Patents

Literature

36results about How to "Improve cornering maneuverability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

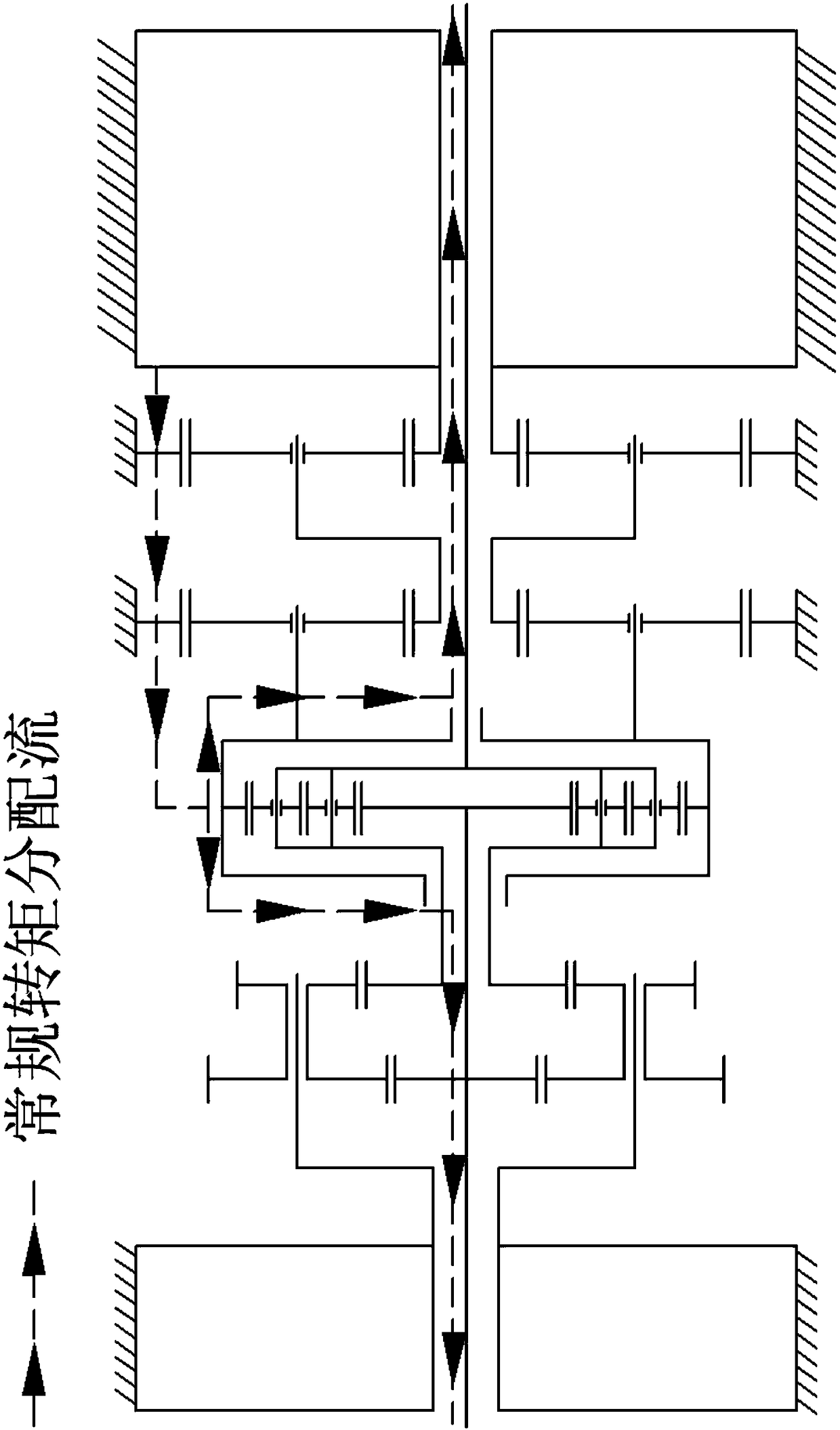

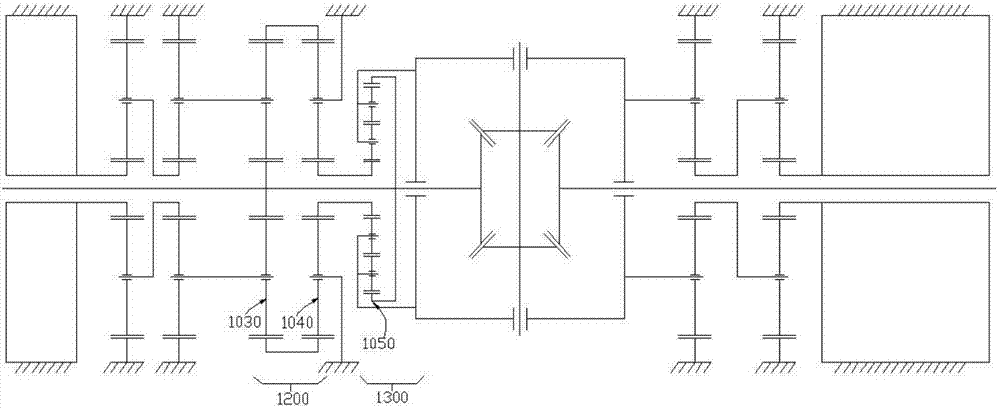

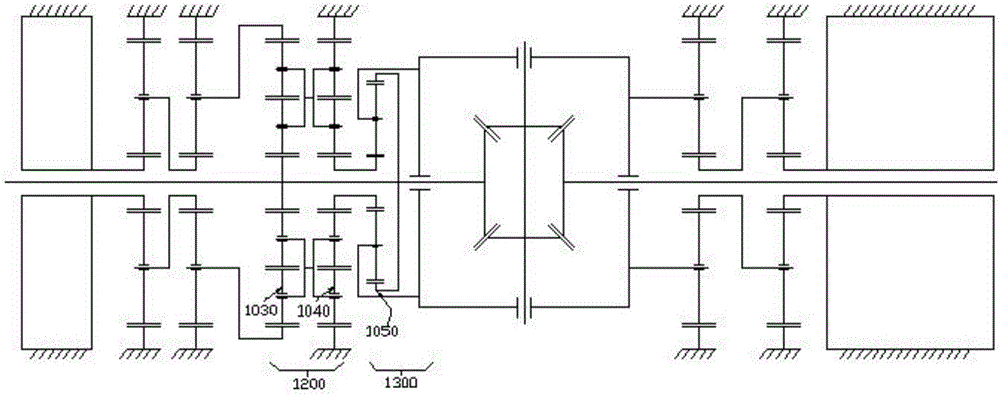

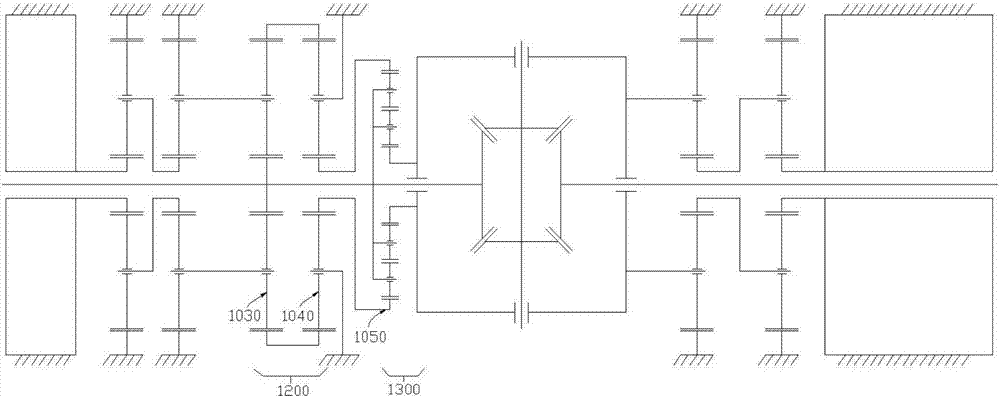

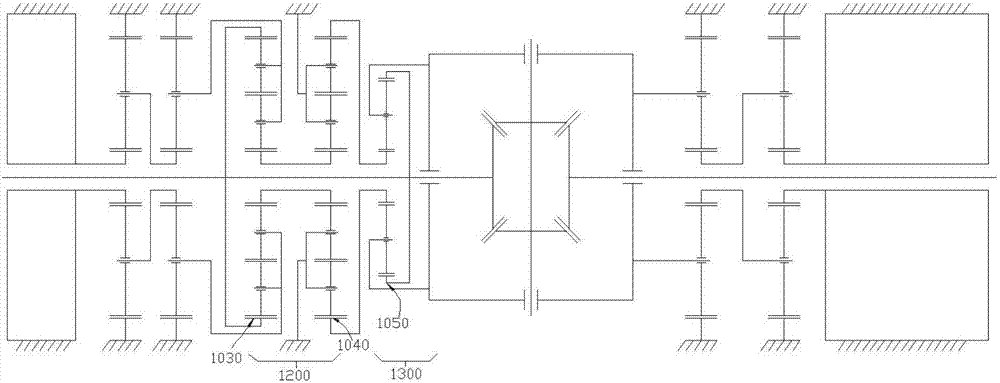

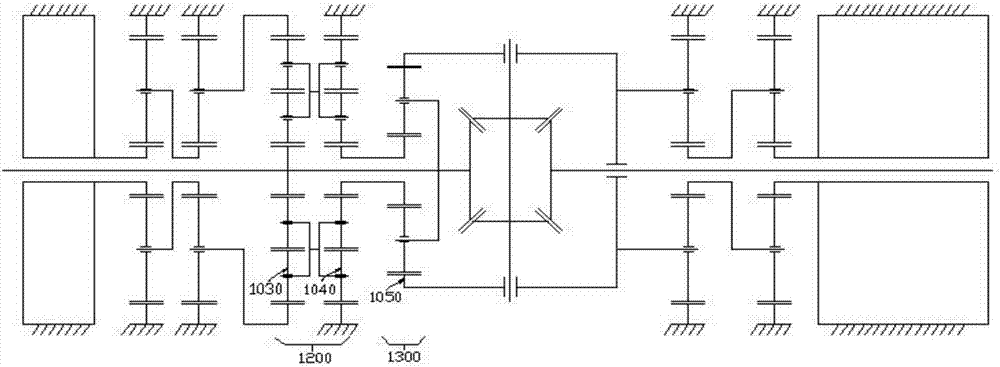

Double-motor coupling drive axle with torque directional distribution function

ActiveCN106965662ASolve the disadvantages of "differential speed is not bad"Improve cornering maneuverabilityElectric propulsion mountingControl devicesCouplingGear wheel

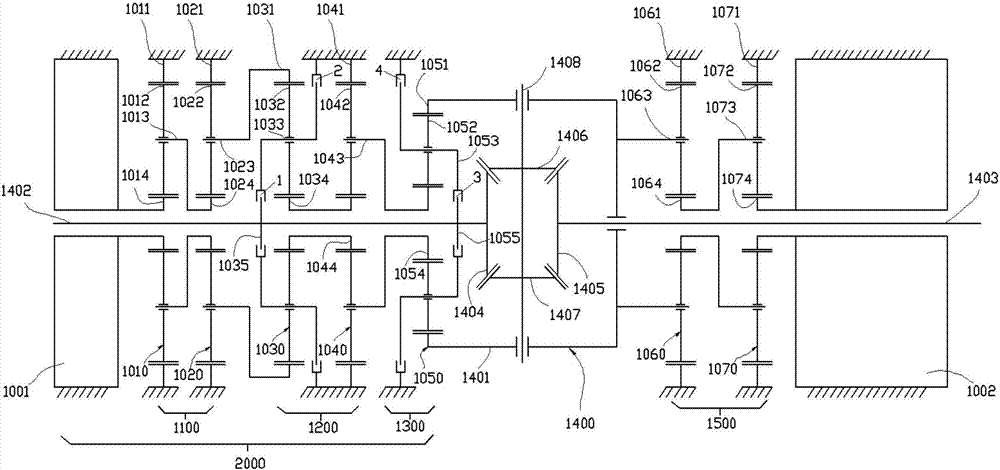

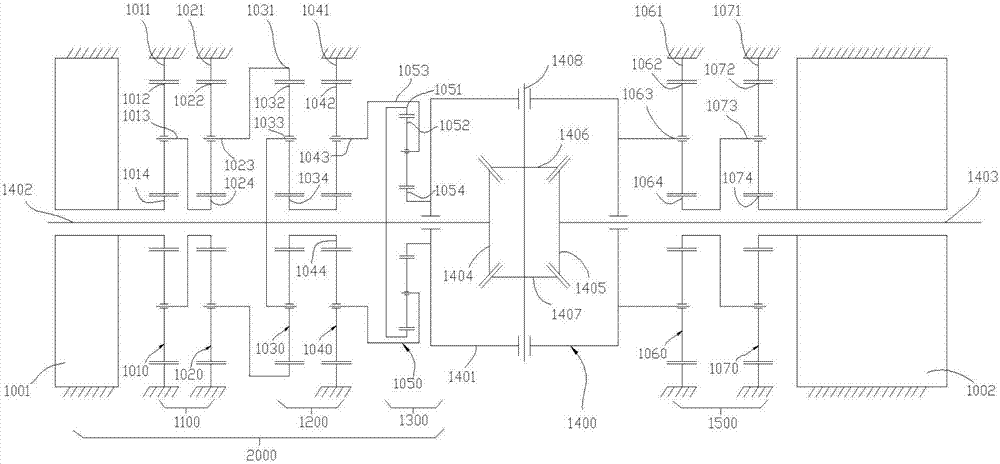

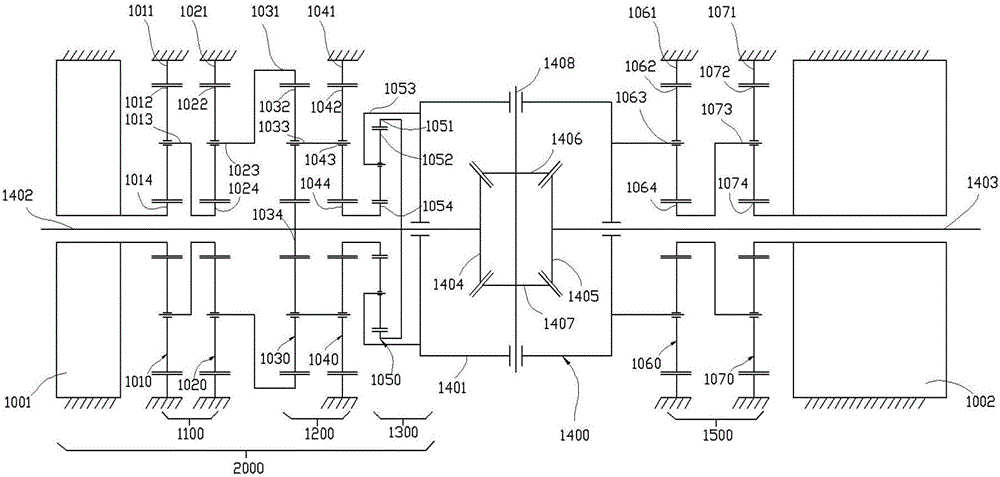

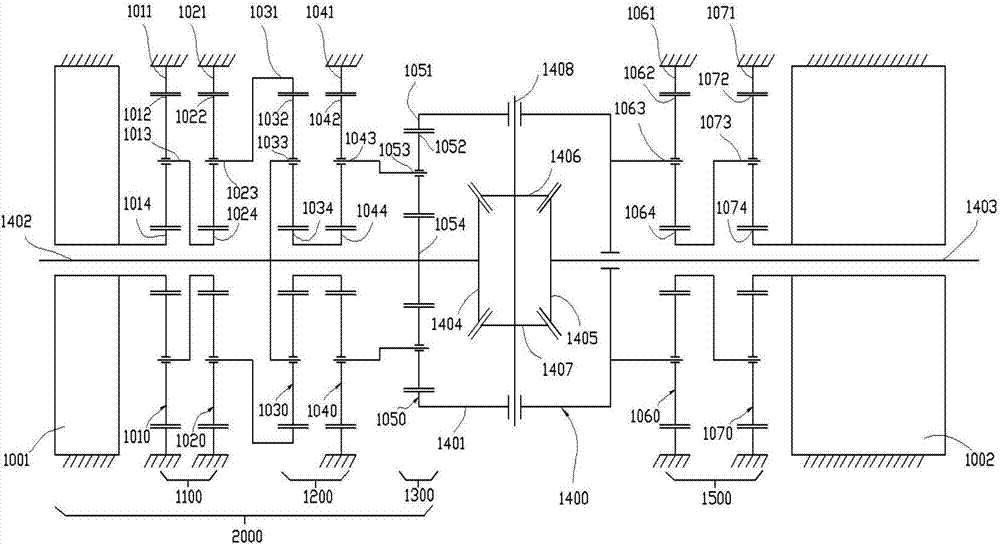

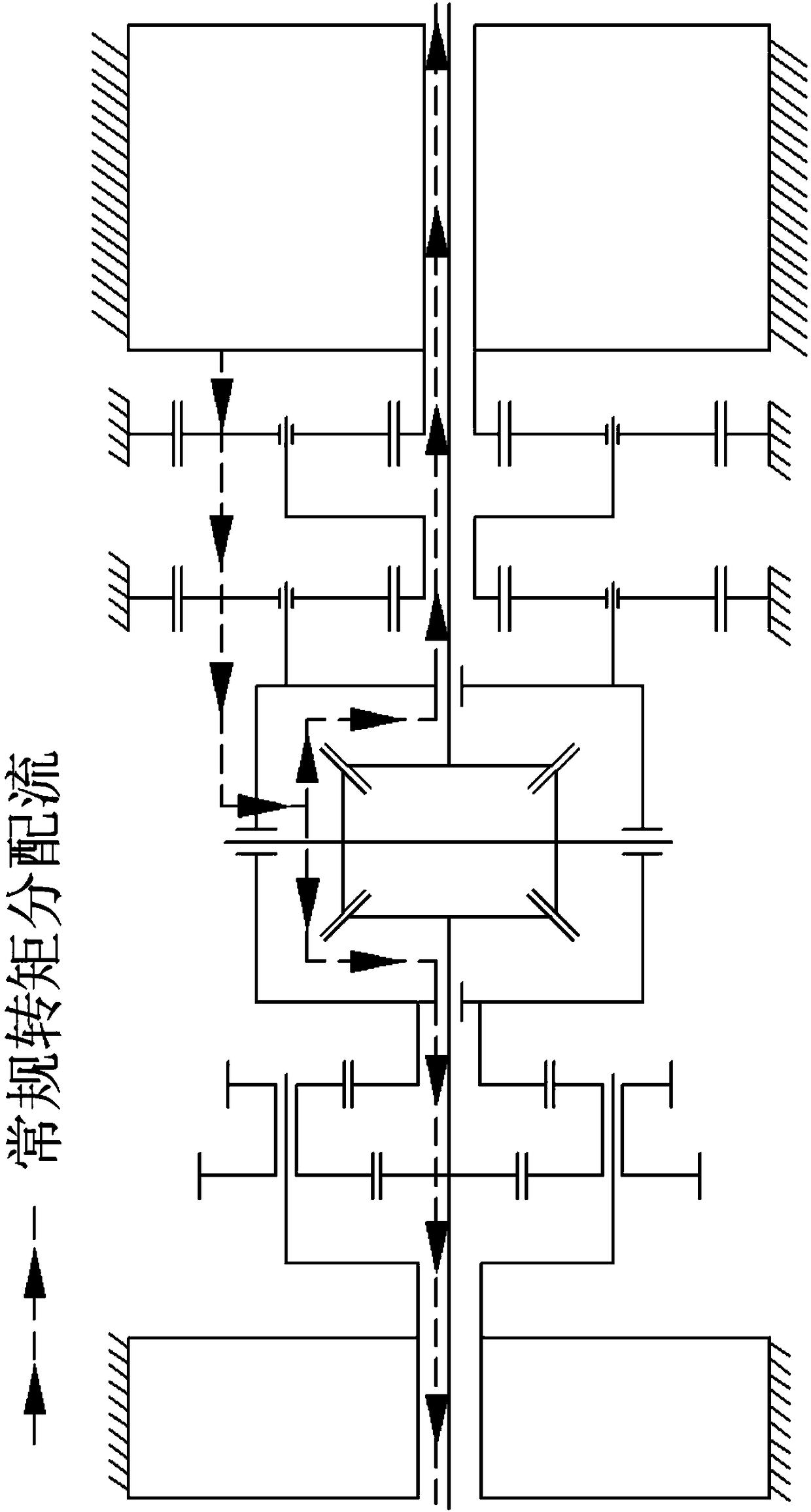

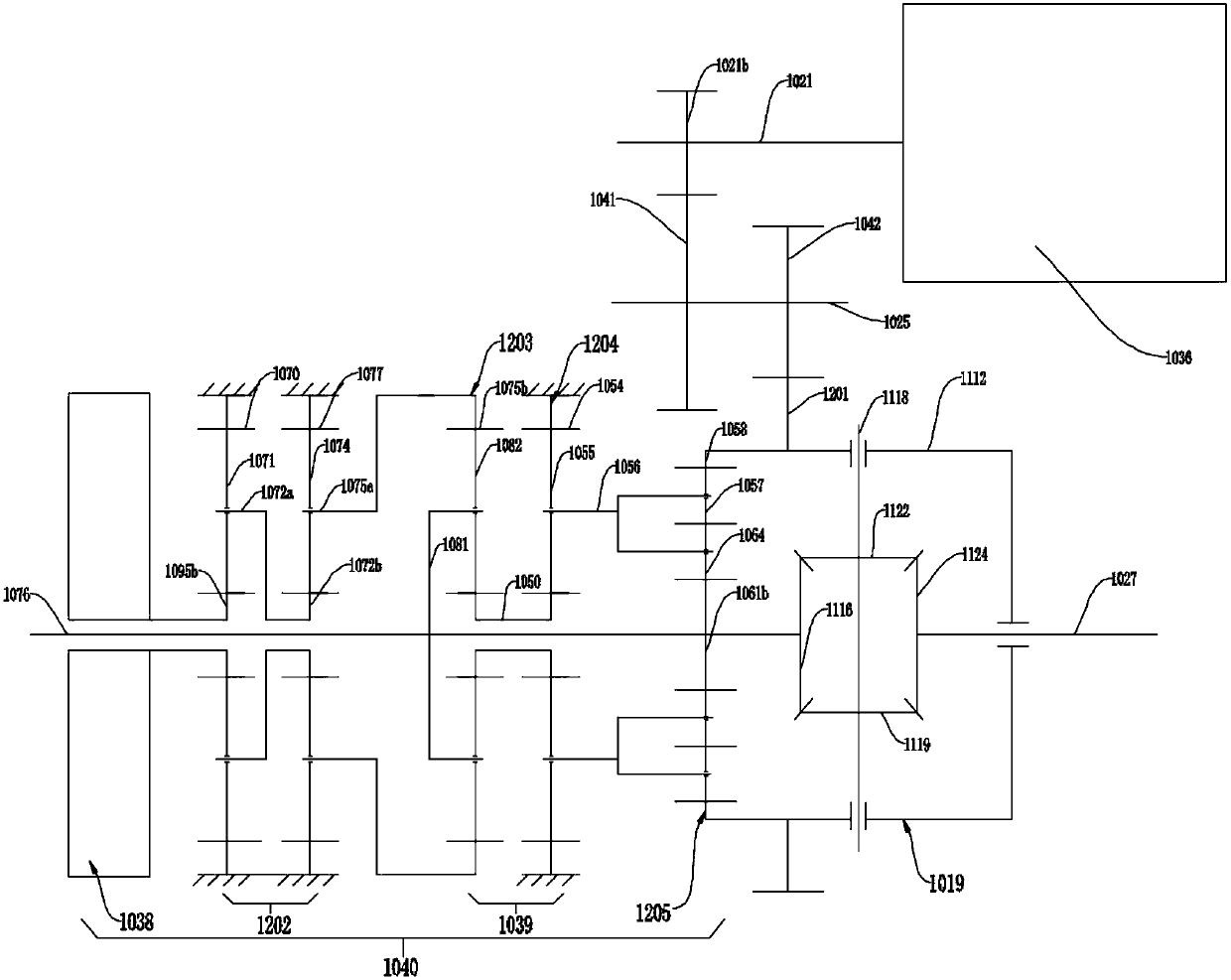

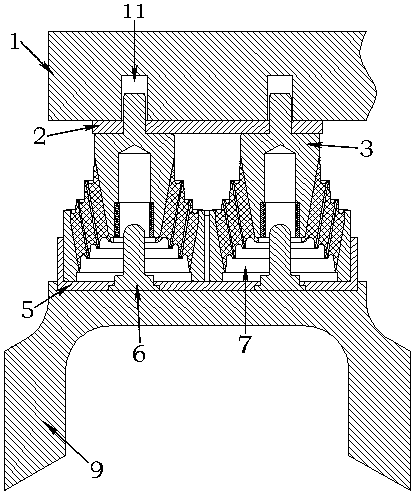

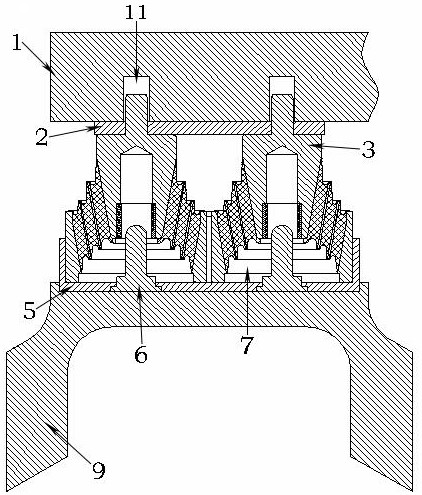

The invention discloses a double-motor coupling drive axle with a torque directional distribution function. The double-motor coupling drive axle comprises a main driving mechanism, a bevel gear differential, a TV control driving mechanism, a first single-row planetary gear system, a second single-row planetary gear system, a third single-row planetary gear system, a first clutch, a third clutch, a second clutch and a fourth clutch. A first sun gear of the first single-row planetary gear system is rotatably supported on a first halt shaft, and a first gear ring is connected with the output end of the TV control driving mechanism. A second gear ring of the second single-row planetary gear system is fixed on a drive axle shell body, and a second sun gear is coaxially and fixedly connected with the first sun gear. A third sun gear of the third single-row planetary gear system is fixedly connected with a second planetary frame, and a third gear ring is fixedly connected with a differential shell. The first clutch is used for separating the first half shaft from a first planetary frame or connecting the first half shaft with the first planetary frame. The third clutch is used for separating the first half shaft from a third planetary frame or connecting the first half shaft with the third planetary frame. The second clutch is used for separating the first planetary frame from the drive axle shell body or connecting the first planetary frame with the drive axle shell body. The fourth clutch is used for separating the third planetary frame from the drive axle shell body or connecting the third planetary frame with the drive axle shell body.

