Lightweight axle box built-in primary suspension device and lightweight design method

A suspension device and lightweight technology, applied in the field of rail vehicles, can solve problems such as difficulty in adapting to mountains, and achieve the effects of reducing weight, improving capacity, improving load capacity, dynamic performance and critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

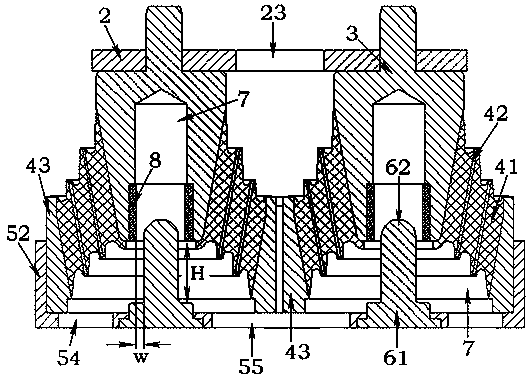

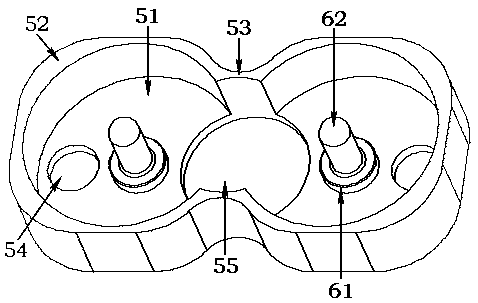

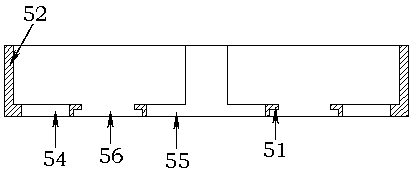

[0023] Such as figure 1 , figure 2 with Figure 5 As shown, a series of suspension devices includes a base 5 , a top plate 2 , a conical spring and a limit stop, wherein the conical spring includes a rubber body 41 , a mandrel 3 and a casing 43 . The lower end of bogie 1 is provided with a stopper hole 11, a single conical spring is a rotating body, and two conical springs are arranged side by side along the longitudinal direction between the base 5 and the top plate 2, and the upper end of the mandrel 3 of the conical spring is separated by a gap. Fitting way is installed in the stopper hole 11. In the middle part of the mandrel 3, the rubber body 41 and the overcoat 43, there are interconnected cavities 7, and the lower end of the limit stop is engaged in the bottom plate 51 at the lower end of the base 5 in an interference fit manner. The upper end extends into the cavity 7 opened in the middle of the mandrel 3 . The upper end and the lower end of the axle box seat 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com