Patents

Literature

73results about How to "Improve antibacterial durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing antimicrobial calcium alginate fiber

ActiveCN101381907AEvenly distributedImprove antibacterial propertiesAlginate artificial filamentsAbsorbent padsCalcium alginateMechanical property

The invention discloses a method for manufacturing an antimicrobial calcium alginate fibre. A sodium alginate is used as spinning stock solution; in a solidification bath containing an antimicrobial agent, the antimicrobial calcium alginate fibre is obtained by a wet-method spinning process; and the antimicrobial agent is a cationic compound which is combined with large molecules of the calcium alginate fibre through ionic bonds. The antimicrobial calcium alginate fibre obtained by the method has no toxicity and no side effect on human body; the antimicrobial agent and the large molecules of the fibre are combined by the ionic bonds in order that the antimicrobial agent has long-lasting antimicrobial function; in addition, the fibre retains the excellent quality of the calcium alginate fibre, has excellent hygroscopic property and good mechanical property, can be used for manufacturing medical dressings, has the advantages of convenient use, comfortable application and good ventilation, the acceleration of the healing of wound, the relieving of the pains of patients and the like, can be also used for manufacturing clothing and industrial textiles by pure spinning or blended spinning with cotton, mucilage glue, bamboo pulp, fur, ramie, soybean protein fibre and the like.

Owner:山东康康新材料科技有限公司

Bamboo viscose fibre and its preparing method

InactiveCN1458306ARetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

Povidone-iodine antibacterial material and its production

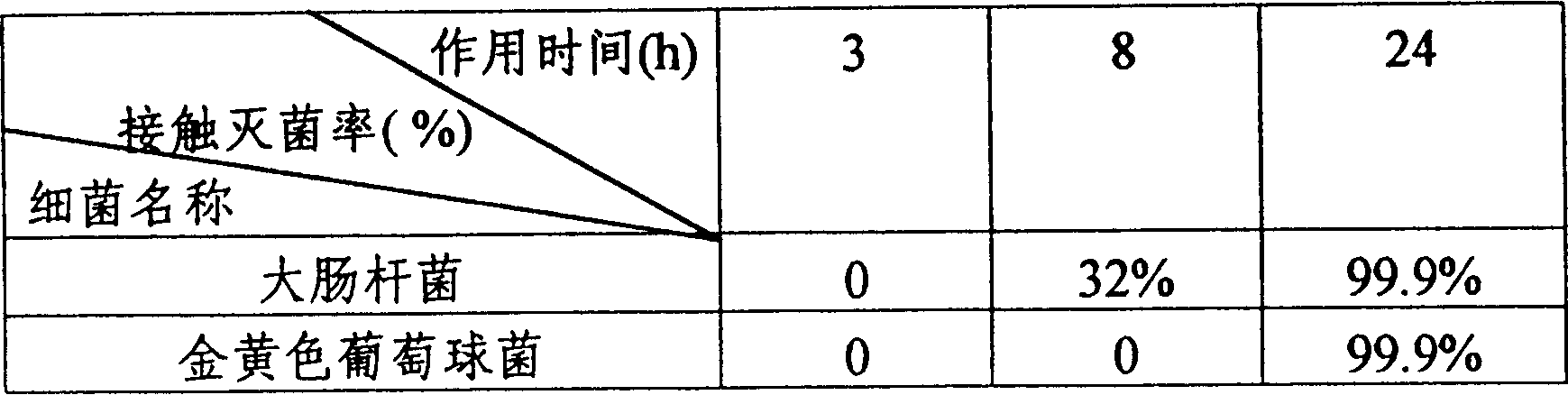

ActiveCN101073325AWith embedding effectImprove antibacterial durabilityBiocideLavatory sanitoryFreeze-dryingDistillation

The invention is concerned with the preparation method for new povidone iodine anit-bacterium dressing that uses the carboxymethyl chitosan to fix. The graft of the carboxymethyl chitosan (Polyacrylates - copolymer - N - vinylpyrrolidone) dissolves in water and processes complexation with iodine, reduces pressure and distillation to wipe off the solvent and part of un-reactive iodine, uses normal heptanes to marinate and wash the produce in order to wipe off the un-reactive iodine, processes freeze drying and crushing to get the new povidone iodine anit-bacterium dressing that uses the carboxymethyl chitosan to fix: t he graft of the carboxymethyl chitosan (Polyacrylates - copolymer - N - vinylpyrrolidone).

Owner:陈煜 +1

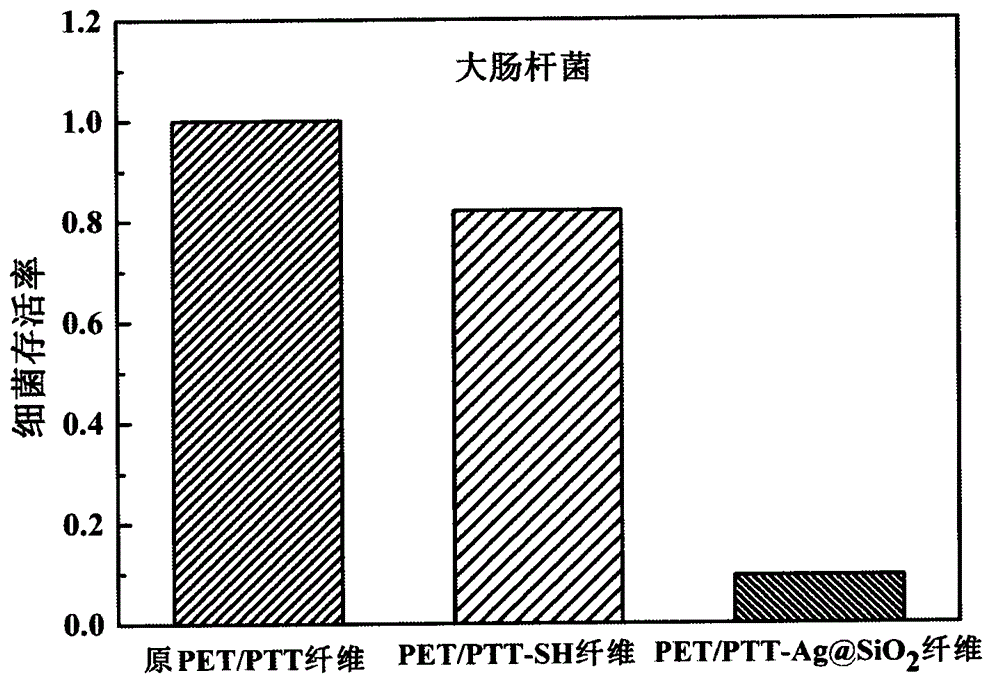

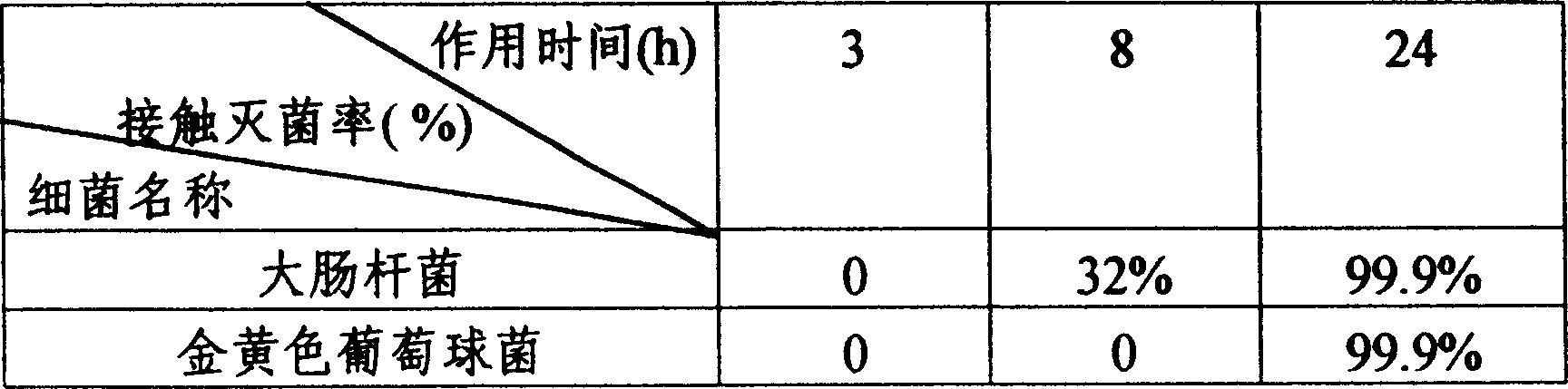

Preparation method of composite yarn

ActiveCN105002614AFluffy goodIncrease elasticityFibre typesConjugated synthetic polymer artificial filamentsYarnFiber

The present invention provides a preparation method of a long-lasting antibacterial and anti-crease composite yarn. According to the method, since methylbenzene has a swelling effect for polyester fibers, GMA is subjected to interfacial free-radical polymerization on the surface of artificial fibers, and generated PGMA can be anchored on the surface of the artificial fibers, and therefore, epoxy groups can be led onto the surface of the fibers; through a grafting reaction, the epoxy groups react with amidogens on cysteamine, so that sulfydryl can be led onto the surface of the fibers; stable S-Ag bonds are formed between the sulfydryl and silver particles, so that composite nanoparticles can be immobilized on the surface of the artificial fibers; and the outer yarn body of the yarn is coated with titanium dioxide / nano silver composite nanoparticles, and the durability of the antibacterial property of the yarn can be improved through the synergistic effect of titanium dioxide and nano silver particles. The composite yarn produced by the preparation method of the invention has the advantages of excellent antibacterial performance and anti-crease effect as well as favorable fluffiness, flexibility and comfort, and excellent gas permeability and moisture absorption performance, and touches soft.

