Patents

Literature

76results about How to "Reduced removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-polymeric organic particles for chemical mechanical planarization

InactiveUS20050005525A1Reduce defectsHigh selectivityPigmenting treatmentOther chemical processesSoft waterSURFACTANT BLEND

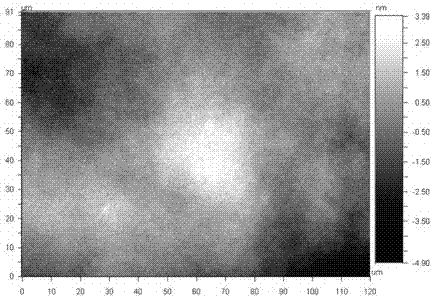

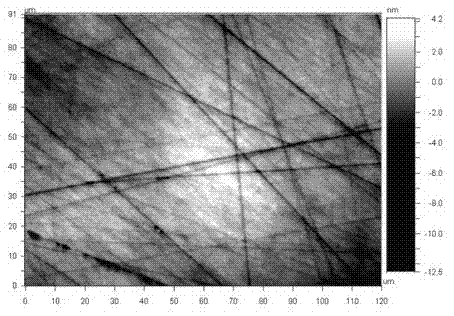

An abrasive composition comprising non-polymeric organic particles that is useful for chemical mechanical planarization (CMP), and which can widely be used in the semiconductor industry. The inventive compositions preferably comprise soft water in combination with 0.001-20 w / w % of non-polymeric organic particles, 0.1-10 w / w % of an oxidizing agent, 0.05-10 w / w % of a chelating agent, 0.01-10 w / w % of a surfactant, and 0-10 w / w % of a passivation agent at a pH in the range of 2-12, wherein said percentages are w / w (weight / weight) percentages, based on the total weight of said compositions. The abrasive compositions provide an efficient polishing rate, excellent selectivity and good surface quality when utilized as a new abrasive composition in CMP applications.

Owner:DYNEA AUSTRIA

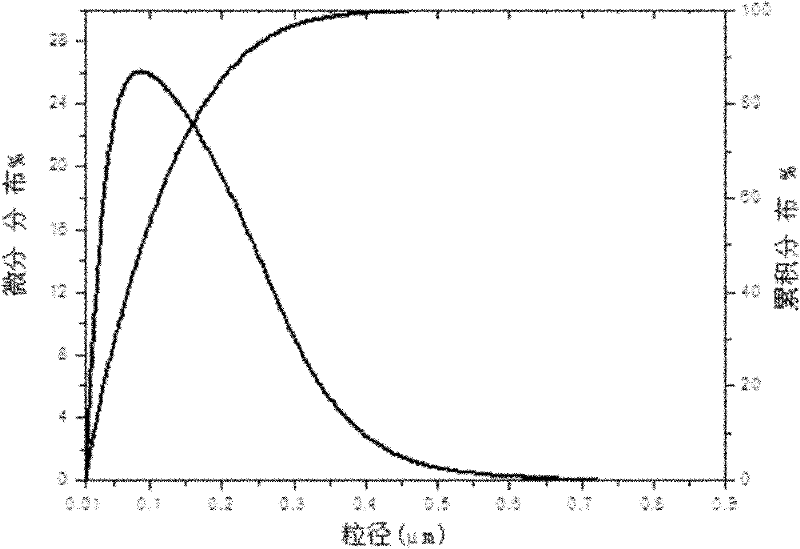

Chemical mechanical polishing solution for processing surface of sapphire or carborundum wafer for LED (Light Emitting Diode) substrate slice and preparation method thereof

InactiveCN102888193AAvoid damageNo subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesActive agentSilicon oxide

The invention discloses a chemical mechanical polishing solution for processing a surface of a sapphire or carborundum wafer for an LED (Light Emitting Diode) substrate slice. The chemical mechanical polishing solution comprises the following raw materials by weight: 2 to 30% of grinding material, 0.01 to 5% of chelating agent, 0.01 to 10% of surface active agent, 0.01 to 10% of dispersing agent, 0.1 to 20% of oxidant and the balance of deionized water. The preparation method comprises the steps as follows: preparing a grinding material-silica sol; then, sequentially adding the chelating agent, surface active agent, dispersing agent, oxidant and deionized water to the obtained silica sol along with agitating; and continuously uniformly agitating to obtain the chemical mechanical polishing solution for processing the surface of the sapphire or carborundum wafer for the LED substrate slice. The chemical mechanical polishing solution disclosed by the invention can not bring damage, scratching and corrosive pits to the surface of the LED substrate and has no pollution to the environment; the raw materials are cheap, and the cost is low; and the chemical mechanical polishing solution is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

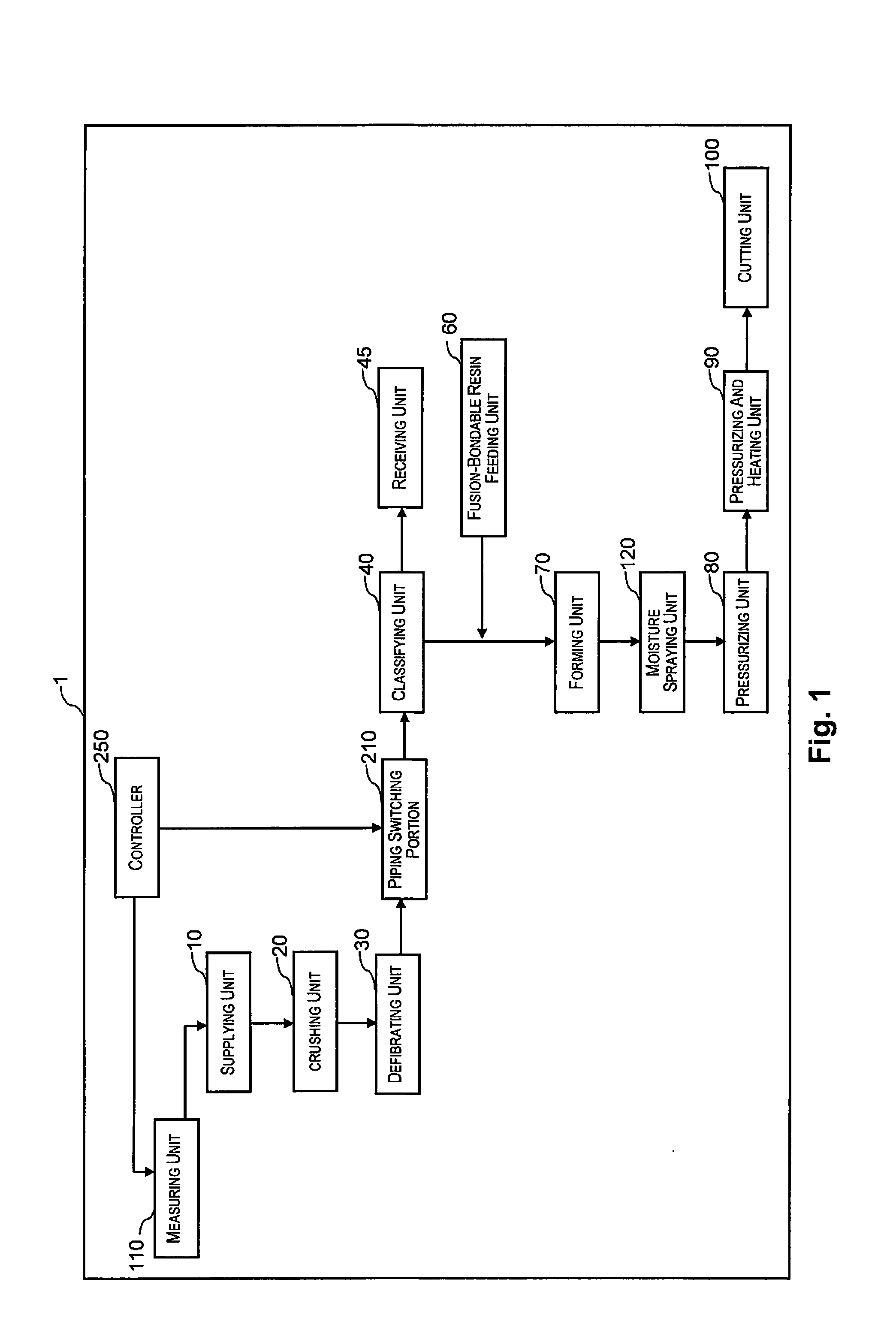

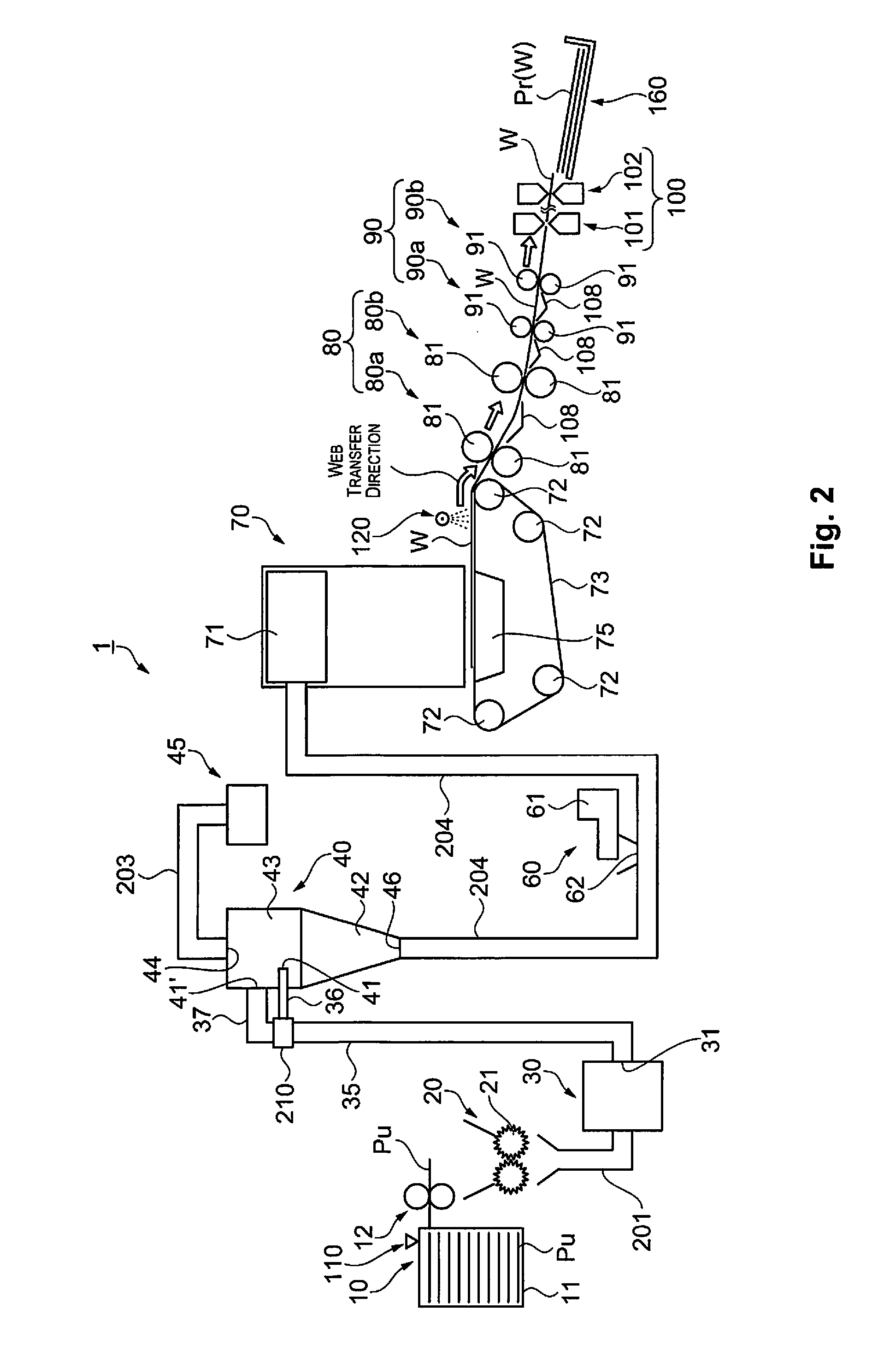

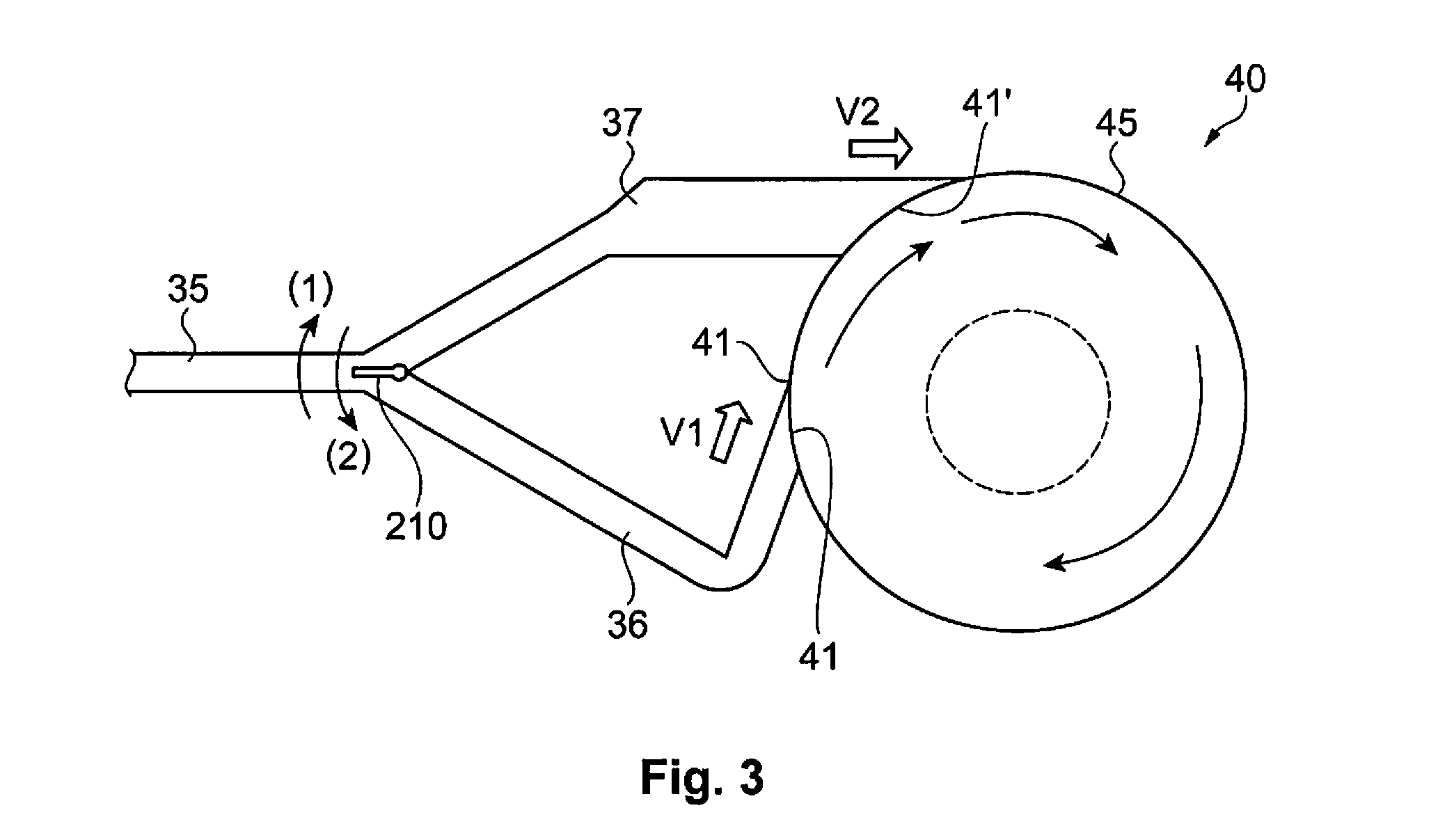

Sheet manufacturing apparatus

ActiveUS20140290888A1Low content rateReduced removal rateMachine wet endDirt cleaningFiberForeign matter

A sheet manufacturing apparatus includes a measuring unit configured to measure thickness and air permeability of a defibration object containing fibers, a defibrating unit configured to dry-defibrate the defibration object, and a classifying unit configured to separate and remove, by airflow classification, foreign substances other than the fibers from the defibrated material defibrated at the defibrating unit.