Owner:JILIN UNIV

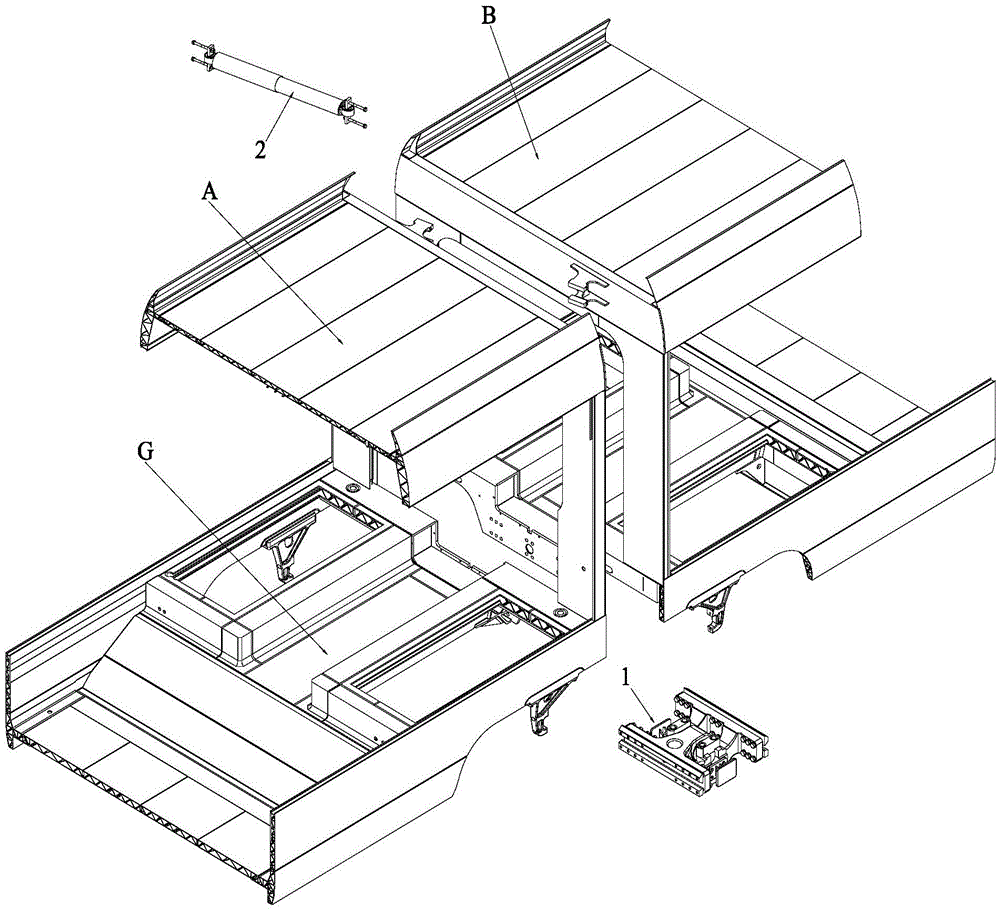

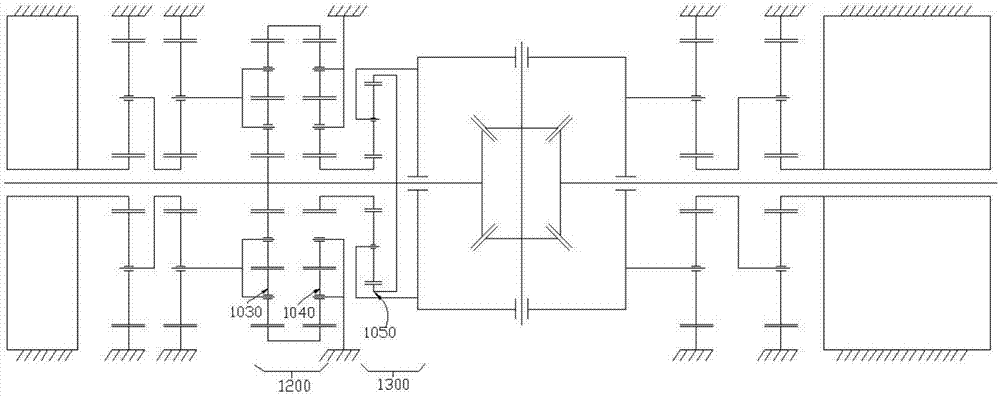

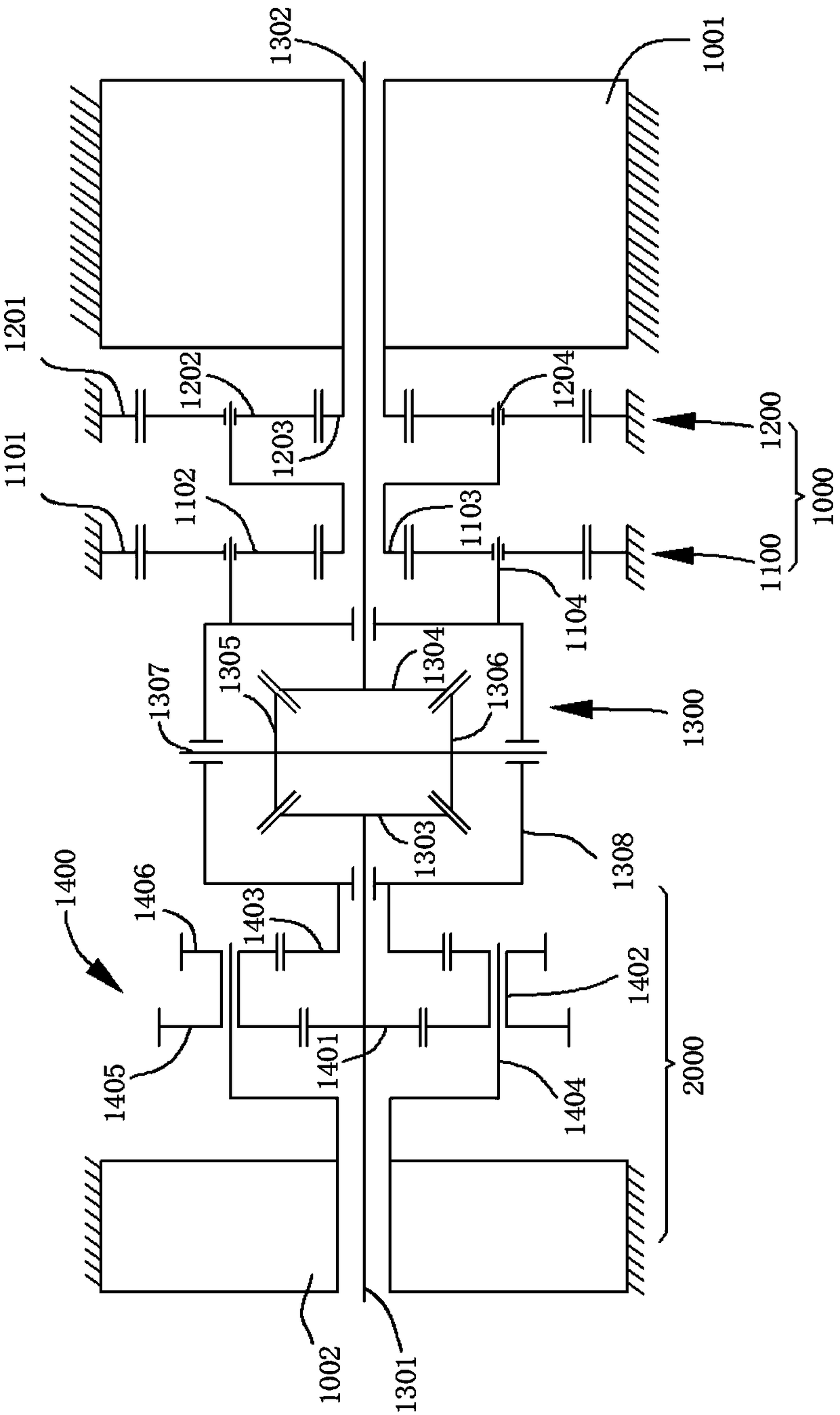

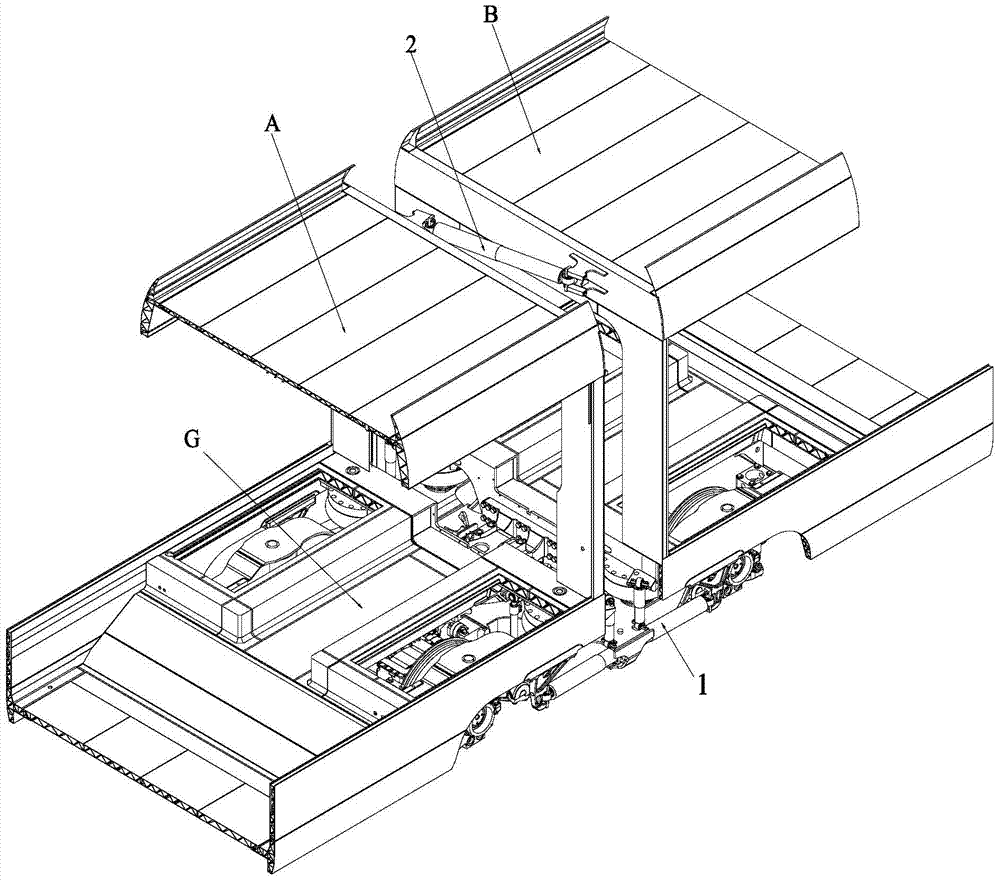

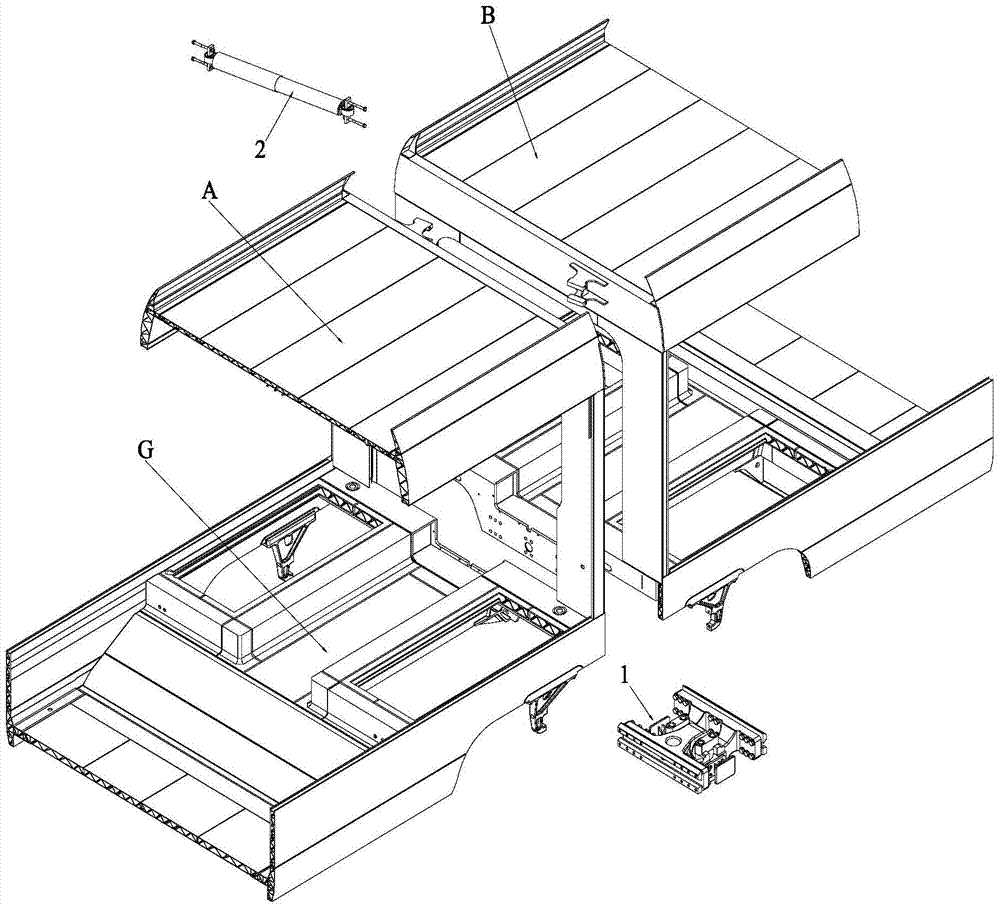

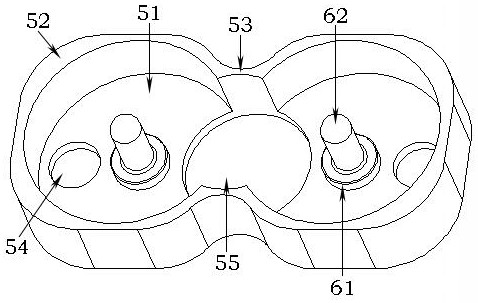

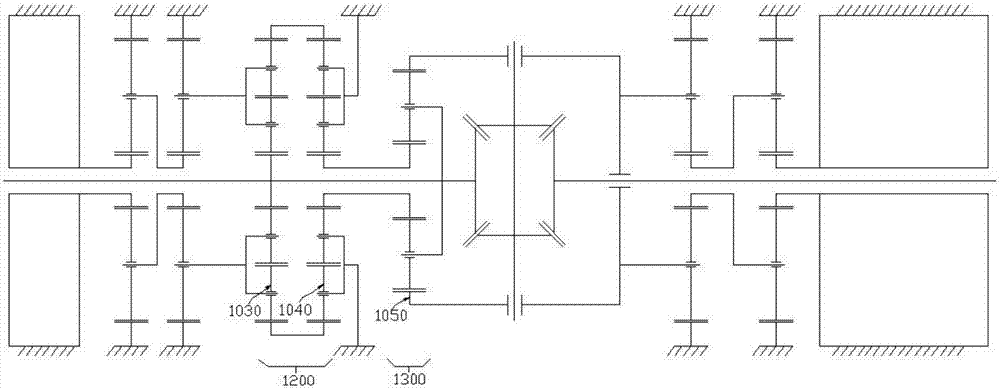

Traveling device used between adjacent train bodies of motor train unit and capable of reducing floor height

ActiveCN105460033AReduce vibrationLower center of gravityAxle-box lubricationRailway couplingsBogieCommon framework

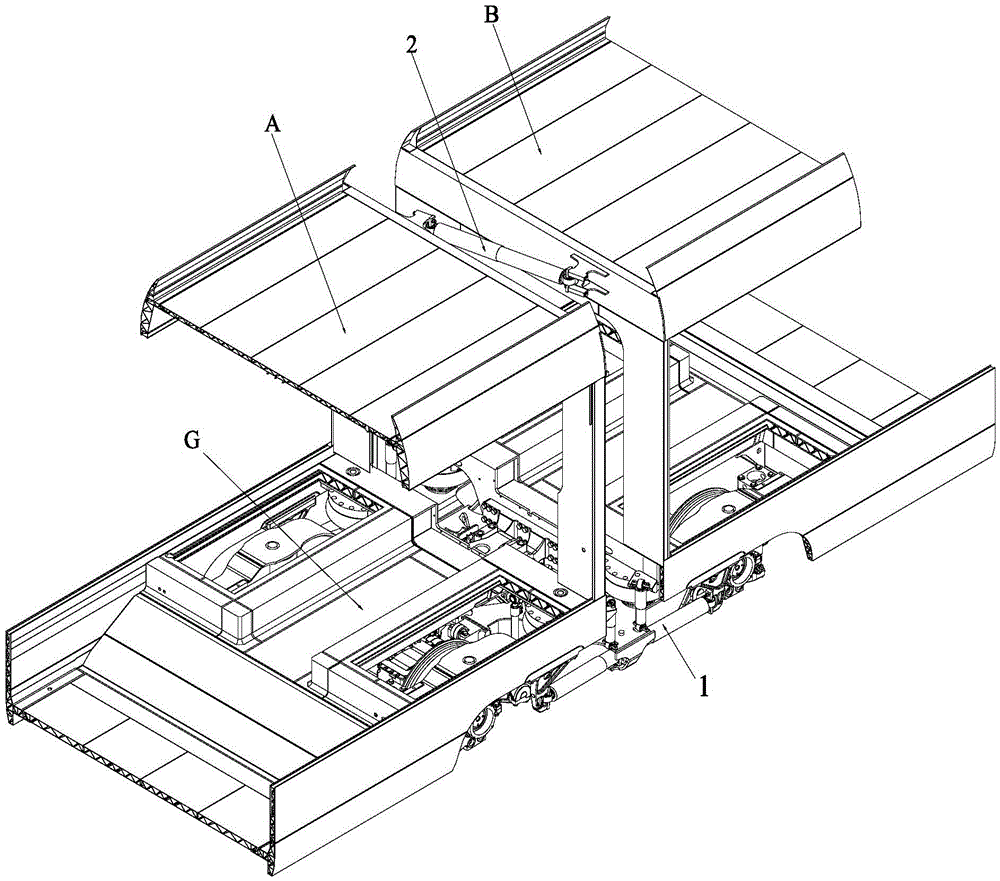

The invention belongs to the field of connection systems for every two adjacent carriages of a railway vehicle and relates to a traveling device used between adjacent train bodies of a motor train unit and capable of reducing the floor height. The traveling device is a low-gravity-center compact common bogie of a brand new form. An oil damper of the traveling device is used for restraining relative rolling pendulum vibration between the top of a carriage A and the top of a carriage B. The two ends of a common connecting device are fixed to underframe end beams of the two adjacent carriages respectively. Four air spring installation positions arranged on two sides are uniquely arranged on a common framework so as to contain sleeper beam middle through grooves. Under the condition that the existing fixed distance of each carriage of the motor train unit is kept unchanged, the traveling device can reduce the total number of bogies of the motor train unit and reduce the manufacturing cost of the motor train unit; moreover, while the un-obstruction performance of the interior floor of the motor train unit is improved, the overall gravity center and the floor height of the motor train unit are lowered, and passengers can conveniently get on or off the motor train unit. In addition, the traveling device remarkably improves the bend curve passage capacity and the turning maneuvering performance of the motor train unit.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

