Continuously variable speed bicycle with friction wheel transmission

A friction wheel drive, continuously variable speed technology, applied in wheel transmission, vehicle gearbox, vehicle components and other directions, can solve the problems of high cost, limited speed change range, complex stepless speed change structure, etc., to achieve low cost, speed change The effect of large amplitude and stepless speed regulation is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific principles of use, but it is not intended to limit the protection scope of the present invention.

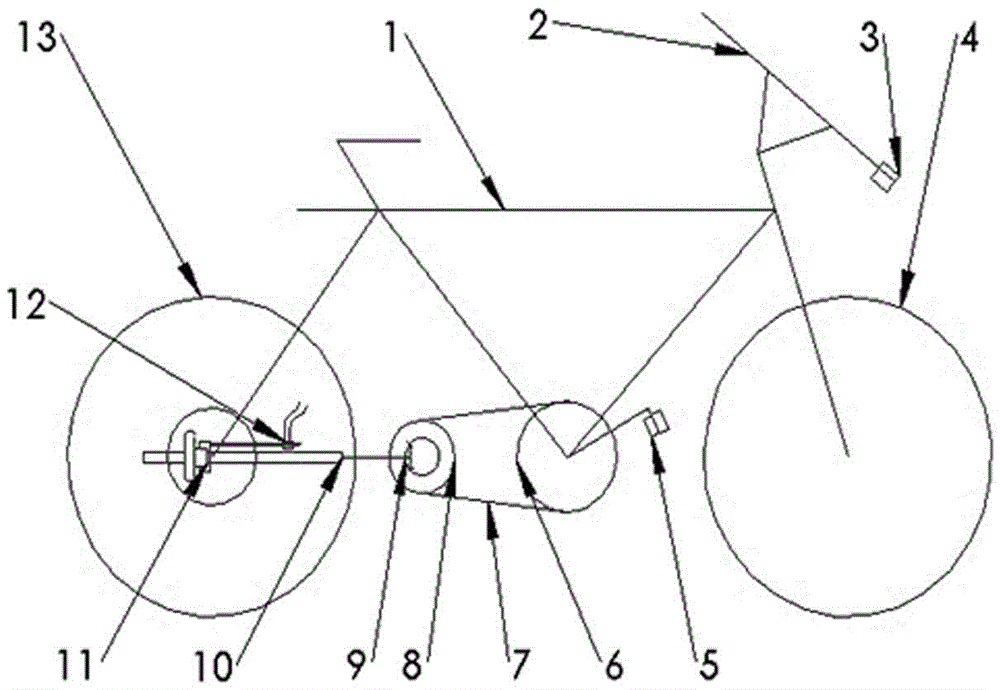

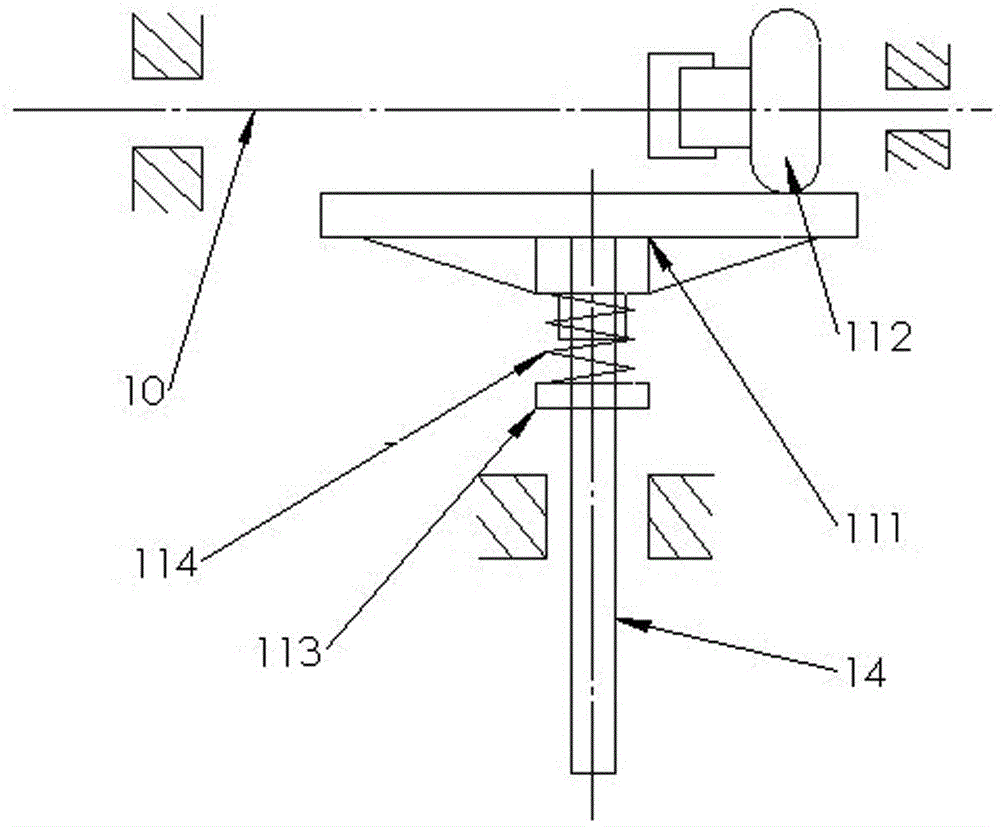

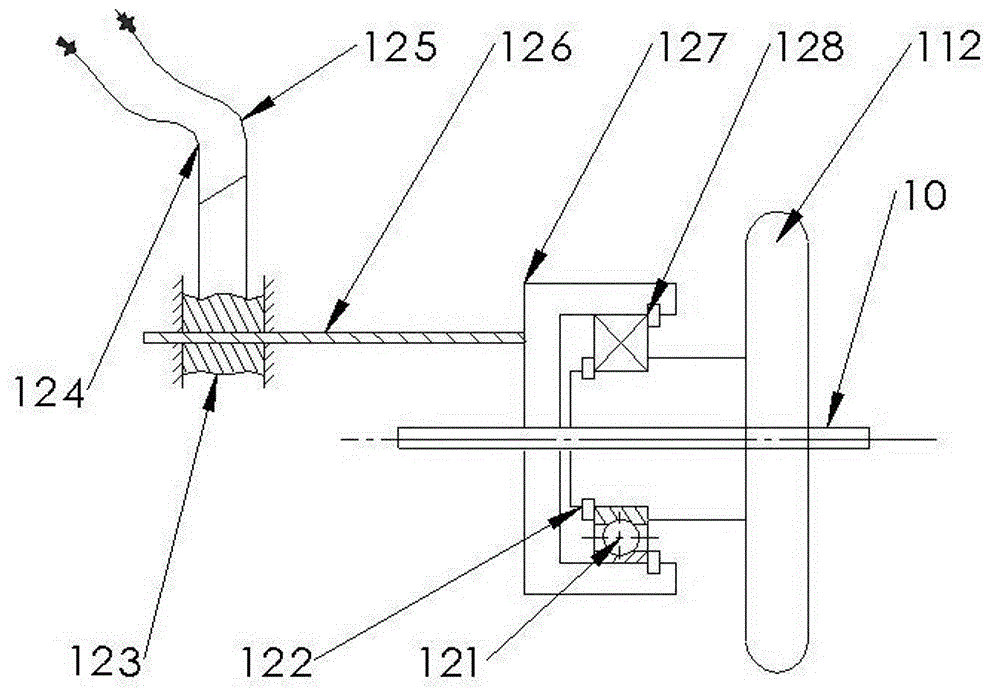

[0037] The continuously variable speed bicycle of the friction wheel transmission of the present invention comprises figure 1 Vehicle frame 1, handle 2, speed control handle 3, front wheel 4, pedal 5, front flywheel 6, chain 7, rear flywheel 8, rotating shaft 10, rear wheel 13 in the figure 2 Friction disc 111, friction wheel 112, adjustment nut 113, spring 114, deep groove ball bearing, rear axle 14 in the image 3 Among 121, snap ring (1) 122, winding nut 123, the first bidirectional steel wire rope 124, the second bidirectional steel wire rope 125, speed regulating screw 126, card wheel 127, snap ring (2) 128, Figure 4 The first bevel gear 91, the second bevel gear 92,

[0038] Rear flywheel 8 is installed on the rear fork of vehicle frame 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com