Patents

Literature

153results about How to "Controllable growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

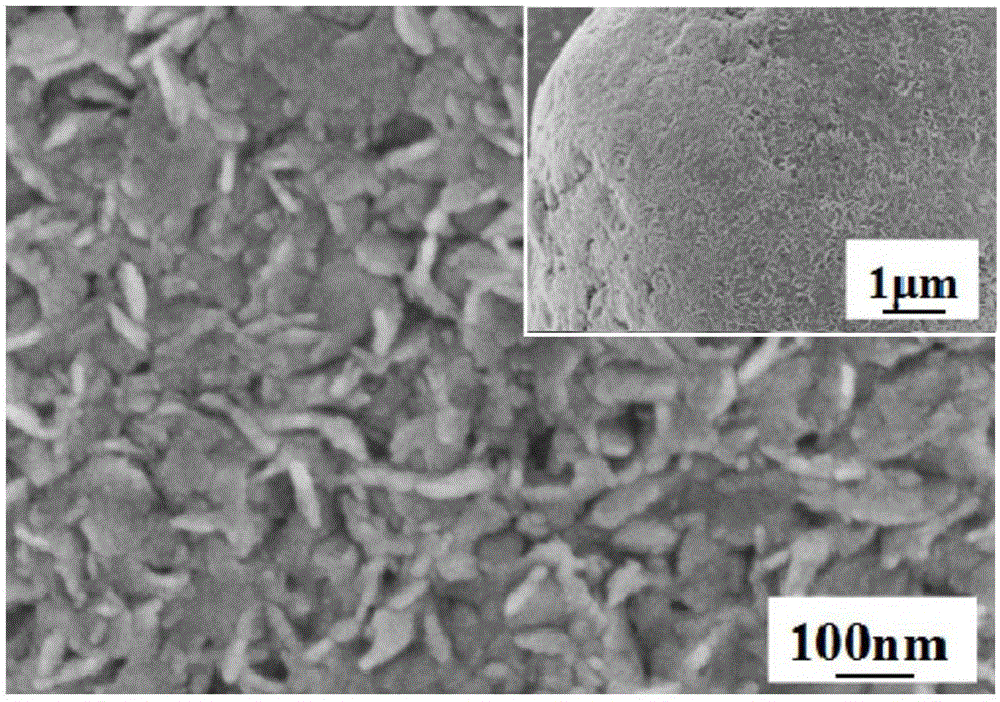

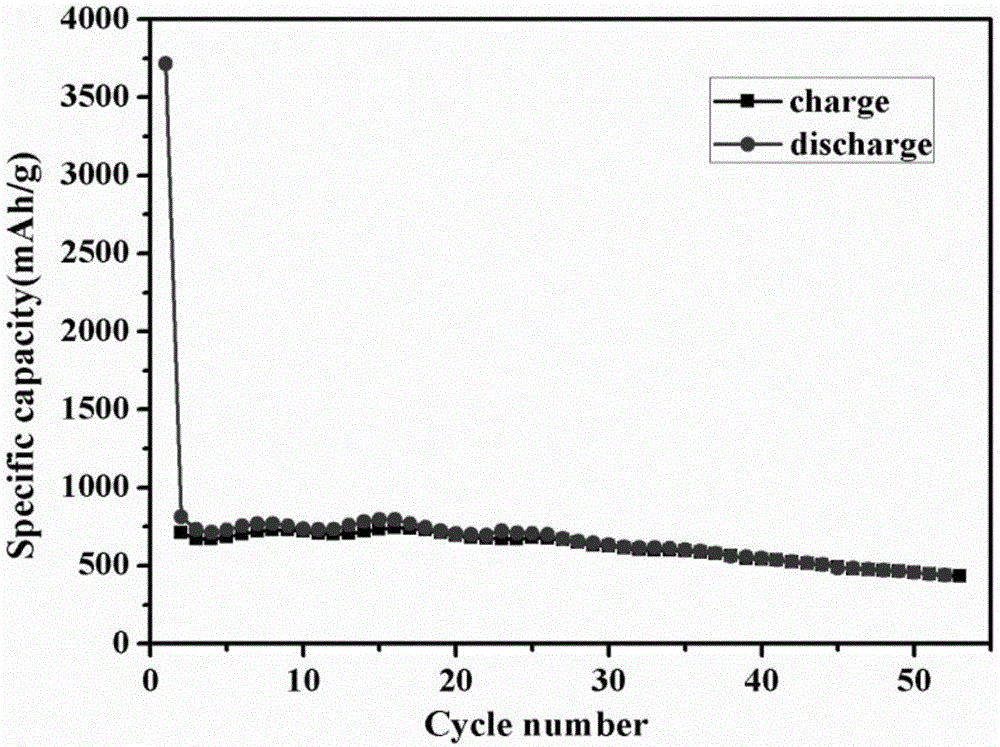

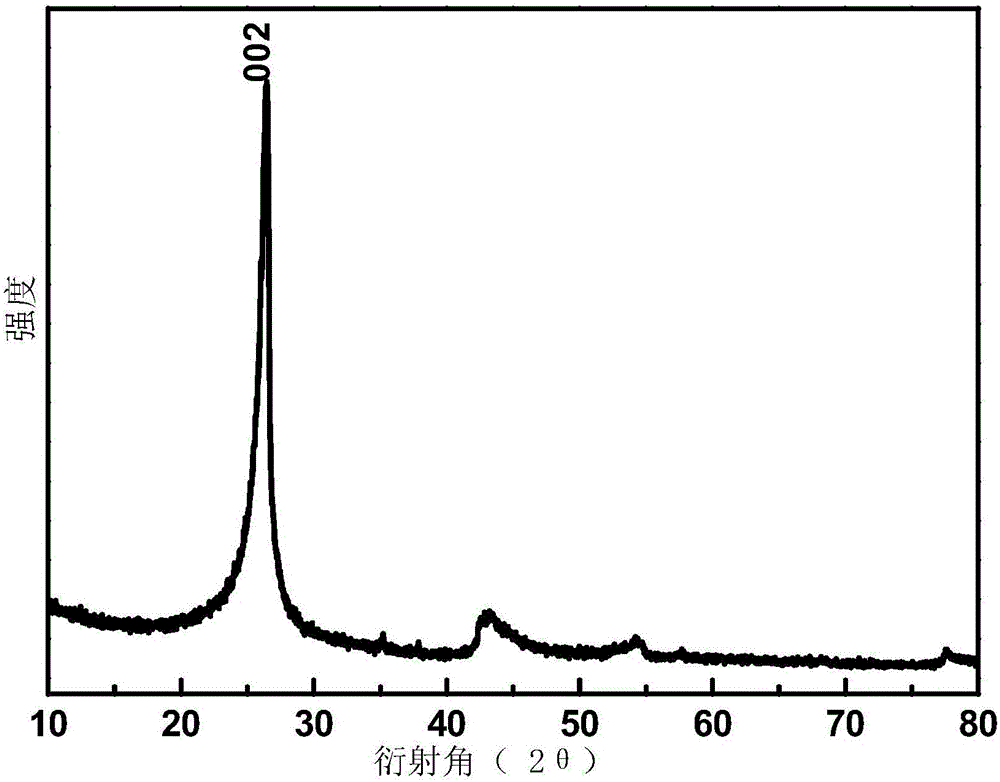

Preparation method for nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability

InactiveCN105098181AReduce manufacturing costImprove charge and discharge performanceNegative electrodesSodium-ion batteryChemistry

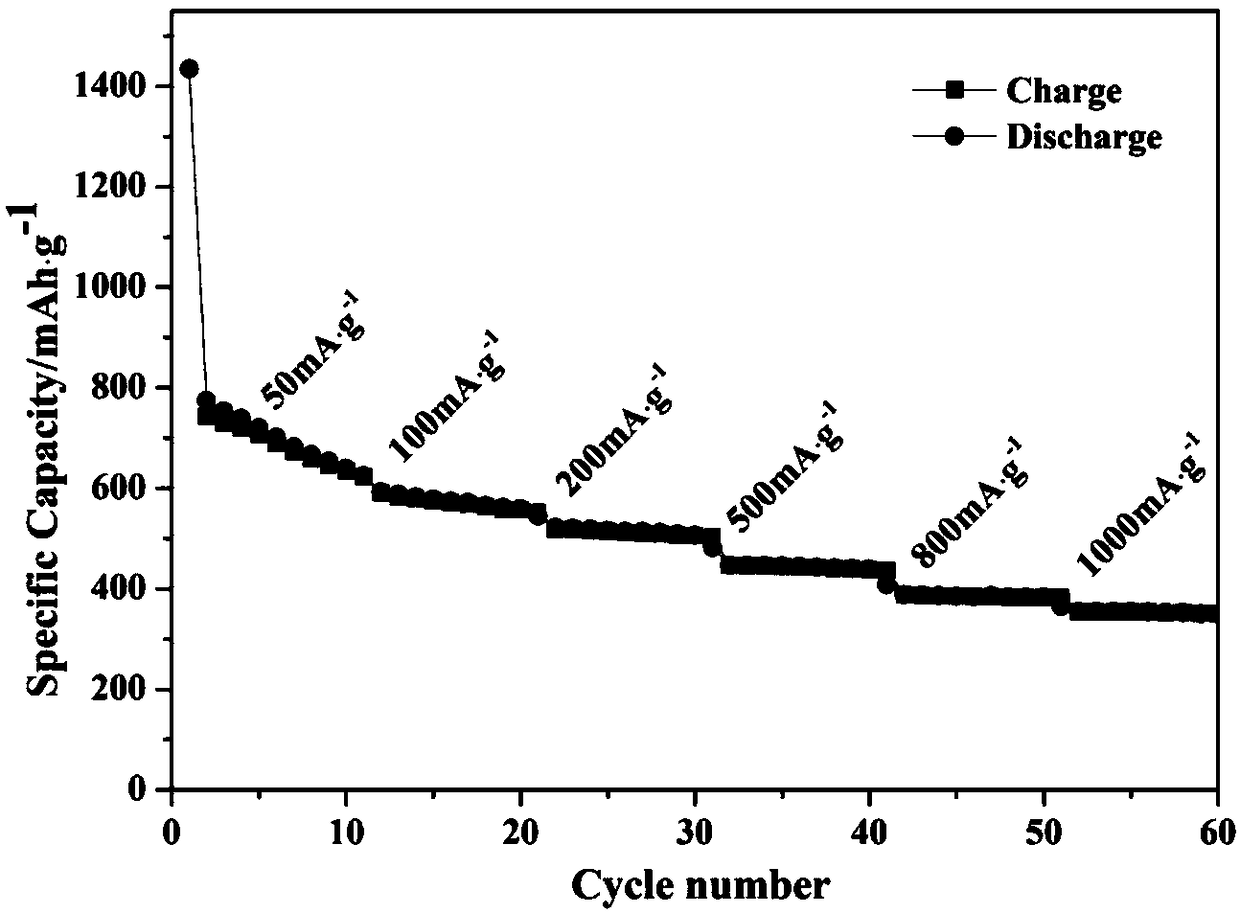

The invention discloses a preparation method for a nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability, comprises: 1) preparing an Sn source solution A with the concentration of 0.5-1.2 mol / L, regulating the pH of the solution A to be 1-9; and preparing an S source solution B with the concentration of 0.1-2.4 mol / L; 2) mixing the solution A and the solution B at an element molar ratio of nSn: nS being equal to (1.0-2.5): (2.0-4.3), and uniformly stirring to form a solution D; 3) putting the solution D into a homogenous phase hydrothermal reaction kettle for performing a homogenous phase hydrothermal reaction; and 4), cooling the reaction kettle, then centrifuging, washing, separating and drying to obtain the nano-flake SnS2 sodium-ion battery negative electrode material, wherein under 100 mA / g current density, the initial discharge capacity of the negative electrode material reaches 745 mAh / g; and after circulating for 100 times, the capacity is kept at 560 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

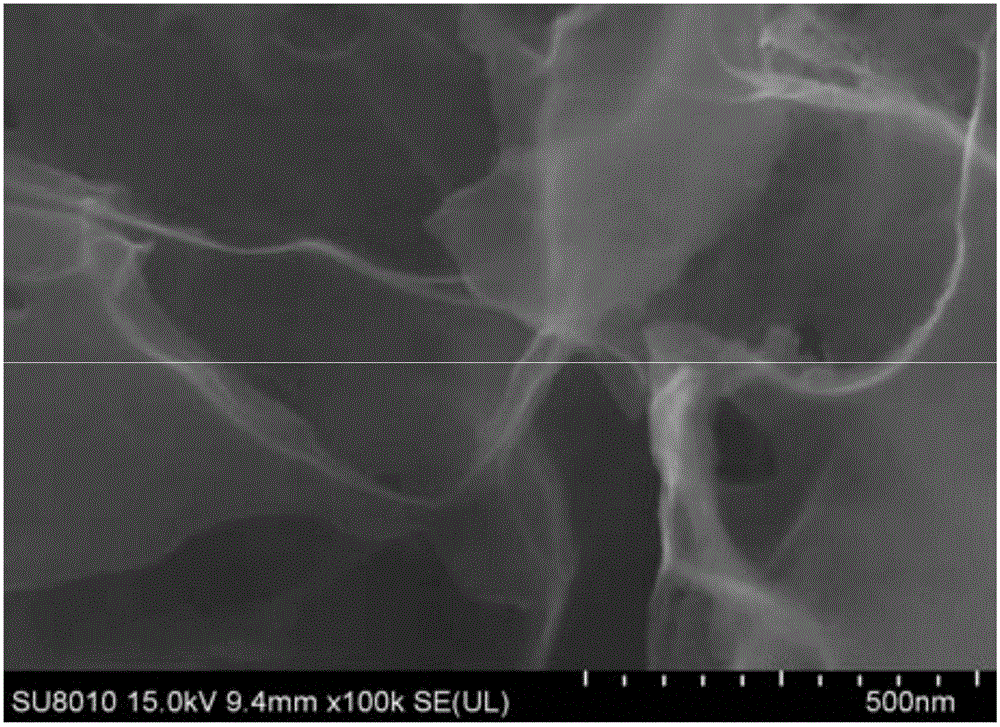

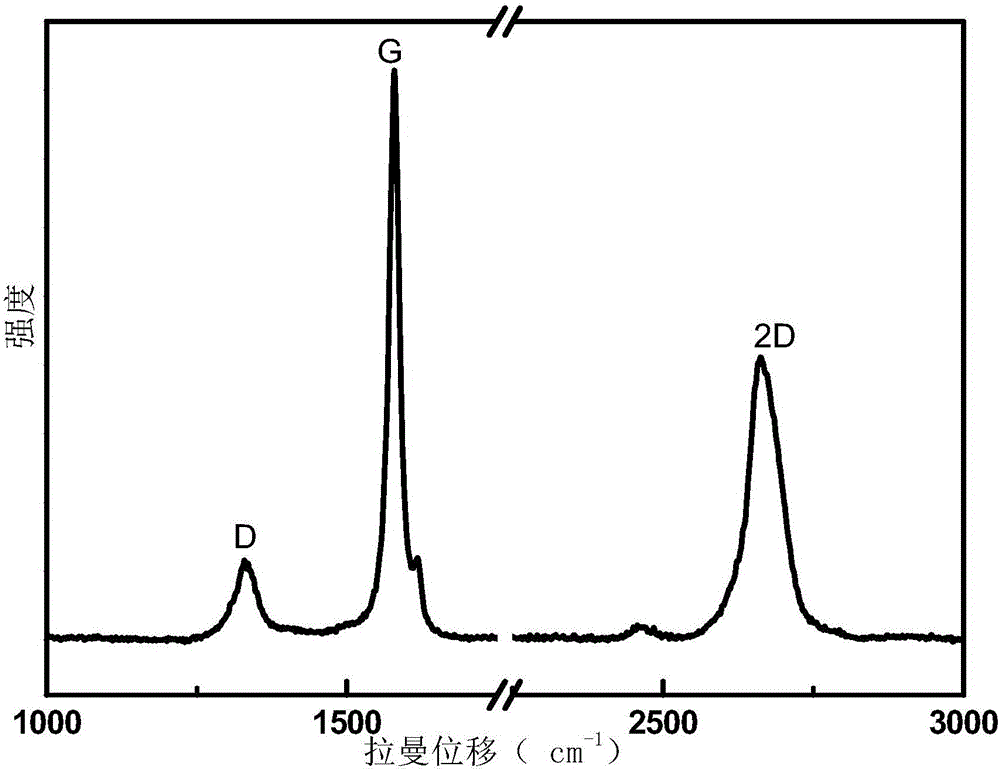

Method for preparing graphene by using lignin

The invention belongs to the technical field of carbon material manufacturing technology, and in particular relates to a method for preparing graphene by using lignin as a raw material. The method is as follows: a layered or powdered material is used as a substrate, the lignin and a catalyst precursor are alternately assembled on the surface of the substrate by a layer-by-layer electrostatic self-assembly method, then a lignin / catalyst precursor / substrate composite is put into a double-temperature-zone tubular furnace, a H2 / Ar mixed gas is introduced into the double-temperature-zone tubular furnace at a certain speed, at the same time the double-temperature-zone tubular furnace is heated by a certain procedure, after the double-temperature-zone tubular furnace is heated to target temperature, the temperature of the double-temperature-zone tubular furnace is held for a certain time, when the double-temperature-zone tubular furnace is cooled to room temperature, the sample is taken out, and is soaked in an acid for catalyst removal, and after a plurality of times of washing and vacuum drying, the graphene is obtained. The method has the advantages of simple process and convenient operation, and the prepared graphene is good in growth, controllable in layer number and considerable in yield.

