Patents

Literature

154results about How to "Eliminate failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

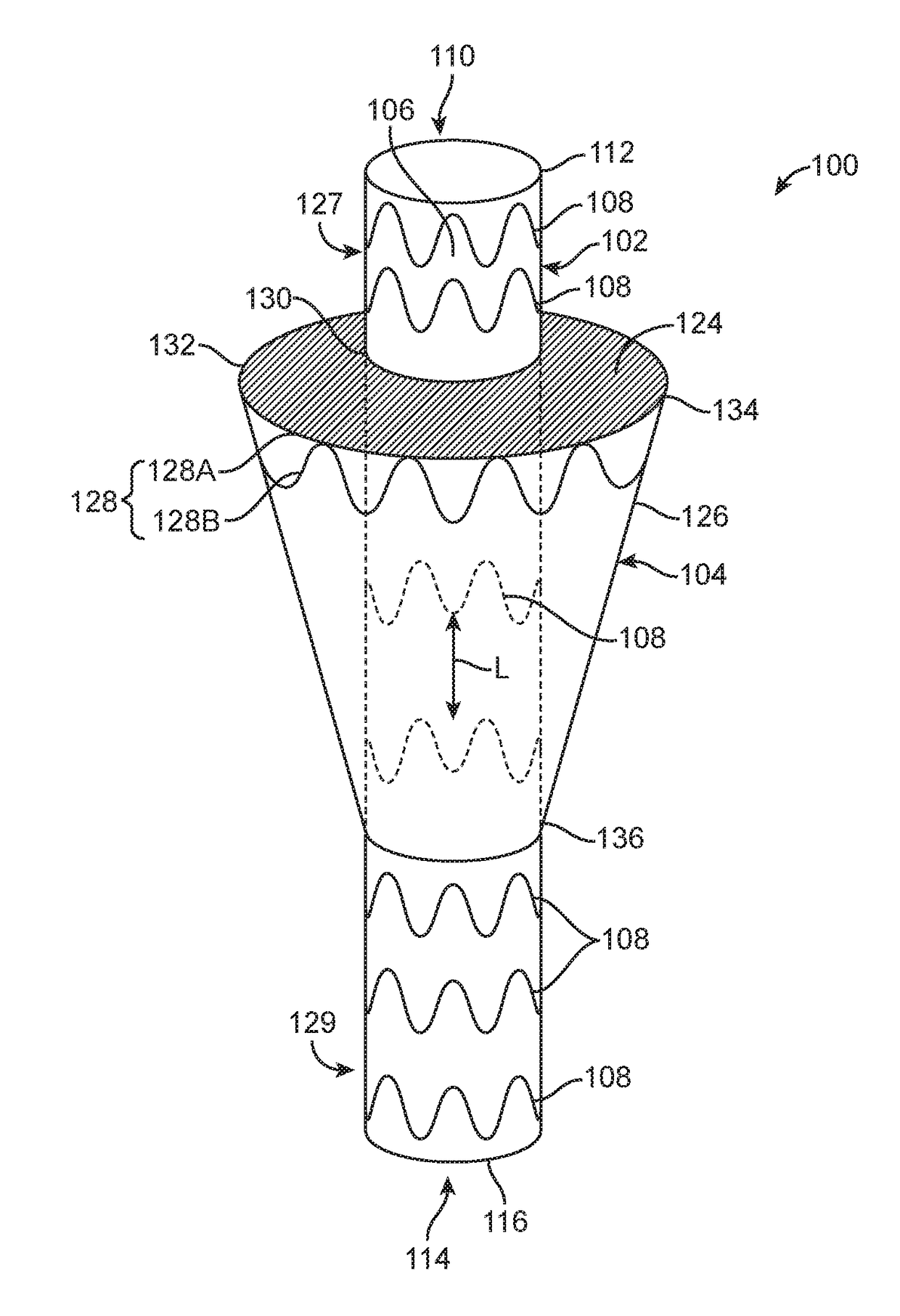

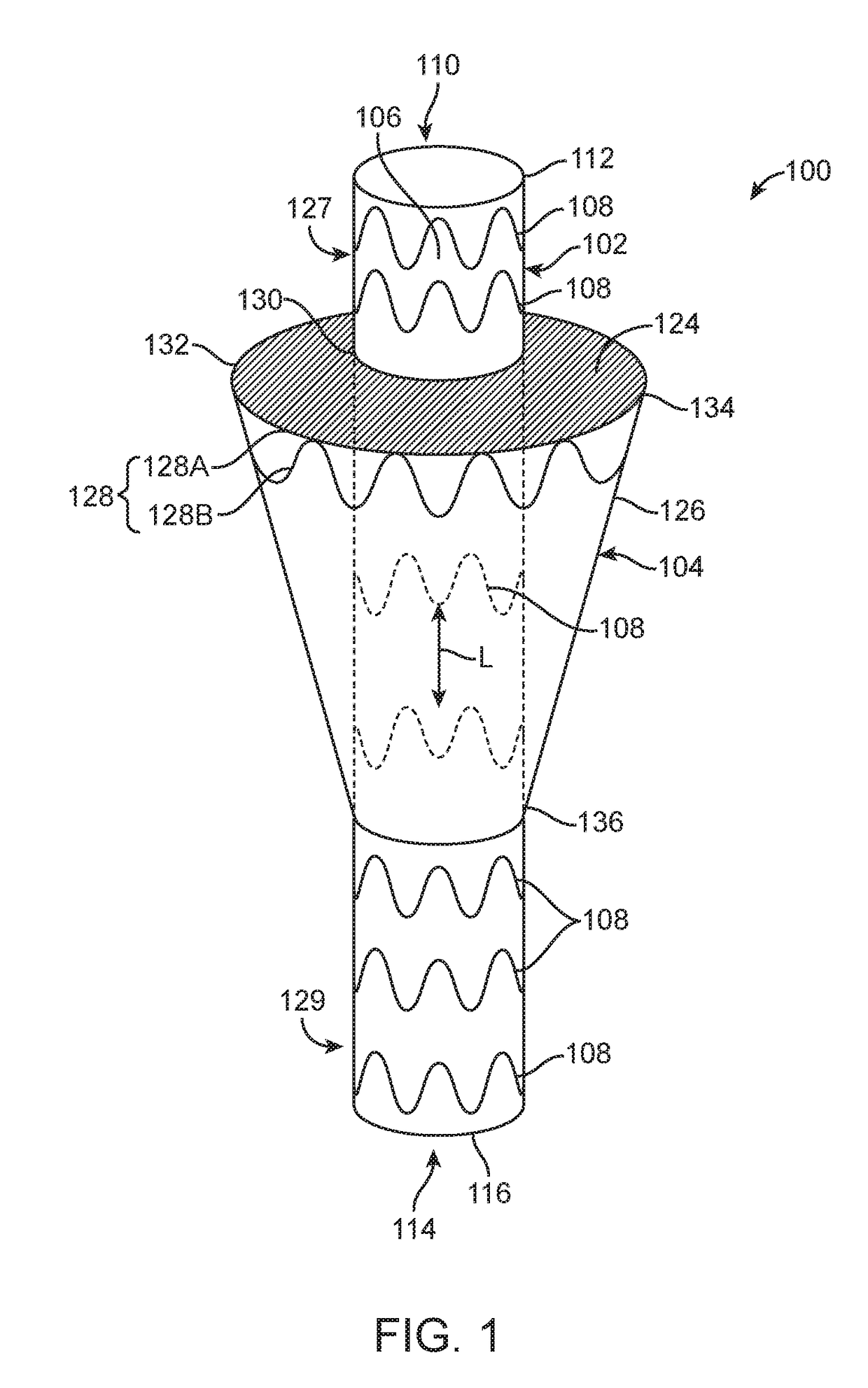

Gutter filling stent-graft and method

ActiveUS20170290654A1Minimizing chanceEliminate chanceStentsBlood vesselsStent graftingInsertion stent

A primary stent-graft is deployed into a primary vessel to exclude an aneurysm. To maintain perfusion to a branch vessel covered by the primary stent-graft, a gutter filling stent-graft is deployed in parallel to the primary stent-graft. The gutter filling stent-graft includes a balloon that is pressurized and inflated by the patient's own blood thereby sealing any gutters formed around the gutter filling stent-graft. By sealing the gutters, the chance of type I endoleaks, migrations, and overall failure to exclude the aneurysm is minimized.

