Patents

Literature

272results about How to "Realize stepless speed change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

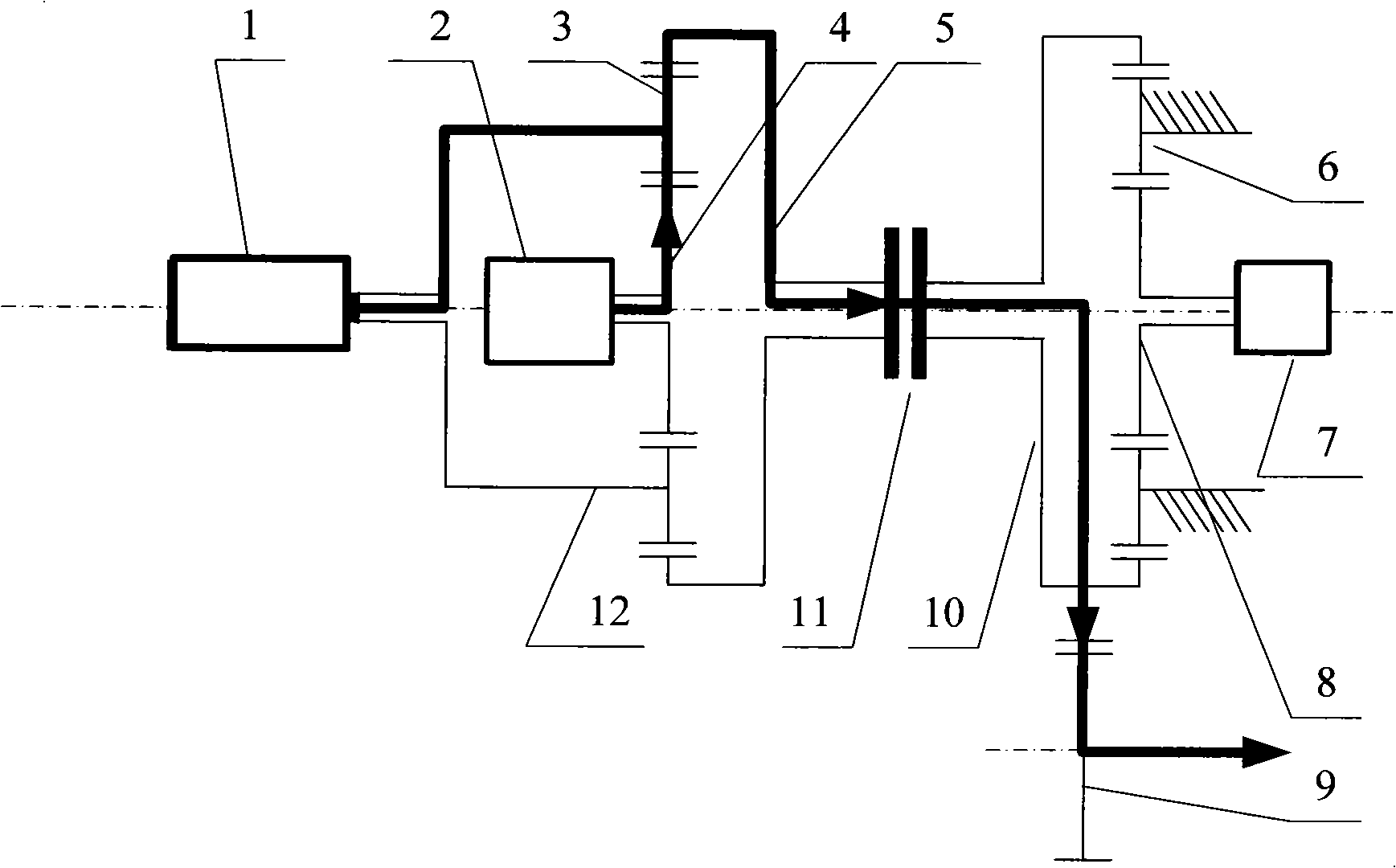

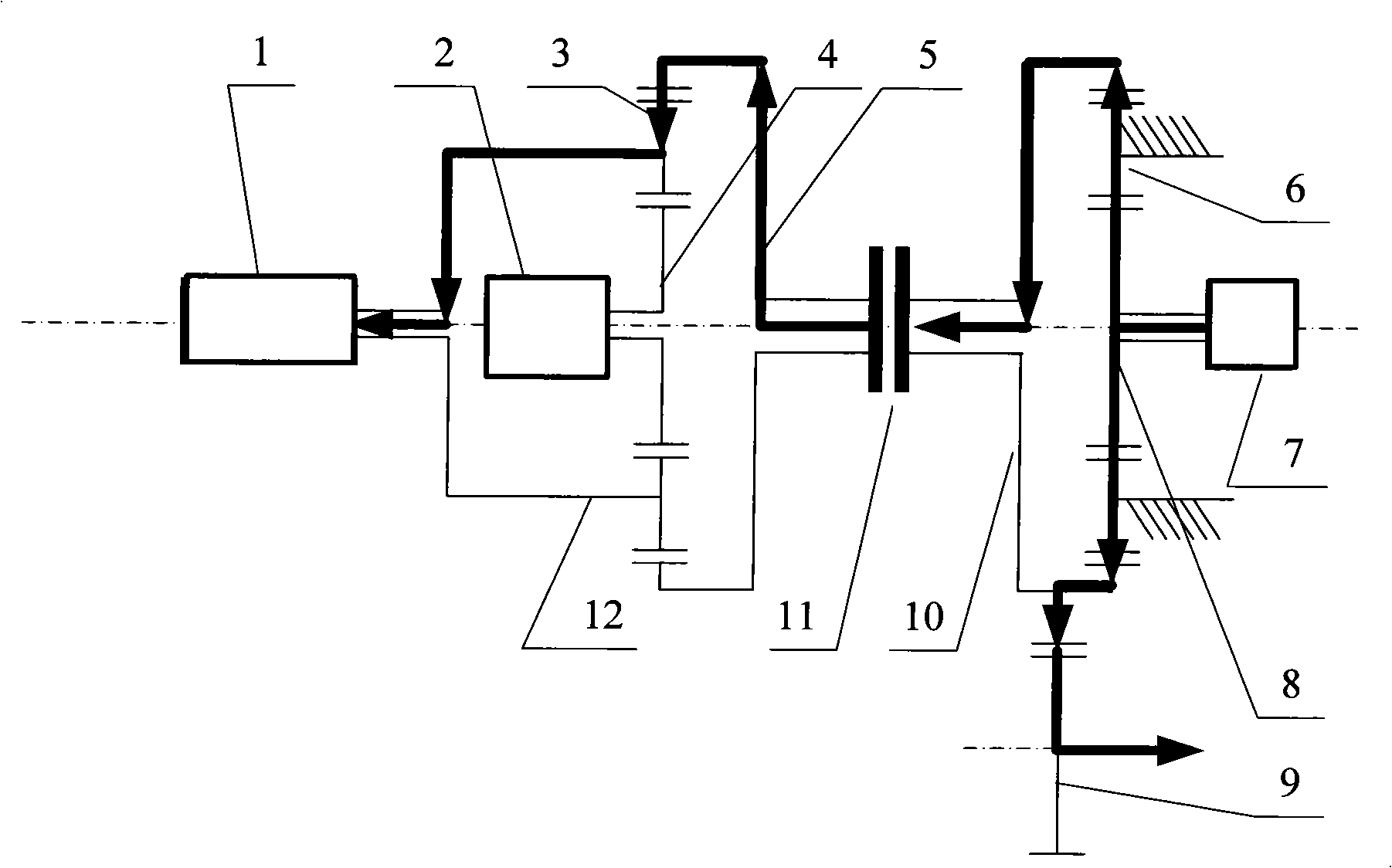

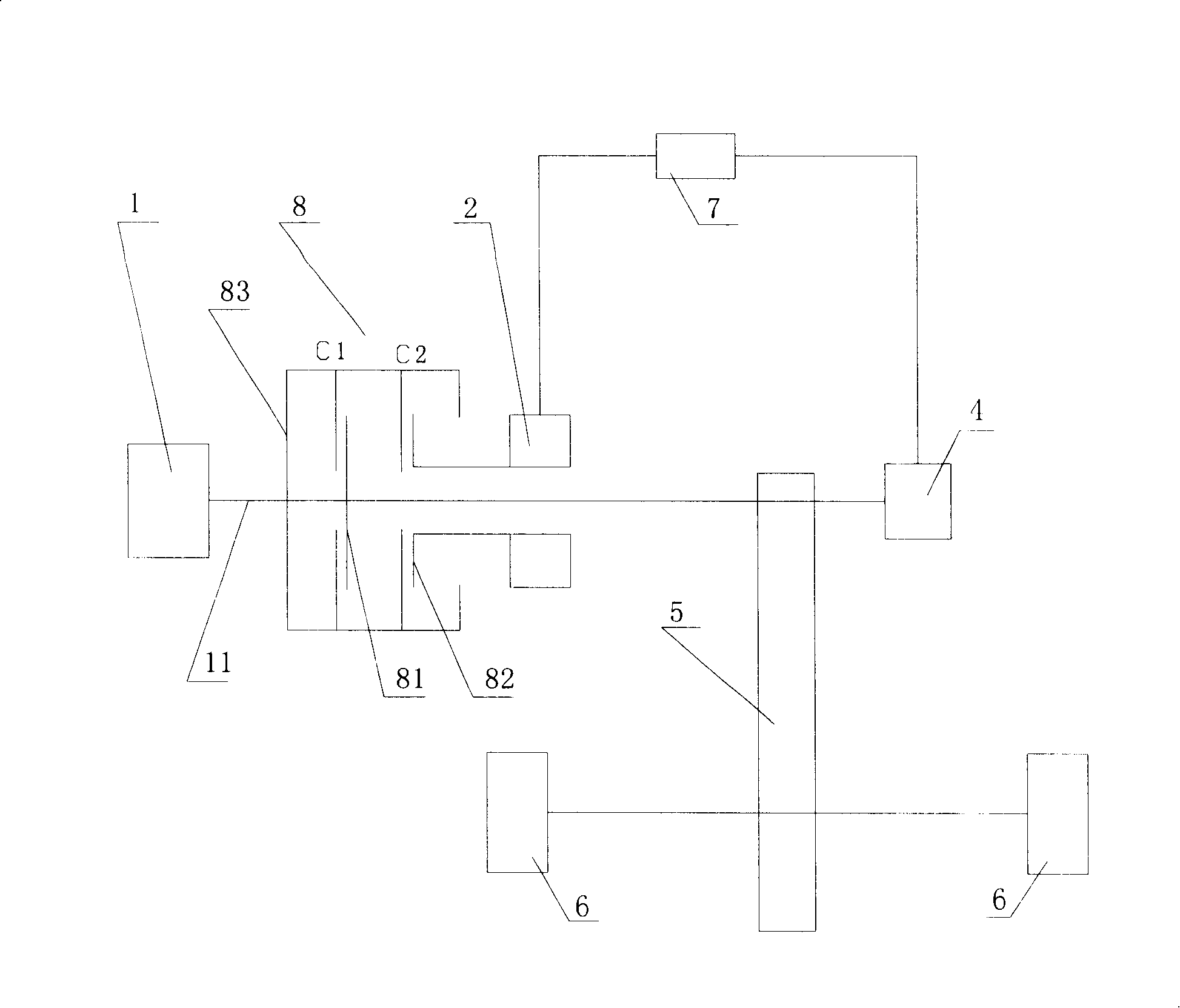

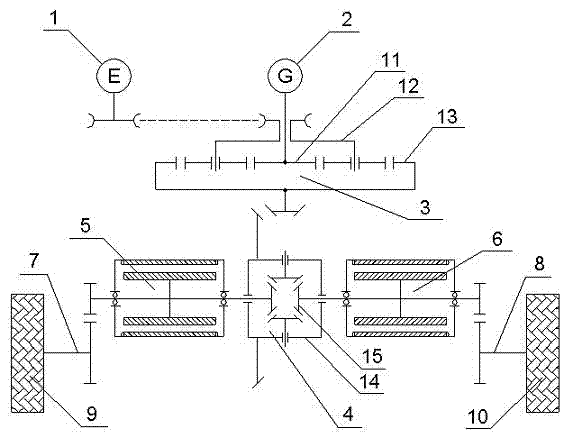

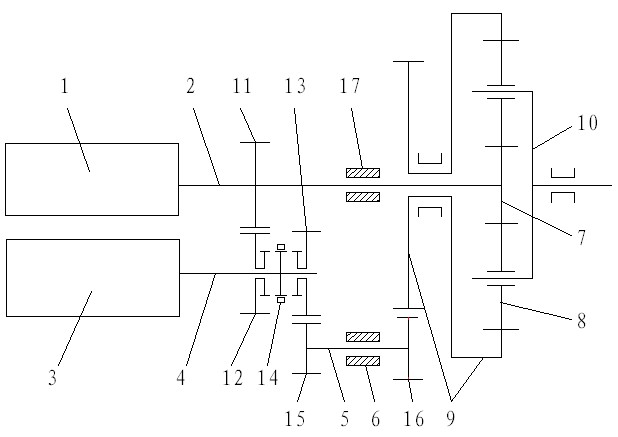

Hybrid power vehicle double electric machine double row planetary gear single clutch drive apparatus

InactiveCN101323243ALower requirementIncrease profitHybrid vehiclesGas pressure propulsion mountingStarter generatorVehicle frame

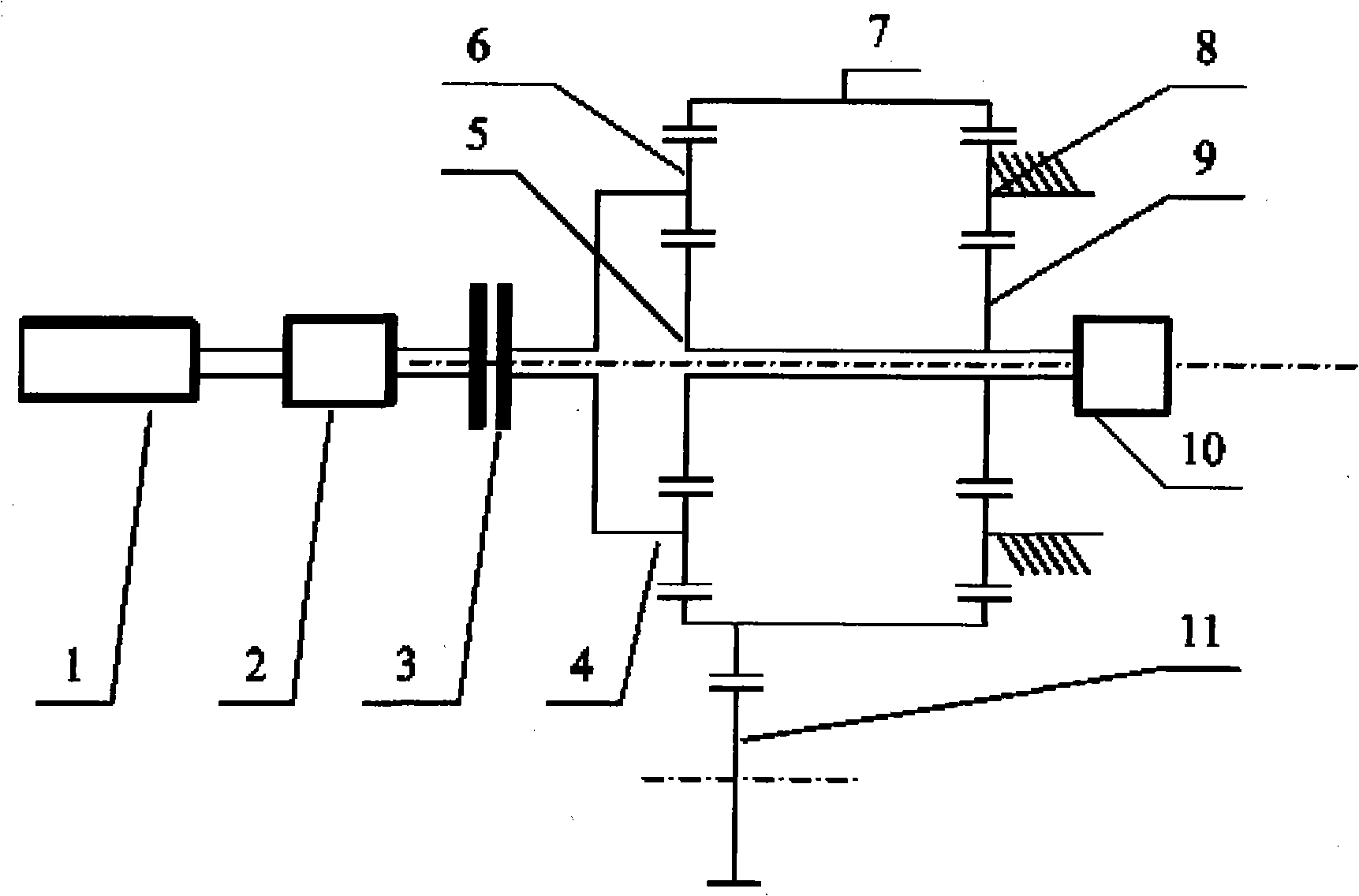

The invention discloses a twin-motor two-planet-row and single clutch driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; the front planet row is provided with a front planet row planet wheel and a front planet row sun gear; the back planet row is provided with a back planet row planet wheel and a back planet row sun gear; the front planet row and the back planet row share a gear ring. The output shaft of an engine is connected with the input end of an integrated starter generator; the output end of the integrated starter generator is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the planet wheel of the front planet row through a planet carrier; the sun gear of the front planet row is connected with a drive motor; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is also connected with the drive motor; the outside gear of the gear ring is normally engaged with a power take-off gear. The twin-motor two-planet-row and single clutch driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

