Patents

Literature

209results about How to "Increase the rate of chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

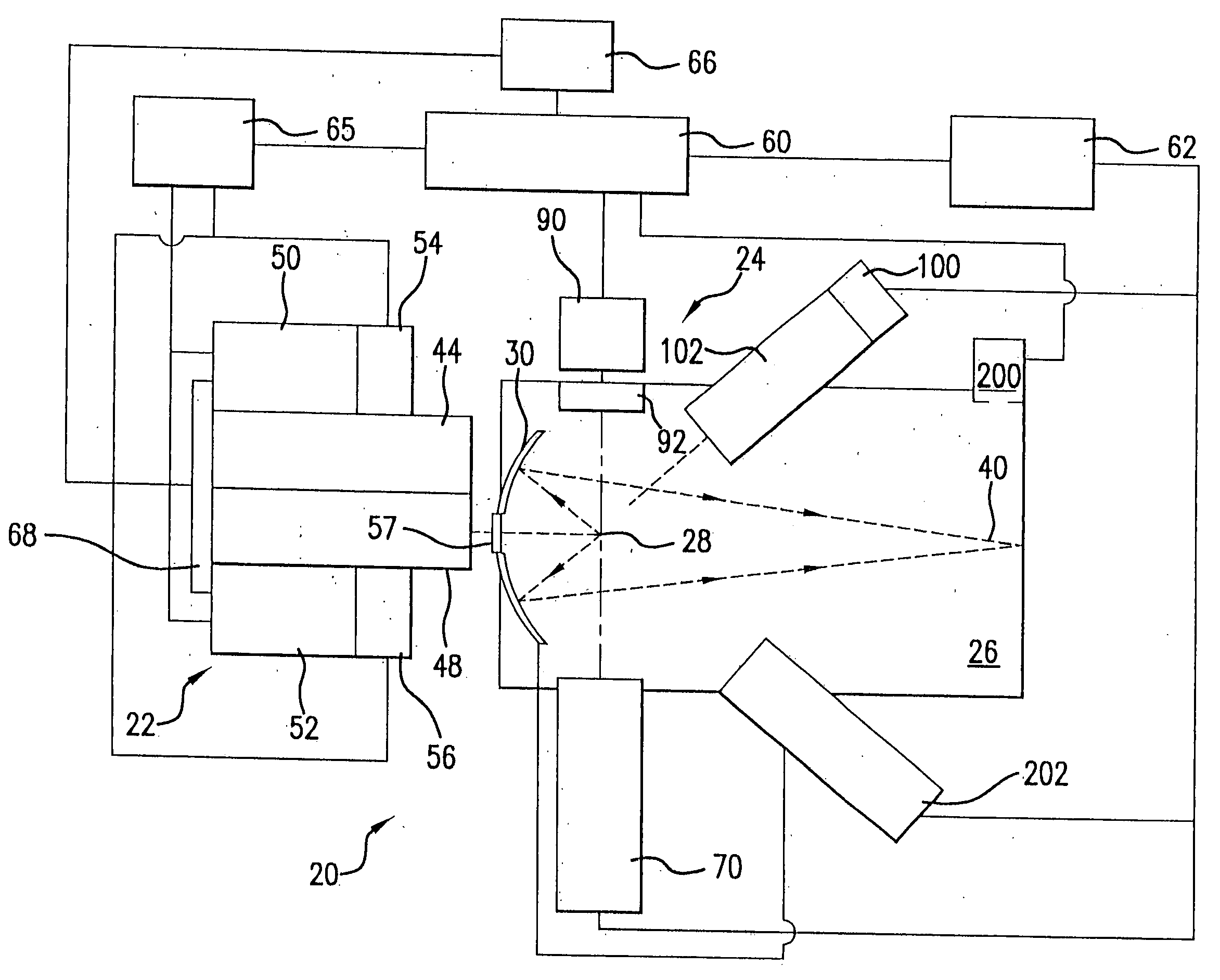

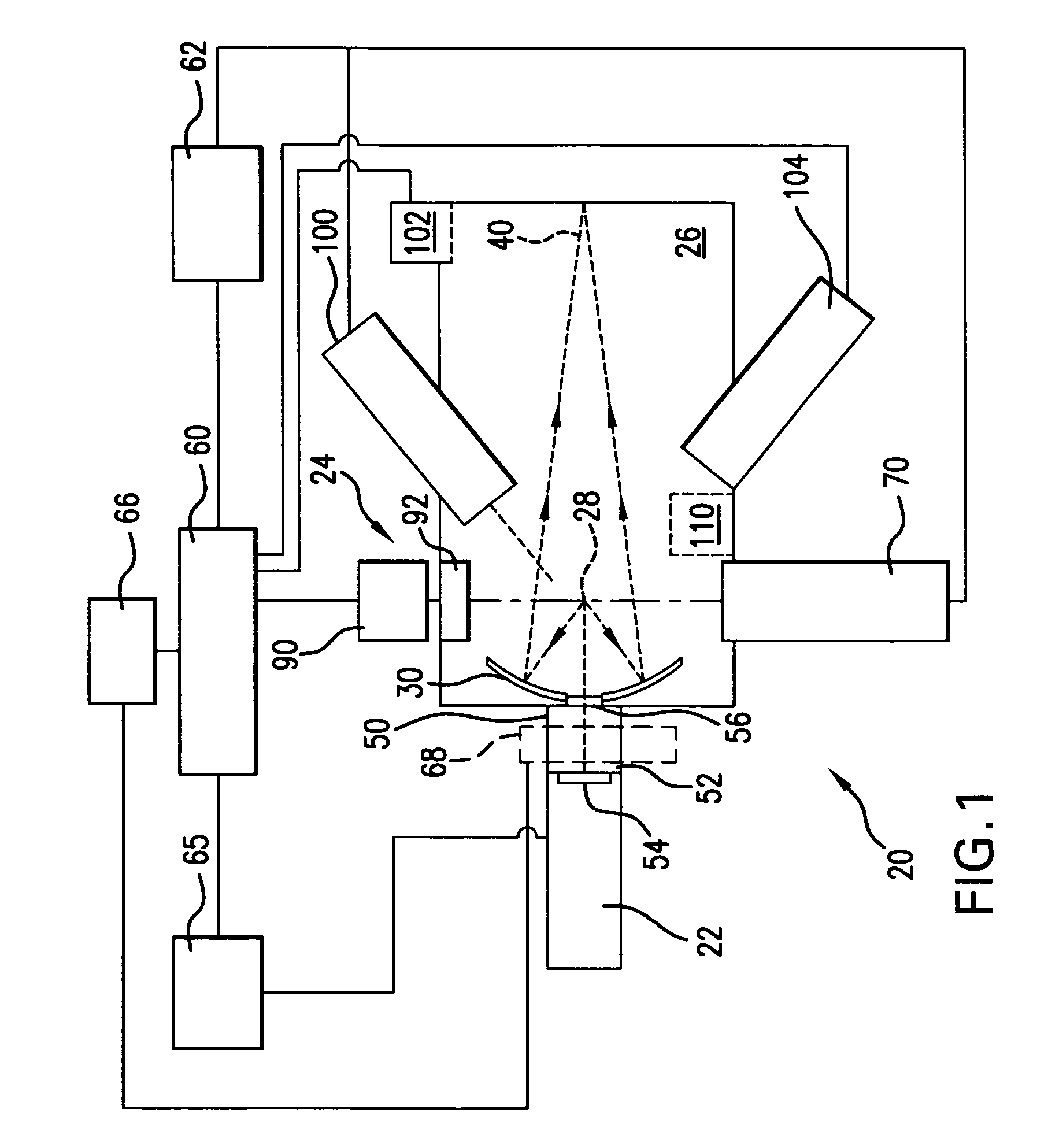

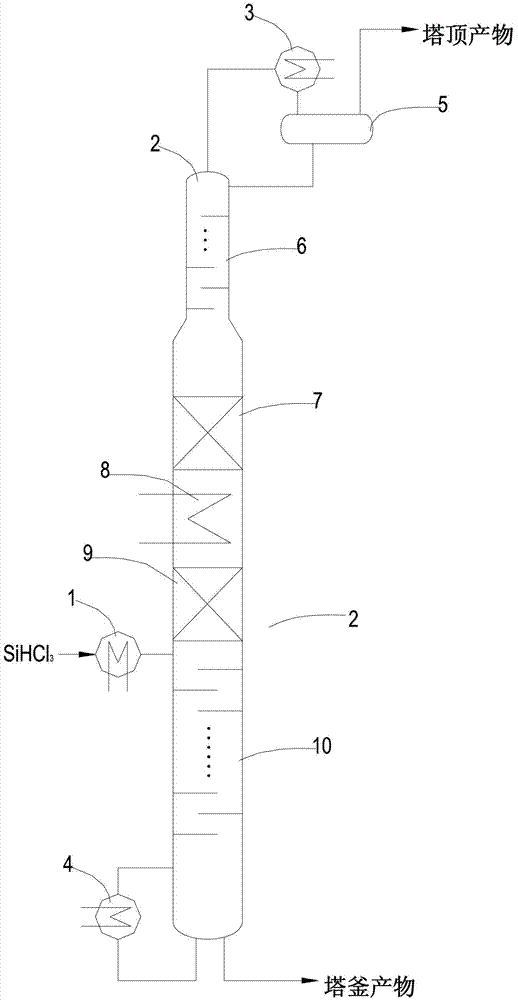

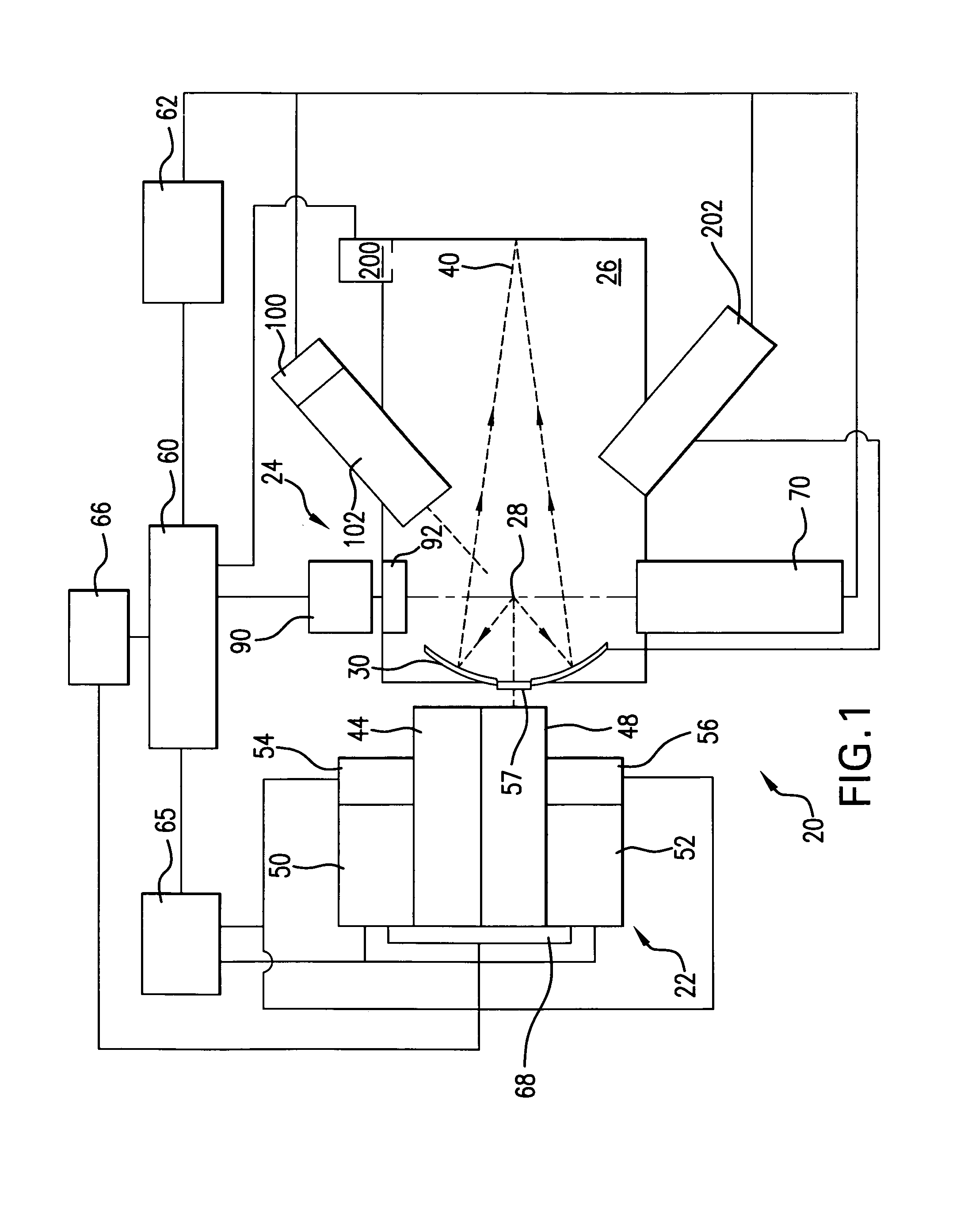

Systems and methods for cleaning a chamber window of an EUV light source

InactiveUS20060097203A1Increase rate of chemical reactionsIncrease the rate of chemical reactionsLaser detailsNanoinformaticsExtreme ultravioletEngineering

Systems and methods are disclosed for cleaning a chamber window of an extreme ultraviolet (EUV) light source. The window may have an inside surface facing a chamber interior and an opposed outside surface and the light source may generate debris by plasma formation. For the system, a subsystem may be positioned outside the chamber and may be operable to pass energy through the window to heat debris accumulating on the inside surface of the window. In a first embodiment, the subsystem may place a flowing, heated gas in contact with the outside surface of the window. In another embodiment, electromagnetic radiation may be passed through the window.

Owner:ASML NETHERLANDS BV

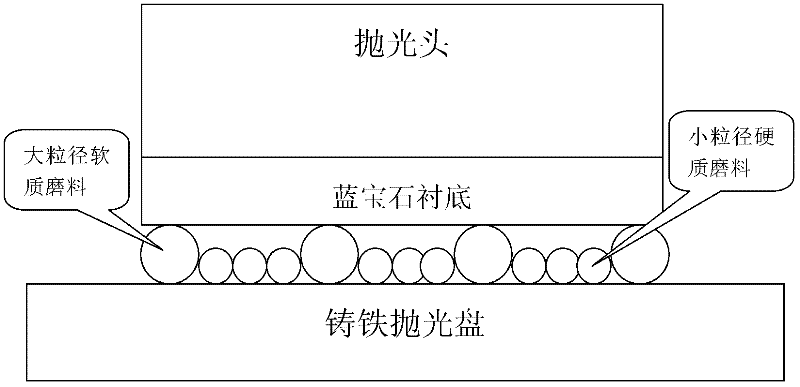

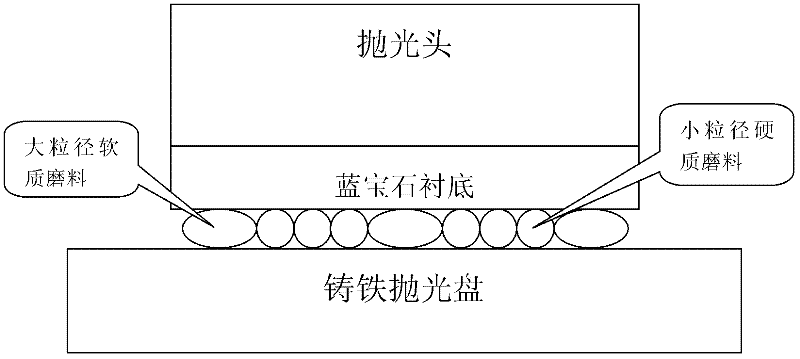

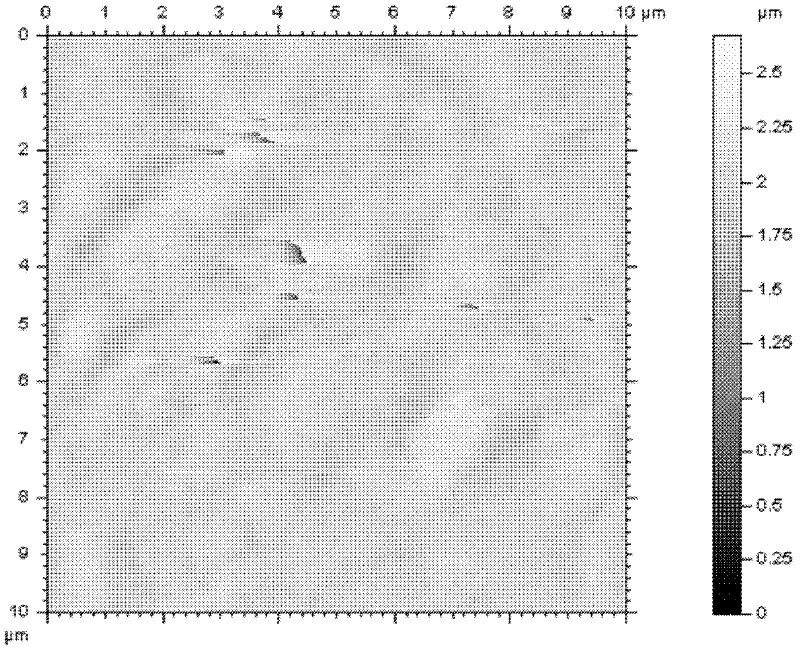

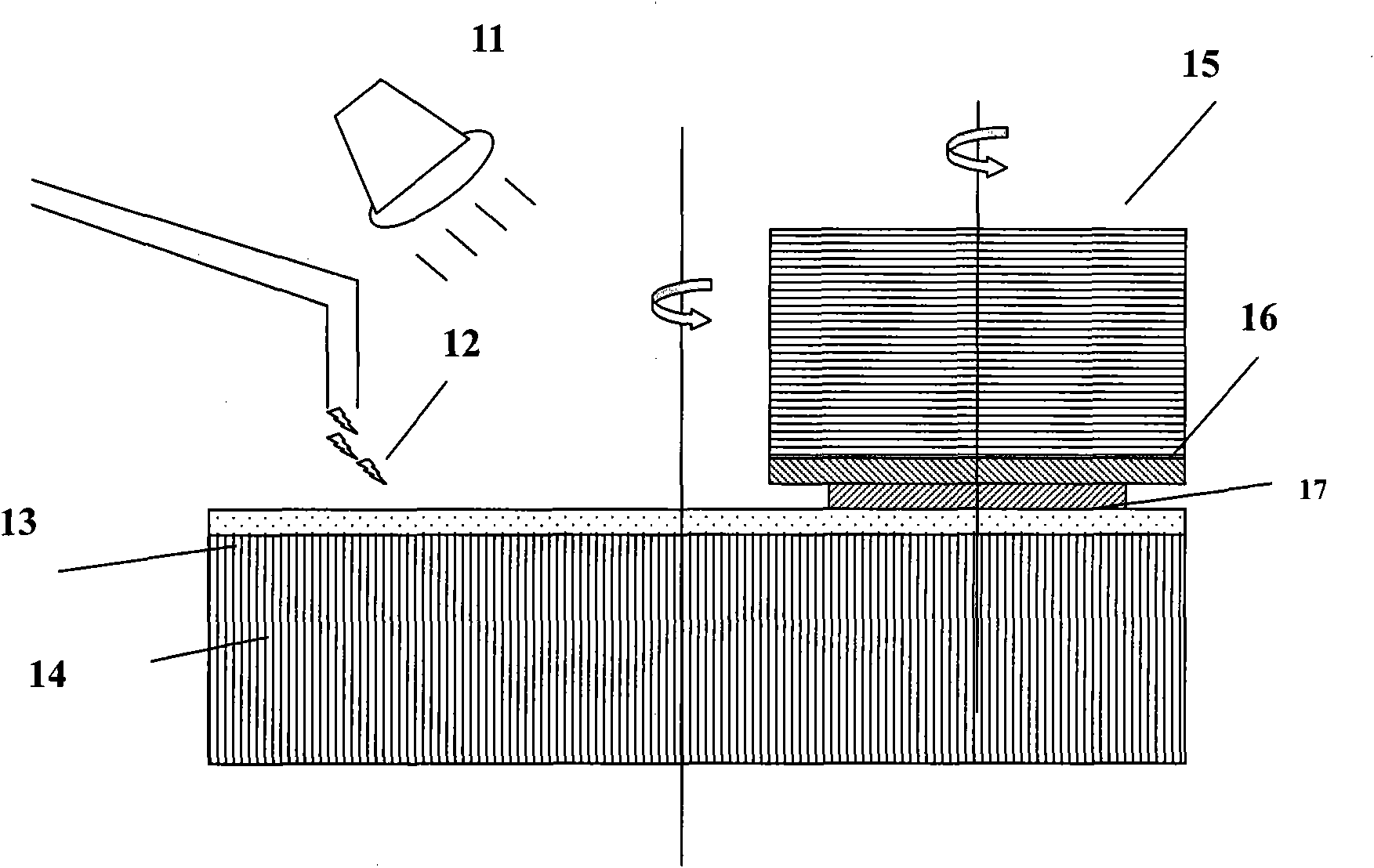

Thermochemistry mechanical polishing method of sapphire substrate material and polishing solution

InactiveCN102343547AImprove polishing rateGuaranteed uniformityLapping machinesPolishing compositions with abrasivesIonSurface-active agents

The invention relates to a thermochemistry mechanical polishing method of a sapphire substrate material; a polishing disk is heated in the polishing process; the temperature of the polishing disk is 30 DEG C-100 DEG C; a polishing solution adopted in the polishing method comprises a compound abrasive material, a pH compound conditioning agent, a surface active agent, a dispersing agent and deionized water, wherein the compound abrasive material is formed by mixing particles of a hard abrasive material and a soft abrasive material; the pH compound conditioning agent comprises organic strong base and organic weak base; and the pH value of the polishing solution is 8-13. The thermochemistry mechanical polishing method has the advantages: in the polishing process, the cast ion polishing disk is heated to promote a reaction rate between the polishing solution and the sapphire substrate material, thereby improving the polishing efficiency; problems such as surface scratch, subsurface cracks and the like can be avoided by using the compound abrasive material in the polishing solution so as to obtain surface characteristics of high quality and high evenness; meanwhile, the polishing efficiency is considered; and the polishing solution also has the advantages that the stability is high, equipment is not corroded, washing is easy and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

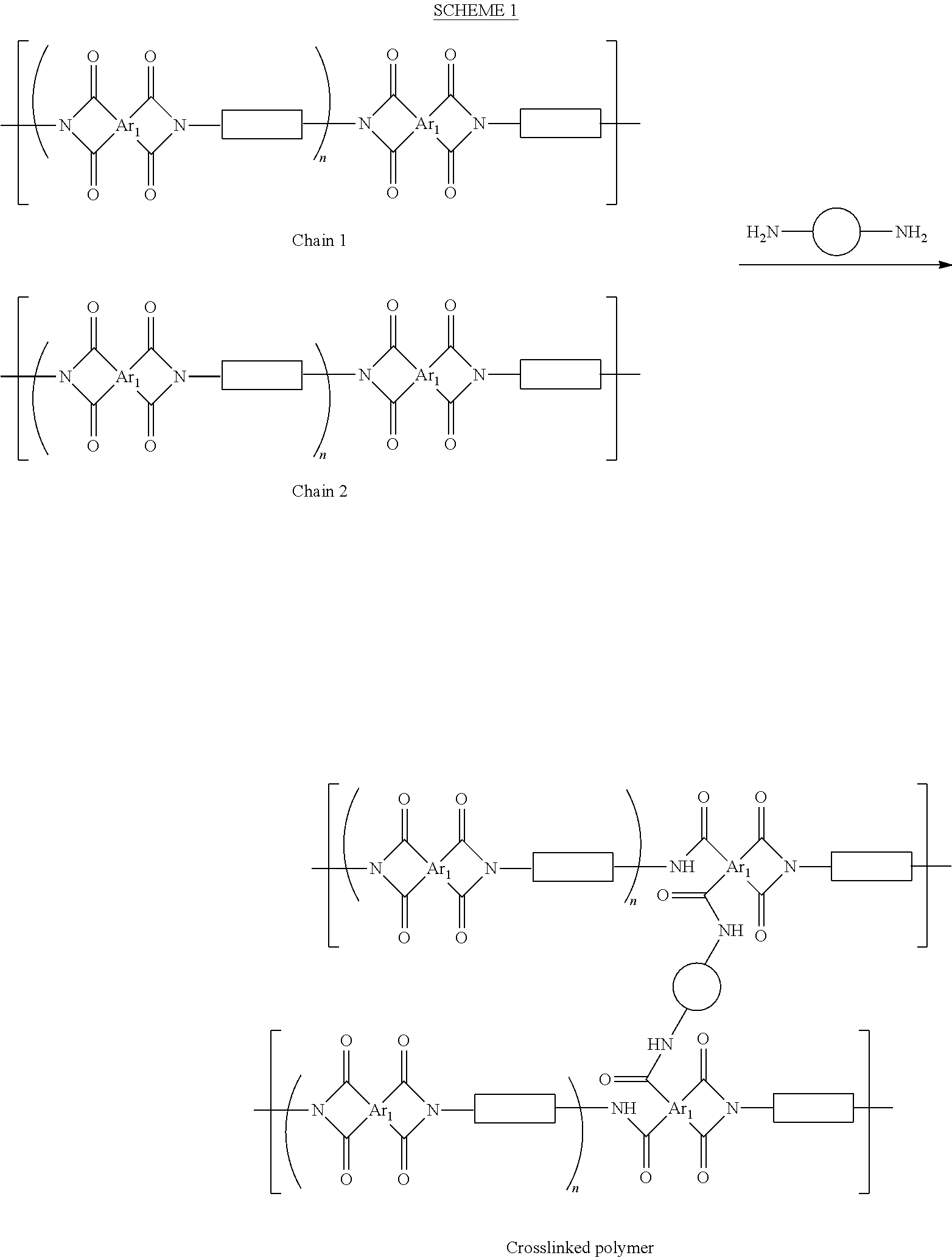

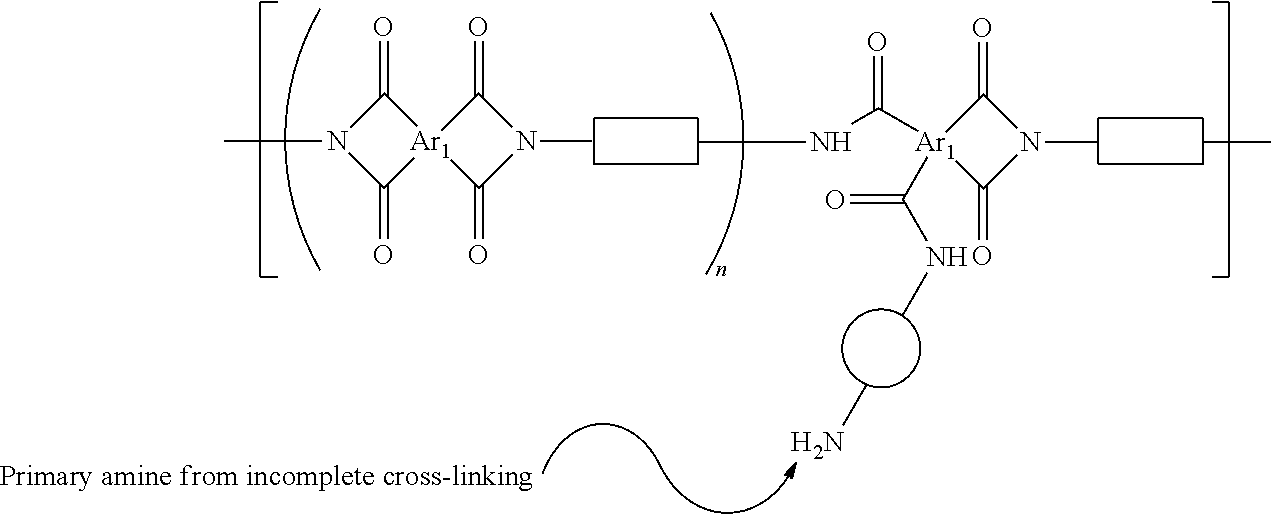

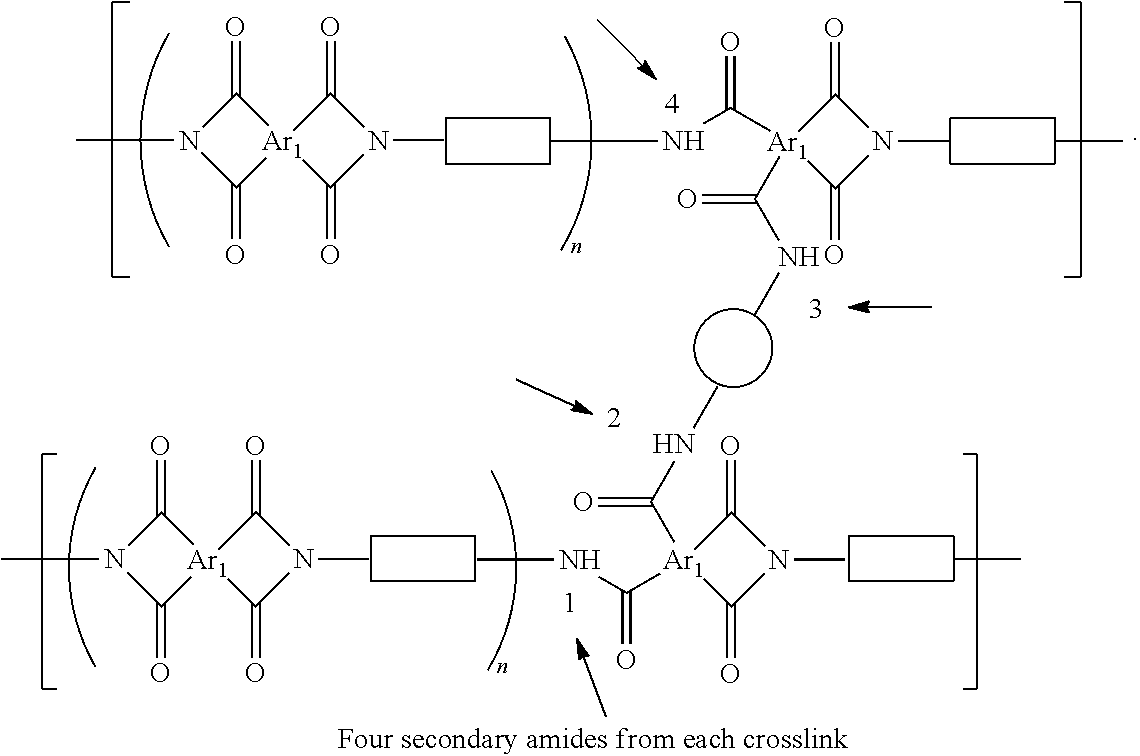

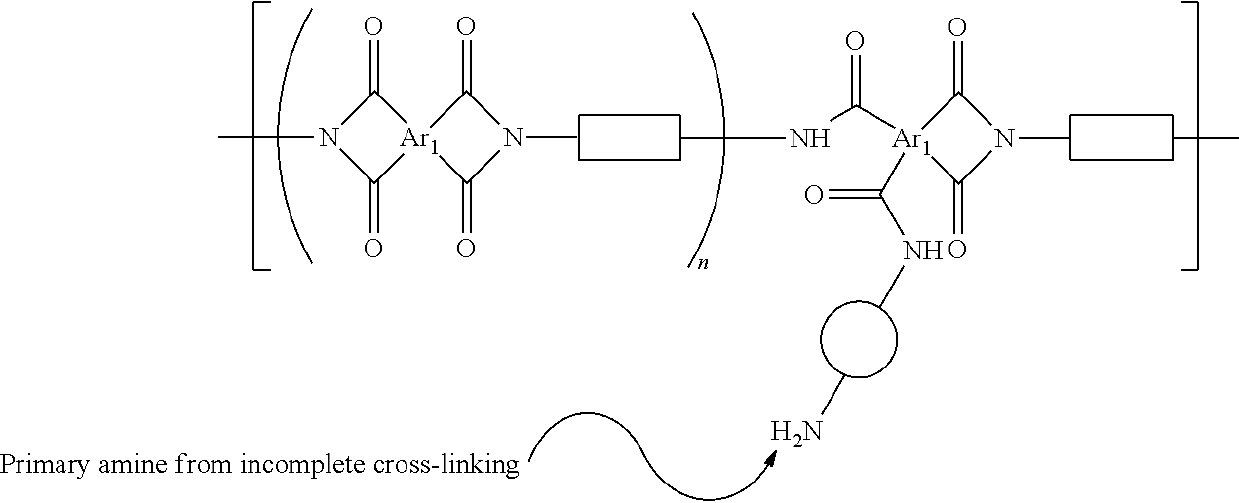

Nanofiltration membranes and methods of use

ActiveUS20160288057A1Low chemical reactivityReduce reactivityMembranesOrganic chemistryChemical reactionCompound (substance)