Owner:SEIKO EPSON CORP

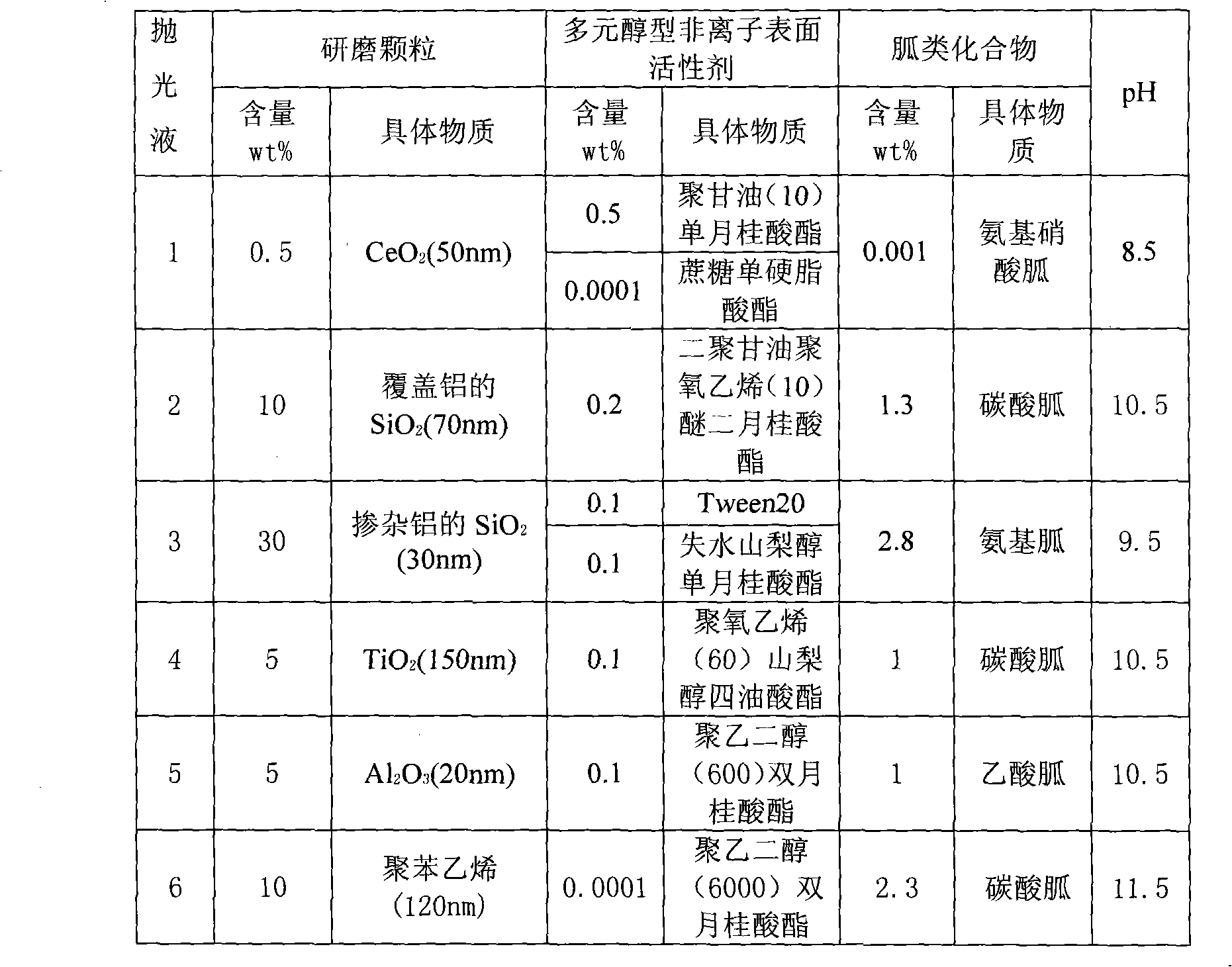

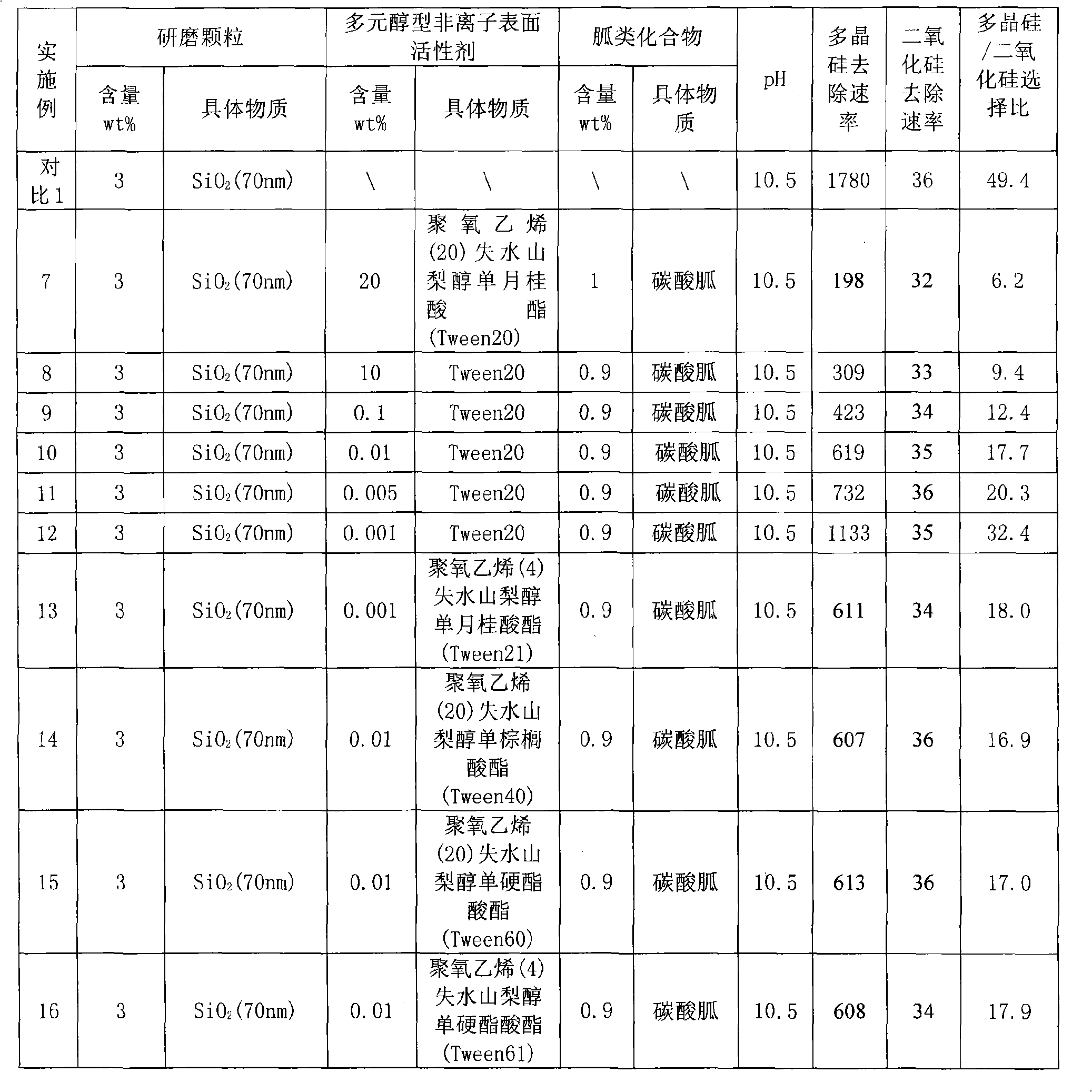

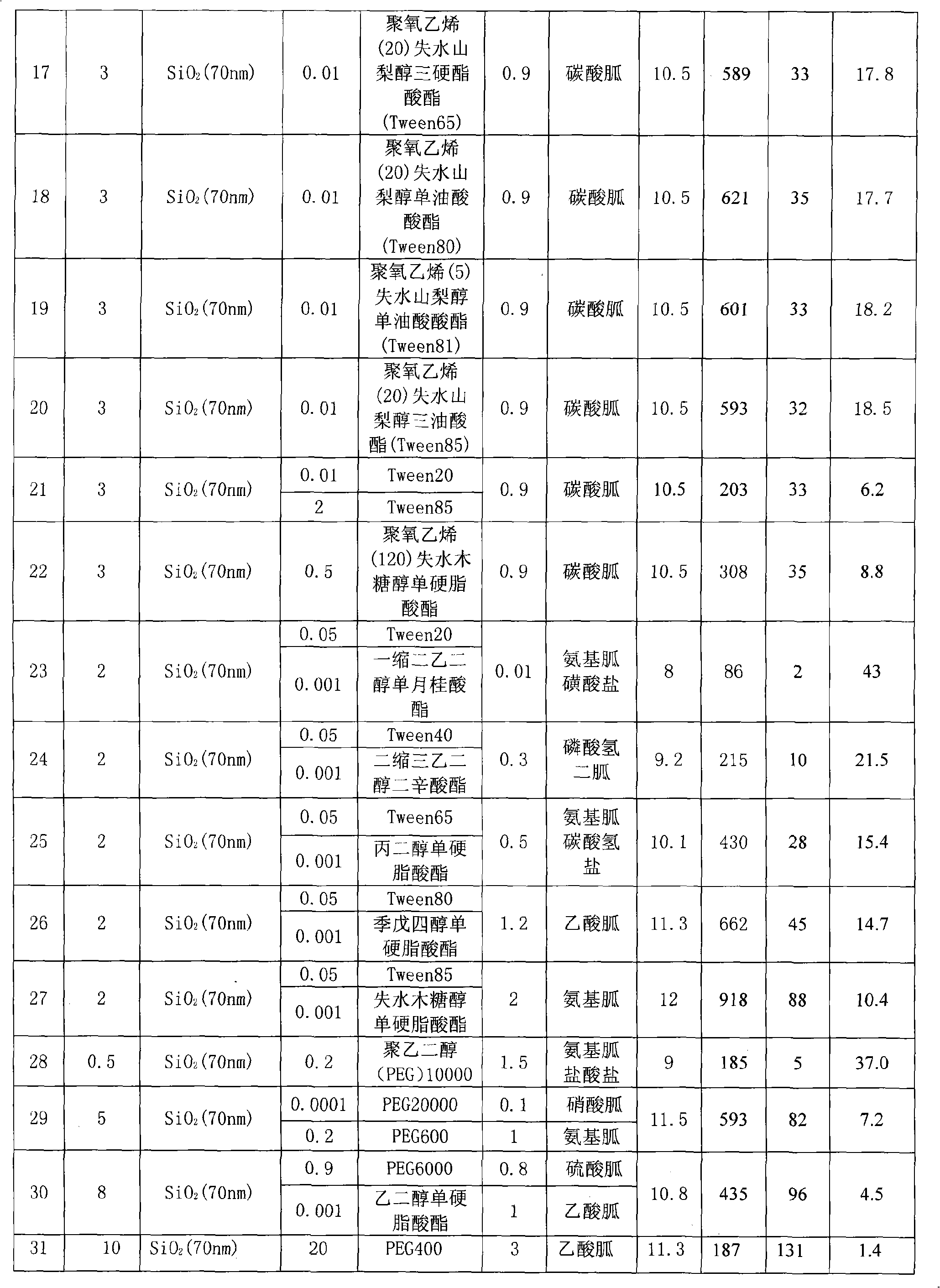

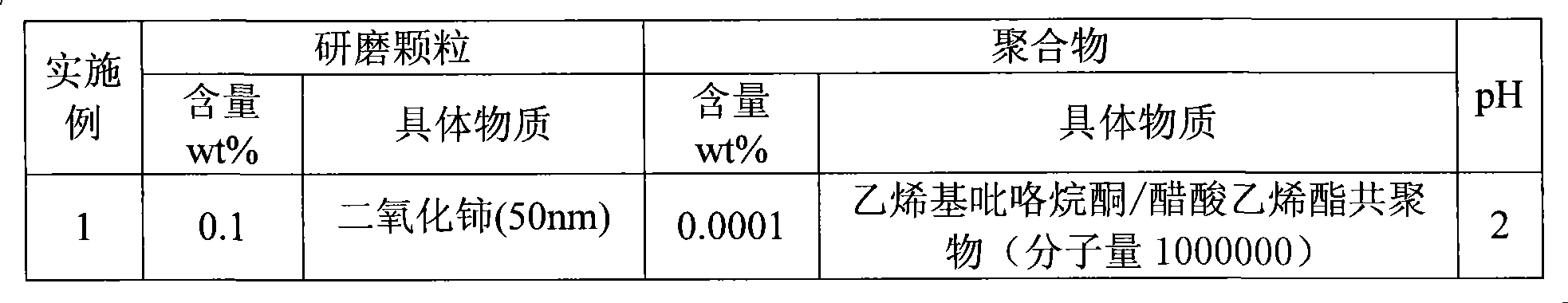

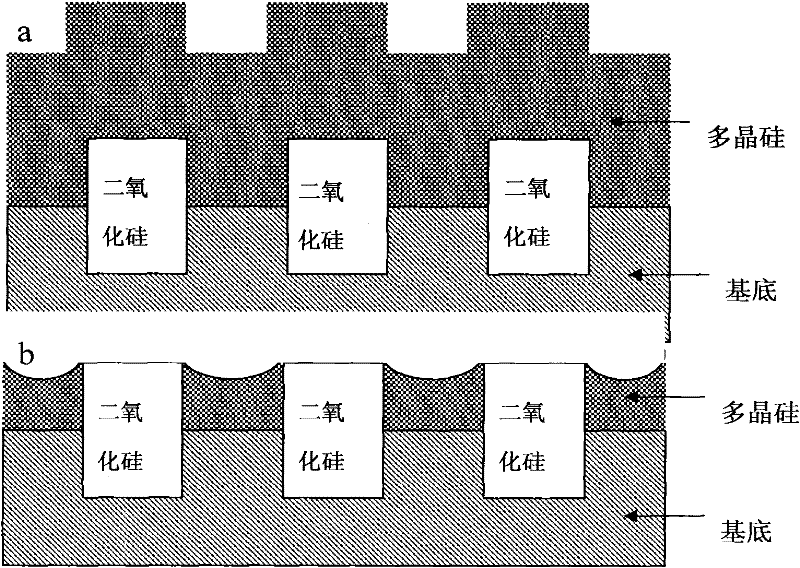

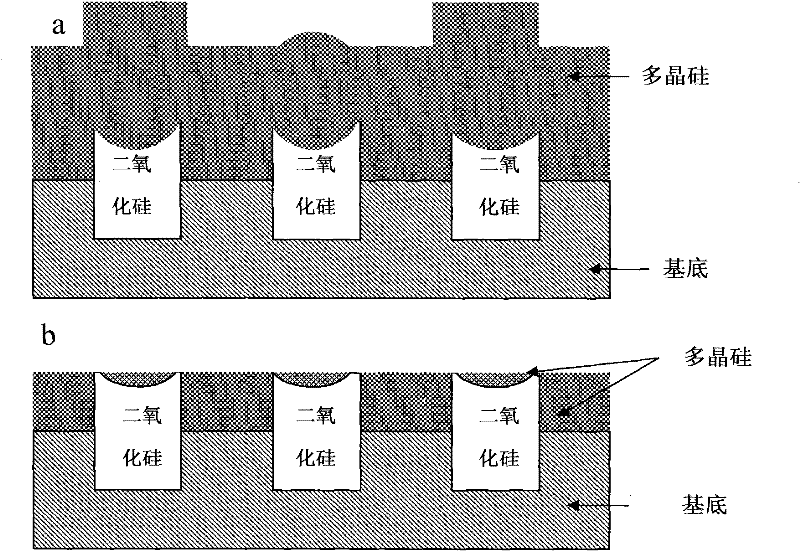

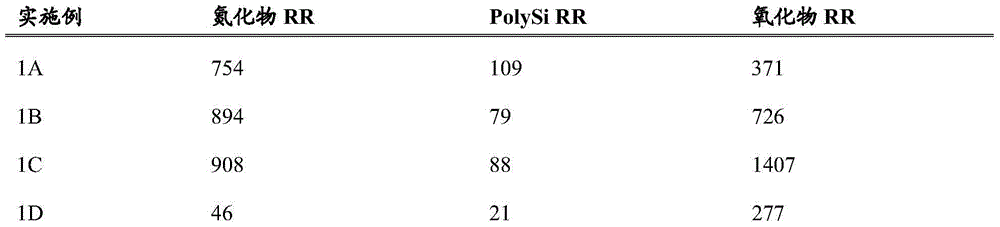

Chemico-mechanical polishing slurry for polysilicon

InactiveCN101280158AReduced removal rateThe removal rate does not decreaseSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurrySilicon dioxide

The invention discloses polysilicon chemical-mechanical polishing slurry which is composed of polyol type nonionic surfactant, guanidine compounds, grinding particles and water. The polishing slurry of the invention can polish the polysilicon film well under the alkali condition; wherein, the polyol type nonionic surfactant can decrease the removal velocity of polysilicon obviously without decreasing the removal velocity of silicon dioxide; thereby, the selectivity-ratio of the polysilicon and the silicon dioxide is decreased obviously; the guanidine compounds also can adjust the selectivity-ratio of the polysilicon and the silicon dioxide and have the effect of pH adjustment, enabling the polysilicon chemical-mechanical polishing slurry to have no need to add common pH regulator; the metal iron pollution and the environmental pollution are reduced greatly.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Polishing solution for chemically and mechanically polishing cobalt barrier layer structure and applications thereof

ActiveCN104830235AReduced removal rateAdjustable removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCopperCobalt

The invention discloses a polishing solution for chemically and mechanically polishing a cobalt barrier layer structure and applications thereof. The polishing solution comprises the following components in percentage by weight: 0.01 to 20 wt% of grinding particles, 0.01 to 10 wt% of oxidant, 0.01 to 10 wt% of metal complexing agent, 0.005 to 5 wt% of metal corrosion inhibitor, 0.001 to 1 wt% of surfactant, and the balance being water. The polishing solution can form a layer of protective passivation film on the surface of cobalt and copper so as to prevent over-corrosion during the polishing process, can reduce the removal rates of cobalt and copper materials, and obtains the removal rate selectivity of an adjustable material.

Owner:TSINGHUA UNIV

Polishing compositions for controlling metal interconnect removal rate in semiconductor wafers

InactiveCN1699444AReduced removal rateChange in removal rateOther chemical processesDecorative surface effectsWaferingPyrrolidinones

A polishing composition suitable for polishing semiconductor substrates comprises 0.001 to 2 wt % of a thermoplastic polymer; and 0.001 to 1 wt % of polyvinylpyrrolidone; wherein varying the weight ratio of thermoplastic polymer to the polyvinylpyrrolidone controls the removal rate of the non-ferrous interconnect.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

