Patents

Literature

41results about How to "Metallic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technological process for lauminizing or coppering on aluminium or aluminium-magnesium alloy substrate

InactiveCN101067204ANo pollutionOvercoming the common magnetic effect problemVacuum evaporation coatingPretreated surfacesCoated surfaceSputtering

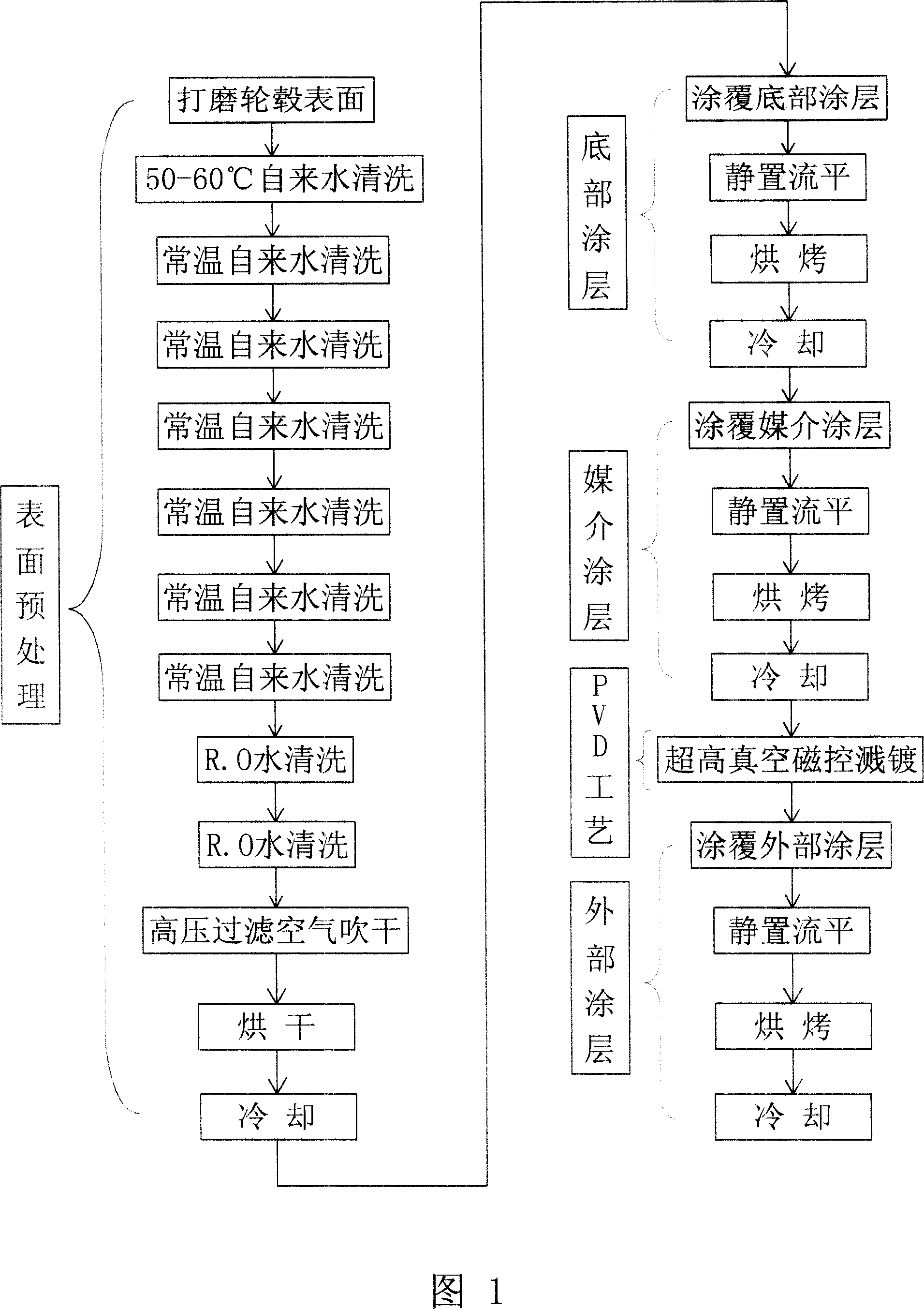

The technological process of forming aluminum or copper coating on aluminum or Al-Mg alloy base material includes the following steps: 1. polishing the surface and washing; 2. applying color paint containing acrylate resin to form the base coating; 3. applying paint containing polybutadiene resin to form the intermediate coating; 4. ultrahigh vacuum magnetically controlled sputtering to form aluminum or copper coating onto the intermediate coating, with the coating color being altered by means of the technological parameters; and 5. painting transparent outer protecting coating. The present invention provides a unique surface treating process, and the coating has environment friendship, excellent adhesion, high heat resistance and good decorating effect.

Owner:YULIN AUTOMOBILE FITTINGS KUNSHAN

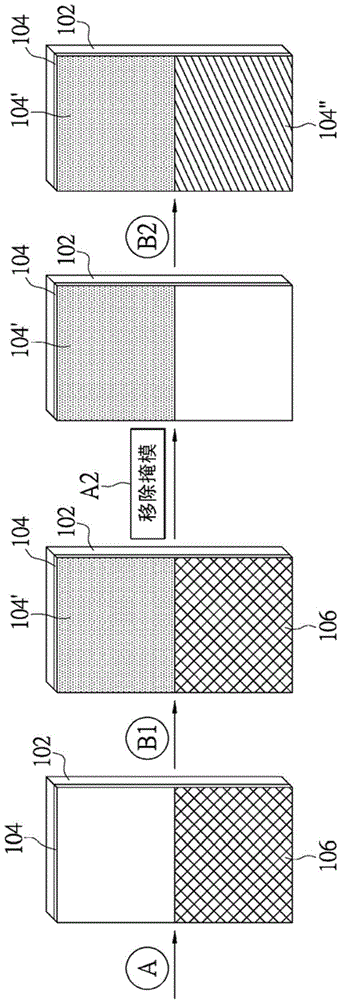

Bicolor anode titanium film forming method and product

InactiveCN102953109AMetallicShort preparation timeSurface reaction electrolytic coatingTitaniumTitanium oxide

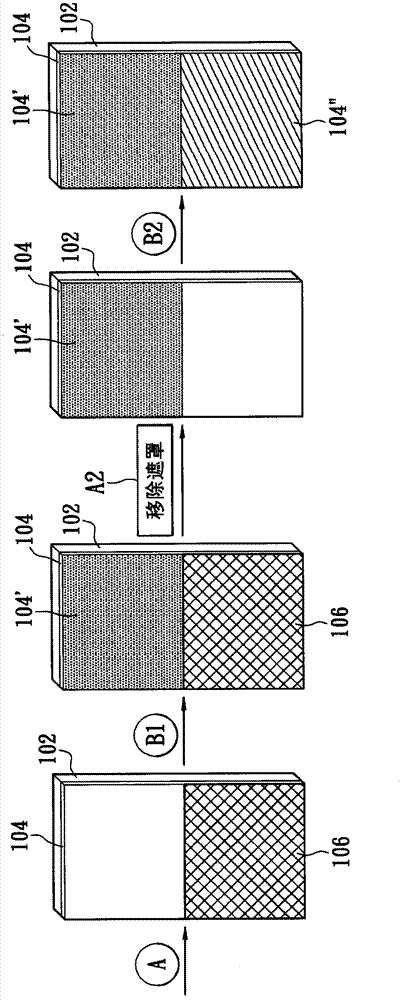

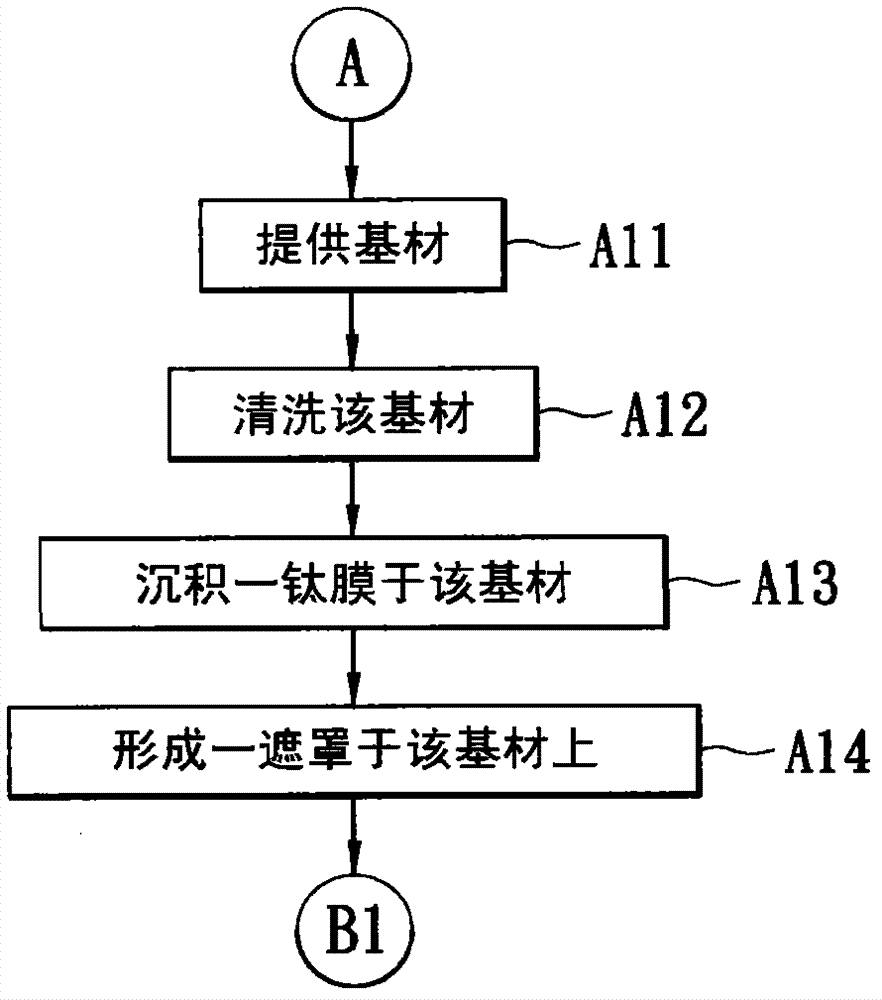

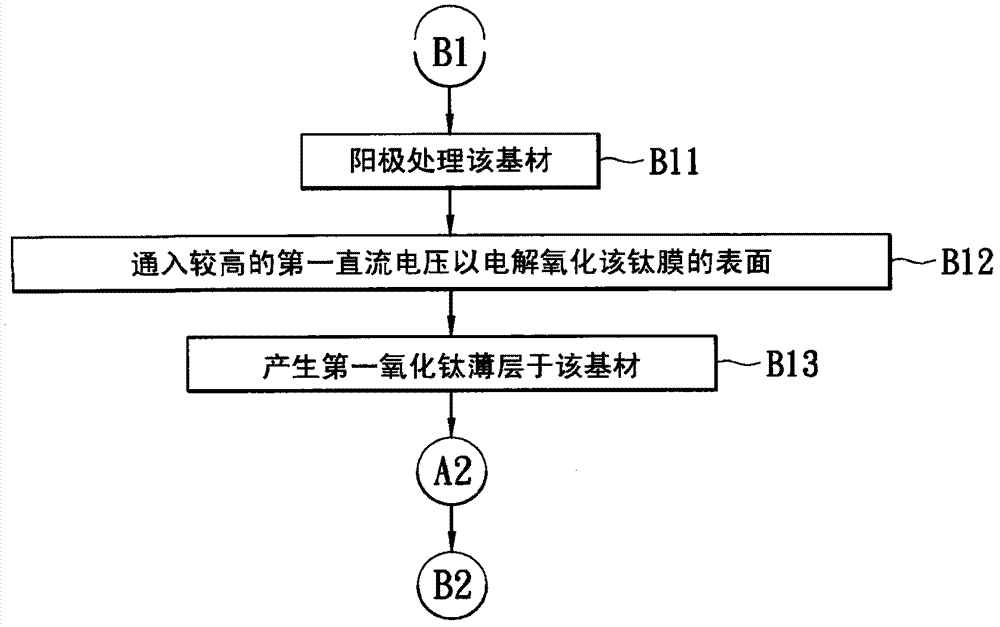

The invention provides a bicolor anode titanium film forming method and a product. The method comprises the following steps: in a preparation procedure, firstly, providing a base material and cleaning the base material, depositing a titanium film on the base material, and forming a shielding cover on the base material; in a primary anode oxidization procedure, immersing the base material with the titanium film as an anode in electrolyte, and filling a first direct current voltage to oxidize the surface of the titanium film and generate a first thin titanium oxide layer on the base material; then, removing the shielding cover, and performing a secondary anode oxidization procedure, wherein the secondary anode oxidization procedure comprises: immersing the base material as the anode in the electrolyte; filling a second direct current voltage lower than the first direct current voltage to oxidize the surface of the titanium film and generate a second thin titanium oxide layer on the base material; and finally, cleaning the base material. The anode oxidization is performed by two different voltages to easily form more than two metallic lustres on a metal shell.

