Patents

Literature

35results about How to "Bright" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

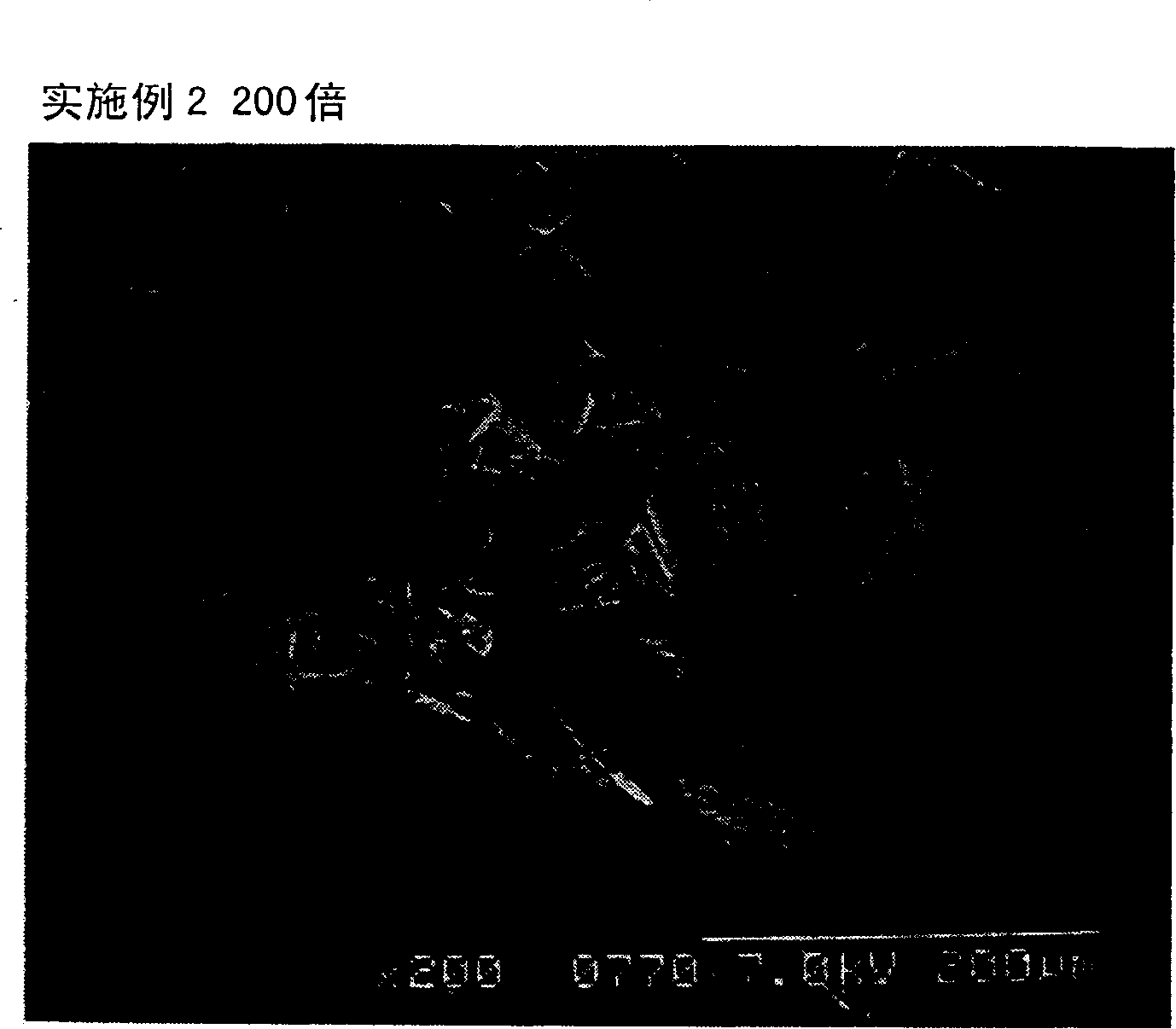

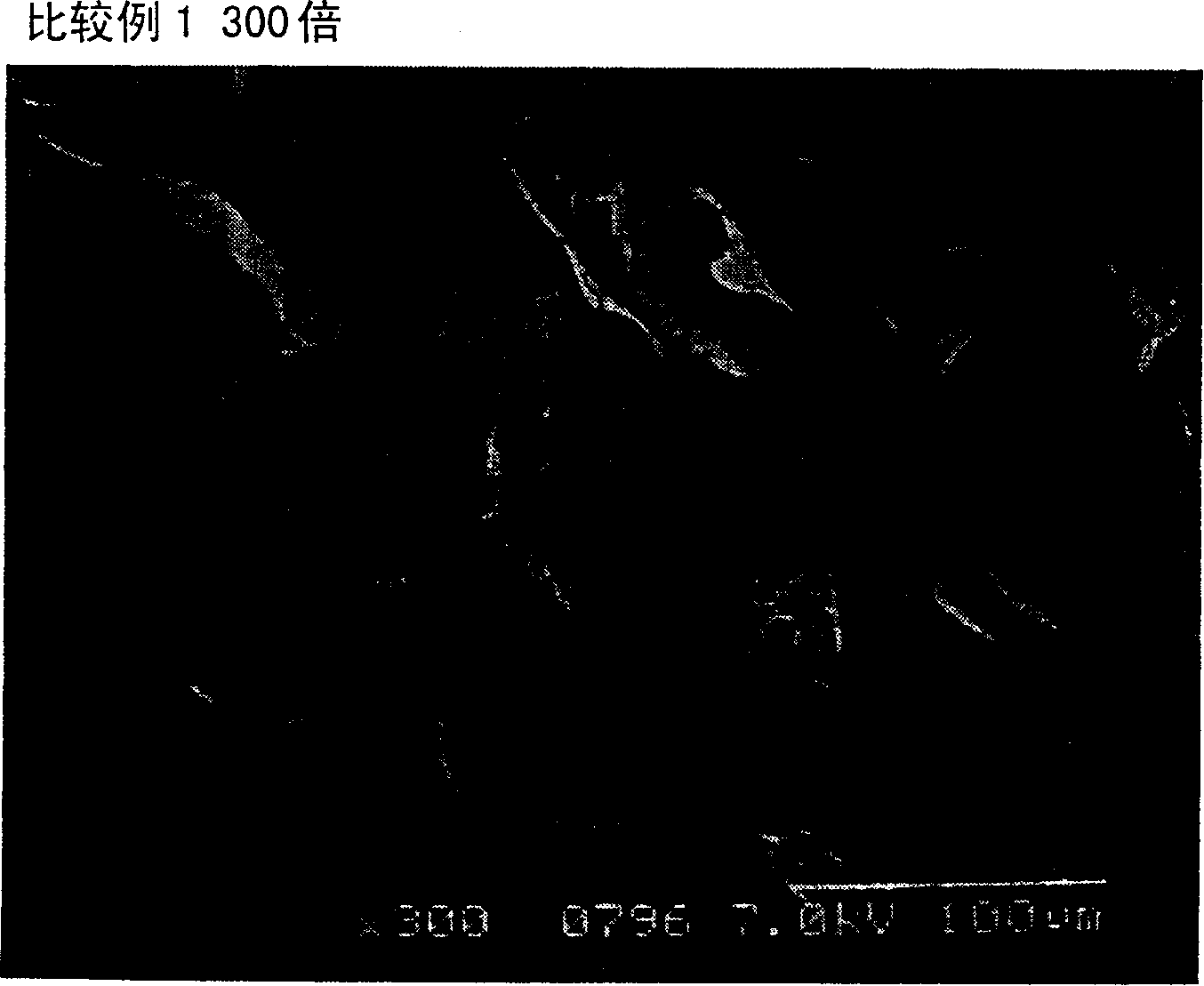

Bamboo viscose fibre and its preparing method

InactiveCN1458306ARetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

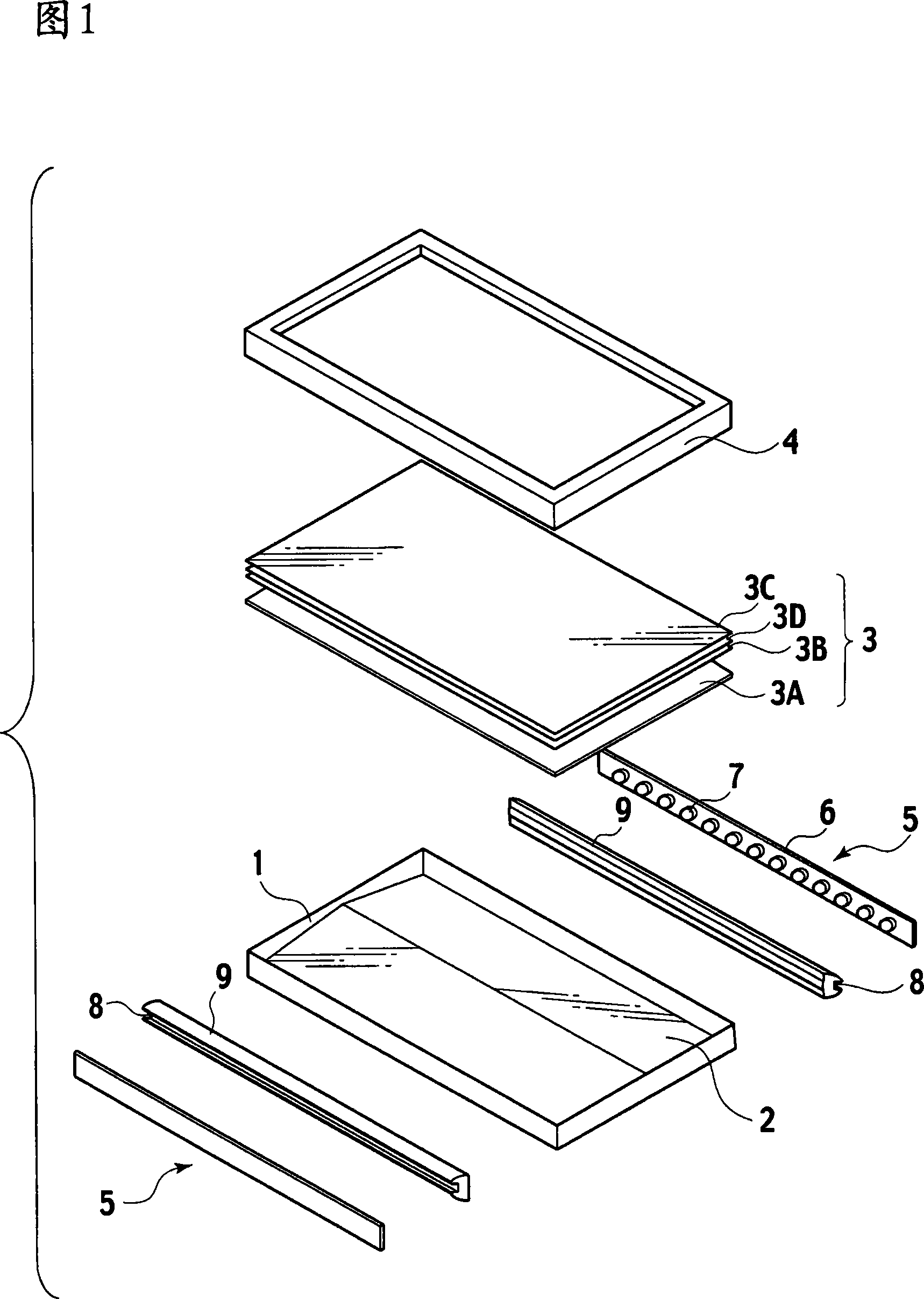

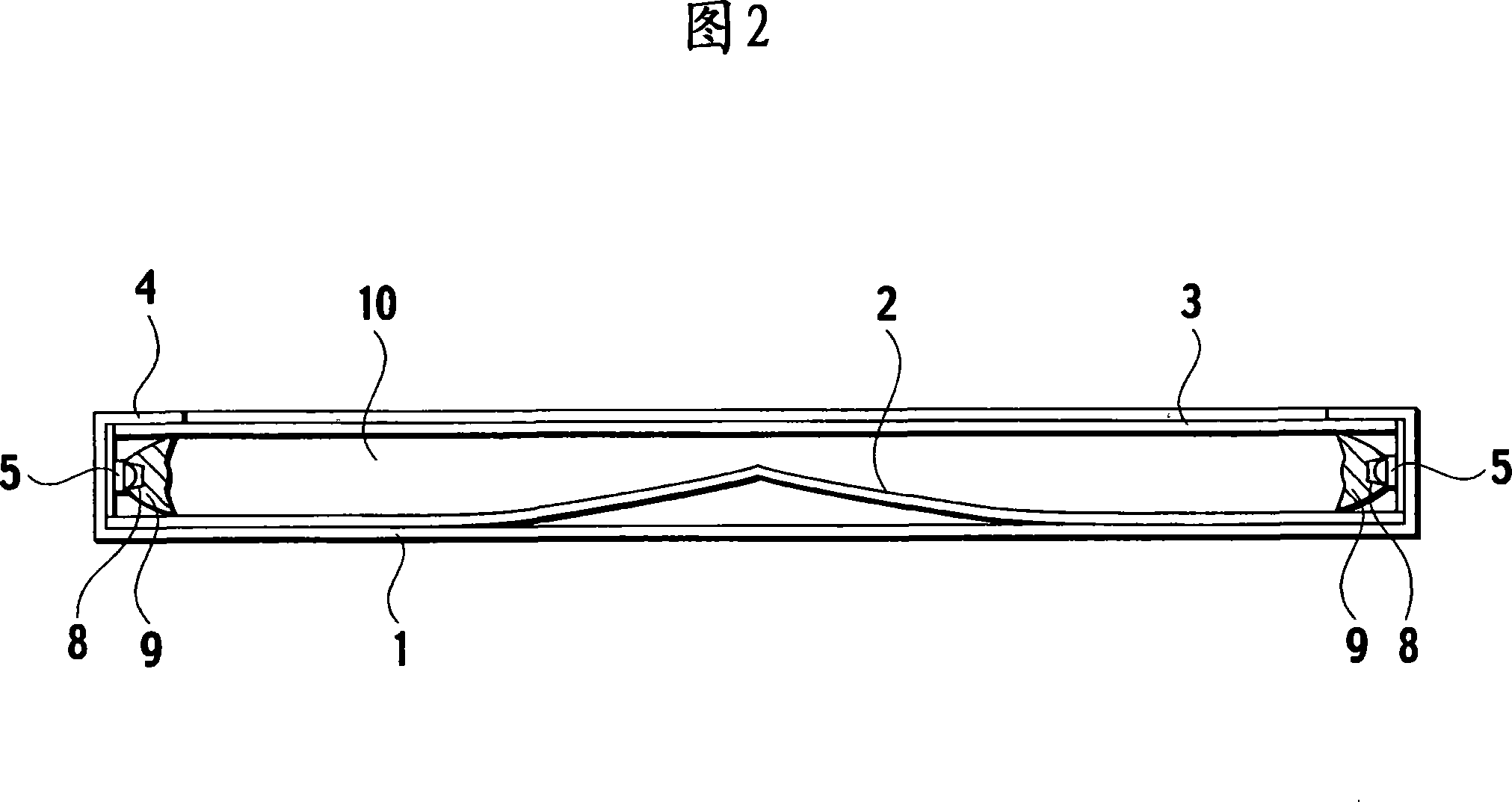

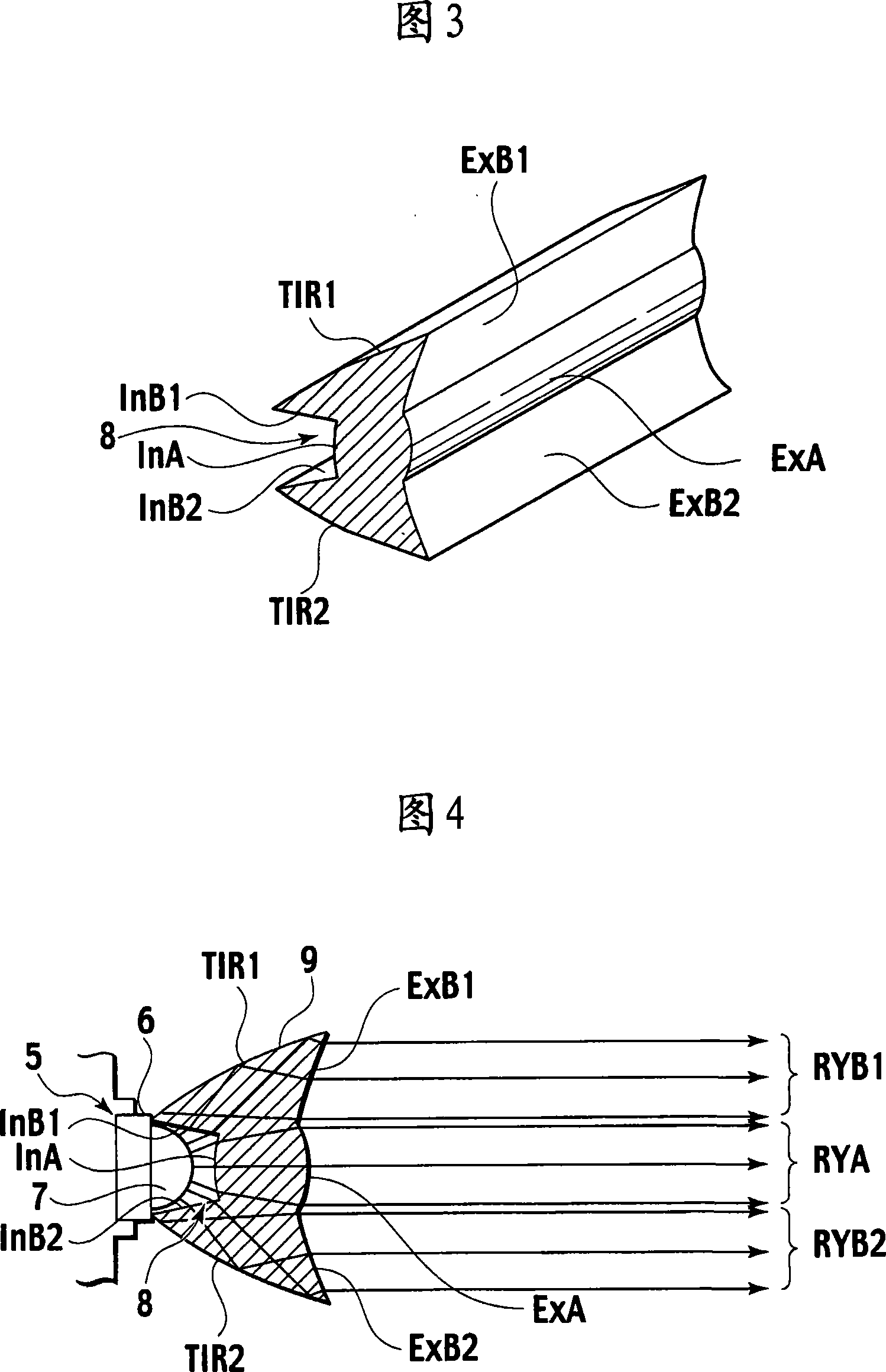

Hollow type plate illuminating device

InactiveCN101118043ABrightUniform lightPlanar light sourcesMechanical apparatusOptoelectronicsCollimated light

Provided is a hollow flat illumination device used for a back light unit, comprising a housing, a reflector arranged at the bottom of the housing and an illuminous surface part arranged on top of the housing. A light guide space arranged between the reflector and the illuminous surface part. A LED light source is adjacent the light guide space. The LED light source is provided with a distribution board and an array of LED arranged on the distribution board. A collimated light tube at the illumination side of the LED light source to converge the light from the LED light source in the thickness direction of the housing and drive the light to diffuse parallel to the light