Owner:NINGBO WUTIAN TEXTILE

Stilbite carrier zine series inorganic germicide

InactiveCN1483318ADoes not affect colorImprove antibacterial durabilityBiocideAnimal repellantsAntibacterial actionBroad spectrum

The present invention provides a preparation method of stilbite carrier zinc series in organic antimicrobial agent. Said invented inorganic antibacterial agent is not limited by physical environment, has strong antibacterial action, good persistent availability, broad-spectrum antibacterial property and good compatibility for making other products. It can solve the product discoloration problem due to addition of antimicrobial agent, can raise the fineness of inorganic antimicrobial agent powder body, and can be uniformly distributed in the product, at the same time it can greatly reduce cost of inorganic antimicrobial agent.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

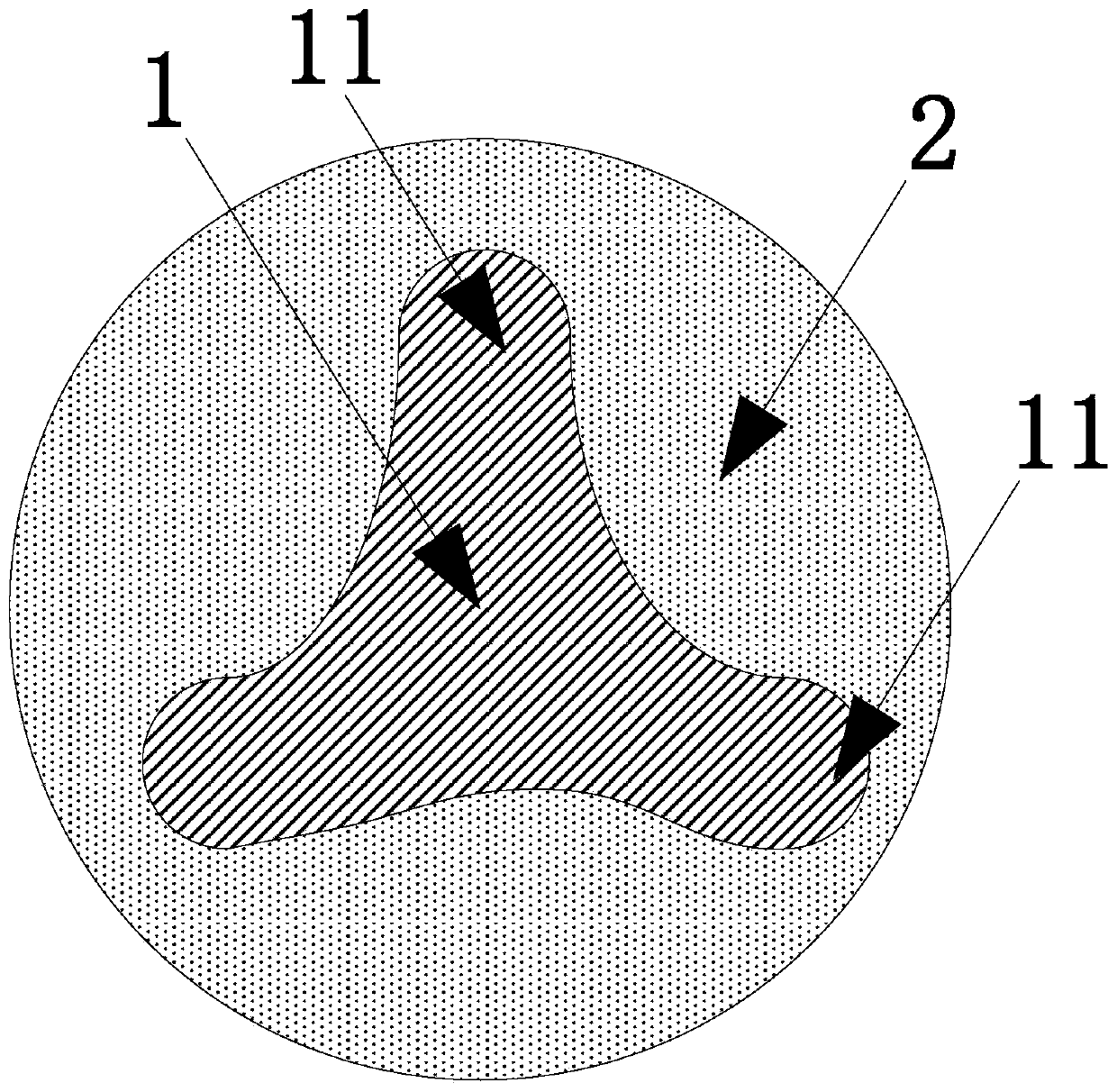

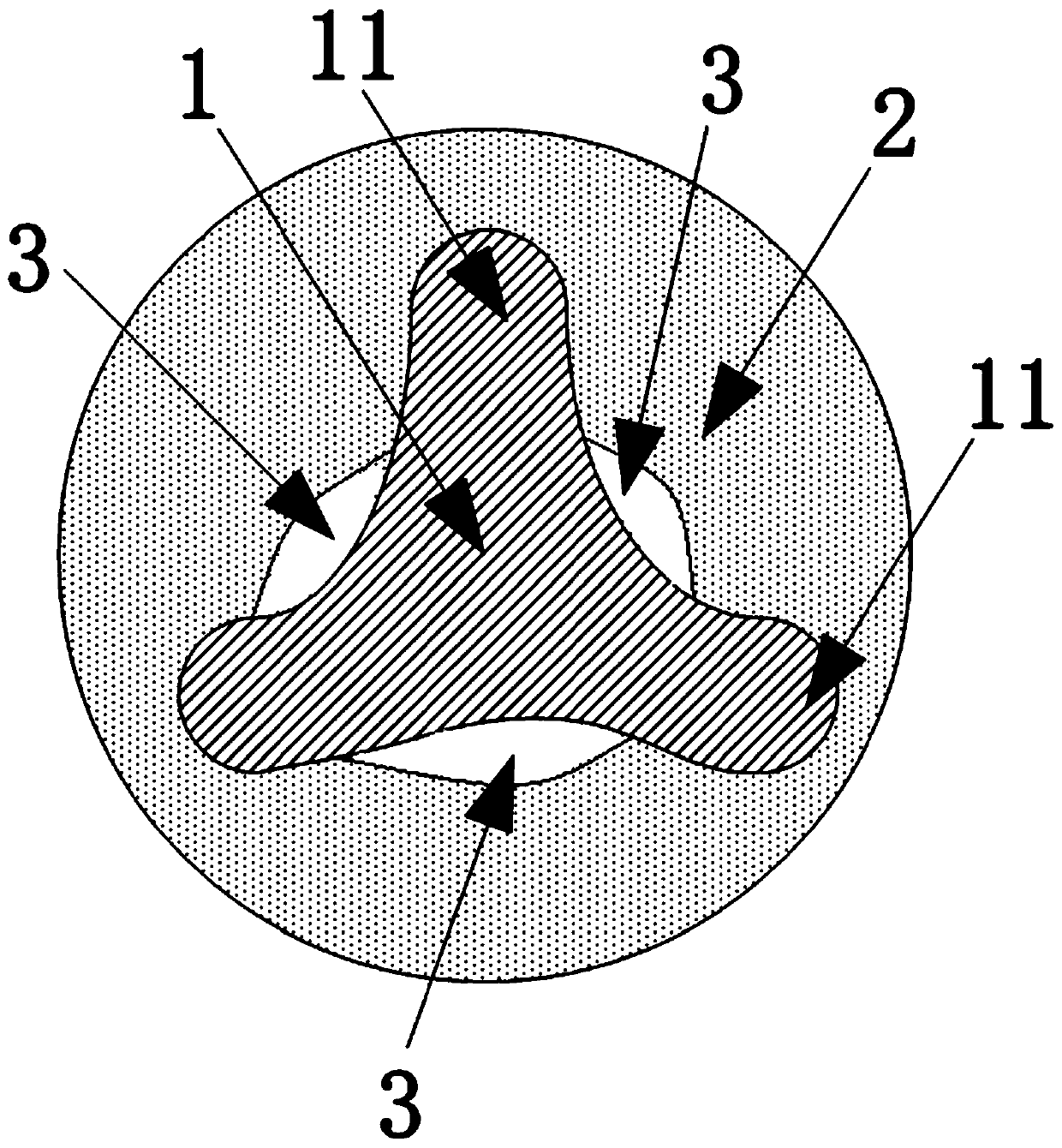

Antibacterial conductive fiber and preparation method thereof

ActiveCN111364121AAchieve antistatic effectImprove antimicrobial durabilityElectroconductive/antistatic filament manufactureFilament/thread formingFiberResin matrix

The invention discloses an antibacterial conductive fiber and a preparation method thereof. The antibacterial conductive fiber comprises a skin layer containing an antibacterial agent and a resin matrix, and a core layer containing an antibacterial agent, a conductive component and a resin matrix, wherein the content of the antibacterial agent is gradually reduced from the skin layer to the core layer, the area of the radial section of the core layer is gradually reduced by extending from the geometric center of the radial section of the fiber to the skin layer, at least three extending ends are formed, and the ends of the extending ends on the radial section are all curves with certain curvatures. The core layer of the provided antibacterial conductive fiber adopts the special-shaped section, so that electrostatic charges generated by the composite fiber in friction are concentrated at the extending ends of the core layer, the charges are dissipated by utilizing a point discharge phenomenon, and an antibacterial agent gradient formed from the core layer to the skin layer provides a lasting antibacterial effect for the fiber.