Owner:CATCHER TECH

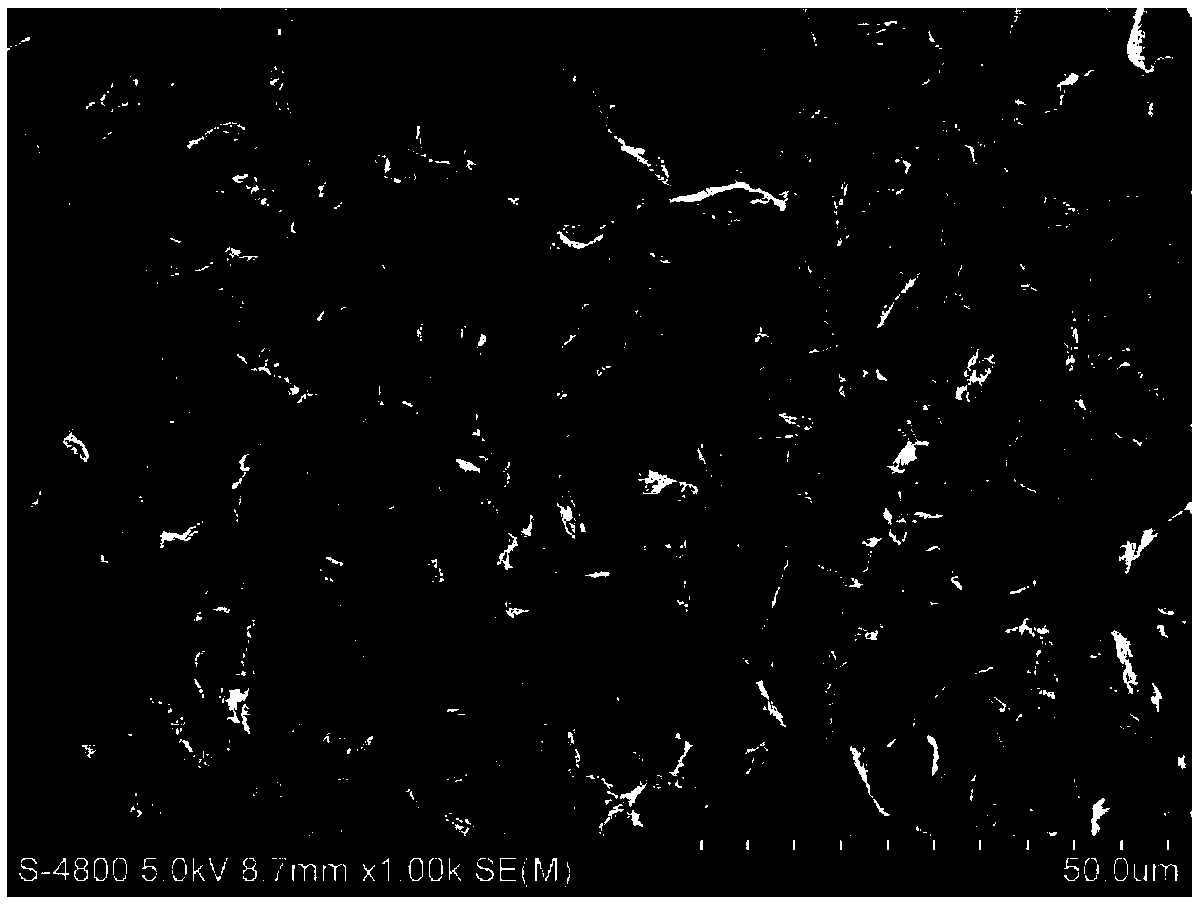

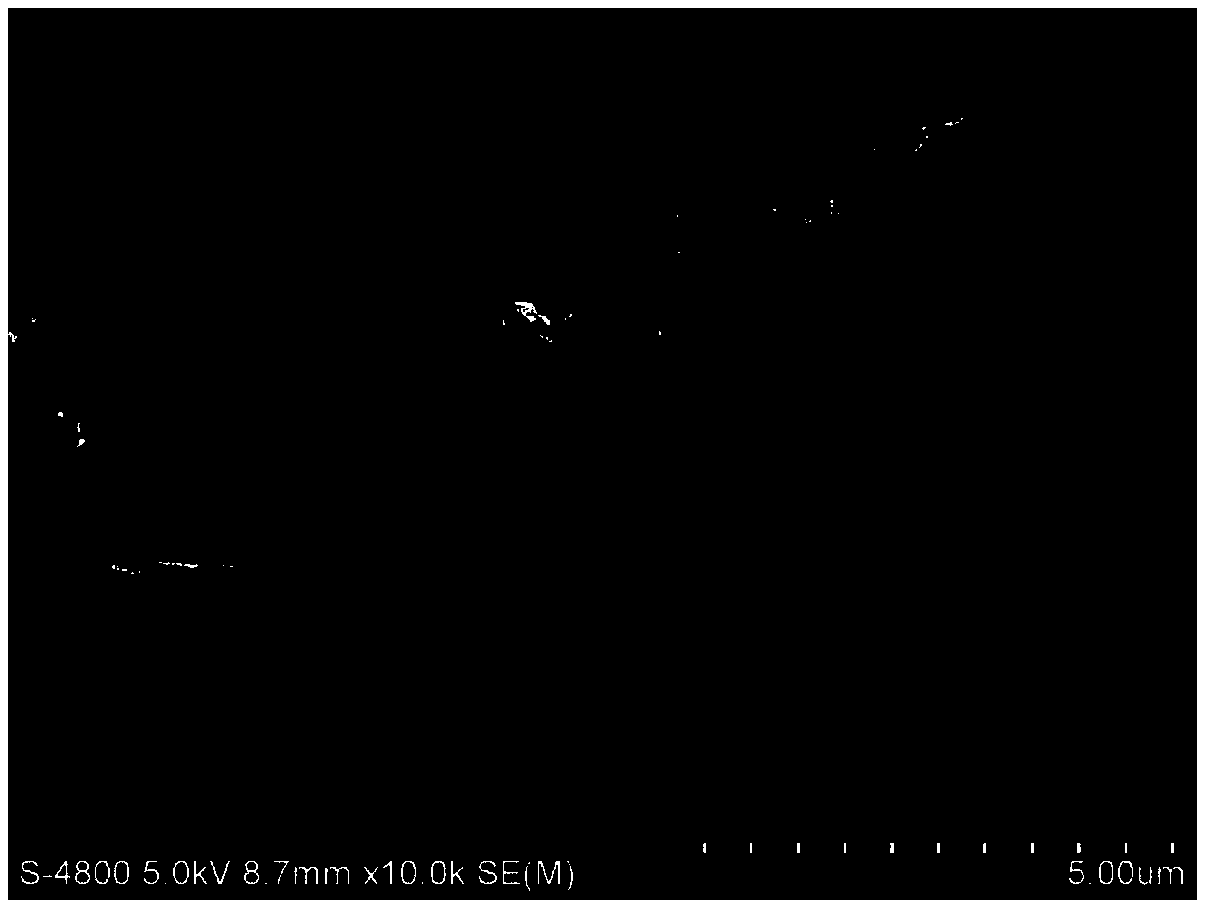

Method for preparing reduced graphene oxide load ReS2 for cathode material of lithium sulfur battery

InactiveCN109546098AInhibition of dissolution and diffusionLarge specific surface areaMaterial nanotechnologyCell electrodesSingle layer grapheneCvd graphene

The invention relates to a method for preparing reduced graphene oxide load ReS2 for a cathode material of a lithium sulfur battery. The method comprises steps that 1), graphene oxide dispersion is prepared through utilizing single-layer graphene oxide powder; preparation of reduced graphene oxide-loaded ReS2 nanosheet, according to the mass ratio of ammonium perrhenate and thiourea and the single-layer graphene oxide powder (0.3-0.7) ): (0.8-1.2): 1, the ammonium perrhenate and thiourea are weighed and added to the graphene oxide dispersion to obtain uniform mixture solution, the mixture solution is transferred to a reaction vessel and then heated to 150-240 DEG C for 10-24 hours, and a reaction product is obtained; the reduced graphene oxide load ReS 2 nanosheet is calcined to improve the crystallinity of the material, and the final product rGO / ReS2 is obtained.

Owner:TIANJIN UNIV

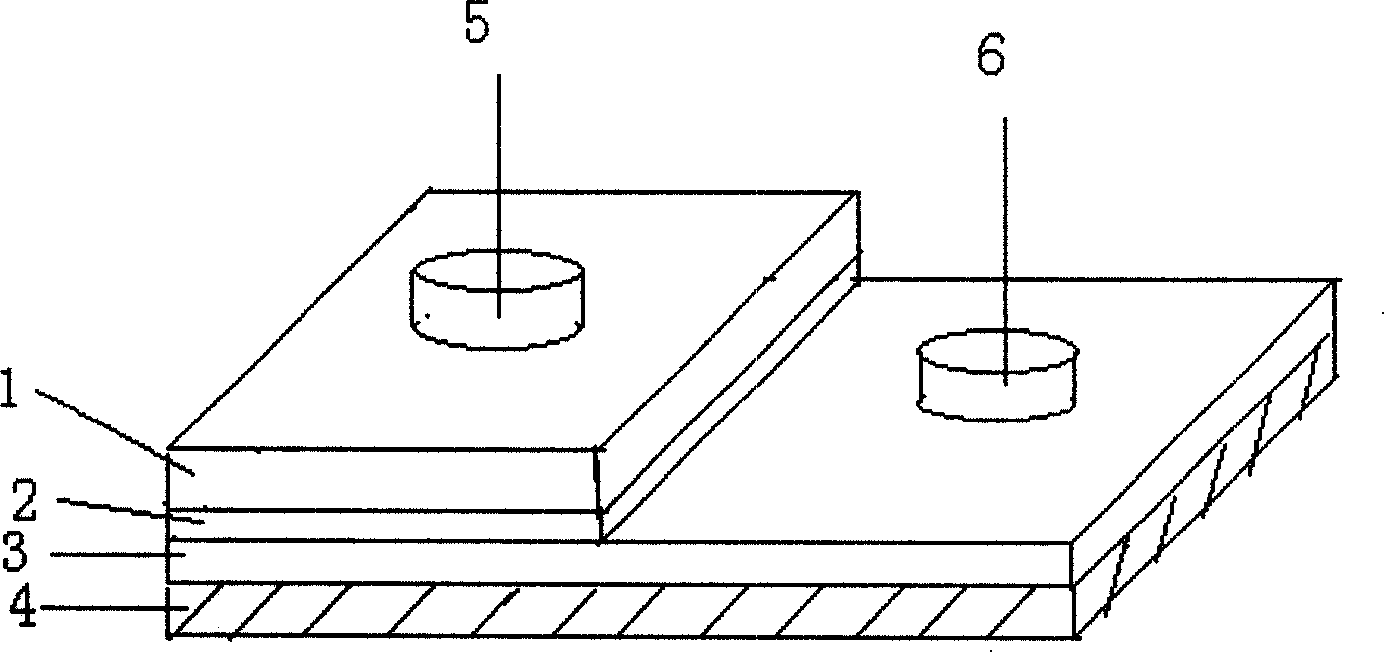

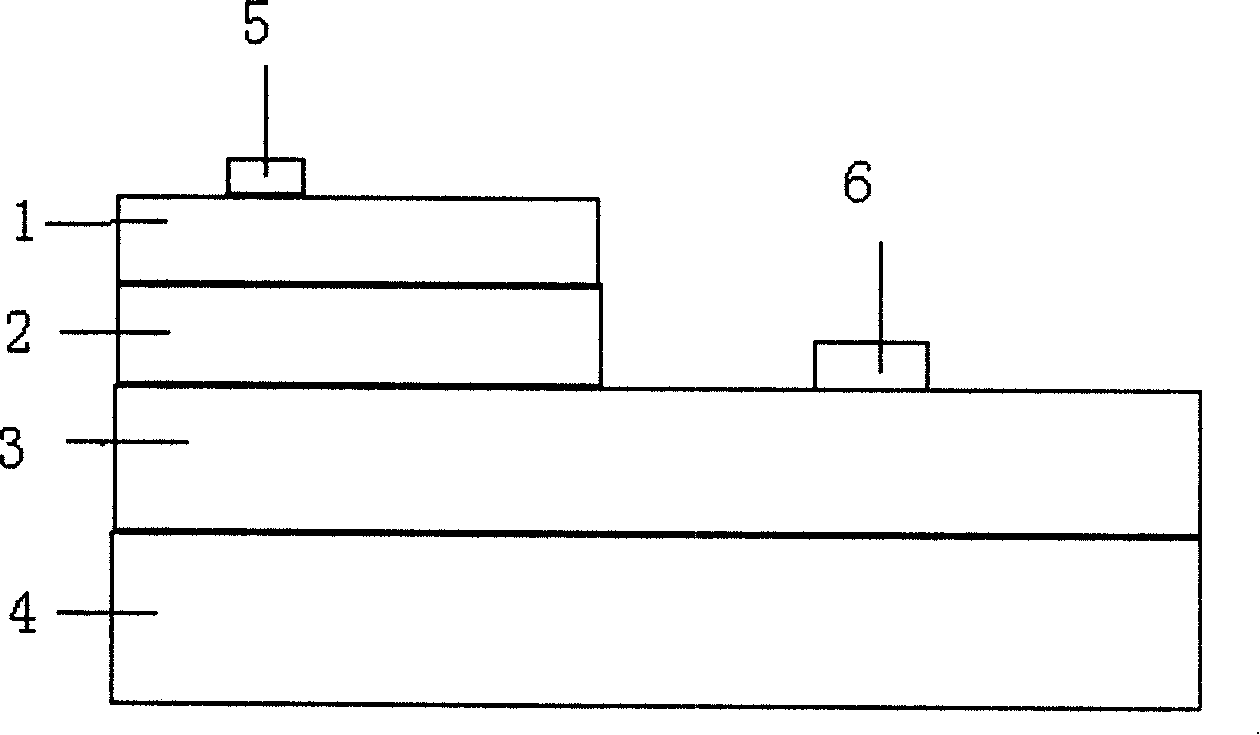

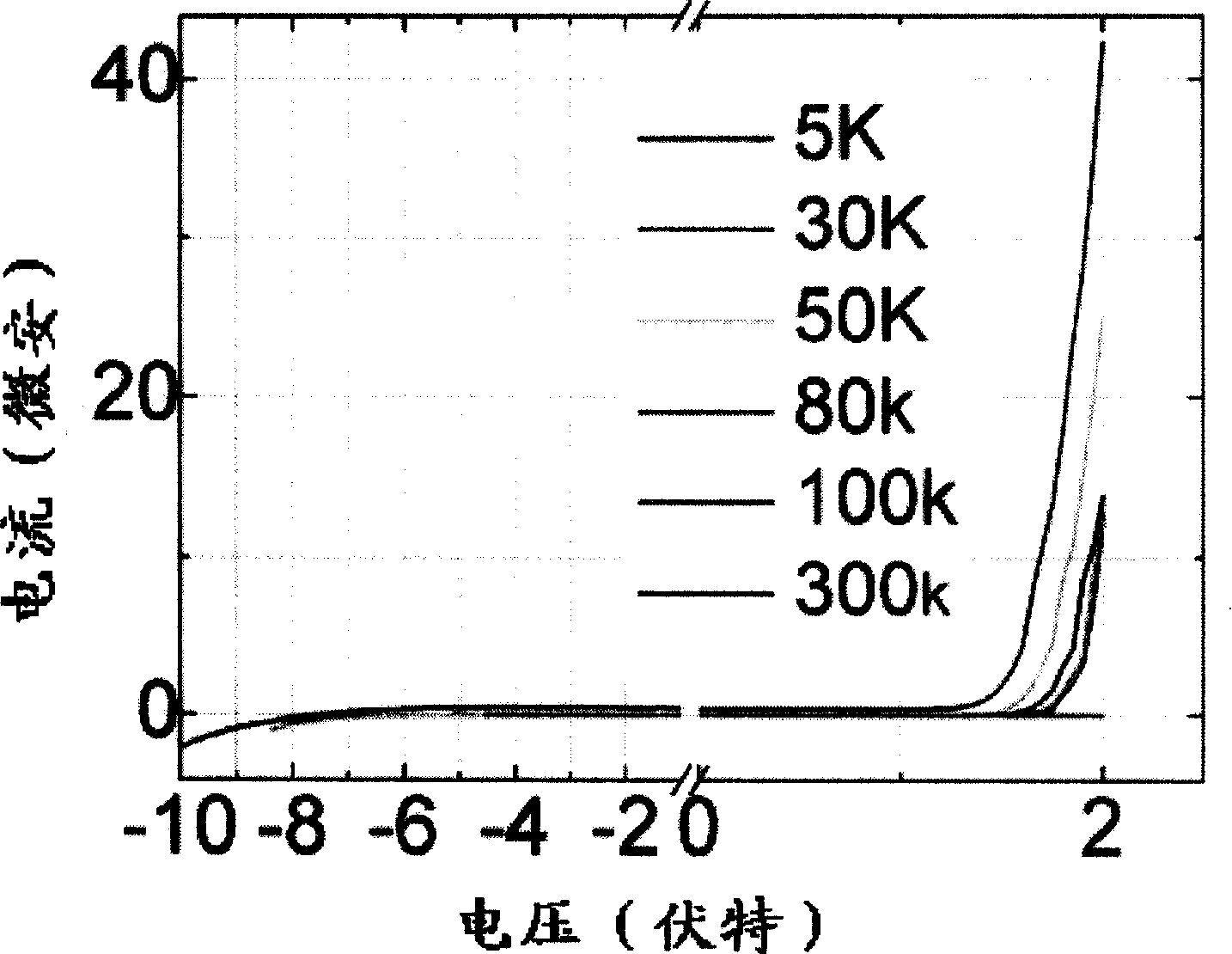

Oxide p-i-n junction device and method for producing the same

InactiveCN101197396AEasy to prepareSimple structureSemiconductor/solid-state device manufacturingSemiconductor devicesChemistryOxide

The invention relates to an oxide p-i-n junction device and a method for preparation the same, wherein the device comprises a substrate, a p-type oxide layer formed on the substrate, an n-type oxide layer formed on the p-type oxide layer, leading-out ends respectively formed on the p-type oxide layer and the n-type oxide layer to be connected with lead wires, and a ferroelectrics potential barrier layer arranged between the p-type oxide layer and the n-type oxide layer; the n-type oxide layer and the ferroelectrics potential barrier layer, which are arranged at one side of the p-type oxide layer, occupy one third to two thirds of the area of the p-type oxide layer with the other part used as the leading-out end of the p-type oxide layer; the surface of the n-type oxide layer is used as the leading-out end of the n-type oxide layer; the leading-out ends of the p-type oxide layer and the n-type oxide layer are respectively provided with precious metal bonding pads used to be connected with the lead wires; moreover, both the p-type oxide layer and the n-type oxide layer are metallic. With a simple preparation method and an easily realized structure, the device realizes diversified functions of a single device.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Spheroidal graphite cast iron-based composite material and method for preparing composite winding drum

ActiveCN107653413AImprove toughnessHigh surface hardnessFoundry mouldsFoundry coresAlloyDuctile iron

The invention discloses a spheroidal graphite cast iron-based composite material and a method for preparing a composite winding drum. A substrate alloy is composed of the following components of, by mass, 3.5-4.0% of C, 2.2-2.7% of Si, 0.3-0.8% of Mn, 1.3-1.7% of Ni, 0.5-0.9% of Cu, 0.2-0.5% of Mo, 0.02-0.08% of Re, 0.03-0.06% of Mg, 0.2-0.3% of Ti, less than or equal to 0.07% of P, less than or equal to 0.02% of S and the balance Fe and other unavoidable impurities. By adopting an advanced resin sand production line and an electric-furnace smelting technology, surface alloying is achieved through a cast infiltration technology to replace heat treatment surface strengthening, the elements of titanium, zirconium, tantalum and tungsten are evenly mixed with inorganic salt to be fixed in a casting mold, metal liquid is casted, and the composite winding drum is obtained after cooling and unpacking. The spheroidal graphite cast iron-based composite material and the method for preparing thecomposite winding drum can improve the toughness and the surface hardness of the spheroidal graphite cast iron composite winding drum, and can prolong the service life of the spheroidal graphite castiron composite winding drum.

