Patents

Literature

648results about How to "Increase centrifugal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

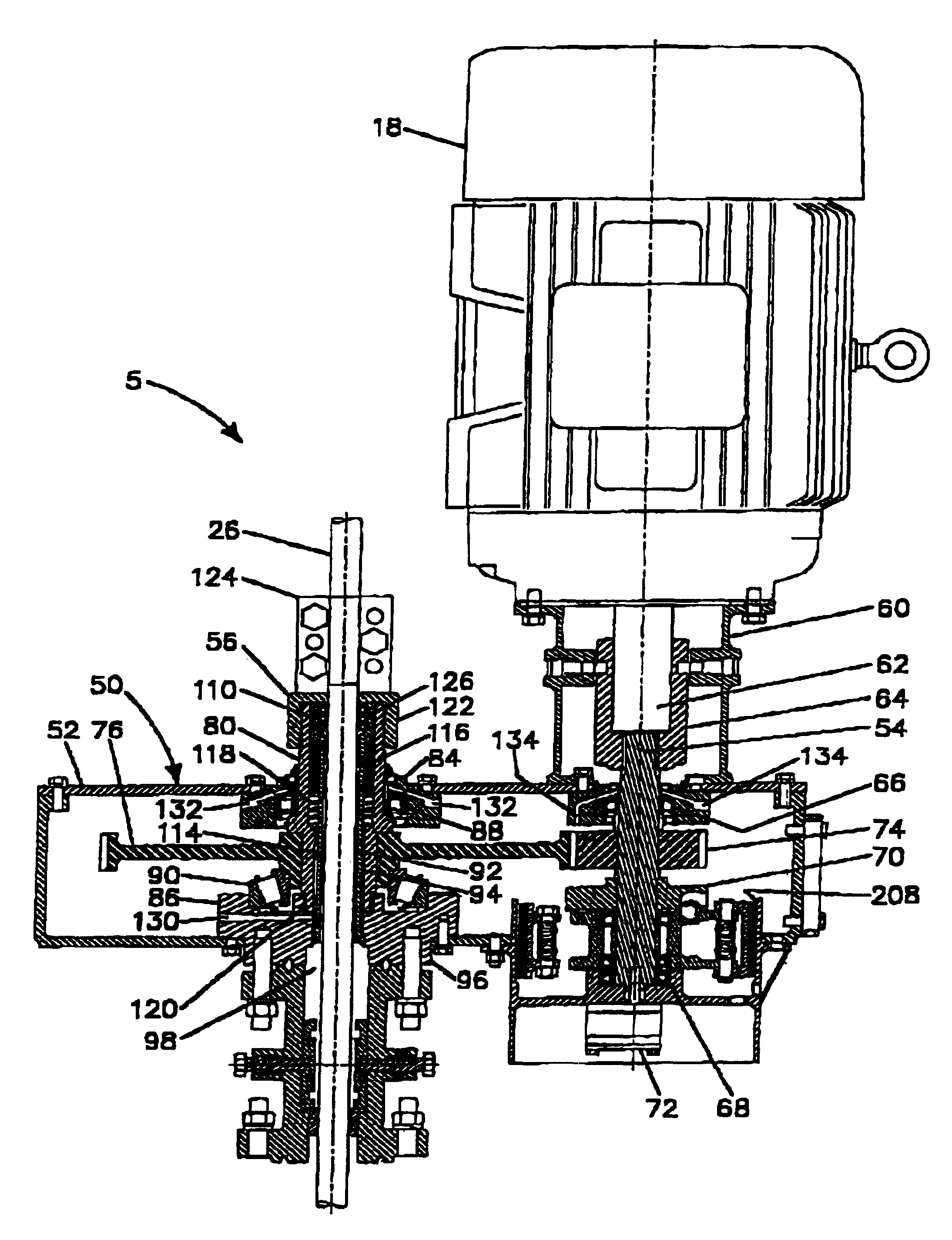

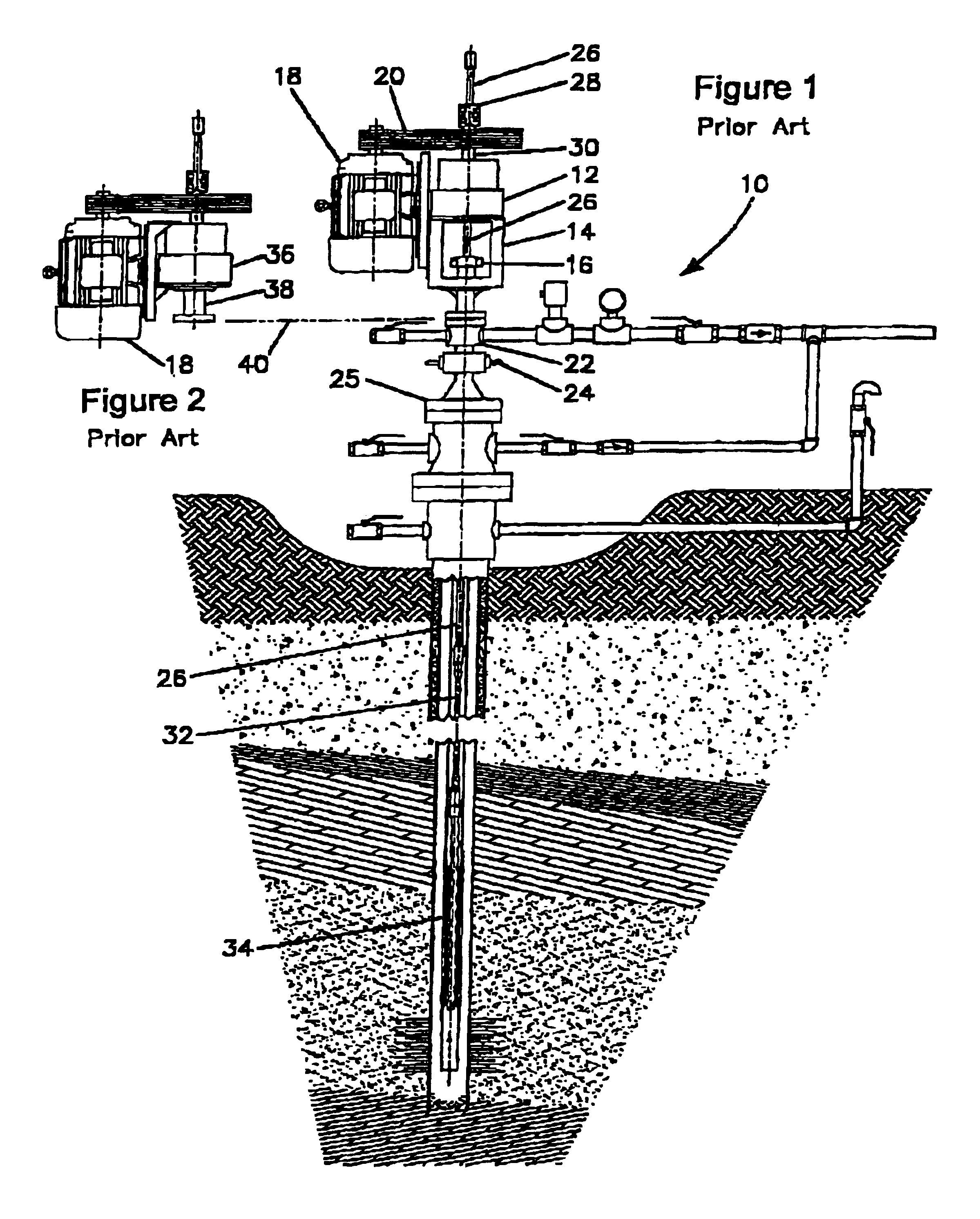

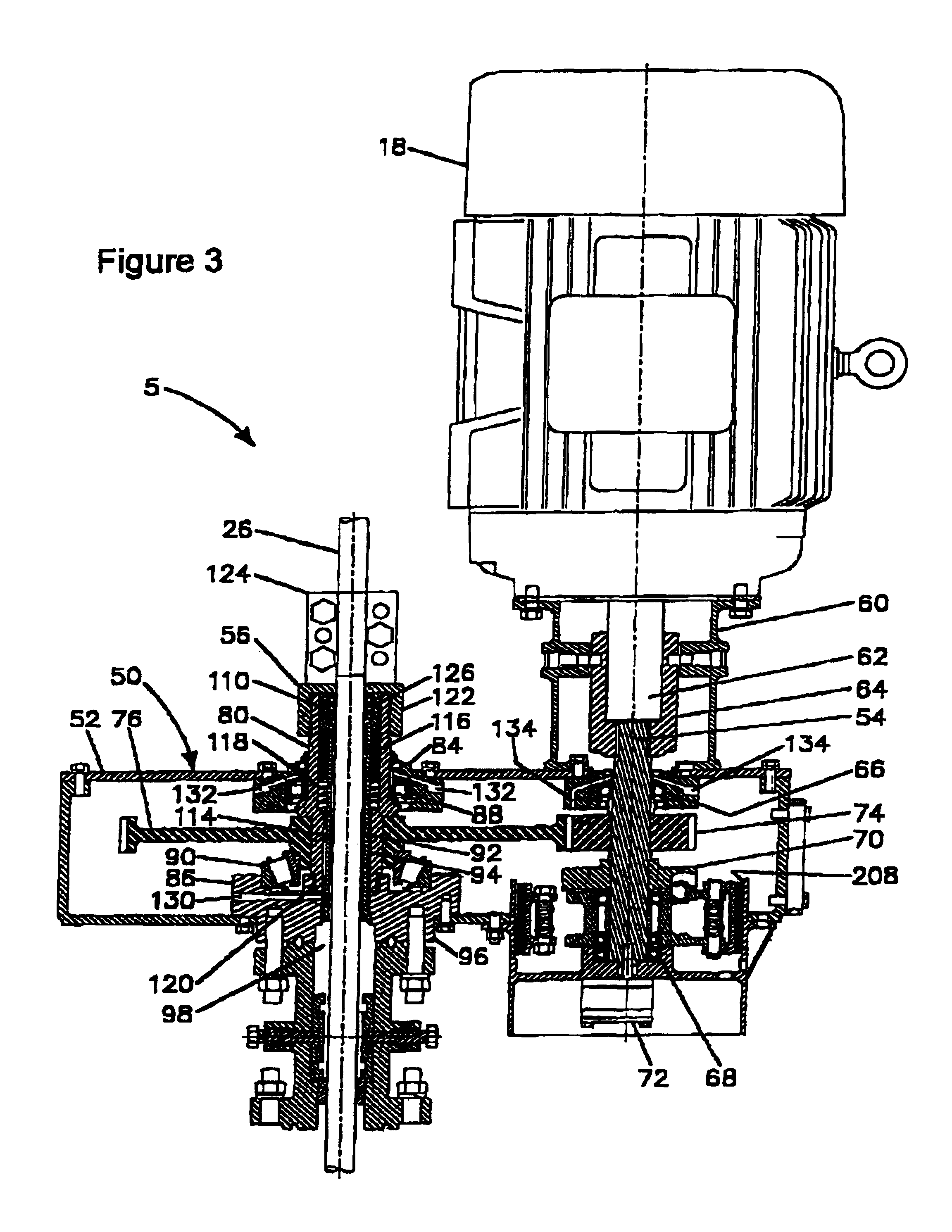

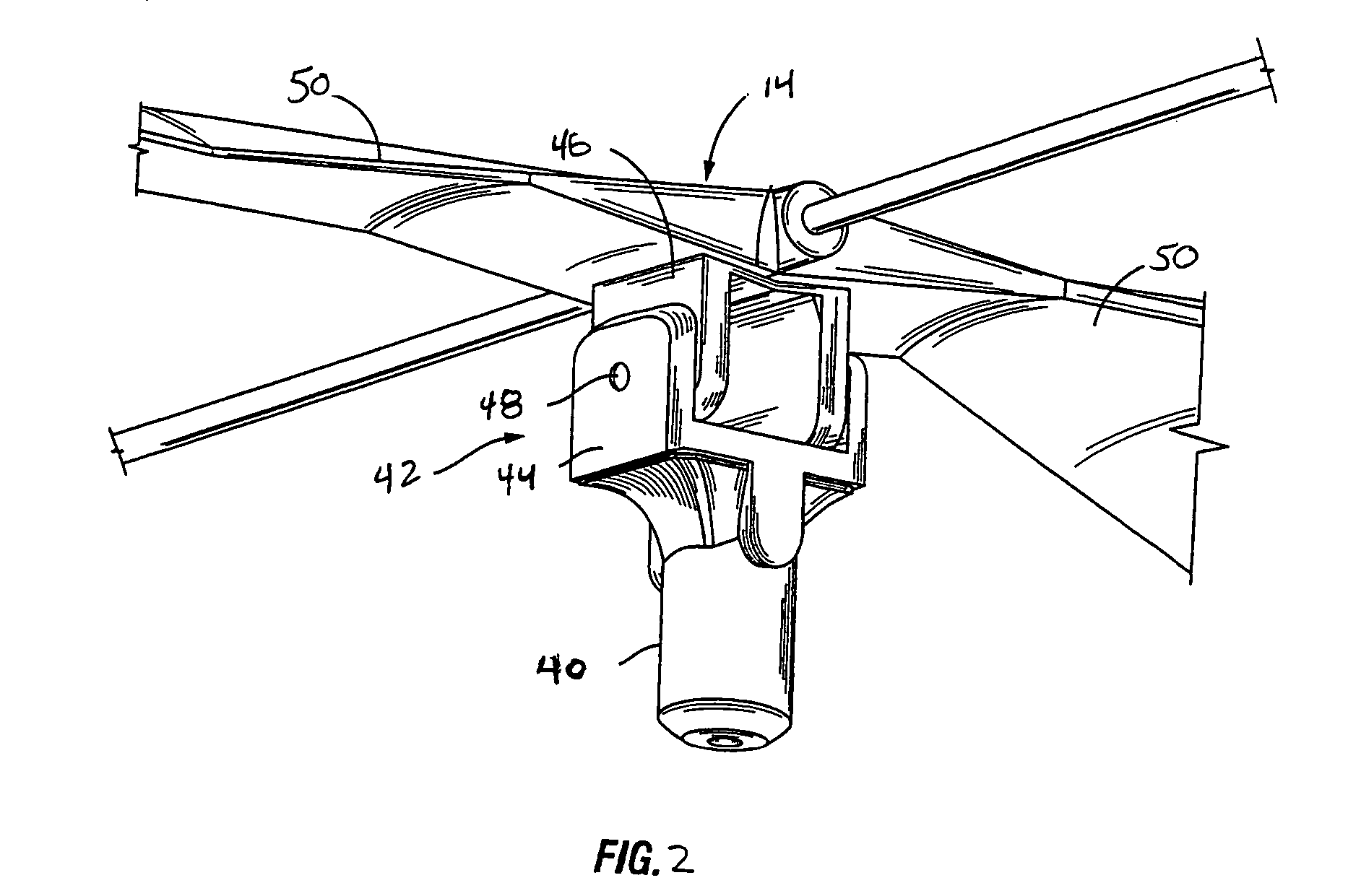

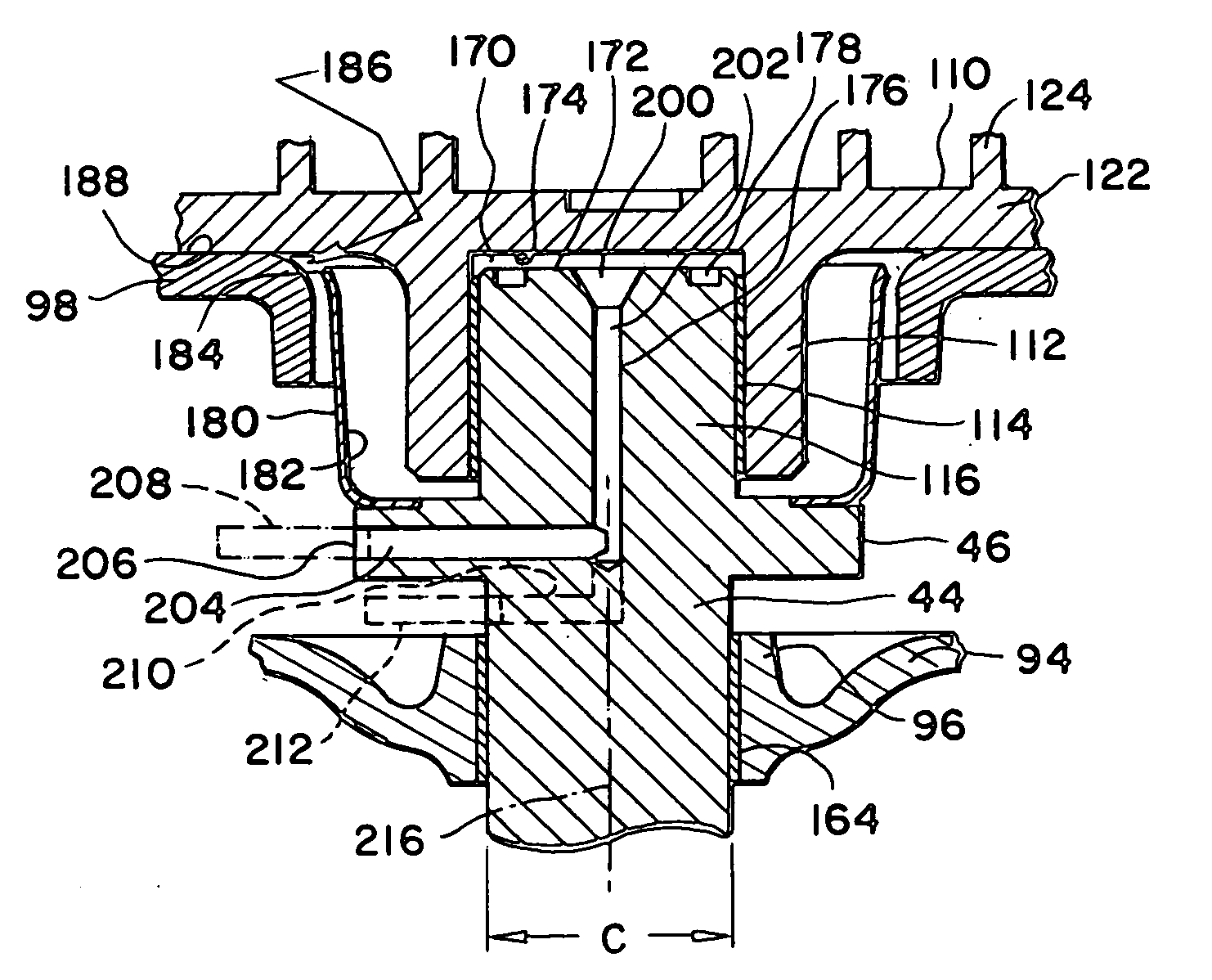

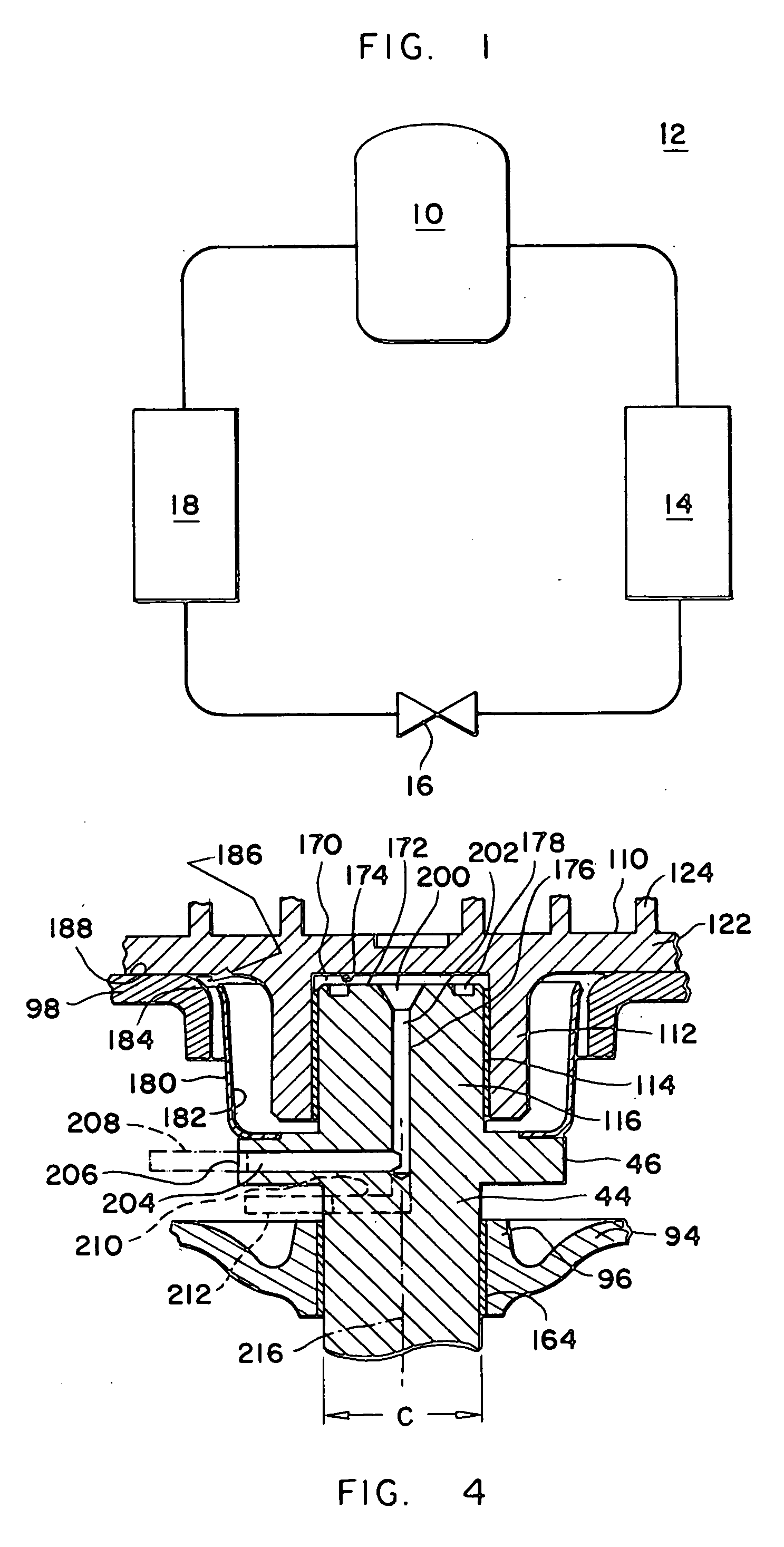

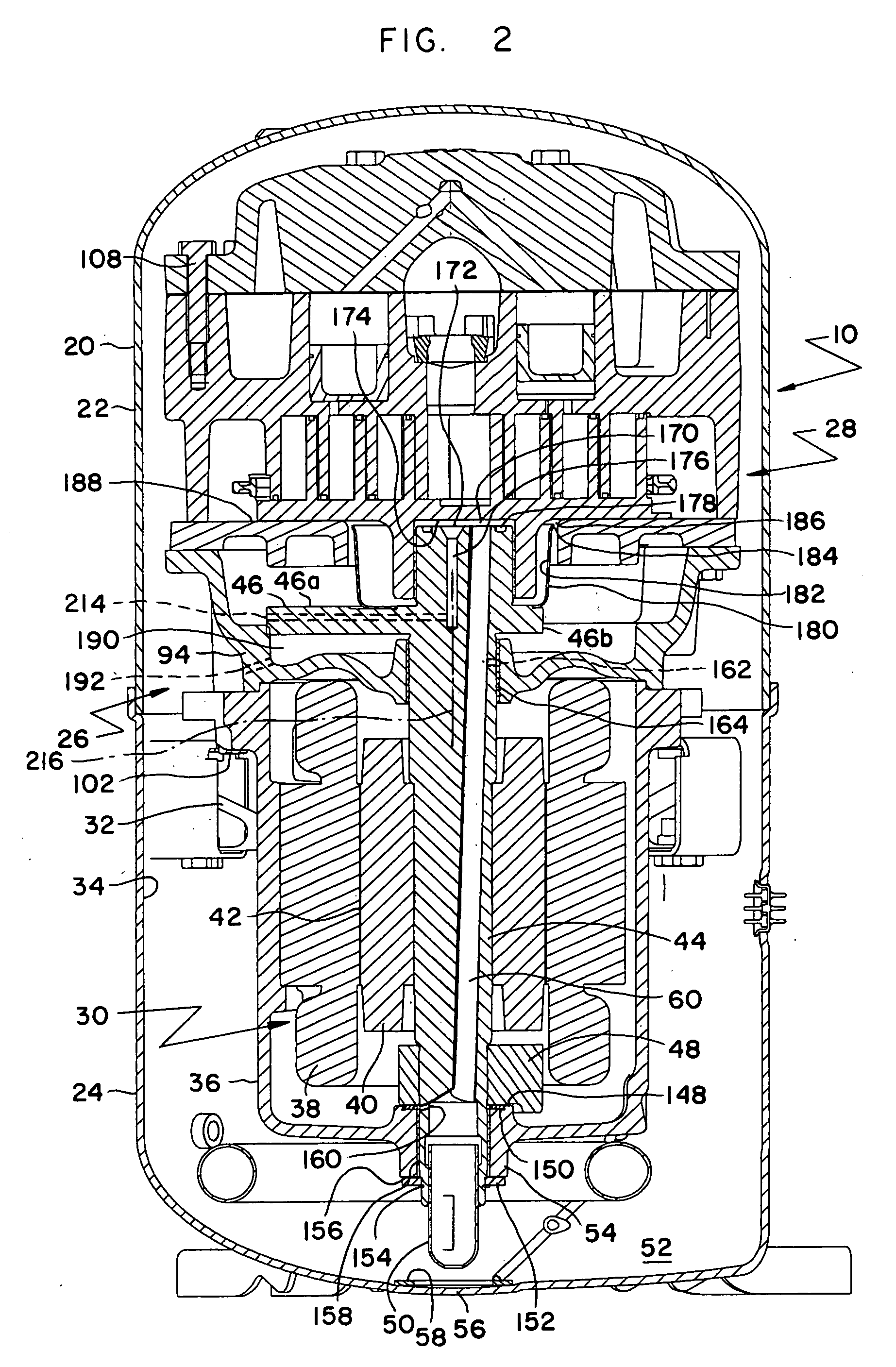

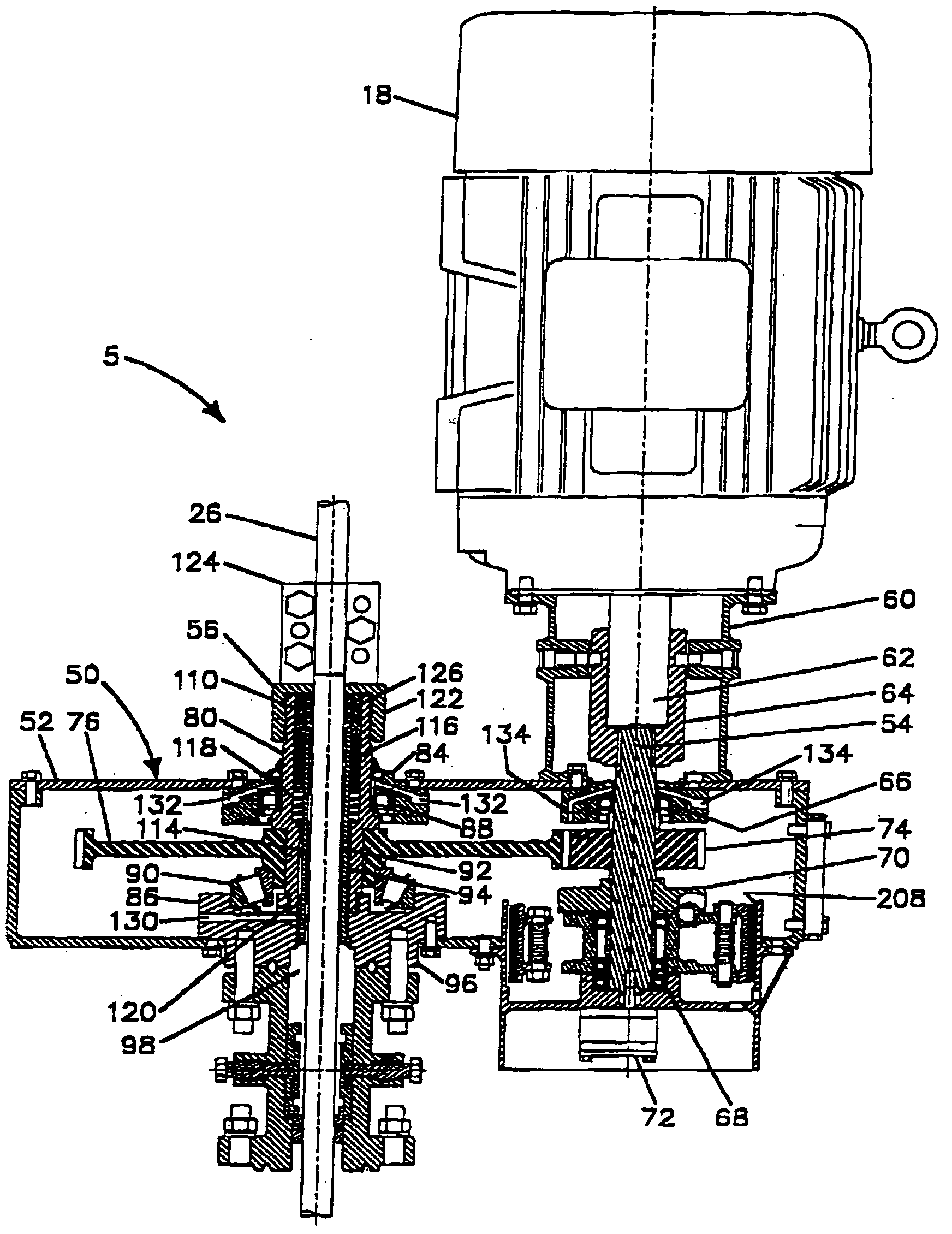

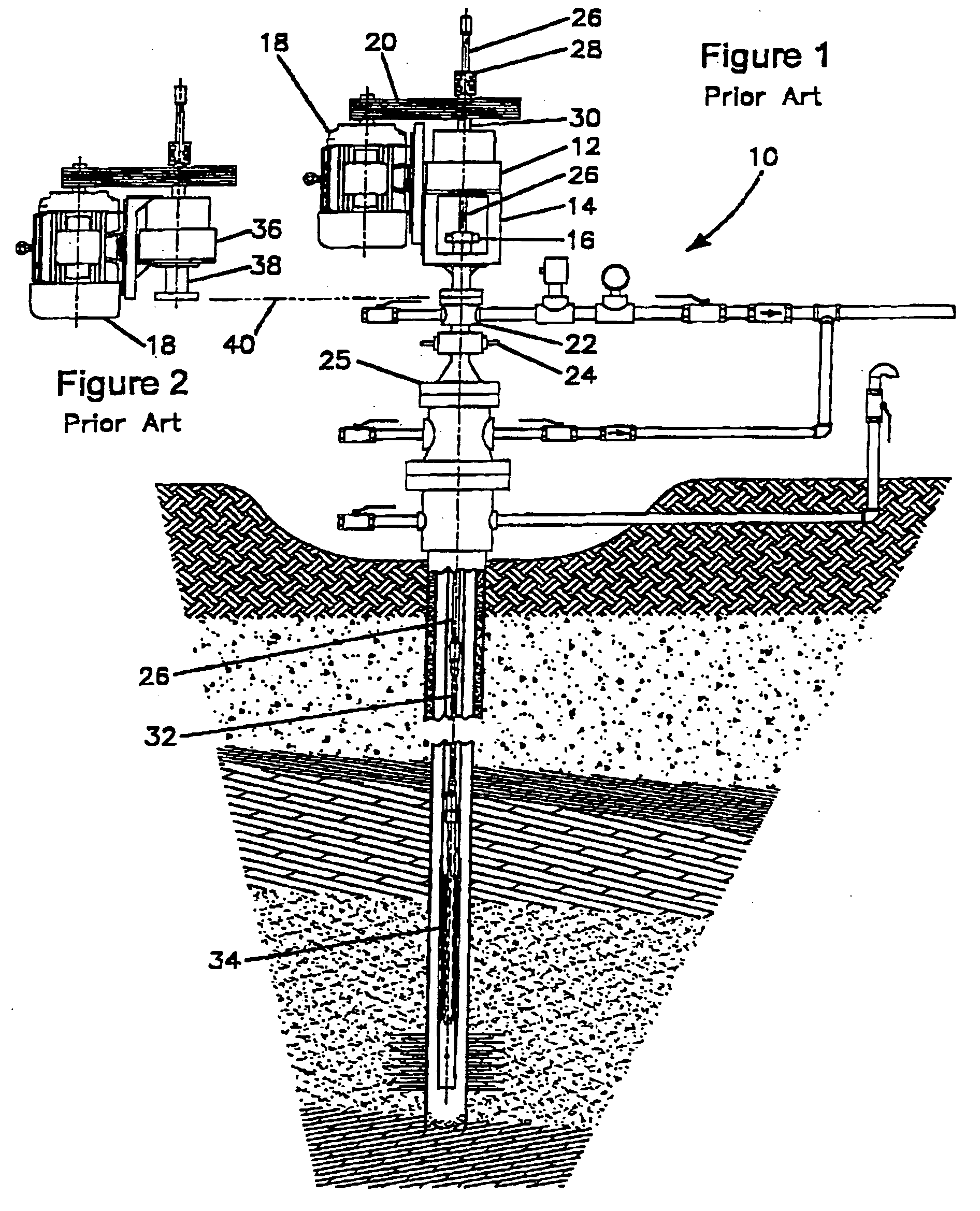

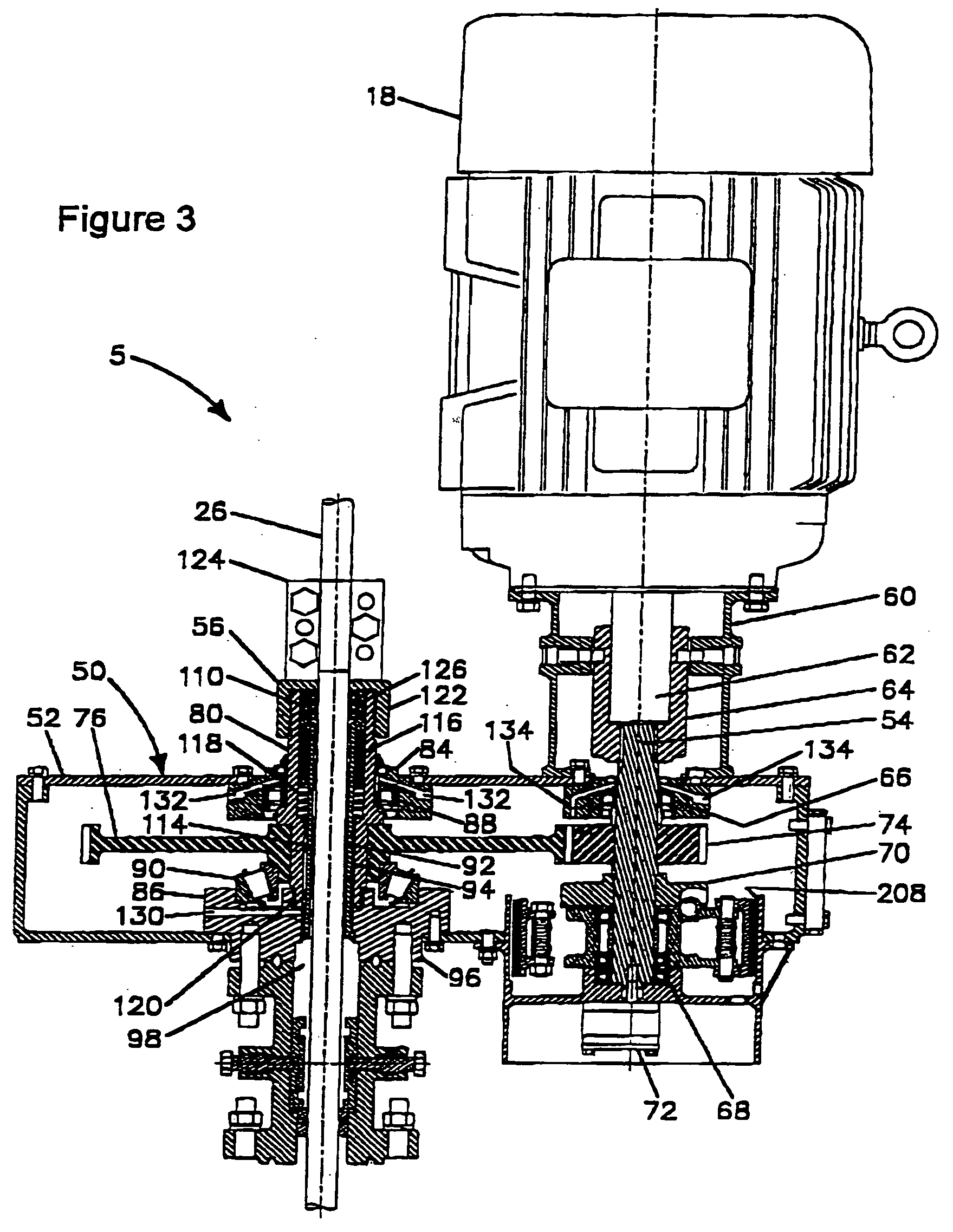

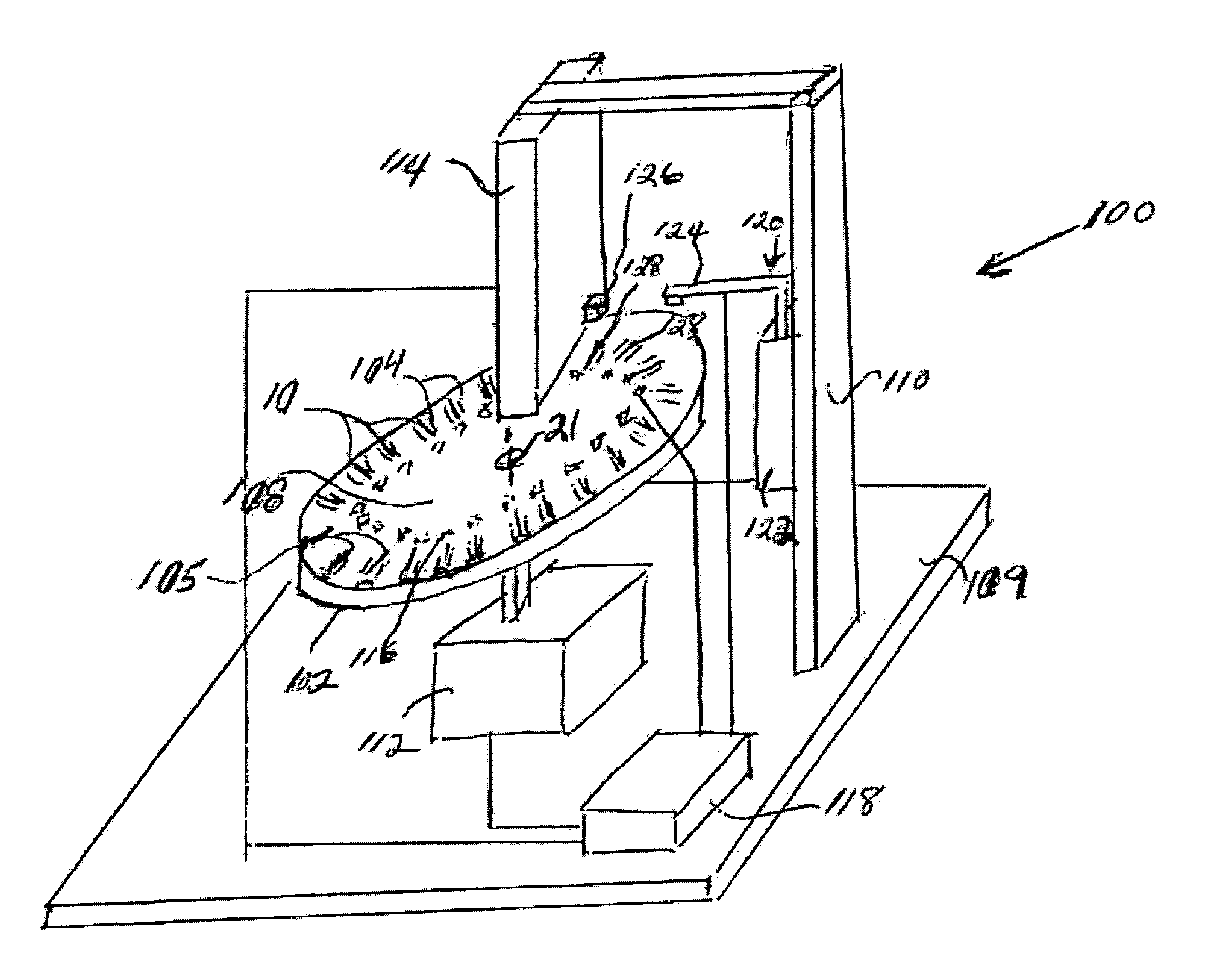

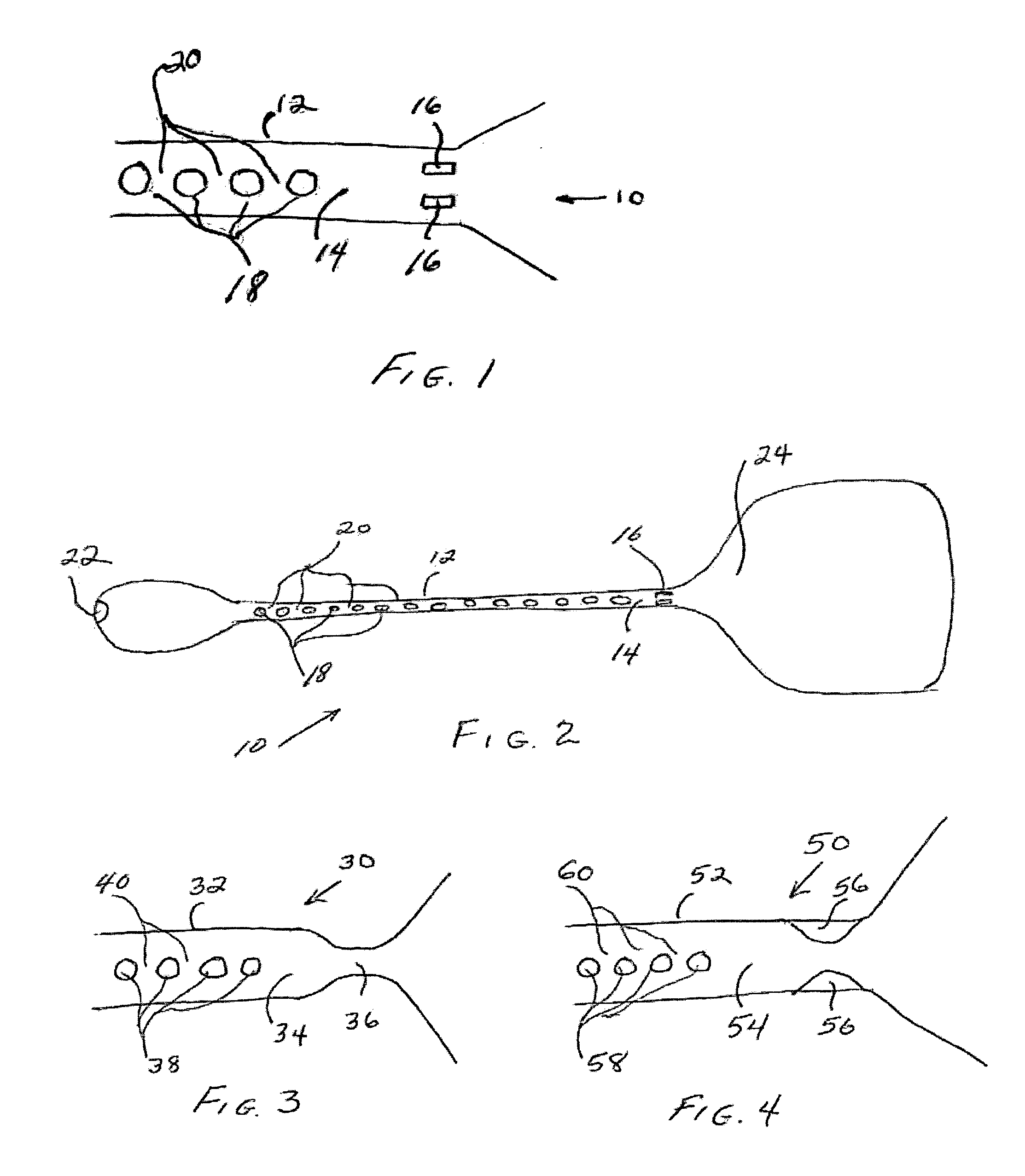

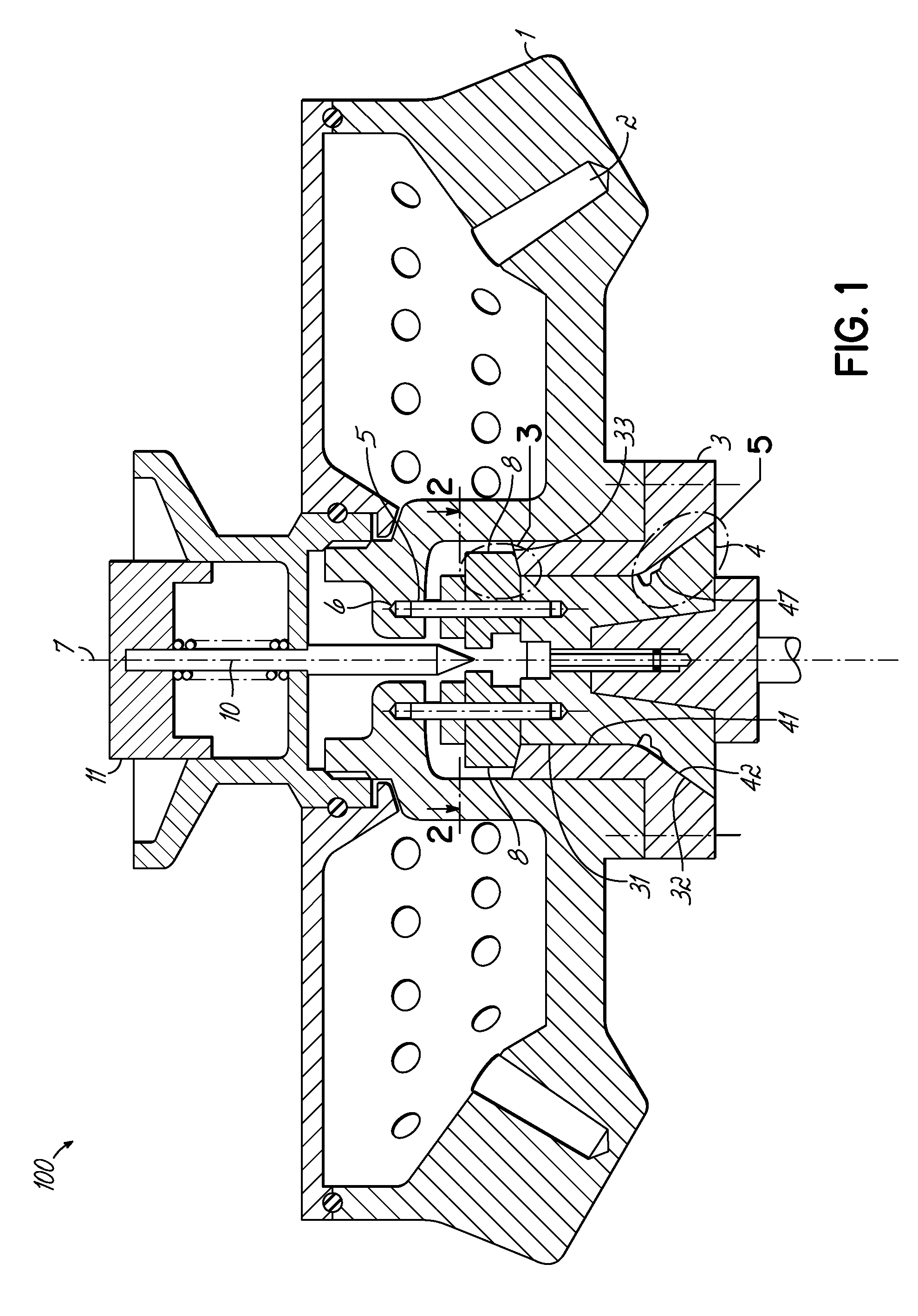

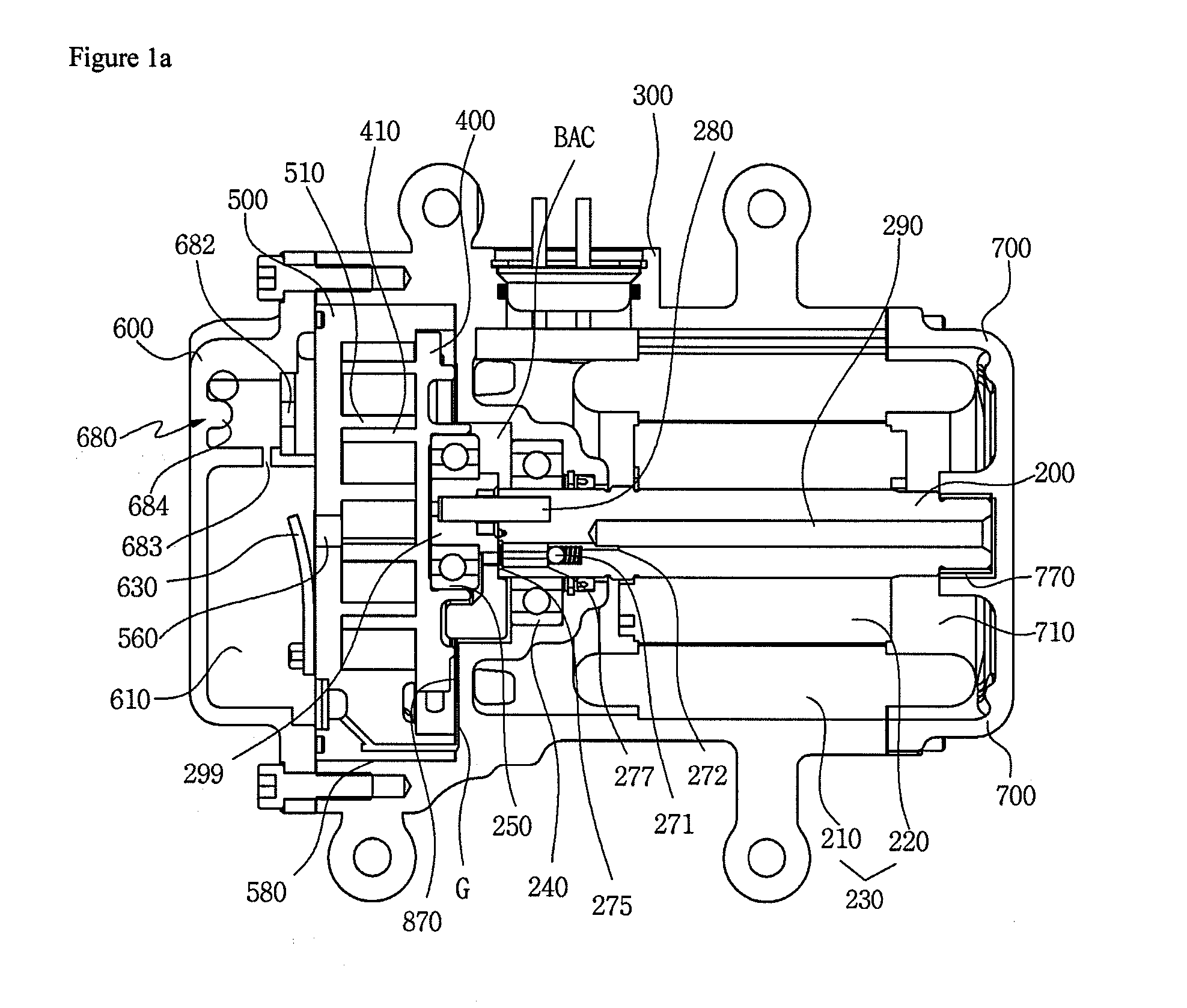

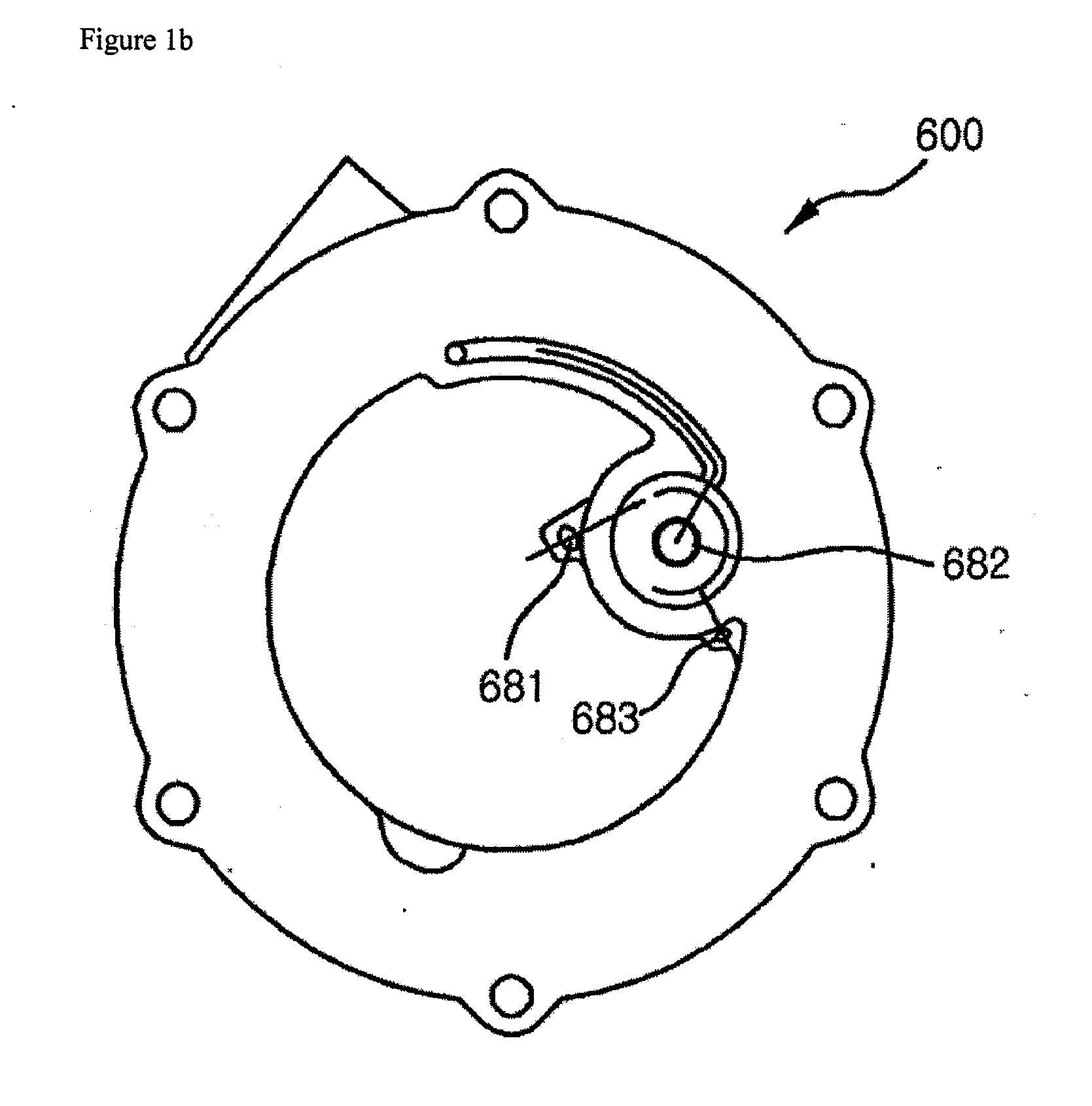

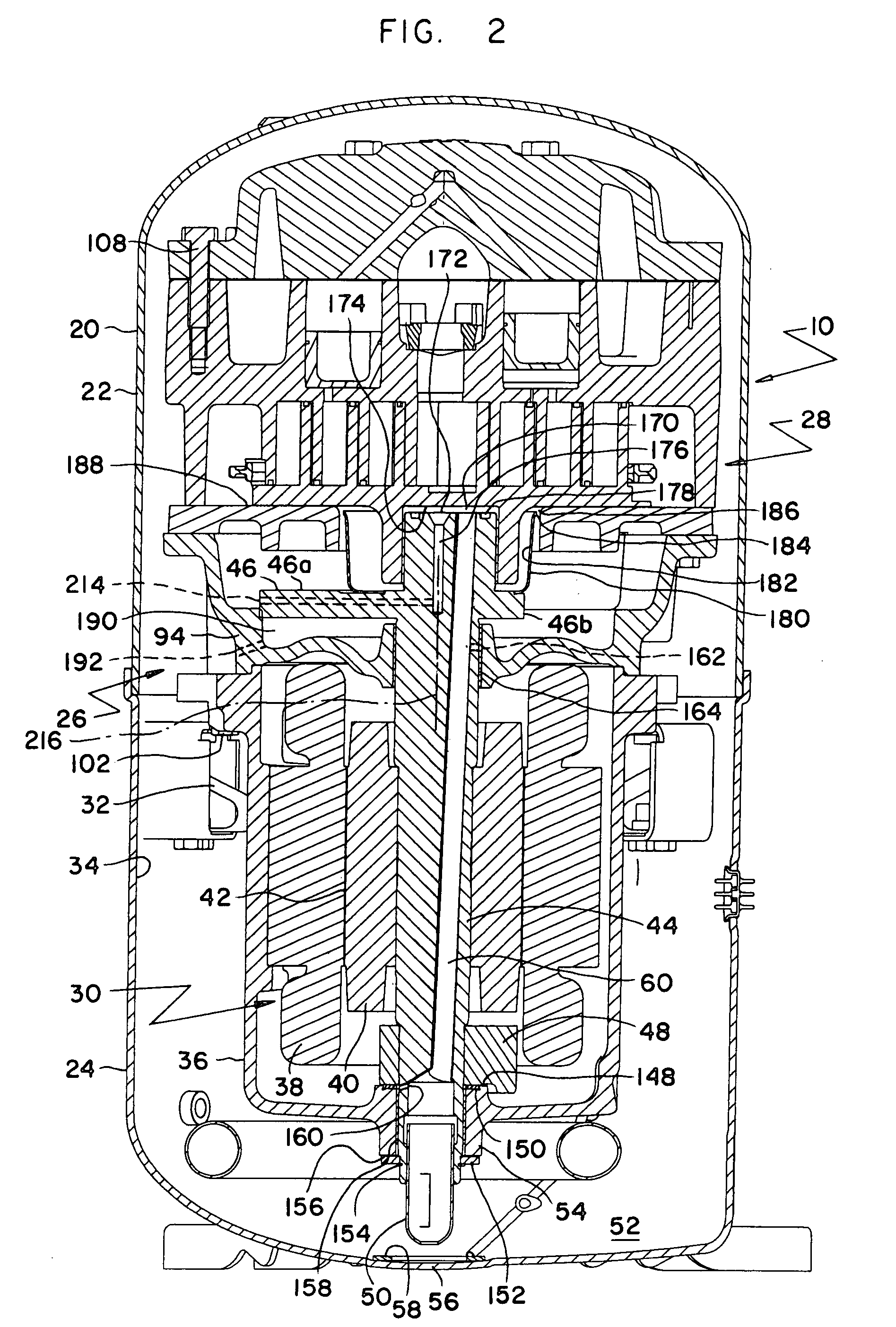

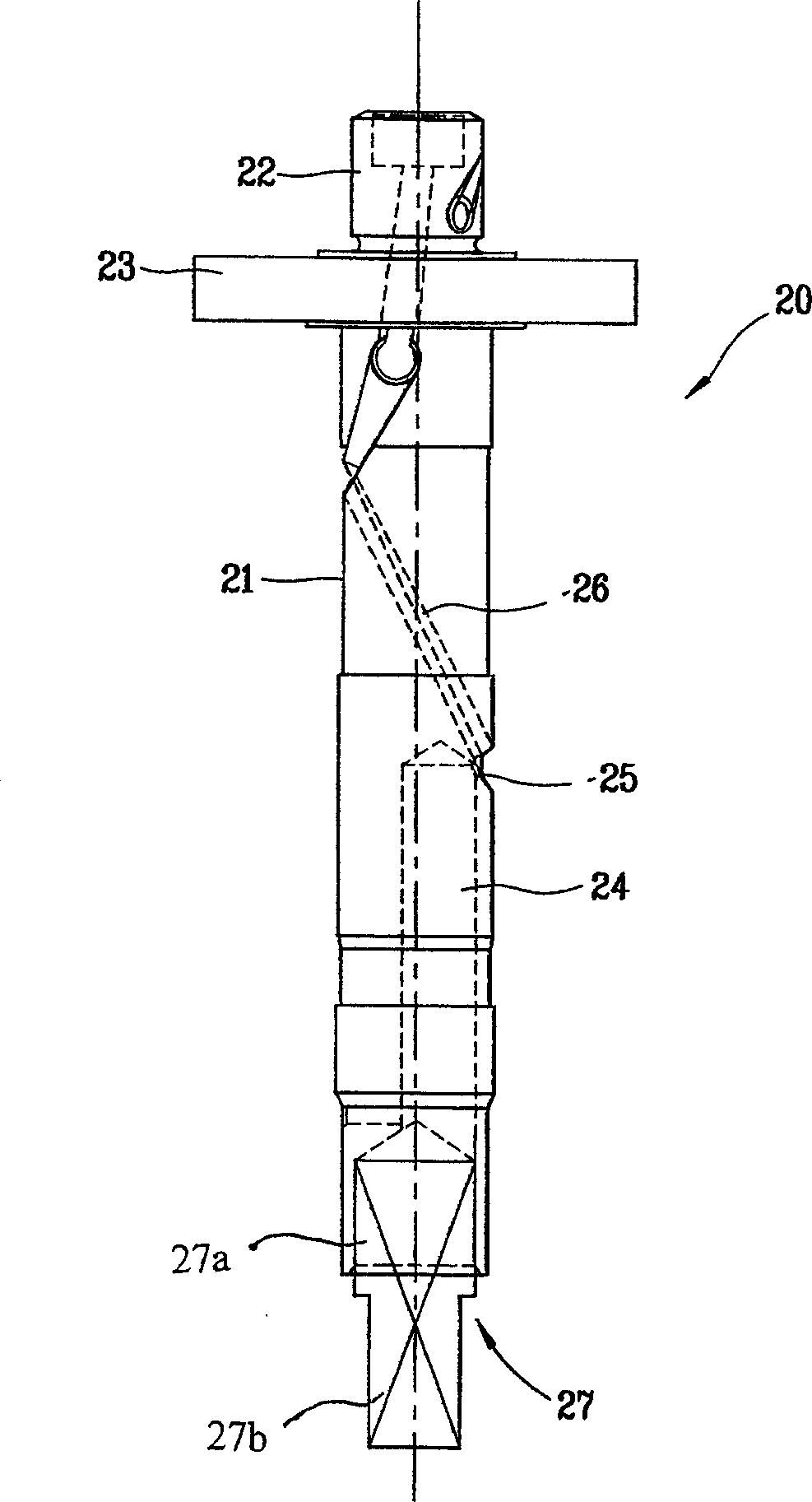

Pump drive head with stuffing box

InactiveUS6843313B2Eliminating belt tensioningEliminate replacementDrilling rodsFluid removalGear driveEngineering

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