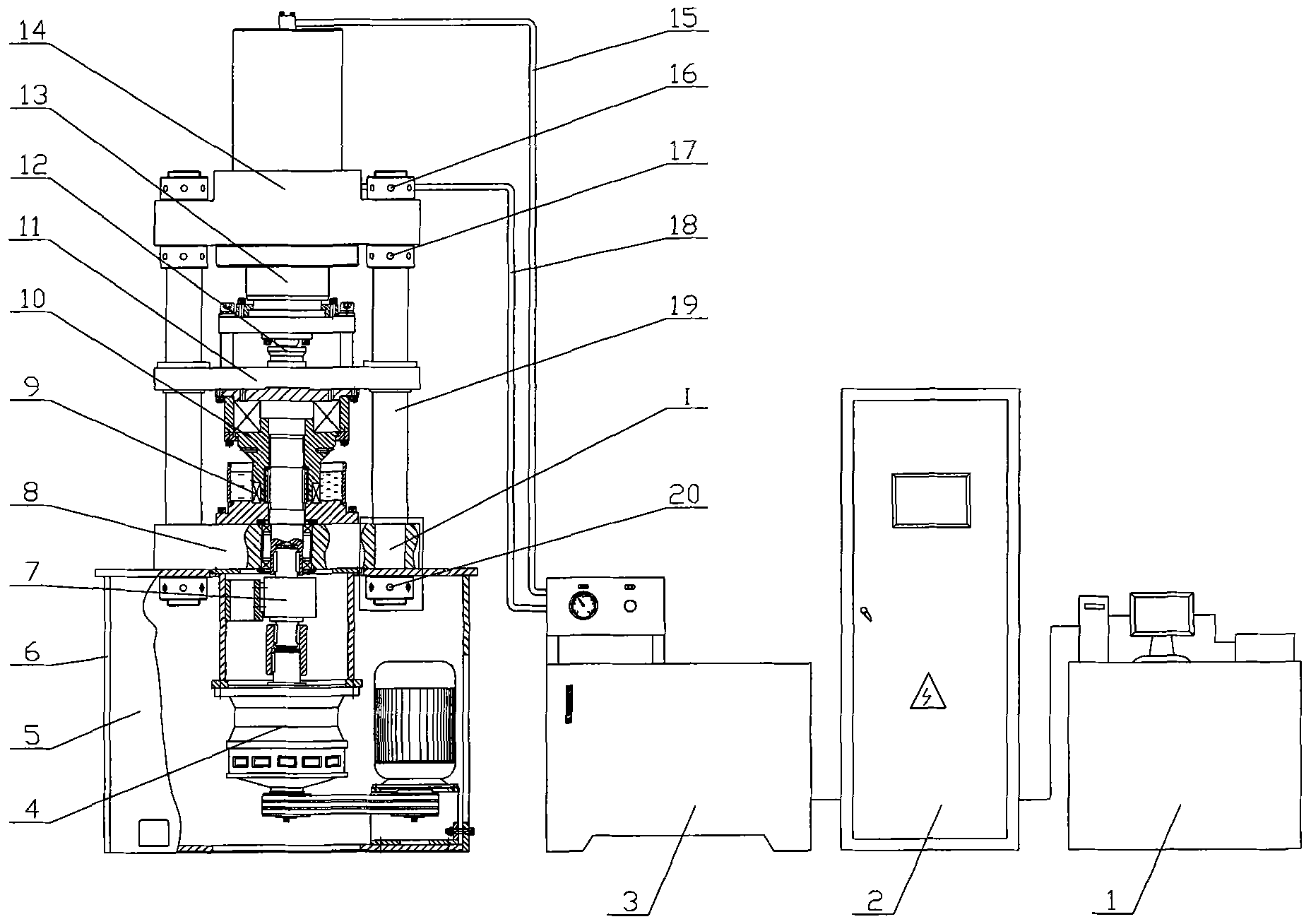

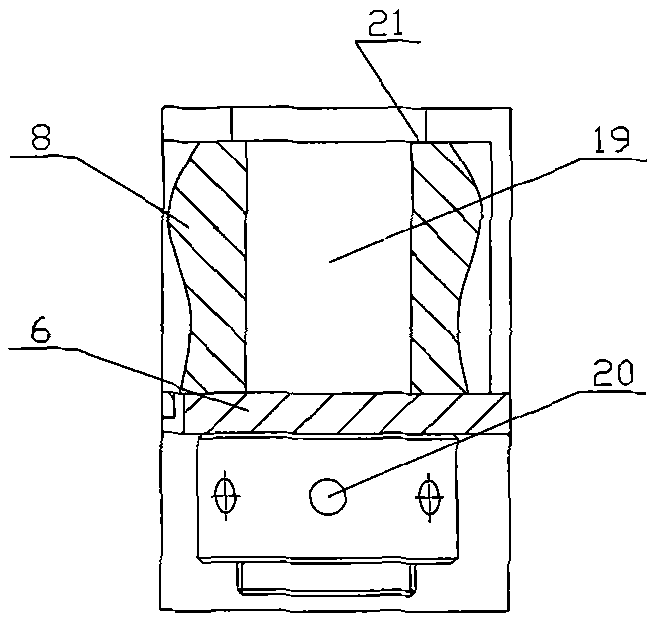

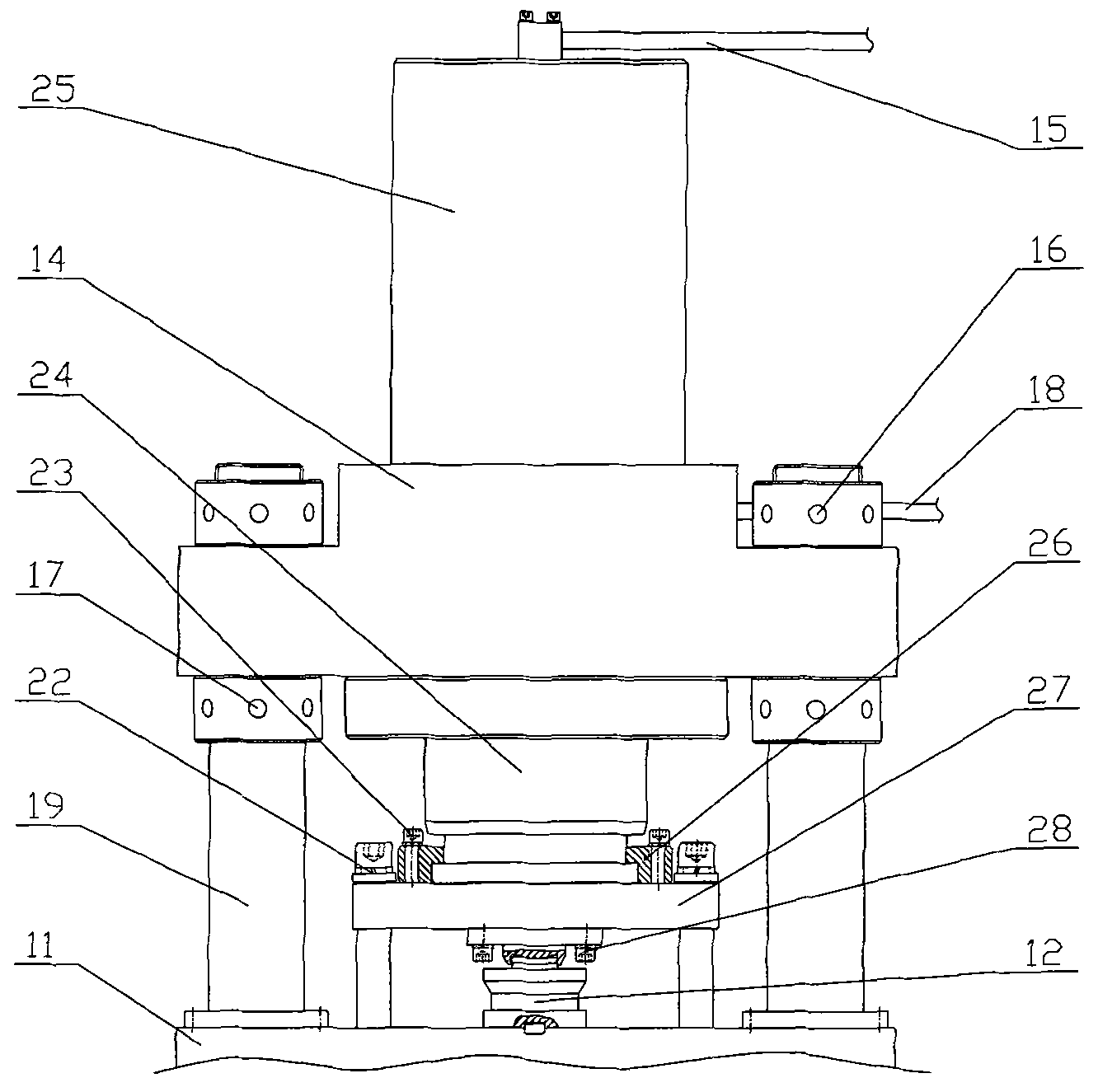

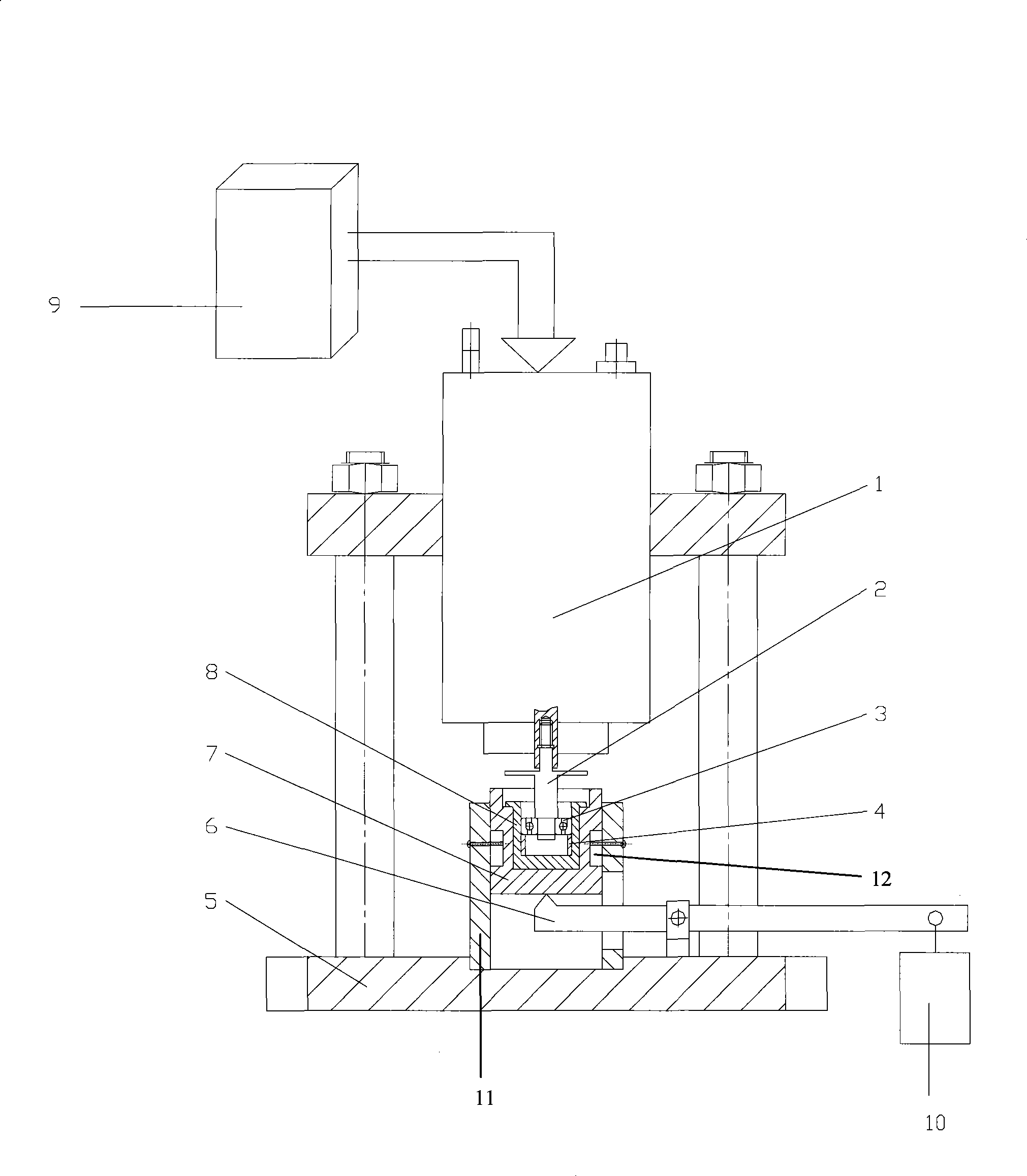

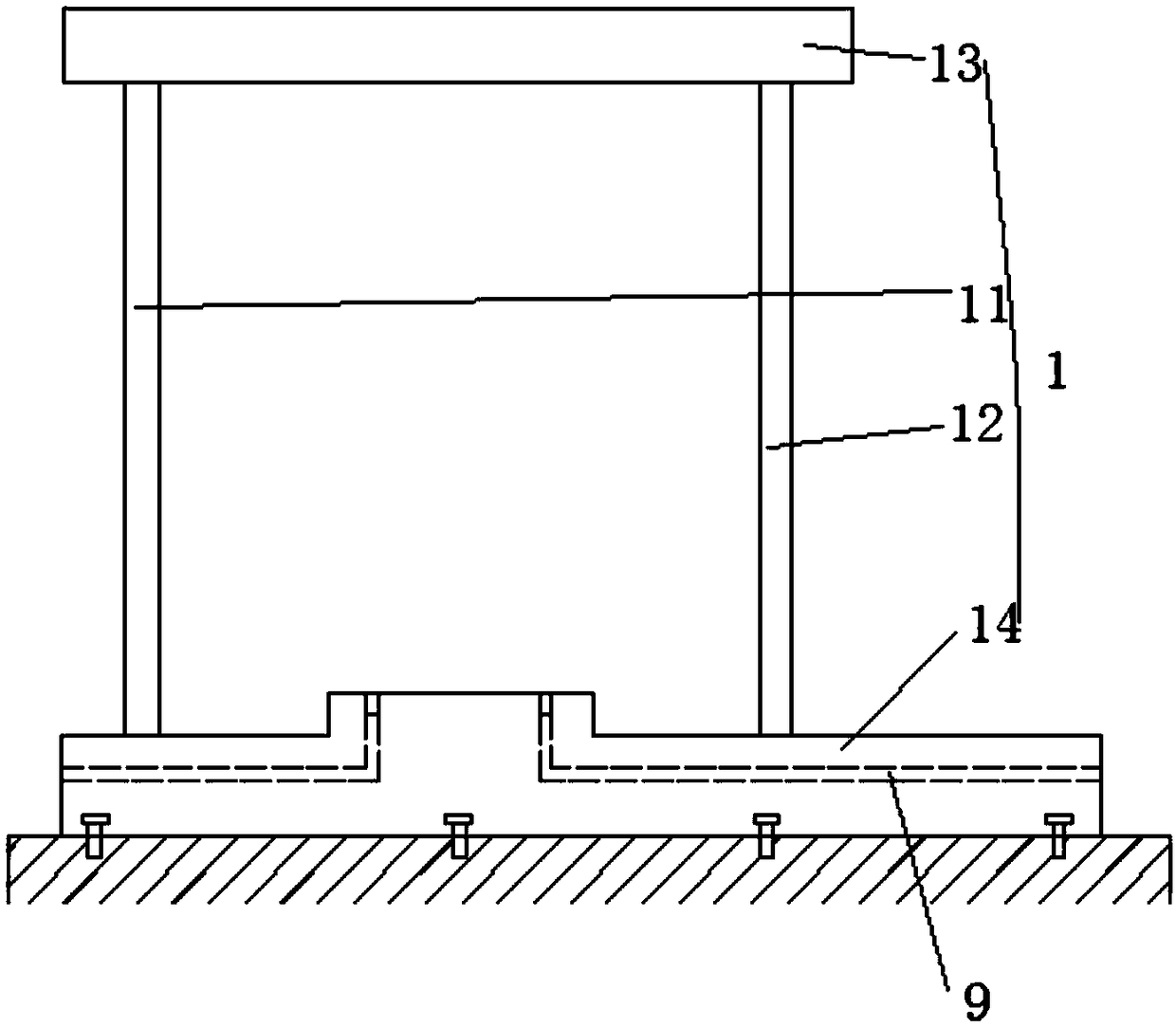

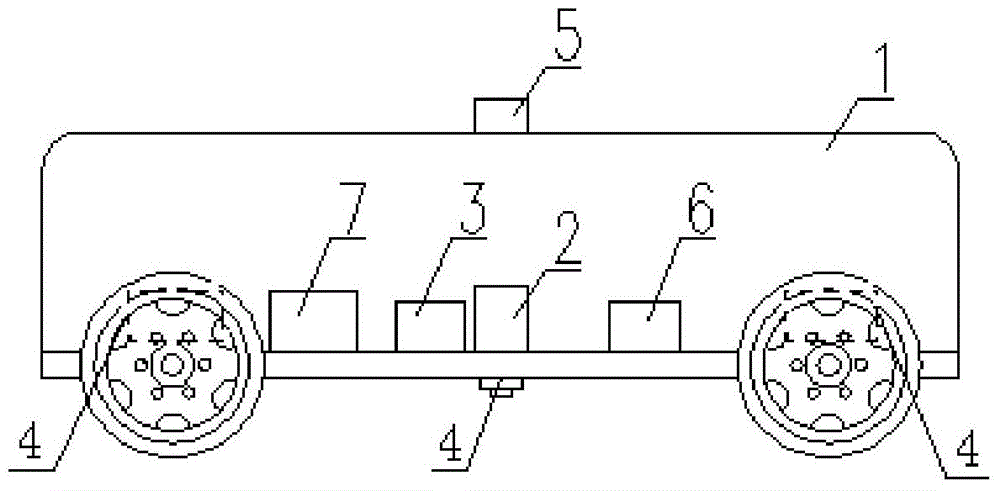

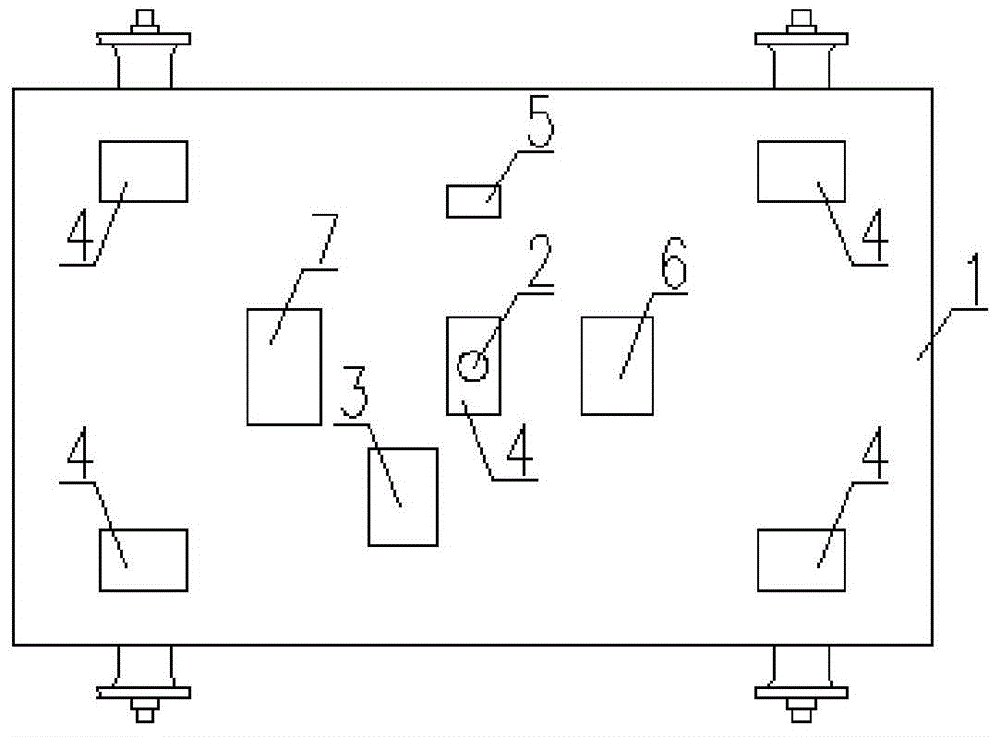

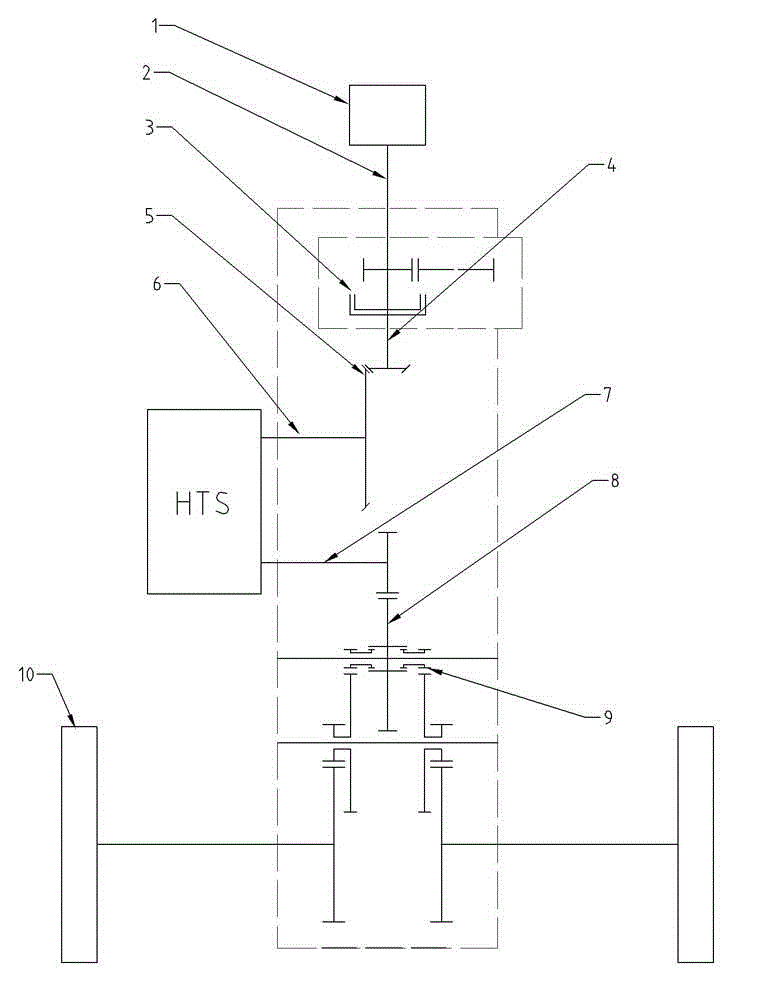

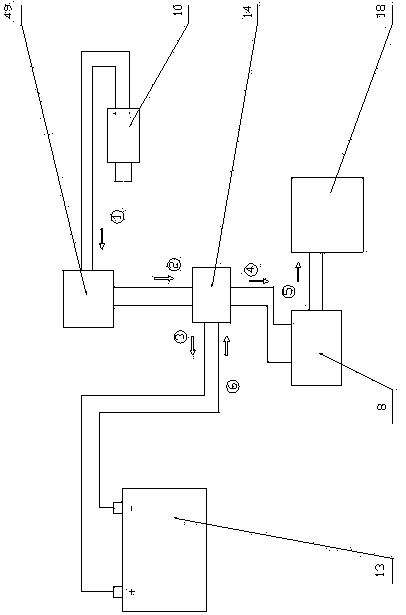

Tester for thrust bearing

ActiveCN102053015AConvenient for continuously variable speedRealize stepless speed changeMachine bearings testingHydraulic cylinderControl system

The invention provides a tester for a thrust bearing, comprising a loading system (13), a test bed component (10), a rotary transmission system (4), an electric system and a control system, wherein the loading system (13), the test bed component (10) and the rotary transmission system (4) are arranged on a stand component (5). The stand component (5) is taken as a basic frame, and the loading system (13) is vertically installed above the test bed component (10). A test press head (40) at the lower section of the test bed component (10) is pressured by a piston of a hydraulic cylinder (25), wherein a test bearing (9) is positioned on the test press head (40). The rotary transmission component (4) is arranged below the test bed component (10) to drive the test press head (40) to rotate by a transmission main shaft (39); and the running situations of the test bearing (9) are tested under the condition of setting parameter sum by utilizing a pressure sensor (12) and a torsion sensor (7). The tester is applied to testing a heavy-load thrust bearing with irregular size, has high degree of automation, and can properly control the feedback by a computer.

Owner:CHINA PETROLEUM & CHEM CORP +1

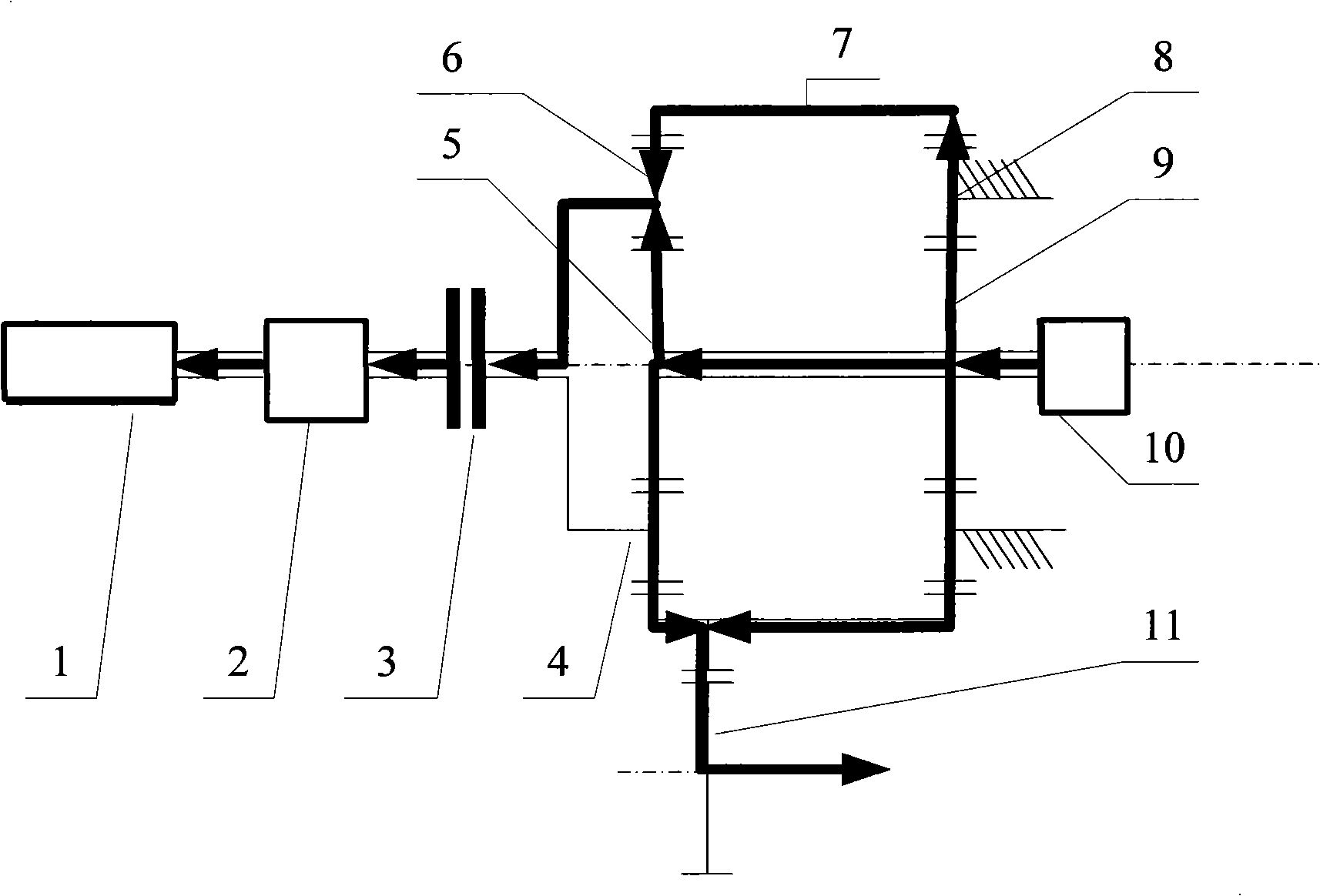

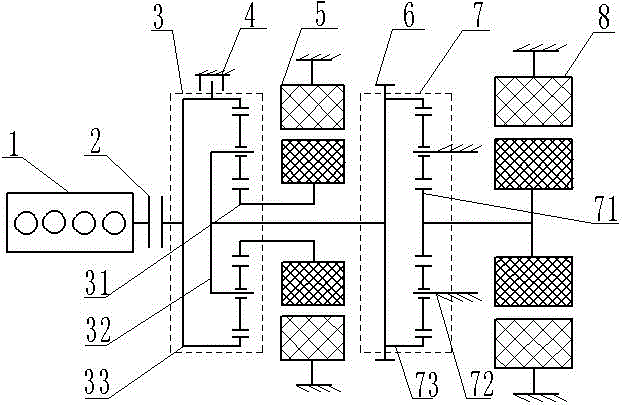

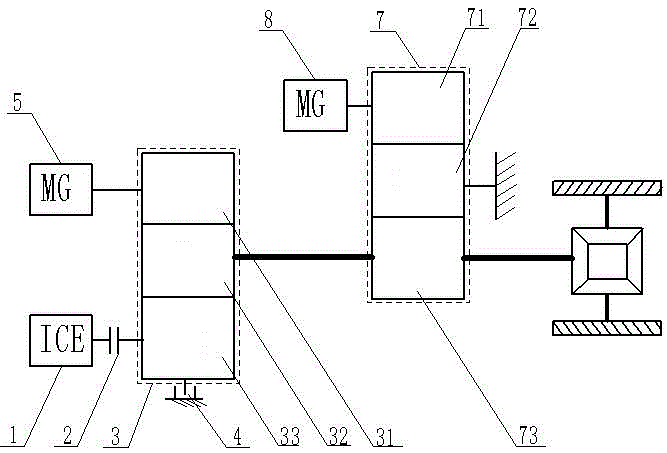

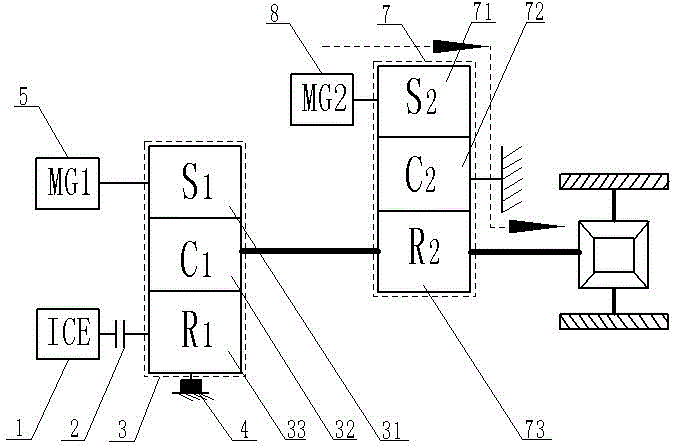

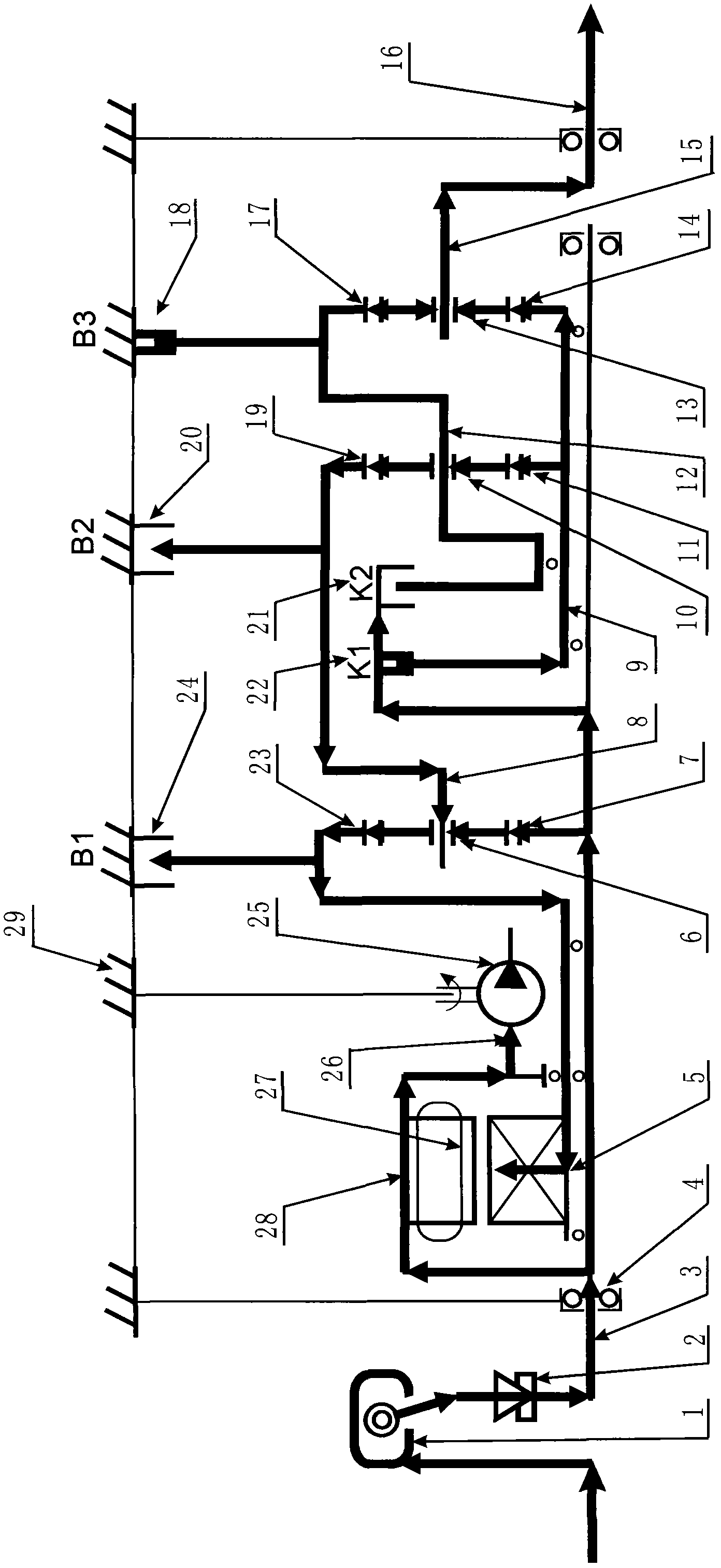

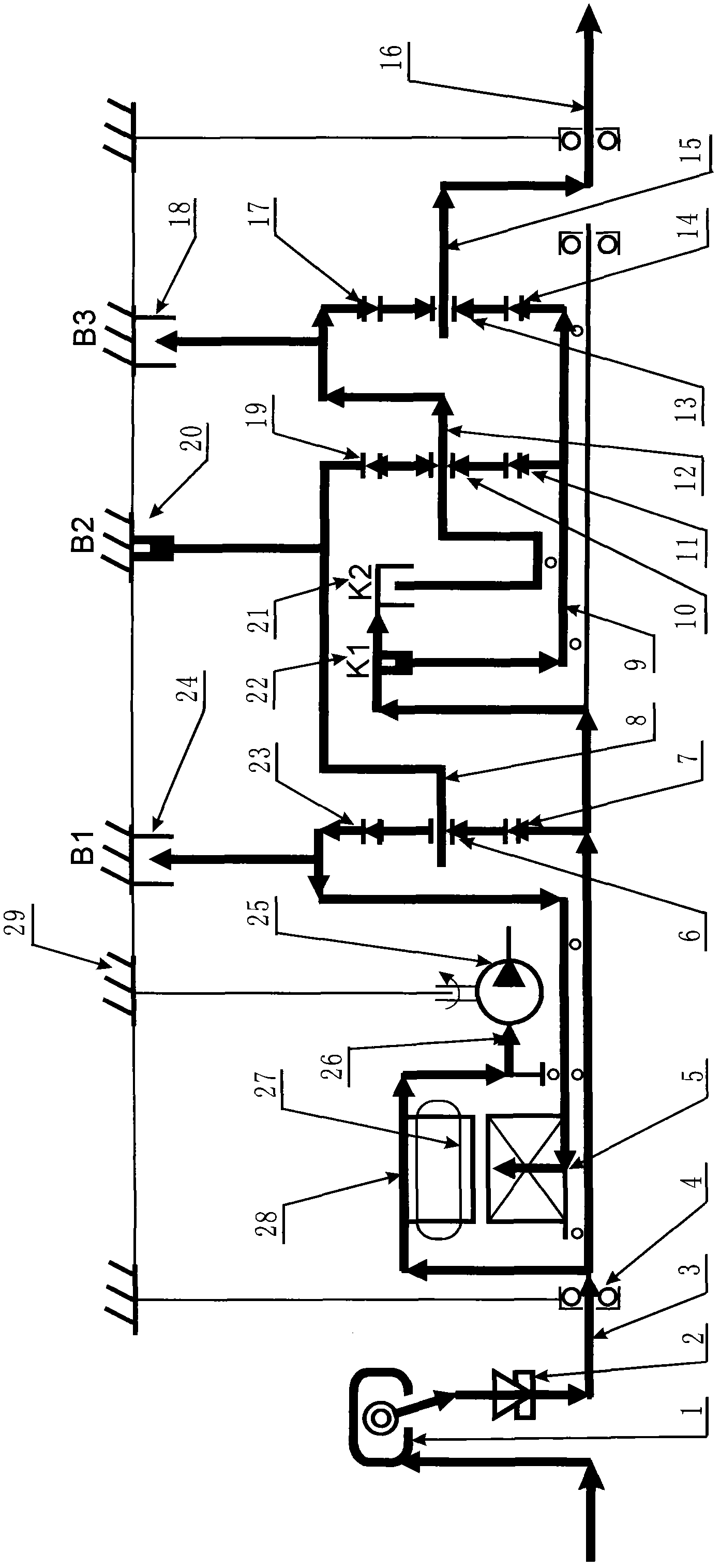

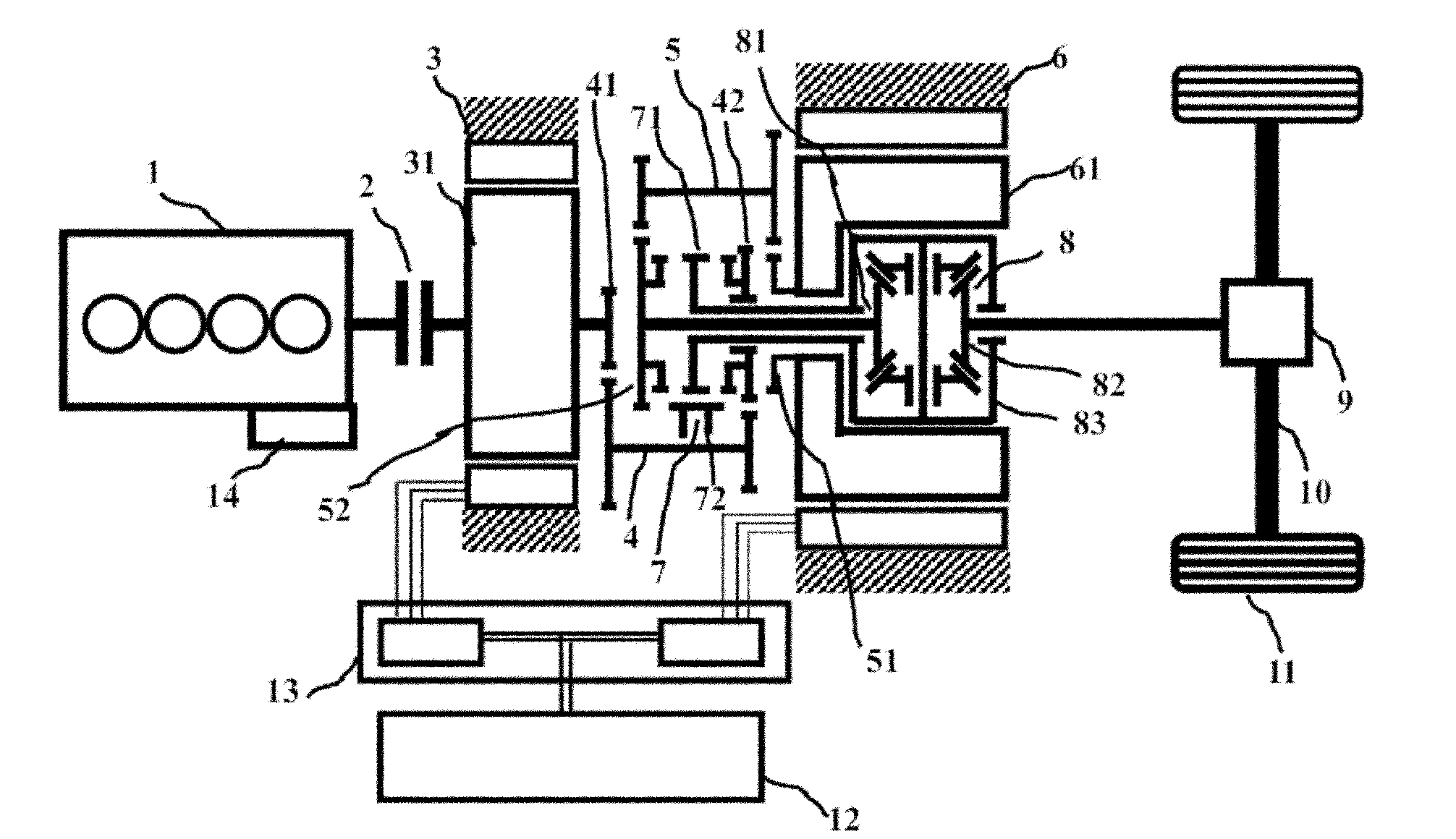

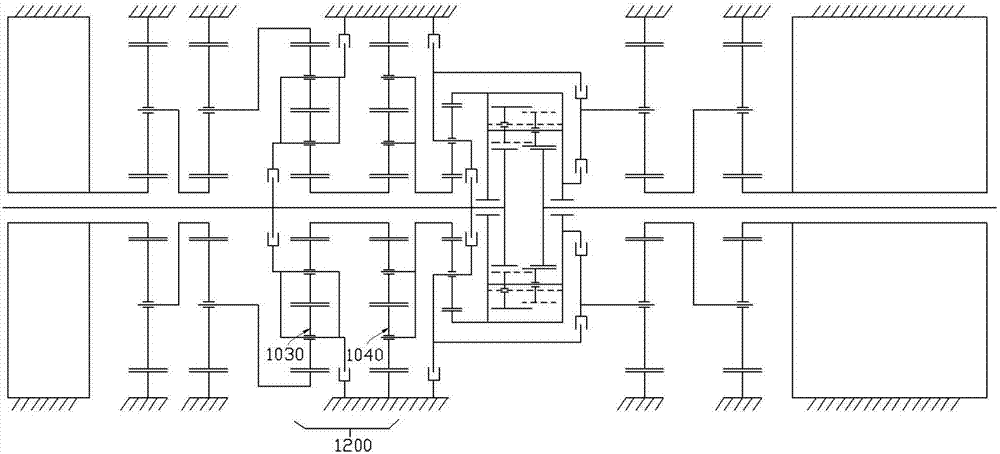

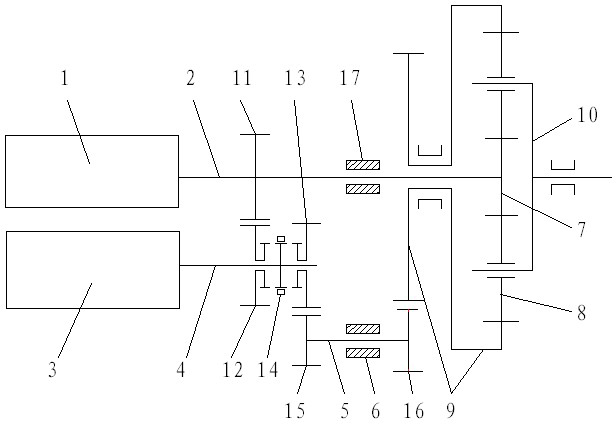

Hybrid electric vehicle series-parallel type double-planetary-gear-train dynamic coupling device and method