Owner:XI AN JIAOTONG UNIV +1

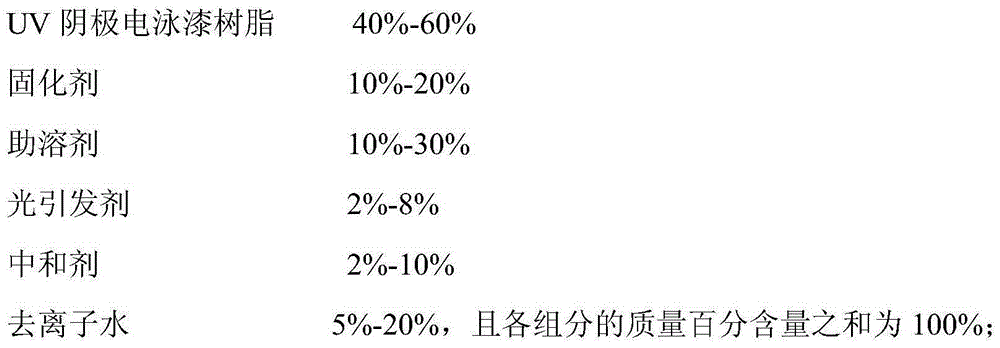

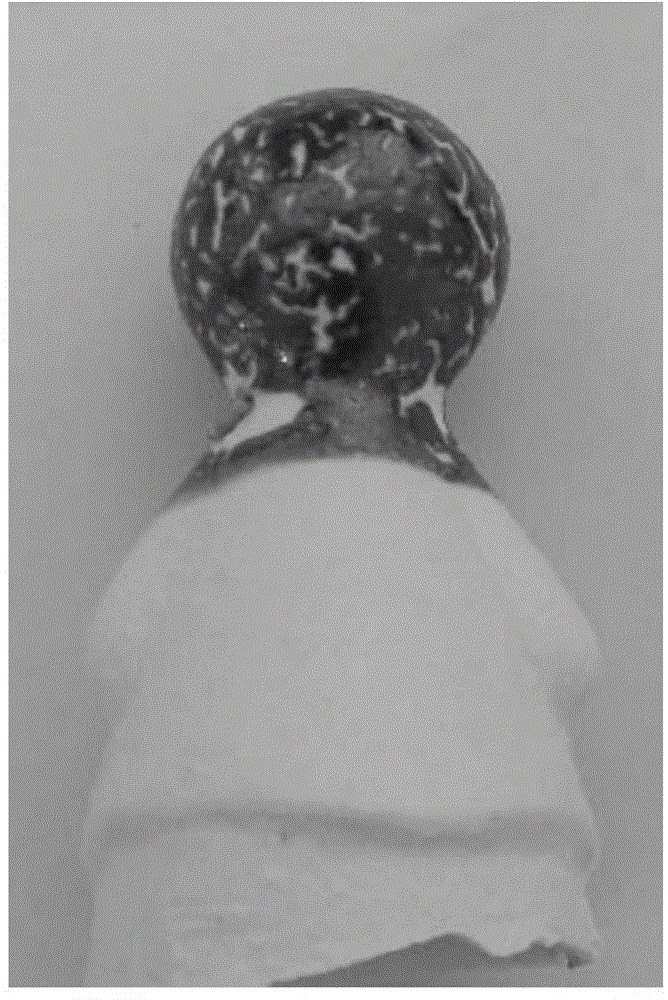

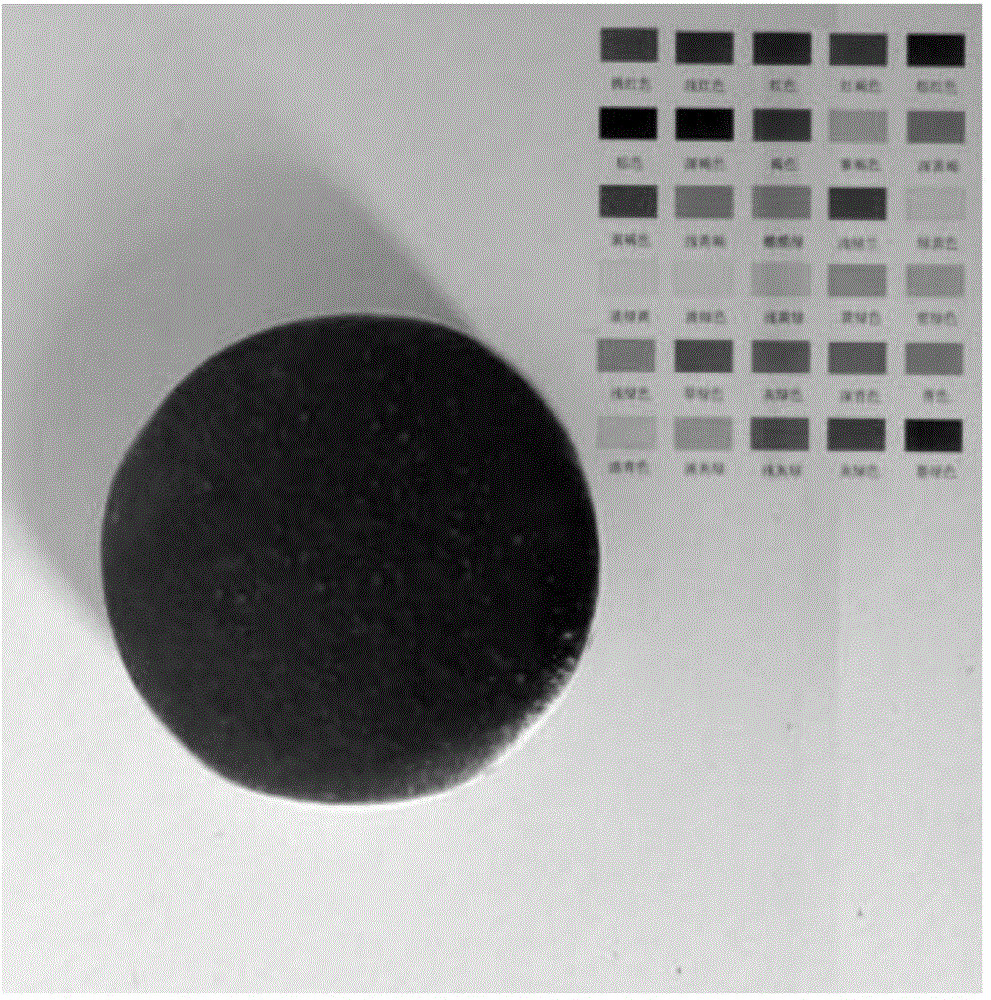

UV cathode electrophoresis paint and coating process of same

InactiveCN104987761AProcess environmental protectionGood film uniformityPaints for electrolytic applicationsSolventChemistry

The present invention belongs to the technical field of coating and electrophoresis paint, and discloses a UV cathode electrophoresis paint and a coating process of same. The UV cathode electrophoresis paint consists of components such as UV cathode electrophoresis paint resin, a curing agent, a co-solvent, and the like, wherein the UV cathode electrophoresis paint resin consists of methacrylate, N-methylolacrylamide, acrylic acid, and styrene and the like. The UV cathode electrophoresis paint is environmentally friendly in process, can be used as a vacuum electroplating base layer, and does no cracking, shedding, or yellowing. A paint coating has good uniformity, high luminance, high flexibility, and high throwing power. The coating process comprises such steps as: pretreatment, UV cathode electrophoresis, water washing, UV curing, vacuum electroplating and the like, the process does not use conventional water electroplating or coating for priming, and can obtain good bonding force, precision and bright crystallization, and decorative and ideal appearance with metallic texture that are same as the water electroplating, and can replace the conventional water electroplating.

Owner:东莞市霖辉金属表面处理材料有限公司

Reddish brown ceramic color glaze and preparation method thereof

The invention relates to reddish brown ceramic color glaze and a preparation method thereof and relates to a colored ceramic color glaze and a preparation method thereof. The reddish brown ceramic color glaze is prepared from volcanic ores and volcanic slurry. The reddish brown ceramic color glaze is prepared from 65-75% of volcanic slurry and 25-35% of soda feldspar, or is prepared from 5-10% of kaolin and 90-95% of volcanic ores. The preparation method comprises the following steps: I, treating raw materials; II, applying glaze; and III, firing. The reddish brown ceramic color glaze provided by the invention can be used to prepare ceramic artwork, articles for daily use, architectural ceramics and building craft ceramics.

Owner:黑龙江火山岩科技有限公司

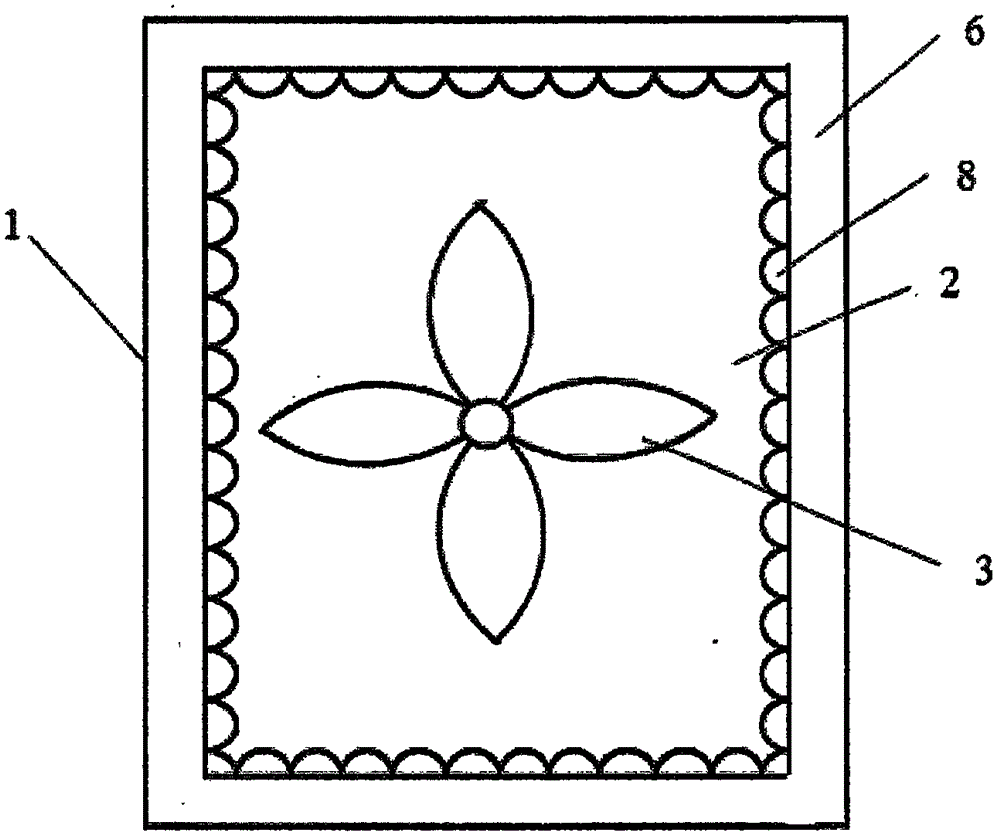

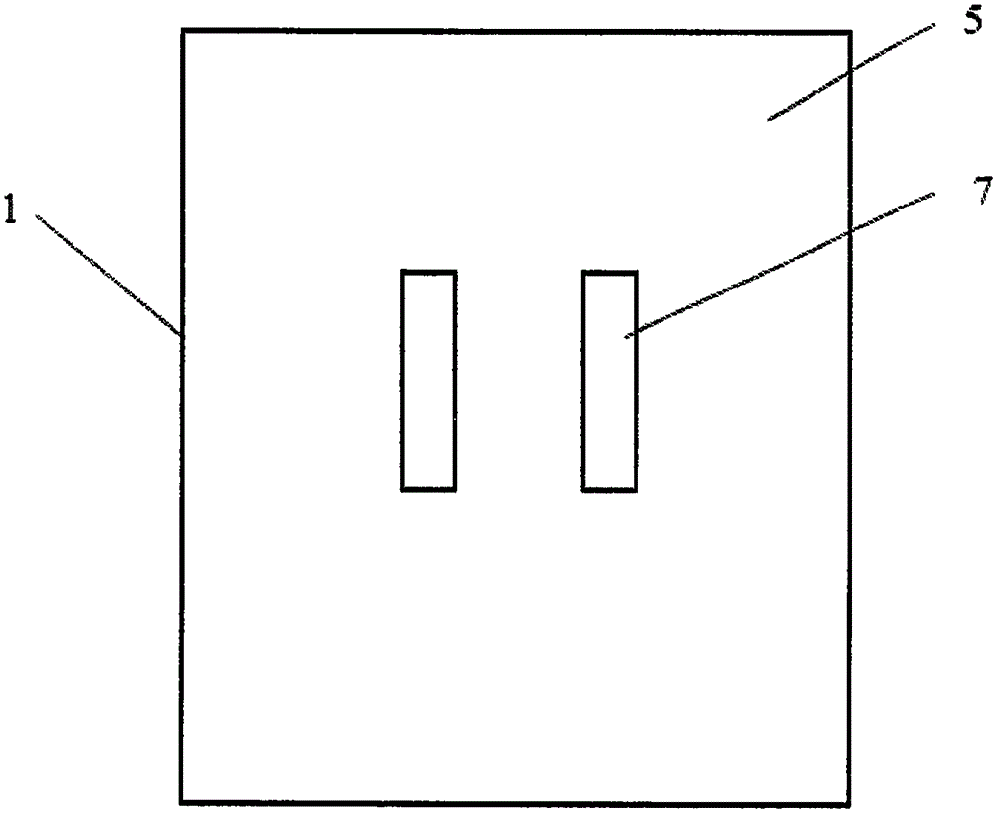

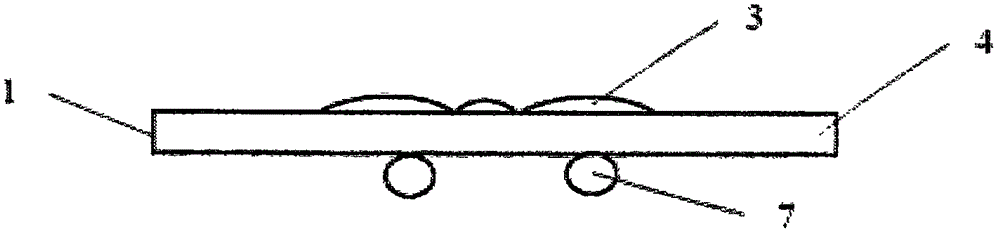

Preparation method of metal wire jewelry pendant

The invention discloses a preparation method of a metal wire jewelry pendant. The method comprises the following steps of (1) preparation material preparation: a, preparing an embroidery sheet; b, preparing a metal wire embroidery wire; c, preparing a metal framework; (2) metal wire pattern embroidering; (3) jewelry pendant assembling: putting the embroidery sheet with the embroidered metal wire patterns into an accommodating cavity of the metal framework to obtain the jewelry pendant. The method provided by the invention has the advantages that the process is simple and practical; the operation is convenient; the method is suitable for the jewelry pendant using thinner metal wires for national artware processing. The jewelry pendant manufactured by the method cannot be easily abraded, cannot easily generate color degradation, can be easily stored and has high collection artistic value; the metal wire patterns have rich metal luster and has the three-dimensional effects; high attractive effect can be given to the jewelry pendant; the practical value is realized; meanwhile, the collection value is also realized. The pendant is used as the Mongol nationality culture carrier, and is favorable for the propagandization, inheritance and protection of the national artware.

Owner:乌云高娃

Injection molded control panel and injection molding process thereof

InactiveCN107932820AHigh strengthHigh modulus of elasticityDomestic articlesCalcium silicatePolyvinyl chloride

The invention discloses an injection molded control panel. The control panel is prepared from, by weight, 45-55 parts of PC resin flakes, 7-11 parts of panel filler, 5-8 parts of powdered metal and 1-2 parts of a light conversion agent. The invention further discloses an injection molding process of the injection molded control panel. The injection molding process comprises the steps of raw material pretreatment, material mixing, material drying, pretreatment through an injection molding system and an injection mold, injection molding, pressure maintaining, mold disassembling and the like. ThePC resin flakes are selected and used as main materials for replacing polyvinyl chloride in the prior art, thus, the manufactured injection molded control panel has high strength and elastic coefficient and good insulation performance; meanwhile, by adding the panel filler comprising calcium silicate, magnesium carbonate, diatom ooze and glass fibers into the raw materials, the abrasion resistance and the fatigue resistance of the control panel can be improved; and the injection molding process is easy and convenient to operate and suitable for mass production.