axis of the LED array. The collimated light tube has the functionality portions (InA, InB1 and InB2) to refract the light from the LED array, guides the refracted light to go through the body of the collimated light tube and illuminates the light to the light guide space. The collimated light tube also has the functionality portions (TIR1 and TIR2), which wholly reflects the light entering into the collimated light tube and illuminates the light to the light guide space. The hollow flat illumination device is compacted and provides the bright and uniform light.

Owner:HARISON TOSHIBA LIGHTING CORP

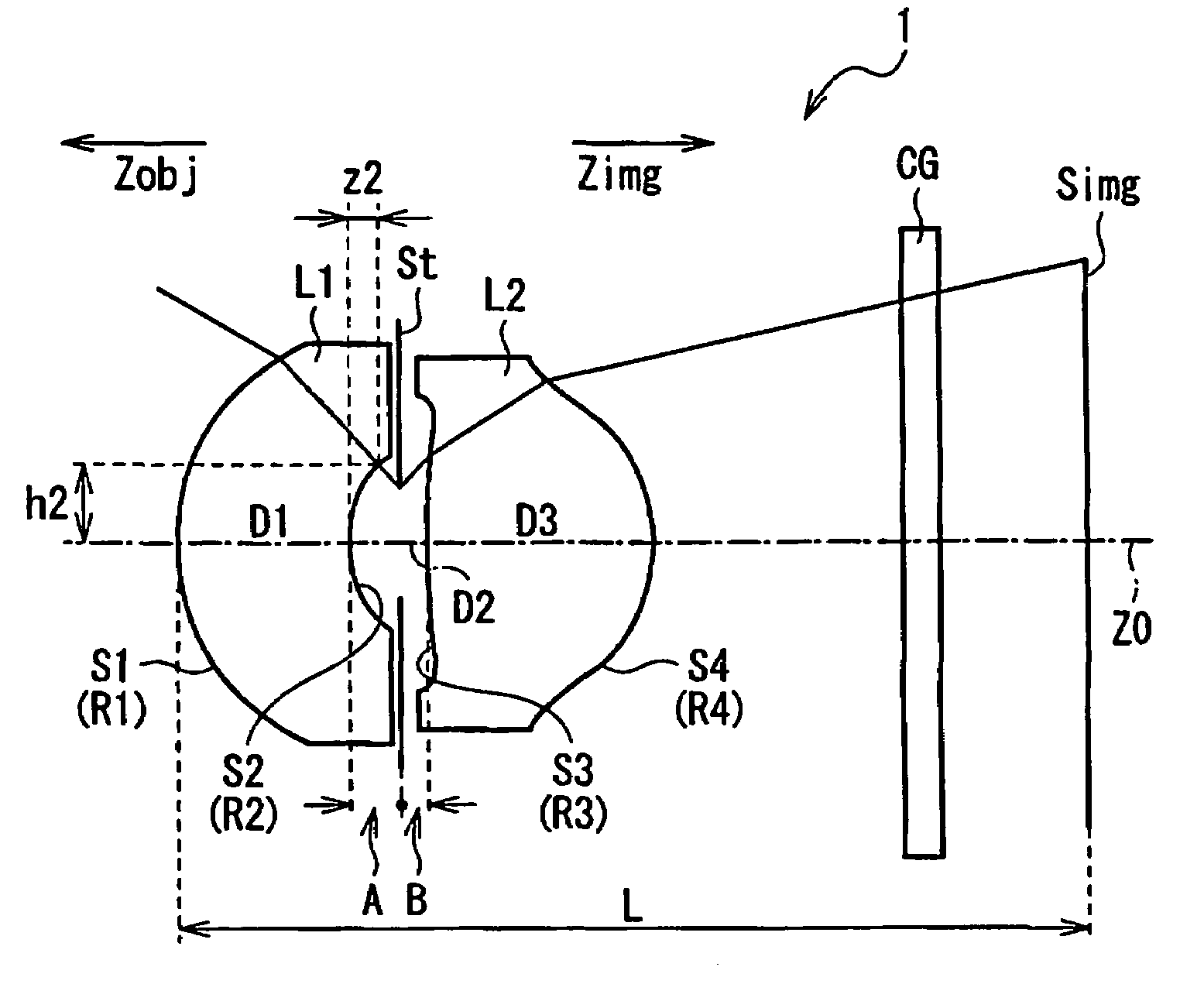

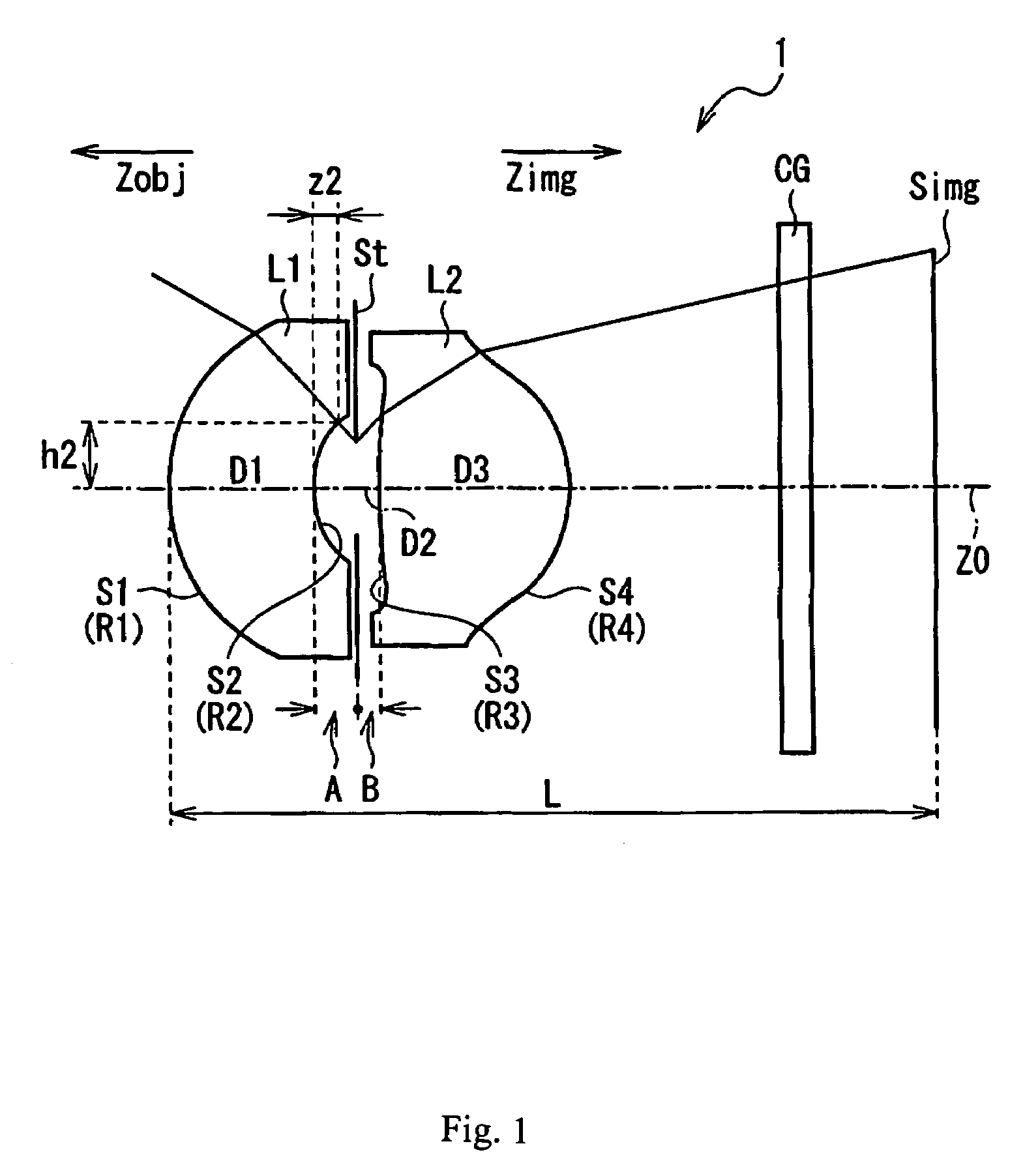

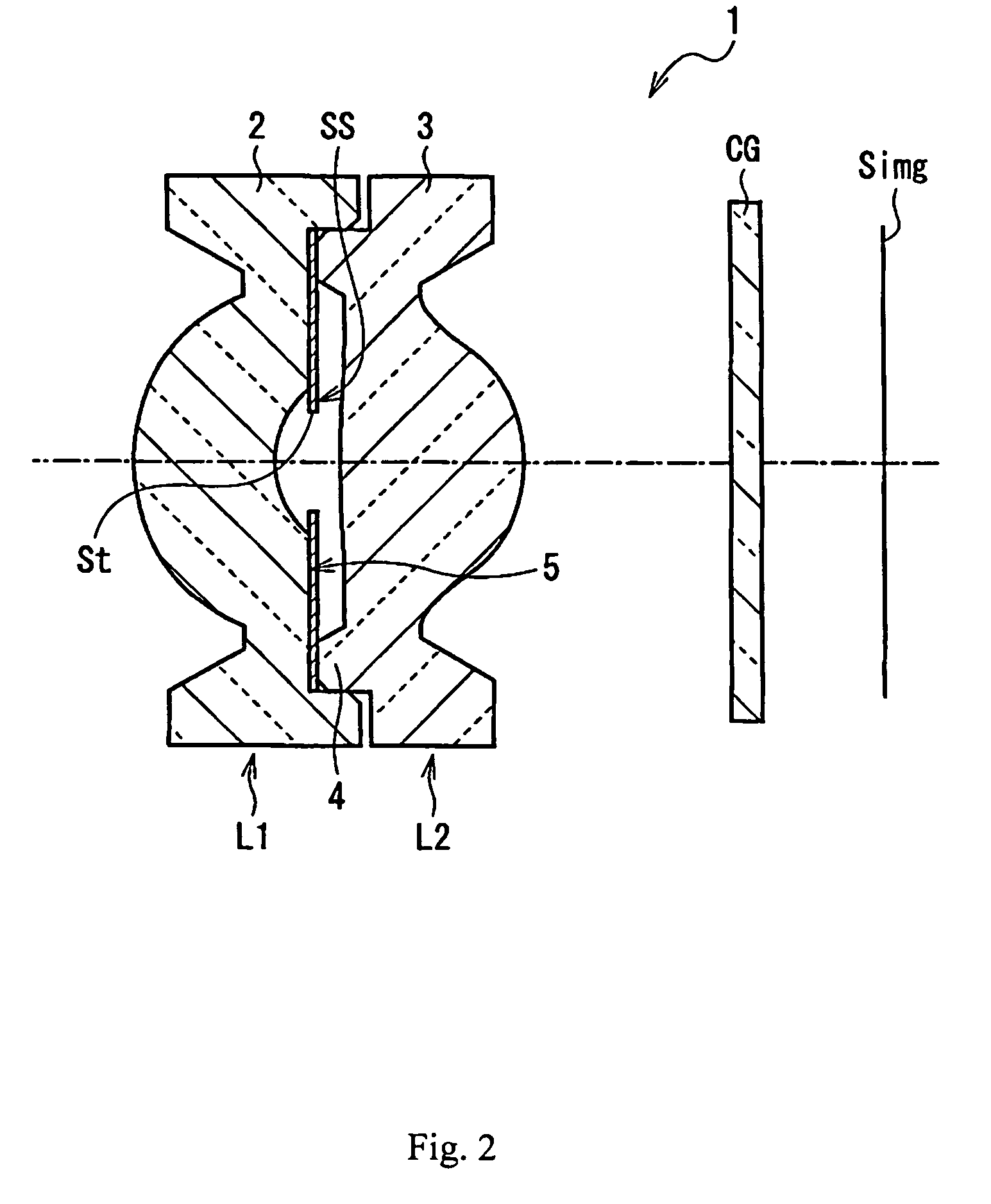

Imaging lens

An imaging lens for an image pickup device consists of two lens components that may each consist of a lens element. In order from the object side, these lens components have negative and positive refractive power, with each lens component having two aspheric surfaces. A stop is positioned between the lens components so as to be closer to the image-side lens component. Specified conditions are satisfied in order to miniaturize the imaging lens, reduce manufacturing and assembly costs, and improve imaging performance.