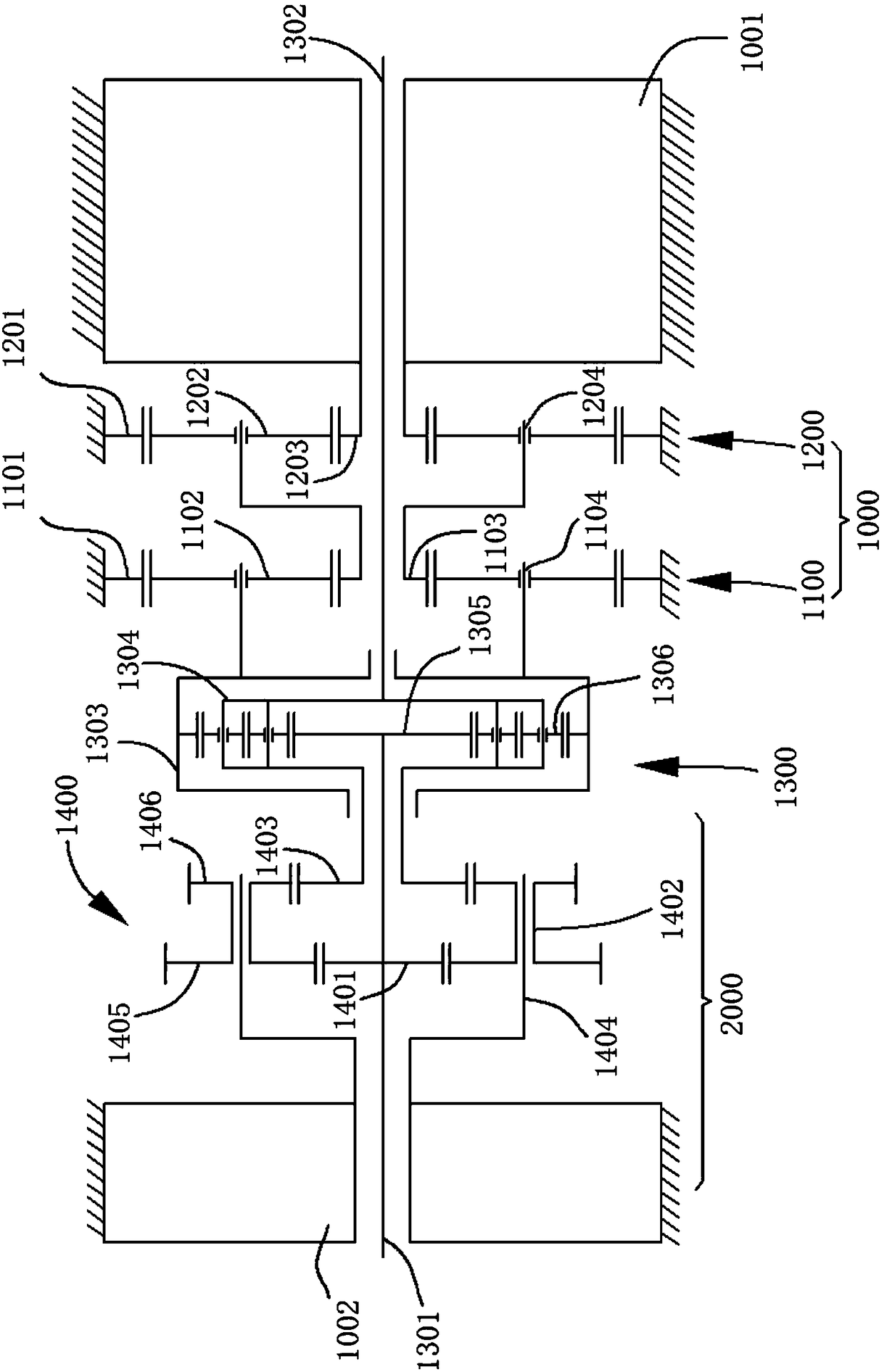

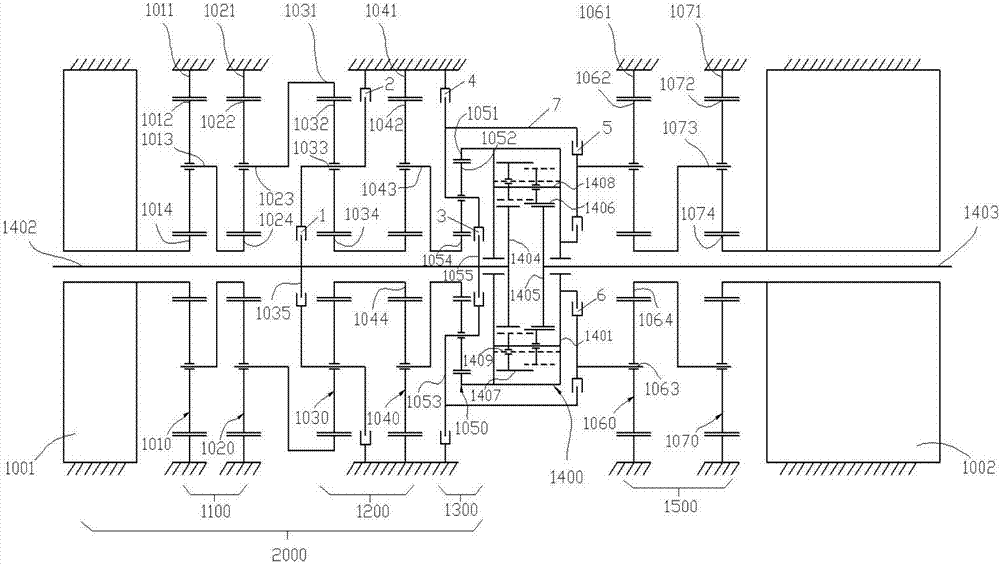

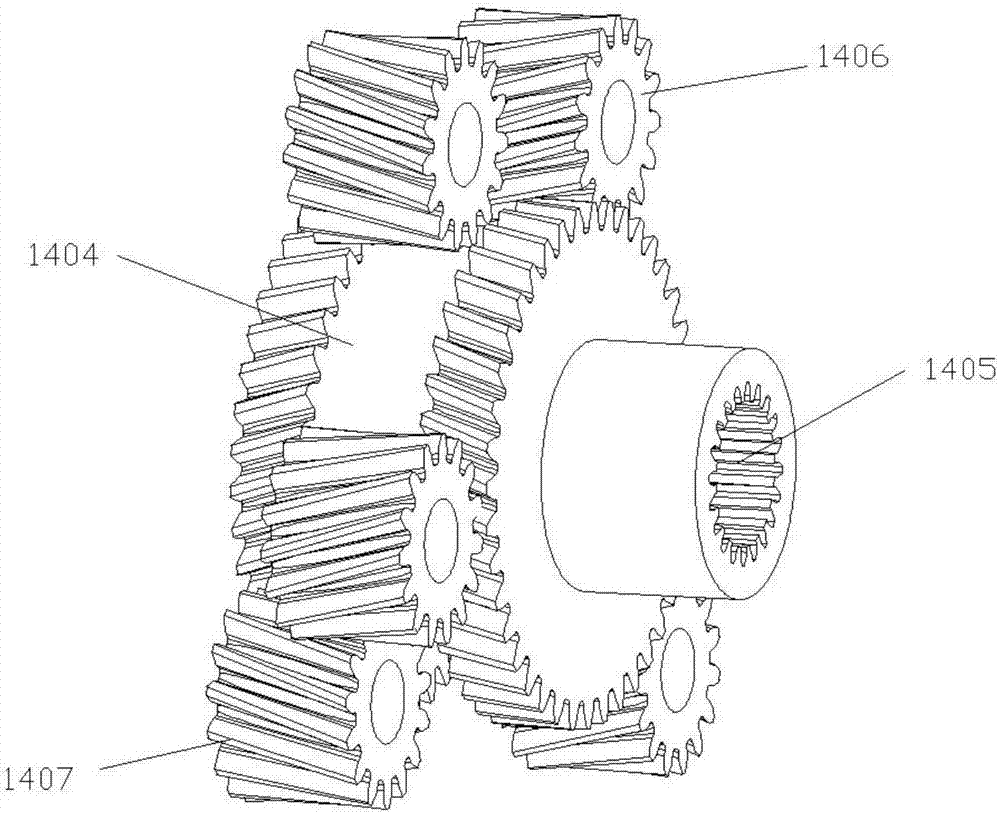

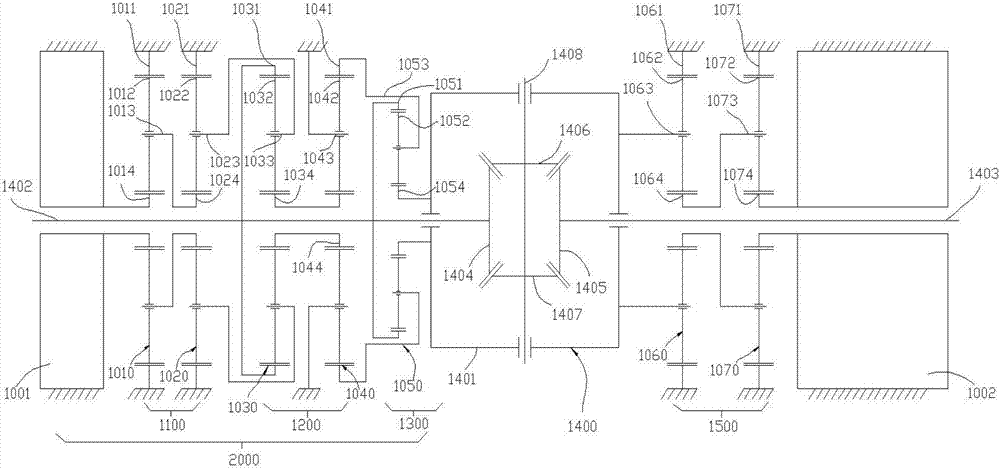

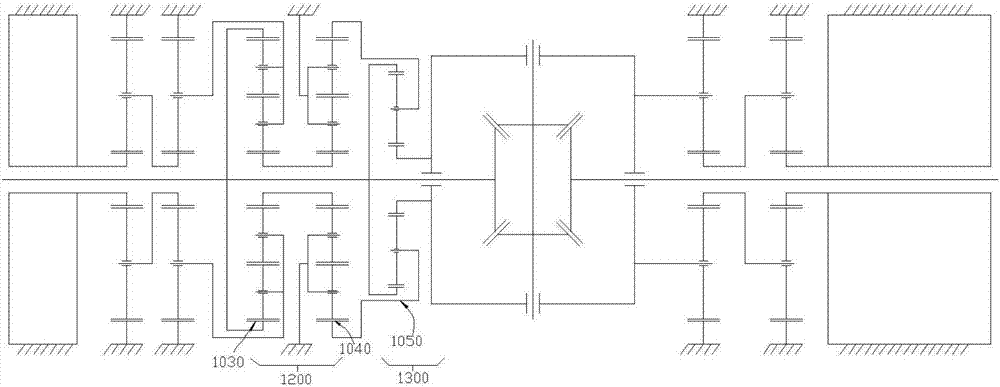

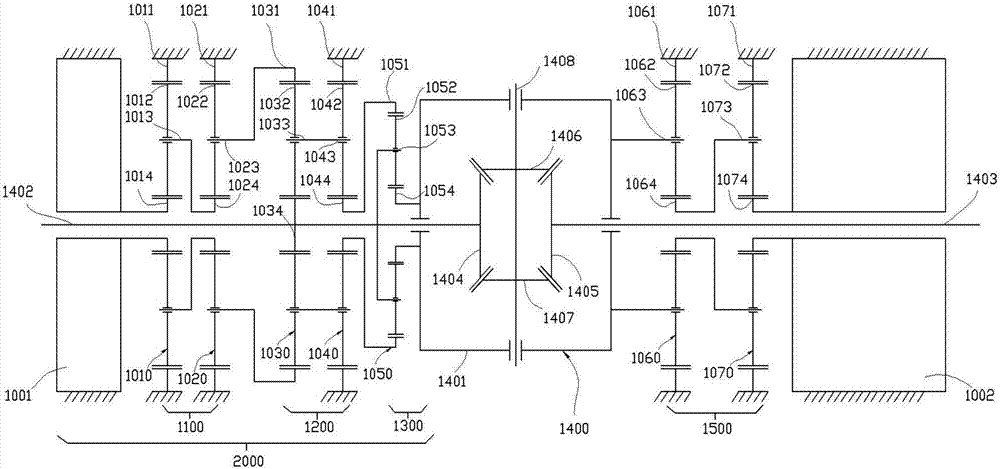

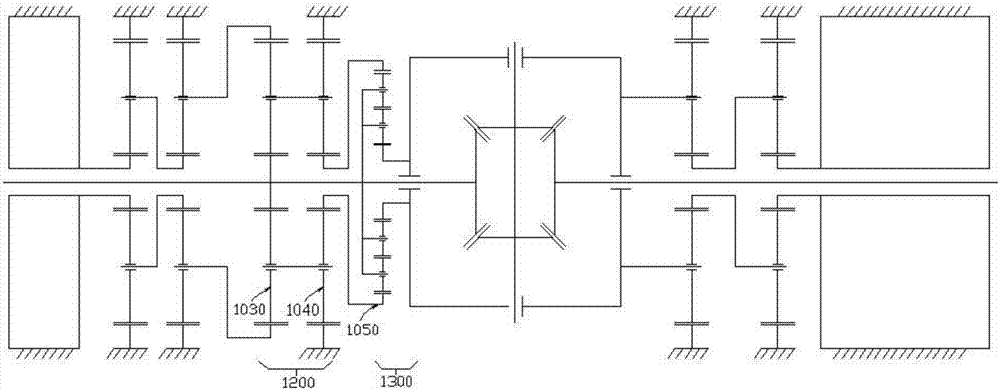

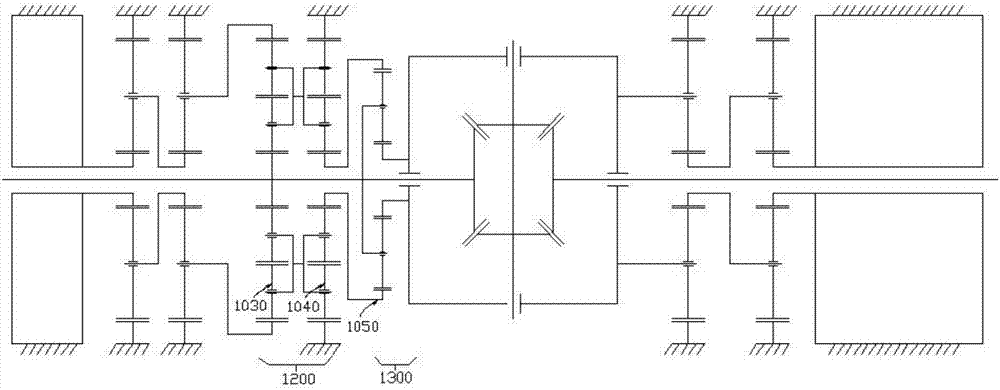

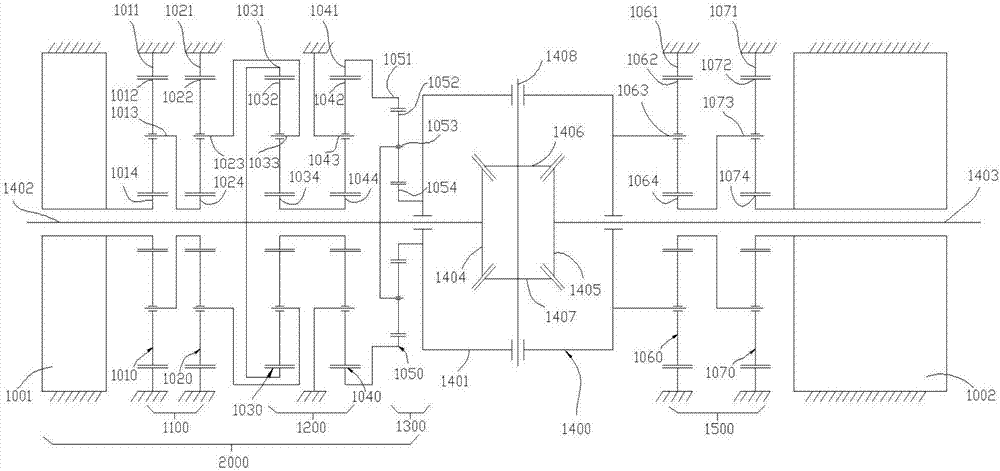

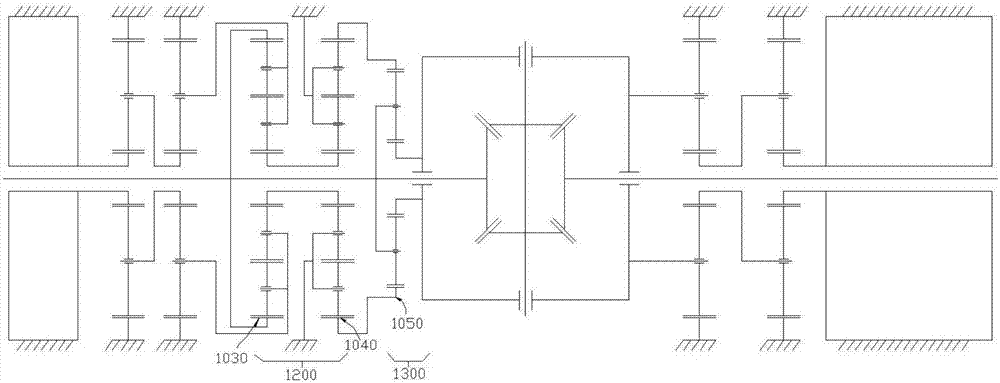

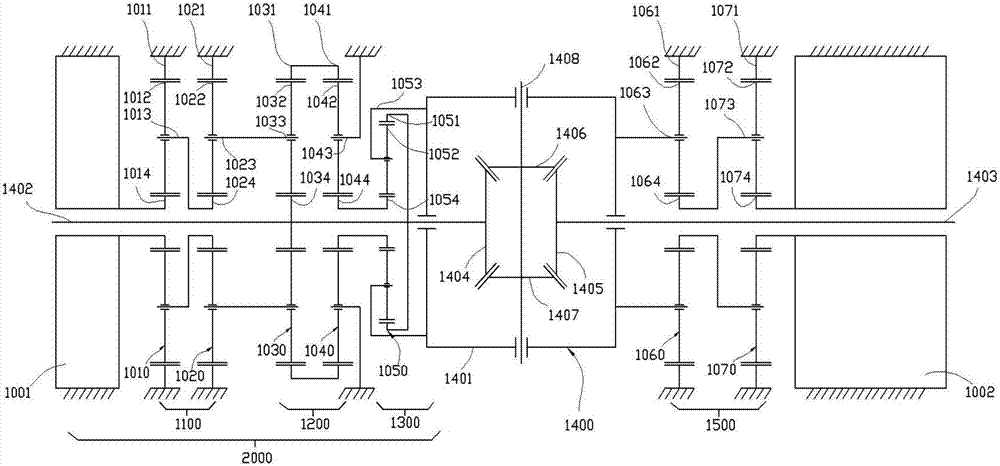

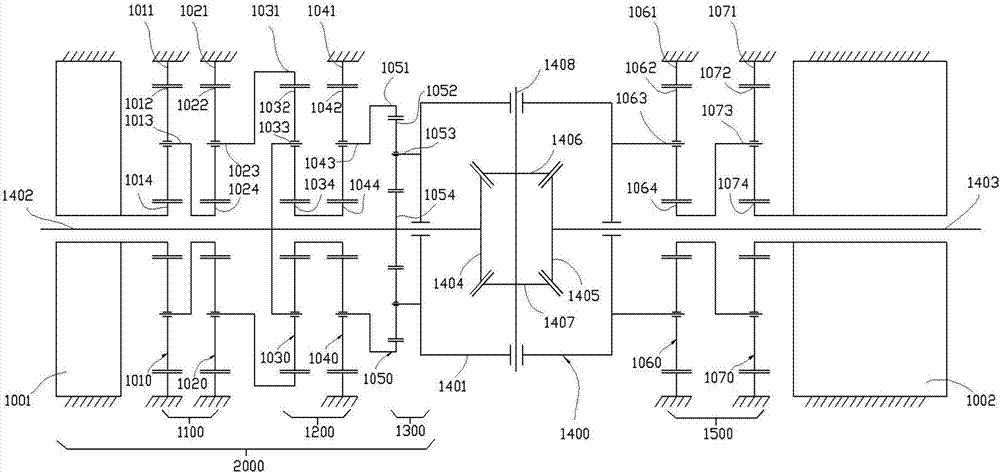

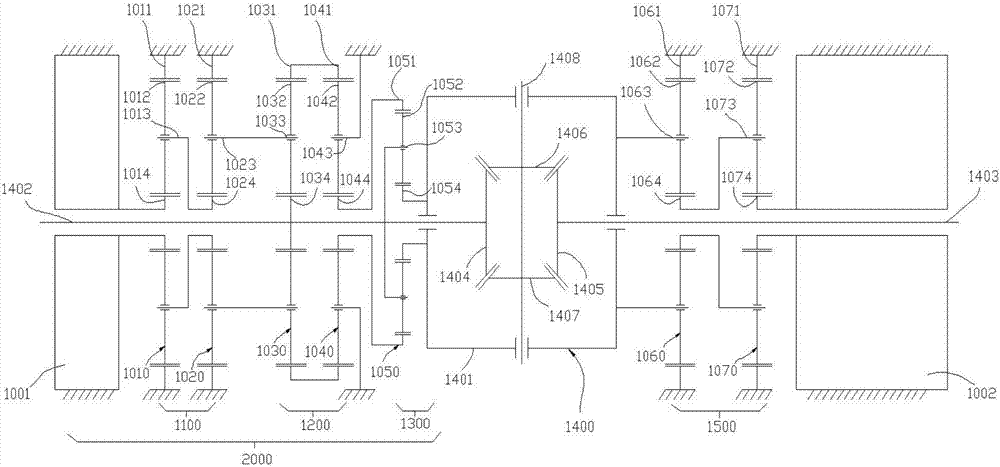

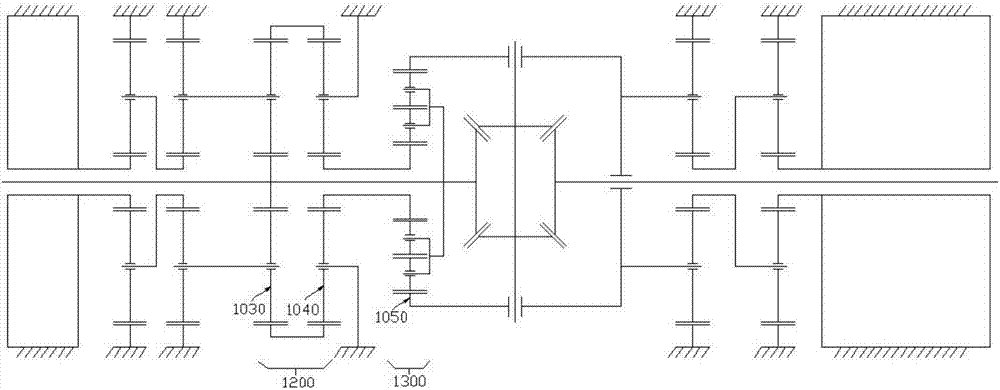

Duplex planetary gear train torque directional distribution electric drive axle

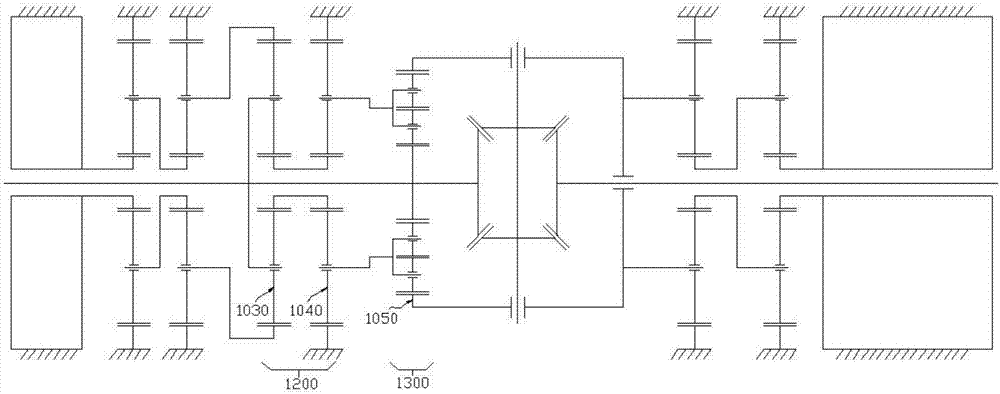

PendingCN108297618ASolve the disadvantages of "differential speed is not bad"Improve cornering maneuverabilityElectric propulsion mountingAxle unitsGear wheelElectric drive