Owner:ANHUI QINGLONGQUAN PRINTING TECH CO LTD

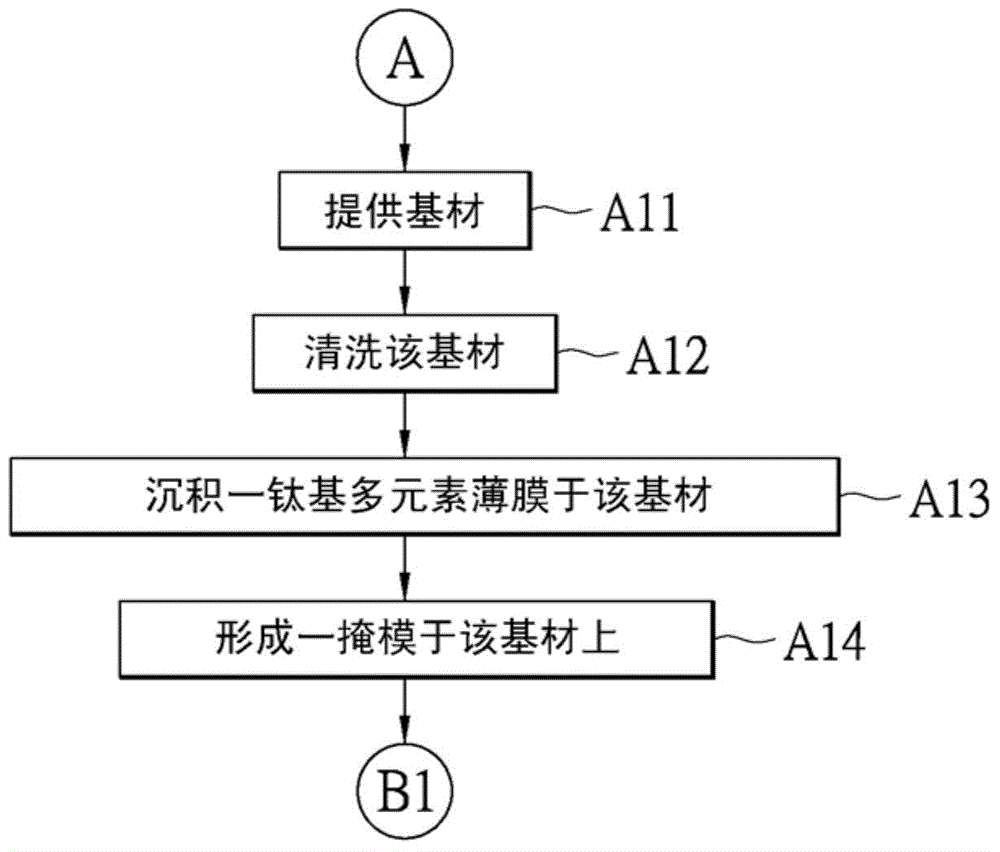

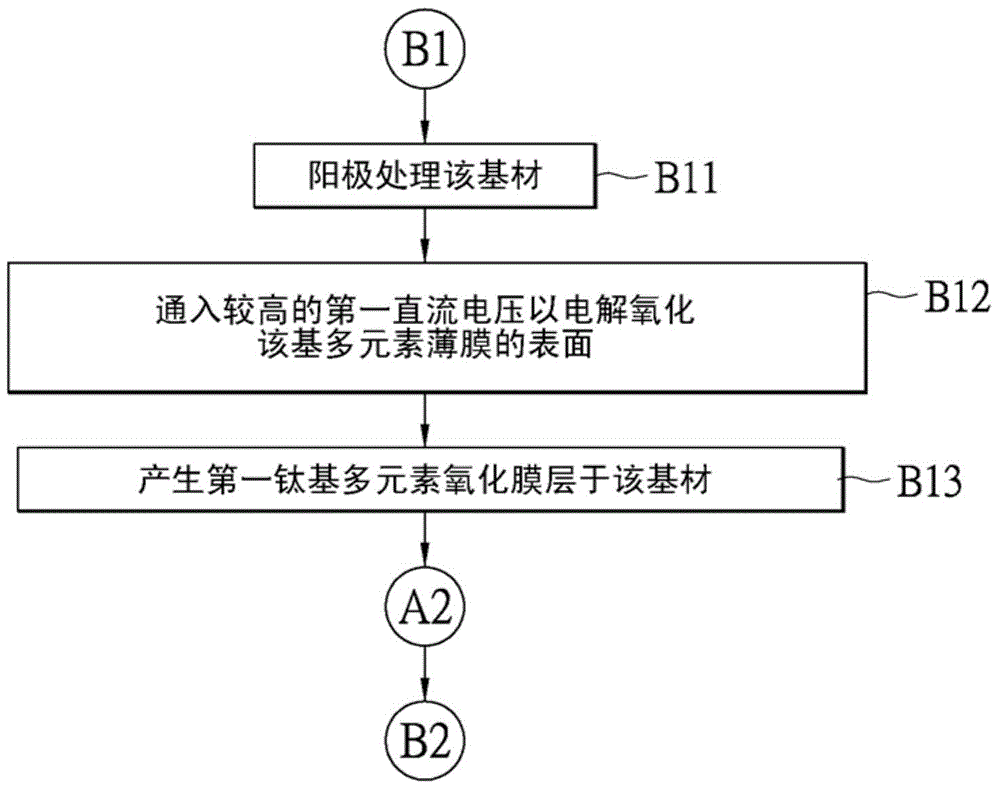

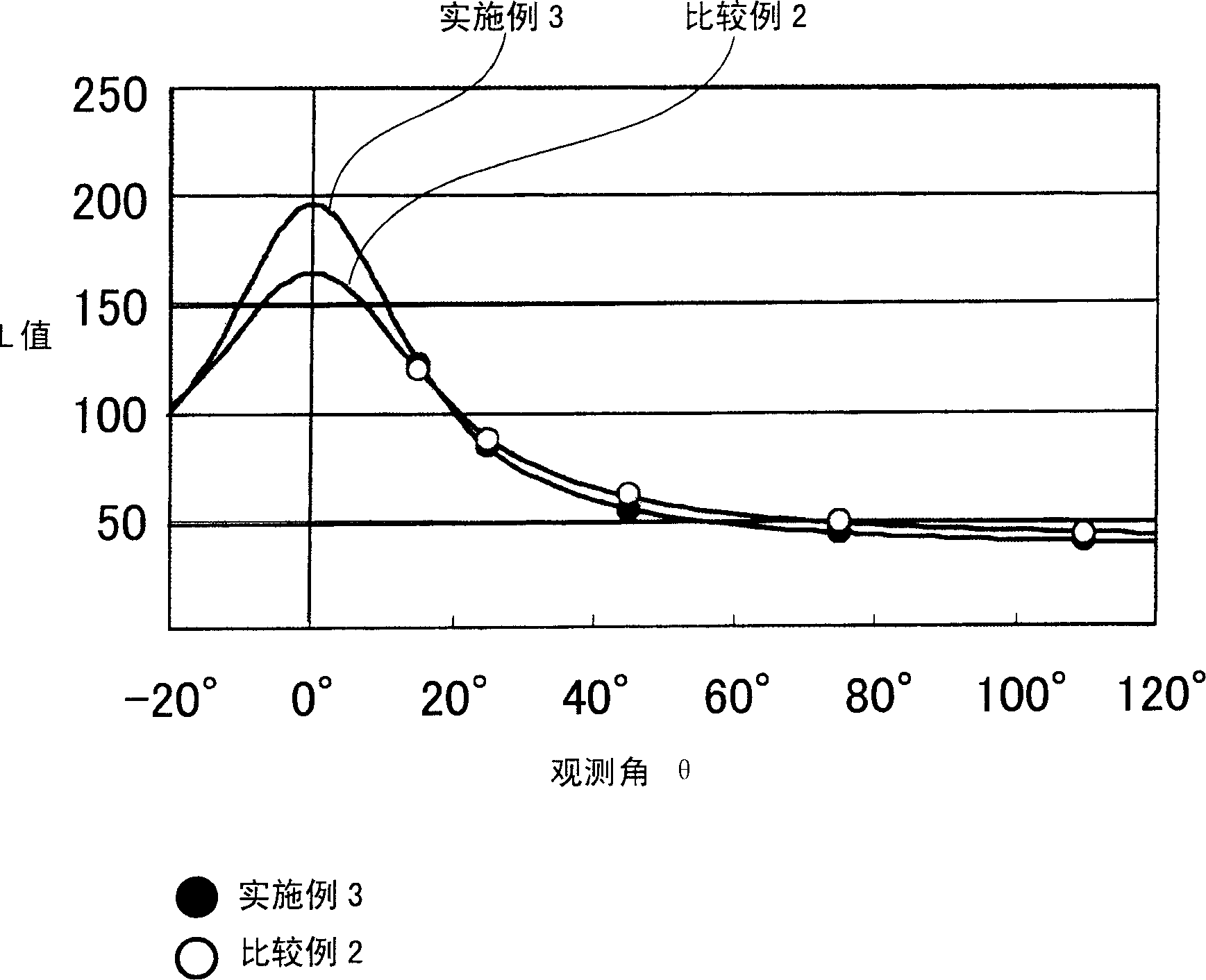

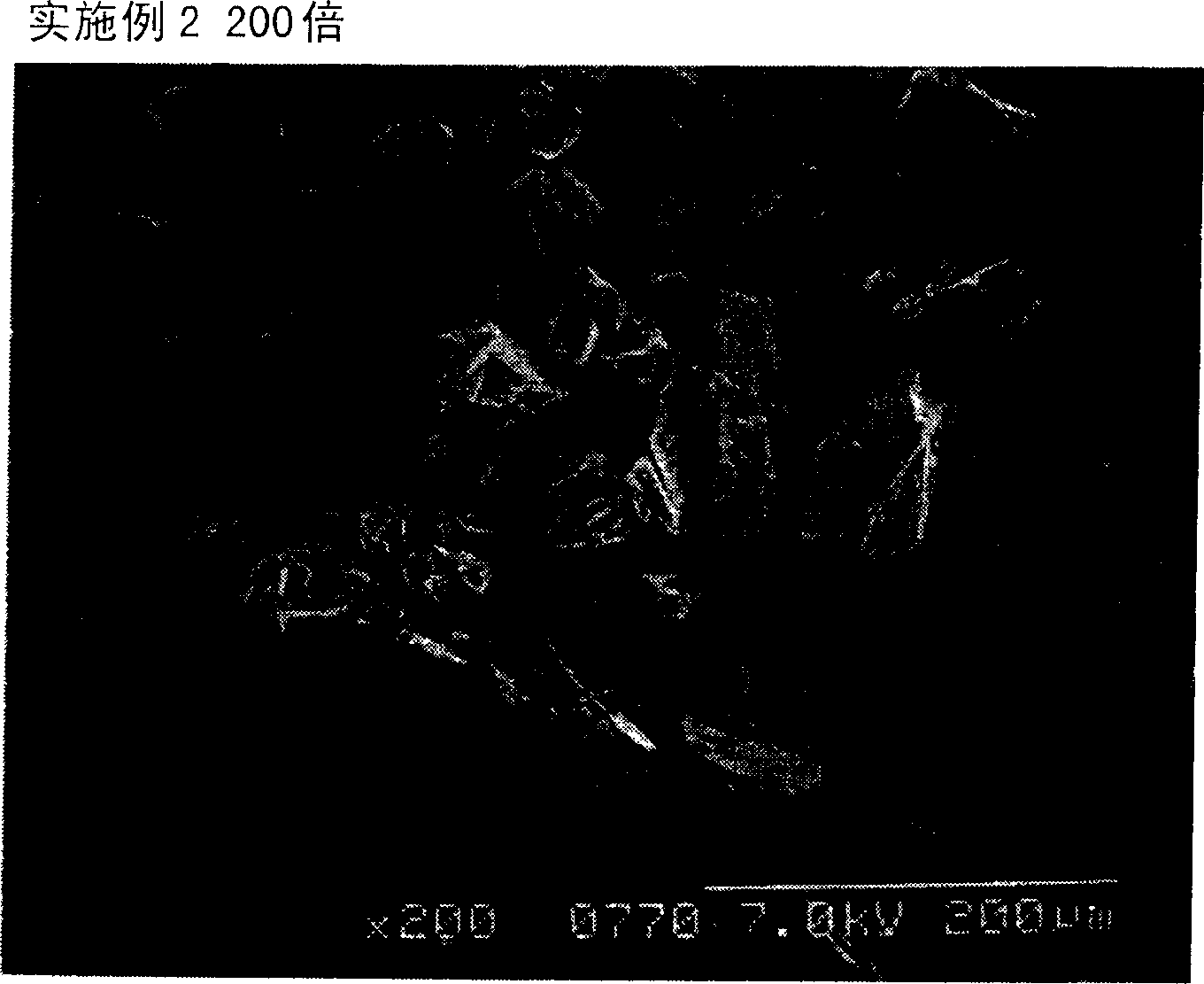

Titanium-based multi-element thin film bicolor anode forming method and product thereof

InactiveCN105586625AHigh hardnessMetallicSurface reaction electrolytic coatingVacuum evaporation coatingAnodizingOptoelectronics

A titanium-based multi-element thin film bicolor anode forming method includes the following steps that a base material is provided; the base material is washed; a titanium-based multi-element thin film is deposited on the base material, wherein the titanium-based multi-element thin film contains titanium and at least one type of another metal; a mask is formed on the base material; the base material with the titanium-based multi-element thin film is used as an anode to be soaked in an electrolyte; a first direct-current voltage is led in so that the surface of the titanium-based multi-element thin film can be oxidized and a first titanium-based multi-element oxidation film layer can be generated on the base material; the mask is removed; the base material is used as the anode to be soaked in the electrolyte to be subjected to anodic treatment; a second direct-current voltage lower than the first direct-current voltage is led in so that the surface of the titanium-based multi-element thin film can be oxidized and a second titanium-based multi-element oxidation film layer can be generated on the base material; and the base material is washed. The invention further provides a product which comprises the titanium-based multi-element thin film and is subjected to bicolor anodic treatment.

Owner:CATCHER TECH

Powder coating composition, process for producing the same and coating film made from the same

An object is to provide a powder coating composition having excellent recyclability, offering superior safety, and containing a flake pigment providing metallic feel, brilliance and brightness to a coating film, as well as a coating film obtained from the former. A powder coating composition containing thermosetting resin powder having a surface adhered to a flake pigment composed of aluminum flake having an average particle size of 1 to 100 mum using an adhesive binder composed of a resin dissolved in a solvent which does not dissolve a thermosetting resin, as well as a coating obtained from the former are provided.

Owner:TOYO ALUMINIUM KK

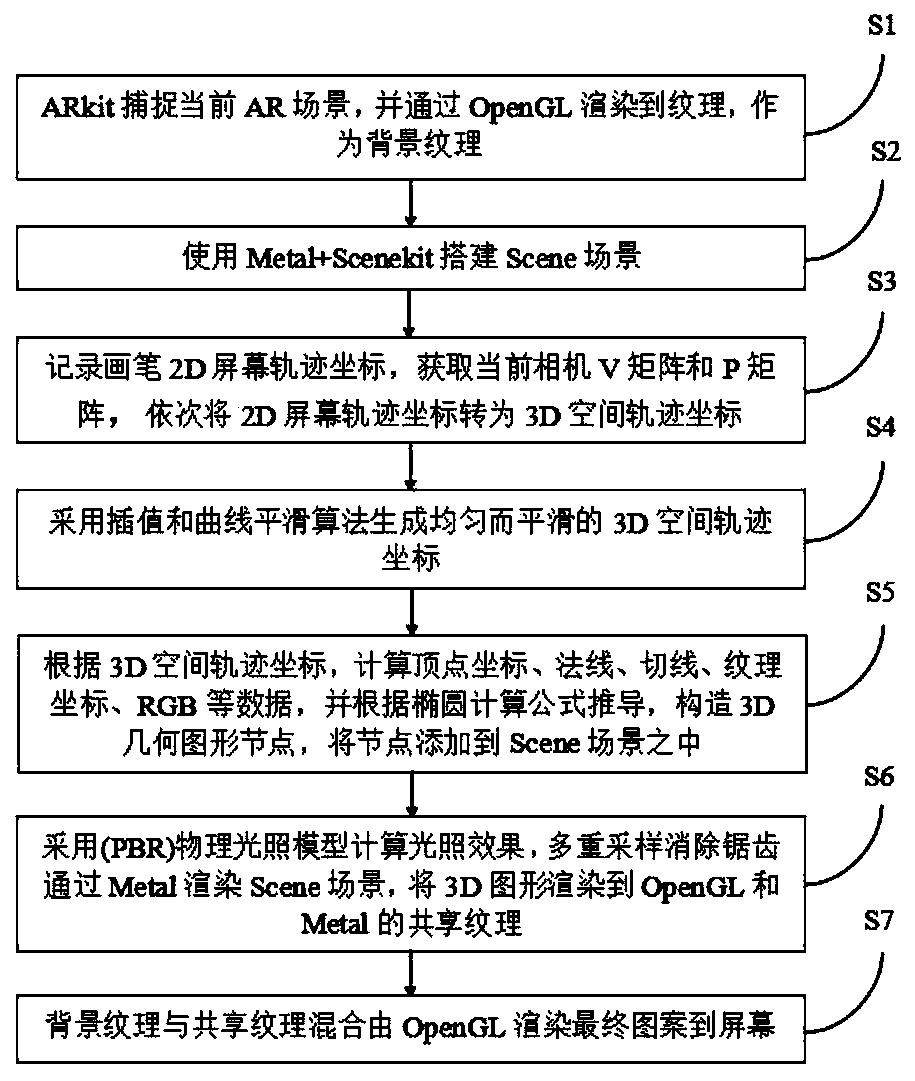

AR drawing method combined with physical illumination model

ActiveCN110136238AHas diffuse propertiesHas a roughness propertyEnergy saving control techniques3D-image renderingGraphicsDeformation effect

The invention discloses an AR drawing method combined with a physical illumination model, and the method comprises the following steps: S1, enabling an ARkit to capture a current AR scene, enabling the ARkit to be rendered to a texture through an OpenGL, and enabling the texture to serve as a background texture; S2, establishing a Scene scene by using Metal + Scene kit; S3, recording 2D screen track coordinates of the paintbrush, obtaining a current camera V matrix and a current camera P matrix, and sequentially converting the 2D screen track coordinates into 3D space coordinate tracks; S4, generating a uniform and smooth 3D space trajectory coordinate by adopting an interpolation and curve smoothing algorithm; S5, calculating data such as vertex coordinates, normal lines, tangent lines, texture coordinates and RGB (red, green and blue) according to the 3D space trajectory coordinates, deducing and constructing 3D geometric figure nodes with a deformation effect according to an ellipsecalculation formula, and adding the nodes into the Scene scene; S6, adopting a PBR physical illumination model to calculate the illumination effect, carrying out multiple sampling to eliminate sawteeth, rendering a Scene scene through Metal, and rendering a 3D graph to OpenGL and Metal shared textures; and S7, fusing the background texture and the shared texture, and rendering the final pattern to the screen by the OpenGL.