Owner:MEDTRONIC VASCULAR INC

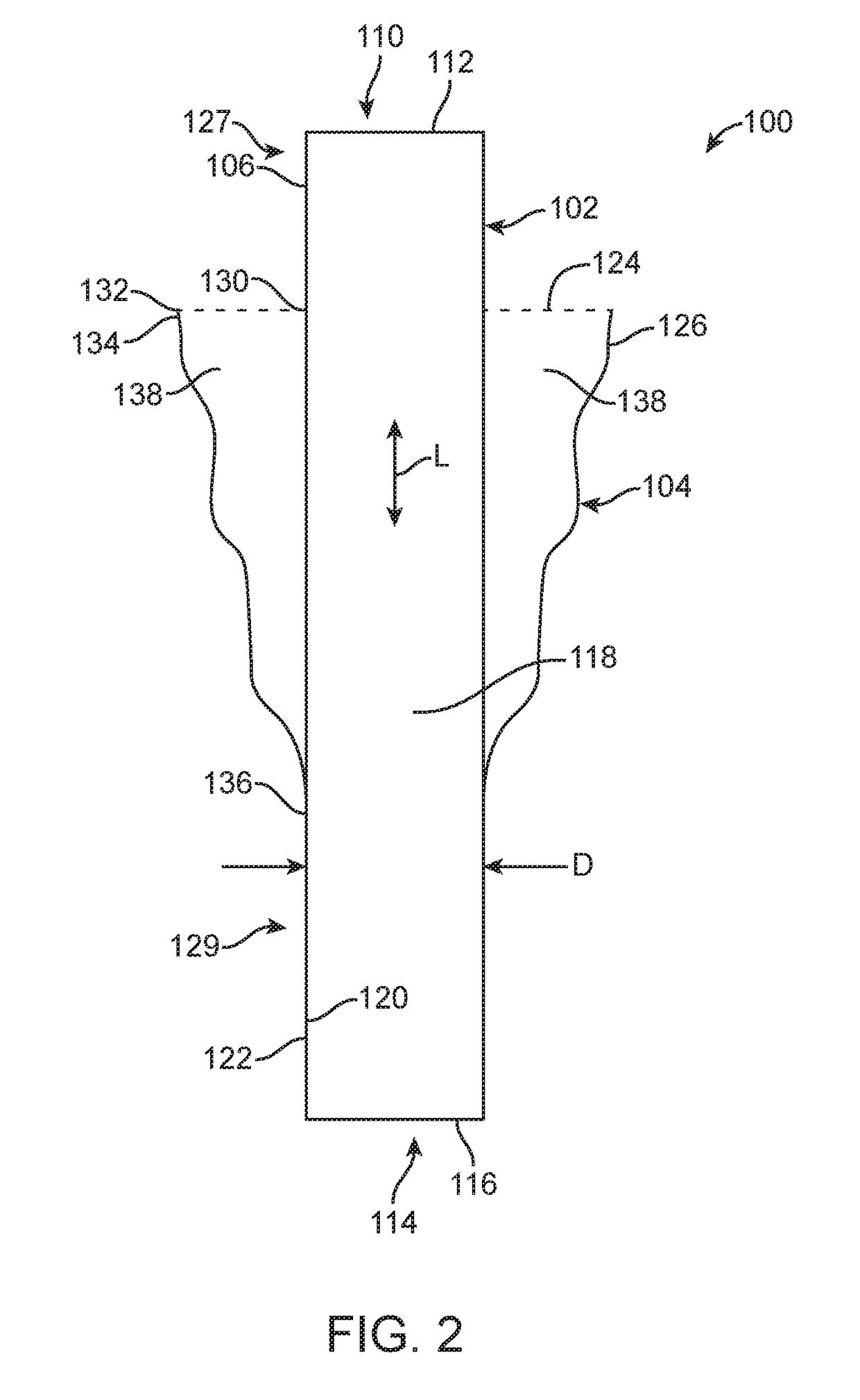

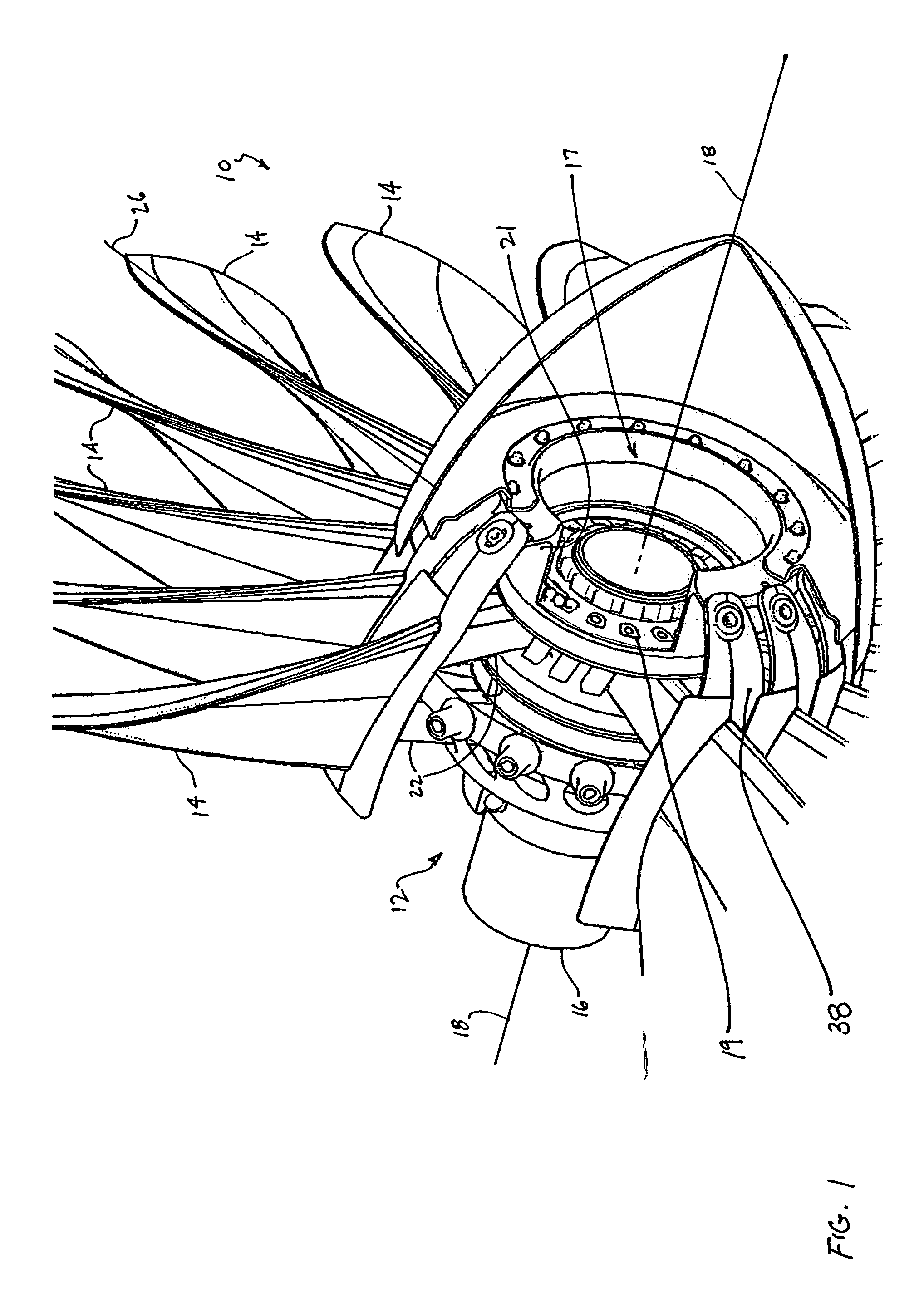

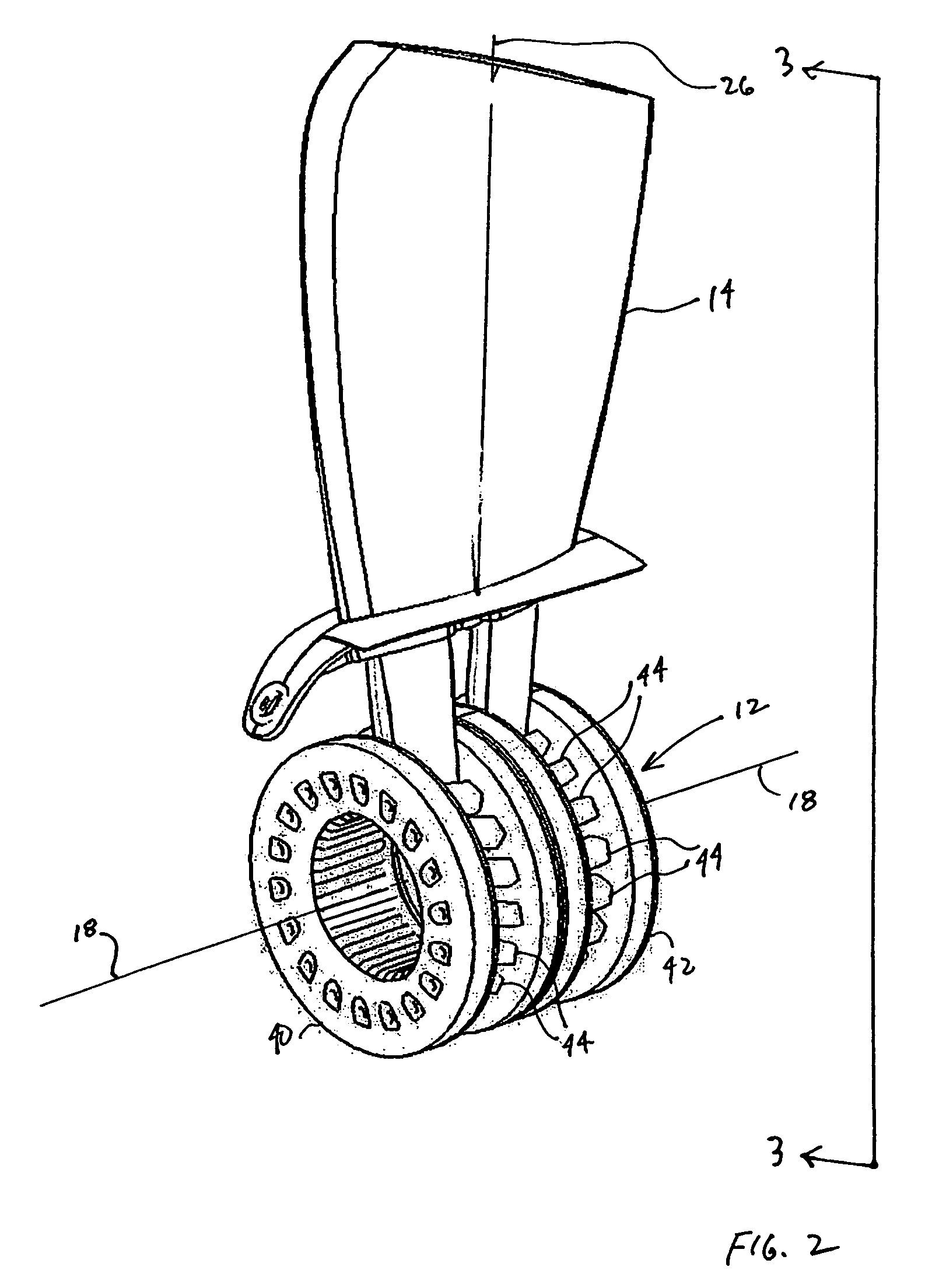

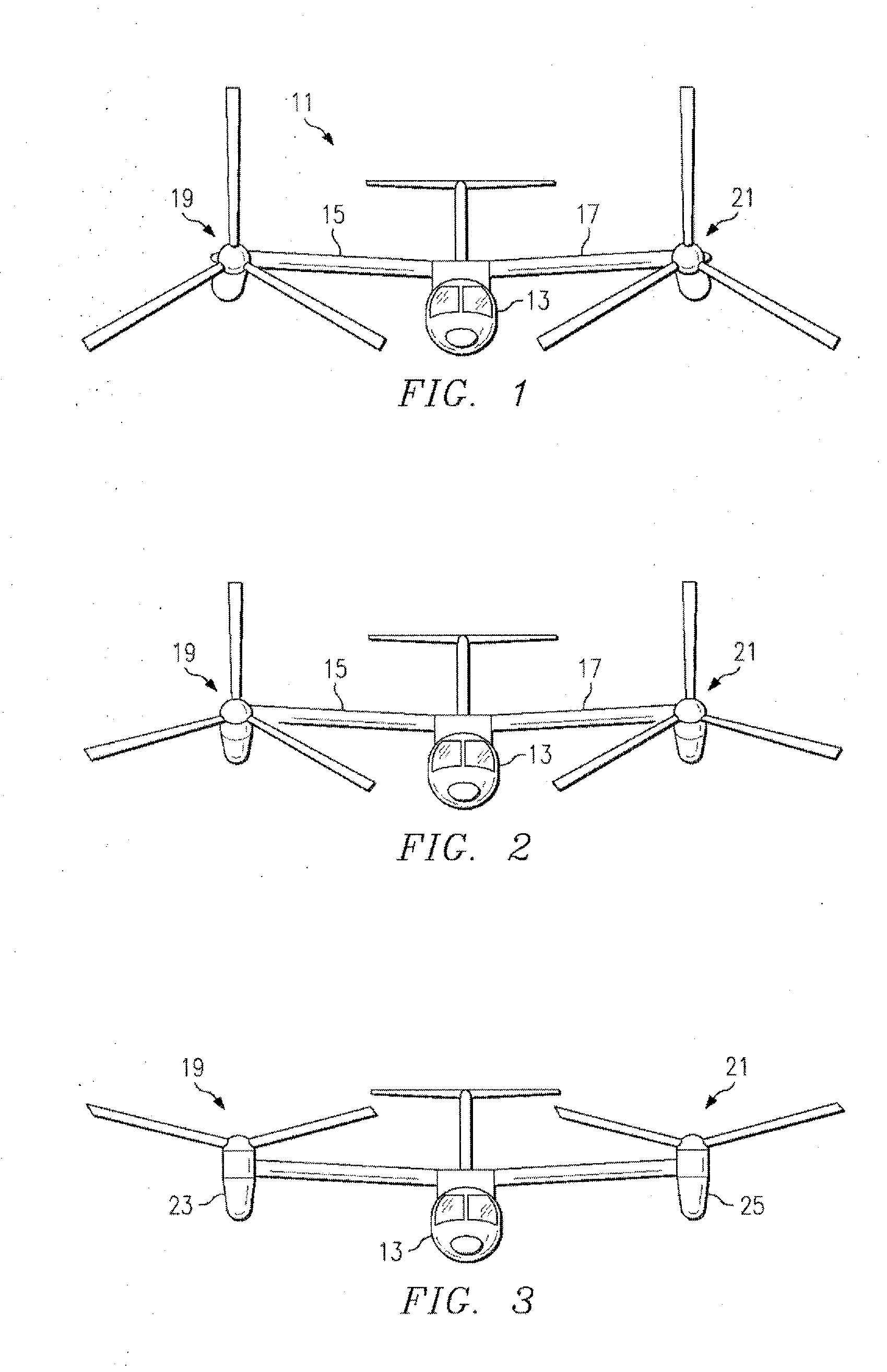

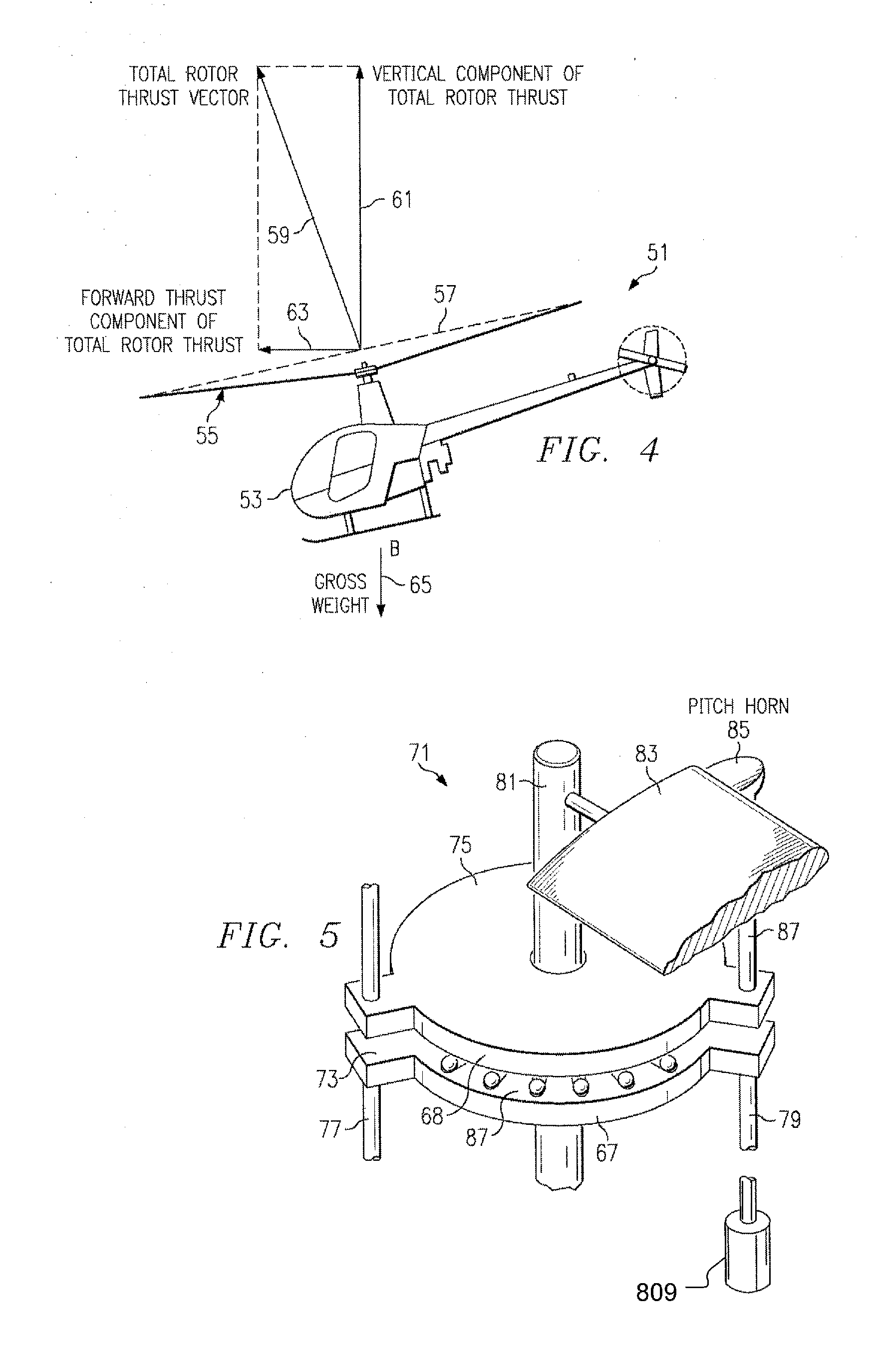

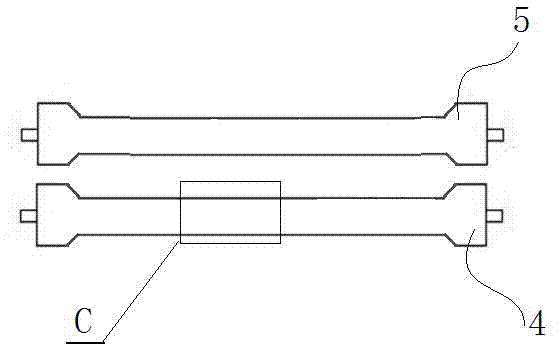

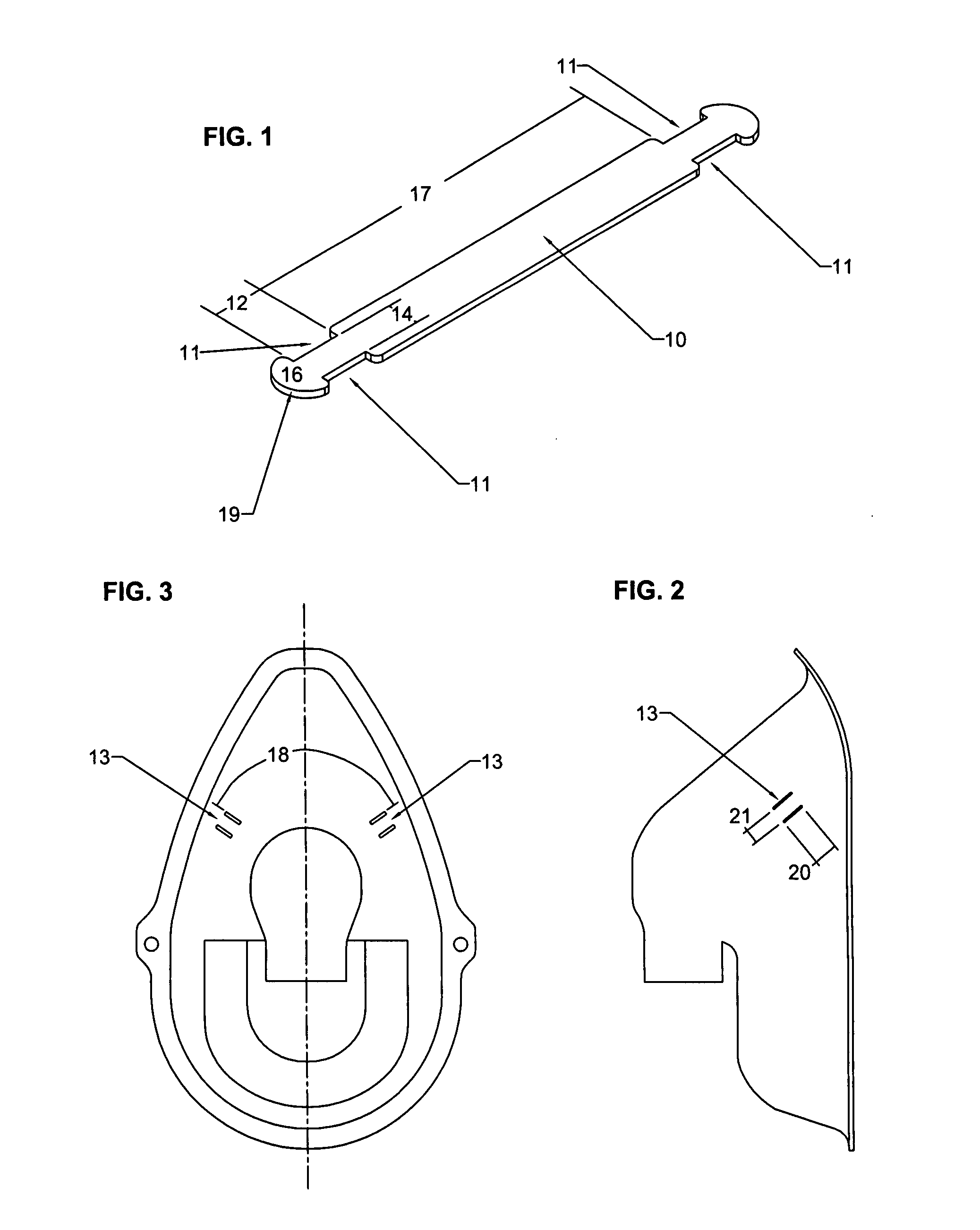

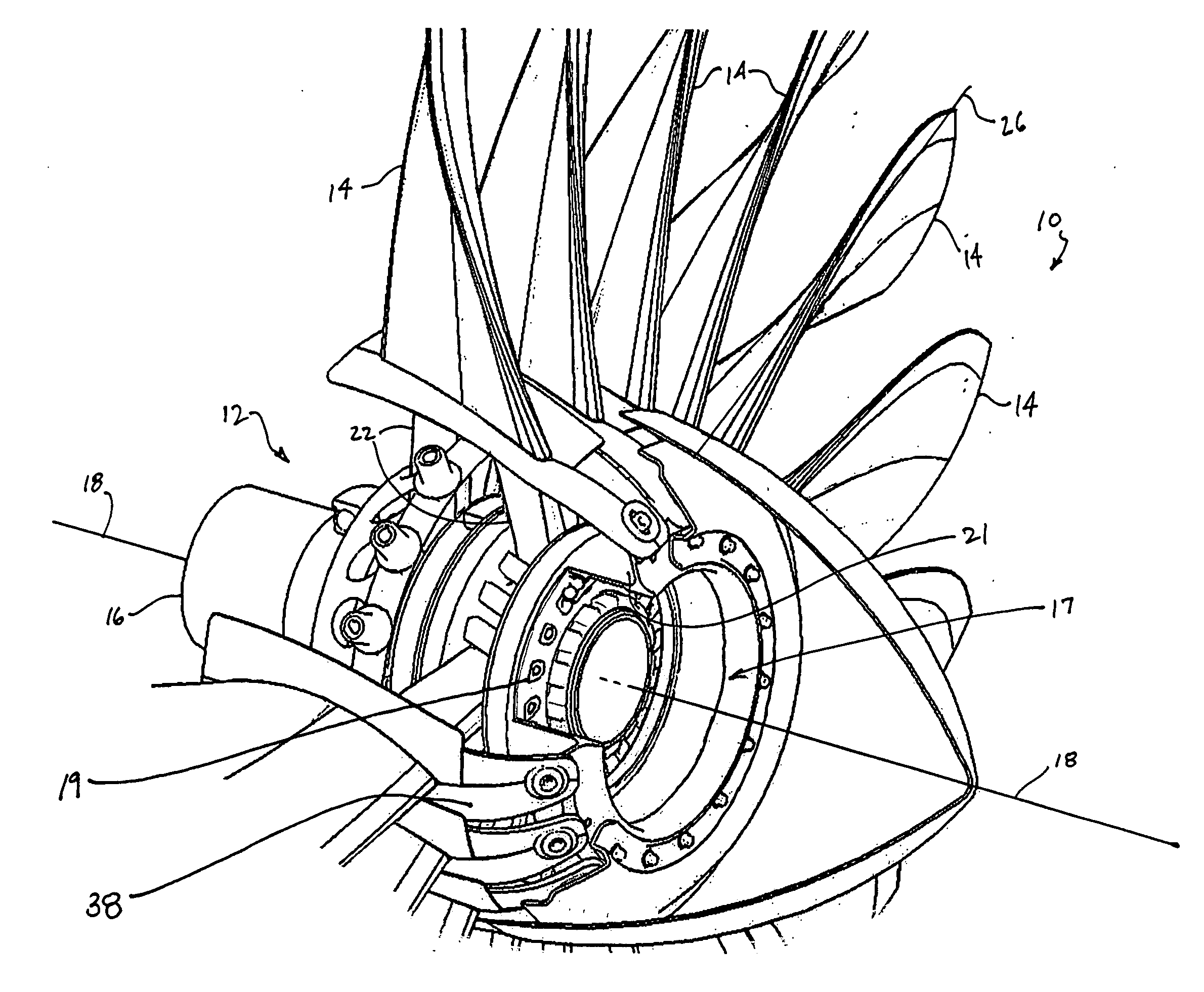

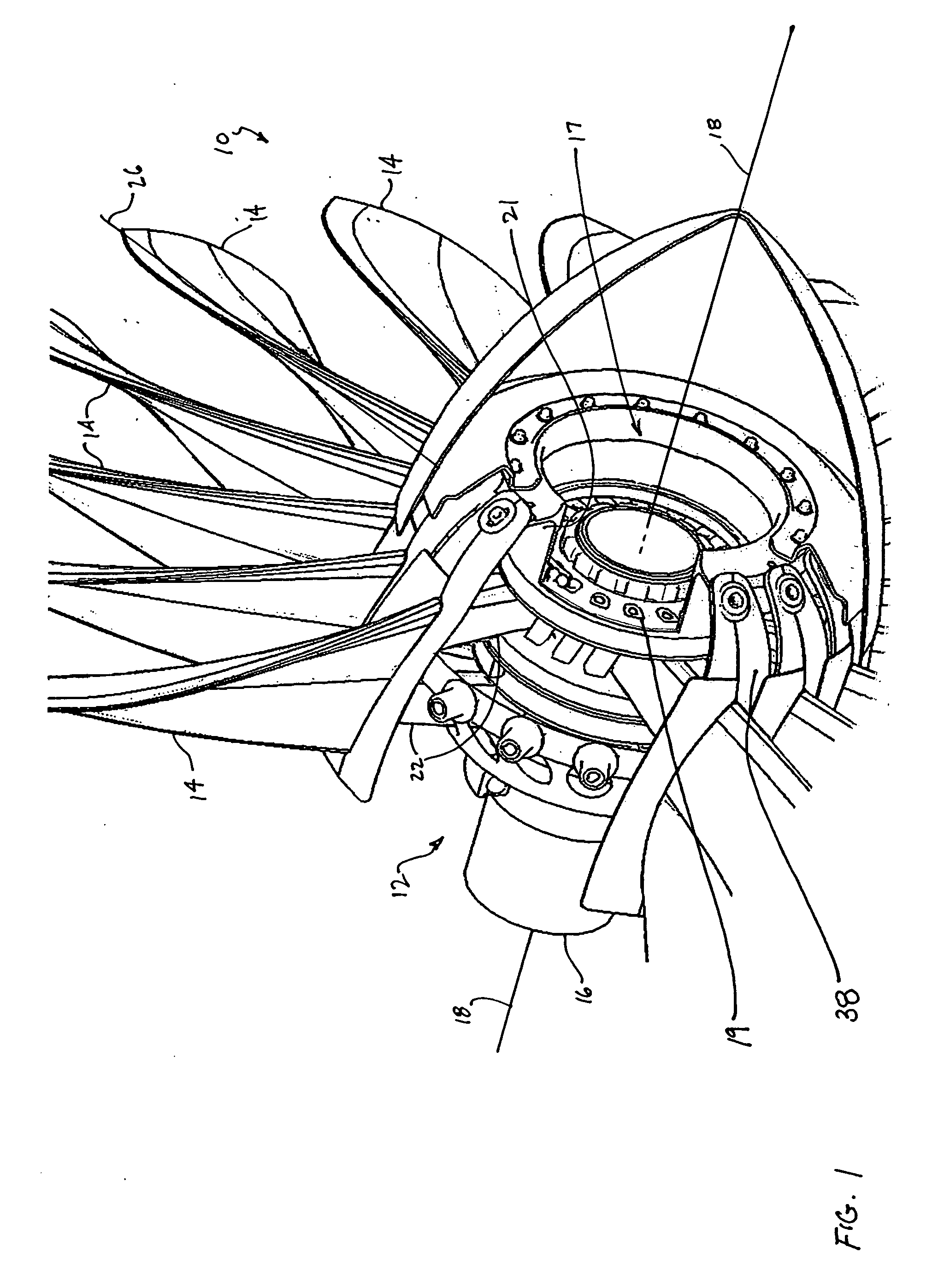

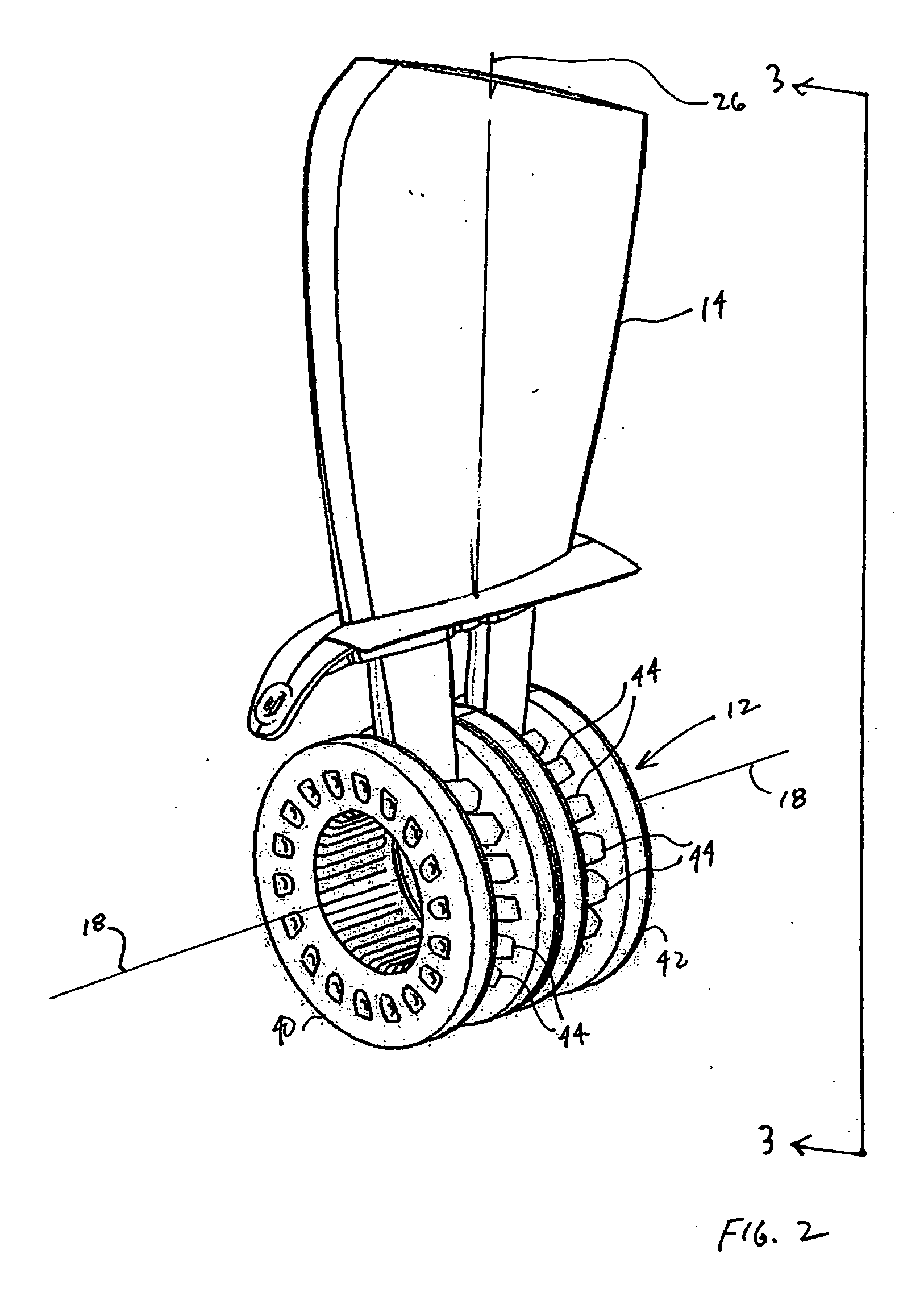

Variable pitch rotor blade with double flexible retention elements

A propulsive thrust device for an engine includes a rotor blade and a hub assembly on which the rotor blade is mounted. The rotor blade comprises an airfoil and at least two support members. A propeller thrust device includes a rotor blade, a central hub at which the rotor blade centrifugal load is supported, and an outer hub supporting a control mechanism mechanically connected to the rotor blade and controllable to vary the pitch of the rotor blade on the central hub. A rotor blade for an aircraft engine or in a separate ducted fan housing driven by a powered shaft or gearbox output shaft includes an airfoil and first and second support members attached to the airfoil. An extended arm or portion of the structure at the root of the airfoil of each blade is attached to a controllable mechanism that can vary the pitch of all blades simultaneously.

Owner:AEROCOMPOSITES +1

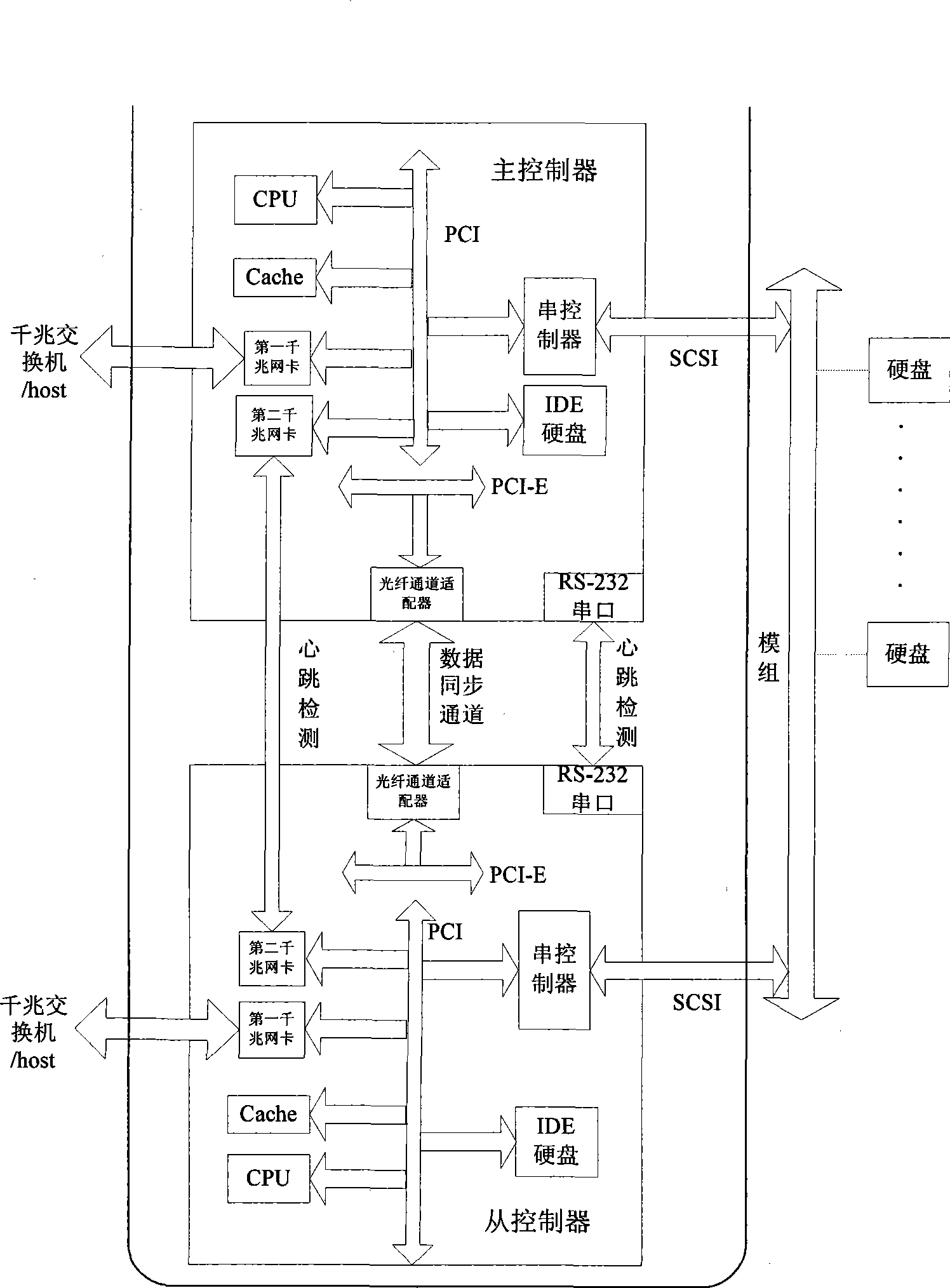

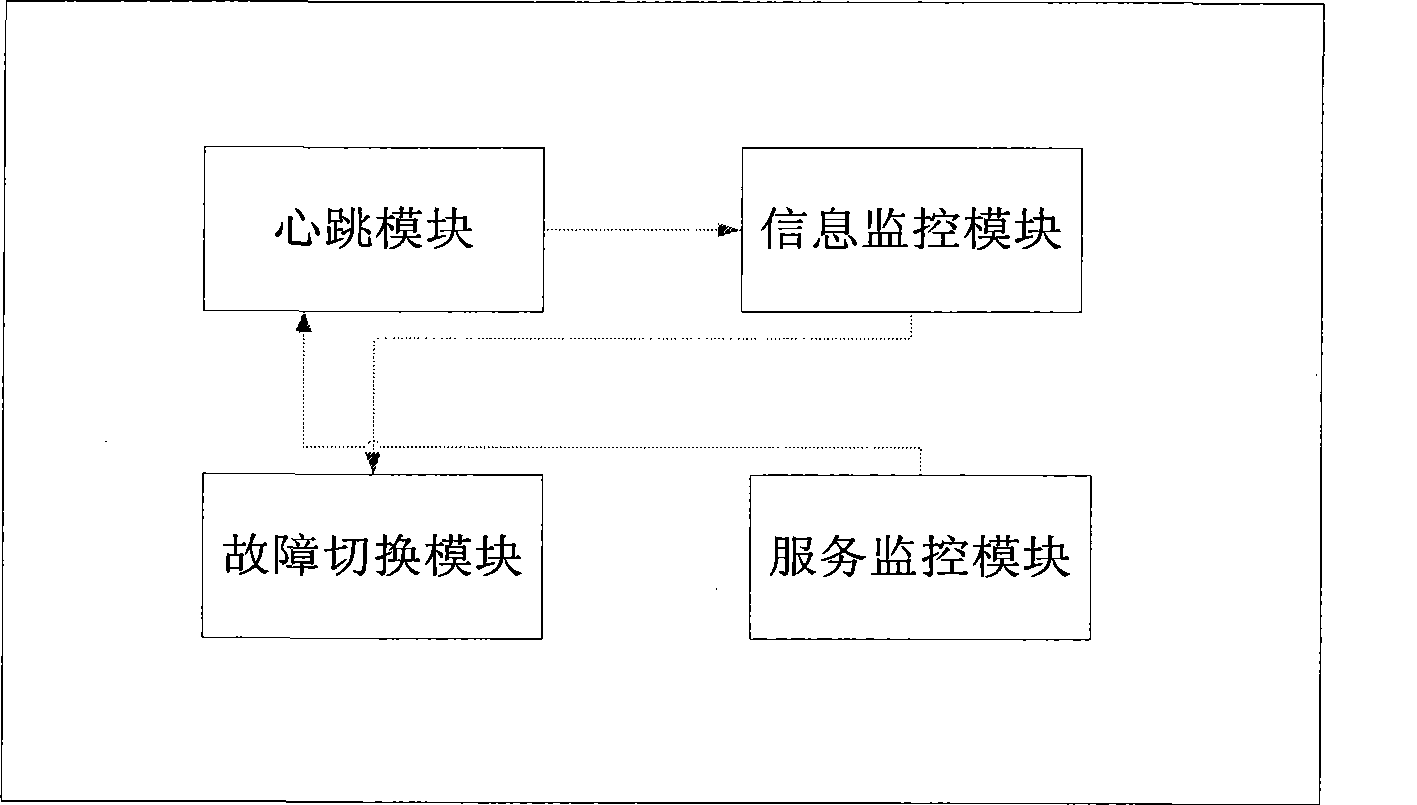

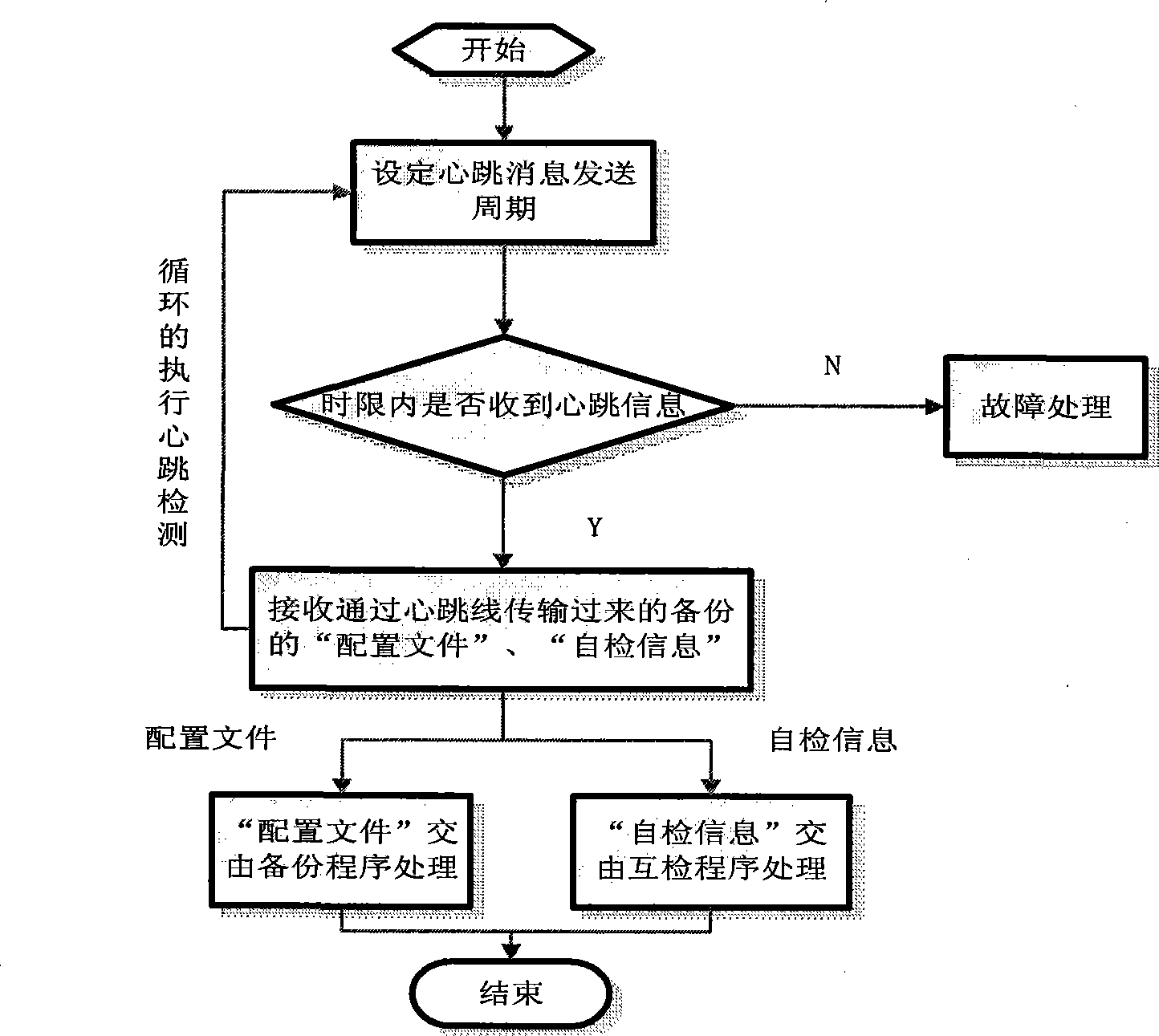

Dynamic fault detection system for dual controller disk array

ActiveCN101465769AEliminate failureSimplify the modeling stepsData switching networksData synchronizationPalpitations

Disclosed is a dynamic fault detection system for a double-controller disk array, belonging to computer storage technical field and solving the problems that a current fault detection system requires large amount of sample information or demands the sample to meet a specific probability distribution and is large in load of the storage system and complicated in calculation process and is unstable. The dynamic fault detection system consists of a primary controller and a secondary controller which are parallel; palpitation fault detection is carried out between the primary controller and the secondary controller through a second kilomega Ethernet interface and data synchronization is carried out between the primary controller and the secondary controller through an optical-fibre channel; and a palpitation module, an information monitoring module, a fault switching module and a service monitoring module are respectively loaded on the primary controller and the secondary controller. The dynamic fault detection system adopts double palpitation detection mechanisms to avoid single-point fault caused by failure of single palpitation detection. A dynamic palpitation setting mechanism is adopted, thus reducing the spending of the system; the fault switching process and the fault recovery process are totally transparent to the user; all the functional modules act on the application layer, so the system is easy to realize and use and has good flexibility and expansibility.

Owner:HUAZHONG UNIV OF SCI & TECH

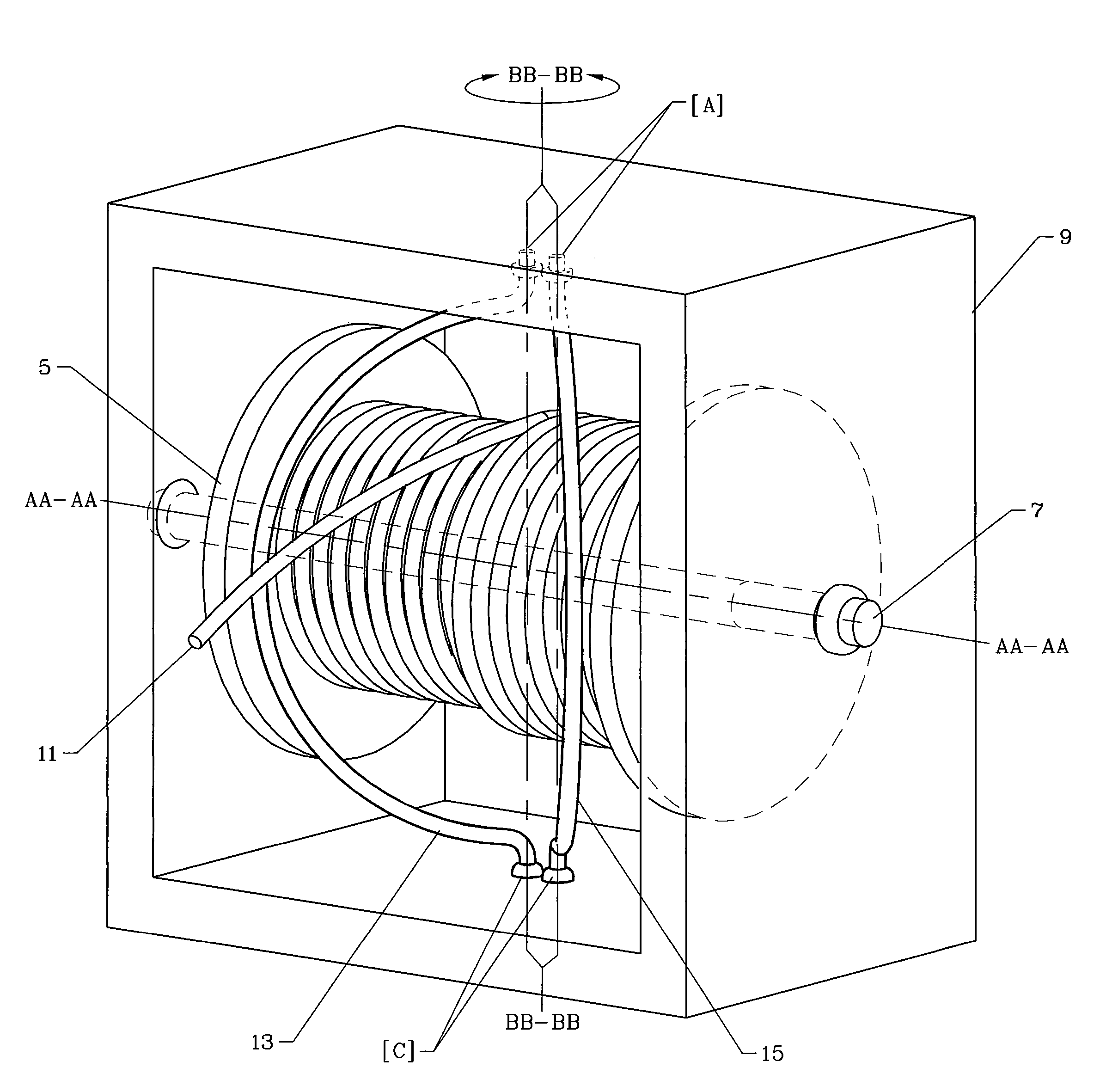

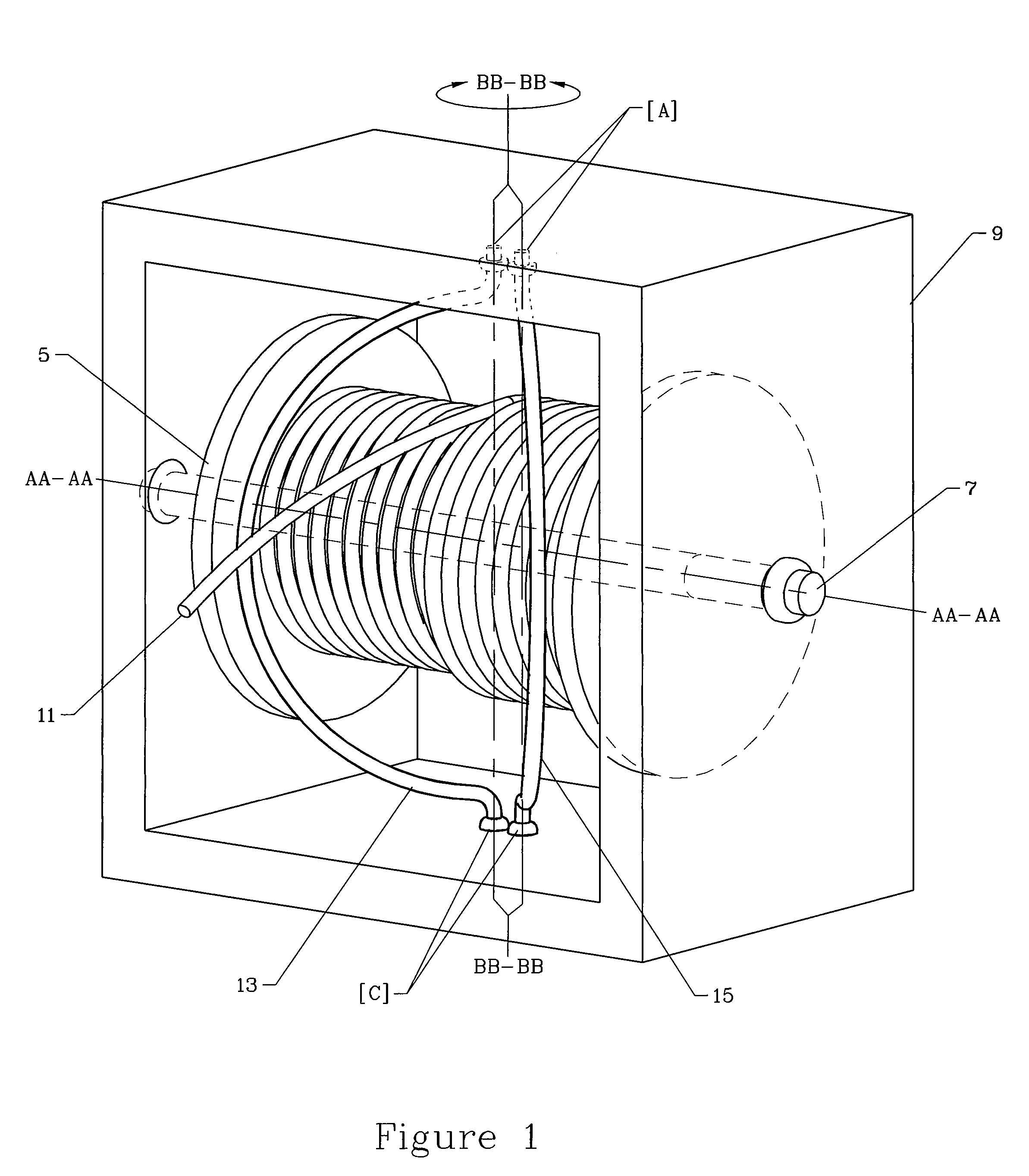

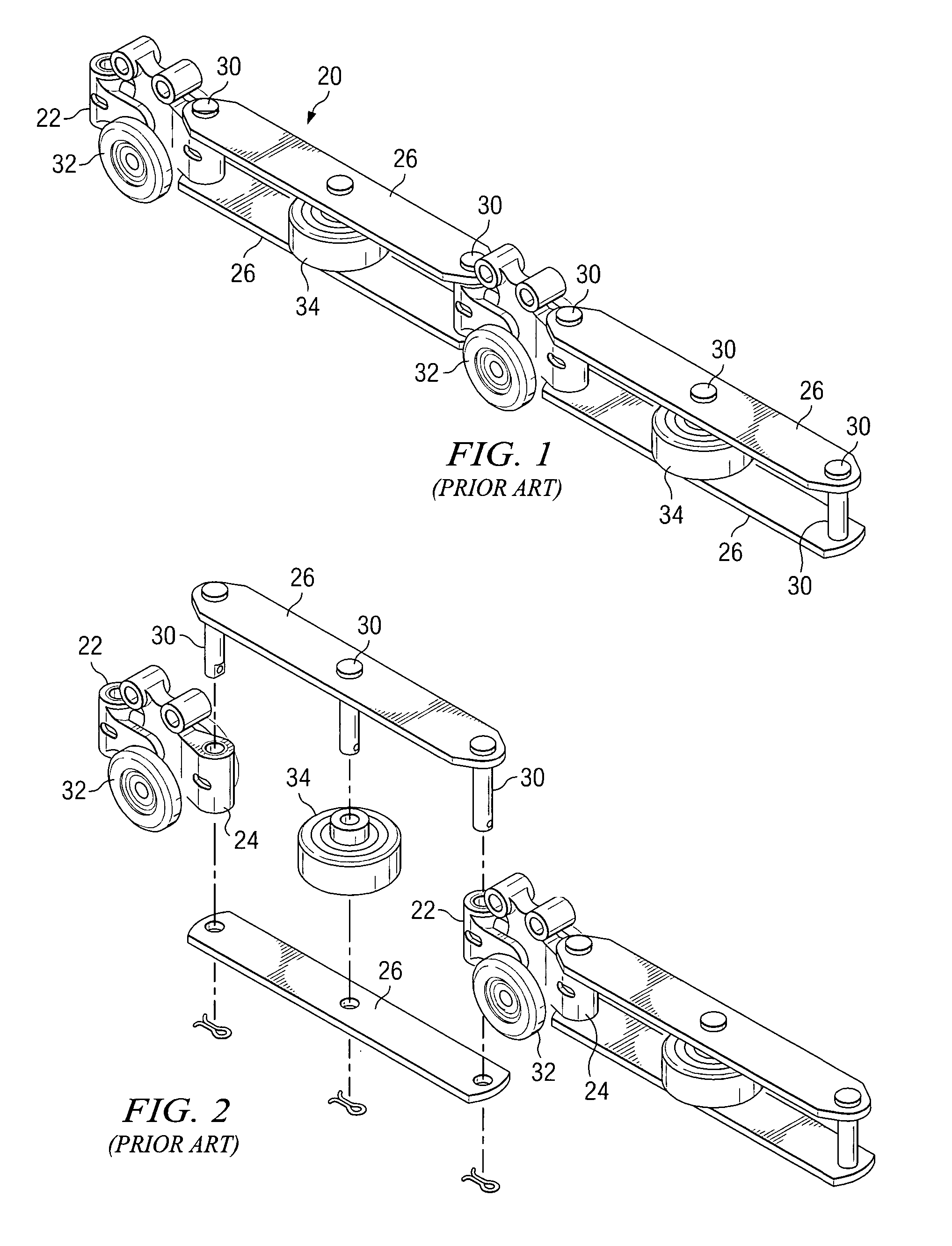

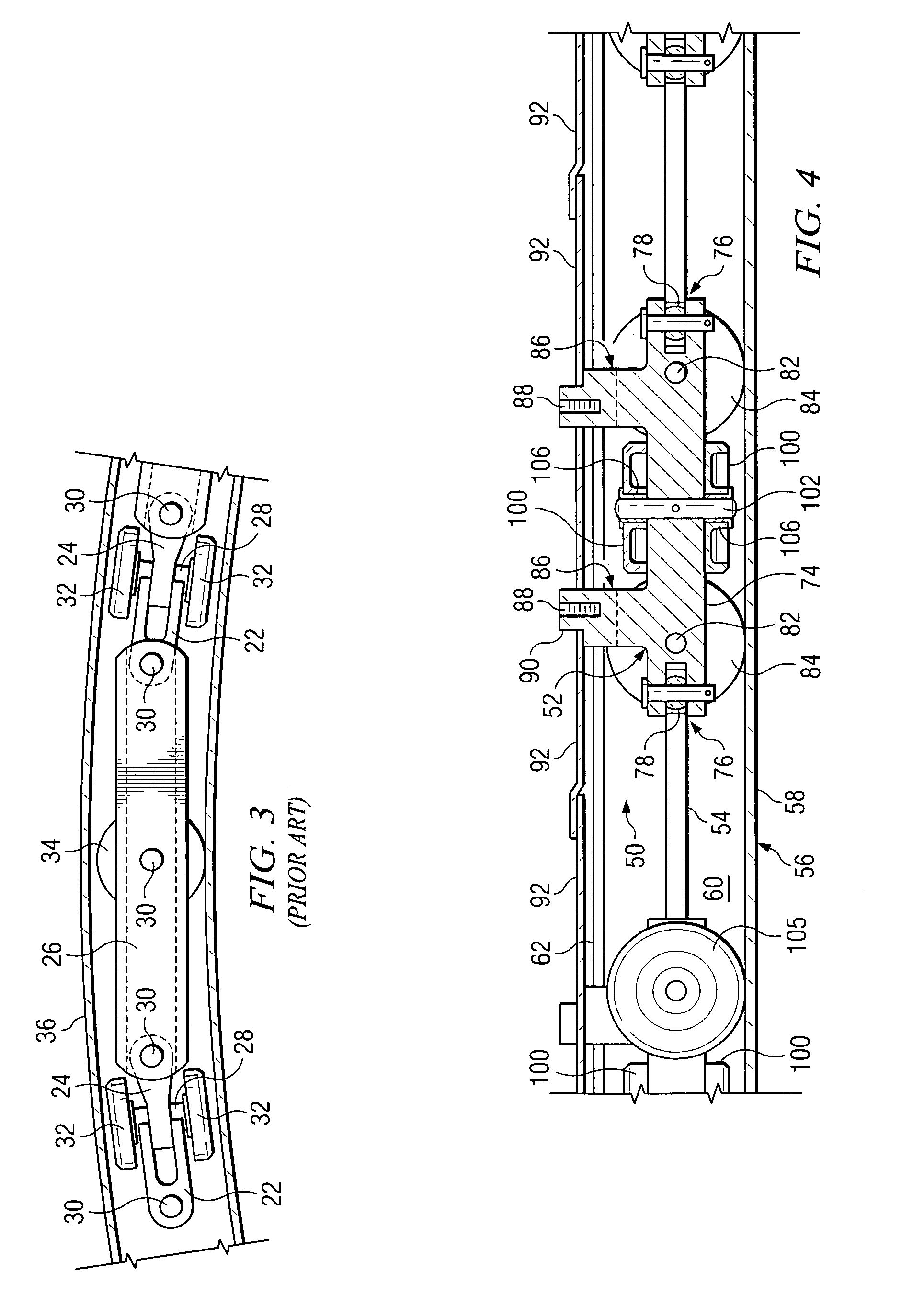

Level Wind Mechanism

InactiveUS20060237565A1Equally distributedEvenly distributedFilament handlingReelsMechanical engineeringDissemination

The present invention provides an alternate design for a level-wind mechanism that eliminates the requirement for the line to be threaded through an enclosed, or multiple device line guide. The present invention guides the line via an open slot created between one or more line guides that pivots about its supporting structure. The line guide(s) oscillate back and forth in concert across the axial length of the spool in order to evenly distribute the line that is being wound upon the spool. Further, the line guide is capable of being pivoted from a first position of line retrieve to a second position of line dissemination when it is desired to pay out the line from the spool.