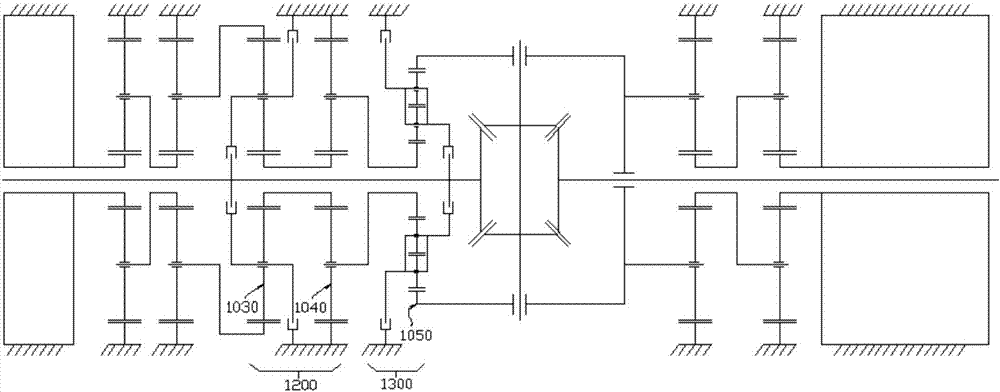

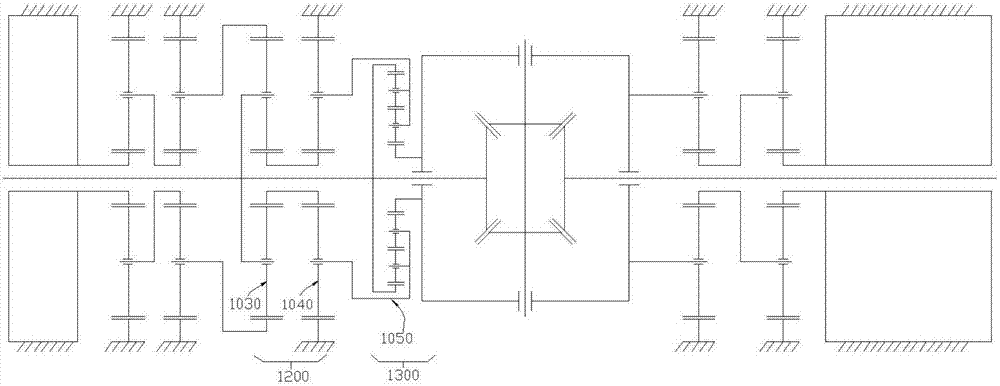

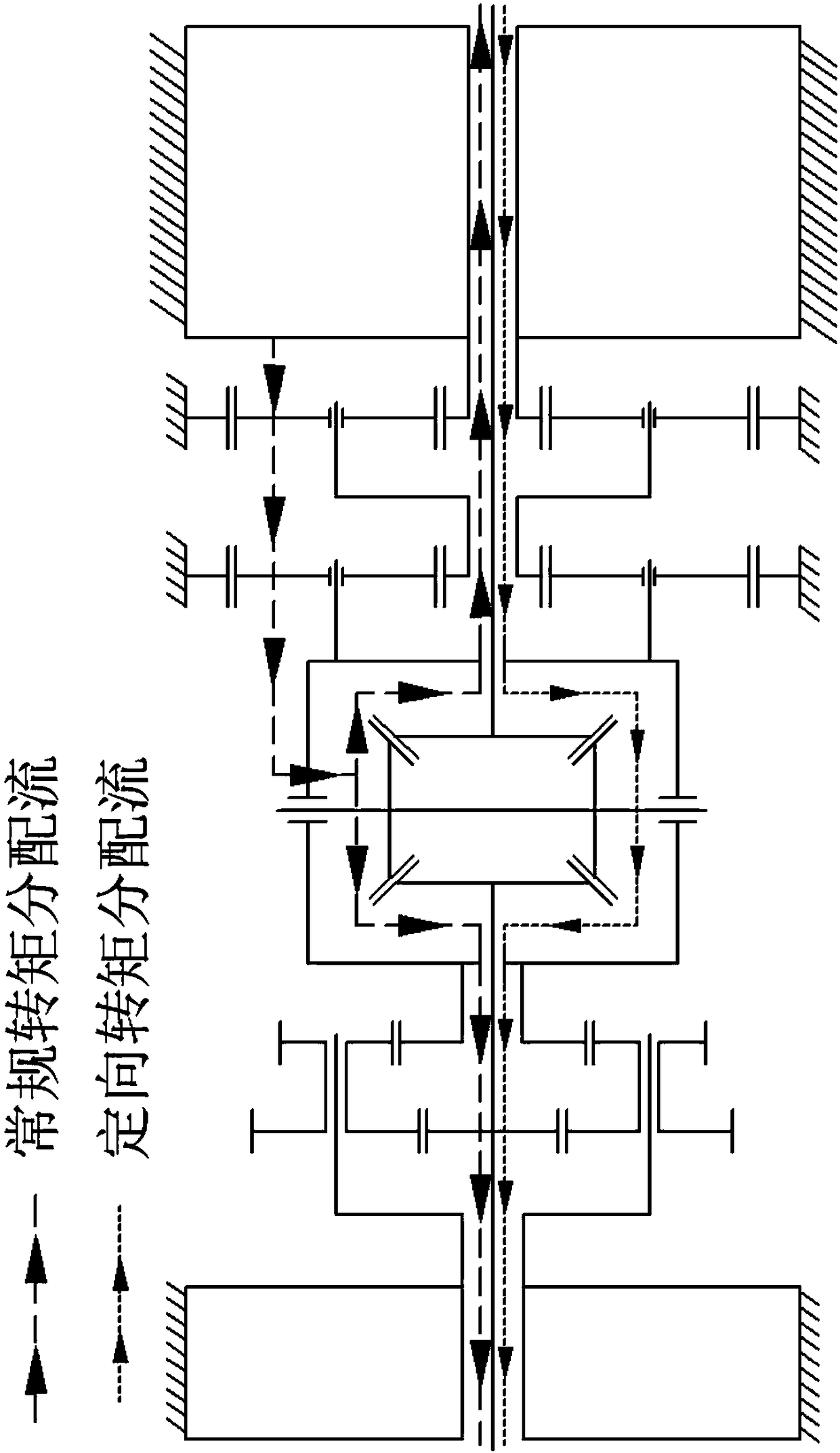

The invention discloses a duplex planetary gear train torque directional distribution electric drive axle. The drive axle comprises a main drive motor, a TV control drive motor and a duplex planetarygear train, wherein a power output shaft of the main drive motor is connected with a gear ring of a two-stage planet gear planet row differential mechanism; a sun gear of the two-stage planet gear planet row differential mechanism is connected with a first axle shaft, and a planet carrier of the two-stage planet gear planet row differential mechanism is connected with a second axle shaft; the duplex planetary gear train comprises a first sun gear, a second sun gear, a first end planet gear, a second end planet gear and a first planet carrier; the first sun gear is connected with the first axleshaft, and the second sun gear is rotationally supported on the first axle shaft and connected with the planet carrier of the two-stage planet gear planet row differential mechanism; and the first end planet gear and the second end planet gear are coaxially arranged on a planet shaft, and the planet shaft is connected with a power output shaft of the TV control drive motor through the first planet carrier. Torque directional distribution of wheels on the two sides can be achieved without a clutch, and the structure is simple.

Owner:JILIN UNIV

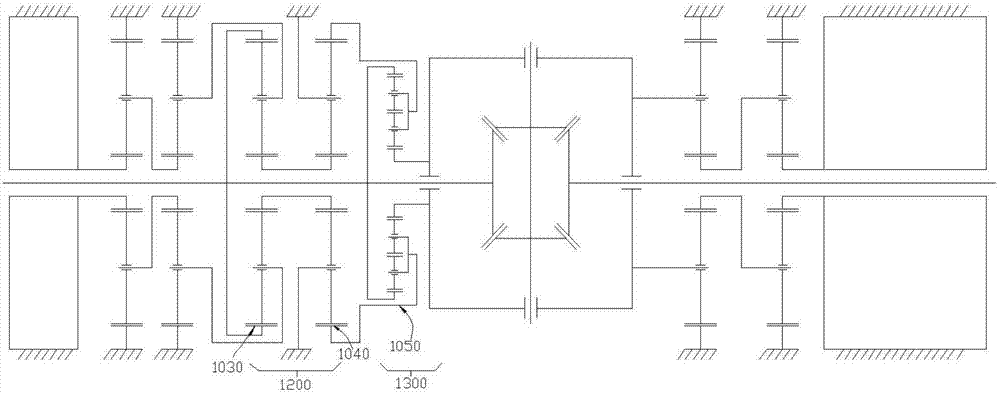

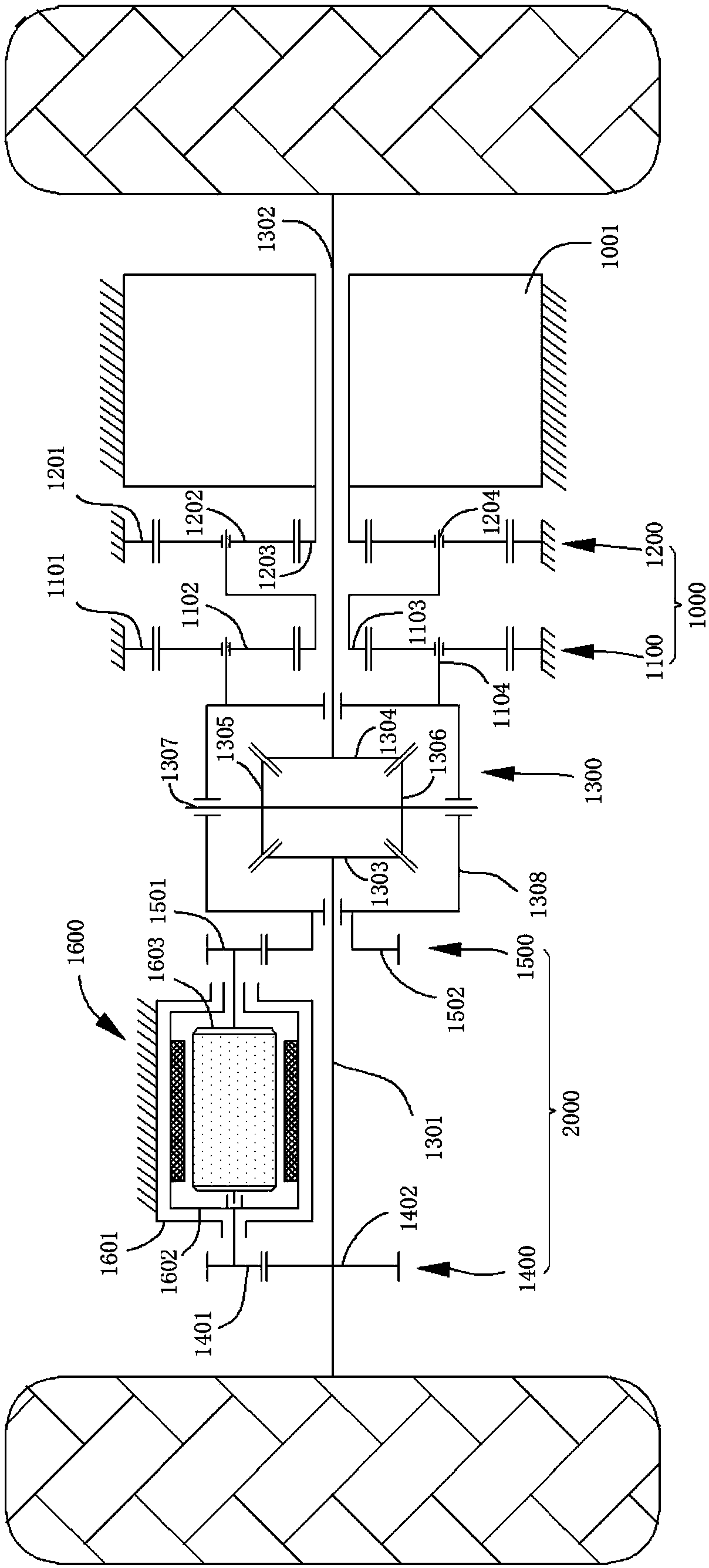

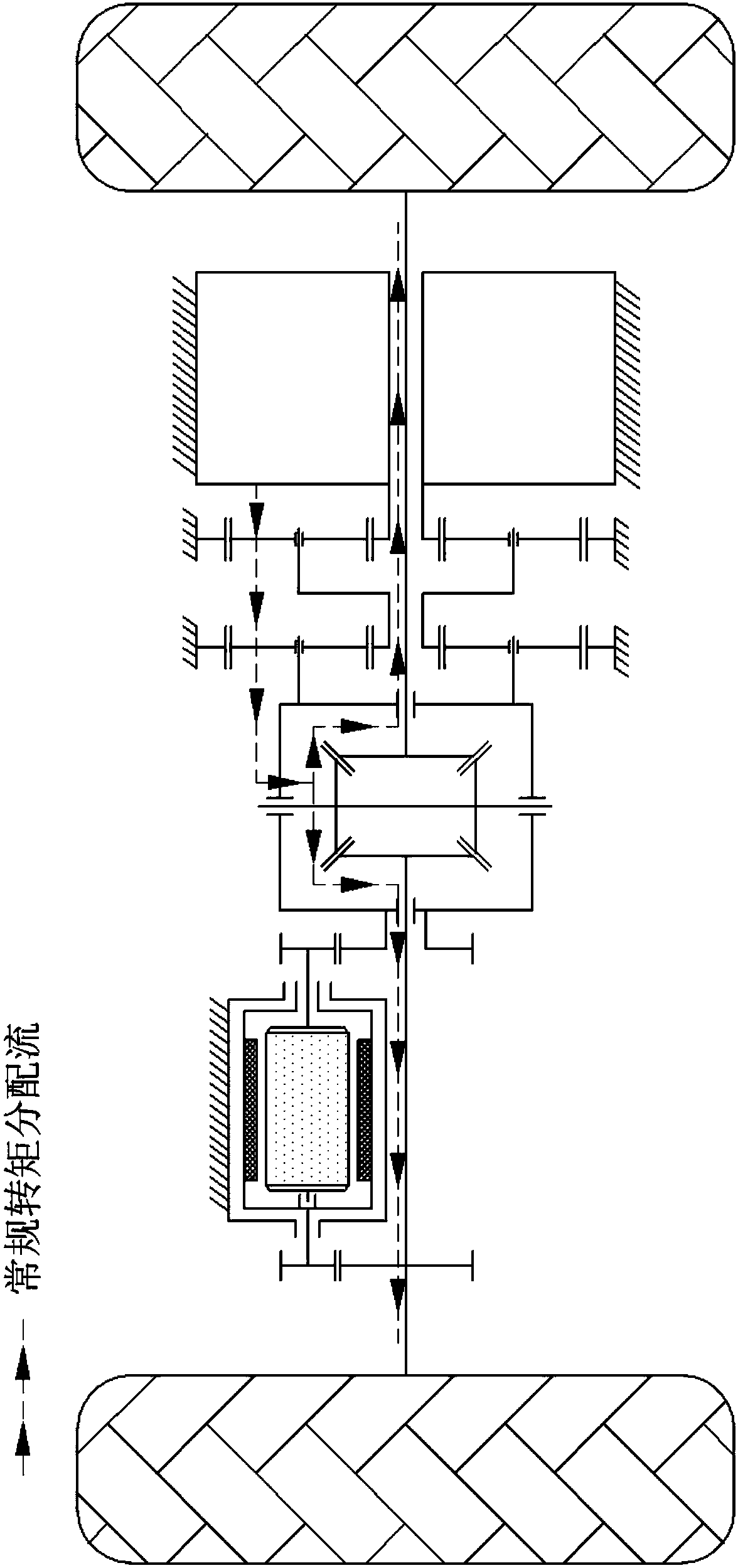

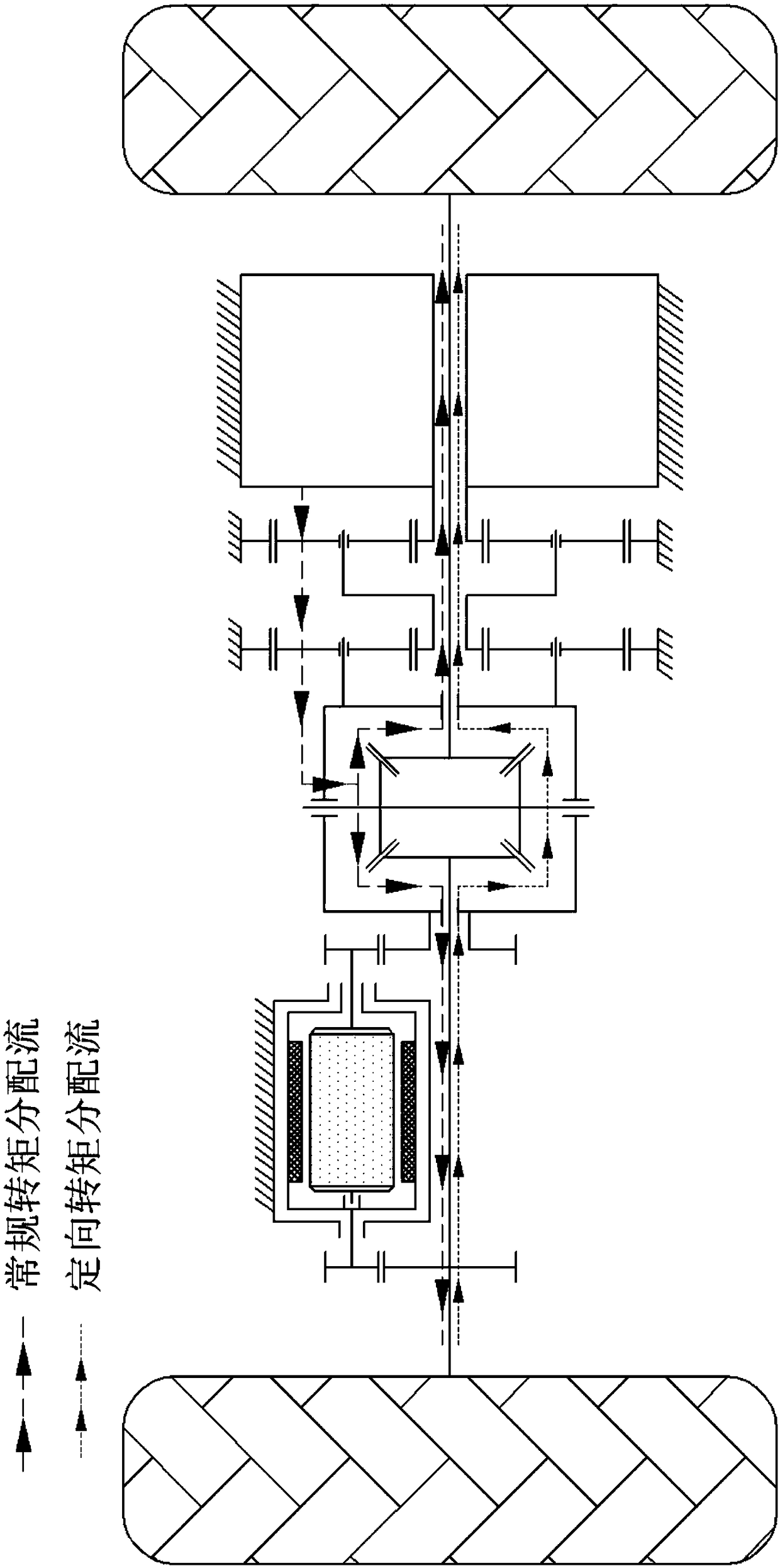

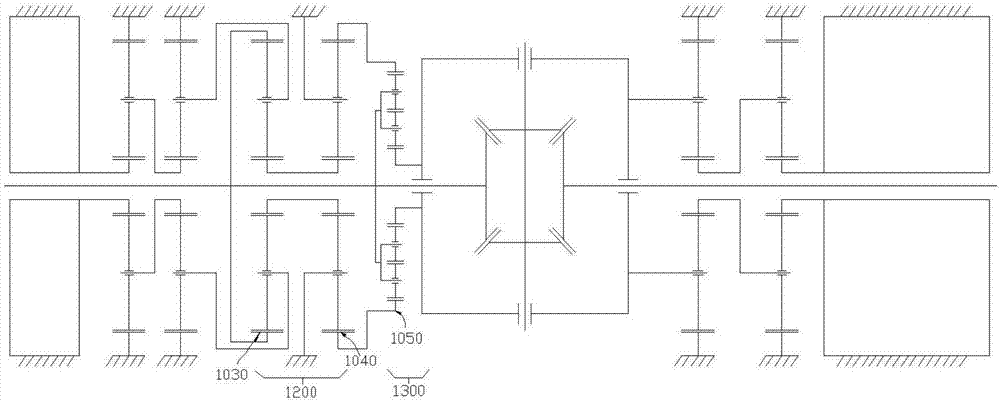

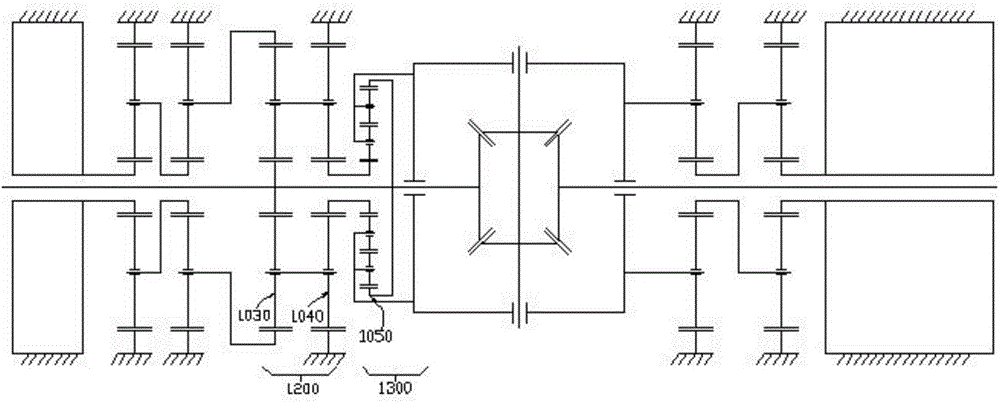

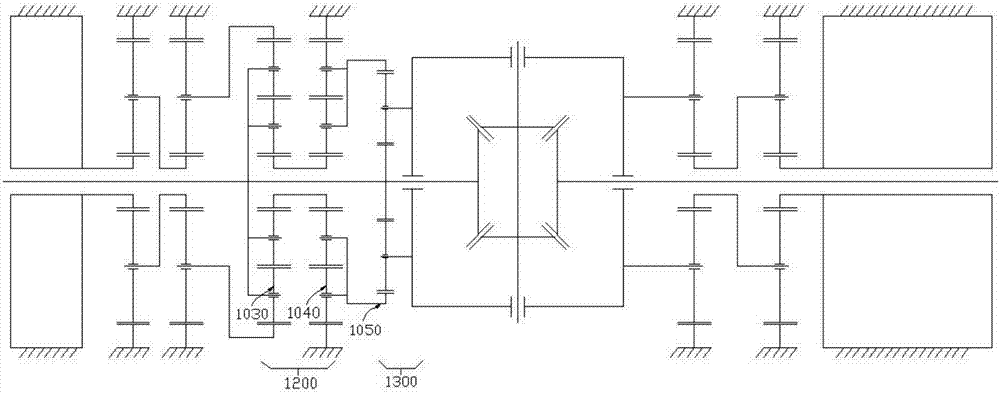

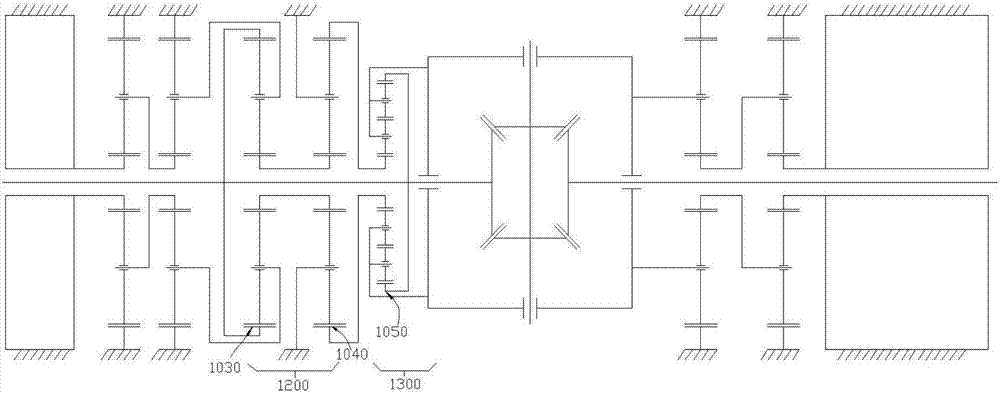

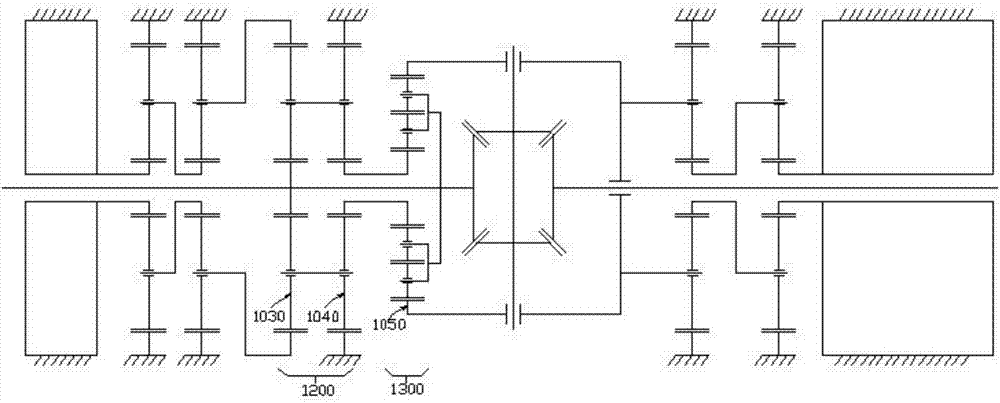

Double-motor coupling driving bridge with torque directional distribution function