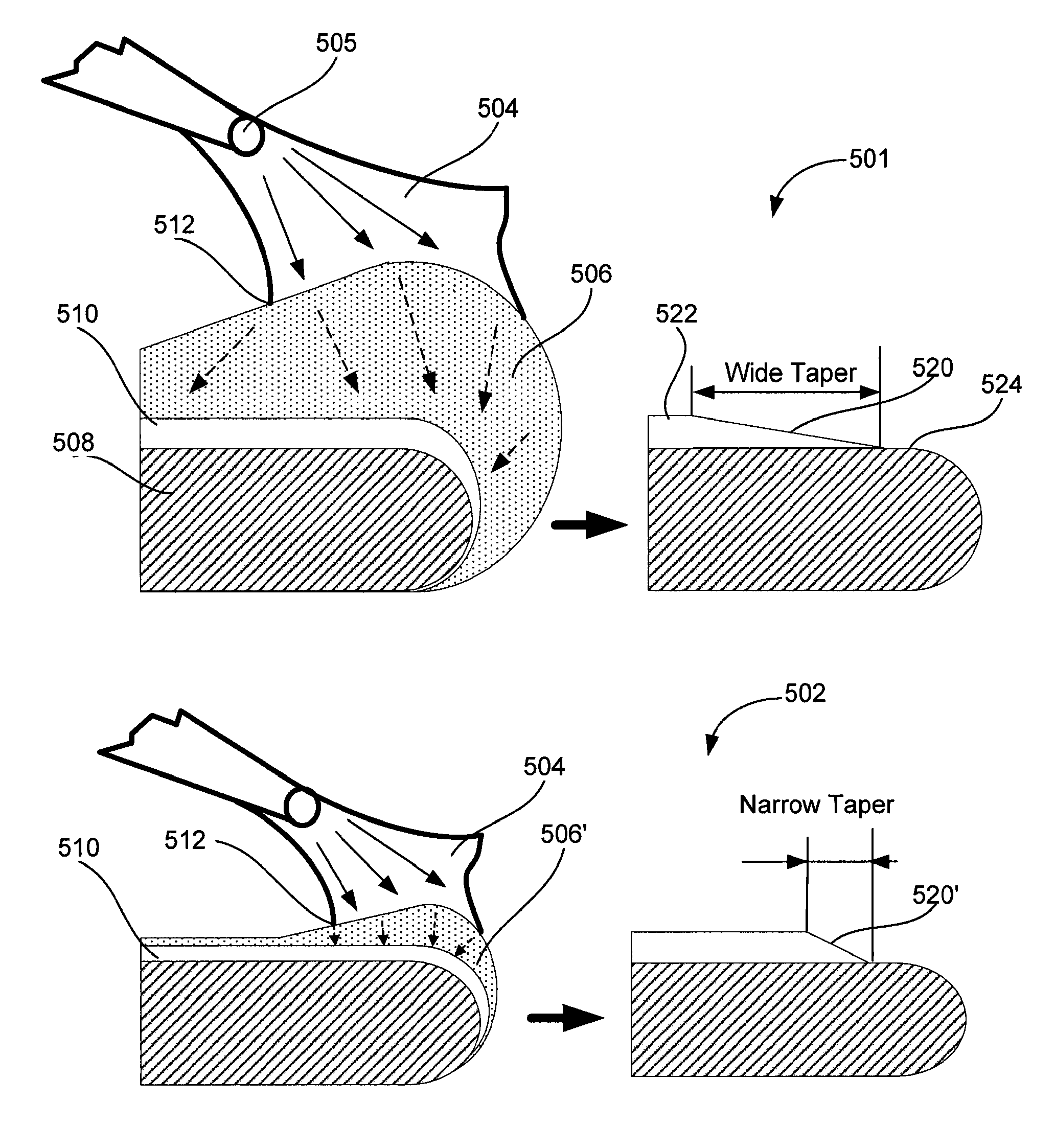

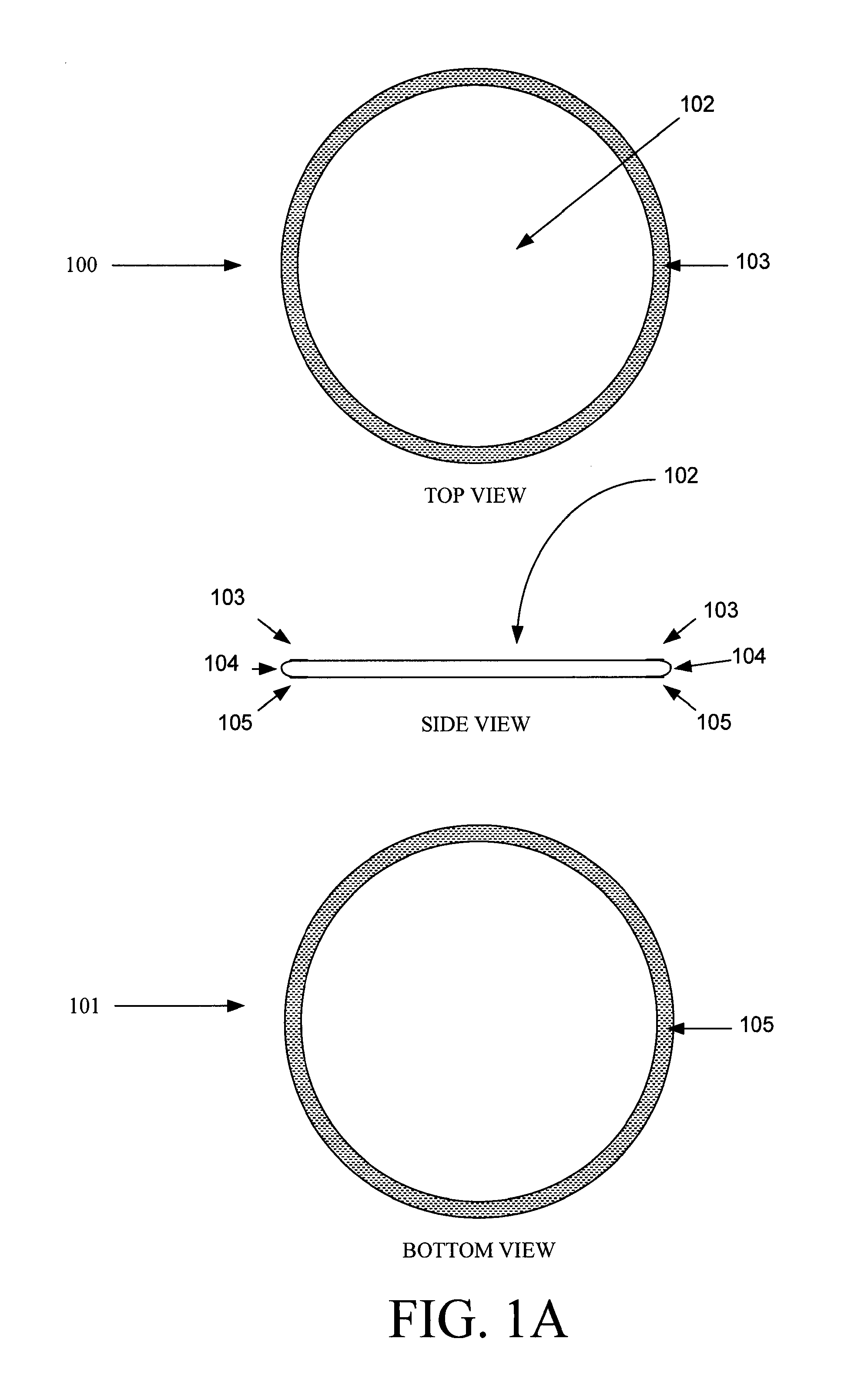

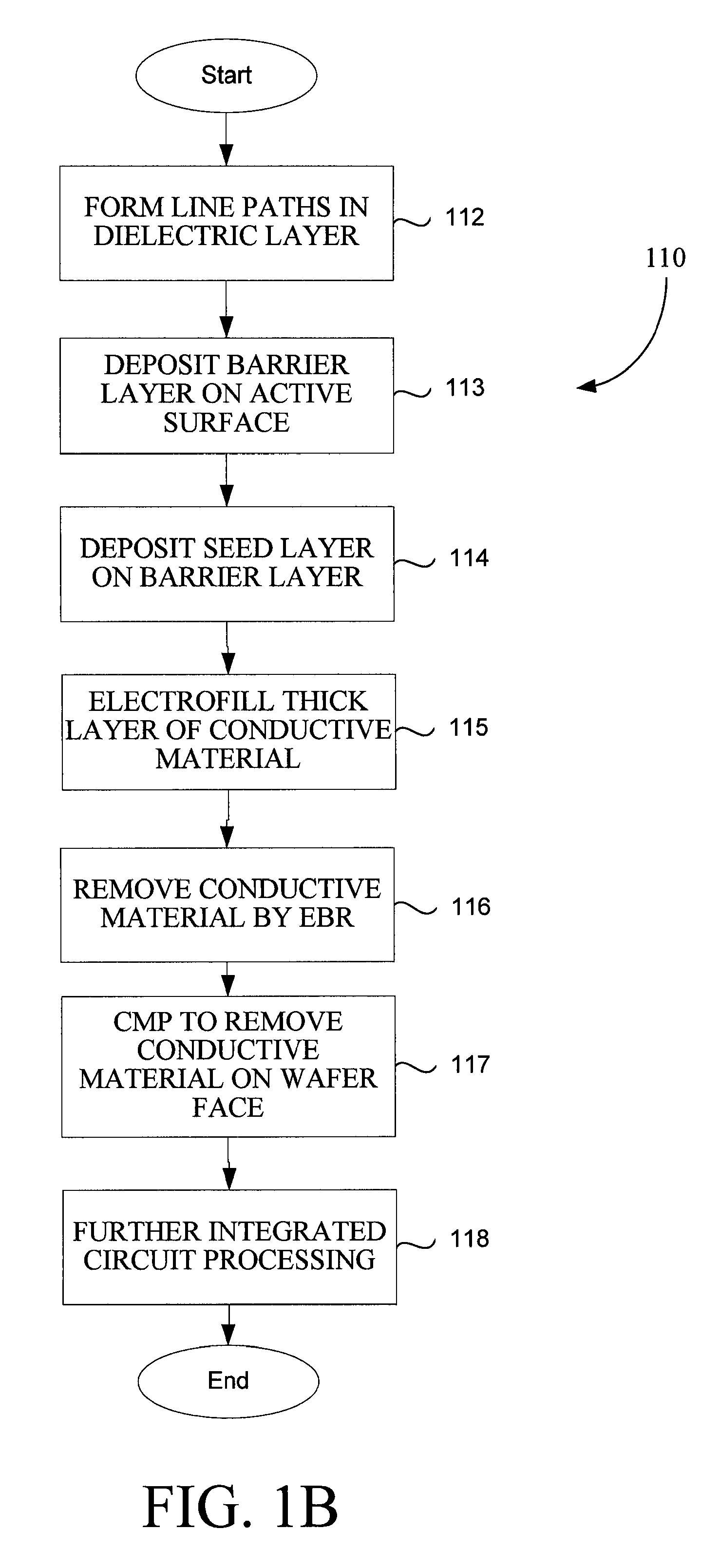

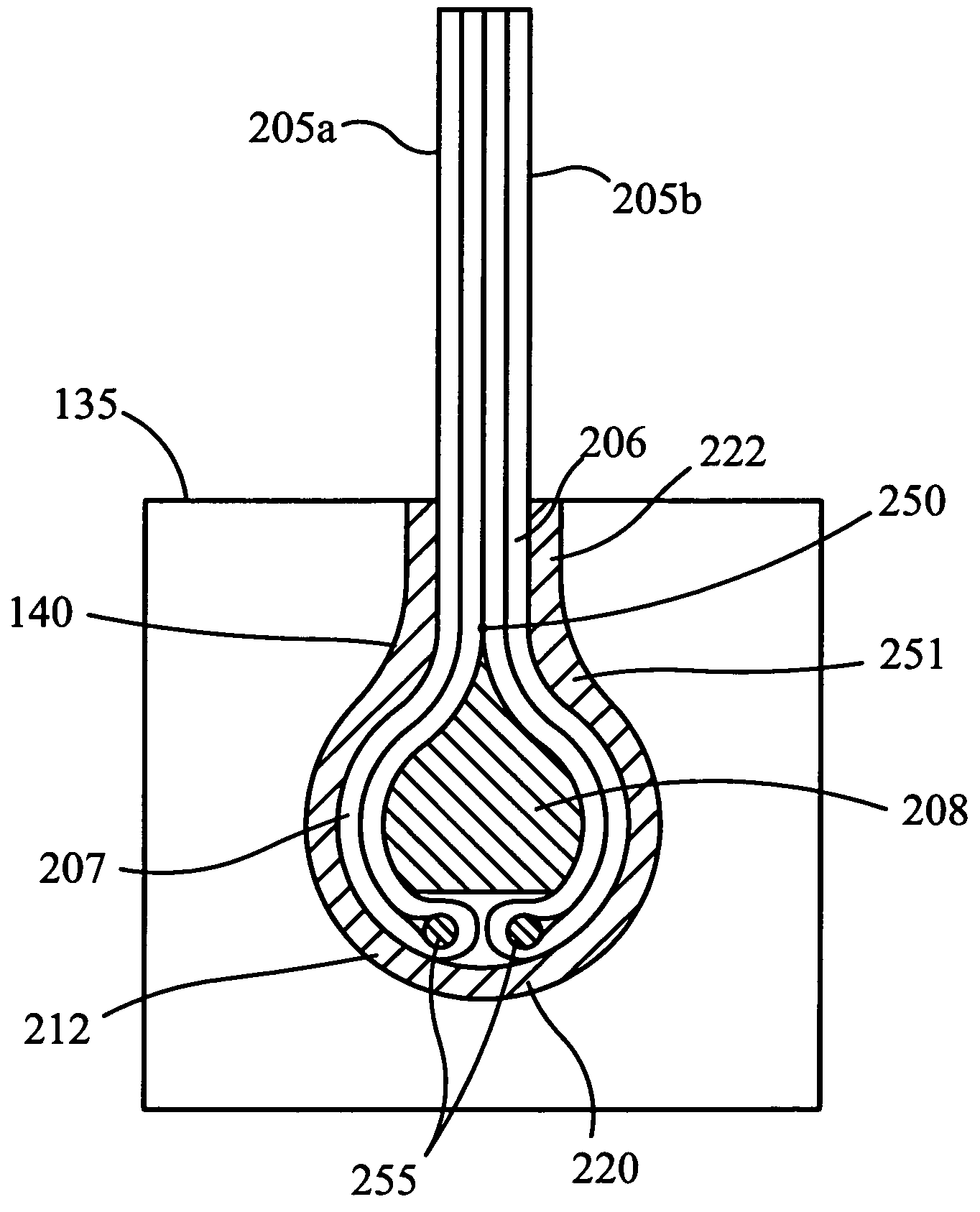

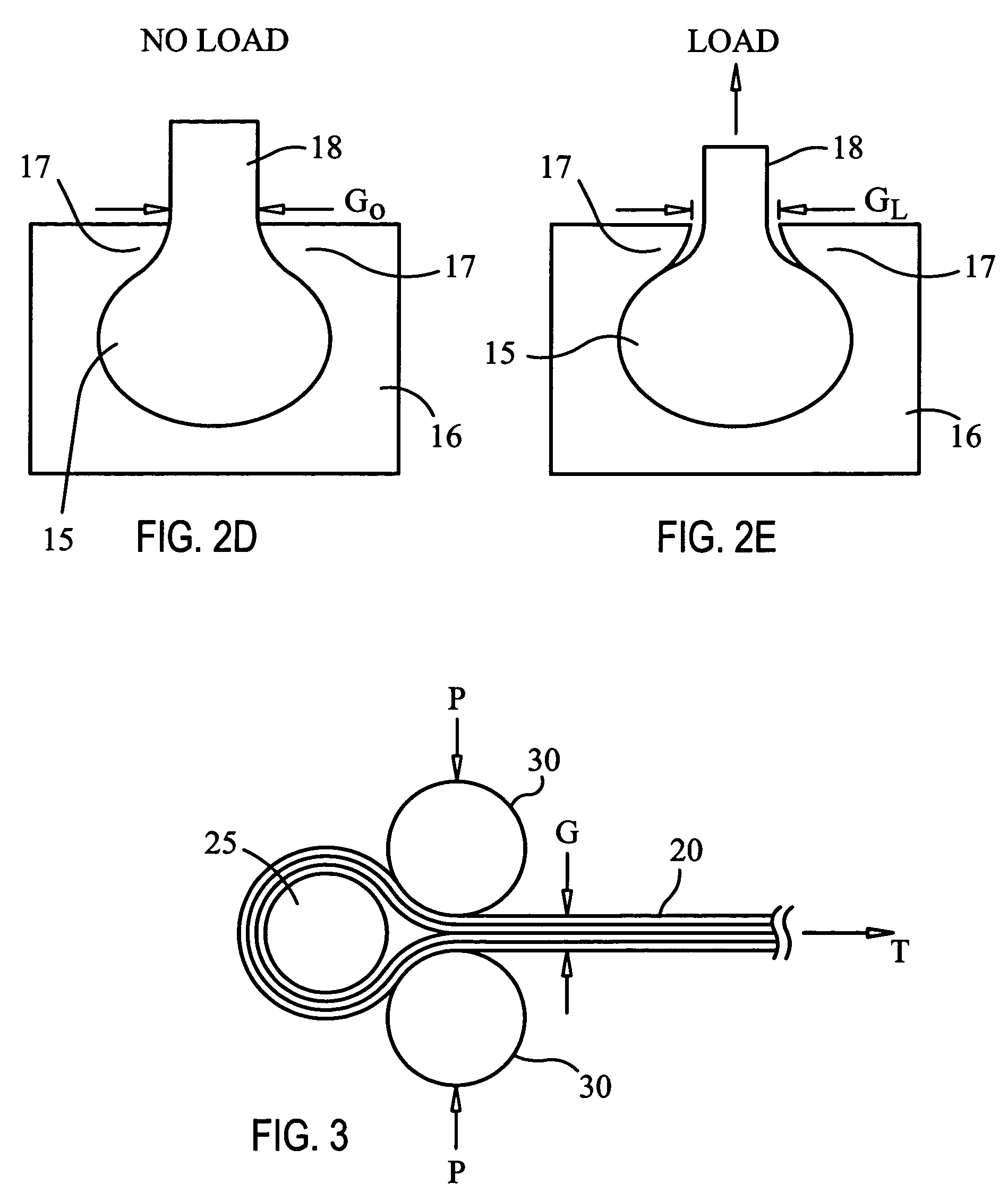

Apparatus and method for edge bevel removal of copper from silicon wafers

ActiveUS20100055924A1Facilitated DiffusionIncrease etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingLiquid layerThin layer

Chemical etching methods and associated modules for performing the removal of metal from the edge bevel region of a semiconductor wafer are described. The methods and systems provide the thin layer of pre-rinsing liquid before applying etchant at the edge bevel region of the wafer. The etchant is less diluted and diffuses faster through a thinned layer of rinsing liquid. An edge bevel removal embodiment involving that is particularly effective at reducing process time, narrowing the metal taper and allowing for subsequent chemical mechanical polishing, is disclosed.