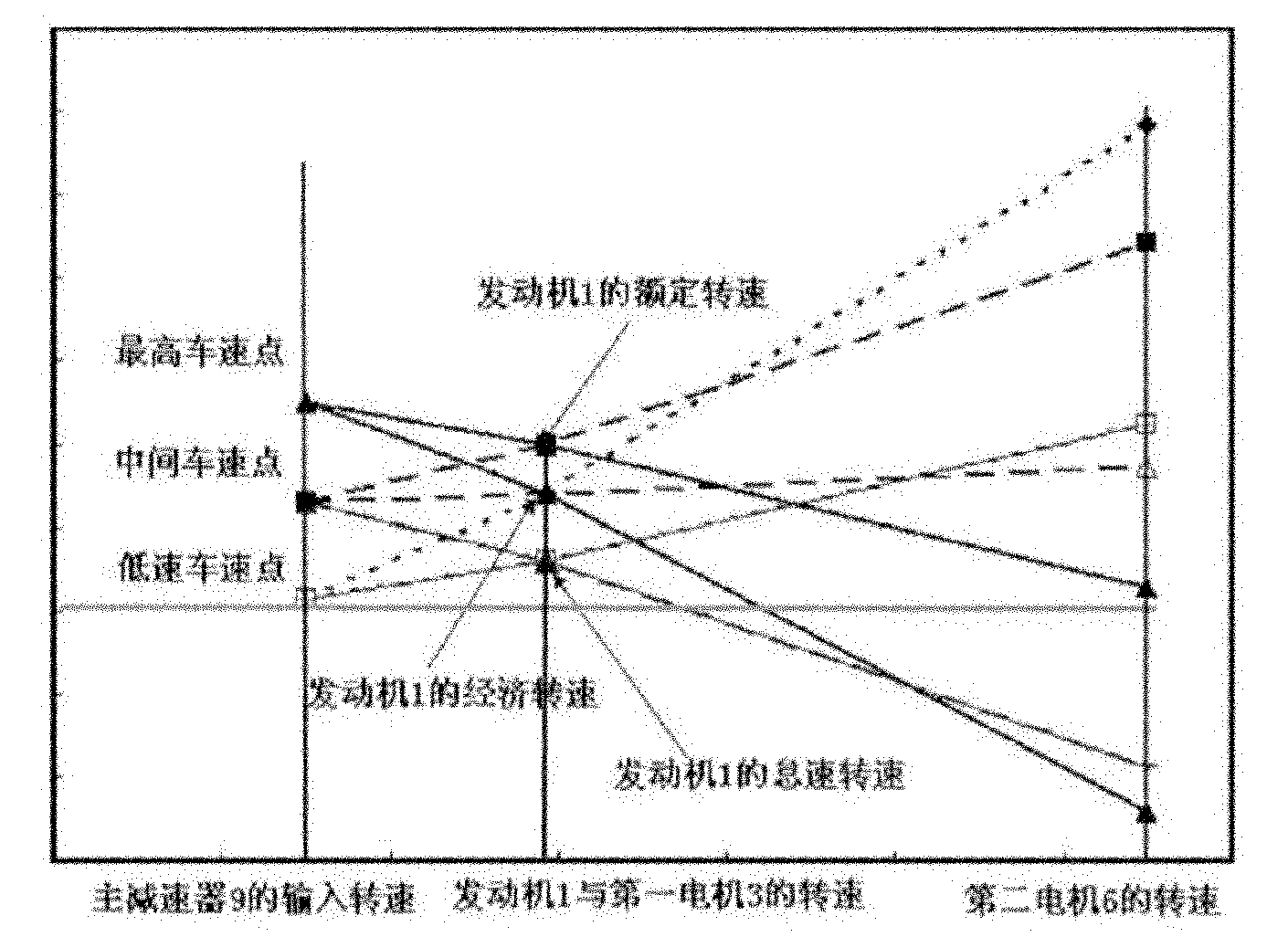

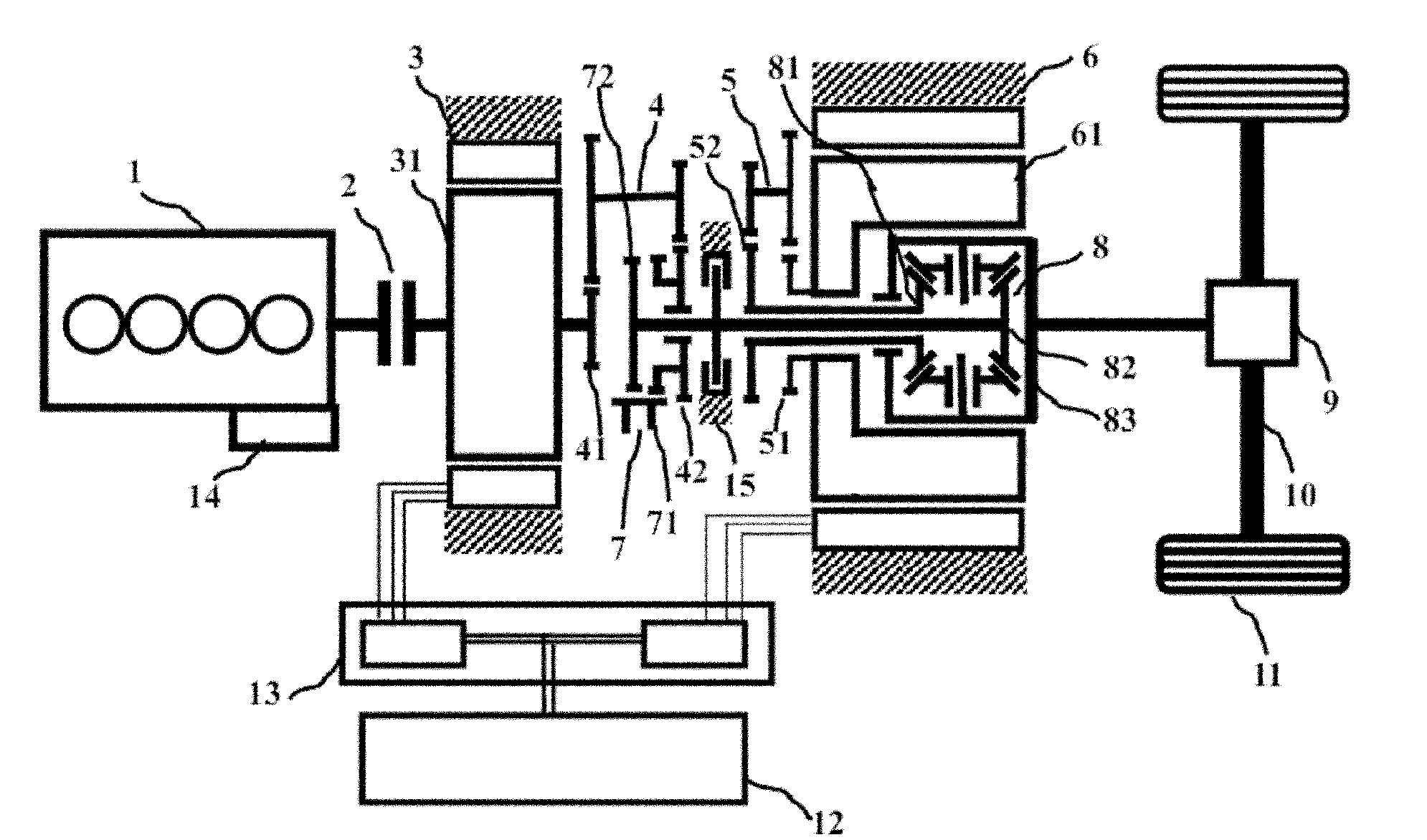

ActiveCN104786818AImprove fuel consumption characteristics and power performanceRealize stepless speed changeHybrid vehiclesGas pressure propulsion mountingClutchPower performance

The invention relates to a hybrid electric vehicle series-parallel type double-planetary-gear-train dynamic coupling device and method. The dynamic coupling device comprises an engine, a first planetary gear train, a second planetary gear train, a first motor and a second motor. The first planetary gear train is composed of a first sun gear, a first planetary gear carrier, a first gear ring and a planetary gear of the first gear ring. The second planetary gear train is composed of a second sun gear, a second planetary gear carrier, a second gear ring and a planetary gear of the second gear ring. The first motor is connected with the first sun wheel. The second motor is connected with the second sun wheel. The engine is connected with the first gear ring through a clutch. The first gear ring is provided with a brake. The first planetary gear carrier and the second gear ring are fixedly connected together to serve as the power output end. The second gear ring is connected with an outer transmission mechanism through a power output gear. The second planetary gear carrier is fixed to a frame. The dynamic coupling device is simple in structure, easy and convenient to control, and capable of switching various dynamic coupling actions and modes, improving the oil consumption characteristic and the power performance and achieving stepless speed change, and a transmission does not need to be additionally arranged.

Owner:CHONGQING LANDAI POWER TRANSMISSION MACHINERY +1

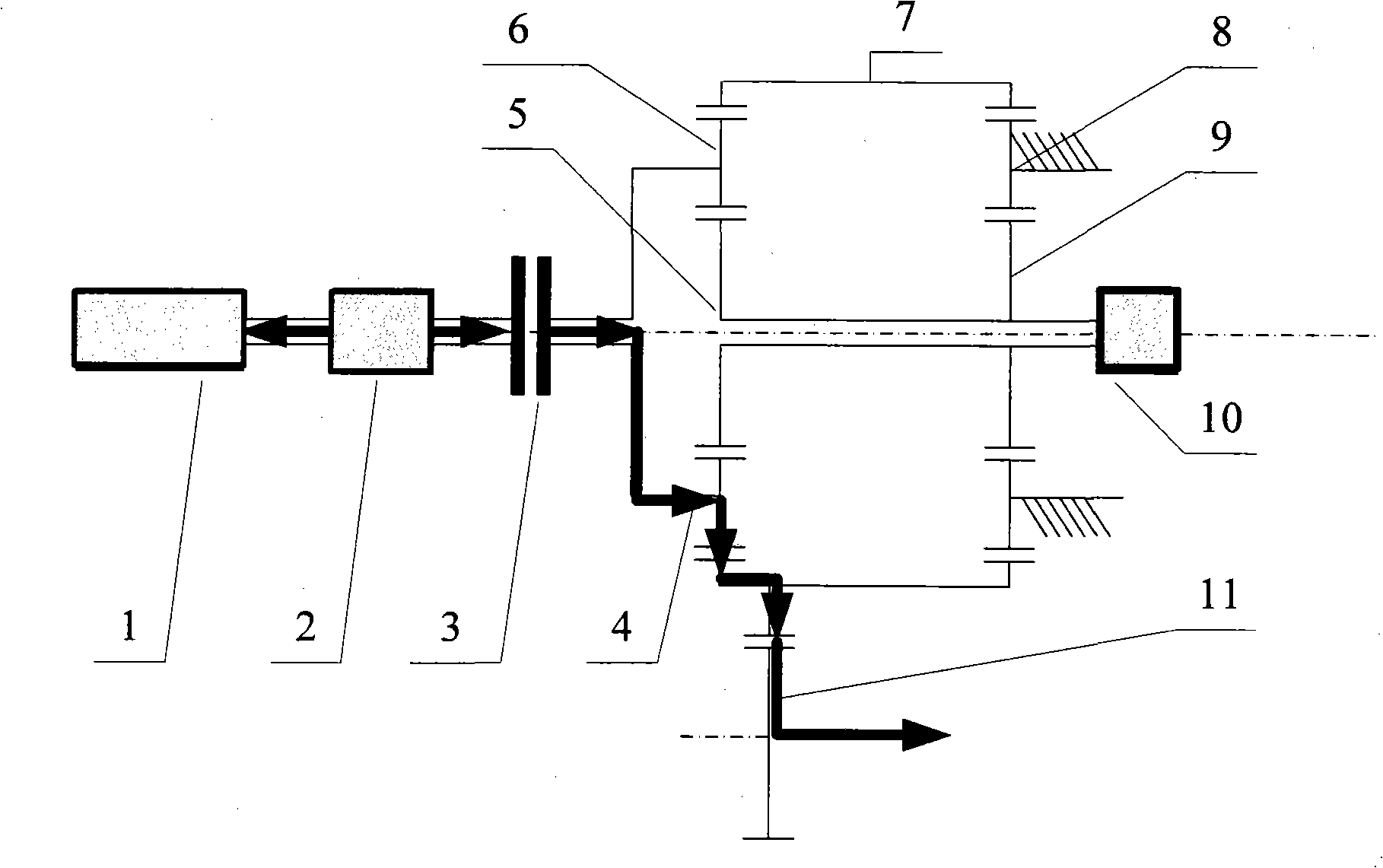

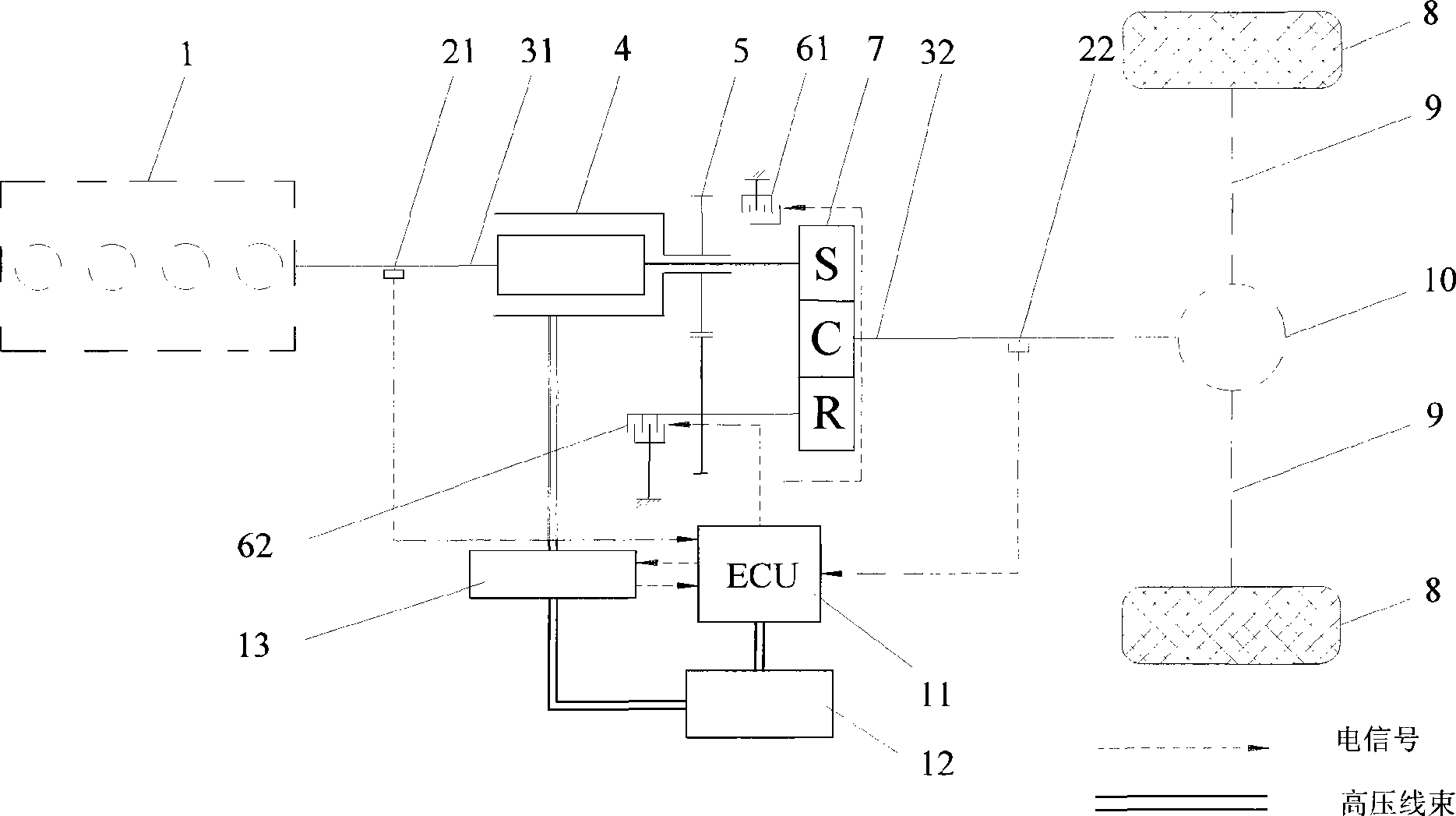

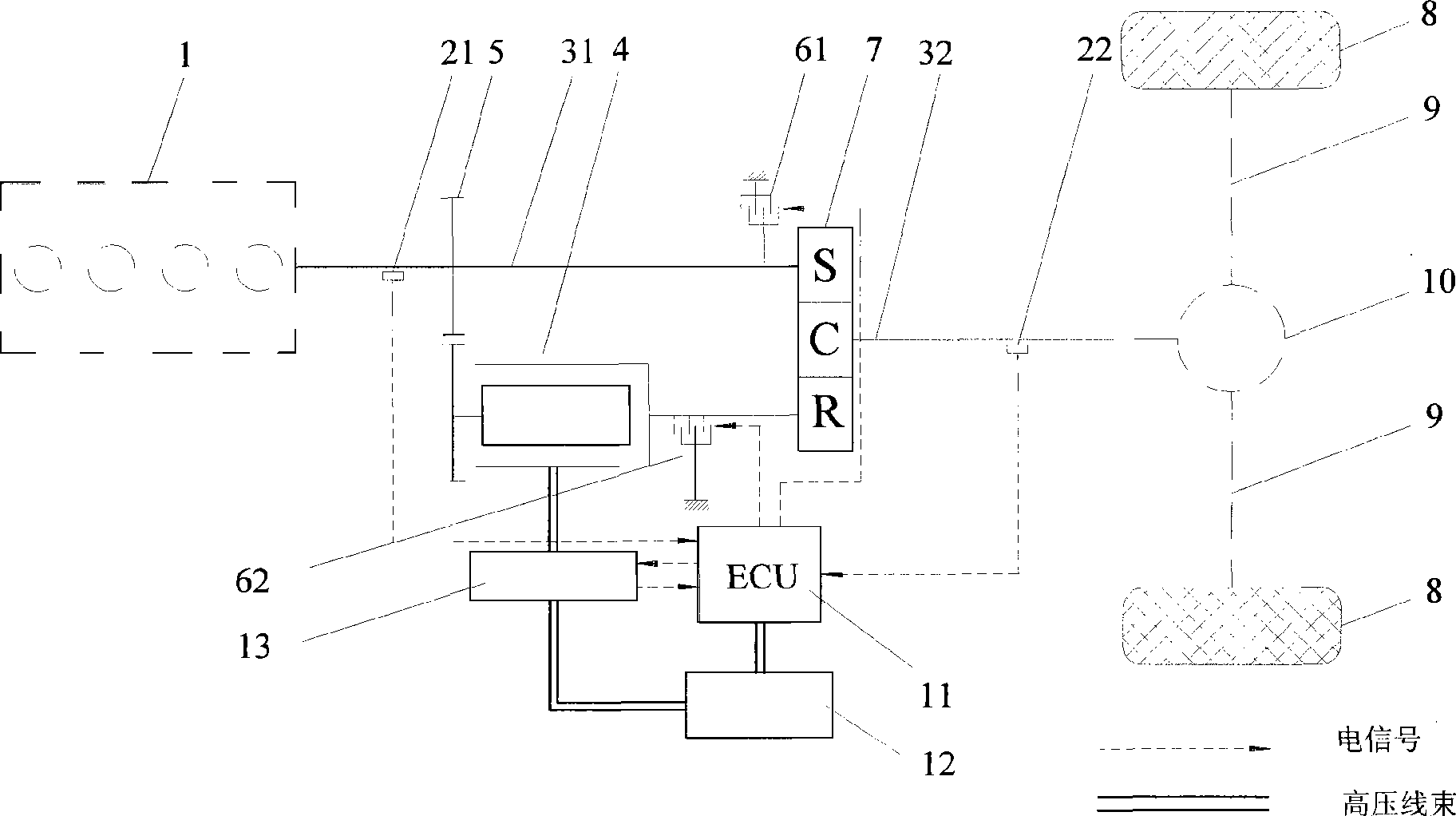

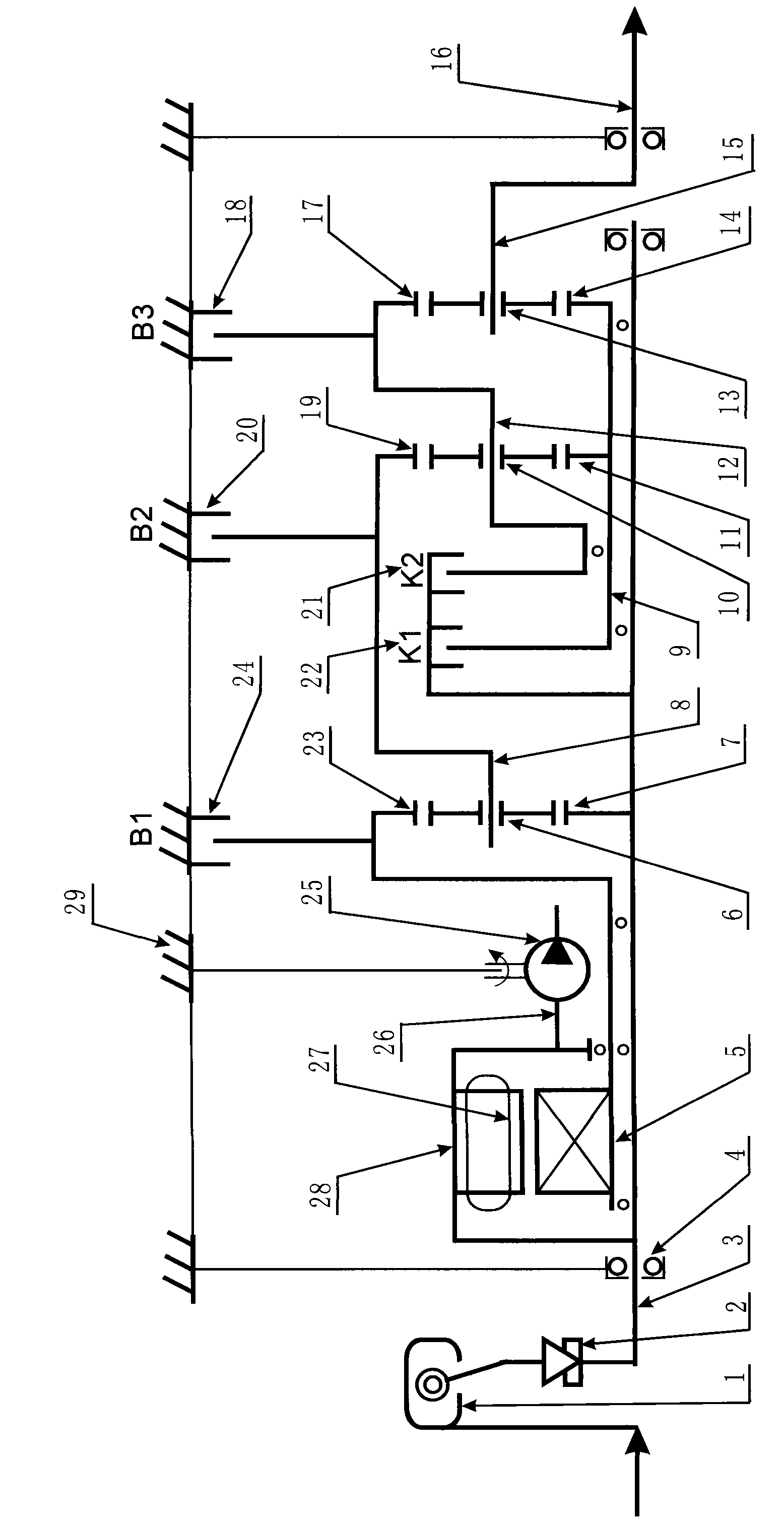

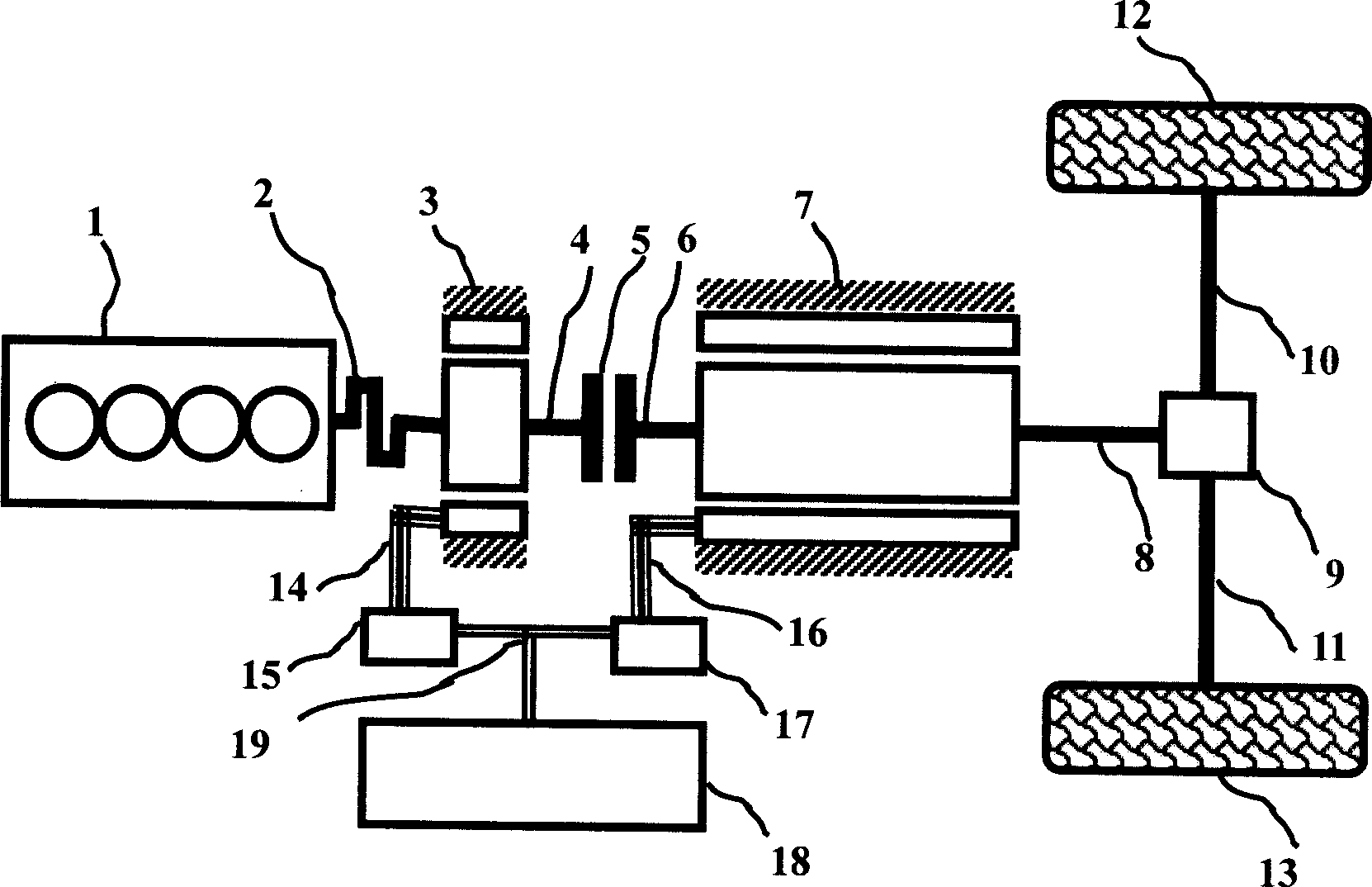

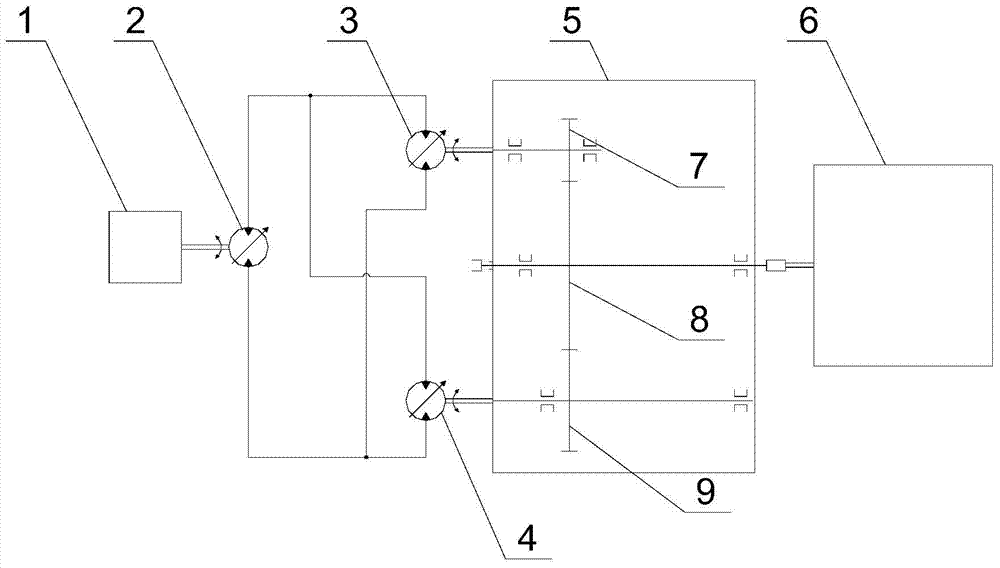

Duel-clutch stepless speed change series parallel hybrid power system

InactiveCN101797884AReduce labor intensityRealize stepless speed changeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchElectricity

