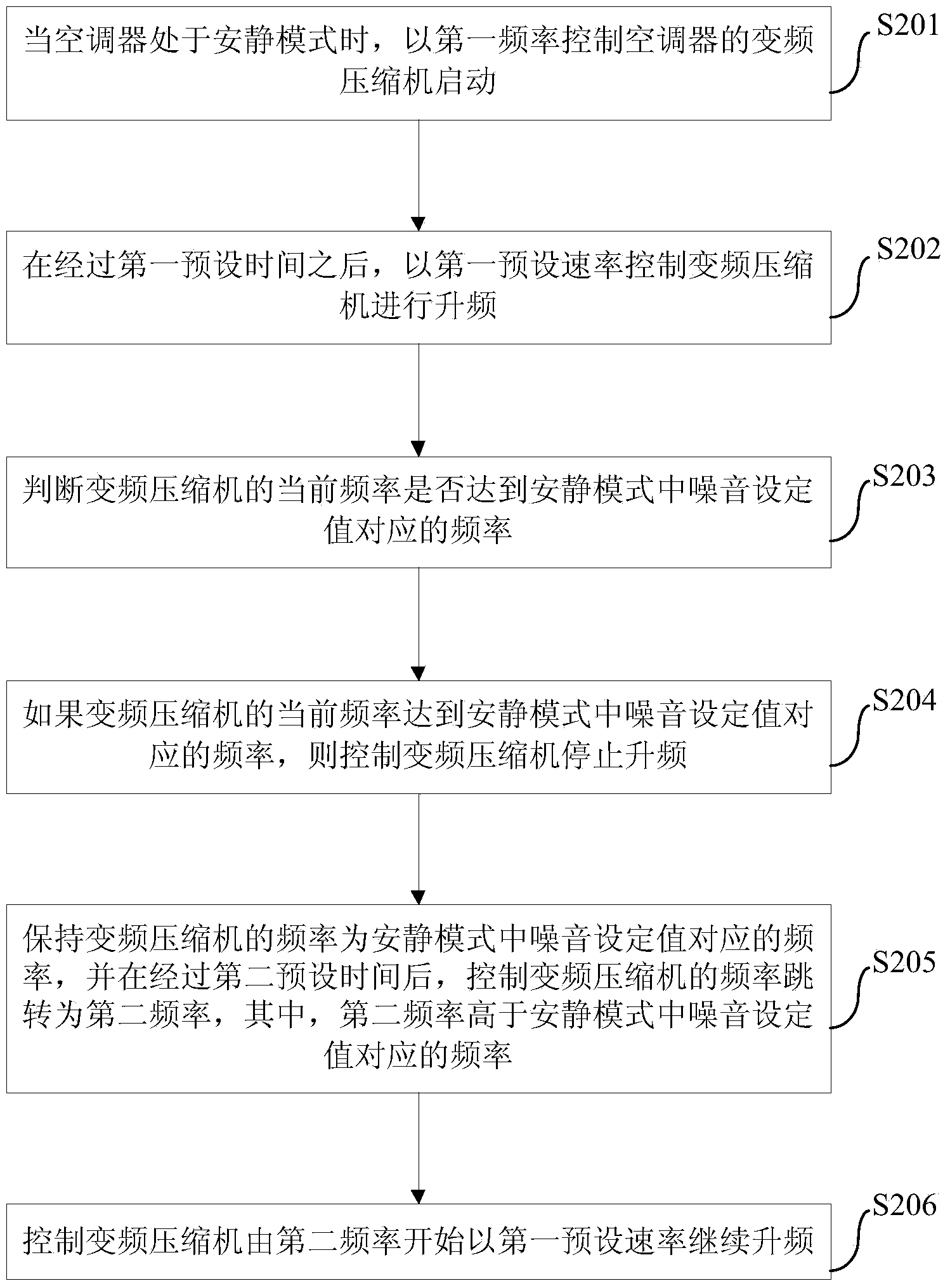

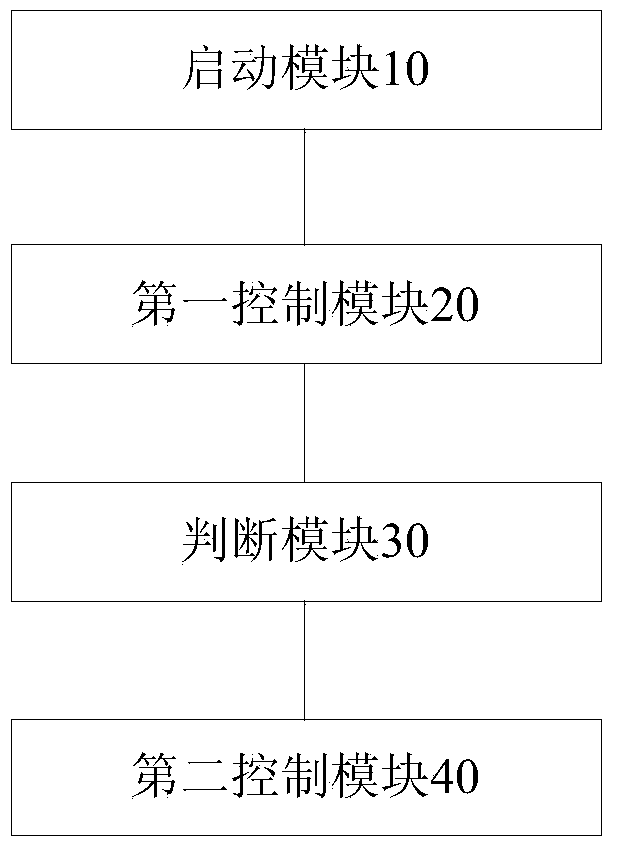

The invention discloses a control method of an air conditioner, a control device of the air conditioner and the air conditioner. The air conditioner comprises a coolant system, a throttle device and a variable frequency compressor; the coolant system is connected with an indoor-outdoor heat exchanger; the throttle device is connected with the indoor-outdoor heat exchanger; the variable frequency compressor drives coolant to circulate. The control method includes the steps of controlling the variable frequency compressor of the air conditioner to start with a first frequency when the air conditioner is in a silent mode; with a first preset time passing by, controlling the variable frequency compressor to increase in frequency at a first preset rate; judging whether or not current frequency of the variable frequency compressor reaches a value corresponding to a set noise value set in the silent mode; if yes, controlling the variable frequency compressor to stop increasing in frequency. The control method according to the embodiment has the advantages that flow of the coolant and impact thereof can be effectively reduced, leading to reduced coolant noise and mechanical noise, interference is avoided for users, and user experience is improved.

Owner:MIDEA GRP CO LTD +1

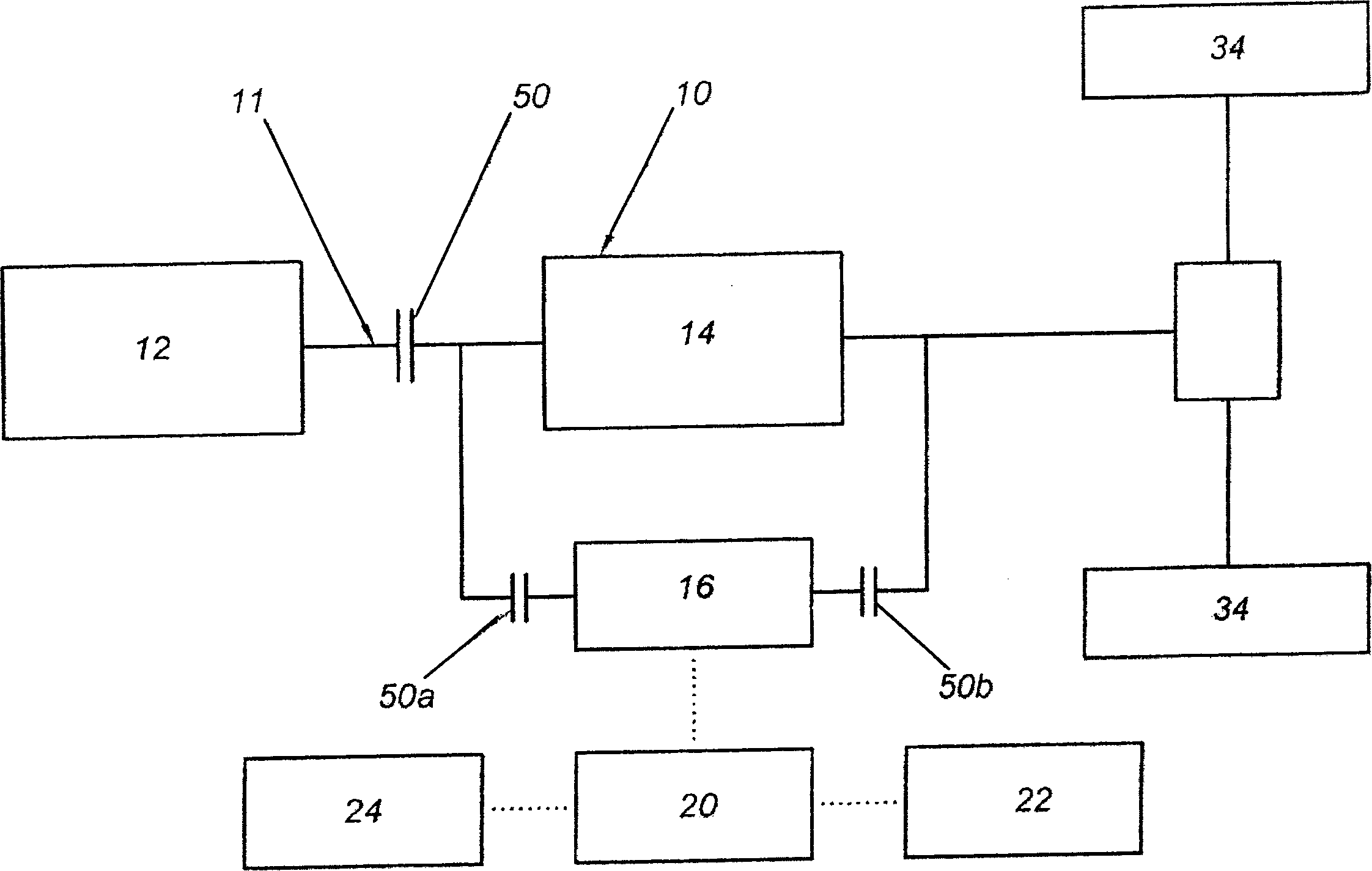

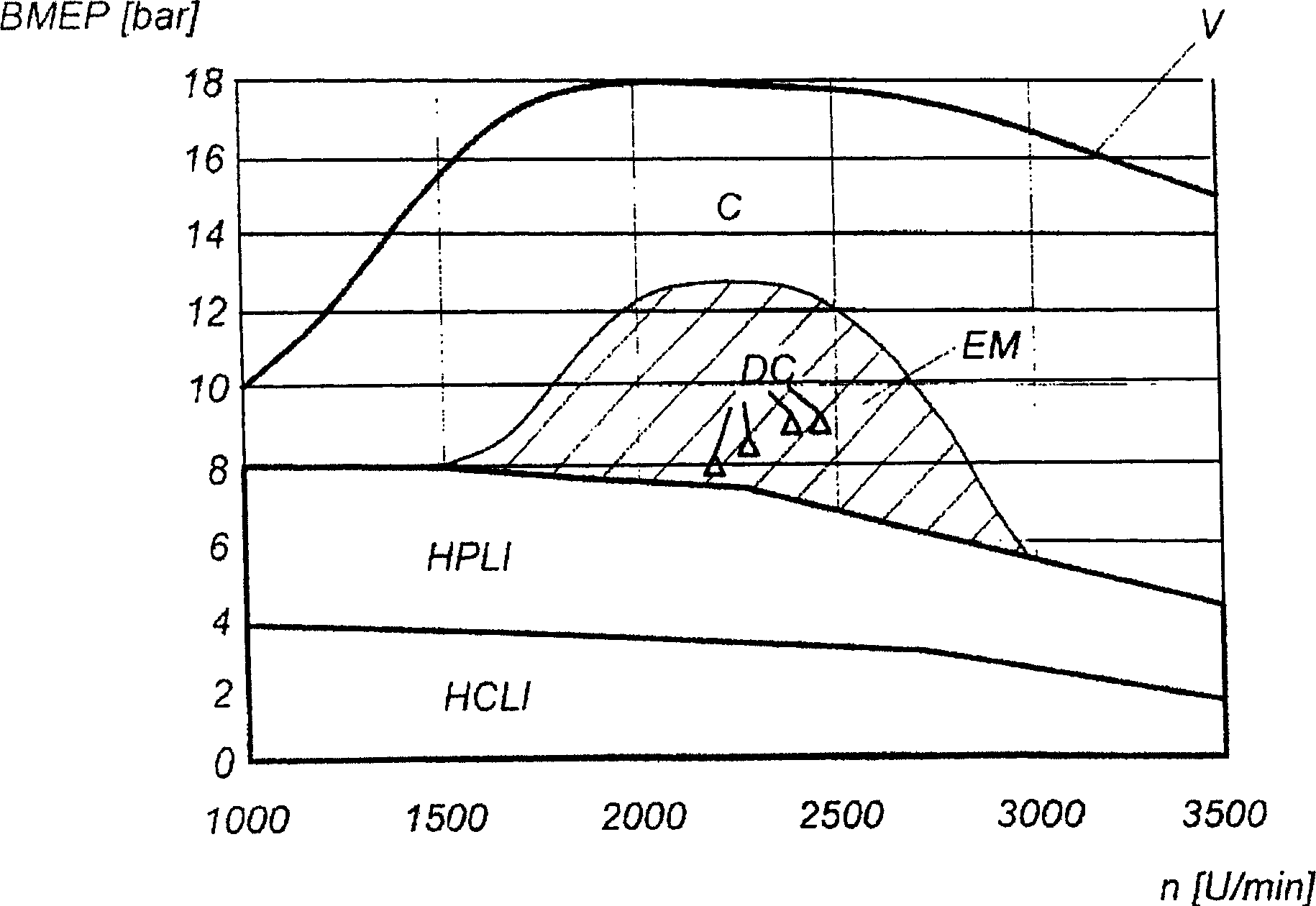

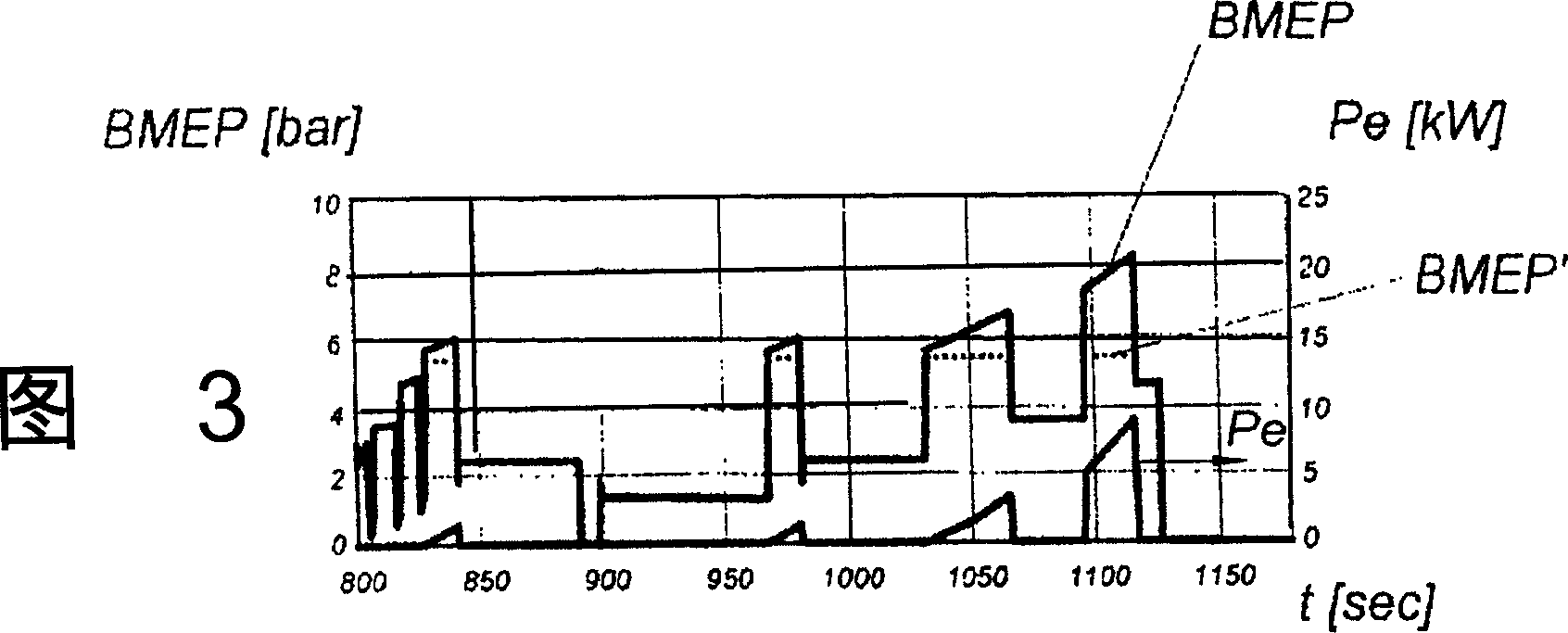

Method for operating a hybrid vehicle

InactiveCN1757555ASmall speed changeElectrical controlInternal combustion piston enginesNitrogen oxidesDiesel combustion

The invention relates to a method for operating a hybrid vehicle with a drive train which comprises an internal combustion engine driven by diesel fuel and at least one electric driving machine. In order to reduce the nitrogen oxide and exhaust particulate emissions it is provided that the internal combustion engine is operated with an alternative diesel combustion method in at least one operating range of the vehicle and the electric driving machine is switched in.

Owner:AVL LIST GMBH

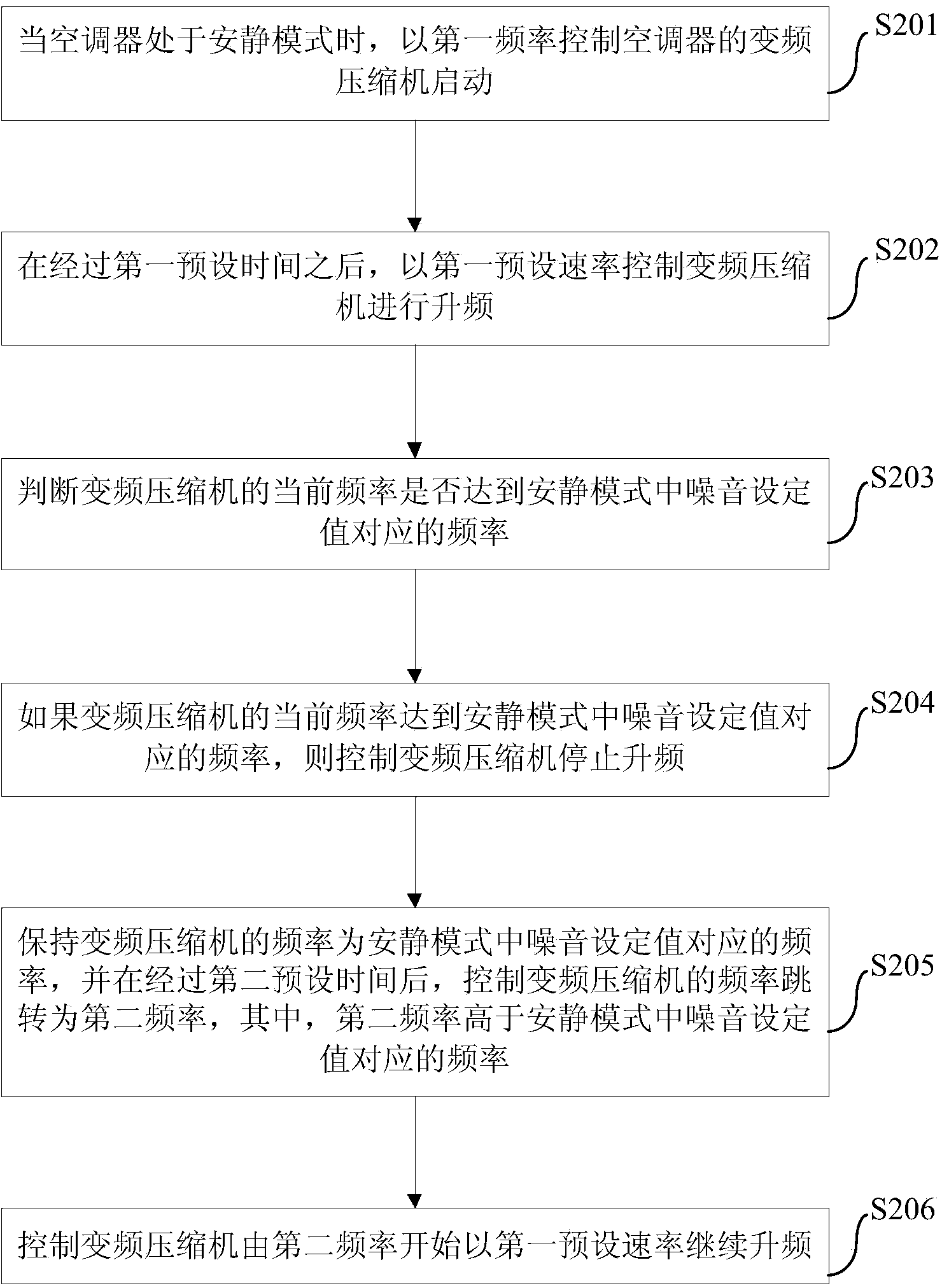

Air conditioner and control method and device thereof

ActiveCN104266311AReduce noiseAvoid noiseMechanical apparatusSpace heating and ventilation safety systemsEngineeringControl theory

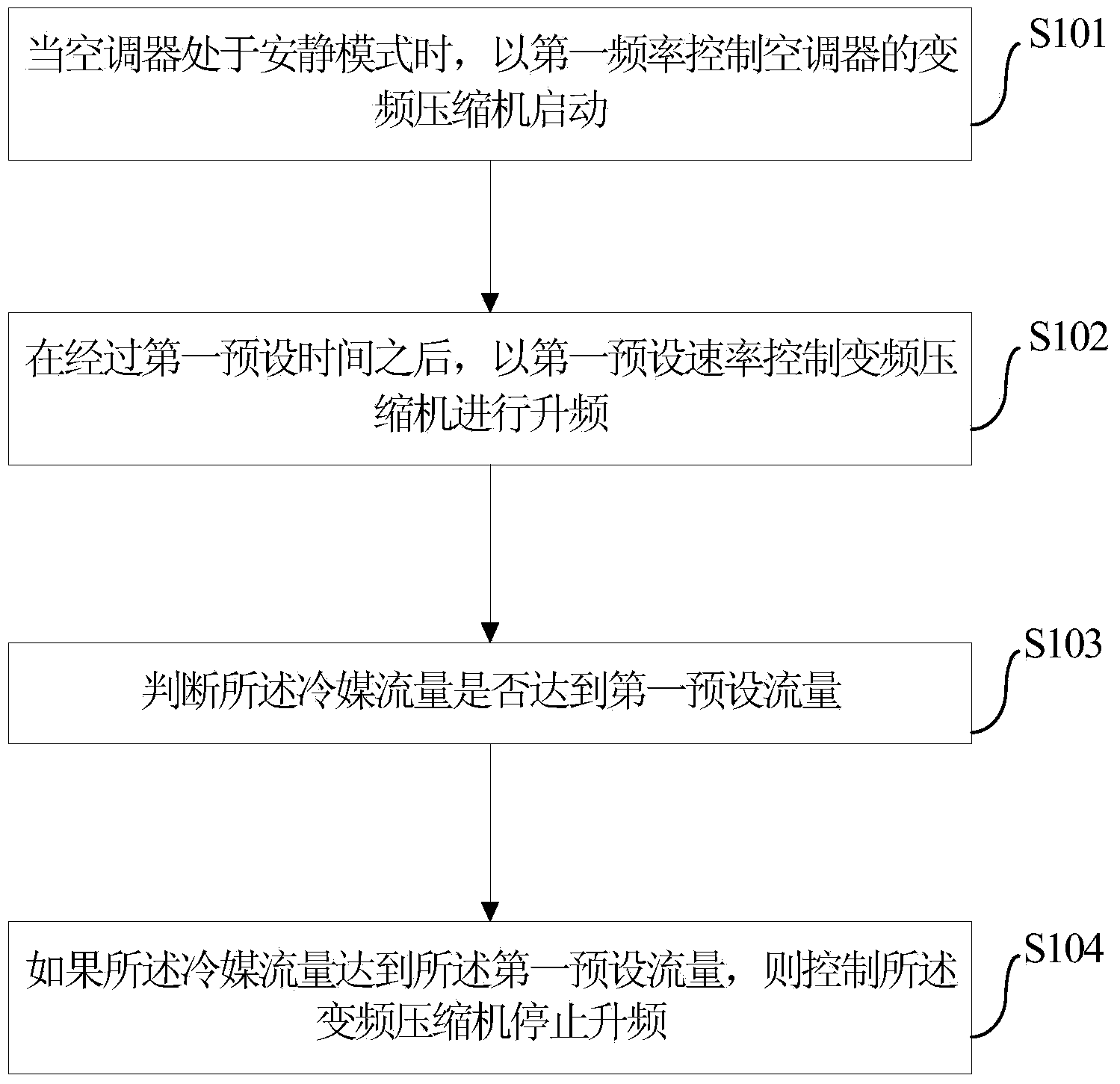

The invention discloses an air conditioner and a control method and device thereof. The air conditioner comprises a coolant system, a throttle device, an outdoor fan and a variable frequency compressor; the coolant system is connected with an indoor-outer heat exchanger; the throttle device is connected with the indoor-outdoor heat exchanger; the variable frequency compressor drives coolant to circulate. The control method includes the steps of controlling the variable frequency compressor of the air conditioner to start with a first frequency when the air conditioner is in a silent mode; with a first preset time passing by, controlling the variable frequency compressor to increase in frequency at a first preset rate; judging whether or not the flow of the coolant reaches first preset flow; if yes, controlling the variable frequency compressor to stop increasing in frequency. The control method according to the embodiment has the advantages that flow of the coolant and impact thereof are effectively reduced, leading to reduced coolant noise and mechanical noise, interference is avoided for users, and user experience is improved.

