Double-sided Schottky controlled fast recovery diode device and preparation method

A recovery diode and Schottky contact technology, applied in the field of microelectronics, can solve the problems of high temperature reverse bias leakage, high induced voltage, affecting circuit reliability, etc., to reduce dynamic loss, improve reverse recovery softness, reduce The effect of small injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific drawings and embodiments.

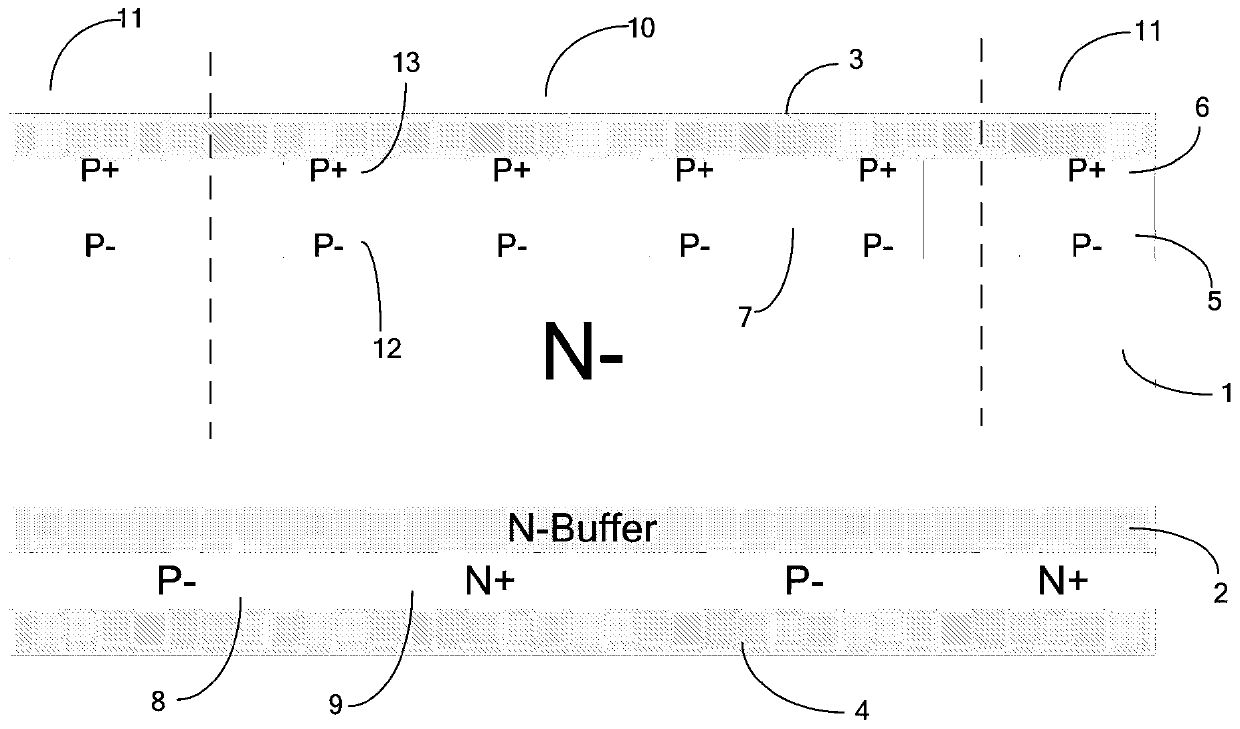

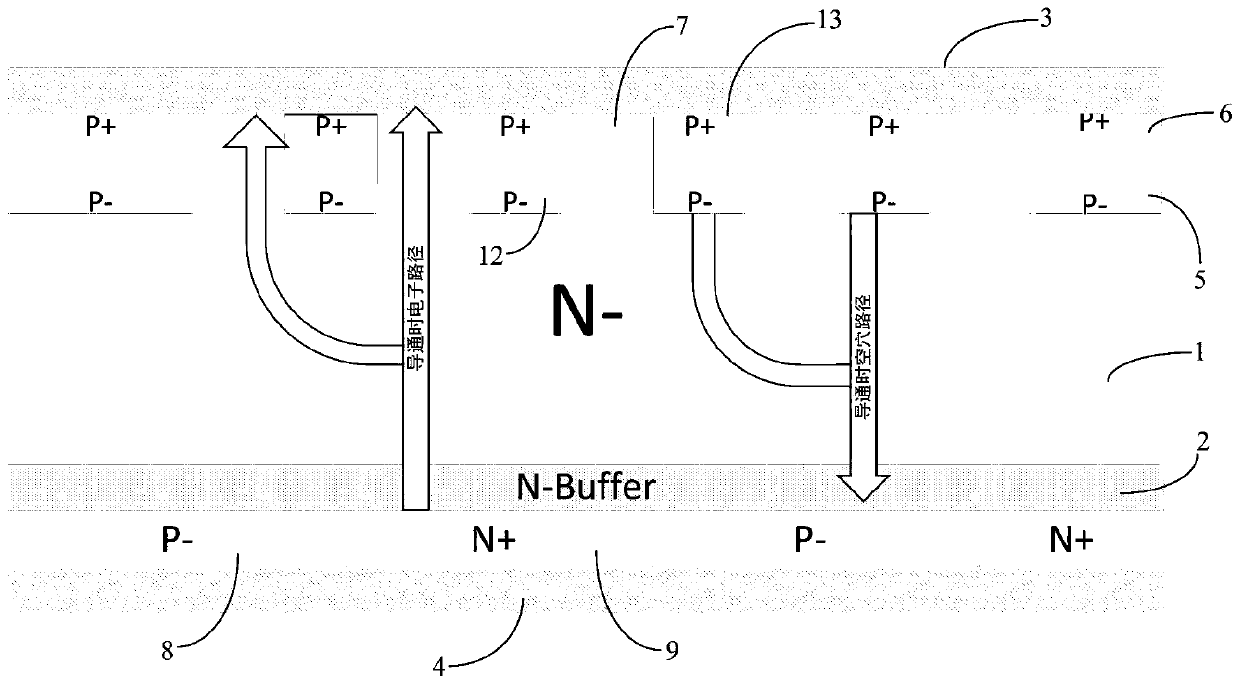

[0040] Such as figure 1 Shown: In order to obtain a faster reverse recovery time, reduce dynamic loss, improve softness, and reduce high-temperature leakage, the present invention includes a semiconductor substrate, and the semiconductor substrate includes an N-type substrate 1 and an N-type substrate. The N-type buffer layer 2 adjacent to the bottom 1 is provided with an active region 10 in the central region of the N-type substrate 1;

[0041] On the cross-section of the diode device, the active region 10 includes a number of alternately distributed active P columns and active N columns 7, the active P columns and active N columns 7 are located in the upper part of the N-type substrate 1 Anode metal 3 is set on N-type substrate 1, the active P column is in ohmic contact with anode metal 3 on N-type substrate 1, and active N column 7 is in contact with anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com