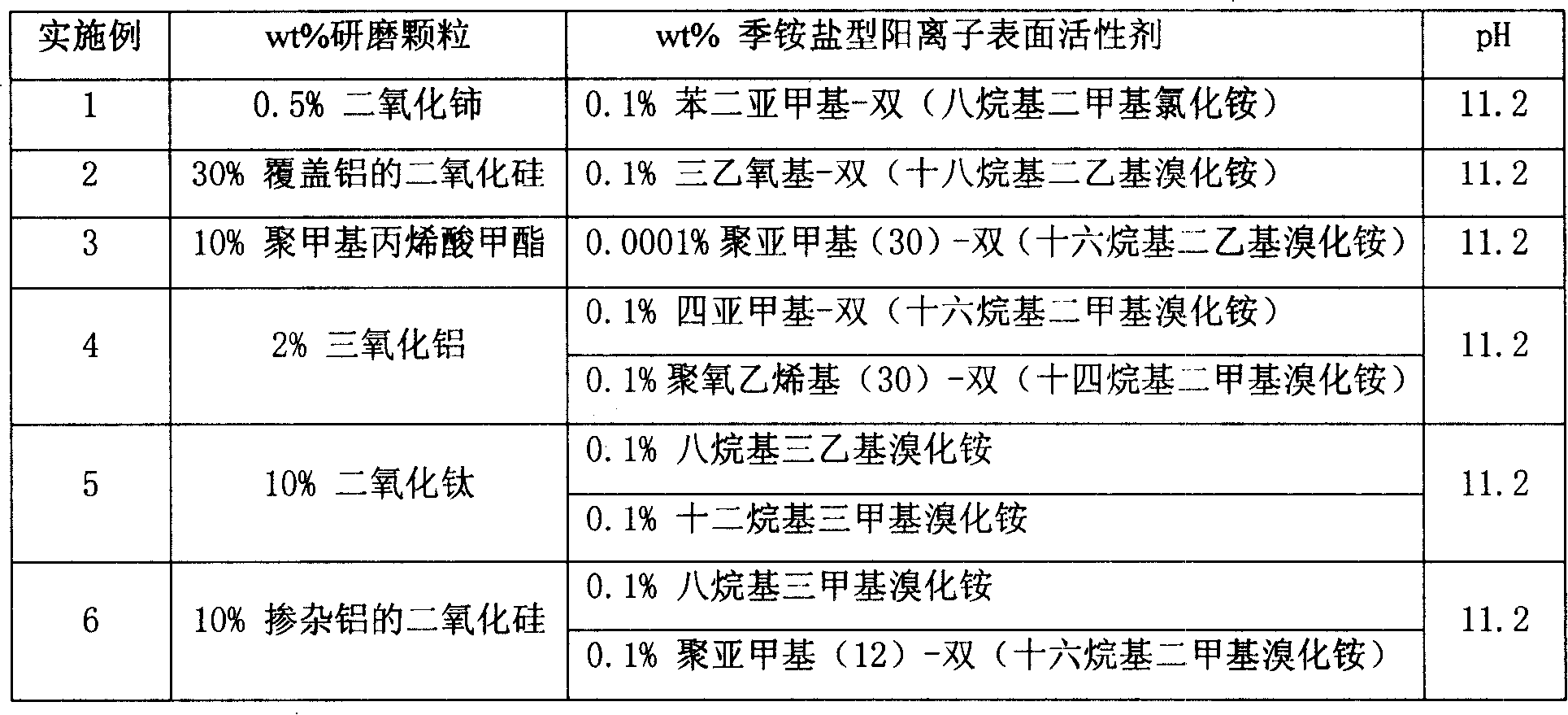

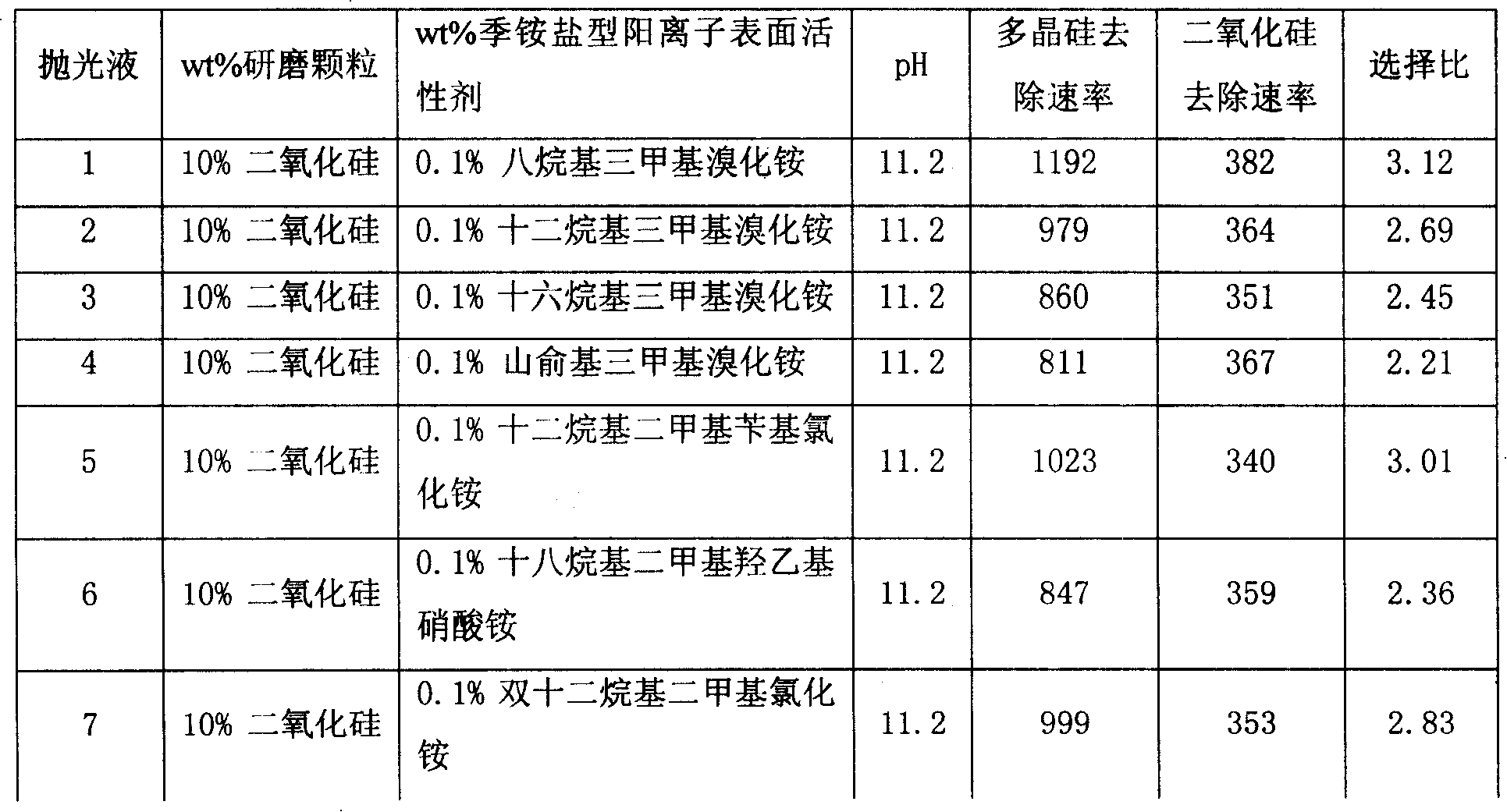

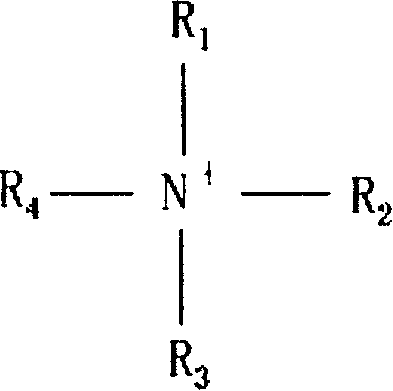

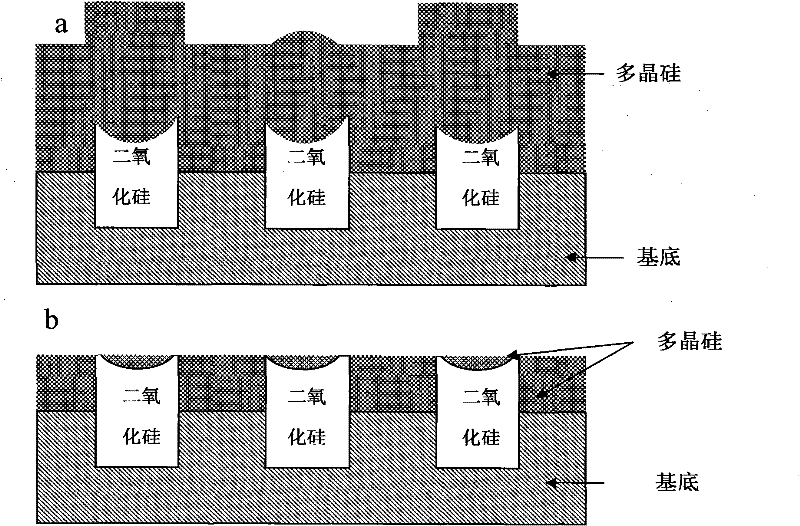

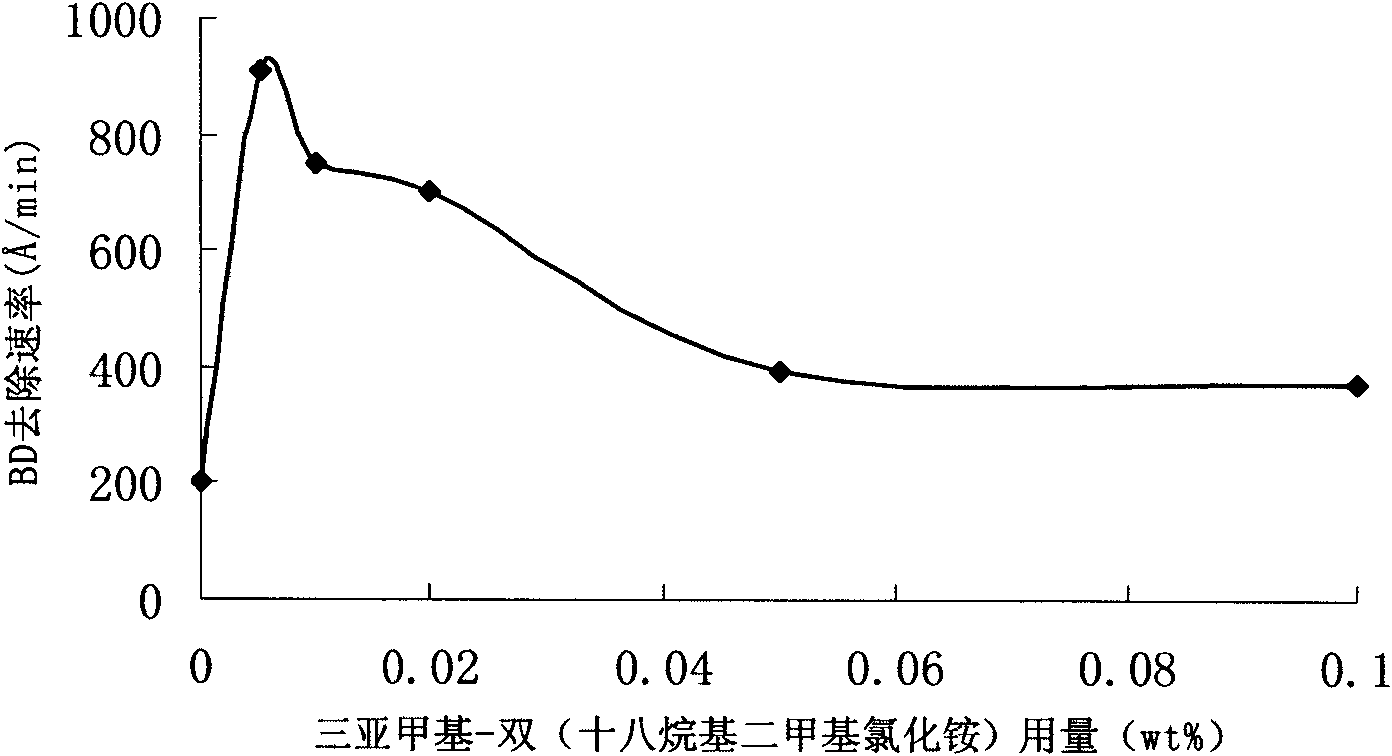

Chemical mechanical polishing fluid for polishing polycrystalline silicon

InactiveCN101168647AReduced removal rateImprove planarization efficiencySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxidePolycrystalline silicon

The invention discloses chemically machinery polishing solution used for polishing polysilicon. The polishing solution which comprises grinding grains and water is characterized in that a kind of or a plurality of kinds of quaternary ammonium salt type positive ion surface activating agent (s) is provided. The polishing solution of the invention can polish the polysilicon under the alkality condition, and also can obviously reduce the removing speed rate of the polysilicon and the selection ratio of the polysilicon and silicon dioxide, and obviously improve the even efficiency of the polysilicon.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemical and mechanical polishing liquid and its use

ActiveCN1900206AAvoid pittingAvoid corrosionOther chemical processesSemiconductor/solid-state device manufacturingHigh surfaceMetal

The chemical and mechanical polishing fluid includes at least one kind of grinding particle and one kind of carrier, as well as at least one kind of metal corrosion inhibitor. The present invention also discloses the use of this chemical and mechanical polishing fluid in polishing metal parts. The chemical and mechanical polishing fluid of the present invention has less faults in the polished metal surface, lowered metal eliminating rate and high surface quality of polished metal parts.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

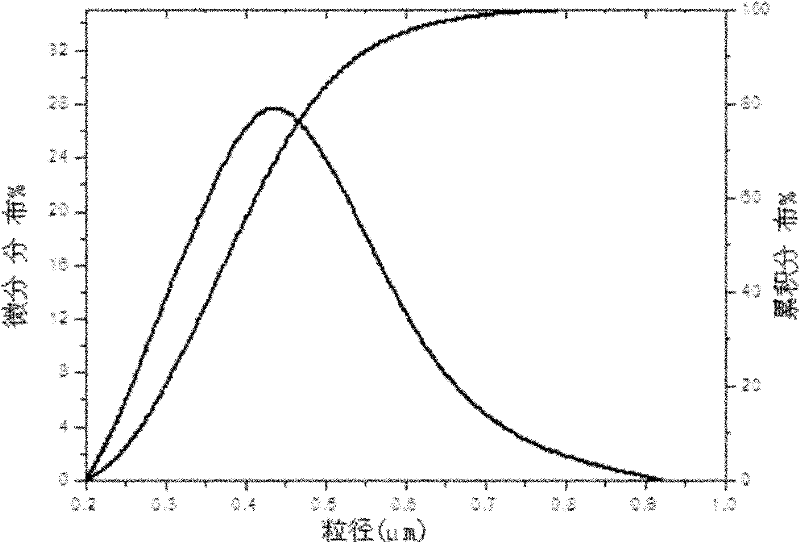

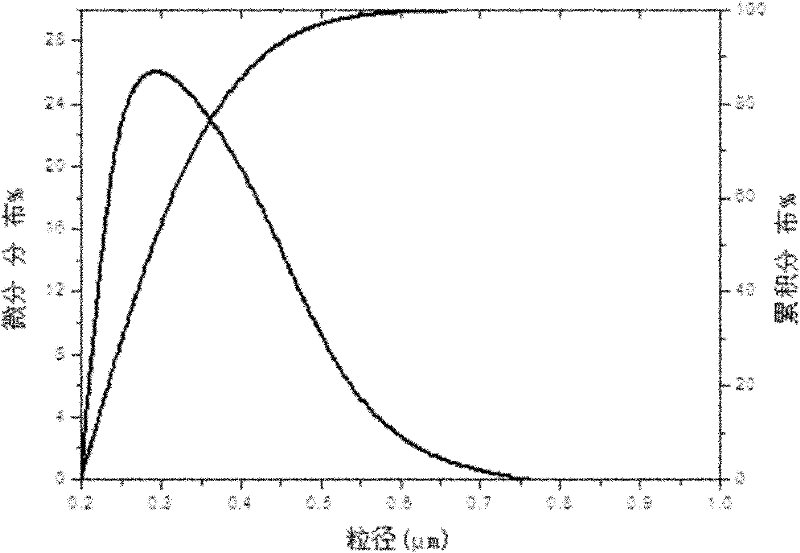

Polishing solution for silicon carbide substrate

InactiveCN102533124AAvoid damageLow subsurface damageSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSURFACTANT BLENDCorrosion

The invention relates to a chemically mechanical polishing solution for a silicon carbide substrate. The chemically mechanism polishing solution comprises the following components in percentage by weight: 1-50 percent of grinding material, 0.01-8 percent of chelant, 0.01-10 percent of surfactant, 0.01-10 percent of dispersing agent, 0.1-20 percent of oxidant and the balance of deionized water. The polishing solution has little damage to the surface of the silicon carbide substrate; the silicon carbide substrate has low roughness degree value and can reach the roughness Ra of being less than 0.5nm; no scratch and corrosion pit defect exists on the surface of the silicon carbide substrate; and the chemically mechanical polishing solution has high removing speed of scratch and corrosion pit, is easy to clean, does not corrode processing equipment and pollute the environment, and is low is price of raw materials, low in cost and easy to store. The chemically mechanical polishing solution is mainly used for chemically mechanical polishing of a silicon carbide wafer for the substrate.

Owner:上海上硅中试基地科技有限公司 +1

Control method for high eliminating rate of saphire substrate material

InactiveCN1857864AImprove removal rateLow costEdge grinding machinesPolishing compositions with abrasivesChemical reactionMetallurgy

The present invention discloses control method for eliminating sapphire substrate material in high speed. Sapphire substrate material is polished in a polishing machine with SiO2 abrasive of 15-40 nm grain size and pH 11-13.5 polishing fluid, and at the technological conditions of 40-60 deg.c temperature, 40-120 rpm rotation speed, 0.10-0.20 MPa pressure and 100-5000 ml / min flow rate for 0.2-3 hr. The said method can realize high speed mass transfer under strong chemical reaction and high polishing rate up to 10-18 micron / hr.