Owner:KORE GEAR

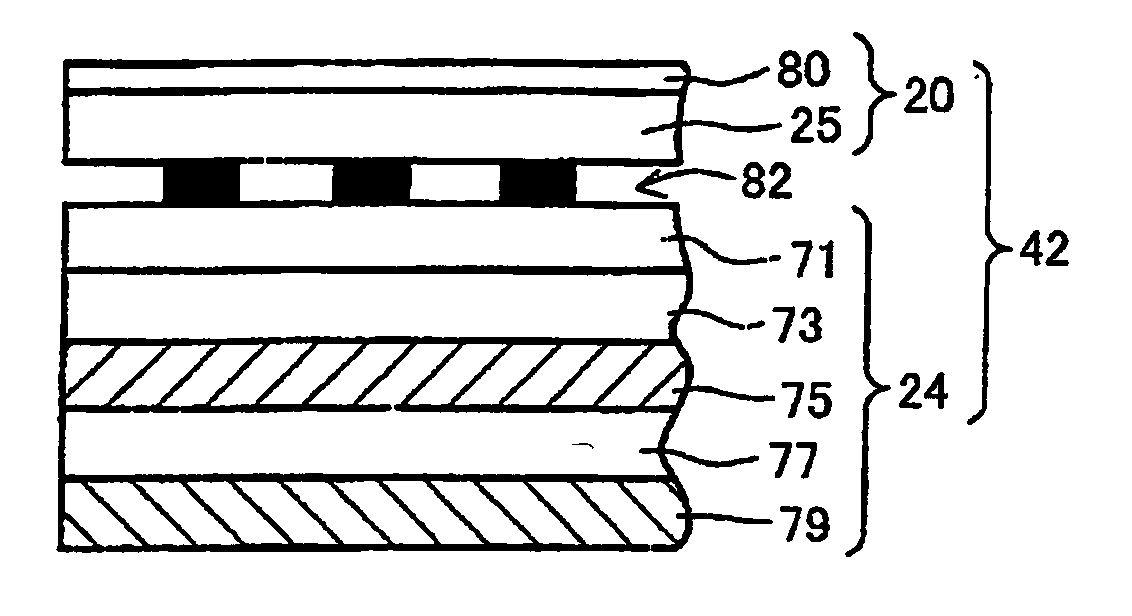

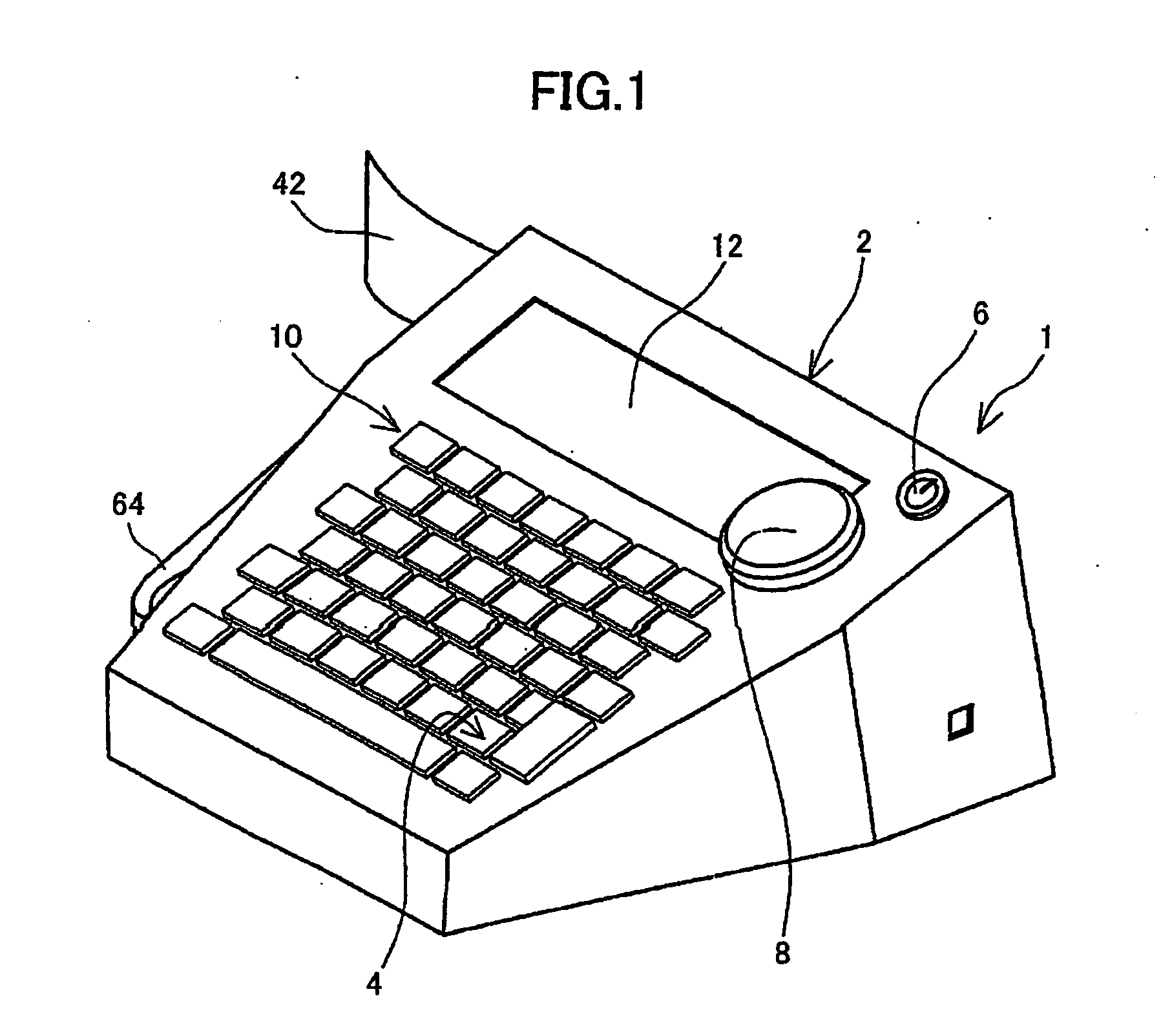

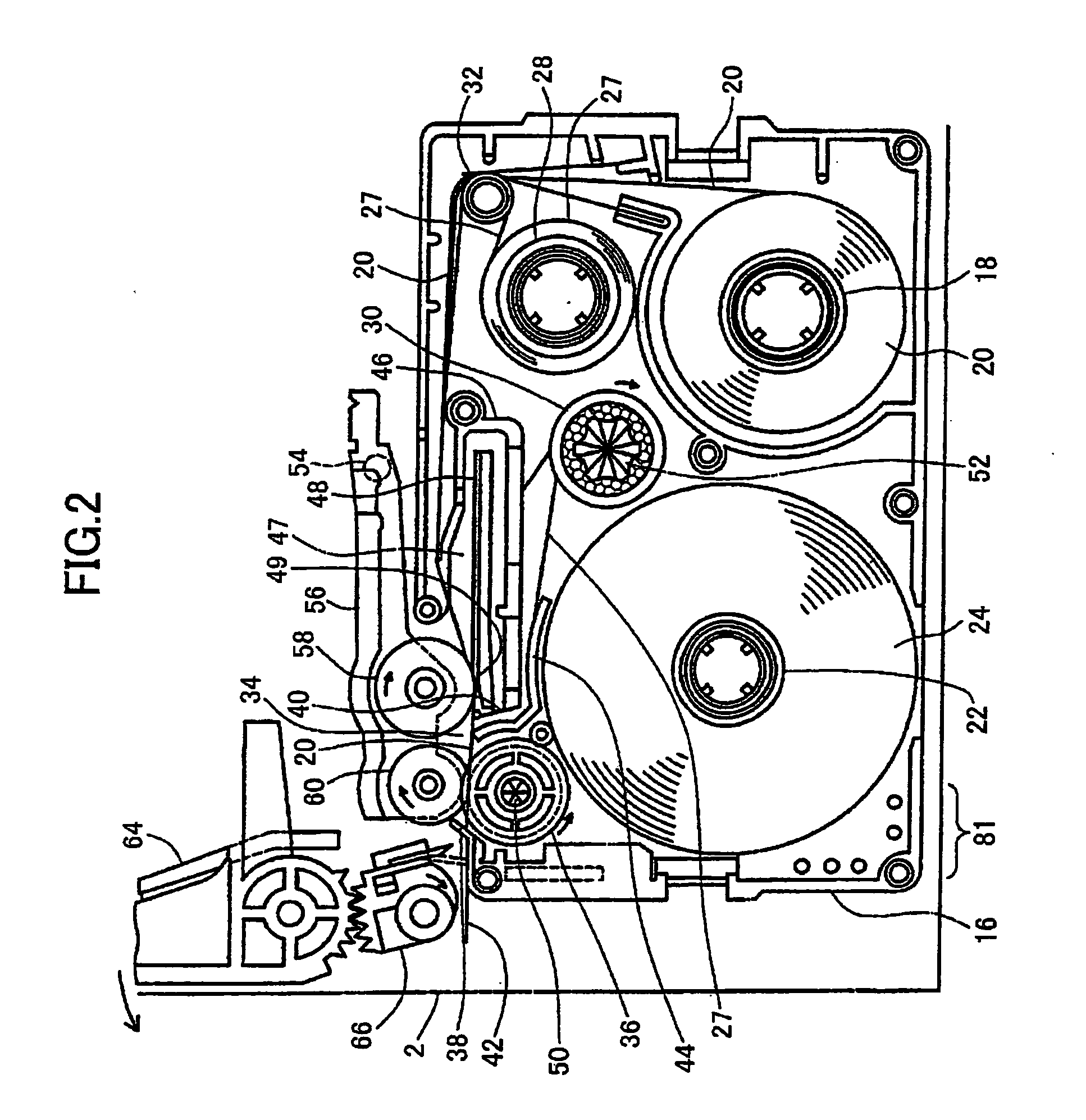

Temperature-indicating tape and device for creating labels using the same

InactiveUS20060121229A1Eliminate failureReliable printingLayered productsFilm/foil adhesivesEngineeringElectrical and Electronics engineering

A tape-like label forming device is capable of forming a label tape that is made up of a printing tape and a double-sided tape. A temperature-indicating material that changes color in response to changes in ambient temperature is applied to the surface of the printing tape. With this construction, since the color of the temperature-indicating material conceals the colors of the double-sided tape and characters such as letters and symbols printed on the underside of the printing tape, the colors of the characters and the double-sided tape can be freely selected and combined.

Owner:BROTHER KOGYO KK

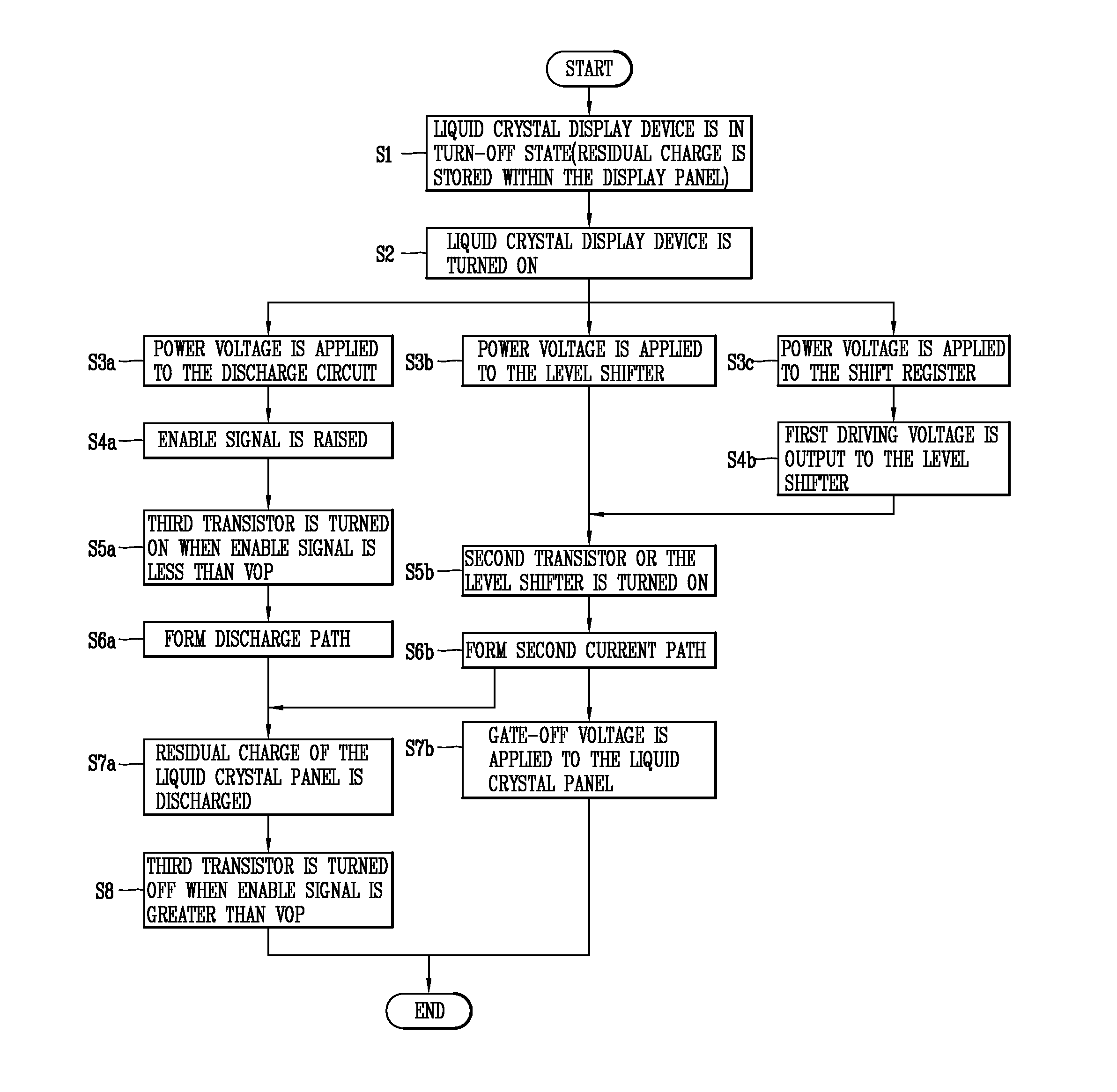

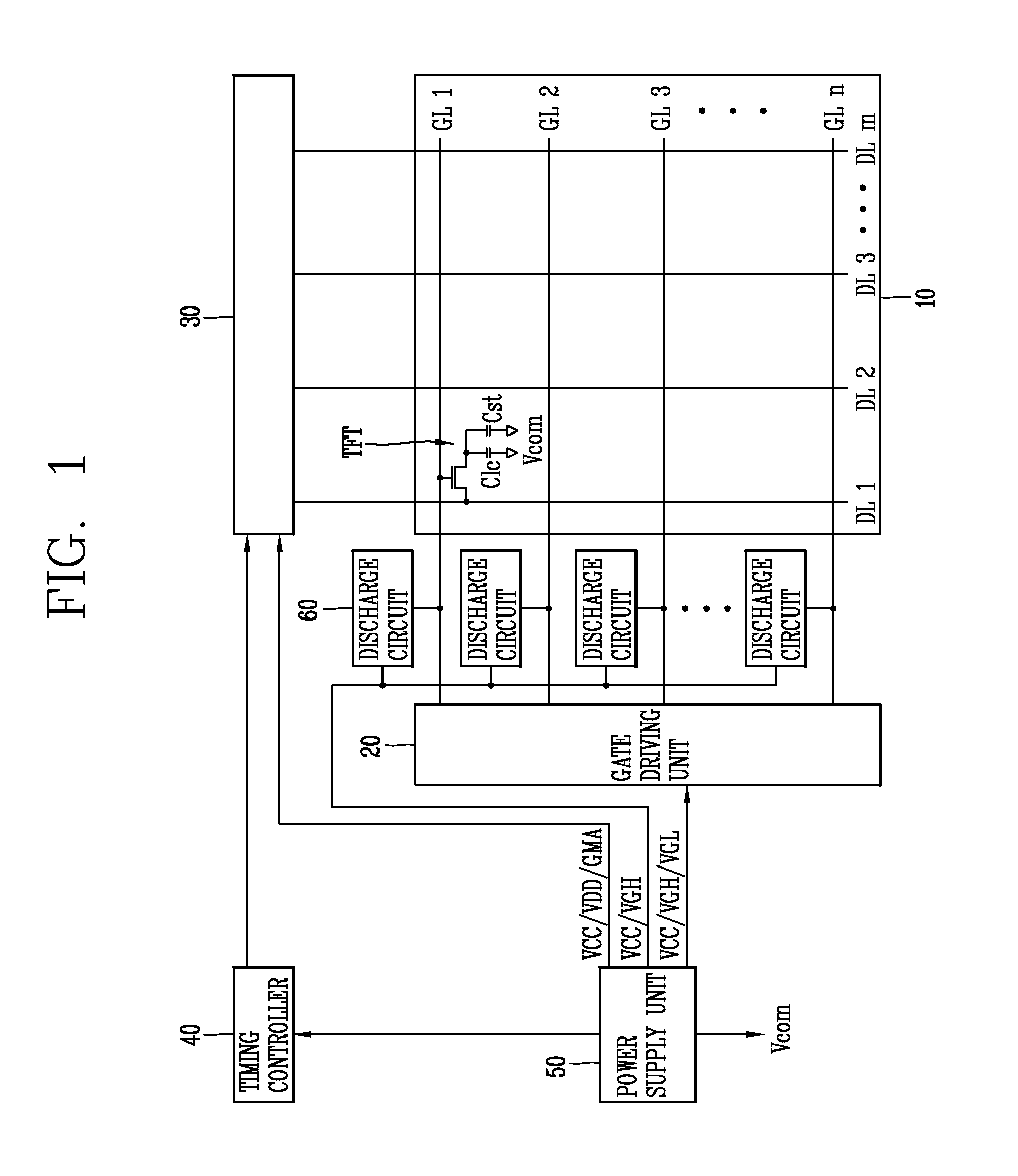

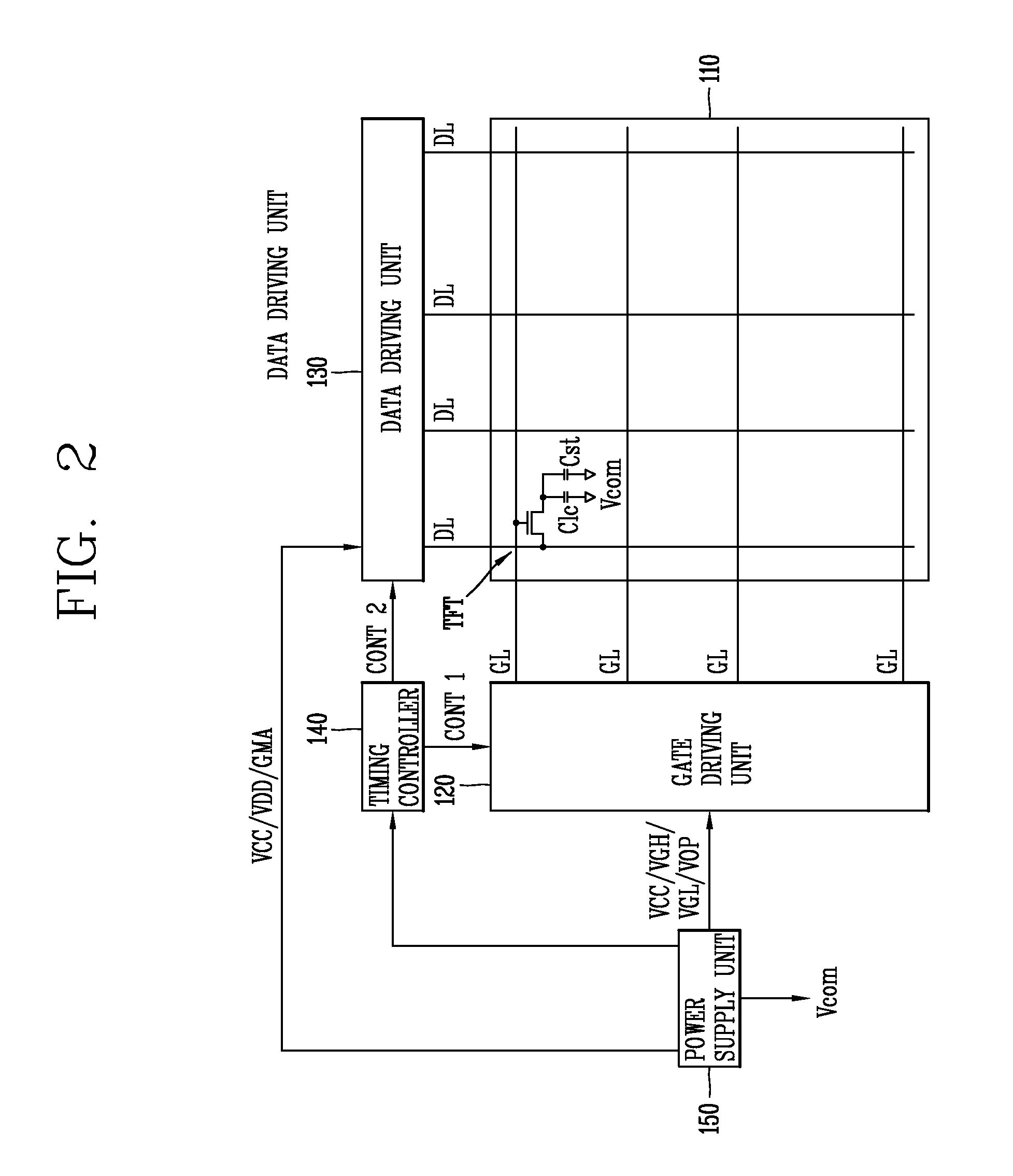

Liquid Crystal Display Device Having Discharge Circuit And Method Of Driving Thereof

ActiveUS20130147697A1Remove failureStable operationStatic indicating devicesNon-linear opticsLiquid-crystal displayResidual charge

A liquid crystal display device discharges residual charge within the liquid crystal display panel. The liquid crystal display device comprises pixels defined by gate lines and data lines intersecting with each other and switching elements for driving the plurality of pixels; a level shifter comprising a first transistor connected between a gate-on voltage terminal and an output terminal and a second transistor connected between a gate-off voltage terminal and the output terminal to selectively output either the gate-on voltage or gate-off voltage to the plurality of gate lines; and a discharge circuit forming a discharge path connecting the gate-off voltage terminal and the ground terminal. The second transistor is turned on during the power-on of the liquid crystal display panel to apply the gate-off voltage. The discharge circuit is turned on to discharge the residual charge of the liquid crystal display panel through the discharge path.

Owner:LG DISPLAY CO LTD

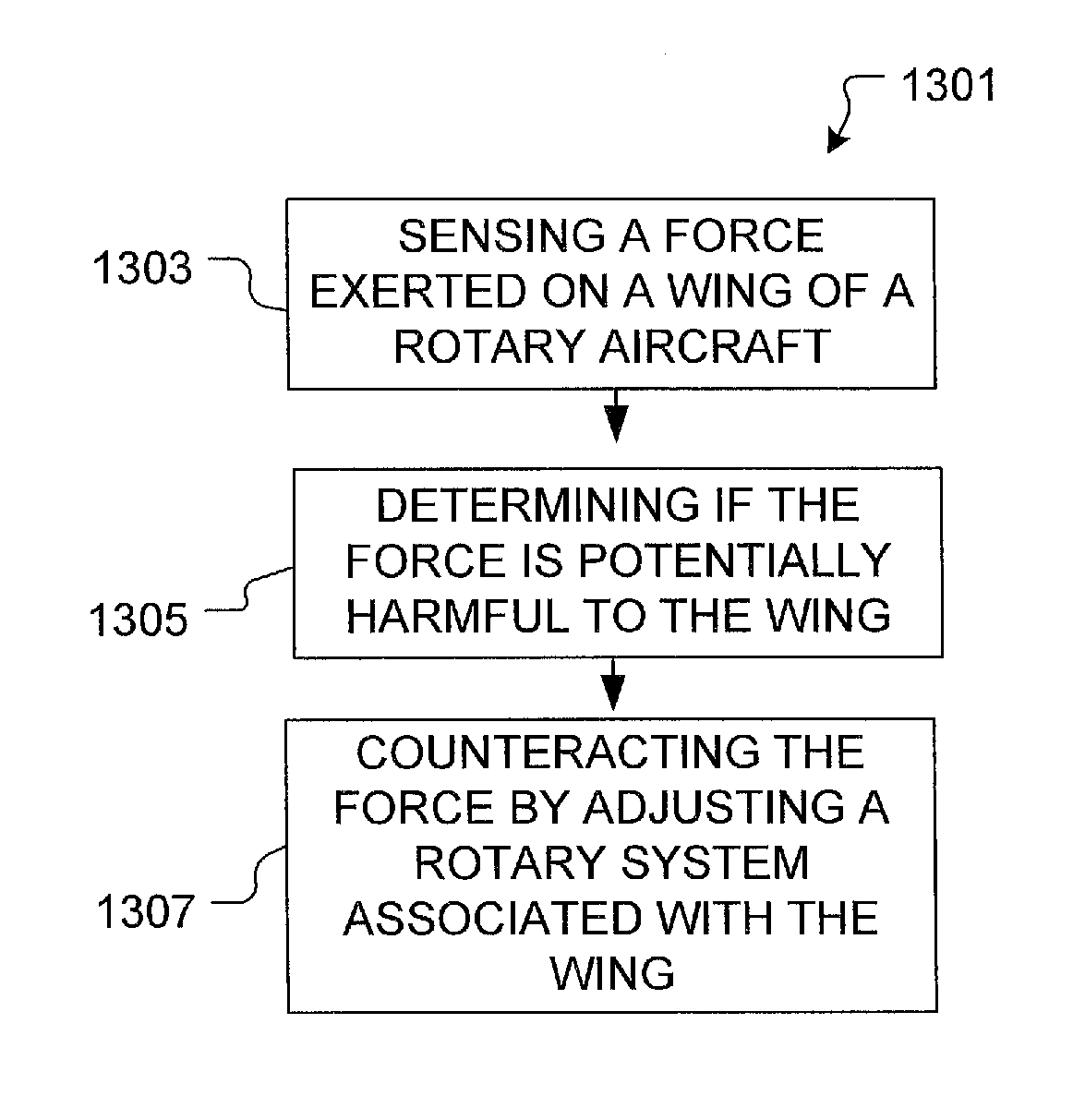

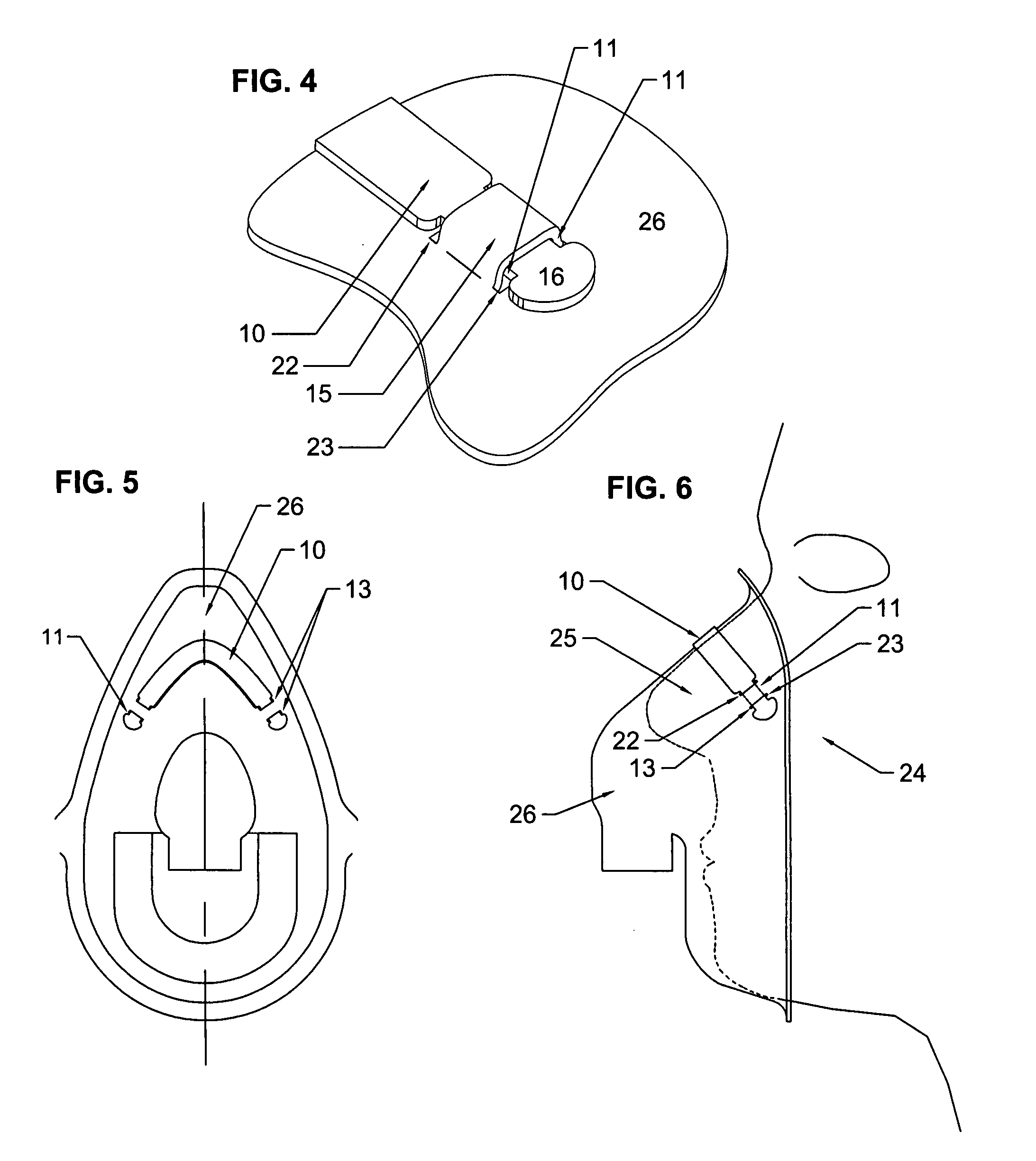

Active Prop Rotor Stability System

ActiveUS20130105637A1Overcome disadvantagesEliminate failureAircraft stabilisationActuated automaticallyAircraft landingStructural integrity

A system and method for adjusting a rotor blade upon detection of a harmful force exerted on an aircraft wing includes a sensor attached to the wing and a subsystem operably associated with the sensor. The method includes sensing the force exerted on the wing with the sensor and determining whether the sensed force is potentially harmful to the structural integrity of the wing. The method further includes counteracting the harmful force by adjusting the rotor blade movement.