Owner:NOVELLUS SYSTEMS

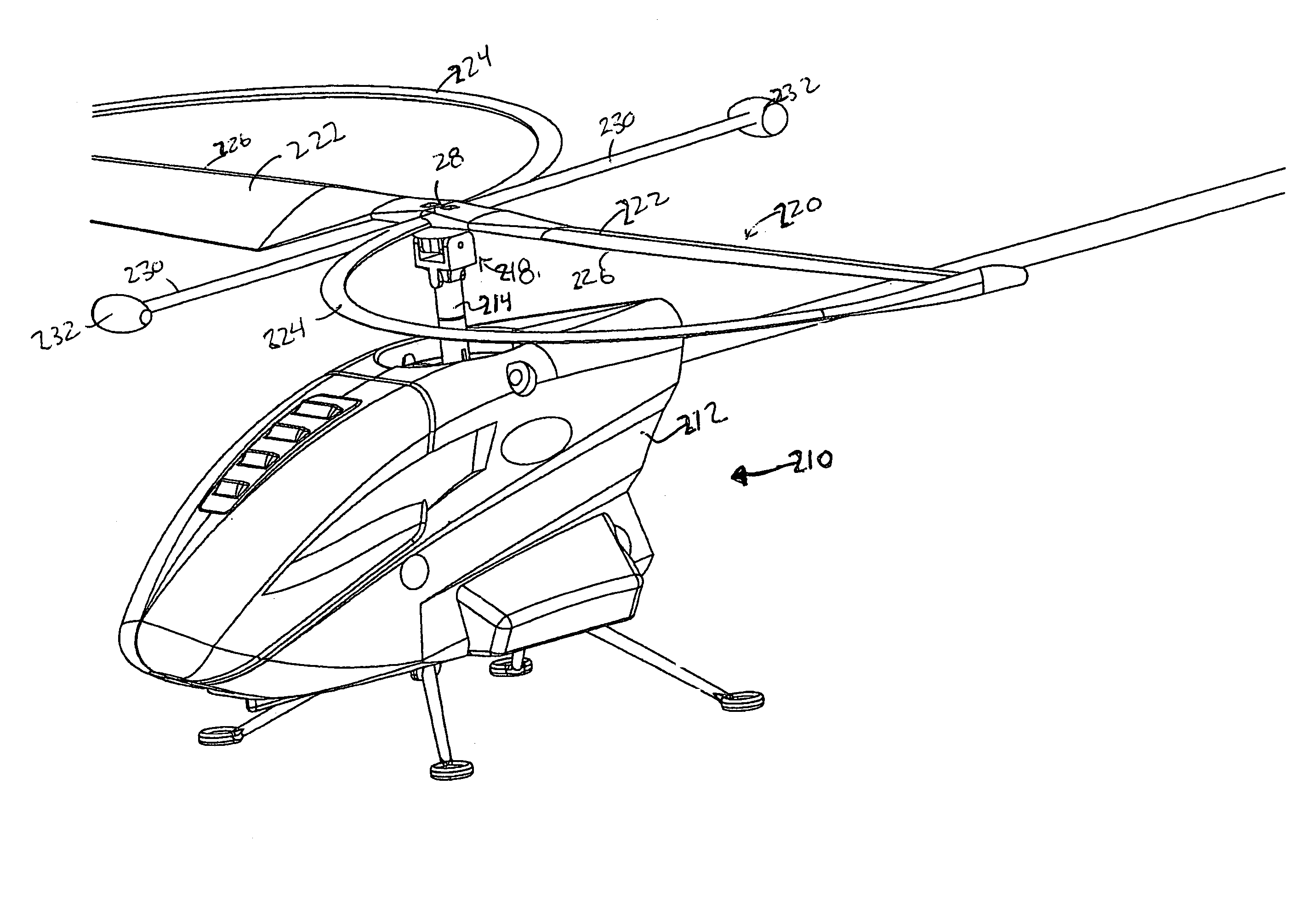

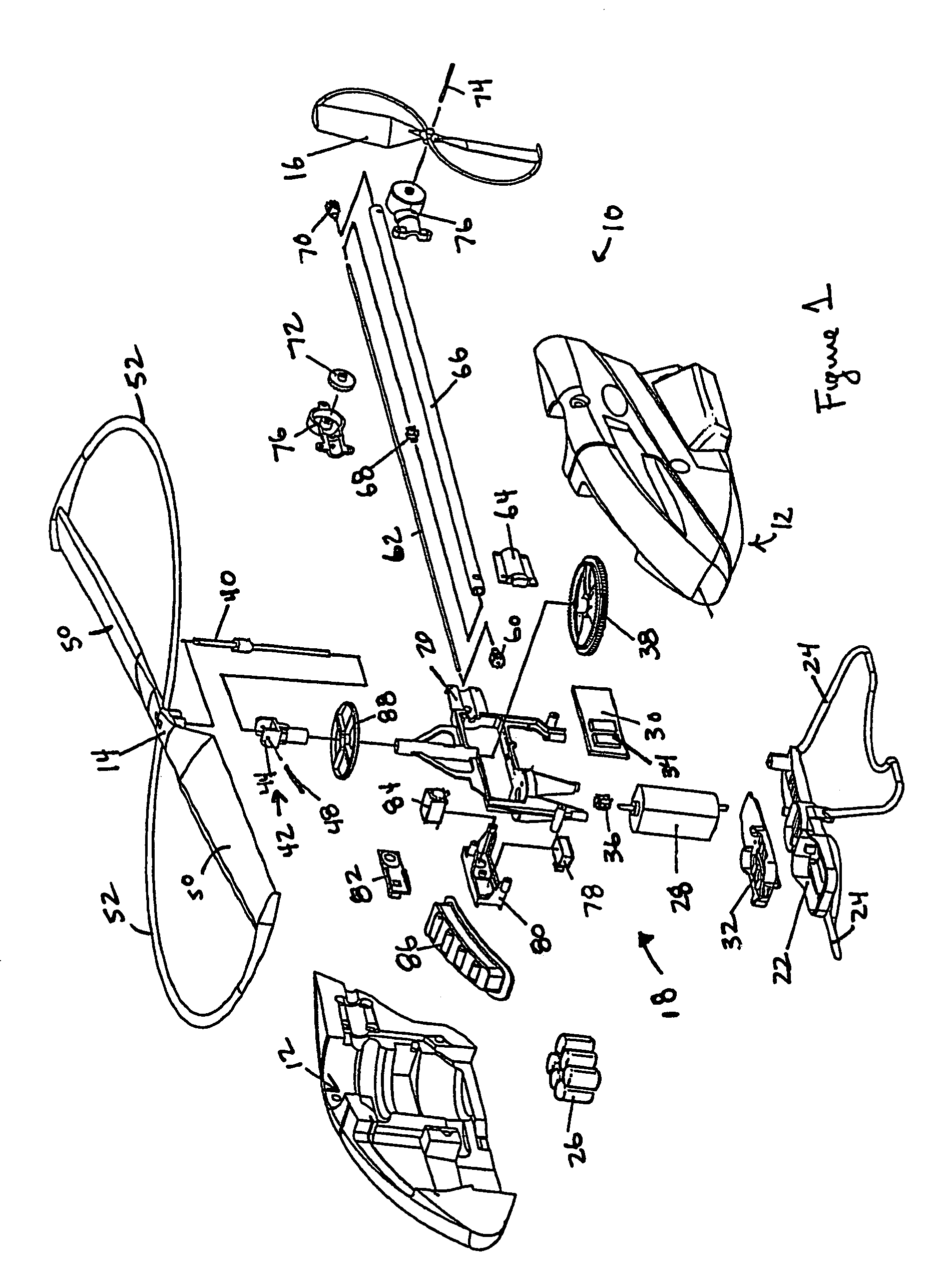

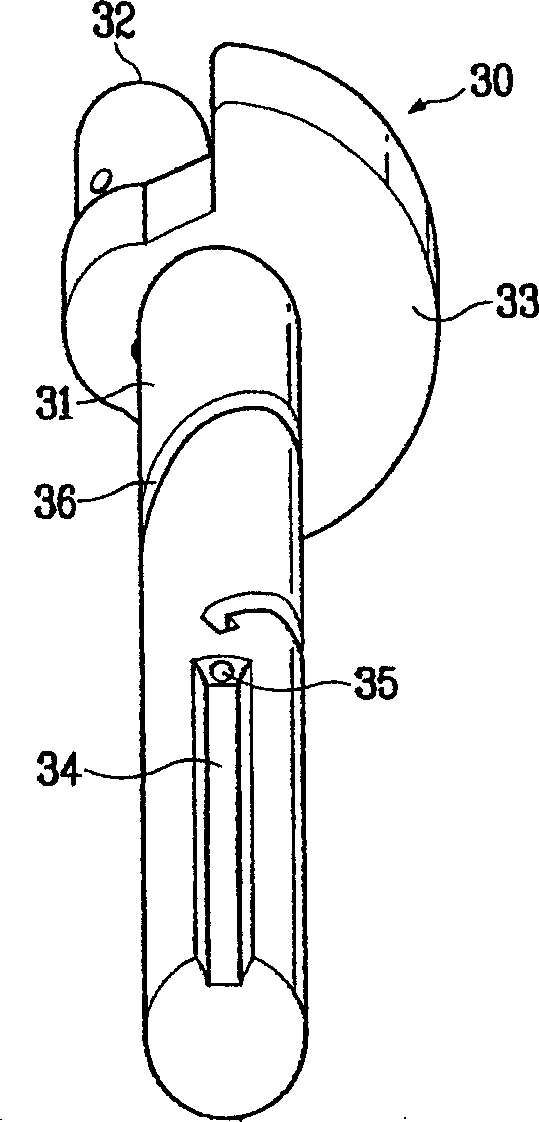

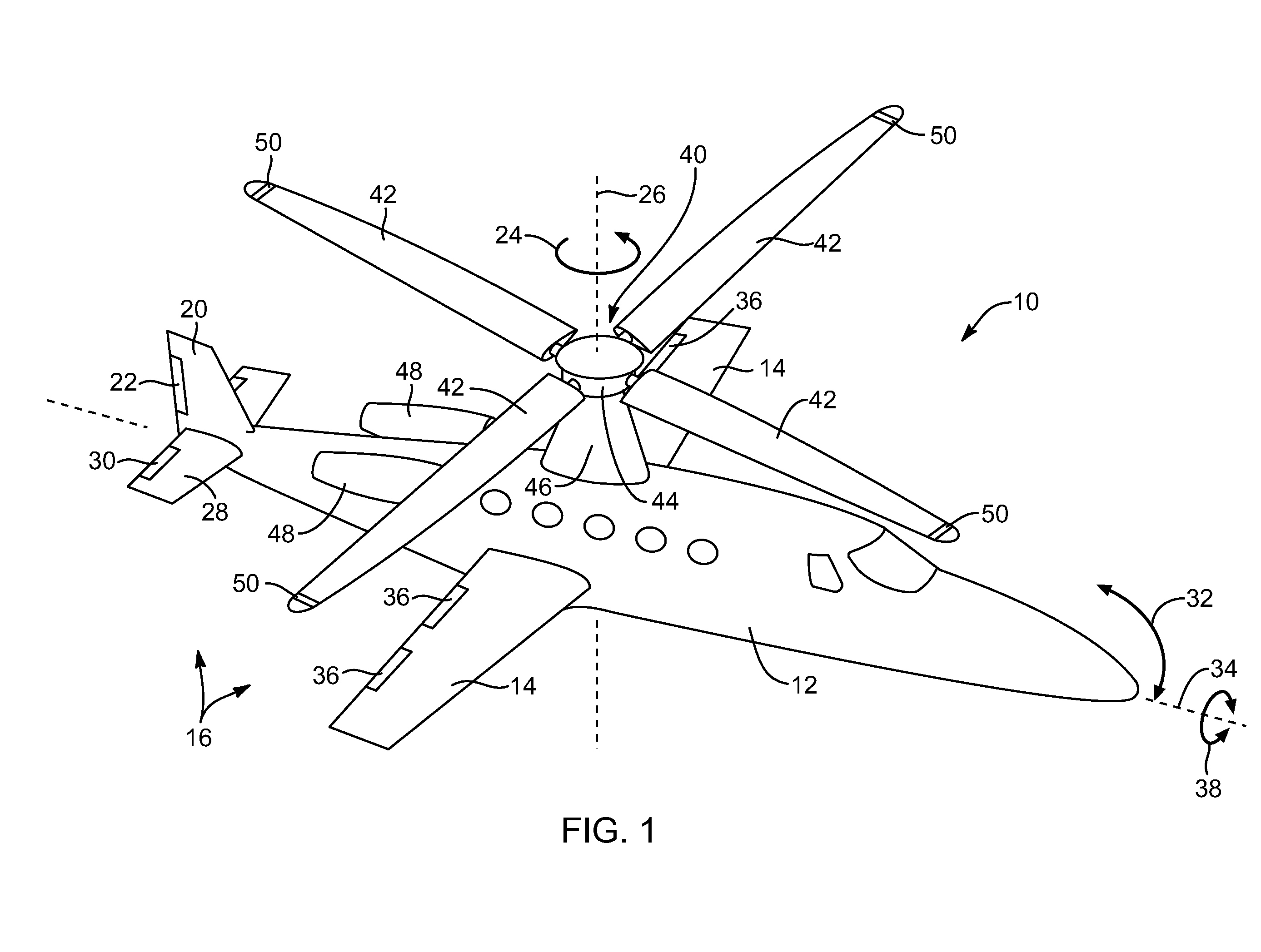

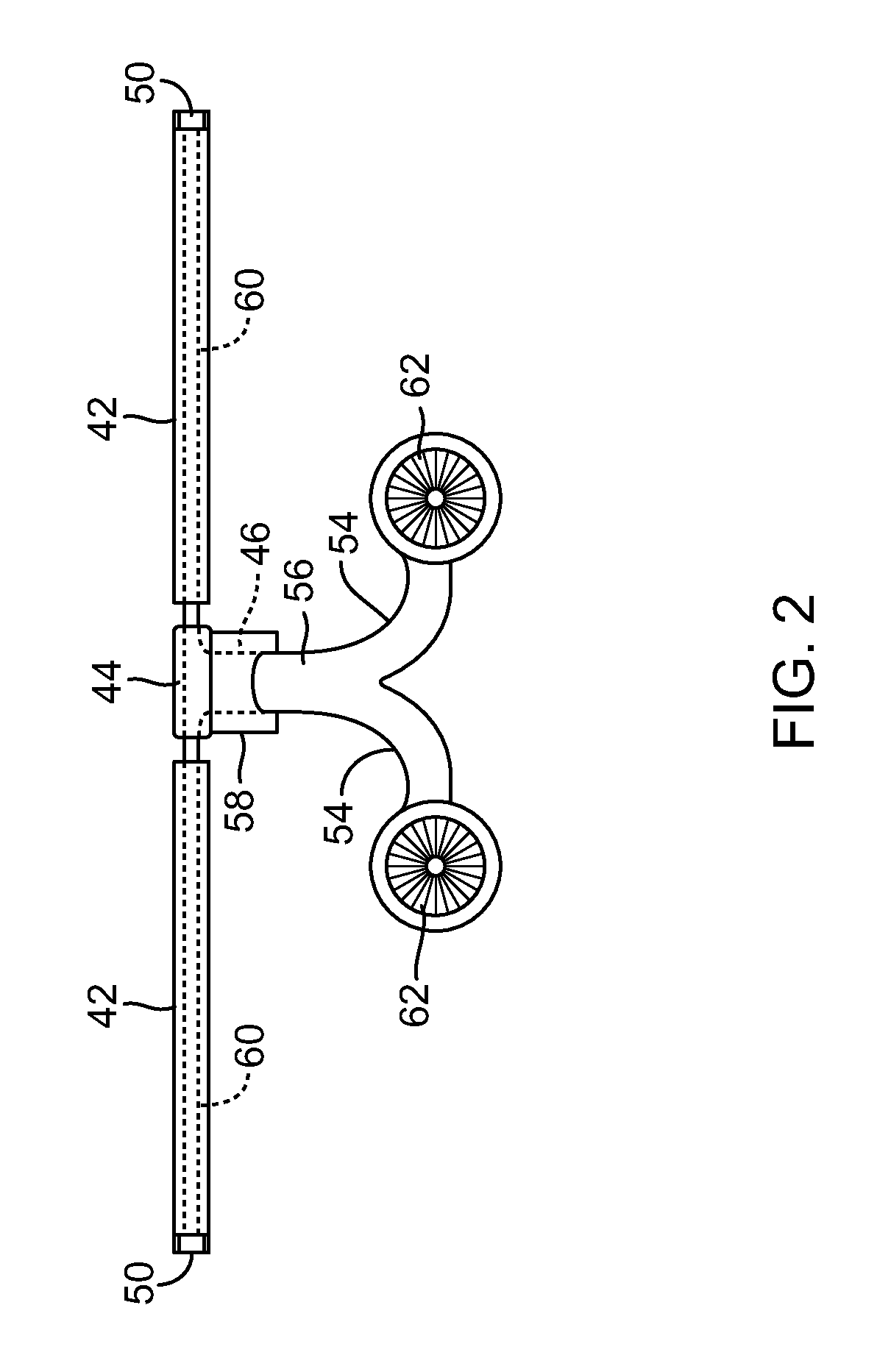

Propellers and propeller related vehicles

InactiveUS7178758B2Reduce the possibilityIncrease centrifugal forceMachines/enginesToy aircraftsDrive shaftPropeller

