Hydraulic drive system of inertial friction welding machine for key parts of aero-engine

A technology of aero-engine and friction welding machine, which is applied in fluid pressure actuation system components, fluid pressure actuation system testing, mechanical equipment, etc. It can solve the problems of high cost and high installed power, and achieve reduced installed power and outstanding cost performance , The effect of reducing the installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

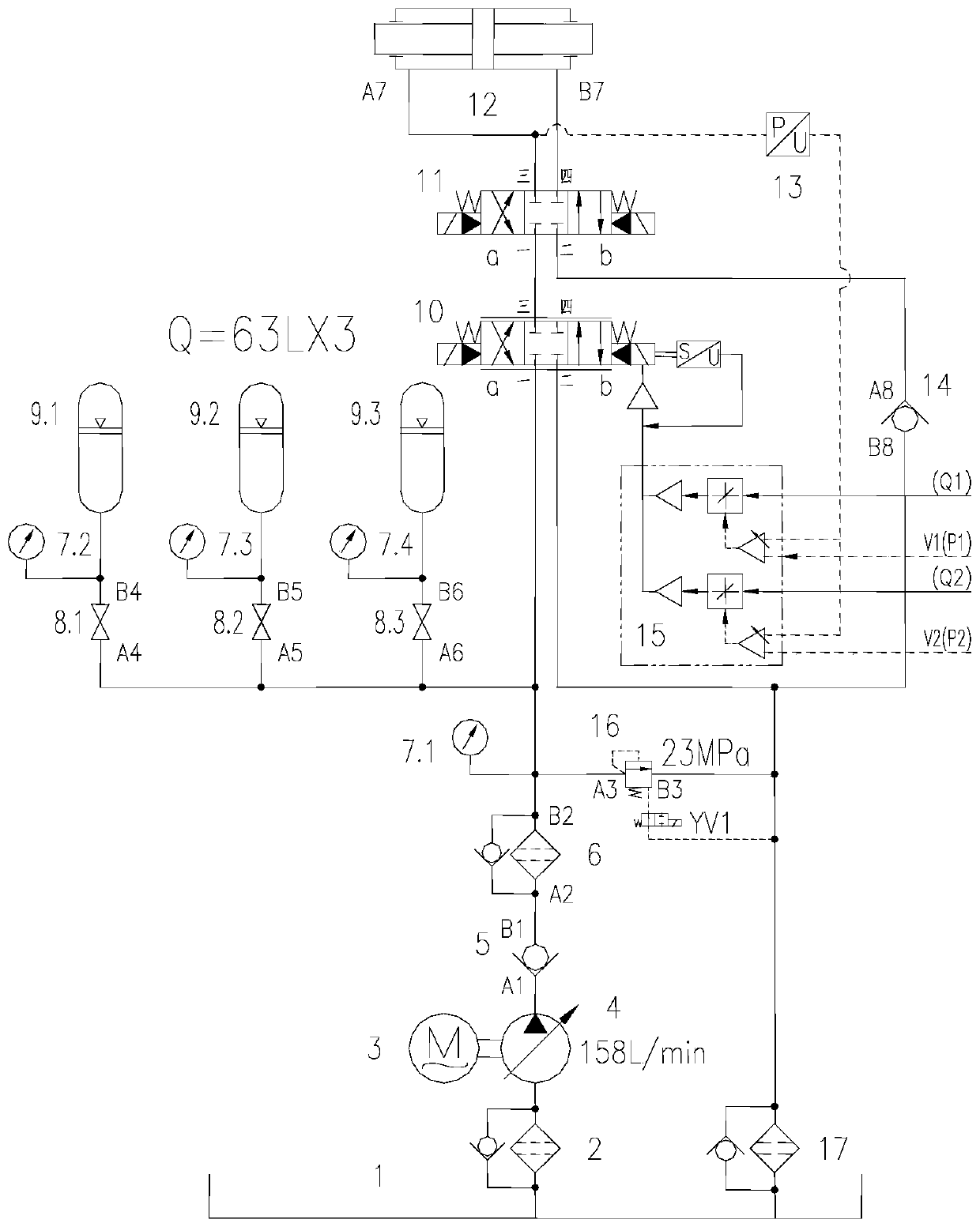

[0017] Such as figure 1 As shown, the hydraulic drive system of the inertial friction welding machine, a key component of the aero-engine of the present invention, includes a high-pressure large-flow plunger pump 4, a first accumulator 9.1, a second accumulator 9.2, a third accumulator 9.3, and a servo valve 10. Three-position four-way electro-hydraulic directional valve 11, upsetting cylinder 12.

[0018] The high-pressure large-flow plunger pump 4 is a variable pump, driven by the motor 3, the pressure is set by the electromagnetic relief valve 16, and the set value is 23MPa; the lower end of the high-pressure large-flow plunger pump 4 is connected to the self-sealing suction filter 2, high pressure The upper outlet of the high-flow plunger pump 4 is connected to the forward port A1 of the tubular check valve 5, and the reverse port B1 of the tubular check valve 5 is connected to the forward inlet A2 of the high-pressure oil filter 6, high pressure filter oil Reverse outlet B2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com