Owner:TEXTRON INNOVATIONS

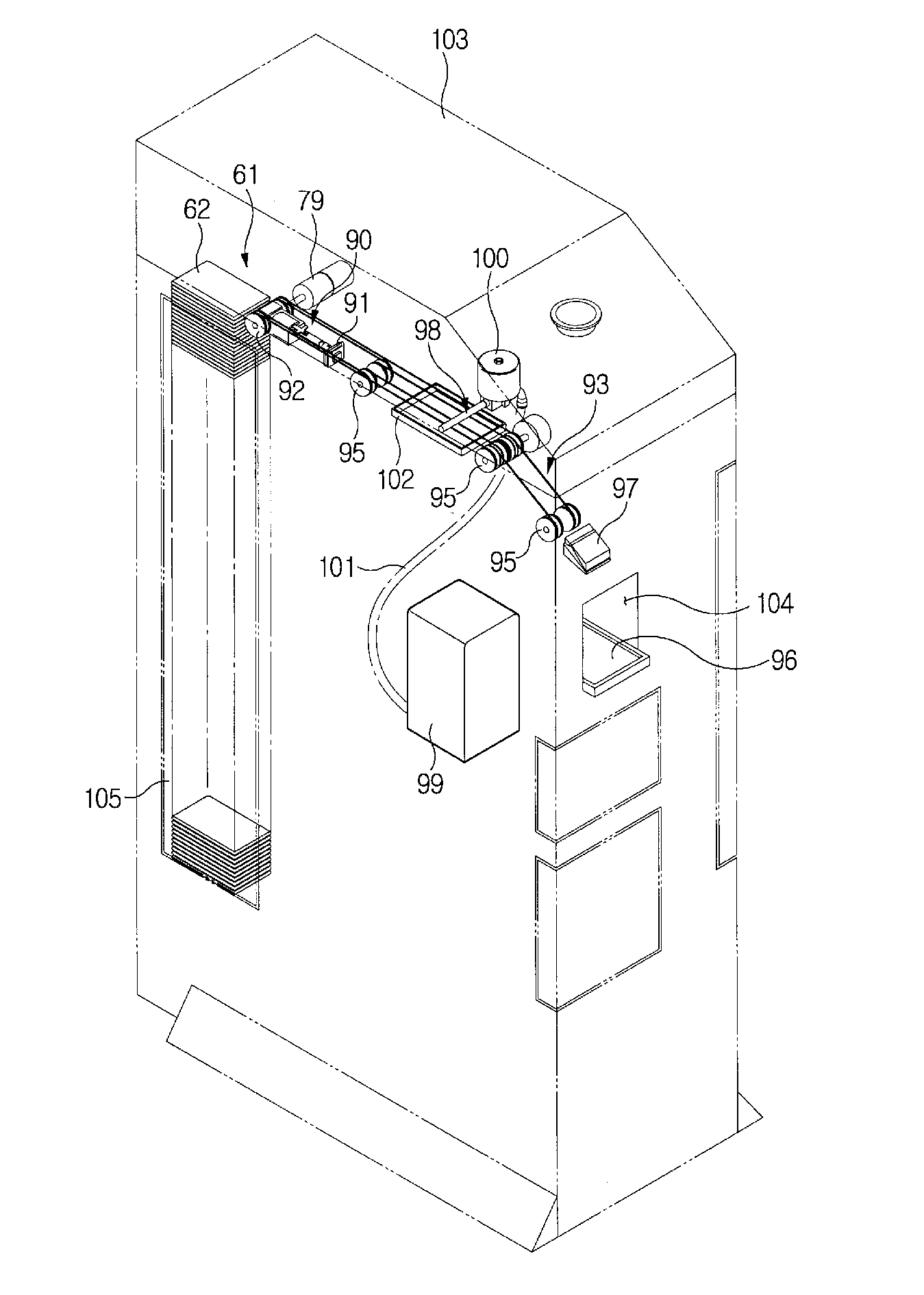

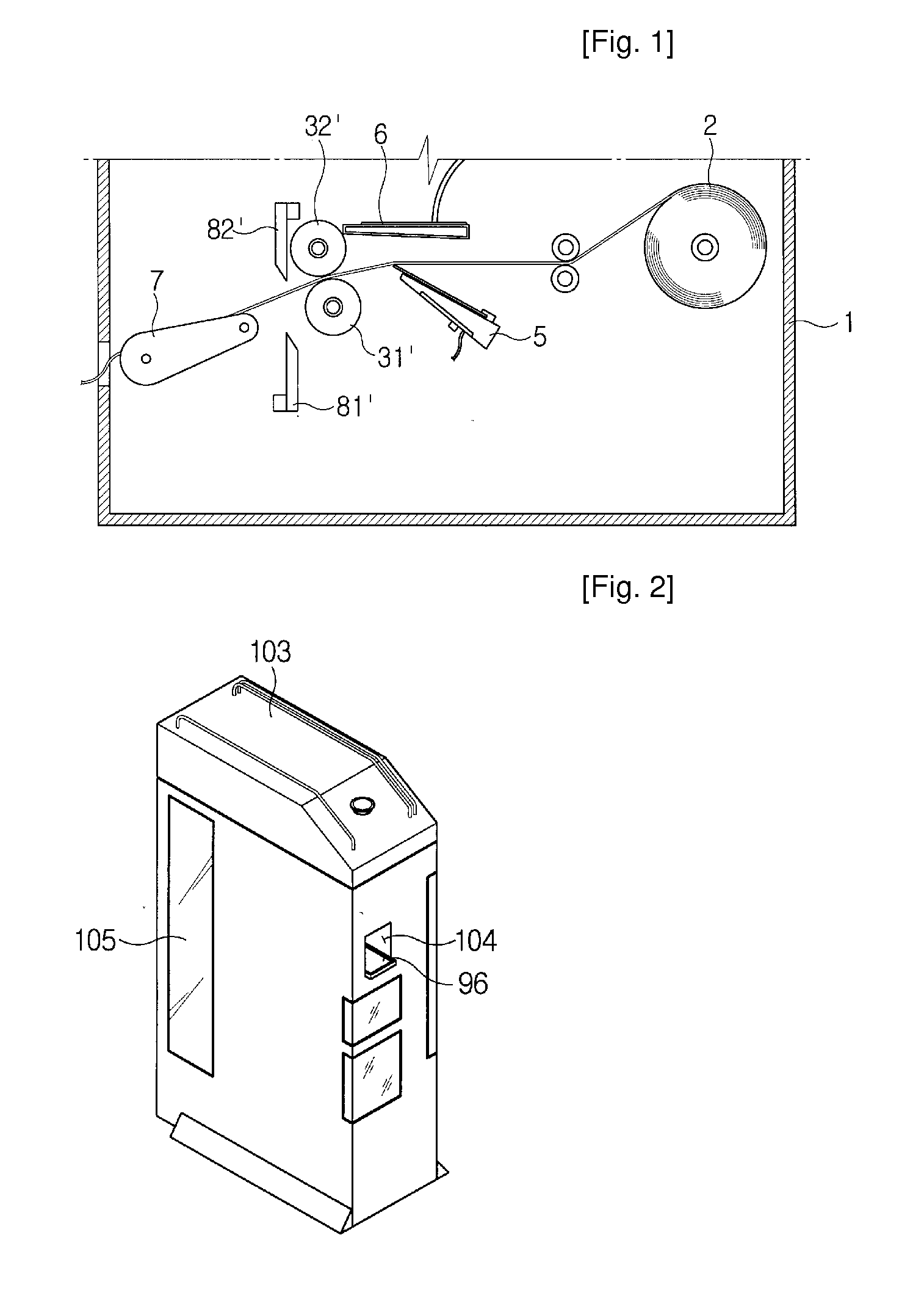

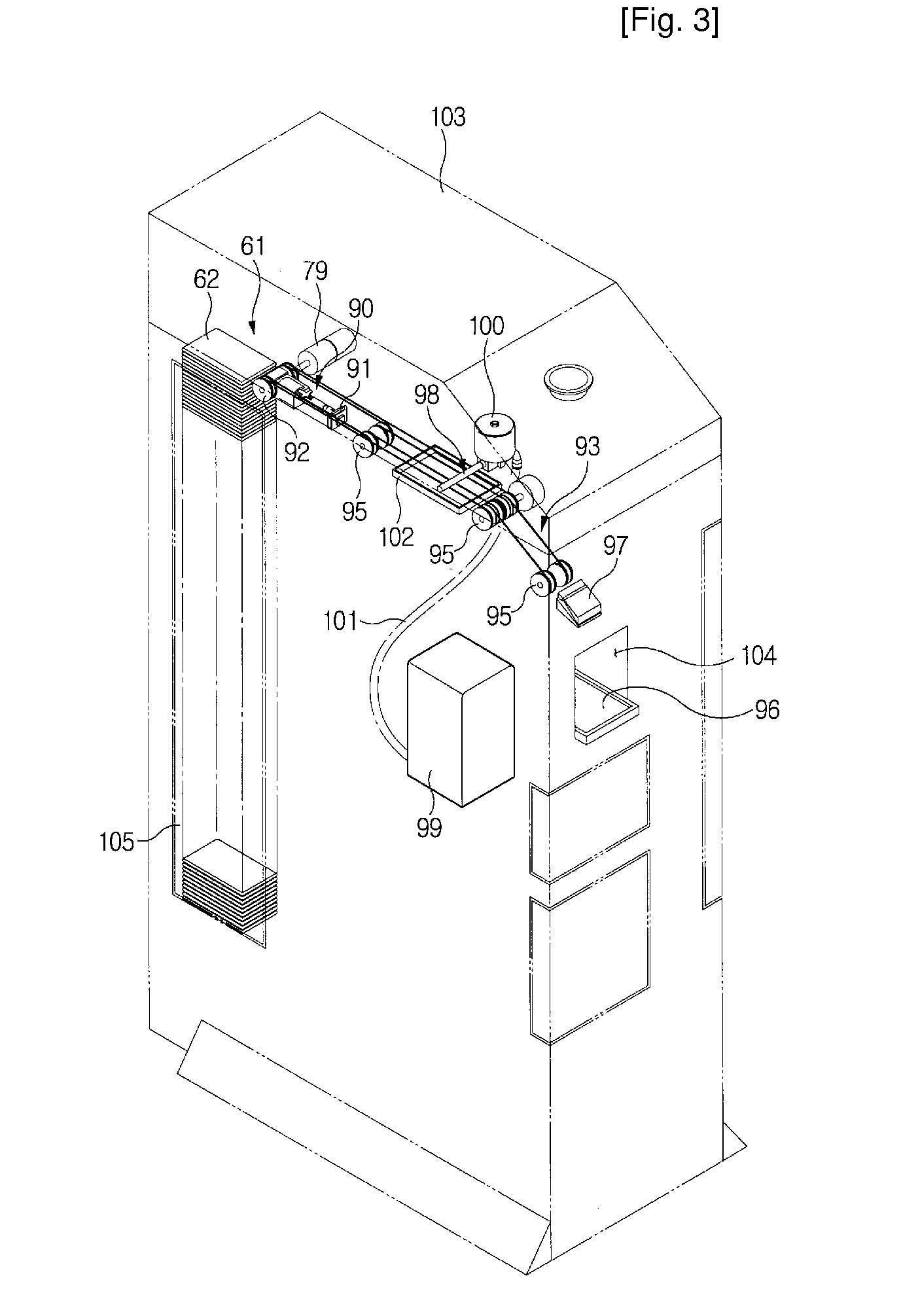

Apparatus for Discharging Tissue

InactiveUS20080135570A1Easily replaceReduce cut effectivenessCoin-freed apparatus detailsDomestic applicationsBiomedical engineering

An apparatus for discharging tissue that is folded several times and stacked is provided. The apparatus includes a cartridge that holds stacked tissue and has a through hole at one end, and a holding member that is disposed adjacent to the through hole of the cartridge and pivots on an axis to grasp and remove tissues one at a time from the top of the stack through an arm. The inventive apparatus allows a user to easily replace tissue and check the amount of tissue used and the amount left to use through visual means. The apparatus virtually eliminates the problem of tissue dispensing failure, and has increased precision and reliability and reduced dispensing time over conventional apparatuses.

Owner:ELIX CO LTD

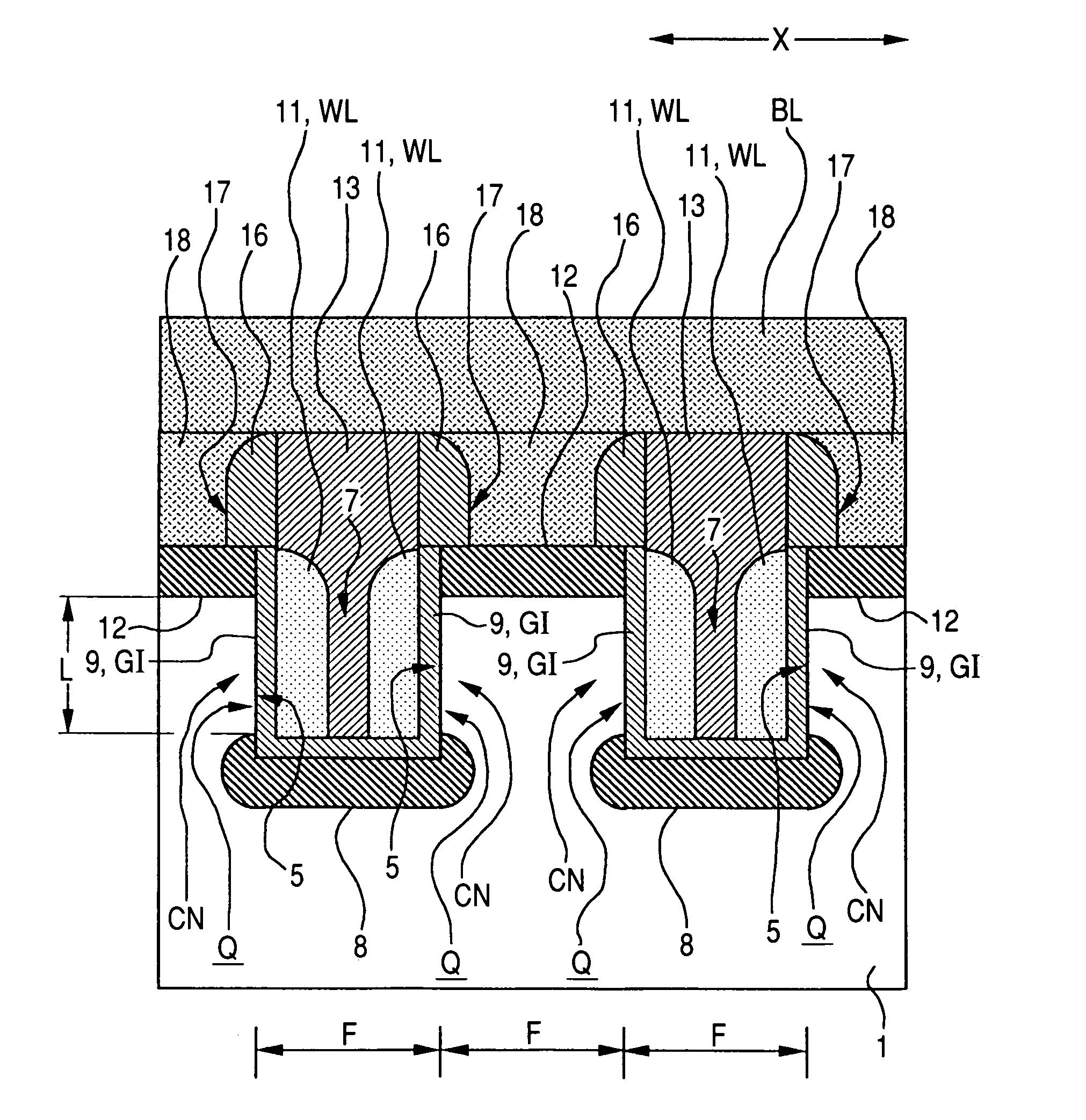

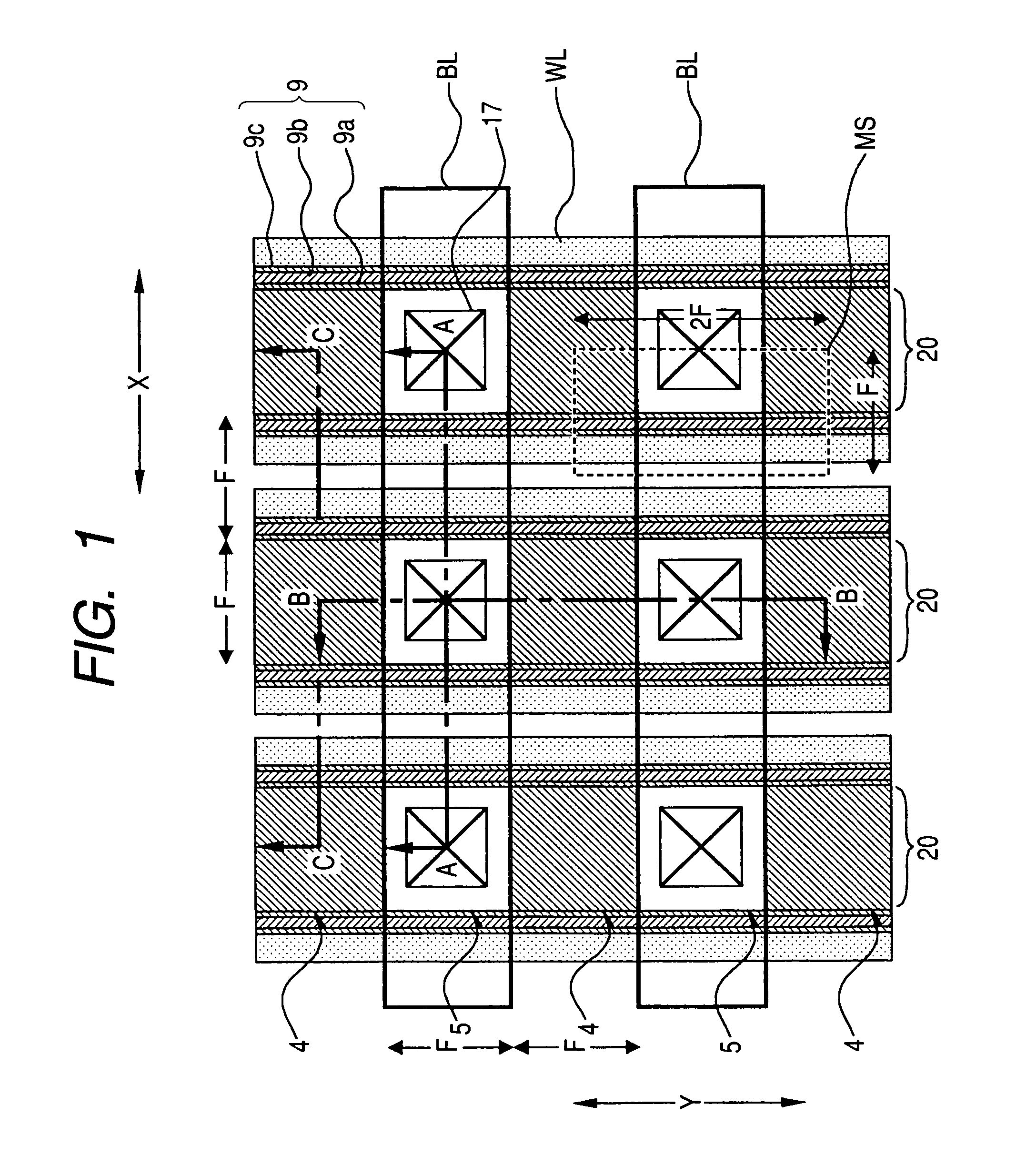

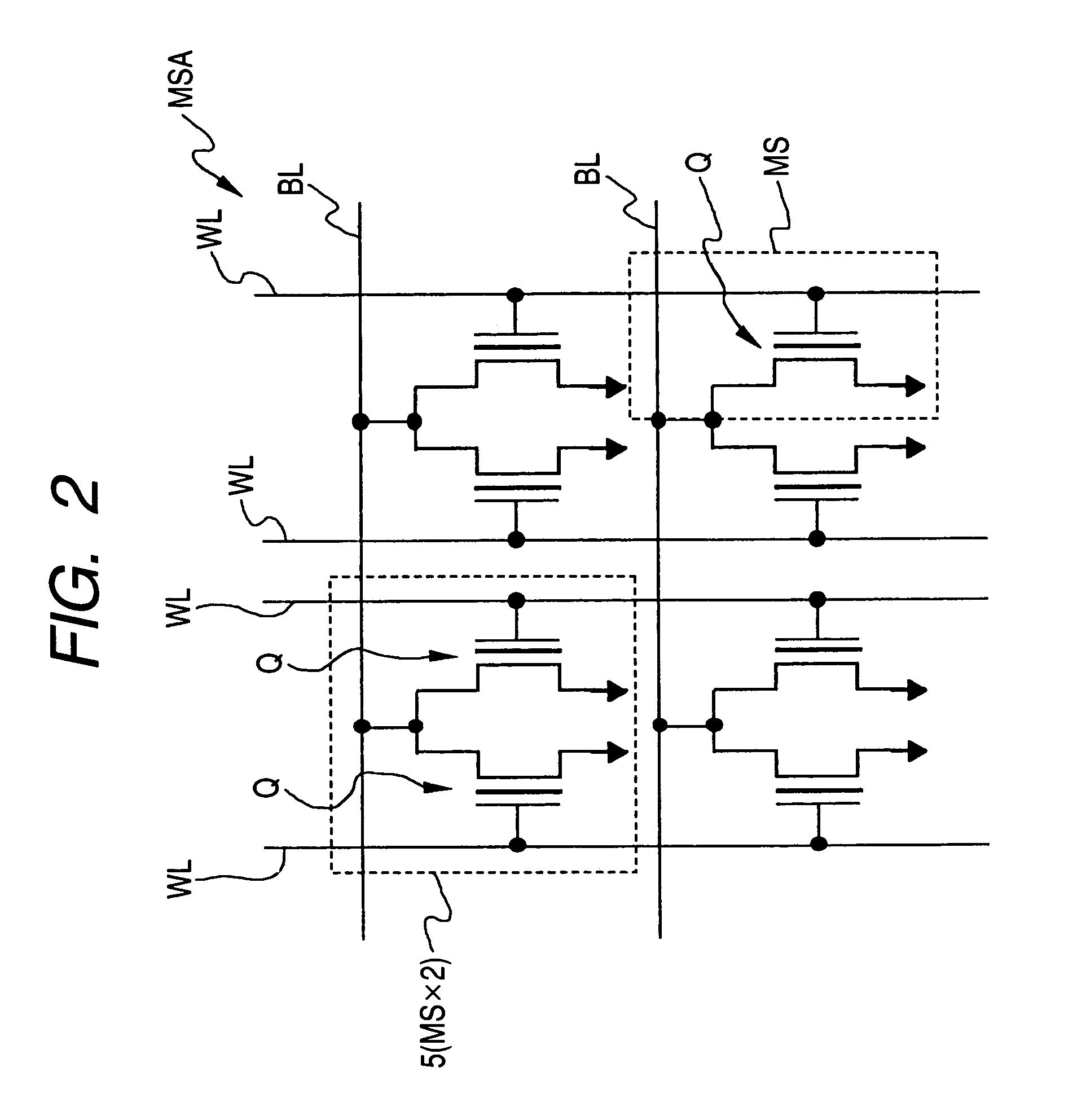

Semiconductor integrated circuit device and its manufacturing method

InactiveUS7067875B2Increase read currentEasy to fallTransistorSolid-state devicesEngineeringSemiconductor

A semiconductor integrated circuit device has a plurality of rows of pillars, each row being composed of semiconductor pillars and insulator pillars alternately arranged in one direction with no gap therebetween, a plurality of nonvolatile memory elements provided individually in the plurality of semiconductor pillars, the plurality of nonvolatile memory elements having control gate electrodes provided over side surfaces of said semiconductor pillars along the one direction via gate insulating films, drain regions provided in upper surface portions of the semiconductor pillars, and source regions provided in bottom surface portions of the semiconductor pillars, and lines including the respective control gate electrodes of the plurality of nonvolatile memory elements and provided along the one direction over the side surfaces of the rows of pillars along the one direction.

Owner:RENESAS ELECTRONICS CORP

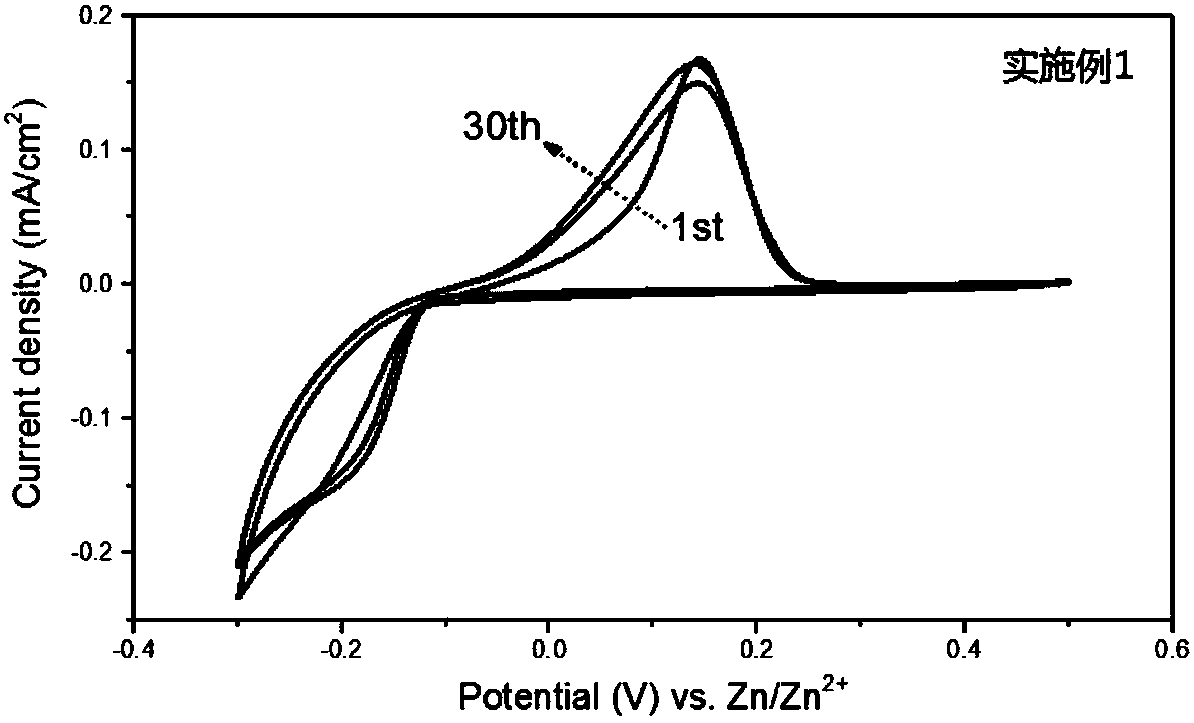

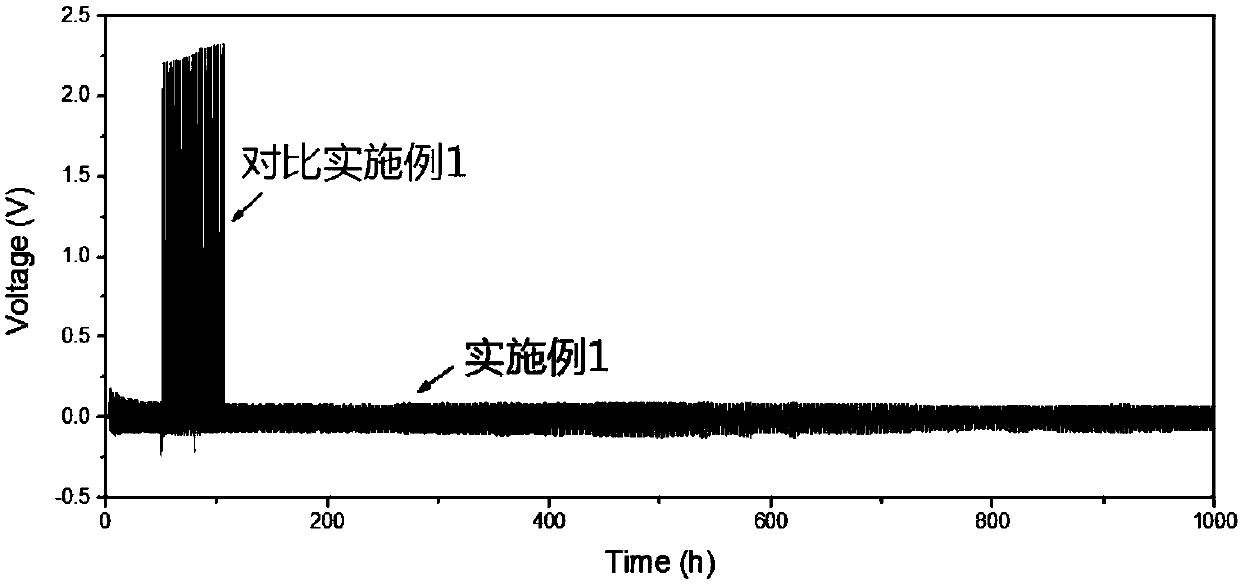

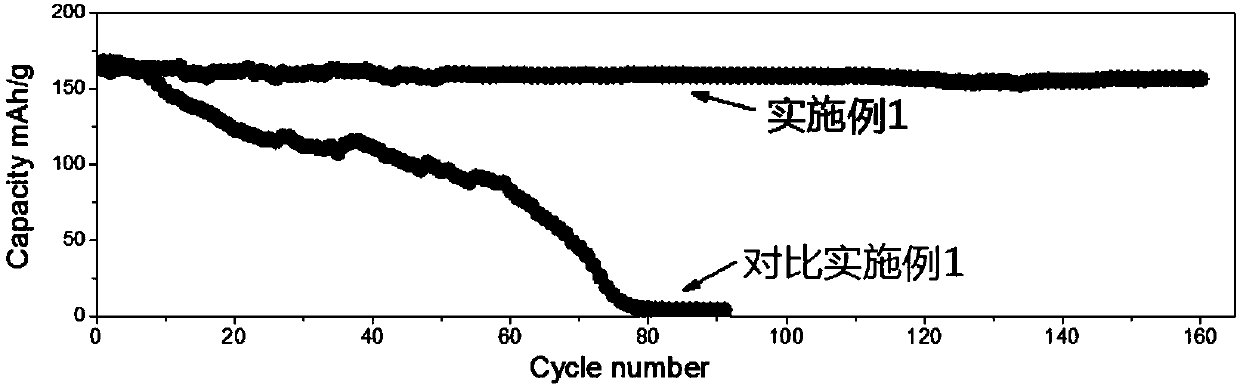

Eutectoid electrolyte and application thereof in secondary zinc battery

The invention relates to eutectoid electrolyte and a secondary zinc battery using the eutectoid electrolyte. The eutectoid electrolyte contains an acylamino-contained compound and an ionizable organicmetal salt. The eutectoid electrolyte provided by the invention has the characteristics of low viscosity, high ionic conductivity, wide electrochemical window, low cost and insensitiveness to water and air; meanwhile, reversibility and stability of electrochemical deposition / dissolution can be remarkably improved by an interface protecting layer formed by in-situ decomposition of organic anions,so that the problem of poor cycle life of the secondary zinc battery is effectively solved. The secondary zinc battery using the eutectoid electrolyte has the advantages of good charge-discharge cycleperformance, greenness, environmental protection and low price.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

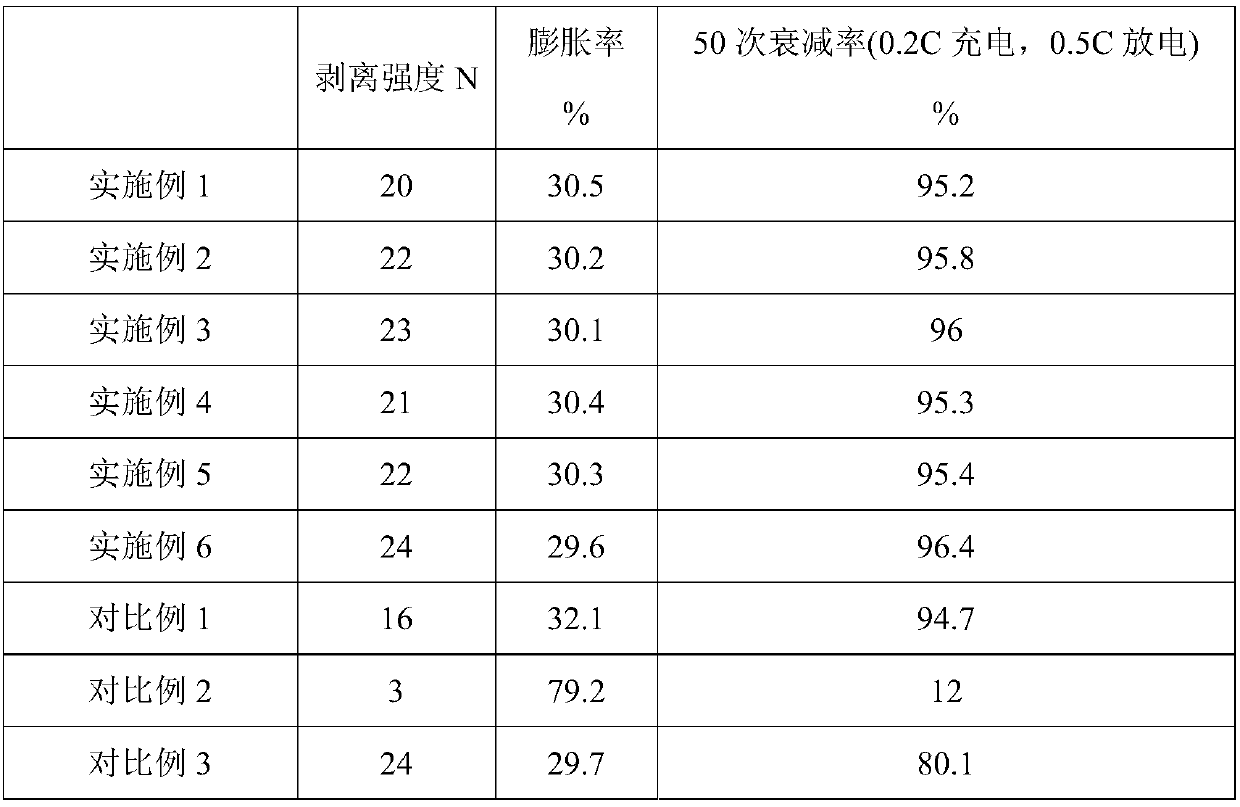

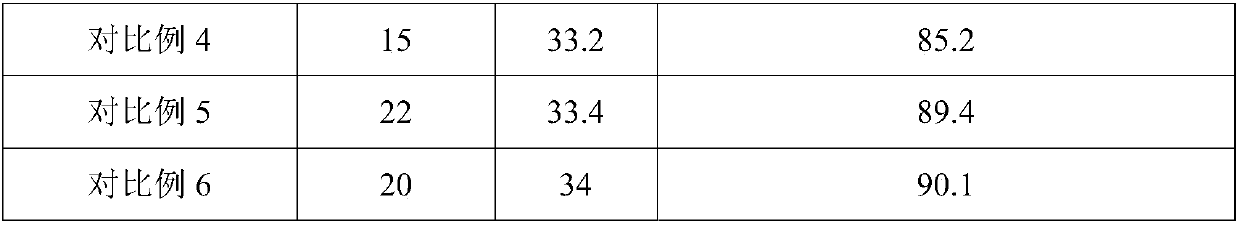

Silicon carbon negative electrode slurry and preparation method thereof

ActiveCN109546127AIncrease the degree of network crosslinkingHigh bonding strengthCell electrodesSecondary cellsCyclic processCarbon nanotube

The invention relates to a silicon carbon negative electrode slurry and a preparation method thereof. The silicon carbon negative electrode slurry comprises a silicon-based / graphite mixture, a binder,a single-walled carbon nanotube, carbon black and a coupling agent. The binder is polyacrylic-acid-based polymer containing a carboxyl functional group. According to the invention, the silicon carbonnegative electrode is modified by using the polyacrylic-acid-based polymer containing a carboxyl functional group and the coupling agent under coordination, so that the expansion and contraction rateof the silicon carbon negative electrode is reduced, the conductivity of the silicon carbon negative electrode and the negative current collector copper foil as well as the utilization rate of the negative active materials are improved, and the cycle life of the battery is prolonged. Meanwhile, the single-walled carbon nanotube serves as an electric bridge, thereby eliminating the phenomenon of active material failure during the cycle process of the battery. According to the invention, a silicon carbon negative electrode slurry is prepared by combining a stepped binder adding method with a dry-wet method, so that the electrical property of the material is further improved. Moreover, the preparation process is simple and the silicon carbon negative electrode slurry and the preparation method thereof have the broad application prospects.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Airplane inertia anti-skid brake system capable of guaranteeing emergency brake

InactiveCN106428533AEnsure implementationEliminate failureBrake regulatorsJet aeroplaneSolenoid valve

An airplane inertia anti-skid brake system capable of guaranteeing emergency brake comprises a normal brake system and an emergency brake system, wherein the normal brake system and the emergency brake system adopt two independent pressure supply source systems and are switched through a switching valve. The system structure is improved through addition of a control device, so that normal brake fails during emergency brake, the switching valve is completely switched under the action of emergency brake pressure, and even though the emergency brake and the normal brake are used simultaneously, the switching valve can be switched to the emergency brake system. The control device adopts an electrical switch, a circuit of a solenoid valve is off by the switch, if the normal brake is used, the solenoid valve releases pressure of the normal brake system, the switching valve is thoroughly switched without hindrance, and emergency brake pressure is output.

Owner:XIAN AVIATION BRAKE TECH

Level wind mechanism

InactiveUS7568650B2Eliminate requirementsAvoid failureFilament handlingReelsEngineeringMechanical engineering

The present invention provides an alternate design for a level-wind mechanism that eliminates the requirement for the line to be threaded through an enclosed, or multiple device line guide. The present invention guides the line via an open slot created between one or more line guides that pivots about its supporting structure. The line guide(s) oscillate back and forth in concert across the axial length of the spool in order to evenly distribute the line that is being wound upon the spool. Further, the line guide is capable of being pivoted from a first position of line retrieve to a second position of line dissemination when it is desired to pay out the line from the spool.