The present invention provides nanofiltration membranes with reduced chemical reactivity that can be utilized in manufacturing processes where reactive feedstocks and / or products are utilized or produced. Methods of making and using the membranes are also provided.

Owner:NOVOMER INC

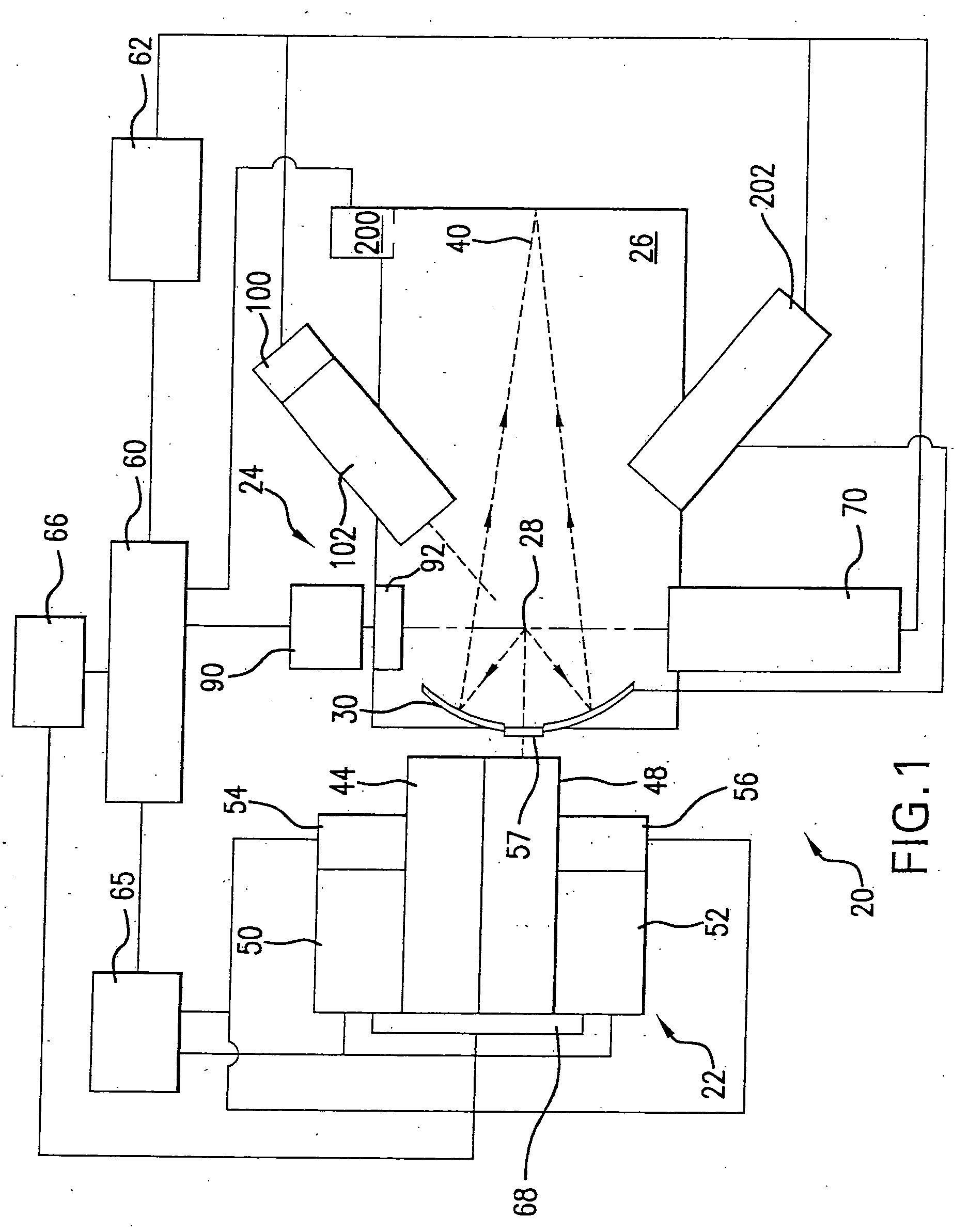

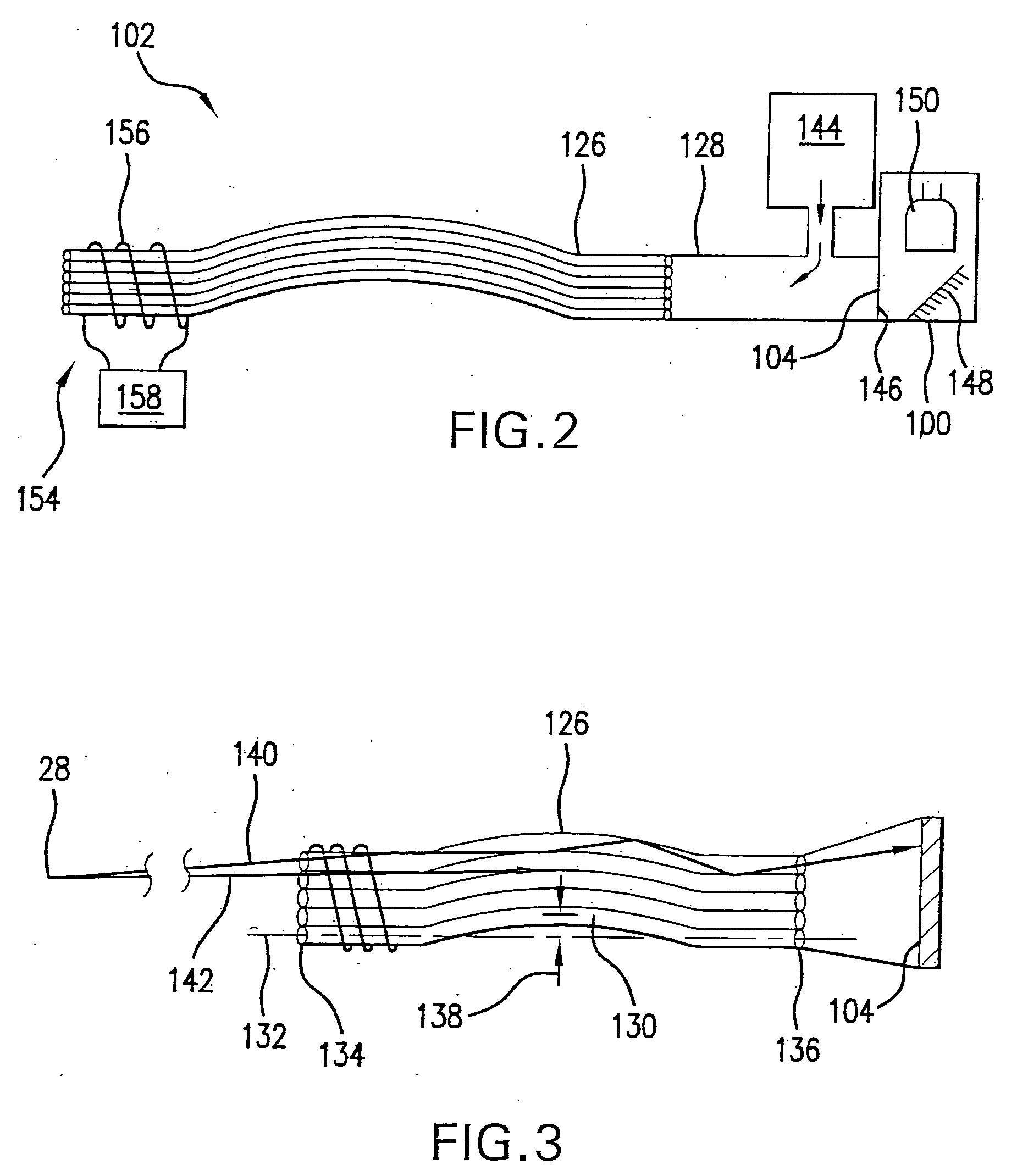

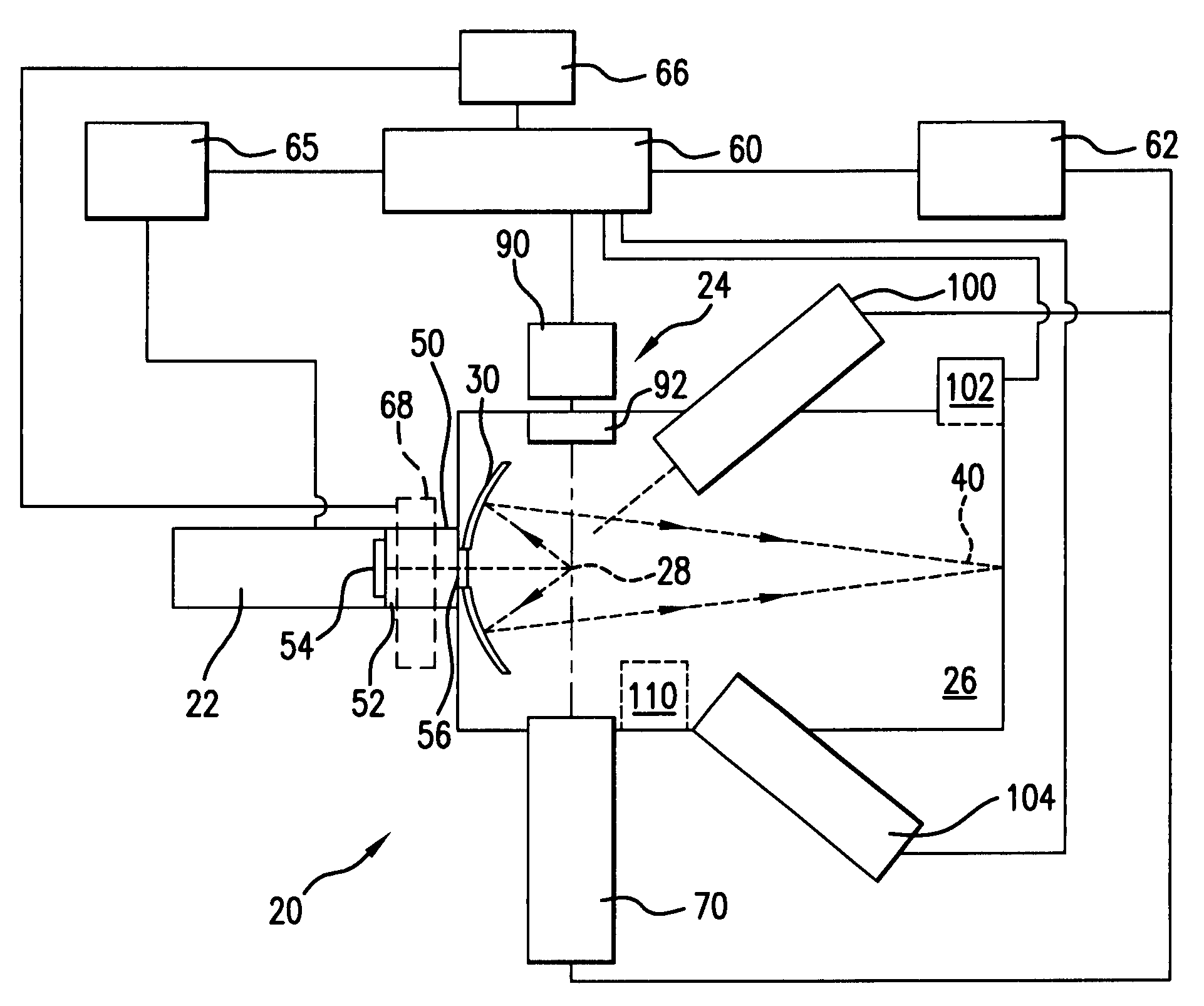

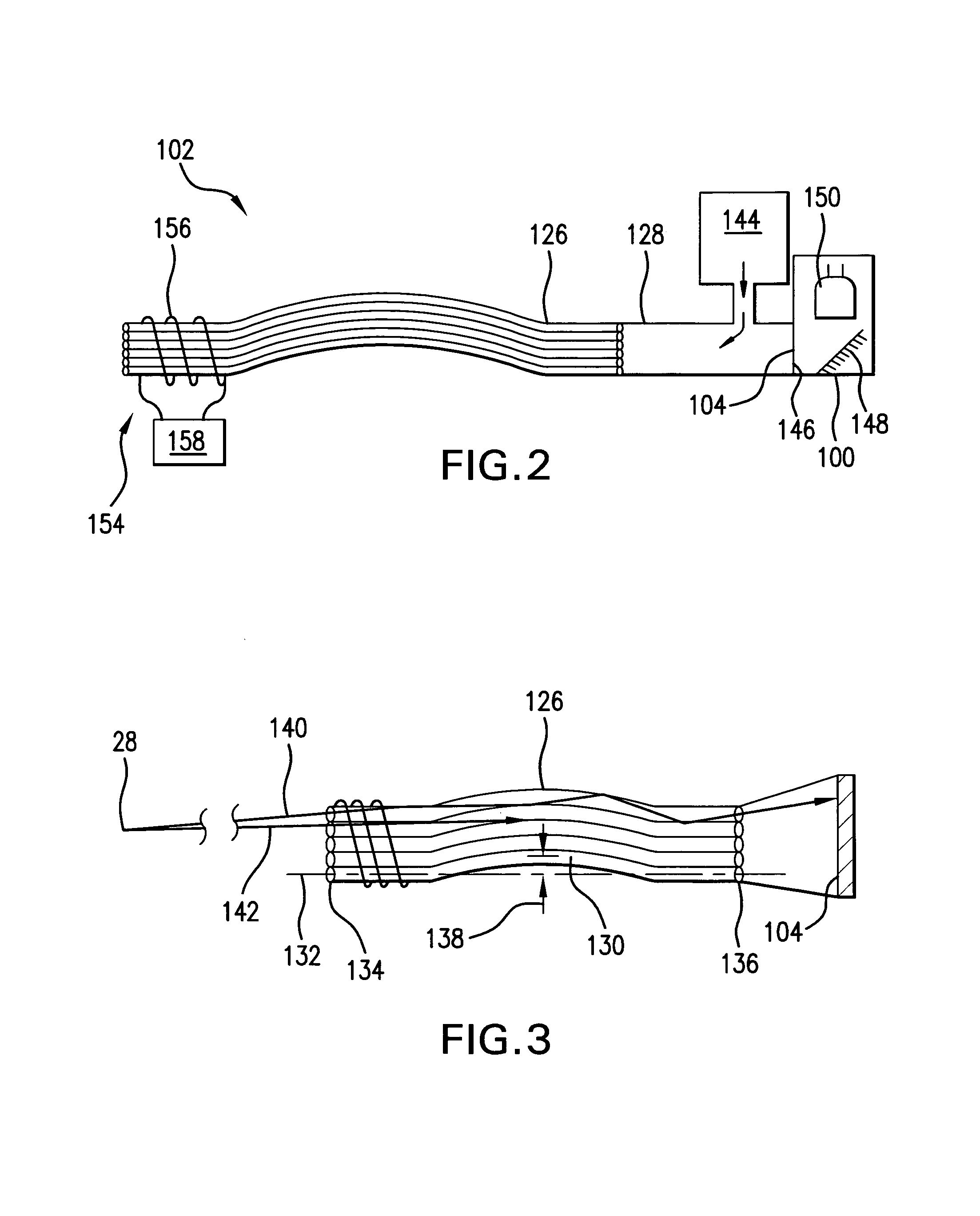

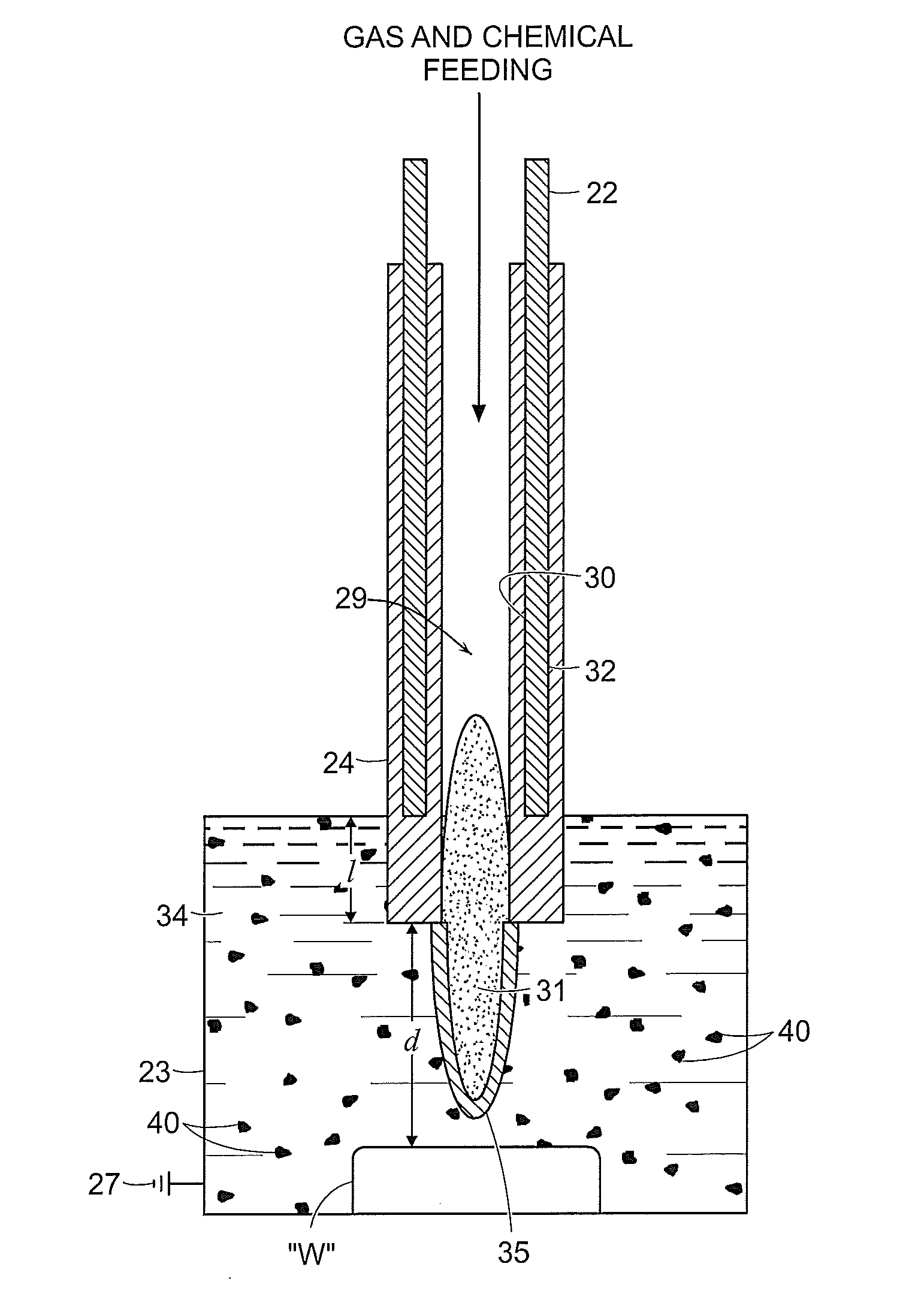

Laser produced plasma EUV light source

ActiveUS7598509B2Increase the rate of chemical reactionsRadiation pyrometryNanoinformaticsLight beamOptoelectronics

An EUV light source is disclosed that may include a laser source, e.g. CO2 laser, a plasma chamber, and a beam delivery system for passing a laser beam from the laser source into the plasma chamber. Embodiments are disclosed which may include one or more of the following; a bypass line may be provided to establish fluid communication between the plasma chamber and the auxiliary chamber, a focusing optic, e.g. mirror, for focusing the laser beam to a focal spot in the plasma chamber, a steering optic for steering the laser beam focal spot in the plasma chamber, and an optical arrangement for adjusting focal power.

Owner:ASML NETHERLANDS BV

Catalysts for epoxide carbonylation

InactiveUS20170080409A1Use in synthesisIncrease the rate of chemical reactionsOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsPtru catalystEthylene oxide

The present invention encompasses catalysts for the carbonylation of heterocycles such as ethylene oxide, as well as methods for their use. The catalysts feature Lewis acidic metal complexes having one or more tethered metal-coordinating groups in combination with at least one metal carbonyl species. In preferred embodiments, the inventive catalysts have improved stability when subjected to product separation conditions in continuous ethylene oxide carbonylation processes.

