Compositions and methods for selective polishing of silicon nitride materials

A nitrogen heterocyclic compound and composition technology, applied in the field of polishing compositions, can solve the problems of structural complexity and changes in performance characteristics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

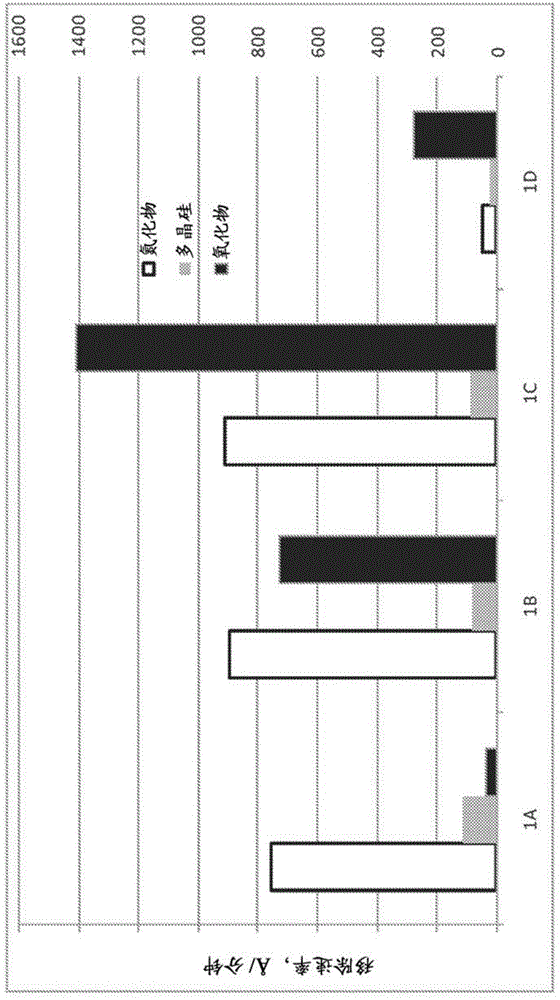

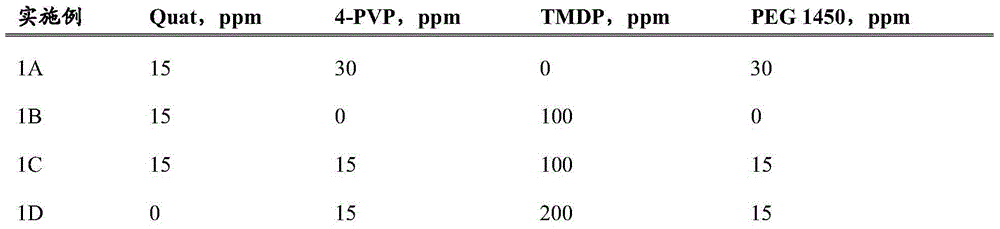

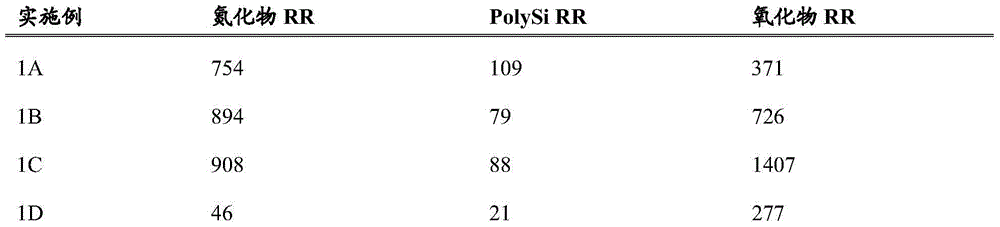

[0044] This example describes the effect of cationic polymers and non-polymeric UNH compounds on the removal of silicon nitride, polysilicon and silicon oxide.

[0045] The polishing compositions were used to chemical mechanically polish silicon nitride, silicon oxide, and polysilicon blanket wafers, respectively, on a Mirra 200 mm CMP apparatus with a D100 polishing pad. Each polishing composition contained 0.2% by weight of an aqueous slurry (in deionized water at a pH of 4). Other components of the CMP composition are shown in Table 1, where "Quat" represents poly(methacryloxyethyltrimethylammonium chloride) from Alco Chemical (Alco 4773); p(4-PV) stands for poly(4-vinylpyridine); TMDP stands for 4,4'-trimethylenedipyridine; and PEG 1450 stands for poly(ethylene glycol) with a number average molecular weight of 1450 Daltons.

[0046] Table 1

[0047]

[0048] Each composition was used individually to polish 200 mm diameter blanket wafers of silicon nitride, polysilico...

Embodiment 2

[0053] Under the following conditions, when having Evaluations of other formulations lacking poly(4-vinylpyridine) were performed on a Mirra polisher of the pad: downforce 3 psi, head speed (HS) 101 rpm, platen speed (PS) 100 rpm, and slurry flow rate 150 ml / min. Each test composition was prepared as in Example 1 using calcined ceria in deionized water and had a pH of 4. The concentrations of the various components of the formulations are shown in Table 3, while the observed polishing rates in Angstroms / minute for nitride, polysilicon and oxide are shown in Table 4. In each of Table 3 and Table 4, the abbreviations used are the same as those used in Example 1.

[0054] table 3

[0055]

[0056] Table 4

[0057]

[0058] * = mean of two independent runs

[0059] As shown by the data in Table 4, all compositions exhibited high oxide removal rates. The removal rates of the compositions of the invention comprising the quaternary polymer were all greater than 1000 angs...

Embodiment 3

[0061]This example describes the effect of including EP / PO block copolymers in addition to PEG 1450 in the CMP compositions of the invention. Evaluations were performed on a Mirra polisher with a D100 pad under the following conditions: downforce 3 psi, polishing head speed (HS) 101 rpm, platen speed (PS) 100 rpm, and slurry flow rate 150 ml / min. Each test composition was prepared as in Example 1 using calcined ceria in deionized water and had a pH of 4, except that Examples 3K and 3L had a pH of 2.3. The individual component concentrations of the formulations are shown in Table 5, while the observed removal rates for nitride, polysilicon and oxide are shown in Angstroms / min and shown in Table 6. In each of Table 5 and Table 6, L31 represents L31 Surfactant (BASF), and the remaining abbreviations are the same as those used in Example 1.

[0062] table 5

[0063]

[0064] Table 6

[0065]

[0066] The results in Table 6 demonstrate a high degree of removal selectivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com