The invention discloses a duel-clutch stepless speed change series parallel hybrid power system in the technical field of automobiles, which comprises an engine, a first clutch, a first motor, a second clutch, a second motor, a speed reduction differential gear, a driving axle, a wheel, an energy storing device, a motor control device, an attachment drive transmission gear and a starting motor, wherein a crank shaft output end of the engine is connected with a rotor of the first motor through the first clutch; the rotor of the first motor is also connected with a rotor of the second motor through the second clutch; the rotor of the second motor is connected with the wheel through the speed reduction differential gear and the driving axle; the energy storing device is electrically connected with the motor control device; the attachment drive transmission gear is connected to the rotor of the first motor to provide hybrid drive for attachments for air-conditioning, braking, steering and the like; and the starting motor is connected with the crank shaft output end of the engine through an input end driving disc of the first clutch. The duel-clutch stepless speed change series parallel hybrid power system has the characteristics of entire car stepless speed change series parallel drive, attachment system hybrid drive, low system cost, low development cost, low maintenance cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

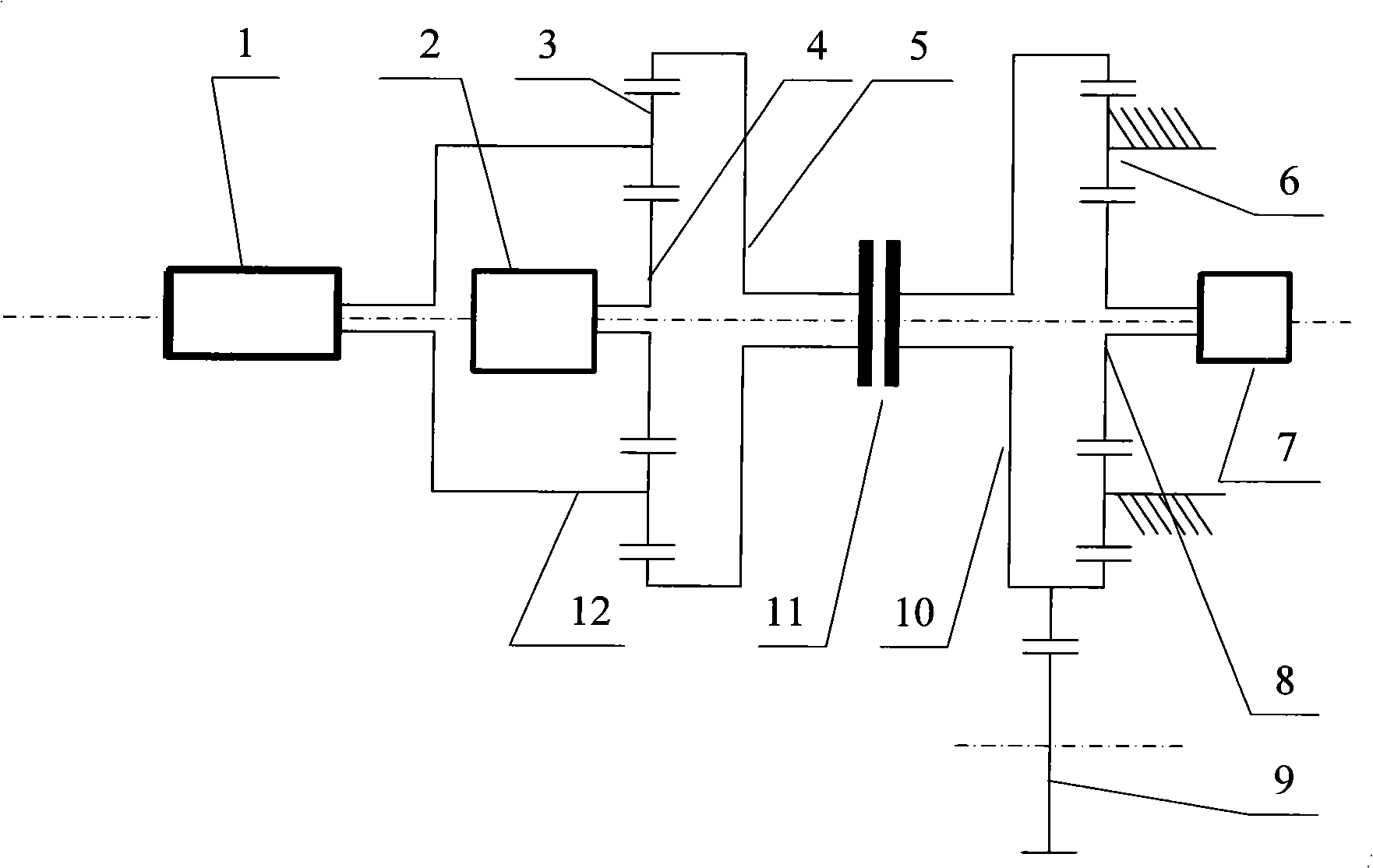

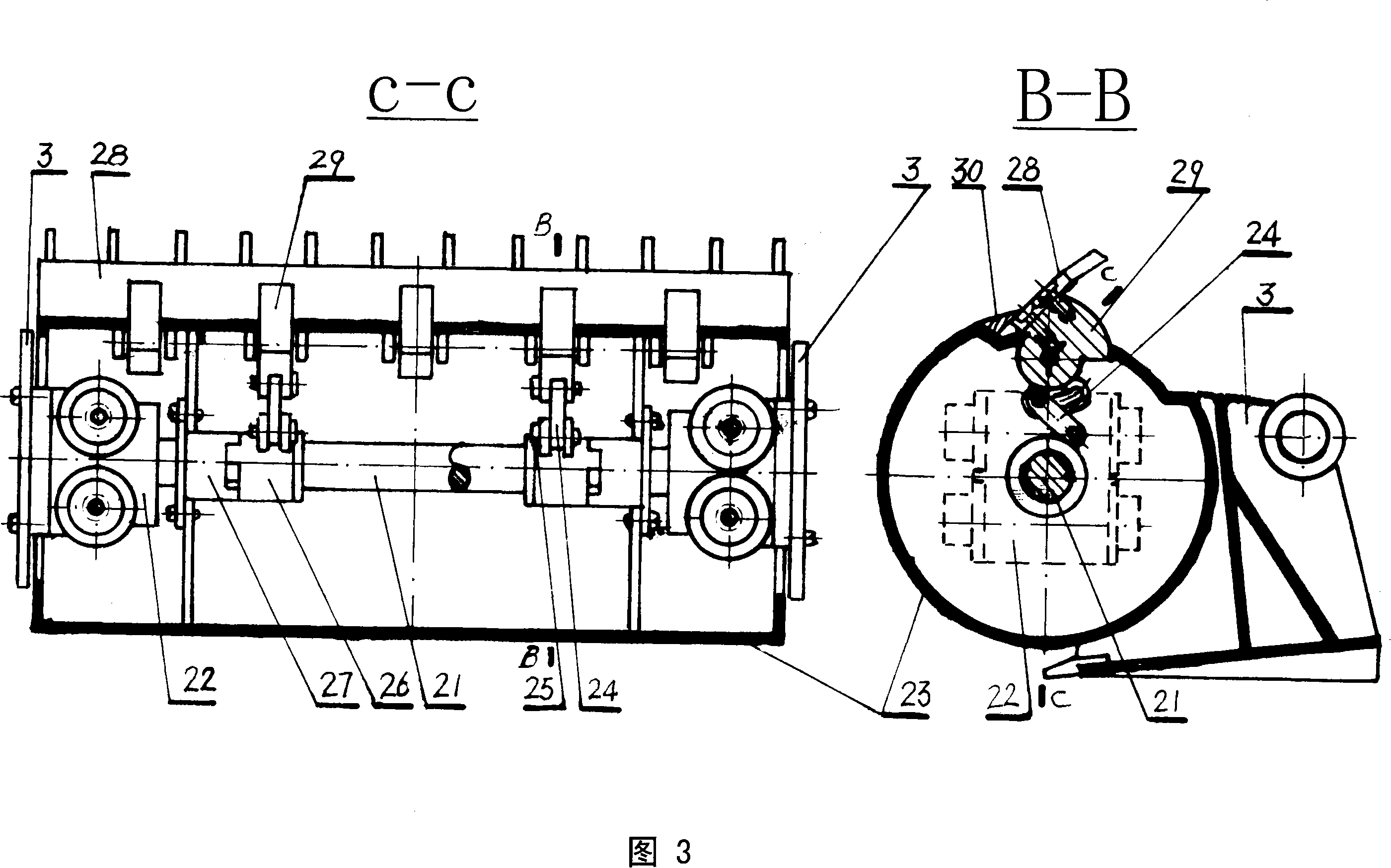

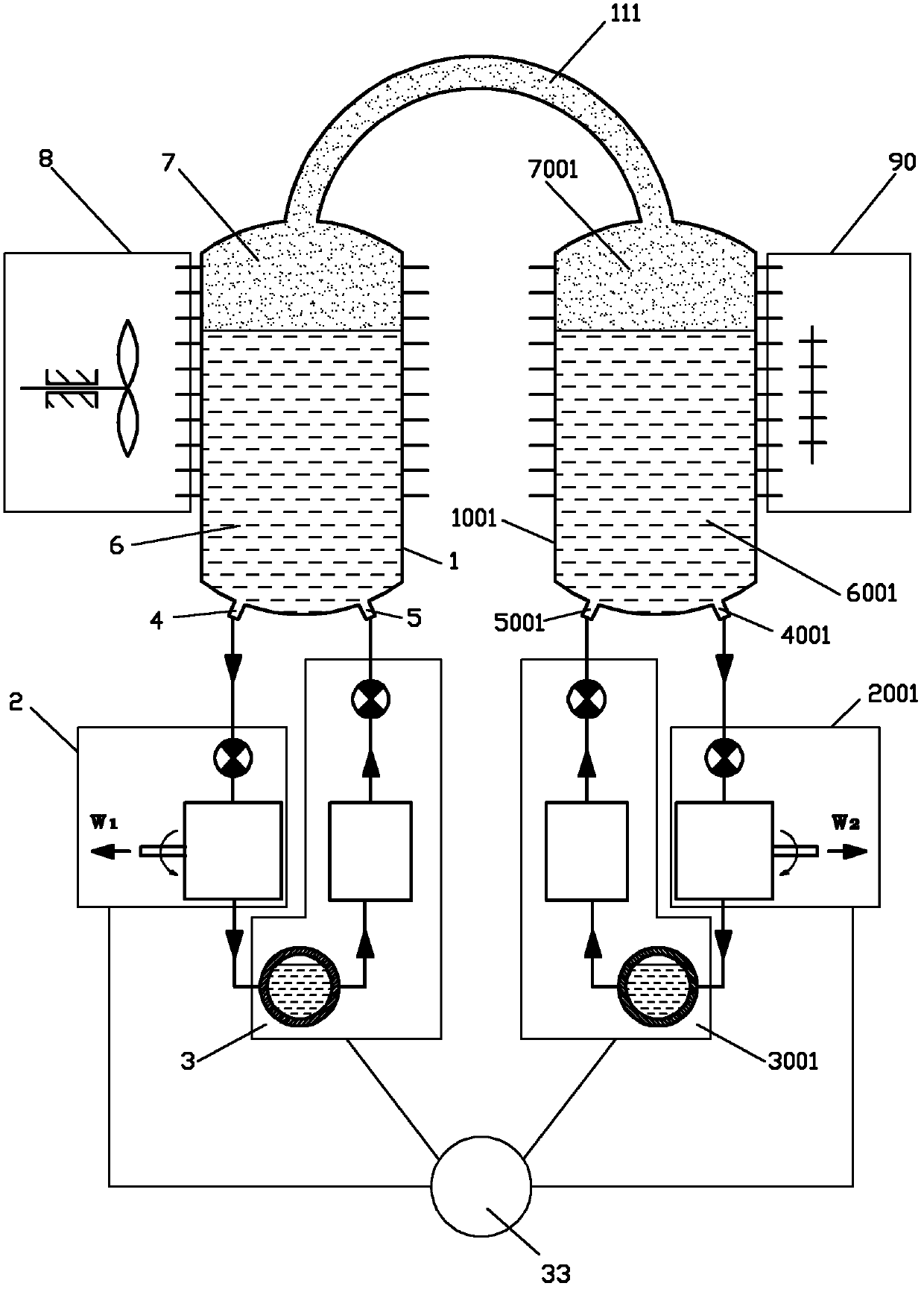

Hybrid power vehicle double row planetary gear electromechanical coupling driving mechanism

InactiveCN101323242AEasy to control independentlyLower requirementHybrid vehiclesGas pressure propulsion mountingVehicle frameGear wheel

The invention discloses a two-planet-row electromechanical coupling driving device of a hybrid vehicle in the technical field of machinery. The device is provided with a front planet row and a back planet row; each of the two planet rows is provided with a planet wheel, a sun gear and a row gear ring; the two planet row gear rings are connected with each other by a clutch. An engine is connected with the planet wheel of the front planet row; an ISG motor is connected with the sun gear of the front planet row; the gear ring of the front planet row is connected with the driving disk of the clutch; the driven disk of the clutch is connected with the gear ring of the back planet row; the planet carrier of the planet wheel of the back planet row is arranged fixedly on a car frame; the sun gear of the back planet row is connected with a drive motor; the outside gear of the gear ring of the back planet row is normally engaged with a power take-off gear. The two-planet-row electromechanical coupling driving device of the hybrid vehicle has the advantages of compact structure, large transmission ratio, large load support capability, stable driving, and high transmission efficiency, thereby realizing power dividing and infinite variable speed at the same time.

Owner:SHANGHAI JIAO TONG UNIV

Electronic infinite variable speed parallel type mixed power driving device

ActiveCN101480913AImprove fuel economyReduce exhaust emissionsGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectricityPower transmission

The invention discloses an electronic stepless variable speed parallel type hybrid power driving device which comprises a counter-rotating double-rotor motor, a motor controller, a planetary mechanism, an accumulator set, a control unit ECU and a dead axle gear pair, wherein an input shaft of an engine is respectively connected with a sun wheel of the planetary mechanism and a gear ring by a power transmission mechanism formed by the counter-rotating double-rotor motor and the dead axle gear pair; at least one brake is connected with the sun wheel of the planetary mechanism and the gear ring; and the accumulator set is respectively electrically connected with the motor controller and the control unit ECU, and the motor controller is electrically connected with the counter-rotating double-rotor motor. The device has the advantages of compact structure, few power transmission parts and low transmission loss; the action of the brake determines different working modes, different modes have different speed ratios and torque output, the vehicle can select different modes to work according to actual power requirements, and the speed ratio range is greatly enlarged, therefore, the system can be suitable for various vehicle types with different requirements for speed ratio.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD +1

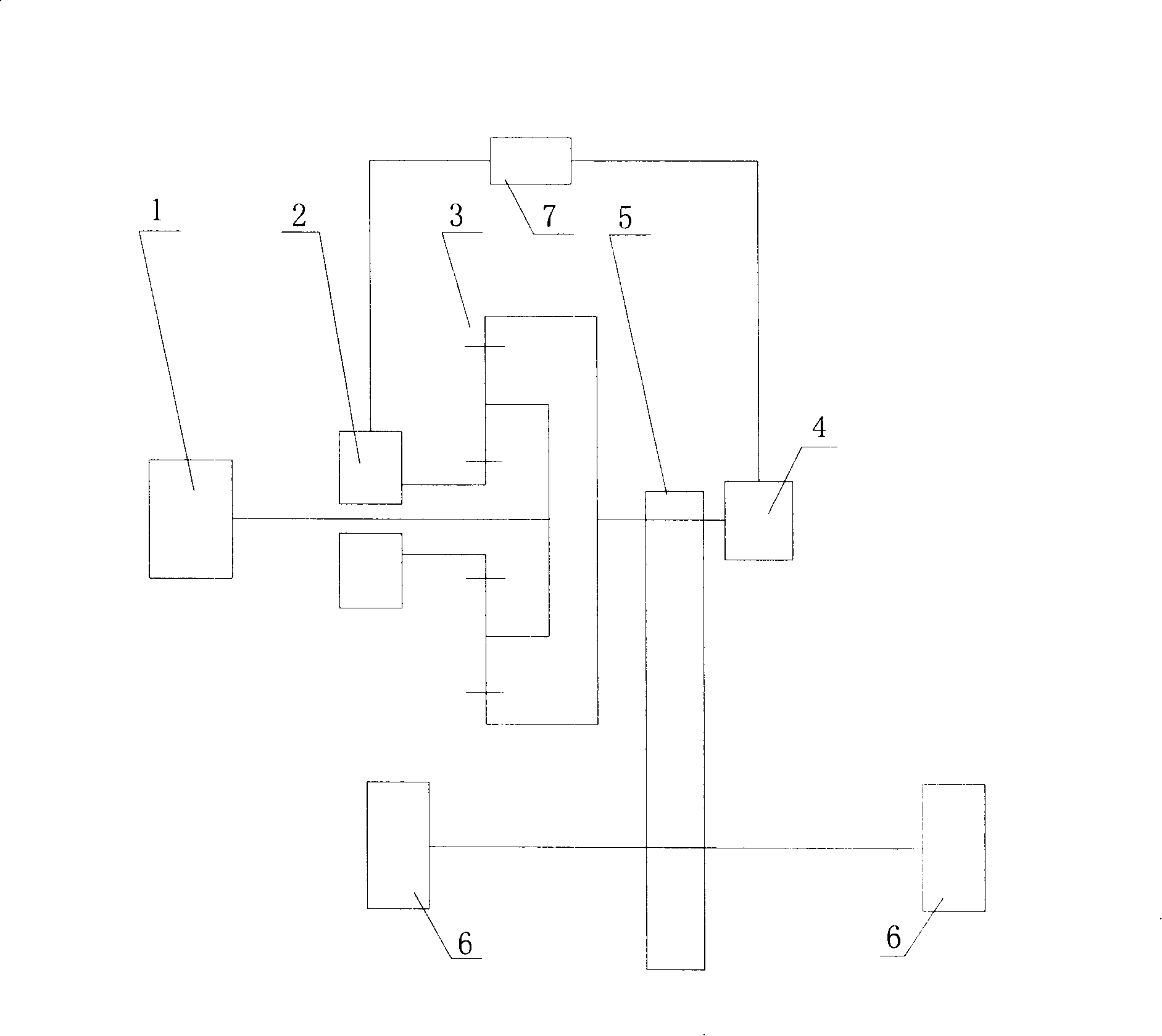

Mixed motor vehicle driving system

InactiveCN101204920ARealize stepless speed changeReduce speedSpeed controllerGas pressure propulsion mountingHybrid carLow speed

The invention provides a drive system for a hybrid car, comprising a motor and an electric motor providing power for a gearing; a generator for receiving the power of the motor to generate electricity; and an electric power between the generator and the electric motor; the system also comprises a double clutch which is connected between the motor and the generator as well as the gearing and is used for transmitting the driving force of the motor selectively to the generator or the gearing. When a vehicle runs at a low speed, the double clutch is controlled to transmit the driving force of the motor to the generator to generate electricity; the electric motor receives the electric energy and outputs mechanical energy to the gearing to drive the vehicle, thus realizing a series type drive of the hybrid car. When the vehicle runs at a high speed, the double clutch is controlled to transmit the driving force of the motor directly to the geraing to drive the vehicle.

Owner:BYD CO LTD

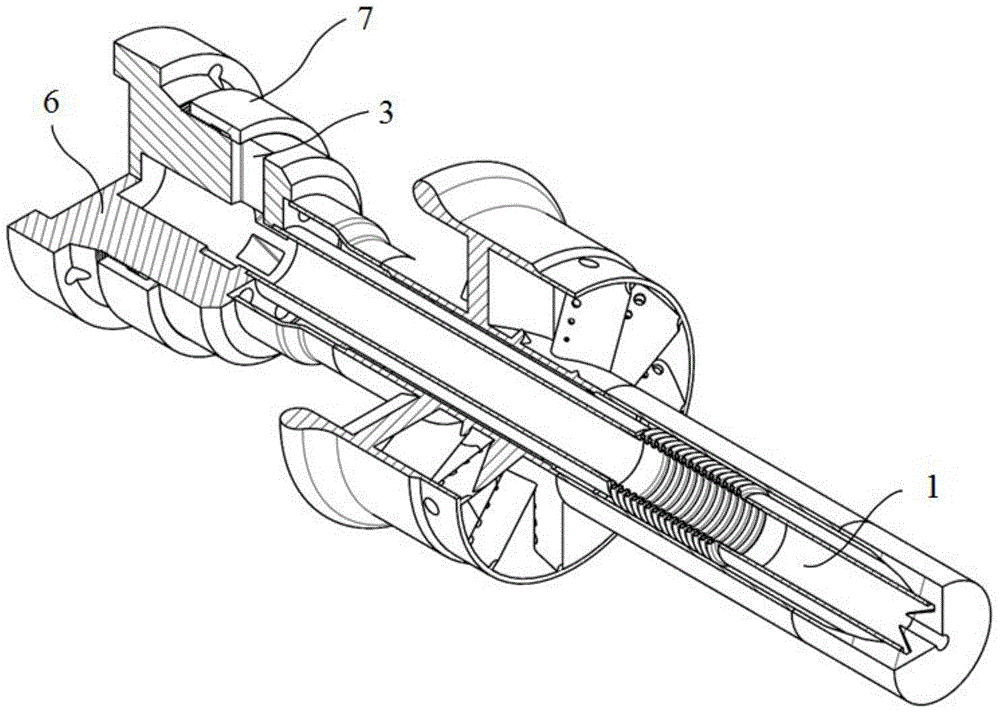

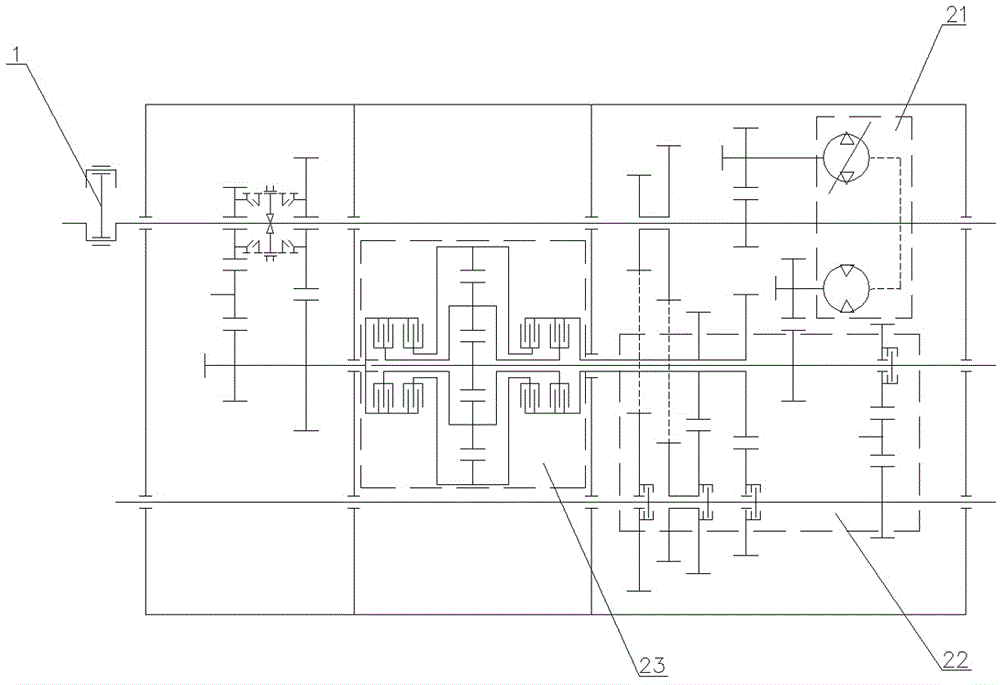

Continuously variable transmission system achieving multi-mode switching of hybrid power