Owner:MIDEA GRP CO LTD +1

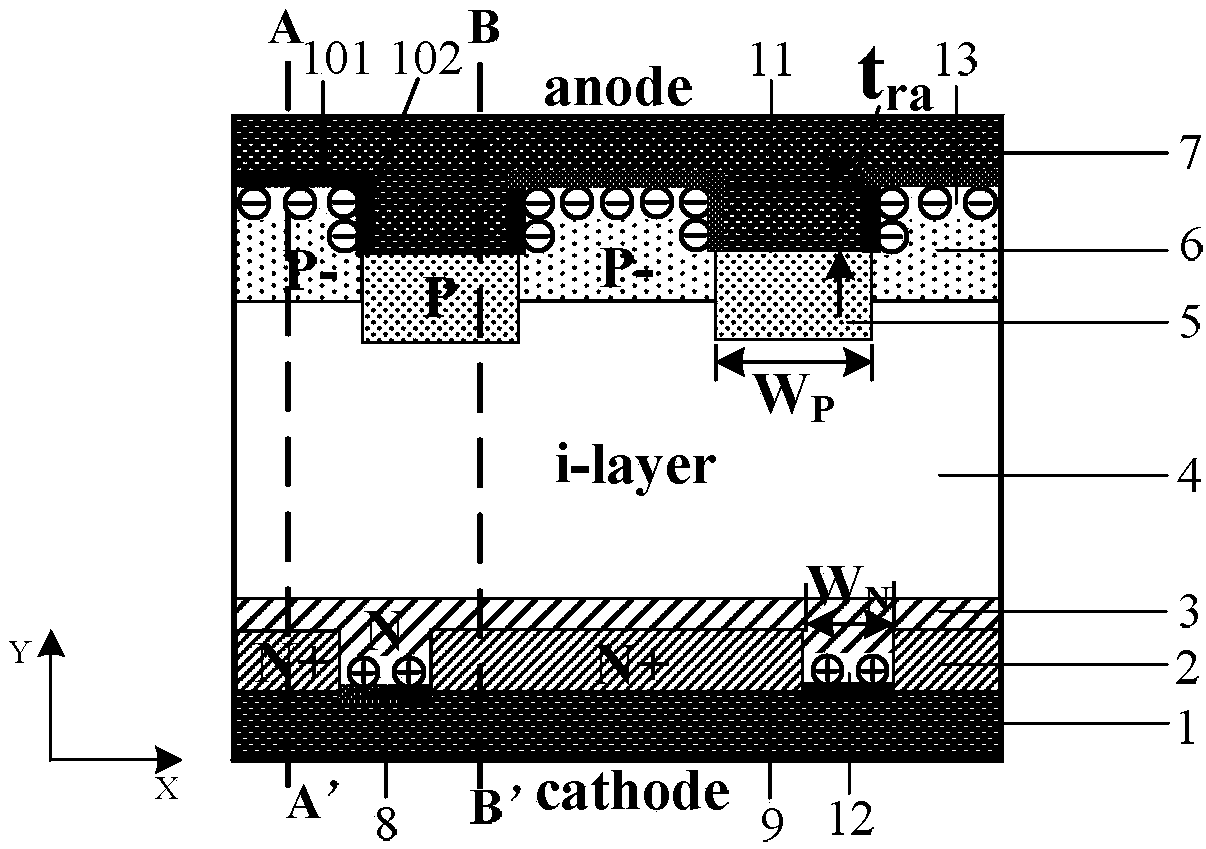

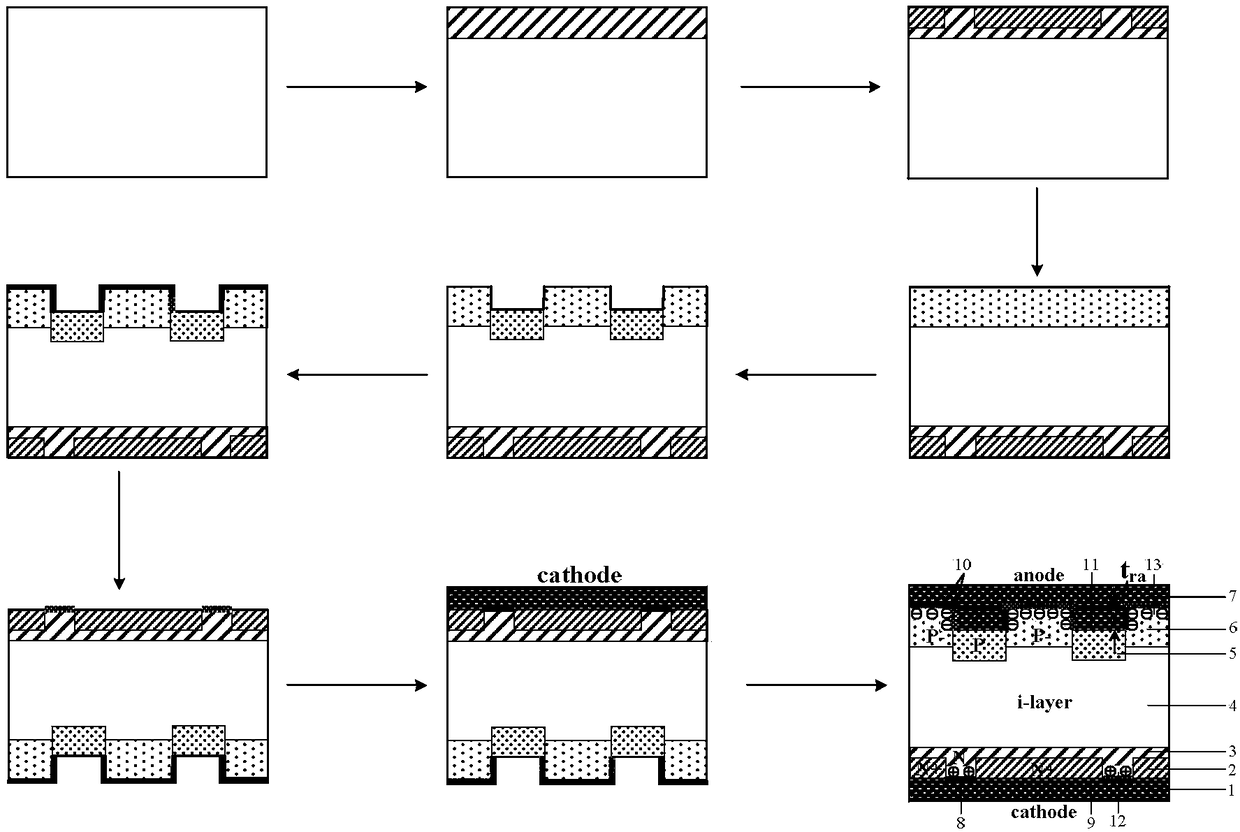

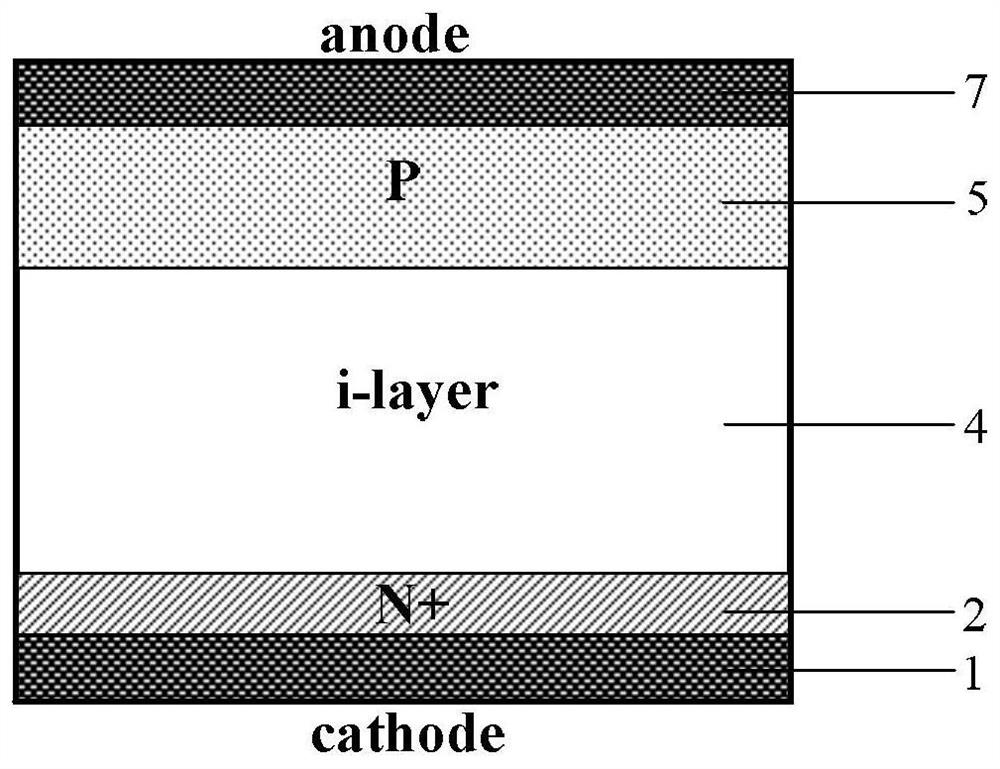

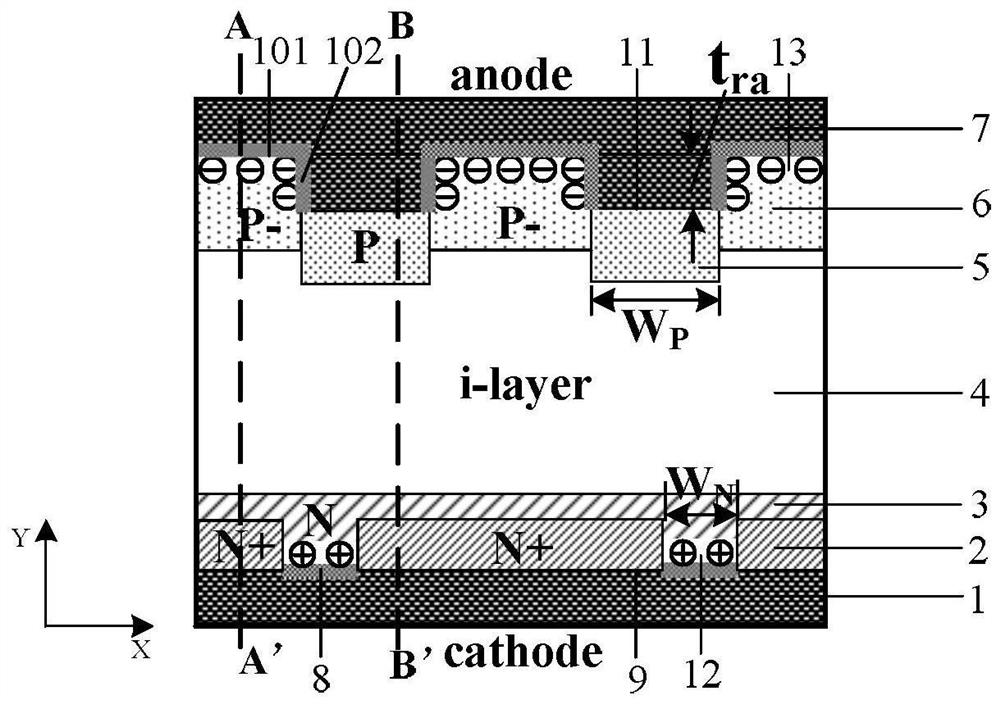

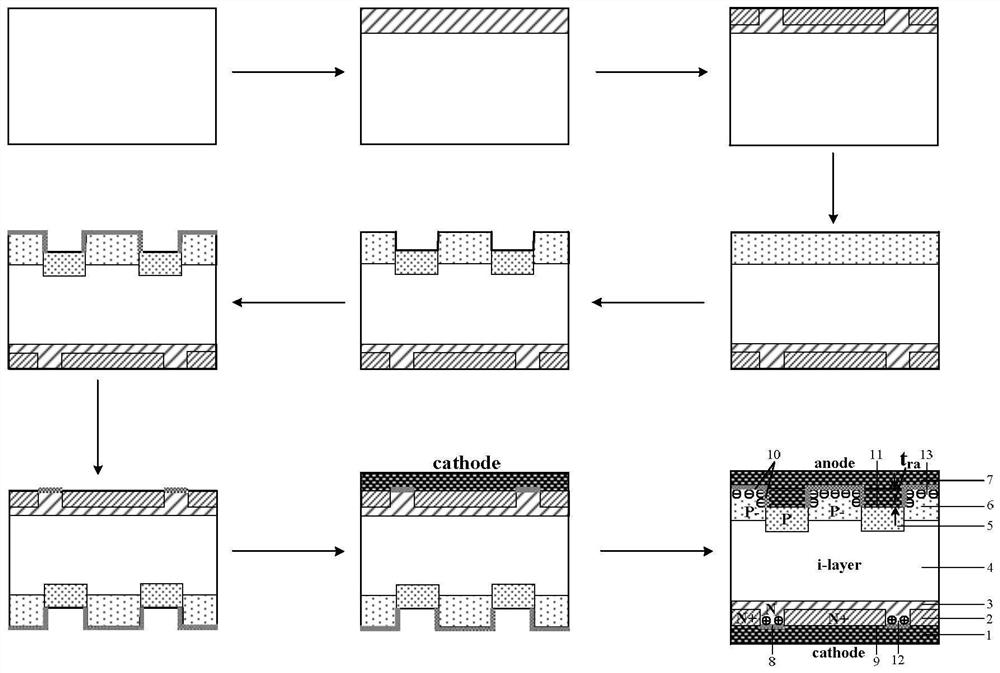

A groove-type anode fast recovery diode with bipolar Schottky control and a manufacturing method thereof

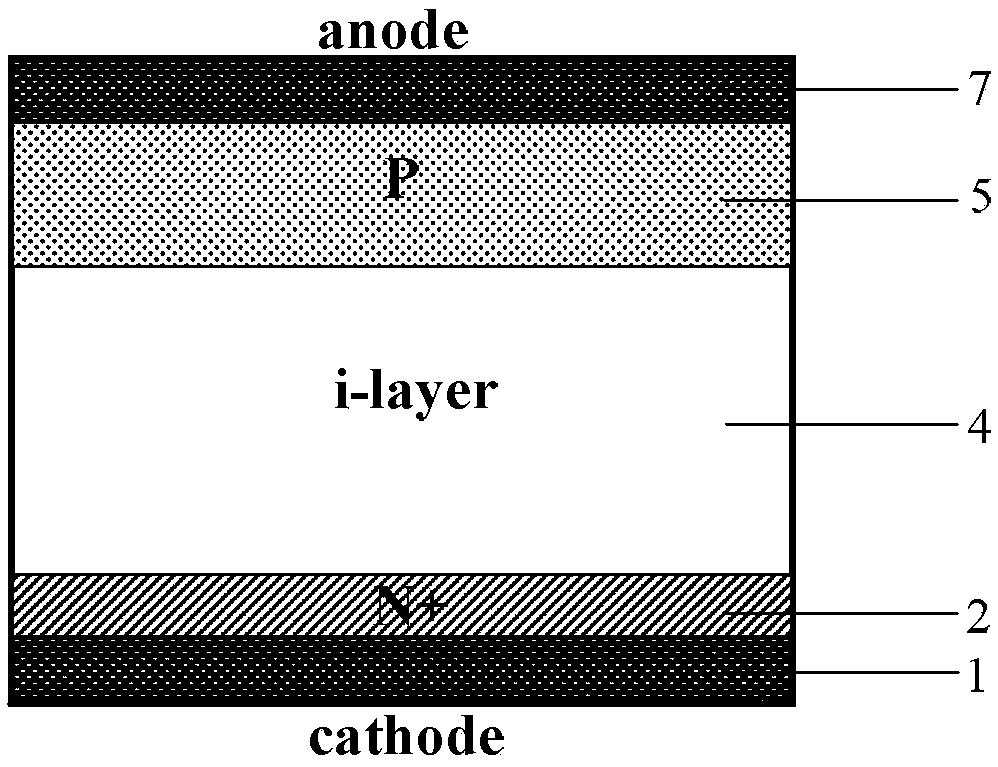

ActiveCN109192787AEasy to passShort reverse recovery timeSemiconductor/solid-state device manufacturingDiodeFast recoveryMetal

The invention relates to a groove-type anode fast recovery diode with bipolar Schottky control and a manufacturing method thereof. The diode includes a cathode metal, Above the cathode metal there isan N-type intrinsic region, Above the N-type intrinsic region there is an anode metal, the cathode metal is provided with a lightly doped N-type region and a heavily doped N-type region spaced apart from each other, the bottom of the lightly doped N-type region is in Schottky contact with the cathode metal, A heavily doped P-type region and a lightly doped P-type region are arranged between the N-type intrinsic region and the anode metal, and the upper surface of the heavily doped P-type region is lower than the upper surface of the lightly doped P-type region, so that a groove-type anode region is formed, and the lightly doped P-type region is in Schottky contact with the anode metal. The manufacturing method of the groove-type anode fast recovery diode with bipolar Schottky control is characterized in that Schottky contacts of an anode surface and a sidewall can be simultaneously formed by one-step etching.

Owner:SOUTHEAST UNIV +1

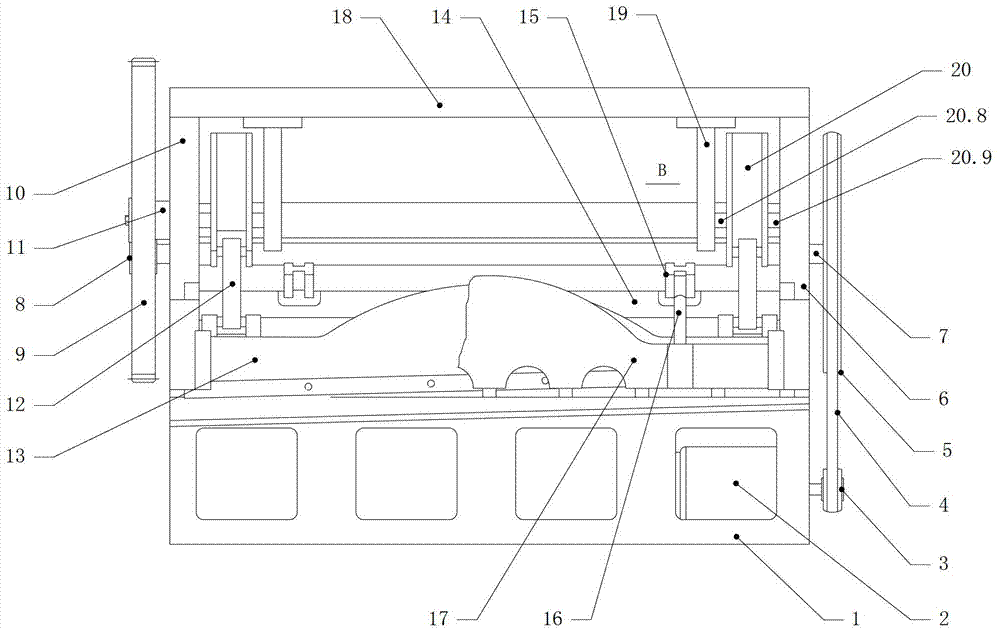

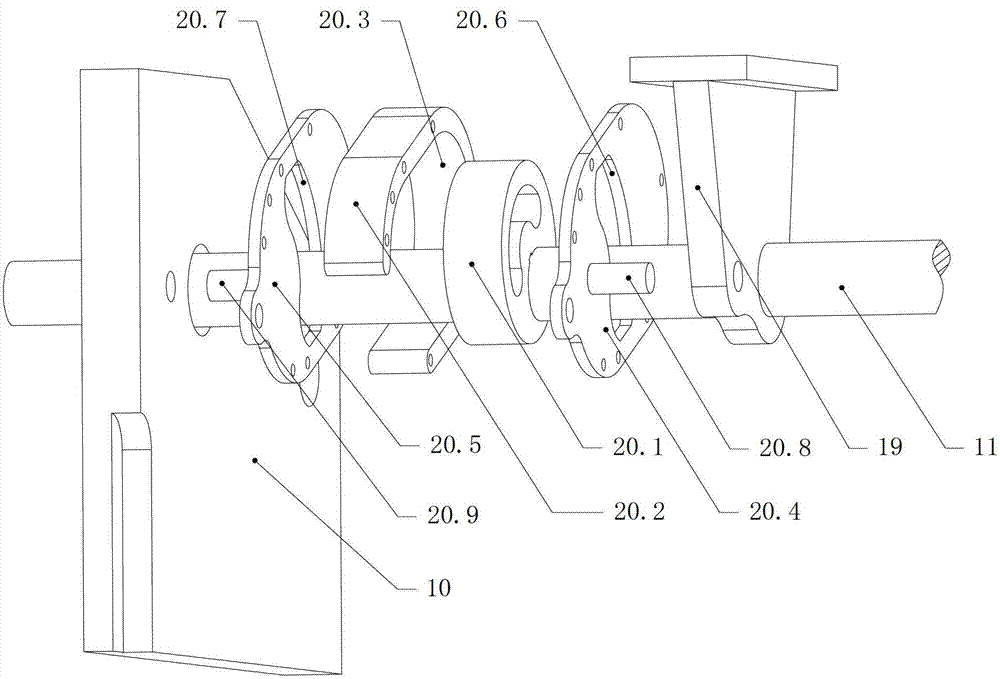

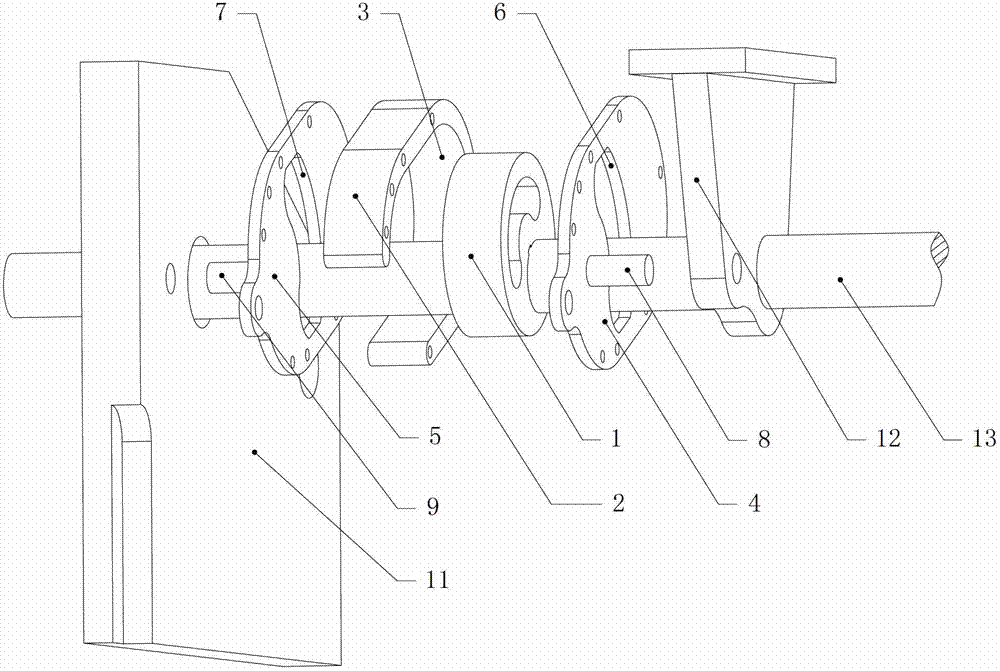

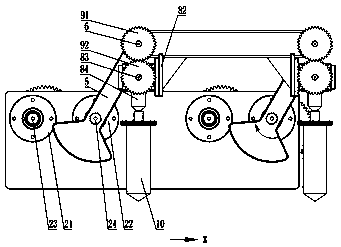

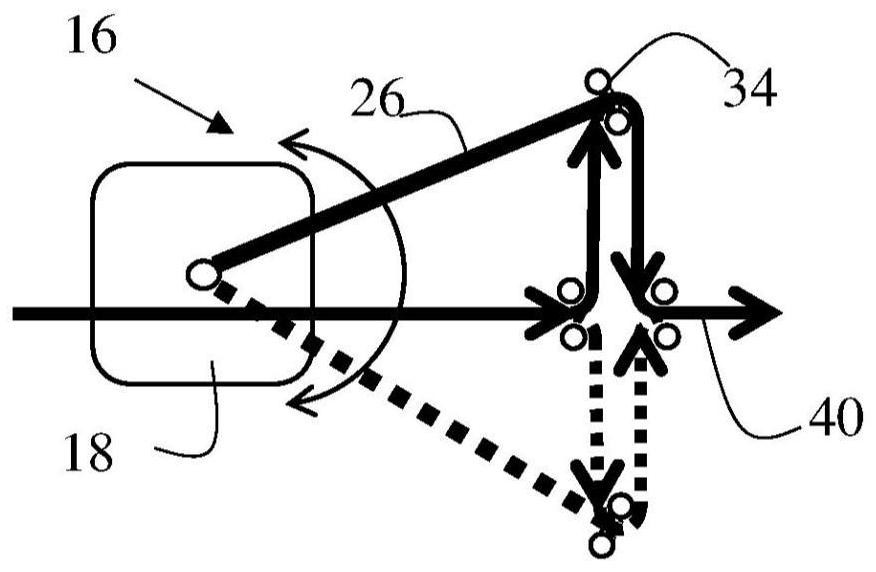

Mechanical plate shearing machine

InactiveCN103192129AWith snap back featureReduce preparation timeShearing machinesMechanical engineeringClassical mechanics

The invention relates to a mechanical plate shearing machine, in particular to a mechanical plate shearing machine utilizing a swing guide rod mechanism. The structure is that a cover plate is fixedly installed at the upper end of a lateral support I and a lateral support II of the plate shearing machine. T-shaped supports are symmetrically installed at two ends on the lower side of the cover plate, the upper ends of the T-shaped supports are fixed with the cover plate, and the lower ends of the T-shaped supports are sleeved on two sides of a spindle in empty mode. Execution mechanisms are symmetrically installed on the spindle section between the lateral support I and one T-shaped support and between the lateral support II and the other T-shaped support. The mechanical plate shearing machine has the advantages of being novel in structure, convenient to modify, low in cost, safe, good in economy and safety and the like, thereby being a novel mechanical plate shearing machine integrating economy and practicability.