Owner:REHCO LLC

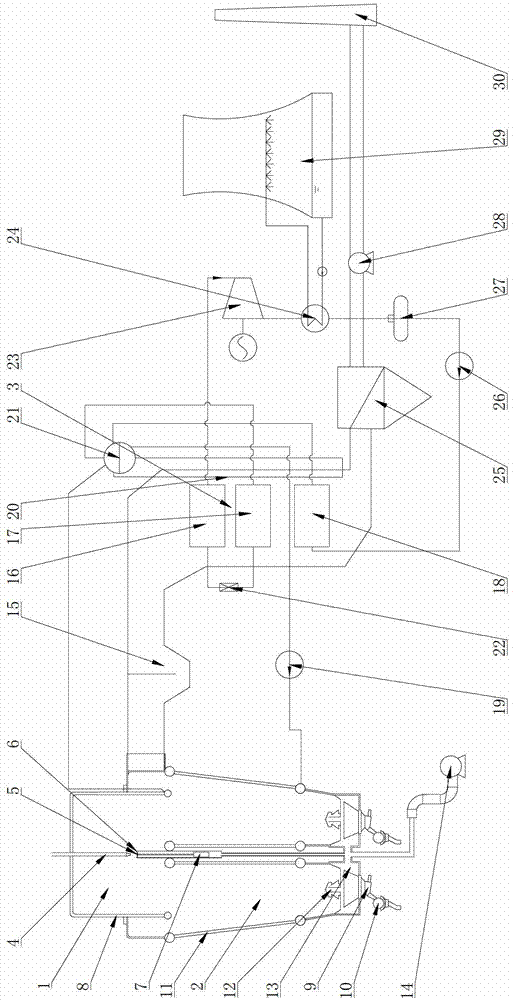

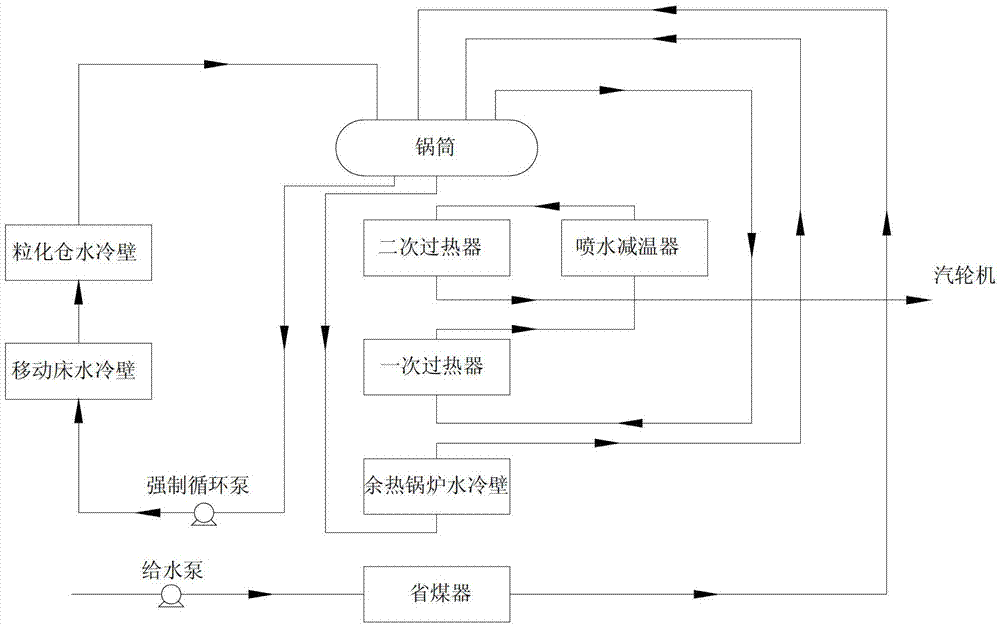

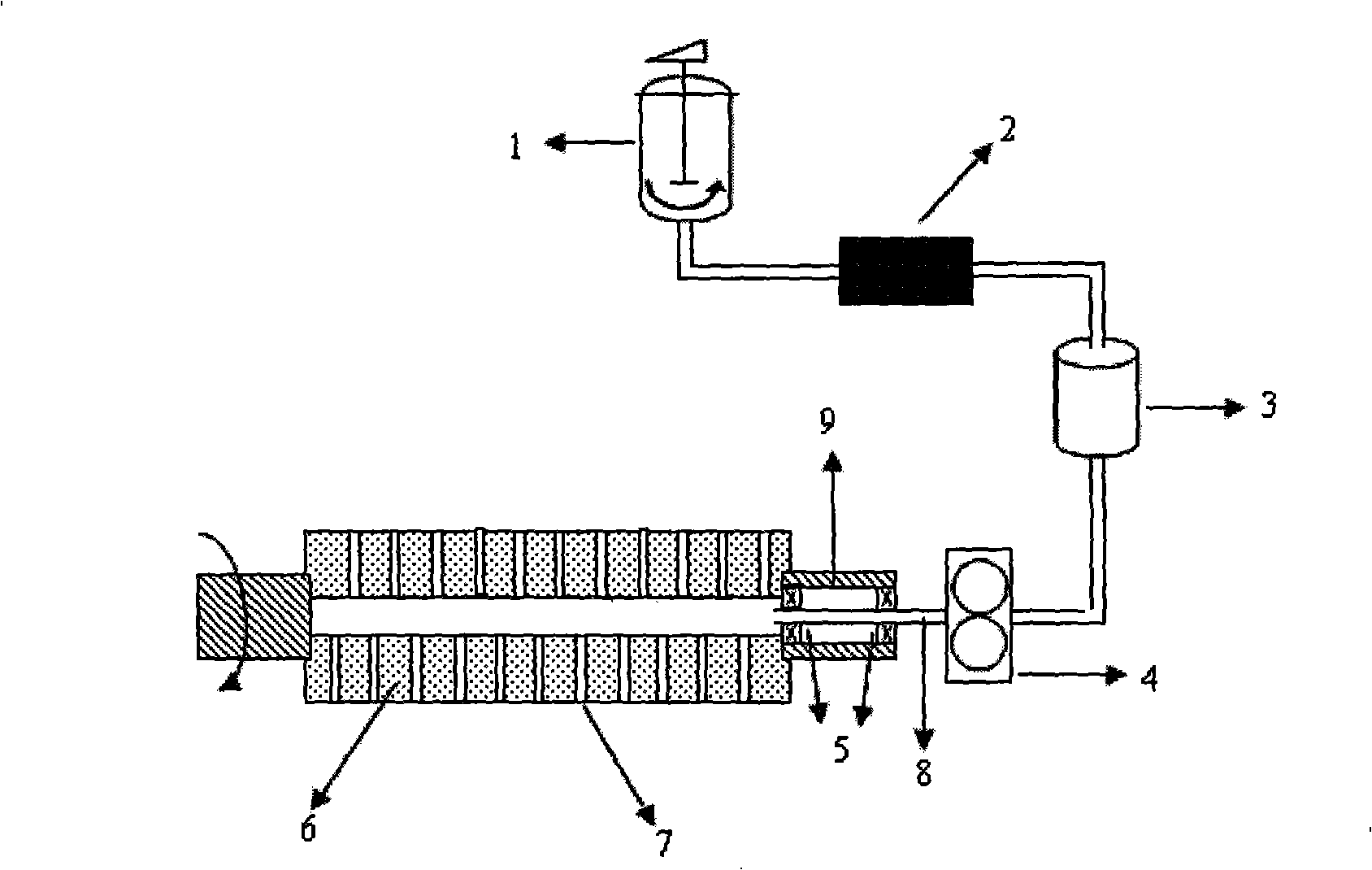

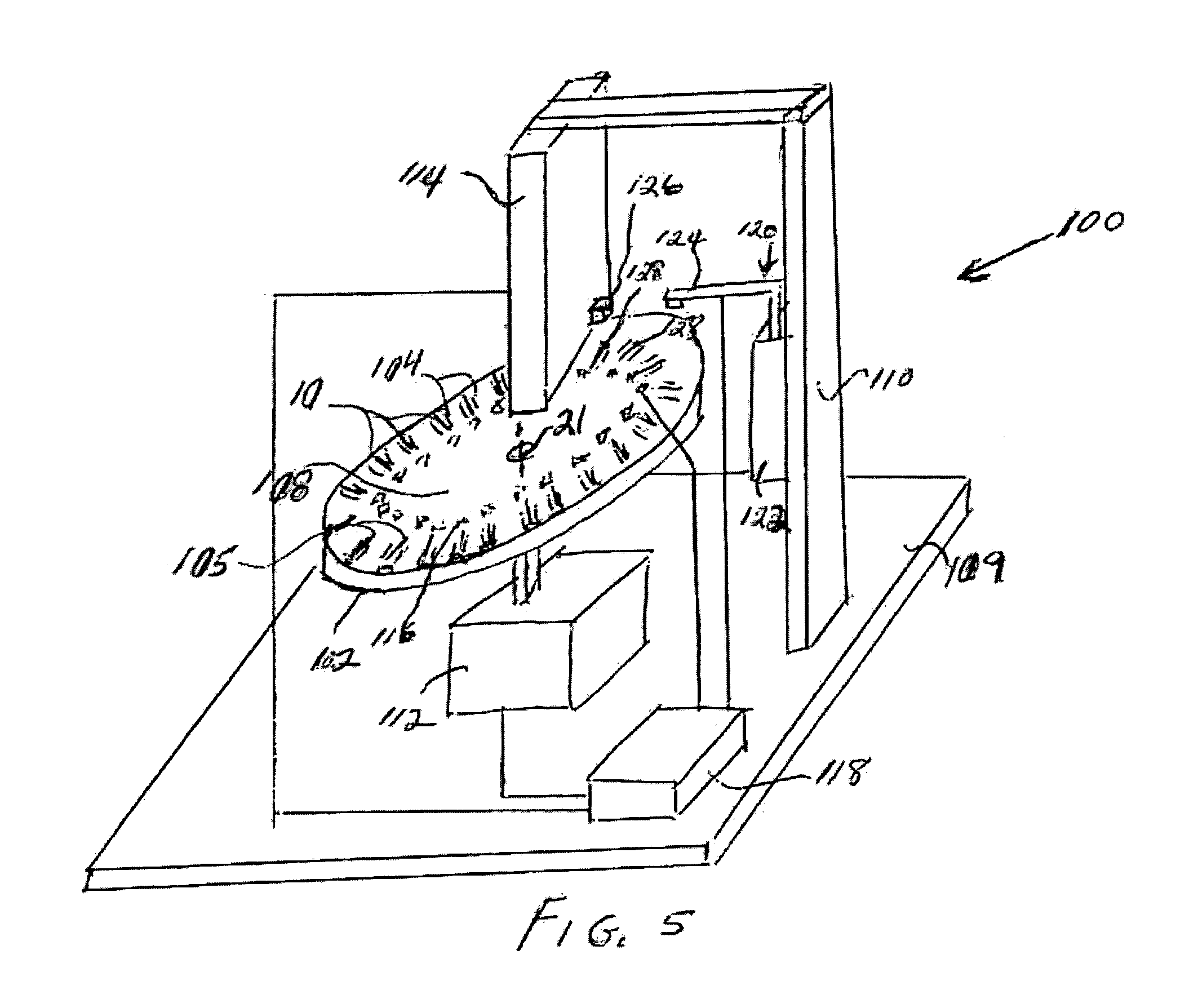

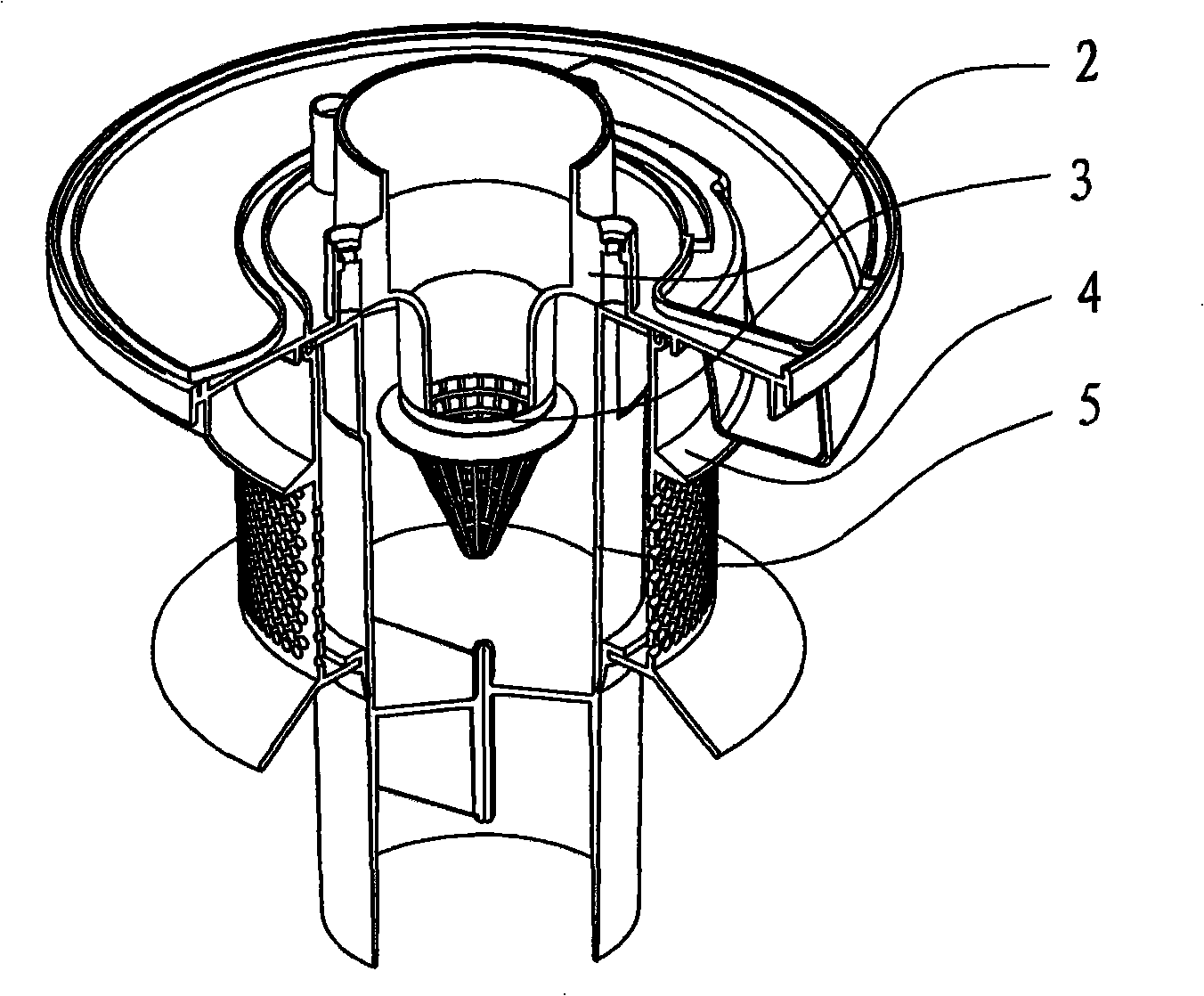

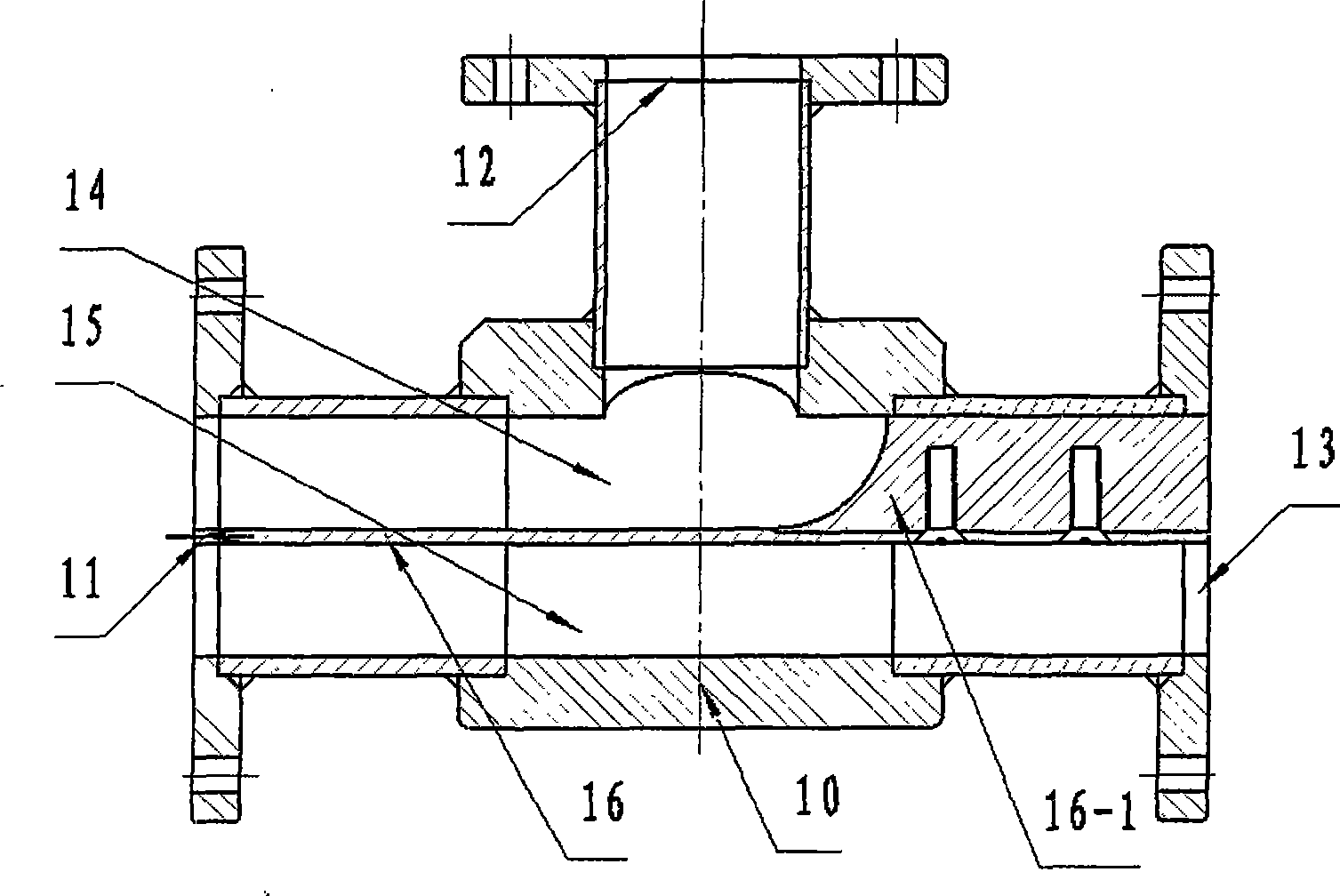

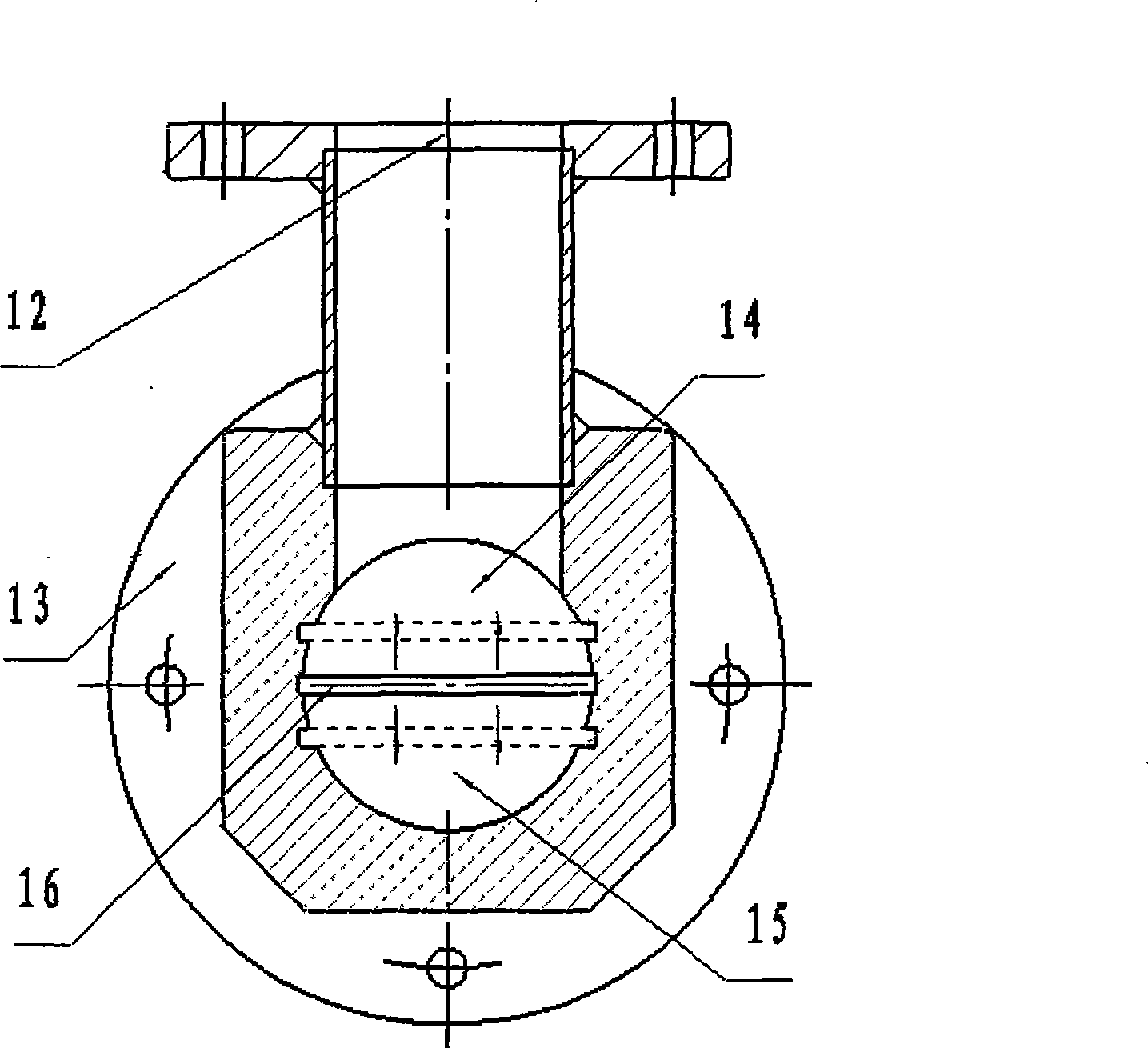

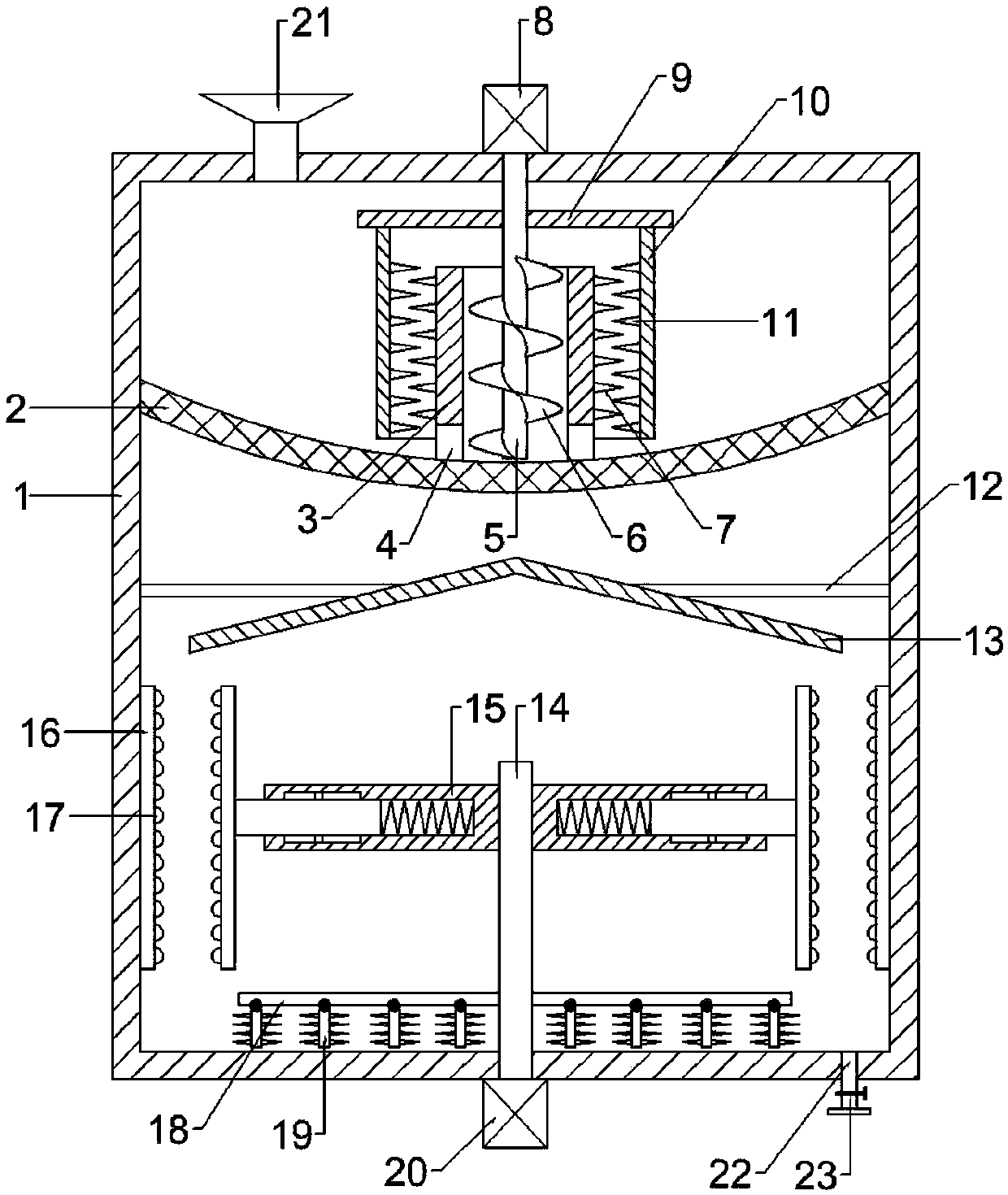

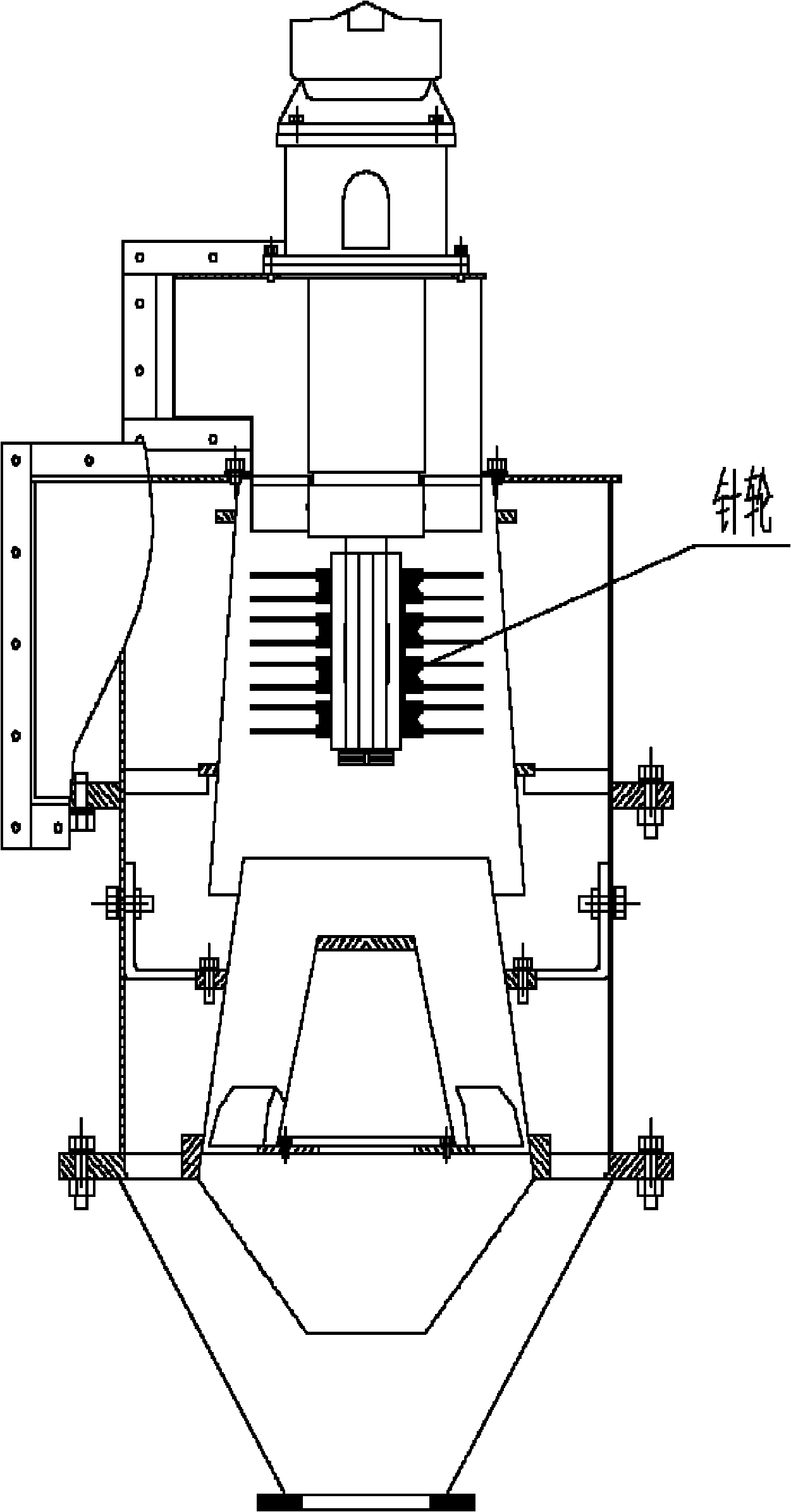

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

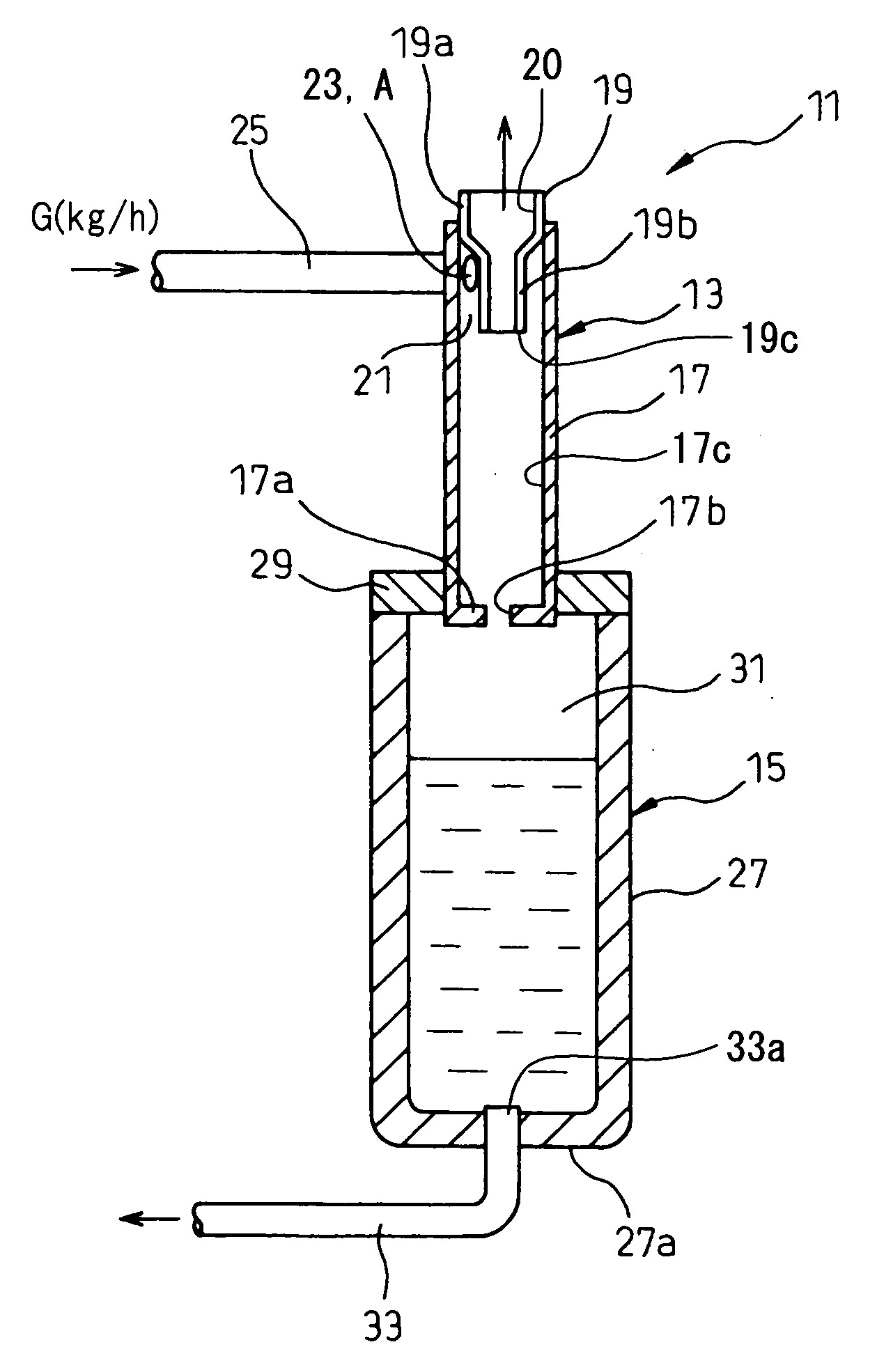

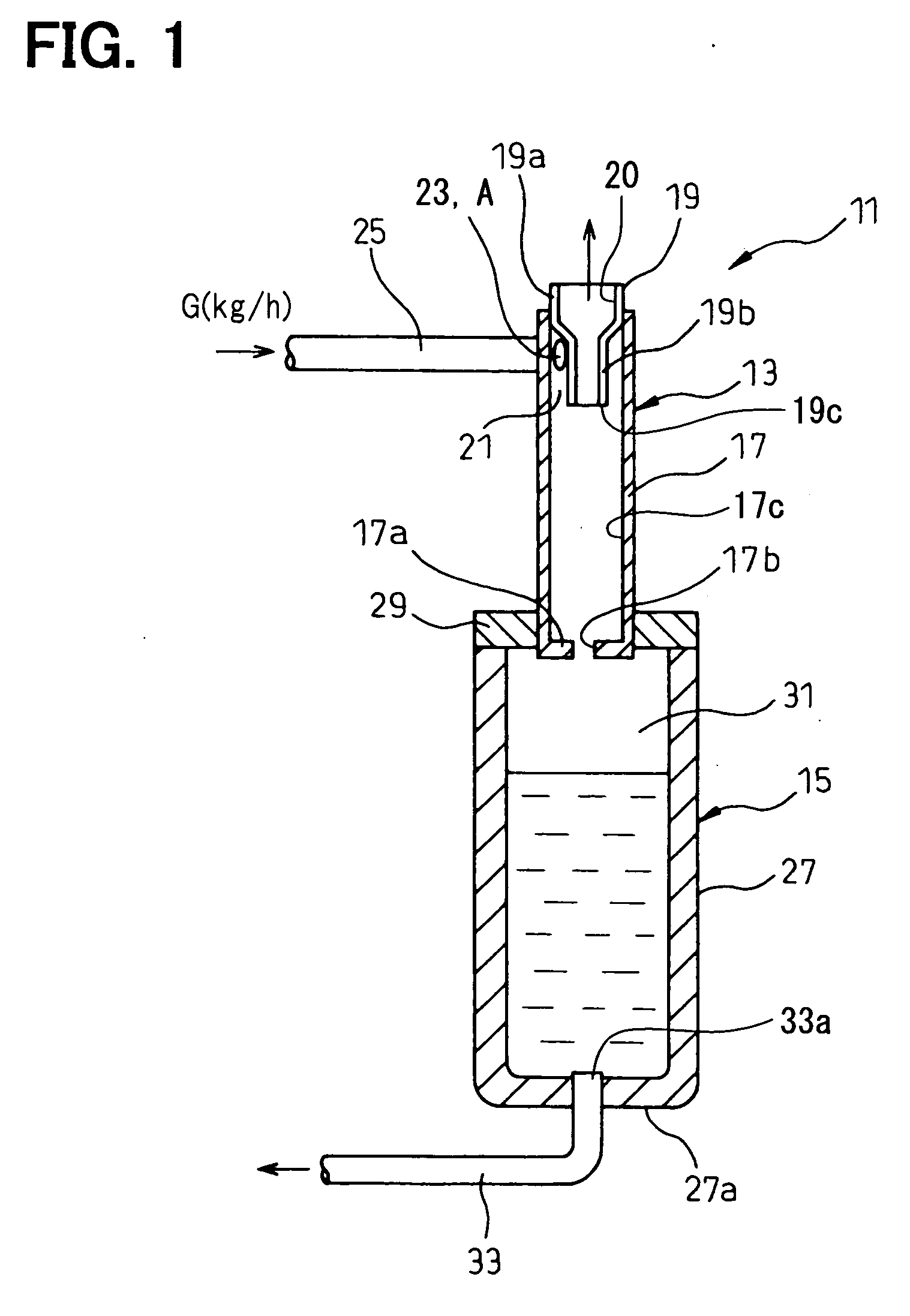

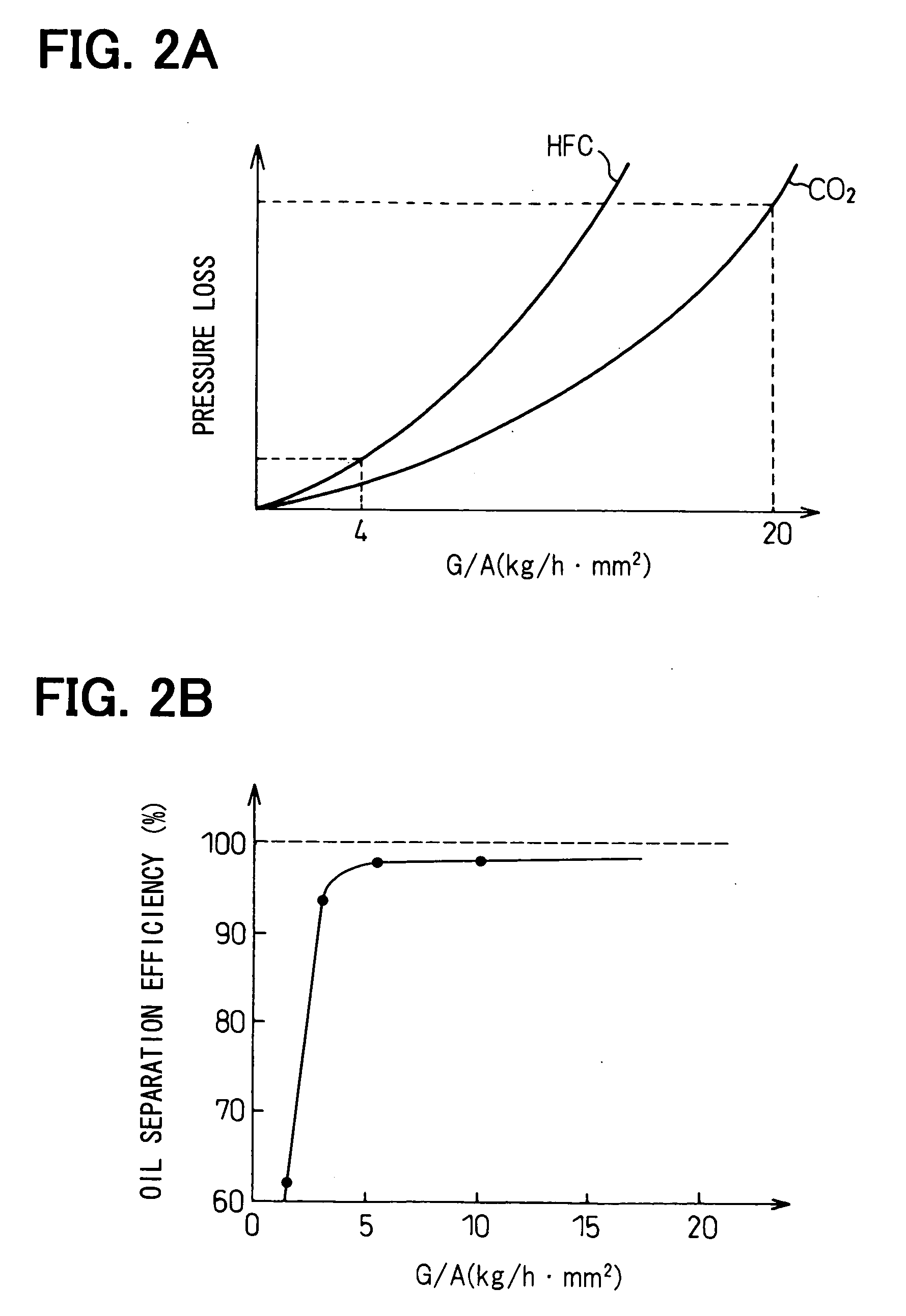

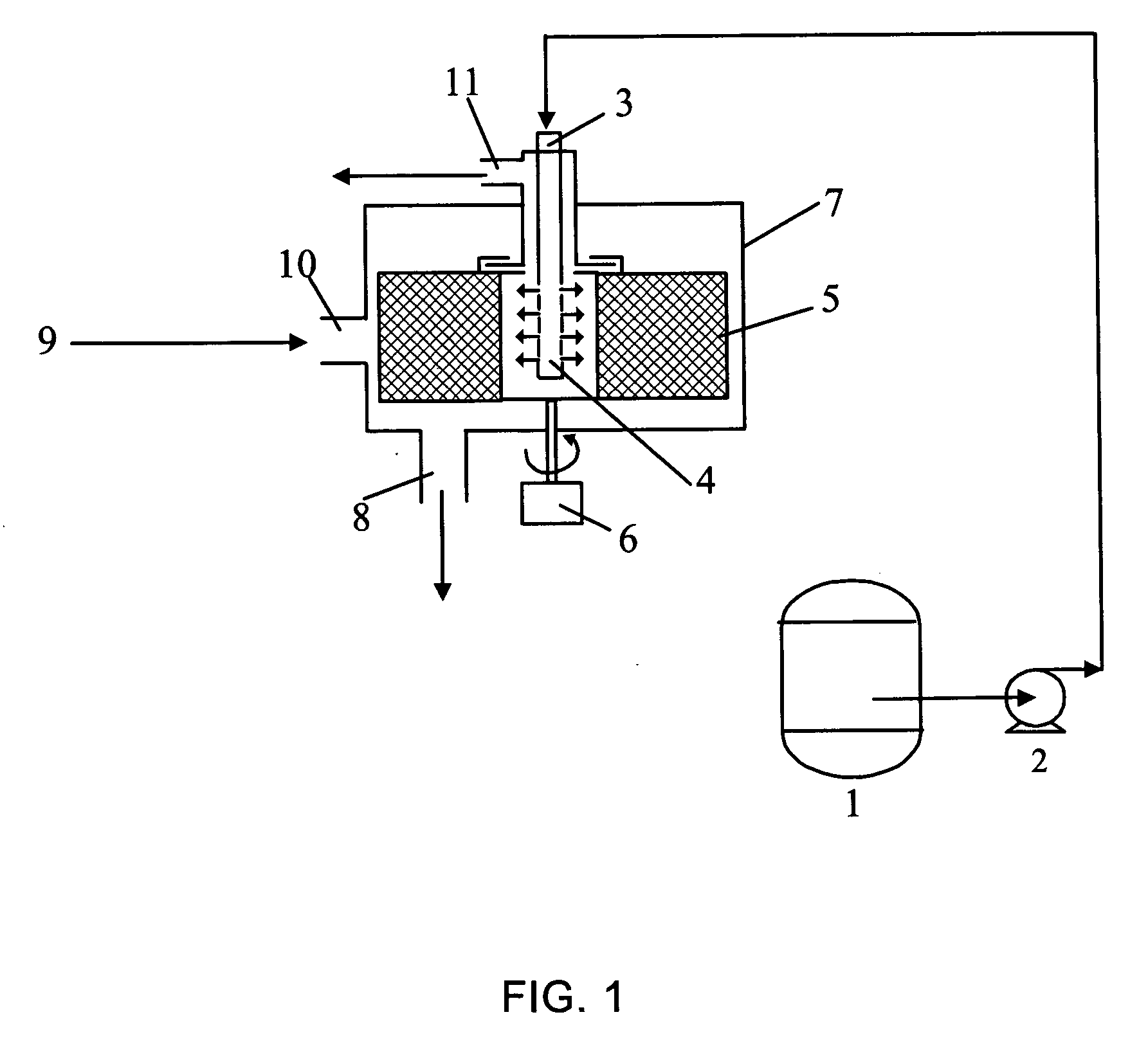

Oil separator and refrigerant compressor having the same

InactiveUS20090071188A1Easy to separateEfficient separationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringCentrifugal force

An oil separator includes a separation part and an oil storage part. The separation part includes a separation cylinder, an inner cylinder disposed in the separation cylinder and an inlet pipe connecting to the separation cylinder tangential to an inner surface of the separation cylinder. The separation part defines an inlet opening to introduce CO2 refrigerant containing oil in the separation cylinder. The separation cylinder separates the oil from the CO2 refrigerant by means of centrifugal force. A ratio of a flow rate (kg / h) of the CO2 refrigerant flowing in the separation cylinder to an area (mm2) of the inlet opening is at least 4. Alternative to or in addition to the above, a ratio of a distance (mm) from an end of the inner cylinder to a bottom wall of the separation cylinder to an inner diameter (mm) of the separation cylinder is at least 2.5.

Owner:DENSO CORP +1

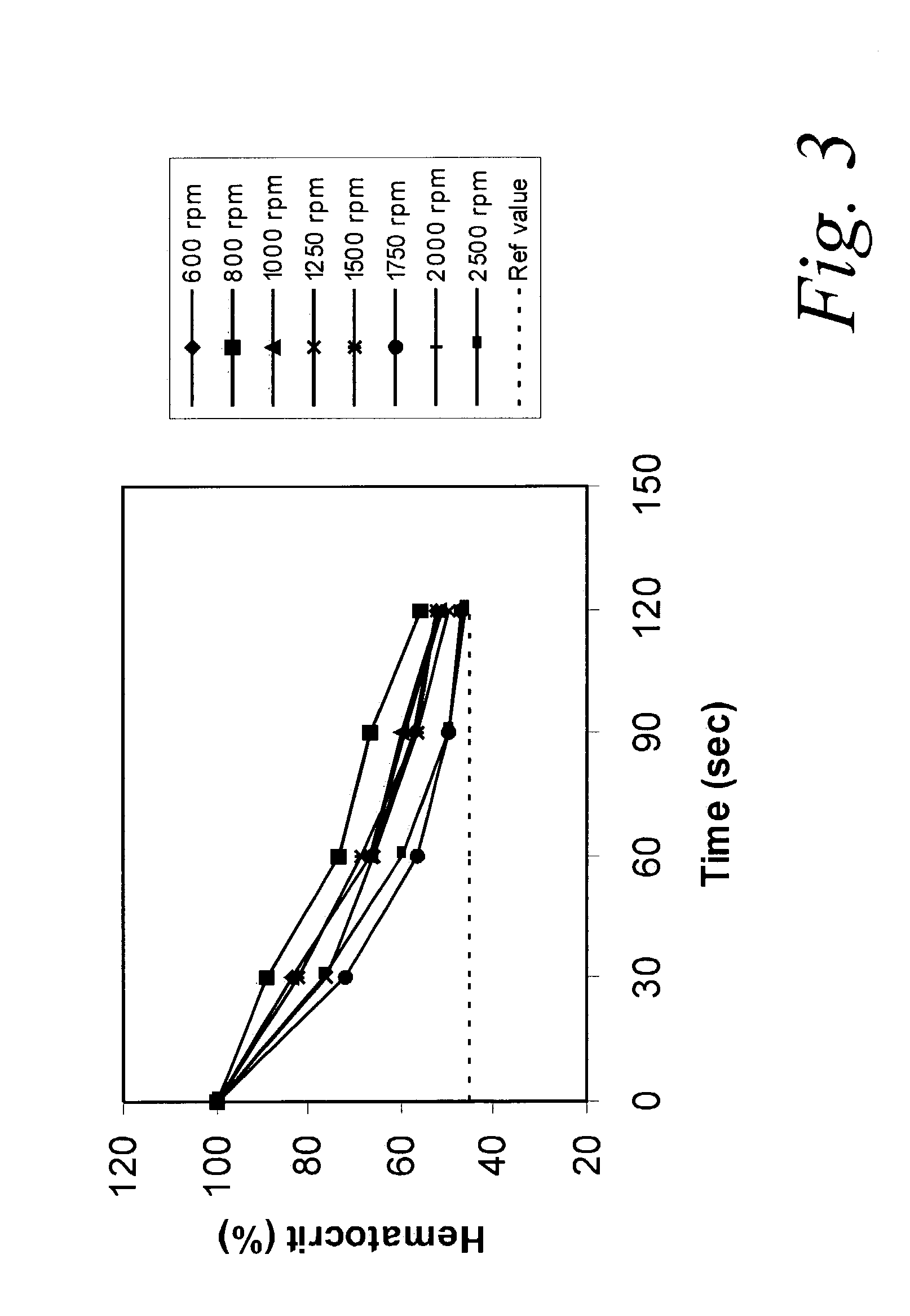

Method and apparatus for separation of particles in a microfluidic device

InactiveUS7094354B2Easy to separateIncrease the areaBioreactor/fermenter combinationsBiological substance pretreatmentsRed blood cellSpecific volume

A microfluidic device provides separation of particles in a liquid sample, particularly, separation of a sample of whole blood into its components for further analysis. Separation into red blood cells and plasma occurs within a few seconds after the blood sample has been transferred into a separation chamber with the application of centrifugal force of less than about five times gravity. With the application of greater force measurement of hematocrit is possible.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

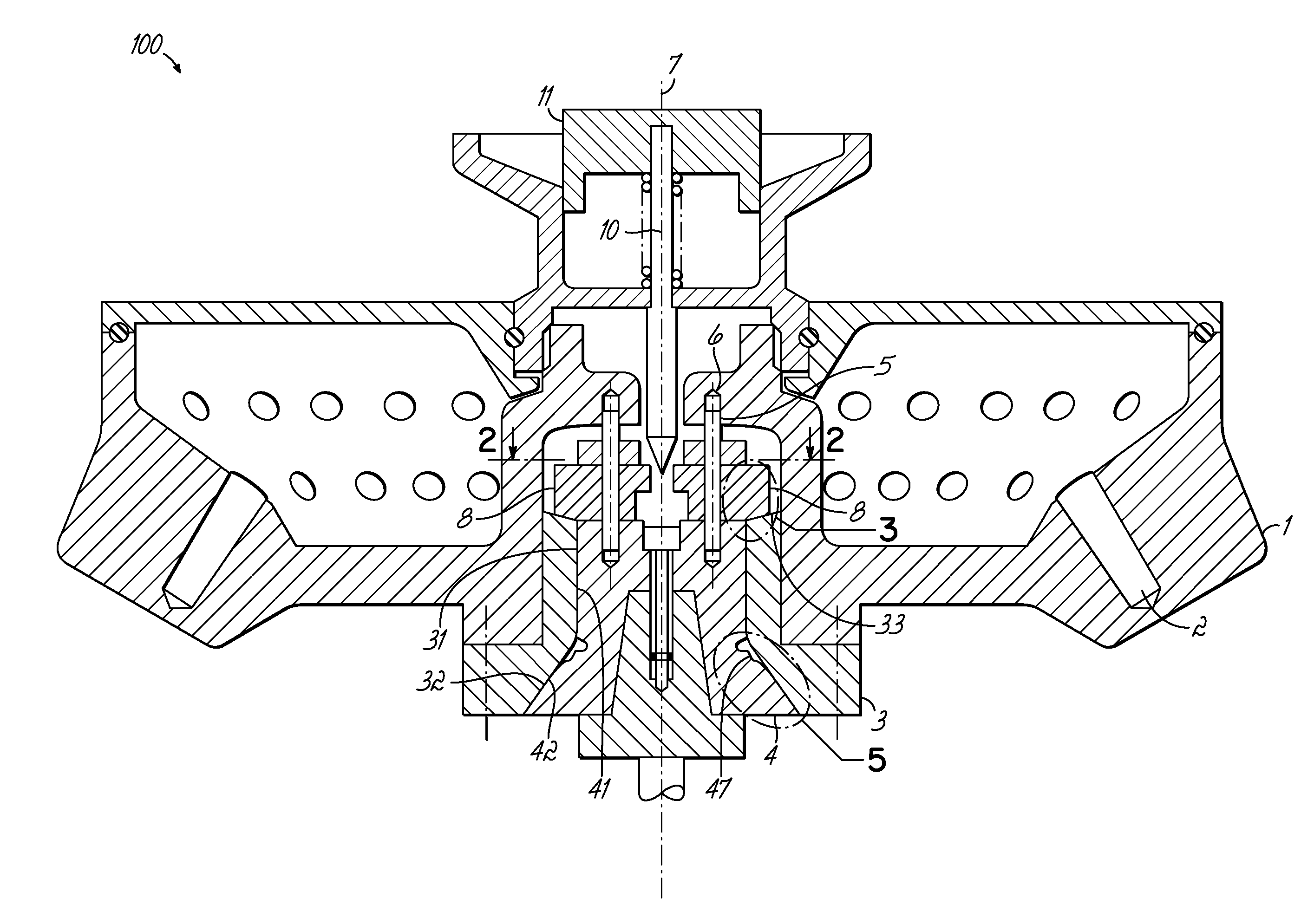

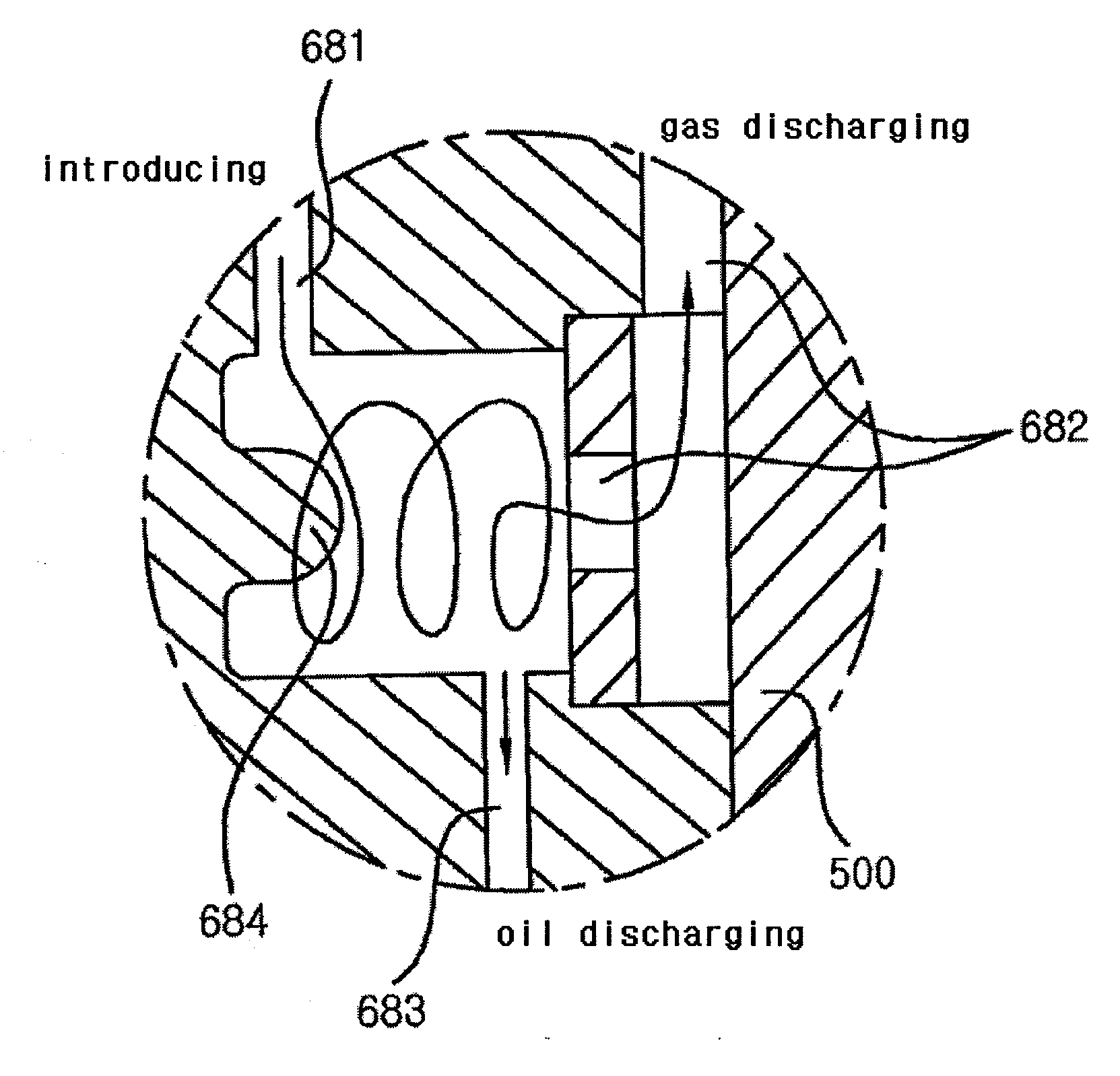

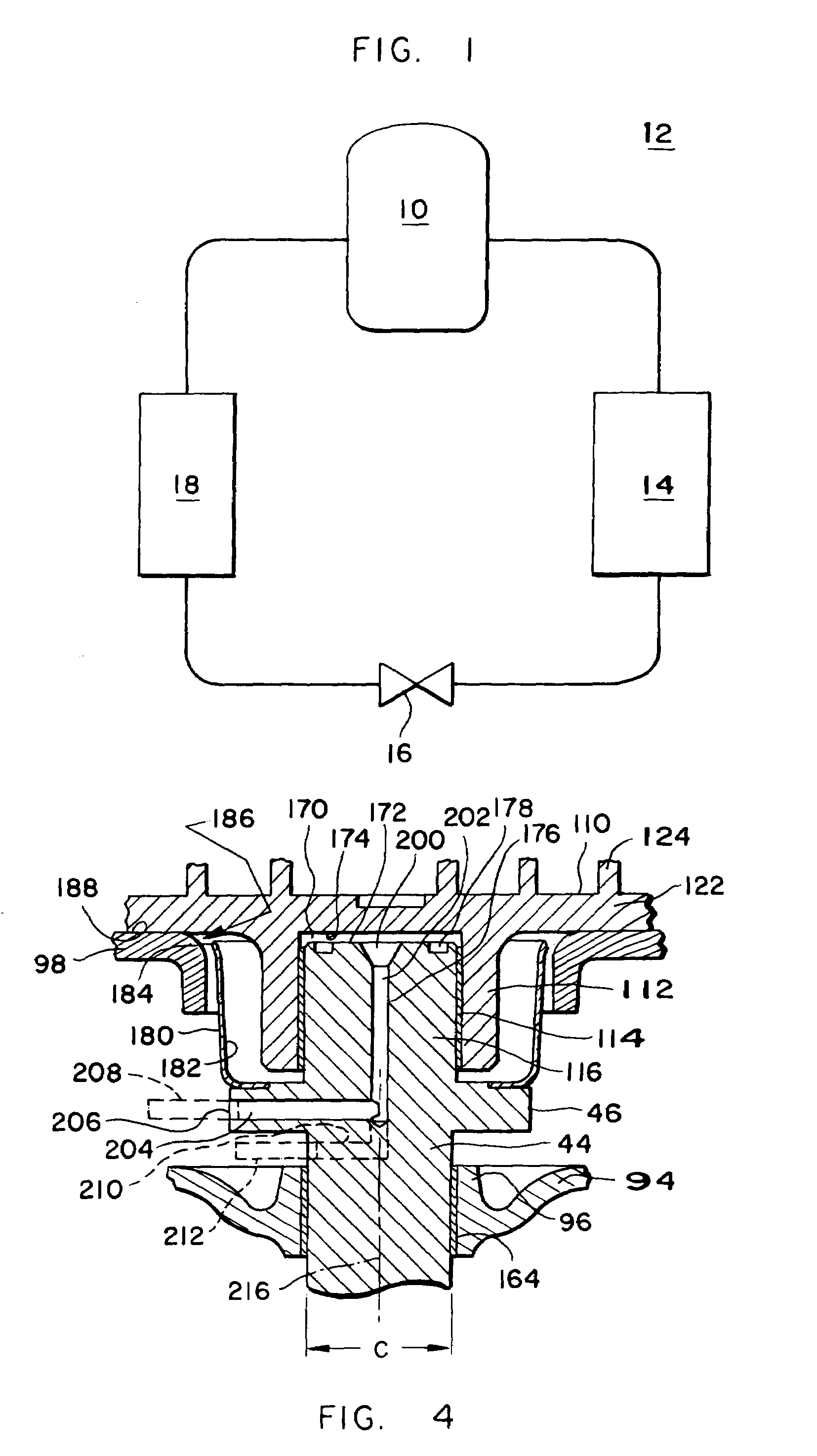

Scroll compressor with enhanced lubrication

ActiveUS20070003424A1Reduce deliveryFacilitates separation and removalRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

Lubrication of bearing surfaces in a scroll compressor is enhanced by a vent arrangement which makes use of increased centrifugal force, achieved by locating the outlet of the vent arrangement radially outside of the nominal circumference of the compressor's drive shaft, to both remove refrigerant gas from compressor locations where such gas can inhibit the flow and delivery of lubricant to such surfaces and to increase the lift of lubricant out of the compressor's lubricant sump. Oil retained in the upper surface of the compressor drive shaft is made immediately available for bearing lubrication upon compressor start-up to further enhance compressor lubrication.