Owner:FUJI PHOTO OPTICAL CO LTD

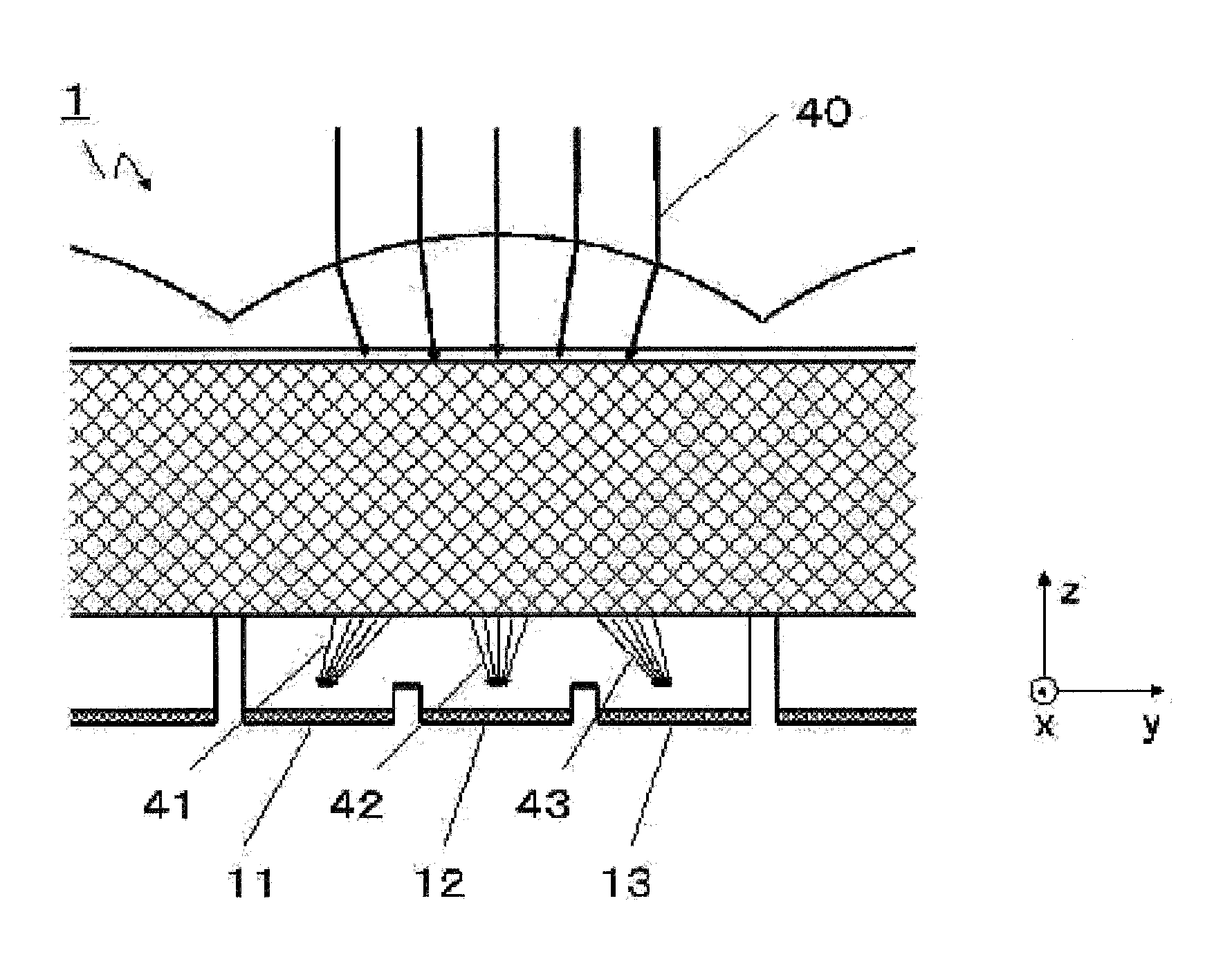

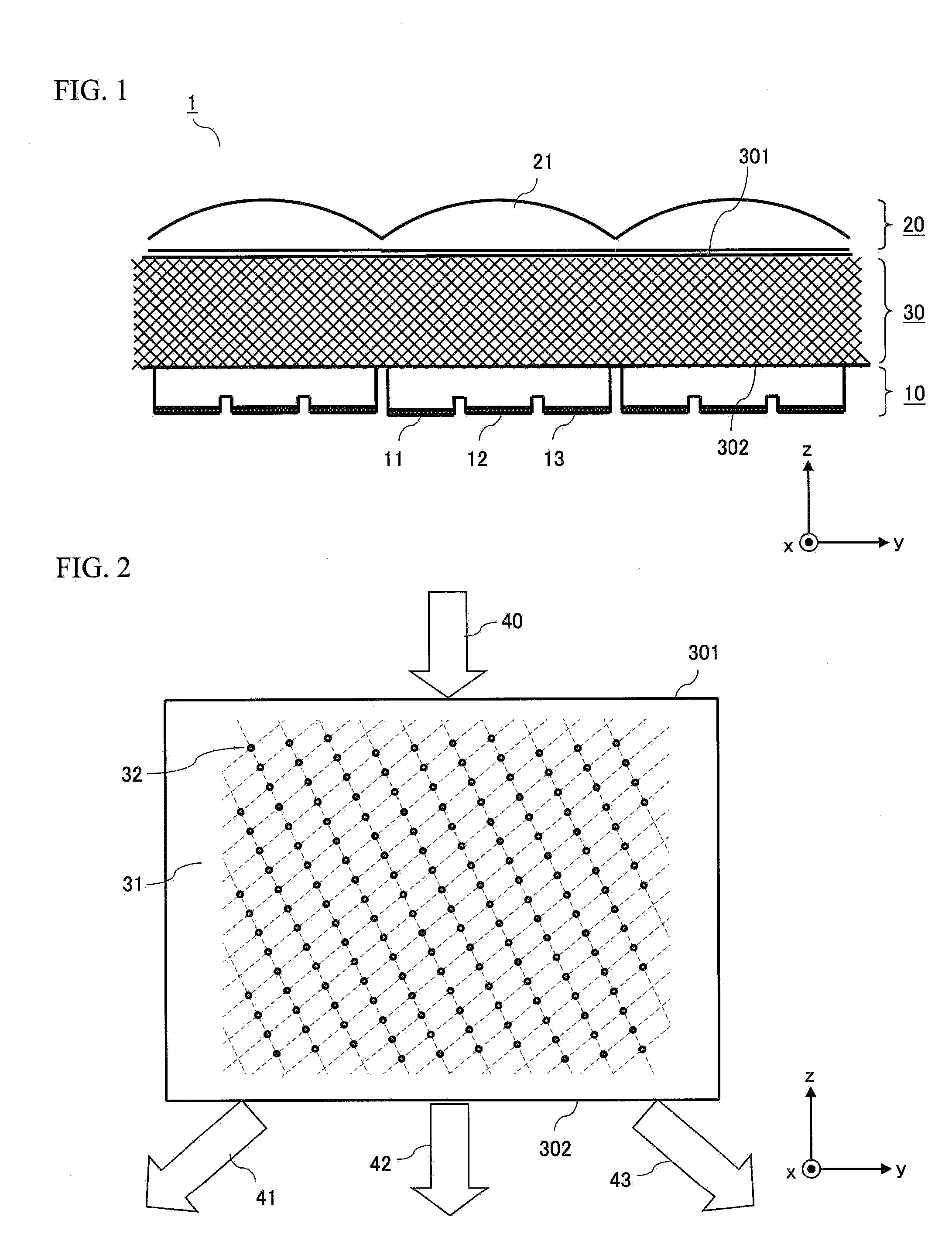

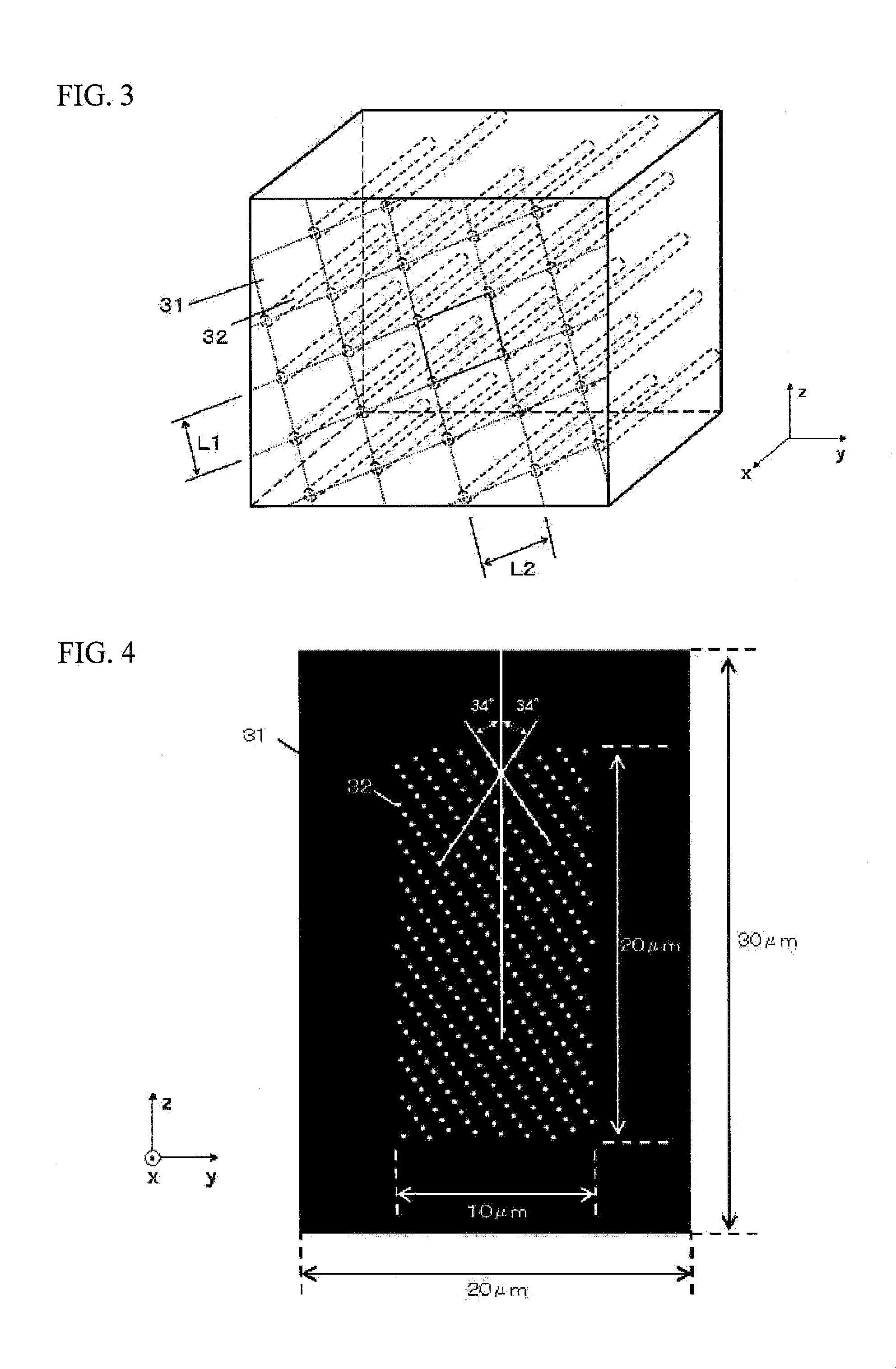

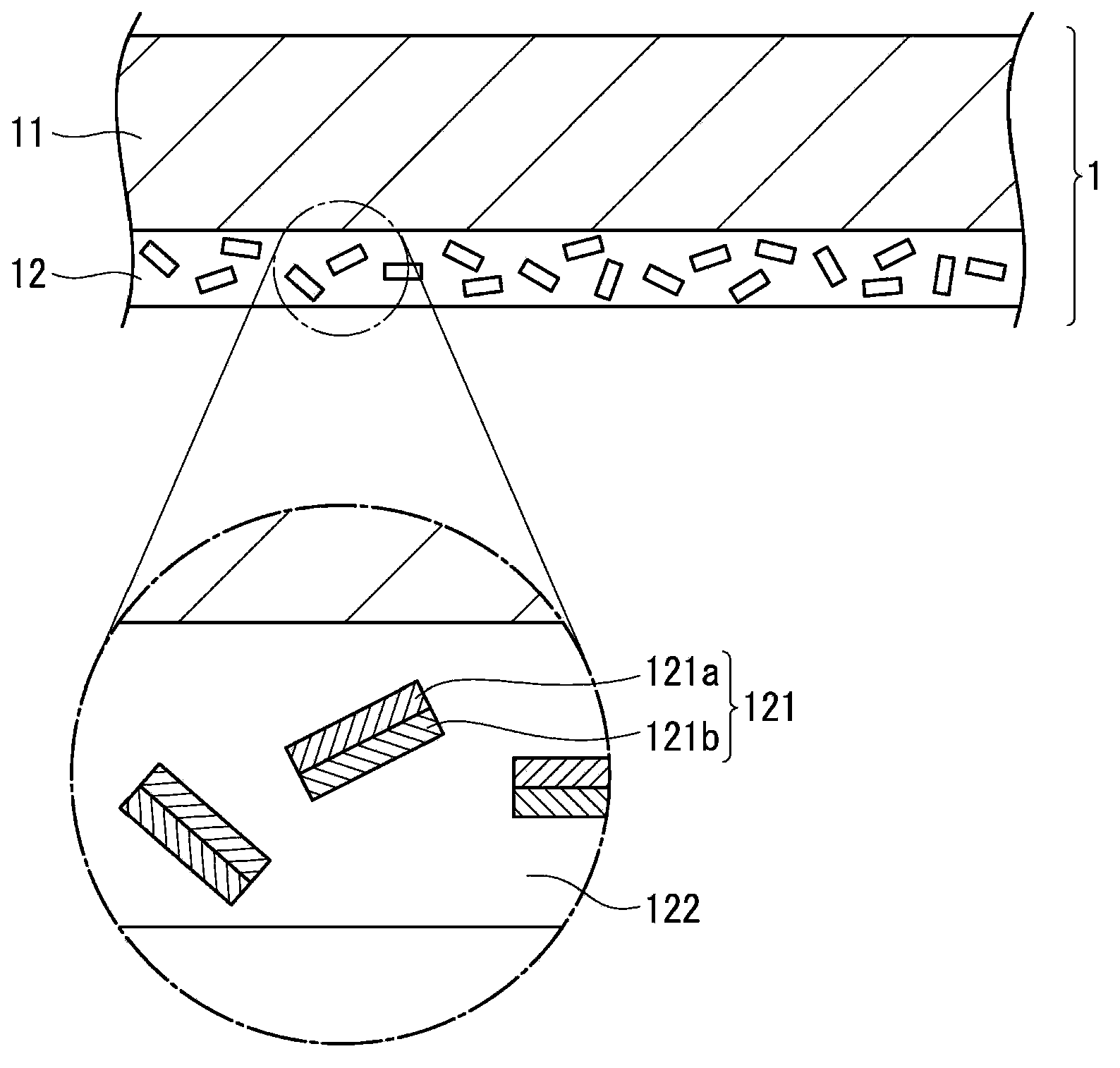

Solid-state image pickup device, imaging device, and dispersing element

InactiveUS20110267487A1Excellent image stabilityLight utilization efficiencyTelevision system detailsSolid-state devicesRefractive indexLight beam

A solid-state image pickup device capable of taking more light into light receiving regions is provided. The solid-state image pickup device of the present invention includes: a photoelectric conversion unit having a plurality of light receiving regions that are two-dimensionally arrayed, the photoelectric conversion unit for photoelectrically converting light incident on each of the light receiving regions, and outputting an electric signal according to the intensity of the incident light; a lens unit comprising a plurality of converging lenses provided on an upper layer of the photoelectric conversion unit, each of the converging lens being provided corresponding to a set of continuous first to third light receiving regions; and a dispersing element provided between the photoelectric conversion unit and the lens unit, the dispersing element being formed of a medium whose refractive index varies periodically, and diffracting beams of a first wavelength band and of a third wavelength band, having been transmitted through the converging lens, and directing the beams onto the first light receiving region and the third light receiving region, and transmitting, without diffracting, a beam of a second wavelength band, having been transmitted through the converging lens, and directing the beam onto the second light receiving region.