Owner:DALIAN UNIV OF TECH

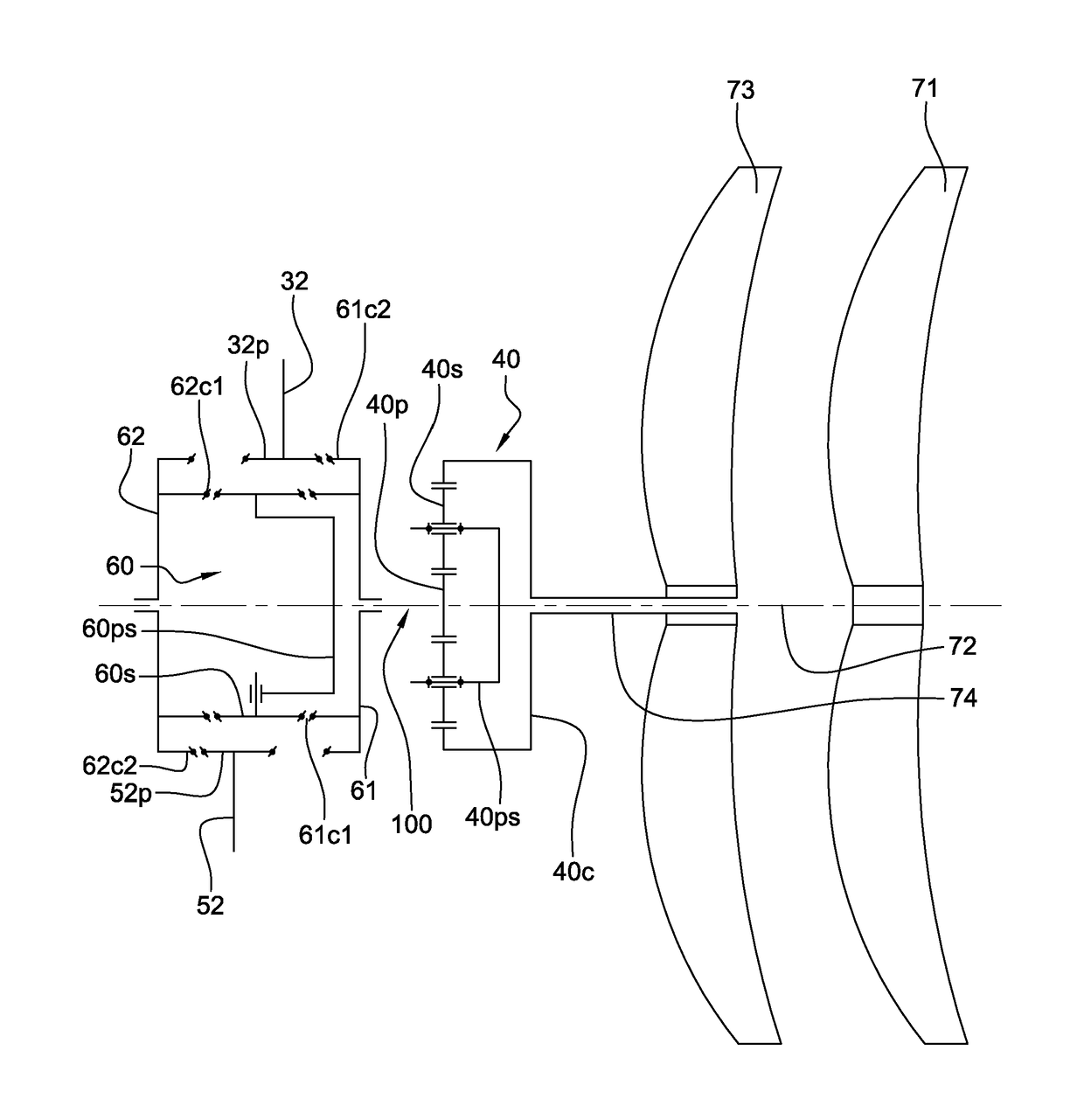

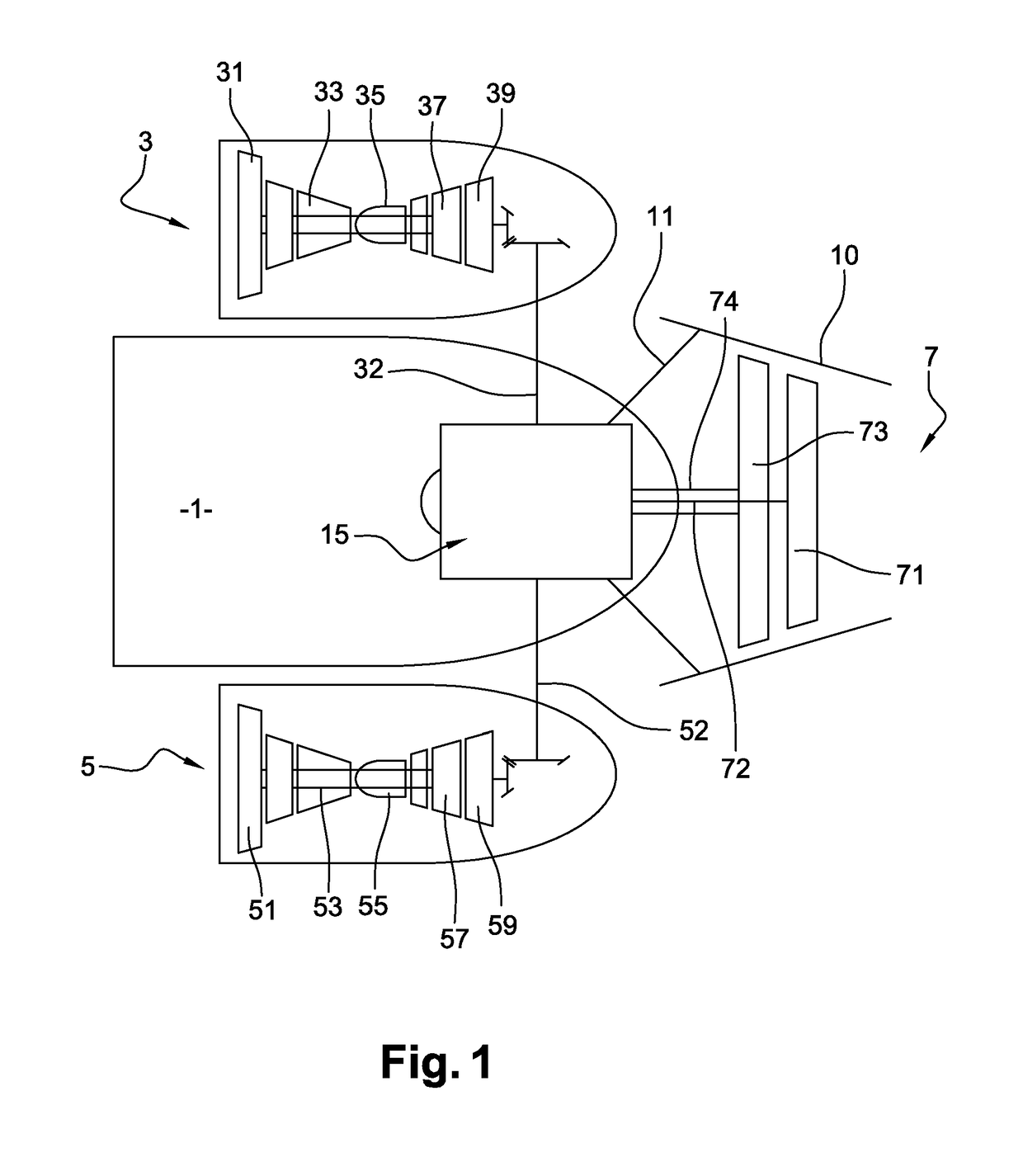

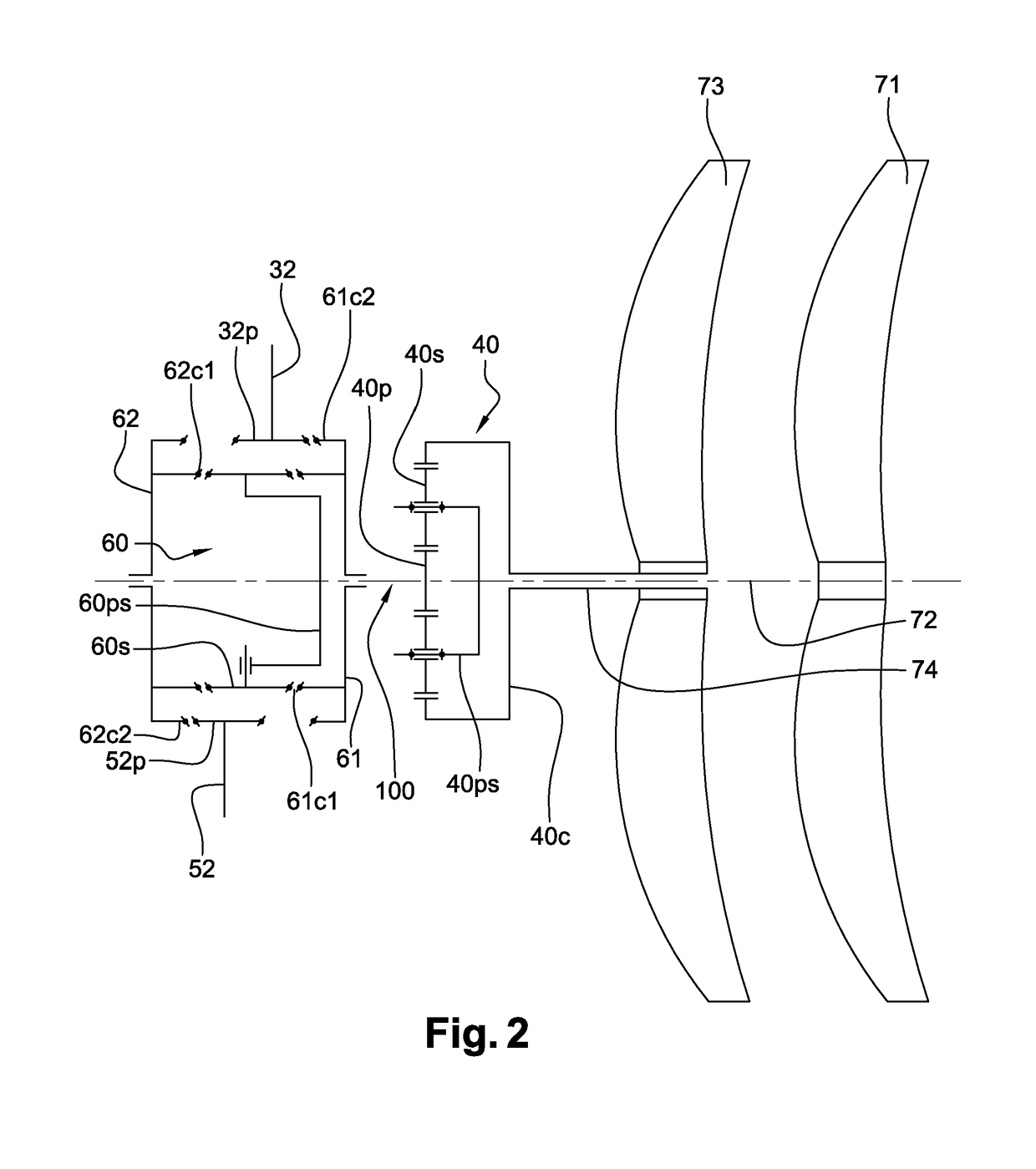

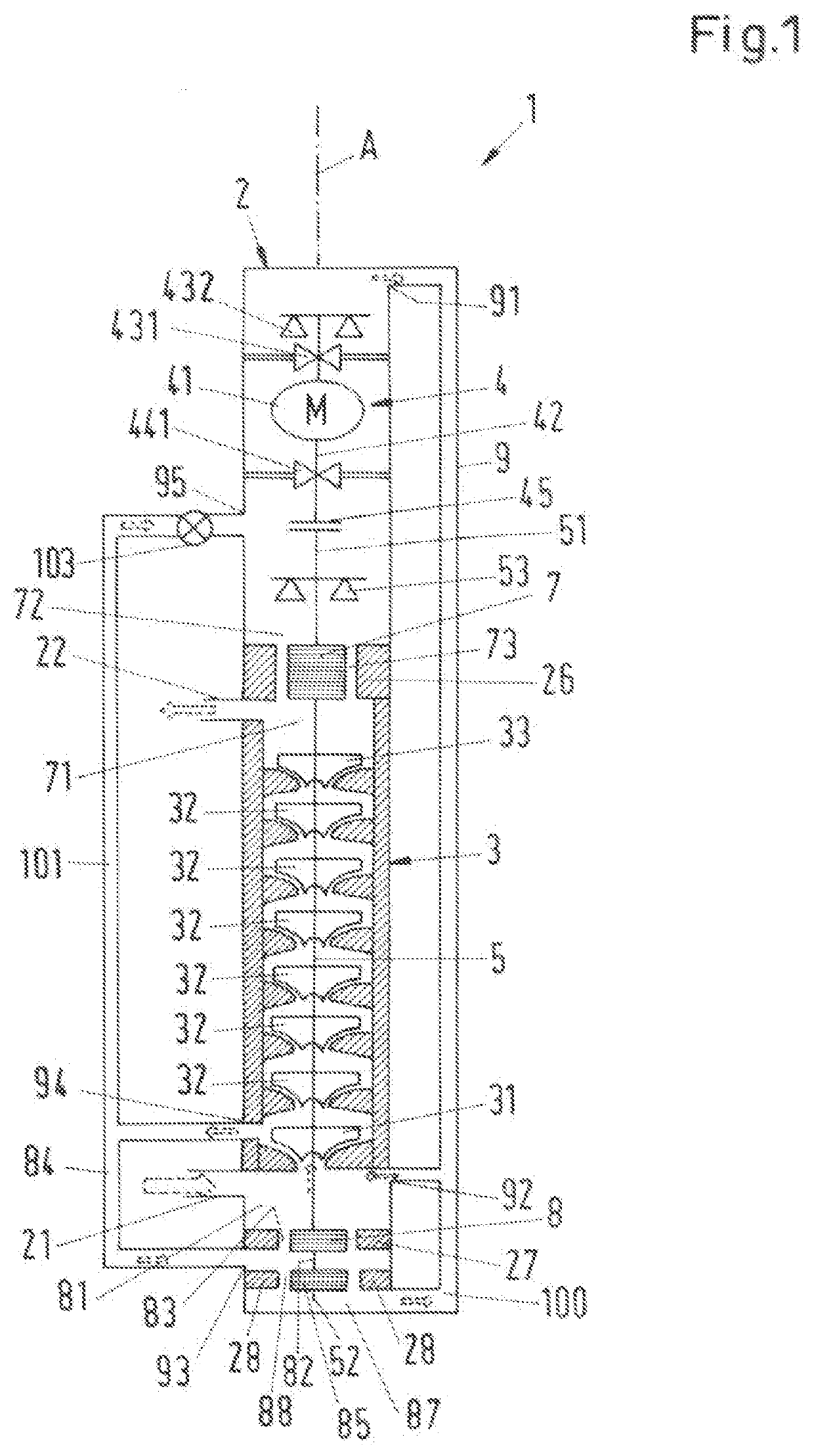

Aircraft comprising a propulsion assembly including a pair of propellers at the rear of the fuselage