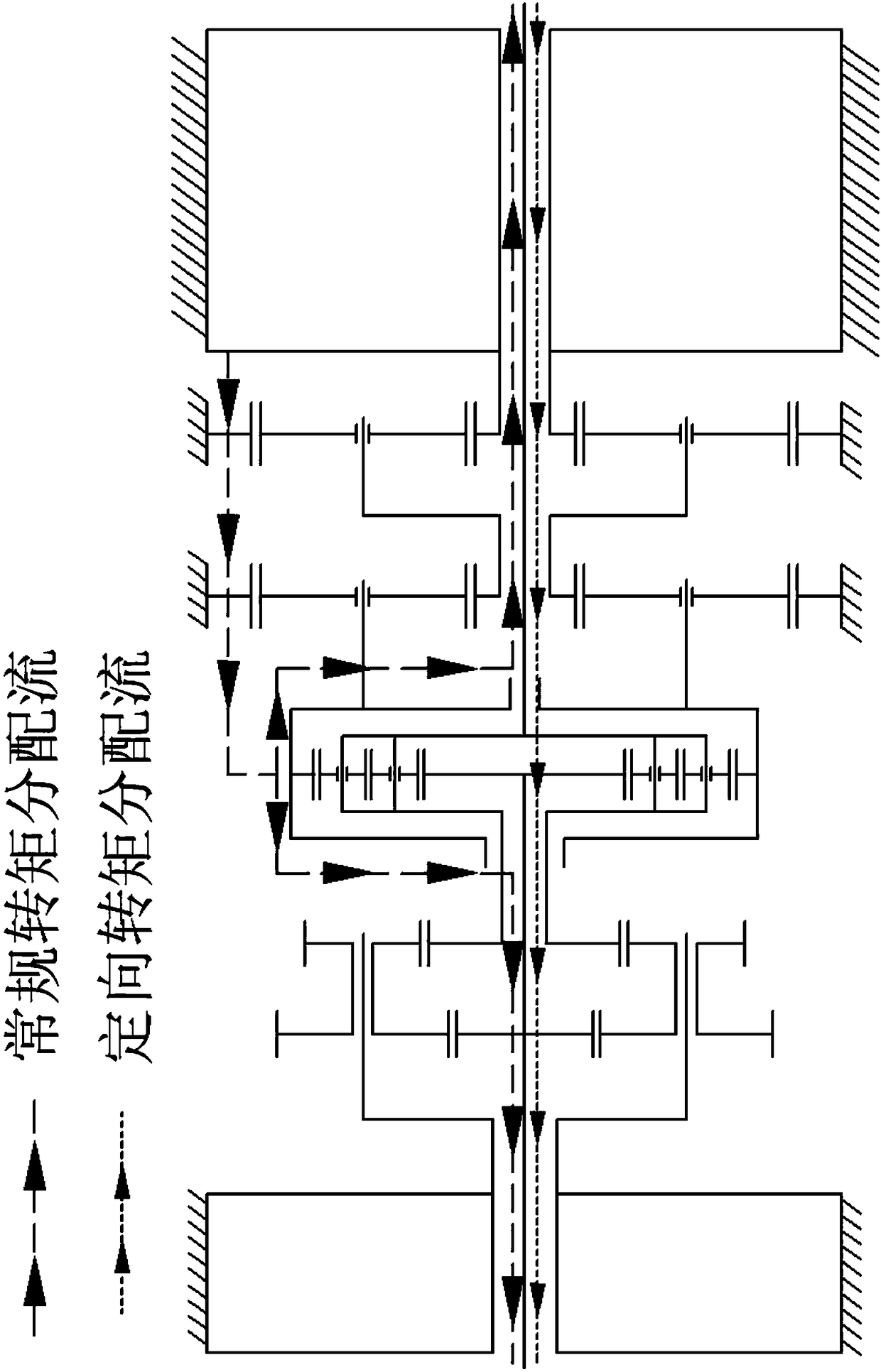

ActiveCN106965661ASolve the disadvantages of "differential speed is not bad"Improve cornering maneuverabilityHybrid vehiclesElectric propulsion mountingGear systemDistribution function

The invention discloses a double-motor coupling driving bridge with a torque directional distribution function. The double-motor coupling driving bridge with the torque directional distribution function comprises a master driving mechanism, a spur gear differential, a TV control driving mechanism, a first single row planetary gear system, a second single row planetary gear system, a third single row planetary gear system, a first clutch, a second clutch, a third clutch and a fourth clutch, wherein a first sun gear of the first single row planetary gear system can be rotatably supported on a first half shaft, and a first gear ring is connected with the output end of the TV control driving mechanism; a second gear ring of the second single row planetary gear system is fixed to a driving bridge shell, and a second sun gear is coaxially and fixedly connected with the first sun gear; a third sun gear of the third single row planetary gear system is fixedly connected with a differential shell, and a third gear ring is fixedly connected with a second planetary frame; the first clutch is used for isolating or combining the first half shaft and a first planetary frame; the second clutch is used for isolating or combining the first planetary frame and the driving bridge shell; the third clutch is used for isolating or combining the first half shaft and a third planetary frame; and the fourth clutch is used for isolating or combining the third planetary frame and the driving bridge shell.

Owner:JILIN UNIV

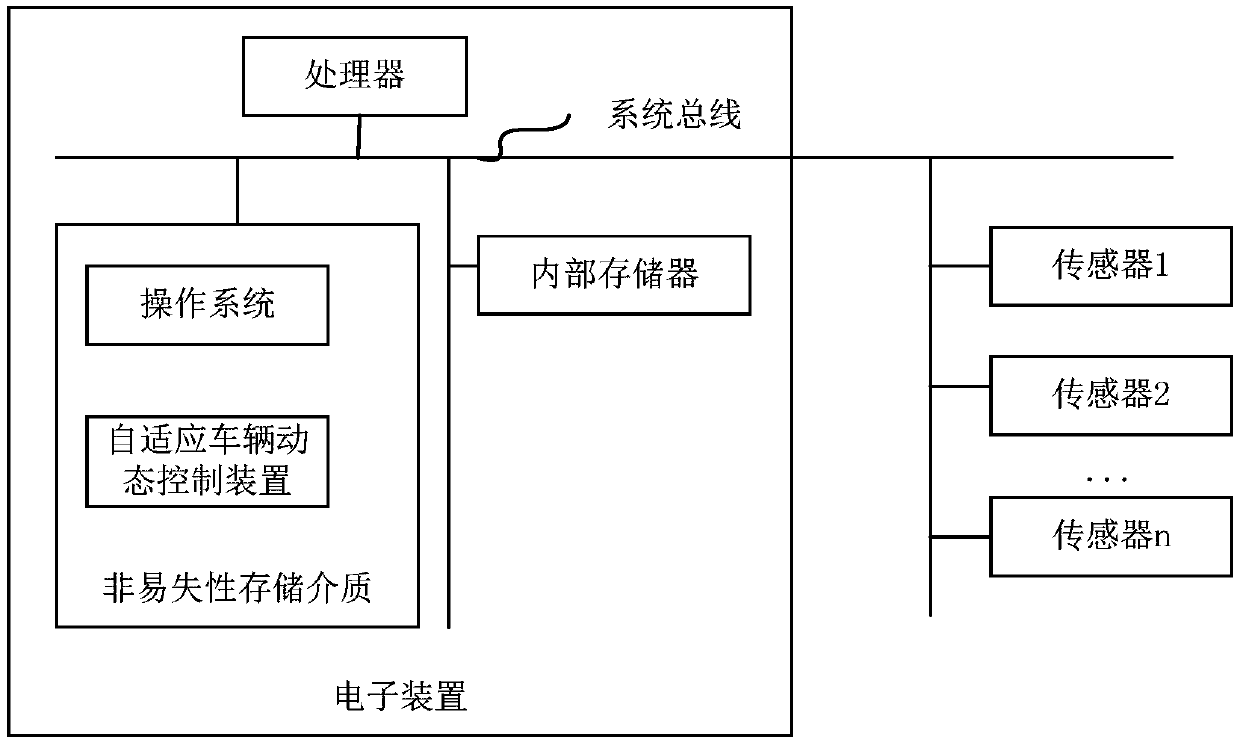

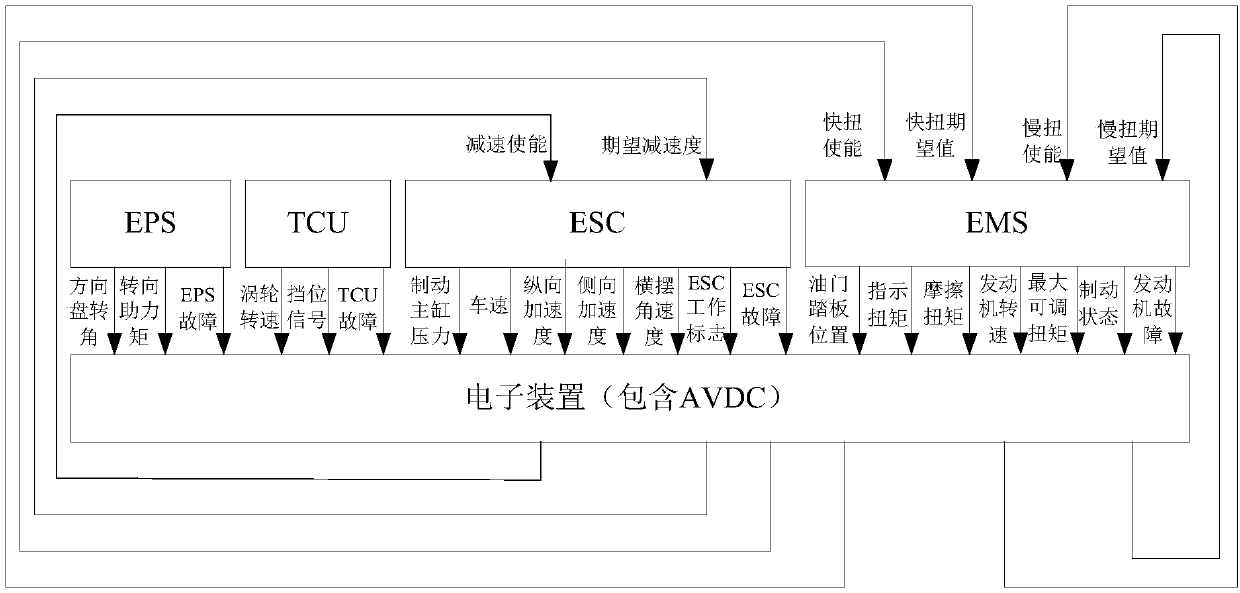

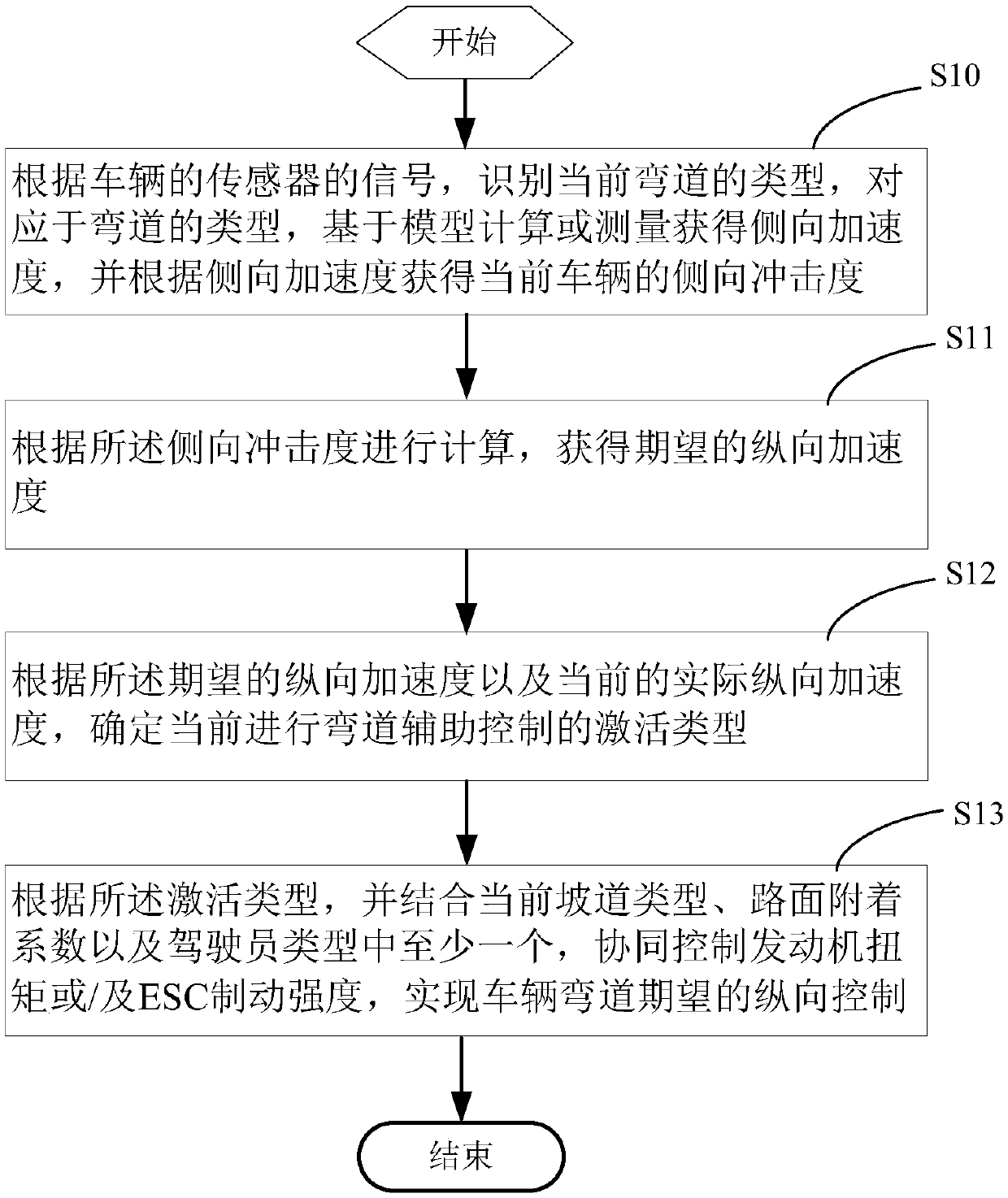

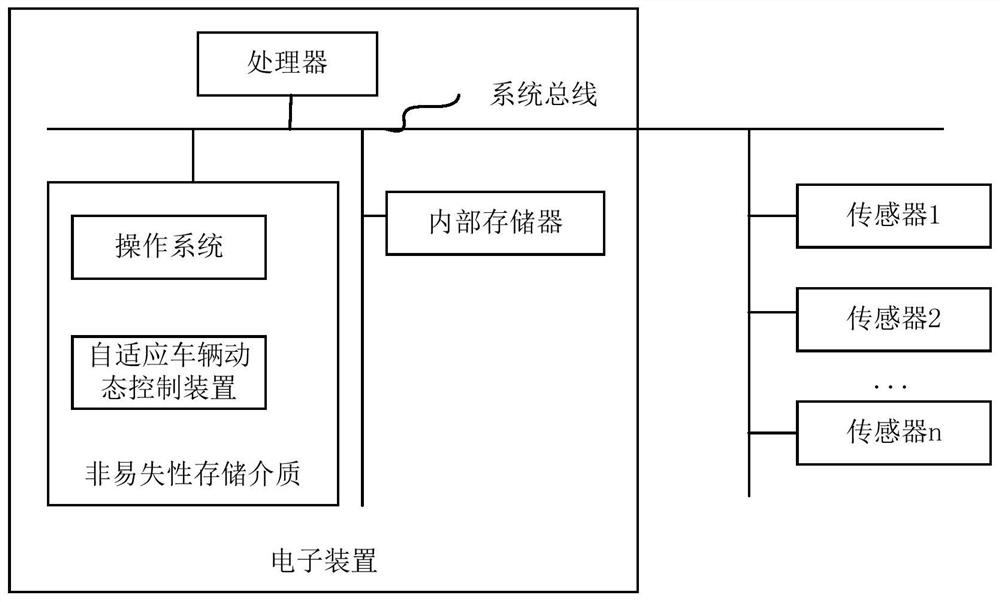

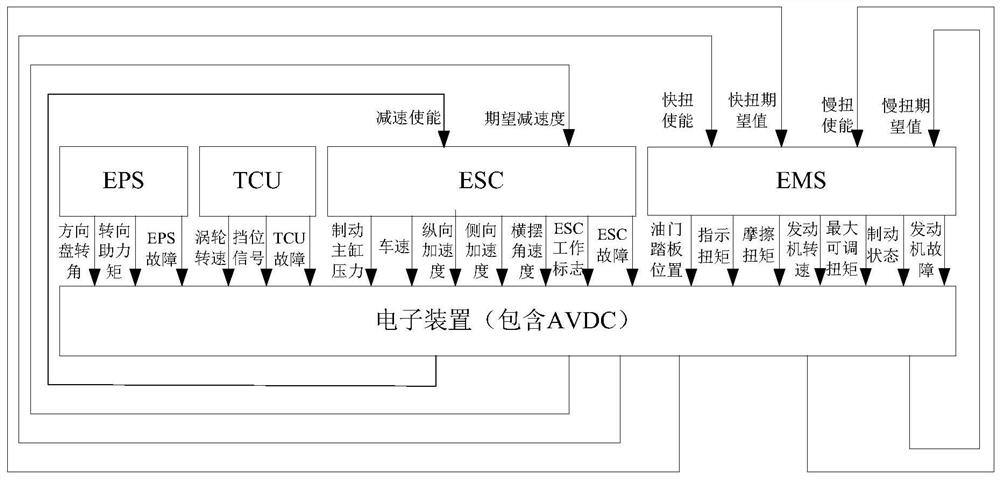

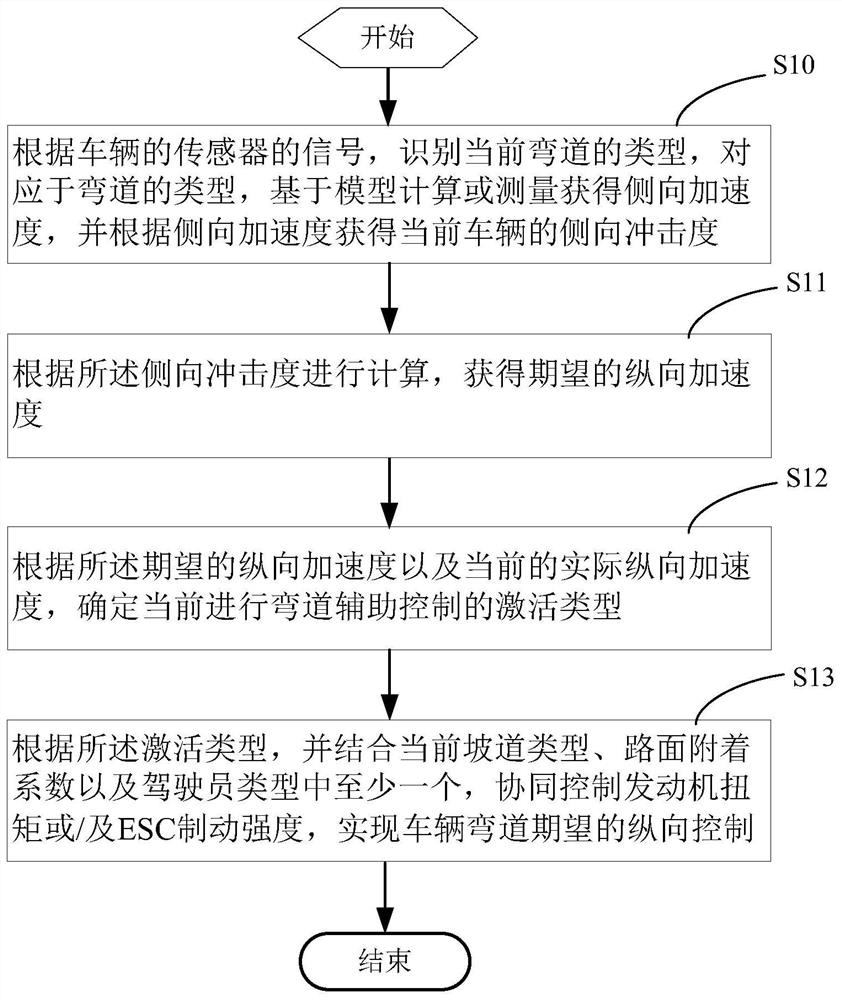

Self-adaptive vehicle curve auxiliary control method and device, computer equipment and storage medium

ActiveCN111267853AImprove cornering performanceEasy corneringExternal condition input parametersSignalling/lighting devicesDriver/operatorSimulation

The invention provides a self-adaptive vehicle curve auxiliary control method and device, computer equipment and a storage medium. The method comprises the steps that S10, the type of a current curveis recognized according to signals of a sensor of a vehicle, and the lateral impact degree of the current vehicle is obtained according to the lateral acceleration corresponding to the type of the curve; S11, calculation is performed according to the lateral impact degree to obtain an expected longitudinal acceleration; S12, according to the expected longitudinal acceleration and the current actual longitudinal acceleration, an activation type of current curve auxiliary control is determined; and S13, according to the activation type, the engine torque or / and the ESC braking strength is / are cooperatively controlled, and expected longitudinal control over the curve of the vehicle is achieved. Certain vehicle longitudinal auxiliary control can be carried out on the premise that a driver doesnot perceive, so that the dynamic performance of the vehicle during turning is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Electric differential mechanism with directed torque distribution function

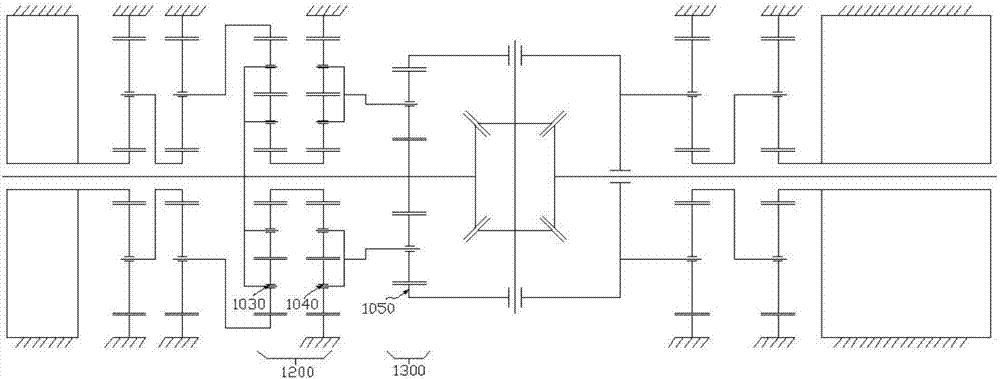

ActiveCN107061682ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

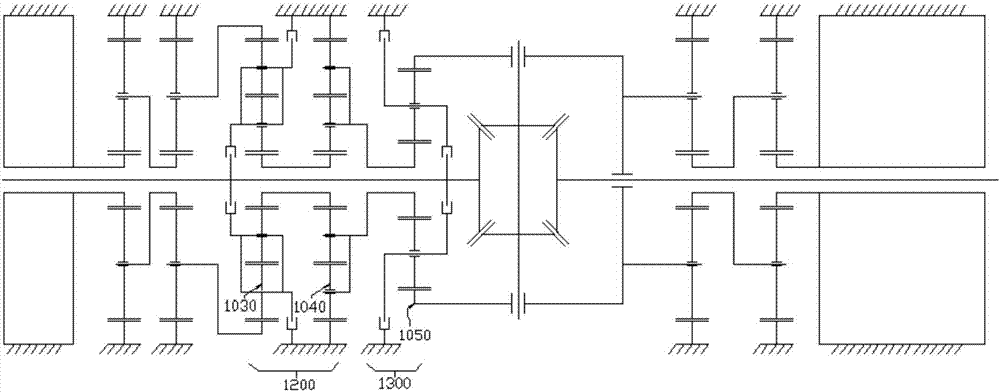

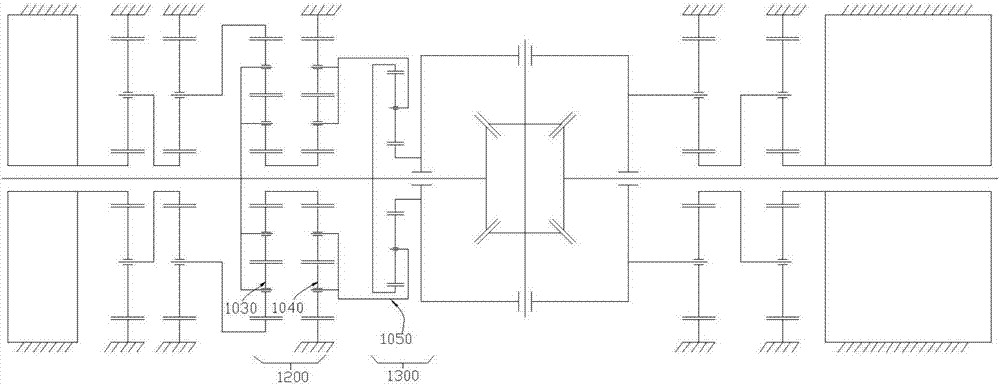

The invention discloses an electric differential mechanism with a directed torque distribution function. The electric differential mechanism with the directed torque distribution function comprises a main drive mechanism, a bevel gear differential mechanism body, a TV control drive mechanism used for outputting control power, a first single-row planetary gear system, a second single-row planetary gear system and a third single-row planetary gear system, wherein a first sun gear is supported on a first half axle through a bearing, a first gear ring is coaxially and fixedly connected with the first half axle, and a first planetary carrier is connected with the control output end; a second planetary carrier is fixed to a drive axle housing, and a second sun gear is fixedly connected with the first sun gear; the second sun gear is supported on the first half axle through a bearing; a third sun gear is fixedly connected with a differential mechanism shell, a third planetary carrier is fixedly connected with a second inner gear ring, and a third gear ring is fixedly connected with the first half axle; and the second single-row planetary gear system and the first single-row planetary gear system have the same characteristic parameters. By means of the electric differential mechanism with the directed torque distribution function, drive torque of an automobile can be distributed to wheels on the left side and the right side in a directed mode according to control demands of control logic.

