Flow adjusting device capable of changing plunger volume

A technology of flow regulating device and plunger, which is used in liquid variable capacity machinery, pump control, machine/engine, etc., and can solve the problems of large shock and vibration, high noise, unable to meet the application of pressure and large flow plunger reciprocating pump, etc. , to achieve the effect of improving life, small viscosity loss and smooth flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

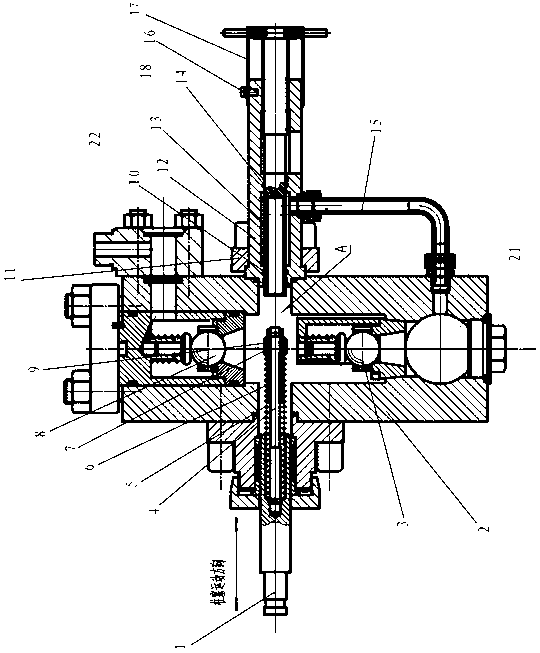

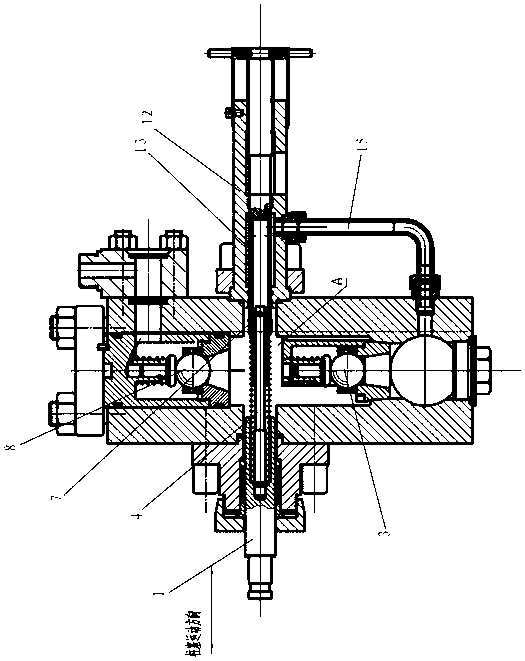

[0036] Specific as figure 1 , figure 2 , image 3 As shown, the plunger reciprocating pump mainly includes a pump body 2, a plunger 1 fitted in the plunger hole of the pump body, a suction valve group 3 and a discharge valve group 8 arranged in the pump body 2, wherein:

[0037] The pump body 2 is provided with an inlet 21 and an outlet 22, as well as a plunger hole for setting the plunger 1, and valve chambers for setting the suction valve group 3 and the discharge valve group 8 respectively, while the pump chamber A of the pump body is It is enclosed by a plunger, a suction valve group, a discharge valve group and the flow regulating device provided by the present invention.

[0038] The plunger 1 is slidingly fitted in the plunger hole of the pump body 2, and is driven to perform reciprocating linear motion in the plunger hole.

[0039] The flow regulating device provided by the present invention is installed on the pump body 2, located on the opposite side of the plung...

Embodiment 2

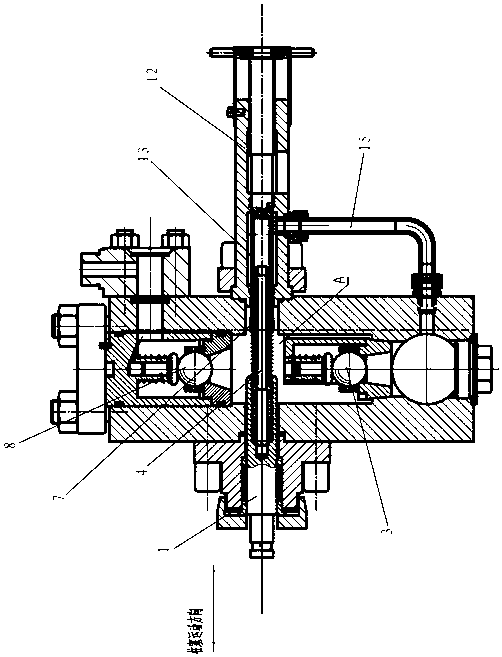

[0055] Specific as Figure 4 , Figure 5 with Image 6 Shown, different from embodiment one is:

[0056] The sealing of spool 7 and auxiliary plunger 4 is changed into the inner hole sealing of small piston 19 and adjusting rod 13, and all the other remain unchanged. That is: the inner hole of the spool 7 is directly slidably matched with the outer diameter of the auxiliary plunger 4, the guide seal 8 is canceled, the spring guide sleeve 6 is threaded at one end of the spool 7, and a coaxial step is added at the valve face end of the spool 7 hole. A pillow block is added to the end of the locking nut installed on the auxiliary plunger 4 for installing the small piston 19 . The small piston 9 is fixed on the end of the auxiliary plunger 4 with a lock nut. The through hole of the adjusting rod 13 must be finished and sealed with the outer diameter of the small piston 19 .

[0057] Its working principle is as follows: when the plunger 1 moves backwards for suction, the smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com