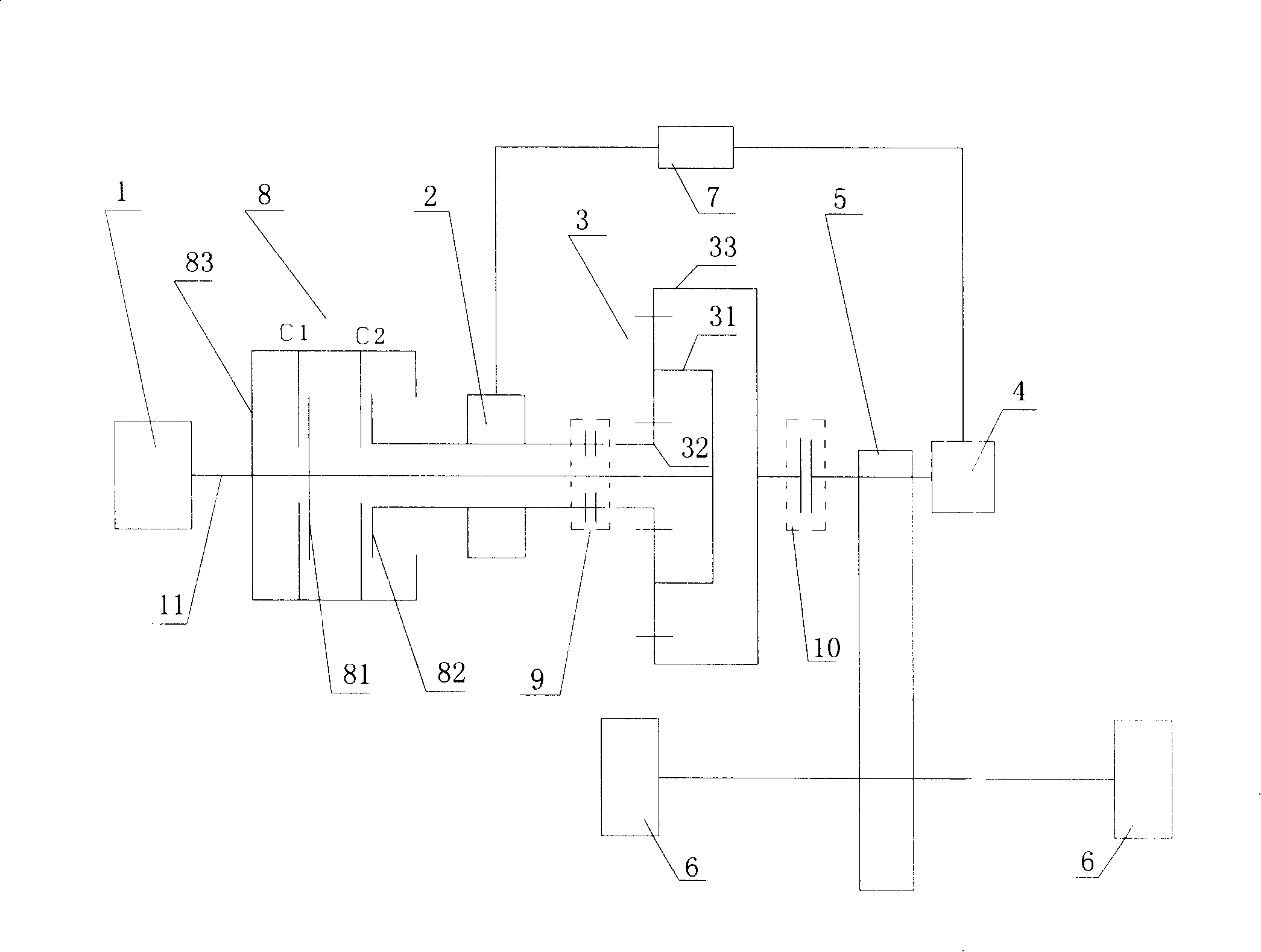

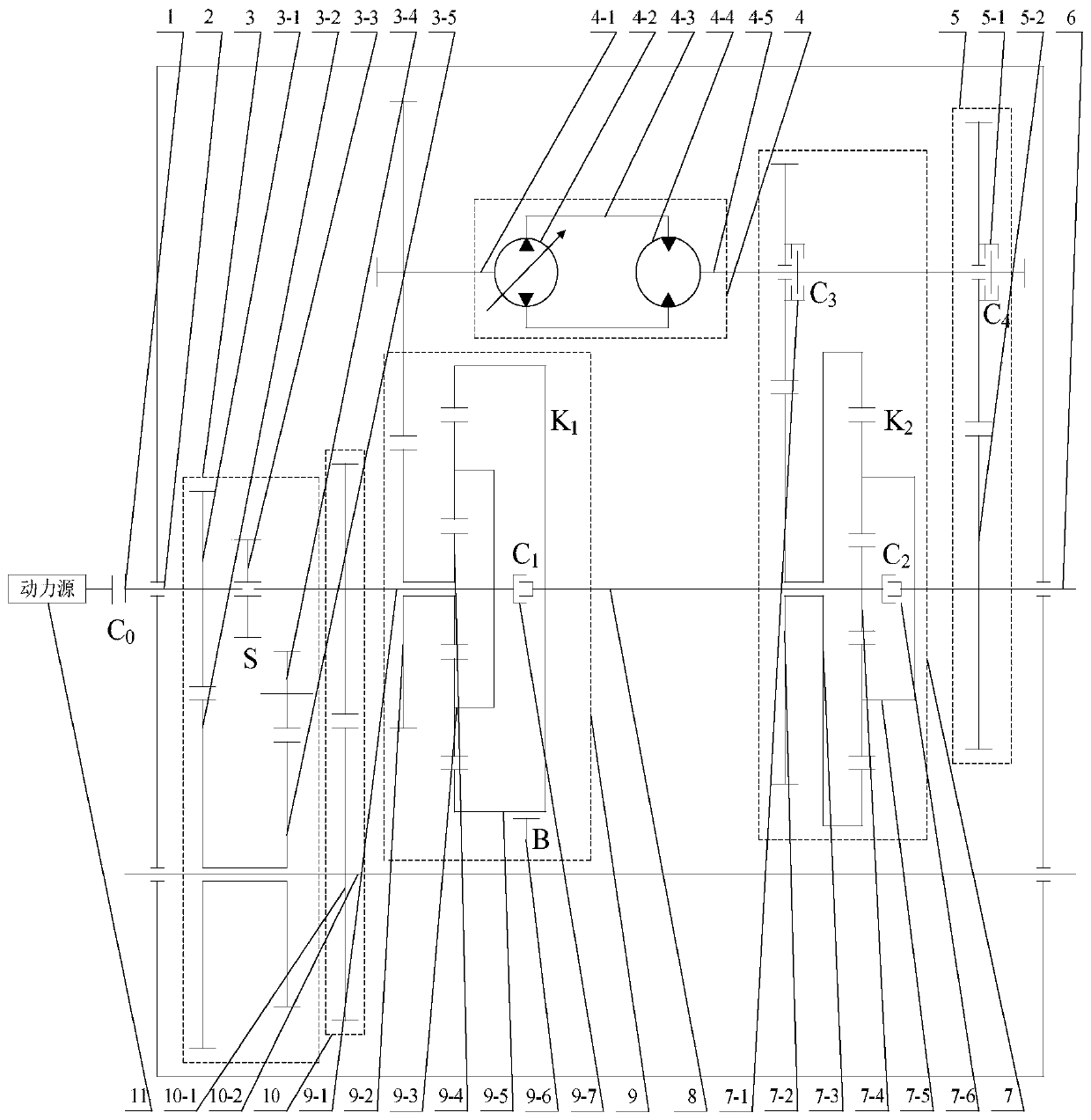

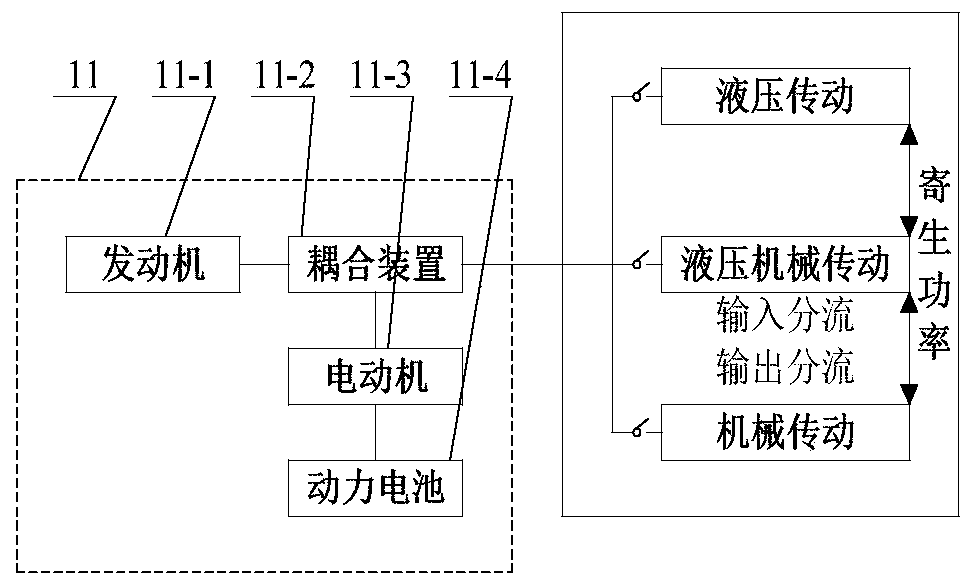

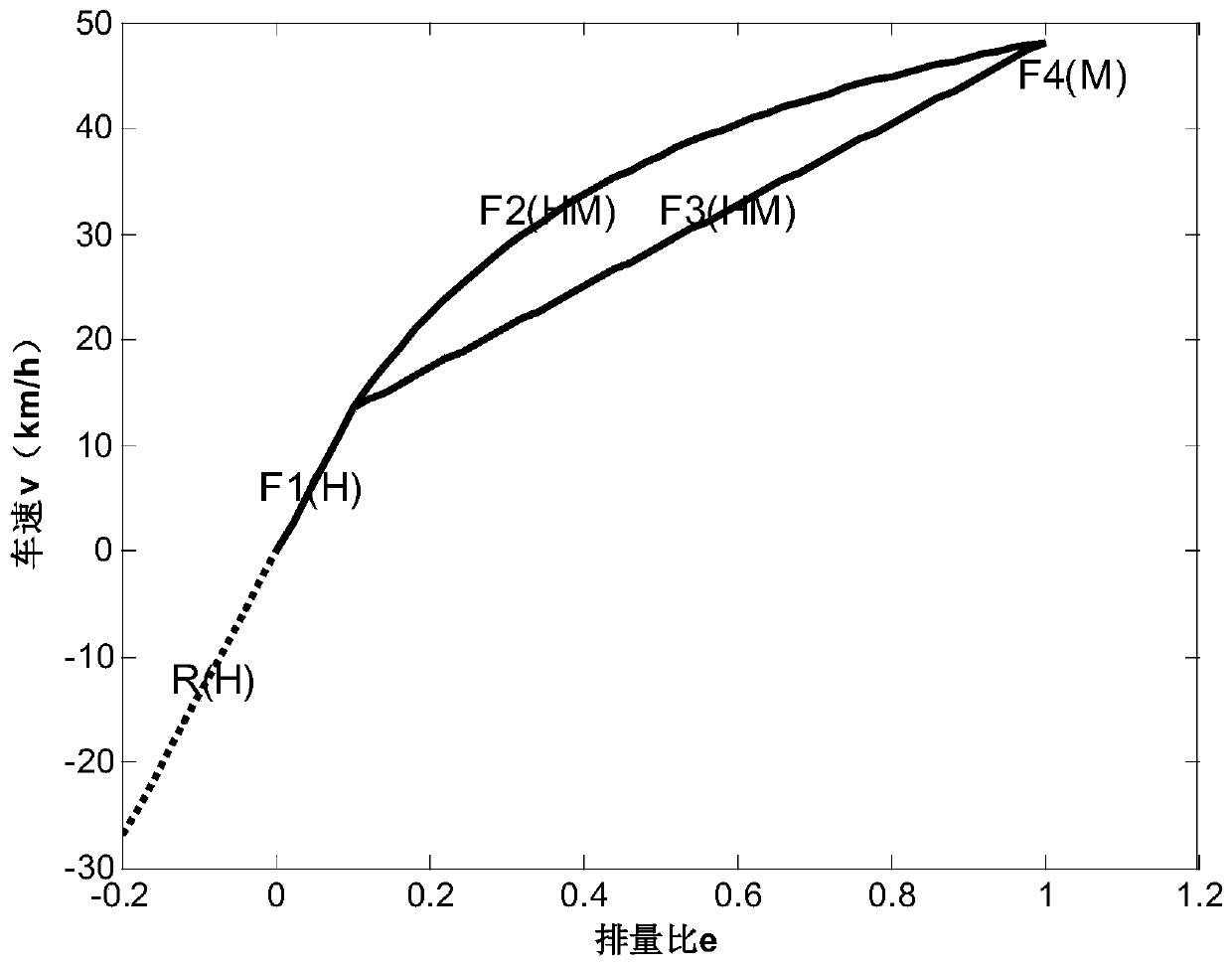

ActiveCN109723789ARealize stepless speed changeCompact structureFluid gearingsQ-switchingMode switching

The invention provides a continuously variable transmission system achieving multi-mode switching of hybrid power. The continuously variable transmission system comprises an input component, an outputcomponent, a clutch assembly, a brake, a hydraulic transmission assembly and a planetary gear assembly. The input component is connected with the hydraulic transmission assembly. The output componentis connected with the planetary gear assembly. The clutch assembly connects the input component and the hydraulic transmission assembly to the planetary gear assembly. The brake and the clutch assembly provides the transmission ratio of continuous advancing or retreating between the input component and the output component. Through linear increase or non-linear increase of the displacement ratioof the hydraulic transmission assembly, hydraulic-mechanical transmission is converted into mechanical transmission. Integrated control can be carried out through a dual power source adopting an engine and an electromotor as power and the transmission and composite transmission adopting hydraulic transmission, mechanical transmission and hydraulic-mechanical transmission as the transmission manner, the statistical method based on test data is used, and matched energy management strategies are provided.

Owner:JIANGSU UNIV

Fatigue life test stand for angular contact ball bearing

InactiveCN101419126AGuaranteed coaxialityReduce the impactMachine bearings testingFrequency changerBall bearing

The invention provides an apparatus for testing the fatigue life of a high-speed angular contact ball bearing. The apparatus tests the fatigue life of the angular contact ball bearing under the working condition of various rotary speeds and loads by adoption of a frequency converter to realize infinite variable speed of a high-frequency motor, adoption of a transmission shaft to drive the angular contact ball bearing to rotate at a high speed under certain pretightening force, and adoption of a weight to adjust and load the axial pretightening force. The apparatus overcomes the defects of complex structure, expensive price, trivial operation, large noise and so on of the prior apparatus for testing the fatigue life of the angular contact ball bearing, realizes zero transmission and lever loading, and has the advantages of superior high-speed performance, reliable test results, simple structure and low cost.

Owner:SOUTHEAST UNIV

Electromechanical hybrid power mobile automatic transmission drive system

ActiveCN102069703ACompact structureReduce manufacturing costGas pressure propulsion mountingToothed gearingsElectricitySystems design

An electromechanical hybrid power mobile automatic transmission drive system is designed as an integral, which only comprises 29 main parts and can generate 6 forward gears and 1 reverse gear. Since a motor is arranged on an input shaft integrally, the whole motor has a synchronous speed with the input shaft. The motor has the functions of a generator and can drive a vehicle to travel by utilizing counterforce generated by the generator field, so as to generate electricity when an automobile travels, the automobile engine power is not additionally consumed due to the load of the generator when electricity is generated while the automobile travels, thereby reaching the energy-saving purpose. When a hybrid power driving pattern is used, a clutch and a brake are not required for gear changing during the vehicle is started or driven, thus realizing stepless speed changing and large torque transmission.

Owner:GUANGZHOU HUADU WORLDWIDE AUTOMATIC TRANSMISSION

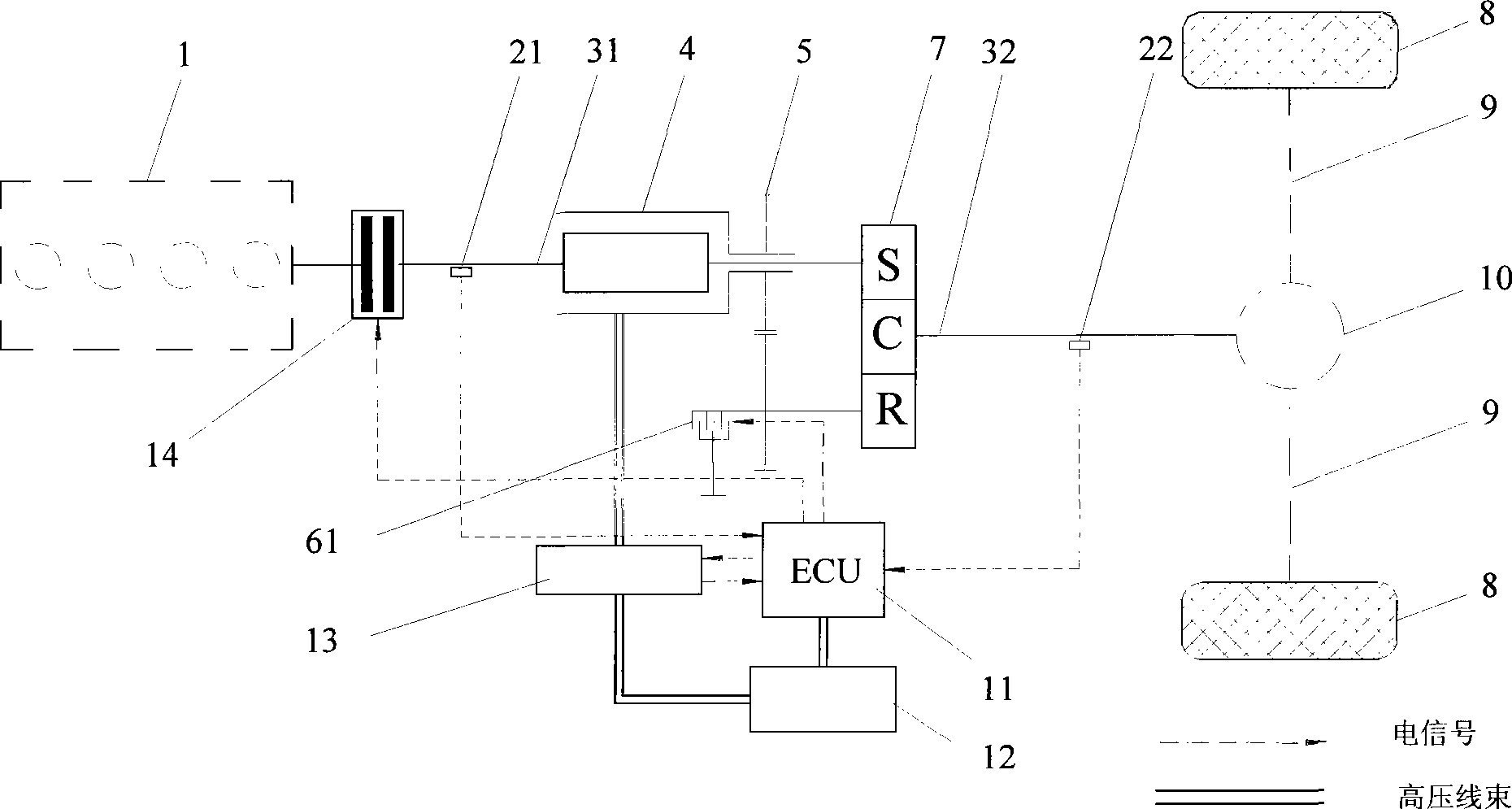

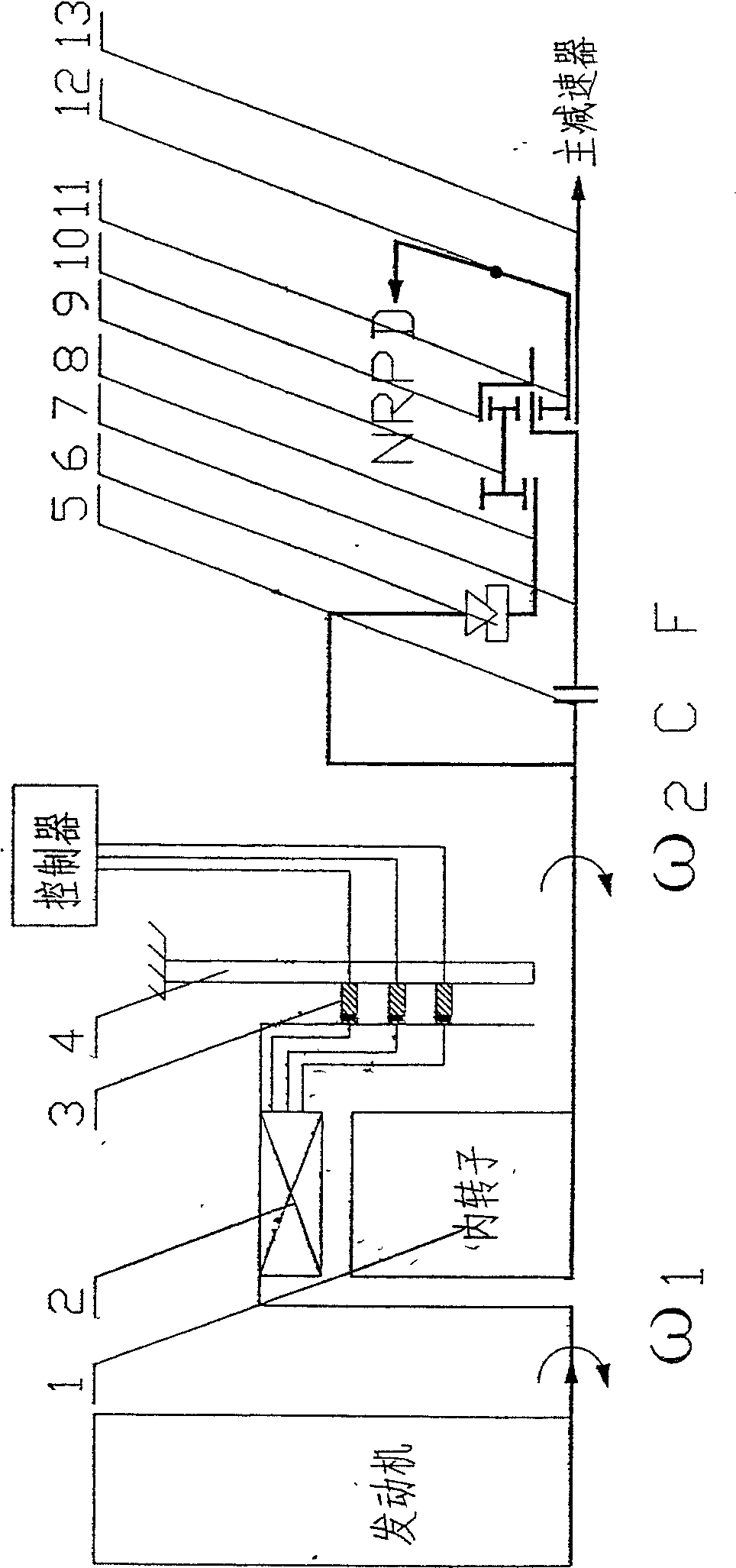

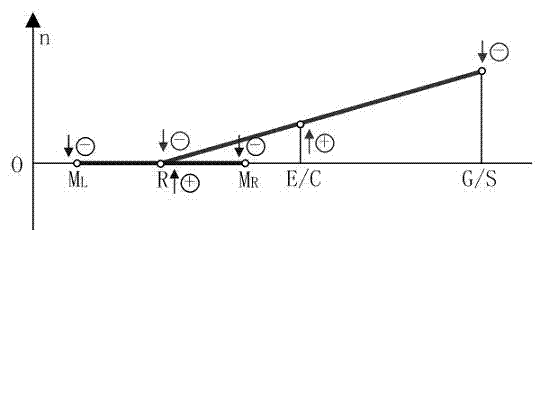

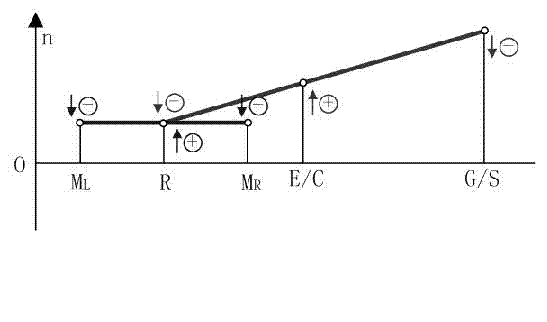

Hybrid drive system in type of multiple series connection stepless speed change

ActiveCN1915702AReduce labor intensityRealize stepless speed changeHybrid vehiclesGas pressure propulsion mountingElectricityElectric machine

A drive system with mixed power and stepless speed variation is composed of engine with crankshaft output, the first and the second motors and their high-voltage circuits and drive controller, clutch, drive shaft, differential speed reducer, the first and the second semi-shafts, energy accumulator, and the high-voltage circuit for the energy accumulator.

Owner:SHANGHAI JIAO TONG UNIV

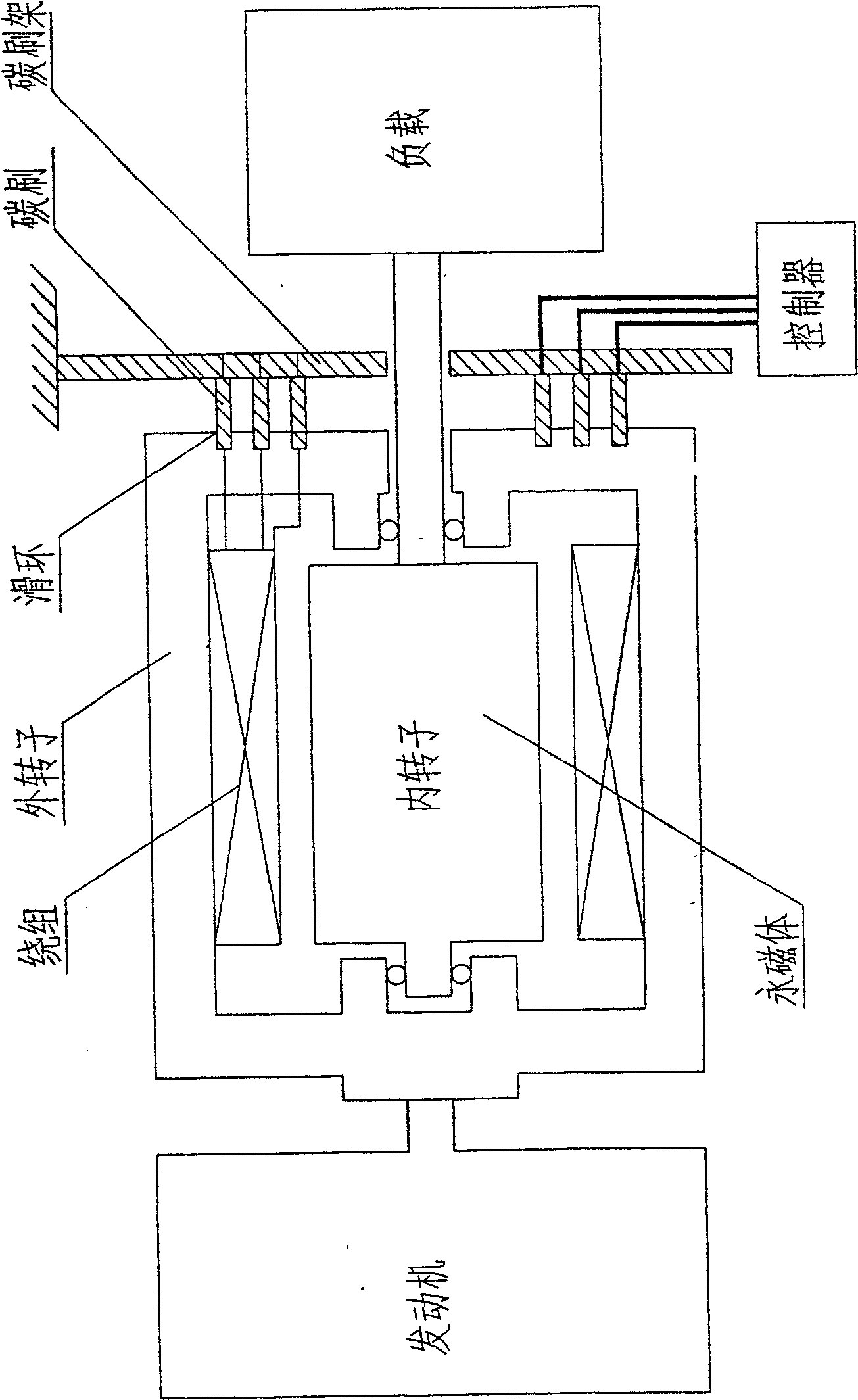

Multifunctional electromagnetic stepless torque changing apparatus

InactiveCN101488690AImprove efficiencyRealize stepless speed changeDynamo-electric gearsEngineeringEnergy recovery

The invention relates to a multifunctional electromagnetic stepless torque conversion device, belonging to the field of a speed changer. The device adopts a motor which consists of an inner rotor, an outer rotor, a motor winding, a slip ring, a carbon brush and a carbon brush holder, wherein, the inner rotor, the outer rotor and the motor winding can freely rotate, the slip ring is connected with a winding terminal, and the carbon brush and a carbon brush holder are connected with the slip ring in a sliding way; when in the process of power transmission, any of the two rotors is taken as a power input end, and other one is taken as a power output end; due to the special use, the functions of stepless speed change, clutch, battery cell charge and energy recovery can be realized when the motor is in a power generation mode, and the functions of starting an engine and pure electric driving and combination driving can be realized when the motor is in a power-driven mode; therefore, when being matched with the engine and a gear for use, the stepless torque conversion device can replace a electric generator, a starting engine, the clutch and a flywheel, so as to have positive effects of small volume, low cost, high transmission efficiency, energy conservation, environmental protection, simple structure and convenient operation.

Owner:颜广博

Four-die stepless speed change series-parallel hybrid power driving system

ActiveCN102050001ATight structureEasy to Modular DesignGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchEnergy storage

The invention discloses a four-die stepless speed change series-parallel hybrid power driving system, belonging to the technical field of automobile hybrid driving. The system comprises an engine, a clutch, two motors, corresponding transmission chains of the two motors, a power transfer switching device, a planetary gear differential device, a deceleration differential device, an energy storage device and a motor control device. The system provided by the invention has the characteristics of better technical inheritance with existing vehicles, overall dynamic property, fuel economy and low emission, and has functions of four-die driving, stepless speed change and series-parallel system; the problems of insufficient driving power, lack in ramp starting ability, large system volume and high cost of the existing similar technologies and the problems that the stepless speed regulation of the engine cannot be realized and the batch industrialization is difficult as the electromechanical components are difficult to manufacture are solved, and organic combination of high performance, low development cost, low system cost and easy implementation of scale industrialization is realized.