Owner:SOUTH CHINA UNIV OF TECH

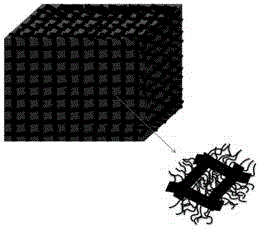

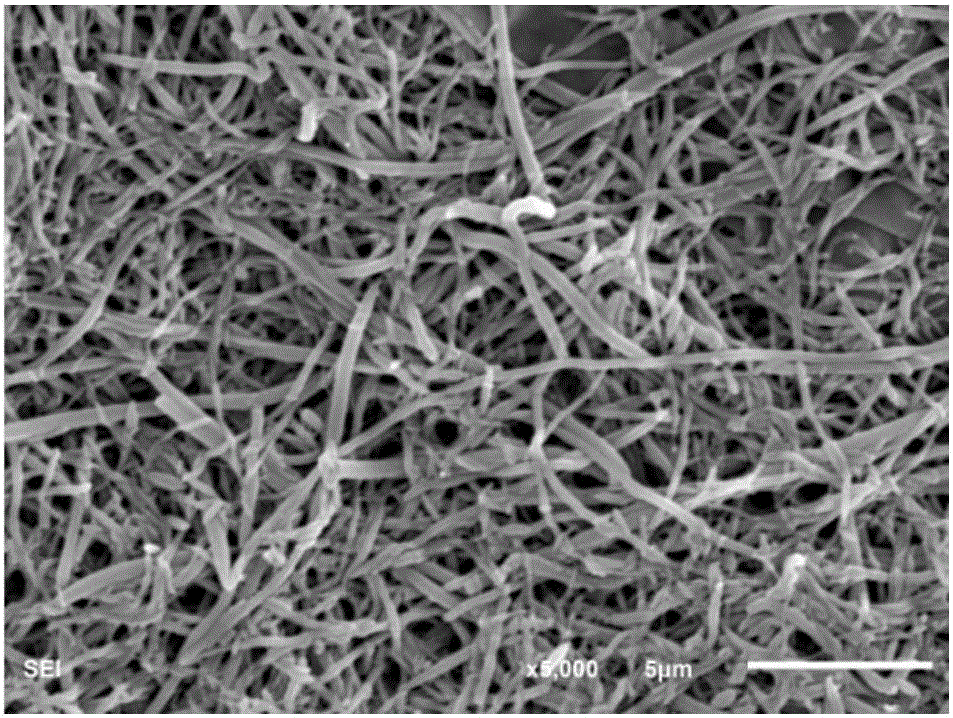

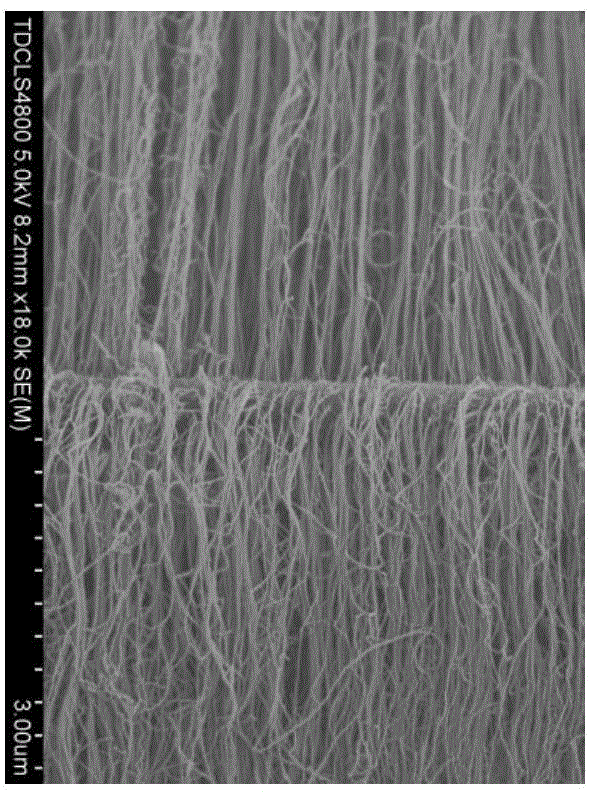

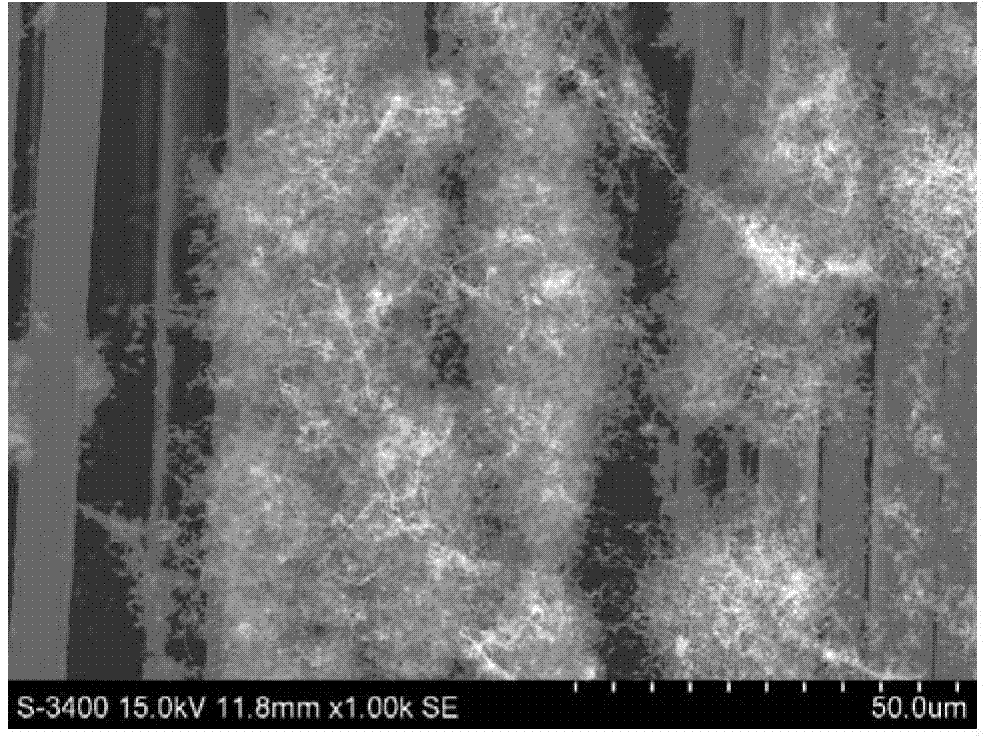

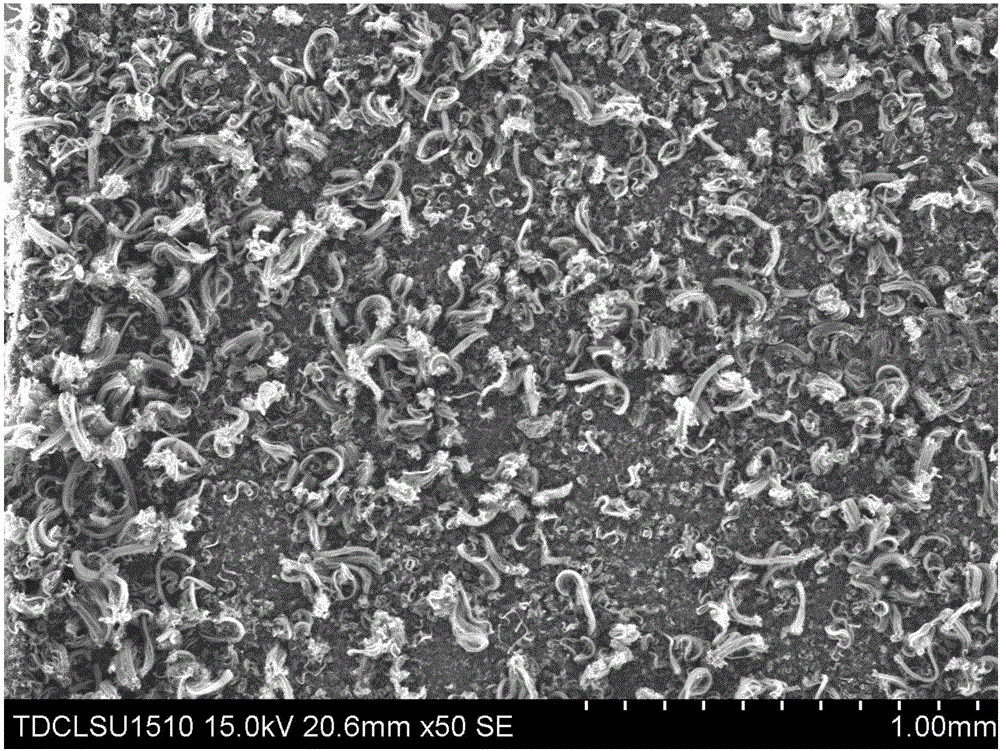

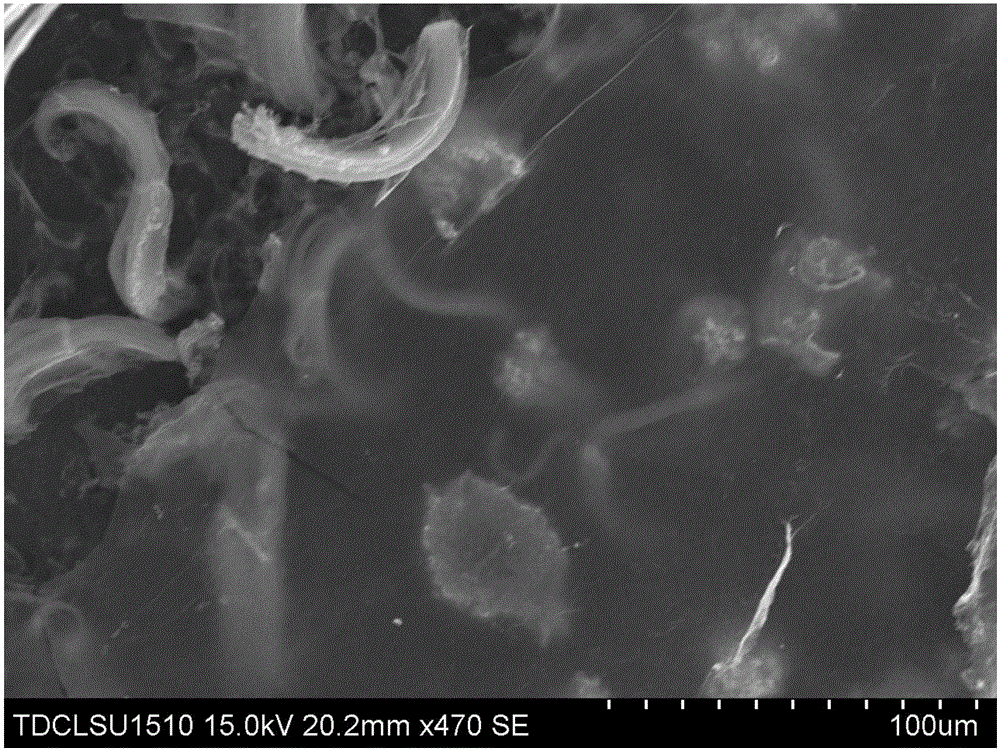

Preparation method of three-dimensional graphene/carbon nano tube composite material having isotropic high heat conduction and elasticity

The invention relates to a three-dimensional graphene sponge body / carbon nano tube composite material having isotropic high heat conduction and elasticity, and a preparation method of the material. In the preparation method, a water dispersion body of graphene oxide is prepared by expanding and oxidizing natural graphite, thereby forming a three-dimensional porous appearance through a hydrothermal reaction; ferrocene, as a catalyst, is used for growing the carbon nano tubes, wherein the ferrocene is decomposed at a high temperature into iron atoms which are adhered onto the surface of the graphene sponge body. Carbon atoms, which are formed by cracking a carbon source, are adhered onto the surface of the graphene by means of the iron atoms, thus growing the carbon nano tubes. Through control on injection speed and temperature maintaining time of the carbon source liquid, growth of the carbon nano tubes is controllable. The carbon nano tubes grow in the internal pores of the graphene sponge body and are connected to graphene mutually, thus obtaining the isotropic heat conduction and elasticity. The composite material has the isotropic heat conduction and is not less than 10 W / (m*K) in heat conduction coefficient, and has the same compression rebound elasticity in all directions, rebound rate being more than 90% under compression of 20%.

Owner:TIANJIN UNIV

Method for tenderizing beef

InactiveCN102429242AImprove tendernessEvenly distributed flesh colorFood preparationChlorideHigh pressure

The invention discloses a method for tenderizing beef, which belongs to the field of food science, comprising the following steps of: pre-cooling the cattle carcass, cutting, injecting 200 mmol / L of calcium chloride liquor; packaging in vacuum; and processing at 250 MPa to obtain the tenderized beef. The method organically combines calcium salt injection with high-pressure process, so that the tenderness of the beef is obviously improved, and the production cost is effectively reduced at the same time. The high-pressure process can control the bacterial growth so as to prolong the shelf life.

Owner:NANJING AGRICULTURAL UNIVERSITY

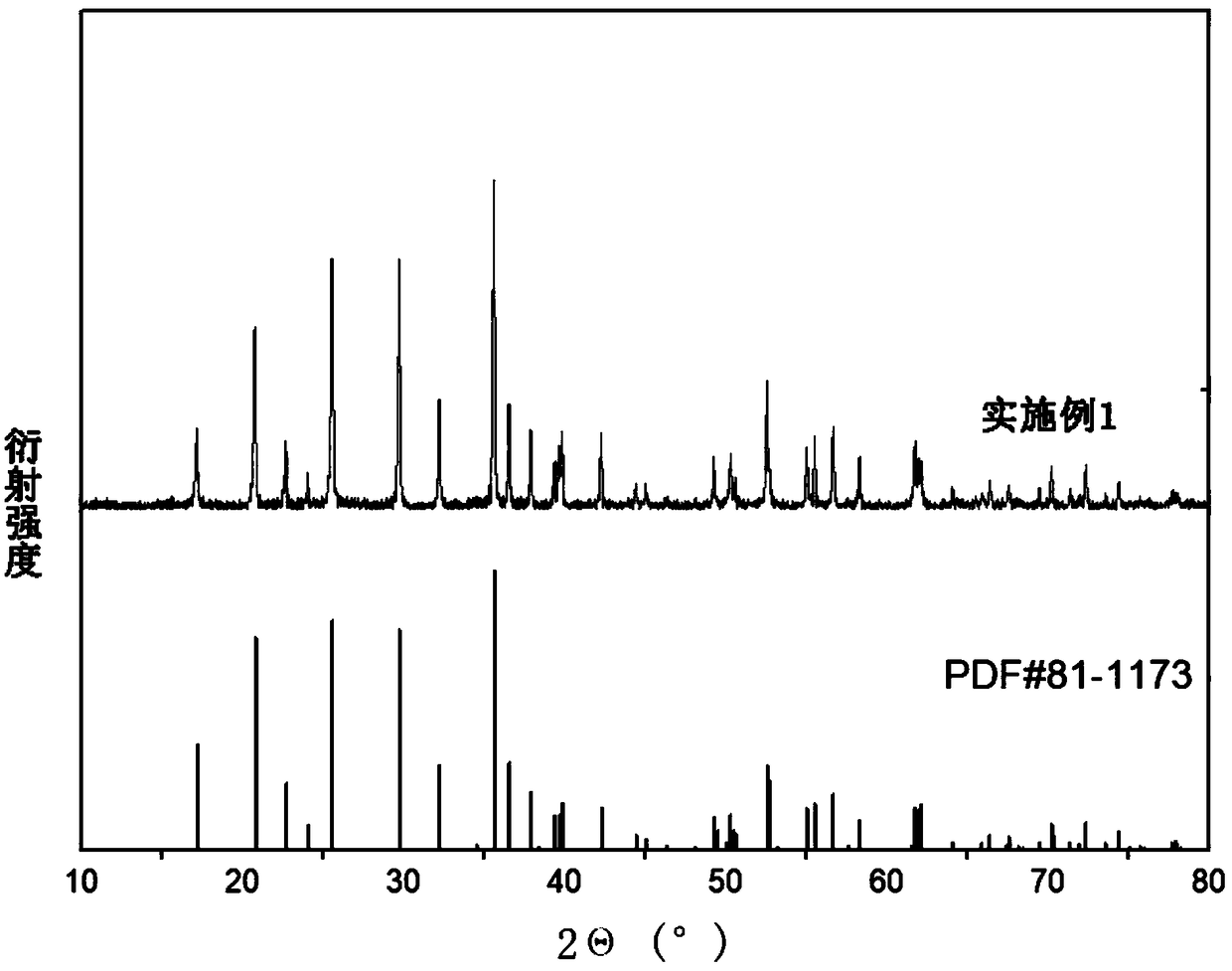

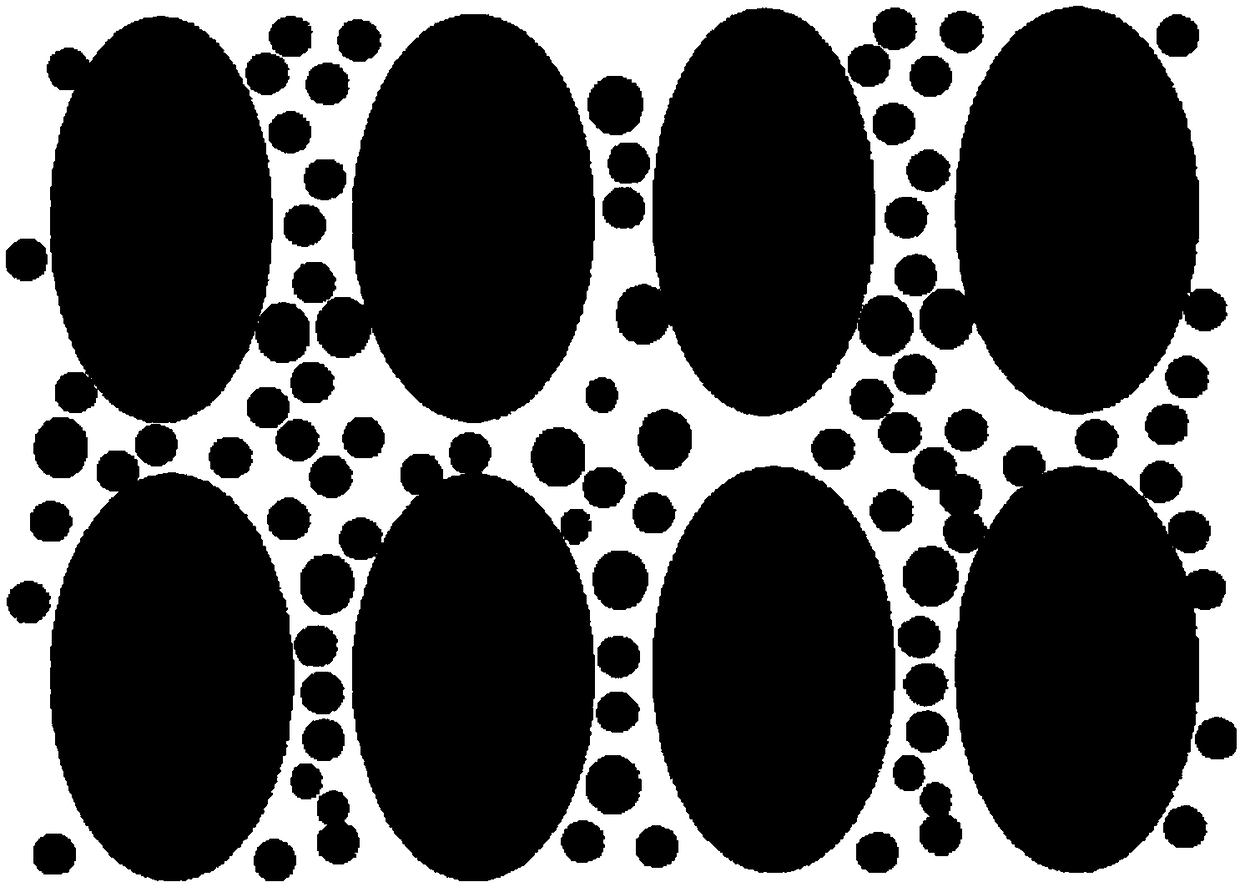

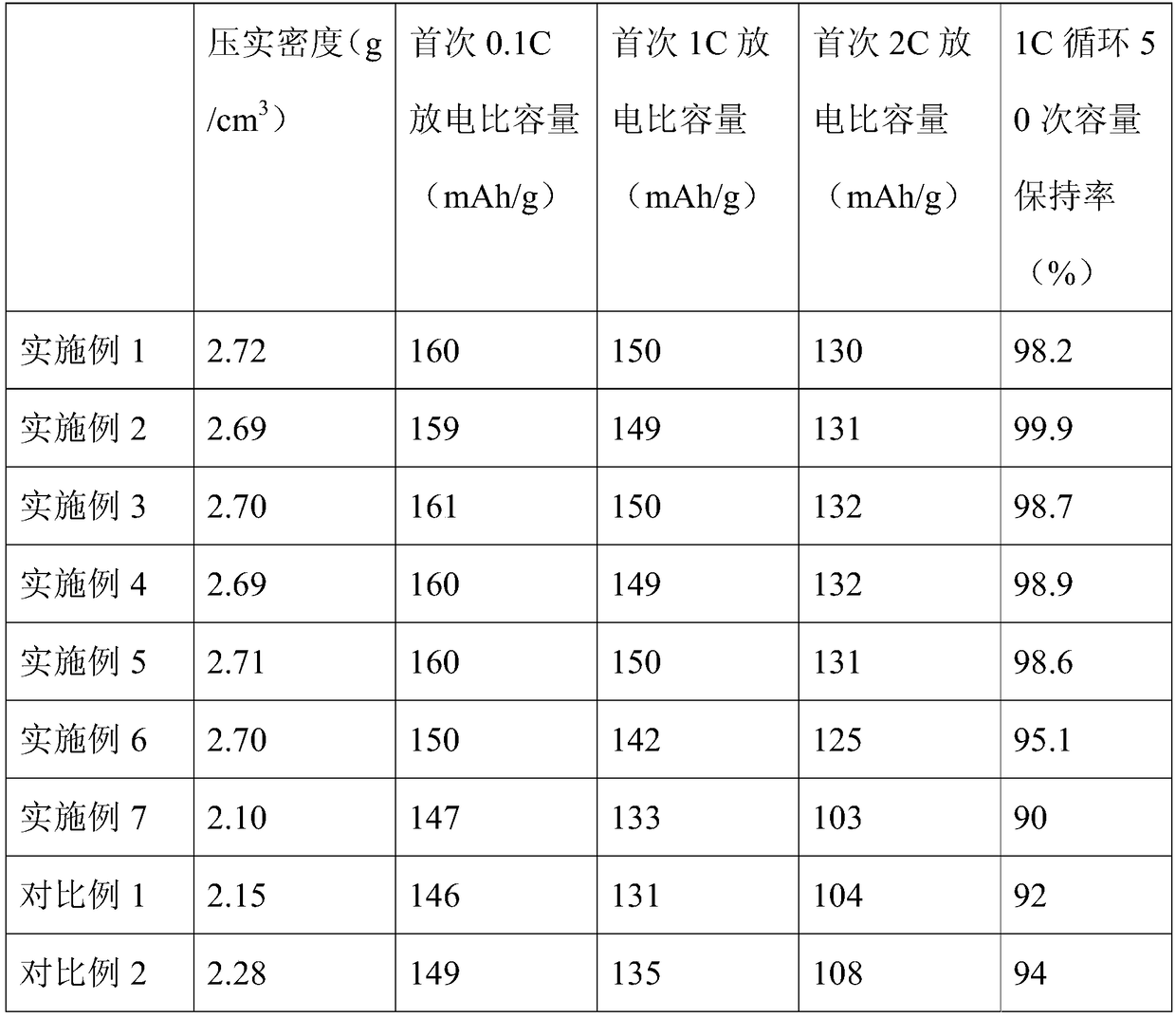

A lithium iron phosphate with high compact density and a preparation method thereof

ActiveCN109192948AIncrease compaction densityReduce porosityCell electrodesSecondary cellsLithium iron phosphateThree stage

The invention provides a lithium iron phosphate with high compact density and a preparation method thereof. The lithium iron phosphate positive electrode material comprise large particles of lithium iron phosphate and small particle of lithium iron phosphate, wherein that small particles of lithium iron phosphate are filled in the voids between the large particle of lithium iron phosphate, and theshape of the small particles of lithium iron phosphate comprises a spherical shape. A method for prepare that lithium iron phosphate precursor comprises sinter the lithium iron phosphate precursor ina protective gas atmosphere, wherein the sintering is three-stage sintering, the sintering temperature of the three-stage sintering is sequentially increased, and aft the three-stage sintering is finished, the lithium iron phosphate positive electrode material is obtained; Wherein the shape of the lithium iron phosphate precursor comprises a spherical shape. The compaction density of the lithiumiron phosphate with high compaction density provided by the invention can reach 2.7 g / cm3, the electrochemical performance is excellent, the first discharge specific capacity of 1C can reach 150 mAh / g, and the capacity retention rate of 50 cycles of 1C can reach 99.9%.