Owner:PANASONIC CORP

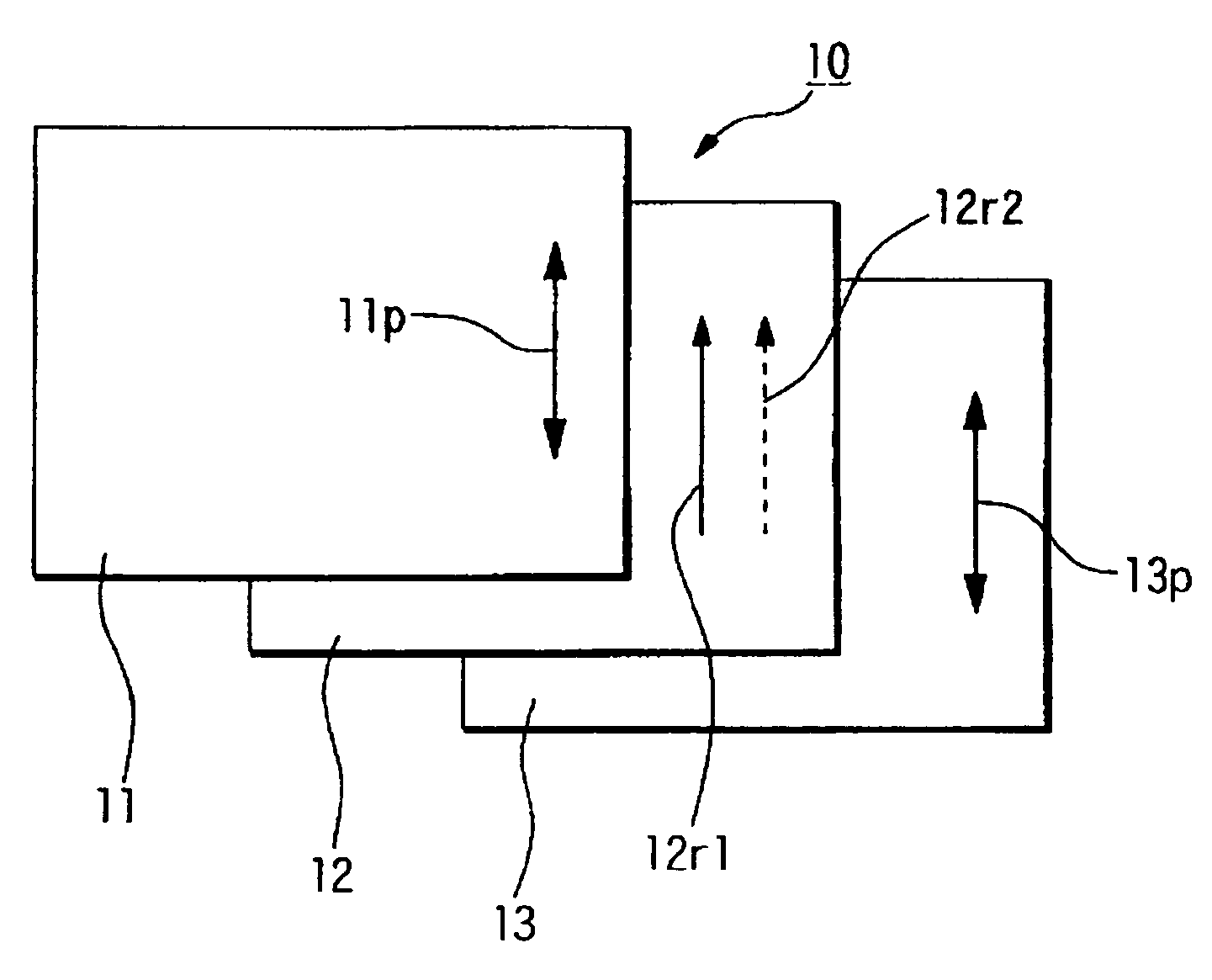

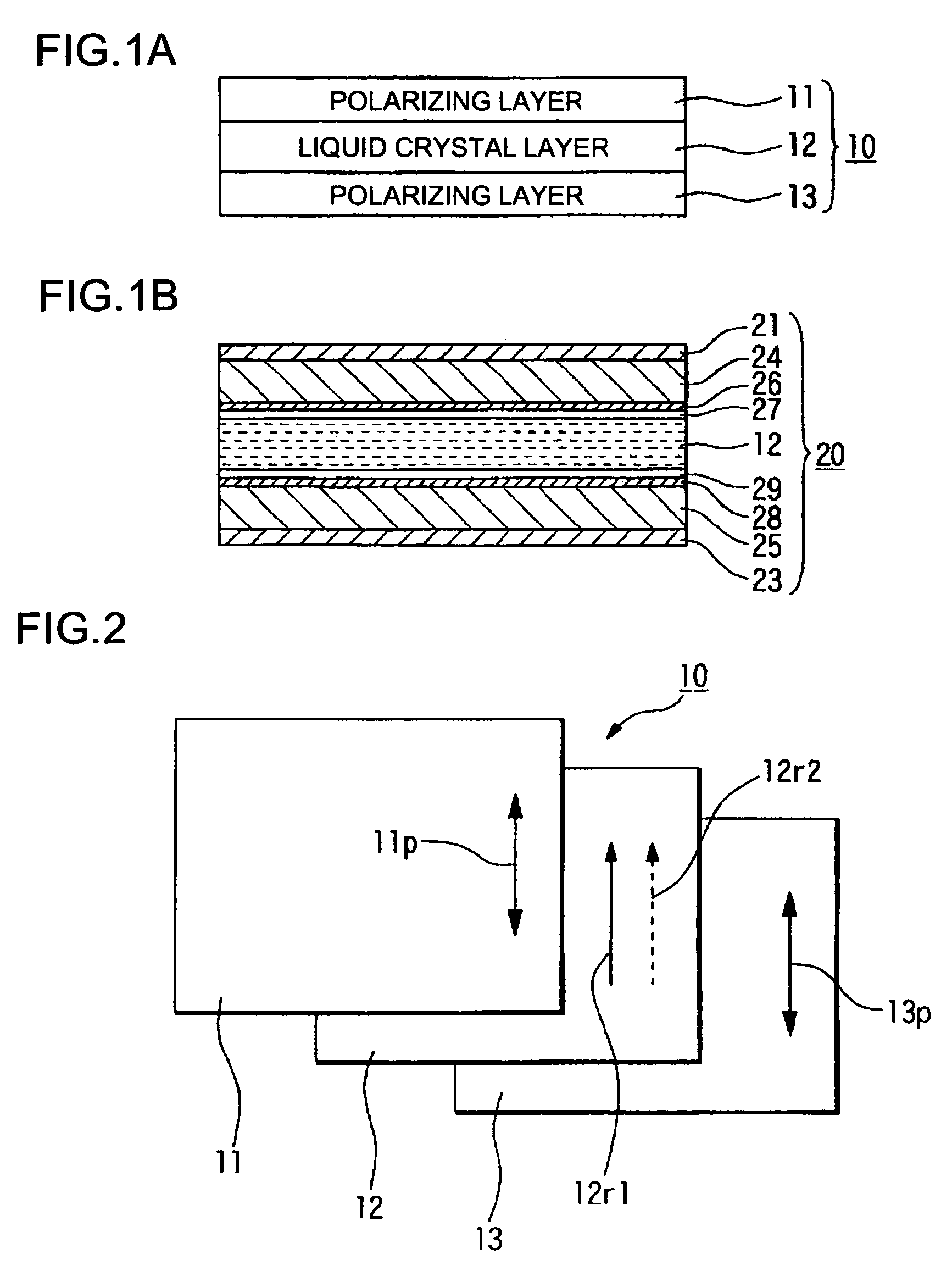

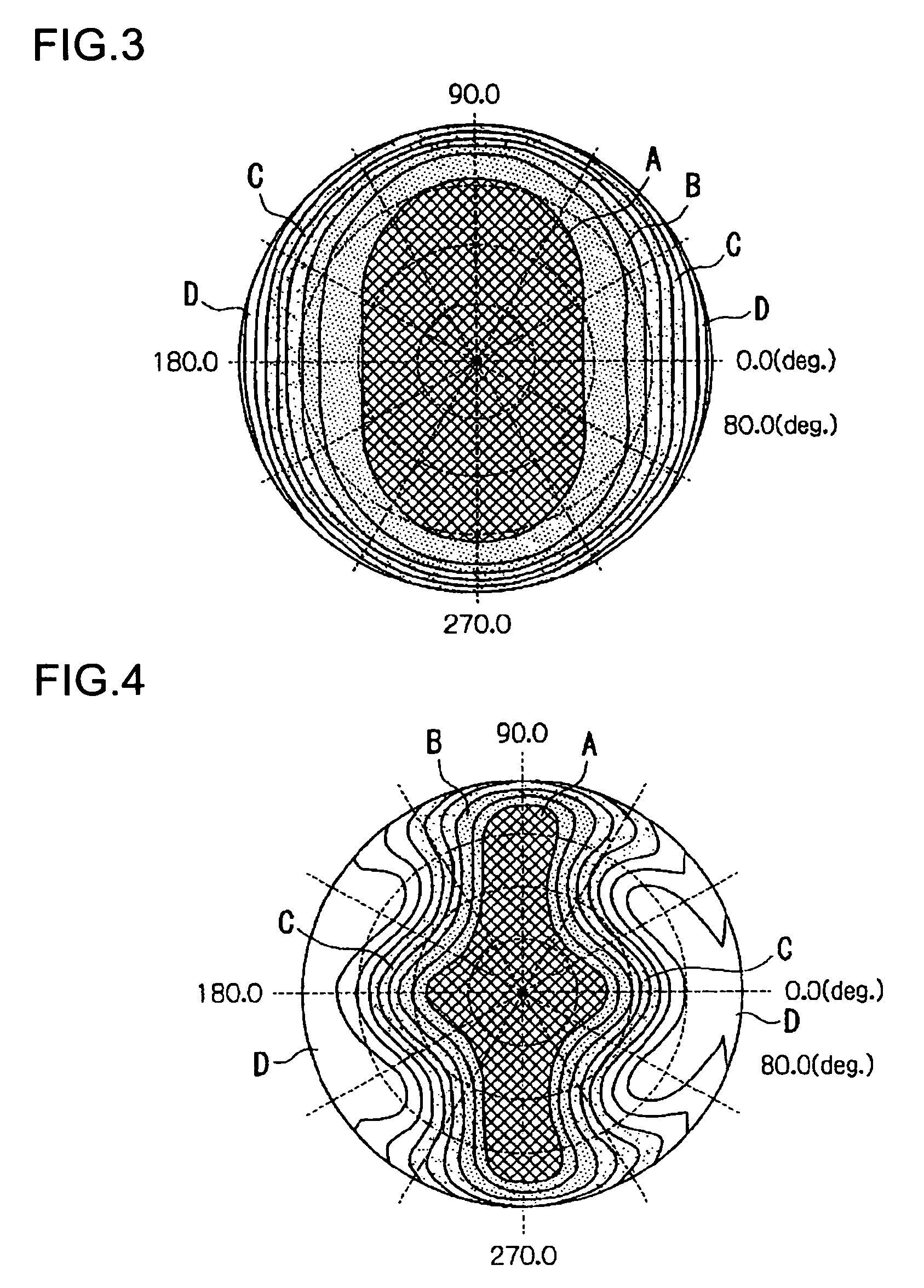

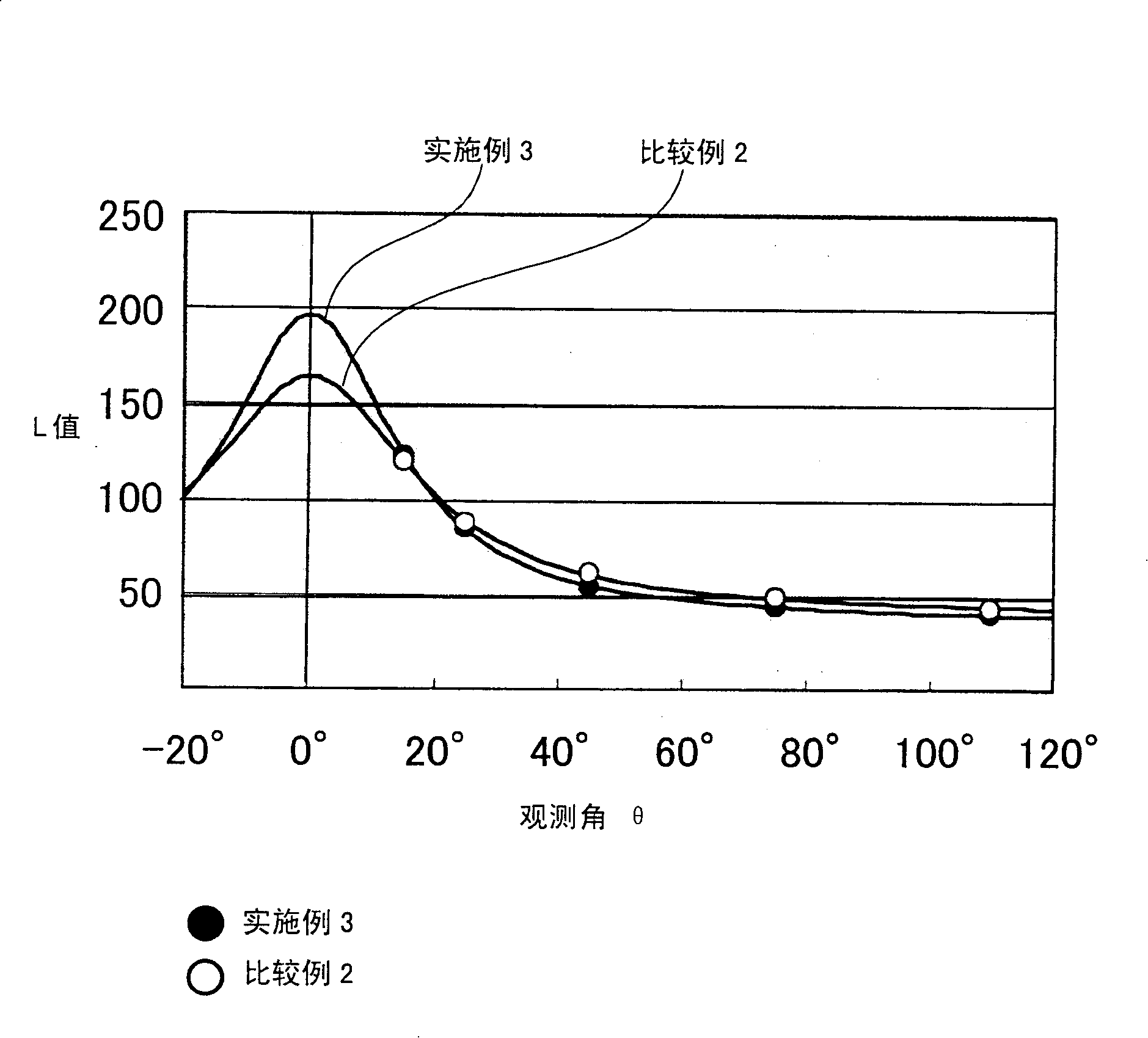

Viewing angle control element, display device, and electronic apparatus

ActiveUS7400367B2BrightAvoid absorptionStatic indicating devicesElectroluminescent light sourcesElectricityOptical axis

The invention provides a viewing angle control element capable of realizing high information concealment without damaging brightness of transmitted light and dynamically changing a viewing angle in accordance with need or no need of information concealment. The viewing angle control element according to the invention can include liquid crystal twist-aligned by approximately 180°, and have a liquid crystal layer being electrically controllable and a pair of polarizing layers provided at both sides of the liquid crystal layer. Optical axes of both polarizing layers can be arranged to be substantially parallel to each other, and liquid crystal molecules of the liquid crystal layer adjacent to the polarizing layers can be aligned to be substantially parallel to the optical axes of the polarizing layers.