Owner:SHANGHAI JIAO TONG UNIV

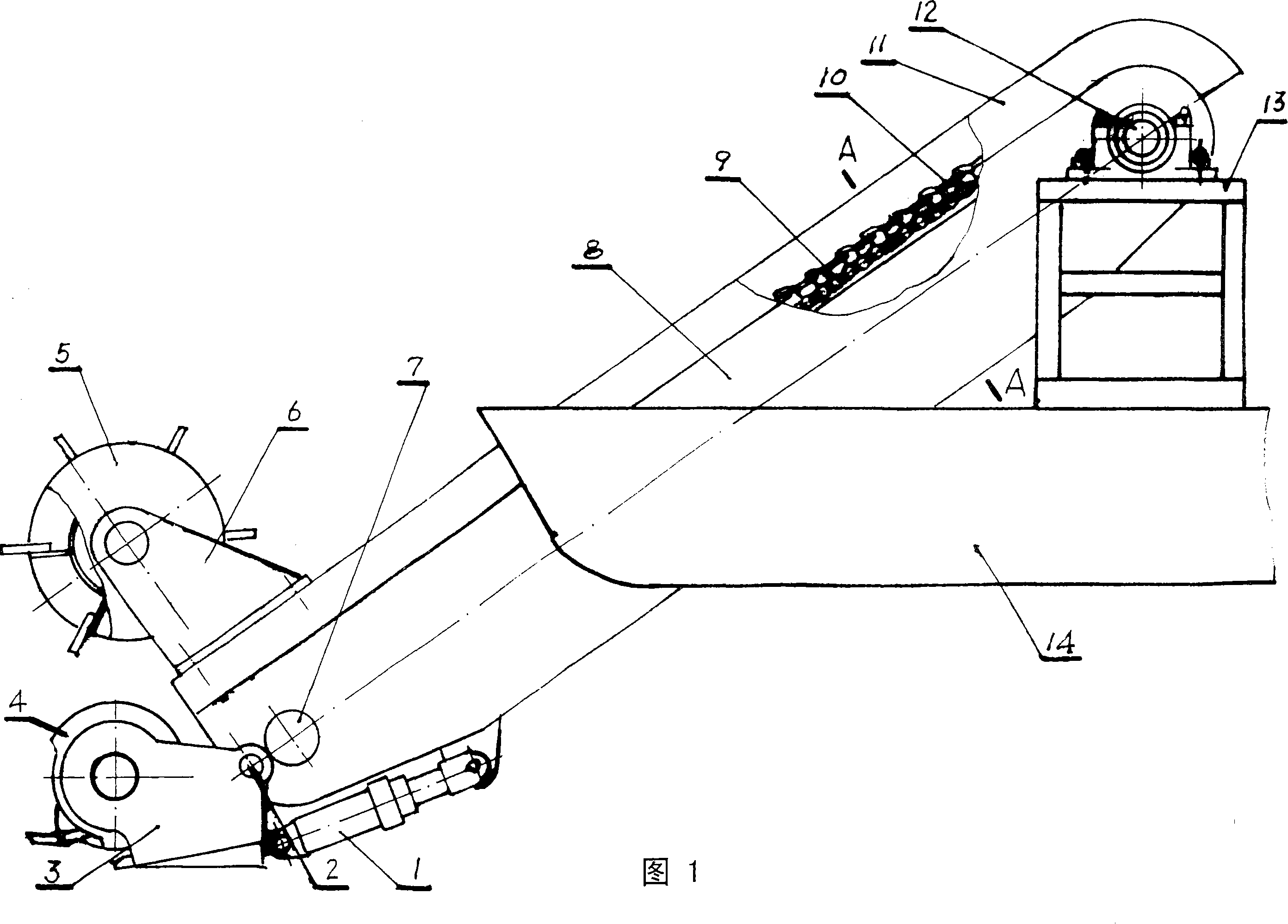

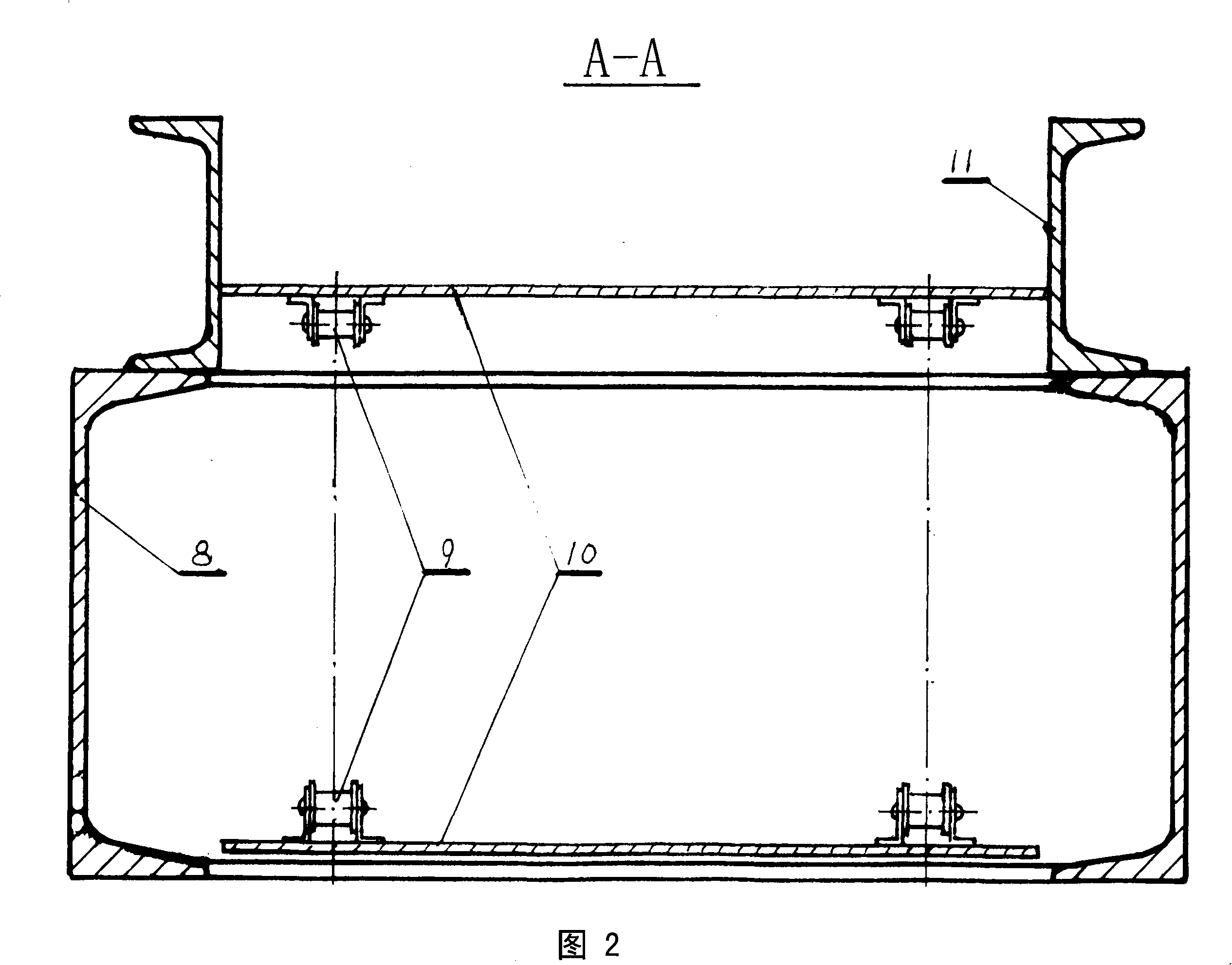

Excavator and sand dredger

InactiveCN101130995AEnhance sand dredging powerImprove delivery capacitySoil-shifting machines/dredgersHydraulic cylinderDrive shaft

The present invention is one kind of excavator and one kind of sand dredging boat, and relates to underwater sand excavation. The excavator is one sand dredging balance wheel with oscillating hydraulic cylinder to drive one balance wheel and the sand dredging board on the balance wheel to rotate reciprocally and periodically for cutting sand. The sand dredging boat includes one mechanical and hydraulic driving system and one conveying chain belt on the boat, and one sand dredging balance wheel in water. The present invention is superior to available chain-bucket sand dredging boat, and has separated excavating assembly and conveying assembly, hydraulic driving, 5-10 times raised production efficiency and easy control.

Owner:熊梓光

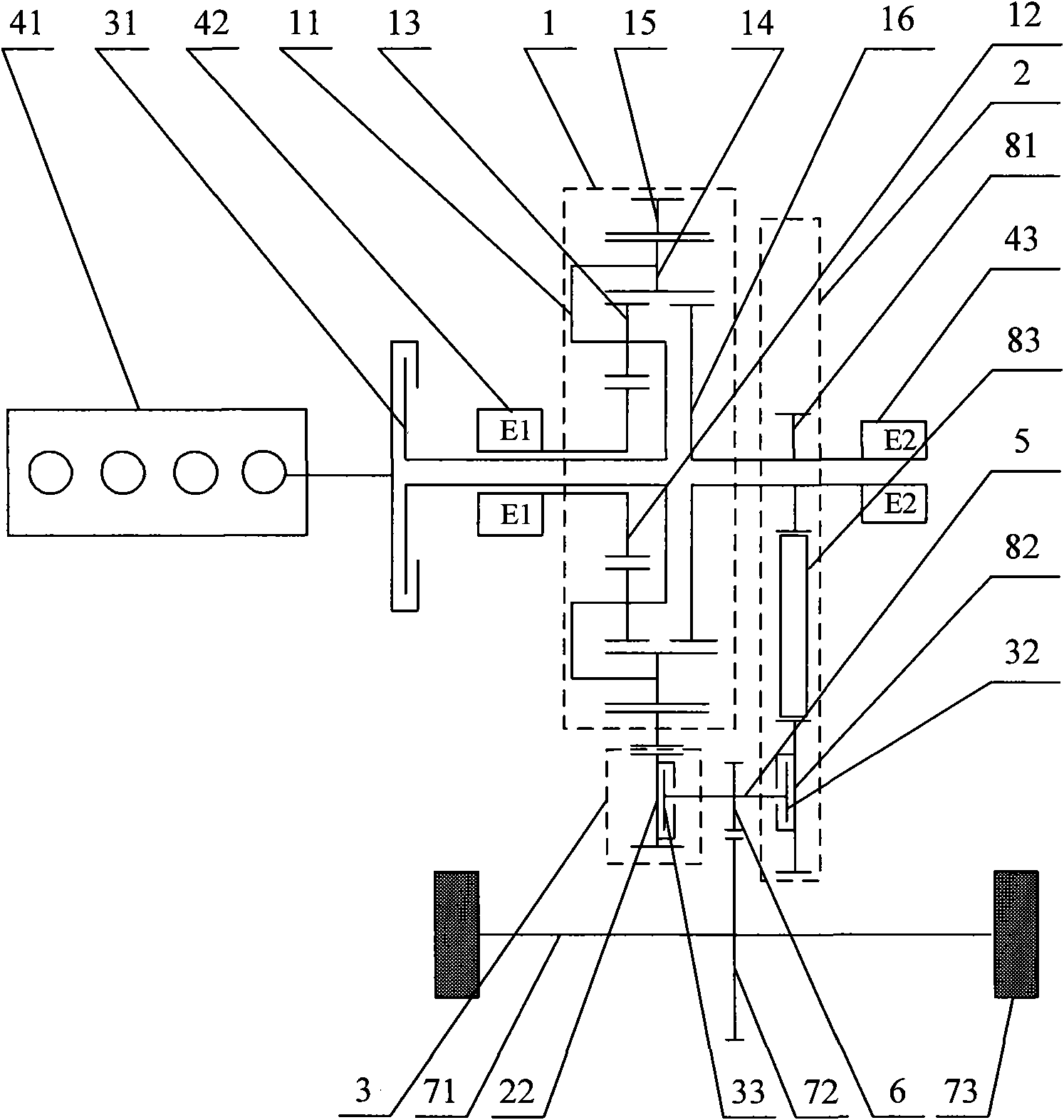

Active drive device for hybrid electric vehicle capable of independently controlling power output of left wheel and right wheel

InactiveCN102951005ARealize stepless speed changeCompact structureGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower couplingControl power

The invention discloses an active drive device for a hybrid electric vehicle capable of independently controlling power output of a left wheel and a right wheel, and the active drive device comprises an engine, a generator, two epicyclic gear trains, a left drive motor and a right drive motor; a first epicyclic gear train is used for realizing the power coupling of the engine, the generator and an input component of a second epicyclic gear train; the second epicyclic gear train is used for realizing the power coupling of the left / right drive motor and an output component of the first epicyclic gear train; the output component of the first epicyclic gear train and the input component of the second epicyclic gear train are connected with each other through a spur gear pair or a bevel gear pair in a driving way; and the left / right drive motor is respectively connected with a left wheel side drive shaft and a right wheel side drive shaft in a driving way. The active drive device has the advantages of compactness in structure, multiple running modes, stepless speed changing of the engine and capability of independently controlling the power output of the left and the right wheels.

Owner:TONGJI UNIV

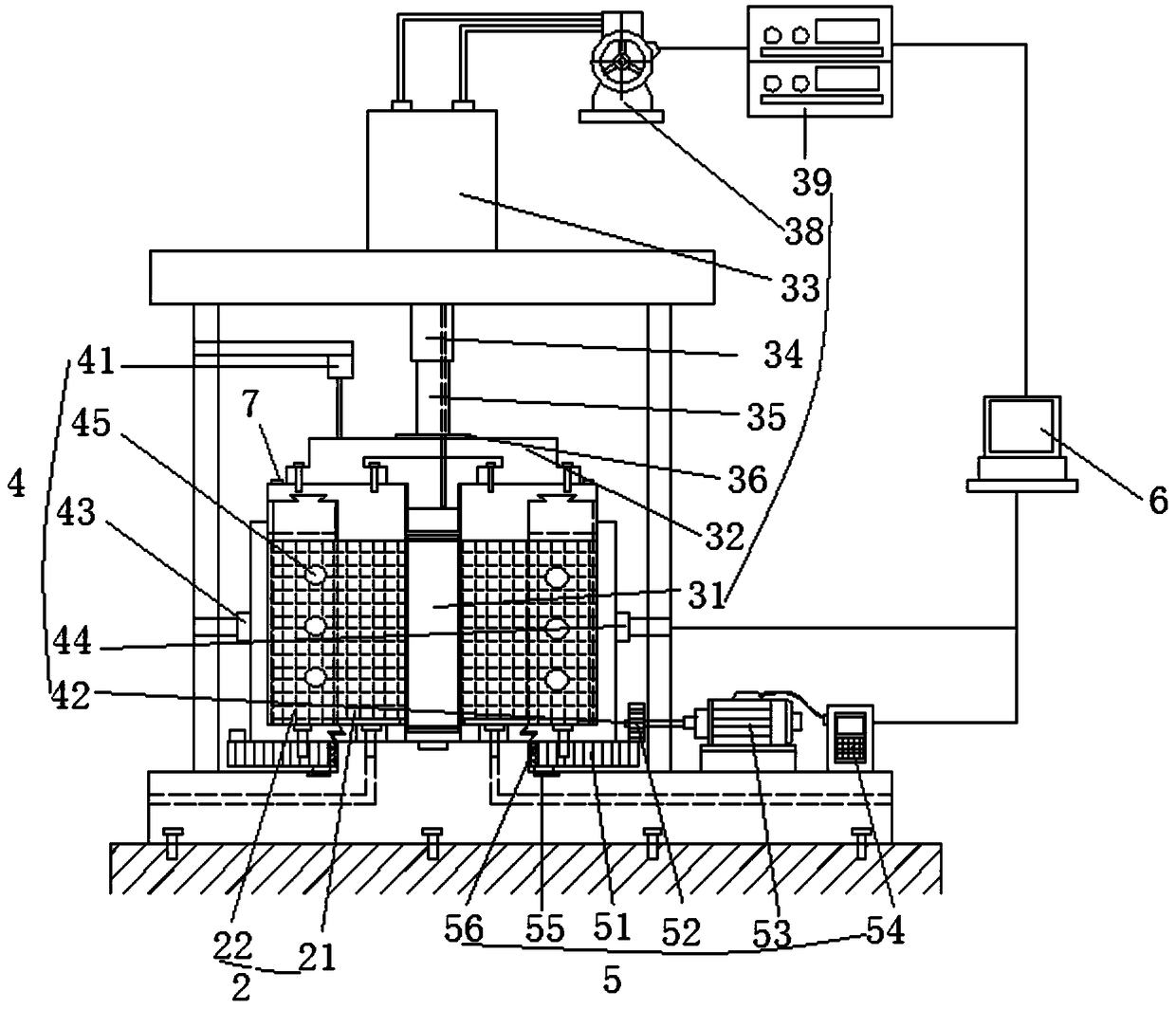

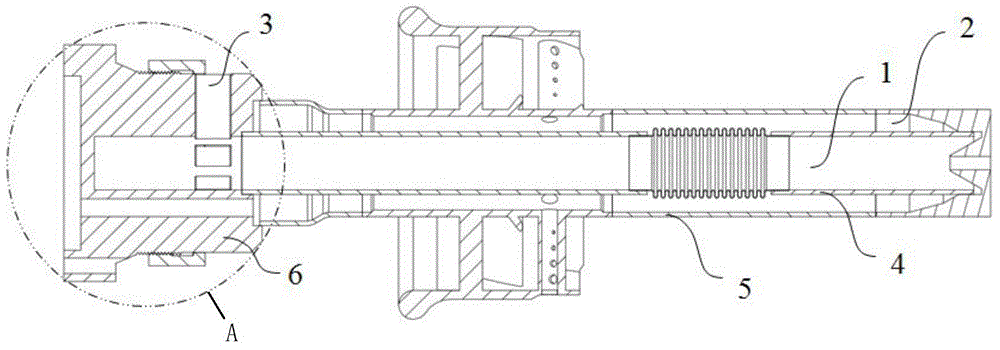

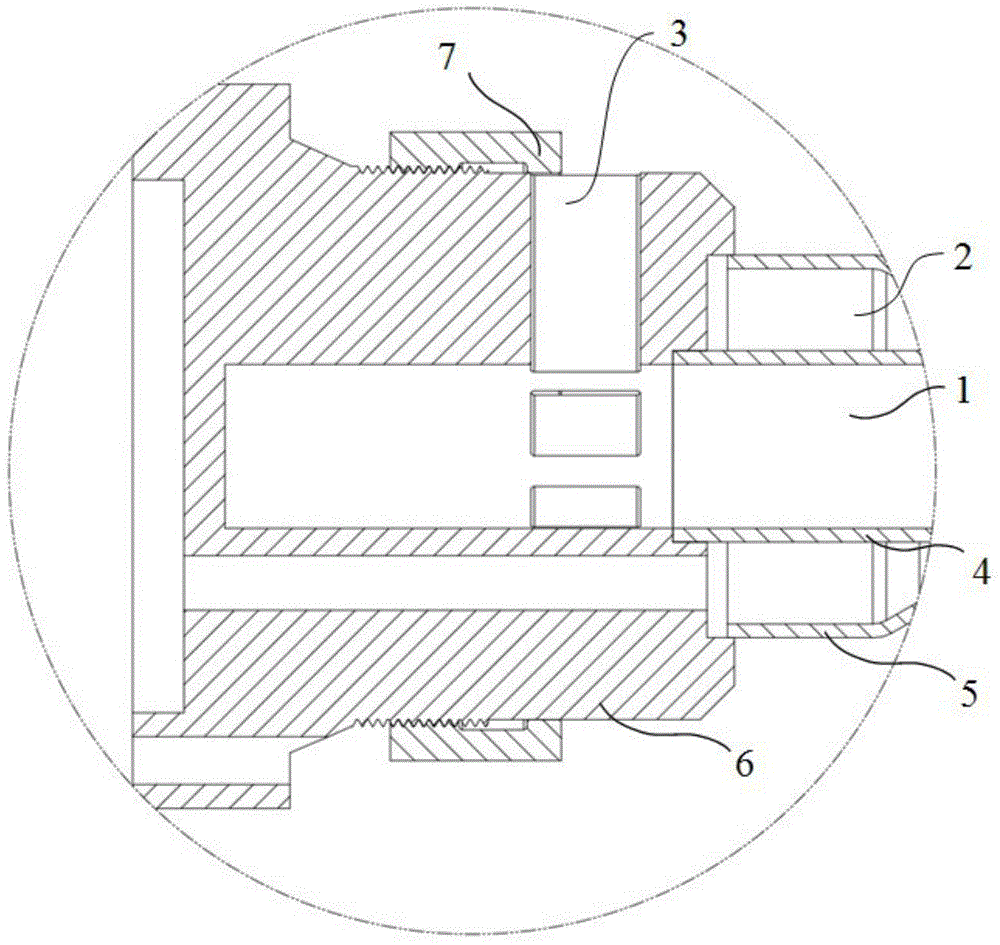

Vertical shearing surface annular shearing testing instrument capable of exerting confining pressure

ActiveCN108801804AStable normal stressAchieve shear failureMaterial strength using steady shearing forcesLandslideEngineering

The invention discloses a vertical shearing surface annular shearing testing instrument capable of exerting confining pressure. The testing instrument comprises a frame, a frame support shearing box,a hydraulic servo loading system, a monitoring sensing system and a shearing power system, wherein the shearing box comprises an inner shearing box and an outer shearing box; the inner shearing box issteady without movement; the outer shearing box is capable of rotating annularly; the shearing power system is connected with the outer shearing box and is capable of driving the outer shearing box to rotate annularly; the hydraulic servo loading system comprises a normal pressurizing device and an annular force conduction plate; the normal pressurizing device is vertically inserted in the middleof the inner shearing box and is used for providing normal stress; the annular force conduction plate is mounted above the shearing box and is used for conducting vertical confining pressure; the monitoring sensing system is used for sensing shearing data of a soil sample in real time and used for transmitting the shearing data to a control device; the control device is used for qualitatively controlling the normal stress of the normal pressurizing device and the vertical confining pressure of the annular force conduction plate. The testing instrument has great significances in studying shearing resistance properties of long-runout landslide slip soil and revealing evolutionary process and mechanisms of landslide.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

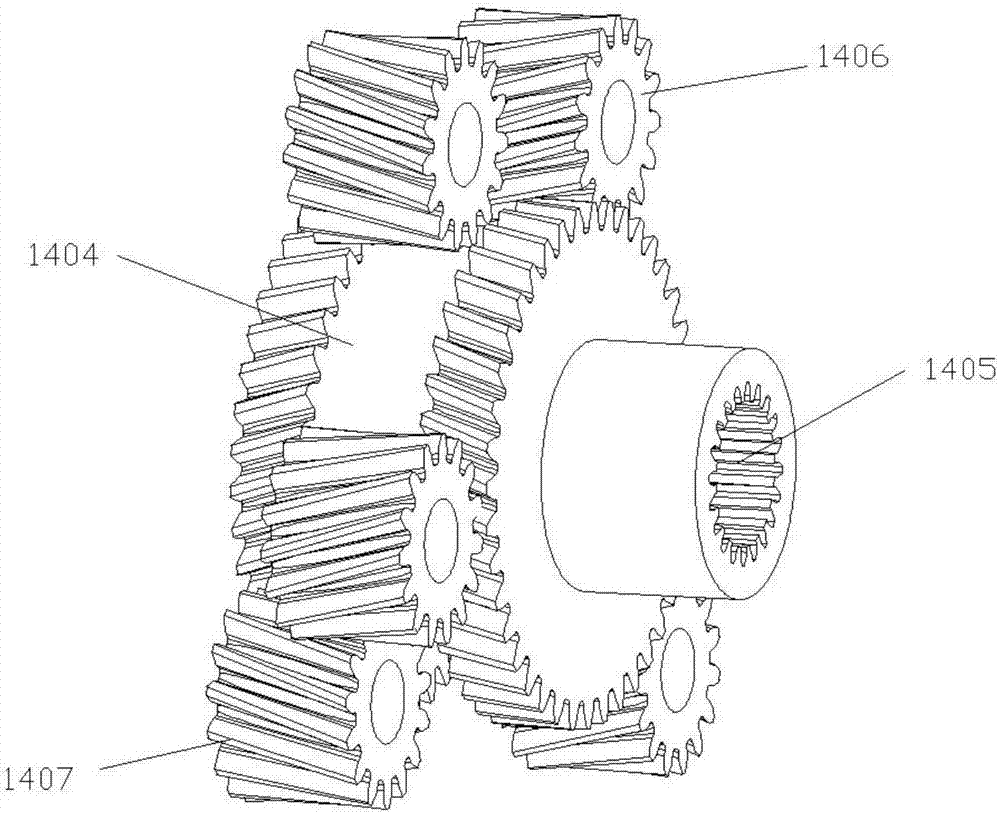

Double-motor coupling driving bridge with torque directional distribution function

ActiveCN106965661ASolve the disadvantages of "differential speed is not bad"Improve cornering maneuverabilityHybrid vehiclesElectric propulsion mountingGear systemDistribution function

The invention discloses a double-motor coupling driving bridge with a torque directional distribution function. The double-motor coupling driving bridge with the torque directional distribution function comprises a master driving mechanism, a spur gear differential, a TV control driving mechanism, a first single row planetary gear system, a second single row planetary gear system, a third single row planetary gear system, a first clutch, a second clutch, a third clutch and a fourth clutch, wherein a first sun gear of the first single row planetary gear system can be rotatably supported on a first half shaft, and a first gear ring is connected with the output end of the TV control driving mechanism; a second gear ring of the second single row planetary gear system is fixed to a driving bridge shell, and a second sun gear is coaxially and fixedly connected with the first sun gear; a third sun gear of the third single row planetary gear system is fixedly connected with a differential shell, and a third gear ring is fixedly connected with a second planetary frame; the first clutch is used for isolating or combining the first half shaft and a first planetary frame; the second clutch is used for isolating or combining the first planetary frame and the driving bridge shell; the third clutch is used for isolating or combining the first half shaft and a third planetary frame; and the fourth clutch is used for isolating or combining the third planetary frame and the driving bridge shell.