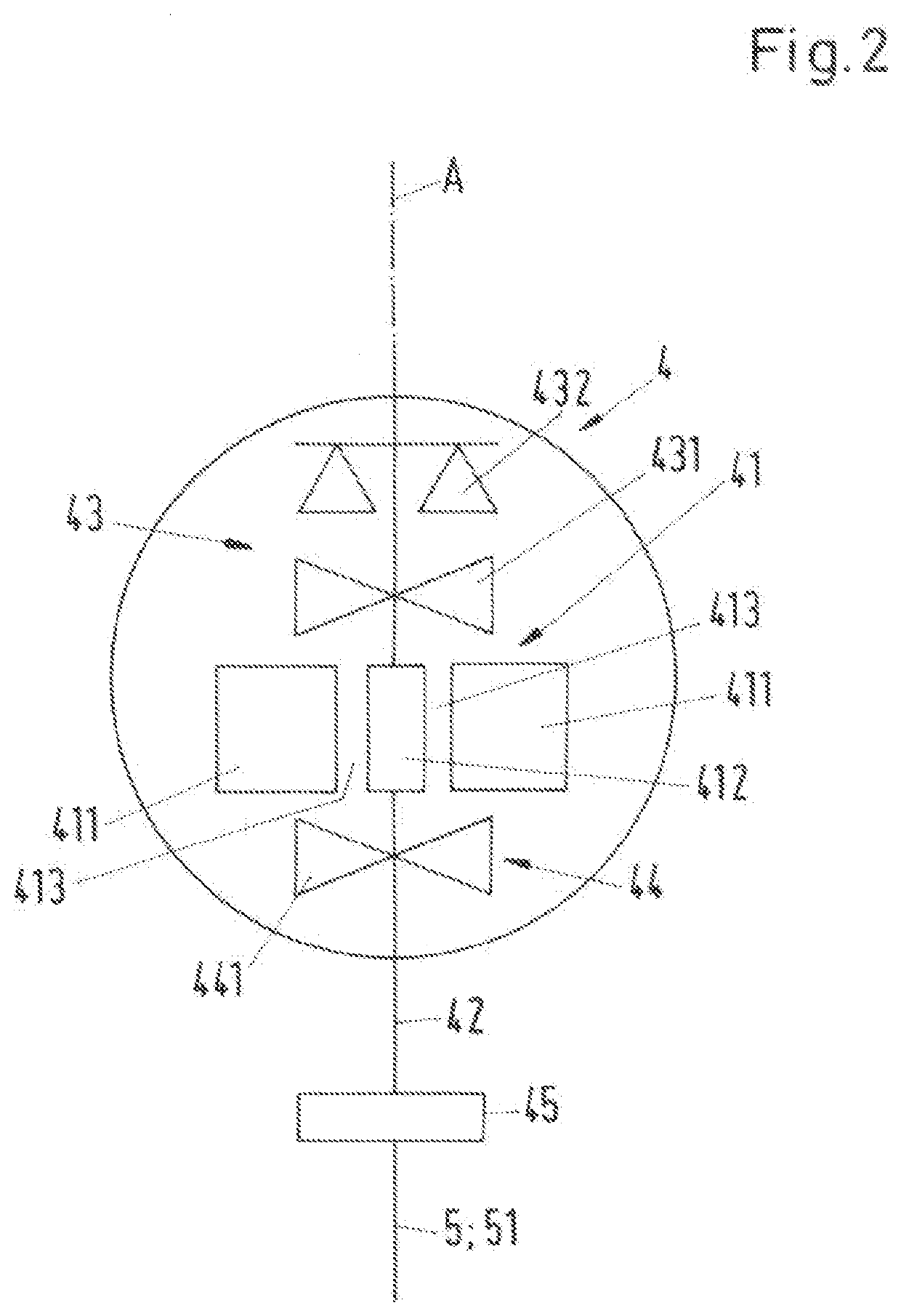

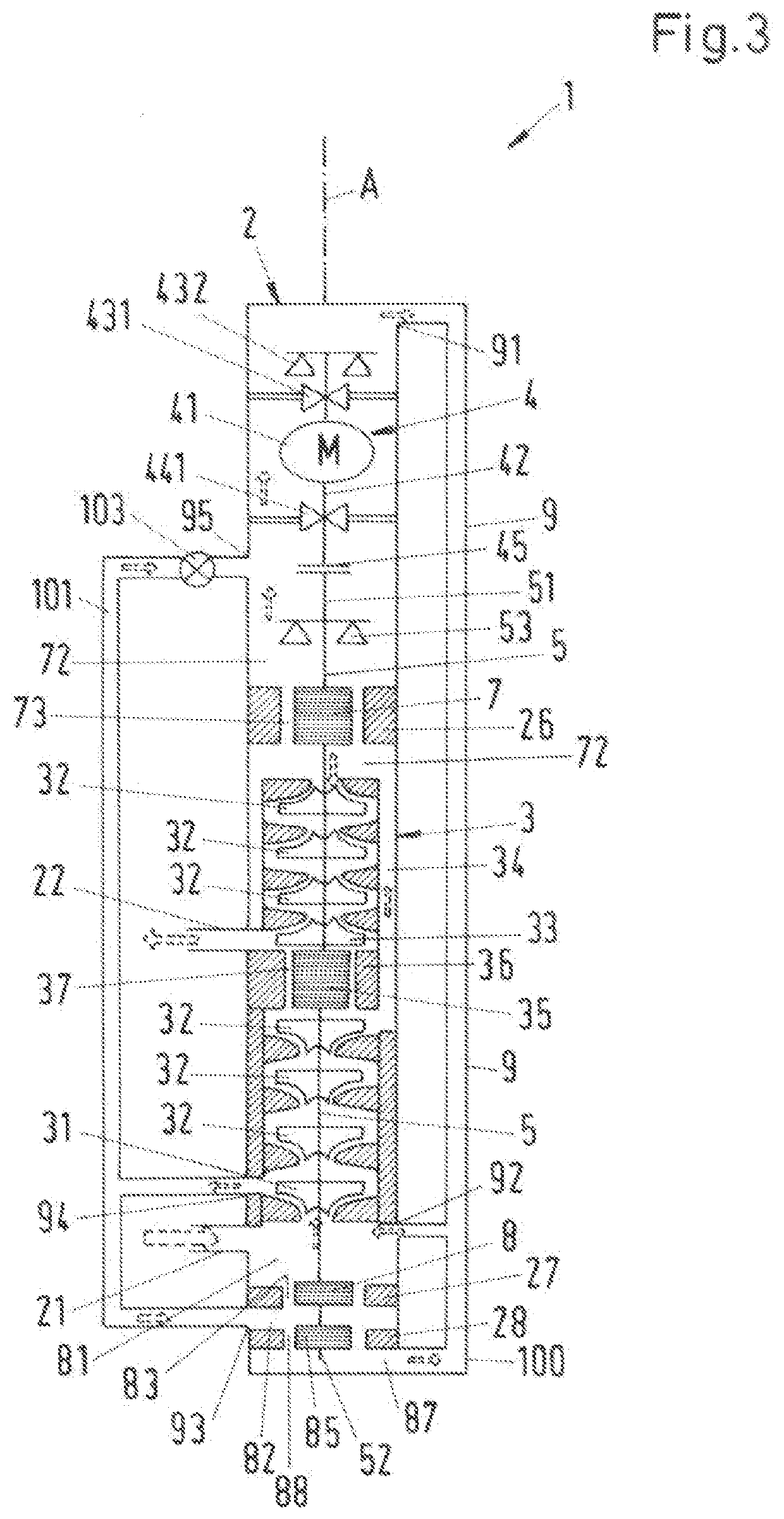

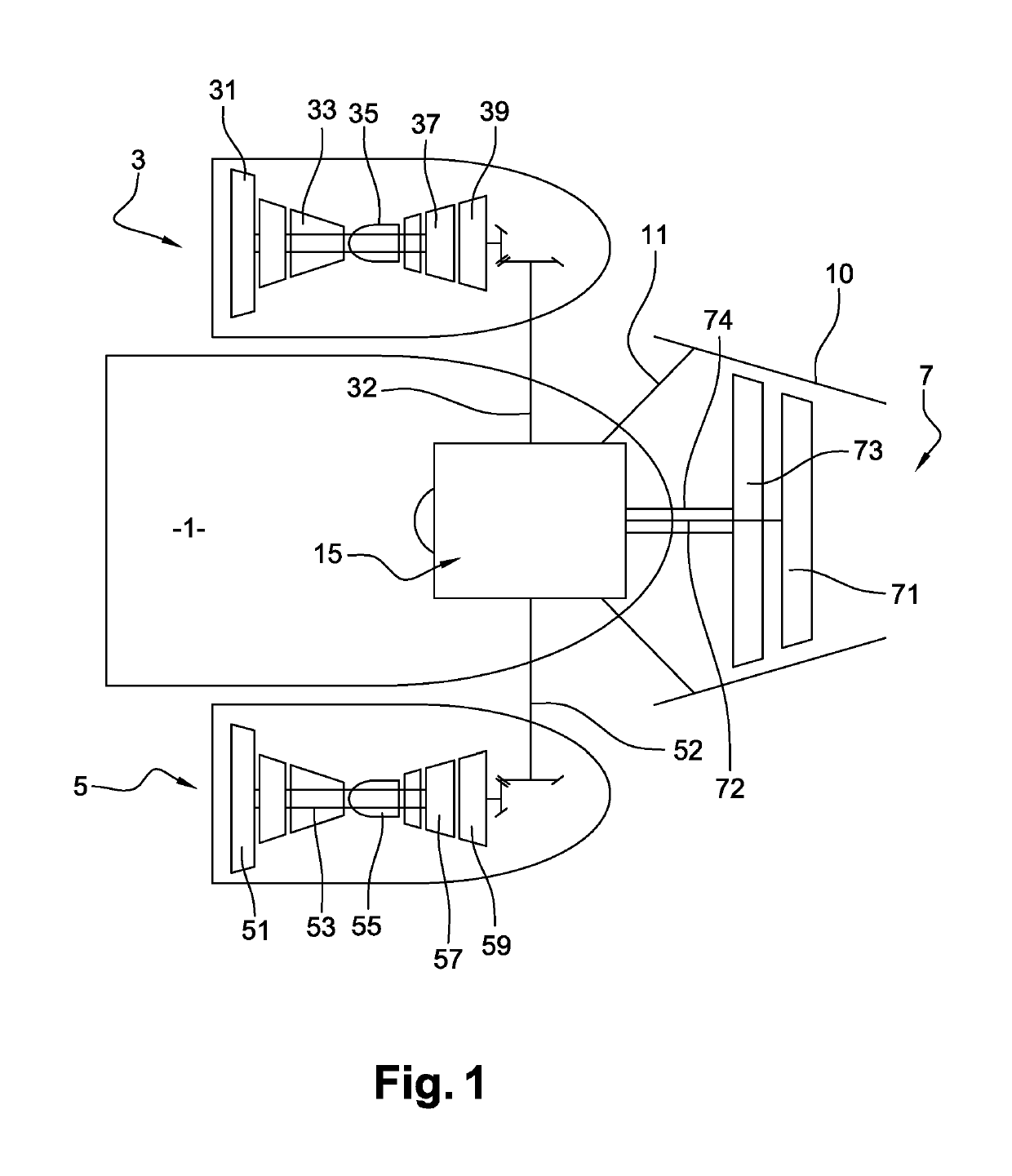

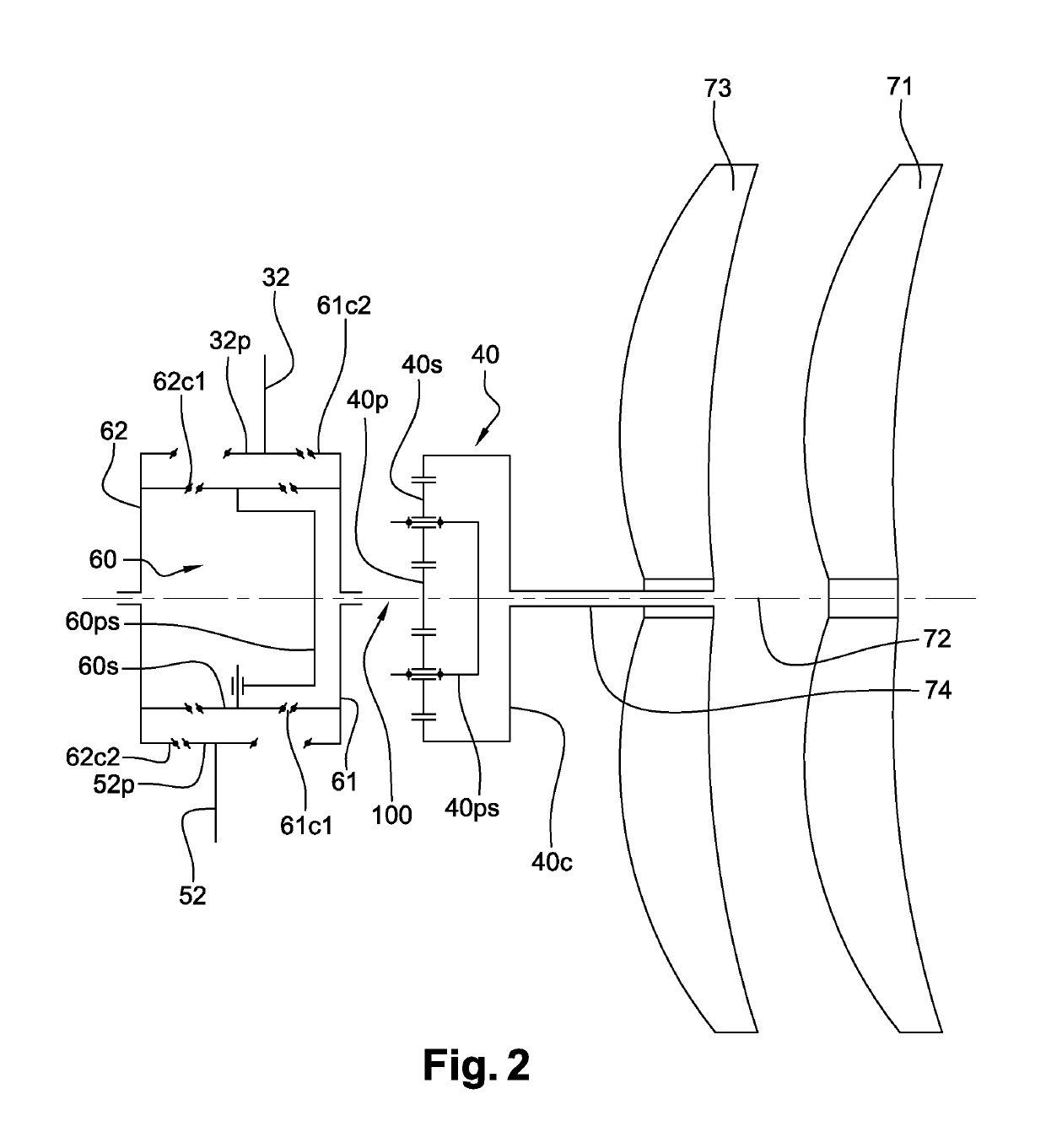

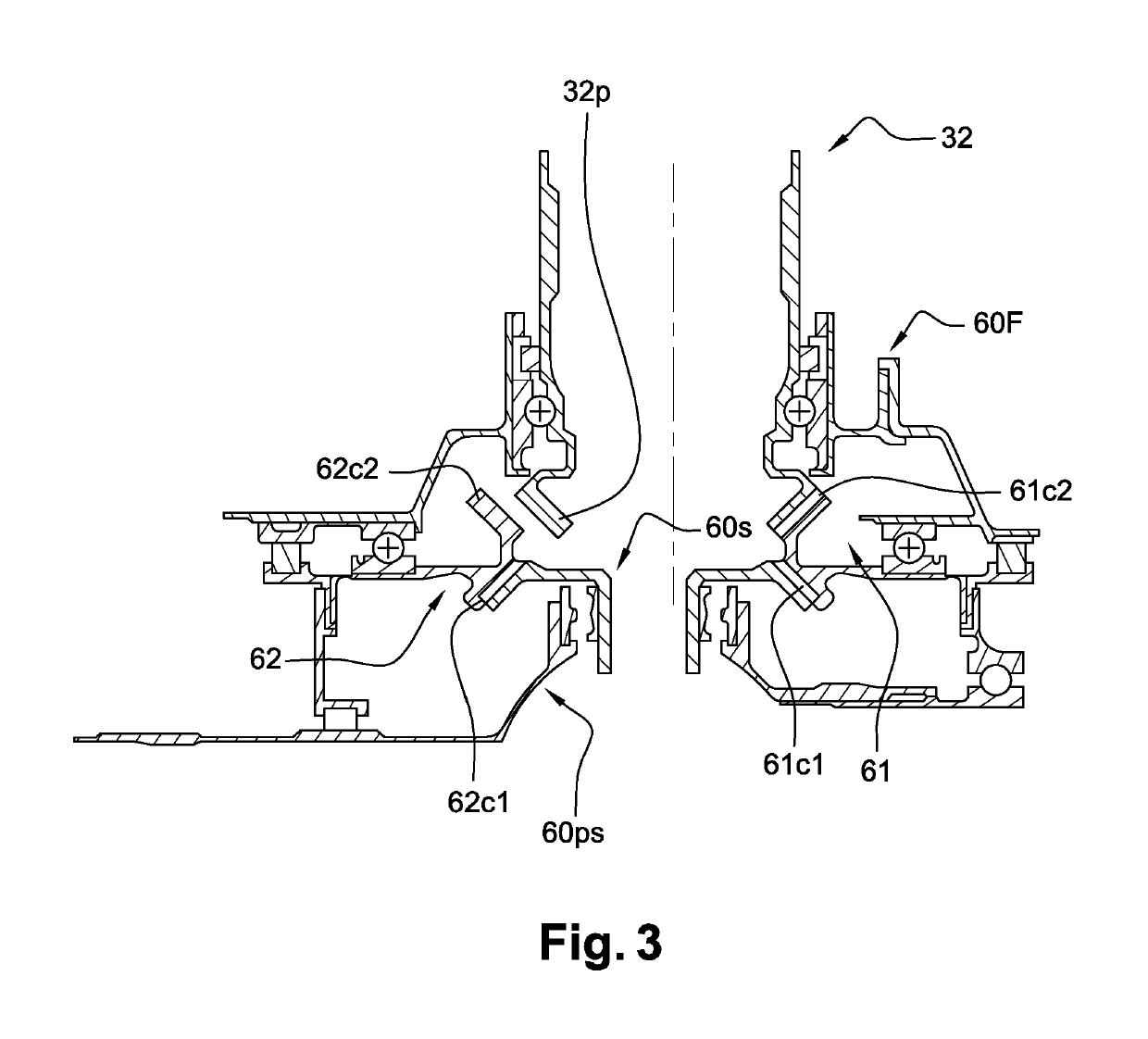

ActiveUS20180281979A1Maximise thermal efficiencyMaximise efficiencyPropellersGas turbine type power plantsPropellerAirplane

The present invention relates to an aircraft comprising a fuselage (1), a propulsion unit (7) at the rear tip of the fuselage and at least two engines (3, 5) each driving an engine shaft (32, 52), the propulsion unit including at least one propeller (71, 73) driven mechanically by the engine shafts (32, 52), characterised in that the propulsion unit (7) includes two propellers (71, 73), each of the propellers being driven by a propeller shaft (72, 74), the two propeller shafts being driven by the engine shafts (32, 52) via a first differential epicyclic gear train (40). Specifically, the input of the first differential gear train (40) is connected to the output of a second differential epicyclic gear train (60), the second differential gear train (60) including two inputs (61c2, 62c2), each of said two inputs being connected mechanically to one of said engine shafts (32, 52).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

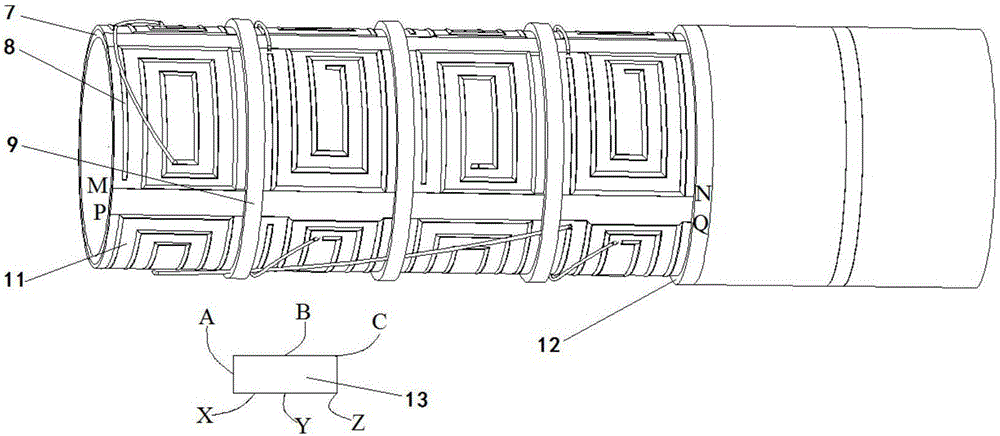

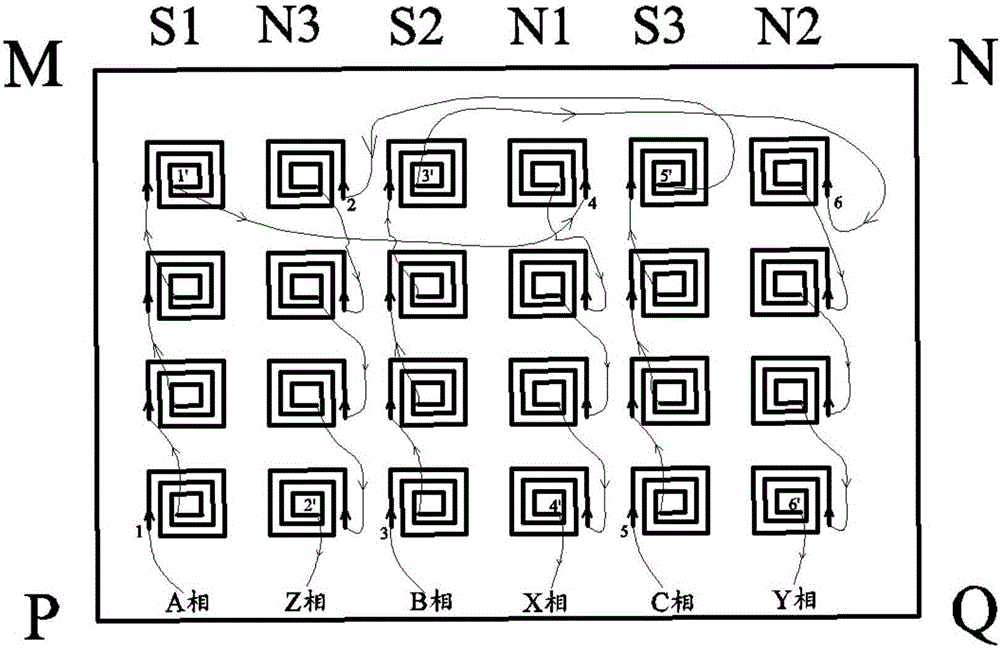

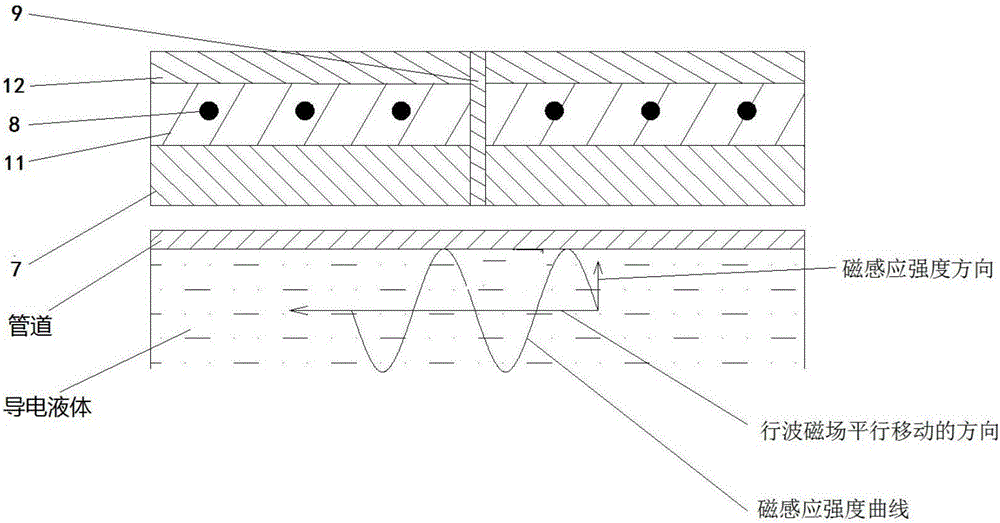

Conductive liquid micro driving device and applications thereof

ActiveCN106655703ASave installation spaceLow environmental requirementsDynamo-electric machinesElectric fieldElectrical and Electronics engineering

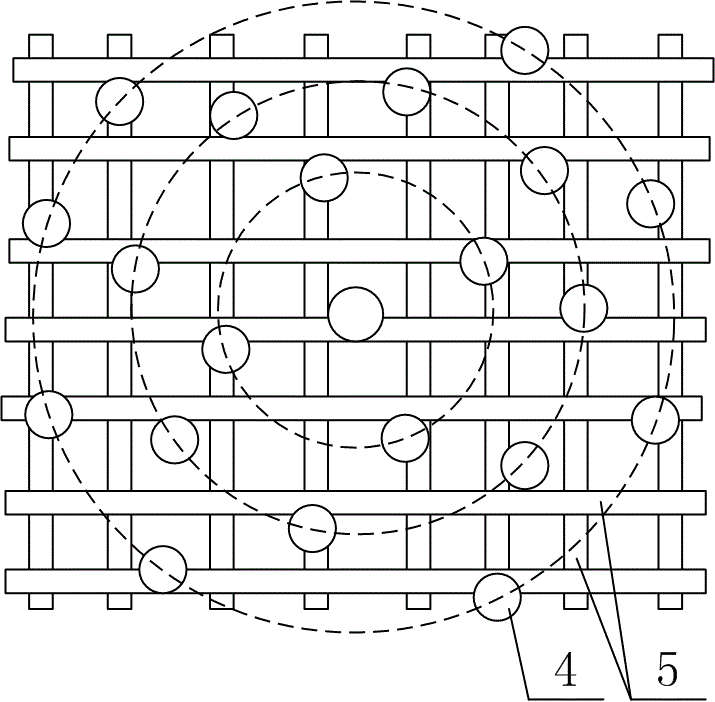

The invention discloses a conductive liquid micro driving device and applications thereof. Multiple rectangular coils form a coil array, multiple sequentially-arranged electromagnetic poles are formed, insulation layers are arranged among wires of the rectangular coils, magnetic conductive layers fills gaps of the wires of the rectangular coils coated by the insulation layers and the outer parts, a sealing cover realizes functions of three protection and mechanics and the like, inverters are connected with the rectangular coil array, a time-varying electric field generates a traveling wave magnetic field in the same direction and an electromagnetic force, the electromagnetic force drives the conductive liquid to flow, a flexible substrate can be connected with a selected mounting part, and a pipeline inner wall or an outer wall phase in a different shape can be matched. Accurate control on different components, the flow amount, the flow direction and the flow speed of the conductive liquid can be realized, and the conductive liquid micro driving device has the advantages that the overall structure is compact; the device is flexible and deformable; pressed driving does not exist; no push rod mechanism is needed; the pipeline can be cleaned by itself; assembly and disassembly are convenient; the space utilization rate is high; the application range is wide; the use is simple; portability is realized; the noise is small; the service life is long and the like.

Owner:SHANGHAI UNIV

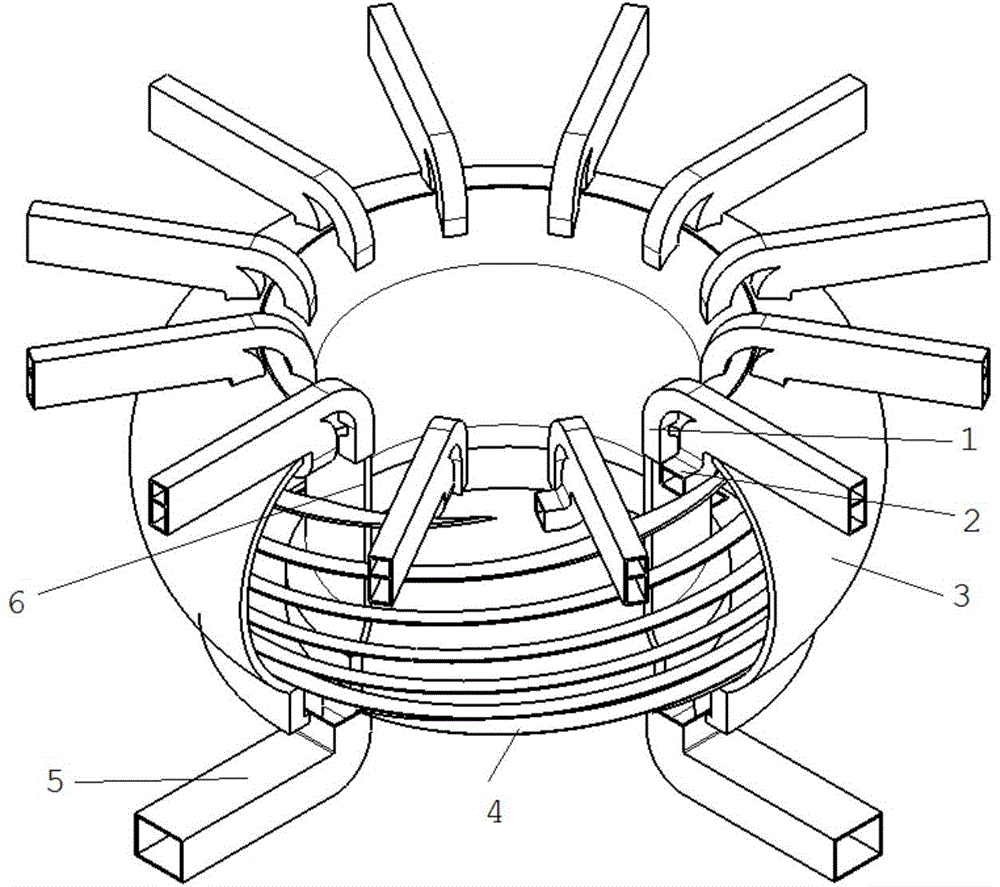

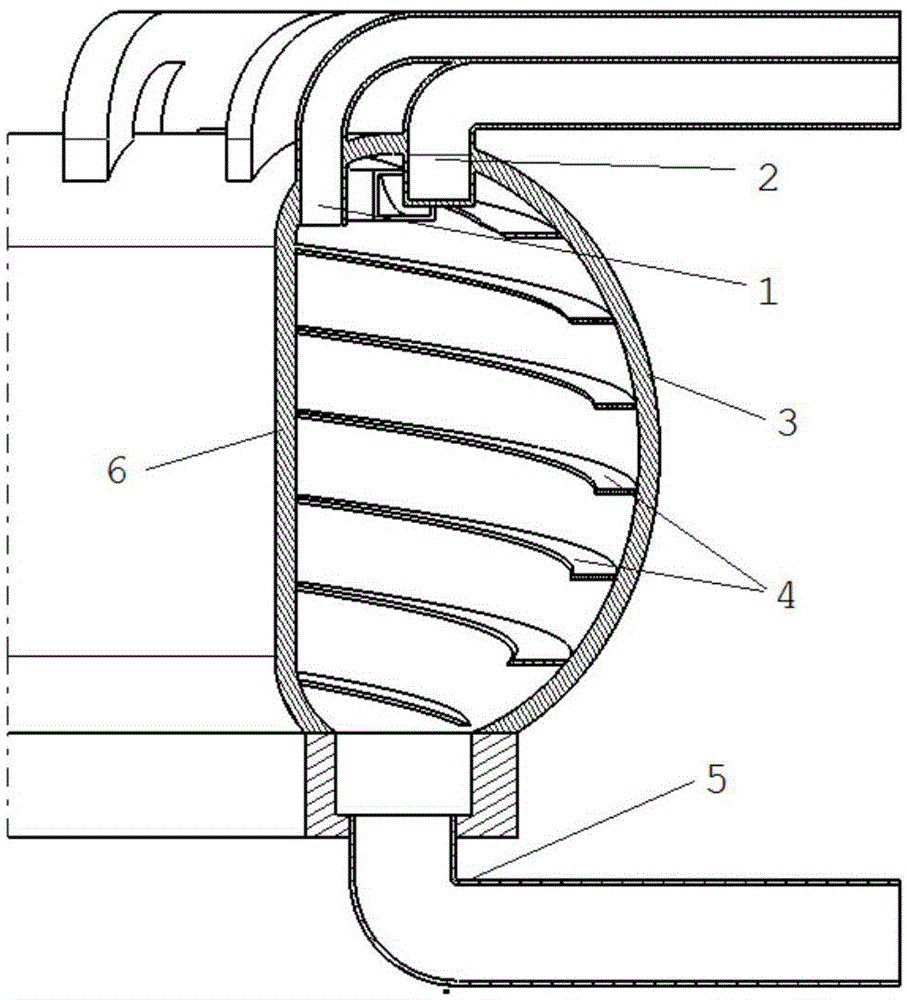

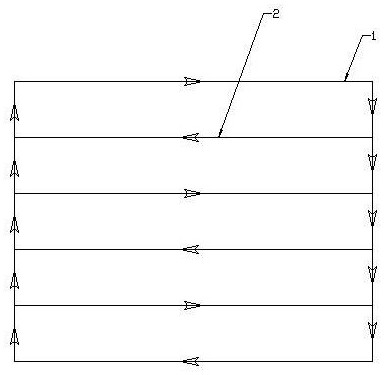

Dual-layer-flow liquid first wall cladding applicable to magnetic confinement fusion reactor

ActiveCN104409108AReduces flow instabilitiesSmall pressure dropNuclear energy generationThermonuclear fusion reactorThinningMagnetic confinement fusion

The invention discloses dual-layer-flow liquid first wall cladding applicable to a magnetic confinement fusion reactor. The cladding structurally comprises a vacuum chamber, liquid metal injection pipes at the top of the vacuum chamber, an outer cladding back wall adopting a spiral insulated runner structure, an inner cladding back wall and a bottom liquid metal discharge structure. In order to solve problems of the MHD (magnetohydrodynamics) effect, the thinning effect and the like encountered by a liquid first wall during application to the fusion reactor, a special structural design is adopted: for inner cladding, the inlet injection pipes inject a liquid metal downwards from the top of the vacuum chamber along the inner cladding back wall; for outer cladding, the liquid metal is injected in the circumferential direction of the vacuum chamber, is closely attached to the outer cladding back wall and flows downwards under the effect of the centrifugal force produced due to the inertia, and overwhelms a spiral insulated runner arranged on the outer cladding back wall, so that a circumferential flow in the insulated runner and a free surface flow outside the runner are formed. The liquid metal finally flows into the bottom liquid metal discharge structure and is applied to heat transfer, tritium extraction and recycling, and the problems of the MHD effect and the thinning effect can be effectively solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

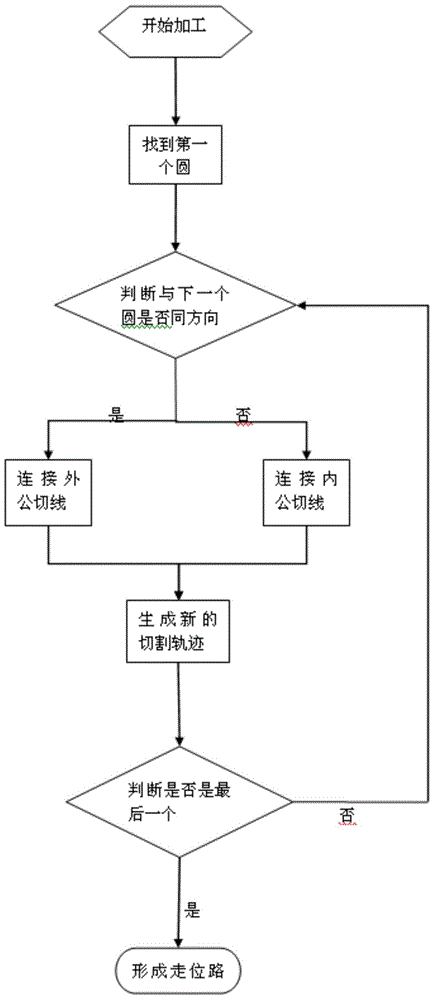

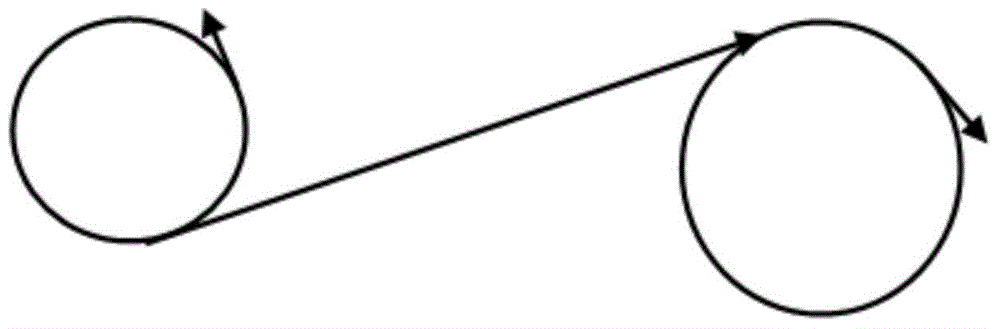

Quick circular arc cutting method

ActiveCN104308370AShorten the timeSmall speed changeLaser beam welding apparatusNumerical controlEngineering

The invention relates to the technical field of numerical control laser cutting machines, in particular to a quick circular arc cutting method. The quick circular arc cutting method comprises a step of conducting circular arc cutting through processing software of a laser cutting machine which is controlled by a computer, and is characterized by comprising the following steps: starting the processing software of the laser cutting machine, conducting laser cutting from a first circle; after laser cutting of the first circle; judging the positional relation between the next circle and the current circle and whether the circles are in the same direction; if yes, connecting an external common tangent and finding the next circle, or connecting an internal common tangent and finding the next circle; generating a novel cutting track, and cutting a second circle; after cutting of the second circle, judging whether the circle is the last one. Compared to the prior art, the circles to be cut can be connected along the tangent, the whole processing track is in smooth connection, and the machine tool cannot be greatly reduced in speed during the cutting process, so that the time can be greatly shortened.