Owner:NOVOMER INC

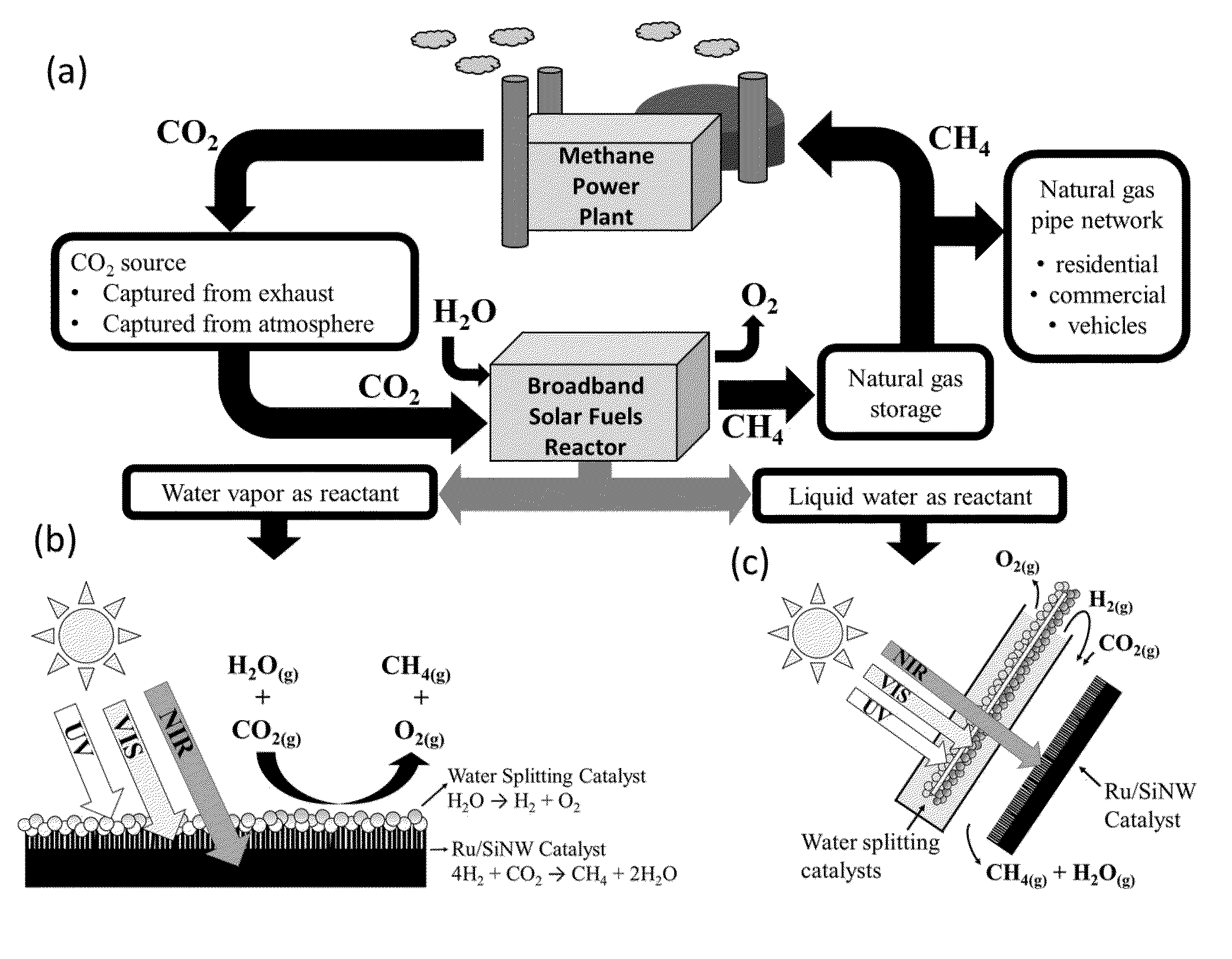

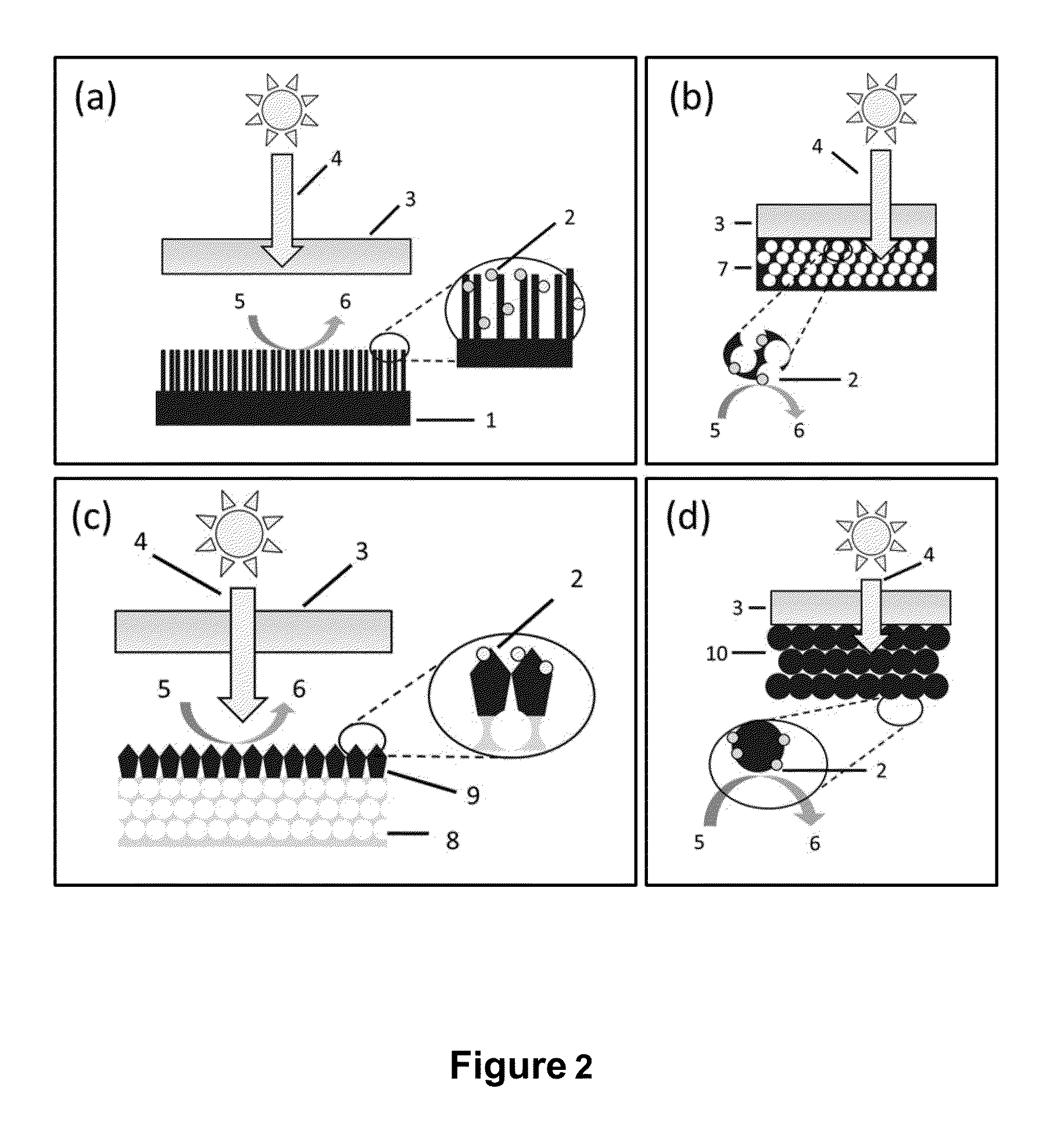

Nanostructured solar selective catalytic supports

ActiveUS20160074833A1Low emissivitySpeed up chemical reactionsCatalytic gas-gas reactionHydrocarbon from carbon oxidesChemical reactionReaction rate

A combined catalyst and catalyst support comprising: a nanostructured solar selective support to which at least one catalyst is affixed; the catalyst comprising at least one material that activates chemical reactions that produce fuels; the nanostructured solar selective support comprising material that is highly absorbing over a portion of the solar spectrum and exhibits low emissivity toward thermal radiation and / or has a surface textured to lower emissivity; the combined catalyst and catalyst support exhibiting at least one of a photochemical effect and a photothermal effect; wherein these effects cause the chemical reaction rates to increase with exposure to an increasing number of incident photons within the solar spectrum.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

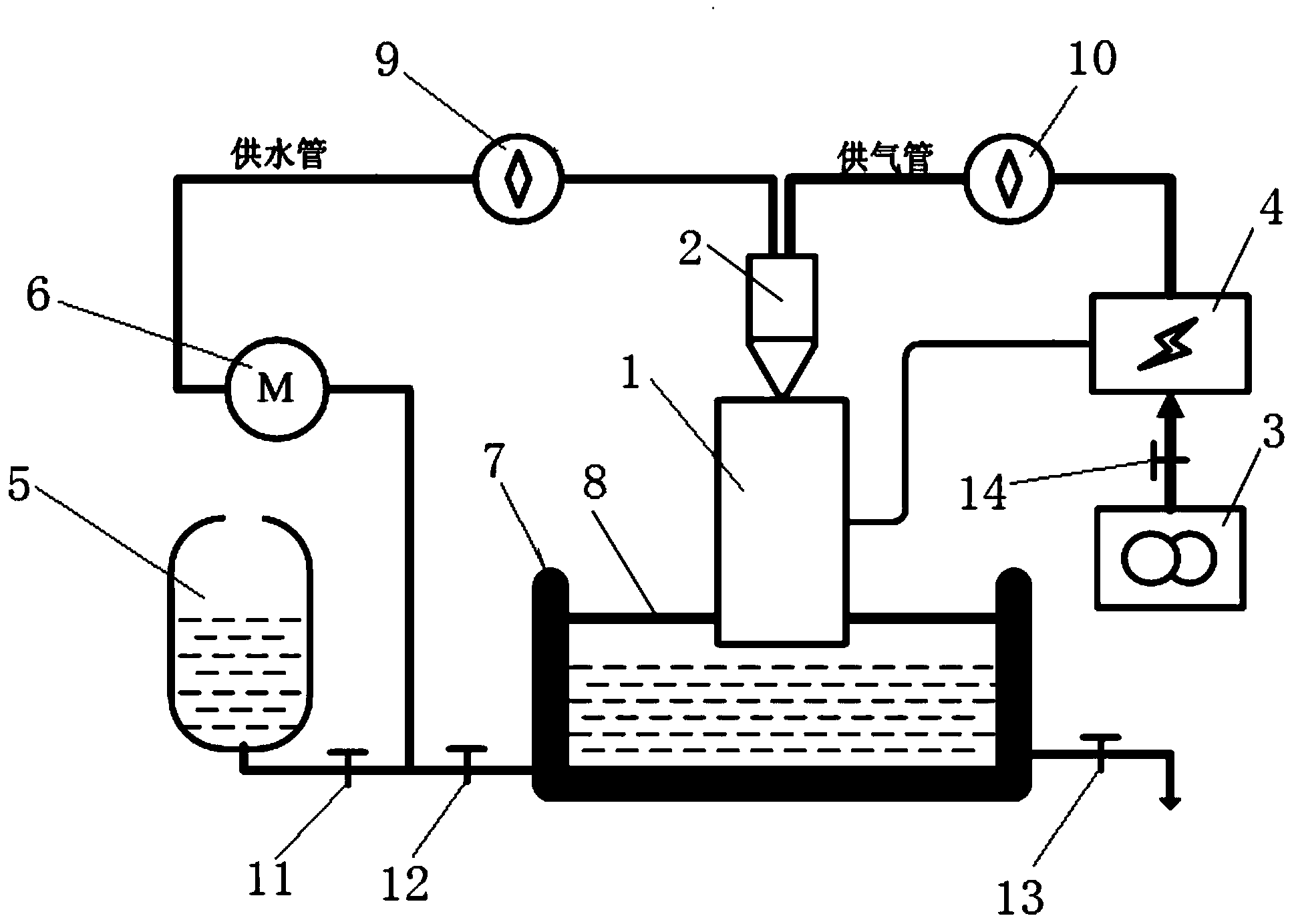

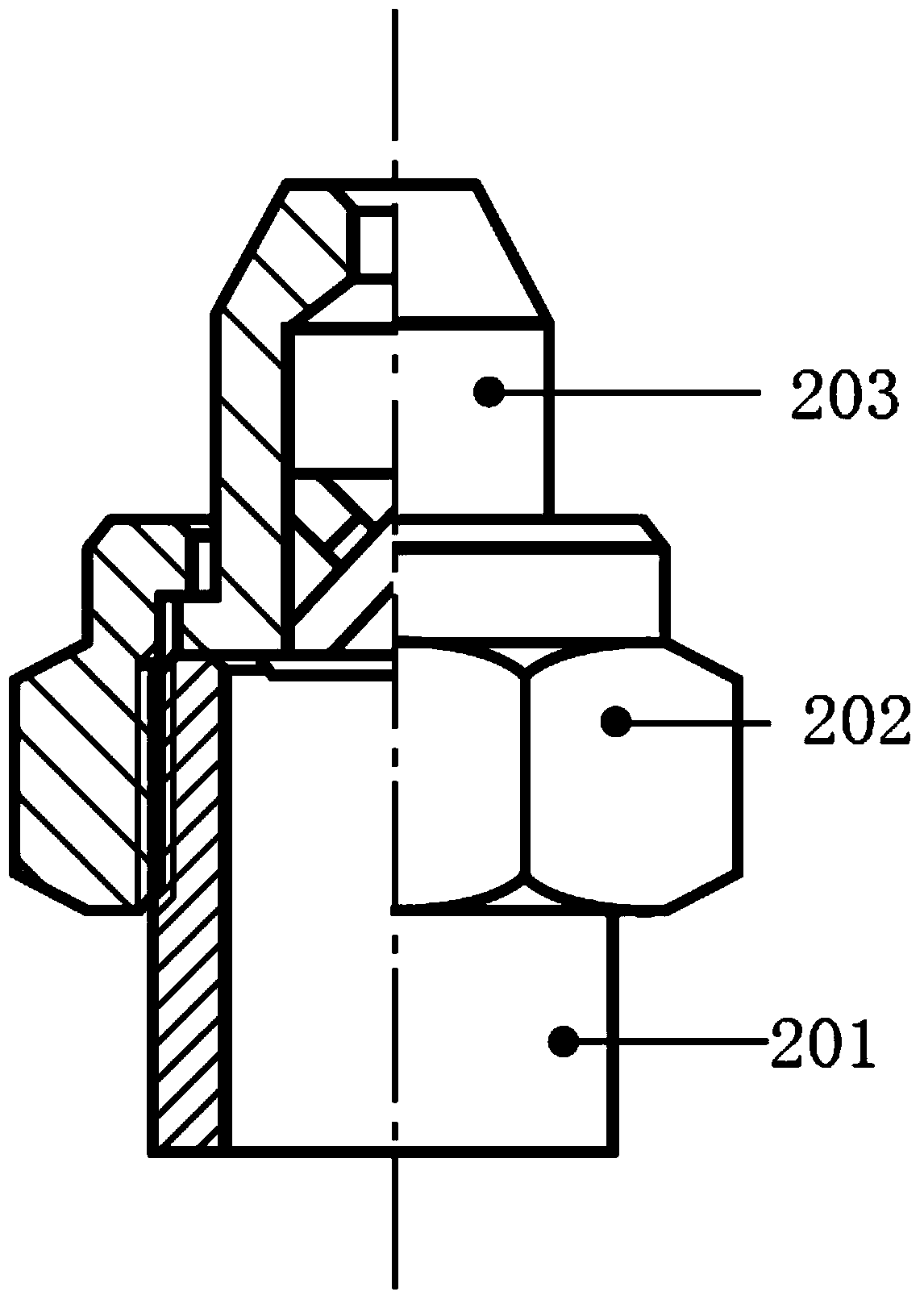

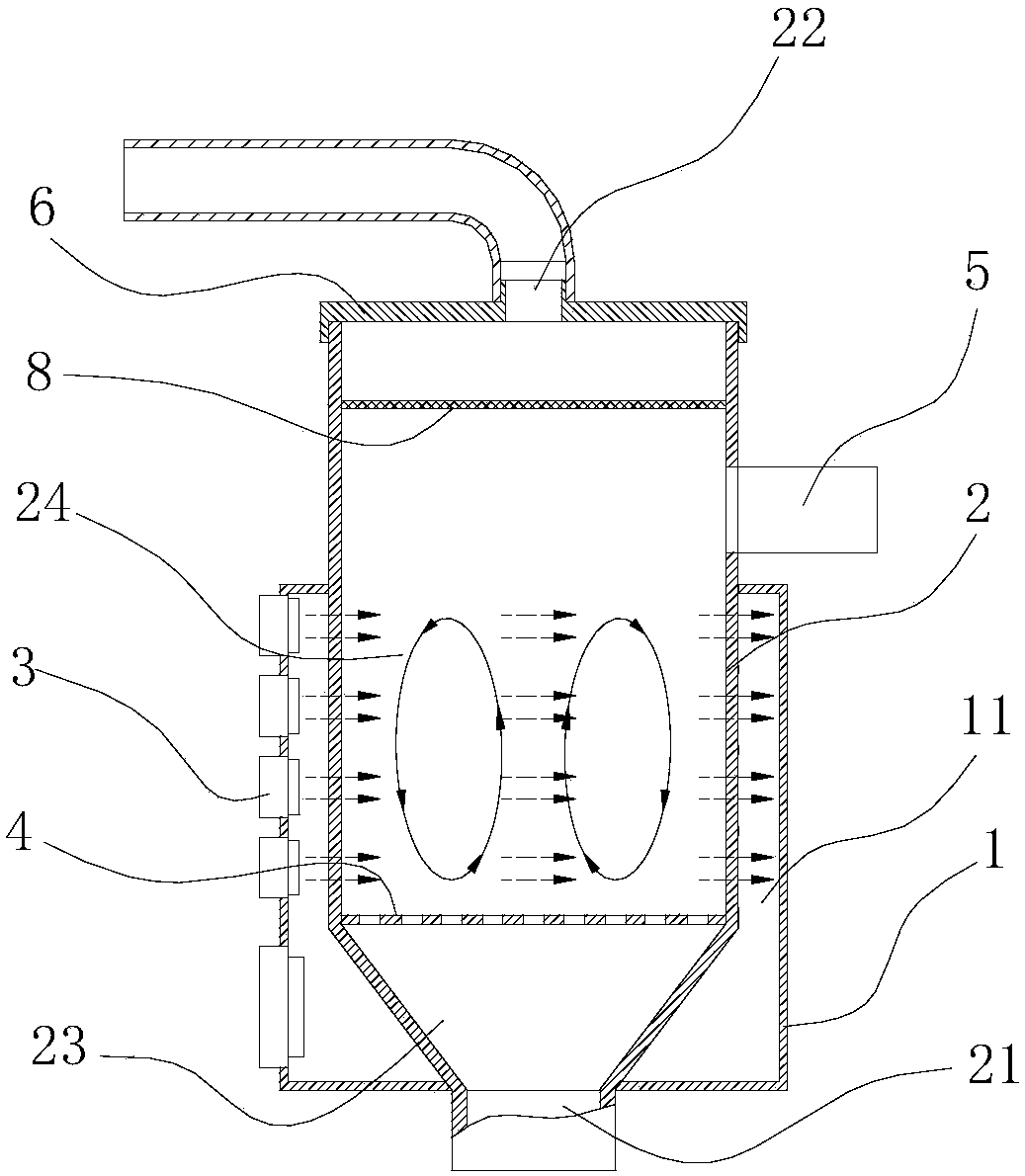

Water spray discharge air plasma jet processing device and high-voltage power source thereof

ActiveCN103482735AIncrease the rate of chemical reactionsGood application prospectWater/sewage treatment by magnetic/electric fieldsAc-ac conversionParameter controlCollision frequency

The invention discloses a water spray discharge air plasma jet processing device and a high-voltage power source thereof. Water to be treated is atomized into a fine mixture of water drops and air at first; consequently, the collision frequency of active particles generated by discharge with toxic and harmful species in water is effectively improved in the discharge reaction processing process, the chemical reaction rate can be effectively increased, the water-air mixing ratio of the water spray jet and the flow velocity of the water spray jet can be adjusted, the chemical reaction kinetics of the water spray jet generated in an atomization reactor are adjusted, the highest efficiency and the most energy-saving state of running of the water processing system are realized, and the processed water is subjected to circulating treatment a plurality of times so that the requirement of emission can be met at last; a voltage and current detection circuit for the input end and the output end of the high-voltage power source is capable of effectively determining whether the system runs normally; therefore, the optimal running parameter control of the water processing system between physical parameters such as the discharge power of the output end, the water spray jet speed and the water-air mixing ratio, and the water processing effect is realized.