Owner:KORE GEAR

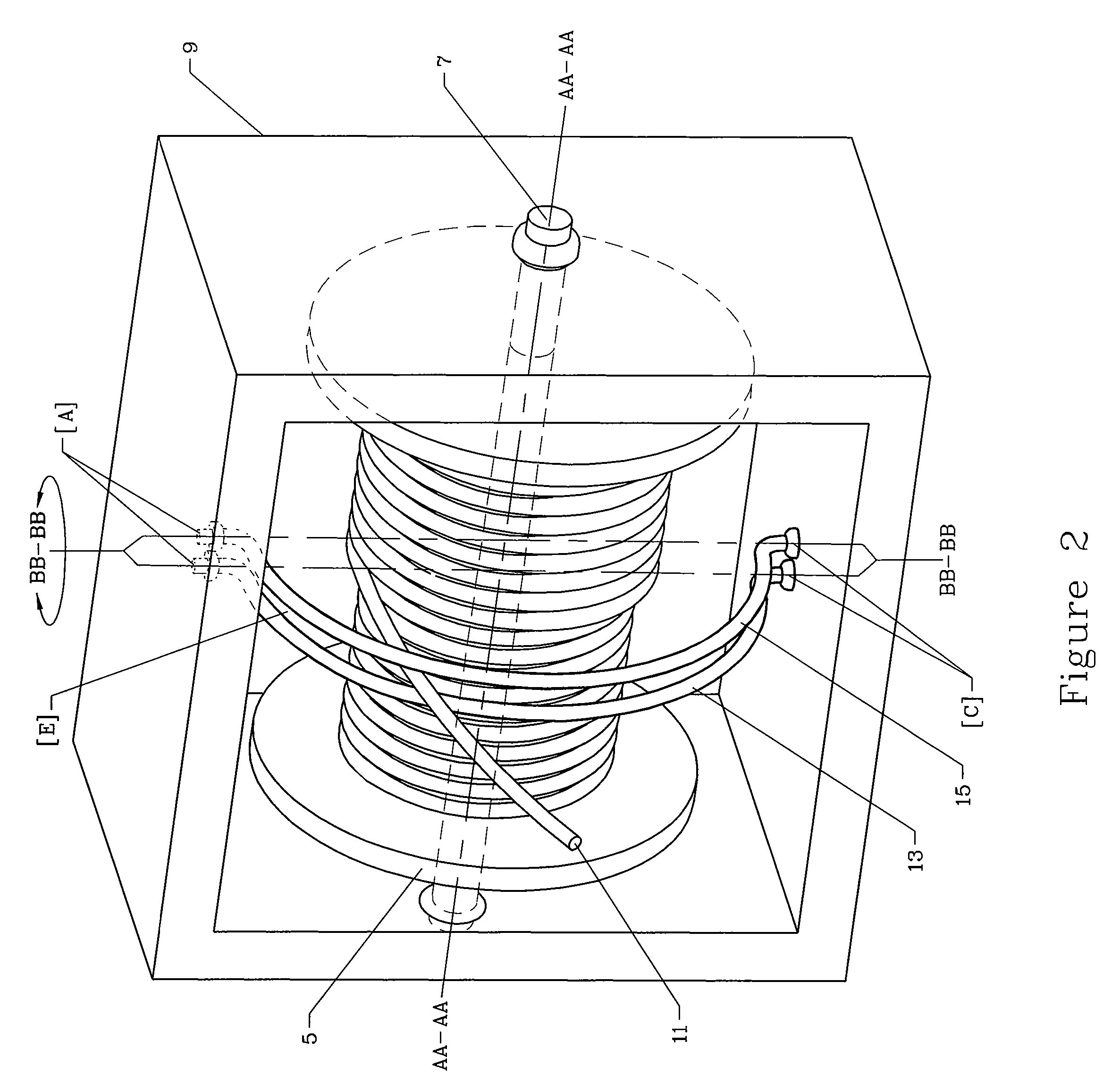

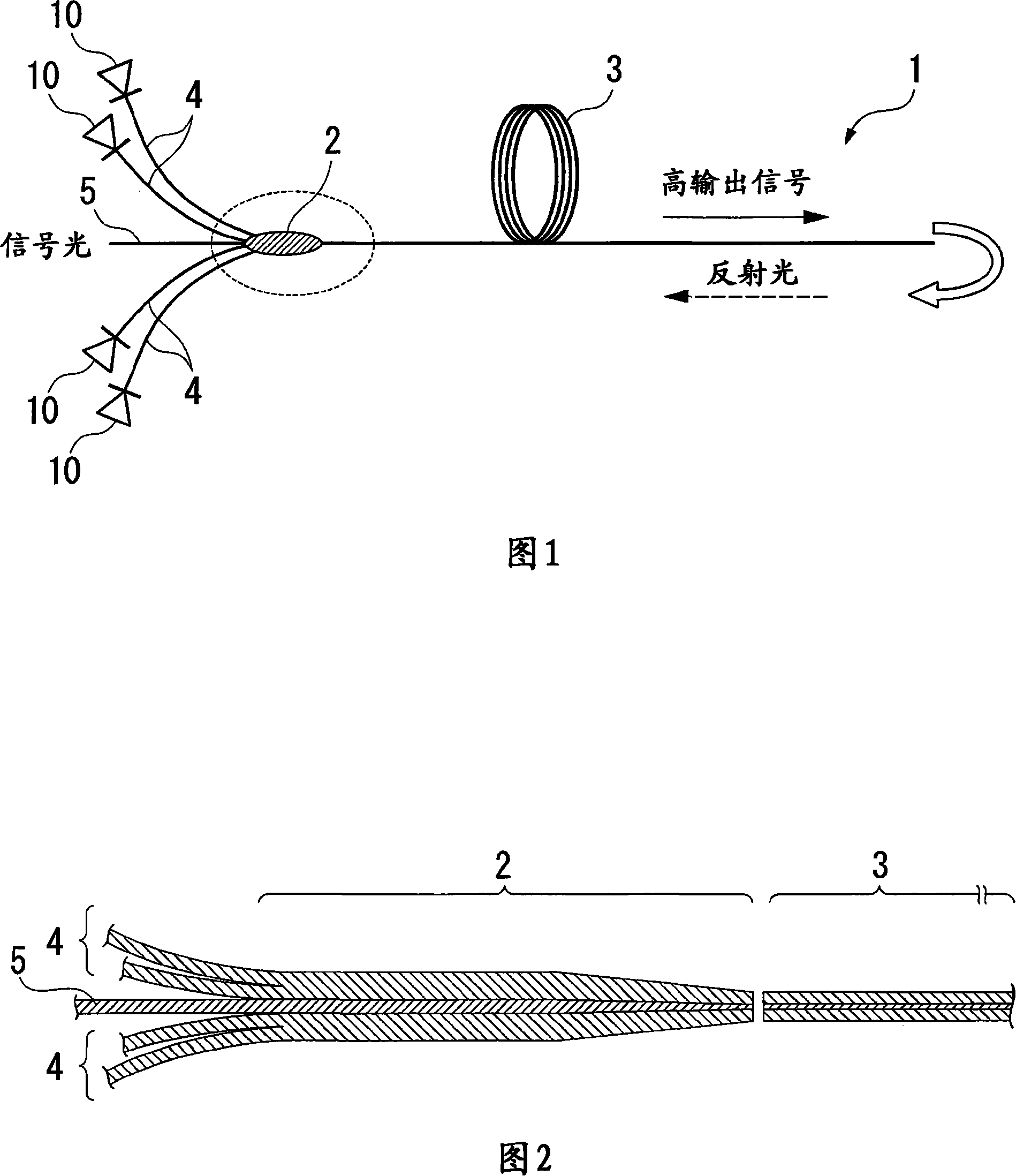

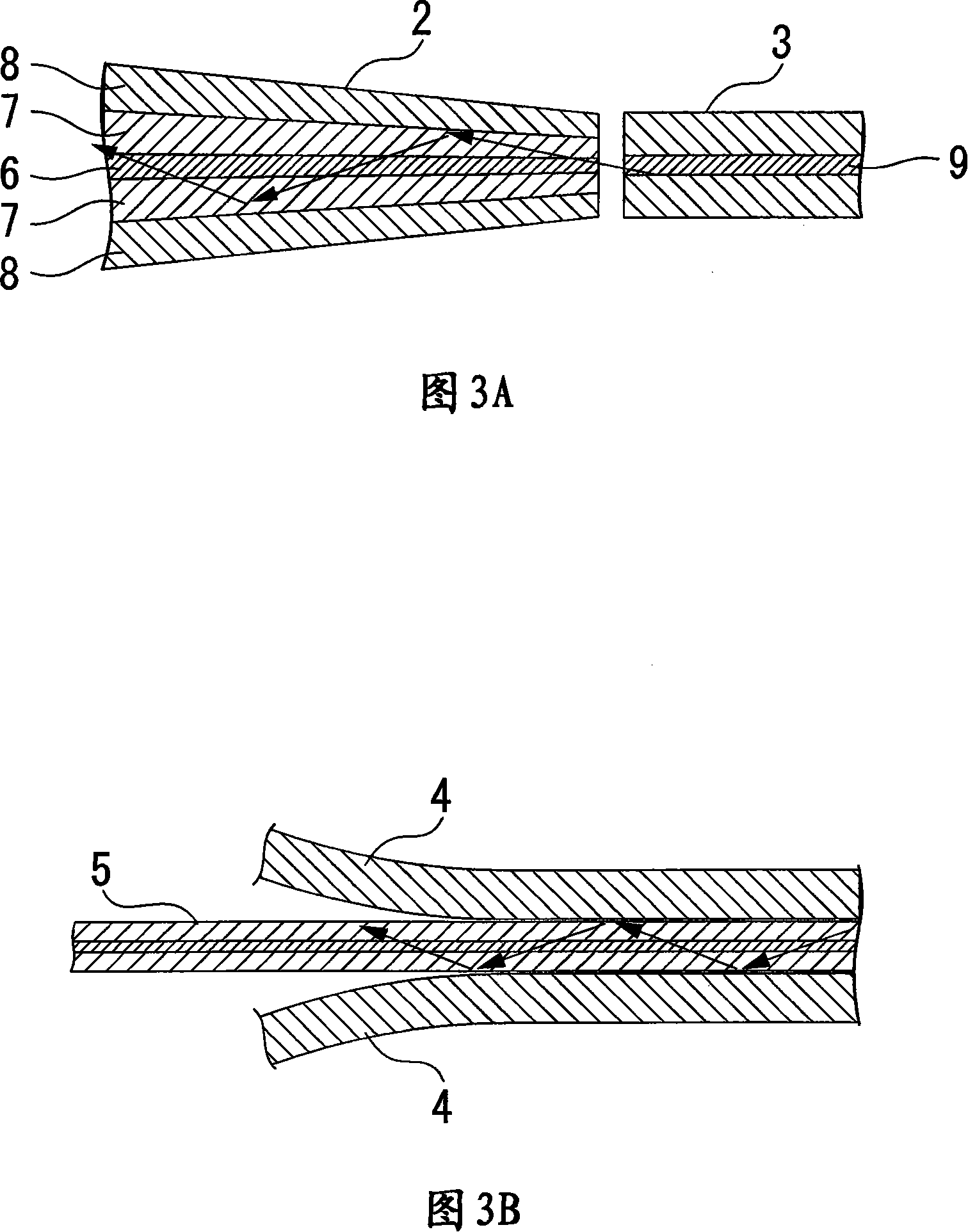

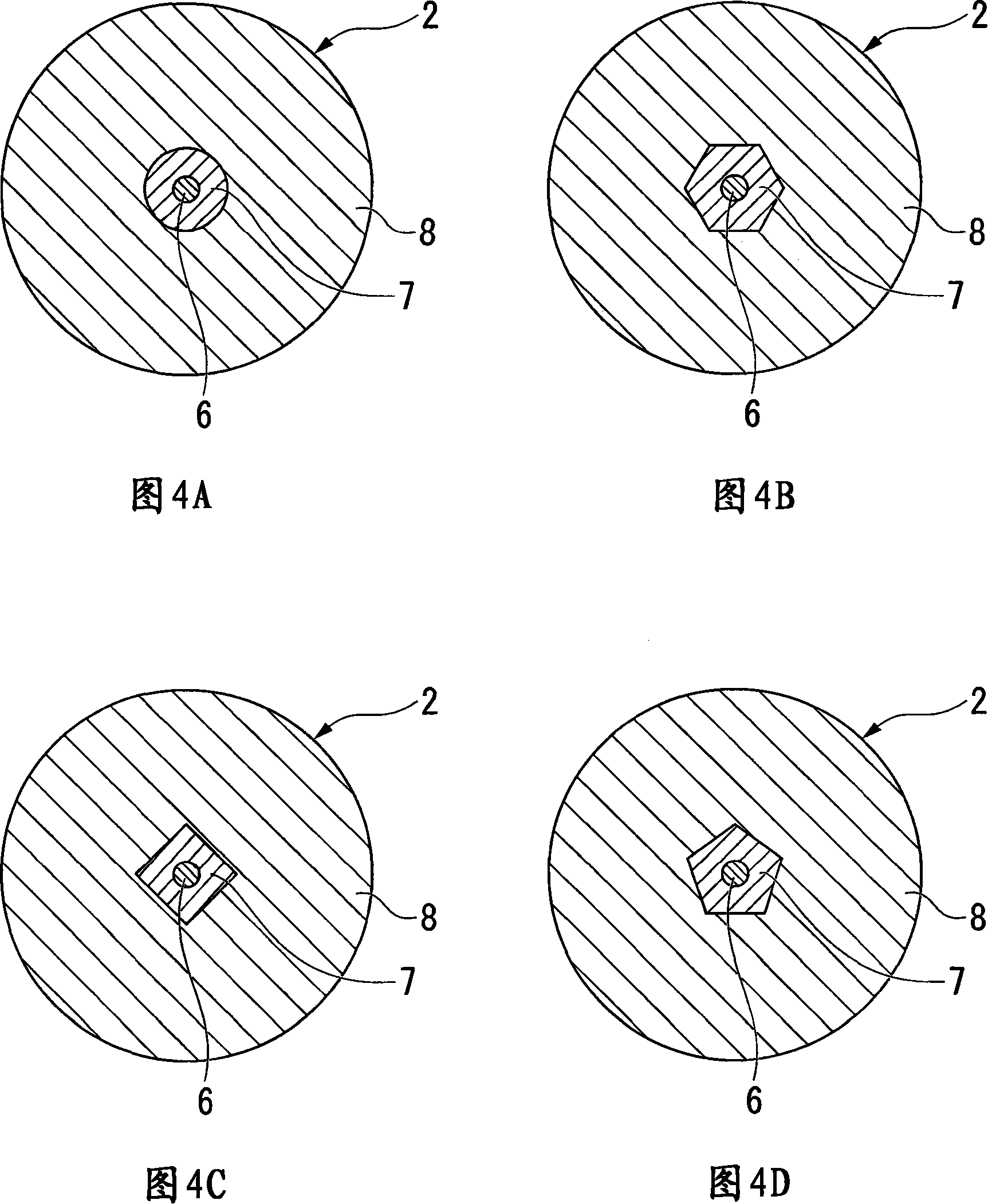

Multi-port coupler, optical amplifier, and fiber laser

InactiveCN101082690AEliminate failureAchieve long lifeLaser detailsCoupling light guidesAudio power amplifierRefractive index

A multi-port coupler for coupling an pumping light source to a cladding pump fiber for optical amplification, includes a central signal fiber and a plurality of pumping fibers arranged around the central signal fiber, the central signal fiber and the plurality of pumping fibers being unified and a front side is reduced in diameter, wherein an emitted light confining waveguide part is provided around a core of the signal fiber located at the center, and the emitted light confining waveguide part whose outer diameter is larger than that of the core has a higher refractive index than a cladding and a lower refractive index than the core and the emitted light confining waveguide part is formed continuously from a splicing point of the cladding pump fiber to a coupler front end branched into multiple fibers.

Owner:THE FUJIKURA CABLE WORKS LTD

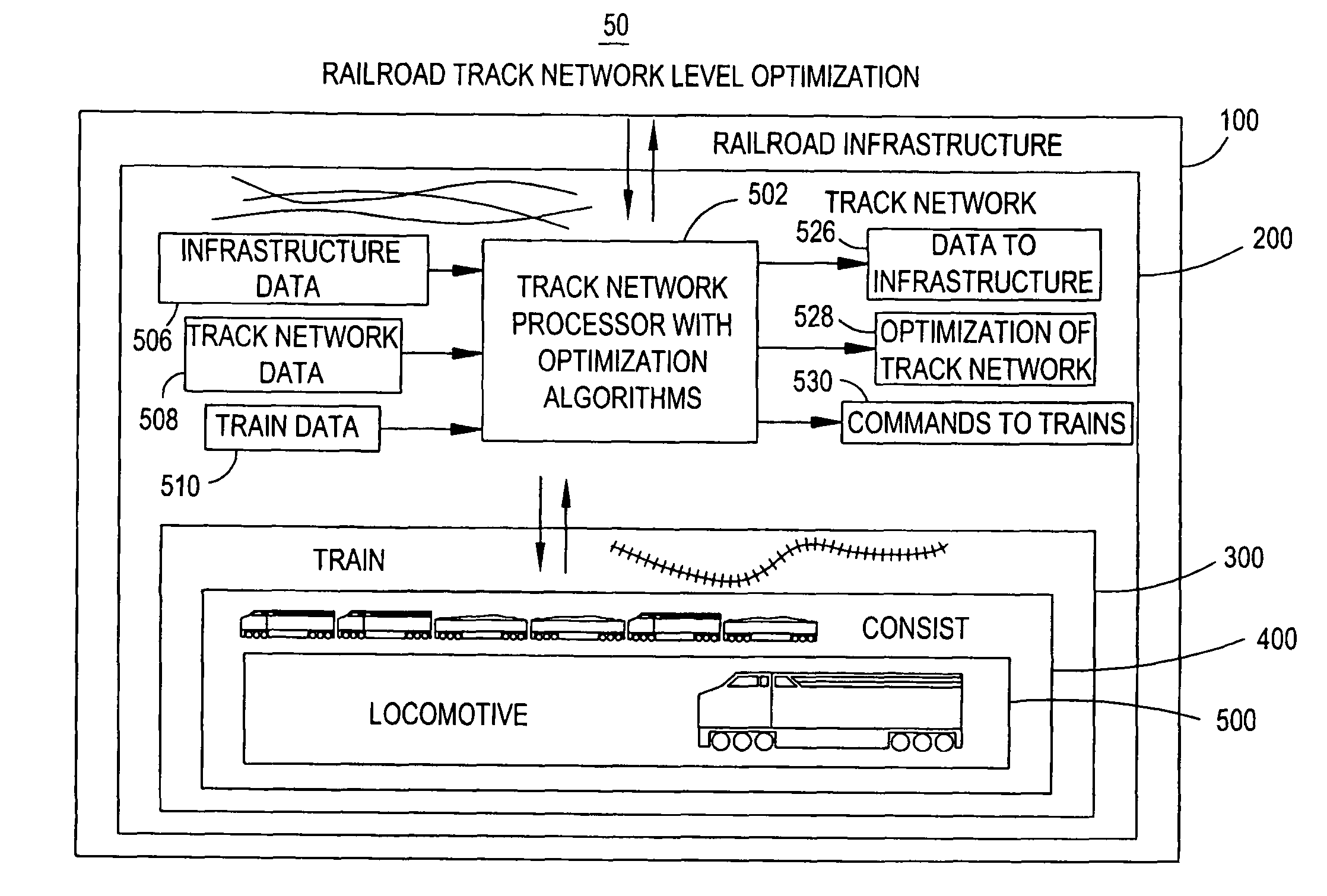

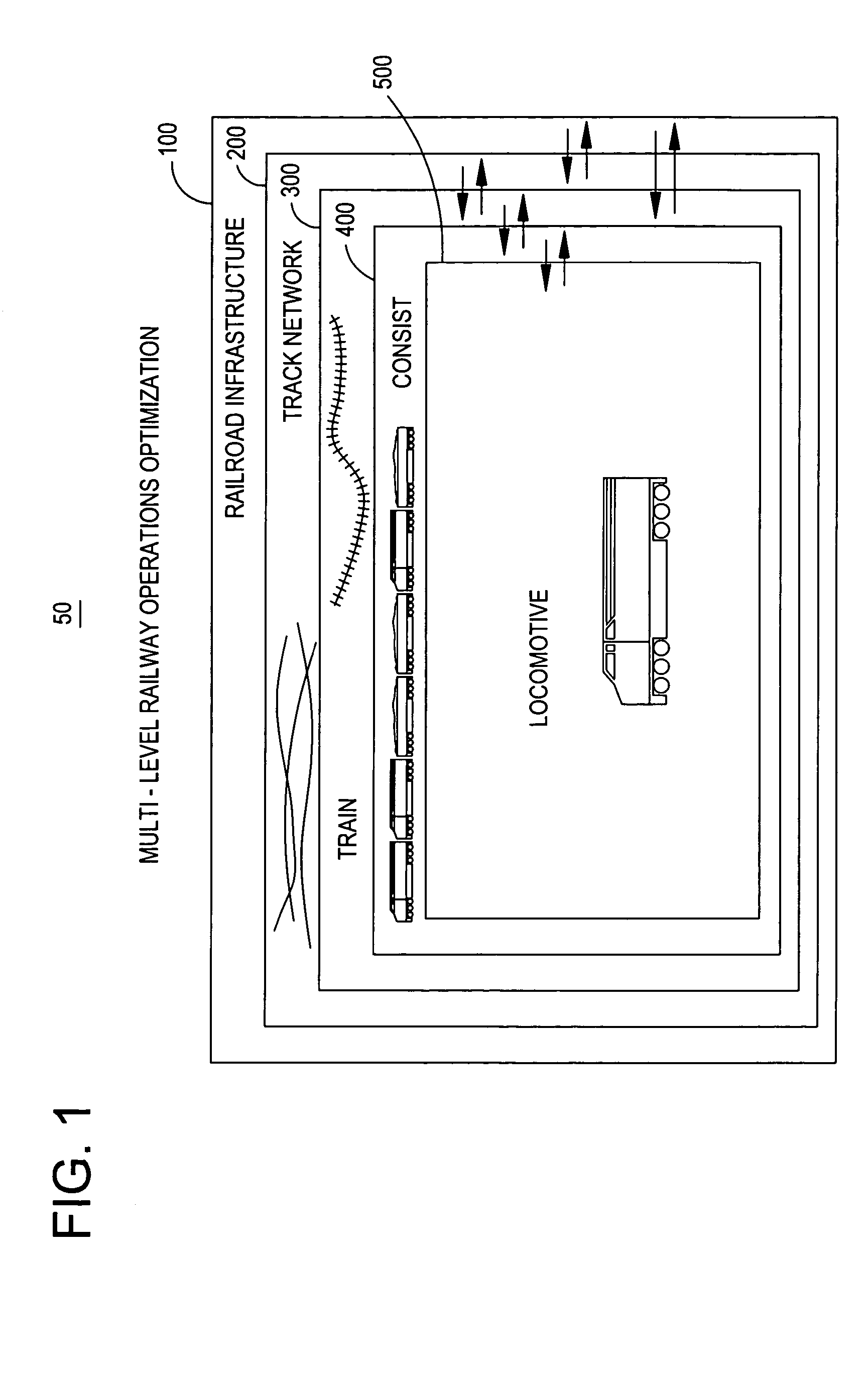

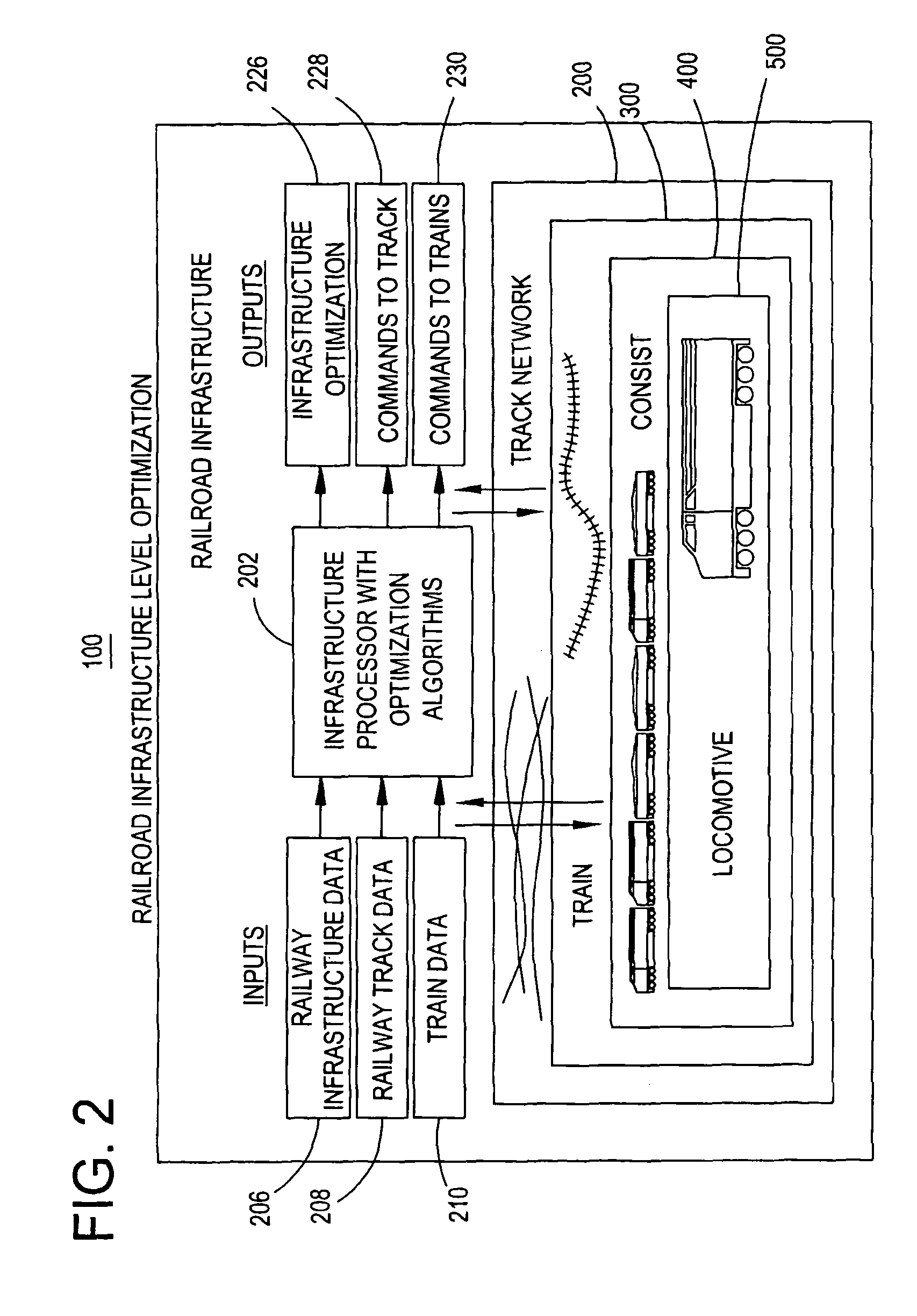

Multi-level railway operations optimization system and method

ActiveUS8538611B2Improve performanceEmission reductionMechanical power/torque controlLevel controlSystem optimizationRail infrastructure

A multi-level system for management of a railway system and its operational components in which the railway system has a first level configured to optimize an operation within the first level that includes first level operational parameters which define operational characteristics and data of the first level, and a second level configured to optimize an operation within the second level that includes second level operational parameters which define the operational characteristic and data of the second level. The first level provides the second level with the first level operational parameters, and the second level provides the first level with the second level operational parameters, such that optimizing the operation within the first level and optimizing the operation within the second level are each a function of optimizing a system optimization parameter. The levels can include a railroad infrastructure level, a track network level, a train level, a consist level and a locomotive level.

Owner:GE GLOBAL SOURCING LLC

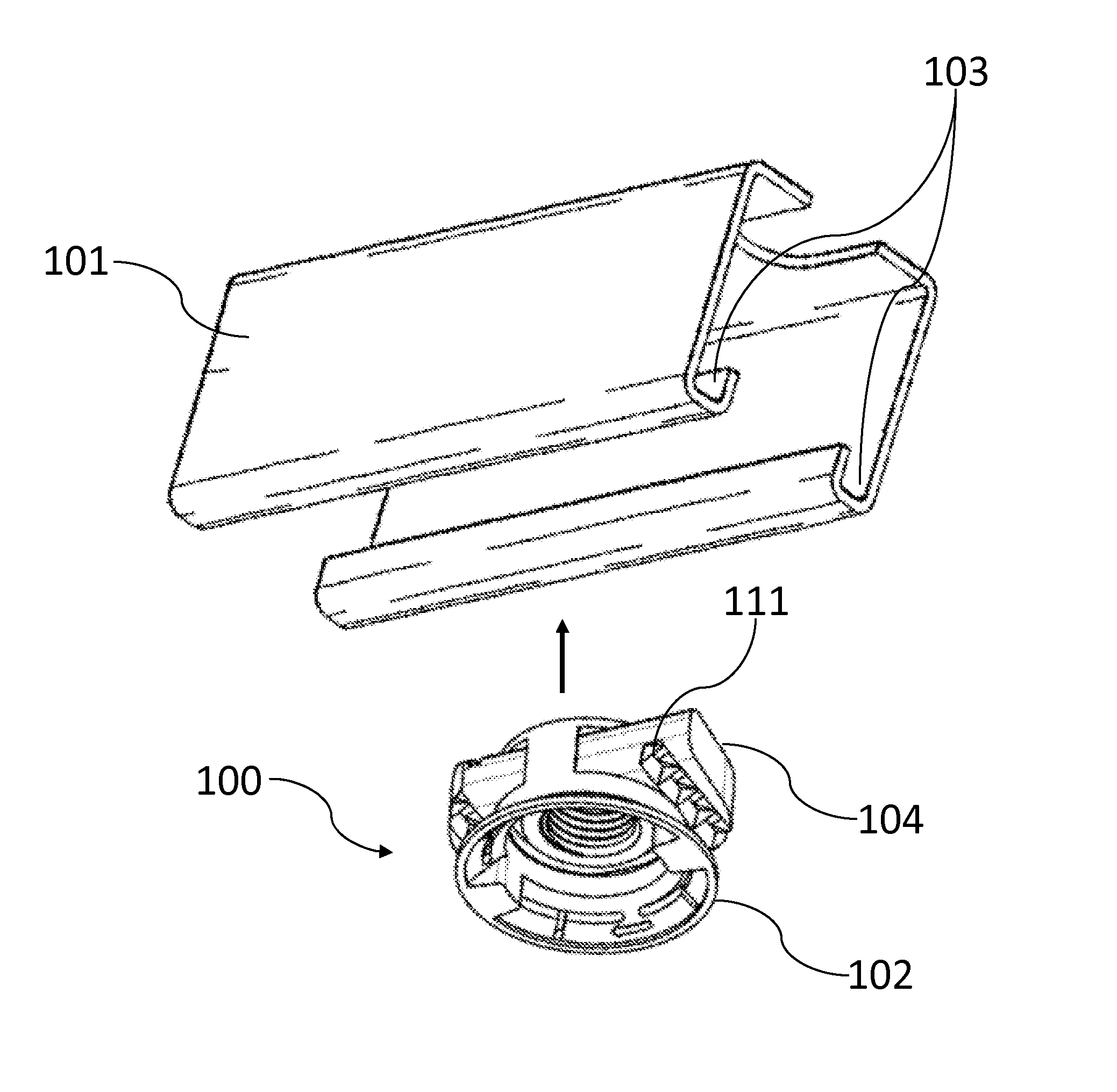

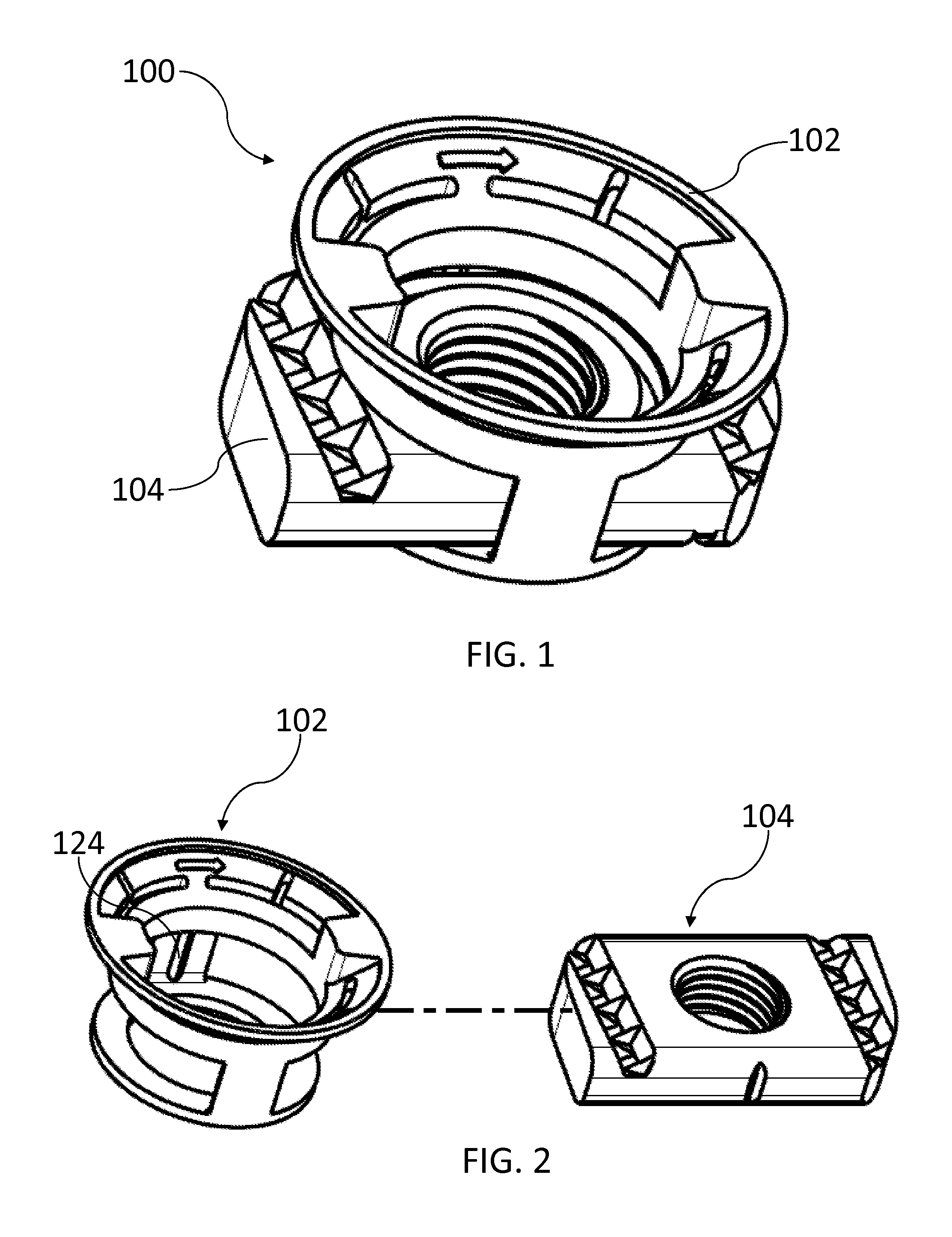

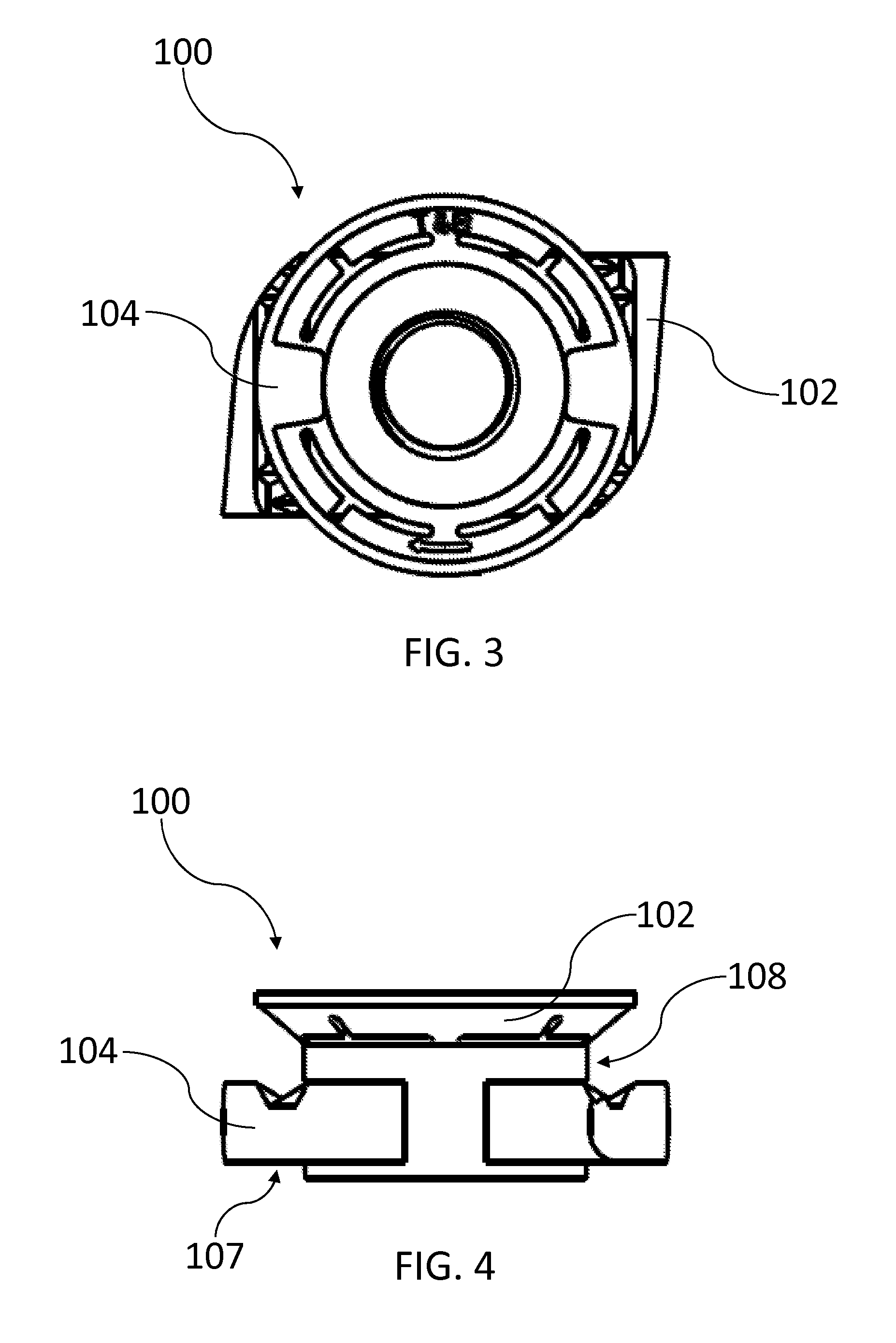

Cone Nut

ActiveUS20150233410A1Time saving and ease of installationEliminate failureNutsEngineeringElectrical and Electronics engineering

An improved cone nut for a structural channel is provided. The cone nut does not require gluing of the cone to the channel nut as in conventional methods. The cone instead houses the channel nut by a friction fit locking mechanism, resulting in a secure attachment of the cone to the channel nut which prevents failure of the cone by separation from the channel nut which would, in turn, render the channel nut useless.