Owner:CTA HIGH TECH FIBER

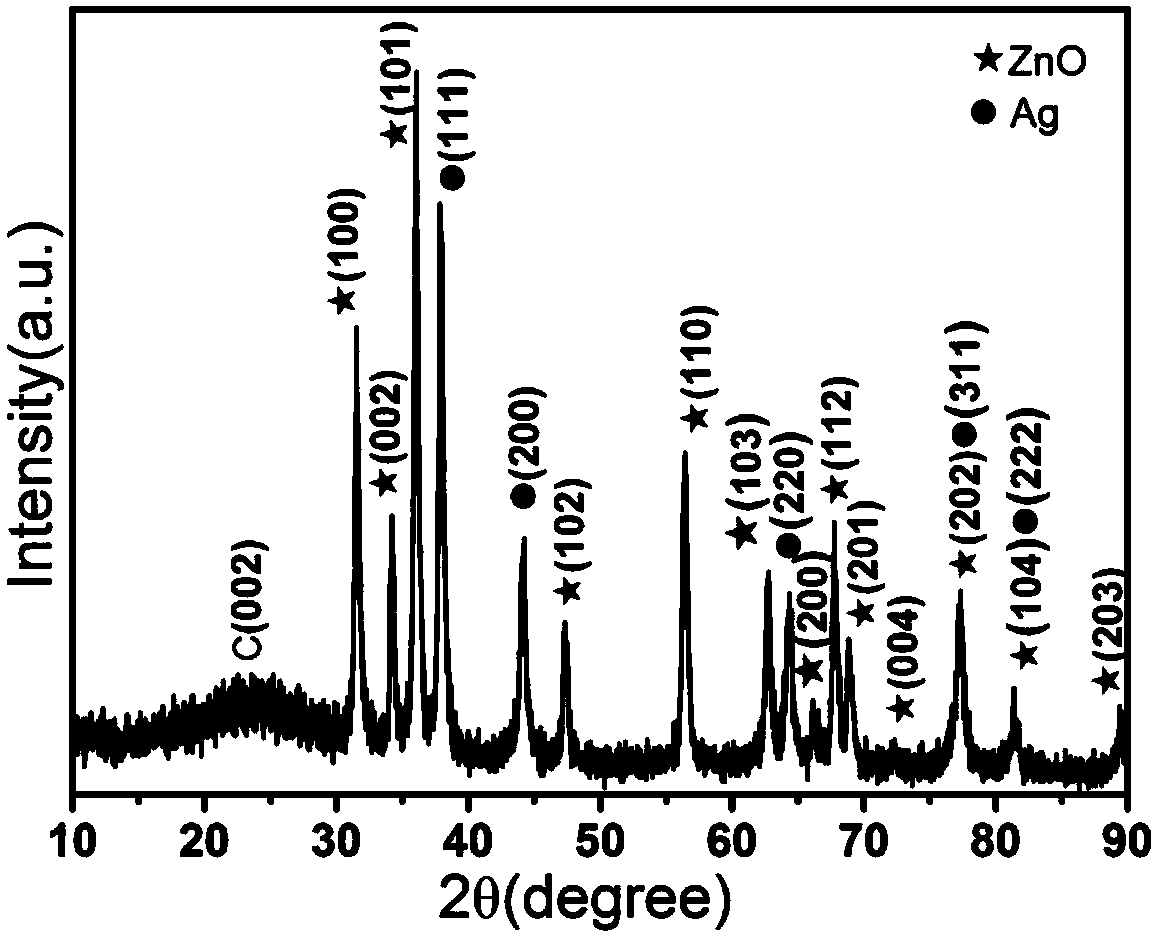

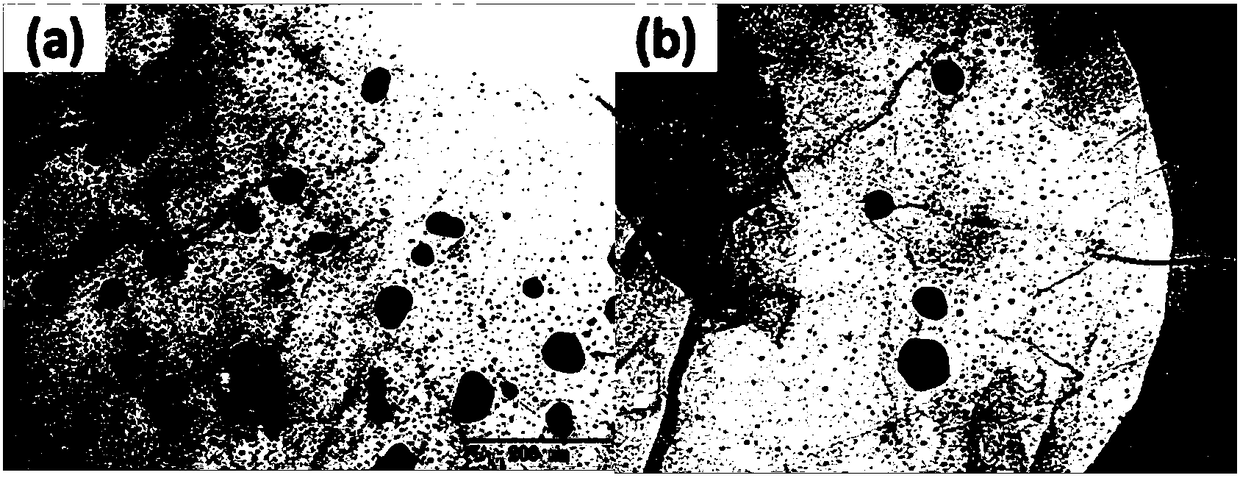

ZnO/Ag/graphene nanometer composite material, preparation method and application thereof

ActiveCN108283178AReduce dosageControllable growthBiocideLavatory sanitoryGraphene nanocompositesNano composites

The invention relates to a ZnO / Ag / graphene nanometer composite material, a preparation method and application thereof, and belongs to the field of nanometer material application and biological materials. The novel antibacterial ZnO / Ag / graphene composite material is prepared through a one-step solvothermal reaction by using environment-friendly ethyl alcohol as a reducer, the preparation process issimple and convenient, the loading of ZnO and Ag nanometer particles on graphene sheets is realized simultaneously in the one-step preparation process, the sizes of the nanometer particles are controlled effectively, and the used reagent is green and environmentally friendly.

Owner:JIANGSU UNIV

Antibacterial super lubricious medical material and preparation method thereof and antibacterial super lubricious urinary catheter

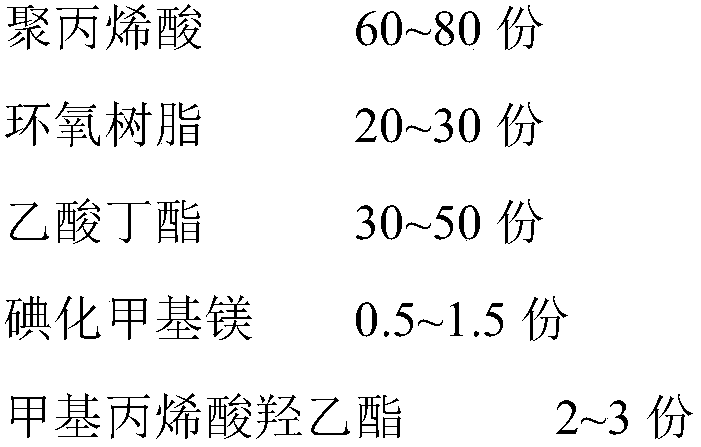

ActiveCN105218810AImprove antibacterial durabilityLong-lasting lubricationCatheterUrinary catheterChemical Linkage

The invention belongs to the field of medical materials and in particular relates to an antibacterial super lubricious medical material and a preparation method thereof and an antibacterial super lubricious urinary catheter. The antibacterial super lubricious medical material provided by the invention is obtained by carrying out a reaction on a medical material matrix and an amino-terminated lubricant in a solvent; and the medical material matrix comprises a medical material loaded with antibacterial substances and a polydopamine layer coating on the surface of the medical material loaded with the antibacterial substances. The antibacterial super lubricious medical material provided by the invention has the advantages that the polydopamine layer coats the surface of the medical material loaded with the antibacterial substance, so that release rate of the antibacterial substances can be effectively reduced, release time of the antibacterial substances is prolonged, and antibacterial durability of the medical material is enhanced; meanwhile, the lubricant on the surface of the antibacterial super lubricious medical material is fixed on the surface of the medical material by virtue of chemical bonds, so that the lubricant hardly falls off, and lubrication durability of the medical material is greatly improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Antibacterial polyvinyl chloride sole material and preparation method thereof

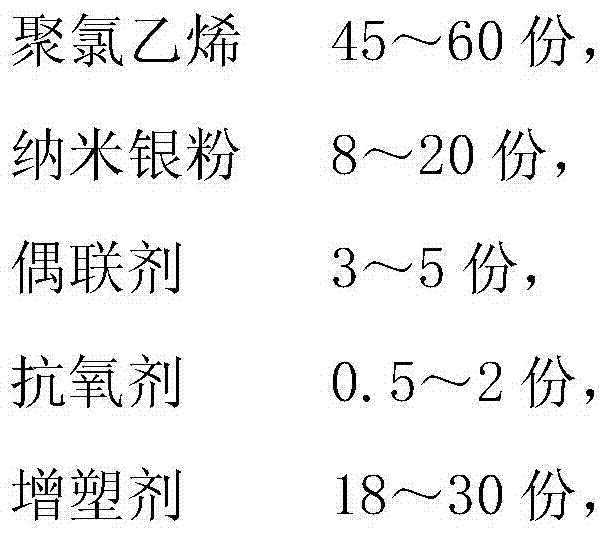

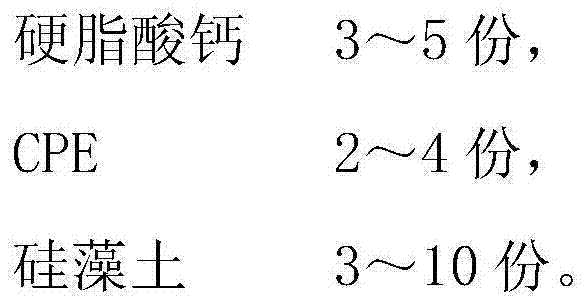

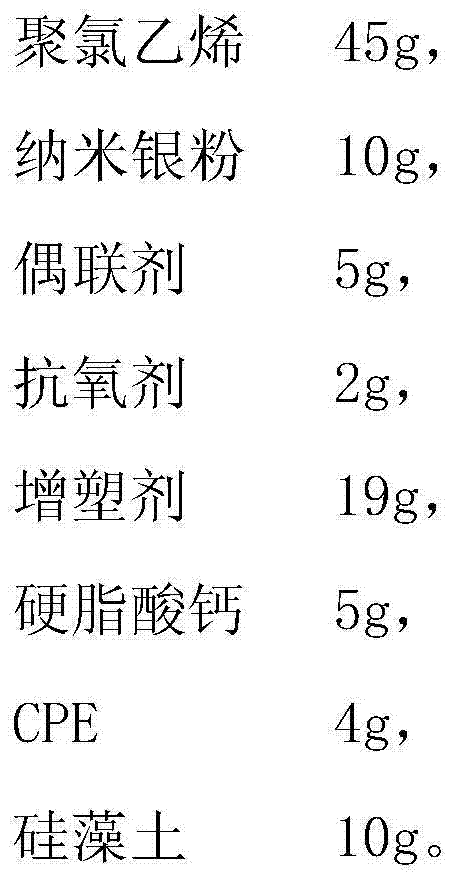

The invention provides an antibacterial polyvinyl chloride sole material which comprises the following components in parts by weight: 45-60 parts of polyvinyl chloride, 8-20 parts of nano silver powder, 3-5 parts of coupling agent, 0.5-2 parts of antioxidant, 18-30 parts of plasticizer, 3-5 parts of calcium stearate, 2-4 parts of CPE (Chlorinated Polyethylene) and 3-10 parts of diatomite. The invention also discloses a preparation method of the antibacterial polyvinyl chloride sole material. The antibacterial polyvinyl chloride sole material provided by the invention has better antibacterial performance.

Owner:SUZHOU JINGRO TECH

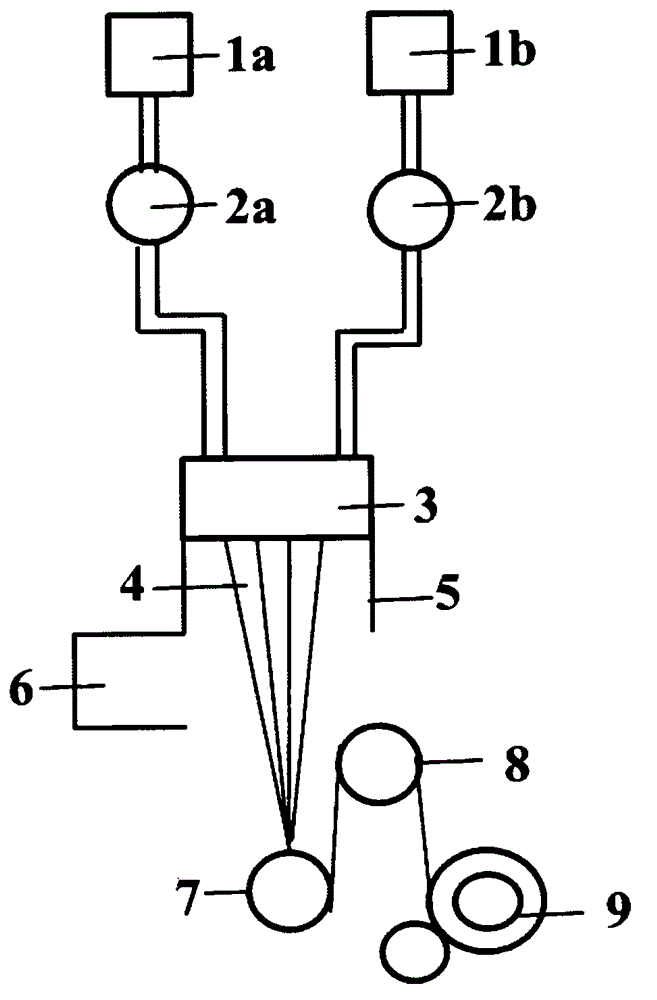

Nanofiber and preparation method thereof

InactiveCN108505143AImprove antibacterial durabilityAvoid reunionConjugated cellulose/protein artificial filamentsArtifical filament manufactureElectrospinningNanofiber