Owner:TIANJIN JINGLING MICROELECTRONIC MATERIALS CO LTD

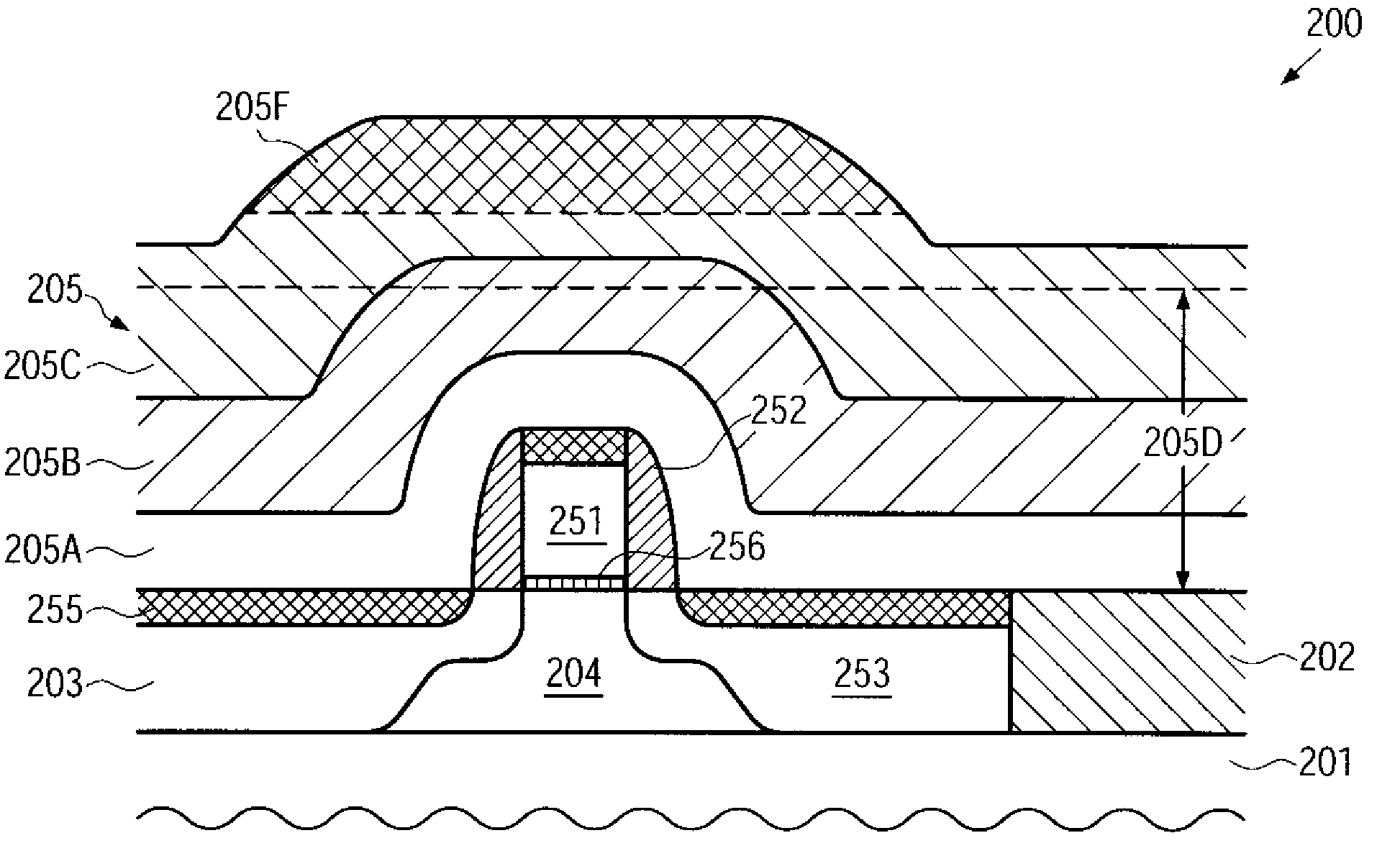

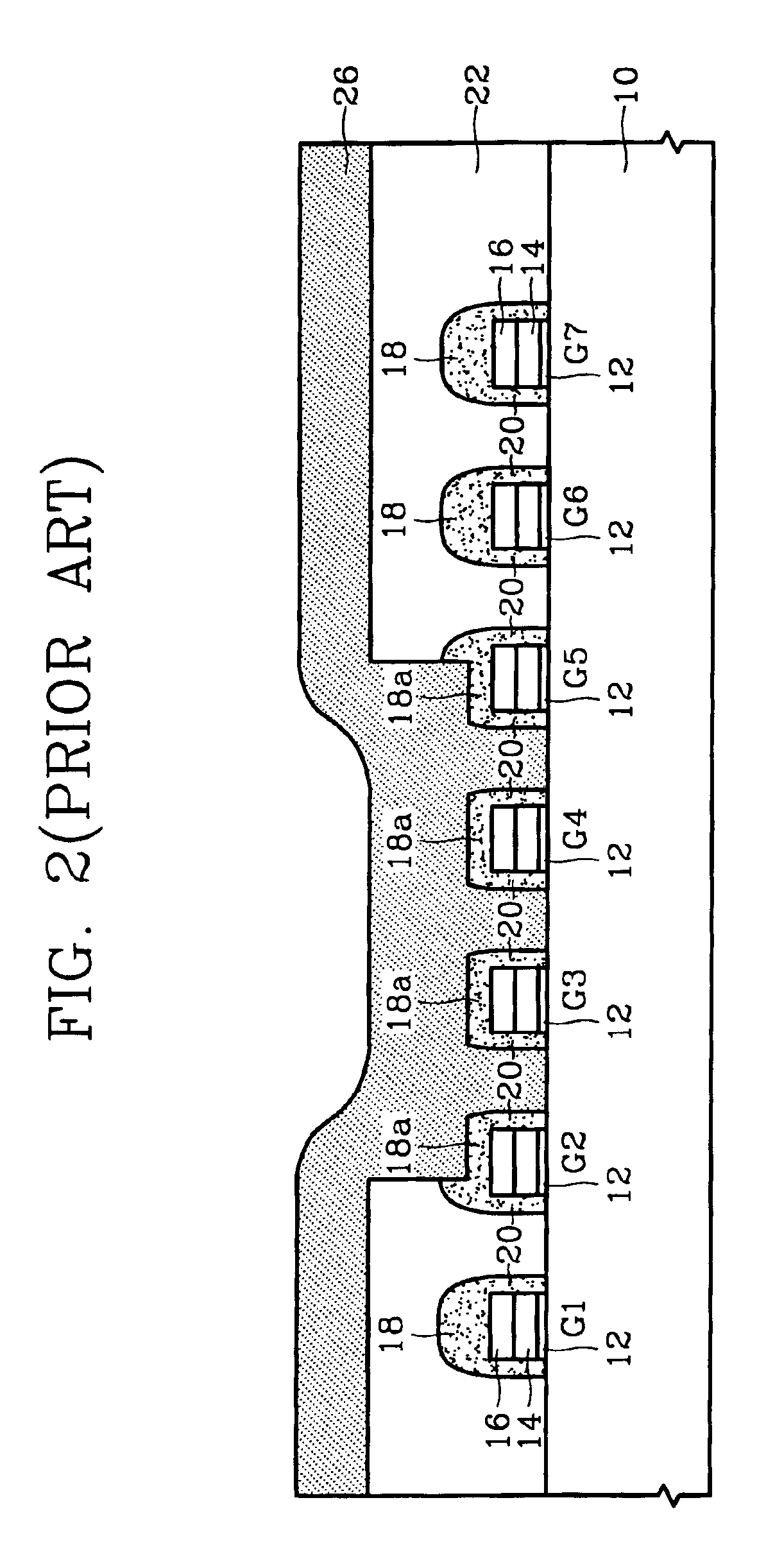

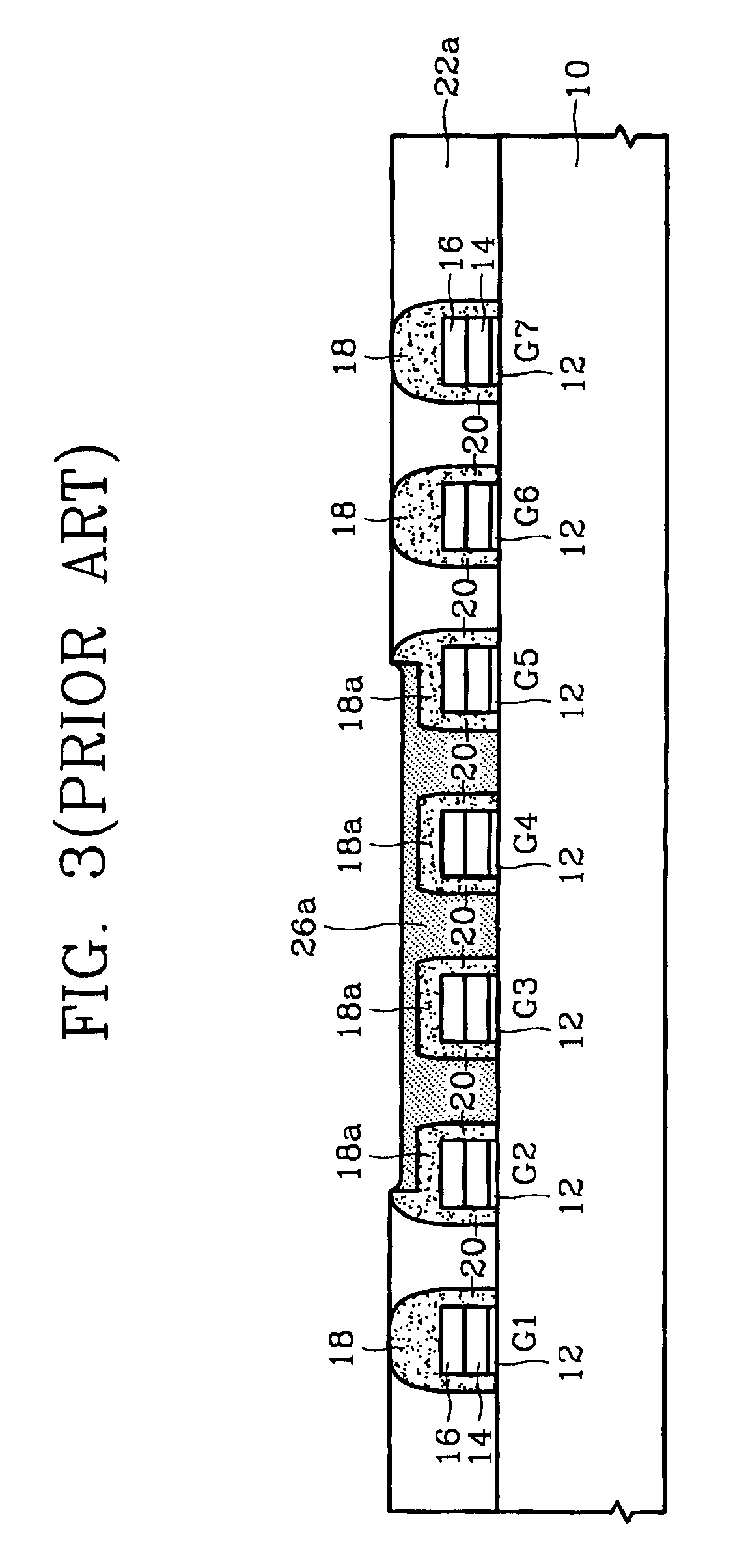

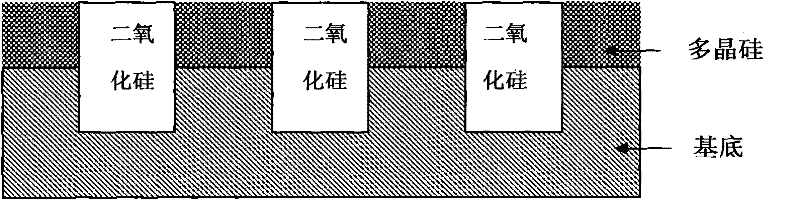

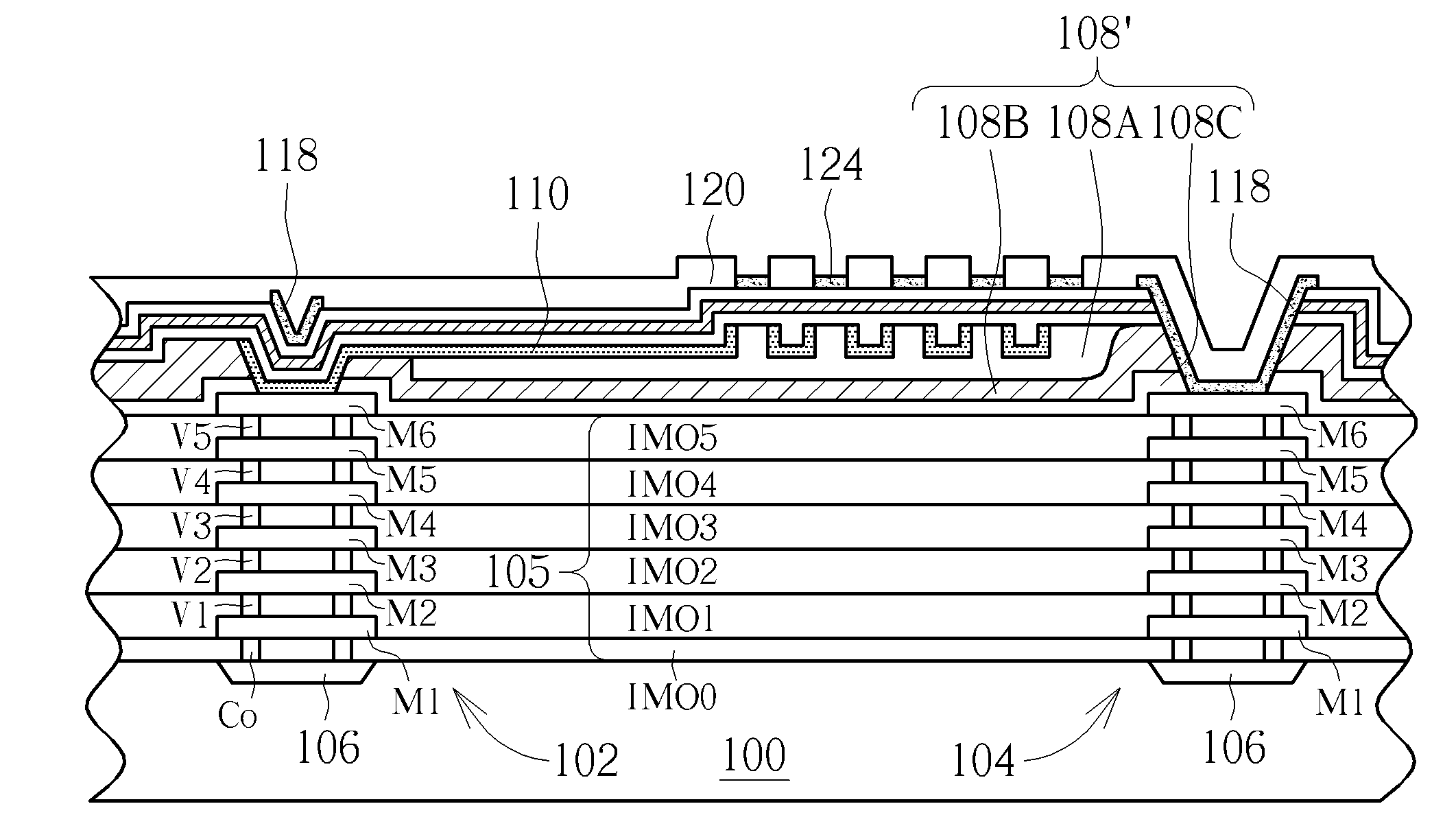

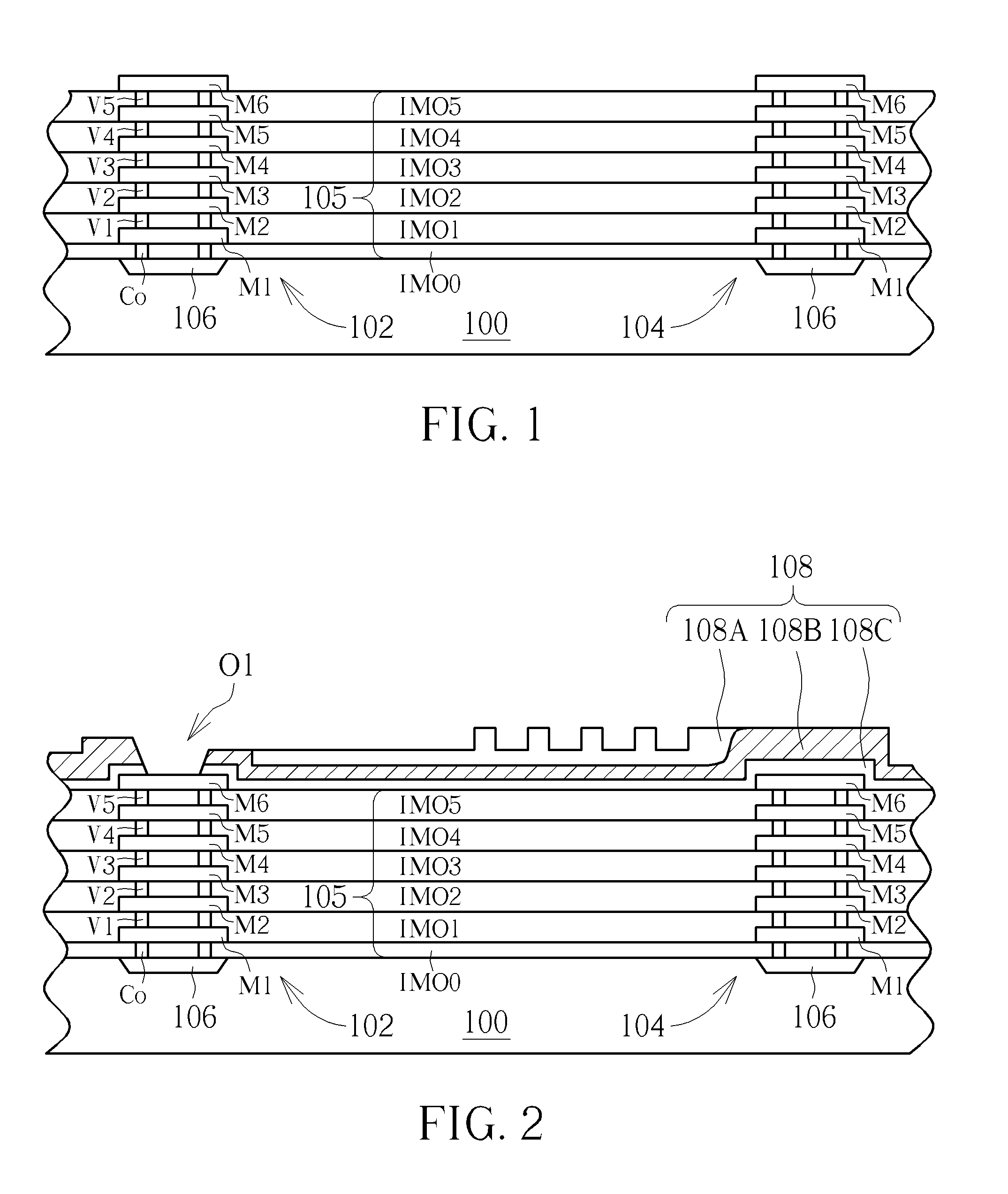

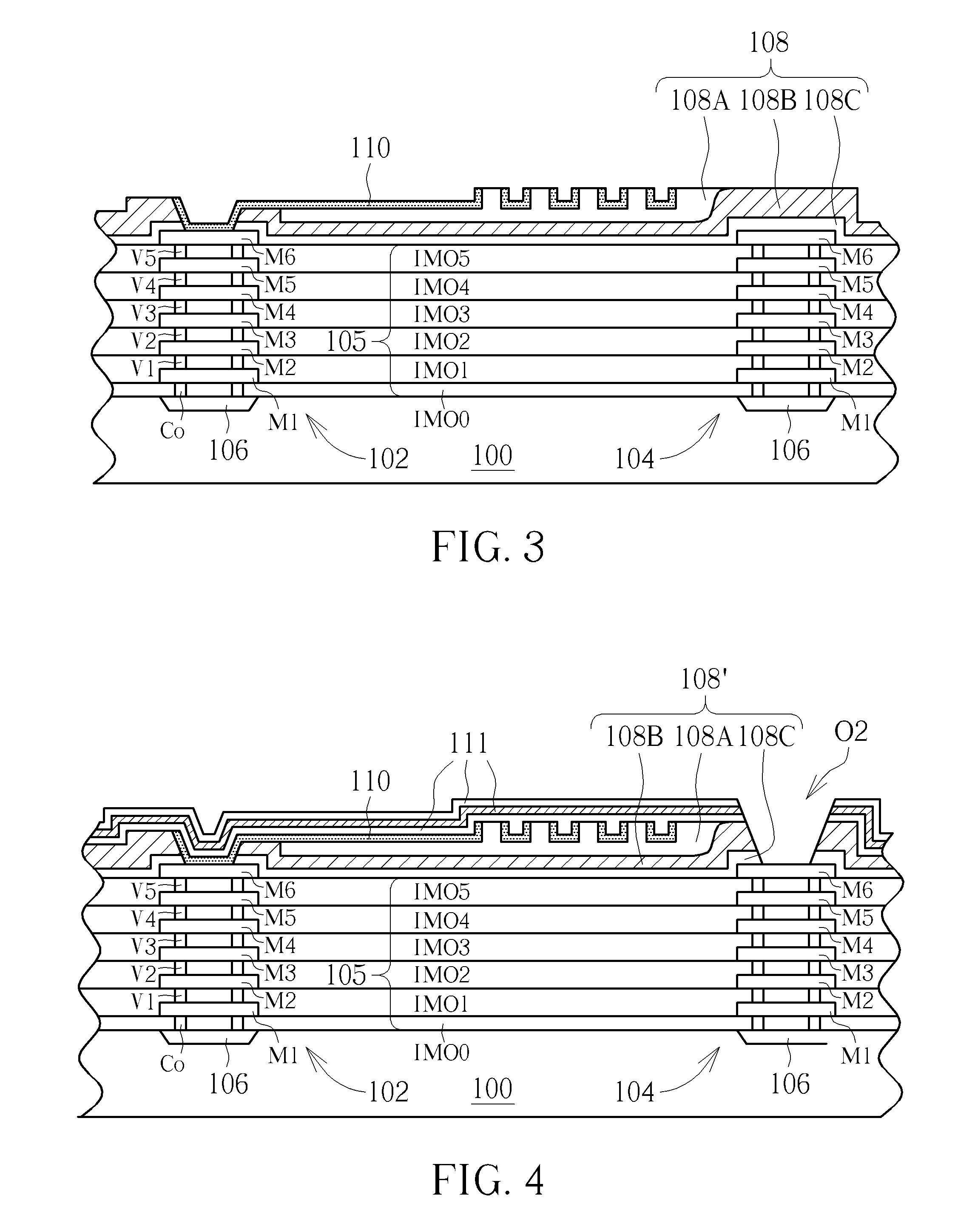

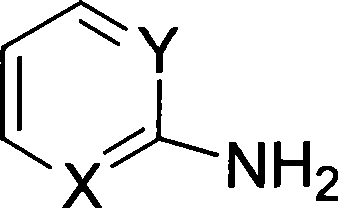

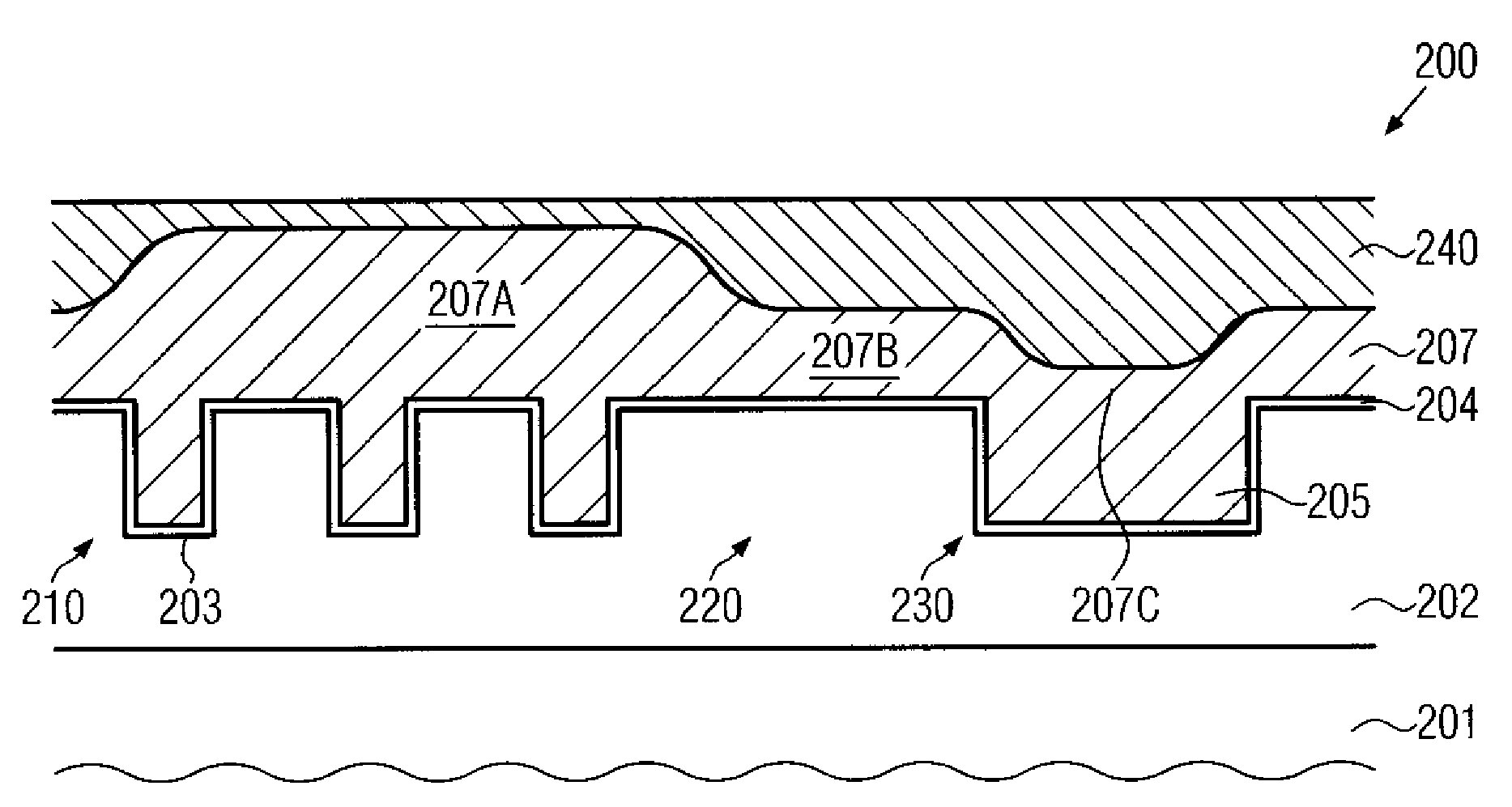

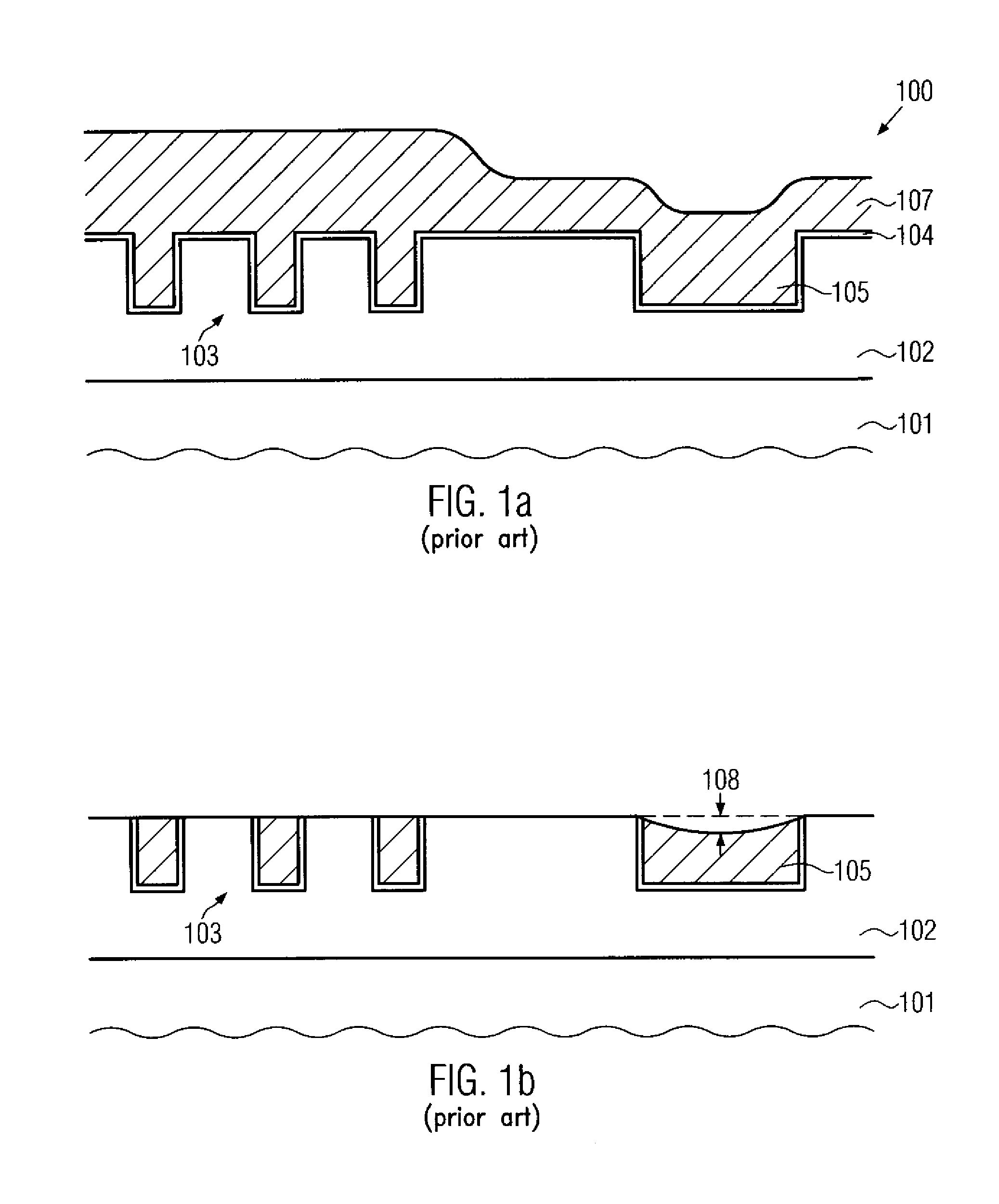

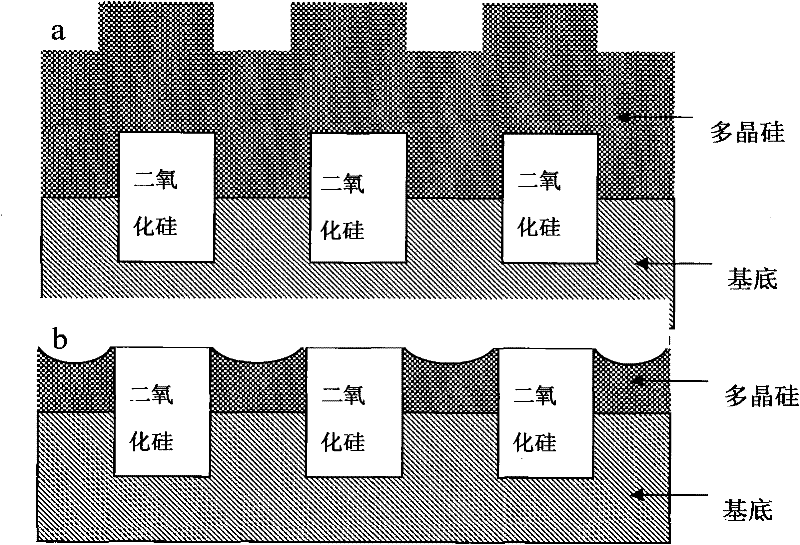

Method of forming an interlayer dielectric material having different removal rates during cmp

ActiveUS20090170319A1Reduced removal rateReduce removal rateDecorative surface effectsSemiconductor/solid-state device manufacturingContact elementDielectric layer

By providing an interlayer dielectric material with different removal rates, a desired minimum material height above gate electrode structures of sophisticated transistor devices of the 65 nm technology or 45 nm technology may be obtained. The reduced removal rate above the gate electrode may thus provide enhanced process robustness during the planarization of the interlayer dielectric layer stack prior to the formation of contact elements.

Owner:GLOBALFOUNDRIES US INC

Chemical mechanical polishing slurry

InactiveUS6855267B2Reduced removal rateRemoval ratePigmenting treatmentOther chemical processesPh controlCompound (substance)

A polishing slurry including an abrasive, deionized water, a pH controlling agent, and polyethylene imine, can control the removal rates of a silicon oxide layer and a silicon nitride layer which are simultaneously exposed during chemical mechanical polishing (CMP) of a conductive layer. A relative ratio of the removal rate of the silicon oxide layer to that of the silicon nitride layer can be controlled by controlling an amount of the choline derivative.

Owner:SAMSUNG ELECTRONICS CO LTD

Chemical mechanical polishing material for barrier layer

ActiveCN1955212AReduce dosageReduced removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesMetallic materialsCopolymer

This invention discloses a chemical mechanical polishing starch material that is used for barrier layer. It includes grinded particle, organic Phosphonic acid, polyacrylic acids and / or its salts and / or polyacrylic acids copolymer, oxidizing agent and carrying agent. The chemical mechanical polishing starch material of this invention can prevent corrosion of part or entirety of metallic material, reduce surface contamination of lining bottom, cut down content of grinded bead, raise tantalum removal velocity and cupric removal velocity, thus obtain polishing selectivity of different basal body.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

