Antibacterial bed sheet and production process thereof

A production process and bed sheet technology, which is applied in the field of fabric processing, can solve the problems of poor antibacterial properties and antibacterial durability of bed sheets, shedding of sheets, etc., and achieve the effect of increasing wash fastness, softness, and uniform sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

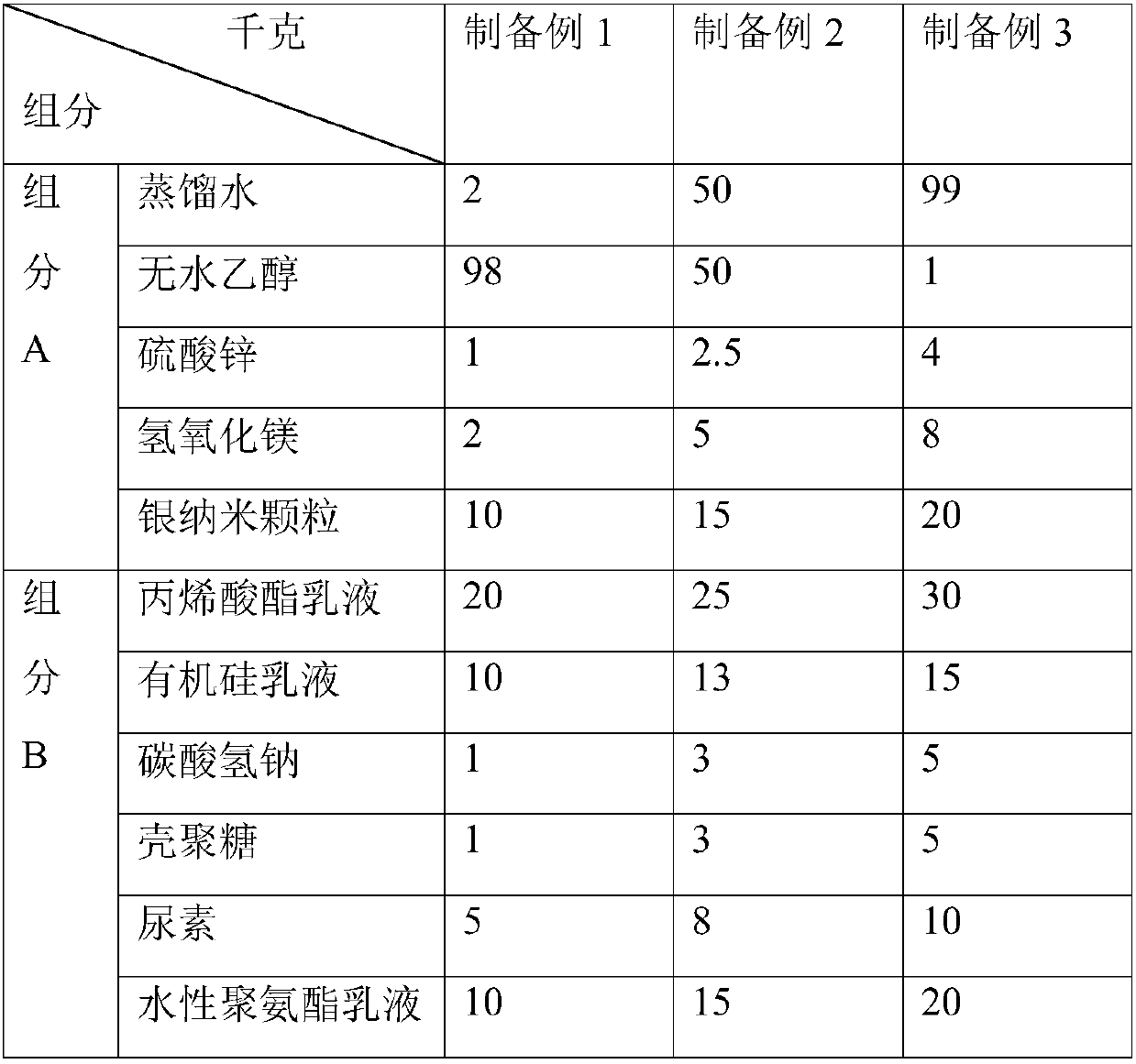

preparation example 1-3

[0042] Distilled water, dehydrated alcohol, zinc sulfate and magnesium hydroxide in Preparation Example 1-3 are all analytically pure, and the silver nanoparticles are selected from the silver nanoparticles of CST-NP-S2 sold by Suzhou Lengshi Nano Material Technology Co., Ltd. The acrylate emulsion is selected from the acrylate emulsion of BLJ-5637 type sold by Beijing Tuduoduo Electronic Commerce Co., Ltd., and the silicone emulsion is selected from the silicone emulsion of E101CN sold by Shanghai Xianglan Chemical Co., Ltd. Chitosan is selected from The chitosan of model R25 sold from Shaanxi Runfeng Biotechnology Co., Ltd., the urea was selected from the urea of model 00NS sold by Beijing Kangpu Huiwei Technology Co., Ltd., and the water-based polyurethane emulsion was selected from Anhui Anda Huatai New Material Co., Ltd. A water-based polyurethane emulsion is sold under the model number AH-1502.

preparation example 1

[0043] Preparation Example 1: (1) According to the proportioning in Table 1, mix 2kg of distilled water and 98kg of absolute ethanol in component A evenly to make a mixed solvent, get 50kg of mixed solvent, add it to 1kg of zinc sulfate, and mix it at 1500Hz After ultrasonically dispersing for 1 min, raise the temperature to 70°C to prepare solution A; add the remaining 50kg of mixed solvent to 2kg of magnesium hydroxide, and ultrasonically disperse at 1600Hz for 1min to prepare solution B, mix solution A and solution B, cool, Centrifuge at a speed of 4000r / min and then vacuum dry, add 10kg of silver nanoparticles and grind to a particle size of 5nm to obtain Component A;

[0044] (2) Heat 10kg of silicone emulsion to 50°C, add 5kg of urea, 1kg of sodium bicarbonate and 1kg of chitosan in sequence, mix well, and then pass in nitrogen gas, add 20kg of acrylate emulsion after 20min, mix and stir, keep warm for 1h, Cool, add 10kg water-based polyurethane emulsion, stir well, and ...

preparation example 2

[0048] Preparation example 2: (1) according to the proportioning in table 1, 50kg distilled water in the component A and 50kg dehydrated alcohol are mixed uniformly, make mixed solvent, get the mixed solvent of 50kg, add in 2.5kg zinc sulfate, in After ultrasonic dispersion at 2000Hz for 2min, heat up to 75°C to prepare solution A; add the remaining 50kg of mixed solvent to 5kg of magnesium hydroxide, ultrasonically disperse at 1800Hz for 2min to prepare solution B, mix solution A and solution B, and cool , centrifuged at a rotating speed of 4500r / min and vacuum-dried, added 15kg of silver nanoparticles, and ground to a particle size of 8nm to obtain Component A;

[0049] (2) Heat 13kg of silicone emulsion to 55°C, add 8kg of urea, 3kg of sodium bicarbonate and 3kg of chitosan in sequence, mix well, and then pass in nitrogen gas, add 25kg of acrylate emulsion after 25min, mix and stir, and keep warm for 1.5h , cooling, adding 15kg water-based polyurethane emulsion, stirring ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com