Etching solution for multilayer thin film having copper layer and molybdenum layer contained therein

A multi-layer thin film and etching solution technology, which is applied to electrical components, circuits, and electric solid-state devices, etc., can solve the problem that it cannot fully cope with the large-scale and high-resolution displays, the cross-sectional shape of the wiring cannot be fully satisfied, and the environmental measures cannot be fully satisfied. and other problems, to achieve the effect of prolonging the life of the plating solution, good wiring cross-section shape, and less unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

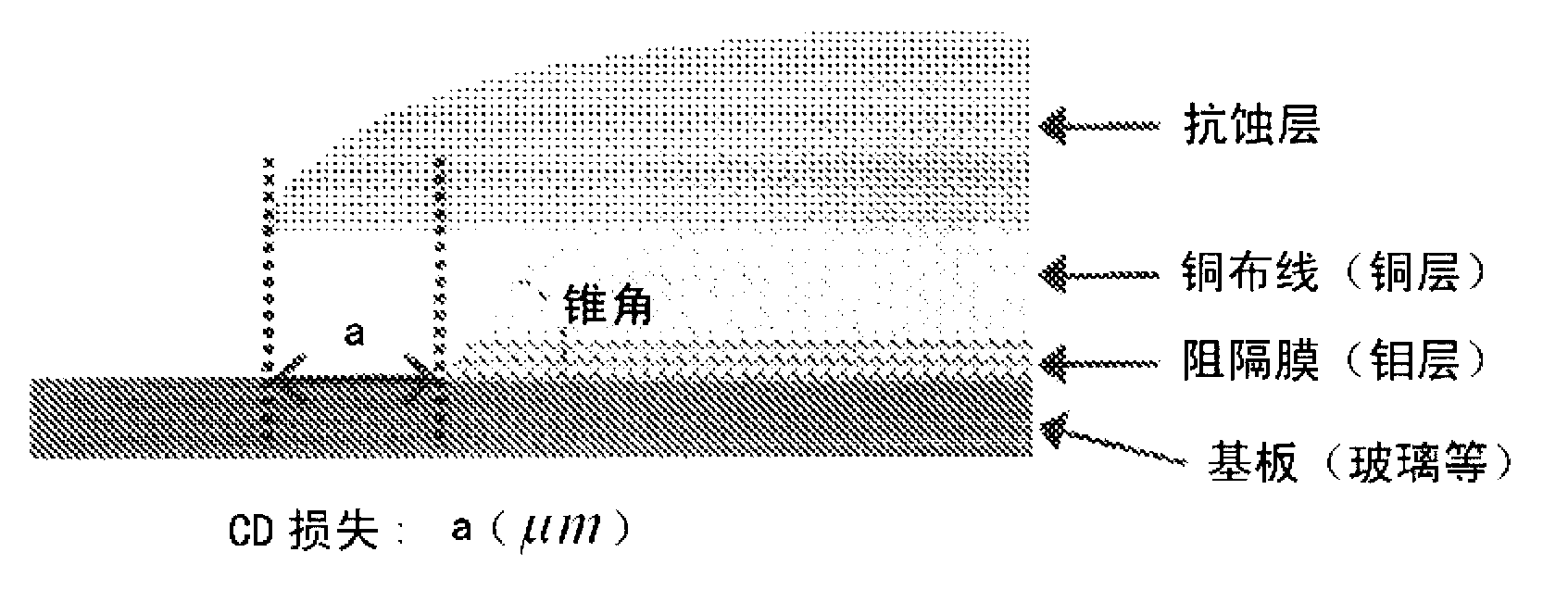

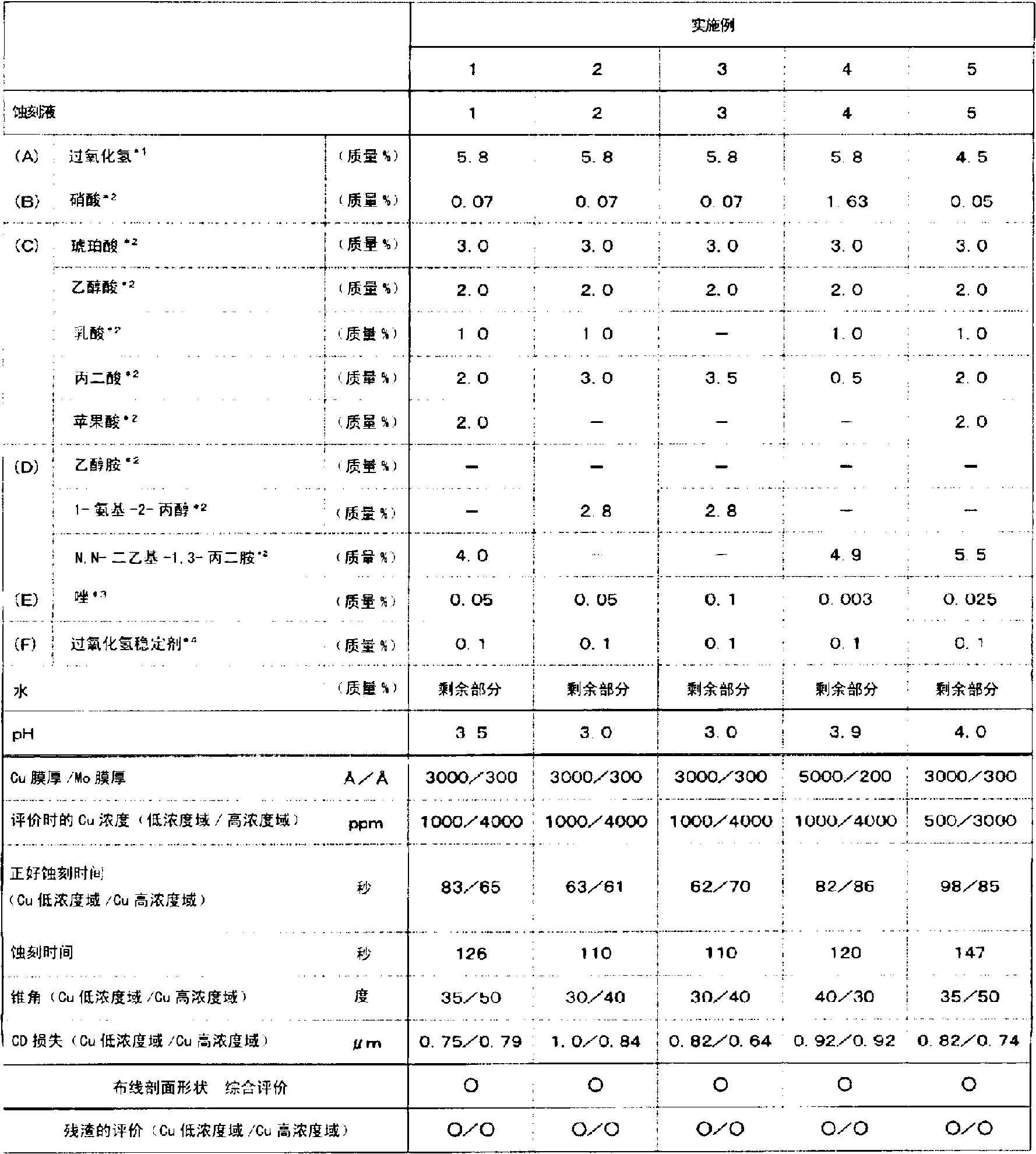

[0084] The multilayer film comprising copper layer and molybdenum layer obtained by the production example is shower sprayed in the etchant shown in Table 2, and the operation of etching is repeated at 35 ° C. For the resulting etched copper layer and molybdenum layer The multi-layer thin film sample of the above-mentioned method is observed by SEM to obtain that the copper ion concentration (sometimes recorded as Cu concentration) in the etching solution is in the low concentration range (200-1000ppm, sometimes recorded as Cu low concentration range) and in the high Cone angle, CD loss (μm) in concentration range (3000-4000ppm, sometimes recorded as Cu high concentration range).

[0085] In addition, the time when the object to be etched in the region where the resist is not patterned is visually judged is etched is set as just etching time (just etching time), and any time within the range of 110 to 300% of the just etching time The time for performing the etching process (o...