Owner:HANGZHOU QUWEI SCI & TECH

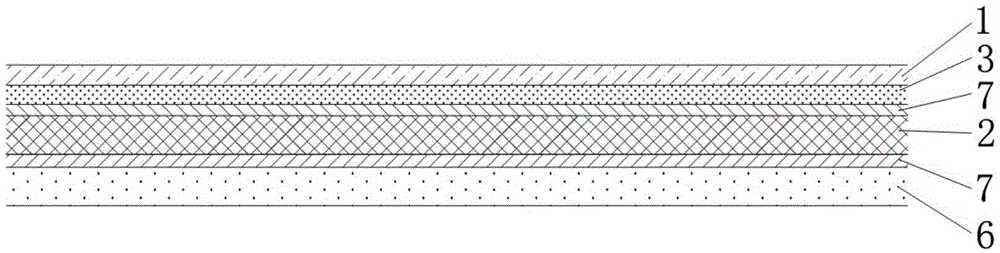

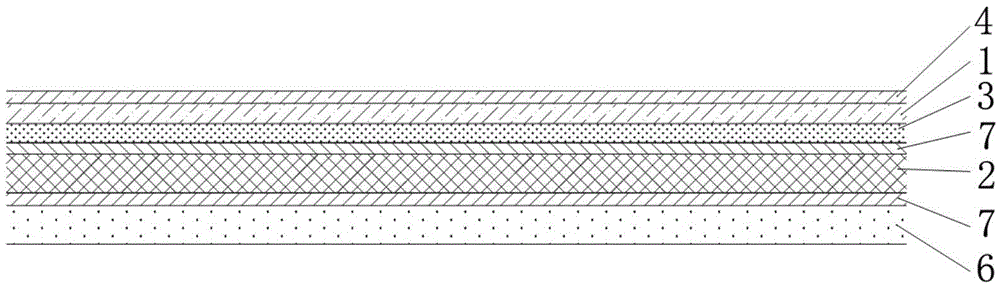

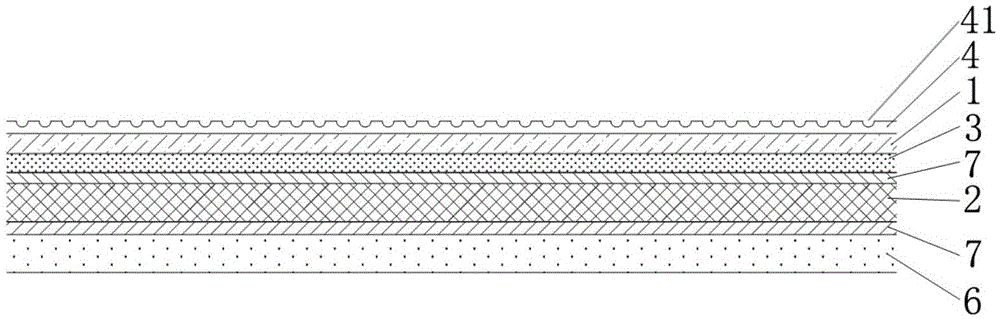

Antifouling composite membrane and antifouling panel containing composite membrane as well as preparation method of composite membrane

InactiveCN105479883AGood adhesionImproved stain resistanceSynthetic resin layered productsLaminationEngineeringComposite membrane

The invention relates to an antifouling composite membrane and an antifouling panel containing the composite membrane as well as a preparation method of the composite membrane. The antifouling composite membrane comprises a PET plastic layer and a PVC plastic layer, wherein a printed pattern layer is arranged at one side of the PET plastic layer; one side, provided with the printed pattern layer, of the PET plastic layer is attached to the PVC plastic layer; the other side of the PET plastic layer is covered with a UV layer; and geometric figures are formed on the surface of the UV layer. The antifouling composite membrane can be attached to the surface of the base material to form the antifouling panel. The composite membrane and the panel disclosed by the invention can show multiple colors and patterns through the printed pattern layer of the PET plastic layer, and can improve surface stain resistance due to the UV layer scribed with tiny geometric figures.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

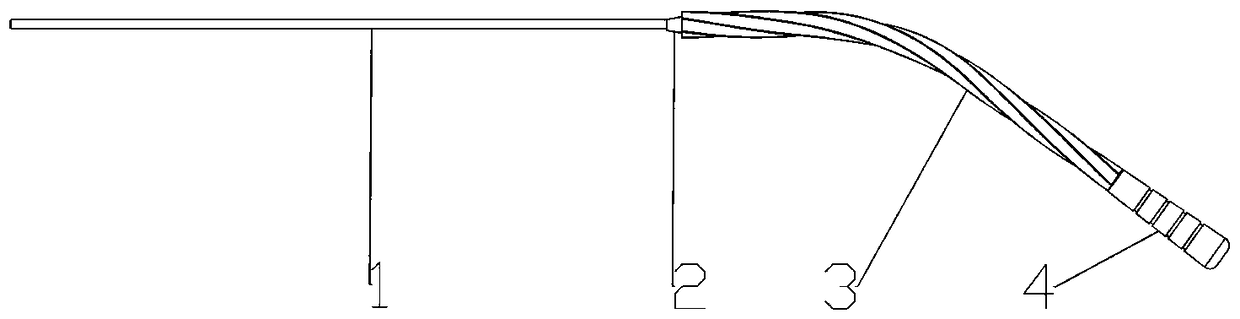

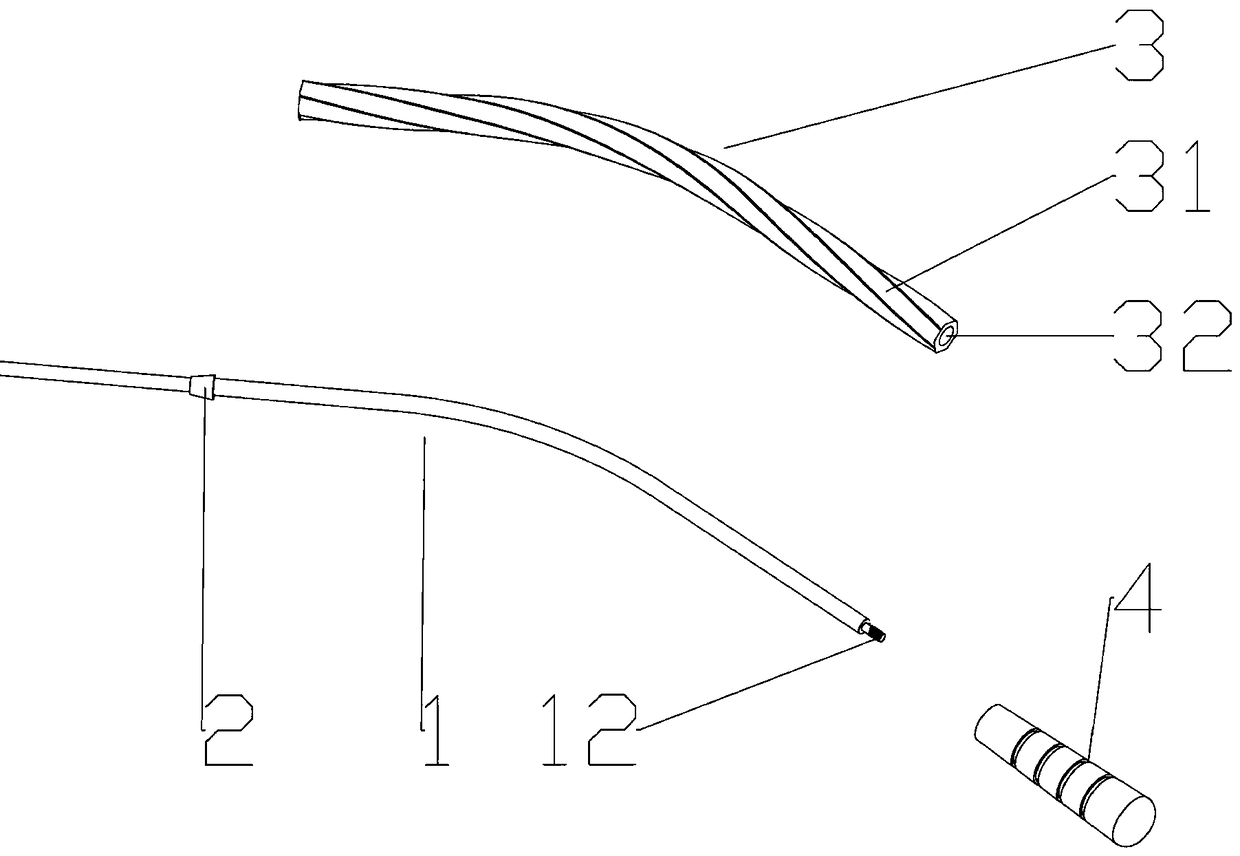

Manufacturing method for antenna

ActiveCN102354808AStable chemical propertiesMetallicAntenna supports/mountingsRadiating elements structural formsCopper coatingHigh volume manufacturing

The invention provides a manufacturing method for an antenna. A plurality of built-in antennas having laminated structures are arranged on an antenna pedestal surface or a mobile phone housing back surface, wherein the surfaces are in an injection-molded state; the laminated structure comprises the following parts from inside to outside: a vacuum coating layer as a first layer; a chemical copper coating layer as a second layer; a chemical nickel coating layer as a third layer; and a chemical gold coating layer as a fourth layer. Beneficial effects of the method are as follows: the antenna hasantioxidation and anticorrosion performances; chemical performances are stable; the antenna surface is fine and smooth and has metal luster; besides, the antenna surface does not discolor and shed; and the antenna highly stands wear and tear. Moreover, the manufacturing cost is low and the yield is high; and therefore, the antenna provided in the invention is suitable for mass production.

Owner:卡内基精密电子塑胶(昆山)有限公司

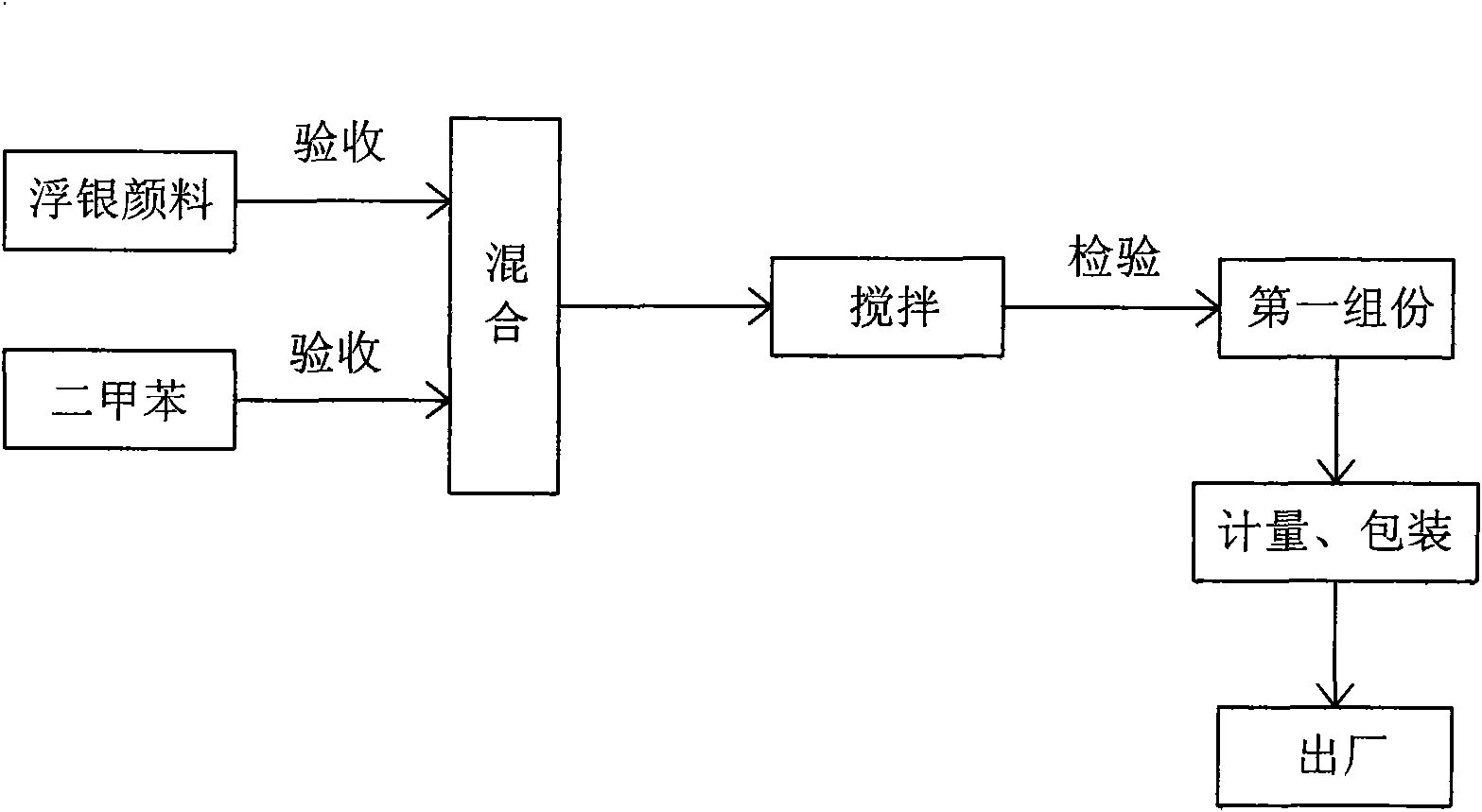

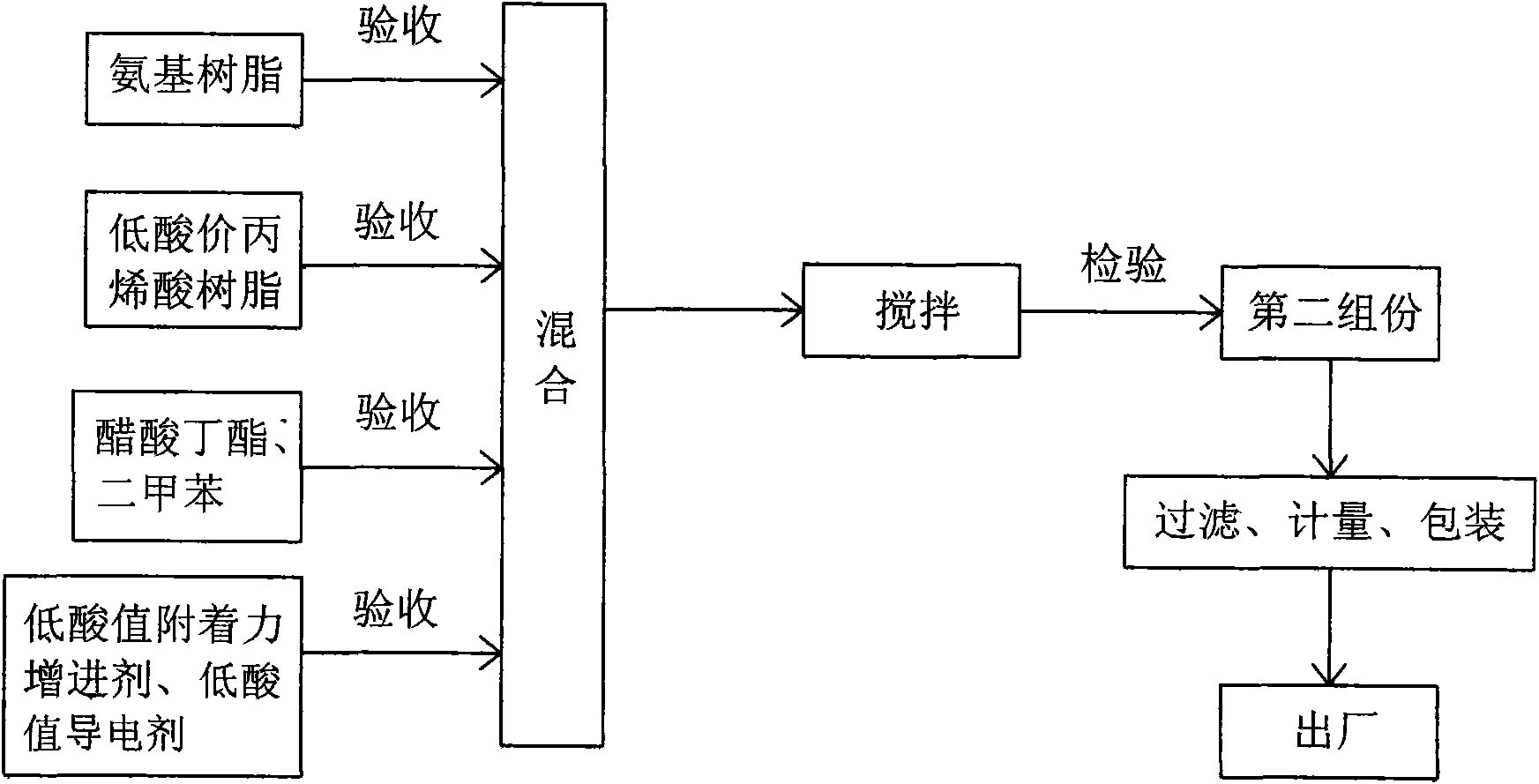

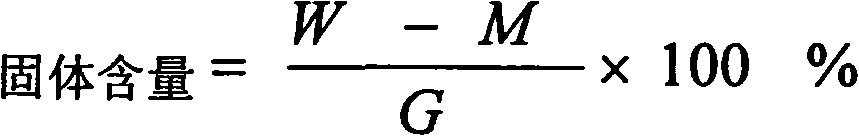

Imitation electroplating coating

InactiveCN101580668AMake up for the defects that cannot be sprayed locallyPromote environmental protectionChemical industryElectrically-conductive paintsAcrylic resinElectroplating

The invention relates to an imitation electroplating coating which can be applied to the products such as a bicycle, a motorcycle, an electric motor car, resin crafts, Buddha tool, ceramics, light fitting, shells, glass, hardware, electric appliances, plastics, etc. The imitation electroplating coating comprises a first component and a second component; wherein, the first component consists of floating silver paint and dimethylbenzene, and the second component consists of amine resin, acrylic resin, butylacetate, dimethylbenzene, adhesion promoter and conductive agent. The invention is energy-saving and environment-friendly, and can be used for replacing electroplating technology.