Owner:上海柏楚电子科技股份有限公司

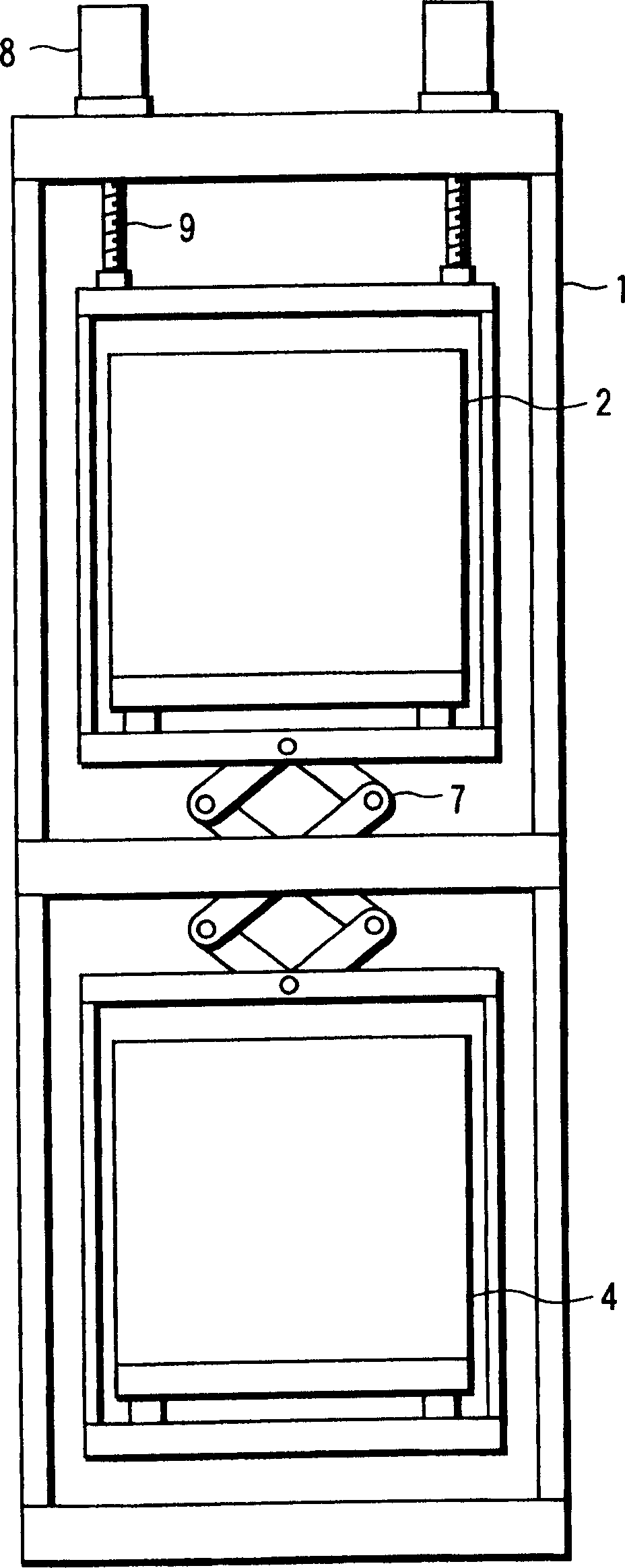

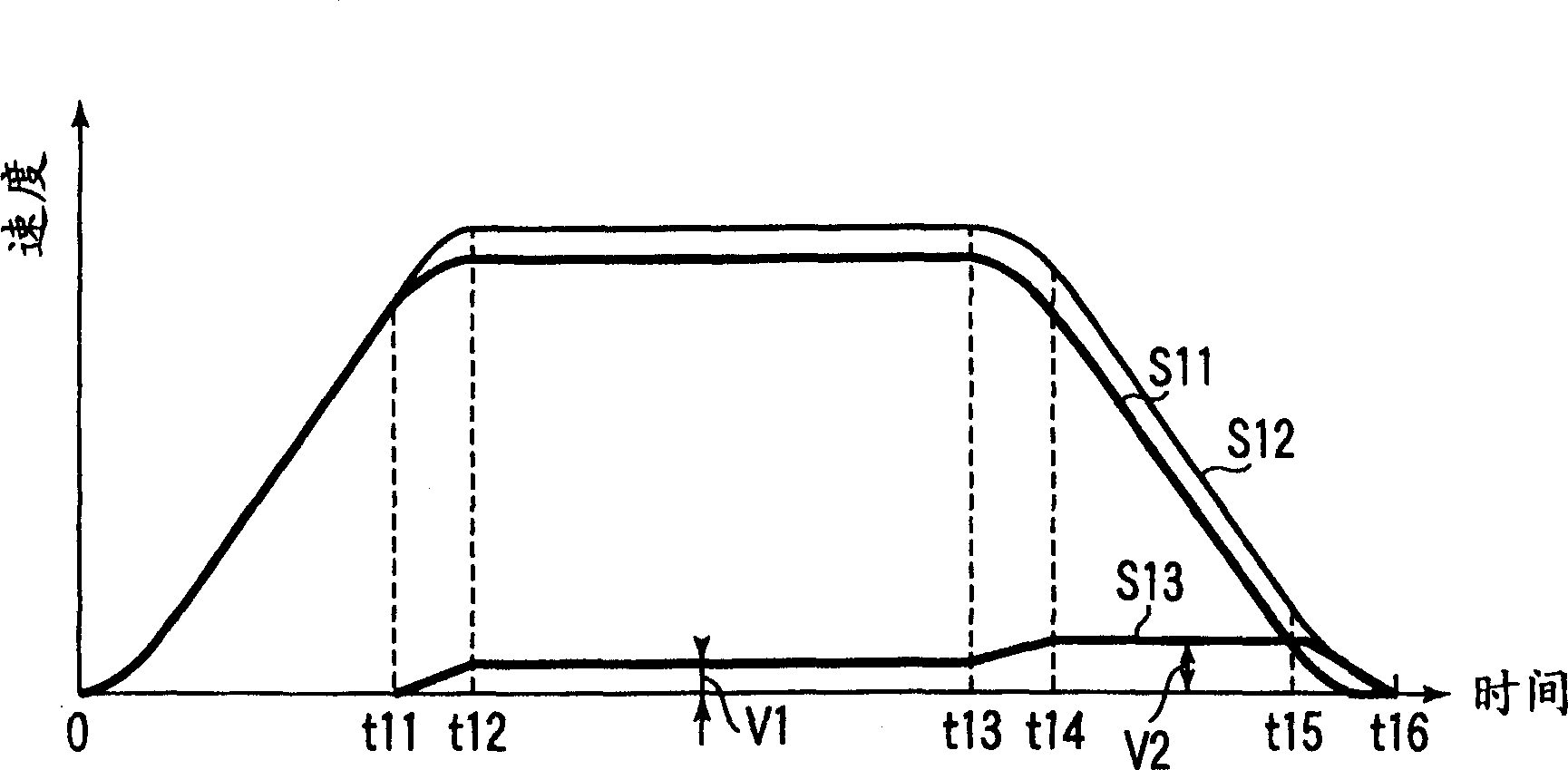

Double deck elevator

InactiveCN1533353ASuppresses speed changesSmall speed changeElevatorsAgricultural lifting devicesWinding machineControl theory

A double deck elevator comprises a winding machine which lifts up / down a cage frame loaded with two cages in a vertical direction, a cage driving unit which changes a relative distance between upper and lower cages, and a cage position controller which starts an inter-cage distance adjustment operation of the cage driving unit almost at the same time when the winding machine is shifted from an acceleration operation to a constant velocity operation, and changes an operating velocity of the inter-cage distance adjustment operation corresponding to a destination floor almost at the same time when the winding machine changes from the constant velocity operation to a deceleration operation after the destination floor is determined, whereby completing the inter-cage distance adjustment operation almost at the same time when the winding machine stops.