Owner:HOHAI UNIV CHANGZHOU

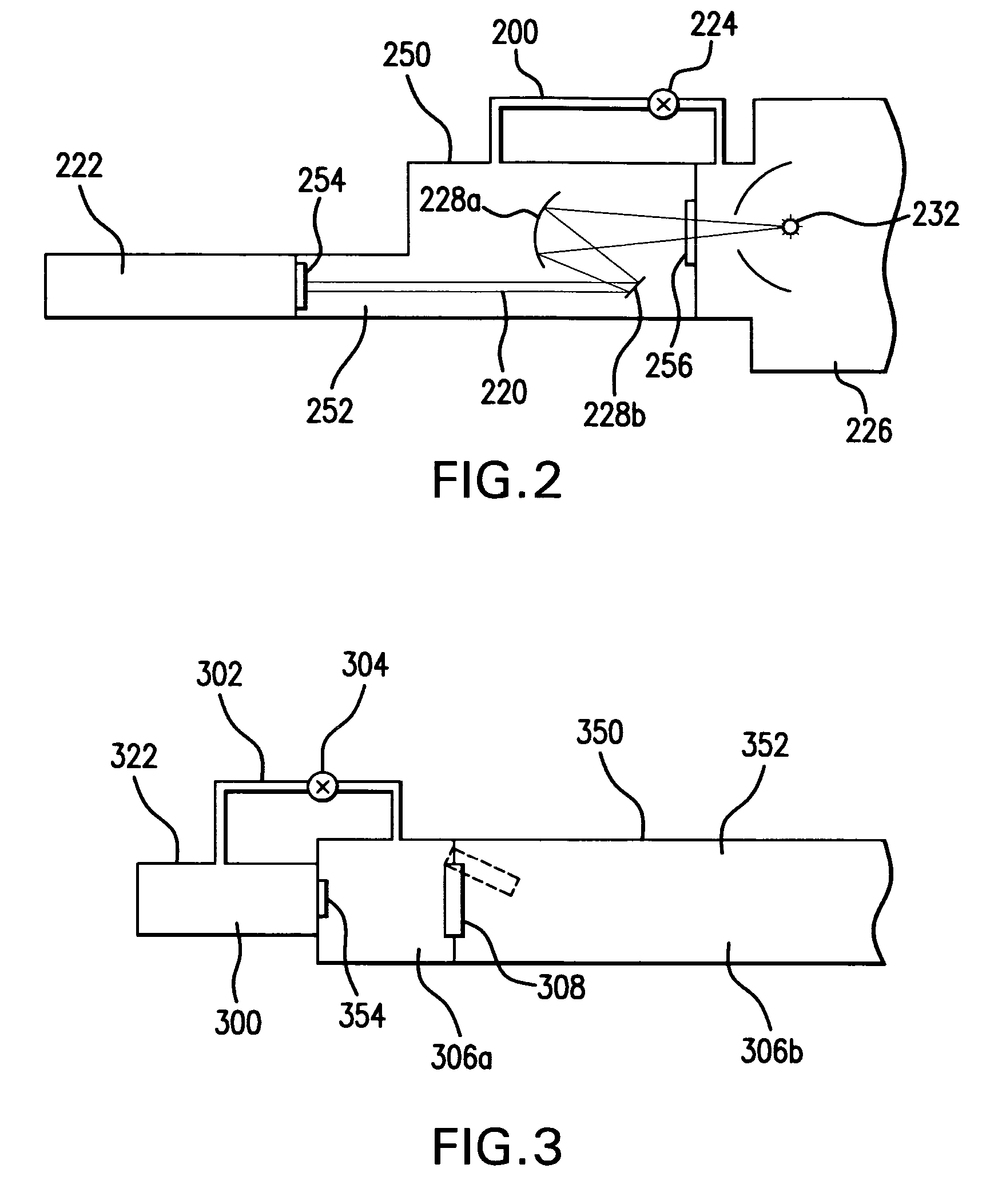

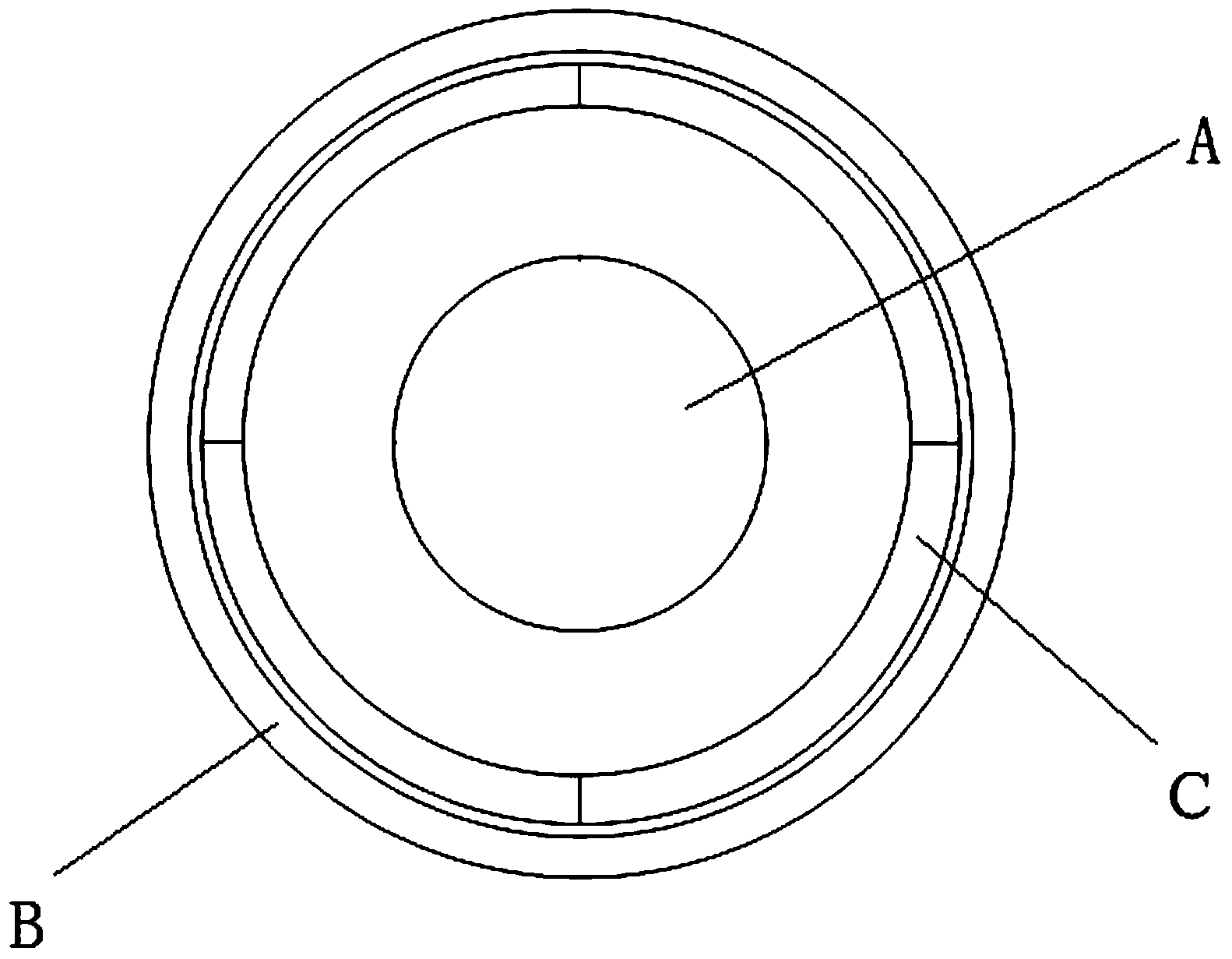

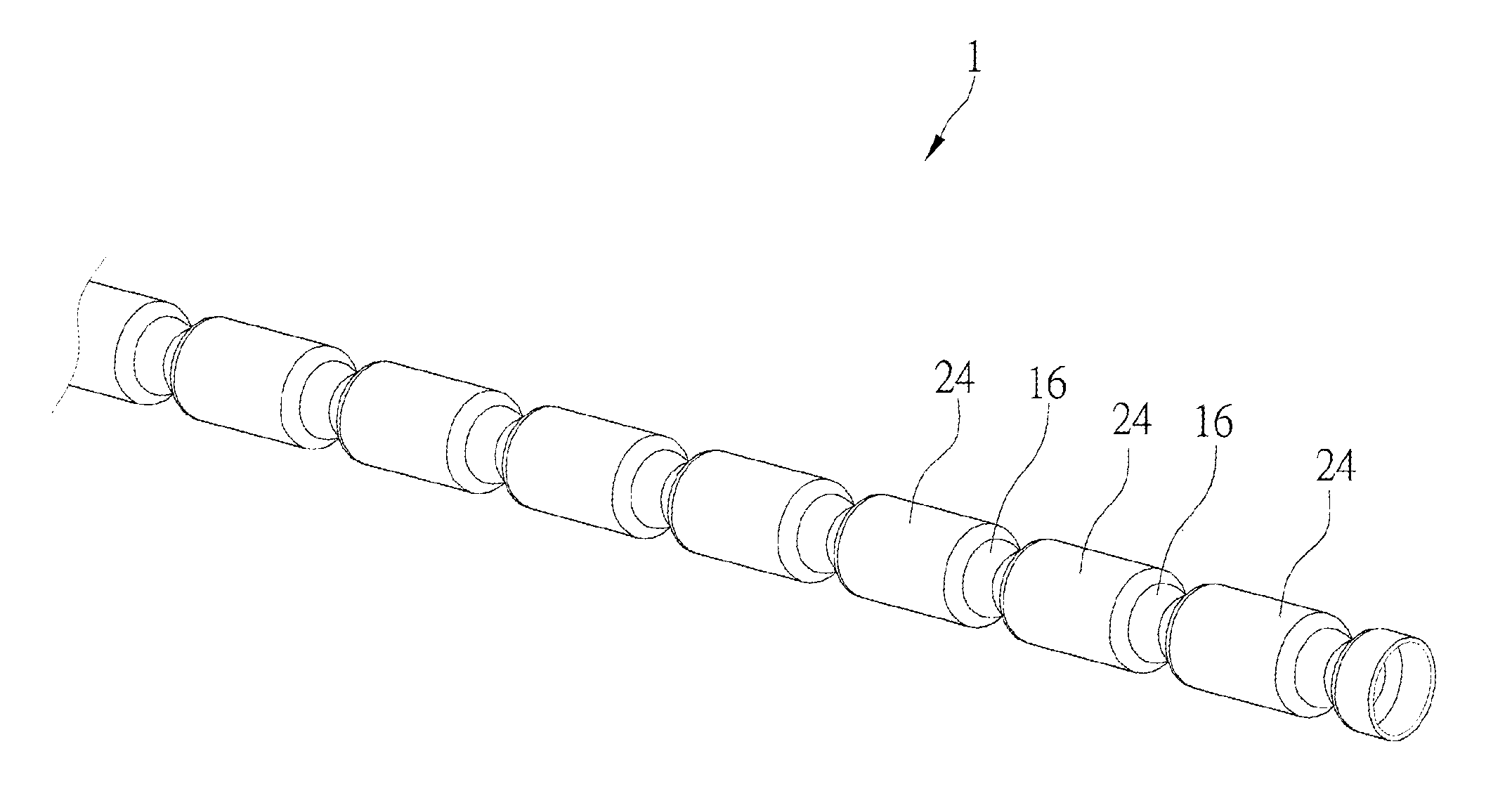

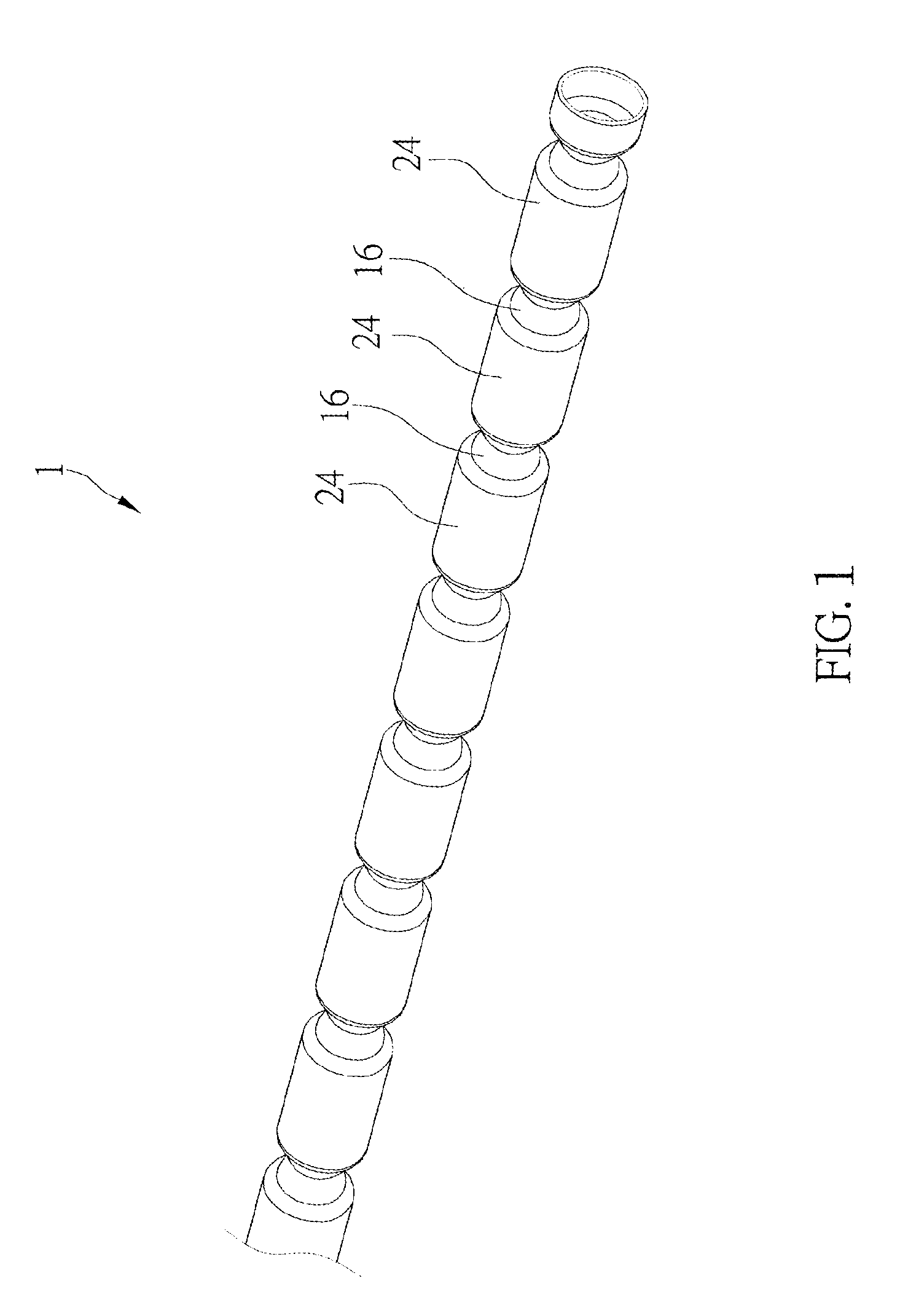

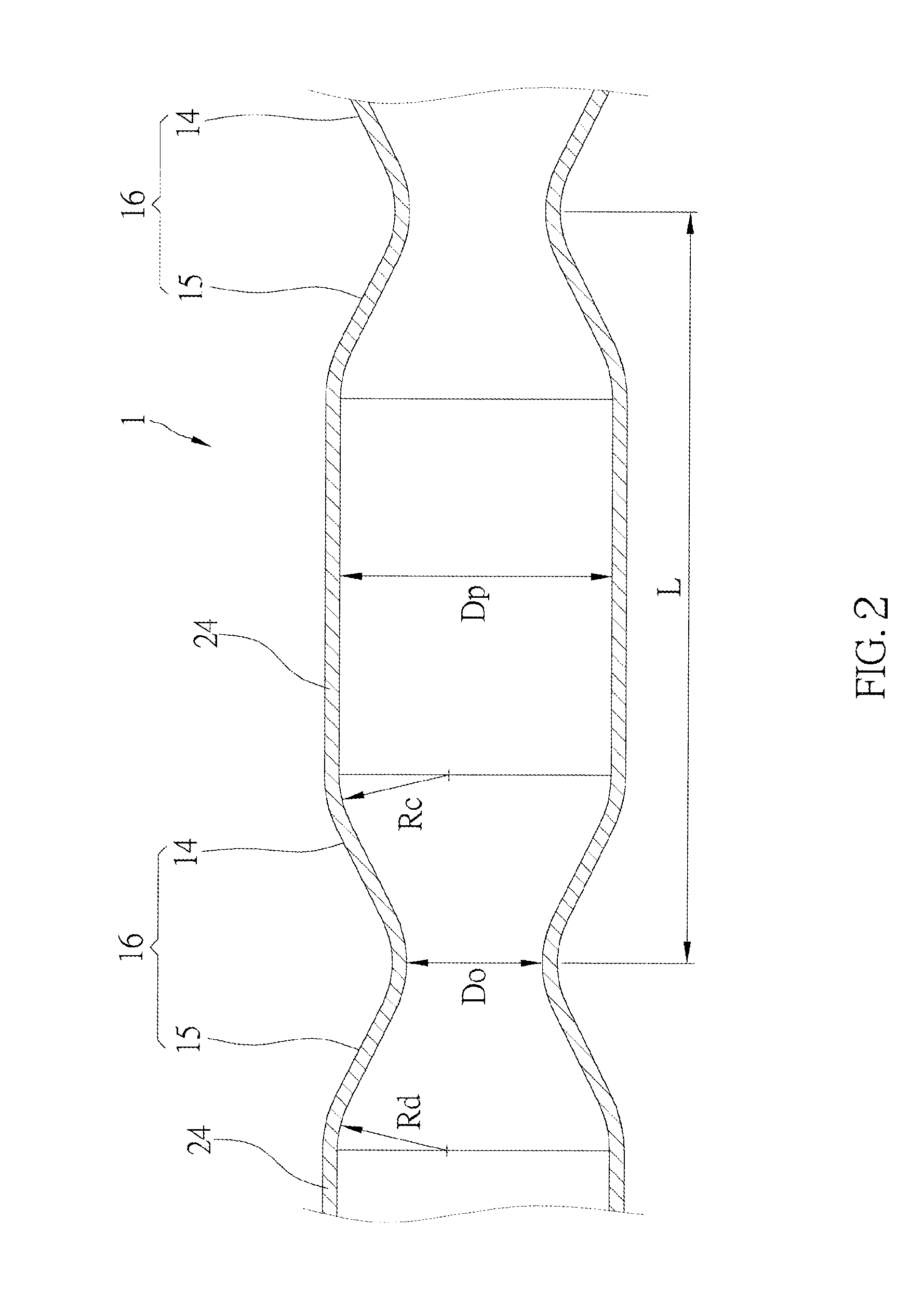

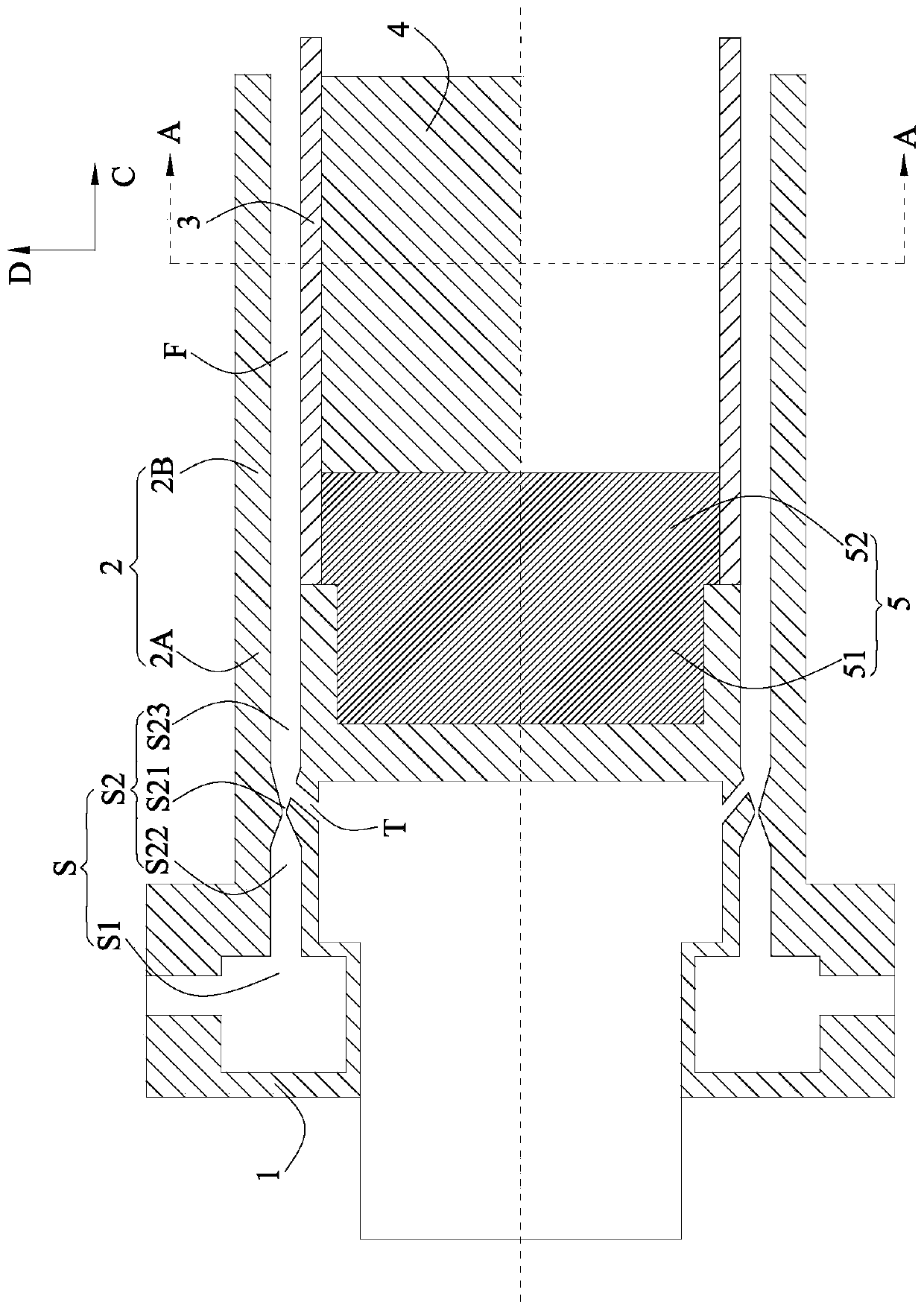

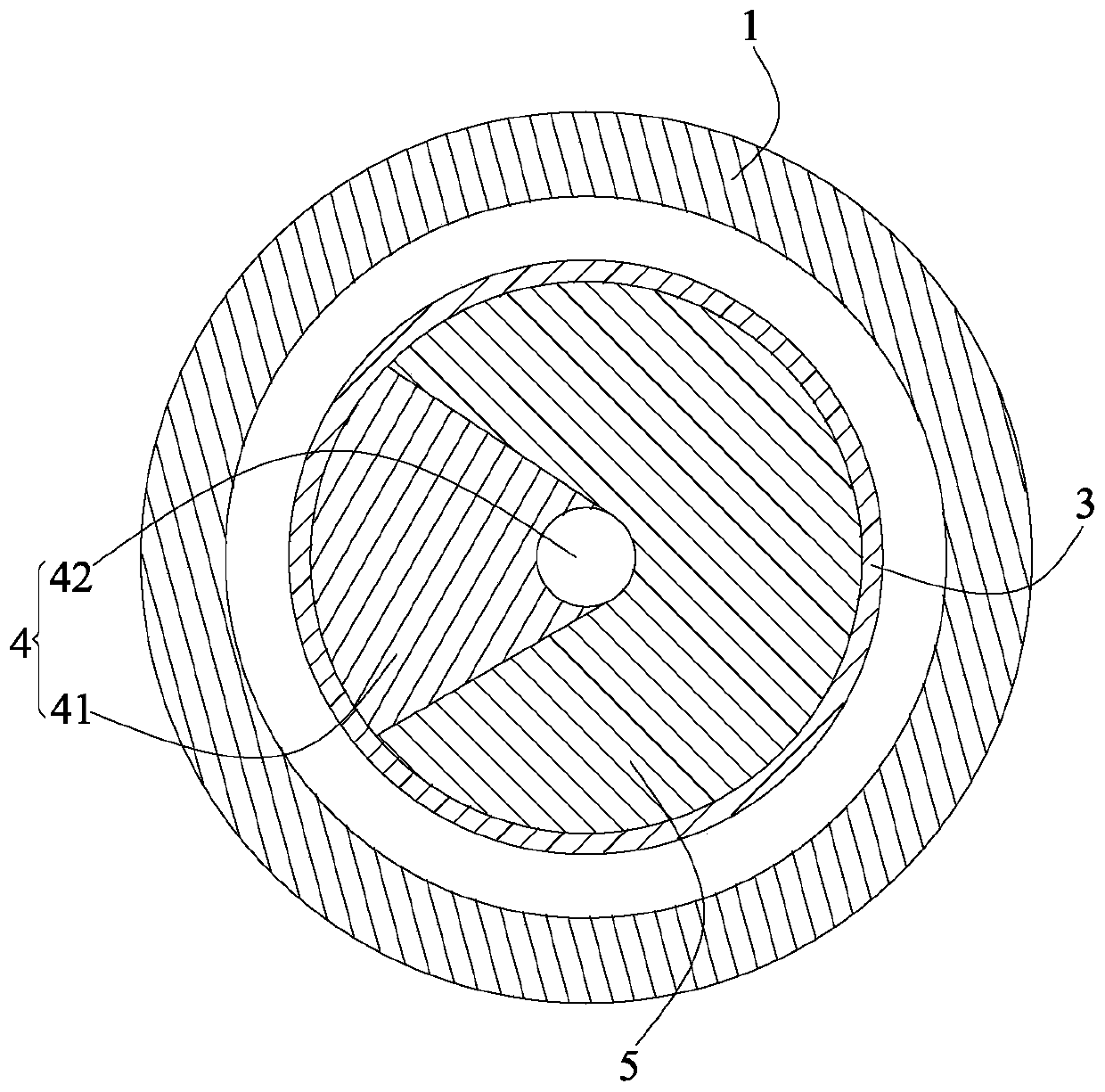

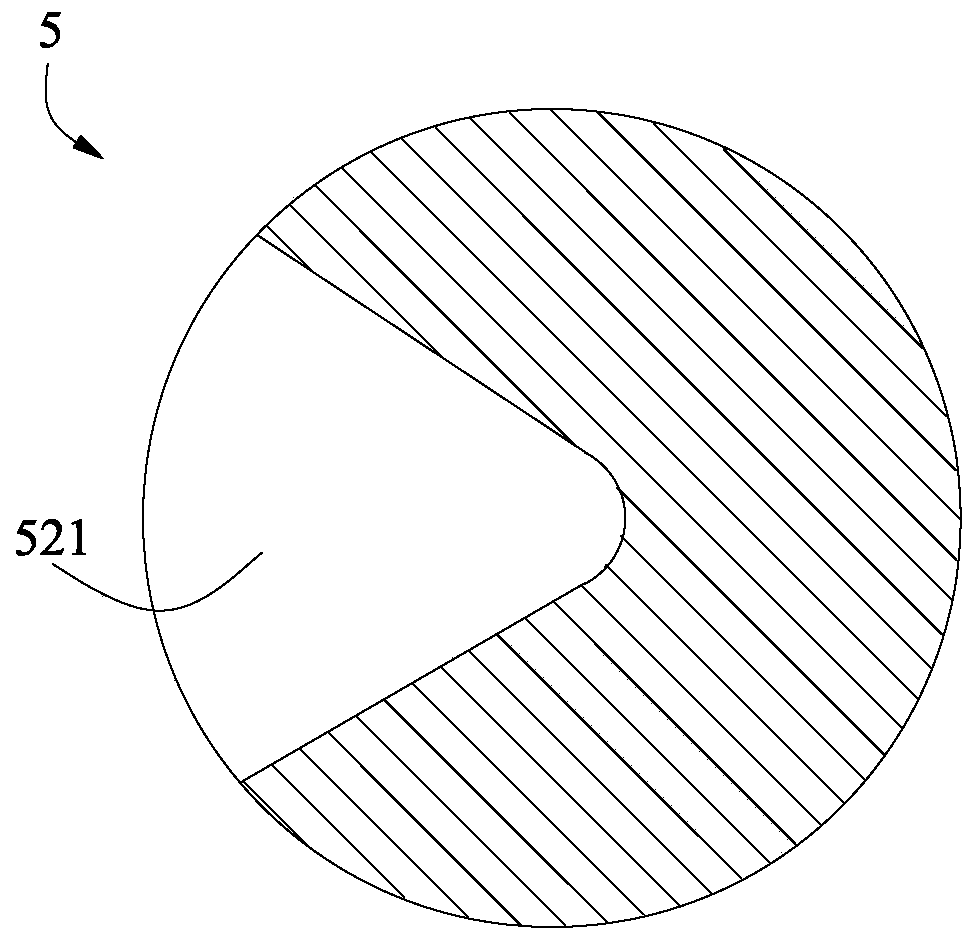

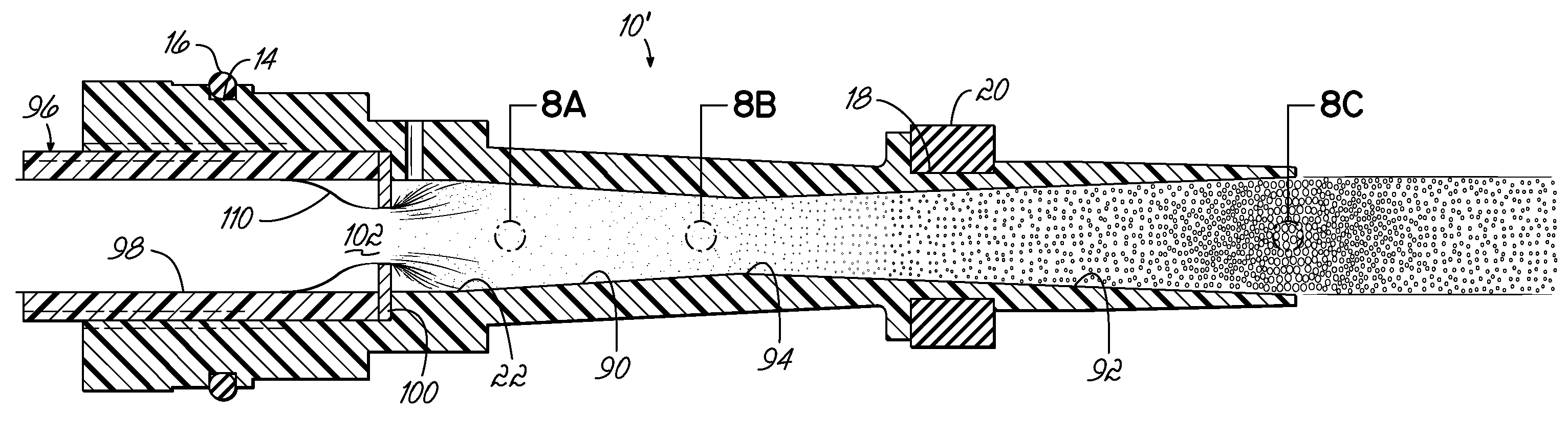

Continuous tubular flow reactor and corrugated reactor tube for the reactor

InactiveUS20120171090A1Extra mixing intensitySimple harmonic motion (SHM) drivingShaking/oscillating/vibrating mixersFlow mixersNuclear engineeringSimple harmonic motion

The present invention provides a continuous tubular flow reactor which consists of a reactor tube module having an inlet port and an outlet port, and a pressuring device connected to the inlet port and the outlet of the reactor tube module. The reactor tube module comprises multiple reactor tubes butt connected in sequence. Each reactor tube has alternating straight sections and convergent-divergent sections, wherein inner diameter of the convergent-divergent section is smaller than that of the straight section. The pressuring device has a simple harmonic motion driving device.

Owner:RESI CORP

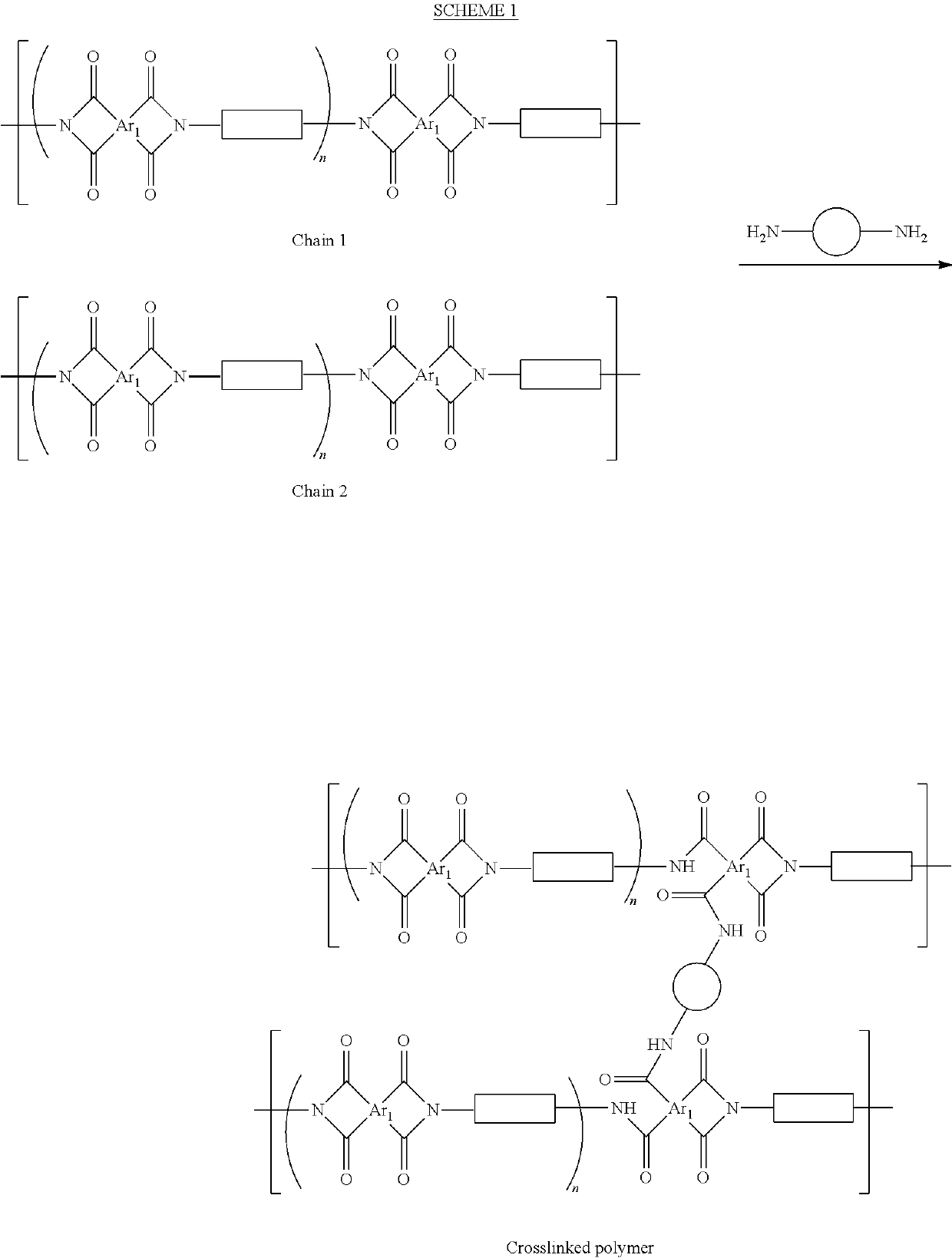

Nanofiltration membranes and methods of use

ActiveUS10245559B2Reduce reactivityIncrease the rate of chemical reactionsMembranesOrganic chemistryChemical reactionCompound (substance)

The present invention provides nanofiltration membranes with reduced chemical reactivity that can be utilized in manufacturing processes where reactive feedstocks and / or products are utilized or produced. Methods of making and using the membranes are also provided.

Owner:NOVOMER INC

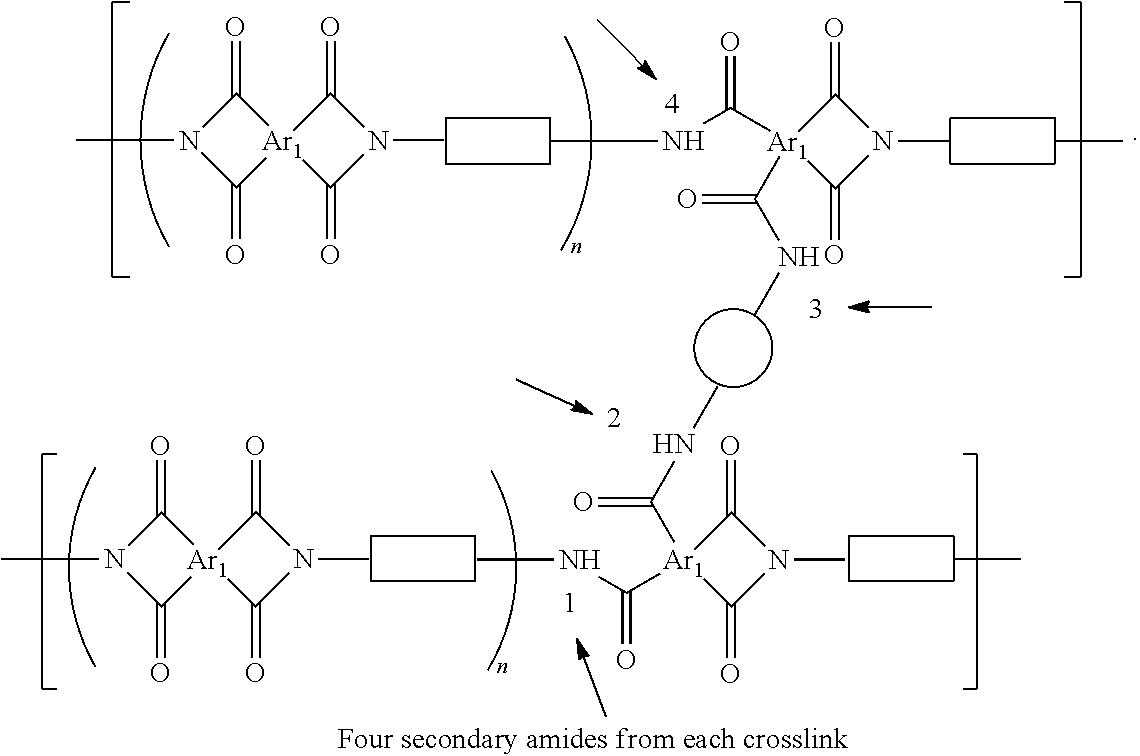

Production method of silane

The invention discloses a production method of silane. The production method comprises the following steps of: heating trichlorosilane to 70-90 DEG C by using a preheater; feeding heated trichlorosilane into a first reaction region of a reaction rectifying tower, and performing a first step catalytic disproportionation reaction of trichlorosilane in the first reaction region to generate dichlorosilane and silicon tetrachloride; feeding silicon tetrachloride generated in the first reaction region into the stripping section of the reaction rectifying tower, separating, purifying and discharging from a tower kettle; raising dichlorosilane generated in the first reaction region to a second reaction region of the reaction rectifying tower, and performing a second step catalytic disproportionation reaction to generate trichlorosilane and silane; refluxing the trichlorosilane generated in the second reaction region into the first reaction region, mixing with trichlorosilane heated by using the preheater, and continually performing the first step catalytic disproportionation reaction; and raising silane generated in the second reaction region into the rectifying section of the reaction rectifying tower, separating, purifying and discharging from the tower top of the reaction rectifying tower to obtain silane.

Owner:覃攀

Method for surface metallization of resin-based composite material compressed by mold

ActiveCN102418090AIncrease the rate of chemical reactionsReduce coarsening timeLiquid/solution decomposition chemical coatingFilling materialsSupersonic waves

The invention discloses a method for surface metallization of a resin-based composite material compressed by a mold. The resin-based composite material compressed by a mold comprises one or more thermosetting resins, one or more fibers and one or more filling materials. The method provided by the invention can realize surface metallization of the resin-based composite material compressed by a mold. The key point of surface metallization is effectiveness in resin-based composite material roughening. Through the technical measures which comprise utilization of supersonic waves in roughening andimprovement of a roughening solution and realize good effects of roughening the one or more fibers and the one or more filling materials in the resin-based composite material by the roughening solution, the method realizes the surface metallization of the resin-based composite material compressed by a mold. The method is suitable for surface metallization of the resin-based composite material compressed by a mold, and has high efficiency, environmentally friendly characteristics and good metalized layer adhesion.