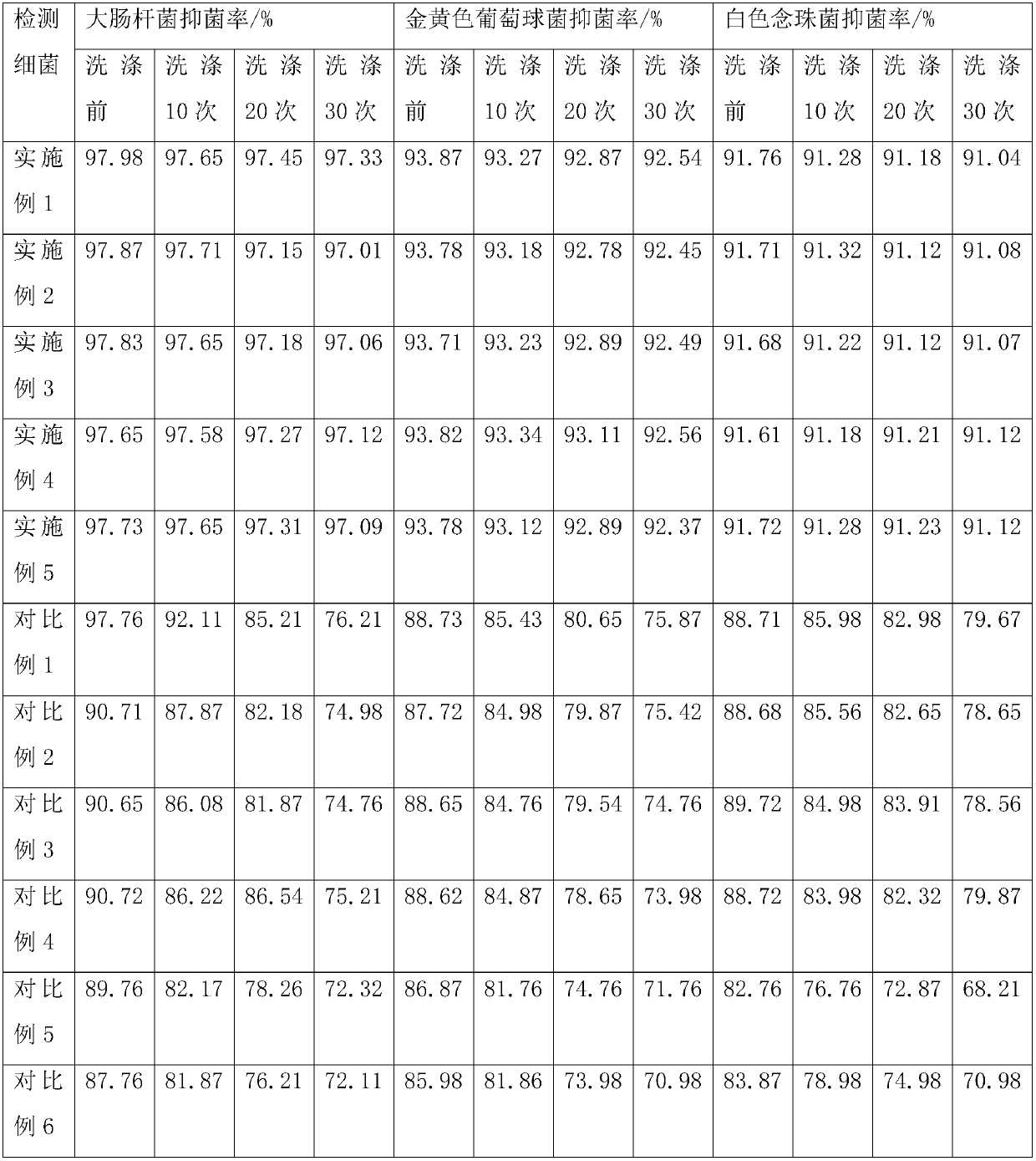

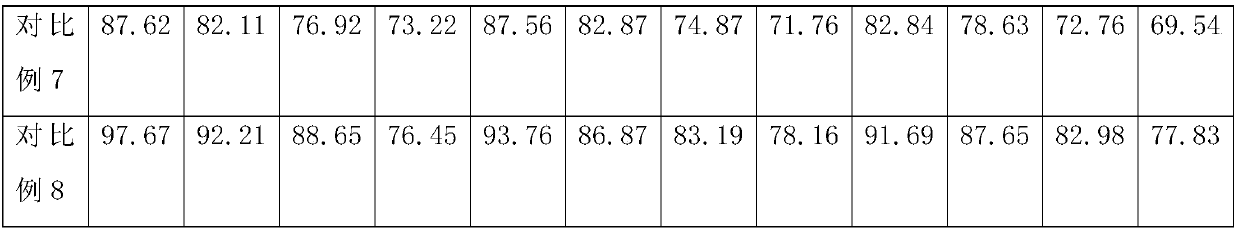

The invention relates to nanofiber and a preparation method thereof. An electrospinning technology is adopted, the electrospinning technology is simple, a used power supply uses alternating current, and the diameter of the nanofiber is much smaller than that of fiber obtained through a technology adopting direct-current voltage and can be up to 130 to 320 nm; since a coupling agent is adopted forpretreating nano titania, aggregation between inorganic particles is avoided, and the dispersity of the nanofiber is favorably improved; in addition, a polymer used for spinning contains chitosan, fibroin, soybean protein, on one hand, the coupling agent can be combined with the nano titania, on the other hand, groups on the coupling agent can be combined with functional groups in the chitosan, the fibroin and the soybean protein, so that the antibacterial durability of the nanofiber can be improved. According to the antibacterial nanofiber prepared by the invention, the mechanical performanceis good, and the antibacterial performance is better and can be up to 97 percent or above; after 30 times of washing, better antibacterial performance still can be obtained, and the antibacterial rate can be up to 90 percent or above.

Owner:郑州智锦电子科技有限公司

Broad-spectrum antiviral antibacterial disinfectant as well as preparation method and application thereof

ActiveCN111802409AImprove antibacterial durabilityGood antibacterial effectBiocideFungicidesPox virusDisinfectant