Owner:TRANE INT INC

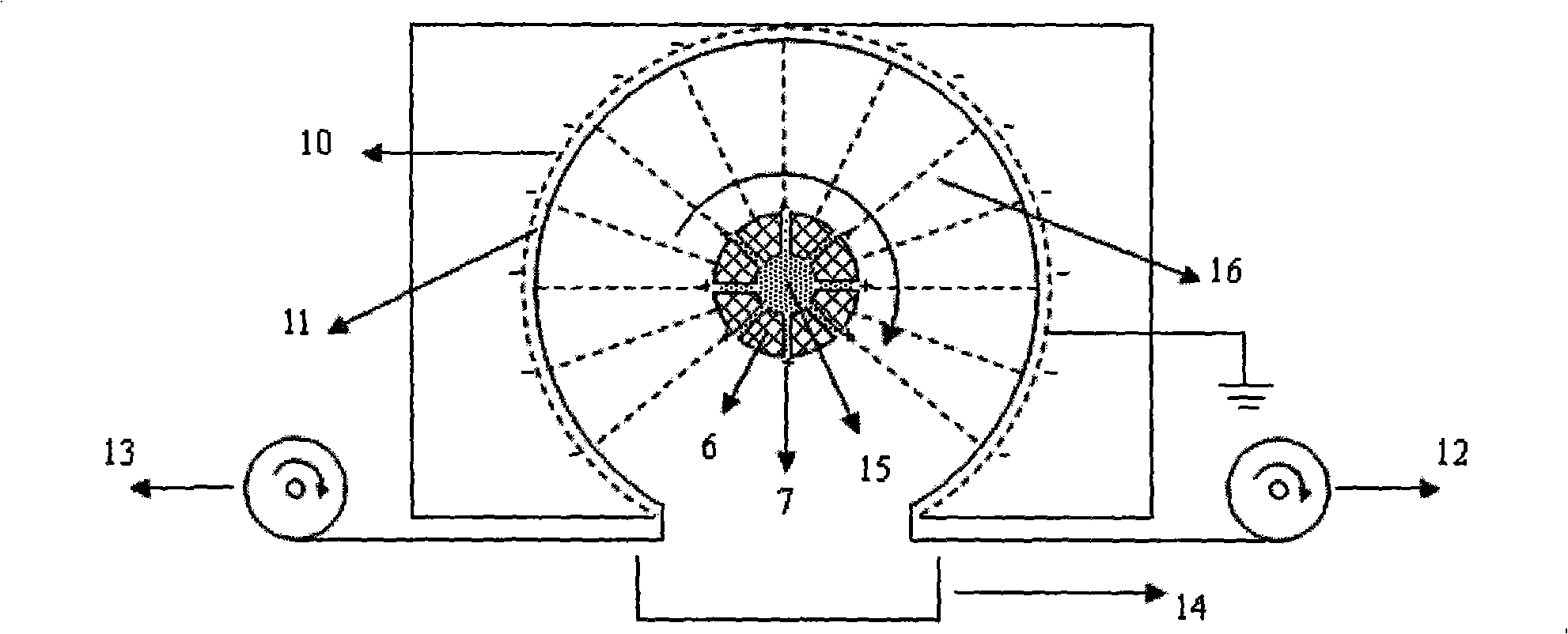

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

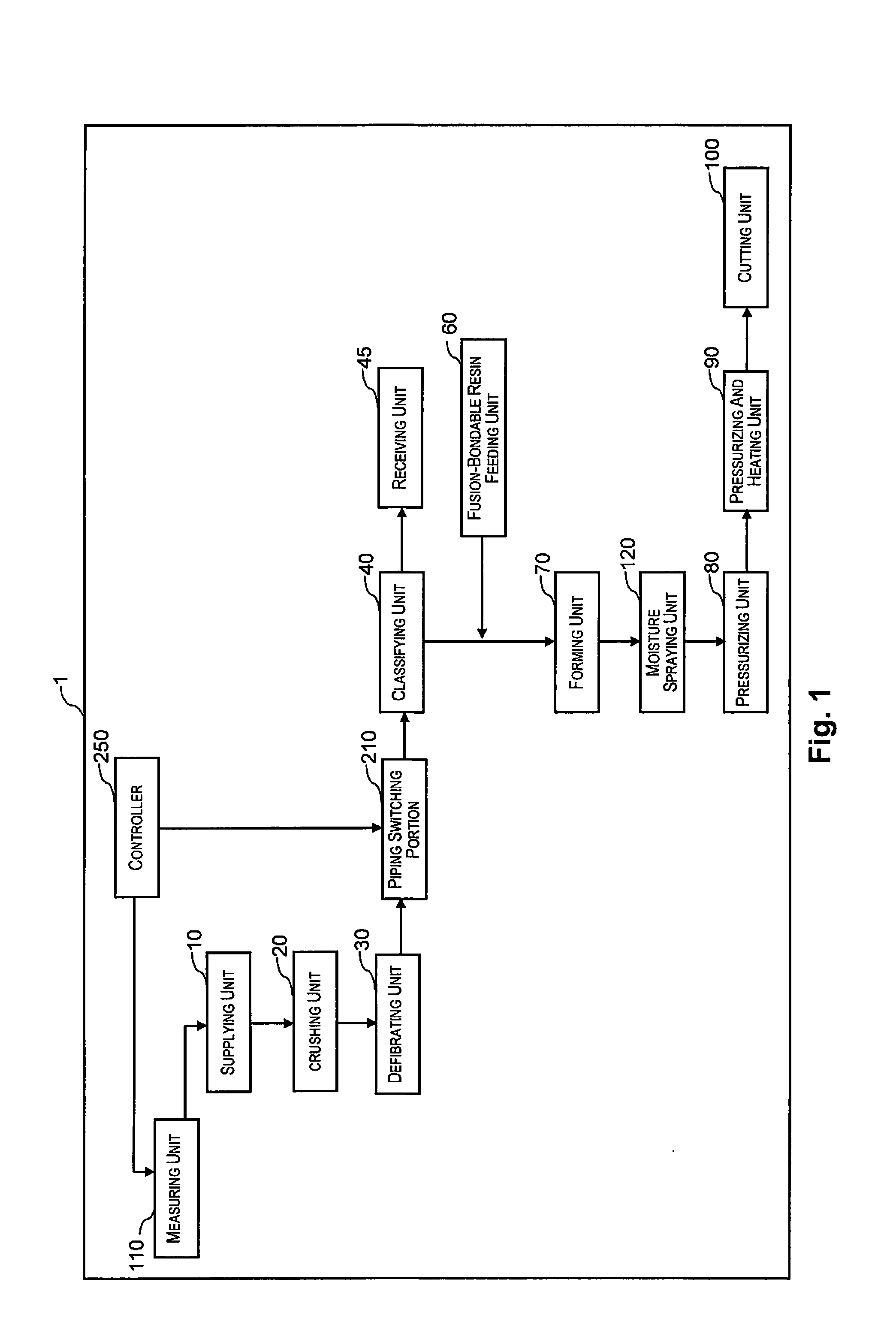

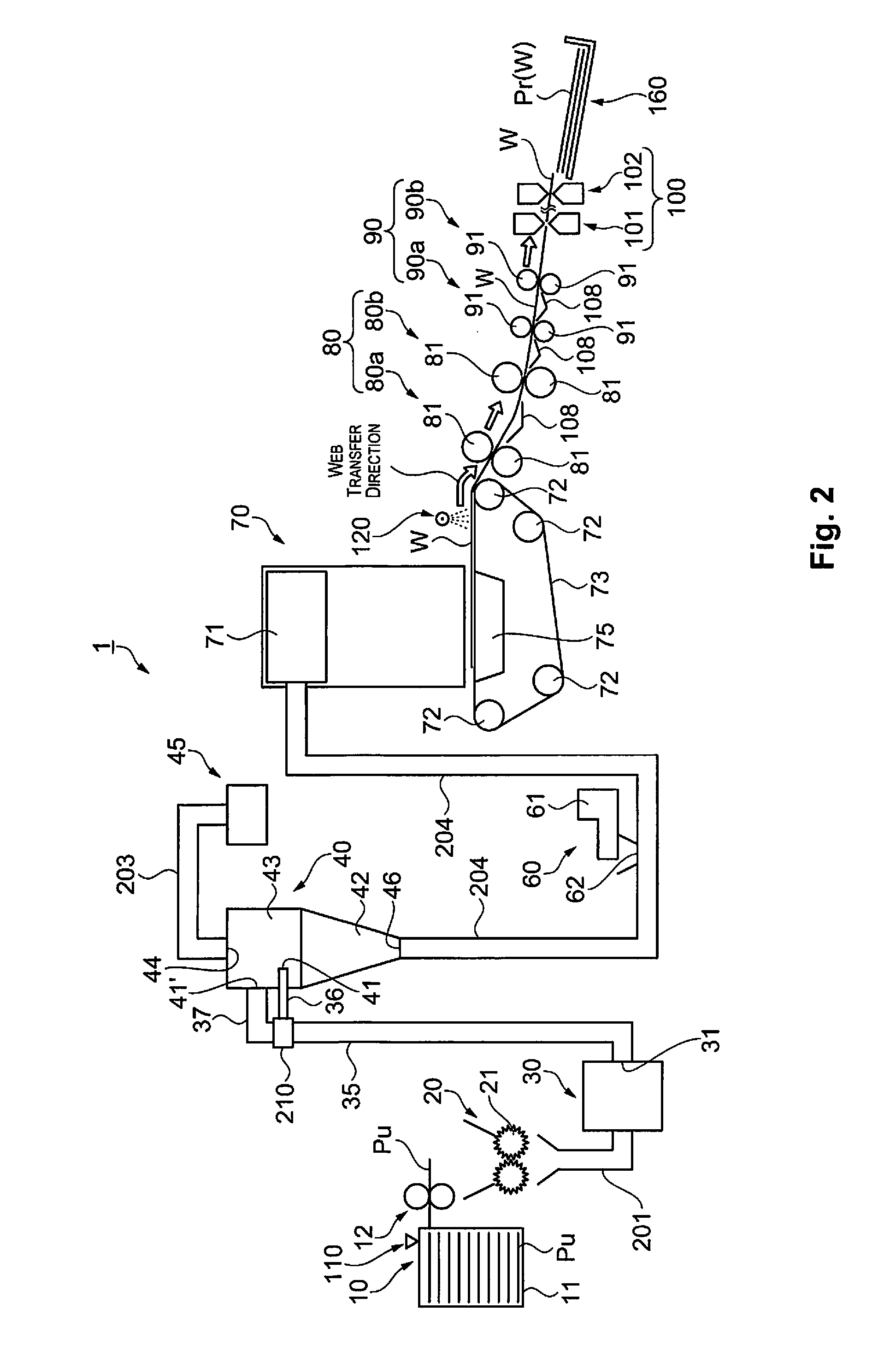

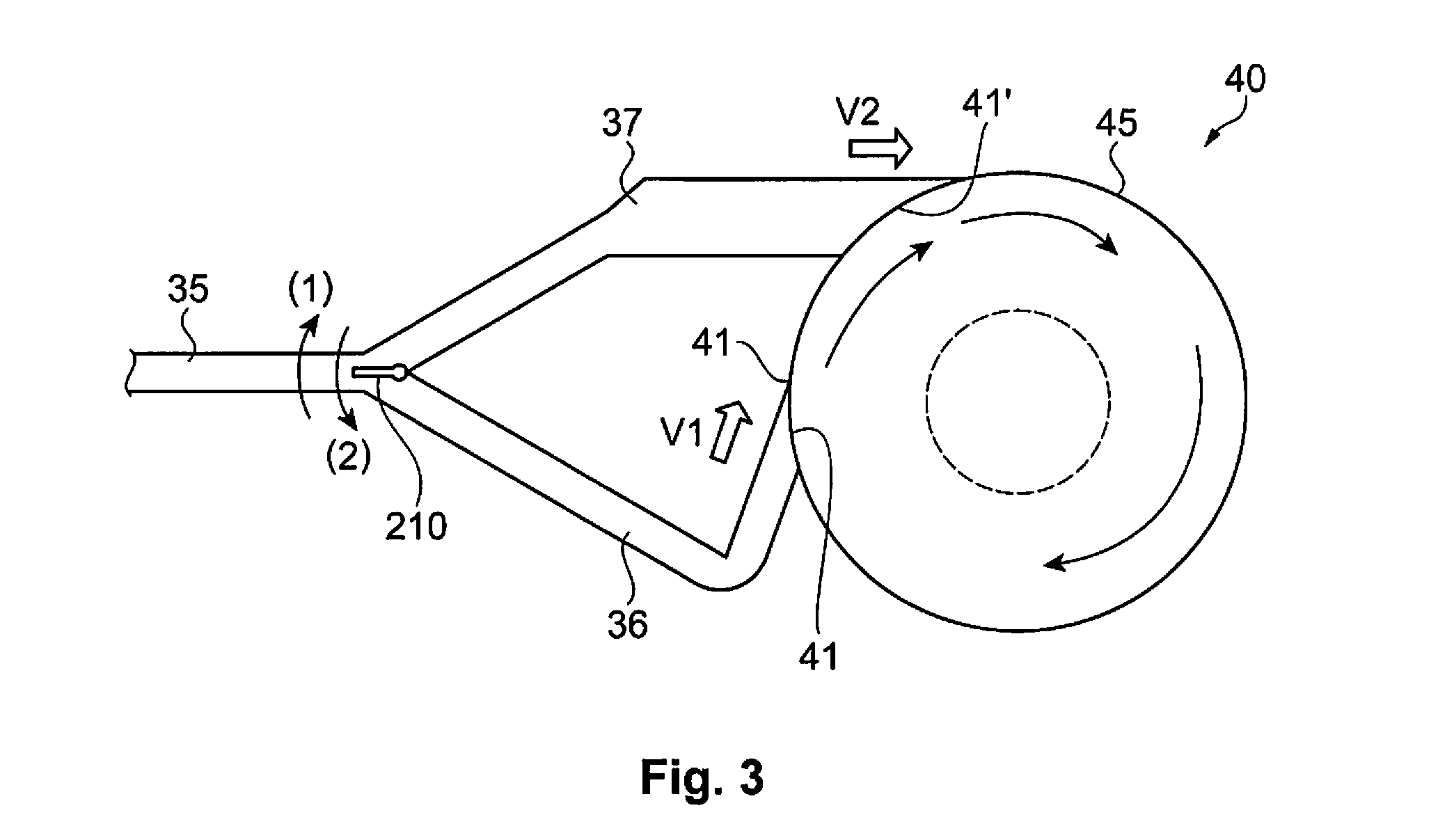

Sheet manufacturing apparatus

ActiveUS20140290888A1Low content rateReduced removal rateMachine wet endDirt cleaningFiberForeign matter

A sheet manufacturing apparatus includes a measuring unit configured to measure thickness and air permeability of a defibration object containing fibers, a defibrating unit configured to dry-defibrate the defibration object, and a classifying unit configured to separate and remove, by airflow classification, foreign substances other than the fibers from the defibrated material defibrated at the defibrating unit.