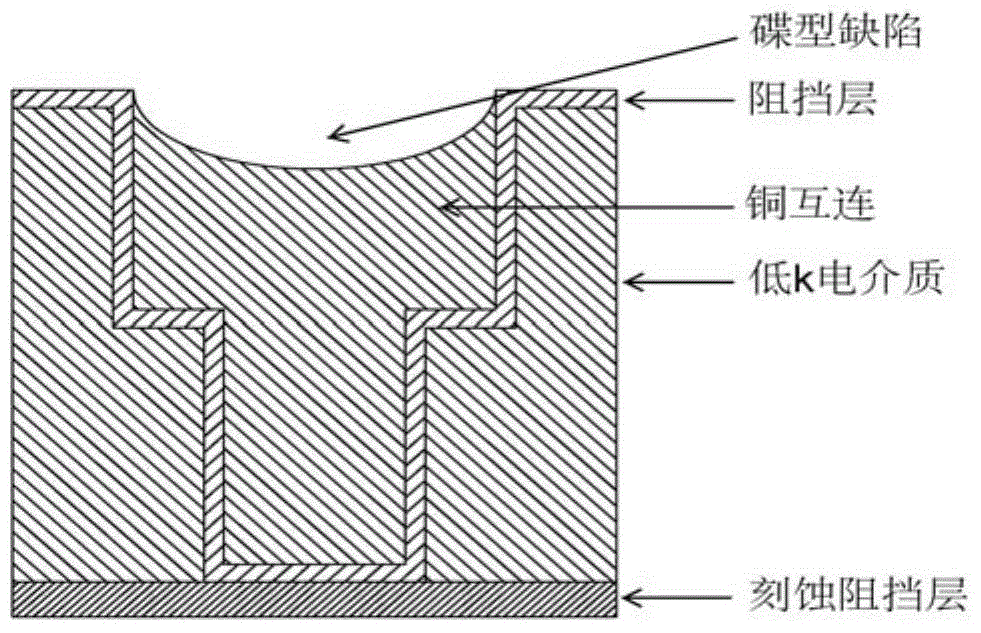

Metal chemical mechanical polishing slurry

The invention provides a slurry used for copper chemical mechanical polishing and application thereof. The slurry comprises: (a) grinding particles, (b) complexing agents, (c) oxidants, (d) corrosion inhibitors, and (e) phosphate ester surface active agents. The use of the slurry provided in the invention can maintain a high removal rate of copper and improve the defects such as butterfly recesses and over-throwing windows of the polished copper wire, and the polished copper surface has few contaminants and no corrosion.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Chemical-mechanical polishing liquid

ActiveCN102559058AGood stabilityReduce scratchesPolishing compositions with abrasivesChemistryPollutant

The invention discloses polishing liquid used for a shallow trench isolation polishing process. The polishing liquid contains silicon-based abrasive, anion type surfactant and water. The polishing liquid has higher removing rate of high-density silicon dioxide (HDP-Oxide) and higher selection ratio to the removing rate of silicon nitride. A polished crystal circle has perfect surface appearance and lower surface pollutant residue.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

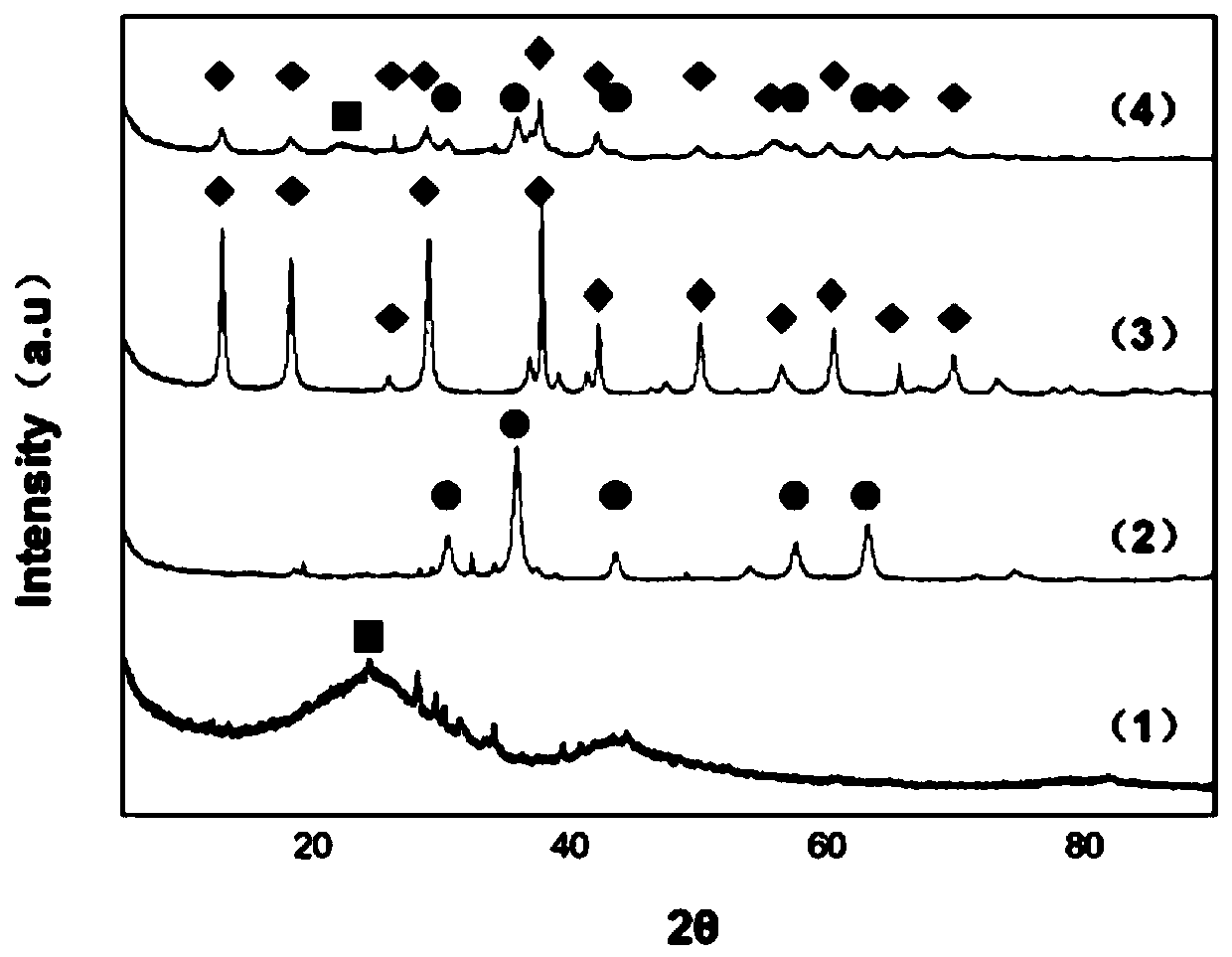

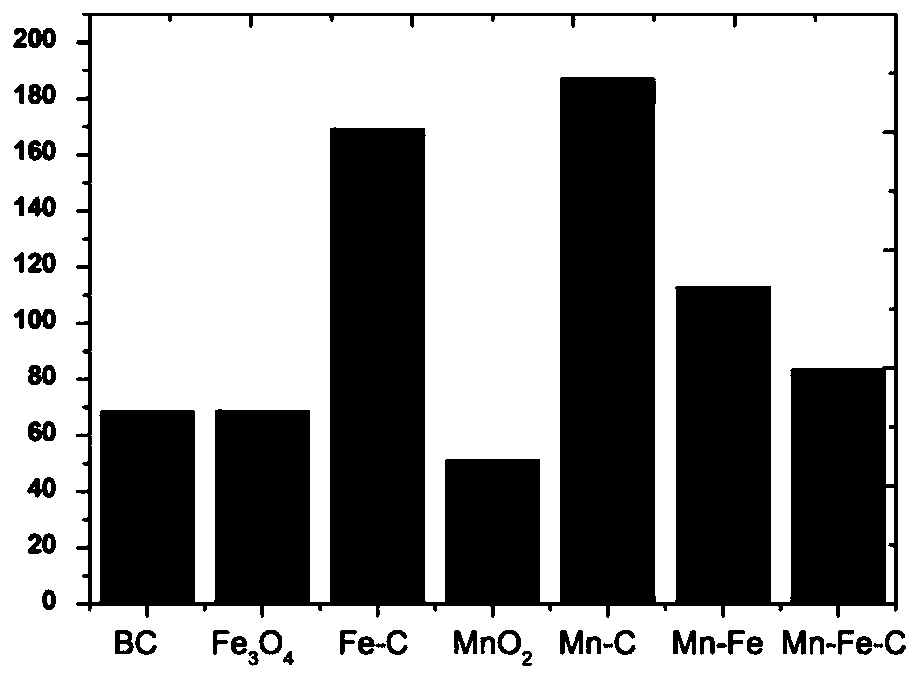

Manganese dioxide-magnetic biochar composite catalyst as well as preparation method and application thereof

ActiveCN110665512AImprove removal rateShortened migration pathwayWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFerrous salts

The invention discloses a manganese dioxide-magnetic biochar composite catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: 1) pyrolyzing biomass under anaerobic or oxygen-limited conditions to generate biochar, washing with water and alcohol for three times respectively, drying, grinding and sieving; 2) uniformly stirring a ferricsalt and a ferrous salt in an aqueous solution, then adding the prepared biochar, and then adding an alkali liquor; under heating, conveying an obtained coprecipitate into ferroferric oxide, and obtaining magnetic biochar; washing with watert for three times, drying, grinding and sieving; 3) adding the magnetic biochar into a manganese salt solution, and uniformly stirring; then adding a potassium permanganate solution, uniformly mixing and heating at a high temperature for a period of time. The method is simple in process, low in cost, and is capable of achieving large-scale industrial production. The prepared manganese dioxide-magnetic biochar composite catalyst is excellent in catalytic performance, can be applied to degradation and removal of various pollutants, is easy to recycle, and is an efficient catalyst.

