Built-in axle box mechanism for axle box built-in bogies

A built-in, bogie technology, which is applied to axle boxes, axle box installation, railway car body parts, etc., can solve problems such as unfavorable bogie turning and speed increase, lack of built-in axle box mechanism, and insufficient compact structure, etc., to eliminate Fault or accident, improve turning maneuverability and agility, facilitate daily inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

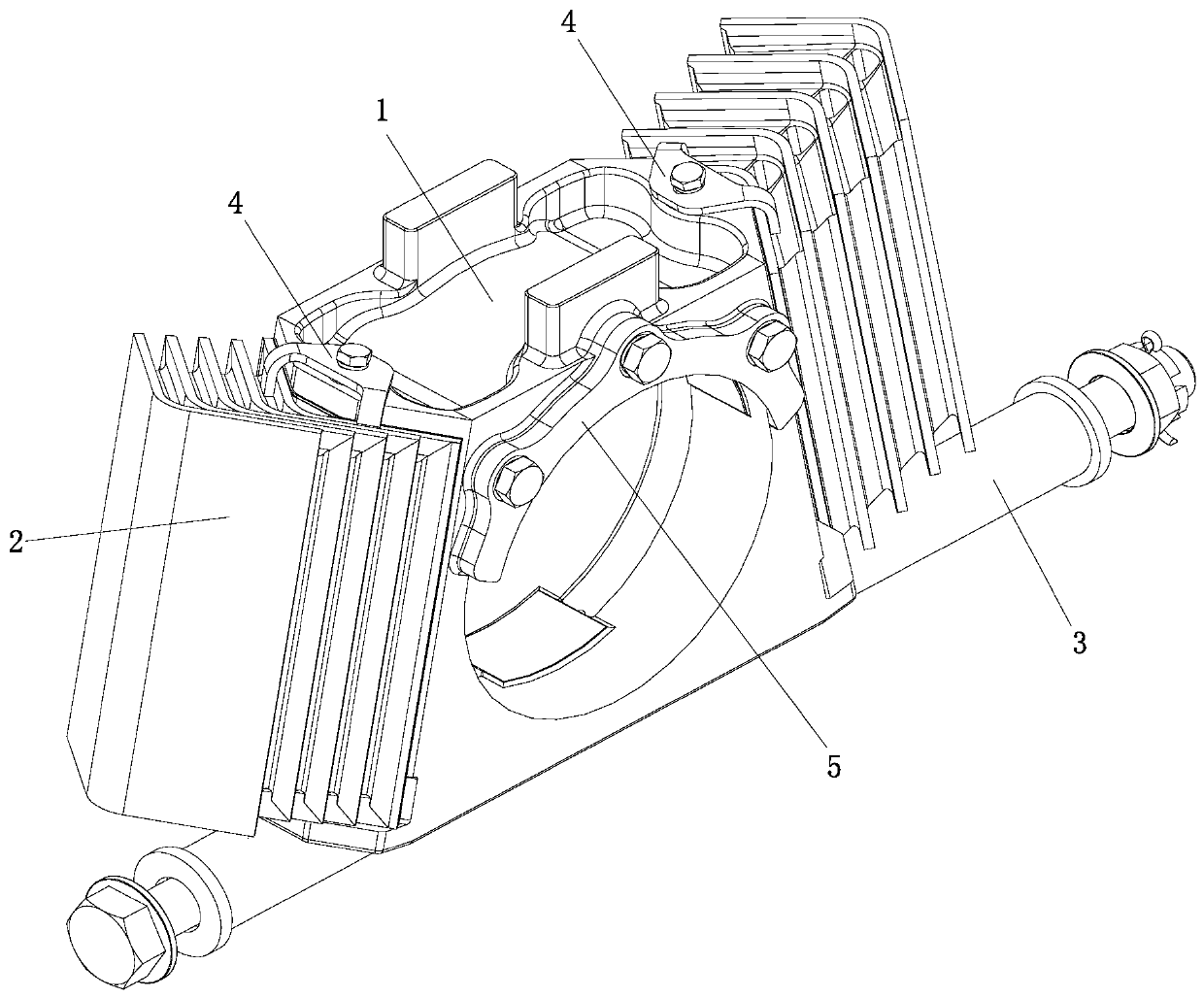