Owner:THOMAS & BETTS INT INC

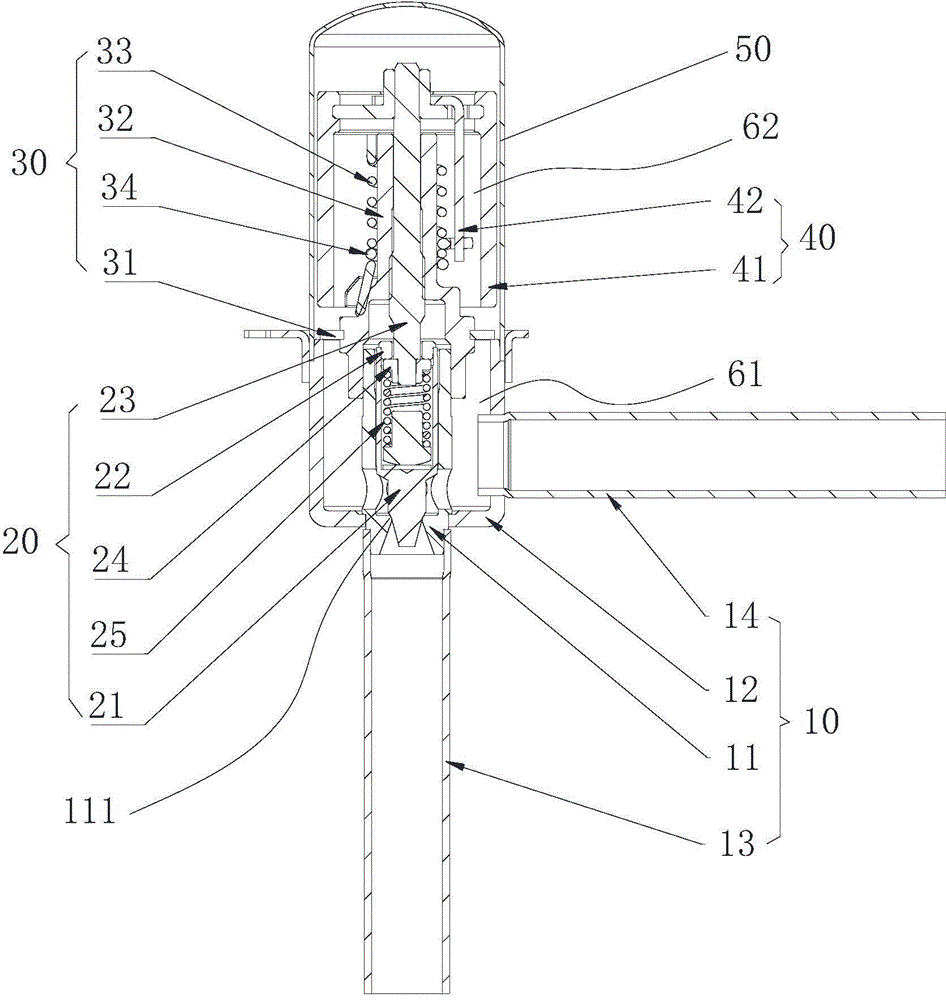

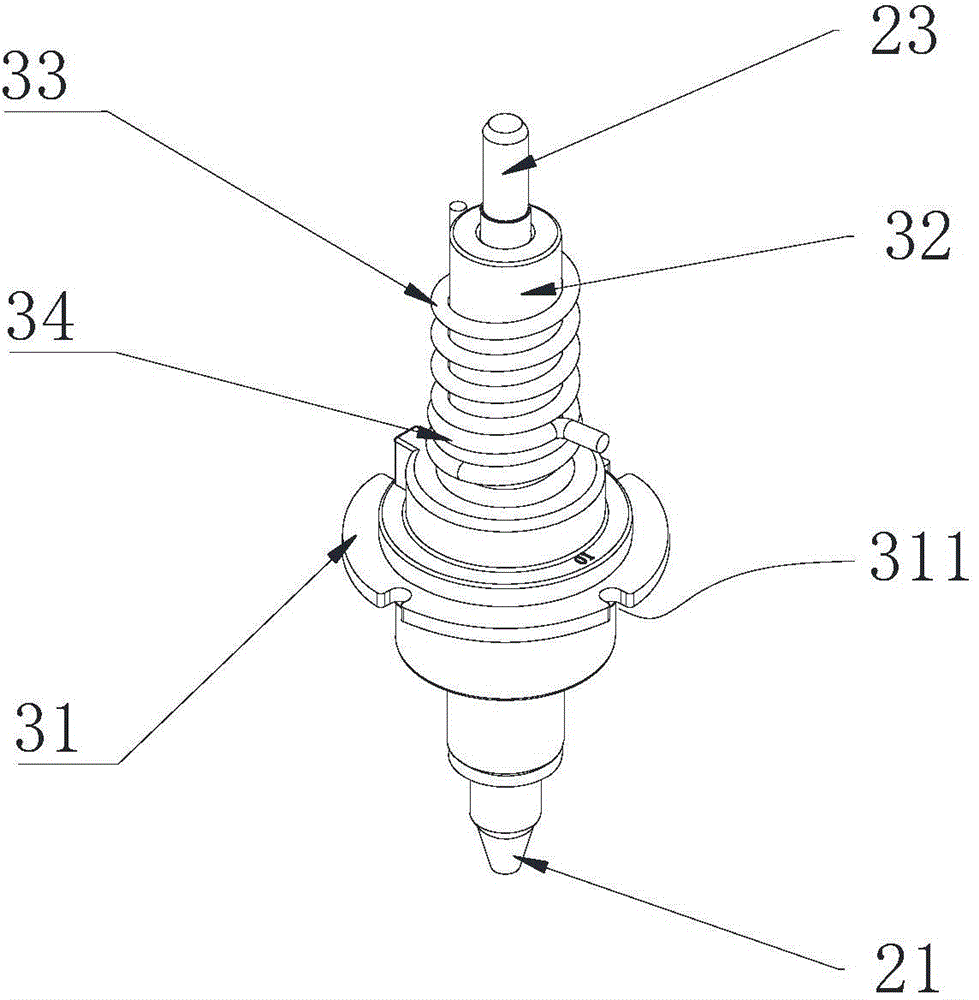

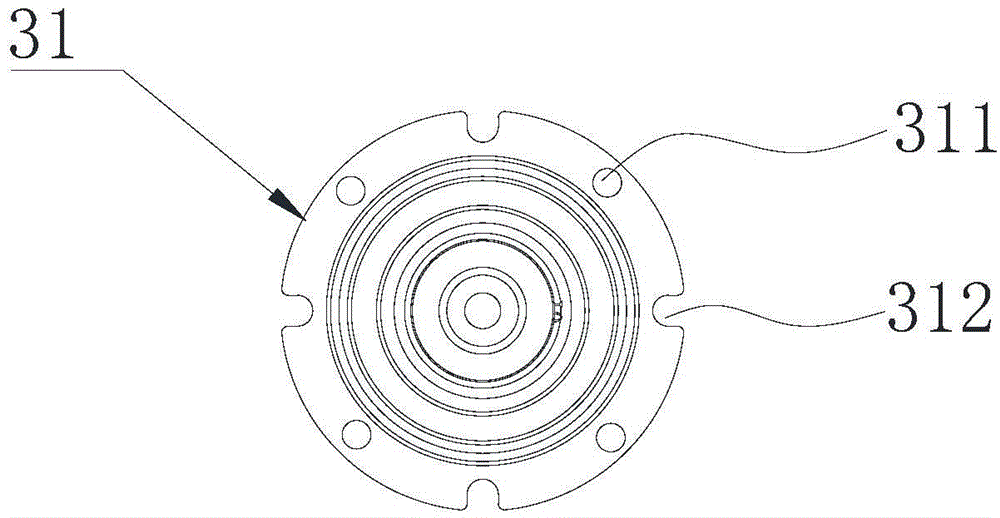

Electronic expansion valve

InactiveCN105587906AEliminate failureGuaranteed connectivityOperating means/releasing devices for valvesEqualizing valvesFiltrationEngineering

The invention provides an electronic expansion valve. The electronic expansion valve comprises a shell, a valve seat, a valve needle and a rotor assembly. The valve seat, the valve needle and the rotor assembly are located in the shell. The rotor assembly drives the valve needle to be matched with the valve seat. The inner space of the shell comprises a main valve cavity and an auxiliary valve cavity. The valve seat is located in the main valve cavity. The rotor assembly is located in the auxiliary valve cavity. The electronic expansion valve further comprises a filtration device. The filtration device is located between the main valve cavity and the auxiliary valve cavity to filter fluid entering the auxiliary valve cavity from the main valve cavity. Due to the fact that the electronic expansion valve comprises the filtration device which is located between the main valve cavity and the auxiliary valve cavity to filter the fluid entering the auxiliary valve cavity from the main valve cavity, impurities in a system where the electronic expansion valve is located cannot enter the auxiliary valve cavity; therefore, the problem that the electronic expansion valve loses efficacy due to the fact that the impurities enter the auxiliary valve cavity can be solved on the basis of ensuring that the main valve cavity and the auxiliary valve cavity communicate with each other.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

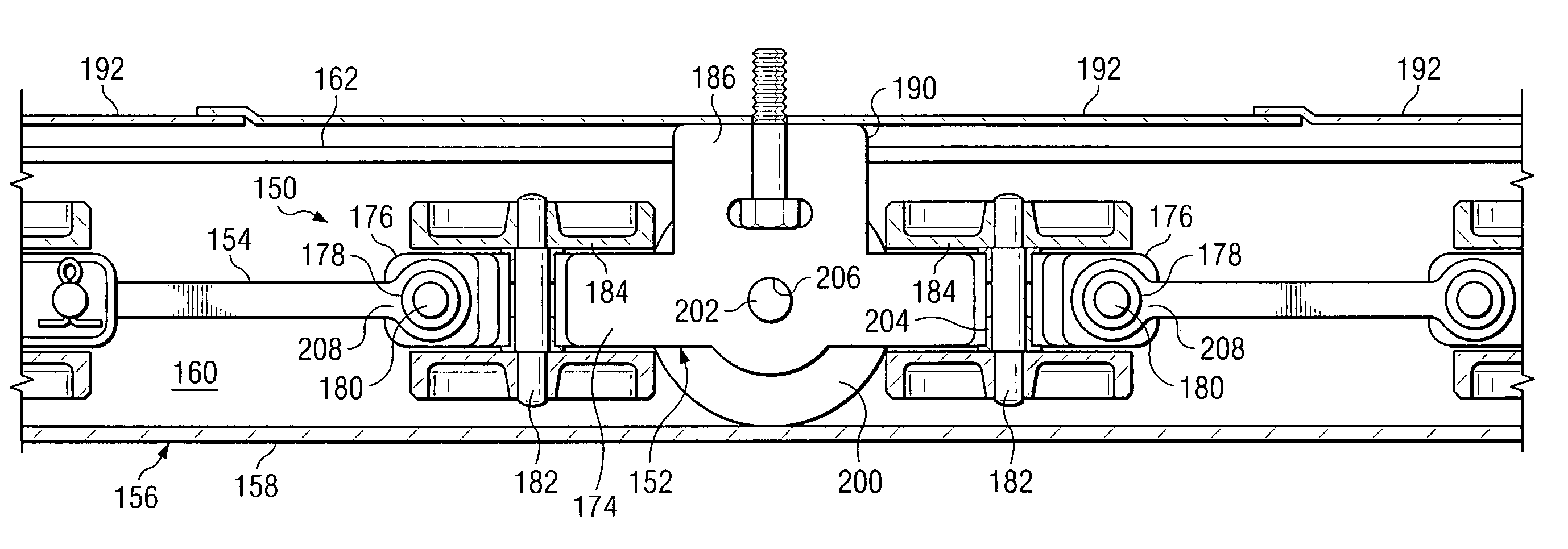

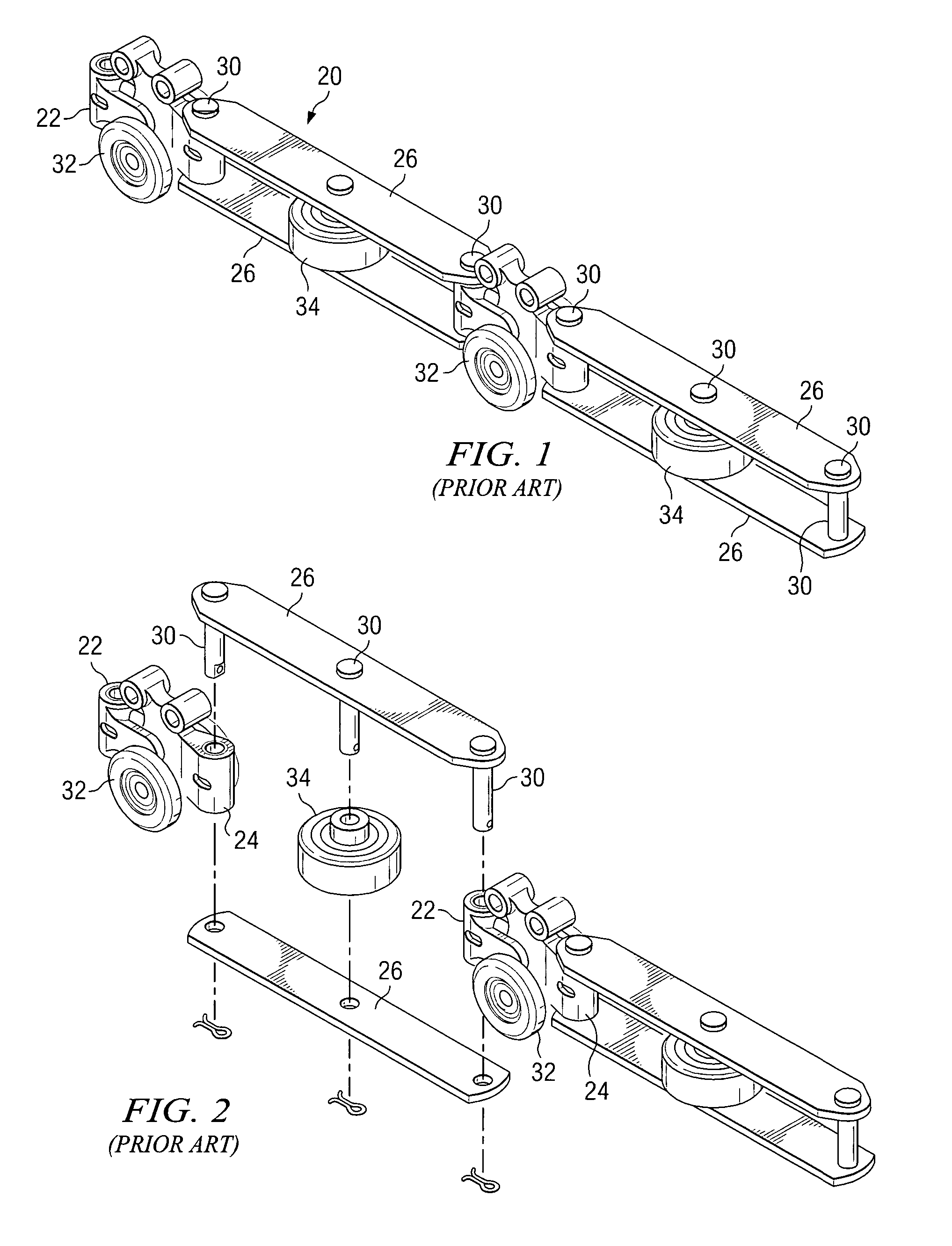

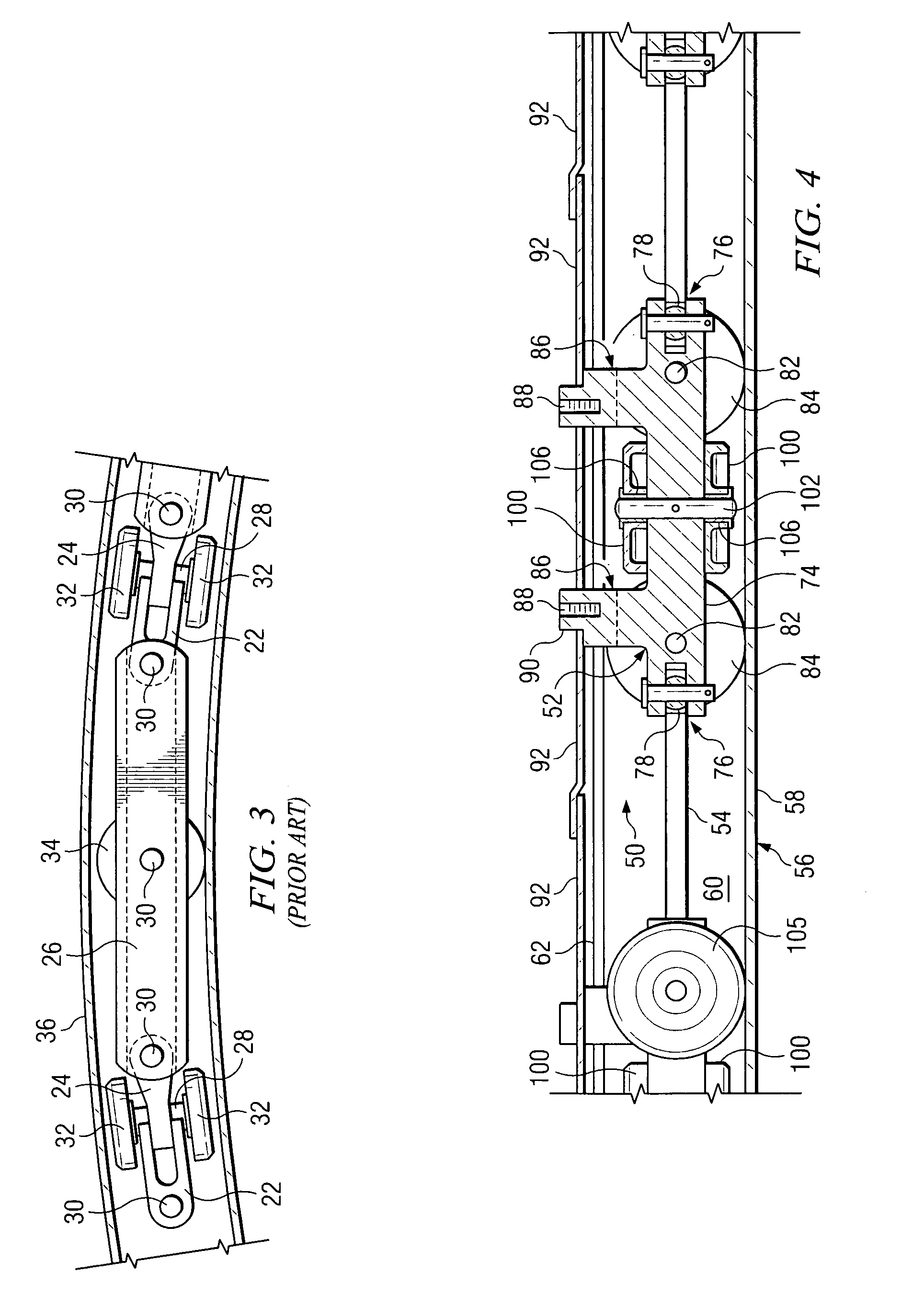

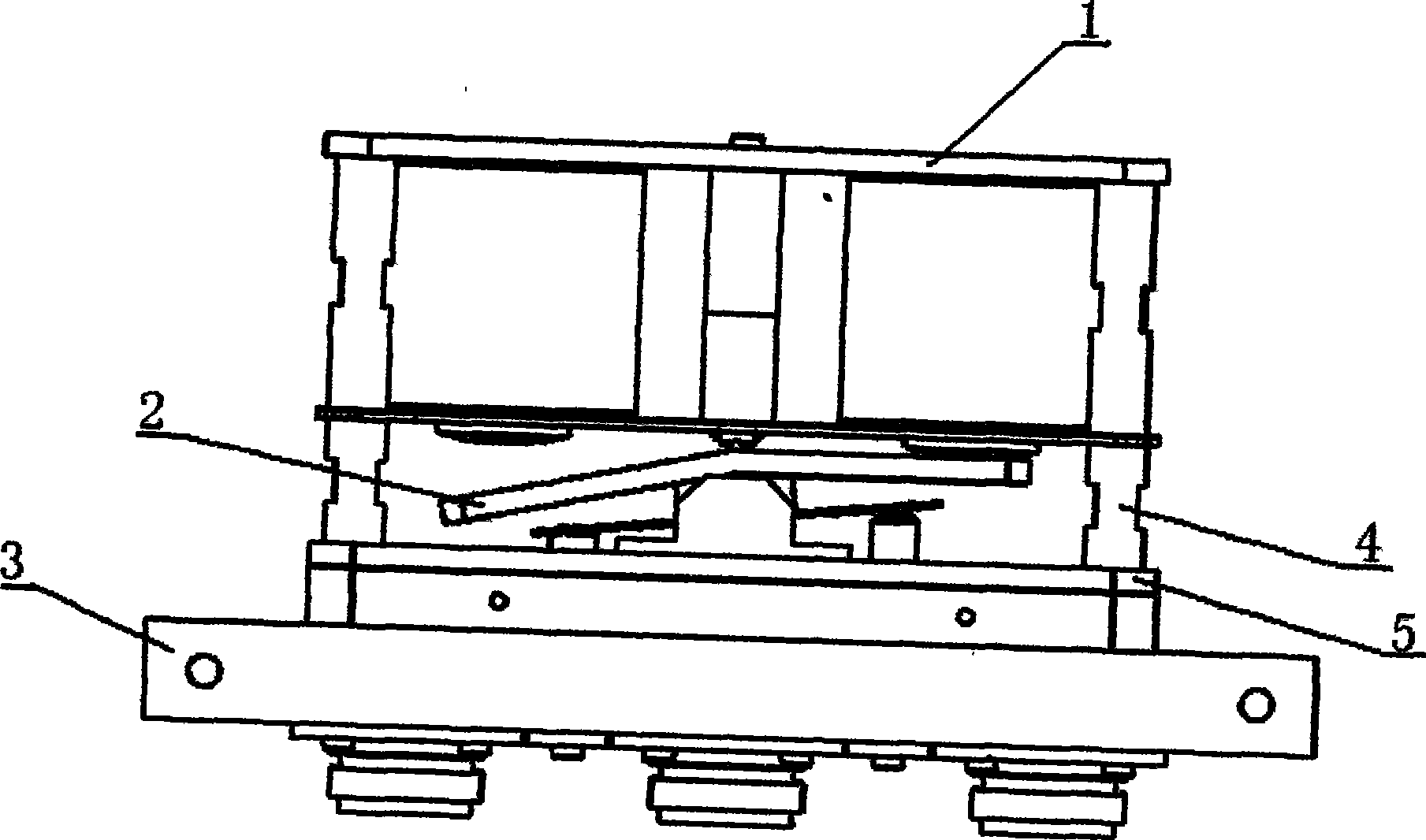

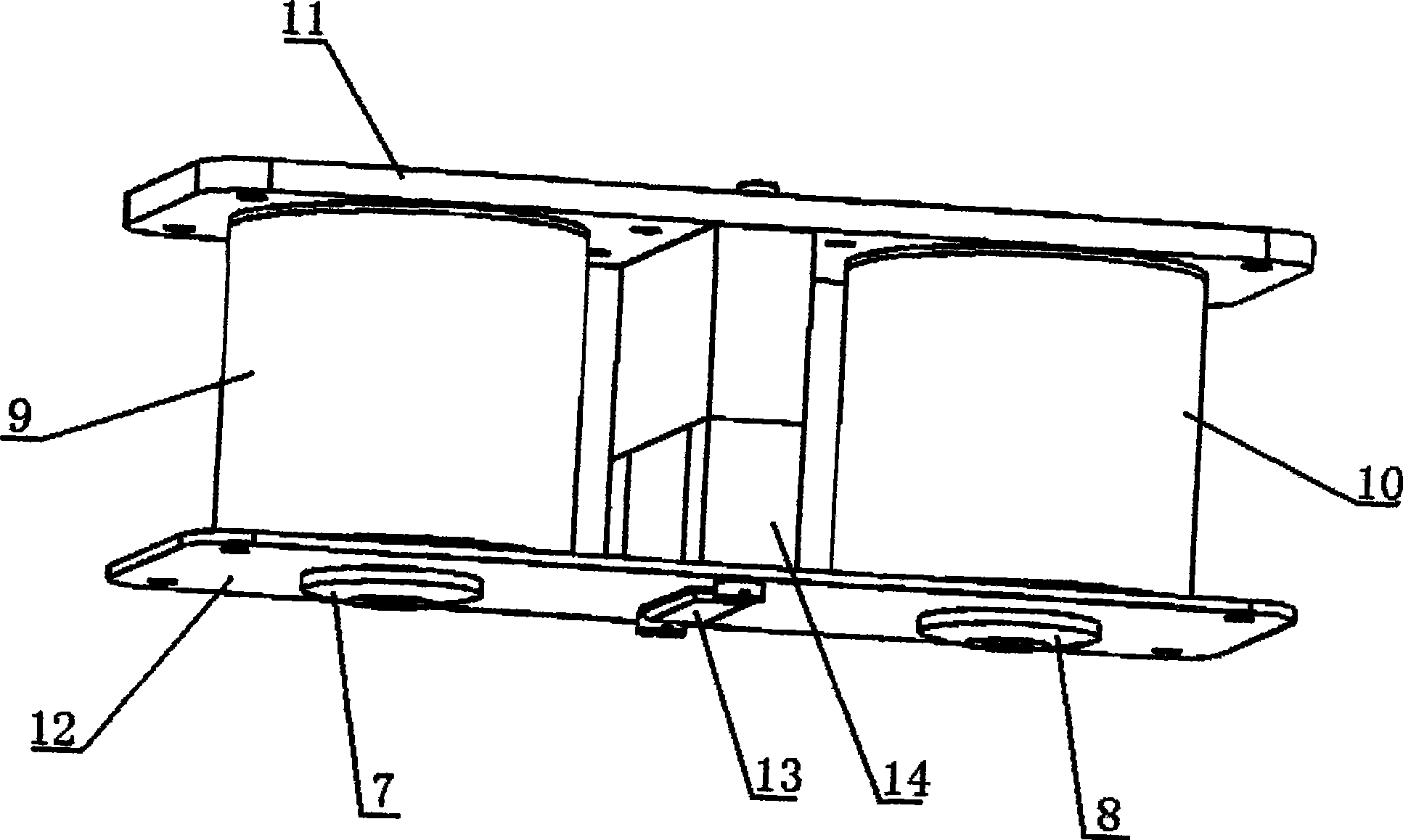

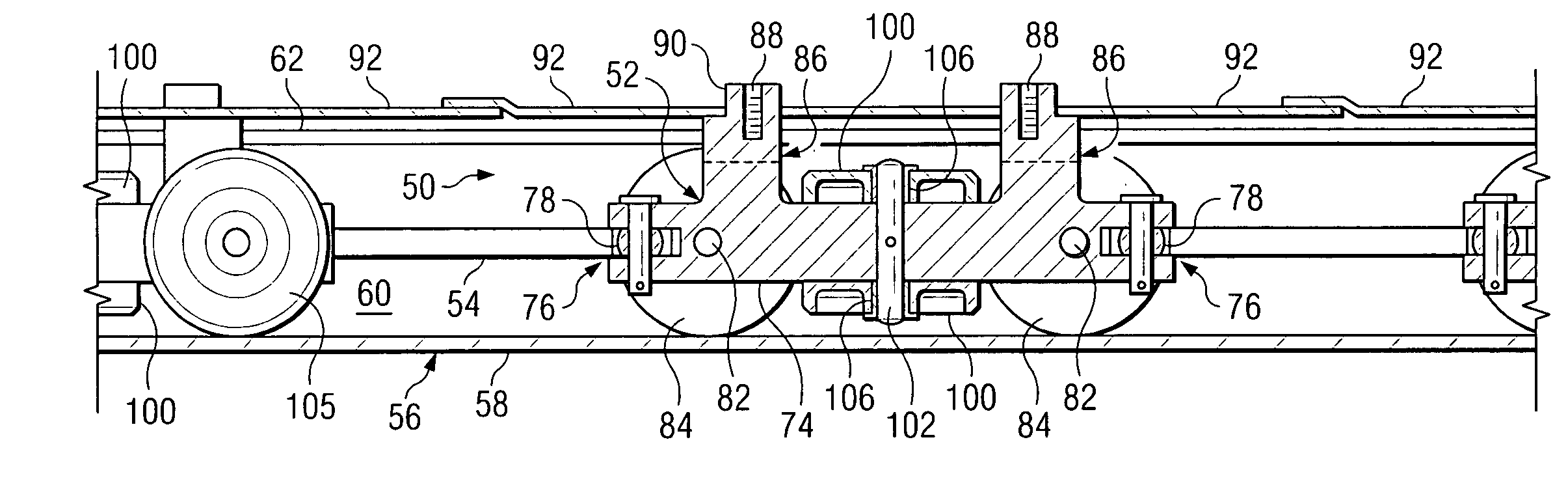

Conveyor for continuous proofing and baking apparatus

InactiveUS7086525B2Low costEliminate failureBearing componentsRollersMechanical engineeringPlain bearing

Conveyor chains of the type utilized in commercial ovens and proofers are provided with improved bearing support for the rotating and pivoting components of the chains. The rotating components comprising antifriction bearings constructed from superior components which support substantial improvements in the service life of the conveyor chains. The pivoting components are provided with plain bearings and / or antifriction coating which also function to extend the service life of the conveyor chains.