Embodiment 6 and 7

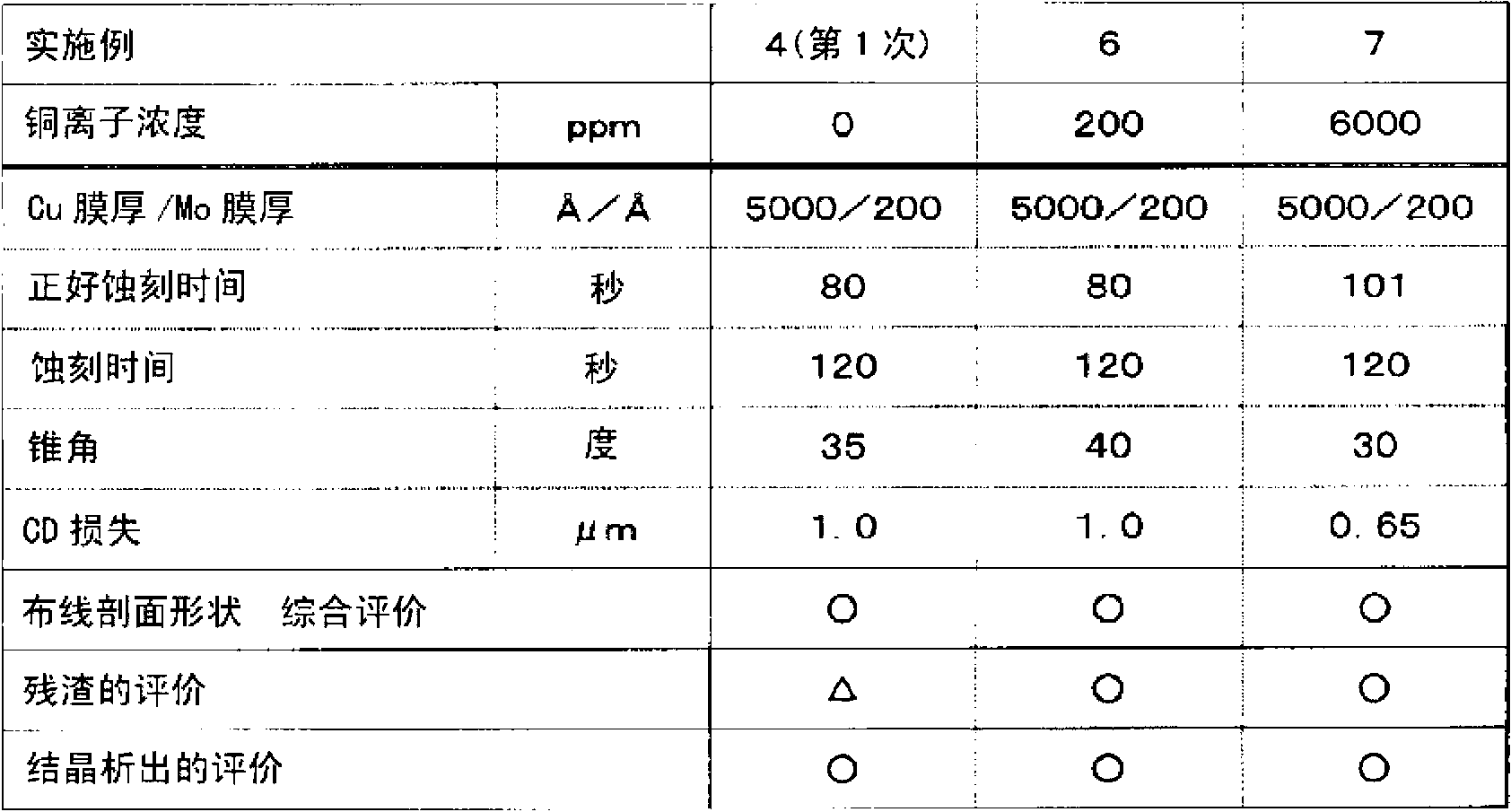

[0093] Except having previously added copper powder to the etching solution 4 used in Example 4 so that the copper ion concentration may be 200ppm and 6000ppm, it carried out similarly to Example 4, and etched, respectively, as Examples 6 and 7. Table 3 shows the evaluation of the taper angle, CD loss (μm), and residue of the multilayer thin film including the copper layer and the molybdenum layer obtained by performing the first etching. In addition, Table 3 shows the evaluation of the taper angle, CD loss (μm), and residue of the multilayer thin film including the copper layer and the molybdenum layer obtained by performing the first etching in Example 4.

[0094] [table 3]

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com