Antibacterial non-woven fabric and four-piece suit

A technology of non-woven fabrics and antibacterial liquid, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc. It can solve the problems of strong irritation, short antibacterial period and inapplicability, achieve long-term antibacterial performance, improve antibacterial performance, less irritating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

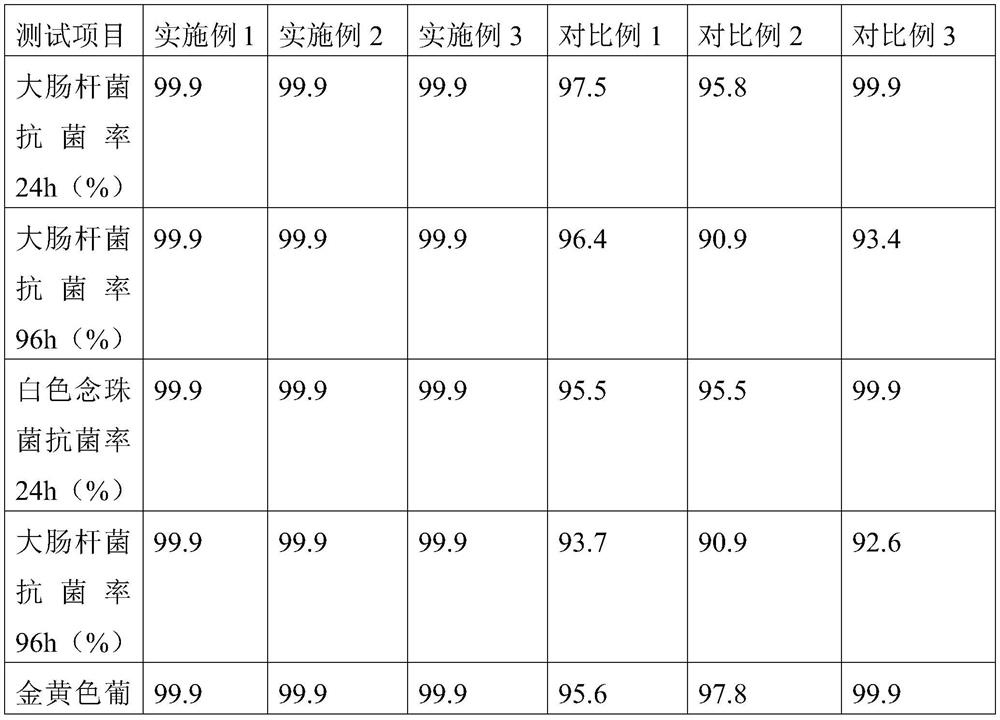

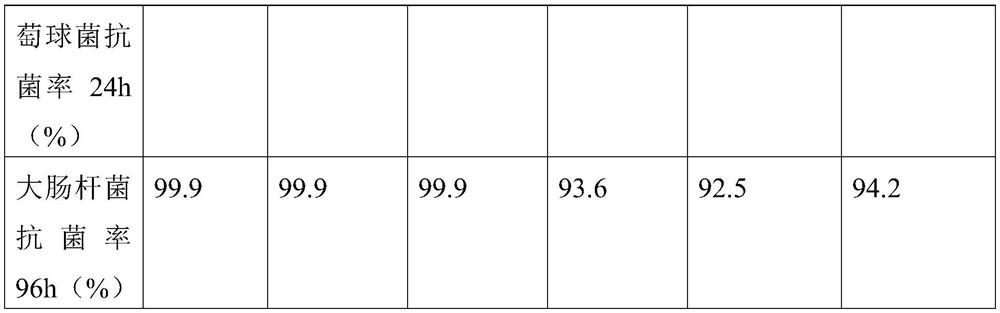

Examples

Embodiment 1

[0024] A kind of antibacterial non-woven fabric is obtained through the following steps:

[0025] (1) After melt-spinning PVC, soak it in an antibacterial solution for 50-60 minutes; after rolling, dry it at a temperature of 60-80°C to obtain the raw silk;

[0026] (2) After drying, the raw silk is drawn and netted and soaked in the Chinese herbal medicine extract for 50-60 minutes, and then hot-rolled after drying to obtain the final antibacterial non-woven fabric;

[0027] Wherein, the antibacterial liquid includes the following raw materials in parts by weight: 20 parts of polystyrene hydantoin, 10 parts of quaternary ammonium salt, 4 parts of sorbic acid, 1 part of carrageenan, 1.5 parts of zinc stearate, 30 parts of ethanol and 150 parts of water.

[0028] The antibacterial liquid is obtained through the following steps: gradually add water after mixing carrageenan and ethanol, add polystyrene hydantoin, quaternary ammonium salt, sorbic acid and zinc stearate after stirr...

Embodiment 2

[0033] A kind of antibacterial non-woven fabric is obtained through the following steps:

[0034] (1) Put the PET into the antibacterial solution and soak it for 50-60 minutes after melt-spinning; after rolling, dry it at a temperature of 60-80°C to obtain the raw silk;

[0035] (2) After drying, the raw silk is drawn and netted and soaked in the Chinese herbal medicine extract for 50-60 minutes, and then hot-rolled after drying to obtain the final antibacterial non-woven fabric;

[0036] Wherein, the antibacterial liquid includes the following raw materials in parts by weight: 10 parts of polystyrene hydantoin, 20 parts of quaternary ammonium salt, 8 parts of sorbic acid, 3 parts of carrageenan, 2 parts of zinc stearate, 40 parts of ethanol and 160 parts of water.

[0037] The antibacterial liquid is obtained through the following steps: gradually add water after mixing carrageenan and ethanol, add polystyrene hydantoin, quaternary ammonium salt, sorbic acid and zinc stearat...

Embodiment 3

[0042] A kind of antibacterial non-woven fabric is obtained through the following steps:

[0043] (1) After melting and spinning PP, soak it in an antibacterial solution for 50-60 minutes; after rolling, dry it at a temperature of 60-80°C to obtain the original silk;

[0044] (2) After drying, the raw silk is drawn and netted and soaked in the Chinese herbal medicine extract for 50-60 minutes, and then hot-rolled after drying to obtain the final antibacterial non-woven fabric;

[0045] Wherein, the antibacterial liquid includes the following raw materials in parts by weight: 16 parts of polystyrene hydantoin, 14 parts of quaternary ammonium salt, 5 parts of sorbic acid, 2 parts of carrageenan, 1.8 parts of zinc stearate, 35 parts of ethanol and 155 parts of water.

[0046] The antibacterial liquid is obtained through the following steps: gradually add water after mixing carrageenan and ethanol, add polystyrene hydantoin, quaternary ammonium salt, sorbic acid and zinc stearate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com