Owner:SHENZHEN DYNANONIC

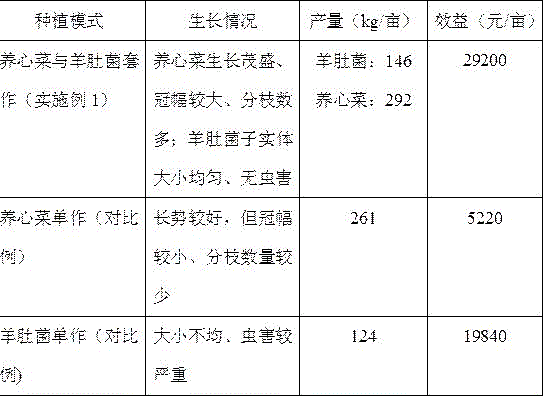

Sedum aizoon and morchella relay intercropping planting method

InactiveCN106211961APromote growthStrong resistance to barrennessCalcareous fertilisersMagnesium fertilisersNutrientSedum aizoon

The invention discloses a sedum aizoon and morchella relay intercropping planting method. The method includes the following steps of firstly, selecting a shed and preparing a land; secondly, applying fertilizer; thirdly, conducting transplanting and planting; fourthly, irrigating a nutrient solution; fifthly, seed dressing; sixthly, sowing morchella; seventhly, preparing a nutrient bag; eighthly, placing the nutrient bag; ninthly, conducting later-period management. By means of the method, the problem of inter-row weeds in the morchella culture process and the problem that after-reap crop is not prone to growth due to sunshade can be effectively solved, the soil utilization rate can be increased, sedum aizoon and morchella act on each other, management is easy, and meanwhile the quality and unit area yield of sedum aizoon and morchella are improved.

Owner:SICHUAN AGRI UNIV

Preparation method for novel nano-silver wire

The invention discloses a preparation method for a novel nano-silver wire. The preparation method comprises the following steps: taking a sliver salt or silver amide complex, adding a solvent for dissolving to obtain liquor A; taking organic substances, adding the solvent for dissolving to obtain liquor B; mixing the liquor A with the liquor B, stirring until dissolving completely; adding a complexing agent, uniformly stirring, stewing and layering to obtain liquor C; taking the liquor C as an electrolyte, inserting an anode to a water layer of the electrolyte, inserting a cathode to an oil layer of the electrolyte, carrying out electrolytic reaction for 1-30 minutes under the condition that voltage is 1-50V; flushing the reacted cathode polar plate by distilled water, naturally drying at the room temperature to obtain the nano-silver wire. The thickness and slenderness ratio of the nano-silver wire can be conveniently controlled by electric fields, so that the controllable growth of a nano structure is realized; morphology of the generated nano-sliver wire is controllable by regulating the current density, voltage and reaction time, and the novel nano-silver wire can be synthesized by a nano-silver wire with the diameter of 1-50nm and a nano rod. The preparation process is simple and low in cost, and efficiency for synthesizing the nano-sliver wire and the nano rod is higher.