Owner:HANGZHOU LIWEI CHEM INDAL PAINT

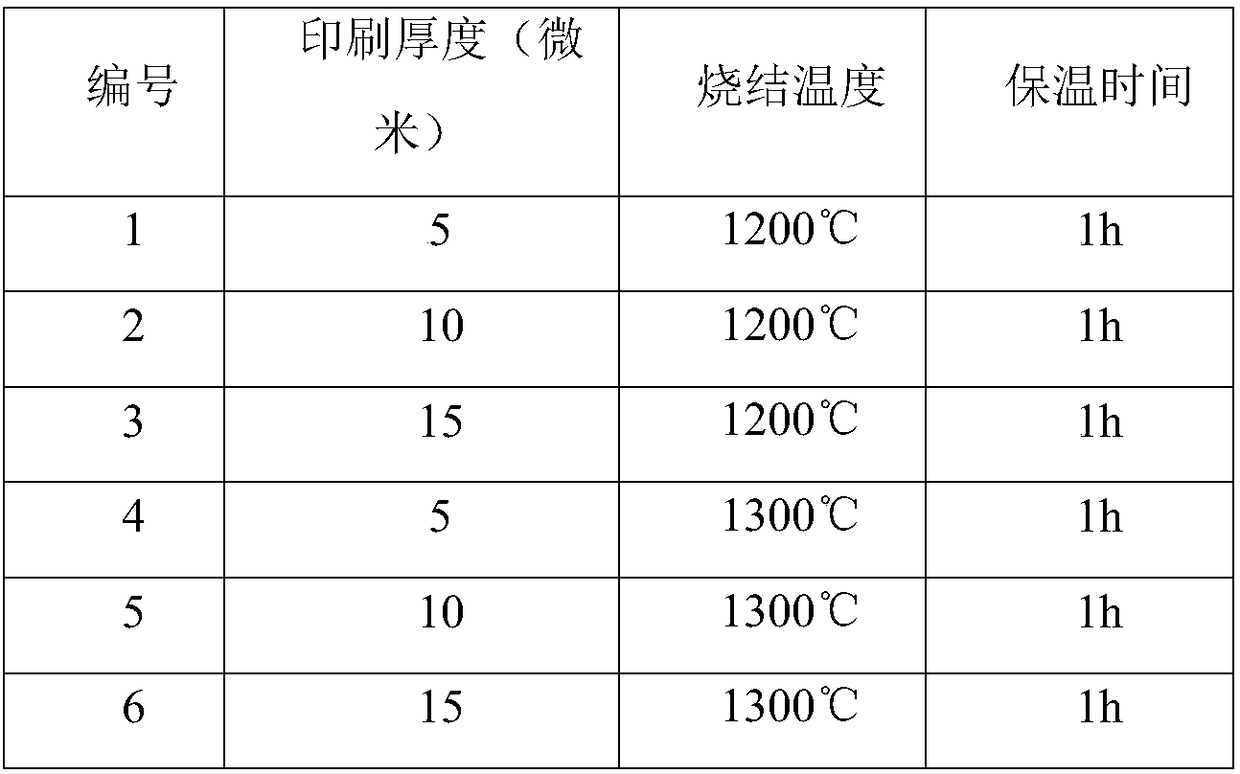

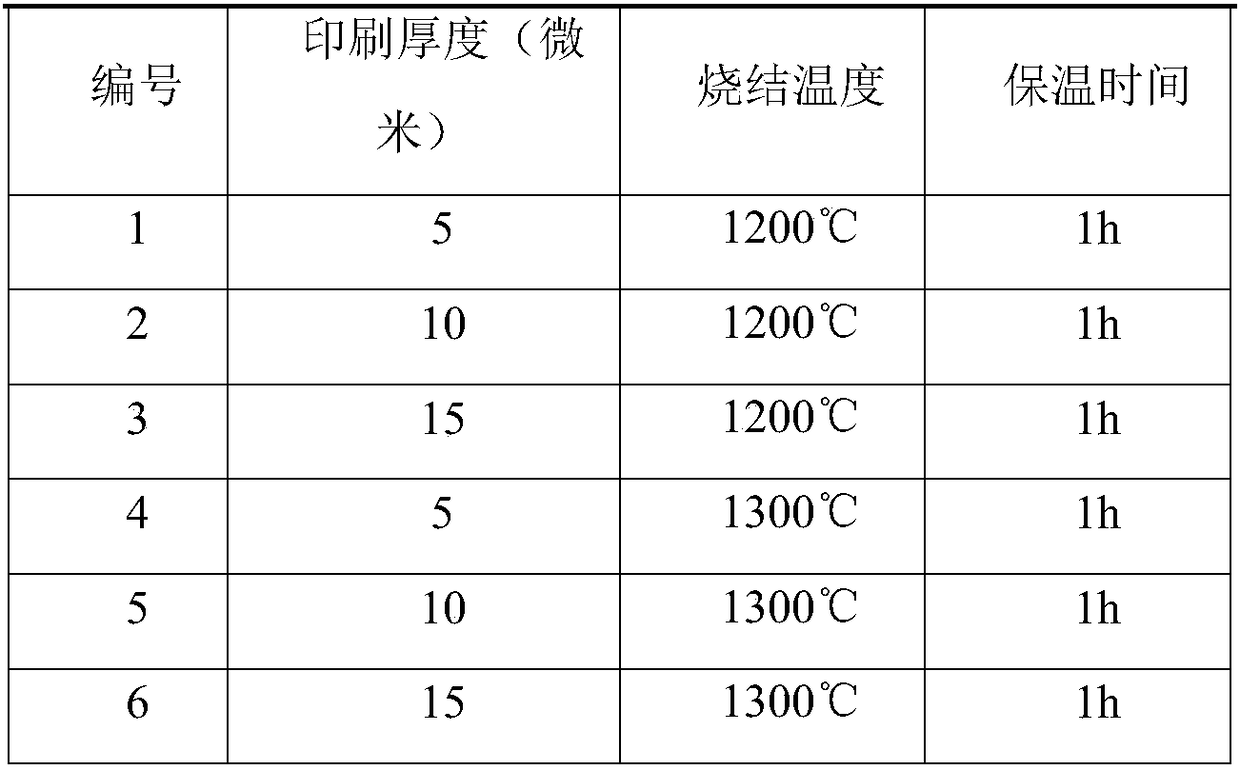

Method for performing surface modification on carbon-based material through metal slurry

The invention discloses a method for performing surface modification on carbon-based material through metal slurry, and aims at solving the problems that the carbon-based material is difficult to wet,difference of expansion coefficients and elasticity modulus between the carbon-based material and Cu is large, and the carbon-based material and the Cu are difficult to connect. The method comprisesthe following steps: configuration of metal powder (weighing, ball milling and drying), preparing of slurry, surface silk-screen printing of the carbon-based material and vacuum sintering. The mass purity of the metal powder is 99.99%; the vacuum sintering temperature and period are respectively 1200 to 1300 DEG C and 30 min to 2 h. The method can produce chromium carbide coating, with excellent bonding strength, on a carbon-based material substrate and can effectively solve the wettability between the carbon-based material and copper, and is low in production cost and suitable for mass manufacture.

Owner:SOUTHWESTERN INST OF PHYSICS +1

Metal glasses legs with spiral lines

InactiveCN109283699AFacilitate automatic processingWeight increaseNon-optical partsInjection mouldingMachining process

The invention discloses metal glasses legs with spiral lines, and belongs to the field of glasses frame structures. The leg sleeves of general glasses legs are machined through injection molding, so that the machining process is complex; glasses easily slide down along the nose bridge in the wearing process; and the leg sleeves made of plastics are not durable and lack of a design sense, and evencan cause skin allergy. Therefore, the invention provides the metal glasses legs with the spiral lines. Each metal glasses leg comprises a glasses leg body, and further comprises a spiral glasses legsleeve and a spiral locking sleeve; the spiral glasses leg sleeve is connected to the rear end of the glasses leg body in a sleeving mode; and the spiral locking sleeve is located at the tail end of the glasses leg body. According to the metal glasses legs, automatic processing is facilitated; the weight of the rear end of each glasses leg is increased, so that a glasses frame does not easily slide down along the nose bridge when a user wears the glasses; a vacuum galvanized coating material is environment-friendly and durable, and does not easily cause the skin allergy; and the shape is novel.

