Belt, magnetic roller, method for producing thereof, and image forming apparatus using the same

A technology of an imaging device and a magnetic roller, which is applied to an electrical recording process using a charge pattern, equipment and instruments for an electrical recording process applying a charge pattern, etc., can solve problems such as insufficient solution of adverse effects, and achieve reduction in non-uniformity. , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

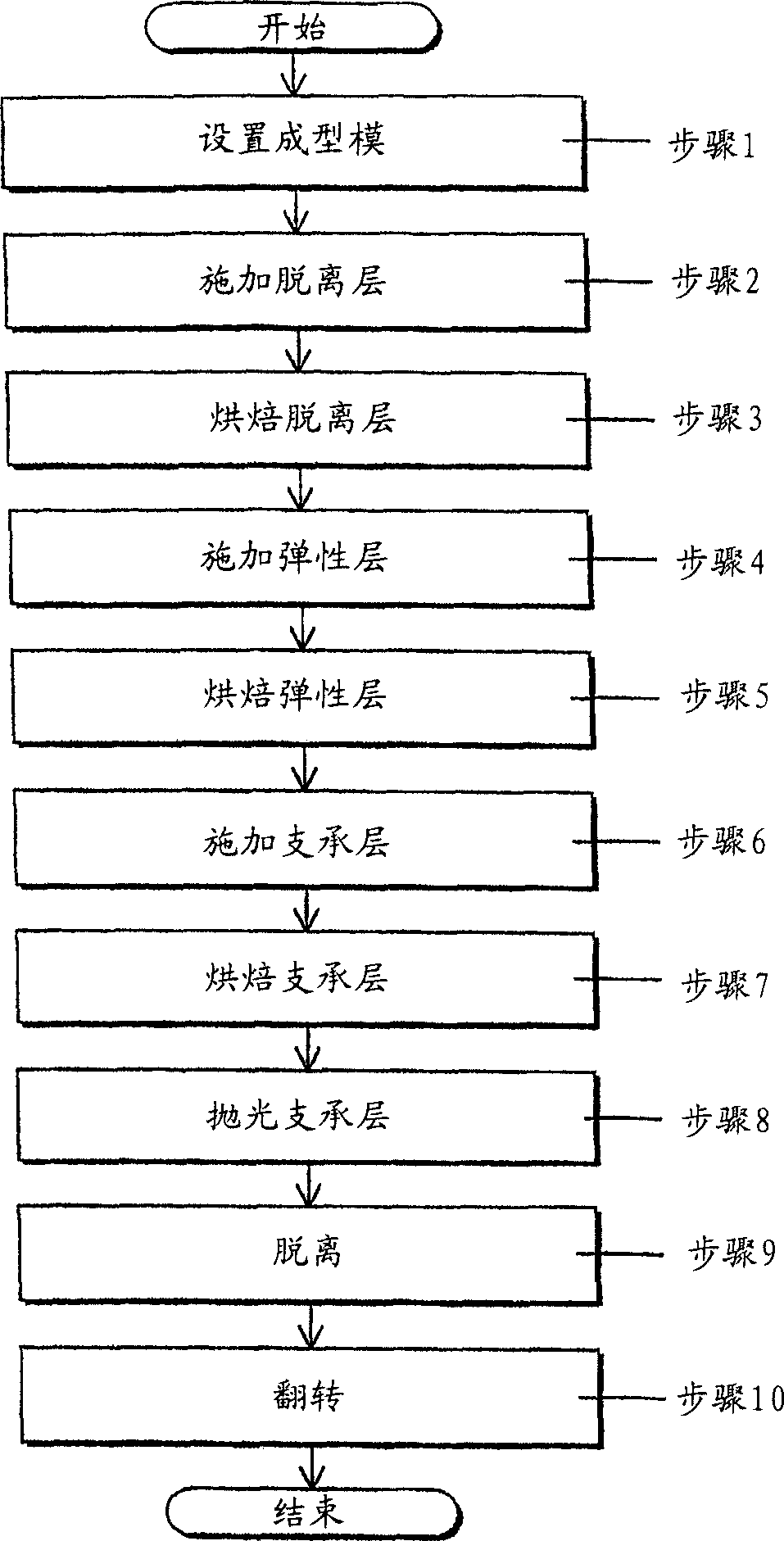

[0094] The method for producing the fixing belt according to Embodiment 1 of the present invention includes:

[0095] Applying a release layer including a fluoropolymer to a mold surface of the molding mold;

[0096] The release layer applied by baking;

[0097] Applying an elastic layer to one surface of the release layer, and the surface of the release layer is opposite to the mold surface when viewed from the release layer;

[0098] The elastic layer applied by baking;

[0099]Applying a support layer including a heat-resistant synthetic resin to one surface of the elastic layer, and the surface of the elastic layer is opposite to the mold surface when viewed from the elastic layer;

[0100] Support layer applied by baking;

[0101] Remove the unevenness of the support layer; and

[0102] The release layer, elastic layer and supporting layer are separated from the mold surface.

