Actuating mechanism of mechanical shearing machine

A technology of executive mechanism and shearing machine, which is applied to shearing equipment, shearing devices, metal processing equipment, etc., can solve the problems of short shearing stroke and increased production cost, so as to improve forming quality, increase production efficiency, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

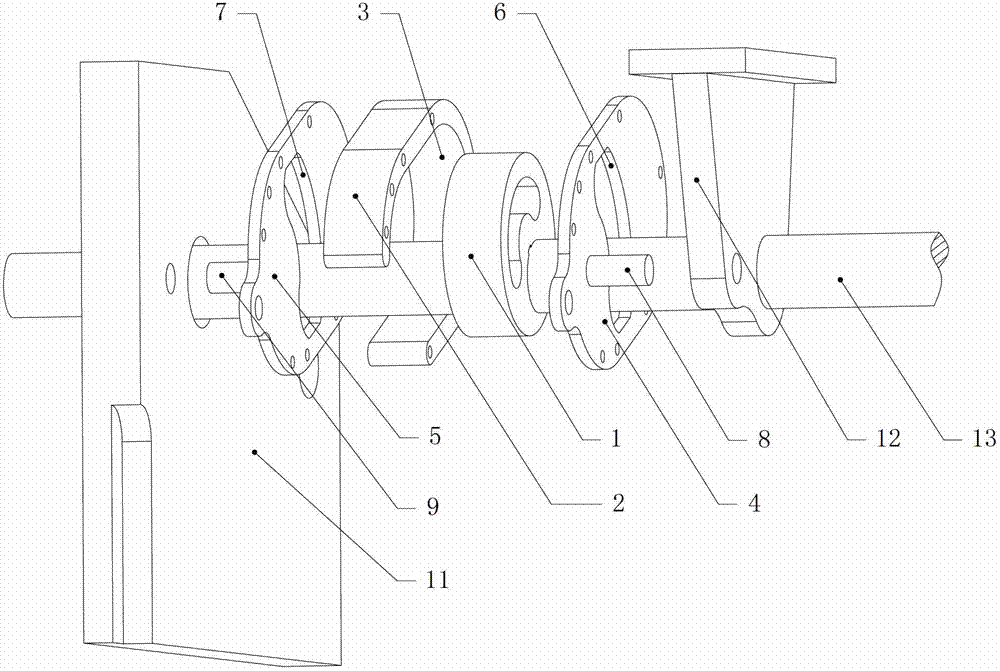

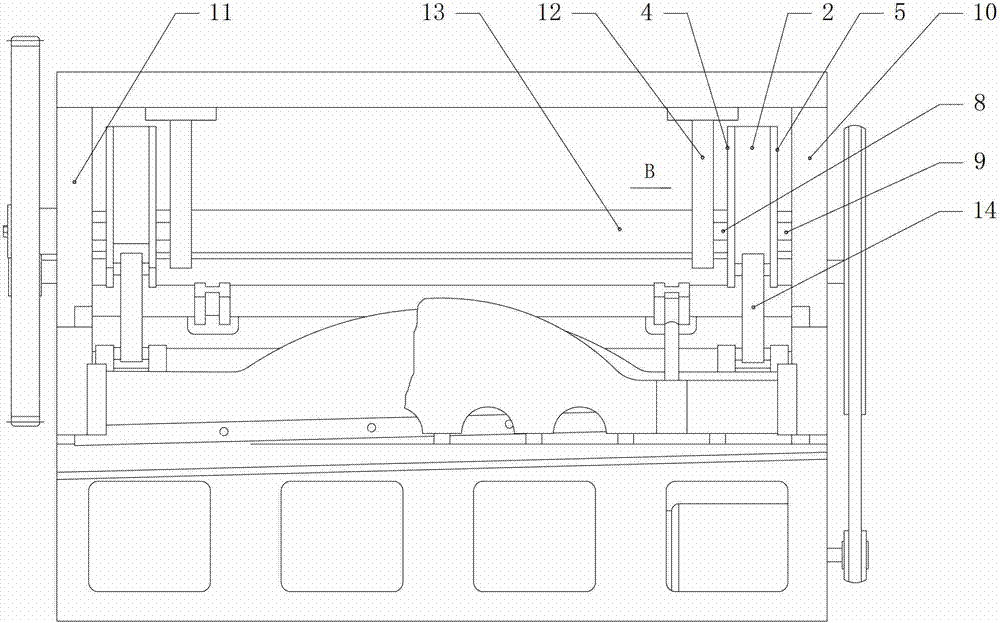

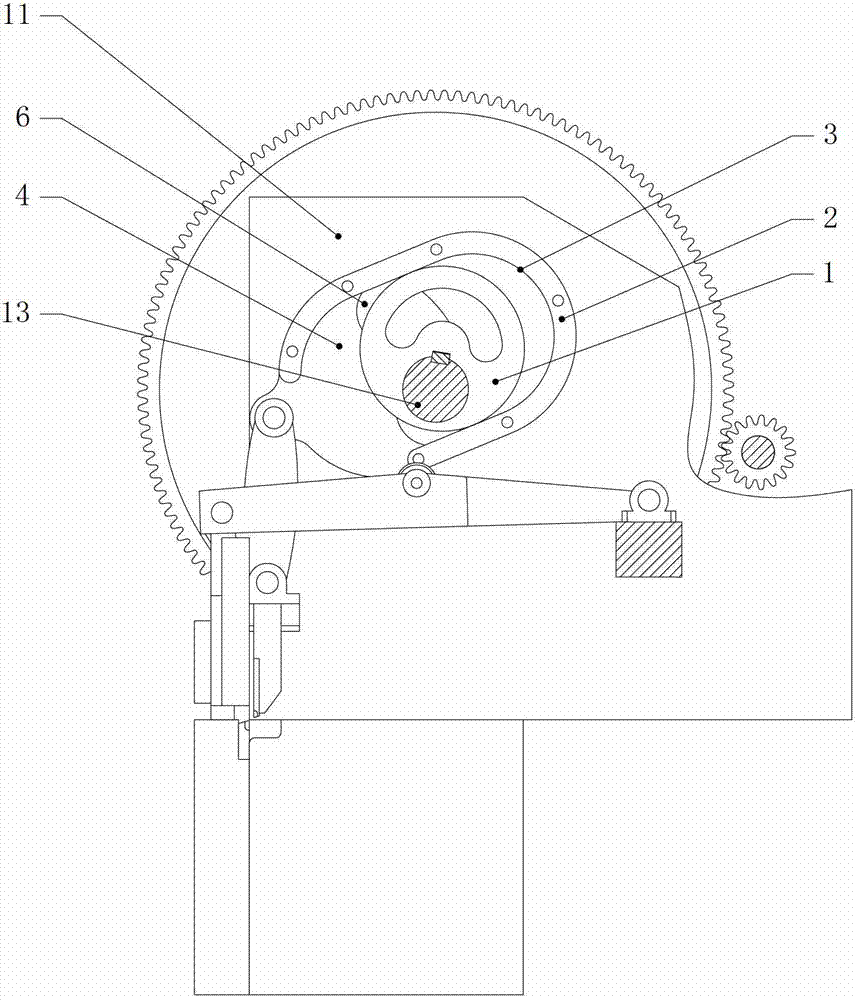

[0018] The specific embodiment of the present invention is shown in the accompanying drawings, which is characterized in that the actuator includes an eccentric wheel 1, a pendulum block housing 2, an eccentric wheel groove 3, a sealing cover I4, a sealing cover II5, an arc-shaped main shaft groove I6, an arc Shaped main shaft groove II7, rotating shaft I8, rotating shaft II9; eccentric wheel 1 is symmetrically installed on the main shaft 13 between the side support I10 and the T-frame 12 of the shearing machine and between the side support II11 and the T-frame 12, and the eccentric The connection mode between the wheel 1 and the main shaft 13 is a key connection; the inside of the pendulum block housing 2 is processed with an eccentric wheel groove 3, the eccentric wheel 1 is placed in the eccentric wheel groove 3, and is connected with the eccentric wheel groove 3 by sliding friction; the sealing cover I4 and the sealing cover II5 are respectively fixed on both sides of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com