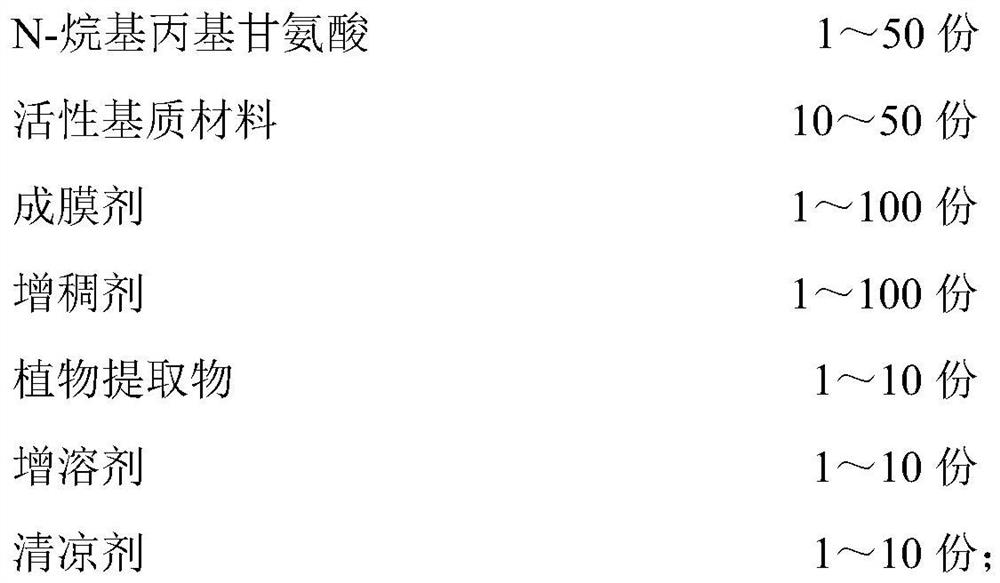

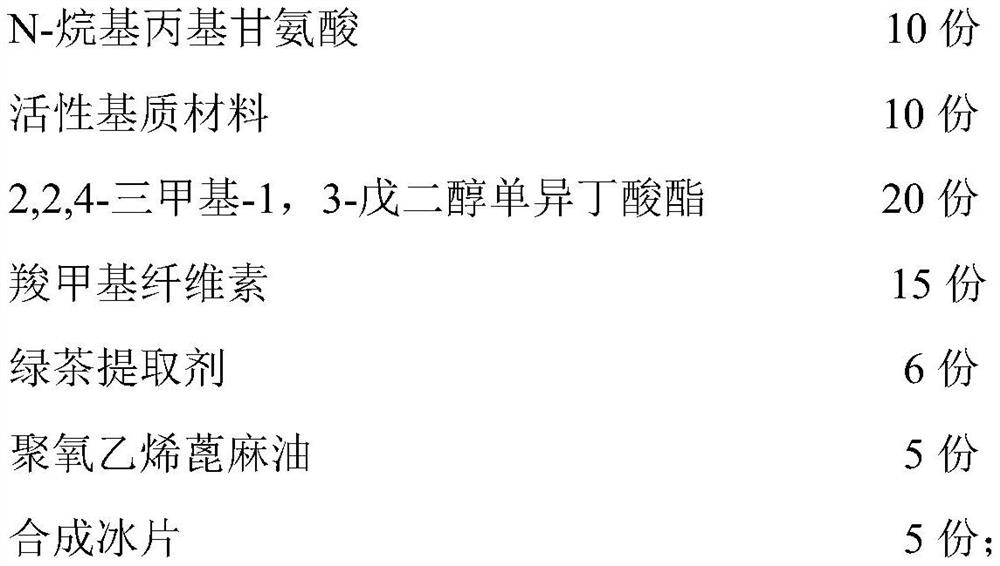

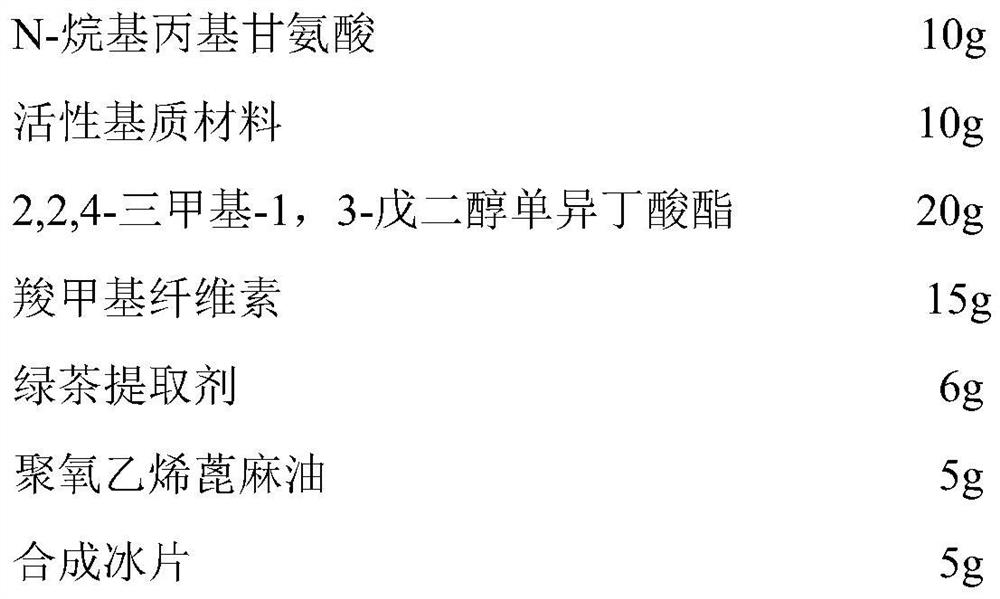

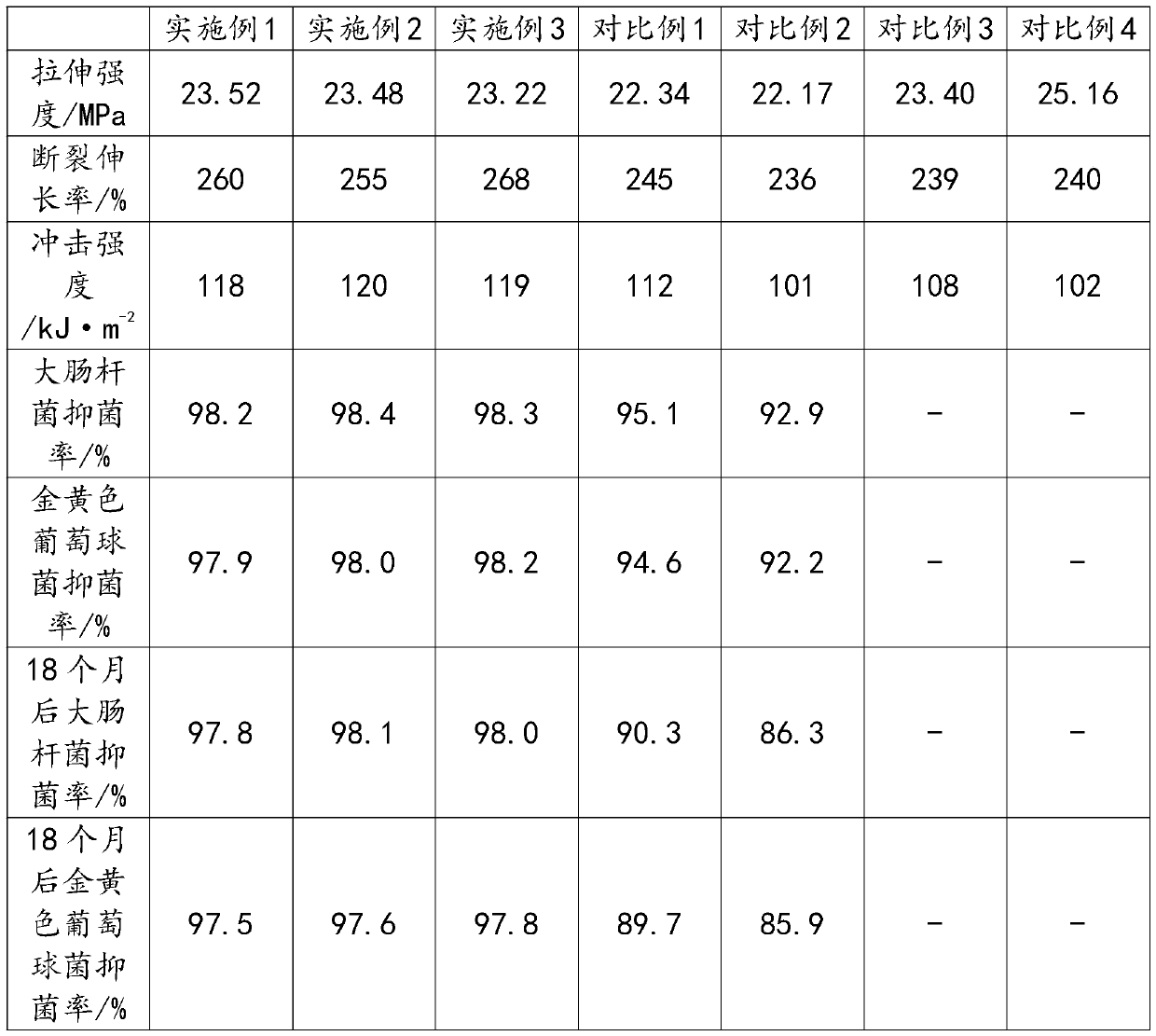

The invention discloses a broad-spectrum antiviral antibacterial disinfectant which comprises the following raw materials in parts by weight: 1-50 parts of N-alkyl propyl glycine, 10-50 parts of an active matrix material, 1-100 parts of a film-forming agent, 1-100 parts of a thickening agent, 1-10 parts of a plant extracting agent, 1-10 parts of a solubilizer and 1-10 parts of a freshener, whereinthe active matrix material is a mixture of carrageenan and chitosan sulfate. The broad-spectrum antiviral and antibacterial disinfectant has good sterilization and bacteriostasis effects, long duration and no toxicity to human bodies, and has a strong sterilization effect on various epidemic infectious diseases such as novel coronavirus, hepatitis virus, HIV, avian influenza virus, influenza A virus, varicella virus, escherichia coli, candida albicans, salmonella enteritidis, candida albicans and staphylococcus aureus. The invention also discloses a preparation method and application of the broad-spectrum antiviral antibacterial disinfectant.

Owner:WUHAN UNIV OF TECH

Antibacterial food packaging film and processing technology thereof

The invention discloses an antibacterial food packaging film which is prepared from the following raw materials in parts by weight: 60-70 parts of modified polypropylene, 2-3 parts of an antibacterialagent, 1.8-2 parts of zinc stearate and 0.5-0.7 part of an antioxidant. The processing technology of the food packaging film comprises the following steps: step 1, preparing plastic master batch from10% by weight of modified polypropylene, an antibacterial agent and an auxiliary agent; and step 2, preparing the packaging film from the plastic master batch and the residual modified polypropylene.Polypropylene is modified and the composite antibacterial agent is prepared, an acyl chloride group is introduced into a polypropylene molecular chain, the acyl chloride group and-OH have extremely high reaction activity and can react with-OH which does not completely react with the surface of silicon dioxide in the antibacterial agent, the antibacterial agent is enabled to be uniformly dispersedin a PP matrix, the antibacterial effect is uniformly and stably exerted, and the modified PP and the antibacterial agent have a relatively strong chemical bonding effect so that antibacterial agentmolecules are not easy to fall off, the antibacterial durability is enhanced and the antibacterial food packaging film is suitable for food packaging.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

Preparation method of bamboo fiber reinforced non-woven fabric and application of non-woven fabric to maternal towel

InactiveCN110670243AImprove antibacterial durabilityEvenly dispersedBiochemical fibre treatmentAbsorbent padsPolymer scienceNonwoven fabric

The invention relates to the technical field of non-woven fabrics, in particular to a preparation method of a bamboo fiber reinforced non-woven fabric and an application of the non-woven fabric to a maternal towel. Pretreated natural raw bamboo fibers and chitosan nano-silver are blended and modified, the surfaces of the bamboo fibers are treated by 0.2% Dacron oiling agents 73, the spunlace non-woven fabric is prepared by a spunlace process, and the maternal towel is prepared from the non-woven fabric. The bamboo fiber reinforced non-woven fabric integrating a bacteriostasis function and a degradable function is researched and serves as a surface material applied to the maternal towel, so that the prepared maternal towel integrates degradability and low sensitivity.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Antibacterial bed sheet and production process thereof

InactiveCN109680481AImprove antibacterial propertiesGood flexibilityBiochemical fibre treatmentLiquid/gas/vapor removalMicrowaveAntibacterial property

The invention discloses an antibacterial bed sheet and a production process thereof. The production process comprises the following steps: (S1) fabric preparation; (2) antibacterial treatment: puttingthe bed sheet fabric into antibacterial treatment liquid, heating the antibacterial treatment liquid to 50-60 DEG C, and soaking for 10-20 hours; (S3) padding an drying: after the antibacterial treatment, padding the bed sheet fabric until the rolling rate is 70%-80%, baking the bed sheet fabric at 80-85 DEG C for 3-5 minutes, and then baking the bed sheet fabric at 100-120 DEG C for 1-3 minutes;(S4) washing and dehydration: washing the dried bed sheet fabric in clean water, and dehydrating the bed sheet fabric until the water content of 50%-60%; (S5) steaming: steaming the dehydrated bed sheet fabric at 100-110 DEG C for 3-5 minutes; and (S6) vacuum microwave drying. The production process has the advantages that the operation process is simple, and the prepared bed sheet has a good antibacterial property and a long antibacterial effect.

Owner:南通开发区翔华纺织品织造有限公司

Disinfecting healthcare hand towel

InactiveCN106835816AGood flexibilityImprove toughnessPaper/cardboardBiocidal agent additionPotato starchPolyvinyl alcohol

The invention discloses a disinfecting healthcare hand towel which is prepared from bamboo pulp, round leaf wood pulp, straw pulp, polyvinyl alcohol, purple sweet potato starch, polyethyleneimine, efficient antibacterial agent, titanium dioxide and nanoscale mica powder. The hand towel prepared according to the method provided by the invention has the advantages of extensive raw materials, mild reaction, no toxicity, environmental protection, and the like; the hand towel conforms to the modern green chemistry concept; after a user wipes hand with the hand towel prepared according to the method provided by the invention, the surface skin on the hand is cooler; the effects of moisturizing, moistening, freezing preventing and cracking preventing can be achieved; the hand can become tender and smooth; an excellent hand care function is achieved; after long-term use, a certain whitening function can be achieved.