[0103] image 3 It is a flowchart showing each process according to Embodiment 1 of the present in...

Embodiment 2

[0143] The method for producing the fixing belt according to Embodiment 2 of the present invention includes:

[0144] Applying a release layer including a fluoropolymer to a mold surface of the molding mold;

[0145] The release layer applied by baking;

[0146] Applying an elastic layer to one surface of the release layer, and the surface of the release layer is opposite to the mold surface when viewed from the release layer;

[0147] The elastic layer applied by baking;

[0148] Applying a support layer including a heat-resistant synthetic resin to one surface of the elastic layer, and the surface of the elastic layer is opposite to the mold surface when viewed from the elastic layer;

[0149] Dry the applied support layer;

[0150] Remove the unevenness of the supporting layer;

[0151] The support layer applied by baking; and

[0152] The release layer, elastic layer and support layer are separated from the mold surface.

[0153] Hereinafter, in this embodiment, the difference...

Embodiment 3

[0167] In Embodiments 1 and 2, the present invention is applied to the fixing belt. However, the present invention can also be applied to a transfer belt as described below.

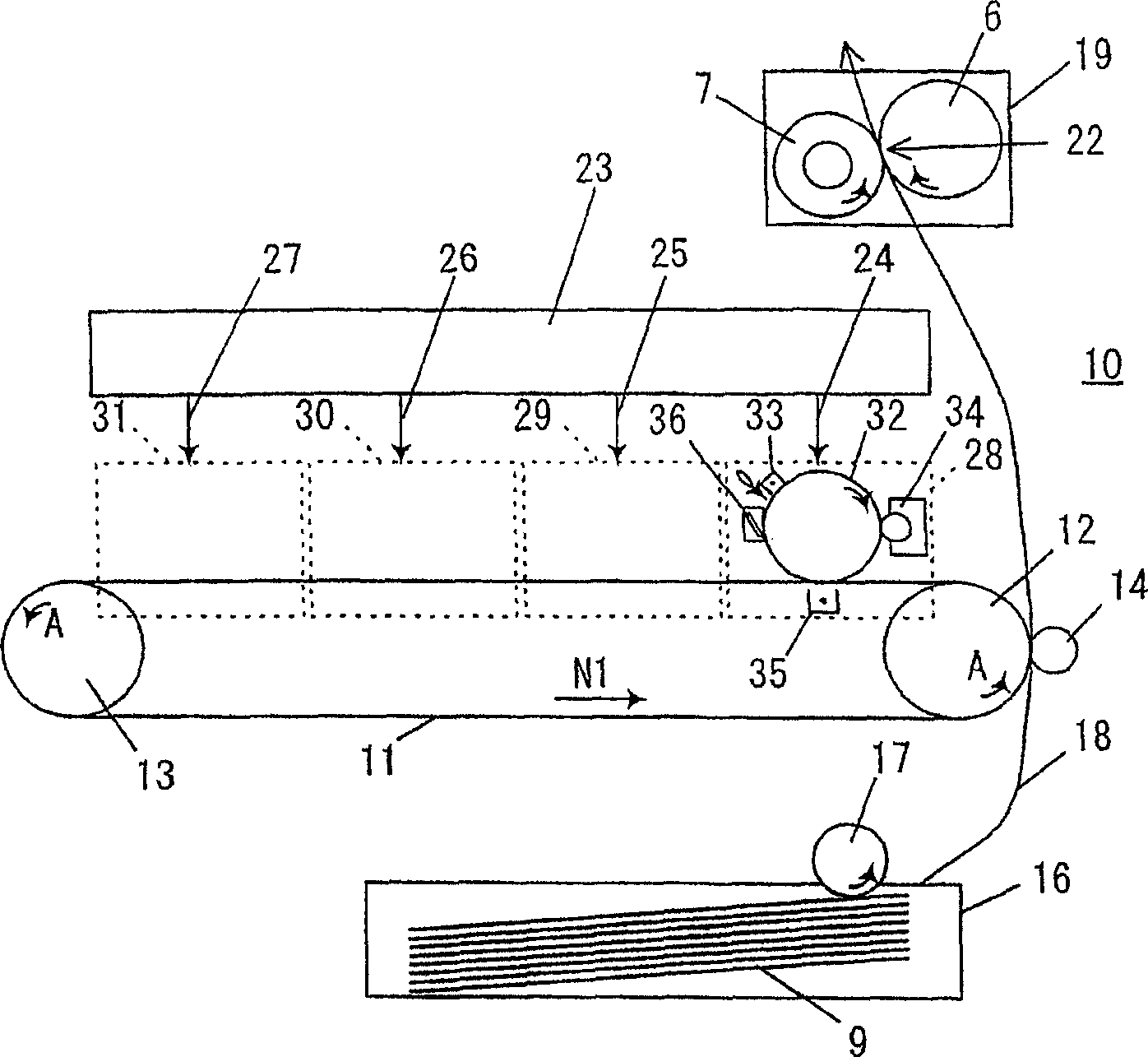

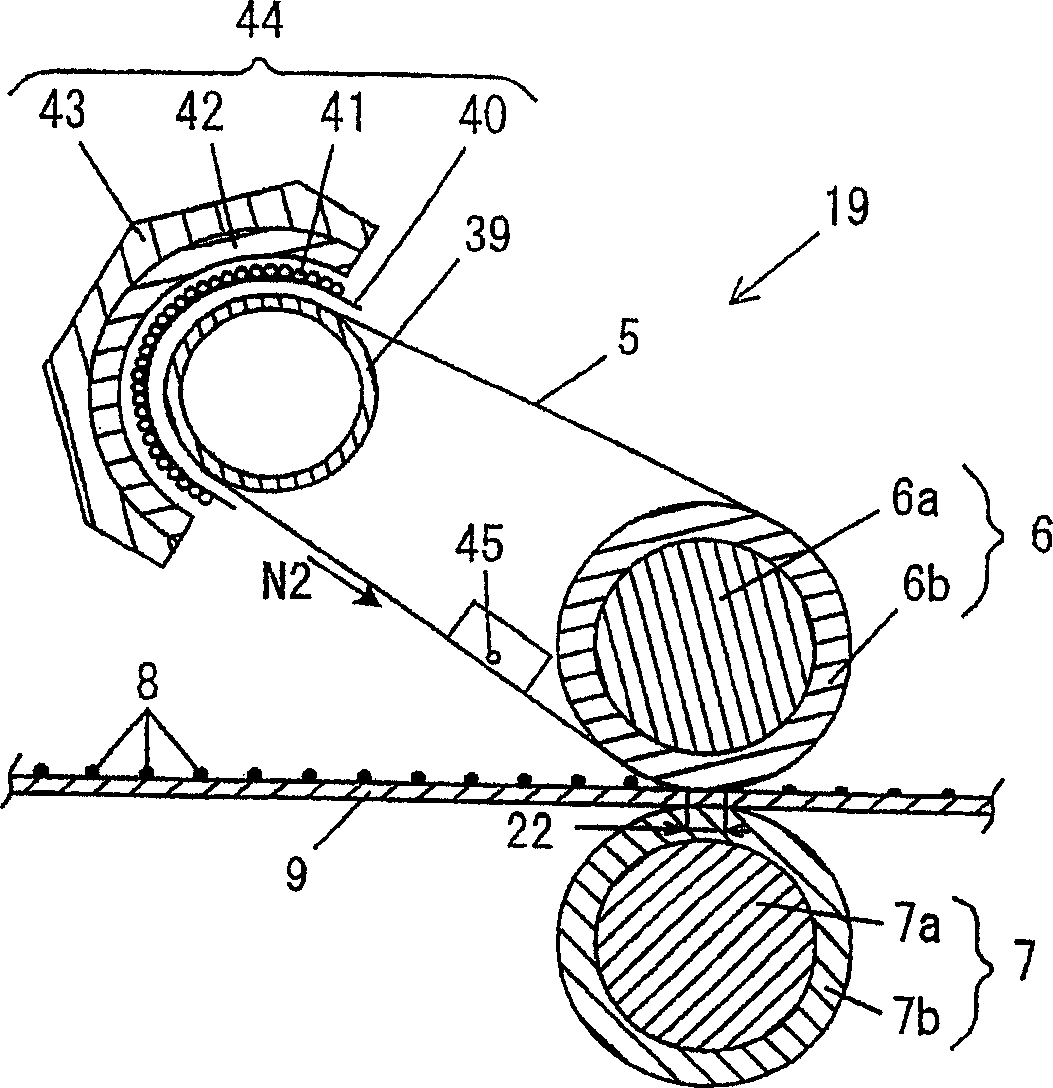

[0168] Below, will refer to Picture 10 And FIG. 11 describes an imaging apparatus according to Embodiment 3 of the present invention. Picture 10 It is a cross-sectional view of an image forming apparatus according to Embodiment 3 of the present invention.

[0169] Picture 10 The imaging device in is compatible with figure 1 Tandem system of similar imaging devices. However, the present invention is not limited to a tandem system of imaging devices, and can be applied to various imaging devices, such as a monochrome imaging device or an imaging device adopting a surface continuous system.

[0170] In this embodiment, the imaging device can form a medium (width, 197 mm) suitable for A4 size. In addition to the other aspects indicated, a length of 210-230mm (its longitudinal and Picture 10 The paper is pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com