Owner:JILIN UNIV

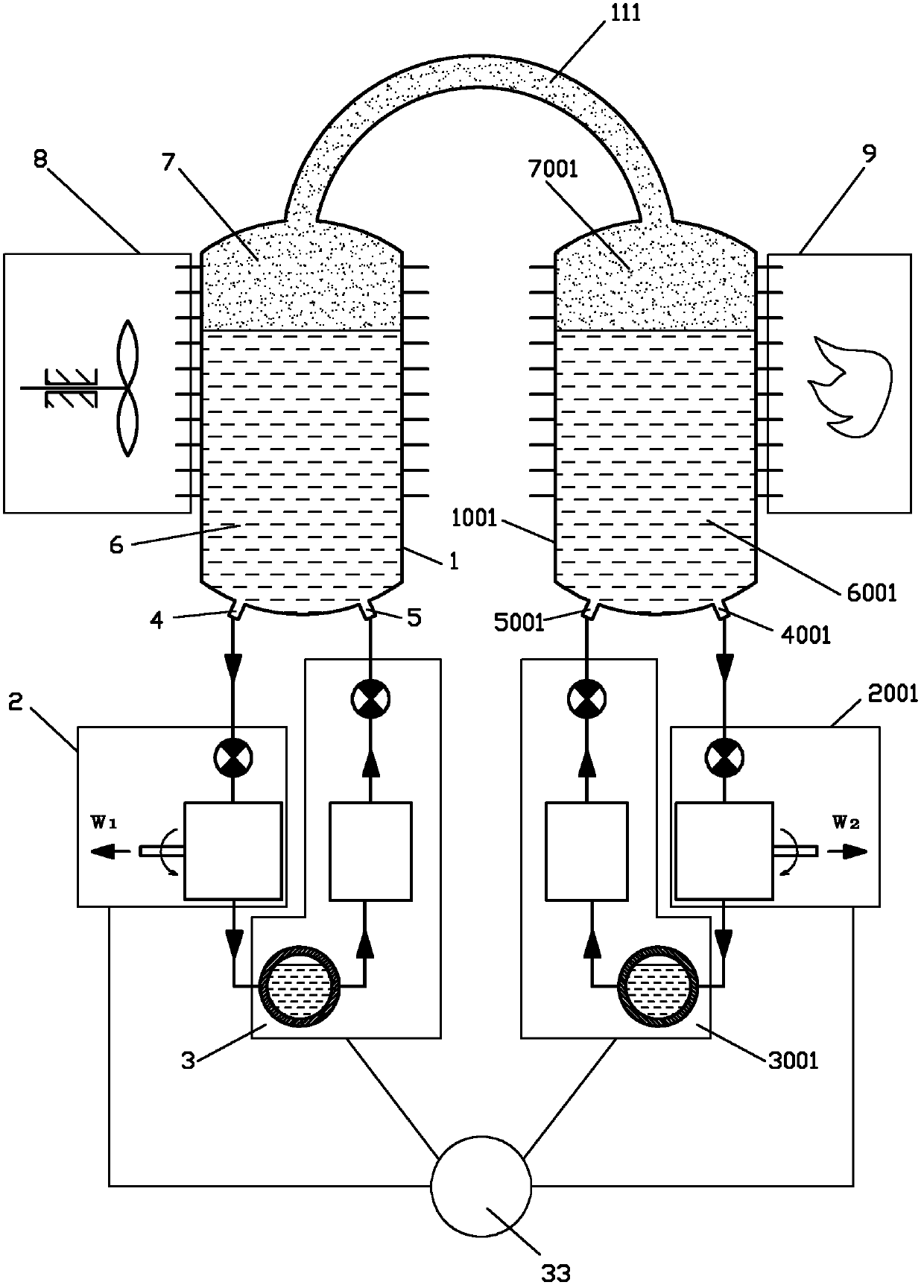

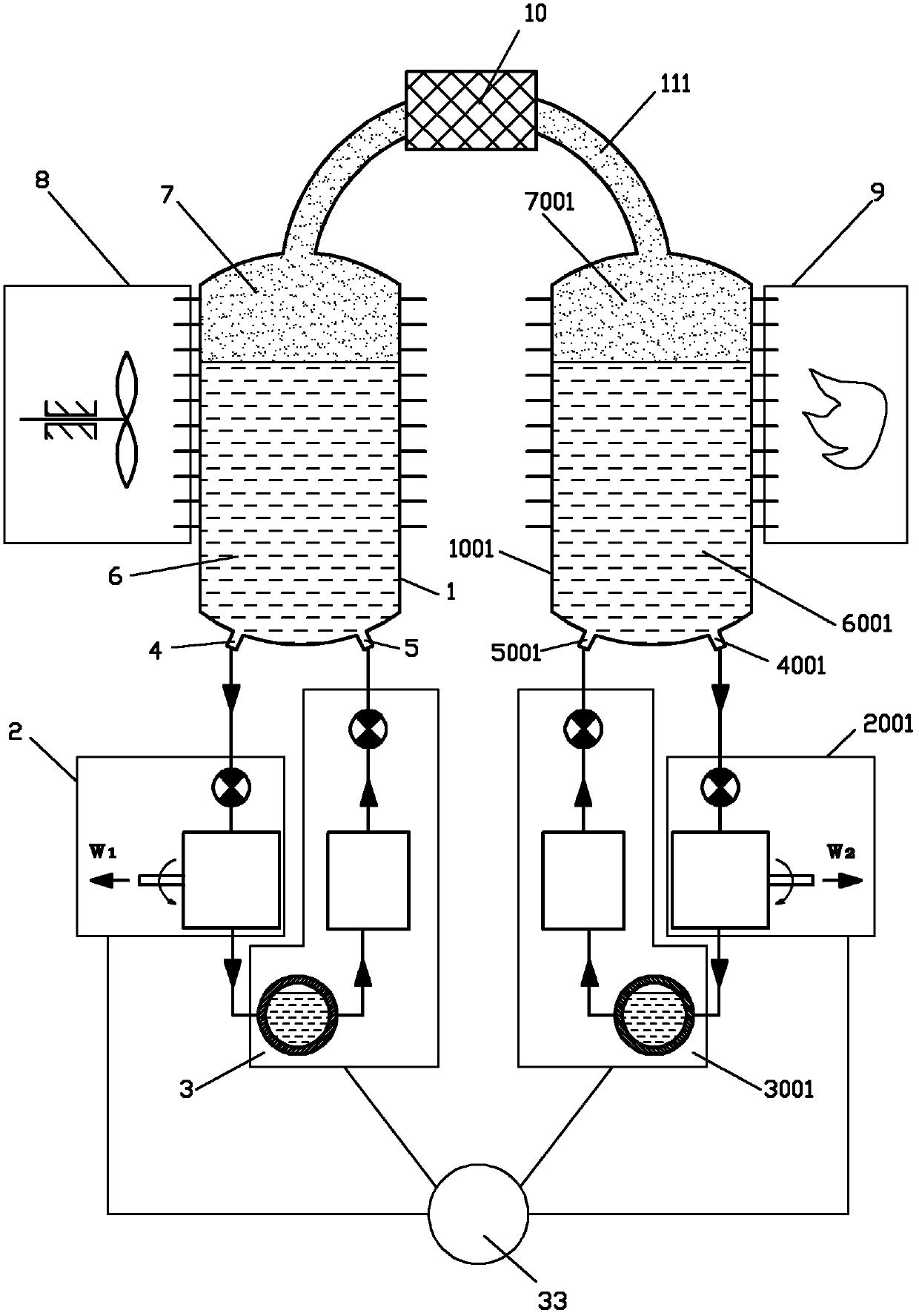

Liquid piston heat engine

InactiveCN102434311ARealize stepless speed changeImplement speed changesInternal combustion piston enginesHot gas positive displacement engine plantsHydraulic cylinderCold air

The invention discloses a liquid piton heat engine which comprises a cold air hydraulic cylinder, a hot air hydraulic cylinder, a cold hydraulic power mechanism, a hot hydraulic power mechanism, a cold liquid medium return system and a hot liquid medium return system, wherein the cold air hydraulic cylinder is communicated with the hot air hydraulic cylinder through an air medium communicating pipeline, a cooler is arranged on the cold air hydraulic cylinder, a heater is arranged on the hot air hydraulic cylinder, a cold liquid medium outlet of the cold air hydraulic cylinder is communicated with a cold liquid medium return hole through the cold hydraulic power mechanism and the cold liquid medium return system, a hot liquid medium of the hot air hydraulic cylinder is communicated with a hot liquid medium return hole through the hot hydraulic power mechanism and the hot liquid medium return system, and the cold hydraulic power mechanism, the cold liquid medium return system, the hot hydraulic power mechanism and the hot liquid medium return system are controlled by a progress control mechanism. According to the invention, a piston crank connecting rod mechanism of an engine is omitted, and a large-power thermomotor with high efficiency and small volume and light weight can be manufactured.

Owner:ZEROQ SCI & TECH

Power transmission system and grader

InactiveCN103758976ARealize stepless speed changeGood speed regulation stabilityGearboxesMechanical machines/dredgersHydraulic motorElectric power transmission

The invention discloses a power transmission system comprising a reduction box and at least two hydraulic motors. The reduction box comprises at least two input shafts, and an output shaft of each hydraulic motor is connected with each input shaft of the reduction box. The invention further provides a grader comprising the power transmission system. By selection of number of the working hydraulic motors and / or regulation of displacement of the hydraulic motors and / or hydraulic pumps, output speed of the transmission system is changed, and the power transmission system has the advantages of good speed regulation stability, enlargement of speed regulation range and the like.

Owner:HUNAN SANY ROAD MACHINERY

Multi-power-source multi-mode coupling drive system

InactiveCN102602277AAchieve Torque CouplingAchieve speed couplingGas pressure propulsion mountingToothed gearingsDrive shaftEngineering

The invention discloses a multi-power-source multi-mode coupling drive system which comprises a first power source, a first transmission shaft, a second power source, a second transmission shaft, a third transmission shaft and a planetary gear mechanism consisting of a sun wheel, a planet wheel, a gear ring and a planet carrier, wherein a first gear and the sun wheel are fixed on the first transmission shaft; the gear ring and the first transmission shaft are in coaxial running fit; a second gear, a third gear and a synchronizer are arranged on the second transmission shaft; a fourth gear and a fifth gear are arranged on the third transmission shaft; the fourth gear is meshed with the third gear; and the fifth gear is meshed with the gear ring. When the synchronizer is combined with the second gear, torque coupling can be realized; when the synchronizer is combined with the third gear, the rotation speed coupling can be realized; and when the first power source and the second power source are the hybrid power of an electromotor and an engine, the system has multiple working modes, the switching among the working modes can be realized by controlling the synchronizer, and the control is simple.

Owner:CHONGQING UNIV

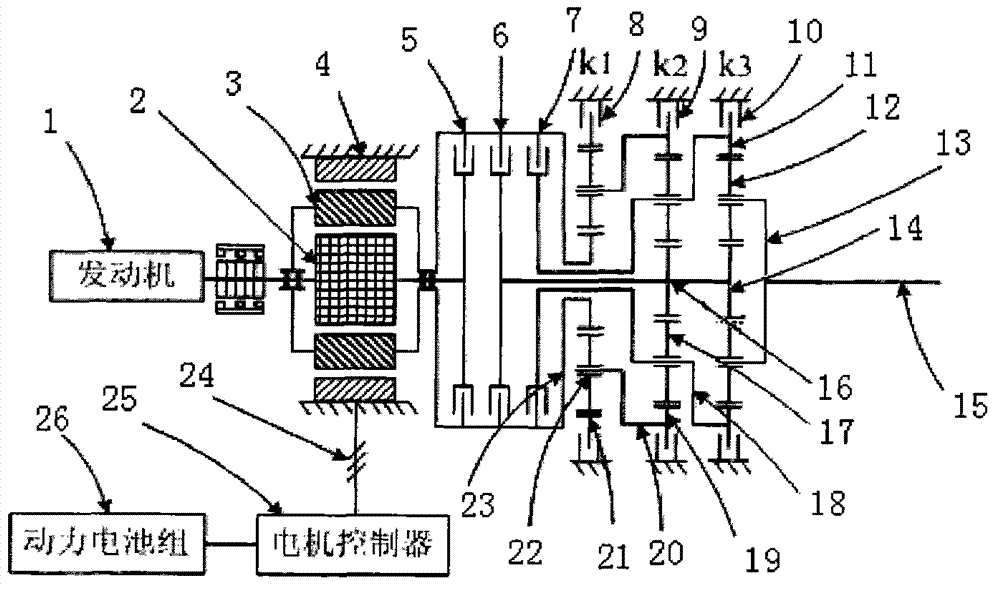

Electromechanical composite stepless transmission device for wheeled load-carrying vehicle with birotor motor

ActiveCN102815199ASimple structureLow costGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPower batteryElectric machine

The invention belongs to the technical field of power transmission, relates to a composite stepless transmission device, and particularly relates to an electromechanical composite stepless transmission device for a wheeled load-carrying vehicle with a birotor motor. The electromechanical composite stepless transmission device comprises an engine, the birotor motor, a k1 planetary row, a k2 planetary row, a k3 planetary row, an output shaft, a birotor motor cable, a motor controller, a power battery pack and six control elements. An input shaft, the output shaft, the motor, a clutch, a brake and the planetary rows can be arranged coaxially to save space and improve power density. Only a two-layer sleeve shaft structure is needed, so that the electromechanical composite stepless transmission device is simple in structure and convenient in process. Power grade of the motor or the engine can be decreased by means of reasonable matching.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

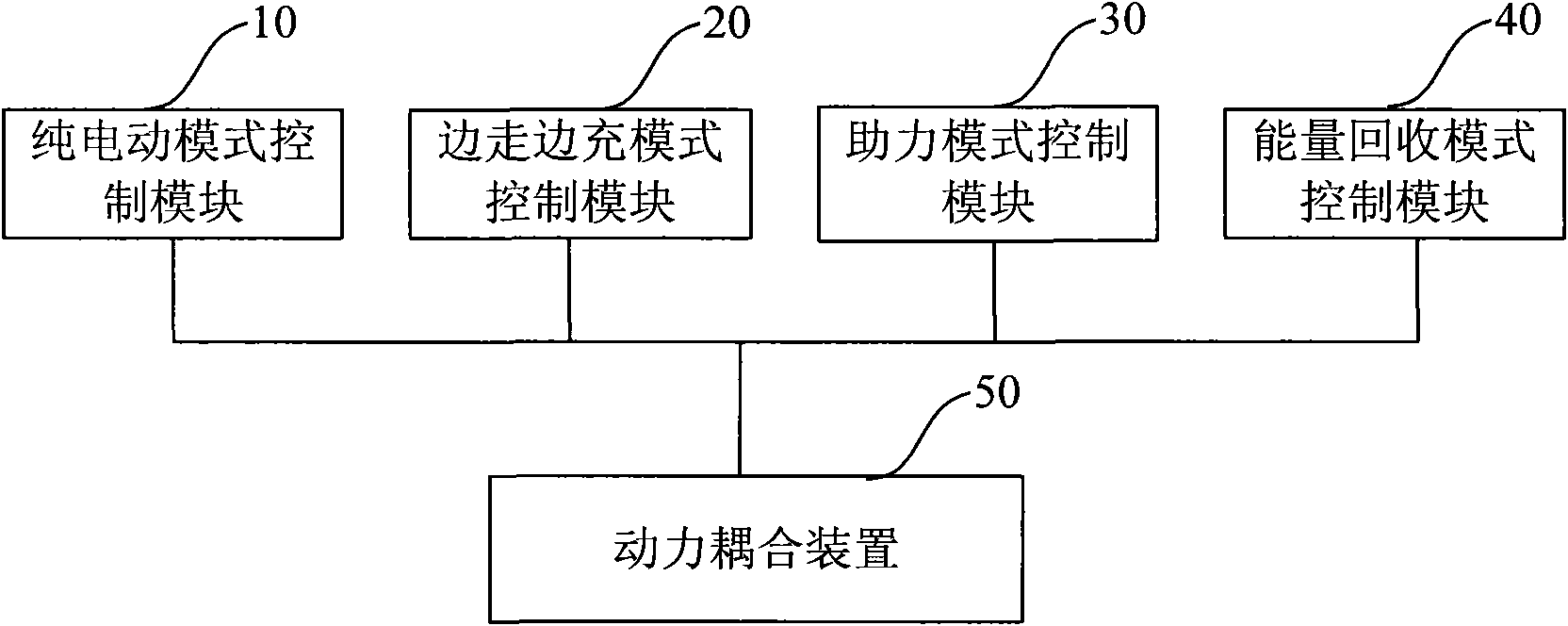

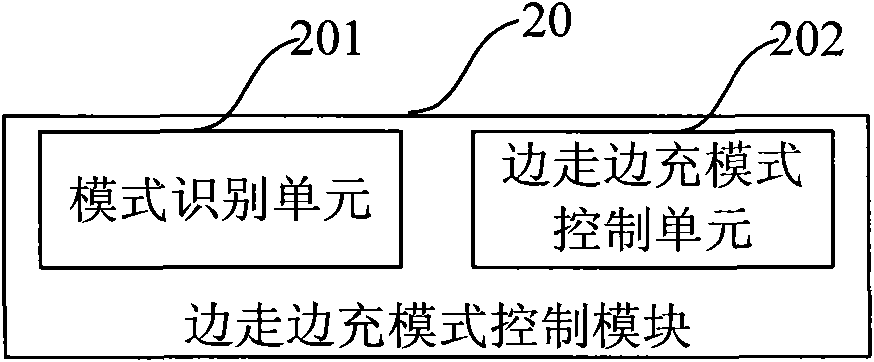

Power coupling device and control device thereof, and hybrid power system

InactiveCN102310755AIncrease the degree of mixingIncrease output powerHybrid vehiclesGearingPower couplingElectric machine

The invention discloses a power coupling device and a control device thereof, and a hybrid power system. The power coupling device comprises a front planet gear train and a power transmission mechanism; a planet carrier of the front planet gear train is provided with a first clutch connected with an engine; power shafts of a small sun gear and a big sun gear of the front planet gear train are connected with a first motor and a second motor; the power transmission mechanism comprises a first transmission mechanism connected with a second motor, and a second transmission mechanism connected with the front planet gear train; the first transmission mechanism and the second transmission mechanism are connected with a second clutch and a third clutch; the first clutch and the second clutch are coaxially arranged on a clutch shaft; and the clutch shaft is provided with a power output mechanism connected with a power input mechanism on an automobile. By the technical scheme, various operating modes of a hybrid power automobile and the reasonable distribution of power output by the engine and the motors under various modes can be realized, so that the fuel economy of the hybrid power automobile is improved.

Owner:BEIQI FOTON MOTOR CO LTD

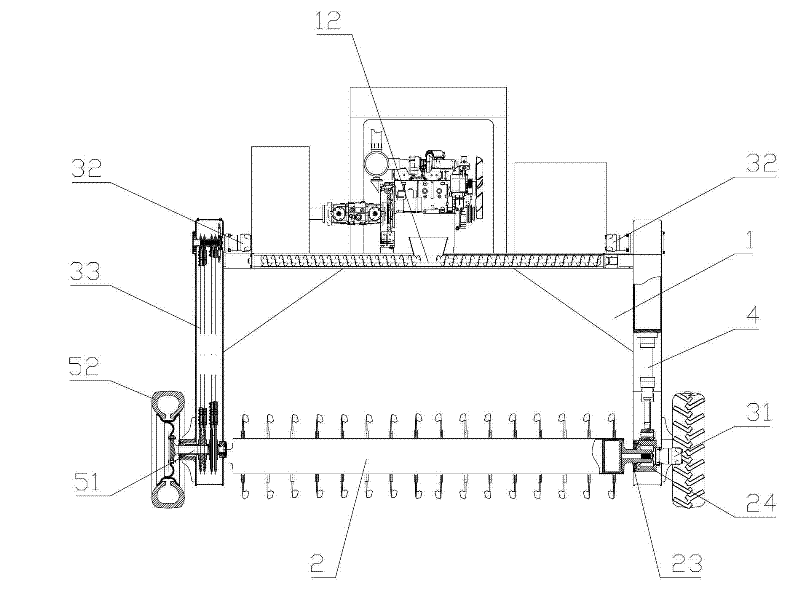

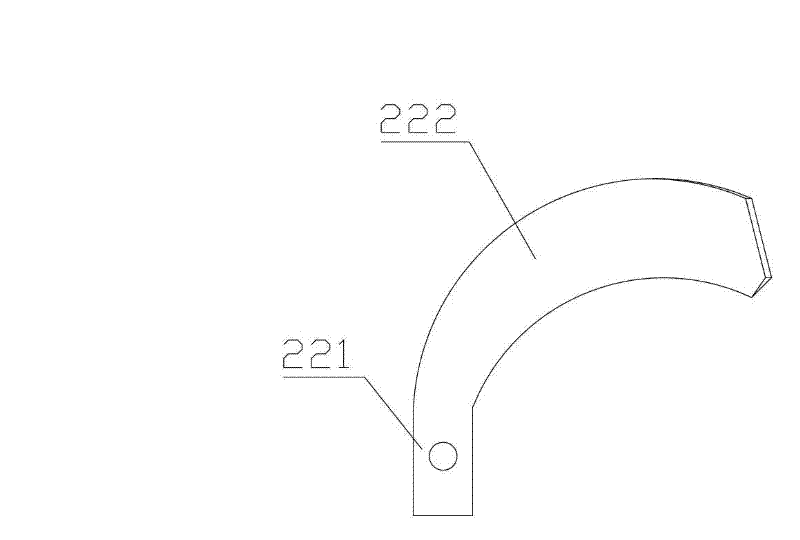

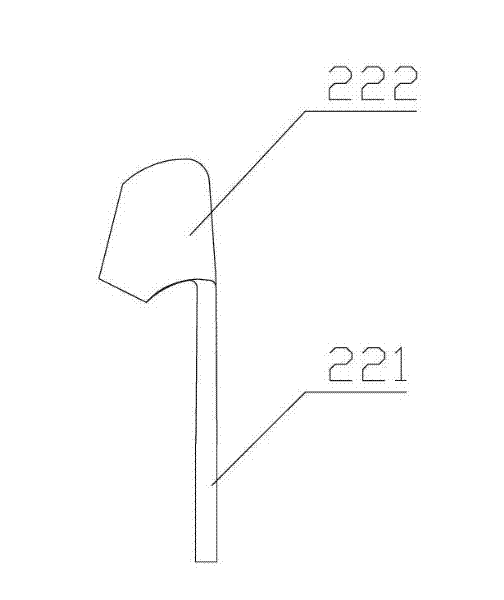

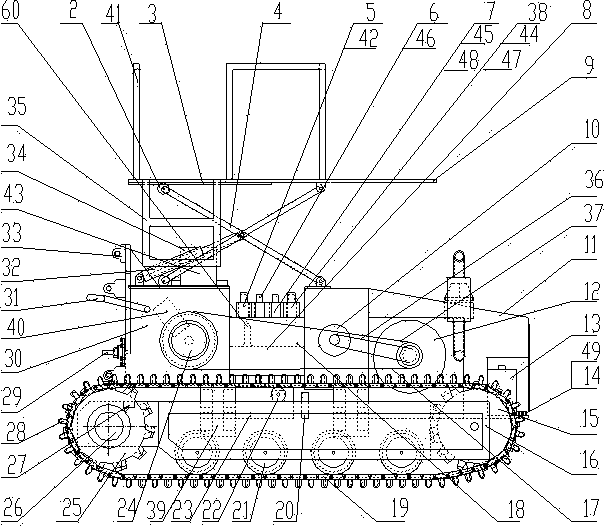

Slipping type all-hydraulic turner

InactiveCN102653480ASave work spaceLow costClimate change adaptationOrganic fertiliser preparationClutchFault rate

The invention discloses a slipping type all-hydraulic turner, comprising a turner body, wherein the turner body is provided with a drive assembly; a turning mechanism is further arranged at the lower part of the turner body; the turning mechanism comprises a turning cylinder; the drive assembly comprises a hydraulic motor for driving the turning cylinder to rotate; and the turning cylinder is provided with a regulating component which is used for connecting the turning cylinder and the turner body and simultaneously regulating the height of the turning cylinder relative to the turner body. The slipping type all-hydraulic turner is powered by hydraulic pressures, members, such as a clutch and a gear box are cancelled, stepless speed changing is realized, the fault rate is greatly reduced, and the technical problems that the traditional turner has big turning radius, large size, high fault rate, low turning efficiency, poor turning effect and the like are solved.

Owner:浙江濠泰机械有限公司

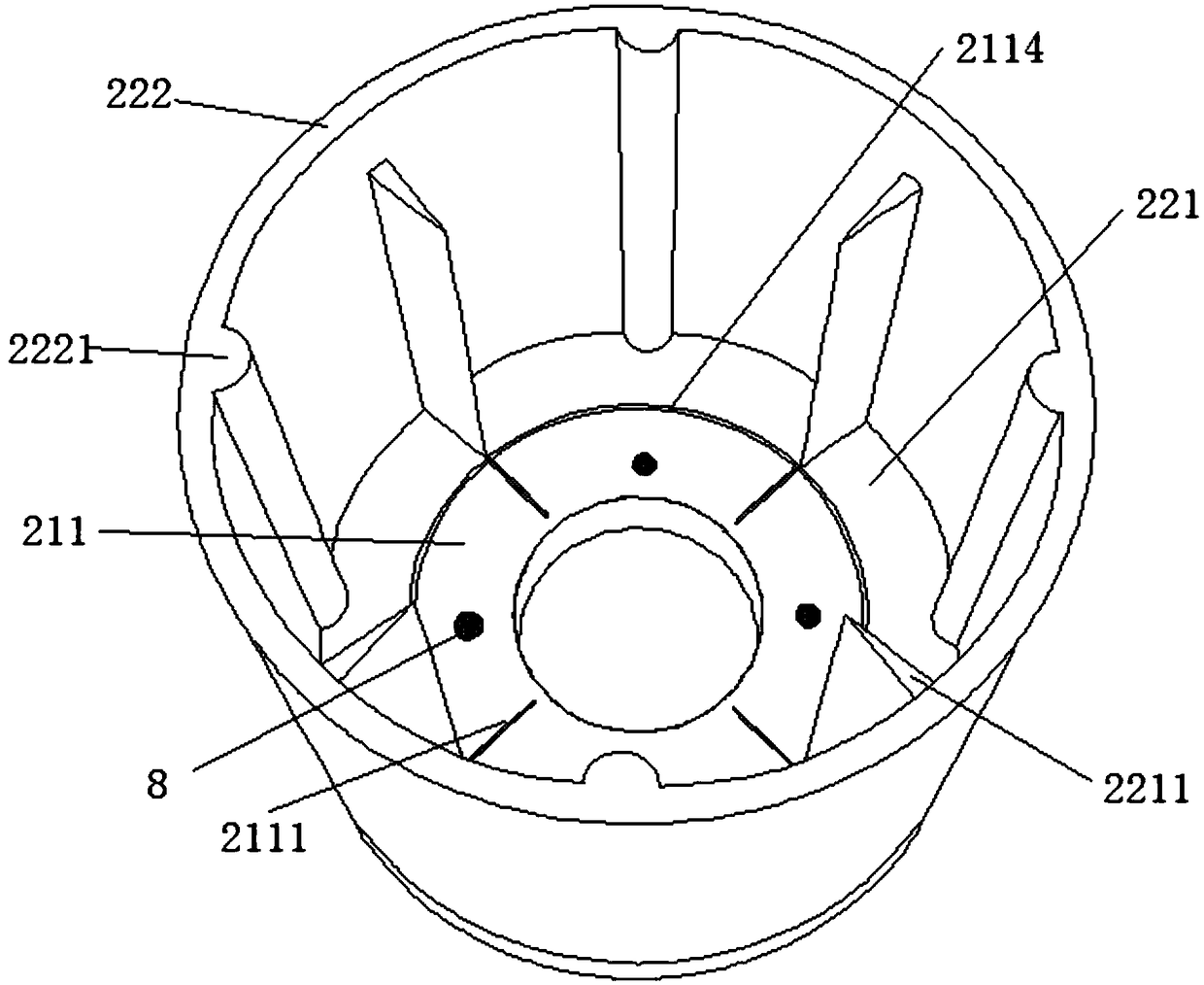

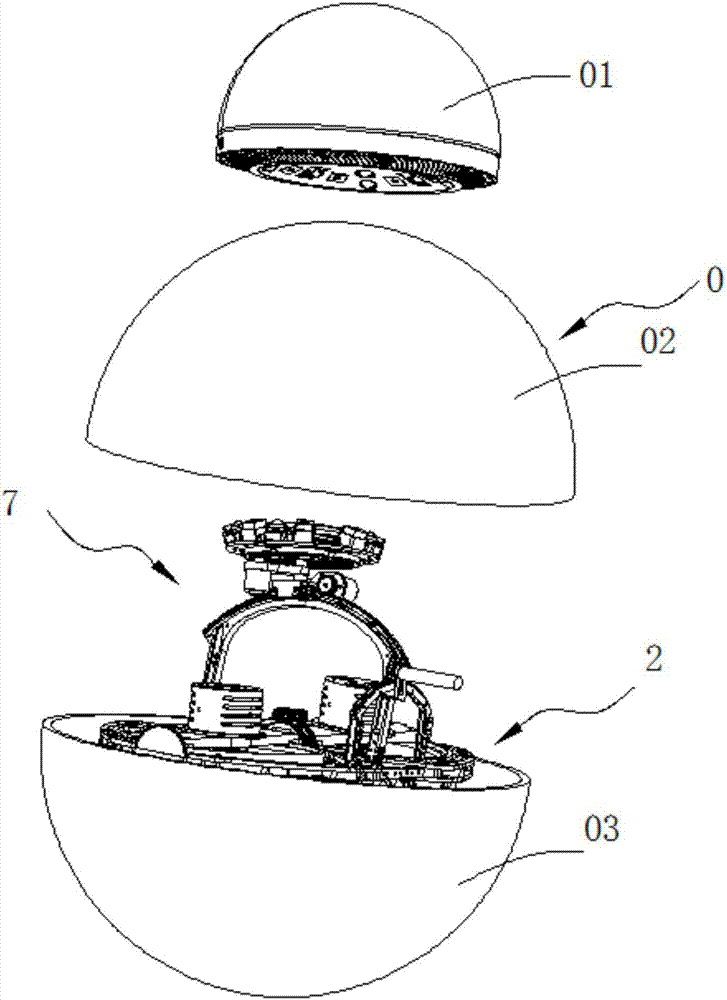

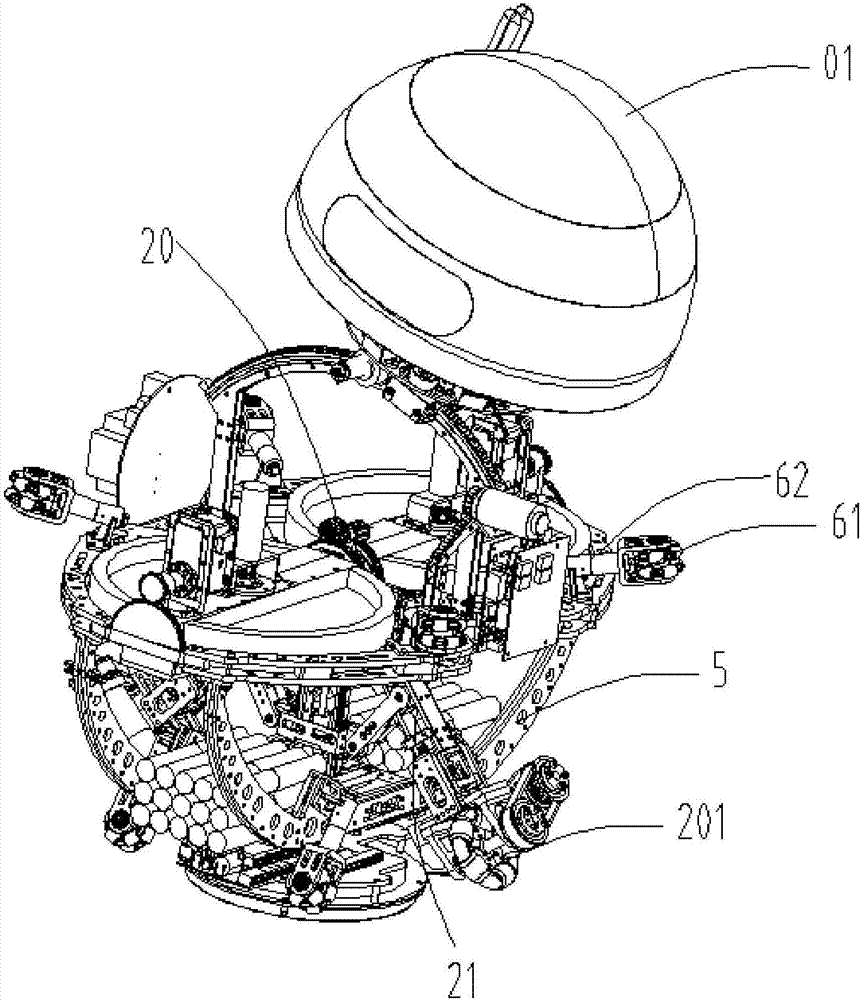

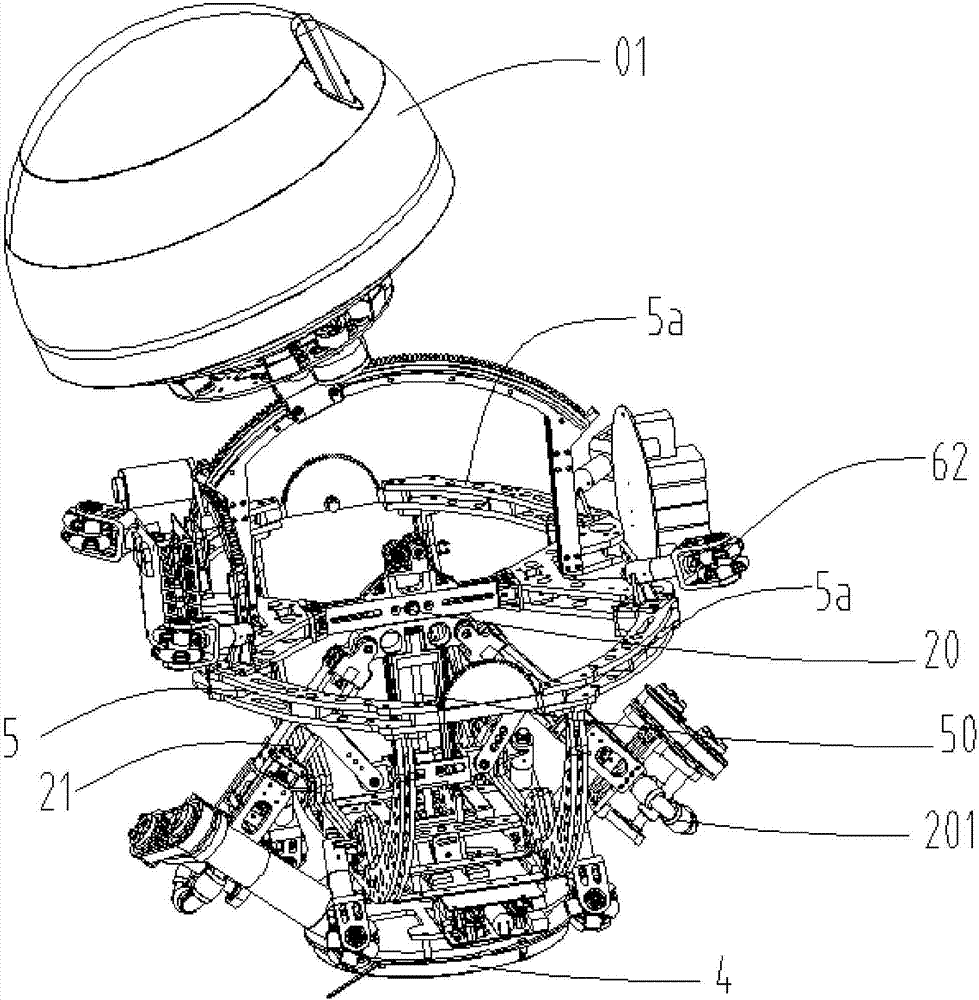

Spherical robot

ActiveCN107128378AFree slide implementationImprove sexual functionJointsVehiclesEngineeringFriction force