Owner:NORTHEASTERN UNIV

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

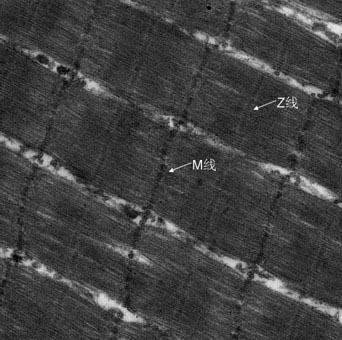

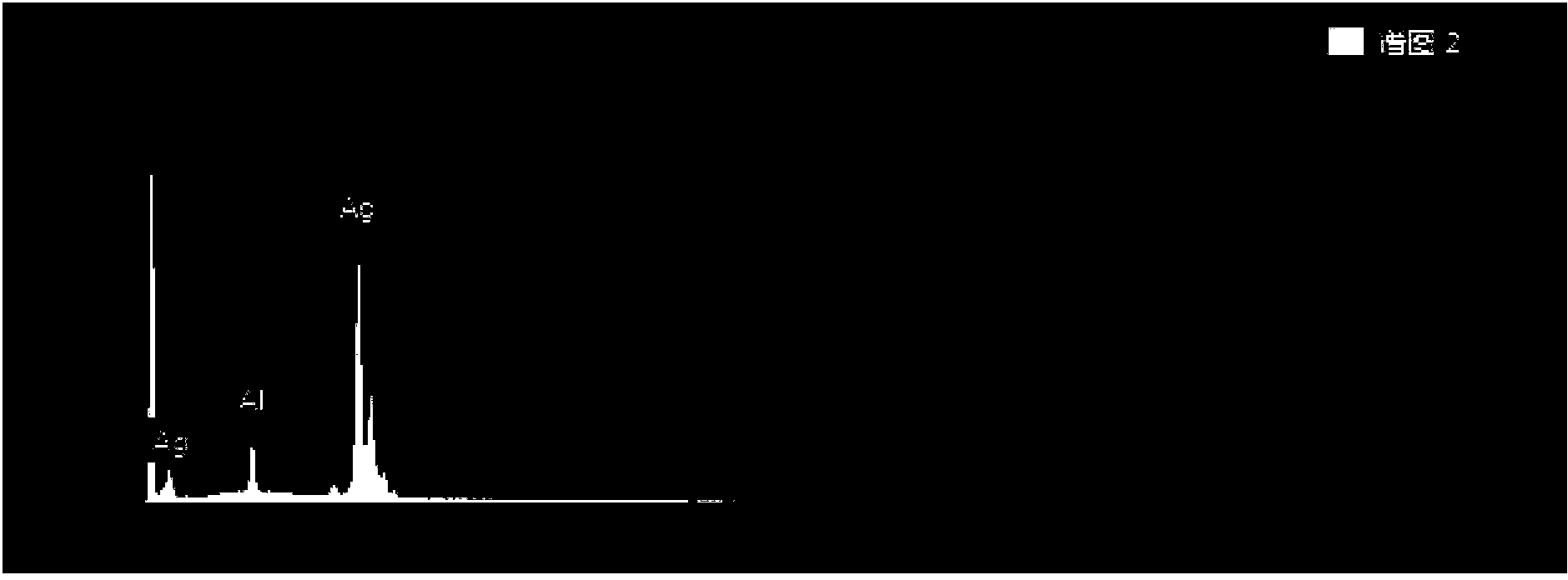

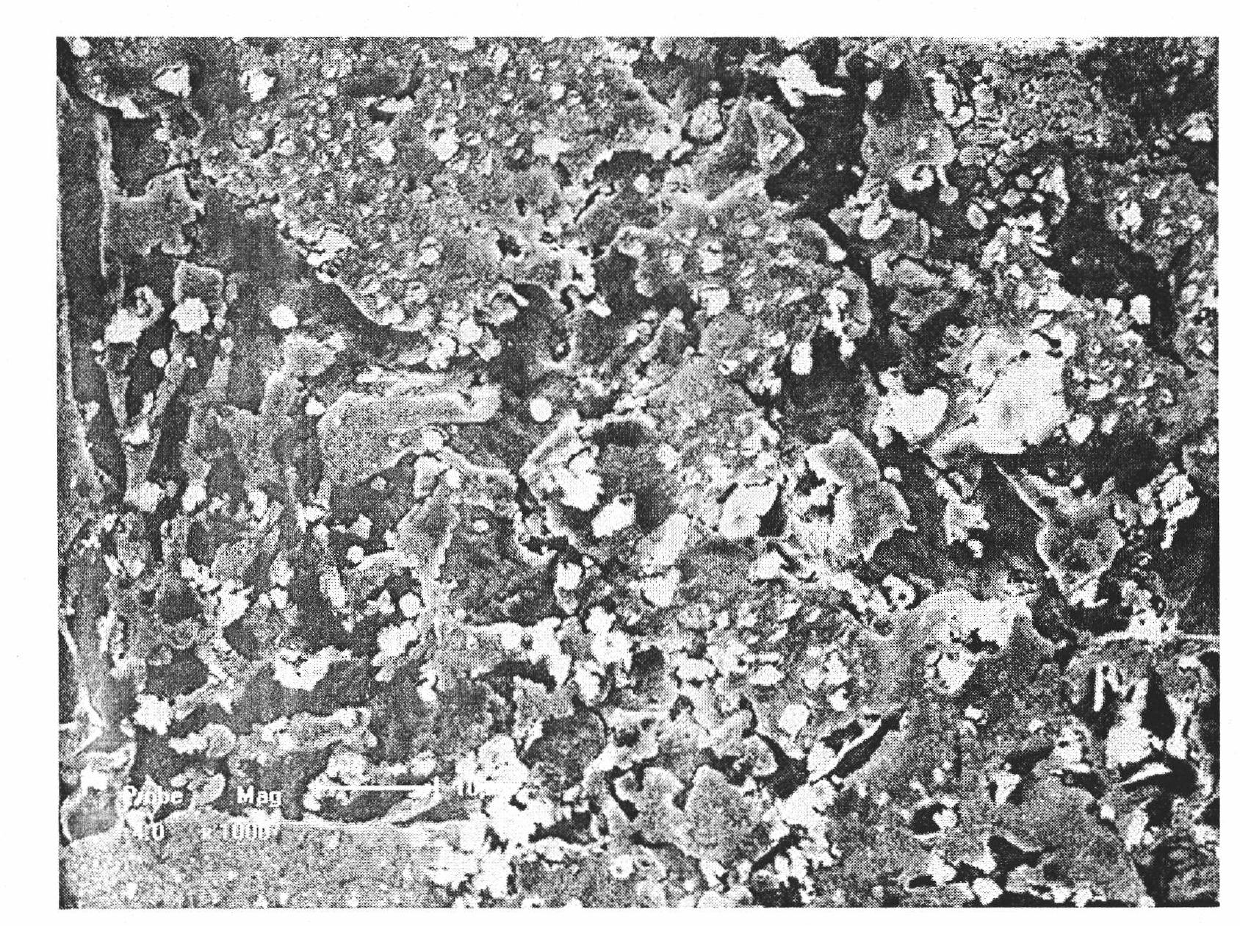

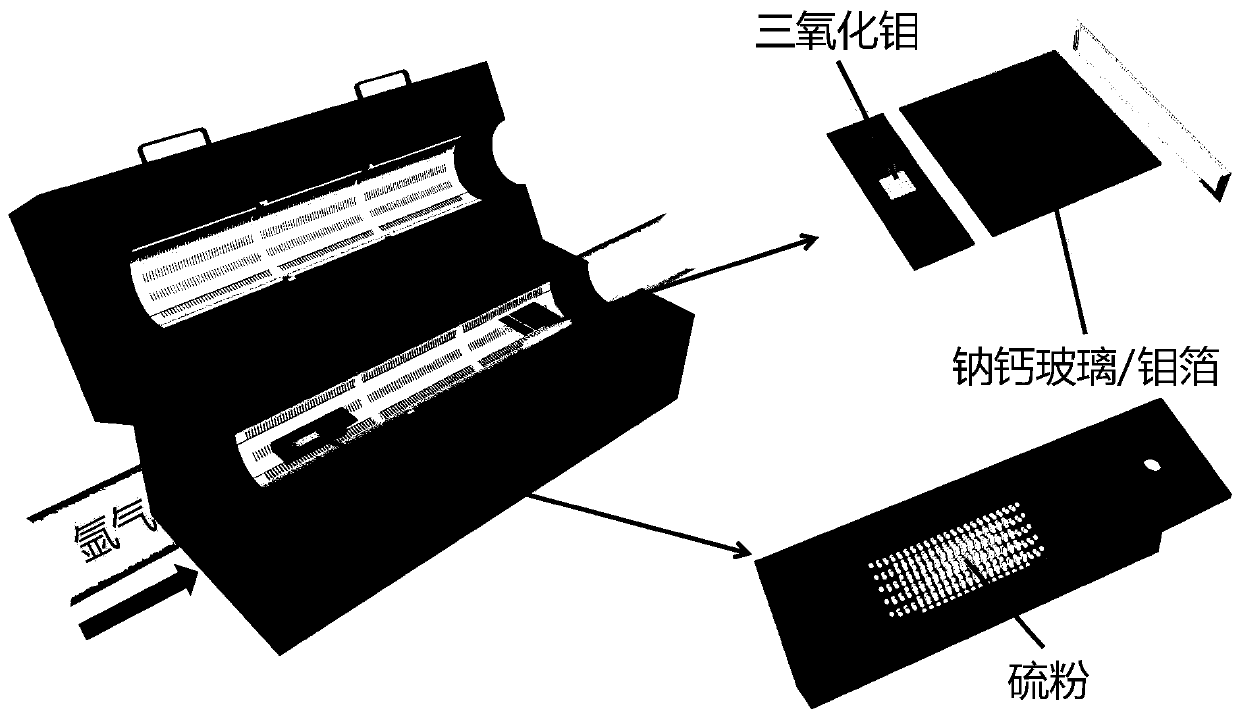

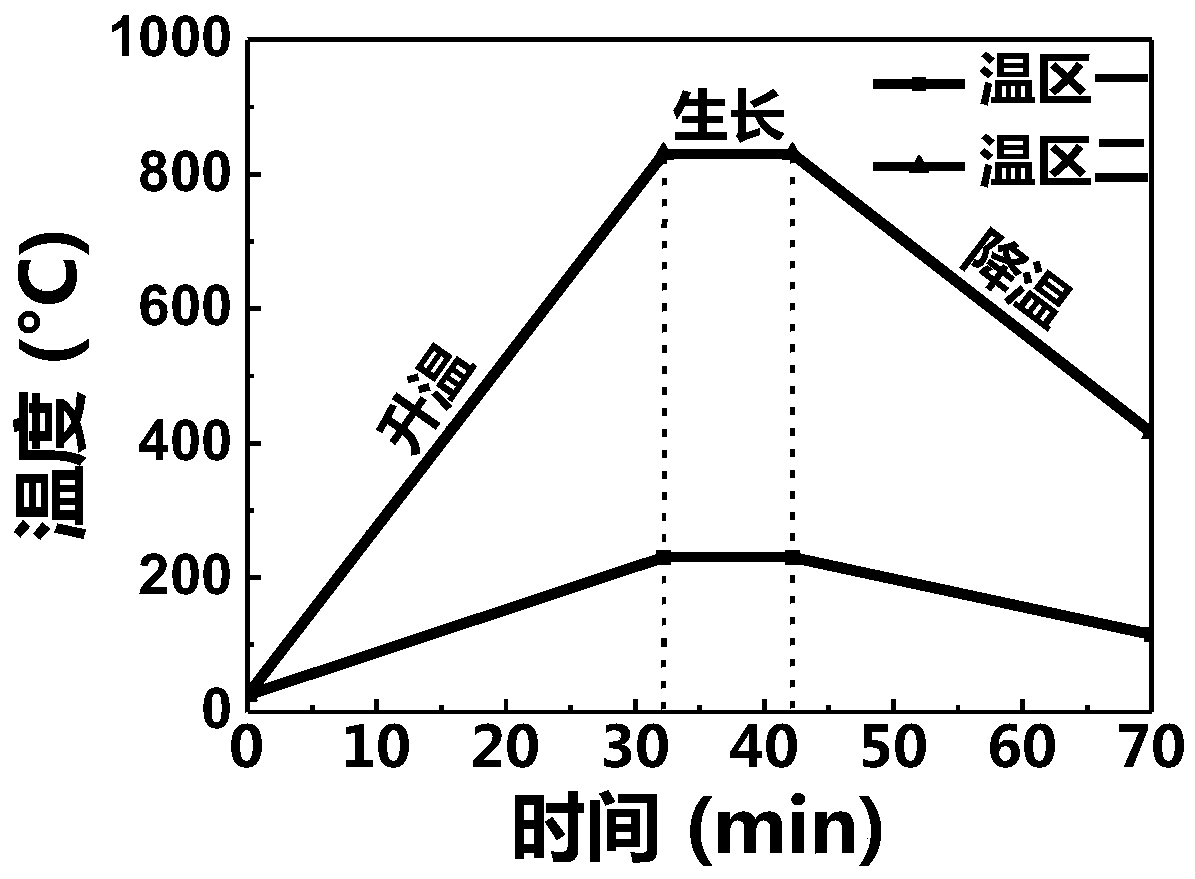

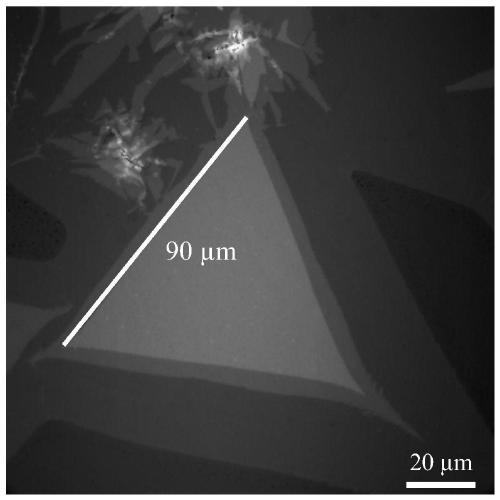

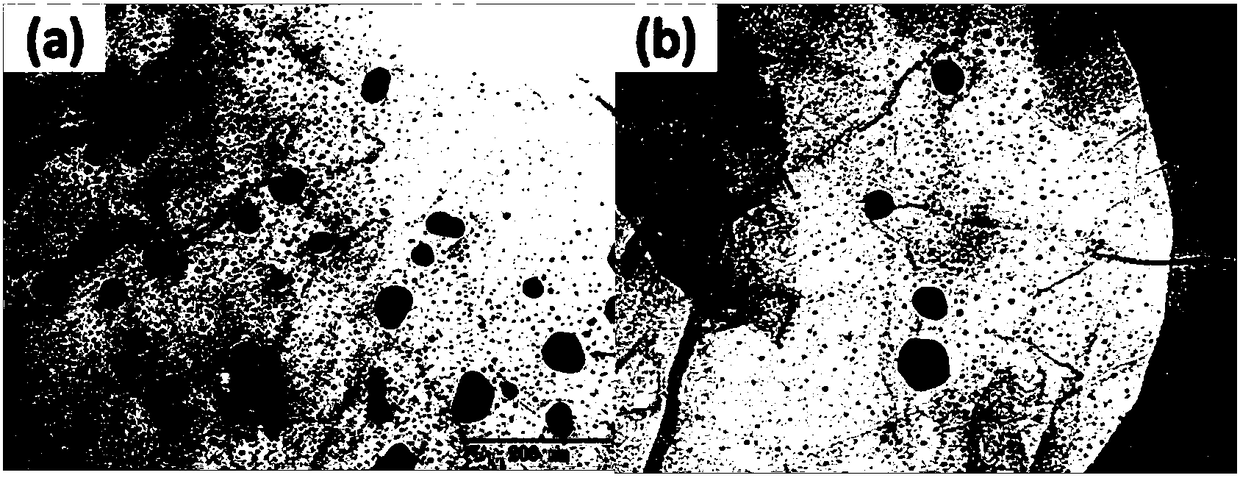

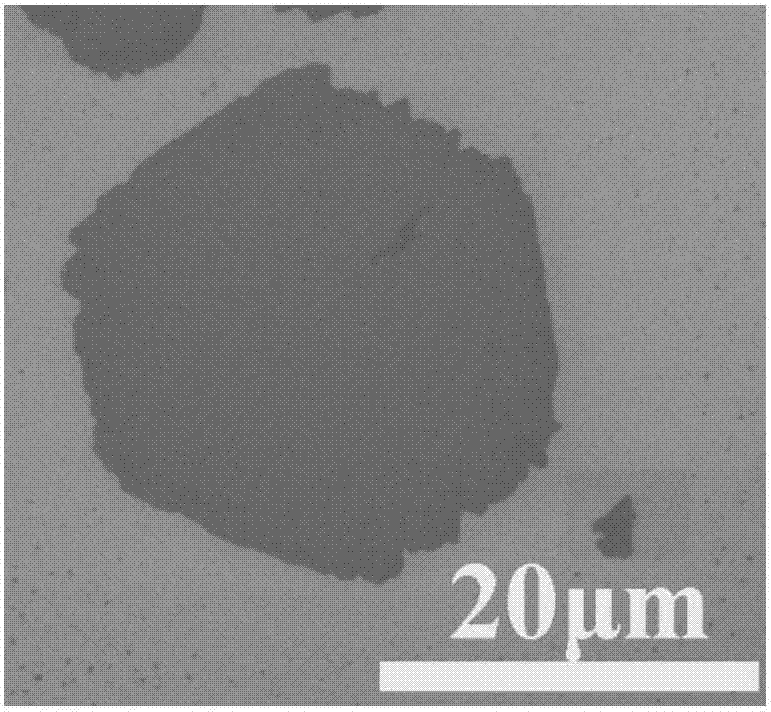

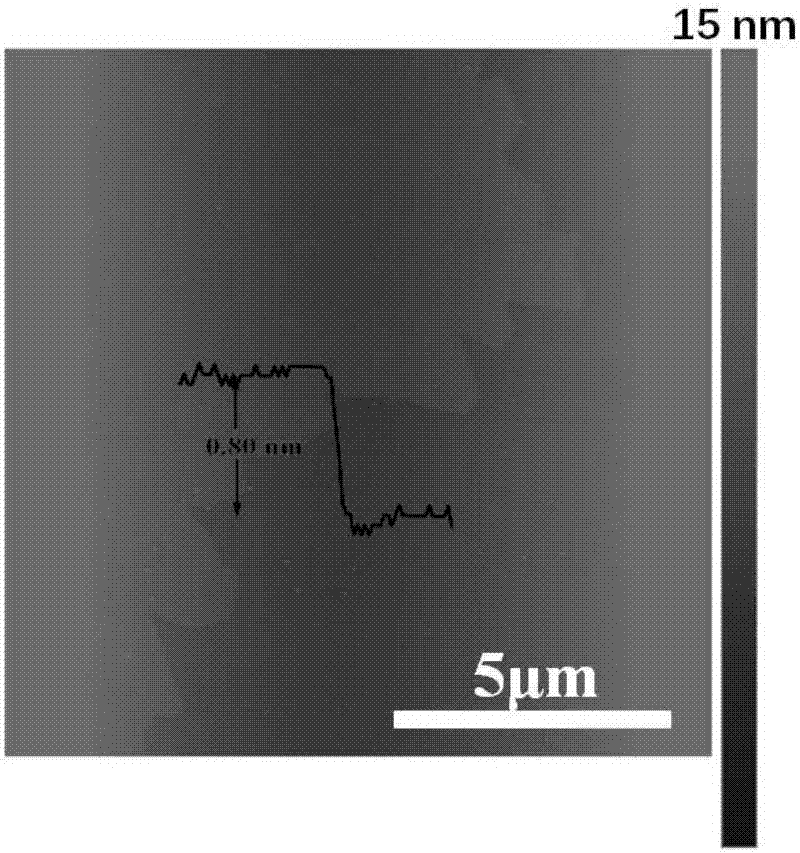

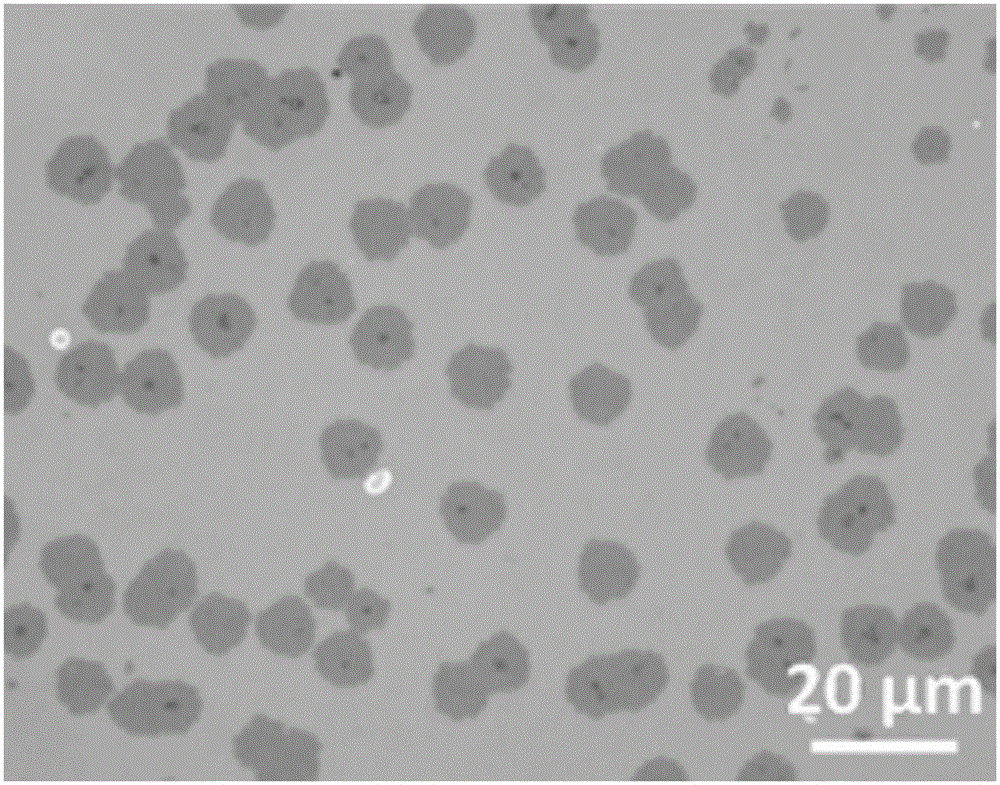

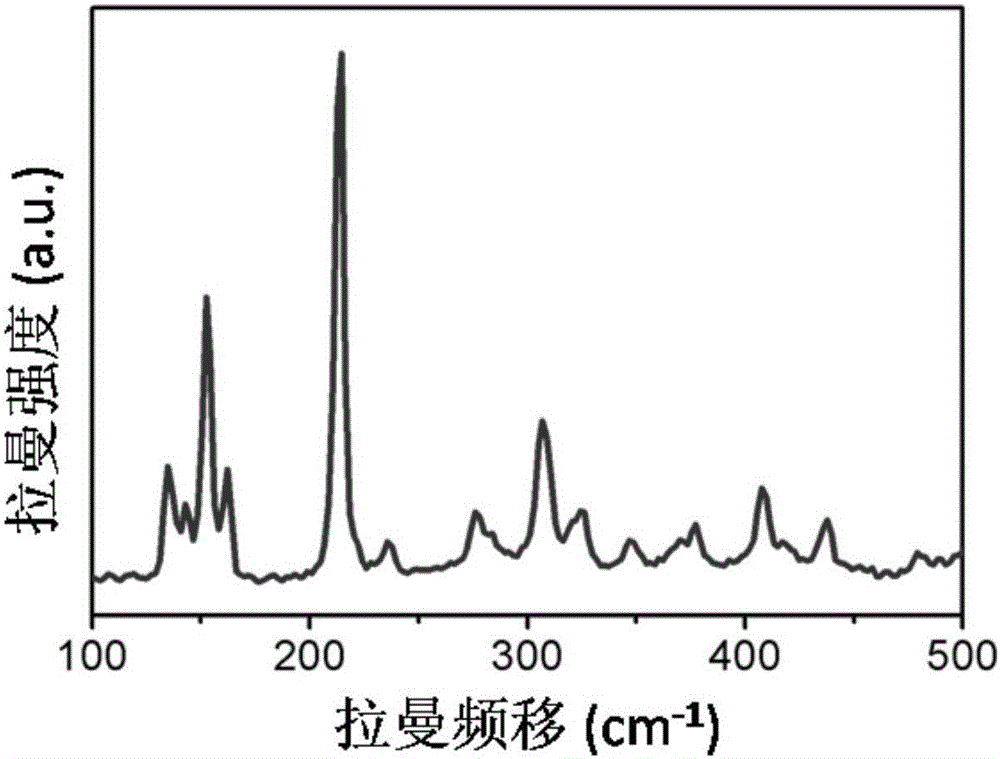

Chemical vapor deposition preparing method of large-size three-layer molybdenum sulfide single crystal

ActiveCN110172736AHigh personal experience requirementsEasy to operatePolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

The invention belongs to the field of two-dimensional material preparation, and discloses a chemical vapor deposition preparing method of a large-size three-layer molybdenum sulfide single crystal. The method is characterized by including the following steps of S1, preparing clean and dry molybdenum foil and soda-lime glass, and weighing elemental sulfur and molybdenum trioxide as precursors; S2,putting a first carrying boat with molybdenum foil, soda-lime glass and molybdenum trioxide and a second carrying boat with elemental sulfur into a chemical vapor deposition (CVD) pipe; S3, conductingdual-temperature-area temperature control CVD on the CVD pipe so that the three-layer molybdenum sulfide single crystal can deposit on the soda-lime glass. By improving the substrate material and thedual-temperature-area temperature arrangement of the key CVD process in the preparing method, compared with the prior art, the novel method for preparing the large-size three-layer molybdenum sulfidesingle crystal is provided, the maximum internal length of the obtained large-size three-layer molybdenum sulfide single crystal can reach 90 micron, and the prepared three-layer molybdenum sulfide single crystal is high in quality.

Owner:HUAZHONG UNIV OF SCI & TECH

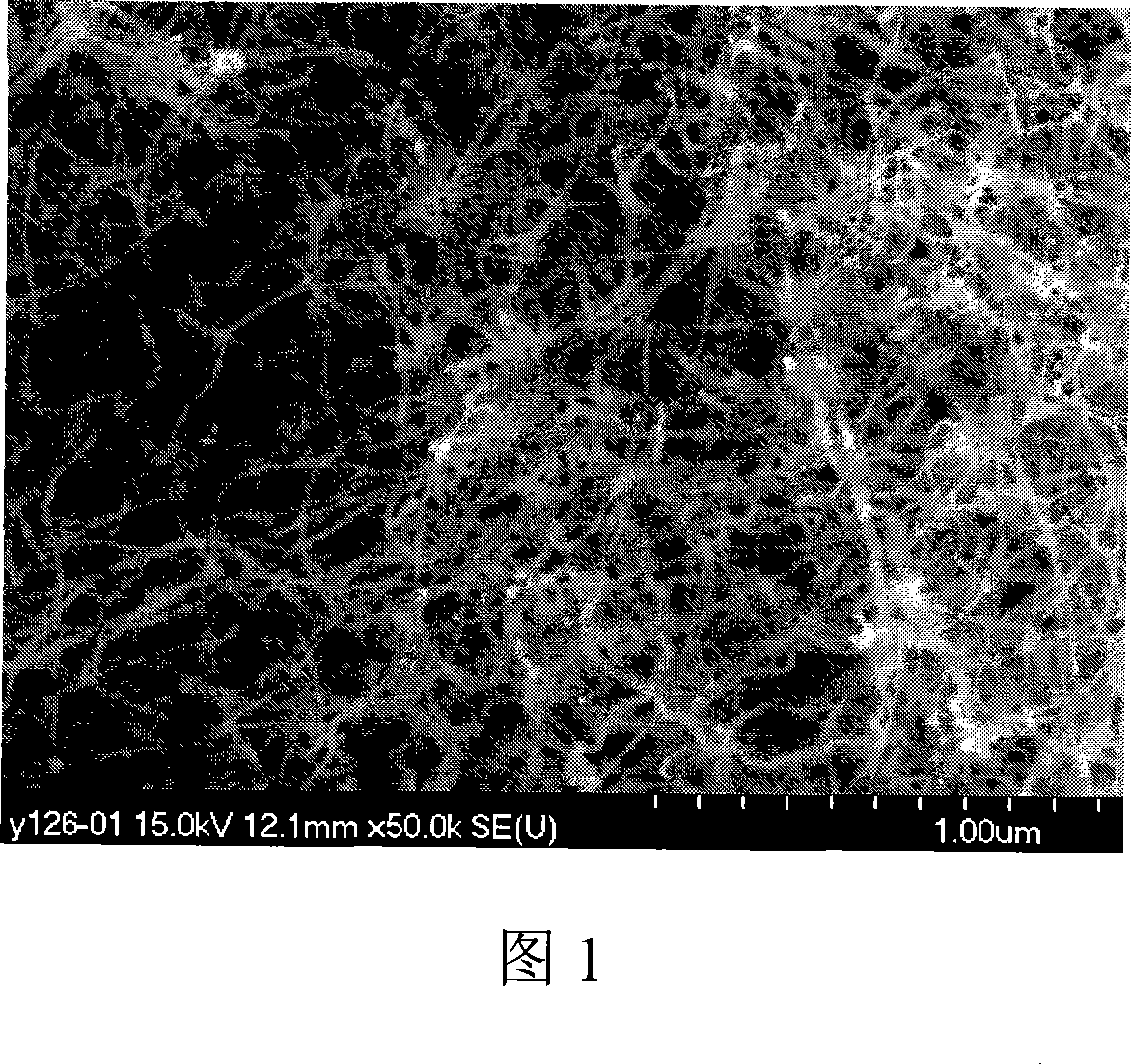

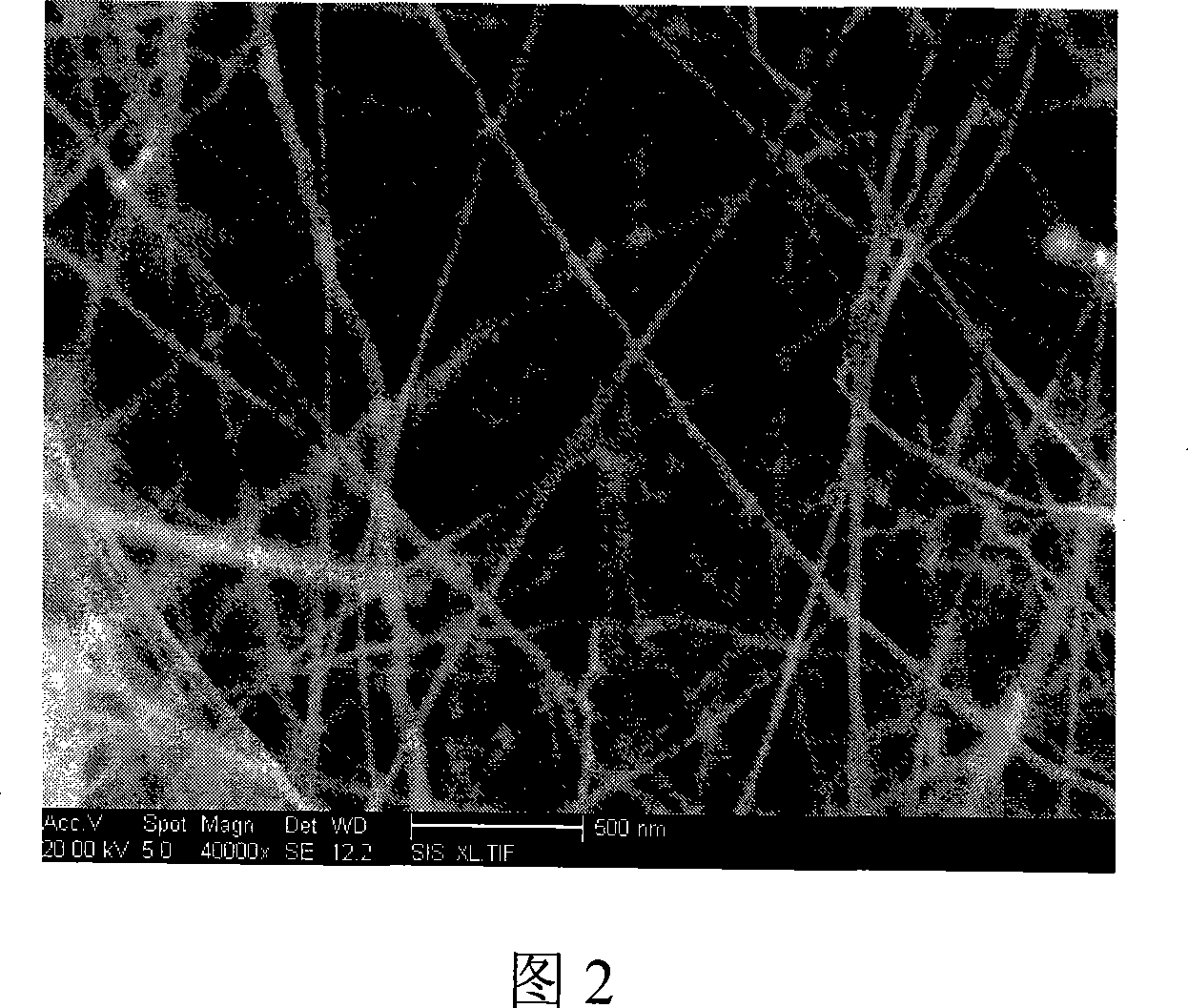

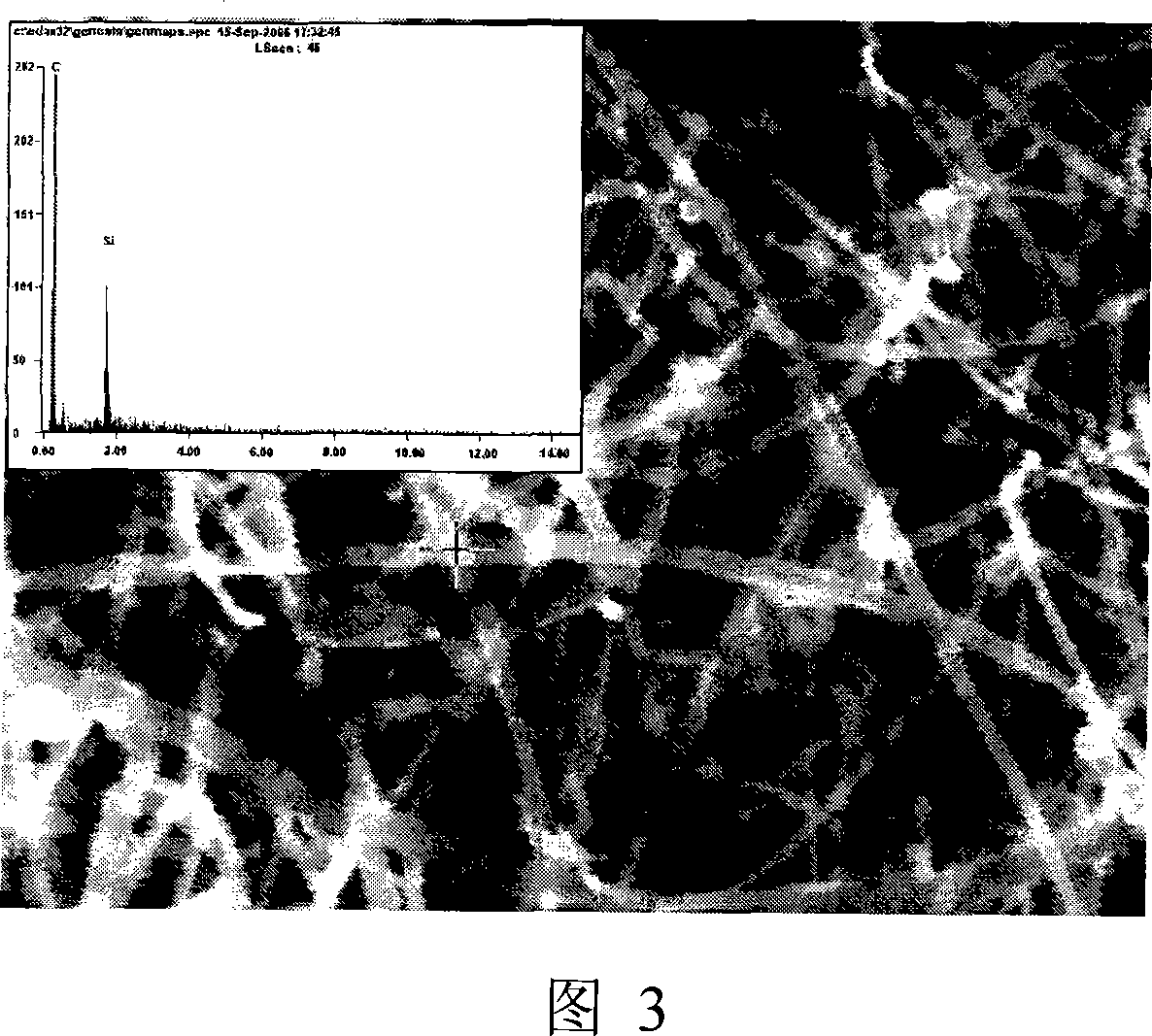

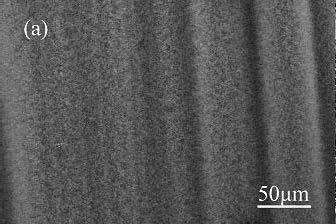

Method for preparing one dimension SiC Nano fiber

This invention discloses a method for preparing one-dimensional SiC nanowires. The method solves the problems of complex process, high cost, and uneasy control of the growth, low purity and low conversion rate. The method comprises: mixing Si powder and graphite powder, ball-milling for 12-48 h, washing with acid, washing with water, adding an organic solvent, dispersing by ultrasonication for 10-15 min, standing for 10 min-2 h, spreading on a substrate or a ceramic boat, placing the substrate or the ceramic boat in a heater, vacuumizing to 10-2-10-1 Pa, introducing Ar to 0.5-1 atmospheric pressure or keeping vacuum, heating at a rate of 5 deg.C / min or 10 deg.C / min to 900-1200 deg.C, and keeping for 1-5 h. The method has such advantages as simple process, no need for catalyst, low cost, easy control of the growth, high purity and high conversion rate.