Owner:SEIKO EPSON CORP

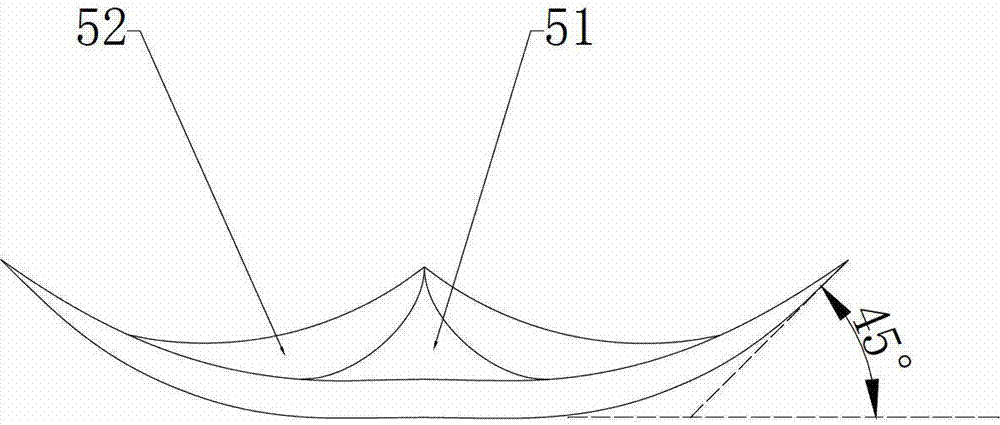

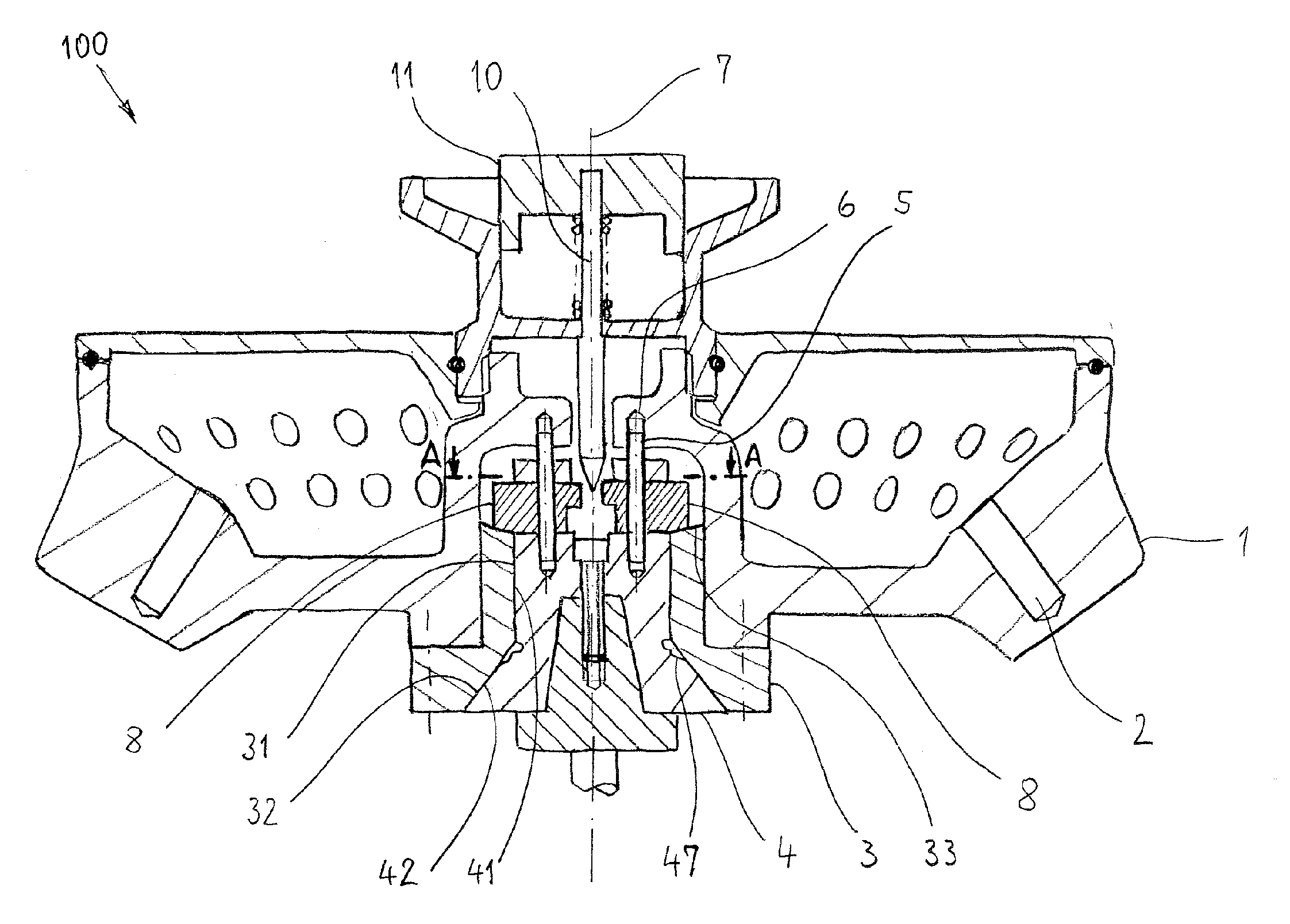

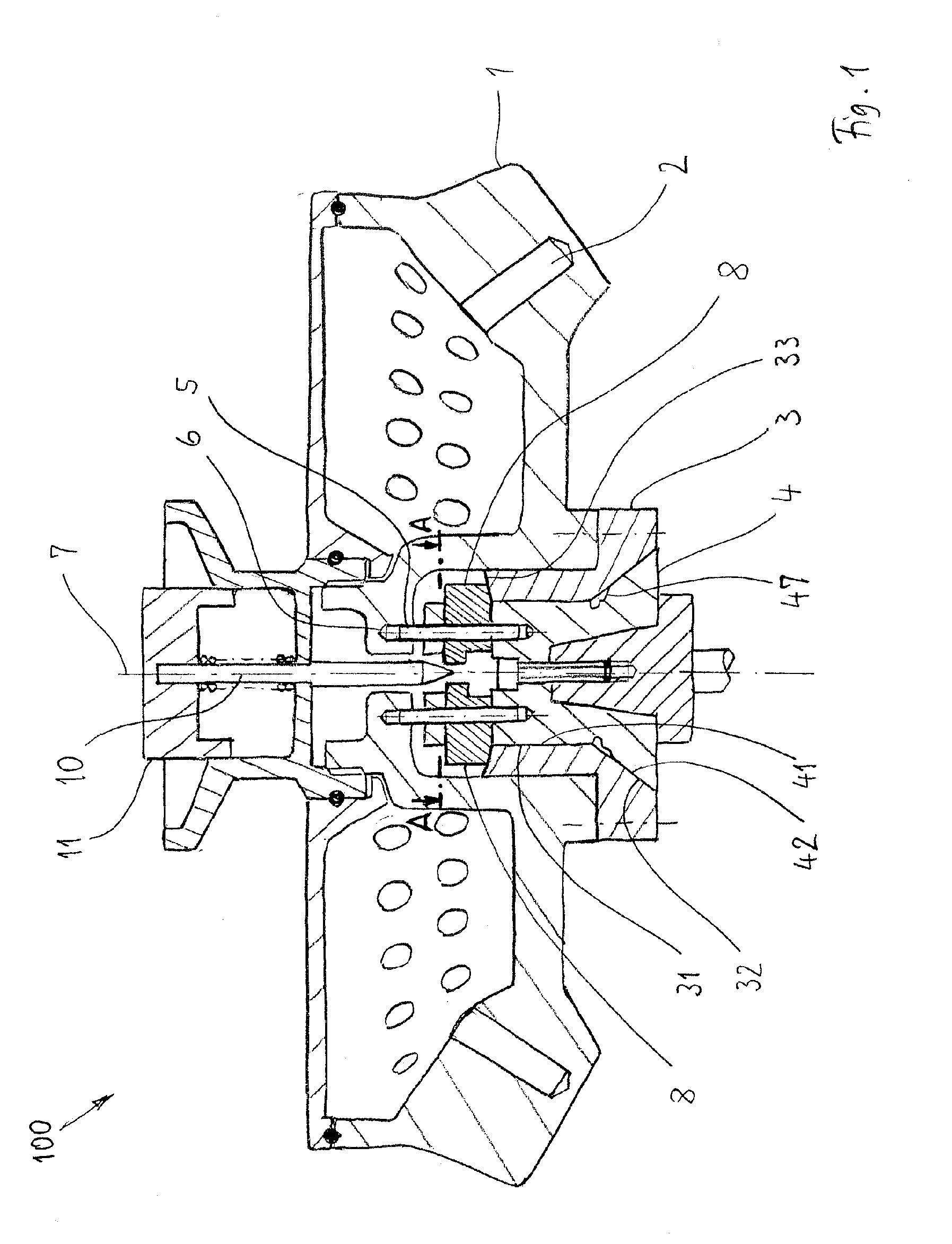

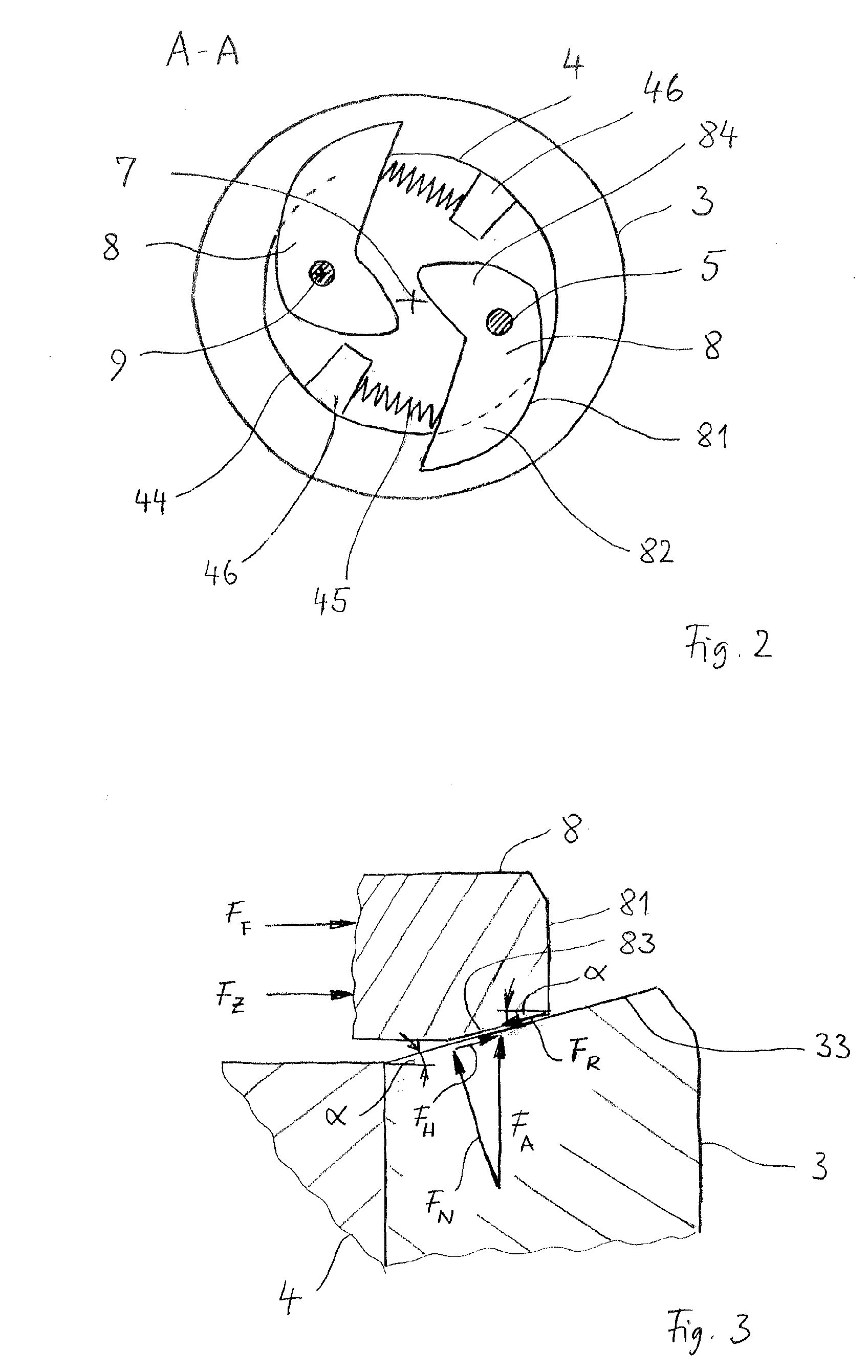

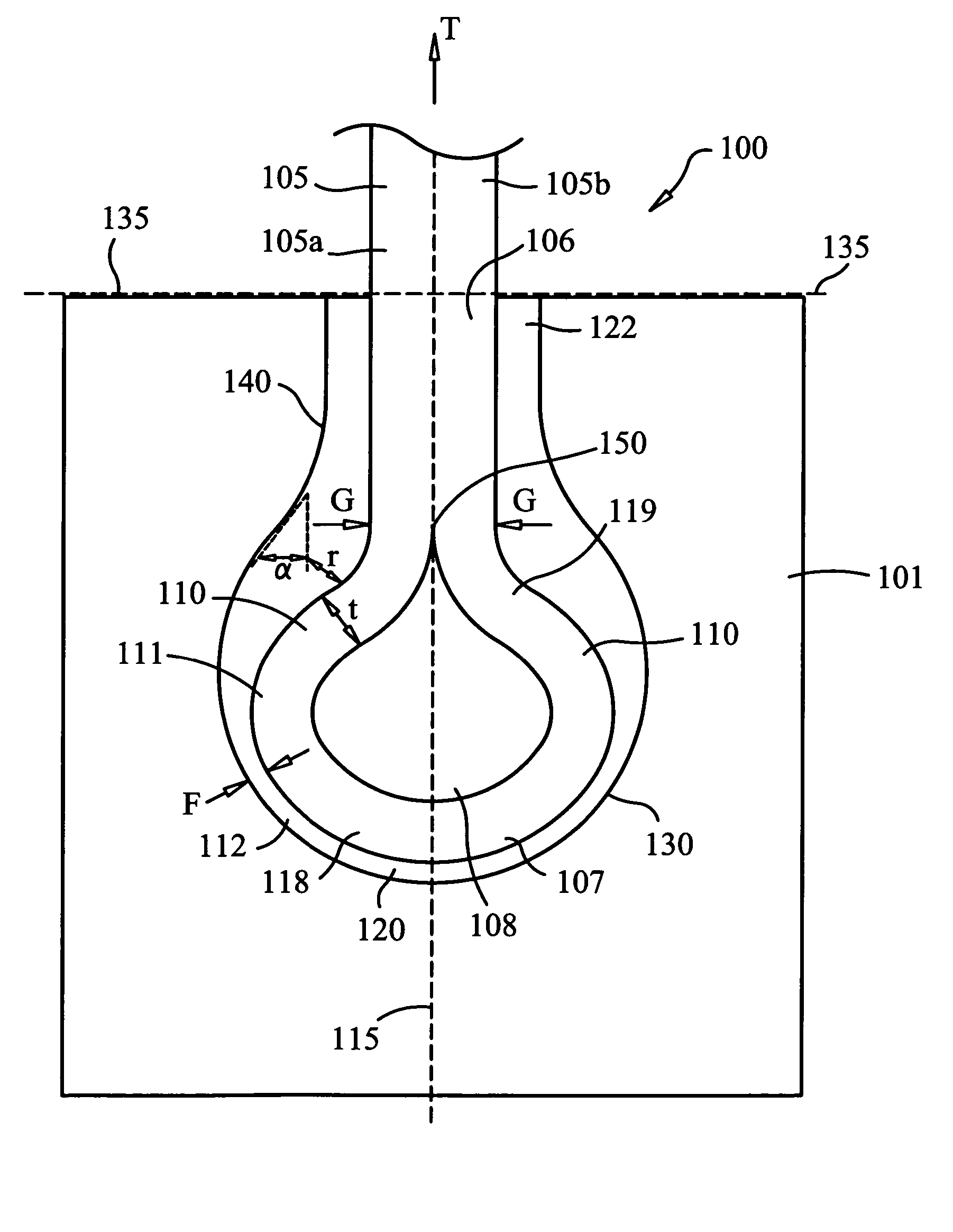

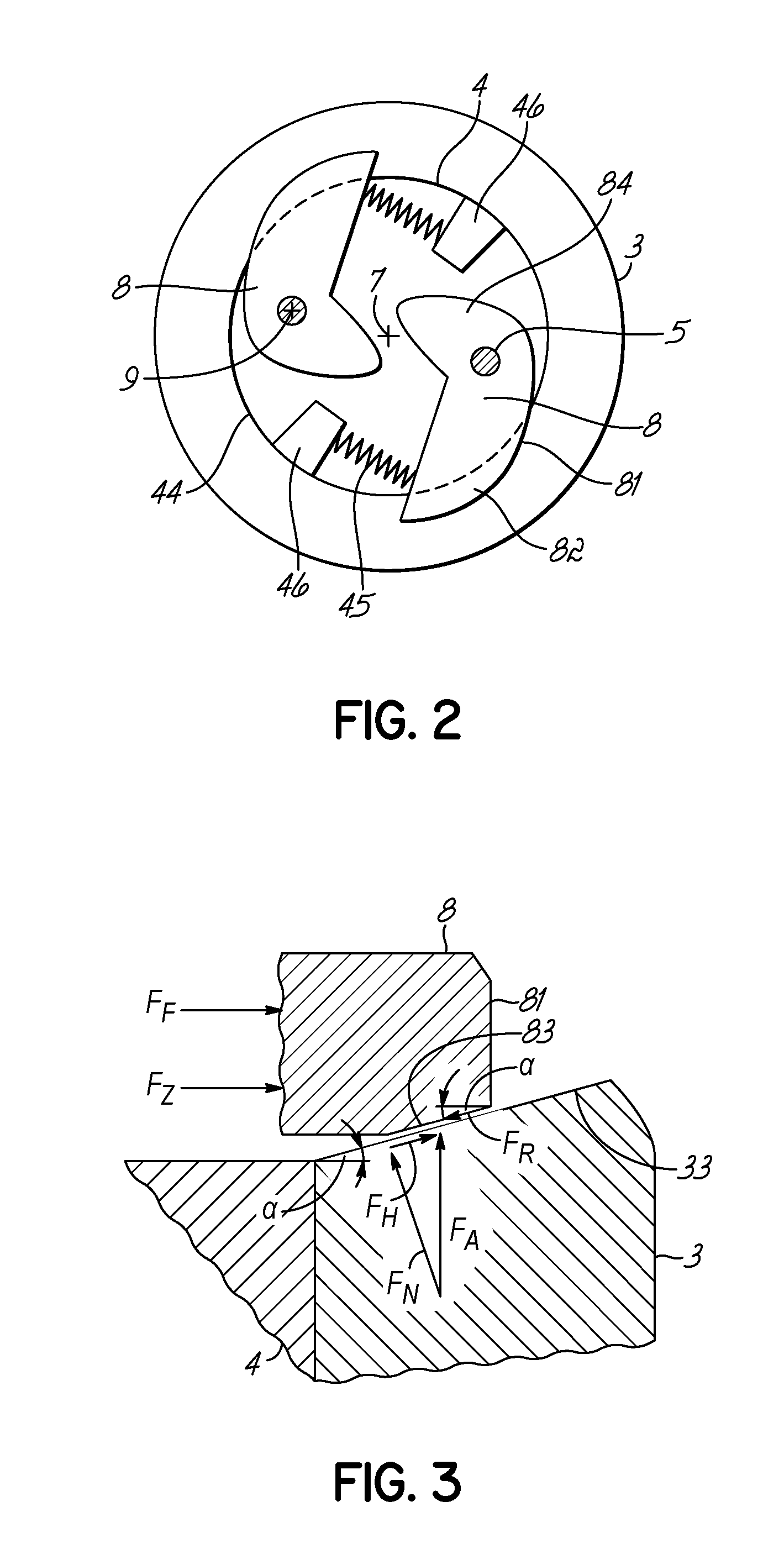

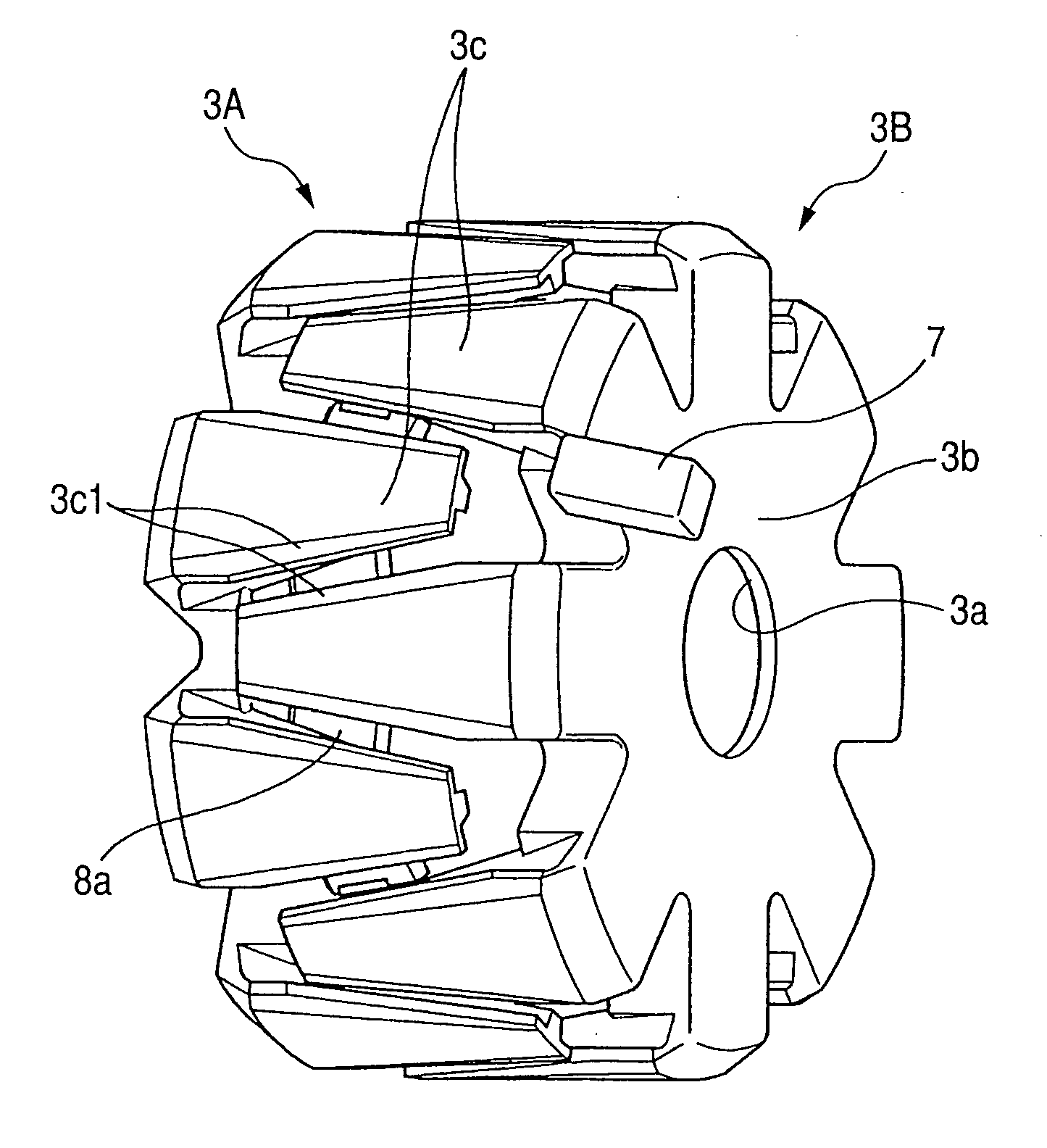

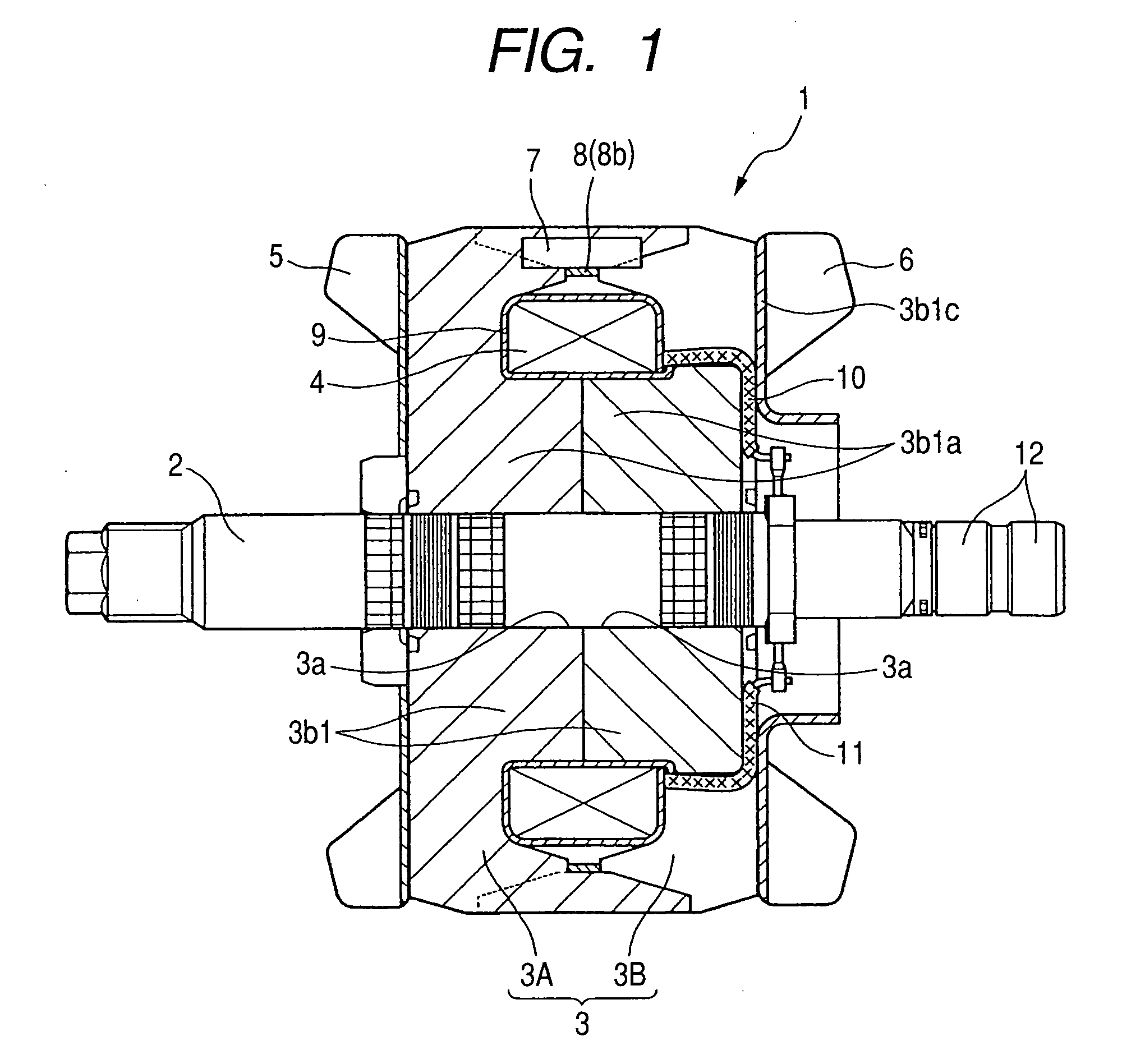

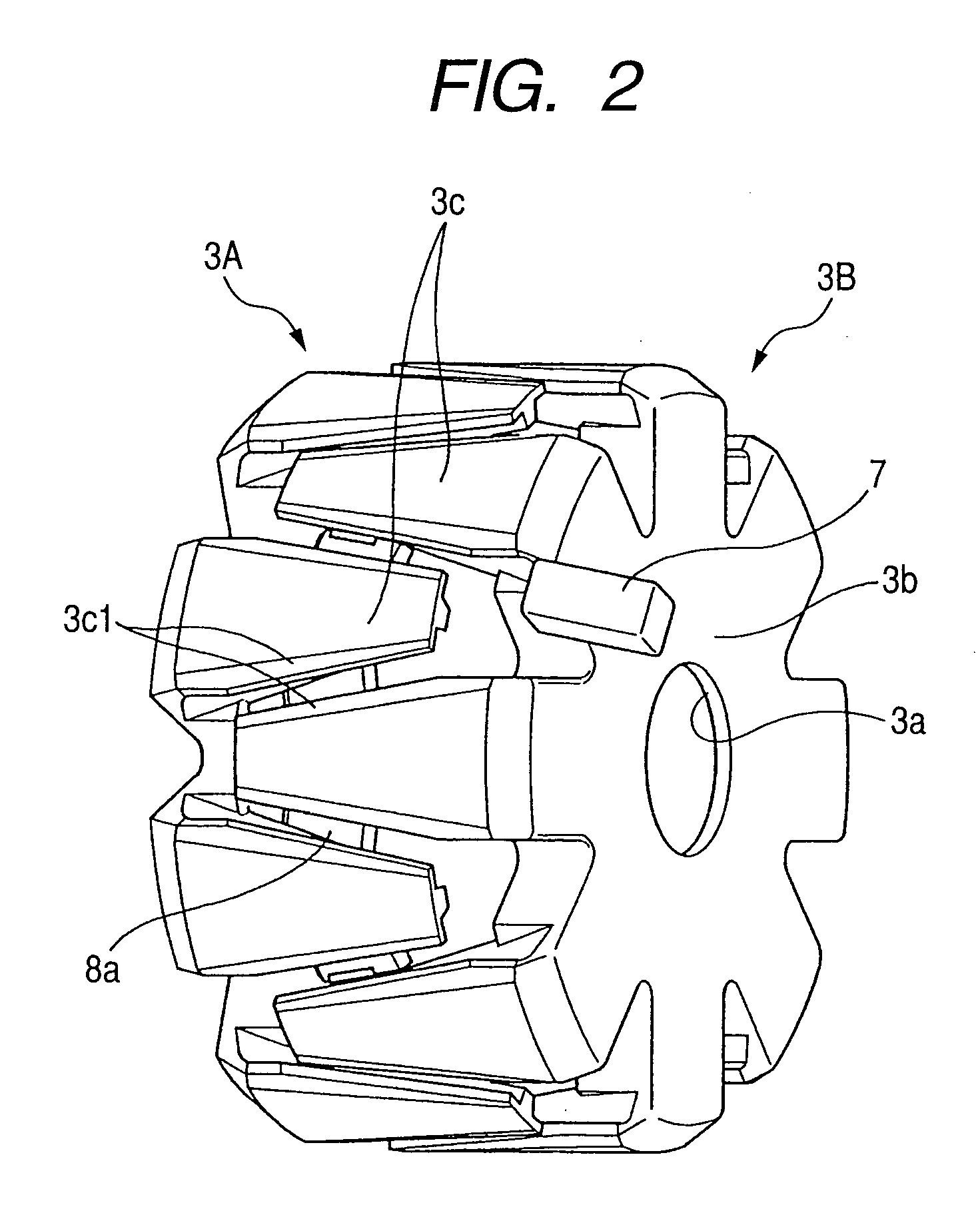

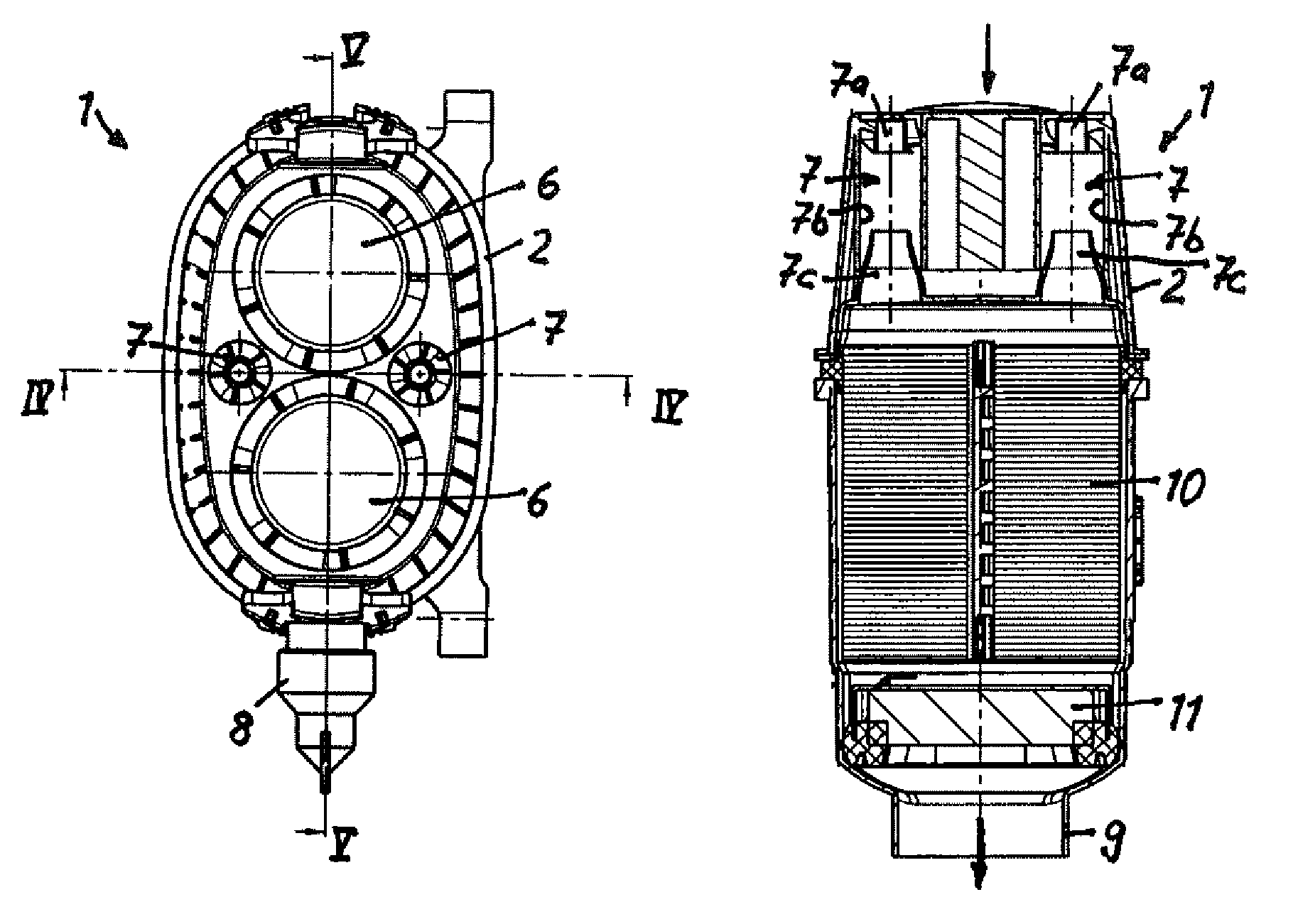

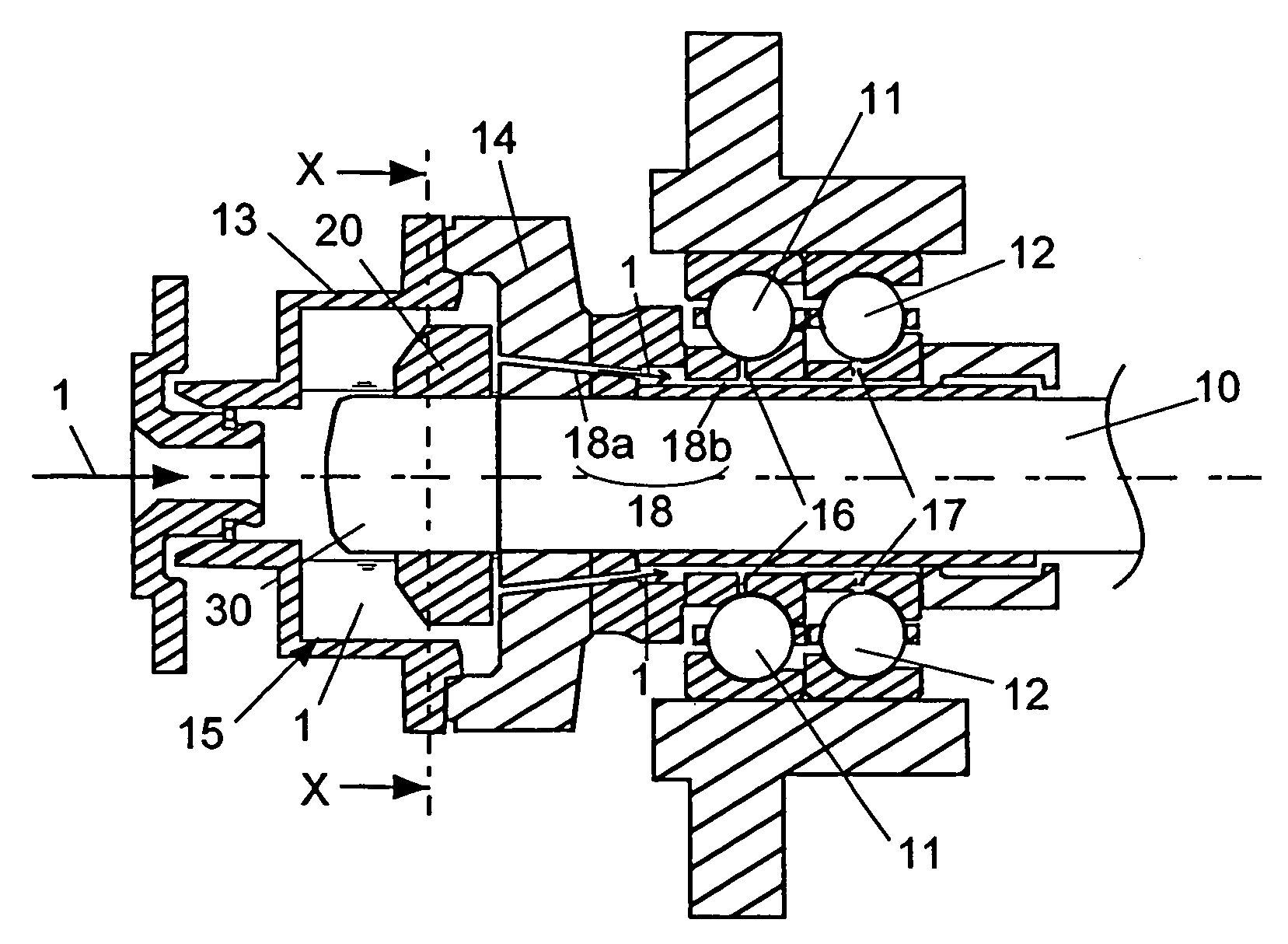

Centrifuge With A Coupling Element For Axially Locking A Rotor

The invention relates to a centrifuge with a drive head which can be connected with a drive, a rotor which can detachably be mounted on the drive head, at least one connection element with which the drive head can be connected in a torsion-proof manner with the rotor, and at least one coupling element which is attached to the drive head and is able to exert an axial force on the rotor in such a way that the rotor can be fixed axially, with the axial force increasing with the rising rotational speed of the drive head, with the coupling element on the rotor transmitting the axial force by means of a ramp surface which is inclined at an angle (α) relative to the horizontal line in a range of more than 0° to 15°. Secure locking of the rotor during standstill and high speeds can thus be achieved.

Owner:QIAGEN

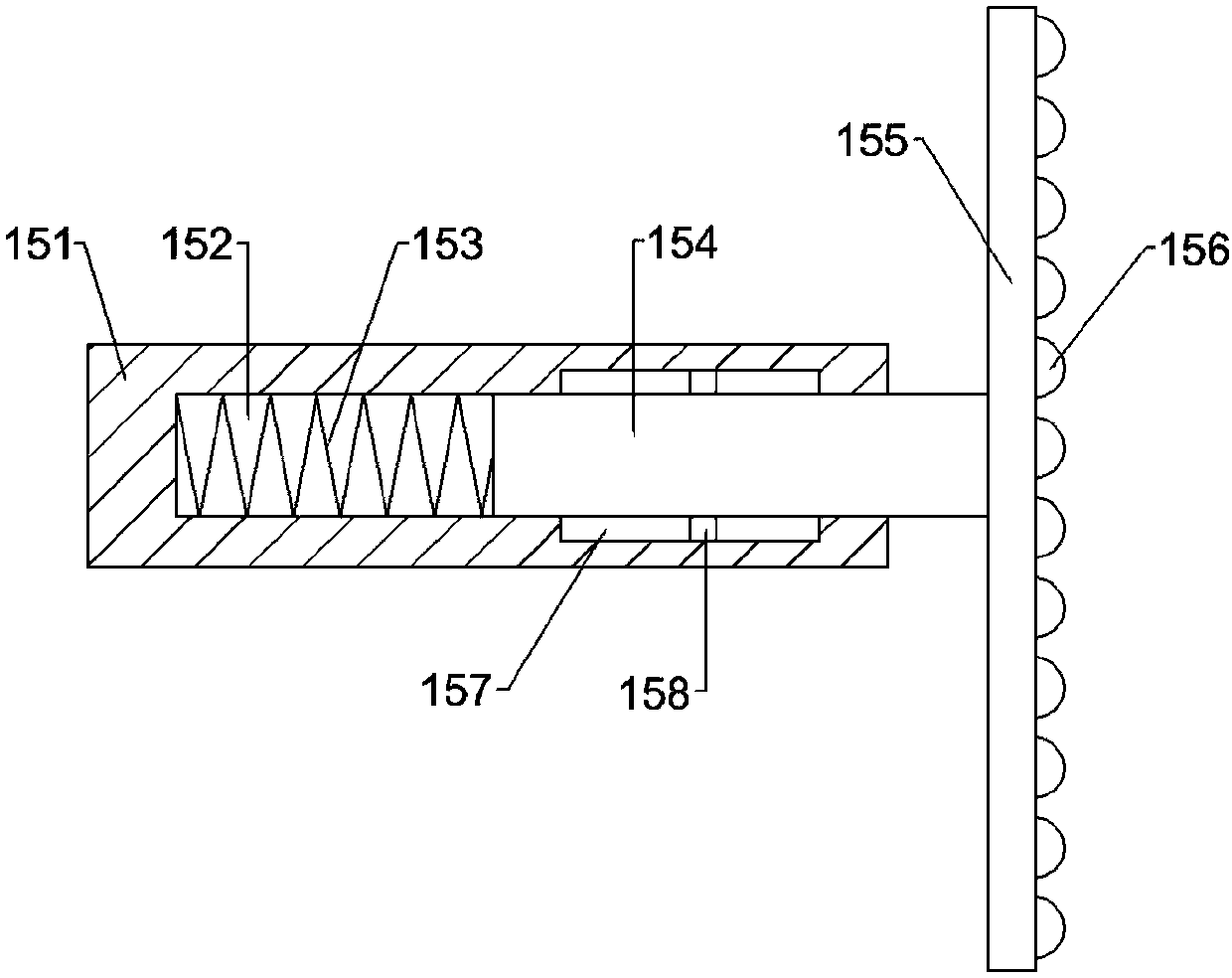

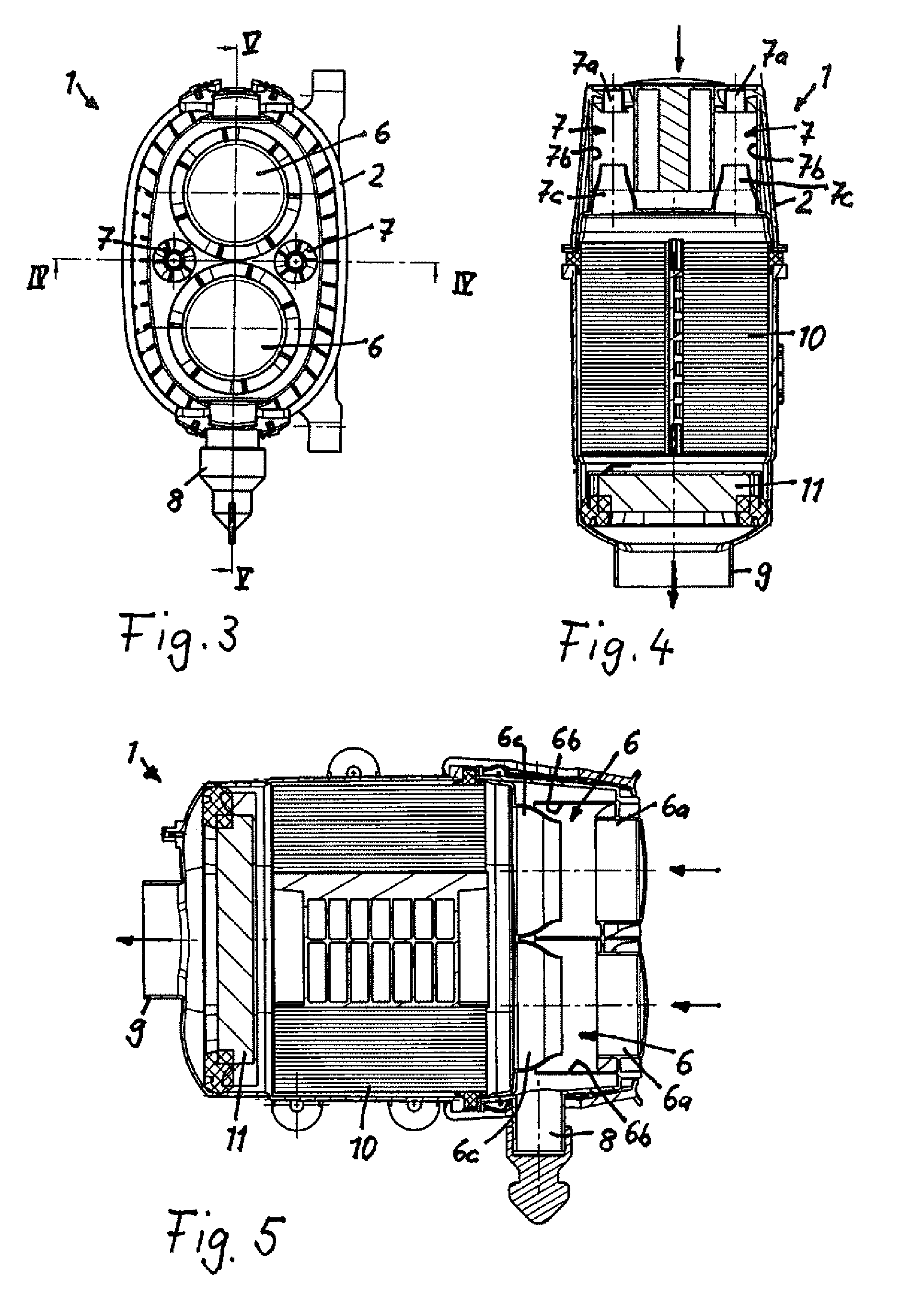

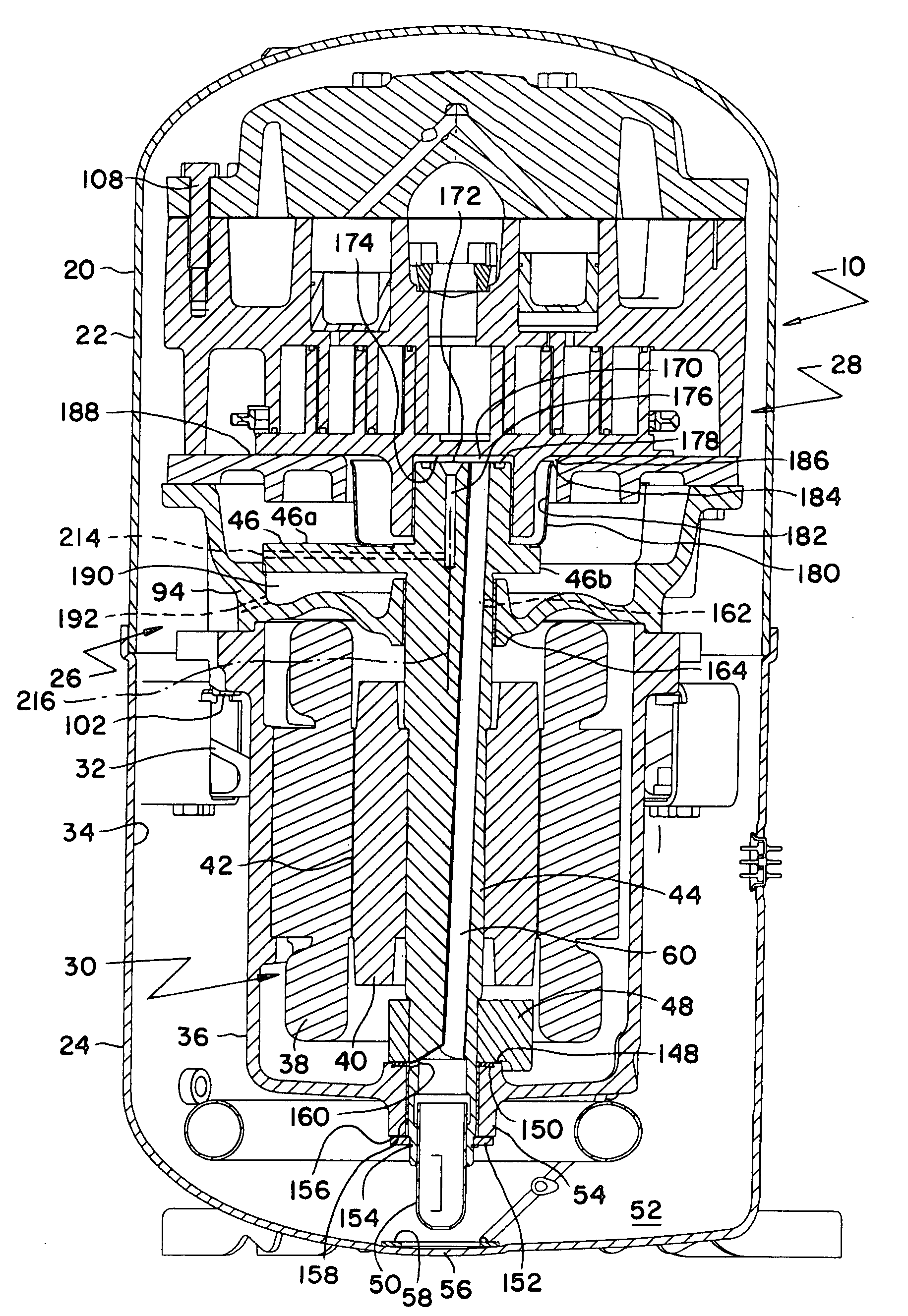

Pump drive head with stuffing box

InactiveUS20050045323A1Eliminate replacementRemove tensionDrilling rodsFluid removalGear driveBraking system

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

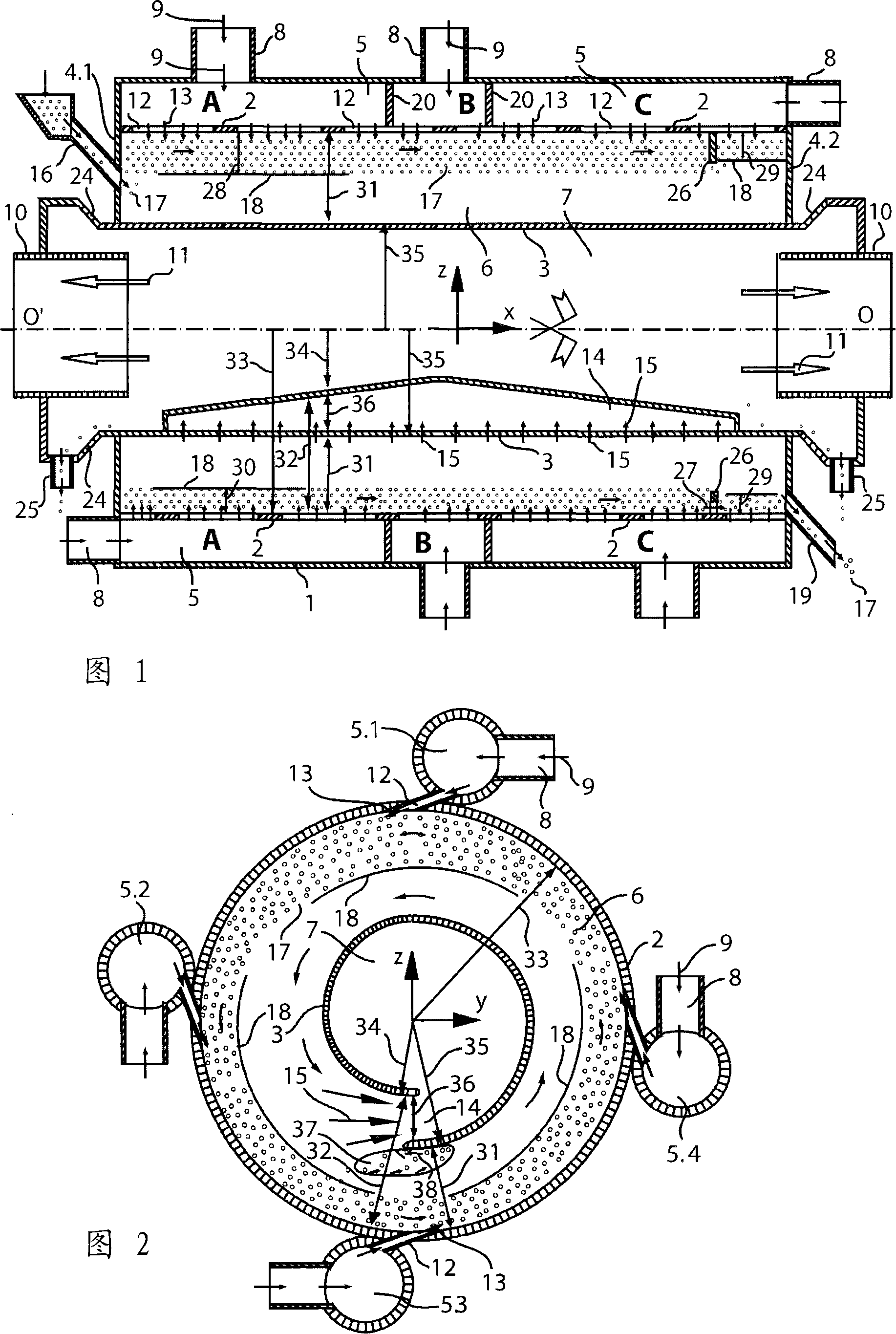

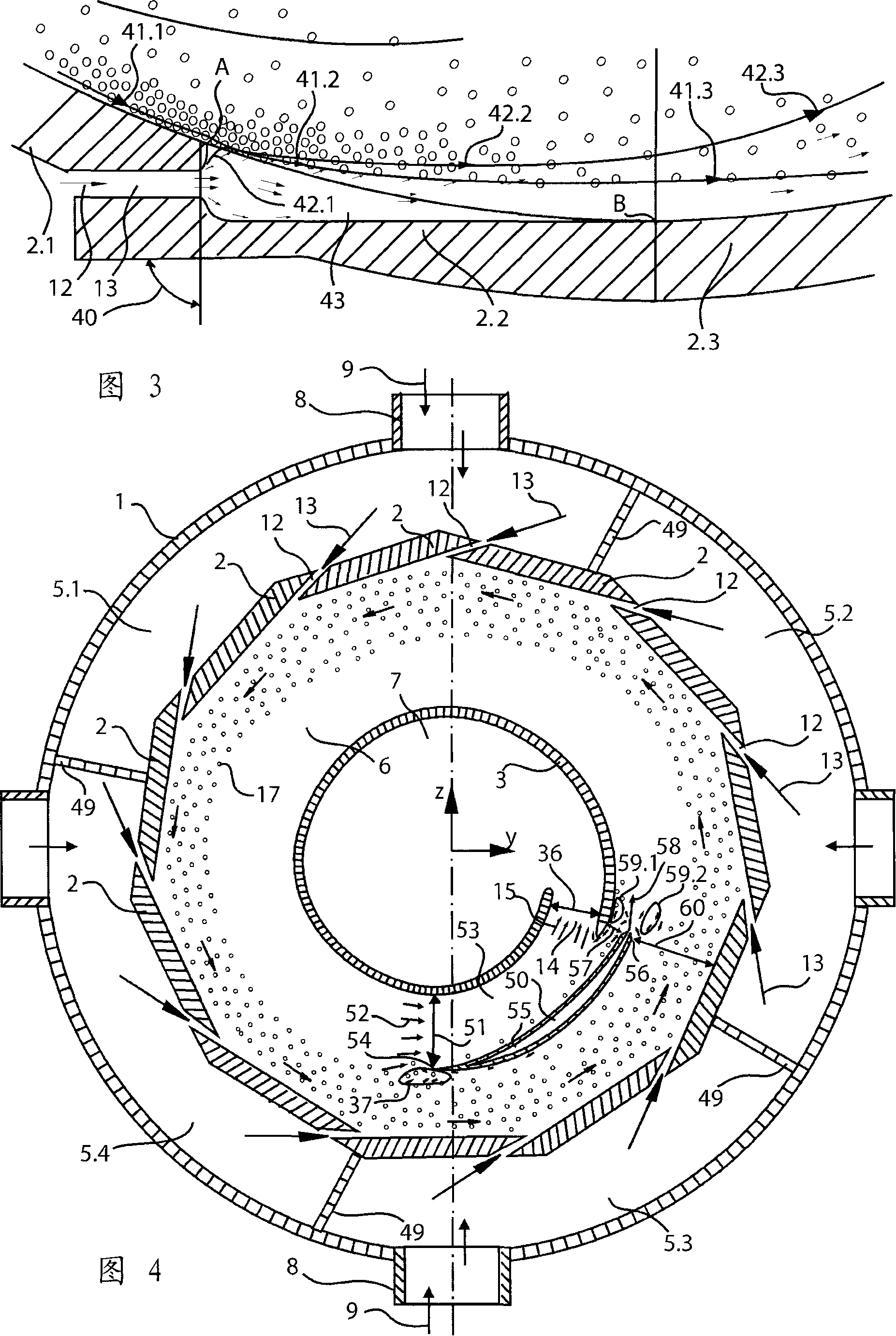

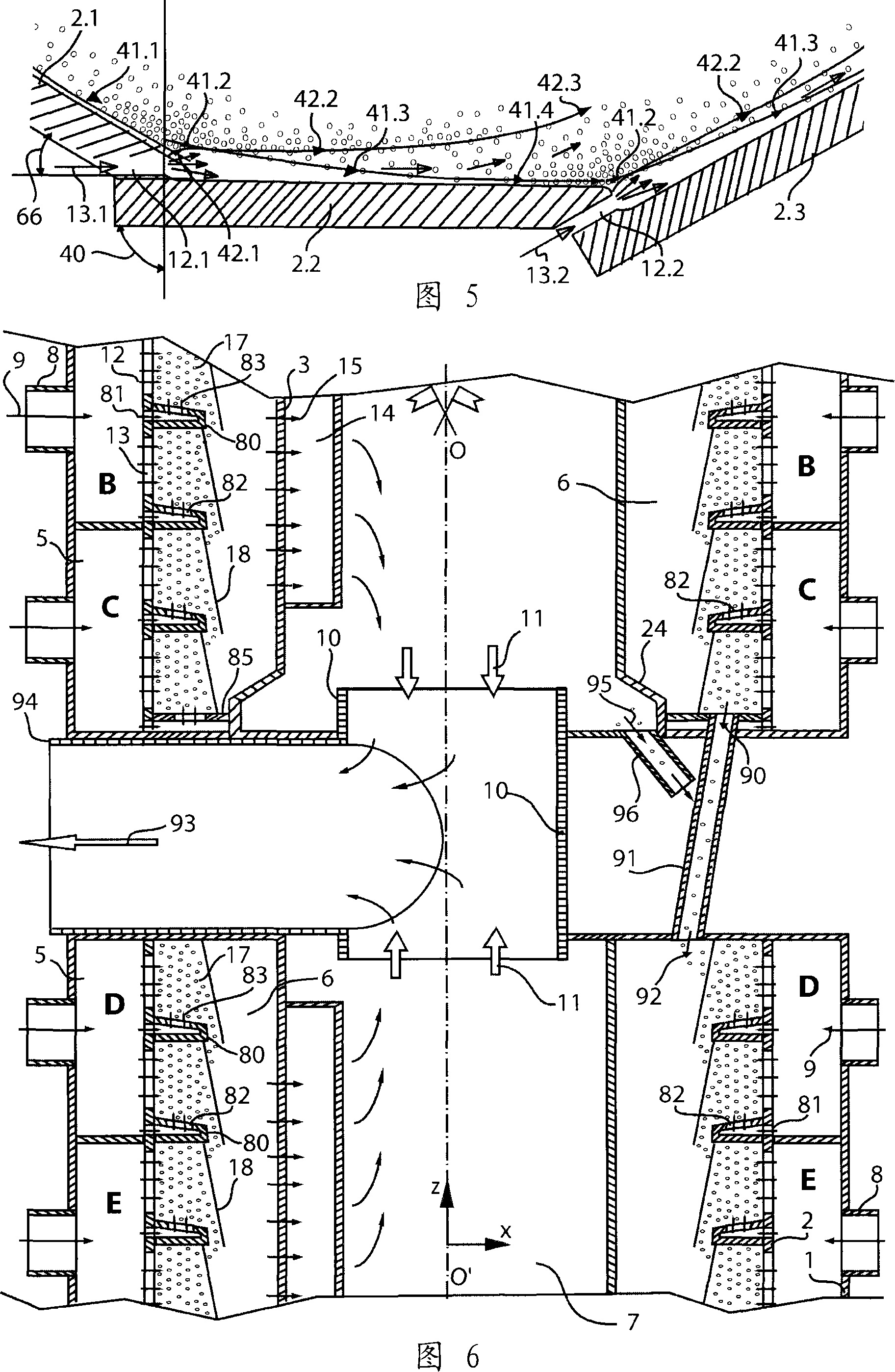

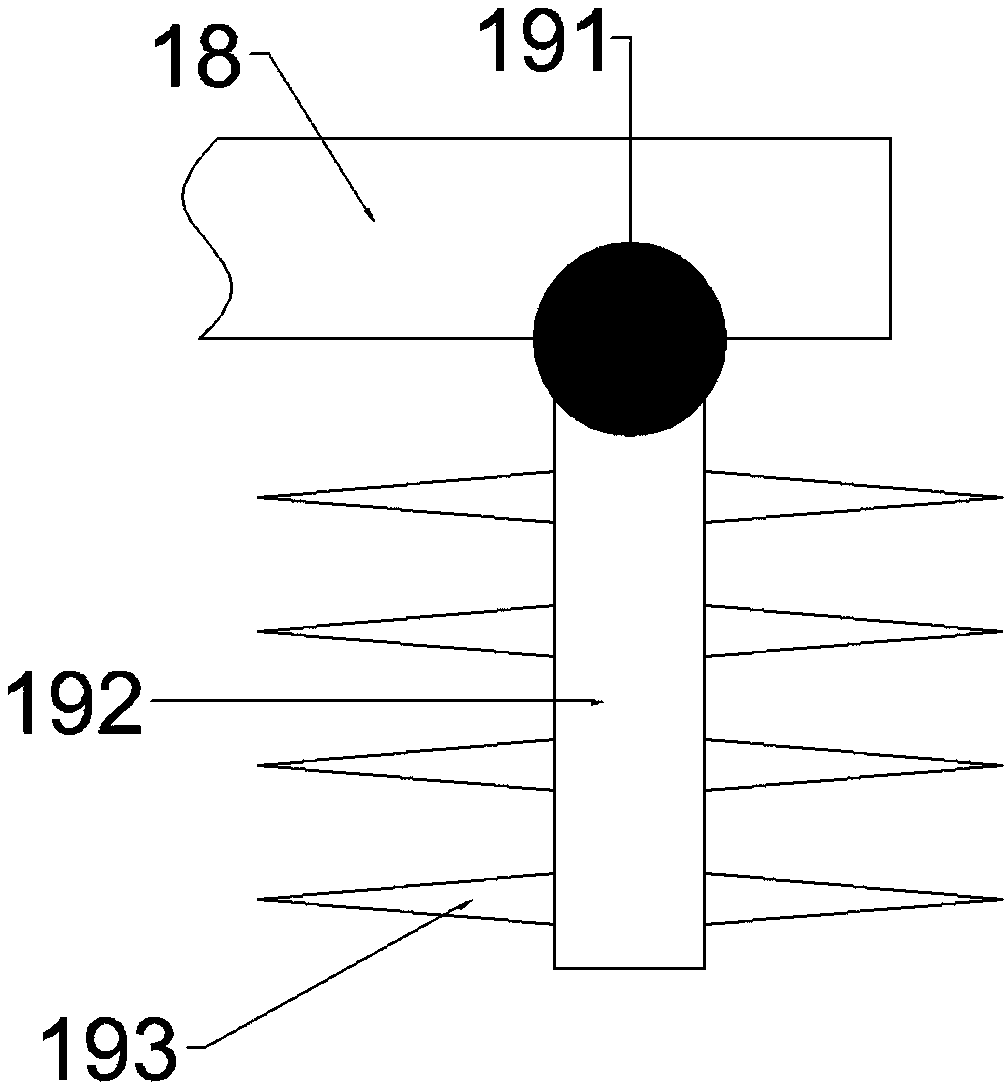

Rotary fluidized bed device and using method thereof

InactiveCN101124039AIncrease flow rateIncrease in sizeDrying solid materials with heatChemical/physical processesSuspended particlesFluidized bed

The invention concerns a device for injecting fluids inside a rotary fluidized bed wherein the fluid jets are oriented in the rotational direction of the fluidized bed and surrounded with at least one deflector delimiting around said jets a space generally convergent then divergent and upstream of said jet passages through which suspended particles in the rotary fluidized bed can penetrate so as to be mixed with the fluid jets which transfer to them part of their kinetic energy before leaving said space.