Owner:STEWART SYST GLOBAL LLC A TEXAS LIMITED LIABILITY

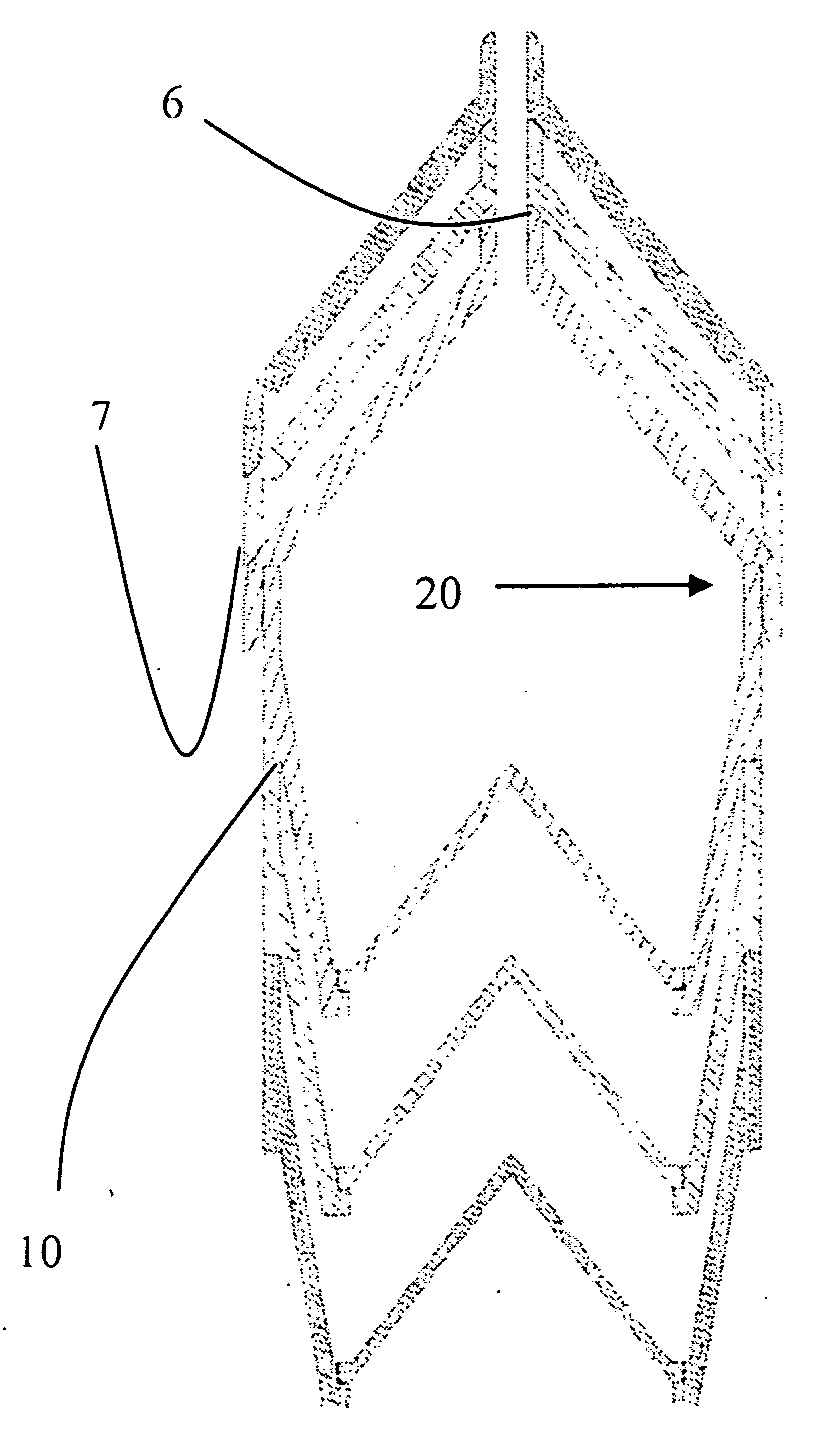

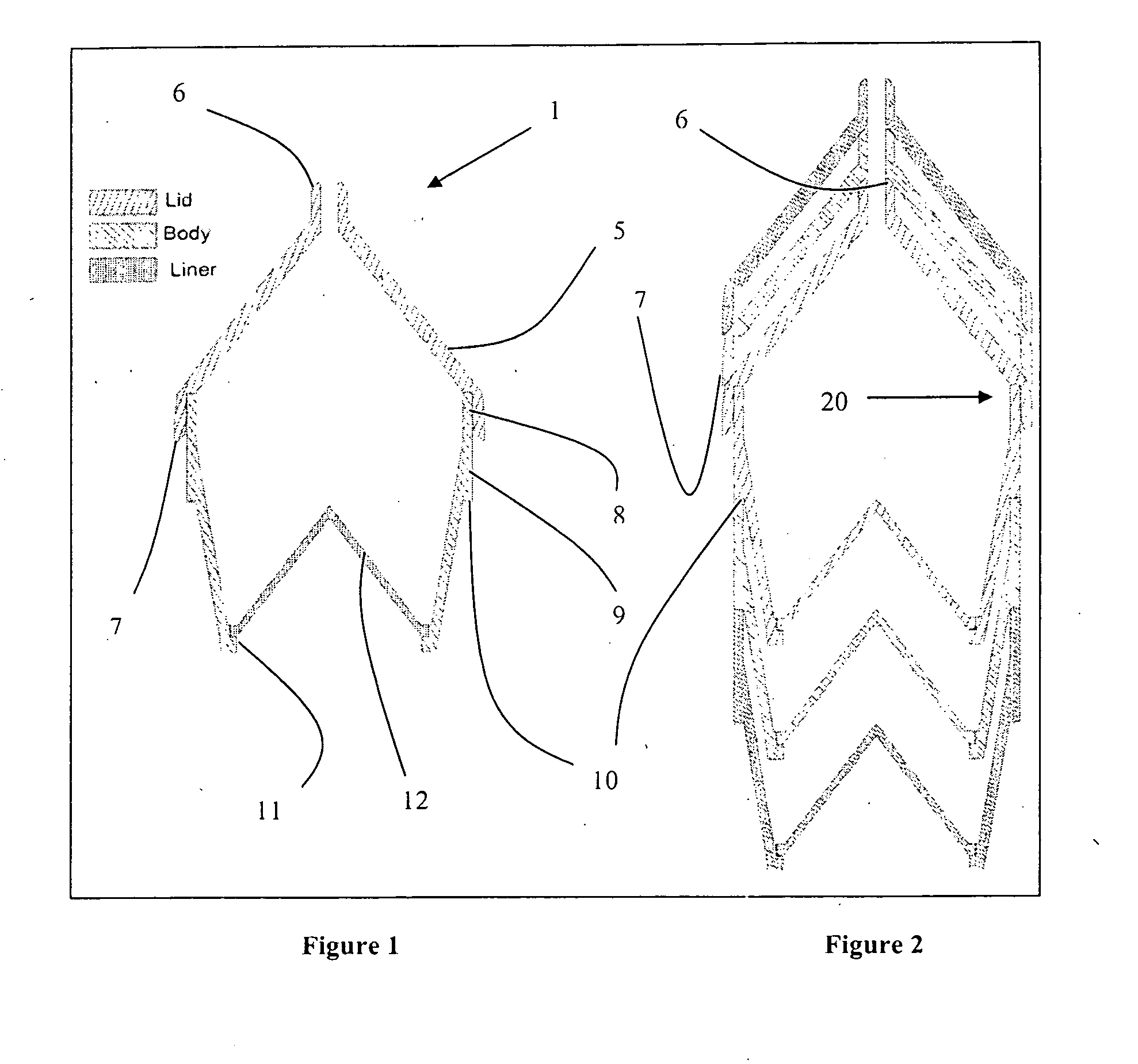

Shaped Charge Casing

ActiveUS20140060369A1Save volumeConvenient nestingAmmunition projectilesExplosive chargesShaped chargeEngineering

A shaped charge casing 1 designed to be nested to reduce overall volume, which benefits storage or carriage. A lid portion 5 is connected at 8 to a body portion 9 by means of a screw thread. A shaped charge liner 12 can be positioned onto lip 11. The lid portion 5 and body portion 9 can be separated to allow filling or unpacking of explosive material.

Owner:THE SEC OF STATE FOR DEFENCE IN HER BRITANNIC MAJESTYS GOVERNMENT OF THE UK OF GREAT BRITAIN & NORTHERN IRELAND

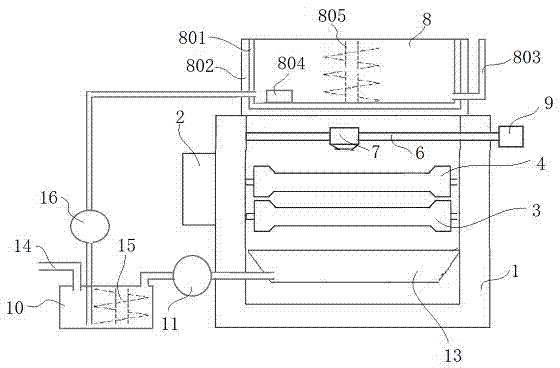

Soundproof-cotton gluing machine application method

ActiveCN104722450AImprove uniformityQuality improvementLiquid surface applicatorsCoatingsAdhesive glueLeather belt

The invention discloses a soundproof-cotton gluing machine application method and belongs to the technical field of gluing machines. The soundproof-cotton gluing machine application method includes the steps of 1), equipment starting, namely respectively starting a gluing mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on a soundproof-cotton gluing machine; 2), gluing, namely allowing glue flowing out from a glue discharging device to flow down along a gap between a gluing roller and a glue mixing roller and a to-be-glued rubber skin to be driven by the gluing roller to move sequentially in gaps of between a glue applying roller and the glue roller as well as between the glue applying roller and the glue mixing roller for gluing; 3), gluing completion, namely allowing the rubber skin coated with the glue to be conveyed to the tail portion of a conveying platform through a conveying belt, wherein the lower surface of the rubber skin is in friction contact with the upper surface of a cushion block, movement speed of the rubber skin is reduced, the rubber skin is taken away by workers, and gluing is completed. With the method, problems that gluing is uneven, waste glue cannot be effectively recycled and the like are solved.

Owner:河北蓝格隔音材料有限公司

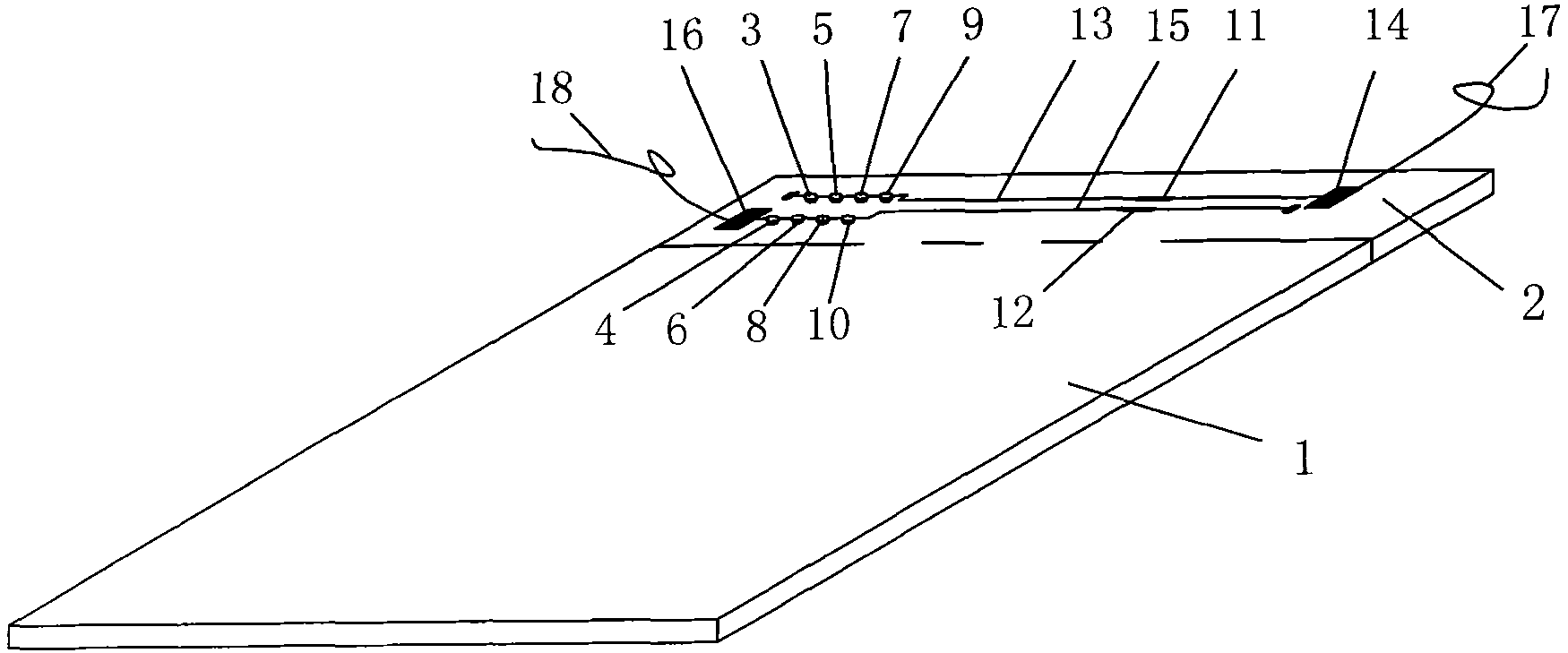

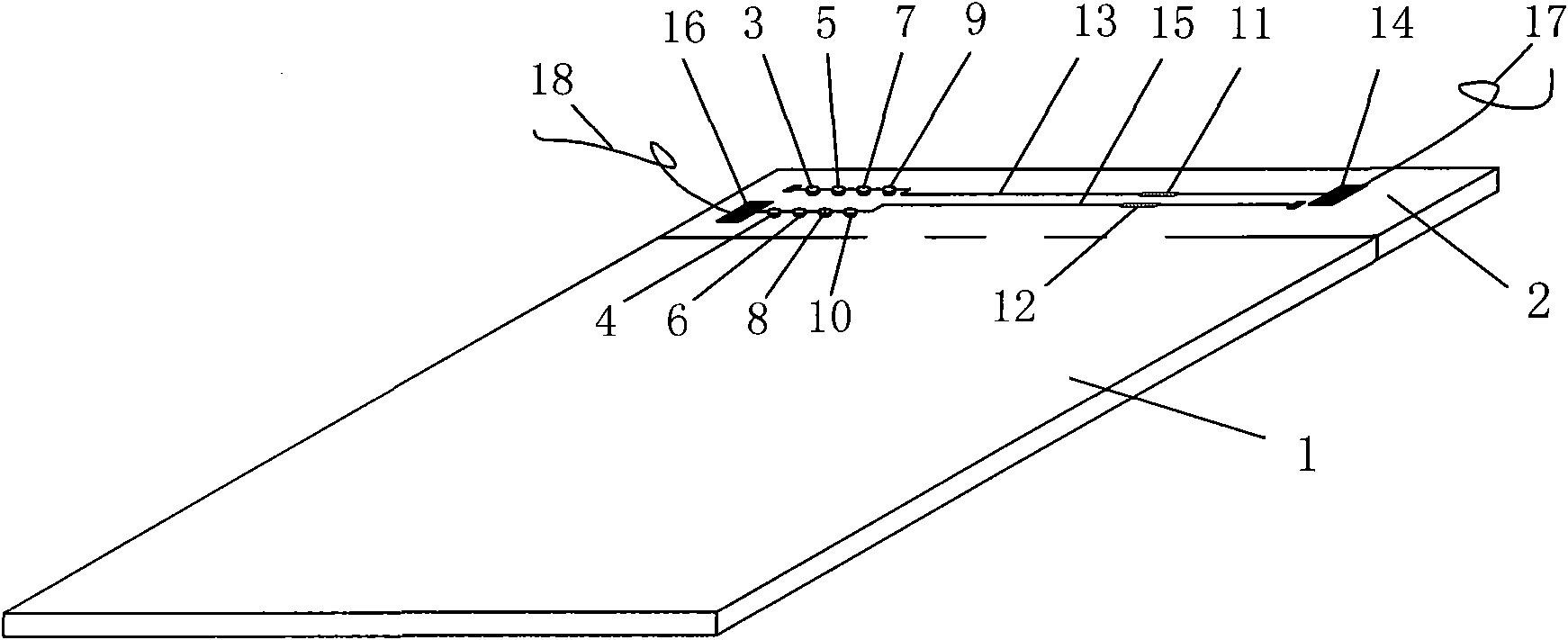

Graphic structure and method for insulation reliability test of finished PCB

InactiveCN101983004AAccurately assess insulationEliminate failureResistance/reactance/impedenceElectrical connection printed elementsElectricityGraphics

The invention discloses a graphic structure for insulation reliability test of a finished PCB, comprising a PCB (1) and a technology edge (2) arranged at one side of the PCB. The graphic structure is characterized in that the technology edge (2) is provided with a plurality of rows of through holes and pads; each row of through holes and pads is connected into a network by a conductor; and a network pad is arranged at one end of the network conductor. The invention also discloses a method for insulation reliability test of the finished PCB. The invention can effectively and accurately test whether the design, materials and technology flow of each PCB can meet the requirement of electrical performance in batch and accurately assess the insulating performances of different PCB so as to stop micro short circuit of the PCB and product failure occurring after unqualified products enter into the markets. The invention can realize small batch test of the samples. The phenomenon similar to micro short circuit of the PCB can be avoided by adopting the method in the earlier stage of PCB design and batch production.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

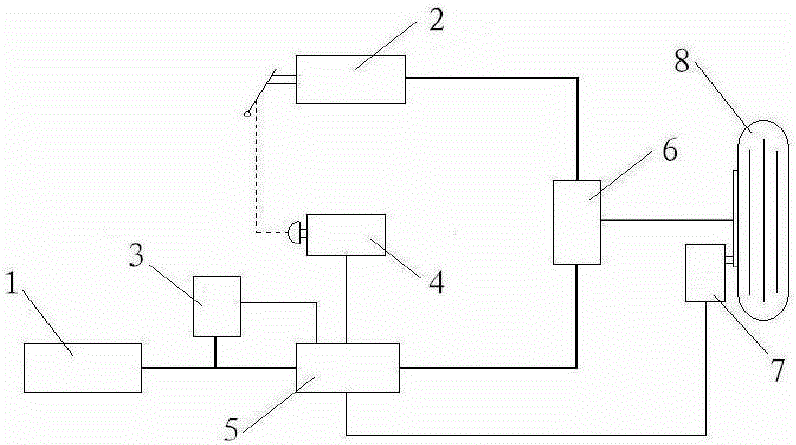

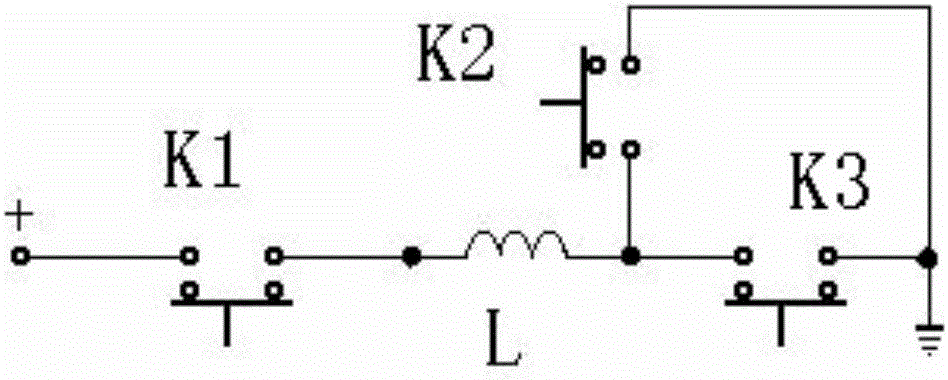

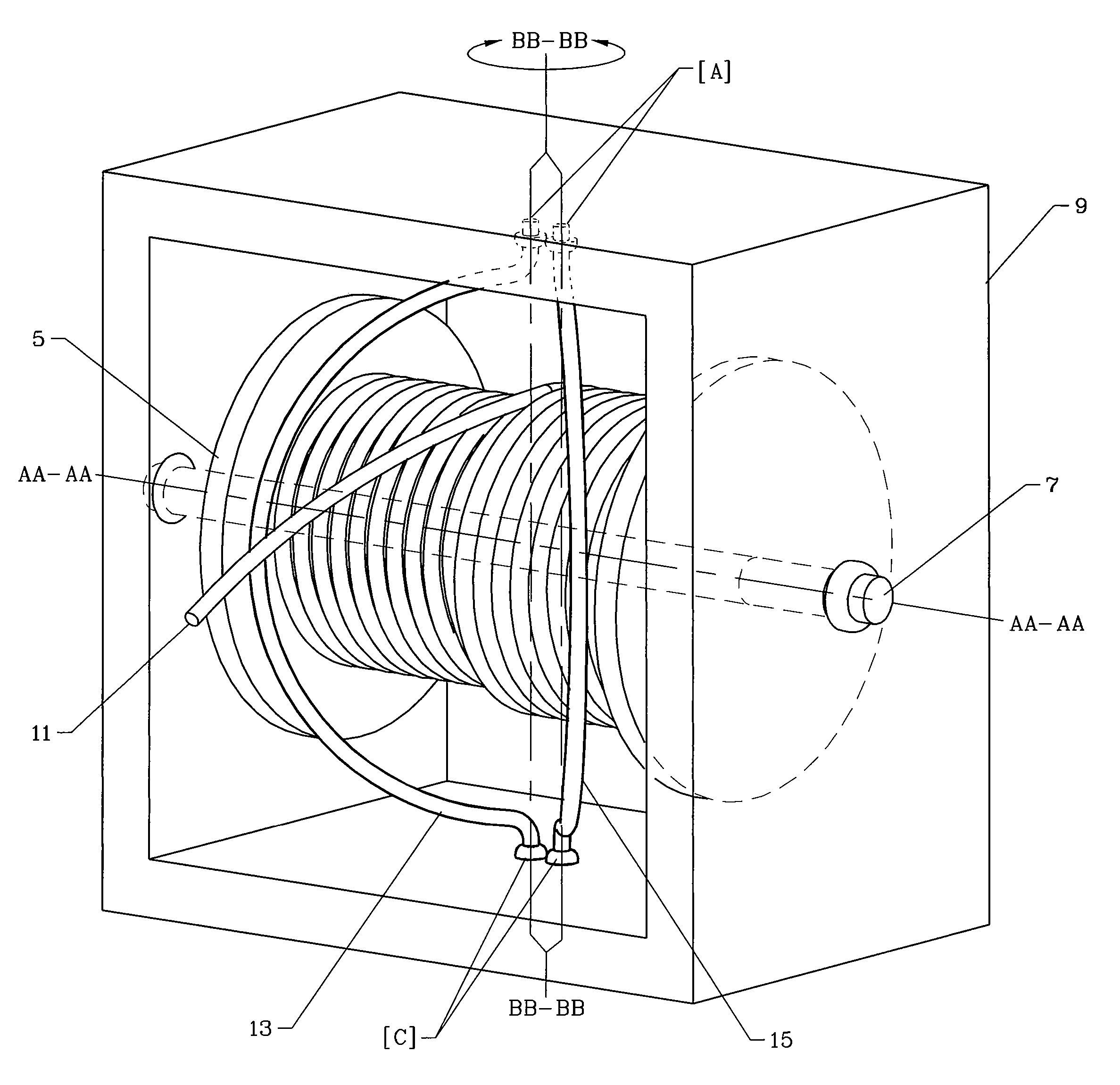

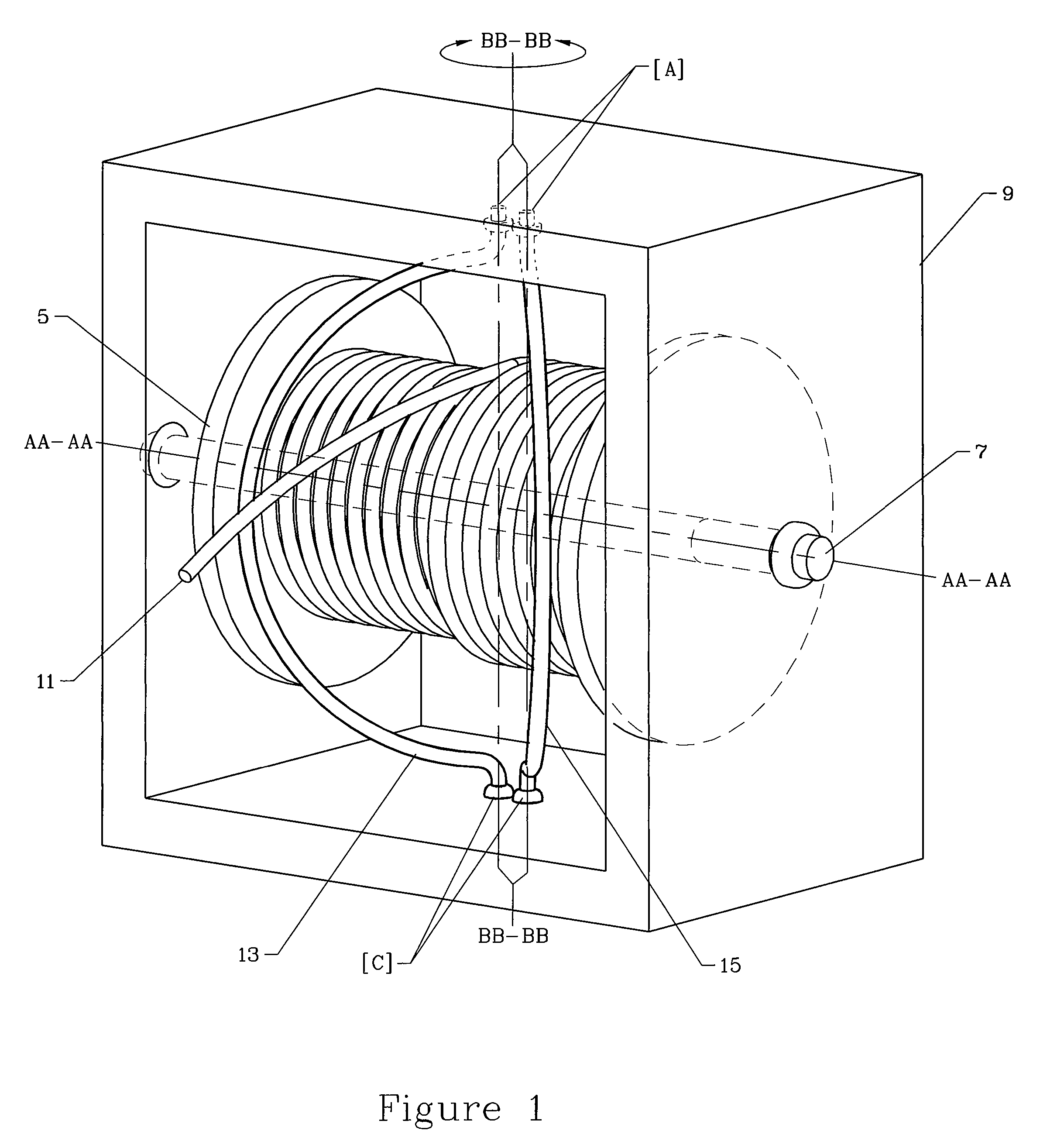

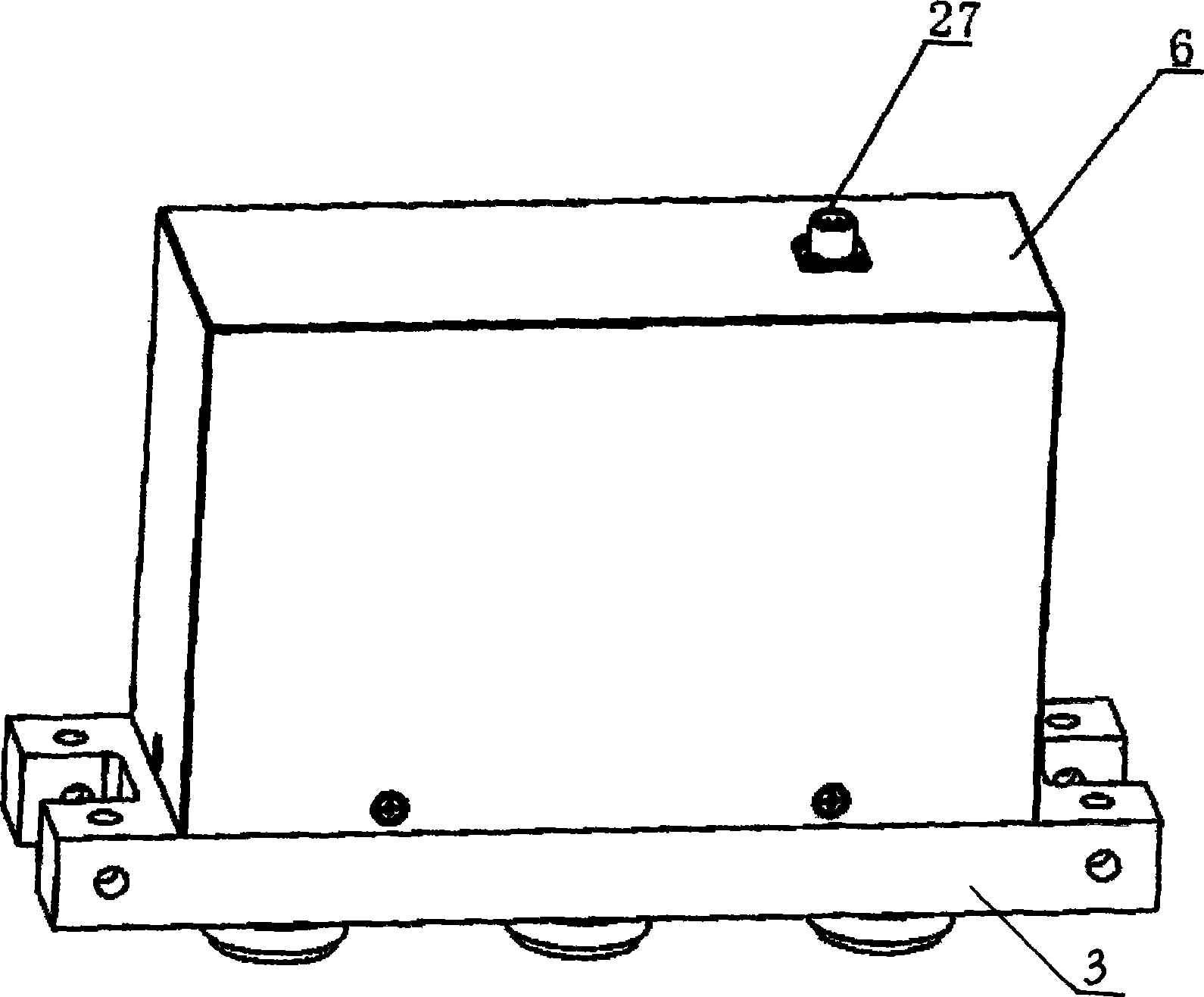

Single-knife dual-close large power coaxial relay

InactiveCN101364502ALow insertion lossEnergy savingElectromagnetic relay detailsPolarised relaysHigh bandwidthMicrowave frequency

The invention relates to a single-pole double throw high-power coaxial relay. An electromagnetic system (1)is fixed on a contact system (3) through an upright post (4); an armature iron part (2) is arranged on a cover plate (5) of the contact system (3) and below the electromagnetic system (1); a closed hood (6)is fixed above the contact system (3); and the electromagnetic system (1), the armature iron part (2) and the cover plate (5) are positioned in the closed hood (6). In the invention, the armature iron part installed on the cover plate of the contact system is driven under the action of the electromagnetic system to rotate, so as to push a push rod of the contact system, and a moveable spring moves freely to complete the contact conversion in the depth direction of a cavity body under the action of the push rod and a reset spring. The invention can work on microwave frequency band with direct current, has very low insertion loss and radio-frequency power transmission capability above 3KW, and is suitable for the occasions, such as high bandwidth, low loss, and high power.

Owner:SHAANXI QUNLI ELECTRIC

Conveyor for continuous proofing and baking apparatus

InactiveUS20050061637A1Low costEliminate failureBearing componentsRollersEngineeringMechanical engineering

Conveyor chains of the type utilized in commercial ovens and proofers are provided with improved bearing support for the rotating and pivoting components of the chains. The rotating components comprising anti-friction bearings constructed from superior components which support substantial improvements in the service life of the conveyor chains. The pivoting components are provided with plain bearings and / or anti-friction coating which also function to extend the service life of the conveyor chains.

Owner:STEWART SYST GLOBAL LLC A TEXAS LIMITED LIABILITY

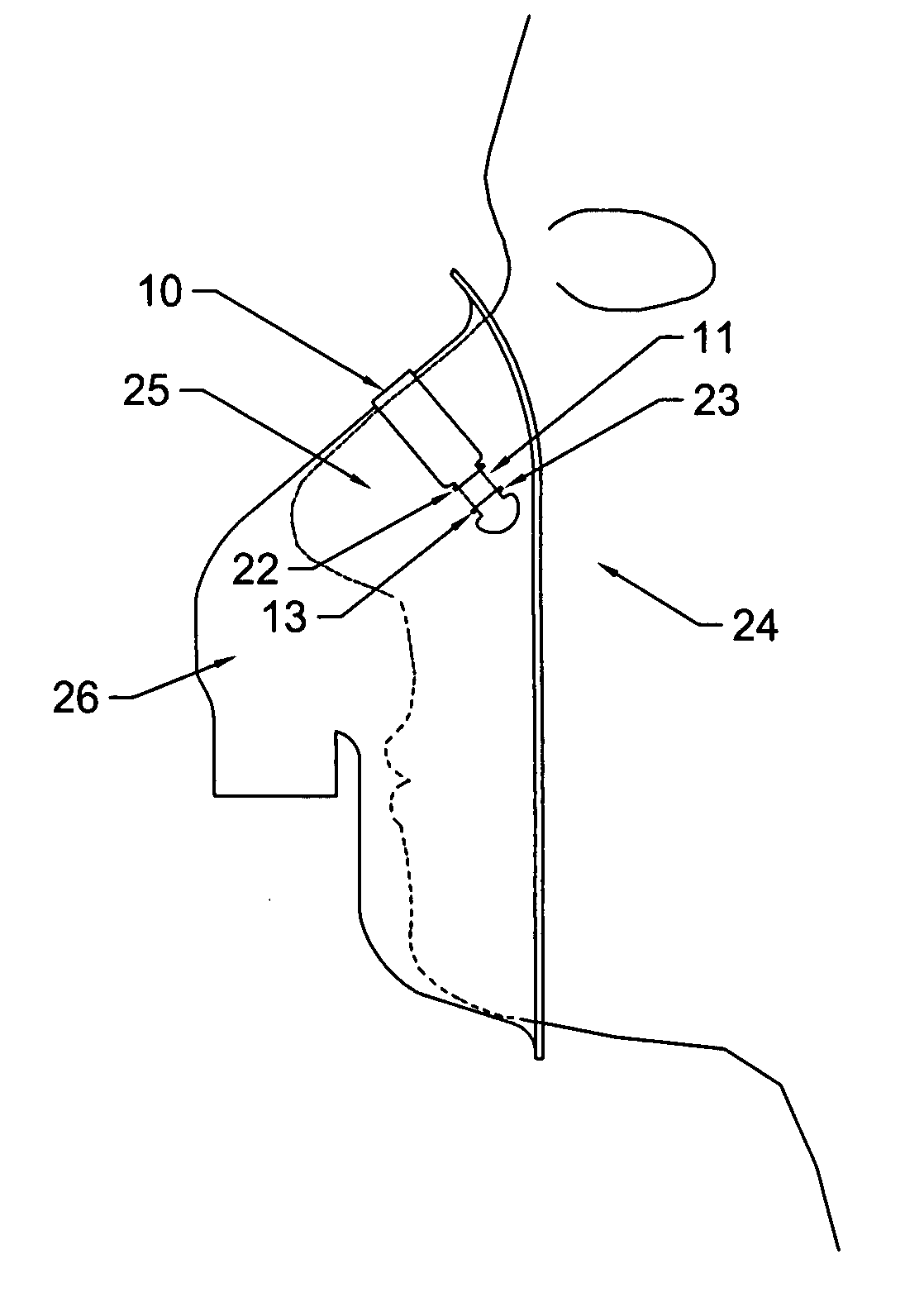

Attachment of a bridge band to an oxygen mask

The present invention is a method by which a bridge band attaches to an interface used to communicate breathing gases to a user. The bridge band contains two opposing recesses towards each end, which create a neck area. The interface contains openings in the nose area that accepts the recesses of the bridge band. There are two parallel openings on each side of the centerline of the mask. One end of the bridge band is inserted into the first opening and then out of the second opening until the recesses are fully engaged in the openings. Accordingly, the second end is laced through the openings in the same manner on the opposite side of the mask. The openings and recesses are sized appropriately such that they will engage together fully and tightly.

Owner:LAU GREGORY YUEN FUN

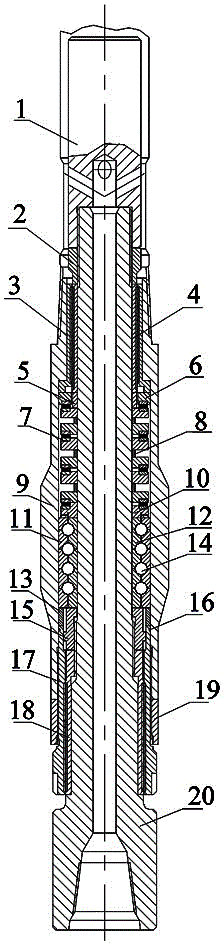

Combined PDC-thrust ball bearing long-life transmission shaft assembly

InactiveCN106285456AReduce wear and tearReduce wearDrilling rodsConstructionsWater savingBall bearing

The invention relates to a combined PDC-thrust ball bearing long-life transmission shaft assembly. The combined PDC-thrust ball bearing long-life transmission shaft assembly comprises a transmission shaft, a lower TC movable sleeve, a lower TC static sleeve, a thrust ball bearing group, a PDC bearing group, an upper TC movable sleeve, an upper TC static sleeve and a transmission shaft shell, wherein the lower TC movable sleeve sleeves part of the shaft head of the transmission shaft; the lower part of the lower TC movable sleeve is connected with the transmission shaft; the lower TC static sleeve is mounted on the outer circumference of the lower TC movable cover in a matched manner; the lower TC static sleeve is connected with the lower end of the transmission shaft shell arranged at the outer circumference of the lower TC static sleeve; an anti-falling half ring, which is coaxial with the lower TC movable sleeve, is arranged at the upper end of the lower TC movable sleeve; the thrust ball bearing group and the PDC bearing group are sequentially mounted on the transmission shaft from top to bottom in a matched manner; the upper TC movable sleeve sleeves the upper part of the transmission shaft; the upper part of the upper TC movable sleeve is connected with that of the transmission shaft; the upper TC static sleeve is mounted on the outer circumference of the upper TC movable sleeve in a matched manner; a universal water-saving cap is also fixed at the upper end of the transmission shaft. The combined PDC-thrust ball bearing long-life transmission shaft assembly has the advantage that the overall service life of a screw drill can be effectively prolonged.