Owner:SHENZHEN XING HONGFA GLASS FRAME TECH LTD

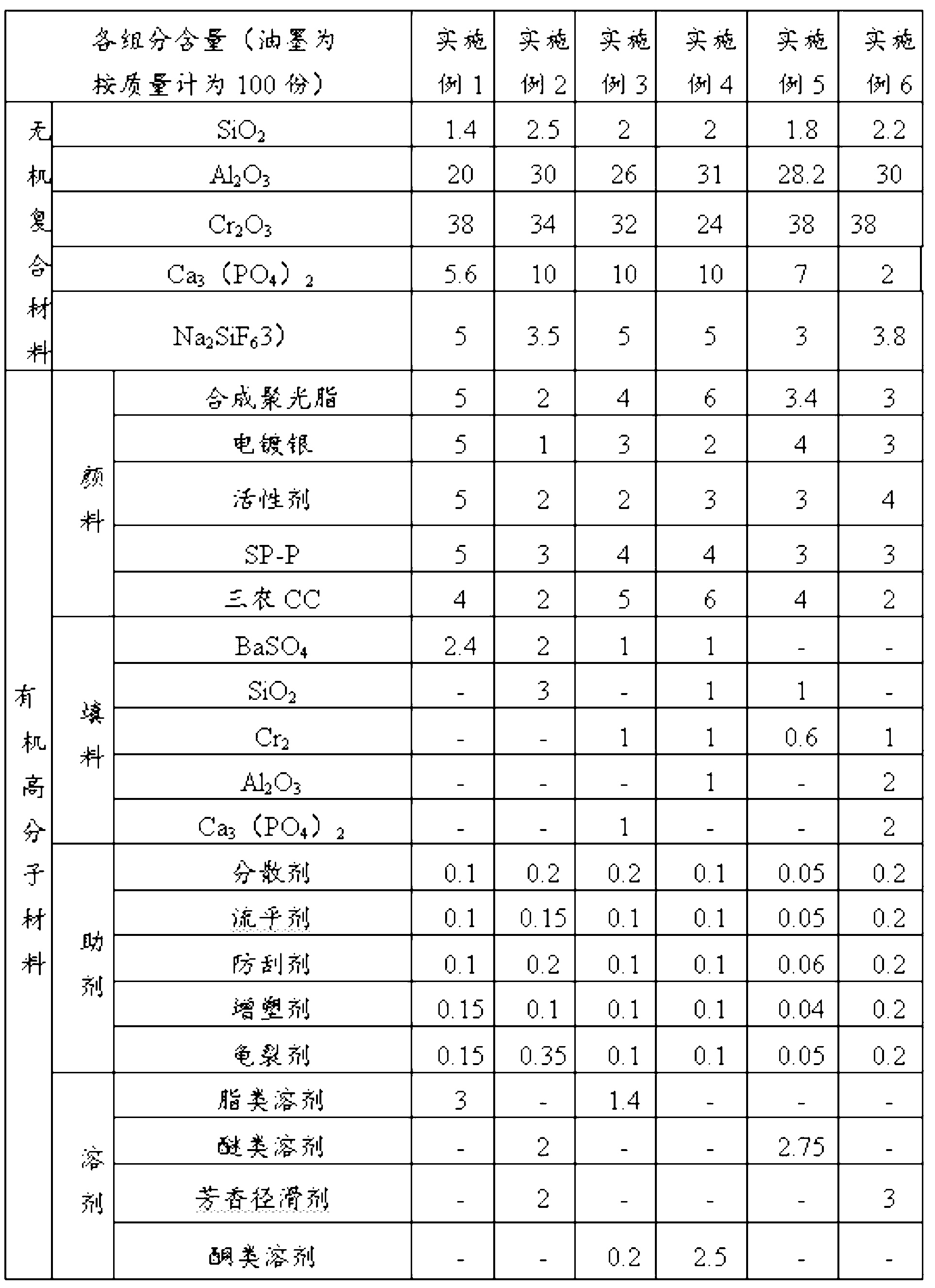

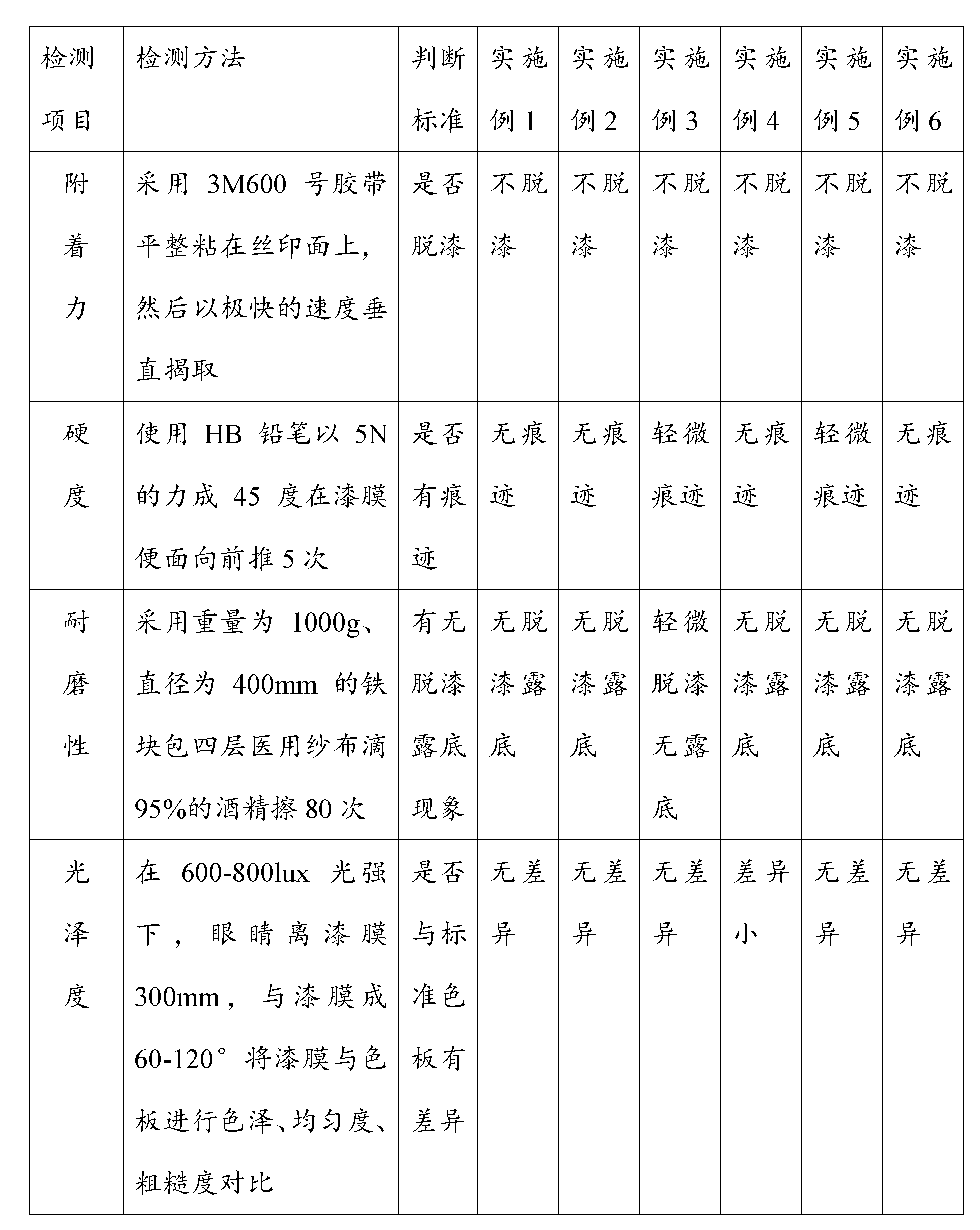

Mirror silver ink and preparation method thereof

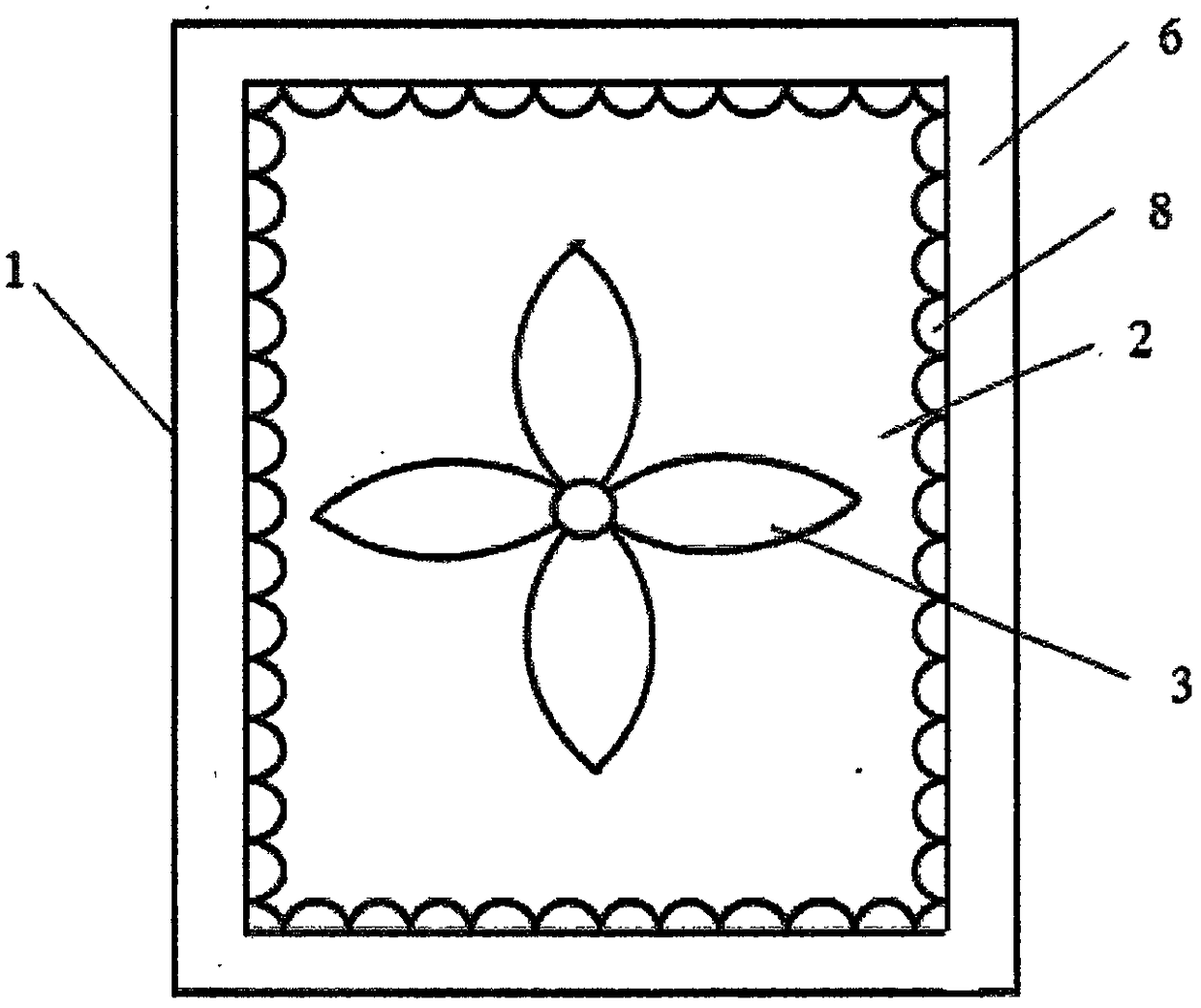

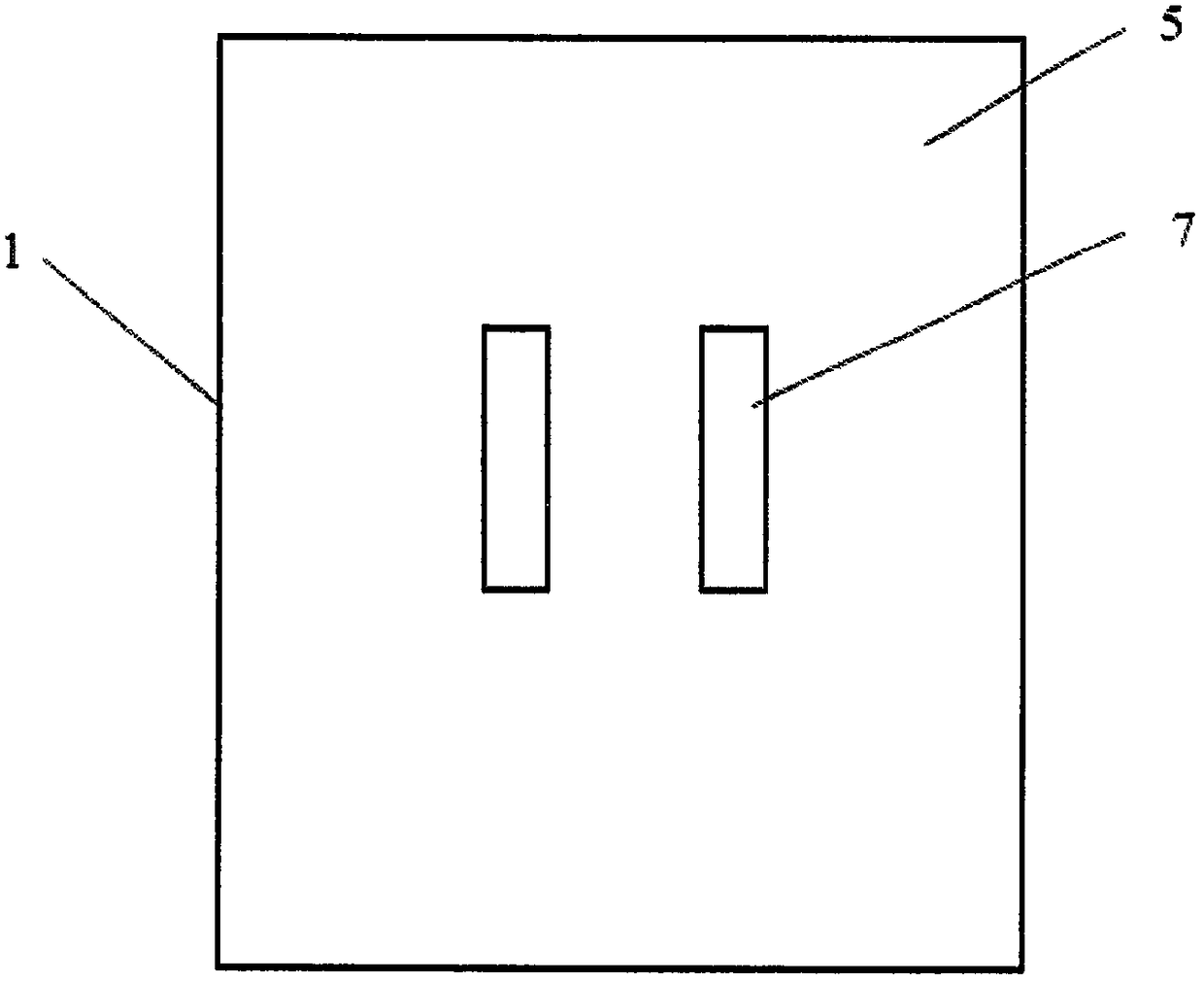

The invention discloses mirror silver ink and a preparation method thereof, wherein the mirror silver ink comprises following components in part by mass: 70-80 parts of inorganic composite material and 20-30 parts of organic high molecular material; the inorganic composite material comprises following components: 1.4-2.5 parts of SiO2, 20-30 parts of Al2O3, 24-38 parts of Cr2O3, 2-10 parts of Ca3 (PO4) and 3-5 parts of Na2SiF6; and the organic high molecular material comprises following components: 10-24 parts of pigment, 1.6-5 parts of filler, 0.25-1 part of assistant and 2.5-4 parts of solvent. In the mirror silver ink and the preparation method, provided by the invention, the mirror silver ink prepared by the preparation method can be directly silkscreened on the surface of a plastic part, so that the surface of the plastic part has effects of mirror surface, metallic feeling and strong silvery reflection.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Method for quickly processing surface oxidation layer of rolled-state molybdenum product

The invention discloses a method for quickly processing a surface oxidation layer of a rolled-state molybdenum product. The method comprises the following steps: at normal temperature and pressure, putting the molybdenum product in a mixed cleaning solution for soak cleaning, then rushing the molybdenum product with flowing water, and finally carrying out drying processing. At normal temperature and pressure, the method adopts a mixture of sodium hydroxide and hydrogen peroxide to clean the molybdenum product. Thus, the method has the advantages of being convenient to operate, quick, efficient and environmental-friendly, the surface of the processed molybdenum product is smooth, has no pit and is rich of metallic luster, and the weight loss ration of the product after being cleaned is smaller than 1 percent.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A kind of preparation method of metal wire jewelry pendant

The invention discloses a preparation method of a metal wire jewelry pendant. The method comprises the following steps of (1) preparation material preparation: a, preparing an embroidery sheet; b, preparing a metal wire embroidery wire; c, preparing a metal framework; (2) metal wire pattern embroidering; (3) jewelry pendant assembling: putting the embroidery sheet with the embroidered metal wire patterns into an accommodating cavity of the metal framework to obtain the jewelry pendant. The method provided by the invention has the advantages that the process is simple and practical; the operation is convenient; the method is suitable for the jewelry pendant using thinner metal wires for national artware processing. The jewelry pendant manufactured by the method cannot be easily abraded, cannot easily generate color degradation, can be easily stored and has high collection artistic value; the metal wire patterns have rich metal luster and has the three-dimensional effects; high attractive effect can be given to the jewelry pendant; the practical value is realized; meanwhile, the collection value is also realized. The pendant is used as the Mongol nationality culture carrier, and is favorable for the propagandization, inheritance and protection of the national artware.

Owner:乌云高娃

Bio-based art paint and its preparation method and application

ActiveCN112266661BReduce usageReduce dependenceAntifouling/underwater paintsPaints with biocidesPolymer sciencePetrochemical

The invention relates to a bio-based art paint and its preparation method and application. The bio-based art paint is prepared from raw materials comprising the following parts by weight: 20-50 parts of bio-based acrylic emulsion, 20-28 parts of pearlescent pigment, and 10-50 parts of water; The glass transition temperature of the acrylic polymer in the bio-based acrylic emulsion is -15°C-0°C. The coating has excellent freeze-thaw resistance and film-forming properties, extremely low VOC, and excellent stain resistance; at the same time, the construction is simple and can be diversified, and it is easy to achieve a strong three-dimensional effect. The surface of the paint film is rich in metallic texture and crystal flash effect. In addition, the use of bio-based raw materials at the same time reduces the dependence on petrochemical raw materials, is highly environmentally friendly, meets people's pursuit of environmental protection and artistic coatings, and has broad application prospects.

Owner:广东嘉宝莉科技材料有限公司

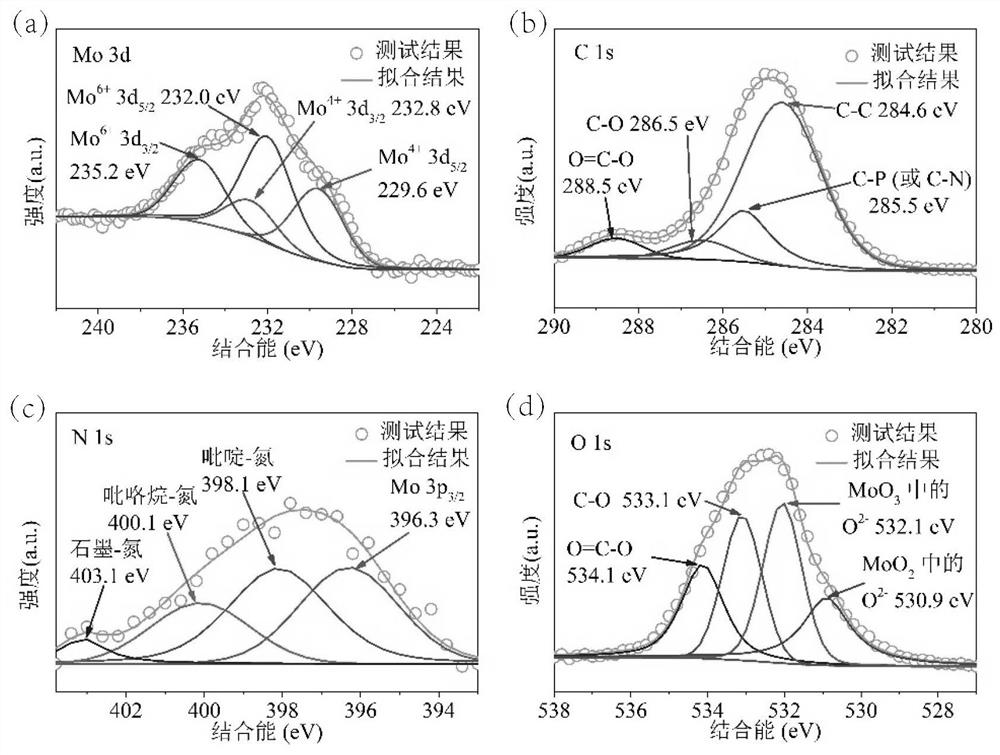

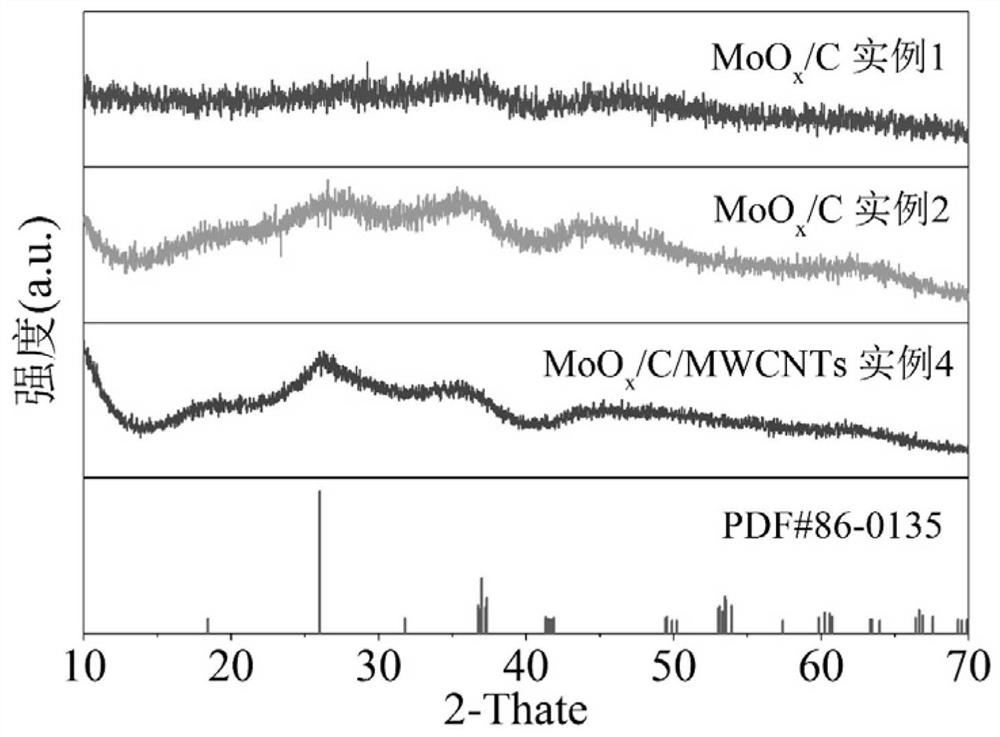

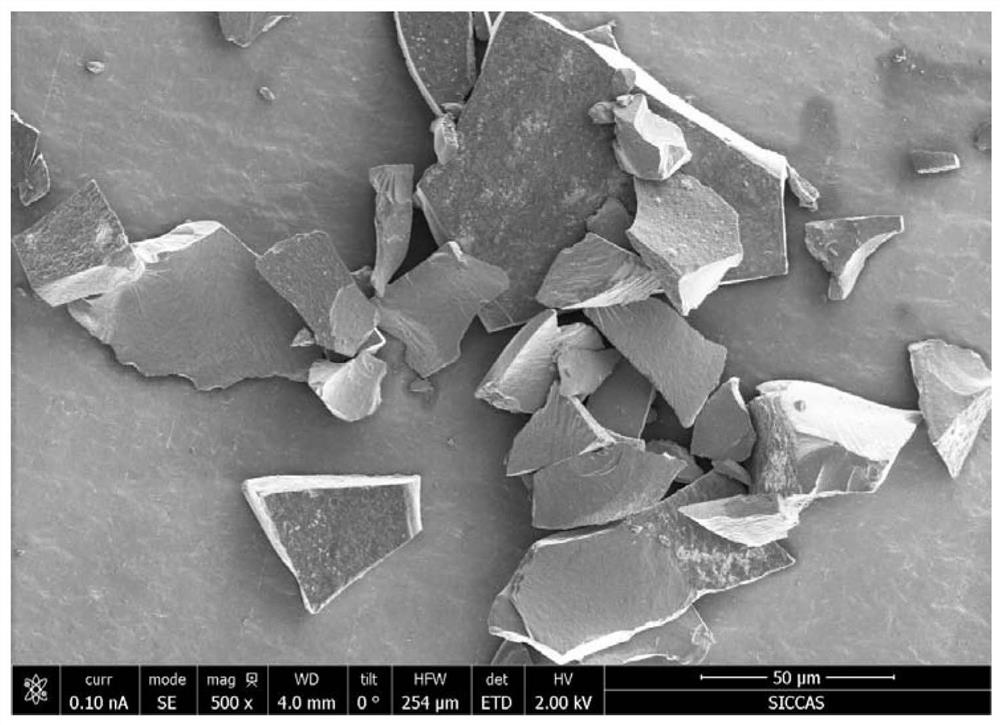

Anode material for high-capacity lithium-ion battery with micron particles based on conversion reaction and its preparation method and application