Owner:HARBIN INST OF TECH

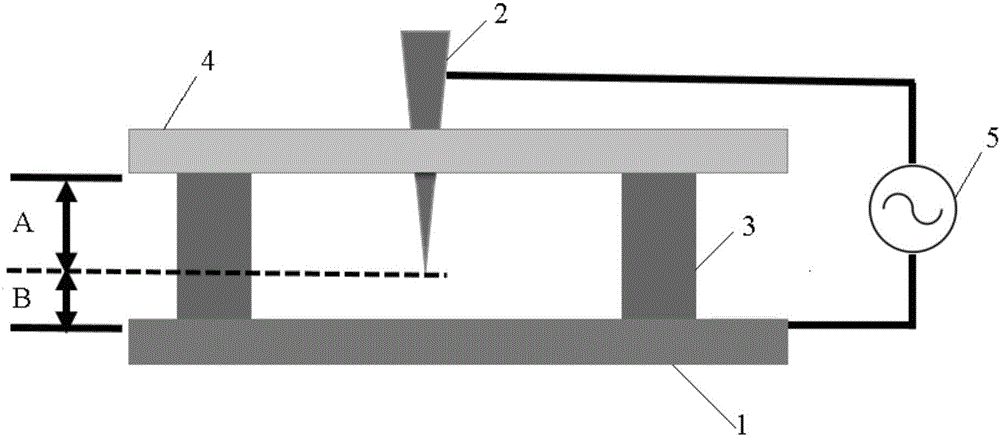

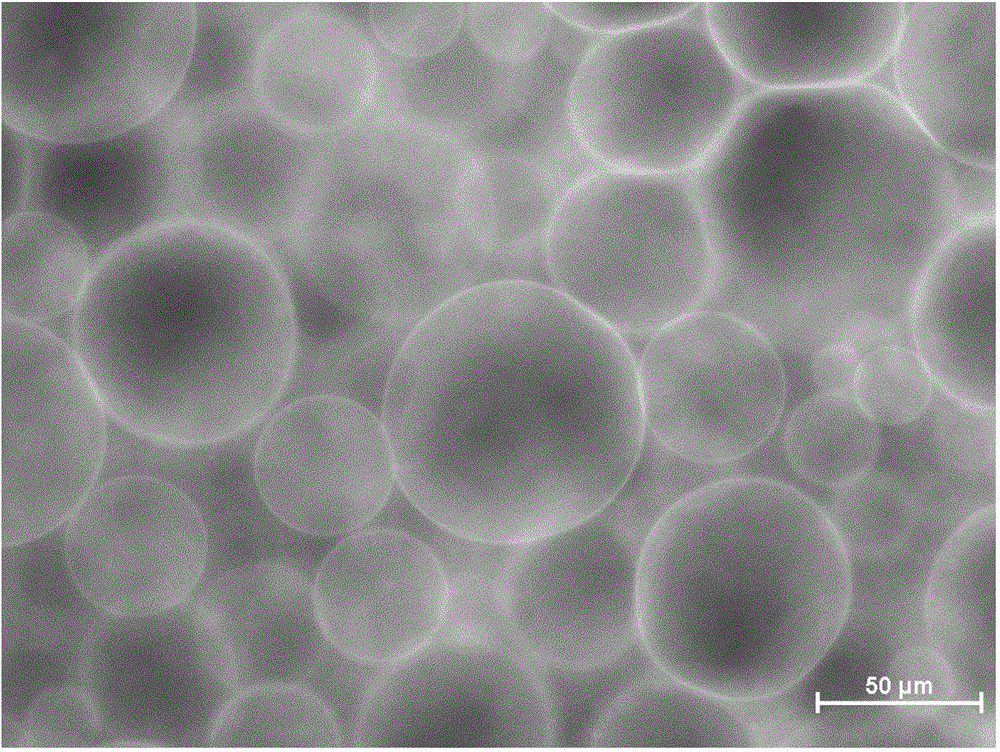

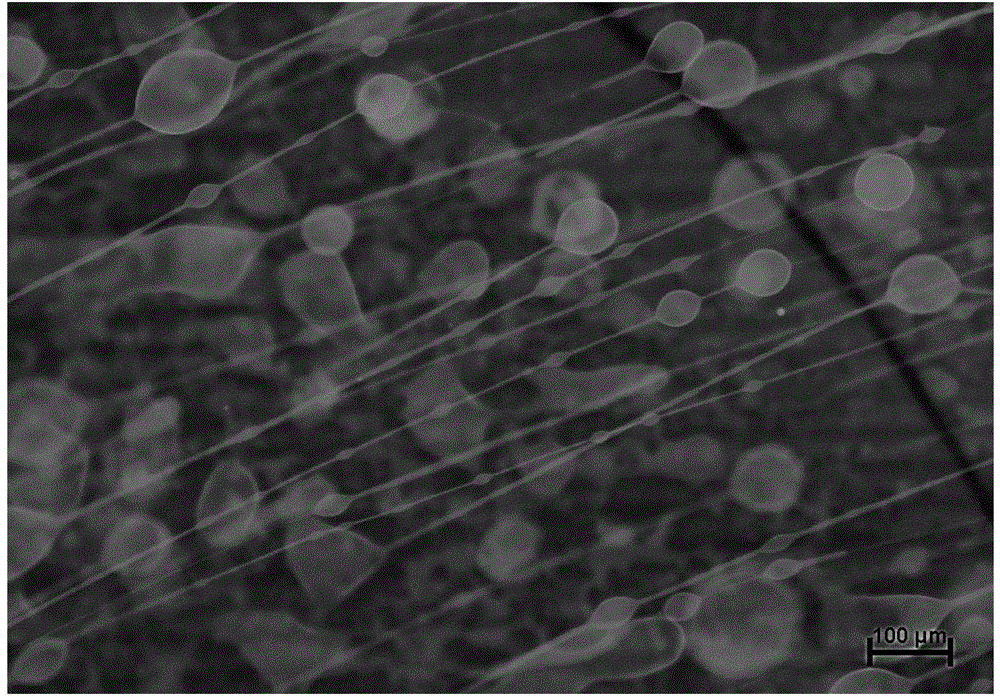

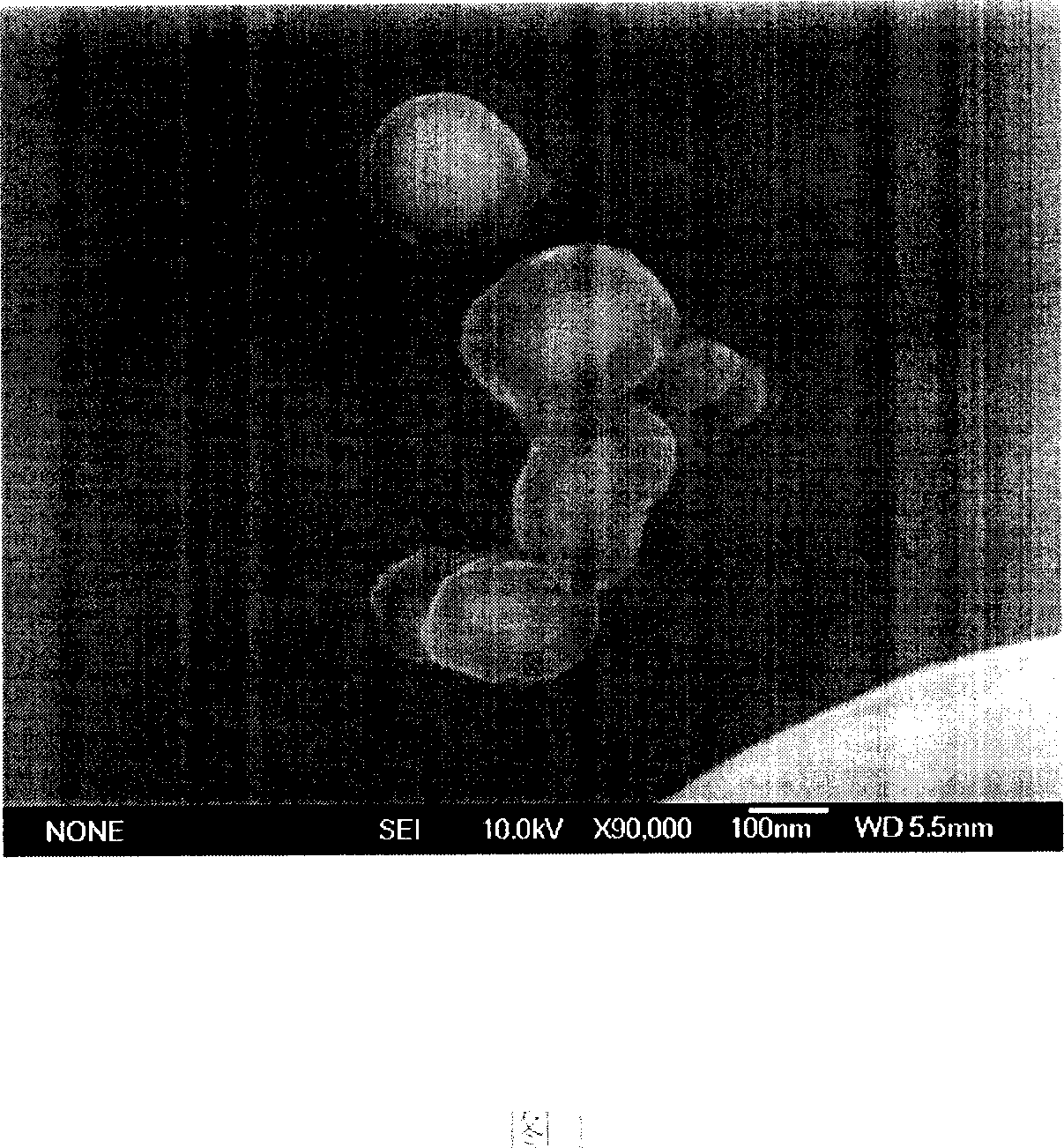

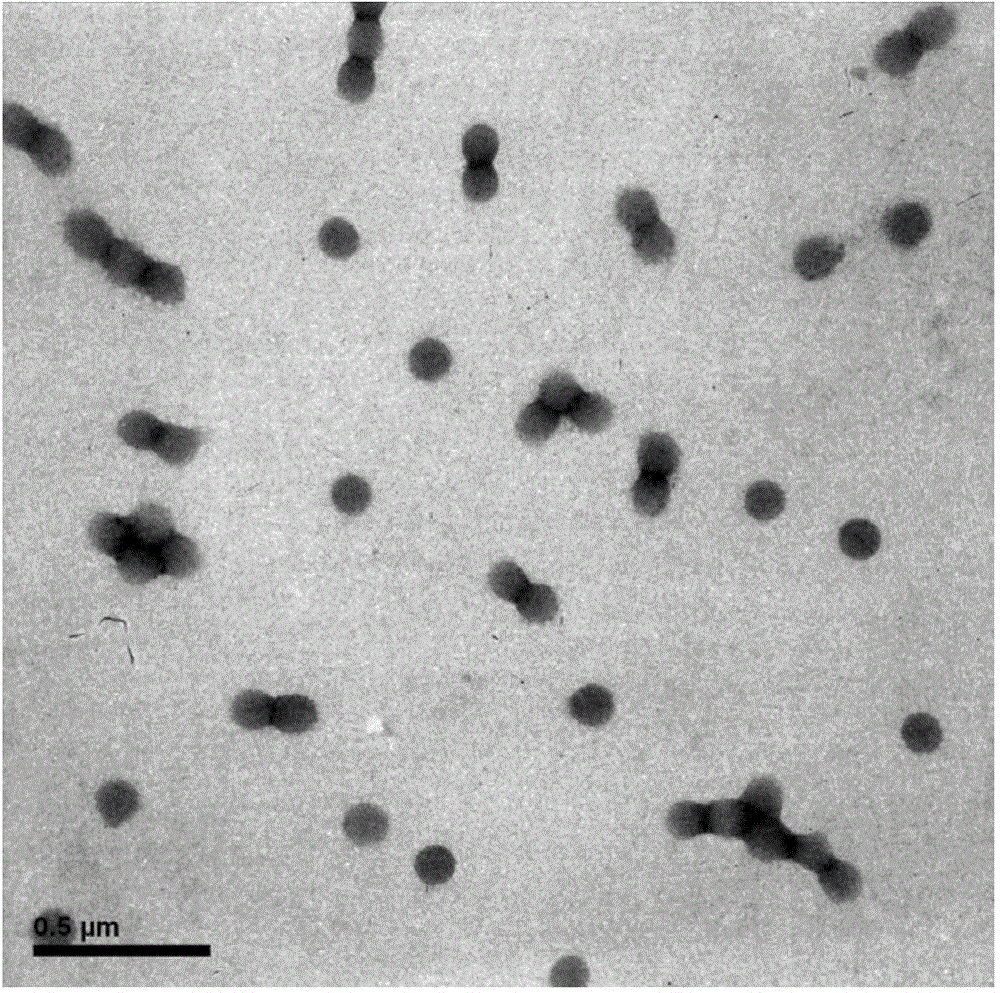

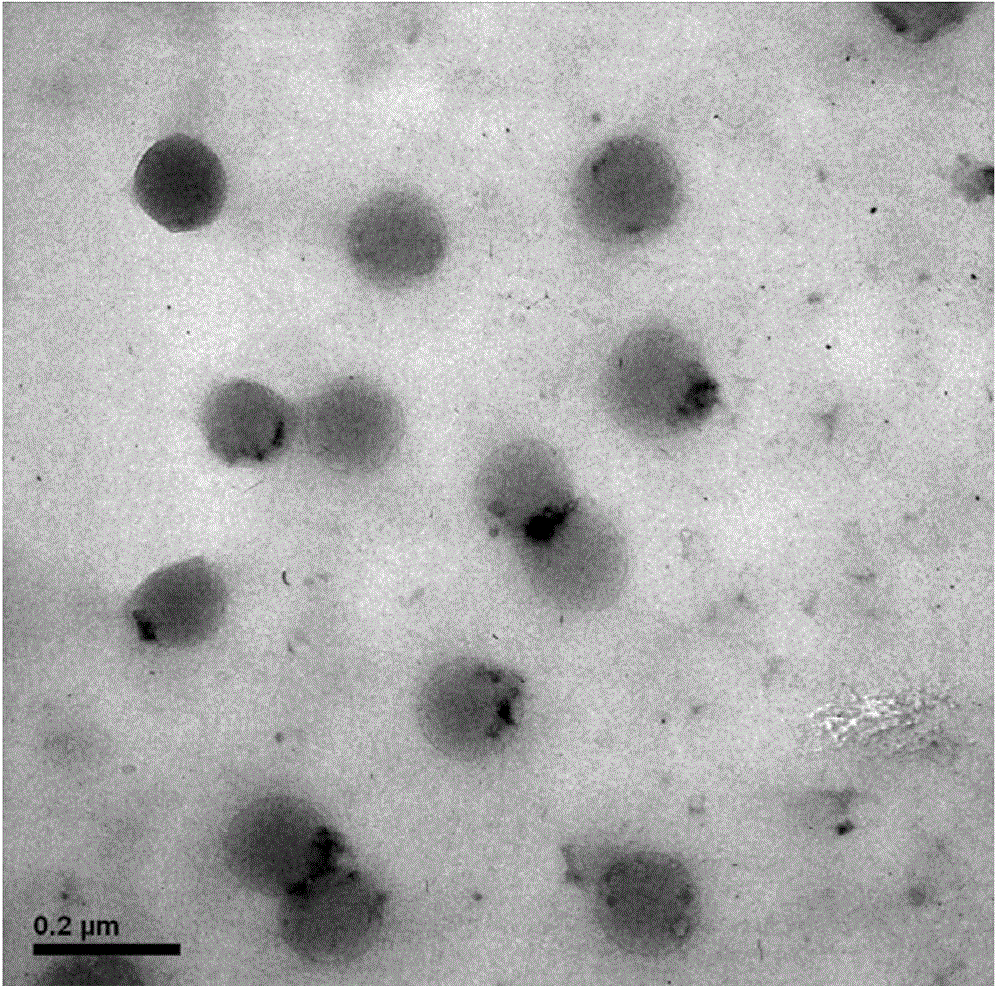

Method used for simultaneous preparation of phospholipid microtubule and vesicle using point-plane electrode electric field

ActiveCN104474990AEasy to shapeHigh yieldEnergy based chemical/physical/physico-chemical processesMicroballoon preparationVesicle/vacuoleGut morphology

The invention discloses to a method used for simultaneous preparation of phospholipid microtubule and vesicle using point-plane electrode electric field. The method is used for solving a problem that existing method is not capable of realizing simultaneous preparation of phospholipid microtubule and vesicle. The method comprises following steps: step 1, electrode cleaning; step 2, preparation of phospholipid dry membrane; step 3, assembling of a sealed preparation apparatus; and step 4, preparation of the phospholipid microtubule and vesicle, and obtaining of the phospholipid microtubule and vesicle. Advantages of the method are that: firstly, the method is capable of realizing simultaneous preparation of the phospholipid microtubule and vesicle using point-plane electrode electric field in a same system, form of the obtained phospholipid microtubule is good, yield is high, and phospholipid microtubule size is relatively large and uniform; and secondly, the length of the obtained phospholipid microtubule ranges from 200 to 1300 mum, and diameter ranges from 1 to 2 mum; and diameter of the obtained phospholipid vesicle ranges from 15 to 120 mum. The method is used for simultaneous preparation of the phospholipid microtubule and vesicle using point-plane electrode electric field.

Owner:宜兴环保产业有限公司

Prepn process of composite onion-shaped fullere material with homogeneous grain size

InactiveCN1931717AUniform particle sizeControllable growthNanostructure manufactureReaction temperatureNitrogen

The present invention discloses preparation process of composite onion-shaped fullerene material with homogeneous grain size. Through chemical vapor deposition with zeolite of different types and homogeneous pore size as template, added catalyst and cheap inert gas and nitrogen as carrier gas, and in effectively controlled technological parameters, including reaction temperature, time, gas flow rate, etc. composite onion-shaped fullerene material in homogeneous grain size is prepared. The technological process of the present invention is simple and fast, and the prepared onion-shaped fullerene has high purity, stable performance and other advantages and great latent application value.

Owner:TAIYUAN UNIV OF TECH

Preparation method for acidic supported hydrodesulfurization catalyst

ActiveCN110465305APromote growthControllable growthMolecular sieve catalystsCatalyst activation/preparationIsolation effectMolecular sieve

The invention discloses a preparation method of an acidic supported hydrodesulfurization catalyst. The preparation method comprises the following steps: loading a molecular sieve on the surface of a carbon-based material to obtain an acidic carbon-based carrier material; preparing a precursor solution of an active component of a hydrodesulfurization catalyst, and impregnating the acidic carbon-based carrier material in the precursor solution to load the active component on the surface of the acidic carbon-based carrier material; and carrying out drying and calcining to obtain the acidic supported hydrodesulfurization catalyst. According to the method, the carbon-based material is used as a carrier, the molecular sieve controllably and directionally grows on the surface of the carbon-basedmaterial, and acid sites and a NiMoS active center are highly dispersed and mutually matched with each other by utilizing the isolation effect of a three-dimensional space structure of the carbon-based material, and thus, the isomerization joint promotion of the active component and B acid is realized. The growth of the active center and molecular sieve grains can be inhibited under hydrodesulfurization reaction conditions, a cracking side reaction caused by excessive concentration of B acid is avoided, and the generation of deposited carbon is reduced.

Owner:UNIV OF SCI & TECH LIAONING

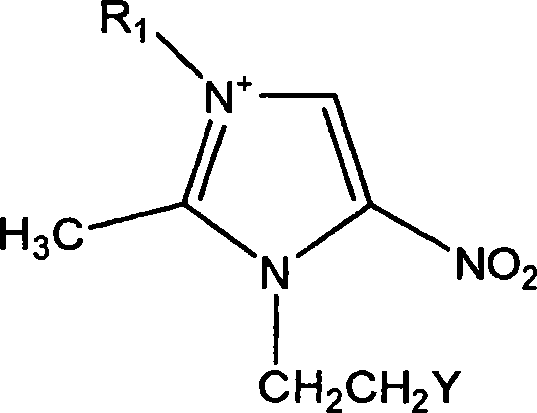

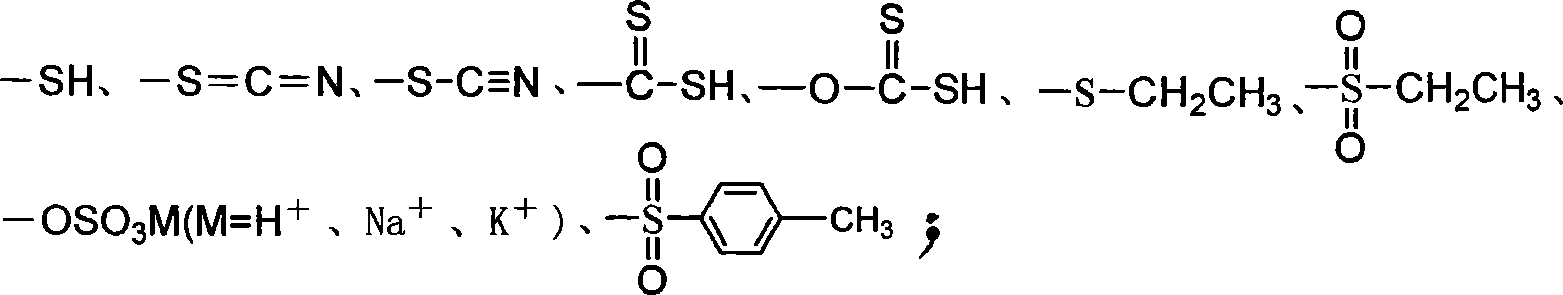

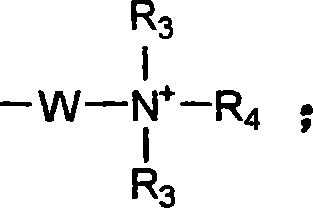

Heterocyclic organic sulfide germicide and its preparation method

InactiveCN101147485ANo washing stripping effectEasy to controlBiocideFungicidesFungicideQuaternary ammonium cation

The present invention relates to a heterocyclic organosulfur fungicide and its preparation method. It is characterized by that in the metronidazole molecular structure simultaneously are introduced a sulfur-containing group and a quaternary ammonium salt structure, and its preparation method includes the following steps: (1), mixing metronidazole, halogenation reagent and solvent, heating to 50-160deg.C and making reaction for 3-16h, then regulating pH value and filtering so as to obtain product M1; (2), according to male ratio of 1:1 making said product M1 and sulfide be dissolved in solvent, heating to 50-120deg.C and making reaction for 2-8h so as to obtain a sulfurized product; and (3), making the sulfruized product be directly mixed with quaterisation reagent, heating to 50-150deg.C, making reaction for 2-12h, then adding a certain quantity of water, mixing them so as to obtain the invented fungicide product.