The invention provides a spherical robot. The spherical robot comprises a head assembly and a spherical body which can rotate relative to the head assembly. The spherical body comprises a ball shell, a connecting part arranged in the central region of the ball shell, and a walking driving mechanism connected between the ball shell and the connecting part. The walking driving mechanism comprises a driving arm which can swing around the connecting part, and a driving wheel which is in contact with the ball shell is arranged at one end of the driving arm; the ball shell is driven to walk through friction force between the driving wheel and the ball shell; the walking speed of the ball shell is changed by changing the swinging position of the driving arm relative to the connecting part; the side, away from the walking driving mechanism, of the connecting part is provided with a head driving assembly, and the head driving assembly drives the head assembly to move on the outer surface of the ball shell.

Owner:湖南坎德拉创新科技有限责任公司

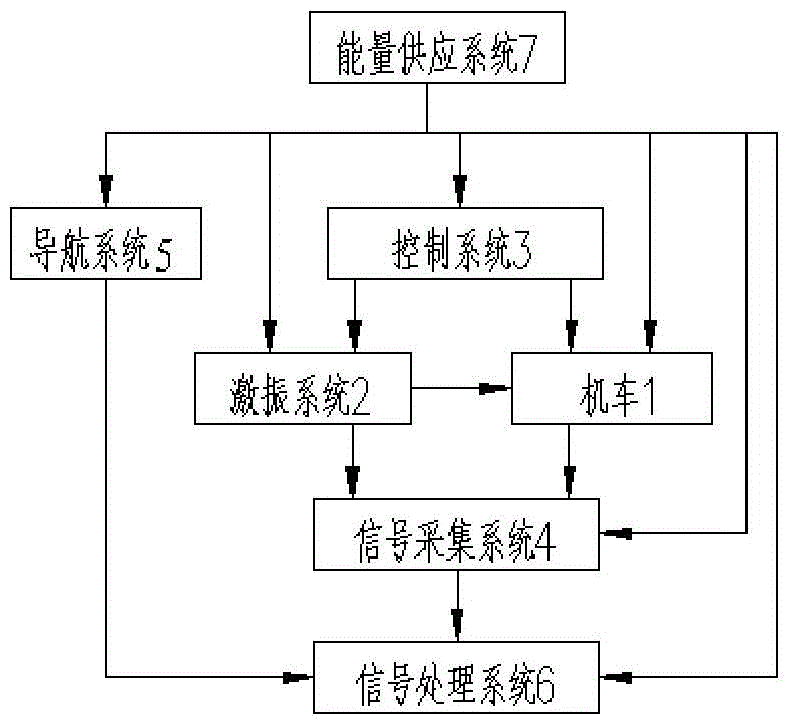

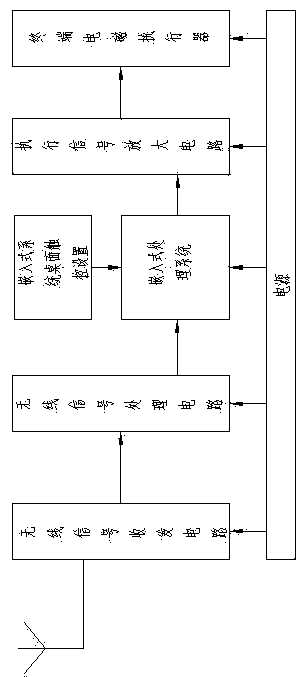

Inspection and evaluation system for track geometric irregularity

ActiveCN105000033ASave human effortSave moneyRailway auxillary equipmentRailway profile gaugesControl systemSimulation

The invention discloses an inspection and evaluation system for the track geometric irregularity, relates to an inspection and evaluation system, and solves the problems that the inspection efficiency is low and inspection results are inaccurate due to manual influence as a track inspection car is required to be pushed by manpower for inspection in the field of track traffic. A comprehensive inspection vehicle has the problems that the construction cost is expensive, and lines are required to be closed frequently to influence the normal traffic operation; in addition, the inspection result variation caused by looseness of an inspection beam of the track inspection car or the comprehensive inspection vehicle is not easy to find out frequently, and as a result, the problem of inspection result distortion is caused. The inspection and evaluation system comprises a locomotive independently running on a track, as well as an excitation system, a control system, signal acquisition systems, a navigation system, a signal processing system and an energy supply system all placed inside the locomotive. According to the invention, the static irregularity can be obtained without manual measurement, so that plenty of manpower and material resources are saved, and the inspection efficiency and inspection precision are effectively improved. The inspection and evaluation system is used for inspection of the track geometric irregularity.

Owner:HARBIN INST OF TECH

Travelling transmission mechanism for track vehicle

InactiveCN102874104AImprove productivityImprove economyFluid gearingsControl devicesDrive wheelSteering control

The invention relates to a travelling transmission mechanism for a track vehicle. The travelling transmission mechanism can be applied to agricultural machines for ploughing, harvesting, planting, sowing and the like. The travelling transmission mechanism comprises an engine (1), a clutch (3), a travelling steering control device (9) and a travelling driving wheel (10); and a static hydraulic transmission system (HST) is connected between the clutch (3) and the travelling steering control device (9). The travelling transmission mechanism is simple in transmission structure, convenient to maintain and capable of reducing the weight of a whole device and improving the mechanical operation performance and the travelling and passing performances of the agricultural machines.

Owner:HUNAN NONGFU ELECTROMECHANICAL

Air inlet structure for fuel nozzle of gas turbine

ActiveCN104456624ARealize stepless speed changeImprove reliabilityContinuous combustion chamberInlet channelMixing effect

The invention relates to the technical field of gas turbines, and provides an air inlet structure for a fuel nozzle of a gas turbine. The fuel nozzle comprises a center air channel and a fuel cavity which are communicated with each other, and the center air channel is used for connecting the air into the fuel cavity. A nozzle hanging flange is arranged at one end of the center air channel, and the nozzle hanging flange is provided with air inlet channels used for connecting the air into the center air channel. The nozzle hanging flange is movably sleeved with an adjusting sleeve, and the adjusting sleeve is used for limiting the sizes of openings of the air inlet channels through axial movement. By axially adjusting the adjusting sleeve, the flow of the air entering the center air channel can be adjusted, hence, it is guaranteed that fuel and air have a good pre-mixing effect, tempering can be prevented from happening to a nozzle outlet, and the reliability of the nozzle is improved; in addition, stepless speed change of the gas turbine can be achieved through the adjusting sleeve.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

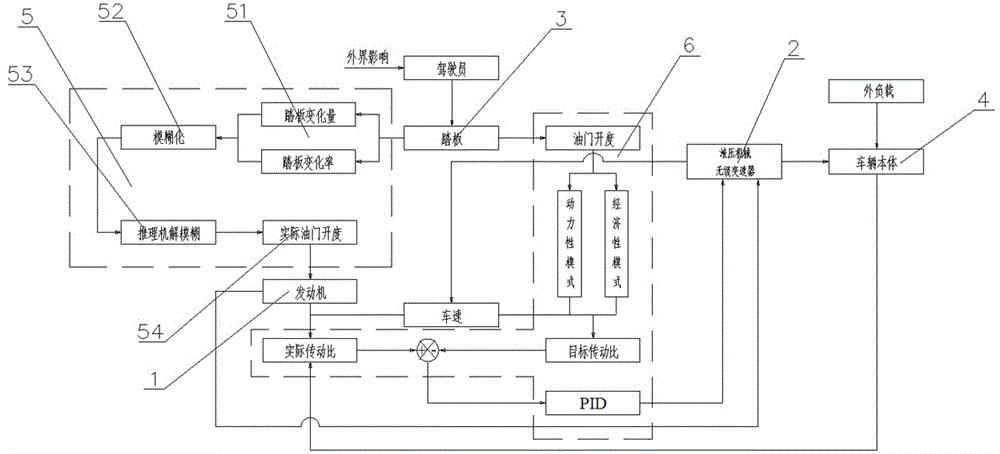

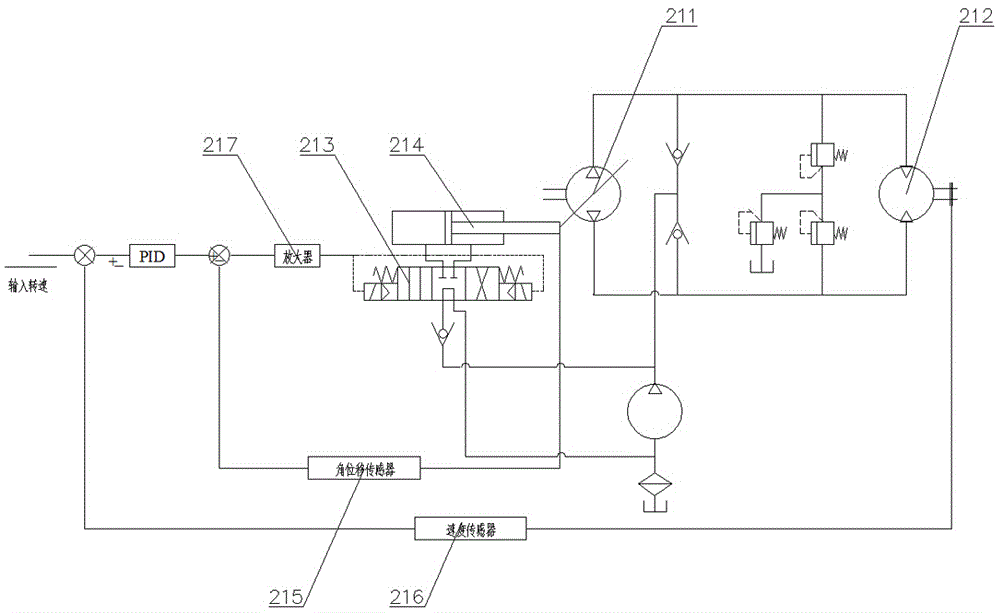

Vehicle power matching system with hydraulic mechanical continuously-variable transmission

InactiveCN104149779AProcess stabilitySmall overshootDriver input parametersTransient stateOptimal control

A vehicle power matching system with a hydraulic mechanical continuously-variable transmission can automatically adjust the transmission ratio of the transmission according to driving intentions of drivers and changes of an external load so that a driving system can provide enough power when in a transient state; during the transient state, an engine works at an optimal economical curve, and accordingly the system performance can be optimal. The vehicle power matching system has the advantages that the engine always works under the working conditions of optimal power performance and optimal economy; infinitely variable speeds are achieved rapidly and stably under the conditions of the driving intentions of the drivers and the changes of the external load; during the process, vibration noise is small, the overshoot is small, and offset is eliminated as far as possible; and the vehicle power matching system can meet the transient state power performance requirements and steady state economy requirements when a vehicle runs.

Owner:JIANGSU UNIV

Hydraulic-drive multifunctional orchard operation machine

InactiveCN104221517AStrong data processing abilityProcessing speedAgricultural undercarriagesHydraulic motorControl system

The invention discloses a hydraulic-drive multifunctional orchard operation machine. The hydraulic-drive orchard operation machine has the advantages that a method for combining an embedded system with a hydraulic electromagnetic valve group is implemented for a control system of the hydraulic-drive multifunctional orchard operation machine, accordingly, hydraulic motor running, platform lifting and agricultural implement elevating work can be controlled, integral vehicle speed and turning can be flexibly controlled, platform lifting and agricultural implement elevating operation can be implemented by the aid of independent pumps, the purpose of saving energy can be achieved, and the problem of insufficient traveling power due to oil supply by a single oil pump can be solved.

Owner:NORTHWEST A & F UNIV

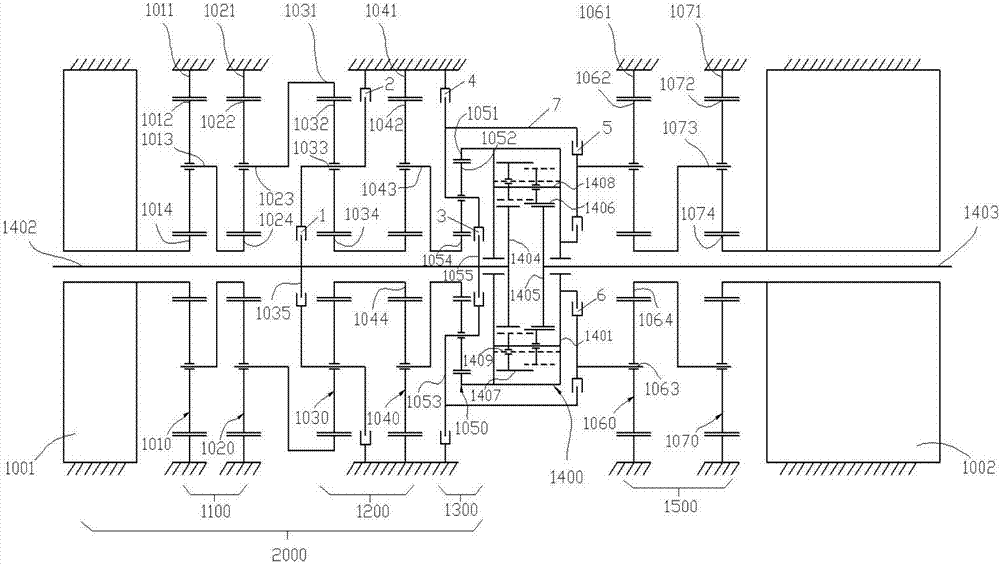

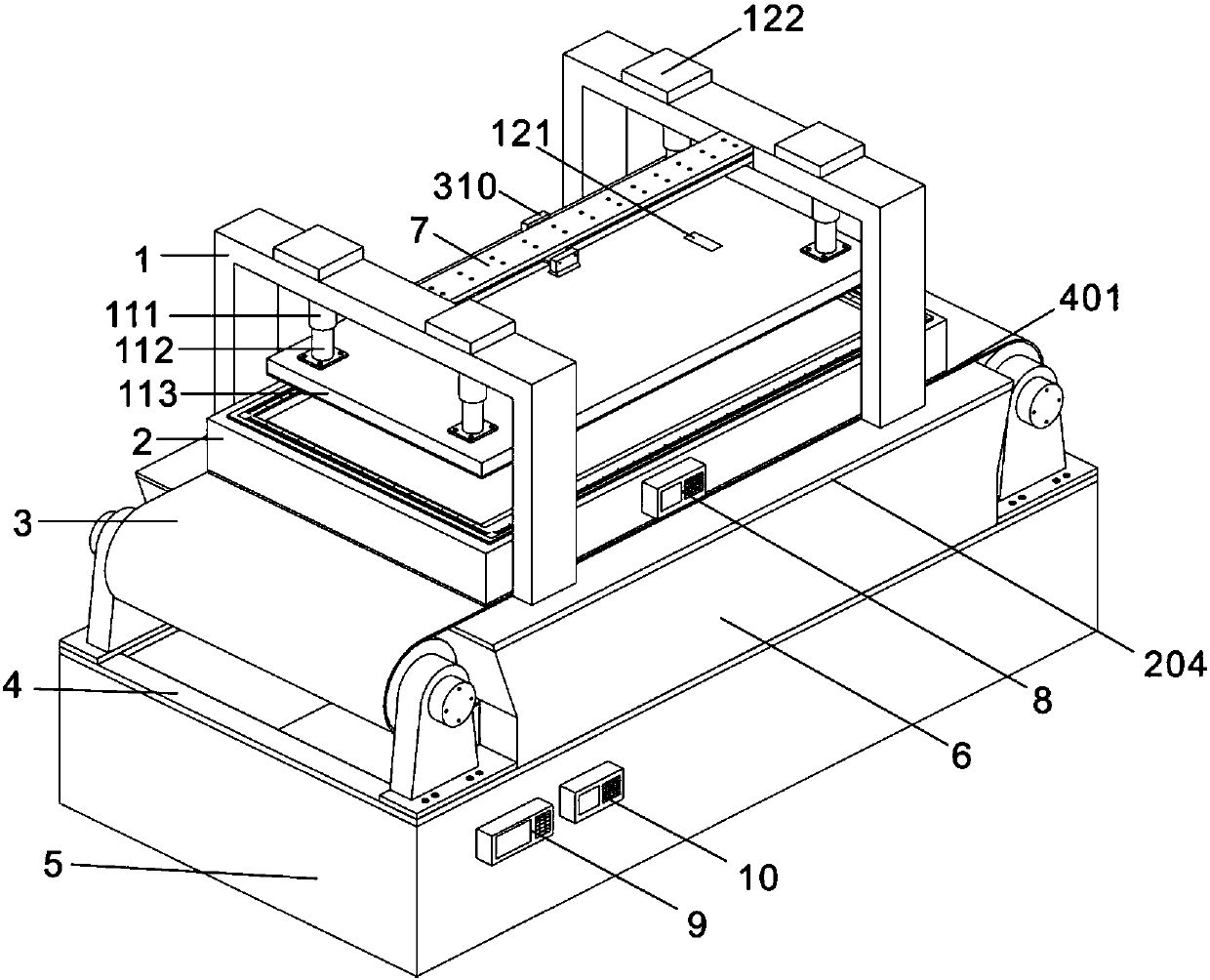

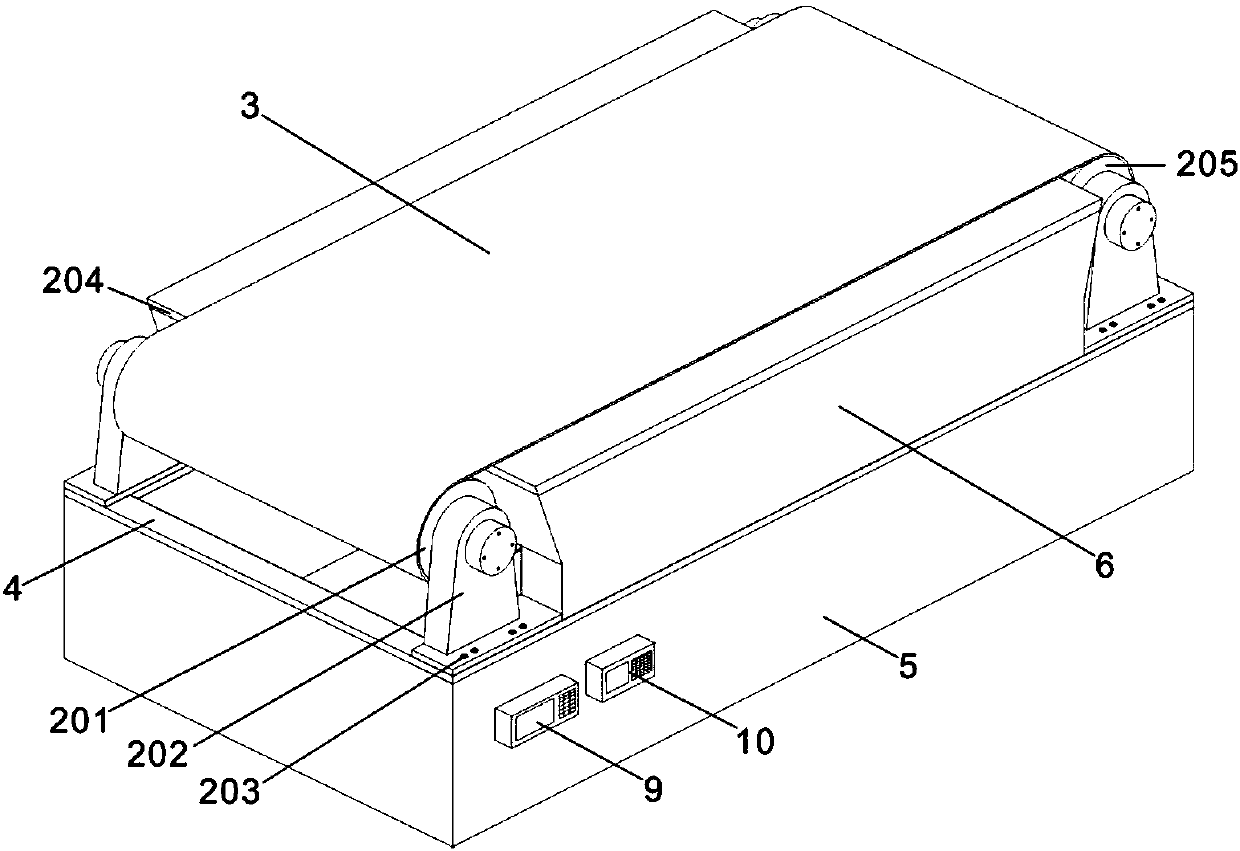

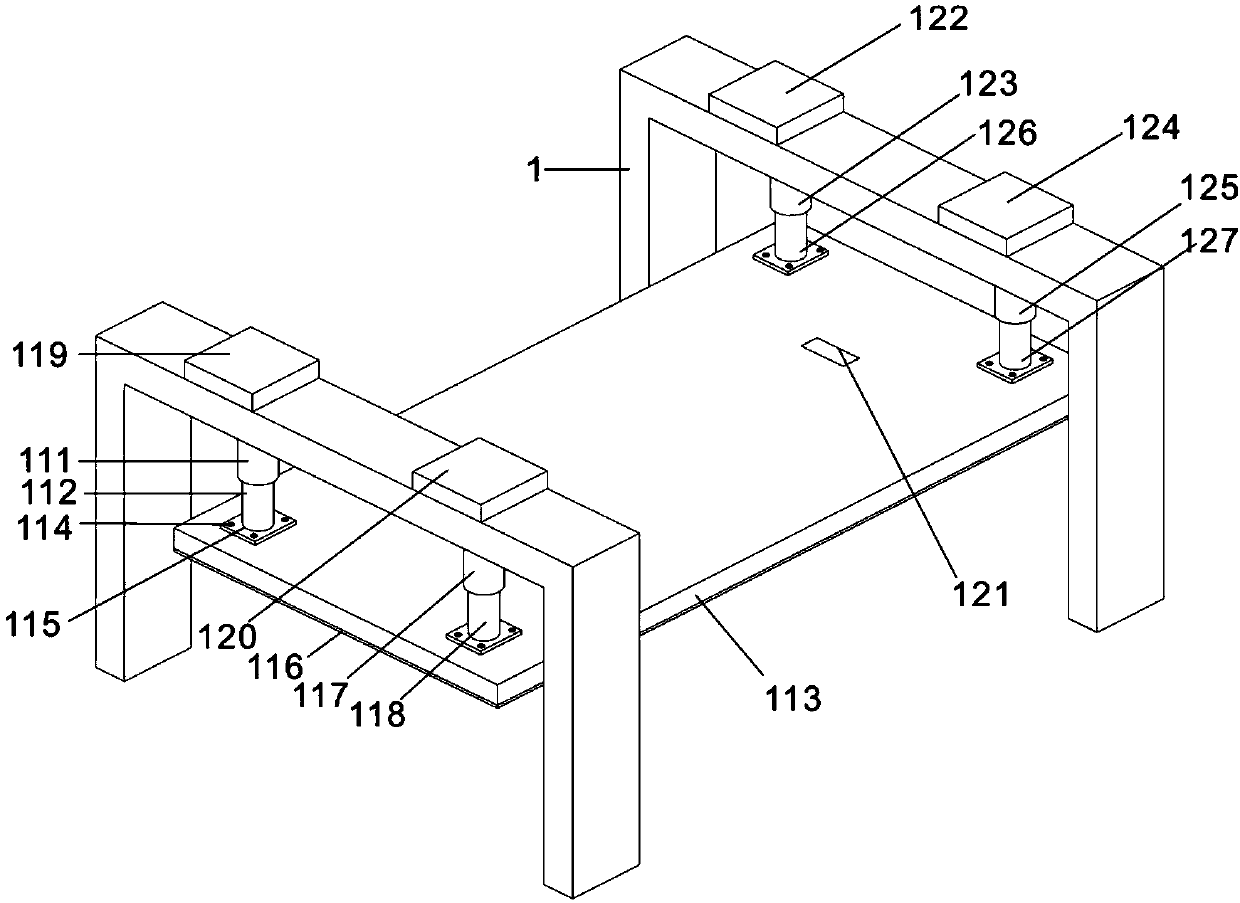

Multi-field real-time monitoring and servo pressurizing bottom friction testing system for large-size rock-soil body

PendingCN107907424AAchieving Quantitative ControlIncrease the simulation rangeMaterial strength using tensile/compressive forcesFrequency changerAlternating current

The invention provides a multi-field real-time monitoring and servo pressurizing bottom friction testing system for a large-size rock-soil body. The multi-field real-time monitoring and servo pressurizing bottom friction testing system comprises a conveyor belt driving system, a model vertical uniform distribution force loading servo system, a friction force determination system and an image acquisition and resolving system. The model vertical uniform distribution force loading servo system comprises a hydraulic column and a pressurizing plate; the pressurizing plate is internally provided with a pressure sensor and is connected with a background controller; the controller is connected with a servo motor connected with a hydraulic oil tank; the conveyor belt driving system comprises an alternating current motor, a frequency converter and a speed monitor; the friction force determination system is composed of a stress sensor and an outer data receiver; the image acquisition and resolving system is composed of a high-speed camera, a sliding rail, an illumination lamp, a scale and a background computer. According to the multi-field real-time monitoring and servo pressurizing bottom friction testing system provided by the invention, a large-size quantitative simulation test of deformation damages of the rock-soil body under the action of gravity and an evolution process of the rock-soil body can be realized; different stress fields are simulated by changing normal stress on a model to be detected and a stress field and a displacement field of the model are monitored in real time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com