Owner:TOSHIBA ELEVATOR KK

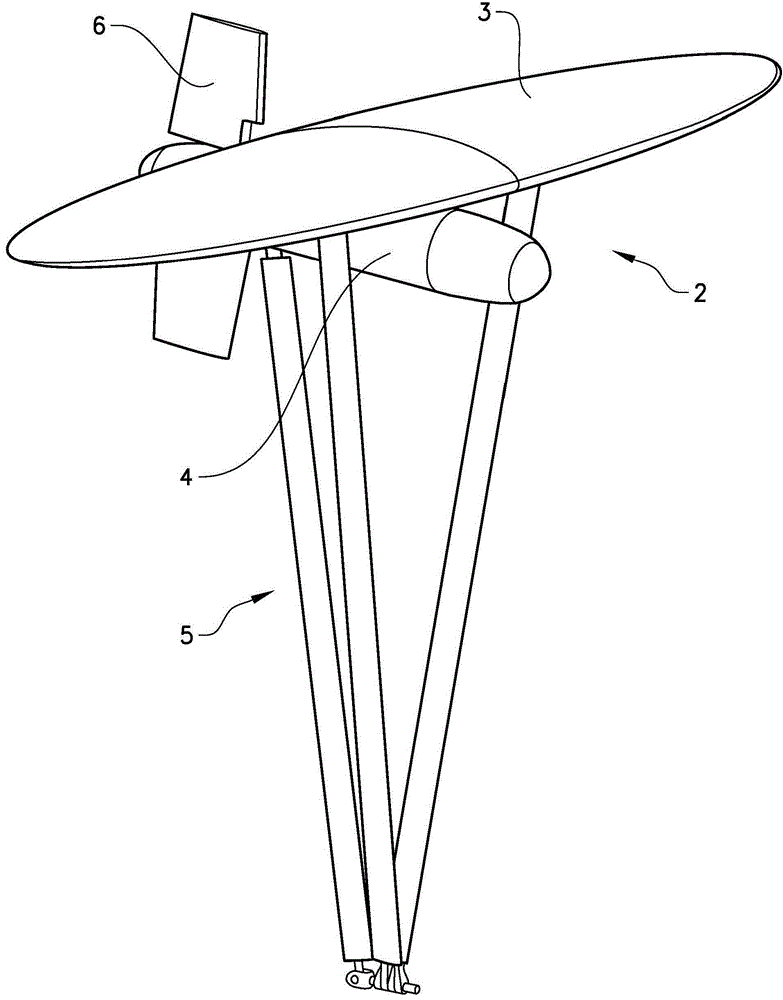

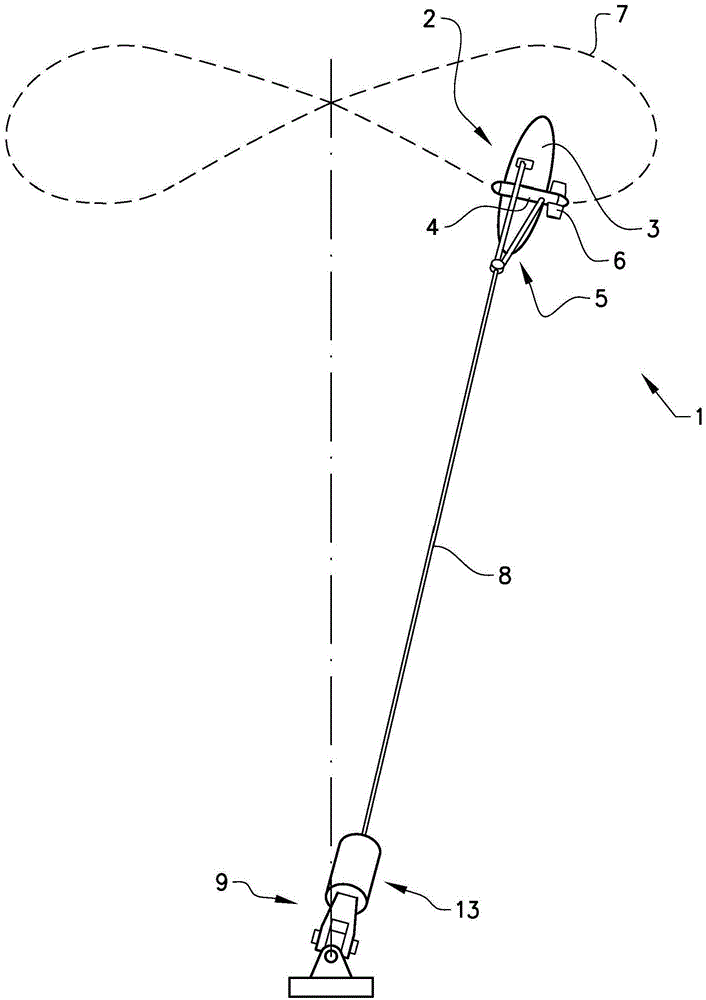

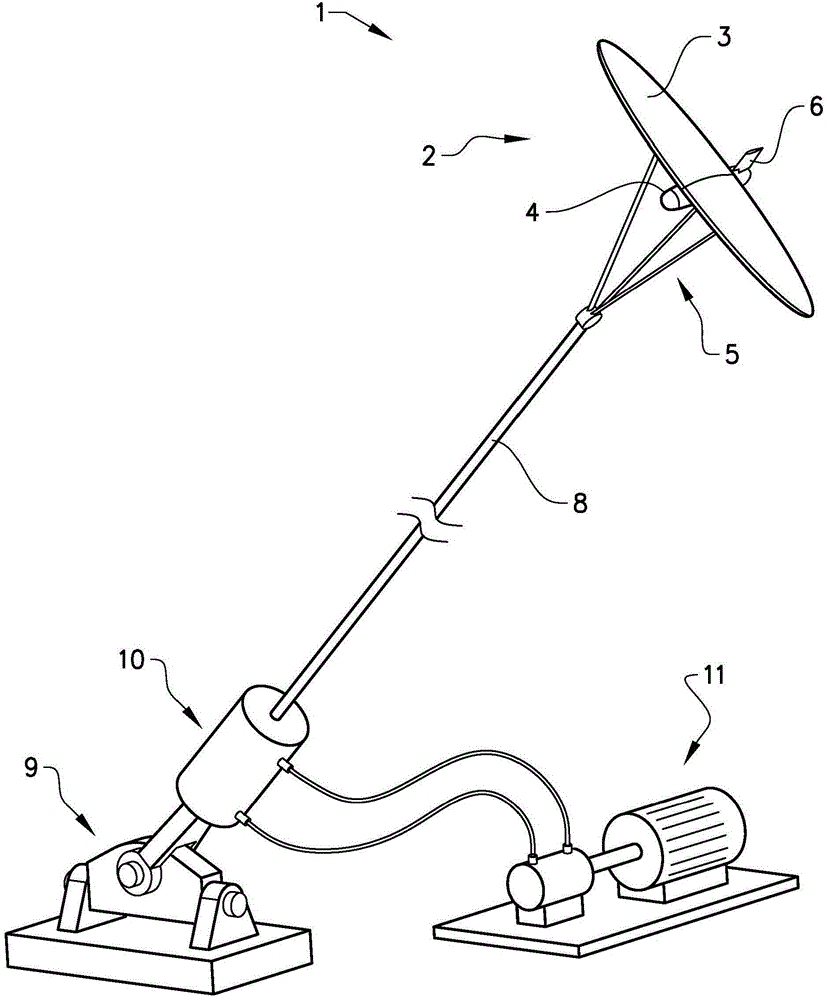

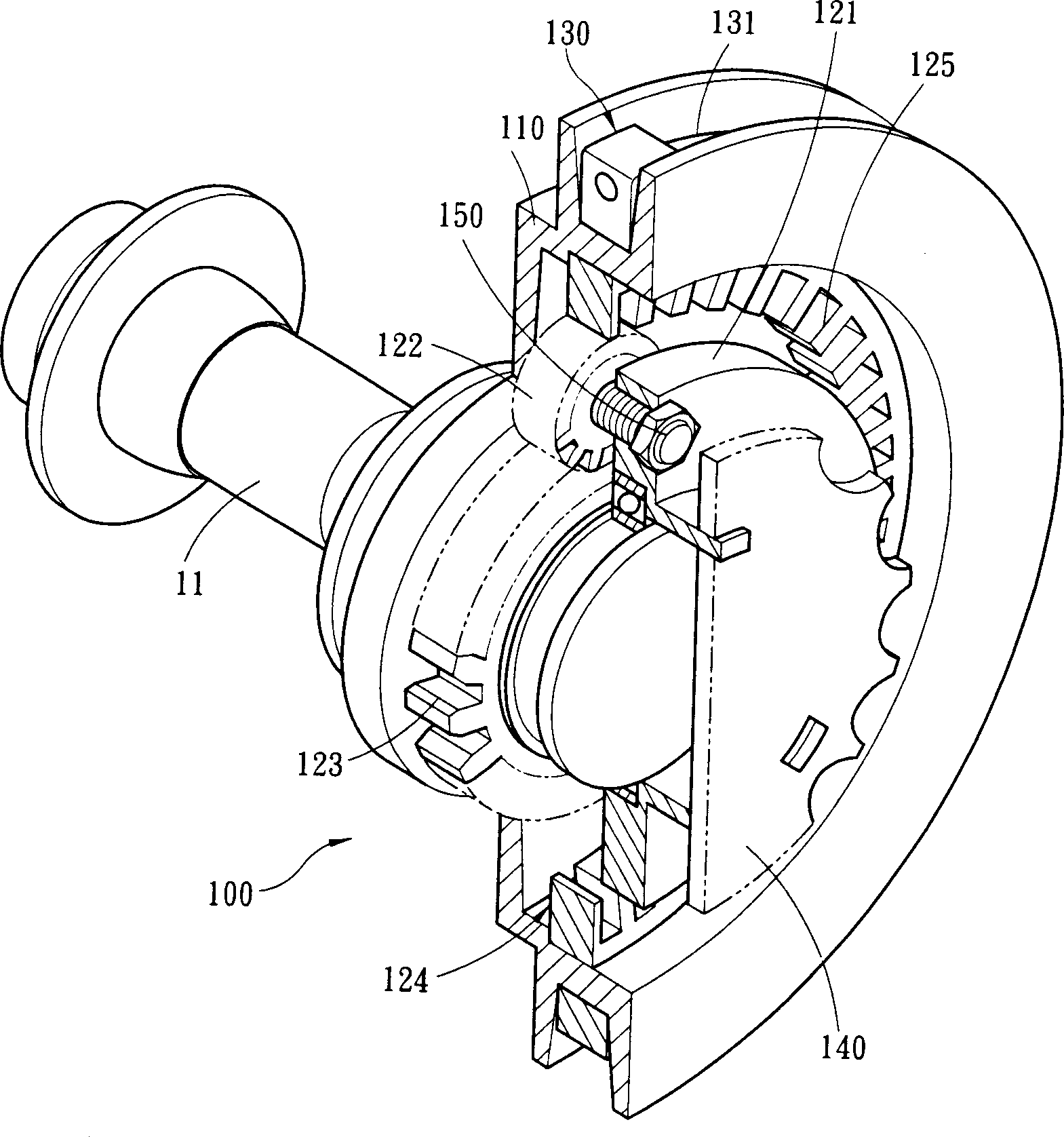

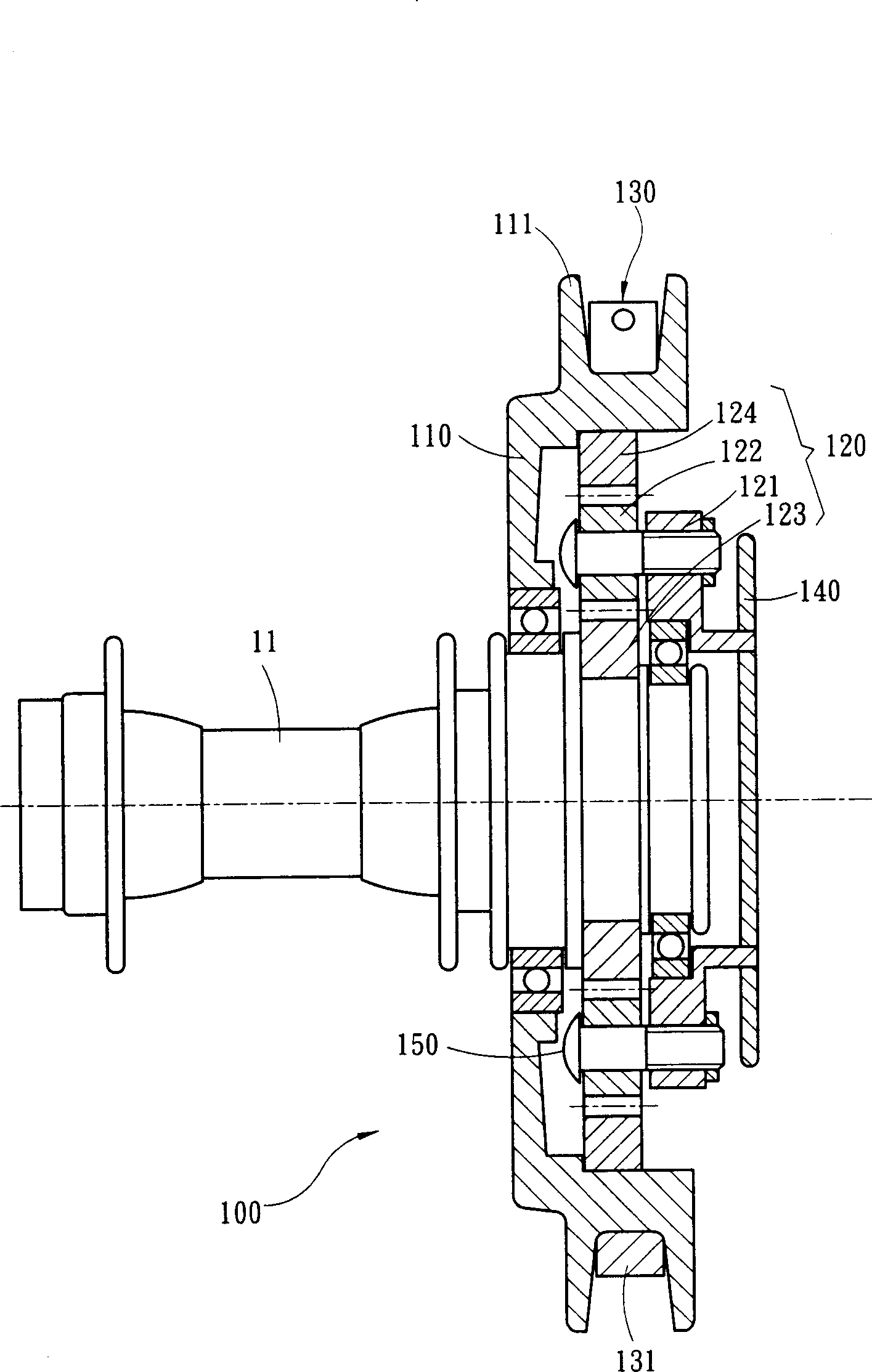

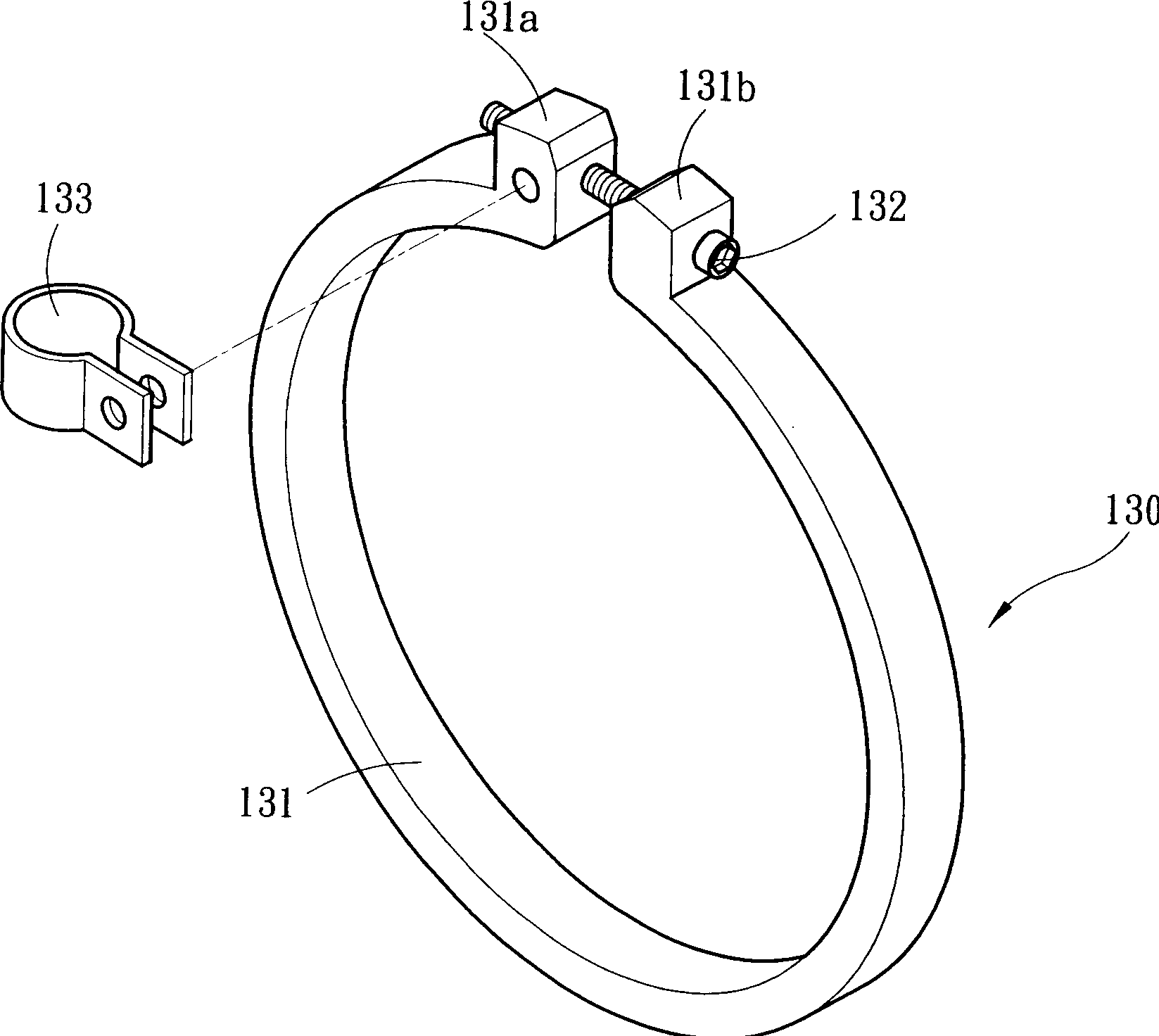

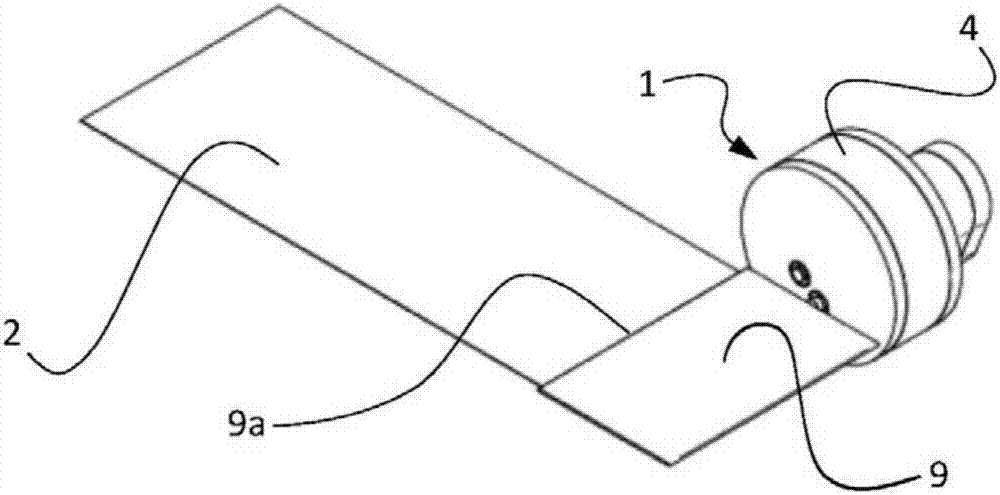

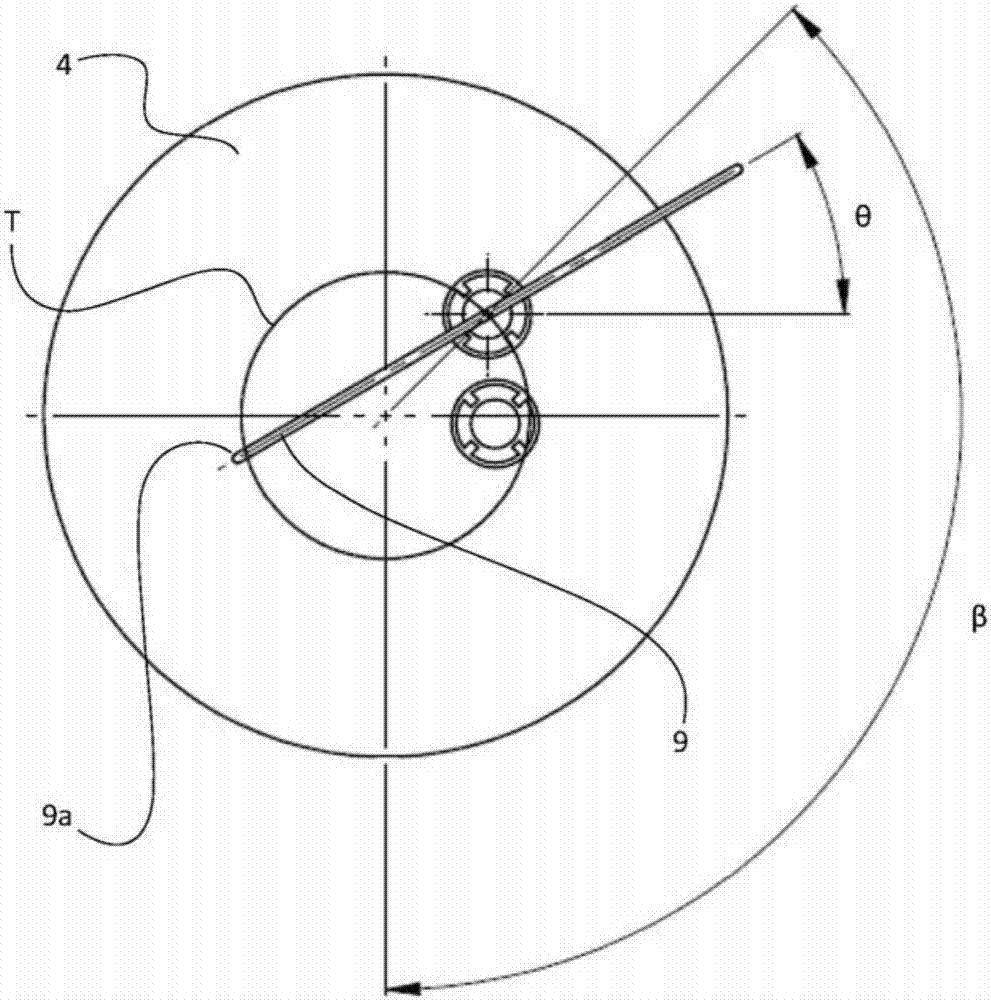

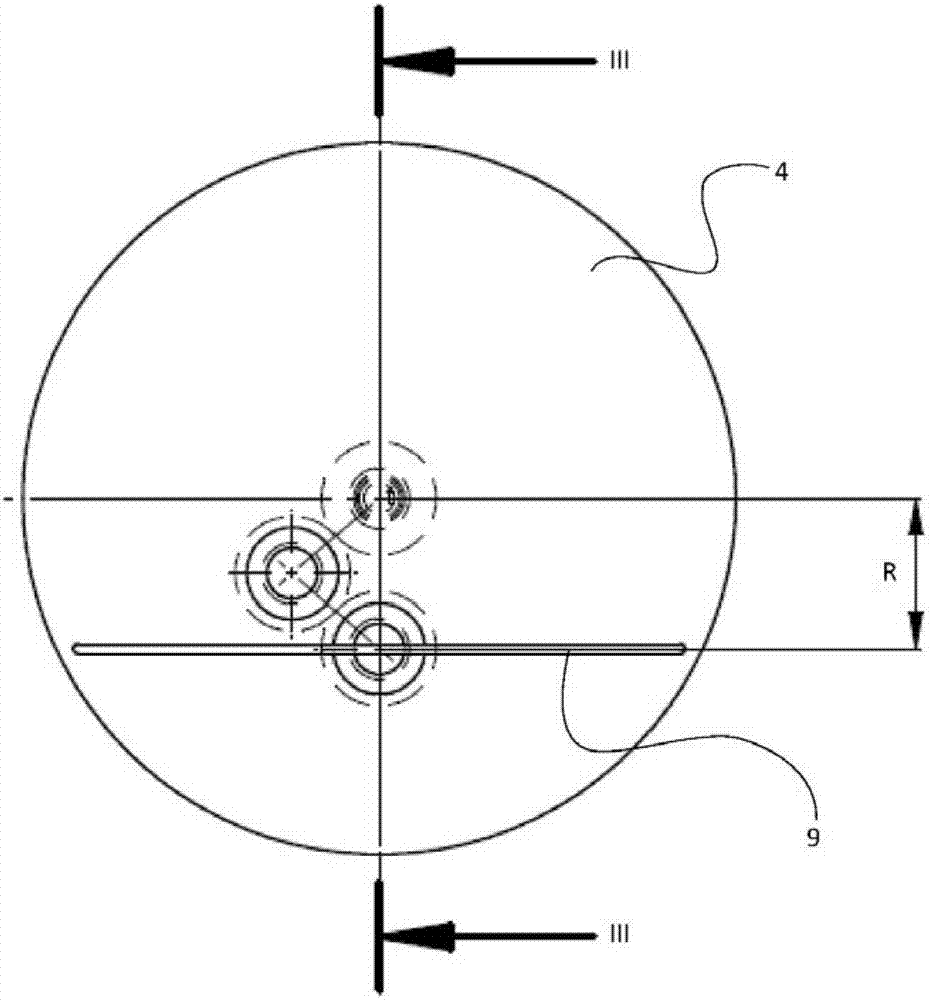

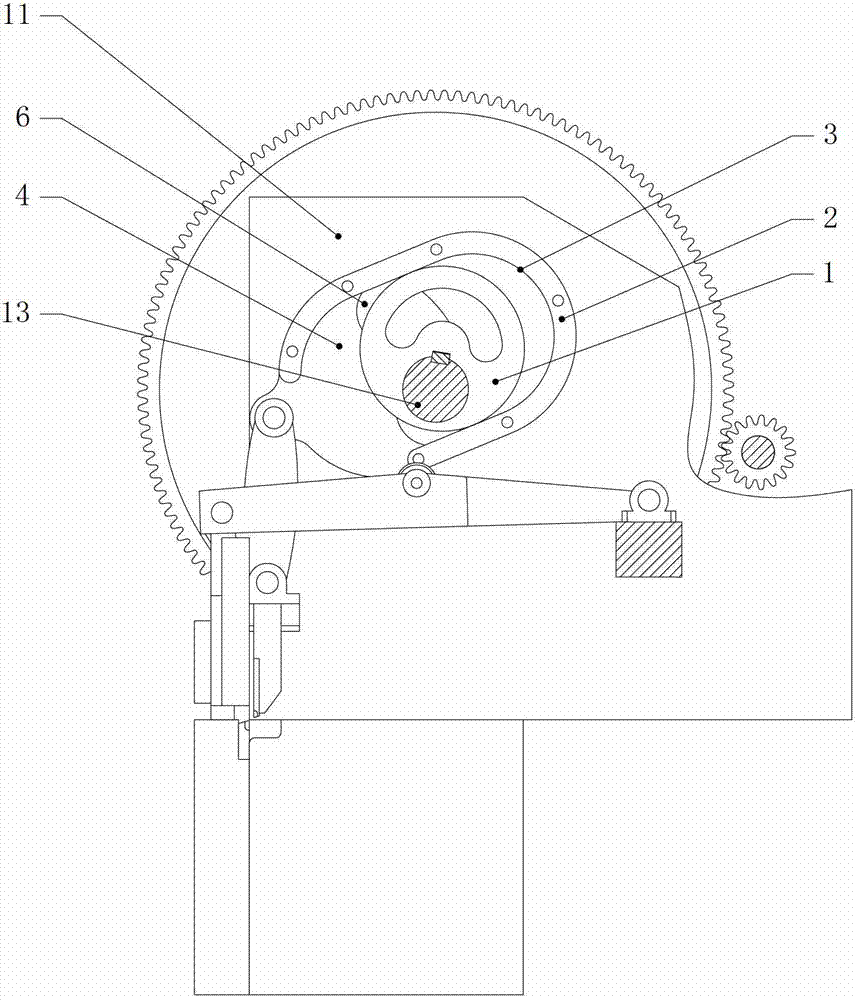

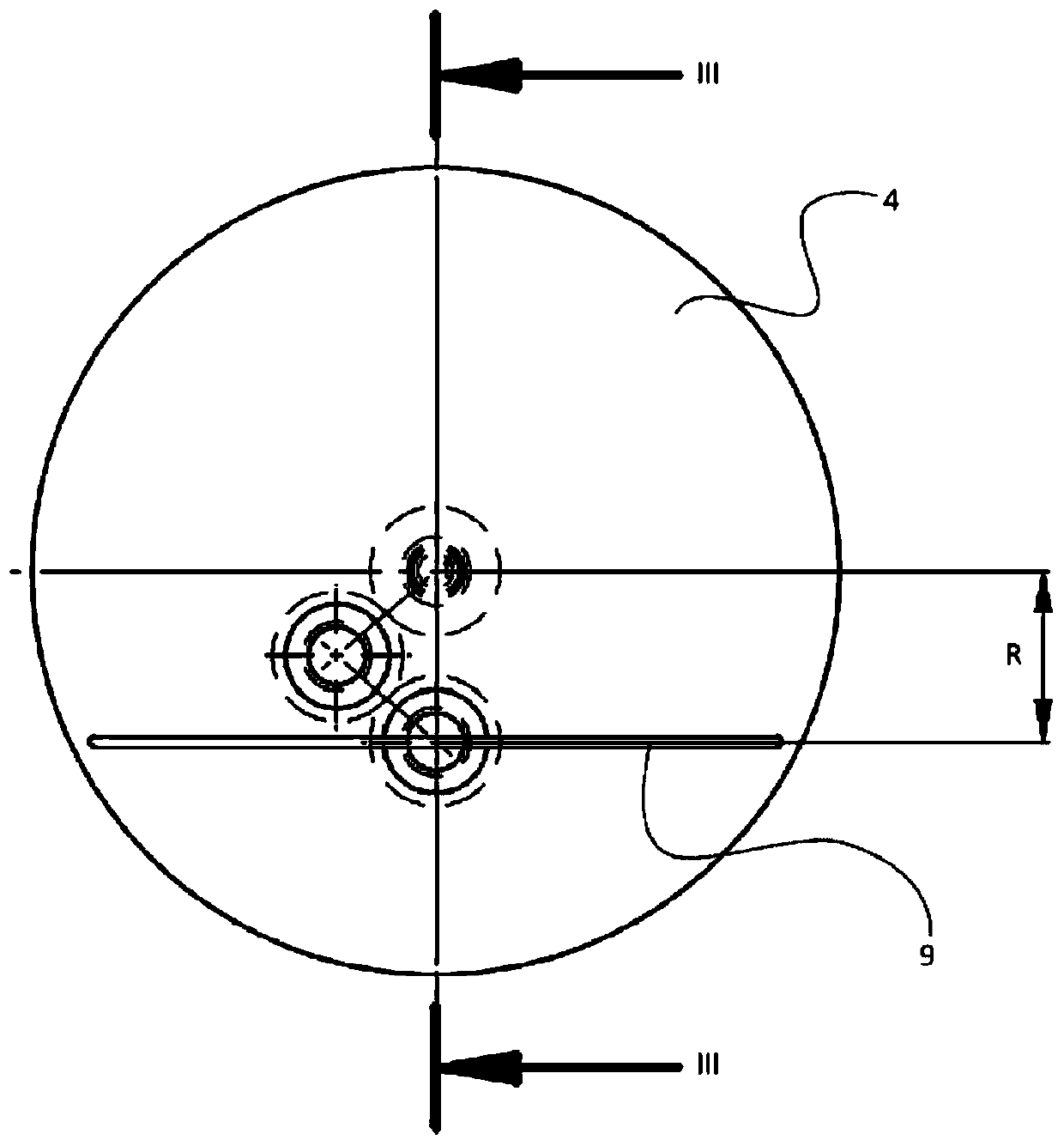

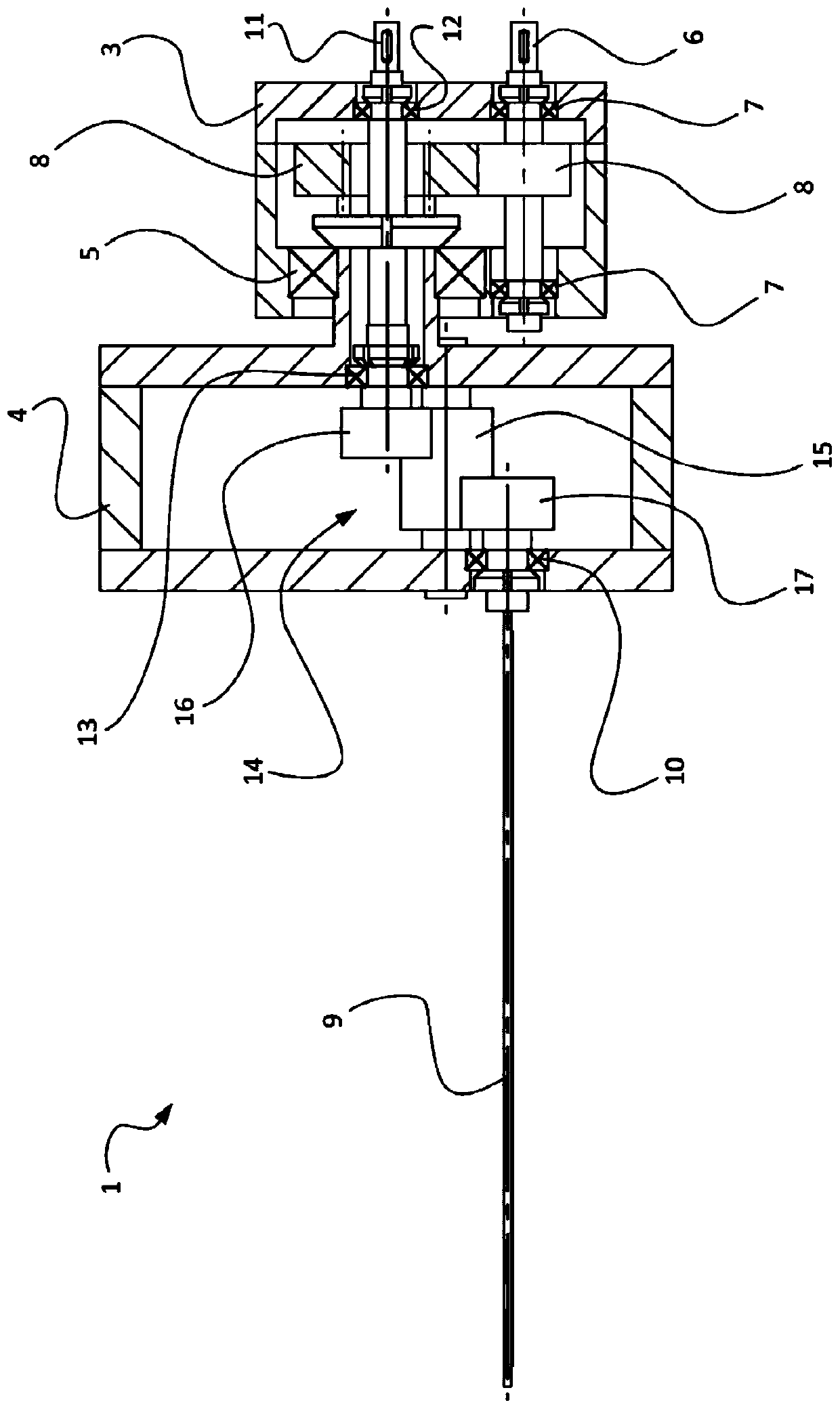

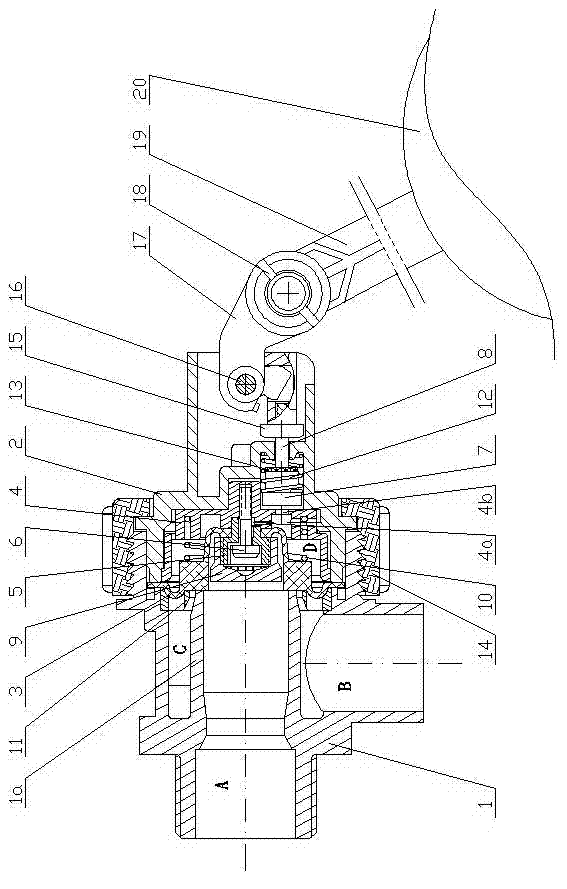

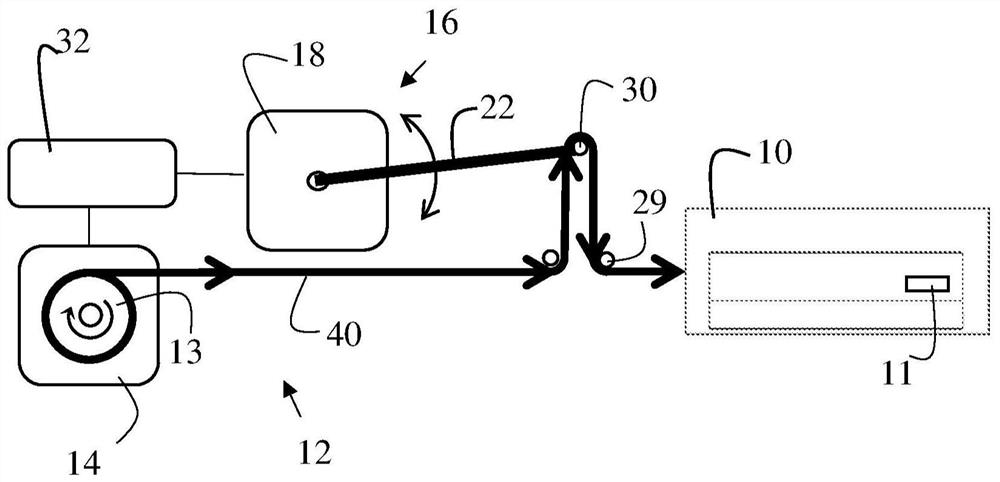

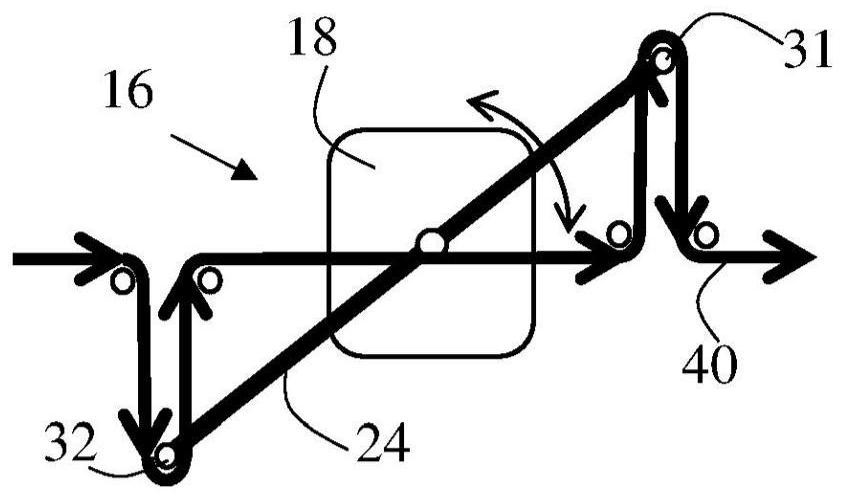

Power plant comprising a structure and a vehicle

ActiveCN104968929ASpeed peak reductionReduce fatigueReaction enginesWind energy generationTransducerElectric power

The invention relates to a power plant (1) for producing electrical power. The power plant (1) comprises a vehicle (2) comprising at least one wing (3) arranged to be secured to a structure (9) by means of at least one tether (8). The vehicle (2) is arranged to move with a varying speed over a predetermined trajectory (7) by means of a fluid stream passing the wing (3). The power plant (1) comprises an element (13) arranged to change or allow change of the distance between the vehicle (2) and the structure (9) continuously over or during parts of the predetermined trajectory (7), thereby reducing the variation in speed of the vehicle (2) over the predetermined trajectory (7) and / or allowing electrical power to be generated from the variation in distance by means of a transducer (10) arranged to be attached to the power plant (1). The advantage of the invention is that an increased efficiency is obtainable for the power plant.

Owner:MINESTO

Automatic stepless transmission for bicycle

InactiveCN1699110AFree from chain dropSafe and reliable shiftingWheel based transmissionCycle brakesGear transmissionVariator

This invention discloses a bicycle stepless automatic gear transmission, which uses the planetary gear as the main structure, including the pallet whose axis sets on the trailing wheel axis of bicycle, the planetary gear suit setting in the pallet and the braking device fixing on the frame; the chain wheel fixing on the planetary gear frame is the driving wheel, the sun gear fixing on the trailing wheel coaxially is the passiveness wheel, the braking device acts on the planetary gear suit by the adjustable designed friction braking force, when the drag is different caused by the change of the road situation, the ring wheel will produce different rotate speed along with it, thus it can change the gear ratio of the whole gear transmission automatically and steplessly, which can make driver in comfortable situation on any road situation.

Owner:高士博

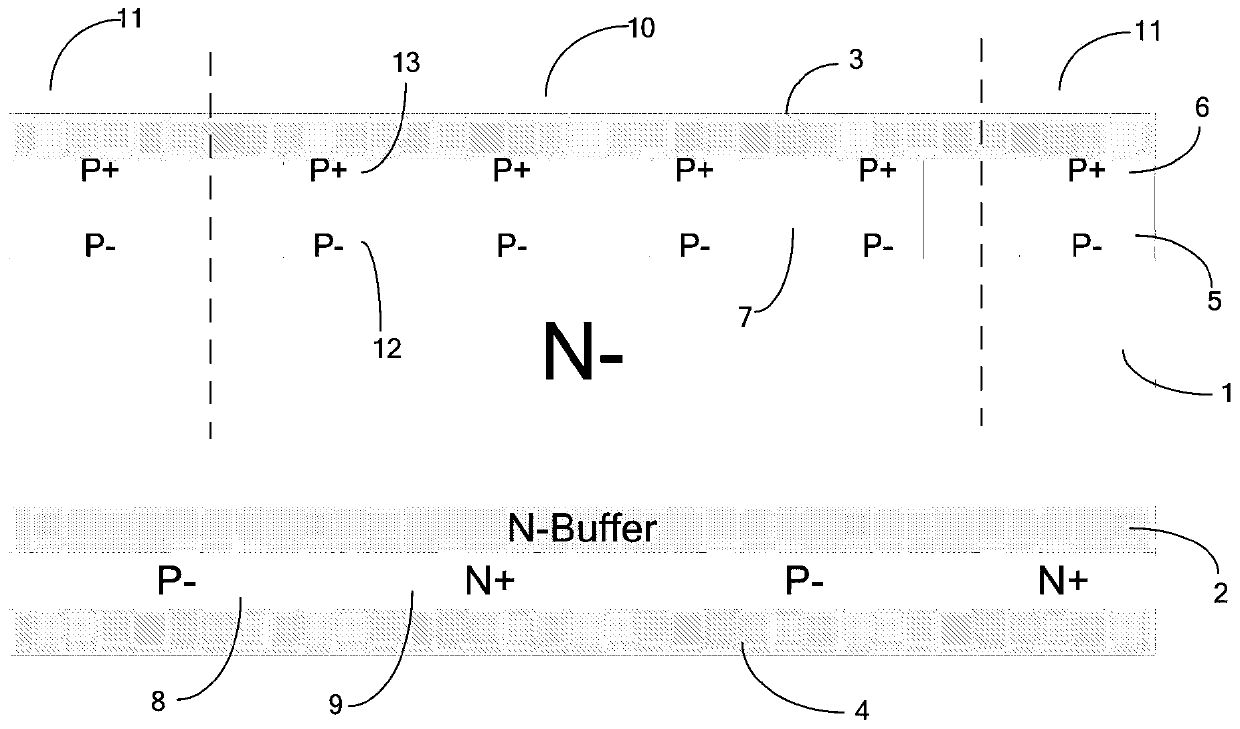

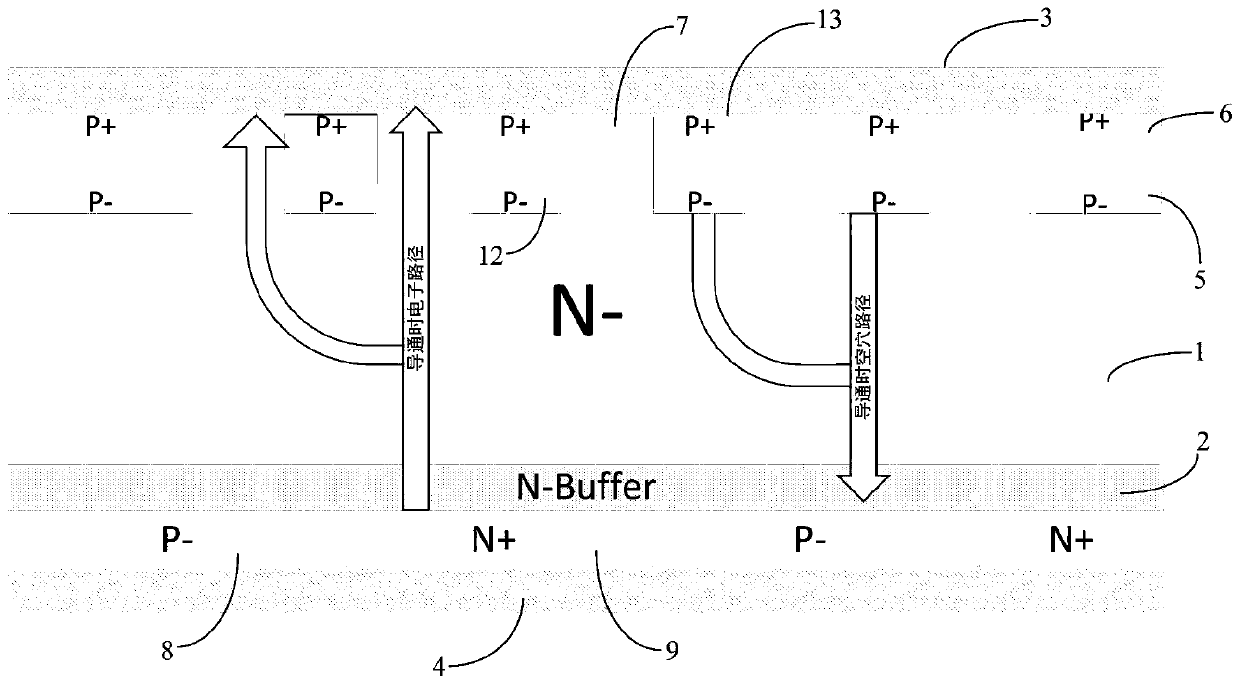

Double-sided Schottky controlled fast recovery diode device and preparation method

ActiveCN110416319ALarge speed changeHigh speedFinal product manufactureSemiconductor/solid-state device manufacturingReverse recoveryOhmic contact

The invention relates to a double-sided Schottky controlled fast recovery diode device and a preparation method. The fast recovery diode device comprises a semiconductor substrate, the semiconductor substrate comprises an N-type substrate and an N-type buffer layer, and an active region is arranged in the central area of the N-type substrate. On the cross section of the diode device, the active region comprises a number of alternately distributed active P-columns and active N-columns. Anode metal is arranged on the N-type substrate. The active P-columns are in ohmic contact with the anode metal on the N-type substrate, and the active N-columns are in Schottky contact with the anode metal on the N-type substrate. A number of alternately distributed cathode P- regions and cathode N+ regionsare arranged on the N-type buffer layer, the cathode N+ regions are in ohmic contact with cathode metal, and the cathode P- regions are in Schottky contact with the cathode metal. Fast reverse recovery can be realized, the dynamic loss can be reduced, the excellent softness can be improved, and the device has high reliability.