Owner:ANHUI BILUN DOMESTIC PAPER CO LTD

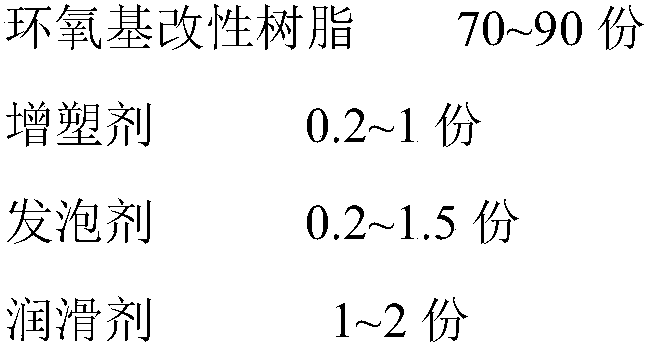

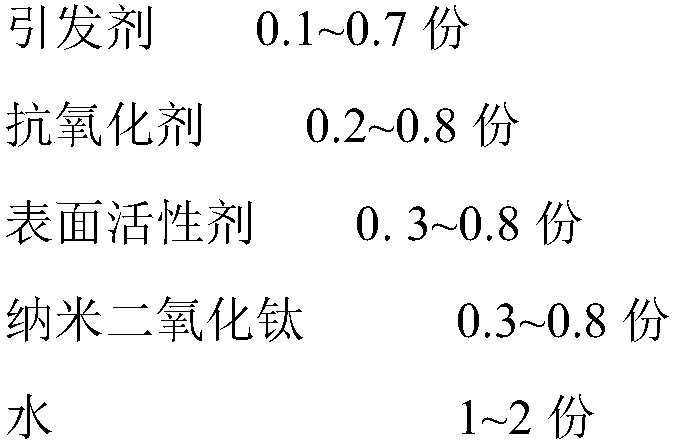

Nanometer titania antibacterial plastic and production process thereof

The invention relates to the technical field of antibacterial plastics and in particular relates to a nanometer titania antibacterial plastic and a production process thereof. The nanometer titania antibacterial plastic is prepared from 70-90 parts of epoxy modified resin, 0.2-1 part of a plasticizer, 0.2-1.5 parts of a foaming agent, 0.5-1 part of ethylene bis-stearamide, 0.5-1 part of zinc stearate, 0.1-0.7 part of an initiator, 0.2-0.8 part of an antioxidant, 0.3-0.8 part of a surfactant, 0.3-0.8 part of nanometer titania and 1-2 parts of water. The nanometer titania antibacterial plastic has uniform and lasting antibacterial effects. The production process of the nanometer titania antibacterial plastic comprises the following steps: 1, preparing epoxy modified resin; 2, performing surface treatment on nanometer titania; 3, performing melt mixing on the epoxy modified resin and the nanometer titania subjected to surface treatment; and 4, performing extruded granulation. The nanometer titania antibacterial plastic has the advantage of being easy to operate.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Process of producing viscose fiber with bamboo material

InactiveCN101046003AImprove washing effectImprove wear resistanceArtificial filaments from viscoseViscose fiberMaterials science

The process of producing viscose fiber with bamboo material includes the first preparing bamboo pulp with bamboo material and through the steps of preparing material, steaming, eliminating sand, concentrating, chloralkalizing, bleaching, etc; and the subsequent preparing viscose fiber with the bamboo pulp and through the steps of squeezing, ageing, yellowing, grinding, dissolving, mixing, filtering, etc. The process maintains the antiseptic matter in bamboo fiber farthest to make the produced viscose fiber possess antiseptic function, and the produced viscose fiber has also high water washability, high wear resistance and lasting bacteria resistance, and is smooth, cool, fine and bright.

Owner:CHTC HELON

Method for preparing antibacterial coating by mugwort

InactiveCN106010050AControlled slow releaseImprove adhesionAntifouling/underwater paintsPaints with biocidesCross-linkAcrylic resin

The invention discloses a method for preparing antibacterial coating by mugwort, mugwort oil is used for microcapsule coating, solid mugwort oil is prepared and used in a core layer and a shell layer of core-shell emulsion polymerization, a cross-linking agent is used for core-shell cross linking, the mugwort oil is controlled to release slowly, and nanometer materials and a cationic emulsifier are used for enhancing the antibacterial effect. The method for preparing the antibacterial coating by the mugwort solves the technical problems that the mugwort oil is coated, the solid mugwort oil is formed and and used in the core layer and the shell layer of core-shell type acrylic resin, the nanometer materials, the cationic emulsifier and a natural antibacterial agent are used for achieving a synergistic effect, the mugwort oil is controlled to release slowly, and the antibacterial property of the acrylic resin is improved.

Owner:CHENGDU YICHUANGSI BIOLOGICAL SCI & TECH

Dendritic electrostatic spinning/electret composite nanofiber membrane filter material and preparation method thereof

InactiveCN106512556AGood storage stabilityImprove filtration efficiencyDispersed particle filtrationElectro-spinningFiberSilicon monoxide

The invention discloses a dendritic electrostatic spinning / electret composite nanofiber membrane filter material. The material is composed of the following raw materials of, by weight, 75 to 90 parts of polythioetherimide, 7 to 13 parts of silicon monoxide, 10 to 16 parts of powdered activated carbon, 2 to 3 parts of a 3-aminopropyltriethoxysilane coupling agent, 0.8 to 2 parts of glacial acetic acid, a proper amount of deionized water, 4 to 7 parts of metatitanic acid, a proper amount of a 0.6 mol / L AgNO3 solution, a proper amount of N-methyl pyrrolidone, 0.5 to 2 parts of dibutyl phthalate and 1 to 3 parts of tetra-n-propylammonium chloride. Silicon nanowires containing alpha-quartz are prepared, the electrostatic spinning / electret composite fiber filter material is prepared through the electrostatic spinning technique and has the excellent electric charge storage performance, and the filter efficiency of the filter material is greatly improved. In addition, nano-silver is added, nano-titanium dioxide is loaded, the antibacterial endurance property of the filter material is improved, and the long-time high-efficiency filter effect is achieved.

Owner:安徽名杰净化科技有限公司

Gelatin/polyetherimide compound electret fiber filtration material prepared through electrostatic spinning and preparation method thereof

InactiveCN106621563AGood storage stabilityImprove filtration efficiencyDispersed particle filtrationConjugated cellulose/protein artificial filamentsFiberPolymer science

The invention discloses a gelatin / polyetherimide compound electret fiber filtration material prepared through electrostatic spinning. The gelatin / polyetherimide compound electret fiber filtration material is prepared from, by weight, 65-80 parts of polyetherimide, 10-18 parts of gelatin, 6-11 parts of silicon oxide, 9-16 parts of powdery activated carbon, 1-3 parts of 3-aminopropyl triethoxy silane coupling agent, 0.8-2 parts of glacial acetic acid, a proper amount of ionized water, 3-6 parts of metatitanic acid, 0.6 mol / L AgNO3 solution, a proper amount of N-methylpyrrolidone and 0.8-2 parts of acetic acid. Alpha-quartz-containing silicon nanowires are prepared by adopting the material, the gelatin / polyetherimide compound electret fiber filtration material is prepared through an electrostatic spinning technology and has excellent charge storage stability, and the filtering efficiency of the filtration material is greatly improved. In addition, nano silver is added and nano titanium dioxide is loaded to improve the antimicrobial persistence performance of the filtration material and to achieve a long-term and efficient filtration effect.