Owner:BOE TECH GRP CO LTD

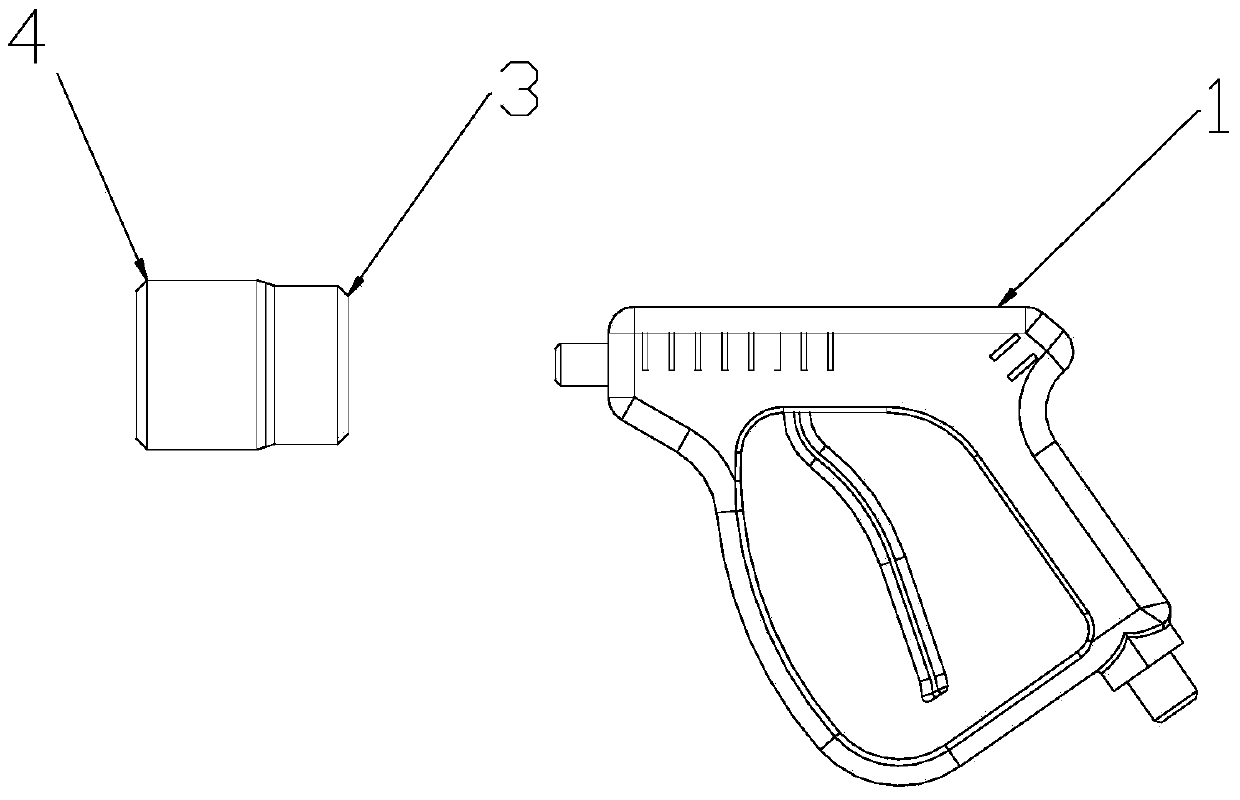

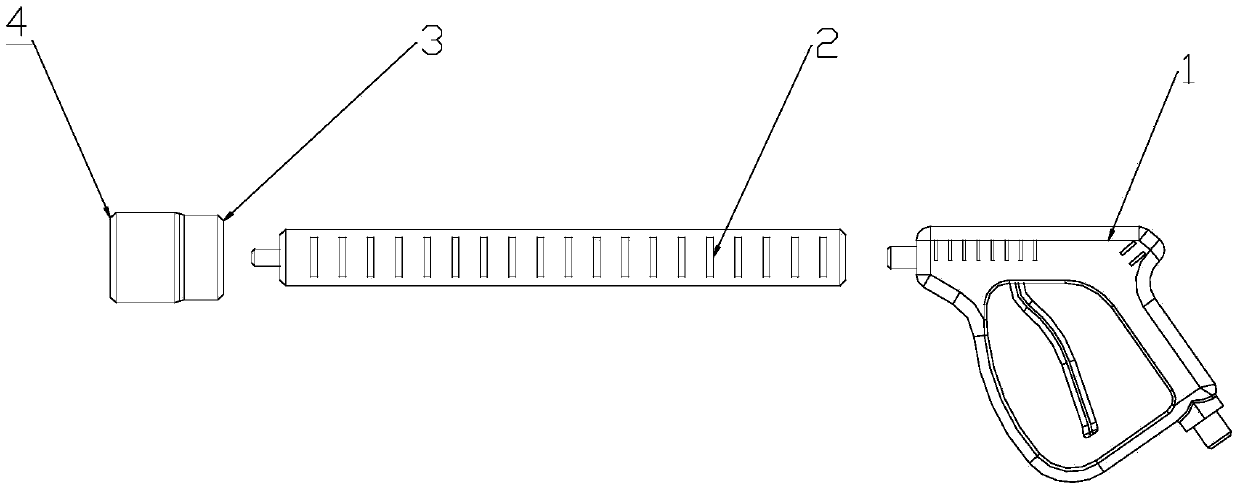

High-pressure airless spray gun without blind spraying corner

InactiveCN103464324AStable forceEliminate the problem of harsh working environmentSingle-unit apparatusDiaphragm pumpSpray coating

The invention discloses a high-pressure airless spray gun without a blind spraying corner. The high-pressure airless spray gun comprises a gun grip and a high-pressure spray nozzle. A pressure-regulating valve is mounted on the high-pressure spray nozzle, an access end of the high-pressure spray nozzle is a connector matched with an exit end of the gun grip, and the exit end of the gun grip is connected with the access end of the high-pressure spray nozzle. The high-pressure airless spray gun further comprises a diaphragm pump driven by a motor. During a spraying operation, the high-pressure airless spray gun sprays coatings directly on the surface of a workpiece to be sprayed and processed by means of taking static pressure generated from the diaphragm pump as driving force to spray the coatings. Due to the fact that compressed air is not taken as the driving force to spray the coatings, rebounding and splashing of the coatings during the spraying process are basically avoided, and coating fog particles sprayed out can smoothly enter corner cracks and edges of the workpiece with less spraying pollution and no dead corner. The high-pressure airless spray gun has the advantage that a sprayed coating is compact, uniform, glossy, high in flatness and the like.

Owner:SHANDONG URBAN MINING ENVIRONMENTAL PROTECTION GRP

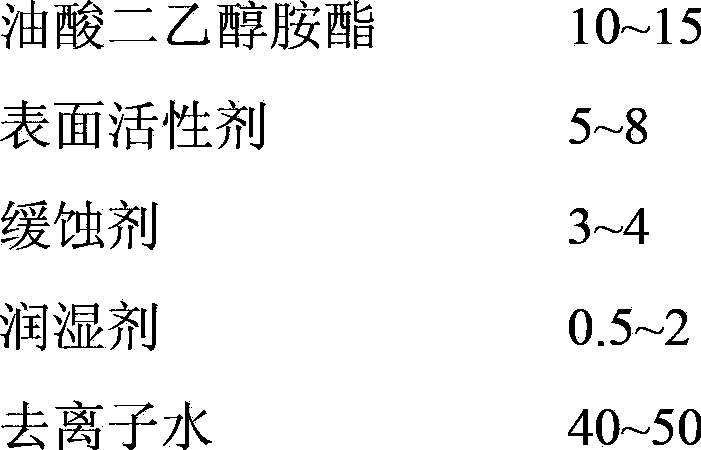

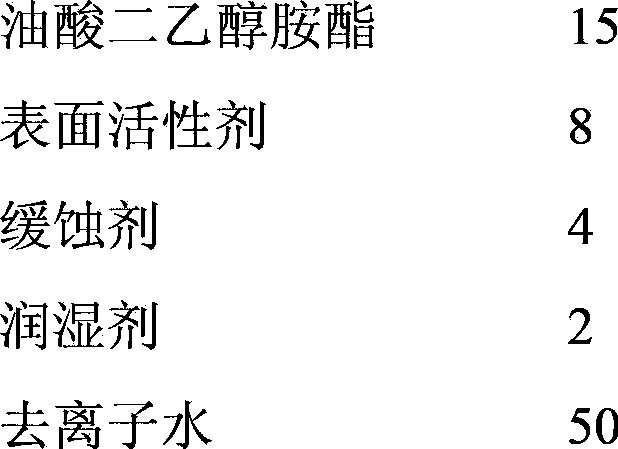

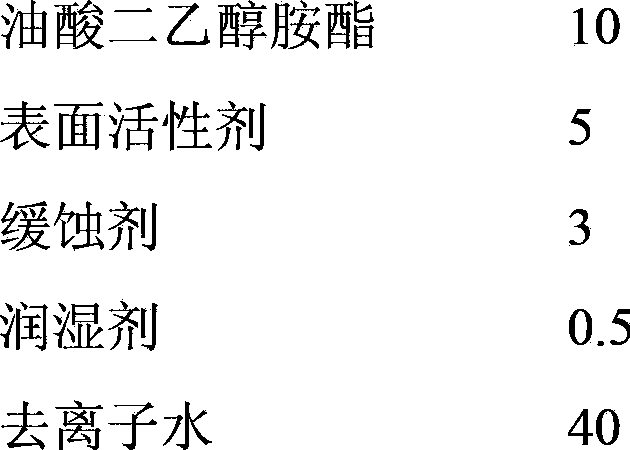

Industrial dewaxing agent

The invention provides an industrial dewaxing agent. The industrial dewaxing agent is prepared by dissolving oleic acid diethanolamine ester, a surfactant, a corrosion inhibiter and a wetting agent in deionized water and then uniformly mixing. The industrial dewaxing agent consists of the following ingredients in parts by mass: 10-15 parts of oleic acid diethanolamine ester, 5-8 parts of the surfactant, 3-4 parts of the corrosion inhibiter and 40-50 parts of deionized water, wherein the oleic acid diethanolamine ester is a reaction product of oleic acid and diethanolamine according to the molar ratio of 1:2; the surfactant comprises span 20, span 60, span 80, tween 40 and tween 60; the corrosion inhibiter is one of benzotriazole, petroleum sulfonate and alpha-hydroxybenzotriazole.

Owner:季爱英

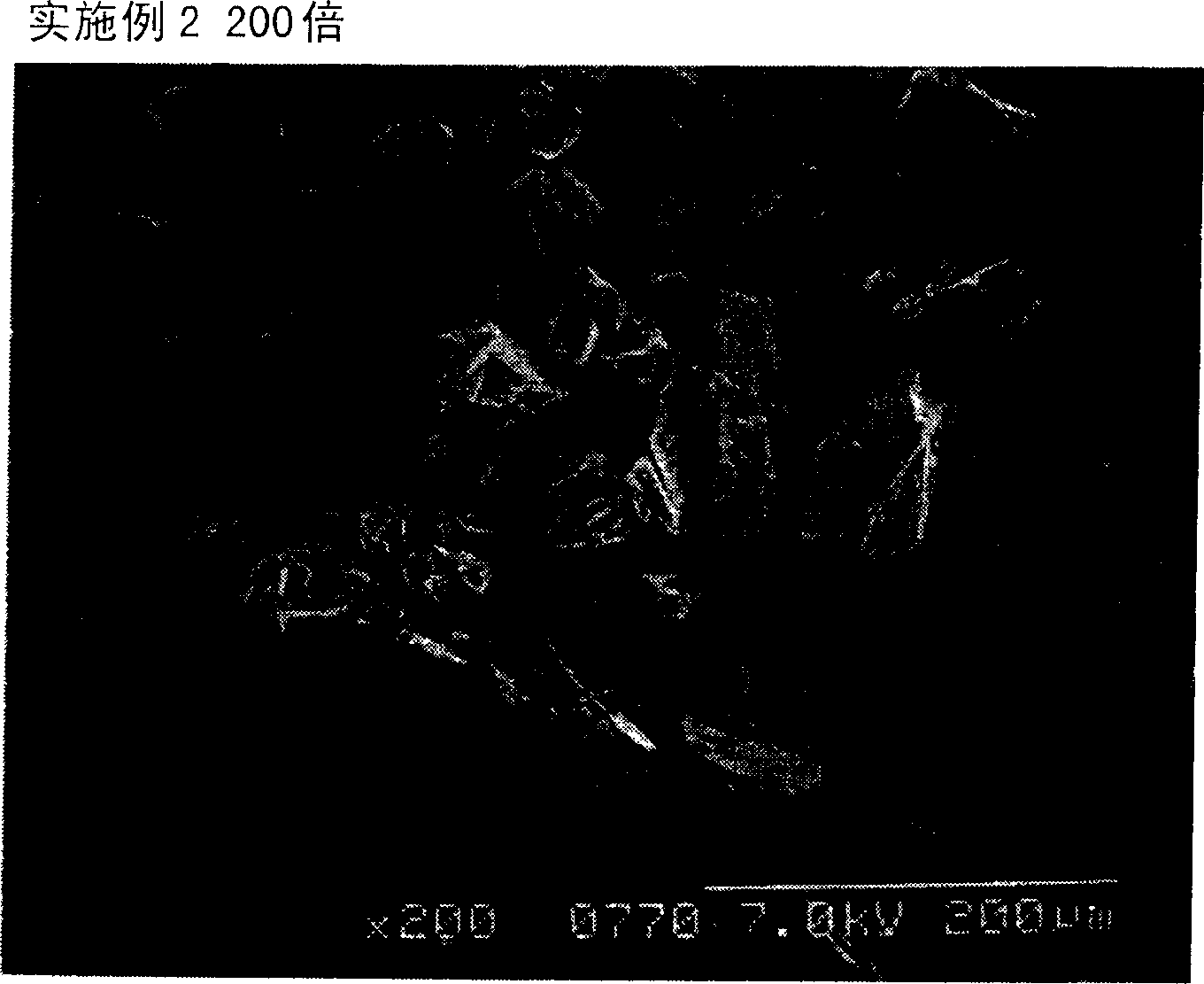

Polished metal brick and production process thereof

The invention discloses polished metal bricks and a production process thereof. The polished metal bricks are made from a green brick material and a glaze slip in a weight ratio of 60-80: 1. The green brick material comprises the following components in percentage by weight: 8 to 15 percent of plaster, 5 to 10 percent of white mud, 1 to 3 percent of talcum, 10 to 20 percent of feldspars, 10 to 15 percent of pottery stone, 30 to 50 percent of ceramic sands and 15 to 20 percent of high-temperature sands; and the glaze slip comprises the following components in percentage by weight: 3 to 10 percent of kaoline, 10 to 20 percent of calcspar, 5 to 15 percent of calcined talcum, 30 to 50 percent of feldspars, 2 to 5 percent of calcined zinc oxide, 0 to 10 percent of barium carbonate, 5 to 15 percent of calcined aluminum and 12 to 42 percent of inert metal powder. The production process comprises the following steps of: subjecting the green brick material to wet-method ball milling, screening, stirring and spray drying sequentially, the press molding the green brick material and drying the molded green brick material to obtain green bricks; subjecting a glaze to wet-method ball milling and screening to obtain the glaze slip; applying the glaze slip on the green bricks; and sequentially sintering, polishing and grinding the green bricks applied with the glaze slip to obtain the product. The polished metal bricks are wearable, shinning and dirt durable and have the effect of metal luster.

Owner:台山市海棠陶瓷有限公司

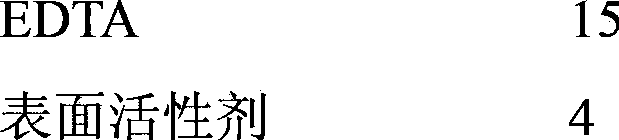

Rust removal cleaning agent

The invention discloses a rust removal cleaning agent, which is prepared by uniformly mixing the following components in parts by mass: 10 to 15 parts of EDTA (ethylene diamine tetraacetic acid), 4 to 10 parts of a surfactant, 1 to 3 parts of bentonite and 3 to 4 parts of a corrosion inhibitor, wherein the surfactant is one of polyoxyethylene stearate and diethylene glycol fatty acid ester; the corrosion inhibitor is one of benzotriazole, petroleum sulfonate, alpha-hydroxybenzotriazole, hexamethylenetetramine, tallow amine and 8-hydroxyquinoline.

Owner:季爱英

Nano leather nourishing essence cream and preparation method thereof

The invention relates to the technical field of daily necessities and particularly discloses nano leather nourishing essence cream and a preparation method thereof. The nano leather nourishing essence cream is prepared from the following components of wool grease, organosilicone, Brazil wax, an emulsifier, water, an environment-friendly penetrant and fluorocarbon resin. The essence cream can easily penetrate into a leather fiber layer, so that a surface curing layer has the effects of excellence, cleanness, water resistance, brightness and the like.