ActiveCN111490235BHigh tap densityLarge conversion reaction theoretical capacityMaterial nanotechnologyNegative electrodesPhysical chemistryBattery cell

The invention relates to a micron-particle high-capacity lithium-ion battery negative electrode material based on conversion reaction and its preparation method and application. The lithium-ion battery negative electrode material is a compound of molybdenum oxide and carbon, and its chemical formula is MoO x / C, x=2~3, where MoO x The content of 60 ~ 90 wt%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of wear-resistant alloy layer based on high boron iron base and method for preparing composite wear-resistant parts

Owner:XI AN JIAOTONG UNIV +1

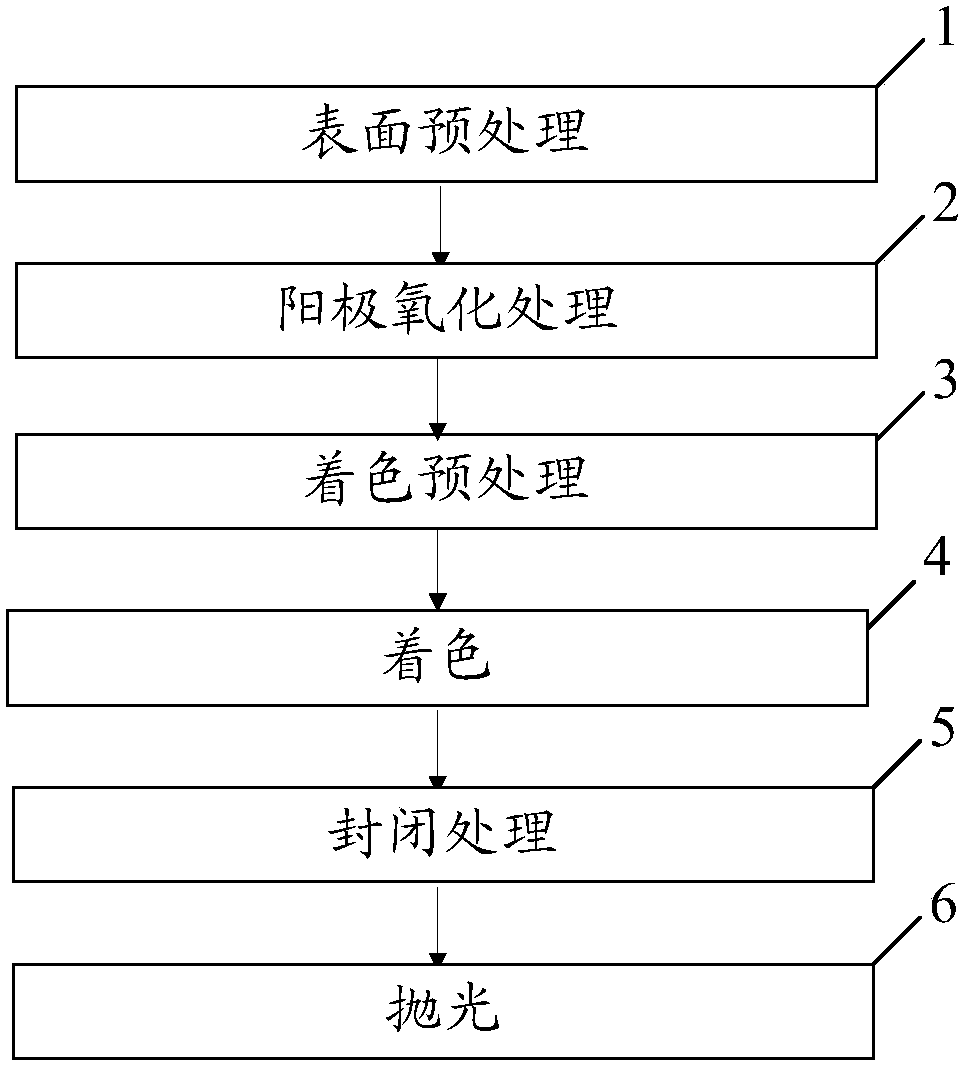

Coloring dye and aluminum alloy die casting brown coloring method

The invention discloses coloring dye and an aluminum alloy die casting brown coloring method, and belongs to the field of aluminum alloy die casting coloring. The coloring dye comprises acid red, acidblack and water solution of glacial acetic acid, wherein the concentration of the acid red is 4-12 g / L; the concentration of the acid black is 0.2-2.5 g / L; and the concentration of the glacial aceticacid is 0.1-5 g / L. The method comprises the following steps: aluminum alloy die castings are colored by adopting the coloring dye; and the coloring dye comprises the acid red, the acid black and thewater solution of the glacial acetic acid. The coloring dye can color brown on the aluminum alloy die castings; and the aluminum alloy die casting brown coloring method colors brown on the aluminum alloy die castings to achieve metal gloss.

Owner:JIANGHAN UNIVERSITY

A kind of glass mosaic and its preparation method and decoration material

The invention discloses glass mosaic, a preparation method thereof, and a decoration material. The preparation method of the glass mosaic comprises the steps that (1) an original glass sheet is preprocessed, and a primary finished mosaic product is obtained; (2) the primary finished glass mosaic product is sintered, and the sintering temperature is larger than 800 DEG C; (3) the sintered primary finished glass mosaic product is cooled; (4) the cooled primary finished glass mosaic product is subjected to bottom grinding processing according to the needed shape; (5) the primary finished glass mosaic product subjected to bottom grinding is soaked by an alkaline solution; (6) the soaked primary finished glass mosaic product is electroplated, and the bottom-ground face of the product is colored; and (7) the colored primary finished glass mosaic product is subjected to oil paint bottom sealing. Correspondingly, the invention further discloses the glass mosaic prepared through the method andthe decoration material comprising the glass mosaic. The glass mosaic shows the stereoscopic impression, the metallic impression and highlight and is rich in color, not prone to fading, and extremelygood in visual effect.

Owner:FOSHAN PAMASE BUILDING MATERIAL CO LTD

Powder coating composition, process for producing the same and coating film made from the same

An object is to provide a powder coating composition having excellent recyclability, offering superior safety, and containing a flake pigment providing metallic feel, brilliance and brightness to a coating film, as well as a coating film obtained from the former. A powder coating composition containing thermosetting resin powder having a surface adhered to a flake pigment composed of aluminum flake having an average particle size of 1 to 100 mum using an adhesive binder composed of a resin dissolved in a solvent which does not dissolve a thermosetting resin, as well as a coating obtained from the former are provided.

Owner:TOYO ALUMINIUM KK

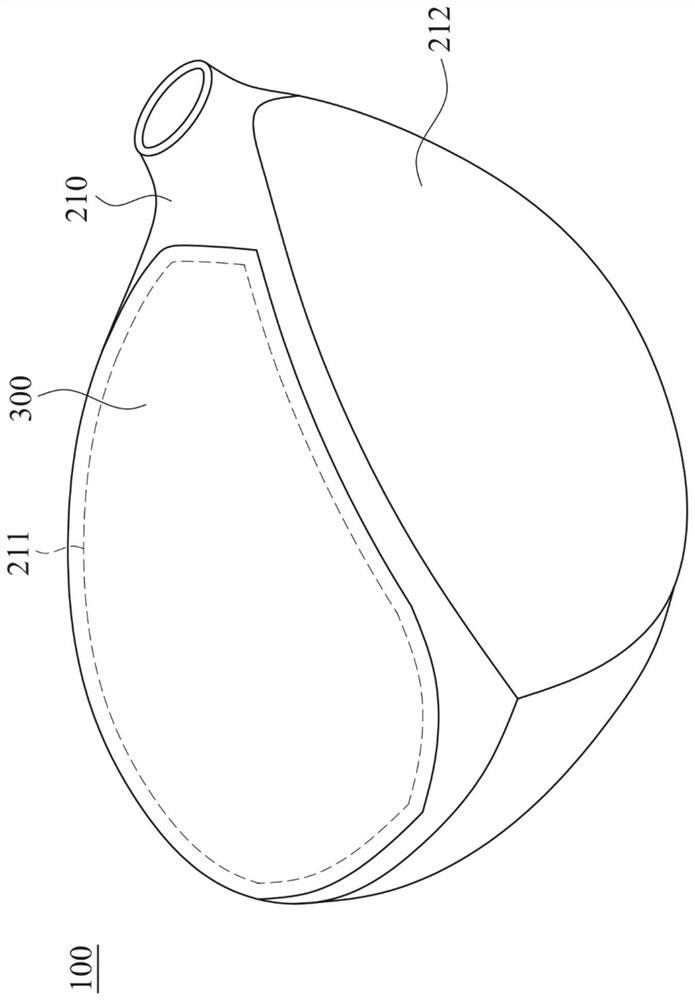

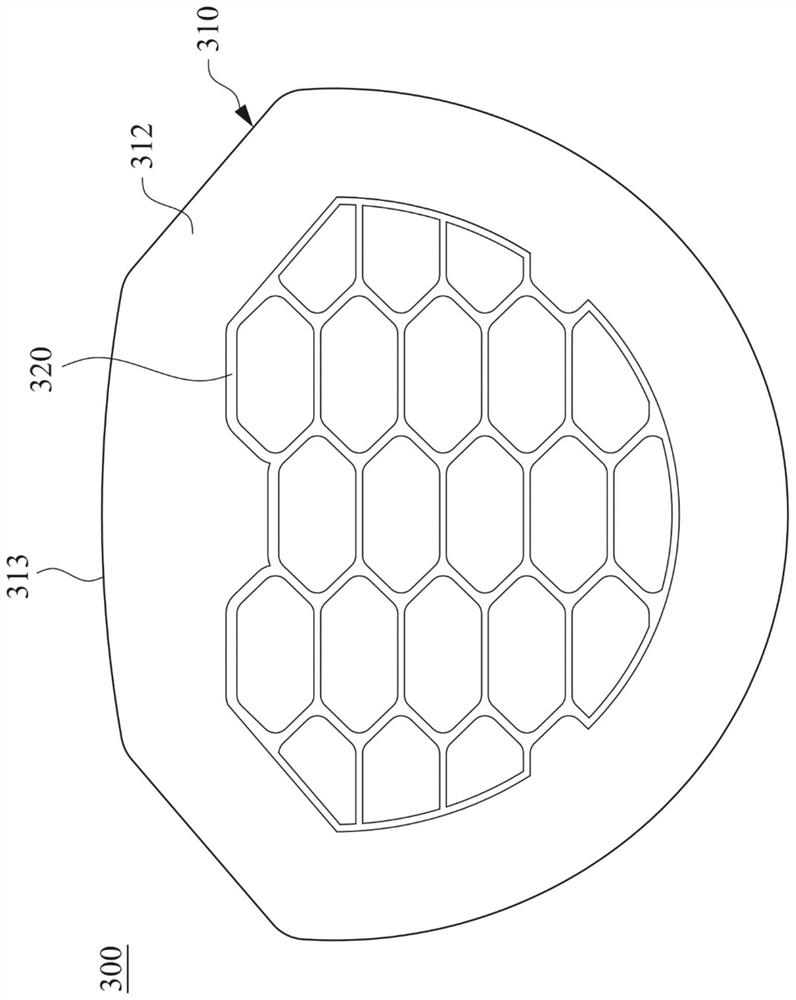

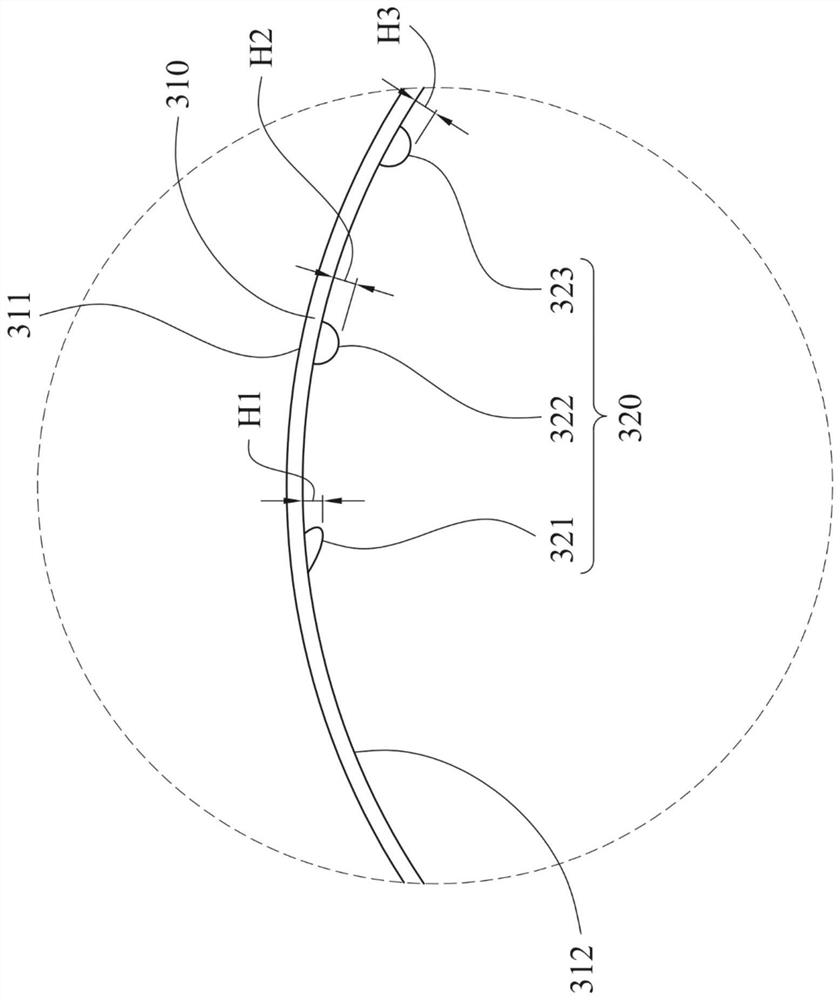

Golf ball head top cover and golf ball head

ActiveCN113856172AThe overall thickness is thinHigh strengthGolf clubsRacket sportsStructural engineeringGolf Ball

The invention discloses a golf ball head top cover and a golf ball head. The golf ball head top cover is configured to be mounted on a ball head body of a golf ball head, wherein the ball head body is provided with a ball hitting surface. The golf ball head top cover comprises a non-metal top cover body and a plurality of convex rib structures. The non-metal top cover body is provided with an outer surface and an inner surface. The convex rib structures are arranged on the inner surface. Each convex rib structure has a height, and the heights are changed along with the change of the distance between the convex rib structures and the ball hitting surface. The golf ball head top cover is provided with the convex rib structure design, so that the overall thickness can be thinned, and the structural strength of the overall golf ball head can be improved.

Owner:O TA PRECISION IND

Aluminum foil paper grinding wheel label and manufacturing method thereof

ActiveCN110534014BImprove high temperature resistanceNot easy to change color and deformStampsIdentification meansAluminum foilAluminium paste

The invention discloses an aluminum foil paper grinding wheel label. The aluminum foil paper grinding wheel label includes label paper and a printed label, the label paper is aluminum foil composite paper or aluminum foil paper coated with aluminum paste; the printed label is printed by high temperature resistant ink made. The label paper is 60-80g per square meter, including a base paper, an adhesive layer and an aluminum foil, and the aluminum foil is bonded to the base paper through the adhesive layer. At the same time, the present invention also provides a method for making the above-mentioned grinding wheel label. The color and brightness of the aluminum foil paper grinding wheel label produced by the method are effectively improved, so that the quality of the grinding wheel can be improved with the same quality.

Owner:郑州市晶森彩印有限公司

Injection molded tungsten fishhook with high specific gravity

InactiveCN109601494AHigh densityTight bondTransportation and packagingFish-hooksHigh densityPolyamide

The invention discloses an injection molded tungsten fishhook with high specific gravity. According to the injection molded tungsten fishhook, tungsten powder is selected as the material of the main body of a counterweight; the tungsten powder is high in density and small in size, thereby improving the weight countering efficiency and being convenient to use; polylactic acid can be degraded, thereby being harmless to the environment; polyamide is taken as binding resin for tightly binding the counterweight with the fishhook, therefore the counterweight is not easy to fall off; the tungsten fishhook is molded by injection according to the shapes of various molds after the tungsten powder and the polyamide are mixed, thereby meeting different demands in weight counting; the tungsten fishhookdoes not pollute the environment, does no harm to a human body and can be degraded after being discarded, thereby being the best choice for replacing the fishing tool made of lead; the final productmade of the tungsten powder is more metallic in the texture and the tungsten powder has higher density, so that a fisherman feels more sensitive in hand feeling and the fish biting possibility is improved.

Owner:灵璧县威科钓具有限公司

A fast repair paint for reducing chromatic aberration of car body repair and preparation method thereof

ActiveCN104893488BStable chemical propertiesImprove electrical performancePolyester coatingsHardnessSolvent

The invention provides rapid repair paint for reducing the repair chromatic aberration of a car body and a preparation method of the rapid repair paint. The repair paint comprises the ingredients in parts by weight: 20-40 parts of resin, 20-40 parts of additive resin, 5-10 parts of a metal pigment, 10-20 parts of a copolymer, 5-10 parts of a solvent, and 1-5 parts of an additive. The preparation process is simple, through the application of the obtained repair paint, the repair chromatic aberration of the car body can be reduced effectively, and the repair efficiency can be improved; after repair, particles of metal paint looks more three-dimensional, metallic and brilliant, the product performance is excellent, the hardness is equal to and higher than H, and the adhesive force is 0-1 level.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com