Owner:ZHEJIANG UNIV

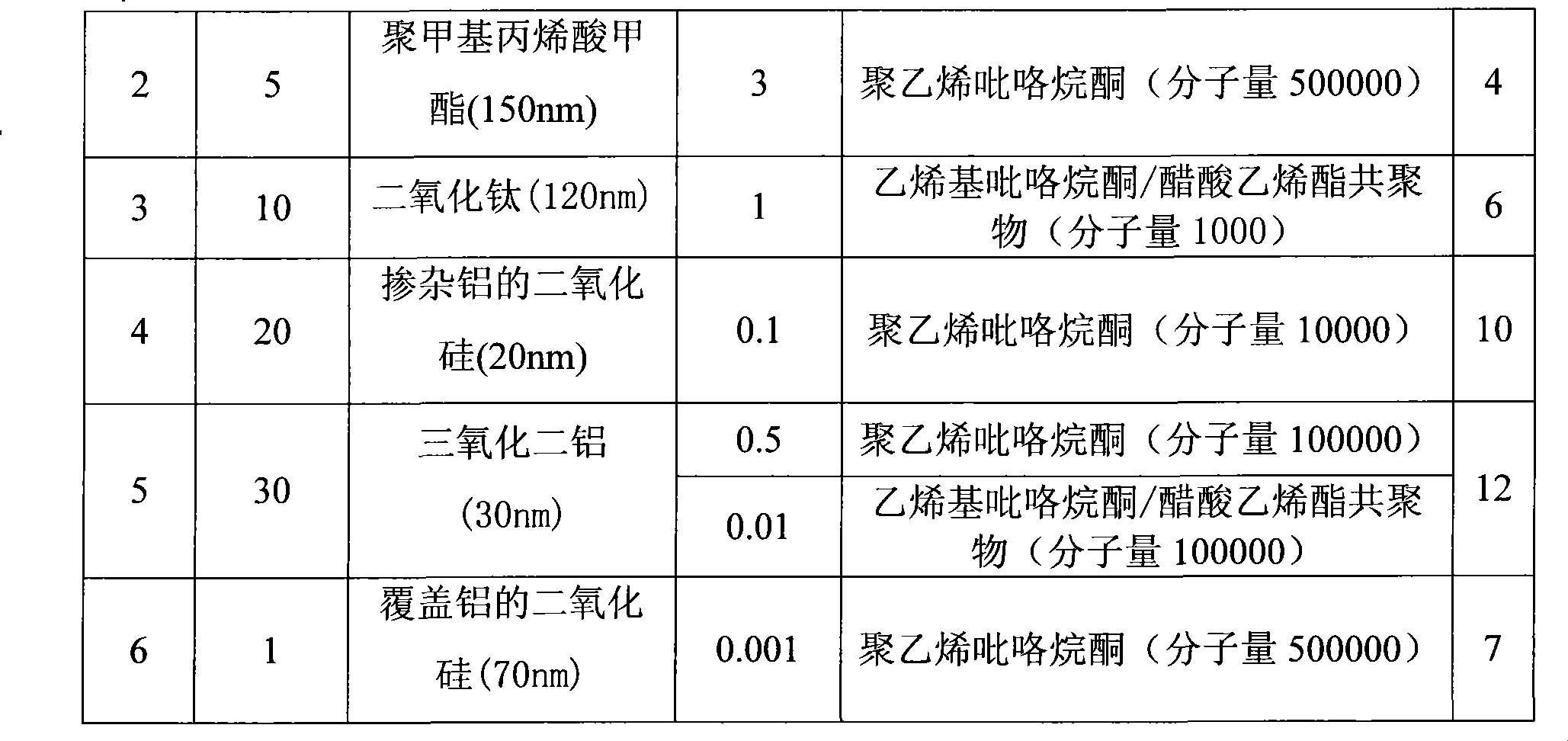

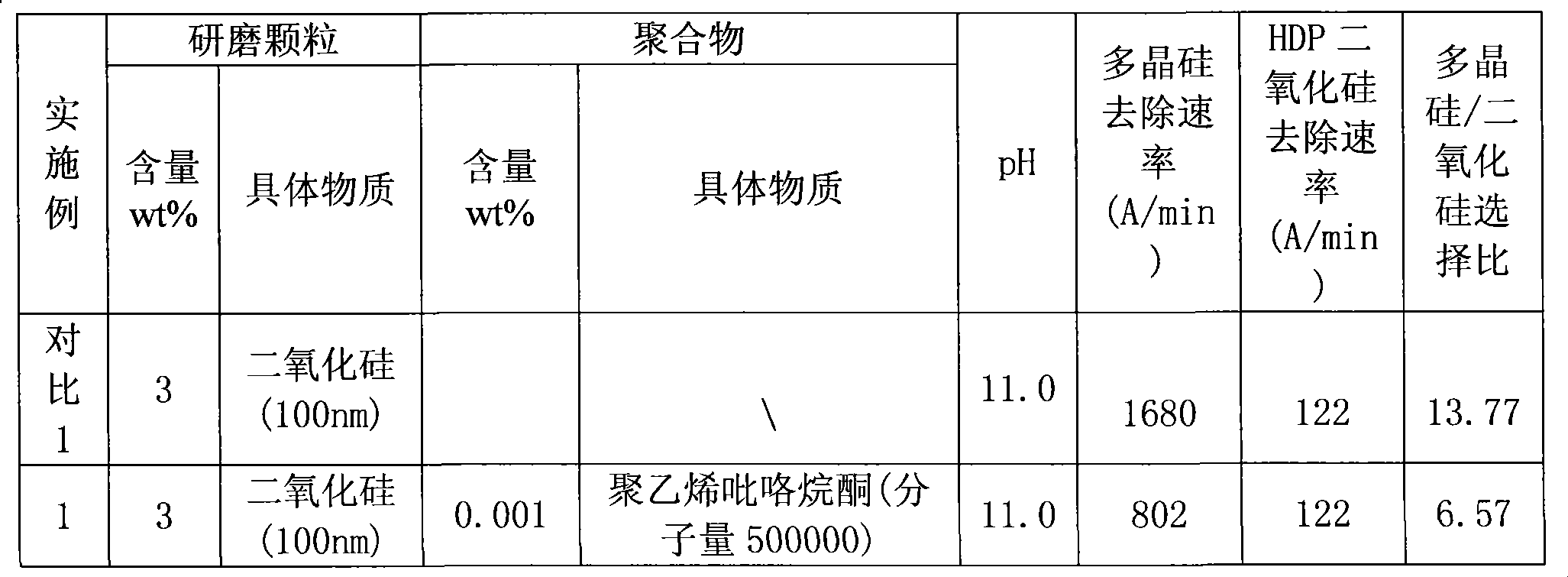

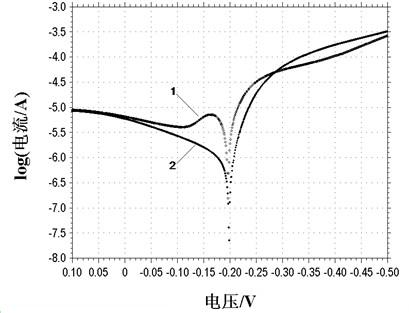

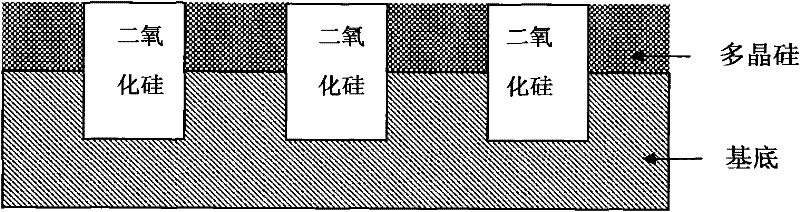

Chemico-mechanical polishing liquid

ActiveCN101457126AReduced removal rateImprove planarization efficiencyPolishing compositions with abrasives2-PyrrolidoneSilicon dioxide

The present invention discloses a chemical machinery polishing solution which contains seat grinding granule and water, and n-vinyl-2-pyrrolidone polymeric compound. The polishing solution provided in the invention has low polycrystalline silicon removal rate, and removal rate selection ratio between polycrystalline silicon and silicon dioxide, which can reduce depression and improve plainness efficiency of polycrystalline silicon significantly.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

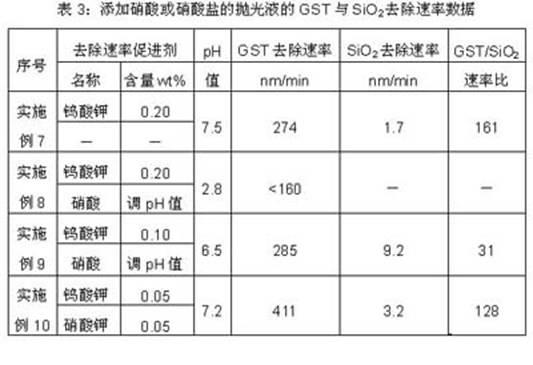

Chemical mechanical polishing liquid for polishing alloy phase change materials

ActiveCN102559056AImprove removal rateReduced removal ratePolishing compositions with abrasivesCorrosionPhase-change material

The invention discloses a chemical mechanical polishing liquid for polishing alloy phase change materials. The polishing liquid contains water, ground particles, an oxidant and a removal rate accelerator, wherein the removal rate accelerator is one ore more kinds of soluble compounds containing tungsten. In the invention, through adding the optimized removal rate accelerator in the polishing liquid, the lower SiO2 removal rate is remained while the removal rate of GST (germanium-stibonium-tellurium) alloy is increased, and the static corrosion of the polishing liquid on the GST material is remained at a lower level.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Barrier polishing solution

ActiveCN1696235AReduced removal rateLimited dielectric erosionOther chemical processesSemiconductor/solid-state device manufacturingDielectricAbrasive agent

The polishing solution is useful for preferentially removing barrier materials in the presence of nonferrous interconnect metals with limited erosion of dielectrics. The polishing solution comprises 0 to 20 weight percent oxidizer, at least 0.001 weight percent inhibitor for reducing removal rate of the nonferrous interconnect metals, 10 ppb to 4 weight percent complexing agent, 0 to 50 weight percent abrasive and balance water; and the solution having a pH of less than 7.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemico-mechanical polishing liquid

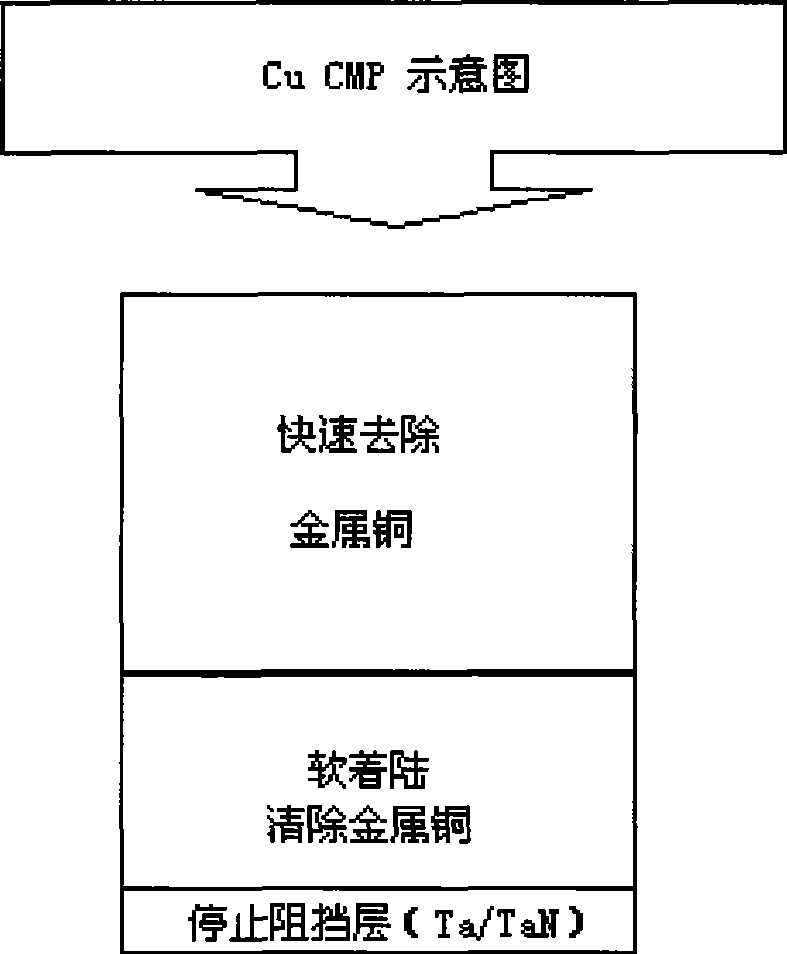

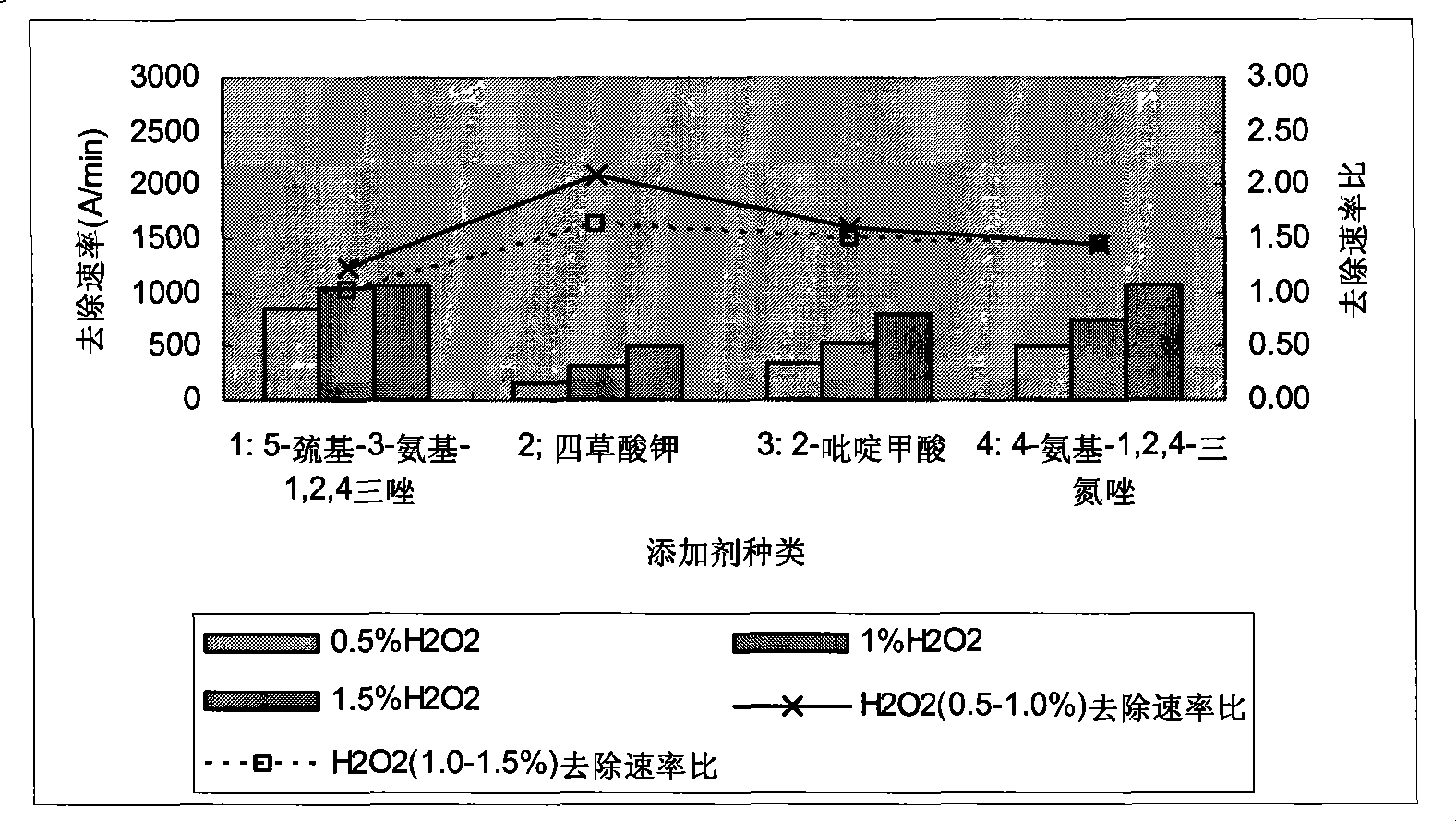

InactiveCN101418187AReduce sensitivityReduced removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCopperPyridine

The invention discloses a chemical-mechanical polishing solution, which is characterized by comprising an abrading agent, an oxidizer, water and the following one or more complexing agents: triazole ring containing sulfydryl, triazoles compound the active nitrogen atom of which contains donative electron substituent, pyridine ring containing carboxyl and oxalate. Cu removing rate of the polishingsolution has low sensitivity to concentration change of oxyful contained in the polishing solution. After the polishing solution is adopted for polishing, the copper has smooth surface and good surface topography.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemically mechanical polishing solution

InactiveCN102533125AIncreased process windowProcess window widthPolishing compositions with abrasivesSilicon dioxideMineralogy

The invention discloses a novel chemically mechanical polishing solution for polycrystal silicon. The novel chemically mechanical polishing solution comprises grinding particles, at least one azoles compound and at least one polyalcohol nonionic surfactant. The novel chemically mechanical polishing solution can be used for adjusting the selection rate between the polycrystal silicon and silicon dioxide and remarkably improving the polarization efficiency of the polycrystal silicon.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Method of patterning platinum layer

ActiveUS20150037974A1Reduce polymer residue formationRemoval rateDecorative surface effectsSemiconductor/solid-state device manufacturingPlatinumChloride

A method of patterning a platinum layer includes the following steps. A substrate is provided. A platinum layer is formed on the substrate. An etching process is performed to pattern the platinum layer, wherein an etchant used in the etching process simultaneously includes at least a chloride-containing gas and at least a fluoride-containing gas.