Owner:JILIN UNIV

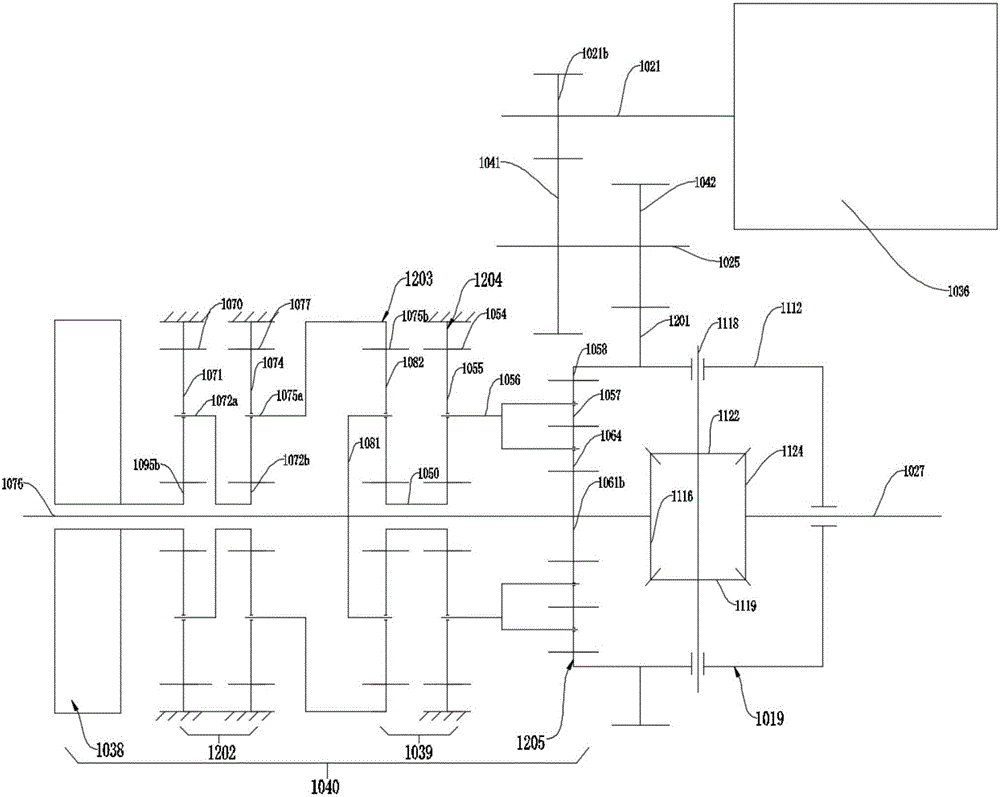

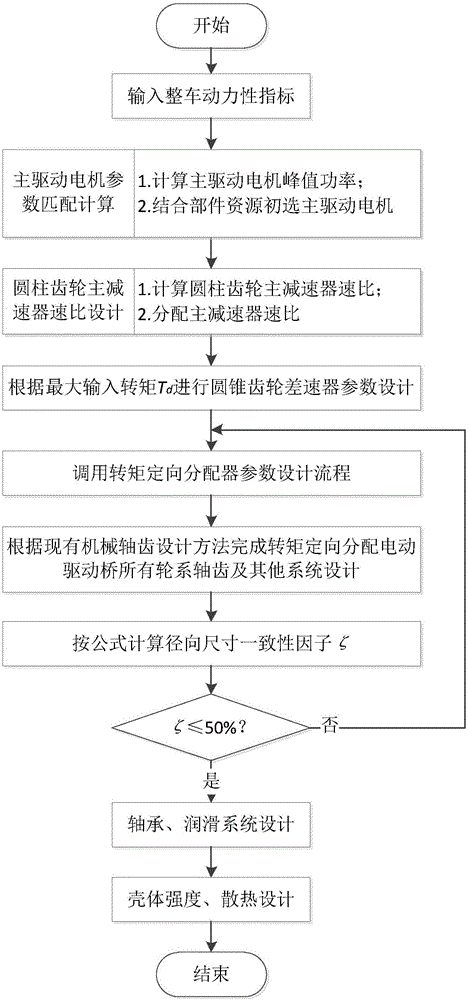

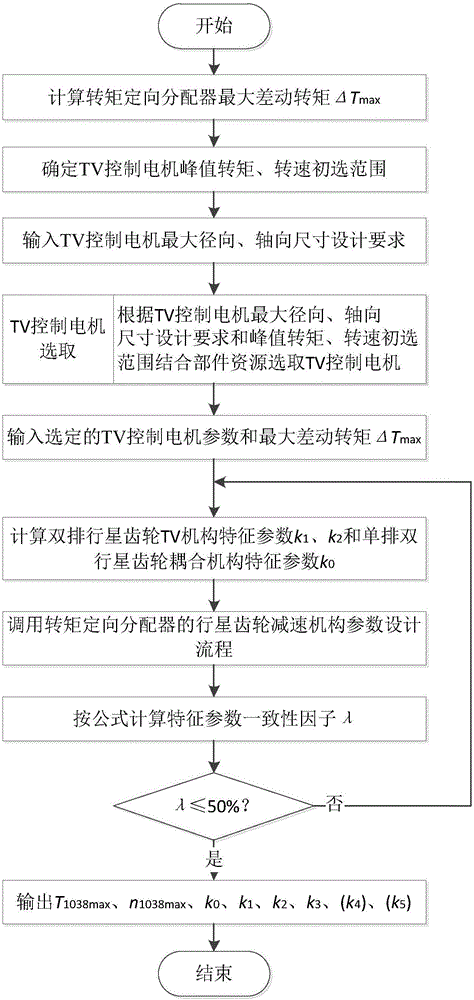

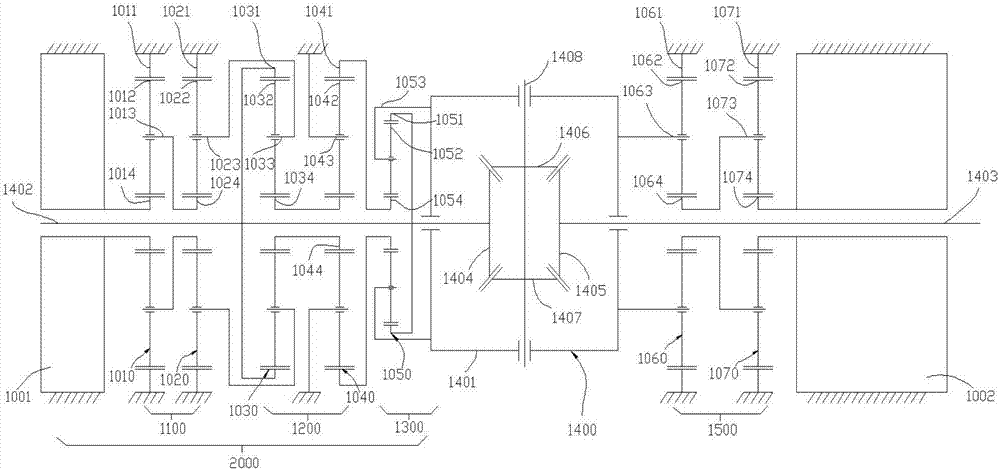

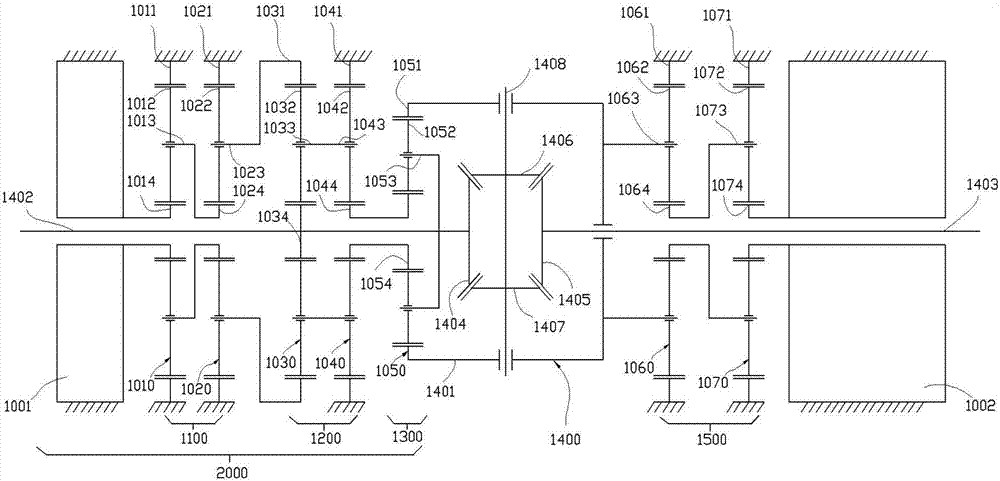

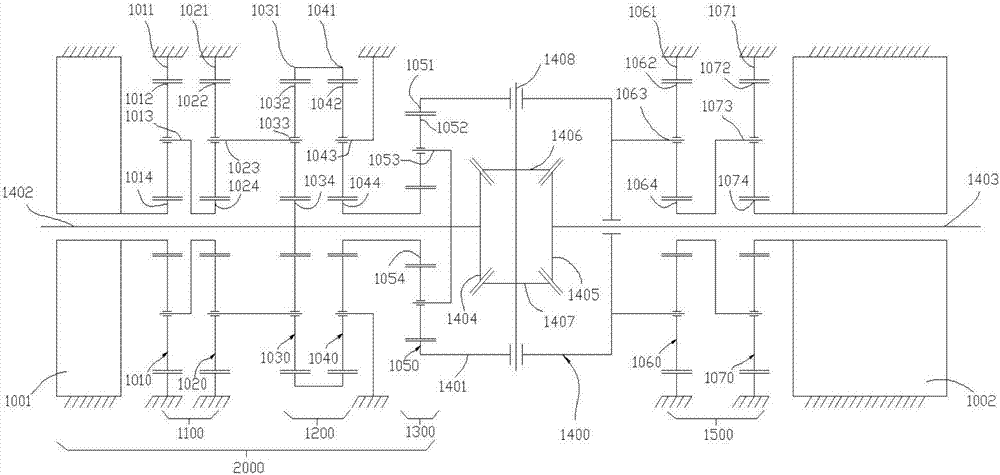

Torque directional distribution electric drive axle design method

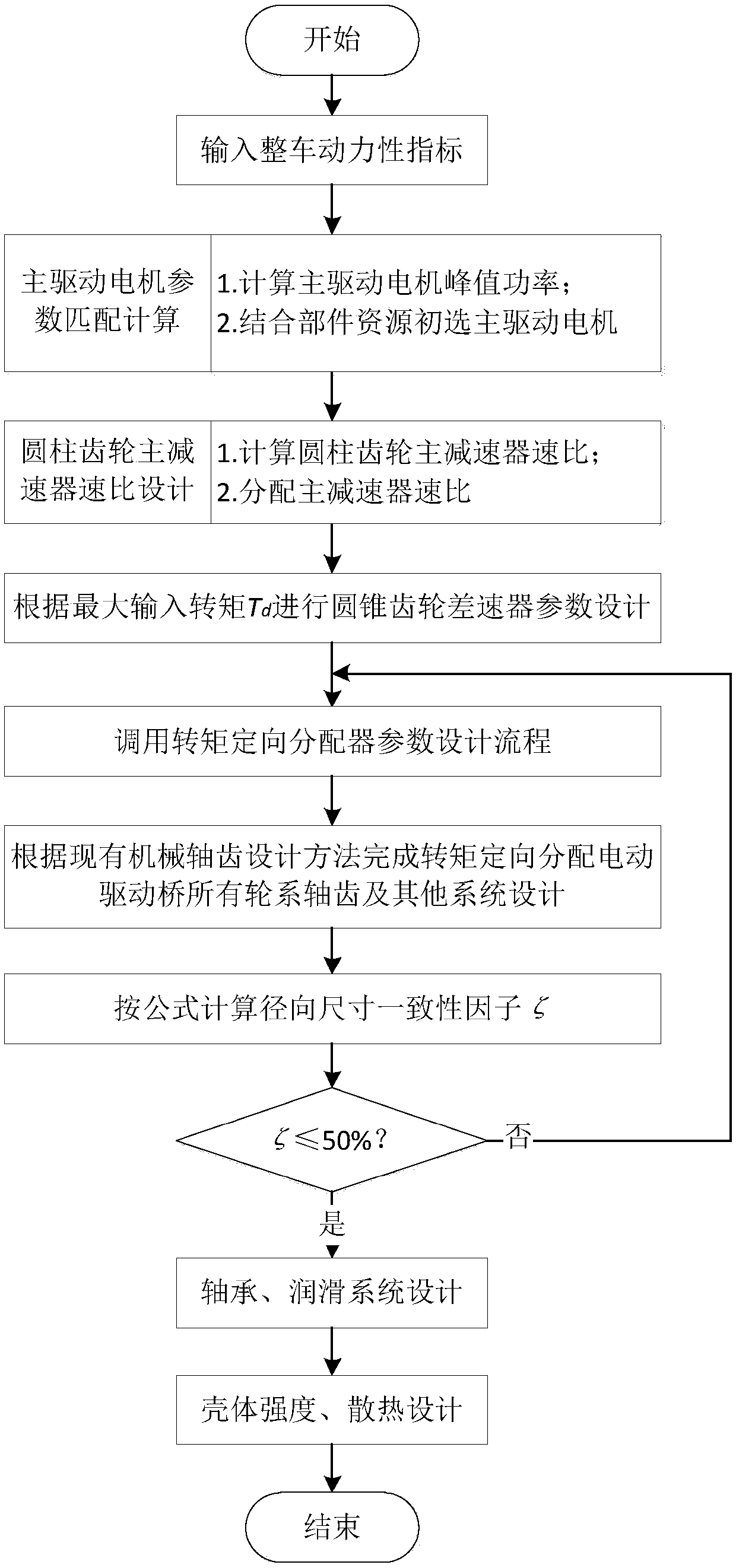

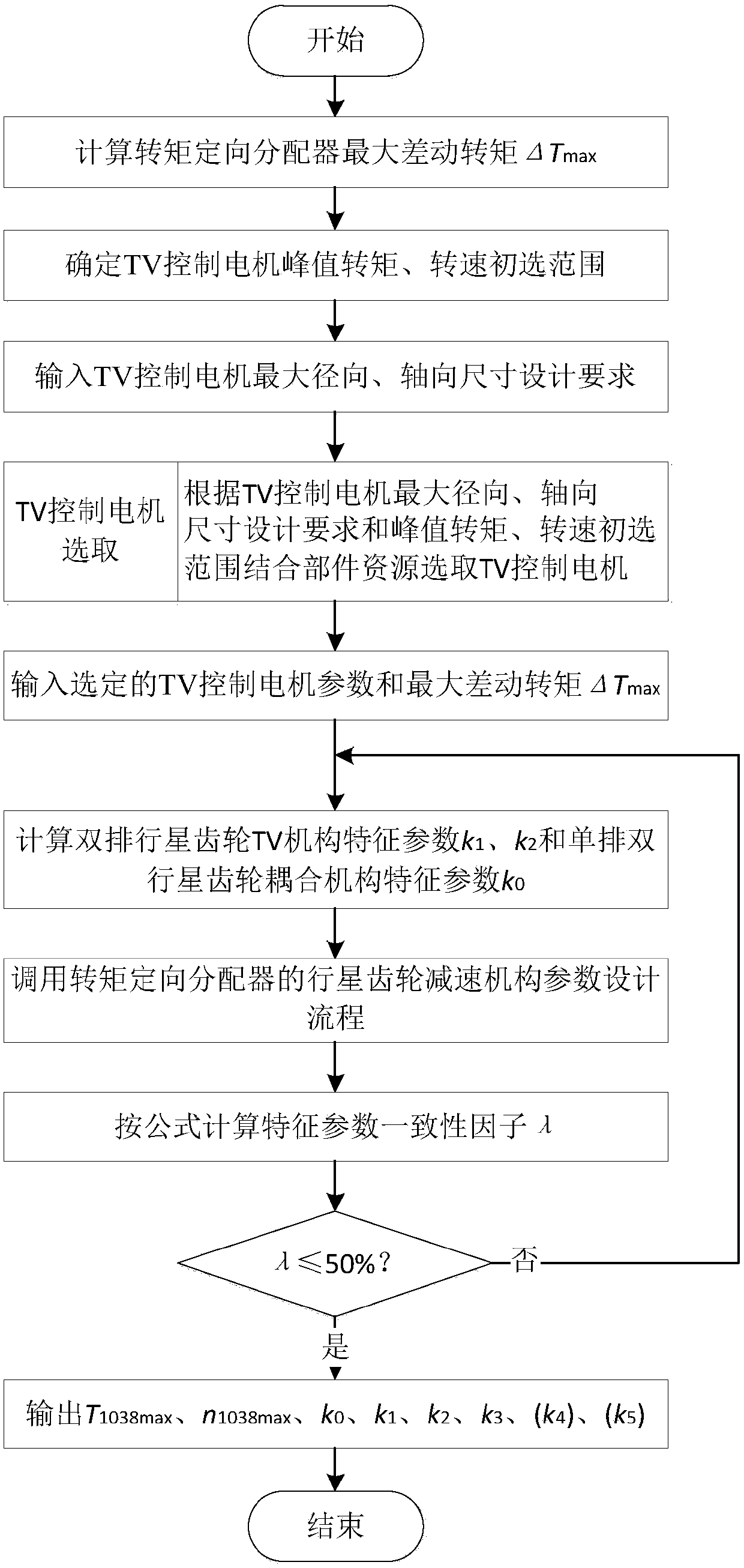

ActiveCN106809054ARealize the functional requirements of torque directional distributionImprove extreme cornering abilitySpeed controllerElectric energy managementVehicle dynamicsDrive motor

The invention provides a torque directional distribution electric drive axle design method. The method includes the following steps that parameter matching calculation of a main drive motor of a torque directional allocation electric drive axle is completed according to vehicle dynamic indexes, the speed ratio of a cylindrical gear main speed reducer of the torque directional allocation electric drive axle is calculated according to the speed of a cruiser, and the number of stages of the main speed reducer is determined; the feature parameters k1 and k2 of a two-row planetary gear TV mechanism and the feature parameter k0 of a single-row two-line planetary gear coupling mechanism are calculated; the maximum differential torque deltaTmax of a torque directional distributor is calculated; the range of the peak torque T1038max of a TV control motor is determined, the range of the peak rotation speed n1038max of the TV control motor is determined, and a TV control motor is selected according to the ranges; the transmission ratio C of planetary gear speed reduction mechanisms is calculated according to deltaTmax and T1038max, the number of rows of the planetary gear speed reduction mechanisms of the torque directional distribution electric drive axle is determined, and feature parameters k3, (k4) and (k5) of each row are determined according to optimization targets, with the minimum feature parameter difference, of the planetary gear speed reduction mechanisms.

Owner:JILIN UNIV

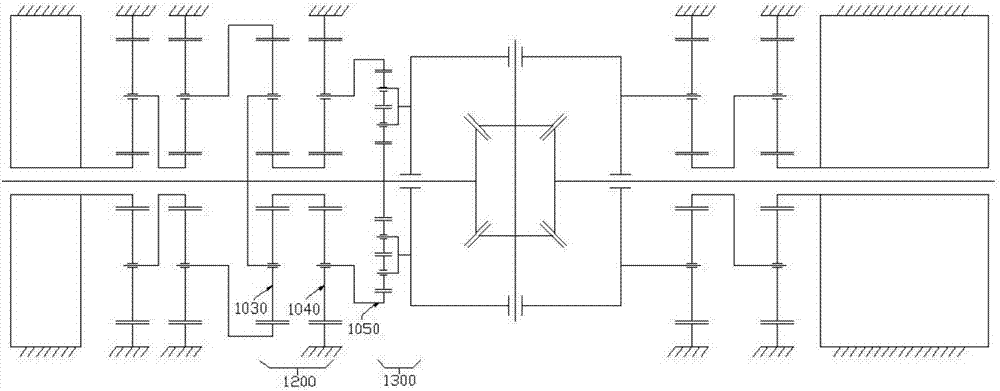

Electric differential mechanism with torque oriented distribution function

ActiveCN107035847ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a torque oriented distribution function. The electric differential mechanism comprises a main drive mechanism, a bevel gear differential mechanism, a TV control drive mechanism, a first single-row planetary gear train, a second single-row planetary gear train and a third single-row planetary gear train. The TV control drive mechanism is used for outputting control power. A first sun gear is coaxially and fixedly connected with a first half shaft. A first gear ring is connected with a control output end. A second gear ring is fixed to a drive axle housing. A second planet carrier is fixedly connected with a first planet carrier. A second sun gear is supported on the first half shaft through a bearing. A third sun gear is fixedly connected with a differential mechanism shell. A third planet carrier is connected with the first half shaft through a spline. A third gear ring is fixedly connected with the second sun gear. The second single-row planetary gear train and the first single-row planetary gear train have the same characteristic parameters. By means of the electric differential mechanism, the drive torque of automobiles can be distributed to wheels on the left side and the right side in an oriented manner according to control requirements of control logic.

Owner:JILIN UNIV

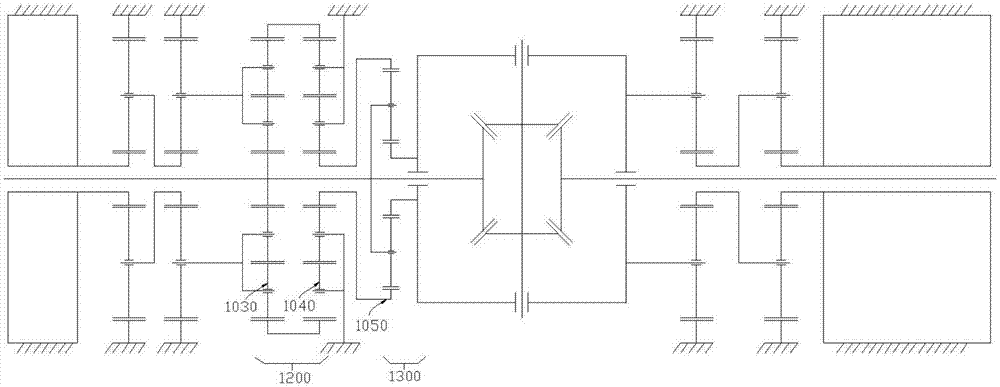

Torque directional distribution electric drive axle based on double-rotor motor

PendingCN108297620AAssign anySolve the disadvantages of "differential speed is not bad"Electric propulsion mountingAxle unitsDrive motorElectric drive

The invention discloses a torque directional distribution electric drive axle based on a double-rotor motor. The drive axle comprises a main drive motor and the relatively-rotating type double-rotor motor, wherein the output end of the main drive motor is connected with a shell of a bevel gear differential mechanism through a speed reduction mechanism; the relatively-rotating type double-rotor motor comprises an outer rotor and an inner rotor which are coaxially arranged and rotate relatively; a first output end drive gear of a first output end gear transmission mechanism is fixedly connectedwith the output end of the outer rotor of the double-rotor motor, and a first output end driven gear is connected with a first axle shaft; a second output end drive gear of a second output end gear transmission mechanism is fixedly connected with the output end of the inner rotor of the double-rotor motor, and a second output end driven gear is fixedly connected with the shell of the bevel gear differential mechanism; and the first output end gear transmission mechanism and the second output end gear transmission mechanism have the same transmission ratio. By the adoption of the provided torque directional distribution electric drive axle based on the double-rotor motor, torque directional distribution of wheels on the two sides can be achieved without a clutch, the action response is madequickly, and the integration degree is high.