Owner:CHINA NAT OFFSHORE OIL CORP +1

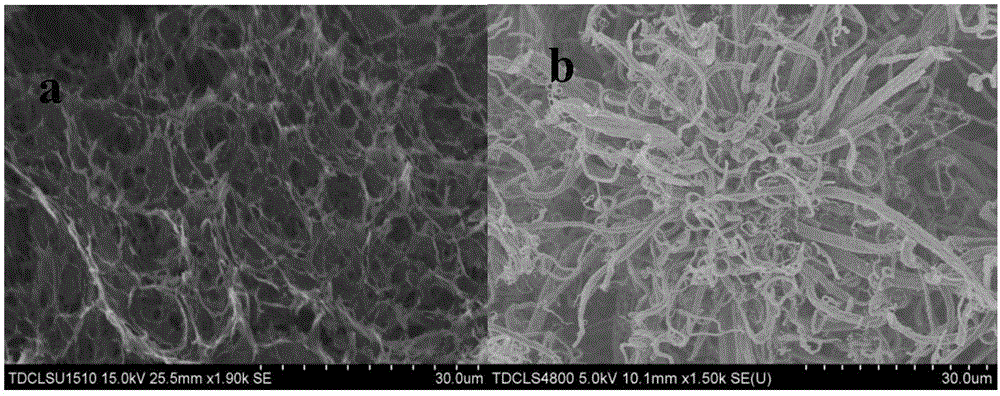

Preparation method of nanosheet self-assembled three-dimensional nano flower tin sulfide/graphitized carbon nitride lithium ion battery anode material

ActiveCN109286009AControllable growthUniform size distributionMaterial nanotechnologyCell electrodesVacuum dryingMaterials science

The invention discloses a preparation method of a nanosheet self-assembled three-dimensional nano flower tin sulfide / graphitized carbon nitride lithium ion battery anode material. Melamine is kept at450-650 DEG C for 2-6 hours, is naturally cooled to room temperature, is ground for prepare use, and is dispersed in ethanol to obtain a suspension, the suspension is centrifuged and washed several times with deionized water and absolute ethanol, vacuum drying is conducted to obtain a product g-C3N4, the product g-C3N4 is dissolved in the deionized water, after stirring, the product g-C3N4 is ultrasonically dispersed to form a suspension A, PVP is added to the suspension A, stirring is conducted until the product g-C3N4 is completely dissolved to form a solution B, TAA and SnCl4 2H2O are addedto the solution B, stirring is uniformly conducted to form a solution C, the solution C is subjected to a microwave hydrothermal reaction, after the reaction is completed, a precursor is obtained, the precursor is centrifuged and washed several times with the deionized water and the absolute ethanol, and vacuum drying is conducted to obtain a nanosheet self-assembled three-dimensional nano flowerSnS2 / g-C3N4 battery material.

Owner:SHAANXI UNIV OF SCI & TECH

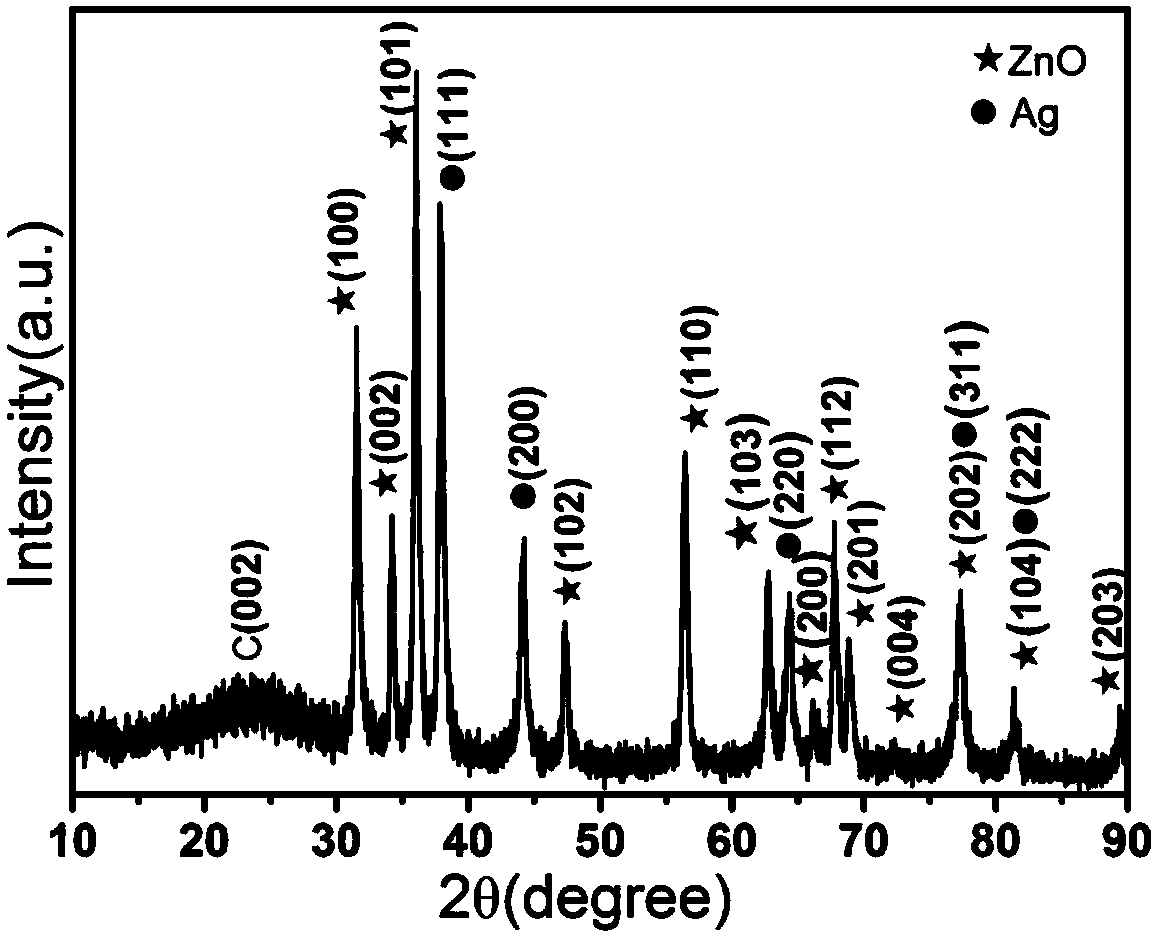

ZnO/Ag/graphene nanometer composite material, preparation method and application thereof

ActiveCN108283178AReduce dosageControllable growthBiocideLavatory sanitoryGraphene nanocompositesNano composites

The invention relates to a ZnO / Ag / graphene nanometer composite material, a preparation method and application thereof, and belongs to the field of nanometer material application and biological materials. The novel antibacterial ZnO / Ag / graphene composite material is prepared through a one-step solvothermal reaction by using environment-friendly ethyl alcohol as a reducer, the preparation process issimple and convenient, the loading of ZnO and Ag nanometer particles on graphene sheets is realized simultaneously in the one-step preparation process, the sizes of the nanometer particles are controlled effectively, and the used reagent is green and environmentally friendly.

Owner:JIANGSU UNIV

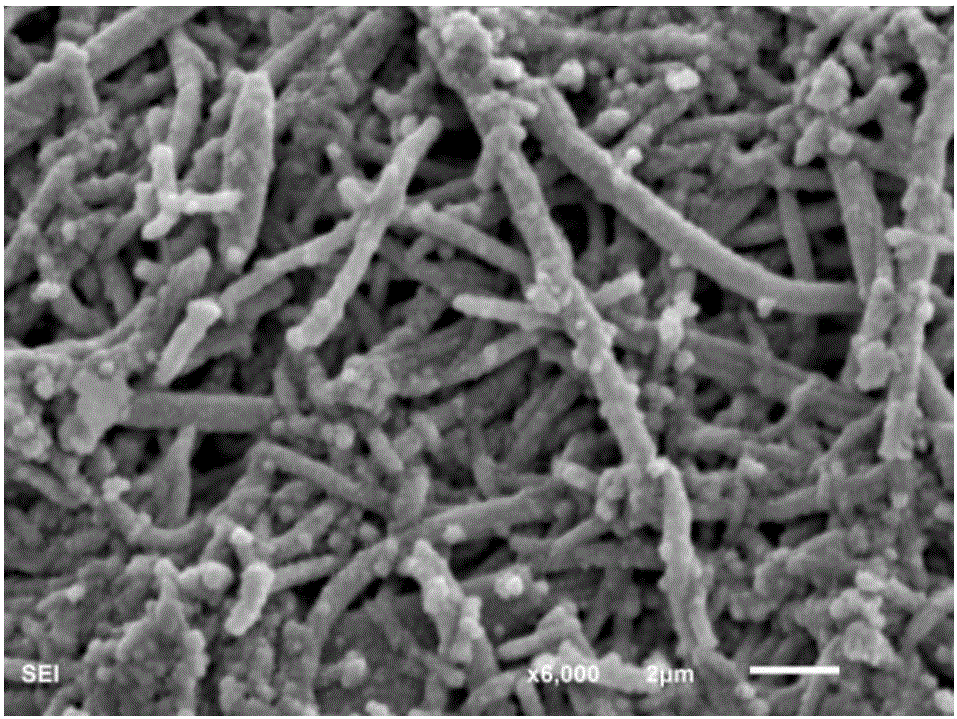

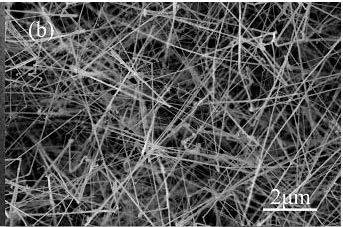

Nickel nanofiber membrane for membrane catalysis and preparation method of nickel nanofiber membrane

ActiveCN105148996APhysically and chemically stableReliable specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsFibre typesSolventChemistry

The invention relates to a nickel nanofiber membrane for membrane catalysis. The nickel nanofiber membrane is composed of a thermoplastic polymer nanofiber membrane and a nickel nano membrane deposited on the thermoplastic polymer nanofiber surface and comprises components in mass of 14%-75% of the thermoplastic polymer nanofiber membrane and 25%-86% of the nickel nano membrane. A preparation process adopts the method that thermoplastic polymers and cellulose acetate butyrate are subjected to blending melt spinning in proportion, thermoplastic polymer nanofibers are prepared through solvent extraction and dispersed and coated to the surface of a smooth substrate, and the thermoplastic polymer nanofiber membrane is taken down after drying. The nanofiber membrane is placed into a nickel bath with a certain formula for chemical nickel-plating after allergy and activating treatment and dried after taken out to obtain the nickel nanofiber membrane for membrane catalysis. The process is simple, the cost is low, and large scale preparation is easy to implement. The nickel nanofiber membrane for membrane catalysis has the characteristics that the porosity is high, the pore diameter is controllable, the flux is large, the catalytic activity is high, and separation is easy.

Owner:佛山市维晨科技有限公司 +1

Method used for limiting composite material matrix internal crack expansion

The invention relates to a method used for limiting composite material matrix internal crack expansion. The method comprises following steps: 1, chemical vapor deposition is adopted for preparation ofa layered PyC interface on the surface of a fiber prefab with surface in-suit growth of SiC nanometer wire so as to obtain a SiCNWs / PyC fiber prefab; 2, at least one method selected from chemical vapor infiltration CVI, precursor infiltration pyrolysis PIP, and reactive melt infiltration RMI is adopted for filling of a ceramic matrix in the SiCNWs / PyC fiber prefab so as to obtain the SiCNWs / PyC synergetically enhanced ceramic based composite material; wherein the ceramic matrix is at least one selected from SiC, Si-C-N, and Si-B-C-N.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

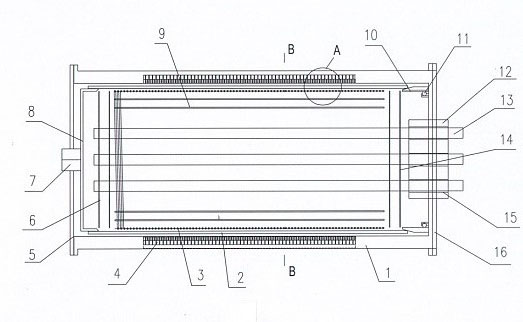

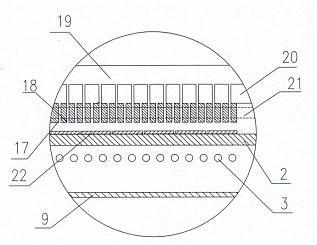

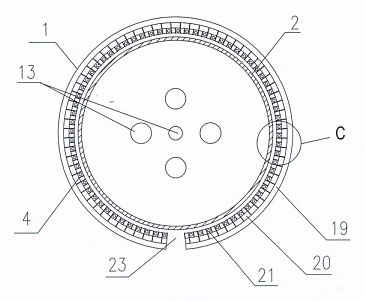

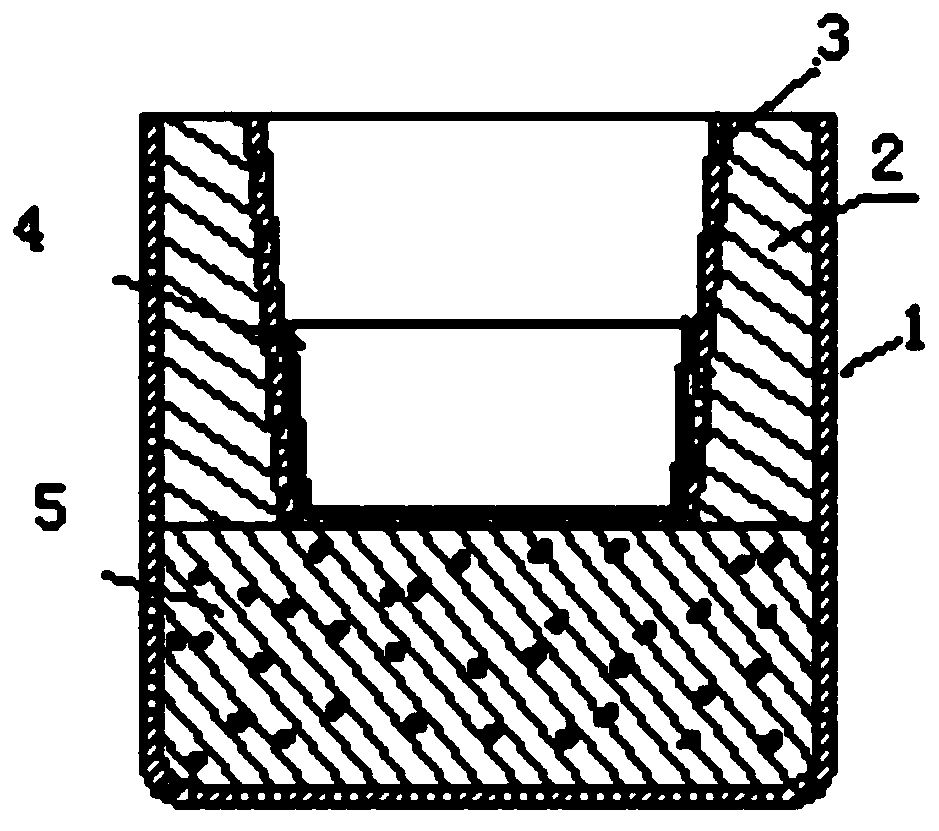

Barrel-shaped metal organic chemical vapor deposition reaction tube

ActiveCN102094185AReduce power consumptionReduce raw material consumptionChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a barrel-shaped metal organic chemical vapor deposition reaction tube which comprises a barrel body. The barrel type metal organic chemical vapor deposition reaction tube is characterized in that the barrel body is in a barrel shape with an open left end and an open right end, and a graphite barrel, an electric stove wire barrel and a molybdenum sheet heat insulation barrel are sequentially sleeved in the barrel body. The left end and the right end of the electric stove wire barrel are respectively provided with a left heat insulation molybdenum sheet and a right heat insulation molybdenum sheet which are sleeved on an electrode stem. A multiple-layer spray tube is arranged in the barrel body and is composed of a liquid cooling tube, an ammonia spray tube and a metal organic source spray tube. An ammonia nozzle connected with the ammonia spray tube and a metal organic source nozzle connected with the metal organic source spray tube are arranged on the inner wall of the barrel body, and an exhaust port is arranged on the inner wall of the barrel body. The barrel type metal organic chemical vapor deposition reaction tube has the advantages that the throughput can be raised on a large scale, the product cost can be reduced, the production efficiency can be increased, the surface temperature uniformity of graphite is good, the product percent of pass is high, and the energy consumption is low. The productivity is 20 times as high as that of three kinds of popular MOVCD great machines at present.

Owner:南昌硅基半导体科技有限公司

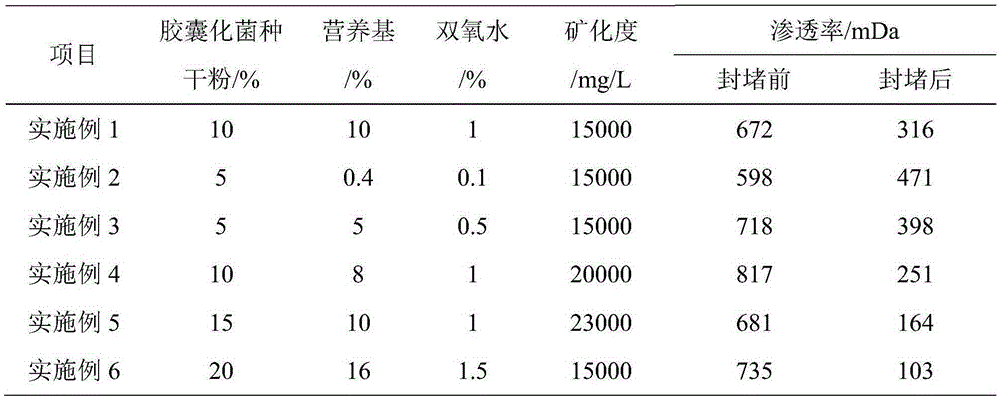

Biological profiling and plugging agent, preparation method and application

ActiveCN105273700AImprove salt toleranceImprove featuresDrilling compositionSalt resistanceBiological profile

The invention discloses a biological profiling and plugging agent, a preparation method and an application, which belongs to the technical field of oil field chemistry. The biological profiling and plugging agent consists of the following components by weight percent: 5 to 20 percent of capsulation strain dry powder, 0.4 to 16 parts of nutrient medium, 0.1 to 2 percent of bacteria amount adjusting agent and the balance of water. The biological profiling and plugging agent has characteristics of good salt resistance and good cutting resistance; moreover, the biological profiling and plugging agent is unlikely to degrade, and after the biological profiling and plugging agent is injected into deep stratum, a purpose of depth profile control can be realized. By adopting the capsule particles, the survival rate of the strain can be increased; the capsule particles pass through large pores along with injection liquid and are remained in an area with a pore radius smaller than the radius of the particle so as to form effective plugging, and the swept volume of the injection liquid can be increased; meanwhile, by adjusting the injection amount of the nutrient medium and strain adjusting agent, the growth situation of the flora can be controlled, the profile control or plugging controllable requirement can be met, and the plugging effect is kept effective for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

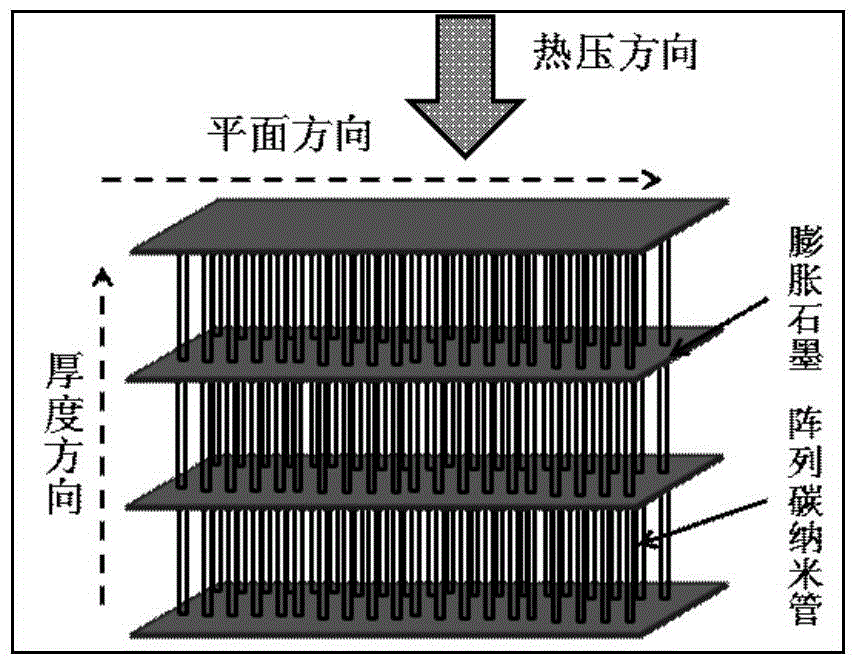

Carbon-based composite with high rebound resilience and high heat conductivity coefficient along thickness direction and preparation method of carbon-based composite

The invention relates to a preparation method of a carbon-based composite with high rebound resilience and high heat conductivity coefficient simultaneously along a thickness direction. Graphite sheets in expanded graphite are connected to one another by arrayed carbon nano tubes; gaps among the graphite sheets are filled with the arrayed carbon nano tubes; the heat conductivity coefficient is greater than or equal to 25W / (m.K) along the thickness direction; and after the graphite sheets are compressed by 10%, the rebound rate is greater than or equal to 90%. The arrayed carbon nano tubes grow through ferrocene carbon source solution; ferrocene cracks into iron atoms which are adhered to the graphite sheets of the expanded graphite, the carbon source solution cracks into carbon atoms which are adhered to surfaces of the iron atoms, so that the arrayed carbon nano tubes grow among the graphite sheets of the expanded graphite, heat flow can be transferred among the graphite sheets in the expanded graphite by high heat conductivity of the carbon nano tubes, the graphite sheets can be oriented along a perpendicular hot-pressing direction, namely a horizontal direction, the arrayed carbon nano tubes are connected to one another in the thickness direction, the graphite sheets and the gaps of the expanded graphite are filled with the arrayed carbon nano tubes, and the carbon-based composite with the high rebound resilience and the high heat conductivity coefficient along the thickness direction is obtained.