Owner:SHENZHEN XINTIAN TECH

Systems and methods for cleaning a chamber window of an EUV light source

InactiveUS7355191B2Increase the rate of chemical reactionsLaser detailsNanoinformaticsEngineeringElectromagnetic radiation

Systems and methods are disclosed for cleaning a chamber window of an extreme ultraviolet (EUV) light source. The window may have an inside surface facing a chamber interior and an opposed outside surface and the light source may generate debris by plasma formation. For the system, a subsystem may be positioned outside the chamber and may be operable to pass energy through the window to heat debris accumulating on the inside surface of the window. In a first embodiment, the subsystem may place a flowing, heated gas in contact with the outside surface of the window. In another embodiment, electromagnetic radiation may be passed through the window.

Owner:ASML NETHERLANDS BV

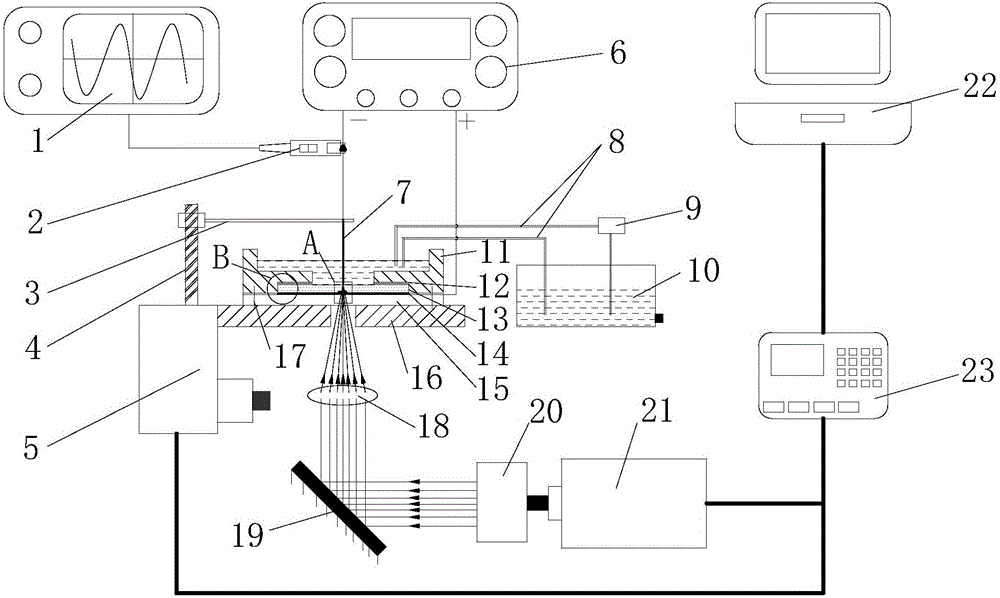

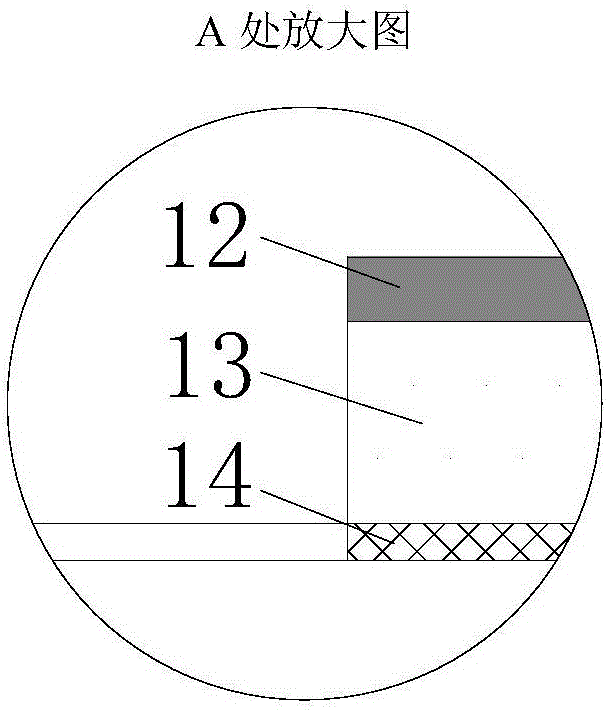

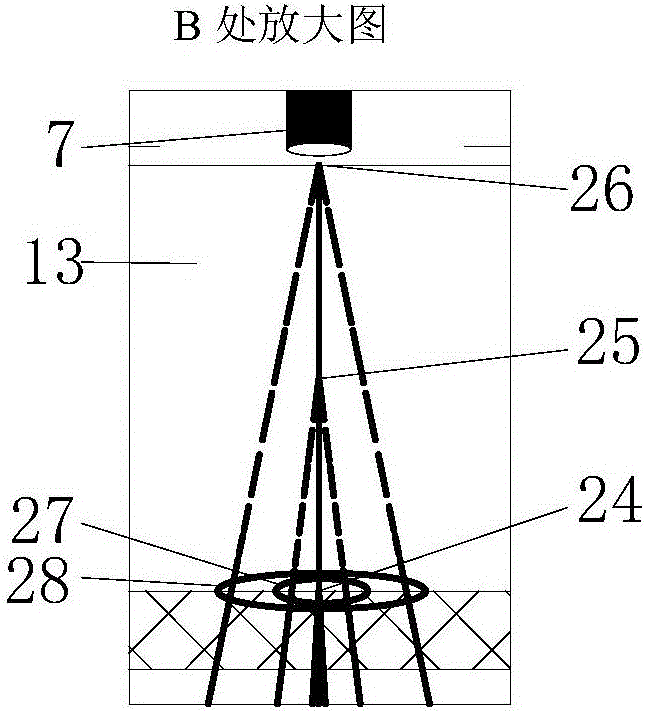

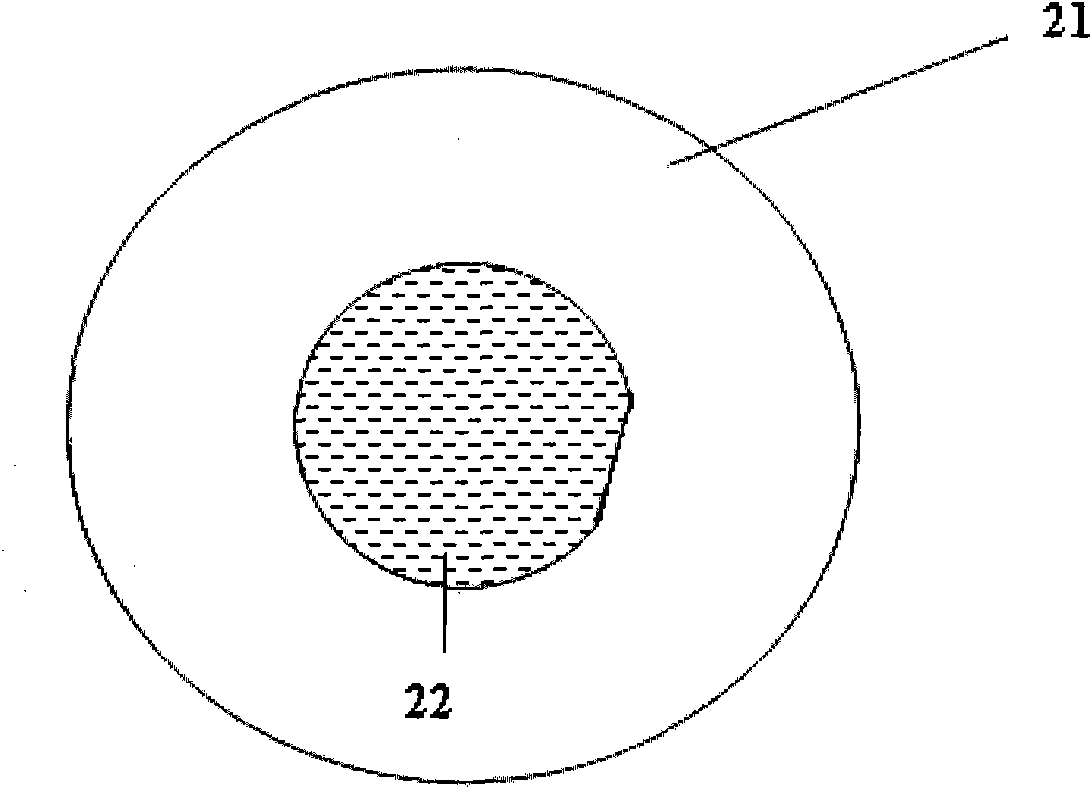

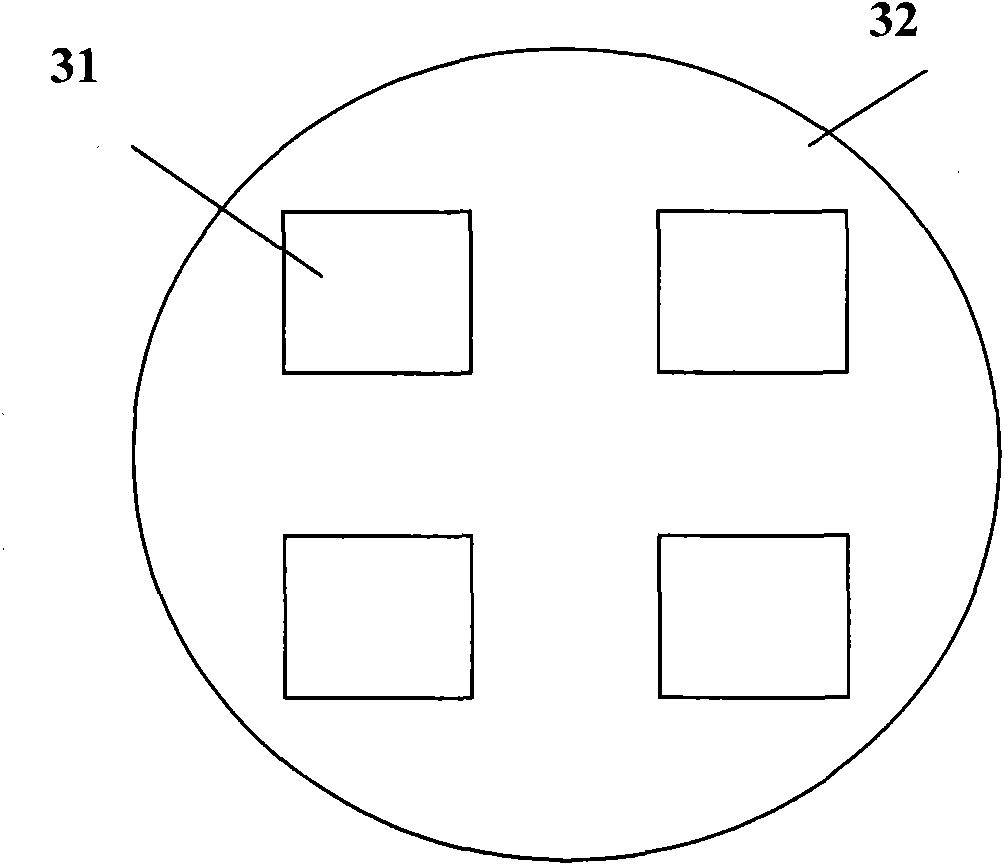

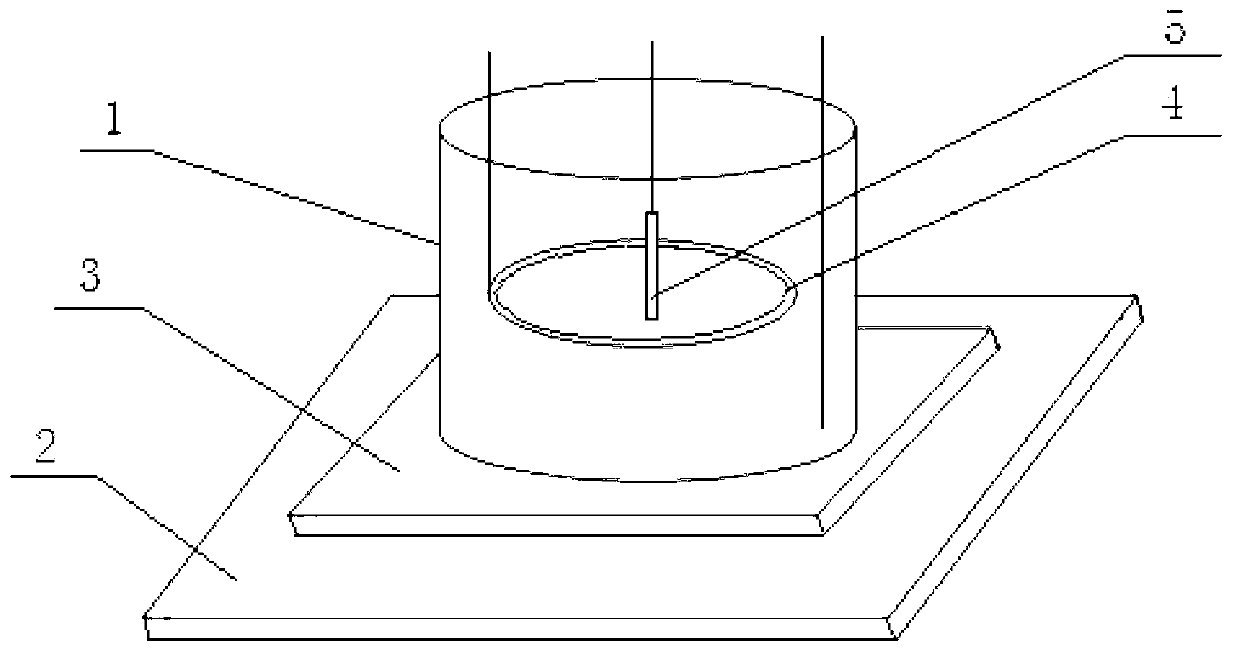

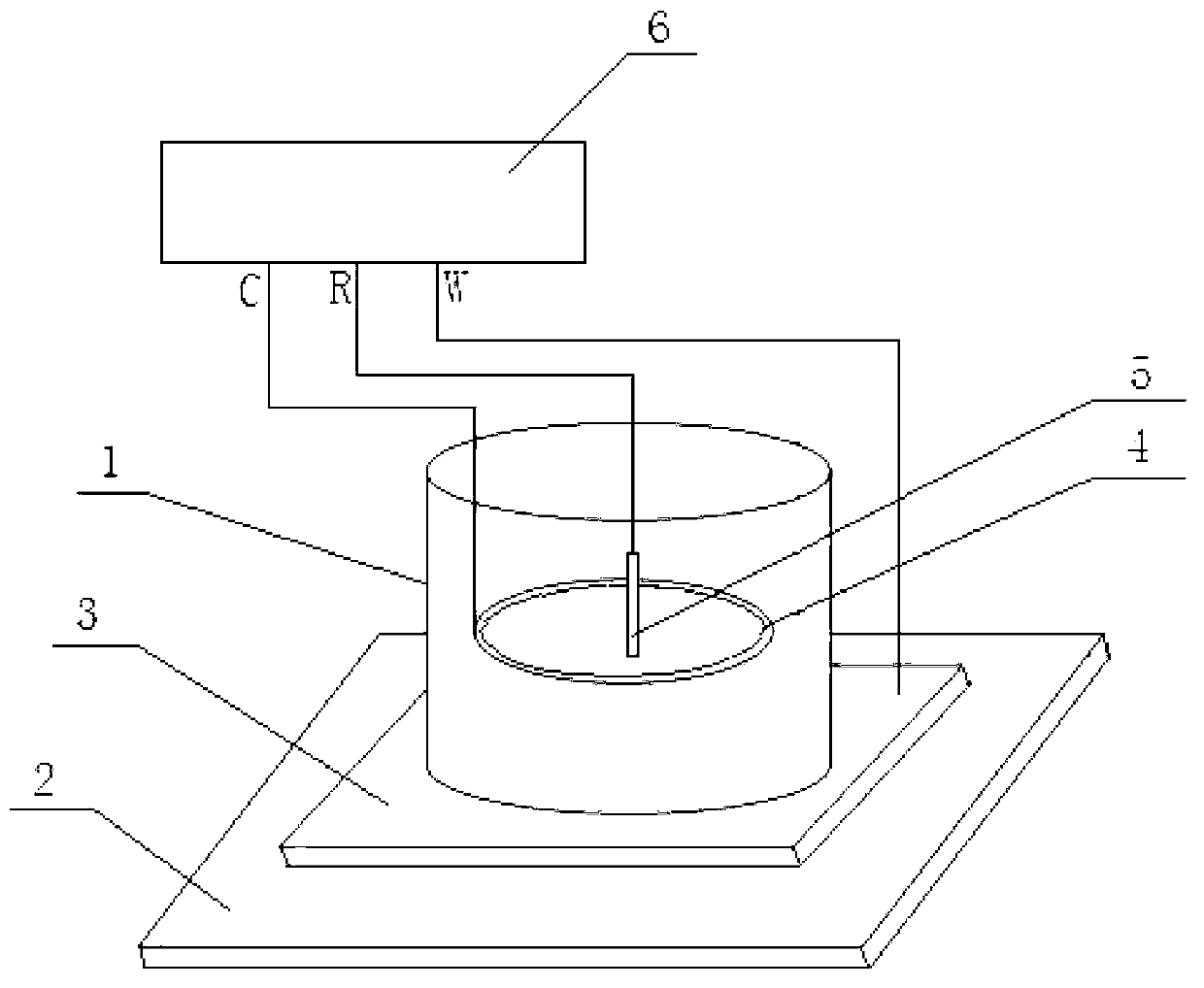

Device and method for processing semiconductor material through backward multifocal lasers and electrochemistry in combined manner

InactiveCN106735866APromotes electrochemical reactionsIncrease potential differenceOther manufacturing equipments/toolsLaser beam welding apparatusElectrochemical responseCorrosion

The invention provides a device and method for processing a semiconductor material through backward multifocal lasers and electrochemistry in a combined manner. The energy, frequency and wavelength of the lasers are regulated, and a multifocal laser beam acts on the back face of a semiconductor sample; on one hand, when the lasers radiate the back face of the semiconductor sample, a large amount of light can be stimulated in the semiconductor sample to generate holes, the holes move to the position of the surface of the polished semiconductor sample to participate in the electrochemistry reaction, and material corrosion removal is achieved; and on the other hand, on the back face of the semiconductor sample, the multifocal lasers gradually conduct processing inwards. A work electrode is a cathode, the semiconductor sample is used as an anode, and when the potential between the two electrodes is high, spark discharge processing is conducted; and when the potential is low, electrochemistry erosion removal is conducted. The multifocal lasers and electrochemistry act on the semiconductor sample in the combined manner, the corrosion efficiency is improved, and the surface quality of through holes is improved. When the high-precision micro-through-holes are processed in the semiconductor material, the combination effect is good in action effect, and the device and the method are suitable for precise processing.

Owner:JIANGSU UNIV

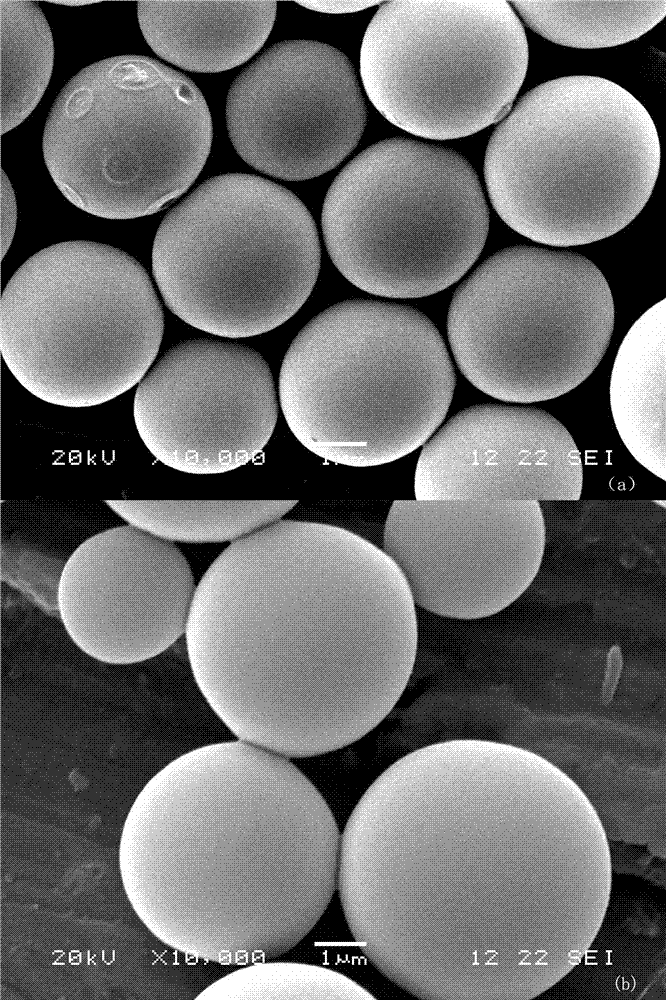

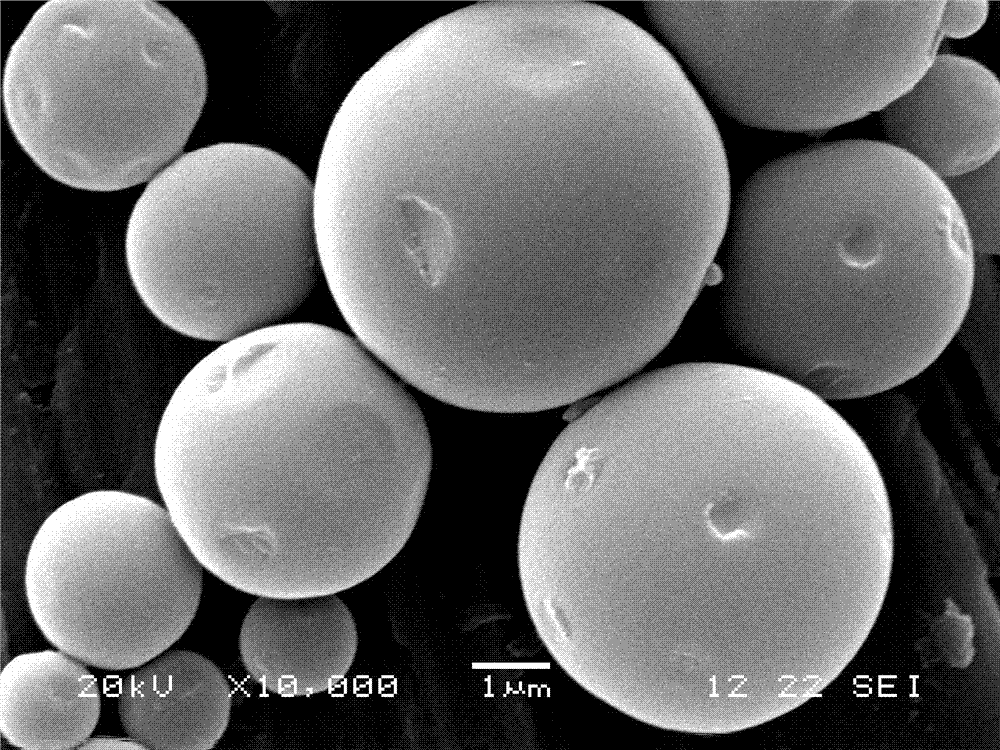

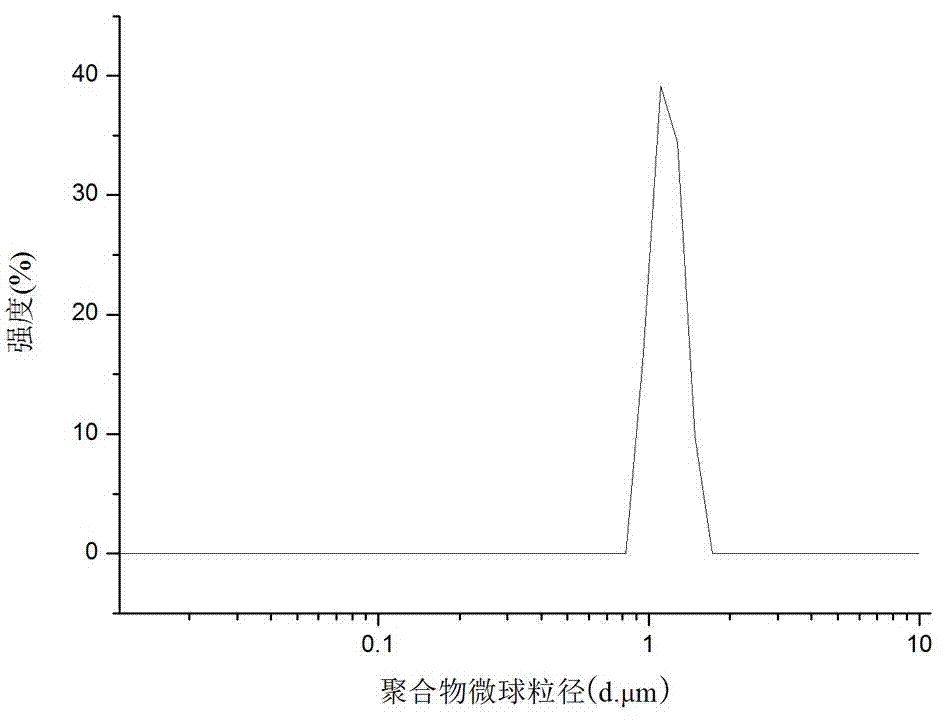

Method for preparing monodisperse polymer microspheres

InactiveCN102731698AStrong microscopic mixing propertiesStrong microscopic mixing properties effectively increase the frequency of molecular collisionsPolymer scienceUltracentrifuge

The invention relates to a method for preparing monodisperse polymer microspheres. The method comprises the following process steps: adding a dispersion medium with a stabilizing agent dissolved inside to an impinging stream reactor, heating the dispersion medium, adding a monomer with an initiating agent dissolved inside in one step, carrying out constant-temperature polymerization reaction, obtaining polymer microsphere emulsion after stopping cooling, then using an ultracentrifuge to carry out centrifugal sedimentation, adding absolute ethyl alcohol after removing supernatant, carrying out ultrasonic washing multiple times and drying the washed microspheres to constant weight, thus obtaining the monodisperse polymer microspheres. Compared with the prior art, the method has the following advantages: the prepared polymer microspheres have good apparent morphology, good smoothness and monodispersity and uniform grain sizes; the process is simple to operate; the grain sizes of the microspheres can be well controlled according to the formula; and the grain size range applicability is better.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

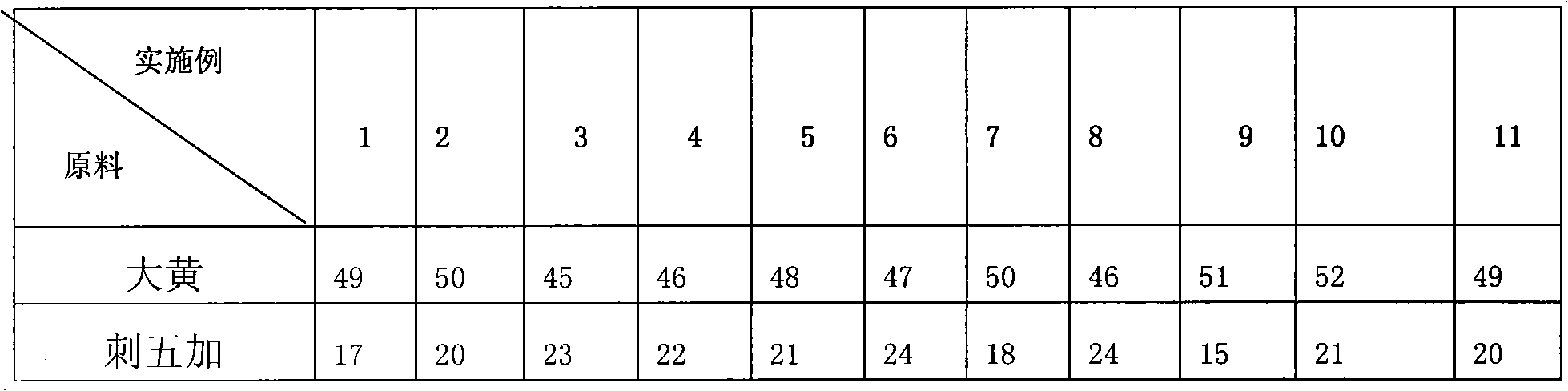

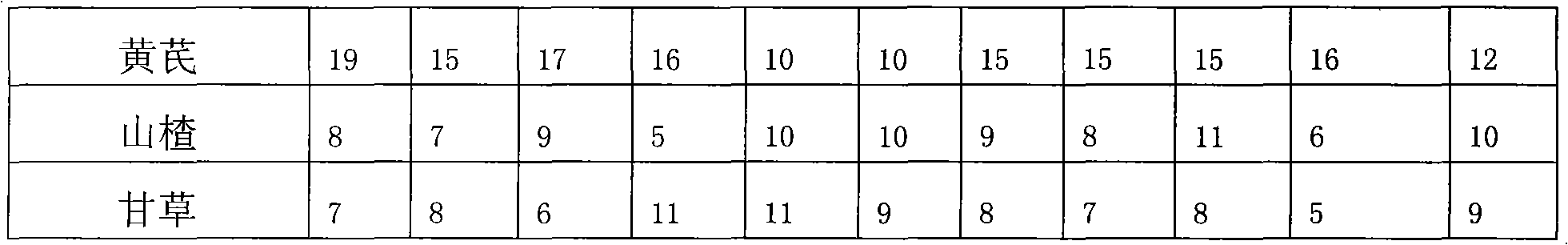

Fish compound traditional Chinese medicinal preparation and preparation method thereof

InactiveCN101829211ASolve the situation that there is no cure for intractable diseasesSolve the situation of no cureMetabolism disorderAntiinfectivesDiseaseHerbal preparations

The invention discloses a fish compound traditional Chinese medicinal preparation prepared from raw materials including rhubarb, acanthopanax, radix astragali, hawthorn and liquorice according a certain weight ratio. A method for preparing fish compound traditional Chinese medicinal preparation comprises the following steps of: A. washing and drying the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice in the sun; B. respectively crushing and sieving the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice to ensure the granularity reaches 140-200 mu; and C. weighing up the rhubarb, the acanthopanax, the radix astragali, the hawthorn and the liquorice according to the ratio and mixing and subpackaging after uniformly mixed to obtain the fish compound traditional Chinese medicinal preparation. The method has the advantages of feasibility, convenient operation, reasonable formulation and convenient use; traditional Chinese medicines have wide sources, low price, remarkable effects and no toxic or side effects; various components mutually act; and the invention simultaneously has two properties of nutrition and medicament, not only contains nutrient substances, but also has components with antibacterial activity and other bioactivities, can improve the metabolism of cultivated fishes, promote the growth and the development, improve the immunologic function, prevent and treat diseases and the like.