Owner:安徽名杰净化科技有限公司

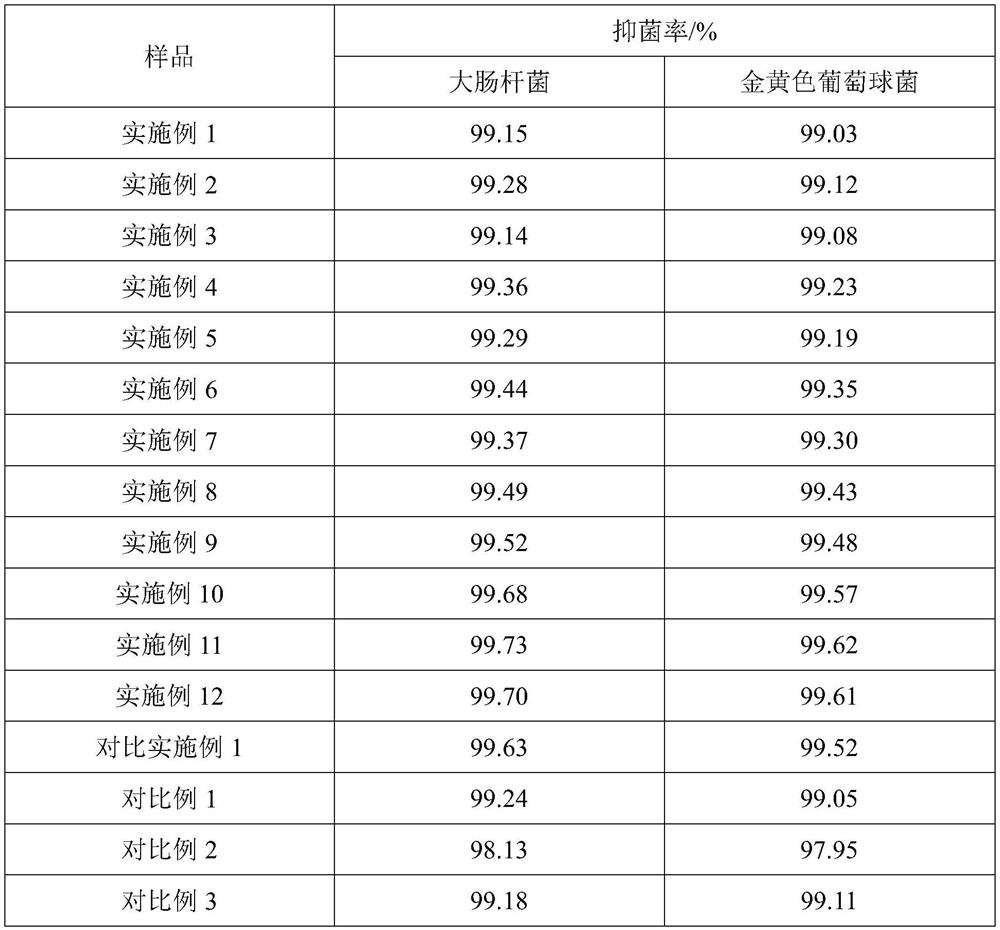

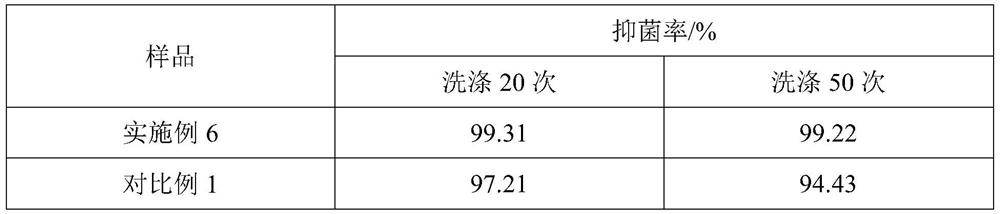

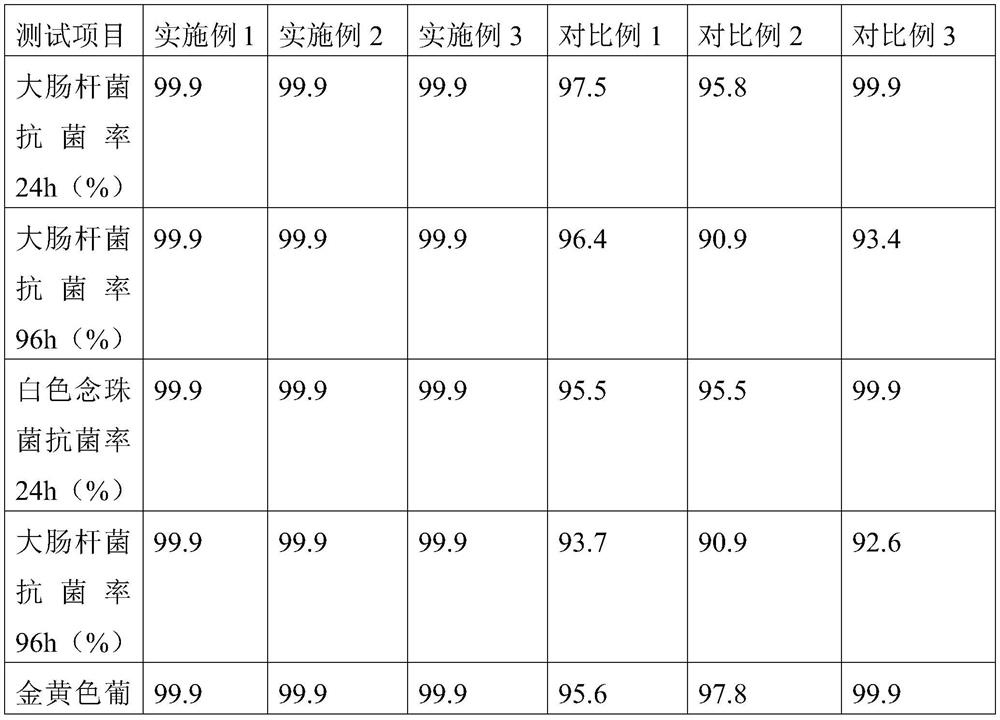

Preparation method of antibacterial polyester

The invention relates to a preparation method of an antibacterial polyester. The method comprises the steps that (1) antibacterial agent is melt blended with polyester to obtain a blend, the antibacterial agent is hydroxybenzoic acid and ester derivatives thereof, and the polyester contains terminal hydroxyl groups and the terminal carboxyl groups; (2) a solid phase reaction is conducted on the blend under vacuum conditions, which allows the antibacterial agent to be combined with the polyester through covalent bond, and the solid phase reaction temperature is 80-190 DEG C. 24-hour bacteriostasis rate of finally obtained antibacterial polyester against staphylococcus aureus and Escherichia coli is >=99%, the 24-hour bacteriostasis rate against the staphylococcus aureus and the Escherichiacoli after the antibacterial polyester is washed 50 times with water is 95%, and after the antibacterial polyester is illuminated for 12 hours by ultraviolet ray of intense of 70 MuW / cm<2>, the 24-hour antibacterial rate against the staphylococcus aureus and the escherichia coli is 98%. The preparation method is simple, the antibacterial agent reacts covalently with polyester molecular chains through low-temperature solid phase viscosity increasing, and excellent antibacterial properties are obtained while the quality of the polyester is ensured.

Owner:DONGHUA UNIV

Antibacterial thermal underwear and production process thereof

InactiveCN112501763AImprove stabilityGuaranteed dispersion stabilityWeft knittingHollow filament manufactureYarnFiber

The invention relates to the field of clothes, and particularly discloses antibacterial thermal underwear and a production process thereof. The antibacterial thermal underwear comprises a surface layer, wherein the surface layer is formed by blending various fibers including antibacterial fibers, and the antibacterial fibers are nano-silver / chitosan / polylactic acid composite fibers; the preparation method of the antibacterial thermal underwear comprises the following steps of S1, spinning, namely, blending various fibers including the antibacterial fibers to prepare blended yarns; S2, weaving,namely, weaving the blended yarns by adopting a single-sided and double-sided alternate weaving mode to weave gray cloth; S3, napping, namely, napping the skin-friendly surface of the gray cloth to obtain napped gray cloth; S4, dyeing, namely, dyeing the napped gray cloth; and S5, sewing, namely, sewing the dyed napped gray cloth to prepare a finished product of the thermal underwear. The thermalunderwear prepared by the invention has good lasting antibacterial property.

Owner:武汉猫人云商科技有限公司

ES large biological fiber containing wormwood active ingredients

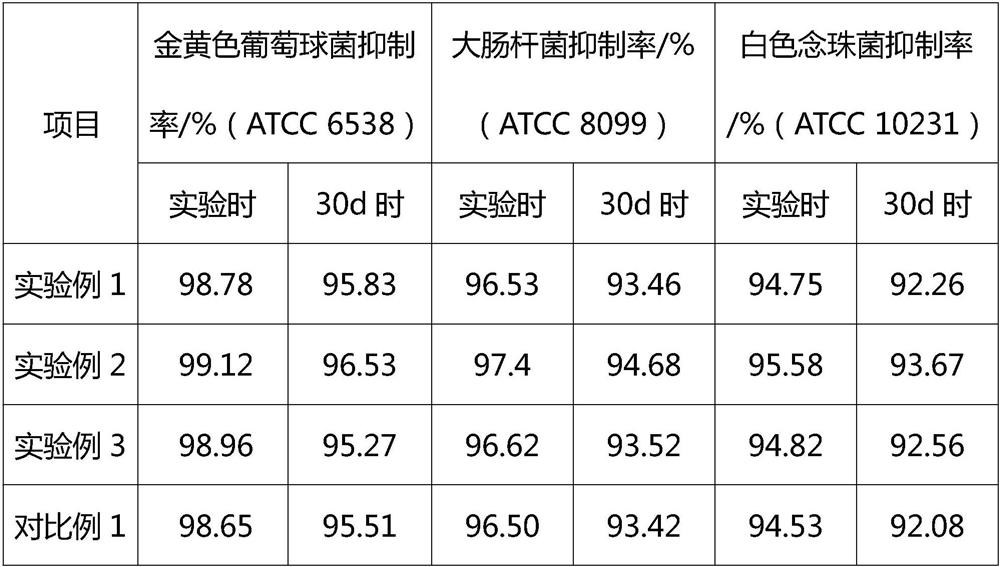

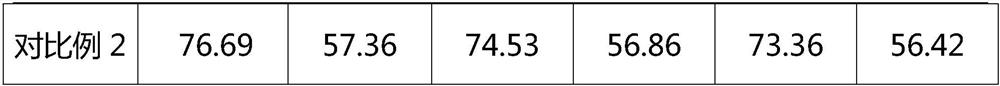

InactiveCN112553709AImprove antibacterial propertiesImprove antibacterial durabilityFilament/thread formingConjugated synthetic polymer artificial filamentsBiotechnologyStaphyloccocus aureus

The invention provides an ES large biological fiber containing wormwood active ingredients. The ES large biological fiber is prepared by the following steps of preparing wormwood extract, preparing amodifier containing wormwood extract, preparing a skin layer material, preparing a core layer material, carrying out composite spinning and carrying out aftertreatment. The ES large biological fiber containing the wormwood active ingredients has the advantages that the antibacterial rate on escherichia coli can reach 98.4 percent, the antibacterial rate on staphylococcus aureus can reach 98.5 percent, and the antibacterial rate on candida albicans can reach 98.1 percent; the fineness of the biological fiber is 2.24-2.35 dtex, the breaking strength of the biological fiber is 3.0-3.5 cN / dtex, the elongation at break of the biological fiber is 91.6%-92.5%, and the moisture regain of the biological fiber is 0.23%-0.26%; and after 100 times of standard washing, the antibacterial rate on escherichia coli can still reach 95.4%, the antibacterial rate on staphylococcus aureus can still reach 95.5%, and the antibacterial rate on candida albicans can still reach 96.1%.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

Antibacterial non-woven fabric and four-piece suit

InactiveCN111607961ALess irritatingSuitable for useBiochemical fibre treatmentFibre typesPolymer scienceNonwoven fabric

The invention discloses an antibacterial non-woven fabric. The antibacterial non-woven fabric is obtained by the following steps that (1), raw materials of the non-woven fabric is immersed in an antibacterial solution for 50-60 min after melt spinning; and after rolling, drying is conducted at 60-80 DEG C to obtain raw silks; and (2) the dried raw silks are immersed in a Chinese herbal medicine extract for 50-60 min after drafting and web forming, and hot-rolling is conducted after drying to obtain the final antibacterial non-woven fabric. According to the antibacterial non-woven fabric, in the production process of the non-woven fabric, an antibacterial solution is added, longer antibacterial performance is achieved, at the same time, the Chinese herbal medicine extract is adopted for synergistic antibacterial, the irritation to the skin surface is less, the Chinese herbal medicine extract is suitable for the non-woven fabric and a four-piece suit, the prepared four-piece suit has antibacterial property, and is suitable for hotel use.

Owner:韩建华

Preparation method of nano-bamboo charcoal antibacterial fibers for pets

InactiveCN109440218AExpand the molecular distanceImprove adsorption capacityMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentMoisture absorptionDissolution

The invention discloses a preparation method of nano-bamboo charcoal antibacterial fibers for pets, and relates to the technical field of textiles. According to the method, modified starch and nano-silver are organically combined, so that the nano-silver cannot be easily aggregated, dissolution and dispersibility of the nano-silver in carrier slices are improved, and the nano-silver has good antibacterial effects. A prepared active addition agent has adhesive property and more active groups, the nano-silver is connected with the fibers through a chemical bond, and the adhesiveness of the nano-silver on the fibers is improved, so that the antimicrobial durability of the fibers is prolonged. The prepared bamboo charcoal fibers have excellent moisture absorption performance, abrasion resistance and excellent antibacterial performance and are applicable to making of pet clothes, and bamboo charcoal is provided with renewable resources, wide in source, economical and environmentally friendly.