Owner:JIANGSU CAS IGBT TECHNOLOGY CO LTD

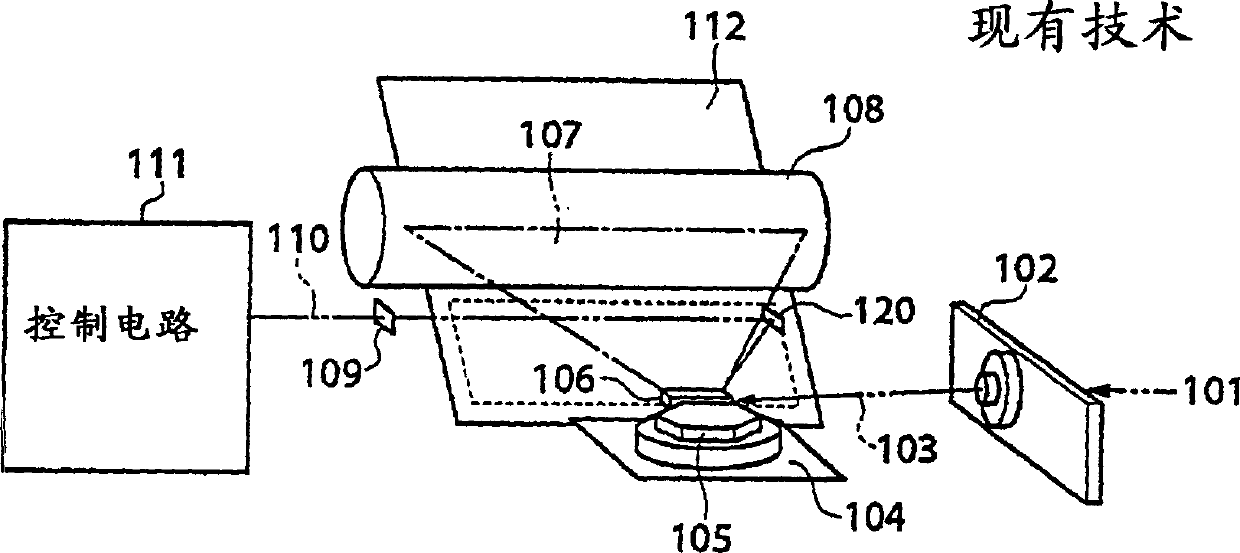

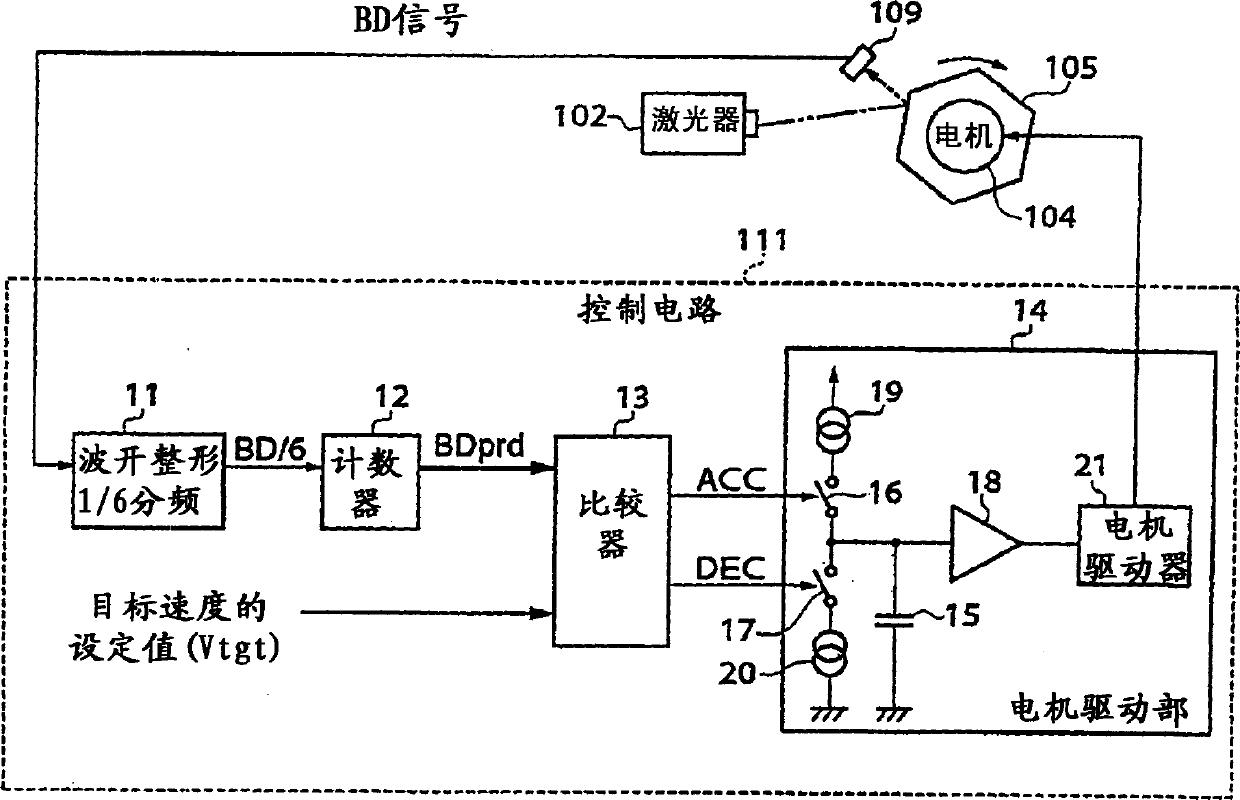

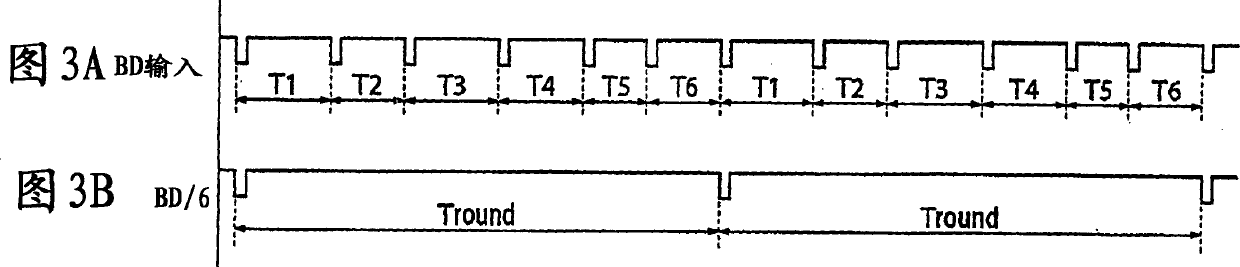

Image forming device

InactiveCN1450423ASmall speed changeSmooth rotationElectrographic process apparatusPictoral communicationRotation velocityLaser beams

It is an object of the present invention to provide an image forming apparatus that is capable controlling the rotational speed of a polygon motor so as to reduce variations in the rotational speed of the polygon motor to the minimum possible level and enable steady rotation of the polygon motor with ease in controlling the rotational speed of the polygon motor to a target speed. When a photosensitive drum is exposure-scanned while the traveling direction of an exposure laser beam is deflected by the polygon mirror, a polygon motor for driving the polygon mirror is controlled according to target periods M or target speeds of the polygon motor, which are determined for respective mirror planes of the polygon mirror.

Owner:CANON KK

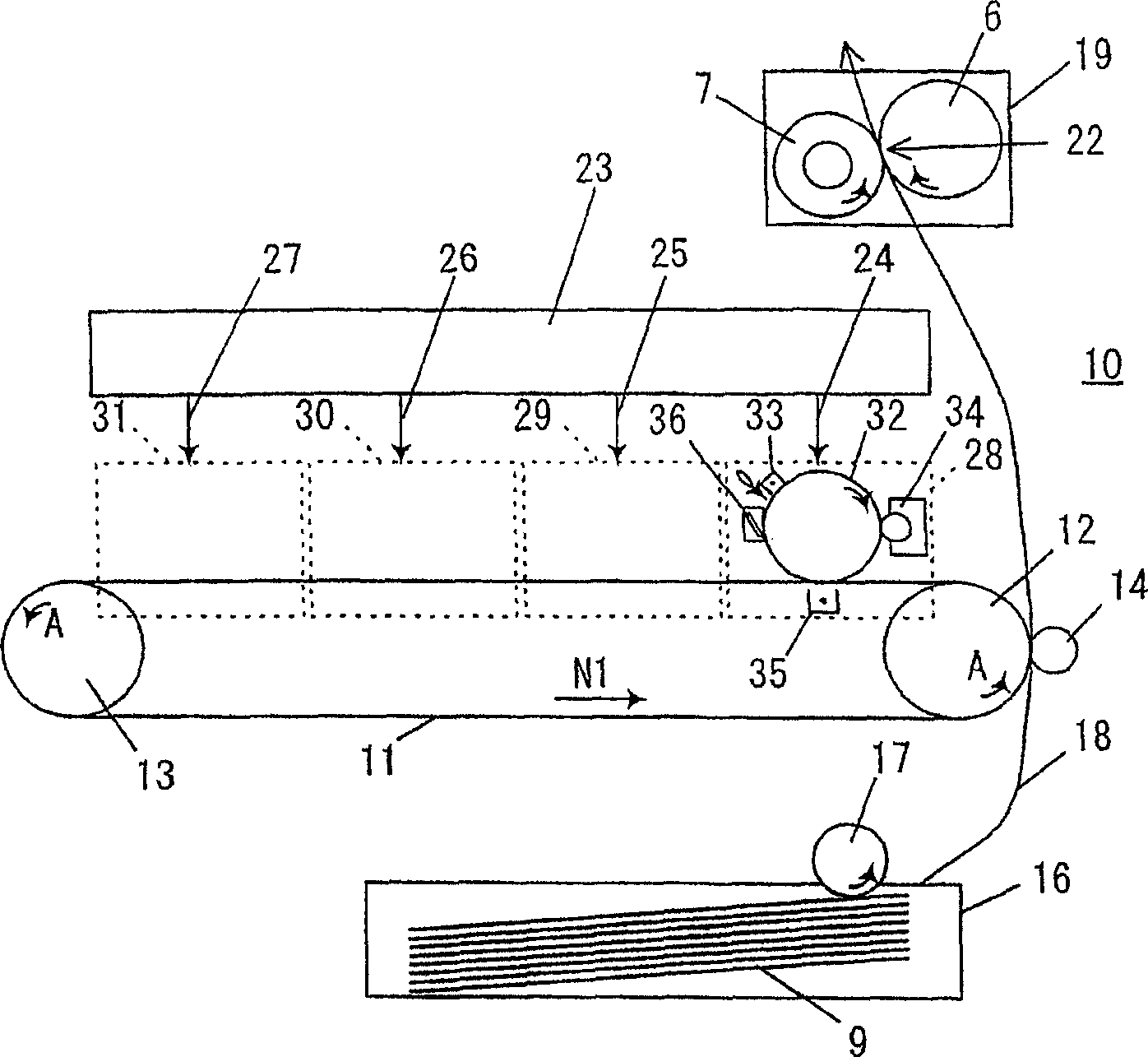

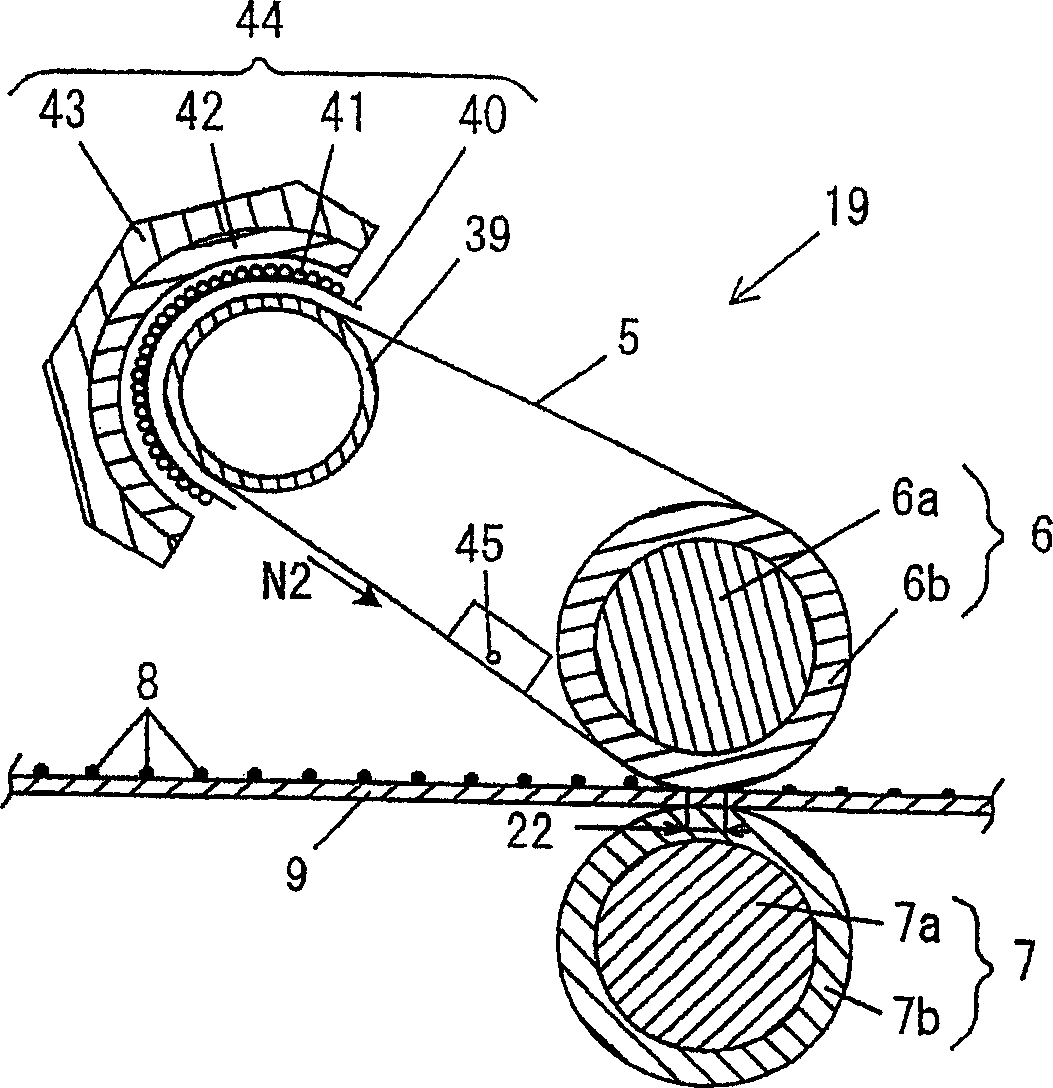

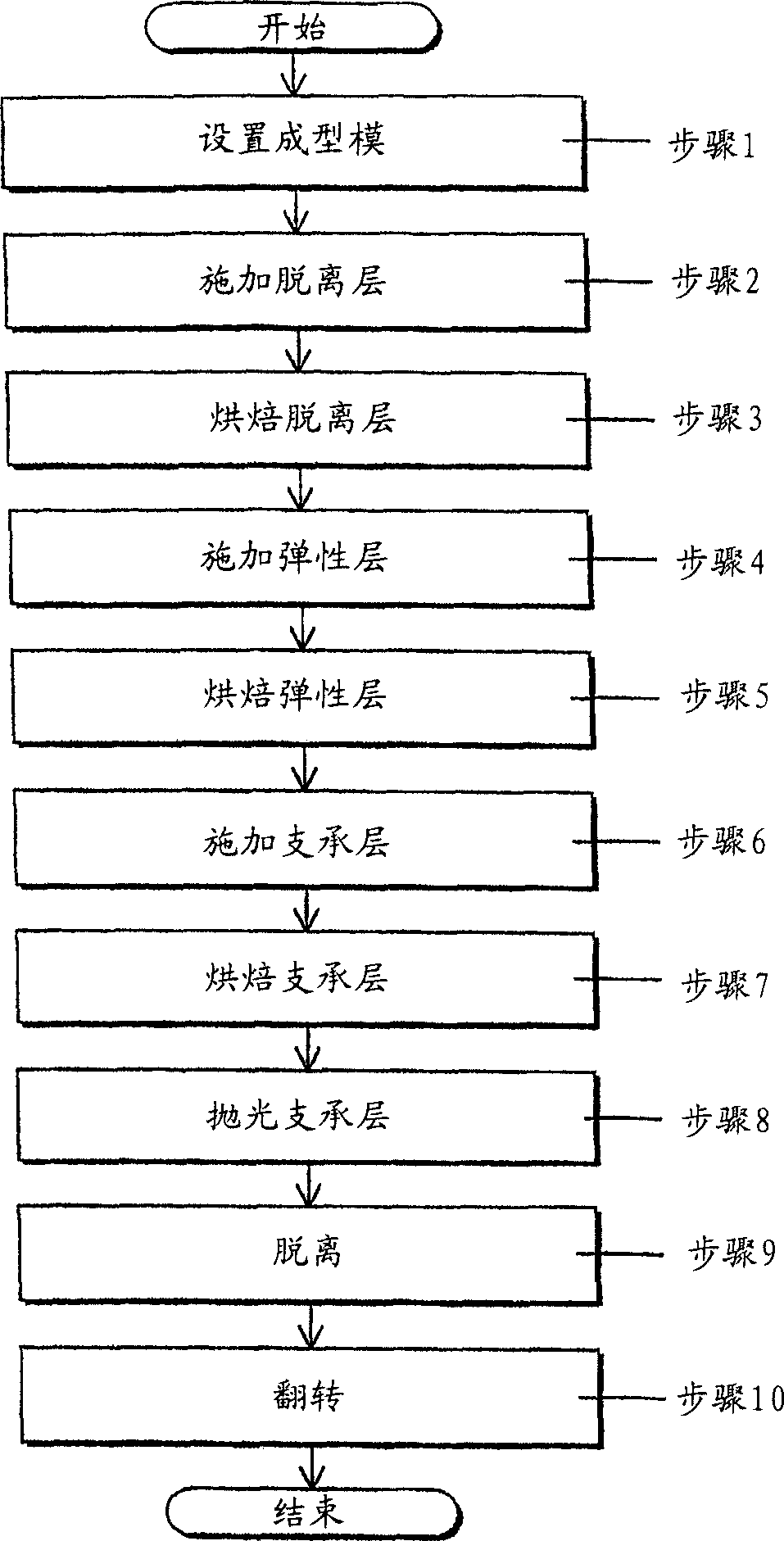

Belt, magnetic roller, method for producing thereof, and image forming apparatus using the same

InactiveCN1757001AReduce unevennessInhomogeneity GuaranteeElectrographic process apparatusFluoropolymerSynthetic resin

A release layer (2), which contains fluoropolymers is applied on a die surface (1a) of a shaping die (1), and is baked. An elastic layer (3) is applied onto the external surface of the release layer and is baked. A supporting layer (4) containing heat-resistant synthetic resin is applied onto the external surface of the elastic layer, and is dried. The dried supporting layer is polished to remove the unevenness, and the supporting layer is baked. The release layer, the elastic layer and the supporting layer are turned inside out to be removed from the die surface. The evenness of the fixing belt is improved, and the pressure unevenness is reduced.

Owner:PANASONIC CORP +1

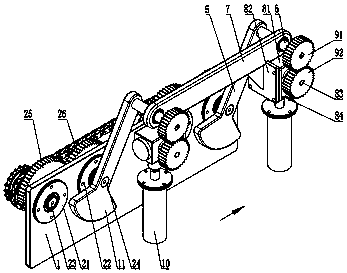

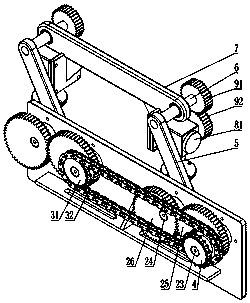

Winding apparatus and method

ActiveCN107082307AWind evenlyReduce oscillationElectrode manufacturing processesAssembling battery machinesMotor driveEngineering

It is described a winding apparatus for wrapping a material around a core of flat shape that rotates around a rotation axis rotating in its turn with a circular trajectory, controlling the laws of motion both of the core rotation around its axis and of the circular trajectory of its rotation axis, motor driven independently by means of electric cams, such as to cancel the variations of position and speed of the material at the entrance of the core The winding apparatus is used for producing electric energy accumulating devices.

Owner:MANZ ITAL

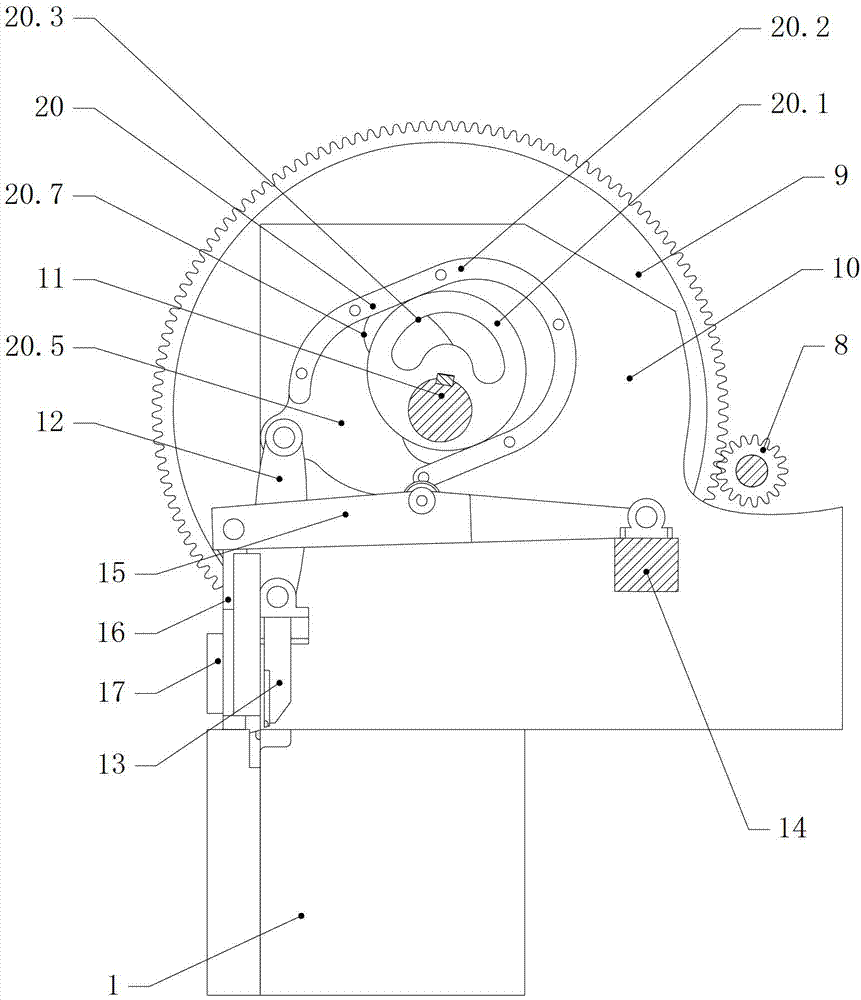

Actuating mechanism of mechanical shearing machine

InactiveCN103182558BWith snap back featureReduce preparation timeShearing machinesEngineeringMechanical engineering

The invention discloses an executing mechanism of a mechanical plate shearing machine and relates to the executing mechanism used on a mechanical plate shearing machine. The executing mechanism of the mechanical plate shearing machine is characterized in that eccentric wheels are symmetrically arranged on a main shaft between the side bracket of the plate shearing machine and the T-shaped frame; an eccentric wheel slot is machined on the inner part of a swinging block shell; the eccentric wheels are placed in the eccentric wheel slot and connected with the eccentric wheel slot in a sliding friction manner; two sealing covers are fixed at the two sides of the swinging block shell, respectively; arc-shaped main shaft slots are machined on the sealing covers; the main shaft slides in the arc-shaped shaft slots relative to the sealing covers; narrow ends of the sealing covers are hinged with the upper end of a connecting rod on the plate shearing machine; one end of a rotor I is fixed at the outer sides of the sealing covers; and the other ends of the rotator I are hinged with the lower end of the T-shaped frame on the plate shearing machine. The executing mechanism of the mechanical plate shearing machine has the characteristics of being novel in structure, simple to modify, low in cost, safe and reliable, good in economical efficiency and safety and the like, and therefore, the executing mechanism of the mechanical plate shearing machine is integrated with economical efficiency and practicability.