Owner:武汉中博水产生物技术有限公司

Method for polishing gallium nitride crystals

InactiveCN101673668AIncrease the rate of chemical reactionsImprove removal ratePolishing machinesSemiconductor/solid-state device manufacturingWater bathsWafering

The invention discloses a method for polishing gallium nitride crystals, comprising the following steps: sticking gallium nitride wafers on a quartz plate; grinding the gallium nitride wafers stuck onthe quartz plate by a grinder; heating up the polishing solution, irradiating the polished gallium nitride wafers by ultraviolet light and carrying out chemical mechanical polishing on the ground gallium nitride wafers by a polisher. In the method, based on the chemical mechanical polishing of the traditional gallium nitride wafers, the ultraviolet light is used for irradiating the wafers and a self-made water-bath heating system is simultaneously used for heating up the polishing solution, thus increasing the chemical reaction rate in the process of chemical mechanical polishing, and by adjusting the weight of the heavy objects, the physical removing effect and the chemical effect are balanced, thus not only solving the problem that the gallium nitride wafers are difficult to polish andincreasing the removal rates of N surface and Ga surface, but also obtaining satisfactory shiny surfaces. The method features obviously lower cost and simple process implementation and effectively increases the polishing efficiency.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Method for remedying soil polluted by organic chloride

ActiveCN101850358AImprove repair effectNo secondary pollutionContaminated soil reclamationHigh concentrationTherapeutic effect

The invention, which belongs to the field of polluted soil remediation, in particular to a method for remedying soil polluted by high concentration of organic chloride with a microwave-ultrasonic wave synergia technique. Organic chloride-polluted soil with a certain water ratio is treated under the irradiation of microwaves and ultrasonic waves, the microwave frequency is 300MHz to 300GHz, the power is 0.8kW to 20kW, the ultrasonic frequency is 20kHz to 100kHz, the power is 100W to 5kW, and the irradiation time is 3min to 120min. The organic chloride is mainly dichloro-diphenyl-trichloroethane, chlordane, mirex and the like. The method mainly utilizes the cavatition of ultrasonic waves and the thermal effect and non-thermal effect of microwaves to degrade organic chloride pollutants in the soil, the basic structure and properties of the soil are not destroyed in the process of efficiently degrading the organic chloride in the soil, the reaction time is short, the treatment effect is good, secondary pollution is not generated, and therefore the method has obvious economic and environmental effects.

Owner:NJTECH ENVIRONMENT TECH CO LTD

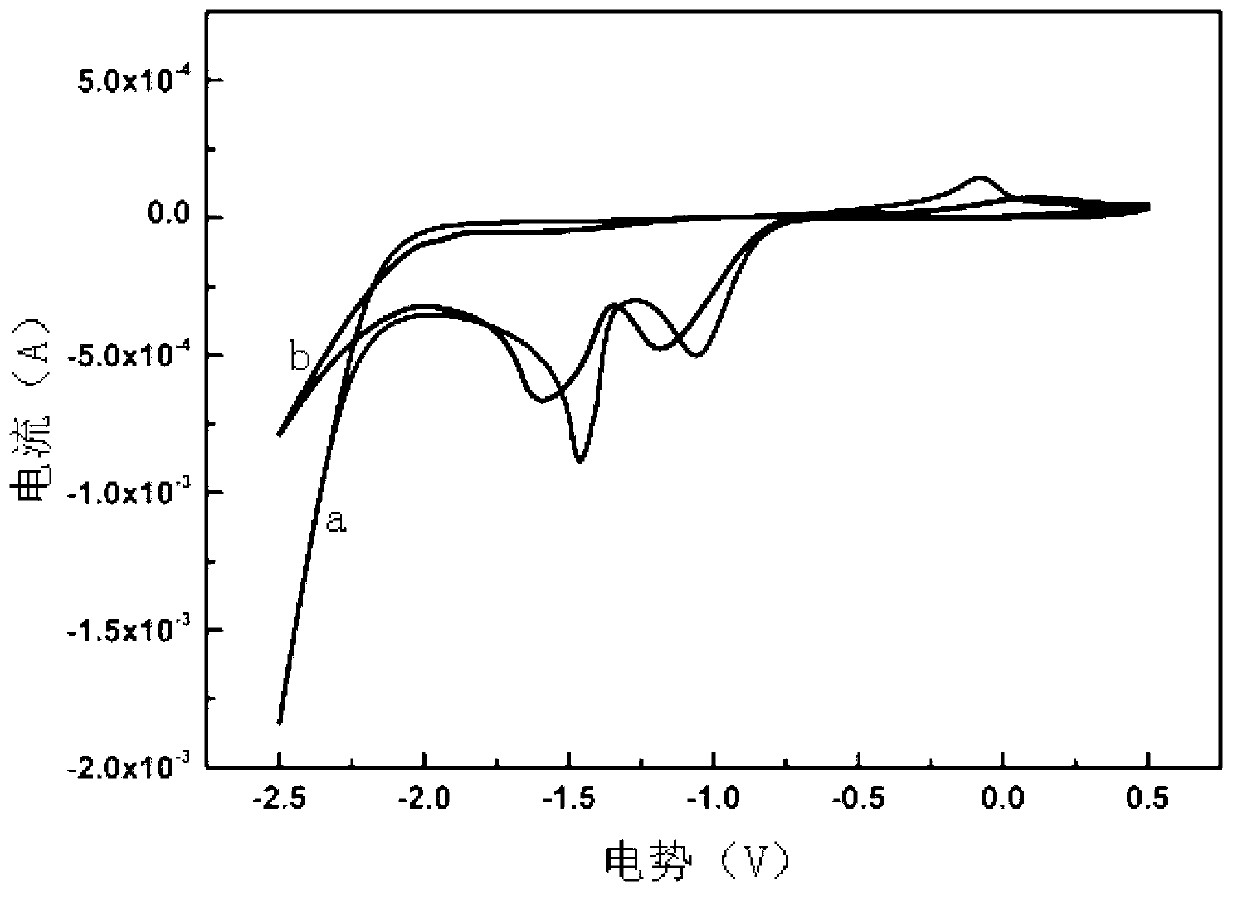

Method for preparing germanium nano cubic crystals through ionic liquid electro-deposition

The invention provides a method for preparing germanium nano cubic crystals through ionic liquid electro-deposition and relates to a preparation method of nano cubic crystal germanium. The method is used for solving the technical problem of difficulty in control and repetition in synthesis of nano cubic particles of germanium by the existing solvent synthetic method. The method comprises the following steps of: building an electrolytic tank for ultraviolet assisted electro-deposition in a glove box, wherein the electrolytic tank contains ionic liquid EmimTF2N electrolyte containing high-purity GeCl4; and then carrying out irradiation by using an ultraviolet lamp with the wavelength of 365nm; firstly, performing cyclic voltammetry curve scanning and then keeping ultraviolet irradiation, and then carrying out potentiostatic method based electro-deposition, and finally, cleaning the sample by using anhydrous isopropyl alcohol, thus obtaining the germanium nano cubic crystals. The method provided by the invention is simple in process and convenient to operate. Besides, the obtained germanium thin film deposited with germanium nano cubic crystals can be applied to a photoluminescent device and the like.

Owner:HARBIN INST OF TECH

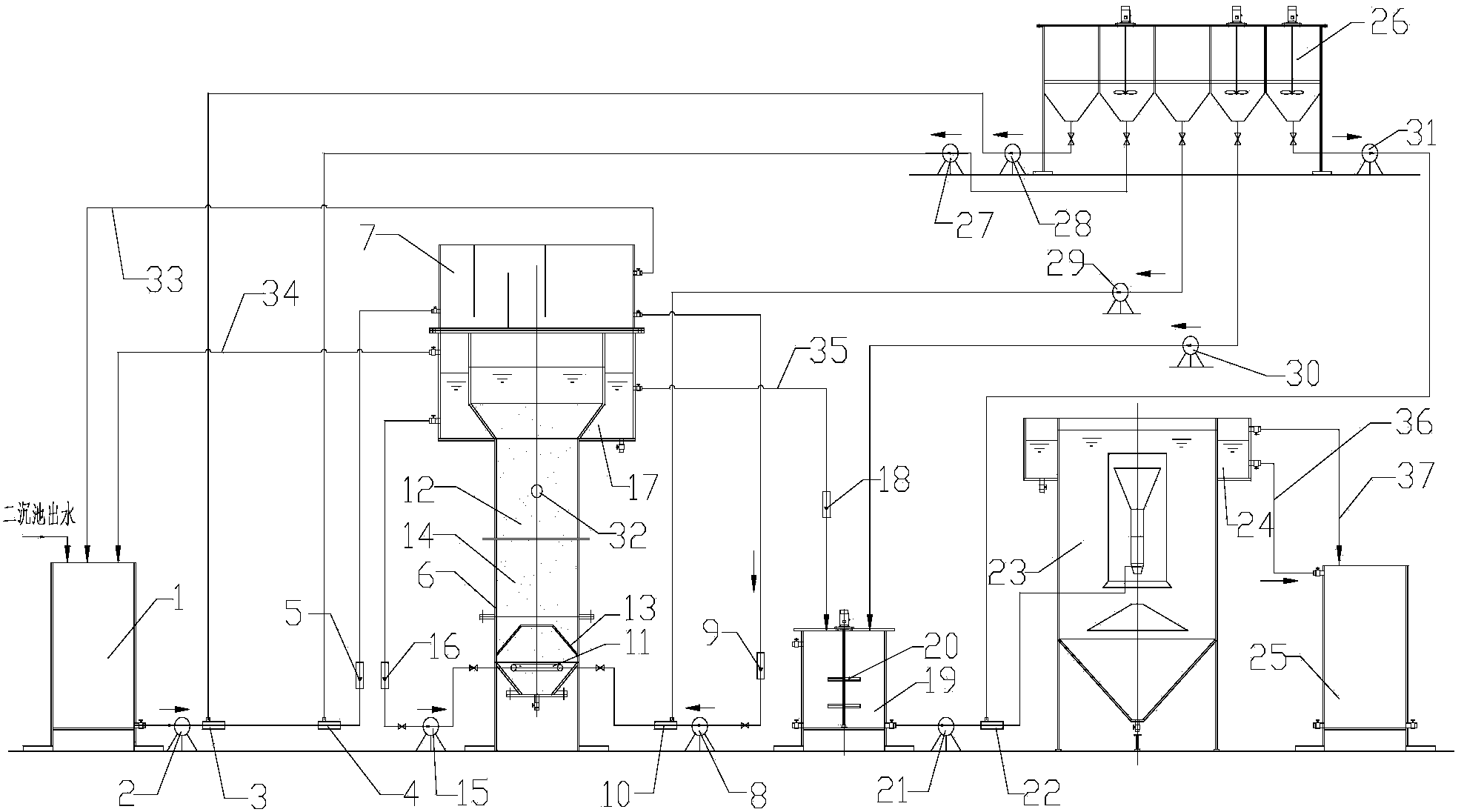

Device and method for treating pulping wastewater by Fenton catalytic oxidation method

InactiveCN103771625AHigh speedHigh degree of fluidizationMultistage water/sewage treatmentSludgeCatalytic oxidation

The invention discloses a device and method for treating pulping wastewater by a Fenton catalytic oxidation method. The device comprises a water collecting tank, a catalytic oxidation tower, a neutralization tank, a coagulative precipitation tower, a clean water tank and a medicament preparation system, wherein a balance regulating tank at the top of the catalytic oxidation tower is connected with the water collecting tank through a pipeline; the balance regulating tank is connected with a water distribution pipe at the bottom of a fluidized catalytic reaction column of the catalytic oxidation tower through a pipeline; a circulating water outlet tank is connected with the water distribution pipe through a pipeline; the neutralization tank is connected with a water distribution pipe of the coagulative precipitation tower through a pipeline; an outlet water tank is arranged on the external wall of the upper part of the coagulative precipitation tower, and the top of the coagulative precipitation tower is connected with the outlet water tank through an overflow port. The method comprises the steps of carrying out balance regulating treatment, carrying out fluidized catalytic oxidation treatment, carrying out coagulative precipitation and purifying. According to the device and the method, by using efficient mass transfer efficiency under fluidized conditions, a relatively high wastewater treatment effect is achieved under the condition that the dosage of hydrogen peroxide and ferrous ions is relatively low, so that the wastewater treatment efficiency is increased, and meanwhile, the amount of generated sludge is reduced.

Owner:SOUTH CHINA UNIV OF TECH

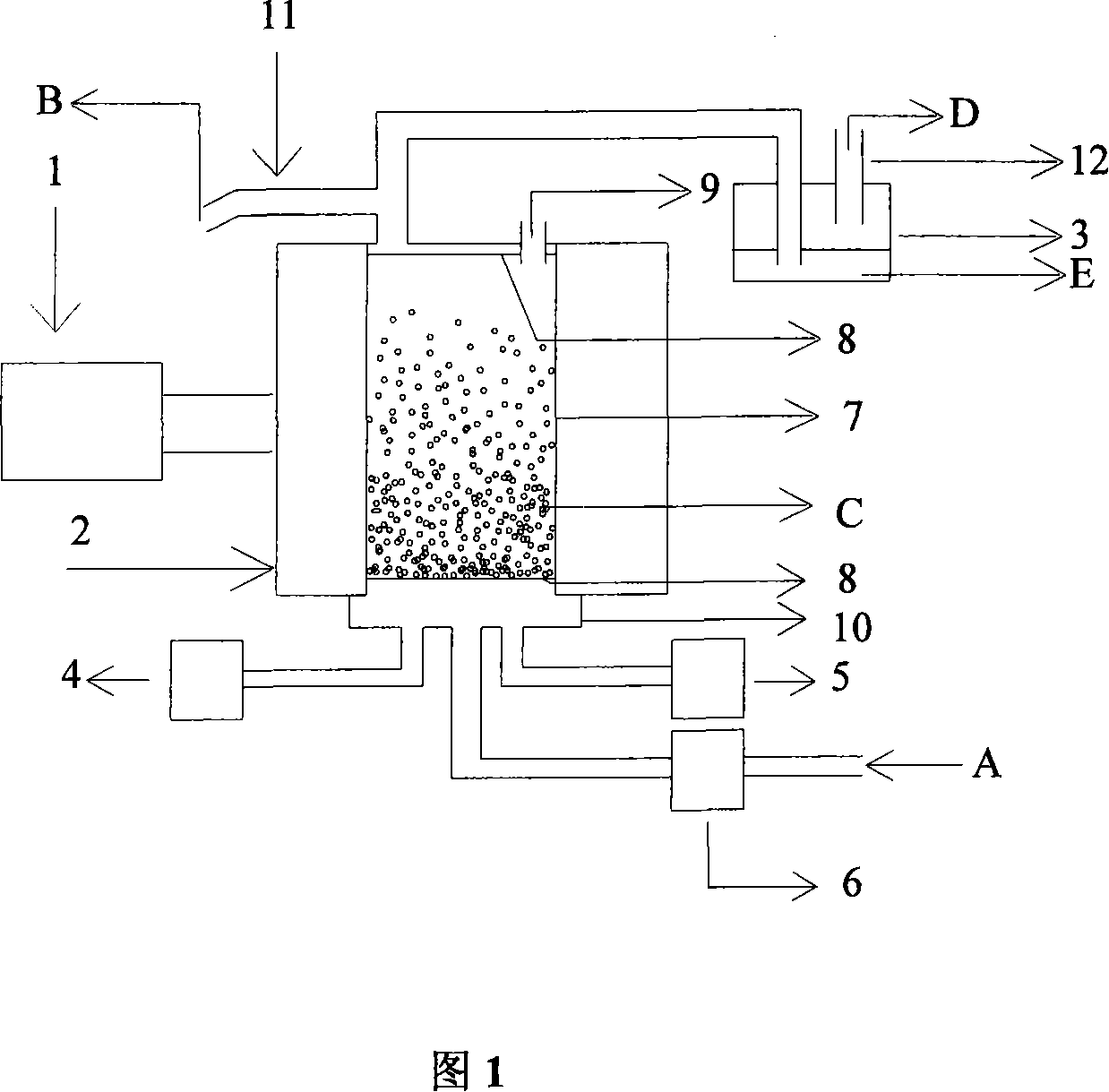

Oxidation strengthening technique and device for processing organic poison waste water

ActiveCN101148287ALow costLess investmentWater/sewage treatment by oxidationCatalytic oxidationWastewater

The present invention relates to reinforced oxidizing process of treating waste water containing toxic organic matter. By means of the excitation of externally applied energy, catalyst, oxidant and oxygen generate synergistic effect to produce strongly oxidizing ozone and free hydroxyl group degrading toxic organic matter, the catalyst being in fluidized or semi-fluidized state during the reaction. The present invention also provides the technological apparatus, which consists of one energy generator, one reactor, one tail gas collector, one water distributor and one water inflow pump. The present invention has short treating period, high treating efficiency and great treating capacity.

Owner:NJTECH ENVIRONMENT TECH CO LTD

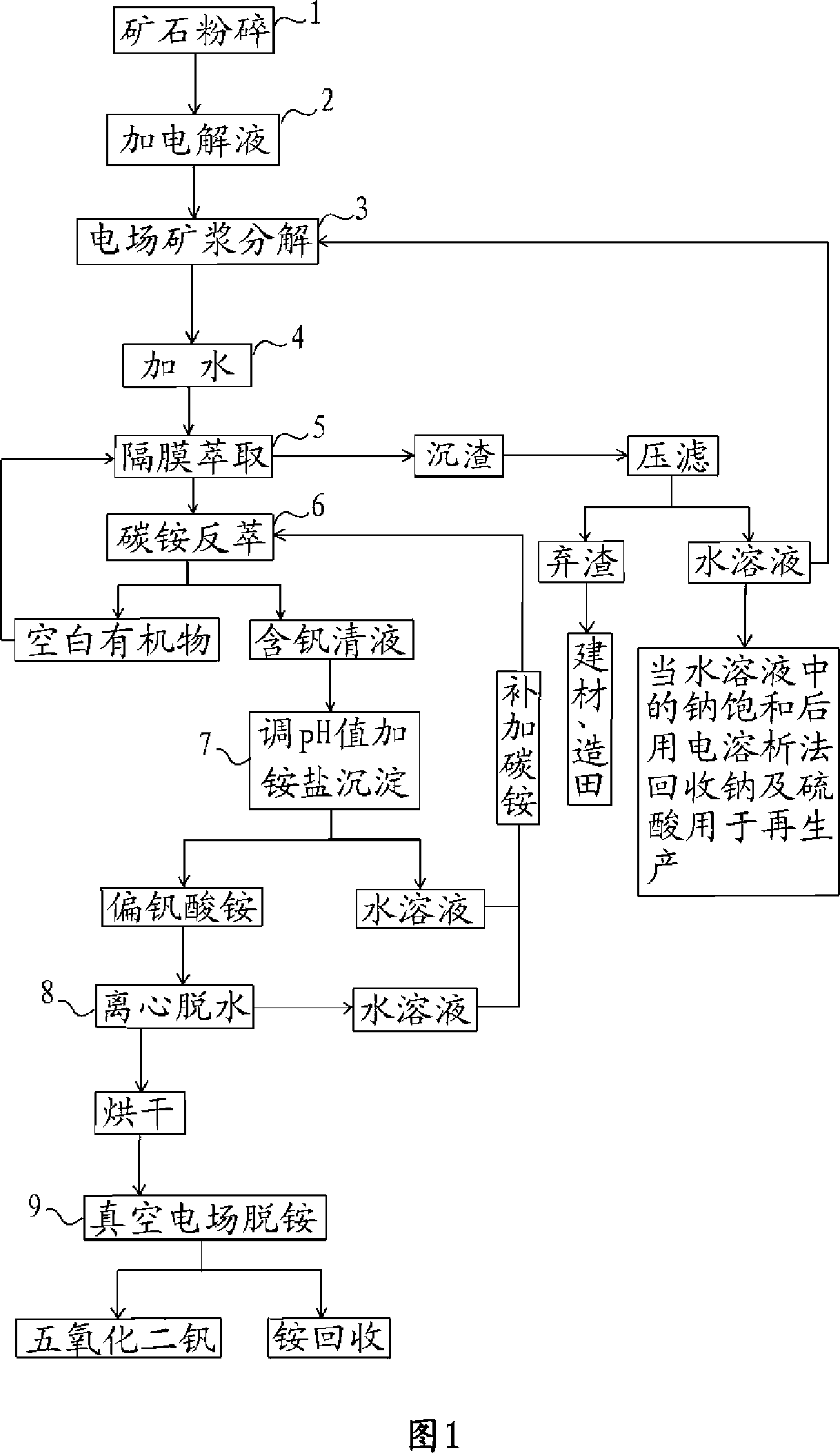

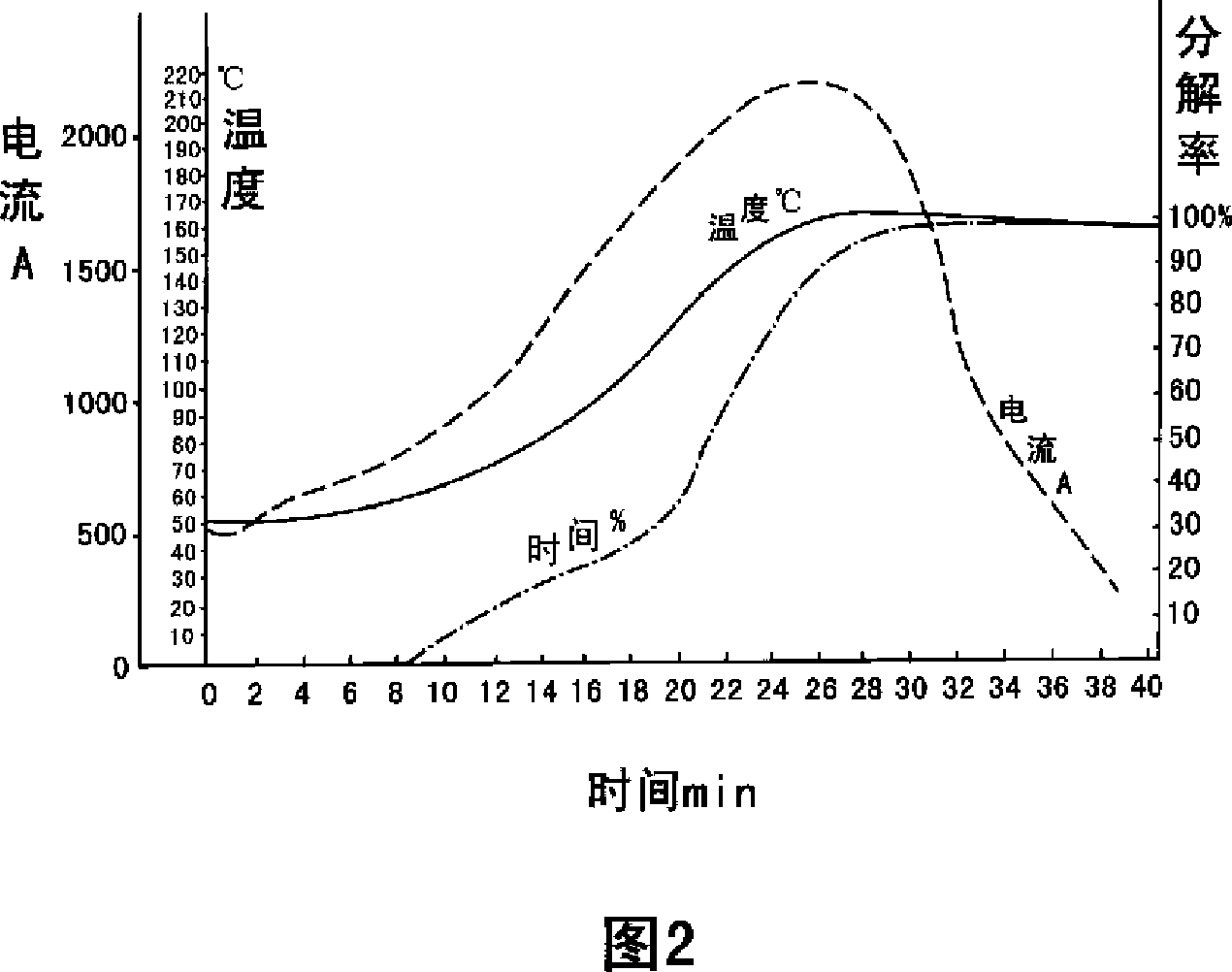

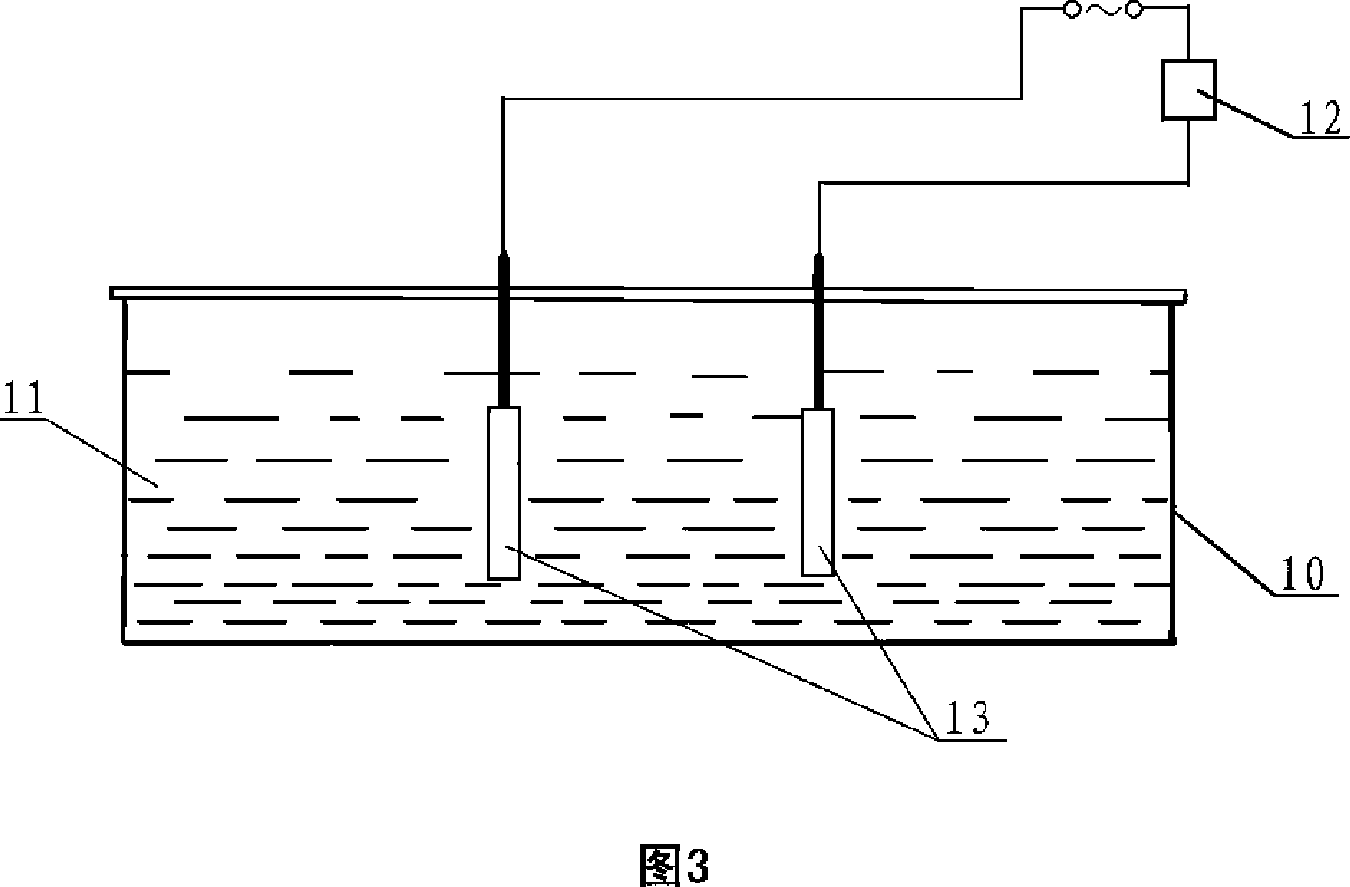

Method for electrolyzing vanadium slurry and extracting vanadium pentexide using film

InactiveCN101008047ASpeed up the extraction processHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisAmmonium metavanadate

The invention relates to a method for preparing vanadic anhydride through electric field disintegrating vanadium ore diaphragm extraction, comprising following steps: disintegrating vanadium ore, grinding into vanadium- containing powdered ore of 100- 250 order; mixing vanadium- containing slurry with liquid and solid ratio being 1: 1.5 - 2 with vanadium- containing powdered ore and electrolytic solution; putting vanadium- containing slurry into alternating current field decomposer for electrolysis, the voltage of electric field is 0 -110 voltage, current is 0- 3000 A, the discharging disintegrating time is 30- 90 minutes, and stopping when vanadium- containing slurry becomes into solid; adding water for diluting and extracting vanadium with diaphragm; feeding got organic phase for teschemacherite back extraction, adding ammonium salt into vanadium- containing liquid, heating and stirring, cooling and aging, getting ammonium vanadate and water solution. The invention is characterized by short production cycle, no pollution, low energy consumption, small investment for production device, small occupying area and high vanadium recovering rate.