Owner:UNITED MICROELECTRONICS CORP

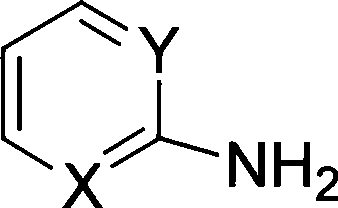

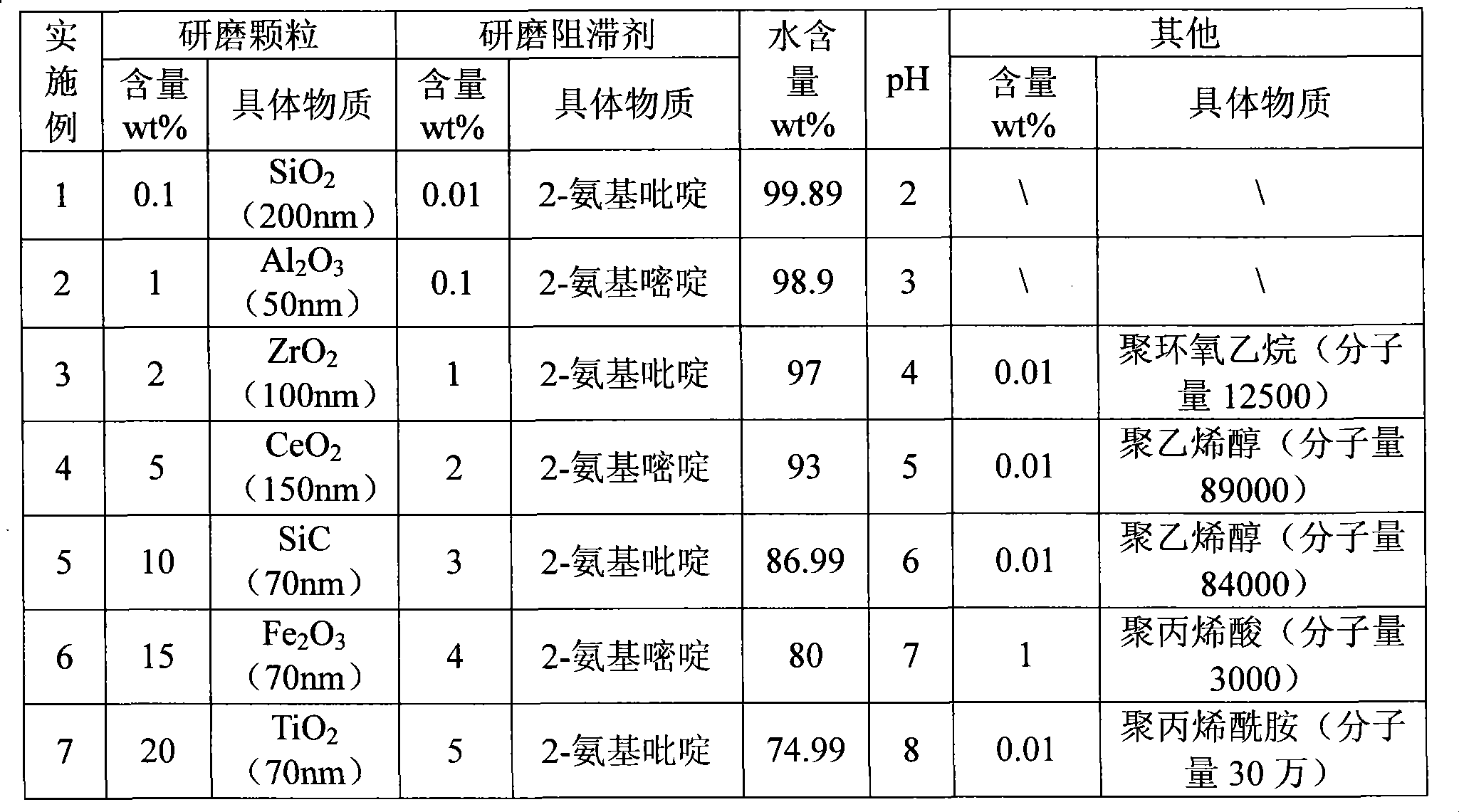

Chemico-mechanical polishing liquid

InactiveCN101457125AReduced removal rateThe removal rate does not affectSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxidePolycrystalline silicon

The present invention discloses a chemical machinery polishing solution which contains seat grinding granule and water, and seat grinding blocker like described in Formula I, wherein X and Y alone is C or N. The polishing solution provided in the invention can reduce polycrystalline silicon removal rate without effecting silicon dioxide removal rate, and can reduce depression caused by differencebetween removal rate of polycrystalline silicon and silicon dioxide in the process of polishing obviously, hence improve plainness of wafer surface.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemi-mechanical polishing fluid for polishing semiconductor wafer

ActiveCN102533123AChange the removal rateAdjust the selection ratioSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxideSURFACTANT BLEND

The invention provides a chemi-mechanical polishing fluid for polishing a semiconductor wafer, which is prepared from the following components in percentage by weight: 0.2-5% of acidic pH regulator, 0.01-5% of piperidine nitroxide free radical, 0.1-15% of surfactant, 0.5-20% of grinding particle and the balance of water. The polishing fluid provided by the invention can obviously change the removal rate of silicon nitride under acidic conditions, can regulate the selection ratio of silicon dioxide to silicon nitride, and has the advantages of simple preparation technique, high polishing precision and the like.

Owner:SHANGHAI HUAMING HI TECH GRP

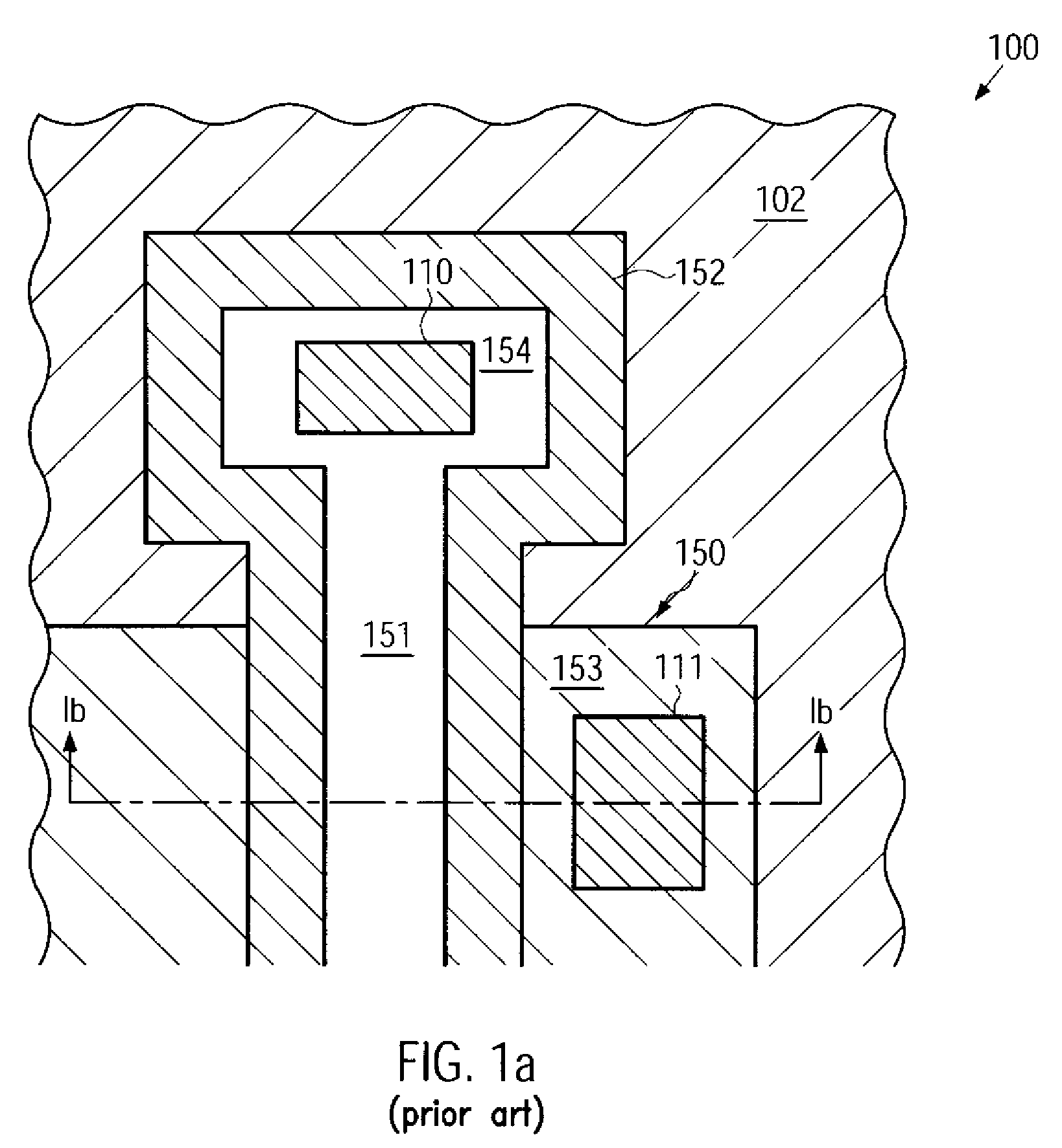

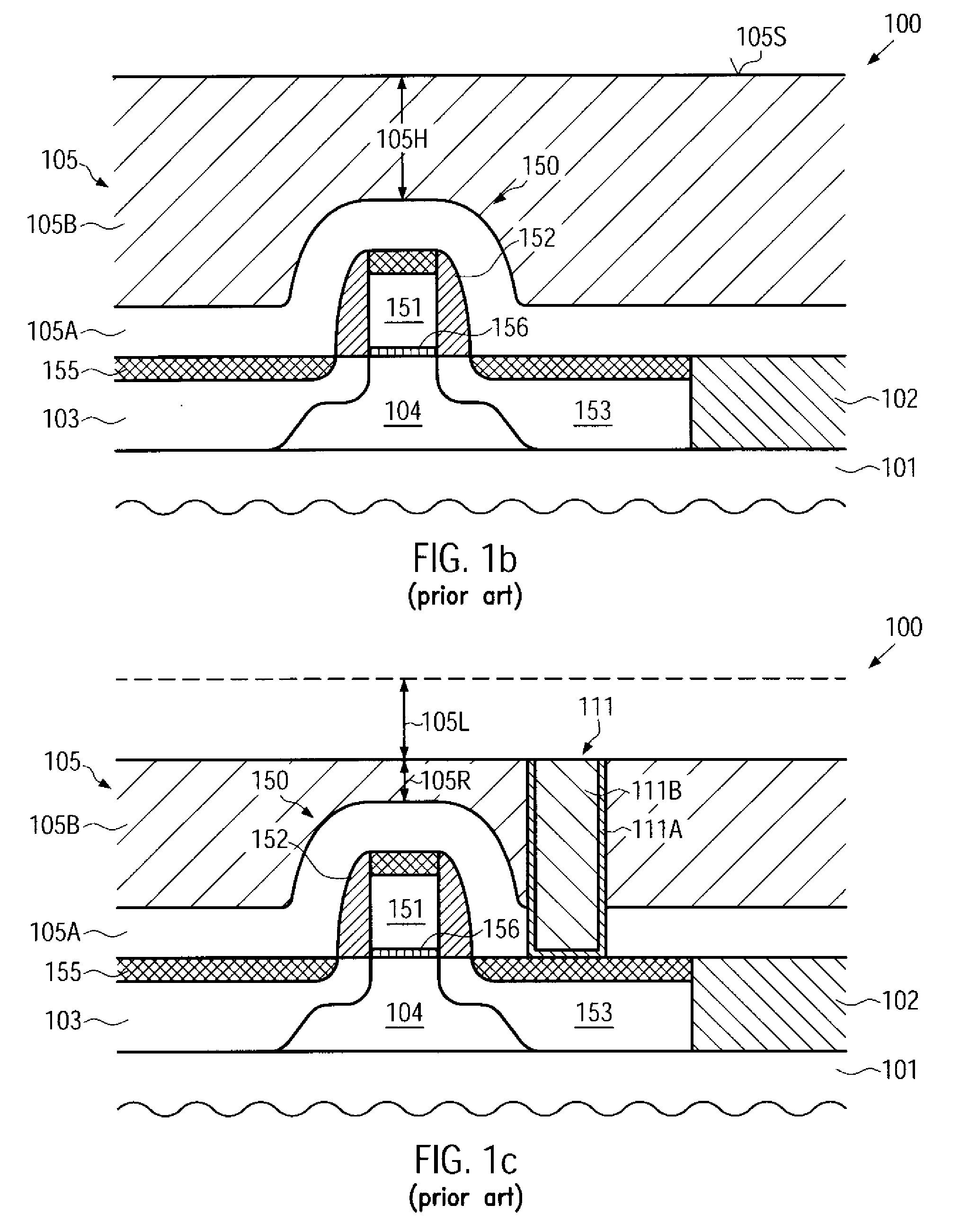

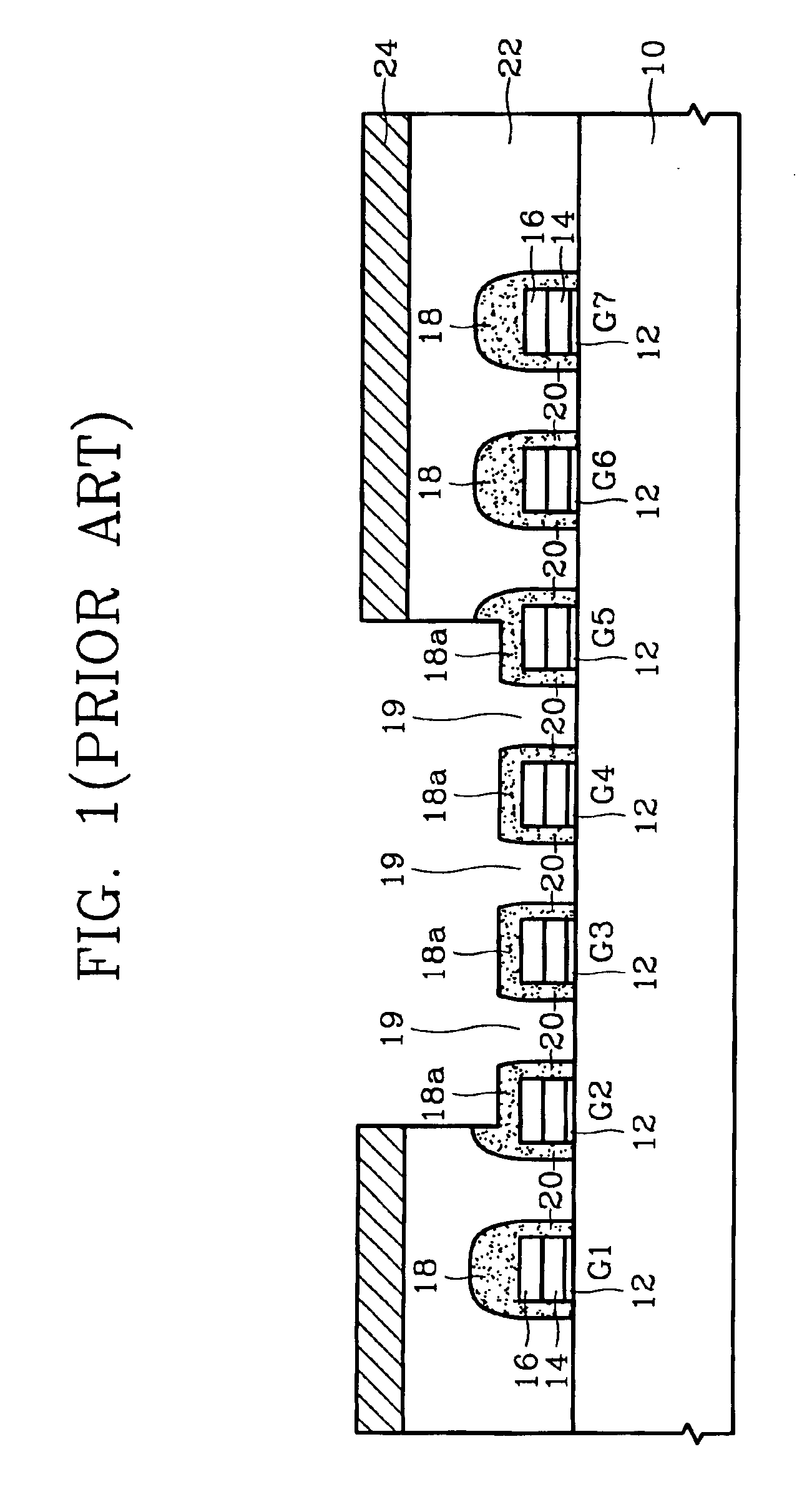

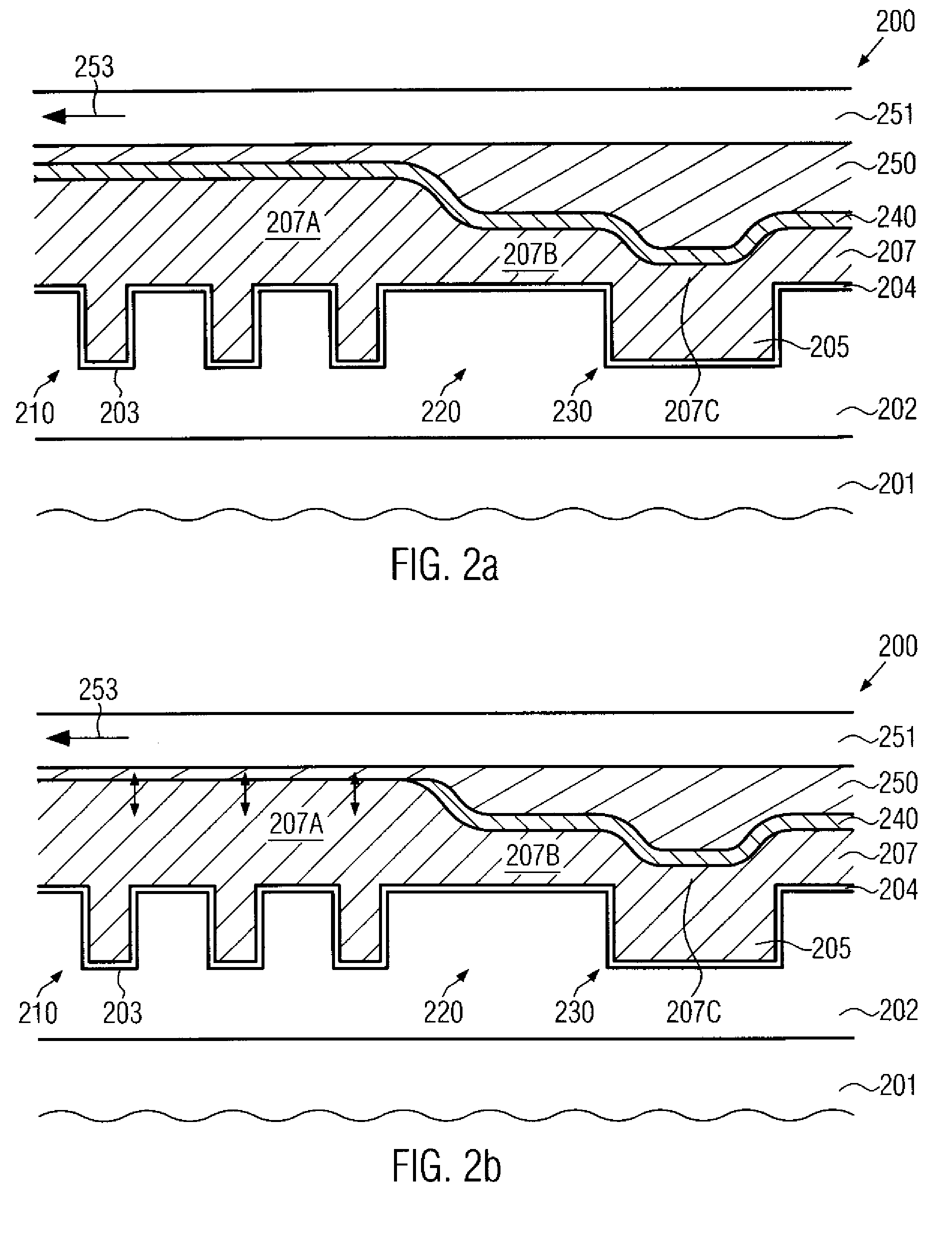

Method of reducing non-uniformities during chemical mechanical polishing of excess metal in a metallization level of microstructure devices

InactiveUS20080206994A1Reduced height levelHigh removal rateSemiconductor/solid-state device manufacturingChemical reactionSlurry

Prior to performing a CMP process for planarizing a metallization level of an advanced semiconductor device, an appropriate cap layer may be formed in order to delay the exposure of metal areas of reduced height level to the highly chemically reactive slurry material. Consequently, metal of increased height level may be polished with a high removal rate due to the mechanical and the chemical action of the slurry material, while the chemical interaction with the slurry material may be substantially avoided in areas of reduced height level. Therefore, a high process uniformity may be achieved even for pronounced initial surface topographies and slurry materials having a component of high chemical reactivity.