Owner:JILIN UNIV

Electric differential mechanism with torque directional allocation function

ActiveCN107061681ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a torque directional allocation function. The electric differential mechanism comprises a main driving mechanism, a bevel gear differential mechanism body, a TV control driving mechanism, a first single-row planetary gear train, a second single-row planetary gear train and a third single-row planetary gear train, wherein the TV control driving mechanism is used for outputting control power; a first sun gear is supported on a first half shaft through a bearing, a first gear ring is coaxially and fixedly connected with the first half shaft, and a first planet carrier is connected with a control output end; a second planet carrier is fixed to a driving axle housing, and a second sun gear is fixedly connected with the first sun gear and supported on the first half shaft through a bearing; a third sun gear is fixedly connected with a differential mechanism shell, a third planet carrier is in spline connection with the first half shaft, and a third gear ring is fixedly connected with a second inner gear ring; and the second single-row planetary gear train and the first single-row planetary gear train have the same characteristic parameters. By adoption of the electric differential mechanism, the driving torque of an automobile can be allocated directionally to left side wheels and right side wheels according to control requirements of control logic.

Owner:JILIN UNIV

Electric differential mechanism with directed torque distribution function

ActiveCN107061675AImprove cornering maneuverabilityImprove driving pleasureDifferential gearingsPhysicsTransaxle

The invention discloses an electric differential mechanism with a directed torque distribution function. The electric differential mechanism with the directed torque distribution function comprises a main drive mechanism, a bevel gear differential mechanism body, a TV control drive mechanism used for outputting control power, a first single-row planetary gear system, a second single-row planetary gear system and a third single-row planetary gear system, wherein a first sun gear is coaxially and fixedly connected with a first half axle, and a first planetary carrier is connected with the control output end; a second planetary carrier is fixed to a drive axle housing, and a second gear ring is fixedly connected with a first gear ring; a second sun gear is supported on the first half axle through a bearing; a third sun gear is fixedly connected with the second sun gear, a third planetary carrier is fixedly connected with a differential mechanism shell, and a third gear ring is fixedly connected with the first half axle; and the second single-row planetary gear system and the first single-row planetary gear system have the same characteristic parameters. By means of the electric differential mechanism with the directed torque distribution function, drive torque of an automobile can be distributed to wheels on the left side and the right side in a directed mode according to control demands of control logic.

Owner:JILIN UNIV

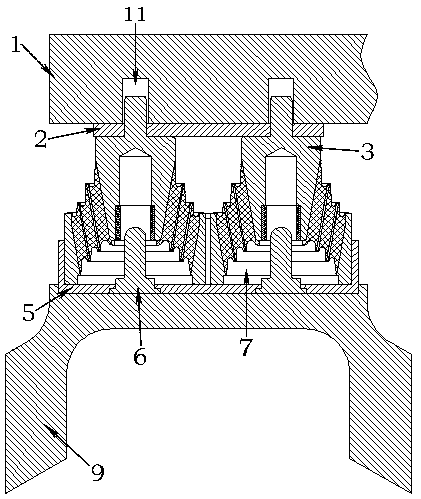

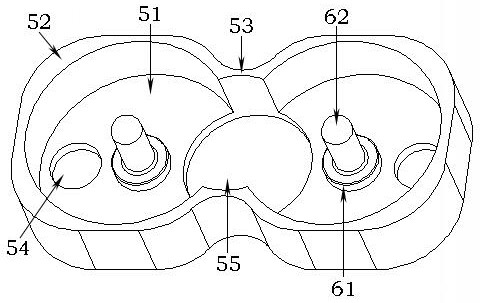

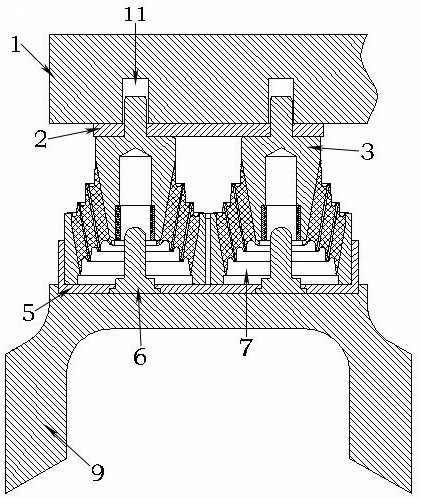

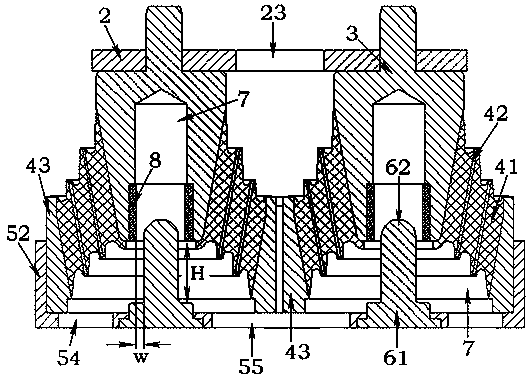

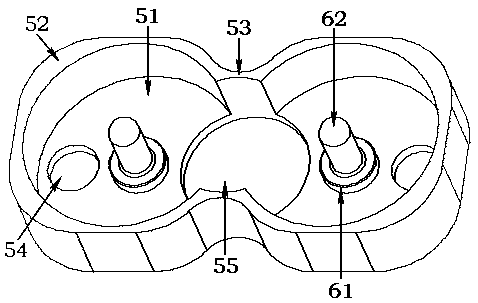

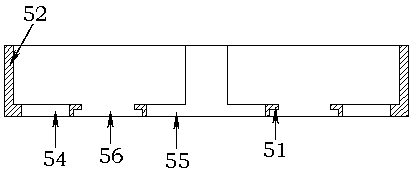

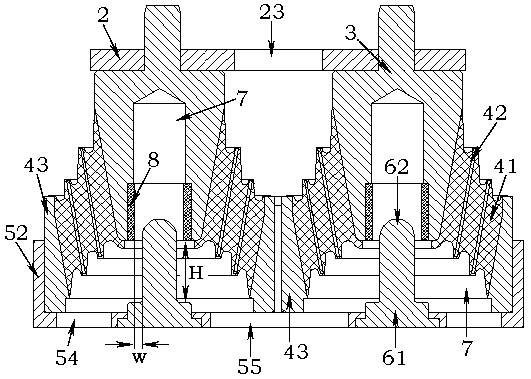

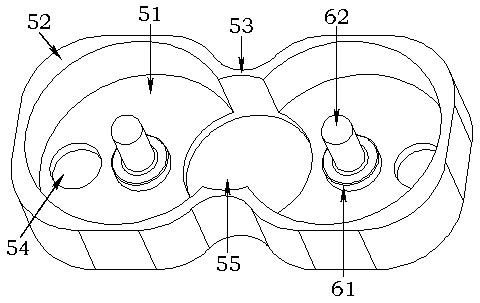

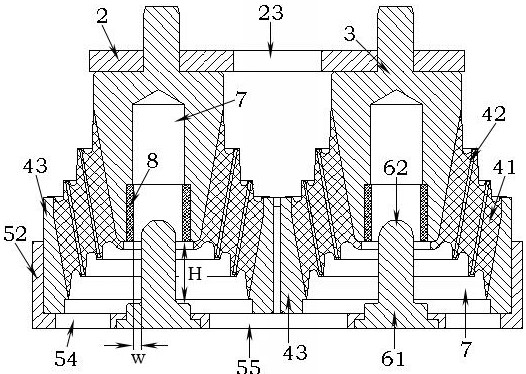

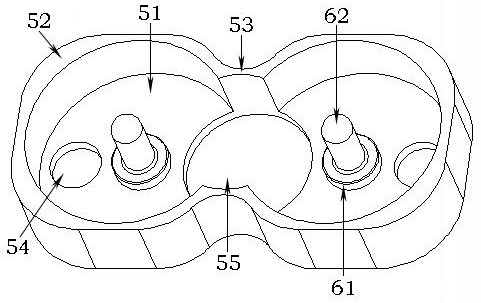

Method and structure for adjusting vertical rigidity of primary suspension device

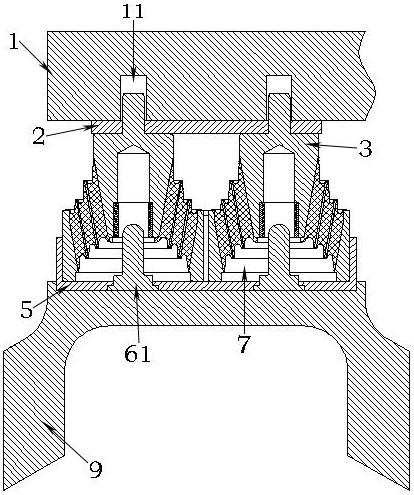

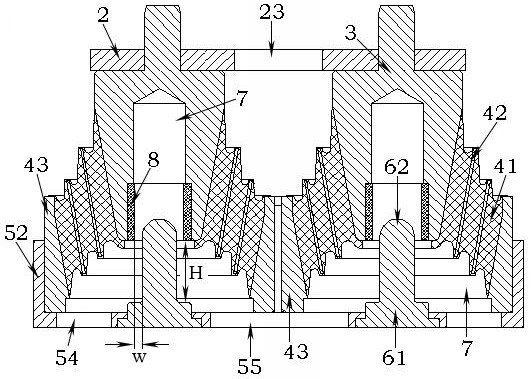

ActiveCN111071278ASave a series of hanging spaceReduce weightBogiesAxle-boxes mountingSuspension (vehicle)Bogie

The invention provides a method and a structure for adjusting the vertical rigidity of a primary suspension device. The primary suspension device comprises a base, conical springs and limiting stoppers, each conical spring comprises a rubber body and a mandrel, a stopping hole is formed in the lower end of a bogie, the upper end of the mandrel is installed in the stopping hole of the bogie, and cavities are formed in the rubber body and the mandrel; the two conical springs are arranged in the base side by side in the longitudinal direction, the limiting stoppers are arranged in the cavities ofthe conical springs, each limiting stopper comprises a stop base and a stop rod, and the stop rod is integrally formed above the stop base; and an axle box is provided with an axle box seat, the baseis installed in the axle box seat, and when the bogie moves relative to the axle box in the vertical direction and the lower end of the mandrel abuts against the stop seats in the vertical direction,the primary suspension device can generate variable rigidity in the vertical direction. The capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of the bogie is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Electric differential mechanism with directed torque distribution function

ActiveCN107061676ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a directed torque distribution function. The electric differential mechanism with the directed torque distribution function comprises a main drive mechanism, a bevel gear differential mechanism body, a TV control drive mechanism used for outputting control power, a first single-row planetary gear system, a second single-row planetary gear system and a third single-row planetary gear system, wherein a first planetary carrier is coaxially and fixedly connected with a first half axle, a first gear ring is connected with the control output end, and a first sun gear is supported on the first half axle through a bearing; a second gear ring is fixed to a drive axle housing, and a second sun gear is fixedly connected with the first sun gear and supported on the first half axle through a bearing; a third sun gear is fixedly connected with a differential mechanism shell, a third planetary carrier is fixedly connected with a second planetary carrier, and a third gear ring is fixedly connected with the first half axle; and the second single-row planetary gear system and the first single-row planetary gear system have the same characteristic parameters. By means of the electric differential mechanism with the directed torque distribution function, drive torque of an automobile can be distributed to wheels on the left side and the right side in a directed mode according to control demands of control logic.

Owner:JILIN UNIV

Electric differential mechanism with torque fixed direction allocation function

ActiveCN106838200ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a torque fixed direction allocation function. The electric differential mechanism comprises a main driving mechanism, a bevel gear main differential mechanism, a TV control driving mechanism, a first single row planetary gear system, a second single row planetary gear system and a third single row planetary gear system. The TV control driving mechanism is used for outputting control power; a first sun gear is fixedly coaxially connected to a first axle shaft, and a first gear ring is connected to a control output end; a second gear ring is fixed on a driving axle housing, and a second planetary frame is fixedly connected to the first planetary frame; a second sun gear is rotatably supported on the first axle shaft; a third sun gear is fixedly connected to the second sun gear, a third planetary frame is fixedly connected to a differential housing, and a third gear ring is fixedly connected to the first axle shaft, wherein the second single row planetary gear system has the same characteristic parameter as the first single row planetary gear system. The electric differential mechanism with the torque fixed direction allocation function enables driving torque of a vehicle to be directionally distributed to wheels at the left and right sides according to a control requirement of control logic.

Owner:JILIN UNIV

Electric differential with torque oriented distribution function

ActiveCN106870683ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential with a torque oriented distribution function. The electric differential comprises a main driving mechanism, a bevel gear differential, a TV control driving mechanism, a first single rod planetary gear train, a second single rod planetary gear train and a third single rod planetary gear train, wherein the TV control driving mechanism is used for outputting control power; a first planet carrier and a first half shaft are coaxially and fixedly connected; a first gear ring is connected with a control output end; a first sun gear is supported on the first half shaft through a bearing; a second gear ring is fixed to a drive axle housing; a second sun gear is fixedly connected with the first sun gear; the second sun gear is supported on the first half shaft through a bearing; a third sun gear is fixedly connected with the first half shaft; a third gear ring is fixedly connected with a second planet carrier; a third planet carrier is fixedly connected with a differential case; and the second single rod planetary gear train and the first single rod planetary gear train have the same characteristic parameters. According to the electric differential, driving torque of an automobile can be distributed to wheels on the left and right sides in an oriented manner according to the control requirement of control logic.

Owner:JILIN UNIV

Electric differential device with torque fixed-direction distribution function

PendingCN107061683AImprove cornering maneuverabilityImprove driving pleasureDifferential gearingsTransaxleGear system

The invention discloses an electric differential device with a torque fixed-direction distribution function. The electric differential device comprises a main drive mechanism, a bevel gear differential device body, a TV control drive mechanism for outputting control power, a first single-row planetary gear system, a second single-row planetary gear system and a third single-row planetary gear system; a first sun gear is coaxially and fixedly connected with a first half shaft, and a first planet carrier is connected with the control output end; a second planet carrier is fixed to a drive bridge shell, and a second gear ring is fixedly connected with a first gear ring; a second sun gear is arranged on the first half shaft through a bearing in a supported manner; a third sun gear is fixedly connected with a differential device shell, a third planet carrier is connected with the first half shaft through a spline, and a third gear ring is fixedly connected with the second sun gear; and the second single-row planetary gear system and the first single-row planetary gear system have the same characteristic parameters. By means of the electric differential device, the drive torque of an automobile can be distributed to wheels on the left side and the right side in a fixed-direction manner according to the control requirement of control logic.

Owner:JILIN UNIV

Electric differential device with torque fixed-direction distribution function

ActiveCN107061684ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential device with a torque fixed-direction distribution function. The electric differential device comprises a main drive mechanism, a bevel gear differential device body, a TV control drive mechanism for outputting control power, a first single-row planetary gear system, a second single-row planetary gear system and a third single-row planetary gear system; a first planet carrier is coaxially and fixedly connected with a first half shaft, a first gear ring is connected with the control output end, and a first sun gear is arranged on the first half shaft through a bearing in a supported manner; a second gear ring is fixed to a drive bridge shell, and a second sun gear is fixedly connected with the first sun gear; the second sun gear is arranged on the first half shaft through a bearing in a supported manner; a third sun gear is fixedly connected with the first half shaft, a third planet carrier is fixedly connected with a second planet carrier, and a third gear ring is fixedly connected with a differential device shell; and the second single-row planetary gear system and the first single-row planetary gear system have the same characteristic parameters. By means of the electric differential device, the drive torque of an automobile can be distributed to wheels on the left side and the right side in a fixed-direction manner according to the control requirement of control logic.

Owner:JILIN UNIV

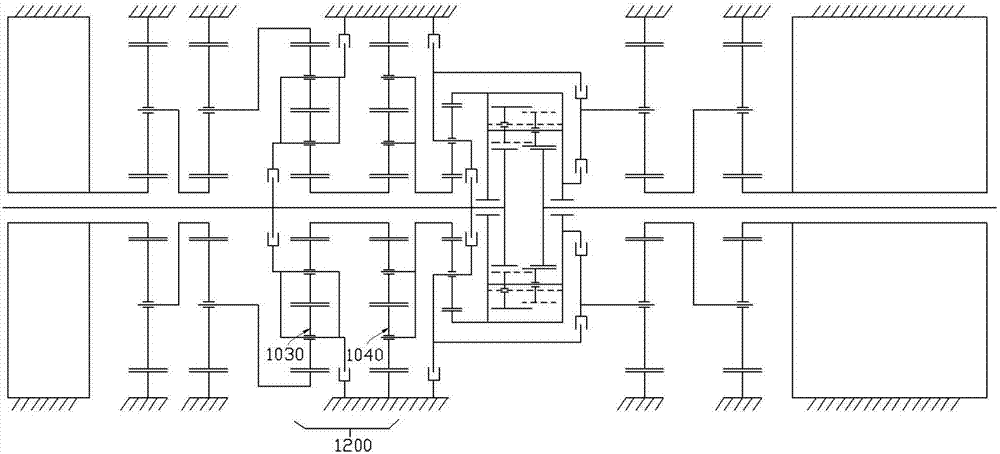

Duplex planetary gear train torque directional distribution electric drive axle

PendingCN108297619ASolve the output torque equalSolve the adjustmentElectric propulsion mountingAxle unitsDrive motorElectric drive

The invention discloses a duplex planetary gear train torque directional distribution electric drive axle. The drive axle comprises a main drive motor, a TV control drive motor and a duplex planetarygear train, wherein a power output shaft of the main drive motor is connected with a shell of a bevel gear differential mechanism through a speed reduction mechanism; a first axle shaft is rotationally supported on the shell, penetrates through the shell and is connected with a first axle shaft gear of the bevel gear differential mechanism, and a second axle shaft is rotationally supported on theshell, penetrates through the shell and is connected with a second axle shaft of the bevel gear differential mechanism; and the duplex planetary gear train comprises a first sun gear, a second sun gear, a first end planet gear, a second end planet gear and a first planet carrier. The torque of wheels on the left side and the right side is distributed at will.

Owner:JILIN UNIV

Stiffness adjustment method and structure of a primary suspension device

ActiveCN110979376BImprove abilitiesImprove cornering maneuverabilityBogiesAxle-boxes mountingBogieClassical mechanics

Provided are a rigidity adjusting method and structure for conical springs of a primary suspension device. The primary suspension device comprises a base, conical springs and limiting stoppers. Each conical spring comprises a rubber body and a mandrel. Stopping holes are formed in the lower end of a bogie, and the upper ends of the mandrels are installed in the stopping holes of the bogie. Cavities are formed in the rubber bodies and the mandrels. The two conical springs are arranged in the base side by side in the longitudinal direction, one limiting stopper is arranged in a cavity of each conical spring, and the lower end of each limiting stopper is connected with the base. An axle box is provided with an axle box seat, and the base is installed in the axle box seat. When the bogie movesrelative to the axle box in the vertical direction and the lower ends of the mandrels abut against the limiting stoppers, the primary suspension device can generate variable rigidity in the verticaldirection. According to the invention, the capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of the bogie is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