Owner:GUANGZHOU ZUOLI CHEM CO LTD

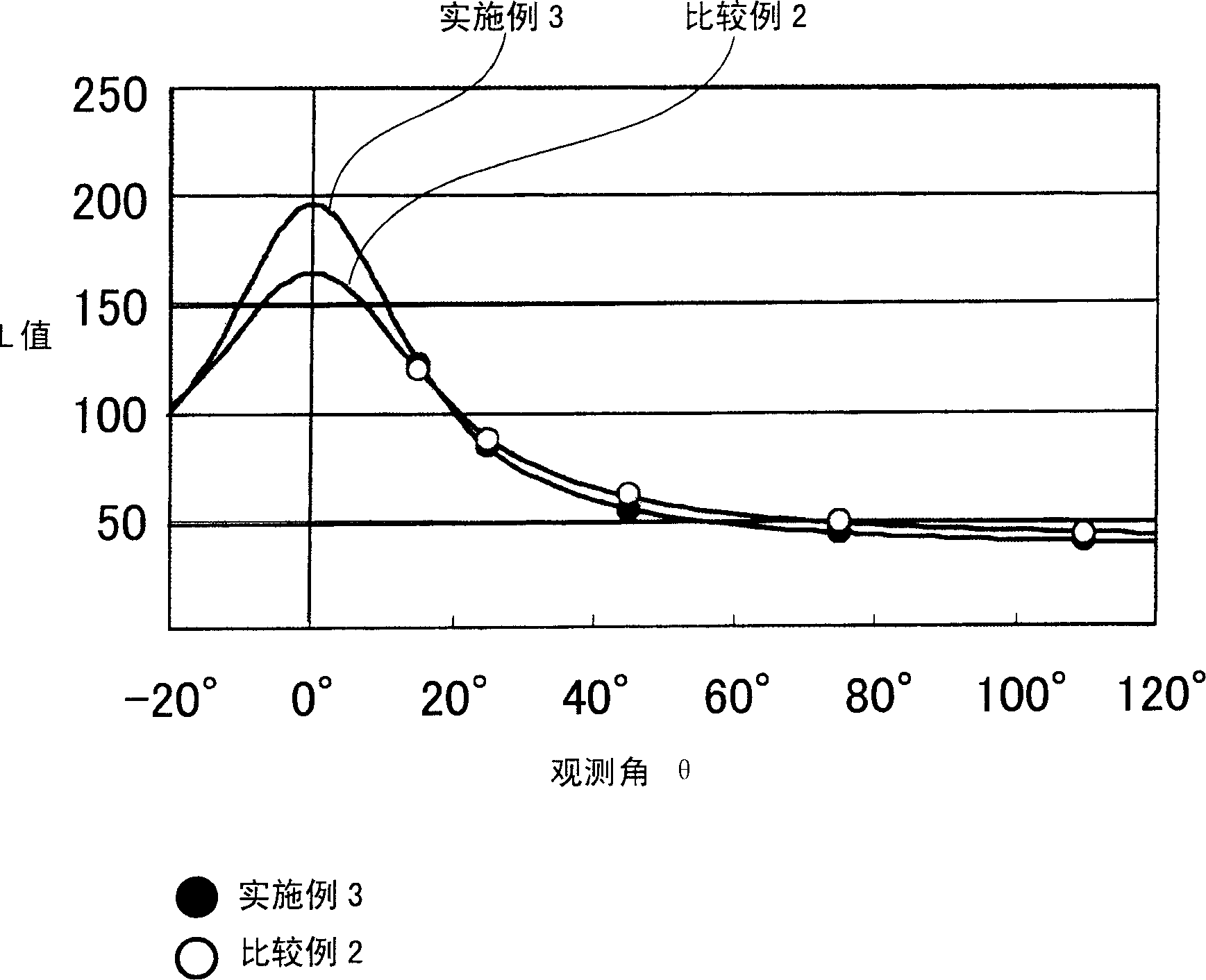

Powder coating composition, process for producing the same and coating film made from the same

An object is to provide a powder coating composition having excellent recyclability, offering superior safety, and containing a flake pigment providing metallic feel, brilliance and brightness to a coating film, as well as a coating film obtained from the former. A powder coating composition containing thermosetting resin powder having a surface adhered to a flake pigment composed of aluminum flake having an average particle size of 1 to 100 mum using an adhesive binder composed of a resin dissolved in a solvent which does not dissolve a thermosetting resin, as well as a coating obtained from the former are provided.

Owner:TOYO ALUMINIUM KK

Process of producing viscose fiber with bamboo material

InactiveCN101046003AImprove washing effectImprove wear resistanceArtificial filaments from viscoseViscose fiberMaterials science

The process of producing viscose fiber with bamboo material includes the first preparing bamboo pulp with bamboo material and through the steps of preparing material, steaming, eliminating sand, concentrating, chloralkalizing, bleaching, etc; and the subsequent preparing viscose fiber with the bamboo pulp and through the steps of squeezing, ageing, yellowing, grinding, dissolving, mixing, filtering, etc. The process maintains the antiseptic matter in bamboo fiber farthest to make the produced viscose fiber possess antiseptic function, and the produced viscose fiber has also high water washability, high wear resistance and lasting bacteria resistance, and is smooth, cool, fine and bright.

Owner:CHTC HELON

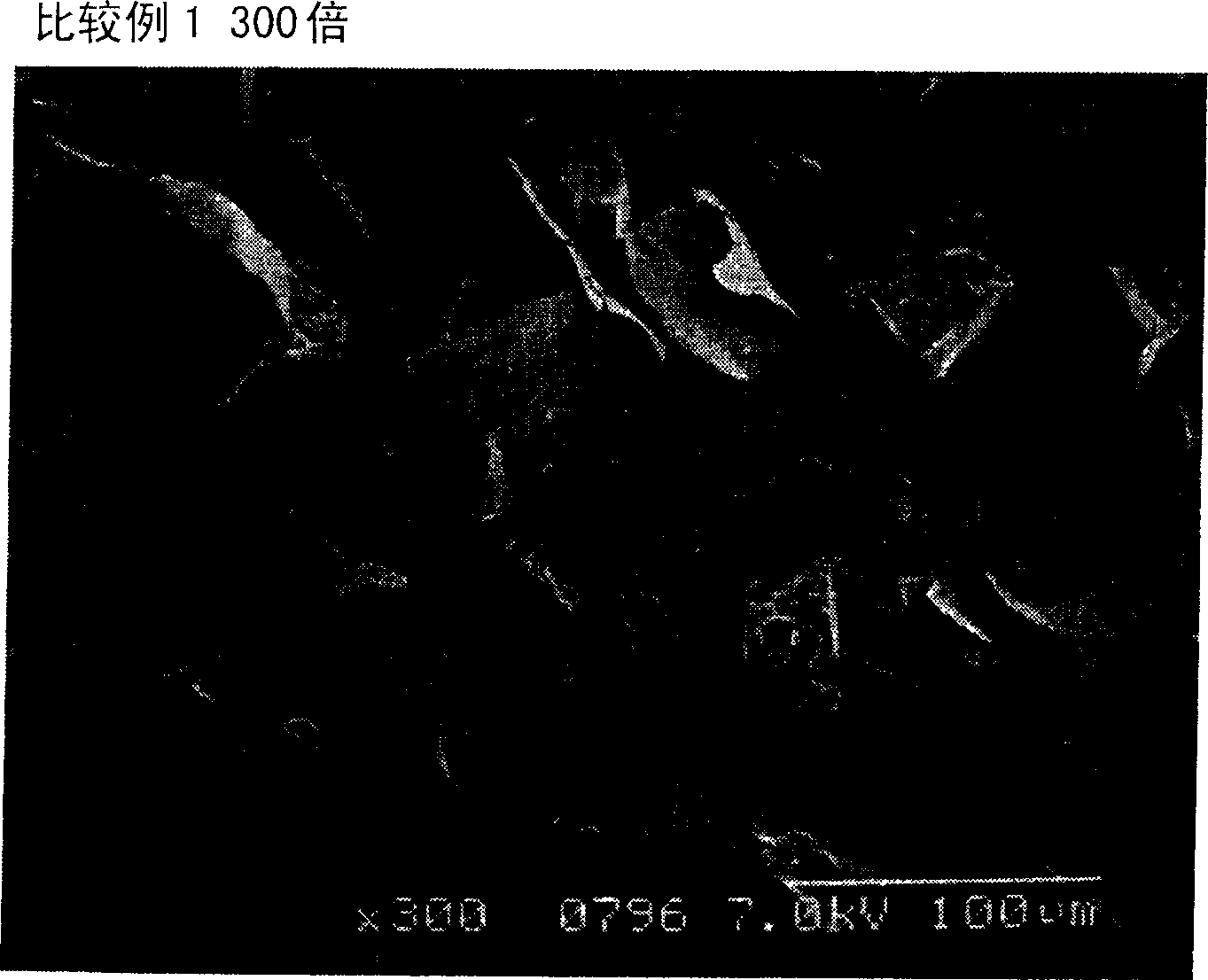

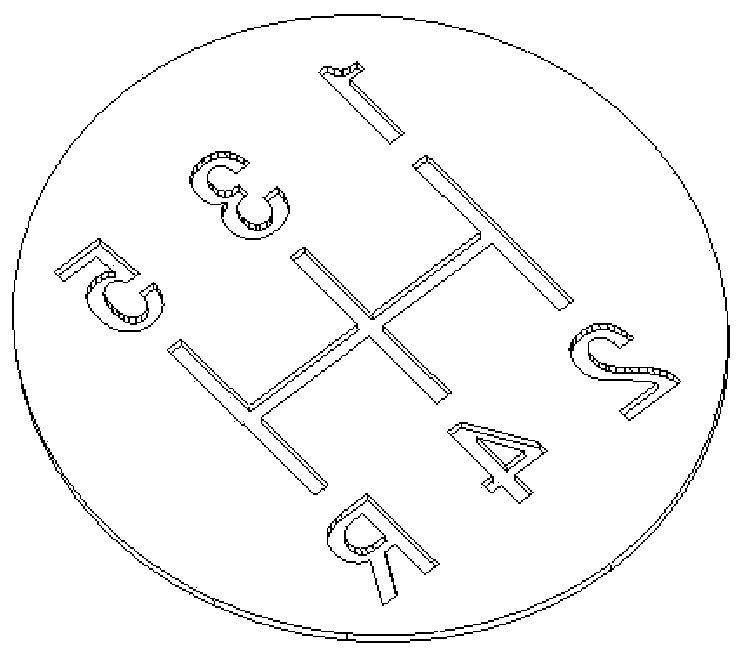

Polyurethane internal wall building mildew-proof paint

InactiveCN106700886AImprove solubilityActs as a film-forming aidFireproof paintsAntifouling/underwater paintsWater basedAcrylic resin

The invention discloses polyurethane internal wall building mildew-proof paint. The polyurethane internal wall building mildew-proof paint is mainly prepared from water-cured polyurethane, water-based acrylic resin and a mildew-proof agent; disadvantages of single polyurethane or single polyacrylic resin, such as poor stability, white thickening property and gloss retention of a film, high solid content and a narrow application range, are overcome; the main components have a complementary action on properties. The composite paint combines advantages of the polyurethane and the acrylic resin and has the characteristics of mildew prevention, wearing resistance, corrosion resistance and brightness, softness and elasticity, good water resistance and mechanical properties, excellent weather resistance and the like, and also has high glossiness, high elasticity and excellent weather resistance. Compared with other traditional polyurethane paint, the polyurethane internal wall building mildew-proof paint has the advantages of convenience for construction, no toxin and no pollution, and is more environment-friendly and the like.

Owner:广西宾阳县荣良农业科技有限公司

Waterborne polyurethane composite paint

The invention discloses waterborne polyurethane composite paint which is characterized by being prepared by the raw materials in parts by weight as follows: 40-60 parts of waterborne polyurethane emulsion, 12-25 parts of polyacrylic acid, 20-30 parts of polyisocyanate, 30-40 parts of cross-linking agent, 10-15 parts of stuffing and 80-100 parts of water. The waterborne polyurethane composite paint prepared by the invention combines the advantages of polyurethane paint and polypropylene paint, and has the characteristics of good wear-resistance, corrosion resistance, bright resistance, waterproofness and mechanical property. In addition, a polyurethane film can be made as a film with high hardness or an elastic film with good flexibility, so that the application range of the polyurethane paint is greatly enhanced.

Owner:JIANGSU JIFU NEW MATERIAL

Bamboo viscose fibre and its preparing method

InactiveCN1194119CRetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

Black shoe polish

InactiveCN106479381ADecontaminationWaterproofInorganic/elemental detergent compounding agentsBiocideParaffin waxShoe polish

The invention discloses black shoe polish. The black shoe polish is prepared from, by weight, 8-15 parts of paraffin, 10-20 parts of carnauba wax, 10-20 parts of turpentine oil, 8-12 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 5-15 parts of nigrosine, 5-10 parts of lemon oil, 5-10 parts of dimethicone, 1-2 parts of tea tree essential oil, 1-3 parts of xanthan gum, 0.1-0.5 part of sodium dioctylsulfosuccinate, 0.05-0.1 part of pyrethrin, 0.05-0.1 part of luteolin and 40-70 parts of water. The black shoe polish has the effects of removing contaminations, resisting water, insects and molds and achieving sterilization and lucency, a leather shoe is soft, clean, moistened and free of oiliness after the black shoe polish is adopted, the service life of the leather shoe is prolonged, and the mechanical strength of the leather shoe is improved.

Owner:LIUZHOU LIJIE TECH

Method for glazing stone

The invention discloses a method for glazing a stone. The method comprises the process steps of: preparing the stone, preparing a ceramic glaze, regulating a shrinkage and expansion ratio between the glaze and the stone, and glazing and baking the stone, wherein the step of preparing the stone specifically comprises the steps of selecting the stone and then removing residues attached to the surface of the stone; the step of preparing the ceramic glaze specifically comprises the step of preparing main materials and auxiliary materials to achieve optimal baking effect; the step of regulating the shrinkage and expansion ratio between the glaze and the stone is performed to avoid separation after the stone and the glaze are baked; the step of glazing the stone specifically comprises the step of attaching the prepared glaze to the surface of the stone after the removal of the residues on the surface of the selected stone; and the step of baking the stone specifically comprises the step of placing the stone attached with the glaze into a furnace for baking at the temperature of 450 to 1,200 DEG C. The method for glazing the stone has the advantages that: procedures are simple; cost is low; and a novel ceramic decoration material prepared by the method has a more gleaming surface, effect remarkably different from that shown by all the conventional market products, and very high novelty.

Owner:俞梦成

Automobile engine cabin coating agent and preparation method thereof

InactiveCN111205764AIncrease brightnessHigh hardnessAntifouling/underwater paintsPaints with biocidesControl theoryPollution prevention

The invention discloses an automobile engine cabin coating agent and a preparation method thereof. The automobile engine cabin coating agent is prepared from the following raw materials in percentageby weight: 70 to 90 percent of isopropanol, 1 to 3 percent of a leveling agent, 1 to 3 percent of a wetting dispersant, 7 to 23 percent of organic silicon resin and 0.1 to 1 percent of a preservative.According to the automobile engine cabin coating agent, organic silicon resin is used as a carrier, the automobile engine cabin coating agent can be cured at normal temperature, and has the characteristics of high film brightness, high hardness, good durability, excellent antifouling effect and the like; long-acting lasting protection is provided for the outer surface of an engine cabin, the constructed cabin surface has the characteristics of brightness, smoothness and pollution prevention, cabin aging, yellowing, cracking and the like are delayed, the later maintenance cost is reduced, thecabin can be bright as new only through simple washing, a formed film layer is transparent after being cured, and the original color and glossiness of the cabin are not affected.

Owner:GUANGZHOU HELIOSON CAR CARE

Preparation method of ceramic tile with geometric textures and ceramic tile

The invention discloses a preparation method of a ceramic tile with geometrical textures and the ceramic tile, and the preparation method comprises the following steps: A, mixing a ceramic backing material raw material and a black pigment to prepare a black backing material with the water content of 13-15%, and carrying out pressure granulation on the ceramic backing material raw material and a white pigment to prepare a white granular material, adding a part of the black backing material into the white granules, and uniformly mixing to obtain a mixture; b, distributing the remaining black backing material to obtain a backing material layer, distributing the mixture on the surface of the backing material layer to obtain a surface material layer, and pressing and drying to obtain a spot green body; and C, printing concave-convex geometric texture patterns on the whole surface of the spot green body through roller printing. According to the preparation method of the ceramic tile with thegeometric textures, the texture of the green body can be presented while the bright effect and the matte effect are combined and presented on the tile surface, and the ceramic tile prepared through the preparation method of the ceramic tile with the geometric textures is good in overall texture, high in stereoscopic impression and rich in layering sense.