Owner:阿克塞尔·德布罗克维尔

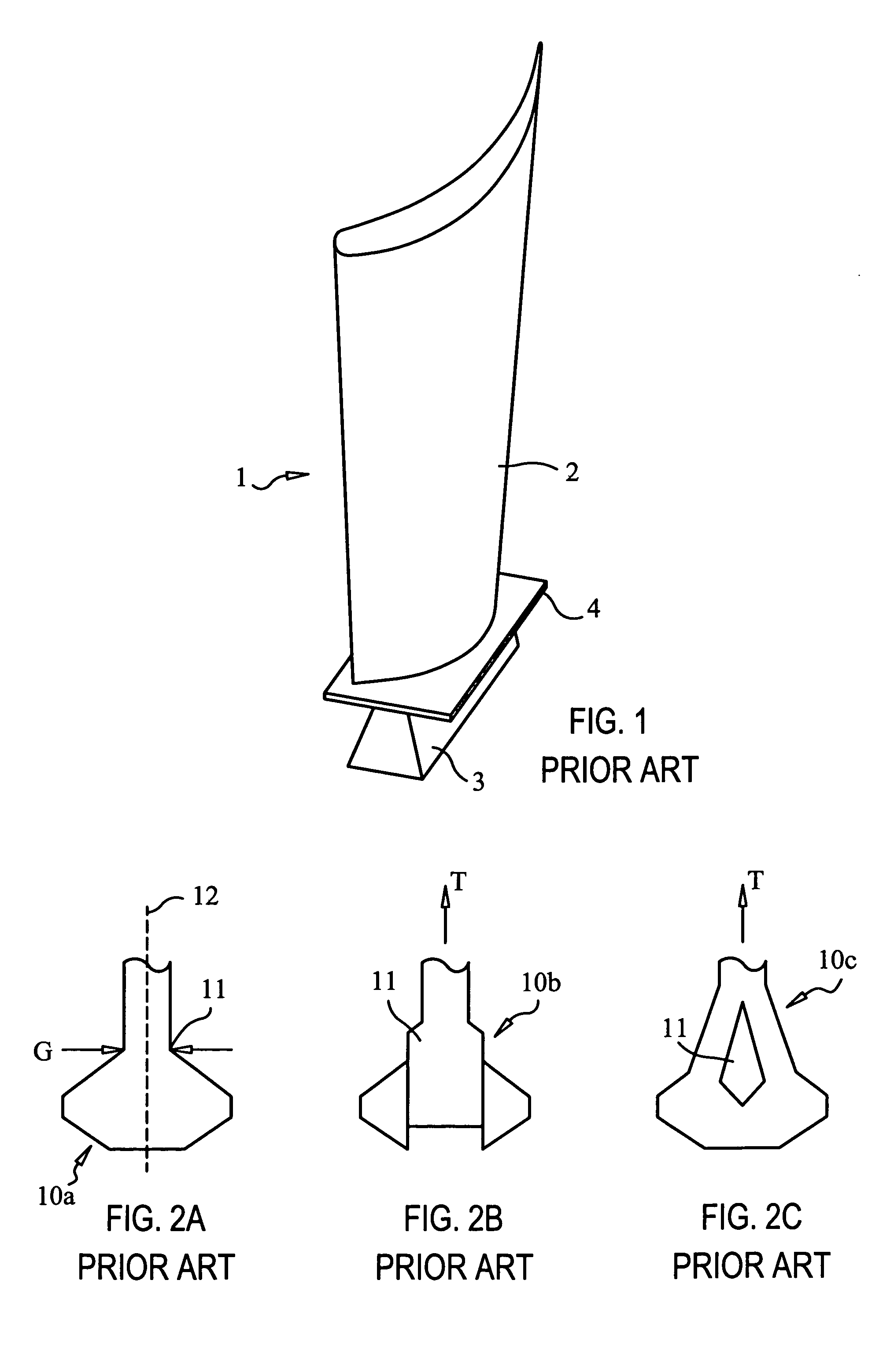

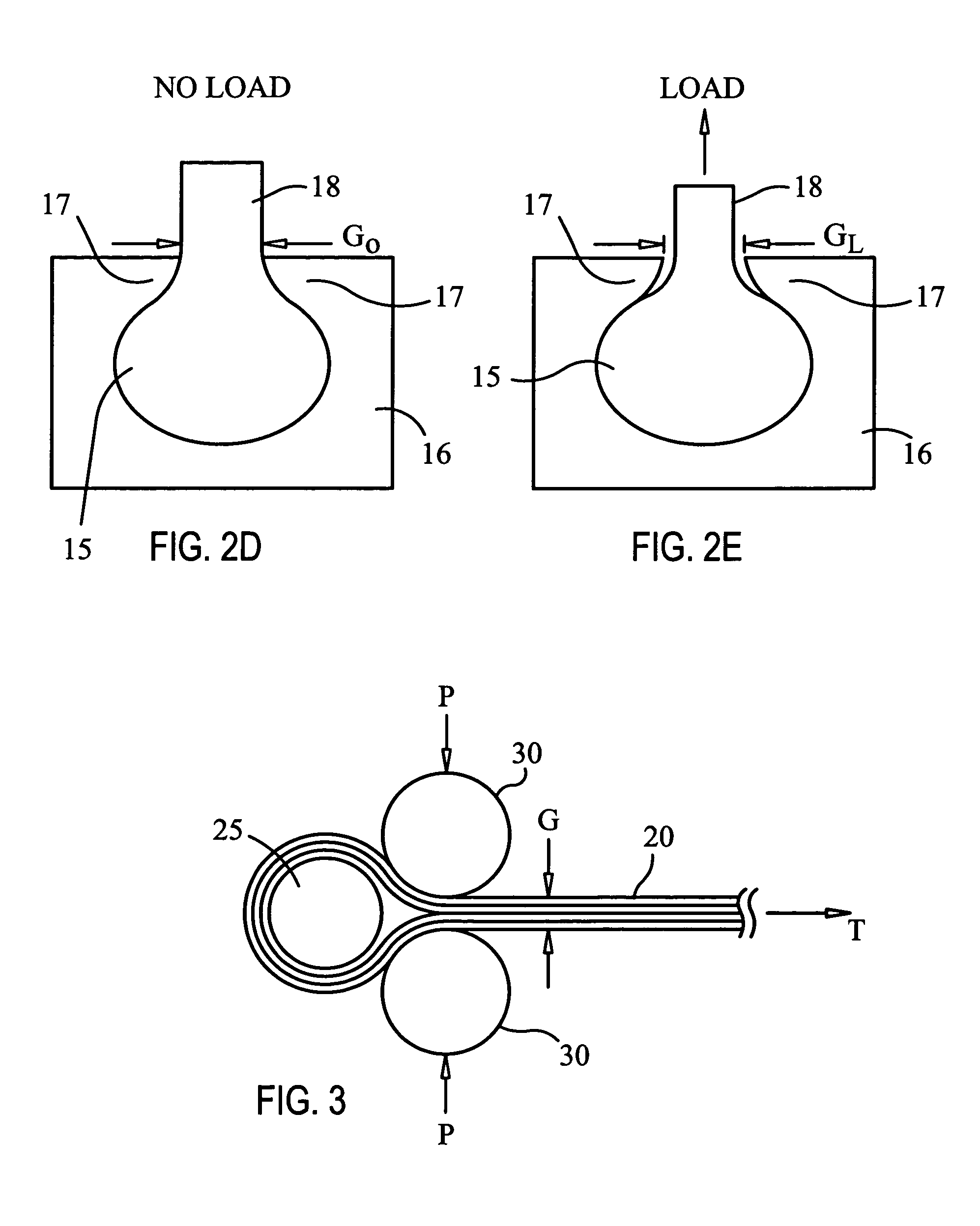

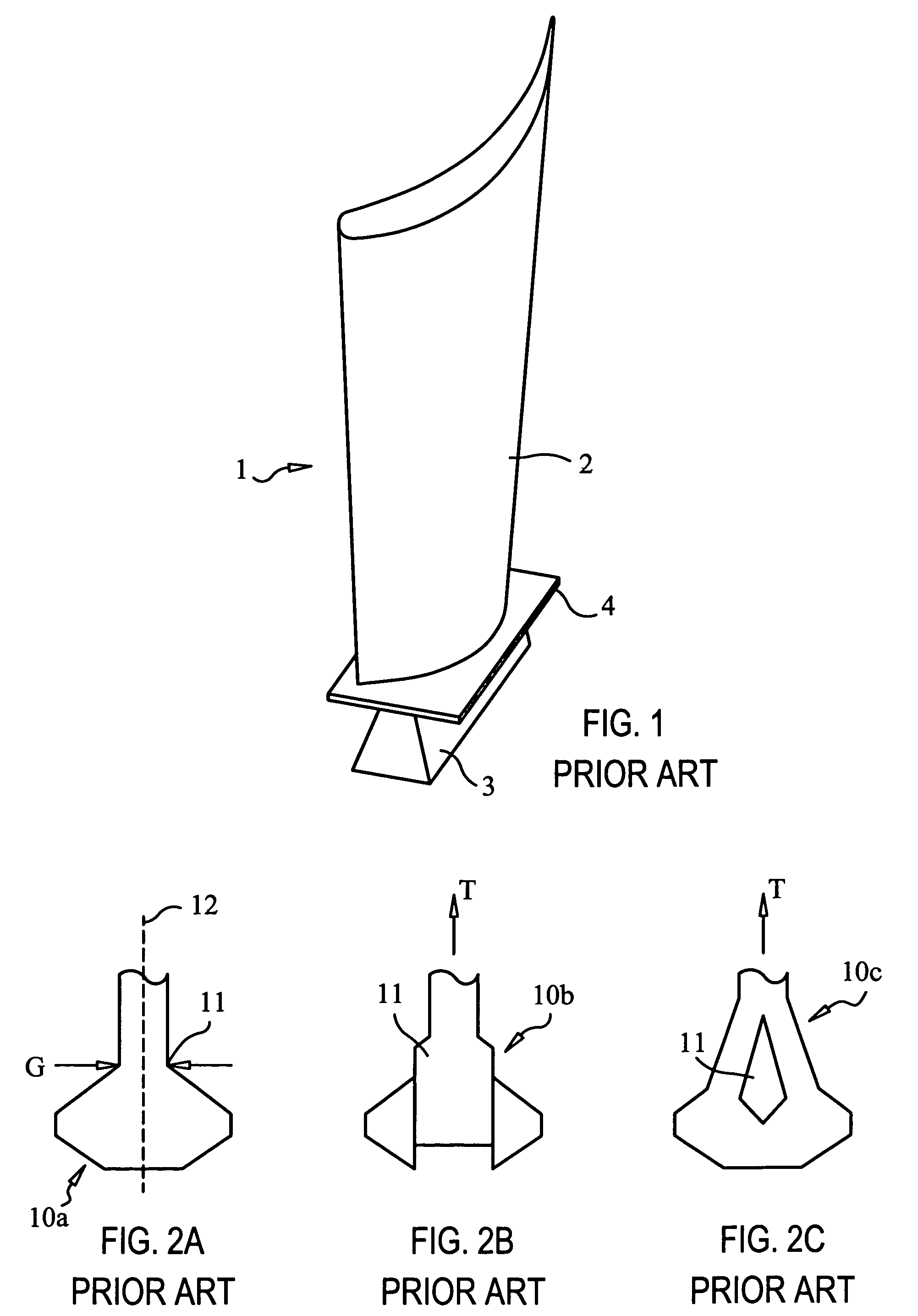

Laminated turbomachine airfoil with jacket and method of making the airfoil

InactiveUS20050260078A1Avoid separationIncreasing the thicknessPropellersRotary propellersEngineeringProviding material

An improvement for a turbomachinery blade having an airfoil portion, a neck portion, and a root portion, the neck portion extending from the root portion, and the airfoil portion extending from the neck portion, and the root portion being tear-drop shaped, includes a jacket attached to the root portion and extending along a portion of the neck portion. Additionally, a process of forming a turbomachinery blade includes steps of providing a laminate of a material; providing a blade insert; wrapping the laminate around to insert to form a blade having a root portion, a neck portion extending from the root portion, and an airfoil portion extending from the neck portion; and providing for a jacket secured around the root portion and a portion of the neck portion extending from the root portion, the jacket having such shape as to prevent delamination of the laminates at a critical point due to centrifugal force acting on the blade.

Owner:FLORIDA TURBINE TECH

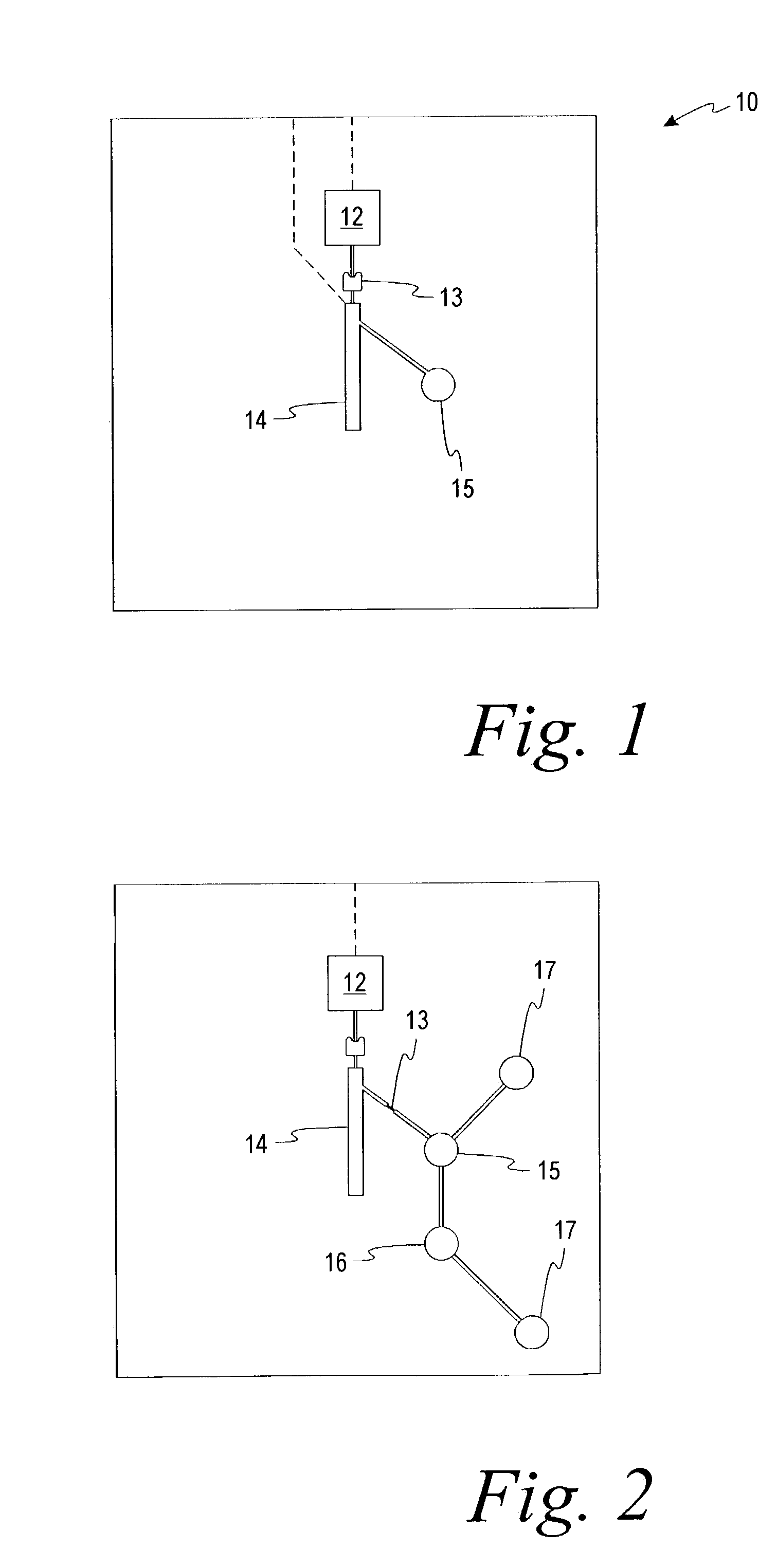

Methods and apparatus for mixing of liquids

InactiveUS20050083781A1Sufficient dimensionIncrease centrifugal forceBioreactor/fermenter combinationsRotating receptacle mixersEngineeringCentrifugal force

An apparatus for mixing fluids comprises a housing having at least a portion of its interior, for example, a channel, with capillary dimensions and at least one structural member in the interior adjacent an end of the channel. The dimensions of and placement of the structural member are sufficient such that intermittent application of centrifugal force to the interior of the housing causes movement of the fluid therein. The housing may comprise a mixing chamber or area that is in fluid communication with the interior. The apparatus may comprise a mechanism adapted to generate centrifugal force within the housing to cause movement of fluid in the interior of the housing without exit of fluid therefrom.

Owner:AGILENT TECH INC

Method for removal of unreacted alcohol from reaction mixture of ester product with rotating packed beds

InactiveUS20050022666A1Short timeIncrease centrifugal forceUsing liquid separation agentAlcoholChemistry

A method is used to remove an unreacted alcohol from an ester product mixture by a gas stripping. The method involves the feeding of the ester product mixture into proximity of an axis of a rotating packed bed, so as to enable the ester product mixture to flow radially to come in contact with a gas which is introduced into the rotating packed bed. The unreacted alcohol and any other volatile component of low molecular weight are thus stripped from the ester product mixture by the gas entrainment, thereby resulting in production of a purified ester product which is collected at the bottom of the rotating packed bed. The unreacted alcohol and the volatile component, which are entrained in the gas, are discharged via an exit located at the top of the rotating packed bed.

Owner:IND TECH RES INST

Centrifuge with a coupling element for axially locking a rotor

The invention relates to a centrifuge with a drive head which can be connected with a drive, a rotor which can detachably be mounted on the drive head, at least one connection element with which the drive head can be connected in a torsion-proof manner with the rotor, and at least one coupling element which is attached to the drive head and is able to exert an axial force on the rotor in such a way that the rotor can be fixed axially, with the axial force increasing with the rising rotational speed of the drive head, with the coupling element on the rotor transmitting the axial force by means of a ramp surface which is inclined at an angle (α) relative to the horizontal line in a range of more than 0° to 15°. Secure locking of the rotor during standstill and high speeds can thus be achieved.

Owner:THERMO ELECTRONICS LED GMBH

Laminated turbomachine airfoil with jacket and method of making the airfoil

InactiveUS7300255B2Avoid separationIncreasing the thicknessPropellersRotary propellersProviding materialEngineering

An improvement for a turbomachinery blade having an airfoil portion, a neck portion, and a root portion, the neck portion extending from the root portion, and the airfoil portion extending from the neck portion, and the root portion being tear-drop shaped, includes a jacket attached to the root portion and extending along a portion of the neck portion. Additionally, a process of forming a turbomachinery blade includes steps of providing a laminate of a material; providing a blade insert; wrapping the laminate around to insert to form a blade having a root portion, a neck portion extending from the root portion, and an airfoil portion extending from the neck portion; and providing for a jacket secured around the root portion and a portion of the neck portion extending from the root portion, the jacket having such shape as to prevent delamination of the laminates at a critical point due to centrifugal force acting on the blade.

Owner:FLORIDA TURBINE TECH

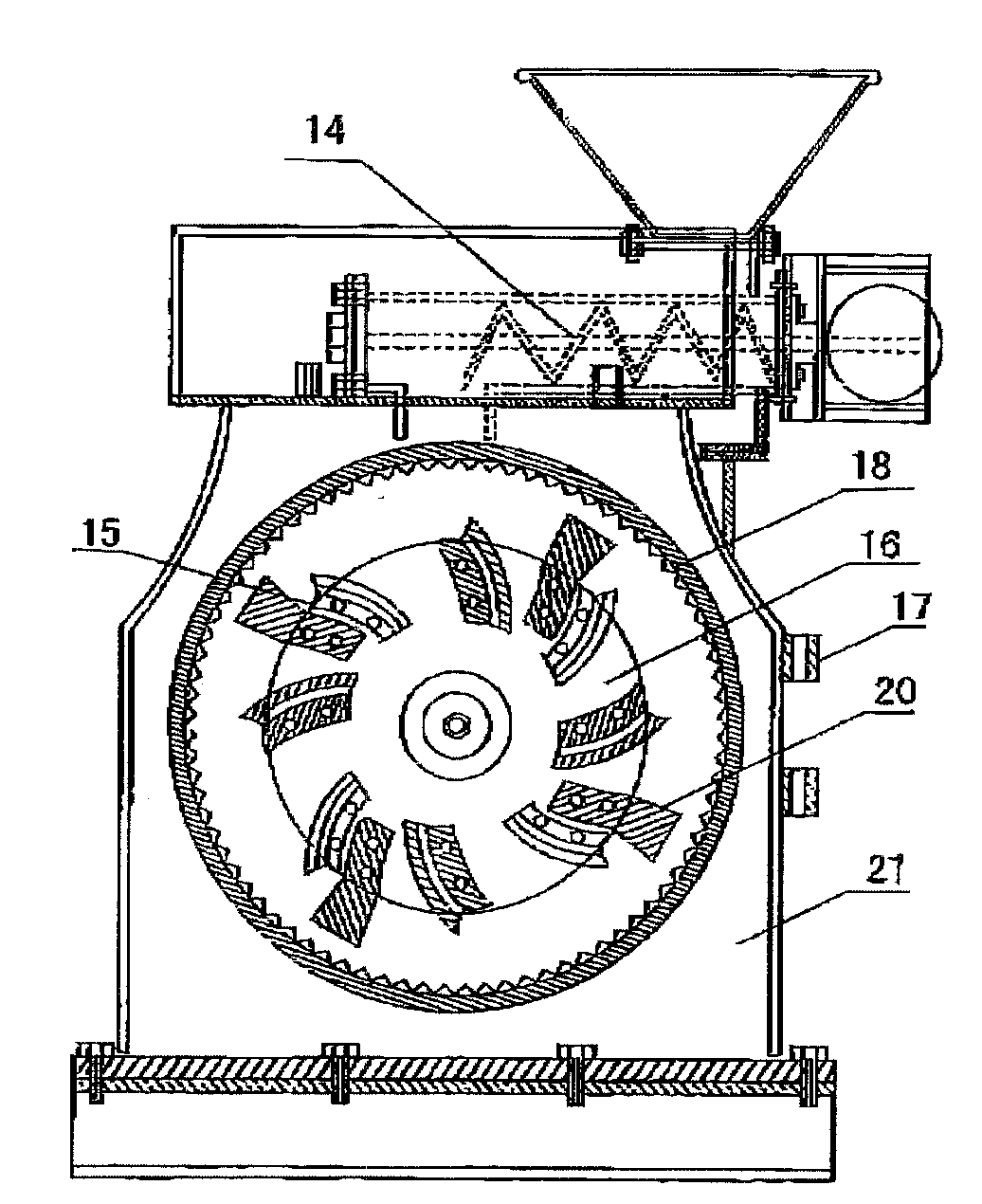

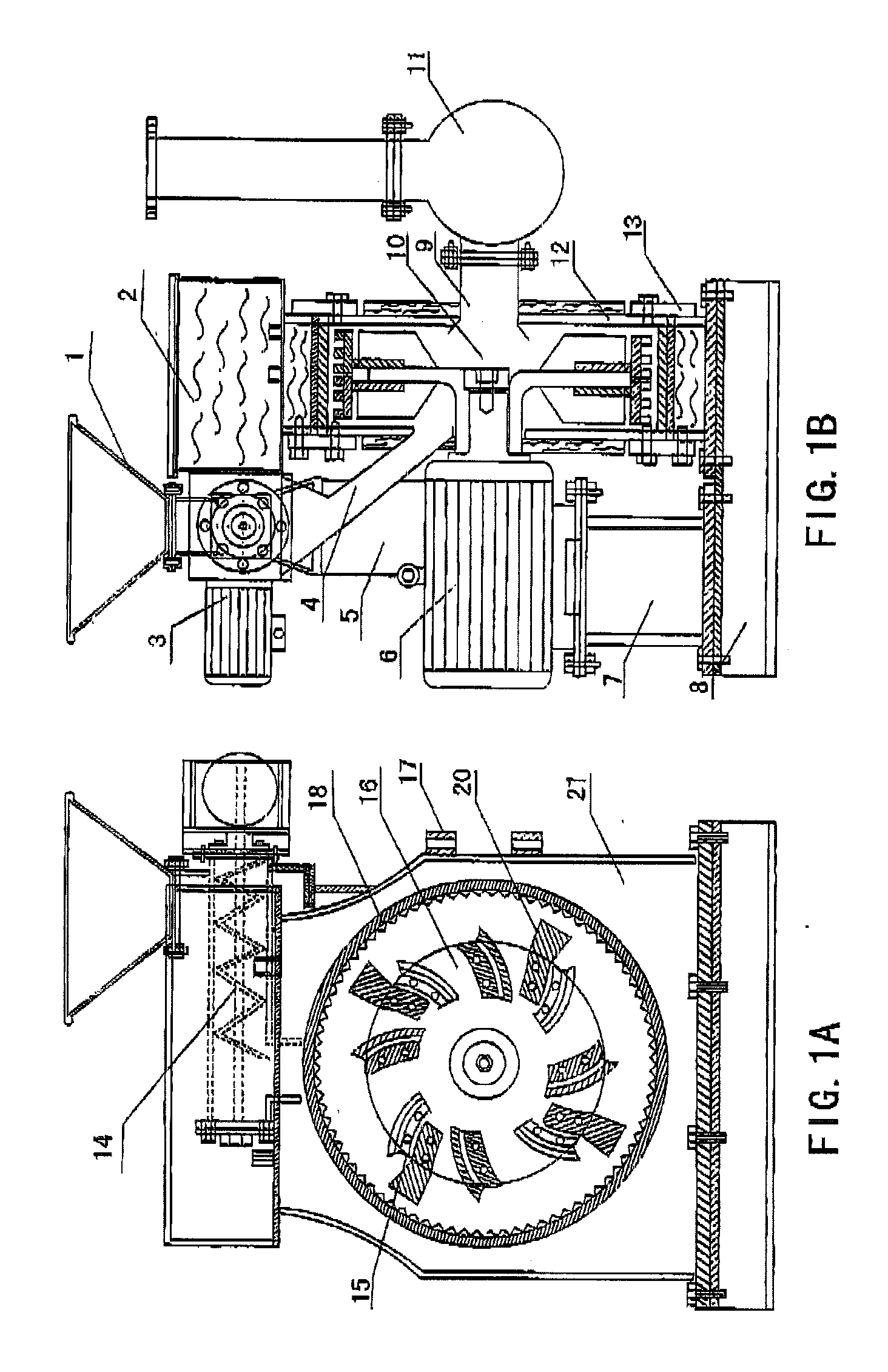

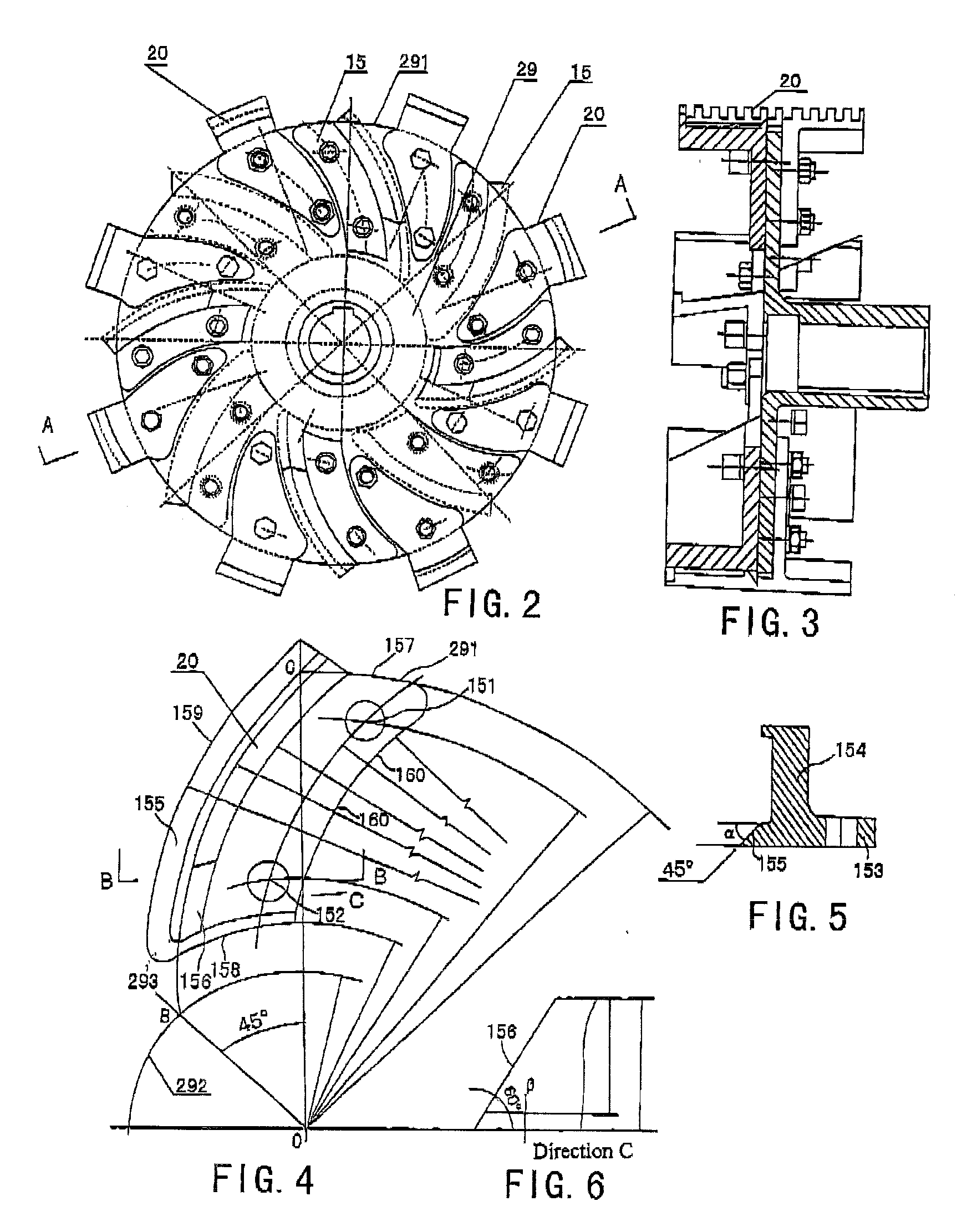

High Turbulence Mill and Bi-Negative Pressure Turbine Thereof

InactiveUS20080245914A1Improve efficiencyIncreased turbulenceGas current separationCocoaGas solidTurbine

A high turbulence mill used for producing supermicro powder and nanomaterials includes: a driving device provided on a base; a hollow grinding casing having a toothed ring-shaped guide stator fixed to an inner circumference thereof; a bi-negative pressure turbine rotatably mounted within the grinding casing; a hopper for delivering materials into the grinding casing via a material feeding pipe; a material discharging pipe communicated with the grinding casing for discharging pulverized products; and a control device for electrically controlling the high turbulence mill. When the specifically designed bi-negative pressure turbine spins at a high speed within the grinding casing under the driving operation of the motor, strong vortexes and high turbulence will be formed in the grinding casing, and thus a gas-solid two-phase flow is formed. Under the high turbulence, the materials are subjected to violent self-grinding effect, strong impact and strong shear force, and then an accelerated and effective pulverization of the materials is obtained.

Owner:YANG FUMAO +1

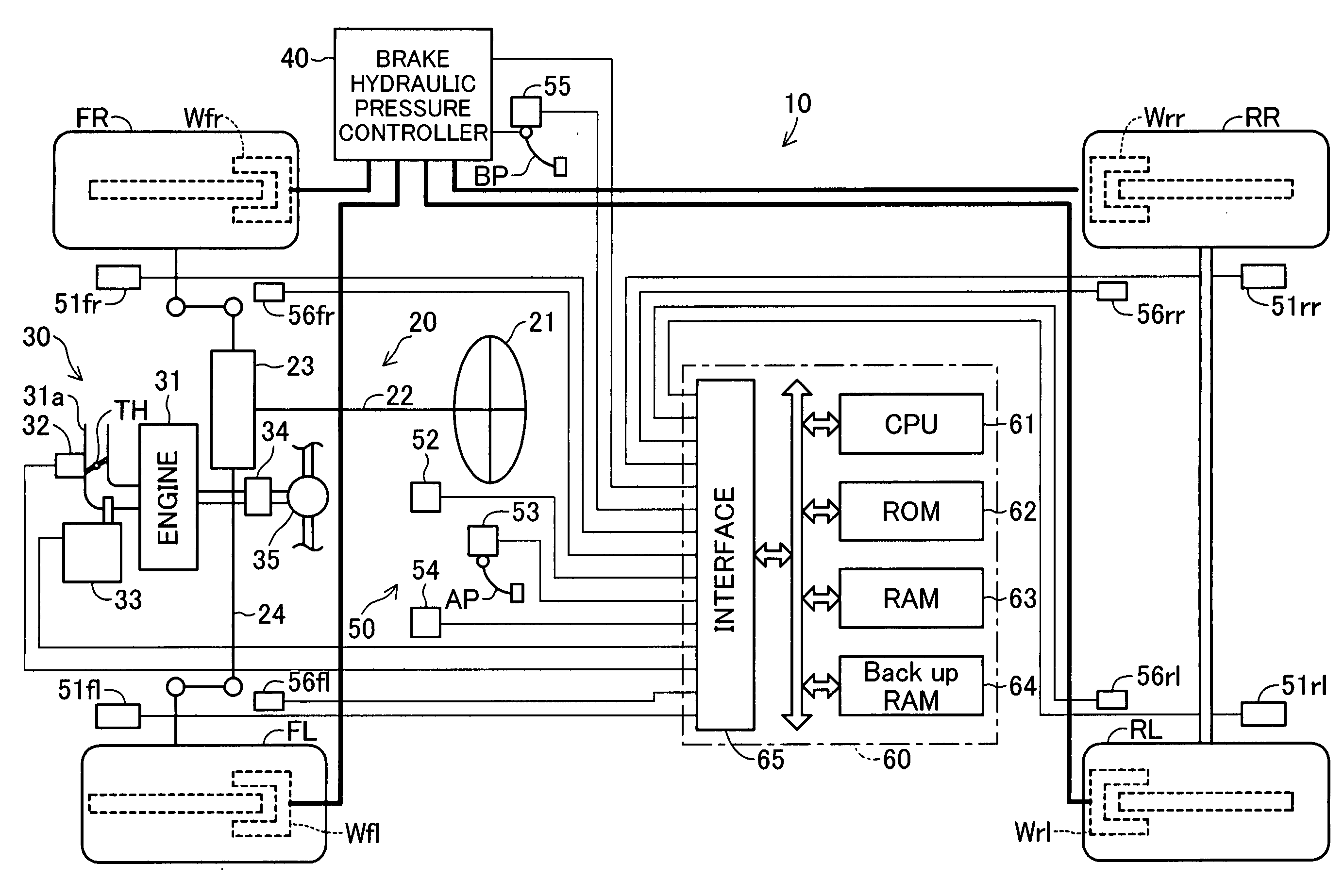

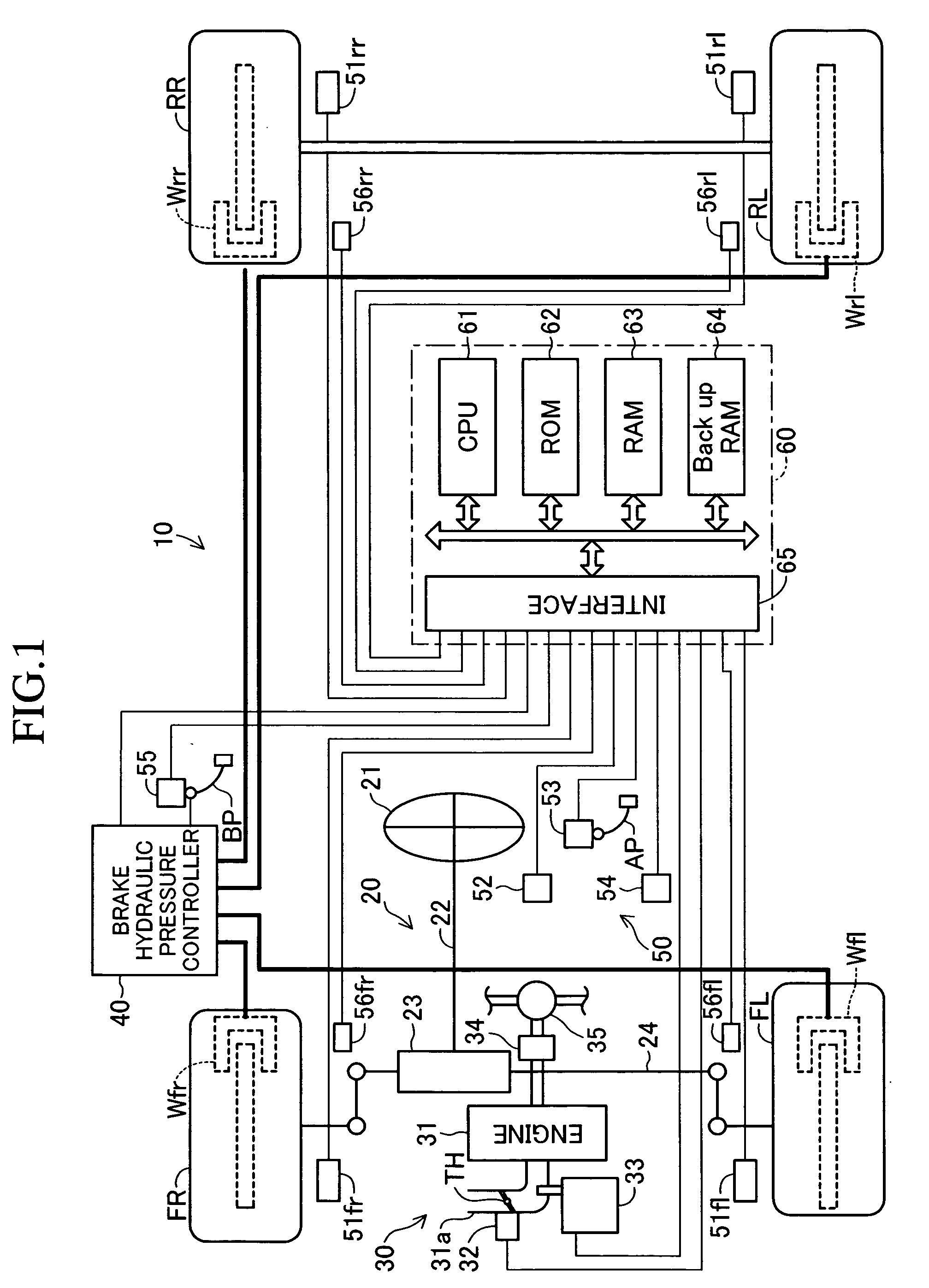

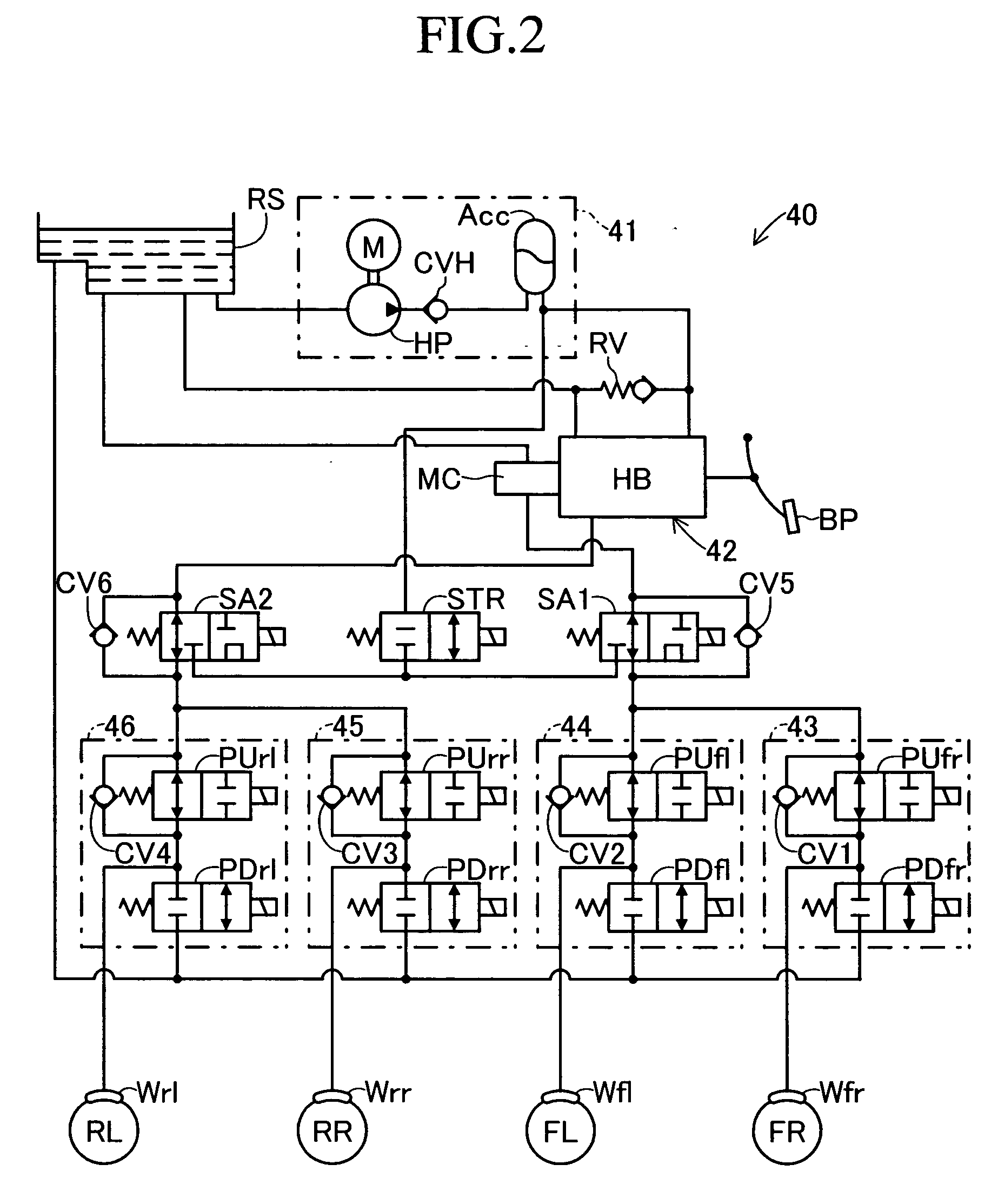

Motion control apparatus for vehicle

InactiveUS20070112498A1Increase in roll angle can be preventedReduce the overall heightHand manipulated computer devicesDigital data processing detailsRolloverEngineering

In rollover prevention control, an inner front wheel braking force is generated only in a front wheel located on the radially inner side of a turning locus in a relatively early stage where the absolute value of actual lateral acceleration is between a first value and a second value. When the absolute value becomes greater than the second value, in addition to the inner front wheel braking force, an inner rear wheel braking force is generated in a rear wheel located on the radially inner side of the turning locus. When the absolute value becomes greater than a third value, in addition to the inner rear wheel breaking wheel, an outer wheel braking force is generated in the front wheel located on the radially outer side of the turning locus. Thus, an increase in the roll angle is suppressed, and a desired turning locus tracing performance is maintained satisfactorily.

