Chemical vapor deposition preparing method of large-size three-layer molybdenum sulfide single crystal

A chemical vapor deposition, molybdenum sulfide technology, applied in chemical instruments and methods, from chemical reactive gases, single crystal growth and other directions, can solve the problems of poor device performance, small size, poor quality, etc., to achieve convenient sample transfer, sample The effect of large size and regular sample morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

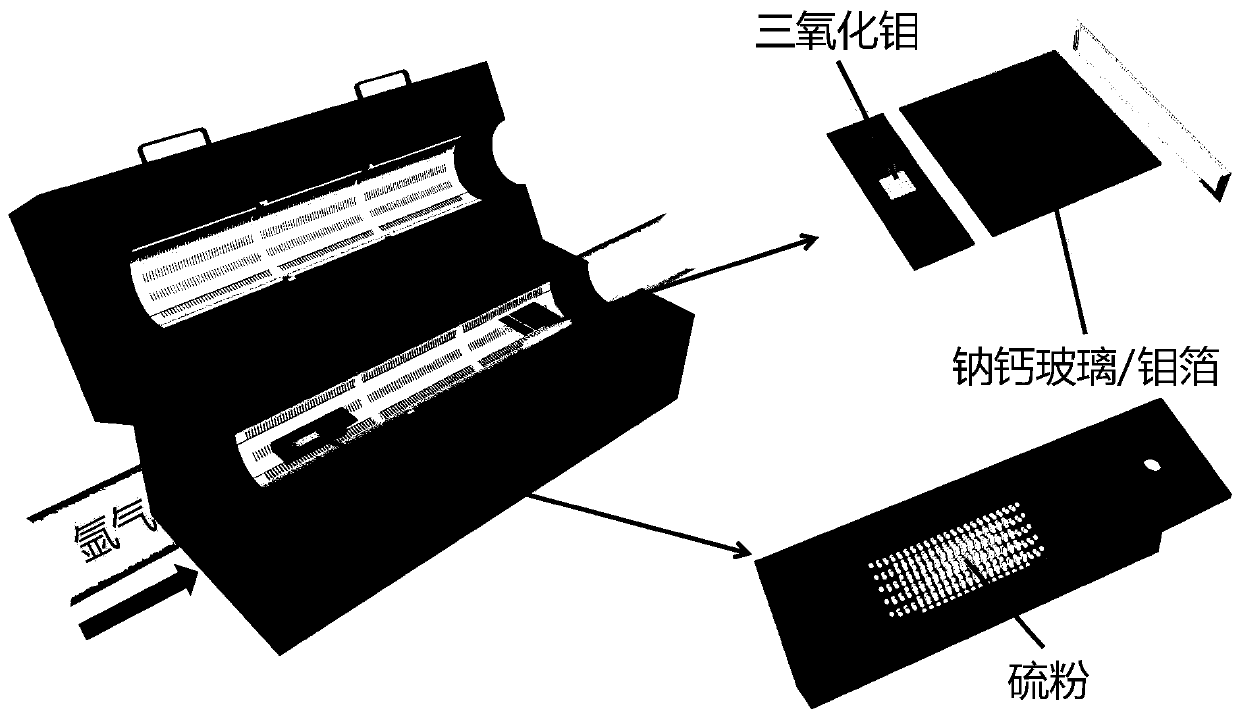

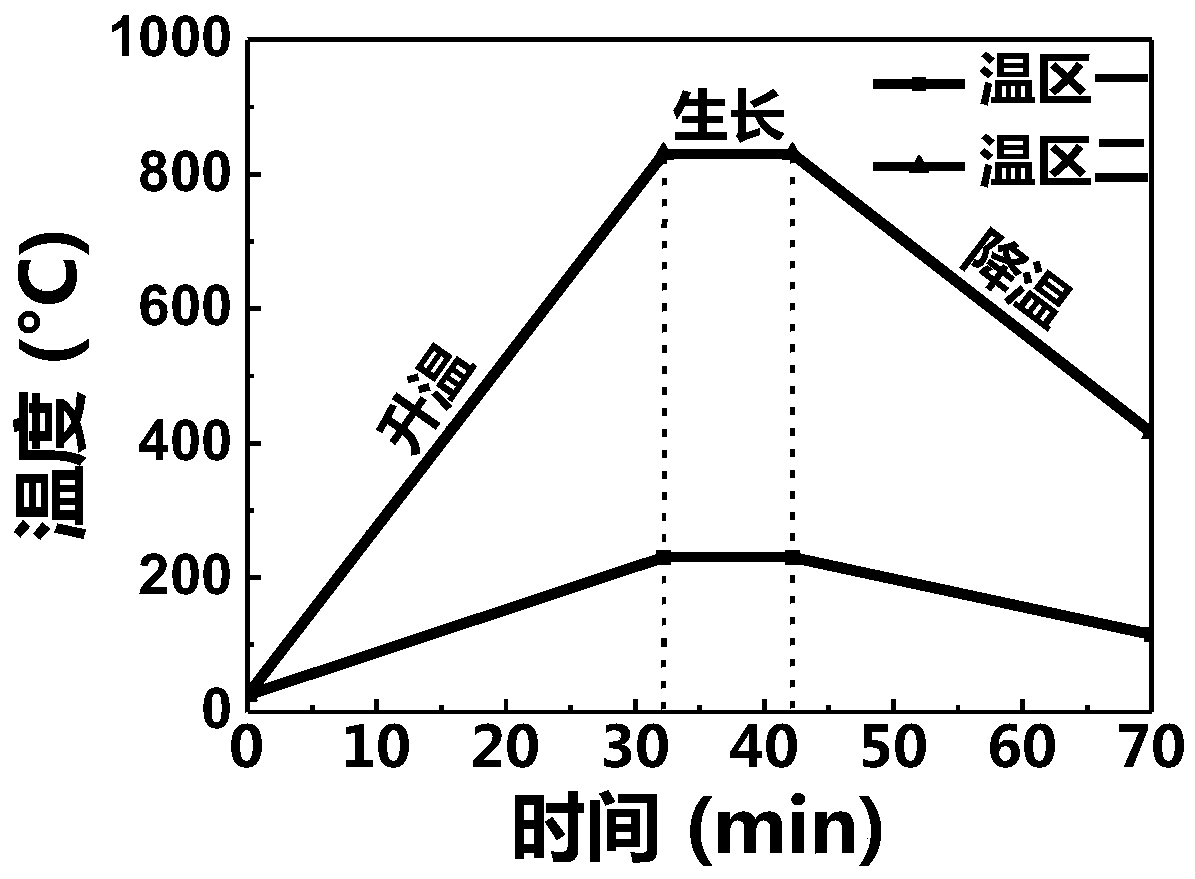

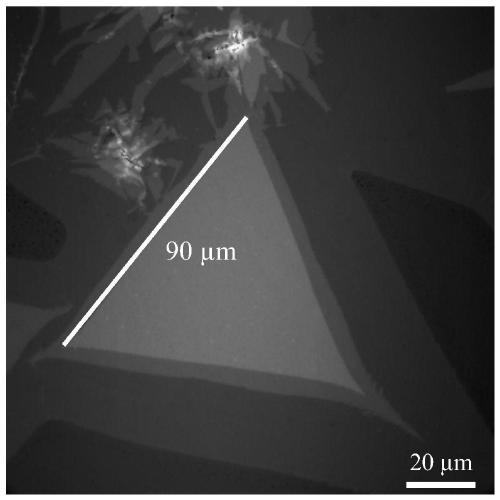

[0040] Embodiment 1: This embodiment provides a chemical vapor deposition (CVD) preparation method of a large-scale three-layer molybdenum disulfide single crystal, and the schematic diagram of the device is as follows figure 1 shown, including the following steps:

[0041] 1. Clean the substrate: Clean the molybdenum foil and soda-lime glass sequentially with acetone, isopropanol, and deionized water for 10 minutes, and blow dry with nitrogen. Then the soda-lime glass substrate is put into the plasma cleaning machine for processing, and the parameters of the plasma cleaning machine are set as argon 40sccm, oxygen 10sccm, power is 11W, time 3.5min (the model of the plasma cleaning machine can be PLASMA CLEANER PDC -002-HP, the model of the plasma flowmeter can be PLASMAFLO PDC-FMG-2);

[0042] 2. Sample weighing: use a weighing balance to weigh the precursor. The quality of sulfur powder is 1.4g, is contained in corundum boat (certainly, also can adopt other can bear the loa...

Embodiment 2

[0061] This embodiment provides a chemical vapor deposition (CVD) preparation method of a large-scale three-layer molybdenum disulfide single crystal, and the schematic diagram of the device is as follows figure 1 shown, including the following steps:

[0062] 1. Clean the substrate: Clean the molybdenum foil and soda-lime glass sequentially with acetone, isopropanol, and deionized water for 10 minutes, and blow dry with nitrogen. Put the soda-lime glass substrate into the plasma cleaning machine for processing again, the parameters of the plasma cleaning machine are set as argon 50 sccm, oxygen 10 sccm, power is 9W, time 2.5min;

[0063] 2. Sample weighing: use a weighing balance to weigh the precursor. The mass of sulfur powder is 1g, packed in a corundum boat. The mass of molybdenum trioxide is 3 mg, which is placed on a quartz boat with a 90nm silicon dioxide / silicon substrate, and a ceramic sheet is placed on it to prevent poisoning by sulfur vapor. Place another piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com