Owner:FOSHAN PINWEIXIAN CERAMICS CO LTD

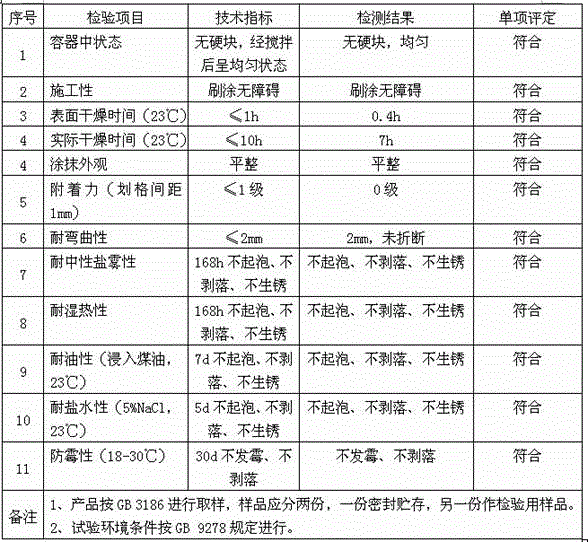

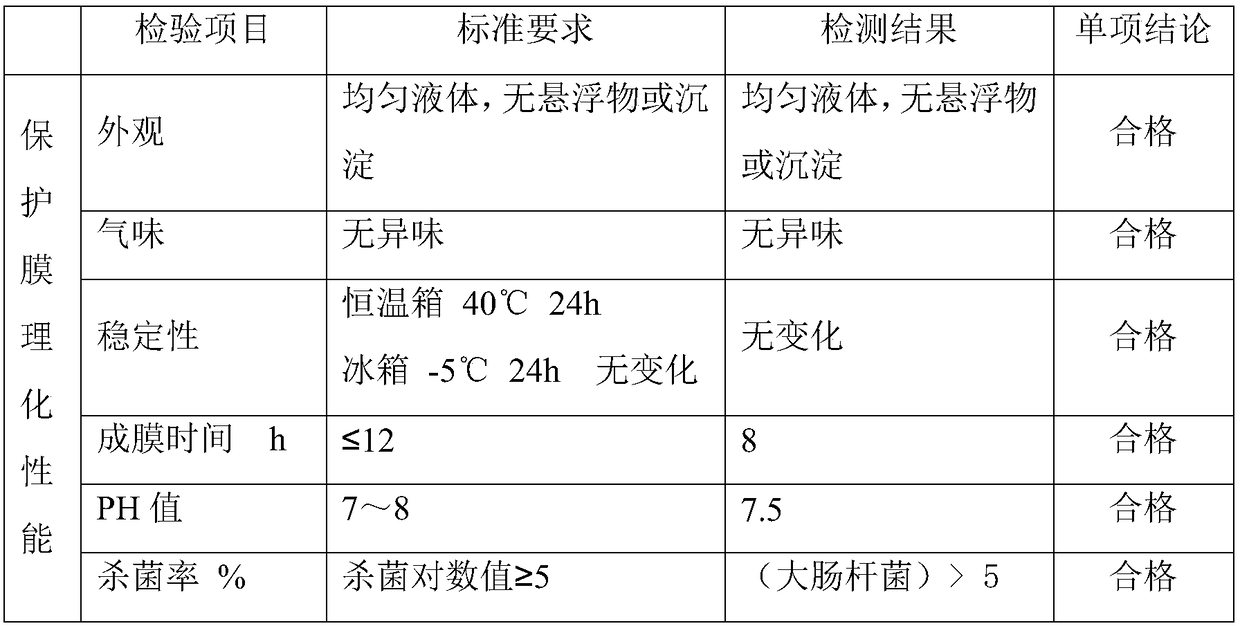

Wall material protecting film and preparation method thereof

InactiveCN109486316AWith anti powderBrightAntifouling/underwater paintsPaints with biocidesTectorial membraneMaterials science

The invention belongs to the technical field of wall material protection and particularly relates to a wall material protecting film and a preparation method thereof. Due to the fact of containing odor, formaldehyde, benzene, methylbenzene, xylene, VOC (volatile organic compounds) and bacteria, existing decorative wall materials can bring harm to users. The wall material protecting film is composed of raw materials including, by weight part, 250-350 parts of emulsion, 30-50 parts of nanometer photocatalysts, 15-250 parts of formaldehyde catching agent, 70-120 parts of active nano-silver ions,and deionized water. The wall material protecting film is less prone to powdering, high in glossiness, good in hand feeling, washable, deodorant, bactericidal and capable of removing formaldehyde, ammonia, benzene, methylbenzene, xylene, VOC and the like, purifying indoor air and beautifying the environment.

Owner:秦皇岛美博士新型材料科技有限公司

Timepiece faceplate, and electrical timepiece equipped with solar battery

InactiveCN103576529ADoes not impede power generation efficiencyBrightVisual indicationElectronic time-piece structural detailsEngineeringSolar battery

To provide a timepiece faceplate having appropriate light permeability with excellent aesthetic appearance having glittering property, and an electrical timepiece equipped with a solar battery, a timepiece faceplate of the invention includes a faceplate main body that has light permeability, and a glittering layer that is provided on either one of a front surface side and a back surface side of the faceplate main body and is configured by dispersing a glittering powder into a light permeable resin. The glittering powder is configured by laminating a metallic oxide film above one surface side of a plate shaped base material, which has light permeability, and the glittering powder is a lamination powder that an average grain diameter is more than 10 mum and less than 90 mum.

Owner:SEIKO EPSON CORP

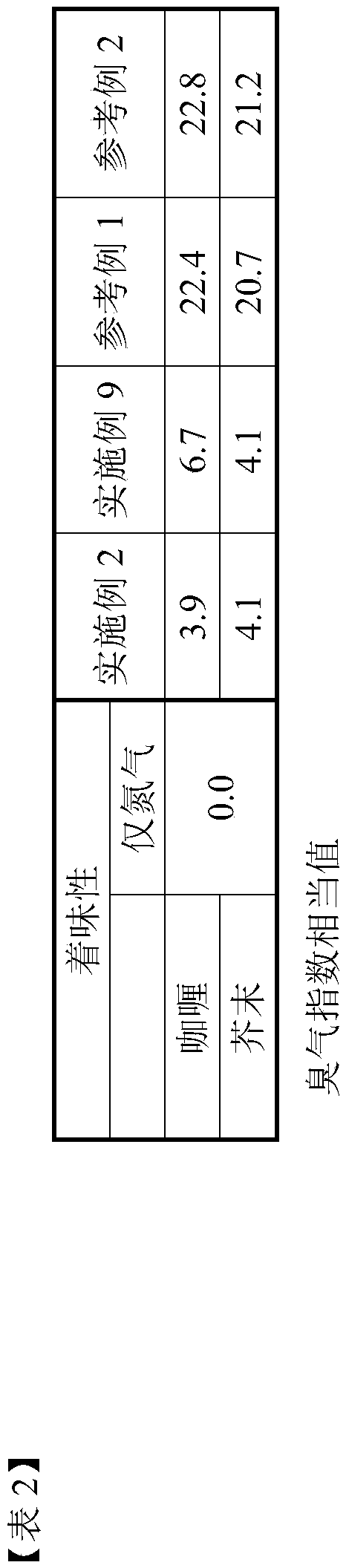

Fluororubber molded article

Owner:DAIKIN IND LTD

Polyurethane building wall edge and corner coating and production method thereof

InactiveCN106675367AHigh mechanical strengthImprove adhesionAntifouling/underwater paintsPaints with biocidesWater leakageAcrylic resin

The problem that a coating used in the prior art has an effect on a large area of building wall, while not always has a function of preventing and controlling water leakage at butt seams and corners, and particularly water leakage is prone to happen at the basement and some seams is always hard to solve. The provided coating is high in adhesive force and good in chemical resistance, acid-base resistance, water resistance, solvent resistance, temperature resistance, weathering resistance and stain resistance, provides a coating film long in life, and can protect the building edges and corners from leaking or cracking. The coating comprises main components of water cured polyurethane, aqueous acrylic resin and additives. The polyurethane building coating is good in bonding property, and is eco-friendly, safe, pollution-free, and toxicity-free.

Owner:GUANGXI JISHUN ENERGY TECH

Implementation process of highlight silver three-dimensional pattern

InactiveCN109910487AStereo hasBrightDecorative surface effectsOrnamental structuresOptoelectronicsCoating

The invention discloses an implementation process of a highlight silver three-dimensional pattern. The implementation process comprises the following steps of (1) selecting a transparent injection molding product, and marking a sunken marking pattern on the back surface of the transparent injection molding product, wherein the back surface of the transparent injection molding product is a plane, and the front surface of the transparent injection molding product is a convex surface; (2) printing the back surface of the transparent injection molding product, and printing all parts except for themarking pattern; (3) spraying UV base coating on the marking pattern on the back surface of the transparent injection molding product; (4) performing vacuum aluminum electroplating on the back surface of the transparent injection molding product; and (5) spraying setting coating on the marking pattern on the back surface of the transparent injection molding product. According to the implementation process of the highlight silver three-dimensional pattern, the marking pattern has three-dimensional and bright effects when being seen from the front surface.

Owner:JIANGSU XINSIDA ELECTRONICS CO LTD

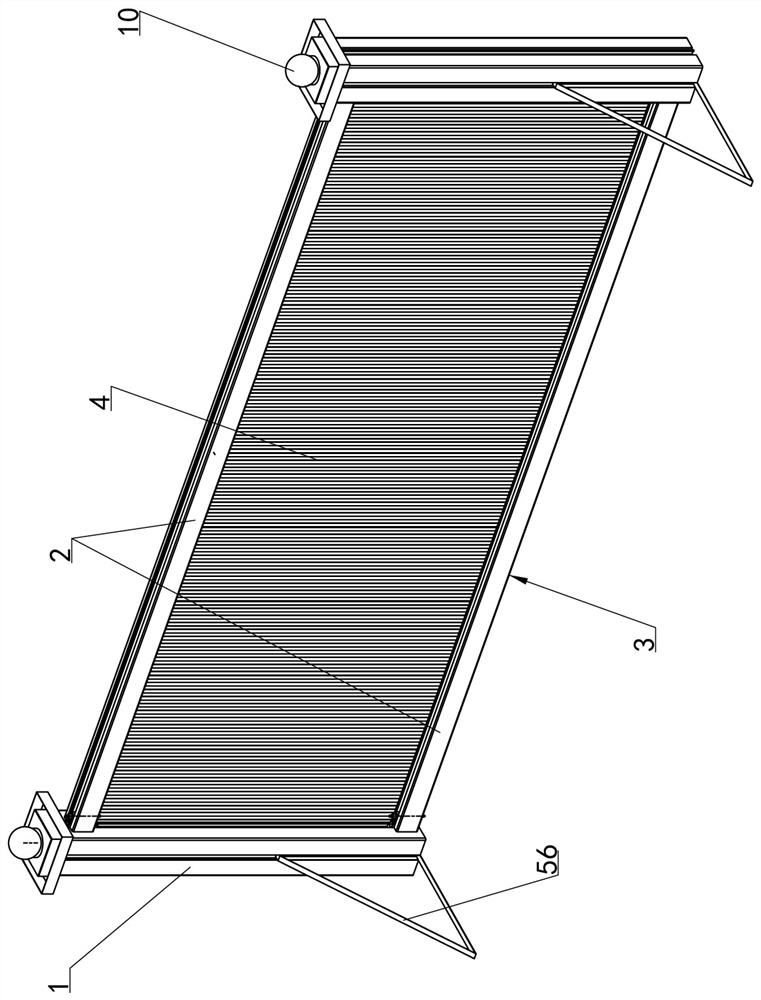

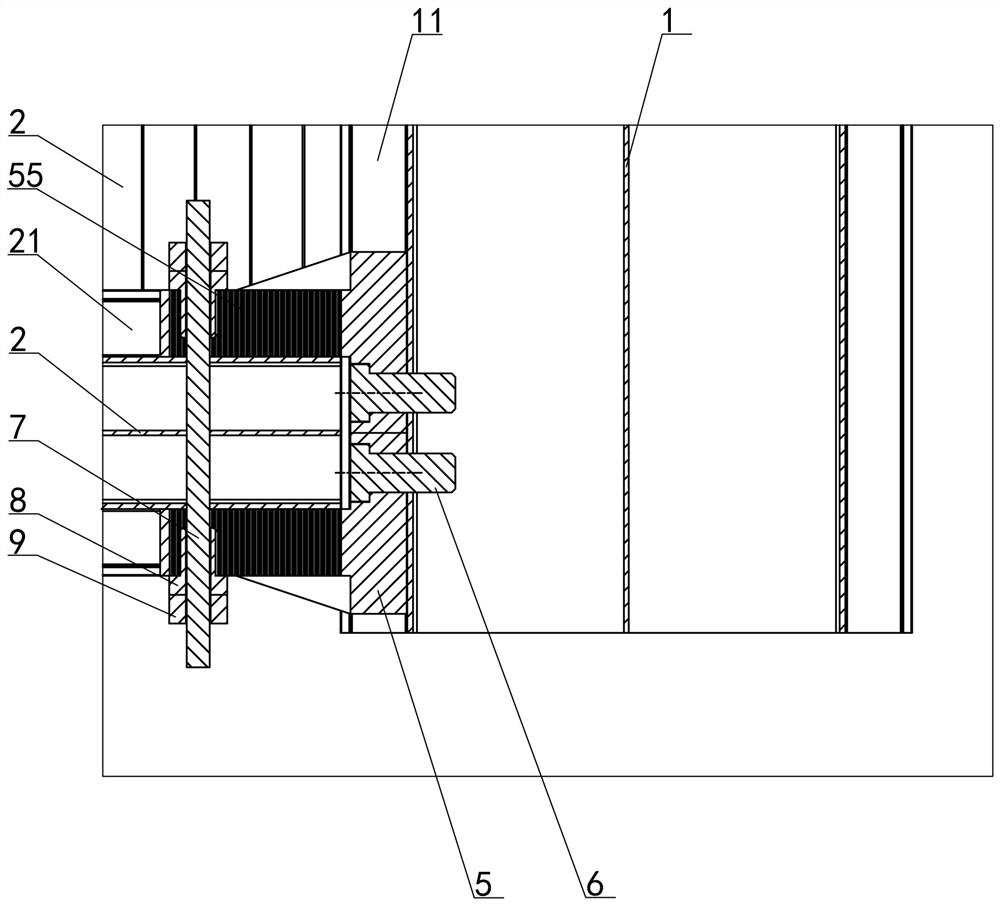

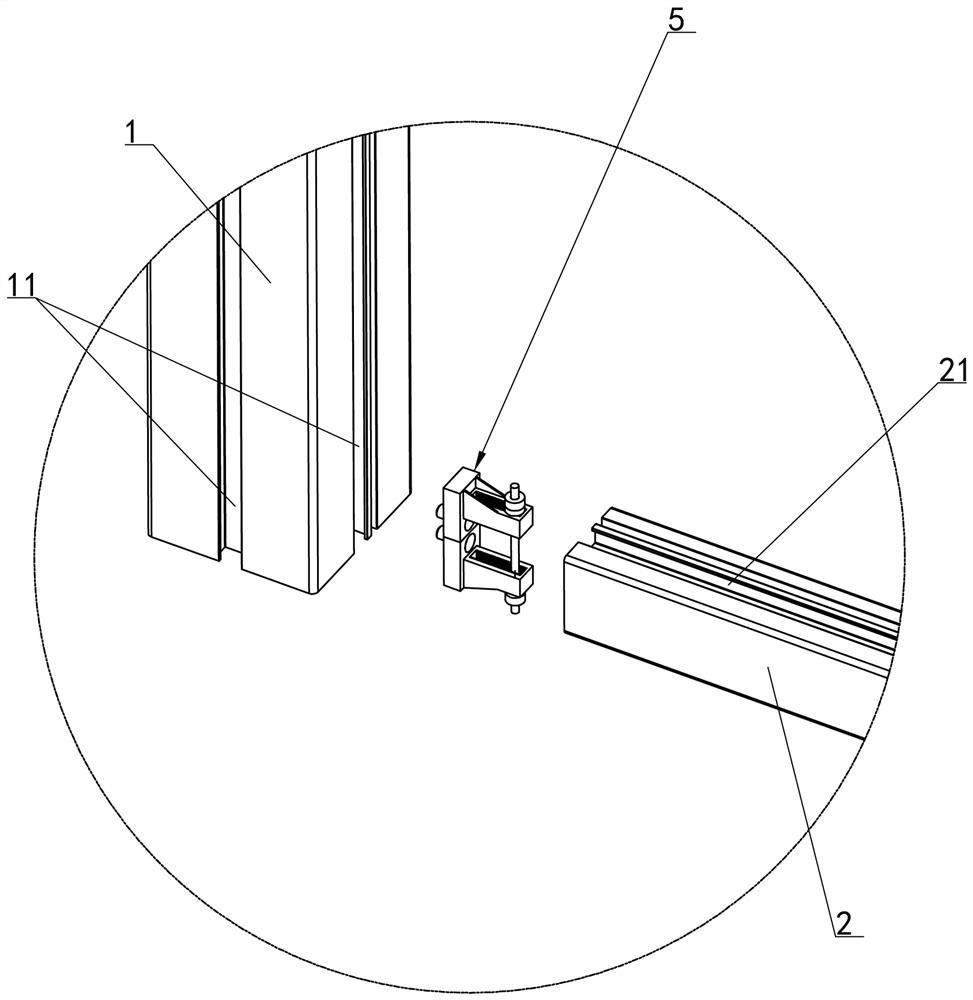

Portable plastic fence L-shaped connecting mechanism

InactiveCN113846903AImprove fastnessHigh strengthLighting elementsFencingStructural engineeringMechanical engineering

Owner:ZHEJIANG HENGDA PLASTIC MOLD

Polished metal brick and production process thereof

The invention discloses polished metal bricks and a production process thereof. The polished metal bricks are made from a green brick material and a glaze slip in a weight ratio of 60-80: 1. The green brick material comprises the following components in percentage by weight: 8 to 15 percent of plaster, 5 to 10 percent of white mud, 1 to 3 percent of talcum, 10 to 20 percent of feldspars, 10 to 15percent of pottery stone, 30 to 50 percent of ceramic sands and 15 to 20 percent of high-temperature sands; and the glaze slip comprises the following components in percentage by weight: 3 to 10 percent of kaoline, 10 to 20 percent of calcspar, 5 to 15 percent of calcined talcum, 30 to 50 percent of feldspars, 2 to 5 percent of calcined zinc oxide, 0 to 10 percent of barium carbonate, 5 to 15 percent of calcined aluminum and 12 to 42 percent of one or more than one inert metal powder selected from the group of copper, silver, palladium, rhodium, ruthenium, iridium or osmium. The production process comprises the following steps of: subjecting the green brick material to wet-method ball milling, screening, stirring and spray drying sequentially, the press molding the green brick material and drying the molded green brick material to obtain green bricks; subjecting a glaze to wet-method ball milling and screening to obtain the glaze slip; applying the glaze slip on the green bricks; and sequentially sintering, polishing and grinding the green bricks applied with the glaze slip to obtain the product. The polished metal bricks are wearable, shinning and dirt durable and have the effect of metal luster.