Owner:襄阳中经九丰矿业科技有限公司

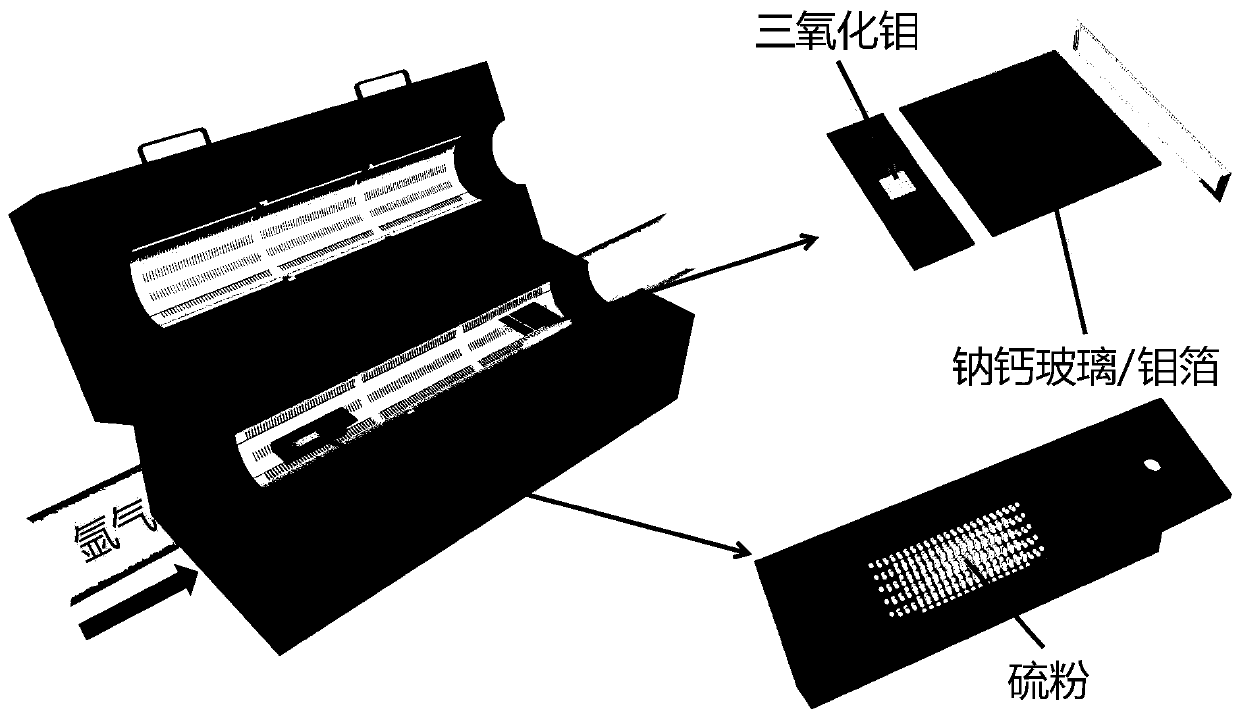

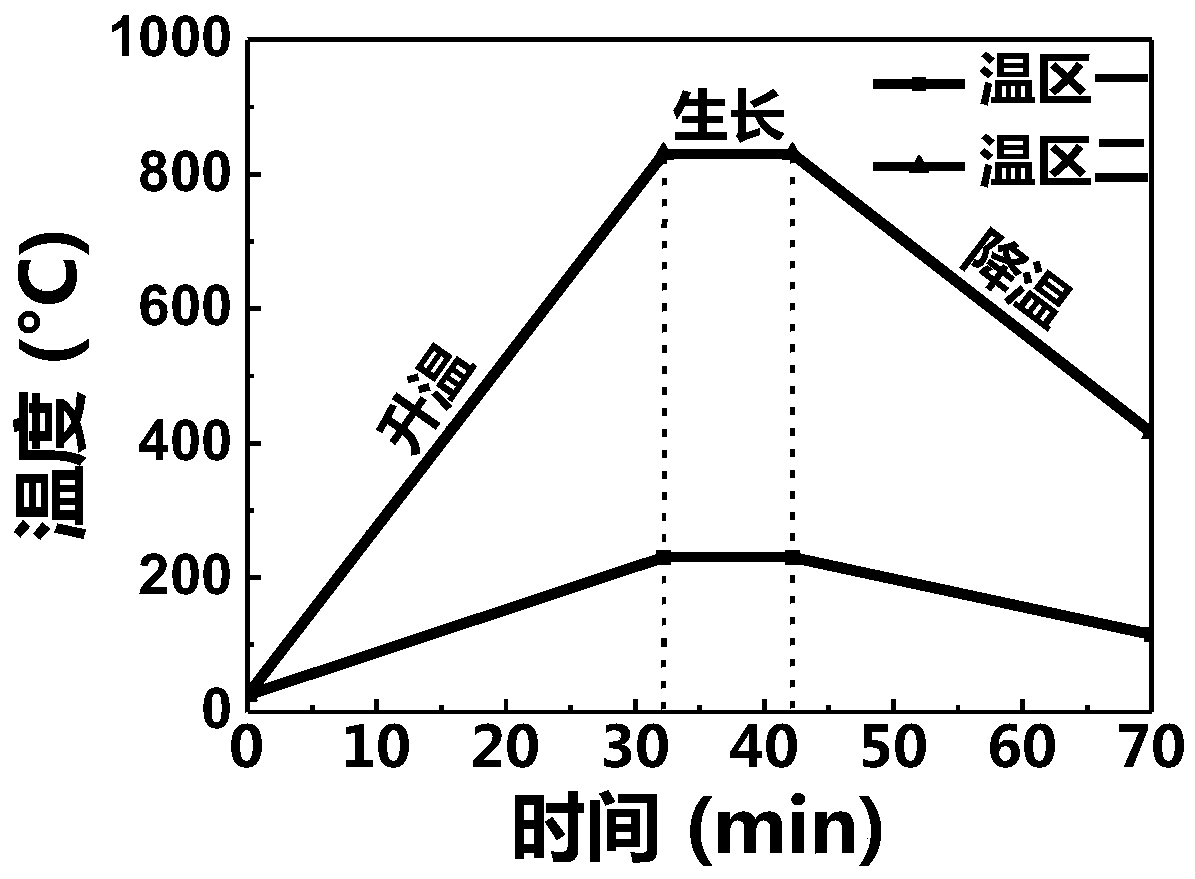

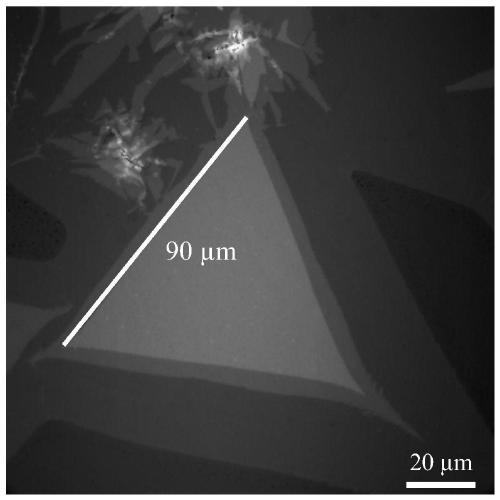

Chemical vapor deposition preparing method of large-size three-layer molybdenum sulfide single crystal

ActiveCN110172736AHigh personal experience requirementsEasy to operatePolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

The invention belongs to the field of two-dimensional material preparation, and discloses a chemical vapor deposition preparing method of a large-size three-layer molybdenum sulfide single crystal. The method is characterized by including the following steps of S1, preparing clean and dry molybdenum foil and soda-lime glass, and weighing elemental sulfur and molybdenum trioxide as precursors; S2,putting a first carrying boat with molybdenum foil, soda-lime glass and molybdenum trioxide and a second carrying boat with elemental sulfur into a chemical vapor deposition (CVD) pipe; S3, conductingdual-temperature-area temperature control CVD on the CVD pipe so that the three-layer molybdenum sulfide single crystal can deposit on the soda-lime glass. By improving the substrate material and thedual-temperature-area temperature arrangement of the key CVD process in the preparing method, compared with the prior art, the novel method for preparing the large-size three-layer molybdenum sulfidesingle crystal is provided, the maximum internal length of the obtained large-size three-layer molybdenum sulfide single crystal can reach 90 micron, and the prepared three-layer molybdenum sulfide single crystal is high in quality.

Owner:HUAZHONG UNIV OF SCI & TECH

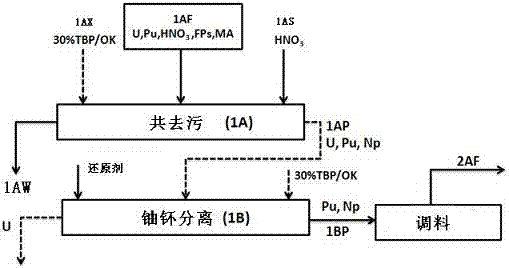

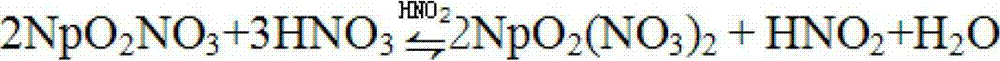

Method for coextracting uranium, plutonium and neptunium

ActiveCN102776372AHigh yieldLow extraction rateNuclear energy generationRecycling and recovery technologiesAfter treatmentPu element

The invention belongs to the technical field of nuclear fuel cycles, and discloses a method for coextracting uranium, plutonium and neptunium. The method is implemented in a way that: neptunium is coextracted with uranium and plutonium at the co-decontamination section, so that the neptunium enters an organic phase 1AP. The key point is to oxidate Np (V) in an extraction apparatus 1A into Np (VI) which can be extracted by the extraction apparatus. The method implements high yields of uraniumm, plutonium and neptunium, does not increase the salt content in the after-treatment process, and can implement quantitative extraction of the uranium, plutonium and neptunium.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Continuous rotary knocking engine

PendingCN110425045AEnhanced ignition effectRapid Formation and Stable SpreadGas turbine plantsJet propulsion plantsHigh concentrationCombustion chamber

The invention provides a continuous rotary knocking engine. The engine comprises an inner shell, an outer shell, an insulating sleeve, an ignition core and an insulating connecting piece, the outer shell comprises a front part and a rear part, the front part and the inner shell together form an annular airflow channel, the rear part is electrically connected with the low-voltage end of a high-voltage power supply, an annular combustion chamber is formed by the insulating sleeve and the rear part, and the ignition core is electrically connected with the high-voltage end of the high-voltage power supply. When the continuous rotary detonation engine is connected with the high-voltage power supply, a large-volume and high-concentration low-temperature plasma discharge streamer is generated inthe annular combustion chamber, further, when the voltage difference between the low-voltage end and the high-voltage end of the high-voltage power supply is large enough, the low-temperature plasma discharge streamer inside the annular combustion chamber is converted into a large amount of discharge streamer filaments and generates a large amount of active substances, explosible mixed gas in theannular combustion chamber is broken down and is subjected to rotary knocking combustion, due to the fact that the chemical reaction rate is accelerated by the active substances, the ignition effect is enhanced, and therefore the time from detonation to knocking is shortened.

Owner:TSINGHUA UNIV

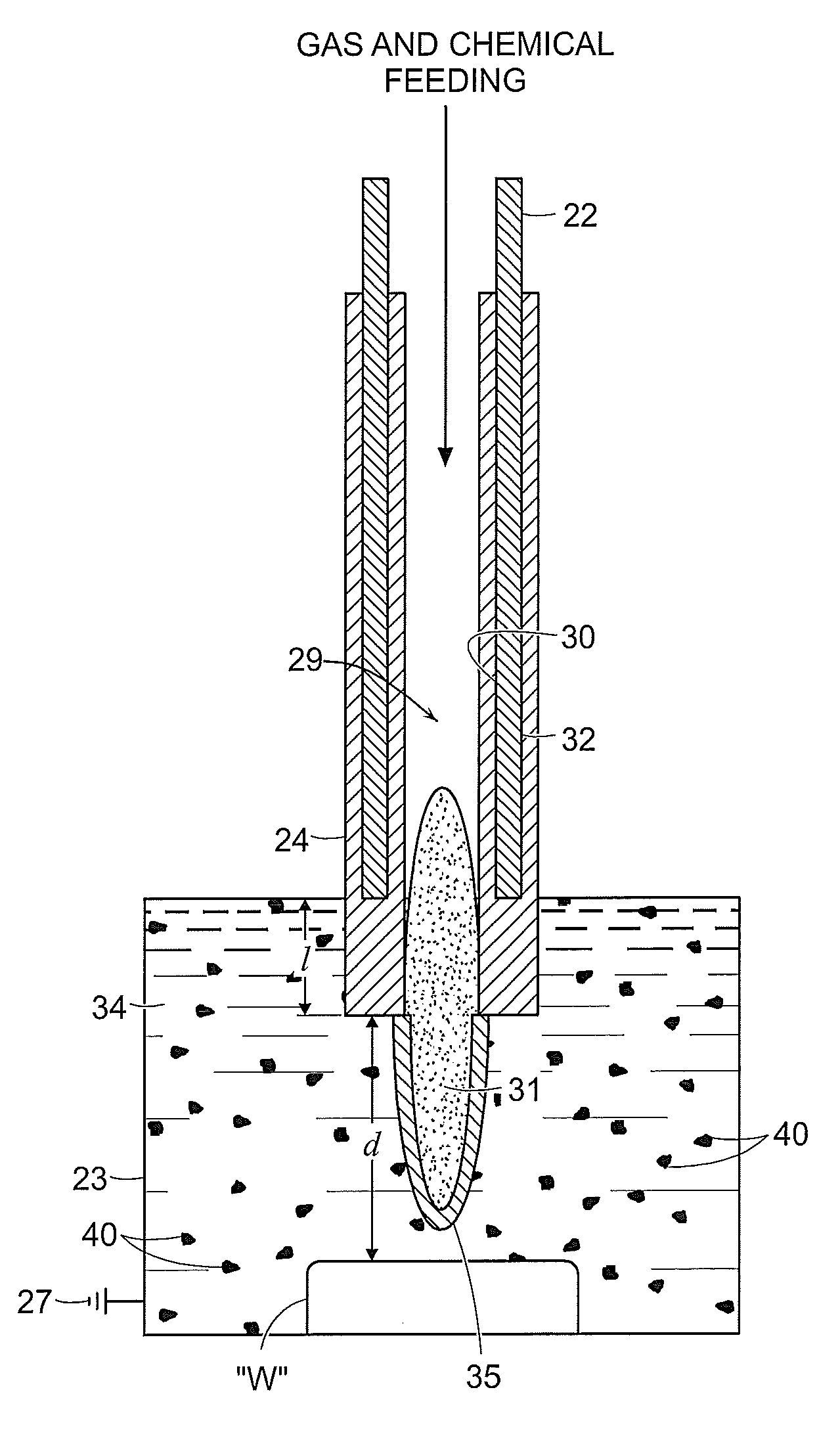

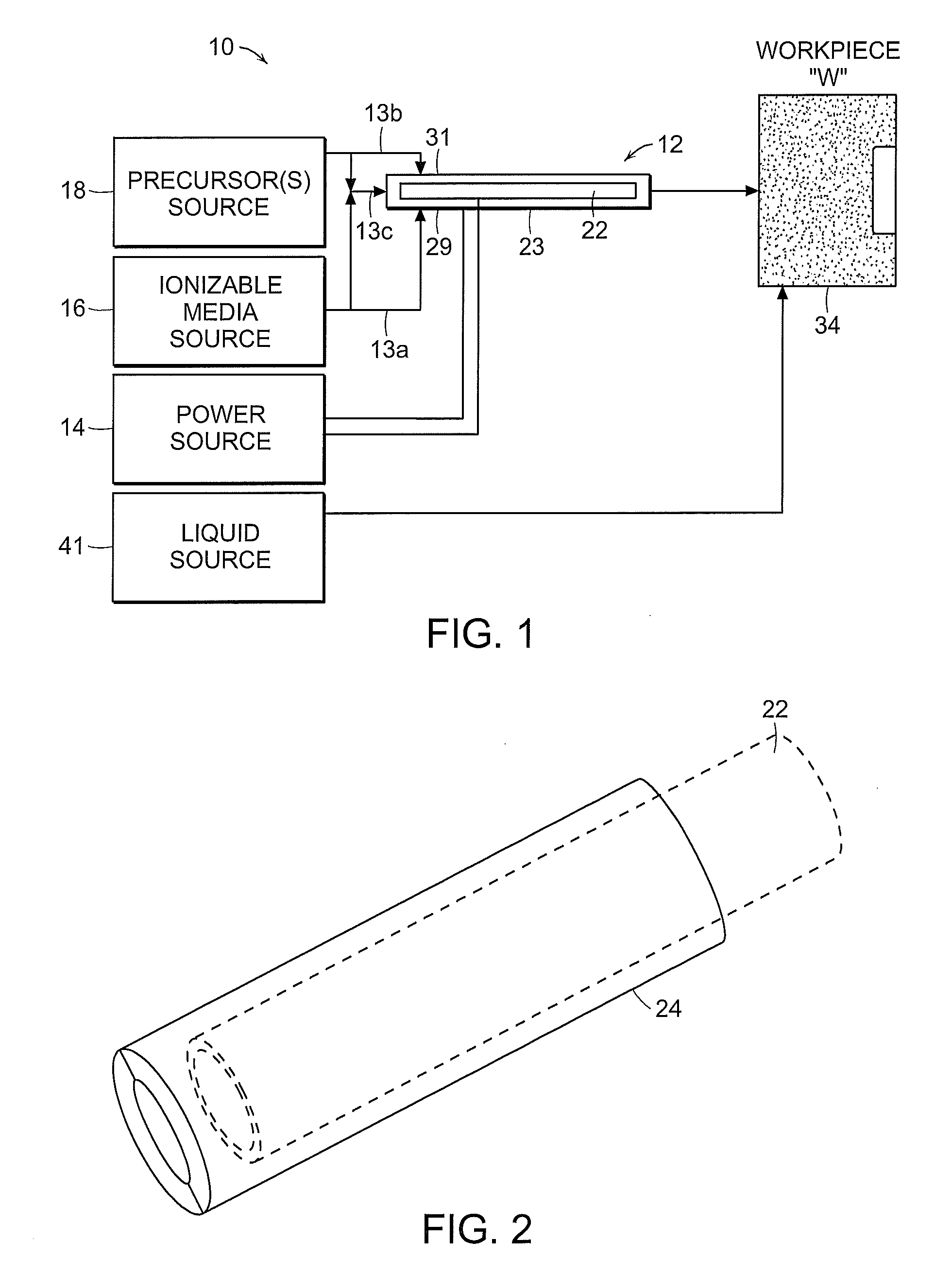

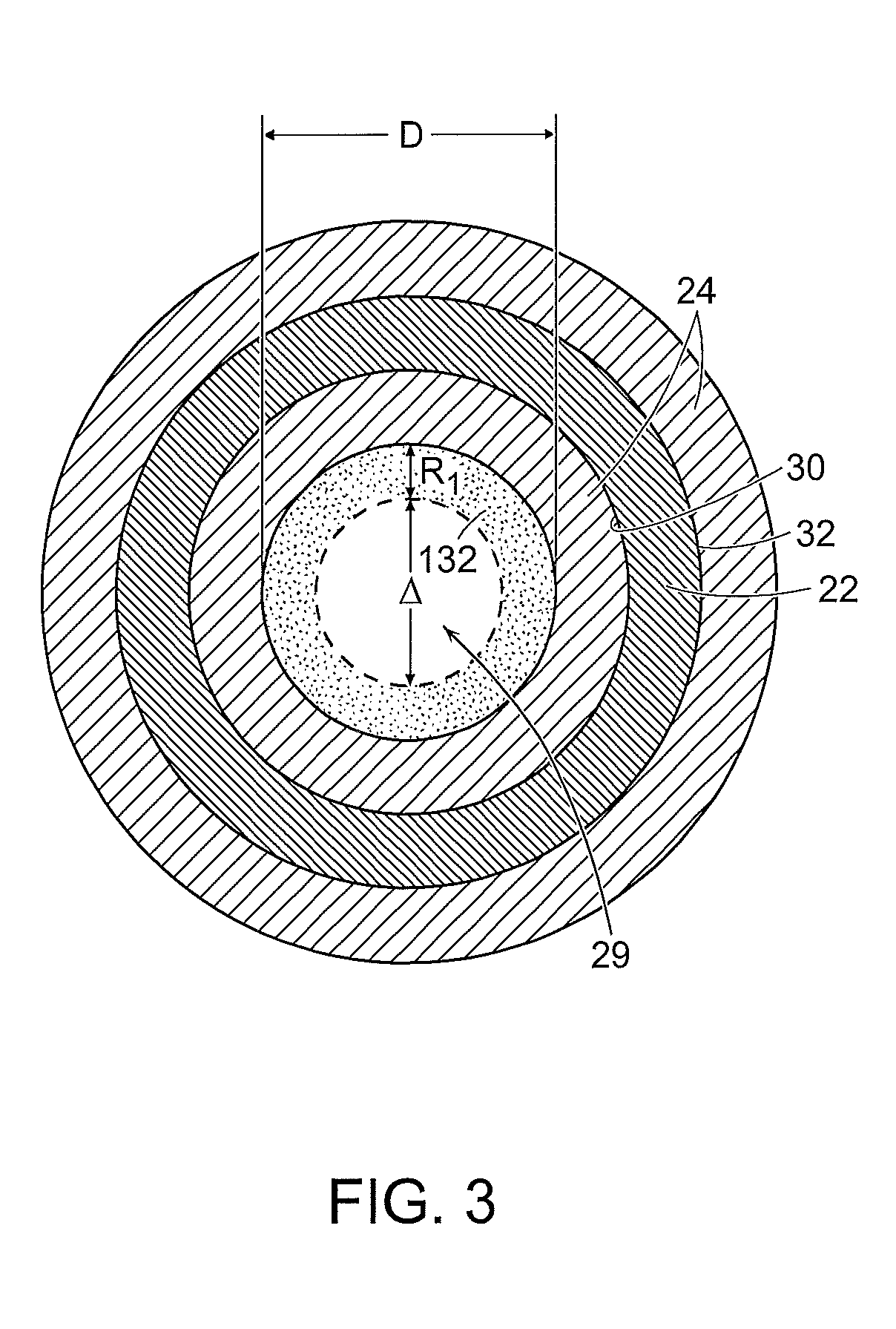

Liquid-gas interface plasma device

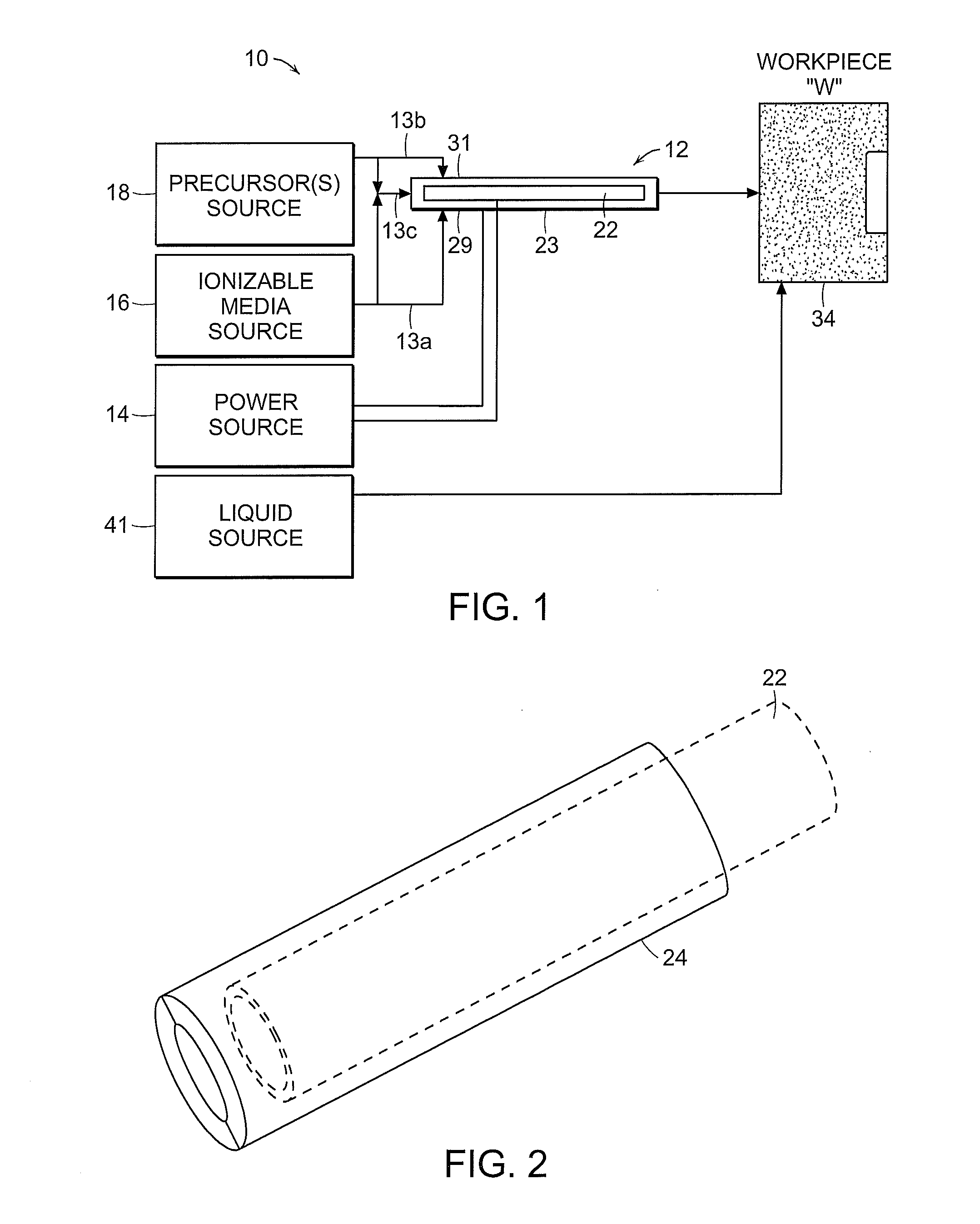

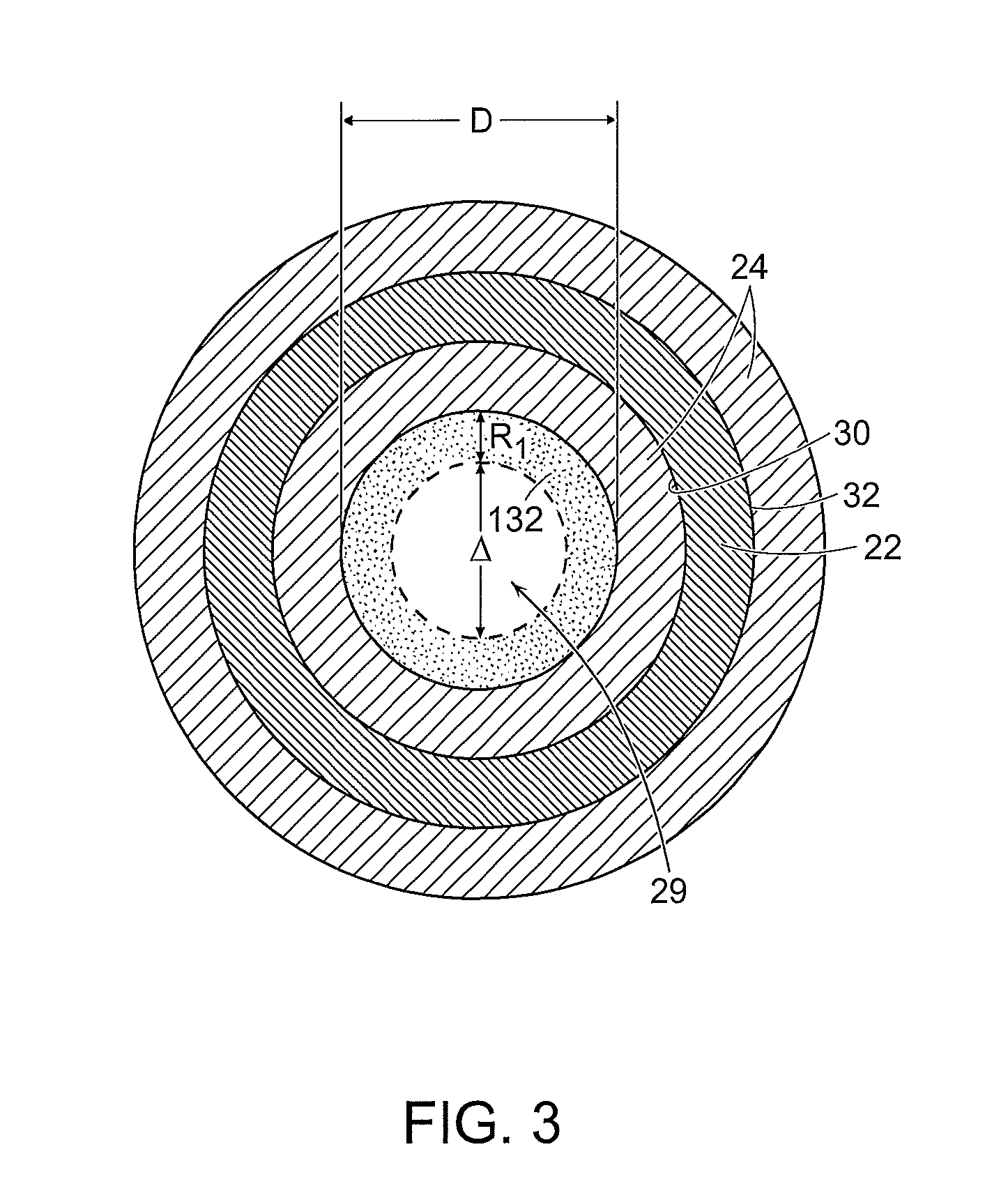

ActiveUS20130059273A1Broad applicabilityWide applicabilityGum massageTooth cleaningDistal portionForeign matter