Owner:ADVICS CO LTD

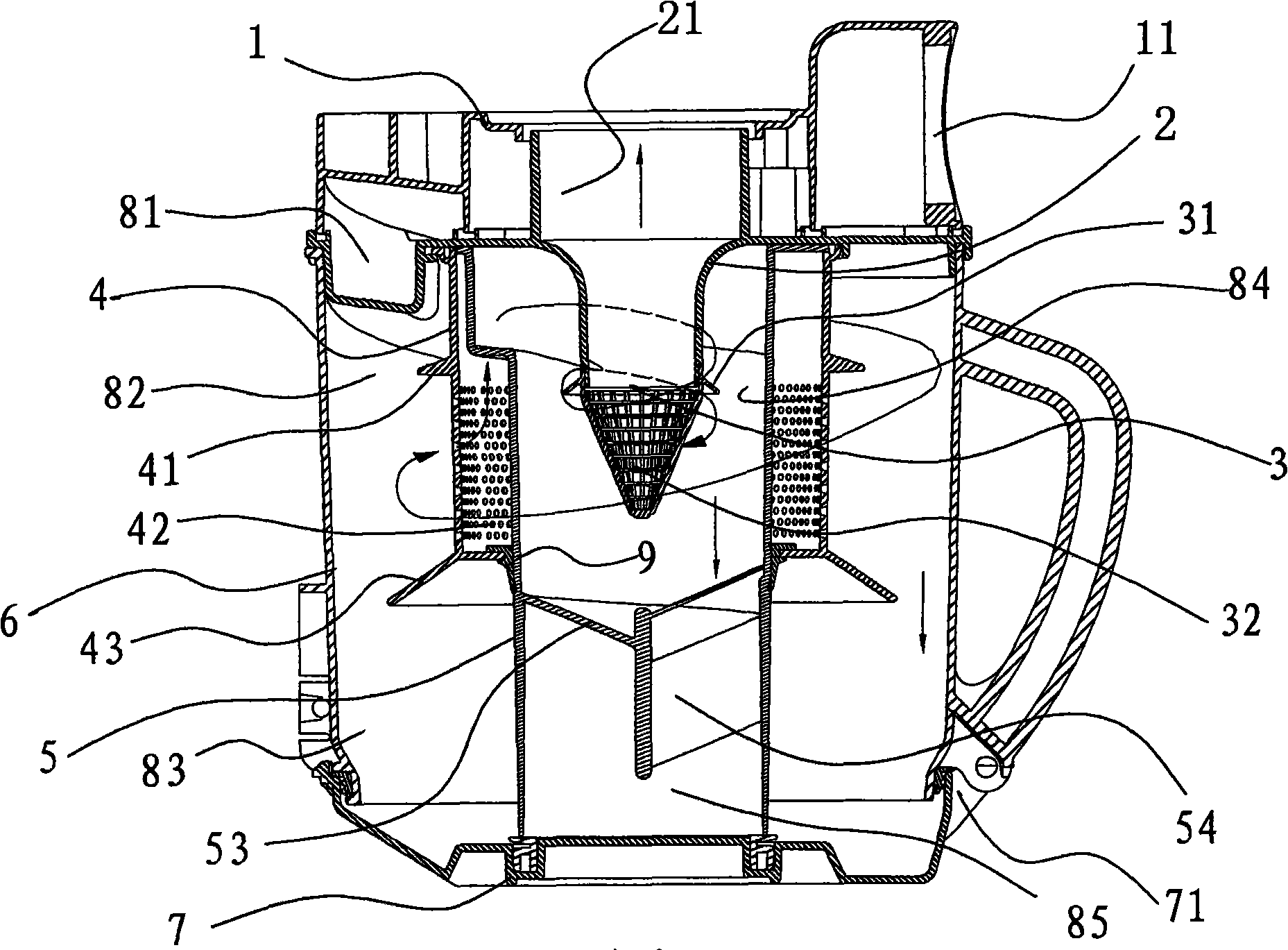

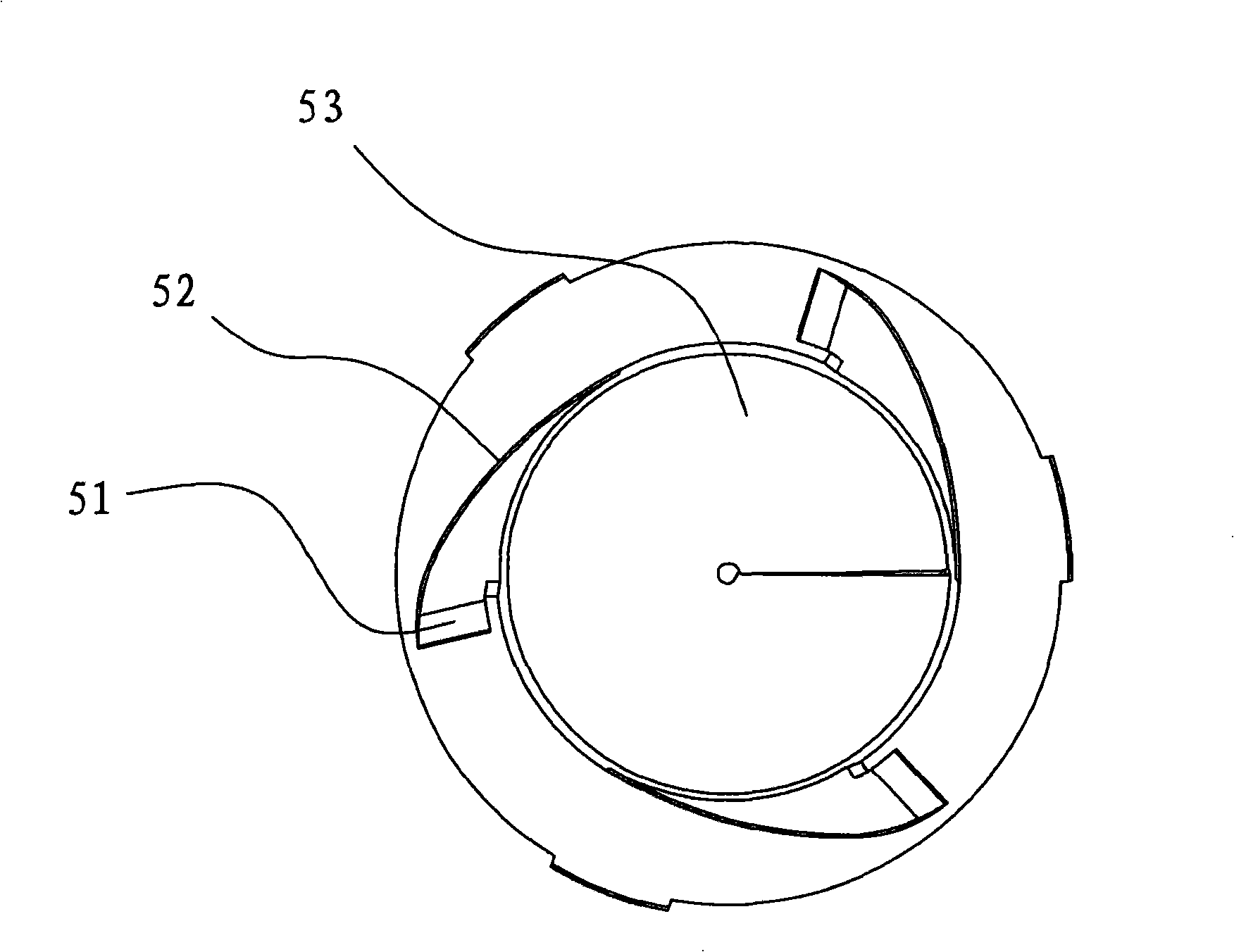

Dust separation cup of suction cleaner

ActiveCN101305897AAvoid secondary pollutionEvenly dispersedSuction filtersVacuum cleanerDust collector

The invention discloses a dust separation cup for a dust collector, which comprises a cup body, a cup bottom, a cup cover base, a cup cover, a primary dust separator on the lower side of the cup cover base, a dust isolation ring at the lower part of the primary dust separator, a cyclone barrel comprising at least one spiral air incoming channel arranged at the upper end on the inner side, an air inlet of a spiral air incoming channel formed by the lateral surfaces of the cup cover and the cup cover base, and an air outlet consisting of the cup cover base and the cup cover. The dust separation cup is characterized in that a tapered secondary dust separator with a filter mesh is arranged on the upper part of the inner cavity of the cyclone barrel, and a guide ring is arranged on the outer side of the upper edge. A guide ring is also arranged at the middle part of the primary dust separator, and a screw rod mechanism is also arranged at the lower part of the cyclone barrel. The screw rod mechanism includes a helical blade, and one end of the helical blade extends downwards to form a dust stop baffle. By arranging the filter meshes in the primary and the secondary dust separators, the guide rings on the lateral surfaces and the screw mechanism in the cyclone barrel, the air is boosted twice and filtered uniformly in the inner cavity of the dust separation cup of the dust collector, thus effectively avoiding the problem of secondary pollution.

Owner:宁波大华电器有限公司

Oil separator

InactiveUS20110146215A1Maximize the effectIncrease centrifugal forceDispersed particle separationRotary piston pumpsCentrifugal forcePetroleum engineering

An oil separator comprises: a hollow outer body having an inlet and a drain hole; and an inner tube spaced apart from an inner peripheral surface of the outer body and having a discharge hole at a center thereof. The inner peripheral surface of the outer tube guides oil toward the drain hole opposite to the discharge hole. The present invention provides an oil separator that maximizes an oil separating effect through enhancement of a centrifugal force. The present invention also provides an oil separator that maximizes an oil separating performance by preventing gas and oil from being remixed by guiding the flow direction of the oil separated by a centrifugal force using a spiral portion and a taper.

Owner:DOOWON TECHN COLLEGE +1

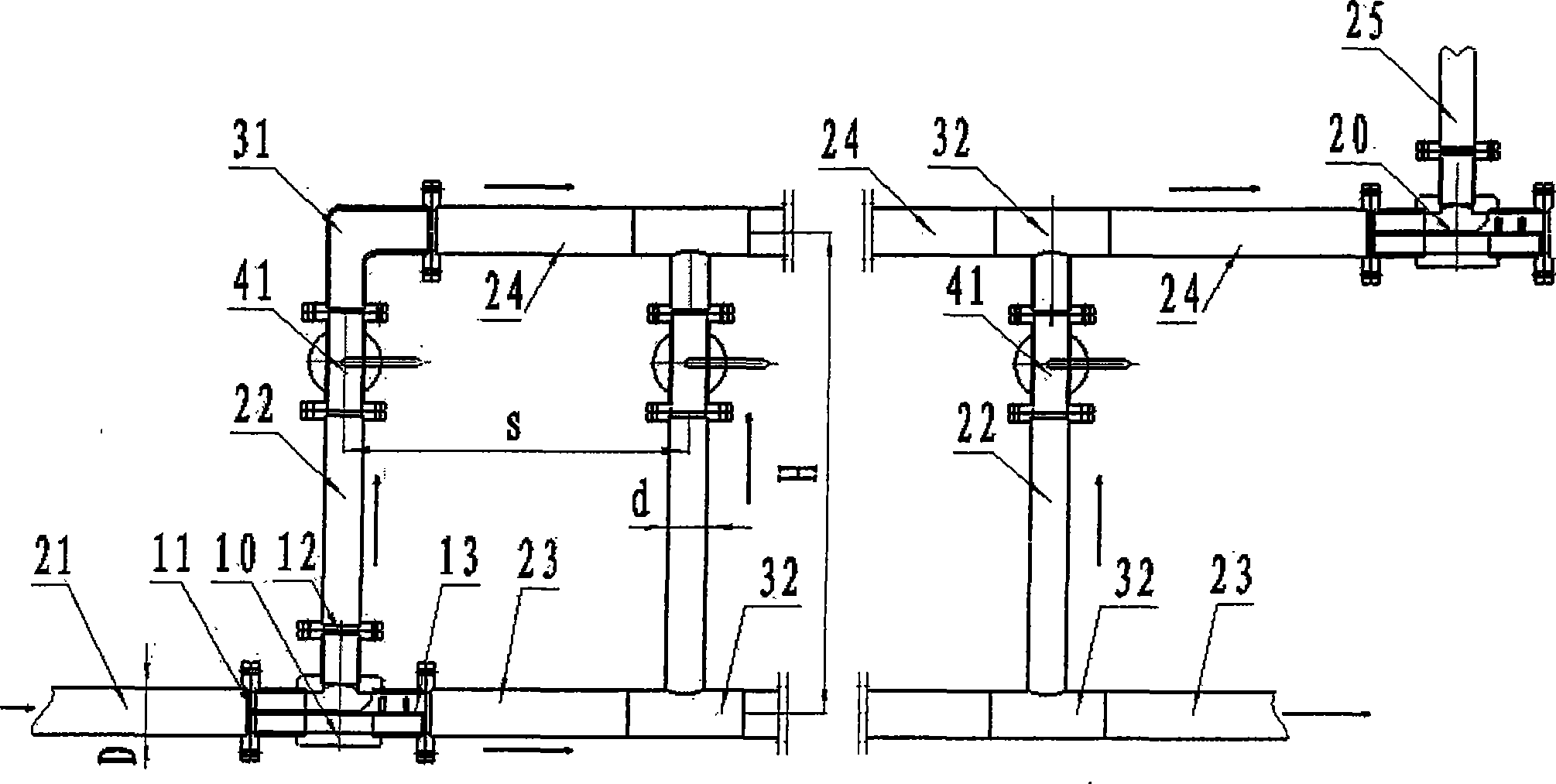

Water-oil separating system and method using centrifugation, gravitation, expansion composite principle

InactiveCN101411951AEasy to adjustBest separationFluid removalNon-miscible liquid separationCentrifugationOil water

The invention relates to a combined type oil-water separating system for onshore treatment stations and offshore oil production platforms, wherein a liquid inlet and a liquid outlet of a current divider are communicated with a horizontal total liquid inlet pipe, a vertical pipe and a lower horizontal pipe; the vertical pipe is communicated with a bend pipe; the lower horizontal pipe is connected with an input port of a helical pipe, the helical pipe is connected with the inner part of a fourth separating box body, and communicated with a second settlement separating box body, and the top part of the helical pipe is communicated with the top part of a fourth settlement separating box body by a middle pipe; the outlet and the middle part of the bottom part of the side wall of the fourth settlement separating box body, which corresponds to the inlet, is provided with horizontal drain pipes and a horizontal oil discharge pipe respectively, and the other end of the horizontal oil discharge pipe penetrates the middle part of a third settlement separating box body; an upper horizontal pipe is communicated with a first helical pipe, the other outlet of the first helical pipe is connected with the inner part of the third settlement separating box body, and the bottom parts and the side walls of the top parts of the first and the third settlement separating box bodies are connected by pipes; the two horizontal drain pipes are provided with a water outlet pipe and an oil outlet pipe respectively.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Rotor for electric rotary machine

ActiveUS20100109466A1Increase the lengthImprove reliabilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesRotary machine

A rotor for an electric rotary machine and a method of manufacturing the same are disclosed wherein none of permanent magnets is fixed to a magnetic supporting segment of a magnet support ring in advance and each permanent magnet is assembled separately of the magnet support ring. Prior to the assembling of the permanent magnets, the magnet support ring is preliminarily located on claw-shaped magnetic poles at inner peripheral sides thereof under a state combined with a pair of field iron cores, after which the permanent magnets are inserted to magnet insertion spaces in longitudinal directions. The rotor includes positioning and restricting means for precluding the occurrence of positional displacement of each permanent magnet with respect to each magnet supporting segment of the magnet support ring.

Owner:DENSO CORP

Crushing equipment used for fish feed with particle size adjustable function

InactiveCN107837905AAchieve final crushingReduce spacingFeeding-stuffGrain treatmentsMotor driveEngineering

The invention provides crushing equipment used for fish feed with a particle size adjustable function. The crushing equipment used for the fish feed with the particle size adjustable function comprises a shell body. A filter screen is fixedly connected on the inner side wall of the shell body and the filter screen is in a circular-arc shape. A first sleeve barrel is fixedly connected in the middleof the upper side of the filter screen and a plurality of second crushing teeth are uniformly arranged on the outer side wall of the first sleeve barrel. A plurality of through holes are formed in the side wall of the bottom of the first sleeve barrel and a first rotary shaft is arranged in the first sleeve barrel. The first rotary shaft is vertically arranged and passes through the upper portionof the shell body and extends upward. The top end of the first rotary shaft is fixedly connected with an output shaft of a first motor which is located at the upper side of the shell body and a spiral auger is arranged on the first rotary shaft. The crushing equipment has the beneficial effects that the first motor drives the first rotary shaft to rotate and the spiral auger on the first rotary shaft drives materials to move upward, so that the crushing retreatment can be conducted; the first rotary shaft drives a second sleeve barrel to rotate by circular plates and the crushing retreatmentcan be conducted on the materials by first crushing teeth and the second crushing teeth.

Owner:张子和

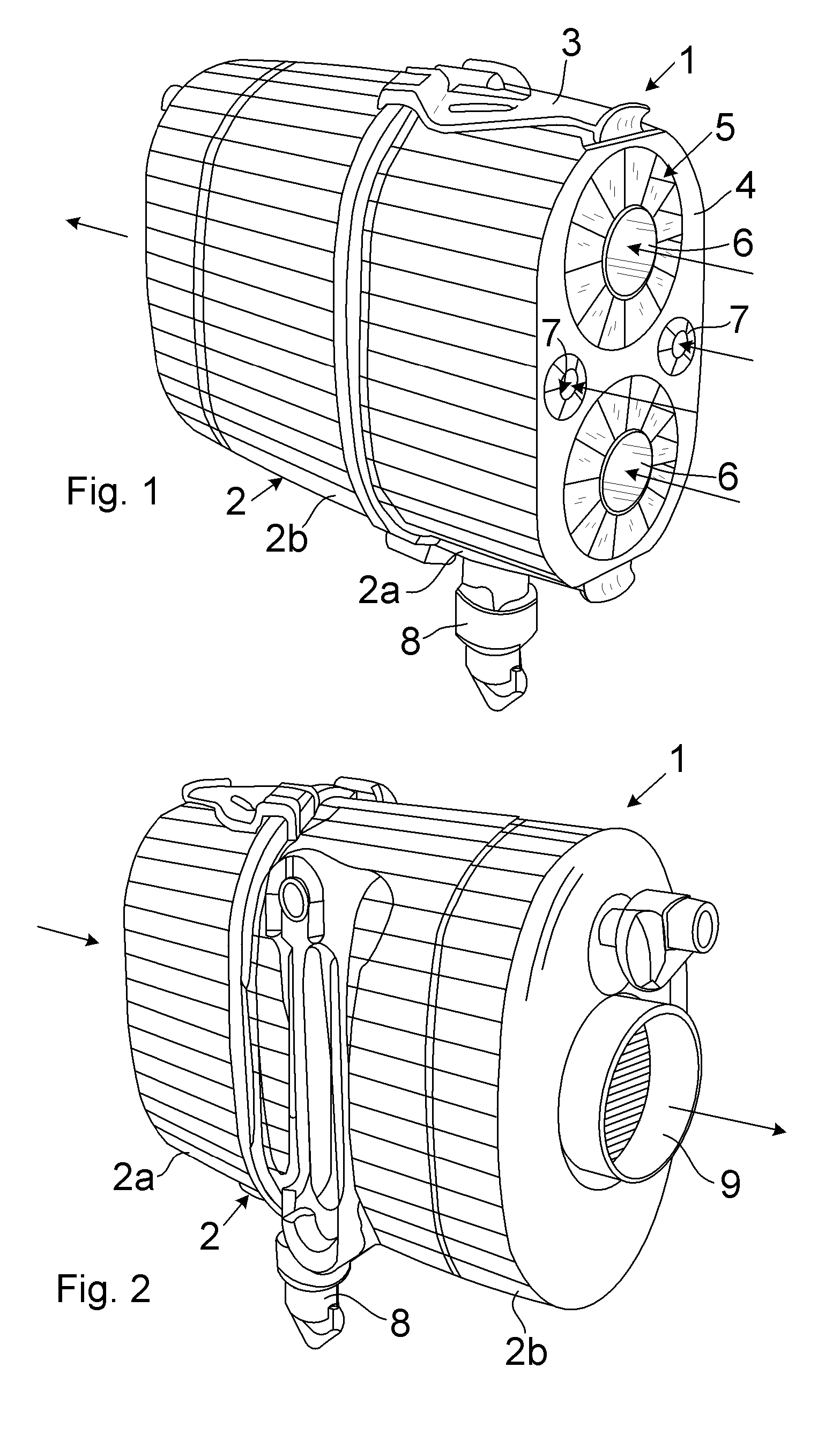

Filter for cleaning a fluid

InactiveUS8012227B2Improve filtration efficiencyEasy to measureCombination devicesDispersed particle filtrationFilter elementWaste management

A filter for filtering a fluid has a filter housing and a filter element arranged in the filter housing. A cyclone preseparator is arranged upstream of the filter element, wherein a fluid to be cleaned is guided through the preseparator to the filter element. The cyclone preseparator has at least two cyclone cells that have a different diameter, respectively.

Owner:MANN HUMMEL GMBH

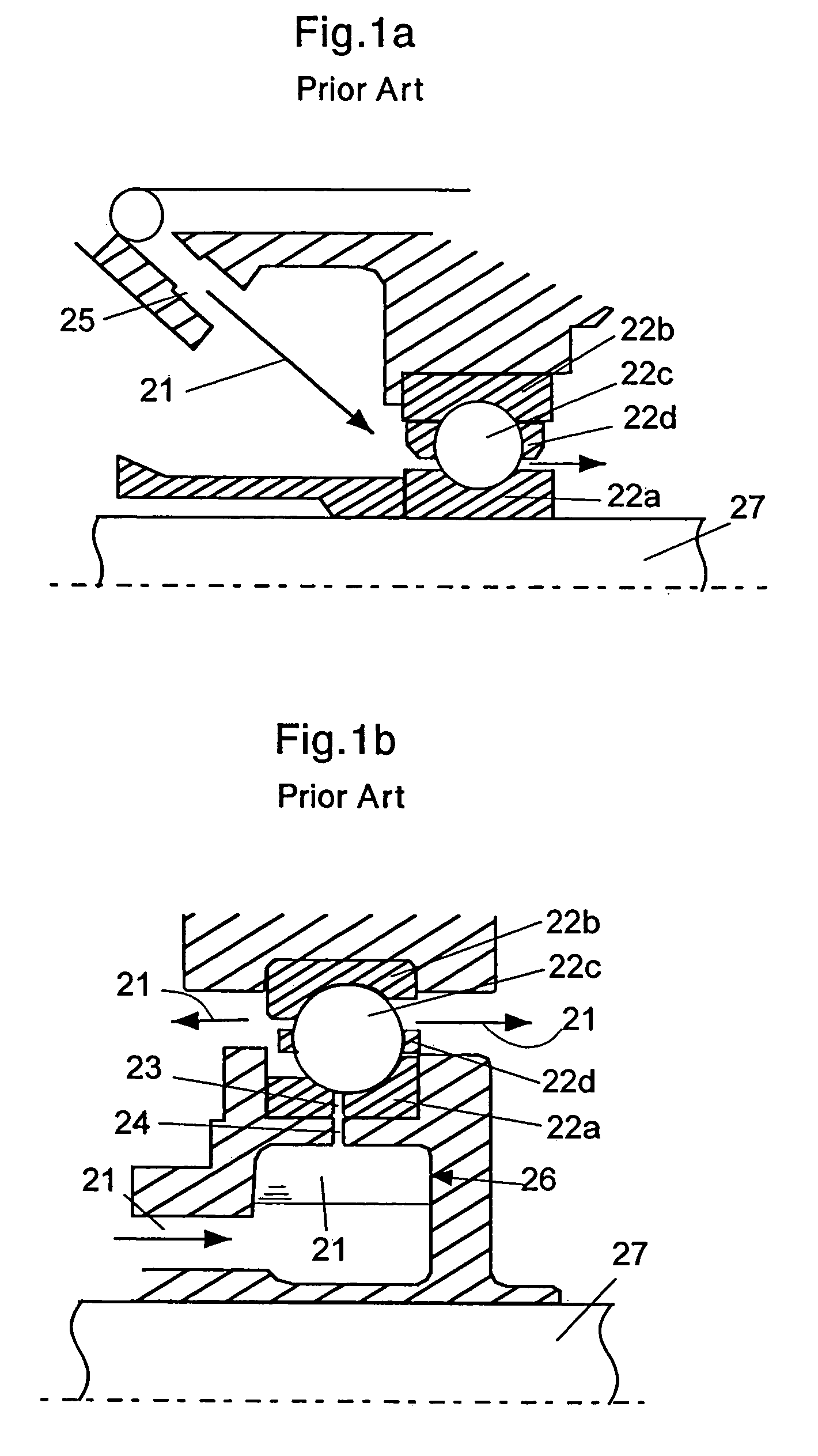

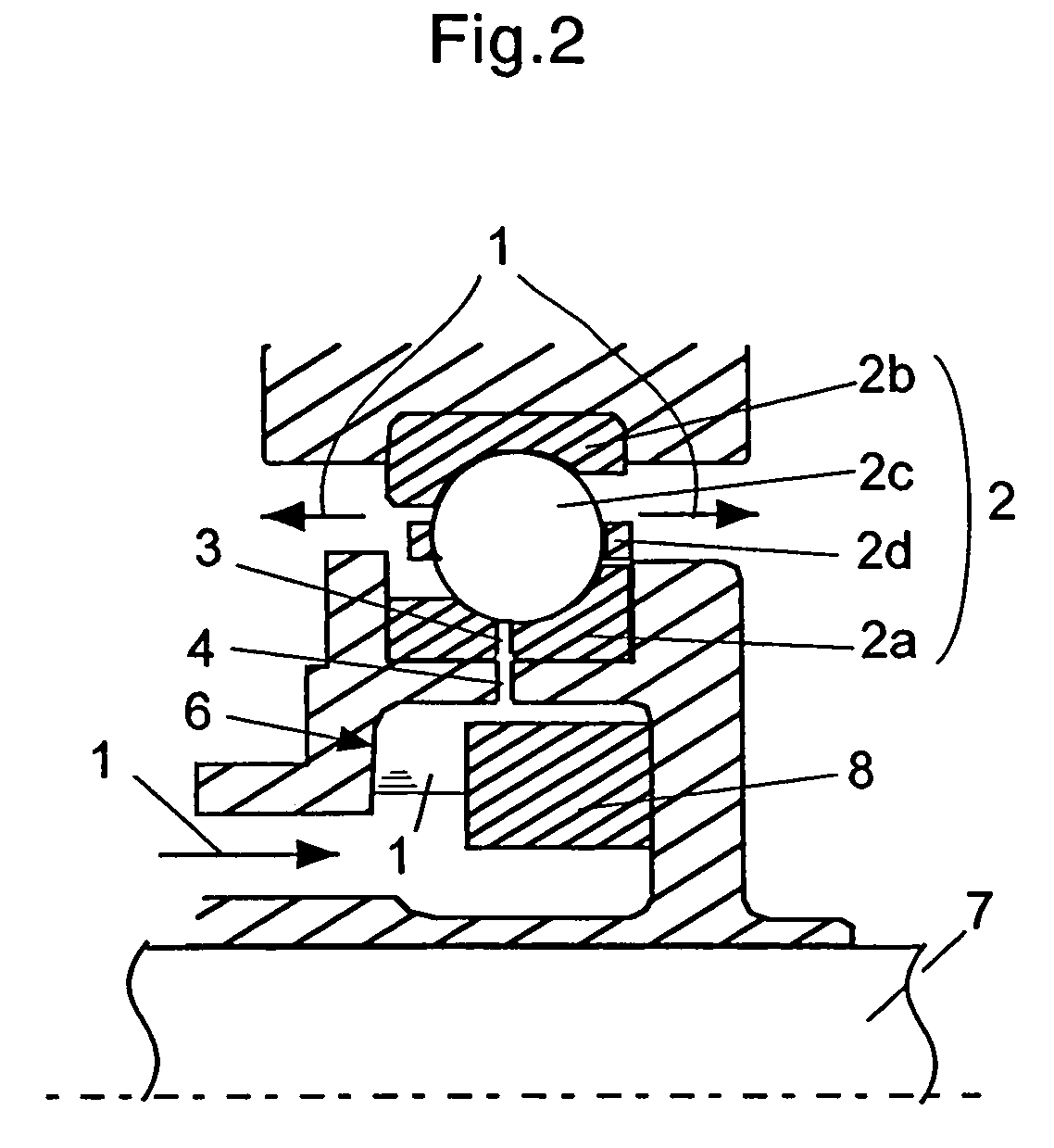

Lubrication structure for rolling bearing

InactiveUS7070333B2Increased load-bearing capacityGood estimateShaftsBall bearingsRolling-element bearingCentrifugal force

A fin member is installed in an oil accumulating room. The fin member causes lubrication oil to follow rotation of the oil accumulating room so that the lubrication oil can be forcibly rotated. In this manner, a rotational speed difference between the oil accumulating room and the lubrication oil is made small, and an adequate oil supplying pressure is generated by the centrifugal force. As a result, a sufficient quantity of the lubrication oil can be supplied. Therefore, estimation of a supplying oil quantity becomes easy, and accuracy in prediction of the lubrication oil quantity actually used for the bearing lubrication can be improved.

Owner:IHI CORP

Scroll compressor with crankshaft venting

ActiveUS20080170955A1Reduce deliveryFacilitates separation and removalRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

Lubrication of bearing surfaces in a scroll compressor is enhanced by a vent arrangement which makes use of increased centrifugal force, achieved by locating the outlet of the vent arrangement radially outside of the nominal circumference of the compressor's drive shaft, to both remove refrigerant gas from compressor locations where such gas can inhibit the flow and delivery of lubricant to such surfaces and to increase the lift of lubricant out of the compressor's lubricant sump. Oil retained in the upper surface of the compressor drive shaft is made immediately available for bearing lubrication upon compressor start-up to further enhance compressor lubrication.

Owner:TRANE INT INC

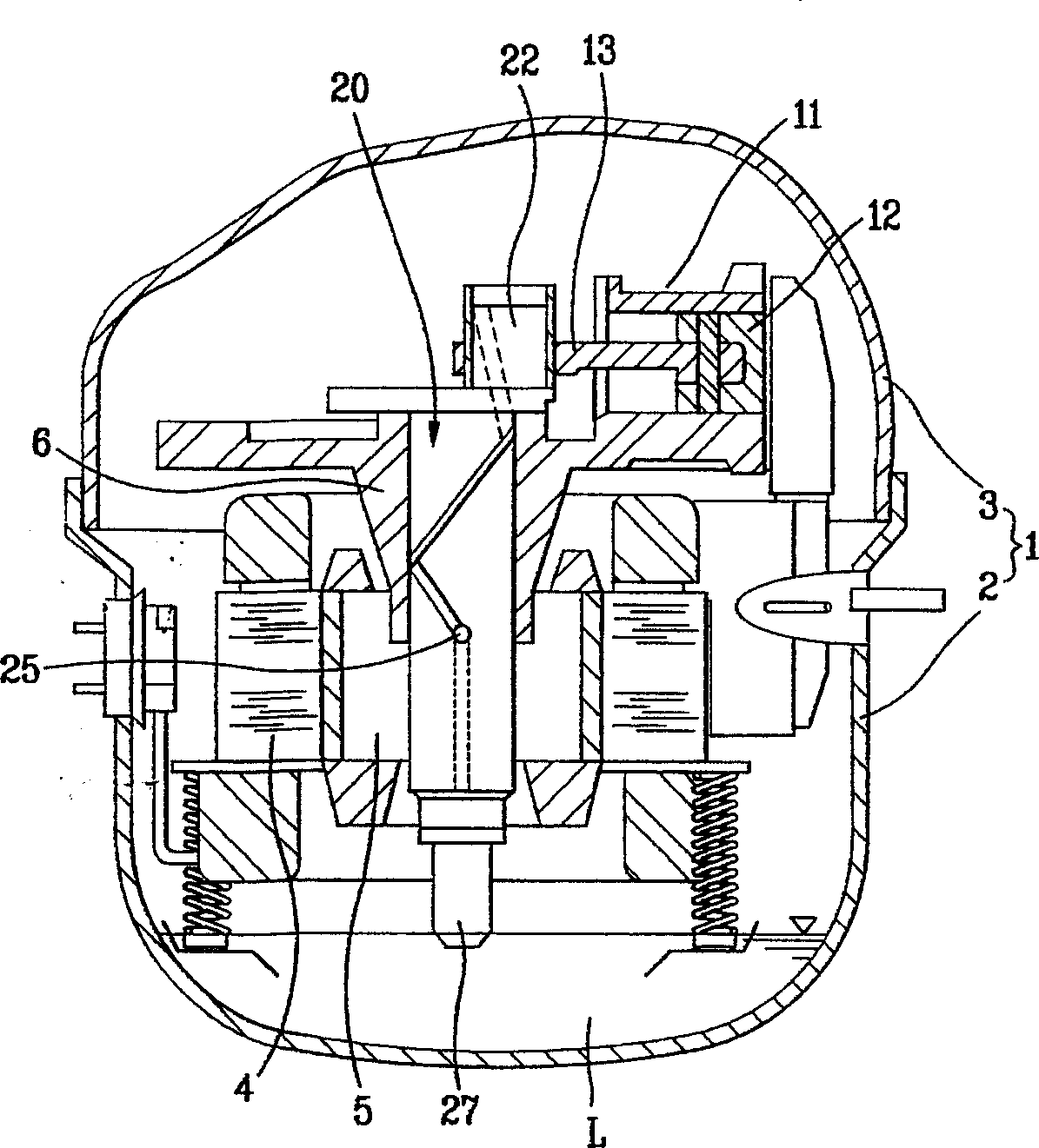

Crank shaft of refrigeration compressor

InactiveCN1427154AIncrease centrifugal forceAvoid oil spillsPositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorLow speed

A crankshaft of refrigerating compressor features that a channel of cooling machine oil is formed along the circumference in order to raise the cooling machine oil up by a centrifugal force. It is composed of a solid cylindrical shaft inserted in rotor and bearing, an eccentrical part communicated with the said channel of cooling oil, and an oil pump for pumping oil to the said channel. Its advantages are supplying cooling oil even at low speed and no leakage of cooling oil.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

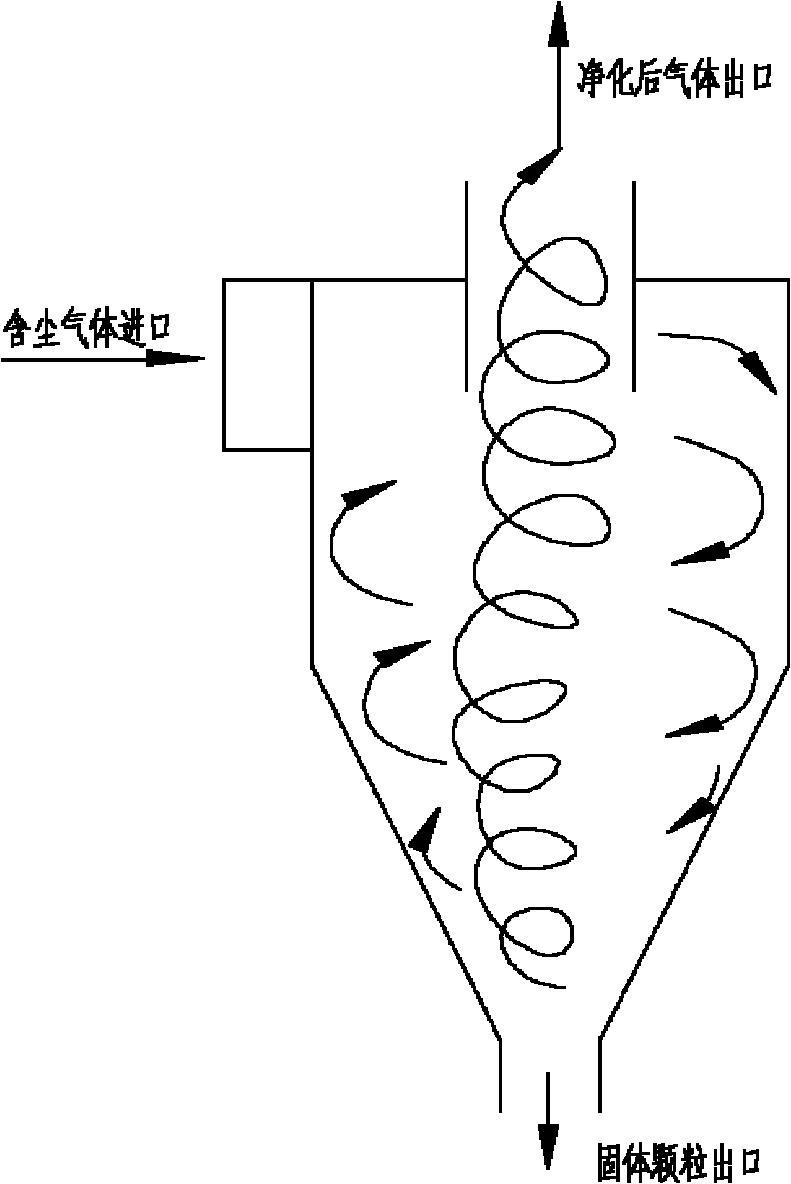

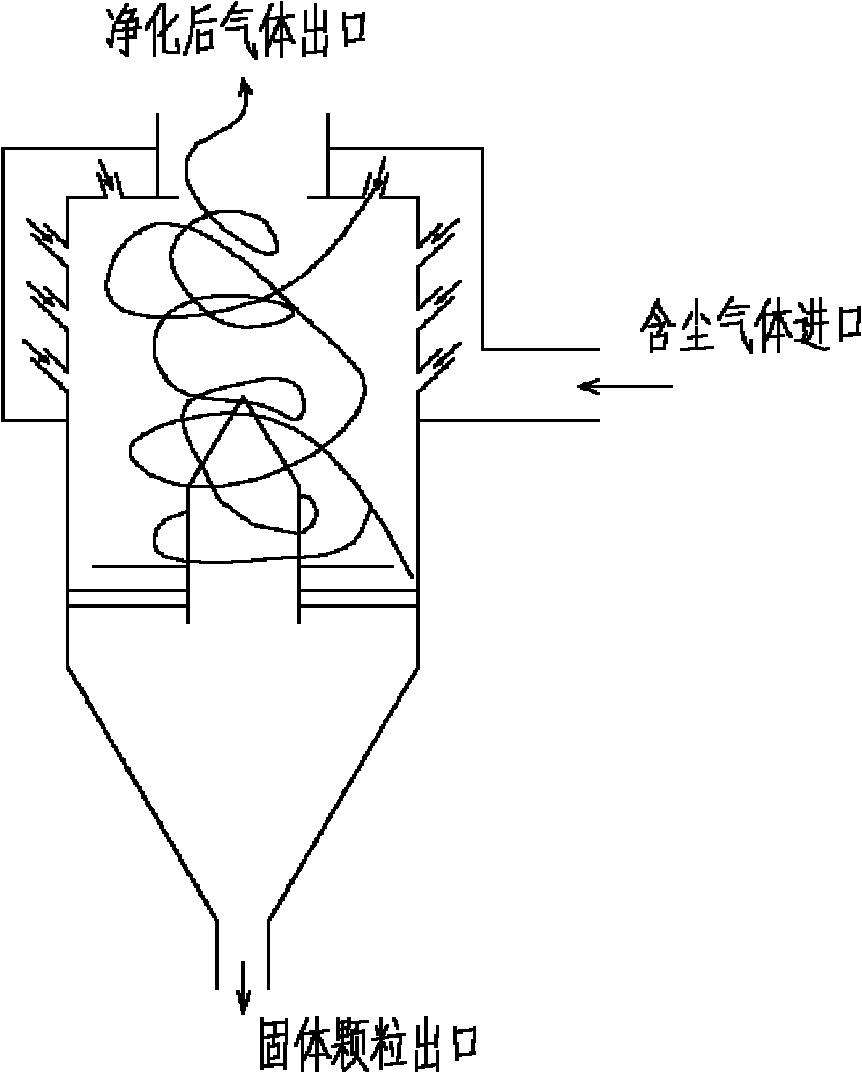

Radial spray regular cyclone separator

ActiveCN101954317AIncrease centrifugal forceImprove separation efficiencyReversed direction vortexImpellerSolid particle

The invention discloses a radial spray regular cyclone separator which mainly comprises an inner cylinder and an outer cylinder, wherein the inner cylinder and the outer cylinder are installed coaxially; a separating chamber is formed between the side walls of the inner cylinder and the outer cylinder; spiral guide blades are installed in the separating chamber; the upper end of the inner cylinder is communicated with an air outlet pipe; an annular channel communicated with the separating chamber is formed between the air outlet pipe and a cylindrical flow regulation pipe sleeved outside the air outlet pipe; a radial impeller is installed in a cavity between the upper end of the outer cylinder and the upper end of the inner cylinder by taking the air outlet pipe as a center; and dust laden air flow enters from the annular channel, is guided to the inner wall of the outer cylinder by the radial impeller, and then enters the separating chamber by turning 90 degrees. In the invention, the solid particles are separated by the combined action of radial spray inertia force and spiral rotation centrifugal force, the centrifugal separation force is enhanced, and the dust laden air flow does regular spiral rotational movement in the spiral flow separating chamber, thus preventing whirlpool caused by air shock in the separating chamber and improving the separation efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

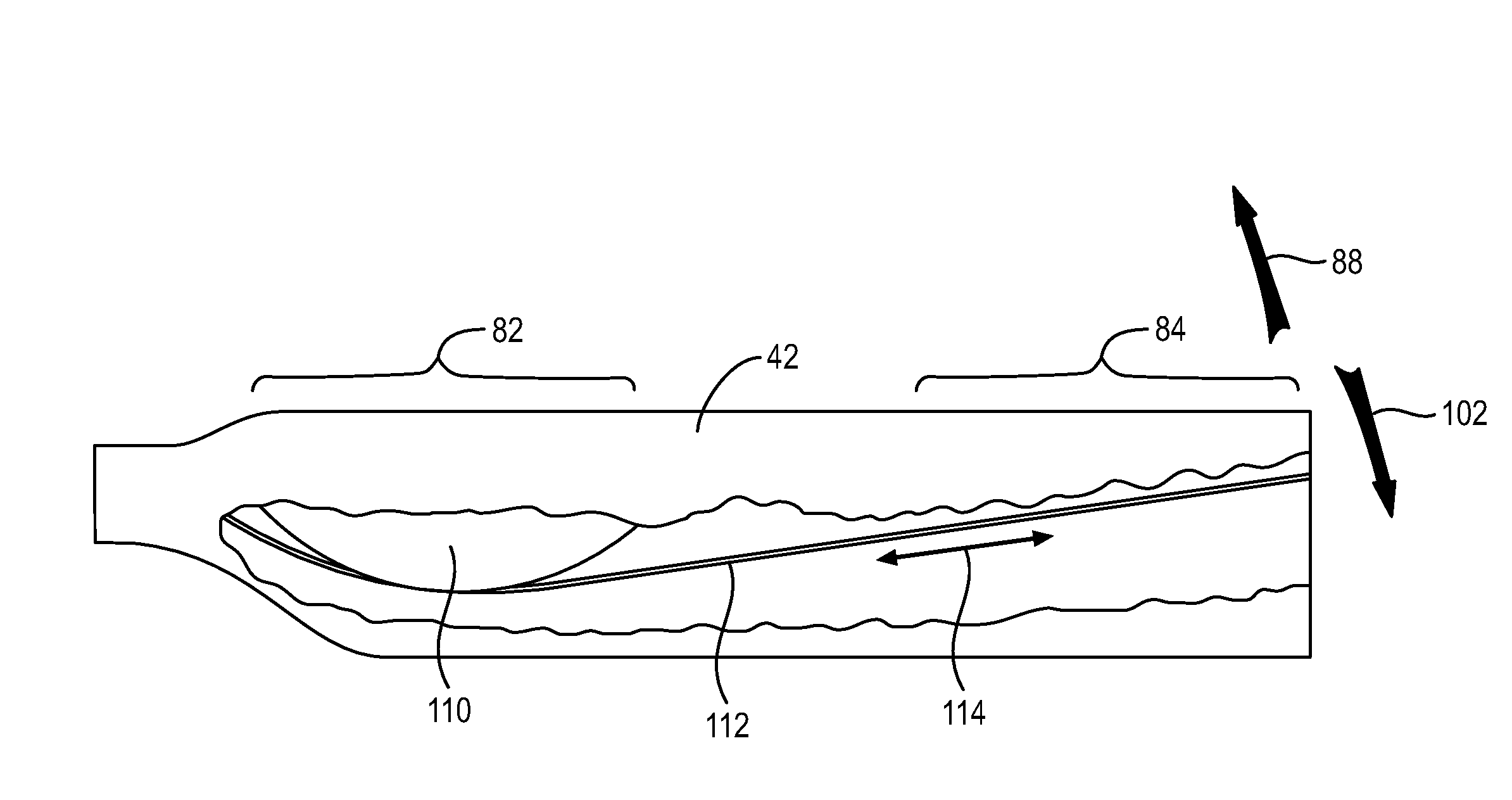

Mission-adaptive rotor blade

ActiveUS20120153073A1Easy to controlIncrease centrifugal forcePropellersPump componentsRotary wingFuselage

A rotorcraft may include an airframe and a rotor connected to the airframe. The rotor may include a hub and a rotor blade connected to the hub to extend radially away therefrom. The rotor blade may include biasing fibers, oriented to increase the twist of the rotor blade in response to an increase in the speed of rotation of the rotor corresponding to a mission, task, or maneuver.

Owner:SKYWORKS GLOBAL INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com