Owner:TIANJIN UNIV

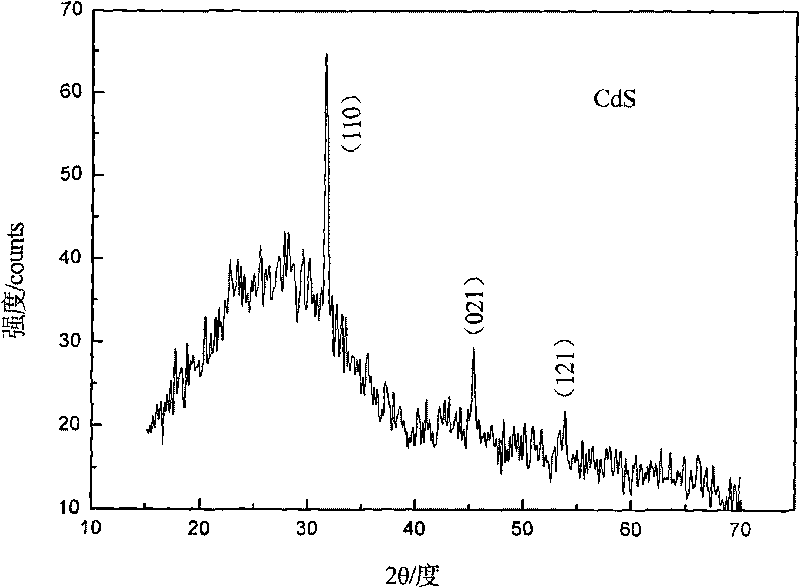

Method for preparing CdS film in microwave hydrothermal mode

InactiveCN101698963AHigh purityGood uniformityPolycrystalline material growthFrom normal temperature solutionsIonChemistry

The invention relates to a method for preparing a CdS film in a microwave hydrothermal mode, which comprises the following steps: adding CdC12.H2O into deionized water to obtain a solution A; adding Na2S2SO3.5H2O or SC(NH2)2 into the solution A to obtain a solution B; adding versene acid or plasmosan into the solution B to obtain a solution C; pouring the solution C into a hydrothermal reaction kettle, putting a substrate in the hydrothermal kettle, and dipping the substrate in a film-coating liquid; sealing the hydrothermal reaction kettle, putting the hydrothermal reaction kettle in an MDS-6 temperature and pressure double-control microwave hydrothermal reaction apparatus, and naturally cooling to room temperature after the reaction is completed; and opening the hydrothermal reaction kettle, taking out the substrate, respectively washing the substrate with distilled water and absolute ethyl alcohol, and vacuum-drying to obtain the CdS photoelectric film on the surface of the substrate. The reaction of the invention is completed in the liquid phase by one time; and the prepared CdS film has the advantages of high purity, favorable evenness, and firm bonding of the film and the substrate, and does not need the crystallization heat treatment in the later period.

Owner:SHAANXI UNIV OF SCI & TECH

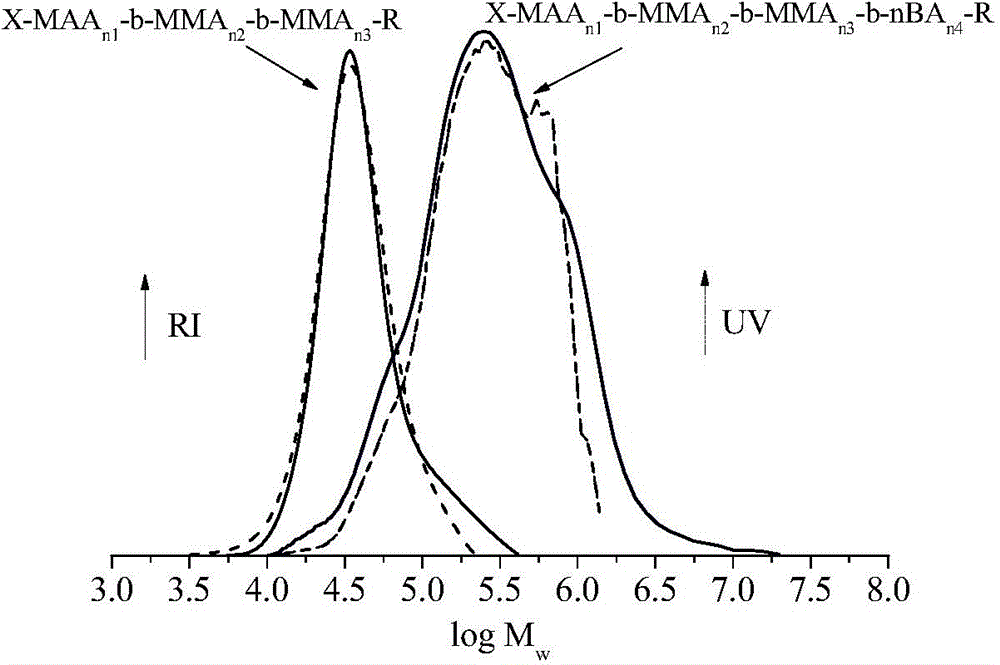

Segmented copolymer flexibilizer as well as preparation method and application thereof

The invention discloses a segmented copolymer flexibilizer as well as a preparation method and application thereof. According to the preparation method disclosed by the invention, poly(methacrylic acid-b-methyl methacrylate-b-n-butyl acrylate) segmented copolymer flexibilizers with different monomer compositions and different molecular weights are prepared by using an emulsion polymerization system and a reversible addition fragmentation chain transfer free radical polymerization technology. The segmented copolymer flexibilizer is blended with polycarbonate to prepare an alloy. The process of the preparation method disclosed by the invention is simple in equipment, environment-friendly, energy-saving and easy to operate. The segmented copolymer flexibilizer is prepared by using an amphiphilic macromolecular reversible addition fragmentation chain transfer reagent, has the double functions of a chain transfer reagent and an emulsifier, realizes good control on monomer polymerization, and avoids the use of the traditional emulsifier; the reaction has no polymerization inhibition period, and has a high reaction speed and a high final conversion rate, colloidal particle growth during the process is stable, and the molecular weight range of the product is wide.

Owner:ZHEJIANG UNIV

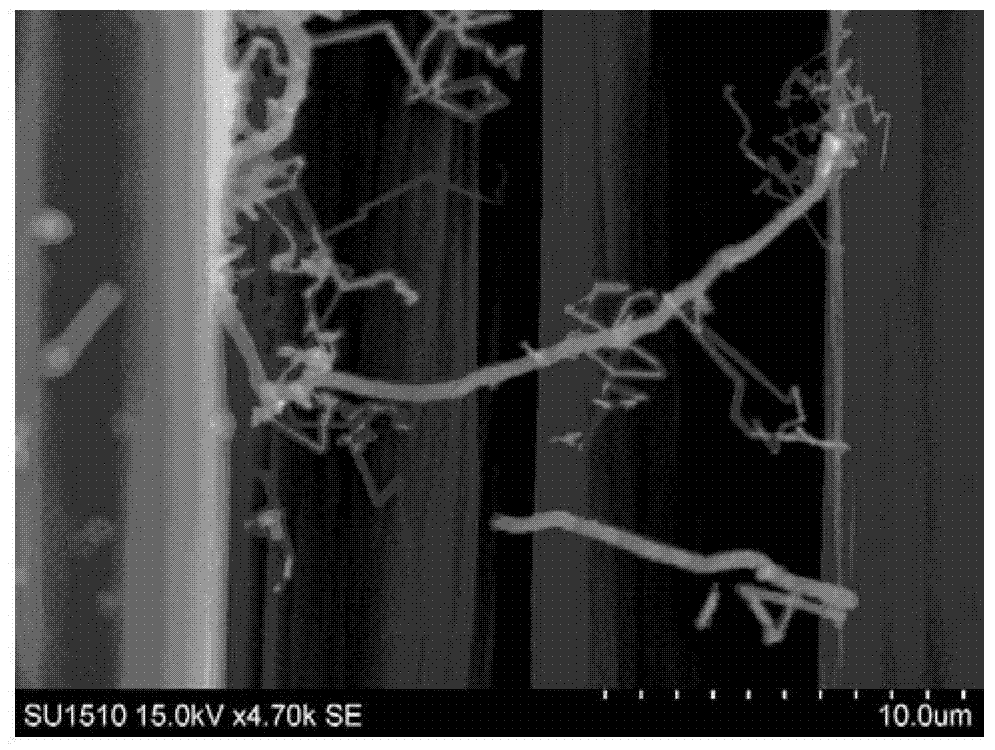

Fiber reinforcement and preparation method thereof

ActiveCN107285793AThe preparation process is simpleGrowth is easy to controlNanoscopic scaleMicron scale

The invention relates to a fiber reinforcement and a preparation method thereof. The reinforcement is formed through in-situ growth of multi-stage SiC nano-wires on the surface of a fiber fabric body; the multi-stage SiC nano-wires comprise a sub-micron scale and a nano scale, wherein the sub-micron scale is 0.1mu m to 1mu m and the nano scale is 5nm to 100nm. The invention innovatively explores the preparation method of the multi-stage SiC nano-wire reinforcement through the in-situ growth on surfaces of fibers for the first time to obtain the needed multi-stage SiC nano-wire reinforcement. A preparation technology provided by the invention has the advantages of simple method, easiness for controlling the growth and high safety.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

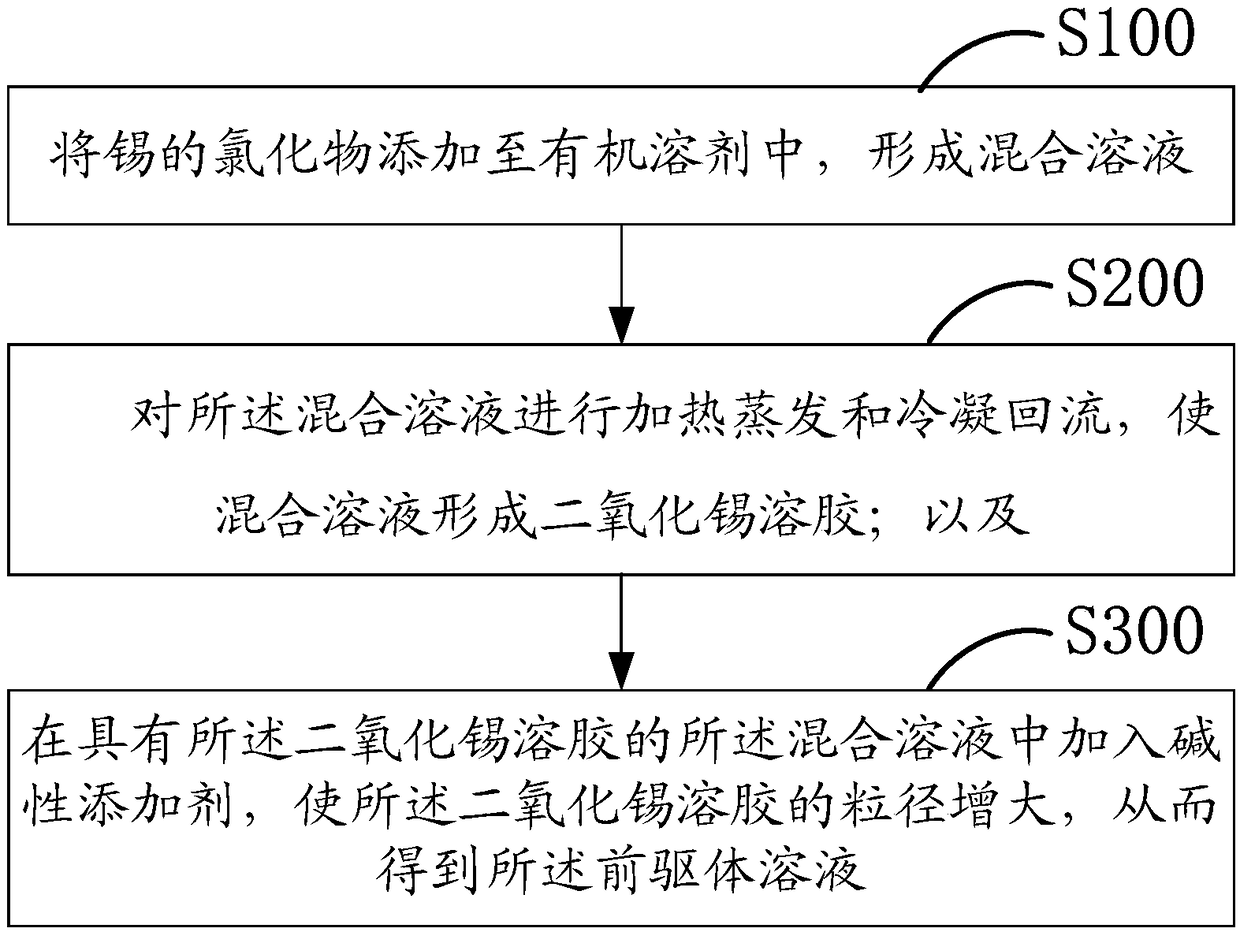

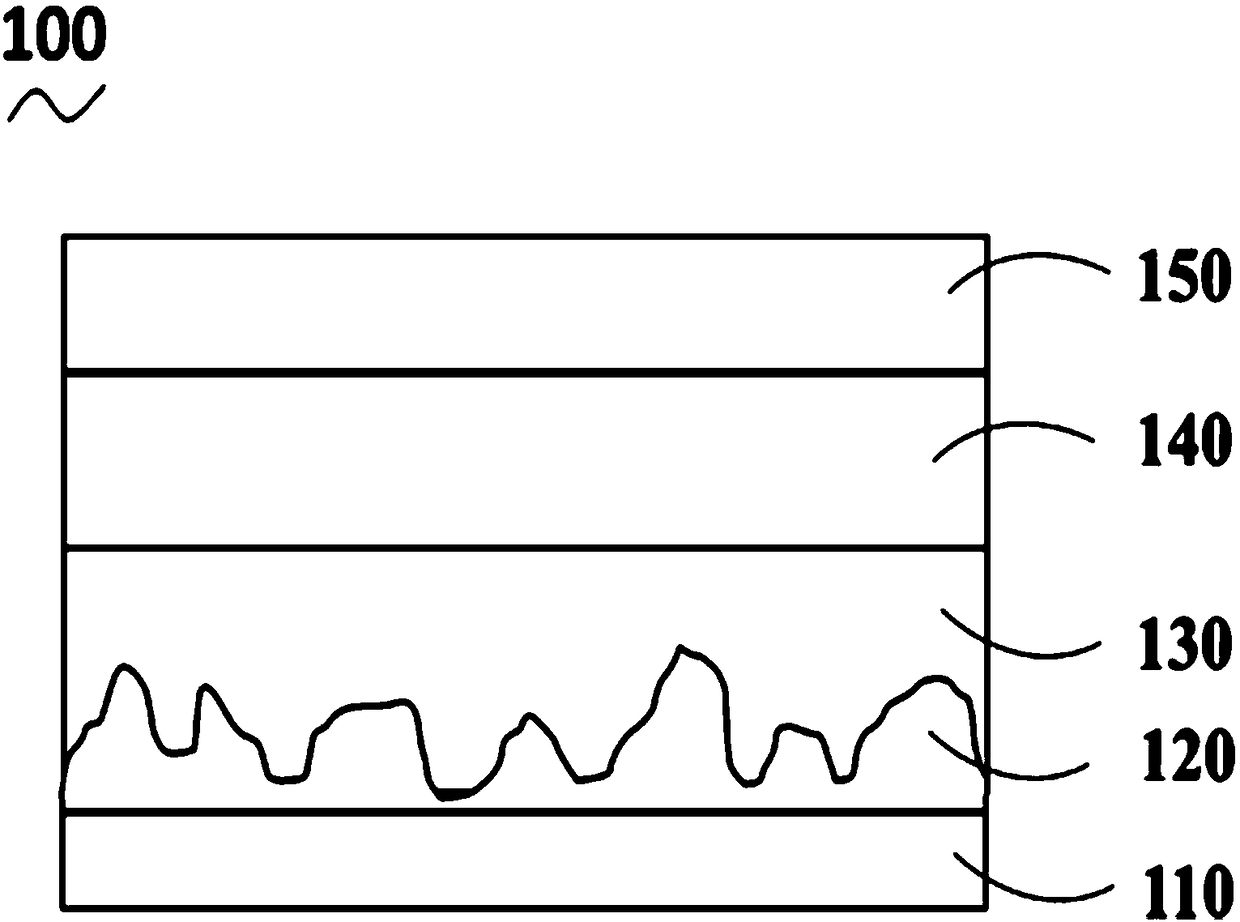

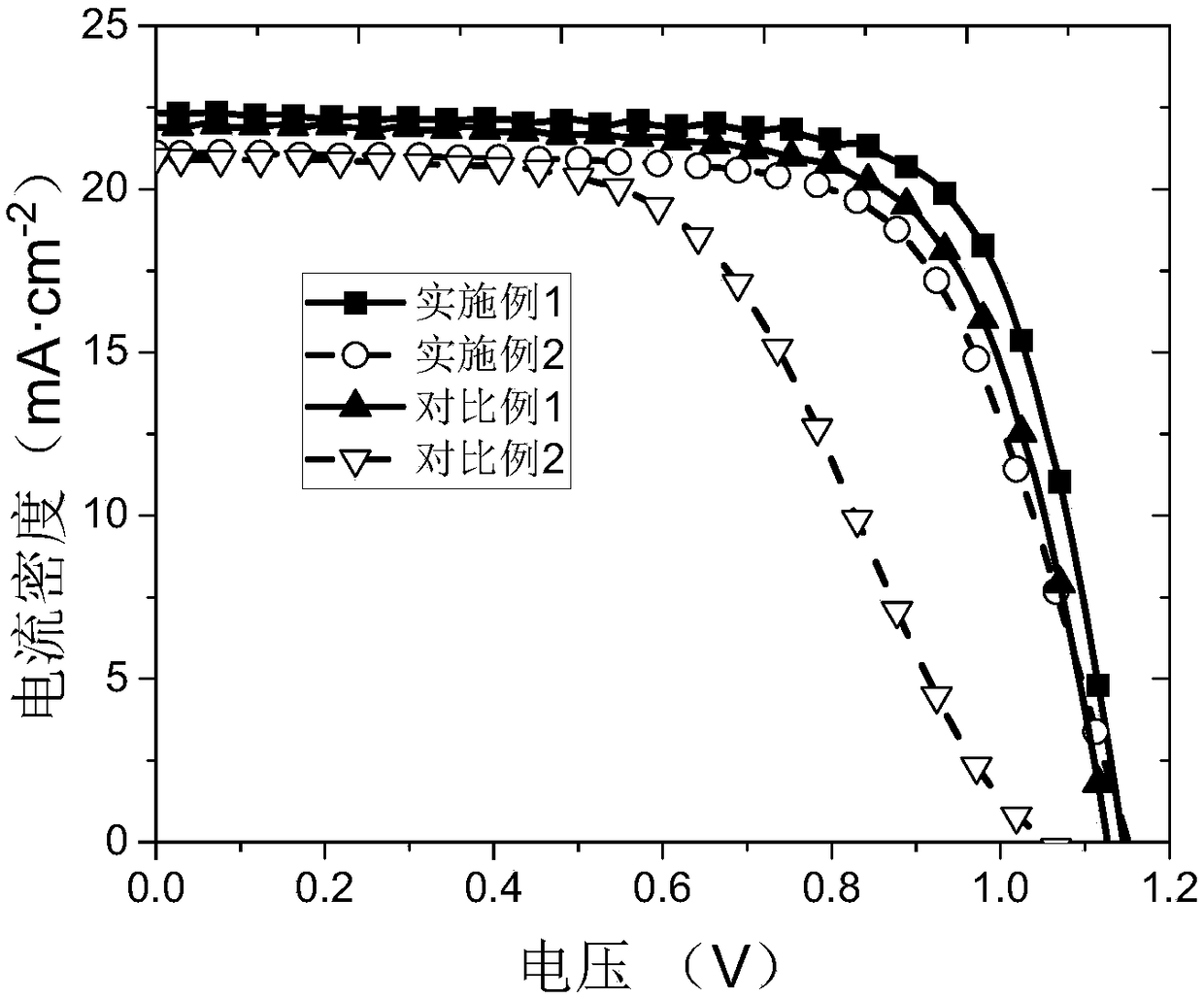

Precursor solution and method for preparing same, preparation of solar cell electron transport layer, and solar cell

ActiveCN108447995AControllable growthPromote cross-linking and polymerizationMaterial nanotechnologySolid-state devicesTin dioxideEvaporation

The embodiment of the invention provides a method for preparing a precursor solution for preparing a solar cell electron transport layer. The method comprises adding tin chloride to an organic solventto form a mixed solution; performing heating evaporation and reflux condensation on the mixed solution to form tin dioxide sol from the mixed solution; and adding an alkaline additive to the mixed solution having the tin dioxide sol to increase the particle size of the tin dioxide sol, thereby obtaining the precursor solution. There is also provided a precursor solution for preparing a solar cellelectron transport layer. The precursor solution comprises an organic solvent, tin dioxide sol, and an alkaline additive, wherein the tin dioxide sol and the alkaline additive are dispersed in the organic solvent. A method of preparing a solar cell electron transport layer and a solar cell including the electron transport layer are also provided.