Owner:台山市海棠陶瓷有限公司

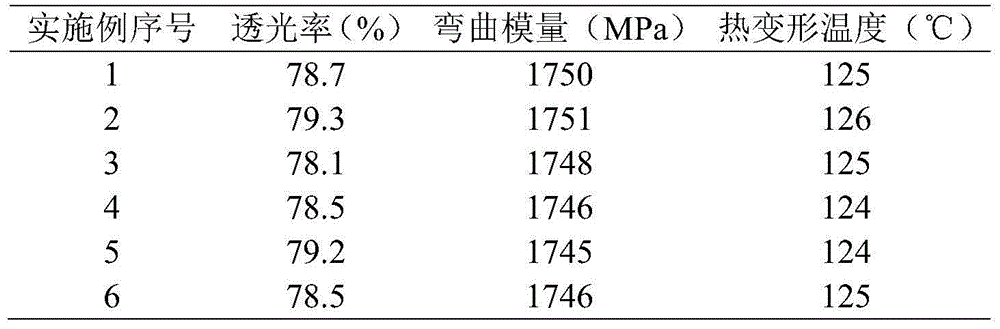

Novel PCR (polymerase chain reaction) tube and preparation method thereof

The invention discloses a novel PCR (polymerase chain react) tube. A formula comprises the following components in parts by weight: 20-30 parts of PP (polypropylene) materials, 0.01-0.1 part of a transparent agent, 0.01-0.1 part of diffusion oil, wherein the PP materials consist of homopolymerization injection-molding-level and transparent-level PP materials. The invention further discloses a preparation method of the novel PCR tube. According to the novel PCB tube and the preparation method, transparency of the finished product is increased, so that reactants and reaction degree in the tube can be conveniently observed, and experiment progress is controlled; moreover, the novel PCR tube is strengthened in flexibility and is not easy to break, so that requirements of PCR are satisfied, and an experimental success rate is improved.

Owner:海南科晶生物技术有限公司

Surface cleaning agent for daily use

InactiveCN103820230ANo escapeBrightInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAcetic acidSurface cleaning

The invention discloses a surface cleaning agent for daily use. The surface cleaning agent is prepared by uniformly mixing a polyoxyethylene ether surfactant, ethylenediamine tetraacetic acid and tetrasodium pyrophosphate according to the following mass part: 30-45 parts of the polyoxyethylene ether surfactant, 10-15 parts of ethylenediamine tetraacetic acid, and 4-10 parts of tetrasodium pyrophosphate, wherein the polyoxyethylene ether surfactant is fatty alcohol-polyoxyethylene ether preferably.

Owner:季爱英

Powder coating composition, process for producing the same and coating film made from the same

An object is to provide a powder coating composition having excellent recyclability, offering superior safety, and containing a flake pigment providing metallic feel, brilliance and brightness to a coating film, as well as a coating film obtained from the former. A powder coating composition containing thermosetting resin powder having a surface adhered to a flake pigment composed of aluminum flake having an average particle size of 1 to 100 mum using an adhesive binder composed of a resin dissolved in a solvent which does not dissolve a thermosetting resin, as well as a coating obtained from the former are provided.

Owner:TOYO ALUMINIUM KK

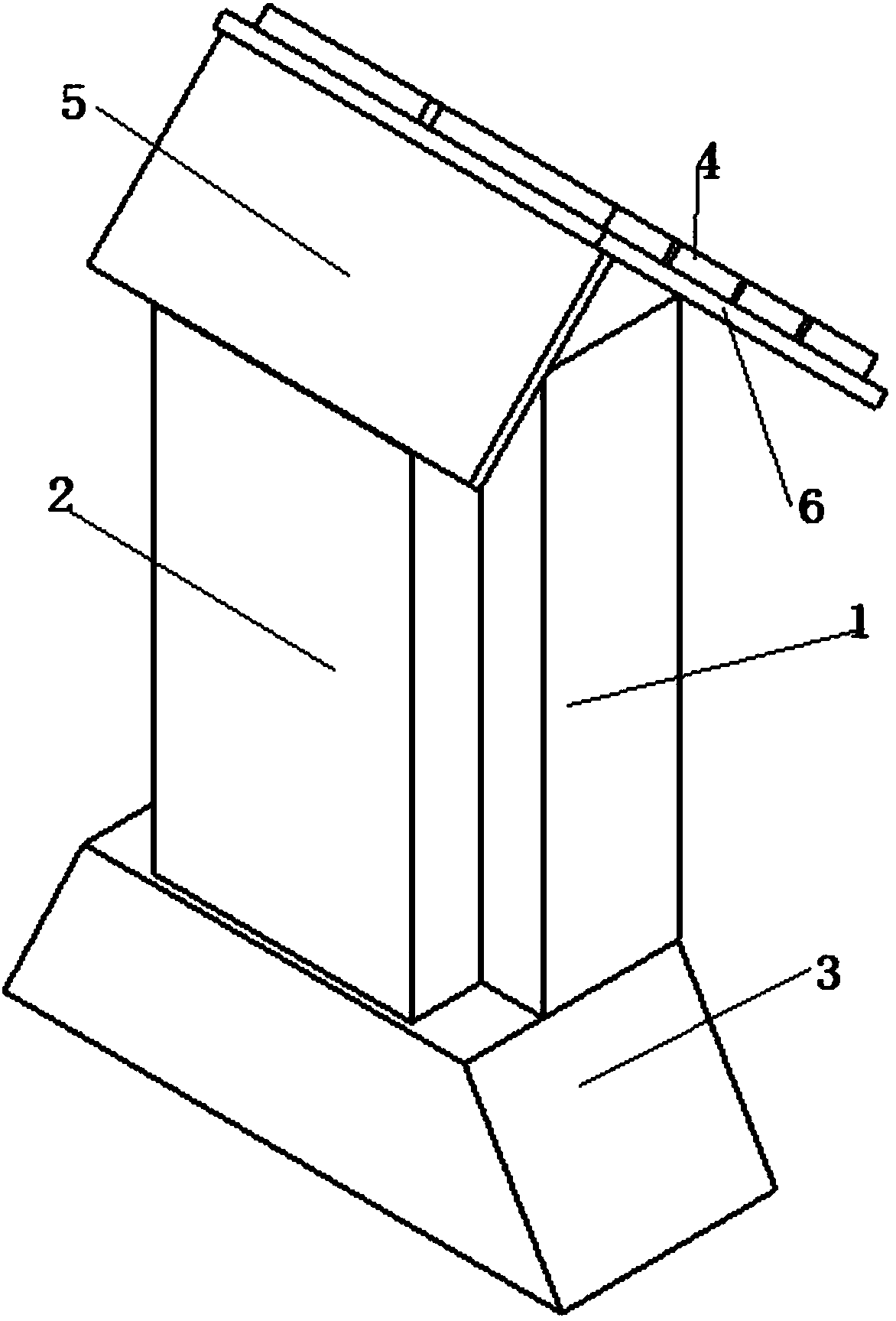

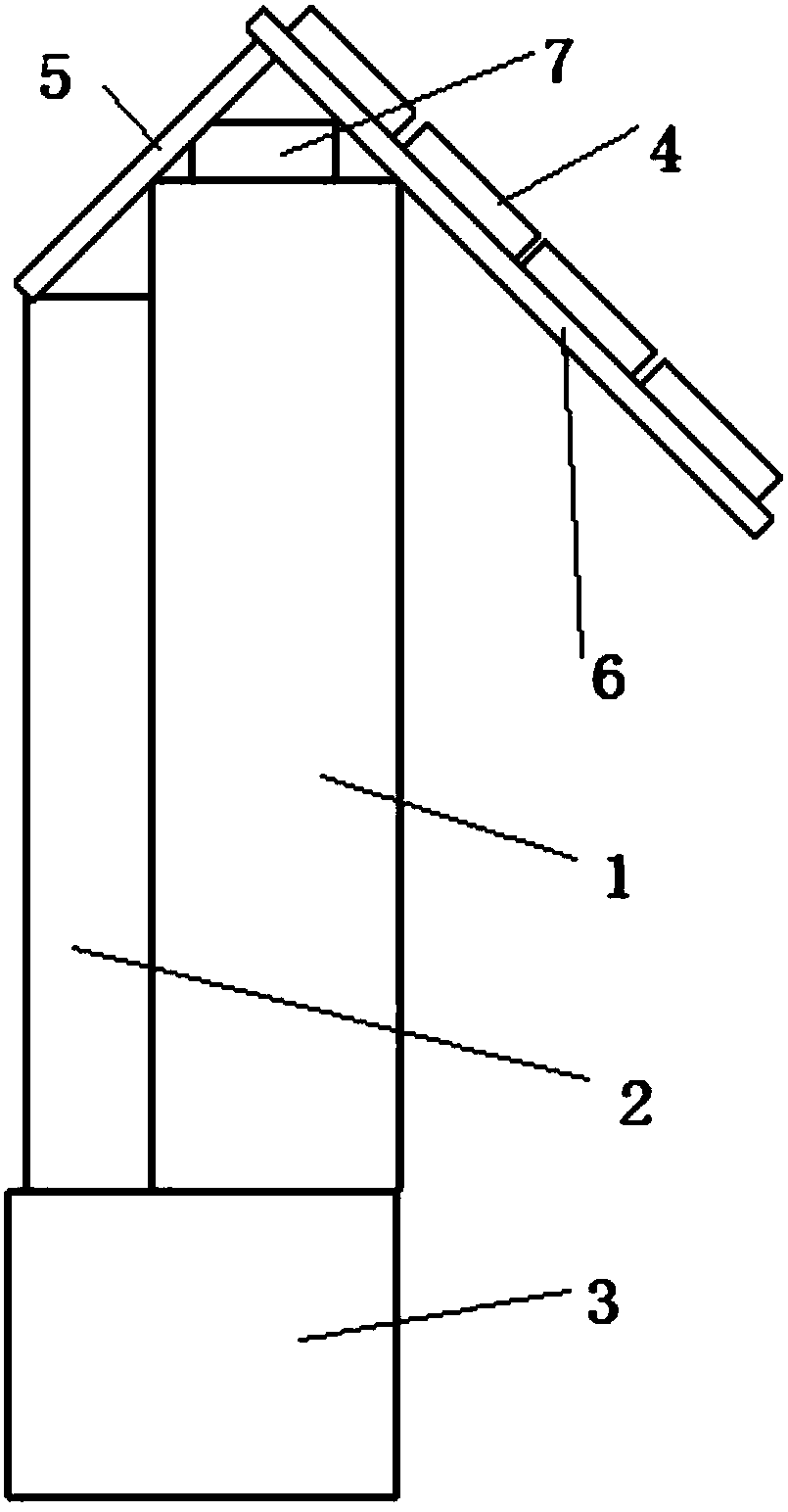

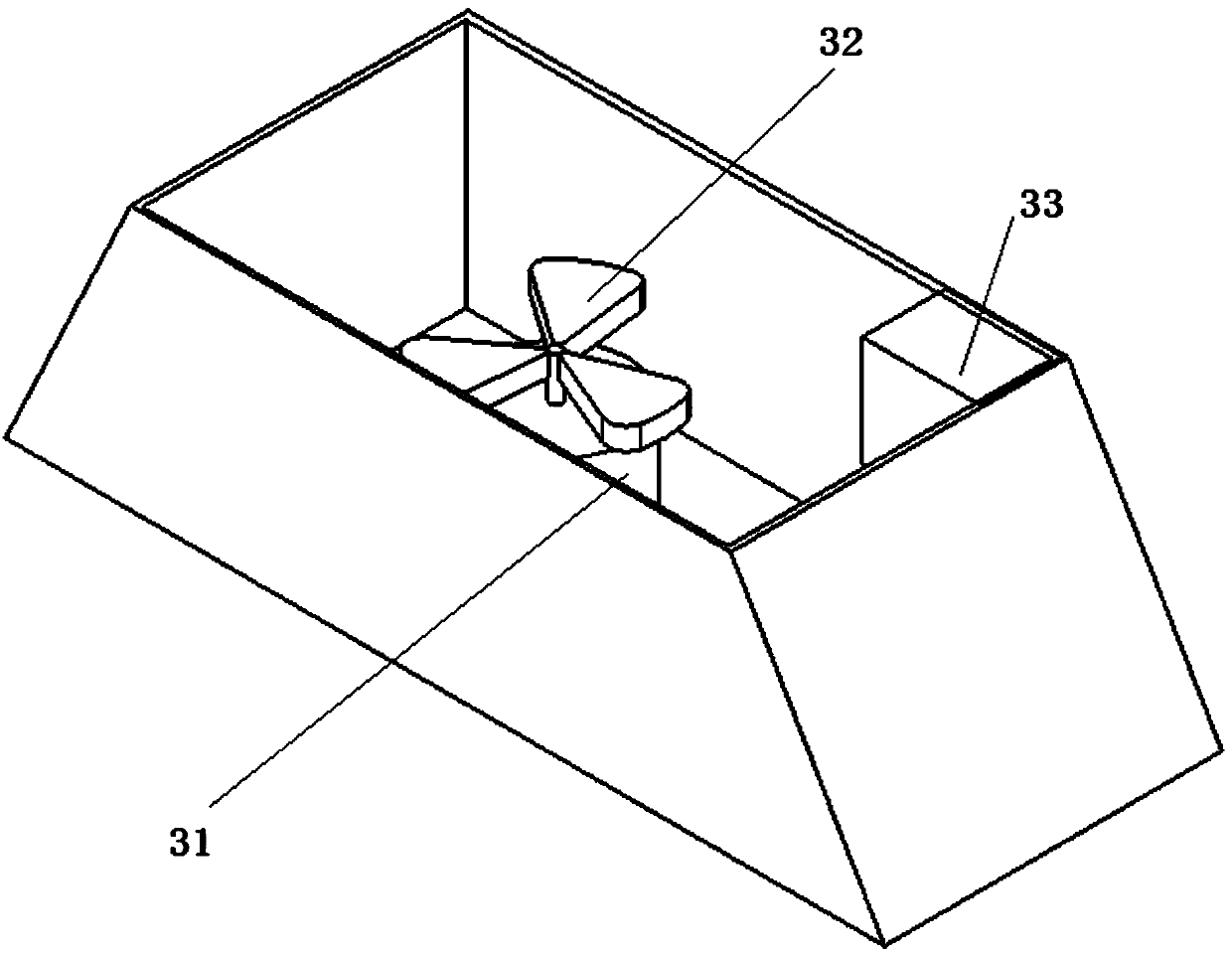

Landscape type solar electronic signboard

InactiveCN107863019AWith anti-power-off functionBrightBatteries circuit arrangementsElectric powerLight sensingElectron

The invention provides a landscape type solar electronic signboard and belongs to the field of signboards. The landscape type solar electronic signboard comprises a signboard body and a base and is characterized in that a glass box part is arranged on the signboard body in an embedded manner, the glass box part comprises a glass box, a pattern and text plate connected with the bottom, a light-sensing detection switch and a fluorescent powder box, the bottom of the glass box is provided with a plurality of through holes, the upper portion of the base is connected with the signboard body and thebottom of the glass box, a first retaining plate and a second retaining plate are arranged at the top of the signboard body, a solar panel is arranged on the second retaining plate, a first storage battery is arranged in a space formed by the top of the signboard body, the first retaining plate and the second retaining plate, a cavity is arranged inside the base, a motor and a second storage battery are arranged in the cavity, and a fan is connected to the motor, the fan directly faces the through holes. The landscape type solar electronic signboard can emit light at night to serve as the landscape, is capable of preventing power failure, uses environment-friendly solar energy, and can use fluorescent powder to emit light when both solar energy and a power grid power supply fail.

Owner:安徽纽创自动化装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com