Owner:ALSEPHINA INNOVATIONS INC

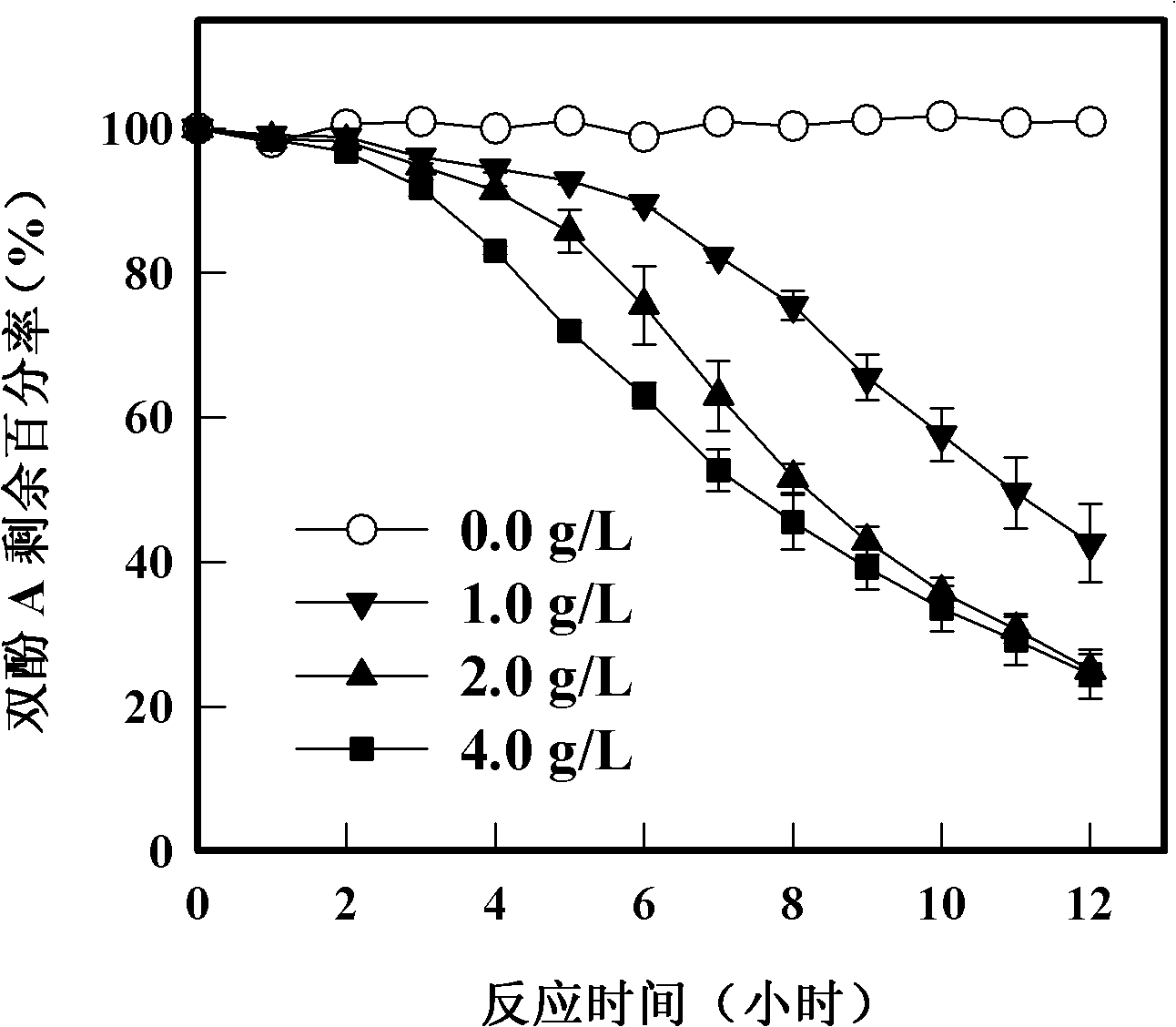

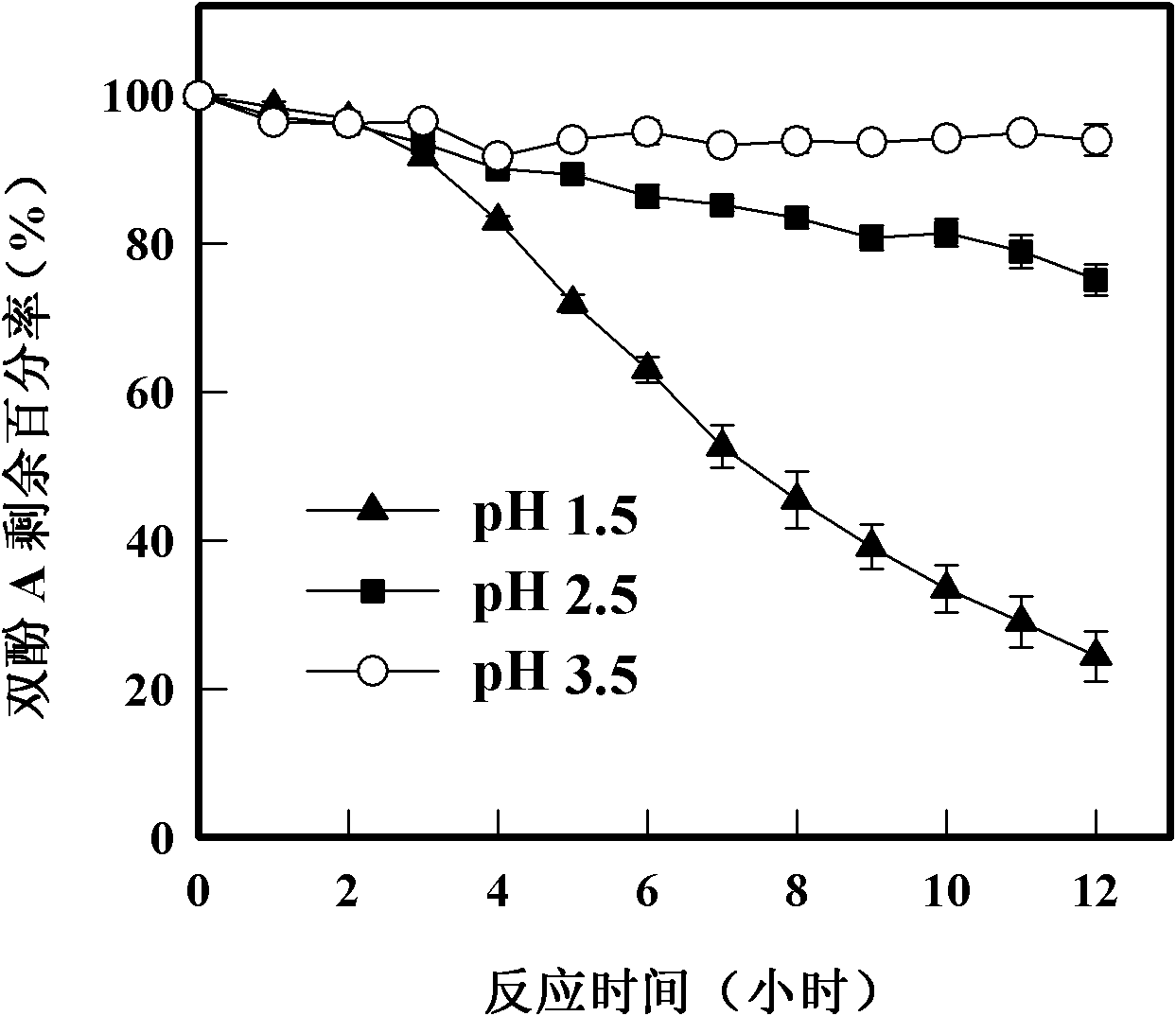

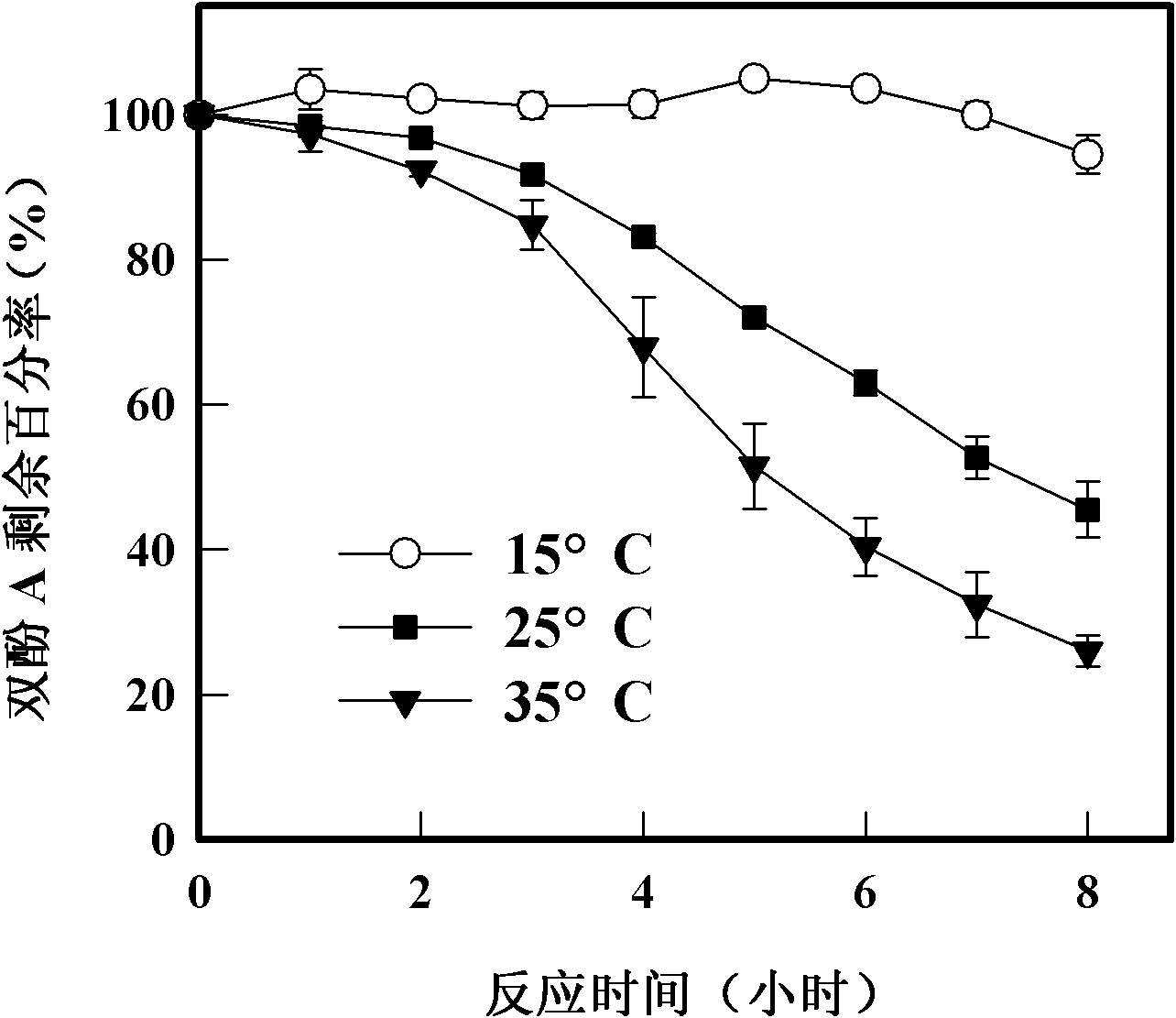

Method for treating bisphenol A-containing wastewater

InactiveCN101962237AReduce consumptionGood removal effectWater contaminantsMultistage water/sewage treatmentReaction temperatureWastewater

The invention provides a method for treating bisphenol A-containing wastewater. The method comprises the following steps of: adjusting pH of the bisphenol A-containing wastewater to be less than 3.5 with acid; adding 1 to 10g of aluminum powder into every liter of wastewater; and reacting the mixture at the temperature of between 20 and 40 DEG C under the condition of stirring or auxiliary aeration for 4 to 12 hours to obtain the treated wastewater. The method has the main advantages that: the method is used for treating the bisphenol A-containing wastewater, the removal effect is obvious and the removal rate of the bisphenol A is over 95 percent within 8 hours under the conditions that the reaction temperature is 25 DEG C, the initial pH is 1.5, bisphenol A concentration is 2.0mg / L and aluminum powder content is 4.0g / L; in addition, if the temperature is raised, the removal rate is obviously enhanced. The method is simple to operate, and has the advantages of low cost, low energy consumption, good treatment effect and the like.

Owner:ZHEJIANG UNIV OF TECH

Chemical Mechanical Polishing Process for Planarizing Copper Surface

InactiveUS20080264901A1Simple processReduce manufacturing costDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Copper

Disclosed is a chemical mechanical polishing planarization method for copper surface, including the following steps: depositing a dielectric layer on the copper surface, and polishing the copper surface having the dielectric layer thereon. The method for planarizing a copper surface by chemical mechanical polishing process according to the present invention can achieve the planarization of the surfaces of both the copper and the dielectric layer, so as to avoid the occurrence of the dishing phenomenon.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Chemi-mechanical polishing fluid

InactiveCN102533120AReduced removal rateLower selection ratioSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSilicon dioxideSilicon

The invention relates to a polishing fluid for chemi-mechanically polishing silicon. The polishing fluid contains water, grinding particles, at least one silicon accelerator and at least one silicon inhibitor. The amounts of the silicon accelerator and the silicon inhibitor can be adjusted to adjust the selection ratio of silicon to silicon dioxide, thereby enhancing the flattening efficiency.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

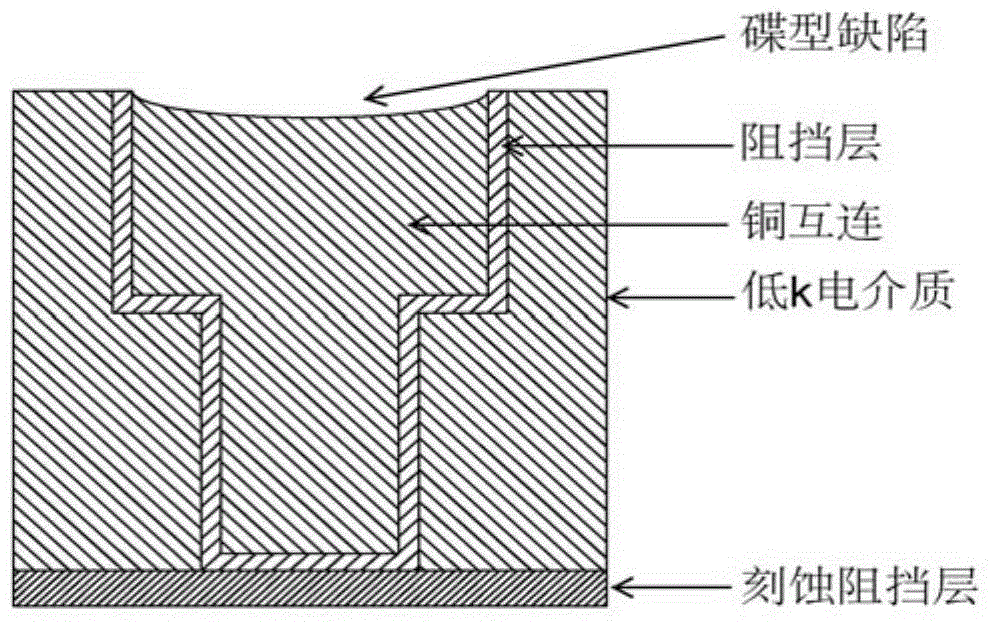

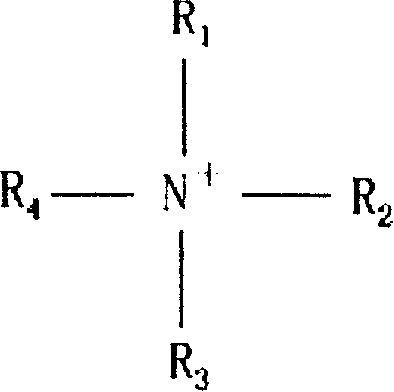

Chemical mechanical polishing solution

InactiveCN102464947AReduced removal rateImprove removal ratePolishing compositions with abrasivesOrganic acidCompound (substance)

The invention discloses a chemical mechanical polishing solution, which comprises grinding particles, a metal corrosion inhibitor, an organic acid, an oxidant, water and one or more quaternary ammonium salt cationic surfactants. The polishing solution plays a role in increasing the polishing rate of a low-dielectric material, but has no remarkable influence on the polishing rates of tantalum and copper, so that the polishing selectivity of a substrate material can be enhanced greatly.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

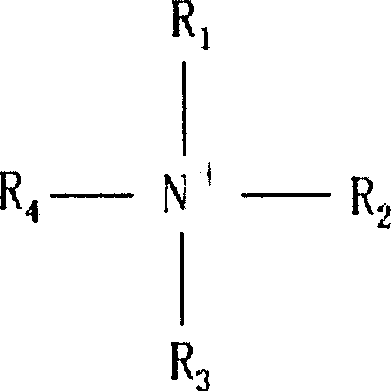

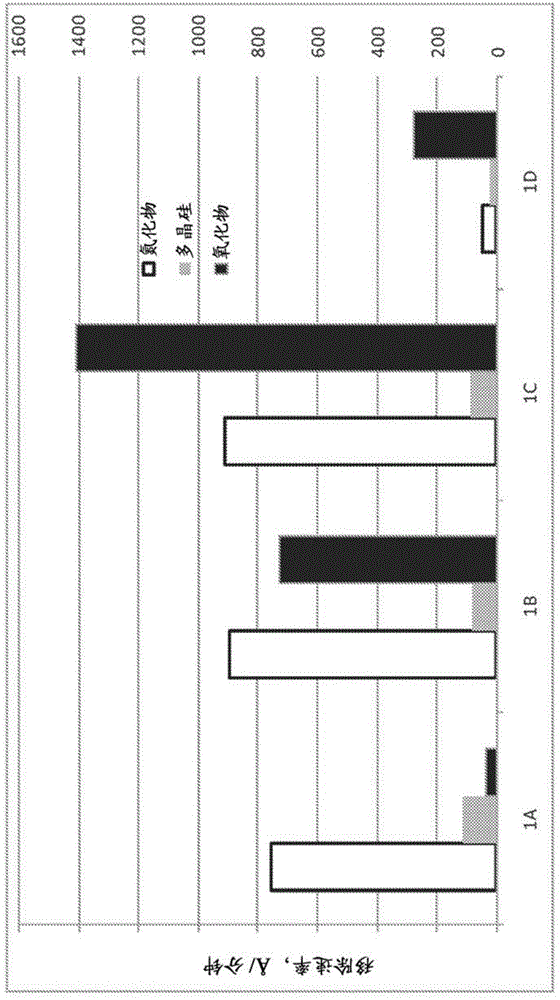

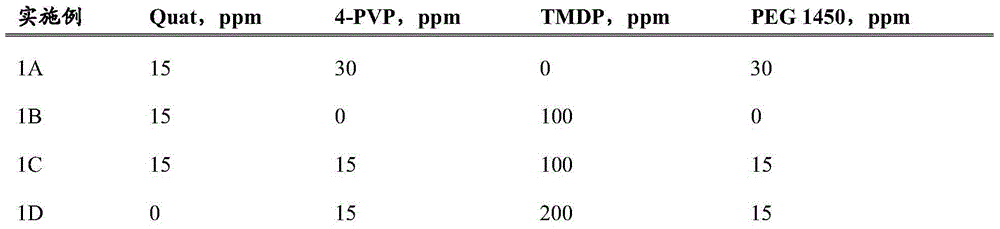

Compositions and methods for selective polishing of silicon nitride materials

ActiveCN104471015AImprove removal rateReduced removal rateOther chemical processesSemiconductor/solid-state device manufacturingParticulatesCerium(IV) oxide

The present invention provides an acidic aqueous polishing composition suitable for polishing a silicon nitride-containing substrate in a chemical-mechanical polishing (CMP) process. The composition, at point of use, preferably comprises 0.01 to 2 percent by weight of at least one particulate ceria abrasive, 10 to 1000 ppm of at least one non-polymeric unsaturated nitrogen heterocycle compound, 0 to 1000 ppm of at least one cationic polymer, optionally, 0 to 2000 ppm of at least one polyoxyalkylene polymer, and an aqueous carrier therefor. The cationic polymer preferably is selected from a poly(vinylpyridine) polymer, a quaternary ammonium-substituted acrylate polymer, a quaternary ammonium-substituted methacrylate polymer, or a combination thereof. Methods of polishing substrates and of selectively removing silicon nitride from a substrate in preference to removal of polysilicon using the compositions are also provided.

Owner:CMC MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com