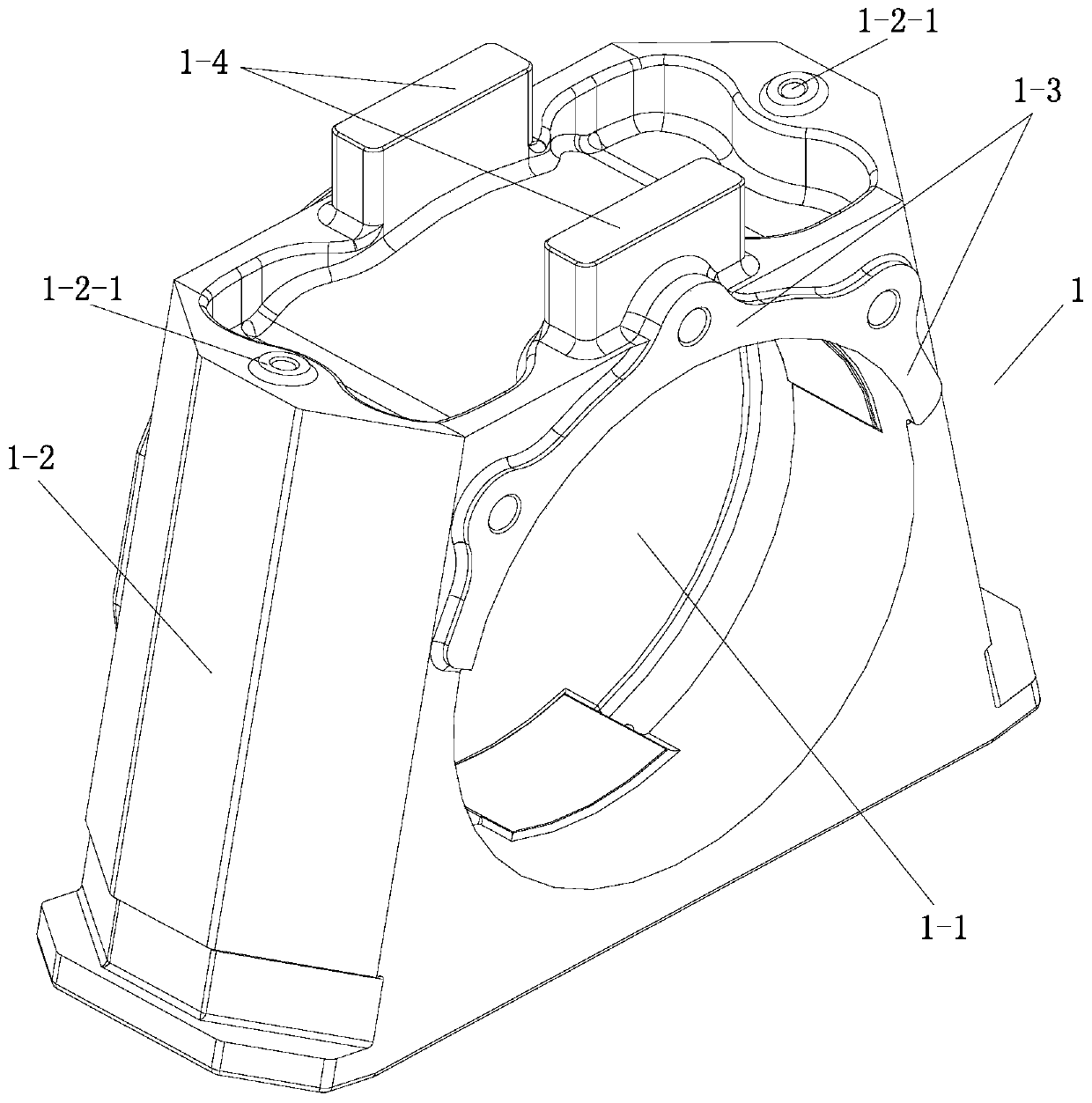

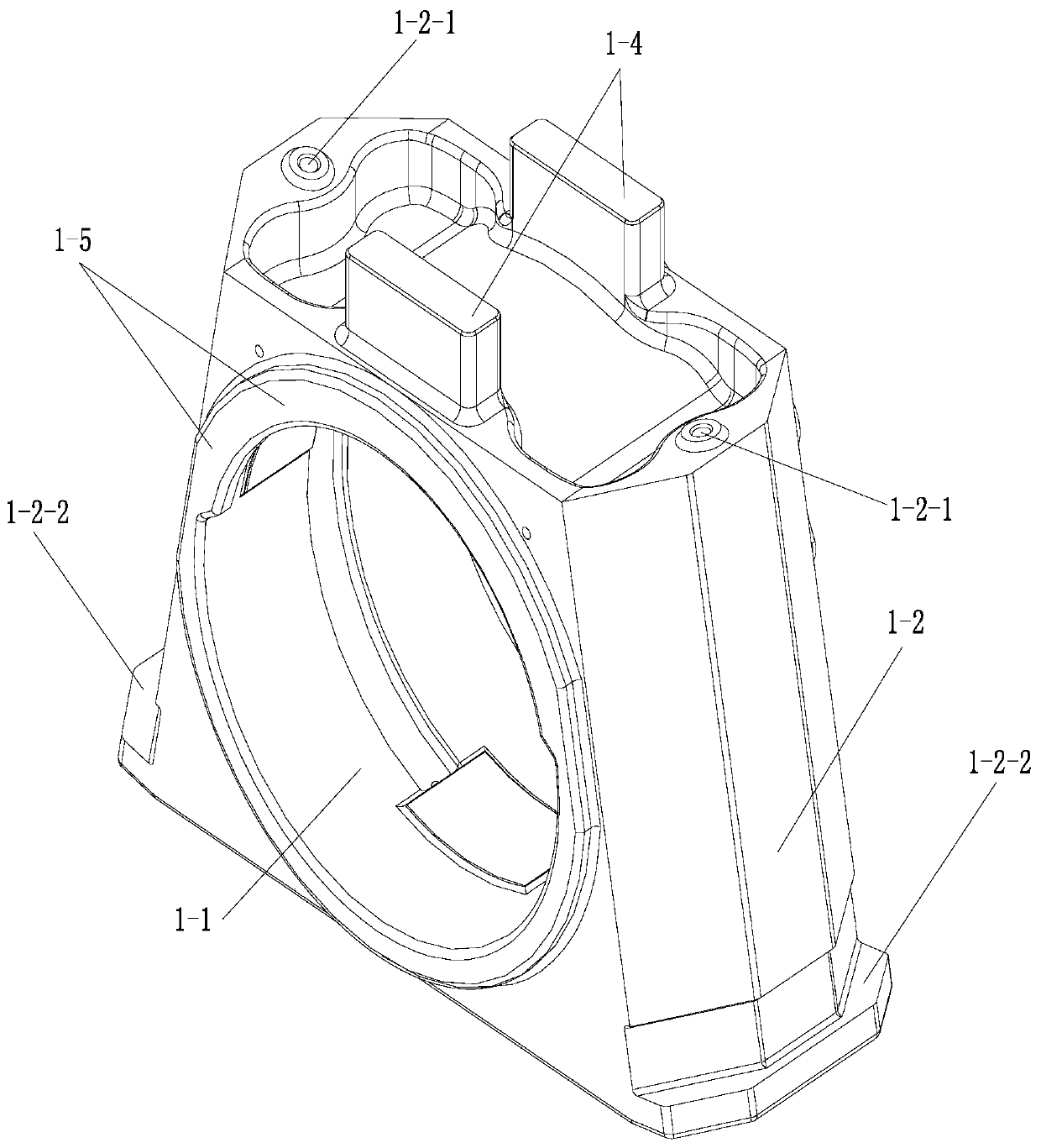

[0024] Such as Figure 1 to Figure 5 As shown, the built-in axle box mechanism of the present invention for the axle box built-in bogie includes a trapezoidal axle box 1, two sets of roof-shaped rubber spring sheets 2, a positioning tow bar 3, two rubber spring sheet positioning clips 4 and half The ring-shaped axle box anti-collision gasket 5; the middle section of the positioning tow bar 3 is flexibly connected with the lower bottom surface of the trapezoidal axle box 1; A waistline of the trapezoidal axle box 1; the lower end of the rubber spring positioning clip 4 is fixedly connected with the upper bottom end of the trapezoidal axle box 1, and the rubber spring positioning clip 4 connects the corresponding group of roof-shaped rubber springs through its claws. The top of the sheet composition 2 is pressed obliquely outward along the waistline outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com