ZnO/Ag/graphene nanometer composite material, preparation method and application thereof

A nanocomposite material and graphene technology, applied in the direction of botanical equipment and methods, applications, sanitary equipment for toilets, etc., can solve the problems of inconvenient conditions, cumbersome preparation process, etc., and achieve reduction of preparation cost, simple preparation process, and enhanced The effect of antibacterial persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

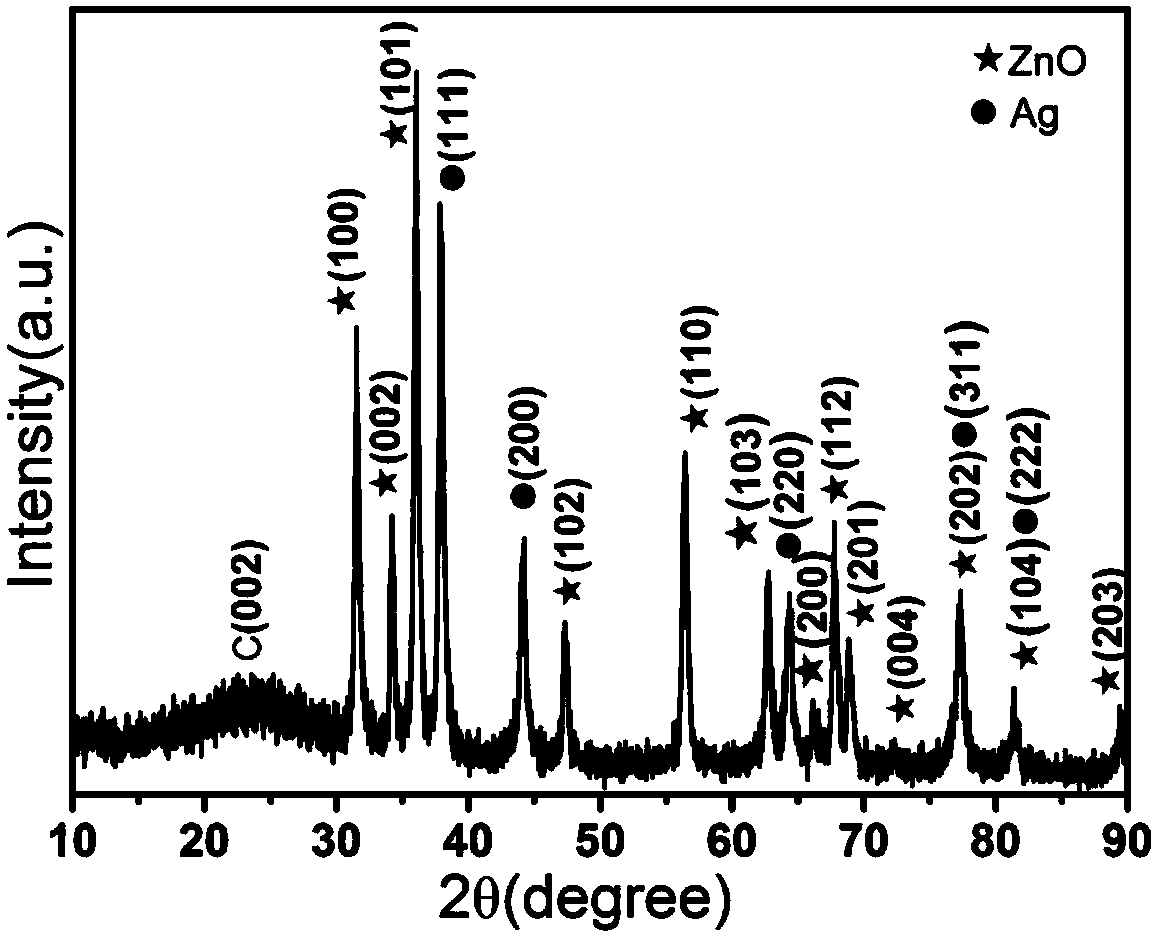

Embodiment 1

[0023] Prepare GO into a suspension with a concentration of 0.5 mg / mL and ultrasonically disperse until it is uniformly dispersed; dissolve zinc acetate hexahydrate in ethanol to prepare a zinc acetate solution with a concentration of 6 mg / mL: mix the above-mentioned zinc acetate solution and GO suspension, and store at room temperature Under magnetic stirring for 15 minutes, ultrasonic for 30 minutes to obtain Zn 2+ / GO suspension; the volume ratio of the zinc acetate solution to the GO suspension is 1:6; then NaOH is prepared as a 3mg / mL aqueous solution, which is added dropwise to the mixed solution while the above mixed solution is stirred; the NaOH solution The volume ratio of the mixed solution to the mixed solution is 1:12; then the silver nitrate is dissolved in ethanol to prepare a 4 mg / mL silver nitrate solution: the above-mentioned silver nitrate solution is added dropwise to the mixed solution under the condition that the above mixed solution is stirred, and magneti...

Embodiment 2

[0027] Prepare GO into a suspension with a concentration of 0.5 mg / mL and ultrasonically disperse until uniformly dispersed; dissolve zinc acetate hexahydrate in ethanol to prepare a zinc acetate solution with a concentration of 12 mg / mL: mix the above-mentioned zinc acetate solution and GO suspension, and store at room temperature Under magnetic stirring for 15 minutes, ultrasonic for 30 minutes to obtain Zn 2+ / GO suspension; the volume ratio of the zinc acetate solution to the GO suspension is 1:6; then NaOH is prepared as a 6mg / mL aqueous solution, which is added dropwise to the mixed solution while the above mixed solution is stirred; the NaOH solution The volume ratio of the mixed solution to the mixed solution is 1:12; then the silver nitrate is dissolved in ethanol to prepare a 4 mg / mL silver nitrate solution: the above-mentioned silver nitrate solution is added dropwise to the mixed solution under the condition that the above mixed solution is stirred, and magnetically...

Embodiment 3

[0033] Prepare GO into a suspension with a concentration of 0.5 mg / mL and ultrasonically disperse until uniformly dispersed; dissolve zinc acetate hexahydrate in ethanol to prepare a zinc acetate solution with a concentration of 12 mg / mL: mix the above-mentioned zinc acetate solution and GO suspension, and store at room temperature Under magnetic stirring for 15 minutes, ultrasonic for 30 minutes to obtain Zn 2+ / GO suspension; the volume ratio of the zinc acetate solution to the GO suspension is 1:6; then NaOH is prepared as a 6mg / mL aqueous solution, which is added dropwise to the mixed solution while the above mixed solution is stirred; the NaOH solution The volume ratio of the mixed solution is 1:12; subsequently, silver nitrate-free ethanol is mixed with the above-mentioned suspension, and the volume ratio of the ethanol and the mixed solution is 1:12; Zn 2+ / NaOH / Ag + / GO suspension was transferred into an autoclave, the filling volume of the suspension was 2 / 3 of the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com