Owner:德州景美石油机械有限公司

Variable pitch rotor blade with double flexible retention elements

ActiveUS20090092493A1Thrust-producing of easilyPower-absorbing of easilyPropellersPump componentsBlade pitchAirplane

A propulsive thrust device for an engine includes a rotor blade and a hub assembly on which the rotor blade is mounted. The rotor blade comprises an airfoil and at least two support members. A propeller thrust device includes a rotor blade, a central hub at which the rotor blade centrifugal load is supported, and an outer hub supporting a control mechanism mechanically connected to the rotor blade and controllable to vary the pitch of the rotor blade on the central hub. A rotor blade for an aircraft engine or in a separate ducted fan housing driven by a powered shaft or gearbox output shaft includes an airfoil and first and second support members attached to the airfoil. An extended arm or portion of the structure at the root of the airfoil of each blade is attached to a controllable mechanism that can vary the pitch of all blades simultaneously.

Owner:AEROCOMPOSITES +1

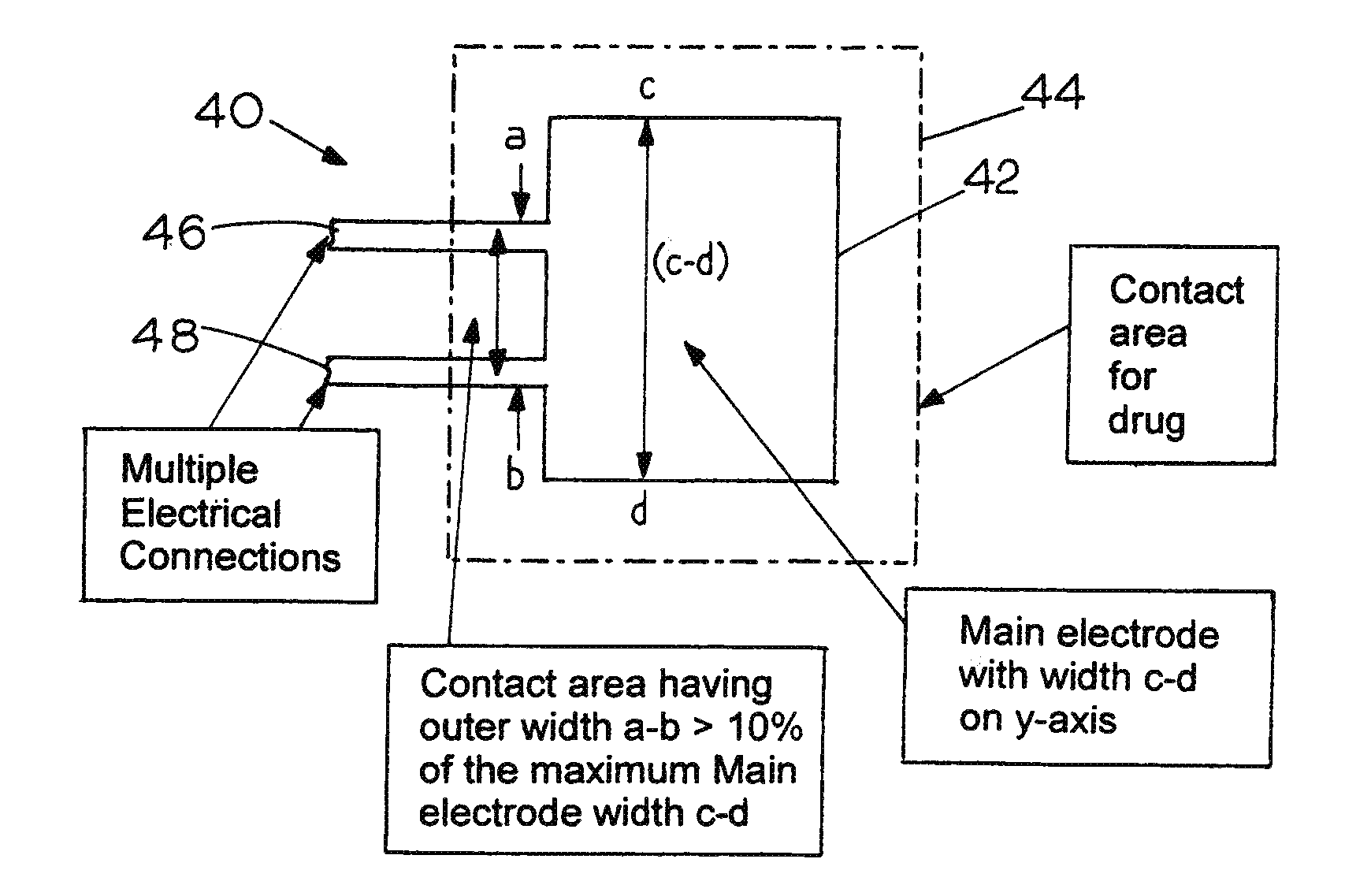

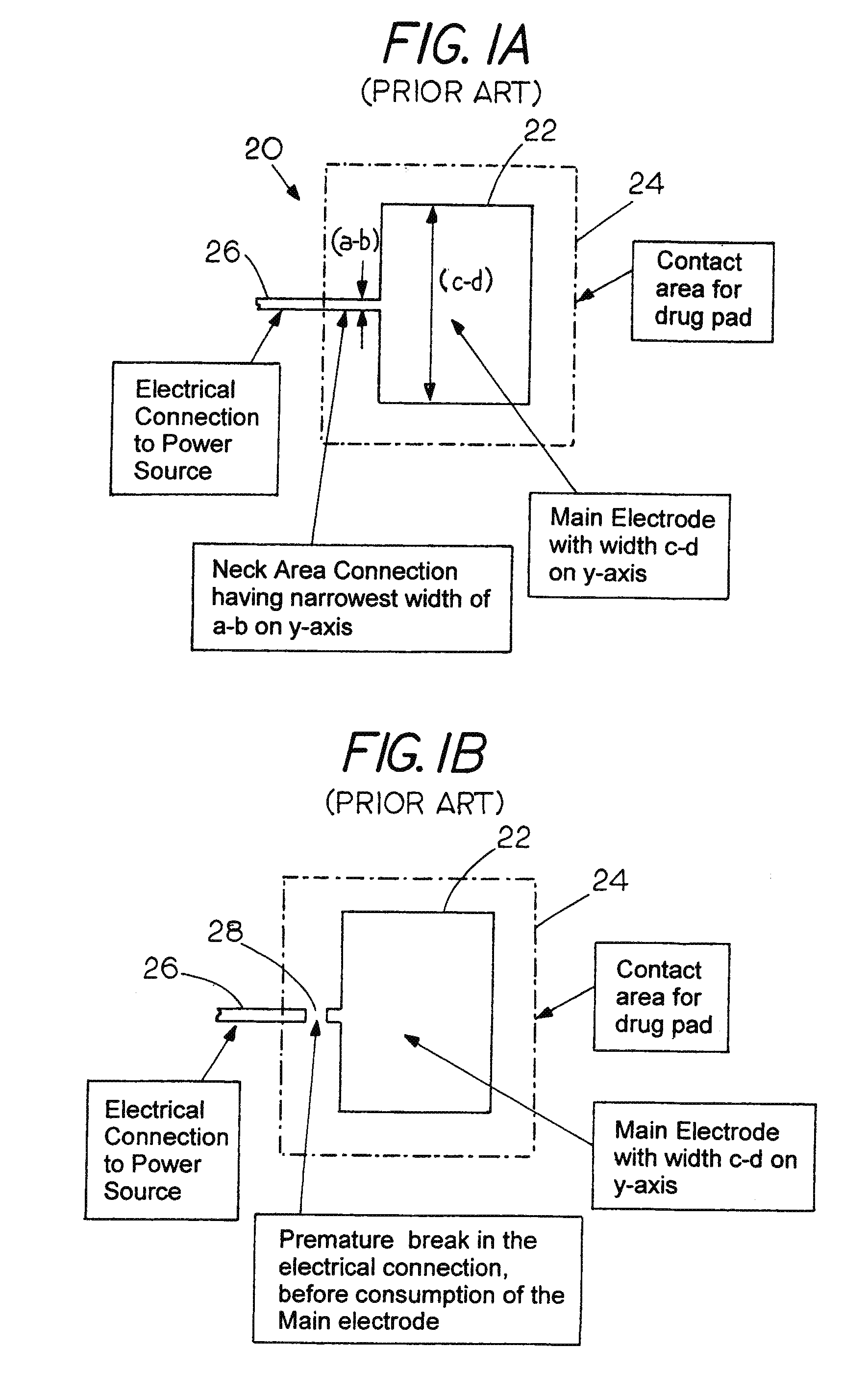

Sacrificial Electrode Design and Delivery Species Suitable for Prolonged Iontophoresis Application Periods

InactiveUS20110245755A1Eliminate premature electrode failureIncrease the effective electrode areaMedical devicesExternal electrodesElectricityOperating life

A wearable iontophoresis device for the prolonged delivery of a positively charged pharmaceutical species from a salt formulation is disclosed that includes a readily oxidizable metal-based sacrificial anode in the form of a generally planar layer having a connecting area that has a width that is sufficient to insure complete consumption of the oxidizable metal wherein the anode is configured to have a minimum operating life of at least 6 hours under skin-safe conditions, and a drug delivery gel pad in electrical contact with said anode for accommodating a gel containing a positively charged pharmaceutical species in salt form formulated for transdermal delivery.

Owner:TEVA PHARMACEUTICALS INTERNATIONAL GMBH

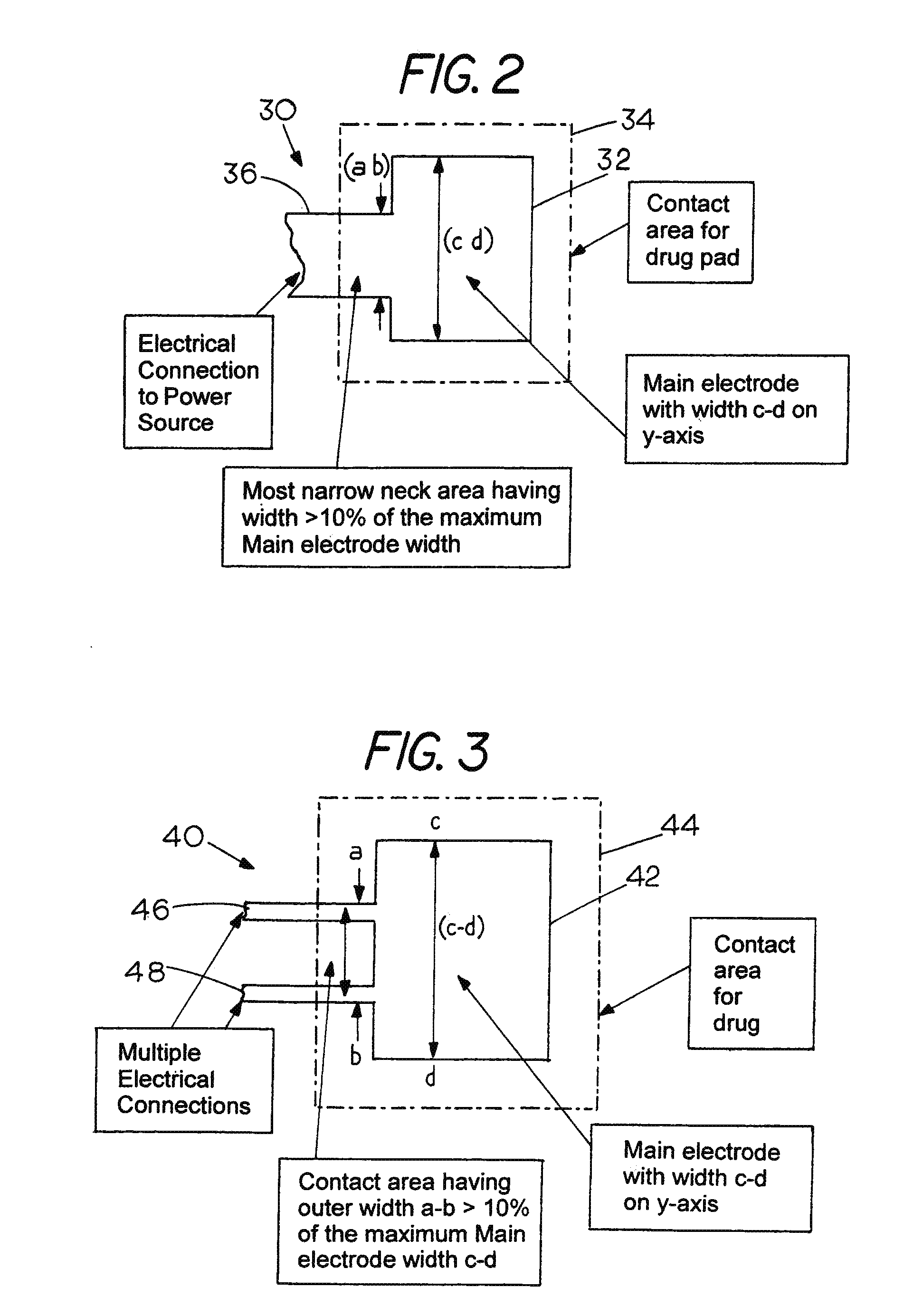

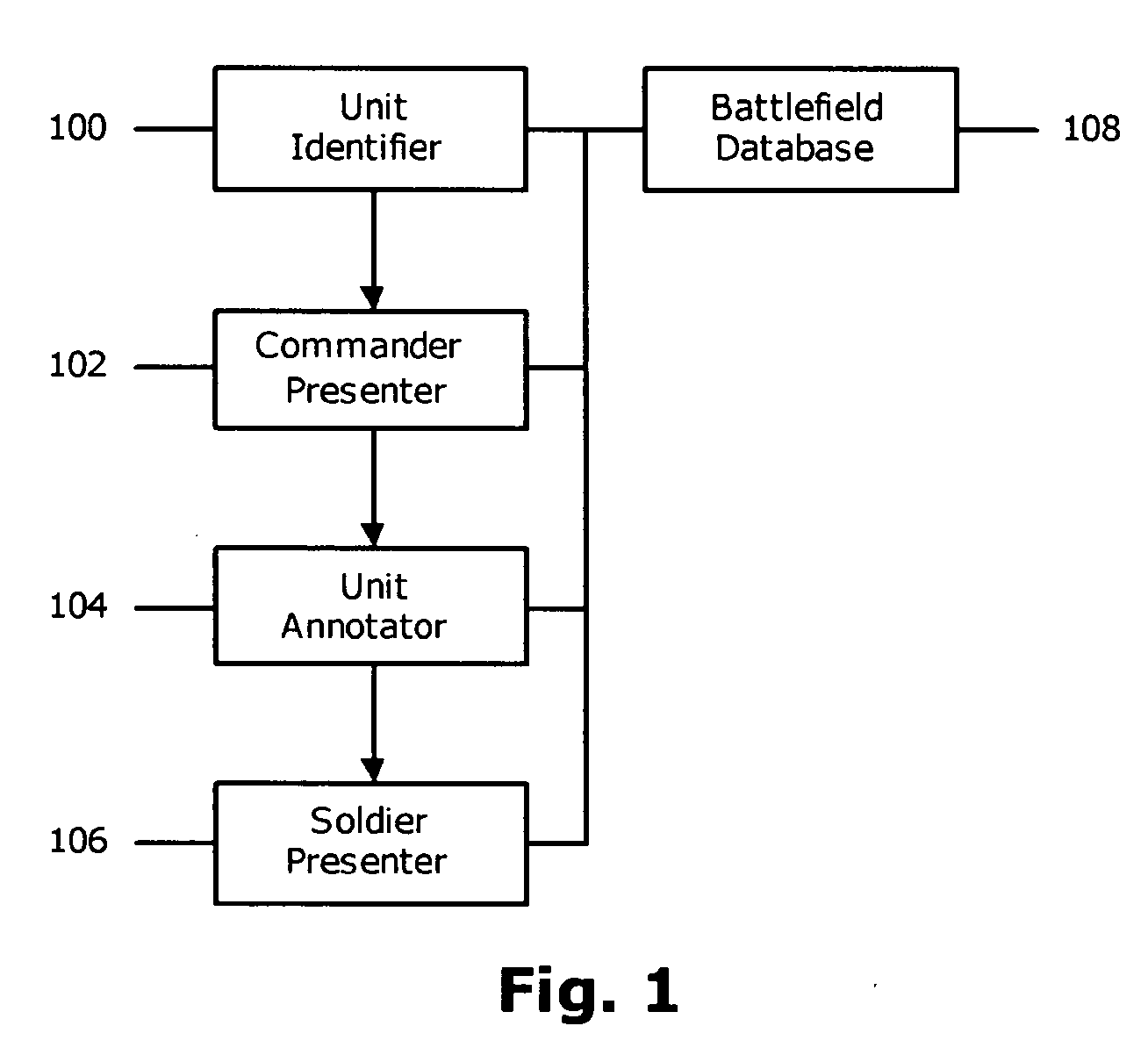

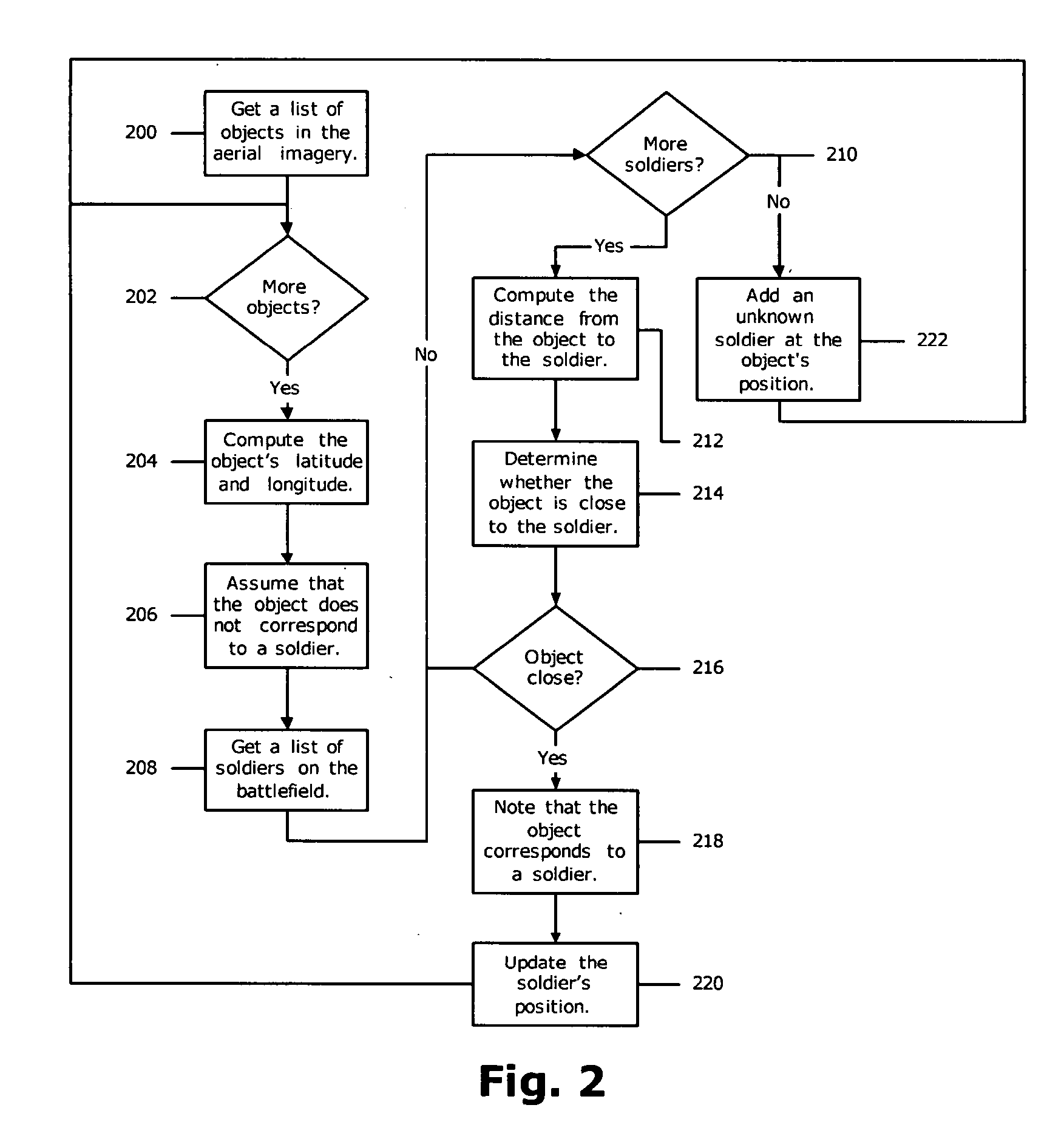

Indicating positions of and directions to battlefield entities in a soldier's head-mounted display

ActiveUS20080008354A1Eliminate failureSusceptible to attackScene recognitionAiming meansHead worn displayAerial image

A computer-implemented method for indicating positions of and directions to battlefield entities in a soldier's head-mounted display using annotated arrows which indicate units both in and out of the soldier's field of view. The method includes a Unit Identifier (100) for associating units in aerial imagery with soldiers on the battlefield, a Commander Presenter (102) for presenting the aerial imagery and unit positions to a commander, a Unit Annotator (104) for enabling commanders to identify unknown units, and a Soldier Presenter (106) for identifying and labeling units that appear in a soldier's head-mounted display.

Owner:PRIMORDIAL

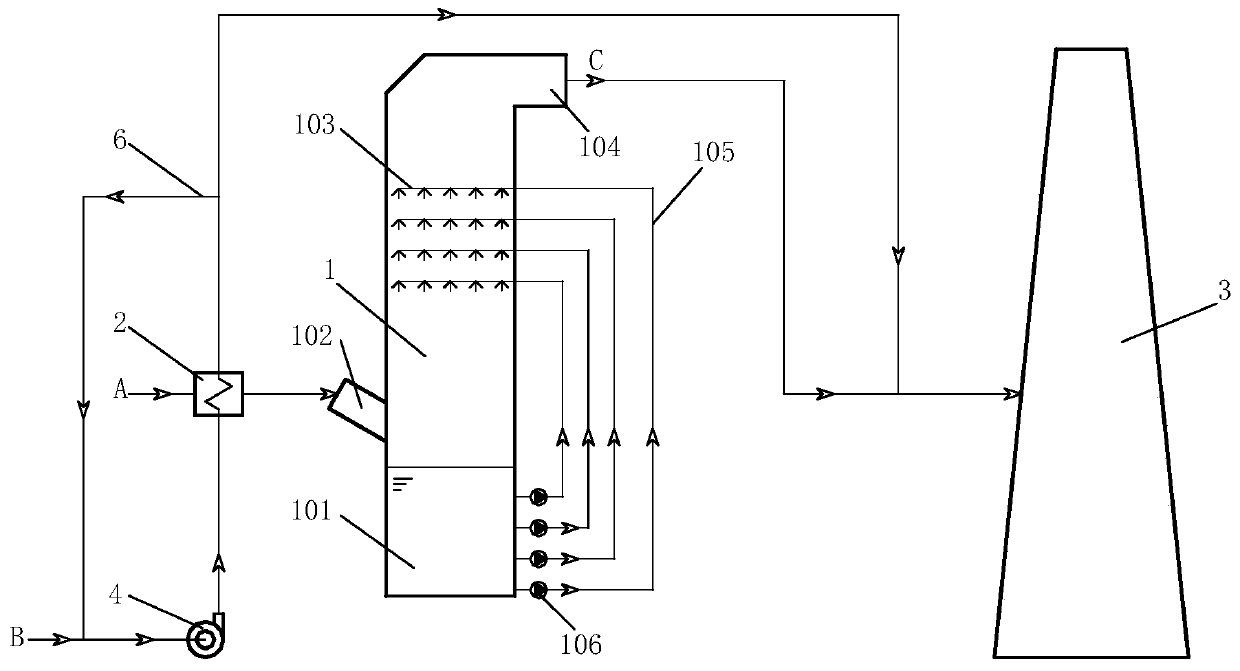

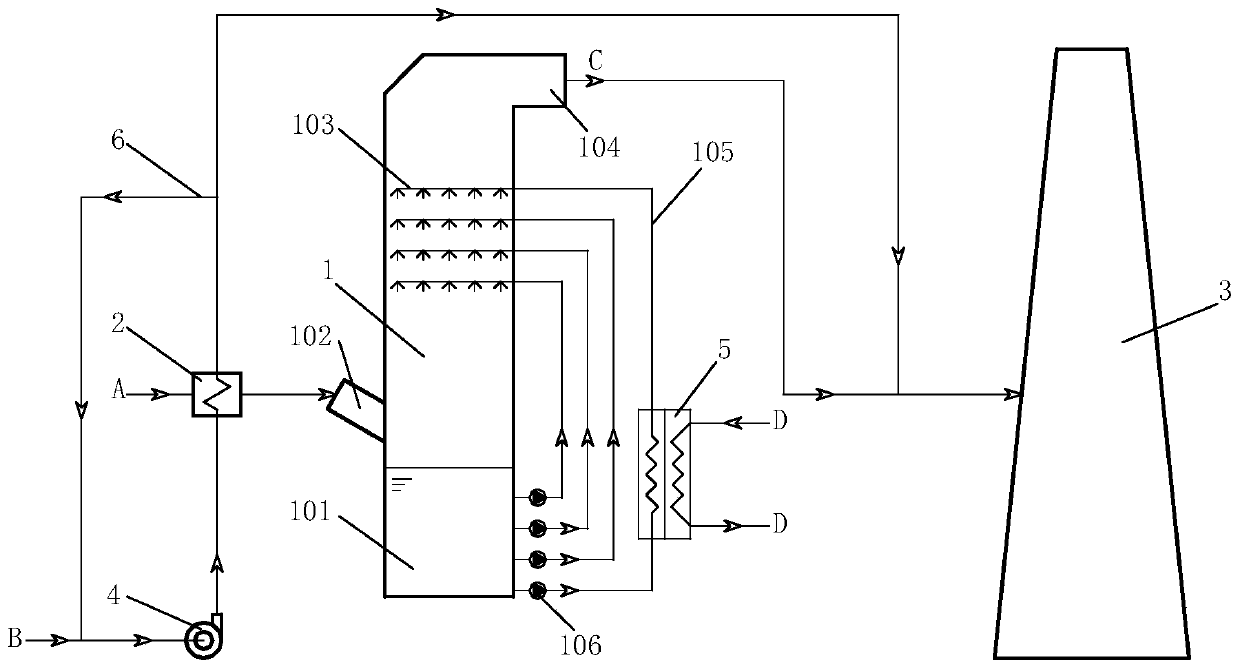

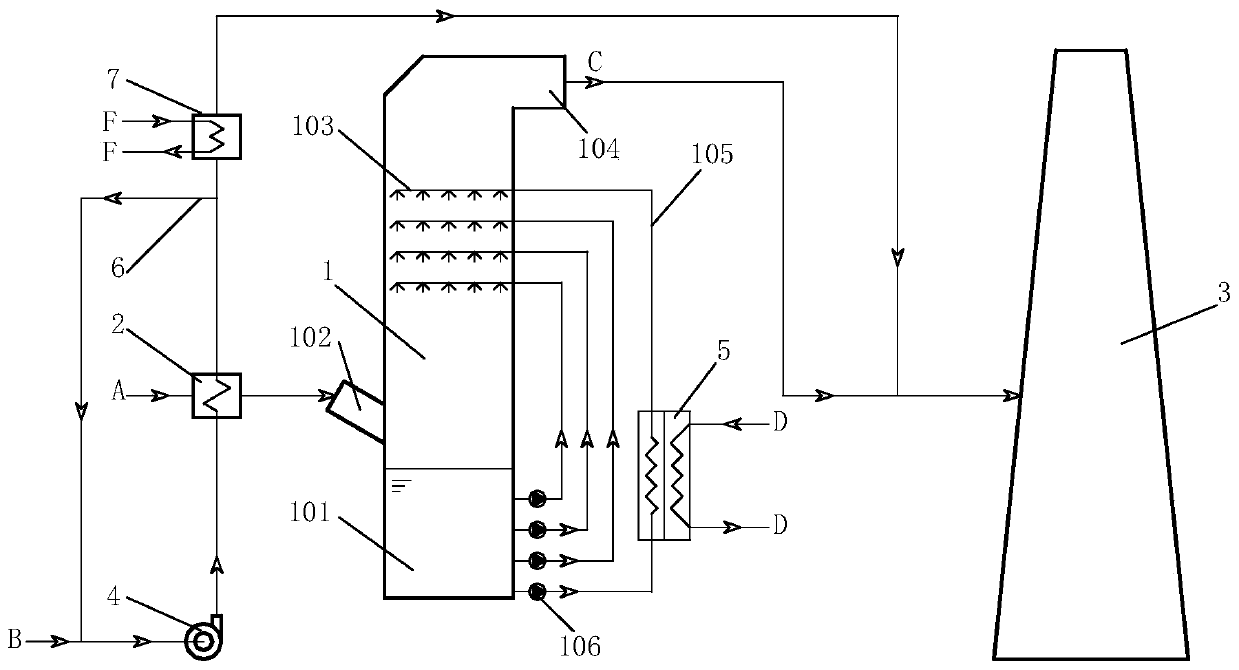

Wet desulphurization and smoke whiteness eliminating system

PendingCN110180344AImprove reliabilityReduce energy consumptionGas treatmentRecuperative heat exchangersSocial benefitsEconomic benefits

The invention relates to a wet desulphurization and smoke whiteness eliminating system, and relates to the fields of wet desulphurization technologies and smoke whiteness eliminating technologies. Thewet desulphurization and smoke whiteness eliminating system comprises an air-smoke heat exchanger, a desulphurization tower, a fan, a chimney, an air bypass, a smoke channel and an air channel, by means of hot air recirculation, air is preheated, then the air is used for exchanging heat with smoke, the smoke enters the desulphurization tower for desulphurization after being cooled, the heated airand the smoke subjected to desulphurization are mixed, temperature is elevated, the humidity is reduced, and the mixed air and smoke are discharged through the chimney, so that smoke whiteness eliminating is achieved. Compared with existing whiteness eliminating technology routes, the wet desulphurization and smoke whiteness eliminating system has the advantages that not only can the problems oflow-temperature corrosion, ash deposition and the like of smoke be effectively solved, but also system equipment is simple, the investment is little, whiteness eliminating modification is simple and easy to implement, and a whiteness eliminating effect is good, so that the wet desulphurization and smoke whiteness eliminating system has excellent economic benefits and social benefits.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

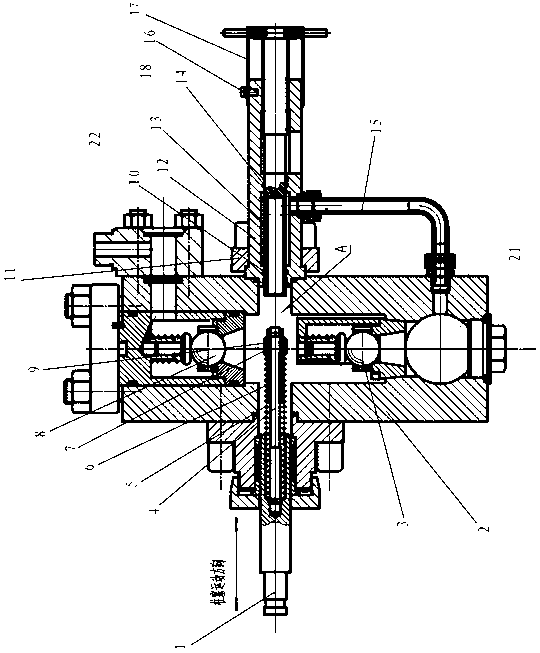

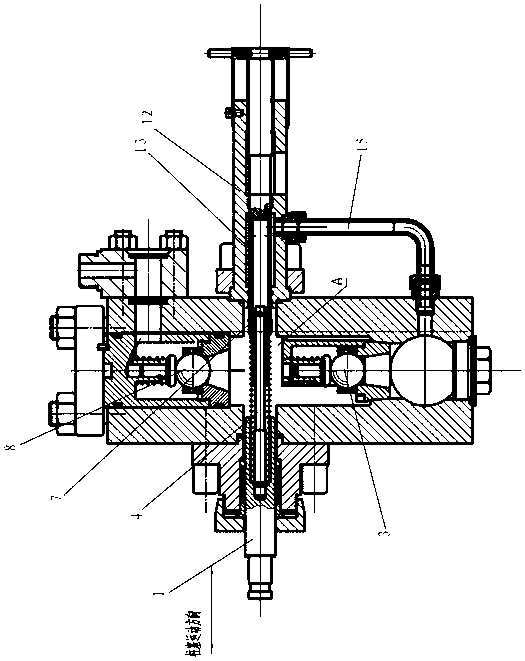

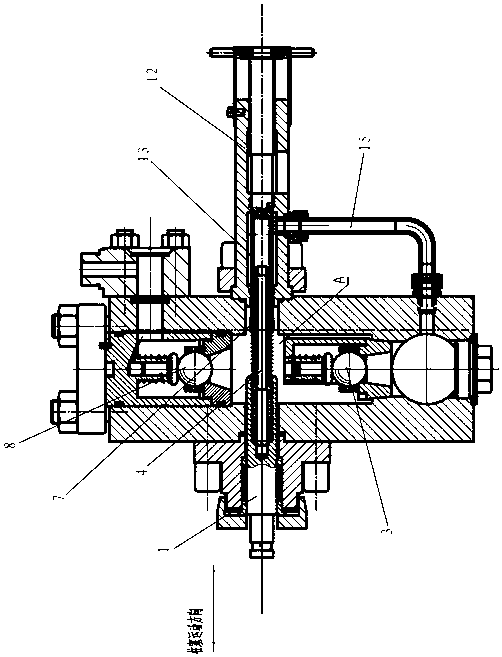

Flow adjusting device capable of changing plunger volume

ActiveCN103267012AEliminate failureExtend your lifePump controlPositive-displacement liquid enginesReciprocating motionEngineering

The invention relates to a flow adjusting device capable of changing a plunger volume. The flow adjusting device is installed on a pump body (2) at the hydraulic end of a plunger reciprocating pump, located at one side, opposite to a plunger (1), of the plunger reciprocating pump, and is located inside a coaxial hole in the same central line of the plunger (1) of the plunger reciprocating pump. The flow adjusting device comprises an adjusting sleeve (12), an adjusting rod (13), and an auxiliary plunger (4) which is arranged on the end portion of the plunger of the plunger reciprocating pump coaxially. The flow adjusting device is characterized in that a plunger hole is formed inside the end portion of the plunger (1) of the plunger reciprocating pump, one end of the auxiliary plunger is arranged inside the plunger hole, the other end of the auxiliary plunger is installed inside a valve core (7) in a sliding, sealing and matching mode, the valve face of the valve core (7) can be matched with the valve face of the adjusting rod to realize the purpose of opening or closing of the valve face of the adjusting rod, and the auxiliary plunger (4) can move reciprocally under the driving of the plunger (1) and can move into and out of a through hole (131) inside the adjusting rod (13). The flow adjusting device is applicable to plunger reciprocating pumps with high pressure and large flow.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com