A method for whitening teeth is disclosed. The method includes supplying a liquid sufficient to at least partially submerge a portion of a tooth; positioning a plasma device adjacent to the submerged portion of the tooth; supplying ionizable media to the plasma device; and igniting the ionizable media at the plasma device sufficient to form a plasma effluent in the presence of the liquid at the distal portion, whereby the plasma effluent reacts with the liquid to form at least one reactive species that interacts selectively with foreign matter disposed on the tooth.

Owner:COLORADO STATE UNIVERSITY

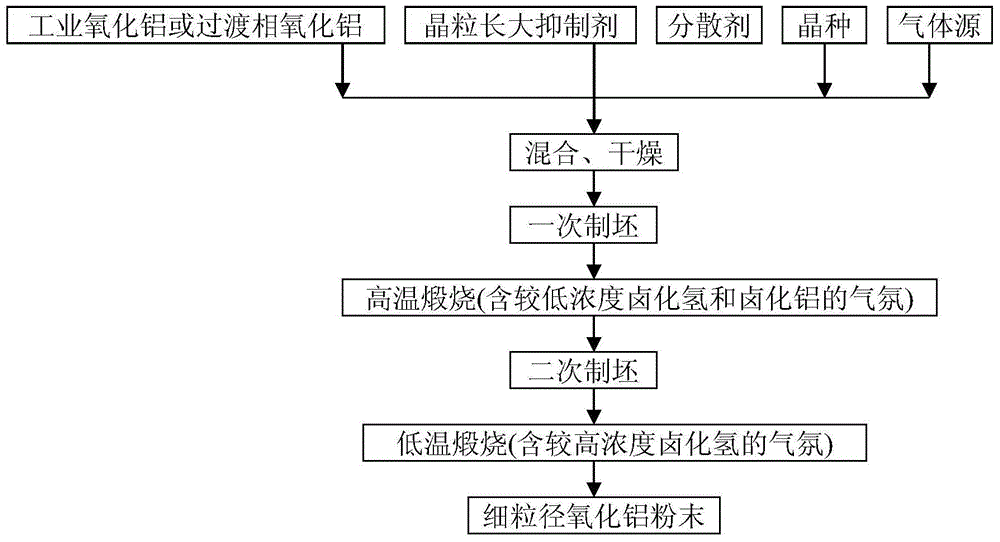

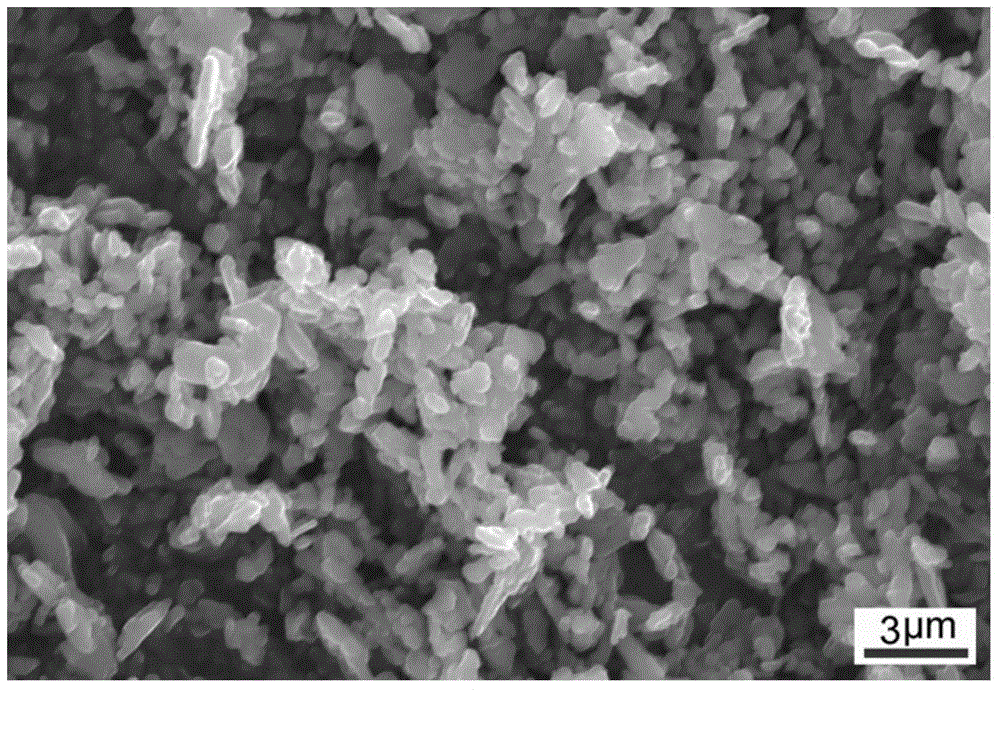

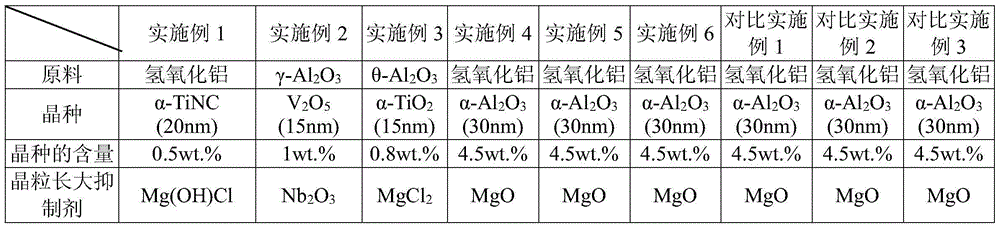

Method for preparing small-particle-size aluminium oxide powder

ActiveCN104528787AProlong the action timeIncrease the speed of diffusionAluminium oxides/hydroxidesHydrogen halideHigh concentration

The invention provides a method for preparing small-particle-size aluminium oxide powder, and belongs to the technical field of powder preparation and particle size control. The process flow is as follows: by taking industrial aluminium hydroxide or transition-phase aluminium oxide powder as a raw material, adding a seed crystal, a dispersant, a particle size control component and a gas-phase source in the raw material powder, and uniformly mixing the raw material powder and then pressing to form a blank; calcining the blank in an atmosphere containing hydrogen halide and the particle size control component at a high temperature, breaking the calcined blank into powder, secondarily forming and then calcining in an atmosphere containing high-concentration hydrogen halide at a low temperature to obtain the submicron-scale or nanoscale aluminium oxide powder with a particle size of less than 0.14mu m and an alpha-Al2O3 content of 100%. The method provided by the invention is low in reaction temperature, short in reaction time and simple in process; the obtained aluminium oxide powder is good in dispersibility.

Owner:贵州天合国润高新材料科技有限公司

Technology for simultaneously preparing metallic magnesium and calcium carbide through carbothermal method

The invention discloses a technology for simultaneously preparing metallic magnesium and calcium carbide through a carbothermal method and belongs to the field of metallic magnesium smelting. The technology comprises the preparation steps that firstly, a magnesium oxide, a calcium oxide, a carbonaceous reducing agent and a fluorite catalyst are prepared according to the weight ratio of components; secondly, the prepared materials are mixed uniformly and then placed into a ball grinding mill with a screen to be ground and screened, and materials with different finenesses are obtained; thirdly, the screened materials are mixed uniformly and then sent into a high-pressure double-roller ball press machine to be pressed into balls and dried; and fourthly, the balls are placed into a vacuum reactor, the vacuum reactor is vacuumized, and metallic magnesium steam and the calcium carbide are produced under a certain pressure and a certain pressure. By utilizing the magnesium oxide and the calcium oxide, the magnesium and the calcium carbide can be produced simultaneously, energy sources are saved, environmental pollution is reduced, and the raw material utilization rate is increased greatly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

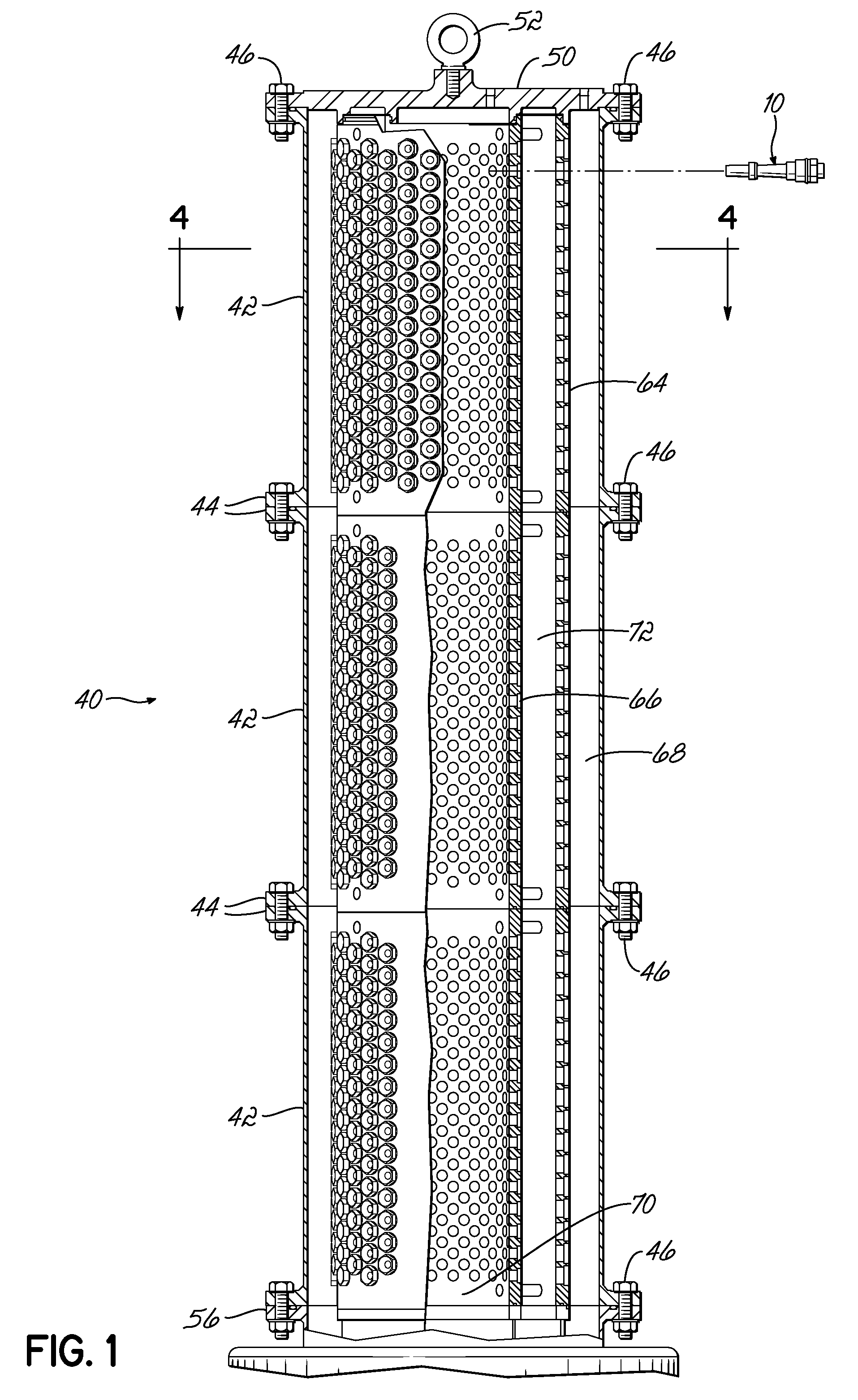

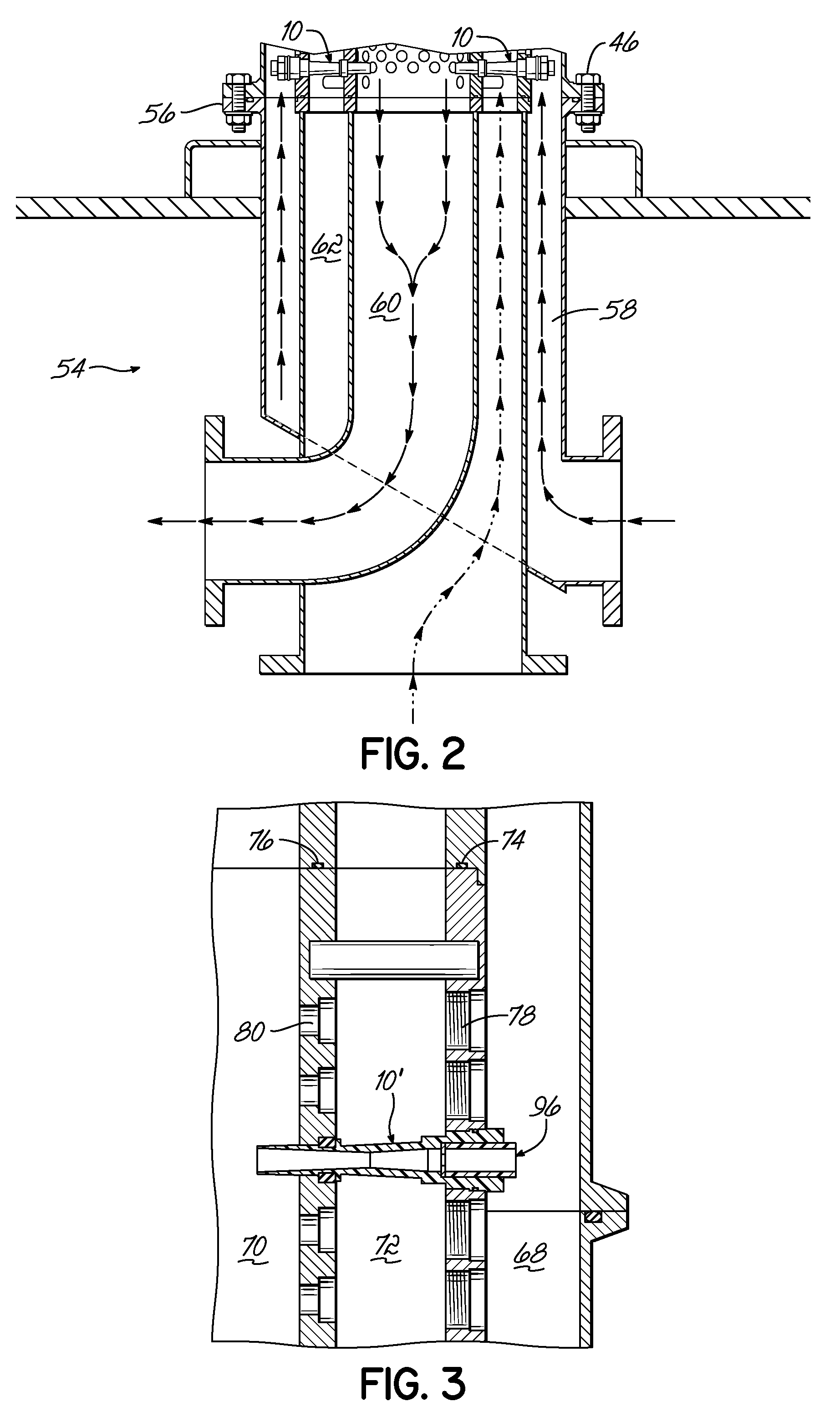

Liquid treatment apparatus and methods

InactiveUS20100237023A1Small sizeIncrease vacuumReversed direction vortexWater/sewage treatment with mechanical oscillationsCavitationDissolution

Apparatus and methods for treatment of liquids by generating hydroxyl radicals through the dissolution of water molecules by hydraulic cavitation.

Owner:FLUID QUIP INC

Liquid-gas interface plasma device

ActiveUS9028656B2Wide applicabilityHigh controlGum massageTooth cleaningForeign matterDistal portion

A method for whitening teeth is disclosed. The method includes supplying a liquid sufficient to at least partially submerge a portion of a tooth; positioning a plasma device adjacent to the submerged portion of the tooth; supplying ionizable media to the plasma device; and igniting the ionizable media at the plasma device sufficient to form a plasma effluent in the presence of the liquid at the distal portion, whereby the plasma effluent reacts with the liquid to form at least one reactive species that interacts selectively with foreign matter disposed on the tooth.

Owner:COLORADO STATE UNIVERSITY

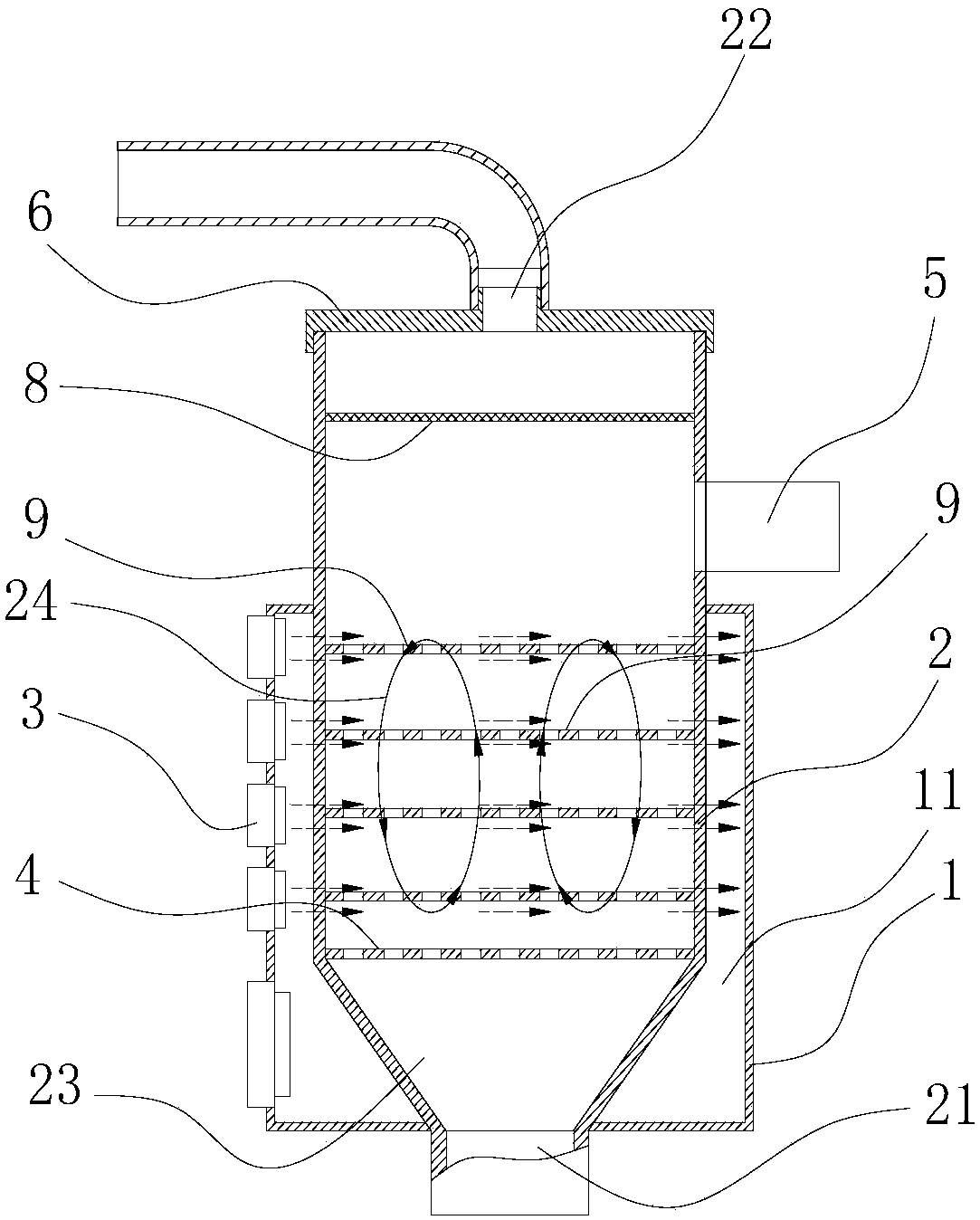

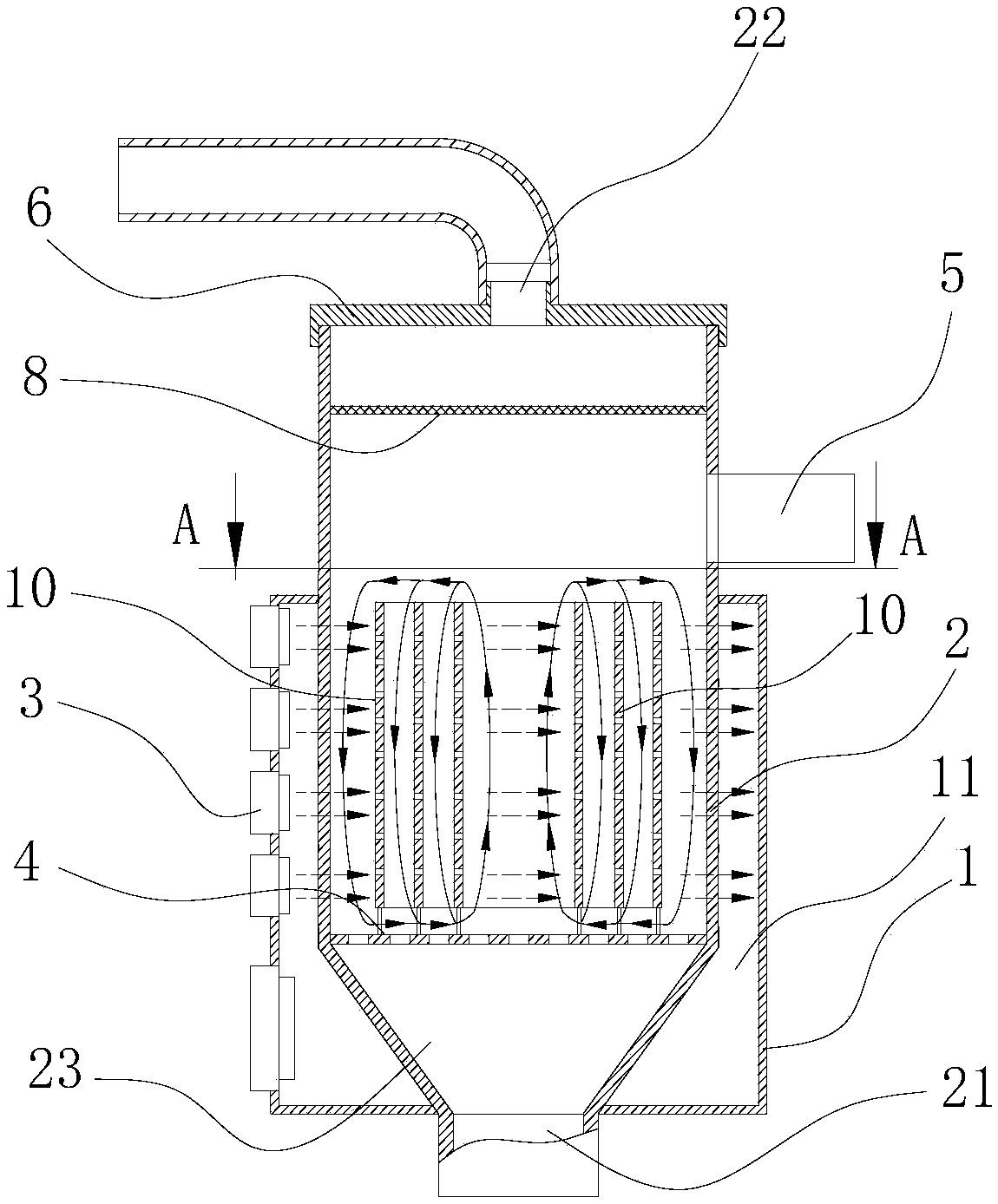

Microwave processing multi-phase fluidized bed reactor and process for treating phosphogypsum

ActiveCN108311066AIdeal flow patternHigh heat and mass transfer efficiencySulfur compoundsChemical/physical processesChemical reactionReaction rate

The invention discloses a microwave processing multi-phase fluidized bed reactor and a process for treating phosphogypsum, in the microwave processing multi-phase fluidized bed reactor, a reactor canbe heated divisionally, material flow fields in the reactor can be controlled, the reactor and microwave generators are separately arranged, the microwave processing multi-phase fluidized bed reactorcomprises the microwave-penetrable reactor and a microwave-reflecting shell sleeving the lower portion of the reactor, and the microwave generators, which are distributed from bottom to top and transmit microwave to a microwave-reflecting chamber, are arranged on the microwave-reflecting shell. The process for treating the phosphogypsum comprises the following steps: placing solid calcium sulfateparticles and liquid sulfur in a molar ratio of 1:1 to 1:10 in the reactor; heating the reactor through the microwave generators, controlling the pressure inside of the reactor to less than 1Mpa; andafter the reaction is completed, discharging a material. The microwave processing multi-phase fluidized bed reactor and the process for treating the phosphogypsum can enhance the heat and mass transfer efficiency among gas, liquid and solid three phases, reduce subsequent separation cost, save the process, and increase the chemical reaction rate.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com