Owner:安徽宠旺宠物用品科技有限公司

Bamboo viscose fibre and its preparing method

InactiveCN1194119CRetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

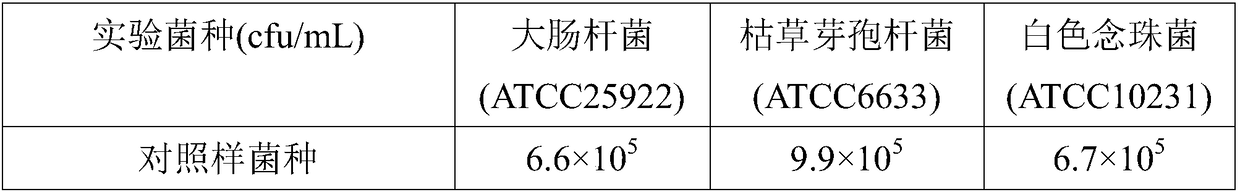

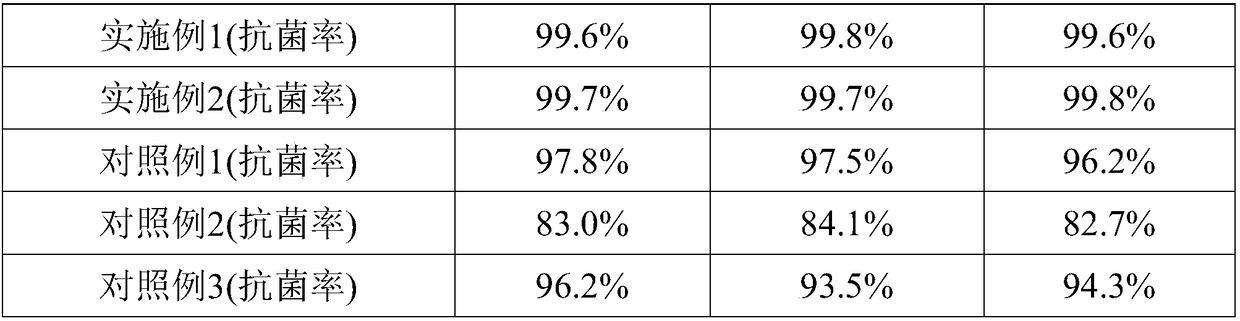

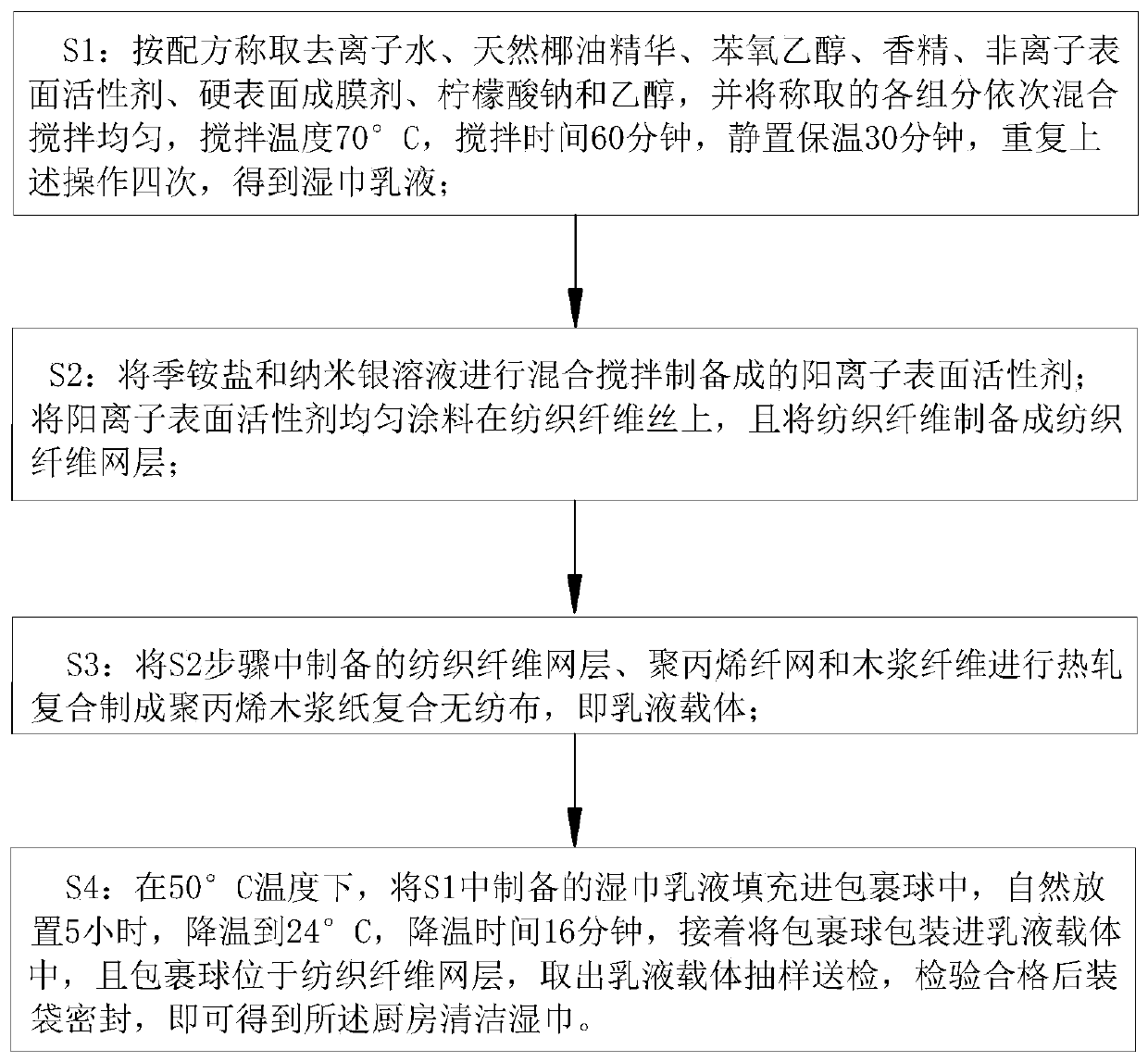

Kitchen cleaning wet tissue

InactiveCN111053489AImprove permeabilityWith strengthCationic surface-active compoundsNon-ionic surface-active compoundsTextile fiberPolymer science

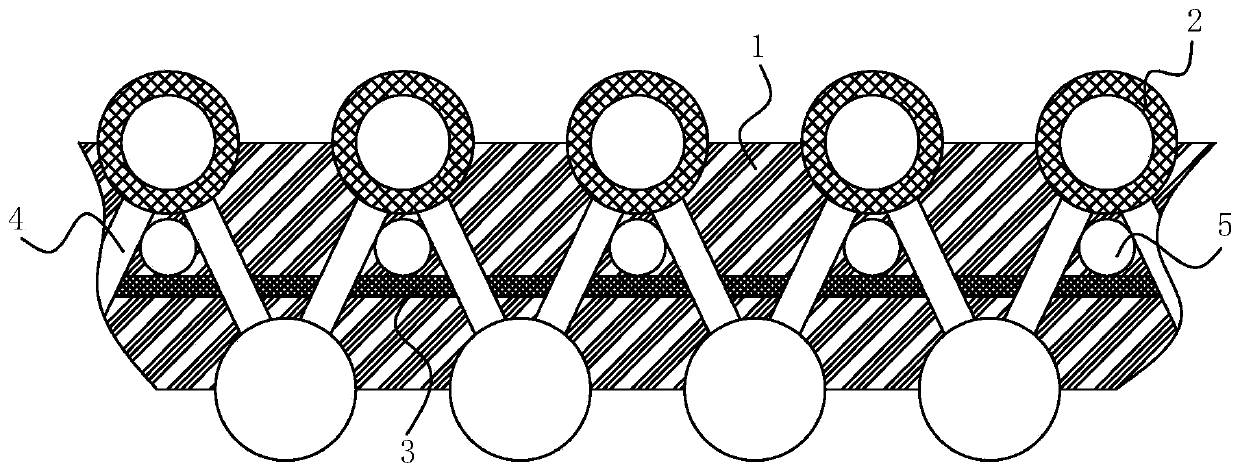

The invention belongs to the technical field of kitchen cleaning supplies, and particularly relates to a kitchen cleaning wet tissue. An emulsion carrier is a polypropylene wood pulp paper composite non-woven fabric; the polypropylene wood pulp paper composite non-woven fabric is formed by hot rolling and compounding an upper textile fiber silk screen layer, a middle wood pulp fiber layer and a lower polypropylene fiber mesh layer; a cationic surfactant is prepared by mixing a quaternary ammonium salt and a nano-silver solution; a non-ionic surfactant is a non-ionic polyacrylamide surfactant;a hard surface film-forming agent is a BASF acrylic acid copolymer; the textile fiber screen mesh layer is located on the upper layer of the polypropylene wood pulp paper composite non-woven fabric, so that the upper surface layer of the emulsion carrier is the textile fiber screen layer, the upper surface layer of the emulsion carrier makes contact with to-be-cleaned pollutants or impurities, theservice life of the emulsion carrier can be prolonged through the textile fiber screen layer, and meanwhile the corrosion resistance of the emulsion carrier is improved.

Owner:铜陵麟安生物科技股份有限公司

Stilbite carrier zine series inorganic germicide

InactiveCN1283154CDoes not affect colorImprove antibacterial durabilityBiocideFungicidesAntibacterial activityZinc

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Preparation method of EPE environment-friendly packaging material

PendingCN112920491ALarge specific surface areaImprove antistatic propertiesMaleic anhydrideActive agent

The invention relates to the technical field of packaging material preparation, in particular to a preparation method of an EPE environment-friendly packaging material. The EPE environment-friendly packaging material is prepared from the following raw materials in parts by weight: 90 to 110 parts of modified low-density polyethylene, 1.8 to 2.5 parts of 2-(2 '-hydroxy-5'-methylphenyl) benzotriazole, 3.2 to 4.0 parts of azodicarbonamide, 2.2 to 2.7 parts of glyceryl monostearate, 1.6 to 2.4 parts of polyethylene wax, 2.5 to 3.5 parts of nano titanium dioxide, 1.5 to 2.0 parts of talcum powder and 2.0 to 2.5 parts of a surfactant. The antistatic additive, the modified sepiolite powder, the maleic anhydride grafted POE and other raw materials are used for performing melt blending on the low-density polyethylene, and the antibacterial property and the antibacterial durability of the EPE packaging material are effectively improved through the synergistic cooperation between the modified sepiolite powder and the nano titanium dioxide; the antistatic additive, glyceryl monostearate and polyethylene wax cooperate with one another to effectively improve the antistatic performance of the prepared EPE packaging material, and the quality of the EPE packaging material is effectively improved.

Owner:杨辉

Water-based non-stick bactericidal environment-friendly coating and preparation method thereof

InactiveCN110746868ASimple processEasy constructionAntifouling/underwater paintsPaints with biocidesThioureaThio-

The invention discloses a water-based non-stick bactericidal environment-friendly coating. The water-based non-stick bactericidal environment-friendly coating is characterized by being prepared from the following raw materials: in parts by weight, 30-40 parts of antibacterial 3,5-diamino-1H-pyrazole-4-propenyl carboxylic ester / 1,4-bis(2',3'-epoxypropyl)perfluorobutane polycondensate, 1-2 parts of[(3,3,3-trifluoro-1-propenyl)thio]benzene, 1-3 parts of 1,3-diallyl-2-thiourea, 1-3 parts of stibene glucoside, 0.5-1.5 parts of zinc quinolone, 10-15 parts of polyethylene glycol diacrylate, 10-15 parts of filler, 1-5 parts of a co-solvent, 15-25 parts of water, 0.5-1.5 parts of a photoinitiator, 2-5 parts of an emulsifier, 1-2 parts of a dispersant, 1-3 parts of a leveling agent and 1-3 parts ofa wetting agent. The invention also discloses a preparation method of the water-based non-stick bactericidal environment-friendly coating. The water-based non-stick bactericidal environment-friendlycoating has excellent comprehensive performance, non-stick performance, good abrasion resistance and high temperature resistance, a remarkable sterilization effect, good and stable performance, a longservice life and environmental protection.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com