Owner:TSINGHUA UNIV

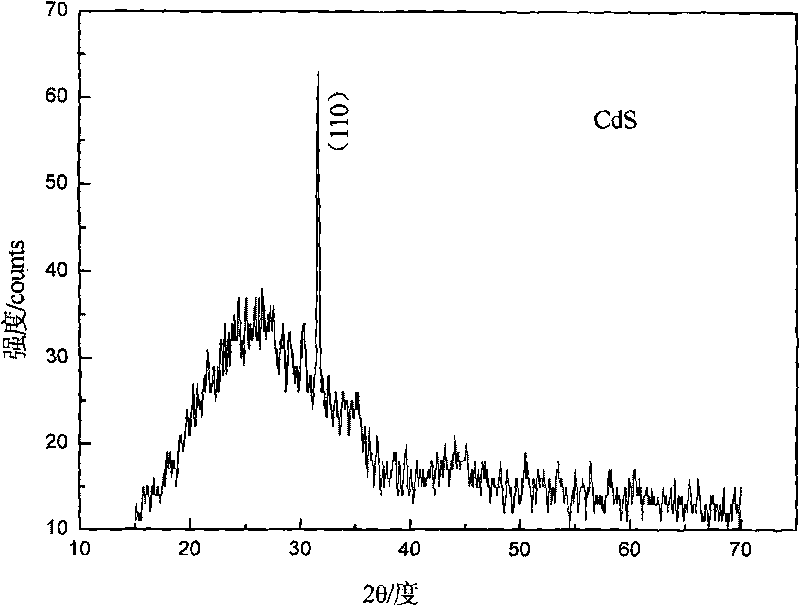

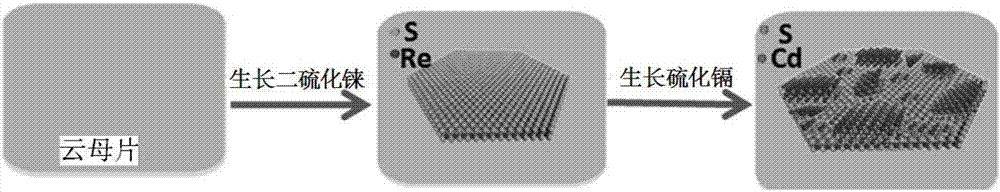

Preparation of rhenium sulfide and cadmium sulfide/rhenium sulfide composite material

ActiveCN108002445AImprove photoresponsivityImprove external quantum efficiencyRhenium compoundsSulfurWater assisted

The invention discloses preparation of rhenium sulfide and a cadmium sulfide / rhenium sulfide composite material. A two-dimensional monolayer rhenium disulfide is grown on a mica sheet substrate through an ordinary pressure chemical vapor deposition method with sulfur powder as a sulfur source and rhenium trioxide as a rhenium source under protection of an inert gas and a water-assisting precondition; by means of a secondary growth method, cadmium sulfide particles are again deposited on the mica sheet substrate with the two-dimensional monolayer rhenium disulfide, and a CdS / ReS2 composite material with the cadmium sulfide particles growing on the surface of the rhenium sulfide is obtained. The preparation of the rhenium sulfide and the cadmium sulfide / rhenium sulfide composite material have the advantages that the process is simple, low-cost, rapid, highly efficient and controllable, and the high-quality single-layer rhenium sulfide is prepared. The CdS / ReS2 composite material obtained by depositing the cadmium sulfide on the two-dimensional material rhenium sulfide has more excellent photoelectric properties and has a high response rate while being applied to a photoelectric device.

Owner:WENZHOU UNIVERSITY

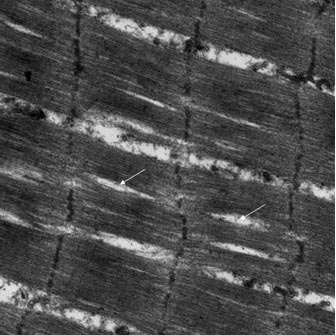

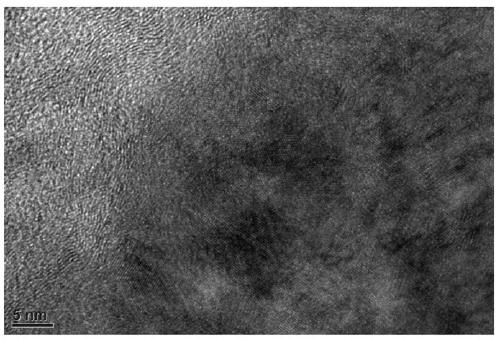

Method for preparing rhenium disulfide thin film through chemical vapor deposition

InactiveCN105839072AImprove growth efficiencyPromotes epitaxial growthChemical vapor deposition coatingRheniumArgon atmosphere

The invention discloses a method for preparing a rhenium disulfide thin film through chemical vapor deposition. According to the method, a two-element eutectoid alloy formed by a mixture of rhenium powder and tellurium powder is used as a rhenium source, powdered sulfur is used as a sulfur source, mica is used as a growth substrate, and the two-dimensional rhenium disulfide thin film grows under the argon atmosphere at the temperature ranging from 500 DEG C to 900 DEG C. Compared with an existing rhenium disulfide preparation method, the requirement for device conditions is low, the operation process is simple, the method has the beneficial effects of being low in reaction temperature, high in growth efficiency, even in layer number, high in lattice quality of the obtained product and good in controllability, large-area, high-quality and layer-number-controllable controlled growth of rhenium disulfide is achieved, and a reliable sample preparation method is provided for application of rhenium disulfide in the field of electronic and photoelectron devices.

Owner:SHAANXI NORMAL UNIV

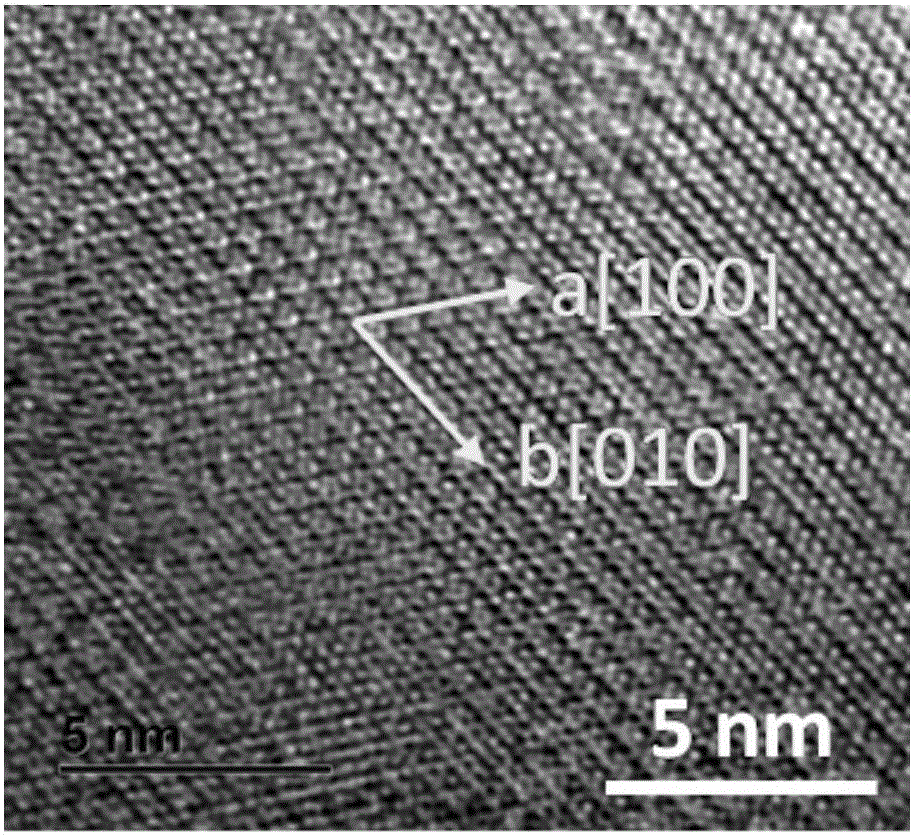

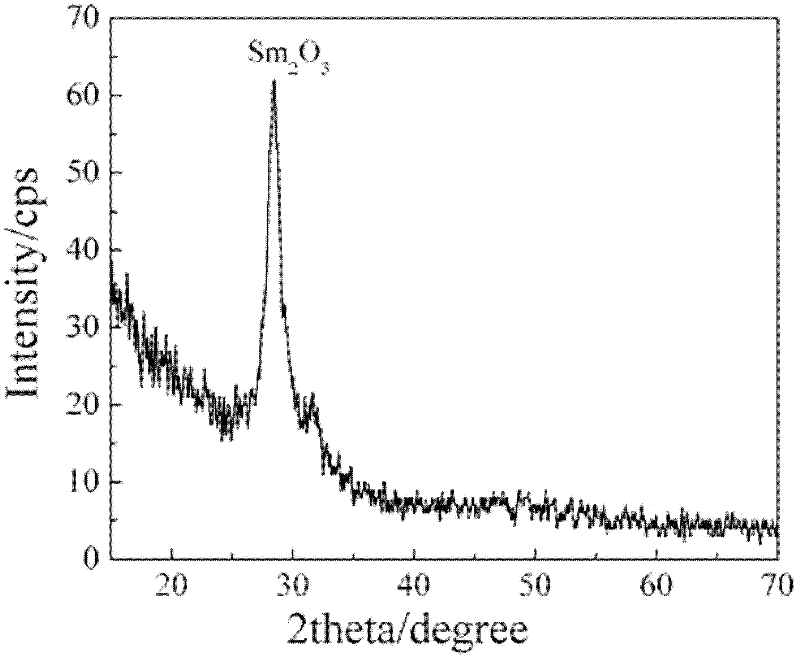

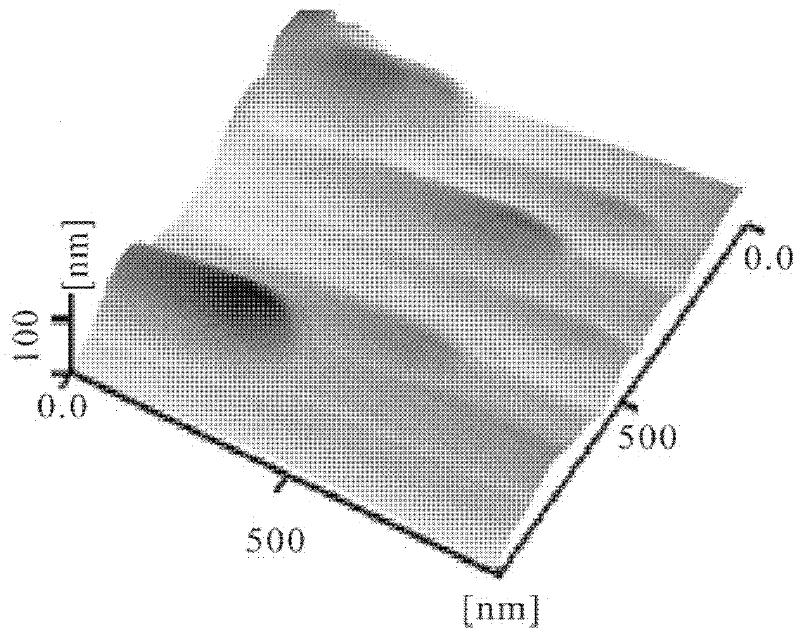

Method for preparing Sm2O3 film by solvent heat method

ActiveCN102330081AHigh purityImprove bindingSolid/suspension decomposition chemical coatingProcess equipmentPolymer science

The invention discloses a method for preparing a Sm2O3 film by a solvent heat method. The method comprises the following steps of: adding analytically pure SmCl3.6H2O into isopropyl alcohol or a mixed solvent of the isopropyl alcohol and water, stirring, and thus obtaining solution A; adjusting the pH value of the solution A by using ammonia water to form coating film liquid; pouring the coating film liquid into a hydrothermal kettle, soaking a substrate into the coating film liquid, sealing the hydrothermal kettle, reacting at the hydrothermal temperature of between 120 and 200 DEG C for 12 to 48 hours, and naturally cooling to room temperature; and opening the hydrothermal kettle, taking the substrate out, washing by using absolute ethanol cleanly, drying in a vacuum drying oven, and thus obtaining the Sm2O3 optical film on the surface of the substrate. In the method, a reaction for preparing the Sm2O3 film is finished in a liquid phase at a time without crystallization thermal treatment at a later stage, so that the defects of curl, seasoning crack, grain coarsening of the Sm2O3 film which are possibly caused in the thermal treatment process, reaction of the film with the substrate or the atmosphere and the like are overcome; the method has simple process equipment, is low in reaction temperatures and makes high pressure easily generated, the obtained film has higher purity, and crystal grains grow controllably. The film which is uniform and compact, does not have visible defects and has higher bonding force and higher appearance quality can be prepared.

Owner:JIANGSU XINGYUAN POWER PLANT & METALLURGICAL EQUIP MFG

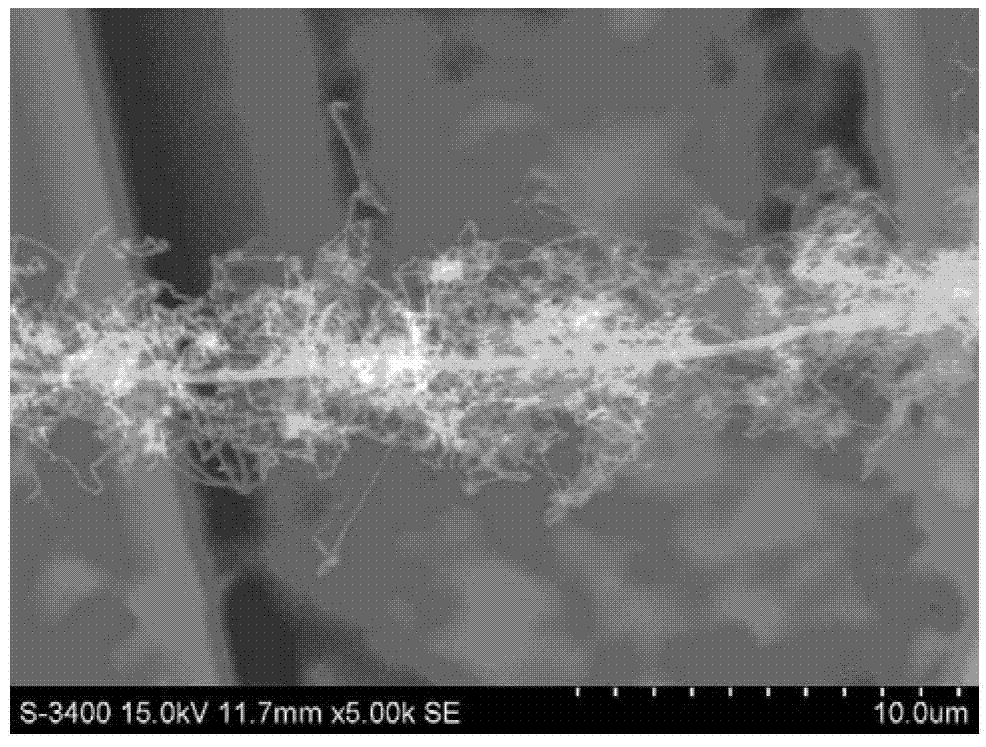

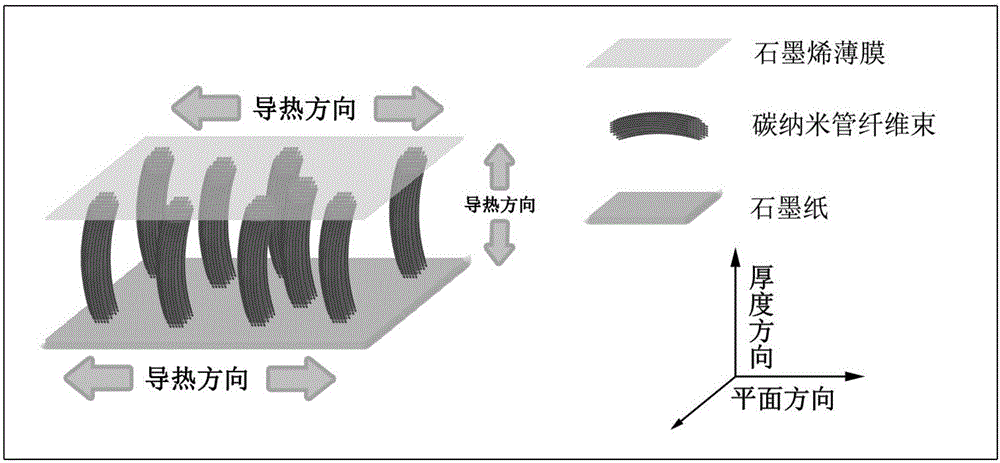

Production method of graphite/carbon nanotube fiber bundle/graphene heat conduction composite film

ActiveCN106543979AImprove thermal conductivityControllable growthMaterial nanotechnologyHeat-exchange elementsXylyleneGraphite carbon

The invention relates to a production method of a graphite / carbon nanotube fiber bundle / graphene heat conduction composite film. The method comprises the following steps: carrying out ablation oxidation on graphite paper at a 400-500 DEG C; dipping the graphite paper in an ethyl orthosilicate solvent, ageing the dipped graphite paper, and drying the aged graphite paper to obtain graphite paper with the surface containing a silicon oxide coating; dissolving ferrocene in a xylene solution to prepare a catalyst precursor solution, pushing the catalyst precursor solution into a vacuum tubular furnace, and growing carbon nanotube fiber bundles to obtain a graphene paper sample with the carbon nanotube fiber bundles; and adding graphene oxide powder into deionized water, carrying out ultrasonic dispersion, placing the obtained graphene paper sample and the obtained aqueous solution of graphene oxide in a hydrothermal reaction kettle, and carrying out a reaction to obtain the graphite / carbon nanotube fiber bundle / graphene heat conduction composite film. The graphite / carbon nanotube fiber bundle / graphene heat conduction composite film has high heat conduction performance along the plane and thickness direction, the heat conductivity of the graphite / carbon nanotube fiber bundle / graphene heat conduction composite film along the plane direction reaches 400 W / (m.K) or above, and the heat conductivity of the graphite / carbon nanotube fiber bundle / graphene heat conduction composite film along the thickness direction reaches 15 W / (m.K) or above.

Owner:TIANJIN UNIV

Production method of 8-inch lithium niobate crystal

InactiveCN111206282ACause polycrystallineCause crackingPolycrystalline material growthAfter-treatment detailsCrystal growthCondensed matter physics

The invention relates to the technical field of optoelectronic materials, and discloses a production method of an 8-inch lithium niobate crystal, wherein the production method comprises the followingsteps: (1) preparation of a polycrystalline raw material: mixing and sintering lithium carbonate and niobium oxide raw materials, briquetting and crushing to obtain a polycrystalline raw material; (2)crystal growth: putting the polycrystalline raw material into a platinum crucible located in a multilayer temperature field, carrying out crystal growth by adopting a pulling method, and carrying outcrystal initiation, necking, shoulder extending, shoulder contracting, equal-diameter growth and pulling-out to obtain a multi-domain crystal; and (3) crystal annealing and polarizing: embedding themulti-domain crystal into the polycrystalline raw material, and annealing and polarizing to obtain the 8-inch lithium niobate crystal. In the crystal growth process, multiple layers of temperature fields are adopted, it is guaranteed that the temperature fields are uniform and free of mutation, crystal polycrystal and cracking are avoided, and crystal growth is easier to control; a powder buryingmethod is adopted for annealing polarization, so that crystals are not easy to crack; during preparation of the polycrystalline raw material, multiple times of mixing and sintering are performed, andstable Curie temperature of crystals can be ensured.

Owner:DEQING JINGHUI OPTOELECTRONICS TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com