Owner:DALIAN UNIV OF TECH

Process fluid lubricated pump

Owner:SULZER MANAGEMENT AG

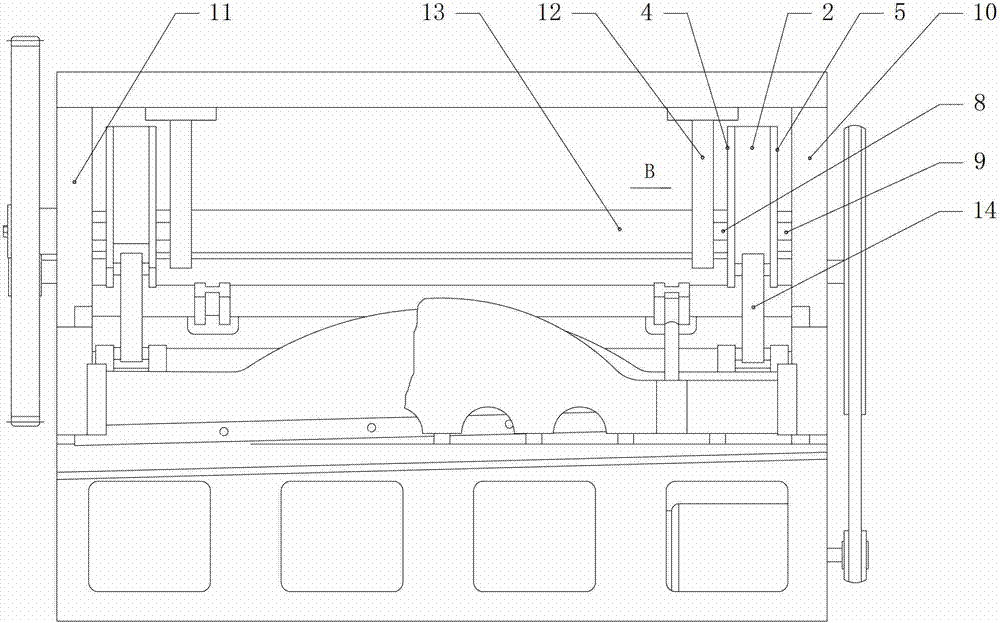

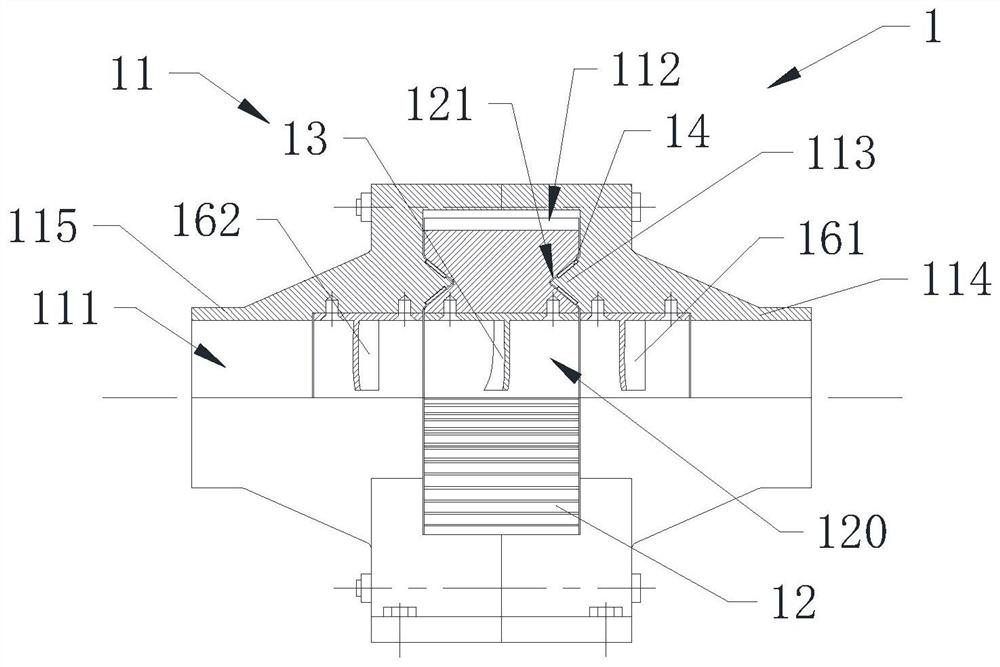

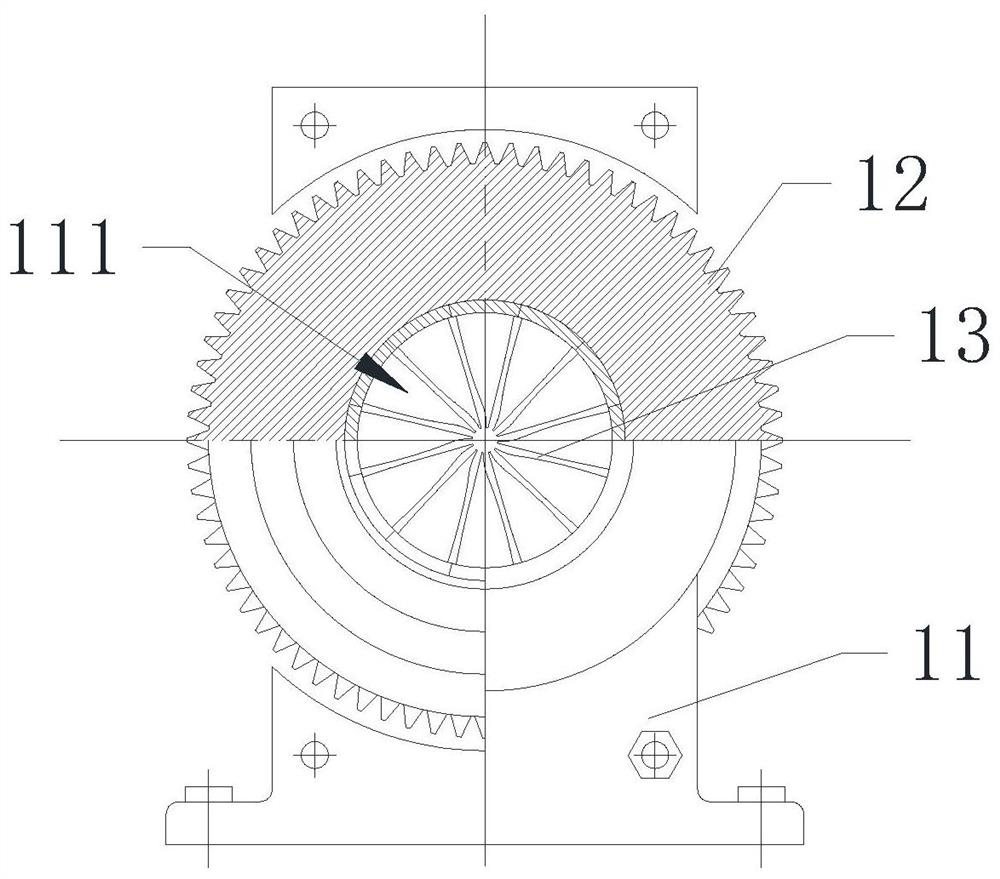

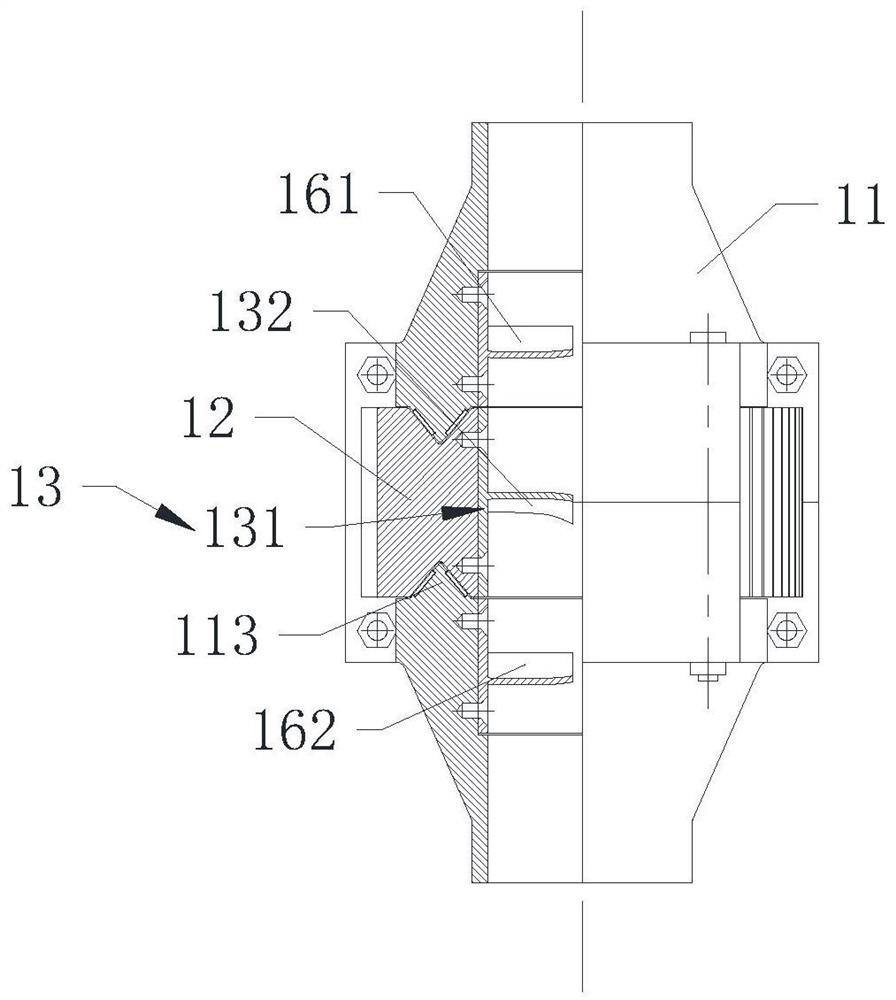

Well kiln type transplanting and cavity forming mechanism

ActiveCN111108855AAchieve variable speed circular motionSmall speed changePlantingFurrow making/coveringGear wheelCrank

The invention discloses a well kiln type transplanting and cavity forming mechanism. The well kiln type transplanting and cavity forming mechanism comprises a cavity forming frame body, wherein two non-circular gear mechanisms having the same structure are mounted on the cavity forming frame body; the two non-circular gear mechanisms are in front-and-rear parallel arrangement in the movement direction of the cavity forming frame body; a power transmission mechanism is in transmission between the two non-circular gear mechanisms; cavity forming cranks are respectively and fixedly connected to output ends of the two non-circular gear mechanisms; the two cavity forming cranks are arranged in parallel, and a crank connecting shaft is fixedly mounted at the top end of each of the two cavity forming frame bodies; a cavity forming connecting rod which is horizontally arranged is hinged between the two crank connecting shafts; two bevel gear commutators which correspond to the two crank connecting shafts are fixedly mounted at the bottom end of the cavity forming connecting rod; a gear mechanism is in transmission between each bevel gear commutator input shaft and a corresponding crank connecting shaft; and each bevel gear commutator output shaft is vertically arranged downwards, and a cavity forming machine which is vertically arranged downwards is fixed to the bottom end of each bevel gear commutator output shaft. The well kiln type transplanting and cavity forming mechanism disclosed by the invention is reasonable in design, can form an approximately cylindrical well kiln regular in shape, and can be used for meeting requirements of insulating, moisturizing and the like of the well kilns.

Owner:SHANDONG JIAOTONG UNIV

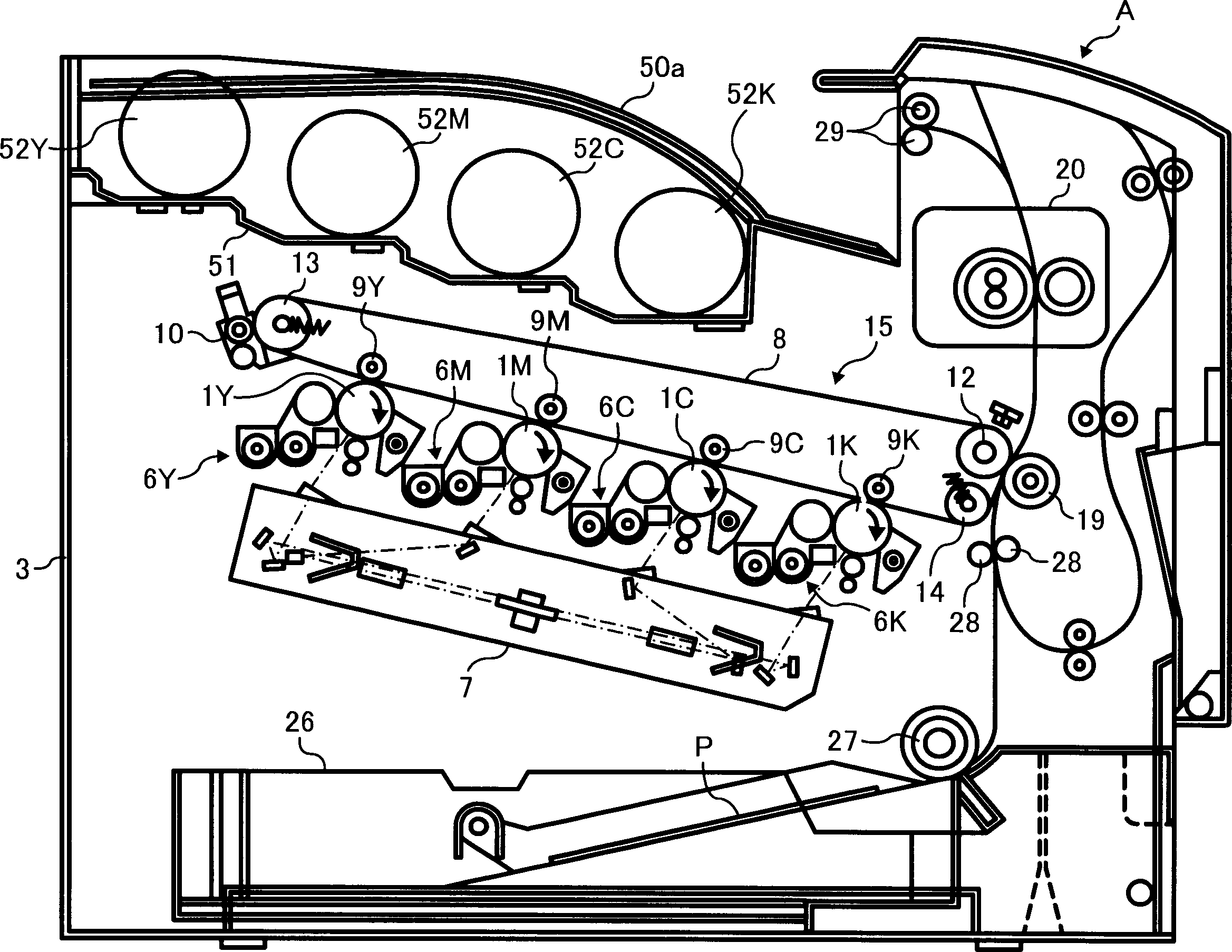

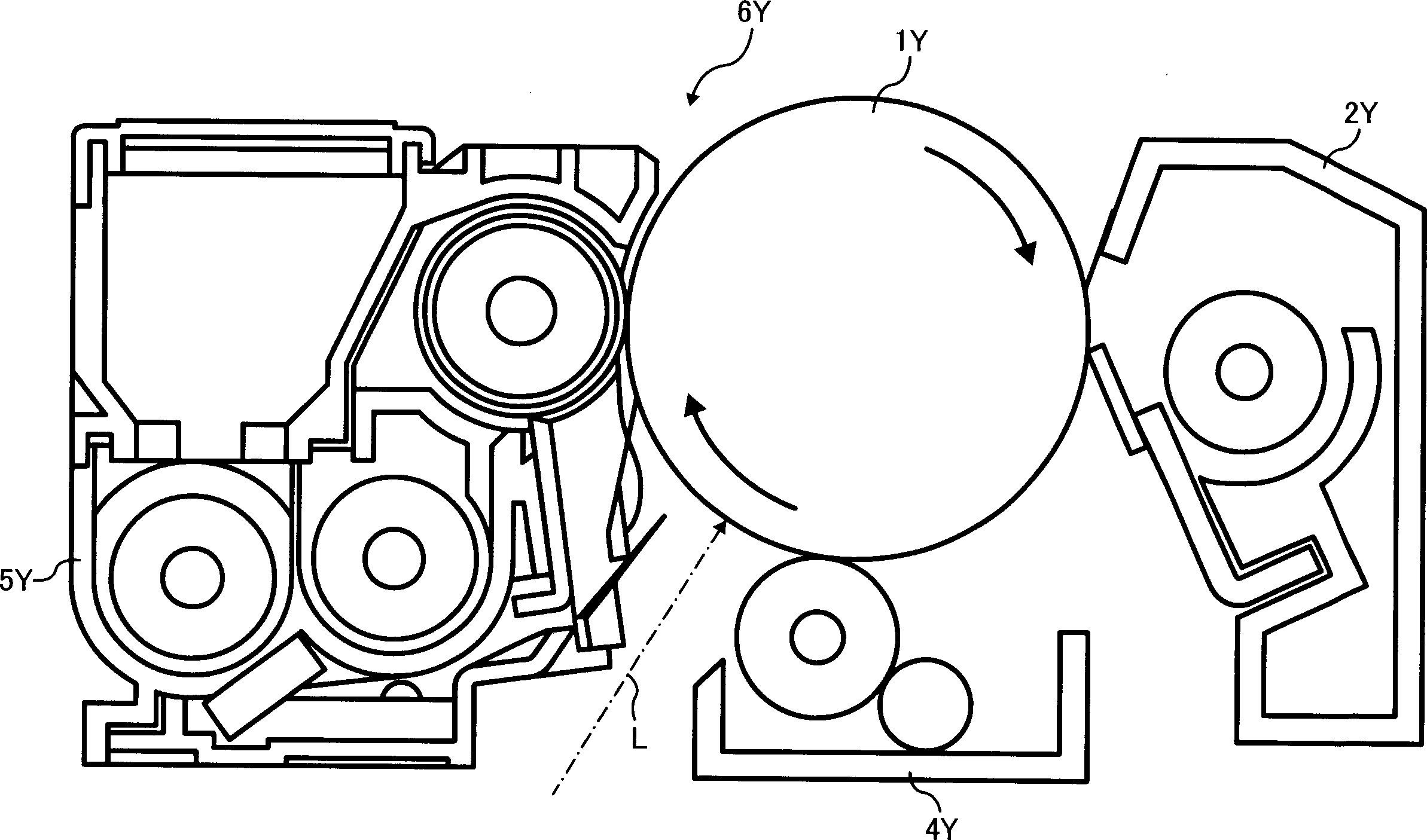

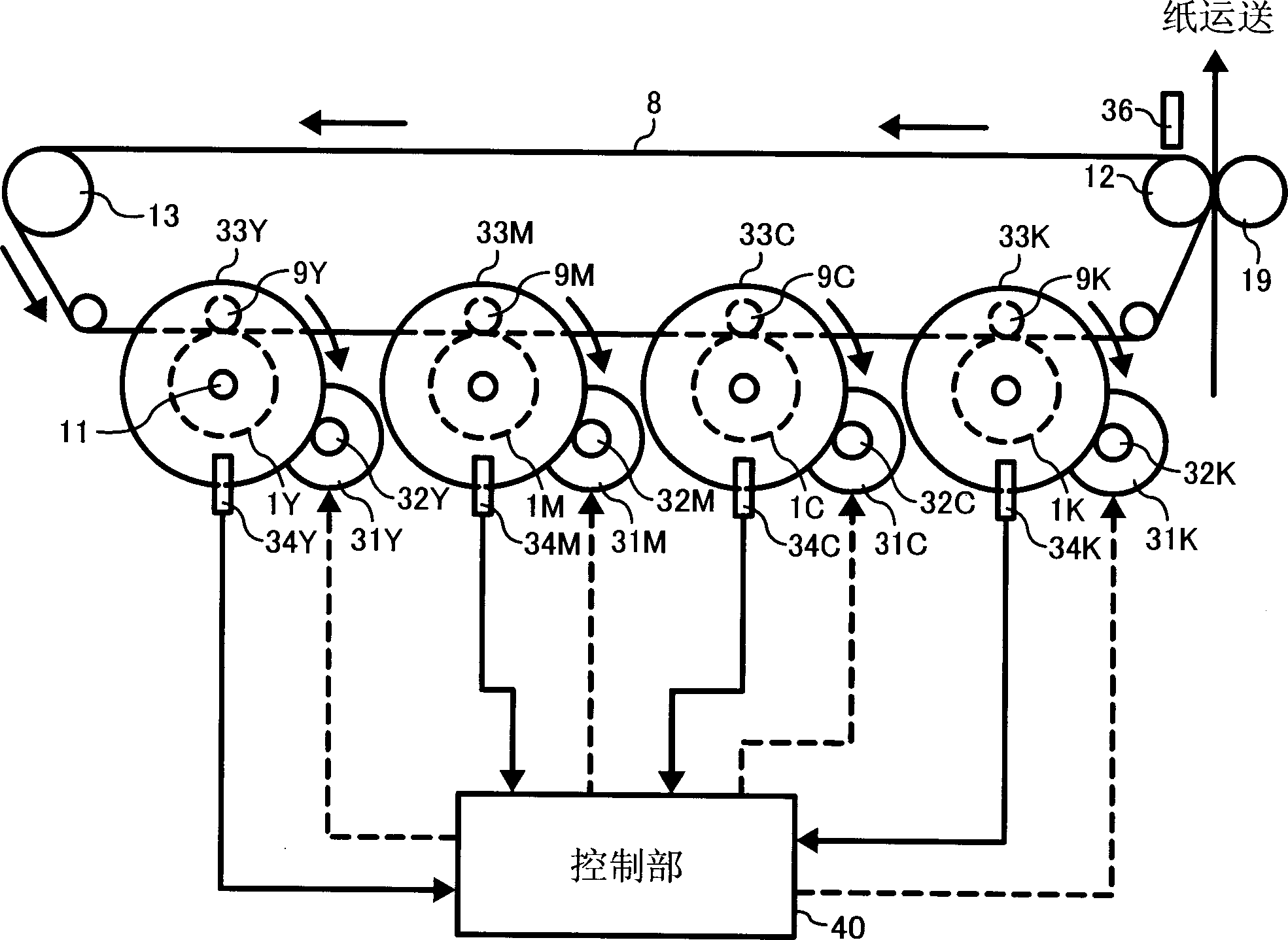

Image forming apparatus

InactiveCN1815382ASmall speed changeControl bit differenceElectrographic process apparatusPhase differenceImage formation

Owner:RICOH KK

Transducer, propeller, output device, power transmission mechanism, vehicle and ship

PendingCN112339553AReduce lossesSimple structureTransmission with non-mechanical gearingControl devicesGear driveGear wheel

The invention discloses a transducer, a propeller, an output device, a stepless speed change power transmission mechanism, a vehicle and a ship. A driver comprises: a base having a fluid passage and agear cavity; a gear which is provided with a hollow cavity, wherein the gear is rotatably installed in the gear cavity, and the hollow cavity corresponds to the fluid channel, at least one part of gear teeth of the gear extends to the outer side of the base to be connected with a power input device or a power output device. and blades which are mounted on the inner wall of the hollow cavity; whenthe gear is connected with the power input device, the power input device can drive the gear to rotate, the gear drives the blades to rotate, and the blades push fluid in the fluid channel to flow. When the gear is connected with the power output device, fluid flowing in the fluid channel can push the blades to rotate, the blades can drive the gear to rotate, and the gear drives the power outputdevice to work. The fluid freely and circularly flows in the pipeline, the speed change is small, the energy loss is small, and the transmission efficiency is high.

Owner:邓云娣

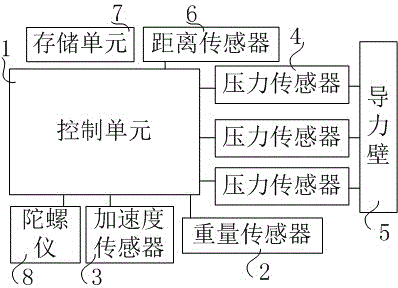

Braking distance judgment system for emergency braking of truck and judgment method

InactiveCN105691368ARelieve pressureReduce inertia momentumAutomatic control systemsBraking systemsGyroscopeEngineering

The invention discloses a braking distance judgment system for emergency braking of a truck and a judgment method. The problem that when large heavy cargos are carried in a cargo compartment, a truck head is likely to be damaged due to the fact that the cargos rush forwards and move in the emergency braking process, and thus safety accidents are caused is solved. The braking distance judgment system comprises a control unit (1) connected with a braking system, one or more pressure sensors arranged on the inner wall in the front of the compartment and an acceleration sensor (3) arranged on a truck body and connected with the control unit (1). A distance sensor (6), a storage unit (7) and a gyroscope (8) are connected to the control unit (1). The pressure sensors (4) are all connected to the control unit (1). By the adoption of the braking distance judgment system, the speed variation rate during emergency braking can be adjusted effectively through the control unit, the situation that the cargos rush forwards during emergency braking, and the safety of drivers is influenced is prevented, and the position with the maximum forward-rush pressure can be effectively detected while the protective capability is enhanced.

Owner:CHENGDU GENCHI TECH CO LTD

Aircraft comprising a propulsion assembly including a pair of propellers at the rear of the fuselage

ActiveUS10351252B2Small speed changeAvoid interferencePropellersGas turbine type power plantsDrive shaftPropeller

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Winding device and method

ActiveCN107082307BSimple and economical constructionEasy to adapt to style changesElectrode manufacturing processesAssembling battery machinesElectric machineCam

This paper describes a winding device for wrapping material around a flat core rotating about an axis of rotation which in turn follows a circular trajectory, controlling the rotation of the core about its axis and the orientation of its axis of rotation The law of motion of both circular trajectories (independently driven by motors via electric cams) to counteract the position and velocity changes of the material at the core inlet. The winding device is used to manufacture an electrical energy storage device.

Owner:MANZ ITAL

Slow-closing type float ball valve

ActiveCN102384284BSmall speed changeReduce adverse impactDiaphragm valvesOperating means/releasing devices for valvesWater flowSmall hole

The invention discloses a slow-closing type float ball valve. A bracket is arranged in a front chamber of a valve cover, an inner cavity of the bracket is provided with a valve chamber, a leather membrane is arranged between the rear end face of an annular lug boss in the valve body and the valve cover, the middle of the leather membrane backwards deforms and extends to form a location lug boss; a check ring is arranged in an inner cavity inside the location lug boss, the rear end of the check ring penetrates through a through hole at the middle of the location lug boss and extends into a location groove on the bracket, a bolt is penetrated through an inner hole of the check ring, a gap is arranged between the bolt and the inner hole wall of the check ring and communicated with the valve chamber through a first small hole of the bracket; and a control chamber is arranged behind the valve chamber, and communicated with the valve chamber through a second small hole of the bracket. The slow-closing type float ball valve is longer in closing time, remarkably reduces adverse impact of water flow to a water supply pipeline and the valve body because the speed change of the water flow isreduced, and has the characteristics of easiness in processing and manufacturing, compact structure, easiness in assembly, reliability in control, long service life and the like.

Owner:卢忠伦

Zero twist yarn feeding device

ActiveCN109415852BEliminate torqueEliminate riskLoomsFilament handlingControl engineeringDrive motor

Owner:范德威尔(中国)纺织机械有限公司

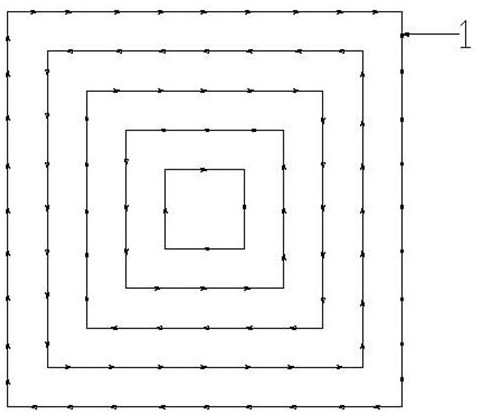

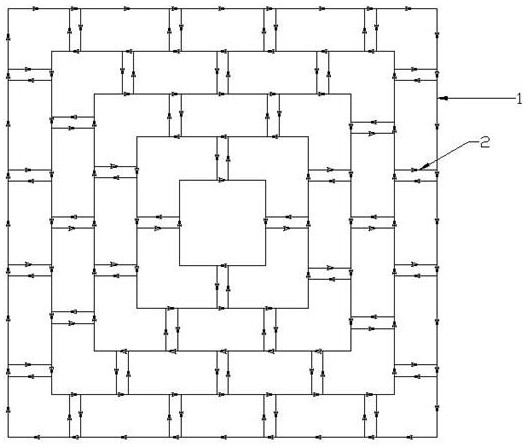

A network-wide one-way road facility that improves overall traffic speed

ActiveCN111041915BImprove traffic efficiencyIncrease average traffic speedRoadwaysTrunk roadSpeed limit

The invention discloses a network-wide one-way driving road facility for improving the overall traffic speed, which comprises more than one one-way driving ring-shaped arterial road and more than one one-way running connecting roads connecting the inside and outside of the one-way driving ring-shaped main road. The above-mentioned connecting road and a part of the corresponding one-way circular arterial road form a circular closed road. Compared with other methods in the prior art, when the maximum speed limit is consistent, the average passing speed increases, but the detour distance is short, thereby reducing the passing time as a whole.

Owner:李益友 +1

A grooved anode FRD with two-pole Schottky control and its manufacturing method

ActiveCN109192787BEasy to passShort reverse recovery timeSemiconductor/solid-state device manufacturingDiodeEtchingEngineering

The invention relates to a groove-type anode fast recovery diode with bipolar Schottky control and its manufacturing method, comprising: a cathode metal, an N-type intrinsic region above the cathode metal, and an N-type intrinsic region above the N-type intrinsic region The anode metal is provided with lightly doped N-type regions and heavily doped N-type regions spaced apart from each other on the cathode metal, the bottom of the lightly doped N-type region is in Schottky contact with the cathode metal, and in the N-type intrinsic region There are heavily doped P-type regions and lightly doped P-type regions spaced apart from the anode metal, and the upper surface of the heavily doped P-type region is lower than the upper surface of the lightly doped P-type region, forming a concave In the slot-type anode area, the lightly doped P-type area and the anode metal are in Schottky contact. The manufacturing method of the two-pole Schottky-controlled recess type anode fast recovery diode is characterized in that the Schottky contacts on the surface of the anode and the side wall can be formed simultaneously by one-step etching.

Owner:SOUTHEAST UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com