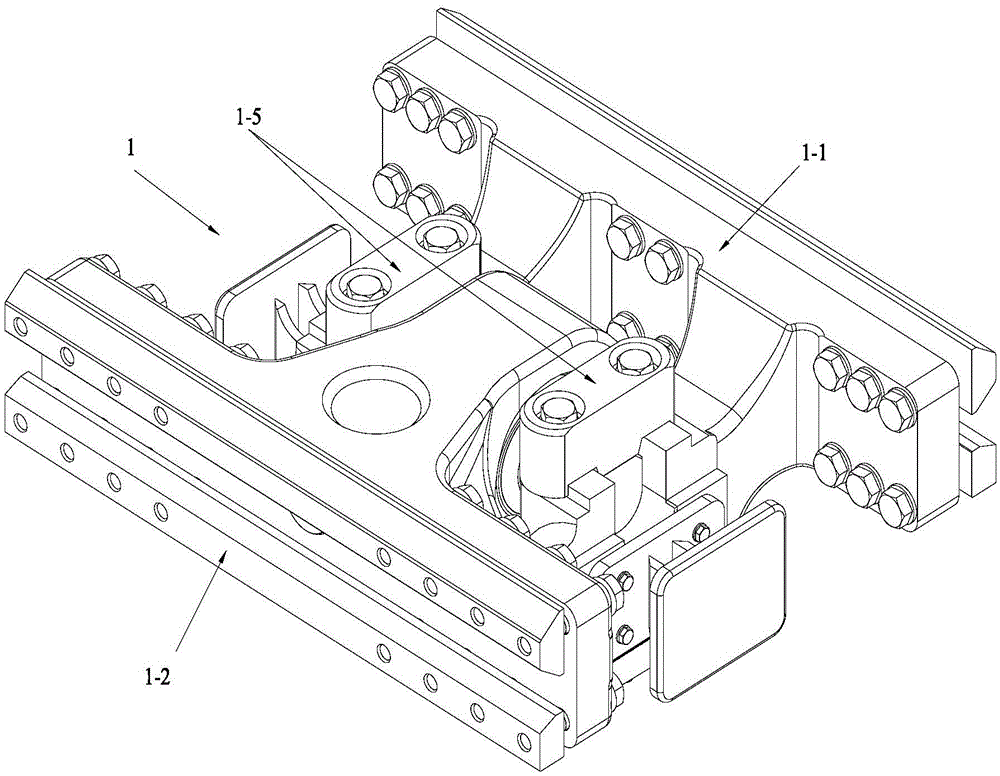

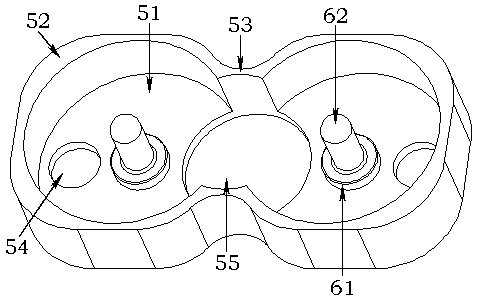

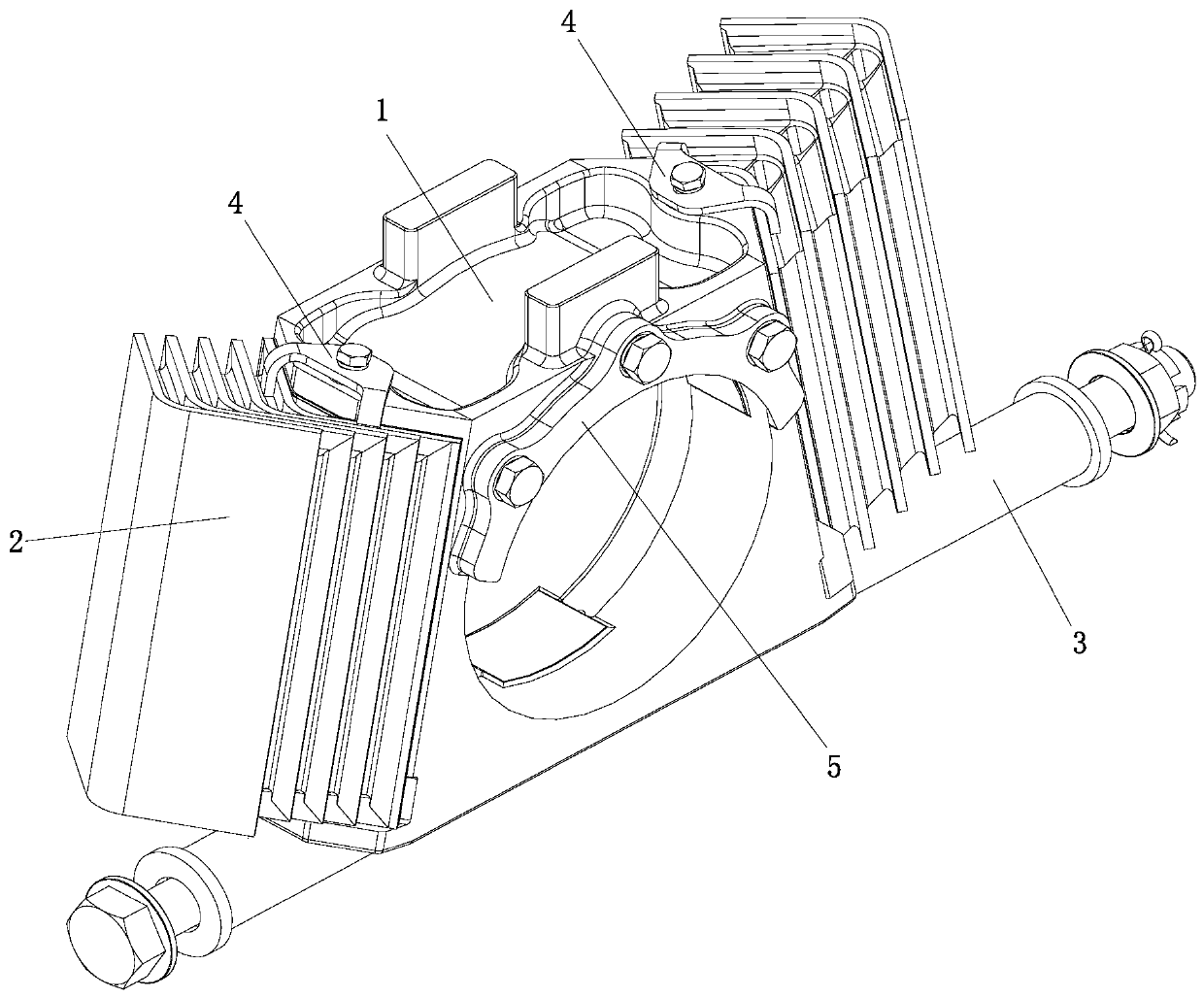

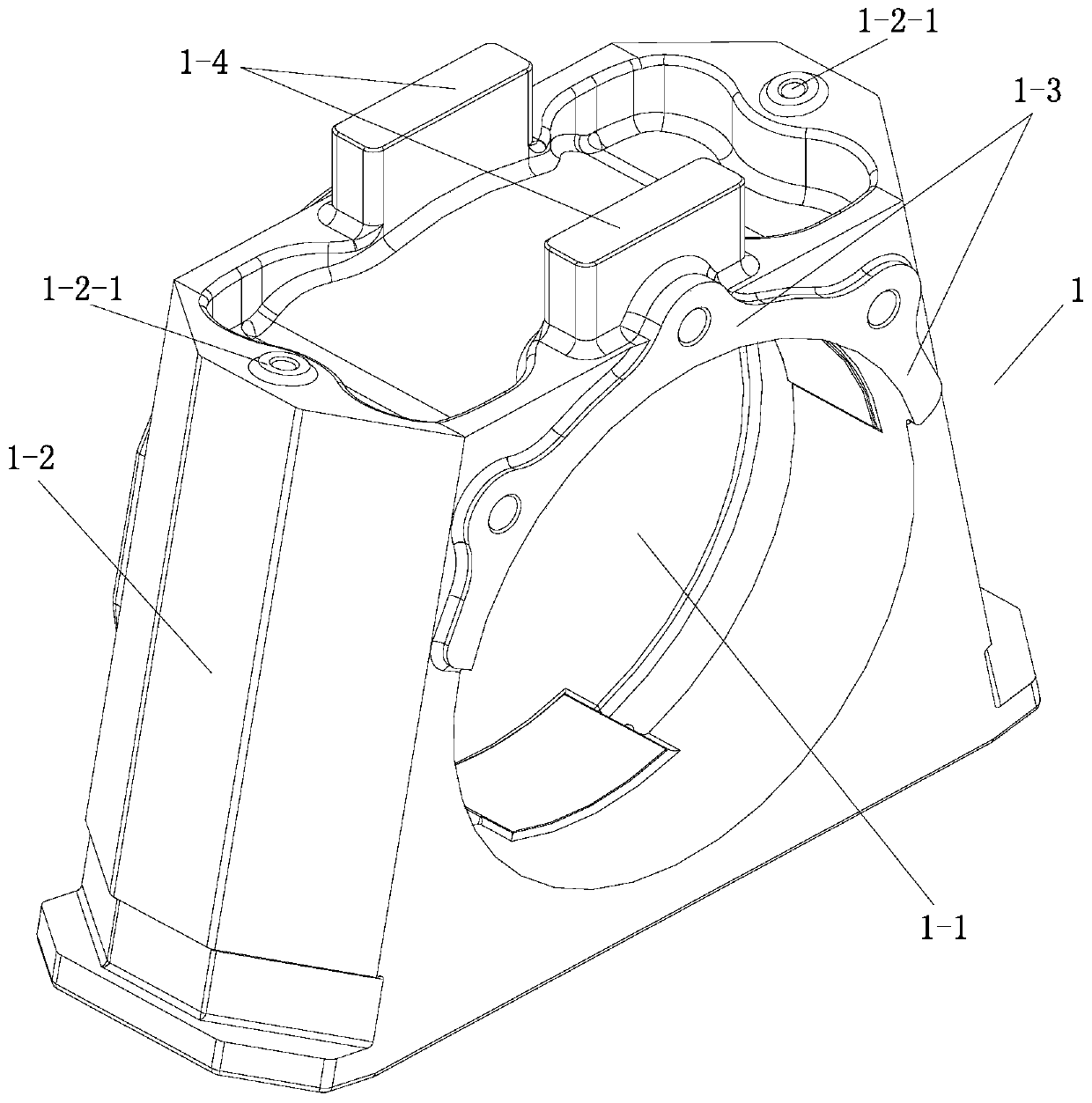

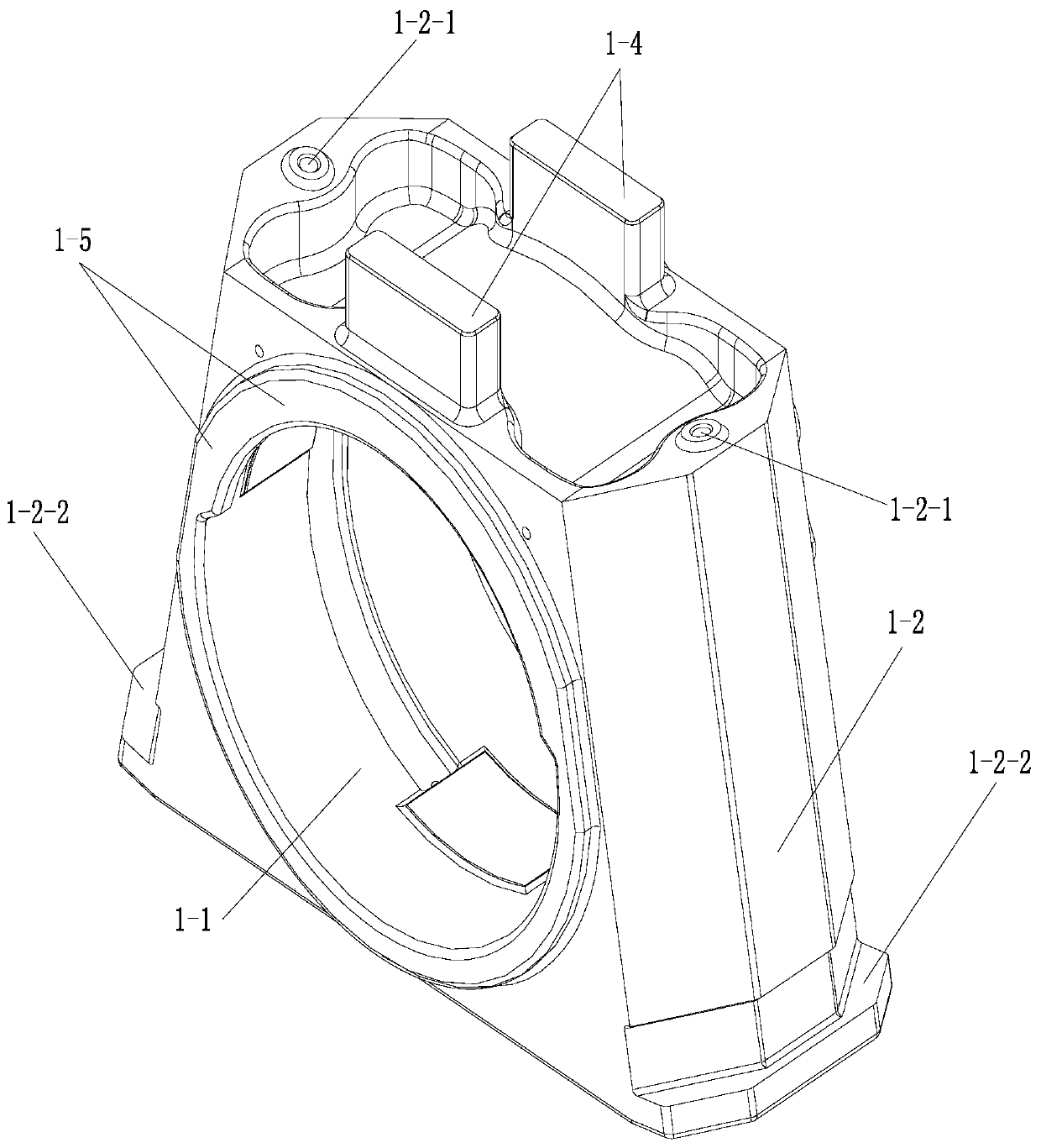

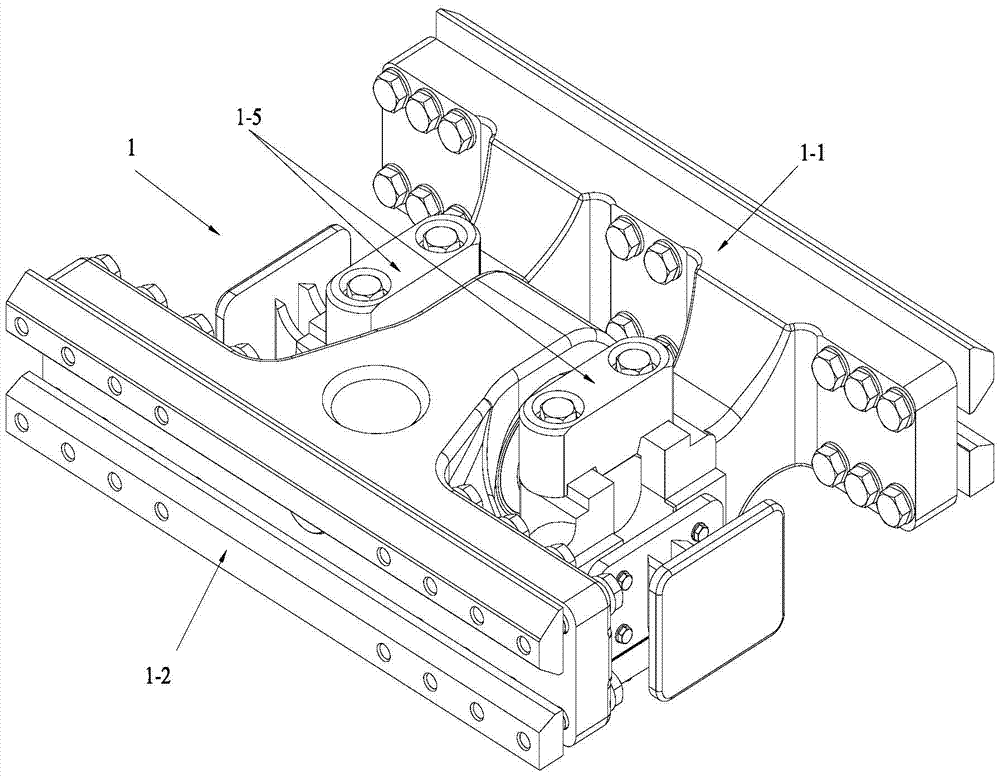

Built-in axle box mechanism for axle box built-in bogies

ActiveCN107628051BImprove high-speed stabilityIncreased longitudinal stiffnessAxle-boxesAxle-boxes mountingBogieMetal rubber

The invention discloses a built-in axle box mechanism for a bogie with built-in axle boxes and belongs to the field of axle boxes for bogies of railway vehicles with axle boxes on the inner sides of wheel sets and auxiliary damping positioning devices of the axle boxes. The built-in axle box mechanism comprises a trapezoidal axle box, two ridged rubber spring pieces, a positioning towing bar, twospring piece positioning clips and a semicircular axle box collision-proof gasket. The built-in axle box mechanism has the advantages that with the ridged rubber spring pieces compared with traditional cone metal rubber springs featuring vertical bearing, the built-in axle box mechanism can obtain extremely high longitudinal stiffness while low vertical stiffness is guaranteed, so that high-speedstability of the vehicles is gained; the axle box mechanism is capable of preventing axial movement of the ridged rubber spring pieces effectively and substituting for previous additional axle box protective covers, and accordingly daily inspection of bearings is facilitated; a minimal curve passing radius of the bogie with the built-in axle box mechanism is decreased from at least 100 meters to at least 36 meters remarkably, so that turning maneuverability and flexibility of the novel bogie are improved substantially.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

A Design Method for Torque Oriented Distribution Electric Drive Axle

ActiveCN106809054BRealize the functional requirements of torque directional distributionImprove cornering maneuverabilitySpeed controllerElectric energy managementVehicle dynamicsDrive motor

The invention provides a torque directional distribution electric drive axle design method. The method includes the following steps that parameter matching calculation of a main drive motor of a torque directional allocation electric drive axle is completed according to vehicle dynamic indexes, the speed ratio of a cylindrical gear main speed reducer of the torque directional allocation electric drive axle is calculated according to the speed of a cruiser, and the number of stages of the main speed reducer is determined; the feature parameters k1 and k2 of a two-row planetary gear TV mechanism and the feature parameter k0 of a single-row two-line planetary gear coupling mechanism are calculated; the maximum differential torque deltaTmax of a torque directional distributor is calculated; the range of the peak torque T1038max of a TV control motor is determined, the range of the peak rotation speed n1038max of the TV control motor is determined, and a TV control motor is selected according to the ranges; the transmission ratio C of planetary gear speed reduction mechanisms is calculated according to deltaTmax and T1038max, the number of rows of the planetary gear speed reduction mechanisms of the torque directional distribution electric drive axle is determined, and feature parameters k3, (k4) and (k5) of each row are determined according to optimization targets, with the minimum feature parameter difference, of the planetary gear speed reduction mechanisms.

Owner:JILIN UNIV

A walking device for reducing the floor height between adjacent car bodies of an EMU

ActiveCN105460033BReduce vibrationLower center of gravityAxle-box lubricationRailway couplingsBogieCommon framework

The invention belongs to the field of connection systems for every two adjacent carriages of a railway vehicle and relates to a traveling device used between adjacent train bodies of a motor train unit and capable of reducing the floor height. The traveling device is a low-gravity-center compact common bogie of a brand new form. An oil damper of the traveling device is used for restraining relative rolling pendulum vibration between the top of a carriage A and the top of a carriage B. The two ends of a common connecting device are fixed to underframe end beams of the two adjacent carriages respectively. Four air spring installation positions arranged on two sides are uniquely arranged on a common framework so as to contain sleeper beam middle through grooves. Under the condition that the existing fixed distance of each carriage of the motor train unit is kept unchanged, the traveling device can reduce the total number of bogies of the motor train unit and reduce the manufacturing cost of the motor train unit; moreover, while the un-obstruction performance of the interior floor of the motor train unit is improved, the overall gravity center and the floor height of the motor train unit are lowered, and passengers can conveniently get on or off the motor train unit. In addition, the traveling device remarkably improves the bend curve passage capacity and the turning maneuvering performance of the motor train unit.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Adjustment Method and Structure of Vertical Stiffness of Primary Suspension Device

ActiveCN111071278BImprove abilitiesImprove cornering maneuverabilityBogiesAxle-boxes mountingBogieEngineering

The invention provides a method and a structure for adjusting the vertical rigidity of a primary suspension device. The primary suspension device comprises a base, conical springs and limiting stoppers, each conical spring comprises a rubber body and a mandrel, a stopping hole is formed in the lower end of a bogie, the upper end of the mandrel is installed in the stopping hole of the bogie, and cavities are formed in the rubber body and the mandrel; the two conical springs are arranged in the base side by side in the longitudinal direction, the limiting stoppers are arranged in the cavities ofthe conical springs, each limiting stopper comprises a stop base and a stop rod, and the stop rod is integrally formed above the stop base; and an axle box is provided with an axle box seat, the baseis installed in the axle box seat, and when the bogie moves relative to the axle box in the vertical direction and the lower end of the mandrel abuts against the stop seats in the vertical direction,the primary suspension device can generate variable rigidity in the vertical direction. The capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of the bogie is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Electric differential mechanism with torque directional distributing function

ActiveCN106884958ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a torque directional distributing function. The electric differential mechanism comprises a main drive mechanism, a bevel gear differential mechanism, a TV control drive mechanism used for outputting control power, a first single-row planet gear train, a second single-row planet gear train and a third single-row planet gear train. A first sun gear is supported on a first half shaft through a bearing, a first gear ring is coaxially and fixedly connected with the first half shaft, and a first planet carrier is connected with the control output end. A second planet carrier is fixed to a drive axle housing, and a second sun gear is fixedly connected with the first sun gear. A second sun gear is supported on the first half shaft through a bearing. A third sun gear is fixedly connected with a second inner gear ring, a third planet carrier is fixedly connected with a differential mechanism shell, and a third gear ring is fixedly connected with the first half shaft. The second single-row planet gear train and the first single-row planet gear train are the same in characteristic parameter. According to the electric differential mechanism, the drive torque of an automobile can be directionally distributed to wheels on the left side and the right side according to the control requirement of the control logic.

Owner:JILIN UNIV

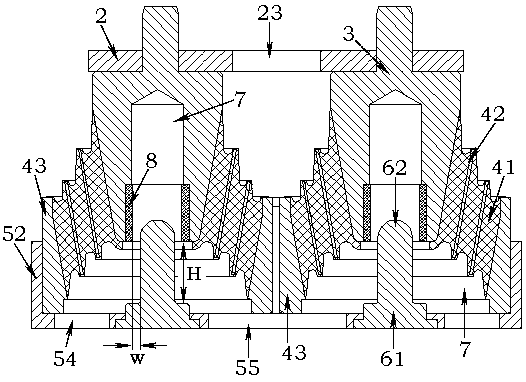

Lightweight axle box built-in primary suspension device and lightweight design method

ActiveCN111055869AImprove cornering maneuverabilityIncrease flexibilityBogiesAxle-boxes mountingBogieSuspension (vehicle)

The invention discloses a lightweight axle box built-in primary suspension device and a lightweight design method. An axle box seat is arranged on an axle box of a vehicle, a stop hole is formed in the lower end of a bogie, the lower end of the primary suspension device is installed in the axle box seat, and the upper end of the primary suspension device is installed in a stop hole of the bogie. According to the invention, the capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of thebogie is reduced. The minimum curve passing radius of the bogie of the vehicle is remarkably reduced compared with that of a common bogie, so that the turning maneuverability and flexibility of the bogie are greatly improved, and the loading capacity, the dynamic performance and the critical speed of the whole vehicle are improved.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Electric differential mechanism with torque directional distribution function

ActiveCN107061680ASolve the disadvantages of "differential speed is not bad"Realize the function of unequal distributionDifferential gearingsControl powerGear wheel

The invention discloses an electric differential mechanism with a torque directional distribution function. The electric differential mechanism comprises a main driving mechanism, a cone gear differential mechanism, a TV control driving mechanism; a first signal row of planetary gear system, a second signal row of planetary gear system, and a third row of planetary gear system, wherein the TV control driving mechanism is used for outputting control power; a first sun wheel is coaxially and fixedly connected with a first half axle, and a first gear ring is connected with a control output end; a second gear ring is fixed on a driving axle shell, and a second planetary rack is fixedly connected with a first planetary rack; a second sun wheel is supported on the first half axle by a bearing; a third sun wheel is fixedly connected with the second sun wheel, a third planetary rack is fixedly connected with the first half axle, and the third gear ring is fixedly connected with a differential mechanism shell; the second signal row of planetary gear system, and the first single row of planetary gear system have same characteristic parameters. According to the electric differential mechanism disclosed by the invention, driving torque of an automobile can be directionally distributed to a left-sided wheel and a right-sided wheel according to a control requirement of control logic.

Owner:JILIN UNIV

Electric differential with directional torque distribution function

ActiveCN107061674AImprove cornering maneuverabilityImprove driving pleasureDifferential gearingsTransaxleBrake force

The invention discloses an electric differential with a directional torque distribution function. The electric differential comprises a main driving mechanism, a bevel gear differential, a TV control driving mechanism, a first single-row planetary gear train, a second single-row planetary gear train and a third single-row planetary gear train, wherein the TV control driving mechanism is used for outputting control power; a first sun wheel and a first half shaft are coaxially and fixedly connected, and a first planetary carrier is connected with the control output end; a second planetary carrier is fixed to a driving axle shell, and a second gear ring is fixedly connected with a first gear ring; a second sun wheel is supported on the first half shaft through a bearing; a third sun wheel is fixedly connected with the second sun wheel, a third planetary carrier is fixedly connected with the first half shaft, and a third gear ring is fixedly connected with a differential shell; and the second single-row planetary gear train and the first single-row planetary gear train have the same characteristic parameters. According to the electric differential, the driving torque of an automobile can be distributed to wheels on the left side and the right side in a directional mode according to control requirements of the control logic.

Owner:JILIN UNIV

A kind of adaptive vehicle curve auxiliary control method, device, computer equipment and storage medium

ActiveCN111267853BImprove cornering performanceEasy corneringExternal condition input parametersSignalling/lighting devicesDriver/operatorIn vehicle

The invention provides an adaptive vehicle curve assist control method, device, computer equipment and storage medium. The method includes: step S10, identifying the type of the current curve according to the signal of the sensor of the vehicle, corresponding to the type of the curve, obtaining the lateral impact of the current vehicle according to the lateral acceleration; step S11, according to The lateral impact is calculated to obtain the expected longitudinal acceleration; step S12, according to the expected longitudinal acceleration and the current actual longitudinal acceleration, determine the current activation type of the curve assist control; step S13, according to the activation Type, cooperatively control the engine torque or / and ESC braking strength to achieve the desired longitudinal control of the vehicle in curves. The present invention can carry out certain vehicle longitudinal auxiliary control on the premise that the driver does not notice, so as to improve the dynamic performance of the vehicle when turning.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Rigidity adjusting method and structure of primary suspension device

ActiveCN110979376AImprove abilitiesImprove cornering maneuverabilityBogiesAxle-boxes mountingSuspension (vehicle)Engineering

Provided are a rigidity adjusting method and structure for conical springs of a primary suspension device. The primary suspension device comprises a base, conical springs and limiting stoppers. Each conical spring comprises a rubber body and a mandrel. Stopping holes are formed in the lower end of a bogie, and the upper ends of the mandrels are installed in the stopping holes of the bogie. Cavities are formed in the rubber bodies and the mandrels. The two conical springs are arranged in the base side by side in the longitudinal direction, one limiting stopper is arranged in a cavity of each conical spring, and the lower end of each limiting stopper is connected with the base. An axle box is provided with an axle box seat, and the base is installed in the axle box seat. When the bogie movesrelative to the axle box in the vertical direction and the lower ends of the mandrels abut against the limiting stoppers, the primary suspension device can generate variable rigidity in the verticaldirection. According to the invention, the capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of the bogie is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

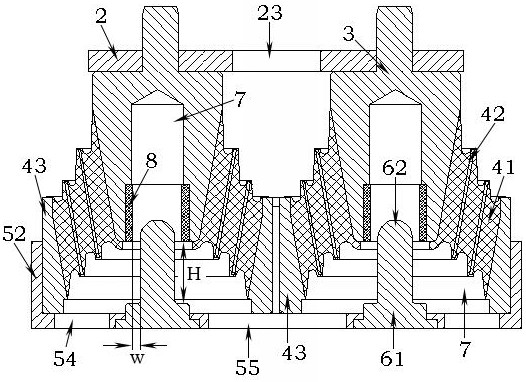

A lateral and longitudinal stiffness adjustment method and structure of a primary suspension device

ActiveCN111038545BImprove abilitiesImprove cornering maneuverabilityWheel axle self-adjustmentsBogieEngineering

The invention discloses a transverse and longitudinal rigidity adjusting method and structure of a primary suspension device. The primary suspension device comprises a base, a top plate, conical springs and a limiting stopper; cavities are formed in the conical springs; and the two conical springs are arranged between the base and the top plate side by side in the longitudinal direction. A limiting stopper is arranged in the cavity of each conical spring; the lower end of the limiting stopper is connected with the base; an axle box seat is arranged on an axle box, the base is installed in theaxle box seat, a stop hole is formed in the lower end of a bogie, the upper end of each conical spring further penetrates through the top plate to extend into the stop hole of the bogie, and when thebogie moves relative to the axle box in the transverse direction or the longitudinal direction and the limiting stop abuts against the inner sides of the conical springs, the primary suspension devicecan generate variable rigidity. According to the invention, the capacity of a vehicle for passing through a small-curvature-radius curve can be remarkably improved, the primary suspension space is greatly saved, and the weight of the bogie is reduced.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com